Page 1

FC

FC

7000

SERIES

user manual

MANUAL NO. FC7000-UM-151

Page 2

ii

Table of Contents

TO ENSURE SAFE AND CORRECT USE .............................................................................................vii

Conventions Used in This Manual.........................................................................................................vii

Description of Safety Symbols ..............................................................................................................vii

PREFACE..................................................................................................................................................xii

Notes on this Manual .............................................................................................................................xii

Registered Trademarks ..........................................................................................................................xii

Copyright ...............................................................................................................................................xii

Special Precautions on Handling Blades ..................................................................................................xiii

Cutting Blades.......................................................................................................................................xiii

Cutter Pens............................................................................................................................................xiii

After Turning on the Plotter......................................................................................................................xiii

Notes on the Stand ....................................................................................................................................xiv

Machine Caution Label.............................................................................................................................xiv

Daily Maintenance and Storage................................................................................................................xiv

Daily Maintenance................................... ...... .................................. ...... ..... ..........................................xiv

Storing the Plotter.................................................................................................................................xiv

Chapter 1: Out of the Box

1.1 Checking the Contents ................................................................................ ...... ..... .........................1-2

1.2 Nomenclature .................................................................................................................................1-3

Front View ...................................................................................................................................1-3

Rear View .....................................................................................................................................1-4

1.3 Assembling the plotter ....................................................................................................................1-5

FC7000-75 (desktop model; stand not provided but is available as an option) ...........................1-5

Attaching the Media Stockers.................................................................................................... 1-5

FC7000-100/130/160 (stand provided) ........................................................................................1-6

Assembling the Stand ................................................................................................................ 1-6

Mounting the stock rollers ...........................................................................................................1-9

1.4 Attaching the FC7000 Basket (Option) ........................................................................................1-10

1.5 Attaching a Cutter Pen ........................................ ...... ...... ..............................................................1-11

Attaching a Pen to the Two-Pen Holder (Option) ......................................................................1-12

Attaching a Plotting Pen to the Pen Station ...............................................................................1-13

1.6 Replacing the Cross-Cutter Unit ..................................................................................................1-14

Chapter 2: Cutter Blades and Cutter Pens

2.1 Blade Application and Features ......................................................................................................2-2

2.2 Cutter Pen Nomenclature ...............................................................................................................2-3

2.3 Replacing the Cutter Blade ........................................................ .....................................................2-4

Structure of Cutter Pen .................................................................................................................2-4

Replacing the Cutter Blade ..........................................................................................................2-4

2.4 Adjusting the Blade Length ............................................................................................................2-5

Chapter 3: Preparing to Cut

3.1 Control Panel .................................................................................................................................. 3-2

Indicator Lamps ...........................................................................................................................3-2

Function Keys ..............................................................................................................................3-2

Position Keys .............................................. ..... ............................................................................3-2

Menu Keys ...................................................................................................................................3-3

Page 3

3.2 Selecting a Function Menu .............................................................................................................3-4

When the FC7000 is in MENU mode ..........................................................................................3-4

When the power is turned on without any media loaded .............................................................3-5

3.3 Connecting to your Computer ........................................................................................................3-6

3.4 Turning on the Power .....................................................................................................................3-7

3.5 Loading Media ................................................................................................................................3-9

Loading Roll Media (Rear Loading) ............................................................................................3-9

Loading Roll Media (Front Loading) .........................................................................................3-10

Loading Sheet Media .................................................................................................................3-11

3.6 Aligning the Pinch Rollers ...........................................................................................................3-13

Standby Position .................................... ...... ...............................................................................3-13

When Feeding Long-axis Media (at least 2 meters) ..................................................................3-14

When the Media Width is 100 to 160 mm ................................................................................. 3-14

When the Media Width is 160 to 540 mm ................................................................................. 3-14

When the Media Width Exceeds 540 mm ..................................................................................3-15

Changing the Hold-down Force .................................................................................................3-15

Switching between the Strong and Weak settings............................................. ...................... 3-15

Hold-down Force Assignments................................................................................................ 3-16

3.7 Selecting the Media Type .............................................................................................................3-17

Chapter 4: Pen Setting Conditions

4.1 Pen Conditions ................................................................................................................................4-2

Precautions to observe when cutting high-intensity reflective film........................................... 4-3

How to improve weedability...................................................................................................... 4-3

4.2 Selecting Cutter-Pen Condition Setting Areas ............................................................................... 4-4

Selection method........................................................................................................................ 4-4

4.3 Setting the Cutter-pen Conditions ..................................................................................................4-5

To Change the FORCE ................................................................................................................4-5

Setting Procedure....................................................................................................................... 4-5

To Change the SPEED .................................................................................................................4-5

Setting Procedure....................................................................................................................... 4-6

To Change the QUALITY ...........................................................................................................4-6

Setting Procedure....................................................................................................................... 4-6

To Change the OFFSET ...............................................................................................................4-7

Setting Procedure....................................................................................................................... 4-7

4.4 Running Cutting Tests ....................................................................................................................4-8

Test Cutting Procedure ............................................................................................................. 4-8

4.5 Adjusting the Blade Length ..........................................................................................................4-10

Test Cutting Procedure ............................................................................................................ 4-10

iii

Chapter 5: BASIC FUNCTIONS AND OPERATIONS

5.1 Using the HOLD Function .............................................................................................................5-2

Setting Procedure....................................................................................................................... 5-2

5.2 Withdrawing the Pen Carriage .......................................................................................................5-3

Setting Procedure....................................................................................................................... 5-3

5.3 Moving the Pen Carriage to the Origin Point .................................................................................5-3

Setting Procedure....................................................................................................................... 5-3

5.4 Using the PRE FEED Function ......................................................................................................5-4

Setting Procedure....................................................................................................................... 5-4

5.5 Moving the Origin Point .................................................................................................................5-5

Setting Procedure....................................................................................................................... 5-5

When the origin is moved after the coordinate axes were rotated ...............................................5-5

When the coordinate axes are rotated after moving the origin point ...........................................5-6

Page 4

iv

5.6 Using the COPY Function ..............................................................................................................5-7

Setting Procedure....................................................................................................................... 5-7

5.7 Pen Up/Down ..............................................................................................................................5-10

Setting Procedure..................................................................................................................... 5-10

5.8 Using the CROSS-CUT Function ................................................................................................5-11

Cutting position........................................................................................................................ 5-11

Cutting width ........................................................................................................................... 5-11

Guidelines for replacing the cross-cutting unit........................................................................ 5-11

Auto Cross-cutting .....................................................................................................................5-11

Setting Procedure..................................................................................................................... 5-12

Manual Cross-cutting .................................................................................................................5-12

Setting Procedure..................................................................................................................... 5-12

5.9 Using the MOVE STEP Function ...............................................................................................5-13

Setting Procedure..................................................................................................................... 5-13

Chapter 6: ADVANCED FUNCTIONS AND OPERATIONS

6.1 Changing the Initial Feed Speed .....................................................................................................6-2

Setting Procedure....................................................................................................................... 6-2

6.2 Setting AUTO PRE FEED .............................................................................................................6-3

Making the setting at the INITIAL MENU screen.................................................................... 6-3

Making the setting at the FUNCTION 2 screen ........................................................................ 6-4

6.3 Setting the ORIGIN in HP-GL Mode .........................................................................................6-5

Setting Procedure....................................................................................................................... 6-5

6.4 Setting the Cutting/Plotting Area ................................................................................................... 6-6

Setting Procedure....................................................................................................................... 6-6

6.5 Expanding the Cutting/Plotting Area .............................................................................................6-9

Setting Procedure....................................................................................................................... 6-9

6.6 Setting the PAGE LENGTH ........................................................................................................6-11

Setting Operation..................................................................................................................... 6-11

6.7 Rotating the Coordinate Axes ......................................................................................................6-13

6.8 Setting the Mirror Mode ...............................................................................................................6-14

Setting Procedure..................................................................................................................... 6-14

6.9 Enlarging or Reducing an Image ..................................................................................................6-15

Setting Procedure..................................................................................................................... 6-15

6.10 Data Sorting Settings ....................................................................................................................6-16

Setting Procedure..................................................................................................................... 6-16

6.11 Auto Registration Mark Reading Function .................................................................................. 6-17

The registration mark pattern .....................................................................................................6-17

The reading area required for registration mark detection .........................................................6-18

The registration mark locations ..................................................................................................6-18

The position of the origin point ..................................................................................................6-19

Media on which registration marks cannot be detected .............................................................6-20

If registration marks cannot be automatically recognized .........................................................6-20

6.12 Setting the Registration Mark Mode ............................................................................................6-21

Setting Procedure..................................................................................................................... 6-21

2-point reading (2POINTS) ........................................................................................................6-22

3-point reading (3POINTS) ........................................................................................................6-23

4-point reading (4POINTS) ........................................................................................................6-25

6.13 Setting the Registration Mark Reading Area ................................................................................6-27

Setting Procedure..................................................................................................................... 6-27

6.14 Selecting the Registration MARK TYPE .....................................................................................6-29

Setting Procedure..................................................................................................................... 6-29

6.15 Specifying the Registration MARK SIZE ....................................................................................6-30

Page 5

Setting Procedure..................................................................................................................... 6-30

6.16 Setting the DISTANCE ADJUSTMENT .....................................................................................6-31

Setting Procedure..................................................................................................................... 6-31

6.17 Setting the AXIS ORIGIN OFFSET ............................................................................................6-33

Setting Procedure..................................................................................................................... 6-33

6.18 Setting the PAPER-WEIGHT Function .......................................................................................6-35

Setting Procedure..................................................................................................................... 6-35

6.19 Setting the SENSOR OFFSET ADJUSTMENT (Method 1) .......................................................6-37

Setting Procedure..................................................................................................................... 6-37

6.20 Setting the AXIS OFFSET ADJUSTMENT (Method 2) .............................................................6-39

Setting Procedure..................................................................................................................... 6-39

6.21 Selecting the Axis Alignment Method .........................................................................................6-41

Selecting the Axis Alignment Method..................................................................................... 6-41

6.22 Selecting the Axis Alignment Tool ..............................................................................................6-42

Selecting the Axis Alignment Tool.......................................................................................... 6-42

6.23 AXIS ALIGNMENT Settings ................................................... ...... .............................................6-43

Selecting an Axis Alignment Method ........................................................................................6-43

2-point method......................................................................................................................... 6-43

3-point method......................................................................................................................... 6-44

4-point method......................................................................................................................... 6-46

6.24 Setting Tangential Emulation .......................................................................................................6-48

Selecting the tangential emulation mode................................................................................. 6-48

Enabling/Disabling Tangential Emulation................................... ..... ...... ................................. 6-49

Setting Overcut ........................................................................................................................ 6-50

6.25 Setting the PEN UP SPEED .........................................................................................................6-51

Setting Procedure..................................................................................................................... 6-51

6.26 Adjusting the Blade OFFSET ANGLE ........................................................................................6-52

Setting Procedure..................................................................................................................... 6-52

6.27 Setting the OFFSET FORCE ........................................................................................................6-53

Setting Procedure..................................................................................................................... 6-53

6.28 Setting the STEP PASS ................................................................................................................6-54

Setting Procedure..................................................................................................................... 6-54

6.29 Setting the INTIAL DOWN FORCE ...........................................................................................6- 55

Setting Procedure..................................................................................................................... 6-55

6.30 Setting the DISTANCE ADJUST Function .................................................................................6-56

Setting Procedure..................................................................................................................... 6-56

Setting the Distance Adjust Parameter .................................................................................... 6-57

6.31 Selecting the Type of Perforated Line ..........................................................................................6-58

Setting Operation..................................................................................................................... 6-58

v

Chapter 7: OPTIONS

7.1 Loupe (PHP61-LOUPE) .................................................................................................................7-2

Axis Alighment and plotting Area Adjustment ...........................................................................7-2

Attaching the Loupe .....................................................................................................................7-2

Using the Loupe ...........................................................................................................................7-3

7.2 Pouncing Tool ................................................................................................................................7-4

Attaching the Pouncing Tool .......................................................................................................7-4

Holder for auto registration mark sensor ........................................................................7-5

Setting Procedure....................................................................................................................... 7-5

7.3 Pen Assignment (for 2-pen models only) .......................................................................................7-6

Setting Procedure....................................................................................................................... 7-6

7.4 Pen Offset (2-pen models only) ......................................................................................................7-7

Setting Procedure....................................................................................................................... 7-7

Page 6

vi

Chapter 8: BACK GROUND SETTINGS

8.1 Description of the Background Settings .........................................................................................8-2

8.2 Setting the Background Settings ....................................................................................................8-5

Setting Procedure....................................................................................................................... 8-5

Chapter 9: TEST MODES AND TROUBLESHOOTING

9.1 Using the Condition List Mode ......................................................................................................9-2

Setting Procedure....................................................................................................................... 9-2

9.2 Running the SELF TEST ................................................................................................................9-3

Setting Procedure....................................................................................................................... 9-3

9.3 Using the DATA DUMP mode ......................................................................................................9-4

Setting Procedure....................................................................................................................... 9-4

9.4 The Plotter Does Not Operate When Turned On ...........................................................................9-5

9.5 The Plotter Does Not Operate Correctly ........................................................................................9-6

9.6 The Cutting Results Are Unsatisfactory .........................................................................................9-9

9.7 Error Messages in GP-GL Command Mode ................................................................................9-11

9.8 Error Messages in HP-GL Command Mode ................................................................................9-12

CAUSE .................................................................................................................................... 9-12

SOLUTION.............................................................................................................................. 9-12

Chapter 10: INTERFACES

10.1 RS-232C Interface ........................................................................................................................10-2

Factory Preset Settings............................................................................................................. 10-2

10.2 USB Interface Settings .................................................................................................................10-3

Supported Operating Systems.................................................................................................. 10-3

10.3 Interface Setting Menu .................................................................................................................10-4

Using the INITIAL MENU to set the functions...................................................................... 10-4

Using the MENU MODE to set the functions......................................................................... 10-4

10.4 Setting the STEP SIZE .................................................................................................................10-5

Setting Procedure..................................................................................................................... 10-5

10.5 Setting the RS-232C Interface Transmission Conditions .............................................................10-6

Setting Procedure..................................................................................................................... 10-6

10.6 COMMAND Settings ................................................................................................................... 10-7

Setting Procedure..................................................................................................................... 10-7

Chapter 11: Specifications

11.1 Main Specifications ......................................................................................................................11-2

11.2 Options .........................................................................................................................................11-3

11.3 Supplies ........................................................................................................................................11-3

11.4 Menu Tree ......................................... ...... ...... ...............................................................................11-4

11.5 External Dimensions ....................................................................................................................11-5

FC7000-75 ..................................................................................................................................11-5

Optional stand and Basket Provided........................................................................................ 11-5

FC7000-100/130/160 .................................................................................................................11-6

Page 7

vii

DANGER

CAUTION

TO ENSURE SAFE AND CORRECT USE

• To ensure the safe and correct use of your plotter, read this manual thoroughly prior to use.

• After reading this manual, keep it in a handy location for quick reference as necessary.

• Do not allow small ch ild ren to touc h the plotter.

• The following describes important points for safe operation. Be sure to observe them strictly.

Conventions Used in This Manual

To ensure the safe and accurate u se of the plotter as well as to prevent human in ju ry and property damage, the safety

precautions provided in this manual are ranked in the three categories described below. Be sure to gain a full understanding of the difference between each of the categories before reading the Manual.

DANGER

WARNING

CAUTION

: This category provi des infor mation tha t, if ig nored, is high ly likel y to caus e fatal or serious

injury to the operator.

: This category provides inform ation t hat, if ig nored, is lik ely to cau se fat al or s eriou s injur y

to the operator.

: This category provides information that, if ignored, could cause injury to the operator or

damage to the plotter.

Description of Safety Symbols

The symbol indicates in formation th at requires ca reful attenti on (including warnings) . The specifi c point

requiring attention is described by an illustration or text within or next to the symbol.

The symbol indicates an action that is prohibited. Such prohibited action is described by an illustration

or text within or next to the symbol.

The symbol indicates an action that must be performed. Such imperative action is described by an

illustration or text within or next to the symbol.

Page 8

viii

Safety Precautions

WARNING

Do not touch the rollers or moving parts such as the carriage

while cutting or plotting is in progress.

• Such action may result in injury.

Be sure to ground the earth terminal.

• If the plotter is not grounded, the operator could suffer an electric

shock in the event of current leakage.

Keep your hands, hair, etc., away from the rollers or moving

parts such as the carriage even if the plotter is stopped, as it

may suddenly start moving when data is received.

• Such action may result in injury.

Do not touch

Ground the plotter

Keep your distance

Do not disassemble, repair, or remodel the plotter.

• Such action may cause electric shock or a fire hazard due to current

leakage.

• Contact with the high-voltage parts within the plotter may cause electric shock.

• If the plotter requires repairs, contact your sales representative or

nearest Graphtec vendor.

Do not connect the plotter to a non-rated power supply.

• Use of a different supply voltage may result in electric shock or a fire

hazard due to current leakage.

Do not use the plotter in a location where it will be exposed to

water, rain, or snow.

• Such locations may cause electric shock or a fire hazard due to current leakage.

No disassembly

Prohibited

Avoid wat e r

Specified

rating

Beware of electric shock

Page 9

Safety Precautions (Continued)

WARNING

If the plotter generates smoke, overheats, emits a strange

odor, or otherwise functions abnormally, do not continue

using it. Turn off the power and unplug the power cord from

the electrical socket.

• Use of the plotter in such a condition may result in a fire hazard or

electric shock.

• After confirming that smoke is no longer being emitted, contact your

sales representative or nearest Graphtec vendor for repairs.

• Never attempt to perform repairs yourself. Repair work by inexperienced personnel is extremely dangerous.

Do not allow dust or metal scraps to adhere to the power

plug.

• A dirty power plug may res ul t in ele ctr ic s hoc k or a fire hazard due to

current leakage.

ix

Prohibited

Prohibited

Do not use the power cord if it is damaged.

• Use of a damaged cord may result in electric shock or a fire hazard

due to current leakage.

• Replace the power cord with a new one.

Be careful when handling the cutter blade.

• Touching the blade with your bare hand may cause injury.

• Do not touch the cutter blade while cutting is in progress.

Beware of electric shock

Unplug the power

cord from the socket

Do not touch

Page 10

x

Safety Precautions (Continued)

CAUTION

Do not use or store the plotter in a location exposed to direct

sunlight or the direct draft of an air conditioner or heater.

• Such locations may impair the performance of the plotter.

Do not use the plotter in an excessively dusty or humid

location.

• Such locations may impair the performance of the plotter.

Do not place any receptacle containing water or other fluid on

top of the plotter.

• Fluid falling inside the plotter may cause electric shock or a fire hazard due to current leakage.

Prohibited

Prohibited

Avoid wat e r

Beware of electric shock

Do not use the plotter in a location subject to excessive

mechanical vibration or electrical noise.

• Use in such locations may impair the performance of the plotter.

When disconnecting the power cord or interface cable, do not

pull on the cord/cable.

• Such action will damage the cord/cable, resulting in a fire hazard or

electric shock.

If water or foreign matter enters the plotter, discontinue use.

Turn off the power and unplug the power cord from the

electrical socket.

• Use of the plotter in such a condition may result in electric shock or a

fire hazard due to current leakage.

• Contact your sales representative or nearest Graphtec vendor for

repairs.

Prohibited

Prohibited

Unplug the power

cord from the socket

Page 11

Safety Precautions (Continued)

CAUTION

Do not attempt to lubricate the cutting-plotter mechanisms.

• Such action may cause it to break down.

Do not clean the plotter using volatile solvents such as

thinner or benzene.

• Such action may impair its performance.

Provide sufficient spa ce around the plotter s o that it does not

strike any objects in its vicinity during cutting or plotting.

• Such contact ma y cause misalignment in cutt in g or plotti ng.

Prohibited

Prohibited

Do not touch

xi

T

h

i

n

n

e

r

e

n

e

z

n

e

B

When using indoor lighting such as fluorescent or other

electrical lamps, provide a distance of at least one meter

between the plotter and the light source.

• Close proximity of such a light source may cause the sensor to malfunction and prevent proper size detection of the media.

When using the cutter, take care not to extend the blade more

than necessary.

• An overly extended blade will damage the cutting mat and adversely

affect the cutting quality.

Move the pen carriage slowly when moving it manually in

order to load the medium or for other reasons.

• Moving it quickly may damage the plotter.

Page 12

xii

PREFACE

Thank you for choosing a Graphtec FC7000 Series plotter. The FC7000 Series plotters employ a digital servo drive

system to achieve high-speed and high-precision cutting. In addition to cutting marking film and othereop media, an

FC7000-series plotter can also be used as a pen plotter. To ensure high cutting quality and optimal productivity, be

sure to read this User's Manual thoroughly prior to use.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, without the prior written permission of Graphtec Corporation.

(2) The product specifications and other information in this manual are subject to change without notice.

(3) While every effo rt has been mad e t o provi de co mplet e an d accura te i nforma tion, p lease cont act yo ur sal es repr e-

sentative or neare st Gra phtec v endor if you find an y unc lear or e rroneous informat ion or wish to mak e other com -

ments or suggestio ns.

(4) Notwithstanding the stipulations in the preceding paragraph, Graphtec Corporation assumes no liability for dam-

ages resulting from either the use of the information contained herein or the use of the product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks or registered

trademarks of their respective companies.

Copyright

This User’s Manual is copyrighted by Graphtec Corporation.

Page 13

xiii

Special Precautions on Handling Blades

Sharp cutter blades are used with this plotter. Handle the cutter blades and holders with care to prevent bodily injury.

Cutting Blades

Cutter blades are very sharp. While handling a cutter blade or cutter pen, be careful to avoid cutting your fingers or

other parts of your body.

Promptly return used blades to the cutter case provided. When the case is completely filled, discard the used blades

together with the case.

Cutter Pens

The tip consists of a sharp blade. Be sure not to extend it too far. Moreover, when you are not using the cutter pen,

make sure that the blade is fully retracted.

After Turning on the Plotter

During the course of turning on the plotter, be sure to observe the following precautions. The pen carriage and loaded

media may suddenl y move duri ng the cutt ing op eration, im mediatel y afte rward and when settin g the plot ter's func tions.

Keep hands, hair, clothing and other object s ou t of the vici nit y of the pen c arriage , grit rol lers a nd loa ded medi a. To prevent operator injury and poor cutting results, be careful not to allow hands, hair, clothing or other foreign objects to

become entangled with the pen carriage or loaded media while the plotter is operating.

.

Page 14

xiv

Notes on the Stand

Be sure to use only the stand designed for the FC7000 Series with your FC7000 Series plotter. The use of a different

stand may cause a plotter malfunction or bodily injury.

Machine Caution Label

The machine's Caution Label is located on the top cover. Be sure to observe all the cautions on the label.

Daily Maintenance and Storage

Daily Maintena n ce

During the course of daily plotter operation, be sure to observe the following precautions:

(1) Never lubricate the mechanisms of the plotter.

(2) Clean the plotter's casing using a dry cloth that has been moistened in a neutral detergent diluted with water.

Never use thinner, benzene, alcohol, or similar solvents to clean the casings; they will damage the casing's finish.

(3) Cle an the cutting mat using a dry cloth. In c as e of st ubborn stains, use a cloth that has been moistened in alcohol

or in a neutral detergent diluted with water.

(4) Cle an the plo tter's p aper se nsors using a cloth mois tened in a neutra l deterge nt dilu ted wi th water. Never use thin-

ner, benzene, alcohol, or similar solvents to clean the sensors; cleaners such as these will damage the sensors.

Storing the Plotter

When your plotter is not in use, be sure to observe the following points:

(1) Remove the pen attached to the penholder

(2) Cover the plotter with a cloth to protect it from dust and dirt

(3) Do not store the plotter in direct sunlight or in high temperatures

Page 15

Chapter 1: Out of the Box

This chapter describes plotter nomenclature and how to

install your plotter.

Topics in this chapter

1.1 Checking the Co ntents

1.2 Nomenclature

1.3 Assembling the plotter

1.4 Attaching the FC7000 Basket (O ption)

1.5 Attaching a Cut ter Pen

1.6 Replacing th e Cross-Cutt er Unit

Page 16

1 - 2

1.1 Checking the Contents

After unpacking your plotter, check that all of the standard accessor ies shown

below are prese nt. If any acces sory is m issing, c ontact your sales representat ive

or the nearest Grapht ec dealer.

AC power cord

1 1 each

USB cable (3-m length)

User Guide CD-ROM

1

Contains:

User’s Manual (pdf)

Windows driver/Macintosh plug-in software

Cutter holder

(PHP32-CB09N)

1

Cutter blades

(CB09UA-2)

1

Media bracket

1

Quick Start Manual, Usage Precautions

1 of each

Water-based fibertip pen

1

Stand

(available as an option for the FC7000-75 model)

1

Base assembly x 2

Stand side bar x 2

Center bar x 1

Socket head cap screw x 20

Allen wrench x 1

Media stocker x 2

Stock roller x 2

M4 binding head screws x 8

Out of the Box: Checking the Contents

Page 17

1.2 Nomenclature

Front View

Power switch

Grit roller position guide

Cutting mat

Cutting groove

Pinch roller

Grit roller

Grit roller

Cross-cutter unit

Pen carriage

Media sensor

Media sensor

1 - 3

Pen holder

Pinch rollers

Control panel

Stand

Pen station

Power switch: ..............Used to turn the plotter on and off.

Control panel: ............ ..Used to access various p lotter f unction s.

Pinch rollers: ............. ..Rollers t hat push the medi a against the grit rollers.

Grit rollers: ..................Metallic rollers with a file-like surface that feed the media

back and forth.

Media sensor s: ............The front senso r is used to sen se t he le ading edge o f t he

media. The rear sens or is used to sen se the trai ling edge

of the media.

Pen carriage: ......... ......Mo ves the cutter -pen or plotti ng pen acr oss the media

during cutting or plo tting.

Pen holder: ..................Holds the cutter-pen or plotting pen and moves it up or

down.

Pen station (i nstalled on 2-pen m odels on ly):

The second pen is moun ted here.

Stand: .........................Used to make the plotter more portable and to free up

counter space

Grit roller position gui de:

Stickers on the front of the Y ra il and the rear side of the

top cover that show the position of eac h grit roller. Use

these alignment mar ks as an aid in locat ing the pinch rol l-

ers.

Cutting groove: ............Used when cross-cutting is performed.

Cross-cutter unit: .........Use d to perform cross -cutting of medi a so that the cut

length can be removed from th e roll.

Out of the Box: Nomenclature

Page 18

1 - 4

Rear View

Pinch roller hold-down force switching lever

AC line inlet

Media stocker

Stock rollers

Media set lever

USB interface connector

Media lock

RS-232C interface connector

Media set lever: .. ... .. ... .Us ed t o r ais e o r lo wer t he pi nch r ol ler s du ri ng th e lo ading

or unloading of medi a.

Pinch roller hold-dow n force switchi ng leve r:

Used to switch between the two pinch roller forces (strong

and weak).

AC line inlet: ................Inlet where the power cord is connected.

Media stocker: ......... ....Use d to carr y roll media and ensure its prop er rotatio n.

Stock rollers: ......... ......A media roll i s placed on the se roll ers.

Media lock: ..................Used to prevent the stock rollers from rotating when the

media roll has been pla ced on top of them . The media

lock ensures that the media is pulled straight out from the

roll.

USB interfac e connector:

Used to conne ct the p lotter to th e computer with a USB

interface cable.

Serial interface conn ector:

Used to conne ct the p lotter to the computer with an RS-

232 serial interf ace cable.

Out of the Box: Nomenclature

Page 19

1.3 Assembling the plotter

FC7000-75 (desktop model; stand not provided but is available as an option)

When the FC700 0-75 i s used w ithout a stand, t he medi a bracket is attach ed

directly to the plotter.

The media bracket is made up of the followi ng parts.

Stock roller x 2Media stocker x 2 M4 binding-head screw x 4

ATTACHING THE MEDIA STOCKERS

1 Fasten the media stocker to the le ft and right inside sur faces of the plotter unit,

using two M4 binding- head screws for each st ocker.

1 - 5

Front

Media stocker

Media stocker

2 Insert an M4 screw in the second hole from the front side of the plotter.

• Check that all of the scr ews used for fast ening have b een tigh tened. The media

may not be fed correctly if even one of the screws is loose.

• When installing the plotter, make sure that there are no objects in its vicinity.

Leave a clear space of at least 300 mm around the plotter.

• When the FC7000-75 is used without a stand, the max imum diameter of the

roll media that can be used is 160 mm.

Out of the Box: Assembling the plotter

Page 20

1 - 6

FC7000-100/130/160 (stand provided)

Assemble the stand, attac h the media brack et to the stand, and the n mount the

plotter on t he stand.

The stand and the media bracke t are made up of th e following parts.

Base assembly x 2 Allen wrench

Media stocker x 2

Center bar x 1Stand side bar x 2 Socket head cap screw

Stock roller x 2

(for M5 screws) x 1

(M5) x 20

ASS EMBLING THE STA N D

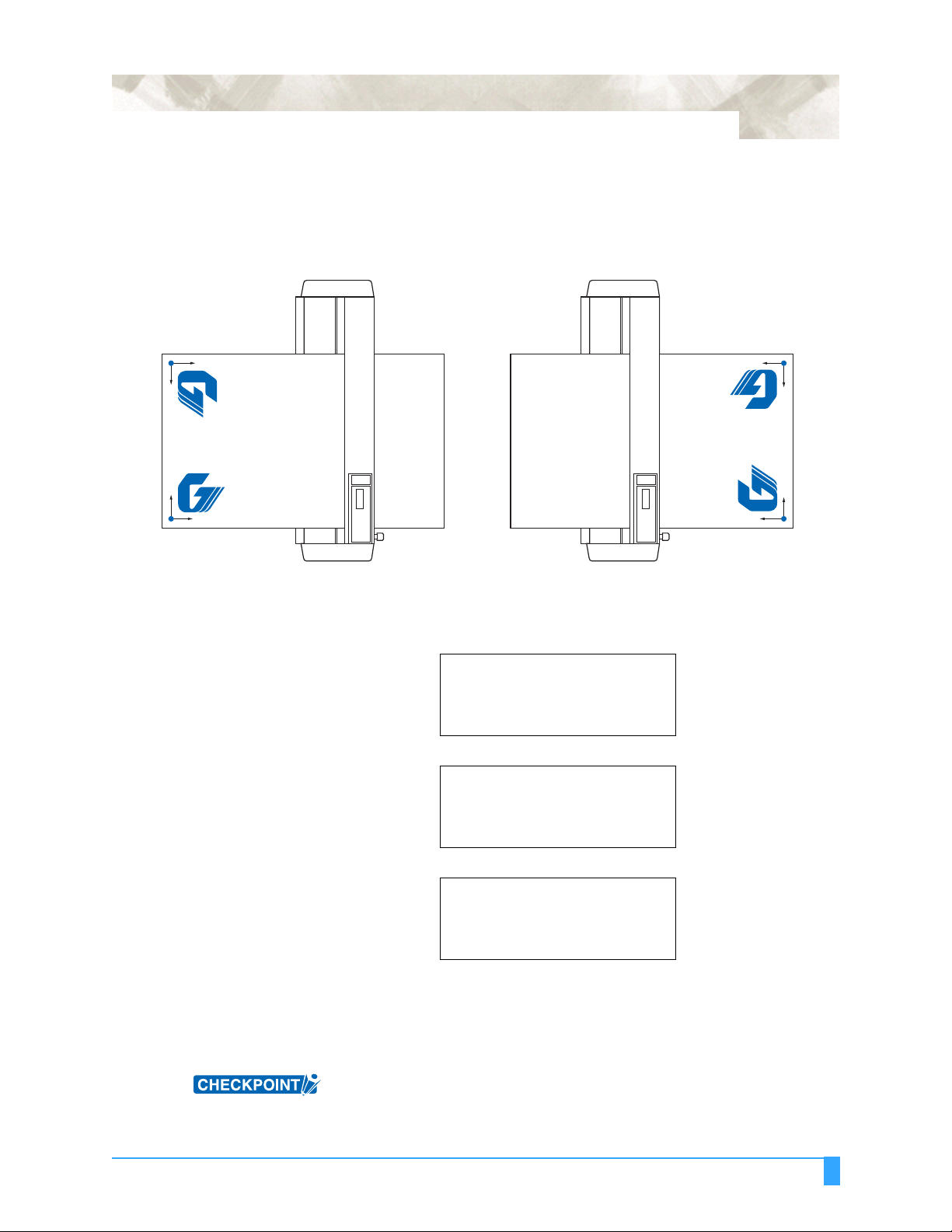

The mounting direc tion is different fo r the front lo ading and the rear loading

models.

<Front loading>

Out of the Box: Assembling the plotter

<Rear loading>

Page 21

1 - 7

1 Assemble the left and ri gh t stand sides . Fa ste n a bas e asse mbl y to eac h of the

stand side bars with fo ur socket head cap scr ews, using the Al len wrench.

Socket head

cap screws

Base assembly

Stand side bar

Stand side bar

Assemble the sta nd so that the front and rear lengths of th e base assem bly are

the same for both the left and right stand sides.

2 Loosely faste n the c enter bar to t he left and right stand sid es with four socke t

head cap screws (two on each side), using the Allen wrench.

Socket head

cap screws

Center bar

Socket head

cap screws

Stand sides

3 Attach a media s tocker t o each of the left and r ig ht stand si des w ith tw o sock et

head cap screws, using the Allen wrench. Mount the media stockers so that

each one protrudes di rectly above t he longer of the tw o base assembly

lengths.

Media stocker

Socket head cap screws

Media stocker

Stand sides

Base assembly

Out of the Box: Assembling the plotter

Page 22

1 - 8

4 Mount the plotte r on the stand by inserti ng the positio ning pins on the stan d

into the position ing holes on the underside of th e plotter. Fasten with four

socket head cap scr ews (two on each side), using the Allen wrench.The cutting

plotter mount ing dire ction is differ ent for th e front loading and the rea r loadin g

models.

<Front loading>

Socket head

cap screws

Positioning pin hole

<Rear loading>

Socket head

Positioning pin

Caster stoppers

cap screws

5 Tighten the socket he ad cap s crews loo sely fas tened i n Step 2.

• Check that all of the scr ews used for fast ening have b een tigh tened. The media

may not be fed correctly if even one of the screws is loose.

• When installing the plotter, make sure that there are no objects in its vicinity.

Leave a clear space of at least 300 mm around the plotter.

Out of the Box: Assembling the plotter

Page 23

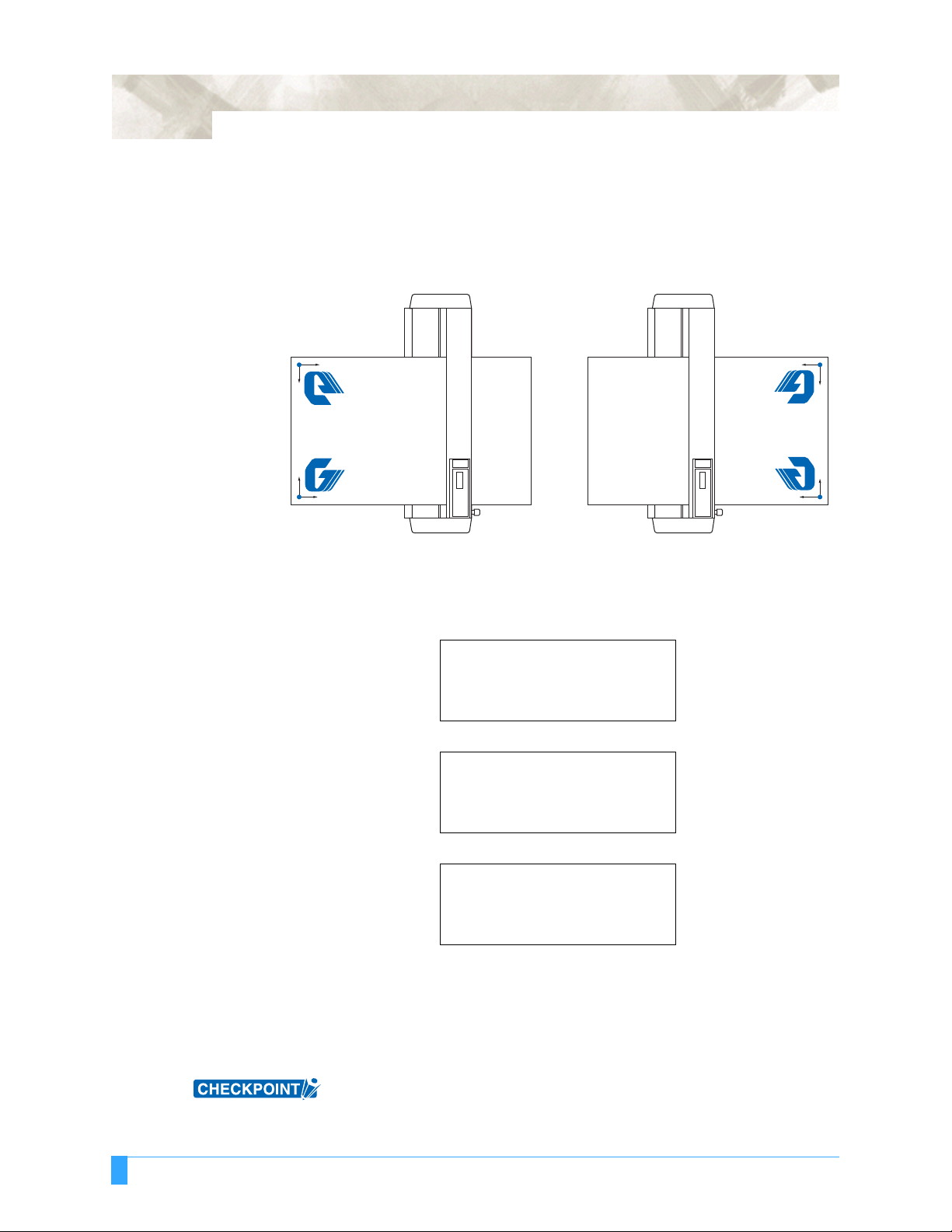

Mounting the stock rollers

Insert the stock ro llers into the slots on the media stocker.

1 - 9

<Front loading>

Stock rollers

<Rear loading>

Front

Stock rollers

Out of the Box: Assembling the plotter

Page 24

1 - 10

1.4 Attaching the FC7000 Basket (Option)

The FC7000 Basket box contains one basket ho lder assembly (on e front basket

tube and one rear basket tube inserted int o two tube brack ets), one cloth ba sket,

and a screw/wrench set.

1 Attach one of the two tube br ackets on the basket holder assembl y to the left

side of the stand with two s ocket head cap scr ews, usin g the Allen w rench.

Repeat this step wit h the other si de.

Socket head

cap screw

Socket head

cap screw

Stand

Basket holder assembly

2 Drape the mid dle sect ion of t he cloth basket over the stand's ce nter b ar, and

then snap the middle section of the cloth basket around the center bar. Snap

the front edg e of t he clot h basket around the fr ont ba sket tube, and t hen snap

the rear edge of the cloth basket around the rear basket tube.

Side view

Holder snap

Front

Center bar

Cloth basket

Out of the Box: Attaching the FC7000 Basket (Option)

Cloth basket

Separate into front and rear baskets,

with the center bar as the center point

Page 25

1.5 Attaching a Cutter Pen

When mounting t he cutter pen in the pen holder, push the pen all the way into t he

holder until its flang e contacts the upper part of the holder and then tighten th e

screw firmly. To prevent injury, avoid touching the pen immediately after the cutting

plotter is turned on or whenever the pe n is moving.

1 Loosen the pen holder screw.

2 While pushing the pen hol der in the upwa rd direc tion, push th e pen al l the w ay

into the holder un til its flange contacts th e upper part of th e holder.

1 - 11

When pushing the pen holder with your fingers, the blade tip may be

protruding. Take care not to cut your fingers.

Upper part of pen holder

Flange

3 Make sure that the pe n bracket is enga ged on the pen’s flang e, and then

tighten the screw.

Flange

Bracket to hold pen

Out of the Box: Attaching a Cutter Pen

Page 26

1 - 12

Attaching a Pen to the Two-Pen Holder (Option)

The two-pen holder is a factory-i nstalled option, an d cannot be ret rofitted.

1 Loosen the pen holder screw.

2 While pushing the pen hol der in the upwa rd direc tion, push th e pen al l the w ay

into the holder un til its flange contacts th e upper part of th e holder.

When you push the pen holder with your fingers, the blade tip may be

protruding. Take care not to cut your fingers.

Flange

Upper part of pen holder

3 Make sure that the pe n bracket is enga ged on the pen’s flang e, and then

tighten the screw.

Flange

Bracket to hold pen

Out of the Box: Attaching a Cutter Pen

Page 27

Attaching a Plotting Pen to the Pen Station

Follow the procedur e below to repla ce the cross-cu tter unit th at is used to cut the

media after the plottin g or cutting ope ration has been com pleted.

1 Open the pen-hold mechanism on the pen station, and then attach a pen.

2 Make sure that the bracket of the pen station is engag ed in the upper groove of

the pen.

1 - 13

3 Close the pen-hold mechanism on the pen station to hold the pen in place.

• Do not leave a pen attached to the pen station for a long period of time, as the

pen tip will dry up and make it unusable.

• To store the pen, remove it from the pen station and replace its protective cap.

Out of the Box: Attaching a Cutter Pen

Page 28

1 - 14

1.6 Replacing the Cross-Cutter Unit

1 Check that the power switch is turned off (the " " side is pressed down).

2 Remove the screw holding the cross-cutter unit in place, and then remove the

cross-cutter unit.

Cross-cutter unit

3 Remove the protective cover from the replacement cross-cutter unit. Be sure

to remove the protect ive cover whi le holding the part of the unit shown in the

figure below.

Protective cover

Out of the Box: Replacing the Cross-Cutter Unit

Page 29

1 - 15

4 Attach the replace ment cross-cutt er unit, and tigh ten the screw to ho ld it in

place.

Cross-cutter unit

WARNING: The cross-cutter unit uses a very sharp blade. Take care not to cut your-

self on the blade.

Out of the Box: Replacing the Cross-Cutter Unit

Page 30

1 - 16

Out of the Box: Replacing the Cross-Cutter Unit

Page 31

Chapter 2: Cutter Blades

and Cutter Pens

This chapter describes the different cutter blades and cutter

pens.

Topics in this chapter

2.1 Blade Ap plicati on and F eatures

2.2 Cutter Pen Nome nclature

2.3 Replacing the C utter Blad e

2.4 Adjustin g the Blade L ength

Page 32

2 - 2

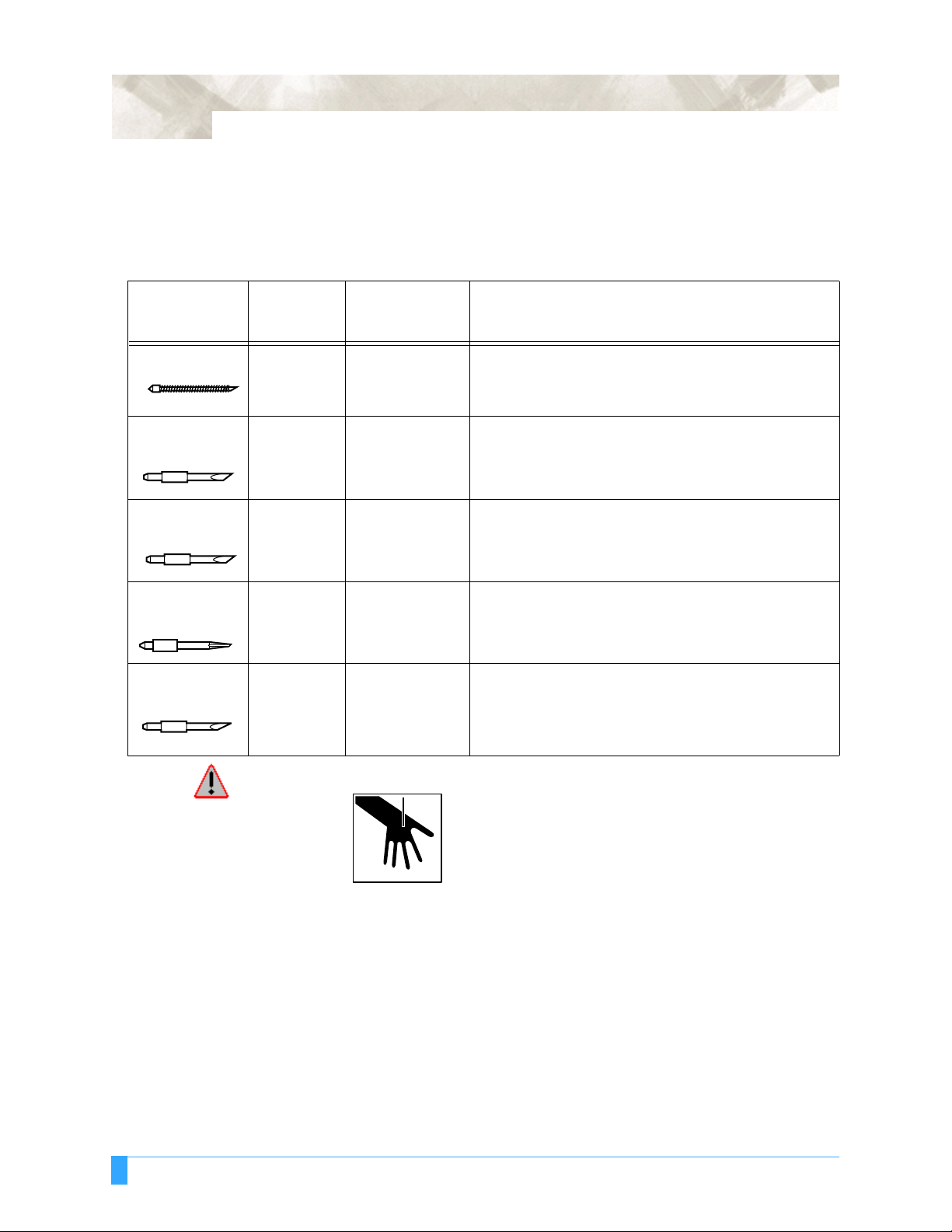

2.1 Blade Application and Features

Individual cutter bl ades have a variety of features. Sel ect the optimal cutte r blade

to suit the medium to be cut.

Blade part

no. and type Diameter

CB09UA 0.9 mm PHP32-CB09N Standard blade for cutting color adhesive media. Suit-

CB15U 1.5 mm PHP32-CB15N For cutting media which is too thick for the CB09UA

CB15UA 1.5 mm PHP32-CB15N For cutting high intensity reflective media.

CB15UB 1.5 mm PHP32-CB15N For cutting small characters on mono-vinyl chloride

CB15U-K30 1.5 mm PHP32-CB15N

Plunger part

no. Applications and features

able for cutting m edia u p to 0.25 mm th ick. M aximum cutting distance of approximately 4000 m.

blade to handle. Sui tab le for c utting med ia f rom 0.2 5 mm

to 0.5 mm thick.

media. Suitable for cutting small size characters that are

less than 10mm.

For cutting sandblast rubber. The sharply angled point

or

PHP32-CB15

provides a longer cutting edge. Suitable for cutting material from 0.05 mm to 1.5 mm thick.

WARNING: To avoid bodily injury, handle the cutter blade with care.

Cutter Blades and Cutter Pens: Blade Application and Features

Page 33

2.2 Cutter Pen Nomenclature

The plotter cuts using a cutter blade mount ed in a cutter-pe n plunger. There are

two different cutter- pen plunger s to suit the diamet er of the cutter bl ade to be

mounted (the 0.9- mm cutter- pen pl unger is p rovid ed as a standar d access ory) . Be

sure to mount the cutter blade in the corresponding cutter-pen plunger.

2 - 3

Cutter blade

Plunger cap

Plunger

Blade-length adjustment knob

(Blue: For 0.9-mm-diameter blades)

(Red: For 1.5-mm-diameter blades)

WARNING: To avoid bodily injury, handle cutter blades with care.

Cutter Blades and Cutter Pens: Cutter Pen Nomenclature

Page 34

2 - 4

2.3 Replacing th e Cu tt er Bla de

Structure of Cutter Pen

1.5-mm-diameter cutter pen

Blade-length adjustment knob

Plunger cap

cross-section

Replacing the Cutter Blade

While referrin g the above figu res, f ollow the pr ocedu re be low to repl ace t he cutt er

blade.

1 Turn the blade-length adjus tment knob in th e direction in dicated by the ar row

to retract the blad e into the plung er.

(red)

Plunger

1.5-mm-dia. blades

Plunger-cap

0.9-mm-diameter cutter pen

Blade-length adjustment knob

(blue)

Plunger

0.9-mm-dia. blades

Spring

Plunger-cap

Plunger-cap

cross-section

2 Turn the plunger cap in the count er-clockwise di rection to remo ve it from the

plunger.

3 Remove the b lade from inside the pl unger c ap.

4 Remove a new blade fro m its pack. Insert t he new blad e into t he hole pro vided

in the plunger cap.

5 With the blade in serted into the plung er cap, screw on the plunge r from above .

Cutter Blades and Cutter Pens: Replacing the Cutter Blade

Page 35

2.4 Adjusting th e Bla de Le n g th

WARNING: To avoid bodily injury, handle cutter blades with care. Make sure to

correctly adjust the blade leng th. If the blade length is too long for the

thickness of the media being used, you may cut through the cutting mat

and damage your plotter.

1 Adjust the blade l ength b y turni ng the bl ade-le ngth ad justment knob. Turn the

knob in direction "A" to extend the blade, or in direc tion "B" to retr act the

blade. When the knob is turned by one scale unit, the blade moves approxi-

mately 0.1 mm. One full turn of the knob moves the bl ade approxima tely 0.5

mm.

The blade moves approximately

0.1 mm per scale unit

2 - 5

B

A

2 First align the blade tip with the tip of the cutter pen, and then extend the blade

from that position t o suit the thickn ess of the media to be cut.

3 Assuming that the medi um thickness is "t," as shown in the fi gure below, the

blade length "l" sho uld be equal to or slightly greate r than "t." Make sure that

"l" is never greater th an the comb ined th icknes s of the medi um and its backi ng

sheet. If it is not possible to accurately determine the medium thickness, adjust

the blade length by gradu ally inc reasi ng it until onl y traces of the blade ap pear

on the backing sheet after a cutting test is conducted.

Medium

Backing sheet

t

l

Cutter Blades and Cutter Pens: Adjusting the Blade Length

Page 36

2 - 6

Cutter Blades and Cutter Pens: Adjusting the Blade Length

Page 37

Chapter 3: Preparing to Cut

This chapter describes how to use the control panel, load

the media, select and install the appropriate cutting tools,

and to achieve the best cutting results.

Topics in this chapter

3.1 Control Panel

3.2 Selecting a Fu nction Menu

3.3 Connecti ng to y our Com puter

3.4 Turning on the P ower

3.5 Loading Media

3.6 Aligning th e Pinch Rolle rs

3.7 Selecting the Med ia Type

Page 38

3 - 2

3.1 Control Panel

Indicator Lamps

POWER lamp: .........Remains lit (green) while the plotter is on.

PROMPT lamp:....... .Li ghts red when the cutti ng data goes beyond t he effective

Function Keys

These four keys [F1, F2, F3 and F4] have fu nctions which chan ge as each menu

changes. Depending on the menu being disp layed, these keys ar e used to:

cutting area.

Position Keys

F1 (FORCE) key: .....When t he FC700 0 is in ME NU mode , press t he F1 key to

select a function. When the FC7000 is onli ne, press F1 to

select the Conditio n numbers 1 and 5. After pre ssing the

CONDITIONS key, use F1 to adjust the cutting/pen FORCE.

F2 (SPEED) key: .....When the FC700 0 is in MENU mode , press the F2 key to

select a function. When the FC7000 is onl ine, press F2 t o

select the Conditio n numbers 2 and 6. After pre ssing the

CONDITIONS key, use F2 to adjust the cutting SPEED.

F3 (QUALITY) k ey: .. When the F C7000 is in MENU mo de, pr ess the F3 key t o

select a function. When the FC7000 is onl ine, press F3 t o

select the Conditio n numbers 3 and 7. After pre ssing the

CONDITIONS key, use F3 to adjust the cutting QUALITY.

F4 (OFFSET) key:. ...W hen the FC7000 is in MEN U mode, press the F4 key t o

select a function. When the FC7000 is onli ne, press F4

select the Conditio n numbers 4 and 8. After pre ssing the

CONDITIONS key, use F4 to adjust the cutting OFFSET.

POSITION keys ....... Depending on t he operatin g status of the FC7000 , the

POSITION keys have the followin g funct ions.

When the FC700 0 is in the MENU mode, use the POSITION

keys to change the set ting val ues sho wn in th e va rious men u

displays. The POSITION keys are also u sed t o move th e p en

carriage and t he media . If a P OSITION key is p ressed onc e,

the pen carriage moves th e length of the step specified in

Section 5.9, “Using th e MOVE STEP Function ”. If t he key is

held down, the movement is continuous. To spe ed up the

movement of the pen carr iage, press the NEXT key together

with a POSITION key.

Preparing to Cut: Con trol Panel

Page 39

Menu Keys

3 - 3

CONDITIONS key: ...Press CONDITIONS to change the pen conditions shown on

the FC7000 dis play panel.

HOLD key:...............Press HOLD to temporarily suspend cutting or plotting. While

the cutting or plott ing opera tion is suspende d, the me dia set

lever can be lowered to enab le skew ed media to be r eset i f

necessary.

MENU key: ..............Press MENU to access the MENU mode. When this key is

pressed, the MENU mode is ac cessed and the green LED

lights. Press it again to cancel MENU m ode. The green LE D

goes out. Use this key to set the various menu functions. If

data is received after the MENU key has been pressed, that

data is temporari ly stored in the plotter 's buffer.

COPY key:...............Press COPY to repeat the cutting operation defined by the

data in the plotter's bu ffer.

HOME/VIEW key:.....Press HOME/VIEW to move the pen carriage to the standby

position. Press it again to move the pen carriage to the origin

point. Press it one mo re time to r eturn t he pe n carr iage t o its

former position .

NEXT key:...............When the FC7000 is in MENU mode, press NEXT to move to

the next menu page .

TEST key: ...............Press TEST to run a cutting test to check whether the cur-

rently-select ed cutting cond itions are compatib le with the

media loaded.

AXIS/R.M.S. key:.....Press AXIS/R.M.S. to initiate automatic reading of the regis-

tration marks. If Off has been sel ected for the regist ration

mark mode, th is key is used t o perf orm axis a lignment .

ORIGIN key:............Press ORIGIN to move the origin point. To reset the FC7000,

press ORIGIN and ENTE R together when th e initial MENU

mode screen is displayed.

ENTER key:.............Press ENTER to register your setting after setting a function.

To reset the FC7000, press ENTER and ORIGIN together

when the INI TIAL M ENU mode screen is d isplayed. The c utting area can a lso be di splayed b y pressing the EN TER key

in Ready status.

Preparing to Cut: Control Panel

Page 40

3 - 4

3.2 Selecting a Function Menu

When the FC7000 is in MENU mode

When the plott er is i n MENU mod e (the MENU l amp is l it), eac h of the functio ns

listed below in the “ Function Selecti on” column can be accessed by pre ssing th e

NEXT key until the desi red menu appea rs and then pre ssing the select key indicated by a box.

Page Main menu Sub menu

NEXT

ASSIGN PEN (2-pen model only)

CROSS CUT

PRE FEED

MOVE STEP

NEXT

NEXT

INTERFACE

AREA PARAMETERS

FUNCTION 1

FUNCTION 2

PEN UP/DOWN

BACKGROUND

SETTINGS

F1

FORCE

F2

SPEED

F3

QUALITY

F4

OFFSET

F1

FORCE

F2

SPEED

STEP SIZE (GP-GL only)

RS-232C

COMMAND

ORIGIN (HP-GL only)

AREA

EXPAND

PAGE LENGTH

PREF. LINE TYPE

ROTATE

MIRROR

SCALE

DATA SORTING

AXIS ALIGNMENT

AUTO FEED

TANGENT EMULATION

OPTION 1

OPTION 2

Preparing to Cut: Se lecting a Function Menu

F3

QUALITY

F4

OFFSET

PEN UP SPEED

OFFSET ANGLE

OFFSET FORCE

STEP PASS

PEN OFFSET ADJ. (2-pen model only)

INITIAL DOWN FORCE

DISTANCE ADJUST

TEST

Page 41

When the power is turned on without any media loaded

If the power is turned on witho ut any med ia loade d in th e plo tt er, the initial menu is

displayed on t he LCD. T he init ial menu c onfigur ation is as foll ows.

Main menu Sub menu

3 - 5

Initial menu

F4

OFFSET

AUTO REG. MARK

AUTO PRE FEED

INITIAL FEED SPEED

INTERFACE

OFFSET

F4

STEP SIZE (GP-GL only)

RS-232C

COMMAND

Preparing to Cut: Selecting a Function Menu

Page 42

3 - 6

3.3 Connecting to your Computer

An interface cable is use d to connect the plotter to a computer. The plotter can be

connected to a comput er via the USB or seri al (RS-232C) port. Selec t which port

to use according to the requirements of your application software and/or which of

your computer's int erface ports are ava ilable for use .

Use a USB cable or serial cable in accordance with the connection method chosen. Obtain a Graphtec-app roved interface ca ble that is compatible with the interface port.

1 Make sure the power switch is turned off (the " " side is pressed down).

2 Connect one end of the cable to the FC7000 and the other end to the computer

port.

RS-232 inter face co nnecti on USB interfac e conn ection

Preparing to Cut: Connecting to your Computer

Page 43

3.4 Turning on the Power

1 Make sure tha t the power swi tch is t urned off (the " " side is presse d down) .

2 Connect one end of the provided power cord to the FC7000 AC line inlet and

the other end to an electrical socket of the rated supply voltage. Make sure

that the FC7000 is grounded.

3 - 7

3 Turn on the FC7000 by pressing th e "|" side of the swit ch. The control panel

POWER lamp lights.

4 If media has not been loaded, the f irmware version number i s displa yed, fo l-

lowed by a prompt to load media.

LOAD MEDIA!

INITIAL MENU>

(The initial feed spe ed setting, inter face settings and other parameter setting s

can be made h ere).

Preparing to Cut: Turning on the Power

Page 44

3 - 8

If media has alread y been loaded, the fo llowing menu appears.

Rear Loading Front Loading

ROLL 1 REAR SET>

ROLL 2 REAR SET>

SHEET>

[NEXT]

←—→

ROLL 1 FRONT SET>

ROLL 2 FRONT SET>

SHEET>

After the Ready status is d isplayed, raise the media set lever to secu re the

loaded media. The foll owing menu app ears.

Rear Loading Front Loading

ROLL 1 REAR SET>

ROLL 2 REAR SET>

SHEET>

CONTINUE>

[NEXT]

←—→

ROLL 1 FRONT SET>

ROLL 2 FRONT SET>

SHEET>

CONTINUE>

The loading method screen (Rear or Front) that is first displayed is the screen

that was last used.

5 Select the media ty pe to suit the med ia used. See Secti on 3.5, "Loadi ng

Media" for instruct ions on how to load med ia.

When to select ROLL 1 REAR SET or ROLL 1 FRONT SET

Select ROLL-1 to beg in cutting or pl otting from the leading edge. ROLL-1

detects the width and leadin g edge of roll media. Press the F1 key to select

ROLL-1 REAR SET or ROLL 1 FRONT SET.

When to select ROLL 2 REAR SET or ROLL 2 FRONT SET

Select ROLL-2 to beg in cutting or pl otting at a point beyond the leadi ng edge.

ROLL-2 detects only th e width of roll media. Pr ess the F2 key to sel ect ROLL-

2 REAR SET or ROLL 2 FRONT SET.

When to select S HEET

Select SHEET when a cut shee t has been loade d in th e plott er. SHEET detects

the leading edge, t he trail ing edg e, and the width of the sheet. Press t he F3

key to select SHEET.

When to select C ONTINUE

The CONTINUE funct ion enables th e continued use of the plotting ar ea, pen

position and ori gin posit ion that we re specif ied before t he media set lever was

lowered. If the cur rent media is the sam e size as the last medi a that was

loaded, the plott er does not detec t the media's edges.

6 After selecting th e media type, spe cify the blade/pe n type and the cut ting/plot -

ting conditions for the selected media type, and then perform cutting or plot-

ting.

Preparing to Cut: T urning on the Power

Page 45

3.5 Loading Media

Both roll media and shee t media can be used w ith the FC7000. Load the media

according to th e instruct ions gi ven for e ach typ e.

The FC7000-100/130 model with three pinch rollers is used for the explanations

in this section. The FC7000-160 model has four pinch rollers, whereas the

FC7000-75 model has only two pinch r ollers.

Loading Roll Media (Rear Loading)

1 Lower the media set lev er to raise the pin ch rollers.

3 - 9

Pinch roller

2 Place the media r oll o n the roll med ia sto cker. Load the media in t he plo tter a s

shown. Pass the leadi ng edge o from th e bac k of the pl ott er so it emer ge s fr om

the front.

3 Press the media lock t o engag e it, and then pull th e leadi ng edge out o f the

front of the plotter so that it completely covers the media sensor.

Media lock

Media sensor

Preparing to Cut: Loading Media

Page 46

3 - 10

4 Pull the media taut to ma ke sure tha t there is no slack in the co nveyan ce path,

and then raise the media set lever to lower the pinch rollers. Release the

media lock.

Loading Roll Media (Front Loading)

1 Lower the media set lev er to raise the pin ch rollers.

Media lock

Pinch roller

2 Place the media r oll o n the roll med ia sto cker. Load the media in t he plo tter a s

shown. Pass the leadi ng edge from th e front of the plot ter so it emerges f rom

the back.

Preparing to Cut: Loading Media

Page 47

3 - 11

3 Press the media lock t o engag e it, and then pull th e leadi ng edge out o f the

back of the plotter so th at it complete ly covers the medi a sensor.

Media lock

Media sensor

4 Pull the media taut to ma ke sure tha t there is no slack in the co nveyan ce path,

and then raise the media set lever to lower the pinch rollers. Release the

media lock.

Media lock

Loading Sheet Media

1 Lower the media set lev er to raise the pin ch rollers.

Pinch roller

Preparing to Cut: Loading Media

Page 48

3 - 12

2 Pass the leading edge of the sheet from the rear of the plotter so that it

emerges from the front, making sure that is completely covers the media sen-

sor.

Media sensor

3 Pull the media taut to ma ke sure tha t there is no slack in the co nveyan ce path,

and then raise the media set lever to lower the pinch rollers. If you align the

right edge of the sh eet wi th the g uides on the p laten, the she et can be load ed

so that it is

straight.

Preparing to Cut: Loading Media

Media

Align with

these holes

Page 49

3.6 Aligning the Pinch Rollers

Position the l eft- and right pinc h roller s to cor respond w ith the width of th e media.

Adjust the pinch rollers so that they are positioned above both the media and the

grit rollers. Posit ion the pinch ro llers within th e grit roller pot ition sticker s ensures

that they are above the grit roller s.

3 - 13

Grid roller potition sticker

NG

OK

NG

OK

Standby Position

CAUTION: To move the pinch rollers, the media set lever must be in the lowered position.

With the FC7000-100/130/160 models, the number of pinch rollers required to hold

down the media vari es according to the width of the loade d media. Be sure to

move a pinch roller that is not used to the standb y position so tha t it does not

affect the cutt ing or p lotting operat ion.

Standby position

Preparing to Cut: Aligning the Pinch Rolle rs

Page 50

3 - 14

When Feeding Long-axis Media (at least 2 meters)

Position the pinch rol lers at least 15 mm inside the edge s of the media.

Pinch rollers

When the Media Width is 100 to 160 mm

Position the two rig ht-hand pinc h rollers so that they are above th e long grit rolle r

at the right edge of the plotter whe n the plotter is vie wed from the front. Positi on

the media so t hat its left edge is ali gned with the l eft edge of the grit r oller, and

then position the pinch rol le rs over both edg es. Move an y pinc h roll er s that ar e no t

used to the standby posit ion.

Media sensor

Media

OK

CAUTION: • The media must be at least 125 mm in length.

• The media must always be positioned over the media sensor.