Page 1

SERVICE MANUAL

MANUAL NO. CSX300-UM-251

300-09

CSX300-UM251-05-9370

Page 2

Page 3

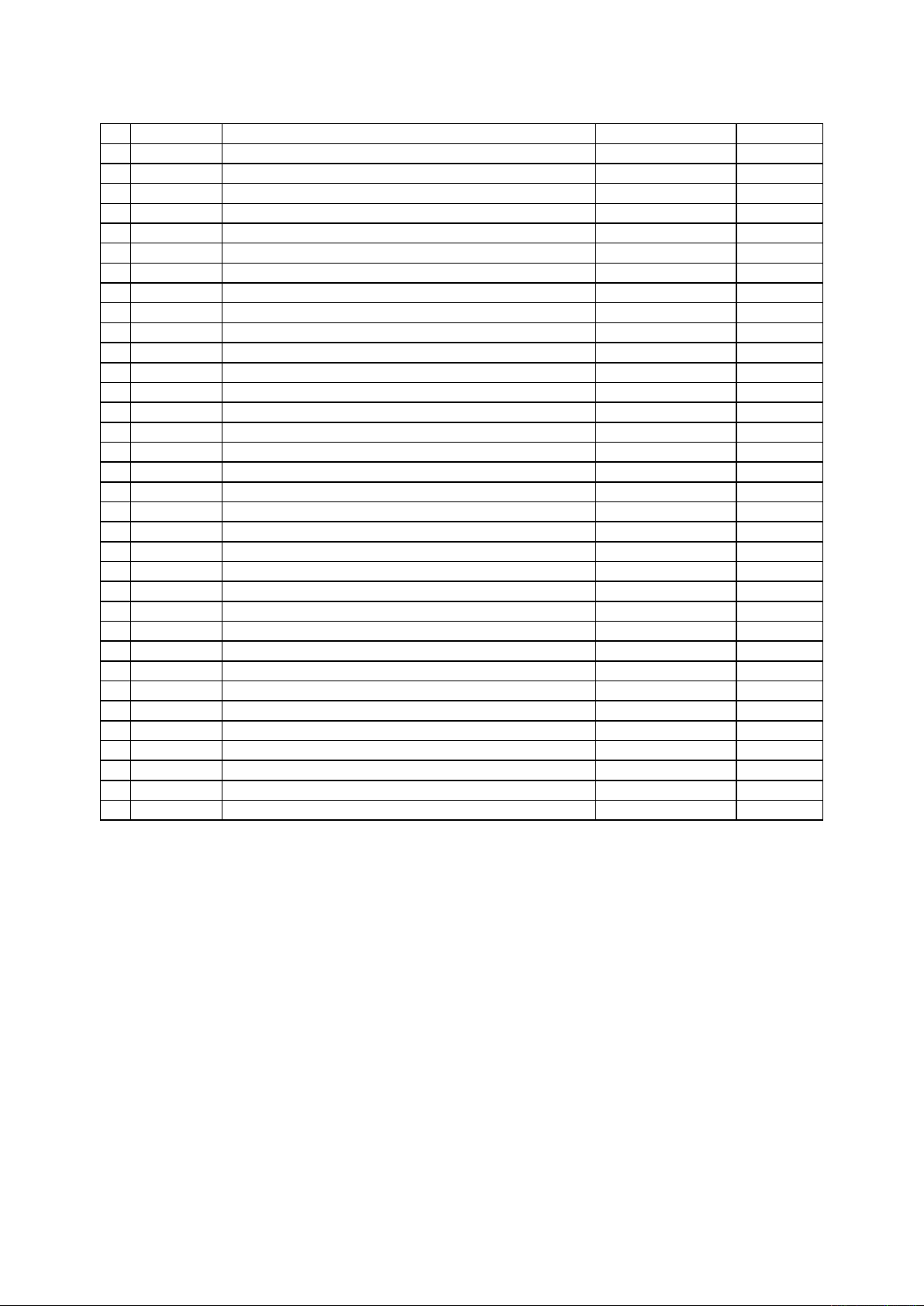

HISTORY OF REVISIONS

No. Date issued Description of revision Page Edition

1 08.02.29 First Printing. All 01

2 08.05.28

3 08.08.29 Item No. 2 and No. 3 were swapped. 12-1 03

4 09.02.12

5 09.02.12

6 09.10.08 The part number for the scan glass A was updated. 6-1,12-5 05

7 09.10.08

8 09.10.08 The figure for the press roller was added. 12-7 05

9 09.10.08 The part number for the CIS sensors were updated. 6-1,12-5 05

10 09.10.13

11 09.10.13

12 09.10.13

13 09.10.13

14 09.10.13

15 09.10.13

16 09.10.13

17 09.10.13

18 09.10.13

19 09.10.13 The part number for the

20 09.10.13 The part number for the

21 09.10.13 The part number for the

22 09.10.13 The part number for the

23 09.10.13 The part number for the

24 09.10.13 The part number for the

25 09.10.13 The part number for the

26 09.10.13 The part number for the

27 09.10.13 The part number for the

28 09.10.13 The part number for the

29 09.10.13 The part number for the

30 09.10.13 The part number for the

The IS0925 was assigned to consumable supplies parts.

The part number for the Press Roller A was corrected.

The item number direction for the Press Roller A was corrected.

The part number for the document guard plastic plates were added.

The part number for the SVC_Main_BD_S was corrected.

The part number for the SVC_CIS_BD was corrected..

The part number for the SVC_PWR_BD was corrected..

The part number for the

The part number for the

The part number for the

The part number for the

The part number for the

The part number for the

Right_Side_Cover_A

Feed_Roller_F

Feed_Roller_R

Pinch_Roller_A

Top_Cover

Left_Side_Cover A

Front_Cover_A was corrected. 12-1 05

Press_ A_2 was corrected. 12-6 05

Press_ A_1 was corrected. 12-6 05

Press_ A_3 was corrected. 12-6 05

Harness 2 was corrected. 12-9 05

Harness 11 was corrected. 12-9 05

Harness 12 was corrected. 12-9 05

Harness 15 was corrected. 12-9 05

Harness 17 was corrected. 12-9 05

Harness 19 was corrected. 12-9 05

Harness 21 was corrected. 12-9 05

Harness 22 was corrected. 12-9 05

was corrected.

was corrected.

was corrected.

was corrected.

was corrected.

was corrected.

12-9 02

6-1,12-6 04

12-6 04

12-6 05

6-1 05

6-1,12-3 05

6-1,12-8 05

6-1 05

6-1,12-6 05

6-1,12-6 05

6-1,12-5 05

12-1 05

12-1 05

CSX300-UM-251-9370 i

Page 4

CSX300-UM-251-9370 ii

Page 5

CONTENTS

1. OVERVIEW .......................................................................................................................................1-1

1.1 Standard Specifications .......................................................................................................... 1-1

1.2 External View ...............................................................................................................................1-3

2. PART NAMES AND FUNCTIONS ......................................................................................2-1

2.1 Part Names and Functions .....................................................................................................2-1

3. CONNECTION AND PREPARATIONS .......................................................................... 3-1

3.1 Connecting to the Power Supply .........................................................................................3-1

3.2 Turning the Power On and Off ..............................................................................................3-2

3.3 System Requirements ............................................................................................................. 3-4

3.4 Connecting the Scanner to a Computer .......................................................................... 3-5

4. INSTALLING THE SOFTWARE ......................................................................................... 4-1

4.1 Installing the Driver Software for Windows Vista .........................................................4-1

4.2 Installing the Driver Software for Windows XP ............................................................ 4-4

4.3 Installing the Driver Software for Windows 2000 ........................................................ 4-6

4.6 Checking the Interface Connection for Windows 2000 ...........................................4-10

4.7 Installing the Scanning Master 21+ Application .........................................................4-11

5. DAILY MAINTENANCE ............................................................................................................ 5-1

5.1 Opening and Closing the Top Cover ..................................................................................5-1

5.2 Cleaning the Feed Rollers ......................................................................................................5-2

5.3 Cleaning the Document support Rollers ......................................................................... 5-3

5.4 Cleaning the Gap Rollers ....................................................................................................... 5-4

5.5 Cleaning the Push Rollers ..................................................................................................... 5-5

5.6 Cleaning the Image Sensors (Contact glass plates) .................................................. 5-6

5.7 Cleaning the Media sensors ..................................................................................................5-7

5.8 Removing a Jammed Document ......................................................................................... 5-8

5.9 Scanner Calibration ................................................................................................................. 5-9

6. RECOMMENDED PARTS LIST .......................................................................................... 6-1

7. LIST OF JIGS AND TOOLS ...................................................................................................7-1

7.1 Jigs ................................................................................................................................................... 7-1

7.2 Tools ................................................................................................................................................ 7-1

7.3 Other ................................................................................................................................................ 7-1

8.

DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.1 Top Cover .......................................................................................................................................8-1

8.2 Front Cover ...................................................................................................................................8-2

8.3 Left Side Cover .......................................................................................................................... 8-3

8.4 Right Side Cover ....................................................................................................................... 8-4

8.5 Front Guide Assembly ............................................................................................................ 8-5

CSX300-UM-251-9370 iii

.......................................... 8-1

Page 6

8.6 Shield Cover ................................................................................................................................ 8-6

8.7 Feed Drive Belt ............................................................................................................................8-7

8.8 Main Board .................................................................................................................................. 8-9

8.9 Board Base Chassis ...............................................................................................................8-10

8.10 CIS Board .................................................................................................................................. 8-11

8.11 CIS Sensor ................................................................................................................................8-12

8.12 Cover Sensor ...........................................................................................................................8-14

8.13 Front Media Sensor ...............................................................................................................8-15

8.14 Rear Media Sensor ................................................................................................................8-16

8.15 Media width sensors .............................................................................................................8-17

8.16 Document Roller Assembly ............................................................................................... 8-18

8.16 Contact Glass Assembly ....................................................................................................8-19

8.17 Pinch Roller ..............................................................................................................................8-21

8.18 Feed Rollers .............................................................................................................................8-22

8.19 CIS Power Board ....................................................................................................................8-24

8.20 Switching Power Supply Board .......................................................................................8-25

8.21 Feed Motor ...............................................................................................................................8-26

9. ADJUSTMENTS USING THE SOFTWARE ................................................................ 9-1

9.1 Starting the Software ................................................................................................................9-1

9.2 Preparations before Making Adjustments ...................................................................... 9-4

9.3 Preparing Adjustment Charts .............................................................................................. 9-5

9.4 Making Adjustments .................................................................................................................9-7

9.4.1 Calibration (white and black correction) .................................................................9-8

9.4.2 Feed distance adjustment .......................................................................................... 9-10

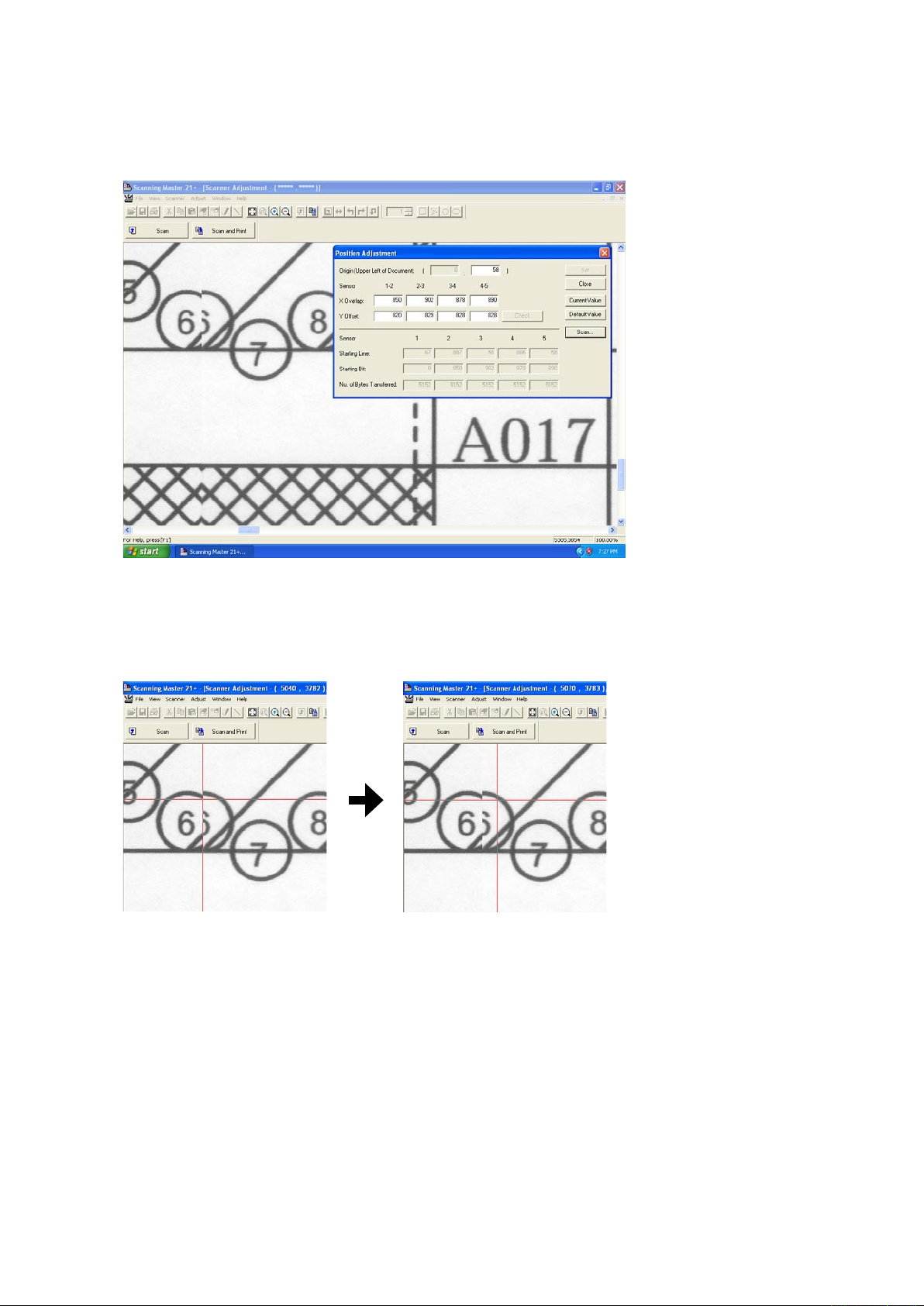

9.4.3 Sensor Stitch Adjustment ........................................................................................... 9-13

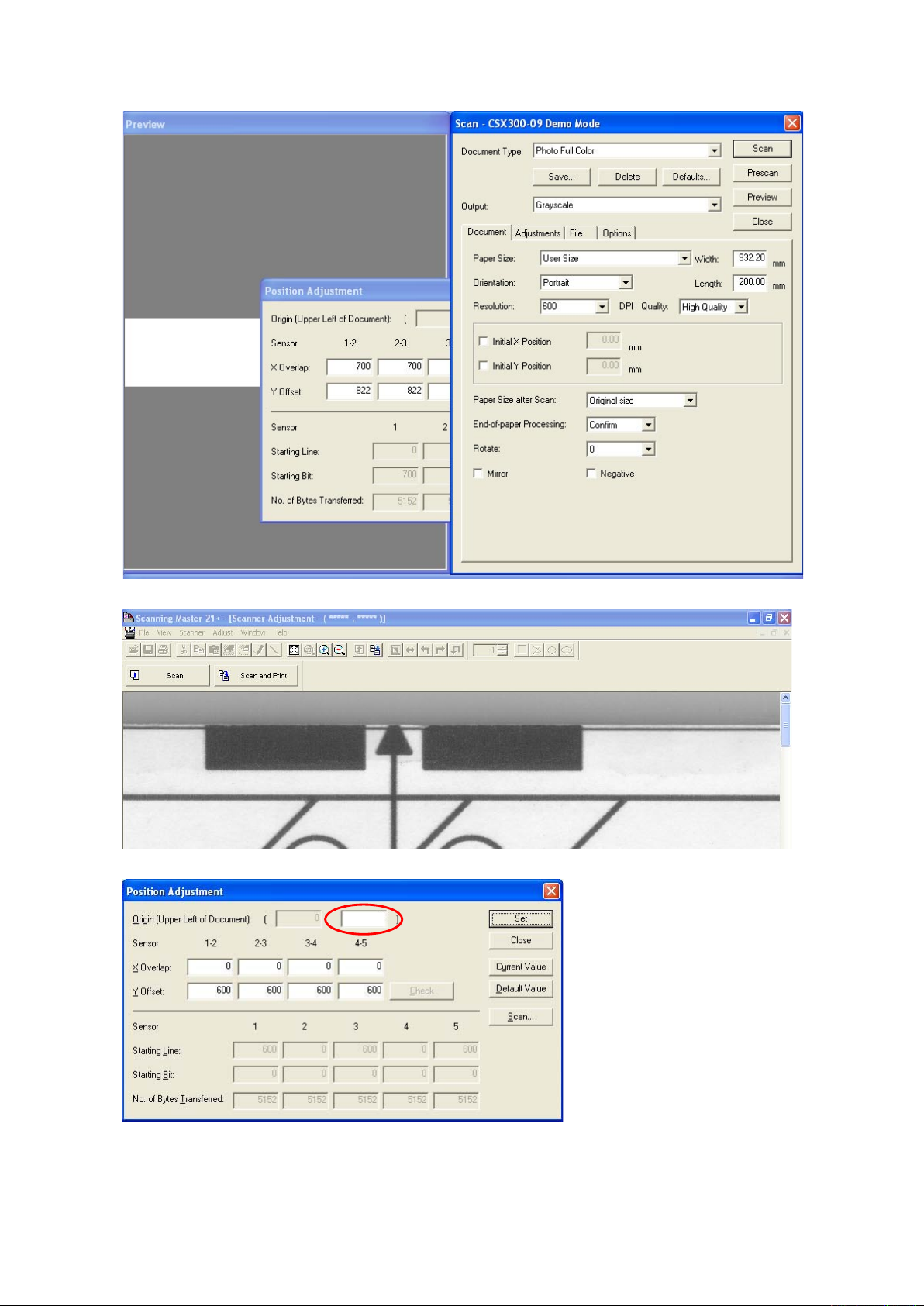

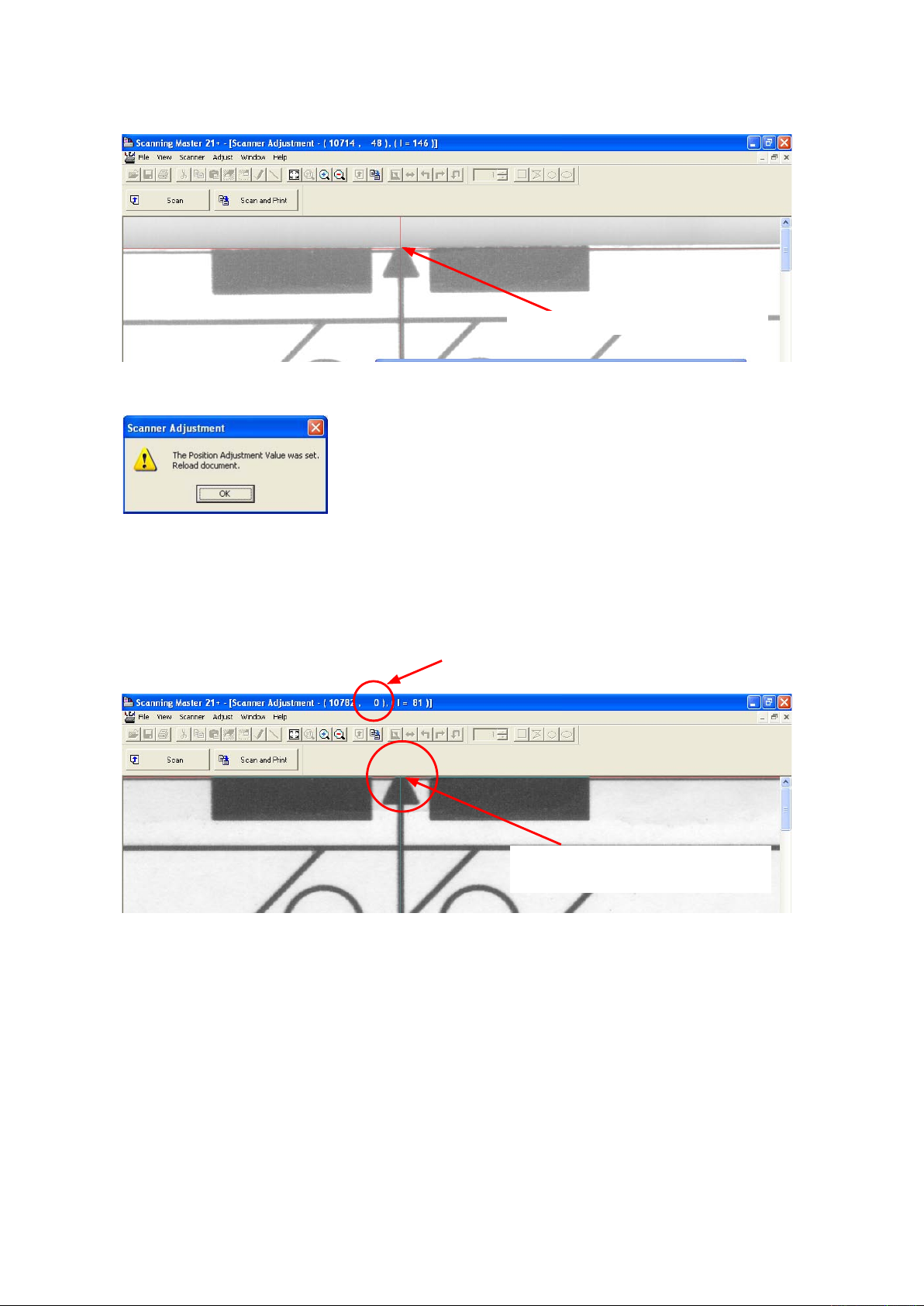

9.4.4 Scanning Start Position Adjustment ...................................................................... 9-19

9.5 Downloading Firmware ..........................................................................................................9-24

10. TROUBLESHOOTING ...........................................................................................................10-1

10.1 TROUBLESHOOTING ............................................................................................................10-1

11. OPTION AND CONSUMABLES .....................................................................................11-1

11.1 Optional Item ............................................................................................................................ 11-1

11.2 Consumables ........................................................................................................................... 11-1

12. PARTS LISTS .............................................................................................................................12-1

12.1 Outer Casing ............................................................................................................................ 12-1

12.2 Shield Cover ............................................................................................................................12-2

12.3 Main Frame ...............................................................................................................................12-3

12.4 Top Frame Bottom .................................................................................................................12-5

12.5 Feed Section ............................................................................................................................12-6

12.6 Bottom Chassis ......................................................................................................................12-8

Page 7

12.7 Harness ......................................................................................................................................12-9

12.8 Inlet ..............................................................................................................................................12-9

12.9 Other Parts ...............................................................................................................................12-9

13. BLOCK DIAGRAM AND CIRCUIT DIAGRAMS ...................................................13-1

13.1 Block Diagram .........................................................................................................................13-1

13.2 Circuit Diagrams ....................................................................................................................13-2

13.2.1 Data Controller Board (Main Board) ..................................................................... 13-2

13.2.2 CIS Controller Board ................................................................................................ 13-17

13.2.3 Power Board .................................................................................................................13-20

13.2.4 Control Panel Board, CN5041-06A ...................................................................... 13-22

13.2.5 USB Relay Board, CN5041-07 ................................................................................13-23

CSX300-UM-251-9370 v

Page 8

Page 9

1. OVERVIEW

1. OVERVIEW

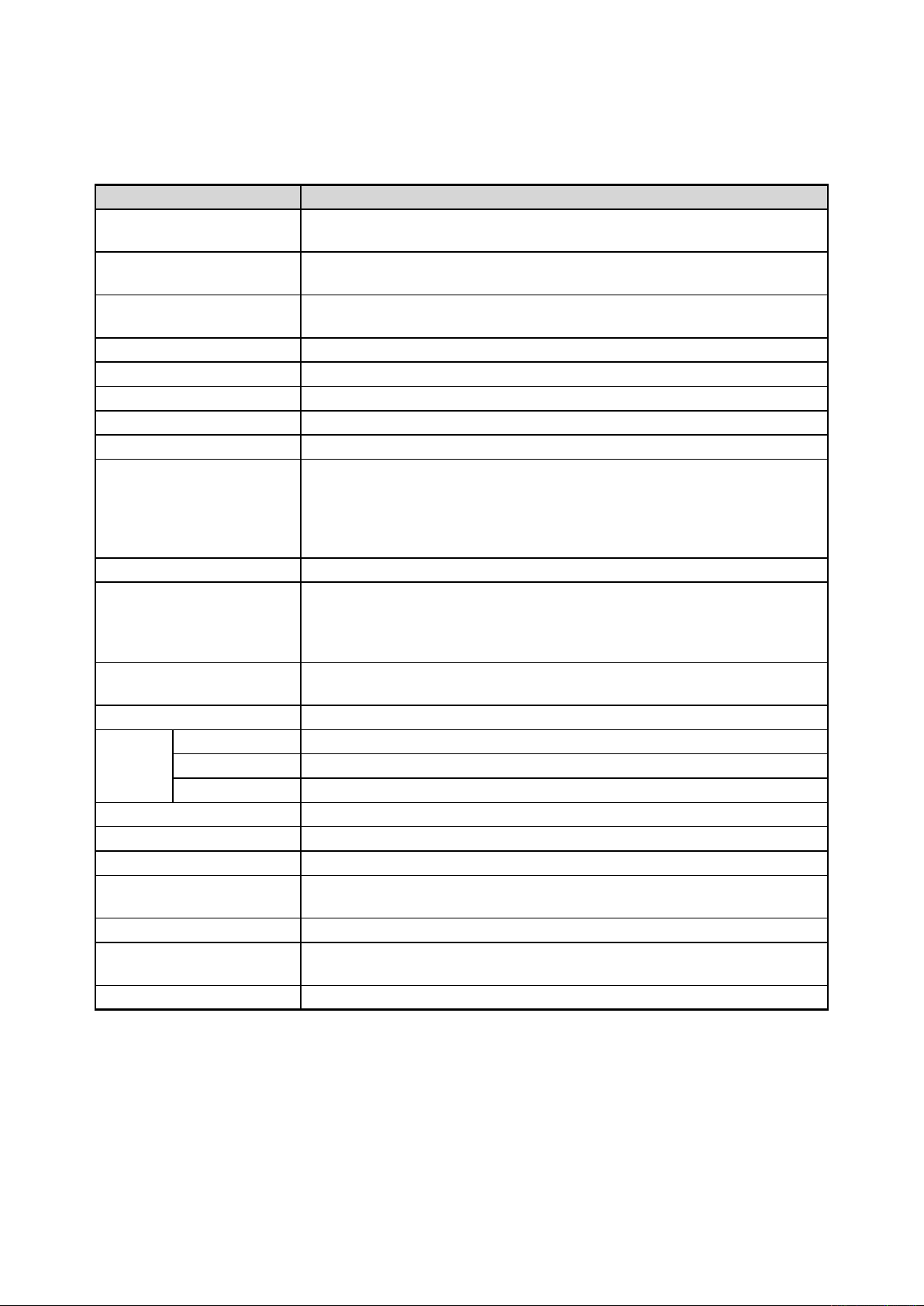

1.1 Standard Specifications

Item CSX300-09

Document size ANSI E to ISO A4

Maximum width: 965 mm; minimum width: 257 mm

Effective scanning area Maximum width : 932.2 mm

Maximum length : 16 m

Guaranteed scanning

precision range

*2

841 mm x 1189 mm

Document thickness Up to 0.8 mm (including the carrier sheet)

Optical resolution 600 dpi

Interpolated resolution 100, 200, 300, 400, 600, 800, 1200 dpi

Main scanning system Contact image sensor system (five A4 sensors in a zigzag pattern)

Sub scanning system Document travel (sheet through) system

Scanning speed

*3

400 dpi, ISO A0 size

High-speed scan Normal scan High quality scan

• Monochrome: 8 s • Monochrome: 14 s • Monochrome: 18 s

• Grayscale: 23 s • Grayscale: 26 s • Grayscale: 33 s

• 24-bit color: 62 s • 24-bit color: 75 s • 24-bit color: 100 s

Scanning precision*3 ±0.1% or ±1 pixel, whichever is larger

Gradation Monochrome : Bilevel, intermediate tones (dithering, error diffusion)

Gray scale : 256 shades

Gray balance : 256 shades

Color : 24-bit

Threshold value A DSP (digital signal processor) enables automatic setting of the threshold

value (monochrome scans only)

Color space sRGB compatible

Sensor

Total number of pixels

Output Color: 42 bits/pixel, Grayscale: 14 bits/pixel

22,020 pixels

Light source LED (RGB)

Interface USB 2.0

Output Image data

Rated power supply 100 to 120/200 to 230 VAC ±10%, 50/60 Hz

Operating environment Temperature: 10˚C to 35˚C

Humidity: 35% to 80% RH (non-condensing)

Power consumption 60 W or less (5 W or less in power-saving mode)

External dimensions

1097 (W) x 160 (H) x 332 (D) mm (without stand)

(approx.)

Weight (approx.)

13 kg (without stand)

*1

*1 If the document is a long-length document, the actual length that can be scanned is limited by the available

memory (hard disk or other data storage device) of the computer to which the scanner is connected, and also by

the grade of the medium being scanned.

*2 Notes on scanning precision

The scanning precision may vary slightly depending on the grade and thickness of the medium being scanned,

and on the operating conditions. The precision figures above were measured under the operating conditions

described below.

• Special test chart: Mylar sheet #300

• Guaranteed precision conditions: Temperature: 23°C ±5°C; Humidity: 55% ±15% RH

CSX300-UM-251-9370 1-1

Page 10

*3 Including data-transfer time

The following system was used to measure the scanning speeds.

• CPU: Pentium 4, 3.2 GHz or better • Memory: 1 GB or more • Interface: USB 2.0

The scanning speeds may be slower depending on the PC system used.

1. OVERVIEW

CSX300-UM-251-9370 1-2

Page 11

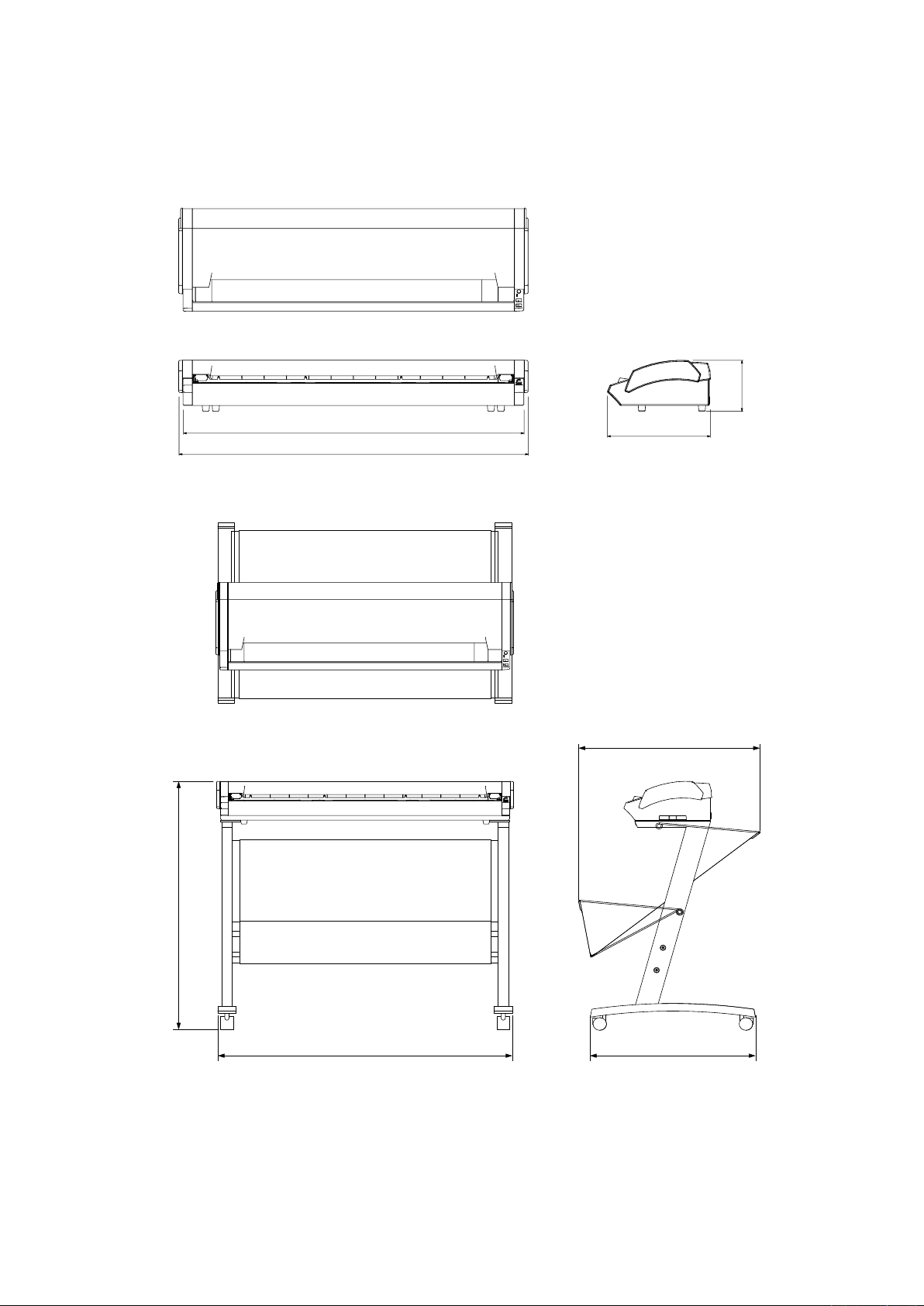

1.2 External View

1070

1097

322

160

972

1097 650

717±10

External Dimensions

1. OVERVIEW

Unit: mm

Dimensional accuracy: ±5 mm

External Dimensions with the option stand

CSX300-UM-251-9370 1-3

Page 12

Page 13

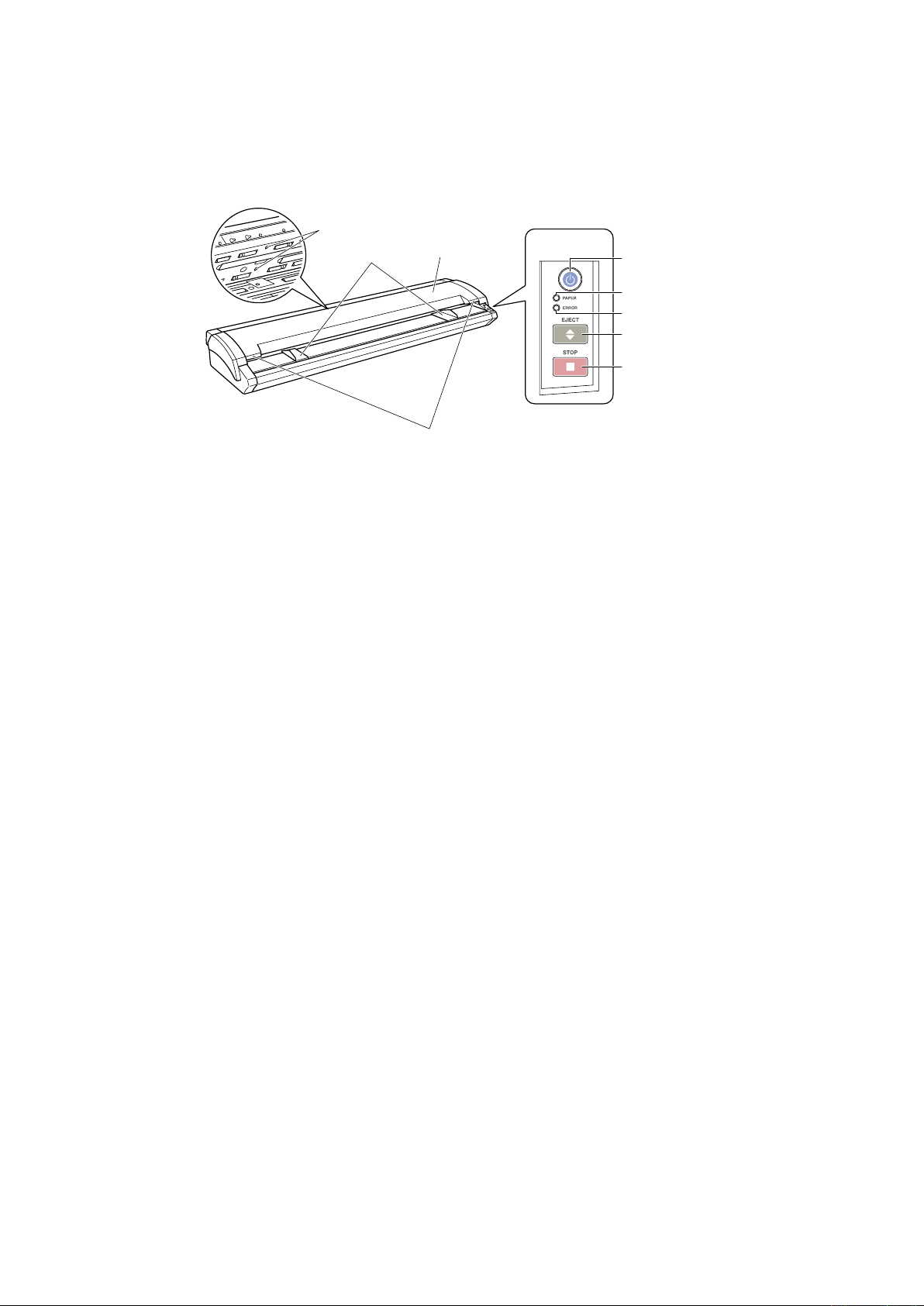

2. PART NAMES AND FUNCTIONS

(1) Top cover

Control Panel

(4) Document guides

(3)

Top cover open levers

(2) Paper sensors

(5) Power button/LED

(6)

PAPER LED

(7) ERROR LED

(8) EJECT key

(9) STOP key

2. PART NAMES AND FUNCTIONS

2.1 Part Names and Functions

Front View/Control Panel

Top cover

(1) Top cover ..............................Open the top cover to clean the document hold-down unit and contact glass

plates.

(2) Media sensors ......................These sense whether a document is present in the scanner.

(3) Top cover open levers ..........Press these levers to open the top cover.

If the top cover is opened during a scanning operation, the operation will be

stopped compulsorily.

(4) Document guides .................Use these guides to determine the position of a document when you load the

document.

Control Panel

(5) Power button/LED (blue) ......Controls the on/off status of the power supply to the scanner.

Lit: The scanner is turned on.

Flashing: Flashes when the scanner is in power-saving mode.

Unlit: The scanner is turned off.

Lit: Lights when the scanner is turned on and remains lit while it is operating

normally.

(6) PAPER LED (green) .............Lit: Lights when a document has been loaded.

Flashing: Flashes while image data is being scanned.

Unlit: Normal status (Local status).

(7) ERROR LED (red) ................Lit: Lights to indicate a hardware error.

Flashing: Flashes when any of the following occurs:

• A document is detected during the self-test when the scanner is turned on

• When a paper jam is detected

• When the top cover is open

• When the document length is shorter than the specified scan length*1

*1 When “Confirm” has been selected for the End-of-paper Processing setting in the driver

software.

Unlit: Normal status

CSX300-UM-251-9370 2-1

Page 14

2. PART NAMES AND FUNCTIONS

(10) USB connector

(11) Power inlet

(12) Main power switch

(8) EJECT key ...........................

Press this key to feed the document.

If this key is pressed when the scanner is in document-loaded status, the

document-loaded status is canceled and the document is ejected to the front

of the scanner.

If this key is pressed after the scanning operation has been canceled or

after scanning of the document was halted partway through the scanning

operation, the document-loaded status is canceled and the document is

ejected to the rear of the scanner.

(9) STOP key .............................Compulsorily stops scanning of the document.

If the ERROR LED flashes when the top cover is in the closed status, press

this key to suspend the scanning operation and check whether a paper jam

has occurred.

Rear View

(10) USB connector ...................Used to connect the USB interface cable.

(11) Power inlet ..........................Used to connect the power cable.

(12) Main power switch .............Used to turn the main power supply on or off.

CSX300-UM-251-9370 2-2

Page 15

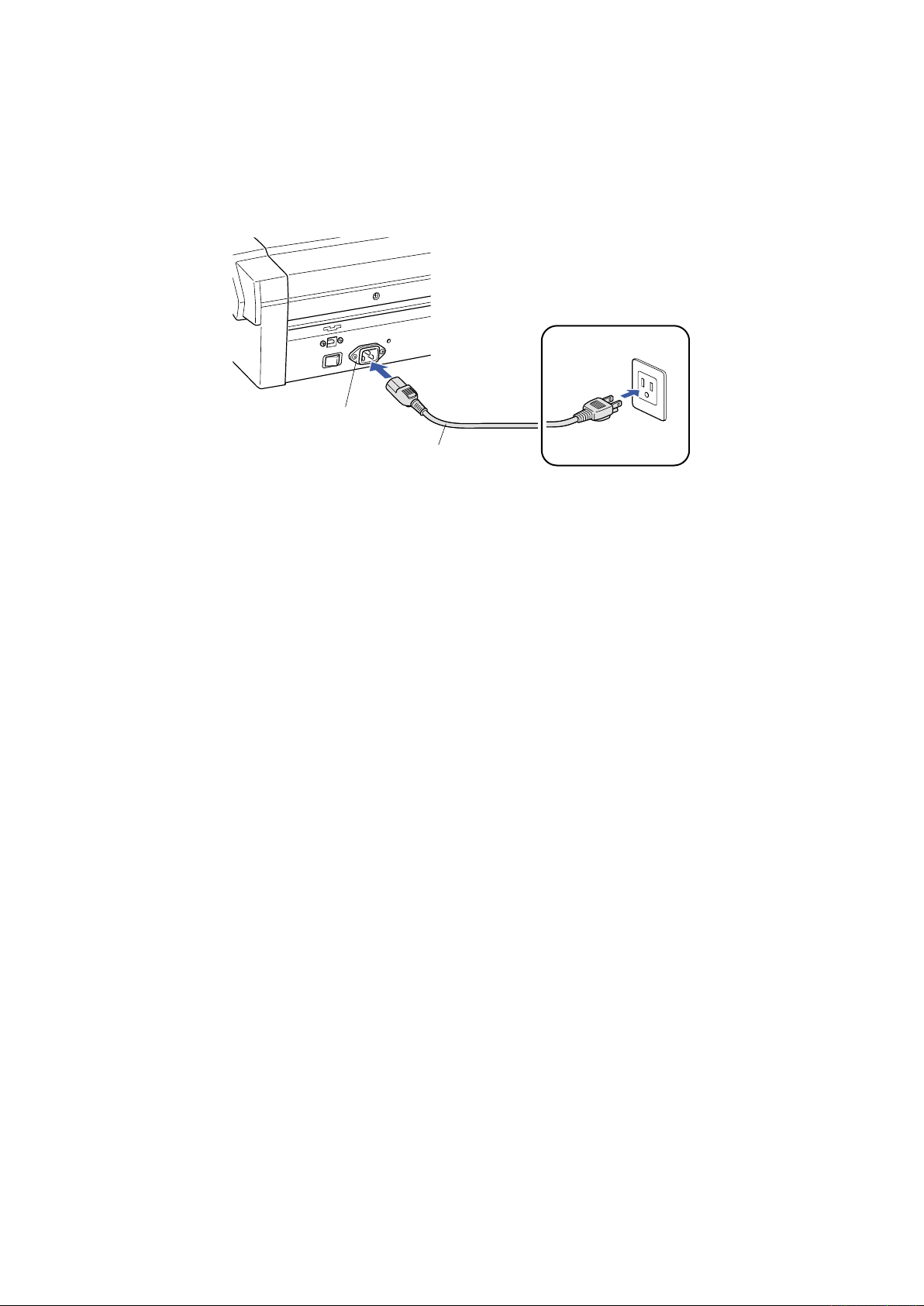

3. CONNECTION AND PREPARATIONS

Power cable

Power inlet

AC power outlet

3. CONNECTION AND PREPARATIONS

3.1 Connecting to the Power Supply

Connect one end of the power cable provided to the scanner’s power inlet and the other end to an AC power

outlet of the rated supply voltage.

CSX300-UM-251-9370 3-1

Page 16

3. CONNECTION AND PREPARATIONS

ON

ON

OFF

Checkpoint

3.2 Turning the Power On and Off

The LED (blue) on the [POWER] button changes as follows to indicate the scanner’s power supply status.

• Unlit: The scanner is turned off.

• Lit: Lights when the scanner is turned on and remains lit while it is operating normally.

• Flashing: Flashes when the scanner is in power-saving mode.

Turning the Power On

(1) Connect the power cable.

(2) Turn on the main power switch (the | side).

Press the [POWER] button on the scanner’s control panel.

When the scanner is in the power-on status, the [POWER] button lights blue.

Turning the Power Off

Press the [POWER] button on the scanner’s control panel.

When the scanner is in the power-off status, the [POWER] button LED is extinguished.

After the scanner has been turned off, wait at least five seconds before turning it on again.

CSX300-UM-251-9370 3-2

Page 17

3. CONNECTION AND PREPARATIONS

To cancel the

powe

r-saving mode

Notes on the power-saving mode

The scanner automatically switches to power-saving mode (the blue LED on the power button flashes) after

approximately 12 minutes have elapsed without a document being loaded in the scanner. To return the

scanner to normal status (Local status), press either the [STOP] or the [EJECT] key.

CSX300-UM-251-9370 3-3

Page 18

3. CONNECTION AND PREPARATIONS

Checkpoint

3.3 System Requirements

The minimum system requirements for running the scanner’s hardware and software are listed below.

• Operating system: Windows 2000 Professional, XP Professional, or XP Home Edition

• CPU: Pentium III, 1 GHz

• Memory: 256 MB or more

• Monitor: 1024 x 768 pixels, True Color or higher

• Disk space: At least 10 GB

• Mouse

• Interface: USB 2.0 interface

*1 When the document length exceeds length of an A0-size document, additional hard disk space is required.

Recommended environment

• CPU: Pentium 4, 2 GHz

• Memory: 1 GB or more

• Disk space: At least 30 GB

• USB 2.0 interface (that comes standard with your computer)

*1

Use with a system configuration below the recommended specifications will affect the scanning speed and prevent

the scanner from operating to its specified capabilities. Moreover, colors may not be displayed correctly if the num-

ber of colors that the monitor can display is 256 or less.

To edit an A1-size or larger grayscale document with a resolution of 400 dpi or higher, or a 24-bit color document,

you may need more than the recommended memory sizes above.

CSX300-UM-251-9370 3-4

Page 19

3. CONNECTION AND PREPARATIONS

Computer

USB inte

rface connector

USB cable

Important

Checkpoint

3.4 Connecting the Scanner to a Computer

USB Connection

A USB cable is used to connect the scanner to the computer, via the respective USB interface connectors.

The connectors at the computer and scanner ends of the USB cable have different shapes. Make sure that

the cable is oriented correctly before making the connection.

Make sure that both the scanner and the computer are in the power-off status when connecting them.

• Make sure that the USB cable is firmly inserted into the interface connectors.

• The operation of the scanner cannot be guaranteed in the following cases:

When the cable is connected to a USB hub or an add-on USB board.

t

When you are using a custom-built computer or one that you have modified.

t

• Do not perform any of the following actions:

Remove or reinsert the cable while you are installing the driver.

t

Remove or reinsert the cable while starting up the computer or the scanner.

t

Remove or reinsert the cable while transferring data.

t

Connect two or more scanners to a single computer.

t

Please see the separate “Quick Start Guide” for the scanner driver installation procedure.

CSX300-UM-251-9370 3-5

Page 20

Page 21

4. INSTALLING THE SOFTWARE

Checkpoint

4. INSTALLING THE SOFTWARE

The procedure outlined below is based on the requirement that you are logged on to Windows with administrator

rights. Consult your Windows manual for more information.

4.1 Installing the Driver Software for Windows Vista

(1) Use the USB cable to connect the scanner to the computer, and then turn on the computer.

(2) When Windows starts up, insert the CD-ROM supplied with the scanner into the CD-ROM drive. The

“Start” screen opens automatically. Click the [Quit] button to close the “Start” screen.

(3) Turn on the power to the scanner.

(4) The screen shown below is displayed. Click "Locate and install driver software (recommended)".

(5) The User Account Control screen is displayed. Click [Continue] to proceed with the installation.

(6) The screen shown below is displayed. Click "Don't search online".

(7) The screen shown below is displayed. Click "I don't have the disc. Show me other options."

CSX300-UM-251-9370 4-1

Page 22

4. INSTALLING THE SOFTWARE

(8) The screen shown below is displayed. Click "Browse my computer for driver software (advanced)".

(9) The screen shown below is displayed. Click [Browse] and either select the [DRIVER] folder in the CD-

ROM drive or enter a CD-ROM drive name and \DRIVER using the keyboard.

Example: For drive E, enter "E:\DRIVER".

(10) Click [Next]. The wizard will start searching for the driver.

(11) The screen shown below is displayed. Click [Install] to proceed with the installation.

CSX300-UM-251-9370 4-2

Page 23

4. INSTALLING THE SOFTWARE

(12) The screen shown below is displayed when the wizard has finished installing the driver.

Click the [Close] button to close the "Found New Hardware" wizard.

(13) The Windows Vista desktop appears, and the scanner is recognized by the computer.

CSX300-UM-251-9370 4-3

Page 24

4. INSTALLING THE SOFTWARE

4.2 Installing the Driver Software for Windows XP

(1) Use the USB cable to connect the scanner to the computer, and then turn on the computer.

(2) When Windows starts up, insert the CD-ROM supplied with the scanner into the CD-ROM drive. The

“Start” screen opens automatically. Click the [Quit] button to close the “Start” screen.

(3) Turn on the power to the scanner.

(4) When Windows XP starts up, the following screen appears (if Service Pack 2 has not been installed, the

screen shown in (5) below appears). Select the option “No, not this time” and then click [Next].

(5) If Service Pack 2 has not been installed, the following screen appears. Select the option “Install from a

list or a specific location (Advanced).” and then click [Next].

(6) The screen shown below is displayed. Select the option “Search for the best driver in these locations”

and select the check box entitled “Include this location in the search.”

Click [Browse] and select the [English]-[DRIVER]-[SCANNER] folders in the CD-ROM drive or enter a

CD-ROM drive name and \English\DRIVER\SCANNER using the keyboard.

Example: For drive D, enter “D:\English\DRIVER\SCANNER”.

CSX300-UM-251-9370 4-4

Page 25

4. INSTALLING THE SOFTWARE

(7) Click [Next]. The wizard will start searching for the driver.

(8) The screen shown below is displayed. Read the explanation and make sure that you understand the

contents.

To continue the installation, click [Continue Anyway].

(9) The screen shown below is displayed when the wizard has finished installing the driver.

Click the [Finish] button to close the “Welcome to the Found New Hardware” wizard.

(10) The Windows XP desktop appears, and the scanner is recognized by the computer.

CSX300-UM-251-9370 4-5

Page 26

4. INSTALLING THE SOFTWARE

4.3 Installing the Driver Software for Windows 2000

(1) Use the USB cable to connect the scanner to the computer, and then turn on the computer.

(2) When Windows starts up, insert the CD-ROM supplied with the scanner into the CD-ROM drive. The

“Start” screen opens automatically. Click the [Quit] button to close the “Start” screen.

(3) Turn on the power to the scanner.

(4) The screen shown below appears. Click [Next] to move to the “Install Hardware Device Drivers” screen.

(5) When this screen is displayed, select the option “Search for a suitable driver for my device

(recommended)” and then click [Next] to display the “Locate Driver Files” screen.

(6) When this screen is displayed, select the check box entitled “Specify a location” and click [Next].

(7) The following screen is displayed. Click [Browse] and select the [English]-[DRIVER]- [SCANNER]

folders in the CD-ROM drive or enter a CD-ROM drive name and \English\DRIVER\SCANNER using

the keyboard.

Example: For drive D, enter “D:\English\DRIVER\SCANNER”.

Click [OK]. The wizard will start searching for the driver.

CSX300-UM-251-9370 4-6

Page 27

4. INSTALLING THE SOFTWARE

(8) The screen shown below is displayed when the wizard has finished searching. Click [Next].

(9) The screen shown below is displayed. Read the explanation and make sure that you understand the

contents.

To continue the installation, click [Yes].

(10) The screen shown below is displayed when the wizard has finished installing the driver.

Click the [Finish] button.

(11) The Windows 2000 desktop appears, and the scanner is recognized by the computer.

CSX300-UM-251-9370 4-7

Page 28

4. INSTALLING THE SOFTWARE

4.4 Checking the Interface Connection for Windows Vista

(1) Launch the Control Panel using the [Start] menu on the Windows desktop.

(2) Click "Hardware and Sound" to display the screen shown below.

(3) Click "Scanners and Cameras" to display the screen shown below.

Check that "Graphtec CSX300-09" is displayed here.

CSX300-UM-251-9370 4-8

Page 29

4. INSTALLING THE SOFTWARE

4.5 Checking the Interface Connection for Windows XP

(1) Launch the Control Panel using the [Start] menu on the Windows desktop.

(2) The screen shown below is displayed when you click on the “Printers and Other Hardware” icon.

(3) The screen shown below is displayed when you click on the “Scanners and Cameras” icon.

CSX300-UM-251-9370 4-9

Page 30

4. INSTALLING THE SOFTWARE

4.6 Checking the Interface Connection for Windows 2000

(1) Launch the Control Panel using the [Start] menu on the Windows desktop.

(2) The screen shown below is displayed when you click on the “Scanners and Cameras” icon.

Check that “Graphtec CSX300-09” is displayed here.

CSX300-UM-251-9370 4-10

Page 31

4. INSTALLING THE SOFTWARE

4.7 Installing the Scanning Master 21+ Application

The Scanning Master 21+ “OPS112” is a software application for using a Graphtec scanner to scan image

data.

Operating Environment

Windows 2000 Professional, XP Professional, XP Home Edition or Vista

Installation Procedure

(The following steps are explained using the Windows 2000 windows.)

(1) Start up Windows 2000.

(2) Insert the CD-ROM supplied with the scanner into the CD-ROM drive.

(3) Select "Run" from the [Start] menu on the Windows desktop.

(4) Enter the CD-ROM drive name and English\OPS112\SETUP.EXE as the name of the file you wish to

open.

If the disk is in drive E, for example, enter “E:\English\OPS112\SETUP.EXE” in the box.

(5) Click the OK button to run the OPS112 setup program. From this point on, follow the setup program’s

instructions to install the OPS112 application.

• If the application has been properly installed, “Scanning Master 21+” will be newly listed in the Programs

menu accessed from the Start button.

For more details, open the README.TXT file provided in the “Scanning Master 21+” folder.

CSX300-UM-251-9370 4-11

Page 32

Page 33

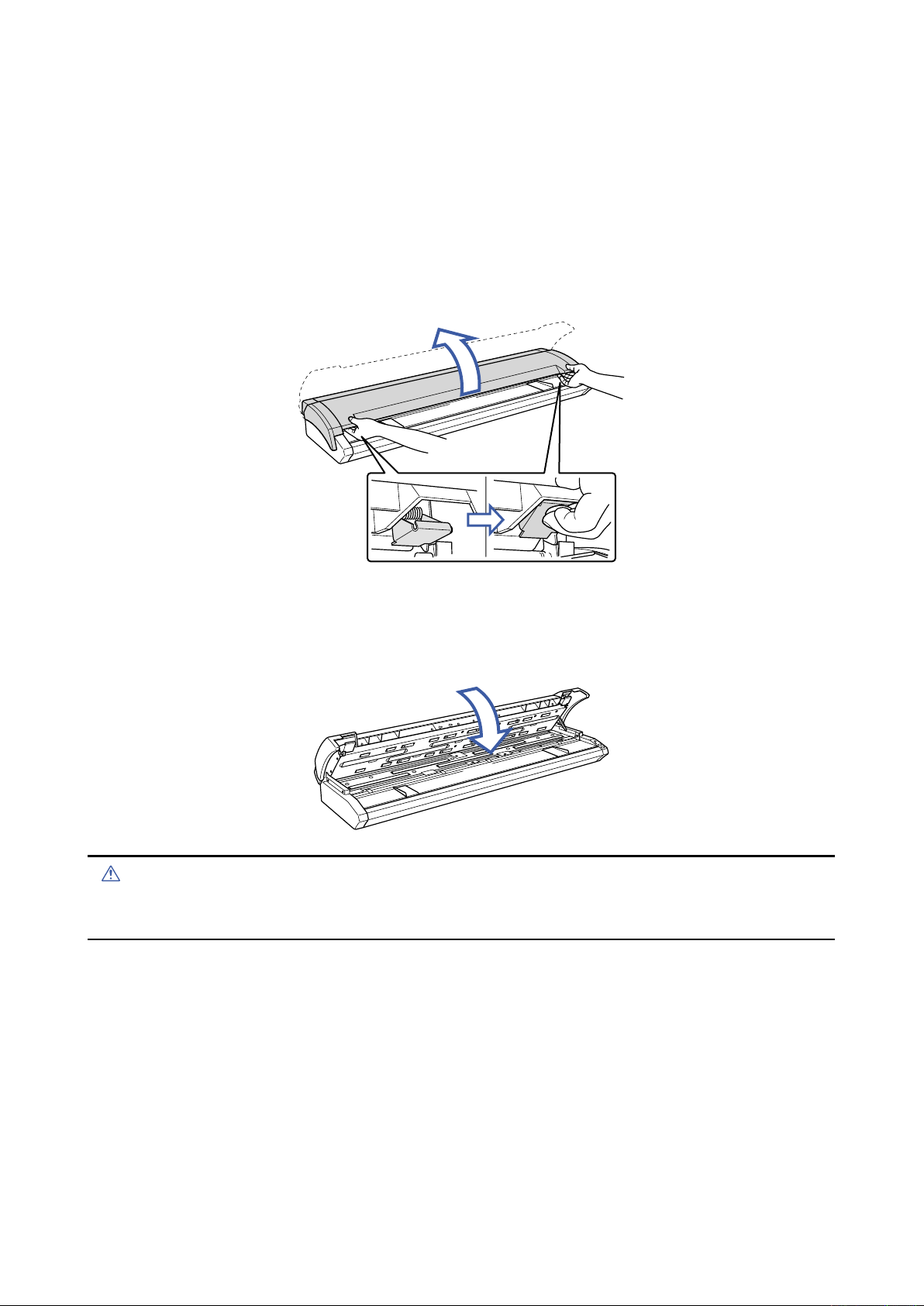

5. DAILY MAINTENANCE

Caution

5. DAILY MAINTENANCE

5.1 Opening and Closing the Top Cover

Opening the top cover

(1) Turn off the scanner.

(2) Using both hands, push up the left and right open levers on the top cover to unlock them.

While still holding on to the levers, open the cover fully (approximately 47 degrees).

(3) When the top cover is fully open, the fixing stay operates to hold the top cover in place.

Closing the top cover

(1) Press the open cover down gently with both hands to close it.

(2) Check that the left and right open levers are locked into position.

• Take care not to get your fingers caught when opening or closing the cover.

• If the levers are not locked correctly, the ERROR LED flashes and a scanning operation cannot be performed.

CSX300-UM-251-9370 5-1

Page 34

5. DAILY MAINTENANCE

Feedrollers

Caution

5.2 Cleaning the Feed Rollers

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

(3) While rotating the feed rollers, wipe them clean using a soft cloth that has been moistened with water or

a neutral detergent (diluted with water) and firmly wrung out.

(4) Wipe the feed rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the top cover.

CSX300-UM-251-9370 5-2

Page 35

5. DAILY MAINTENANCE

Documentsupportrollers

Caution

5.3 Cleaning the Document support Rollers

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

(3) While rotating the document support rollers, wipe them clean using a soft cloth that has been moistened

with water or a neutral detergent (diluted with water) and firmly wrung out.

(4) Wipe the document support rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the top cover.

• Scanning may be affected if the document support rollers becomes scratched or dirty.

CSX300-UM-251-9370 5-3

Page 36

5. DAILY MAINTENANCE

Gaprollers

Caution

5.4 Cleaning the Gap Rollers

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

(3) While rotating the gap rollers, wipe them clean using a soft cloth that has been moistened with water or

a neutral detergent (diluted with water) and firmly wrung out.

(4) Wipe the gap rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the top cover.

CSX300-UM-251-9370 5-4

Page 37

5. DAILY MAINTENANCE

Pushrollers

Caution

5.5 Cleaning the Push Rollers

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

(3) While rotating the push rollers, wipe them clean using a soft cloth that has been moistened with water or

a neutral detergent (diluted with water) and firmly wrung out.

(4) Wipe the push rollers once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the top cover.

CSX300-UM-251-9370 5-5

Page 38

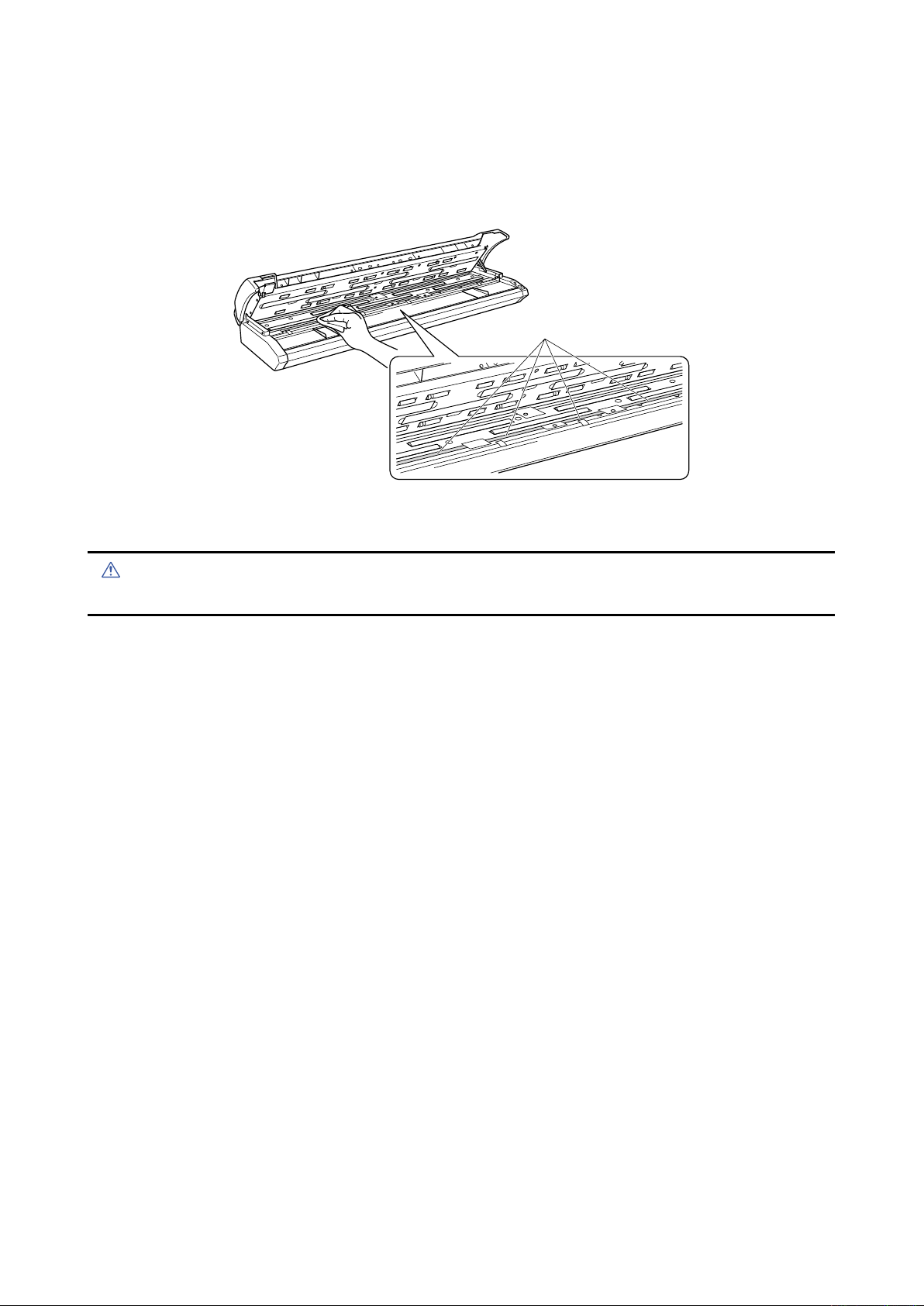

5. DAILY MAINTENANCE

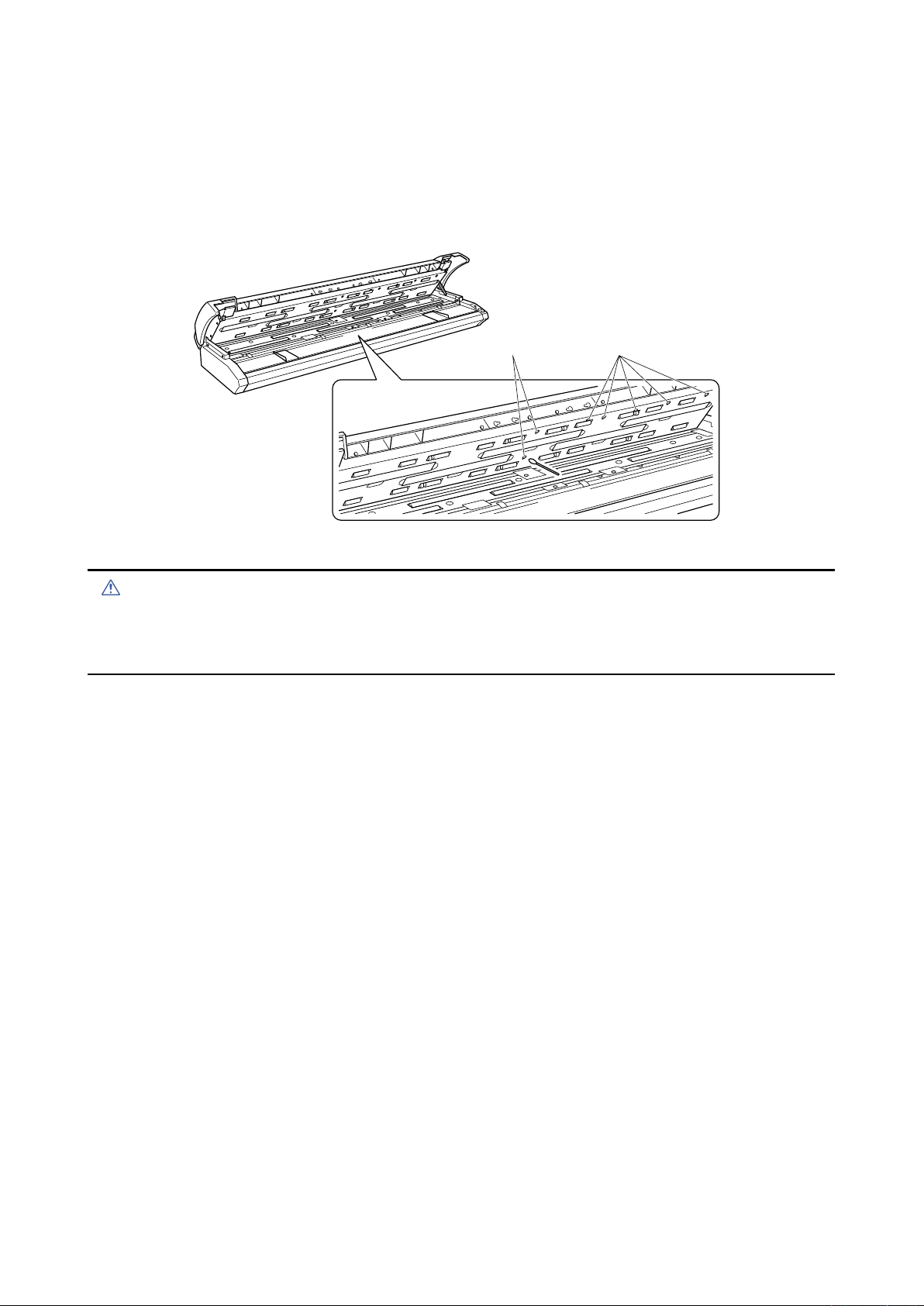

Transparentcontactplates

Caution

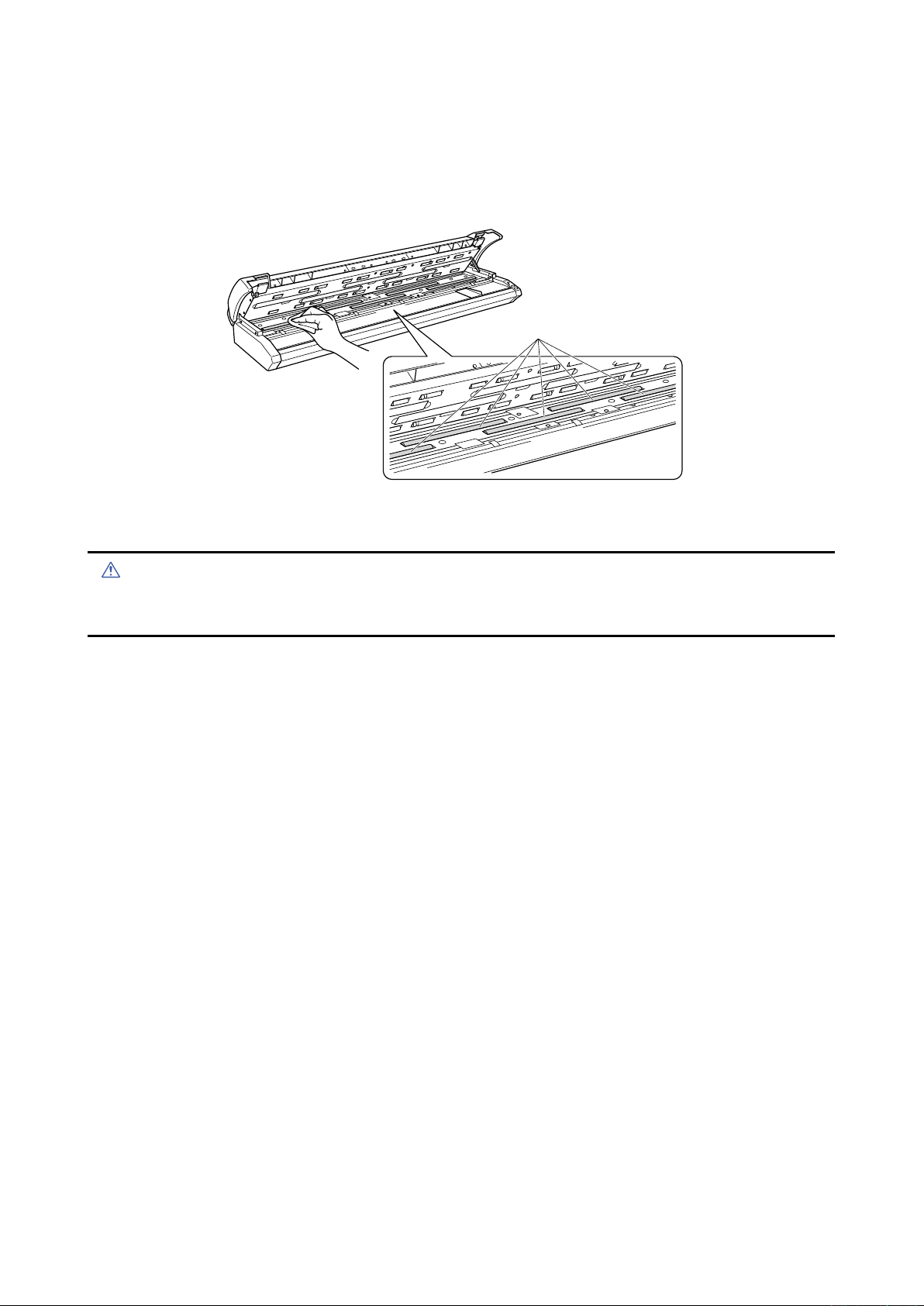

5.6 Cleaning the Image Sensors (Contact glass plates)

The scanner’s image quality drops when the contact glass plates over the image sensors become dirty, so

clean the image sensors whenever necessary.

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

(3) As shown below, wipe off any soiled areas on the contact glass plates using a soft cloth that has been

moistened with water or a neutral detergent (diluted with water) and firmly wrung out.

(4) Wipe the contact glass plates once again using a soft, dry cloth to remove all the moisture.

(5) Close the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the cover.

• Do not use a commercial cleaner for office equipment, a glass cleaner, or chemical solvents such as solutions

containing alcohol. Moreover, although the contact glass plates is not a maintenance part that requires periodic

replacement, it is a consumable part because its surface may receive slight scratches due to minute particles of

dust and other foreign matter. If document scanning produces unsatisfactory results (unexpected white or black

streaks in the data) due to scratches on one or more of the contact glass plates or other reasons, please perform

the calibration procedure (see Section 5.9, “Scanner Calibration”). If the scanning results do not improve after

calibration, the contact glass plate(s) will need to be replaced.

CSX300-UM-251-9370 5-6

Page 39

5. DAILY MAINTENANCE

documentsize

detectionsensors

Papersensors

Caution

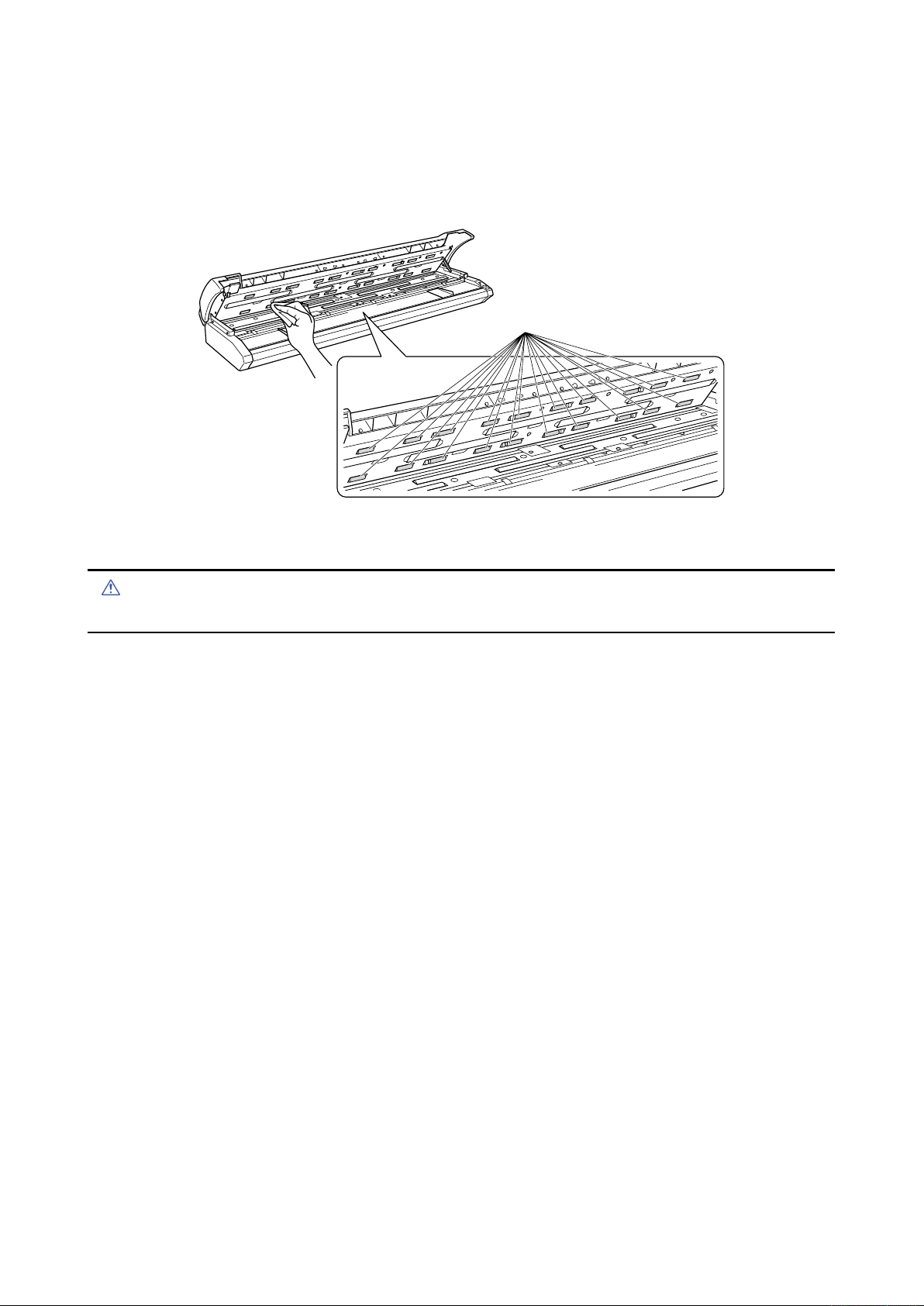

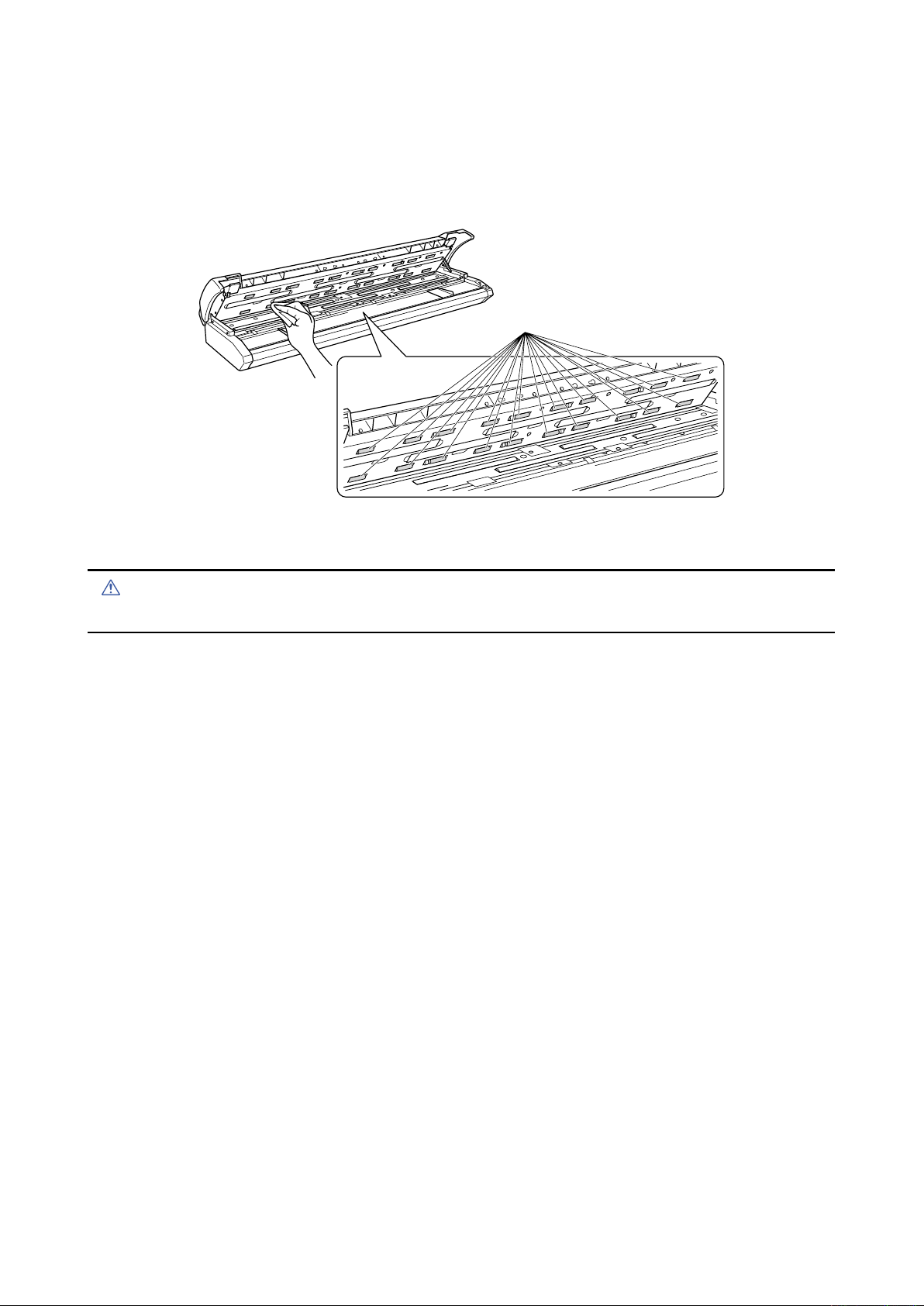

5.7 Cleaning the Media sensors

Accumulated dust on the paper sensors or on the document size detection sensors may prevent the

document from being scanned correctly. The sensors must be cleaned when necessary.

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

(3) Wipe the media sensors (at the front and rear) using a cotton swab.

(4) Close the top cover as described in Section 5.1 “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the top cover.

• Use a cotton swab or something equally soft to gently wipe the media sensors.

Do not use any chemicals to clean the sensors.

CSX300-UM-251-9370 5-7

Page 40

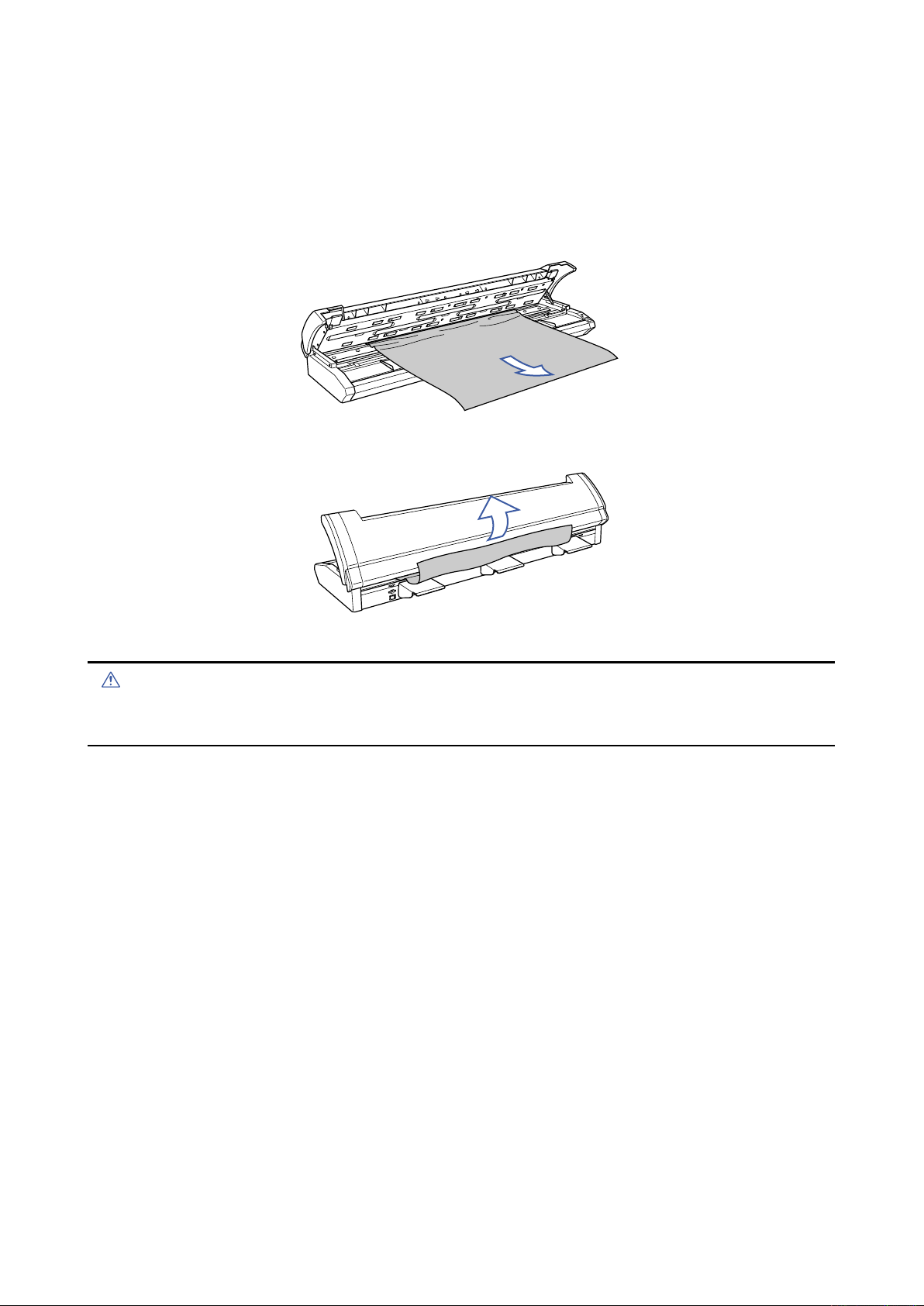

5. DAILY MAINTENANCE

Caution

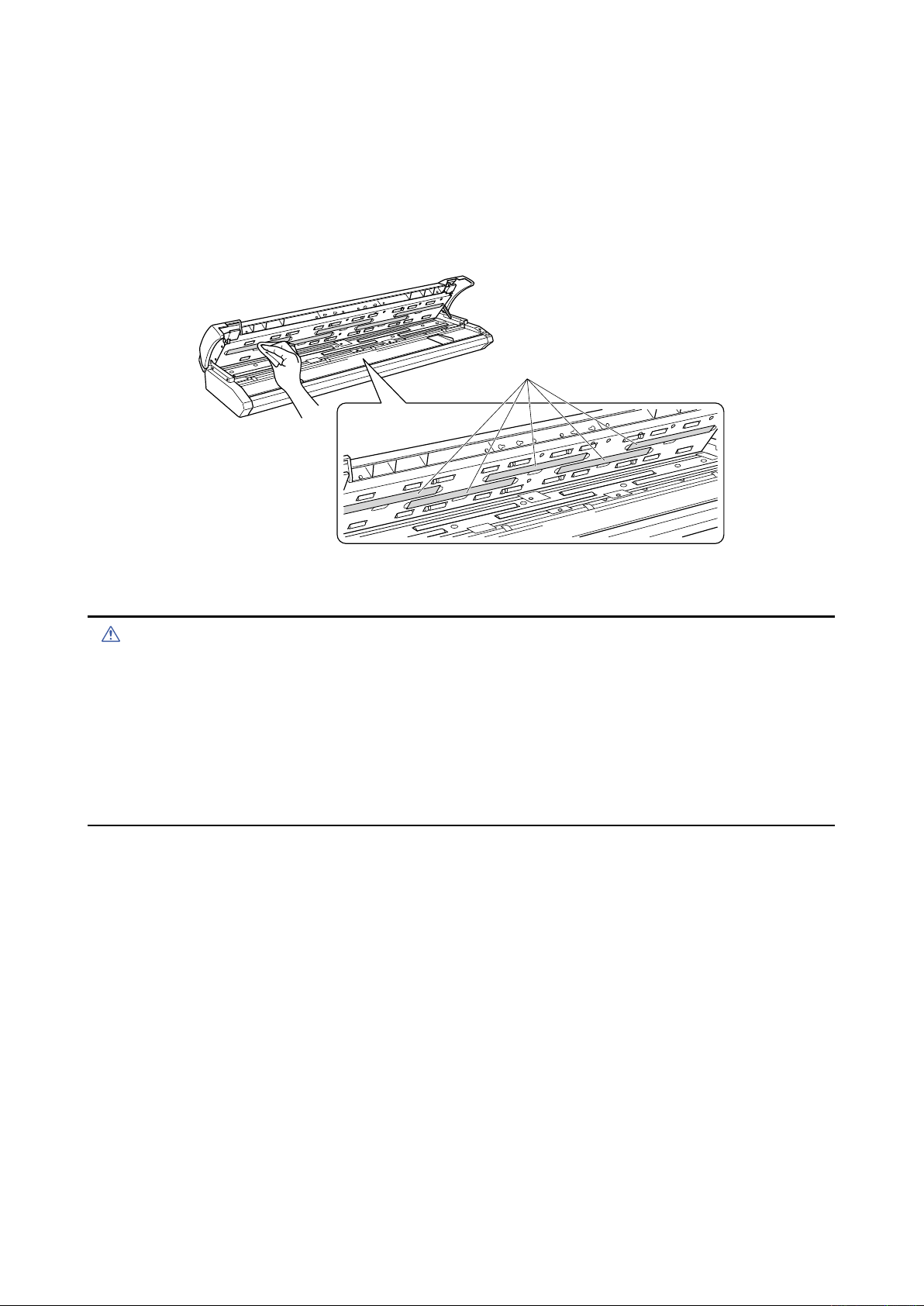

5.8 Removing a Jammed Document

If a document becomes jammed in the scanner during scanning or another operation, follow the procedure

described below to remove the jammed document.

(1) Turn off the scanner.

(2) Open the top cover as described in Section 5.1 “Opening and Closing the Top Cover”.

(3) If the document is jammed at the front, remove the document from the inside by pulling it forward.

(4) If the document is jammed at the rear, remove the document by pulling it out along the rear guides.

(5) Close the top cover as described in Section 5.1, “Opening and Closing the Top Cover”.

• Take care not to get your fingers caught in the top cover.

• When removing a jammed document, pull on it gently to prevent damage to the document.

CSX300-UM-251-9370 5-8

Page 41

5. DAILY MAINTENANCE

Checkpoint

5.9 Scanner Calibration

Calibrate the scanner if scanning quality is observed to deteriorate, with scanned results such as those

described below

• The scanned image is distorted

• Areas of uneven color appear in the scanned image

• Other unsatisfactory results (but excluding problems related to media quality, such as folds, creases, or

paper curl)

Preparation and checks

Recommended usage environment

• Monitor: 1024 x 768 pixels, High Color or better resolution

A low-resolution monitor will make it difficult to discern any problem areas.

Launching the Scanner Adjustment Program

(1) Connect the scanner to the computer, turn on the scanner, and then turn on the computer.

(2) Install the Scanning Master 21+ “OPS112” software if it is not already installed.

(3) Click the [Start] button on the Windows desktop, then select Programs > Scanning Master 21+ >

Scanner Adjustment.

(4) Click Scanner Adjustment to launch the Scanner Adjustment program.

(5) Select the desired adjustment item from the Scanner menu.

CSX300-UM-251-9370 5-9

Page 42

5. DAILY MAINTENANCE

Caution

Checkpoint

Calibration sheet

Arrow mark

Scanner

Insertion direction

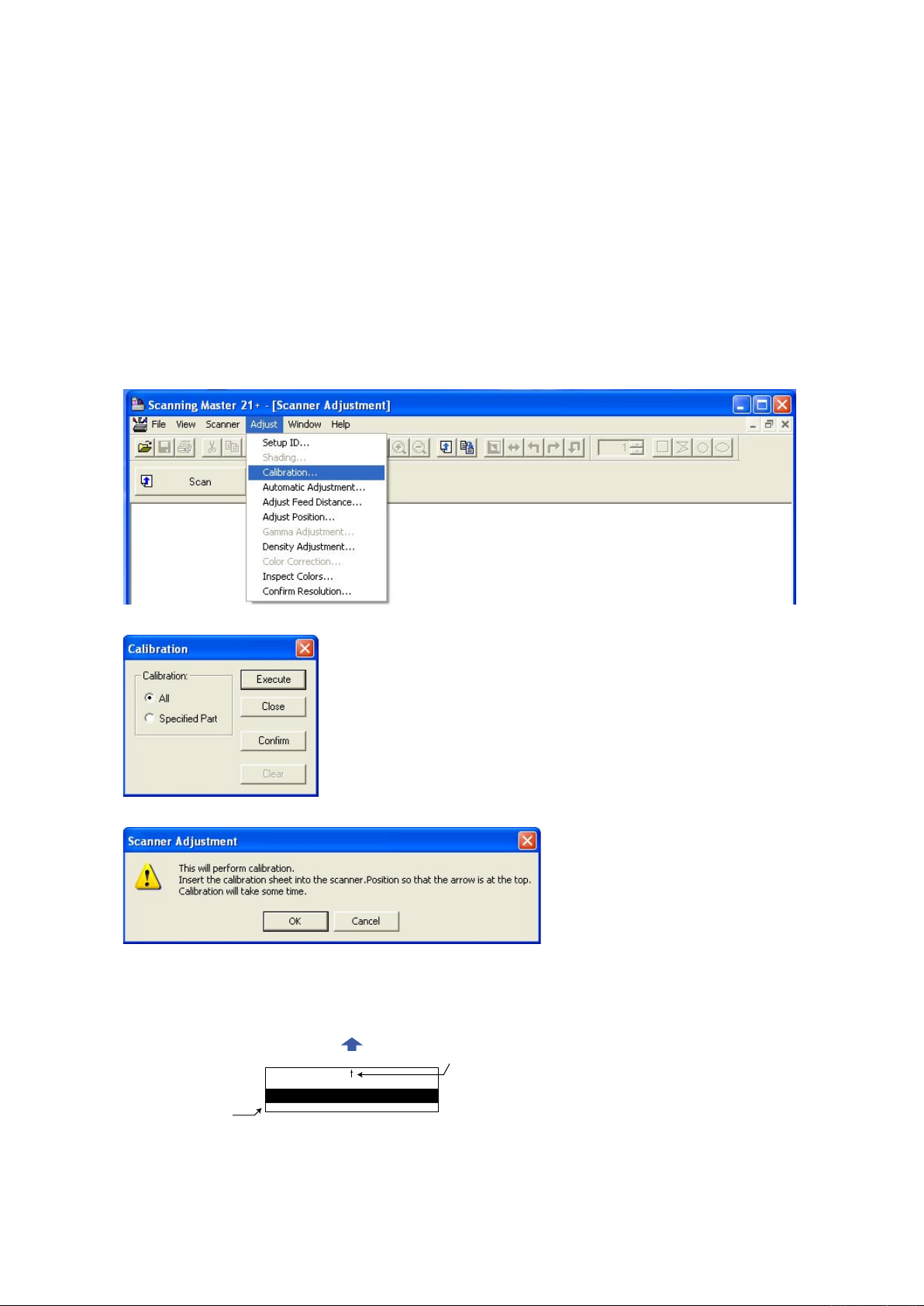

Calibration

Before beginning calibration, clean the contact glass plates located inside the scanner and the surface of

the document-scanning table. Any dust or dirt on these surfaces may affect the calibration results and the

resulting image quality.

Check that the calibration sheet is free of any dust or dirt.

• The calibration procedure will take some time. Do not turn off the scanner while calibration is underway.

Accidentally turning off the scanner may result in damage that requires servicing.

• Handle the calibration sheet with care so that it does not get bent. To prevent soiling, store it in its special storage

box.

• The calibration sheet is a consumable item. It cannot be used if it is bent or soiled.

• The calibration sheet is a paper product. Do not attempt to clean it with any type of liquid cleaner.

A prompt instructing you to insert the calibration sheet in the scanner will be displayed in Step 3. At that time, insert

the calibration sheet as instructed, with the arrow at the top, as shown in the diagram below.

(1) Launch the Scanner Adjustment program (as described earlier), and then display the Scanner menu.

Select Calibration on the Scanner menu.

(2) Select All in Calibration and click the [Execute] button.

(3) The following prompt is displayed. Insert the calibration sheet into the scanner as instructed.

(4) Click the [OK] button to begin calibration.

(5) Calibration ends after approximately 10 minutes.

Click the [OK] button to complete calibration.

CSX300-UM-251-9370 5-10

Page 43

5. DAILY MAINTENANCE

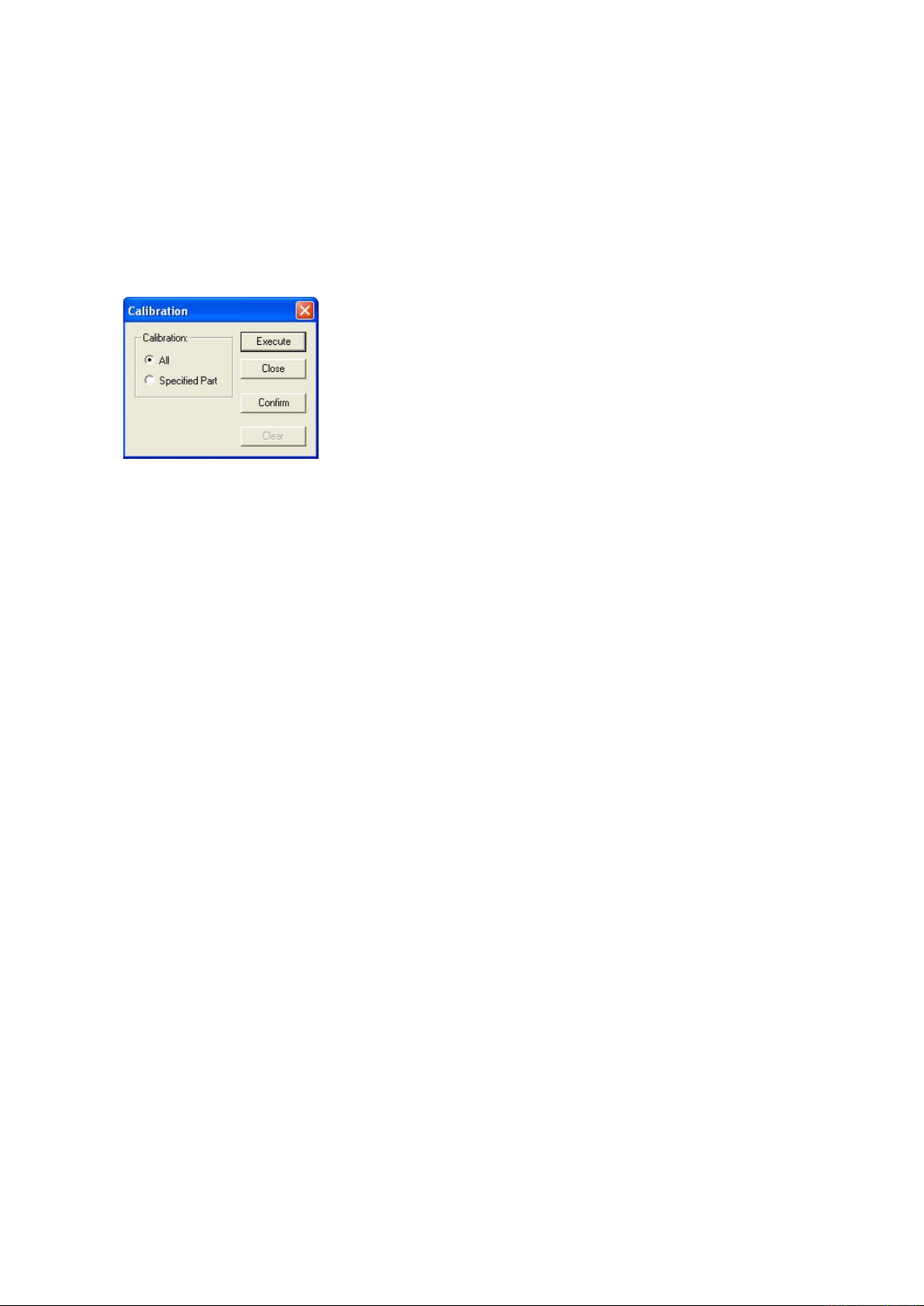

(6) To check the calibration results, click the [Confirm] button in the Calibration screen (shown in step (2)

above).

(7) The following prompt is displayed. Insert the calibration sheet into the scanner once again as instructed.

(8) Click the [OK] button to start scanning.

The scanned data is displayed when scanning is complete. Colors may differ slightly for individual

sensors to make it easier to identify problem areas in calibration. This does not indicate a defect.

Check that there are no vertical streaks, such as white patches, in the scanned data.

(Streaks occur when calibration is not performed correctly due to contamination by dust or dirt.)

(9) If the data is normal, calibration is complete. Click the [Close] button and exit the Scanner Adjustment

Program.

(10) If any abnormal data is observed, specify the problem areas as follows:

Select Calibration from the Scanner menu, and then select Specified Part in the Calibration screen.

(11) The mouse arrow cursor changes to a cross cursor when moved over the data. Click the left mouse

button with the mouse positioned over the streak data. The selected area is shown in blue. Repeat this

procedure for any additional streaks.

Areas that have been selected (shown in blue) can be deselected by clicking the left mouse button

again. To deselect all selected areas, click the [Clear] button.

(12) Once all the required areas have been specified, remove the calibration sheet and clean the contact

glass plates and document-scanning table surface. Check the calibration sheet for dust and dirt.

(13) Click the [Execute] button and then follow the instructions displayed on the screen. The procedure will

be the same as that described in Steps (3) to (5) above. (The time required for calibration will vary

according to the number of repeats specified.)

(14) Perform Steps (8) to (10) once more, and verify the calibration results.

CSX300-UM-251-9370 5-11

Page 44

Page 45

6. RECOMMENDED PARTS LIST

6. RECOMMENDED PARTS LIST

No. Part No. Part Name Description Q'ty Remarks RL

444063052 SVC_Main_BD_S Main Board 1 A

1

2 444063101 SVC_CIS_BD CIS Control Board 5

3 444063083 SVC_PWR_BD CIS Power Board 1

4 444063601 Right_Side_Cover_A

5 444063825 Scan_Glass_A Contact Glass Plate Assy 5 A

6 444063891 Calibration Sheet (IS0925)

7 641710002 Feed_Roller_F Front Feed Roller 1 B

8 641710012 Feed_Roller_R Rear Feed Roller 1 B

9 444063722 Pinch_Roller_A Pinch Roller Assy 20 B

10 561080004 Media_Sensor PS117ED1 7 B

11

444063681 Press_Roller_A Document Roller Assy 5 B

12 694450111 FPC_Cable FPC, CS20A, CIS to CIS B 5 A

13 561080012 Cover_Sensor KI139 1-AALF 2 B

444065201 CIS Sensor A, (Rank A)

444065211 CIS Sensor B, (Rank B)

444065221 CIS Sensor C, (Rank C)

14

444065231 CIS Sensor D, (Rank D)

444065251 CIS Sensor F, (Rank F)

444065261 CIS Sensor G, (Rank G)

444065271 CIS Sensor H, (Rank H)

With Control Panel Relay Board

IS0925 (Ordered by this options model name)

Select the same rank of sensor

that is used in your scanner.

1 B

1 A

5 A

A

A

CSX300-UM-251-9370 6-1

Page 46

Page 47

7. LIST OF JIGS AND TOOLS

7. LIST OF JIGS AND TOOLS

7.1 Jigs

Jigs Adjustments Remarks

CSX300-09 firmware •Downloading system program Firmware (CSX300.X)

Scanning Master 21+

(Ver. 6.60 or later)

Calibration sheet •Shading (white & black correction) Standard accessory

Adjustment test chart for CSX300 •Adjusting feed distance

Auto adjustment chart •Aligning sensor images Auto adjustment chart

7.2 Tools

Tools Usage Remarks

Screwdriver

Allen wrench (2 mm to 4 mm)

Needle-nose pliers

7.3 Other

Item Usage Remarks

Water-diluted neutral detergent or

absolute ethanol wiper (cloth)

PC

USB cable

•Downloading system program

•Shading (white & black correction)

•Adjusting feed distance

•Aligning sensor images

•Adjusting offset

•Adjusting offset

•Aligning sensor images

Disassembly, reassembly, and other

operations

Cleaning

Used to determine whether the problem

is caused by the scanner or other

equipment.

Software supplied with the scanner

(Scanning Master 21+)

1050 mm x 200 mm

Record measured values between C010

and C090.

Large, medium, and small flat blade

screwdrivers and Phillips screwdrivers

CSX300-UM-251-9370 7-1

Page 48

Page 49

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.

DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

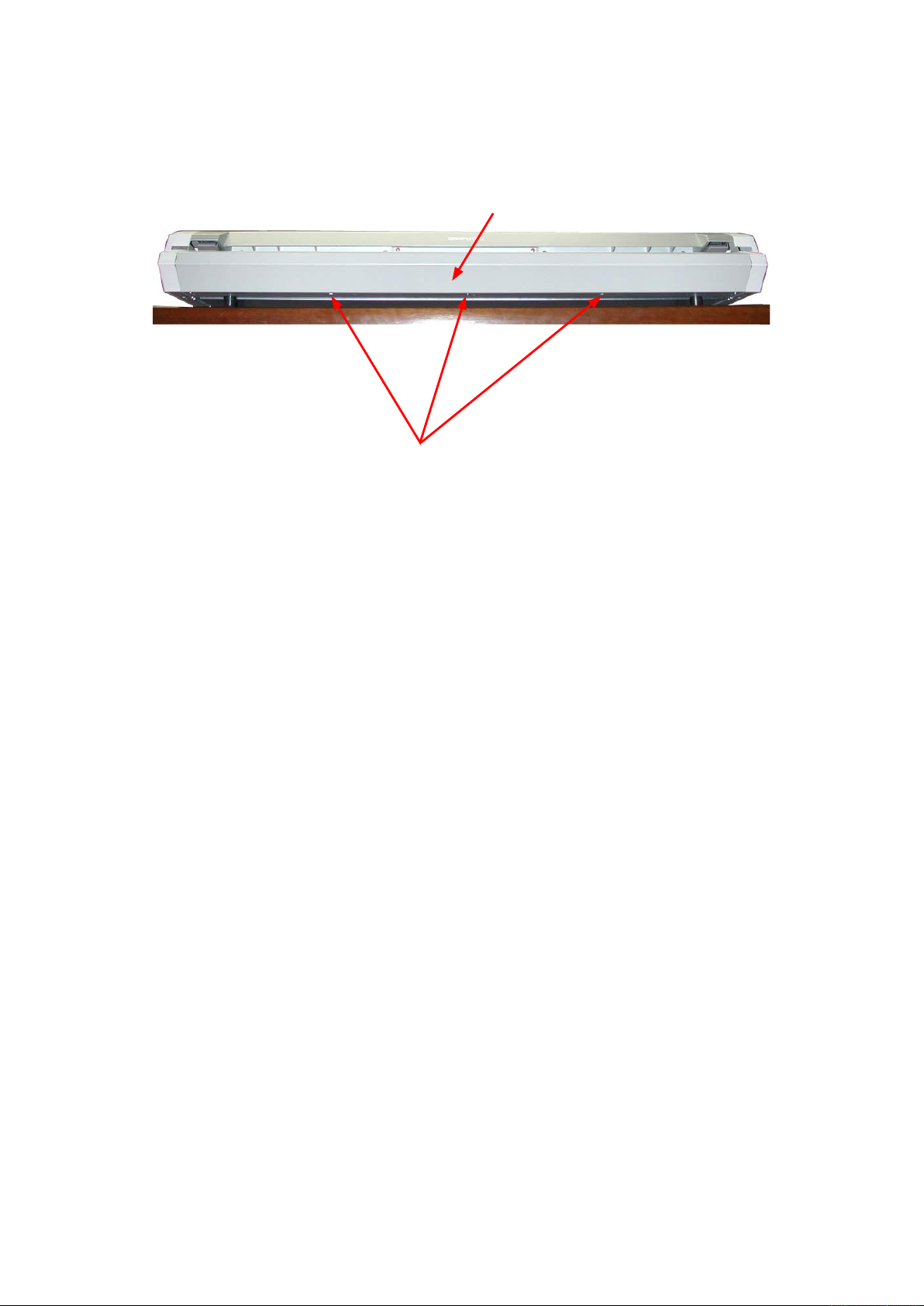

8.1 Top Cover

Detaching the top cover

(1) Remove the four M4L8 binding head screws on the front side of the top cover.

Top cover

M4L8 binding head screw

(2) Remove the four M4L8 binding head screws on the rear side of the top cover.

Top cover

M4L8 binding head screw

(3) Detach the top cover from the scanner unit in the upward direction.

Reattaching the top cover

(1) Reattach the top cover in the reverse order in which it was detached.

CSX300-UM-251-9370 8-1

Page 50

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.2 Front Cover

Detaching the front cover

(1) Remove the three M4L8 thin flat head screws holding the front cover.

Front cover

M4L8 thin flat head screw

(2) Pull out the front cover from the scanner unit.

Reattaching the front cover

(1) Reattach the front cover in the reverse order in which it was detached.

CSX300-UM-251-9370 8-2

Page 51

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

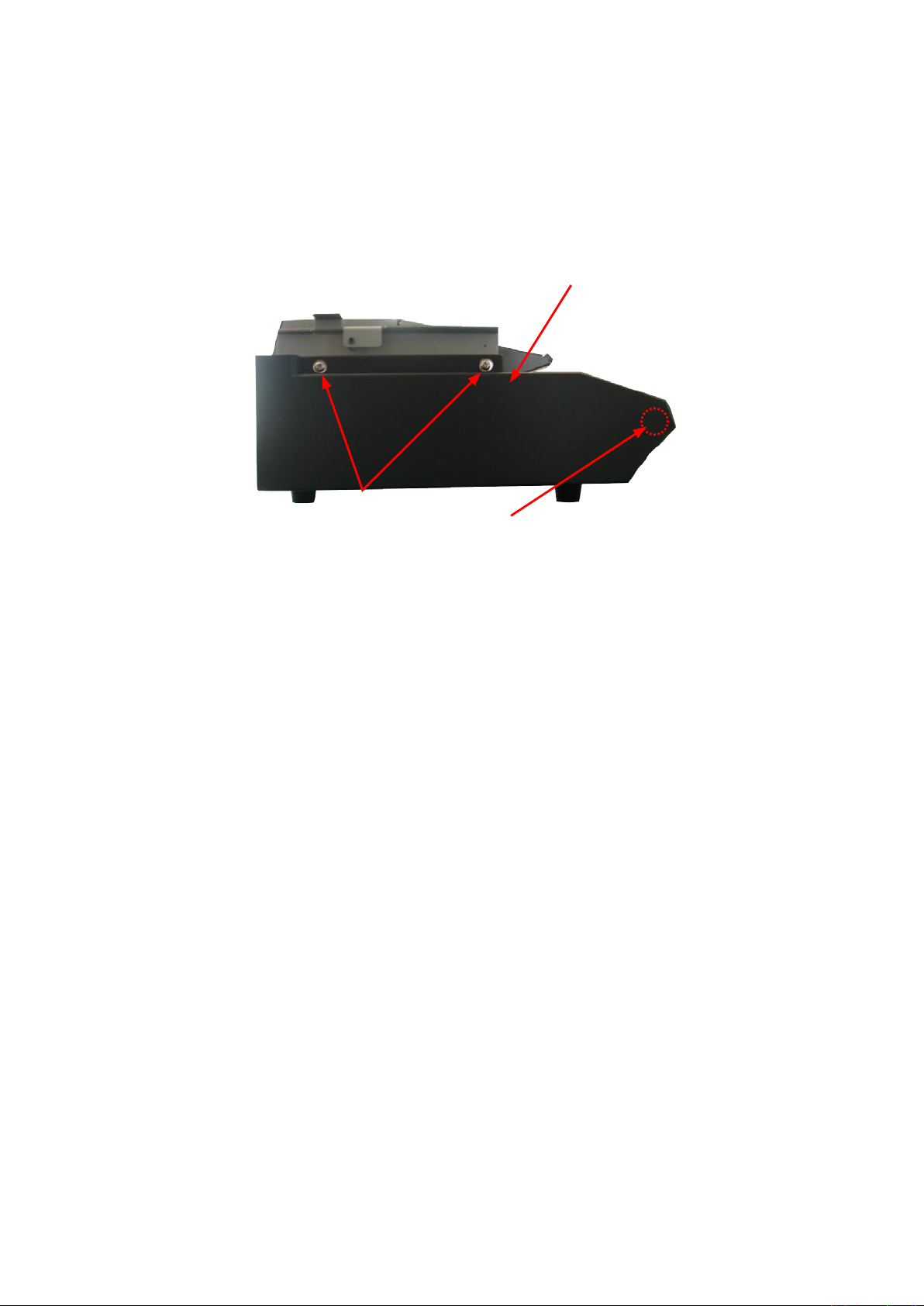

8.3 Left Side Cover

Detaching the left side cover

(1) Detach the top cover (see Section 8.1).

(2) Detach the front cover (see Section 8.2).

(3) Remove the two M4L8 TP screws on the left side of the scanner unit.

(4) Detach the left side cover.

Left side cover

M4L8 TP screw

Note:

There is a positioning pillar inside the left side cover.

Do not twist the cover when removing the cover.

Otherwise, you will break the positioning pillar.

Reattaching the left side cover

(1) Reattach the left side cover in the reverse order in which it was detached.

CSX300-UM-251-9370 8-3

Page 52

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.4 Right Side Cover

Detaching the right side cover

(1) Detach the top cover (see Section 8.1).

(2) Detach the front cover (see Section 8.2).

(3) Remove the two M4L8 TP screws on the right side of the scanner unit.

Right side cover

M4L8 TP screw

Note:

There is a positioning pillar inside the right side cover.

Do not twist the cover when removing the cover.

Otherwise, you will break the positioning pillar.

(2) Disconnect the control panel cable from the control panel board.

Positioning pillar

Control panel cable

Right side cover

Control panel board

(3) Detach the right side cover.

Reattaching the right side cover

(1) Reattach the right side cover in the reverse order in which it was detached.

CSX300-UM-251-9370 8-4

Page 53

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

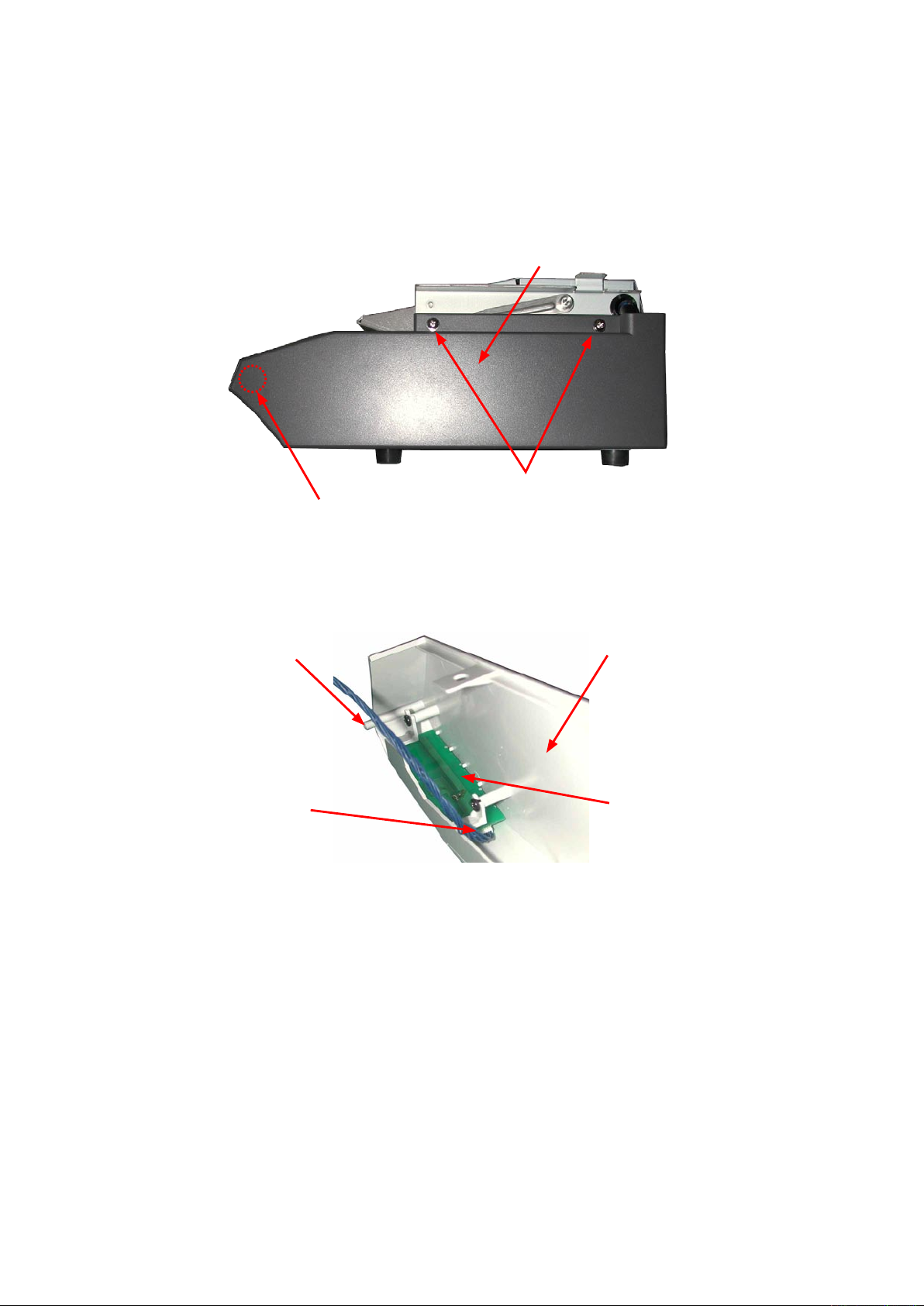

8.5 Front Guide Assembly

Detaching the front guide assembly

(1) Detach the top, front, left side and right covers (see Sections 8.1, 8.2, 8.3 and 8.4).

(2) Remove the two M3L6 binding head screws holding the front guide assembly from each side.

Front guide assembly

M3L6 binding head screw

(2) Remove the four M3L6 binding head screws holding the front guide assembly.

Front guide assembly

(3) Detach the front guide assembly from the scanner unit.

M3L6 binding head screw

Reattaching the front guide assembly

(1) Reattach the front guide assembly in the reverse order in which it was detached.

CSX300-UM-251-9370 8-5

Page 54

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

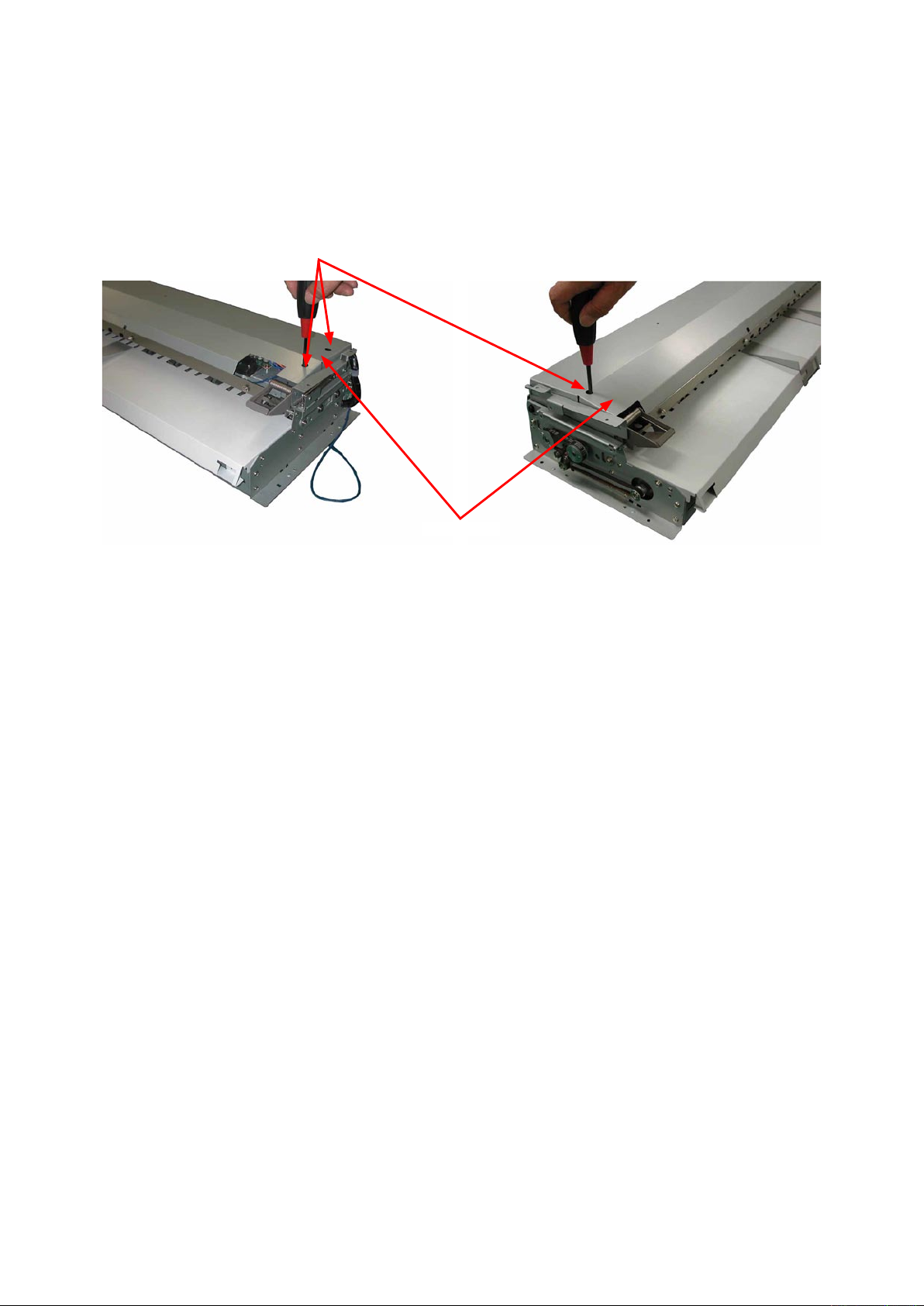

8.6 Shield Cover

Detaching the shield cover

(1) Detach the top cover (see Section 8.1).

(2) Remove the three M3L4 binding head screws from the access holes of the shield cover as shown in the

photographs below.

M3L4 binding head screw

Shield cover

(3) Detach the shield cover.

Reattaching the rear cover

(1) Reattach the shield cover in the reverse order in which it was detached.

CSX300-UM-251-9370 8-6

Page 55

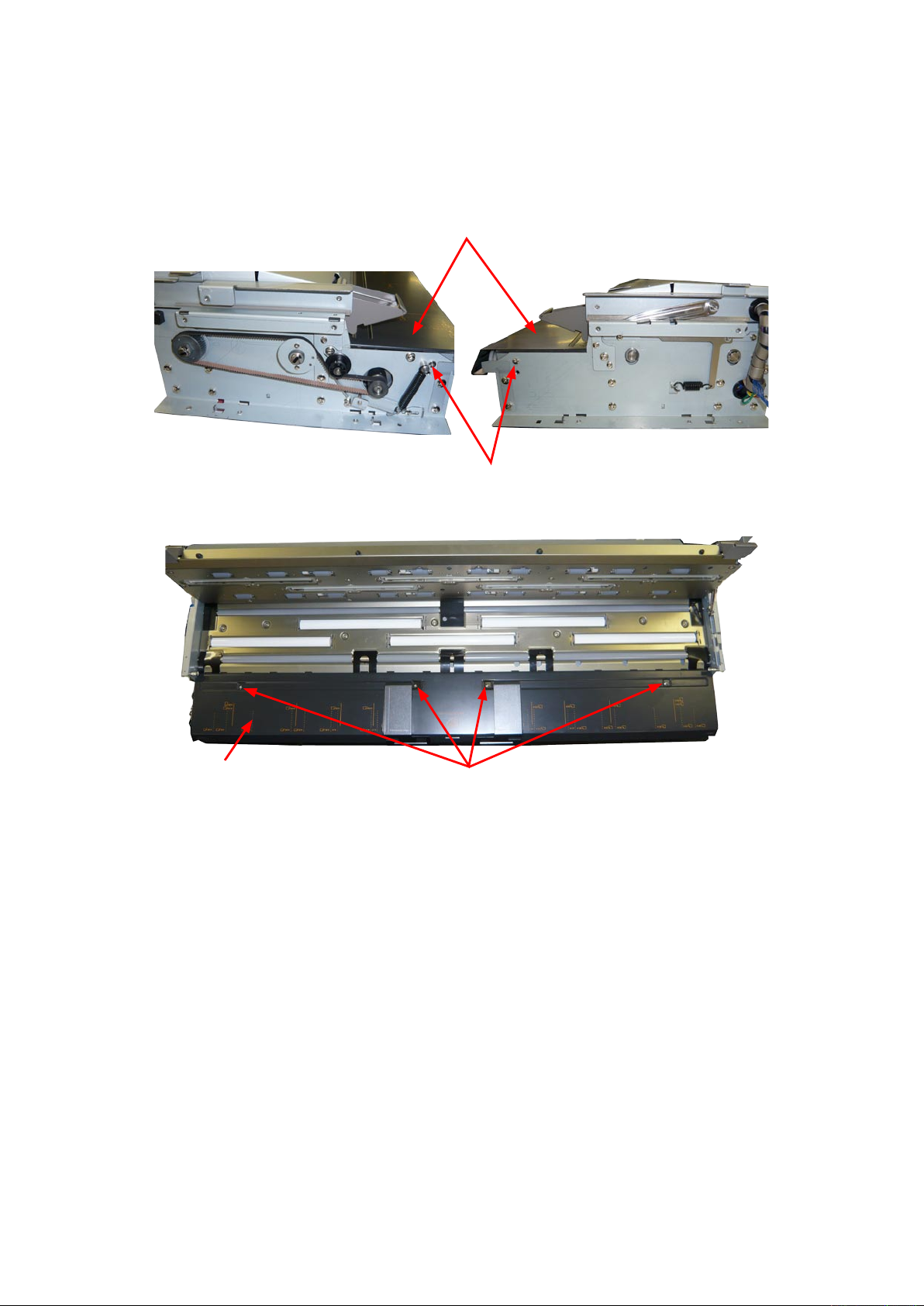

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

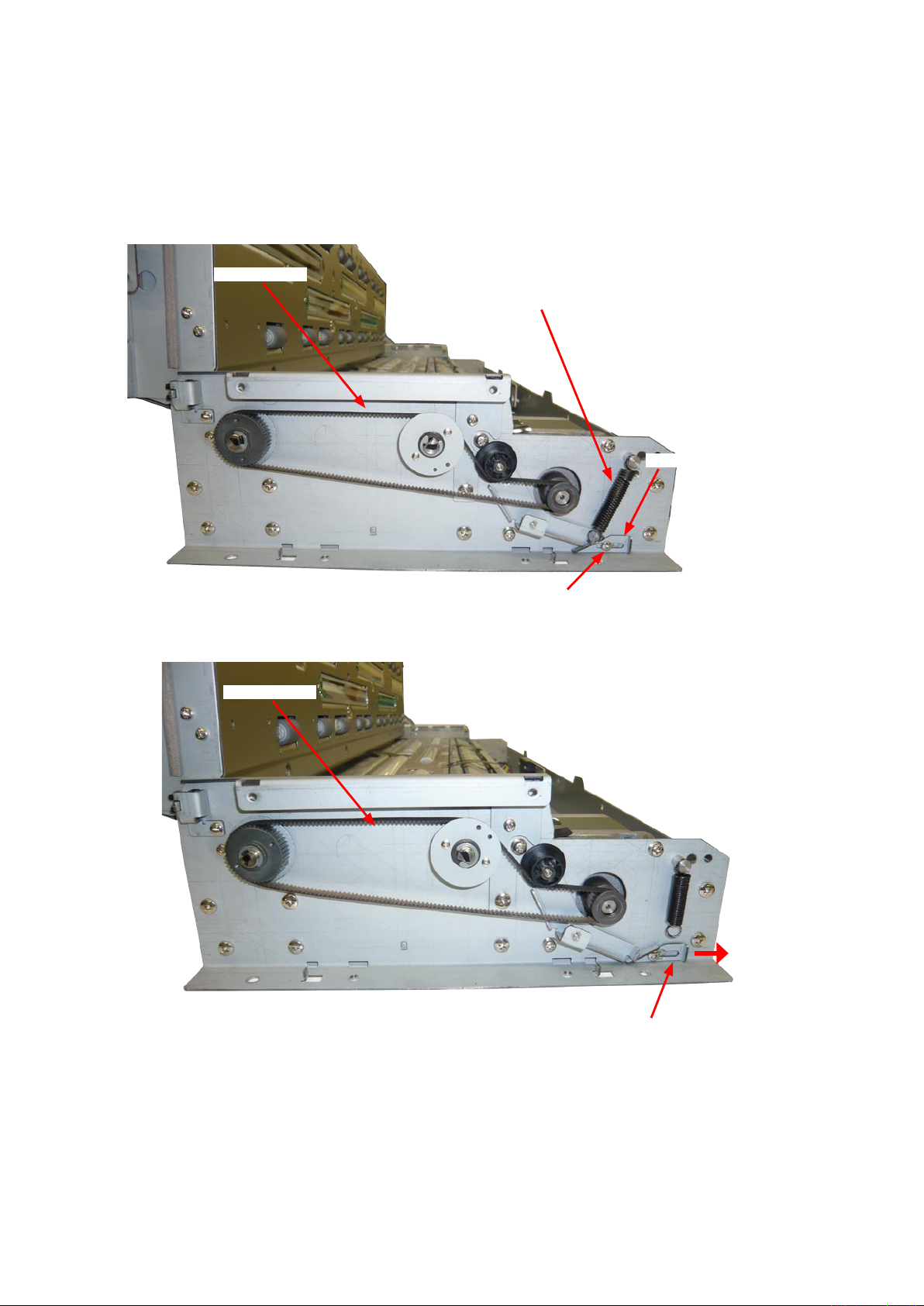

8.7 Feed Drive Belt

Detaching the feed drive belt

(1) Detach the top cover (see Sections 8.1).

(2) Detach the front covers (see Section 8.2).

(3) Detach the left side cover (see Sections 8.3).

Feed drive belt

Tension spring

Tension stopper bracket

(4) Detach the tension spring from the feed belt tension pin.

Feed drive belt

M2L6 binding head screw

Tension stopper bracket

(5) Loosen the M2L5 binding screw holding the tension stopper bracket, and then slide it to right side.

(6) Detach the feed drive belt from the feed pulley.

CSX300-UM-251-9370 8-7

Page 56

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

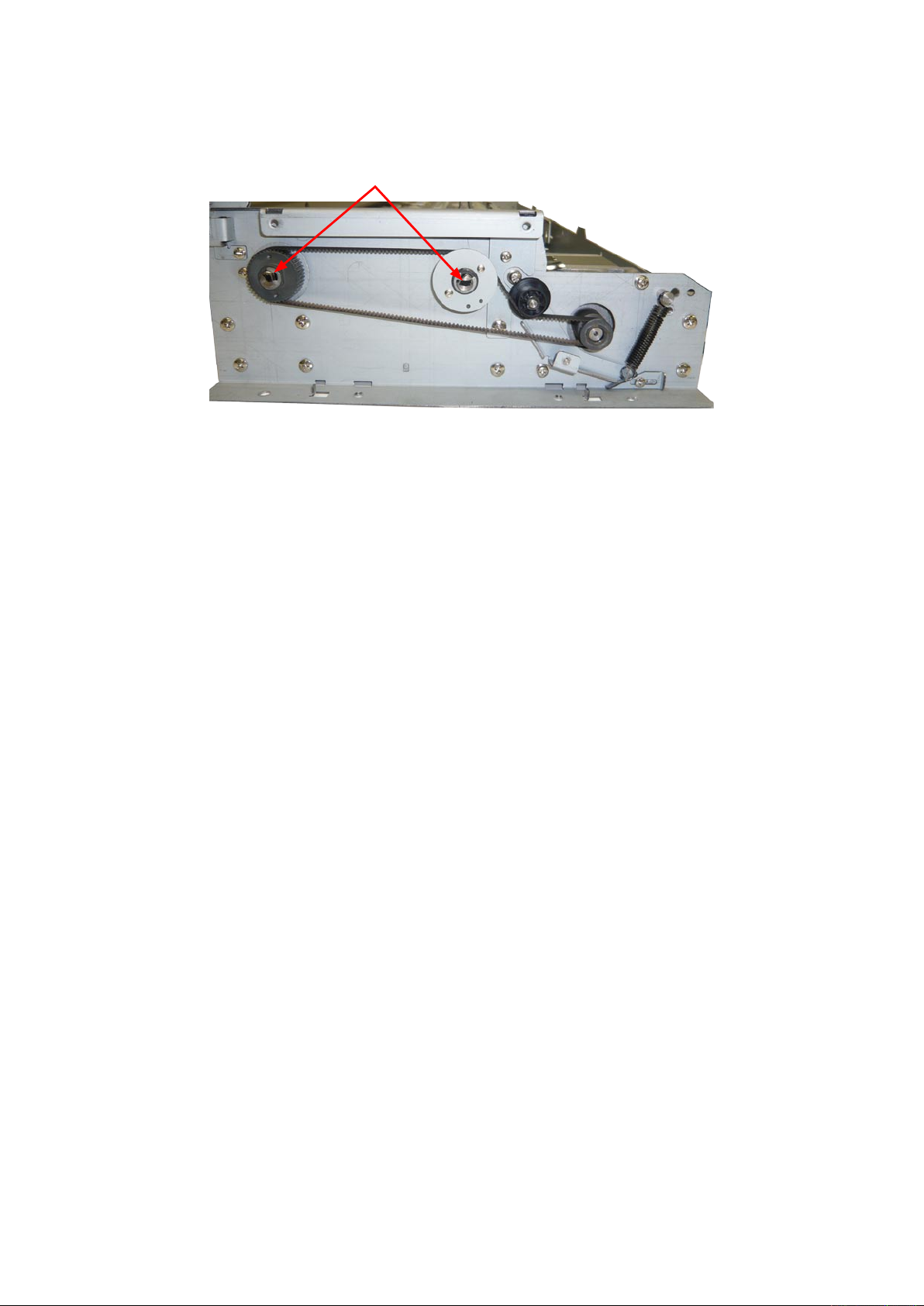

Reattaching the feed drive belt

(1) Reattach the feed drive belt by reversing the sequence of steps in which it was detached.

These black lines should be parallel

when installing the feed drive belt.

CSX300-UM-251-9370 8-8

Page 57

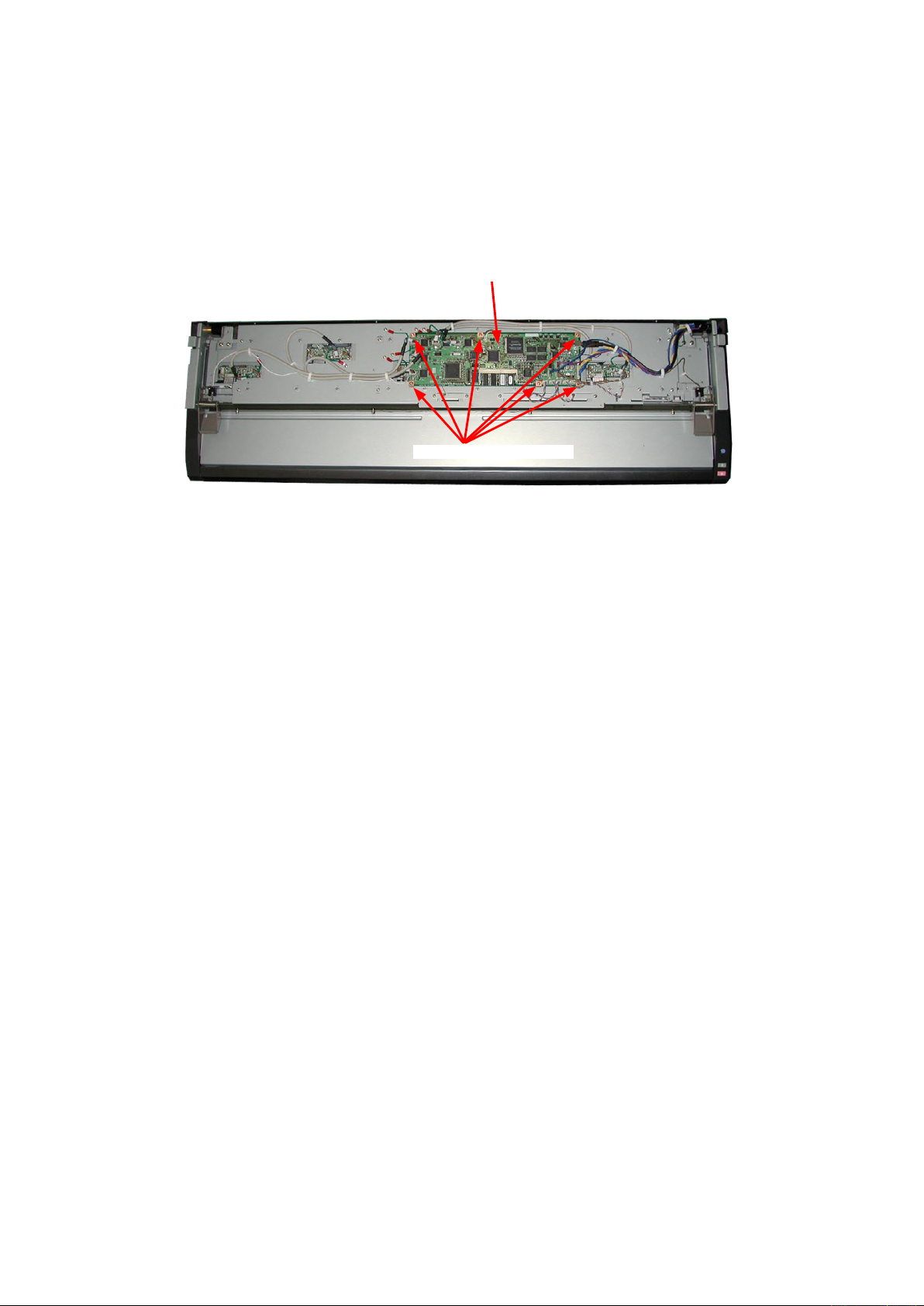

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

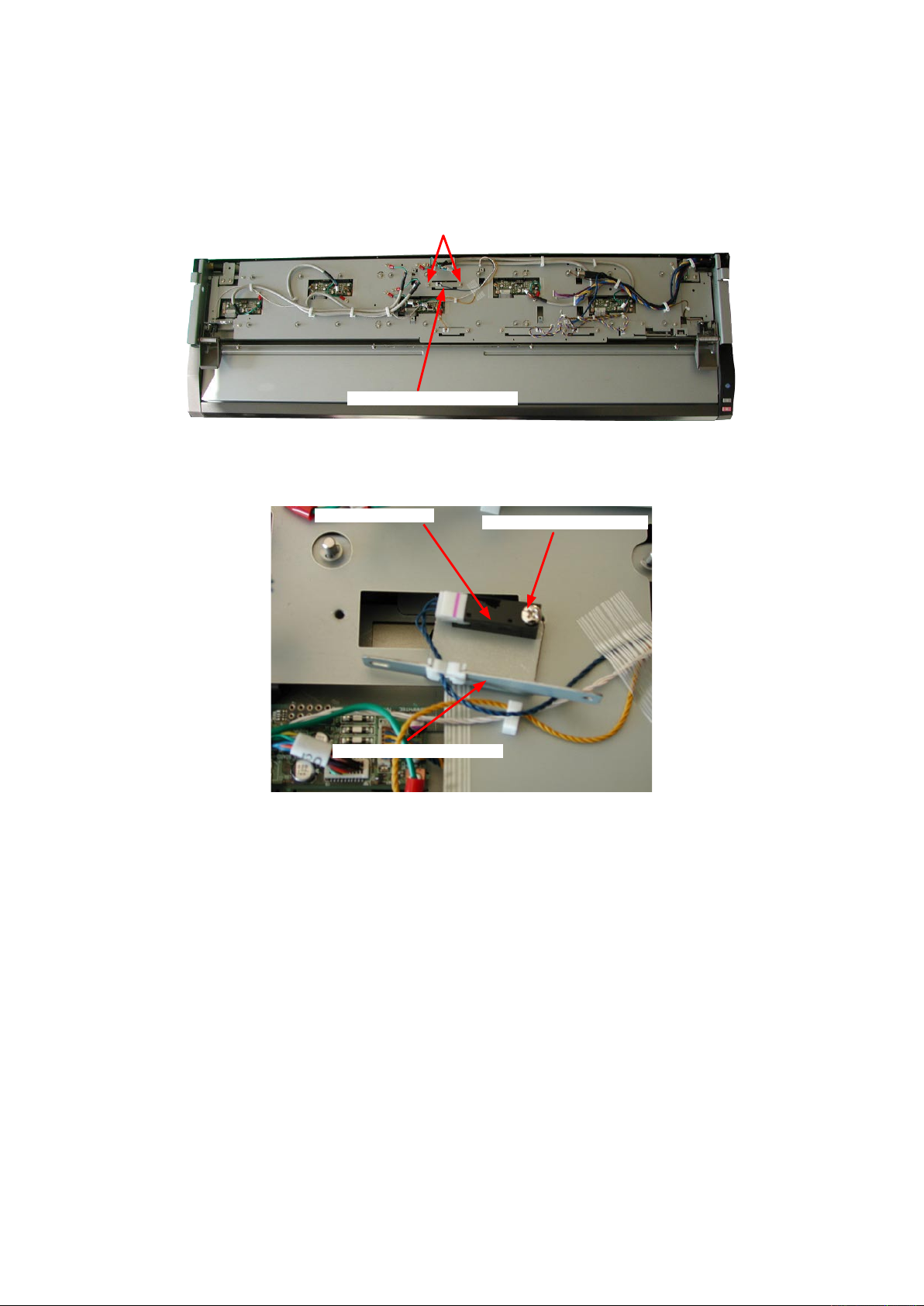

8.8 Main Board

Detaching the main board

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

(2) Disconnect the all cables from the main board.

(3) Remove the six M3L6 binding head screws holding the main board.

(4) Detach the main board from the board base bracket.

Main board

M3L6 binding head screw

Reattaching the main board

(1) Reattach the main board by reversing the sequence of steps in which it was detached.

(2) Perform the calibration and the software adjustment if the main board was replaced.

CSX300-UM-251-9370 8-9

Page 58

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

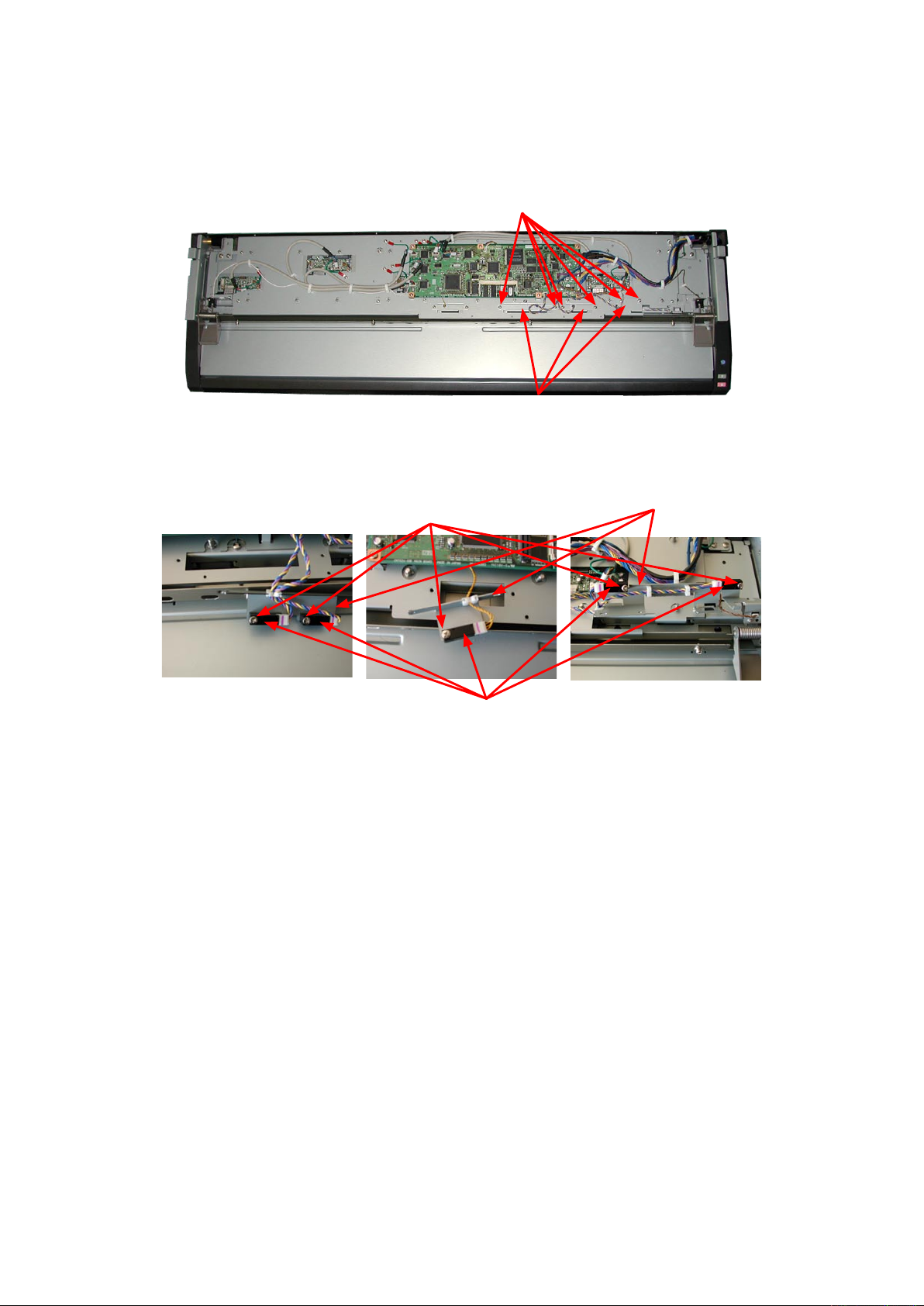

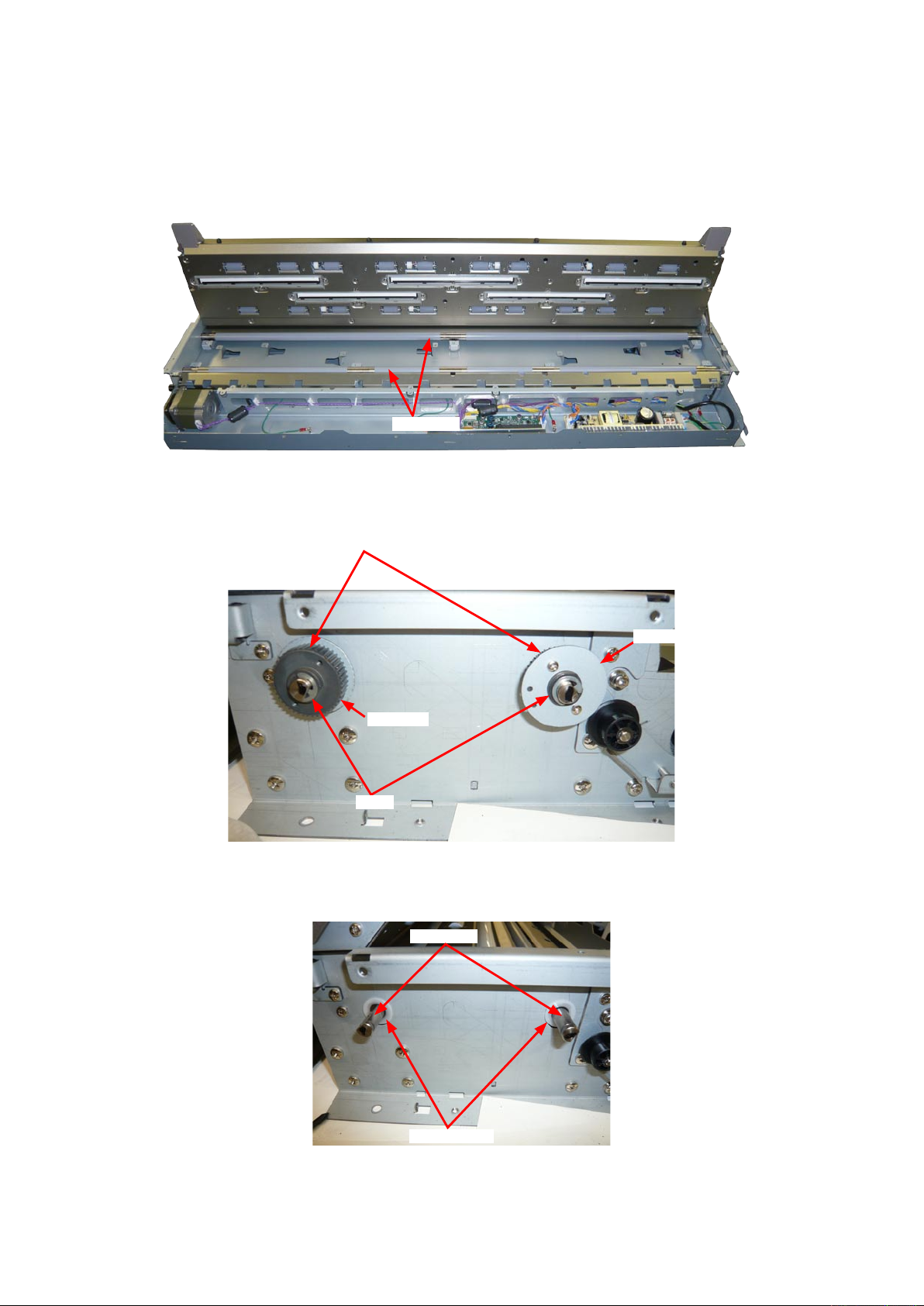

8.9 Board Base Chassis

Detaching the board base chassis

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

(2) Detach the main board. (see Sections 8.8).

(3) Remove the eight M3L6 binding head screws holding the board base chassis.

M3L6 binding head screw

Board base chassis

(4) Disconnect the cables from the CIS boards.

CIS board

Board base chassis

(5) Lay the board base chassis down at the rear of the main unit as shown below.

Board base chassis

Reattaching the board base chassis

(1) Reattach the board base chassis by reversing the sequence of steps in which it was detached.

CSX300-UM-251-9370 8-10

Page 59

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.10 CIS Board

Detaching the CIS board

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

(2) Detach the main board. (see Sections 8.8).

(3) Detach the board base chassis. (see Sections 8.9).

Board base chassis

CIS board

(4) Remove the two M2L5 binding head screws holding the CIS board.

M2L5 binding head screw

CIS board

(5) Disconnect the cables from the CIS board.

(6) Detach the CIS board from the main unit.

Reattaching the board base chassis

(1) Reattach the CIS board by reversing the sequence of steps in which it was detached.

(2) Perform the calibration if the CIS board was replaced.

CSX300-UM-251-9370 8-11

Page 60

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.11 CIS Sensor

Detaching the CIS sensor

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

(2) Detach the main board. (see Sections 8.8).

(3) Detach the board base chassis. (see Sections 8.9).

(4) Detach the CIS board. (see Sections 8.10).

(5) Remove the four M3L4 binding head screws holding the CIS sensor bracket, and then detach the CIS

sensor bracket.

M3L4 binding head screws

CIS sensor bracket

(6) Detach the CIS sensor from the main unit.

CIS sensor

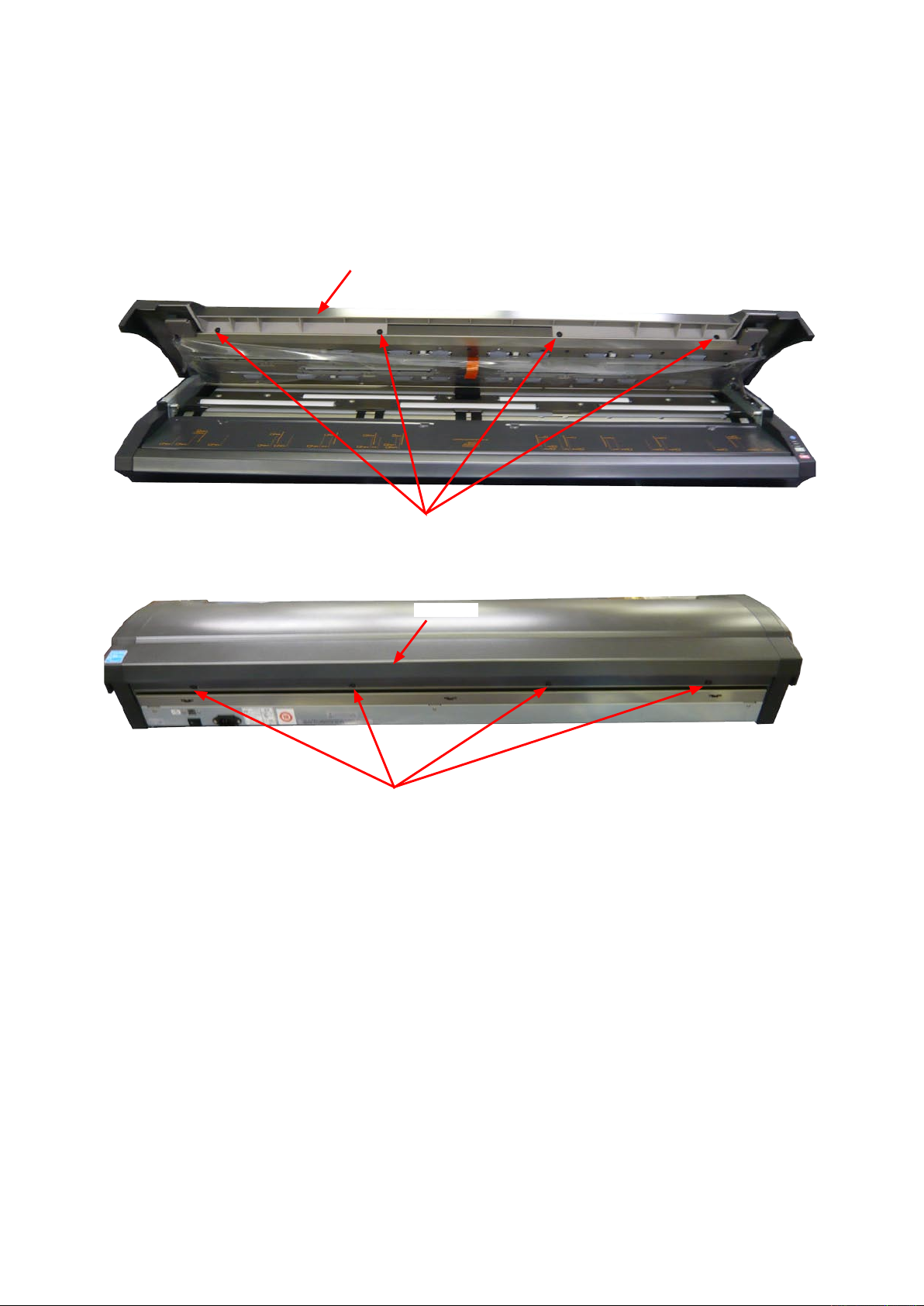

Reattaching a CIS sensor

(1) Reattach the CIS sensor by reversing the sequence of steps in which it was detached.

(2) Use a CIS sensor of the same rank when replacing a CIS sensor.

The CIS sensor rank is indicated on the CIS sensor unit and the bottom of the scanner chassis.

(3) Perform the calibration and the software adjustment if the main board was replaced.

CSX300-UM-251-9370 8-12

Page 61

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

How to find out the CIS sensor rank

There is the CIS sensor rank label on the bottom chassis as shown in a picture below. So prepare same rank

of the CIS sensor before replacing the CIS sensor.

CSX300-UM-251-9370 8-13

Page 62

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.12 Cover Sensor

Detaching the cover sensor

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

Cover sensor

(2) Remove the M3L6 binding head screw holding the cover sensor.

Cover sensor

M3L6 binding head screw

(3) Disconnect the cable that is connected to the cover sensor.

(4) Detach the cover sensor from the board base assembly.

Reattaching the cover sensor

(1) Reattach the cover sensor by reversing the sequence of steps in which it was detached.

CSX300-UM-251-9370 8-14

Page 63

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.13 Front Media Sensor

Detaching the front media sensor

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

M3L6 binding head screw

Front media sensor bracket

(2) Remove the tow M3L6 binding head screws holding the front media sensor bracket.

(3) Disconnect the cable that is connected to the front media sensor.

Front media sensor bracket

M3L12 binding head screw

(4) Remove the M3L12 binding head screws holding the front media sensor.

(5) Detach the front media sensor from the front media sensor bracket.

Front media sensor

Reattaching the front media sensor

(1) Reattach the front media sensor by reversing the sequence of steps in which it was detached.

(2) Perform the software adjustment (scanning start position adjustment) if the front media sensor was

replaced.

CSX300-UM-251-9370 8-15

Page 64

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.14 Rear Media Sensor

Detaching the rear media sensor

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

(2) Detach the main board. (see Sections 8.8).

M3L6 binding head screw

Rear media sensor bracket

(3) Remove the tow M3L6 binding head screws holding the rear media sensor bracket.

(4) Disconnect the cable that is connected to the rear media sensor.

Rear media sensor

Rear media sensor bracket

(5) Remove the M3L12 binding head screws holding the rear media sensor.

(6) Detach the rear media sensor from the rear media sensor bracket.

M3L12 binding head screw

Reattaching the rear media sensor

(1) Reattach the rear media sensor by reversing the sequence of steps in which it was detached.

(2) Perform the software adjustment (scanning start position adjustment) if the rear media sensor was

replaced.

CSX300-UM-251-9370 8-16

Page 65

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.15 Media width sensors

Detaching the media width sensors

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

M3L6 binding head screw

Media width sensor bracket

(2) Remove the tow M3L6 binding head screws holding the media width sensor brackets.

(3) Disconnect the cable that is connected to the media width sensors.

M3L12 binding head screw

Media width sensor

(4) Remove the M3L12 binding head screws holding the media width sensors.

(5) Detach the media width sensors from the media width sensor brackets.

Media width sensor bracket

Reattaching the media width sensors

(1) Reattach the media width sensors by reversing the sequence of steps in which they were detached.

CSX300-UM-251-9370 8-17

Page 66

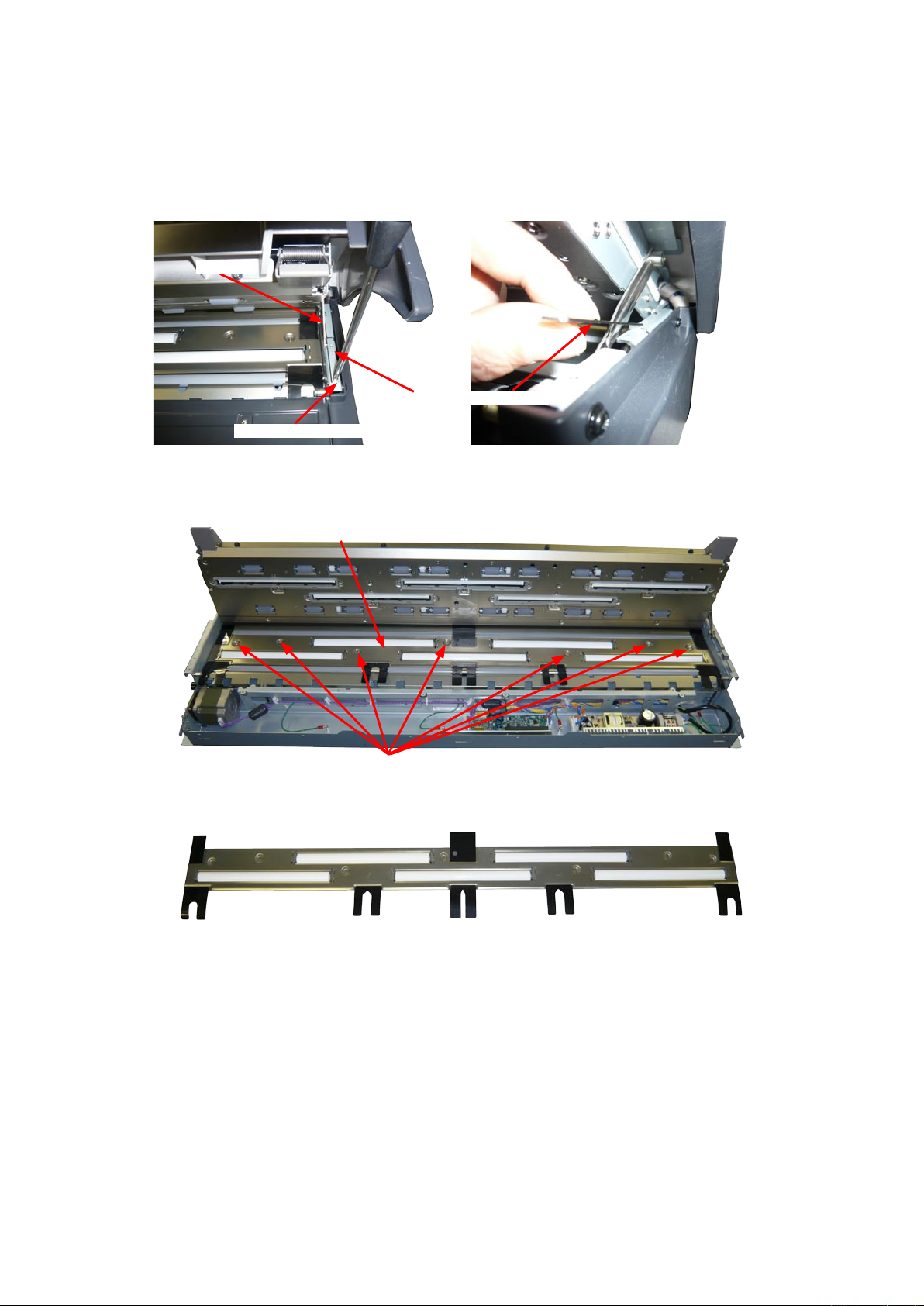

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.16 Document Roller Assembly

Detaching the document roller assembly

(1) Detach the top, front, left side and right side covers (see Sections 8.1, 8.2, 8.3 and 8.4).

(2) Remove the M3L6 binding head screw holding the flap stay stopper bracket.

Flap stay

Flap stay stopper bracket

M3L6 binding head screw

(3) Detach the flap stay stopper bracket.

(4) Remove the seven M3L6 binding head screws holding the document roller assembly.

Document roller assembly

M3L6 binding head screw

(5) Detach the document roller assembly from the main unit.

Reattaching the document roller assembly

(1) Reattach the document roller assembly by reversing the sequence of steps in which it was detached.

(2) Perform the calibration and the software adjustment if the document roller assembly was replaced or

detached.

CSX300-UM-251-9370 8-18

Page 67

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.16 Contact Glass Assembly

Detaching the contact glass assembly

(1) Remove the M3L6 binding head screw holding the flap stay stopper bracket.

Flap stay

Flap stay stopper bracket

M3L6 binding head screw

(2) Detach the flap stay stopper bracket.

(3) Open the top cover.

Contact glass assembly

(4) Remove the four M3L6 binding head screws holding the contact glass assembly.

M3L6 binding head screw

Contact glass assembly

(5) Detach the contact glass assembly from the top cover unit.

CSX300-UM-251-9370 8-19

Page 68

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Reattaching the contact glass assembly

(1) Reattach the contact glass assembly by reversing the sequence of steps in which it was detached.

(2) Keep clean the surface of the contact glass assembly and do not make the finger-print on glass when

installing the contact glass.

(3) Blow out any dust from the surface of the CIS sensor when installing the contact glass.

(4) Perform the calibration and the software adjustment if the contact glass assembly was replaced or

detached.

CSX300-UM-251-9370 8-20

Page 69

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

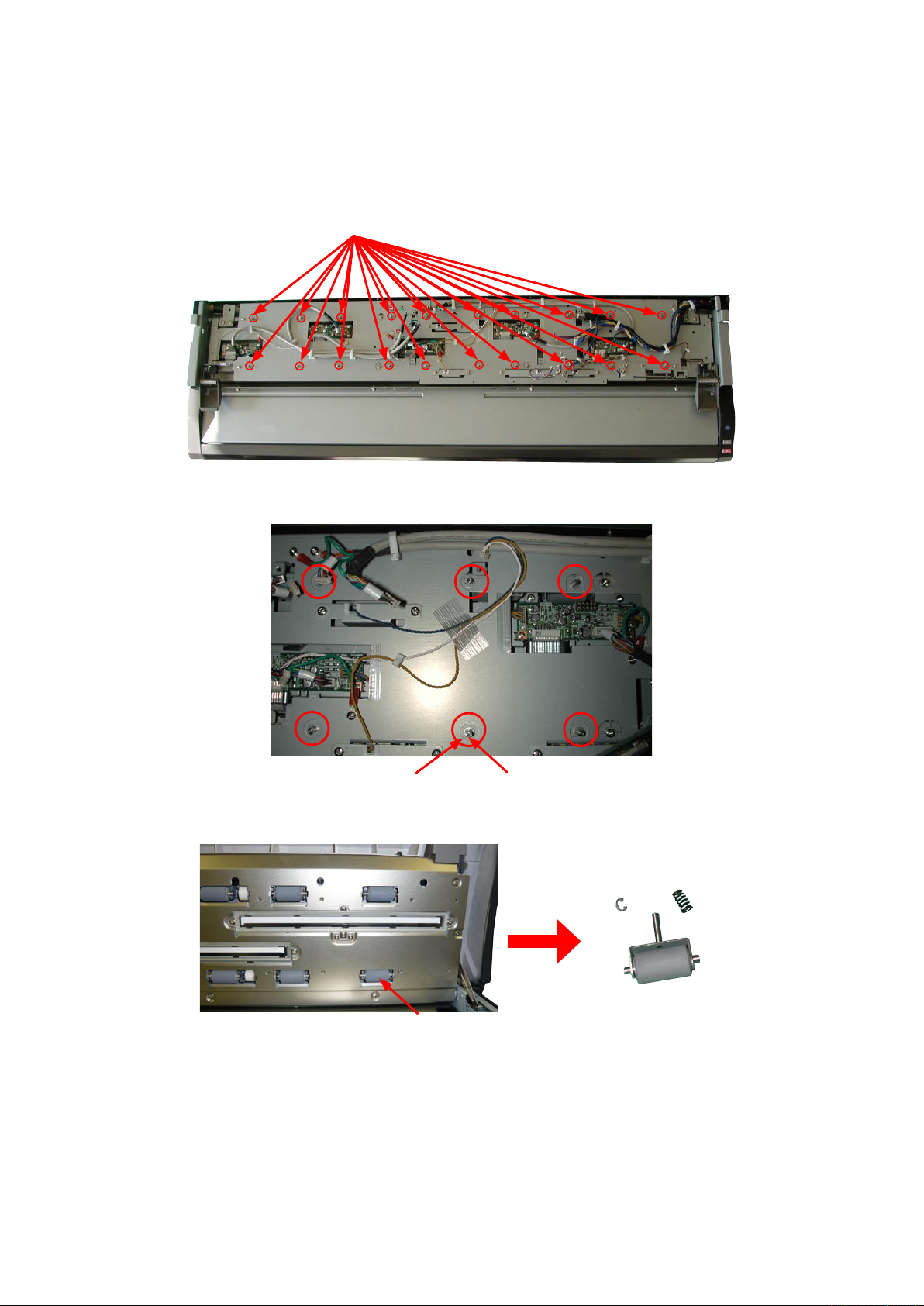

8.17 Pinch Roller

Detaching the pinch roller

(1) Detach the top and shield covers (see Sections 8.1 and 8.6).

(2) Detach the main board when the pinch roller under the main board is replaced. (see Sections 8.8).

Pinch roller holder shaft

(3) Remove the E-ring holding the pinch roller holder shaft.

E-ring

(4) Detach the pinch roller and the spring from the bottom of the top cover unit.

Pinch roller

Pinch roller holder shaft

Reattaching the pinch roller

(1) Reattach the pinch roller by reversing the sequence of steps in which it was detached.

(2) Perform the calibration and the software adjustment if the pinch roller was replaced or detached.

CSX300-UM-251-9370 8-21

Page 70

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.18 Feed Rollers

Detaching the feed rollers

(1) Detach the top, front, left side and right side covers (see Sections 8.1, 8.2, 8.3 and 8.4).

(2) Detach the document roller assembly (see Section 8.16).

Feed roller

(3) Detach the feed drive belt (see Section 8.7).

(4) Remove the E-ring from the feed roller holding the feed pulleys.

Feed pulley

Set screw

Set screw

E-ring

(5) Loosen the set screw holding the feed pulley.

(6) Remove the feed pulley from the feed roller. Then remove the nylon washer from the feed roller.

Feed roller

Nylon washer

CSX300-UM-251-9370 8-22

Page 71

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

(7) Remove the bearing from the feed roller.

Feed roller

Bearing

(8) Remove the E-rings holding the right side feed roller bearings.

Bearing

E-ring

(9) Detach the bearing from the feed roller.

(10) Slide the feed roller to the left side, and then lift up the right side of the feed roller to detach it.

Slide the feed roller to the left side, and then lift

up the right side of the feed roller to detach it.

Feed roller

Reattaching the feed rollers

(1) Reattach the feed rollers by reversing the sequence of steps in which they were detached.

(2) Perform the calibration and the software adjustment if the feed roller was replaced or detached.

CSX300-UM-251-9370 8-23

Page 72

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

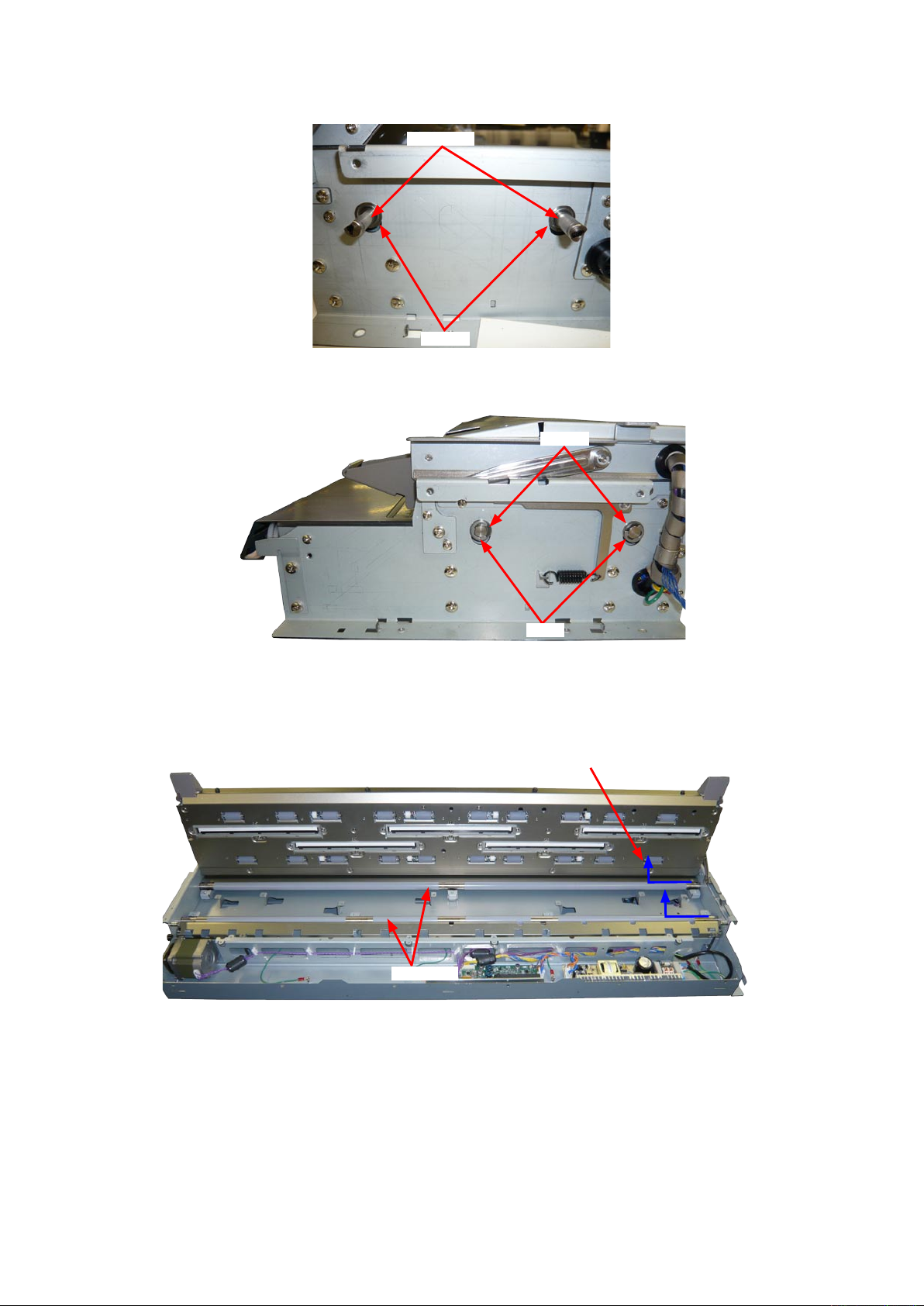

8.19 CIS Power Board

Detaching the CIS power board

(1) Detach the top, front, left side and right side covers (see Sections 8.1, 8.2, 8.3 and 8.4).

CIS power board

(2) Disconnect all the connectors on the CIS power board and remove the four M3L6 binding head screws

holding the CIS power board.

M3L6 binding head screw

(3) Detach the CIS power board from the unit.

Power supply board

Reattaching the CIS power board

(1) Reattach the CIS power board in the reverse order in which it was detached.

CSX300-UM-251-9370 8-24

Page 73

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

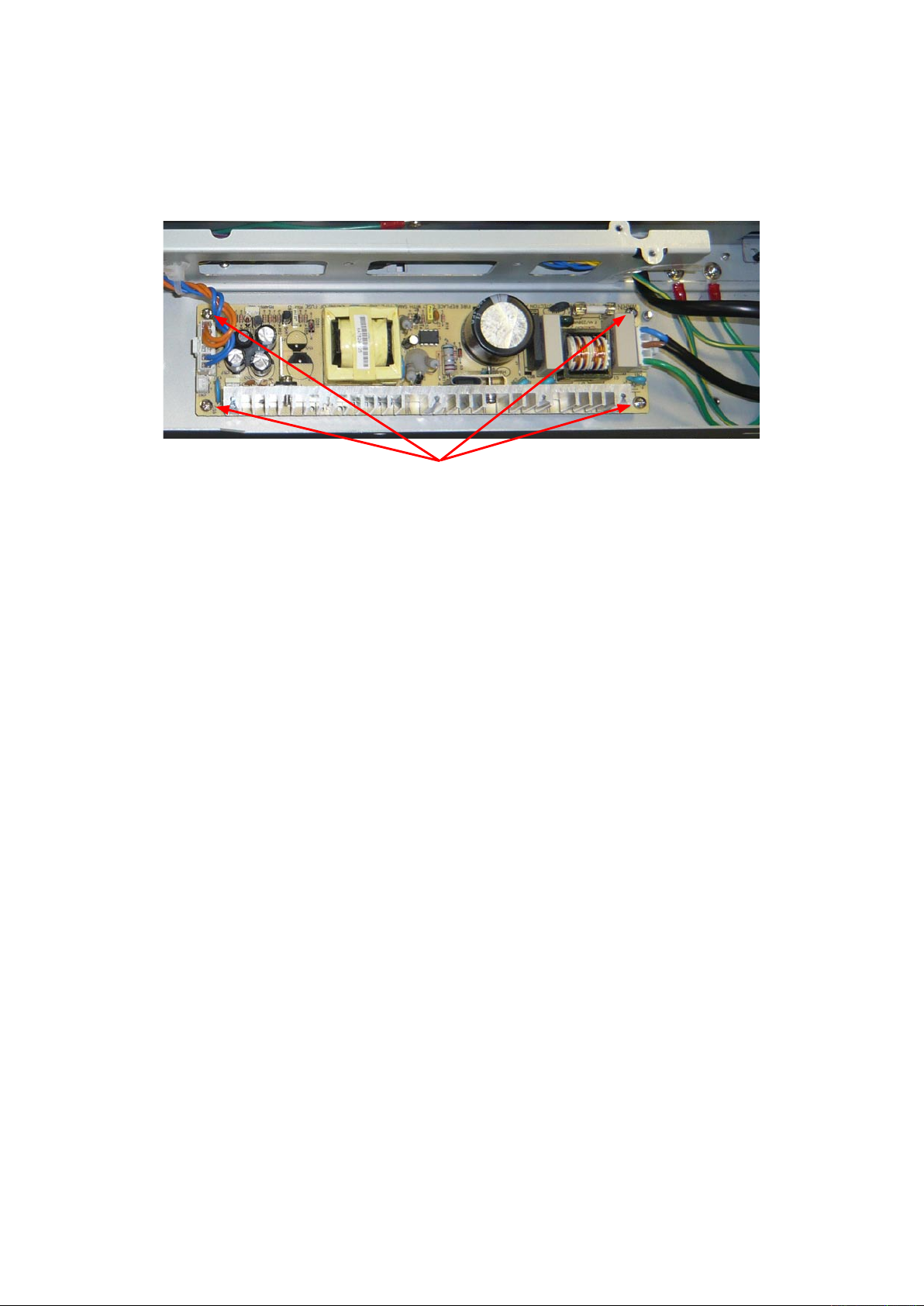

8.20 Switching Power Supply Board

Detaching the switching power supply board

(1) Detach the top, front, left side and right side covers (see Sections 8.1, 8.2, 8.3 and 8.4).

(2) Remove the four M3L6 binding head screws holding the switching power supply board.

M3L6 binding head screw

(4) Disconnect all the connectors on the switching power supply board.

(5) Detach the switching power supply board from the unit.

Reattaching the switching power supply board

(1) Reattach the switching power supply board in the reverse order in which it was detached.

CSX300-UM-251-9370 8-25

Page 74

8. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

8.21 Feed Motor

Detaching the feed motor

(1) Detach the top, front, left side and right side covers (see Sections 8.1, 8.2, 8.3 and 8.4).

(2) Detach the feed drive belt (see Section 8.7).

(3) Remove the two M4L8 pan head screws with washer holding the feed motor.

M4L8 pan head screw with washer

(4) Disconnect the cable from the feed motor.

Feed motor

Feed motor cable

Reattaching the feed motor

(1) Reattach the feed motor in the reverse order in which it was detached.

(2) Perform the calibration and the software adjustment if the feed motor was replaced or detached.

CSX300-UM-251-9370 8-26

Page 75

9. ADJUSTMENTS USING THE SOFTWARE

9. ADJUSTMENTS USING THE SOFTWARE

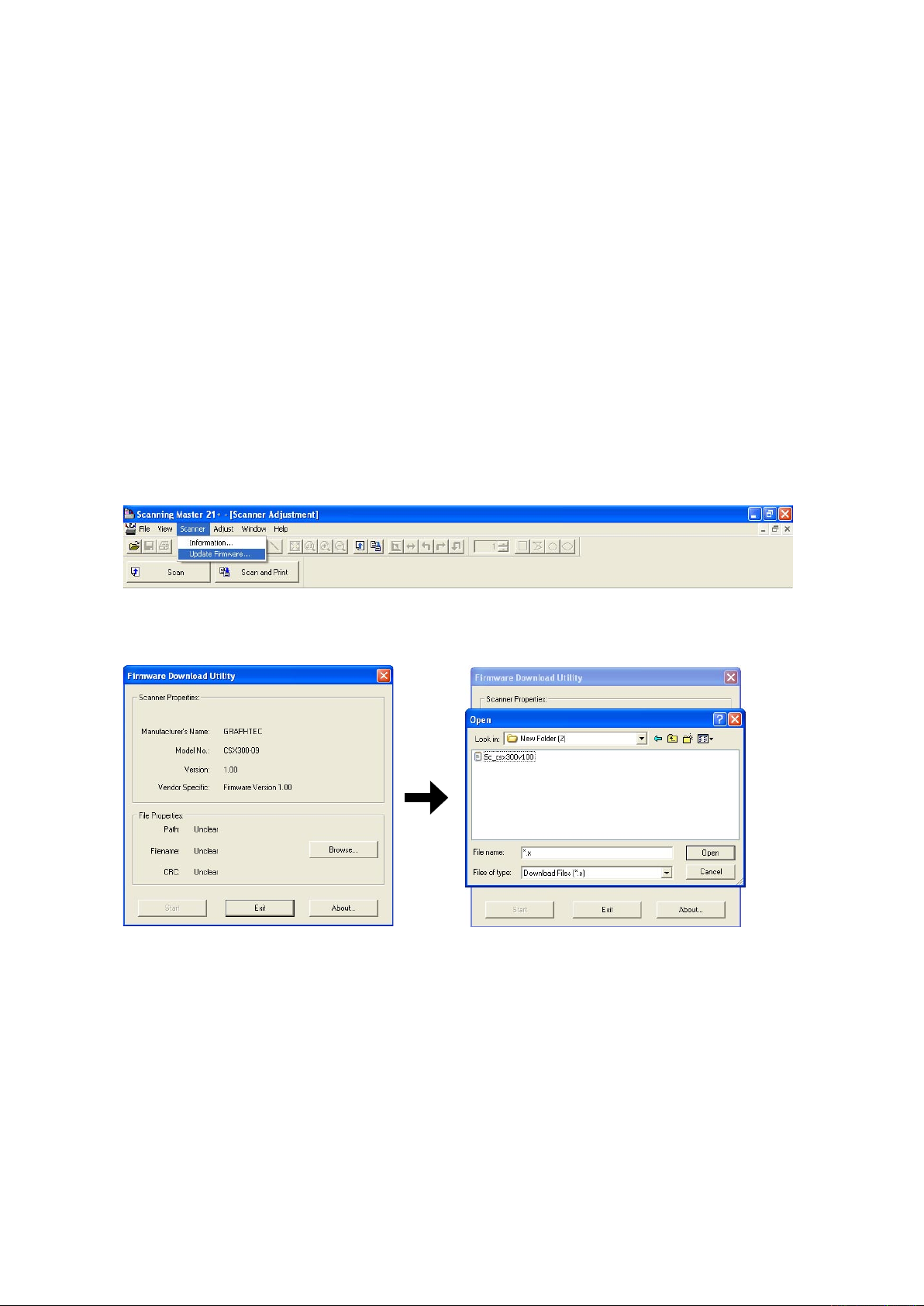

9.1 Starting the Software

• Ensure that OPS112 (Scanning Master 21+ Ver 6.60 or later) is installed.

(1) Connect the scanner to the PC using a USB cable and turn it on.

(2) Start Windows (OS).

(3) Run the Scanning Master 21+ (OPS112) from the Start.

(4) Select "Model Setup" from the "Scan" menu.

(5) Select "CSX300-09" from the pull down menu.

(6) Click the "Confirm" button to confirm the scanner is connected.

CSX300-UM-251-9370 9-1

Page 76

9. ADJUSTMENTS USING THE SOFTWARE

(7) The following message is displayed when the scanner is detected.

Click "OK" button.

(8) Select "About" from the "Help" menu.

(9) Click the scanner icon while pressing and holding down the "Ctrl" key.

Next, click the "OK" button while pressing and holding down the "Shift" key.

Icon

(10) Select "Adjust Scanner" from the "Tools" menu.

(11) Select "Yes".

CSX300-UM-251-9370 9-2

Page 77

9. ADJUSTMENTS USING THE SOFTWARE

(12) When you click the "OK" button in the following window, the Scanner Adjustment window will appear

with an Adjust menu.

CSX300-UM-251-9370 9-3

Page 78

9. ADJUSTMENTS USING THE SOFTWARE

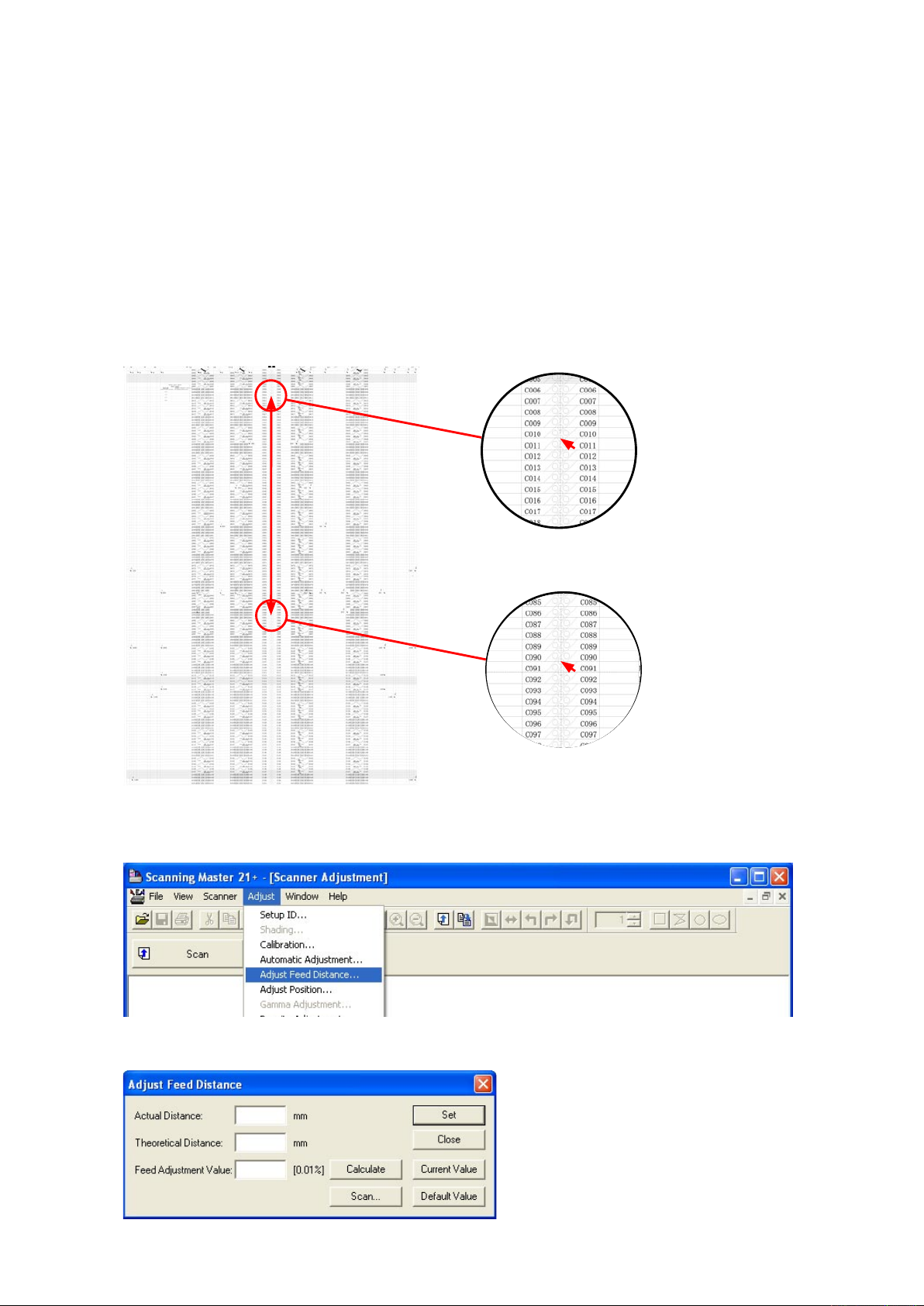

9.2 Preparations before Making Adjustments

Note the current feed distance adjustment and position adjustment values while making adjustments.

This enables the values to be entered directly from the keyboard to restore the scanner to its previous status

if adjustment fails.

In main board replacement, the time required for adjustment can be reduced by setting the previously noted

feed distance adjustment and position adjustment values. However, for image sensor unit replacement, all

settings must be adjusted, eliminating the need to record the previous values.

Procedure to get the previous adjustment value

(1) Start the Scanning Master 21+ (see Section 9.1).

(2) Select "Adjust Feed Distance" from the "Adjust" menu.

(3) Click the "Current Value" button and note the value shown in the Feed Adjustment Value box. After

finishing, click the "Close" button.

(4) Similarly, select "Adjust Position" from the "Adjust" menu and click the "Current Value" button. Note the

values shown in the Origin, the X Overlap and Y Offset boxes and click the "Close" button.

CSX300-UM-251-9370 9-4

Page 79

9. ADJUSTMENTS USING THE SOFTWARE

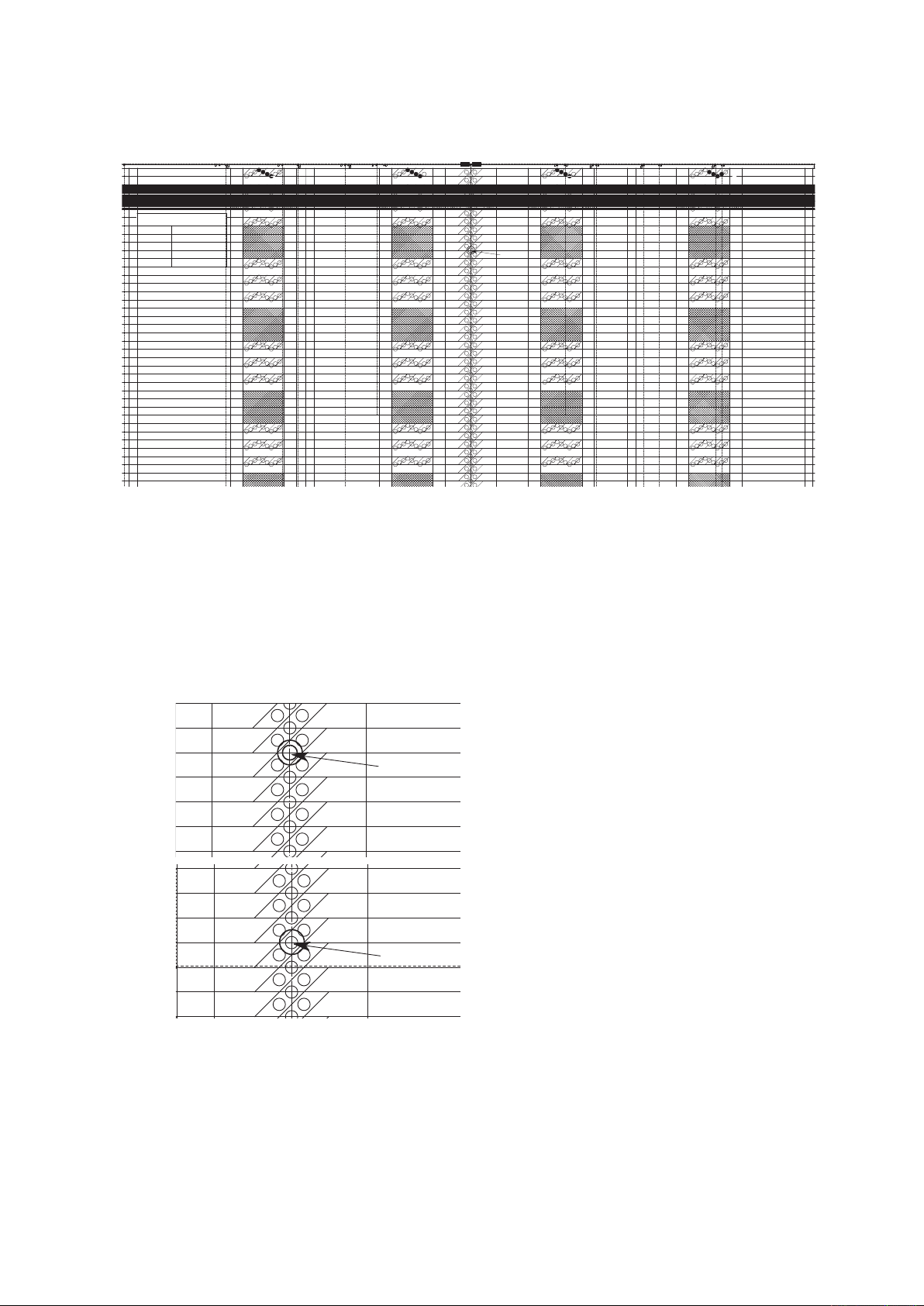

CSX300 Adjustment Chart

Distances between two points Note measured distances below

C010-C090

A001

A002

A003

A004

A005

A006

A007

A008

A009

A010

A011

A008

A009

A010

A011

A008

A009

A010

A011

A008

A009

A010

A011

A012

A013

A014

A015

A016

A017

A018

A019

A020

A021

A018

A019

A020

A021

A018

A019

A020

A021

A018

A019

A020

A021

A022

A023

A024

A025

A026

A027

A028

A029

A030

A031

A028

A029

A030

A031

A028

A029

A030

A031

A028

A029

A030

A031

A032

A034

A035

A036

A037

A038

A039

A040

A041

A038

A039

A040

A041

A038

A039

A040

A041

A038

A039

A040

A041

A042

A043

A044

A045

A046

A047

A048

A049

A050

A051

A048

A049

A050

A051

A048

A049

A050

A051

A048

A049

A050

A051

A052

A053

A054

A055

A056

A057

A058

A059

A060

A061

A058

A059

A060

A061

A058

A059

A060

A061

A058

A059

A060

A061

A062

A063

A064

A065

A066

A067

A068

A069

A070

A071

A068

A069

A070

A071

A068

A069

A070

A071

A068

A069

A070

A071

A072

A073

A074

A075

A076

A077

A078

A079

A080

A081

A078

A079

A080

A081

A078

A079

A080

A081

A078

A079

A080

A081

A082

A083

A084

A085

A086

A088

A087

A089

A090

A091

A088

A089

A090

A091

A088

A089

A090

A091

A088

A089

A090

A091

A092

A093

A094

A095

A096

A097

A098

A099

A100

A101

A098

A099

A100

A101

A098

A099

A100

A101

A098

A099

A100

A101

A102

A103

A104

A105

A106

A107

A108

A109

A110

A111

A108

A109

A110

A111

A108

A109

A110

A111

A108

A109

A110

A111

A112

A113

A114

A115

A116

A117

A033

A001

A002

A003

A004

A005

A006

A007

A008

A009

A010

A011

A012

A013

A014

A015

A016

A017

A018

A019

A020

A021

A022

A023

A024

A025

A026

A027

A028

A029

A030

A031

A032

A034

A035

A036

A037

A038

A039

A040

A041

A042

A043

A044

A045

A046

A047

A048

A049

A050

A051

A052

A053

A054

A055

A056

A057

A058

A059

A060

A061

A062

A063

A064

A065

A066

A067

A068

A069

A070

A071

A072

A073

A074

A075

A076

A077

A078

A079

A080

A081

A082

A083

A084

A085

A086

A088

A087

A089

A090

A091

A092

A093

A094

A095

A096

A097

A098

A099

A100

A101

A102

A103

A104

A105

A106

A107

A108

A109

A110

A111

A112

A113

A114

A115

A116

A117

A033

B001

B002

B003

B004

B005

B006

B007

B008

B009

B010

B011

B008

B009

B010

B011

B008

B009

B010

B011

B008

B009

B010

B011

B012

B013

B014

B015

B016

B017

B018

B019

B020

B021

B018

B019

B020

B021

B018

B019

B020

B021

B018

B019

B020

B021

B022

B023

B024

B025

B026

B027

B028

B029

B030

B031

B028

B029

B030

B031

B028

B029

B030

B031

B028

B029

B030

B031

B032

B034

B035

B036

B037

B038

B039

B040

B041

B038

B039

B040

B041

B038

B039

B040

B041

B038

B039

B040

B041

B042

B043

B044

B045

B046

B047

B048

B049

B050

B051

B048

B049

B050

B051

B048

B049

B050

B051

B048

B049

B050

B051

B052

B053

B054

B055

B056

B057

B058

B059

B060

B061

B058

B059

B060

B061

B058

B059

B060

B061

B058

B059

B060

B061

B062

B063

B064

B065

B066

B067

B068

B069

B070

B071

B068

B069

B070

B071

B068

B069

B070

B071

B068

B069

B070

B071

B072

B073

B074

B075

B076

B077

B078

B079

B080

B081

B078

B079

B080

B081

B078

B079

B080

B081

B078

B079

B080

B081

B082

B083

B084

B085

B086

B088

B087

B089

B090

B091

B088

B089

B090

B091

B088

B089

B090

B091

B088

B089

B090

B091

B092

B093

B094

B095

B096

B097

B098

B099

B100

B101

B098

B099

B100

B101

B098

B099

B100

B101

B098

B099

B100

B101

B102

B103

B104

B105

B106

B107

B108

B109

B110

B111

B108

B109

B110

B111

B108

B109

B110

B111

B108

B109

B110

B111

B112

B113

B114

B115

B116

B117

B033

B001

B002

B003

B004

B005

B006

B007

B008

B009

B010

B011

B012

B013

B014

B015

B016

B017

B018

B019

B020

B021

B022

B023

B024

B025

B026

B027

B028

B029

B030

B031

B032

B034

B035

B036

B037

B038

B039

B040

B041

B042

B043

B044

B045

B046

B047

B048

B049

B050

B051

B052

B053

B054

B055

B056

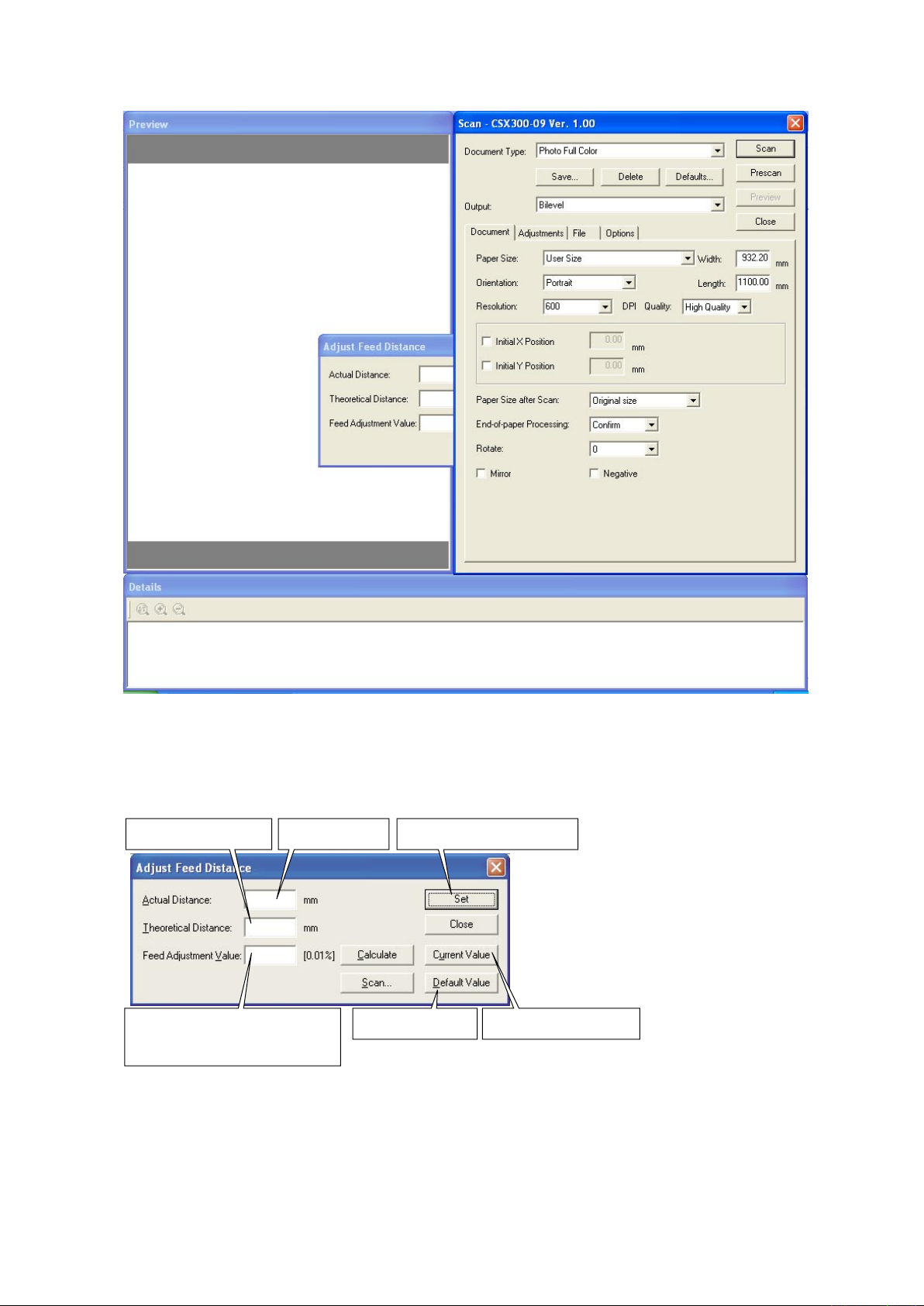

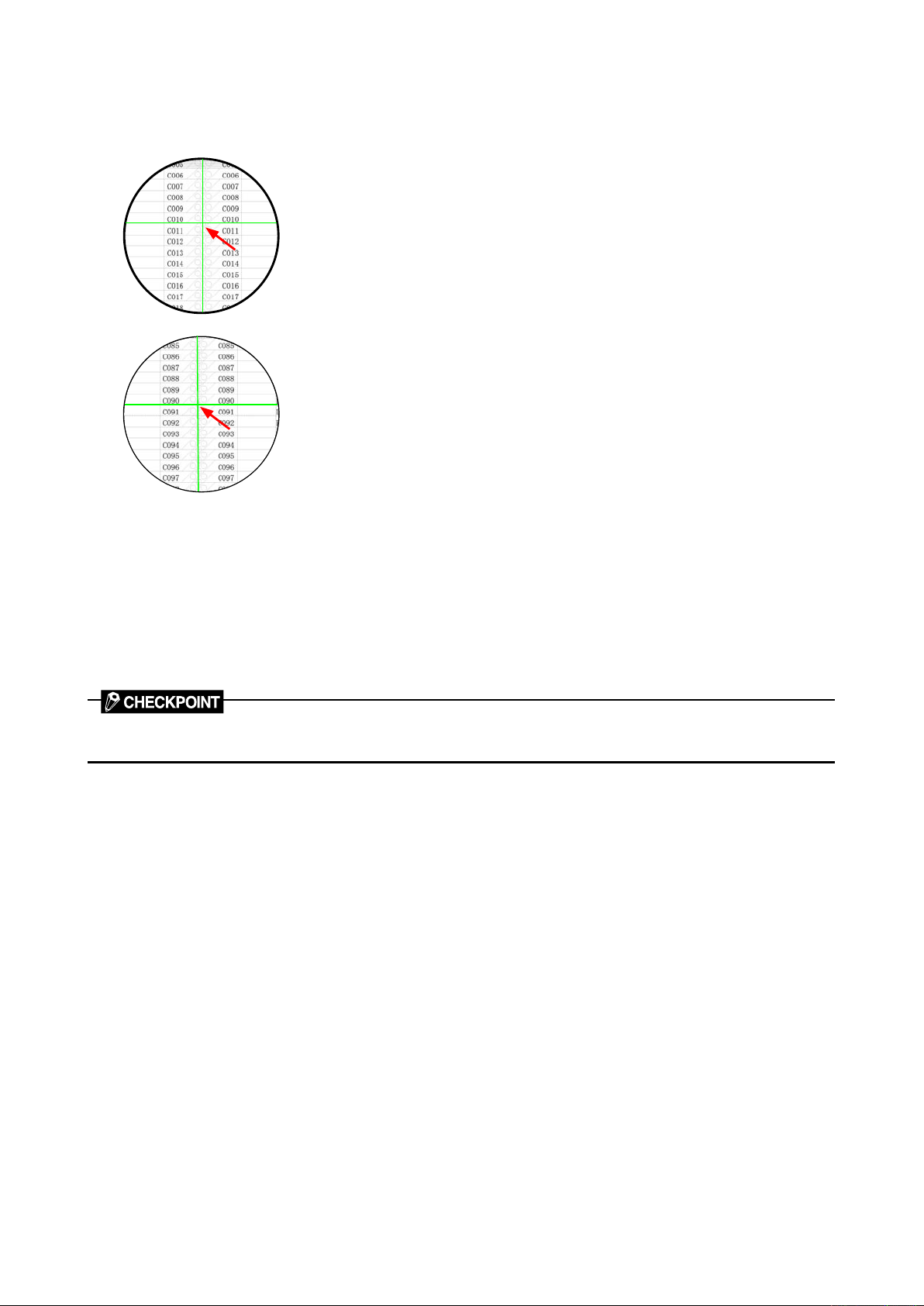

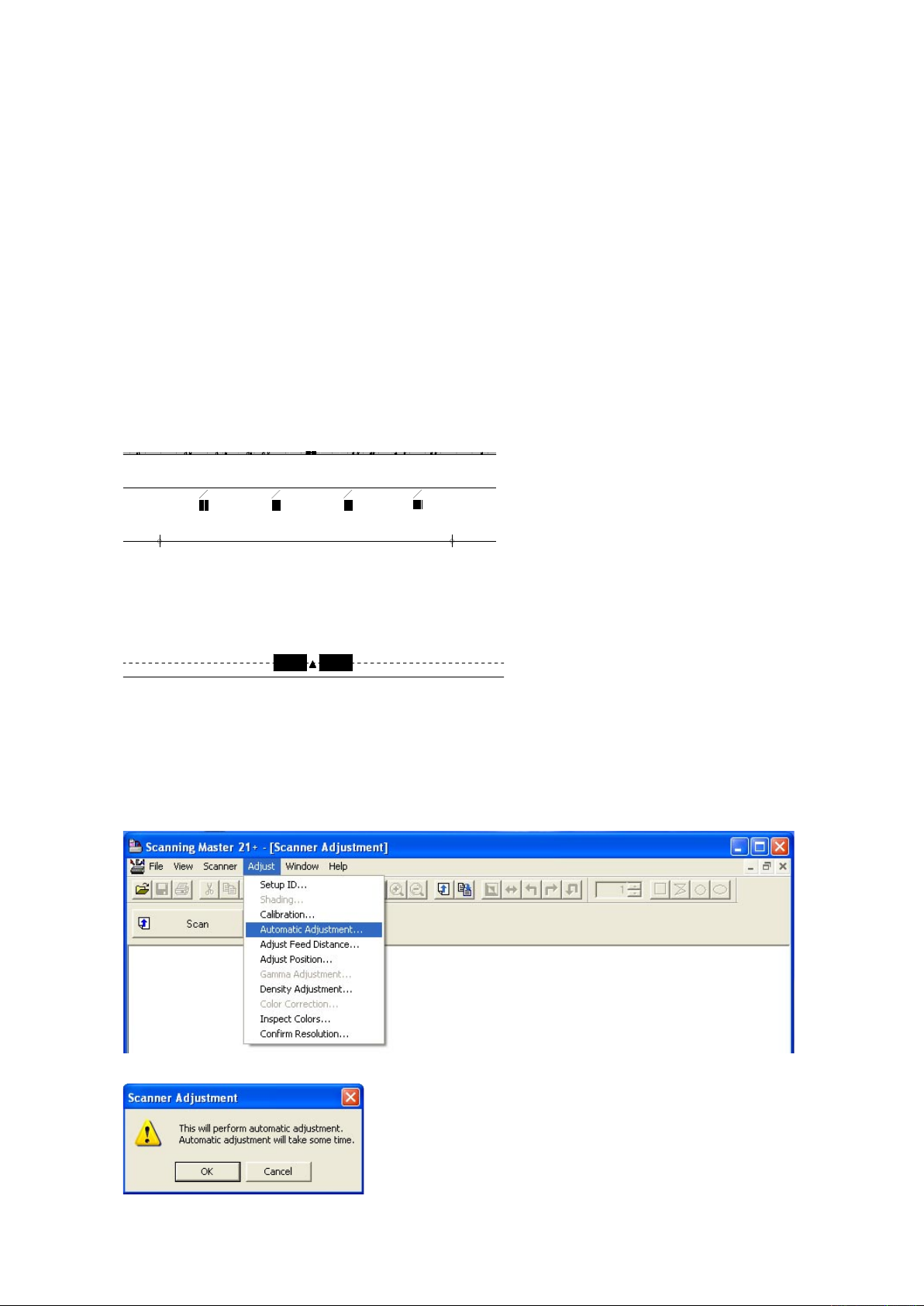

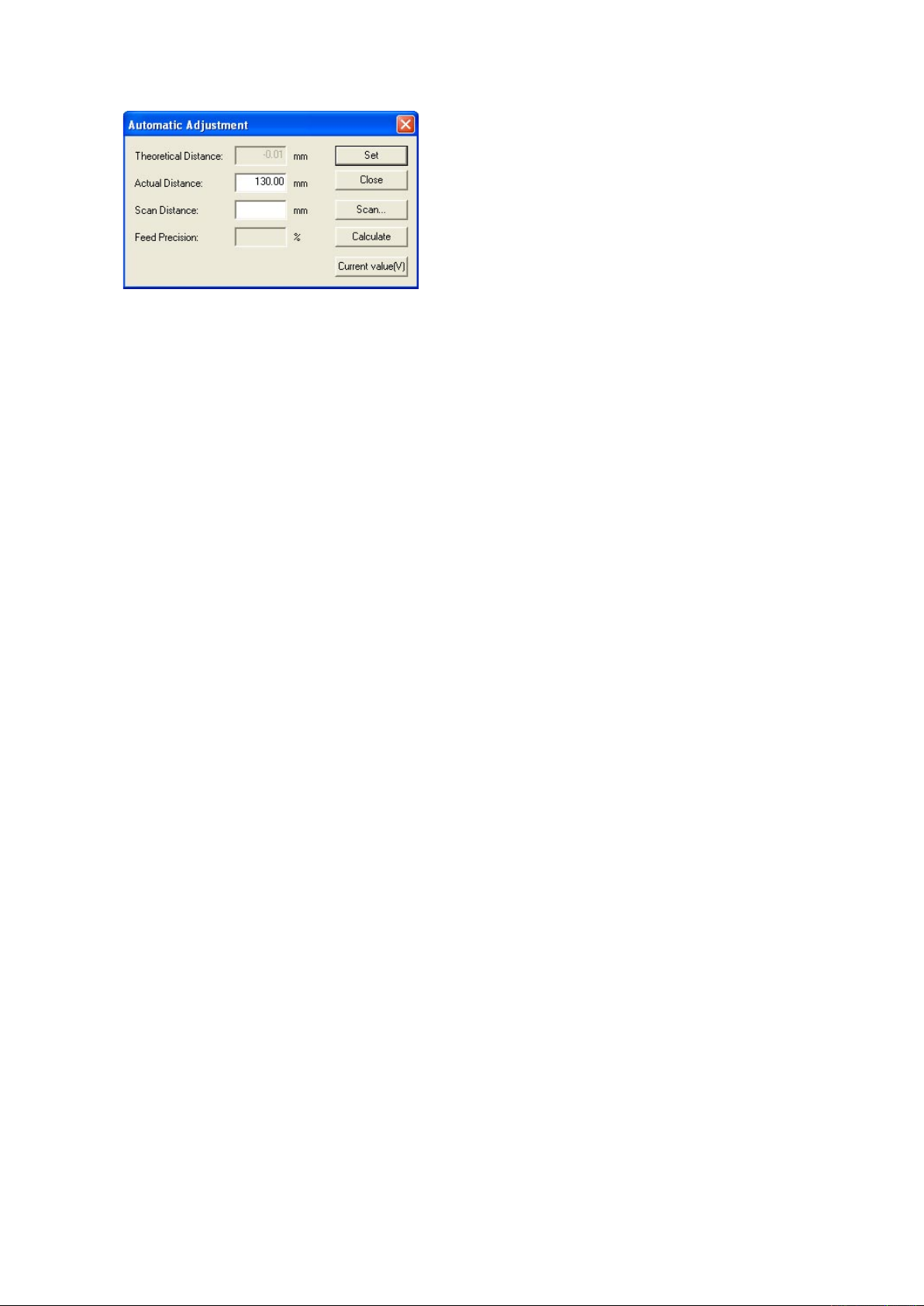

B057