Page 1

8950DAC

COMPONENT VIDEO D-TO-A CONVERTER

Instruction Manual

SOFTWARE VERSION 4.0.2

071060403

JUNE 2005

Page 2

Contacting Grass Valley

Region Voice Fax Address Web Site

North America (800) 547-8949

Support: 530-478-4148

Pacific Operations +852-2585-6688

Support: 852-2585-6579

U.K., Asia, Middle East +44 1753 218 777 +44 1753 218 757

France +33 1 45 29 73 00

Germany, Europe +49 6150 104 782 +49 6150 104 223

Copyright © Thomson Broadcast and Media Solutions All rights reserved.

Grass Valley Web Site

Sales: (530) 478-3347

Support: (530) 478-3181

+852-2802-2996

Grass Valley

P.O. Box 599000

Nevada City, CA 959597900 USA

www.thomsongrassvalley.com

The www

Online User Documentation

.thomsongrassvalley.com web site offers the following:

— Current versions of product catalogs, brochures,

data sheets, ordering guides, planning guides, manuals, and release notes

in .pdf format can be downloaded.

FAQ Database

— Solutions to problems and troubleshooting efforts can be

found by searching our Frequently Asked Questions (FAQ) database.

Software Downloads

— Software updates, drivers, and patches can be down-

loaded.

2 8950DAC Instruction Manual

Page 3

Contents

Preface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

8950DAC Component Digital to Analog Converter

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Frame Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Module Placement in the 8900 Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Loop-through Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Analog Video Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Analog Composite Sync Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Indicator LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Configuration Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Format Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Level Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Timing/Blanking Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Standard Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

User Settings Save and Recall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Local On-board Configuration Switches and LEDs . . . . . . . . . . . . . . . . . . . . . . . 19

On-board Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Remote Configuration and Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8900NET Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Newton Control Panel Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8950DAC Links and Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Status Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Levels Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Timing/Blanking Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Standard Selections Web Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

User Settings Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Slot Config Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Software Update Web Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Frame Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Web Browser Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SNMP Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8950DAC Instruction Manual 3

Page 4

Contents

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Serial Input and Deserializer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Phase Lock Loop (PLL) 2 Times Clock Generator . . . . . . . . . . . . . . . . . . . . . . . . 42

Digital to Analog Converter (DAC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Output Low Pass Filters (LPF) and Buffers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Delay Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Embedded Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Digital Signal Processing FPGA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 8950DAC Instruction Manual

Page 5

Preface

About This Manual

This manual describes the features of a specific module of the Gecko 8900

Signal Processing System. As part of this module family, it is subject to

Safety and Regulatory Compliance described in the Gecko 8900 Series

frame and power supply documentation (see the 8900TX/8900TF/8900TFN

Frames Instruction Manual

).

8950DAC Instruction Manual 5

Page 6

Preface

6 8950DAC Instruction Manual

Page 7

8950DAC Component Digital to Analog Converter

Introduction

The 8950DAC converts serial component digital signals to analog for use in

applications such as component analog switchers, display on analog GBR

monitors, or recording on analog component VTRs. The module provides

two sets of analog component outputs.

The 8950DAC is compact and fits in the 8900 frame which holds up to 10

modules in 2 RU.

Key features include:

• 10-bit D-to-A,

• Four times oversampling for outstanding resolution,

• Error detection and handling (EDH),

•Two lines output delay adjustment,

• Supports all popular Component Analog Video (CAV) formats,

• Passive loop-through input,

• Part of the 8900 family of audio and video modules, and

•With an 8900NET module installed, provides support for:

•SNMP monitoring,

•Remote web browser, and

•Newton Control Panel interface.

8950DAC Instruction Manual 7

Page 8

Installation

Installation

Frame Capacity

Installation of the 8950DAC module is a simple process of:

• Placing the module in the proper frame slot, and

•Cabling and terminating signal ports.

The 8950DAC module can be plugged in and removed from an 8900 Series

frame with power on. When power is applied to the module, LED indicators reflect the initialization process (see

The maximum number of 8900 modules allowed in a frame is determined

by frame cooling capacity. Table 1 provides the power capacity, cooling

capacity, and maximum module count for the 8950DAC in each frame type.

Power Up

on page 11).

Table 1. Power, Cooling, and Module Capacity of 8900 Frames

Capacity Calculated

Power (W) 100 100 100

Recommended Module Cooling (W) 30 90 90

8950DAC Modules 5 10 10

Note

Module capacity figures assume no other modules are in the frame.

If the maximum number of modules a frame can handle is less than ten,

provide as much space between the modules as possible.

8900TX

Module Placement in the 8900 Frame

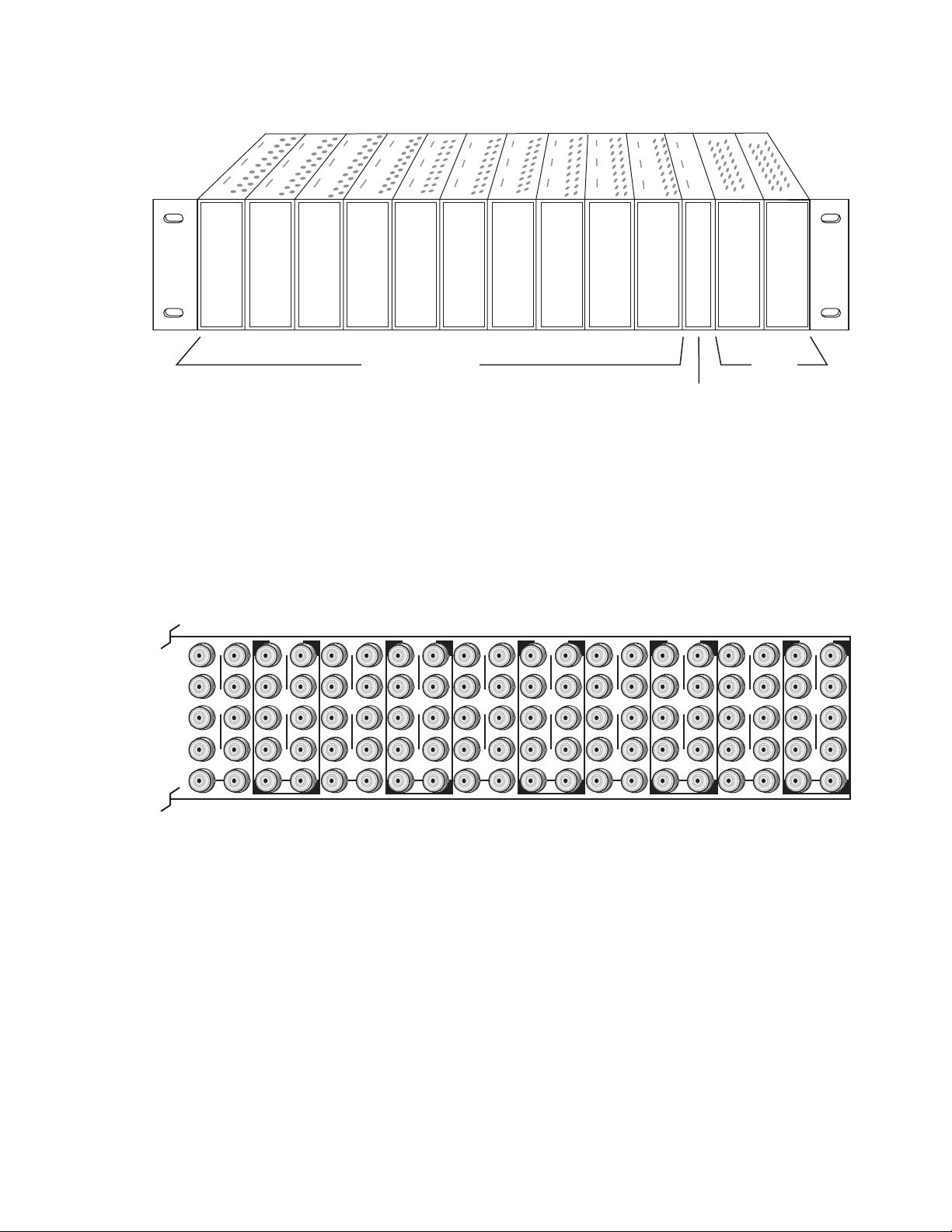

There are ten cell locations in the frame to accommodate either analog or

digital modules. These are the left ten locations. Refer to Figure 1 on page 9.

The two cells on the right are allocated for the power supplies. For additional information concerning the Power Supply module, refer to the 8900

Power Supply manual.

The third cell from the right is allocated for the Frame Monitor or 8900NET

Network Interface module. These modules provide health bus monitoring

and control options.

Frame

8900TF

Frame

8900TFN

Frame

8 8950DAC Instruction Manual

Page 9

1.

2.

3.

Figure 1. 8900 Series Frame

Installation

8208_04r1

10

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

J2

J1 J2

O

J4

J3 J4

J6

J5 J6

J8

J7 J8

J9 J10

IN

Any 8900 Module

Power

Supplies

Frame Controller or

(only)

8900NET Network

Interface Module

8900 modules are interchangeable within the module cells. There are 10

BNC connectors in each cell’s I/O group. The functional assignment of

each connector in a group is determined by the module that is placed in

that cell. The maximum number of modules a Gecko 8900 frame can accept

is ten. Figure 2 illustrates the rear connector plate for an 8900 Series frame.

Figure 2. 8900 Series Frame Rear Connectors

9

U

T

8

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

7

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

6

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

5

J1 J2

J2

O

J3 J4

J4

U

T

J5 J6

J6

J7 J8

J8

J9 J10

IN

4

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

3

J2

J1 J2

O

J4

J3 J4

U

T

J6

J5 J6

J8

J7 J8

J9 J10

IN

2

J1 J2

O

J3 J4

U

T

J5 J6

J7 J8

J9 J10

IN

J1 J2

J3 J4

J5 J6

J7 J8

J9 J10

1

O

U

T

0604-03

IN

To install a module in the frame:

Insert the module, connector end first, with the component side of the

module facing to the right and the ejector tab to the top.

Verify that the module connector seats properly against the backplane.

Press the ejector tab in to seat the module in place.

8950DAC Instruction Manual 9

Page 10

Installation

Cabling

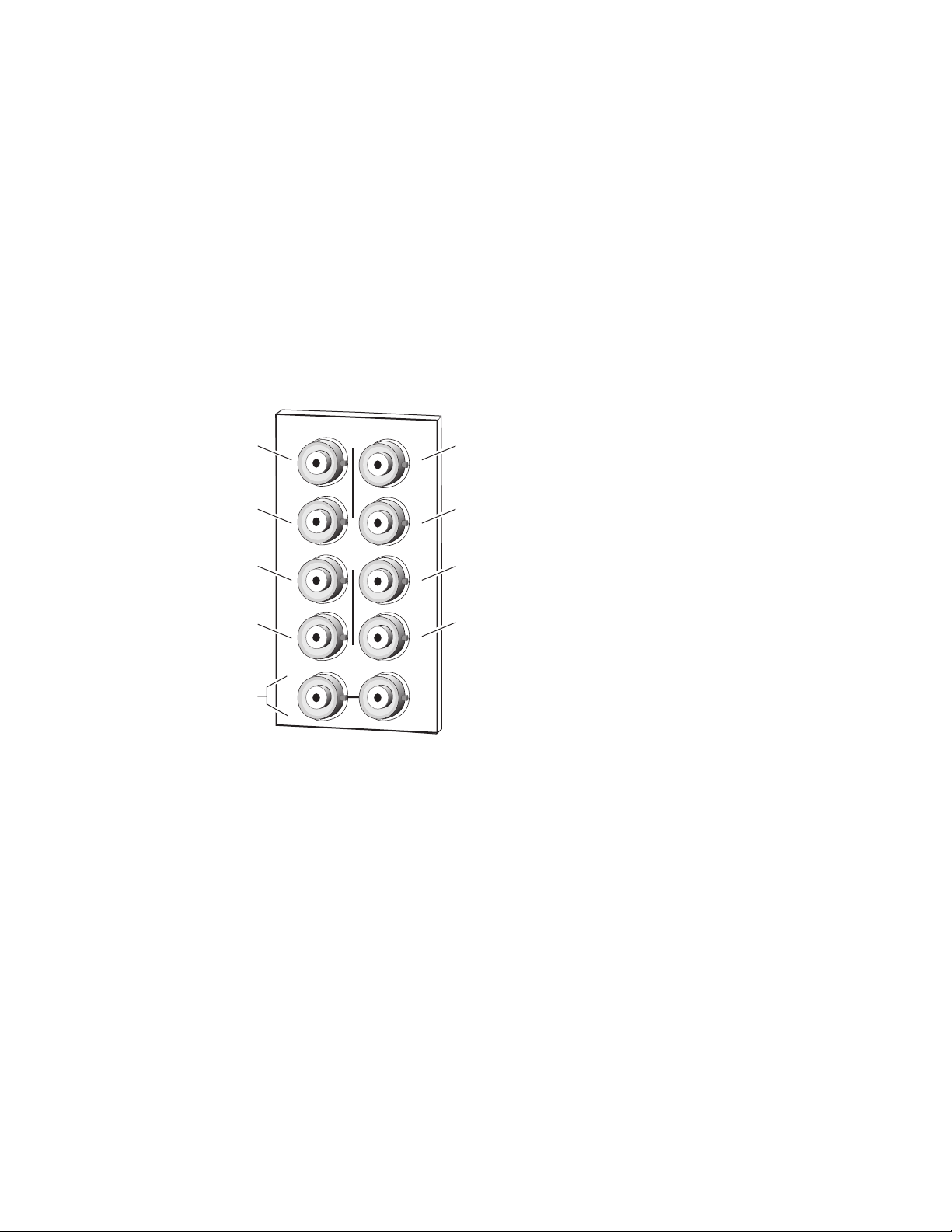

Loop-through Input

Y/G Output 1

B-Y/B Output 1

R-Y/R Output 1

Composite Sync Output 1

Note

At the back of this manual (hard-copy only) are die-cut overlay cards that can

be placed over the rear connector BNCs to identify the specific 8950DAC connector functions.

Connect an input source to one of the loop-through input connectors, J9 or

J10 (see Figure 3). The 8950DAC input accepts SMPTE 259M 10-bit serial

4:2:2 component video. Terminate the unused connector into 75 Ω if the

signal is not looped to other equipment.

Figure 3. 8950DAC Input/Output Connectors

Y/G Output 2

J2

J2J1

B-Y/B Output 2

J3

J5

O

U

T

J4

J6

J4

R-Y/R Output 2

J6

Composite Sync Output 2

J7

J9 J10

Loop-through

SDI 4:2:2 Input

IN

Analog Video Outputs

The 8950DAC has two sets of three analog component video output BNCs:

• J1 and J2 for Y/G output 1 and 2,

• J3 and J4 for B-Y/B output 1 and 2, and

• J5 and J6 for R-Y/R output 1 and 2.

The destination equipment should have a 75

through inputs that are terminated into 75

Analog Composite Sync Output

The 8950DAC generates analog composite sync (C Sync) from the serial

video input and provides two sync signal outputs on BNCs J7 and J8.

J8

J8

0604-02

Ω input impedance or loop

Ω

.

10 8950DAC Instruction Manual

Page 11

Power Up

Operation Indicator LEDs

Power Up

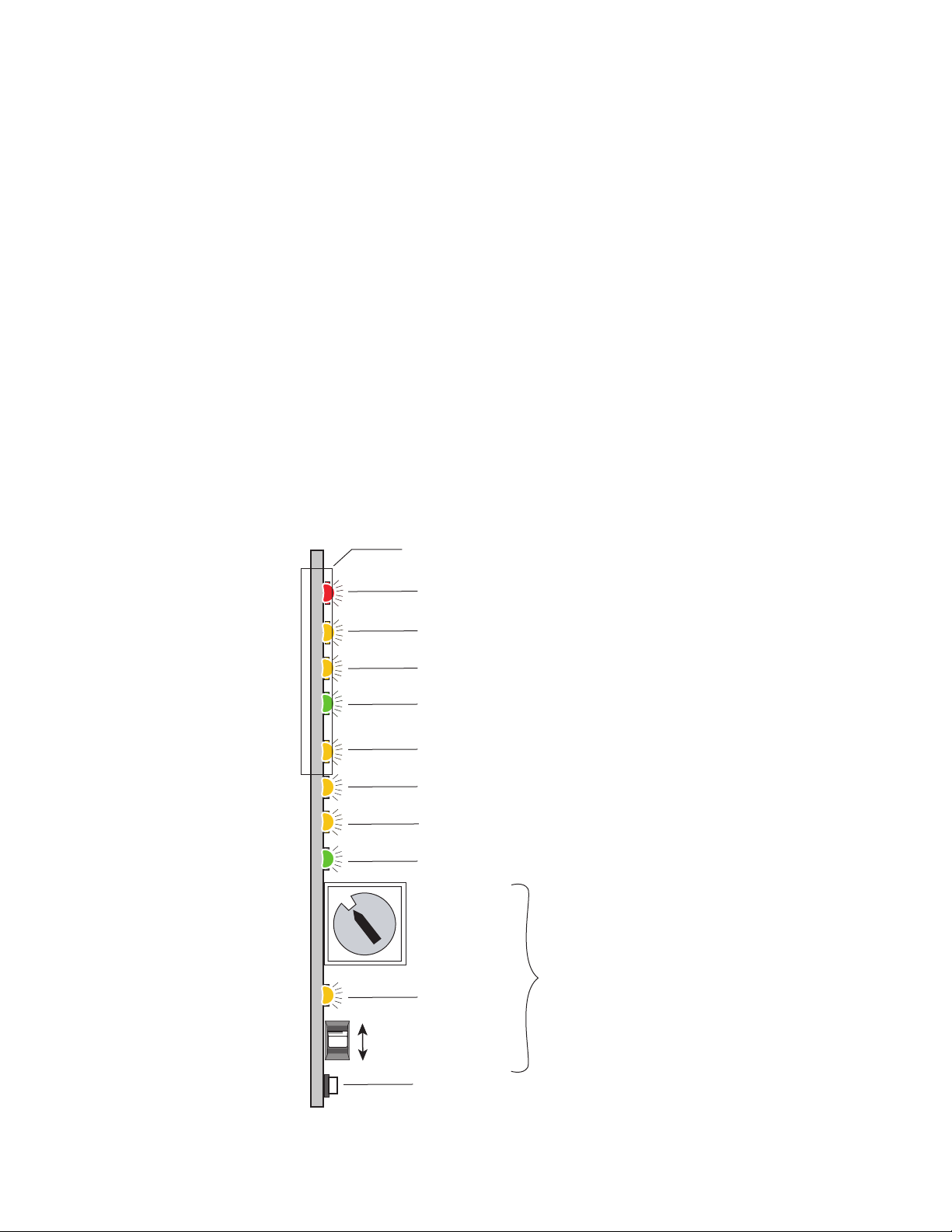

The various front LED indicators and configuration switches are illustrated

in Figure 4. Upon power-up, the green PWR LED should light and the

yellow CONF LED should illuminate for the duration of module initialization.

With factory default configuration and a valid input signal connected, the

green PWR LED, and one of the yellow signal standard LEDs (525 or 625)

should illuminate (refer to Table 2 on page 12 to see the possible operating

indicator combinations).

Video input presence is indicated by an illuminated VID PRES LED and the

appropriate 525 or 625 LED (indicating a 525-line or 625-line input signal

has been detected). The MAN LED, when on, indicates that manual standard selection is enabled.

Figure 4. LEDs and Configuration Switches

Ejector Tab

FAULT – Red LED is off during normal operation

COMM (Yellow)

CONF (Yellow)

PWR – Green LED on indicates power OK

525 – Yellow LED on indicates 525 mode input

MAN MODE – Yellow LED on indicates manual input selection

625 – Yellow LED on indicates 625 mode input

VID PRES – Green LED on indicates a valid video input signal is present

5

6

4

7

3

8

2

9

A

B

C

16-position

Rotary switch

1

0

F

E

D

Module Configuration Switches and LED

2nd Function

(Yellow)

Momentary toggle switch

0604_06

GND

8950DAC Instruction Manual 11

Page 12

Power Up

A red FAULT LED indicates an error situation and, with the previously

described LEDs, can indicate the operational conditions presented in

Table 2.

Table 3 on page 13 provides the possible output conditions and LED states

that result from different configuration and input conditions.

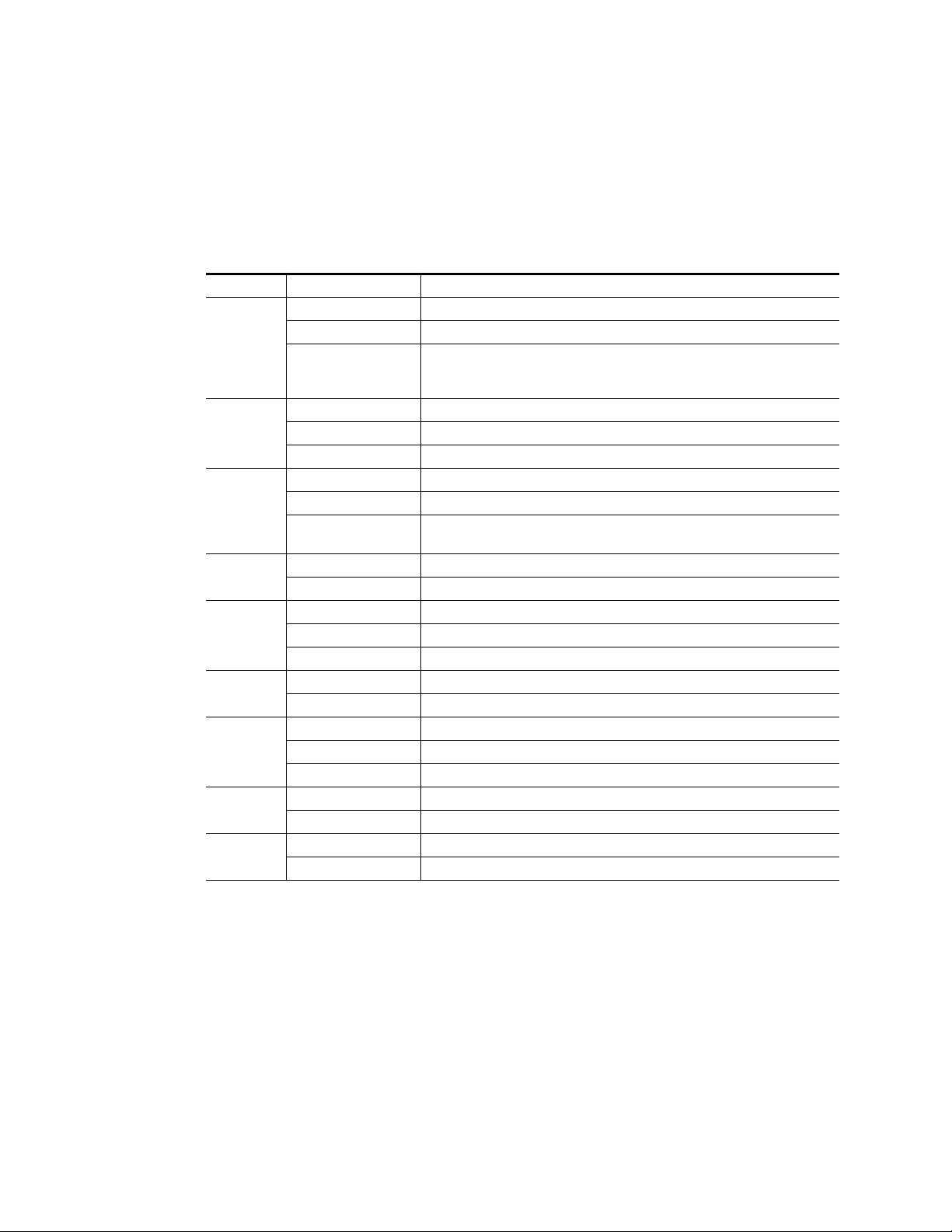

Table 2. Indicator LEDs and Conditions Indicated

LED Indication Condition

Off Normal operation

Fault

(red)

COMM

(yellow)

CONF

(yellow)

PWR

(green)

525

(yellow)

MAN

(yellow)

625

(yellow)

VID PRES

(green)

2ND

(yellow)

1

If no valid video signal is present, all four analog outputs will be 0.0 VDC with some occasional low level noise.

On continuously Module has detected internal fault

Short flash

Off No activity on frame communication bus

Long flash Location Command received by the module from a remote control system

Short flash Activity present on the frame communication bus

Off Module is in normal operating mode

On continuously Module is initializing, changing operating modes or updating firmware

Flashing

Off No power to module or module’s DC/DC converter failed

On continuously Normal operation, module is powered

Off Input signal is 625 standard (Auto-select active) or no signal is present

On continuously Input signal is 525 standard

Flashing Input signal is 625 standard and mode select is in manual position

On Input is forced by configuration to accept one format, either 525 or 625

Off Module will detect and accept either input signal format

Off Input signal is 525 standard (Auto-select active) or no signal is present

On continuously Input signal is 625 standard

Flashing Input signal is 525 standard and mode select is in manual position

Off No valid input signal is present

On A valid video input signal is present

On Second bank of setup functions is accessed by the rotary switch

Off First bank of setup functions is accessed by the rotary switch

EDH errors will cause short flashes. In most applications a few, infrequent EDH

errors will not be of consequence. Continuous EDH errors result in obvious output

signal degradation.

Indicates rate of change of toggle switch controlled analog setting. The longer the

switch is held, the more the flashing rate and the change-of-setting rate increases

1

12 8950DAC Instruction Manual

Page 13

Power Up

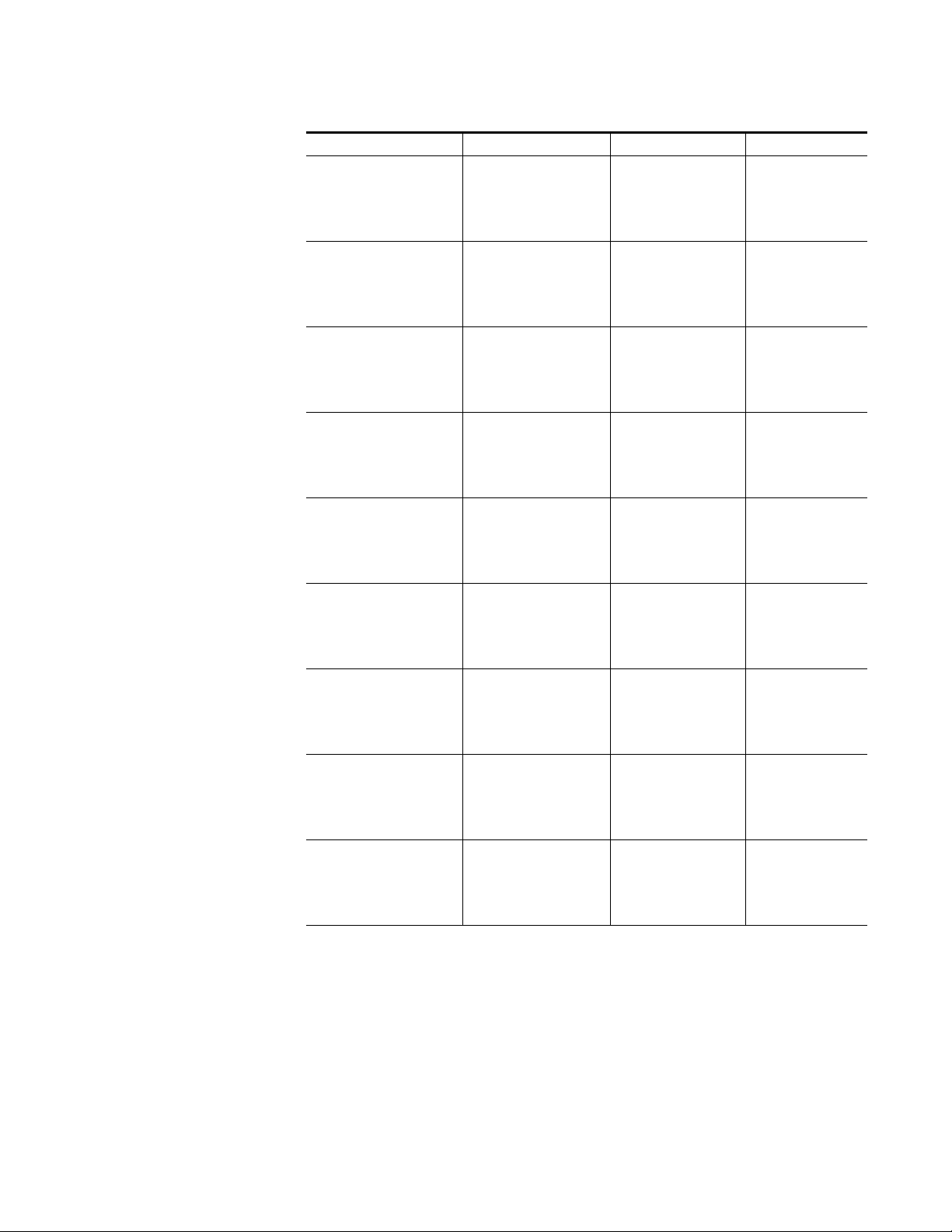

Table 3. Input and Output Conditions

Input Signal Standard Detection LED State Output Signal

VID PRES off

No signal

No signal

No signal

Signal present 525

Signal present 625

Signal present 525

Signal present 625

Signal present 525

Signal present 625

Auto mode

Manual mode 525

Manual mode 625

Auto mode

Auto mode

Manual 525

Manual 525

Manual 625

Manual 625

625 off

525 off

MAN mode off

FAULT flashing

VID PRES off

625 off

525 on

MAN mode on

FAULT flashing

VID PRES off

625 on

525 off

MAN mode on

FAULT flashing

VID PRES on

625 off

525 on

MAN mode off

FAULT off

VID PRES on

625 on

525 off

MAN mode off

FAULT off

VID PRES on

625 off

525 on

MAN mode on

FAULT off

VID PRES on

625 off

525 flashing

MAN mode on

FAULT off

VID PRES on

625 flashing

525 off

MAN mode on

FAULT off

VID PRES on

625 on

525 off

MAN mode on

FAULT off

0 V ±20 mV

0 V ±20 mV

0 V ±20 mV

Valid video output

Valid video output

Valid video output

Invalid video output

Invalid video output

Valid video output

8950DAC Instruction Manual 13

Page 14

Configuration

Configuration

The 8950DAC can be configured locally using onboard switches or

remotely using the 8900NET network interface GUI or a networked control

panel.

Refer to the following sections for configuration instructions:

•Configuration Summary (page 14)

• Local On-board Module Configuration (page 19)

•Remote Control and Monitoring (page 22)

Operation of these control types is explained in detail in their respective

sections of this manual.

Configuration Summary

This section provides a summary of all parameters that can be configured

on the 8950DAC module. Table 5 on page 17 provides a summary in table

format of all parameters and their ranges, default values, and remote, local,

and control panel function names and locations for setting each value.

Format Selections

The 8950DAC converts a SMPTE 259M (270 Mb/s) D1 serial component

digital signal to any one of the following analog Color Difference or GBR

video signals:

•SMPTE

•GBR

• Beta (US/525)

• Beta (Japan/525)

•MII (US/525)

•MII (Japan/525)

• EBU N10 (625)

Once a format is selected, the default values for that format will be loaded

to the module. The overall factory default for the module is GBR.

14 8950DAC Instruction Manual

Page 15

Configuration

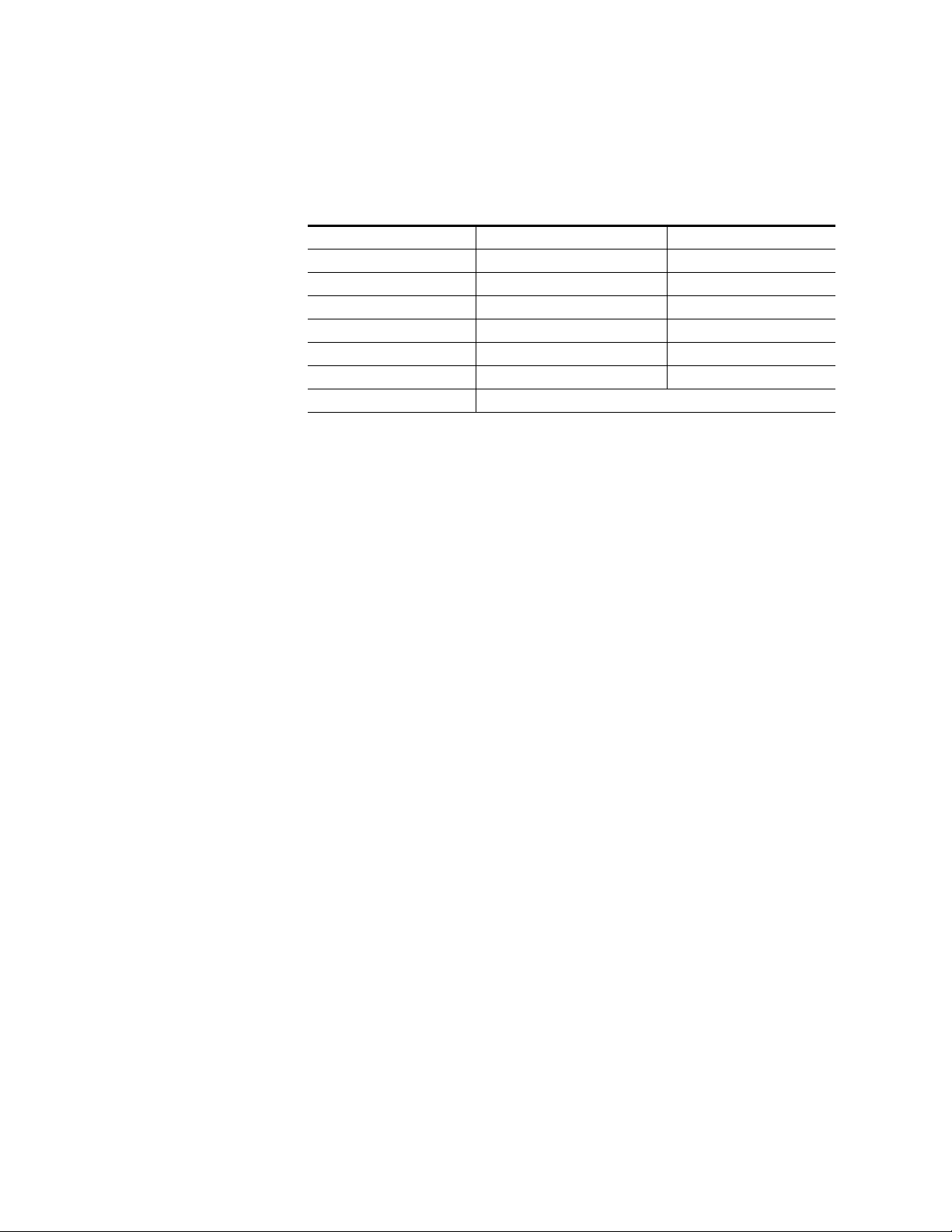

Format Setup

Table 4 lists the nominal output signal levels for each format selection with

a 100% saturated/100% luminance color bar signal.

Table 4. Format Setup Signal Levels

Format Y Channel Level Peak to Peak Chroma

MII (US) 647.5 mV video plus 52.5mV setup 647.5 mV

MII (Japan) 700 mV 700 mV

BETA (US) 660.4mV video plus 53.6mV setup 933.3 mV

BETA (Japan) 714 mV 1009 mV

SMPTE (525 & 625) 700 mV 700 mV

EBU N10 (625) 700 mV 700 mV

GBR G, B, R channels, all 700 mV

Level Adjustments

The factory (default) settings for signal processing functions are set to pass

a calibrated broadcast quality signal at optimum levels. Signal video and

composite sync DC offset and output level adjustments are available to

correct deficiencies in the input signal.

Once any video or composite sync adjustments are made, it is recommended to save these settings on the User Settings web page (

Web Page

Level values will return to the factory defaults for that format.

on page 31). If the format is reselected from the pulldown, the

Timing/Blanking Adjustments

The following adjustments can be made to the signal that affect timing and

blanking:

•Horizontal delay – adjust the amount of horizontal delay in ns,

• Sync On G – sync may be turned on or off on the Y/G channel output

in GBR, and

•Vertical blanking – set vertical blanking to Pass or Blank all vertical

data.

User Settings

8950DAC Instruction Manual 15

Page 16

Configuration

Standard Recognition

The module can be set to for auto recognition of the input standard or set

for manual 525 or 625.

Setup

Setup can be enabled or disabled on 525 video standards and the Setup

level can be adjusted.

User Settings Save and Recall

A function is provided to save and recall the adjusted parameters for the

selected standard. This function is useful for saving configured parameters

because recalling a standard will return the values to the factory defaults

for that specific standard.

16 8950DAC Instruction Manual

Page 17

Table 5 provides a complete summary of the 8950DAC processing func-

tions and a comparison of the functionality available with each control type

along with the ranges and default values for each parameter.

Table 5. Summary of 8950DAC Configuration Functions

Function

Type

Format/Standard GBR

Levels control action Independent

Y/G Video level 100% See list below

SMPTE/MII-Japan/EBU N10

MII/US 54.44 to 127.54%

GBR 54.44 to 141.14%

Beta/US 54.44 to 125.84%

Beta/Japan 54.44 to 119.72%

Cb/B Video level 100% See list below

SMPTE/MII-Japan/EBU N10

MII/US 73.48 to 143.86%

GBR 55.12 to 140.80% B Video

Beta/US 38.12 to 114.96%

Beta/Japan 29.28 to 114.96%

Cr/R Video level 100% See list below

SMPTE/MII-Japan/EBU N10

MII/US 73.48 to 143.86%

GBR 55.12 to 140.80% R Video

Beta/US 55.80 to 139.10%

Beta/Japan 26.90 to 94.90%

Composite Sync

output level

Composite Sync DC 100%

Setup Level for

US/525 MII and Beta

Horizontal delay

adjust

Default

100%

100%

0 ns

Range/Choices

Resolution

SMPTE

GBR 1:7

M II (US/525) 1:1

M II (Japan/525) 1:2

Beta (US/525) 1:3

Beta (Japan/525) 1:4

EBU N10 (625) 1:5

Independent or

Locked

54.44 to 121.08%

(0.34% steps)

67.02 to 143.86%

(0.34% steps)

55.80 to 132.64%

(0.34% steps)

87.35 to 100.10

(0.05% steps)

92.20 to 104.95

(0.05% steps)

76.57 to 118.15

(0.05% steps)

0 to 148000 ns

(37 ns steps)

Web Page/

Function Name

Levels/

Format/Standard pulldown

Levels/

Control Action pulldown

Levels/

Y or G Video (%)

Levels/

Cb/B Video (%)

Levels/

Cr/R Video (%)

Levels/

Composite Sync Output (%)

Levels/

Composite Sync DC (%)

Levels/

Setup Level (%)

Timing/Blanking/

Horizontal Delay (ns)

Rotary Switch

Bank/Setting

1:6

1:8 Action

1:9

1:A

1:B

1:C

1:D

1:E

2:3

Newton

Control

Panel

Format

YG video

(PID 719)

CbBvideo

(PID 721)

Cb Vid

CrRvideo

(PID 723)

Cr Vid

Sync Out

(PID 725)

Sync DC

(PID 727)

SetupLvl

(PID 729)

HDelay

(PID 731)

Configuration

Note/

Conditions

Selecting format recalls factory defaults for

that standard.

1

Adjust each

video level sep-

1

arately or tie

controls

together.

All formats.

1

1

1

1

Setup must be

enabled.

1

8950DAC Instruction Manual 17

Page 18

Configuration

Table 5. Summary of 8950DAC Configuration Functions

Function

Type

Sync On G On On or Off

Vertical Blanking Pass Blank or Pass

Standard Recognition Auto

Output Video Setup Setup Setup or No Setup

Recall User Settings – –

Save User Settings – –

Get Factory Defaults GBR values –

1

Two Newton Control Panel controls are present. Use the second one in the list corresponding to the PID value in Newton Configurator as indicated

in this table.

Default

Range/Choices

Resolution

Auto, Manual 525 or

Manual 625

Web Page/

Function Name

Timing/Blanking/

Sync On G pulldown

Timing/Blanking/

Vertical Blanking pulldown

Standard Selection/

Standard Recognition pull-

down

Standard Selection/

Output Video Setup pulldown

User Settings/

Recall User Settings

button

User Settings/

Save User Settings

button

User Settings/

Get Factory Defaults\

button

Rotary Switch

Bank/Setting

(Down 1X=Man-

Down 2X=525

Down 3X=625)

2:F (up)

(press down 3X

successively)

2:2 SyncOnG GBR only

2:4 VBlank

2:1

ual,

1:F Setup

2:F

1:7

(GBR)

Newton

Control

Panel

Auto Std

N/A

Conditions

Beta and MII

US/525 formats only

Save Levels

settings after

configuration

Module factory

default is GBR

Note/

18 8950DAC Instruction Manual

Page 19

Local On-board Configuration Switches and LEDs

The 8950DAC module can be configured using the rotary and paddle

switches shown in Figure 5. The CONF and 2ND function LEDs are configuration status indicators. These four components perform the following:

• Function (rotary) switch — Addresses two banks of 16 possible positions (0 through 9 and A through F) to access a desired function for configuration. Not all positions are used (see Table 6 on page 20).

Note The Function switch should be kept in position 0 when not in use to avoid any

inadvertent change in configuration. 0 is an inactive position.

•SW2 (paddle) switch — Actuates or selects the desired setting for the

selected function when the switch is held momentarily in either the Up

or Down position.

•2ND LED — When on, rotary switch is accessing the second bank of

configuration items.

• CONF (configuring) LED — When on, indicates the module is initializing or processing configuration information.

Configuration

CONF – configuration LED

GRASS VALLEY GROUP

JP2

LOCAL

JP2

REMOTE

Figure 5. Module Configuration Switches and LEDs

8950DAC 671-4798-

FUNCTION – rotary switch

2nd – second function LED

SW2 – paddle switch

0604_05r1

8950DAC Instruction Manual 19

Page 20

Configuration

On-board Module Configuration

Note Module configuration items described here do not apply to the initial version

number 061-4798-00 of the 8950DAC module.

The 8950DAC offers a selection of one of seven output signal standards

(Function Switch settings 1 through 7 of Bank 1, see Table 6). These stan-

dard setups are factory default (pre-set) setups that can always be recalled

by re-selecting one of the seven. A user default setup configuration can also

be stored in memory for recall. A description of each factory default standard is provided in Table 4.

Note When module power recycles the last setup state is restored. The module

does not revert to a factory or the user default.

To make a configuration setting:

1. Rotate the Function Switch to the desired Bank (1 or 2) and function.

2. Move the paddle switch to the up or down position and hold

momentarily to set the desired function.

Table 6. 8950DAC Configuration Functions

Function

Switch

0----Inactive position

1 MII (US/525) -- Recalls factory default parameters for MII (US) standard.

2 MII (Japan/525) -- Recalls factory default parameters for MII (Japan) standard.

3 BETA (US/525) -- Recalls factory default parameters for BETA (US) standard.

4 BETA (Japan/525) -- Recalls factory default parameters for BETA (Japan) standard.

5 EBU N10 (625) -- Recalls factory default parameters for EBU N10 standard.

6 SMPTE -- Recalls factory default parameters for SMPTE standard.

7 GBR -- Recalls factory default parameters for GBR standard.

8 Increase Decrease Output video level adjustment for all inputs.

Bank 1

9 Increase Decrease Y/G output video level adjustment.

A Increase Decrease Cb/B output video level adjustment.

B Increase Decrease Cr/R output video level adjustment.

C Increase Decrease Sync output level adjustment

D Increase Decrease Sync output DC offset adjustment.

E Increase Decrease (Y/G) Setup level adjustment

F Setup No Setup Setup on composite output enable for Beta/US and MII/US 525 only

Paddle

Switch Up

Paddle

Switch Down

Function Description

20 8950DAC Instruction Manual

Page 21

Table 6. 8950DAC Configuration Functions - (continued)

Configuration

Function

Switch

0----Inactive position.

1 Auto

2 Add Remove Adds or removes sync on the G/Y channel.

3 Increase Decrease Sets amount of signal delay.

Bank 2

4 Blank Pass Blank or pass vertical blanking information.

5 thru 9 – – Not used.

A thru E – – Not used.

F Recall

1

Subsequent presses toggle between 525 and 625.

2

To Save current settings the toggle switch must be pressed down three times successively.

Paddle

Switch Up

Paddle

Switch Down

Manual

Down x 2 Manually sets 525 line standard.

Down x 3

Save

(Down x 3

Standard recognition – Toggle switch up enables automatic input standard recognition.

First press down enables manual selection; second and third press select standard.

1

Manually sets 625 line standard.

Recall previously saved user default configuration, or Save current configuration settings

2

)

as the user default.

Note To activate the Save function (position F) you must toggle the activation

switch down three times successively. The Save function saves the current

settings as the new user default configuration.

Function Description

8950DAC Instruction Manual 21

Page 22

Configuration

Remote Configuration and Monitoring

8950DAC configuration and monitoring can be performed using a web

browser GUI interface or a networked Newton Control Panel when the

8900NET Network Interface module is present in the video frame (Gecko

8900TFN-V frame). Each of these interfaces is described below.

Note For remote access, make sure the jumper block on the module is set for both

Local and Remote access (Figure 5 on page 19).

8900NET Module Information

Refer to the 8900NET Network Interface Module Instruction Manual for

information on the 8900NET Network Interface module and setting up and

operating the Gecko 8900 frame network.

Note The 8900NET module in the frame must be running software version 3.2.0 or

higher for proper remote and control panel operation. Upgrade software and

instructions for the 8900NET can be downloaded from the Grass Valley web

site.

Newton Control Panel Configuration

A Newton Control Panel (hard or soft version) can be interfaced to the

Gecko 8900 Series frame over the local network. Refer to the documentation that accompanies the Newton Modular Control System for installation, configuration, and operation information.

Control panel access offers the following considerations for module configuration and monitoring:

•Ability to separate system level tasks from operation ones, minimizing

the potential for on-air mistakes.

•Ability to group modular products—regardless of their physical locations—into logical groups (channels) that you can easily manipulate

with user-configured knobs.

•Update software for applicable modules and assign frame and panel IP

addresses with the NetConfig Networking application.

•Recommended for real-time control of module configuration parameters, providing the fastest response time.

Note Not all module functions are available with the control panel, such as E-MEM

and factory default recalls. The available control panel controls for the

8950ADC module are listed in Table 5 on page 17.

An example of the Newton Configurator is shown in Figure 6 on page 23.

22 8950DAC Instruction Manual

Page 23

Figure 6. Newton Configurator Example

Configuration

Web Browser Interface

The web browser interface provides a graphical representation of module

configuration and monitoring.

Use of the web interface offers the following considerations:

•Provides complete access to all module status and configuration func-

tions, including naming of inputs and outputs, factory parameter and

name default recalls, E-MEM functions, slot configuration, and SNMP

monitoring controls.

•Web access will require some normal network time delays for pro-

cessing of information.

•Configuration parameter changes may require pressing

Enter, upload processing time, and a manual screen refresh to become

effective.

•Web interface recommended for setting up module signal and slot

names, E-MEMS, and reporting status for SNMP and monitoring.

Refer to the Frame Status page shown in Figure 7 on page 24. The 8900

modules can be addressed by clicking either on a specific module icon in

the frame status display or on a module name or slot number in the link list

on the left.

Apply button or

8950DAC Instruction Manual 23

Page 24

Configuration

Note The physical appearance of the menu displays on the web pages shown in

this manual represent the use of a particular platform, browser and version

of 8900NET module software. They are provided for reference only. Displays

will differ depending on the type of platform and browser you are using and

the version of the 8900NET software installed in your system. This manual

reflects 8900NET software version 3.2.2.

For information on status and fault monitoring and reporting shown on the

Status page, refer to Status Monitoring on page 38.

Figure 7. Gecko 8900 Frame Status Page

The Links section lists the frame and its current modules. The selected link's Status

page is first displayed and the sub-list of links for the selection is opened. The sub-list

allows you to select a particular information page for the selected device.

Content display section displays the information page

for the selected frame or module (frame slot icons are also

active links).

Refresh button for manual

update of page

0604_08

24 8950DAC Instruction Manual

Page 25

8950DAC Links and Web Pages

The 8900 GUI provides the following links and web pages for the 8950DAC

module (Figure 8):

• Status – reports input and reference signal status and module informa-

tion (page 26),

• Levels – select output format for module and adjust the levels for video,

composite sync and DC output, and video setup amplitude (page 27),

•Timing/Blanking – adjust horizontal timing, select SAV/EAV, sync

source, and vertical blanking width (page 29)

• Standard Selections – select standard recognition method, add or

remove output video setup, and turn Kalypso 0:4:4 compressed chroma

key signal on or off (page 30)

•User Settings – Save or recall user settings, select factory defaults

(page 31)

• Slot Config – provides a Locate Module function and Slot Memory and

SNMP reporting status information (page 32), and

Configuration

• Software Update – provides information on software updating

(page 34).

Figure 8. 8950DAC Web Page Links

Refer to Table 5 on page 17 for a summary in table format of all parameters

and their ranges, and default values.

8950DAC Instruction Manual 25

Page 26

Configuration

Status Web Page

Use

this

link

The Status web page (Figure 9) shows the input signal status of the component analog video input. Color coding of the display indicated the signal

status. Refer to Status Monitoring on page 38 for an explanation of the color

coding.

Information about the module, such as part number, serial number, hardware revision and software and firmware versions are given in a read-only

section at the bottom of the display.

Figure 9. 8950DAC Status Web Page

26 8950DAC Instruction Manual

Page 27

Use

this

link

Configuration

Levels Web Page

The output format/standard for the module is selected on the Levels web

page shown on Figure 10 on page 28. This web page also provides adjustment for the following:

•Video levels on each channel,

•Composite sync output and DC levels, and

•Video setup amplitude level.

All adjustments are made in percentage. 100% equals the default value of

the currently chosen format. Refer to Table 4 on page 15 for 100% level

values for each analog component format.

Select either

mode, you may set each channel level individually. In

changing a value in any channel will move all three channels together.

From the

standard from the following displayed choices:

•SMPTE

•GBR

•MII (US/525)

•MII (Japan/525)

• Beta (US/525)

• Beta (Japan/525)

• EBU N10 (625)

Adjust the video levels individually (

using the Y/G Video, Cb/B Video or Cr/B Video controls.

If you have made any adjustments in the levels and wish to keep them, you

must store them using the

page (see User Settings Web Page on page 31).

Independent or Locked mode to make adjustments. In Independent

Locked mode,

Format/Standard pulldown, select an analog component output

Independent) or all at once (Locked)

Save User Setting button on the User Settings web

You can recall default settings for a particular component standard by reselecting and applying that standard. Horizontal delay, sync on G (GBR

only), and vertical blanking settings are not changed by this reset so these

user adjustments are retained. This differs from the

tion which returns these values to factory calibration.

Adjust the output level and DC offset of the composite sync with the

posite Sync Output and Composite Sync DC controls.

8950DAC Instruction Manual 27

Get Factory Defaults func-

Com-

Page 28

Configuration

Adjust the percentage of video setup level with the Setup Level control. This

display will be grayed out in analog component formats with no setup.

Setup is enabled (

described in Standard Selections Web Page on page 30.

Figure 10. Levels Web Page – GBR Standard

Setup/No Setup) on the Standards Selection web page

28 8950DAC Instruction Manual

Page 29

Timing/Blanking Web Page

Set the following parameters on the Timing/Blanking web page shown in

Figure 11:

Configuration

Use

this

link

• Amount of horizontal delay in ns,

•

Sync on/off on G Channel (GBR format only, grayed out in all other formats),

and

•

Blank or Pass vertical blanking information.

Figure 11. Timing/Blanking Web Page

8950DAC Instruction Manual 29

Page 30

Configuration

Standard Selections Web Page

The Standards Selection web page shown in Figure 12 is used to select the

following module parameters:

Use

this

link

• Standard Recognition (

• If

Manual is selected, set signal standard (525 or 625), and

•Output video setup add or remove (appears when 525 analog component format is selected).

Figure 12. Standard Selection Web Page

Auto or Manual),

30 8950DAC Instruction Manual

Page 31

User Settings Web Page

The User Settings web page (Figure 13) allows you to set the following

parameters:

Configuration

Use

this

link

• Select the

• Save the currently selected settings for the entire module into User Set-

tings with the

•Recall the GBR factory default video levels and timing settings on the

module using the

Figure 13. User Settings Web Page

Recall User Settings button to recall previously saved settings,

Save User Settings button, and

Get Factory Defaults button.

8950DAC Instruction Manual 31

Page 32

Configuration

Use

this

link

Slot Config Web Page

Use the Slot Config web page (Figure 14 on page 33) to perform the following functions on the 8950DAC module:

•

Locate Module – selecting the Flash radio button flashes the yellow

COMM and CONF LEDs on the front of the module so it can be located

in the frame.

•

Slot Identification – You may identify the module by typing a specific

name in the

module and travels with the 8900NET module if it is moved to another

frame. Select

You may also enter a name in the Input Signal Name field.

•

Slot Memory – the slot configuration for each media module is automati-

cally saved periodically (once an hour) to the 8900NET module in that

frame. You may also select the

save the current configuration for this slot. The configuration is saved

on the 8900NET module. If the 8900NET module is removed or

powered down, the stored configurations are not saved.

Name field. The assigned name is stored on the 8900NET

Default to enter the factory default module name.

Learn Module Config button at any time to

When the

ration saved to this slot is saved as slot memory. When the current

module is removed and another module of the same type is installed,

the configuration saved to the 8900NET module will be downloaded to

the new module. The box must be checked before the current module

with the saved configuration is removed.

•

Frame Heath Reporting – this function is not active with the latest version

of the 8900NET module that controls this page.

•

Hardware Switch Controls – a read-only status report of 8900NET module

switch settings for Module Status Reporting and Asynchronous Status

Reporting. These functions must be enabled for the following Slot

SNMP Trap Reports to function.

Slot SNMP Trap Reports – displayed only when the SNMP Agent software

•

has been installed on the 8900NET module. Slot SNMP traps can be

enabled only when the hardware switches for Module Fault reporting

and Asynchronous Status reporting are in enabled on the 8900NET

module (dipswitch S1 segment 5 and dipswitch S2 segment 1).

The enabled SNMP traps will be reported to any SNMP manager that

is identified as an SNMP Report Destination in 8900NET configuration.

Trap severity is read-only hard-coded information that is interpreted

and responded to by the SNMP Manager software configuration.

Restore upon Install box has been checked, the current configu-

32 8950DAC Instruction Manual

Page 33

Figure 14. 8950DAC Slot Config Web Page

Configuration

8950DAC Instruction Manual 33

Page 34

Configuration

Use

this

link

Software Update Web Page

The Software Update page (Figure 15) indicates that module software

updates via the web or using the NetConfig networking application are not

supported. For instructions on updating to the latest software, refer first to

the 8950DAC Release Notes that accompany the software update for complete details.

Currently, the only recommended method of software updating is done

with a software kit (8900-FLOAD-CBL) that includes a CD-ROM with the

current software files and a serial cable assembly available from Grass

Valley.

Refer to the 8900-FLOAD-CBL Software Upgrade Instruction Manual in

PDF format on the CD-ROM for complete updating instructions and the

required software files for the module.

Figure 15. 8950DAC Software Update Web Page

34 8950DAC Instruction Manual

Page 35

Specifications

Specifications

Table 7. 8950DAC Specifications

Parameter Value

SDI Input

Signal type SMPTE 259M serial 10-bit 4:2:2 component video

Number of inputs 1 loop-through

Connector type 75 Ω BNC

Return loss > 18 dB up to 270 MHz

Signal level SDI: maximum cable length for pathological signal

CAV Outputs

Number of outputs 2 sets (GBR or Y/B-Y/R-Y)

Connector type 75 Ω BNC

Signal formats SMPTE, GBR, EBU N10, MII Japan, Beta US, Beta Japan, MII US

Signal DC level‘ 0 V DC ± 20 mV

Signal level CAV from 0.5 V up to 1.5 V (75 Ω terminated)

Factory default – SMPTE output ± 1% (after SMPTE setup in

Y/B-Y/R-Y, default GBR level accuracy is ± 5%)

Vertical blanking 525:

Narrow – 9 lines

Wide – 19 lines

625:

Narrow – 9 lines

Wide – 25 lines

Return loss > 40 dB up to 5.5 MHz

Analog Sync Output

Connectors 2 BNC

Signal type Analog composite sync

Output impedance 75 Ω

Output level 0.2 V up to 2.5 V p-p (75 Ω terminated)

Factory default: –2 V p-p ± 10%, DC: 0 V ± 20 mV

Output DC level 0 V DC ± 200 mV

Factory default: 0 V DC ± 1%

Performance

Support standards 525 or 625 (auto or manual)

Internal DSP 12 + 1 bit precision

X4 oversampling

Output D/A 10-bit

Analog output frequency response Y, G, B,R: ± 0.1 dB (10 Hz to 5.5 MHz, ± 0.1dB, ref. 1 MHz)

R-Y, B-Y: ± 0.1 dB (10 Hz to 2.75 MHz, ± 0.1dB, ref. 1 MHz)

Analog output group delay error Y: < 5 ns peak to peak (10 Hz to 5.5 MHz)

R-Y, B-Y: < 5 ns peak to peak (10 Hz to 2.75 MHz)

Analog output 3 channels delay error < 2 ns

Error checking and reporting EDH processor

Signal-to-noise ratio S/N ≥ 68 dB

K-factor 2T pulse 0.3/0.4%

Module delay 2.68 µsec

≤ 275 m

8950DAC Instruction Manual 35

Page 36

Specifications

Table 7. 8950DAC Specifications - (continued)

Parameter Value

User control delay Up to 2.5 lines

Environmental

Frame temperature range See Gecko 8900 Frame

Operating humidity range 0 to 90% non-condensing

Non-operating temperature -10 to 70 degrees C

Mechanical

Frame type Gecko 8900 Series Video

Power Requirements

Supply voltage + 12 V

Power consumption < 7.8 W (signal present: 0.65 A at 12 V)

< 6.6 W (no signal: 0.55 A at 12 V)

36 8950DAC Instruction Manual

Page 37

Service

Service

The 8950DAC Digital to Analog Converter modules make extensive use of

surface-mount technology and programmed parts to achieve compact size

and adherence to demanding technical specifications. Circuit modules

should not be serviced in the field unless otherwise directed by Customer

Service.

If your module is not operating correctly, proceed as follows:

•Check frame and module power and signal present LEDs.

•Check fuse and voltage testpoints (Figure 16).

•Check for presence and quality of input signals.

•Verify that source equipment is operating correctly.

•Check cable connections.

•Check output connections for correct I/O mapping (correct input connector is used for the corresponding channel output).

Refer to Figure 4 for the location of PWR LED and Table 2 on page 12 for

proper LED indications.

GRASS VALLEY GROUP 8950DAC

Voltage Testpoints

JP9

JP9

+5V

If the module is still not operating correctly, replace it with a known good

spare and return the faulty module to a designated Grass Valley repair

depot. Call your Grass Valley representative for depot location.

Refer to Contacting Grass Valley at the front of this document for the Grass

Valley Customer Service Information number.

Figure 16. 8950DAC Fuse and Voltage Testpoints

671-4798-

GND

+3.3V

-5V

Fuse

F2

F2A 125V

Solder side

(back)

0604_07

8950DAC Instruction Manual 37

Page 38

Status Monitoring

Status Monitoring

This section provides a summary of status monitoring and reporting for a

Gecko 8900 Series system. It also summarizes what status items are

reported and how to enable/disable reporting of each item. There are a

number of ways to monitor status of modules, power supplies, fans and

other status items depending on the method of monitoring being used.

8900 Frame status will report the following items:

• Power supply health,

• Status of fans in the frame front cover,

•Temperature,

•Module health, and

• Frame bus status.

Module health status will report the following items:

• Internal module state (and state of submodule or options enabled)

including configuration errors (warning), internal faults, and normal

operation (Pass).

LEDs

• Signal input states including valid/present (pass), not present or

invalid (warning), not monitored, and not available (no signal inputs).

•Reference input states including locked/valid (pass), not

locked/invalid (warning), and not monitored.

• Signal output states with reporting functionality (reference output).

LEDs on modules in the frame and on the front of the 8900TF/TFN frames

indicate status of the frame and the installed power supplies, fans in the

front covers, and modules. (The 8900TX-V/A frames have no LED indicators on the front cover.)

When a red FAULT LED is lit on a frame front cover, the fault will also be

reported on the 8900NET or Frame Monitor module. The LEDs on the front

of these modules can then be read to determine the following fault conditions:

• Power Supply 1 and 2 health,

• Fan rotation status,

• Frame over-temperature condition,

• Frame Bus fault (8900NET only), and

•Module health bus.

38 8950DAC Instruction Manual

Page 39

Frame Alarm

Status Monitoring

In general, LED colors used on the frame and modules indicate:

•Green – normal operation, (Pass) or signal present, module locked.

•Red – On continuously = fault condition, flashing = configuration error.

•Yellow – On continuously = active condition (configuration mode or

communication), flashing in sequence = module locator function.

Status LEDs for this module are described in Operation Indicator LEDs on

page 11. LEDs for the 8900NET module are described in the 8900NET

Network Interface Instruction Manual.

A Frame Alarm connection is available on pins 8 and 9 of the RS-232 connector on the rear of 8900 frame (Frame Monitor or 8900NET Network

Interface module required). This will report any of the status items enabled

with the 8900NET or Frame Monitor module configuration DIP switch.

Connection and use of the Frame Alarm is covered in detail in the 8900NET

Network Interface Instruction Manual.

Web Browser Interface

When the 8900NET module is installed in the frame, a web browser GUI

can indicate frame and module status on the following web pages:

• Frame Status web page – reports overall frame and module status in

graphical and text formats.

•Module Status web page – shows specific input and reference signal

status to the module along with enabled options and module versions.

•A Status LED icon on each web page to report communication status

for the frame slot and acts as a link to the Status web page where warnings and faults are displayed (8900NET version 3.0 or later).

In general, graphics and text colors used indicate the following:

•Green = Pass – signal or reference present, no problems detected.

•Red = Fault – fault condition.

•Yellow = Warning – signal is absent, has errors, or is mis-configured.

•Gray = Not monitored (older 8900 module).

•White = Not present.

Status reporting for the frame is enabled or disabled with the configuration

DIP switches on the 8900NET module. Some module status reporting items

can also be enabled or disabled on individual configuration web pages.

8950DAC Instruction Manual 39

Page 40

Status Monitoring

SNMP Reporting

The Gecko 8900 Series system uses the Simple Network Monitoring Protocol (SNMP) internet standard for reporting status information to remote

monitoring stations. When SNMP Agent software is installed on the

8900NET module, enabled status reports are sent to an SNMP Manager

such as the Grass Valley’s NetCentral application.

There are both hardware and software report enable switches for each

report. Both must be enabled for the report to be sent. Software report

switches are set on the 8900NET Configuration web page for the Frame, the

8900NET module, and each module slot. Refer to the 8900NET Network

Interface Instruction Manual for installation instructions.

40 8950DAC Instruction Manual

Page 41

Functional Description

Refer to the block diagram in Figure 17 while reading the following functional description.

Figure 17. 8950DAC Block Diagram

Functional Description

Serial input

LEDs

Setup

To Host

Deserializer

User

Sw.

Embedded

Processor

Y/B-Y/R-Y Y/B-Y/R-Y

54 MHz Osc.

and PLL

Delay

(3 line

max.)

Parallel

Interface

DSP FPGA

Timing

Analog Sync Gen.

4 Times Over-sampling

Filters

Color Space Converter

Matrix select

Bypass control

Comp. Sync

Y/G

B-Y/B

R-Y/R

DAC LPF

DAC

DAC

DAC

LPF

LPF

LPF

8 X

DAC

Composite

Sync

B

Y/G

B

B-Y

B

R-Y

B

OFFSETGAIN

0604_01

The 8950DAC converts SMPTE 259M (270 Mb/s D1 serial component

digital signal) to Y/B-Y/R-Y, or GBR analog video.

The major functional blocks are:

• Serial input and deserializers,

• Phase Lock Loop (PLL) 2 times clock generator,

•Digital to Analog converter (DAC),

•Output Low Pass Filters (LPF) and buffers,

•Delay line,

•Embedded processor, and

•Digital Signal Processing (DSP) Field Programmable Gate Array

(FPGA).

8950DAC Instruction Manual 41

Page 42

Functional Description

Serial Input and Deserializer

Phase Lock Loop (PLL) 2 Times Clock Generator

Digital to Analog Converter (DAC)

The serial input and deserializer are a standard chip set for receiving and

converting a D1 serial digital video stream into the 10-bit parallel 601

digital video signal. This section regenerates a 27 MHz clock from the

incoming serial data stream.

From the incoming 27 MHz clock, the PLL generates a 54 MHz clock used

for 4 times oversampling. This clock also servers as a free-running clock

when no input signal is present.

This board has four 10-bit high speed DACs producing Y/G, B-Y/B,

R-Y/R and analog Composite Sync outputs.

Output Low Pass Filters (LPF) and Buffers

After the DACs, the video signal passes through Low Pass Filters (4 per

board) and finally through the output amplifiers/buffers to the output

BNCs. Additional slow, I2C, 8x DAC provides the calibration and user

control for the output signal level and output black level.

Delay Line

On board delay line provides an additional 2.5 lines signal delay. The delay

time is under user control with the 37 ns step.

Embedded Processor

The embedded processor provides the interface between user and all the

processing logic inside the 8950DAC, as well as communication between a

remote host processor and the 8950DAC.

42 8950DAC Instruction Manual

Page 43

Digital Signal Processing FPGA

The FPGA performs all signal processing on the 8950DAC module

including:

•Timing,

•Analog sync generation,

• Four times over-sampling,

• Signal filtering, and

•Color space conversion.

Power Handling

From the external +12V source, the on board power supply provides +5V,

-5V, and +3.3V to the 8950DAC.

Functional Description

8950DAC Instruction Manual 43

Page 44

Functional Description

44 8950DAC Instruction Manual

Page 45

Index

Numerics

2ND LED 12, 19

525 LED 11, 12

525 line standard 21

625 LED 11, 12

625 line standard 21

8900 frame

frame alarm

status reporting 38

8900-FLOAD-CBL option 34

8900NET module

required software version

8950DAC

features

functional description 41

A

analog video outputs

cabling

specifications 35

39

7

10

22

specification 35

CONF (configuring) LED 11, 12, 19

configuration

local on-board

overview 14

Remote, GUI 22

summary table 17

connectors 9

input 10

input/output 10

control panel

control summary table

overview 22

controller module 8

19

17

D

documentation online 2

E

enable SNMP 40

environmental 36

B

backplane 9

block diagram 41

C

COMM LED 12

composite sync

DC offset

local adjustment

remote adjustment 27

summary table 17

output

cabling

output level

local adjustment

remote adjustment 27

summary table 17

8950DAC Instruction Manual 45

10

20

20

F

factory defaults

levels for each format

summary table 17

factory defaults recall

remote control

FAQ database 2

fault 12

FAULT LED 12

troubleshooting 38

formats

local controls

nominal signal levels 15

remote control 27

signal level summary table 15

summary table 17

31

20

15

Page 46

Index

frame 8, 36

frame capacity 8

Frame Status page 39

frequently asked questions 2

Function rotary switch 19, 20

fuse 37

G

graphical user interface (GUI) 25

Grass Valley web site 2

H

horizontal delay

local control

overview 15

remote control 29

summary table 17

21

I

N

Newton Control Panel

overview

summary table 17

22

O

online documentation 2

operational modes 12

outputs 35

connectors 10

specification 35

termination 10

overlay 10

P

performance 35

power 36

power supply 8

PWR LED 11, 12

impedance 10

indicators 12

input 35

loopthrough 10

specification 35

input formats

overview

14

L

Levels web page 27

locate module 32

loop-through 10

M

MAN LED 11, 12

module

controller

installation 8

power supply 8

slots 9

module health status 38

Module Status page 39

8

R

repair depot 37

report enable switches 40

S

setup enable (composite output)

local control

remote control 30

summary table 18

setup level

local adjustment

remote adjustment 28

summary table 17

Slot Config web page 32

slot memory 32

SNMP reporting

enabling

overview 40

software download from web 2

software update

8900-FLOAD-CBL

Software Update web page 34

20

20

32

34

46 8950DAC Instruction Manual

Page 47

Index

specifications 35

standard recognition 16

standard selection

local control

overview 16

remote control 30

summary table 18

Standard Selection web page 30

status monitoring 38

Status web page 26

switches (onboard) 19

sync on G channel

local control

remote control 29

summary table 18

21

21

T

termination 10

Timing/Blanking web page 29

toggle switch 19

troubleshooting 37

W

web site

documentation

FAQ database 2

Grass Valley 2

software download 2

2

U

user settings

local control

overview 16

remote control 31

summary table 18

User Settings web page 31

V

vertical blanking

local control

overview 15

remote control 29

summary table 18

VID PRES LED 12

video level adjustments

local control

overview 15

remote control 27

summary table 17

voltage (supply) 36

voltage testpoints 37

21

21

20

8950DAC Instruction Manual 47

Page 48

Index

48 8950DAC Instruction Manual

Loading...

Loading...