Page 1

USER’S MANUAL

CE LITE-50-UM-151

Page 2

Page 3

Introduction

Introduction

Thank you for purchasing Cutting Plotter CE LITE-50. This device is a cutting plotter that realizes high-speed

and high-precision work. In addition to cutting marking lms, this device can also be used as a pen plotter.

Please carefully read through this manual prior to use in order to ensure safe and proper use of the device.

This product is manufactured and sold under license from Gerber Scientic Products, Inc. for US Patent No.

5,537,135 and its foreign patents.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by

any means, without the prior written permission of Graphtec Corporation.

(2) The product specications and other information in this manual are subject to change without notice.

(3) While every effort has been made to provide complete and accurate information, please contact your sales

representative or nearest Graphtec vendor if you nd any unclear or erroneous information or wish to make

other comments or suggestions.

(4) Not with standing the stipulations in the preceding paragraph, Graphtec Corporation assumes no liability

for damages resulting from either the use of the information contained herein or the use of the product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks or

registered trademarks of their respective companies.

Copyright

This User's Manual is copyrighted by Graphtec Corporation.

i

Page 4

Introduction

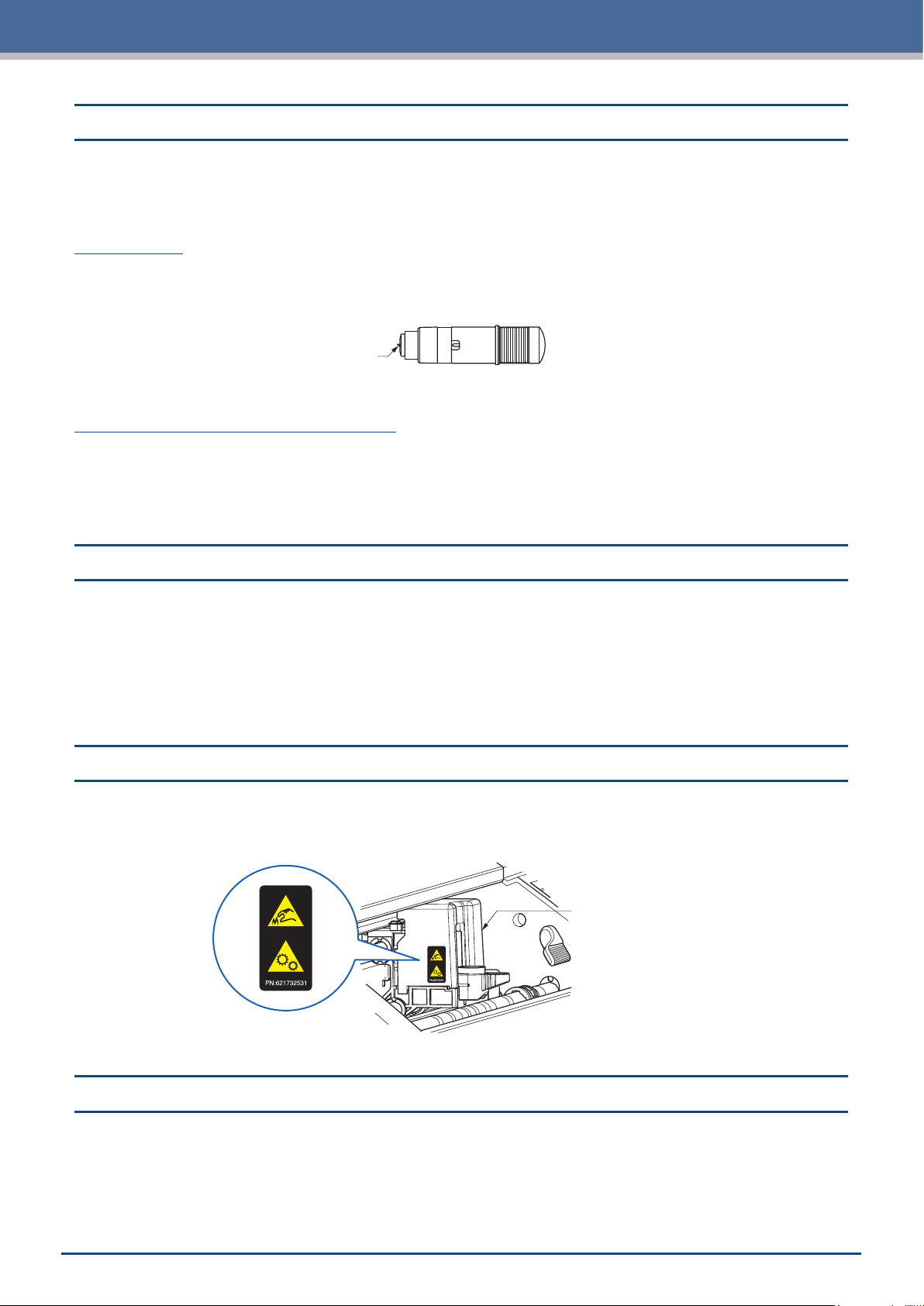

This product uses a blade. In order to prevent injury accidents due to the blade, please be very careful when

handling the cutter blade such as when attaching the cutter pen to the main unit.

Cutter Pen

The tip is a sharp blade. Be careful not to use an excessive blade depth. In addition, refrain from protruding the

blade from the tip of the cutter pen when the cutter pen is not in use.

After Attachment to the Main Unit

Refrain from touching the pen tip after the power has been turned ON and during operation as doing so is

dangerous.

Precautions on Handling the Cutter Blade

Cutter blade

Precautions After Turning the Power ON

The tool carriage and media that is set may suddenly move during work, immediately after work has ended,

and while conguring various settings. Keep hands, hair, and clothes, etc. away from moving parts and their

range of motion and refrain from placing objects on these places. When using the device, be very careful to

avoid injury due to getting hands, hair, or clothes, etc. caught in the device.

Notes regarding Warning Labels

The warning label shown below has been placed on the tool carriage of the device. Be sure to observe the

precautions listed.

Tool carriage

Notes regarding the Wording in This Manual

"Cutting" as used in this manual refers to the device operating to draw gures with a drawing pen or cut

•

media with the cutter pen.

"Media" as used in this manual collectively refers to paper, roll paper, sheet paper, and marking lm.

•

ii

Page 5

Introduction

Before Work

Be sure to read through the included "TO ENSURE SAFE AND CORRECT USE" Performing work without

•

reading this section may lead to an unexpected accident or cause a re.

Precautions when Using Curled Media

An upward curl, even when weak, can cause the media to jam.

•

Either use media that is not curled or manually x the curl so that the media has a weak downward curl that

•

ts along the main unit of the plotter.

iii

Page 6

Contents

CONTENTS

Introduction ................................................................. i

Notes on this Manual ..................................................i

Registered Trademarks ................................................ i

Copyright ...........................................................i

Cutter Pen ..........................................................ii

After Attachment to the Main Unit ........................................ii

Precautions After Turning the Power ON ...........................................ii

Notes regarding Warning Labels .................................................ii

Notes regarding the Wording in This Manual........................................ii

Before Work ................................................................ iii

Precautions when Using Curled Media ........................................... iii

Chapter 1 Notes Before Use

1.1 Standard Accessories .................................................1-2

1.2 Names and Functions of Each Component .................................1-3

1.3 Operation Panel ......................................................1-4

Types of Screens and Operations ......................................1-4

Other Displays and Operations ........................................1-5

1.4 Installing the Main Unit.................................................1-6

Installation Space ...................................................1-6

1.5 Media Size and Cutting Area ............................................1-7

Compatible Media Sizes..............................................1-7

Cutting Area .......................................................1-7

1.6 Installing the Driver and Software ........................................1-8

1.7 Connecting and Turning ON the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.8 Connecting a Computer ...............................................1-10

1.9 Settings when Turning the Power ON for the First Time ......................1-11

Chapter 2 Basic Operations

2.1 Setting the Tool ......................................................2-2

Adjusting the Blade Depth of the Cutter ..................................2-2

Reference and Precautions regarding Blade Depth Adjustment ...............2-2

Setting the Tool ....................................................2-3

2.2 Setting the Media Set Levers............................................2-4

2.3 Setting the Push Rollers................................................2-5

Moving the Push Rollers .............................................2-5

Push Roller Setting Positions ..........................................2-5

2.4 Loading Sheet Media ..................................................2-6

Loading the Media Up Against the Push Rollers ...........................2-6

Loading the Media upon Releasing the Push Rollers .......................2-8

Unloading Sheet Media ..............................................2-9

2.5 Conrming the CONDITION NO. (Cutting Condition).........................2-10

2.6 Precautions when Creating Data ........................................ 2 -11

Notes regarding the Cutting Origin Position ..............................2 -11

Notes regarding the Cutting Area......................................2-12

iv

Page 7

2.7 Sending Cutting Data.................................................2-13

2.8 Ordinary Care ......................................................2-14

Cleaning the Cutter Pen .............................................2-14

Chapter 3 Cutting along Printed Data

3.1 What is Printing & Cutting? .............................................3-2

3.2 Simple Printing & Cutting ...............................................3-3

3.3 Registration Mark Scanned Printing & Cutting...............................3-5

3.4 Types and Arrangement of Registration Marks ..............................3-6

Registration Mark Shapes ............................................3-6

Positions for Registration Mark Arrangement..............................3-7

Automatic Registration Mark Position Detection ...........................3-8

3.5 Flow of Creating Registration Marks to Cutting ..............................3-9

Graphtec Pro Studio.................................................3-9

Cutting Master 4 ...................................................3-12

Graphtec Studio ...................................................3-15

Contents

Chapter 4 Convenient Functions

4.1 Cutting Roll Media ....................................................4-2

Assembling the Roll Media Stocker .....................................4-2

Loading and Scanning Roll Media ......................................4-4

Setting the Page Length..............................................4-8

4.2 Cutting using the Carrier Sheet ..........................................4-9

Loading Media onto the Carrier Sheet ..................................4-10

Loading the Carrier Sheet ...........................................4 -11

4.3 Plotting with the Drawing Pen ..........................................4-14

Setting the Drawing Pen in the Pen Adapter .............................4-14

Setting the Pen Adapter .............................................4-15

4.4 Cutting from a USB Memory ...........................................4 -17

Saving Data on a USB Memory .......................................4-17

Cutting upon Loading USB Memory Data ...............................4 -17

Cutting Barcode-equipped Data.......................................4-18

4.5 Cutting Multiple Media using the Same Data (Copy Function)..................4 -19

Copying Multiple Cuts on a Single Media................................4-19

Copying Repeatedly on Multiple Media .................................4-21

4.6 Cutting upon Specifying the Cutting Position...............................4-22

4.7 Expanding the Cutting Area ............................................4-23

4.8 Aborting and Pausing during a Cut ......................................4-24

4.9 Withdrawing the Tool Carriage..........................................4-25

Chapter 5 Detailed Settings

5.1 Individually Registering Settings for Cutting Conditions .......................5-2

5.2 Adjusting the Cutting Quality ............................................5-3

Selecting the Tool and Setting the Offset Value............................5-3

Setting the Cutting Force .............................................5-4

Setting the Offset Force ..............................................5-4

Setting the Condition Priority ..........................................5-5

v

Page 8

Contents

Setting the Distance Adjustment .......................................5-5

Setting the Blade Tip Orientation Initialization Position ......................5-6

5.3 Adjusting the Cutting Time..............................................5-7

Setting the Speed...................................................5-7

Setting the Acceleration ..............................................5-7

Setting the Tool Up Speed ............................................5-8

5.4 Cutting Thick Media ...................................................5-9

What is the Tangential Mode? .........................................5-9

Setting the Tangential Mode...........................................5-9

Setting the Overcuts................................................5-10

5.5 Performing Cut Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 -11

Cutting 1 Test with the Setting Values ..................................5 -11

Cutting 3 Tests to include Setting Values ± 1.............................5 -12

Conrming the Cut Test .............................................5 -12

5.6 Registration Mark Scan Settings ........................................5-13

Setting the Scan Mode ..............................................5-13

Conrming Registration .............................................5-14

Correcting the Registration Mark Position ...............................5-16

Setting Automatic Registration Mark Position Detection ....................5 -19

5.7 Adjusting the Media Operation..........................................5-20

Setting the Pre Feed Operation .......................................5-20

Setting the Auto Pre Feed ...........................................5-21

Setting the Initial Feed ..............................................5-21

Setting the Media Width Detection .....................................5-22

5.8 Setting Commands ..................................................5-24

Selecting the Command .............................................5-24

Setting the HP-GL Origin Point .......................................5-24

Setting the HP-GL Model Emulated ....................................5-24

Setting the GP-GL Step Size .........................................5-25

5.9 Setting the Operation Panel............................................5-26

Language Selection ................................................5-26

Selection of Unit for Lengths .........................................5-26

Setting the Beep for Key Operation ....................................5-26

Chapter 6 Troubleshooting

6.1 Responding to Trouble .................................................6-2

When the device does not operate even when the power is turned ON .........6-2

Operation is Irregular ................................................6-2

6.2 Conrming Error Messages .............................................6-3

GP-GL Command Errors .............................................6-3

HP-GL Command Errors .............................................6-3

ARMS Errors ......................................................6-4

Other Error Displays.................................................6-4

6.3 Conrming the Operation of the Main Unit..................................6-5

Plotting the Self Test Pattern ..........................................6-5

Plotting the Test Pattern ..............................................6-5

Adjusting the Width Detection Sensor ...................................6-6

Main Unit Diagnosis Test .............................................6-6

vi

Page 9

Contents

6.4 Conrming the Main Unit Firmware Version.................................6-7

Appendix

A.1 Standard Specications ................................................A-2

A.2 Supply Items ........................................................A-3

A.3 Appearance Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

A.4 Menu Tree ..........................................................A-5

A.5 List of Initial Values ...................................................A-9

INDEX ....................................................................I-1

vii

Page 10

Page 11

Chapter 1 Notes Before Use

An overview of this device and connections with a computer are explained in this chapter.

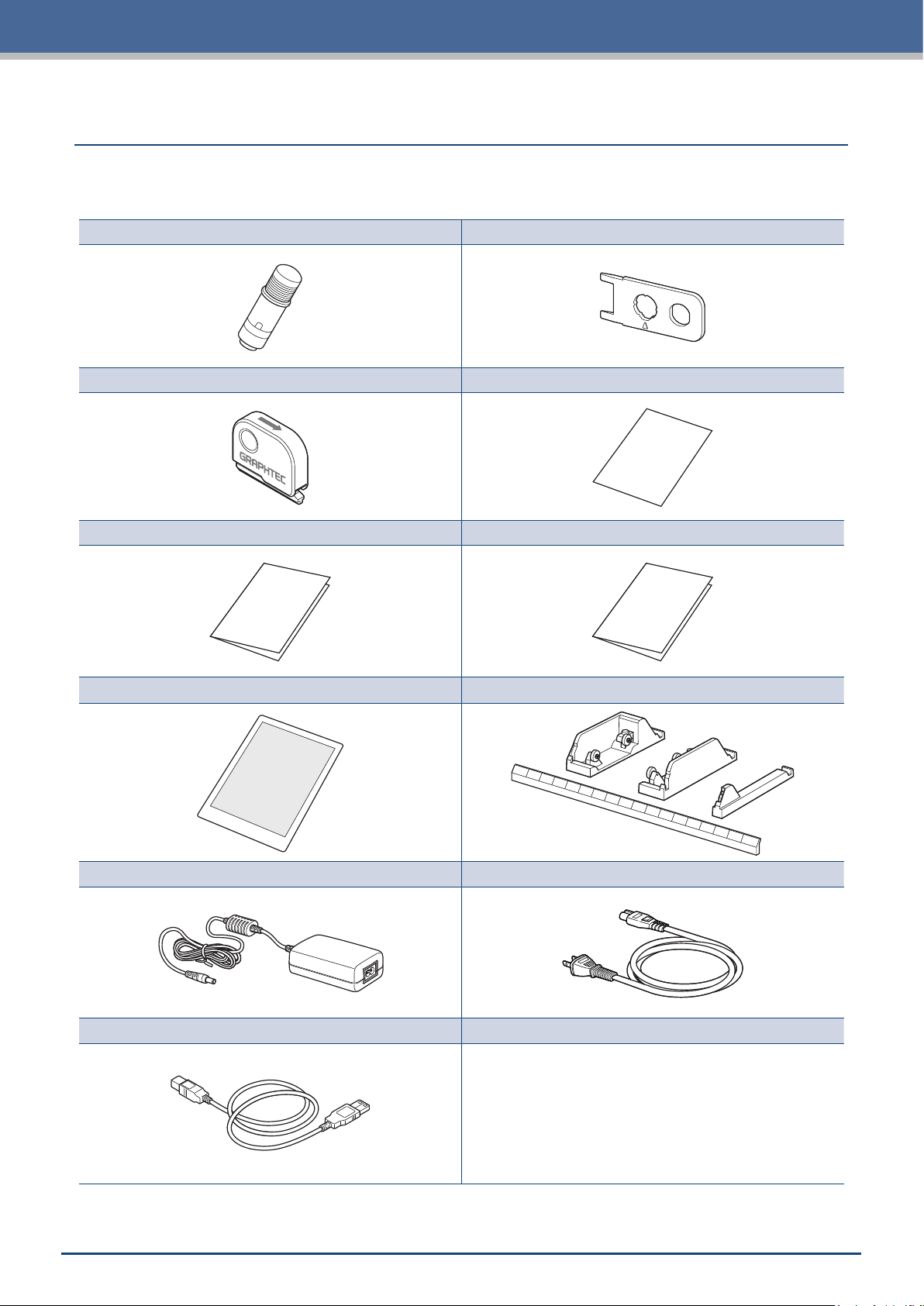

1.1 Standard Accessories

1.2 Names and Functions of Each Component

1.3 Operation Panel

Installing the Main Unit

1.4

1.5

Media Size and Cutting Area

1.6 Installing the Driver and Software

Connecting and Turning ON the Power

1.7

1.8

Connecting a Computer

1.9 Settings when Turning the Power ON for the First Time

Page 12

Chapter 1 Notes Before Use

1.1

Please conrm that all accessories are included. If any of the accessories are missing, please immediately

contact your store of purchase or our company's customer service.

Cutter Set (Standard Blade) [PM-BS-001] 1 set Blade Tip Cap Jig 1 unit

Cross Cutter [PM-CC-001] 1 unit Software Activation Code 1 sheet

SETUP MANUAL 1 copy TO ENSURE SAFE AND CORRECT USE 1 copy

Standard Accessories

Carrier Sheet (13-inch) 1 sheet Roll Media Stocker 1 set

AC Adapter 1 unit AC Cable 1 unit

USB Cable (1.5 m) 1 unit

1-2

Page 13

Chapter 1 Notes Before Use

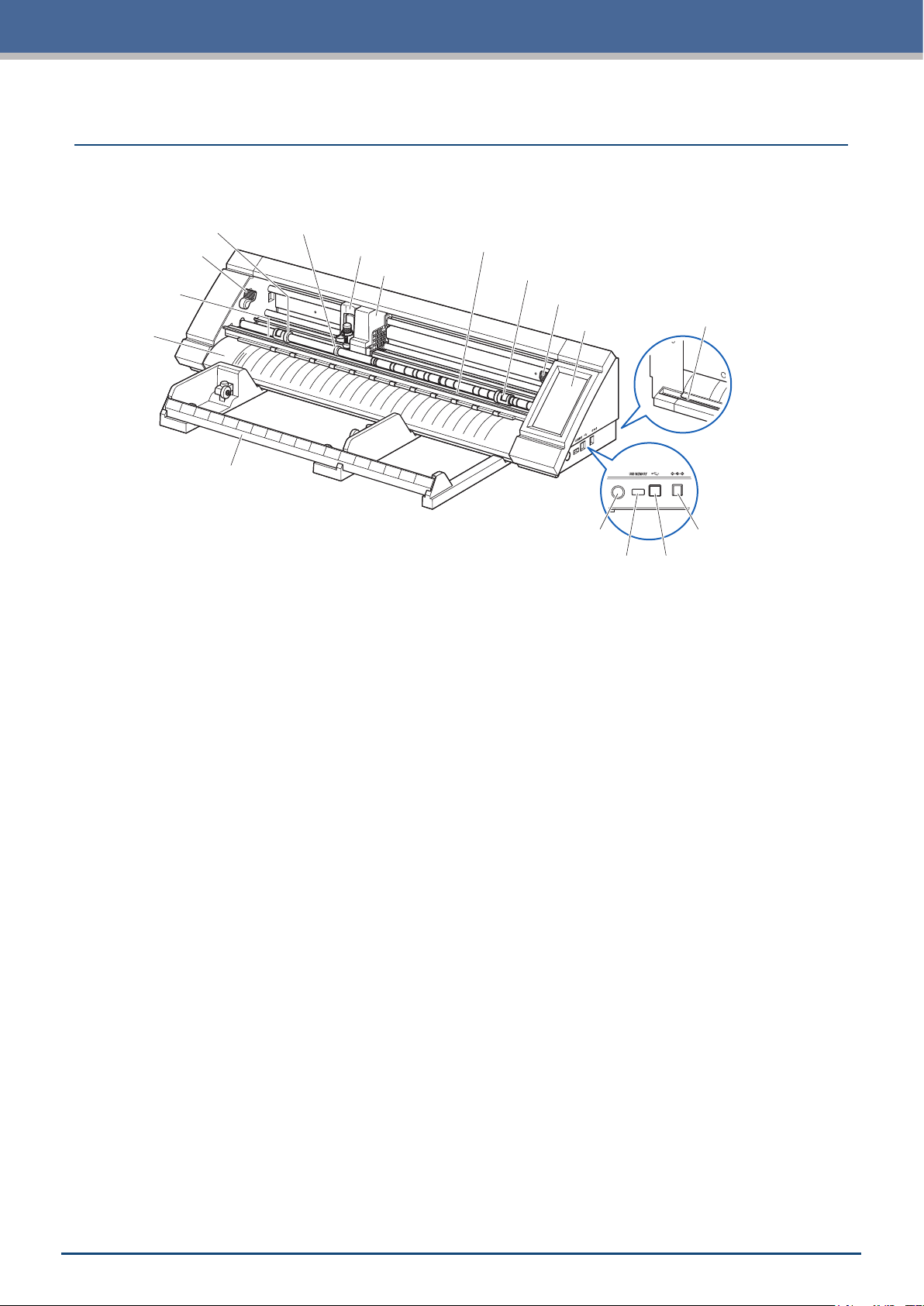

1.2

Media sensor

Names and Functions of Each Component

Push roller Media holding roller (movable)

Tool holder

Tool carriage

Roll media stocker

Push roller positioning guide

Push roller

Media set lever - right

Operation panel

Power switch Power supply connector

USB memory-dedicated port USB interface

Cutter groove

Operation panel: Used to operate the device and congure various settings.

Media set lever-right: Used to raise/lower the push roller when setting media and x (3 positions) / release

the media. Adjust this lever according to the width of the media.

Media set lever-left: Used to raise/lower the push roller when setting media and x/release the media.

Push rollers: Touches the media to x/transport the media. Adjust this roller according to the type

and size of the media.

Push roller positioning guide:

Sets the push rollers at the position of the indicated marking.

Tool carriage: Drives the tool left/right and scans registration marks and barcodes.

Tool holder: Holds the tool and drives it up/down.

Media holding roller (movable):

Holds down media to prevent low cutting quality and malfunction of register mark

detection. Set it in the center or the most lifted part of the media.

Media sensor: Scans media.

Front Guide: Sets the media at the position of the indicated marking.

Roll media stocker: Holds roll media.

Power switch: Used to turn the power ON/OFF.

USB memory-dedicated port:

Used to connect and load data from a USB memory.

USB interface: Used to connect the device with a computer.

Power supply connector: Used to connect the power cable.

Cutter groove:

Used when registrationping roll media with the cross cutter.

1-3

Page 14

Chapter 1 Notes Before Use

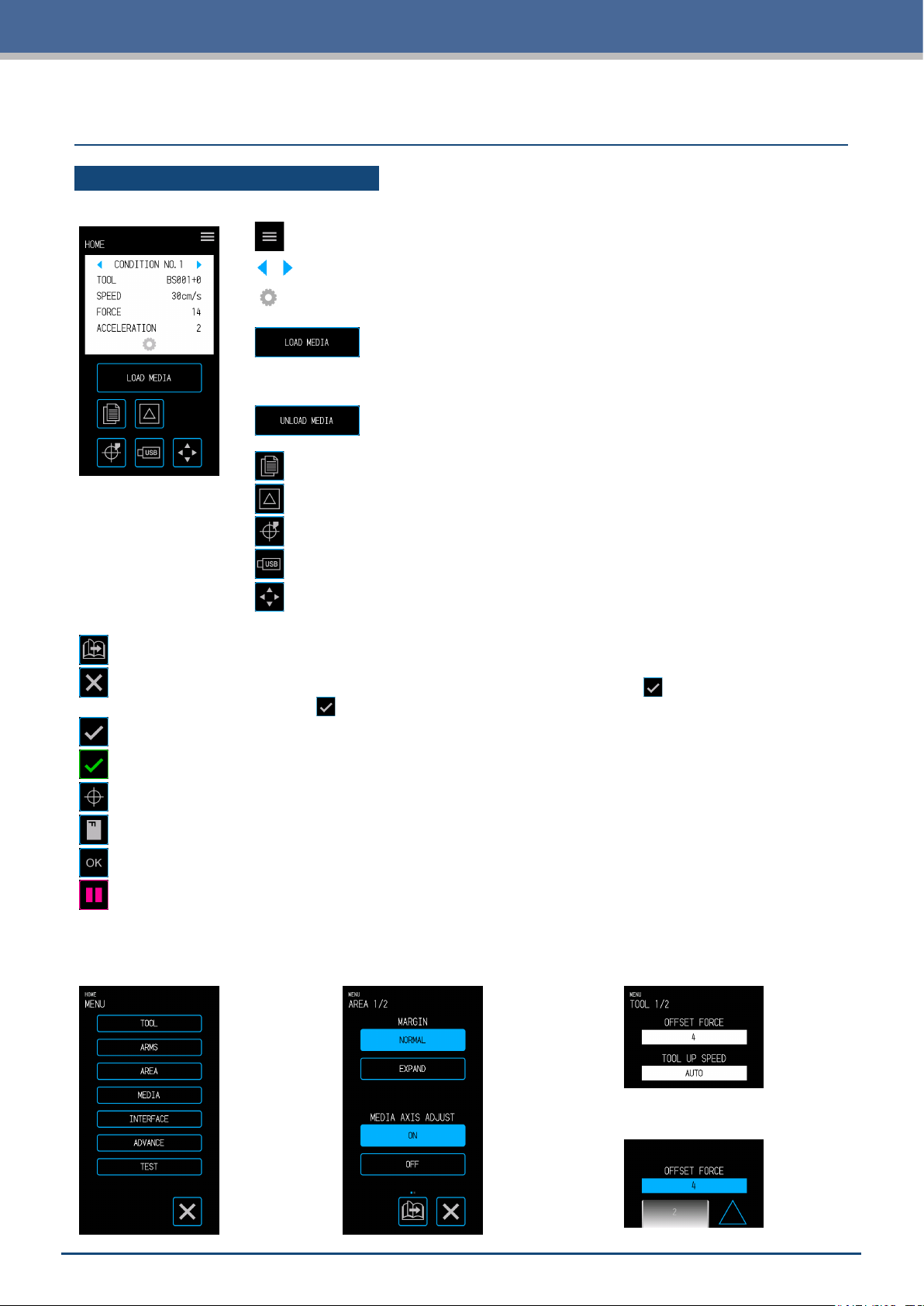

1.3

Operation Panel

Types of Screens and Operations

HOME Screen and Functions of Buttons

"MENU" button:

"CONDITION NO. Selection" buttons:

"CONDITION" button:

setting screen.

"LOAD MEDIA" button:

Used to transition to the Load Media screen.

The following screen is displayed when media is set.

"UNLOAD MEDIA" button:

Used to Unload Media that has been set.

"COPY" button:

"CUT TEST" button:

"HOME" button:

"USB" button:

Used to transition to the copy mode.

Used to move the tool carriage to the home point.

Used to transition to the menu for cutting from a USB memory.

Used to transition to the "MENU" screen.

Used to select the CONDITION NO.

Used to transition to the CONDITION (cutting condition)

Used to transition to the cut test screen.

Position key:

Other Buttons

"Page" button:

"Exit" button:

"Conrm" button:

"Execute" button:

"Origin" button:

"Cutting Area" button:

"OK" button:

"Stop" button:

Used to transition to the next page on the same tier level.

Used to exit the current screen. When touched before the

where the

Used to conrm settings.

Used to execute settings.

Used to congure the plot origin.

Used to display th cutting area of the media that has been loaded.

Used to conrm the position of the tool moved with the position keys.

Stops the cutting operation.

Menu Selection Screen

This screen is used to select setting

items. Please touch the button to set.

Used to transition to the position key screen.

(Conrm) in a screen

(Conrm) is displayed, the screen is exited without setting the item.

Different Button Colors

Light blue indicates the selected setting.

Please touch the button to set

.

Different Display Boxes

White boxes can be touched to

transition to the input screen.

1-4

Light blue boxes display the

current setting value.

Page 15

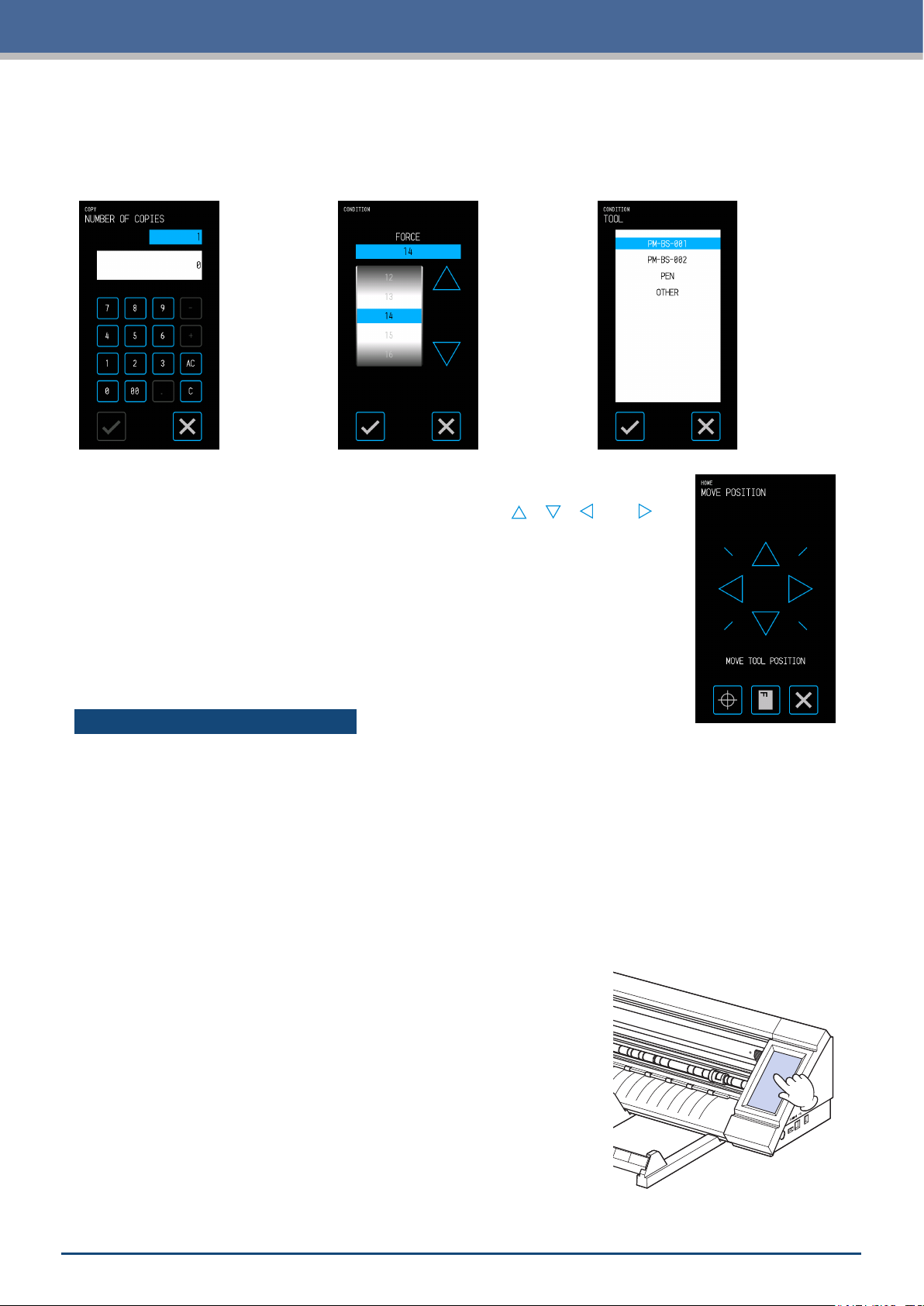

Input Screen

Number Input

Touch the buttons to input a

numb er.

Drum Selection

Rotate the drum to scroll through

the list and select a setting value.

Chapter 1 Notes Before Use

List Selection

Touch the item you wish to select

from the list to set the item.

Position Keys

The tool carriage or media moves to each direction when the " ", " ", " " and " "

position keys are touched.

The movement will be started from slow speed when the position keys are touched.

The movement speed changes to fast speed when key is touching more than a few

seconds.

Other Displays and Operations

Instruction Screen

If the power is turned ON while in a state where the media set levers are released, the message "SET THE

•

MEDIA SETTING LEVER." will appear on the operation panel. Once the media set levers are lowered, the

"LOAD MEDIA" screen will be displayed.

When setting the media, a message regarding the media or the push rollers may appear. In such case,

•

operate the device by following the on-screen instructions.

Operate the device by following the on-screen instructions also when other operation related messages

•

appea r.

Sleep Release

The touch panel function will be turned off (Sleep Mode) in a few minutes

when it is not touched.

To restart it, touch the touch panel.

1-5

Page 16

Chapter 1 Notes Before Use

1.4

Installing the Main Unit

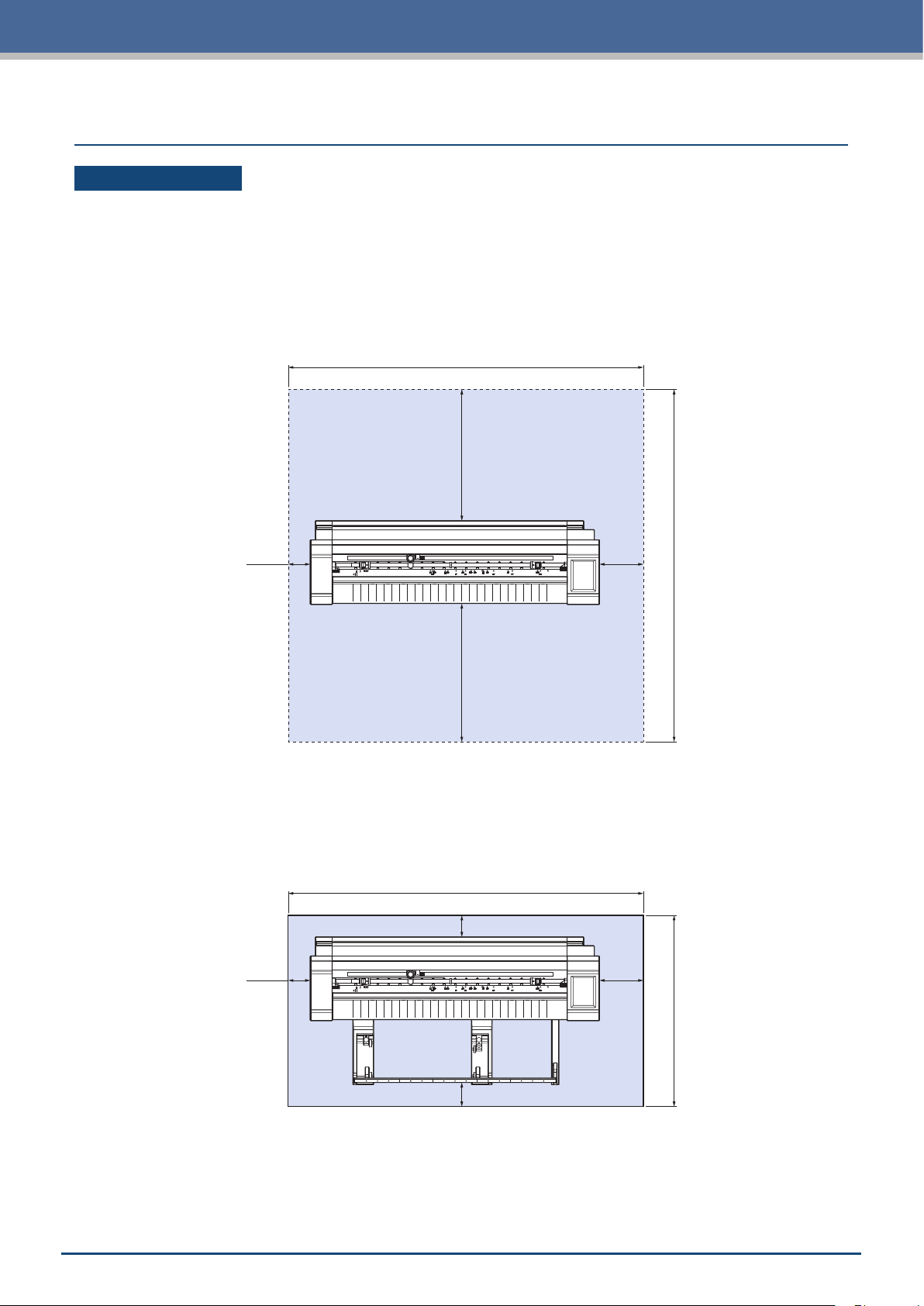

Installation Space

Secure enough space to install the device so that the cutting operation is not affected.

The space required to the front and rear of the device will vary depending on the size of the media being

•

used.

Refrain from placing obstacles in front of or behind the main unit that will interfere with transportation of the

•

media.

Installation Space when Using Carrier Sheets

934mm

296mm

50mm

100mm

834mm

311mm

When using the roll media stocker and installing the device on a table, use a table that is leveled and solid with

a top panel that is at least 934 × 502 mm in size.

When using roll media, refrain from placing obstacles in front of or behind the main unit that will interfere with

•

transportation of the media.

934mm

50mm

50mm

50mm

100mm

502mm

1-6

Page 17

Chapter 1 Notes Before Use

1.5

Media Size and Cutting Area

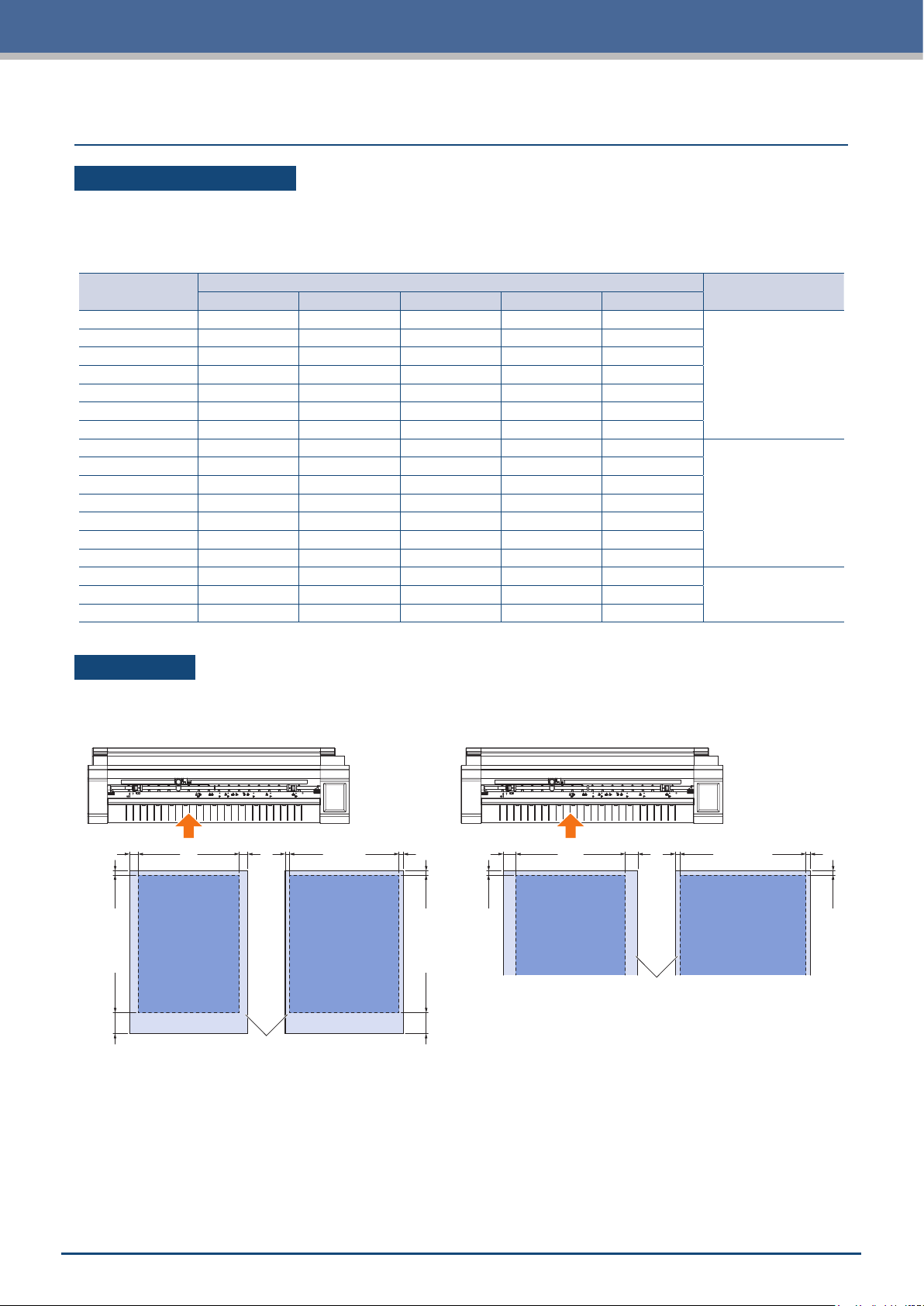

Compatible Media Sizes

This cutter is able to use only width of standard media size as shown in the table below.

Use the carrier sheet when the media width is other than below.

For more information on the carrier sheet, refer to "4.2 Cutting using the Carrier Sheet".

Compatible

Media Width

210.0mm A4

215.9 mm 8.5inch

220.0mm OK

250.0mm B4

25 7. 0m m B4

279.4mm 11i n ch

29 7. 0m m A3

304.8mm 12inch

320.0mm OK

329.0mm A3+

353.0mm B3

364.0mm B3

381.0m m 15inch

420.0mm A2

431.8mm 17inch

508.0mm 20inch

ISO A/JIS A JIS B ISO B Inch Non-Standard

Size

Position of right side

Media Set Lever

1

2

3500.0mm B2

Cutting Area

The cutting area and cutting direction will be as shown below.

Sheet Media Roll Media

10mm 10mm

5mm30mm

Cutting Area

Sheet Media

When margin is normal

5mm 5mm

Cutting Area

When margin is narrowed

5mm30mm

15mm 15mm

5mm

When margin is normal

Cutting Area

5mm 5mm

5mm

Cutting Area

Sheet Media

When margin is narrowed

1-7

Page 18

Chapter 1 Notes Before Use

1.6

Download the device driver and application software from Graphtec website to install these on your computer.

Installing the Driver and Software

Notes on Compatible OS

The software for this device is compatible with the following OS environments:

Graphtec Pro Studio & Cutting Master 4 & Divece Driver (Windows)

Windows 10 (32-bit / 64-bit), Windows 8.1 (32-bit / 64-bit), Windows 8 (32-bit / 64-bit),

Windows 7 (32-bit / 64-bit)

Graphtec Studio & Cutting Master 4 (Mac)

Macintosh Mac OS X 10.11 - 10.7 / mac OS 10.13 - 10.12 (Graphtec Studio is also compatible with Mac OS X 10.6)

Please conrm the latest compatible OS environment on our company website.

Installing the Cutting Plotter Driver (Windows)

Download the devoce driver from Graphtec website website.

For installation procedures, refer to the documented procedures available on the website.

URL: http://www.graphtec.co.jp/en/imaging/celite/support.html

The device driver for Mac does not need install.

CAUTION

Do not connect this device and the computer with a USB cable before installing the printer driver.

Connecting these prior to installation may prevent the printer driver from being properly installed.

Installing Graphtec Pro Studio (Windows)

Download the software from the following Graphtec website.

URL: http://www.graphtec.co.jp/en/imaging/celite/support.html

For installation procedures, refer to the documented procedures available on the website.

Installing Cutting Master 4 (Windows/Mac)

Download the software from the following Graphtec website.

URL: http://www.graphtec.co.jp/en/imaging/celite/support.html

For installation procedures, refer to the documented procedures available on the website.

Installing Graphtec Studio (Mac)

Download the software from Graphtec website.

URL: http://www.graphtec.co.jp/en/imaging/celite/support.html

For installation procedures, refer to the documented procedures available on the website.

1-8

Page 19

Chapter 1 Notes Before Use

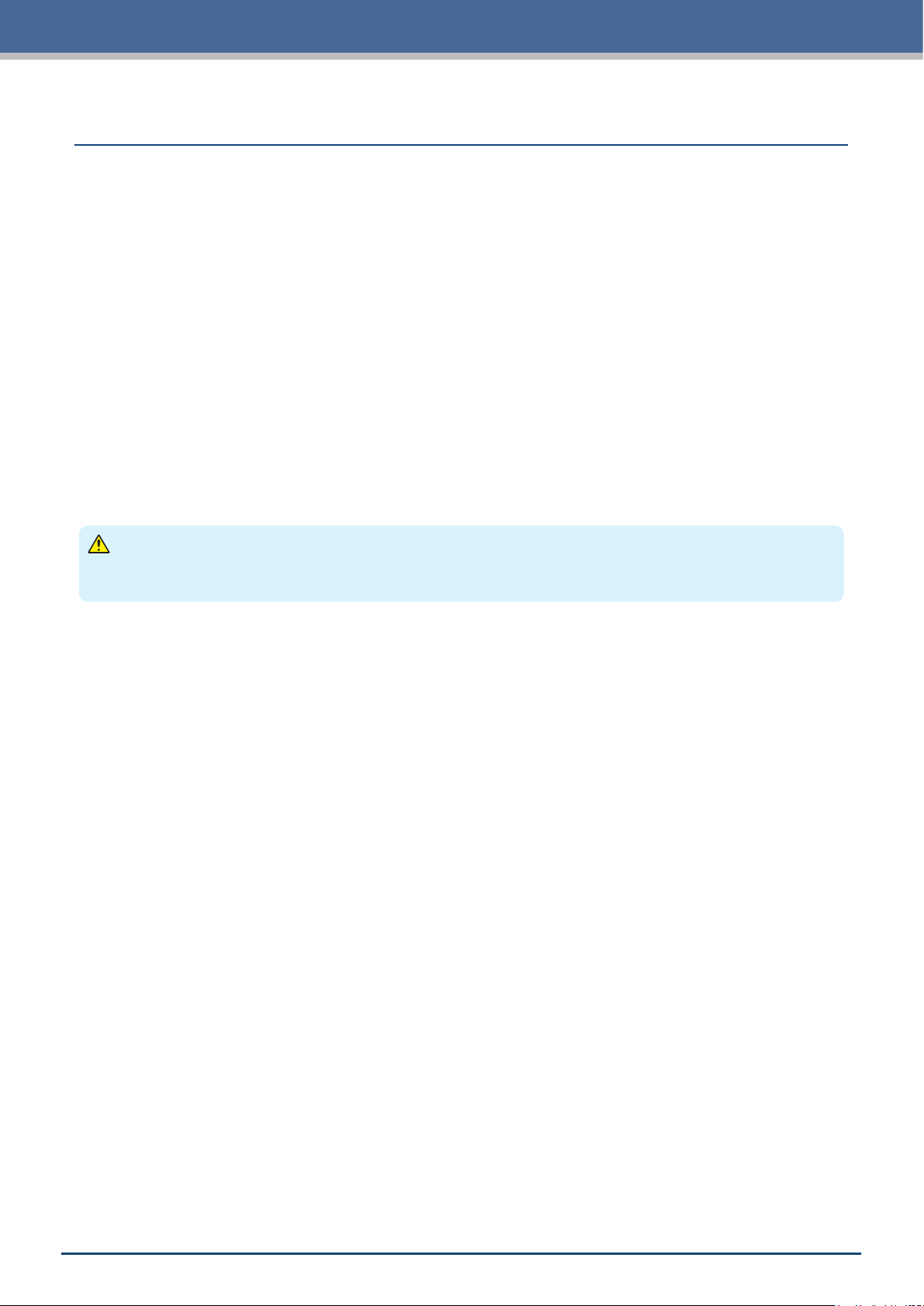

1.7

Connect this device and the AC outlet via the standard accessory of AC adapter, and then turn ON the power.

Connecting and Turning ON the Power

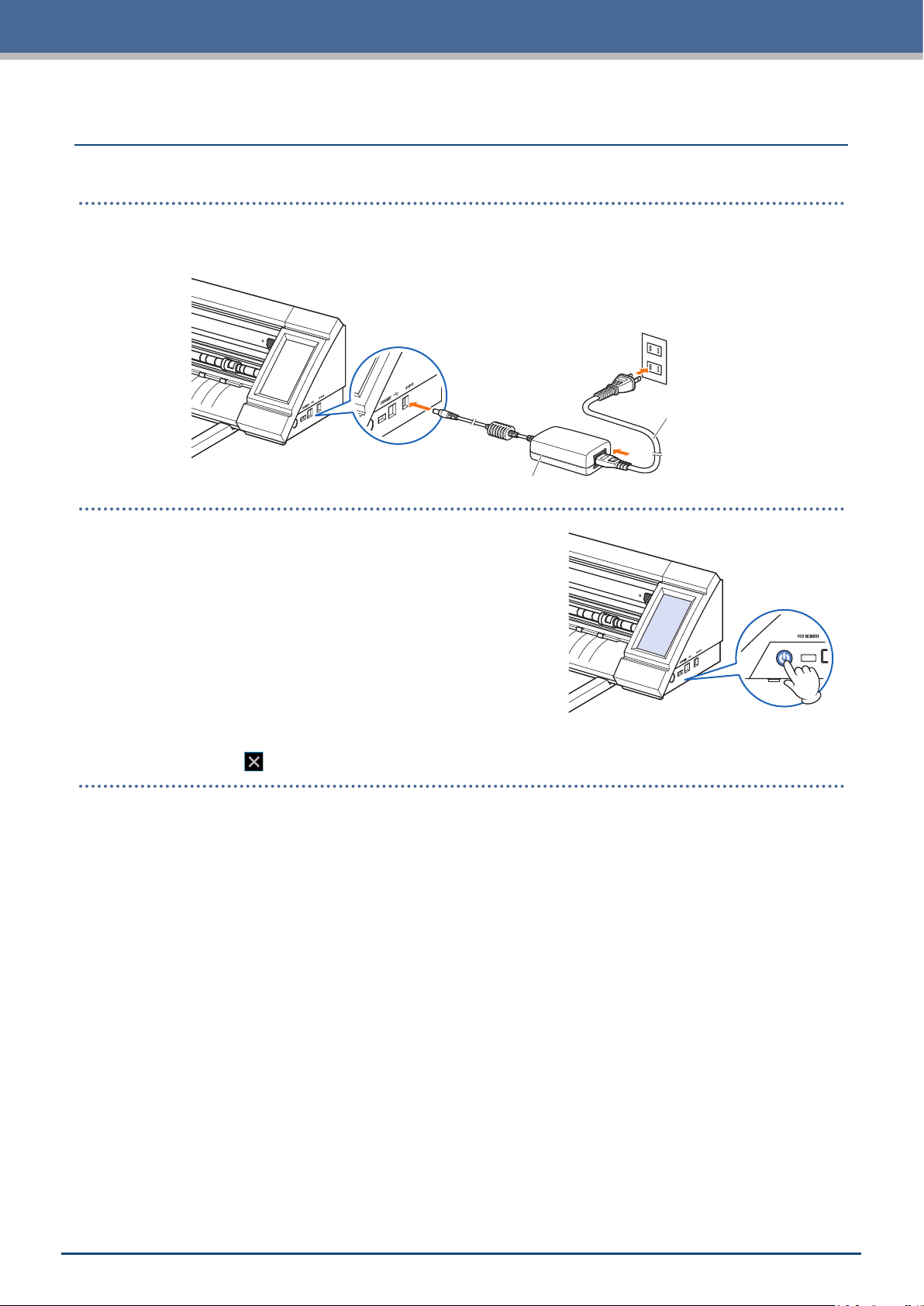

1. Connect the AC adapter and the AC cable (1). Connect the AC adapter to the power supply connector of

this device (2). Connect the AC cable to the AC outlet of specied voltage (3).

(3)

(2)

AC Cable

(1)

AC Adapter

2. Press the power switch to turn ON the power.

Conrm that the touch panel has started up.

When turning ON the power, wait at least 20 seconds to turn

on the power after the power was turned OFF.

The device may fail when immediately the power turned ON,

after the power was turned OFF.

After the power was turned ON when the media set lever

•

was not set, the "SET THE MEDIA SETTING LEVER." is

displayed.

At this time, lower the set lever, and then the "LOAD MEDIA" is displayed.

Then touch the

(Exit) to exit to the HOME menu.

1-9

Page 20

Chapter 1 Notes Before Use

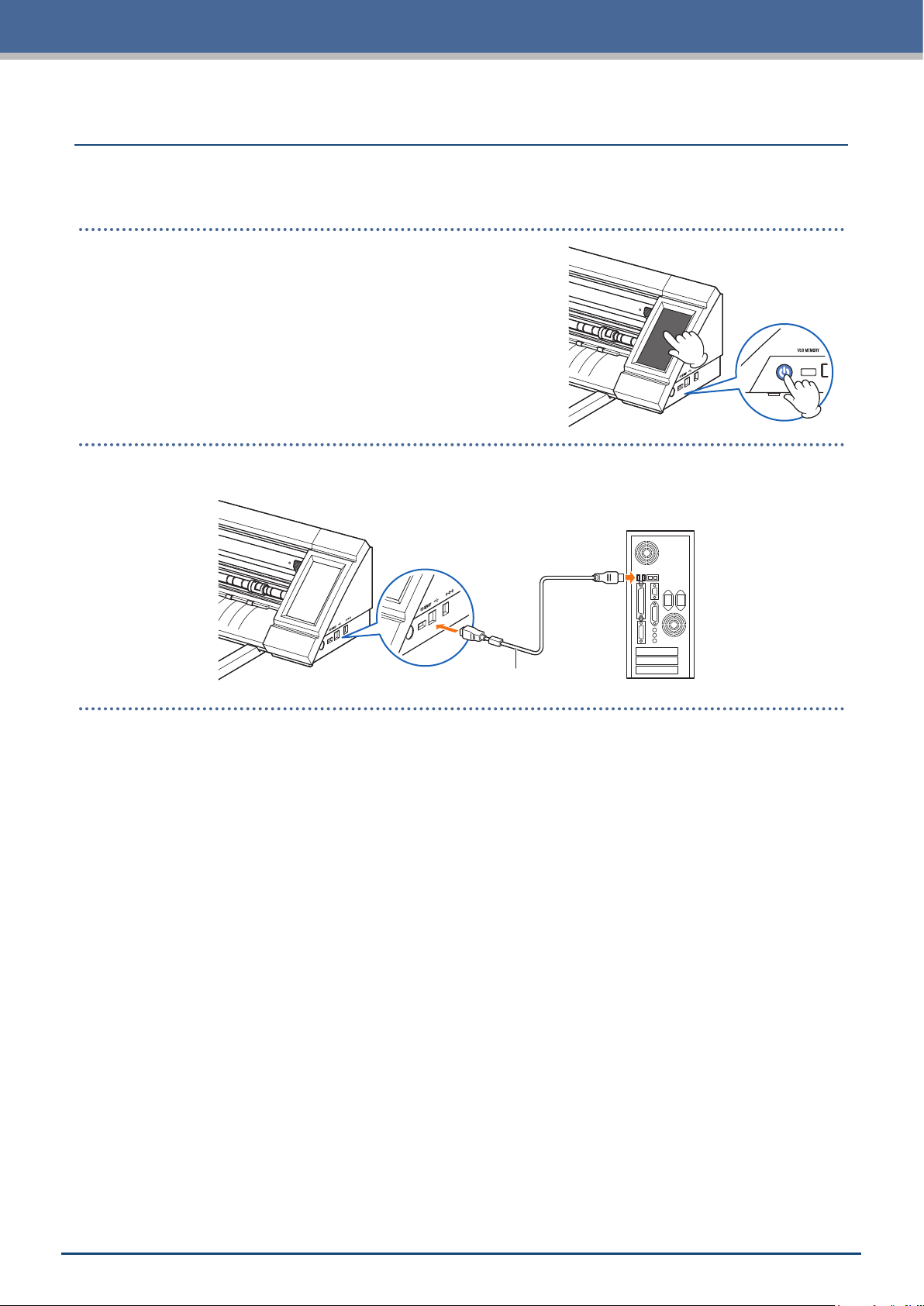

1.8

Connect this device and a computer by using the supplied USB Cable.

For Windows: Connect the USB cable after the device driver was installed to the PC.

•

Connecting a Computer

1. Turn OFF the power.

Touch the touch panel and conrm that the screen does not

start up.

2. Connect this device and the computer by the USB cable.

Computer

USB Cable

1-10

Page 21

Chapter 1 Notes Before Use

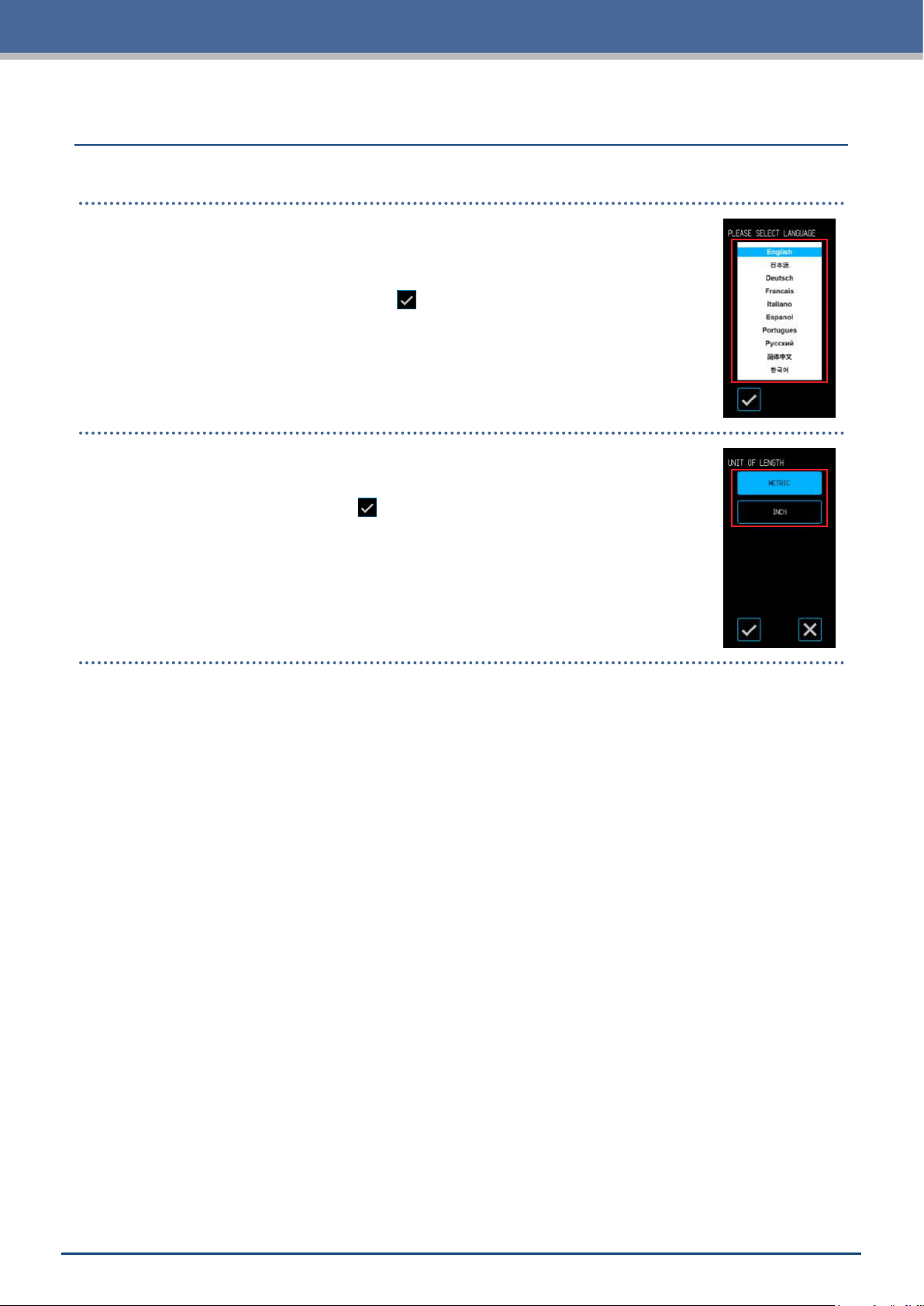

1.9

When the device is started up for the rst time, it will be necessary to set the language and the unit for lengths.

Language Selection

When the power of this device is turned ON for the rst time, the startup screen will be

followed by a language selection screens.

Select the language used, and then touch the

Selection of Unit for Length

Once the language has been set, the screen for selecting the unit for length will appear.

Select the unit used, and then touch the

Settings when Turning the Power ON for the First Time

(Conrm).

(Conrm).

Once the unit for lengths has been set, the HOME screen will be displayed.

1-11

Page 22

Page 23

Chapter 2 Basic Operations

Perform basic cuts by following the items explained in this chapter.

2.1 Setting the Tool

2.2 Setting the Media Set Levers

2.3 Setting the Push Rollers

Loading Sheet Media

2.4

2.5

Conrming the CONDITION NO. (Cutting Condition)

2.6 Precautions when Creating Data

Sending Cutting Data

2.7

2.8

Ordinary Care

Page 24

Chapter 2 Basic Operations

2.1

The cutter pen (PM-BS-001) is an consumption goods.

Purchase a new cutter pen when the cutter blade becomes dull.

Setting the Tool

Adjusting the Blade Depth of the Cutter

The blade depth needs to be adjusted in order to perform optimal cutting. Perform the test cutting several times

to set an optimal blade depth.

CAUTION

Be careful when handling the cutter blade to avoid cutting your hands, etc.

•

An excessive blade depth will damage the cutter blade and cutting mat or lead to wasteful consumption of

•

media. Keep the blade depth less than the thickness of the media.

The blade depth is adjusted by turning the tip of the cutter pen.

Align the number with the red line to adjust the blade depth.

Aligning a larger number to the line will increase the blade depth. The blade depth is

changed in approximately 0.1 mm for each number. The blade depth is able to adjust

to a maximum of approximately 1 mm.

CAUTION

Do not turn the cap clockwise (towards 10) from the state where the blade tip is not

protruding (at 0). Similarly, do not turn the cap further counter-clockwise (towards 0)

past the state where the blade tip is protruding by 1 mm (at 10). Doing either of these

may damage the cutter pen.

Reference and Precautions regarding Blade Depth Adjustment

Commonly available vinyl sticker sheets are congured of two layers - a sheet with an adhesive and a backing.

Adjust the blade depth so as not to penetrate the backing.

Adjust the blade depth so that the vinyl sheet is penetrated

and a light trace of the cut is left on the backing.

Good

Vinyl Sheet

Backing

When adjusting the blade depth, start with a shallow blade depth and make adjustments to a greater depth.

•

The appropriate blade depth will vary depending on the thickness of the media. Make adjustments and

•

perform cut tests every time the type of media is switched.

Cutter Blade

An excessive blade depth will be cause to dull cutting not

only, it damages the tip of blade also.

No Good

Vinyl Sheet

Backing

Cutter Blade

2-2

Page 25

Chapter 2 Basic Operations

Setting the Tool

To attach the tool, insert the tool into the tool holder completely, and then x the tool by the locking lever.

CAUTION

Don't touch to the tool while it is moving, it is extremely dangerous.

•

Be careful not to injure yourself with the cutter blade when setting the tool.

•

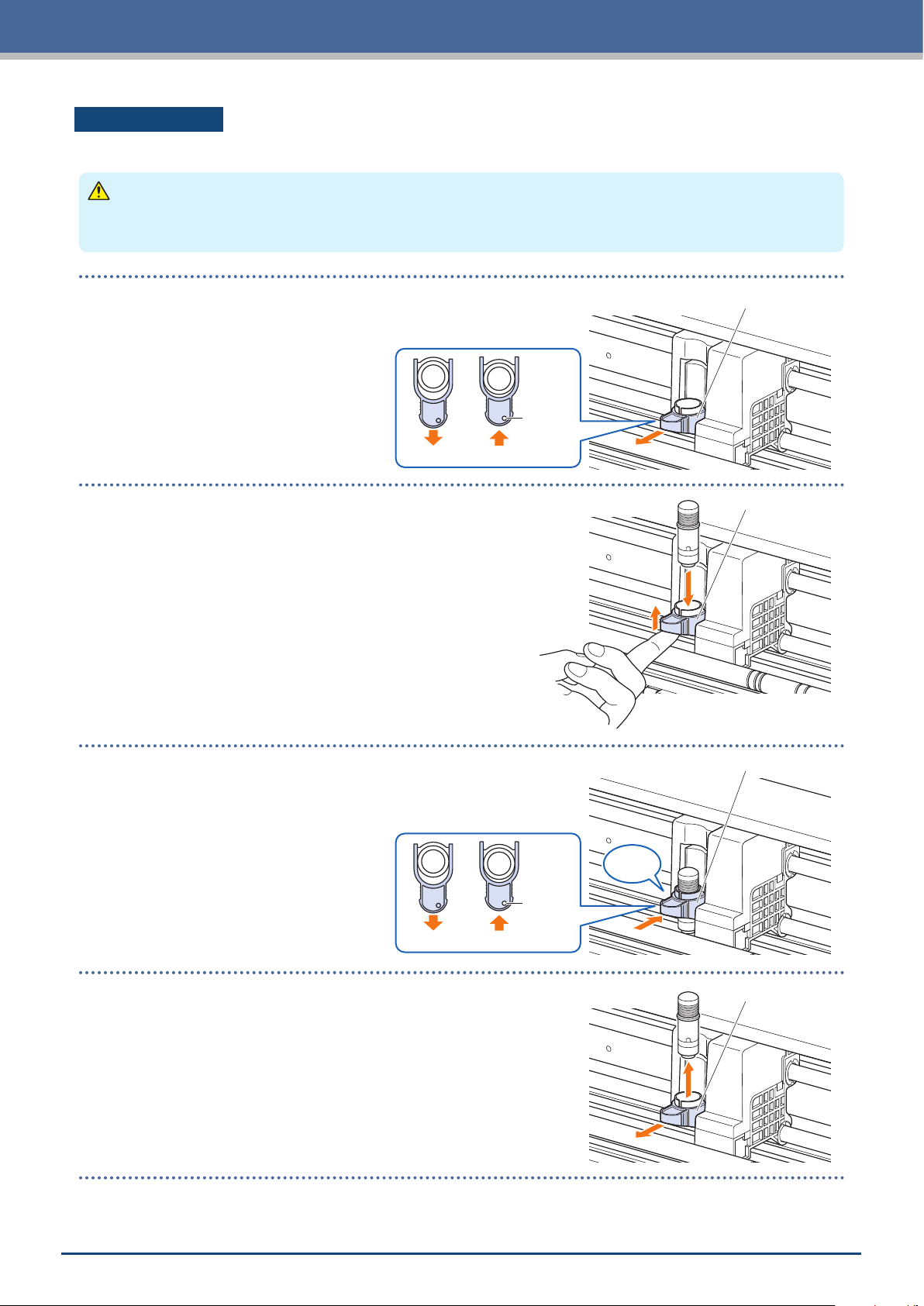

1. Pull the locking lever to open the lock.

2. Insert the cutter pen to the tool holder while holding it.

Locking Lever

Locking

indicator

LockUnlock

Locking Lever

3. Push the locking lever until it clicks to hold the cutter pen.

Conrm the locking indicator became the white.

LockUnlock

4. Pull the locking lever to open the lock, and then remove the

cutter pen from the tool holder.

Locking Lever

Click

Locking

indicator

Locking Lever

2-3

Page 26

Chapter 2 Basic Operations

2.2

Set the media set levers to the locked position, except the following conditions.

Moving the push roller position or removing jammed media.

When this device will not be used for a long period, set the media set levers to the released position.

The "SET THE MEDIA SETTING LEVER." is displayed when the media set levers did not set to the locked

position when the HOME menu is selected.

Setting the Media Set Levers

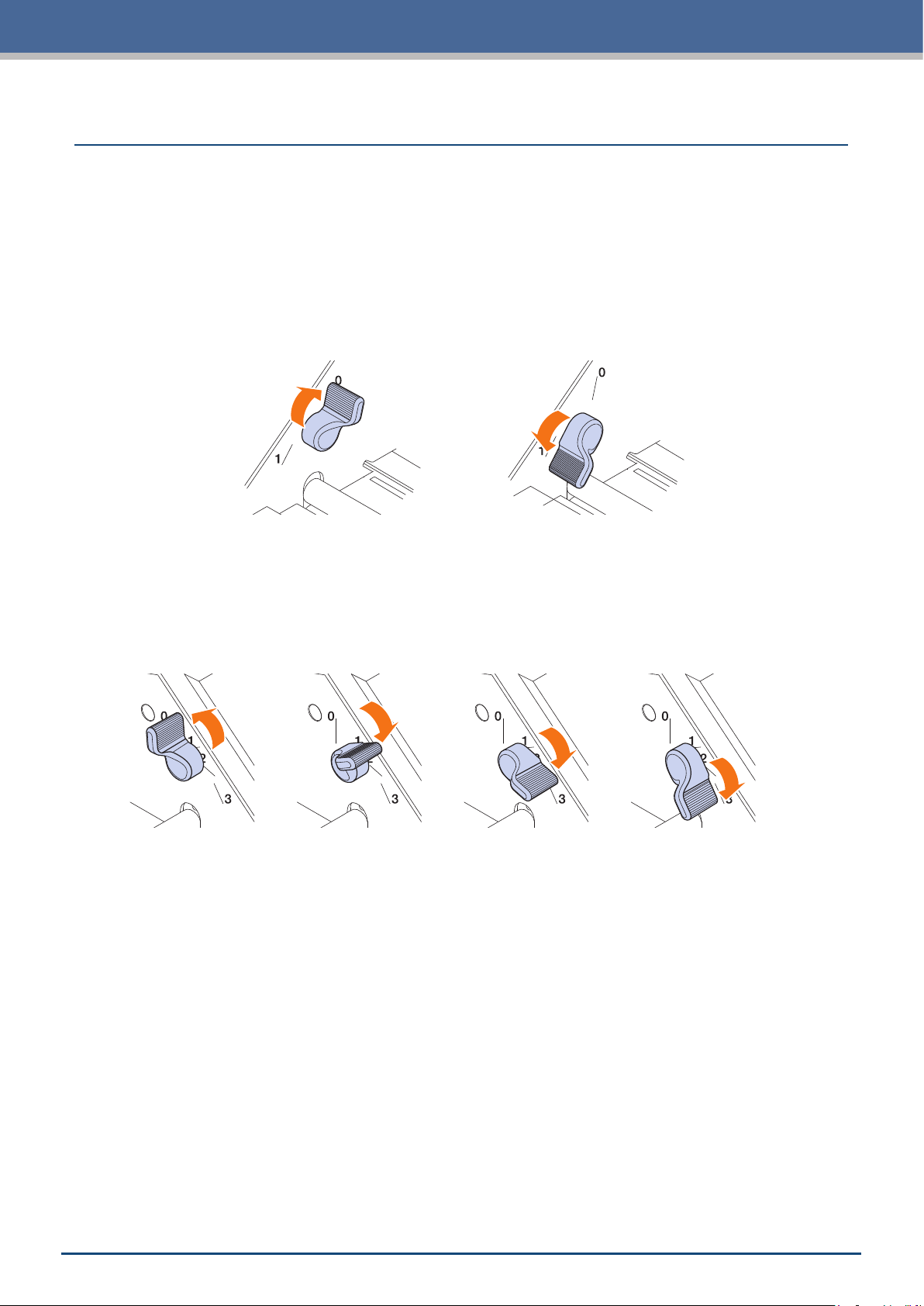

Setting the Media Set Lever - Left

Set the media set lever - left to the lock position to hold the media with the left side push roller.

Release

Lock

Setting the Media Set Lever - Right

There are three lock positions for the media set lever - right.

The lock position depends on the width of media.

Set the media set lever - right to the correct position.

Refer to the "1.5 Media Size and Cutting Area" to set the right side Media Set Lever to correct position.

Release

When the media lock lever was set to incorrect position, the message of correct position will be displayed.

Set the media set lever - right to the correct position according with the message

Lock 1

Lock 2

Lock 3

Media Width and Lock Position

Lock 1: A4 / 8.5” / 220mm / B4 / 11” / A3

Lock 2: 12” / 320mm / A3+ / CARRIER SHEET / B3 / 15” / A2

Lock 3: 17” / 500mm / 20”.

2-4

Page 27

Chapter 2 Basic Operations

2.3

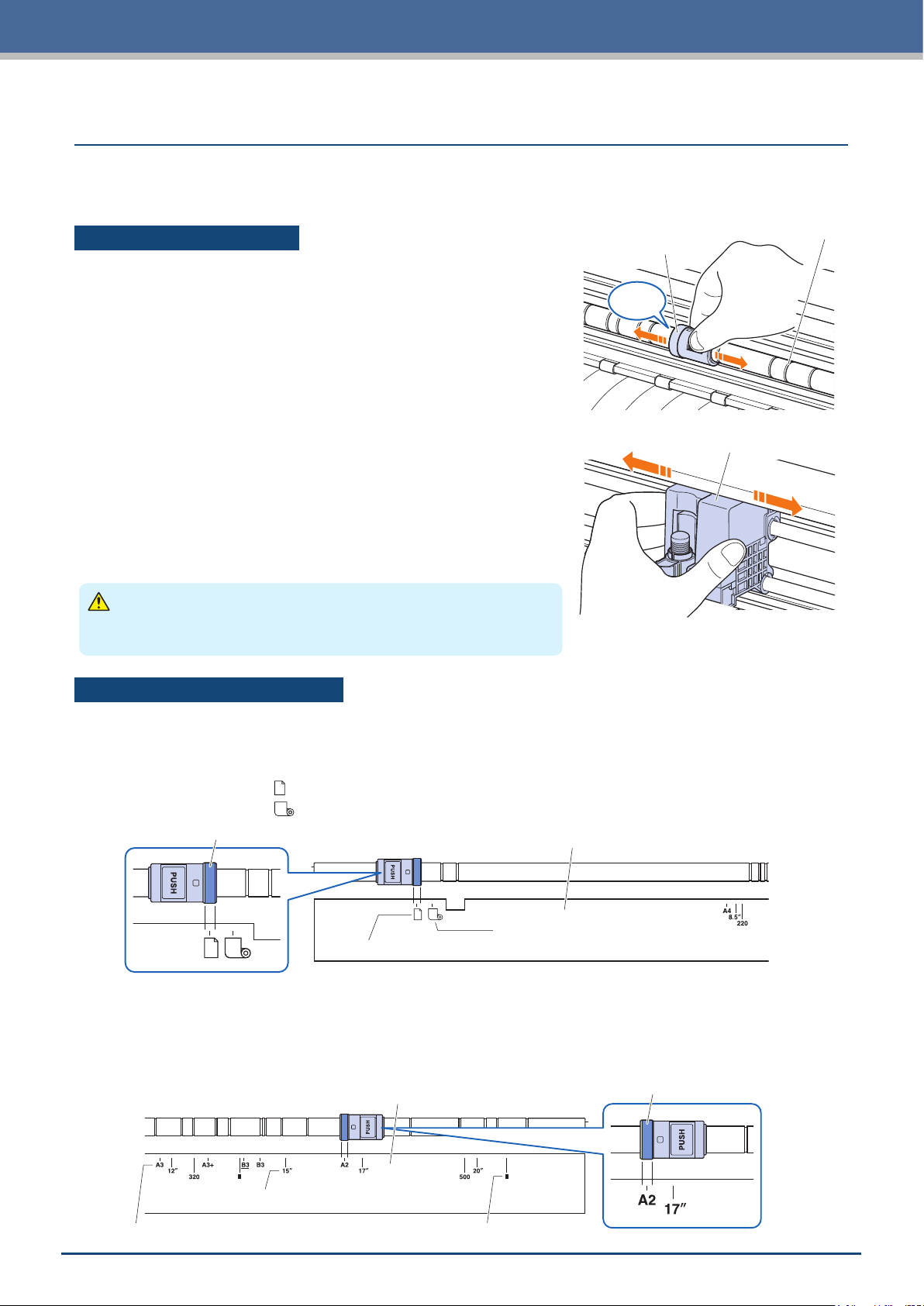

Adjust the positions of the left and right push rollers to suit the width of the media.

Set the push rollers positioned onto both edges of the media.

Moving the Push Rollers

To move the push rollers, raise the media set levers and release the

push rollers. Squeeze the "PUSH" part with your ngers, and then

move the push roller left and right while pressing the "PUSH" part. If

the "PUSH" is in a position that is difcult to press, rotate the roller

so that it can easily be pressed. When the push roller reaches to the

desired position, release the "PUSH" part and place it in the position

where it "clicks" into the positioning groove. After setting the push

roller, move slightly to the left and right without pressing the "PUSH"

part to check that it ts in the positioning groove.

If the tool carriage obstructs the setting the push rollers, release

the left and right media set levers and slowly move the tool carriage

away. Gently hold the tool carriage from both sides. Holding this at a

different position or forcefully moving it may cause damage. The tool

carriage that has been moved will return to its home position when

the power is turned ON.

Setting the Push Rollers

Push Roller

Click

Positioning Groove

Tool carriage

CAUTION

Be sure to operate/move the media set lever, push rollers, and tool

carriage when operating the load media menu.

Push Roller Setting Positions

Left Side Push Roller Setting Positions

Align the "media pressing portion" of the push roller with the position of the push roller positioning guide to set

the push roller in place.

Align the push roller to the " " position when using the sheet media or the carrier sheet.

Align the push roller to the " " position when using the roll media.

Media Pressing Portion

Roll Media

Sheet Media/Carrier Sheet

Push Roller Positioning Guide

Right Side Push Roller Setting Positions

Set the "Media pressing portion" of the push roller according to the width of media.

Align the media pressing portion with the markings on the top row for standardized sizes (mm), the middle row

for standardized sizes (inch), and the bottom row for non-standardized sizes or the carrier sheet.

Push Roller Positioning Guide

Media Pressing Portion

Standardized Sizes (mm)

Standardized Sizes (inch)

Non-standardized sizes/Carrier Sheet

2-5

Page 28

Chapter 2 Basic Operations

2.4

Use the standard media size of sheet media. Use the carrier sheet when using the non standard media size of

sheet media.

Depending on the type of media (especially with high transparency), the media cannot be set because CE

•

LITE-50 cannot detect the leading edge /width /position of the media. In this case, use a carrier sheet or

disable the Media width detection.

Depending on the type of media, the center of the media may be lifted up because the push rollers cannot

•

hold down the media sufciently. In this case, move the Media holding rollers (movable) to the position where

the media is lifted up. When the media is load at, move them to the right push roller.

Move the Media holding rollers (movable) after raising the Media set levers.

•

Limp or too much thin media cannot be cut.

•

For more information on the carrier sheet, refer to "4.2 Cutting using the Carrier Sheet".

For more information on the media width detection, refer to "5.7 Setting the Media Width Detection".

Supported sheet media size: A4 - 20inch (refer to "1.5 Media Size and Cutting Area")

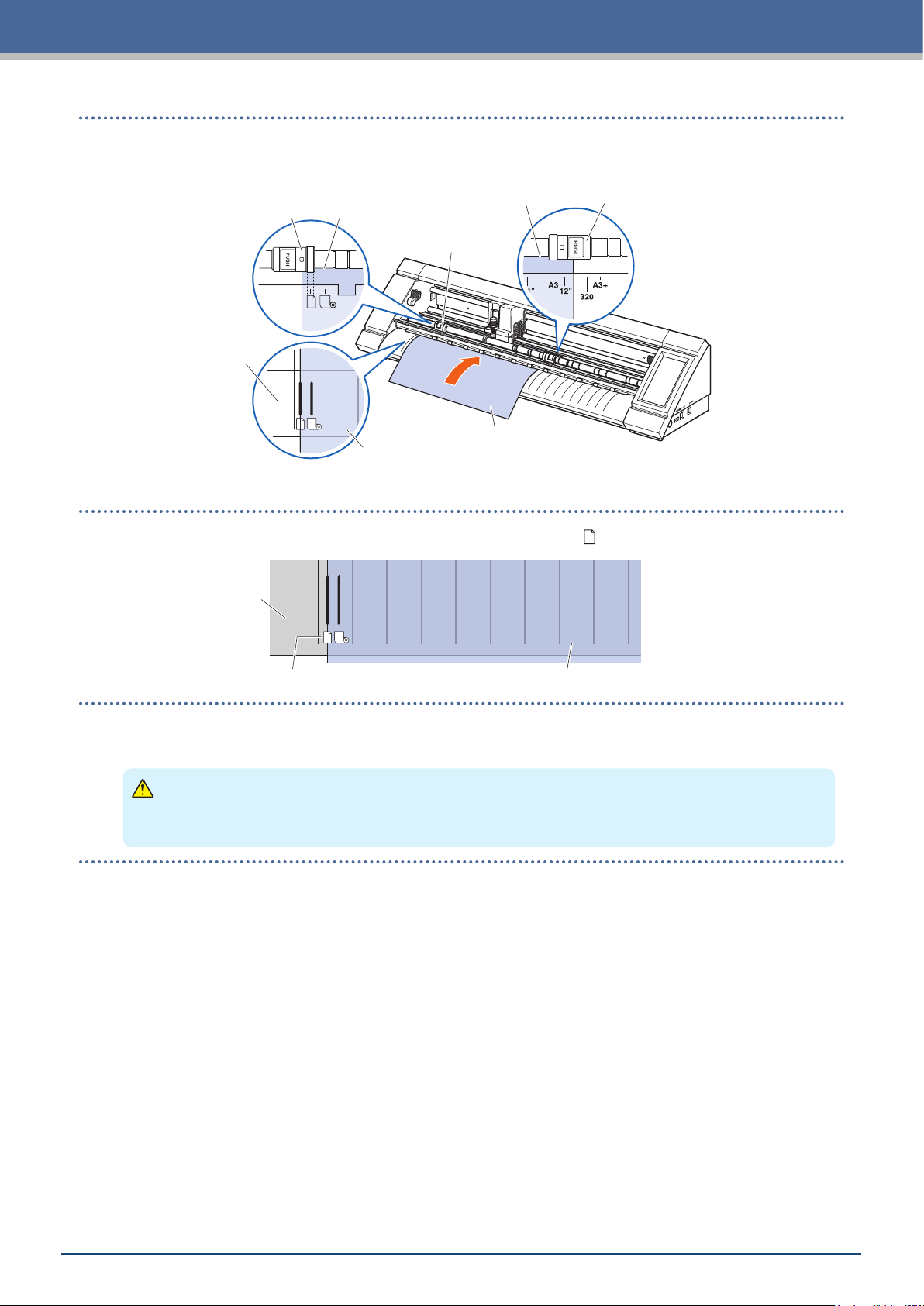

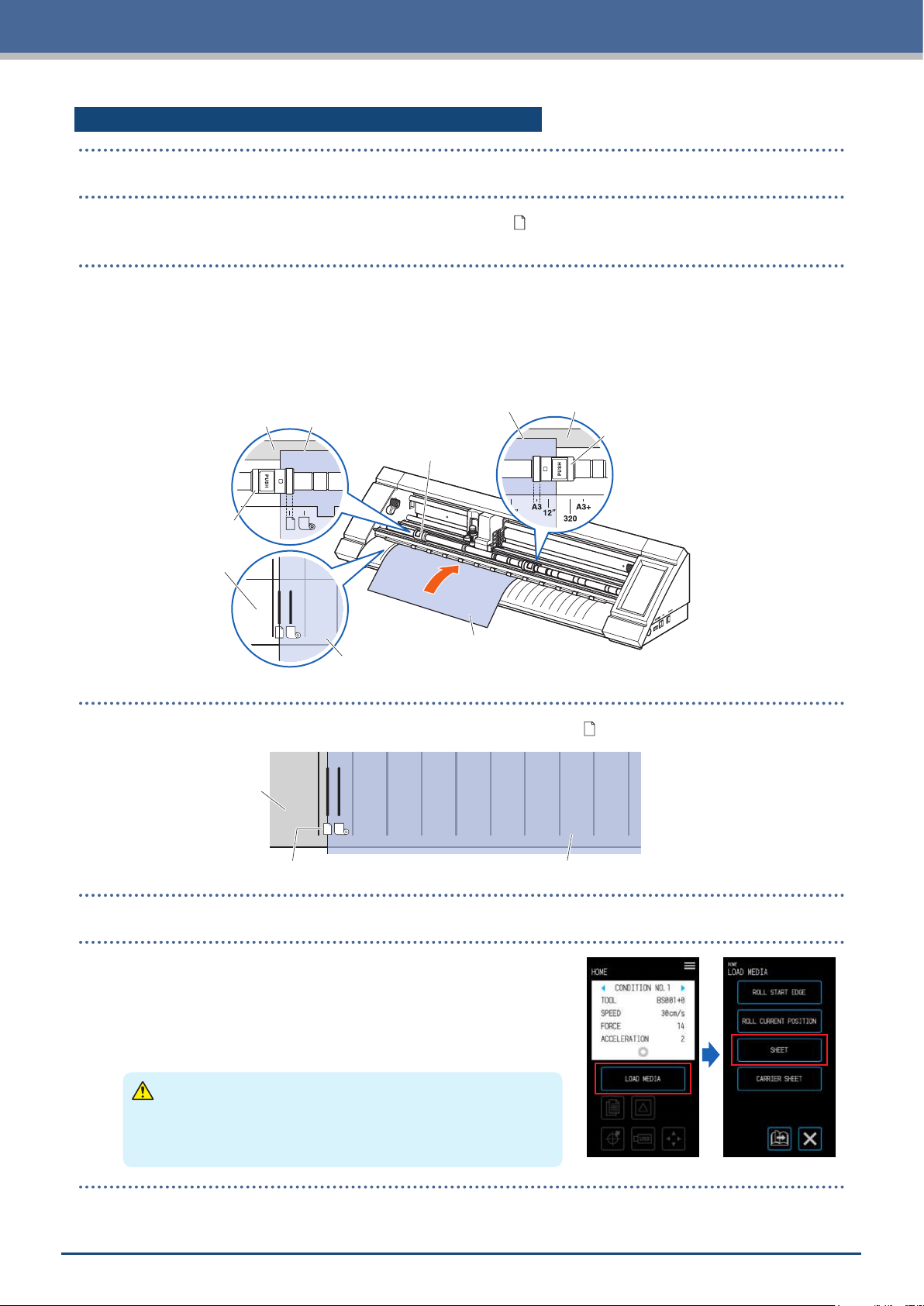

Loading the Media Up Against the Push Rollers

Loading Sheet Media

1. Raise the media set levers and release the push rollers.

2. Set the push roller on the left side at the position of the " " mark.

Set the push roller on the right side according to the width of the sheet media.

3. Lower the media set levers on both sides to lock the push rollers.

4. On the "HOME" screen, touch the "LOAD MEDIA" − "SHEET".

2-6

Page 29

Chapter 2 Basic Operations

5. Evenly position the edge of the sheet media up against the push rollers. Pass the sheet media under the

push roller positioning guide and load it so that it is parallel with the front guide.

Push Roller Edge of Sheet Media

Front Guide

Sheet Media

Set to be parallel

Edge of Sheet Media Push Roller

Push Roller

Sheet Media

6. Align the left edge of the sheet media with the " I " marking of the " " mark on the front guide.

Front Guide

Sheet Media / Carrier Sheet Marking Sheet Media

7. The width, front edge, and rear edge of the media are scanned and the sheet media is loaded. If an error

is displayed, operate the device by following the on-screen instructions.

CAUTION

When the "SHEET" is touched, the media and tool carriage will start moving. Be careful to avoid contact

with your body or any object.

2-7

Page 30

Chapter 2 Basic Operations

Loading the Media upon Releasing the Push Rollers

1. Raise the media set levers and release the push rollers.

2. Set the push roller on the left side at the position of the " " mark.

Set the push roller on the right side according to the width of the sheet media.

3. Insert the front edge of the sheet media in until it reaches the cutting mat (white translucent mat) behind

the push rollers.

Pass the sheet media under the push roller positioning guide and load it so that it is parallel with the front

guide.

If the sheet media is inserted too far, there may be cases when the media cannot be scanned.

Cutting Mat

Edge of Sheet Media

Edge of Sheet Media Cutting Mat

Push Roller

Push Roller

Push Roller

Front Guide

Sheet Media

Sheet Media

Set to be parallel

4. Align the left edge of the sheet media with the " I " marking of the " " mark on the front guide.

Front Guide

Sheet Media / Carrier Sheet Marking Sheet Media

5. Lower the media set levers on both sides and lock the push rollers.

6. On the "HOME" screen, touch the "LOAD MEDIA".

When the "SHEET" is touched, the width, front edge, and rear

edge of the media are scanned and the sheet media is loaded.

If an error is displayed, operate the device by following the on-

screen instructions.

2-8

CAUTION

When the "SHEET" is touched, the media and tool carriage will

start moving. Be careful to avoid contact with your body or any

object.

Page 31

Chapter 2 Basic Operations

Unloading Sheet Media

1. Conrm that the cutting operation has stopped.

2. Touch the "UNLOAD MEDIA" and the media will be unloaded from the front of the

device.

2-9

Page 32

Chapter 2 Basic Operations

2.5

Select a CONDITION NO. to which a cutting condition for the tool is registered and conrm the setting details.

That which is displayed in the currently selected CONDITION NO. and cutting condition.

Select the CONDITION NO. to use with the "

conrm the setting details.

For more details on setting the CONDITION NO. and cutting conditions, refer to "5.1

Individually Registering Settings for Cutting Conditions".

Conrming the CONDITION NO. (Cutting Condition)

" and " " on the "HOME" screen and

2-10

Page 33

Chapter 2 Basic Operations

2.6

Precautions when Creating Data

Notes regarding the Cutting Origin Position

The position of the cutting origin will vary depending on the settings for "Cutting Area". Create cutting data in

reference to the following:

Tilt correction: Enabled

Margin: Normal/Expanded

The cutting origin (0, 0) will always

be near the vertex of the media edge

regardless of the state in which the

margin has been set.

Media Transport

Direction

As the area between the media edge

•

approximately 5 mm inward from the

edge is outside of the cutting area,

the media will not be cut in this area

even if cutting data exists.

For information on the cutting origin when scanning registration marks, refer to "3.3 Printing & Cutting upon

•

X

Y

Cutting Origin

Scanning Registration Marks".

For information on how to change the cutting origin, refer to "4.6 Cutting upon Specifying Cutting Positions".

•

For information on how to change the tilt correction, refer to "3.2 Simple Printing & Cutting".

•

For information on how to change the margin settings, refer to "4.7 Expanding the Cutting Area".

•

Tilt correction: Disabled

Margin: Normal

The cutting origin (0, 0) will be the

vertex of the effective cutting area.

The point approximately 5 mm inward

from the front edge and approximately

10 mm from the left edge.

Media Transport Direction

Y

X

Cutting

Origin

Approx.

10 mm

Approx. 5 mm

Tilt correction: Disabled

Margin: Expanded

The cutting origin (0, 0) will be the

vertex of the effective cutting area.

The point approximately 5 mm inward

from the front edge and the left edge.

Media Transport Direction

Y

X

Cutting

Origin

Approx. 5 mm

Approx. 5 mm

2-11

Page 34

Chapter 2 Basic Operations

Notes regarding the Cutting Area

The cutting area will vary depending on the media and the settings for "Cutting Area". Create cutting data in

reference to the following:

Media: Sheet media

Tilt correction:

Enabled/Disabled

, Margin: Normal

Front Edge: 5 mm / Left/Right: 10 mm / Rear Edge: 30 mm

Media Transport Direction

Y

X

Cutting Area

5mm

30mm

10mm10mm

Media: Carrier sheet

Margin: Normal/Expanded

Front Edge: 5 mm / Left/Right: 5 mm / Rear Edge: 5 mm

Media Transport Direction

Y

X

Cutting Area

5mm

Media: Sheet media

Tilt correction:

Enabled/Disabled

, Margin: Expanded

Front Edge: 5 mm / Left/Right: 5 mm / Rear Edge: 30 mm

Media Transport Direction

Y

X

Cutting Area

5mm

30mm

5mm5mm

5mm

5mm5mm

For information on how to change the margin settings, refer to "4.7 Expanding the Cutting Area".

•

For more information on the carrier sheet, refer to "4.2 Cutting using the Carrier Sheet".

•

2-12

Page 35

Chapter 2 Basic Operations

2.7

From a computer, send cutting data created in one of the environments listed below.

For more details, refer to the manuals respective to each software.

Dedicated software: Graphtec Pro Studio Plus (optional)

•

Dedicated software: Graphtec Pro Studio

•

Dedicated software: Graphtec Studio for Mac

•

Dedicated plug-in software: Cutting Master 4

•

Dedicated Windows Driver

•

Sending Cutting Data

2-13

Page 36

Chapter 2 Basic Operations

2.8

Conduct ordinary care while being careful of the items listed below.

Refrain from lubricating the mechanical section.

•

To clean the main unit, wipe the unit with either a dry cloth or a cloth soaked in a diluted neutral detergent.

•

Refrain from using substances such as paint thinner, benzene, or alcohol, etc. as these will damage the

surface.

If the cutting mat is dirty, clean it by wiping is with a dry cloth.

•

If the cutting mat is very dirty, wipe it with a cloth moistened with

alcohol or a diluted neutral detergent.

Dust or dirt, etc. attaching to the sensor unit which scans the media or the

•

roller unit that transports the media can cause the device to malfunction.

Regularly wipe these components with a cloth or cotton swabs moistened

with alcohol or a diluted neutral detergent.

* Absolutely refrain from using benzene, paint thinner, etc.

If the Y-rail sliding surface has become dirty, gently wipe off the dirt with a clean dry cloth.

•

* Lubricant seeps out onto the sliding surface. Avoid forcefully wiping this off.

Ordinary Care

Cutting Mat

Push Roller

Media Sensor

Storage Method

Be careful of the following items for storage when the device will not be used.

Be sure to remove the tool from the tool holder when storing the device.

•

Prevent dust from accumulating by covering the main unit with a cover cloth cover.

•

Refrain from storing the device in a location exposed to direct sunlight or subject to high temperatures and

•

humidity.

Raise the media set levers and place the push rollers in their unlocked state for storage.

•

Cleaning the Cutter Pen

Media scraps, etc. attached to the tip of the cutter blade will lower the quality of the cuts.

Regularly clean the cutter pen to remove any media scraps, etc.

CAUTION

Be very careful when handling the cutter blade to avoid cutting your hands, etc.

•

Clean the tip of the cutter blade with air or a soft material. Using a stiff material can cause the blade to chip or break.

•

1. Align the red line on the cutter pen with "0" to place it in a state

where the blade is not protruding.

Blade Tip Cap

Blade Tip

Cap Jig

2. Turn the Blade Tip Cap to counterclockwise to remove it by using

the Blade Tip Cap Jig.

Attach the Blade Tip Cap Jig to the Blade Tip Cap, and then

remove the Blade Tip Cap while holding the number part of

cutter pen as shown in the picture.

Cutter Blade

3. Clean the removed blade tip cap and cutter blade with air or a

soft material.

4. Attach the Blade Tip Cap to the Cutter pen, and then manually turn the Blade Tip Cap clockwise to install it.

Securely tighten the Blade Tip Cap by using the Blade Tip Cap Jig.

2-14

Page 37

Chapter 3 Cutting along Printed Data

"Printing & Cutting" which involves cutting the media along printed data is explained in this

chapter along with registration marks.

3.1 What is Printing & Cutting?

3.2 Simple Printing & Cutting

3.3 Registration Mark Scanned Printing & Cutting

3.4 Types and Arrangement of Registration Marks

3.5 Flow of Creating Registration Marks to Cutting

Page 38

Chapter 3 Cutting along Printed Data

3.1

Stickers, etc. can be created by placing a cutting line in the media along with the cutting of printed data.

In order to realize this printing & cutting function, this device has been equipped with two functions. Use each

function according to the environment of use.

What is Printing & Cutting?

Cutting Line

Plot

Simple Printing & Cutting

With this function, the edge of the media is scanned and cutting lines are made upon predicting the cutting

positions of the printed data based on the position of this scanned edge. This method is useful when working

with media on which registration marks cannot be printed.

However, as the edge of the media needs to be scanned, there are conditions such as the media having to be

a standardized size and the cutting line being affected by the positioning precision of the printer used.

Edge of Media

Cutting Line

Plot

Registration Mark Scanned Printing & Cutting

The data is printed on the media with registration marks (reference lines) added. These registration marks are

scanned with the sensor and cutting lines are made upon predicting the cutting positions of the printed data

based on the positions of these scanned registration marks.

Because this method is affected by the base, etc. of the media, media on which registration marks are difcult

to scan cannot be used.

Registration Mark

Cutting Line

Plot

3-2

Page 39

Chapter 3 Cutting along Printed Data

3.2

When the media is loaded, the position and tilt of the media is scanned in order to layer the cutting line over the

printed media.

As this method does not use registration marks, it is not affected by issues such as not being able to scan

•

the registration marks depending on the image on the base.

However, as this method is affected by the print positioning precision of the printed media, it is recommended

that a printer with excellent print positioning precision be used.

Be sure to use the standard size of media.

•

Transparent media cannot be used. When using transparent media, also use release media that is not transparent.

•

Media with roughly cut edges and media that is damaged can cause erroneous scans.

•

This method cannot be used with roll media.

•

For available media setting on the software,you must congure the standard paper size the same as that of

•

your congured plotter.

Simple Printing & Cutting

1. On the "HOME" screen, select the CONDITION NO. to use by using the " " and " "

and set the tool.

2. From the "MENU" screen, open the "AREA 1/2" screen and set

"MEDIA AXIS ADJUST" to "ON".

3. Touch the (Exit) to return to the "HOME" screen and load the

printed media to make a sample cut.

4. Measure the displacement of the cutting line from the printed media that has been loaded.

Deciding the Offset Volume

Measure the offset volume (displacement amount) along the X-axis (vertical) and Y-axis (lateral) between

the position at which you intended to make the cut and the position that was actually cut.

In the image below, the values are negative for both X and Y.

Y Value

+–

Media Transport Direction

X Value

–+

Intended Cutting Position

Origin

Media

X

Actually

Cut Position

Y

3-3

Page 40

Chapter 3 Cutting along Printed Data

Deciding the Distance Adjustment Volume

Measure the lengths of X (vertical) and Y (lateral) for the shape of the data (printed media) and the

shape that was cut.

Media Transport Direction

Data Value X

Cut Value X

Origin

Data Value Y

Cut Value Y

"AREA 1/2" screen, proceed to the "AREA

2/2" screen, and input the offset and the

correction value for distance adjustment.

The space inside the white boxes for

numerical input can be touched to transition

to the input screen. Input the values for the

offset value in the X/Y directions and the

distance adjustment volumes in the X/Y

directions.

Intended Shape to be Cut

Shape

Actually Cut

5. From the "MENU" screen, open the

Media

How to Input Numbers

Offset Volume:

Input the displacement amount and conrm the input with the

.

Distance adjustment volume:

Input the enlargement/reduction rate (%) and conrm the

input with the

.

When the cut value is 50 mm and the data value is 51 mm,

(Data value [51] – Cut value [50) / Cut Value [50]) × 100 (%) = 2

so set +2% (after being set, the cut will be made at a length of

51 mm).

6. Touch the (Exit) to return to the "HOME" screen, load the printed media, and perform the cutting

operation.

7. To make multiple cuts, send the data while changing the media.

Printing & cutting will be performed according to the tilt when the printed media is set.

3-4

Page 41

Chapter 3 Cutting along Printed Data

3.3

With this method, cuts will be made upon scanning the registration marks (reference lines) drawn on the media.

High-precision cutting is realized with this method as displacement of the printing position is adjusted when

cutting the outline of a printed shape or when re-cutting media.

If the registration marks cannot be scanned due to a registration mark scanning error or when the positions

•

are off despite the registration marks being scanned, refer to "5.6 Registration Mark Scan Settings" and

change the settings.

Registration Mark Scanned Printing & Cutting

1. Create printed media on which registration marks have been drawn (refer to "3.4 Types and Arrangement

of Registration Marks).

2. On the "HOME" screen, select the CONDITION NO. to use by using the " " and " "

and set the tool.

3. Load the printed media on which registration marks have been drawn.

4. Touch the (Position) to open the "MOVE POSITION" screen.

5. Use the " ", " ", " " and " " to move the tool to the

registration mark scan starting area.

If the current position of the tool is far away from the registration

mark scan starting area, it may take time to search for the

registration marks or the process may even end in an error.

Registration Mark Type 1 Registration Mark Type 2

Y

X

Media Transport Direction

Registration Mark

Scan Starting Area

Y

X

Media Transport Direction

Registration Mark

Scan Starting Area

6. Touch the (Exit) to return to the "HOME" screen and perform the cutting operation.

7. To make multiple cuts, send the data while changing the media.

Printing & cutting will be performed according to the tilt when the printed media is set.

3-5

Page 42

Chapter 3 Cutting along Printed Data

3.4

The types of registration marks that can be scanned with this device are explained in this chapter.

Upon understanding the details, create the registration marks using the dedicated application software of

"Graphtec Pro Studio", "Cutting Master 4", or "Graphtec Studio for Mac".

Download the application software from our company website.

URL: http://www.graphtec.co.jp/en/imaging/celite/support.html

Types and Arrangement of Registration Marks

Registration Mark Shapes

The shape of the registration marks can be one of two types - Type 1 or Type 2.

Create the registration marks as plot data using the dedicated application software. Registration marks unique

to the application software cannot be used.

Line thickness of registration marks: 0.3 - 1.0 mm

Registration mark size: 5 - 20 mm

Registration Mark Type 1

Used when registration marks are preferably left

outside of the cutting area. The cutting area within

the media will become smaller to account for the size

of the registration marks.

Y

Registration Mark Type 2

Used when the cutting area is preferably kept as

close as possible to the size of the media. Care must

be taken as the registration marks will be placed

within the cutting area. Cutting cannot be performed

near the registration marks.

Y

X

Media Transport Direction

X

Media Transport Direction

3-6

Page 43

Positions for Registration Mark Arrangement

Registration marks are arranged on the edge of the media with a margin.

Chapter 3 Cutting along Printed Data

Unit: mm

Numbers within brackets

"( )" are for when the

margin is expanded

1136

X

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

10 (5) 10 (5)

1132

Y

X

16 (11) 16 (11)

The area required to scan the registration marks is as shown below.

When a plot other than a registration mark exists in the registration mark scanning area, the plot may be

•

mistaken for a registration mark.

Be sure to clean the media so that it is free of dirt and dust, etc. Dirt or dust may be mistaken for a

•

registration mark.

Create the registration marks using a contrast that is easy to scan such as black on white media. Adjust the

•

registration mark settings when using the media other than white or glossy media. (Refer to "5.6 Registration

Mark Scan Settings")

Y

Registration Mark Type 2 Registration Mark Type 2

X

Media Transport Direction

6

Registration Mark Scanning Area Registration Mark Scanning Area

If a registration mark scan error occurs, congure the registration mark scan settings. (Refer to "5.6

•

6

Y

X

6

Unit: mm

6

Registration Mark Scan Settings")

For details on creating registration marks using the dedicated application, refer to "3.5 Flow of Creating

•

Registration Marks to Cutting".

3-7

Page 44

Chapter 3 Cutting along Printed Data

Automatic Registration Mark Position Detection

The area of "A" is scanned from the registration mark scan starting position (position of the tool), and if a

registration mark is not located in the area of "A", the area of "B" is scanned.

Registration marks can be recognized as registration marks if they exist within the areas of "A" or "B".

Media Transport Direction

Registration Mark

ScanStarting Position

B

B

AA

100100

100

It may be difcult to scan registration marks depending on the state of the media being used.

Transparent media

•

Media with blurry printed registration marks

•

Bent media

•

Media with a dirty surface

•

Media having a thickness of 0.6 mm or more

•

Laminated media (depending on the type and state of lamination)

•

Media on which black registrations mark lines are not printed on a white surface.

•

When using media on which black registrations mark lines are not printed on a white surface, set AUTO MARK

SCAN to OFF. (Refer to "Setting Automatic Registration Mark Position Detection")

Otherwise, congure the registration mark scan settings. (Refer to "5.6 Registration Mark Scan Settings")

100

3-8

Page 45

Chapter 3 Cutting along Printed Data

3.5

The ow from creating the registration marks using the dedicated application to cutting the plot is explained in

this chapter.

Flow of Creating Registration Marks to Cutting

Graphtec Pro Studio

[1] Creating the registration marks

1. Using the "Rectangle" tool in Graphtec Pro Studio, create a rectangle over

the design.

A margin is required at the edge of the media when creating the rectangle.

As the printing position may vary depending on the printer used to print

the design, it is recommended that a few extra millimeters be allowed for

the margin.

Y

Media Transport Direction

X

Margin

2. Select the rectangle, and then select "Effects" – " Rectangle to Contour

Cut Mark...".

3. On the "Design Central" screen, select the type of registration mark.

4. Click the "Options".

The "Graphtec Mark Options" screen

will appear where you can specify

the length and line thickness of the

registration marks.

After specifying each item, close the

screen.

5. On the "Design Central" screen, click the

"

".

Registration marks will be created over the

design.

Media Transport Direction

X

Y

Registration Mark Type 1 Registration Mark Type 2

3-9

Page 46

Chapter 3 Cutting along Printed Data

[2] Creating data for printing & cutting

1. Create data for printing & cutting.

2. Select the printing data, and then select "Effects" – "Contour

Cut...".

On the "Design Central" screen, select the offset for the outline.

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

3. On the "Design Central" screen, click the " ".

Cutting data will be created over the design.

[3] Printing the created data

1. Print the created data.

CAUTION

Be careful to observe the following items as doing otherwise will lead to not being able to scan the

registration marks and perform the cutting.

Set the enlargement/reduction scale to 100%.

•

Set the printing position (center / bottom left, etc.) to "Do Not Change".

•

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Cutting Data

3-10

Page 47

[4] Cutting the printed media

1. Load the printed media onto CE LITE-50.

(Refer to "2.4 Loading Sheet Media")

2. Click the "Cut Contour" icon.

3. The "Cut Contour" screen will launch.

In order to match the orientation in

which the media has been loaded, set

ROTATE to "

When the "Cut Contour" screen is

•

displayed for the rst time, the "Add

Device" screen will be displayed.

Follow the on-screen instructions to

select "CE LITE-50" for the model

name and "Graphtec USB" for the

connection destination.

".

Chapter 3 Cutting along Printed Data

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

4. Click the "Send".

5. A conrmation screen will appear.

Move the tool to the registration mark (red square) at the top

left and click the "OK".

Scanning of the registration marks will begin, and once all

of the registration marks have been scanned, the cutting will

begin.

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Move tool

here

3-11

Page 48

Chapter 3 Cutting along Printed Data

Cutting Master 4

[1] Creating the registration marks

1. Using the "Rectangle" tool in Illustrator or CorelDRAW, create a rectangle

over the design.

A margin is required at the edge of the media when creating the rectangle.

As the printing position may vary depending on the printer used to print

the design, it is recommended that a few extra millimeters be allowed for

the margin.

2. After selecting the rectangle, when using Illustrator,

access the File menu and select "Cutting Master4" –

"Registration Marks".

When using CorelDRAW, go to the tool bar and select

"Launch" – "Registration Marks (CM4)".

When using a version of CorelDRAW that is X7

•

or earlier, the registration marks screen will be

displayed when it is selected from the application

launcher.

The screen to the right is the screen that appears

•

when it is launched from Illustrator.

Y

Media Transport Direction

X

Margin

3. Specify the registration mark type, line thickness, and

length.

Place a check in "Convert rectangle".

4. Close the registration marks screen.

Registration marks will be created over the design.

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

3-12

Page 49

[2] Creating data for printing & cutting

1. Create data for printing & cutting.

It is recommended that the printing data and cutting data be

created on separate layers.

[3] Printing the created data

1. Print the created data.

Before printing the data, set the layer containing the cutting data to be hidden.

Chapter 3 Cutting along Printed Data

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Cutting Data

CAUTION

Be careful to observe the following items as doing otherwise will lead to not being able to scan the

registration marks and perform the cutting.

Set the enlargement/reduction scale to 100%.

•

Set the printing position (center / bottom left, etc.) such that the relative positioning of the position of

•

the created document and the printed results are the same.

3-13

Page 50

Chapter 3 Cutting along Printed Data

[4] Cutting the printed media

1. Load the printed media onto CE LITE-50.

(Refer to "2.4 Loading Sheet Media")

2. When using Illustrator, access the File menu and select "Cutting Master4" – "Cut / Plot".

When using CorelDRAW, go to the tool bar and select "Launch" – "Cut / Plot (CM4)".

When using a version of CorelDRAW that is X7 or earlier, this can be selected from the application

•

launcher.

Before selecting the cutting plot, set the layer containing the printing data to be hidden.

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

3. The "Cut / Plot" screen will launch.

In order to match the orientation in which the

media has been loaded, set ROTATE to "

When the "Cut / Plot" screen is displayed

•

for the rst time, the "Add Device" screen

will be displayed.

Follow the on-screen instructions to select

"CE LITE-50" for the model name and

"Graphtec USB" for the connection

destination.

".

4. Click the "Send".

5. A conrmation screen will appear.

Move the tool to the registration mark (red square) at the top

left and click the "OK".

Scanning of the registration marks will begin, and once all

of the registration marks have been scanned, the cutting will

begin.

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Move tool

here

3-14

Page 51

Graphtec Studio

[1] Creating the registration marks

Chapter 3 Cutting along Printed Data

1. From the "Registration Marks" tab in Graphtec Studio, create registration

marks over the design.

A margin is required at the edge of the media when creating the

registration marks. As the printing position may vary depending on the

printer used to print the design, it is recommended that a few extra

millimeters be allowed for the margin.

2. Specify the registration mark pattern, length, line thickness, and

arrangement positions.

Y

3. Registration marks will be created over the design.

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Y

Media Transport Direction

X

Margin

[2] Creating data for printing & cutting

1. Create printing data and cutting data for printing & cutting.

Create the cutting data upon specifying a color that is not

used in the printing data.

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Cutting Data

3-15

Page 52

Chapter 3 Cutting along Printed Data

[3] Printing the created data

1. Print the created data.

CAUTION

Be careful to observe the following items as doing otherwise will lead to not being able to scan the

registration marks and perform the cutting.

Set the enlargement/reduction scale to 100%.

•

Set the printing position (center / bottom left, etc.) such that the relative positioning of the position of

•

the created document and the printed results are the same.

[4] Cutting the printed media

1. Load the printed media onto CE LITE-50.

(Refer to "2.4 Loading Sheet Media")

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

2. Open the "Congure Cut Job" panel.

From "Apply Conditions", select "By Color" and select the color to cut

along.

3. Open the "Page" panel.

In order to match the orientation in which the media has been loaded,

set ROTATE to "180°".

4. Open the "Cutters" panel.

5. Move the tool to the upper left registration mark (indicated

in red).

Y

Registration Mark Type 1 Registration Mark Type 2

Media Transport Direction

X

Move tool

here

6. Click the "Sent to Cutter".

Scanning of the registration marks will begin, and once all

of the registration marks have been scanned, the cutting will

begin.

3-16

Page 53

Chapter 4 Convenient Functions

Convenient cutting functions that this device is equipped with are explained in this chapter.

4.1 Cutting Roll Media

4.2 Cutting using the Carrier Sheet

4.3 Plotting with the Drawing Pen

Cutting from a USB Memory

4.4

4.5

Cutting Multiple Media using the Same Data

(Copy Function)

Cutting upon Specifying the Cutting Position

4.6

4.7

Expanding the Cutting Area

4.8 Aborting and Pausing during a Cut

4.9 Withdrawing the Tool Carriage

Page 54

Chapter 4 Convenient Functions

4.1

To use roll media, load media to the roll media stocker. Roll media of standard media width can be used.

Depending on the type of media (especially with high transparency), the media cannot be set because CE

•

Depending on the type of media, the center of the media may be lifted up because the push rollers cannot

•

Move the Media holding rollers (movable) after raising the Media set levers.

•

Limp or too much thin media cannot be cut.

•

For more information on the media width detection, refer to "5.7 Setting the Media Width Detection."

Supported widths: A4 - 20 inch (refer to "1.5 Media Size and Cutting Area")

Mountable diameters: 2 inch media core Maximum diameter of 150 mm, Minimum diameter of 52.8 mm

Mountable weight: 2.5 kg or less

Cutting Roll Media

LITE-50 cannot detect the leading edge /width /position of the media. In this case, disable the Media width

detection.

hold down the media sufciently. In this case, move the Media holding rollers (movable) to the position where

the media is lifted up. When the media is load at, move them to the right push roller.

3 inch media core Maximum diameter of 150 mm, Minimum diameter of 78.2 mm

Assembling the Roll Media Stocker

Set the roll media stocker along the roll media stocker guide rail on the bottom of the main unit. Pay attention to

the orientation of each part and set Part A on the left, Part C on the right, and Part B in a position that suits the

width of the roll media.

Roll Media Stocker Guide Rail

A

B

C

Set Part D to the groove on the edge of Part A, B, and C as shown in the gure below.

D

4-2

Page 55

Chapter 4 Convenient Functions

Slide the rollers toward forward when using a 2 inch media core or toward backward when using a 3 inch media

core. Loosen the knob to move the roller and fasten the knob to x the roller in place. Place the roll media on

top of the rollers so that the media can be pulled out from the top.

Roll Media

Knob

Roller

Roller

Roller

Roller

Knob

When using the roll media stocker, pay attention to the installation space so that the cutting operation is not

affected (refer to "1.4 Installing the Main Unit").

4-3

Page 56

Chapter 4 Convenient Functions

Loading and Scanning Roll Media

There are two types of ways to load roll media with this device.

ROLL START EDGE

Use this option if you wish to cut from the edge of the roll media. The width and the leading

edge of the roll media will be scanned.

ROLL CURRENT POSITION

Use this option if you wish to cut from the middle of the roll media. Only the width of the

roll media will be scanned.

Loading the Media Up Against the Push Rollers

When loading the roll media up against the push rollers, the detection method will be "ROLL START EDGE".

1. Raise the media set levers on both sides and release the push rollers.

2. Set the push roller on the left side at the position of the " " mark.

Set the push roller on the right side according to the width of the roll media.

3. Lower the media set levers on both sides and lock the push rollers.

4. Pull out the roll media and create slack in the roll media that is the same amount as the length used at

the front of the main unit.

Create slack equivalent to

length being used

5. Press "LOAD MEDIA" on the "HOME" screen, and select "ROLL

START EDGE".

4-4

Page 57

Chapter 4 Convenient Functions

6. Evenly position the leading edge of the roll media up against the push rollers.

Pass the roll media under the push roller positioning guide and load it so that it is parallel with the Front

front guide.

Push Roller

Front Guide

Leading Edge of Roll Media Push Roller

Leading Edge of Roll Media

Push Roller

Roll Media

Set to be parallel

Roll Media

7. Align the left edge of the roll media with the "I" marking of the " " mark on the front guide.

Front Guide

Roll Media Marking Roll Media

8. The roll media is set after detecting the width and leading edge.

Operate the device by following the on-screen instructions when an error message appears.

CAUTION

When the "ROLL START EDGE" is touched, the media and tool carriage will start moving. Be careful to

avoid contact with your body or any object.

4-5

Page 58

Chapter 4 Convenient Functions

Loading the Media upon Releasing the Push Rollers

When loading the roll media upon releasing the push rollers, there are two types of ways to scan the roll media

- "ROLL START EDGE" and "ROLL CURRENT POSITION".

1. Raise the media set levers on both sides and release the push rollers.

2. Set the push roller on the left side at the position of the " " mark.

Set the push roller on the right side according to the width of the roll media.

3. When Scanning at the Edge of the Roll Media

Insert the front edge of the roll media in until it reaches the cutting mat (white translucent mat) behind the

push rollers.

Pass the roll media under the push roller positioning guide and load it so that it is parallel with the front

guide.

If the roll media is inserted too far, there may be cases when the media cannot be scanned.

When Scanning the Roll Media at the Loaded Position

Insert the roll media until the position at which you wish to start cutting is at the home point.

Pass the roll media under the push roller positioning guide and load it so that it is parallel with the front

guide.

Roll Media

Home Point

Cutting Mat

Leading Edge of Roll Media

Push Roller

Push Roller

Scan at

Loaded Position

Front Guide

Scan at

Edge

Roll Media

Roll Media

Set to be parallel

4. Align the left edge of the roll media with the "I" marking of the " " mark on the front guide.

Front Guide

Roll Media Marking Roll Media

5. Lower the media set levers on both sides and lock the push rollers.

4-6

Page 59

Chapter 4 Convenient Functions

6. Pull out the roll media and create slack in the roll media that is the same amount as the length used at

the front of the main unit.

Create slack equivalent to

length being used

7. On the "HOME" screen, touch the "LOAD MEDIA".

When Scanning at the Edge of the Roll Media

By touching the "ROLL START EDGE", the width and the

leading edge of the roll media will be scanned and the roll

media will be loaded.

When Scanning the Roll Media at the Loaded Position

By touching the "ROLL CURRENT POSITION", only the width

of the roll media will be scanned and the roll media will be

loaded.

If an error is displayed, operate the device by following the on-