Page 1

8960ENC

SDI TO NTSC/PAL ENCODER

Instruction Manual

SOFTWARE VERSION 8.1.0

071064205

JUNE 2007

Page 2

Affiliate with the N.V. KEMA in The Netherlands

CERTIFICATE

Certificate Number: 510040.001

The Quality System of:

Grass Valley, Inc.

400 Providence Mine Road

Nevada City, CA 95945

United States

15655 SW Greystone Ct.

Beaverton, OR 97006

United States

10 Presidential Way

3

rd

Floor, Suite 300

Woburn, MA 01801

United States

Nederland B.V.

4800 RP BREDA

The Netherlands

Weiterstadt, Germany

Brunnenweg 9

D-64331 Weiterstadt

Germany

Rennes, France

Rue du Clos Courtel

Cesson-Sevigne, Cedex

France

Technopole Brest Iroise

CS 73808

29238 Brest Cedex 3

France

17 rue du Petit Albi-BP 8244

95801 Cergy Pontoise

Cergy, France

2300 South Decker Lake Blvd.

Salt Lake City, UT 84119

United States

7140 Baymeadows Way

Suite 101

Jacksonville, FL 32256

United States

Including its implementation, meets the requirements of the standard:

ISO 9001:2000

Scope:

The design, manufacture and support of video hardware and software products and

related systems.

This Certificate is valid until: June 14, 2009

This Certificate is valid as of: August 30, 2006

Certified for the first time: June 14, 2000

H. Pierre Sallé

President

KEMA-Registered Quality

The method of operation for quality certification is defined in the KEMA General Terms

And Conditions For Quality And Environmental Management Systems Certifications.

Integral publication of this certificate is allowed.

KEMA-Registered Quality, Inc.

4377 County Line Road

Chalfont, PA 18914

Ph: (215)997-4519

Fax: (215)997-3809

CRT 001 073004

ccredited By:

ANAB

A

Page 3

8960ENC

SDI TO NTSC/PAL ENCODER

Instruction Manual

SOFTWARE VERSION 8.1.0

071064205

JUNE 2007

Page 4

Contacting Grass Valley

International

Support Centers

Local Support

Centers

(available

during normal

business hours)

France

24 x 7

Australia and New Zealand: +61 1300 721 495 Central/South America: +55 11 5509 3443

Middle East: +971 4 299 64 40 Near East and Africa: +800 8080 2020 or +33 1 48 25 20 20

Europe

+800 8080 2020 or +33 1 48 25 20 20

+800 8080 2020 or +33 1 48 25 20 20

Hong Kong, Taiwan, Korea, Macau: +852 2531 3058 Indian Subcontinent: +91 22 24933476

Asia

Southeast Asia/Malaysia: +603 7805 3884 Southeast Asia/Singapore: +65 6379 1313

China: +861 0660 159 450 Japan: +81 3 5484 6868

Belarus, Russia, Tadzikistan, Ukraine, Uzbekistan: +7 095 2580924 225 Switzerland: +41 1 487 80 02

S. Europe/Italy-Roma: +39 06 87 20 35 28 -Milan: +39 02 48 41 46 58 S. Europe/Spain: +34 91 512 03 50

Benelux/Belgium: +32 (0) 2 334 90 30 Benelux/Netherlands: +31 (0) 35 62 38 42 1 N. Europe: +45 45 96 88 70

Germany, Austria, Eastern Europe: +49 6150 104 444 UK, Ireland, Israel: +44 118 923 0499

Copyright © Grass Valley. All rights reserved.

This product may be covered by one or more U.S. and foreign patents.

United States/Canada

24 x 7

+1 800 547 8949 or +1 530 478 4148

Grass Valley Web Site

The www.thomsongrassvalley.com web site offers the following:

Online User Documentation — Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database — Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads — Download software updates, drivers, and patches.

4 8960ENC — Instruction Manual

Page 5

Contents

Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8960ENC SDI to NTSC/PAL Encoder Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Frame Sync Submodule (8900FSS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Gecko 8900 Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Frame Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Module Placement in the 8900 Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

GeckoFlex Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rear Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Front Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Loop-through Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reference Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuration Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuration Summary Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Local Onboard Module Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Onboard Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Adding/Deleting Setup for 525 Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Remote Configuration and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8900NET Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Newton Control Panel Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8960ENC Links and Web Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Status Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Standard Selection Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Levels Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Timing Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Video Processing Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Recall Factory Defaults Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Software Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Equipment Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Acquiring Software Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Serial 4:2:2 Input Stage & Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8960DEC — Instruction Manual 5

Page 6

Contents

Cross-Color Remover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Synchronizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

10-bit Encoder and Output Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Color-frame Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Frame Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Web Browser Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

SNMP Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 8960DEC — Instruction Manual

Page 7

Preface

About This Manual

This manual describes the features of a specific 8900 module in the Gecko

and GeckoFlex Signal Processing System families. As part of this module

family, it is subject to Safety and Regulatory Compliance described in the

Gecko 8900 Series frame and power supply documentation (see the Gecko

8900 Frames and the GeckoFlex Frames Instruction Manuals).

8960ENC — Instruction Manual 7

Page 8

Preface

8 8960ENC — Instruction Manual

Page 9

8960ENC SDI to NTSC/PAL Encoder Module

Introduction

The 8960ENC module is an encoder solution for converting 4:2:2 component serial digital SDI video inputs into multi-standard composite analog

video signals by using 10-bit processing throughout the conversion

process.

The 8960ENC features:

• 10-bit signal processing,

• 4 NTSC/PAL outputs,

• 2 reclocked SDI (Serial Digital Interface standard) outputs,

• Full-frame output phasing with 8900FSS frame sync submodule option,

• 2 reference inputs for multi-format facilities,

• EDH detection, and

• Remote interface with the 8900NET module (version 3.2.2 or later) providing support for the following:

• Web browser configuration and control

• SNMP trap reports for use with NetCentral and other SNMP appli-

cations

• NetConfig Networking application

• Newton Control Panel control

8960ENC—Instruction Manual 9

Page 10

Installation

8900FSS

0642-08r1

Temination

jumpers in

high impedance

position

JP3 NTSC

Ref.

JP4 PAL

Ref.

75

75

HI IMP

HI IMP

Insert and tighten screw

to secure submodule.

Installation

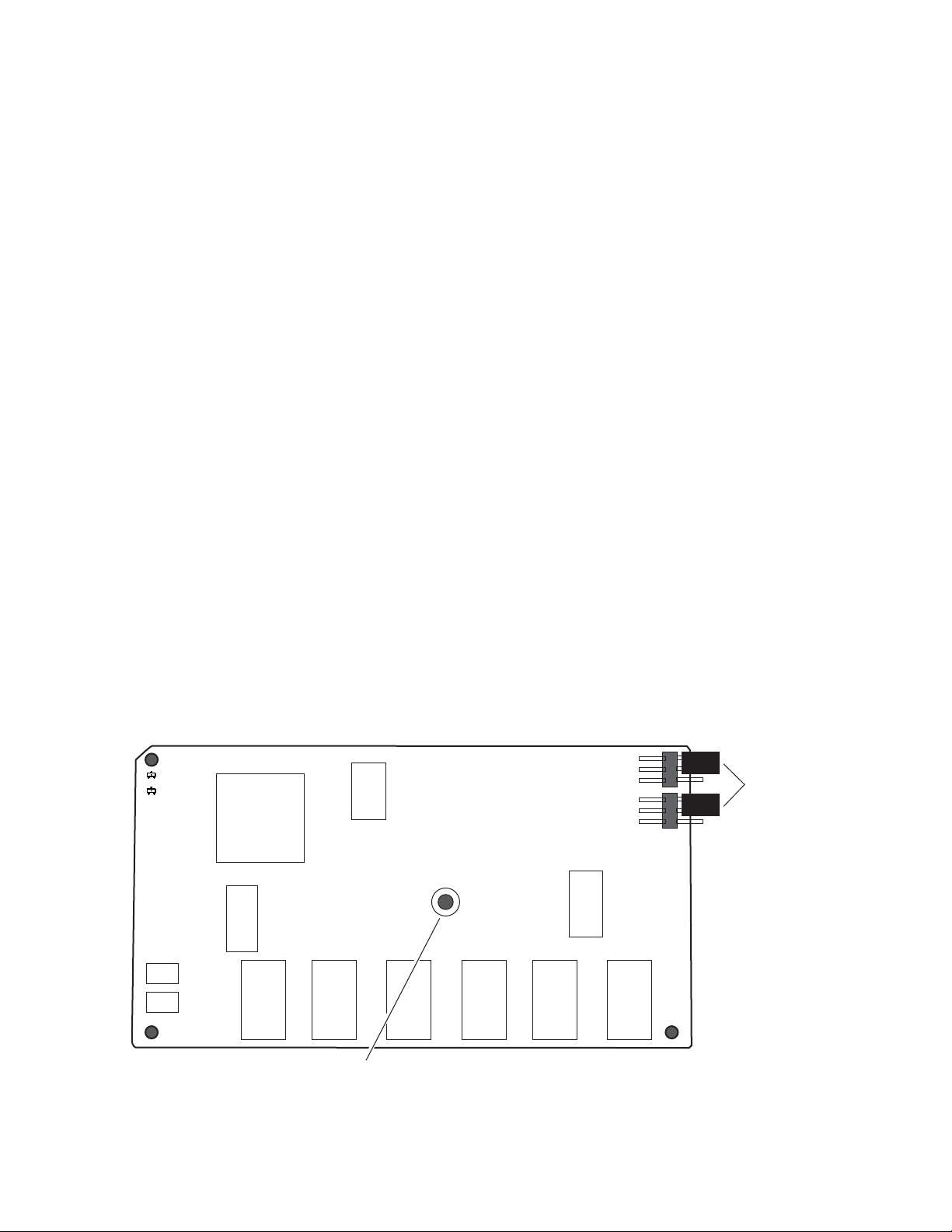

Frame Sync Submodule (8900FSS)

Installation

The 8960ENC can be installed in either an 8900 Gecko or an 8900FN

GeckoFlex frame. An 8900V-R rear module is required for use in the

GeckoFlex frame.

If using an 8900FSS Frame Sync submodule, mount it onto the 8960ENC

circuit board first below before installing the 8960ENC in the frame.

An optional Frame Sync submodule is available for providing frame synchronization to an external reference. The submodule installs on the

8960ENC circuit board.

Install the submodule onto the main circuit board by lining up the two connectors on the submodule with the connectors on the module. Make sure

the connectors are aligned properly then press to seat the submodule.

Insert and tighten the center screw to secure the submodule and assure that

the connectors are in proper alignment.

Termination

When used on the 8960ENC host module, the Frame Sync Submodule reference signal input termination should be set to high impedance (see

Figure 1).

Figure 1. Frame Sync Submodule Reference Signal Termination Selection

10 8960ENC—Instruction Manual

Page 11

Gecko 8900 Frame

Installation of the 8960ENC module in a Gecko 8900 frame is a process of:

1. Placing the module in the proper frame slot, and

2. Cabling and terminating signal ports.

The 8960ENC module can be plugged in and removed from any Gecko

8900 frame with power on. When power is applied to the module, LED

indicators reflect the initialization process (see Power Up on page 16).

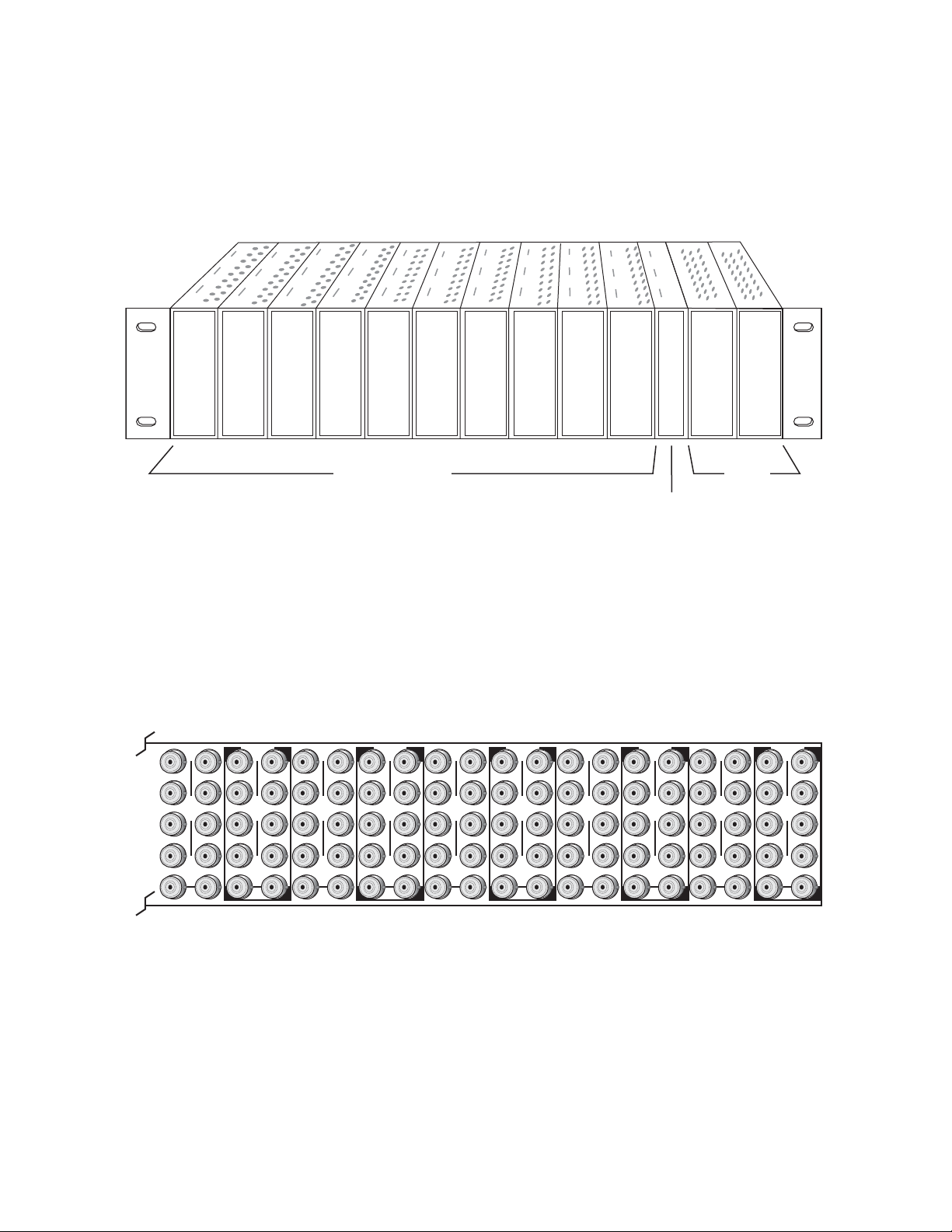

Frame Capacity

The 8960ENC module can be installed in all 8900 Series video frames but

with varying maximum quantities determined by frame cooling capacity.

Ta bl e 1 provides the power capacity, cooling capacity, and maximum

8960ENC module count for each frame type.

Table 1. Power, Cooling, and Module Capacity of 8900 Frames

Power (W)

Recommended Module Cooling (W)

8960ENC Modules

8960ENC Modules with 8900FSS

Capacity Calculated

8900TX

Frame

100 100 100

30 90 90

8900TF-V

Frame

51010

X1010

8900TFN-V

Frame

Installation

Note Module capacity figures assume no other modules are in the frame.

X = Not recommended without forced air cooling.

If you are using an 8900NET module running software version 4.0.0 or

later, you may link to the 8900 Frame Status web page (Figure 10 on

page 28) then select the link to the Power Supply/Demand web page for

determining the power capacity for the frame. Using this function, the

8900NET module will determine how much power is being consumed and

report back when power has been exceeded.

Module Placement in the 8900 Frame

There are ten slot locations in the frame to accommodate either analog or

digital modules. These are the left ten locations. Refer to

page 12.

The two slots on the right are allocated for the power supplies. For additional information concerning the Power Supply module, refer to the Gecko

8900 Frames Instruction Manual.

Figure 2 on

8960ENC—Instruction Manual 11

Page 12

Installation

Frame Monitor or

8900NET Network

Interface Module

Any 8900 Module

Power

Supplies

(only)

0642_04r1

0642-03

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA1

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA3

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA5

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA2

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA7

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA9

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA4

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA6

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA8

J2

J4

J6

J8

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

IN

DA10

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

O

U

T

The third slot from the right is allocated for the controller module—either

a Frame Monitor Module or a 8900NET Network Interface Module. For

additional information concerning the controller module options, refer to

the 8900NET Network Interface Module Instruction Manual.

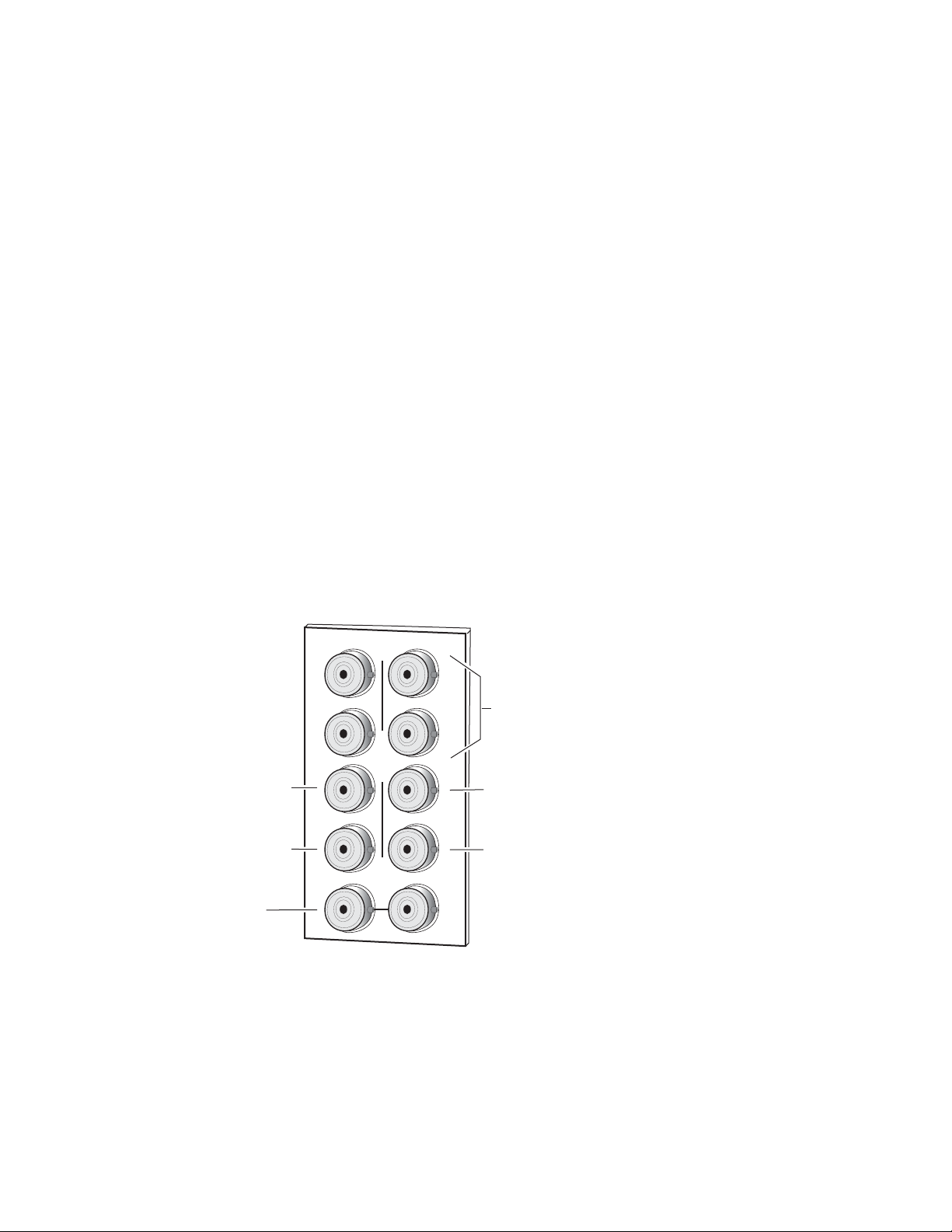

Figure 2. Gecko 8900 Series Frame

8900 module slots are interchangeable within the frame. There are 10 BNC

connectors in each slot’s I/O group. The functional assignment of each con

nector in a group is determined by the module that is placed in that slot.

The maximum number of modules an 8900 frame can accept is ten.

Figure 3

illustrates the rear connector plate for an 8900 Series frame.

Figure 3. Gecko 8900 Series Frame Rear Connector

To install a module in the frame:

1. Insert the module, connector end first, with the component side of the

module facing to the right and the ejector tab to the top.

-

2. Verify that the module connector seats properly against the backplane.

12 8960ENC—Instruction Manual

3. Press in the ejector tab to seat the module.

Page 13

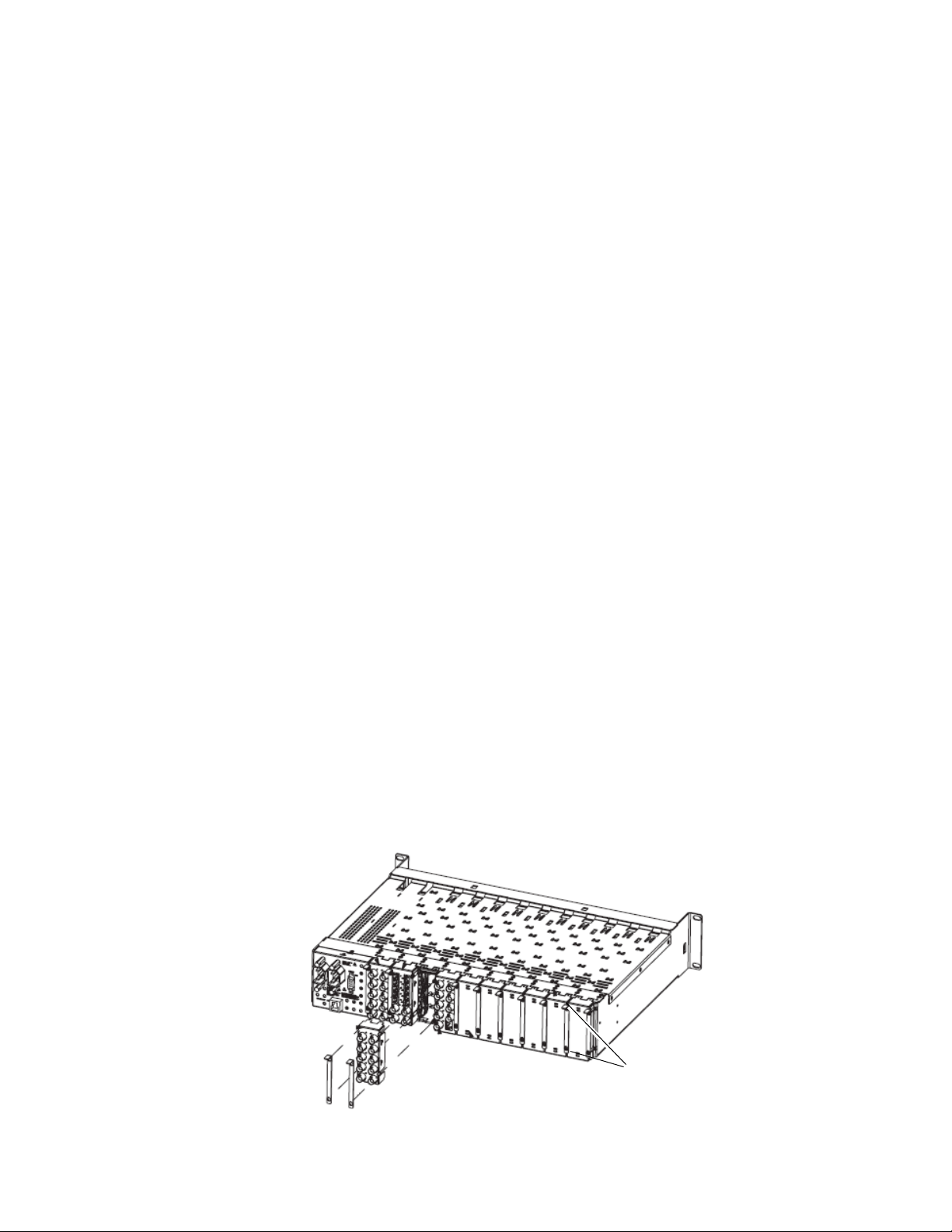

GeckoFlex Frame

Use needlenose pliers

to pull out blank after

removing retainers.

Installation of the 8960ENC module in a GeckoFlex frame is a process of:

1. Installing the 8900V-R rear module into the rear of the frame,

2. Placing the 8960ENC module in the corresponding front frame slot, and

3. Cabling and terminating signal ports.

Rear Module Installation

To install a rear module into the frame, follow these steps:

1. Each 8900V-R rear module or blank rear adapter cover is held in place

CAUTION Be careful to leave the screws in place as they can be easily lost or fall into

Installation

by two retainer strips as shown in Figure 4. Loosen (but do not remove

completely) the two screws holding each retainer strip to the frame

with a 2 mm (5/64”) hex screwdriver. Pull up on the retainer to remove

it, leaving the screws in place.

equipment below the frame creating a shorting hazard.

2. Remove the blank rear adapter cover by inserting needlenose pliers

into the slots in the top and bottom of the blank and pulling it off.

Note To remove a rear module already installed, follow the same steps. It is helpful

to first remove the front module so the rear can be pulled out more easily.

3. Insert the rear module into the empty slot.

4. Replace each retainer strip over the two screws on both sides of the

module and push down to seat the retainer.

5. Tighten the screws for each retainer just until they are snug. Do not

force or torque the screws too tightly.

Figure 4. Installing Rear Module

8960ENC—Instruction Manual 13

Page 14

Installation

Slide top and bottom card carriers on module

over top and bottom guides on right of slot.

Module installed

Locking Pin

Front Module Side View

0642_10r0

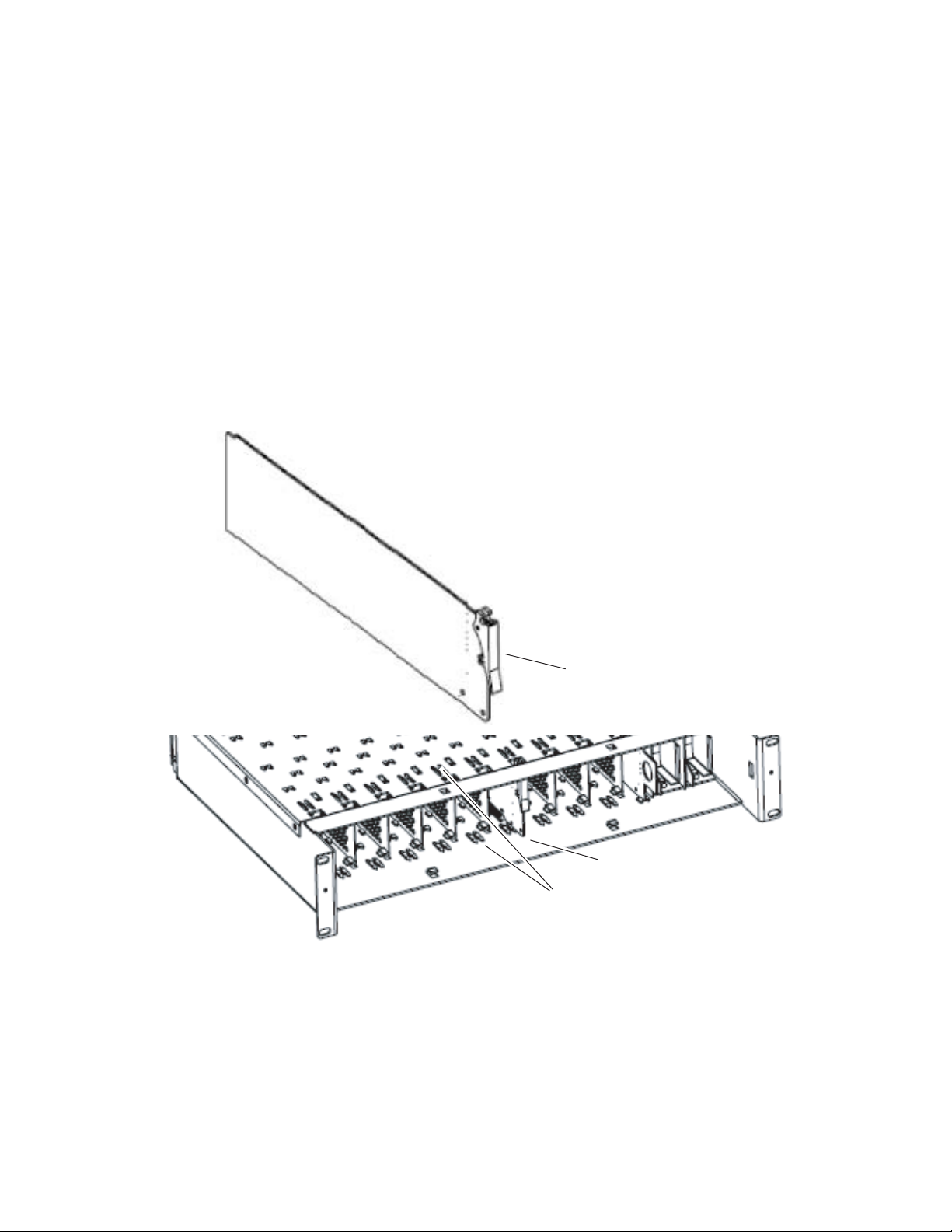

Front Module Installation

After installing the rear module, install the front module as follows:

1. Remove the front cover of the frame if required.

2. Locate the corresponding front slot.

3. Insert the front module so that the plastic card guides on the module

top and bottom edges go over the upper and lower raised rail guides on

the right of the top and bottom of the slot(Figure 5).

4. Carefully slide the module into the rear connector.

5. Lock the front module ejector tab into the locking pin.

Figure 5. Front Module Installation

14 8960ENC—Instruction Manual

Page 15

Cabling

J2

J4

J6

J8

J1

J9 J10

IN

Four NTSC/PAL

Outputs J1 - J4

X

O

U

T

J3

J5

J7

J2

J4

J6

J8

0642_02r1

SDI Loop-through

Input

625 Reference

Input

525 Reference

Input

Reclocked SDI OutputReclocked SDI Output

Loop-through Input

Outputs

Reference Inputs

Installation

Cable the module as described below for either frame type.

Connect an input source to one of the loop-through input connectors, J9 or

J10 (see

Figure 6). The 8960ENC input will accept serial digital video con-

forming to SMPTE 259M 10-bit, 4:2:2 component digital standard. Terminate the unused connector into 75 Ω if the signal is not looped to other

equipment.

The 8960ENC has four analog NTSC/PAL outputs—J1 through J4. Connectors J-5 and J-6 are reclocked SDI outputs.

Separate input BNCs are provided for either 625-line (J7) or 525-line (J8)

black burst reference signals. The reference inputs are 75 ohm or high

impedance (jumper selectable, see

Local Onboard Module Configuration on

page 22).

Figure 6. 8960 Input/Output Connectors

8960ENC—Instruction Manual 15

Page 16

Power Up

0642_06r1

0

1

2

3

4

5

6

7

8

9

A

B

C

D

16-position

Rotary switch

Momentary toggle switch

525 – Green LED on indicates 525-line input is present

PWR – Green LED on indicates power OK

FAULT – Red LED is off during normal operation

Ejector Tab

COMM – Yellow LED indicates communication activity

CONF – Yellow LED indicates configuration activity

Auto/Manual MODE – Yellow LED on indicates automatic input detection mode

625 – Green LED on indicates 625-line input is present

Filter – Yellow LED on indicates signal is being cross-color filtered

Module Configuration Switches and LED

GND

2nd Function

(yellow)

Power Up

Operation Indicator LEDs

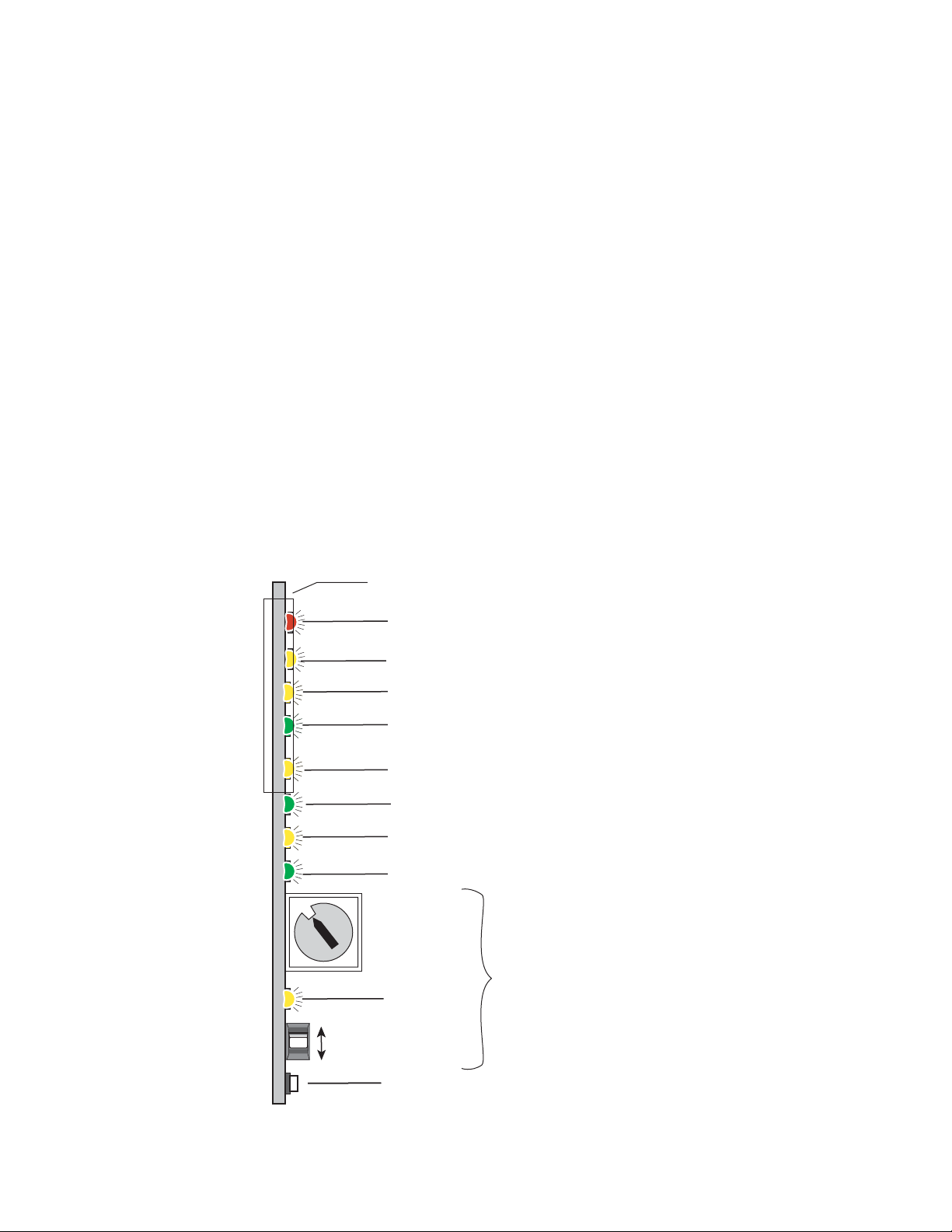

The front LED indicators and configuration switches are illustrated in

Figure 7. Upon power-up, the green PWR LED should light and the yellow

CONF LED should illuminate for the duration of module initialization.

Note When a media module is first plugged into a Gecko or GeckoFlex frame, the

8900NET module (if present) may report a momentary fault. This will clear

once the media module has booted up.

With factory default configuration and a valid input signal connected, the

green PWR LED, the yellow AUTO, and one of the green signal standard

LEDs (525 or 625) should illuminate (refer to

Ta bl e 2 on page 17 to see the

possible operating indicator combinations).

Video input presence is indicated by the 525 or 625 LED (indicating a

525-line or 625-line input signal has been detected). The AUTO LED indicates that automatic standard selection is enabled.

Figure 7. LEDs and Configuration Switches

16 8960ENC—Instruction Manual

Page 17

Power Up

A red FAULT LED indicates an error situation and, with the previously

described LEDs, can indicate the operational conditions presented in

Tab le 2 . The table describes LED indications and the signal input/output

conditions and user settings that are indicated.

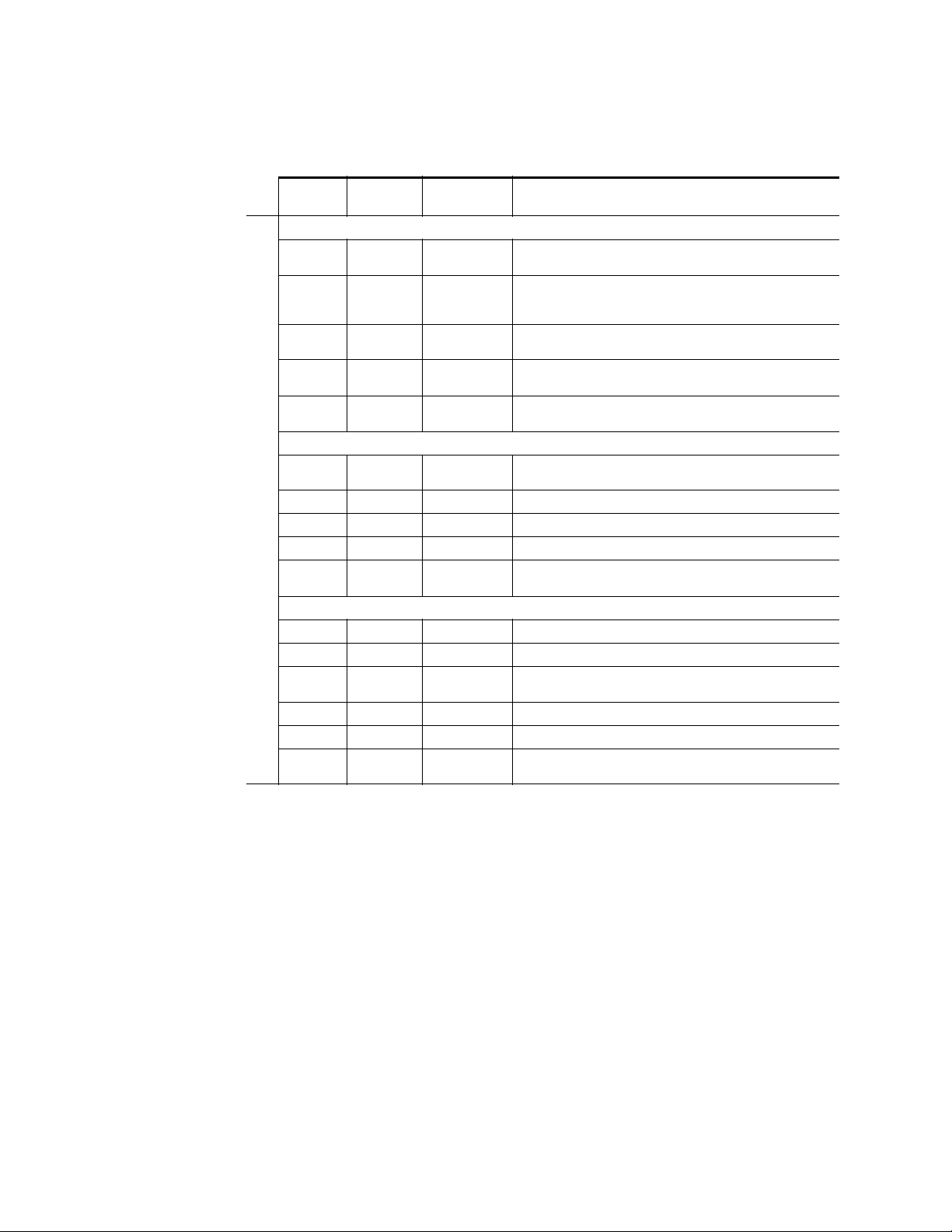

Table 2. Input Conditions and Resulting Output signals and Indicators

Fault

(red)

OFF ON OFF

OFF OFF ON

Flashing OFF OFF

Flashing ON OFF

Flashing OFF ON

Flashing OFF Flashing

Flashing Flashing OFF

Flashing Flashing OFF

Flashing OFF Flashing

525

(green)

625

(green)

Mode

Input Condition Output Signal

Normal operation; SDI input signal and 525 reference standard selected.

Normal operation; SDI input signal and 625 reference standard selected.

Missing or invalid SDI input signal. No signal.

EDH or format error in the input signal. Output signal has errors.

EDH or format error in the input signal. Output signal has errors.

SDI 625 signal present; selected 625 reference missing or

invalid.

SDI 525 signal present; selected 525 reference missing or

invalid.

525 configued with Manual control, wrong input signal. Corrupted output signal.

625 configured with Manual contol, wrong input signal. Corrupted output signal.

Correct encoded signal with correct color-framing.

Correct encoded signal with correct color-framing.

Correct encoded output; color framing and delay adjustment

from frame sync submodule is free running.

Correct encoded output; color framing and delay adjustment

from frame sync submodule is free running.

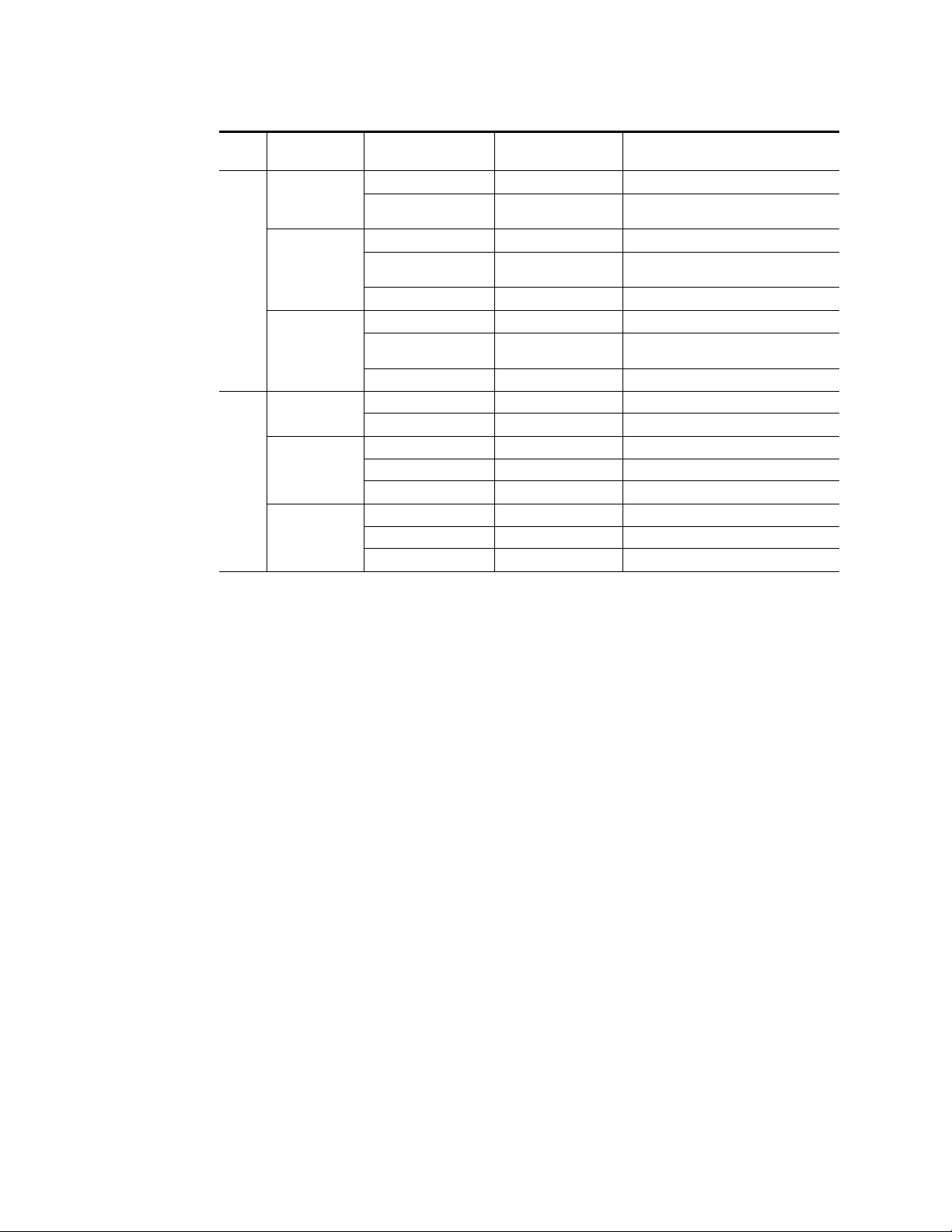

Tab le 3 describes the outputs that will be seen for the operating modes and

input conditions listed.

Table 3. Operating Mode, Input Conditions and Resulting Outputs

Standard

Selection

AUTO

Manual 525-line

Manual 625-line

Frame Sync Submodule Present — Module In Sync Mode

Video Input Reference Input Output

Video present Valid reference present Correct output signal with correct timing

No video signal present Valid reference present Corrupted output signal

Or last field if autofreeze is on

Video present Reference not present Correct output signal with free run timing

Video present Invalid reference input Corrupted output signal

Video present Valid reference present Correct output signal with correct timing

No signal present Valid reference present Corrupted output signal

Or last field if autofreeze is on

Video present Reference not present Correct output signal with free run timing

Video present Invalid reference input Corrupted output signal

Invalid Video present Valid reference present Corrupted output signal

Invalid Video present Invalid reference input Corrupted output signal

Video present Valid reference present Correct output signal with correct timing

No video signal present Valid reference present Corrupted output signal

Or last field if autofreeze is on

Video present Reference not present Correct output signal with free run timing

Video present Invalid reference input Corrupted output signal

Invalid Video present Valid reference present Corrupted output signal

Invalid Video present Invalid reference input Corrupted output signal

8960ENC—Instruction Manual 17

Page 18

Power Up

Table 3. Operating Mode, Input Conditions and Resulting Outputs - (continued)

Mode

Frame Sync Submodule Present

Standard

Selection

Manual 525-line

Module In Delay Mode

Manual 625-line

Manual 525-line

Manual 625-line

No Frame Sync Submodule

AUTO

AUTO

Video Input Reference Input Output

Video present Not needed Correct output signal w correct timing

No video signal present Not needed Corrupted output signal

Or last field if autofreeze is on

Video present Not needed Correct output signal w correct timing.

No video signal present Not needed Corrupted output signal

Or last field if autofreeze is on

Invalid Video input Not needed Corrupted output signal

Video present Not needed Correct output signal w correct timing

No video signal present Not needed Corrupted output signal

Or last field if autofreeze is on

Invalid Video input Not needed Corrupted output signal

Video present Not needed Correct output signal

No video signal present Not needed No output signal

Video present Not needed Correct output signal

No video signal present Not needed No output signal

Invalid Video input Not needed Corrupted output signal

Video present Not needed Correct output signal

No video signal present Not needed No output signal

Invalid Video input Not needed Corrupted output signal

18 8960ENC—Instruction Manual

Page 19

Configuration

Configuration Summary

Configuration

The 8960ENC can be configured locally using onboard switches or

remotely using the 8900NET network interface GUI or a networked control

panel.

Refer to the following sections for configuration instructions:

• Configuration Summary (page 19)

• Local Onboard Module Configuration (page 22)

• Remote Control and Monitoring (page 26)

Operation of these control types is explained in detail in their respective

sections of this manual.

The configuration of the 8960ENC establishes:

• Reference signal input impedance (jumper selection),

• Local only or Remote/Local control (jumper selection),

• Input/Output standard setup,

• Signal processing adjustment,

• Signal filtering setup, and

• Optional Frame Sync module setup.

Output standard setup provides multi-standard support of analog output

signals such as NTSC, Japanese NTSC, PAL-B, PAL-M.

The factory (default) settings for signal processing functions are set to pass

a calibrated broadcast quality signal at optimum levels. Signal processing

amplifier adjustments are available to correct deficiencies in the input

signal.

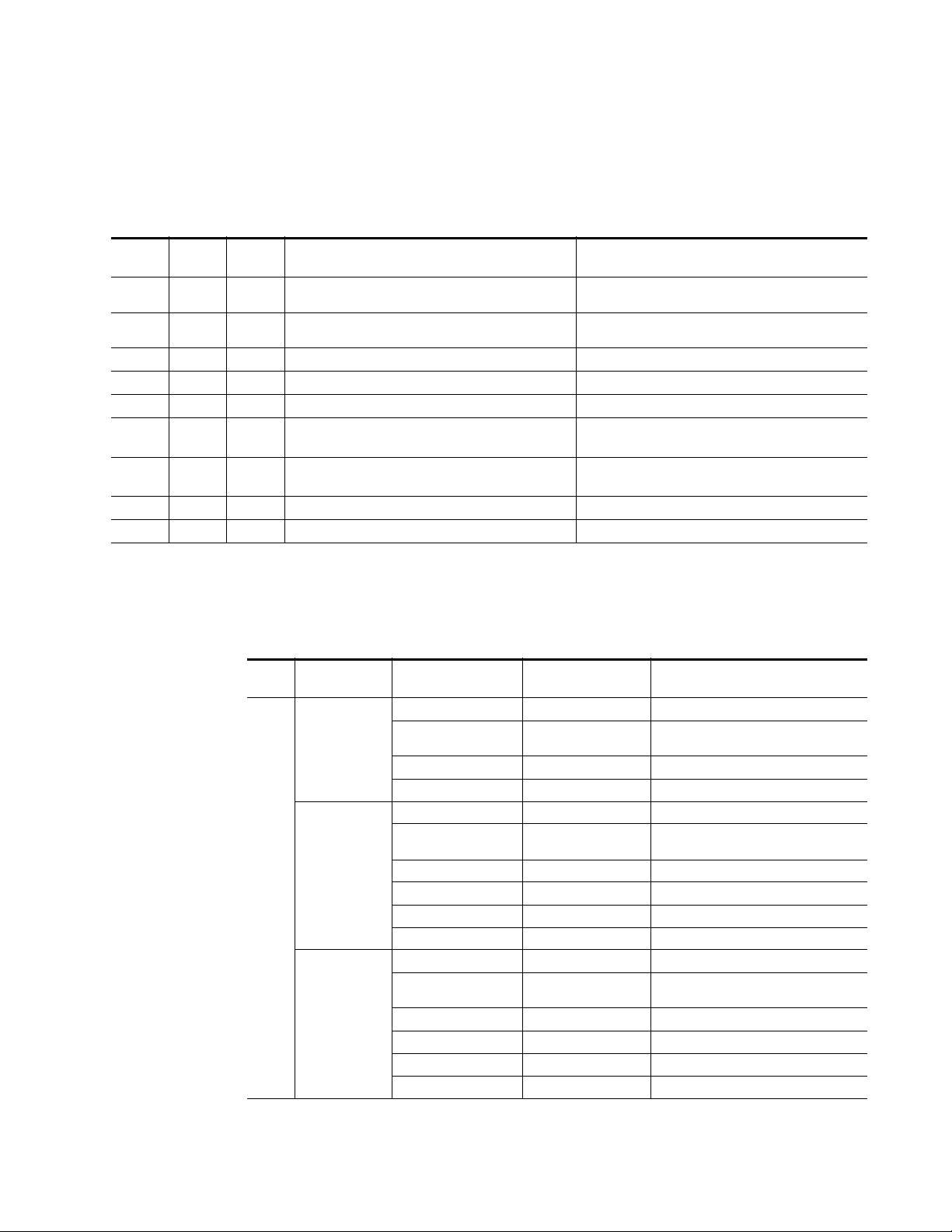

Table 4 on page 20 provides a summary in table format of all parameters

and their ranges, default values, and remote, local, and control panel function names and locations for setting each value.

8960ENC—Instruction Manual 19

Page 20

Configuration

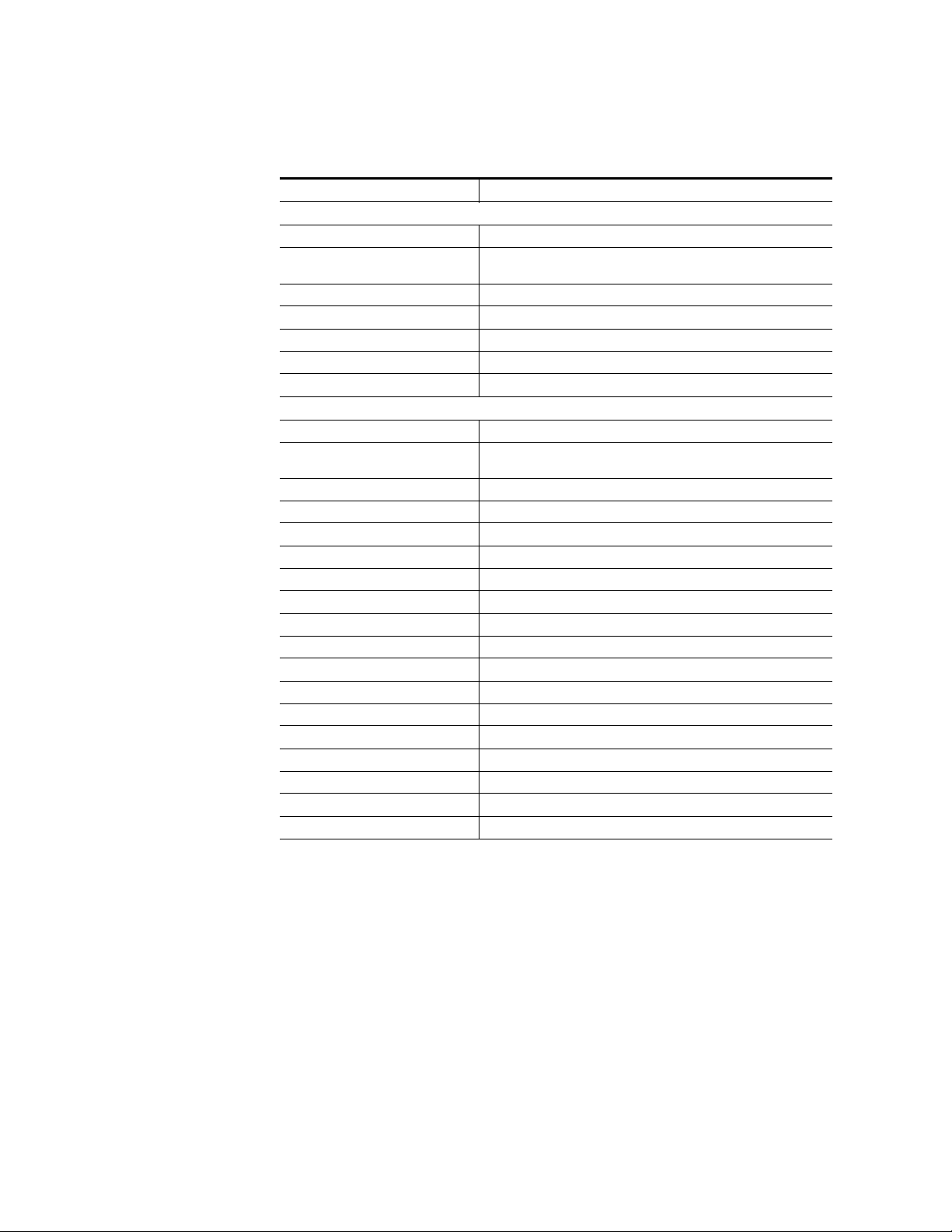

Configuration Summary Table

Ta bl e 4 provides a complete summary of the 8960ENC functions and a

comparison of the functionality available with each control type along with

the ranges and default values for each parameter.

Table 4. Summary of Configuration Functions

Function

Type

Standard Recognition Auto Auto or Manual

Manual Standard

Selection

Output Video Setup Setup Setup or No Setup

Vertical Interval Setup Off On or Off

Line 21 Setup Off On or Off

Line 22 Setup Off On or Off

NTSC or PAL-M

selection

Standards Selection

Controls Type

Output Video Level 97.09%

User Adjustments Calibrate Calibrate or User

Levels Control Type Numeric Numeric2 or Slider

Luma Level adjustment

to set luma gain

Chroma Level adjustment to set chroma gain

Hue Level adjustment

(525 only)

Black Level adjustment 7.54%

Lock Source selection Reference Video or Reference

Default

525 525 or 625

NTSC NTSC or PAL-M

Numeric Numeric

99.74%

99.52%

0 degrees

Range/Choices

Resolution

b

or Slider

41.5 to 171.55%

(0.51% steps)

89.5 to109.9%

(0.08% steps)

88 to 110.95%

(0.09% steps)

0 to 358.05 degrees

(0.35 degree steps)

-14.22 to 21.48%

(0.34% steps)

Web Page/

Function Name

Standard Selection/

Standard Recognition pulldown

Standard Selection/

Manual Selection pulldown

Standard Selection/

Output Video Setup pulldown

Standard Selection/

VI Setup pulldown

Standard Selection/

Line 21 Setup pulldown

Standard Selection/

Line 22 Setup pulldown

a

2

2

2

2

2

Standard Selection/

NTSC/PAL-M Select pulldown

Standard Selection/

Controls Type pulldown

Standard Selection/

Output Video Level (% 1Vpp)

Slider or arrow controls

Levels/

User Adjustments pulldown

Levels/

Controls Type pulldown

Levels/

Luma Level (% White)

Luma Level slider

or arrow controls

Levels/

Chroma Level (% saturation)

Chroma Level slider

or arrow controls

Levels/

Hue (degrees)

Hue Level slider

or arrow controls

Levels/

Black Level (% White)

Black Level slider or arrow

controls

Timing/

Lock Source pulldown

Function Switch

Bank/Setting

1:0 Auto Std

1:1 Lines

1:2 FF Setup

2:F VI Setup

1:D L21Setup

1:E L22Setup

1:3 525 Std

N/A N/A Web page only

1:4 Video

1:5 Levels

N/A N/A Web page only

1:6 Luma

1:8 Chroma

1:9 Hue

1:7 Black

2:0 Lock To

Newton

Control

Panel

Notes/

Conditions

Manual mode

selected in

Standard Recognition above.

525 only

User mode

selected in User

Adjustments

above

20 8960ENC—Instruction Manual

Page 21

Configuration

Table 4. Summary of Configuration Functions

Function

Type

Timing Control Type Numeric Numeric or Slider

Fine Delay control 0 ns

Horizontal Delay 0

Vertical Delay 0

Freeze Recognition Manual Manual or Auto

Freeze Mode Frame Field or Frame

Freeze Field Field 1 Field 1 or Field 2

Freeze Signal Last Field Last Field or Black

Force Manual Freeze Off On or Off

Cross Color Removal Disable Enable or Disable

Chrominance Signal Disable Enable or Disable

Burst Signal Disable Enable or Disable

VI Processing Pass Pass or Delete

Test Mode Disable Enable or Disable

Test Signal Colorbar Colorbar or Linearity

Recall factory defaults N/A See Defaults column

a

Grass Valley no longer supports PAL-M in any of its modular products. Although this setting may work in certain applications, Grass Valley will not warrant that it works

or provide support if problems are encountered using this product with PAL-M signals. This product has not been modified to eliminate support for PAL-M. If this product

has been used with PAL-M in the past without problems, there shouldn’t be any issues using it for the same application. However, it is not recommended that customers

use it in any new PAL-M applications.

b

The numeric displays are approximate values only. Calculation of displayed values are subject to decimal place truncation. Variation from the absolute value increases

at higher adjustment levels.

Default

Range/Choices

Resolution

0 to 40.80 ns

(0.16 ns steps)

0 to 63418 ns (525)

0 to 63862 ns (625)

(37 ns steps)

0 to 524 lines (525)

0 to 624 lines (625)

(1line steps)

Web Page/

Function Name

Timing/

Controls Type pulldown

Timing/

Fine Delay

Fine Delay slider or arrow

controls

Timing/

Horizontal Delay slider or arrow

controls

Timing/

Vertical Delay slider or arrow

controls

Timing/

Freeze Recognition pulldown

Timing/

Freeze Mode pulldown

Timing/

Freeze Field pulldown

Timing/

Freeze Signal pulldown

Timing/

Freeze button

Video Processing/

Cross Color Removal pulldown

Video Processing/

Chrominance Signal pulldown

Video Processing/

Burst Signal pulldown

Video Processing/

VI Processing pulldown

Video Processing/

Test Mode pulldown

Video Processing/

Test Signal Select pulldown

Recall Factory Defaults/

Factory Defaults button

Function Switch

Bank/Setting

N/A N/A Web page only

2:1 Fine Dly

2:2 H Delay

2:3 V Delay

2:4 Frz Rec

2:6 Frz Mode

2:7 FrzField

2:8 Frz Sig

2:5 Freeze

2:A CrossClr

2:A Chr Sig

1:B Burst

1:C VI Proc

2:D Tst Mode

2:C Tst Sel

1:F (down) N/A

Newton

Control

Panel

Notes/

Conditions

No submodule

required

8900FSS

submodule

installed.

Output signal

processing

Replace output

signal with test

pattern

8960ENC—Instruction Manual 21

Page 22

Configuration

GRASS VALLEY GROUP 8960ENC COMPOSITE ENCODER 671-4698-

GND

FUNCTION – rotary switch

SW1 – actuator toggle switch

2nd – second function LED

CONF – configuration LED

JP1

Place jumper in

Local position to

lock out remote

access.

Local

Local &

Remote

JP1

JP10 JP11

Remote Lockout

Reference Input

Impedance

75 Hi Z

JP11 (625)

75 Hi Z

0642_07r1

Local Onboard Module Configuration

The 8960ENC module can be configured locally using the rotary and toggle

switches shown in

Figure 8. Two LEDs (CONF and 2nd) indicate status of

the configuration process. These four components perform the following:

• Function (rotary) switch addresses a desired function for configuration

and provides two sets (banks) of 16 functions (0 through 9,

A through F), although not all positions are used.

• 2nd (second function) LED when on, indicates that the rotary switch is

addressing the second (Bank 2) of functions (see Table 5 on page 24)

that control the optional 8900FSS Frame Sync Submodule.

• SW1 (paddle) switch actuates or selects the desired setting for the

selected function when the switch is held momentarily in either the up

or down position.

• CONF (configuring) LED when on, indicates the module is initializing

or processing configuration information.

Note Function switch position F (Recall) in Bank 1 can be used to return the

module configuration to the factory default.

The following onboard jumpers are used to permit or lockout remote

control and set reference input impedance.

• Remote Control Lockout – When a jumper is placed across pins 1 and 2

of jumper block JP1 (see Figure 8), module output mode settings are

adjustable from the Local on-board switches only. To have both Local

and Remote access, set the jumper across pins 2 and 3.

• Reference Input Impedance – When a jumper is placed across pins 1

and 2 of jumper block JP10 (525 line reference) or JP11 (625 line reference), Reference Input is terminated into 75 Ω (see Figure 8). To have

high impedance termination, set the jumper across pins 2 and 3 of the

appropriate jumper block.

Figure 8. Module Configuration Switches, LEDs, and Jumpers

22 8960ENC—Instruction Manual

Page 23

Onboard Module Configuration

To make configuration settings:

1. Rotate the Function Switch to Bank 1 (2nd LED off) or Bank 2 (2nd LED

on) and to the desired function within that bank.

Note The Function switch should be kept in Bank 2 position E when not in use to

avoid any inadvertent change in configuration. E is an inactive position.

2. Move the paddle switch to the up or down position and hold

momentarily to set the desired function (refer to Table 5 on page 24).

3. Return the Function switch to Bank 2 position E when finished with

entire configuration process.

Adding/Deleting Setup for 525 Format

Bank 1, Position 2

Bank 1, position 2 is an overall setup on/off selection which overwrites all

other setup controls. When

lines in the full-field (FF) picture—which is composed of AP (active pic

ture) and VI (vertical interval)—have 54 mV setup added. The luma

chroma gain is reduced to provide a 1 V peak-to-peak nominal level. When

No Setup (off) is selected, AP and VI have no setup, and luma chroma gain is

increased to provide a 1 V peak-to-peak nominal level.

Setup (on) is selected for NTSC 525 format, all

Configuration

-

When Setup is selected, setup can be selectively removed from lines 21, 22

or the vertical interval. When

any line.

Bank 1, Position D

Bank 1, position D controls setup ON/OFF for line 21 in both fields.

Bank 1, Position E

Bank 1, position E controls setup ON/OFF for line 22 in both fields.

Bank 2, Position F

Bank 2, position F controls setup ON/OFF VI lines only both fields.

When Factory Default is selected setup is on AP lines, no setup on VI lines, no

setup on line 21, setup on line 22.

No Setup is selected, setup cannot be added to

8960ENC—Instruction Manual 23

Page 24

Configuration

Table 5. Encoder Configuration Functions

Function

Switch

Input/Output Signal Adjustments

0 Auto Manual

1525 625

2On Off

3NTSCPAL-M

4 Increase Decrease

Signal Processing Adjustments

5 Enable Calibrated

6 Increase Decrease

7 Increase Decrease

8 Increase Decrease

Bank 1 - 2nd LED Off

9 Increase Decrease

Signal Filtering Setup

A Enable Disable

B Enable Disable

C Pass Delete

DOn Off

EOn Off

F – Recall

Paddle

Switch Up

Paddle

Switch Down

Function Description

Standard Recognition – Automatic standard recognition or manual

select enable.

Manual Standard – Selection of 525-line or 625-line signal. The

internal automatic standard detection is disabled when Manual is

selected.

Setup in the output video (this function is disabled if the standard is

625). Select On for NTSC, select Off for Japanese NTSC.

525 NTSC/PAL-M Selection – Defines the subcarrier frequency of

a

the output video signal (Function is Disabled if standard is 625).

Output Video Level – controls ± 6 dB gain adjustment of the output

video signal in 256 steps.

User Adjustments – Enables processing amplifier functions (6-9) or

selects Calibrated presets optimized for a calibrated video output.

Luma Level b – Can be adjusted ±10% in 256 incremental steps.

Black Level 2 – Can be adjusted ±100 mV in 256 incremental steps.

Chroma Level 2 – Can be adjusted ±10% in 256 incremental steps.

Hue 2 – Chroma phase can be rotated from 0 to 360 degrees. Disabled if standard is PAL.

Enable/Disable modulated chroma signal

Enable/Disable burst reference in the output signal

VI Processing Options – Select Pass for picture content processed

and passed through, or Delete to remove picture content.

Adds or removes setup for line 21 in both fields

Adds or removes setup for line 22 in both fields

Factory Default – Resets all user adjustable parameters to optimized

setting for a calibrated SDI input signal.

24 8960ENC—Instruction Manual

Page 25

Configuration

Table 5. Encoder Configuration Functions - (continued)

Function

Switch

0 Video Reference

1 Increase Decrease

2 Increase Decrease

3 Increase Decrease

4Manual Auto

5 Off On

6Frame Field

7 Field 1 Field 2

8 Last Field Black

Bank 2 - 2nd LED On

9

A Enable Disable

B

C Colorbar Linearity

D Enable Disable

E

FOn Off

a

Grass Valley no longer supports PAL-M in any of its modular products. Although this setting may work in certain applications,

Grass Valley will not warrant that it works or provide support if problems are encountered using this product with PAL-M signals.

This product has not been modified to eliminate support for PAL-M. If this product has been used with PAL-M in the past without

problems, there shouldn’t be any issues using it for the same application. However, it is not recommended that customers use it in

any new PAL-M applications.

b

Inactive if User Adjustments (switch position 5) is set to Calibrated.

c

Inactive if Frame Sync Submodule is not present.

Paddle

Switch Up

currently not used

currently not used

Inactive Position

Paddle

Switch Down

Function Description

Lock Source – Selecting Video forces delay mode even if a reference

signal is present

Fine delay adjustment

Horizontal Delay c – Provides synchronizer delay adjustment in clock

increments and line increments accordingly.t

Vertical Delay 3 – Provides synchronizer delay adjustment in clock

increments and line increments accordingly

Freeze Recognition 3 – Selecting Auto stores the last field in the

frame synchronizer to use if the input video is lost or corrupted.

Freeze Manual 3 – Enables/Disables manual selection of Freeze

Mode according to positions 6&7.

Freeze Mode 3 – Select between Frame and Field.

Freeze Field 3 – Select between Field 1 and Field 2.

Freeze Signal 3 – Selects the freeze output signal if Auto or manual

freeze is activated.

Cross color removal – Enables/Disables the cross-color removing

2D filter.

Test Signal – Select between colorbar and linearity signal.

Test Mode – If Test is selected, the input SDI is replaced with the test

pattern selected in 2:C.

Adds or removes setup for vertical interval in both fields

8960ENC—Instruction Manual 25

Page 26

Configuration

Remote Configuration and Monitoring

8960ENC configuration and monitoring can be performed using a web

browser GUI interface or a networked Newton Control Panel when the

8900NET Network Interface module is present in the video frame (Gecko

8900TFN-V frame). Each of these interfaces is described below.

Note For remote access, make sure the jumper block on the module is set for both

Local and Remote access (Figure 8 on page 22).

8900NET Module Information

Refer to the 8900NET Network Interface Module Instruction Manual for

information on the 8900NET Network Interface module and setting up and

operating the Gecko 8900 frame network.

Note The 8900NET module in the frame must be running software version 3.2.2 or

higher for proper remote and control panel operation. Upgrade software and

instructions for the 8900NET can be downloaded from the Grass Valley web

site.

Newton Control Panel Configuration

A Newton Control Panel (hard or soft version) can be interfaced to the

Gecko 8900 Series frame over the local network. Refer to the documentation

that accompanies the Newton Modular Control System for installation,

configuration, and operation information.

Control panel access offers the following considerations for module configuration and monitoring:

• Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

• Ability to group modular products—regardless of their physical locations—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

• Update software for applicable modules and assign frame and panel IP

addresses with the NetConfig Networking application.

• Recommended for real-time control of module configuration parameters, providing the fastest response time.

Note Not all module functions are available with the control panel, such as factory

default recalls. The available Newton control panel controls for the 8960ENC

module are listed in Table 4 on page 20.

An example of the Newton Configurator is shown in Figure 9 on page 27.

26 8960ENC—Instruction Manual

Page 27

Figure 9. Newton Configurator Example

Configuration

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

• Provides complete access to all module status and configuration func-

tions, including naming of inputs and outputs, factory parameter and

name default recalls, E-MEM functions, slot configuration, and SNMP

monitoring controls.

• Web access will require some normal network time delays for pro-

cessing of information.

• Configuration parameter changes may require pressing

Enter, upload processing time, and a manual screen refresh to become

effective.

• Web interface recommended for setting up module signal and slot

names, E-MEMS, and reporting status for SNMP and monitoring.

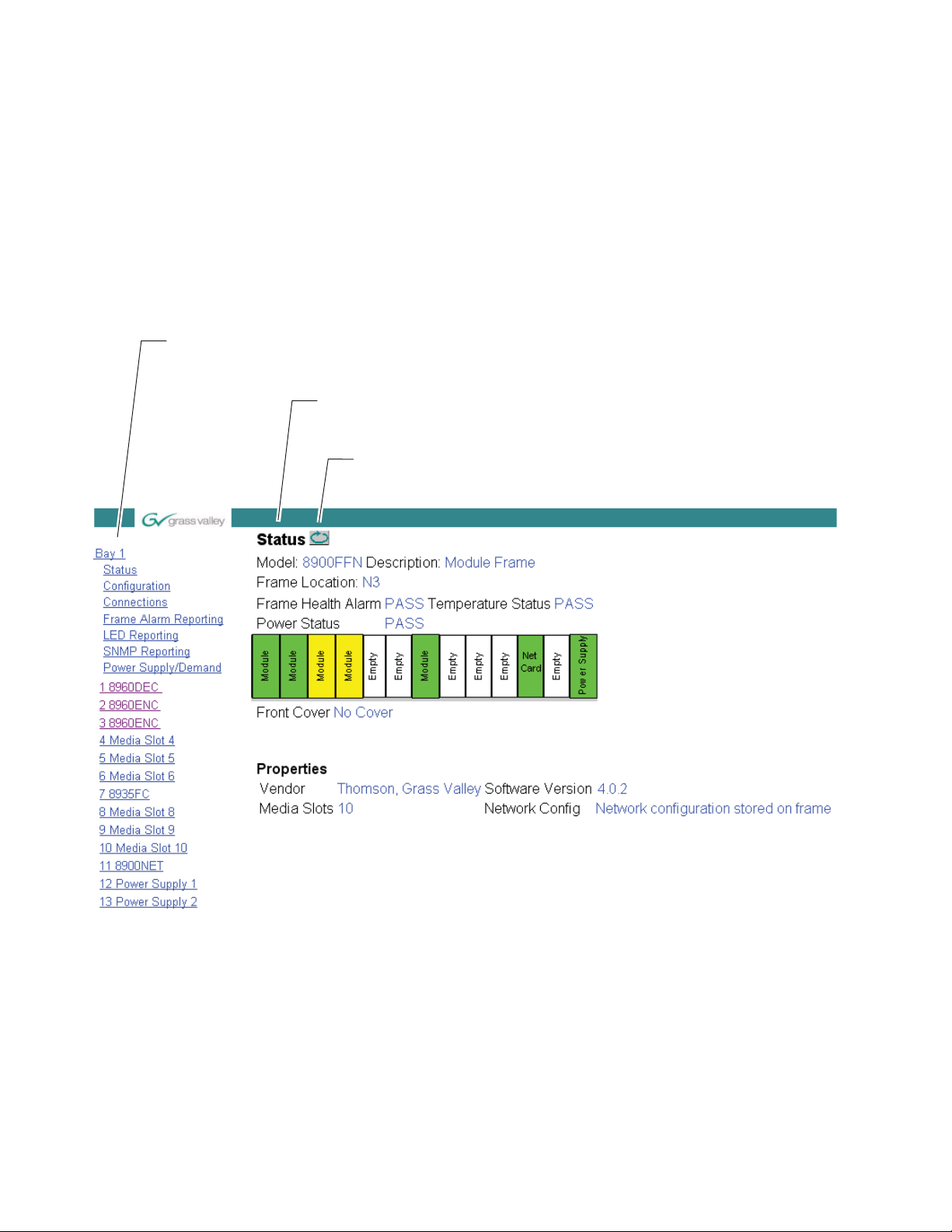

Refer to the Frame Status page shown in Figure 10 on page 28. The 8900

modules can be addressed by clicking either on a specific module icon in

the frame status web page or on a module name or slot number in the link

list on the left.

Apply button or

8960ENC—Instruction Manual 27

Page 28

Configuration

0612-12r2

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

refresh of page

Note The physical appearance of the graphics on the web pages shown in this

manual represent the use of a particular platform, browser and version of

8900NET module software. They are provided for reference only. Web pages

will differ depending on the type of platform and browser you a

the version of the 8900NET software installed in your system. This manual

reflects 8900NET software version 4.0.2.

re using and

For information on status and fault monitoring and reporting shown on the

Status page, refer to Status Monitoring on page 51.

Figure 10. Gecko 8900 Frame Status Page

28 8960ENC—Instruction Manual

Page 29

8960ENC Links and Web Pages

The 8900 web interface GUI provides the following links and web pages for

the 8960ENC module (

• Status – reports input and reference signal status and module informa-

tion (page 30),

• Standard Selection – provides controls for setting module line standard

and setting output video levels (page 31),

• Levels – provides access to controls for adjusting luma, chroma, hue,

and black levels (page 34),

• Timing – provides lock source and fine phase adjustments and hori-

zontal and vertical timing adjustments when the 8900FSS is installed

(page 37),

• Video Processing – provides controls for enabling and disabling video

functions on the encoded output (page 40),

• Recall Factory Defaults – use this web page to recall factory defaults for

the module (page 41), and

Figure 11):

Configuration

• Slot Config – provides a Locate Module function, Slot Identification

fields, Slot Memory controls, and links to the Frame Alarm and SNMP

Trap enables on the 8900NET module web pages (page 42).

Figure 11. 8960ENC Web Page Links

On all web pages, click on Apply to activate settings in each selection then

refresh the web page at the top of the page with the

shown at left).

Refer to Table 4 on page 20 for a complete summary of controls, defaults,

and parameter ranges.

Refresh button (both

8960ENC—Instruction Manual 29

Page 30

Configuration

Use

this

link

Status Web Page

The Status web page (Figure 12) shows the input signal status of the component analog video input. Color coding of the display indicated the signal

status. Refer to

coding.

Information about the module, such as part number, serial number, hardware revision and software and firmware versions are given in a read-only

section at the bottom of the display.

Figure 12. 8960ENC Status Web Page

Status Monitoring on page 51 for an explanation of the color

30 8960ENC—Instruction Manual

Page 31

Standard Selection Web Page

Use

this

link

The Standard Selections web page provides controls to set the line standard, enable setup on the vertical interval and the output video, and set the

video output level from the module.

Set the following parameters on this web page:

Configuration

• Set the Standard Recognition control to either

allows the module to detect and accept either a 525-line or 625-line

input signal. The line standard value will be reported as a read-only

value in the menu when

Figure 13. Standard Selection Web Page

Auto is selected (see Figure 13).

Auto or Manual. Auto mode

8960ENC—Instruction Manual 31

Page 32

Configuration

Manual Mode

The Manual setting forces the module to operate in the mode chosen by

the user. If

allow selection of either

Figure 14. Standard Selection Web Page – Manual Mode

Manual is selected, the Line Standard control will appear and

525 or 625 (Figure 14).

• The Output Video Setup control appears only when a 525-line standard

is enabled, either manually or automatically. For output video with

54 mV of setup, select

Setup. Select No Setup for Japanese NTSC or other

requirements with no setup.

When Setup (on) is selected for NTSC 525 format, all lines in the

full-field (FF) picture—which is composed of AP (active picture) and VI

(vertical interval)—have 54 mV setup added. The luma chroma gain is

reduced to provide a 1 V peak-to-peak nominal level. When

No Setup

(off) is selected, AP and VI have no setup, and luma chroma gain is

increased to provide a 1 V peak-to-peak nominal level.

When Setup is selected, setup can be selectively removed from lines 21,

22 or the vertical interval. When

No Setup is selected, setup cannot be

added to any line. Factory default provides setup on AP lines, no setup

on VI lines, no setup on line 21, and setup on line 22.

• Select NTSC or PAL-M subcarrier format.

Note Grass Valley no longer supports PAL-M in any of its modular products.

Although this setting may work in certain applications, Grass Valley will not

warrant that it works or provide support if problems are encountered using

this product with PAL-M sig

inate support for PAL-M. If this product has been used with PAL-M in the past

without problems, there shouldn’t be any issues using it for the same application. However, it is not recommended that customers use it in any new

PAL-M applications.

nals. This product has not been modified to elim-

32 8960ENC—Instruction Manual

Page 33

Configuration

• Adjust the Output Video Level using either the Slider or Numeric adjust-

ment mode (see Figure 13 on page 31 for numeric control and Figure 15

for slider control).

The gain of the output video is adjusted relative to a calibrated value of

1

V p-p (100%). For example, if you have an output of 1V p-p, the value

would be set to 100%.

In either adjustment mode, the single arrow will increment the value by

approximately 0.5% per click. The double arrows increment or decre

ment the value by approximately 10x (5% per click).

Note Numeric displays are for approximate values only. Calculation of displayed

values are subject to decimal place truncation. Variation from the absolute

value increases at higher adjustment levels.

Figure 15. Output Level Adjustments – Slider Control Type

-

8960ENC—Instruction Manual 33

Page 34

Configuration

Use

this

link

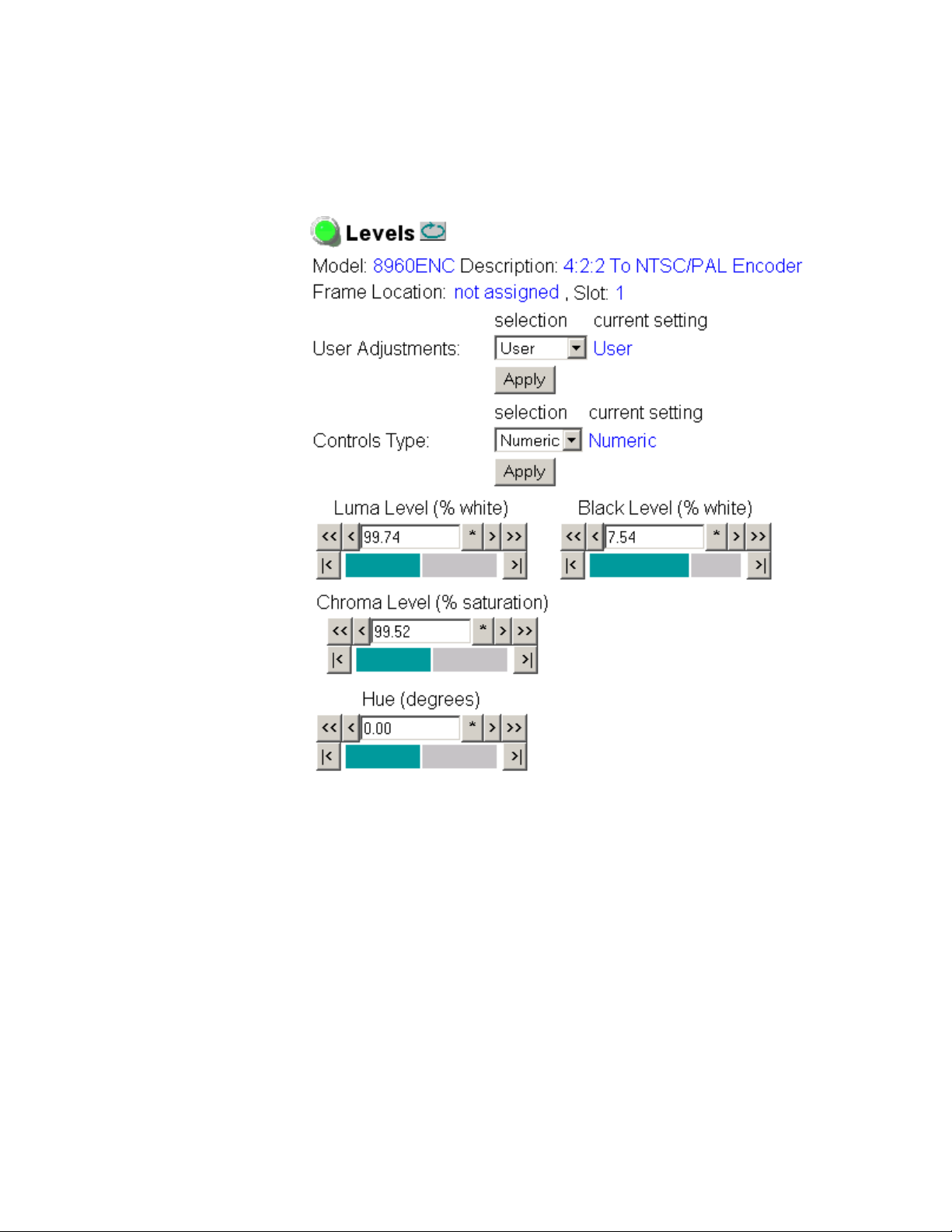

Levels Web Page

The Levels web page provides access to processing amplifier controls. You

may select user adjustable to set the values or set the module to factory calibrated levels.

Set the User Adjustments pulldown to either Calibrate or User.

In

Calibrate mode, the module selects preset factory default values opti-

mized for a calibrated video output. The values will be reported as

read-only as shown in Figure 16.

Figure 16. Levels Web Page – Calibrate Mode

In User mode, select Slider or Numeric adjustment mode to adjust the following output video parameters (see Figure 17 on page 35 for numeric controls and Figure 18 on page 36 for slider controls):

• Luma level (luminance gain relative % white),

• Chroma level (chrominance gain relative % saturation),

• Hue, 0 – 360 degrees (525 standard only), and

• Black level (black level relative to % white).

In either adjustment mode, the single arrow will increment/decrement the

values by approximately 1x the parameter value. The double arrows will

increment/decrement the values by approximately 10x. In

ment mode, you may also enter a value directly into the window.

Numeric adjust-

34 8960ENC—Instruction Manual

Page 35

Configuration

Note Numeric displays are for approximate values only. Calculation of displayed

values are subject to decimal place truncation. Variation from the absolute

value increases at higher adjustment levels.

Figure 17. Levels Web Page – User Mode – Numeric Control Type

8960ENC—Instruction Manual 35

Page 36

Configuration

Figure 18. Levels Web Page – Slider Control Type

36 8960ENC—Instruction Manual

Page 37

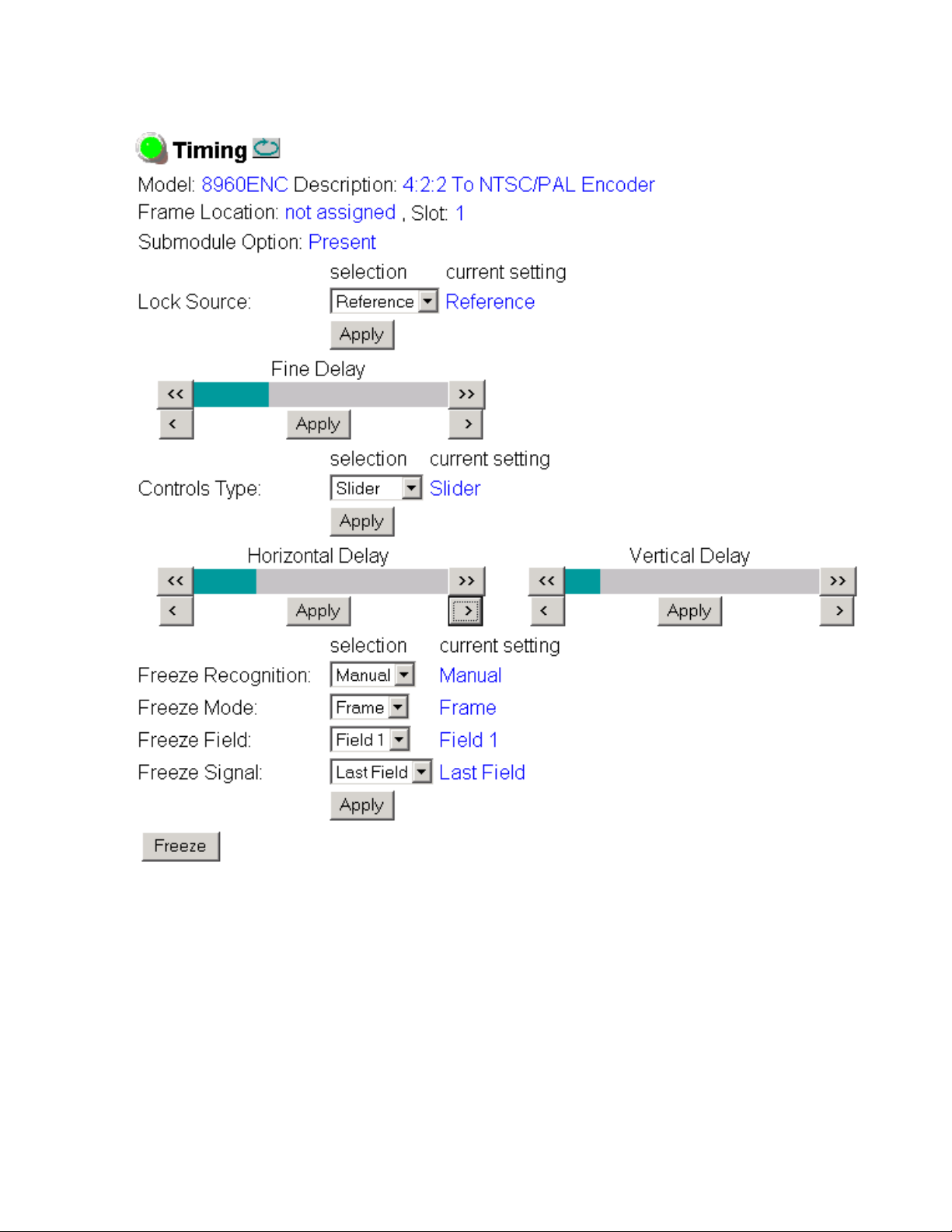

Timing Web Page

Use

this

link

The Timing web page shown in Figure 19 on page 38 (Numeric control

mode) or Figure 20 on page 39 (Slider control mode) provides lock source

selection and fine phase adjustments for the output video. When the

optional Frame Sync submodule is installed, additional horizontal and ver

tical phase adjustments and freeze options become available.

Select the Apply button to activate each selection.

Configuration

-

Adjustment parameters may be selected in

Slider or Numeric mode. Select the

desired mode in the Controls Type window. In either mode, the single

arrow will increment/decrement the values by approximately 1x the value

of the parameter. The double arrows will increment/decrement the values

by approximately 10x. In

Numeric adjustment mode, you may also enter a

value directly into the window.

Set the following parameters in this web page:

• Choose a Lock Source from

• Adjust the

Fine Delay in nanoseconds with either Slider or Numeric

Reference input or Video input.

adjustment mode.

If the optional 8900FSS Frame Sync submodule is installed (Submodule

Option: Present as shown in Figure 19 on page 38), you can also make the

following delay adjustments and set freeze operation parameters:

• Adjust Horizontal Delay in nanosecond increments and Vertical Delay

phase adjustment in line increments in either

• Set Freeze Recognition to

Manual or Auto. Selecting Auto stores the last

Slider or Numeric mode.

field in the Frame Synchronizer to use if the input video is lost or corrupted.

• Set the Freeze Mode to

Frame or Field.

• Set the Freeze Field to

• Set the Freeze Signal to

output signal when a freeze is activated in either

• To perform a manual freeze, click the

Field 1 or Field 2.

Last Field or Black. This will determine the freeze

Auto or Manual mode.

Freeze button at the lower left of

the web page.

8960ENC—Instruction Manual 37

Page 38

Configuration

Figure 19. Timing Web Page – Numeric Control Type

38 8960ENC—Instruction Manual

Page 39

Figure 20. Timing Web Page – Slider Control Type

Configuration

8960ENC—Instruction Manual 39

Page 40

Configuration

Use

this

link

Video Processing Web Page

Use the Video Processing web page shown in Figure 21 to enable or disable

the:

• Cross-color removing 2D filter,

• Modulated chrominance signal,

• Burst reference in the output signal, and

• Test Mode signal output.

In the VI Processing pulldown select

selected, the picture content in the vertical interval is processed and passed

through. If

tical interval.

Test Mode is enabled, choose Colorbar or Linearity as the test output signal.

If

Figure 21. Video Processing Web Page

Delete is selected, the picture content is removed from the ver-

Pass or Delete VI signal. When Pass is

40 8960ENC—Instruction Manual

Page 41

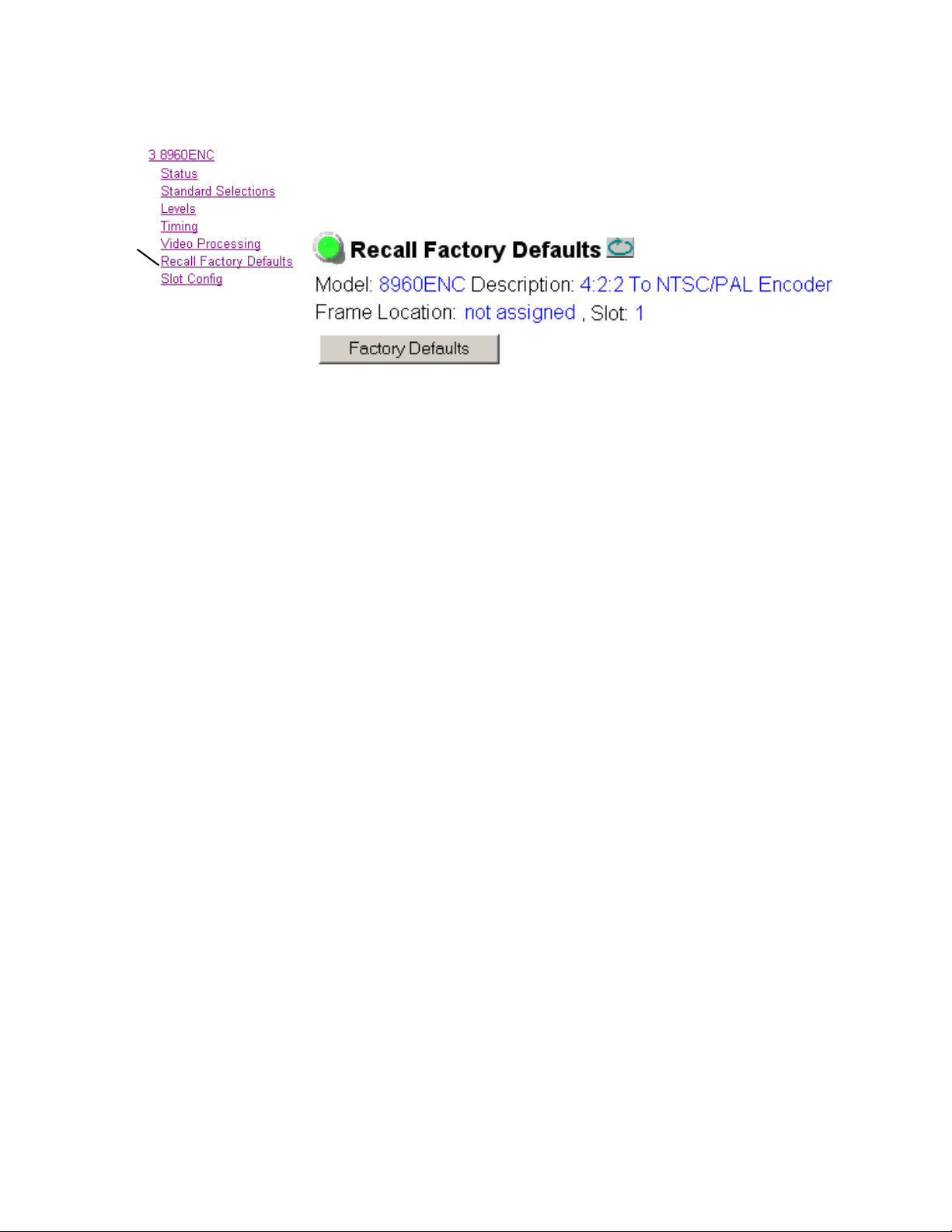

Recall Factory Defaults Web Page

Use

this

link

Factory default settings can be recalled by selecting the Factory Defaults

button shown in Figure 22 on the Recall Factory Defaults web page.

Figure 22. Factory Default Recall Web Page

Configuration

8960ENC—Instruction Manual 41

Page 42

Configuration

Use

this

link

Slot Config Web Page

Use the Slot Config web page (Figure 23 on page 43) to perform the following functions on the 8960ENC module:

• Locate Module – selecting the Flash radio button flashes the yellow

COMM and CONF LEDs on the front of the module so it can be located

in the frame.

Slot Identification – you may identify the module by typing a specific

•

name in the

module and travels with the 8900NET module if it is moved to another

frame. Select

An Input Signal Name field is also provided for entering a name for the

input signal. Press the

name.

• Slot Memory – the slot configuration for each media module is automatically saved periodically (once an hour) to the 8900NET module in that

frame. You may also select the

save the current configuration for this slot. The configuration is saved

on the 8900NET module. If the 8900NET module is removed or

powered down, the stored configurations are not saved.

Name field. The assigned name is stored on the 8900NET

Default to enter the factory default module name.

Default button to return to the factory default

Learn Module Config button at any time to

When the Restore upon Install box has been checked, the current configuration saved to this slot is saved as slot memory. When the current

module is removed and another module of the same type is installed,

the configuration saved to the 8900NET module will be downloaded to

the new module. The box must be checked before the current module

with the saved configuration is removed.

• Frame Health Reports Link – select the Frame Health Reports link to open

the 8900NET module Frame Alarm Reporting web page. This web page

allows configuration of the alarms and warnings that are reported to

the external Frame Health Alarm connector on the rear of the GeckoFlex frame.

LED Reports – This link appears when the 8900NET module has software

•

version 4.0.2 or later installed. When the link is selected, a read-only

status report of the 8900NET Hardware Switch state is given. In the

LED Reporting section of the web page, LED Reporting on the 8900NET

module can be enabled or disabled as desired.

SNMP Trap Reports Link – select the SNMP Trap Reports link to open the

•

8900NET SNMP Reporting web page. This link will only be present

when SNMP Agent software has been installed on the 8900NET

module. This web page allows configuration of which alarms and

warnings that are reported to the SNMP management software.

Refer to the 8900NET Instruction Manual for complete details on using the

8900NET web pages.

42 8960ENC—Instruction Manual

Page 43

Figure 23. 8960ENC Slot Config Web Page

Configuration

8960ENC—Instruction Manual 43

Page 44

Software Updating

Software Updating

Software updating for the module is done using the 8900-FLOAD-CBL

assembly available from Grass Valley Customer Service.

The 8900-FLOAD-CBL assembly consists of a circuit board and serial and

ribbon cables that connect between a serial port on a PC and the ISP con

nector on an 8900 or 2000 module. The software upgrade requires downloading files from a PC to the module through the cable assembly.

Equipment Required

The following items are required for this procedure:

• 8900-FLOAD-CBL assembly (circuit board and 2 cables),

• Software CD containing ModLoad.exe application (comes with the

• PC with unused Serial Com port that can be connected serially to the

-

8900-FLOAD-CBL kit) and 8900/2000 module software files and

Release Notes, and

8900 or 2000 frame.

Acquiring Software Updates

For information on acquiring the upgrade kit and available software

updates, contact Grass Valley Customer Service at the location given in

Contacting Grass Valley on page 4 at the front of this manual.

44 8960ENC—Instruction Manual

Page 45

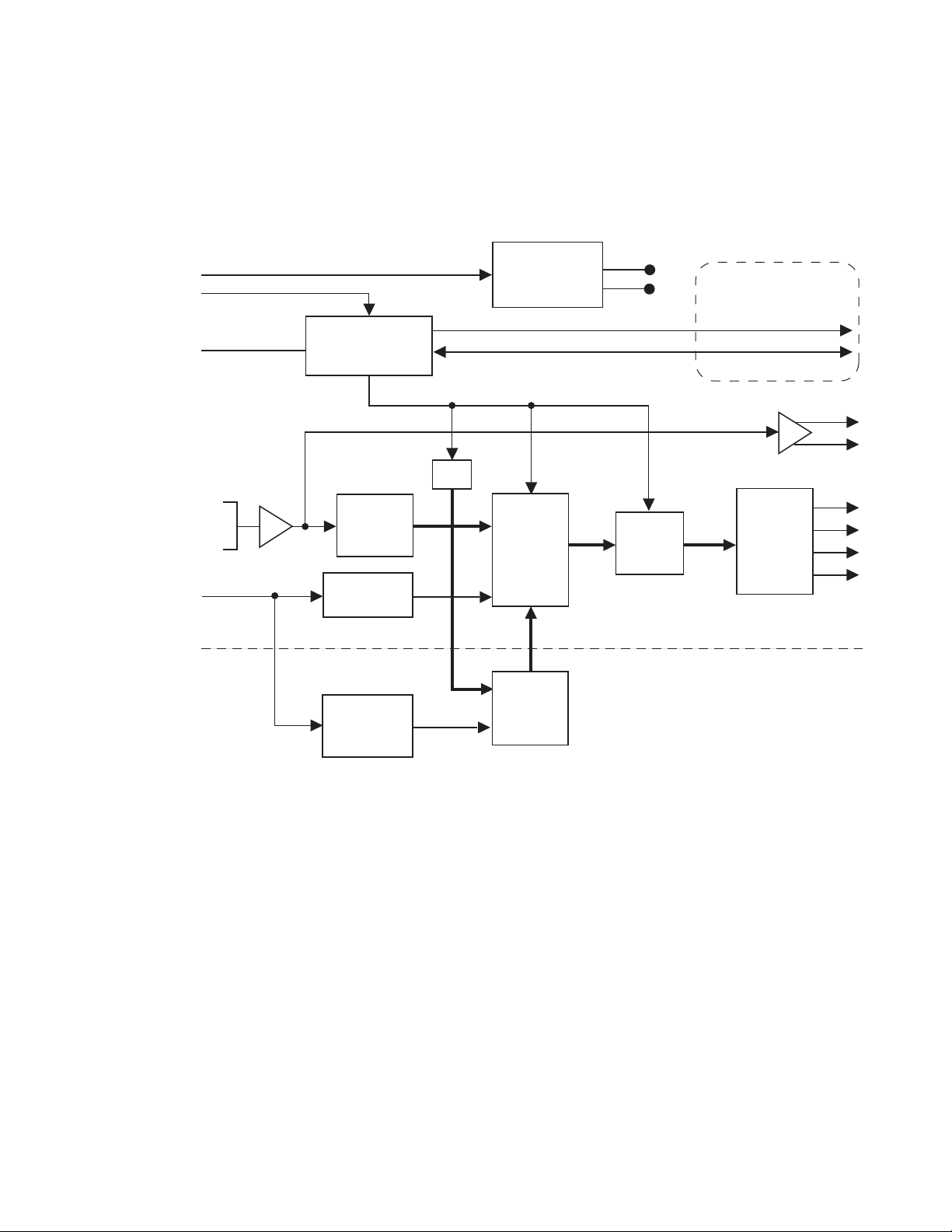

Functional Description

+12V

Module Slot ID

Fault Reporting

Local User

Interface

Intra-frame Control Interface

4:2:2

SDI

Input

10

10

10

4X NTSC/PAL

2X SDI

Optional Submodule *

Available with Frame

Communication Upgrade

* The main encoder module automatically recognizes the attachment of the frame synchronizer submodule.

NTSC/PAL

Reference

-5V

+5V

Microcontroller

On-board

Switching Mode

Power Supply

module

Serial to

Parallel

Converter

EDH

Frame Delay/

Synchronizer

H Genlock to

External Video

Color Frame

ID Generation

Output

Filter and

Driver

Cross-color

Remover

&

Genlock

with

FIFO

10-bit

Composite

Encoder

0642-01

RC

Refer to the block diagram in Figure 24 while reading the following functional description.

Figure 24. 8960ENC Block Diagram

Functional Description

Serial 4:2:2 Input Stage & Output

The SDI signal is connected to the high impedance loop-through input. The

input amplifier auto-equalizes the signal up to 24 dB loss (300 meters of

Belden 8281 cable). The reclocked signal is available on two SDI output con

nectors and also on an internal 10-bit parallel bus for further processing.

Error Detection Handling (EDH) is tested by the microcontroller which

flashes the Fault LED when errors are detected.

-

8960ENC—Instruction Manual 45

Page 46

Functional Description

Cross-Color Remover

Synchronizer

The encoder accepts 525/625 component video and before the composite

encoding, removes luminance components that could cause discoloration

in high detail diagonal content areas. By doing this at the decoder side,

there are no artifacts when using digital comb filtering based decoders such

as the 8960DEC Adaptive Decoder. The pre-filtering is done in a Field Pro

grammable Gate Array (FPGA) using a spatio-temporal comb filter that

gives full vertical resolution while removing all unwanted cross-color

details. All the necessary timing and interfacing signals are generated inter

nally and adjusted automatically to the incoming signal’s standard.

Phasing range is infinite with the addition of the optional frame synchronizer module. The frame synchronizer is locked to the selected reference in

the horizontal and vertical domain in 37 ns steps.

-

-

10-bit Encoder and Output Driver

The 10-bit precision encoder can be switched through auto/manual standard selection to multi-standard outputs:

•NTSC

•PAL-B

•PAL-M

Fine phase adjustment is available within a 0-45 ns range.

The oversampling restoration filter gives an exceptionally flat response and

a linear phase signal that is amplified and automatically DC-restored

before it is output to the four BNC connectors.

Color-frame Lock

When the Lock Source is set to Reference (factory default configuration),

the composite output video is automatically color-frame locked when a

blackburst reference signal is present. The composite analog video output

signal and the reference have to be frequency-locked and the phase differ

ence has to be within ±10 video lines for color-frame locking.

-

If during module configuration Lock Source is set to Video, color-frame

lock is free-running. If the output signal is PAL-M encoded, the board locks

to NTSC reference signal.

46 8960ENC—Instruction Manual

Page 47

Microcontroller

At power up, the microcontroller configures the encoder chip and loads the

firmware according to the last stored user settings. The user adjustable

parameters are input through a multifunction rotary and toggle switch

combination interface with a preset option of the factory recall settings. All

the functions are remote read/writable through the intraframe control

interface (available in 8900TX/TF/TFN frames). The Fault Reporting

output is pulsed in case of loss of input signal.

Regulator

The input +12 V is stepped down to +5 V and -5 V using an on-board

switched mode drop (buck) regulator. The regulator does not start up until

the main supply voltage reaches approximately 80% of its nominal value.

Functional Description

8960ENC—Instruction Manual 47

Page 48

Specifications

Specifications

Table 6. 8960ENC Specifications

Parameter Value

Input

Number of inputs 1

Input signal formats Serial digital video conforming to SMPTE 259M 10-bit, 4:2:2 component

Common Mode Rejection 2 V p-p to 60 Hz

Impedance 75 Ω, loop-through

Return loss > 15 dB up to 270 MHz

Equalization 300 meters (984 ft.) Belden 8281 cable

Connector 75 Ω on 8900 frame

Analog Outputs

Number of outputs 4

Signal type Composite analog video conforming SMPTE170M for NTSC and

Signal level 1 V peak to peak nominal ±6 dB

Clamping level 0.0 VDC +20 mV/-0.0 mV

Output impedance 75 Ω

Connector type 75 Ω on 8900 frame

Output return loss > 40 dB to 5.5 MHz

Output isolation > 46 dB to 5.5 MHz

Frequency response ± 0.1 dB to 5.5 MHz

Differential phase < 0.5 degrees

Differential gain < 0.9%

Group delay < 10 ns to 5.5 MHz

RMS signal-to-noise > 59 dB to 5.5 MHz

Resolution 10 bits

Phasing Full-frame with optional frame synchronizer

Fine Phase 0-45 ns

Electrical length 2.1 µs ±0.1 µs

Accuracy 9.2 bits

digital signal

CCIR624 for PAL-B

a

48 8960ENC—Instruction Manual

Page 49

Specifications

Table 6. 8960ENC Specifications - (continued)

Parameter Value

Serial Digital Outputs

Number of outputs 2

Signal type Serial digital video conforming to SMPTE259M 10bit 4:2:2component

Signal Level 800 mV +/-10%

Connector type 75 Ω on 8900 frame

Output Return Loss > 15 dB up to 270 MHz

Jitter Conforms to SMPTE 17.2/002

Rise/Fall Times 400-700 ps (20-80% amplitude)

Reference Input

Number of references 2

Signal type Black Burst

Signal level Sync: 300 mV p-p ±3 dB

Input impedance 75 Ω or high impedance, jumper selectable

Connector type 75 Ω on 8900 frame

Return loss > 36 dB to 5 MHz

RMS signal-to-noise > 40 dB to 5 MHz

SCH error ≤ 60 degrees

Color-frame locking Composite analog video output and reference signal must be within ±10

Environmental

Frame temperature range See Gecko Frame manual

Operating Humidity Range 0 to 90% non-condensing

Non-operating Temperature -10 to +70 degrees C

Mechanical

Frame type 8900 Gecko Video or GeckoFlex with 8900V-R rear module

Power Requirements

Supply voltage + 12V

Power Consumption < 6.5 Watts, < 8.5 Watts with Frame Sync option

a

Grass Valley no longer supports PAL-M in any of its modular products. Although this setting may work in certain applications, Grass Valley will not warrant that it works or provide support if problems are encountered using this product with

PAL-M signals. This product has not been modified to eliminate support for PAL-M. If this product has been used with

PAL-M in the past without problems, there shouldn’t be any issues using it for the same application. However, it is not recommended that customers use it in any new PAL-M applications.

digital signal

Separate input assigned for SMPTE170M signal (525) and

CCIR624 signal (625)

video lines phase difference or color-frame lock will be in free-run mode

8960ENC—Instruction Manual 49

Page 50

Service

GRASS VALLEY GROUP 8960ENC COMPOSITE ENCODER 671-4698-

GND

JP3

JP3

Voltage

Test Points

1

+5V

+3.3V

-5V

F1

F2A 125V FAST

Fuse

Service

The 8960ENC modules make extensive use of surface-mount technology

and programmed parts to achieve compact size and adherence to

demanding technical specifications. Circuit modules should not be ser

-

viced in the field unless directed otherwise by Customer Service.

If your module is not operating correctly, proceed as follows:

• Check frame and power and signal present LEDs.

• Check module voltage testpoints and fuse (Figure 25).

• Check for presence and quality of input signals.

• Verify that source equipment is operating correctly.

• Check cable connections.

Refer to Figure 7 for the location of PWR LED and Table 2 on page 17 for

proper LED indications.

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to the Contacting Grass Valley on page 4 at the front of this document

for the Grass Valley Customer Service Information number.

Figure 25. Module Voltage Testpoints and Fuse

50 8960ENC—Instruction Manual

Page 51

Status Monitoring

This section provides a summary of status monitoring and reporting for a

8900 Series system. It also summarizes what status items are reported and

how to enable/disable reporting of each item. There are a number of ways

to monitor status of modules, power supplies, fans and other status items

depending on the method of monitoring being used.

8900 Frame status will report the following items:

• Power supply health,

• Status of fans in the frame front cover,

• Temperature,

• Module health, and

• Frame bus status.

Module health status will report the following items:

• Internal module state (and state of submodule or options enabled)

Status Monitoring

including configuration errors (warning), internal faults, and normal

operation (Pass).

• Signal input states including valid/present (pass), not present or

invalid (warning), not monitored, and not available (no signal inputs).

• Reference input states including locked/valid (pass), not

locked/invalid (warning), and not monitored.

• Signal output states with reporting functionality (reference output).

LEDs

LEDs on modules in the frame and on the front of the 8900 frames indicate

status of the frame and the installed power supplies, fans in the front

covers, and modules. (The 8900TX-V/A frames have no LED indicators on

the front cover.)

When a red FAULT LED is lit on a frame front cover, the fault will also be

reported on the 8900NET or Frame Monitor module. The LEDs on the front

of these modules can then be read to determine the following fault conditions:

• Power Supply 1 and 2 health,

• Fan rotation status,

• Frame over-temperature condition,

• Frame Bus fault (8900NET only), and

• Module health bus.

8960ENC—Instruction Manual 51

Page 52

Status Monitoring

Frame Alarm

In general, LED colors used on the frame and modules indicate:

• Green – normal operation, (Pass) or signal present, module locked.

• Red – On continuously = fault condition, flashing = configuration error.

• Yellow – On continuously = active condition (configuration mode or