Page 1

CSX500 SERIES

MANUAL NO.CSX500-UM-152

USER’S MANUAL

IMAGE SCANNER

Page 2

TO ENSURE SAFE AND CORRECT USE

Danger

Warning

Caution

• To ensure the safe and correct use of your Image Scanner, read this manual thoroughly prior to use.

• After reading this manual, store it in a safe place for reference as necessary.

• Do not allow small children to touch the Image Scanner.

• The following describes important points for safe operation. Be sure to observe them strictly.

Conventions Used in This Manual

To ensure the safe and correct use of the Image Scanner as well as to prevent human injury and

property damage, the safety precautions provided in this manual are ranked into the three categories

described below. Be sure to gain a full understanding of the difference between each of the categories

before reading the manual.

This category provides information that, if ignored, is highly likely to

cause fatal or serious injury to the operator.

This category provides information that, if ignored, is likely to cause

fatal or serious injury to the operator.

This category provides information that, if ignored, could cause

injury to the operator or physical damage to the Image Scanner.

Description of Safety Symbols

The symbol indicates information that requires careful attention

(including warnings). The specic point requiring attention is described

by an illustration or text within or next to the symbol.

The symbol indicates an action that is prohibited. Such prohibited

action is described by an illustration or text within or next to the

symbol.

The symbol indicates an action that must be performed. Such

imperative action is described by an illustration or text within or next to

the symbol.

i

Page 3

ii

SAFETY PRECAUTIONS

Warning

Thinner

Benzine

Caution

To ensure the safe and correct use of your Image Scanner, be sure to observe the following points.

Installation Precautions

Do not install the scanner in the vicinity of volatile

solvents such as alcohol or thinner.

• A volatile solvent coming into contact with any of the internal

electrical components may result in a re hazard or electric shock.

Do not place objects such as those listed below on top

of the scanner.

• Objects such as these coming into contact with any of the internal

electrical components may result in a re hazard or electric shock.

♦ Metallic objects such as necklaces

♦ Objects such as glasses, vases, houseplants, etc. that contain

water or other uids

If any of these objects does come into contact with the internal

electrical components immediately turn off the power, remove the

plug from the power outlet, and either contact the store where you

purchased your scanner or your nearest Graphtec representative.

Do not use the scanner in an unstable location such

as on a slope or a location that is subject to a lot of

vibration.

• Such locations may cause the scanner to tip over and cause

injuries.

Do not place heavy objects on the scanner.

• Such objects may tip over or fall off, causing injuries.

Do not use sharp, pointed articles on the scanner.

• Such action may impair the scanner’s performance and cause the

scanner to malfunction or break down.

Page 4

When using the scanner on a desktop

At least 300 mm

At least 200 mm

At least

300 mm

At least

300 mm

Do not exert pressure on the scanner.

• Such action may impair the scanner’s performance and cause the

scanner to malfunction or break down.

• Such action could cause injury to the operator.

Avoid installing the scanner in any of the following

locations.

• Use in such locations may result in a re hazard or electric shock.

♦ Excessively humid or dusty locations

♦ Locations exposed to direct sunlight

♦ Locations exposed to high temperatures

♦ Locations near ames or moisture

Do not install, use, or store the scanner in a location that

does not meet the specied temperature and humidity

ranges.

• Such location may impair the scanner’s performance due to

deformation or damage, and cause the scanner to malfunction or

break down.

Do not install, use, or store the scanner in a location

subject to excessive mechanical vibration or electrical

noise.

• Such location may impair the scanner’s performance and cause

the scanner to malfunction or break down.

Leave plenty of space around the scanner.

• Leave sufcient space for operations in front of and behind the

scanner.

iii

Page 5

iv

Power Supply Precautions

Warning

Do not damage the power cable, or modify it in any way.

Moreover, do not place heavy objects on the power

cable, pull on the cable, or bend it excessively.

• There may be current leakage from the damaged parts, resulting

in a re hazard or electric shock.

• Do not unplug or plug in the power cable when your hands are

wet. Such action may result in electric shock.

Do not connect multiple devices to the same power

outlet.

• Use of the scanner in such a condition may result in a re hazard

or electric shock.

Do not bundle or tie-wrap the power cable.

• Use of a bundled power cable may result in a re hazard or electric

shock.

Make sure that the power cable is rmly inserted into the

power outlet.

• Use of a power cable when the plug is not completely inserted into

the power outlet may result in a re hazard or electric shock.

Do not use a power cable other than the one supplied

with your scanner.

• Use of a different power cable may result in a re hazard or

electric shock.

Page 6

Caution

Prohibited

Specified

rating

Do not connect the scanner to a non-rated power supply.

• Use of a different supply voltage may result in electrical shock or a

re hazard due to current leakage.

Before disconnecting or reconnecting the power cable,

be sure to turn off the scanner.

• Failure to do so may impair the scanner’s performance and cause

the scanner to malfunction or break down.

• Failure to do so may result in electric shock.

When disconnecting the power cable, be sure to hold on

to the plug, and not pull on the cable itself.

• Pulling on the cable will expose the core wires, or cause damage

such as broken wires. Current leakage from the exposed or

damaged areas may result in a re hazard or electric shock.

Before cleaning the scanner, be sure to unplug the power

cable from the power outlet.

• Failure to do so may result in electric shock.

Do not allow dust or metallic matter to adhere to the

power plug.

• If the power plug becomes dirty, thoroughly wipe it clean.

• The use of a dirty power plug may result in a re hazard or electric

shock.

As a general rule, do not use an extension cord.

• Use of an extension cord may result in a re hazard or electric

shock.

If you must use an extension cord, unbundle it, and make sure that

the power plug is rmly inserted into the extension cord socket.

Make sure that the power plug can be readily unplugged

at any time, and that there are no objects placed in its

vicinity.

• Objects placed in the vicinity of the power plug will prevent its

removal in an emergency.

v

Page 7

vi

Handling Precautions

Warning

Do not disassemble or modify the scanner.

• Such actions may result in a re hazard or electric shock.

If the scanner makes an unusual noise, generates smoke,

overheats, emits a strange odor, or otherwise functions

abnormally, immediately turn off the power, remove the

plug from the power outlet, and either contact the store

where you purchased your scanner or your nearest

Graphtec representative.

• Use of the scanner in such a condition may result in a re hazard

or electric shock.

Do not use ammable aerosols or similar products in the

vicinity of the scanner.

• The gas contained in the spray may cause a re hazard or electric

shock if it comes into contact with the scanner’s internal electrical

components.

Before moving the scanner, make sure that the main

power switch is in the “off” position and that the power

plug has been removed from the power outlet.

• If the scanner is moved while it is still plugged into the power

outlet, the power cable may be damaged and cause a re hazard

or electric shock.

If the scanner is damaged from being dropped or other

impact, turn off its power and remove the power plug

from the power outlet.

• Use of the scanner in such status may result in a re hazard or

electric shock.

• Request repair by contacting the store where you purchased your

scanner or your nearest Graphtec representative.

• Never try to perform repair yourself. Repair work by inexperienced

personnel is extremely dangerous.

Page 8

Caution

Take care not to drop metallic items such as paper

clips or staples, or spill water, other uids or ammable

solvents (alcohol, benzene, thinner, etc.) inside the

scanner.

• Metallic items or uids coming into contact with the internal

electrical components may result in a re hazard or electric shock.

If such items or uids fall or are spilled inside the scanner,

immediately turn off the power, remove the power plug from the

power outlet and either contact the store where you purchased

your scanner or your nearest Graphtec representative.

Do not insert your hands inside the scanner during a

scanning operation or when a document is being fed.

• Moving parts inside the scanner may cause injuries.

If the scanner will not be used for an extended length of

time, such as at night, turn off the main power switch as

a safety precaution.

• In addition, if the scanner will not be used for longer periods of

time, such as a long weekend, remove the power plug from the

power outlet as an additional safety precaution.

vii

Page 9

viii

Maintenance and Inspection Precautions

Warning

Neutral

Detergent

Caution

Be sure to turn off the power and remove the power plug

from the power outlet before performing any cleaning

operations.

• Failure to do so may result in a re hazard or electric shock.

Moreover, there is a risk of injury if the scanner starts to move

during a cleaning operation.

To clean the scanner, use a cloth that has been

dampened with neutral detergent and then well wrung

out. Do not use volatile solvents such as alcohol,

benzene or thinner to clean the scanner.

• A volatile solvent coming into contact with any of the internal

electrical components may result in a re hazard or electric shock.

Do not attempt to lubricate the scanner’s mechanisms.

• Such action may impair the scanner’s performance and cause the

scanner to malfunction or break down.

• Such action may cause a re hazard or electric shock due to a

short circuit or overheating.

At least once a year, remove the power plug from the power outlet and clean the

prongs and surrounding areas.

• A build-up of dust may result in a re hazard.

When cleaning or checking the inside of the scanner, make sure that metallic objects

such as a necklace or bracelet do not come into contact with any of the internal

components.

• Such actions may result in injuries or an electric shock.

When removing a document that has become jammed inside the scanner, take care

not to cut your ngers on the edges of the document.

• Such actions may result in injuries.

Page 10

WARNING

Only computers or peripherals (computer input/output devices, terminals, printers, etc.)

certied as complying with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules, may be attached to this product when this product is operated in a residential

environment. Operation with non-certied peripherals is likely to result in interference to

radio and TV.

FED ER AL CO MM UN IC ATI ONS COM M IS SI ON R A DI O FRE QU EN CY

INTERFERENCE STATEMENT

"This equipment has been tested and found to comply with the limits for a Class B digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help."

ix

Page 11

INTRODUCTION

Thank you for choosing the Graphtec CSX500 Series Image Scanner.

Please read this manual thoroughly before attempting to use your new product to ensure that you use

it safely and correctly.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, without the prior written permission of Graphtec Corporation.

(2) The product specications and other information in this manual are subject to change without

notice.

(3) While every effort has been made to provide complete and accurate information, please contact

your nearest Graphtec representative if you nd any unclear or erroneous information or wish to

make other comments or suggestions.

(4) Notwithstanding the stipulation in the preceding paragraph, Graphtec Corporation assumes no

liability for damages resulting from either the use of the information contained herein or the use of

the product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks

or registered trademarks of their respective companies.

Copyright

This User’s Manual is copyrighted by Graphtec Corporation.

International ENERGY STAR® Program

As an ENERGY STAR®* Partner, Graphtec. has determined that this product

meets the ENERGY STAR® guidelines for energy efciency.

* The International ENERGY STAR® Ofce Equipment Program is a global

program that promotes energy saving through the use of computer and other

ofce equipment. The program backs the development and dissemination of

products with functions that effectively reduce energy consumption. It is an open

system in which businesses can participate voluntarily. The targeted products

are ofce equipment such as computers, monitors, printers, faxes, copiers. Their

standards and logos are uniform among participating nations.

I

Page 12

Usage precautions

OK

NG

Top cover section

<Closing the top cover>

Keep your hands away from the front of the

scanner when closing the top cover.

<Opening the top cover>

Do not hold the rear section of the

top cover when opening it.

Top cover

Document guides

Top cover

Do not lift or move the scanner by holding the top cover section, as doing so may damage the scanner.

Always lift the scanner by holding the underside.

Take care not to get your ngers caught in the gap between the top cover and the scanner unit when

opening and closing the top cover.

When closing the top cover, please be careful not to pinch the document guides.

Always ensure that you open the top cover and remove the cushion material before using the scanner.

(See Section 4.1, “Opening and Closing the Top Cover”.)

Scanner warm-up

A warm-up period is not usually required for the CSX500 Series. However, if you plan to scan a color

document (in particular a document with many light colors), we recommend that you allow the scanner

to warm up for 10 minutes before scanning the document.

II

Page 13

CONTENTS

TO ENSURE SAFE AND CORRECT USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Description of Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Power Supply Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Handling Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Maintenance and Inspection Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Notes on this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Registered Trademarks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

International ENERGY STAR® Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

Usage precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

Scanner warm-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

CHAPTER 1 BEFORE USING THE SCANNER

1.1 Checking the Contents of the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Front View/Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Rear View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.3 Assembling the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Attaching the document suppor t plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1- 4

Attaching and using the cable clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

CHAPTER 2 CONNECTION AND PREPARATIONS

2.1 Connecting to the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Turning the Power On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Turning the Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Turning the Power Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Notes on the power-saving mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.3 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2- 4

2.4 Connecting the Scanner to a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

USB Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Network Connection (CSX550-09 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.5 Installing the Scanner Driver Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

For Windows 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

For Windows Vista . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

For Windows XP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.6 Installing the Scanning Master Pro Color Application . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.7 Network Connection (CSX550-09 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Device Setup Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Installing the Graphtec Network Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Setting up the Graphtec Network Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

How to initialize the settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

C-1

Page 14

C-2

CHAPTER 3 LOADING A DOCUMENT

3.1 Compatible Document Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -1

Compatible Media Widths for Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -1

Compatible Media Lengths for Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Compatible Document Thicknesses for Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Compatible Media Grades for Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -2

3.2 Loading a Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

How to use the document guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.3

Handling Documents According to their Material and Thickness . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Distance Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Adjustment method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

3.5 Using the Carrier Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

CHAPTER 4 DAILY MAINTENANCE

4.1 Opening and Closing the Top Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Opening the top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Closing the top cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 -1

4.2 Cleaning the Feed Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Cleaning the Document support Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Cleaning the Gap Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.5 Cleaning the Push Rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6 Cleaning the Image Sensors (Transparent Contact Plates) . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7 Cleaning the Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.8 Removing a Jammed Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.9 Scanner Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Preparation and checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Launching the Scanner Adjustment Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

3-5

CHAPTER 5 TROUBLESHOOTING PROCEDURES

5.1 The scanner Is turned on but doesn’t operate at all . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2

5.3 The control panel’s red ERROR LED is lit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 The control panel’s red ERROR LED is ashing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.5

5.6

5.7 The image quality has dropped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.8 The scanned data is incorrectly aligned . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -3

5.9

5.10 The color intensity of the image data differs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.11

5.12

5.13 The scanned image data is distorted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.14 The scanned image data is patchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

The scanner operates improperly after connection to the computer . . . . . . . . . . . . . . . . . . . . . . . .

The document isn’t properly fed to the initial scanning position . . . . . . . . . . . . . . . . . . . . . . . .

The scanned image data is completely white or completely black . . . . . . . . . . . . . . . . . . . . . . .

Smudges not appearing in the original document appear in the scanned data . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The document length differs from the scanned data length . . . . . . . . . . . . . . . . . . . . . . .

Stripes or moire patterns which are not in the original document appear in the scanned data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

5-2

5-2

5-4

5-4

5-4

Page 15

5.15 The document cannot be fed correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -5

5.16 Automatic Deskew is not performed correctly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

APPENDIX

Appendix A Options and Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix C External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

C-3

Page 16

1.1 Checking the Contents of the Package

Scanner unit ...1

USB cable ...1Cable clamp ...1

Power cable ...1

Driver software ...1 USER’S MANUAL ...1

Calibration sheet ...1

Cleaning paper ...1

Carrier sheet (A0) ...1

(CSX530/CSX550 only)

CSX500 SERIES

USER’S MANUAL

MANUAL NO.CSX500-UM-152

IMAGE SCANNER

Document support plates ...3

Document guides ...2

CHAPTER 1 BEFORE USING THE SCANNER

Check to conrm that all of the items shown below are present. If any item is missing, promptly contact

the store where you purchased your scanner or your nearest Graphtec representative.

Scanner unit Power cable Document guides Cable clamp USB cable

Document suppor t plates Calibration sheet Carrier sheet Cleaning paper

Driver software User's manual

1-1

Page 17

1-2

Control Panel

(5) POWER button/LED

(6) PAPER LED

(7) ERROR LED

(8) EJECT key

(9) STOP key

(3) Top cover open levers

(4) Document guides

(2) Paper sensors

(1) Top cover

1.2 Part Names and Functions

Front View/Control Panel

Front View

(1) Top cover ............................ Open the top cover to clean the document hold-down unit and

transparent contact plates.

(2) Paper sensors .................... These sense whether a document is present in the scanner.

(3) Top cover open levers ........ Press these levers to open the top cover.

If the top cover is opened during a scanning operation, the operation

will be stopped compulsorily.

(4) Document guides ............... Use these guides to determine the position of a document when you

load the document.

Control Panel

(5) POWER button/LED (blue)

................................. Controls the on/off status of the power supply to the scanner.

Lit: The scanner is turned on.

Flashing: Flashes when the scanner is in power-saving mode.

Unlit: The scanner is turned off.

(6) PAPER LED (green) ........... Lit: Lights when a document has been loaded.

Flashing: Flashes while image data is being scanned.

Unlit: Normal status (Local status).

(7) ERROR LED (red) .............. Lit: Lights to indicate a hardware error. (see Section 5.3)

Flashing: Lights to indicate a hardware error. (see Section 5.4)

Unlit: Normal status

(8) EJECT key .......................... Press this key to feed the document.

If this key is pressed when the scanner is in document-loaded status,

(9) STOP key ........................... Compulsorily stops scanning/feeding of the document.

the document-loaded status is canceled and the document is ejected

to the front of the scanner.

If this key is pressed after the scanning operation has been canceled

or after scanning of the document was halted partway through the

scanning operation, the document-loaded status is canceled and the

document is ejected to the rear of the scanner.

If the ERROR LED ashes when the top cover is in the closed status,

press this key to suspend the scanning operation and check whether a

paper jam has occurred.

Page 18

Rear View

(15) Document support plates

(16) Cable clamp

(14) Main power switch

(10) USB connector (13) Power inlet

(12) Reset button (for network)

(11) Network connector

Caution

(10) USB connector ................. Used to connect the USB interface cable.

(11) Network connector * ......... Used to connect the Network interface cable.

(12) Reset button (for network) *

................................. This will initialize the network environment. Use the Network Utility to

recongure your settings. (see Section 2.7)

(13) Power inlet ........................ Used to connect the power cable.

(14) Main power switch ............ Used to turn the main power supply on or off.

(15) Document support plates

................................. Used to support the document that is being ejected.

(16) Cable clamp ...................... Used to bundle the power cable and USB cable together and fasten

them in place.

CSX550-09 only

*

Both USB and network connection cannot be executed simultaneously. Please refrain

from connecting the USB cable and the network cable to a single computer at the same

time.

1-3

Page 19

1-4

1.3 Assembling the Scanner

Document support plateHooks

Checkpoint

Caution

Cable clamp attachment location

Please see the separate Stand Assembly Instruction Manual for instructions on how to assemble the

stand.

Attaching the document support plates

Always be sure to install the document support plates, irrespective of the type of documents to be

scanned.

(1) Take one of the document support plates provided, and insert its hooks into the slots at the rear of

the scanner. Insert the hooks from the top of the slots.

(2) Attach the other document support plates in the same manner.

Detach the document support plates when moving or packing the scanner. Lift the plates

up and out of the slots to detach them.

Attaching and using the cable clamp

Attach the cable clamp to the scanner, and then pass the power cable, USB cable and network cable

(CSX550-09 only) through the clamp to fasten them in place.

Be sure to attach the cable clamp to the scanner and use it to fasten the power cable,

USB cable and net work cable (CSX550- 09 only) in place. Failure to do so may af fect the

scanning operation.

Attaching the clamp

(1) Using a soft cloth that has been soaked in water or diluted neutral detergent and then rmly wrung

out, wipe off any dust or dirt on the surface of the attachment location before attaching the cable

clamp.

Page 20

(2) Wipe the area once again with a soft, dry cloth to thoroughly remove any traces of moisture.

Cable clamp

Latch

Power cable Network cable

USB cable

(3) Peel off the adhesive sticker on the rear of the clamp and then attach the clamp to the scanner.

Using the clamp

(1) Pull up the latch at the top of the cable clamp to open the clamp.

(2) Pass the power cable, the USB cable and the network cable (CSX550- 09 only) through the cable

clamp, and then close it.

1-5

Page 21

CHAPTER 2 CONNECTION AND PREPARATIONS

Power inlet

AC power outlet

Power cable

Caution

2.1 Connecting to the Power Supply

Connect one end of the power cable provided to the scanner’s power inlet and the other end to an AC

power outlet of the rated supply voltage.

Be sure to use the cable clamp provided with the scanner to fasten the power cable in

place. Please see “Attaching and using the cable clamp” in Section 1.3, “Assembling the

Scanner” for further details.

2-1

Page 22

2-2

2.2 Turning the Power On and Off

ON

ON

OFF

Checkpoint

Caution

The LED (blue) on the [POWER] button changes as follows to indicate the scanner's power supply

status.

• Unlit: The scanner is turned off.

• Lit: The scanner is turned on.

• Flashing: Flashes when the scanner is in power-saving mode.

Turning the Power On

(1) Connect the power cable.

(2) Turn on the main power switch (the I side).

(3) Press the [POWER] button on the scanner's control panel.

When the scanner is in the power-on status, the [POWER] button LED lights blue.

Turning the Power Off

Press the [POWER] button on the scanner's control panel.

When the scanner is in the power-off status, the [POWER] button LED is extinguished.

• After the scanner has been turned off, wait at least ve seconds before turning it on

again.

• If you do not plan to use the scanner for any length of time, turn off the main power

switch (the O side).

Do not turn of f the main power switch (the O side) on the rear of the scanner while the

scanner is the power-on status.

Page 23

Notes on the power-saving mode

To cancel the

power-saving mode

Checkpoint

The scanner automatically switches to power-saving mode (the blue LED on the power button ashes)

after approximately 13 minutes have elapsed without a document being loaded in the scanner. To

return the scanner to normal status (Local status), press either the [STOP] or the [EJECT] key.

If a document has been loaded in the scanner, the scanner will not switch to power-

saving mode.

2-3

Page 24

2-4

2.3 System Requirements

Checkpoint

The minimum system requirements for running the scanner’s hardware and software are listed below.

OS: Windows XP Professional/Home Edition

Windows Vista Ultimate/Business/Home Premium/Home Basic

Windows 7 Ultimate/Enterprise/Professional/Home Premium

PC: Environment that the OS is working properly

(Recommended environment

CPU: Dual Core or higher grade Memory: 3 GB or more)

Hard Disk Drive: Disk space amount that can contain the scanned-in data

Monitor: 1024 x 768 pixels, True Color display

Mouse

Network Interface: 10BASE-T/100BASE-TX/1000BASE-T

(to connect the scanner via the Network interface)

USB 2.0 Interface: that comes standard with your computer

(to connect the scanner via the USB interface)

If you want to scan in and edit grayscale or color data, you may need a memor y larger

than the recommended size.

Depending on the document, it may not be possible to scan in the images it contains or

the process may slow down even if the memory size is increased.

If you encounter such a problem, from the Scanning Master Pro Color ‘OPS115’ menu

select Tools menu > Options > General tab and enable "Use Work File". In addition,

enable "Specify Folder" and then specify a folder that contains sufcient available

space.

Page 25

2.4 Connecting the Scanner to a Computer

Important

Caution

Computer

USB interface connector

USB cable

• Make sure that the USB cable is rmly inserted into the interface connectors.

• The operation of the scanner cannot be guaranteed in the following cases:

♦ When the cable is connected to a USB hub or an add-on USB board.

♦ When you are using a custom-built computer or one that you have modied.

♦ When you are using a cable that is longer than 3 meters in length.

(Please use the USB cable that is provided with your scanner.)

• Do not per form any of the following actions:

♦ Remove or reinsert the cable while you are installing the driver.

♦ Remove or reinsert the cable while starting up the computer or the scanner.

♦ Remove or reinsert the cable while transferring data.

♦ Connect two or more scanners to a single computer.

Be sure to use the cable clamp provided with the scanner to fasten the USB cable and

the network cable (CSX550- 09 only) in place. Please see “Attaching and using the cable

clamp” in Section 1.3, “Assembling the Scanner” for further details.

USB Connection

A USB cable is used to connect the scanner to the computer, via the respective USB interface

connectors. The connectors at the computer and scanner ends of the USB cable have different

shapes.

Make sure that the cable is oriented correctly before making the connection.

2-5

Page 26

2-6

Network Connection (CSX550-09 only)

Caution

Checkpoint

Computer

Network connector

Reset button

(for network)

Network

Network cable

Network connector

POWER lampLINK lamp

Reset button

(for network)

Both USB and network connection cannot be executed simultaneously. Please refrain

from connecting the USB cable and the network cable to a single computer at the same

time.

• You will need a network (LAN) cables and network hub to connect via Network. You will

need to purchase them separately.

• Structures of the network equipment and necessity of the router function depends on

the environment. For description, refer to the manual of the equipment, check with the

manufacturer or the network administrator.

• The scanner is compliant with 10BASE-T/100BASE-TX/1000BASE-T. Check your network

environment.

A Network cable is used to connect the scanner to the computer, via the respective Network interface

connectors.

Network Connector

After turning the scanner’s power on, conrm that the POWER lamp (right side) is ashing yellow.

LINK lamp (left side) ashes orange when connected to the 10Base-T/100Base-TX, and green when

connected to the 1000BASE-T.

Reset Button (for network)

This is used when the network environment has changed.

Turning the power on while pressing the reset button will cause the network environment to be

initialized.

Use the Network Utility to recongure your settings. (see Section 2.7)

Page 27

2.5 Installing the Scanner Driver Software

Checkpoint

The procedure outlined below is based on the requirement that you are logged on to

Windows with administrator rights. Consult your Windows manual and Windows Help for

more information.

For Windows 7

(1) Turn on the computer. (Do not connect the scanner yet.)

(2) Insert the "IMAGE SCANNER USER GUIDE CD-ROM," which came with the scanner, into the

CD-ROM drive.

AutoPlay screen will appear shortly. Select [Run MultiSetup.exe] from there.

(3) The User Account Control screen is displayed. Click [Yes] to proceed with the installation.

(4) The “Setup menu” screen starts automatically. Next, select the "Pre-install the scanner driver"

button.

If the “Setup menu” screen does not start, open Windows Explorer, and double-click on

"MultiSetup.exe" within the CD-ROM folder.

2-7

Page 28

2-8

(5) The screen shown below appears. Click the [Next] button

Checkpoint

(6) The screen shown below is displayed. Click [Install] to proceed with the installation.

(7) The screen shown below is displayed when the wizard has nished installing the driver. Click the

[Finish] button to close the “Device Driver Installation Wizard”.

(8) Turn on the scanner, and then the scanner connects to the computer.

(9) The following message appears on the taskbar when you connects to the scanner. Wait for the

driver installation is nished. (It may take several minutes.)

• If the computer is not connected to the net work, the installation nishes immediately,

and the message from the next step [10] appears on the screen.

• If the computer is connected to the network, this message may disappear during the

installation. In this case, wait until the message from the next step [10] appears on the

screen.

• The following screen appears when you click the message. In this case, by selecting

the "Skip obtaining driver sof tware from Windows Update" link the installation can be

nalized early.

Page 29

(10) The following message appears on the taskbar when the driver installation is nished.

Checkpoint

After clicking the taskbar message in step [9] the following screen appears when the

driver installation is nished.

(11) Select "Devices and Printers" using the [Start] menu on the Windows desktop to display the

screen shown below. Check that connected scanner is displayed here.

The installation of driver software is complete.

2-9

Page 30

2-10

For Windows Vista

(1) Turn on the computer. (Do not connect the scanner yet.)

(2) Insert the "IMAGE SCANNER USER GUIDE CD-ROM," which came with the scanner, into the

CD-ROM drive.

AutoPlay screen will appear shortly. Select [Run MultiSetup.exe] from there.

(3) The User Account Control screen is displayed. Click [Continue] to proceed with the installation.

(4) The “Setup menu” screen starts automatically. Next, select the "Pre-install the scanner driver"

button.

If the “Setup menu” screen does not start, open Windows Explorer, and double-click on

"MultiSetup.exe" within the CD-ROM folder.

(5) The screen shown below appears. Click the [Next] button.

Page 31

(6) The screen shown below is displayed. Click [Install] to proceed with the installation.

Checkpoint

Checkpoint

(7) The screen shown below is displayed when the wizard has nished installing the driver. Click the

[Finish] button to close the “Device Driver Installation Wizard”.

(8) Turn on the scanner, and then the scanner connects to the computer.

(9) The following message appears on the taskbar when you connects to the scanner. Wait for the

driver installation is nished.

The following screen appears when you click the message.

(10) The following message appears on the taskbar when the driver installation is nished.

After clicking the taskbar message in step [9] the following screen appears when the

driver installation is nished.

(11) Launch the Control Panel using the [Start] menu on the Windows desktop.

2-11

Page 32

2-12

(12) Click "Hardware and Sound" to display the screen shown below.

(13) Click "Scanners and Cameras" to display the screen shown below. Check that connected scanner

is displayed here.

The installation of driver software is complete.

Page 33

For Windows XP

(1) Turn on the computer. (Do not connect the scanner yet.)

(2) Insert the "IMAGE SCANNER USER GUIDE CD-ROM," which came with the scanner, into the

CD-ROM drive.

(3) The “Setup menu” screen starts automatically after a while. Next, select the "Pre-install the

scanner driver" button. If the “Setup menu” screen does not start, open Windows Explorer, and

double-click on "MultiSetup.exe" within the CD-ROM folder.

(4) The screen shown below appears. Click the [Next] button.

(5) The screen shown below is displayed. Read the explanation and make sure that you understand

the contents. To continue the installation, click [Continue Anyway].

2-13

Page 34

2-14

(6) The screen shown below is displayed when the wizard has nished installing the driver. Click the

[Finish] button to close the “Device Driver Installation Wizard”.

(7) Turn on the scanner, and then the scanner connects to the computer.

(8) When the following screen appears, Select the option “No, not this time” and then click [Next].

(When Service Pack 2 or later has been installed, the following screen may appears.)

(9) The following screen appears. Select the option “Install the software automatically

(Recommended).” and then click [Next].

(10) The screen shown below is displayed. Read the explanation and make sure that you understand

the contents. To continue the installation, click [Continue Anyway].

Page 35

(11) The screen shown below is displayed when the wizard has nished installing the driver. Click the

[Finish] button to close the “Welcome to the Found New Hardware” wizard.

(12) Launch the Control Panel using the [Start] menu on the Windows desktop.

(13) The screen shown below is displayed when you click on the “Printers and Other Hardware” icon.

(14) The screen shown below is displayed when you click on the “Scanners and Cameras” icon. Check

that connected scanner is displayed here.

The installation of driver software is complete.

2-15

Page 36

2-16

2.6 Installing the Scanning Master Pro Color Application

Scanning Master Pro Color "OPS115" is a software application for using a Graphtec scanner to scan

image data.

Operating environment

Windows XP Professional/Home Edition

Windows Vista Ultimate/Business/Home Premium/Home Basic

Windows 7 Ultimate/Enterprise/Professional/Home Premium

Installation procedure

The following steps are explained using the Windows 7 screens.

(1) Start up Windows 7.

(2) Insert the attached "IMAGE SCANNER USER GUIDE CD-ROM" into the CD-ROM drive.

AutoPlay screen will appear shortly. Select [Run MultiSetup.exe] from there.

(3) Click “Yes” on the User Count Control screen, which appears, to continue the installation.

(4) The “Setup menu” screen starts automatically. Next, click the "Install the Scanning Master Pro

Color" button.

If the “Setup menu” screen does not start, open Windows Explorer, and double-click on

"MultiSetup.exe" within the CD-ROM folder.

Page 37

(5) The Scanning Master Pro Color ‘OPS115’ set-up program will start shortly.

From this point on, follow the set-up program’s instructions to install the "Scanning Master Pro

Color ‘OPS115’" application.

If the application has been properly installed, "Scanning Master Pro Color" will be added to the

[Start] menu on the Windows desktop.

2-17

Page 38

2-18

2.7 Network Connection (CSX550-09 only)

Caution

Checkpoint

Both USB and network connection cannot be executed simultaneously. Please refrain

from connecting the USB cable and the network cable to a single computer at the same

time.

• The procedure outlined below is based on the requirement that you are logged on to

Windows with administrator rights. Consult your Windows manual and Windows Help for

more information.

• Before executing Graphtec Network Utility, please be sure to rst install the scanner

driver software. (see Section 2.5, “ Installing the Scanner Driver Software”)

Installation procedure

The following procedure assumes that you are using the Scanner connected via a Network interface

as part of your system.

The windows shown are those for Windows 7.

(1) Turn on the Scanner and computer power, and connect to a Network interface.

(2) Insert the "IMAGE SCANNER USER GUIDE CD-ROM," which came with the scanner, into the

CD-ROM drive.

AutoPlay screen will appear shortly. Select [Run MultiSetup.exe] from there.

(3) The User Account Control screen is displayed. Click [Yes] to proceed with the installation.

Page 39

(4) The “Setup menu” screen starts automatically. Next, click the "Install the Network Utility" button.

If the “Setup menu” screen does not start, open Windows Explorer, and double-click on

"MultiSetup.exe" within the CD-ROM folder.

(5) When the following screen is displayed, click [Setup].

2-19

Page 40

2-20

Device Setup Settings

(6) When the following screen is displayed, click [Device Setup].

Note: For Windows 7, Windows Vista, and Windows XP Service Pack2, the following “Firewall

Exception List Registration Conrmation” will be displayed. Click [Yes].

(7) The screen shown below appears. Click [Next].

(8) When the following screen is displayed, please read the “User License Agreement”, and click [Yes].

Page 41

(9) When the following screen appears, select the scanner displayed on the “Search result overview”,

Caution

and click [Next].

Note: The Ethernet address cannot be found at the back of the product.

Note: If the scanner is not displayed, conrm that the scanner is connected to your computer, and

click [Search].

• If the IP address has been set to a setting other than the initial setting (0.0.0.0), the IP

address of the computer used to make the setting must belong to the same subnet as

the IP address that was set for the scanner.

• This setting cannot be made if there is an existing IP address that is the same as that of

the scanner.

• When the setting will be performed from a location that a router is used to access,

depending on the type of router used, there may be locations that cannot be searched.

In this case, make the setting within the same segment.

(10) This will calibrate your IP address settings.

Note: Depending on the environment, the screen displayed may vary.

• In case the following screen is displayed:

Select “Assign IP Address”, and then click the

[Next] button after entering your desired IP

• In case the following screen is displayed:

Specify your desired IP address, and then

click [Next].

address.

Note: If you don’t know your IP address,

Note: If you don’t know your IP address,

please ask your network manager. If

there exist 2 or more of the same IP

address on one network, the network

may be damaged.

please ask your network manager. If

there exist 2 or more of the same IP

address on one network, the network

may be damaged.

2-21

Page 42

2-22

(11) The screen shown below appears. Check the settings and click [Execute].

(12) The screen shown below appears. Select “Yes” and click [Finish].

This completes the Device Setup operation.

Installing the Graphtec Network Utility

(13) The screen shown below appears. Click the [Next] button.

(14) The screen shown below appears. Check the contents of the “User License Agreement” and click

[Yes].

Page 43

(15) The following window appears.

Select the destination folder for installation. To specify a folder, click [Reference] and then select a

folder.

Note: The default destination folder is C:\Program Files\Graphtec\Graphtec Network Utility.

Click [Next].

(16) The screen shown below appears. Set the name of the program folder and click [Next].

(17) Click [Start] to start the installation procedure.

Note: In Windows 7 and Windows Vista, the “Windows Security” screen below appears. Click

[Install].

2-23

Page 44

2-24

Note: If you are using Windows 7, Windows Vista or Windows XP Service Pack 2, the following

Checkpoint

Checkpoint

conrmation screen asking you whether you want to add this application to the Windows

rewall exception list appears. Click [Yes].

(18) When installation has been completed, click [Finish].

This completes the setup operation of the Graphtec Network Utility.

Setting up the Graphtec Network Utility

Before executing Graphtec Network Utility, please be sure to rst install the scanner

driver software. (see Section 2.5, “ Installing the Scanner Driver Software”)

(1) Set up the Graphtec Network Utility.

Launch the “Graphtec Network Utility” from the [Start] menu.

(2) Register the server to connect to.

When launching the Graphtec Network Utility, the screen for server registration appears.

Click [Yes] to perform registration of the server.

Note: Even if [No] is selected, you can still proceed to the registration window by clicking the

[Register].

In the Graphtec Network Utility, ser ver refers to the scanner.

Page 45

(3) The screen below appears. Click [Search].

Checkpoint

(4) Select the connected server, and then click [OK].

(5) Click [Register] to connect from the Graphtec Network Utility.

(6) Click the [Connect] button.

Note: The install screen for the Scanner Driver Software appears. (see Section 2.5, “Installing

the Scanner Driver Software”)

Windows 7 ............. Step 9 of “When using Windows 7”

Windows Vista ....... Step 9 of “When using Windows Vista”

Windows XP .......... Step 8 of “When using Windows XP”

• When using the Scanner connected to a Network interface, be sure to launch the

Graphtec Network Utility and click the [Connect] button. Furthermore, when you have

nished using the scanner, click the [Disconnect] button to put the scanner in a status

that enables it to be used with other computers.

2-25

Page 46

2-26

• If the [Connect] button is displayed in gray, the scanner is being used with another

Caution

Network connector

POWER lampLINK lamp

Reset button

(for network)

Checkpoint

computer. Please connect the scanner when the [Connect] button display returns to

black indication.

• When the scanner is connected to the computer and no commands are received, it will

be disconnected after approximately 10 minutes.

• If the scanner is disconnected with the Scan window left open, the scanner will remain

in the scanning status, and cannot be used other computers. In this case, the scanner

must be turned off and then on again.

• The scanner’s net work inter face sleeps when the scanner is in energy-saving mode.

When connecting the scanner, bring it out of the energy-saving mode.

How to initialize the settings

The following methods will allow you to initialize the network environment for the scanner.

• Initialize with the scanner

• Initialize with the Network Utility

Once initialized, the IP address will become (0.0.0.0).

After initialization, insert the "IMAGE SCANNER USER GUIDE CD-ROM", which came with the

scanner, into the CD-ROM drive.

Go to “Install the Network Utility” and use “Setup” to execute the “Device Setup”.

(Refer to the “Setup procedure” mentioned before.)

Initialize with the scanner

Initialize the scanner if you change the environment of the network to which the scanner is connected.

Remove the Network Cable, and turn the scanner OFF.

Turn the scanner ON while holding down the Reset Button. (the POWER lamp on the right will light up)

Keep holding down the Reset Button until the LINK lamp on the left lights up.

When the LINK lamp lights up, let go of the Reset Button.

Turn the main power on the scanner OFF (on the O side), and switch the power ON after at least 5

seconds (on the I side).

This will initialize the network environment.

Initialize with the Network Utility

Initialize the settings when changing the Network environment for the scanner.

Set the browser’s proxy server to off when per forming the initialization settings.

(1) Launch Internet Explorer.

Page 47

(2) Enter “http://scanner IP address/en/index.htm” in the Address bar at the top of the screen.

Example: http://192.168.16.77/en/index.htm

(3) Select the “System Information” tab and click [Reset].

(4) Enter “root” in the User name box and then click [OK].

(User name: root; Password: blank box)

2-27

Page 48

2-28

(5) Click the [Start] button for “Reset to Factory Default”.

(6) “Are you sure you want to reset to factory default?” appears.

Click [OK].

(7) The following window is displayed after the setting has been made.

Page 49

(8) Reboot the Network Board.

Select the “System Information” tab and click [Reset].

(9) Click the [Start] button for “Reboot”.

(10) “Are you sure you want to reboot?” appears.

Click [OK].

2-29

Page 50

(11) After the settings, the screen below appears.

(12) This completes the initialization of the Scanner Network.

2-30

Page 51

CHAPTER 3 LOADING A DOCUMENT

3.1 Compatible Document Types

Because the scanner scans a document while feeding it, the document types that it can scan are

subject to the following restrictions.

Compatible Media Widths for Scanning

Documents with a maximum width of 965 mm

Size ANSI Architectural Size ANSI Engineering

A 9 x 12 in A 8.5 x 11 in

B 12 x 18 in B 11 x 17 in

C 18 x 24 in C 17 x 22 in

D 24 x 36 in D 22 x 34 in

E1 30 x 42 in E 34 x 44 in

E 36 x 48 in

Size DIN

A4 9.44 x 12.99 in

A3 12.99 x 17.71 in

A2 17.71 x 24.60 in

A1 24.60 x 34.64 in

A0 34.64 x 48.42 in

Size JIS (ISO) Size JIS (ISO)

A4 210 x 297 mm B4 257 x 364 mm

A3 297 x 420 mm B3 364 x 515 mm

A2 420 x 594 mm B2 515 x 728 mm

A1 594 x 841 mm B1 728 x 1030 mm

A0 841 x 1189 mm

Compatible Media Lengths for Scanning

Length can be set up to 999.99999 m.

Long documents might be unreadable depending on the connected computer’s environment.

Compatible Document Thicknesses for Scanning

The CSX510-09/CSX530-09/CSX550-09 cannot scan a document that is thicker than 1.6 mm.

When using the carrier sheet, ensure that the combined thickness of both the document and carrier

sheet does not exceed 1.6 mm.

Moreover, documents of an uneven thickness cannot be scanned.

Note: The carrier sheet alone is 0.2 mm thick.

3-1

Page 52

3-2

Compatible Media Grades for Scanning

Media Grades

• The scanning precision is guaranteed for the special chart (Mylar) used in the test (see APPENDIX B,

“SPECIFICATIONS”).

• The compatible media types are listed below.

♦ High-grade paper : 60 g/m

♦ Tracing paper : 50 to 55 g/m

♦ Mylar : 50 μm

♦ Copy paper

♦ Diazo photo-sensitive paper

Be sure to use the carrier sheet when scanning a document where the ink or toner comes off when it

is rubbed. If the carrier sheet is not used, there is a risk of the document feed path becoming stained,

and causing subsequent documents to become stained as well.

2

2

Page 53

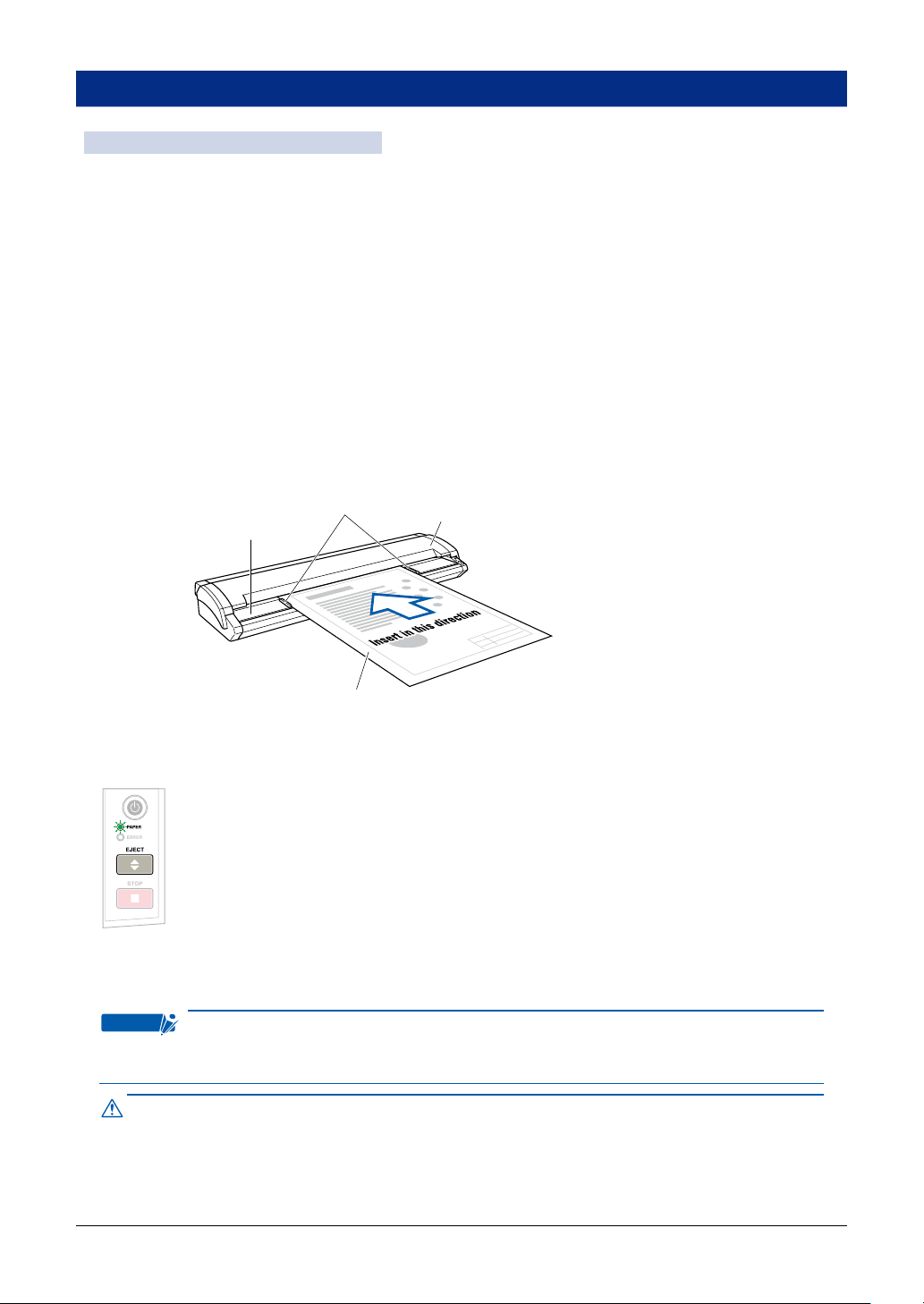

3.2 Loading a Document

Document to be scanned

Document-scanning table

Top cover

Document guides

Checkpoint

Caution

How to use the document guides

Insert the document (the surface to be scanned) face up into the scanner until the top edge of the

document contacts the feed rollers. At this time, make sure that the document is straight and that it is

centered in the scanner.

(1) With the top cover in the closed status, turn on the scanner’s power supply.

(2) The document guides are attached to the document-scanning table via magnets. Place them at

the edges of the document in alignment with the document width.

(3) Place the document between the document guides, and then inser t the document into the gap

between the top cover and the document-scanning table, making sure that it is straight.

(4) When the preset delay time specied in the driver software has elapsed, the rollers start turning

to automatically feed the document to the position to start scanning. The document is now loaded.

(Manual loading: OFF)

(5) Remove the document guides after you have loaded the document in order to ensure that the

document does not get damaged if it is fed at an angle.

Remove the document guides after the document has been loaded correctly. If the document

guides are not removed, the document might get damaged when it s being fed.

• The delay time (automatic feed time) after the scanner has been turned on is set to three

There are two document setting modes available.

(For more information, refer to "Section 3 Scanning Settings" of the "Scanning Master Pro

Color ‘OPS115’" Instructions Manual (PDF))

• The rollers start turning at a preset delay time after the document has been inserted

so that they automatically feed the document to the position to start scanning. (Manual

loading: OFF)

• The rollers start turning when the [EJECT] key on the control panel is pressed after a

document is inserted so that they automatically feed the document to the position to start

scanning. (Manual loading: ON)

If you want to reload the document, press the [EJECT] key to eject the document. Reload

the ejected document.

When the document has been loaded, the [PAPER] LED (green) lights.

If the PAPER LED does not light after the document feed operation has stopped, press

the EJECT key, and the document gets reset without being ejected and the PAPER LED

lights.

• If the document is inserted at an angle, the image may be scanned in at an angle or a

scanning error may occur. Make sure that the document is aligned with the document

guides when it is inser ted.

seconds.

3-3

Page 54

3-4

• Load the document in the scanner with the surface to be scanned face up.

• Do not place anything other than the document to be scanned on the documentscanning

table. If you do so, the scanner rollers may start rotating, which is extremely dangerous.

• The document may not be fed in correctly if it is curled. The carrier sheet should be used

for curled documents (see Section 3.5, “Using the Carrier Sheet” for details).

• Load the document in the center of the scanner, as the document may be fed in at an

angle and not scanned correctly if it is signicantly off-center.

• Load the document in the center of the scanner. If it is signicantly off- center, the

document may shift and may not be scanned correctly.

Page 55

3.3

“Scan” screen

Slider position

(1) (2) (3) (4) (5) (6) (7) (8)

Handling Documents According to their Material and Thickness

The following problems may occur, depending on the thickness and sur face condition of the document

being scanned.

• The document cannot be loaded.

• Scanning of the document stops half-way through.

• The document slips (resulting in displaced images).

• The end of the document is not scanned.

Such problems may be avoided by taking the following corrective measures.

<Adjust the scanning speed>

Adjust the scan speed using the table below as a guide and following the steps.

(1) Start up the “Scanning Master Pro Color (OPS115)” software that is provided with your scanner,

and then display the [Scan] screen.

(2) Select the [Document] tab to conrm the set "Resolution (DPI)."

(3) Next, select the [Options] tab, and then move the “Scan Speed” slider to the conrmed resolution

position.

"Scan Speed" settings guide (set in the "Scanning Master Pro Color ‘OPS115’")

Note: When “Quality” is set to “High quality” and “Output” is set to “Grayscale” in "Scanning Master

Pro Color ‘OPS115’"

These values are suggested as a guideline only. The actual values will vary according to the

type of document and its condition.

Model Document

Thickness

(mm)

CSX510-09 0.65 to 0.8

0.8 to 1.6

CSX530-09 0.65 to 0.8

0.8 to 1.6

CSX550-09 0.65 to 0.8

0.8 to 1.6

200 300 400 600 800 1200

Position of the

below gure (2)

Position of the

below gure (4)

Position of the

below gure (5)

Position of the

below gure (7)

Position of the

below gure (6)

Position of the

below gure (8)

Position of the

below gure (1)

(Standard)

Position of the

below gure (3)

Position of the

below gure (5)

Position of the

below gure (6)

Position of the

below gure (6)

Position of the

below gure (8)

Resolution (dpi)

Position of the

below gure (1)

(Standard)

Position of the

below gure (4)

Position of the

below gure (4)

Position of the

below gure (6)

Position of the

below gure (6)

Position of the

below gure (8)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (5)

Position of the

below gure (5)

Position of the

below gure (5)

Position of the

below gure (8)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (6)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

Position of the

below gure (1)

(Standard)

3-5

Page 56

3-6

TI P

Refer to the examples below regarding the “Scan speed” slider position in "Scanning

(1)

(Standard)

(4)

(4th from the left)

(5)

(5th from the left)

(6)

(6th from the left)

Master Pro Color ‘OPS115.’"

<Lower the scanning speed>

(1) Start up the “Scanning Master Pro Color (OPS115)” software that is provided with your scanner,

and then display the [Scan] screen.

(2) Select the [Options] tab, and then move the “Scan Speed” slider to the Low end of the scale.

<Support the document at the front and the back of the scanner>

Place tables or similar objects in front of and behind the scanner to support the document while it is

being fed.

Page 57

3.4 Distance Correction

Corrections to the distance can be achieved using the driver software. The driver software included

with your scanner (“Scanning Master Pro Color”) enables you to perform distance correction from the

menu Tool → Adjust Scanner in order to adjust the scanning accuracy.

The adjustment function must be set up when a scanned drawing needs to approximate the accuracy

of the original drawing closely. (This is for making ne adjustments to the accuracy of the scanned

drawing to suit the quality of the paper being used.) It is not normally necessary to perform this

adjustment.

Adjustment method

Perform the distance correction process according to the type of document to be scanned.

Distance correction can be set in a range of ±1%, which remains effective until the scanner’s power is

turned off.

The practice of distance correction necessitates that you measure a vertical line drawn on the

document before following the procedure described below.

(1) Choose a document that has one or more vertical lines drawn on it and scan it at a resolution of

600 dpi (Portrait (vertical) format).

(2) Measure the length of the vertical line of the document and classify it as x (distance on the

document).

(3) Measure the length of the same vertical line in the image data using the command to measure the

distance between two specied points of relative measurement, and classify it as y (distance after

the scan has taken place).

(4) Click on the Distance Correction button in the Adjust Scanner window to open the Distance

Correction window.

(5) Enter the value “x” (distance on the document) and the value “y” (distance after the scan has taken

place) in this window. The values entered here must be within the range of the distance correction.

(6) Click the OK button to calculate the correction value. The distance will be corrected the next time

a document is scanned.

3-7

Page 58

3.5 Using the Carrier Sheet

Transparent sheet (top surface)

Target document

(the surface to be scanned faces up)

White surface

(background surface)

Checkpoint

Use the carrier sheet according to the condition of the document to be scanned.

In the case of scanning the following types of media, always place the document in the carrier sheet

before loading it into the scanner.

• To scan a document that is smaller than Letter size or a document of non-standard size

• To scan a document that is as limp as or limper than a newspaper

• To scan a document that tears or becomes damaged easily

• To scan a document that is considerably damaged

• To scan a document that is badly creased

• To scan a curled document

• To scan a transparent or translucent document

• To scan a document to which other pieces of paper have been attached

• When the target document cannot be properly advanced to the initial position of scanning (because

the target document is not at, or otherwise hard to load in the scanner)

As shown in the gure below, place the document in the carrier sheet with the document’s surface to

be scanned face up (against the transparent top sheet). For scanning, load the carrier sheet into the

scanner with the document’s target sur face (the transparent top sheet) face up.

• When handling the carrier sheet, be ver y careful not to scratch or otherwise damage it.

• If you use the carrier sheet when scanning color documents, the colors may shift slightly

in some cases.

• In the case of CSX510-09 the carrier sheet is an optional item.

3-8

Page 59

CHAPTER 4 DAILY MAINTENANCE

Checkpoint

Caution

4.1 Opening and Closing the Top Cover

Opening the top cover

(1) Turn off the scanner.

(2) Using both hands, push up the left and right open levers on the top cover to unlock them. While

still holding on to the levers, open the cover fully (approximately 47 degrees).

(3) When the top cover is fully open, the xing stay operates to hold the top cover in place.

Closing the top cover

(1) Press the open cover down gently with both hands to close it.

(2) Check that the left and right open levers are locked into position.

If the levers are not locked correctly, the ERROR LED ashes and a scanning operation

cannot be performed.

• Take care not to get your ngers caught when opening or closing the cover.

• When closing the top cover, please be careful not to pinch the document guides.

4-1

Page 60

4-2

4.2 Cleaning the Feed Rollers

Feed rollers

Caution

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1, “Opening and Closing the Top Cover”.

(3) While rotating the feed rollers manually, wipe them clean using a soft cloth that has been

moistened with water or a neutral detergent (diluted with water) and rmly wrung out.

(4) Wipe the feed rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 4.1, “Opening and Closing the Top Cover”.

• Take care not to get your ngers caught in the top cover.

• Only perform this action when the scanner is turned off.

• Please refrain from inserting cloth, etc. into the openings.

Page 61

4.3 Cleaning the Document support Rollers

Document support rollers

Caution

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1, “Opening and Closing the Top Cover”.

(3) While rotating the document support rollers manually, wipe them clean using a soft cloth that has

been moistened with water or a neutral detergent (diluted with water) and rmly wrung out.

(4) Wipe the document support rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 4.1, “Opening and Closing the Top Cover”.

• Take care not to get your ngers caught in the top cover.

• Scanning may be af fected if the document support rollers becomes scratched or dir ty.

• Only perform this action when the scanner is turned off.

• Please refrain from inserting cloth, etc. into the openings.

4-3

Page 62

4-4

4.4 Cleaning the Gap Rollers

Gap rollers

Caution

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1, “Opening and Closing the Top Cover”.

(3) While rotating the gap rollers manually, wipe them clean using a soft cloth that has been

moistened with water or a neutral detergent (diluted with water) and rmly wrung out.

(4) Wipe the gap rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 4.1, “Opening and Closing the Top Cover”.

• Take care not to get your ngers caught in the top cover.

• Only perform this action when the scanner is turned off.

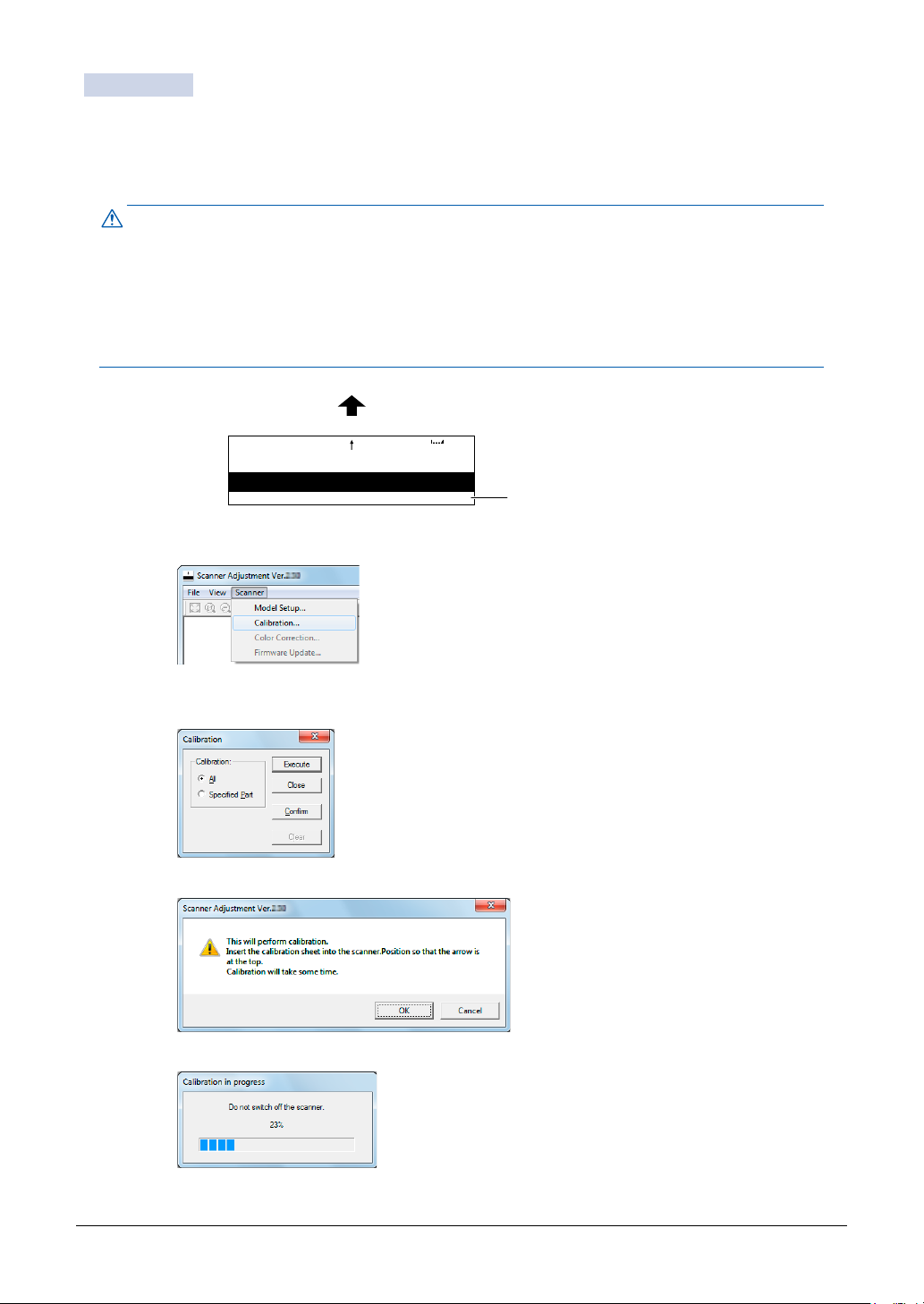

• Please refrain from inserting cloth, etc. into the openings.