Page 1

COLOR IMAGE SCANNER

SERVICE MANUAL

CS600 SERIES

CS600-UM251-12-9370

Page 2

Page 3

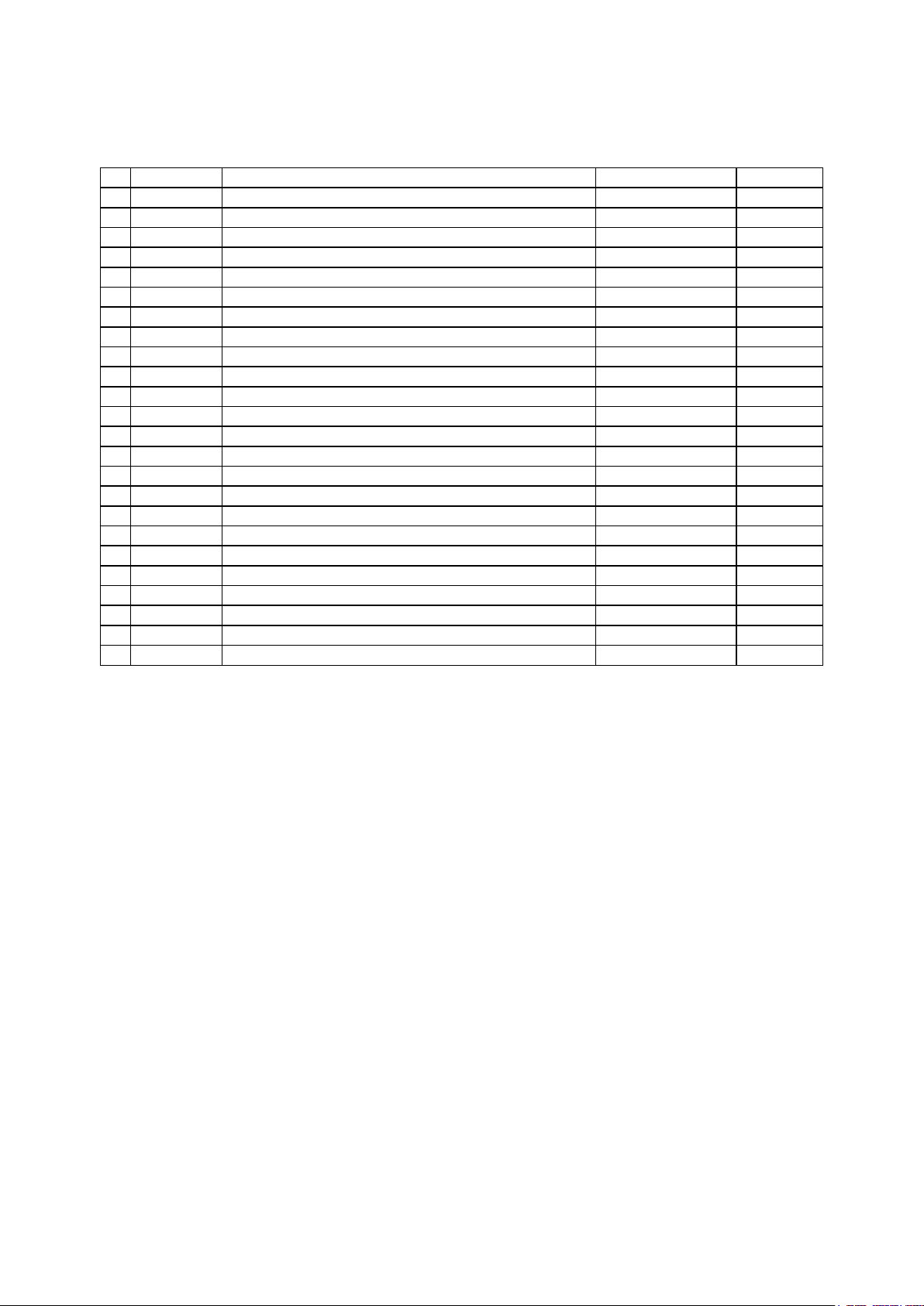

HISTORY OF REVISIONS

No. Date issued Description of revision Page Edition

1 04.10.13 First Printing. All 01

2 04.11.11 Part number for the hold down roller corrected. 5-1,12-7 02

3 05.01.06 Firmware update procedure corrected. 8-9 03

4 05.01.14 Part item No.9 corrected. 12-6 04

5 05.03.09 Part number for stand corrected. 12-10 05

6 05.03.09 Figure for stand added. 12-10 05

7 05.06.15 Part number for the data controller board corrected. 5-1,12-2 06

8 06.08.22 Part number for the paper sensor corrected. 12-5 07

9 06.09.20 Part number for the ethernet board corrected. 12-2 08

10 06.09.20 Part number for the

11 07.07.09 The data control board was added for CS600-11-A. 5-1,12-2 09

12 07.07.09 The CIS control board was added for CS600-11-A. 5-1,12-7 09

13 07.07.09 The power board was added for CS600-11-A. 5-1,12-2 09

14 07.07.09 Part number for CIS sensor assembly corrected. 5-1,12-7 09

15 07.07.09 Wiring diagram added for CS600-11-A. 9-6 09

16 08.05.28

17 08.10.31 Item 9 was shown wrong part. 12-1 11

18 08.10.31 Part number for the front guide was corrected. 12-4 11

19 08.10.31 Rank of parts was added. 12-1 to 12-14 11

20 08.10.31

21 09.10.08 Part number for the cover sensor was corrected. 5-1, 12-9 12

22 09.10.08 Part number for the thickness sensor was corrected. 5-1, 12-9 12

23 09.10.08 Part number for the safety sensor was corrected. 12-9 12

24 09.10.08 Wiring diagram was corrected. 8-7 12

The IS0917 and the IS0907 were assigned to consumable supplies parts.

Part number for the A version of data controller board corrected.

enhanced I/F board added. 12-2 08

12-12 10

5-1, 12-2 11

CS600-UM-251-9370 i

Page 4

CONTENTS

1. OVERVIEW ............................................................................................1-1

1.1 Features .............................................................................................................. 1-1

1.2 Standard Specifications .................................................................................... 1-2

1.3 External View .....................................................................................................1-4

2. PART NAMES AND FUNCTIONS ......................................................... 2-1

2.1 Part Names and Functions ............................................................................... 2-1

3. INSTALLING THE SOFTWARE ............................................................3-1

3.1 Installing the Driver Software for Windows 2000 ...........................................3-1

3.2 Installing the Driver Software for Windows XP ...............................................3-4

3.3 Checking the Interface Connection for Windows 2000 ..................................3-6

3.4 Checking the Interface Connection for Windows XP .....................................3-7

3.5 Installing the Scanning Master 21+ Application .............................................3-8

4. DAILY MAINTENANCE .........................................................................4-1

4.1 Opening and Closing the Top Cover ................................................................ 4-1

4.2 Cleaning the Document Hold-Down Unit .........................................................4-2

4.3 Cleaning the Image Sensors .............................................................................4-3

4.4 Cleaning the Paper Sensors .............................................................................4-4

4.5 Removing a Jammed Document ......................................................................4-5

4.6 Calibration ..........................................................................................................4-6

5. RECOMMENDED PARTS LIST ............................................................5-1

6. LIST OF JIGS AND TOOLS .................................................................. 6-1

6.1 Jigs ...................................................................................................................... 6-1

6.2 Tools .................................................................................................................... 6-1

6.3 Other ...................................................................................................................6-1

7.

DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS ..................................7-1

7.1 Right Side Cover ................................................................................................ 7-1

7.2 Left Side Cover ................................................................................................... 7-1

7.3 Top Cover Assembly .......................................................................................... 7-2

7.4 Front Guide Assembly ....................................................................................... 7-5

7.5 Rear Cover .......................................................................................................... 7-6

7.6 Motor ................................................................................................................... 7-7

7.7 Drive Roller Pulley ............................................................................................. 7-8

7.8 Drive Rollers ..................................................................................................... 7-10

7.9 Drive Belt ...........................................................................................................7-12

7.10 Front and Rear Paper Detection Sensors .......................................................7-14

7.11 Control Panel Sheet Switch .............................................................................7-15

7.12 Contact Glass Assembly ................................................................................. 7-16

CS600-UM-251-9370 ii

Page 5

7.13 CIS (Charge Coupled Device Imaging Sensor) Assembly ............................7-17

7.14 CIS (Charge Coupled Device Imaging Sensor) Board .................................. 7-18

7.15 Pinch Roller Covers ......................................................................................... 7-19

7.16 Document Hold-down Rollers ........................................................................ 7-22

7.17 Pinch Roller Units ............................................................................................ 7-23

7.18 Cover Sensors .................................................................................................. 7-24

7.19 Safety Sensors ................................................................................................. 7-25

7.20 Thickness Sensor ............................................................................................ 7-27

7.21 Elevator Sensor ................................................................................................ 7-28

7.22 Adjusting the Thickness Sensor and the Elevator Sensors ........................ 7-29

7.23 Adjusting the Safety Sensors ......................................................................... 7-32

7.24 Elevator Gear Box ............................................................................................ 7-33

7.25 Elevator Control Board .................................................................................... 7-35

7.26 Adjusting the Elevator Slider Plate ................................................................ 7-36

7.27 IEEE 1394 Board (Only for IEEE1394 model) .......................................................... 7-37

7.28 Data Controller Board ...................................................................................... 7-38

7.29 Power Board ..................................................................................................... 7-40

7.30 Switching Power Supply Board ...................................................................... 7-41

8. BOARDS AND ELECTRICAL COMPONENTS .................................... 8-1

8.1 Wiring Diagrams ................................................................................................8-1

8.1.1 Wiring Diagrams (CS600-11) ................................................................... 8-1

8.1.2 Wiring Diagrams (CS600-11-A) ............................................................... 8-7

8.2 Replacing the Data Controller Board ...............................................................8-8

1. Precautions for replacing the data controller board .................................. 8-8

2. Replacing the data controller board ............................................................ 8-8

8.3 Replacing the IEEE 1394 Board ........................................................................8-9

Input the MAC address to the IEEE 1394 board ............................................. 8-9

8.4 Downloading Firmware ...................................................................................8-10

1. Items required to download firmware ........................................................ 8-10

2. Procedure ..................................................................................................... 8-10

9. ADJUSTMENTS USING THE SOFTWARE .......................................... 9-1

9.1 Starting the Software ........................................................................................ 9-1

9.2 Preparations before Making Adjustments .......................................................9-3

9.3 Preparing a Test Chart .......................................................................................9-4

9.4 Making Adjustments ..........................................................................................9-5

Scanner Calibration ........................................................................................... 9-5

1. Calibration (white correction) ....................................................................... 9-5

2. Feed distance adjustment ............................................................................ 9-7

3. Position adjustment ...................................................................................... 9-9

CS600-UM-251-9370 iii

Page 6

4. Color correction (using a color correction sheet) .................................... 9-15

10. TROUBLESHOOTING ........................................................................10-1

11. OPTION ............................................................................................... 11-1

11.1 Optional Item .................................................................................................... 11-1

11.2 Consumables ................................................................................................... 11-1

12. PARTS LIST ........................................................................................ 12-1

12.1 Outer Casing .................................................................................................... 12-1

12.2 Main Frame ....................................................................................................... 12-2

12.3 Front Guide ....................................................................................................... 12-4

12.4 Drive Roller ....................................................................................................... 12-6

12.5 CIS Unit ............................................................................................................. 12-7

12.6 Top Cover .......................................................................................................... 12-9

12.7 Cables ..............................................................................................................12-11

12.8 Other Parts ..................................................................................................... 12-12

CS600-UM-251-9370 iv

Page 7

1. OVERVIEW

1. OVERVIEW

1.1 Features

• 600-dpi optical resolution for high-precision image scanning

Scanning with an optical resolution of 600 dpi allows even complex and difficult-to-scan documents,

such as CAD drawings, electronic files, and mapping data to be scanned rapidly and with high precision.

Scanning Master 21+ (scanner software included as a standard accessory) can be used to adjust the

resolution in five levels (50 dpi to 800 dpi/50 dpi to 4800 dpi, in 1-dpi increments) to suit the scanned

document.

• Compatible document widths range from 210 mm to 1066 mm

Compatible with document sizes from ISO A4 up to ANSI E (42 inches)

• Capable of color and grayscale scanning

Capable of scanning in color (24-bit color, 8-bit color) or grayscale (256 shades)

• Support of automatic thickness detection

ITA (Intelligent Thickness Adjustment) supports automatic document-thickness detection.

• Capable of reading long-axis data

Scanning of long-axis images is supported.

• Compact and lightweight design

A compact design was achieved by using a document travel system that employs contact image sensors

in the sensor unit (five rows arranged in a zigzag pattern).

• Image-processing functions

Use of the scanning software provided lets you set image-processing functions for the scanning of a

document.

• Interface

USB 2.0, IEEE 1394

CS600-UM-251-9370 1-1

Page 8

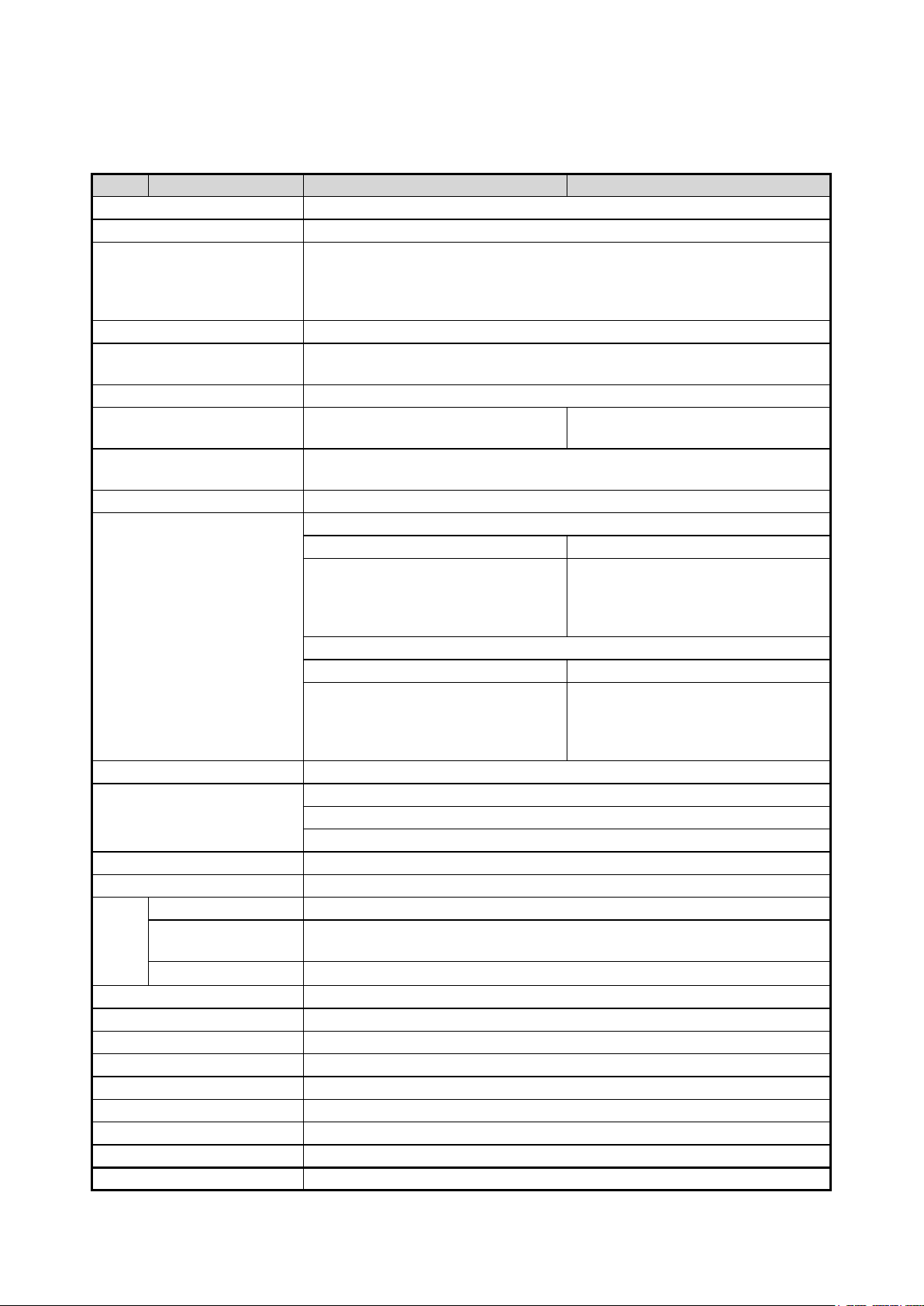

1.2 Standard Specifications

Item CS600-11 CS600-11PRO

Document size ANSI E to ISO A4

Effective scanning area

Guaranteed scanning precision

*3

range

Document thickness 20.32 mm (0.8 inches) or less (including the carrier sheet)

Document thickness-detection

process

Optical resolution 600 dpi

Interpolated resolution From 50 to a maximum of 800 dpi, in

Main scanning system Contact image sensor system

Sub scanning system Document travel (sheet through) system

Scanning speed

Scanning precision*3 ±0.1%, ±5 pixels

Gradation Monochrome: Bilevel, intermediate tones (dither, error diffusion)

Threshold value Automatic threshold setting by DSP in monochrome mode

Color space sRGB compatible

Sensor

Interface

Output Image data

Rated power supply 100 to 120 VAC / 200 to 240 VAC ±10%, 50/60 Hz

Operating environment Temperature: 10˚C to 35˚C;Humidity: 35% to 80% RH (no condensation)

Power consumption 60 W or less

External dimensions 1205 mm (W) X 957 mm (H) X 650 mm (D) (main unit with stand)

Weight

Conforming standards VCCI class A (Japan), UL, FCC class A (USA), CE mark (EU)

Operating system (OS)

*2

Total number of pixels 25,200 pixels

Output Color: 42 bits/pixel

Light source LED (RGB)

*4

1092 mm

Width: 1,066.8 mm (42 inches) (centered)

Length: 16 m (maximum)

762 mm (30 inches) or less if the document thickness exceeds 1.5 mm.

2,060 mm (81.1 inches) when the optional Document scanning table is used.

Automatic detection by ITA

1-dpi increments

Five A4 sensors in staggered arrangement

When the document thickness is 1.5 mm or less (400 dpi, A0)

Normal scan High-speed scan

Monochrome: 13 s

Gray scale: 25 s

8-bit color: 47 s

24-bit color: 47 s

When the document thickness is 1.5 mm to 20.32 mm (400 dpi, A0)

Normal scan High-speed scan

Monochrome: 34 s

Gray scale: 41 s

8-bit color: 45 s

24-bit color: 45 s

Gray : 256 shades

Color: 8-bit, 24-bit

Grayscale: 14 bits/pixel

USB 2.0, IEEE 1394

45 kg (main unit with stand)

Windows XP Professional, Windows XP Home Edition, Windows 2000 Professional

*1

From 50 to a maximum of 4800 dpi, in

1-dpi increments

Monochrome: 8 s

Gray scale: 22 s

8-bit color: 33 s

24-bit color: 33 s

Monochrome: 34 s

Gray scale: 41 s

8-bit color: 40 s

24-bit color: 40 s

1. OVERVIEW

CS600-UM-251-9370 1-2

Page 9

1. OVERVIEW

* 1

Documents up to approximately 16 m in length (driver software limitation) can be scanned. However, the actual

document length that can be scanned is limited by the available memory (hard disk or other data storage device)

of the computer to which the scanner is connected, and also by the grade of the medium being scanned.

* 2

Including data-transfer time

Scanning system requirements (Scanning speed may decrease depending on PC specifications.)

•

CPU: Pentium 4, 3.2 GHz or higher

Memory: 1 GB or more

Interface: USB 2.0

* 3

Notes on scanning precision

Scanning precision may vary slightly depending on the grade and thickness of the medium being scanned, and on

the operating conditions. The precision figures above were measured under the operating conditions described

below.

• Test chart used : Mylar sheet #200

• Guaranteed precision conditions : Temperature 20 ±3˚C; humidity: 60% ±10% RH

* 4

The USB 2.0 and IEEE 1394 interface cannot be used at the same time.

CS600-UM-251-9370 1-3

Page 10

1.3 External View

947

1205

610

CS600

External Dimensions

1. OVERVIEW

Unit : mm

Dimensional precision error : ±5 mm

CS600-UM-251-9370 1-4

Page 11

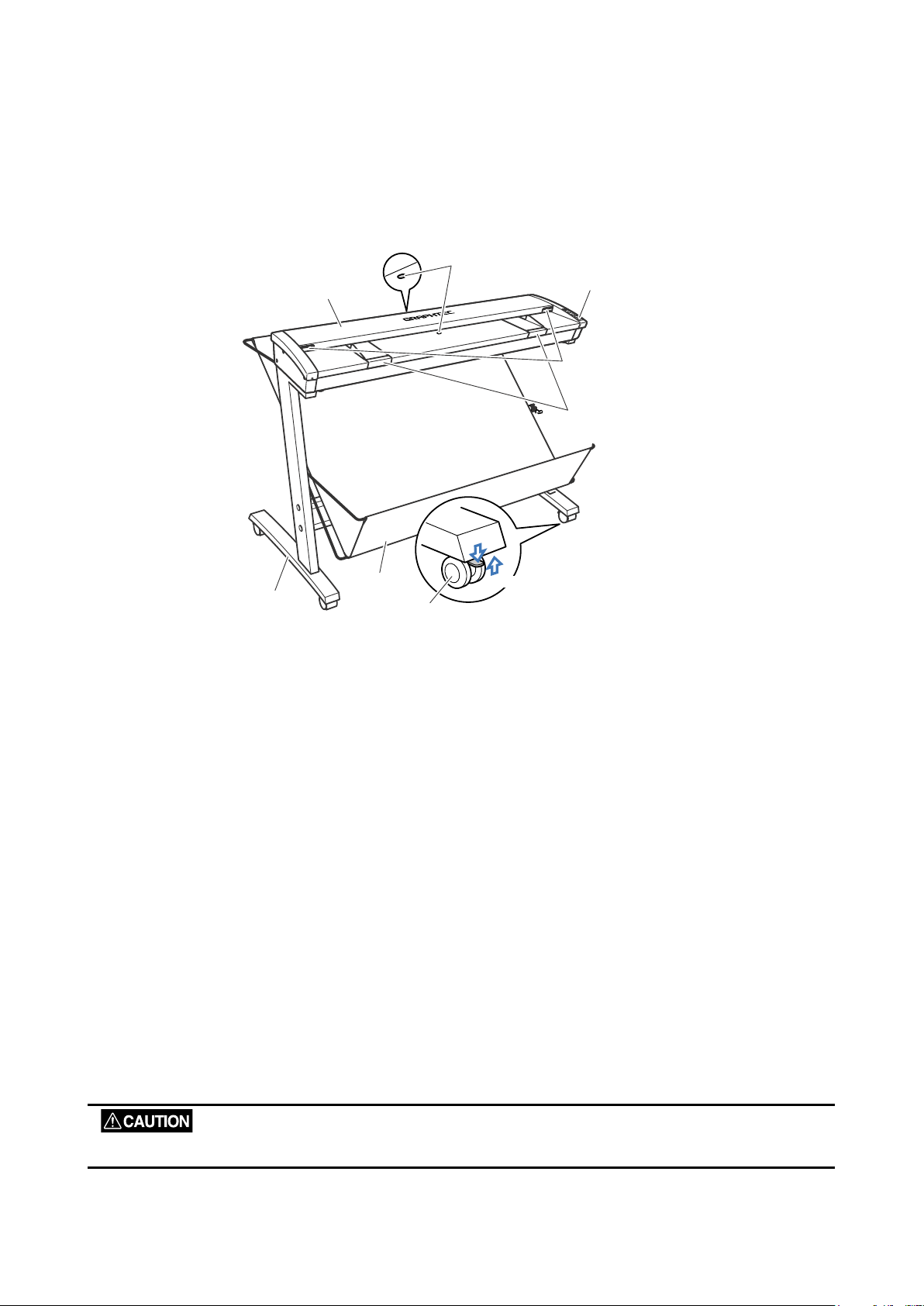

2. PART NAMES AND FUNCTIONS

Stand

Basket

Top cover

Paper sensor

Cover sensor

Control panel

Caster

Lock

Document guides

Release

2.1 Part Names and Functions

Front View

2. PART NAMES AND FUNCTIONS

Top cover

Open the top cover to clean the document hold-down unit and transparent contact plates.

Paper sensors

These sense whether a document is present in the scanner.

Cover sensor

This senses whether the top cover is open or closed, and interrupts scanner operation if the top cover is

opened during operation.

Document guides

Use these guides to determine the position of a document when you load the document.

Control panel

Use the keys to operate the scanner and the LEDs to monitor the operating status.

Stand

The stand unit is assembled for mounting of the scanner unit.

Basket

Receives the document that has been scanned.

Casters

Release the lock on the casters to allow the unit to be moved.

Do not touch the cover sensors or paper sensors.

CS600-UM-251-9370 2-1

Page 12

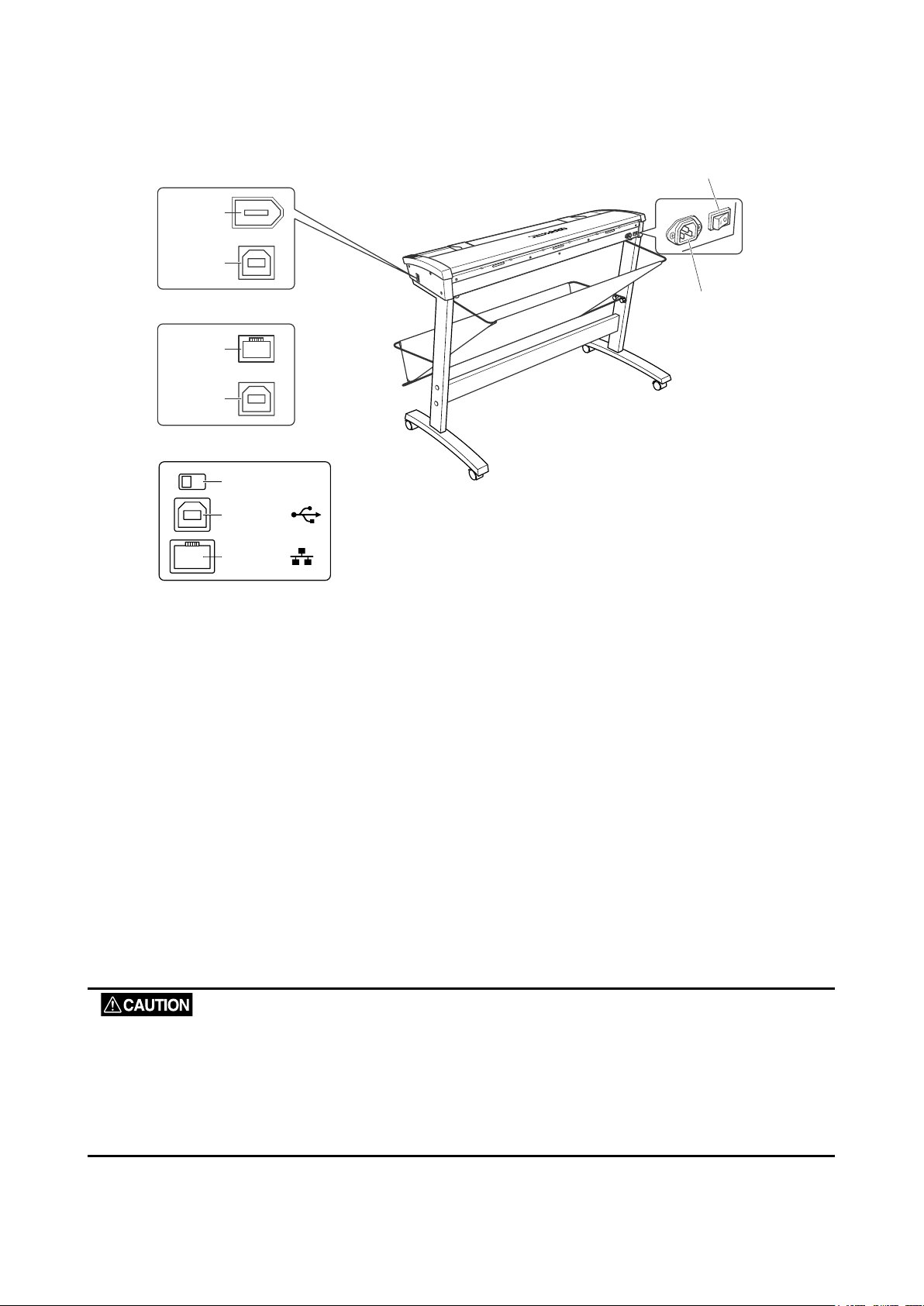

Rear View

AC line inlet

Power switch

IEEE 1394

connector

USB

connector

Ethernet

connector

USB

connector

CS600-11

CS600-11eN

CS600-11-A

Ethernet

connector

USB

connector

Interface

selection switch

2. PART NAMES AND FUNCTIONS

Power switch

Controls the on/off status of the power supply to the scanner.

AC line inlet

Connect the power cord’s female plug here.

USB connector

Used to connect the USB interface cable.

IEEE 1394 connector

Used to connect the IEEE 1394 interface cable.

Ethernet connector*

Used to connect the Ethernet cable.

*Please do not connect with an Ethernet connector other than an Ethernet cable.

Interface selection switch

Used to switch between USB and Ethernet (LAN) connection.

This switch is set to USB connection at the time of shipment.

Make sure that the scanner’s power supply is turned off before using the interface selection switch to select an

interface.

The USB 2.0 interface cannot be used at the same time as the IEEE 1394 or the Ethernet interface.

both the USB and IEEE 1394 or Ethernet cables to a computer, or to two separate computers, at the same time.

The USB and IEEE 1394 connectors cannot be used at the same time. Do not connect both the USB and IEEE

1394 cables to a computer, or to two separate computers, at the same time.

Do not connect

CS600-UM-251-9370 2-2

Page 13

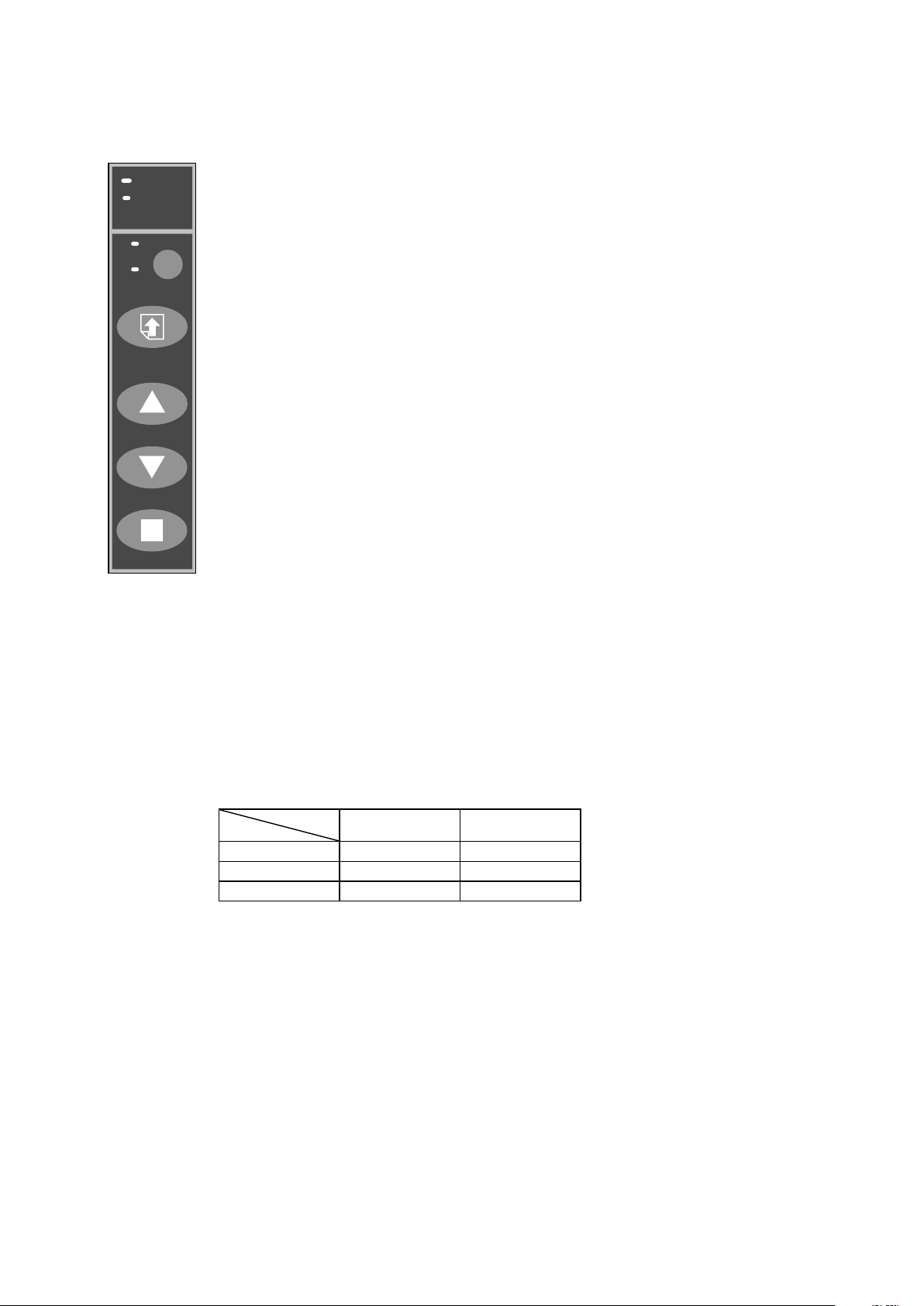

POWER

P

READY

ITA

APER

ERROR

SCAN

FORWARD

REVERSE

STOP

ITA

Control panel

2. PART NAMES AND FUNCTIONS

POWER LED

Not lit : Power is turned off.

Lit green : The power is on and the scanner is operating in normal mode.

Flashing orange : The scanner is in power-saving mode.

PAPER LED

Not lit : Normal mode.

Lit green : The scanner is ready to scan.

Flashing green : The scanner is currently scanning a document (reading image data) or

an abnormality in raising/lowering the top cover is detected.

ERROR LED

Not lit : Normal mode (no errors)

Lit red : Hardware error.

Flashing red : The LED flashes red when a document is detected in the scanner

during the power-on selftest, when the STOP button is pressed during

scanning, when a paper jam is detected, when the document length

is shorter than the scan length,

*1

or when an abnormality in raising/

lowering the top cover is detected.

*1 If the driver software has been set to check end-of-paper processing.

ITA button

Switch between ITA (thickness-detection) and READY (normal) modes.

READY LED

Lit green : READY mode.

Not lit : ITA mode.

ITA LED

Not lit : READY mode.

Lit green : ITA mode.

Flashing green : The scanner is operating in ITA mode.

Mode

LED

READY mode

ITA mode

READY LED ITA LED

Lit green Not lit

Not lit Lit green

Safety mode* Not lit Not lit

*When something is blocking the scanner.

SCAN button

If the scanner is connected to a computer, it scans the current document in accordance

with the parameters set by the Scanning Master 21+ software. If the software is not

active, it is started in order to receive the data from the scanner.

*2

*2 This button works during READY mode, but has no effect during ITA mode.

FORWARD button

• During READY mode

Moves a document into position. If this button is pressed while the scanner is in READY

mode, READY mode is cleared and the document is ejected to the rear of the scanner.

• During ITA mode

If a thick document has been placed in the front paper sensor section of the scanner at

the time this button is pressed, the thickness-detection process will begin automatically.

CS600-UM-251-9370 2-3

Page 14

2. PART NAMES AND FUNCTIONS

REVERSE button

• During READY mode

Moves the document in the scanner backward. If this button is pressed while the

scanner is in READY mode, READY mode is cleared and the document is ejected to

rear of the scanner.

• During ITA mode

If a thick document is inserted into the scanner during ITA mode, this button allows you

to lower the top cover.

STOP button

Stops scanning/the automatic thickness-detection process.

CS600-UM-251-9370 2-4

Page 15

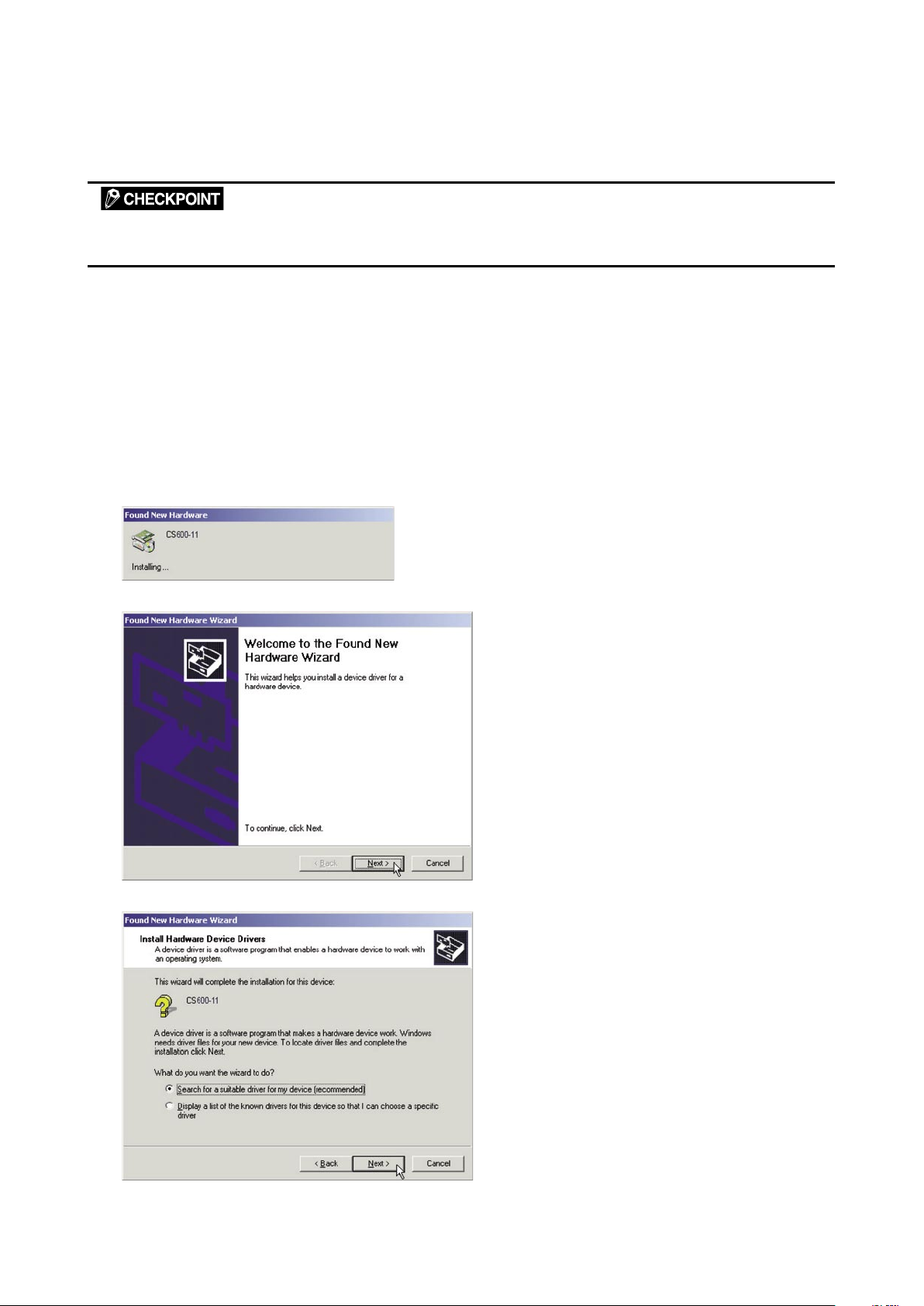

3. INSTALLING THE SOFTWARE

3. INSTALLING THE SOFTWARE

The procedure outlined below is based on the requirement that you are logged on to Windows with administrator

rights. Consult your Windows 2000 or Windows XP manual for more information.

3.1 Installing the Driver Software for Windows 2000

The following procedure assumes that you are using the CS600 as part of your system, and that you are

using the USB interface. If you are using the IEEE 1394 interface, GRAPHTEC CS600-11 IEEE 1394 SBP2

Device will be displayed where CS600-11 is displayed when the USB interface is used. Substitute CS600-

11PRO for CS600-11 for guidelines as to how to use the CS600-11PRO.

(1) Connect the scanner to the computer, and turn on the computer’s power. Insert the

(included with your computer) into the CD-ROM drive of the computer after Windows has started up,

and then turn on the scanner’s power.

(2) The message below appears.

CD-ROM disk

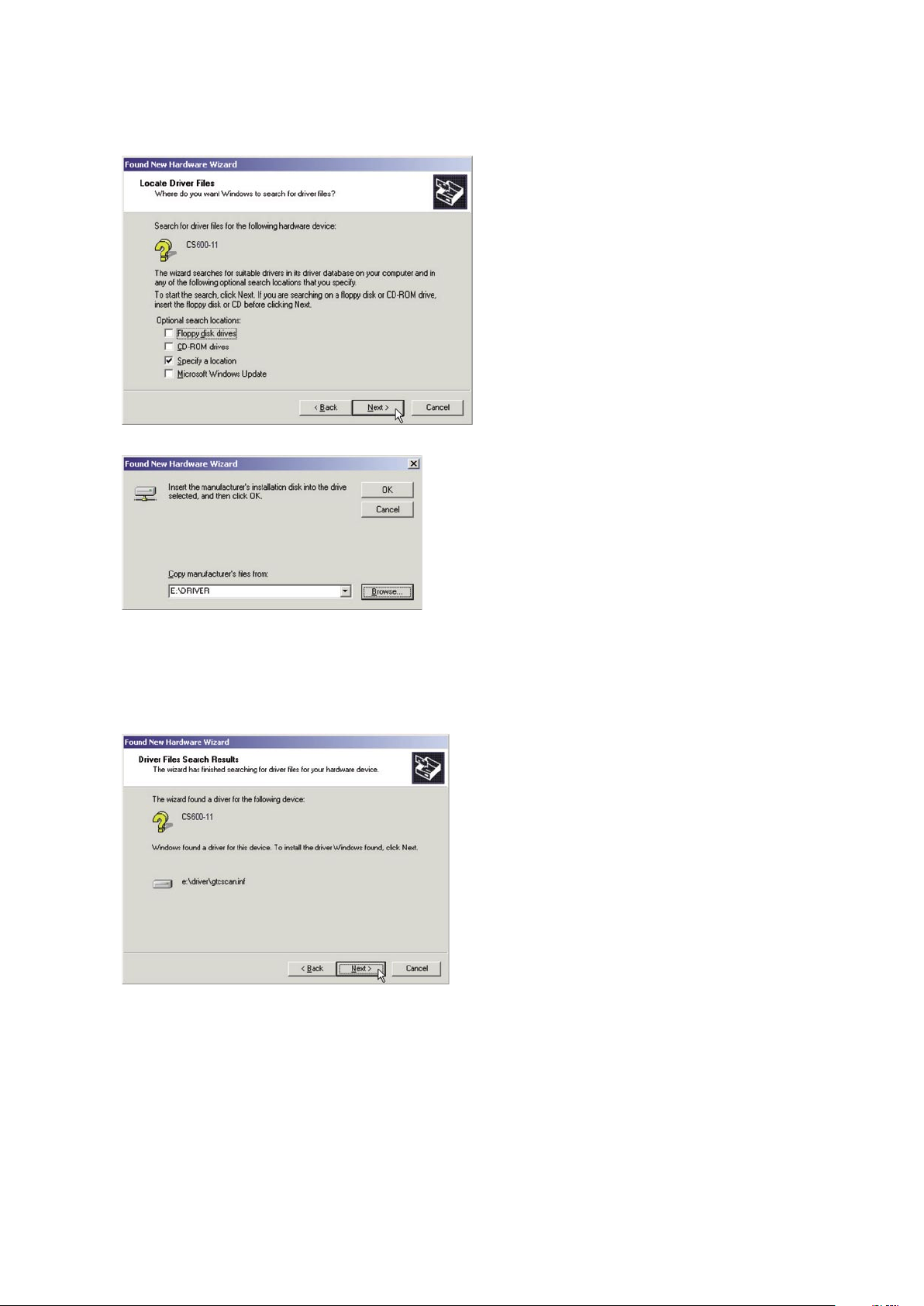

(3) Next, the Found New Hardware Wizard appears.

(4) Click the Next button to proceed to the menu for installing the driver.

CS600-UM-251-9370 3-1

Page 16

3. INSTALLING THE SOFTWARE

(5) Select the option “Search for a suitable driver for my device (recommended)” and click Next.

(6) Select the check box entitled “Specify a location” and click Next.

Click Browse and select the DRIVER folder in the CD-ROM drive or enter a CD-ROM drive name and

\DRIVER using the keyboard.

Example: For drive E, enter “E:\DRIVER.”

(7) When you click OK the wizard will start searching for the driver. The screen shown below is displayed

when the wizard has finished searching.

CS600-UM-251-9370 3-2

Page 17

3. INSTALLING THE SOFTWARE

(8) The screen shown below is displayed when you click Next.

Click Yes to continue the installation.

(9) The screen shown below is displayed when the wizard has finished installing the driver.

Click the Finish button.

(10) The Windows 2000 Desktop appears and the Scanner is acknowledged by the computer.

CS600-UM-251-9370 3-3

Page 18

3. INSTALLING THE SOFTWARE

3.2 Installing the Driver Software for Windows XP

The following procedure assumes that you are using the CS600 as part of your system, and that you are

using the USB interface. If you are using the IEEE 1394 interface, GRAPHTEC CS600-11 IEEE 1394 SBP2

Device will be displayed where CS600-11 is displayed when the USB interface is used. Substitute CS600-

11PRO for CS600-11 for guidelines as to how to use the CS600-11PRO.

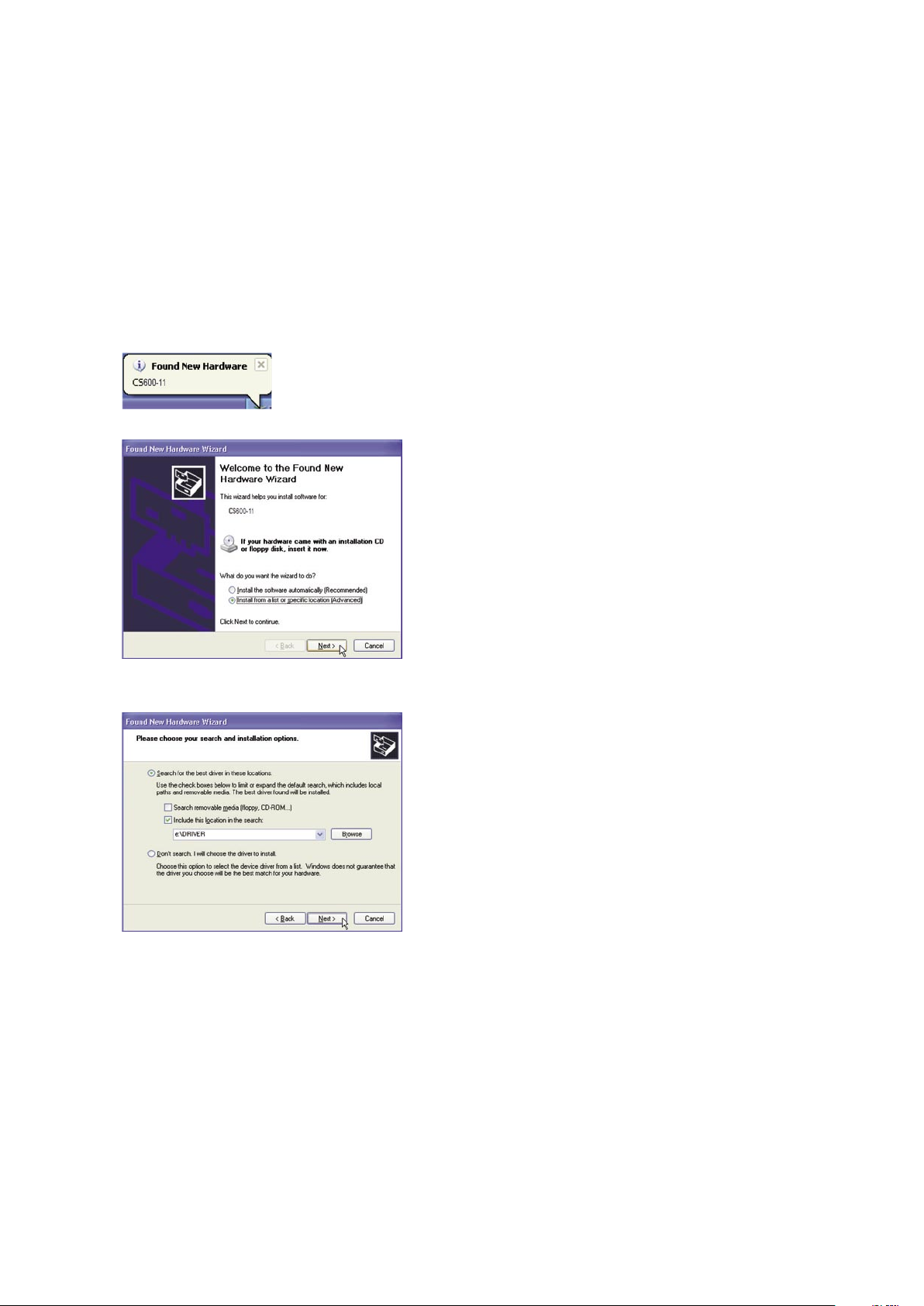

(1) Connect the scanner to the computer, turn on the scanner first, and then turn on the computer. When

Windows starts up, insert the CD-ROM supplied with the scanner in the CD-ROM drive. Turn on the

power to the scanner.

(2) When Windows XP starts up, the following window appears.

(3) Next, the Found New Hardware Wizard window appears.

Select the option “Install from a list or specific location (Advanced)”.

(4) The screen shown below is displayed when you click Next.

Select the option “Search for the best driver in these locations” and select the check box entitled “Include

this location in the search”.

Click Browse and select the DRIVER folder in the CD-ROM drive or enter a CD-ROM drive name and

\DRIVER using the keyboard.

Example: For drive E, enter “E:\DRIVER.”

CS600-UM-251-9370 3-4

Page 19

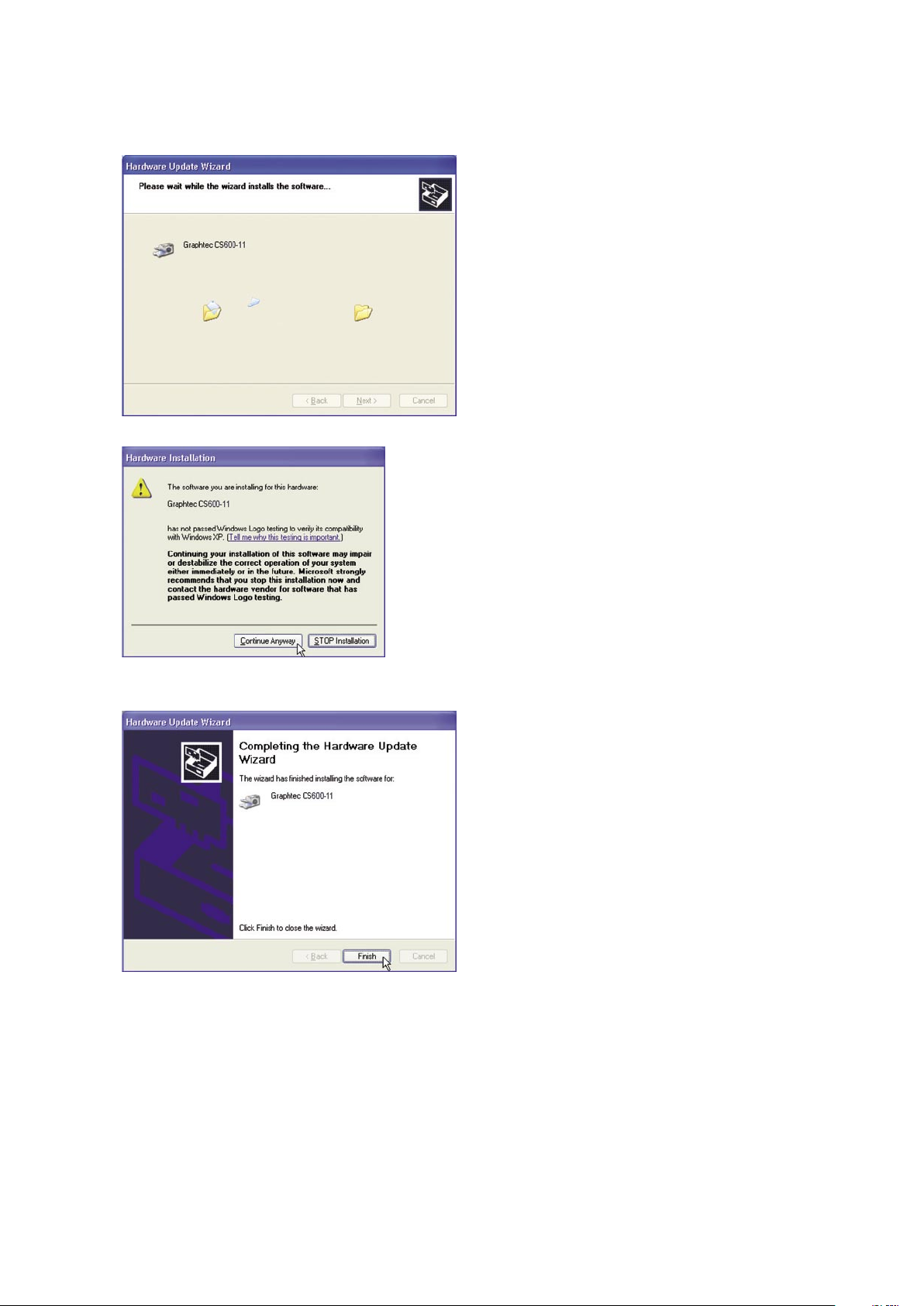

(5) When you click Next the wizard will start searching for the driver.

(6) The screen shown below is displayed.

3. INSTALLING THE SOFTWARE

Click Continue Anyway to continue the installation.

(7) The screen shown below is displayed when the wizard has finished installing the driver.

Click the Finish button to close the “Welcome to the Found New Hardware” wizard.

(8) The Windows XP desktop appears, and the scanner is recognized by the computer.

CS600-UM-251-9370 3-5

Page 20

3. INSTALLING THE SOFTWARE

3.3 Checking the Interface Connection for Windows 2000

The procedure outlined below assumes that the CS600 is connected in your system.

Substitute CS600-11PRO for CS600-11 for guidelines as to how to use the CS600-11PRO.

(1) Launch the Control Panel using the Start menu.

(2) The screen shown below is displayed when you click on the “Scanners and Cameras” icon.

Ensure that “Graphtec CS600-11 or CS600-11PRO” is indicated here.

CS600-UM-251-9370 3-6

Page 21

3. INSTALLING THE SOFTWARE

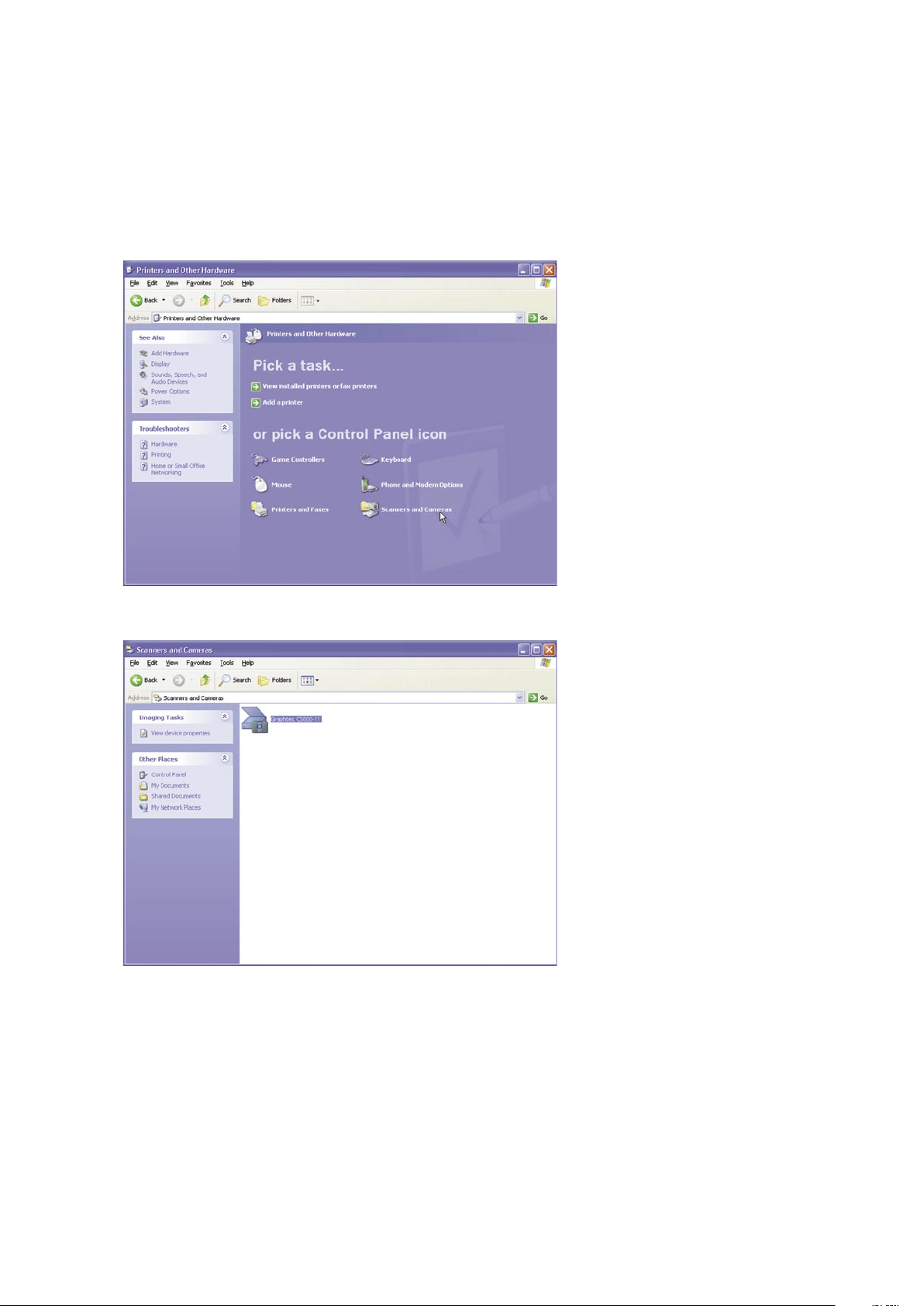

3.4 Checking the Interface Connection for Windows XP

The procedure outlined below assumes that the CS600 is connected in your system.

Substitute CS600-11PRO for CS600-11 for guidelines as to how to use the CS600-11PRO.

(1) Launch the Control Panel using the Start menu.

(2) The screen shown below is displayed when you click on the “Printers and Other Hardware” icon.

(3) The screen shown below is displayed when you click on the “Scanners and Cameras” icon.

Ensure that “Graphtec CS600-11” or “Graphtec CS600-11PRO” is indicated here.

CS600-UM-251-9370 3-7

Page 22

3. INSTALLING THE SOFTWARE

3.5 Installing the Scanning Master 21+ Application

The Scanning Master 21+ “OPS112” is a software application for using a Graphtec scanner to scan image

data.

Operating Environment

Windows 2000 Professional/XP Professional/XP Home Edition

Installation Procedure

(The following steps are explained using the Windows 2000 windows.)

(1) Boot Windows 2000.

(2) Insert the User Guide CD-ROM containing the OPS112 program files into the computer’s CD-ROM

drive.

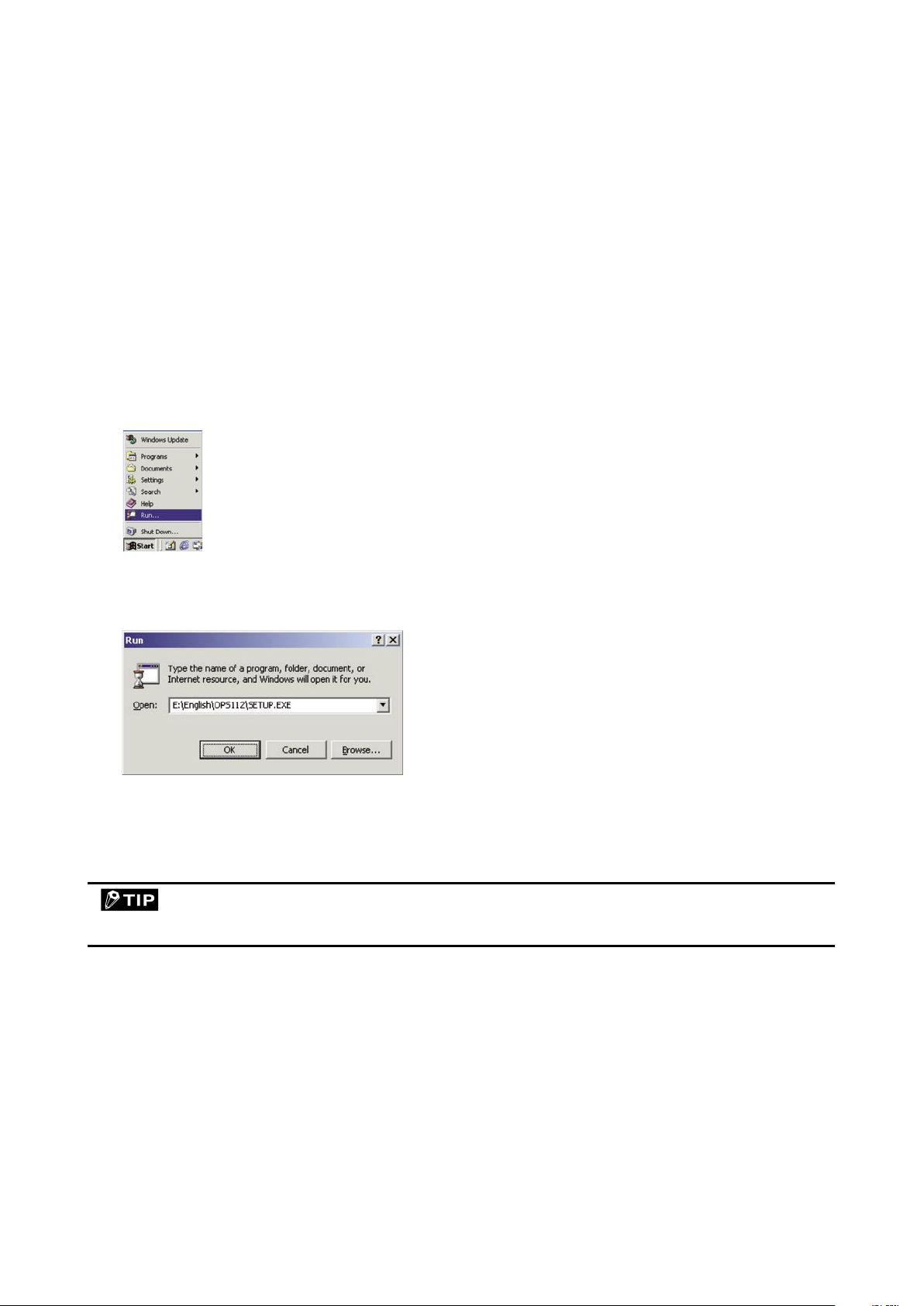

(3) Click the Taskbar’s Start button, then click the Run... icon.

(4) Enter the CD-ROM drive name and English\OPS112\SETUP.EXE as the name of the file you wish to

open.

If the disk is in drive E, for example, enter “E:\English\OPS112\SETUP.EXE” in the box.

(5) Click the OK button to run the OPS112 setup program. From this point on, follow the setup program’s

instructions to install the OPS112 application.

• If the application has been properly installed, “Scanning Master 21+” will be newly listed in the Programs

menu accessed from the Start button.

For more details, open the README.TXT file provided in the “Scanning Master 21+” folder.

CS600-UM-251-9370 3-8

Page 23

4. DAILY MAINTENANCE

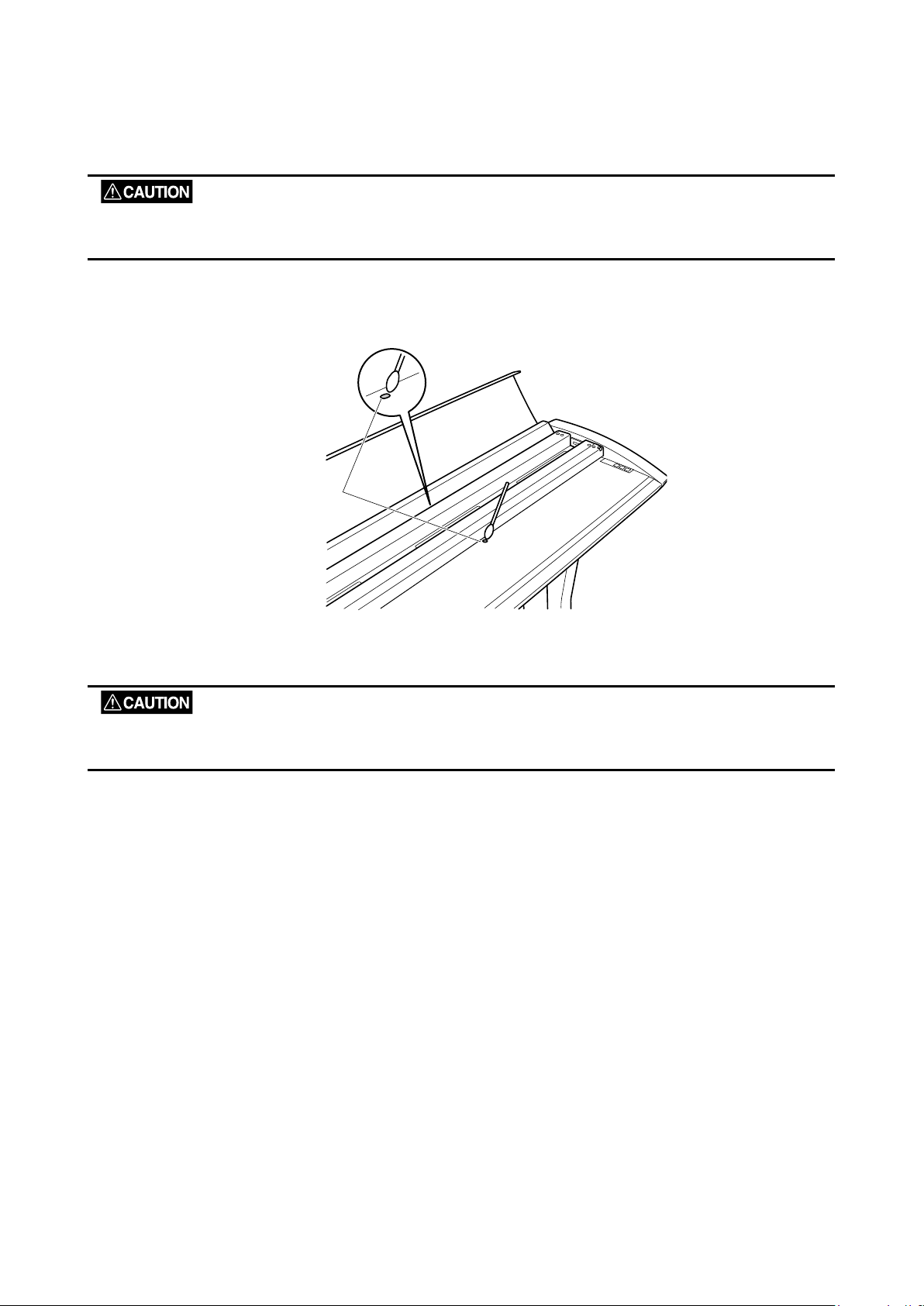

Top cover

Open levers

4. DAILY MAINTENANCE

4.1 Opening and Closing the Top Cover

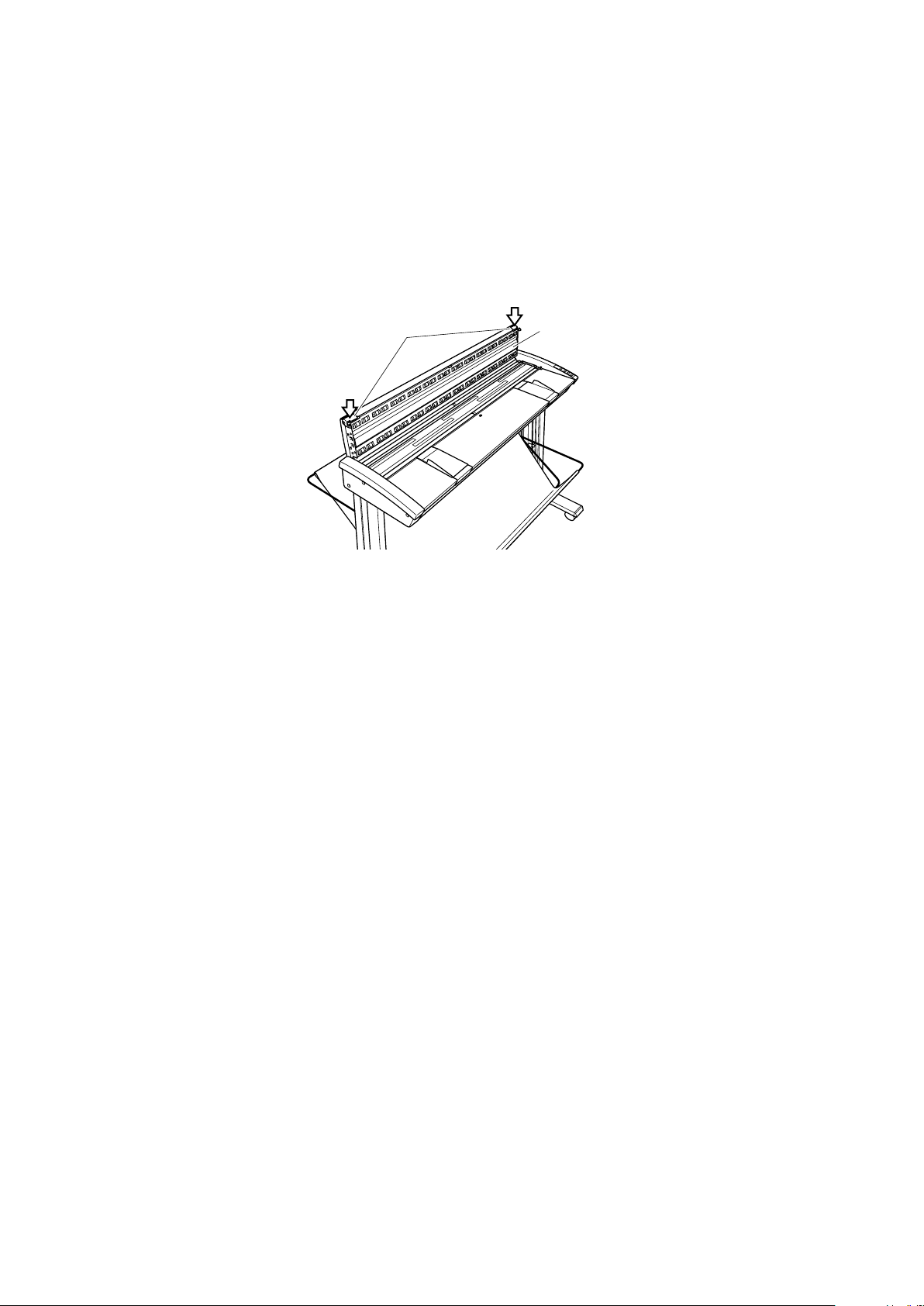

(1) Turn off the scanner’s power.

(2) Push the left and right open levers on the top cover to unlock them, and hold the middle part of the top

cover while you open the top cover by about 90 degrees.

(3) Close the top cover until the left and right latches on the top cover lock into position, making sure that you

don’t get your fingers caught.

CS600-UM-251-9370 4-1

Page 24

4. DAILY MAINTENANCE

Document hold-down unit

Latch

Latch

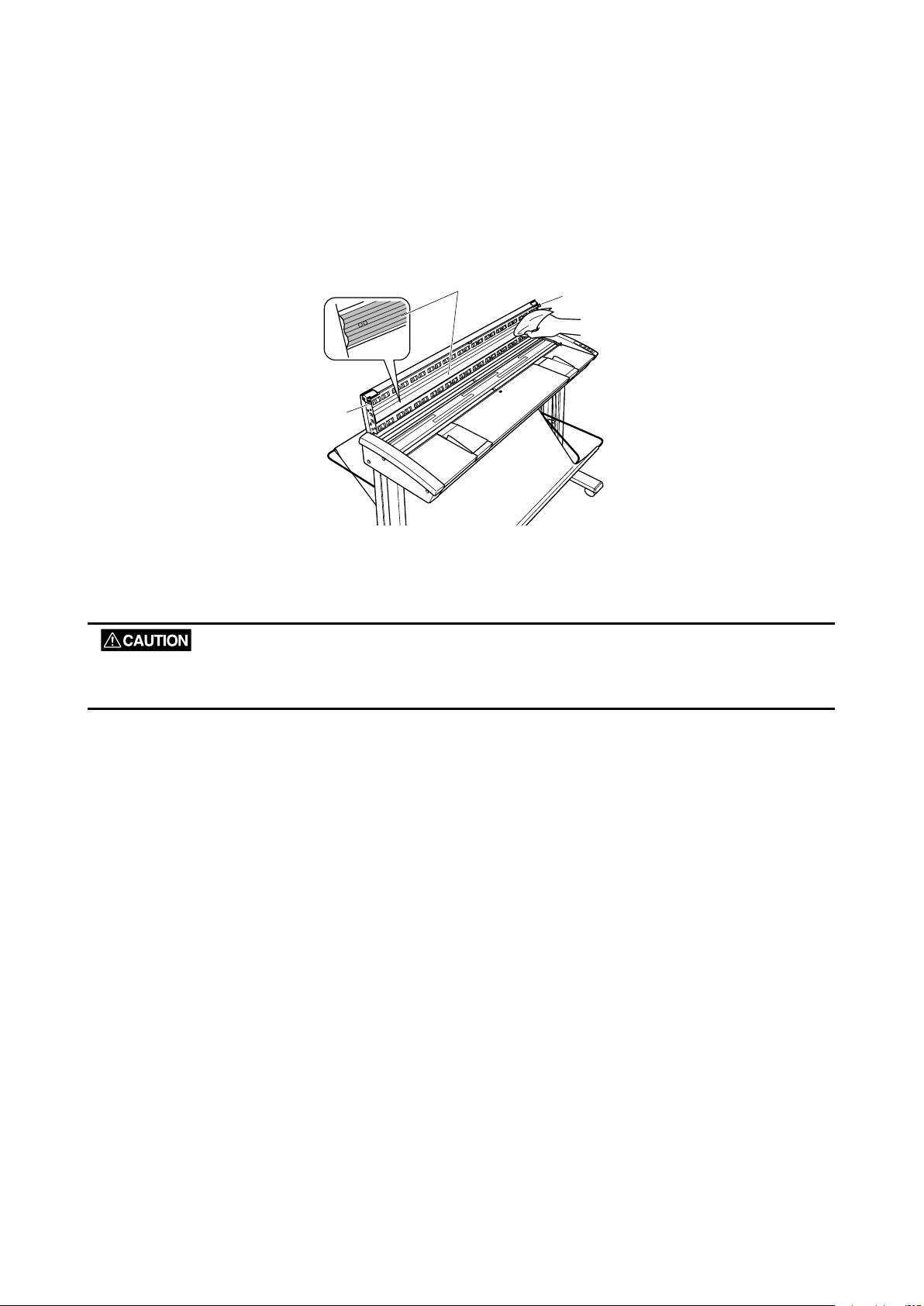

4.2 Cleaning the Document Hold-Down Unit

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

(3) Wipe clean the underside of the document hold-down unit (see below) using a soft cloth that has been

soaked in water or diluted neutral detergent and thoroughly wrung out.

(4) Wipe the document hold-down unit once again using a soft, dry cloth (remove all moisture).

(5) Close the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

Take care not to get your fingers caught in the cover.

Scanning may be affected if the underside of the document hold-down unit becomes scratched or dirty. It must be

cleaned when necessary.

CS600-UM-251-9370 4-2

Page 25

4. DAILY MAINTENANCE

Transparent contact plates

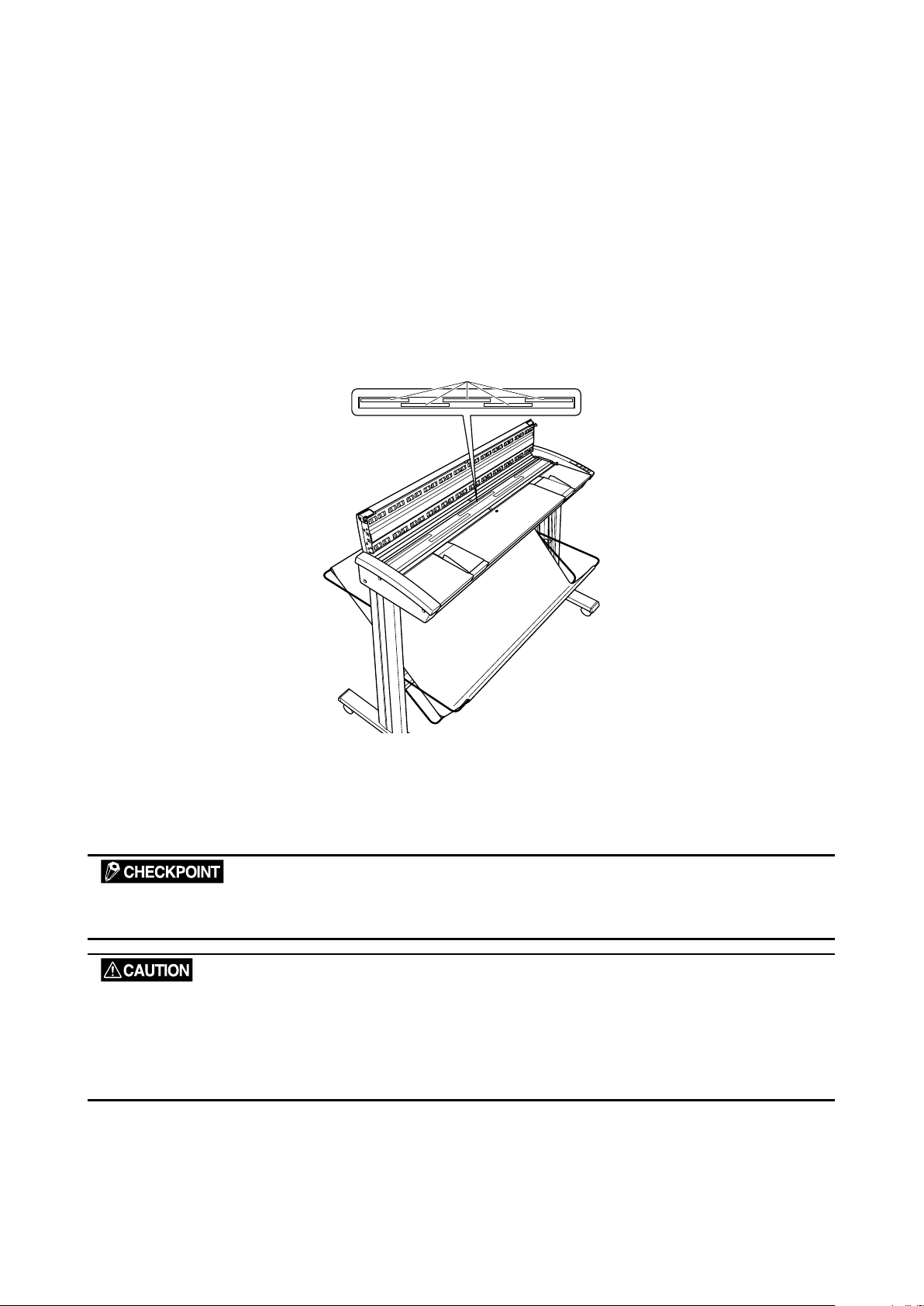

4.3 Cleaning the Image Sensors

The scanner’s image quality drops when the transparent contact plates over the image sensors become dirty,

so clean the image sensors whenever necessary.

Procedure

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

(3) As shown below, wipe off any soiled areas on the transparent contact plates using a soft cloth that has

been moistened with water or a neutral detergent (diluted with water) and firmly wrung out.

(4) Completely remove any moisture on the transparent contact plates by wiping them off again using a

soft, dry cloth.

(5) Close the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

Take care not to get your fingers caught in the cover.

Do not use a commercial cleaner for office equipment, a glass cleaner, or chemical solvents such as solutions con-

taining alcohol.

Although the glass scanning table is not a maintenance part that requires periodic replacement, it is a consumable

part because its surface may receive slight scratches due to minute particles of dust and other foreign matter. If

document scanning produces unsatisfactory results (unexpected white or black streaks in the data) due to scratch-

es on the glass table or other reasons, please perform the calibration procedure (see Section 4.6, “Calibration”). If

the scanning results do not improve after calibration, the glass table will need to be replaced.

CS600-UM-251-9370 4-3

Page 26

4. DAILY MAINTENANCE

Paper sensors

4.4 Cleaning the Paper Sensors

Accumulated dust on the paper sensors may prevent the document from being detected. The sensors must be

cleaned when necessary.

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

(3) Wipe the two paper sensors using a cotton swab.

(4) Close the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

Take care not to get your fingers caught in the cover.

Use a cotton swab or something equally soft to gently wipe the paper sensors. Do not use any chemicals to clean

the sensors.

CS600-UM-251-9370 4-4

Page 27

4. DAILY MAINTENANCE

4.5 Removing a Jammed Document

If a document becomes jammed in the scanner during scanning or another operation, immediately turn off

the scanner, and then remove the jammed document.

Procedure

(1) Turn off the scanner.

(2) Open the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

(3) If the document is jammed at the front, remove the document from the inside by pulling it forward.

(4) If the document is jammed at the rear, remove the document from the inside by pulling it toward the rear.

(5) Close the top cover as described in Section 4.1 “Opening and Closing the Top Cover”.

Take care not to get your fingers caught in the cover.

CS600-UM-251-9370 4-5

Page 28

4. DAILY MAINTENANCE

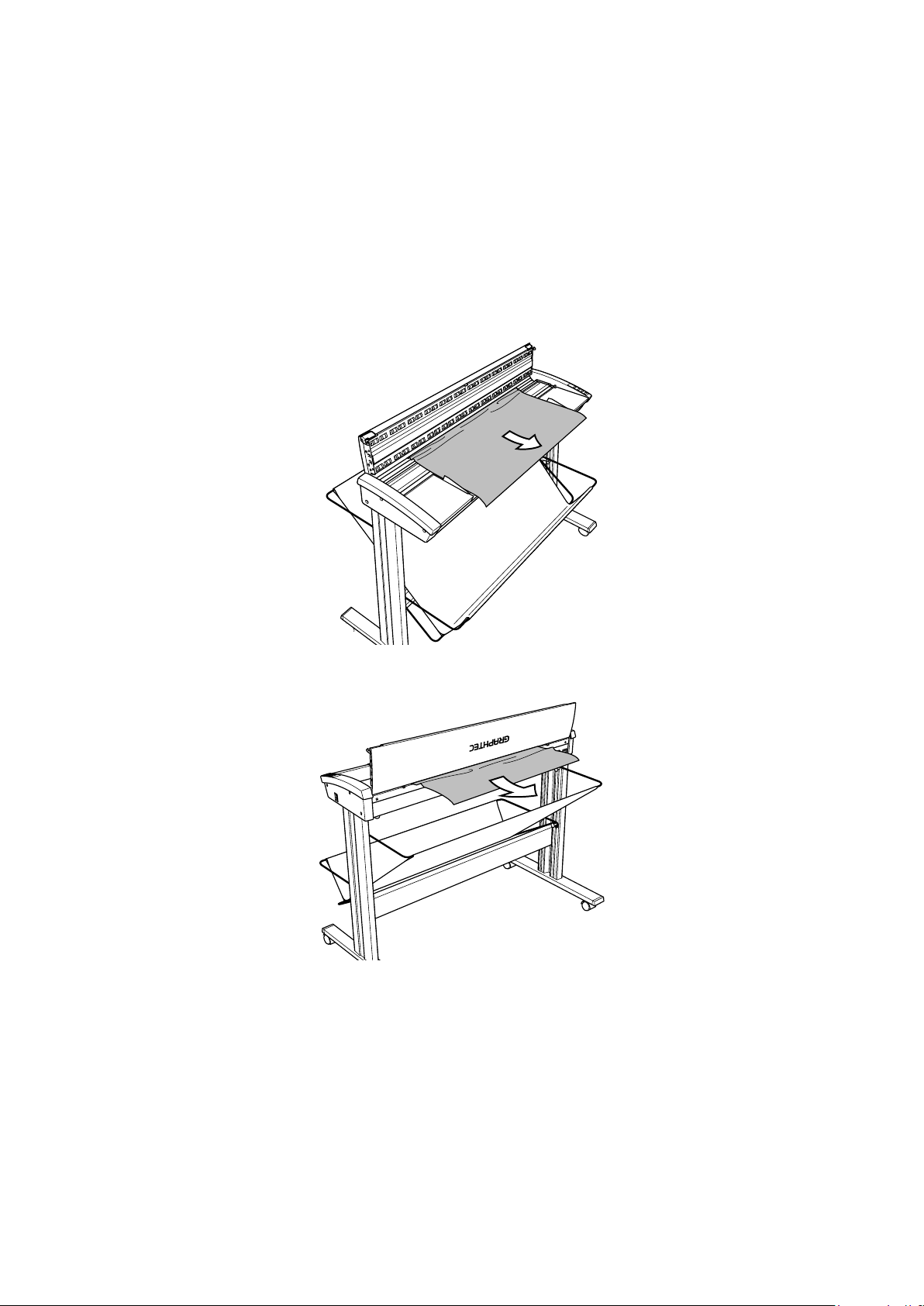

4.6 Calibration

Calibrate the scanner if scanning quality is observed to deteriorate, with scanned results such as those

described below:

• The scanned image is distorted

• Areas of uneven color appear in the scanned image

• Other unsatisfactory results (but not including problems related to media quality, such as folds, wrinkling, or

paper curling)

• Handle the calibration sheet with care so that it does not get bent. To prevent soiling, store it in its special storage

box. The calibration sheet cannot be used if it is bent or soiled.

• The calibration sheet is a paper product. Do not attempt to clean it with any type of liquid cleaner.

• The calibration sheet is a consumable item. Replacement sheets can be purchased from your sales representative

or nearest Graphtec vendor.

Preparation and checks

Recommended usage environment

• Monitor: 1024 x 768 pixels, High Color or better resolution

A low-resolution monitor will make it difficult to discern any problem areas.

Launching the Scanner Adjustment Program

(1) Connect the scanner to the PC and switch on the scanner. Switch on the PC.

(2) Install Scanning Master 21+ (OPS112) if it is not already installed.

(3) Click the Start button, then select Programs > Scanning Master 21+ > Scanner Adjustment.

(4) Click Scanner Adjustment to launch the Scanner Adjustment program.

CS600-UM-251-9370 4-6

Page 29

4. DAILY MAINTENANCE

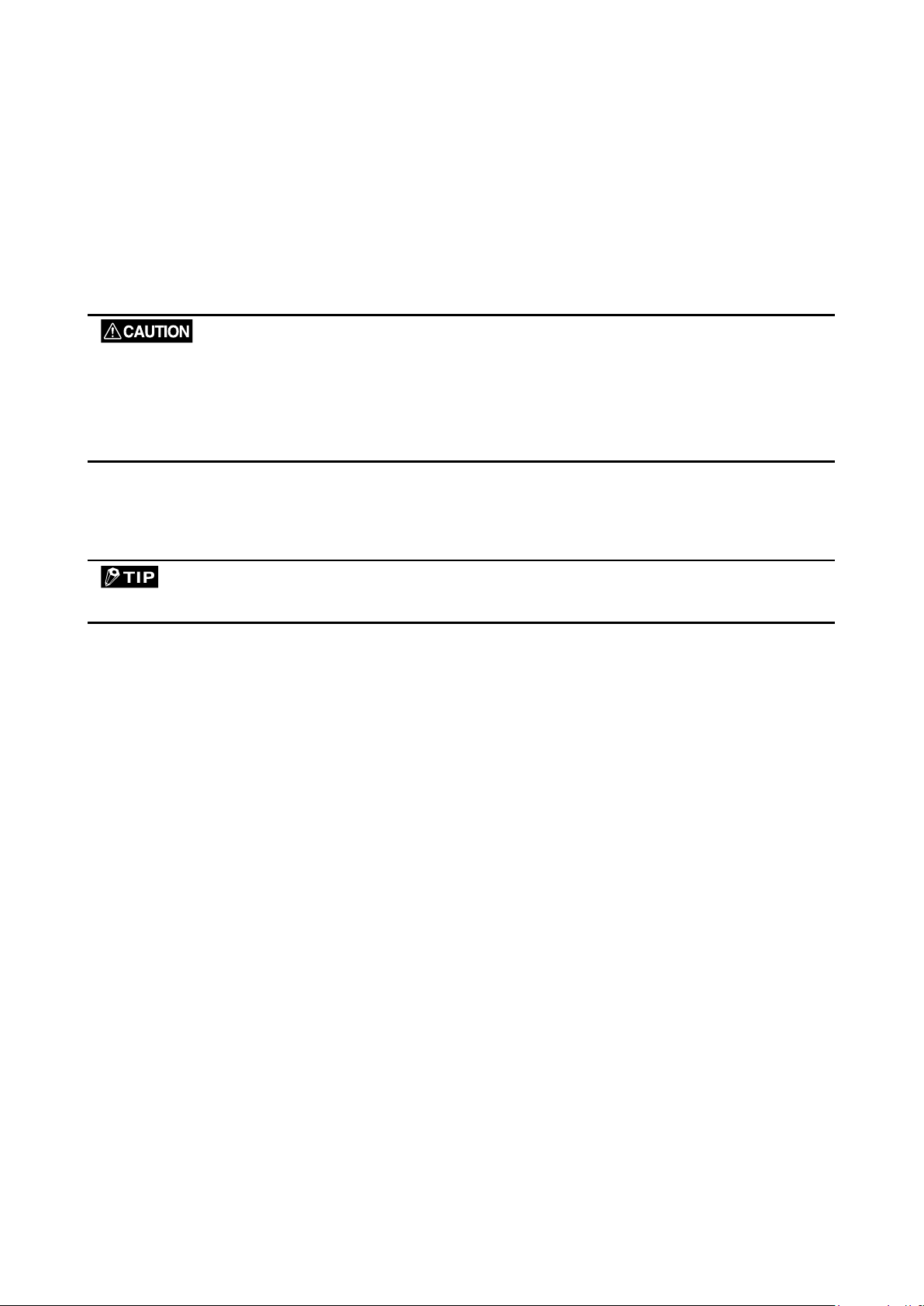

Scanner Calibration

Before beginning calibration, clean the transparent contact plates and scanner table surface.

Any dust or dirt on this surface may affect calibration results and resulting image quality.

Check that the calibration sheet is free of any dust or dirt.

The calibration procedure will take some time. Do not switch off the scanner while calibration is underway. Acciden-

tally switching off the scanner may result in damage that requires servicing.

(1) Connect the scanner to the computer. Switch on the scanner, then switch on the PC.

(2) Launch the Scanner Adjustment program (as described earlier).

(3) Select Model Setup on the Scanner menu.

(4) Select the connected scanner and click the OK button.

(5) Select Calibration on the Scanner menu.

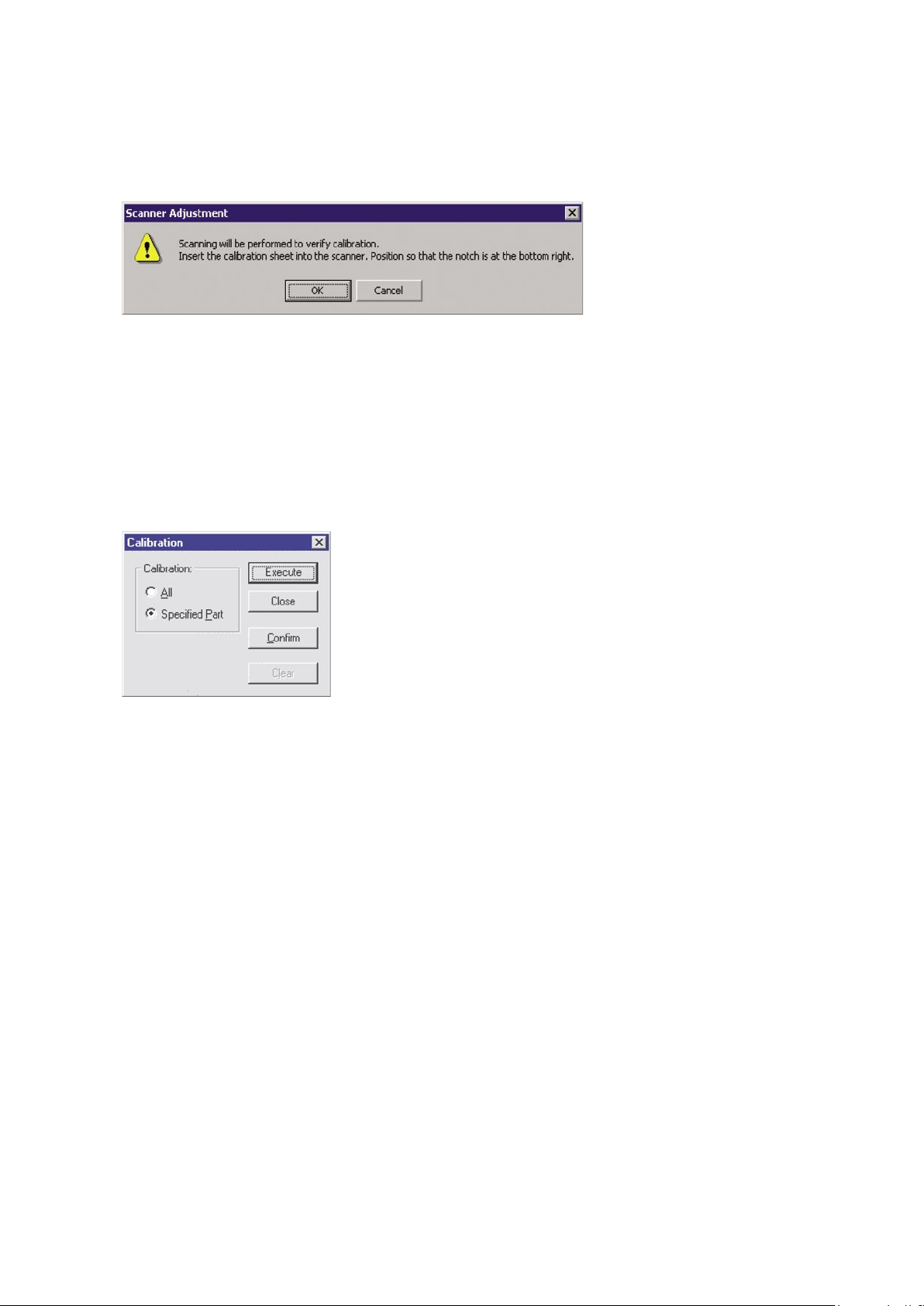

(6) Select All in Calibration and click the Execute button.

(7) The following message is displayed. Insert the calibration sheet into the scanner as instructed.

(8) Clicking the OK button begins calibration.

(9) Calibration ends after approximately 10 minutes.

Click the OK button to complete calibration.

CS600-UM-251-9370 4-7

Page 30

4. DAILY MAINTENANCE

(10) To check the calibration results, click the Confirm button in the Calibration menu (shown in step (5)

above).

(11) The following message is displayed. Insert the calibration sheet into the scanner as instructed.

(12) Click the OK button to start scanning.

The scanned data is displayed when scanning is complete. Colors may differ slightly for individual

sensors to make it easier to identify problem areas in calibration. This does not indicate a defect.

Check that there are no vertical streaks, such as white patches, in the scanned data.

(Streaks occur when calibration is not performed correctly due to contamination by dust or dirt.)

(13) If the data is normal, calibration is complete.

Click the Close button and exit the Scanner Adjustment Program.

(14) If any abnormal data is observed, specify the problem areas as follows:

Select Specified Part in Calibration.

(15) The mouse arrow cursor changes to a cross cursor when moved over the data. Click the left mouse

button with the mouse positioned over the streak data. The selected area is shown in blue. Repeat this

procedure for any additional streaks.

Areas that have been selected (shown in blue) can be deselected by clicking the left mouse button

again. To deselect all selected areas, click the Clear button.

(16) Once all required areas have been specified, remove the calibration sheet and clean the glass and table

surfaces. Check the calibration sheet for dust and dirt, then click the Execute button.

(17) Return to step (10) and verify the calibration results.

CS600-UM-251-9370 4-8

Page 31

4. DAILY MAINTENANCE

Cursor lines (red)

Align with the printed lines, then click.

Color Correction

Perform color correction if there is any discrepancy in color in parts of the scanned image even after you

have calibrated the scanner.

(1) Select Color Correction on the Scanner menu.

(2) Click the Scan button.

(3) The following message is displayed. Insert the color correction sheet in the scanner.

Position the color correction sheet so that the red bar in the center of the sheet is centered in the scanner (but with

the printed side down).

(4) Click the OK button to start scanning.

The scanned data is displayed when scanning is complete. Colors may differ slightly for individual

sensors, but this does not indicate a defect.

(5) When the data is displayed, click the Get button.

(6) Click in the center of the color tile indicated by the numbers 1 to 6, in ascending order.

For numbers 1 to 5, click the center of the upper left tile; for number 6, click in the center of the bottom

right tile. Align the cursor crosshairs with the printed lines at the sides of the tile.

• The next reference point to be checked is displayed on the Status bar.

• If you click in error, click the Esc. key to cancel the operation and return to the immediately previous step.

• If you click on the wrong tile, color correction will not be performed correctly and the colors of the image displayed

after color correction will be incorrect.

CS600-UM-251-9370 4-9

Page 32

4. DAILY MAINTENANCE

(7) After you have clicked tile number 6, click the Set button.

Click the OK button.

(8) To check the color correction results, click the Confirm button.

(9) The following message is displayed. Insert the color correction sheet in the scanner as instructed.

Position the color correction sheet so that the red bar in the center of the sheet is centered in the scanner (but with

the printed side down).

(10) Click the OK button to start scanning.

After scanning has been completed, an enlarged view of the color-corrected data is displayed.

(11) Click the Fit icon to display the entire image, and check whether there is any discrepancy in color. If

there is no discrepancy, color correction is complete. Click the Close button.

If there is still some color discrepancy after performing Color Correction, repeat steps (6) through (11).

CS600-UM-251-9370 4-10

Page 33

5. RECOMMENDED PARTS LIST

5. RECOMMENDED PARTS LIST

No. Part No. Part Name Description Q'ty Remarks

774019605 Data Controller Board CS600

774019606 Data Controller Board CS600PRO

1

794060001 Data Controller Board CS600-PRO-A Use for A version

794060003 Data Controller Board CS600-A Use for A version 1 CS600-11-A

774015501 CIS Controller Board 5

2

794050003 CIS Controller Board CS600-A Use for A version 5 CS600-11-A

774016502 CIS Power Board 1

3

794050004 CIS Power Board (For A version) Use for A version 1 A version

774019980 CIS Sensor Assembly, Rank A

774019981 CIS Sensor Assembly, Rank B

774019982 CIS Sensor Assembly, Rank C

774019983 CIS Sensor Assembly, Rank D

4

774019984 CIS Sensor Assembly, Rank E

774019985 CIS Sensor Assembly, Rank F

774019986 CIS Sensor Assembly, Rank G

774019987 CIS Sensor Assembly, Rank H

5 500051794 Motor KT60KM06-551 1

6 500052381 Control Panel 52610-10 1

7 500051793 Inlet FN-9222R-3-06 1

8 502112009 Power Switch AJ7201B 1

9 502210002 Paper Sensor PS-R50L-A 2

10 500052694 Cover Sensor, Thickness Sensor LG217L-3 1

11

500051630 Switching Power Supply Board ZWS75AF-24/J 1

12 314690020 Bearing 6900ZZNXR 4

13 341511001 O Ring 1AP12 12

14 378020021 Drive Belt BELT 60S2M400 1

15 774017027 Contact Glass Assembly 1

16 641300130 Drive Roller DRIVE ROLLER 2

17 641301502 Paper Hold-down Roller 5

18 641300102 Pinch Roller PINCH ROLLER G 52

19 641300112 Pinch Roller Shaft SHAFT 26

20 774018010 Front Guide Assembly ASSY-CS5-11 1

21 774017139 Elevator Gear Box Assembly 1

774017150

22

794060002 Elevator Control Board for CS600-A Use for A version 1 CS600-11-A

23 500524130 Safety Sensor Switch D3M-01K1

Elevator Control Board 1

Select the same rank of

sensor that is used in your

scanner.

1 CS600

1 CS600PRO

1

CS600-11-PRO-A

Same as CS400-10

Same as CS400-06

5

Same as CS400-10

Same as CS400-10

Same as CS400-10

Same as CS400-10

Same as CS400-10

Same as CS2000

Same as CS2000

Same as CS400-10

Same as CS500/IS200

Same as CS400-10

Same as CS500/IS200

Same as CS400-10

Same as CS400-10

Same as CS500

CS600-UM-251-9370 5-1

Page 34

Page 35

6. LIST OF JIGS AND TOOLS

6. LIST OF JIGS AND TOOLS

6.1 Jigs

Jigs Adjustments Remarks

Firmware •Downloading system program

OPS112 (Ver. 5.22 or later) •Downloading system program

•Shading (white correction)

•Adjusting feed distance

•Aligning sensor images

•Adjusting offset

•Color correction

Calibration sheet •Shading (white correction)

•Replacing main board

Color correction sheet •Color correction Standard accessory

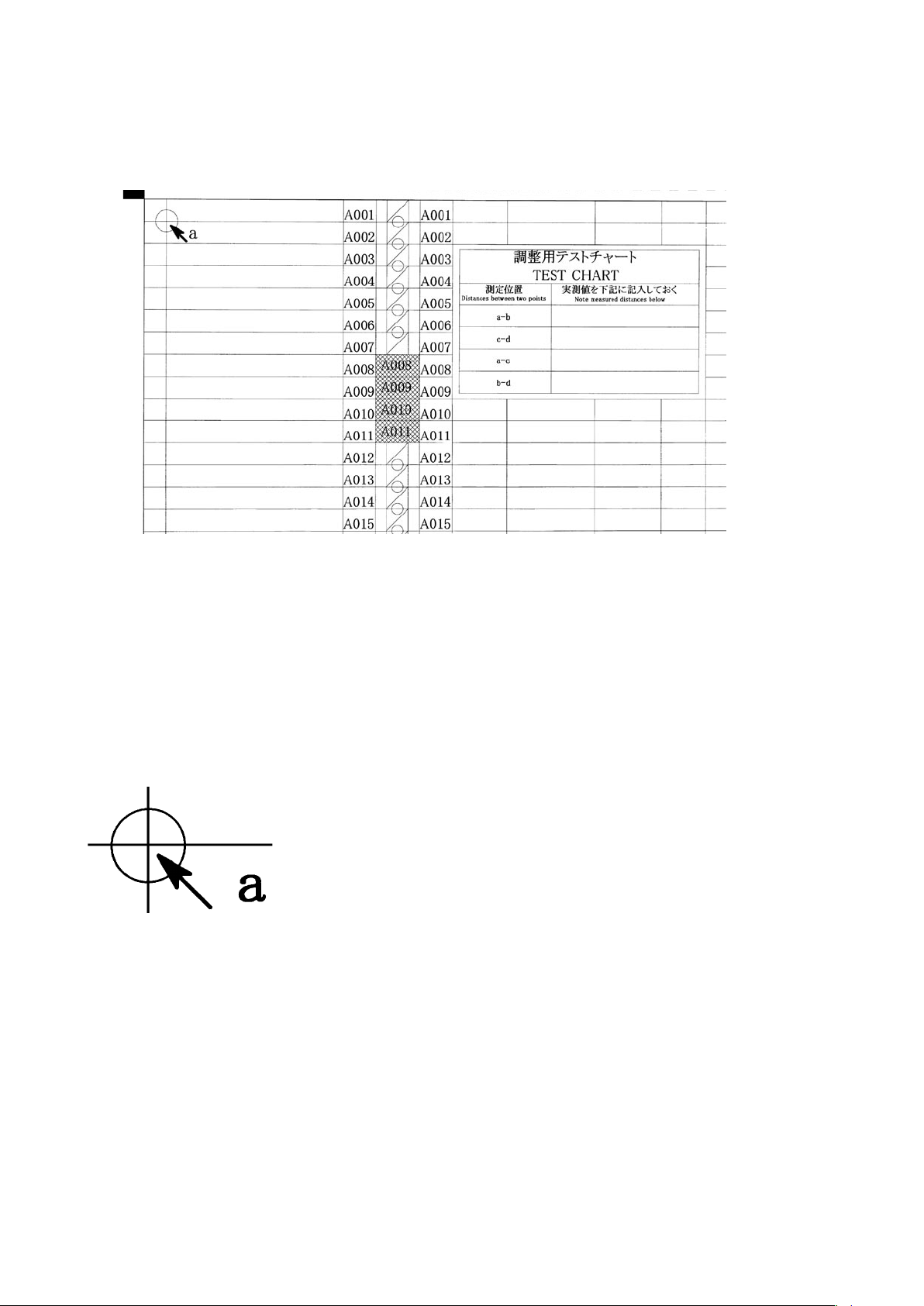

42-inch

adjustment test chart •Adjusting feed distance

•Adjusting offset

•Aligning sensor images

Thick paper test chart •Adjusting for thickness mode

Software supplied with the scanner

(Scanning Master 21+)

Standard accessory

1050 mm x 200 mm

Record measured values between a and

c, b and d, a and b, c and d, a and d, and

b and c.

6.2 Tools

Tools Usage Remarks

Screwdriver

Allen wrench

Needle-nose pliers

Colex gauge Adjusting belt tension 200g / 4 mm displacement

Multimeter Checking voltage level

Disassembly, reassembly, and other

operations

Large, medium, and small flat blade

screwdrivers and Phillips screwdrivers

6.3 Other

Item Usage Remarks

Water-diluted neutral detergent or

absolute ethanol wiper (cloth)

PC

USB cable

Cleaning

Used to determine whether the problem

is caused by the scanner or any other

equipment.

CS600-UM-251-9370 6-1

Page 36

Page 37

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Right Side Cover

J3

M4L6 Binding

Head Screw

Left Side Cover

M4L6 Binding

Head Screw

7.

DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.1 Right Side Cover

Detaching the right side cover

(1) Remove the three M4L6 binding head screws on the right side of the scanner unit.

(2) Detach the right side cover as shown below.

(3) Disconnect the connectors from the control panel relay board.

Reattaching the right side cover

(1) Reattach the right side cover in the reverse order in which it was detached.

7.2 Left Side Cover

Detaching the left side cover

(1) Remove the three M4L6 binding head screws on the left side of the scanner unit.

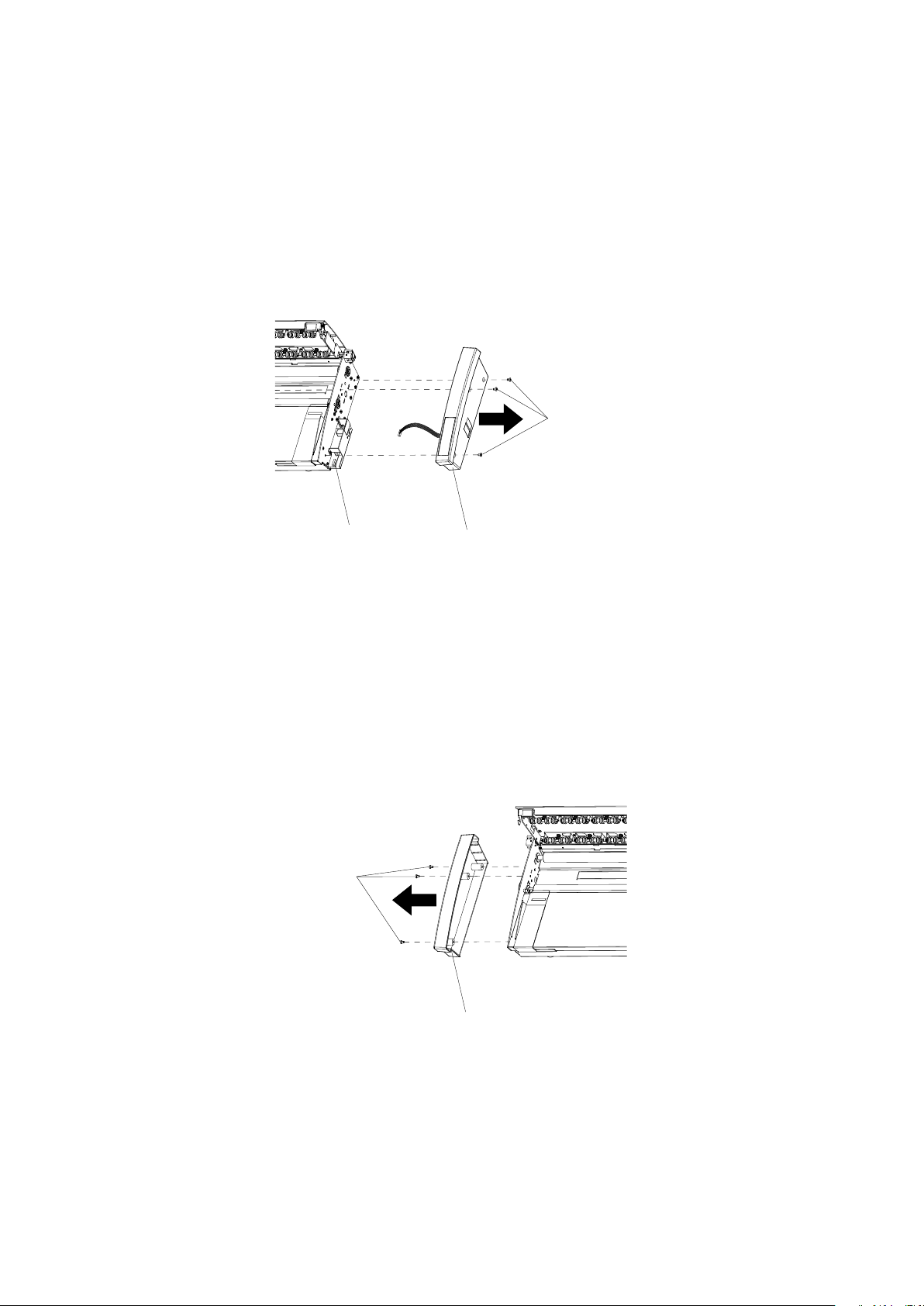

(2) Detach the left side cover as shown below.

CS600-UM-251-9370 7-1

Reattaching the left side cover

(1) Reattach the left side cover in the reverse order in which it was detached.

Page 38

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.3 Top Cover Assembly

Detaching the top cover assembly

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Verify that the POWER LED and READY LED are lit.

(3) Press the ITA button and then verify that the READY LED goes out, and that the ITA LED lights instead.

(4) Press the FORWARD button to raise the top cover to the upper limit position.

(5) Open the top cover.

(6) Loosen the two M3L6 binding head screws holding the right top cover plate.

M3L6 binding head screw

(7) Disconnect the connector from the top cover assembly as shown below.

Disconnect this connector

CS600-UM-251-9370 7-2

Page 39

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

(8) Place the disconnected connector as shown below.

Place the cable here.

(9) Close the top cover.

(10) Loosen the M3L6 binding head screw holding the right top cover plate as shown below.

Loosen the M3L6 binding

head screw which is

concealed in this location.

(11) Hold the top cover assembly and then release the top cover shaft as shown below.

Push the top cover shaft

and then lift up the top

cover assembly.

CS600-UM-251-9370 7-3

Page 40

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

(12) Detach the top cover assembly from the right side of the scanner unit as shown below.

Reattaching the top cover assembly

(1) Reattach the top cover assembly in the reverse order in which it was detached.

CS600-UM-251-9370 7-4

Page 41

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

M3L6 Binding

Head Screw

M3L6 Binding

Head Screw

Front Guide Assembly

7.4 Front Guide Assembly

Detaching the front guide assembly

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Remove the four M3L6 binding head screws holding the front guide assembly from each side.

(3) Detach the front guide assembly as shown below.

Reattaching the front guide assembly

(1) Reattach the front guide assembly in the reverse order in which it was detached.

When reattaching the front guide assembly, make sure that the front guide assembly does not touch the front drive

roller.

CS600-UM-251-9370 7-5

Page 42

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

M3L6 Binding Head Screw

7.5 Rear Cover

Detaching the rear cover

(1) Remove the four M3L6 binding head screws at the back of the scanner unit.

(2) Detach the rear cover.

Reattaching the rear cover

(1) Reattach the rear cover in the reverse order in which it was detached.

When reattaching the rear cover, make sure that the rear cover does not touch the rear drive roller.

CS600-UM-251-9370 7-6

Page 43

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Belt

M4L6 binding

head screws

M3L6WP set screw

Pull

e

y

Motor mount

Motor

M4L12 binding

head screw

7.6 Motor

Detaching the motor

(1) Detach the left side cover (see Section 7.2).

(2) Detach the front guide assembly (see Section 7.4).

(3) Disconnect the J4 connector from the data power board.

(4) Remove the two M4L6 binding head screws holding the motor.

(5) Detach the drive belt from the pulleys.

Reattaching the motor

(1) Reattach the motor by reversing the sequence of steps in which it was detached.

(2) Adjust the drive belt tension (see Section 7.9).

Disassembling the motor

(1) Loosen the M3L6WP set screws to detach the motor pulley.

Remove the two silver M4L12 binding head screws holding together the motor and motor mount.

Reassembling the motor

(1) Reassemble the motor by reversing the sequence of steps in which it was disassembled.

CS600-UM-251-9370 7-7

Page 44

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Belt

M4L6 binding

head screws

M3L6WP set screw

Drive roller pulley

Drive roller belt

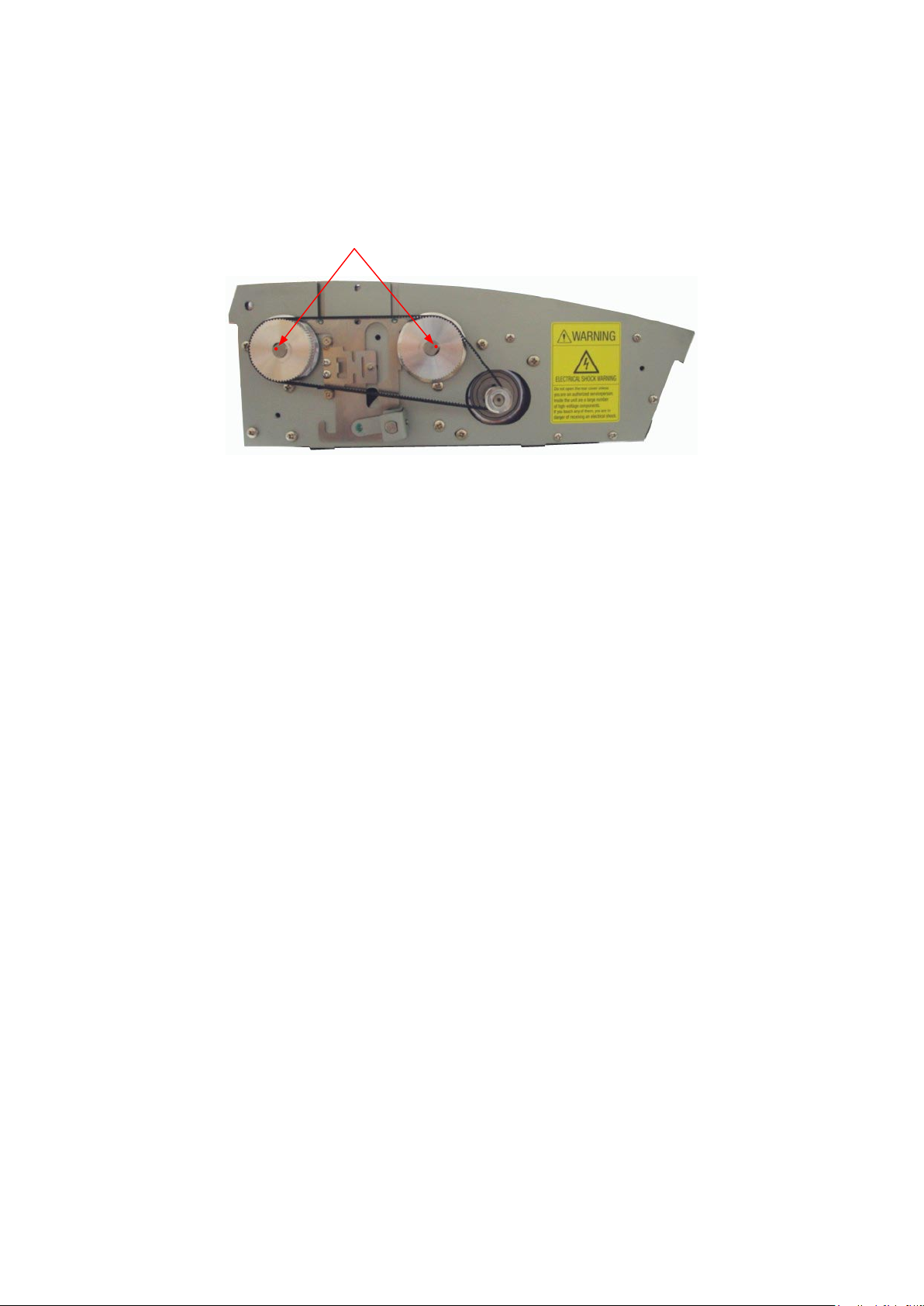

7.7 Drive Roller Pulley

Detaching the drive roller pulleys

(1) Detach the left side cover (see Section 7.2).

(2) Loosen the two M4L6 binding head screws holding the motor.

(3) Detach the drive belt from the pulleys.

(4) Loosen the M3L6WP set screw to detach the drive roller pulleys.

CS600-UM-251-9370 7-8

Page 45

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Reattaching the drive roller pulleys

(1) Reattach the drive roller pulleys by reversing the sequence of steps in which they were detached.

(2) Install the belt to the 180-degree punched markings of the drive roller shaft as shown below.

Adjust the punched

holes by 180 degrees.

(3) Adjust the belt tension (see Section 7.9).

CS600-UM-251-9370 7-9

Page 46

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Rear drive roller

Front drive roller

Bearing

E-ring

Rear paper sensor

M3L6 binding head screw

7.8 Drive Rollers

Detaching the front drive roller

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Detach the front guide assembly (see Section 7.4).

(3) Detach the top cover assembly (see Section 7.3).

(4) Detach the drive roller belt and the pulley from the drive roller (see Section 7.7).

(5) Detach the E-ring holding the drive roller.

(6) Detach the two bearings holding both ends of the drive roller.

(7) Slide the drive roller to the left, lift up the drive roller from the right side, and then detach it.

Detaching the rear drive roller

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Detach the rear cover (see Section 7.5).

(3) Loosen the M3L6 binding head screw holding the rear paper sensor bracket.

(4) Detach the drive roller belt and the pulley from the drive roller (see Section 7.7).

(5) Detach the E-ring holding the drive roller.

(6) Detach the two bearings holding both ends of the drive roller.

(7) Slide the drive roller to the left, lift up the drive roller from the right side, and then detach it.

CS600-UM-251-9370 7-10

Page 47

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Reattaching the drive rollers

(1) Reattach the drive rollers by reversing the sequence of steps in which they were detached.

(2) The front drive roller and the rear drive roller are different.

When installing a drive roller, check the mark on it to make sure that you have the correct one.

Install the drive roller with

this mark at the front.

Install the drive roller with

this mark at the rear.

(3) Adjust the drive belt tension (see Section 7.9).

CS600-UM-251-9370 7-11

Page 48

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Belt

M4L6 binding

head screws

7.9 Drive Belt

Detaching the drive belt

(1) Detach the left side cover (see Section 7.2).

(2) Loosen the two M4L6 binding head screws holding the motor.

(3) Detach the drive belt from the pulleys.

Reattaching the drive belt

(1) Reattach the drive belt by reversing the sequence of steps in which it was detached.

(2) Install the belt to the 180-degree punched markings of the drive roller shaft as shown below.

Adjust the punched

holes by 180 degrees.

(3) Adjust the drive belt tension.

Adjusting the drive belt tension

(1) Loosen the two M4L6 binding head screws holding the motor.

(2) Pull the motor in the "A" direction as shown below.

(3) Use the Colex gauge to adjust the belt tension so that the belt displacement is approximately 1.6 mm

when pressed with a force of 167 gf.

CS600-UM-251-9370 7-12

Page 49

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Belt

M4L6 binding

head screws

A

1.6 mm

167 g

Belt

Motor pulley

Drive roller pulley

(4) Tighten the two M4L6 binding head screws holding the motor.

CS600-UM-251-9370 7-13

Page 50

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

M3L10 binding

head screw

M3L10 binding

head screw

Rear paper

detection sensor

Front paper

detection sensor

7.10 Front and Rear Paper Detection Sensors

Detaching the front paper detection sensor

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Detach the front guide assembly (see Section 7.4).

(3) Remove the M3L10 binding head screws holding the front paper detection sensor.

(4) Disconnect the front paper detection sensor cable from the connector and then detach the front paper

detection sensor.

Detaching the rear paper detection sensor

(1) Detach the rear cover (see Section 7.5).

(2) Remove the M3L10 binding head screws holding the rear paper detection sensor.

(3) Disconnect the rear paper detection sensor cable from the connector and then detach the rear paper

detection sensor.

Reattaching the paper detection sensors

(1) Reattach the paper detection sensors by reversing the sequence of steps in which they were detached.

CS600-UM-251-9370 7-14

Page 51

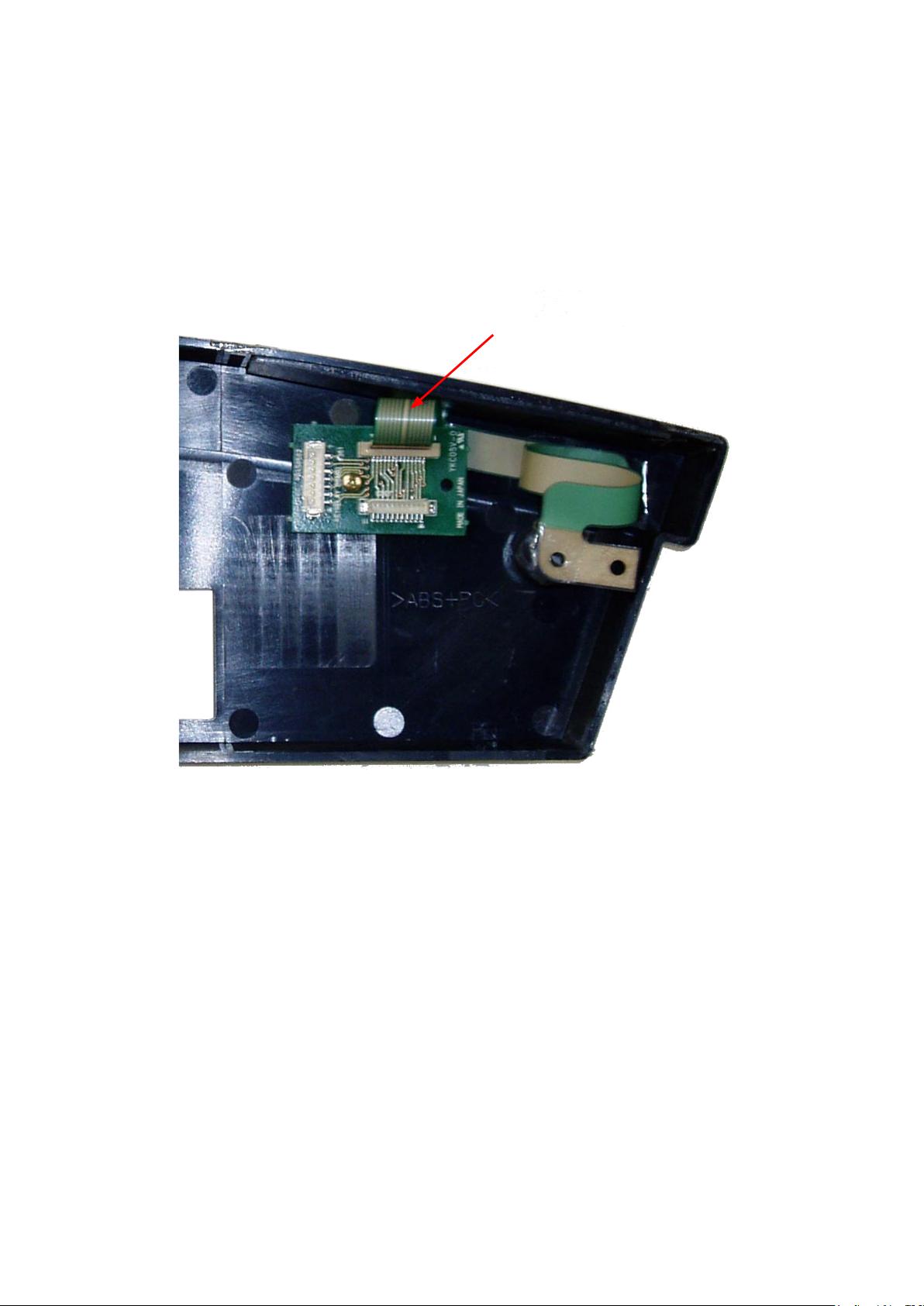

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.11 Control Panel Sheet Switch

Detaching the control panel sheet switch

(1) Detach the right cover (see Section 7.1).

(2) Disconnect the flexible cable from the control panel relay board and then pull off the control panel sheet

switch from the right side cover.

Flexible cable

Reattaching the control panel sheet switch

(1) Reattach the new control panel sheet switch in the reverse order in which it was detached.

CS600-UM-251-9370 7-15

Page 52

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

M2L5 binding head screwM2L5 binding head screw

M2L5 binding head screw

M2L5 binding head screw

7.12 Contact Glass Assembly

Detaching the contact glass assembly

(1) Open the center cover.

(2) Remove the six M2L5 binding head screws holding the front contact glass stopper plate.

(3) Detach the front contact glass stopper plate from the unit.

(4) Remove the six M2L5 binding head screws holding the rear contact glass stopper plate.

(5) Detach the rear contact glass stopper plate from the unit.

(6) Slide the contact glass assembly to the right side, lift up the contact glass from the left side, and then

detach the contact glass assembly from the unit.

Reattaching the contact glass assembly

(1) Reattach the contact glass in the reverse order in which it was detached.

(2) Make sure that each of the CIS assembly surfaces lies flat against the inside of the contact glass

assembly when you reattach the contact glass assembly.

(3) Perform the software adjustment.

When replacing the contact glass assembly, be sure to clean the interior of the image sensor unit and the inside of

the contact glass assembly. A soiled or dusty unit can affect scanning performance.

CS600-UM-251-9370 7-16

Page 53

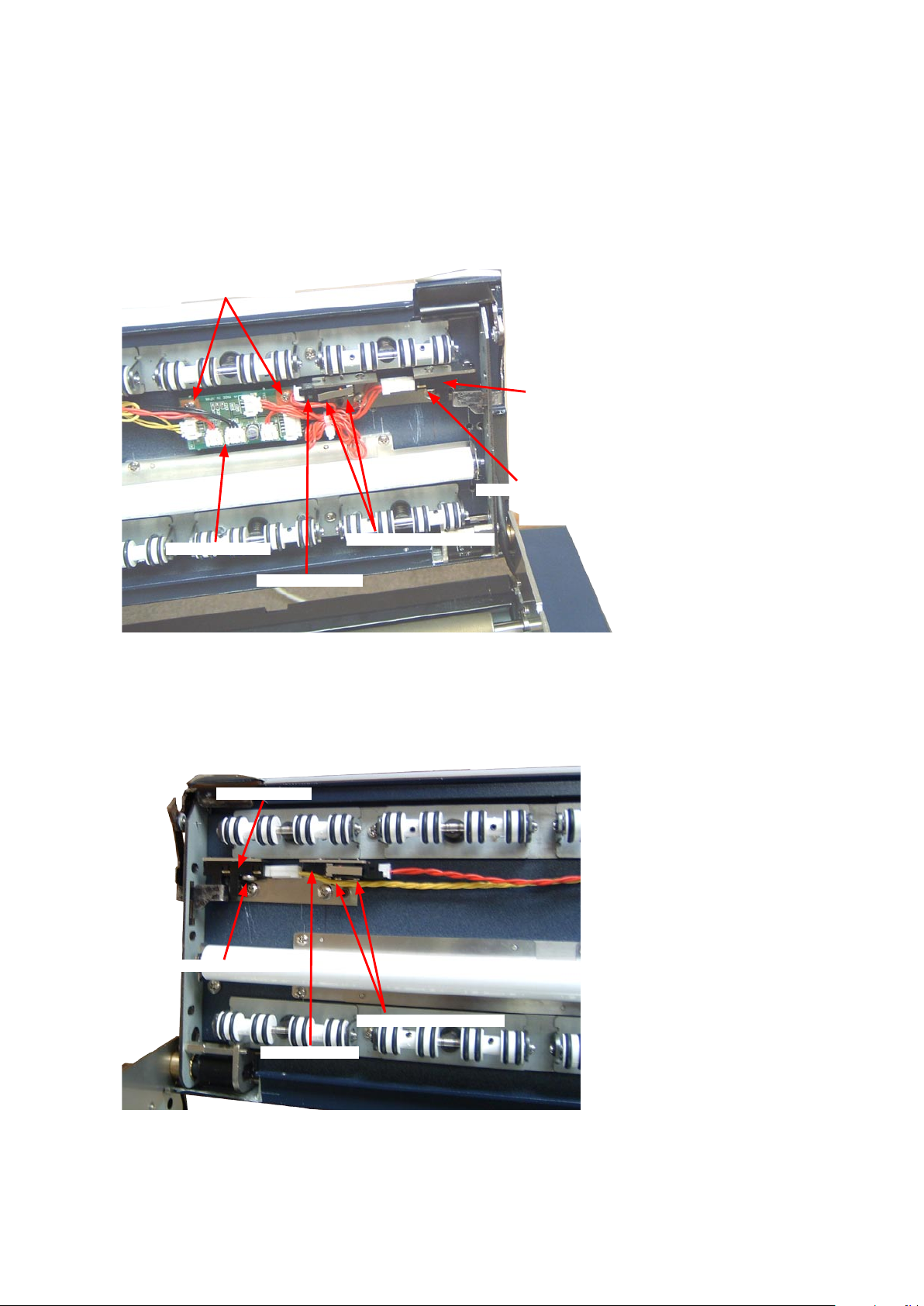

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Flexible cableFlexible cable

7.13 CIS (Charge Coupled Device Imaging Sensor) Assembly

Detaching the CIS assembly

(1) Detach the contact glass assembly (see Section 7.12).

(2) Slide each CIS assembly to the left side, lift it up from the right side, and then detach each CIS

assembly.

(3) Disconnect the flexible cable from each CIS assembly and then detach each CIS assembly.

Reattaching the CIS assembly

(1) Reattach each CIS assembly in the reverse order in which it was detached.

(2) Perform the software adjustment.

When replacing the CIS assembly, be sure to clean the interior of the image sensor unit and the inside of the

contact glass assembly. A soiled or dusty unit can affect scanning performance.

CS600-UM-251-9370 7-17

Page 54

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

M2L5 binding head screwM2L5 binding head screw

CIS boardCIS board

CableCable

7.14 CIS (Charge Coupled Device Imaging Sensor) Board

Detaching the CIS boards

(1) Detach the contact glass assembly (see Section 7.12).

(2) Detach each CIS assembly (see Section 7.13).

(3) Remove the two M2L5 binding head screws supporting each CIS board.

(4) Disconnect the cables from each CIS board and then detach each CIS board.

Reattaching the CIS boards

(1) Reattach each CIS board in the reverse order in which it was detached.

(2) When you have replaced the CIS boards, perform calibration using the software adjustment.

When replacing the

glass assembly. A soiled or dusty unit can affect scanning performance.

CS600-UM-251-9370 7-18

CIS boards

, be sure to clean the interior of the image sensor unit and the inside of the contact

Page 55

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

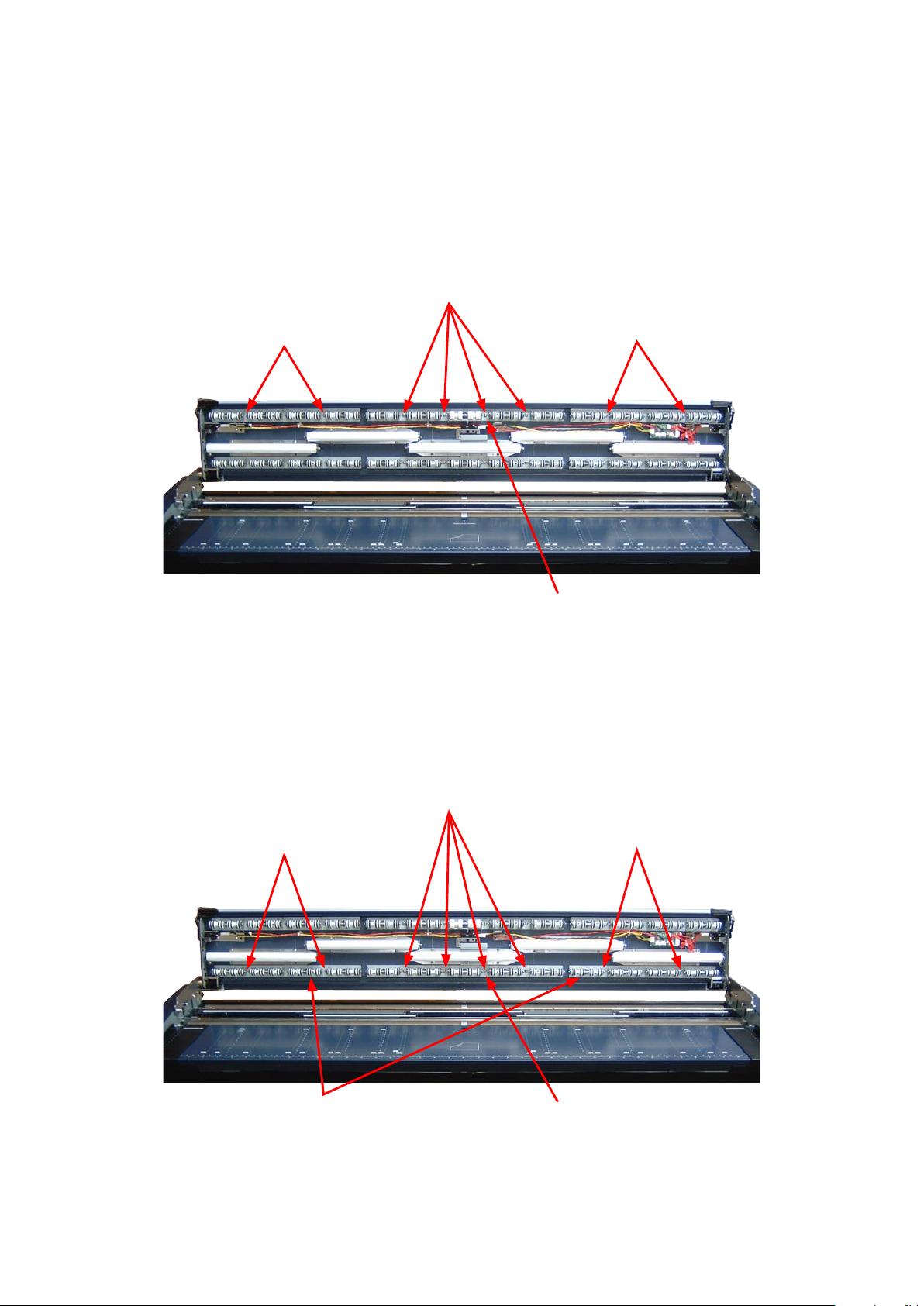

7.15 Pinch Roller Covers

Detaching the rear pinch roller cover

(1) Remove the two M3L8 binding head screws and the bushes holding the rear pinch roller cover.

M3L8 binding head screw

(2) Remove the three M3L6 binding head screws holding the rear pinch roller cover from the rear of the

scanner.

M3L6 binding head screw

(3) Detach the rear pinch roller cover from the top cover assembly.

CS600-UM-251-9370 7-19

Page 56

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Detaching the front pinch roller cover

(1) Remove the four M3L8 binding head screws and the bushes holding the front pinch roller cover.

M3L8 binding head screw

(2) Loosen the two M3L6 binding head screws holding the front pinch roller cover holding bracket.

(3) Slide the front pinch roller cover holding bracket to the left and then detach the front pinch roller cover.

Loosen the two M3L8 binding head screws.

Slide the front pinch roller

cover holding bracket to

the left.

CS600-UM-251-9370 7-20

Page 57

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Reattaching the pinch roller covers

(1) Reattach the pinch roller covers in the reverse order in which they were detached.

CS600-UM-251-9370 7-21

Page 58

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.16 Document Hold-down Rollers

Detaching the document hold-down rollers

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the three M3L6 binding head screws holding each document hold-down roller spring plate.

M3L6 binding head screw

M3L6 binding head screw

Document hold-down roller

Document hold-down roller spring plate

M3L6 binding head screw

M3L6 binding head screw

M3L6 binding head screw

Front pinch roller cover holding bracket

(3) Detach the document hold-down rollers from the top cover assembly.

(4) For the center document hold-down roller, remove the two M3L6 binding head screws holding the front

pinch roller cover holding bracket and then detach the front pinch roller cover holding bracket.

Remove the three M3L6 binding head screws holding the center document hold-down roller spring

plate. Detach the center document hold-down roller from the top cover assembly.

Reattaching the document hold-down rollers

(1) Reattach the document hold-down rollers in the reverse order in which they were detached.

CS600-UM-251-9370 7-22

Page 59

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.17 Pinch Roller Units

Detaching the front pinch roller units

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the two M3L6 binding head screws holding the four pinch rollers unit assembly.

Detach the four pinch rollers unit assembly from the top cover assembly.

M3L6 binding head screw

M3L6 binding head screw

Front center pinch rollers unit assembly

M3L6 binding head screw

(3) Remove the four M3L6 binding head screws holding the center pinch rollers unit assembly.

Detach the center pinch rollers unit assembly from the top cover assembly.

Detaching the rear pinch roller units

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the two M3L6 binding head screws holding the four pinch rollers unit assembly.

Detach the four pinch rollers unit assembly from the top cover assembly.

M3L6 binding head screw

M3L6 binding head screw

Four pinch rollers unit assembly

Five pinch rollers unit assembly

M3L6 binding head screw

(3) Remove the four M3L6 binding head screws holding the five pinch rollers unit assembly.

Detach the five pinch rollers unit assembly from the top cover assembly.

Reattaching the pinch roller units

(1) Reattach the pinch roller units in the reverse order in which they were detached.

CS600-UM-251-9370 7-23

Page 60

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.18 Cover Sensors

Detaching the right cover sensor

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the M4L12 binding head screws holding the right cover sensor.

M3L6 binding head screw

Right cover sensor

M4L12 binding head screw

Sensor relay board

Right safety sensor

M2L10 binding head screw

(3) Disconnect the cable from the right cover sensor and then detach the right cover sensor.

Detaching the left cover sensor

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the M4L12 binding head screws holding the left cover sensor.

Left cover sensor

M4L12 binding head screw

M2L10 binding head screw

Left safety sensor

(3) Disconnect the cable from the left cover sensor and then detach the left cover sensor.

Reattaching the cover sensors

(1) Reattach the cover sensors in the reverse order in which they were detached.

CS600-UM-251-9370 7-24

Page 61

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.19 Safety Sensors

Detaching the right safety sensor

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the two M2L10 binding head screws holding the right safety sensor.

M3L6 binding head screw

Right cover sensor

M4L12 binding head screw

Sensor relay board

Right safety sensor

M2L10 binding head screw

(3) Disconnect the cable from the right safety sensor and then detach the right safety sensor.

Detaching the left safety sensor

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the two M2L10 binding head screws holding the left safety sensor.

Left cover sensor

M4L12 binding head screw

M2L10 binding head screw

Left safety sensor

(3) Disconnect the cable and then detach the left safety sensor from the top cover assembly.

CS600-UM-251-9370 7-25

Page 62

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Detaching the center safety sensor

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the two M2L10 binding head screws holding the center safety sensor.

Thickness sensor

M4L12 binding head screw

M2L10 binding head screw

Center safety sensor

(3) Disconnect the cable from the center safety sensor and then detach the center safety sensor.

Reattaching the safety sensors

(1) Reattach the safety sensors in the reverse order in which they were detached.

(2) Adjust the height level of the safety sensors (see Section 7.23).

CS600-UM-251-9370 7-26

Page 63

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.20 Thickness Sensor

Detaching the thickness sensor

(1) Detach the pinch roller covers (see Section 7.15).

(2) Remove the two M2L10 binding head screws holding the thickness sensor.

Thickness sensor

M4L12 binding head screw

M2L10 binding head screw

Center safety sensor

(3) Disconnect the cable from the thickness sensor and then detach the thickness sensor.

Reattaching the thickness sensor

(1) Reattach the thickness sensor in the reverse order in which it was detached.

(2) Adjust the thickness sensor height level (see Section 7.22).

CS600-UM-251-9370 7-27

Page 64

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.21 Elevator Sensor

Detaching the elevator sensors

(1) Detach the right cover (see Section 7.1).

(2) Remove the two M2L10 binding head screws holding each elevator sensor.

High position elevator sensor

Low position elevator sensor

M2L10 binding head screw

M2L10 binding head screw

(3) Disconnect the cable from each elevator sensor and then detach each elevator sensor.

Reattaching the elevator sensors

(1) Reattach the elevator sensors in the reverse order in which they were detached.

(2) Adjust the elevator sensor positions (see Section 7.22).

CS600-UM-251-9370 7-28

Page 65

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.22 Adjusting the Thickness Sensor and the Elevator Sensors

Adjusting the thickness sensor

(1) Detach the right cover but do not disconnect any cables from the right cover (see Section 7.1).

(2) Remove the two M2L10 binding head screws holding the low position elevator sensor and then detach

the low position elevator sensor.

High position elevator sensor

Low position elevator sensor

M2L10 binding head screw

M2L10 binding head screw

(3) Verify that the POWER LED and READY LED are lit.

(4) Press the ITA button and then verify that the READY LED goes out, and that the ITA LED lights instead.

(5) Place a sheet of copy paper (paper which is thinner than 1 mm) on the front paper sensor and insert it

into the recess. The top cover starts to rise automatically.

(6) When the top cover has risen to the upper limit position, insert the copy paper further so that it can

be seen from the rear of the scanner. (Lowering starts approximately 5 seconds after the test target is

detected by the front and rear paper sensors.)

(7) When the copy paper is inserted into position, the top cover automatically descends to detect the

thickness.

(8) Confirm the gap between the 4-mm holes in the slider and the side panel.

Side Panel

Slider

4 mm hole

The gap between the 4-mm holes in the slider and the side panel

High position elevator sensor

Low position elevator sensor

CS600-UM-251-9370 7-29

To be within 0.2 mm.

Page 66

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

(9) Adjust the gap so that it is within 0.2 mm, using the screw in the center adjustment hole.

(The slider will lower when you turn the screw clockwise.)

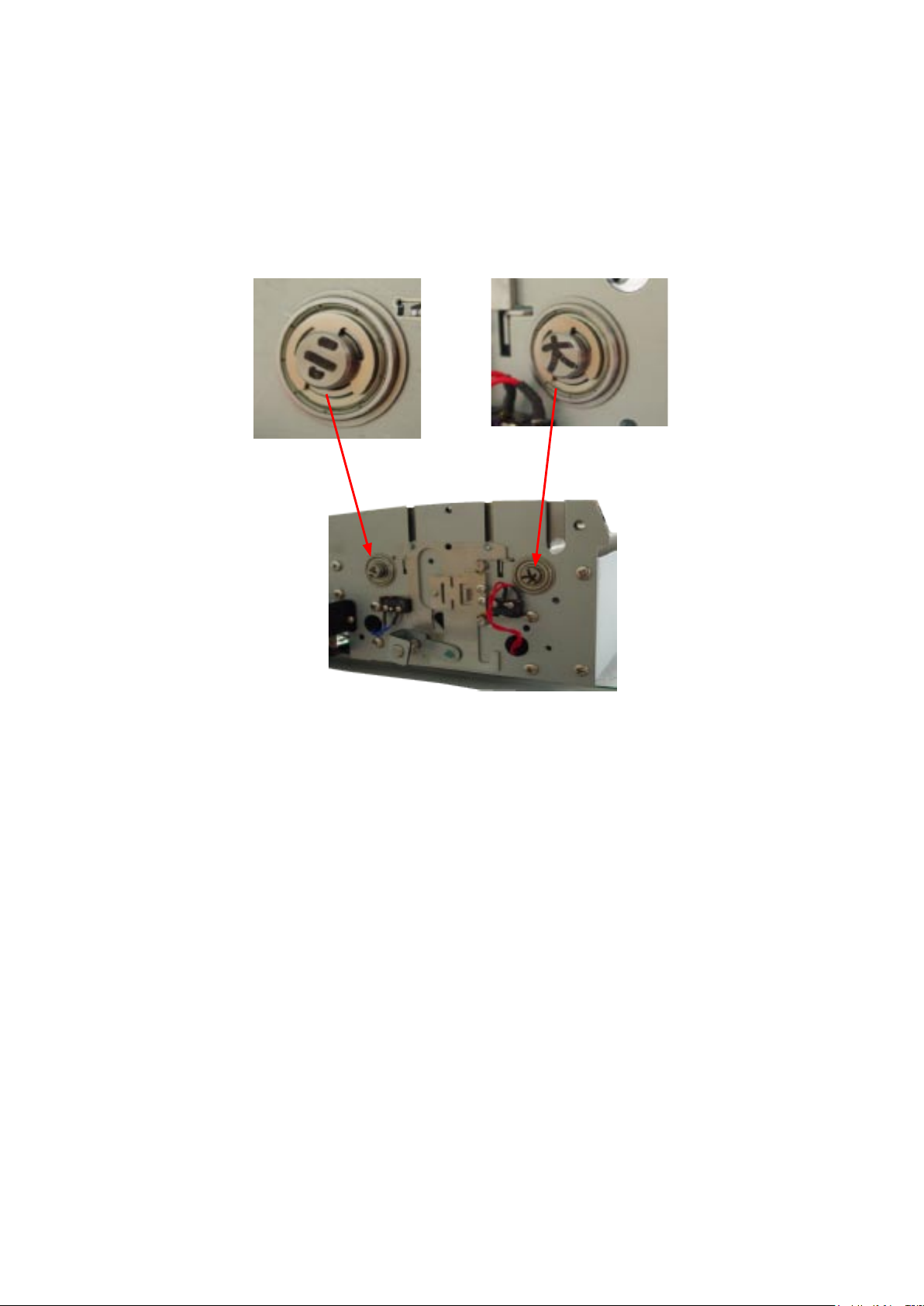

Adjusting the low position elevator sensor (Thickness mode sensor)

(1) After adjusting the thickness sensor, install the sensor at the position where the slider goes down. The

sensor should be on at this position.

Low position elevator sensor

M2L10 binding head screw

CS600-UM-251-9370 7-30

Page 67

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

Adjusting the high position elevator sensor

(1) After adjusting the low position elevator sensor, press the FORWARD button until the slider goes up.

(2) Confirm the gap between the 4-mm holes in the slider and the side panel.

(3) Adjust the gap using the FORWARD button and the REVERSE button.

(4) Install the sensor at the position where the slider goes up. The sensor should be on at this position.

High position elevator sensor

Side Panel

4 mm hole

Slider

M2L10 binding head screw

The gap between the 4-mm holes in the slider and the side panel

To be within 2 mm.

CS600-UM-251-9370 7-31

Page 68

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.23 Adjusting the Safety Sensors

Adjusting the safety sensors

(1) Open the top cover assembly.

(2) Insert a piece of sponge (thickness about 20 mm) or something similar under the center safety sensor.

The left safety sensor adjustment hole

Sponge

The center safety sensor adjustment hole

Sponge

The right safety sensor adjustment hole

Sponge

(3) Close the top cover assembly.

(4) Verify that the POWER LED and READY LED are lit.

(5) Press the ITA button and then verify that the READY LED goes out, and that the ITA LED lights instead.

(6) Place a sheet of copy paper on the front paper sensor and insert it into the recess. The top cover starts

to rise automatically.

(7) When the top cover has risen to the upper limit position, insert the copy paper further so that it can be

seen from the rear of the scanner.

(8) Lowering starts. If the top cover does not start to lower, press the REVERSE button.

(9) When the top cover has descended, and the error lamp is not lit, make the following adjustment.

When the top cover has descended, and the error lamp is lit, make the adjustment described in step (12).

(10) Adjust the center safety sensor height, using the screw in the center safety sensor adjustment hole.

(The sensor will lower when you turn the screw clockwise.)

(11) Turn off the scanner and then redo the procedure starting from step (2).

(12) Remove the piece of sponge from the scanner and then redo the procedure starting from step (4).

(13) When the top cover has descended, and the error lamp is not lit, adjustment is complete.

When the top cover has descended, and the error lamp is lit, turn the center safety sensor adjustment

screw counterclockwise.

(14) Turn off the scanner and then redo the procedure starting from step (2).

(15) Make adjustments for the left and right sensors in the same way.

CS600-UM-251-9370 7-32

Page 69

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.24 Elevator Gear Box

Detaching the elevator gear box

(1) Detach the front guide assembly (see Section 7.4).

(2) Disconnect connector J3 on the elevator control board.

J3

Elevator control board

(3) Loosen the three M3L6 binding head screws holding the rear of the bottom cover.

(4) Remove the three M3L6 binding head screws holding the front of the bottom cover and the two M3L6

binding head screws holding both sides of the bottom cover.

M3L6 binding head screw

Bottom cover

M3L6 binding head screw

(5) Detach the bottom cover from the scanner.

CS600-UM-251-9370 7-33

Elevator gear box

Page 70

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

(6) Remove the two M3L6 binding head screws holding the gear box.

M3L6 binding head screw

M3L6 binding head screw

Gear box

Gear shaft clamp bracket

(7) Remove the M3L6 binding head screws holding the gear shaft clamp bracket.

(8) Detach the gear box from the scanner.

Reattaching the elevator gear box

(1) Reattach the elevator gear box in the reverse order in which it was detached.

CS600-UM-251-9370 7-34

Page 71

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.25 Elevator Control Board

Detaching the elevator control board

(1) Detach the front guide assembly (see Section 7.4).

(2) Remove the four M3L6 binding head screws holding the elevator control board.

(3) Disconnect all the connectors on the elevator control board.

Elevator control board

M3L6 binding head screw

(4) Detach the elevator control board from the scanner.

Reattaching the elevator control board

(1) Reattach the elevator control board in the reverse order in which it was detached.

(2) Prepare corresponded the elevator control board before replacing the data controller board.

If the model name is CS600-11, use the elevator control board for CS600-11.

If the model name is CS600-11-A, use the elevator control board for CS600-11-A.

CS600-UM-251-9370 7-35

Page 72

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

7.26 Adjusting the Elevator Slider Plate

(1) Detach the front guide assembly (see Section 7.4).

(2) Detach the right and left side covers (see Sections 7.1 and 7.2).

(3) Detach the top cover assembly (see Section 7.3).

(4) Remove the M4L14 binding head screw holding the elevator lever plate.

Elevator lever plate

M4L14 binding head screw

(5) Loosen the three M3L8 binding head screws and the slider pressure adjustment shaft.

M3L8 binding head screw

Elevator slider plate

Slider pressure adjustment shaft

(6) Adjust the slider pressure using the slider pressure adjustment shaft and then tighten those screws.

(7) Confirm that there is no play and that the slider moves smoothly.

(8) Adjust the left side slider pressure adjustment shaft in the same way.

CS600-UM-251-9370 7-36

Page 73

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

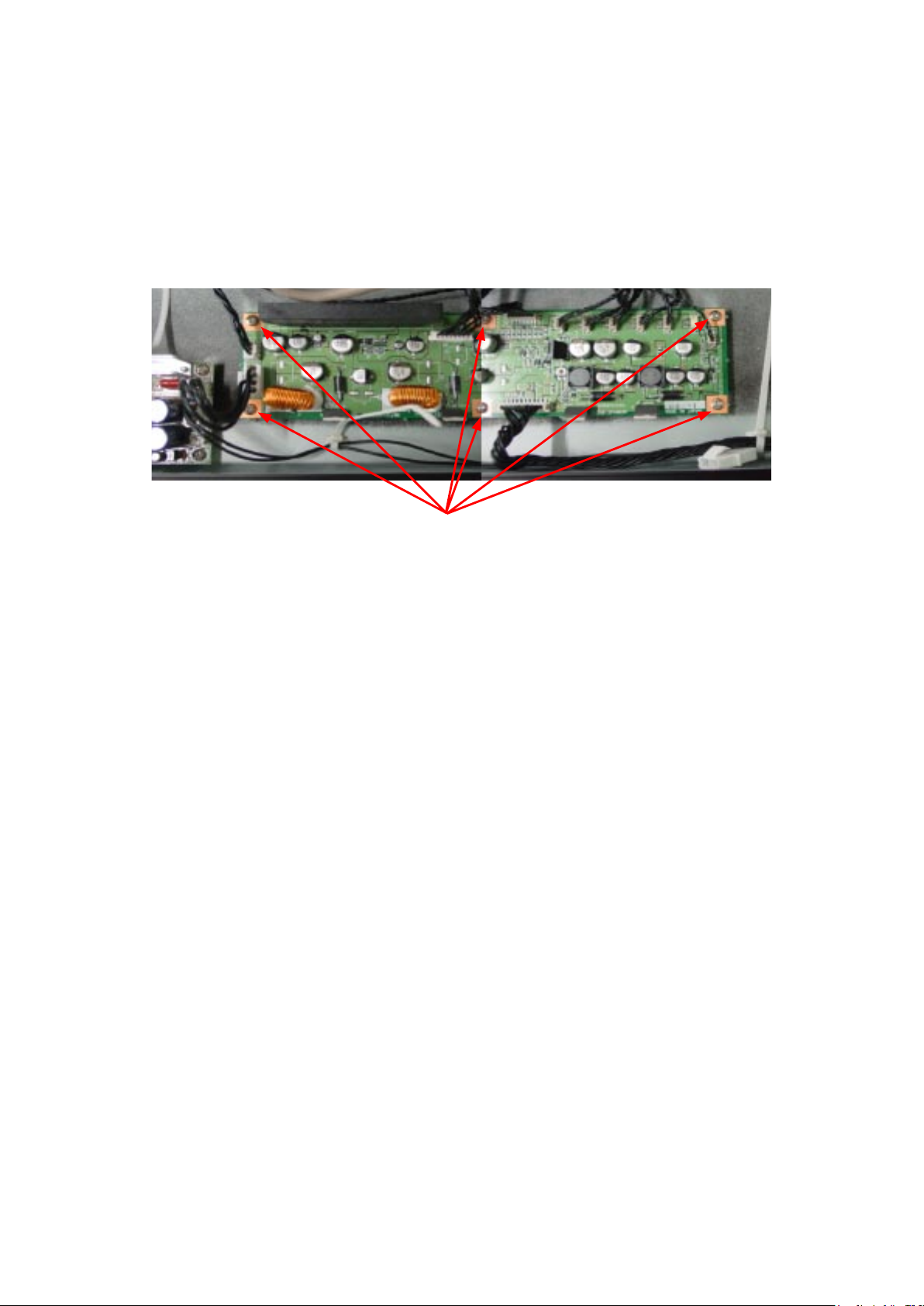

Data power boardData power board

CIS power board

CIS power board

Switching power supply boardSwitching power supply board

Data controller boardData controller board

IEEE1394 boardIEEE1394 board

M2L6 binding head screwM2L6 binding head screw

M3L6 binding head screwM3L6 binding head screw

7.27 IEEE 1394 Board (Only for IEEE1394 model)

Detaching the IEEE 1394 board

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Detach the front guide assembly (see Section 7.4).

(3) Remove the two M3L6 binding head screws and the one M2L6 binding head screw holding the IEEE

1394 board.

(4) Detach the IEEE 1394 board from the data controller board.

Reattaching the IEEE 1394 board

(1) Reattach the IEEE 1394 board in the reverse order in which it was detached.

(2) When replacing the IEEE 1394 board, perform the software adjustment to input the MAC address for

CS600-UM-251-9370 7-37

the IEEE 1394 board (See "Replacing the IEEE 1394 Board" in Section 8.3).

Page 74

7. DISASSEMBLING AND ADJUSTING THE MECHANICAL PARTS

M3L6 Flat head screw

M3L6 Flat head screw

M2 Spacer

M3 Spacer

M3L6

binding head

screw

USB cover

7.28 Data Controller Board

When replacing the data controller board, perform the software adjustment to obtain the former setting values from

the data controller board.

Detaching the data controller board

(1) Detach the right and left side covers (see Sections 7.1 and 7.2).

(2) Detach the front guide assembly (see Section 7.4).

(3) Detach the IEEE 1394 board (see Section 7.27).

(4) Remove the two M3L6 flat head screws holding the USB cover and then detach the USB cover from the

unit.

(5) Disconnect all the connectors on the data controller board and remove the two M3L6 binding head