Page 1

CE

5000 Series

USER’S MANUAL

MANUAL NO. CE5000-UM-153

CUTTING PLOTTER

Page 2

Page 3

i

PREFACE

Thank you for choosing a Graphtec CE5000 Series cutting plotter. The CE5000-60/120 cutting plotters

employ a digital servo drive system to achieve high-speed, high-precision cutting. In addition to cutting

marking film and other media, a CE5000 Series cutting plotter can also be used as a pen plotter. To ensure

high cutting quality and optimal productivity, be sure to read this User’s Manual thoroughly prior to use.

Notes on this Manual

(1) No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form

or by any means, without the prior written permission of Graphtec Corporation.

(2) The product specifications and other information in this manual are subject to change without notice.

(3) While every effort has been made to provide complete and accurate information, please contact your

sales representative or nearest Graphtec vendor if you find any unclear or erroneous information or

wish to make other comments or suggestions.

Notwithstanding the stipulations in the preceding paragraph, Graphtec Corporation assumes no liabil-

ity for damages resulting from either the use of the information contained herein or the use of the

product.

Registered Trademarks

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks or

registered trademarks of their respective companies.

Copyright

This User’s Manual is copyrighted by Graphtec Corporation.

Page 4

Page 5

iii

Contents

PREFACE

..................................................................................................................................................i

Notes on this Manual .........................................................................................................................i

Registered Trademarks .....................................................................................................................i

Copyright ...........................................................................................................................................i

Contents

.................................................................................................................................................. iii

1. INTRODUCTION

1.1 Checking the Accessories .............................................................................................. 1-2

1.2 Parts Names and Functions ........................................................................................... 1-3

Front View ......................................................................................................................... 1-3

Rear View.......................................................................................................................... 1-4

Control Panel..................................................................................................................... 1-5

2. SETTING UP THE CUTTER PLOTTER

2.1 Connecting to Your Computer ....................................................................................... 2-2

2.2 Turning on the Power ...................................................................................................... 2-3

2.3 Loading the Medium ........................................................................................................ 2-4

Loading a Roll Medium...................................................................................................... 2-4

Loading Sheet Media......................................................................................................... 2-8

Aligning the Push Rollers .................................................................................................. 2-9

2.4 Upon detection of no medium during roll media cutting ........................................... 2-11

2.5 Adjusting and Mounting the Cutter Pen ...................................................................... 2-11

Types and Features of Cutter Blades.............................................................................. 2-12

Cutter-Pen Construction.................................................................................................. 2-12

Replacing the Cutter Blade.............................................................................................. 2-12

Adjusting the Blade Length.............................................................................................. 2-13

Mounting a Cutter Pen..................................................................................................... 2-14

3. BASIC SETTINGS AND OPERATIONS

3.1 Setting the Format of Data to be Received ................................................................... 3-2

Setting the Command Mode.............................................................................................. 3-2

Setting the STEP SIZE...................................................................................................... 3-3

Setting the ORIGIN POINT................................................................................................ 3-3

3.2 Setting the Interface Conditions .................................................................................... 3-4

3.3 Setting the Cutter-Pen Conditions ................................................................................. 3-5

Selecting Cutter-Pen-Condition Setting Areas .................................................................. 3-6

Storing Cutter-Pen-Condition Setting Areas...................................................................... 3-6

Setting TOOL (cutter blade or pen) ................................................................................... 3-7

Setting OFFSET ................................................................................................................ 3-7

Setting FORCE.................................................................................................................. 3-8

Setting SPEED .................................................................................................................. 3-8

Setting QUALITY............................................................................................................... 3-9

3.4 Displaying the Effective Cutting Area ........................................................................... 3-9

3.5 Moving the Pen ................................................................................................................ 3-9

3.6 Setting the Initial Cutting Position ............................................................................... 3-10

3.7 Stop Function ................................................................................................................ 3-11

Page 6

iv

3.8 Moving the Pen Carriage in +100 mm Steps ............................................................... 3-12

3.9 Test Cutting .................................................................................................................... 3-12

4. FUNCTION SETTINGS AND OPERATIONS

4.1 PAUSE Menu List ............................................................................................................ 4-2

4.2 Reading the Auto Registration Marks ........................................................................... 4-3

4.3 Setting the FEED function .............................................................................................. 4-4

4.4 Setting AUTO PRE-FEED ................................................................................................ 4-5

4.5 Setting TANGENTIAL Mode ............................................................................................ 4-6

4.6 Auto-Registration-Mark-Reading Settings .................................................................... 4-8

Registration-Mark Menu Tree.......................................................................................... 4-10

Setting the Registration-Mark Mode ................................................................................ 4-11

4.7 Clearing the Buffer Memory ......................................................................................... 4-22

4.8 Aligning the Coordinate Axes ...................................................................................... 4-23

4.9 Distance Adjustment ..................................................................................................... 4-25

4.10 Setting the PAGE LENGTH ........................................................................................... 4-27

4.11 Setting the Cutting/Plotting Area ................................................................................. 4-28

4.12 Expanding the Cutting/Plotting Area ........................................................................... 4-29

4.13 Rotating the Coordinate Axes ...................................................................................... 4-30

4.14 Mirroring ......................................................................................................................... 4-31

4.15 Cutting/Plotting Using the Buffer Memory .................................................................. 4-32

4.16 Sorting Settings ............................................................................................................. 4-34

4.17 Interface Settings .......................................................................................................... 4-35

4.18 Setting the Format of Data to be Received ................................................................. 4-36

Setting the Command Mode............................................................................................4-36

Setting the STEP SIZE .................................................................................................... 4-37

Setting the ORIGIN POINT.............................................................................................. 4-37

4.19 Blade Wear Detection .................................................................................................... 4-38

Checking the Wear Rate ................................................................................................. 4-38

Setting Wear-Rate Groups .............................................................................................. 4-39

Setting Wear-Rate Factors .............................................................................................. 4-40

Clearing the Total Distance (Wear Rate)......................................................................... 4-40

4.20 Raising and Lowering the Pen ..................................................................................... 4-42

4.21 TEST Mode ..................................................................................................................... 4-43

Condition-List Printing ..................................................................................................... 4-43

Self-Test-Pattern Printing ................................................................................................ 4-44

Dump Mode ..................................................................................................................... 4-44

Cutting Demo................................................................................................................... 4-45

Cutting Force Test Cutting............................................................................................... 4-46

4.22 Setting the PEN UP SPEED .......................................................................................... 4-48

4.23 Setting the OFFSET FORCE ......................................................................................... 4-49

4.24 Setting the OFFSET ANGLE ......................................................................................... 4-50

4.25 Setting the STEP PASS ................................................................................................. 4-51

4.26 Setting the Initial Down Force ...................................................................................... 4-52

4.27 Setting the LENGTH UNIT ............................................................................................. 4-53

Page 7

v

5. Setting and Using the Special Functions

5.1 Description of Special Functions A ............................................................................... 5-2

Enabling/Disabling the “:” and “;” Commands (when the COMMAND setting is GP-GL) .. 5-2

Moving the Pen While Raised or Lowered in Response to the “W” Command (when the

COMMAND setting is GP-GL) ........................................................................................... 5-2

Model ID Response (when the COMMAND setting is HP-GL).......................................... 5-2

SETTING PRIORITY ......................................................................................................... 5-2

Blade-Tip Initial Position Setting........................................................................................ 5-2

Enabling/Disabling PEN UP MOVE................................................................................... 5-3

Enabling/Disabling the Media Sensors.............................................................................. 5-3

Enabling/Disabling the Home Sensors.............................................................................. 5-3

Circle-Command Resolution Setting (when the COMMAND setting is HP-GL) ................ 5-3

Enabling/Disabling Blade Wear Detection......................................................................... 5-3

Setting up the PAUSE KEY............................................................................................... 5-3

Setting up the COPY MENU.............................................................................................. 5-3

5.2 Setting Special Functions A ........................................................................................... 5-4

5.3 Description of Special Functions B ............................................................................... 5-5

Display Language Setting (MENU LANGUAGE SELECTION) ......................................... 5-5

5.4 Setting Special Functions B ........................................................................................... 5-5

6. TROUBLESHOOTING

6.1 The Cutting Plotter Does Not Operate When Turned On ............................................. 6-2

6.2 The Cutting Plotter Does Not Operate Correctly .......................................................... 6-2

6.3 The Cutting Results Are Unsatisfactory ........................................................................ 6-3

6.4 An Error Message Was Displayed ................................................................................. 6-5

APPENDIX

Appendix A Main Specifications .........................................................................................................A-2

Appendix B Options and Supplies ......................................................................................................A-3

Appendix C External Dimensions .......................................................................................................A-4

Appendix D Menu Tree .........................................................................................................................A-5

INDEX

Page 8

vi

Page 9

1

1

INTRODUCTION

1.1 Checking the Accessories

......................................................1-2

1.2 Parts Names and Functions

...................................................1-3

Page 10

1 – 2

1.1 Checking the Accessories

Check to confirm that all of the standard accessories listed below are present. If any item is missing,

please contact your sales representative or nearest Graphtec vendor promptly.

AC power cord

USB cable

Quick Start Manual, Usage Precautions

User Guide CD-ROM

Stand

Cutter blade (CB09UA)

Water-based fiber-tip pen

1

1

1 each

1

1

1

1

Cutter plunger

1

Media cutter

1

Page 11

1 – 3

1.2 Parts Names and Functions

■

Front View

Cutting mat

; Cutting or plotting is performed on this mat.

Grit roller

; Feeds the medium backward or forward

Push rollers

; Pushes the medium against the grit rollers

Pen carriage

; Moves the cutter pen to the left and right

Pen holder

; Holds the cutter pen and moves it up and down

Media set lever

; Raises or lowers the push rollers during loading of a medium

Control panel

; Used to operate the cutting plotter and set functions

USB interface connector

; Used to connect a USB cable

Serial (RS-232C) interface connector

; Used to connect an RS-232C serial interface cable

Media set lever

Pen holder

Pen carriage

Grit roller

Cutting mat

Push rollers

The above illustration is of the CE5000-120 model.

USB interface

connector

Serial (RS-232C)

interface connector

Control panel

Page 12

1 – 4

■

Rear View

AC power inlet

: Connects the power cord to the cutting plotter

Power switch

: Turns the power supply to the cutting plotter on or off

Stand

: Supports the cutting-plotter unit

Stock rollers : Holds the roll media

Stoppers : Used to determine the position of the roll media loaded

Power switch

AC power inlet

Stock rollers

Stoppers

Stand

The above illustration is of the CE5000-120 model.

Page 13

1 – 5

■ Control Panel

STATUS: Lights (green) while the power to the

cutting plotter is turned on, and is not lit

when the cutting plotter is in PAUSE

status. This lamp flashes when data is

being received from an interface,

regardless of whether or not the cutting

plotter is in PAUSE status.

TEST: Press this function key to conduct a cut-

ting test and check the cutting conditions.

PREV.: Press this function key to view the previ-

ous display on the LCD when in PAUSE

status.

NEXT: Press this function key to view the next

display on the LCD when in PAUSE status.

COND.: Press this function key to view the cut-

ter-pen condition settings.

PAUSE: Press this function key once in READY

status to switch to PAUSE status in

order to change the various settings

(see “4.1 PAUSE Menu List”). Press it

again to cancel the PAUSE status.

Pressing this key while cutting or plotting is in progress stops the cutting or

plotting (see “3.7 Stop Function”).

ENTER: Pressing this function key registers the

cutting or plotting conditions set.

POSITION:

These keys are used to move the cursor

or change the settings on the LCD display on the function setting screens.

Press these keys when in PAUSE status

to move the pen carriage or the

medium.

ORIGIN: Press this function key to set the origin

point. The pen position is set as the origin point when this key is pressed.

Indicator Lamp

Panel Keys

Page 14

1 – 6

Page 15

2

2

SETTING UP THE CUTTER PLOTTER

2.1 Connecting to Your Computer................................................2-2

2.2 Turning on the Power................................................................2-3

2.3 Loading the Medium..................................................................2-4

2.4 Upon detection of no medium during roll media

cutting

..........................................................................................2-11

2.5 Adjusting and Mounting the Cutter Pen...........................2-11

Page 16

2 – 2

2.1 Connecting to Your Computer

The cutting plotter can be connected to a computer via the serial (RS-232C) port or USB port. Select which

port to use according to the requirements of your application software and/or which of your computer’s

interface ports are available for use.

Use a serial cable or USB cable in accordance with the connection method chosen. Obtain a Graphtecapproved interface cable that is compatible with the selected interface port (an RS-232C cable can be purchased separately; a USB cable is provided as a standard accessory).

Check to confirm that the Power switch is turned off (the “O” side is down).

Connect the cable between the cutting plotter and the computer. Make sure the connectors at the cutting

plotter and computer ends are correctly oriented.

Step

1

Step

2

* The illustration below is of the CE5000-120 model.

* The illustration above is of the CE5000-120 model.

Page 17

2 – 3

2.2 Turning on the Power

Connect the cutting plotter to the AC electrical socket using the power cord provided, and turn on the

power.

Check to confirm that the Power switch is turned off (the “O” side is down).

Connect the cutting-plotter AC power inlet to a correctly rated electrical socket using the power cord provided.

Turn on the cutting plotter by pressing the “|” side of the Power switch. The STATUS lamp on the control

panel will light up.

Step

1

Step

2

Step

3

* The illustration below is of the CE5000-120 model.

* The illustration below is of the CE5000-120 model.

* The illustration below is of the CE5000-120 model.

Page 18

2 – 4

If no medium has been loaded, the message below appears on the display, prompting the loading of a

medium.

If a medium has already been loaded, the current media setting is displayed as shown below.

Select the media mode to suit the medium used. For instructions on loading media and selecting the media

mode, see “2.3 Loading the Medium.”

2.3 Loading the Medium

Load the medium, aligning it with the right-hand grit roller when viewed from the front so that it registers

with the media sensor. Then, adjust the push-roller position to match the width of the medium. The cutting

plotter can use media in roll or sheet form. Load the desired medium type by following the appropriate

instructions.

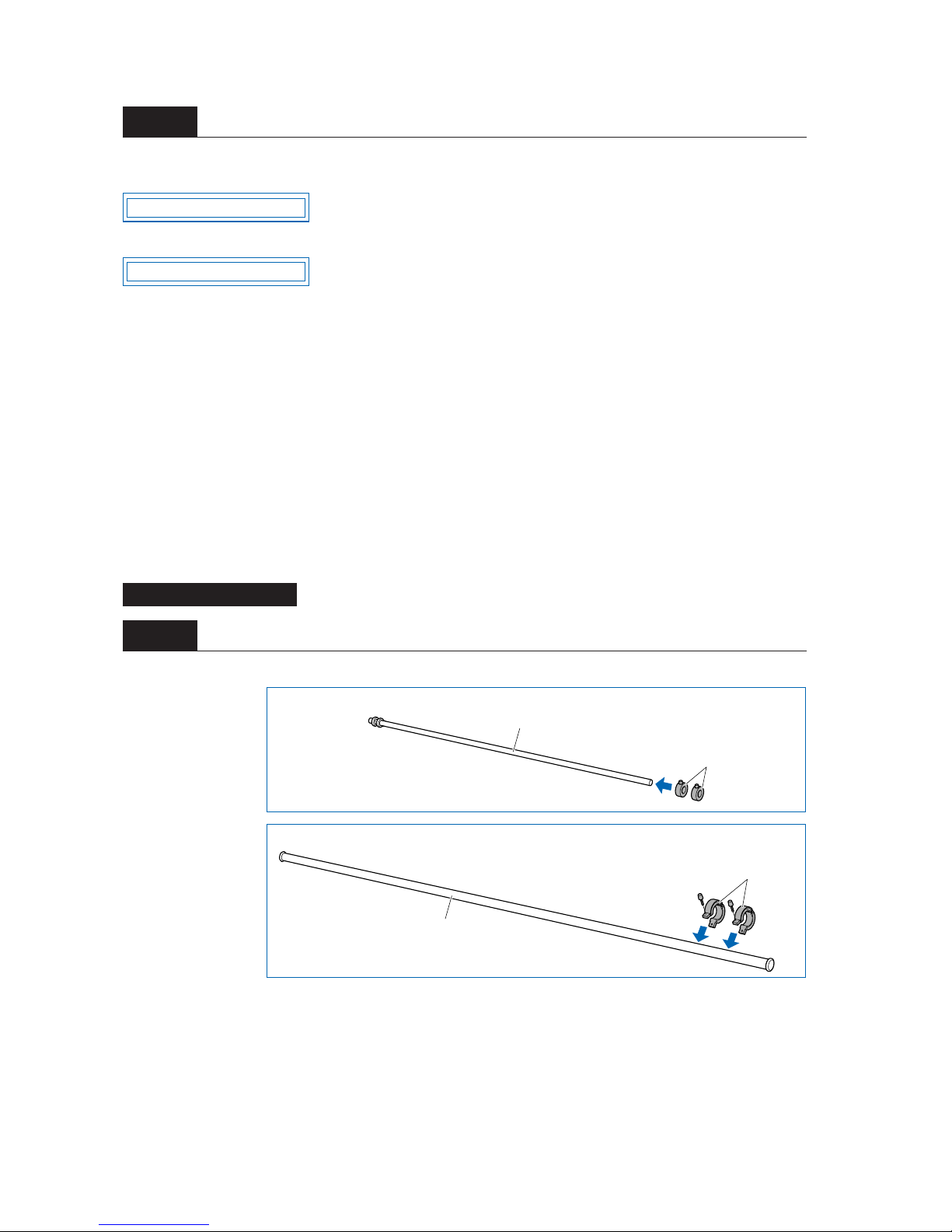

■ Loading a Roll Medium

Load the roll medium onto the stand stock rollers.

Fit the stoppers to one of the stock rollers (loosen the screws on the stoppers first).

Step

4

Placing on the Stand

Step

1

LOAD MEDIA!!

ROLL2 PRESS ENTR

Stoppers

Stock roller

Stoppers

Stock roller

For the CE5000-60:

For the CE5000-120:

Page 19

2 – 5

Position the stock roller with the stoppers towards the front, and place the other stock roller toward the rear

to suit the roll-medium size.

Place the roll medium on the stock rollers, and clamp it between the stoppers. Once the position is fixed,

tighten the screws on the stoppers.

Lower the media set lever to raise the push rollers.

Step

2

Step

3

Loading the Roll Medium

Step

1

* The illustration below is of the CE5000-120 model.

* The illustration below is of the CE5000-120 model.

* The illustration above is of the CE5000-120 model.

Page 20

2 – 6

Place the roll medium on the stand stock rollers, and then pass the leading edge of the medium from the

back of the cutting plotter so it emerges from the front, while making sure to remove any slack in the

medium conveyance path.

Pull the leading edge out of the front of the cutting plotter so that it completely covers the media sensor. If

the leading edge has been pulled out too far, turn the roll to adjust the length of the medium that is protruding.

Adjust the position of the left- and right-hand push rollers to suit the width of the roll medium.

Step

2

Step

3

Load the medium so that it passes over the media sensor.

Step

4

* The illustration below is of the CE5000-120 model.

Media sensor

* The illustration below is of the CE5000-120 model.

CHECKPOINT

Page 21

2 – 7

After ensuring that there is no slack in the medium’s conveyance path, raise the media set lever to lower

the push rollers and provide slack in the medium for a length corresponding to the length of the medium to

be used.

Raising the media set lever displays a menu for selection of the media mode. Select the media mode.

Pressing the or key displays “ROLL1 PRESS ENTR”, “ROLL2 PRESS ENTR”, and “SHEET

PRESS ENTR”. Select “ROLL2 PRESS ENTR” or “ROLL1 PRESS ENTR” and then press the

(ENTER) key to confirm. When “ROLL2 PRESS ENTR” is selected, only the medium width is detected.

Select this mode to begin cutting at a point beyond the leading edge. When “ROLL1 PRESS ENTR” is

selected, the leading edge and width of the medium are detected. Select this mode to begin cutting from

the leading edge.

After the medium size has been detected, the pen carriage returns to the origin point and the cutting plotter

awaits cutting data. If the INTERFACE conditions or COMMAND mode have not yet been set, they should

be set. If they have already been set, adjust the cutter pen. Once the cutter pen has been adjusted, the

cutting plotter is ready to perform cutting, so cutting data can be sent from the application software on the

computer.

Step

5

Step

6

If the “REALIGN ROLLERS” message is displayed when the medium is loaded

and the media set lever is raised, either the right-hand push roller is not positioned

over the right-hand wide grit roller or the left-hand or center (CE5000-120) push

roller is not positioned over the grit roller. Check to confirm that they are positioned

correctly.

Step

7

Step

8

Raise media set lever to

clamp medium

Provide slack

ROLL2 PRESS ENTR

CHECKPOINT

Page 22

2 – 8

■ Loading Sheet Media

Lower the media set lever to raise the push rollers.

With the CE5000-120, load the medium, aligning the edges with the upper and lower scales on the front

guide.

Adjust the position of the left- and right-hand push rollers to suit the medium width.

Raising the media set lever displays a menu for selecting the media mode. Select the media mode.

Step

1

Step

2

Load the medium so that it passes over the media sensor.

Step

3

Step

4

If the “REALIGN ROLLERS” message is displayed when the medium is loaded

and the media set lever is raised, either the right-hand push roller is not positioned

over the right-hand wide grit roller, or the left-hand or center (CE5000-120) push

rollers are not positioned over the grit roller. Check to confirm that they are positioned correctly.

* The illustration above is of the CE5000-120 model.

Align with scale

Media sensor

* The illustration below is of the CE5000-120 model.

CHECKPOINT

SHEET PRESS ENTR

CHECKPOINT

Page 23

2 – 9

Pressing the or key displays “ROLL1 PRESS ENTR”, “ROLL2 PRESS ENTR”, and “SHEET

PRESS ENTR”. Select “SHEET PRESS ENTR” and then press the (ENTER) key to confirm the

selection. When “SHEET PRESS ENTR” is selected, the front and rear edges are detected.

After the medium size has been detected, the pen carriage returns to the origin point and the cutting plotter

awaits cutting data. If the INTERFACE conditions or COMMAND mode have not yet been set, they should

be set. If they have already been set, adjust the cutter pen. Once the cutter pen has been adjusted, the

cutting plotter is ready to perform cutting, so cutting data can be sent from the application software on the

computer.

■ Aligning the Push Rollers

Adjust the position of the left- and right-hand push rollers to suit the medium width. Position the push rollers at either edge of the medium so that they are above the grit rollers. Adjust the push rollers so that they

are positioned above both the medium and the grit rollers. Positioning the push rollers within the pushroller alignment marks ensures that they are above the grit rollers.

The push roller on the right-hand edge when viewed from the front must always be moved over the righthand wide grit roller.

Step

5

Step

6

To move the push rollers, the media set lever must be in the lowered position.

Push-roller alignment mark

NG NG

OK OK

CAUTION

Right-hand push roller

Right-hand grit roller

Page 24

2 – 10

Position the push rollers over the grit rollers to grip each edge of the medium.

Position push rollers (1) and (3) over the grit rollers to grip each edge of the medium, and position push

roller (2) over the grit roller nearest the center of the medium. The medium is gripped by the three push rollers (1), (2), and (3).

To move the push rollers, the media set lever must be in the lowered position.

If the “REALIGN ROLLERS” message is displayed when the medium is loaded

and the media set lever is raised, either the right-hand push roller is not positioned

over the right-hand wide grit roller, or the left-hand push roller is not positioned

over the grit roller. Check to confirm that they are positioned correctly.

For the CE5000-60

• The push roller (1) must be positioned over the right-hand wide grit roller.

• The medium must always be positioned over the media sensor.

For the CE5000-120

CAUTION

CHECKPOINT

Media sensor

Push roller (1)

Push roller (2)

Grit roller

Medium

OK OK

CAUTION

Push roller (1)

Push roller (2)

Push roller (3)

Grit roller

Media sensor

OK OK

NG NG

Page 25

2 – 11

Position all of the rollers over the right-hand wide grit roller. Position the medium with the left-hand edge

aligned with the left-hand edge of the grit roller, and position the push rollers over both edges. The minimum width of the medium that can be set is 50 mm for the CE5000-60 and 85 mm for the CE5000-120.

2.4 Upon detection of no medium during roll media cutting

If the media sensor detects no medium while the roll media is being cut, cutting stops automatically. Check

the remaining medium length and select whether to continue cutting or quit.

If the media sensor detects no medium while the roll media is being cut, cutting stops and the display

appears as shown below.

Press the (ENTER) key to continue cutting/plotting and to disable any subsequent “Paper End” detection.

To enable subsequent “Paper End” detection, lower the media set lever and perform a feed operation.

2.5 Adjusting and Mounting the Cutter Pen

Individual cutter blades have a variety of features. Select the optimal cutter blade to suit the medium to be

cut.

• Push roller (1) must be positioned over the right-hand wide grit roller.

• The medium must always be positioned over the media sensor.

For Minimum-Size Media

• The medium must be at least 125 mm in length.

• The medium must always be positioned over the media sensor.

Step

1

Step

2

To avoid cutting your fingers, always handle the cutter blade with caution.

CAUTION

Medium

Push roller (2)

Grit roller

Media sensor

Push roller (1)

CE5000-60

Medium

Push roller (1)

Push roller (3)

Grit roller

Media sensor

Push roller (2)

CE5000-120

OK OK

CAUTION

NO MEDIA

CAUTION

Page 26

2 – 12

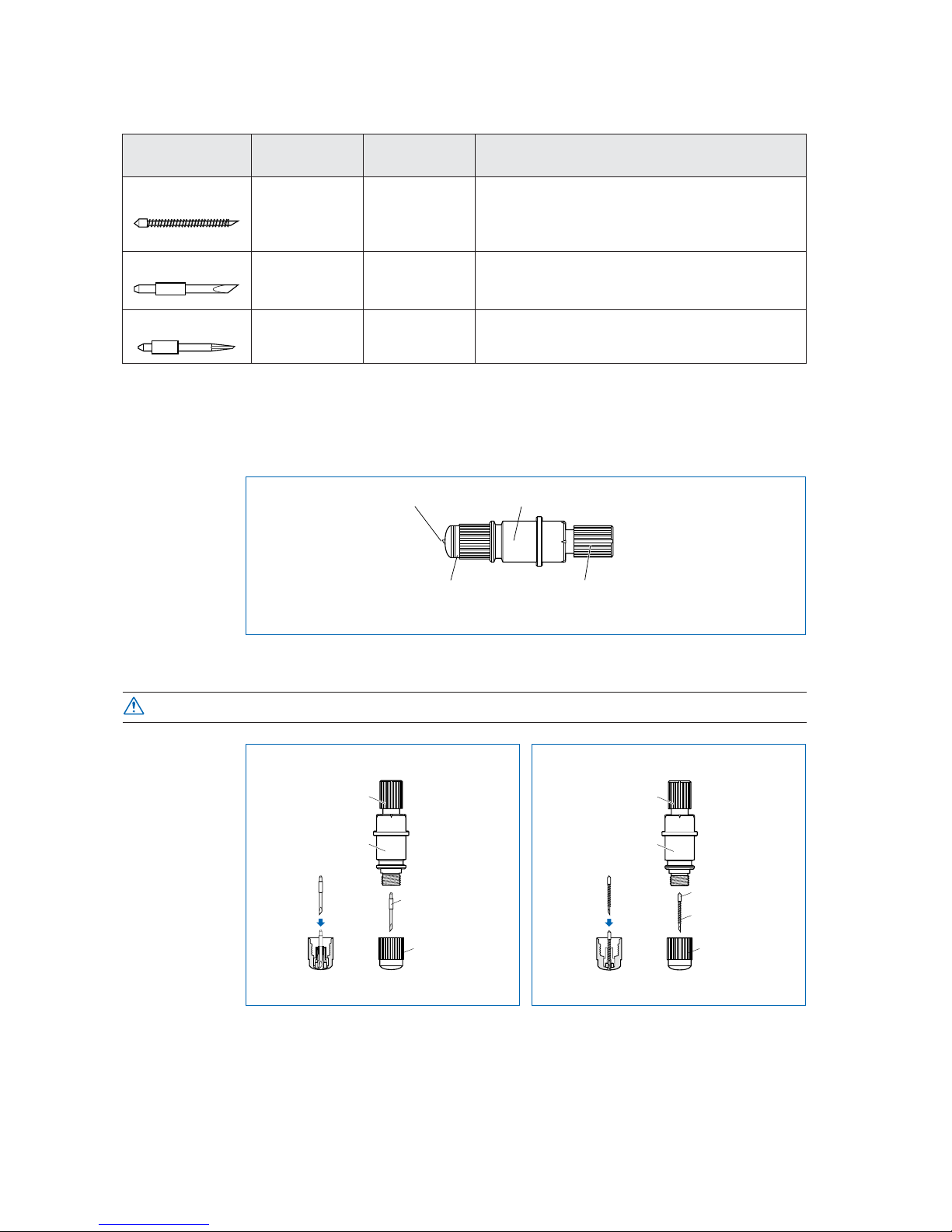

■ Types and Features of Cutter Blades

■ Cutter-Pen Construction

The cutting plotter cuts using a cutter blade mounted in a cutter-pen plunger. There are two different cutterpen plungers to suit the diameter of the cutter blade to be mounted (the 0.9-mm cutter-pen plunger is provided as standard equipment). Be sure to mount the cutter blade in the corresponding cutter-pen plunger.

■ Replacing the Cutter Blade

Part No. and

profile

Blade diameter

and offset

Compatible

plunger

Use and features

CB 09UA ø0.9 mm

0.45

PHP32-CB09N The standard blade for cutting color adhesive-

backed media. Suitable for cutting media up to 0.25

mm in thickness.

Max. cutting distance: Approx. 4,000 m

CB 15U ø1.5 mm

0.75

PHP32-CB15N Capable of cutting thicker media than possible with

the CB09UA blade. Suitable for cutting media 0.25

mm to 0.5 mm in thickness.

CB 15UB ø1.5 mm

0.15

PHP32-CB15N Suitable for detailed cutting (e.g., letters less than 10

mm in size) of media up to 0.25 mm in thickness.

To prevent cutting your fingers, always handle the cutter blade with caution.

Cutter blade

Plunger cap

Plunger

Blade-length adjustment knob

(Blue: For 0.9-mm-diameter blades)

(Red: For 1.5-mm-diameter blades)

CAUTION

1.5-mm-diameter cutter pen

Plunger-cap

cross-section

Plunger cap

1.5-mm-dia. blades

Blade-length

adjustment knob (red)

Plunger

Spring

Plunger cap

Plunger-cap

cross-section

0.9-mm-dia. blades

0.9-mm-diameter cutter pen

Blade-length

adjustment knob (blue)

Plunger

Page 27

2 – 13

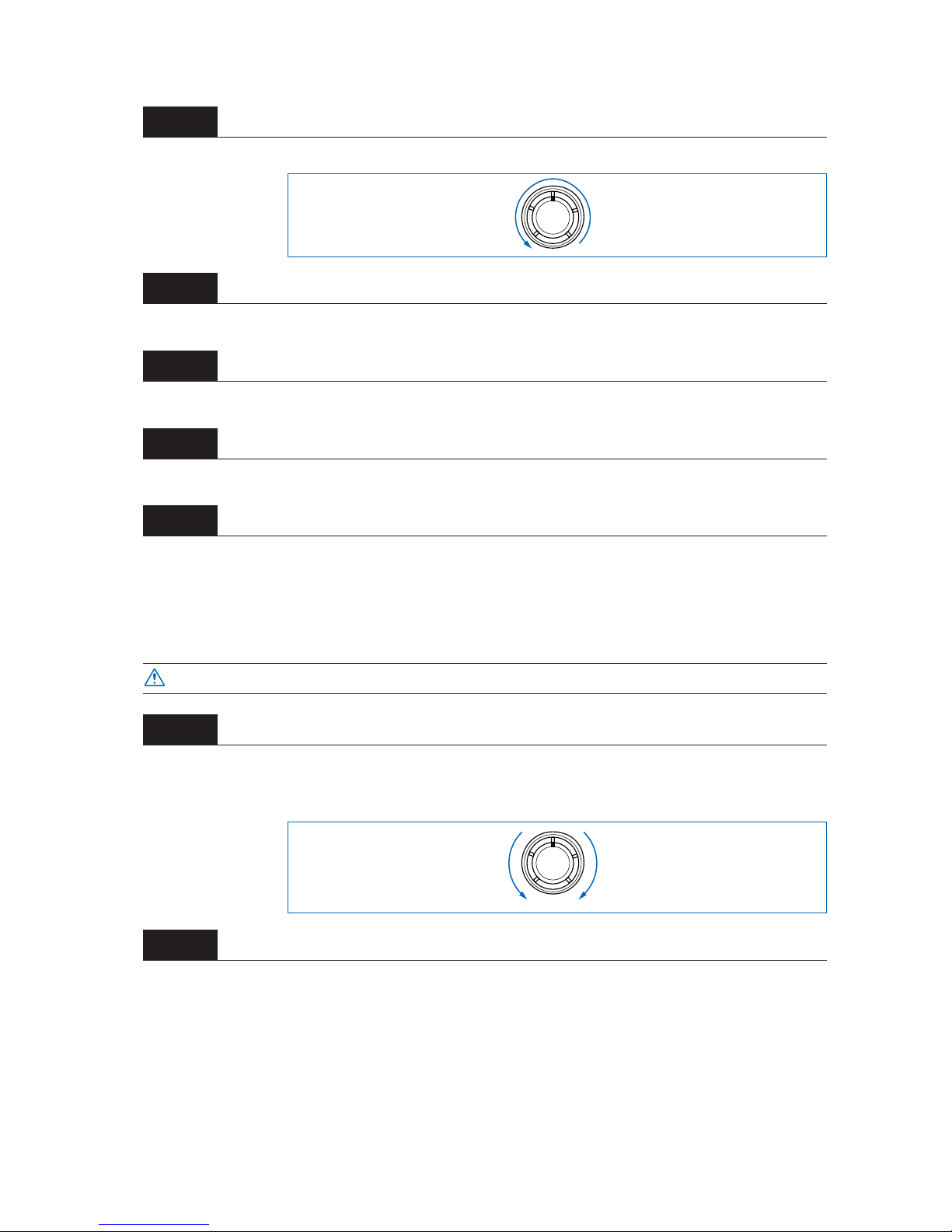

Turn the blade-length adjustment knob to retract the blade into the plunger.

Turn the plunger cap in the counter-clockwise direction to remove it from the plunger.

Remove the blade from inside the plunger cap.

Insert the new blade into the hole provided in the plunger cap.

With the blade inserted into the plunger cap, screw on the plunger from above.

■ Adjusting the Blade Length

If the blade is extended too far in relation to the thickness of the medium being cut, it will damage the cutting mat. Be sure to adjust the blade length correctly.

Adjust the blade length by turning the blade-length adjustment knob. Turn the knob in direction “A” to

extend the blade, or in direction “B” to retract the blade. When the knob is turned by one scale unit, the

blade moves approximately 0.1 mm. One full turn of the knob moves the blade approximately 0.5 mm.

First align the blade tip with the tip of the cutter pen, and then extend the blade from that position to suit the

thickness of the media to be cut.

Step

1

Step

2

Step

3

Step

4

Step

5

To prevent cutting your fingers, always handle the cutter blade with caution.

Step

1

Step

2

CAUTION

AB

Page 28

2 – 14

Assuming that the medium thickness is “t,” as shown in the figure below, the blade length “rrrr” should be

equal to or slightly greater than “t.” Make sure “rrrr” is never greater than the combined thickness of the

medium and its backing sheet. If it is not possible to accurately determine the medium thickness, adjust the

blade length by gradually increasing it until only traces of the blade appear on the backing sheet after a cutting test is conducted.

■ Mounting a Cutter Pen

Adjust the blade to the correct length before mounting the cutter pen.

Loosen the pen holder screw.

Step

3

Take care not to cut your fingers on the cutter blade when handling the cutter pen.

Step

1

t

Medium

Backing sheet

R

CAUTION

Page 29

2 – 15

While pushing the pen holder in the upward direction, push the pen all the way into the holder until its

flange contacts the upper part of the holder. Make sure that the pen bracket is engaged on the pen’s

flange.

When the cutter pen has been mounted, tighten the screw to hold it in place.

Step

2

When you push the pen holder up with your fingers, take care not to cut your fingers on

the cutter blade.

Step

3

Flange

Pen bracket

CAUTION

Flange

Pen bracket

Page 30

2 – 16

Page 31

3

3

BASIC SETTINGS AND OPERATIONS

3.1 Setting the Format of Data to be Received .......................3-2

3.2 Setting the Interface Conditions ...........................................3-4

3.3 Setting the Cutter-Pen Conditions ....................................... 3-5

3.4 Displaying the Effective Cutting Area.................................3-9

3.5 Moving the Pen............................................................................ 3-9

3.6 Setting the Initial Cutting Position (Origin Point) ...........3-10

3.7 Stop Function ............................................................................3-11

3.8 Moving the Pen Carriage in +100 mm Steps ................... 3-12

3.9 Test Cutting ................................................................................3-12

Page 32

3 – 2

3.1 Setting the Format of Data to be Received

Before data is sent from the computer, the format (command mode) of the data sent by the application software must be checked. The cutting plotter accepts two data formats (command modes): GP-GL (Graphtec)

and HP-GL commands. Set the command mode to suit the application used.

■ Setting the Command Mode

Check to confirm that the cutting plotter is in READY mode (displaying the current pen settings).

Press the (PAUSE) key to switch to PAUSE mode, and then press the (NEXT) or (PREV.) key

until the menu shown below is displayed.

Press the (ENTER) key to display the menu shown below.

Press the or key to select “GP-GL” or “HP-GL,” and then press the (ENTER) key to confirm.

To cancel the selection, press the (NEXT) or (PREV.) key.

If “GP-GL” is selected, set the STEP SIZE. If “HP-GL” is selected, set the ORIGIN POINT. If a different

command from that set previously is selected, the PAUSE mode is automatically cancelled once the STEP

SIZE (GP-GL) or ORIGIN POINT (HP-GL) is set.

Step

1

Step

2

Step

3

Step

4

Step

5

1 PEN 12 30 2

COMMAND

COMMAND HP-GL

Page 33

3 – 3

■ Setting the STEP SIZE

If the GP-GL command mode is set, it is possible to change the minimum unit of distance that the cutter

pen or pen can travel to one of four settings: 0.01 mm, 0.025 mm, 0.05 mm, or 0.1 mm. The default setting

is 0.1 mm, so this setting should be changed if your application specifies a different step size.

Set the command setting to “GP-GL.”

Press the (ENTER) key to display the step-size setting.

Press the or key to select “0.100 mm,” “0.050 mm,” “0.025 mm,” or “0.010 mm,” and then press

the (ENTER) key to confirm. To cancel the selection, press the (NEXT) or (PREV.) key.

Press the (PAUSE) key to cancel PAUSE mode.

■ Setting the ORIGIN POINT

If the HP-GL command mode is set, the origin point can be set to the lower left or center. The default setting is the lower left, so this setting should be changed if your application specifies a different origin position.

Set the command setting to “HP-GL.”

Press the (ENTER) key to display the origin-point setting.

Press the or key to select “L.L. (LOWER LEFT)” or “CENTER,” and then press the (ENTER)

key to confirm. To cancel the selection, press the (NEXT) or (PREV.) key.

Press the (PAUSE) key to cancel PAUSE mode.

Step

1

Step

2

Step

3

Step

4

Step

1

Step

2

Step

3

Step

4

COMMAND GP-GL

STEP SIZE 0.100mm

COMMAND HP-GL

ORIGIN PT L.L.

Page 34

3 – 4

3.2 Setting the Interface Conditions

The interface conditions must be set if the RS-232C serial interface is being used. The data transfer rate

(baud rate), data length, parity settings, and the handshaking mode for the cutting plotter must be set to

match those of the computer operating system. This section describes the cutting-plotter interface conditions. For details on the proper settings for your application or computer operation system, refer to the

manual provided with the application or operating system.

Check to confirm that the cutting plotter is in READY mode (displaying the current pen settings).

Press the (PAUSE) key to switch to PAUSE mode, and then press the (NEXT) or (PREV.) key

until the menu shown below is displayed.

Press the (ENTER) key to display the interface settings.

The current settings are displayed (from the left): transfer rate (baud rate), parity, data length, and handshaking mode.

The baud rate can be set to “19200,” “9600,” “4800,” “2400,” “1200,” “600,” or “300.”

The parity can be set to “N” (None), “E” (Even parity), or “O” (Odd parity). The data length can be set to 7

or 8 bits.

The handshaking mode can be set to “H” (hard-wired handshaking) or “X” (Xon/Xoff handshaking). “E”

(ENQ/ACK handshaking) can also be selected when the command mode is set to HP-GL.

All of these interface conditions must be set to match the corresponding settings in the application software

and the computer operating system.

The parameter that can be changed is displayed immediately to the right of the mark. Use the or

key to select the parameter to be changed, and use the or key to select the setting details. Press

the (ENTER) key to confirm. To cancel the selection, press the (NEXT) or (PREV.) key.

Press the (PAUSE) key to cancel PAUSE mode.

Step

1

Step

2

Step

3

Step

4

1 PEN 12 30 2

RS-232C

9600 N 8 H

Page 35

3 – 5

3.3 Setting the Cutter-Pen Conditions

Before starting cutting, set the TOOL (cutter blade or pen), cutter-blade length, OFFSET, FORCE, SPEED,

and QUALITY settings to ensure the optimal cutting conditions.

(1) TOOL (cutter blade or pen): Set to suit the material to be cut.

(2) Cutter-blade length: Adjust the blade length by referring to the media thickness table below.

For details on adjusting the blade length, see “2.5 Adjusting and

Mounting the Cutter Pen.”

(3) OFFSET: Set to suit the cutter blade being used.

(4) FORCE: Set the FORCE by referring to the table below.

(5) SPEED: Set the SPEED by referring to the table below.

(6) QUALITY: Set the QUALITY by referring to the table below.

When the TOOL (cutter blade or pen) has been selected from among “09U,” “15U,” and “15B,” the OFF-

SET is automatically adjusted by ±5 with respect to the default cutter offset value for that blade type. Select

the PEN setting for plotting using a pen. When the PEN setting is selected, no OFFSET setting is required.

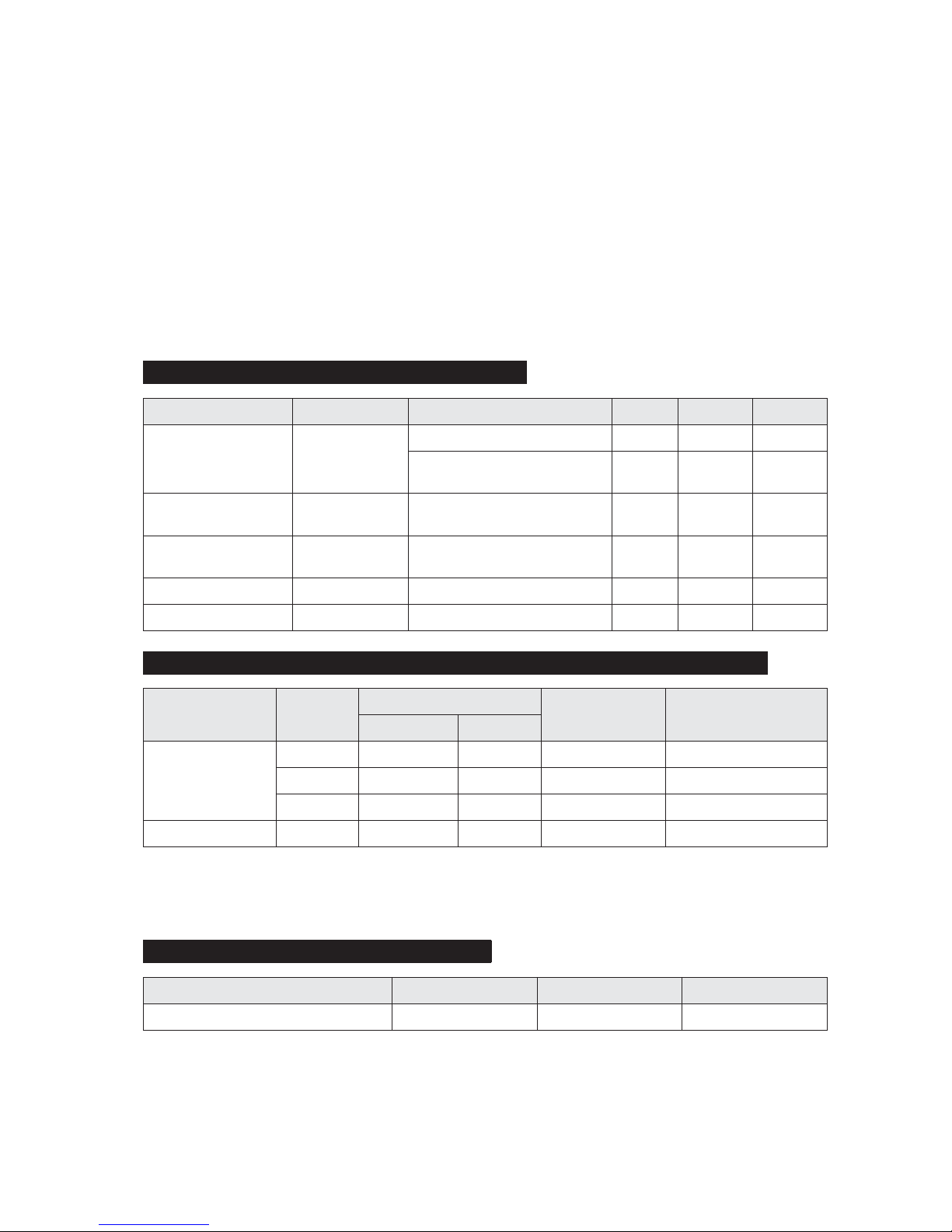

Optimal Cutting Conditions for Each Media Type

Media type Thickness (mm) Blade used FORCE SPEED QUALITY

Film for outdoor use 0.05 to 0.08 CB09UA 10 to 14 30 or less 2

CB15UB (for small-letter cutting)

10 to 14 20 or less 1

Film for decorative

use

0.08 to 0.1 CB09UA 14 to 17 30 or less 2

Transparent or

semi-transparent film

0.08 to 0.1 CB09UA 14 to 20 30 or less 2

Reflective film 0.08 to 0.1 CB09UA 14 to 20 30 or less 2

Fluorescent film 0.20 to 0.25 CB09UA, CB15U 20 to 21 20 or less 1

Blade Part Nos., Displayed Blade Types, and Displayed CUTTER OFFSET Values

Blade material Part No.

LCD display indication

Specifiable range Initial CUTTER OFFSET

Blade type Default

Supersteel blades CB09UA 09U 0 ±5 18

CB15U 15U 0 ±5 28

CB15UB 15B 0 ±5 5

Pens Pen — — 0

Reference Pen Conditions for Plotting Pens

Pen type FORCE SPEED QUALITY

Water-based fiber-tip pen 10 to 12 30 2

Page 36

3 – 6

To preserve the pen life, set the FORCE to the lowest setting, and set the SPEED after checking to confirm

that there are no faint lines or other problems during plotting.

■ Selecting Cutter-Pen-Condition Setting Areas

To set the cutter-pen conditions, first select the setting area (condition number). Switching between these

setting areas enables any of up to eight predefined media types to be selected easily.

Press the (COND.) key in READY mode to display the cutter-pen conditions.

To select condition settings that have previously been stored, use the or key to select the desired

condition number stored on the cutter-pen-condition settings display (the number at the left of the display),

and then press the (ENTER) key. To cancel the selection, press the (NEXT), (PREV.), or

(COND.) key.

■ Storing Cutter-Pen-Condition Setting Areas

The cutter-pen conditions can be stored in nine setting areas numbered “1” to “9.”

To display the cutter-pen conditions, either press the (COND.) key when the cutting plotter is in READY

mode, or when the media set lever is lowered and the buffer is in the empty (cleared) status.

The current settings are displayed (from the left): condition number, PEN TYPE (cutter blade), CUTTER

OFFSET, FORCE, SPEED, and QUALITY.

The item to be changed is indicated by the symbol. Press the key to change the symbol to , and

press again to move it to the right. Press the key to move it to the left. Use the or key to select

the parameter to be changed, and use the or key to select the setting details. Press the

(ENTER) key to confirm. To cancel the selection, press the (NEXT), (PREV.), or (COND.) key.

• If the SPEED and QUALITY settings are set to high values, the cut/plotted

results will have a coarser finish, but the overall cutting/plotting time will be

reduced.

• If the SPEED and QUALITY settings are set to low values, the cut/plotted results

will have a finer finish, but the overall cutting/plotting time will be longer.

Selection method

Data from the controller is used for condition number 9.

Storage method

When using the optional registration mark scanner, condition settings 1 and 2 are

used for the pen settings when performing “Adjusting the Registration-Mark Reading Sensor (2)” (refer to page 4-18). It is therefore more convenient if the cutter pen

settings are assigned to 3 to 8 first.

CHECKPOINT

2 09U +1 14 30 2

CHECKPOINT

2 09U +1 14 30 2

CHECKPOINT

Page 37

3 – 7

■ Setting TOOL (cutter blade or pen)

Set the type of pen (cutter blade) to be used.

To display the cutter-pen conditions, either press the (COND.) key when the cutting plotter is in READY

mode, or when the media set lever is lowered and the buffer is in the empty (cleared) status.

Select the setting area (condition number) to be set, and then press the or key to move the sym-

bol to the position shown below.

Press the or key to select “09U,” “15U,” “15B,” or “PEN.” Press the (ENTER) key to confirm

the selection. If other conditions are to be set, press the or key to move the symbol to the param-

eter to be set.

■ Setting OFFSET

This setting adjusts the offset of the cutter blade to suit the blade type used. The tip of the blade mounted

in the cutter-pen plunger is not positioned at the center of the pen, so correction is required. This correction

is referred to as the OFFSET setting. The cutting plotter has been preset with OFFSET values for each cutter-blade type. Selecting “09U,” “15U,” or “15B” for the PEN TYPE setting also sets the appropriate OFF-

SET, allowing fine adjustment within the range of ±5. When the “PEN” setting is selected, the OFFSET

cannot be set.

Press the (COND.) key in READY mode to display the cutter-pen conditions.

Select the setting area (condition number) to be set, and then use the or key to move the sym-

bol to the position shown below.

Use the or key to select the value to be changed in the range of “-5” to “+5.” Press the

(ENTER) key to confirm the selection. If other conditions are to be set, press the or key to move

the symbol to the parameter to be set.

Step

1

Step

2

Step

3

Step

1

Step

2

Step

3

2 09U +1 14 30 2

2 09U +1 14 30 2

Page 38

3 – 8

■ Setting FORCE

Sets the pressure applied by the cutter pen during cutting. Set the FORCE value based on the guidelines

in the table entitled “Optimal Cutting Conditions for Each Media Type” on page 3-5.

Press the (COND.) key in READY mode to display the cutter-pen conditions.

Select the setting area (condition number) to be set, and then use the or key to move the symbol

to the position shown below.

Press the or key to select the value to be changed in the range specified below.

CE5000-60: “1” to “31”

CE5000-120: “1” to “38”

Press the (ENTER) key to confirm the selection. If other conditions are to be set, press the or

key to move the symbol to the parameter to be set.

■ Setting SPEED

Sets the speed used for cutting. Set the SPEED value based on the guidelines in the table entitled “Optimal Cutting Conditions for Each Media Type” on page 3-5.

Press the (COND.) key in READY mode to display the cutter-pen conditions.

Select the setting area (condition number) to be set, and then use the or key to move the symbol

to the position shown below.

Press the or key to select the value to be corrected in the range specified below.

CE5000-60: “1” to “60”

CE5000-120: “1” to “60”; “*”

For all cutting plotters, “1” to “10” is in increments of 1, and “10” to “40” or “60” is in increments of 5.

Press the (ENTER) key to confirm the selection. If other conditions are to be set, press the or

key to move the symbol to the parameter to be set.

Step

1

Step

2

Step

3

Step

1

Step

2

Step

3

Selecting “*” for the CE5000-120 sets the maximum speed. QUALITY is also set to

“*”, and the acceleration of the cutter is calculated automatically.

2 09U +1 14 30 2

2 09U +1 14 30 2

CHECKPOINT

Page 39

3 – 9

■ Setting QUALITY

Sets the acceleration used in cutting.

Press the (COND.) key in READY mode to display the cutter-pen conditions.

Select the setting area (condition number) to be set, and then use the or key to move the symbol

to the position shown below.

Press the or key to select the value to be changed in the range specified below

CE5000-60: “1”, “2”, “3”

CE5000-120: “1”, “2”, “*”

Press the (ENTER) key to confirm the selection. If other conditions are to be set, press the or

key to move the symbol to the parameter to be set.

3.4 Displaying the Effective Cutting Area

Press the (ENTER) key in READY mode to display the current effective cutting area.

3.5 Moving the Pen

In READY mode, press the or key to move the pen carriage to the left or right, and the or

key to feed the medium backward or forward. Pressing the (NEXT), or (PREV.) key together with

the (POSITION) keys enables high-speed or low-speed movement.

(POSITION) keys + (NEXT) key: High-speed movement

(POSITION) keys + (PREV.) key: Low-speed movement

Step

1

Step

2

Step

3

• If SPEED is set to “*” for the CE5000-120, QUALITY is also set to “*” and accel-

eration is calculated automatically.

2 09U +1 23 30 2

CHECKPOINT

X 0000mm Y 000mm

Page 40

3 – 10

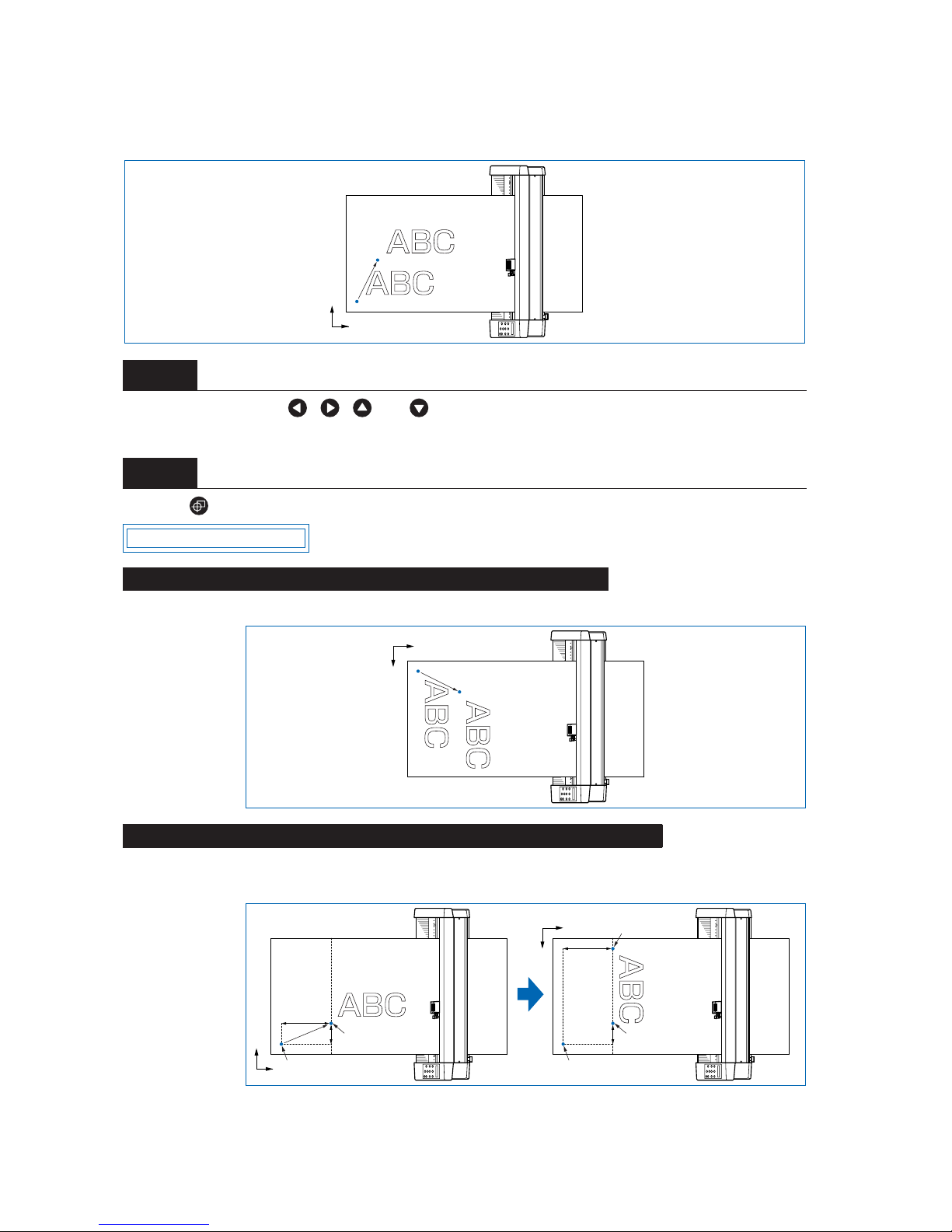

3.6 Setting the Initial Cutting Position (Origin Point)

This function allows the starting position for cutting or plotting to be moved to the desired position.

In READY mode, use the , , , and (POSITION) keys to move the cutter pen to the new origin

point.

Press the (ORIGIN) key. The following menu is displayed and the new origin is set.

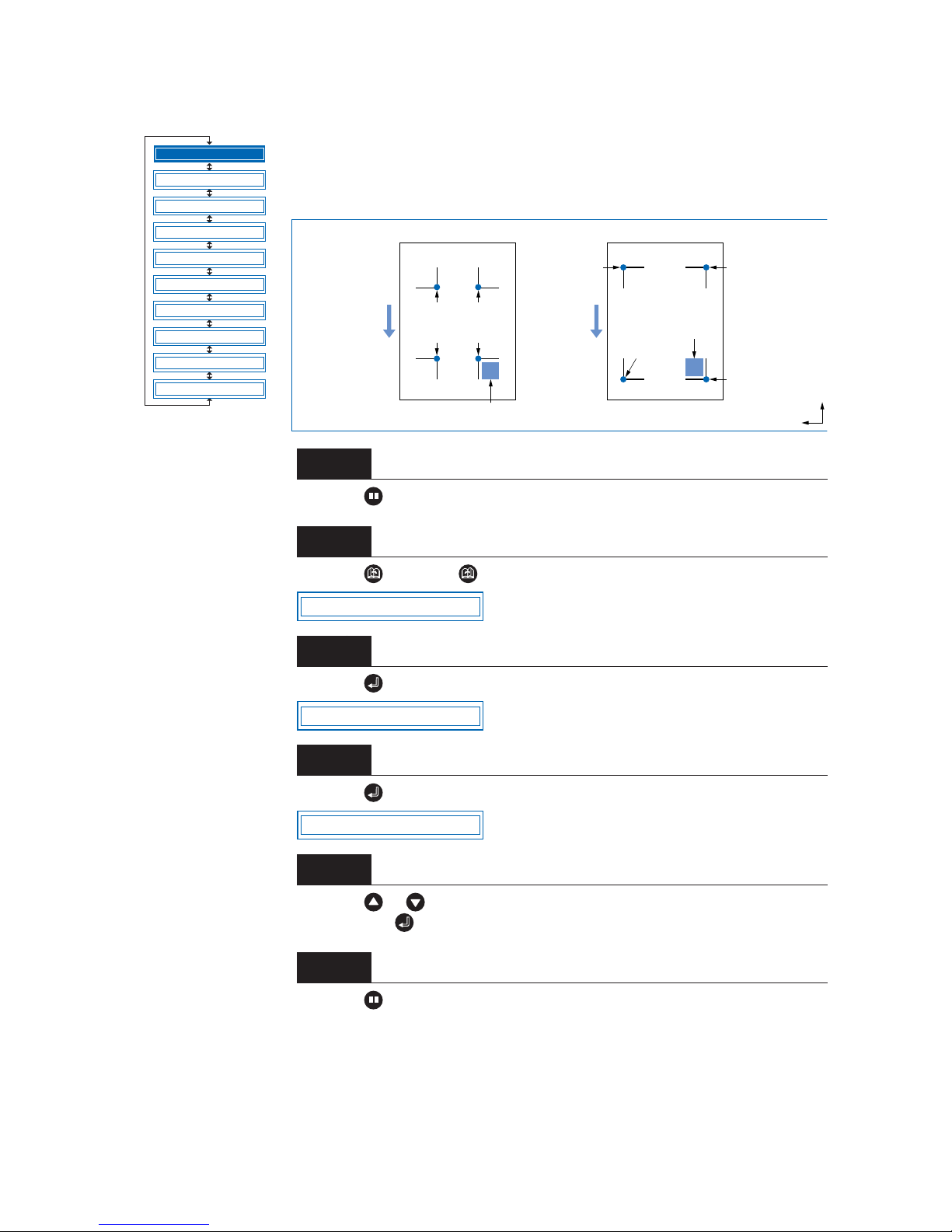

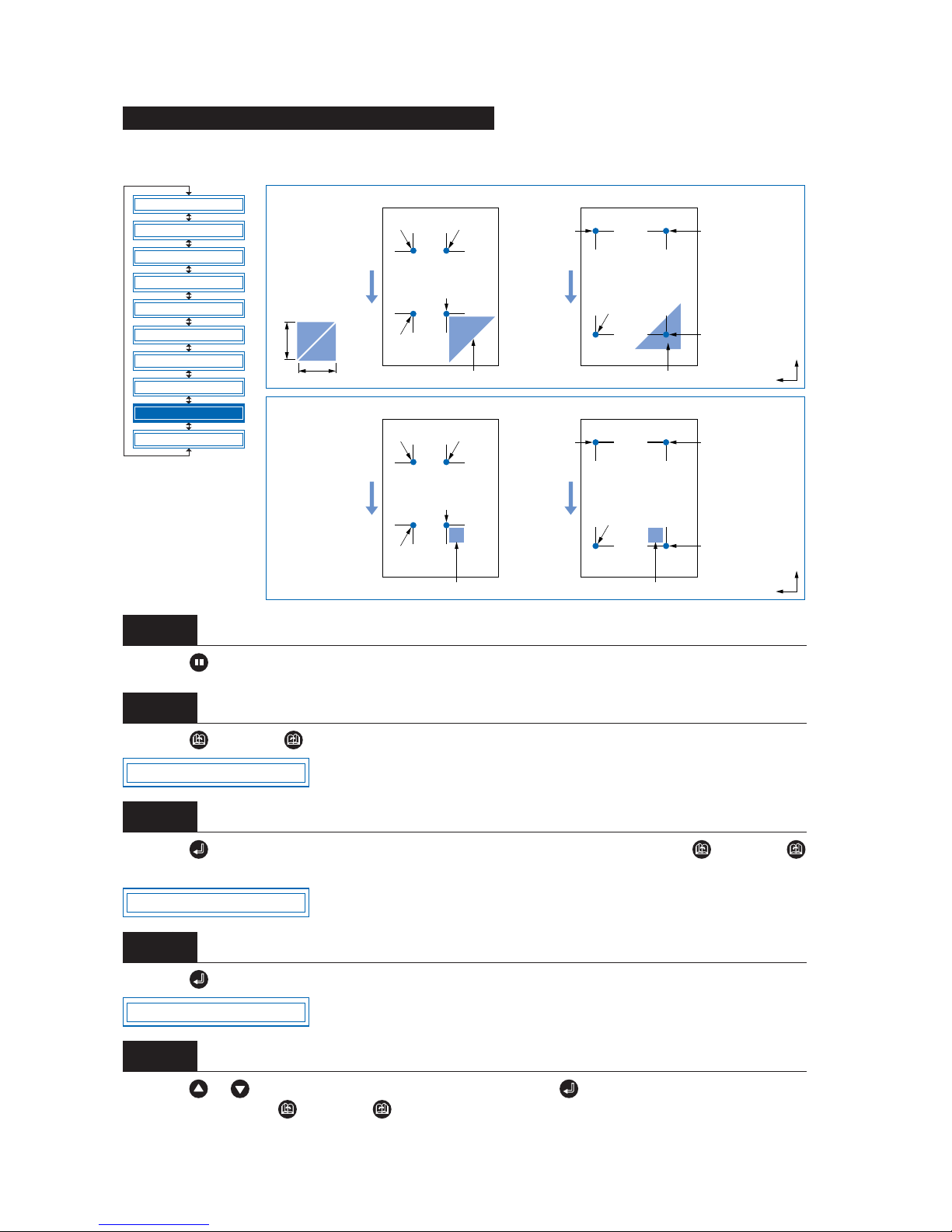

Moving the origin when the coordinate axes have been rotated gives the following results.

When the coordinate axes are rotated after the origin point is moved, the origin point is reset as shown in

the figure below. The distance “a” is retained, but the distance “b” is reset.

Step

1

Step

2

When the Origin is Moved After Rotating the Coordinate Axes

When the Coordinate Axes are Rotated After Moving the Origin Point

Original origin

New origin

Y

X

ORIGIN PT SET

Original origin

New origin

X

Y

a

Origin moved

a

b

b

Origin moved

after rotation

X

Y

Y

X

Original origin

Origin moved

Original origin

Origin moved Rotation

Page 41

3 – 11

When it is necessary to both move the origin and rotate the coordinate axes, be sure to rotate the coordinate axes first.

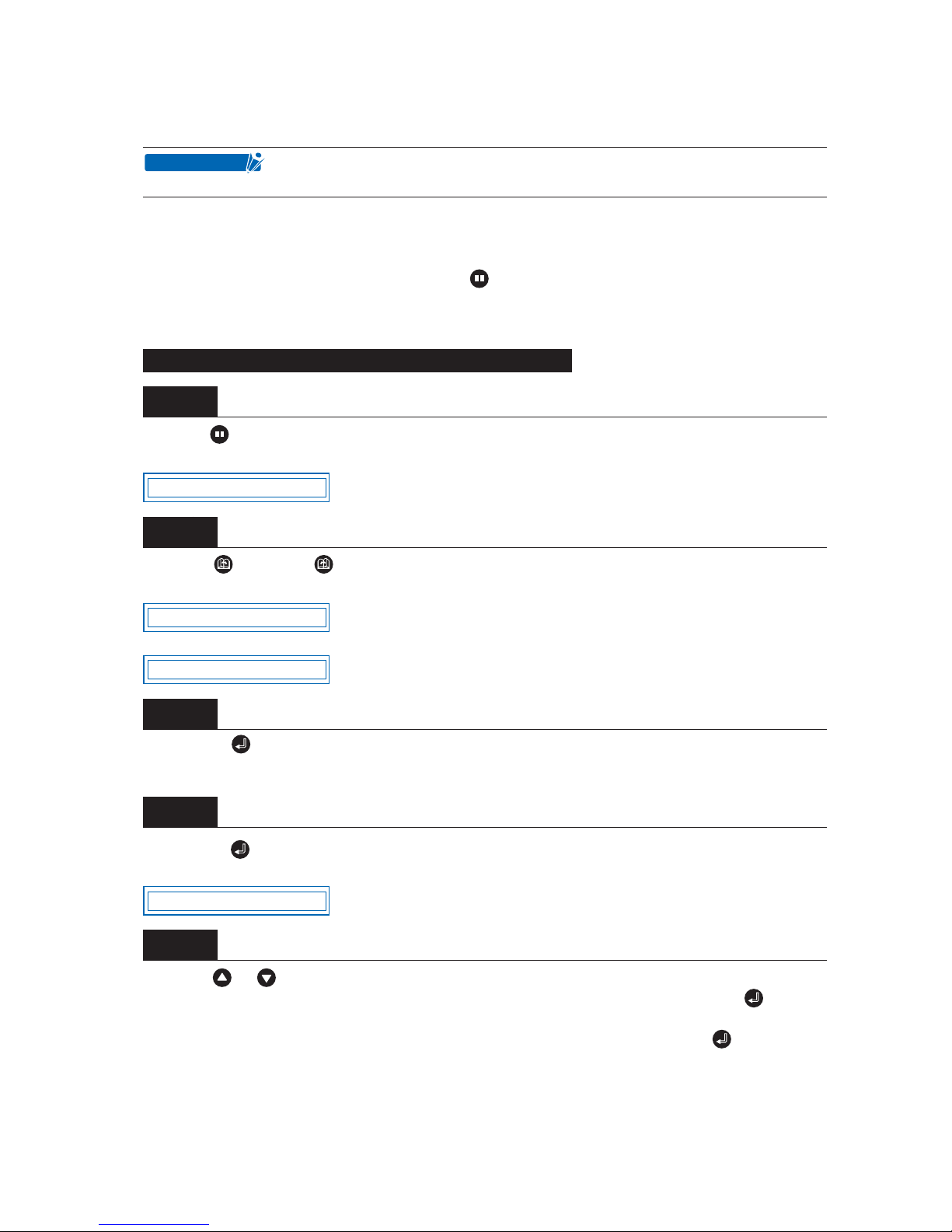

3.7 Stop Function

Cutting or plotting can be stopped by pressing the (PAUSE) key while cutting or plotting is in progress.

Raising or lowering the media set lever while the cutting or plotting is stopped does not require the medium

to be selected, so the medium can be replaced or reset.

Press the (PAUSE) key while cutting or plotting is in progress to stop cutting or plotting and display the

PAUSE menu.

Press the (NEXT) or (PREV.) key key to alternate the display between “CONTINUE JOB” and

“QUIT JOB”.

Pressing the (ENTER) key key while “CONTINUE JOB” is displayed cancels the pause function and

restarts cutting or plotting.

Pressing the (ENTER) key while “QUIT JOB” is displayed displays the BUFFER CLEAR confirmation

screen for aborting the cutting/plotting operation.

Press the or key to alternate the display between “YES” or “NO”. To abort the cutting/plotting

operation, stop the transmission of data from the computer, select “YES”, and then press the (ENTER)

key. All the cutting/plotting data stored in the buffer is cleared and the plotter returns to Ready status.

To cancel the aborting of the cutting/plotting operation, select “NO” and then press the (ENTER) key.

The plotter returns to the “CONTINUE JOB” display.

After a new origin point is set, the displayed coordinate values of X= and Y= represent the respective distances from the new origin.

If the Special Function "PAUSE KEY" is set to "HOLD"

Step

1

Step

2

Step

3

Step

4

Step

5

CHECKPOINT

CONTINUE JOB

CONTINUE JOB

QUIT JOB

CLEAR <YES>

Page 42

3 – 12

* This is set by default when shipped from the factory.

The Pause menu is displayed after the cutting plotter has stopped, allowing you to alter the settings.

Press the (PAUSE) key while cutting or plotting is in progress to stop cutting or plotting and display the

screen shown below.

In the Pause menu, alter settings as necessary.

Pressing the (PAUSE) key cancels the pause function and restarts cutting or plotting.

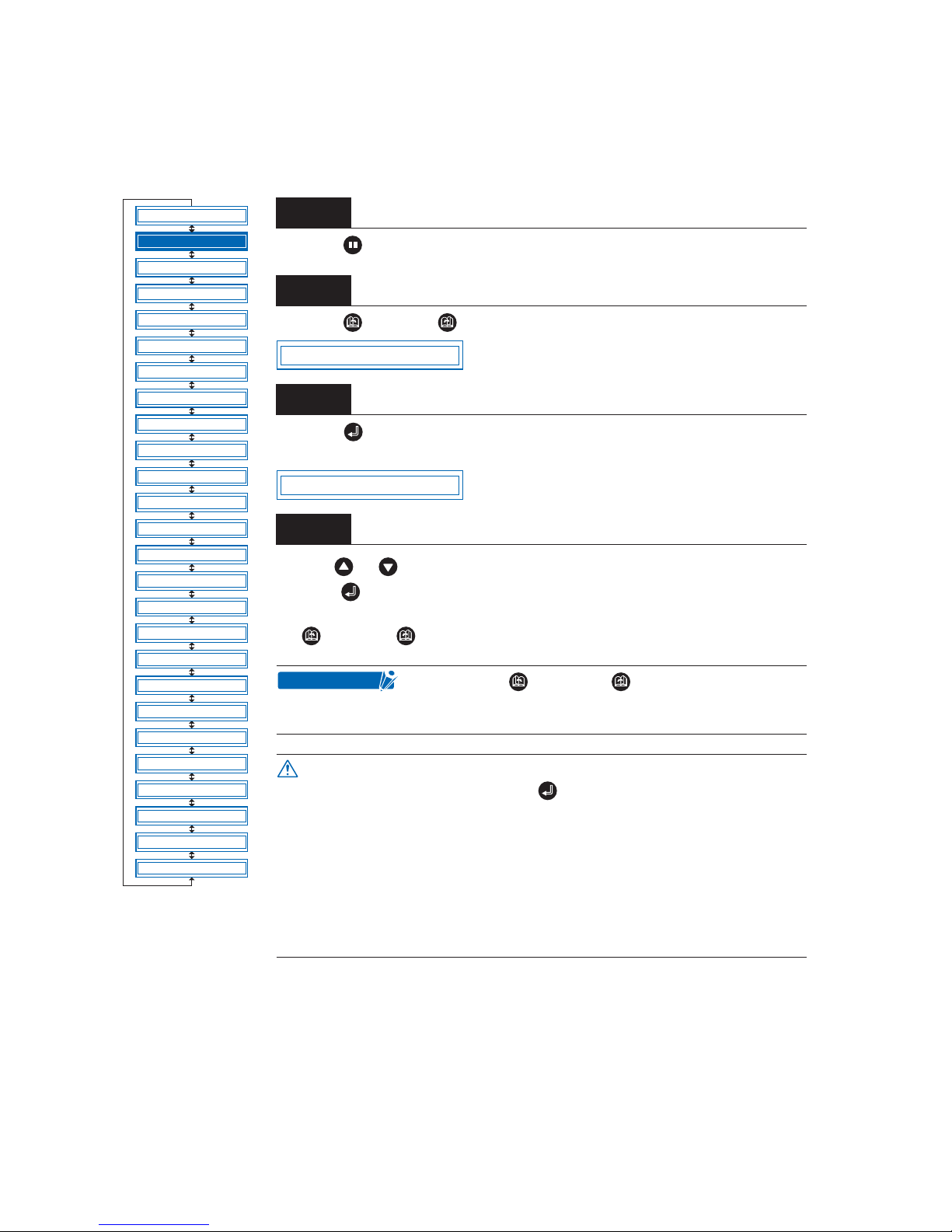

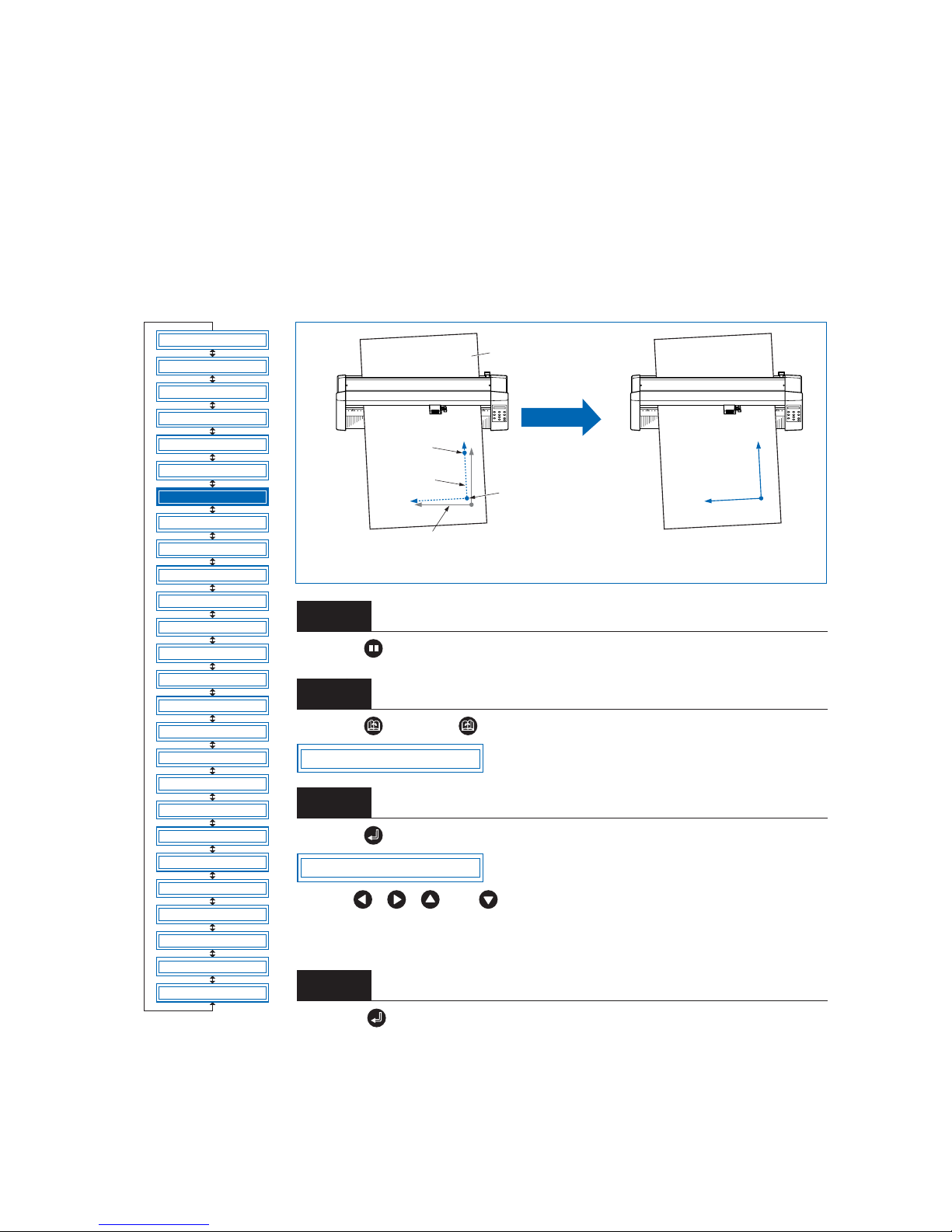

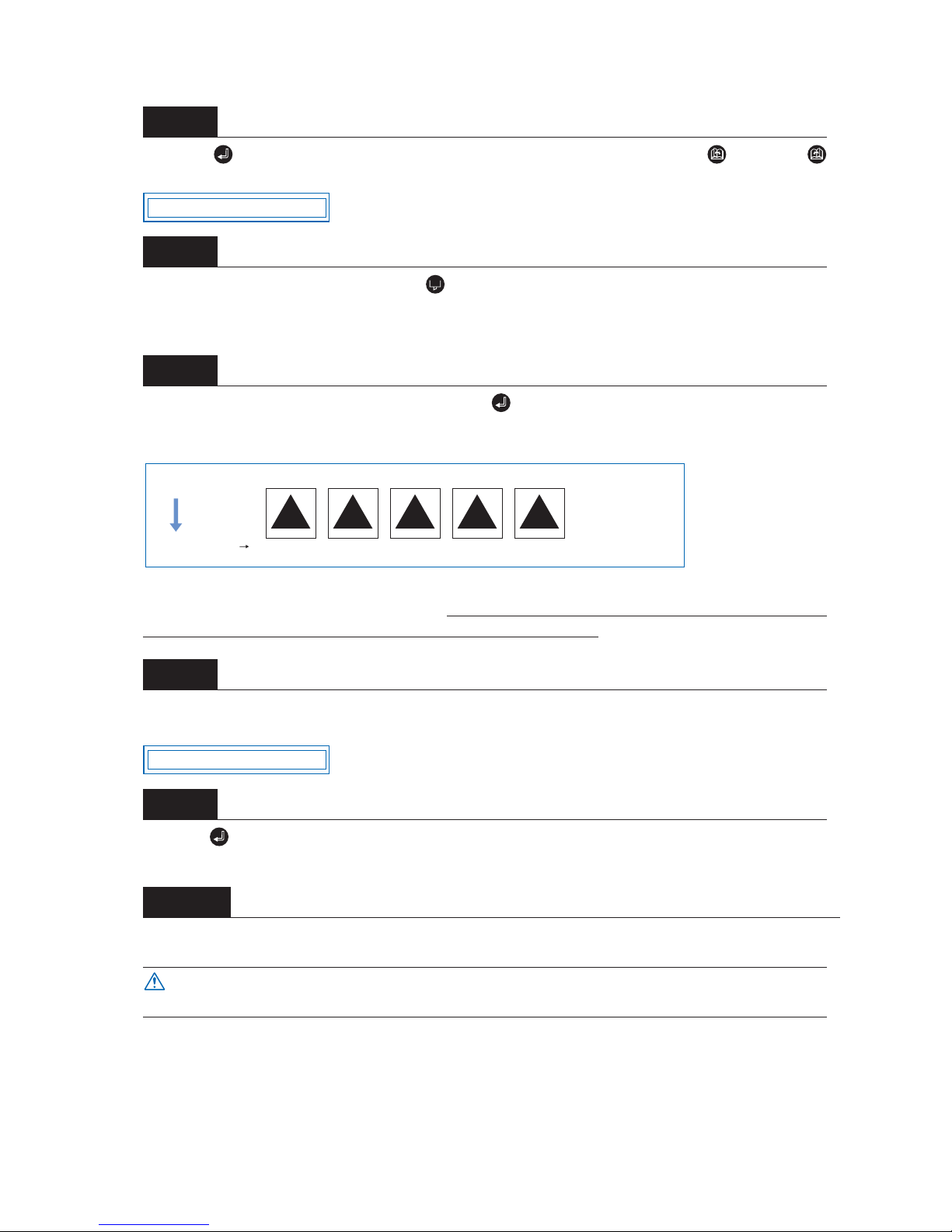

3.8 Moving the Pen Carriage in +100 mm Steps

This function allows the pen carriage to be moved from its current position in +100 mm steps along the Xand Y-axes.

In READY mode, press the key while holding down the (ENTER) key to move the pen carriage in

+100 mm steps along the X- and Y-axes.

In READY or PAUSE mode, press the key while holding down the (ENTER) key to return the pen

carriage to the origin.

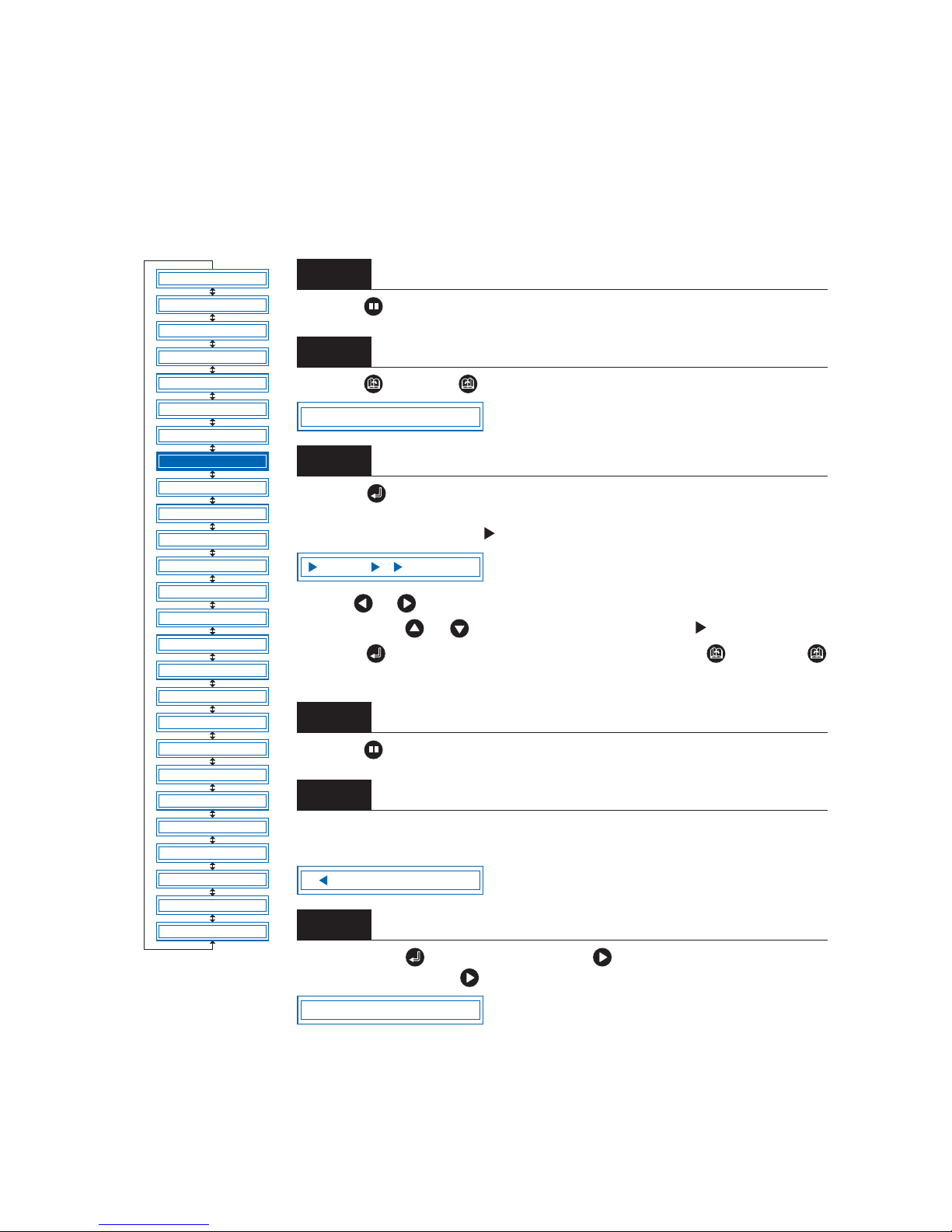

3.9 Test Cutting

Test cutting can be performed after selecting the TOOL (cutter blade) and specifying the cutter-blade

length, OFFSET, FORCE, SPEED, and QUALITY settings to ensure that the selected cutting conditions

actually produce the desired cutting results. Check how far the blade cuts into the film and how corners are

being cut; if the cutting results are not satisfactory, reset the cutting conditions and repeat the test cutting

until the optimal settings are achieved. If you perform test cutting while the cutter-pen conditions are being

set, the test cutting will be performed under the conditions being set.

If the Special Function "PAUSE KEY" is set to "MENU"

Step

1

Step

2

Step

3

Returning to the original position

Original pen-carriage position

Moved pen-carriage

position

Y

X

100mm

100mm

Page 43

3 – 13

Load the medium for test cutting on the cutting plotter.

Use the , , , and (POSITION) keys to move the pen carriage to the position for test cutting.

Switch to READY mode, and then press the (TEST) key.

When test cutting has been completed, the pen carriage moves to the standby position and the following

menu is displayed.

Press the (ENTER) key to return the pen carriage to its previous position and to switch the cutting plotter to READY mode.

Adjust the CUTTER OFFSET value to suit the type and thickness of the medium being used, and fineadjust the finish of each corner. Set the FORCE so that only faint cutting lines remain on the base sheet

when the blade length is properly adjusted.

Upon completion of fine adjustment, actual cutting data can be sent to the cutting plotter.

Step

1

Step

2

Step

3

Step

4

Step

5

Step

6

Step

7

PRESS ENTER KEY

CUTTER

OFFSET

is too low

Increase

(by +1 to +5)

Correct

CUTTER

OFFSET

setting

CUTTER

OFFSET

is too high

Decrease

(by -1 to -5)

Page 44

3 – 14

Page 45

4

4

FUNCTION SETTINGS AND OPERATIONS

4.1 PAUSE Menu List ........................................................................4-2

4.2 Reading the Auto Registration Marks.............................4-3

4.3 Setting the FEED function.......................................................4-4

4.4 Setting AUTO PRE-FEED .........................................................4-5

4.5 Setting TANGENTIAL Mode.....................................................4-6

4.6 Auto-Registration-Mark-Reading Settings .....................4-8

4.7 Clearing the Buffer Memory..................................................4-22

4.8 Aligning the Coordinate Axes..............................................4-23

4.9 Distance Adjustment...............................................................4-25

4.10 Setting the PAGE LENGTH ....................................................4-27

4.11 Setting the Cutting/Plotting Area........................................4-28

4.12 Expanding the Cutting/Plotting Area.................................4-29

4.13 Rotating the Coordinate Axes..............................................4-30

4.14 Mirroring ......................................................................................4-31

4.15 Cutting/Plotting Using the Buffer Memory

(COPY Function)............................................................................4-32

4.16 Sorting Settings ........................................................................4-34

4.17 Interface Settings .....................................................................4-35

4.18 Setting the Format of Data to be Received ..................... 4-36

4.19 Blade Wear Detection (When Blade Wear Setup is On) ......4-38

4.20 Raising and Lowering the Pen............................................. 4-42

4.21 TEST Mode..................................................................................4-43

4.22 Setting the PEN UP SPEED................................................... 4-48

4.23 Setting the OFFSET FORCE (Initial Cutting Force) .......... 4-49

4.24 Setting the OFFSET ANGLE ................................................. 4-50

4.25 Setting the STEP PASS...........................................................4-51

4.26 Setting the Initial Down Force..............................................4-52

4.27 Setting the LENGTH UNIT......................................................4-53

Page 46

4 – 2

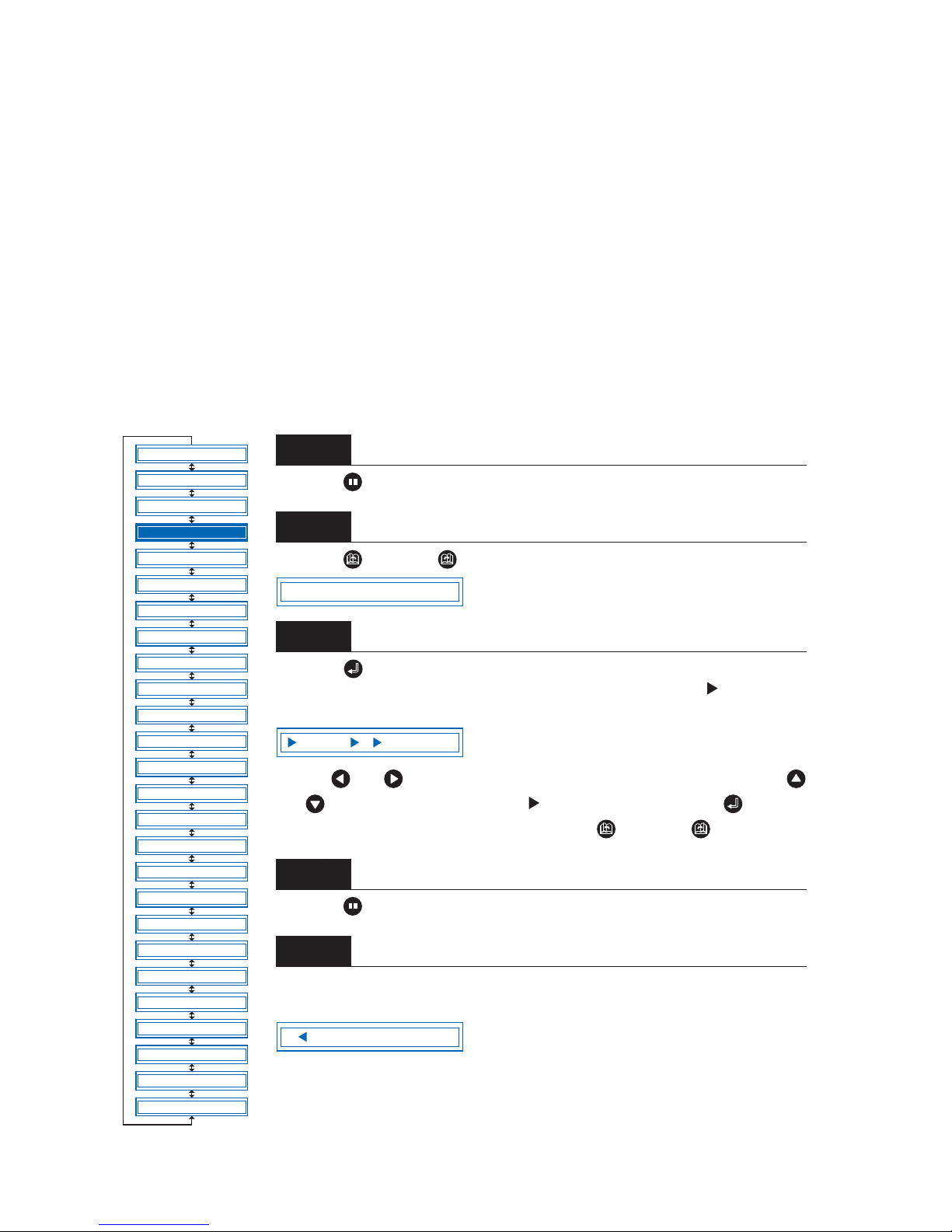

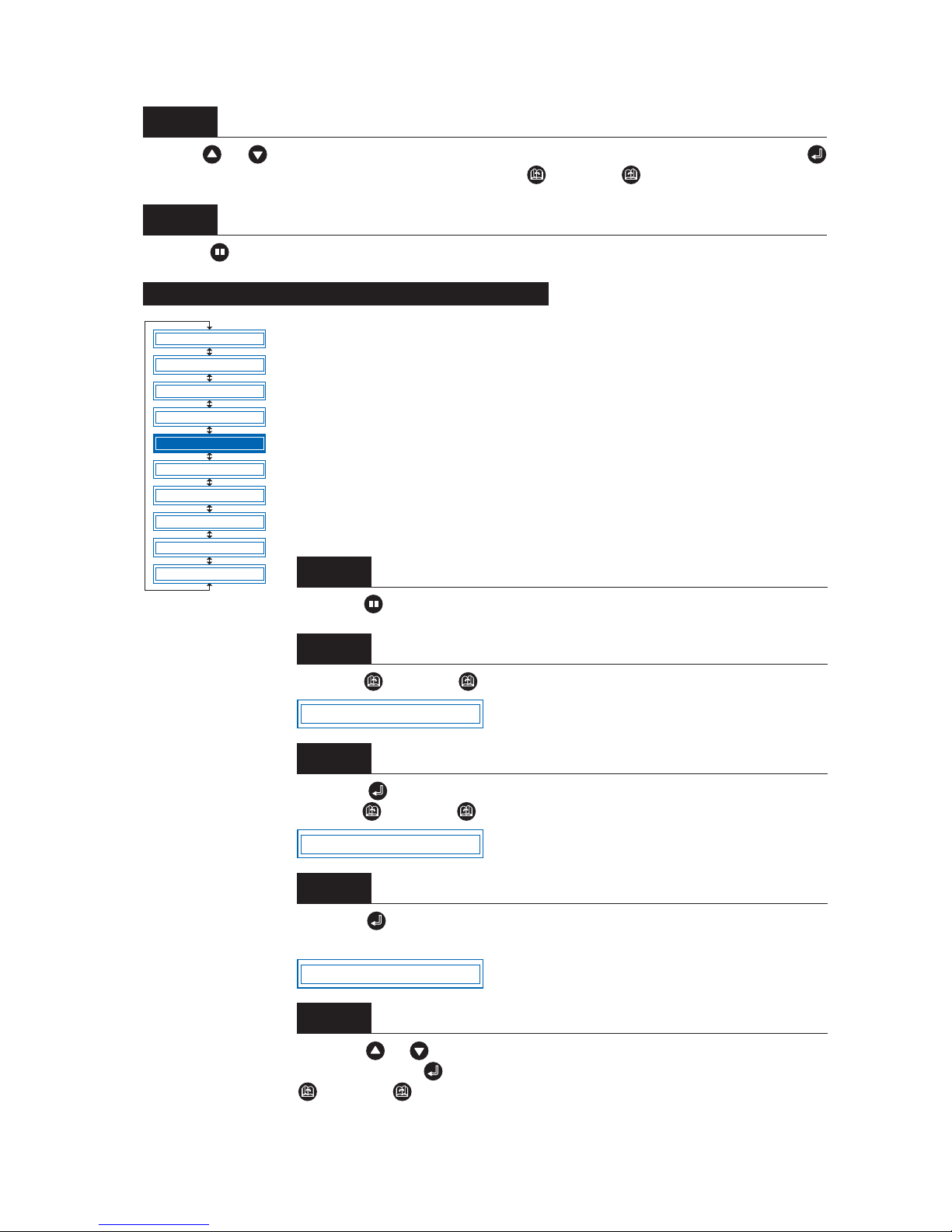

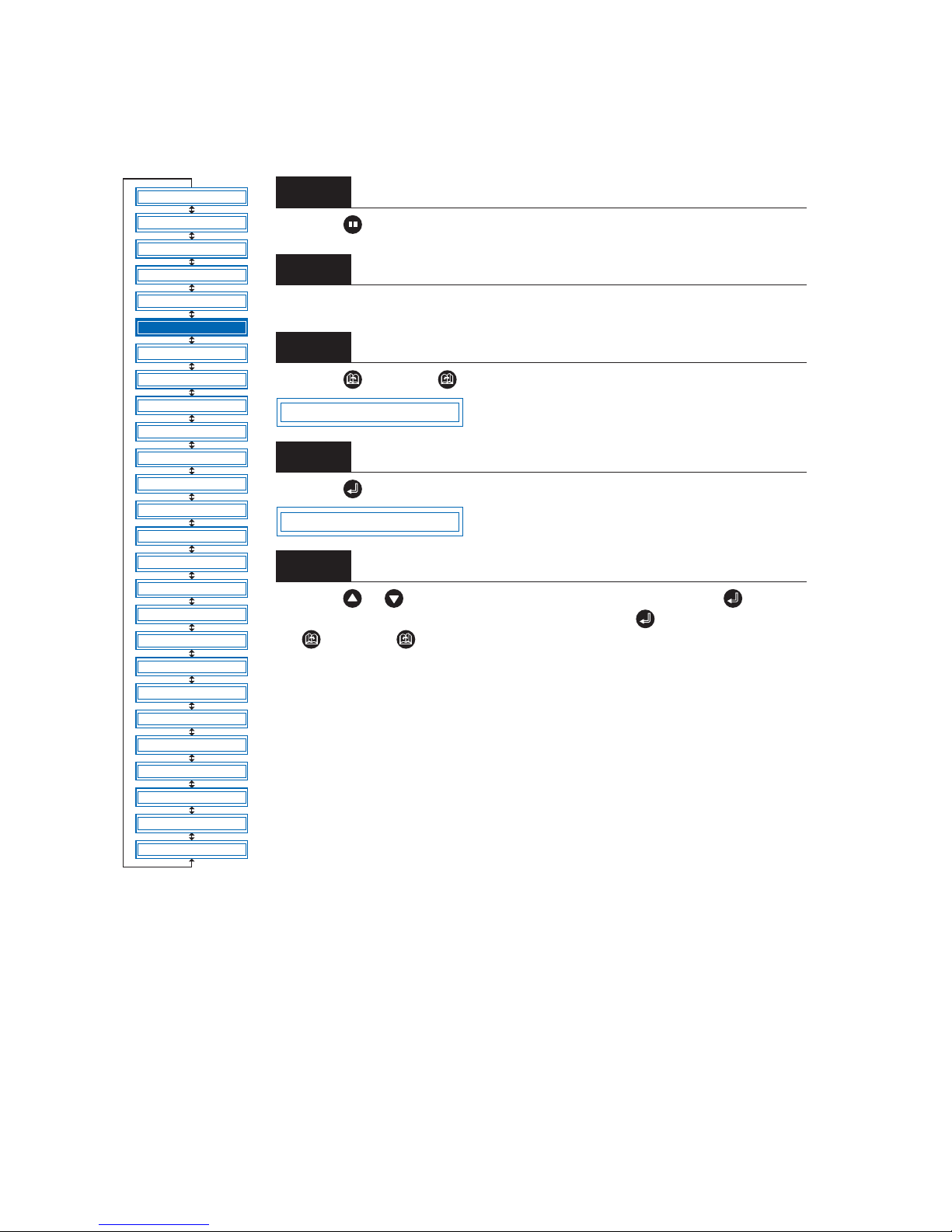

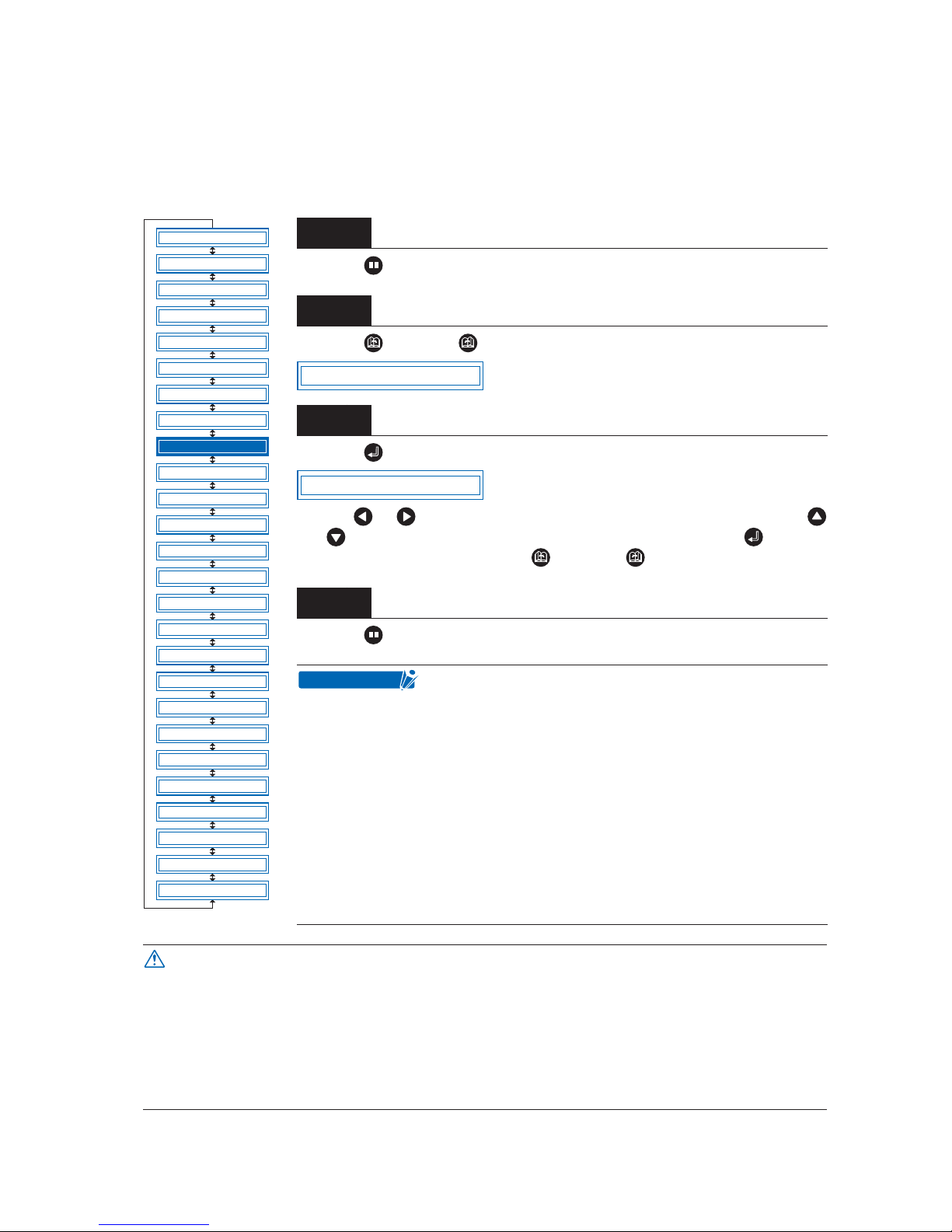

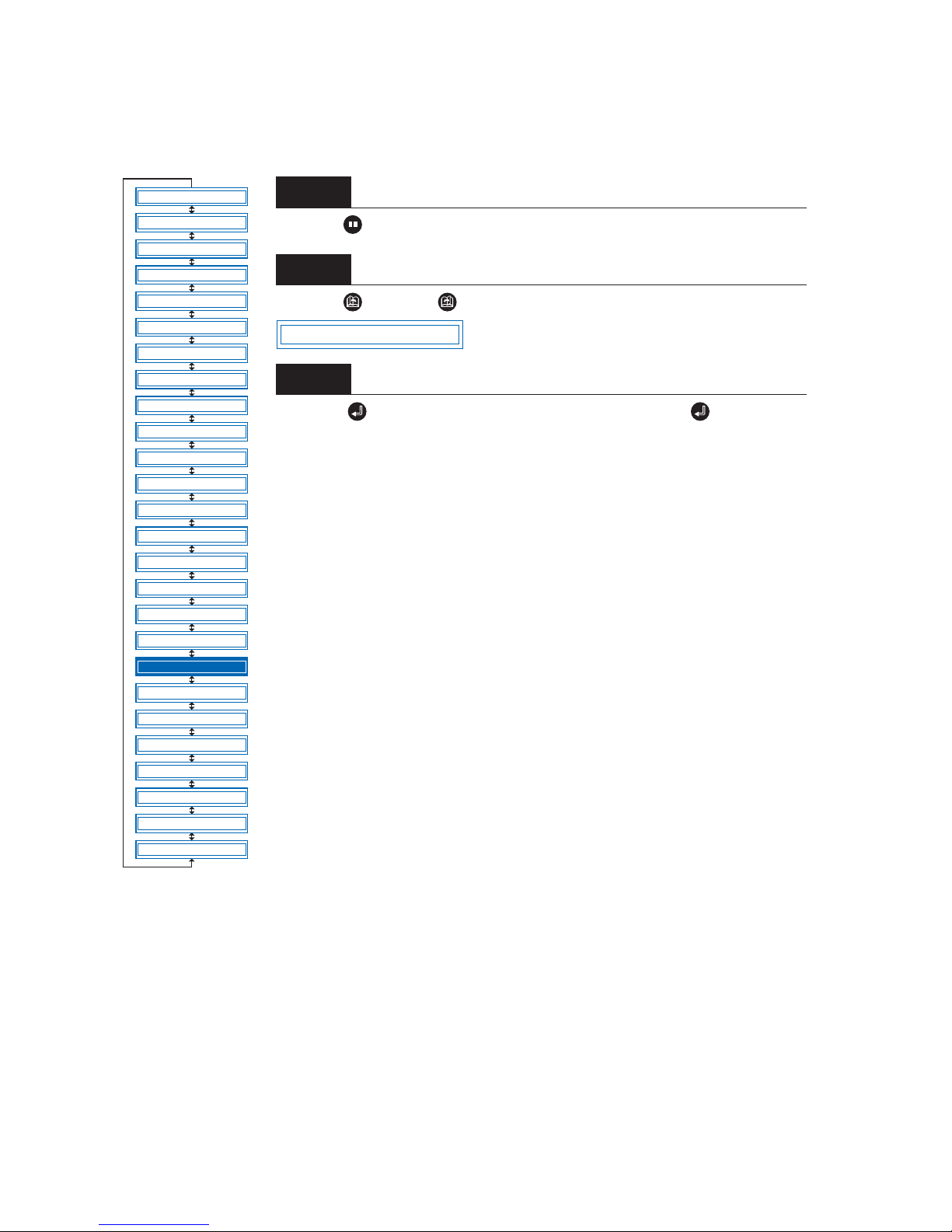

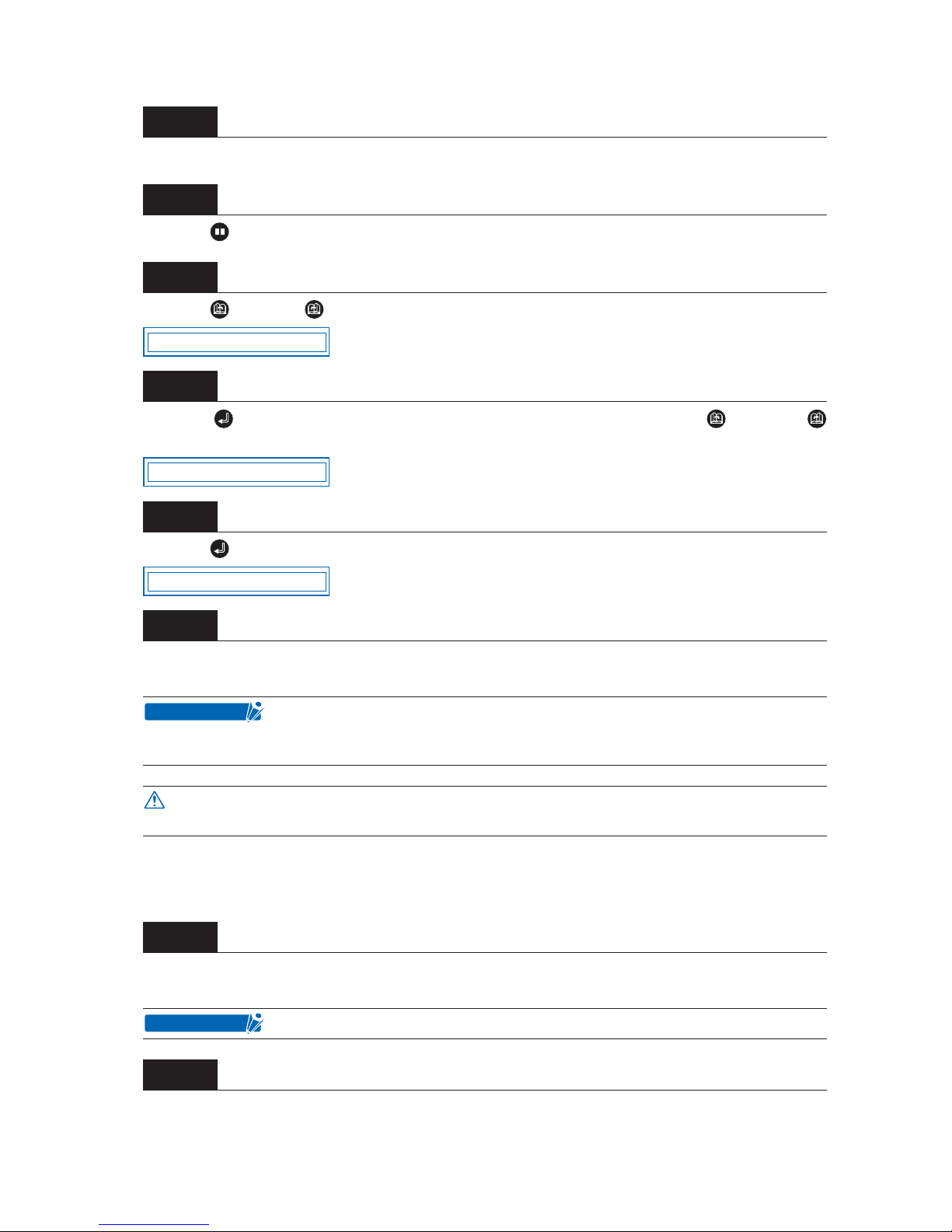

4.1 PAUSE Menu List

Pressing the (PAUSE) key in READY mode displays the PAUSE menu, enabling the various settings to

be made. Select the required menu by scrolling through the list using the (NEXT) or (PREV.) key.

FEED

MOVE TO R. MARK

AUTO PRE FEED

TANGENTIAL

AUTO REG. MARK

CLEAR BUFFER

AXIS ALIGNMENT

DISTANCE ADJUST

PAGE LENGTH

PLOT AREA

EXPAND

ROTATE

MIRROR

COPY

SORT

RS-232C

COMMAND

BLADE WEAR SETUP

PEN UP/DOWN

TEST

PEN UP SPEED

OFFSET FORCE

OFFSET ANGLE

STEP PASS

INIT. DOWN FORCE

LENGTH UNIT

4.2 Reading the Auto Registration Marks

4.3 Setting the FEED function

4.4 Setting the AUTO PRE-FEED

4.5 Setting TANGENTIAL Mode

4.6 Auto-Registration-Mark-Reading Settings

4.7 Clearing the Buffer Memory

4.8 Aligning the Coordinate Axes

4.9 Distance Adjustment

4.10 Setting the PAGE LENGTH

4.11 Setting the Cutting/Plotting Area

4.12 Expanding the Cutting/Plotting Area

4.13 Rotating the Coordinate Axes

4.14 Mirroring

4.15 Cutting/Plotting Using the Buffer Memory

(COPY Function)

*Displayed on the first page when you select "TOP" on the "COPY" menu of Special Functions.

4.16 Sorting Settings

4.17 Interface Settings

4.18 Setting the Format of Data to be Received

4.19 Cutter-Blade Wear Detection

(Special function only displayed for BLADE WEAR SETUP “ON”)

4.20 Raising and Lowering the Pen

4.21 TEST Mode

4.22 Setting the PEN UP SPEED

4.23 Setting the OFFSET FORCE (Initial Cutting Force)

4.24 Setting the OFFSET ANGLE

4.25 Setting the STEP PASS

4.26 Setting the INITIAL DOWN FORCE

4.27 Setting the LENGTH UNIT

COPY

Page 47

4 – 3

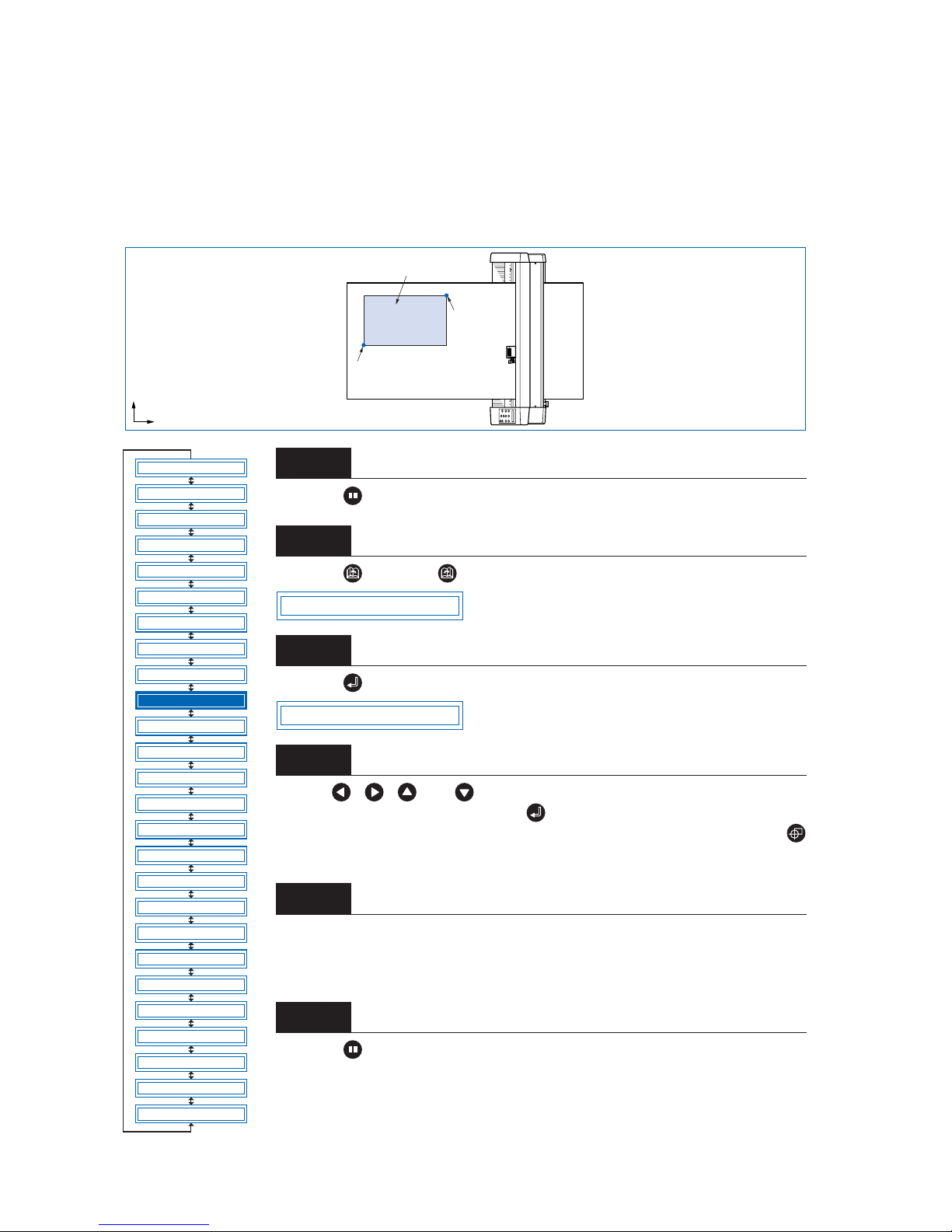

4.2 Reading the Auto Registration Marks

When “2 POINT,” “3 POINT,” or “4 POINT” has been set (see “4.6 Auto-Registra-

tion-Mark-Reading Settings”), press the (PAUSE) key to switch to PAUSE

mode and display the following menu.

Use the , , , and (POSITION) keys to move the cutter pen to the

lower-right registration mark, and then press the (ENTER) key. The sensor

reads between points 1 and 2 (and also between points 1 and 3 for 3-point alignment or 4-point alignment), and the following is displayed.

The distance between X-axis registration marks (points 1 and 2) read by the cutting plotter is displayed on the left. Enter the actual distance on the right. Use the

or key to move the cursor to the digit to be entered, use the or key

to increase or decrease the values, and then press the (ENTER) key to confirm. For 3-point alignment or 4-point alignment, the distance between the Y-axis

registration marks (points 1 to 3) is also displayed and should be set in the same

way. To cancel the selection(s), press the (NEXT) or (PREV.) key.

Step

1

Step

2

• If the registration-mark distance correction is set to

“5 mm,” “10 mm,” “50 mm,” or “STD.” the alignment

input screen is not displayed.

• The registration marks are read in accordance with the

registration-mark-detection movement distance setting.

Step

3

FEED

MOVE TO R. MARK

AUTO PRE FEED

TANGENTIAL

AUTO REG. MARK

CLEAR BUFFER

AXIS ALIGNMENT

DISTANCE ADJUST

PAGE LENGTH

PLOT AREA

EXPAND

ROTATE

MIRROR

COPY

SORT

RS-232C

COMMAND

BLADE WEAR SETUP

PEN UP/DOWN

TEST MODE

PEN UP SPEED

OFFSET FORCE

OFFSET ANGLE

STEP PASS

INIT. DOWN FORCE

LENGTH UNIT

MOVE TO R. MARK

X00308.9 00308.9

CHECKPOINT

Page 48

4 – 4

4.3 Setting the FEED function

The FEED function feeds the medium forward and backward to leave faint tracks of the grit rollers on it and

prevent the media from slipping during a cutting or plotting operation.

Press the (PAUSE) key to switch to PAUSE mode.

Press the (NEXT) or (PREV.) key until the following menu is displayed.

Press the (ENTER) key to display the feed-length setting. Set the length to be

fed.

Use the or key to set a value within the range of 1 m to 50 m, and then

press the (ENTER) key. The cutting plotter performs the feed operation (moves

the medium forward and then back to the origin). To cancel the operation, press

the (NEXT) or (PREV.) key.

Step

1

Step

2

Step

3

Step

4

Pressing the (NEXT) or (PREV.) key during the

feed operation aborts the feed operation and returns the

medium to its original position.

• The feed operation starts immediately once the feed length

has been set and the (ENTER) key is pressed. Make sure

there are no obstructions at the front or rear of the cutting plotter.

• When using roll media, either extend and load the length to be

used beforehand or use the media feed procedure (“4.3 Setting the FEED function”, “4.4 Setting AUTO PRE-FEED”).

Beginning cutting or plotting without feeding the media first

may generate a position error or may cause the roll media to

fall off the stock shaft.

FEED

MOVE TO R. MARK

AUTO PRE FEED

TANGENTIAL

AUTO REG. MARK

CLEAR BUFFER

AXIS ALIGNMENT

DISTANCE ADJUST

PAGE LENGTH

PLOT AREA

EXPAND

ROTATE

MIRROR

COPY

SORT

RS-232C

COMMAND

BLADE WEAR SETUP

PEN UP/DOWN

TEST MODE

PEN UP SPEED

OFFSET FORCE

OFFSET ANGLE

STEP PASS

INIT. DOWN FORCE

LENGTH UNIT

FEED

FEED 1m

CHECKPOINT

CAUTION

Page 49

4 – 5

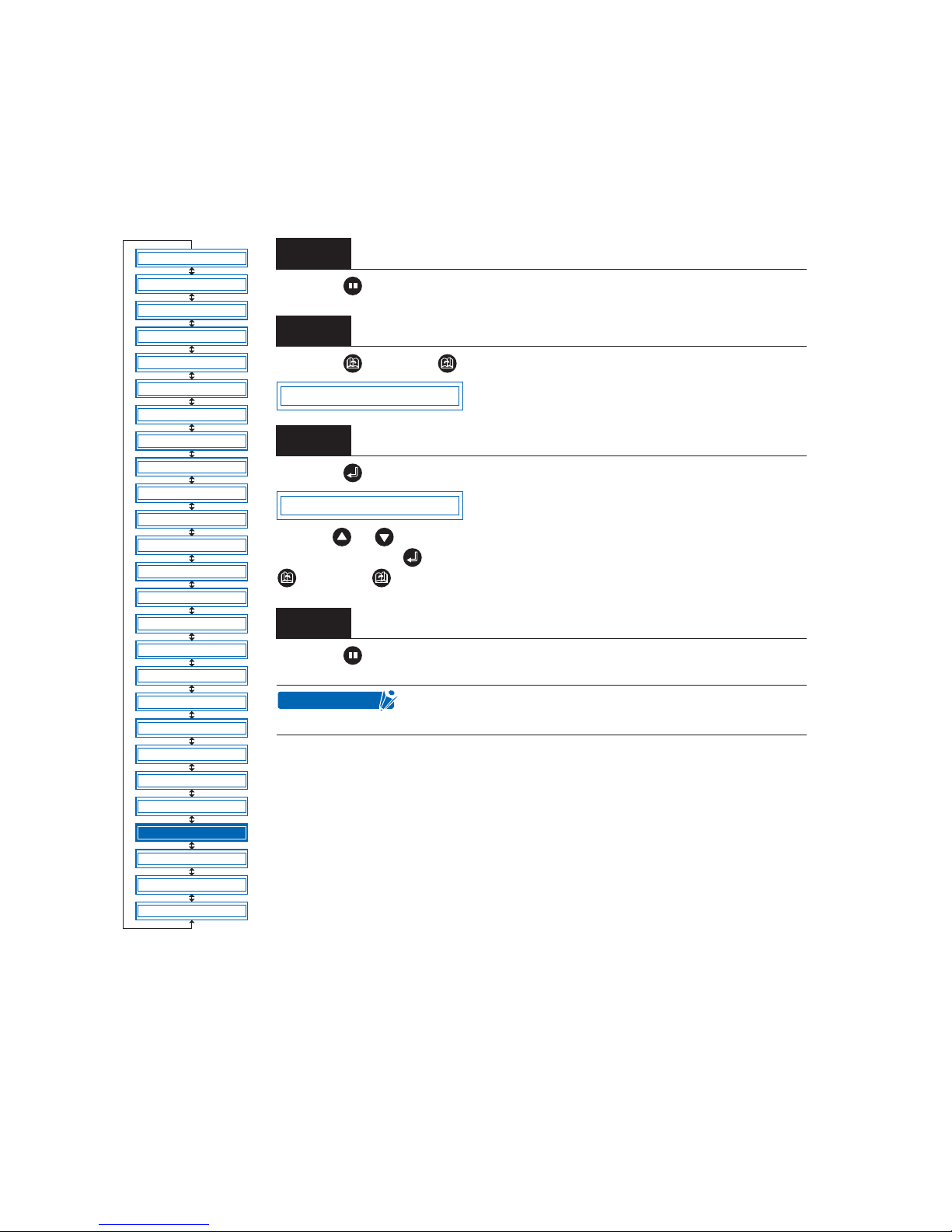

4.4 Setting AUTO PRE-FEED

When the AUTO PRE-FEED function is set to “ON,” the medium is automatically fed forward and back-

ward by the preset length when data is received. This operation leaves traces of the grit rollers on the

media and prevents it from slipping during a cutting or plotting operation. Similarly, if roll media is used, the

medium is automatically pulled out by the cutting plotter.

Press the (PAUSE) key to switch to PAUSE mode.

Press the (NEXT) or (PREV.) key until the following menu is displayed.

Press the (ENTER) key to display the AUTO PRE-FEED setting.

Press the or key to select “ON” or “OFF,” and then press the (ENTER)

key to confirm.

If “ON” is selected and the (ENTER) key pressed, the feed-length setting is

displayed.

Use the or key to set a value within the range of 1 m to 50 m, and then

press the (ENTER) key to confirm. To cancel the selection, press the

(NEXT) or (PREV.) key.

Press the (PAUSE) key to cancel PAUSE mode.

Step

1

Step

2

Step

3

Step

4

Step

5

When using roll media, either extend and load the length to be

used beforehand or use the media feed procedure (“4.3 Setting

the FEED function”, “4.4 Setting AUTO PRE-FEED”).

Beginning cutting or plotting without feeding the media first may

generate a position error or may cause the roll media to fall off

the stock shaft.

FEED

MOVE TO R. MARK

AUTO PRE FEED

TANGENTIAL

AUTO REG. MARK

CLEAR BUFFER

AXIS ALIGNMENT

DISTANCE ADJUST

PAGE LENGTH

PLOT AREA

EXPAND

ROTATE

MIRROR

COPY

SORT

RS-232C

COMMAND

BLADE WEAR SETUP

PEN UP/DOWN

TEST MODE

PEN UP SPEED

OFFSET FORCE

OFFSET ANGLE

STEP PASS

INIT. DOWN FORCE

LENGTH UNIT

AUTO PRE FEED

AUTO PRE FEED ON

AUTO PRE FEED 1m

CAUTION

Page 50

4 – 6

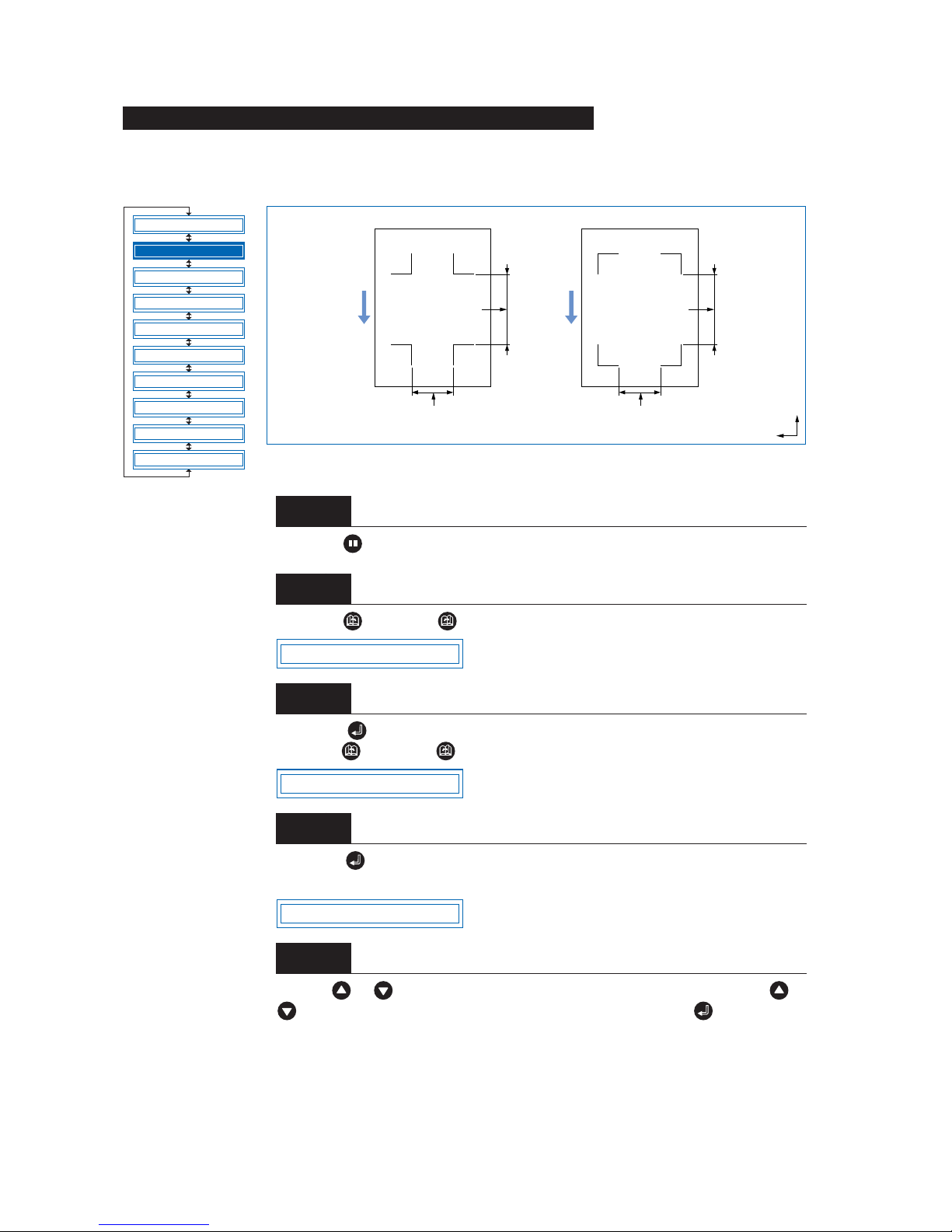

4.5 Setting TANGENTIAL Mode

This function should be used for the cutting of thick media (more than 0.3 mm in thickness) and when the

cutter blade is not able to turn properly due to the cutting depth, resulting in discrepancies between the

start and finish point and the inability to cut sharp corners. This function can be set on or off individually for

each of the eight cutter-pen setting areas, and it should be set to suit the media used. The overcut-amount

setting screen is displayed for cutter-pen setting areas for which the TANGENTIAL mode is “ON.”

This setting has two modes: Mode 1 and Mode 2.

Mode 1: Overcuts the start and finish cutting positions and acute-angle corner sections to avoid leaving

uncut sections. In addition, the cutter blade is moved on the surface of the medium during cutting

when it is rotated significantly, ensuring sharp cutting unaffected by the medium toughness or

thickness.

Mode 2: Overcuts the start and finish cutting positions only. In addition, the cutter is rotated on the medium

surface for the start cutting position only. This uses simpler cutter control than Mode 1, and provides a shorter cutting time.

Press the (PAUSE) key to switch to PAUSE mode.

Press the (NEXT) or (PREV.) key until the following menu is displayed.

Press the (ENTER) key to display the TANGENTIAL setting. The numbers “1”

to “8” indicate the cutter setting areas, and those marked with a symbol have

the TANGENTIAL mode set to “ON.”

Use the and keys to move the cursor and select a setting area. Use the

and keys to display/not display the symbol, and then press the (ENTER)

key to confirm. To cancel the selection, press the (NEXT) or (PREV.) key

Press the (PAUSE) key to cancel PAUSE mode.

Select the condition-setting area to be set to “ON” (refer to “Selecting Cutter-Pen-

Condition Setting Areas” on page 3-6).

Step

1

Step

2

Step

3

Step

4

Step

5

FEED

MOVE TO R. MARK

AUTO PRE FEED

TANGENTIAL

AUTO REG. MARK

CLEAR BUFFER

AXIS ALIGNMENT

DISTANCE ADJUST

PAGE LENGTH

PLOT AREA

EXPAND

ROTATE

MIRROR

COPY

SORT

RS-232C

COMMAND

BLADE WEAR SETUP

PEN UP/DOWN

TEST MODE

PEN UP SPEED

OFFSET FORCE

OFFSET ANGLE

STEP PASS

INIT. DOWN FORCE

LENGTH UNIT

TANGENTIAL

1 2 3 4 5 6 7 8

5 15U 0 20 30 1

Page 51

4 – 7

Press the (ENTER) key or use the key to move the cursor to the right-hand side, and then press

the key again to display the menu shown below. If the distance adjustment is set for the setting area

selected, the distance adjustment will be displayed here. Either press the (ENTER) key or move the

cursor to the right-hand side and press the key.

Press the or key to select “Mode 1” or “Mode 2,” and then press the (ENTER) key. The over-

cut setting is displayed.

“STR” indicates the initial overcut amount, and “END” indicates the end overcut amount for the line sec-

tion. Press the or key to select “STR” or “END”, use the or key to increase or decrease the

values, and then press the (ENTER) key to confirm. To cancel the selection(s), press the (NEXT) or

(PREV.) key.

Step

6

Step

7

Step

8

TANGENTIAL MODE 1

STR=0.2 END=0.2

Page 52

4 – 8

4.6 Auto-Registration-Mark-Reading Settings

These settings enable pre-plotted media to be cut without any offset by reading the registration marks

using the cutting-plotter sensor and adjusting the axes to suit the coordinate data.

The following precautions must be observed when the registration marks are automatically read.

• Registration-mark pattern

• Reading range required for the detection of registration marks

• Medium and registration-mark position

• Drawing origin point

• Medium type

The registration-mark conditions that can be read by the cutting plotter are as follows.

• Registration-mark line width: 0.3 mm to 1.0 mm (The registration-mark center lines are used as the reference points.)

• Registration-mark size: 5 mm to 20 mm (See “Setting the Registration-Mark Size.”)

• Registration-mark pattern: Pattern 1 or 2 (See “Setting the Registration-Mark Pattern.”)

• Registration marks must be formed of single lines.

• Registration marks must be drawn in black.

The cutting plotter cannot detect registration marks on the following media types.

• Transparent media: The writing surface is also read, preventing the registration-mark lines

from being read.

• Non-monochrome drawings: The registration marks cannot be read on colored media or if the registra-

tion marks are not black.

• Untidy drawings or media: The registration marks cannot be read if the medium surface is dirty or

creased, or if the registration marks are defaced.

• Medium thickness: The registration marks cannot be read if the medium is more than 0.3 mm

in thickness.

Registration-mark reading accuracy *: Within 0.3 mm

* Accuracy when using pens provided with the cutting plotter, high-grade media,

and reading the specified pattern.

• The registration marks used in the application software cannot be used. The registration marks must always be created as drawing data.

• If auto mark reading is not possible, use the axis alignment function (see “Setting

Axis Alignment”).

• Auto mark reading cannot be performed when MIRROR is set to ON.

CHECKPOINT

Sensor

CHECKPOINT

Page 53

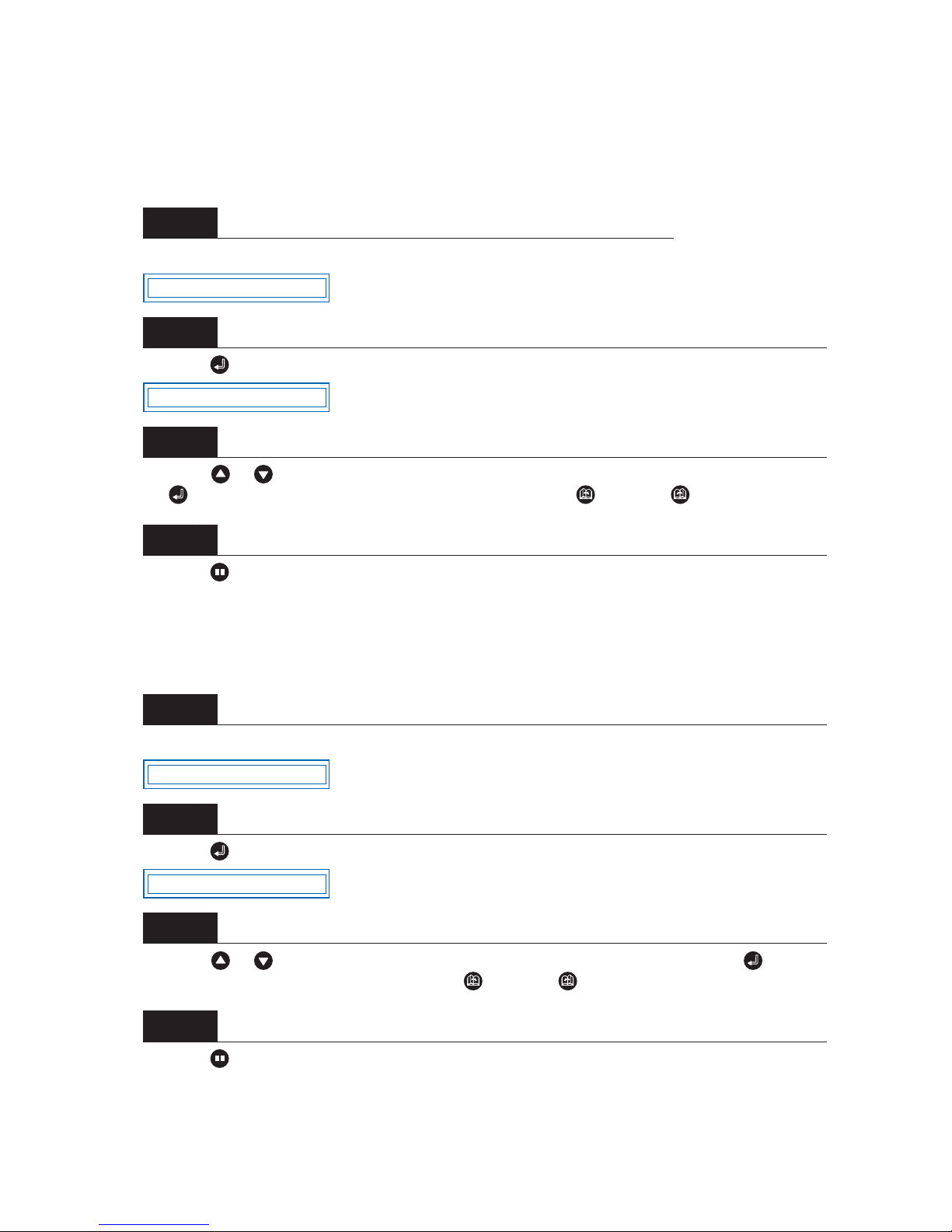

4 – 9

The cutting plotter is capable of reading the following registration-mark patterns.

The range required for the detection of registration marks is as shown below.

Blank margins must be left between the medium edges and the registration marks to enable the marks to

be read.

Note: The margins in parentheses are the blank margins that must be left between the medium edges and

the cutting area in SHEET mode.

Registration-Mark Pattern

Reading Range Required for the Detection of Registration Marks

• Incorrect detection may occur if there are marks other than registration marks

within the reading range. If drawings overlap the registration-mark reading range,

refer to “Setting the Registration-mark detection movement distance.”

• Incorrect detection may occur if the registration-mark reading range is dirty or

foreign matter is adhering to the medium surface.

Medium and Registration-Mark Position

Registration-mark pattern 1

Medium feed direction

Registration-mark pattern 2

X

Y

Registration-mark reading range

a=6mm

a

a

a

a

Registration-mark pattern 2Registration-mark pattern 1

Medium feed direction

X

Y

Registration-mark reading range

a=6mm

a

a

CHECKPOINT

Registration-mark pattern 1

Medium feed direction

Registration-mark pattern 2

Right-hand

push roller

1515

5010

Left-hand

push roller

Right-hand

push roller

1515

50

(30)

(30)

10

Left-hand

push roller

Units: mm

X

Y

Page 54

4 – 10

The drawing origin point following reading of the registration marks will be at the bottom-right registration

mark, as shown below.

■ Registration-Mark Menu Tree

Drawing Origin Point

Registration-mark pattern 1

Medium feed direction

Registration-mark pattern 2

Origin point

Origin point

X

Y

MARK MODE

MARK POSITION

MARK TYPE

MARK SIZE

MARK DIST. ADJ.

MARK OFFSET

MARK SENSOR ADJ1

MARK SENSOR ADJ2

MARK AUTO SCAN

MARK SENSOR ADJ

FEED

MOVE TO R. MARK

AUTO PRE FEED

TANGENTIAL

AUTO REG. MARK

CLEAR BUFFER

AXIS ALIGNMENT

DISTANCE ADJUST

PAGE LENGTH

PLOT AREA

EXPAND

ROTATE

MIRROR

COPY

SORT

RS-232C

COMMAND

BLADE WEAR SETUP

PEN UP/DOWN

TEST

PEN UP SPEED

OFFSET FORCE

OFFSET ANGLE

STEP PASS

INIT. DOWN FORCE

LENGTH UNIT

Key

Setting the Registration-Mark Mode

Setting the Registration-Mark Detection Movement Distance

Setting the Registration-Mark Pattern

Setting the Registration-Mark Size