Page 1

CS1000-UM-251-04-9370 1

CS1000

COLOR IMAGE SCANNER

SERVICE MANUAL

Page 2

CS1000-UM-251-01-9370 2

Service Manual Licensing Agreement

Graphtec Corporation ("Graphtec") grants permission for customers to use this Service Manual ("this Service

Manual") provided together with these stipulations within Japan only in accordance with the conditions

described below, and requires customers to agree to the terms below.

1. Copyrights

All copyrights in this Service Manual remain the property of Graphtec.

2. Terms of Use

Customers may not export or carry this Service Manual outside Japan.

3. Copying or Modification

(1) Customers may make copies of this Service Manual for the purpose of backing up. The customer

must indicate the copyrights for this Service Manual on all copies made.

(2) Customers may not alter, compile, amend, or otherwise adapt this Service Manual

4. Third Party Usage

Customers may not permit reuse, assignment, transfer, or any other form of disposal of this Service

Manual or usage rights to a third party.

5. Warranty

(1) If this Service Manual does not work due to the physical faults of the storage media of this Service

Manual, contact the retailer from which the product was purchased. In cases where physical faults

are the responsibility of Graphtec, replacement will be made free of charge.

(2) Replacement as described in the previous section 5.(1) is Graphtec's only guarantee regarding the

storage media of this Service Manual.

(3) Graphtec supplies this Service Manual "as is." Graphtec and its suppliers do not guarantee the

performance or results that may be obtained by customers using this Service Manual. Similarly,

Graphtec and its suppliers make no explicit or implied guarantee of non-violation of rights by third

parties, merchantability, or suitability for a particular purpose. Graphtec and its suppliers can accept

no liability for any form of circumstantial, incidental, or specific damages that may arise. Graphtec

and its suppliers can accept no liability even if the retailer indicates the possibility of such damages

occurring. No liability can be accepted for claims against the rights of third parties.

Page 3

CS1000-UM-251-9370 2

HISTORY OF REVISIONS

No. Date issued Description of revision Page Edition

1 01.11.12 First Printing All 01

2 02.07.25

8.10 Revised due to changed power supply unit in-

stallation positions

8-12

02

8.11 CIS Board (A/B) - Errors corrected 8-13

10.1 Adjustment details added due to addition of

CS1100 software adjustment

10-1, 10-3,

10.4 Shading (undesired line removal) - Revised 10-5, 10-6, 10-8,

10-13 to 10-17

10.5 Resolution Adjustment Check - Revised 10-18 to 10-21

10.6 Color Difference Test Chart - Revised 10-22

14.1 Parts List - Jigs added 14-2

3 02.07.25

1 OVERVIEW 1-1 to 1-6

03

2.1 Part Names and Functions 2-3

3.6 Attaching the Document Support Wires 3-8, 3-9

3.7 Document Hold-down Unit EV 3-10, 3-11

8.9 Main Board 8-10 to 8-12

8.10 Power Boards 8-13, 8-14

8.11 CIS (Charge Coupled Device Imaging Sensor)

Boards A and B

8-15

9.1 Wiring Diagrams 9-1, 9-2, 9-4

14.12 Accessory Changes from CS1000 14-16

14.13 Disassembled Views of Changed Parts

Adjustment details added due to addition of

CS1000EV/1100EV

14-17 to 14-19

4 04.02.16 Contents of the 2nd cautions corrected. 8-3, 8 - 4 04

Page 4

CS1000-UM-251-01-9370 4

CONTENTS

Service Manual Licensing Agreement..................................................................................2

1. OVERVIEW...................................................................................................................1-1

1.1 Features...................................................................................................................................... 1-1

CS1000 Features........................................................................................................................ 1-1

CS1000EV Series Features........................................................................................................ 1-1

1.2 Additional Functions of CS1000EV Series ................................................................................. 1-2

1.3 Cautions for CS1000EV Series .................................................................................................. 1-2

1.4 Product Differences .................................................................................................................... 1-2

1.5 Standard Specifications .............................................................................................................. 1-3

1.3 External View.............................................................................................................................. 1-4

1.4 System Requirements ................................................................................................................ 1-6

2. PART NAMES AND FUNCTIONS................................................................................2-1

2.1 Part Names and Functions ......................................................................................................... 2-1

Front View................................................................................................................................... 2-1

Control panel .............................................................................................................................. 2-2

Rear View ................................................................................................................................... 2-3

2.2 Unpacking the Scanner .............................................................................................................. 2-4

3. PREPARING TO OPERATE THE SCANNER..............................................................3-1

3.1 Assembling the Scanner............................................................................................................. 3-1

3.2 Connecting the Scanner to a Power Supply ............................................................................... 3-3

3.3 Connecting the SCSI Cable........................................................................................................ 3-4

Compatible Cables ..................................................................................................................... 3-4

Connection Procedure ................................................................................................................ 3-4

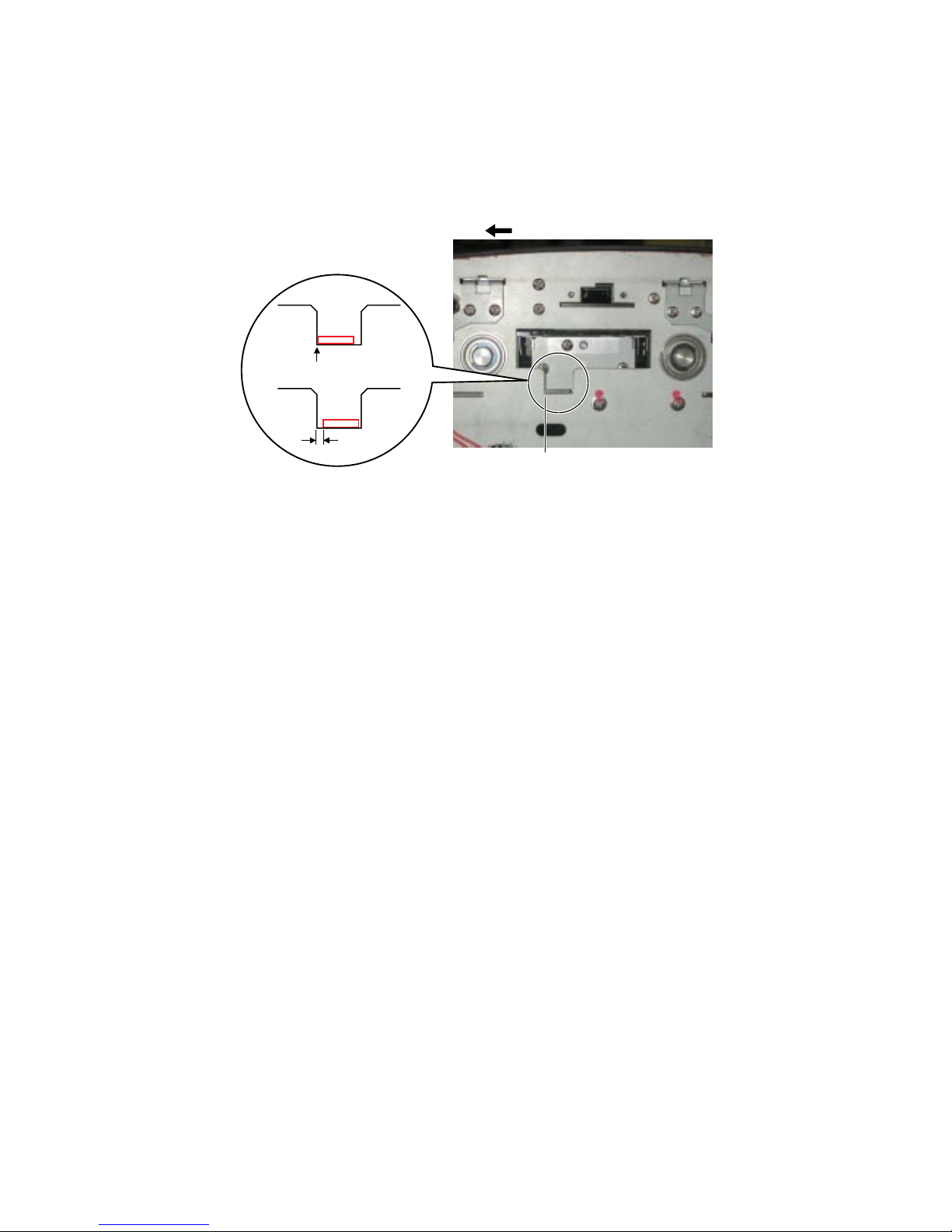

3.4 Setting the ID Number ................................................................................................................ 3-6

3.5 Turning the Scanner On or Off.................................................................................................... 3-7

3.6 Attaching the Document Support Wires...................................................................................... 3-8

3.7 Document Hold-down Unit EV .................................................................................................. 3-10

Storing the Document Hold-down Unit EV................................................................................ 3-10

Attaching the hooks (for CS1000EV and CS1100EV with stand *)............................................3-11

Replacement method.................................................................................................................3-11

Distance correction method .......................................................................................................3-11

4. OPERATION AND CONNECTION...............................................................................4-1

4.1 Connecting the Scanner to a Computer ..................................................................................... 4-1

Connecting the CS1000 to a Computer for the First Time.......................................................... 4-1

4.2 Checking the Interface Connection............................................................................................. 4-7

4.3 Installing the Scanning Master 21+ Application.......................................................................... 4-9

4.4 Installing the Scanning Master Copy Color Application ............................................................ 4-10

4.5 Document Types Compatible with the CS1000 .........................................................................4-11

Compatible Media Widths for Scanning.....................................................................................4-11

Compatible Media Lengths for Scanning...................................................................................4-11

Compatible Grades & Thickness for Scanning ..........................................................................4-11

4.6 Loading a Document................................................................................................................. 4-12

For standard-size documents ................................................................................................... 4-12

Page 5

CS1000-UM-251-01-9370 5

4.7 Using the Carrier Sheet ............................................................................................................ 4-13

4.8 Scanner Driver Software’s Compatibility with Windows 2000 .................................................. 4-14

4.9 How to Obtain (Install) the ASPI Manager................................................................................ 4-15

1. What you will need................................................................................................................ 4-15

2. How to obtain ASPI Manager................................................................................................ 4-15

3. How to install ASPI Manager ................................................................................................ 4-15

4.10 Checking the ASPI Layer.......................................................................................................... 4-16

4.11 Checking Windows 2000 ASPI32 Status and Starting the Software ........................................ 4-17

If “Running” does not appear (Windows 2000 ASPI32 is not running), .................................... 4-18

4.12 Changing Transfer Rate with the AVA-2915LP (Ultra SCSI-compliant) .................................... 4-20

4.13 Factory Settings........................................................................................................................ 4-22

DIP Switch ................................................................................................................................ 4-22

ID Number ................................................................................................................................ 4-22

5. DAILY MAINTENANCE................................................................................................5-1

5.1 Cleaning the Image Sensors ...................................................................................................... 5-1

5.2 Cleaning the Paper Sensors....................................................................................................... 5-3

5.3 Cleaning the Document Hold-Down Unit .................................................................................... 5-4

5.4 Removing a Jammed Document ................................................................................................ 5-5

6. RECOMMENDED PARTS LIST...................................................................................6-1

7. LIST OF JIGS AND TOOLS .........................................................................................7-1

7.1 Jigs ............................................................................................................................................. 7-1

7.2 Tools ........................................................................................................................................... 7-1

7.3 Other........................................................................................................................................... 7-1

8. DISASSEMBLING AND ADJUSTING MECHANICAL PARTS......................................8-1

8.1 Considerations before starting disassembly ............................................................................... 8-1

8.2 Document Hold-down Unit.......................................................................................................... 8-2

8.3 CS Retaining Plate ..................................................................................................................... 8-4

8.4 Side Covers ................................................................................................................................ 8-5

8.5 Top Cover ................................................................................................................................... 8-6

8.6 Front Cover................................................................................................................................. 8-7

8.7 Rear Cover ................................................................................................................................. 8-8

8.8 Bottom Plates, Large and Small ................................................................................................. 8-9

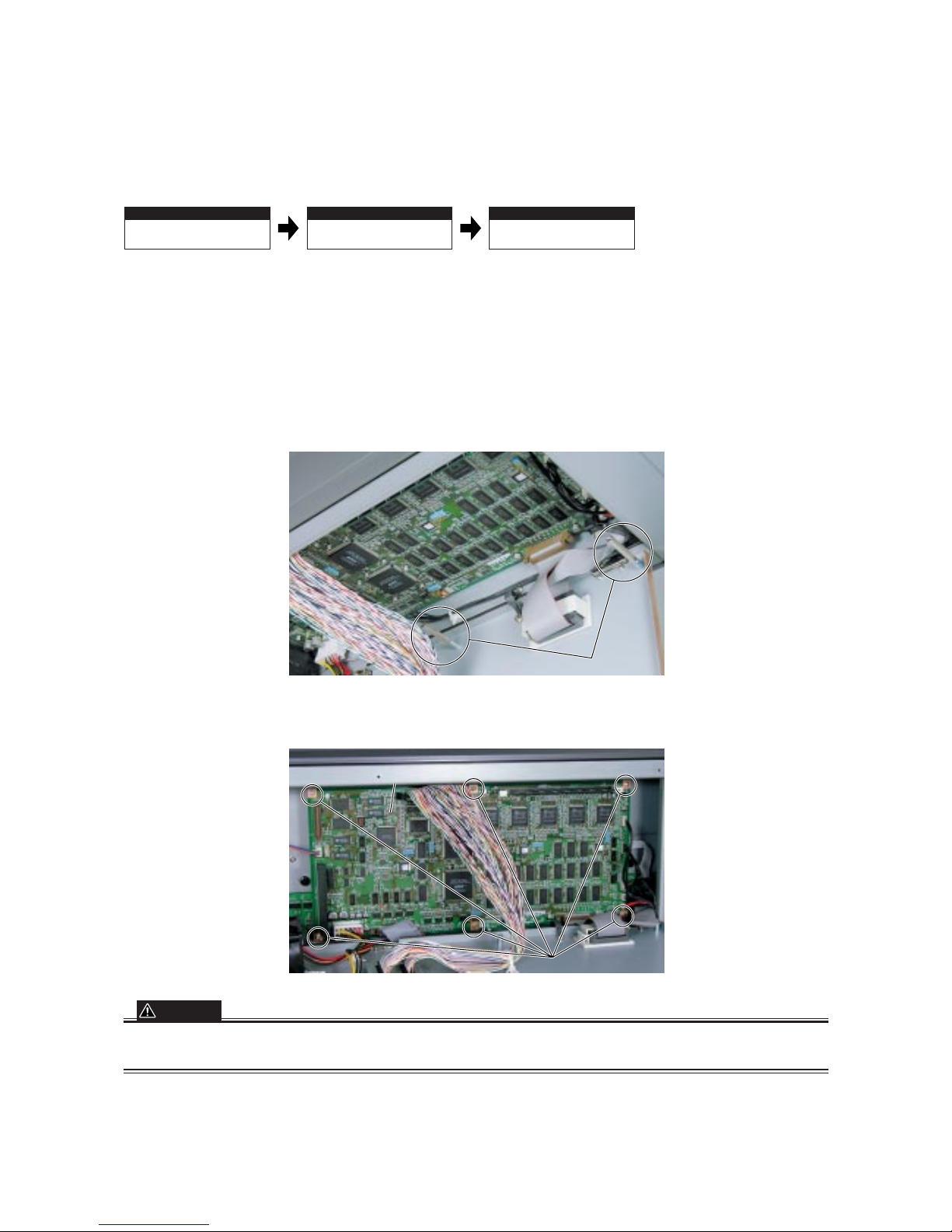

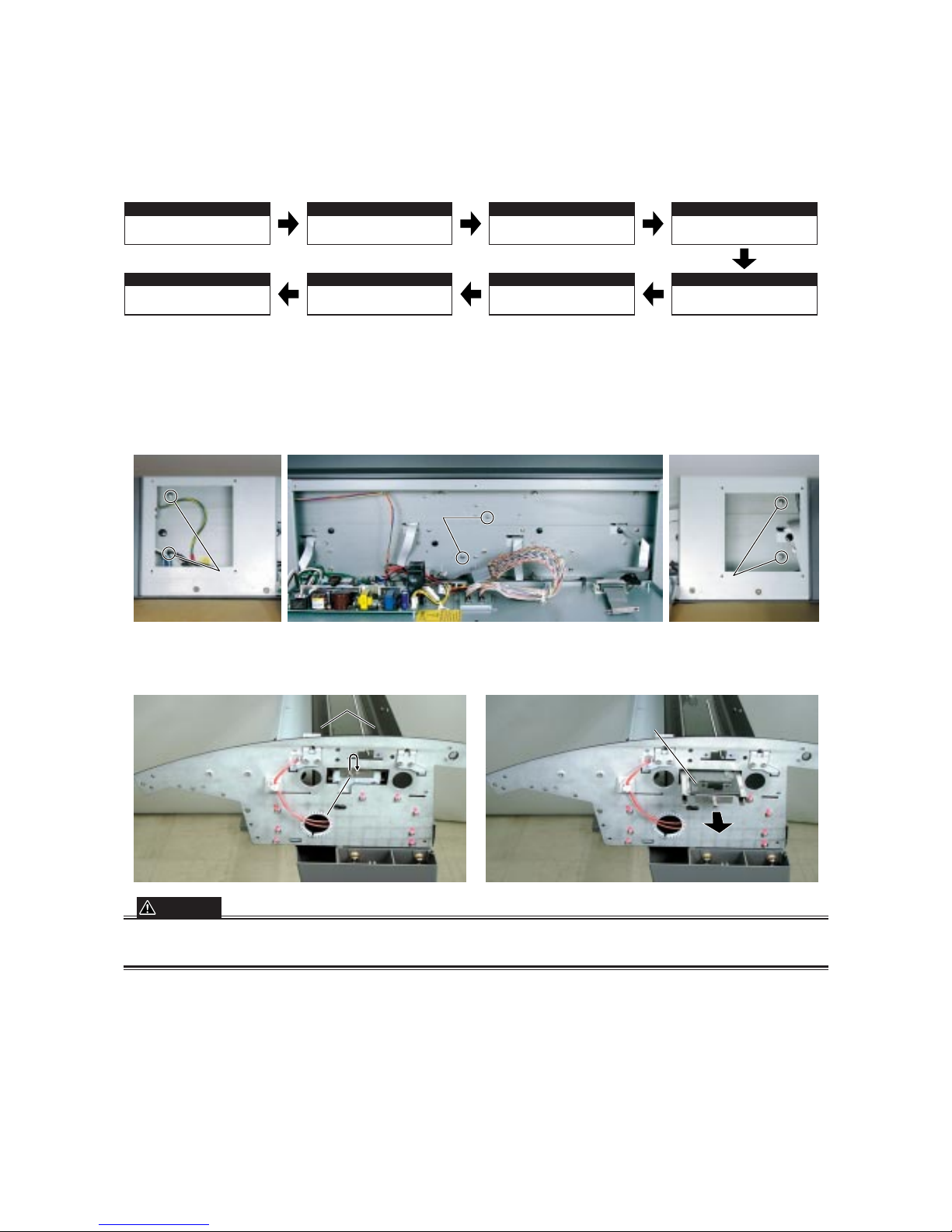

8.9 Main Board ............................................................................................................................... 8-10

CS1000/1000EV disassembly procedure ................................................................................. 8-10

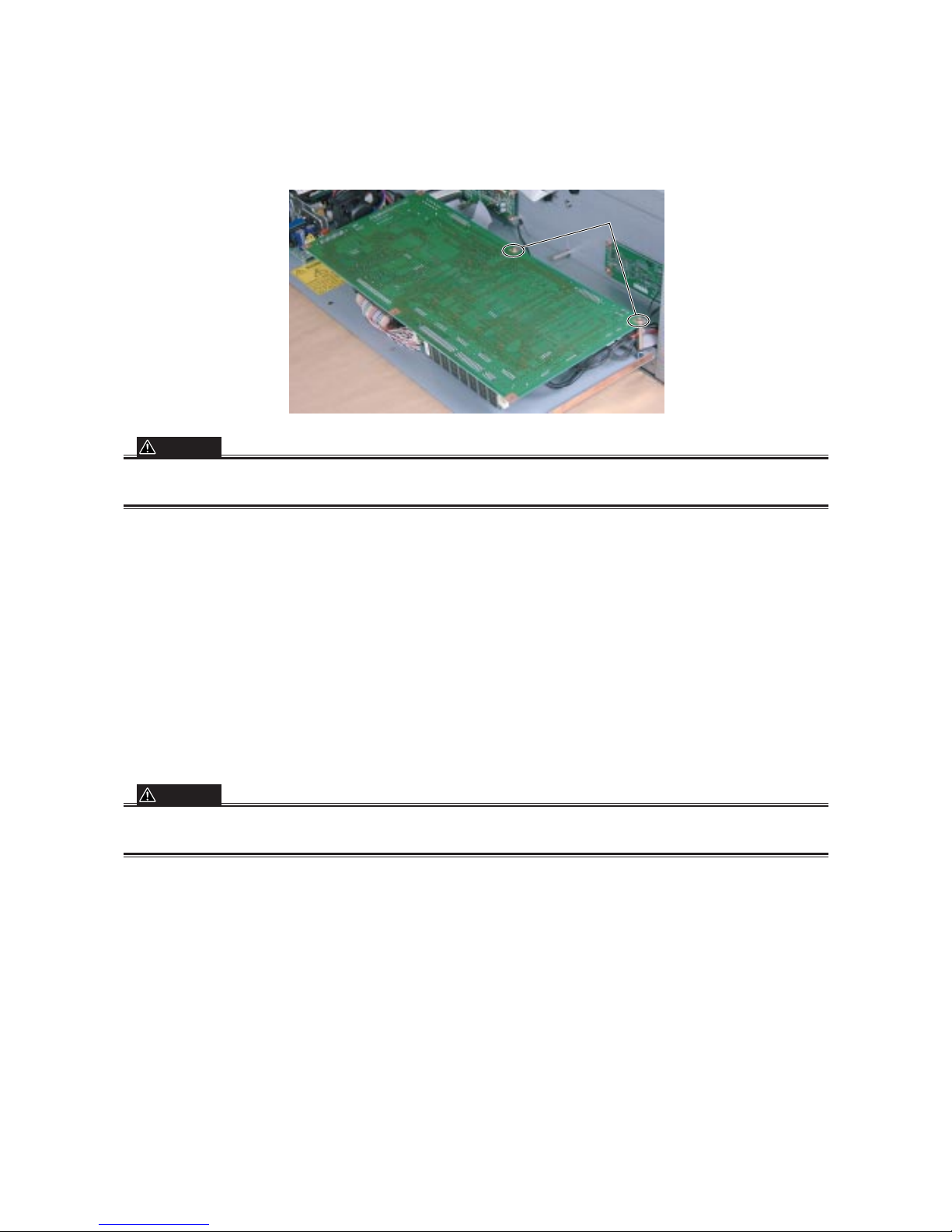

When securing the main board to the jig (BSB-335) ................................................................ 8-10

When detaching the main board completely (not for securing it to the jig) ................................8-11

CS1100EV disassembly procedure .......................................................................................... 8-12

8.10 Power Boards ........................................................................................................................... 8-13

8.11 CIS (Charge Coupled Device Imaging Sensor) Boards A and B .............................................. 8-15

CS1000/1000EV disassembly procedure ................................................................................. 8-15

CS1100EV disassembly procedure .......................................................................................... 8-15

8.12 Cooling Fan .............................................................................................................................. 8-16

8.13 Separator Plates....................................................................................................................... 8-17

8.14 Pinch Roller Units ..................................................................................................................... 8-18

8.15 Front Guide............................................................................................................................... 8-20

8.16 Rear Guide ............................................................................................................................... 8-21

Page 6

CS1000-UM-251-01-9370 6

8.17 Control Panel............................................................................................................................ 8-22

8.18 Cover Open Sensor.................................................................................................................. 8-23

8.19 Front and Rear Paper Detection Sensors................................................................................. 8-24

8.20 Motor......................................................................................................................................... 8-26

Adjusting the Tension Belt ........................................................................................................ 8-27

8.21 Pulleys ...................................................................................................................................... 8-28

Adjusting the Tension Belt ........................................................................................................ 8-28

8.22 Drive Rollers ............................................................................................................................. 8-29

8.23 Image Sensor Unit.................................................................................................................... 8-30

Replacing the Entire Image Sensor Unit................................................................................... 8-30

Replacing the Glass Base Unit Only......................................................................................... 8-33

9. BOARDS AND ELECTRICAL COMPONENTS.............................................................9-1

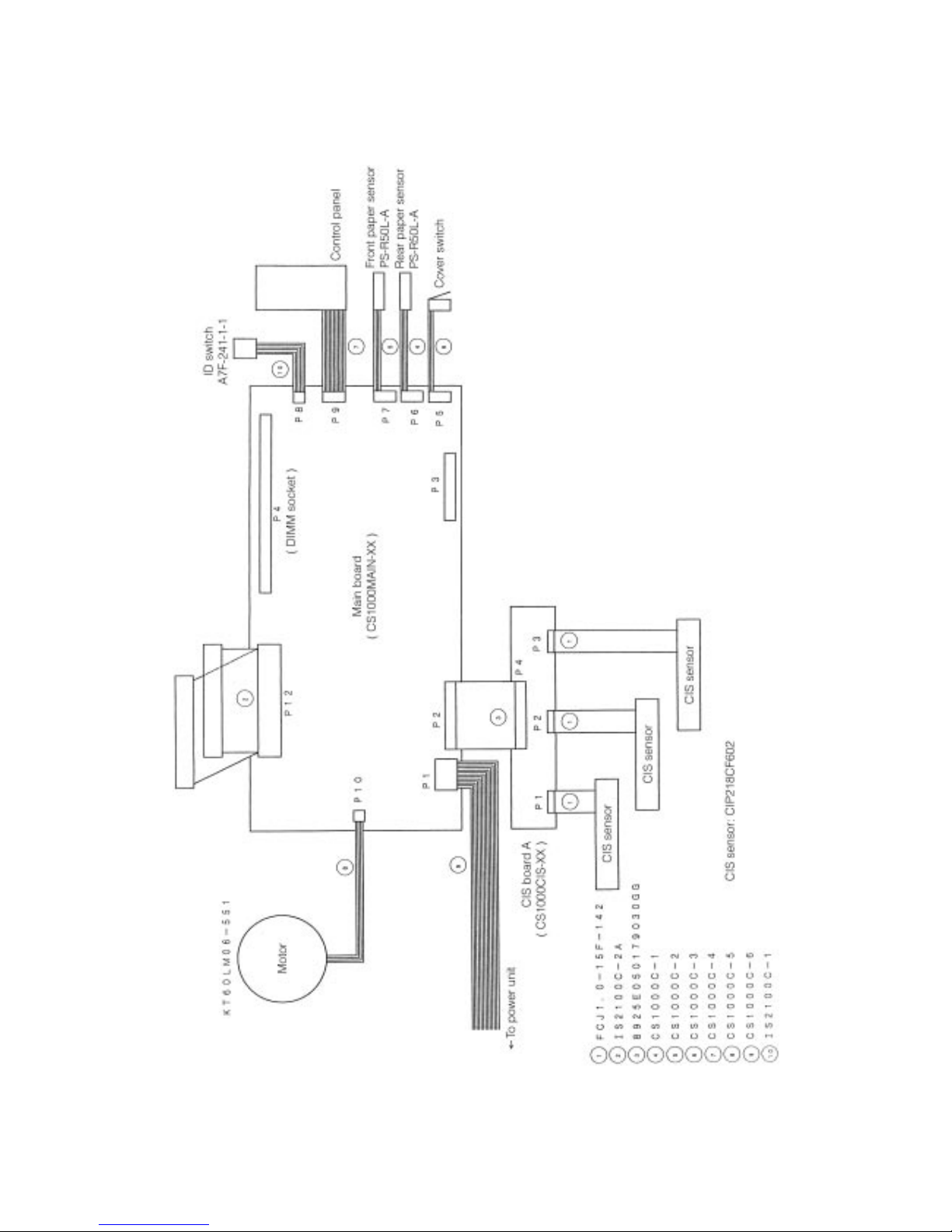

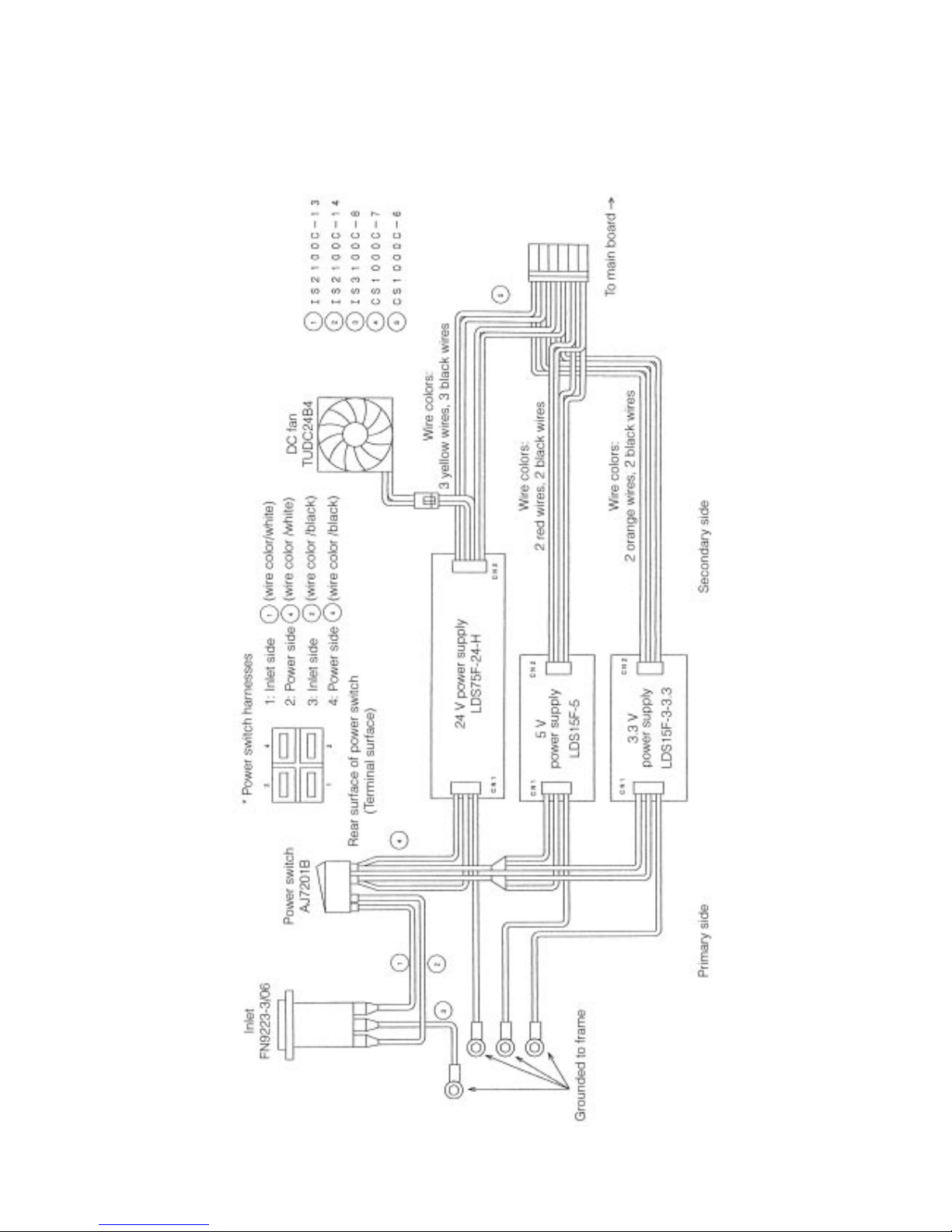

9.1 Wiring Diagrams ......................................................................................................................... 9-1

Overall Configuration (CS1000/1000ES).................................................................................... 9-1

Overall Configuration (CS1100ES) ............................................................................................. 9-2

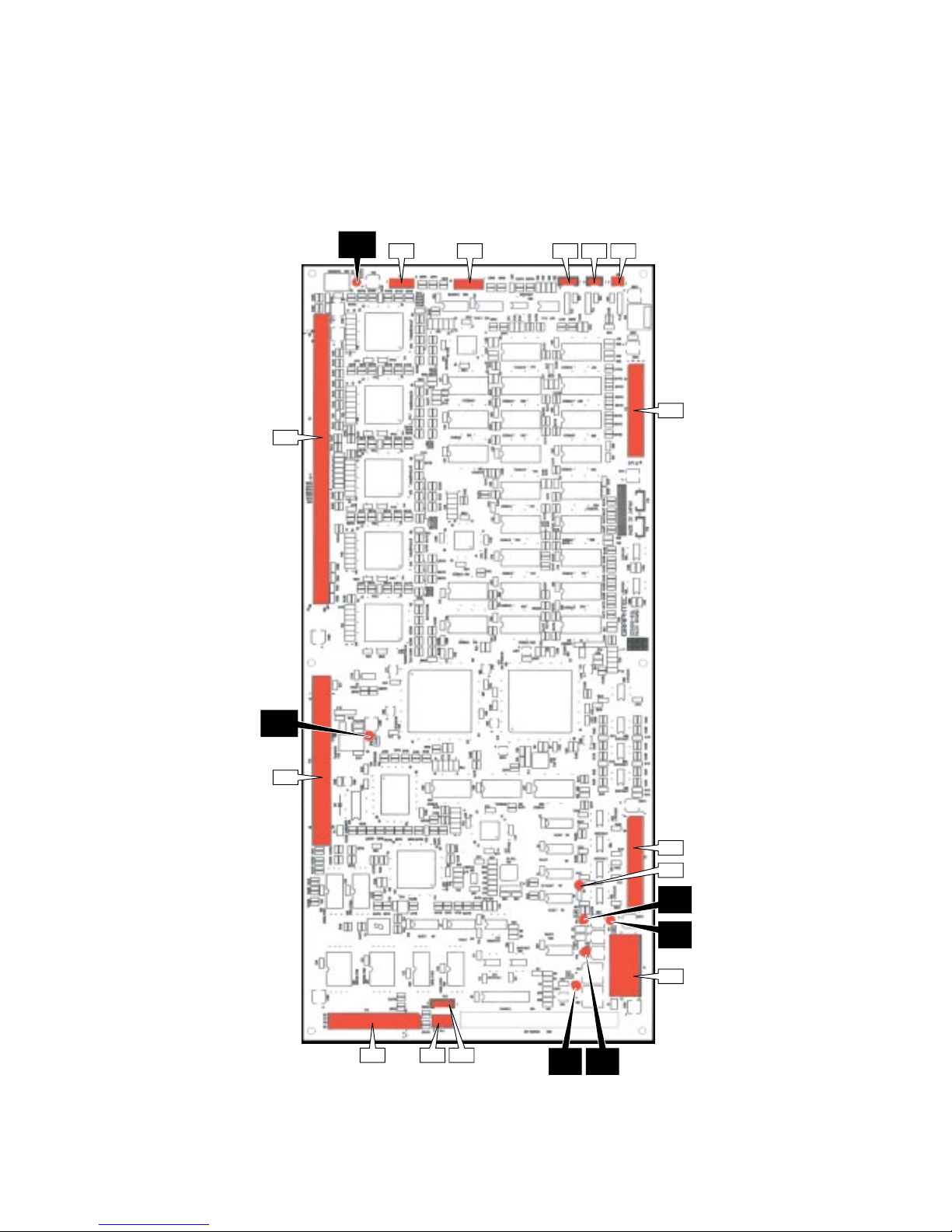

Component Layout on the Main Board ....................................................................................... 9-3

Power Unit Wiring ....................................................................................................................... 9-4

9.2 Power Supply Unit ...................................................................................................................... 9-5

1. Checking Voltage Levels ........................................................................................................ 9-5

9.3 Main Control Board..................................................................................................................... 9-6

1. Precautions for replacing the main board ............................................................................... 9-6

2. Checking voltage levels .......................................................................................................... 9-6

3. LED status .............................................................................................................................. 9-6

4. Replacing the main board....................................................................................................... 9-6

9.4 At-a-glance Guide to Adjustment Functions ............................................................................... 9-8

Key operations............................................................................................................................ 9-8

9.5 Downloading the Boot Program.................................................................................................. 9-9

1. Items required to download the boot program ........................................................................ 9-9

2. Procedure ............................................................................................................................... 9-9

9.6 Downloading Firmware ............................................................................................................. 9-10

1. Items required to download firmware.................................................................................... 9-10

2. Procedure ............................................................................................................................. 9-10

9.7 Test Mode ..................................................................................................................................9-11

1. Procedure ..............................................................................................................................9-11

10. ADJUSTMENTS WITH SOFTWARE ........................................................................10-1

10.1 Starting the Software ................................................................................................................ 10-1

10.2 Preparations before Making Adjustments ................................................................................. 10-3

10.3 Preparing a Test Chart.............................................................................................................. 10-4

10.4 Making Adjustments.................................................................................................................. 10-5

1. Shading (white correction) .................................................................................................... 10-5

2. Feed distance adjustment..................................................................................................... 10-6

3. Position adjustment .............................................................................................................. 10-8

4. Shading (undesired color line removal) .............................................................................. 10-13

5. Shading (undesired gray line removal) ............................................................................... 10-16

10.5 Resolution adjustment check.................................................................................................. 10-18

1. Paper-feed distance accuracy check.................................................................................. 10-18

2. Image-sensor offset (joint accuracy)................................................................................... 10-18

3. Offset check........................................................................................................................ 10-18

Page 7

CS1000-UM-251-01-9370 7

4. Resolution check ................................................................................................................ 10-18

5. Checking sensor color density (using a color test chart) .................................................... 10-19

10.6 Color difference measurement chart ...................................................................................... 10-22

11. TROUBLESHOOTING ..............................................................................................11-1

12. SCHEMATIC DIAGRAMS .........................................................................................12-1

12.1 Control Board............................................................................................................................ 12-1

13. OPTION ....................................................................................................................13-1

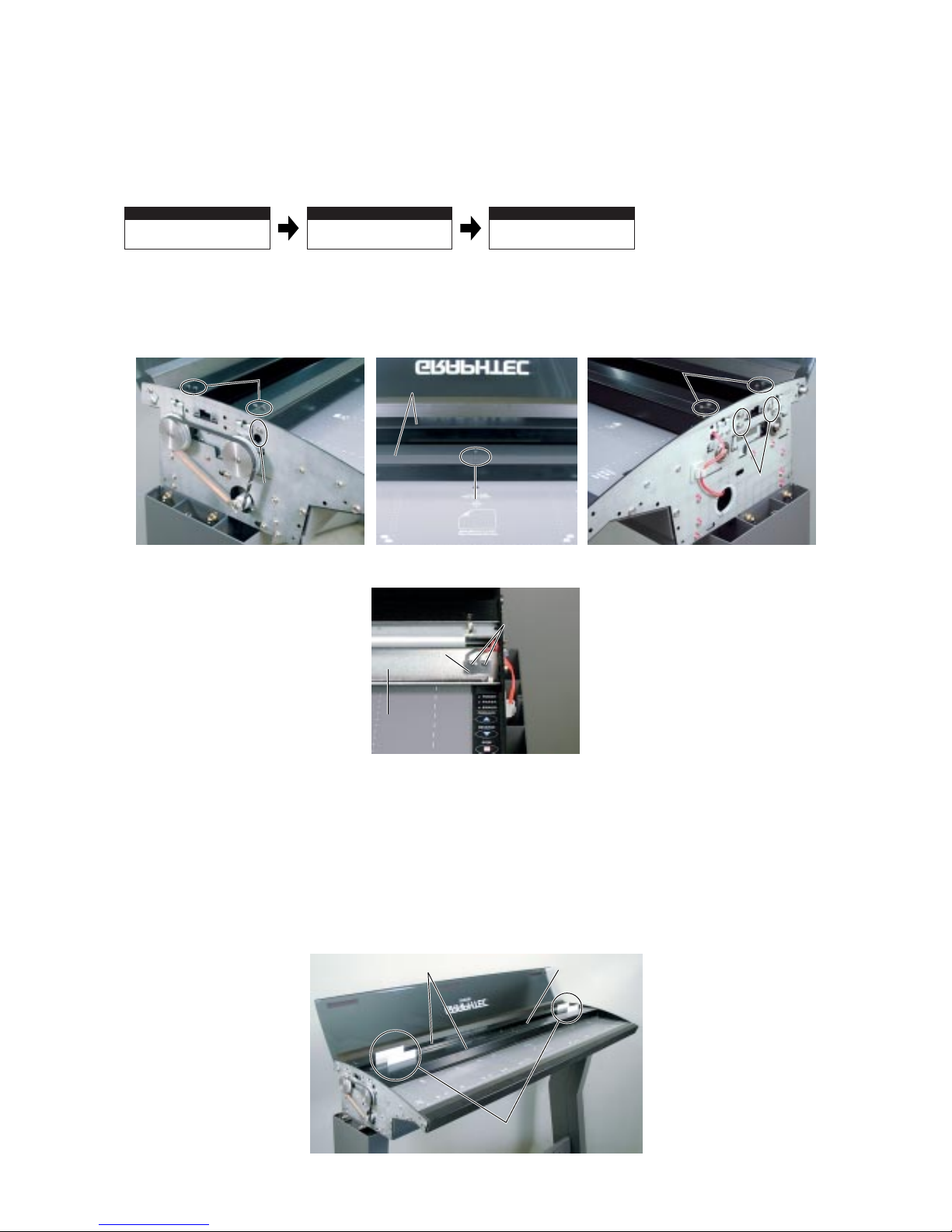

13.1 Basket Assembly Procedure (PG0010) .................................................................................... 13-1

Parts List................................................................................................................................... 13-1

Assembly Procedure................................................................................................................. 13-1

14. PARTS LISTS............................................................................................................14-1

14.1 Parts List................................................................................................................................... 14-1

14.2 External Casing 1 ..................................................................................................................... 14-3

14.3 External Casing 2 ..................................................................................................................... 14-4

14.4 External Casing 3 ..................................................................................................................... 14-6

14.5 Document Hold-down Unit........................................................................................................ 14-7

14.6 Pinch Roller Unit....................................................................................................................... 14-8

14.7 Drive Unit................................................................................................................................ 14-10

14.8 Drive Roller Unit.......................................................................................................................14-11

14.9 Sensor Unit............................................................................................................................. 14-12

14.10 Board Unit............................................................................................................................... 14-13

14.11 Accessories ............................................................................................................................ 14-15

14.12 Accessory Changes from CS1000.......................................................................................... 14-16

Changed Accessory List ......................................................................................................... 14-16

14.13 Disassembled Views of Changed Parts.................................................................................. 14-17

CS1100 foot assy.................................................................................................................... 14-17

CS11 Hold-down unit EV maintenance (for CS1100) ............................................................. 14-18

CS11 Hold-down unit EV maintenance (for CS1100) ............................................................. 14-19

Page 8

CS1000-UM-251-03-9370 1-1

1. OVERVIEW

1. OVERVIEW

1.1 Features

CS1000 Features

600-dpi optical resolution for high-precision image scanning

Scanning with an optical resolution of 600 dpi allows even complex and difficult-to-scan documents, such

as CAD drawings, electronic files, and mapping data to be scanned rapidly and with high precision.

Scanning Master 21+ (scanner software included as a standard accessory) can be used to adjust the

resolution in five levels (200 dpi to 800 dpi) to suit the scanned document.

Compatible document widths range from 210 mm to 1000 mm

Compatible with document sizes from ISO A4 up to ANSI E

Capable of color and grayscale scanning

Capable of scanning in color (8-bit color) or grayscale (256 shades)

Capable of reading long-axis data

Long-axis images are supported with a maximum length of approximately four meters each.

Compact and lightweight design

A compact design was achieved by using a document travel system that employs closely-adhered image

sensors in the sensor unit (five rows arranged in a zigzag pattern).

Image-processing functions

Use of the scanning software provided lets you set image-processing functions for the scanning of a

document.

Interface

The CS1000 interface conforms to the SCSI-2 standard.

CS1000EV Series Features

Extremely fine scanning is made possible by the highest resolution in its class of True 600 dpi ±0.1% ±5

pixels 0.1% ±3 pixels for CS1100EV).

Resolution can be selected in the range 200 dpi to 800 dpi(*1) according to the image density and intended

purpose.

High-speed scanning of approximately 1.28 inch/s(*2) for color and approximately 3.8 inch/s(*2) for monochrome allows for efficient digitizing of even large volumes of documents.

Incorporates a C.D. Reduction (Color Depth Reduction) function to convert 24-bit color data to practical 8bit color data for smooth color scanning.

ScanningMaster 21+ is included and is compatible with ScanningMaster 21, the benchmark for high

performance and high operability.

*1Interpolated resolution

*2At 200 dpi, not including data transfer time.

Page 9

CS1000-UM-251-03-9370 1-2

1. OVERVIEW

1.2 Additional Functions of CS1000EV Series

Includes the new Express Mode for high-speed data transfer for color scanning.

Includes correction functions to smooth the intensity differences for the join sections of image sensors,

which are arranged in a zigzag pattern, in the primary scanning direction.

A high-pressure medium hold-down unit (document hold-down unit EV) is included as standard for thick

media (e.g., with folds, or creasing).

1.3 Cautions for CS1000EV Series

The CS1100EV should always be used with the document support wires on the main unit, regardless of

the type of document being scanned. There is a risk of damage to the document if it comes into contact

with the SCSI cable.

Do not scan thin or limp documents such as plain paper less than 0.08 mm thick using the document holddown unit EV. This may damage the document or cause paper jamming.

The number of attachment holes for the document hold-down CS on the hold-down unit EV differs from

the standard unit. When replacing, use "Hold-down CS-JEC" (new).

The power supply unit installation positions differ from the CS1000.

CS1000: In sequence 3.3 V, 5 V, 24 V from top

CS1000EV (B0 size or larger): In sequence 5 V, 3.3 V, 24 V from top

CS1100EV (A0 size or larger): In sequence 5 V, 3.3 V, 24 V from top

TM9000 (A0 size or larger): In sequence 3.3 V, 5 V, 24 V from top

TM9000 (B0 size or larger): In sequence 5 V, 3.3 V, 24 V from top

1.4 Product Differences

Electrical

Mechanical

Firmware

Functions

Accessories

CS1000

Ver 0.9X to Ver 1.XX

Note: Do not install

CS1000EV firmware.

CS1000EV

•Same as CS1000

• Power supply unit

installation positions

changed.

• Document hold-down unit

EV (new)

• Hold-down CS-JEC

(new)

Ver 2.0 onward

• Supports Express Mode.

• Includes Express Mode high-speed transfer (24-bit to

12-bit processing)

• Join correction between sensors

• Hooks

• Document hold-down unit EV (new)

CS1100EV

• Main board (new)

• Image sensor unit

maintenance (new)

• Cable items (new)

• Power supply unit

installation positions

changed.

• Pinch roller unit maintenance (new)

• Glass base unit maintenance (new)

• C1 hold-down CS (new)

• Desktop mounted

(Optional stand)

Ver 1.0 onward

• Supports Express Mode.

• Hooks are contained in

stand.

Page 10

CS1000-UM-251-03-9370 1-3

1. OVERVIEW

1.5 Standard Specifications

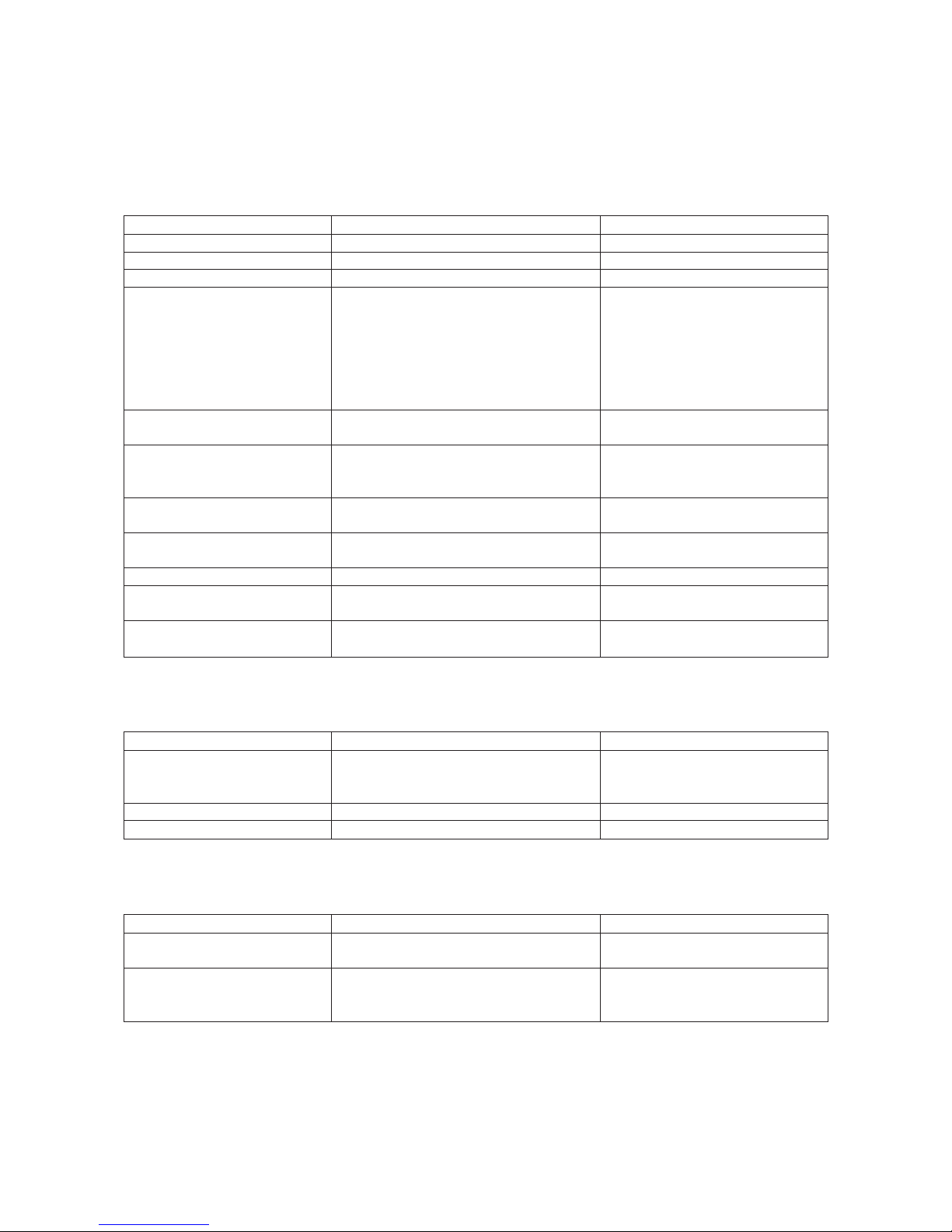

Item CS1000 CS1000EV CS1100EV

Document size ANSI E to ISO A4 (all sizes centered)

Effective scanning area Width: 914 mm (max. 1,000 mm width) sensored Width: 594 mm

(max. 630 mm width) sensored

Length: 1,188 mm Length: 1,188 mm

(banner format up to approx. 4 m possible)*

1

(banner format up to

approx. 4 m possible)*

1

Document thickness 1.5 mm or less (including the carrier sheet)*

2

Optical resolution 600 dpi

Interpolated resolution Main scanning direction : 200 dpi, 300 dpi, 400 dpi, 600 dpi

Secondary scanning direction : 200 dpi, 300 dpi, 400 dpi, 600 dpi, 800 dpi

Main scanning system Close-contact image sensor system

Close-contact image sensor system

5 A4 sensors in zigzag pattern

3 A4 sensors in zigzag pattern

Sub scanning system Document travel (sheet through) system

Scanning speed*

3

Monochrome: Approx. 1.3 ms/line (at 600 dpi)

3.8 inch/s (at 200 dpi)

1.9 inch/s (at 400 dpi)

1.26 inch/s (at 600 dpi)

Color: Approx. 3.9 ms/line (at 600 dpi)

1.28 inch/s (at 200 dpi)

0.64 inch/s (at 400 dpi)

0.42 inch/s (at 600 dpi)

Scanning precision*

4

±0.1%, ±5 pixels ±0.1%, ±3 pixels

Gradation Monochrome: Bilevel, intermediate tones (dithering, error diffusion)

Gray : 256 shades

Color : 256 colors

Light source LED (RGB)

Interface SCSI-2

Output Image data

Rated power supply 100 to 120/200 to 240 VAC ±10%, 50/60 Hz

Operating environment Temperature: 10°C to 35°C, Humidity: 35% to 80% R.H. (no condensation)

Power consumption 115 VA or less

External dimensions (approx.)

1205 × 1020 × 600 mm (W × H × D) (including stand)

850 × 381 × 169 mm (W × H × D)

Weight (approx.) 48 kg (including stand) 24 kg

*1Documents up to approximately 4 m in length can be scanned. (Mechanical restriction)

For long-length documents, the document length that can be scanned is limited by the available memory (hard disk or

other data storage device) of the host computer to which it is connected, and also by the grade of the medium being

scanned.

*2Carrier sheet thickness: 0.2 mm

*3Excluding data-transfer time

*4Notes on scanning precision

Scanning precision may vary slightly depending on the grade and thickness of the medium being scanned, and on

the operating conditions. The precision figures above were measured under the operating conditions described

below.

• Test chart used : Mylar sheet (thickness: 55 mm)

• Guaranteed precision conditions : Temperature 20 ±3°C; humidity: 60% ±10% RH

• Guaranteed scanning precision range : 1188 mm × 841 mm

Page 11

CS1000-UM-251-03-9370 1-4

1. OVERVIEW

1.3 External View

External Dimensions of the CS1000/CS1000EV

156

1020

1205 600

Unit : mm

Dimensional precision error : ±5 mm

Page 12

CS1000-UM-251-03-9370 1-5

1. OVERVIEW

External Dimensions of the CS1100EV

169

850

426

381

When mounted on the optionnal stand

156

1020

850 600

640

Unit : mm

Dimensional precision error : ±5 mm

Page 13

CS1000-UM-251-03-9370 1-6

1. OVERVIEW

1.4 System Requirements

The minimum system requirements for running the scanner’s hardware and software are listed below.

Operating system: Windows 95/98/Me, Windows NT 4.0, Windows 2000 or later

CPU: Pentium 133 MHz or higher

Memory: 32 MB or more

Monitor: 1024 × 768 pixels, 256 colors or more

Enough disk space to store data

Mouse

SCSI board by Adaptec

Recommended environment

For binary monochrome data

CPU: Pentium 200 MHz or higher

Memory: 64 MB or more

SCSI board by Adaptec (PCI type)

For grayscale data

CPU: Pentium III 550 MHz or higher

Memory: 256 MB or more

Monitor: 1024 × 768 pixels, High Color or higher resolution

SCSI board by Adaptec (PCI type)

For 8-bit color data

CPU: Pentium III 866 MHz or higher

Memory: 512 MB or more

Monitor: 1024 × 768 pixels, True Color or higher

SCSI board by Adaptec (PCI type)

CHECKPOINT

The system configuration should correspond to the recommended specifications listed here, in order to ensure the

optimum capabilities of the scanner.

Use with a system configuration below the recommended specifications will affect the scanning speed and prevent

the scanner from operating to its specified capabilities.

To edit an A1-size or larger grayscale document with a resolution of 400 dpi or higher, or an 8-bit color document,

you may need more than the recommended memory sizes above. Depending on the type of document, you may not

be able to scan in the document even if you increase the memory size.

Page 14

CS1000-UM-251-01-9370 2-1

2. PART NAMES AND FUNCTIONS

2. PART NAMES AND FUNCTIONS

2.1 Part Names and Functions

Front View

Cover sensor

Paper sensor

Top cover

Caster

Control panel

Stand

Top cover

Opening the top cover allows the document hold-down unit to be removed.

Cover sensor

This senses whether the top cover is open or closed, and interrupts scanner operation if the top cover is

opened during operation.

Stand

The stand unit is assembled for mounting of the scanner unit.

Casters

Release the lock on the casters to allow the unit to be moved.

Paper sensor

This senses whether a document is present in the scanner.

CAUTION

Do not touch the cover sensor or paper sensor.

Page 15

CS1000-UM-251-01-9370 2-2

2. PART NAMES AND FUNCTIONS

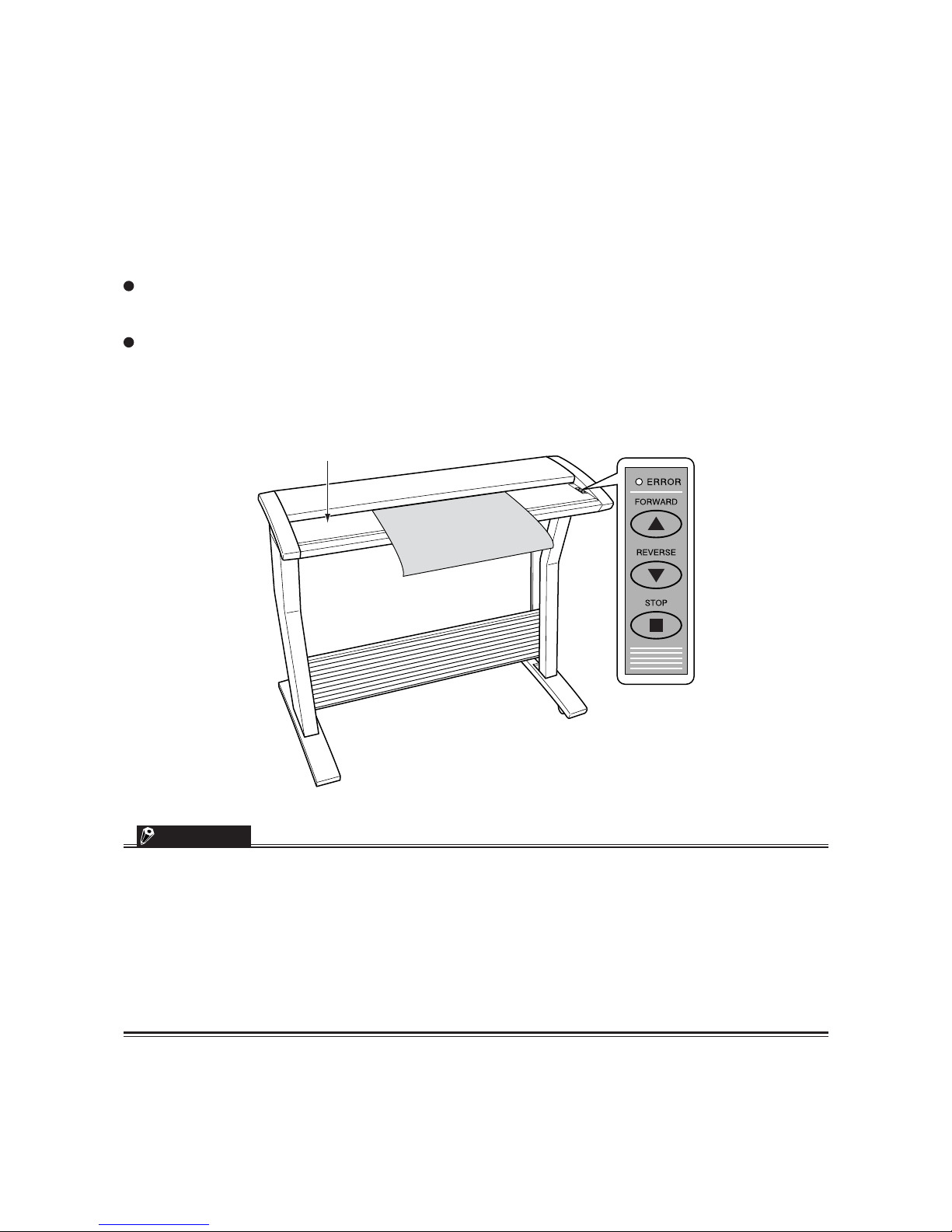

Control panel

POWER LED

Unlit : Is unlit while the scanner is turned off.

Lit : Lights (green) when the scanner is turned and remains lit while it is operating normally.

PAPER LED

Unlit : Normal status (Local status).

Lit : Lights (green) when the scanner enters Scan READY status.

Flashing : Flashes (green) while image data is being scanned.

ERROR LED

Lit : Lights (red) to indicate a hardware error.

Flashing : Flashes (red) when a document is detected during the self-test when the scanner is turned on or

when the scanning is suspended by pressing the STOP key.

Unlit : Normal status

FORWARD key

Advances the document into the scanner. When this key is pressed in Scan READY status, the Scan

READY status is cancelled and the document is ejected toward the rear of the scanner.

REVERSE key

Feeds the document toward you. When this key is pressed in Scan READY status, the Scan READY status

is cancelled and the document is ejected toward the front of the scanner.

STOP key

Compulsorily stops scanning of the document.

Page 16

CS1000-UM-251-03-9370 2-3

2. PART NAMES AND FUNCTIONS

Rear View

CS1000/1000EV

SCSI-ID switches

DIP switch

Power switch

AC line inlet

SCSI connectors

CS1100EV

4321

SCSI-ID switches

DIP switch

AC line inlet

Power switch

SCSI connectors

SCSI-ID switches

Used to specify the ID numbers of the SCSI interfaces.

DIP switch

Used to set the scanner’s functions.

Power switch

Controls the on/off status of the power supply to the scanner.

AC line inlet

Connect the power cord’s female plug here.

SCSI connectors

Used to connect SCSI interface cables. The two connectors are connected in parallel inside the scanner.

Page 17

CS1000-UM-251-01-9370 2-4

2. PART NAMES AND FUNCTIONS

2.2 Unpacking the Scanner

After unpacking the Image Scanner, check its outer casing and check that the standard accessories listed

below are all present. If you detect a surface flaw or a missing accessory, please promptly contact your

sales representative or nearest Graphtec vendor.

Power cable 1 Carrier sheet (IS0902)

User’s Manual CS1000 User Guide CD-ROM

Document support wires

Cable clamp

CS1000 User Guide

CD-ROM

1

11

11

Page 18

CS1000-UM-251-01-9370 3-1

3. PREPARING TO OPERATE THE SCANNER

3. PREPARING TO OPERATE THE SCANNER

3.1 Assembling the Scanner

Assemble the stand before mounting the scanner unit. Eight bolts and an Allen wrench are provided with the

stand.

(1) Using the four bolts, loosely attach the center bar (3) to side stay R (1) and side stay L (2).

(1)

(2)

(3)

TIP

Attach the center bar loosely. Tighten the bolts securely after the scanner unit has been mounted on the stand.

Page 19

CS1000-UM-251-01-9370 3-2

3. PREPARING TO OPERATE THE SCANNER

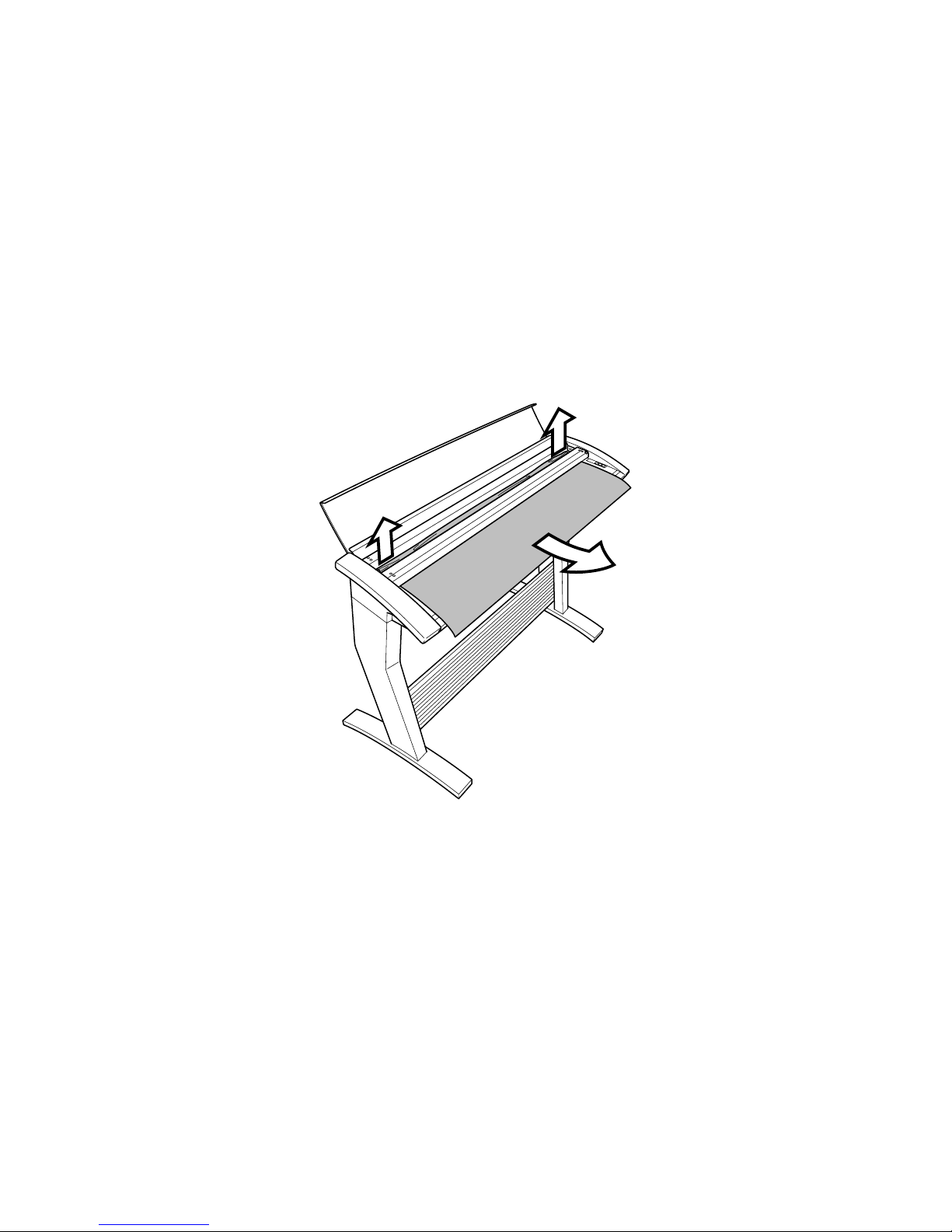

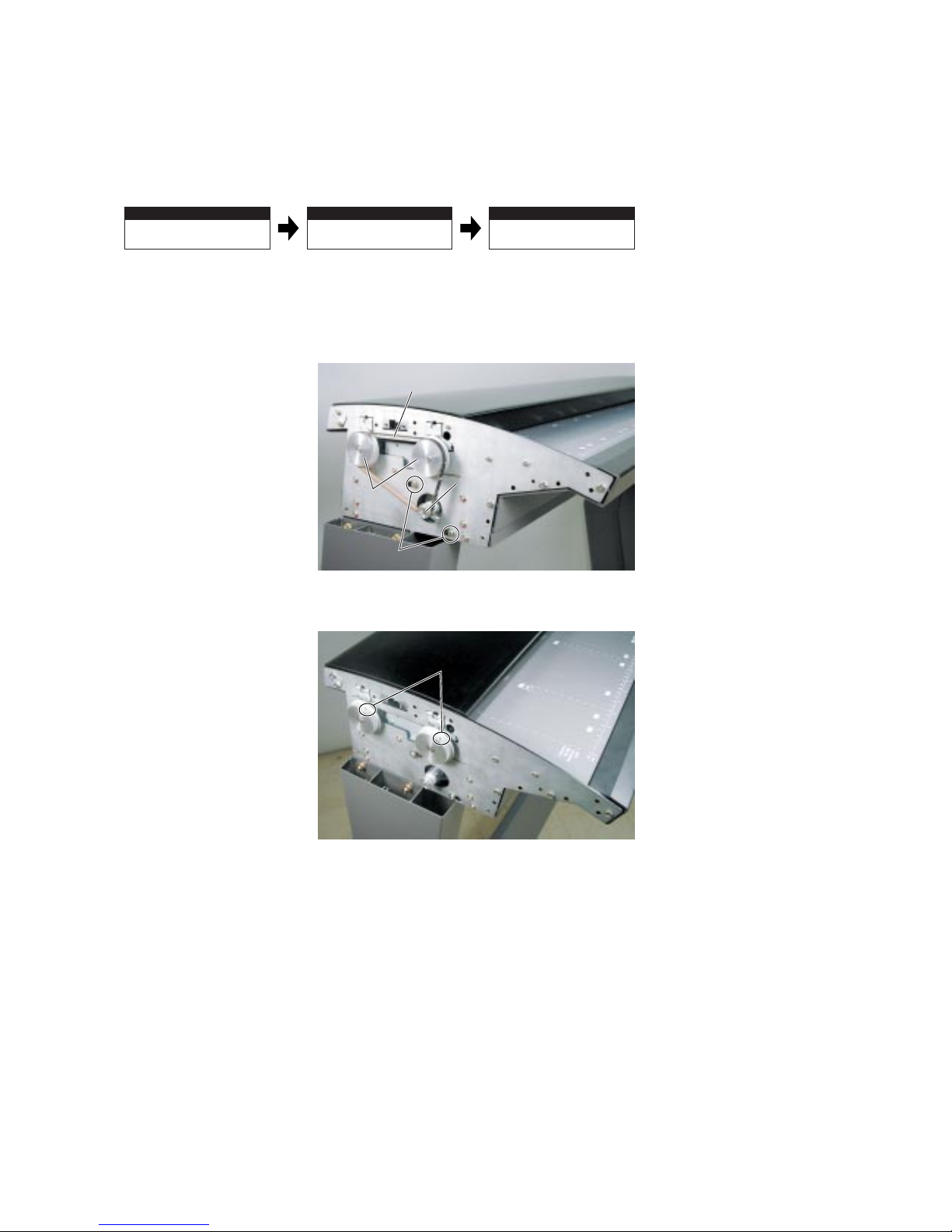

(2) Hold the scanner unit by the side covers on both sides, and mount the scanner so that the positioning

pins on the stand align with the positioning holes on the underside of the scanner. Secure using the

four bolts.

CAUTION

Holding the scanner by the rear part of the top cover may cause damage to the scanner or to the person doing the

installation. Always hold the scanner by the side covers, at the positions indicated by the shaded circles in the

figure below.

Positioning pin

Side cover

Side cover

(3) Fully tighten the four bolts on the center bar to secure the side stays (see the diagram for step (1)).

(4) Before beginning scanner operation, be sure to remove the plastic sheet from the bottom of the docu-

ment hold-down unit. Please refer to Section 8.2 “Document Hold-Down Unit” for the removal and

mounting procedures.

Page 20

CS1000-UM-251-01-9370 3-3

3. PREPARING TO OPERATE THE SCANNER

3.2 Connecting the Scanner to a Power Supply

Insert the female plug of the power cord provided into the scanner’s AC line inlet and insert its male plug into

an electrical socket supplying AC voltage.

Check that the scanner’s Power switch remains in the Off position until the connection of both the power

cable and SCSI interface cable has been completed.

CHECKPOINT

Ensure that the scanner’s Power switch is in the Off position.

Page 21

CS1000-UM-251-01-9370 3-4

3. PREPARING TO OPERATE THE SCANNER

3.3 Connecting the SCSI Cable

Obtain a SCSI interface cable (optional) that is compatible with the computer to be connected.

Compatible Cables

The cable must have half-pitch pin-type 50-pin connectors.

To connect multiple SCSI devices in a daisy-chain* arrangement, the total cable length must be no longer

than three meters.

Among Graphtec cables, the SC0006 or SC0006 2M model can be used (depending on the shape of the

connector on the computer’s SCSI interface board).

TIP

* Daisy-chain: A method for connecting peripheral devices in a ring arrangement

CAUTION

The use of an incompatible cable may cause the scanner to malfunction or damage the interface.

If the cable comes into contact with the document, use the cable clamp provided as a standard accessory to fasten

the cable to the underside of the scanner.

Connection Procedure

(1) Insert one end of the SCSI cable’s into one of the two SCSI connectors on the scanner’s rear panel.

* Firmly insert the cable’s connector into the scanner’s SCSI connector until it locks into place.

Page 22

CS1000-UM-251-01-9370 3-5

3. PREPARING TO OPERATE THE SCANNER

(2) If the SCSI cable comes into contact with the document, use the cable clamp provided as a standard

accessory to fasten the cable to the underside of the scanner, at either the left or right side.

SCSI cable

Cable clamp

(3) Insert the cable’s other end into the computer’s connector.

(4) If this scanner will be a terminal within the network configuration, set Bit 4 of the DIP switch on the

scanner’s rear panel to enable the internal terminator function.

1 2 3 4

4 3 2 1

ON

DIP switch’s bits

ON

OFF

Usually OFF

Terminator

Disable

Enable

CAUTION

Turn off the scanner before changing a DIP switch setting.

NOTE

The scanner comes with the Terminator setting of “Enable” as its factory-preset default.

Page 23

CS1000-UM-251-01-9370 3-6

3. PREPARING TO OPERATE THE SCANNER

3.4 Setting the ID Number

The SCSI bus is designed to allow up to eight devices to be connected at the same time. As a result, a

single computer can be used to exchange data with multiple SCSI devices, including a scanner and disk

drives. Each device must be assigned an ID number (device number) to enable the devices to be distinguished on the SCSI bus.

Using a mechanical pencil or other pointed object at the SCSI-ID switches on the scanner’s rear panel, set

the scanner’s ID number that corresponds to the host computer’s applications.

2

3

2

1

• The ID can be set from 0 to 7.

• The scanner’s default ID number is 2.

If the host computer cannot communicate with the scanner, first check that both of the SCSI cable’s connectors are firmly inserted. Note that the host computer and scanner cannot communicate if the scanner shares

the same ID as another device or its ID does not correspond to the host computer’s applications.

The ID number for the host computer is normally 7.

CAUTION

Turn off the scanner before setting the SCSI-ID number.

CHECKPOINT

The scanner comes with the default SCSI-ID number of 2.

Page 24

CS1000-UM-251-01-9370 3-7

3. PREPARING TO OPERATE THE SCANNER

3.5 Turning the Scanner On or Off

Whenever the scanner’s Power switch is turned on, the POWER, PAPER, and ERROR lamps on the control

panel light up. When the scanner has been initialized, the POWER lamp lights up.

CHECKPOINT

When resetting the scanner by turning it off then back on again, wait at least three seconds before turning it back on.

Page 25

CS1000-UM-251-03-9370 3-8

3. PREPARING TO OPERATE THE SCANNER

3.6 Attaching the Document Support Wires

The document support wires should be attached to the CS1000EV when scanning carrier sheets or heavy

documents.

CS1000/1000EV

Document support wires

The document support wires should always be attached to the CS1100EV regardless of the type of document being scanned.

CS1100EV

Document support wires

CAUTION

The CS1100EV must always be used with the document support wires attached.

Scanning without using the document support wires may damage the document if it comes into contact with the

SCSI cable.

Page 26

CS1000-UM-251-03-9370 3-9

3. PREPARING TO OPERATE THE SCANNER

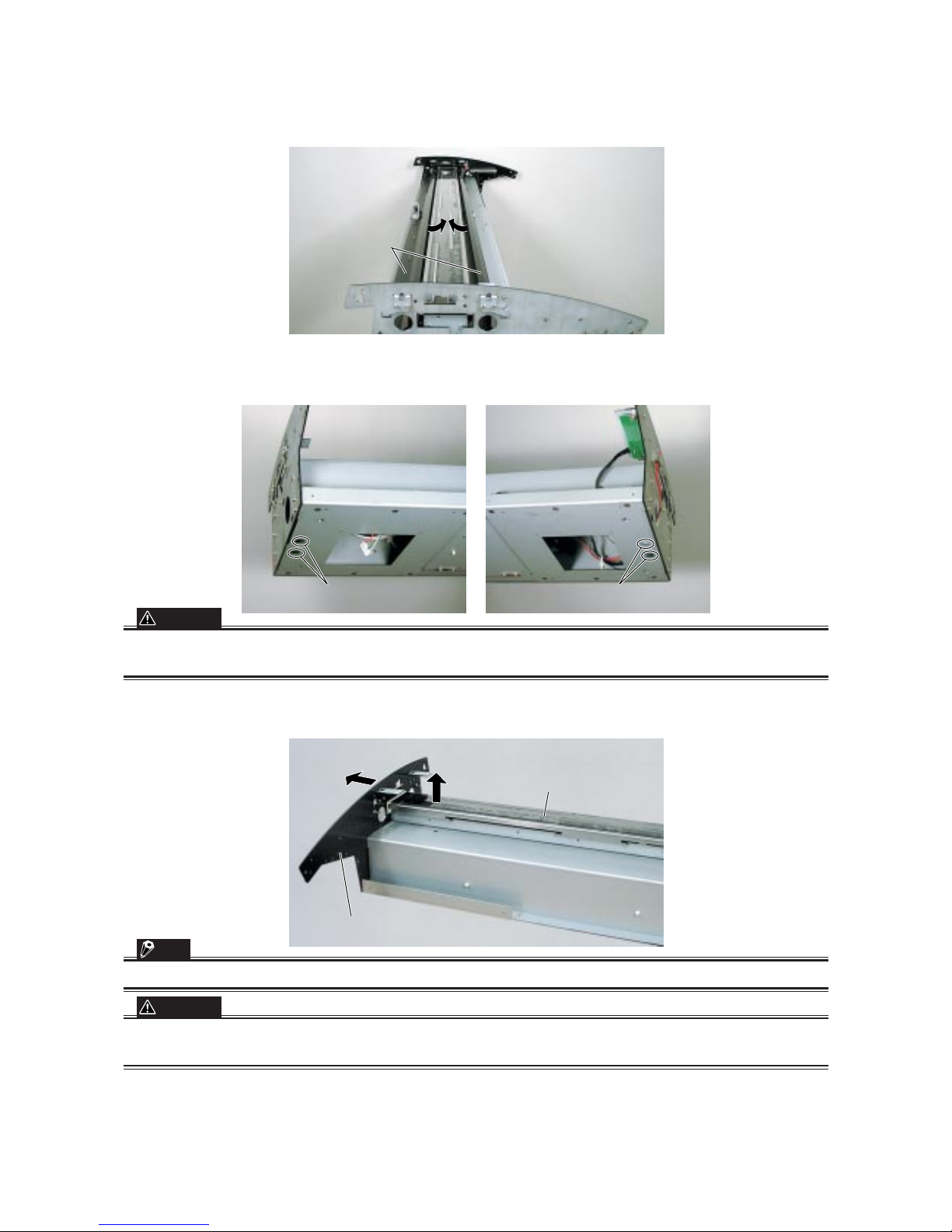

Attaching the document support wires

(1) Insert one end of the document support wire provided into the hole at the rear of the scanner.

(2) Squeeze the document support wire and insert the other end.

(3) Press down on both sides of the document support wire.

(4) Attach the other document support wires in the same manner.

CAUTION

Detach the document support wires when moving or packing the scanner. To remove the document support wires,

squeeze gently and lift up.

Page 27

CS1000-UM-251-03-9370 3-10

3. PREPARING TO OPERATE THE SCANNER

3.7 Document Hold-down Unit EV

The document hold-down unit EV should be used according to the type of documents being scanned.

The document hold-down unit EV is normally stored on the center bar of the stand and should be used in

place of the standard document hold-down unit when required.

The document hold-down unit EV should be used for the following types of documents.

Plain paper more than 0.08 mm thick with prominent folds or curling that is likely to affect scanning quality.

CAUTION

Do not use the document hold-down unit EV when scanning thin or limp documents such as plain paper less than

0.08 mm thick. This may result in damage to the document and paper jamming.

The document hold-down unit EV uses a greater document restraining force than the standard document hold-down

unit. Some types of documents may be more susceptible to damage.

Use a carrier sheet when scanning film.

The scanning precision is different from that using the standard document hold-down unit, and so distance correction

may be necessary.

Storing the Document Hold-down Unit EV

Store the document hold-down unit EV by attaching it to the hooks on the center bar of the stand (for

CS1000EV and CS1100EV with stand *).

For the CS1100EV with no stand, store the document hold-down unit EV in the cardboard box in which it

was packed.

Hooks

Document hold-down unit EV

Page 28

CS1000-UM-251-03-9370 3-11

3. PREPARING TO OPERATE THE SCANNER

Attaching the hooks (for CS1000EV and CS1100EV with stand *)

(1) Hook the rear of the hooks provided over the center bar of the stand. (Refer to diagram below.)

(2) Store the document hold-down unit EV by mounting it on the hooks with its handles opened outward.

Hooks

Document hold-down unit EV

* The CS1100EV stand is optional.

Replacement method

Detach the document hold-down unit currently fitted and replace it with the document hold-down unit EV.

(Refer to sections 8.2, "Document Hold-down Unit". )

Distance correction method

Distance correction can be performed via the driver software. In the ScanningMaster 21+ driver software

provided, run distance correction from the "Tools/Scanner Adjustment" menu to adjust the scanning precision.

CHECKPOINT

The handles at both ends of the document hold-down unit EV are silver, whereas the handles at the ends of the

standard document hold-down unit are black. Take care to ensure that the correct document hold-down unit is used.

The document hold-down units are symmetrical and can be fitted either way round. However, they are factory

adjusted, and installing left-to-right may cause paper jamming.

Always check the directions indicated by labels on the document hold-down units and scanner when installing.

Insert the document hold-down unit fully. If the document hold-down unit is not fully down, it will cause reduced

image quality or paper jamming.

Page 29

CS1000-UM-251-01-9370 4-1

4. OPERATION AND CONNECTION

4. OPERATION AND CONNECTION

4.1 Connecting the Scanner to a Computer

Before you can start connecting the scanner to the computer, you need to prepare (confirm) the computer

system’s environment.

(1) Confirm that the computer’s operating system has been properly installed.

(2) Confirm that a SCSI adapter has been connected to the computer.

(3) Confirm that the SCSI driver has been installed in the computer.

Connecting the CS1000 to a Computer for the First Time

For Windows 95 or Windows 95 Version a:

(1) After checking that the scanner and the computer are properly connected via the SCSI interface cable,

turn on the scanner first and then turn on the computer.

(2) When Windows 95 has been booted, the window below appears.

(3) Select ”Do not install a driver,” then click the “OK” button.

(4) The Windows 95 Desktop appears and the CS1000 is acknowledged by the computer.

For Windows 95 Version B:

(1) After checking that the scanner and the computer are properly connected via the SCSI interface cable,

turn on the scanner first and then turn on the computer.

Page 30

CS1000-UM-251-01-9370 4-2

4. OPERATION AND CONNECTION

(2) When Windows 95 has been booted, the window below appears.

(3) Click the Next button to initiate the computer’s search for a new driver.

(4) When the new driver has been detected, the menu below appears. Click the Finish button.

(5) The Windows 95 Desktop appears and the CS1000 is acknowledged by the computer.

For Windows 98:

(1) After checking that the scanner and the computer are properly connected via the SCSI interface cable,

turn on the scanner first and then turn on the computer.

(2) When Windows 98 has been booted, the window below appears.

Page 31

CS1000-UM-251-01-9370 4-3

4. OPERATION AND CONNECTION

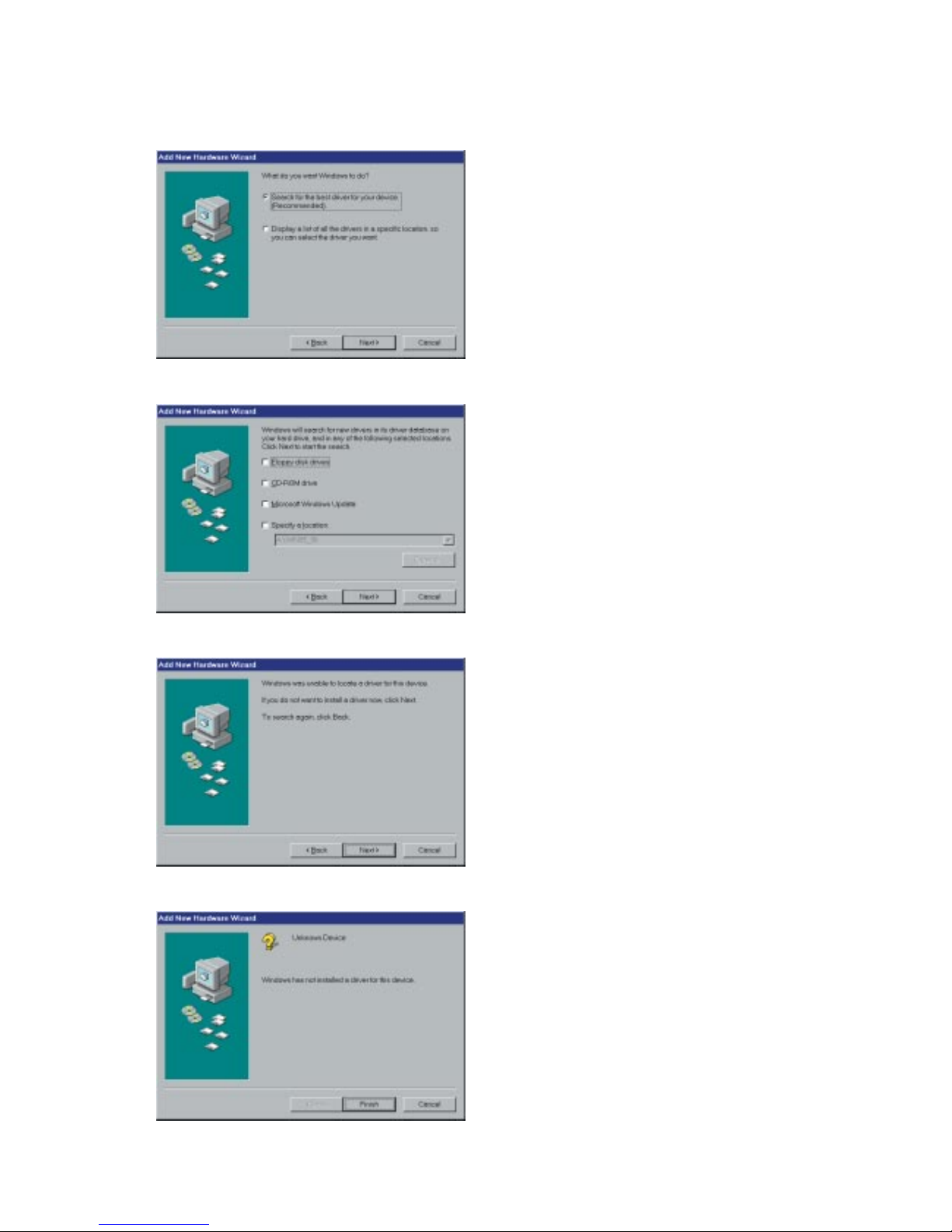

(3) Click the Next button.

(4) Point to “Search for the best driver for your device” and then click the Next button.

(5) Remove the check marks from all boxes and then click the Next button.

(6) Click the Next button.

Page 32

CS1000-UM-251-01-9370 4-4

4. OPERATION AND CONNECTION

(7) Click the Finish button.

(8) The Windows 98 Desktop appears and the CS1000 is acknowledged by the computer.

For Windows ME:

(1) Connect the CS1000 to the computer, turn on the CS1000 first, and then turn on the computer.

(2) Once Windows Me has started up, the window shown below is displayed.

(3) Click on “Next” to search for the driver.

(4) Upon completion of the search for the driver, the window shown below is displayed. Click on the

“Finish” button.

(5) The Windows Me desktop is displayed, and the CS1000 is recognized by the computer.

For Windows NT 4.0:

(1) After checking that the scanner and the computer are properly connected via the SCSI interface cable,

turn on the scanner first and then turn on the computer.

Page 33

CS1000-UM-251-01-9370 4-5

4. OPERATION AND CONNECTION

For Windows 2000

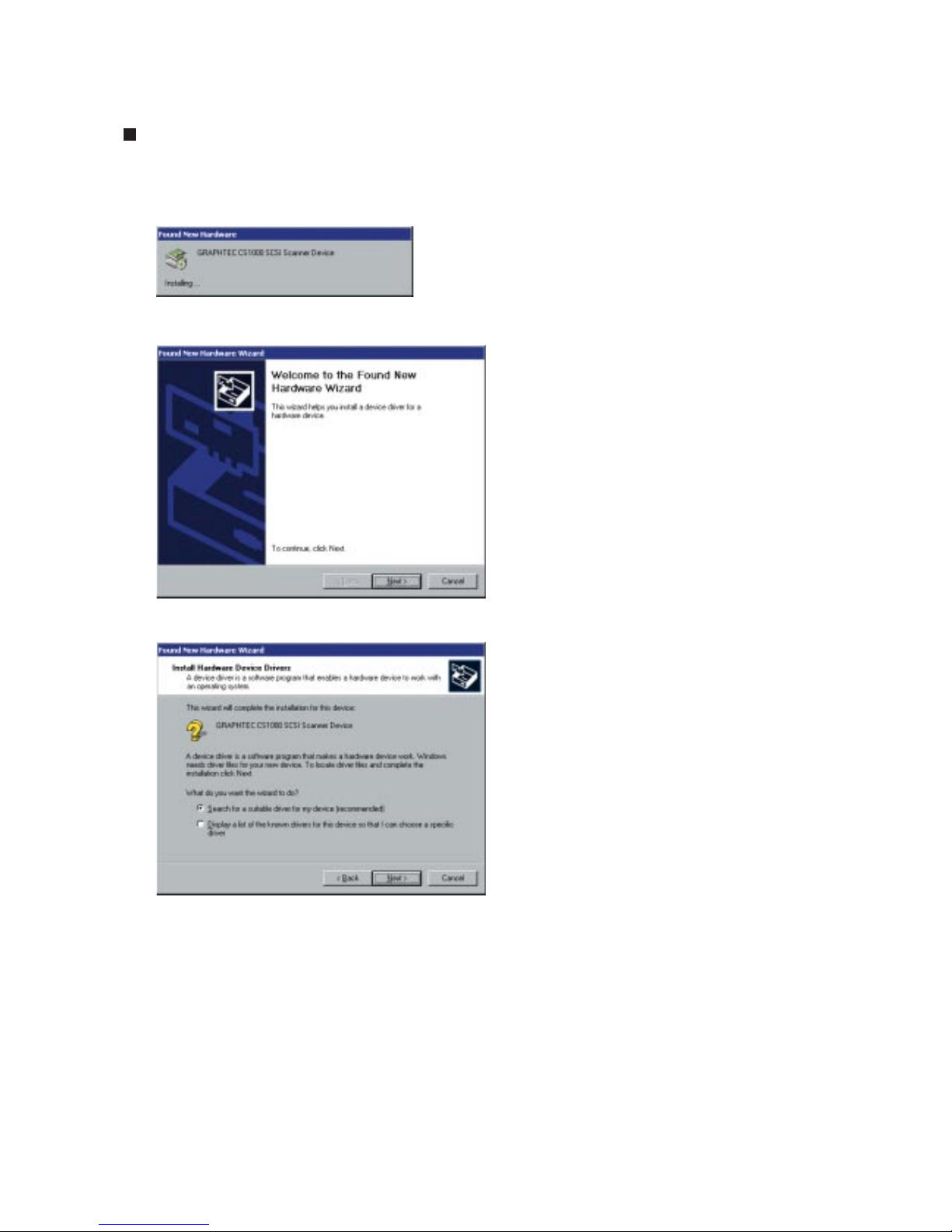

(1) After connecting the CS1000 to the computer, turn on the CS1000 and then turn on the computer.

(2) When Windows 2000 boots, the message below appears.

(3) Next, the Found New Hardware Wizard appears.

(4) Click the Next button to proceed to the menu for installing the driver.

Page 34

CS1000-UM-251-01-9370 4-6

4. OPERATION AND CONNECTION

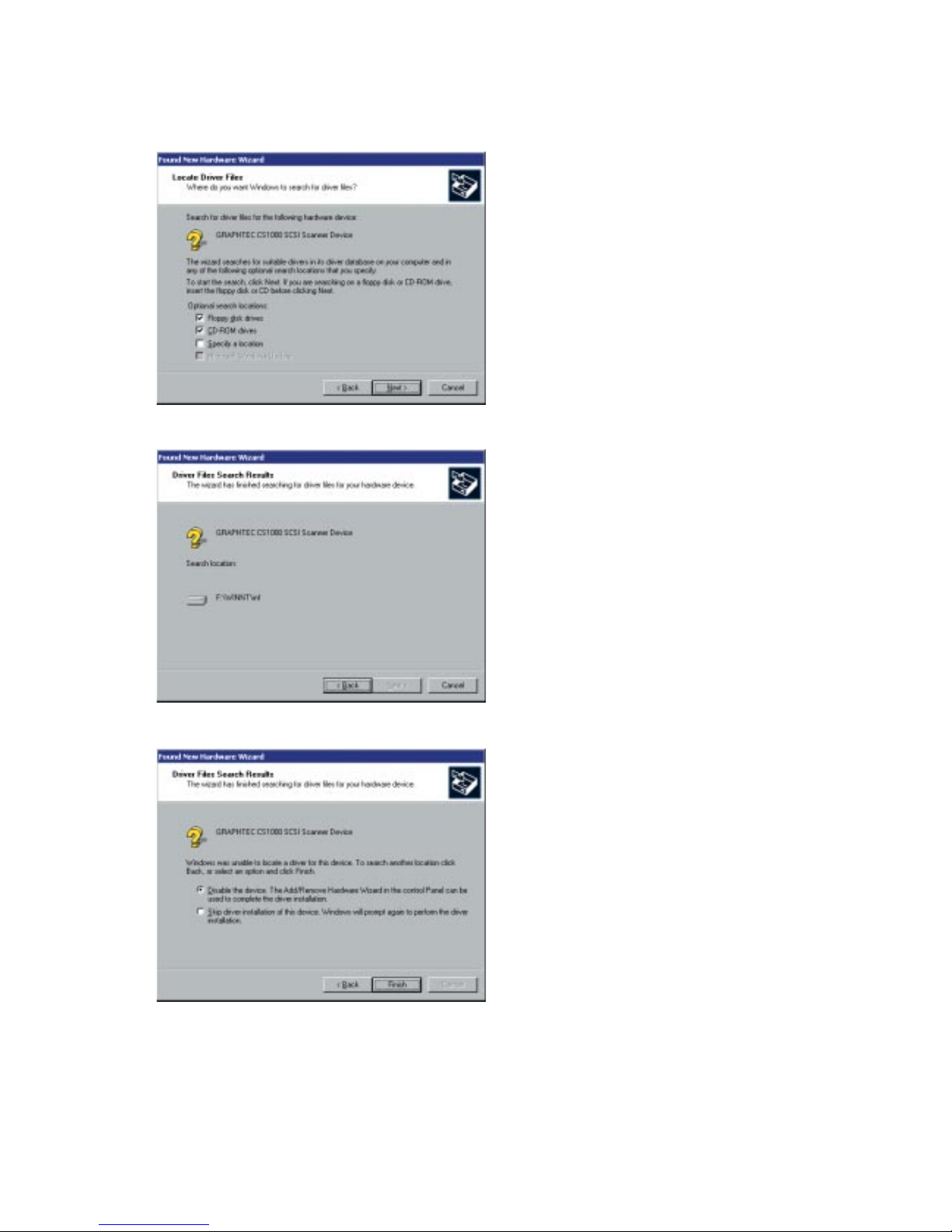

(5) Click the Next button to proceed to the Locate Driver Files menu shown below.

(6) Click the Next button to start searching for the driver files.

(7) When the wizard has finished its search, the menu below appears.

Insert a check in the “Disable the device” box, then click the Finish button.

(8) The Windows 2000 Desktop appears and the CS1000 is acknowledged by the computer.

Page 35

CS1000-UM-251-01-9370 4-7

4. OPERATION AND CONNECTION

4.2 Checking the Interface Connection

CHECKPOINT

If the scanner is connected to a system with Adaptec EZ-SCSI DELUXE* installed, the scanner will be recognized

under “Scanner” in the Device Manager.

* EZ-SCSI DELUXE is the software included with the SCSI adapter. For details, see the SCSI adapter instruction

manual.

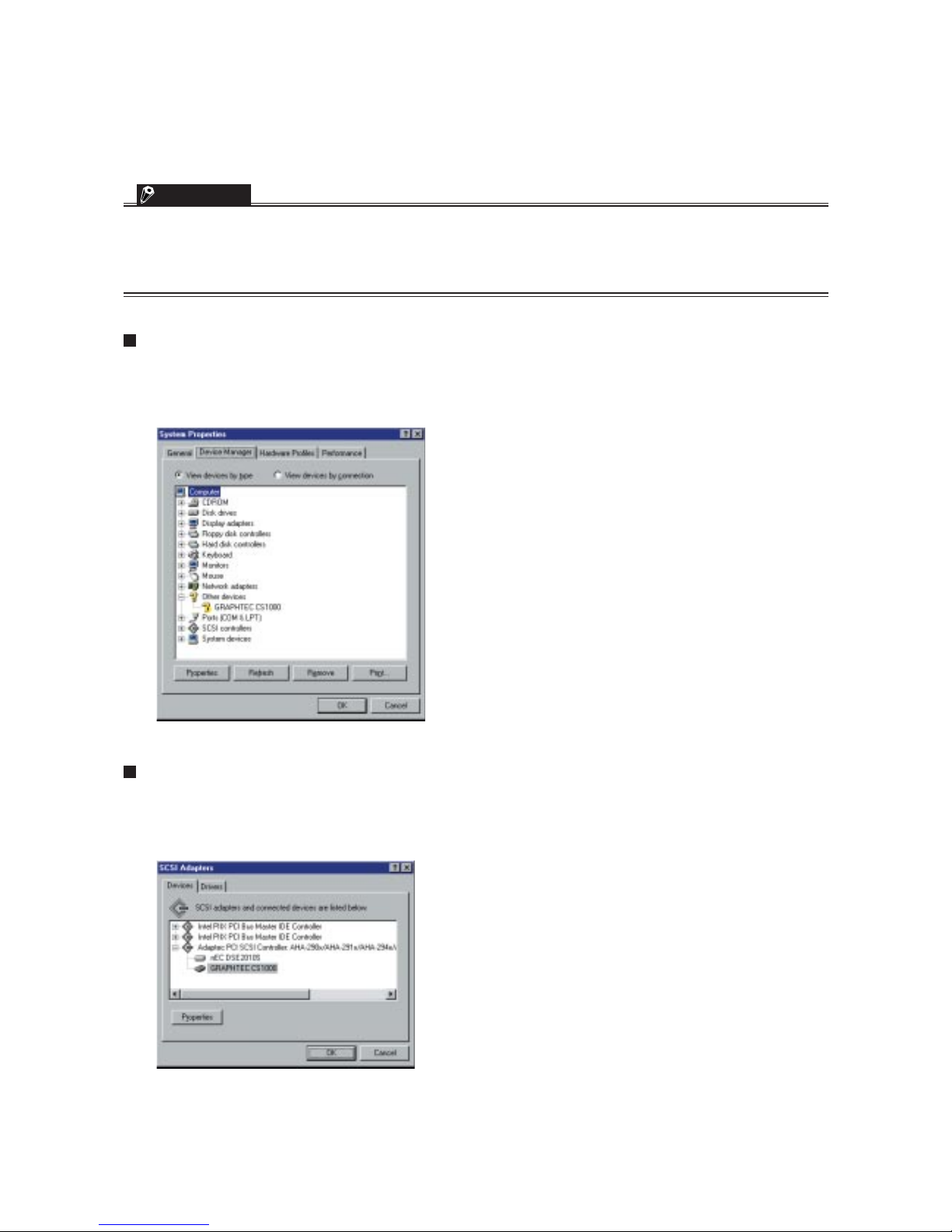

For Windows 95/98/Me

Open the System window from within the Control Panel in My Computer.

Click on the Device Manager tab to display the list of installed devices. Confirm that the CS1000 is recognized under “Other devices.”

For Windows NT 4.0:

From the Control Panel window in the My Computer folder, boot the SCSI adapter. Select the SCSI adapter

that is connected to the scanner by double-clicking it, then check that the scanner (CS1000) is listed below

the SCSI adapter and is thus acknowledged.

Page 36

CS1000-UM-251-01-9370 4-8

4. OPERATION AND CONNECTION

For Windows 2000

From the Control Panel folder in the My Computer directory, select the System icon. Next, click the Hardware tab and then click the Device Manager button to display a list of the installed devices.

Check that the CS1000 scanner is acknowledged by the computer under “Other devices.”

Page 37

CS1000-UM-251-01-9370 4-9

4. OPERATION AND CONNECTION

4.3 Installing the Scanning Master 21+ Application

The Scanning Master 21+ “OPS112” is a software application for using a Graphtec scanner to scan image

data. The OPS112 User’s Manual is contained in the file name “OPS112-1.pdf”.

Operating Environment

Windows 95/Windows 98/Windows Me, Windows NT 4.0, or Windows 2000.

Installation Procedure

(The following steps are explained using the Windows 95 windows.)

(1) Boot Windows 95.

(2) Insert the CS1000 User Guide CD-ROM containing the OPS112 program files into the computer’s CD-

ROM drive.

(3) Click the Taskbar’s Start button, then click the Run... icon.

(4) Enter the CD-ROM drive name and OPS112\DISK1\SETUP.EXE as the name of the file you wish to

open. If the disk is in drive D, for example, enter “D:\OPS112\DISK1\SETUP.EXE” in the box.

(5) Click the OK button to run the OPS112 setup program. From this point on, follow the setup program’s

instructions to install the OPS112 application.

• If the application has been properly installed, “Scanning Master 21+” will be newly listed in the Program

menu accessed from the Start button.

NOTE

For more details, open the README.TXT file provided in the “Scanning Master 21+” folder.

Page 38

CS1000-UM-251-01-9370 4-10

4. OPERATION AND CONNECTION

4.4 Installing the Scanning Master Copy Color Application

The Scanning Master Copy Color “OPS116” is a software application for outputting image data scanned in by

a Graphtec scanner to a plotter or printer.

Operating Environment

Windows 95/Windows 98/Windows Me, Windows NT 4.0, or Windows 2000.

Installation Procedure

(The following steps are explained using the Windows 95 windows.)

(1) Boot Windows 95.

(2) Insert the CS1000 User Guide CD-ROM containing the OPS116 program files into the computer’s CD-

ROM drive.

(3) Click the Taskbar’s Start button, then click the Run... icon.

(4) Enter the CD-ROM drive name and OPS116\DISK1\SETUP.EXE as the name of the file you wish to

open. If the disk is in drive D, for example, enter “D:\OPS116\DISK1\SETUP.EXE” in the box.

(5) Click the OK button to run the OPS116 setup program. From this point on, follow the setup program’s

instructions to install the OPS116 application.

• If the application has been properly installed, “Scanning Master Copy Color” will be newly listed in the

Program menu accessed from the Start button.

NOTE

For more details, open the README.TXT file provided in the “Scanning Master Copy Color” folder.

Page 39

CS1000-UM-251-01-9370 4-11

4. OPERATION AND CONNECTION

4.5 Document Types Compatible with the CS1000

Because the CS1000 scans a document while feeding it, the document types that it can scan are subject to

the following restrictions.

Compatible Media Widths for Scanning

Documents with a maximum width of 1000 mm

Compatible Media Lengths for Scanning

When loaded in the usual manner, a document with a maximum length of 4 meters can be scanned (due

to restrictions such as the computer’s available memory, the hard disk’s storage capacity, and so on).

Compatible Grades & Thickness for Scanning

Media Grades

The scanning precision is guaranteed for high-grade tracing paper (see “Operating environment” in

Section 1.2, “Standard Specifications”).

Other compatible media types are listed below.

High-grade paper : 60 g/m

2

Tracing paper : 50 to 55 g/m

2

Mylar : 50 mm

Copy paper

Diazo photo-sensitive paper

Media Thicknesses

Observe the following points when scanning a thick medium.

• The CS1000 cannot scan a document that is thicker than 1.5 mm.

•When using the carrier sheet, ensure that the combined thickness of both the document and carrier

sheet does not exceed 1.5 mm.

• The carrier sheet alone is 0.2 mm thick.

Size ISO Size ANSI

A4 210 mm × 297 mm A 8.5 in × 11 in

A3 297 mm × 420 mm B 11 in × 17 in

A2 420 mm × 594 mm C 17 in × 22 in

A1 594 mm × 841 mm D 22 in × 34 in

A0 841 mm × 1189 mm E 34 in × 44 in

Page 40

CS1000-UM-251-01-9370 4-12

4. OPERATION AND CONNECTION

4.6 Loading a Document

For standard-size documents

Insert the document into the document-scanning table with the face to be scanned facing downward, so that

it is aligned with the center section, to ensure that it is not scanned at an angle. The two modes described

below are provided for loading the document (set from the driver software).

The rollers start rotating after a preset delay time after the document is inserted, to automatically advance

the document to the initial position for scanning.

The rollers start rotating when the FORWARD switch is pressed on the control panel after the document is

inserted, to automatically advance the document to the initial position for scanning (manual loading).

To reposition the document, press the REVERSE switch to remove it, and load it again.

Scanning table

Document

CHECKPOINT

After the CS1000 is turned on and the driver settings have been enabled in the Scan window, it waits for approximately two seconds before beginning the specified scan operation.

Load the document in the scanner with the face to be scanned facing downward.

Do not place anything other than the document to be scanned on the scanning table, as the scanner rollers may start

rotating, which is extremely dangerous.

The document may not be fed in correctly if it is curled. The carrier sheet provided should be used for curled

documents (see “4.7 Using the Carrier Sheet” for details).

Load the document in the center of the scanner, as the document may be fed in at an angle and not scanned

correctly if it is significantly off-center.

Page 41

CS1000-UM-251-01-9370 4-13

4. OPERATION AND CONNECTION

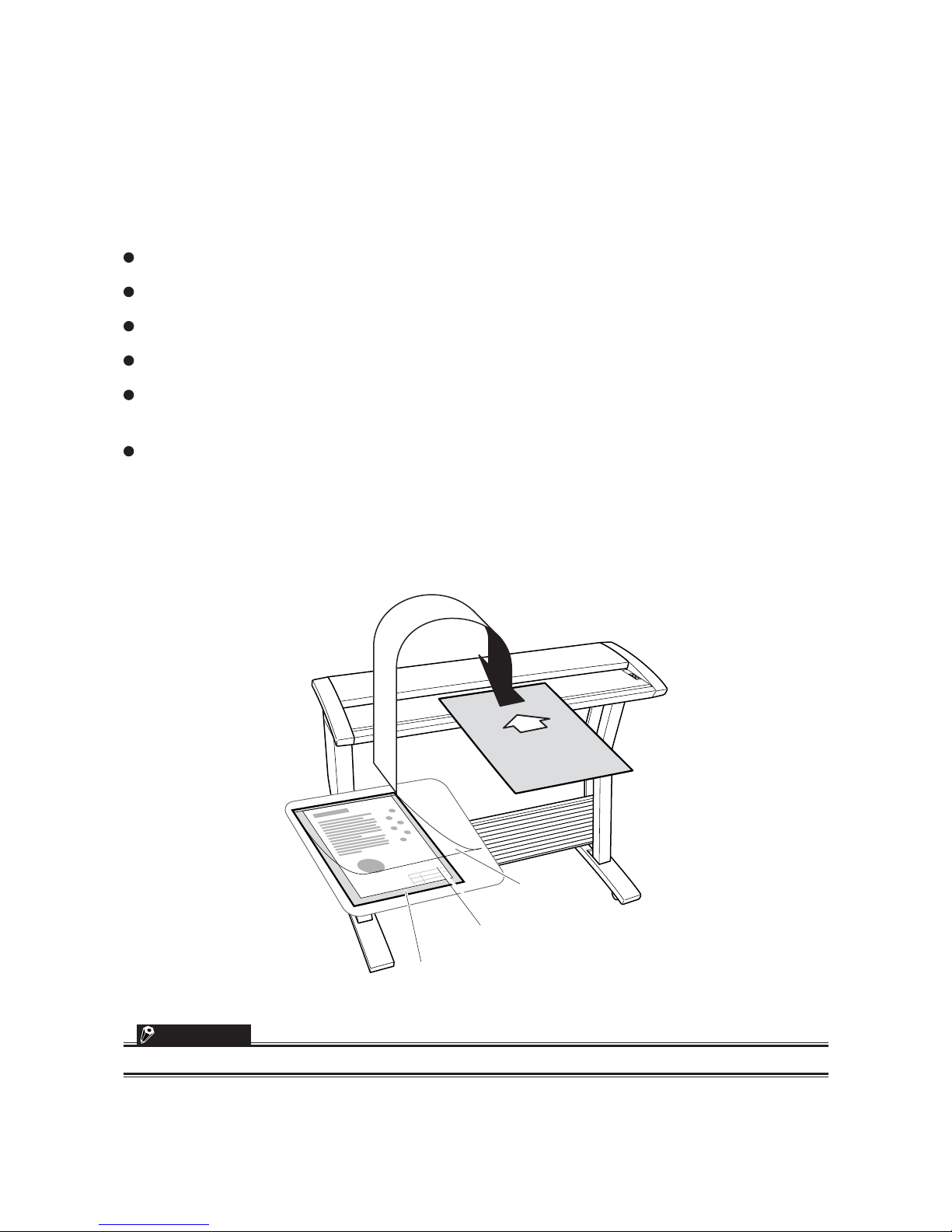

4.7 Using the Carrier Sheet

Use the carrier sheet according to the condition of the document to be scanned.

In the case of scanning the following types of media, always place the document on the carrier sheet before

loading it into the scanner.

To scan a medium that is as limp as or limper than a newspaper

To scan paper that is badly curled

To scan a document that is smaller than A4 size or a document of non-standard size

To scan a medium that tears easily

When the target document cannot be properly advanced to the initial position of scanning (because the

target document is folded, wrinkled, or otherwise hard to load in the scanner)

To scan transparent or translucent documents

As shown in the figure below, place the document in the carrier sheet with the document’s surface to be

scanned facing up (against the transparent top sheet). For scanning, load the carrier sheet into the scanner

with the document’s target surface (the transparent top sheet) facing down.

Insert in this

direction

Transparent sheet

(front surface)

Target document

(the surface to be scanned faces up)

White surface

(background surface)

CHECKPOINT

When handling the carrier sheet, be very careful not to scratch it or otherwise damage it.

Page 42

CS1000-UM-251-01-9370 4-14

4. OPERATION AND CONNECTION

4.8 Scanner Driver Software’s Compatibility with Windows 2000

Precautions for installing scanner driver software (Scanning Master, TWAIN32) on your PC

to run under Windows 2000

Running the scanner driver software under Windows 2000 requires the ASPI Manager in addition to the

SCSI board driver software (provided with Windows 2000). This software is to be supplied by Adaptec.

Page 43

CS1000-UM-251-01-9370 4-15

4. OPERATION AND CONNECTION

4.9 How to Obtain (Install) the ASPI Manager

1. What you will need

(1) Copy of the warranty accompanying the purchased SCSI board

(2) ASPI layer update software available at the Adaptec website

You can find this software or “ASPI32.EXE” among updates at the http://www.adaptec.com/worldwide/

support/driverdetail.html?filekey=aspi32.exe.

2. How to obtain ASPI Manager

ASPI Manager for Windows 2000 will be available at the Adaptec website.

You can find this software at the http://www.adaptec.com.

3. How to install ASPI Manager

(1) Install the SCSI card in your PC.

(2) Install programs in the floppy disk from Adaptec into Windows 2000.

To do this, double-click “Setup32.exe” in the floppy disk.

(3) Use the update software obtained in Step (2) of Section 1 to update the ASPI layer.

When you are finished, you are ready to run the scanner driver.

Page 44

CS1000-UM-251-01-9370 4-16

4. OPERATION AND CONNECTION

4.10 Checking the ASPI Layer

You can follow the steps given below to check whether the ASPI layer is compatible with Windows 2000.

(1) Download the ASPICHK.EXE file from the Adaptec website at http://www.adaptec.com/worldwide/

support/driverdetail.html?filekey=aspichk.exe.

(2) Start your PC and run “ASPICHK.EXE.”

Compatible with Windows 2000

Version information

ASPI is properly installed and is fully operational.

One host adapter has been detected.

Not compatible with Windows 2000

ASPI is not properly installed.

Page 45

CS1000-UM-251-01-9370 4-17

4. OPERATION AND CONNECTION

4.11

Checking Windows 2000 ASPI32 Status and Starting the Software

(1) Select “Start” → “Settings” → “Control Panel” → “Management Tools” → “Manage Computer”.

(2) Select “System Tools” → “System Info” → “Software Config.” → “Drivers”. Next, select “Display” →

“Detailed Settings”.

Check that “Running” appears under “Status” for “aspi32.”

Check that “Running” appears under “Status” for “aic78xx.” (AHA-2910C,AHA-2940AU)

Check that “Running” appears under “Status” for “adf6u160.” (AVA-2915LP, AVA-2930LP)

Page 46

CS1000-UM-251-01-9370 4-18

4. OPERATION AND CONNECTION

If “Running” does not appear (Windows 2000 ASPI32 is not running),

follow the steps given below:

(1) Right-click the My Computer icon and select “Properties”.

(2) Click the “Device Manager” from the “Hardware” tab.

(3) Select “Display non-displayed devices” from the “View” menu.

(4) Double-click “Non-Plug and Play Drivers”, then select and right-click “ASPI32.”

Then, click “Properties”.

(5) Click the “Driver” tab. Check that “Started” appears as the current status. If “Started” does not appear,

click the “Start” button.

Page 47

CS1000-UM-251-01-9370 4-19

4. OPERATION AND CONNECTION

(6) If “Automatic” is selected as Startup Type, click the down-arrow, select “System,” and click on the “OK”

button to change the Startup Type to “System.”

(7) Check that “System” and “Running” respectively appear under “Start Mode” and “Status” for ASPI32.

Page 48

CS1000-UM-251-01-9370 4-20

4. OPERATION AND CONNECTION

4.12

Changing Transfer Rate with the AVA-2915LP (Ultra SCSI-compliant)

With the ADAPTEC A VA-2915LP UltraSCSI card, the transfer rate is set by default to 20 Mbps.

This may cause problems. For example, your PC may not detect the scanner when it is connected.

To avoid such problems, reduce the transfer rate to 10 Mbps.

Procedure

(1) Have the floppy disk supplied with the SCSI card ready.

Floppy disk name: Adaptec SCSI Select v2.57.4 For AVA-2915LP/2930LP To start SCSI Select

(2) Insert the floppy disk into the floppy disk drive and turn on your PC.

(3) When “AVA-2915/30LP at Bus; 00h Device; 09h” appears, select “Configure/View Host Adapter set-

tings” and press the Enter key.

(4) Use the down-arrow key to select “SCSI Device Configuration.” Press the “Enter” key.

Page 49

CS1000-UM-251-01-9370 4-21

4. OPERATION AND CONNECTION

(5) Change “Maximum Sync Transfer Rate” for the corresponding SCSI ID.

If (for example) your scanner’s SCSI ID is 2, select “Sync Transfer Rate (MB/Sec)” for the SCSI Device

ID #2 and press the “Enter” key. Then use the down-arrow key to select “10.0” and press the “Enter”

key.

(6) Press the “Esc” key twice. When “Save Changes Made?” appears, select “Yes” and press the “Enter”

key.

(7) Press the “Esc” key. When “Exit Utility?” appears, select “Yes” and press the “Enter” key.

(8) When “Please press any key to reboot” appears, remove the floppy disk and press any key. At this

time, your PC will restart.

CHECKPOINT

Checkpoint: If you have a FastSCSI card such as AHA-2910C or AHA-1520B, you do not need to change the

transfer rate.

Page 50

CS1000-UM-251-01-9370 4-22

4. OPERATION AND CONNECTION

4.13 Factory Settings

DIP Switch

1234

ON

DIP Switch's bits

Terminator

Enable

Disable

Usually OFF

OFF

ON

4321

All of 1 to 4 are OFF (Terminator is enabled).

ID Number

Set to No. 2

Page 51

CS1000-UM-251-01-9370 5-1

5. DAILY MAINTENANCE

5. DAILY MAINTENANCE

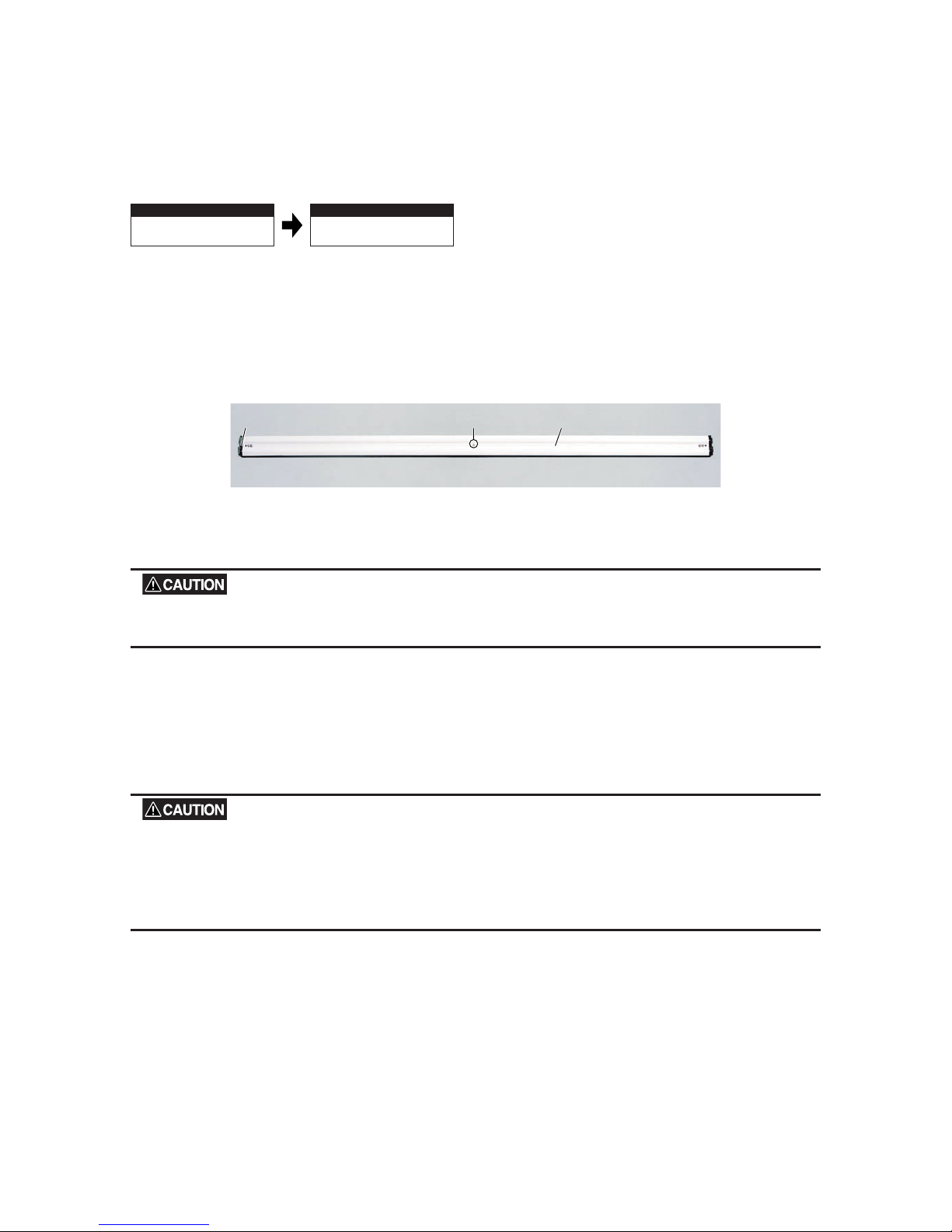

5.1 Cleaning the Image Sensors

The scanner’s image quality drops when the transparent contact plates over the image sensors become

dirty, so clean the image sensors whenever necessary.

Procedure

(1) Turn off the scanner.

(2) Remove the document hold-down unit as described in Section 8.2 “Document Hold-Down Unit.”

(3) As shown below, wipe off any soiled areas on the transparent contact plates using a soft cloth that has

been moistened with water or a neutral detergent (diluted with water) and firmly wrung out.

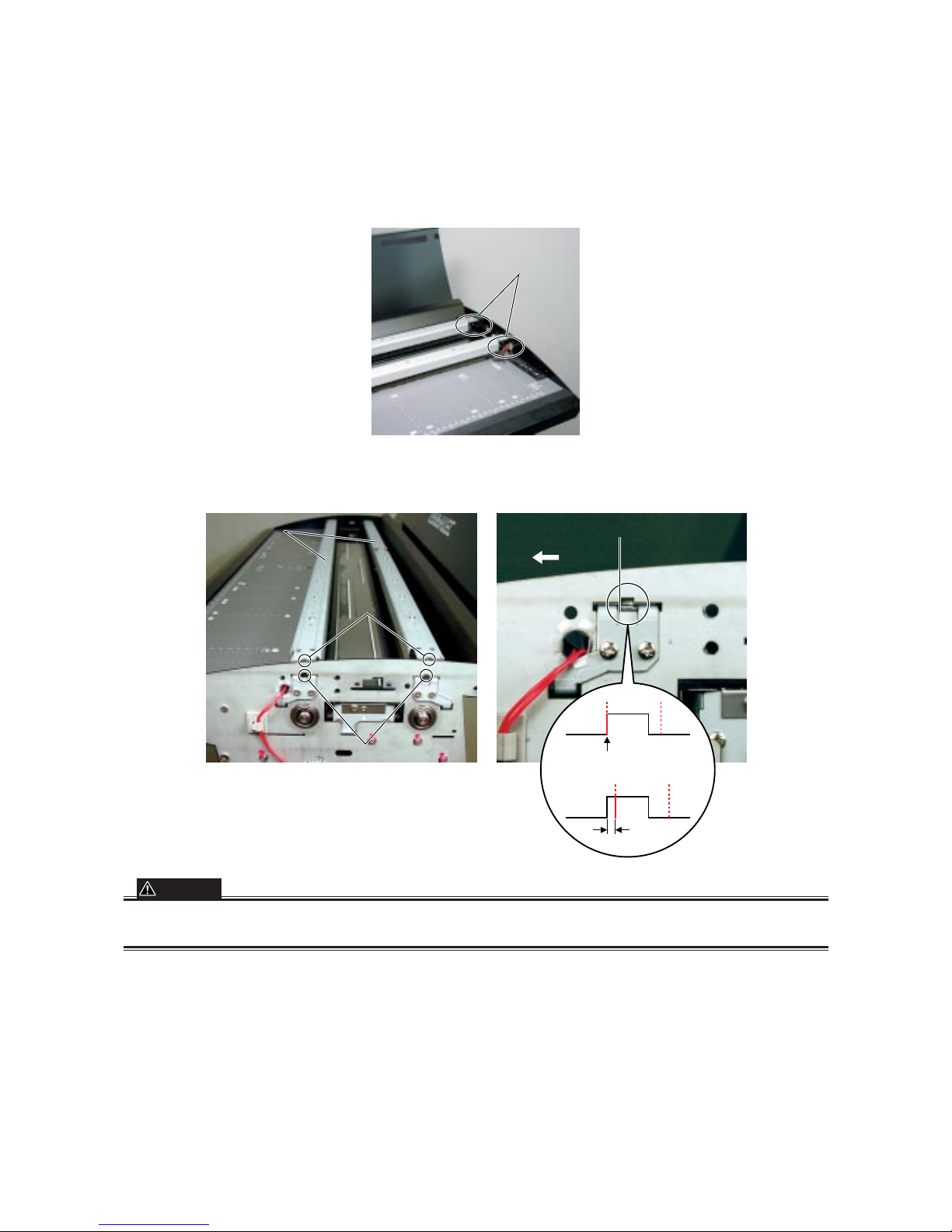

Transparent contact plates

(4) Completely remove any moisture on the transparent contact plates by wiping them off again using a

soft, dry cloth.

(5) Mount the document hold-down unit as described in Section 8.2 “Document Hold-Down Unit.”

Page 52

CS1000-UM-251-01-9370 5-2

5. DAILY MAINTENANCE

CHECKPOINT

Do not use a commercial cleaner for office equipment, a glass cleaner, or chemical solvents such as solutions

containing alcohol.

CAUTION

Although the glass base unit is not a maintenance part that requires periodic replacement, it is a consumable part

because its surface may receive slight scratches due to minute particles of dust and other foreign matter. If document scanning produces unsatisfactory results (unexpected white or black streaks in the data) due to scratches on

the glass base unit or other reasons, the glass base unit will be replaced for no charge while the service warranty is

in effect but will be replaced for a charge after the service warranty has expired. To request replacement, contact

your nearest Graphtec vendor.

Page 53

CS1000-UM-251-01-9370 5-3

5. DAILY MAINTENANCE

5.2 Cleaning the Paper Sensors

Accumulated dust on the paper sensors may prevent the document from being detected. The sensors must

be cleaned when necessary.

(1) Turn off the scanner.

(2) Open the top cover, holding it in the center.

(3) Wipe the two paper sensors using a cotton swab.

Paper sensors

(4) Close the top cover, holding it in the center.

Page 54

CS1000-UM-251-01-9370 5-4

5. DAILY MAINTENANCE

5.3 Cleaning the Document Hold-Down Unit

Scanning may be affected if the underside of the document hold-down unit becomes scratched or dirty. It

must be cleaned when necessary.

(1) Turn off the scanner.

(2) Remove the document hold-down unit as described in Section 8.2 “Document Hold-Down Unit.”

(3) Wipe clean the underside of the document hold-down unit (see below) using a soft cloth that has been

soaked in water or diluted neutral detergent and thoroughly wrung out.

Underside

(4) Wipe the document hold-down unit once again using a soft, dry cloth (remove all moisture).

(5) Reattach the document hold-down unit as described in Section 8.2 “Document Hold-Down Unit.”

Page 55

CS1000-UM-251-01-9370 5-5

5. DAILY MAINTENANCE

5.4 Removing a Jammed Document

If a document becomes jammed in the scanner during scanning or another operation, immediately turn off

the scanner, remove the document hold-down unit, and then remove the jammed document.

Procedure

(1) Turn off the scanner.

(2) Remove the document hold-down unit as described in Section 8.2 “Document Hold-Down Unit.”

(3) If the document is jammed at the front, remove the document from the inside or by pulling it forward.

Page 56

CS1000-UM-251-01-9370 5-6

5. DAILY MAINTENANCE

(4) If the document is jammed at the rear, remove the document from the inside by pulling it toward the

rear.

(5) Reattach the document hold-down unit as described in Section 8.2 “Document Hold-Down Unit,” and

close the top cover.

Page 57

CS1000-UM-251-01-9370 6-1

6. RECOMMENDED PARTS LIST

6. RECOMMENDED PARTS LIST

No Parts No. Description Part name

Q’ty

1 378019021 Drive Belt Belt 60S2M380 1

2 500050305 ID Switch ID Switch 1

3 500050731 Memory 64MB D2V4A8D-CL2 1

4 500050736 24V Switching Power Supply LDA75F-24-H 1

5 500050745 Motor KT60LM06-551 1

6 500050747 Connection Cable (CIS Board to Main Board) 8925E050179030GG 2

7 500050803 3.3V Switching Power Supply LDA15F-3-3.3 1

8 500050804 5V Switching Power Supply LDA15F-5 1

9 500050807 Cooling Fan TUDC24B4-500 1

10 502112009 Power Switch SW, AJ7201B, 1

11 502210002 Paper Sensor PS-R50L-A 1

12 640100533 A0 Carrier Sheet IS10 Carrier Sheet 1

641110720 A1 Carrier Sheet CS1100 Carrier Sheet 1

13 641000221 Document Hold-down Unit CS1000 CS Retaining Plate 1

641110200 Document Hold-down Unit CS1100 CS Retaining Plate 1

14 774012830 Document Hold-down Unit Stanard CS1000EV 1

774012840 Document Hold-down Unit EV Hight Pressure CS1000EV 1

774013830 Document Hold-down Unit Stanard CS1100EV 1

774013840 Document Hold-down Unit EV Hight Pressure CS1100EV 1

15 641000240 Drive Roller CS1000/CS1000EV CS Drive Roller 2

641110240 Drive Roller CS1100EV CS Drive Roller 1100EV 2

16 641000840 Operation Panel CS10 Operation Panel 1

17 774012500 Main Board Main Board CS1000/CS1100EV 1

774013500 Main Board Main Board CS1100EV 1

18 774012510 CIS Control Board A CIS Control Board A 1

19 774012520 CIS Control Board B CIS Control Board B 1

20 774012800 Image Sensor Unit (Maintenance)CS1000/1000EV 1

774013800 Image Sensor Unit (Maintenance)CS1100EV 1

21 774012810 Pinch Roller Unit (Maintenance)CS1000/1000EV 2

774013810 Pinch Roller Unit (Maintenance)CS1100EV 2

22 774012820 Grass Base Unit CS1000/CS1000EV (Maintenance)CS1000/1000EV 1

774013820 Grass Base Unit CS1100EV (Maintenance)CS1100EV 1

23 794021091 Operation Panel Board IS21 Operation Panel Board 1

24 640007300 A1 Shading Sheet Assy CS1100EV 1

641000560 A0 Shading Sheet Assy CS1000EV 1

25 641110740 A1 Shading Sheet CS1100EV 1

641000590 A0 Shading Sheet CS1000EV 1

Page 58

CS1000-UM-251-01-9370 7-1

7. LIST OF JIGS AND TOOLS

7. LIST OF JIGS AND TOOLS

7.1 Jigs

Jigs Adjustments Remarks

IS3100 ROM jig •Downloading boot program CS1000/EPROM

CS1000 system floppy disk •Downloading system program CS1000.X

Spacer (BSB-335) •Attaching main board to bottom plate, large Hexagonal, 35 mm in length

OPS112 •Adjusting feed distance Software supplied with the

(Scanning Master 21+) •Adjusting offset scanner

•Aligning sensor images

•Shading (undesired color line removal)

•Shading (undesired gray line removal)

•Used to check resolution

•Checking sensor color density

Shading paper •Shading IJ-RC-GN (Mitsubishi Paper Mills)

•Replacing main board 1050 mm x 200 mm

CS1000 adjustment test chart •Adjusting feed distance

Record measured values between

•Adjusting offset

a and c, b and d, a and b, c and d,

•Aligning sensor images

a and d, and b and c.

Undesired color line removal •Shading (undesired color line removal) For checking undesired color or white

check paper lines

Fax test chart No. 3 •Shading (undesired gray line removal) For checking undesired gray or black

lines

MTF adjustment test chart •Resolution checking 6-line-pair resolution pattern

Color difference measurement •Checking sensor color density Excel file

sample.xls

Color test chart •Checking sensor color density Red, green, blue, black, white pattern

To be stored in a darkroom

7.2 Tools

Jigs Adjustments Remarks

Screwdriver Disassembly, reassembly, Large, medium, and small flatblade

Allen wrench and other operations screwdrivers and Phillips screwdrivers

Needle-nose pliers

Colex gauge Adjusting belt tension 200 g/4 mm displacement

Multimeter Checking voltage level

7.3 Other

Other Adjustments Remarks

Water-diluted neutral detergent

Cleaning

or absolute ethanol wiper (cloth)

PC Used to determine whether the problem

SCSI card is caused by the scanner or any other

SCSI cable equipment.

Page 59

CS1000-UM-251-01-9370 8-1

8. DISASSEMBLING AND ADJUSTING MECHANICAL PARTS

8.

DISASSEMBLING AND ADJUSTING MECHANICAL PARTS

8.1 Considerations before starting disassembly

To prevent damage to image sensors, remove the document hold-down unit before disassembling any

mechanical parts.

Removing screws and any parts other than those shown in this chapter may adversely affect scanner

performance, including degraded scanning accuracy.

In particular, never attempt to remove or turn the red shielded screws and height adjustment screws.

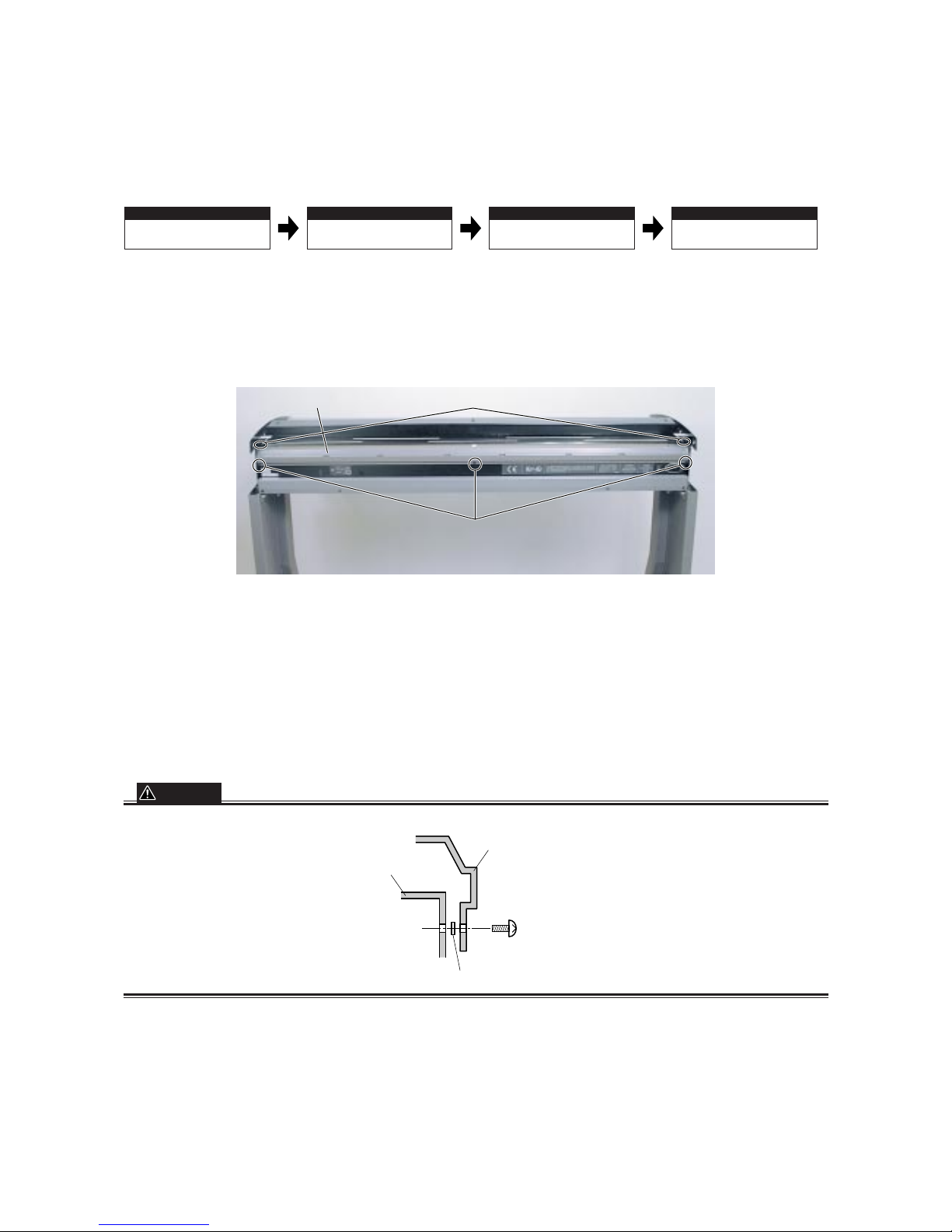

Mapped screwsMapped screws

Height adjustment screwsHeight adjustment screws

Inside bottom plate LInside bottom plate L

The directions "left" and "right" given in this chapter assume that the scanner unit is viewed from the front.

Page 60

CS1000-UM-251-01-9370 8-2

8. DISASSEMBLING AND ADJUSTING MECHANICAL PARTS

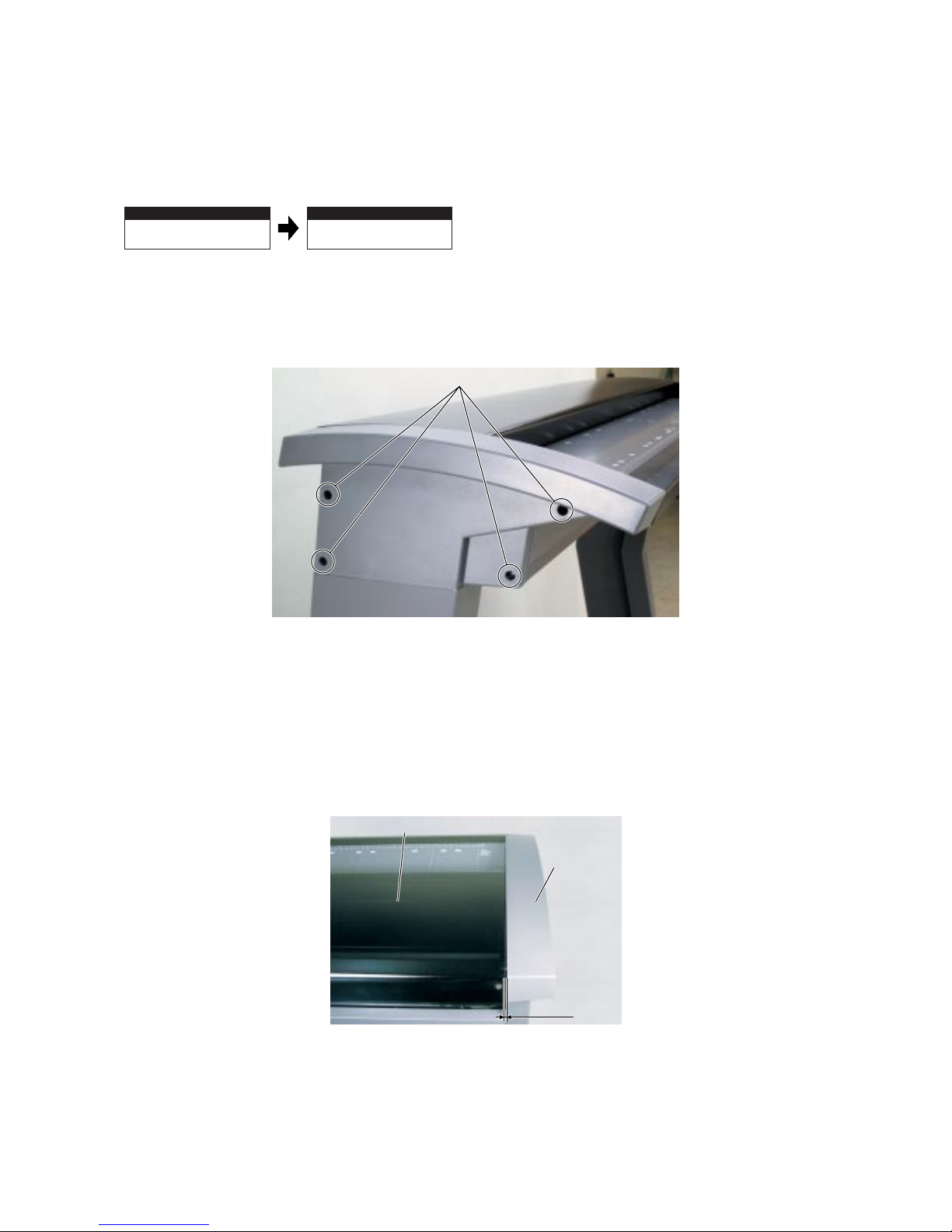

8.2 Document Hold-down Unit

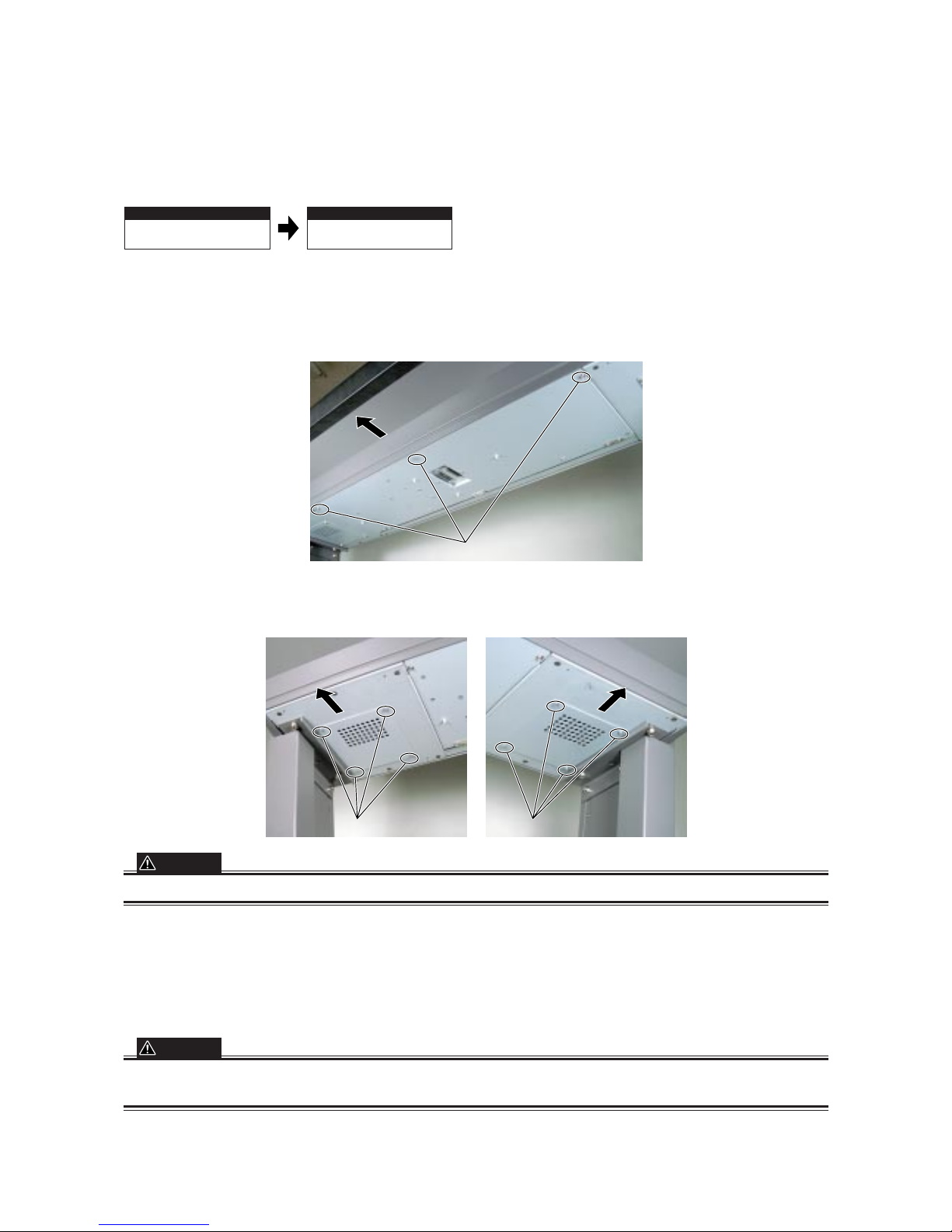

Detaching the document hold-down unit

(1) Turn off the scanner.

(2) Open the top cover, grasping it at the center.

Top cover