Page 1

CUTTING PLOTTER

SERVICE MANUAL

FC7000-75/100/130/160

FC7000MK2-60/75/100/130/160

FC7000-UM-251-10-9370

Page 2

Page 3

FC7000-UM-251-9370 I

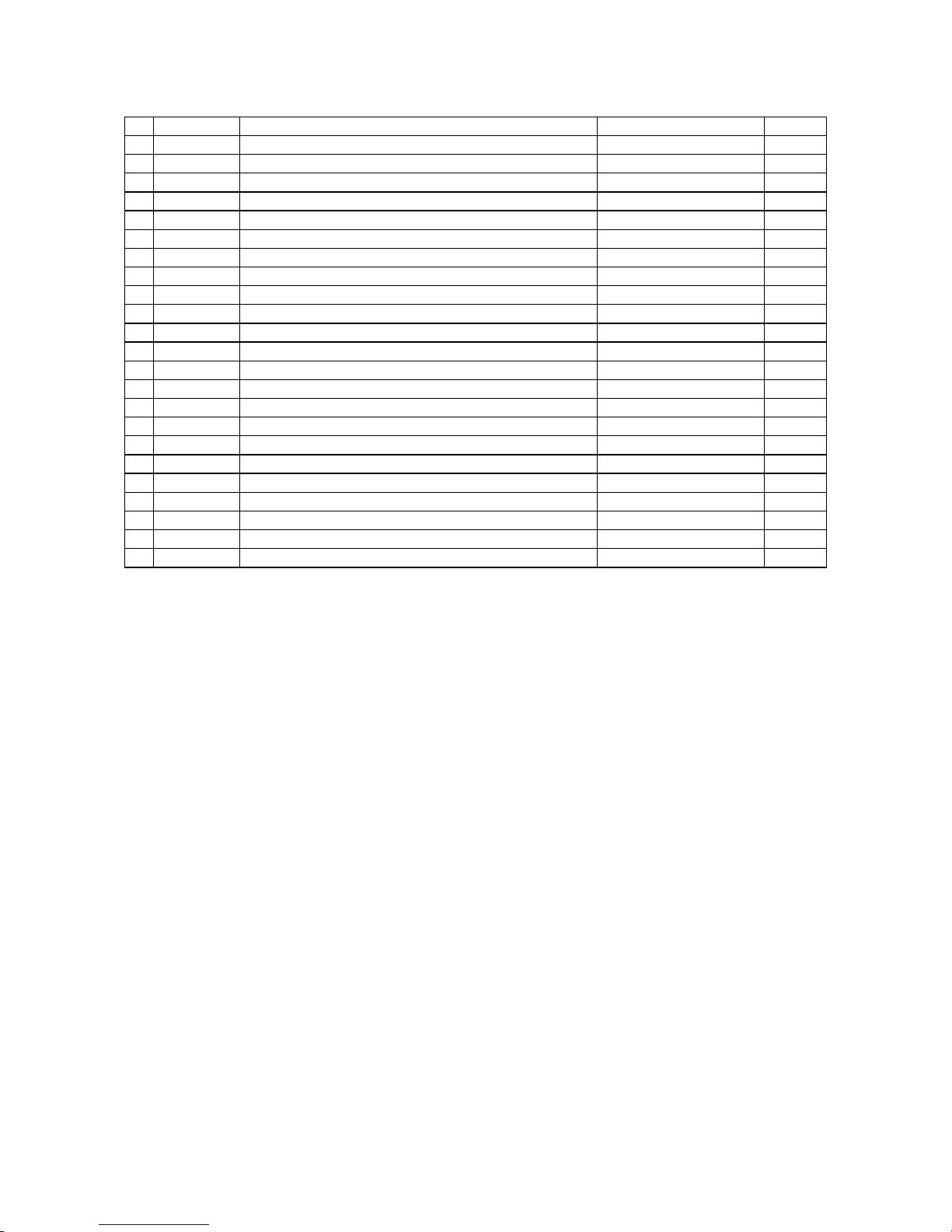

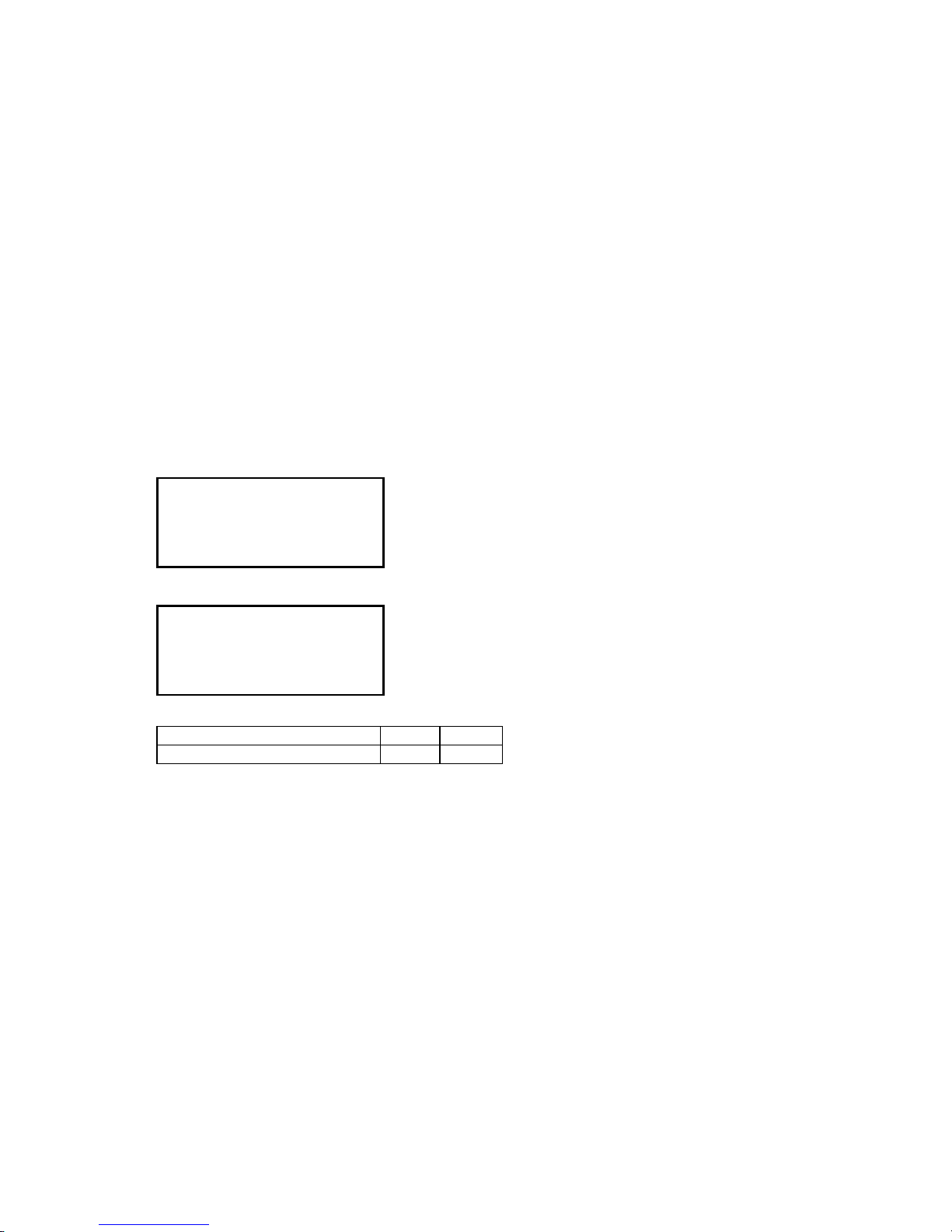

HISTORY OF REVISIONS

No. Date issued Description of revision Page Edition

1 05.06.21 First Printing All 01

2 05.08.29

The cutting mats are added for the recommended parts list.

4-1 02

3 05.08.29

Part number for the right and left media stocker bracket corrected.

10-13 02

4 05.08.31 List of item requiring readjustment corrected. 7-1 02

5 05.11.24 Part number for the bracket bottom corrected. 10-3 03

6 05.11.24 Part number for the media sensor bracket corrected. 10-7 03

7 05.11.24 Part number for the labels added. 10-12 03

8 05.12.13 Part number for the model labels corrected. 10-12 04

9 05.12.13 Part number for the X motor belt corrected. 10-7 04

10 05.12.13 Part number for the pinch roller corrected. 10-10 04

11 06.02.26 The distance adjustment pattern size changed. 7-18 05

12 06.07.04 Part number for the Y drive pulley 38 assy corrected. 10-9 06

13 06.07.04 Part number for the idler pulley assy corrected. 10-9 06

14 06.08.08 Item number for the pinch roller sensor dog corrected. 10-10 07

15 06.10.19 Part number for the idler pulley assy corrected. 10-7 08

16 07.07.11 Information of the FC7000MK added. All 09

17 07.07.13

Information of the new main board for FC7000 added.

4-1,7-1,7-31 09

18 07.10.19

Information of the sensor dog position added.

6-28 10

19 07.10.19 Correction of procedure. 7-14 10

20 07.10.19 Part number for the X motor corrected. 4-1,4-2,10-7,10-9 10

21 07.10.19 Part number for the Y motor corrected. 4-1,4-2,10-7,10-9 10

22 07.10.19 Part number for the Y drive pulley corrected. 10-9 10

Page 4

FC7000-UM-251-9370 II

CONTENTS

1. INTRODUCTION ..................................................................1-1

1.1 Main Specifications ................................................................................................... 1-1

1.1.1 Main Specifications (FC7000 Series) ......................................................................................... 1-1

1.1.2 Main Specifications (FC7000MK2 Series) .................................................................................. 1-1

1.2 External Dimensions .................................................................................................. 1-3

2. PARTS NAMES and FUNCTIONS ..........................................2-1

2.1 Parts Names and Functions ....................................................................................... 2-1

2.2 Assembling the Plotter ..............................................................................................2-3

2.3 Attaching the FC7000 Basket (Option) .......................................................................2-8

2.4 Attaching a Cutter Pen ..............................................................................................2-9

2.5 Replacing the Cross-Cutter Unit ............................................................................... 2-12

3. OPERATIONS .................................................................... 3-1

3.1 Control Panel ............................................................................................................3-1

3.2 Menu List ..................................................................................................................3-3

3.3 Description of Background Settings ...........................................................................3-5

3.4 Setting the Background Settings ................................................................................3-8

4. RECOMMENDED PARTS LIST ............................................. 4-1

5. LIST OF TOOLS ................................................................. 5-1

5.1 Tools ......................................................................................................................... 5-1

5.2 Greasing And Gluing Points ........................................................................................5-1

6. DISASSEMBLY AND REASSEMBLY ..................................... 6-1

6.1 Exterior Parts ............................................................................................................ 6-1

6.1.1 How to Replace the Right Side Cover ........................................................................................6-1

6.1.2 How to Replace the Left Side Cover .......................................................................................... 6-2

6.1.3 How to Replace the Center Cover .............................................................................................6-3

6.1.4 How to Replace the Front Guide ................................................................................................6-4

6.1.5 How to Replace the Rear Guide ................................................................................................. 6-5

6.1.6 How to Replace the Rear Writing Panel .....................................................................................6-6

6.1.7 How to Replace the Front Writing Panel Assembly ..................................................................... 6-7

Page 5

FC7000-UM-251-9370 III

6.2 Mechanical Parts ......................................................................................................6-8

6.2.1 How to Replace the Rear Media Sensor .....................................................................................6-8

6.2.2 How to Replace the Front Media Sensor .................................................................................... 6-9

6.2.3 How to Replace the Pinch Roller ............................................................................................. 6-10

6.2.4 How to Replace the Control Panel Board, LCD Assembly ......................................................... 6-11

6.2.5 How to Replace the Pen Block ................................................................................................ 6-13

6.2.6 How to Replace the Y-belt ....................................................................................................... 6-15

6.2.7 How to Replace the Pinch Roller Sensor .................................................................................. 6-17

6.2.8 How to Replace the Y-relay Board ........................................................................................... 6-19

6.2.9 How to Replace the Cam Sensor .............................................................................................6-20

6.2.10 How to Replace the Y-motor ................................................................................................... 6-21

6.2.11 How to Replace the X-motor ...................................................................................................6-22

6.2.12 How to Replace the Main Board ..............................................................................................6-23

6.2.13 How to Replace the Vacuum Fan ............................................................................................. 6-24

6.2.14 How to Replace the Drive Roller .............................................................................................. 6-25

6.2.15 How to Replace the Cutting Mat .............................................................................................. 6-27

6.2.16 Home Dog Position ................................................................................................................. 6-28

6.2.17 Cross Cutter Dog Position .......................................................................................................6-28

7. ADJUSTMENTS ..................................................................7-1

7.1 List of Items Requiring Readjustment ......................................................................... 7-1

7.2 Mechanical Adjustments ............................................................................................ 7-2

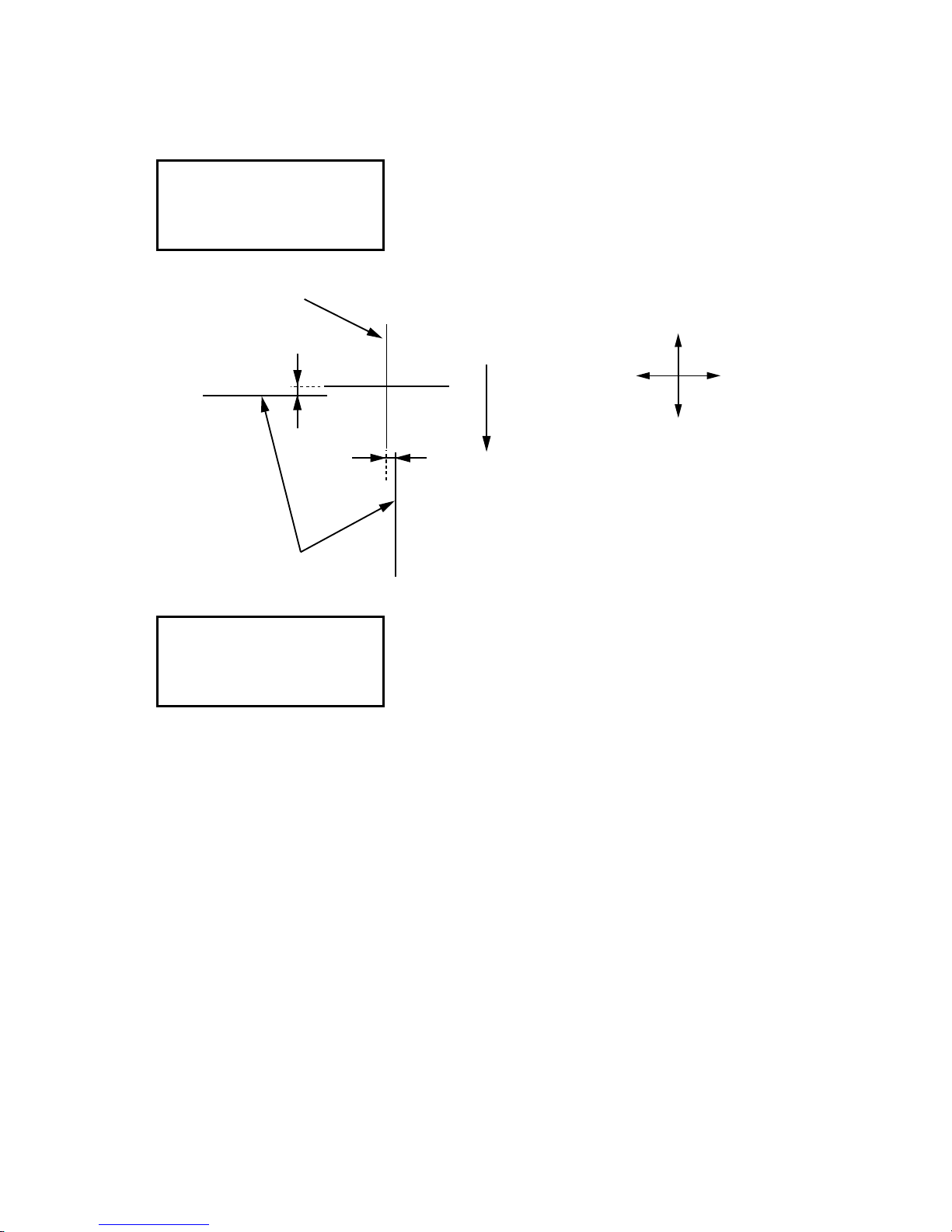

7.2.1 Y-Belt Tension Adjustment ........................................................................................................ 7-2

7.2.2 Y-Drive Belt Tension Adjustment ............................................................................................... 7-3

7.2.3 X-Drive Belt Tension Adjustment ...............................................................................................7-4

7.2.4 Pinch Roller Pressure Adjustment ............................................................................................. 7-5

7.3 Electrical Adjustments ............................................................................................... 7-7

7.3.1 Position of the DIP Switch and Connectors ................................................................................ 7-7

7.3.2 DIP Switch Settings .................................................................................................................. 7-9

7.3.3 Checking the Power Supply Board Voltage Levels .................................................................... 7-10

7.3.4 Explanation of the Values of the Main Board Settings .............................................................. 7-11

7.3.5 Clearing the Non-Volatile RAM ................................................................................................ 7-12

7.3.6 How to Enter the Adjustment Menu ......................................................................................... 7-14

7.3.7 Adjusting the Pen Force .......................................................................................................... 7-16

7.3.8 Adjusting the Distance Accuracy ............................................................................................ 7-18

Page 6

FC7000-UM-251-9370 IV

7.3.9 Adjusting the Auto-Registration Mark Sensor Sensitivity .......................................................... 7-20

7.3.10 Adjusting the Offset of the Auto-Registration Mark Sensor ...................................................... 7-21

7.3.11 Adjusting the Cross Cutter Home Position ............................................................................... 7-23

7.3.12 Adjusting the Offset of the Light Pointer Position ..................................................................... 7-25

7.3.13 Confirming the 2-Pen Model (2-pen model) ............................................................................. 7-26

7.3.14 Adjusting the Pen Exchange Y Direction Value (2-pen model) .................................................. 7-27

7.3.15 Adjusting the Spacing Between Pen 1 and Pen 2

(2-pen model) ............................................................ 7-29

7.3.16 Adjusting the Servo Gain ........................................................................................................ 7-31

7.4 Upgrading the System Firmware .............................................................................. 7-32

8. SERVICE MODES ................................................................8-1

8.1 Sensor Test Mode ...................................................................................................... 8-1

8.2 Control Panel Switch Test Mode .................................................................................8-2

9. TROUBLESHOOTING .......................................................... 9-1

9.1 The Plotter is Turned On But Doesn’t Operate .............................................................9-1

9.2 Media Loading Operations .........................................................................................9-2

9.3 Cutting Operations ....................................................................................................9-3

9.4 Error Messages .........................................................................................................9-4

9.4.1 Hardware Error Messages ........................................................................................................9-4

9.4.2 Error Messages in GP-GL Command Mode ................................................................................9-5

9.4.3 Error Messages in HP-GL Emulation Mode ................................................................................9-6

10. PARTS LIST ......................................................................10-1

10.1 Outer Casing ........................................................................................................... 10-1

10.2 Control Panel .......................................................................................................... 10-3

10.3 Pen Block ................................................................................................................10-5

10.4 Main Frame ............................................................................................................. 10-7

10.5 Y Rail ......................................................................................................................10-9

10.6 Y Slider ................................................................................................................. 10-11

10.7 Wiring Harness ...................................................................................................... 10-12

10.8 Labels ................................................................................................................... 10-13

10.9 Media Stocker,

Stand .................................................................... 10-14

10.10 Option Basket ........................................................................................................ 10-15

Page 7

FC7000-UM-251-9370 V

10.11 Other Parts ........................................................................................................... 10-15

11. BLOCK DIAGRAMS AND CIRCUIT DIAGRAMS ..................... 11-1

11.1 Block Diagrams ....................................................................................................... 11-1

11.1.1 Block Diagrams FC7000 ......................................................................................................... 11-1

11.1.2 Block Diagrams FC7000MK2 .................................................................................................. 11-2

11.2 Circuit Diagrams ..................................................................................................... 11-3

11.2.1 Main Board Top Section .......................................................................................................... 11-3

11.2.2 Main Board (CONNECTOR 1 BLOCK) ....................................................................................... 11-4

11.2.3 Main Board (CONNECTOR BLOCK) .......................................................................................... 11-5

11.2.4 Main Board (CPU BLOCK) ....................................................................................................... 11-6

11.2.5 Main Board (DC DRIVER) ........................................................................................................ 11-7

11.2.6 Main Board (I/F BLOCK) ......................................................................................................... 11-8

11.2.7 Main Board (GRC SERVO BLOCK) ............................................................................................ 11-9

11.2.8 Main Board (MEMORY BLOCK) ...............................................................................................11-10

11.2.9 Main Board (USB BLOCK) .......................................................................................................11-11

11.2.10 Control Board ........................................................................................................................11-12

11.2.11 Relay Board, Pinch Roller Sensor Board, RMS Board ..............................................................11-13

11.3 Circuit Diagrams (FC7000MK2 Main Board) ............................................................11-14

11.3.1 Main Board (CPU) ..................................................................................................................11-14

11.3.2 Main Board (CPU) ..................................................................................................................11-15

11.3.3 Main Board (FPGA) ................................................................................................................11-16

11.3.4 Main Board (I/F) ....................................................................................................................11-17

11.3.5 Main Board (Motor Drive) ......................................................................................................11-18

11.3.6 Main Board (Memory) ............................................................................................................11-19

11.3.7 Main Board (Power Supply) ................................................................................................... 11-20

Page 8

Page 9

FC7000-UM-251-9370 1-1

1. INTRODUCTION

1. INTRODUCTION

1.1 Main Specifications

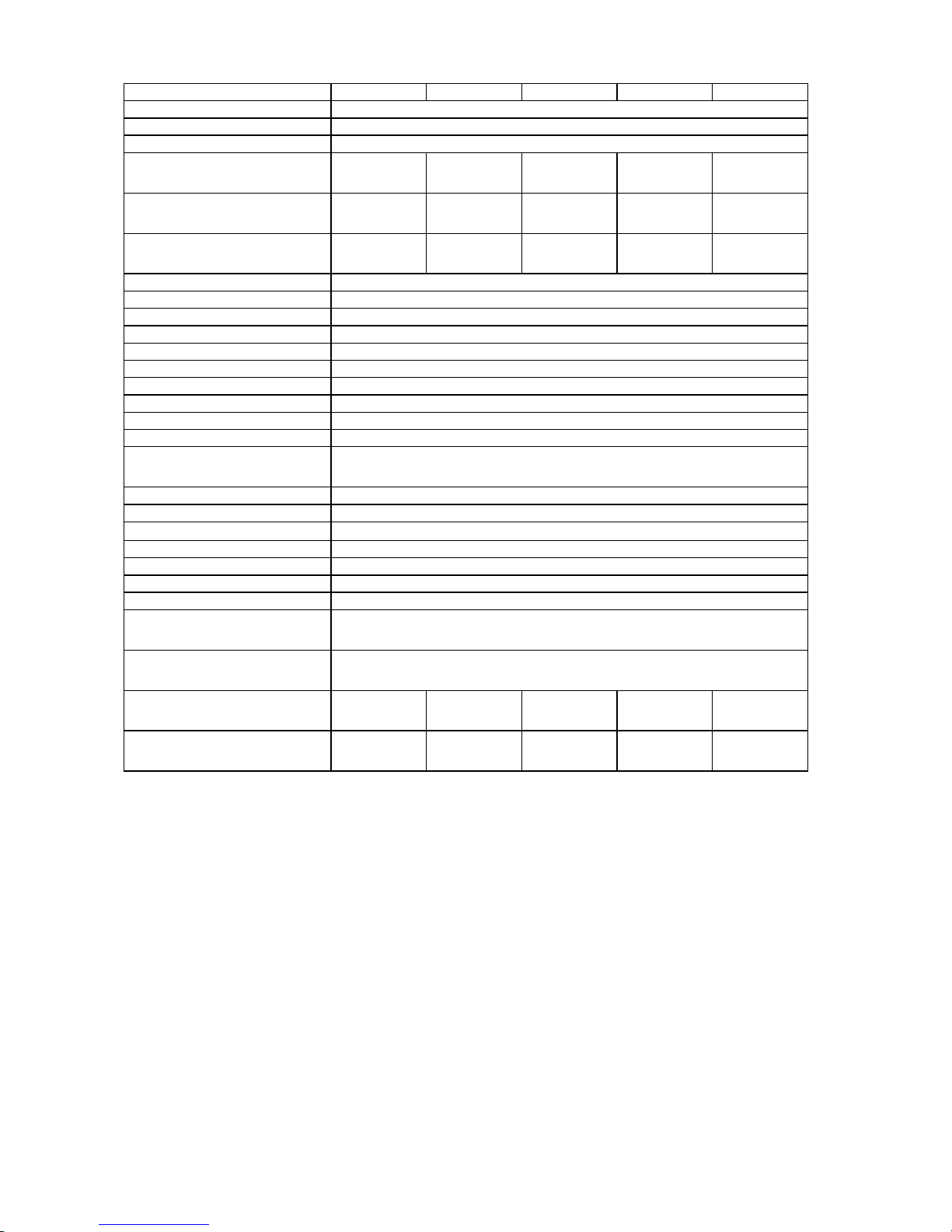

1.1.1 Main Specifications (FC7000 Series)

FC7000-75 FC7000-100 FC7000-130 FC7000-160

CPU 32-bit

Configuration Grit-rolling plotter

Drive Digital servo

Max. cutting area

(expanded mode)

50m x 762 mm 50m x 1067 mm 50m x 1372 mm 50m x 1626 mm

Guaranteed precision cutting area *110m x 742 mm 10m x 1047 mm 10m x 1352 mm 10m x 1606 mm

Mountable media width Max. 920 mm, Min.

50 mm

Max. 1224 mm, Min.

50 mm

Max. 1529 mm, Min.

50 mm

Max. 1834 mm, Min.

50 mm

Max. cutting speed (Axial) 148.5cm/sec (45 ips)

Specifiable speeds

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100, 105 cm/sec

Cutting pressure 48 steps, 0.196-5.88N (20-600gf)

Min. character size 3mm (0.125 in.) alphanumeric Helvetica med. Font

Mechanical resolution 0.005mm

Programmable resolution GP-GL: 0.01/0.05/0.025/0.01mm, HP-GL: 0.025mm

*2

Repeatable accuracy

*1

Max. 0.1 mm/2-m unit (excluding media shrinkage)

Number of cutters/pens 1 (2 for the optional 2-pen models)

*3

Pen types Water-based fiber-tip, oil-based ballpoint, ceramic, and disposable ink pens

Pouncing tool type Pouncing tool: PPA33-TP12, 1.2-mm pin diameter)

*4

Compatible media Mono-vinyl chloride media, fluorescent media, and media for illuminated displays,

high reflective media, up to 0.25mm thick, Sandblast rubber up to 1mm thick

*5

Compatible paper for pouncing Regular paper from 0.06 to 0.13 mm thick

Standard interfaces RS-232C/USB (Auto switching)

Buffer memory 2 MB

Resident command sets GP-GL/HP-GL(Control panel switching)

LCD Panel 20x4 - Supports 7 languages: with amber backlight

Power supply 100-240VAC/50-60 Hz (Auto switching)

Power consumption 140VA max.

Operating environment Temperature: +10˚C to +35˚C

Humidity: 35% to 75% (non-condensing)

Guaranteed accuracy environment Temperature: +16 ˚C to +32 ˚C

Humidity: 35% to 70%(non-condensing)

External dimensions without stand

1260 x 402 x 477mm

1560 x1210 x 715mm

1860 x 1210 x 715mm 2120 x 1210 x 715mm

Weight 29 kg 43 kg

(including stand)

51 kg

(including stand)

59 kg

(including stand)

*1 When the optional basket and Graphtec-specified media are used.

*2 HP-GL is a registered trademark of Hewlett-Packard Company.

*3 The 2-pen unit is a factory-installed option. It cannot be retrofitted.

*4 The PPA32-TP12 pouncing pen cannot be used.

*5 The CB15UA cutter blade and a reinforced backing sheet must be used when cutting high-intensity reflective film.

1.1.2 Main Specifications (FC7000MK2 Series)

Page 10

FC7000-UM-251-9370 1-2

1. INTRODUCTION

FC7000MK2-60 FC7000MK2-75 FC7000MK2-100 FC7000MK2-130 FC7000MK2-160

CPU 32-bit

Configuration Grit-rolling plotter

Drive Digital servo

Max. cutting area

(expanded mode)

50m x 610 mm 50m x 762 mm 50m x 1067 mm50m x 1372 mm50m x 1626

mm

Guaranteed precision cutting area *115m x 590 mm 15m x 742 mm 15m x 1047 mm15m x 1352 mm15m x 1606

mm

Mountable media width Max. 866 mm,

Min. 50 mm

Max. 920 mm,

Min. 50 mm

Max. 1224 mm,

Min. 50 mm

Max. 1529 mm,

Min. 50 mm

Max. 1834 mm,

Min. 50 mm

Max. cutting speed (Axial) 148.5cm/sec (45 ips)

Specifiable speeds

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100, 105 cm/sec

Cutting pressure 48 steps, 0.196-5.88N (20-600gf)

Min. character size 3mm (0.125 in.) alphanumeric Helvetica med. Font

Mechanical resolution 0.005mm

Programmable resolution GP-GL: 0.01/0.05/0.025/0.01mm, HP-GL: 0.025mm

*2

Repeatable accuracy

*1

Max. 0.1 mm/2-m unit (excluding media shrinkage)

Number of cutters/pens 1 (2 for the optional 2-pen models)

*3

Pen types Water-based fiber-tip, oil-based ballpoint and disposable ink pens

Pouncing tool type Pouncing tool: PPA33-TP12, 1.2-mm pin diameter)

*4

Compatible media Mono-vinyl chloride media, fluorescent media, and media for illuminated displays,

high reflective media, up to 0.25mm thick, Sandblast rubber up to 1mm thick

*5

Compatible paper for pouncing Regular paper from 0.06 to 0.13 mm thick

Standard interfaces RS-232C/USB (Auto switching)

Buffer memory 2 MB

Resident command sets GP-GL/HP-GL(Control panel switching)

LCD Panel 20x4 - Supports 7 languages: with amber backlight

Power supply 100-240VAC/50-60 Hz (Auto switching)

Power consumption 160VA max.

Operating environment Temperature: +10˚C to +35˚C

Humidity: 35% to 75% (non-condensing)

Guaranteed accuracy environment Temperature: +16 ˚C to +32 ˚C

Humidity: 35% to 70%(non-condensing)

External dimensions without stand

1110 x 402 x

477mm

1260 x 402 x

477mm

1560 x1210 x

715mm

1860 x 1210 x

715mm

2120 x 1210 x

715mm

Weight 22 kg 29 kg 43 kg

(including stand)

51 kg

(including stand)

59 kg

(including stand)

*1 When the optional basket and Graphtec-specified media are used.

*2 HP-GL is a registered trademark of Hewlett-Packard Company.

*3 The 2-pen unit is a factory-installed option. It cannot be retrofitted.

*4 The PPA32-TP12 pouncing pen cannot be used.

*5 The CB15UA cutter blade and a reinforced backing sheet must be used when cutting high-intensity reflective film.

Page 11

FC7000-UM-251-9370 1-3

1. INTRODUCTION

1.2 External Dimensions

FC7000-75, FC7000MK2-60/75

922 (FC7000MK2-60)

1072 (FC7000-75,FC7000MK2-75)

62

170

476.763

383

21

123

94

1110

(FC7000MK2-60)

1260 (FC7000-75,FC7000MK2-75)

Units: mm

Dimensional accuracy: ±5 mm

FC7000-75, FC7000MK2-60/75 with Option Stand

1110 (FC7000MK2-60)

1260 (FC7000-75, FC7000MK2-75)

209 715 90

1190 20

209

715

1014

90

Units: mm

Dimensional accuracy: ±5 mm

Page 12

FC7000-100/130/160

1560 (FC7000-100)

1860 (FC7000-130)

2120 (FC7000-160)

209 715 90

1190 20

209

715

1014

90

Units: mm

Dimensional accuracy: ±5 mm

Page 13

FC7000-UM-251-9370 2-1

2. PARTS NAMES and FUNCTIONS

2. PARTS NAMES and FUNCTIONS

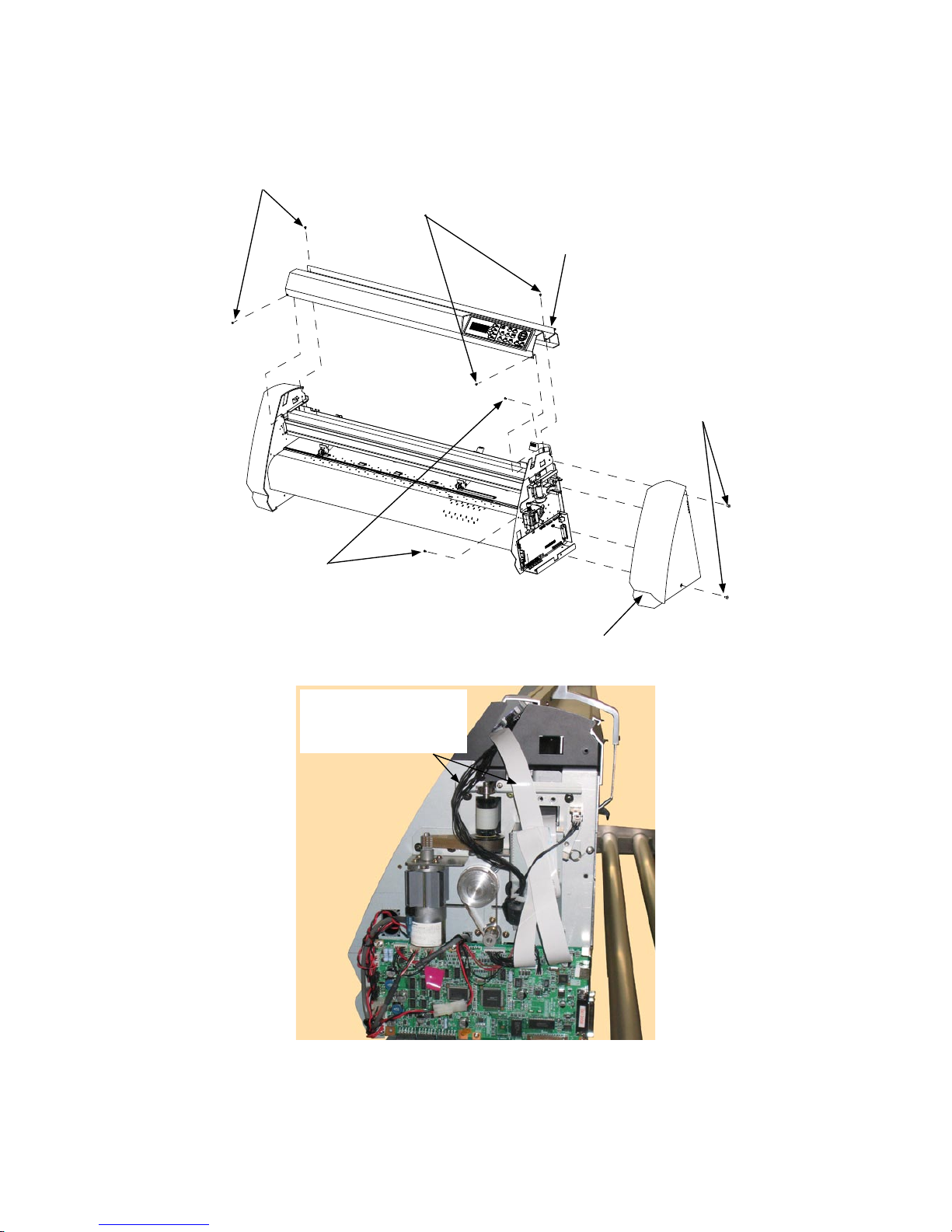

2.1 Parts Names and Functions

Front View

Grit roller

Media sensor

Power switch

Pinch roller

Pen carriage

Cross-cutter unit

Pen holder

Pinch rollers

Control panel

Stand

Cutting groove

Cutting mat

Grit roller position guide

Pen station

Grit roller

Media sensor

Power switch: ................. Used to turn the plotter on and off.

Control panel: ................. Used to access various plotter functions.

Pinch rollers: ................... Rollers that push the media against the grit rollers.

Grit rollers: ...................... Metallic rollers with a file-like surface that feed the media back and forth.

Media sensors: ............... The front sensor is used to sense the leading edge of the media. The rear sensor is

used to sense the trailing edge of the media.

Pen carriage: .................. Moves the cutter-pen or plotting pen across the media during cutting or plotting.

Pen holder: ..................... Holds the cutter-pen or plotting pen and moves it up or down.

Pen station (installed on 2-pen models only):

The second pen is mounted here.

Stand: ............................. Used to make the plotter more portable and to free up counter space.

Grit roller position guide:

Stickers on the front of the Y rail and the rear side of the top cover that show the

position of each grit roller. Use these alignment marks as an aid in locating the

pinch rollers.

Cutting groove: ............... Used when cross-cutting is performed.

Cross-cutter unit: ............ Used to perform cross-cutting of media so that the cut length can be removed from

the roll.

Page 14

FC7000-UM-251-9370 2-2

2. PARTS NAMES and FUNCTIONS

Rear View

Media set lever

AC line inlet

Media stocker

Stock rollers

USB interface connector

Serial interface connector

Media lock

Pinch roller hold-down force switching lever

Media set lever: .............. Used to raise or lower the pinch rollers during the loading or unloading of media.

Pinch roller hold-down force switching lever:

Used to switch between the two pinch roller forces (strong and weak).

AC line inlet: ................... Inlet where the power cord is connected.

Media stocker: ................ Used to carry roll media and ensure its proper rotation.

Stock rollers: ................... A media roll is placed on these rollers.

Media lock: ..................... Used to prevent the stock rollers from rotating when the media roll has been placed

on top of them. The media lock ensures that the media is pulled straight out from

the roll.

USB interface connector:

Used to connect the plotter to the computer with a USB interface cable.

Serial interface connector:

Used to connect the plotter to the computer with an RS-232 serial interface cable.

Page 15

FC7000-UM-251-9370 2-3

2. PARTS NAMES and FUNCTIONS

2.2 Assembling the Plotter

FC7000-75 (desktop model; stand not provided but is available as an option)

When the FC7000-75 is used without a stand, the media stocker bracket is attached directly to the plotter.

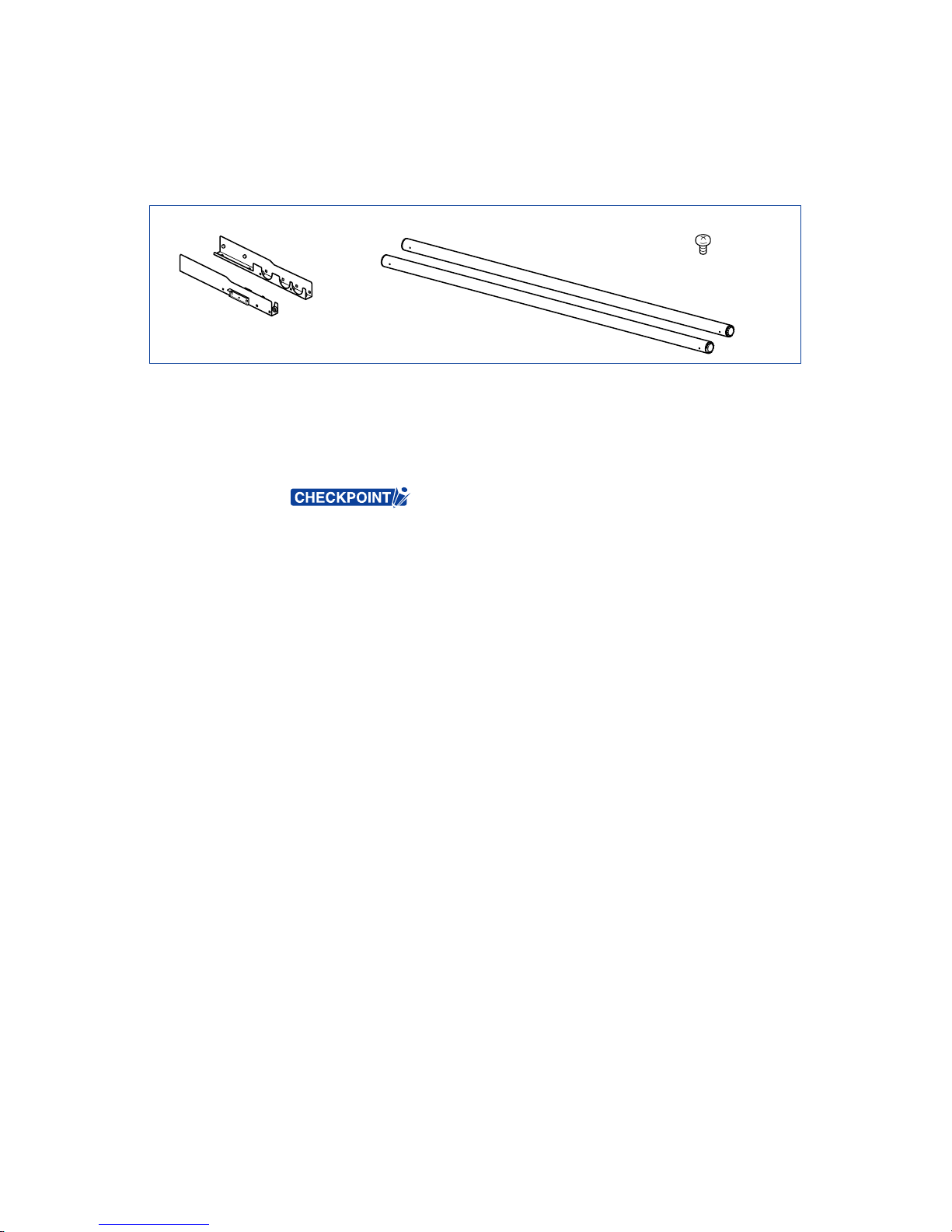

The media stocker is made up of the following parts.

Stock roller x 2Media stocker bracket x 2 M4 binding-head screw x 4

ATTACHING THE MEDIA STOCKER

(1) Fasten the media stocker brackets to the left and right inside surfaces of the plotter unit, using two M4

binding-head screws for each media stocker bracket.

(2) Insert an M4 screw in the second hole from the front side of the plotter.

• Check that all of the screws used for fastening have been tightened. The media

may not be fed correctly if even one of the screws is loose.

• When installing the plotter, make sure that there are no objects in its vicinity.

Leave a clear space of at least 300 mm around the plotter.

• When the FC7000-75 is used without a stand, the maximum diameter of the roll

media that can be used is 160 mm.

Page 16

FC7000-UM-251-9370 2-4

2. PARTS NAMES and FUNCTIONS

FC7000-100/130/160 (stand provided)

Assemble the stand, attach the media stocker to the stand, and then mount the plotter on the stand.

The stand and the media stocker are made up of the following parts.

Base assembly x 2 Allen wrench

(for M5 screws) x 1

Center bar x 1Stand side bar x 2 Socket head cap screw

(M5) x 20

Stock roller x 2

Media stocker bracket x 2

ASSEMBLING THE STAND

The mounting direction is different for the front loading and the rear loading models.

<Front loading>

<Rear loading>

Page 17

FC7000-UM-251-9370 2-5

2. PARTS NAMES and FUNCTIONS

(1) Assemble the left and right stand sides. Fasten a base assembly to each of the stand side bars with four

socket head cap screws, using the Allen wrench.

Socket head

cap screws

Stand side bar

Base assembly

Stand side bar

• Assemble the stand so that the front and rear lengths of the base assembly are

the same for both the left and right stand sides.

(2) Loosely fasten the center bar to the left and right stand sides with four socket head cap screws (two on

each side), using the Allen wrench.

Socket head

cap screws

Socket head

cap screws

Center bar

Stand sides

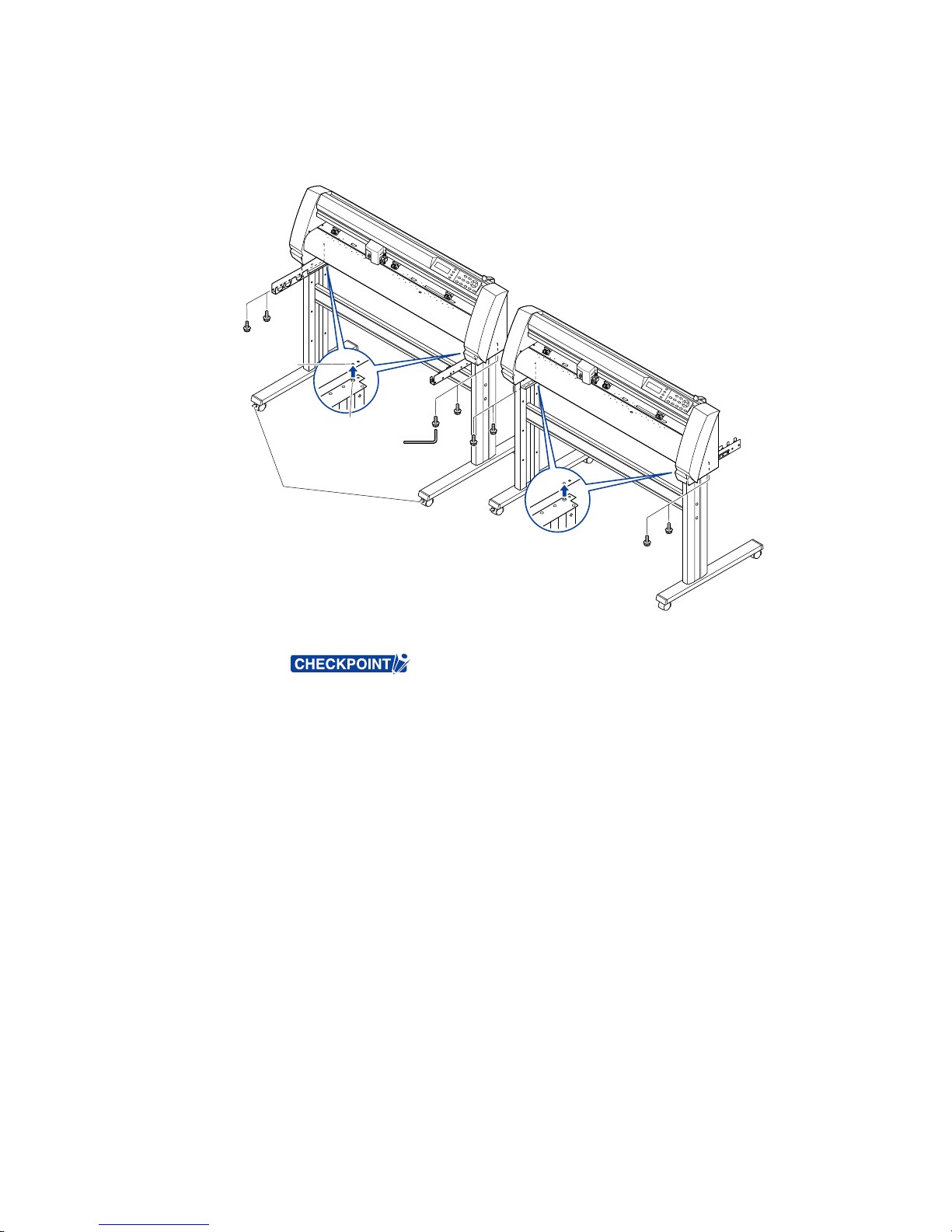

(3) Attach a media stocker bracket to each of the left and right stand sides with two socket head cap screws,

using the Allen wrench. Mount the media stocker brackets so that each one protrudes directly above the

longer of the two base assembly lengths.

Base assembly

Stand sides

Media stocker bracket

Media stocker bracket

Socket head cap screws

Page 18

FC7000-UM-251-9370 2-6

2. PARTS NAMES and FUNCTIONS

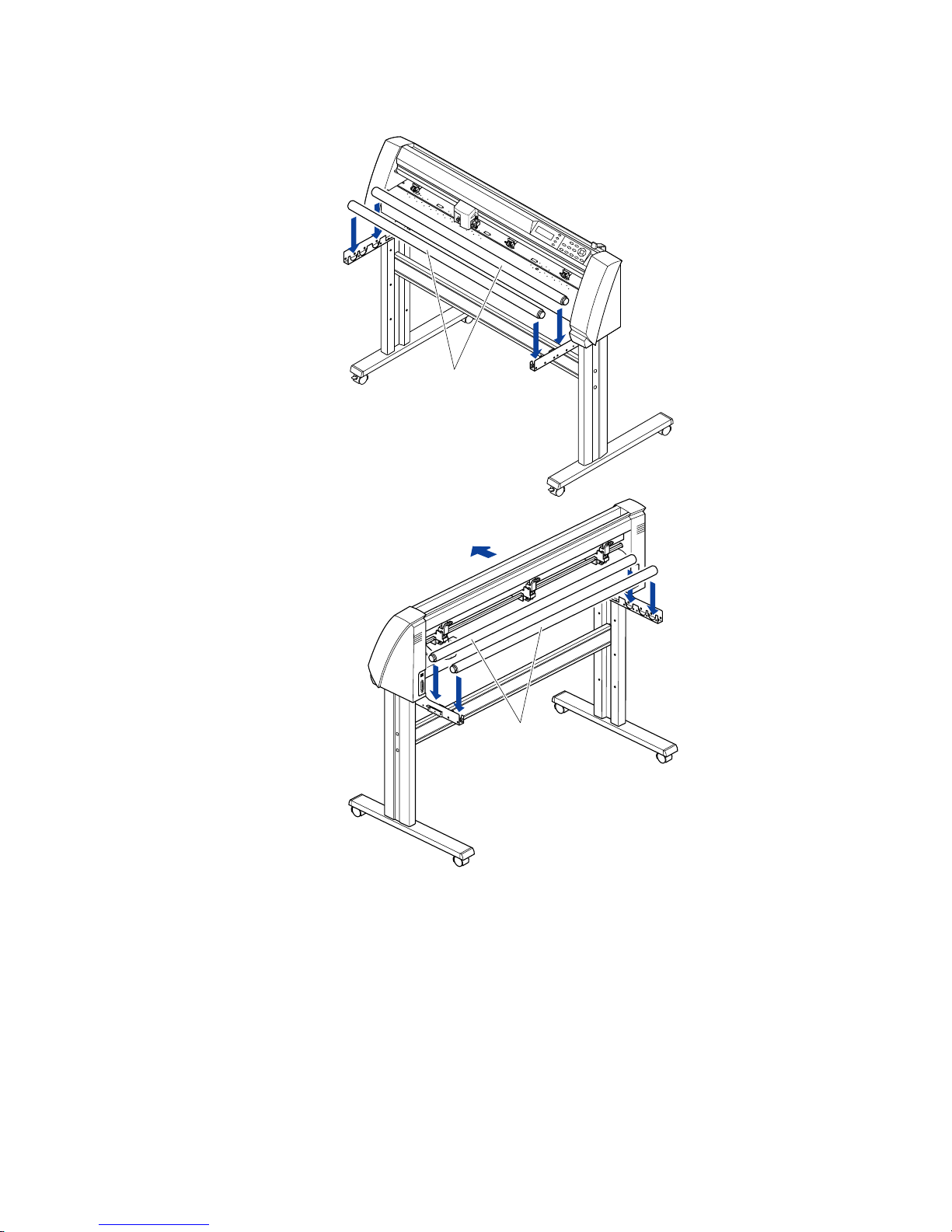

(4) Mount the plotter on the stand by inserting the positioning pins on the stand into the positioning holes

on the underside of the plotter. Fasten with four socket head cap screws (two on each side), using the

Allen wrench.The cutting plotter mounting direction is different for the front loading and the rear loading

models.

Socket head

cap screws

Positioning pin

Socket head

cap screws

Caster stoppers

Positioning pin hole

<Front loading>

<Rear loading>

(5) Tighten the socket head cap screws loosely fastened in Step 2.

• Check that all of the screws used for fastening have been tightened. The media

may not be fed correctly if even one of the screws is loose.

• When installing the plotter, make sure that there are no objects in its vicinity.

Leave a clear space of at least 300 mm around the plotter.

Page 19

FC7000-UM-251-9370 2-7

2. PARTS NAMES and FUNCTIONS

Mounting the stock rollers

Insert the stock rollers into the slots on the media stocker brackets.

Front

Stock rollers

Stock rollers

<Front loading>

<Rear loading>

Page 20

FC7000-UM-251-9370 2-8

2. PARTS NAMES and FUNCTIONS

2.3 Attaching the FC7000 Basket (Option)

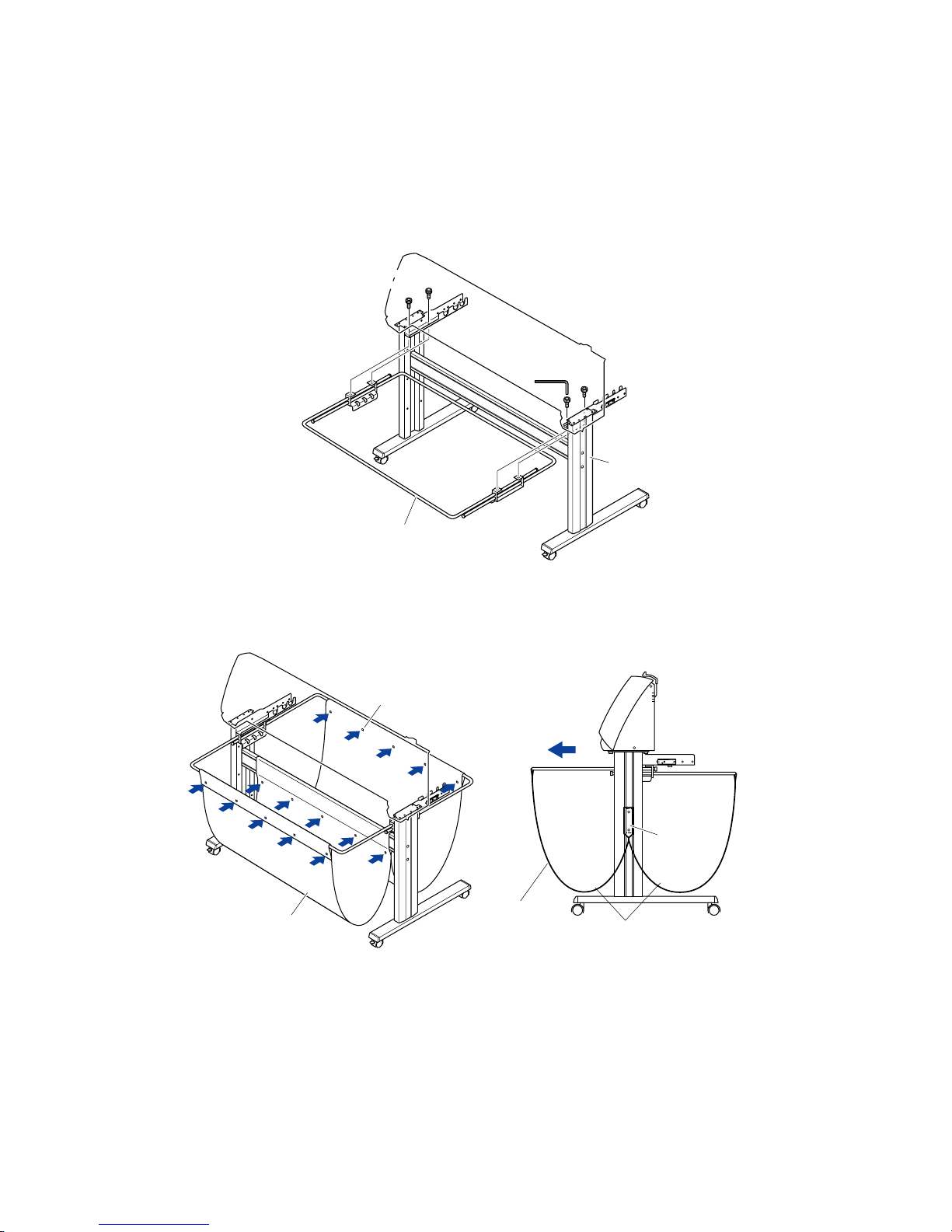

The FC7000 Basket box contains one basket holder assembly (one front basket tube and one rear basket

tube inserted into two tube brackets), one cloth basket, and a screw/wrench set.

(1) Attach one of the two tube brackets on the basket holder assembly to the left side of the stand with two

socket head cap screws, using the Allen wrench.

Repeat this step with the other side.

Socket head

cap screw

Basket holder assembly

Stand

Socket head

cap screw

(2) Drape the middle section of the cloth basket over the stand’s center bar, and then snap the middle

section of the cloth basket around the center bar. Snap the front edge of the cloth basket around the

front basket tube, and then snap the rear edge of the cloth basket around the rear basket tube.

Cloth basket

Holder snap

Front

Cloth basket

Side view

Separate into front and rear baskets,

with the center bar as the center point

Center bar

Page 21

FC7000-UM-251-9370 2-9

2. PARTS NAMES and FUNCTIONS

2.4 Attaching a Cutter Pen

When mounting the cutter pen in the pen holder, push the pen all the way into the holder until its flange

contacts the upper part of the holder and then tighten the screw firmly. To prevent injury, avoid touching the

pen immediately after the cutting plotter is turned on or whenever the pen is moving.

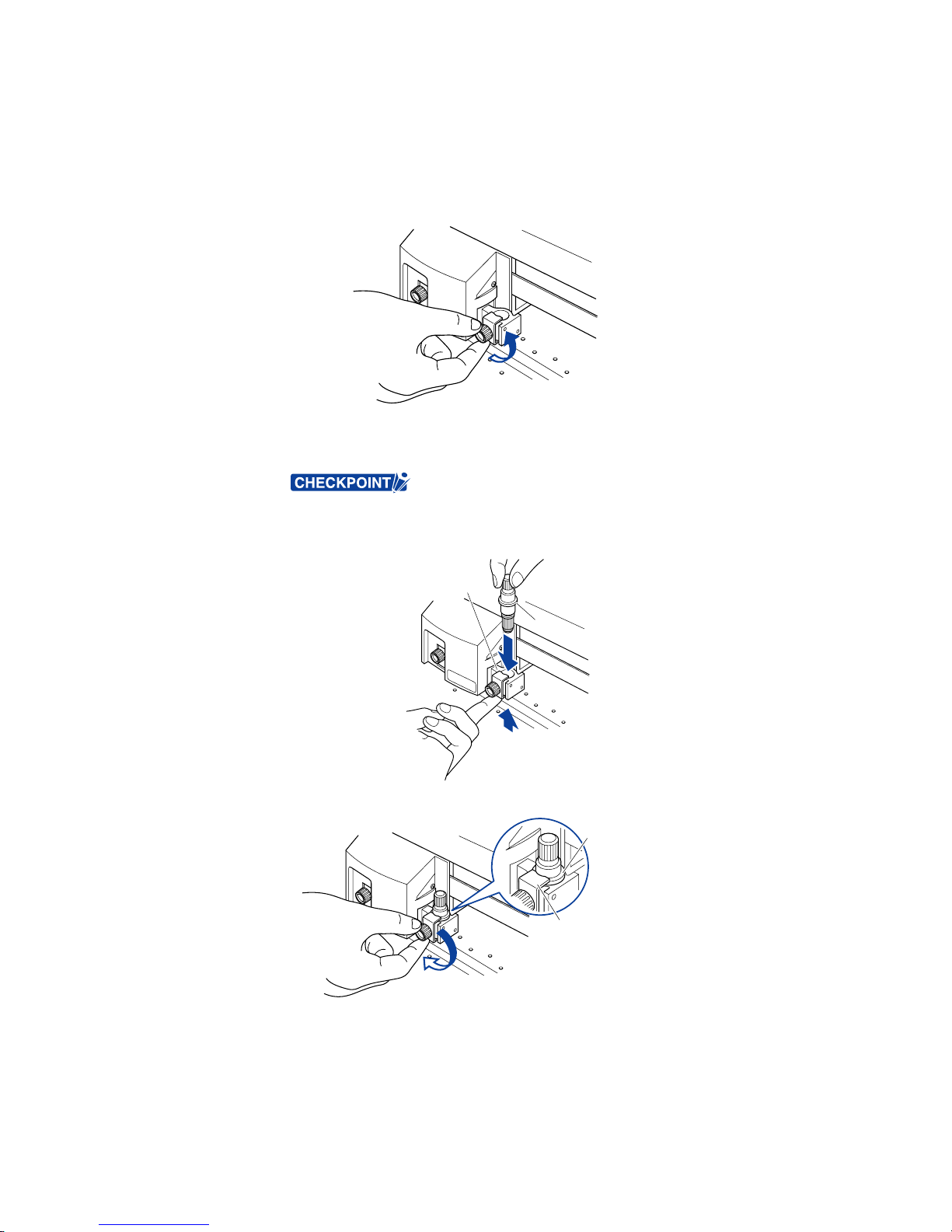

(1) Loosen the pen holder screw.

(2) While pushing the pen holder in the upward direction, push the pen all the way into the holder until its

flange contacts the upper part of the holder.

• When pushing the pen holder with your fingers, the blade tip may be protruding.

Take care not to cut your fingers.

Flange

Upper part of pen holder

(3) Make sure that the pen bracket is engaged on the pen’s flange, and then tighten the screw.

Bracket to hold pen

Flange

Page 22

FC7000-UM-251-9370 2-10

2. PARTS NAMES and FUNCTIONS

Attaching a Pen to the Two-Pen Holder (Option)

The two-pen holder is a factory-installed option, and cannot be retrofitted.

(1) Loosen the pen holder screw.

(2) While pushing the pen holder in the upward direction, push the pen all the way into the holder until its

flange contacts the upper part of the holder.

• When you push the pen holder with your fingers, the blade tip may be protruding.

Take care not to cut your fingers.

Flange

Upper part of pen holder

(3) Make sure that the pen bracket is engaged on the pen’s flange, and then tighten the screw.

Bracket to hold pen

Flange

Page 23

FC7000-UM-251-9370 2-11

2. PARTS NAMES and FUNCTIONS

Attaching a Plotting Pen to the Pen Station

(1) Open the pen-hold mechanism on the pen station, and then attach a pen.

(2) Make sure that the bracket of the pen station is engaged in the upper groove of the pen.

(3) Close the pen-hold mechanism on the pen station to hold the pen in place.

• Do not leave a pen attached to the pen station for a long period of time, as the

pen tip will dry up and make it unusable.

• To store the pen, remove it from the pen station and replace its protective cap.

Page 24

FC7000-UM-251-9370 2-12

2. PARTS NAMES and FUNCTIONS

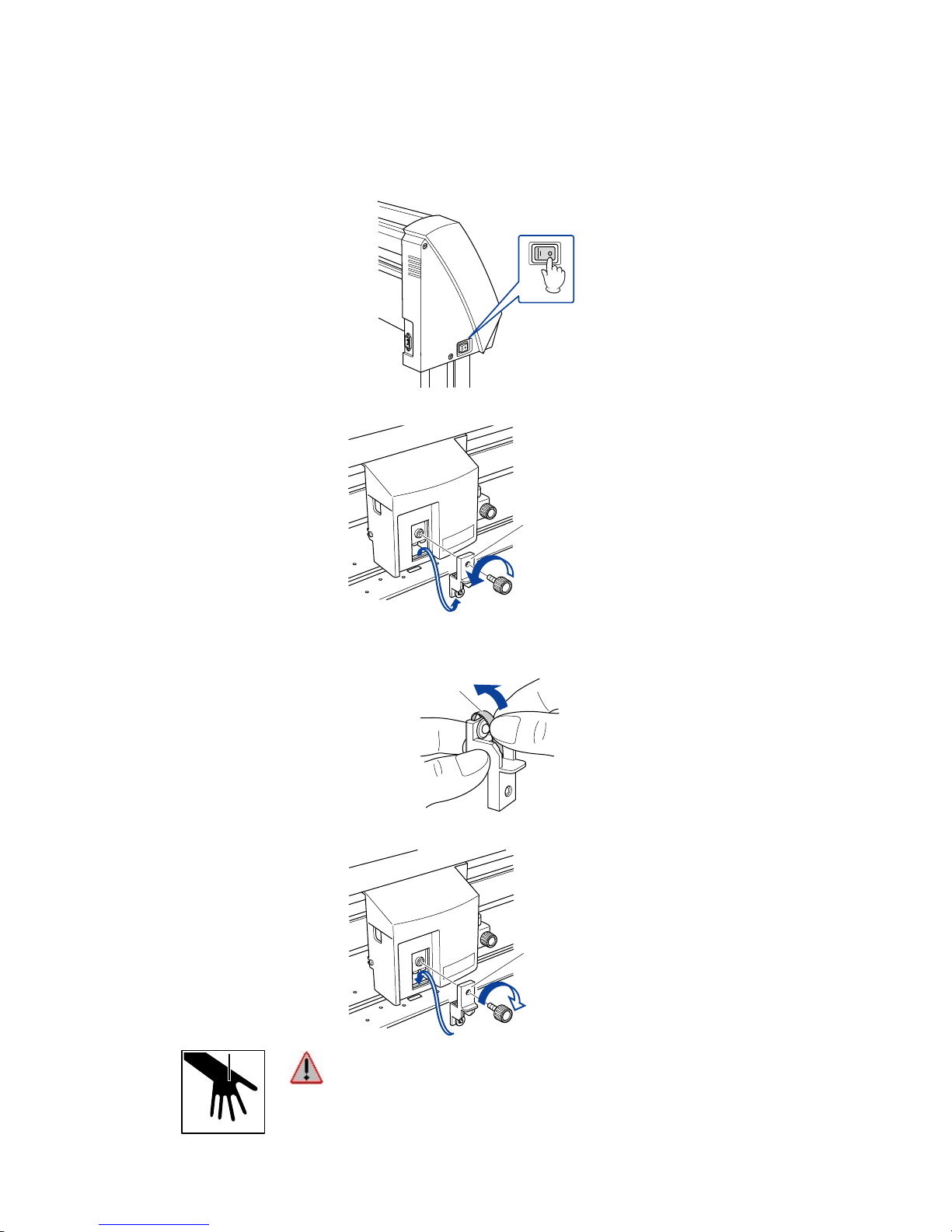

2.5 Replacing the Cross-Cutter Unit

Follow the procedure below to replace the cross-cutter unit that is used to cut the media after the plotting or

cutting operation has been completed.

(1) Check that the power switch is turned off (the “O“ side is pressed down).

(2) Remove the screw holding the cross-cutter unit in place, and then remove the cross-cutter unit.

Cross-cutter unit

(3) Remove the protective cover from the replacement cross-cutter unit. Be sure to remove the protective

cover while holding the part of the unit shown in the figure below.

Protective cover

(4) Attach the replacement cross-cutter unit, and tighten the screw to hold it in place.

Cross-cutter unit

WARNING: The cross-cutter unit uses a very sharp blade. Take care not to cut

yourself on the blade.

Page 25

FC7000-UM-251-9370 3-1

3. OPERATIONS

3. OPERATIONS

3.1 Control Panel

Indicator Lamps

POWER lamp: ................ Remains lit (green) while the plotter is on.

PROMPT lamp: .............. Lights green when the cutting data goes beyond the effective cutting area.

Function Keys

These four keys [F1, F2, F3 and F4] have functions which change as each menu changes. Depending on the

menu being displayed, these keys are used to:

F1 (FORCE) key: ............ When the FC7000 is in MENU mode, press the F1 key to select a function. When

the FC7000 is online, press F1 to select the Condition numbers 1 and 5. After

pressing the CONDITIONS key, use F1 to adjust the cutting/pen FORCE.

F2 (SPEED) key: ............ When the FC7000 is in MENU mode, press the F2 key to select a function. When

the FC7000 is online, press F2 to select the Condition numbers 2 and 6. After

pressing the CONDITIONS key, use F2 to adjust the cutting SPEED.

F3 (QUALITY) key: ......... When the FC7000 is in MENU mode, press the F3 key to select a function. When

the FC7000 is online, press F3 to select the Condition numbers 3 and 7. After

pressing the CONDITIONS key, use F3 to adjust the cutting QUALITY.

F4 (OFFSET) key: .......... When the FC7000 is in MENU mode, press the F4 key to select a function. When

the FC7000 is online, press F4 select the Condition numbers 4 and 8. After

pressing the CONDITIONS key, use F4 to adjust the cutting OFFSET.

Position Keys

POSITION keys .............. Depending on the operating status of the FC7000, the POSITION keys have the

following functions.

When the FC7000 is in MENU mode, use the POSITION keys to change the

setting values shown in the various menu displays. The POSITION keys are also

used to move the pen carriage and the media. If a POSITION key is pressed once,

the pen carriage moves the length of the step specified in Section 5.9, “Using the

MOVE STEP Function of the FC7000 User’s Manual”. If the key is held down, the

movement is continuous. To speed up the movement of the pen carriage, press the

NEXT key together with a POSITION key.

Page 26

FC7000-UM-251-9370 3-2

3. OPERATIONS

Menu Keys

CONDITIONS key: ......... Press CONDITIONS to change the pen conditions shown on the FC7000 display

panel.

HOLD key: ...................... Press HOLD to temporarily suspend cutting or plotting. While the cutting or plotting

operation is suspended, the media set lever can be lowered to enable skewed

media to be reset if necessary.

MENU key: ..................... Press MENU to access the MENU mode. When this key is pressed, the MENU

mode is accessed and the green LED lights. Press it again to cancel MENU mode.

The green LED goes out. Use this key to set the various menu functions. If data is

received after the MENU key has been pressed, that data is temporarily stored in

the plotter’s buffer.

COPY key: ...................... Press COPY to repeat the cutting operation defined by the data in the plotter’s

buffer.

HOME/VIEW key: ........... Press HOME/VIEW to move the pen carriage to the standby position. Press it again

to move the pen carriage to the origin point. Press it one more time to return the

pen carriage to its former position.

NEXT key: ...................... When the FC7000 is in MENU mode, press NEXT to move to the next menu page.

TEST key: ....................... Press TEST to run a cutting test to check whether the currently-selected cutting

conditions are compatible with the media loaded.

AXIS/R.M.S. key: ............ Press AXIS/R.M.S. to initiate automatic reading of the registration marks. If Off

has been selected for the registration mark mode, this key is used to perform axis

alignment.

ORIGIN key: ................... Press ORIGIN to move the origin point. To reset the FC7000, press ORIGIN and

ENTER together when the initial MENU mode screen is displayed.

ENTER key: .................... Press ENTER to register your setting after setting a function.

To reset the FC7000, press ENTER and ORIGIN together when the INITIAL MENU

mode screen is displayed. The cutting area can also be displayed by pressing the

ENTER key in Ready status.

Page 27

FC7000-UM-251-9370 3-3

3. OPERATIONS

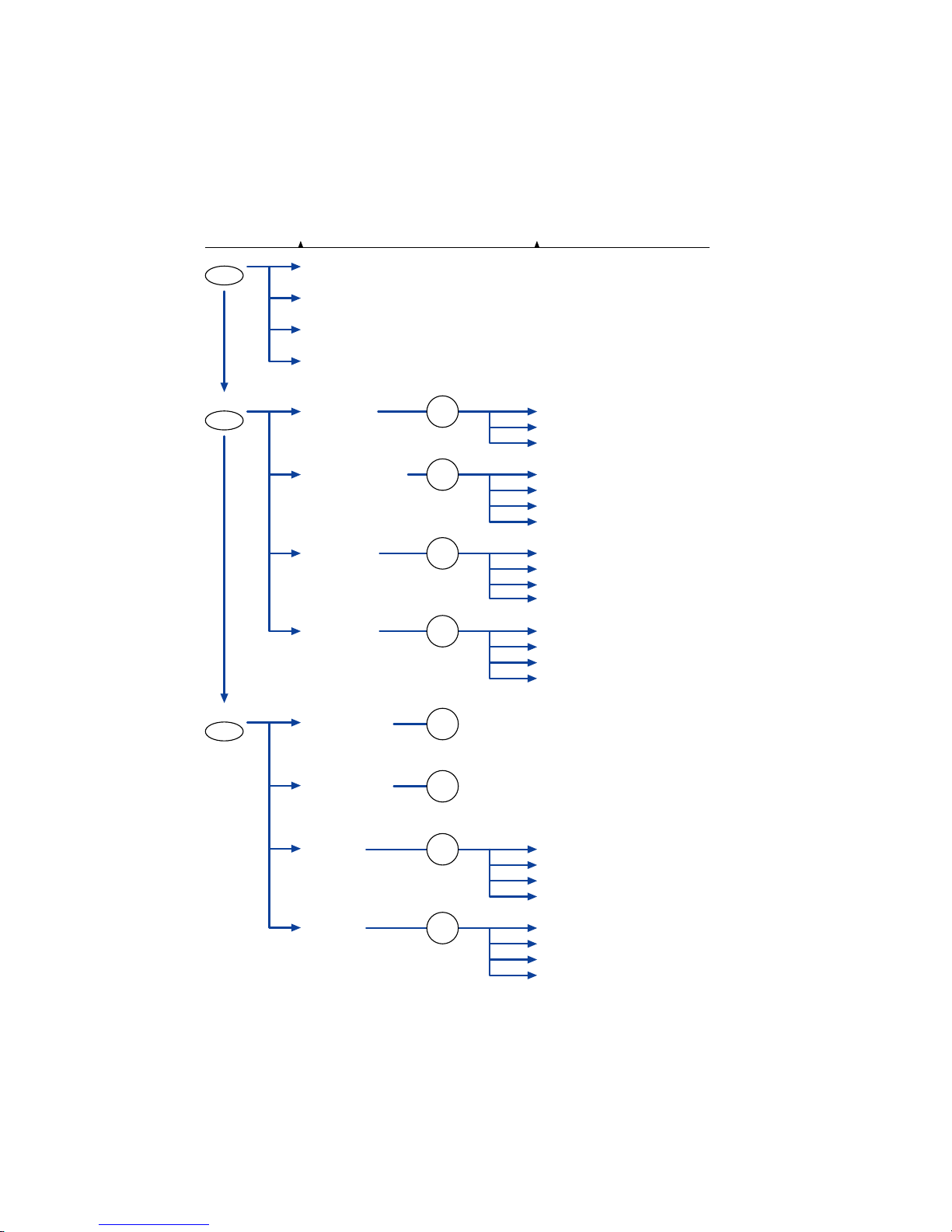

3.2 Menu List

When the FC7000 is in MENU mode

The Main menu can be accessed by pressing the NEXT key when the plotter is in MENU mode (the MENU

lamp is lit). Press the corresponding function key to select the sub menu when the desired main menu

appears.

Page Main menu Sub menu

ASSIGN PEN (2-pen model only)

INTER

FACE

AREA PARAMETERS

FUNCTION 1

FUNCTION 2

CROSS CUT

PRE FEED

MOVE STEP

STE

P SIZE (GP-GL only)

ORIGIN (HP-G

L only)

ROTATE

PER

F. LINE TYPE

DATA SORTING

RS-232C

COMMAND

AREA

PAGE LENGTH

EX

PAND

SCALE

MIRROR

AXIS

ALIGNMENT

AU

TO FEED

TANGENT EMULATION

NEXT

NEXT

F1

FORCE

F2

SPEED

F3

QUALITY

F4

OFFSET

BACKGROUND

SETTINGS

OPTION 1

OPTION 2

PEN U

P SPEED

OFFSE

T ANGLE

OFFSE

T FORCE

STE

P PASS

NEXT

PEN OFFSET ADJ. (2-pen model only)

INITIA

L DOWN FORCE

DIS

TANCE ADJUST

TEST

F3

QUALITY

F2

SPEED

PEN UP/DOWN

F1

FORCE

F4

OFFSET

Page 28

FC7000-UM-251-9370 3-4

3. OPERATIONS

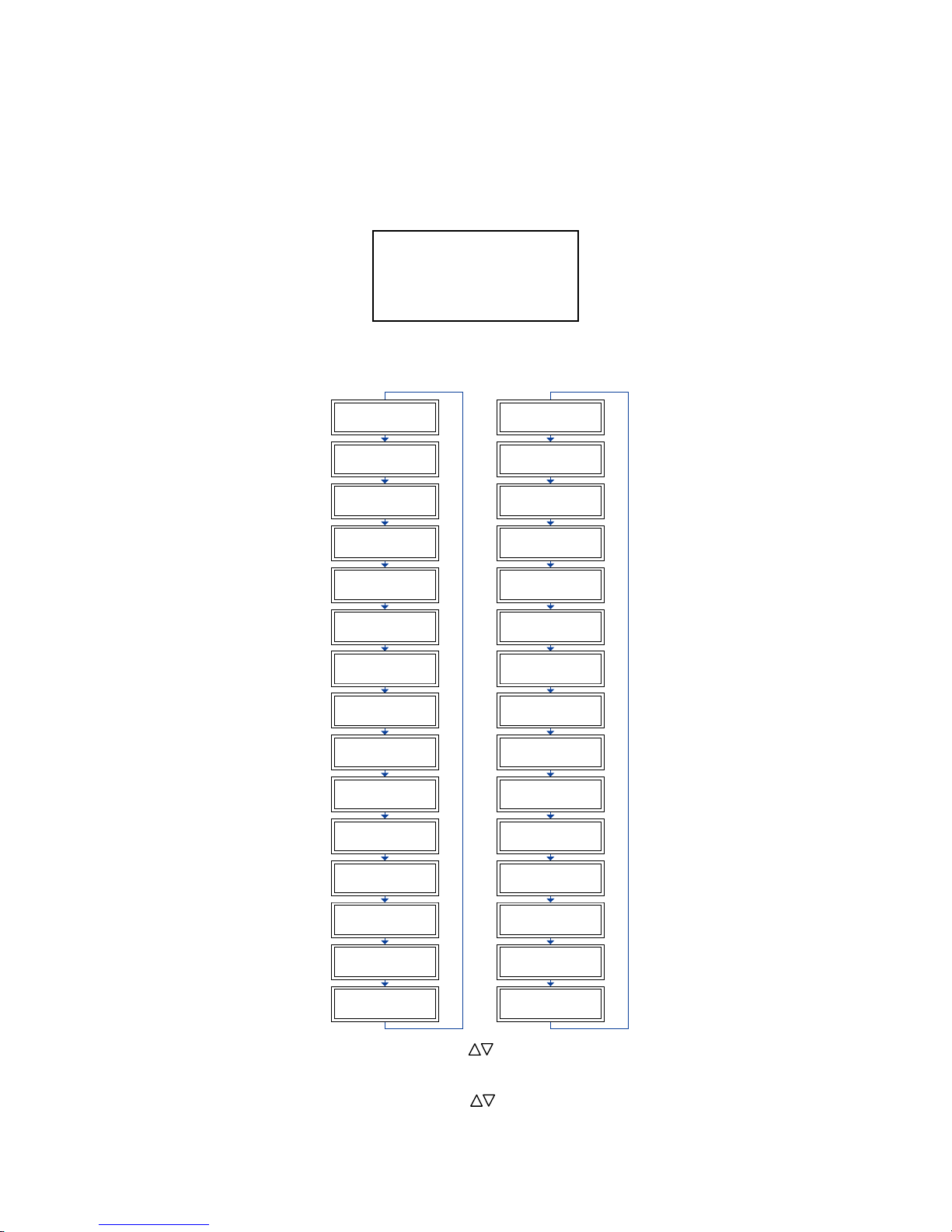

When the power is turned on without any media loaded

If the power is turned on without any media loaded in the plotter, the initial menu is displayed on the LCD.

The initial menu configuration is as follows.

Main menu Sub menu

Initial menu

STEP SIZE (GP-GL only)

AUTO REG. MARK

RS-232C

COMMAND

AUTO PRE FEED

INITIAL FEED SPEED

INTERFACE

F4

OFFSET

F4

OFFSET

Page 29

FC7000-UM-251-9370 3-5

3. OPERATIONS

3.3 Description of Background Settings

The FC7000 is provided with the special functions listed below.

• Display Language Setting (LANGUAGE SELECTION)

This function sets the language used on the display. One of seven languages can be selected: English,

French, German, Italian, Portuguese, Spanish, or Japanese.

• Enabling/Disabling the “;” and “:” Commands (COMMAND ; and :)

Note: This function can only be specified when the COMMAND setting is GP-GL.

This function enables or disables the “;” and “:” commands when the COMMAND setting is GP-GL. If

the first part of the data is lost, these commands may be having an adverse effect. In this case, set this

function to DISABLED (the default setting is ENABLED).

• Moving the Pen While Raised or Lowered in Response to the “W” Command (“W” COMMAND)

Note: This function can only be specified when the COMMAND setting is GP-GL.

This function selects whether, upon receipt of the “W” command for the drawing of arcs, the plotter

moves the pen to the specified starting position in the raised status or in the pen status (raised or

lowered) that was in effect immediately prior to receipt of the “W” command.

When PEN DOWN is selected, the pen is moved to the starting position for the drawing of arcs in the

pen status (raised or lowered) that was in effect immediately prior to receipt of the “W” command. When

PEN UP is selected, the pen is moved to the starting position for the drawing of arcs in the raised status.

This setting is only effective if a cutter blade has been selected in the cutter-pen settings.

• Model ID Response (MODEL EMULATED)

Note: This function can only be specified when the COMMAND setting is HP-GL™.

This function sets the response to the “OI” command when the COMMAND setting is HP-GL™.

When 7550 is set, the “OI” command response is 7550.

When 7586 is set, the “OI” command response is 7586.

• Setting Priority (CONDITION PRIORITY)

This function sets whether the plotter places priority on the cutting conditions specified through command

input from the computer or through manual settings (on the plotter control panel).

When MANUAL is selected, cutting is performed using the cutting conditions set at the control panel,

and cutting conditions sent from the computer are ignored.

When PROGRAM is selected, the cutting conditions can be set either at the plotter’s control panel or by

command input from the computer. The most recent setting conditions are set. When the power is turned

off, only the conditions set at the control panel are retained in the plotter’s internal memory.

• Enabling/Disabling the Pen Select Command (PEN SELECT)

Note: This function can only be specified for a 2-pen model.

This function enables or disables the PEN SELECT command (“J” Command in GP-GL mode or the “SP”

command in HP-GL™ mode) for a 2-pen model.

Page 30

FC7000-UM-251-9370 3-6

3. OPERATIONS

• Initial Blade Tip Position Setting (INITIAL BLADE CONTROL POSITION)

The cutter blade is placed on the medium to orient it after the power is turned on or the cutter-pen

conditions are set. This is referred to as “initializing” the cutter blade.

This function sets the “Initial Blade Tip Position” for this operation.

When 2 mm BELOW is selected, initial blade control is performed at a position 2 mm below the cutting

start position.

When OUTSIDE is selected, initial blade control is performed outside of the effective cutting/plotting

area.

• Setting the Display Length Unit (LENGTH UNIT)

This function enables you to set the unit for coordinates appearing on the display panel to either

millimeter or inch units.

• Enabling/Disabling Pen Up Move (PEN UP MOVE)

This function sets whether the pen will travel to each point specified or only from the initially specified

point to the last specified point when consecutive commands are received specifying pen movement

while it is raised.

When ENABLED is selected, the pen travels consecutively to each coordinate specified by the data

received.

When DISABLED is selected, the pen travels directly from the initially specified point to the last specified

point.

• Enabling/Disabling the Media Sensors (MEDIA SENSOR)

This function enables or disables the media sensors that detect the size of the medium in the feed

direction.

When ENABLED is selected, the feed-direction media sensors are enabled.

When DISABLED is selected, the feed-direction media sensors are disabled.

• Enabling/Disabling the Pinch Roller Sensors (PINCH ROLLER SENSOR)

This function enables or disables the pinch roller sensors that detect the width of the medium.

When ENABLED is selected, the pinch roller sensors are enabled.

When DISABLED is selected, the pinch roller sensors are disabled.

• Since the pinch roller sensors are also used for the cross-cutting operation, cross-

cutting cannot be performed if DISABLED is selected.

• Circle-Command Resolution Setting (CIRCLE RESOLUTION)

Note: This function can only be specified when the COMMAND setting is HP-GL™.

This function sets whether the resolution is automatically set or fixed at a constant 5 degrees when a

plotter circle command is output while the COMMAND setting is HP-GL™.

• Cross-cut Force Setting (CROSS CUT PRESSURE)

This function sets the cutting force for the cross-cut operation.

The default value is 30, but the setting should be changed to suit the media type.

Thin media: Decrease the value.

Thick media: Increase the value.

Page 31

FC7000-UM-251-9370 3-7

3. OPERATIONS

• Enabling or Disabling the 1/2 Pen Setting (CHECK PEN)

Note: This function can only be specified for a 2-pen model.

This function checks whether the physical PEN 2 is actually mounted in the pen station during the media

detection operation on a 2-pen model.

When ENABLED is selected, a check is performed

When DISABLED is selected, a check is not performed. If DISABLED is selected, always check that

PEN 2 is mounted in the pen station before turning on the power.

• Fan Suction Setting (FAN POWER)

This function sets the suction force used to affix media to the plotter.

Thin media: Weak

Normal media: Normal

• Enabling/Disabling the Beep Setting (BEEP FOR KEY OPERATION)

This function selects whether to enable or disable the beep that is emitted whenever a control panel key

is pressed.

ON: The beep sounds.

OFF: The beep does not sound.

• Enabling/Disabling Auto Registration Mark Recognition (MARK AUTO SCAN)

This function enables or disables the automatic sensing of registration marks from the plug-in software.

ON: The registration marks are sensed automatically.

OFF: The registration marks are not sensed automatically.

CAUTION: If DISABLED was selected for the media or pinch roller sensors, be sure

to specify the cutting or plotting area. If the cutting or plotting area is not

specified, the blade tip and the cutting mat may be damaged, and the pen

carriage may strike the sides of the plotter.

Page 32

FC7000-UM-251-9370 3-8

3. OPERATIONS

3.4 Setting the Background Settings

SETTING PROCEDURE

(1) Use the following procedure to display the background setting menus.

Load media in the plotter, and then turn on the power. Press the MENU key and then press the NEXT

key until the following menu appears.

PEN UP/DOWN>

BACKGROUND SETTINGS>

OPTION 1>

OPTION 2>

Press the F2 key (BACKGROUND SETTINGS) to enter the setting mode.

(2) Press the NEXT key to move through the BACKGROUND SETTINGS menus in the displayed sequence.

GP-GL

Background Settings

*2-Pen Model

*2-Pen Model

*2-Pen Model

*2-Pen Model

LANGUAGE SELECTION

[ JA

PANESE ]

COMMAND ;

AND :

ENABLE

D *

DISABLED

"W" COMMAND

PEN U

P

PEN DOW

N*

CONDITION PRIORITY

MANUA

L*

PROGRAM

INITIA

L BLADE

CONTRO

L POSITION

2mm BELOW *

OUTSIDE

LENGTH UNI

T

INCH

METRIC*

PEN U

P MOVE

ENABLE

D *

DISABLED

MEDIA SENSOR

ENABLED

*

DISABLED

PINCH ROLLER SENSOR

ENABLED

*

DISABLED

CROSS CUT PRESSURE

30

CHECK PEN

ENABLED

*

DISABLED

FAN POWER

WEAK

NORMAL*

BEEP

FOR KEY OPERATION

OFF

ON*

MARK AUTO SCAN

ON

OF F *

LANGUAGE SELECTION

[ JA

PANESE ]

MODEL EMULATED

7550*

7586

CONDITION PRIORITY

MANUAL*

PROGRAM

PEN SELECT

ENABLE

D*

DISABLED

PEN SELECT

ENABLED

DISABLED

INITIA

L BLADE

CONTRO

L POSITION

2mm BELOW*

OUTSIDE

LENGTH UNI

T

INCH

METRIC

*

PEN U

P MOVE

ENABLED

DISABLED

*

MEDI

A SENSOR

ENABLE

D*

DISABLED

PINCH ROLLER SENSOR

ENABLE

D*

DISABLED

CIRCLE RESOLUTION

AU

TO

DE

FAULT*

CROSS CUT PRESSURE

30

CHECK PEN

ENABLED

*

DISABLED

FAN POWER

WEAK

NORMAL*

BEEP

FOR KEY OPERATION

OFF

ON*

MARK AUTO SCAN

ON

OF F*

HP-GL

TM

Background Settings

(3) At the LANGUAGE SELECTION menu, use the ( ) POSITION keys to select the desired language

and then press the ENTER key.

At the CROSS CUT PRESSURE menu, use the ( ) POSITION keys to increase or decrease the value

and then press the ENTER key.

Page 33

FC7000-UM-251-9370 3-9

3. OPERATIONS

For all other displays, press the F3 or the F4 key to move the asterisk to your desired choice, and then

press the ENTER key. The asterisk indicates the currently selected setting. If you do not wish to change

the currently displayed setting, press the NEXT key to move to the next menu.

(4) Turn off the power when all the settings are completed.

• These settings are retained in the plotter’s memory even when the power is

turned off.

Page 34

Page 35

FC7000-UM-251-9370 4-1

4. RECOMMENDED PARTS LIST

4. RECOMMENDED PARTS LIST

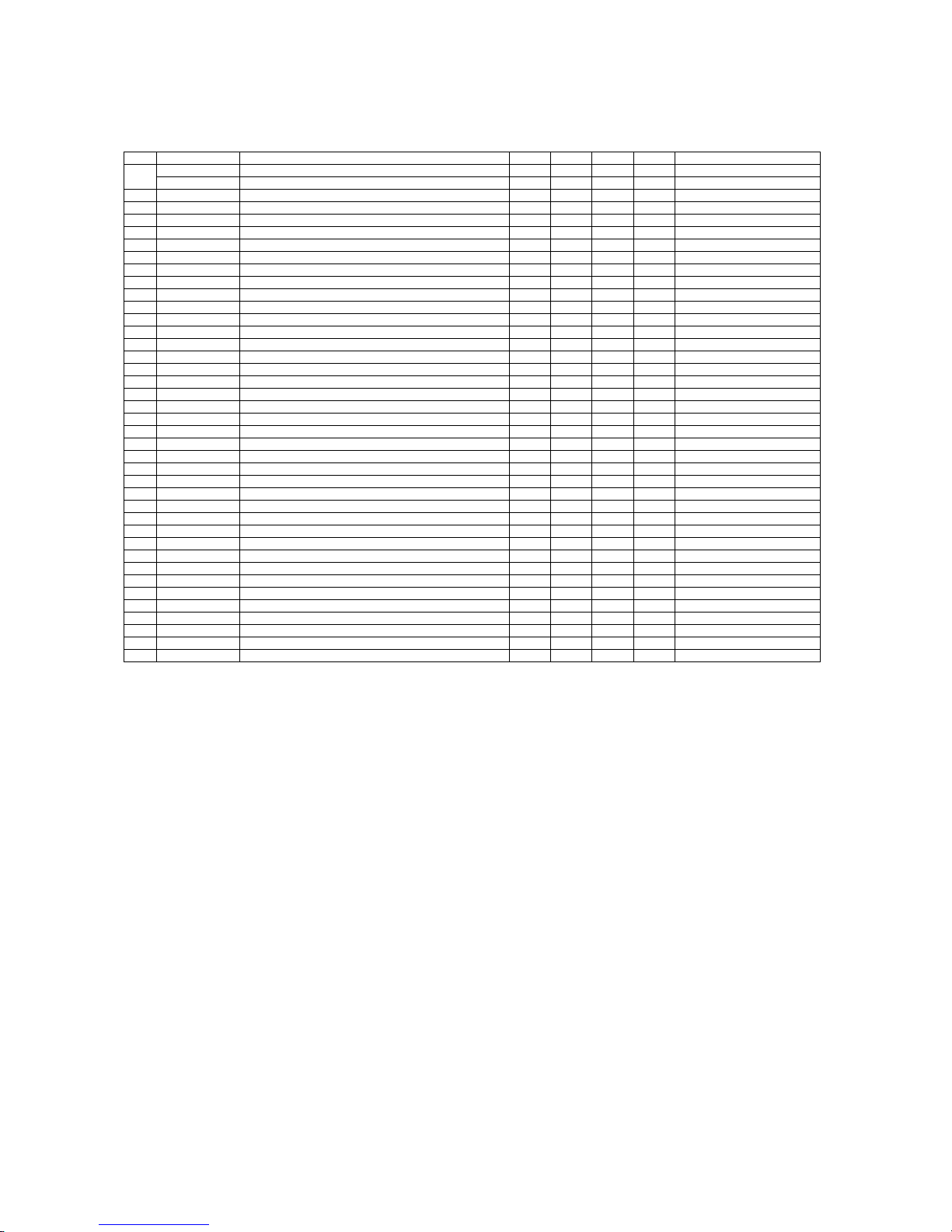

FC7000-75/100/130/160

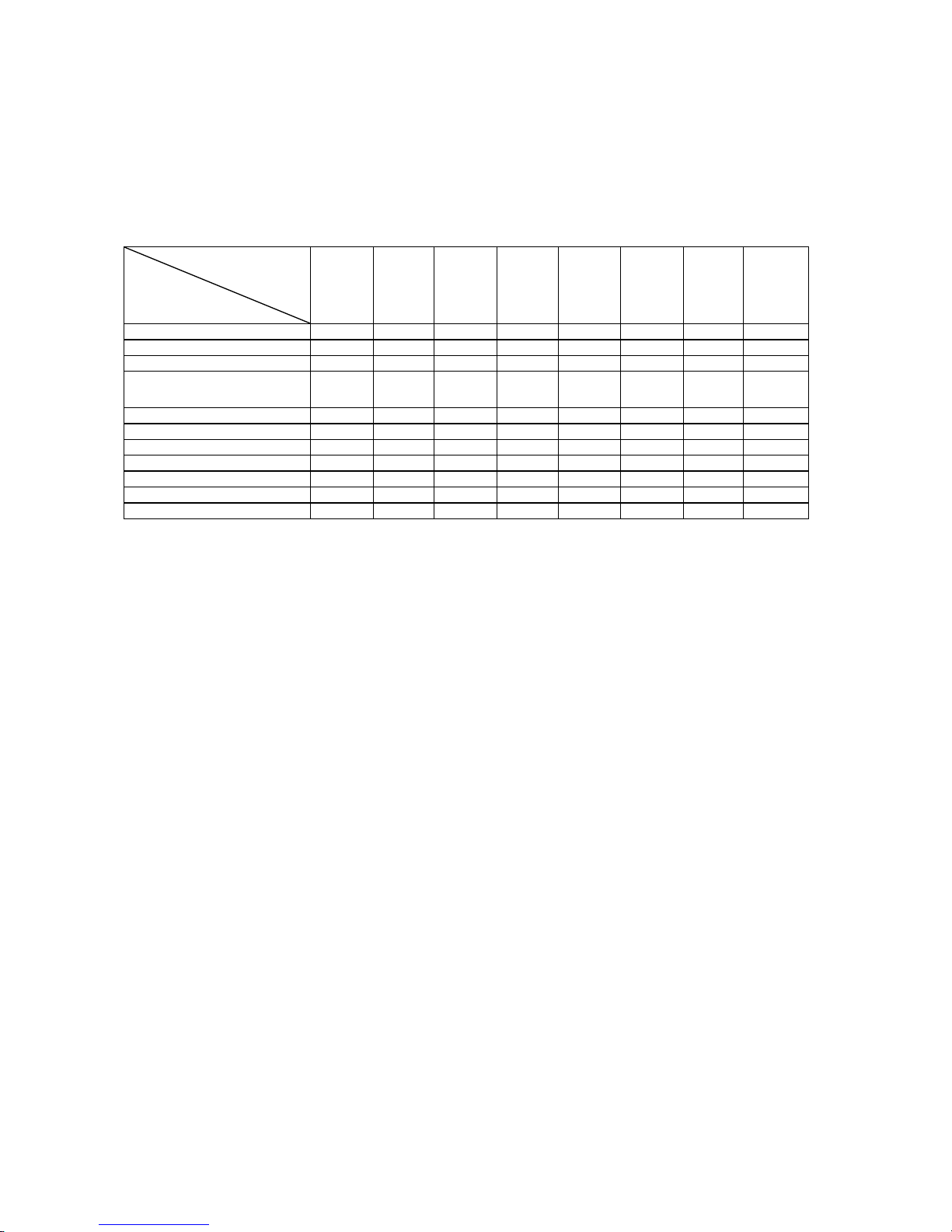

No. Par t No. Description -75 -100 -130 -160 Remarks

1 772126500 Main Board for FC7000 1 1 1 1 FC7000

792700703 New Main Board for the FC7000 1 1 1 1 Same as FC7000Mk2

2 50 0052449 Switching Power Supply Unit 1 1 1 1 PS3122

3 500052478 LG-217D-3, Cam Sensor 1 1 1 1

4 500052515 PS-117ED1 2 2 2 2 Paper Sensor

5 682132430 UGJMEE-A7JGR34 – 1 1 1 X motor

6 682132440 UGJMEE-A7MGR73 2 1 1 1 Y motor, XY motor for 75

7 772126660 Pen Board 1 1 1 1

8 772126650 Pinch Roller Sensor Board 1 1 1 1

9 692126531 FFC312203A , Flexible Cable 75 1 – – –

10 692126541 FFC312204A, Flexible Cable 100 – 1 – –

11 692126551 FFC312205A, Flexible Cable 130 – – 1 –

12 692126561 FFC312206A, Flexible Cable 160 – – – 1

13 772126700 Pen Block Assembly 1 1 1 1

14 772126710 Light Pointer Assembly 1 1 1 1

15 772126720 Registration Mark Sensor Board, PR312207A 1 1 1 1

16 50 0052472 TDS- 05B-DC12V, Fan 1 2 2 2

17 772126560 LCD Assembly 1 1 1 1

18 772126570 Control Panel Board, PR312208A 1 1 1 1

19 692126521 FFC312202A, Control Panel Flexible Cable 1 1 1 1

20 772126340 Cross Cutter Assembly 1 1 1 1

21 621261220 150S2M-1150, Y Belt 75 1 – – –

22 621262020 Drive Roller Set 75 1 – – –

23 621262010 Drive Roller Shaft 75 1 – – –

24 621271220 300S2M-1450, Y Belt 100 – 1 – –

25 621272020 Drive Roller Set 100 – 1 – –

26 621272010 Drive Roller Shaft 100 – 1 – –

27 621281220 300S2M-1750 – – 1 –

28 621282020 Drive Roller Set 130 – – 1 –

29 621282010 Drive Roller Shaft 130 – – 1 –

30 621291220 300S2M-2010 – – – 1

31 621292020 Drive Roller Set 160 – – – 1

32 621292011 Drive Roller Shaft 160 – – – 1

33 095002121 Push Roller 2 3 3 3

34 378413041 130TN15-10W, Motor Belt 2 2 2 2

35 095013010 Roller BB13, Y Slider Roller 7 7 7 7

36 621261053 Cutting Mat 75 1 – – –

37 621271053 Cutting Mat 100 – 1 – –

38 621281053 Cutting Mat 130 – – 1 –

39 621291053 Cutting Mat 160 – – – 1

Page 36

FC7000-UM-251-9370 4-2

4. RECOMMENDED PARTS LIST

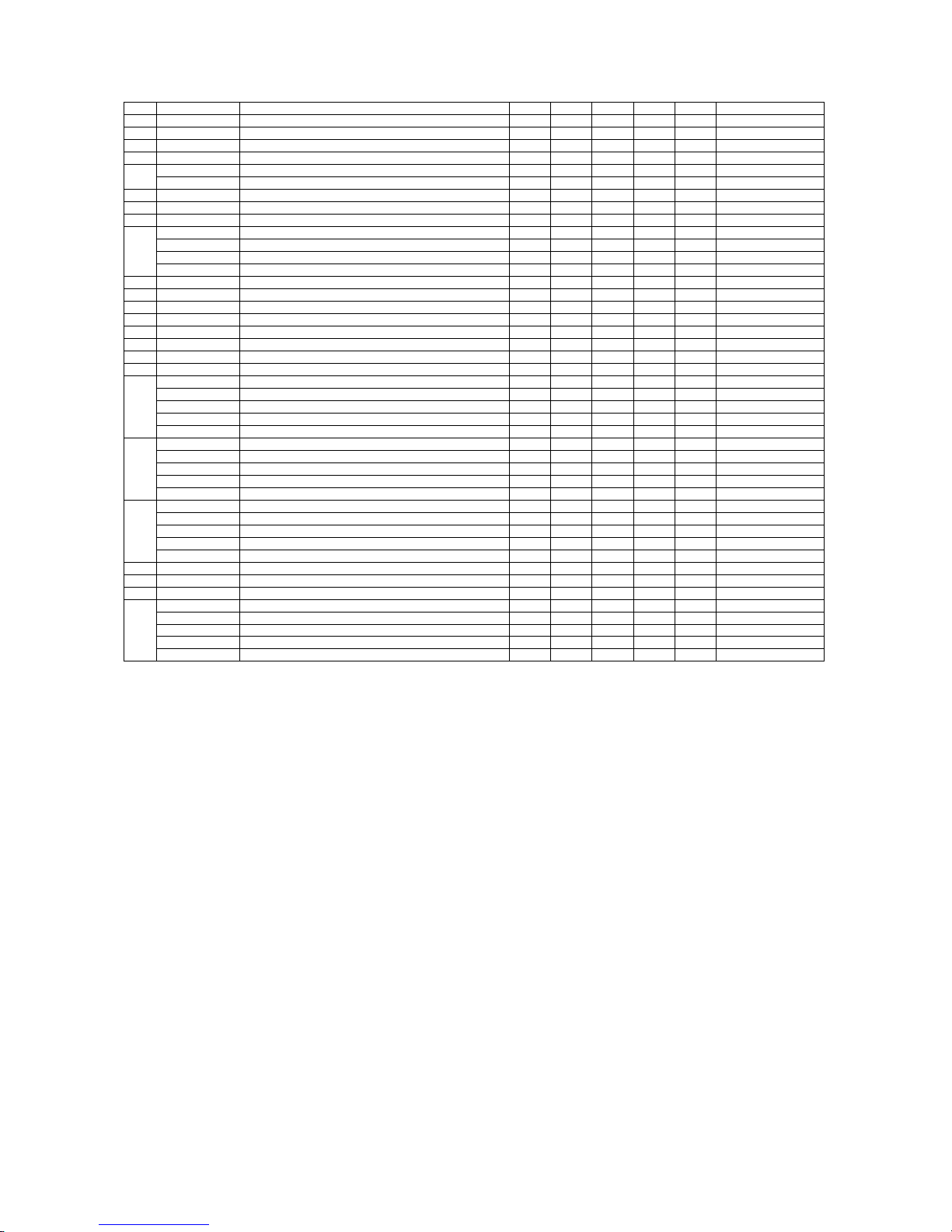

FC7000MK2

No. Par t No. Description -60 -75 -100 -130 -160 Remarks

1 792700703 Main Board for FC7000Mk2 1 1 1 1 1 FC7000MK2

2 50 0052449 Switching Power Supply Unit 1 1 1 1 1 PS3122

3 500052478 LG-217D-3, Cam Sensor 1 1 1 1 1

4 500052515 PS-117ED1 2 2 2 2 2 Paper Sensor

5 682126200 DMN37HE-0 03 1 1 – – – X motor

682132430 UGJMEE-A7JGR34 – – 1 1 1

6 682126200 DMN37HE-0 03 1 1 1 1 1 Y motor

7 772126660 Pen Board 1 1 1 1 1

8 772126650 Pinch Roller Sensor Board 1 1 1 1 1

9 692126531 FFC312203A , Flexible Cable 60/75 1 1 – – –

692126541 FFC312204A, Flexible Cable 100 – – 1 – –

692126551 FFC312205A, Flexible Cable 130 – – – 1 –

692126561 FFC312206A, Flexible Cable 160 – – – – 1

10 772126700 Pen Block Assembly 1 1 1 1 1

11 772126710 Light Pointer Assembly 1 1 1 1 1

12 772126720 Registration Mark Sensor Board, PR312207A 1 1 1 1 1

13 500052472 TDS- 05B-DC12V, Fan 1 1 2 2 2

14 772126560 LCD Assembly 1 1 1 1 1

15 772126570 Control Panel Board, PR312208A 1 1 1 1 1

16 692126521 FFC312202A, Control Panel Flexible Cable 1 1 1 1 1

17 772126340 Cross Cutter Assembly 1 1 1 1 1

18 621391220 150S2M1000, Y Belt 60 1 – – – –

621261220 150S2M-1150, Y Belt 75 – 1 – – –

621271220 300S2M-1450, Y Belt 100 – – 1 – –

621281220 300S2M-1750, Y Belt 130 – – – 1 –

621291220 300S2M-2010, Y Belt 160 – – – – 1

19 621392020 Drive Roller set 60 1 – – – –

621262020 Drive Roller Set 75 – 1 – – –

621272020 Drive Roller Set 100 – – 1 – –

621282020 Drive Roller Set 130 – – – 1 –

621292020 Drive Roller Set 160 – – – – 1

20 621391340 Drive Roller Shaft 60 1 – – – –

621262010 Drive Roller Shaft 75 – 1 – – –

621272010 Drive Roller Shaft 100 – – 1 – –

621282010 Drive Roller Shaft 130 – – – 1 –

621292011 Drive Roller Shaf t 160 – – – – 1

21 095002121 Push Roller 2 2 3 3 3

22 378413041 130TN15-10W, Motor Belt 2 2 2 2 2

23 095013010 Roller BB13, Y Slider Roller 7 7 7 7 7

24 621390050 Cutting Mat 60 1 – – – –

621261053 Cutting Mat 75 – 1 – – –

621271053 Cutting Mat 100 – – 1 – –

621281053 Cutting Mat 130 – – – 1 –

621291053 Cutting Mat 160 – – – – 1

Page 37

FC7000-UM-251-9370 5-1

5. LIST OF TOOLS

5. LIST OF TOOLS

5.1 Tools

No. Adjustment Item Jig Tool

1 Pen force adjustment Cutter Pen Holder (CB09) Colex gauge (50,300,500 gf)

2 Distance adjustment Glass scale

3 Pen block height adjustment 10 mm height block

4 Firmware update PC, USB I/F cable

5 X-drive belt tension adjustment Push-pull gauge (2 kg)

6 Y-drive belt tension adjustment Push-pull gauge (2 kg)

7 Replacing the main board

Screwdriver

8 Replacing the vacuum fan

5.2 Greasing And Gluing Points

No. Grease or Glue Point Grease or Glue name Application quantity

1 Cam Shinetu silicon grease G501 Suitable quantity

2 X-drive motor pulley Shinetu silicon grease G501 Suitable quantity

3 Y-drive motor pulley Shinetu silicon grease G501 Suitable quantity

4 X-drive pulley Shinetu silicon grease G501 Suitable quantity

5 Y-drive pulley Shinetu silicon grease G501 Suitable quantity

6 Y-tension pulley Shinetu silicon grease G501 Suitable quantity

7 Y-rail, pinch roller assy sliding area Shinetu silicon grease G501 Suitable quantity

8 Y-motor drive pulley set screws Loctite 222 Small quantity

9 X-motor drive pulley set screws Loctite 222 Small quantity

10 X-drive pulley set screws Loctite 222 Small quantity

Page 38

Page 39

FC7000-UM-251-9370 6-1

6. DISASSEMBLY AND REASSEMBLY

6. DISASSEMBLY AND REASSEMBLY

6.1 Exterior Parts

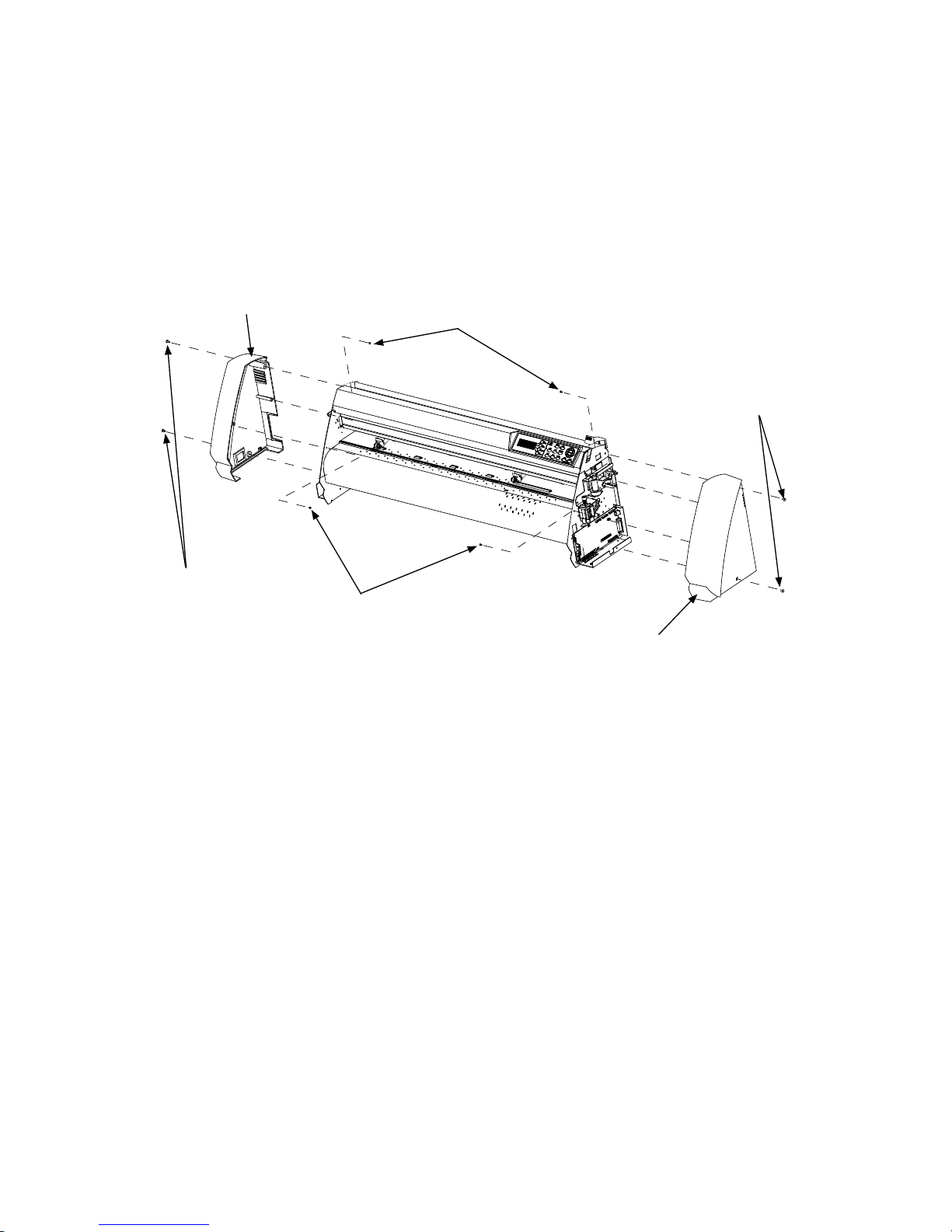

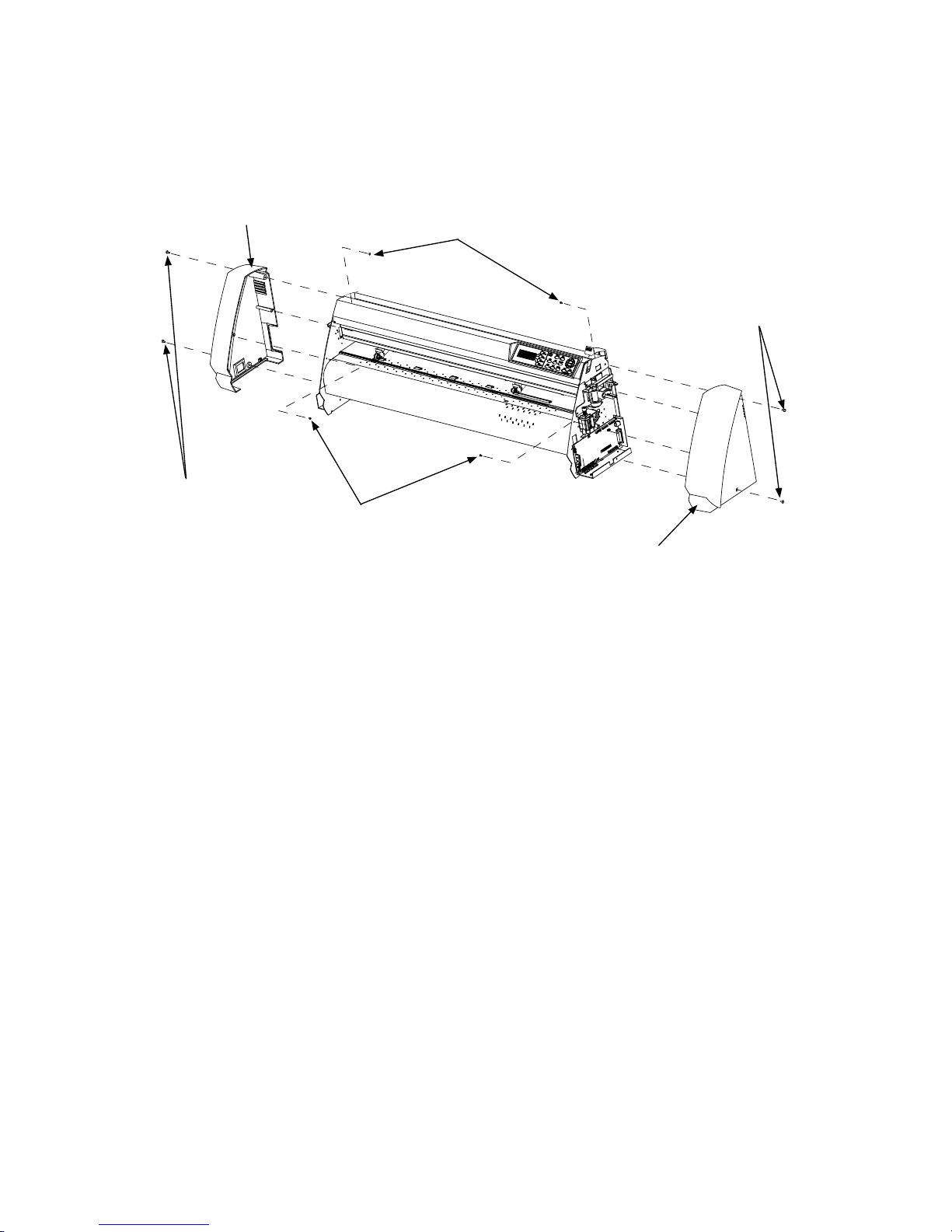

6.1.1 How to Replace the Right Side Cover

How to detach the right side cover

(1) Remove the two M4L6 binding head screws from the right side cover.

(2) Remove the two M3L6 binding head screws from the right side plate.

M4L6 binding head screw

M4L6 binding head screw

M3L6 binding head screw

M3L6 binding head screw

Right side cover

Left side cover

How to reinstall the right side cover

(1) Mount the right side cover to the right side plate.

(2) Fasten the two M4L6 binding head screws and the two M3L6 binding head screws.

Page 40

FC7000-UM-251-9370 6-2

6. DISASSEMBLY AND REASSEMBLY

6.1.2 How to Replace the Left Side Cover

How to detach the left side cover

(1) Remove the two M4L6 binding head screws from the left side cover.

(2) Remove the two M3L6 binding head screws from the left side plate.

M4L6 binding head screw

M4L6 binding head screw

M3L6 binding head screw

M3L6 binding head screw

Right side cover

Left side cover

How to reinstall the left side cover

(1) Mount the left side cover to the left side plate.

(2) Fasten the two M4L6 binding head screws and the two M3L6 binding head screws.

Page 41

FC7000-UM-251-9370 6-3

6. DISASSEMBLY AND REASSEMBLY

6.1.3 How to Replace the Center Cover

How to detach the center cover

(1) Detach the right side cover (see Subsection 6.1.1).

M4L6 binding head screw

M3L6 binding head screw

M3L6 binding head screw

Right side cover

Center cover assembly

M3L6 binding head screw

(2) Disconnect the cables from connector J2 and J3 on the main board.

Disconnect the cables

from connector J2 and

J3 on the main board.

(3) Remove the four M3L6 binding head screws from the center cover assembly.

(4) Detach the center cover assembly.

How to reinstall the center cover assembly

(1) Reattach the center cover assembly in the reverse order in which it was detached.

Page 42

FC7000-UM-251-9370 6-4

6. DISASSEMBLY AND REASSEMBLY

6.1.4 How to Replace the Front Guide

How to detach the front guide

(1) Remove the four M3L6 binding head screws from the front guide for the FC7000-75.

(Remove the five M3L6 binding head screws from the front guide for the FC7000-100.

Remove the six M3L6 binding head screws from the front guide for the FC7000-130.

Remove the seven M3L6 binding head screws from the front guide for the FC7000-160.)

(2) Detach the front guide.

Front guide

M3L6 binding head screw

How to reinstall the front guide

(1) Reattach the front guide in the reverse order in which it was detached.

Page 43

FC7000-UM-251-9370 6-5

6. DISASSEMBLY AND REASSEMBLY

6.1.5 How to Replace the Rear Guide

How to detach the rear guide

(1) Remove the four M3L6 binding head screws from the rear guide for the FC7000-75.

(Remove the five M3L6 binding head screws from the rear guide for the FC7000-100.

Remove the six M3L6 binding head screws from the rear guide for the FC7000-130.

Remove the seven M3L6 binding head screws from the rear guide for the FC7000-160.)

(2) Detach the rear guide.

Rear guide

M3L6 binding head screw

How to reinstall the rear guide

(1) Reattach the rear guide in the reverse order in which it was detached.

Page 44

FC7000-UM-251-9370 6-6

6. DISASSEMBLY AND REASSEMBLY

6.1.6 How to Replace the Rear Writing Panel

How to detach the rear writing panel

(1) Detach the rear guide (see Subsection 6.1.5).

(2) Remove the M3L6 binding head screw from the top of the rear writing panel.

(3) Remove the five M3L6 binding head screws from the rear of the rear writing panel for the FC7000-75.

(Remove the five M3L6 binding head screws from the rear of the rear writing panel for the FC7000-100.

Remove the six M3L6 binding head screws from the rear of the rear writing panel for the FC7000-130.

Remove the seven M3L6 binding head screws from the rear of the rear writing panel for the

FC7000-160.)

(4) Detach the rear writing panel.

Rear writing panel

M3L6 binding head screw

M3L6 binding head screw

How to reinstall the rear writing panel

(1) Reattach the rear writing panel in the reverse order in which it was detached.

Page 45

FC7000-UM-251-9370 6-7

6. DISASSEMBLY AND REASSEMBLY

6.1.7 How to Replace the Front Writing Panel Assembly

How to detach the front writing panel assembly

(1) Detach the front guide (see Subsection 6.1.4).

(2) Detach the rear writing panel (see Subsection 6.1.6).

(3) Remove the five M3L6 binding head screws from the front writing panel assembly for the FC7000-75.

(Remove the six M3L6 binding head screws from the front writing panel assembly for the FC7000-100.

Remove the seven M3L6 binding head screws from the front writing panel assembly for the FC7000-130.

Remove the eight M3L6 binding head screws from the front writing panel assembly for the FC7000-160.)

(4) Loosen the five M3L6 binding head screws at the top of the front writing panel assembly for the

FC7000-75.

(Loosen the six M3L6 binding head screws at the top of the front writing panel assembly for the

FC7000-100.

Loosen the seven M3L6 binding head screws at the top of the front writing panel assembly for the

FC7000-130.

Loosen the eight M3L6 binding head screws at the top of the front writing panel assembly for the

FC7000-160.

(5) Detach the front writing panel assembly.

Front writing panel

M3L6 binding head screw

Loosen these M3L6 binding head screws

How to reinstall the front writing panel assembly

(1) Reattach the front writing panel in the reverse order in which it was detached.

Page 46

FC7000-UM-251-9370 6-8

6. DISASSEMBLY AND REASSEMBLY

6.2 Mechanical Parts

6.2.1 How to Replace the Rear Media Sensor

How to detach the rear media sensor

(1) Detach the rear guide (see Subsection 6.1.5).

(2) Remove the M3L10 binding head screw attaching the rear media sensor.

(3) Disconnect the sensor from the connector.

Rear media sensor

M3L10 binding head screw

How to reinstall the rear media sensor

(1) Reattach the rear media sensor in the reverse order in which it was detached.

Page 47

FC7000-UM-251-9370 6-9

6. DISASSEMBLY AND REASSEMBLY

6.2.2 How to Replace the Front Media Sensor

How to detach the front media sensor

(1) Detach the front writing panel (see Subsection 6.1.7).

(2) Remove the M3L6 binding head screw attaching the front media sensor bracket.

Front media sensor

M3L6 binding head screw

Front media sensor

(3) Remove the M3L10 binding head screw attaching the front media sensor.

M3L10 binding head screw

(4) Disconnect the sensor from the connector.

How to reinstall the front media sensor

(1) Reattach the front media sensor in the reverse order in which it was detached.

Page 48

FC7000-UM-251-9370 6-10

6. DISASSEMBLY AND REASSEMBLY

6.2.3 How to Replace the Pinch Roller

How to detach the pinch roller

(1) Detach the right side of the E-ring from the pinch roller shaft.

E-ring

Pinch roller shaft

Pinch roller

(2) Detach the pinch roller shaft from the pinch roller arm from the left side.

(3) Detach the pinch roller.

How to reinstall the pinch roller

(1) Reattach the pinch roller in the reverse order in which it was detached.

Page 49

FC7000-UM-251-9370 6-11

6. DISASSEMBLY AND REASSEMBLY

6.2.4 How to Replace the Control Panel Board, LCD Assembly

How to detach the control panel board, LCD assembly

(1) Detach the right side cover (see Subsection 6.1.1).

(2) Detach the center cover (see Subsection 6.1.3).

(3) Remove the three M3L6 binding head screws attaching the control panel board from the top of the

center cover.

M3L6 binding head screw

(4) Remove the three M3L6 binding head screws holding the control panel bracket and the center cover.

M3L6 binding head screw

Control panel bracket

(5) Detach the control panel board assembly from the center cover.

(6) Remove the three M3L6 binding head screws holding the control panel bracket to the control panel

cover.

M3L6 binding head screw

Control panel bracket

Control panel cover

Page 50

FC7000-UM-251-9370 6-12

6. DISASSEMBLY AND REASSEMBLY

(7) Detach the control panel bracket from the control panel cover.

Control panel bracket

(8) Disconnect the cable from the LCD assembly.

(9) Detach the control panel board from the control panel cover.

Control panel cover

Control panel board

(10) Detach the LCD assembly from the control panel cover.

LCD assembly

Control panel board

How to reinstall the control panel board, LCD assembly

(1) Reattach the control panel board and LCD assembly in the reverse order in which they were detached.

Page 51

FC7000-UM-251-9370 6-13

6. DISASSEMBLY AND REASSEMBLY

6.2.5 How to Replace the Pen Block

How to detach the pen block

(1) Detach the right side cover (see Subsection 6.1.1).

(2) Detach the center cover (see Subsection 6.1.3).

(3) Loosen the two M3L6 binding head screws attaching the pen block cover.

M3L6 binding head screw

(4) Detach the pen block cover.

(5) Disconnect the cables from connector J502, J504, J505 and J506 on the Y-relay board.

Disconnect these cables from the connectors.

(6) Remove the two M4L6 binding head screws attaching the Y-relay block.

M4L6 binding head screw

Page 52

FC7000-UM-251-9370 6-14

6. DISASSEMBLY AND REASSEMBLY

How to reinstall the pen block

(1) Attach the pen block to the Y-slider.

(2) Fasten the two M4L6 binding head screws to attach the pen block so that there is

a gap of 10 mm

between the bottom of the pen block and the cutting mat. Perform a visual check to make sure that

the pen block is not mounted at an angle.

10 mm

(3) Reattach the other parts in the reverse order in which they were detached.

(4) Perform the pen force adjustment (see Section 7.3.7).

(5) Perform the auto registration mark sensor sensitivity adjustment (see Section 7.3.9).

(6) Perform the auto registration mark sensor offset adjustment (see Section 7.3.10).

Page 53

FC7000-UM-251-9370 6-15

6. DISASSEMBLY AND REASSEMBLY

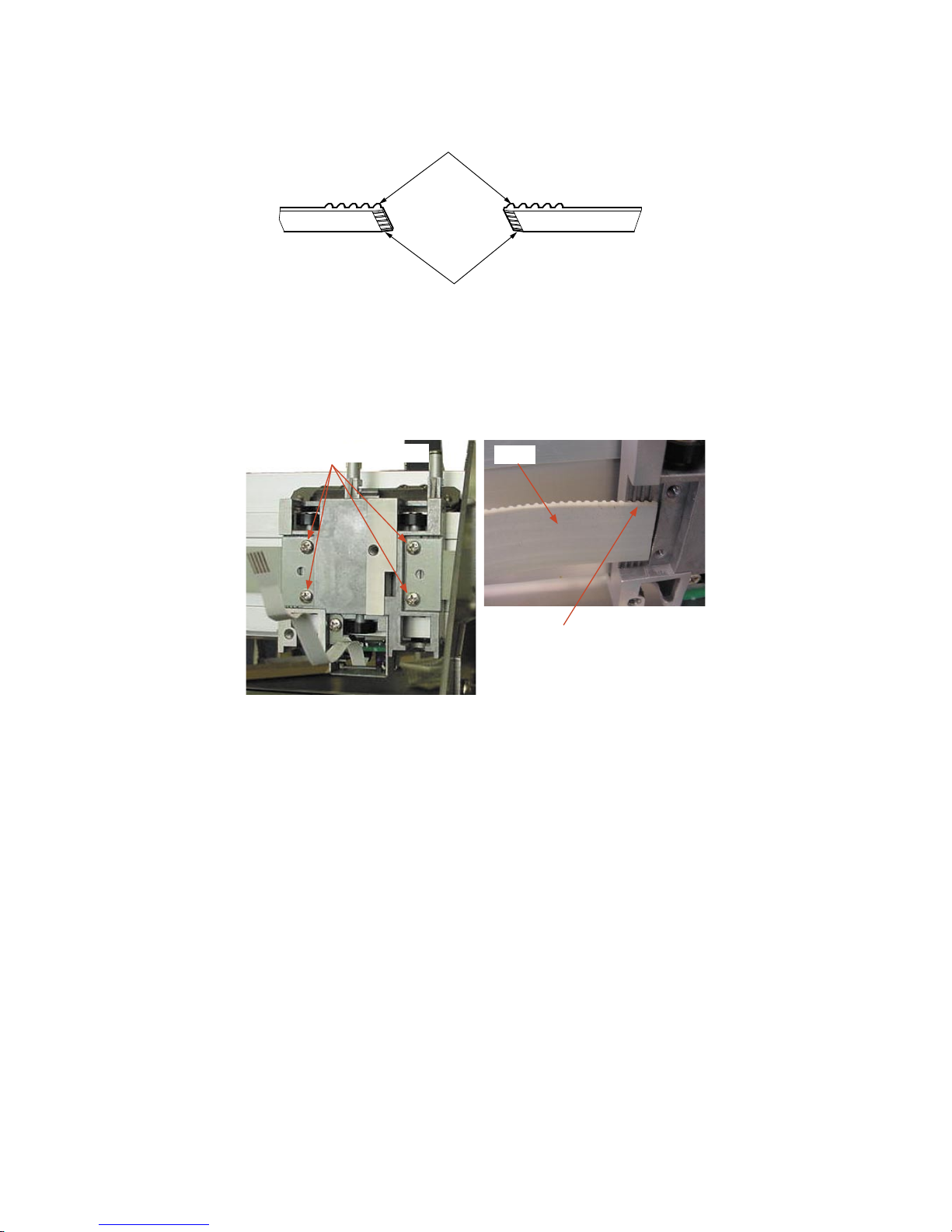

6.2.6 How to Replace the Y-belt

How to detach the Y-belt

(1) Detach the right and left side covers (see Subsection 6.1.1 and Subsection 6.1.2).

(2) Detach the center cover (see Subsection 6.1.3).

(3) Detach the pen block (see Subsection 6.2.5).

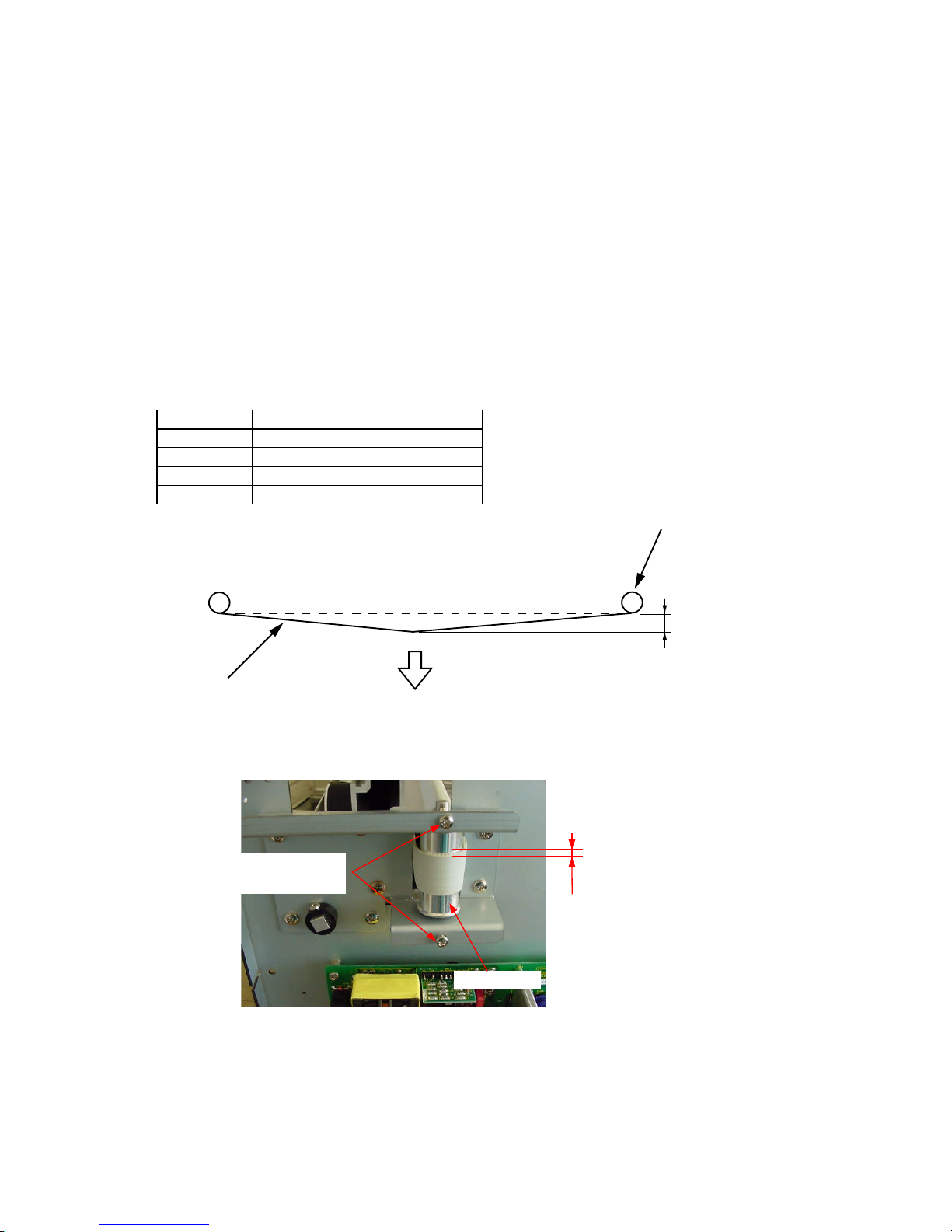

(4) Loosen the two M3L35 binding head screws adjusting the Y-belt tension.

M3L35 binding head screw

(5) Remove the four M3L6 binding head screws attaching the right and left Y-belt stopper plates to the

slider.

Y belt

M3L6 binding head screw

(6) Detach the Y-belt from the unit.

Page 54

FC7000-UM-251-9370 6-16

6. DISASSEMBLY AND REASSEMBLY

How to reinstall the Y-belt

(1) Shave 2 to 3 mm off both ends of the Y-belt until the wire comes out as shown below.

Y-belt

Shave 2 to 3 mm off both ends of

the Y-belt until the wire comes out.

(2) Hang the Y-belt on both sides of the pulley.

(3) Attach both ends of the Y-belt to the Y-slider so that four notches of the Y-belt fi t into the Y-slider, then

attach with the Y-belt stopper plates removed in step (5) in the previous subsection.

M3L6 binding head screw

Y belt

Four notches of the Y-belt fi t into

the Y-slider.

(4) Attach the pen block (see Subsection 6.2.5).

(5) Reattach the other parts in the reverse order in which they were detached.

(6) Perform the Y-belt tension adjustment. (see Subsection 7.2.1).

Page 55

FC7000-UM-251-9370 6-17

6. DISASSEMBLY AND REASSEMBLY

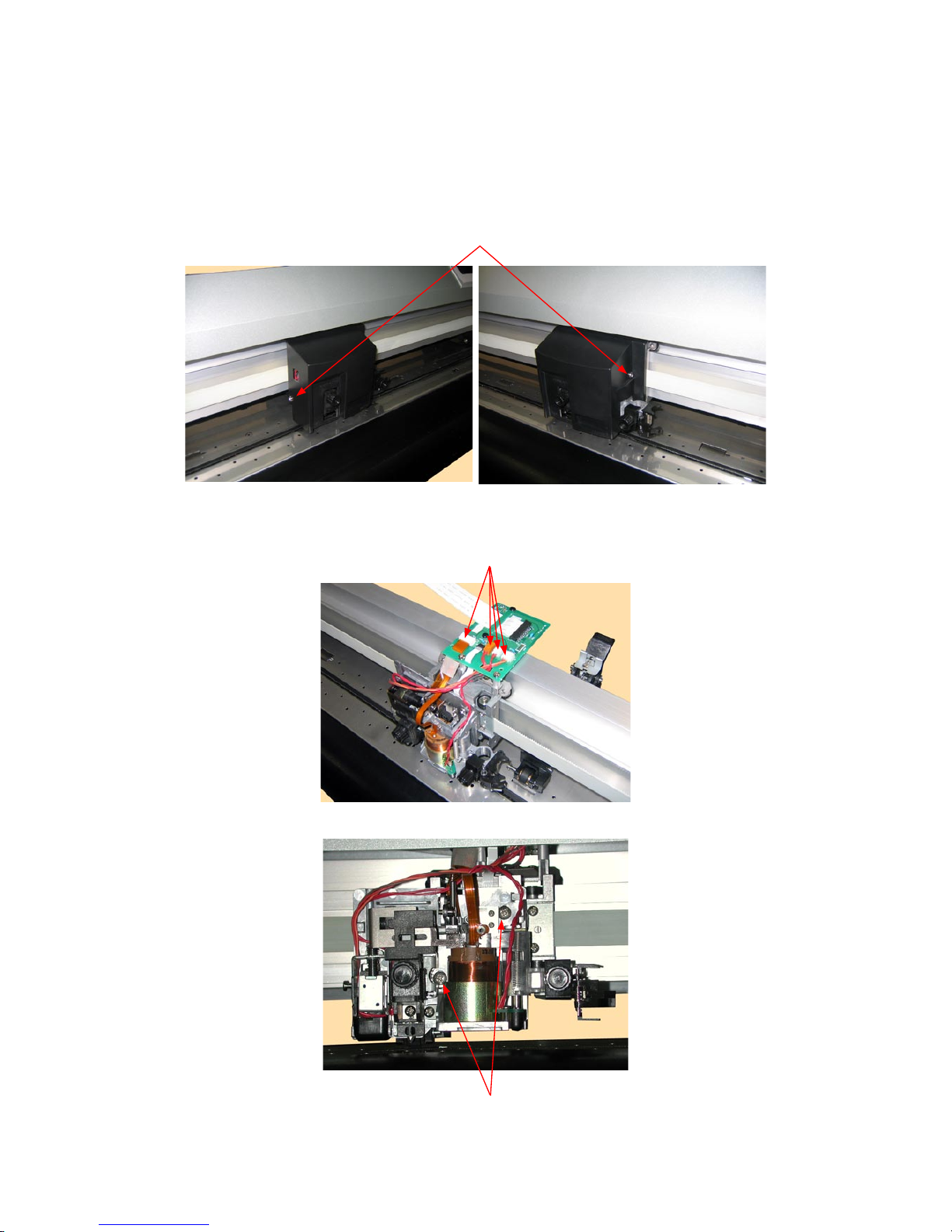

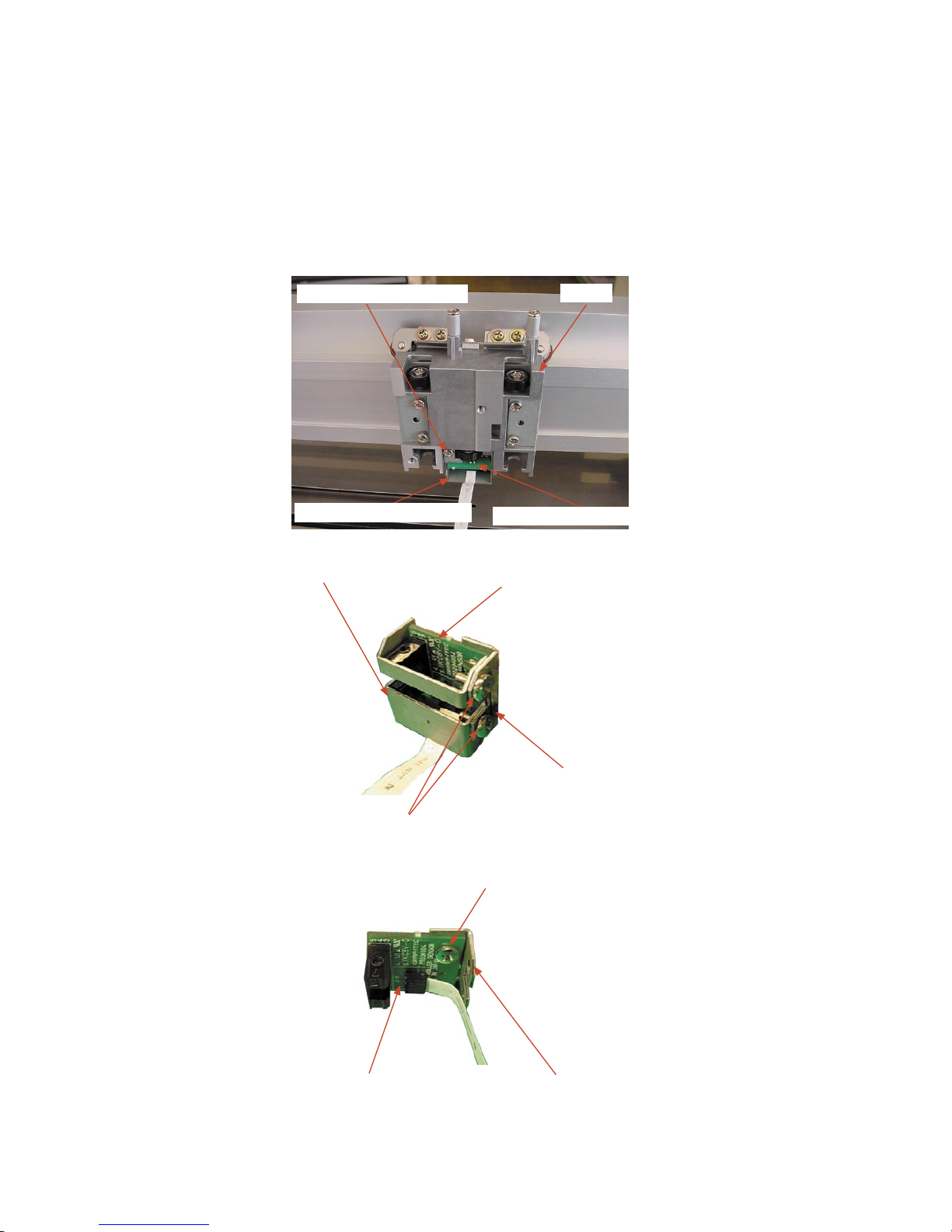

6.2.7 How to Replace the Pinch Roller Sensor

How to detach the pinch roller sensor

(1) Detach the center cover (see Subsection 6.1.3).

(2) Detach the pen block (see Subsection 6.2.5).

(3) Disconnect the pinch roller fl exible cable from the Y-relay board.

(4) Remove the pinch roller fl exible cable that is attached with double-sided adhesive tape to the Y-slider.

(5) Remove the M3L6 binding head screw attaching the pinch roller sensor bracket to the slider.

Y slider

M3L6 binding head screw

Pinch roller sensor bracket

Pinch roller sensor board

(6) Remove the two M3L6 binding head screws attaching the pinch roller sensor guard.

Pinch roller sensor guard

M3L6 binding head screw

Pinch roller sensor bracket

Pinch roller sensor board

(7) Remove the M3L6 binding head screw attaching the pinch roller sensor board.

M3L6 binding head screw

Pinch roller sensor bracketPinch roller sensor board

(8) Disconnect the pinch roller fl exible cable from the pinch roller sensor board.

Page 56

FC7000-UM-251-9370 6-18

6. DISASSEMBLY AND REASSEMBLY

How to reinstall the pinch roller sensor

(1) Attach the pinch roller bracket to the pinch roller sensor board.

(2) Connect the pinch roller flexible cable to the pinch roller sensor board.

(3) Attach the pinch roller sensor guard to the pinch roller sensor board bracket.

(4) Attach the pinch roller bracket to the Y-slider.

Fit the top and left edges of the pinch roller bracket to the Y-slider as shown in the figure below.

M3L6 binding head screw

Pinch roller sensor bracket

(5) Attach the pen block (see Subsection 6.2.5).

(6) Reattach the other parts in the reverse order in which they were detached.

Page 57

FC7000-UM-251-9370 6-19

6. DISASSEMBLY AND REASSEMBLY

6.2.8 How to Replace the Y-relay Board

How to detach the Y-relay board

(1) Detach the center cover (see Subsection 6.1.3).

(2) Remove the two plastic rivets attaching the fl exible cable holding plate.

Plastic rivet

Flexible cable holding plate

(3) Disconnect all the cables from the Y-relay board.

(4) Remove the two M3L35 binding head screws attaching the Y-relay board.

M3L35 binding head screw

(5) Detach the Y-relay board from the Y-slider.

How to reinstall the Y-relay board

(1) Reattach the Y-relay board in the reverse order in which it was detached.

Page 58

FC7000-UM-251-9370 6-20

6. DISASSEMBLY AND REASSEMBLY

6.2.9 How to Replace the Cam Sensor

How to detach the cam sensor

(1) Detach the right side cover (see Subsection 6.1.1).

(2) Disconnect the cable from the cam sensor.

M3L6 binding head screw

Cam sensor

(3) Remove the M3L6 binding head screw attaching the cam sensor.

How to reinstall the cam sensor

(1) Reattach the cam sensor in the reverse order in which it was detached.

Page 59

FC7000-UM-251-9370 6-21

6. DISASSEMBLY AND REASSEMBLY

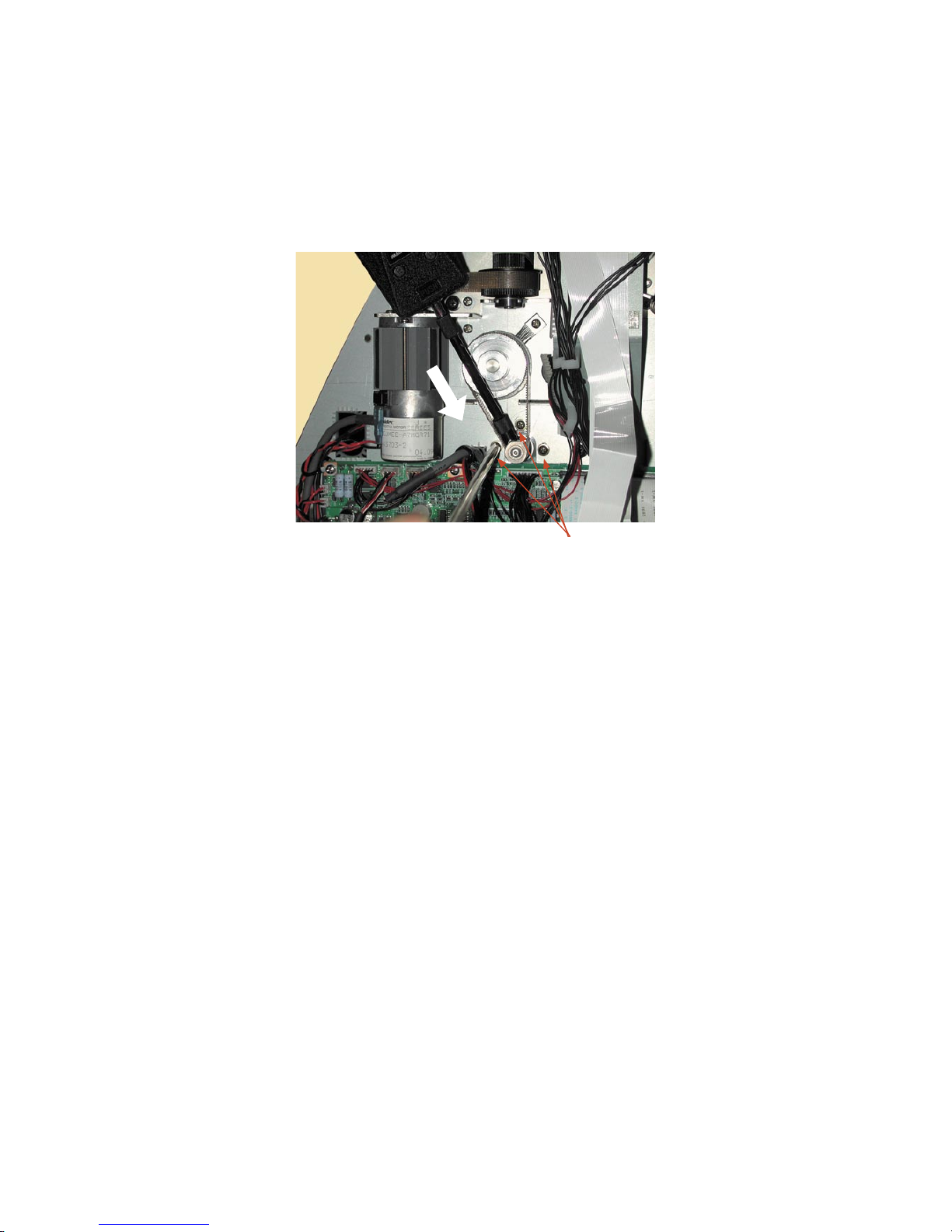

6.2.10 How to Replace the Y-motor

How to detach the Y-motor

(1) Detach the right side cover (see Subsection 6.1.1).

(2) Disconnect the Y-motor cables from connector J7 and J13 on the main board.

(3) Loosen the two M3L4WP set screws to detach the Y-motor pulley.

Y motor

M3L6 binding head screw

M3L4WP set screw

Y motor pulley

(4) Remove the four M3L6 binding head screws holding the Y-motor.

(5) Detach the Y-motor pulley, then detach the Y-motor.

How to reinstall the Y-motor

(1) Attach the Y-motor to the Y-motor bracket.

(2) Hang the Y-drive belt on the Y-motor pulley and the Y-idler pulley.

(3) Attach the Y-motor pulley to the Y-motor.

(4) Tighten the two M3L4WP set screws that hold the Y-motor pulley.

(5) Spread a suitable quantity of Loctite 222 on the two M3L4WP set screws that hold the Y-motor pulley.

(6) Spread a suitable quantity of the Shinetu silicon grease G501 on the Y-motor pulley and Y-idler pulley.

(7) Perform the Y-drive belt tension adjustment. (see Subsection 7.2.2).

(8) Reattach the other parts in the reverse order in which they were detached.

Page 60

FC7000-UM-251-9370 6-22

6. DISASSEMBLY AND REASSEMBLY

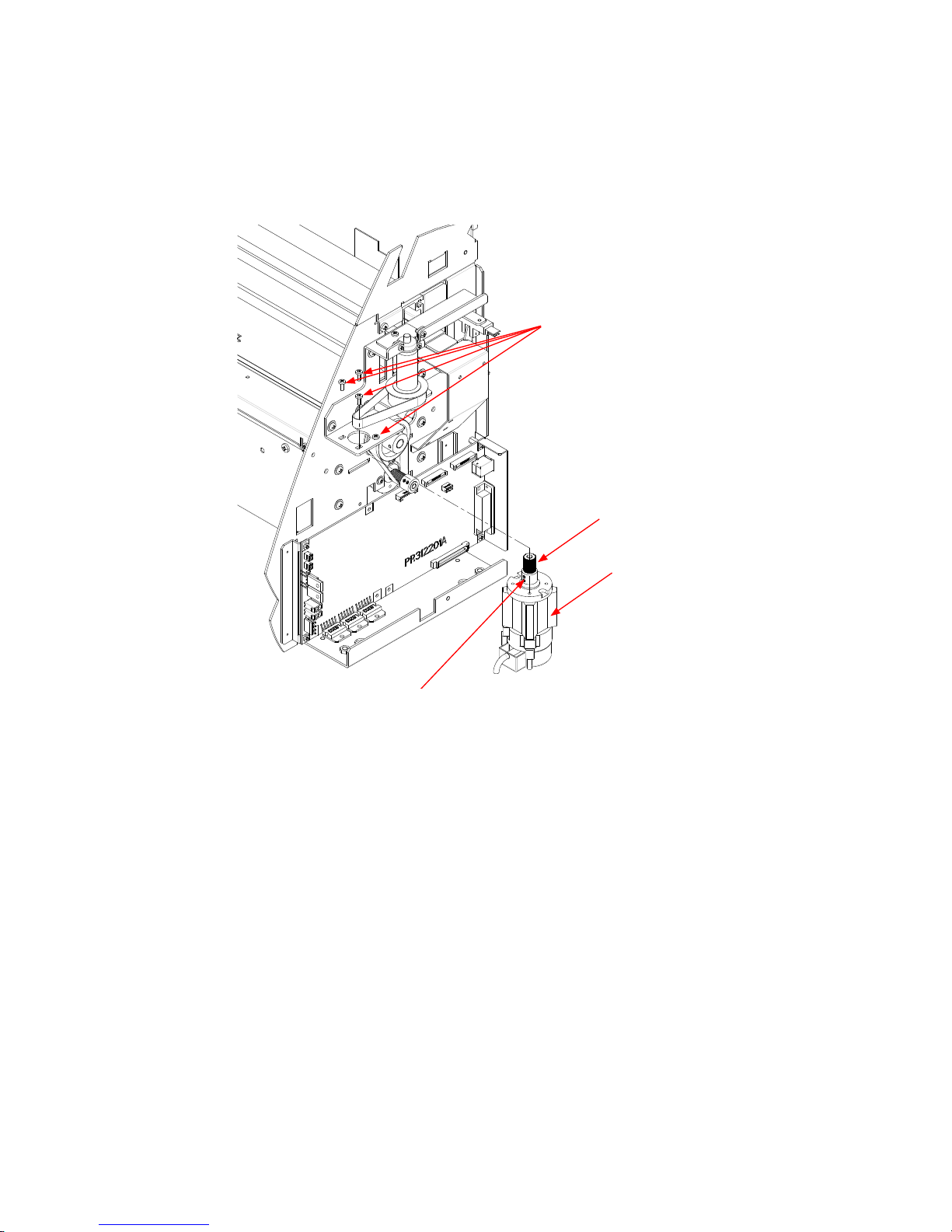

6.2.11 How to Replace the X-motor

How to detach the X-motor

(1) Detach the right side cover (see Subsection 6.1.1).

(2) Detach the main board (see Subsection 6.2.12).

(3) Loosen the two M3L4WP set screws holding the X-motor pulley, then detach the X-motor pulley.

M3L6 binding head screw

M3L4WP set screw

X motor pulley

X motor

(4) Remove the three M3L6 binding head screws holding the X-motor, then detach the X-motor.

How to reinstall the X-motor

(1) Attach the X-motor to the right side plate.

(2) Hang the X-drive belt on the X-drive pulley.

(3) Attach the X-motor pulley to the X-motor.

(4) Tighten the two M3L4WP set screws that hold the X-motor pulley.

(5) Spread a suitable quantity of Loctite 222 on the two M3L4WP set screws that hold the X-motor pulley.

(6) Perform the X-drive belt tension adjustment. (see Subsection 7.2.3).

(7) Tighten the mounting screws that hold the X-motor.

(8) Spread a suitable quantity of the Shinetu silicon grease G501 on the X-motor pulley.

(9) Move the X-drive pulley and check the tension of the X-drive belt.

(10) Reattach the other parts in the reverse order in which they were detached.

Page 61

FC7000-UM-251-9370 6-23

6. DISASSEMBLY AND REASSEMBLY

6.2.12 How to Replace the Main Board

How to detach the main board

(1) Detach the right side cover (see Subsection 6.1.1).

(2) Disconnect all the cables and flexible cables from their connectors on the main board.

(3) Remove the four M3L6 binding head screws holding the main board to the chassis.

(4) Detach the main board from the chassis.

M3L6 binding head screw

Main board

How to reinstall the main board

(1) Reattach in the reverse order in which it was detached.

(2) Perform any adjustments required (see Section 7.1).

Page 62

FC7000-UM-251-9370 6-24

6. DISASSEMBLY AND REASSEMBLY

6.2.13 How to Replace the Vacuum Fan

How to detach the vacuum fan

(1) Detach the front guide (see Subsection 6.1.4).

(2) Disconnect the vacuum fan from the relay connector.

Relay connector

Vacuum fan

(3) Use a long screwdriver to remove the two M3L35 binding head screws holding the vacuum fan as shown

in the figure below.

Vacuum fan

(4) Detach the vacuum fan.

How to reinstall the vacuum fan

(1) Reattach in the reverse order in which it was detached.

Page 63

FC7000-UM-251-9370 6-25

6. DISASSEMBLY AND REASSEMBLY

6.2.14 How to Replace the Drive Roller

How to detach the drive roller

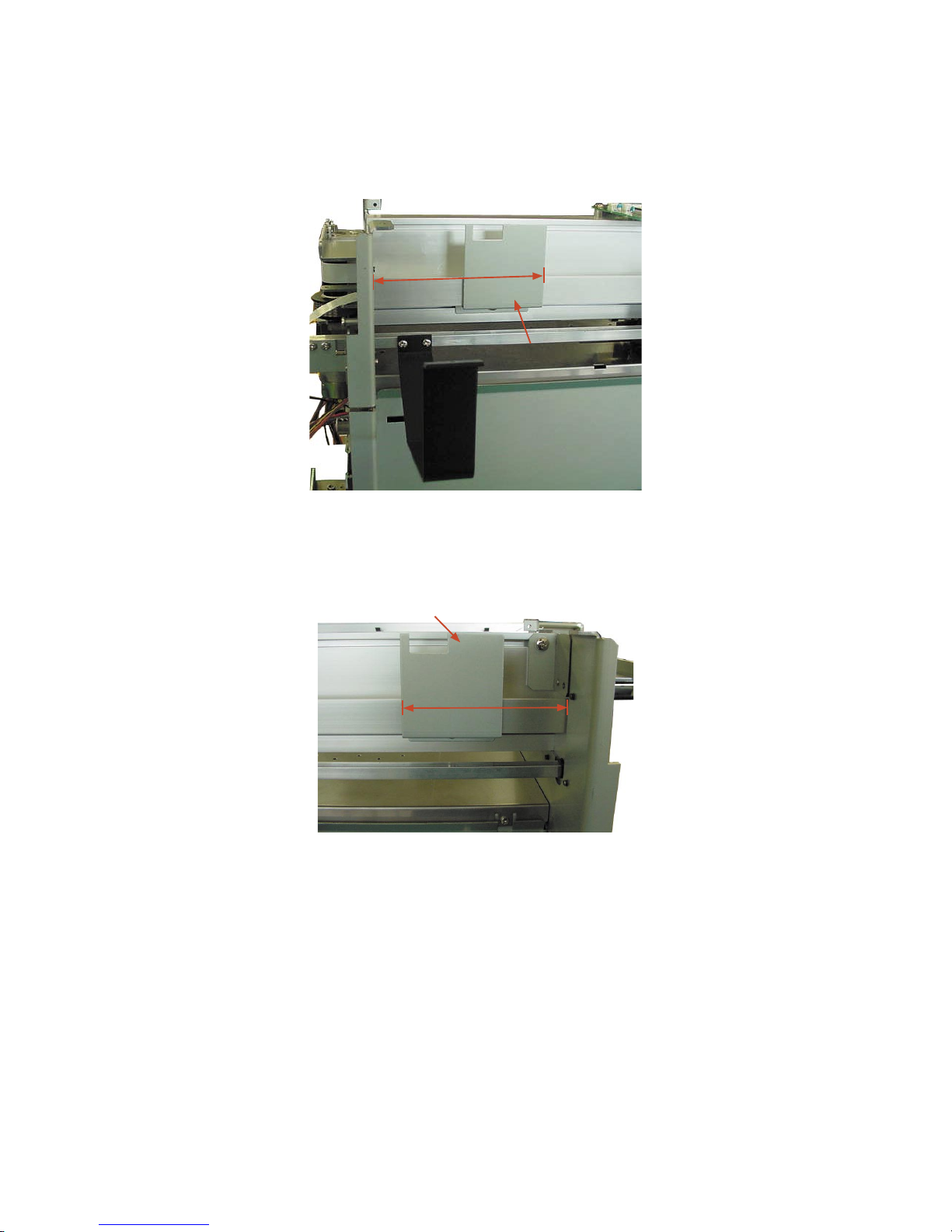

(1) Detach the right and left side covers (see Subsection 6.1.1).