Page 1

CE6000 SERIES

CUTTING PLOTTER

SETUP MANUAL

MANUAL NO.CE6000-UM-8M4

Preface

Thank you for choosing this product. Carefully keep this manual in a handy location for quick reference as necessity

prior to use to ensure safe and correct use and also to thoroughly understand the functions and operate them

effectively.

Prior to use

Be sure to read the attached "TO ENSURE SAFE AND CORRECT USE" prior to use. Otherwise, it may cause an

unexpected accident or re.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

without the prior written permission of Graphtec Corporation.

(2) The product specications and other information in this manual are subject to change without notice.

(3) While every effort has been made to provide complete and accurate information, please contact your sales

representative or nearest Graphtec vendor if you nd any unclear or erroneous information or wish to make other

comments or suggestions.

(4) Notwithstanding the stipulations in the preceding paragraph, Graphtec Corporation assumes no liability for damages

resulting from either the use of the information contained herein or the use of the product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks or registered

trademarks of their respective companies.

Copyright

This User's Manual is copyrighted by Graphtec Corporation.

Roles of each manual

Setup Manual (this manual) Read it to understand Displaying method for User's Manual, Method for connecting

•

User's Manual (PDF data) Read it to thoroughly understand the functions.

•

Cutting Plotter Controller Manual (PDF data)

•

Read it to run the software "Cutting Plotter Controller" for operation of this Cutting

this Cutting Plotter with the PC, Installing method for controller driver software, and to

prepare for the operation.

Plotter through your PC.

621588810

Page 2

Before starting the Setup

Make the following preparations before starting Setup.

Check that all of the items included in the package. (Please see the User's Manual (PDF).)

•

For the Parts Names, please see the User's Manual (PDF).

Assemble this Cutting Plotter, and set up it. For the assembling procedures, see either Manual attached to the Stand or

•

User's Manual (PDF).

To use the Cutting Master 4, previously install the Design application (Adobe Illustrator or CorelDRAW) that is used.

•

For the latest supported version, please visit our website.

When there are virus detection program or system resident program, terminate them beforehand.

•

Upon installation, be sure to log into Windows using an account with administrator privileges on your computer.

•

CAUTION

Usage of the software

Each of the Cutting Plotter Controller/Graphtec Studio software is engaged in various settings on the Cutting Plotter. Do not use them at

the same time.

Flow of setup

Setting up the Plotter main unit

1. Attaching a Tool

2. Loading Media (Paper or Marking Film)

3. Aligning the Push Rollers

4. About the Initial Setup screen

5. Set the media type into the Plotter

6 Tool adjustment and test cutting

The cutter blade can replaced depending on the material or thickness of the

media.

Fix the media to the Plotter. P. 0 4

Adjust the position of the push roller. P. 0 9

Select "Display Language" and "Length Unit". P.1 0

Set the media type to the Cutting Plotter, depending on the set media. P.1 0

Adjust the protruded cutter edge length and the cutting Force depending on the material

and thickness of the media. Make test cutting for the set media to adjust the best condition.

Installing the Software

Setup in a Windows operating environment

•

Launching the Start menu

A. Install CE6000Plus Software

Installing the Cutting Plotter Controller

Installing the Driver software

(Cutting Plotter Driver)

• To connect using the USB

For each software, install them using the Installer housed in the attached

DVD-RO M.

Once Cutting Plotter Controller is installed, you can control main functions of

the Cutting Plotte through the PC.

The Driver software controls the Plotter and makes plotting according to the

data created by the PC.

Turn on the power source of Plotter in the middle of installing, and connect the USB cable.

P. 0 3

P.11

P.14

P.1 6

P.1 6

P.17

Install the software as necessity.

B. Setup the Graphtec Pro Studio

C. Setup the Cutting Master 4

D. Install the User's Manual

Setup in a Macintosh operating environment

•

A. Setup the Cutting Master 4

B. Setup the Graphtec Studio

Software enabling cutting data to be created through simple commands.

Create designs and edit characters/shapes using this software.

Plug-in driver that enables simple cutting through direct operation from within

Adobe Illustrator and CorelDRAW.

Installs the User's Manual. P.1 8

Plug-in driver that enables simple cutting through direct operation from within

Adobe Illustrator.

Software enabling cutting data to be created through simple commands.

Create designs and edit characters/shapes using this software.

P.1 8

P.1 8

P.1 9

P.1 9

2

Page 3

Setting up the Plotter main unit

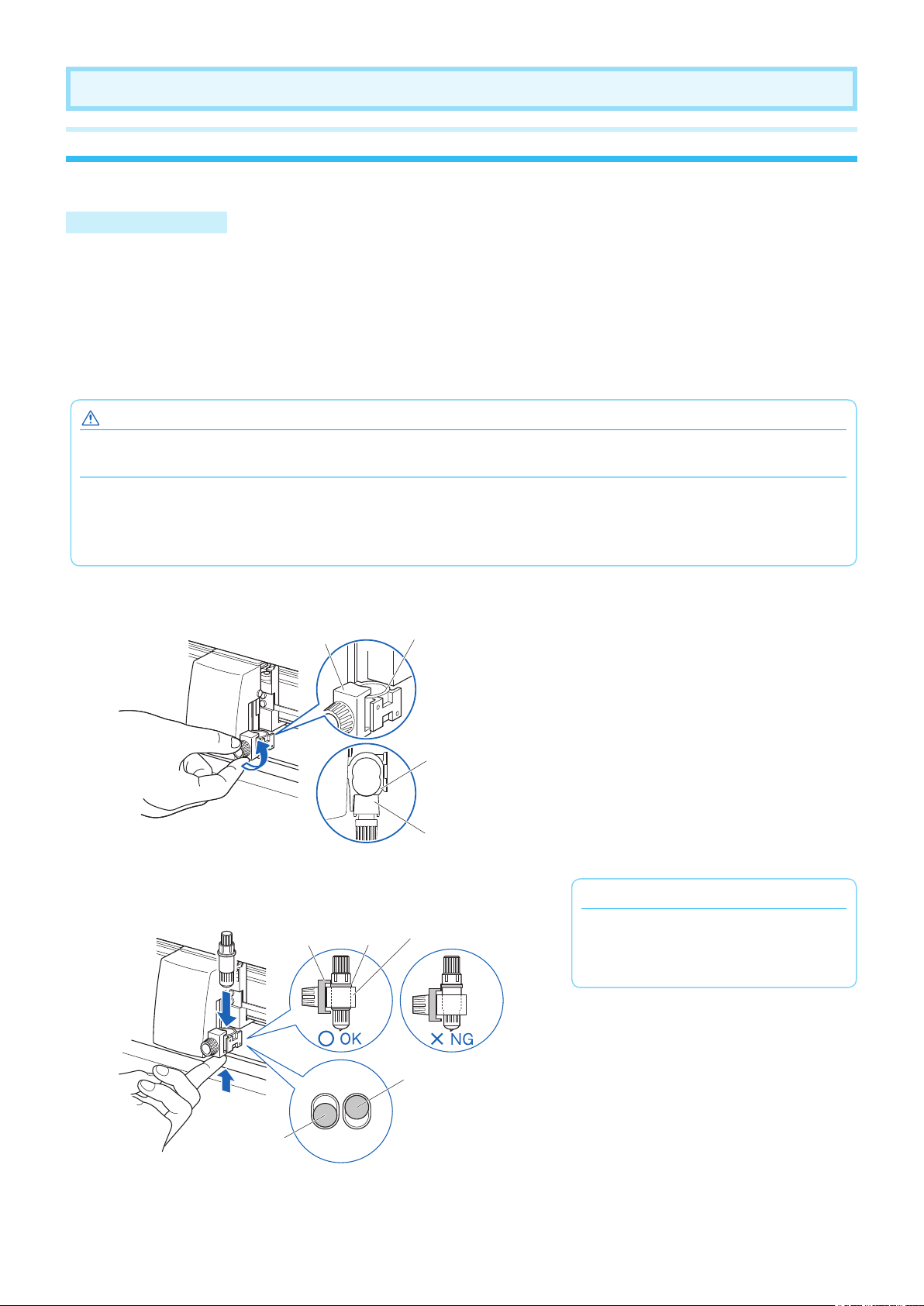

1. Attaching a Tool

Attach a tool (cutter plunger, plotter pen) to the plotter.

Attaching a Tool

When mounting the tool in the tool holder, please note the following.

Push the tool all the way into the holder until its ange contacts the upper part of the holder and then tighten the screw

•

rmly.

To prevent injury, avoid absolutely touching the tool immediately after the cutting plotter is turned on or whenever the tool

•

is moving.

For details, see “Attaching a Tool” on in User’s Manual.

It is explained here using cutter plunger as an example.

CAUTION

When pushing the tool holder with your ngers, the blade tip may be protruding. Take care not to cut your ngers.

Supplement

When using with half cutting and plotter pen, set the seal in Tool Holder 1 (backward), and when using cutting out (perforated cut), set

•

the seal in Tool Holder 2 (forward).

Cutting out means that the media is cut out completely.

•

Half cutting means that only the marking lm is cut out, leaving the backing sheet uncut.

•

1 Loosen the tool holder screw.

Bracket to hold tool

Top

2 While pushing up the tool holder, push until its ange completely touches

the upper part of the holder.

Bracket to

hold tool

Flange

Tool holder

Tool holder

Bracket to hold tool

Tool holder

Supplement

When using with half cutting and plotter pen,

set the seal in Tool Holder 1 (backward), and

when using cutting out (perforated cut), set the

seal in Tool Holder 2 (forward).

Tool holder 2

(Forward : Using

cut ting)

Tool holder 1

(Backward : Half cutting/Plotting Pen)

3

Page 4

3 Make sure that the tool bracket is engaged on the tool's ange, and then tighten the screw.

Bracket to hold tool

Flange

Removing the tool

When removing the tool, turn it counterclockwise to remove the tool.

2. Loading Media (Paper or Marking Film)

Both roll media and sheet media can be used with the CE6000.

Load the media according to the instructions given for each type. Use the grit roller on the right side of the media (looking

from the front) as a guide when setting it in the media sensor. Afterwards, adjust the push roller so that it's lined up with the

side of the media.

For details, see User's Manual (PDF).

Loading Roll Media

1 Lower the media set lever to raise the push rollers.

Push roller

Media sensor

2 Set the roll media on top of the stock shaft, and then insert the roll media into the stopper. Once it's set, tighten the

stopper's screws.

Media set

lever

Supplement

For more information about the position of the

push roller, see "Adjust the Push Roller".

Stopper

4

Page 5

3 Push the tip of the roll media forward from the back of the CE6000.

Make sure to pull it so that there is no slackening across the roll media's

route.

When using the roll media tray

Put the roll media on the roll media tray and

then push the tip of the roll media forward from

the back of the machine.

4 Press the media stopper to engage it, and then pull the leading edge

out of the front of the plotter, making sure that it completely covers the

media sensor.

Media sensors

Media stopper

Slide th e

media

stopper

5 Position the media and the push rollers to correspond with the width of

the media.

When using the model with 2 push rollers

The push rollers push down on either side of the media. Use the grit

roller position guide to make sure the push rollers are set on top of the

grit rollers.

Push roller

Grit roller

Grit roller position guide

Push roller

Media stopper

This stops the stock shaft from spinning when

setting in media. It is also utilized when pulling

roll media straight out.

Supplement

When actually cutting, please release the lock

from the media stopper (while pulling to the

exterior, slide it forward).

Supplement

The media must always be positioned over

•

the media sensor.

See "Aligning the Push Rollers" about the

•

position of the push rollers.

Media

Media sensor

5

Page 6

When using the model with 4 push rollers

Use the 4 push rollers to push down the sides and center of the media.

Use the grit roller position guide and make sure the push rollers are on

top of the grit rollers.

You can adjust the center push roller's hold-down force.

Push roller

Grit roller position guide

Push roller

Grit roller

Media sensor

(The push roller is on top of the grit roller.)(The push roller is on top of the grit roller.)

Supplement

The media must always be positioned over

•

the media sensor.

See "Aligning the Push Rollers" about the

•

position of the push rollers.

See "Aligning the Push Rollers" for

•

information about push roller hold-down

force.

(The center push roller is not on top of the

grit roller.)

(The center push roller is near the edge.)

When Feeding Long-axis Media (at exceeds 2 meters)

Position the push rollers at least 15 mm inside the edges of the media.

Push roller

15mm 15mm

Media

When Feeding Long-axis Media (at least 2 meters)

Position the push rollers at least 5 mm inside the edges of the media.

Push roller

5mm 5mm

Media

6 Pull the media taut to make sure that there is no slack in the conveyance path, and then raise the media set lever to

lower the push rollers.

Media set lever

6

Page 7

7 Release the lock from the media stopper (Pull the sides and slide it forward).

Release

the media

stopper

Media stopper

8 When the set lever is up (and the media is held down by the push rollers)

and the media stopper is unlocked, pull out the roll media and give it

slack.

Give it slack

Create the same amount of slack in the media as will be used for the

back of the machine.

Supplement

Dirt from the oor may stick to the media when

giving it slack, so please be careful.

When using the roll media tray

Create the same amount of slack in the media

as will be used for the back of the machine.

Step 1: Raise the set lever

and x the media.

Step 2: Create slack.

Give it slack

Loading Sheet Media

1 Lower the media set lever to raise the push rollers.

Push roller

Media sensor

Media set lever

7

Supplement

See "Aligning the Push Rollers" about the

position of the push rollers.

Page 8

2 Make sure that the sheet media completely covers the media sensor.

Media sensor

3 Position the media and the push rollers to correspond with the width of

the media.

Supplement

Refer to the description of "Loading Roll

Media".

4 Pull the media taut to make sure that there is no slack in the conveyance path, and then raise the media set lever to

lower the push rollers.

Set the sheet media so that the paper's edges line up with the guideline on the front side.

Media set lever

Line up

When using the model with media guide bar

4 Pull out the front media under the media guide bar.

Media guide bar

5 You can set the media straight by stacking media you pull out and matching the edges up together.

After you check to make sure there's no slack, raise the media set lever and xate the sheet media in the push roller.

Media set lever

Line up

Media guide bar

8

Page 9

3. Aligning the Push Rollers

This section describes how to alignment of the push rollers.

Aligning the Push Roller

Position the left and right push rollers to correspond with the width of the media. Adjust the push rollers so that they are

positioned above both the media and the grit rollers.

Position the push rollers within the grit roller position guides ensures that they are above the grit rollers.

Push roller

Grit roller position guide

(It isn't on the grit roller.) (It isn't on the grit roller.)

Grit roller

CAUTION

To move the push rollers, the media set lever must be in the lowered position.

Supplement

If a [conrming push roller point] message appears after setting the media and raising the media set lever, it means the right push

roller is not on the right grit roller, or that the left or center push roller is not on the proper grit roller. Make sure everything is set

correctly.

For minimum width media

Make sure that all push rollers are on the long right grit roller.Use the left side of the grit roller as a starting point and then

set the push rollers so that they're on both sides of the media.

The settable width of the media is 55 mm or more (Model with 2 push rollers) or 125 mm* or more (Model with 4 push

rollers).

* When using the model with 4 push rollers, and all push rollers are on the right grit

roller (wide), turn the center (all rollers but the side rollers) push roller hold-down

for c e O F F.

The model with 2 push rollers

Grit roller

Media sensor

Push roller

The model with 4 push rollers

Grit roller

Push roller

Media sensor

Supplement

The model with 4 push rollers requires the

center push roller hold-down force to be set

based on the media's width and material type

in order to keep the media in place.

Media

Media

9

Lever Lever

Hold- down force:

Normal

Refer to "Changing the Hold-down Force".

Hold- down force: Low

(OFF)

Page 10

4. About the Initial Setup screen

The Initial Setup screen appears only when powering up the Cutting Plotter for the rst time after purchase. Here, you can

set "Display Language" and "Length Unit".

After the initial setup is completed, you can also select the menu from the READY status.

See "Connecting to the Power" for turning on the power.

1 Once the machine is powered on (with the " | " switch) a message will be displayed after the version is displayed.

Here, PLEASE DISPLAY LANGUAGE setting screen is displayed.

2 Use the POSITION ( ) keys to select the language.

(This manual assumes you chose the English language setting.)

3 Press the [ENTER] key.

After the DISPLAY LANGUAGE is selected, the LENGTH UNIT screen will appear.

4 Press the [1] key (METRIC) or the [2] key (INCH) to select the length unit setting.

5 Conrm the setting and press the [ENTER] key (SET).

Setting will be set, and the default screen is displayed.

5. Set the media type into the Plotter.

Set the media type into the Plotter depending on the preset media.

1 If you have already loaded the media, the MEDIA TYPE menu appears.

Select the media type to suit the loaded media.

Plot starting with the edge of

Roll media

Sheet media Set a sheet media. [3] SHEET

CONTINUE When similar media is reset [4] CONTINUE

media.

Plot starting with the preset

position.

[1] ROLL-1 FRONT EDGE

[2] ROLL-2 CURRENT POSITION

2 After the media is detected, the plotter is ready to receive data for cutting

or plotting. This status is called "READY status" of the default screen.

When setting is nished, the tool carriage's location will become the

initial point.

Dfault screen is displayed.

Menu screen

(Normal mode)

Menu screen

(Simple mode)

Release the media stopper.

Supplement

The CONTINUE menu parameter appears when

the media set lever is raised and then lowered

again after media was previously loaded, making

it possible to select the previous settings.

Simple mode/ Normal mode

You can use the [SIMPLE] key on the default

screen to switch between Simple mode and

Normal mode. CE6000 will be reset once when

you switch.

In Simple mode you can change easy settings

from the menu screen.

In Normal mode, you will be able to change

more detailed settings.

Simple mode and Normal mode are independent

from one another. The settings of the mode

you're currently in will take precedence.

For details, see "About Simple mode".

CAUTION

10

Page 11

6. Tool adjustment and test cutting

After setting the Tool/Speed/Force/Acceleration, make test cutting, and repeat until optimal condition is achieved.

1 Load the media for test cutting in the plotter.

2 Press the [COND/TEST] key in the default screen.

In Normal mode, CONDITION screen (1/3) is displayed.

In Simple mode, CONDITION screen (1/5) is displayed.

CONDITION screen

(Normal mode)

CONDITION screen

(Simple mode)

3 Set the Tool conditions (Tool, Speed, Force, Acceleration).

Ex.) TOOLS CONDITION

Settings screen (Normal mode)

Ex.) TOOLS CONDITION

Settings screen (Simple mode)

To make 1 cut with set value

4 Make test cutting for one piece while Tool conditions are

being set.

CAUTION

Do not touch the Tool edge when power is

turned on or during operation.

Setting the Tool conditions

For more information about the various cutting

conditions, see “Selecting Tool Condition”.

To make 3 cuts with set value and ±1 of set value

4 Make test cutting for three pieces while Tool conditions

are being set.

CONDITION screen

(Normal mode)

CONDITION screen

(Simple mode)

(1) Press the POSITION ( ) key (CUT TEST).

(2) Press the POSITION ( ) key the tool carriage

to the location you wish to perform the test cutting.

Tool carriage

Press the [ENTER] key.

Cut test pattern is cut.

CAUTION

When the [ENTER] key is

pressed, the tool carriage

will start moving, so take

care not to cut your ngers.

CONDITION screen

(Normal mode)

CONDITION screen

(Simple mode)

(1) Press the POSITION ( ) key (CUT TEST).

CUT TEST screen is displayed.

CUT TEST screen

(Normal mode)

CUT TEST screen

(Simple mode)

(2) Press the POSITION ( ) key the tool carriage

to the location you wish to perform the test cutting.

(3) Press the [1] key (FORCE).

3 cutting test patterns are cut,

with current FORCE in the

center, and 1 each of FORCE

increased and decreased for 1

+1 Setting

Cut Order

–1

values

(4) Press the [ENTER] key after completion.

It will return to CUT TEST menu screen.

(5) Press the [2] key (CUTTER OFFSET). (Normal mode

only)

3 cutting test patterns are cut, with current CUTTER

OFFSET in the center, and 1 each of CUTTER OFFSET

increased and decreased for 1.

(6) Press the [ENTER] key after completion.

It will return to CUT TEST menu screen.

11

Page 12

5 Check if the cut test is appropriate.

Conrm the cutting test results, and adjust to optimal setting. Repeat cutting test and adjustment until optimal cut is

achieved.

Adjustment of Offset

Check the corners of the triangles and rectangles. See "Setting the Tool"

and adjust the offset value if the corner is not cut or if it is cut too much.

Adjust offsets in Normal mode.

Adjustment for Half Cutting

Peel off the triangle area, and adjust so it cuts slightly into the backing

sheet.

If the backing sheet has been cut through, either the FORCE setting is

too high or the cutter-blade tip is extended too far. If the backing sheet

shows only a few traces of the cutter blade, either the FORCE setting is

too low or the cutter blade tip is not sufciently extended.

See "Adjusting the Blade Length" and "Setting the Force" and adjust the

settings.

How to check offset

Check if the offset value is set correctly by

following.

Not enough adjustment. Increase

the offset value.

Optimal offset value.

Too much adjustment. Decrease

the offset value.

Adjustment for Cutting Out

Adjust so the media is completely cut out.

If the media is not completely cut, either the FORCE setting is too low or the cutter blade tip is not sufciently extended.

See "Adjusting the Blade Length" and "Setting the Force" and adjust the settings.

Adjustment When Using Plotting Pen

Adjust the FORCE so there will be no faint lines. To prolong the pen life, set the FORCE to the lowest setting without any

faint lines. See"Setting the Force" or setting the FORCE.

Adjust the Blade Length (Automatic Height Adjust)

Test cutting must be performed several times in order to conrm the optimal blade length setting. However, if the blade

length adjustment function is used, the optimal length can be easily set.

1 Load the media for test cutting in the plotter.

2 Press the POSITION ( ) key the tool carriage to the location you wish to perform the blade length adjustment.

3 Press the [COND/TEST] key in the default screen.

CONDITION setting screen (1/3) is displayed.

4 Press the POSITION ( ) key.

CONDITION setting screen (3/3) is displayed.

Supplement

Perform the settings in Normal mode.

5 Press the [3] key (BLADE ADJUST).

Message prompting to turn the blade-length adjustment knob is displayed.

12

Page 13

6 As instructed, turn the blade length adjustment knob to the left to fully

retract the blade.

Blade

7 Set the cutter Plunger in Tool Holder 1 (Backward).

8 Press the [ENTER] key.

You can calculate the height by moving the tool up and down.

TO ACHIEVE THE TARFET LENGTH screen is displayed.

9 Press the [1] key (BLADE LENGTH TARGET).

BLADE LENGTH TARGET screen (TARGET) is displayed.

CAUTION

Do not touch the Tool edge when power is

turned on or or during operation.

Supplement

See "Structure of Cutter Plunger" for

bladelength adjustment knob.

Supplement

Adjustment is only possible for the cutter pen

set in Tool Holder 1 (Backward). It does not

apply to Tool Holder 2 (Forward).

See "Attaching a Tool" for instructions on

setting.

10 Press the POSITION ( ) key and increase or decrease the setting value.

11 Conrm the settings and press the ENTER key (SET).

The Blade Length Target will be selected, and you will return to the TO

ACHIEVE THE TARGET LENGTH screen.

12 Press the [2] key (CHECK).

You can calculate the height by moving the tool up and down.

The amount and direction to turn the adjustment knob is displayed.

13 Turn the blade-length adjustment knob and adjust the cutter blade length.

[2] Current blade length is displayed by pressing the [2] key (CHECK) , so

adjust the blade length until it matches the thickness of the media.

14 Press the [3] key (END).

Adjustment is completed and it will return to CONDITION screen (3/3).

15 Press the [COND/TEST] key.

I will be return to default screen. After completing the settings, press [ENTER] key.

Supplement

"T" is the target value of the blade length, and

"H" is the current blade height (amount).

Turning the blade-length adjustment knob

displays the number of turns and direction.

CAUTION

Depending on the loaded media, the blade

might sink in to the media, making accurate

measurement impossible.

13

Page 14

Installing the Software

Install the software housed in the attached DVD-ROM into the PC that is used.

This section explains how to install the software when using a Windows 10 (64 bit) operating environment.

Note

• Graphtec Studio : Software application that enables cutting data to be created through simple commands.

• Cutting Master 4 : Plug-in driver that can be directly operated from within Adobe Illustrator.

When checking the manual in the Macintosh operating environment, open the pertinent manual on the accompanying

• Upon installation, be sure to log on Windows using an account with administrator privileges on your computer.

If you have logged on using a standard user account, an [User Account Control] screen asking you to enter the

administrator account password may appear.

Supported OS

•

This software supports the following OS environments:

Windows 10 (32 bit/64 bit), Windows 8.1 (32 bit/64 bit), Windows 8 (32 bit/64 bit), Windows 7 (32bit/64bit),

(Plotter driver/Cutting Plotter Controller also supports Windows Vista.)

Mac OS X 10.11 to 10.7 / mac OS 10.12

(Graphtec Studio also supports Mac OSX 10.6.)

When Using Macintosh

•

Macintosh operating environments are supported by the following software.

Proceed with installation in accordance with your operating environment.

Note that Adobe Illustrator must be installed on your computer prior to use.

DVD-ROM in the following sequence: [Mac] > [Manuals] > [English (Each language)] > [Manual According to Software].

Setup in a Windows operating environment

•

1. Launching the Start Menu

< When using the DVD >

After starting up Windows, insert the [USER GUIDE & SOFTWARE DVD] provided with the CE6000 into your computer's

DVD drive.

The below screen will appear before the Start Menu launches.

Continue with installation in accordance with the following procedures.

1 The start-up message of DVD drive is displayed. Click on the message.

* When setting up the DVD in the computer, this message will disappear after a few seconds.

2 DVD operation screen is displayed.

Select the “Run MultiSetup.exe” from the DVD operation screen.

* If the DVD operation screen is not displayed, select the set DVD drive from the Explorer.

Open the DVD and double-click on [MultiSetup.exe].

14

Page 15

3 Click [Yes] if you have logged on using an administrator account.

Supplement

If you have logged on using a standard user

account, an [User Account Control] screen asking

you to enter the administrator account password

may appear. Enter the password, and then click

[Yes].

4 The [Start] will appear.

"Use this menu to install the software you require to use the Cutting Plotter

First-time users should proceed with installation by clicking on [Install CE6000Plus Software]."

Proceed with installation according to your operating environment.

A. Install CE6000Plus Software:

Install the [Cutting Plotter Controller] and [Plotter Driver].

A

B

C

D

B. Setup Graphtec Pro Studio:

"Software enabling cutting data to be created through simple commands.

Create designs and edit characters/shapes using this software."

C. Setup Cutting Master 4:

Plug-in driver that enables simple cutting through direct operation from

within Adobe Illustrator and CorelDRAW.

Adobe Illustrator or CorelDRAW must be installed on your computer prior

to use.

D. Install User's Manual:

Installs the User's Manual.

15

Page 16

A. Install CE6000Plus Software

If you are using the Cutting Plotter for the rst time, click on

[Install CE6000Plus Software] to install the device.

This operation will install the [Cutting Plotter Controller]

and [Plotter Driver].

Note

Do not connect the accompanying USB cable yet.

Doing so may prevent the [Plotter Driver] from

being installed properly.

Refer to the procedures in this User's Manual

when connecting the USB cable.

Installing the [Cutting Plotter Controller]

1 Click on [Install CE6000Plus Software].

The [Setup] screen to setup Cutting Plotter Controller

for CE6000 will appear momentarily.

Click on [Next].

3 The [Select Program Folder] window will appear.

Simply click on [Next].

4 When the next screen appears, click on [Finish].

This concludes the installation of the [Cutting Plotter

Controller].

Next, install the [Plotter Driver].

2 The [Chose Destination Location] screen will appear.

Check the installation destination folder displayed. If

there is no need to change it, click on [Next].

Installing the [Plotter Driver]

5 After installation of the [Cutting Plotter Controller]

is complete, the [Setup] screen for the [Graphtec

CE6000Plus Driver] will appear momentarily.

When it does, click on [OK].

6 Next, check to make sure the [Cutting Plotter] is not

connected to your computer, then click on [Next].

7 Click on [Next] again.

16

Page 17

8 A window for selecting the [Port Name] to be used

appears.

Select [USB].

Clicking on [Next] will begin the driver installation

process.

Available Port Names

USB : Selected when a USB cable is used for

connection.

COM1 : Selected when an RS-232C (serial) cable is

used for connection.

FILE : Selected to save outputted data (plot data) to

a le.

Select "USB"

Supplement (When selecting the COM1)

To select "COM1" in "Selecting Port Name", do the

installation according to the message.

After the installation is completed, connect the RS-232C

cable. ( For more information about connecting the RS232C cable, see "Connecting the computer" in User's

Manu al.)

To connect the COM1 for RS-232C, the Cutting Plotter must

be set to "Normal mode". For more information about setting

the COM1, see "Preparing to Cut" in User's Manual.

Connecting the USB Cable

11 First, make sure that Windows 10 has been launched

successfully.

Next, connect the USB cable accompanying the Cutting

Plotter to your computer. Ensure that the Cutting Plotter

is turned off when you do.

(1) Ensure that the Plotter's power is turned off (" "

position).

(2) Connect the power cable.

(3) Connect the USB cable.

1. Connect to your computer.

9 The [Windows Security] screen will appear momentarily.

Click on [Install] to install the [Plotter Driver].

10 Next, the [Update for the Graphtec CE6000Plus driver

was completed] screen will appear.

Click on [OK] to reboot your computer.

This concludes the installation of the [Plotter Driver].

After rebooting your computer, follow the below procedures

to connect the USB cable.

2. Connect to the

Cutting Plotter.

USB cable

12 Turn on the Cutting Plotter.

13 Installation of the device starts.

After a while, the printer icon of Plotter will be added

in the "Devices and Printers" screen.

* To display the "Devices and Printers" screen, display the

"Control Panel" screen from the Start menu and then click

on the [Devices and Printers] in the [Hardware and Sound].

his concludes the installation of the driver software.

Next, please install the software applications.

Install the software in accordance with your operating

environment.

17

Page 18

B. Setup Graphtec Pro Studio

Please download the User's Manual separately from our website and perform the setup.

C. Set Up Cutting Master 4

Please download the User's Manual separately from our website and perform the setup.

D. Install User's Manual

Follow the below procedures to install the User's Manual

(pdf format).

Adobe Reader must be installed on your computer in order

to read the manual.

Installing "User's Manual"

1 Click on [Install User's Manual].

The [CE6000 User's Manual Setup] screen will appear

momentar ily.

Click on [Next].

2 When this screen appears, click on [Finish].

This concludes the installation of the [User's Manual].

The newly-installed [User's Manual] will be registered

under your Windows Start Menu.

18

Page 19

Setup in a Macintosh operating environment

•

A. Set Up Cutting Master 4

Please download the User's Manual separately from our website and perform the setup.

B. Setup Graphtec Studio

Please download the User's Manual separately from our website and perform the setup.

19

Page 20

621588810

Loading...

Loading...