Page 1

CE2000-60/120

USER’S MANUAL

MANUAL NO. CE2060-UM-151

CUTTING PLOTTER

Page 2

PREFACE

Thank you for choosing a Graphtec CE2000 series cutting plotter.

This cutting plotter employs a digital servo drive system to achieve high-speed and high-precision cutting

operations. Besides cutting marking film and other media, it can also be used as a pen plotter.

To ensure good cutting quality and optimum productivity, be sure to read this User’s Manual thoroughly

before use.

•

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form or by any means, without the prior written permission of Graphtec Corporation.

•

The specifications and other information in this manual are subject to change without notice.

•

While every effort has been made to provide complete and accurate information, please contact your

sales representative or nearest Graphtec vendor if you find any unclear or mistaken information or

wish to make other comments or suggestions.

•

Notwithstanding the stipulation in the preceding paragraph, Graphtec Corporation assumes no liability

for damages resulting from either the use of the information contained herein or from use of the

product.

All names of companies, brands, logotypes, and products appearing in this manual are the trademarks

or registered trademarks of their respective companies.

Page 3

i

TO ENSURE SAFE AND CORRECT USE

• To ensure safe and correct use of your cutting plotter, read this Manual thoroughly before use.

• After having read this Manual, keep it in a handy location for quick reference as needed.

• Do not permit small children to touch the cutting plotter.

• The following describes important points for safe operation. Please be sure to observe them strictly.

Conventions Used in This Manual

To promote safe and accurate use of the cutting plotter as well as to prevent human injury and property

damage, safety precautions provided in this manual are ranked into the three categories described below.

Be sure you understand the difference between each of the categories.

DANGER

: This category provides information that, if ignored, is highly likely to cause fatal

or serious injury to the operator.

WARNING

: This category provides information that, if ignored, is likely to cause fatal or

serious injury to the operator.

CAUTION

: This category provides information that, if ignored, could cause injury to the

operator or physical damage to the cutting plotter.

Description of Safety Symbols

The symbol indicates information that requires careful attention (which includes warnings). The point requiring attention is described by an illustration or text within or next

to the symbol.

The symbol indicates action that is prohibited. Such prohibited action is described by

an illustration or text within or next to the symbol.

The symbol indicates action that must be performed. Such imperative action is described

by an illustration or text within or next to the symbol.

Page 4

ii

Safety Precautions

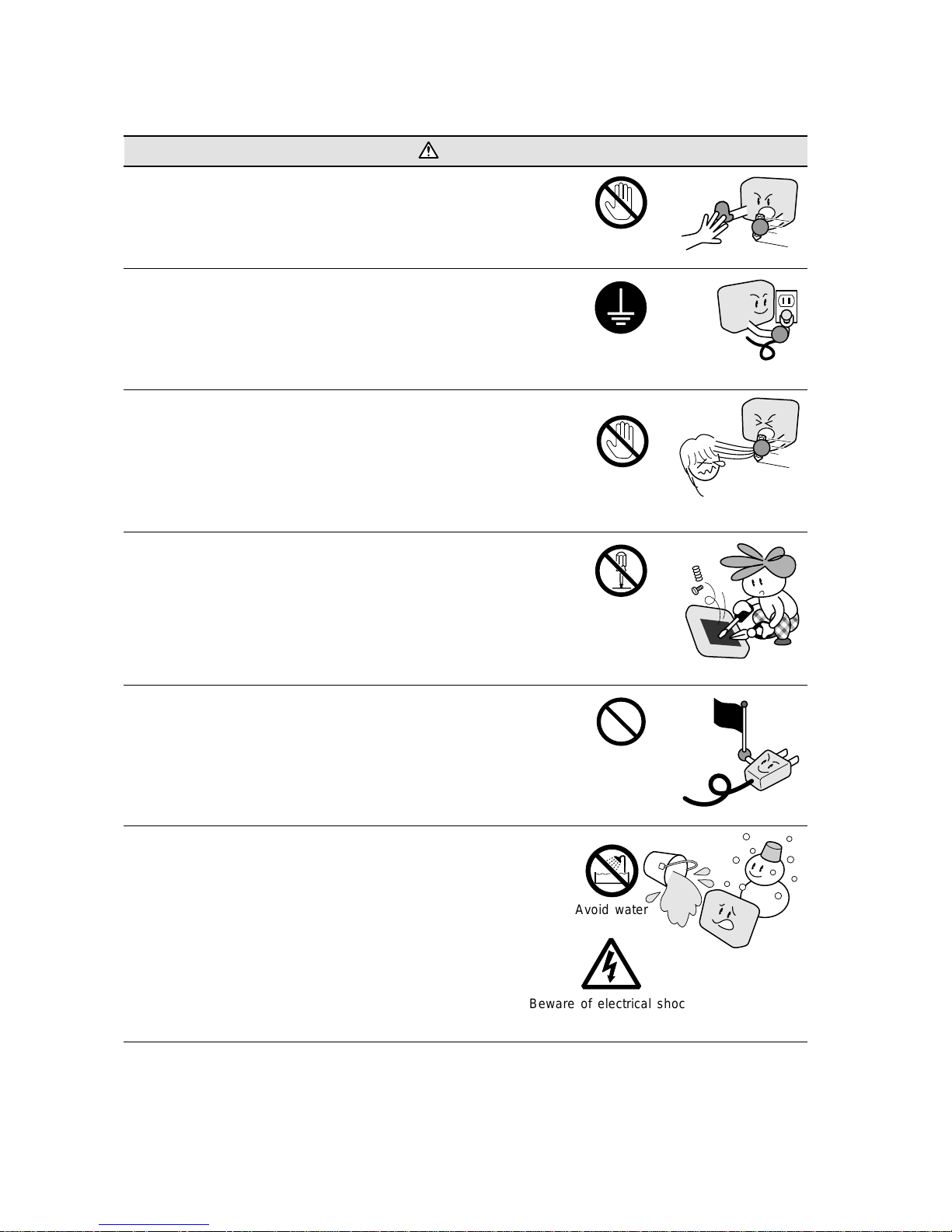

WARNING

During a cutting or plotting operation, do not touch the writing

panel or moving parts such as the carriage.

• Such action may cause human injury.

Be sure to ground the earth terminal.

• If the cutting plotter is not grounded, the operator could suffer

an electrical shock in case of current leakage.

Keep your hands, hair, etc. away from the writing panel and

moving parts such as the carriage even if the cutting plotter

is stopped, because it may suddenly start moving when data

is received.

• Such action may cause human injury.

Do not disassemble, repair, or remodel the cutting plotter.

• Such action may cause electrical shock or a fire hazard due to

current leakage.

• Contact with the high-voltage parts within the cutting plotter may

cause electrical shock.

• If the cutting plotter requires repair, contact your sales representative or nearest Graphtec vendor.

Do not connect the cutting plotter to a non-rated power supply.

• Use of a different supply voltage may result in electrical shock

or a fire hazard due to current leakage.

Do not use the cutting plotter in a location where it will be

exposed to water, rain or snow.

• Such location may cause electrical shock or a fire hazard due

to current leakage.

Do not touch

Keep your distance

Specified

rating

Prohibited

Ground the

cutting plotter

No disassembly

;

Q

¢

Avoid water

Beware of electrical shock

Page 5

iii

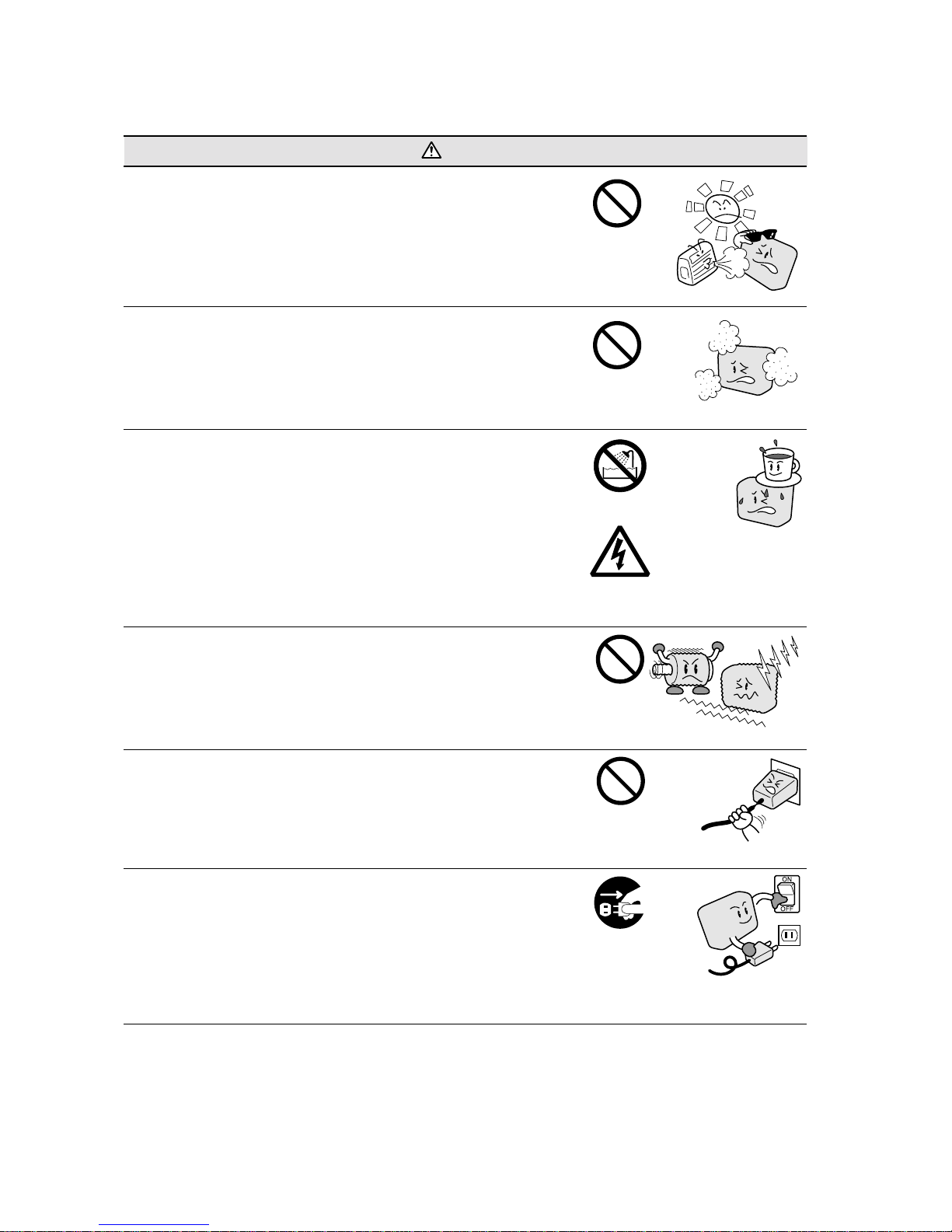

Safety Precautions (Continued)

WARNING

If the cutting plotter generates smoke, is too hot, emits a

strange odor, or otherwise functions abnormally, do not continue

using it. Turn off its power and unplug its power cord from

the electrical socket.

• Use of the cutting plotter in such status may result in a fire hazard

or electrical shock.

• After confirming that smoke is no longer being generated, contact

your sales representative or nearest Graphtec vendor to request

repair.

• Never try to perform repair yourself. Repair work by inexperienced personnel is extremely dangerous.

Do not allow dust or metallic matter to adhere to the power

plug.

• A dirty power plug may result in electrical shock or a fire hazard

due to current leakage.

Do not use the power cord if it is damaged.

• Use of a damaged cord may result in electrical shock or a fire

hazard due to current leakage.

• Replace the power cord with a new one.

Be careful when handling the cutter blade.

• Touching the blade with your bare hand may cause injury.

• During a cutting operation, keep away from the cutter blade.

Avoid contact

Prohibited

Beware of electrical shock

Unplug the power

cord from the socket

Prohibited

Page 6

iv

Safety Precautions (Continued)

CAUTION

Do not use or store the cutting plotter in a location exposed

to direct sunlight or the direct draft of an air conditioner or

heater.

• Such location may impair the performance of the cutting plotter.

Do not use the cutting plotter in an excessively dusty or humid

location.

• Such location may impair the performance of the cutting plotter.

Do not place any receptacle containing water or other fluid

on top of the cutting plotter.

• Fluid falling inside the cutting plotter may cause electrical shock

or a fire hazard due to current leakage.

Do not use the cutting plotter in a location subject to excessive

mechanical vibration or electrical noise.

• Such location may impair the performance of the cutting plotter.

When disconnecting the power cord or an interface cable, do

not pull on the cord/cable.

• Such action will damage the cord/cable, resulting in a fire hazard

or electrical shock. Be sure to hold the power cord’s plug or

the interface cable’s connector.

If water or foreign matter enters inside the cutting plotter, do

not continue using it. Turn off its power and unplug its power

cord from the electrical socket.

• Use of the cutting plotter in such status may result in electrical

shock or a fire hazard due to current leakage.

• Contact your sales representative or nearest Graphtec vendor

to request repair.

Prohibited

Prohibited

Avoid water

Beware of electrical shock

Prohibited

Prohibited

Unplug the power

cord from the socket

Page 7

v

Safety Precautions (Continued)

CAUTION

Do not attempt to lubricate the cutting plotter’s mechanisms.

• Such action may cause it to break down.

Do not clean the cutting plotter using a volatile solvent such

as thinner or benzine.

• Such action may impair its performance.

During cutting or plotting, provide enough space around the

cutting plotter so that the medium will not hit any objects in

its vicinity.

• Such contact may cause cutting or plotting to go out of

alignment.

When using indoor lighting such as a fluorescent lamp or an

electrical lamp, provide a distance of at least one meter between

the cutting plotter and the light source.

• Closer proximity of such a light source may cause the sensor

to malfunction and prevent proper size detection of the media.

When using the cutter, be sure not to extend its blade more

than necessary.

• An overly extended blade will damage the cutting mat and

adversely affect the cutting quality.

When manually moving the pen carriage in order to load a

medium or other reasons, move the pen carriage slowly.

• Moving it quickly may cause damage to the cutting plotter.

T

h

i

n

n

e

r

B

e

n

z

i

n

e

Prohibited

Prohibited

Contact prohibited

Page 8

vi

For CE2000-60 models

WARNING:

Only computers or peripherals (computer input/output devices, terminals, printers, etc.) certified as

complying with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules, may be

attached to this product when this product is operated in a residential environment. Operation with

non-certified peripherals is likely to result in interference to radio and TV.

The United States Federal Communications Commission has specified that the following notice must

be brought to the attention of users of this product.

FEDERAL COMMUNICATIONS COMMISSION RADIO FREQUENCY

INTERFERENCE STATEMENT

“This equipment has been tested and found to comply with the limits for a Class B digital device pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try to correct interference

by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

– Consult the dealer or an experienced radio/TV technician for help.”

USE SHIELDED CABLES

To comply with FCC Class B requirements, all external data interface cables and connectors must be

properly shielded and grounded. Proper cables and connectors are available from GRAPHTEC’s

authorized dealers or manufacturers of computers or peripherals.

GRAPHTEC is not responsible for any radio or television interference caused by using cables and

connectors other than those recommended or by unauthorized changes or modifications to this equipment. Unauthorized changes or modifications could void the user’s authority to operate the equipment.

Page 9

vii

For CE2000-120 models

WARNING:

The United States Federal Communications Commission has specified that the following notice must be

brought to the attention of users of this product.

FEDERAL COMMUNICATIONS COMMISSION RADIO FREQUENCY

INTERFERENCE STATEMENT

NOTE : This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

USE SHIELDED CABLES

To comply with FCC Class A requirements, all external data interface cables and connectors must be

properly shielded and grounded. Proper cables and connectors are available from GRAPHTEC’s

authorized dealers or manufacturers of computers or peripherals. GRAPHTEC is not responsible for

any interference caused by using cables and connectors other than those recommended or by unauthorized changes or modifications to this equipment. Unauthorized changes or modifications could void

the user’s authority to operate the equipment.

Page 10

viii

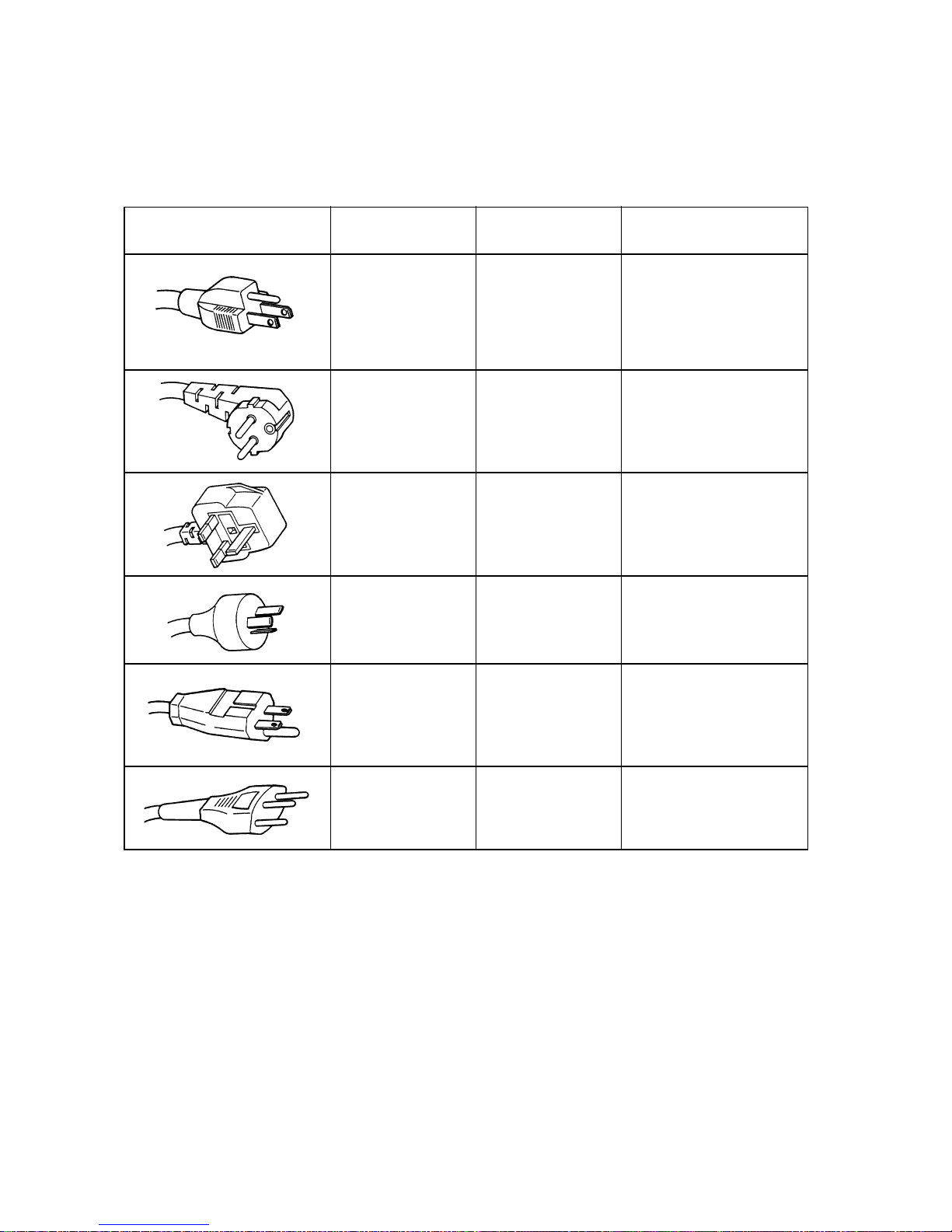

Selecting a Power Cable

Be sure to refer to the following table if you wish to use a cable other than the one supplied as an

accessory.

Plug Configuration Plug Type Reference Power Cable

Standards

North America ANSI C73.11 UL Listed

125 V NEMA 5-15

10 A UL498/817/62 Type SJT

CSA22.2 No.18AWG × 3

NO.42/21/49 300 V, 10 A

Europe CEE(7)VII TYPE: H05VV-F

250 V IEC320 3 × 1.0 mm

2

10 A CEE13

UK BS1363 TYPE: H05VV-F

250 V BS4491 3 × 1.0 mm

2

5 A BS6500

Australia AS3112 TYPE: OD3CFC

250 V AS3109 3 × 1.0 mm

2

10 A AS3191

UL Listed

North America ANSI C73.20

250 V NEMA 6-15 Type SJT

15 A UL 198.6 No.18AWG × 3

300 V, 10 A

Switzerland SEV1011 TYPE: H05VV-F

250 V SEV1004 3 × 0.75 mm

2

6 A SEV1012

Page 11

ix

Contents

TO ENSURE SAFE AND CORRECT USE

Conventions Used in This Manual .............................................................................................. i

Description of Safety Symbols .................................................................................................... i

Safety Precautions ....................................................................................................................... ii

Selecting a Power Cable ............................................................................................................. viii

1. INTRODUCTION

1.1 Overview ............................................................................................................................ 1-2

1.2 Standard Accessories ....................................................................................................... 1-2

1.3 Assembling Your Plotter (CE2000-120) .......................................................................... 1-3

2. NAMES OF THE MAIN PARTS

2.1 Front View .......................................................................................................................... 2-2

2.2 Rear View .......................................................................................................................... 2-3

2.3 Control Panel ..................................................................................................................... 2-4

3. SETTING UP THE CUTTING PLOTTER

3.1 Connecting to Your Computer ......................................................................................... 3-2

3.2 Turning on the Power ....................................................................................................... 3-3

3.3 Loading the Medium ......................................................................................................... 3-4

3.3.1 Loading a Roll Medium ......................................................................................... 3-4

3.3.2 Loading Single Sheets ........................................................................................... 3-8

3.4 Selecting the COMMAND Mode and INTERFACE Conditions ..................................... 3-11

3.4.1 Selecting the COMMAND Mode ........................................................................... 3-11

3.4.2 Selecting the STEP SIZE or ORIGIN POINT ..................................................... 3-12

3.4.3 Selecting the Interface Conditions ........................................................................ 3-13

4. PREPARING FOR A CUTTING OPERATION

4.1 Types and Features of Cutter Blades ............................................................................. 4-2

4.2 Replacing the Cutter Blade and Adjusting Its Length ................................................... 4-2

4.3 Mounting the Cutter Pen Plunger .................................................................................... 4-5

4.4 Setting the Cutting Conditions ......................................................................................... 4-6

4.4.1 Selecting a Set of Cutting Conditions .................................................................. 4-7

4.4.2 Specifying the Cutting FORCE ............................................................................. 4-8

4.4.3 Specifying the Cutting SPEED ............................................................................. 4-9

4.4.4 Specifying the CUTTER OFFSET ........................................................................ 4-10

4.4.5 Specifying the Cutting QUALITY .......................................................................... 4-11

4.5 Running a Cutting TEST .................................................................................................. 4-12

5. USING THE BASIC FUNCTIONS

5.1 Moving the Initial Cutting Position (Origin Point) ........................................................... 5-2

5.2 Moving the Pen Carriage in +100-mm Steps ................................................................. 5-3

5.3 Clearing Data from the Internal Memory ........................................................................ 5-3

5.4 Raising and Lowering the Pen ........................................................................................ 5-4

5.5 Feeding the Medium ......................................................................................................... 5-5

5.6 Selecting the LENGTH UNIT ........................................................................................... 5-6

Page 12

x

6. USING APPLIED FUNCTIONS

6.1 Rotating the Coordinate Axes .......................................................................................... 6-2

6.2 Using the COPY Function ................................................................................................ 6-3

6.3 Enabling the AUTO PRE FEED Mode ............................................................................ 6-5

6.4 Adjusting the Distance Precision ..................................................................................... 6-6

6.5 Aligning the Coordinate Axes ........................................................................................... 6-7

6.6 Specifying the Page Length ............................................................................................. 6-9

6.7 Specifying the PLOT AREA ............................................................................................. 6-10

6.8 Expanding the Width of the Plot Area ............................................................................ 6-12

7. USING THE EXTENDED FUNCTIONS

7.1 Specifying the PEN UP SPEED ...................................................................................... 7-2

7.2 Specifying the OFFSET FORCE...................................................................................... 7-3

7.3 Specifying the OFFSET ANGLE ...................................................................................... 7-4

7.4 Selecting the STEP PASS ............................................................................................... 7-5

8. USING THE SPECIAL FUNCTIONS

8.1 Description of the Special Functions ............................................................................... 8-2

8.2 Specifying the Special Functions ..................................................................................... 8-4

9. TROUBLESHOOTING PROCEDURES

9.1 Printing a List of the Currently Selected Conditions ..................................................... 9-2

9.2 Running a SELF TEST ..................................................................................................... 9-4

9.3 Using the DUMP Mode ..................................................................................................... 9-5

9.4 Cutting the Demo Pattern................................................................................................. 9-7

9.5 The Plotter is Turned On But Doesn’t Operate ............................................................. 9-8

9.6 Mechanical Error Messages and Their Causes ............................................................. 9-8

9.7 Command Error Messages and Their Causes ............................................................... 9-9

9.8 The Cutting Results are Unsatisfactory .......................................................................... 9-12

APPENDIX

A.1 Main Specifications ........................................................................................................... A-2

A.2 Options and Supplies ........................................................................................................ A-3

A.3 External Dimensions ......................................................................................................... A-4

A.4 Menu Tree ......................................................................................................................... A-6

INDEX................................................................................................................................................. I-1

Page 13

1

1

INTRODUCTION

1.1 Overview........................................................................................ 1-2

1.2 Standard Accessories ............................................................. 1-2

1.3 Assembling Your Plotter (CE2000-120) ........................... 1-3

Page 14

1 – 2

1.1 Overview

The CE2000-60/120 is a cutting plotter that was developed for the specific purpose of cutting color

adhesive-backed film.

It is equipped with various functions that aim at improving the cutting quality. To ensure good cutting

quality and optimum productivity, be sure to read this User’s Manual thoroughly before use.

1.2 Standard Accessories

After unpacking the cutting plotter, check that the standard accessories listed below are all present.

If an accessory is missing, please promptly contact your sales representative or nearest Graphtec vendor.

CE2000-60/120

OPERATION MANUAL

MANUAL NO. CE2060-UM-451

CUTTING PLOTTER

Power cord: 1 Operation Manual: 1 User Guide CD-ROM: 1

Cutter pen plunger: 1 Cutter blade: 1 (CB09UA) Roll media tray: 1

(CE2000-60 only)

Media cutter: 1 Water-based fiber-tip pen: 1

Stand : 1 (CE2000-120 only, packed in a separate box).

Stopper : 2 (CE2000-120 only, packed together with main unit).

Stock roller : 2 (CE2000-120 only, packed together with main unit).

Page 15

1 – 3

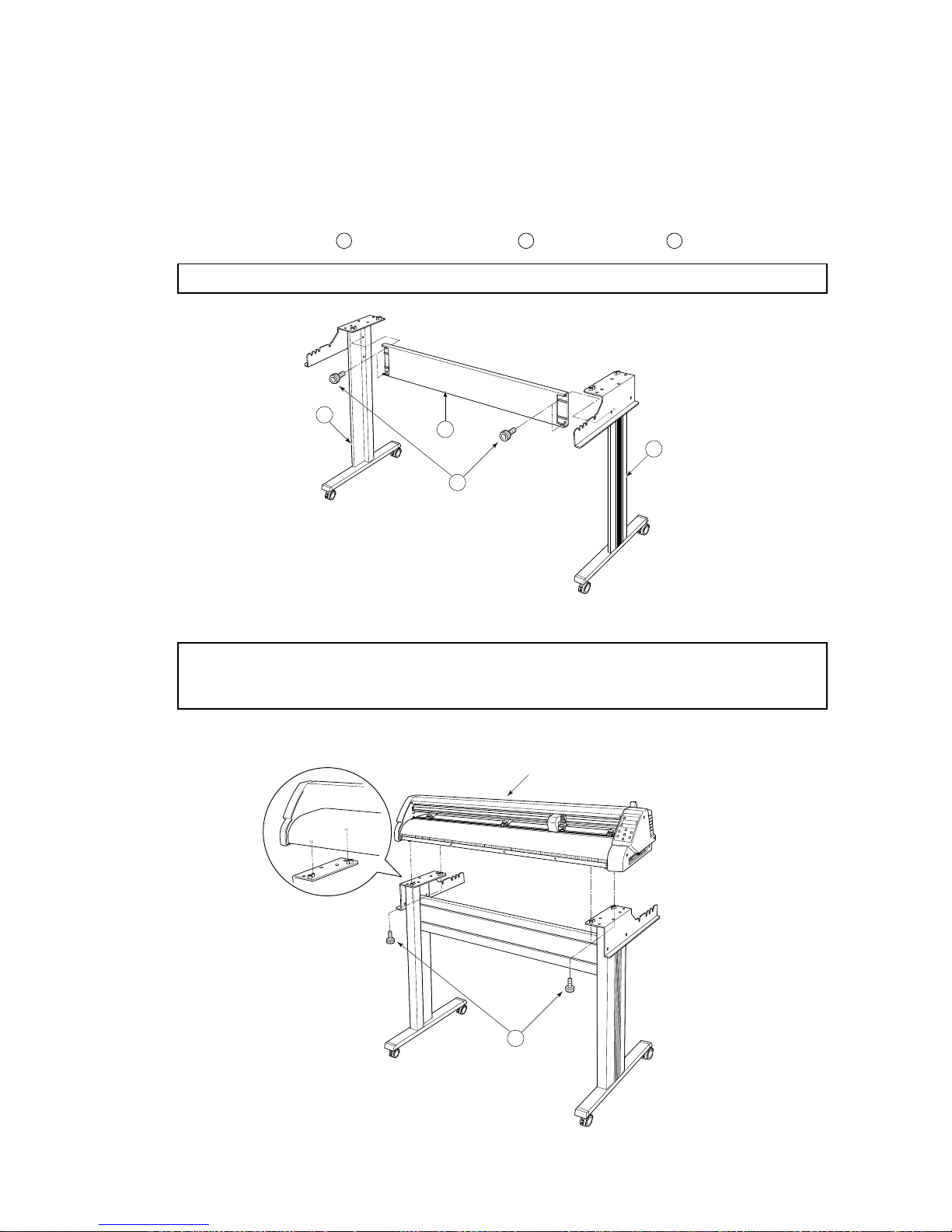

1.3 Assembling Your Plotter (CE2000-120)

Before You Begin Assembly (When Using the Basket)

If you will be mounting the optional basket, assemble the basket after you have completed Step (1)

in the section entitled “Assembling the Stand.”

(1) Mount the center bar (3) onto the R side foot (1) and L side foot (2).

NOTE: At such time, loosely fasten the hexagon bolts.

(2) Place the CE2000-120 main unit onto the stand, then secure it in place using hexagon bolts.

NOTE: While adjusting the positions of the temporarily fastened R and L side feet, mount

the main unit onto the stand by fitting the stand’s pins into the corresponding holes

in the main unit.

Secure the center bar by tightening its hexagon bolts.

1

2

3

4

5

CE2000-120

Page 16

1 – 4

7

8

6

E-Ring

(3) After passing each roll shaft (4) through a stopper (7) and plastic hexagon screw (8), mount

each roll shaft as shown in the figure above to complete the assembly procedure.

Page 17

2

2

NAMES OF THE MAIN PARTS

2.1 Front View ..................................................................................... 2-2

2.2 Rear View...................................................................................... 2-3

2.3 Control Panel .............................................................................. 2-4

Page 18

2 – 2

2.1 Front View

CE2000-60

Cutting mat : Cutting or plotting is performed on this mat.

Grit rollers : Feeds the medium forward or backward.

Push rollers : Pushes the medium against the grit rollers.

Pen holder : Holds the cutter pen and moves it up and down.

Medium set lever : Raises or lowers the push rollers when loading a medium.

Control panel : Used to operate the cutting plotter and set its functions.

Parallel connector : Used to connect a Centronics-compatible parallel interface cable.

Serial connector : Used to connect an RS-232C serial interface cable.

Pen carriage : Moves pen left & right.

CE2000-120

Grit rollers : Feeds the medium forward or backward.

Push rollers : Pushes the medium against the grit rollers.

Pen holder : Holds the cutter pen and moves it up and down.

Medium set lever : Raises or lowers the push rollers when loading a medium.

Control panel : Used to operate the cutting plotter and set its functions.

Parallel connector : Used to connect a Centronics-compatible parallel interface cable.

Serial connector : Used to connect an RS-232C serial interface cable.

Pen carriage : Moves pen left & right.

Stand : The main unit is placed on this stand (a stand is optional for the CE2000-60 model).

Pen holder

Control panel

Grit rollers

Push rollers Pen carriage

Medium set lever

Serial connector

Parallel connector

Stand

Push rollers

Pen holder

Pen carriage

Media set lever

Control panel

Serial connector

Parallel connector

Cutting mat

Grit rollers

Page 19

2 – 3

2.2 Rear View

CE2000-60

Roll media tray : Holds a roll medium for feeding to the cutting plotter.

Roll media tray guide rail : Used to mount the roll media tray.

AC power inlet : Connects one end of the power cord to the cutting plotter.

Power switch : Controls the on/off status of the power supply to the cutting plotter.

CE2000-120

AC power inlet : Connects one end of the power cord to the cutting plotter.

Power switch : Controls the on/off status of the power supply to the cutting plotter.

Stopper : Used to adjust the position of roll film by preventing the film from sliding from side to side.

Stock roller : Holds the roll film for feeding to the cutting plotter.

Stopper

Stock roller

AC power inlet

Power switch

AC power inletRoll media tray guide railRoll media tray

Power switch

Page 20

2 – 4

2.3 Control Panel

Lamps

POWER

: Remains lit while the cutting plotter is being

supplied with power.

PROMPT

: Lights upon the receipt of plot data speci-

fying a coordinate point outside of the effective plotting area.

Panel Keys

F1/ORIGIN

: Press this function key to reposi-

tion the origin point or to select

a menu function in PAUSE status.

F2/TEST

: Press this function key to run a

cutting test for checking the cutting conditions or to select a menu

function in PAUSE status.

NEXT PAGE

: Press this function key to switch

through COND1 to COND4. When

a menu is being displayed in

PAUSE status, press this key to

proceed to the next menu.

PAUSE

: This key functions differently according to the current operating status.

Press it once to enter the PAUSE status and light up the PAUSE lamp. Press it again to cancel

the PAUSE status and turn off the PAUSE lamp.

Press this key when you wish to discontinue cutting or plotting or set functions at menus on

the display panel.

ENTER

: After setting a cutting or plotting condition, press this key to register the setting.

POSITION

: These keys function differently according to the current operating

status.

When the cutting plotter is not in PAUSE status, they are used

to move the pen carriage.

When the cutting plotter is in PAUSE status, they are used to

change the settings of functions at menus on the display panel.

Setting the Multilingual Display

Your cutting plotter’s display can be set to one of six different languages: English, French, German,

Italian, Japanese, or Spanish. To access the language selection menu, hold down the

ENTER

and

F1/ORIGIN

keys while turning on the power. Hold down the keys until a two-line language display menu appears.

Next, press the POSITION key to move through the six language selections. When the desired

language is displayed, press the

ENTER

key to register your selection.

F1 / ORIGIN

F2 / TEST

PAUSE

ENTER

POWER

PROMPT

NEXT PAGE

POSITION

Page 21

3

3

SETTING UP THE CUTTING PLOTTER

3.1 Connecting to Your Computer ............................................ 3-2

3.2 Turning on the Power ............................................................. 3-3

3.3 Loading the Medium................................................................ 3-4

3.3.1 Loading a Roll Medium ...................................................... 3-4

3.3.2 Loading Single Sheets ....................................................... 3-8

3.4 Selecting the COMMAND Mode and INTERFACE

Conditions

.................................................................................. 3-11

3.4.1 Selecting the COMMAND Mode ...................................... 3-11

3.4.2 Selecting the STEP SIZE or ORIGIN POINT................. 3-12

3.4.3 Selecting the Interface Conditions ................................ 3-13

Page 22

3 – 2

3.1 Connecting to Your Computer

The cutting plotter and a computer are connected using an interface cable. At the computer, the interface

cable is connected to either the printer (Centronics-compatible parallel) port or the serial (RS-232C)

port. Determine which port to use according to the requirements of your application software and/or

which of your computer’s communication ports are available for use.

Use either a Centronics-compatible parallel interface cable or a serial interface cable. Obtain a Graphtecauthorized interface cable that is compatible with your computer and can be connected to either the

computer’s printer or serial port. (The interface cables are optional.)

Centronics Parallel Interface

Caution : Make sure that the interface cable is no longer than 2 meters.

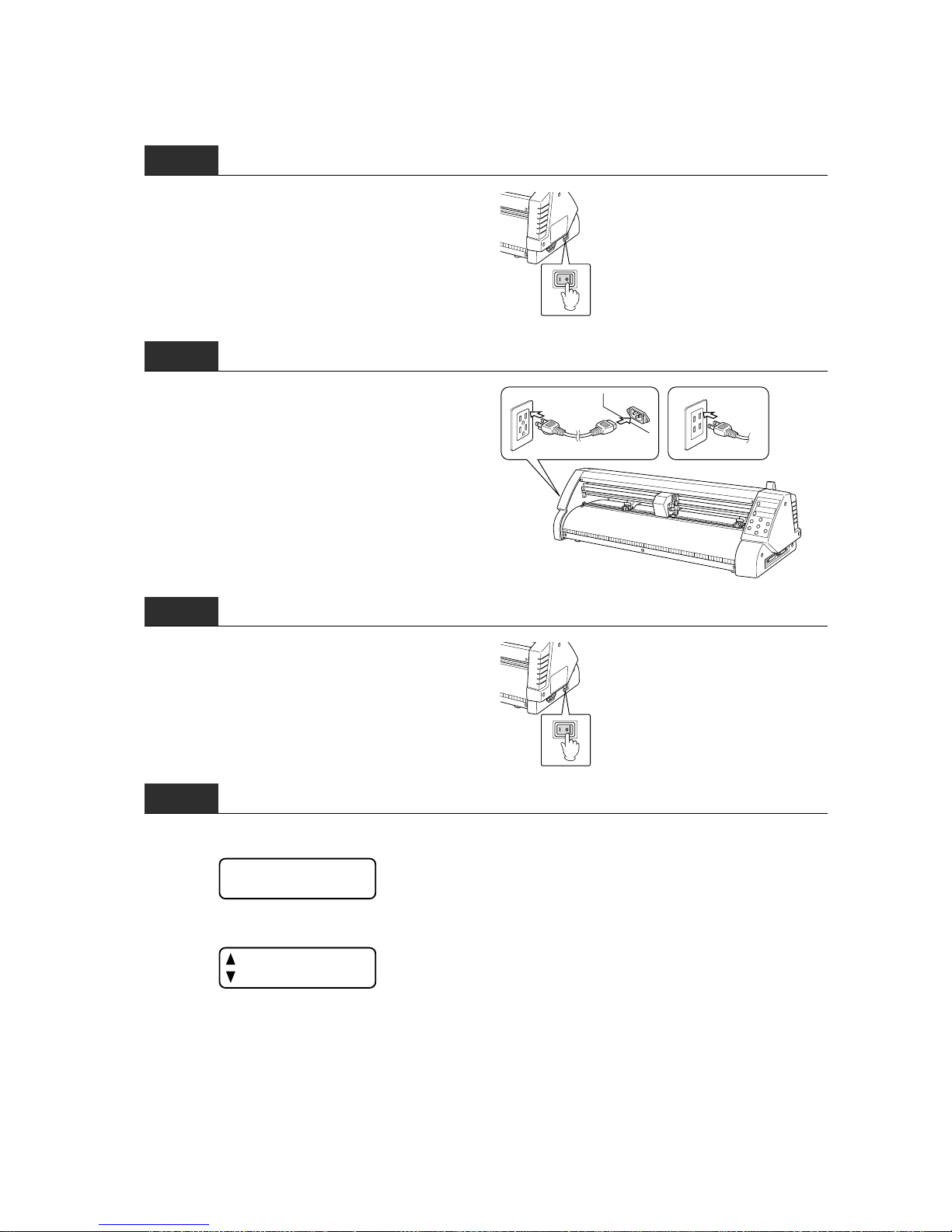

Step 1

Check that the Power switch is turned

off (its “O” side is down).

Step 2

Connect the cable between the cutting

plotter and the computer. Data cannot

be properly transferred if the cable is

connected in reverse, so be sure that

its connectors are correctly oriented.

After turning on the cutting plotter as described on the next page, load the medium and select the interface

conditions.

Page 23

3 – 3

3.2 Turning on the Power

Step 1

Check that the Power switch is turned off (its “O”

side is down).

Step 2

Connect the female plug of the power cord provided to the cutting plotter’s AC power inlet and

connect its male plug to an electrical socket. Be

sure to ground the cutting plotter.

Step 3

Turn on the cutting plotter by pressing the “|” side

of its Power switch (the control panel’s POWER

lamp lights).

Step 4

If no medium has been loaded, the message below appears to prompt you to load a medium.

LOAD MEDIA!

If a medium has been loaded, the menu below appears for selecting the media mode.

ROLL 1

ROLL 2

For instructions on loading a medium and selecting the media mode, see Section 3.3, “Loading the

Medium.”

Page 24

3 – 4

3.3 Loading the Medium

The cutting plotter can use film in rolls or in single sheets. Loading the desired medium by following

the pertinent instructions.

3.3.1 Loading a Roll Medium

CE2000-60

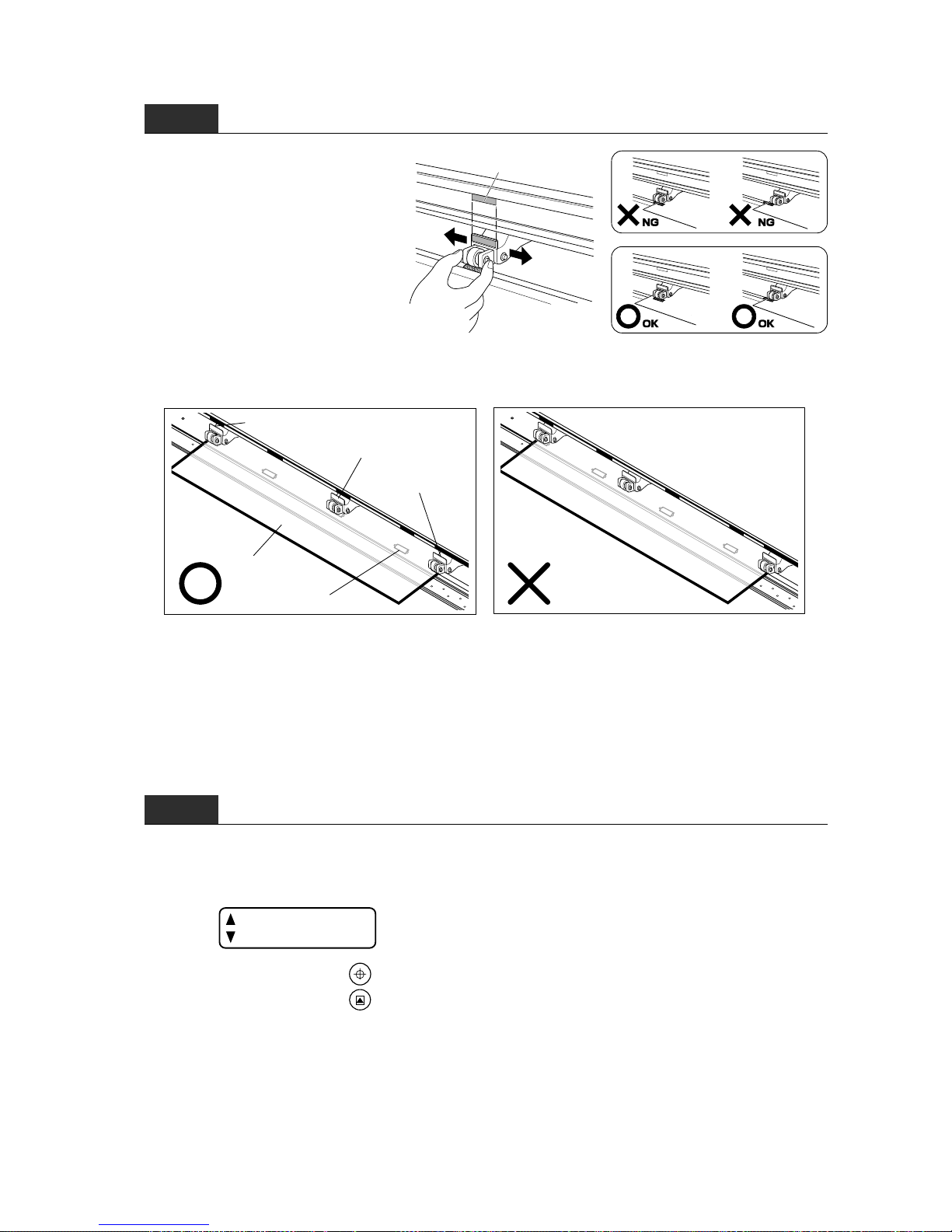

Step 1

Lower the media set lever to raise the push

rollers.

Step 2

Place the roll medium on the tray and then pass

the medium’s leading edge from the back of the

cutting plotter so it emerges from the front while

making sure to remove any slack in the medium’s conveyance path.

NOTE: Load the medium so that it passes

over the media sensor.

Media sensor

Step 3

At this point, pull the leading edge out of the

front of the cutting plotter so that it completely

covers the media sensor. If its leading edge

has been pulled out so much that slack cannot

be provided at the back of the plotter, turn the

roll to adjust the length of the medium in front

of the cutting plotter by retracting the leading

edge.

Media sensor

Page 25

3 – 5

Step 4

Adjust the position of the right and left

push rollers to suit the width of the

medium. Position each push roller at

its corresponding edge of the medium

so that it is above the grit roller. Move

the push rollers so that they are positioned inside the push roller alignment marks provided. (To move the

push rollers, the media set lever must

be in lowered position.)

Push roller alignment mark

If the "RELOAD MEDIA!" message appears when you lower the media set lever, the right pinch roller

is not positioned over the wider grit roller on the right. This message also appears if the left pinch roller

is not positioned over a grit roller or is positioned over the wider grit roller on the right. Check that

the right pinch roller is positioned over the wider grit roller on the right and that the left pinch roller

is positioned over a grit roller other than the wider one on the right.

Step 5

After ensuring that there is no slack in the medium’s conveyance

path, raise the media set lever to lower the push rollers. As shown

in the figure, provide slack in the medium for a length corresponding

to the length of the medium you intend to cut or plot.

Provide slack

Step 6

If the cutting plotter has already been turned on when the push rollers are lowered by raising the media

set lever, a menu for selecting the media mode appears. Select the media mode (ROLL 1 or ROLL

2) to suit the roll medium you have just loaded.

ROLL 1

ROLL 2

To select ROLL 1, press the

F1/ORIGIN

key.

To select ROLL 2, press the

F2/TEST

key.

When ROLL 1 is selected, the leading edge and side edges of the medium are detected. Select this

mode when you wish to begin cutting from the medium’s leading edge. In this case, the origin point

is positioned along the leading edge.

When ROLL 2 is selected, only the medium’s side edges are detected. Select this mode when you

wish to begin cutting at a point past the medium’s leading edge. In this case, the position of the pen

carriage at the time the medium was loaded becomes the origin point.

Step 7

After the medium size has been detected, the cutting plotter awaits cutting data.

If the INTERFACE conditions and COMMAND mode have not been selected yet, select these settings

at this time (see Section 3.4, “Selecting the COMMAND Mode and INTERFACE Conditions”). If they

have already been set, proceed to adjust the cutter pen. After the cutter pen has been adjusted (see

Chapter 4, “PREPARING FOR A CUTTING OPERATION”), the cutting plotter is ready to perform cutting

so send cutting data from your application software at the computer.

Page 26

3 – 6

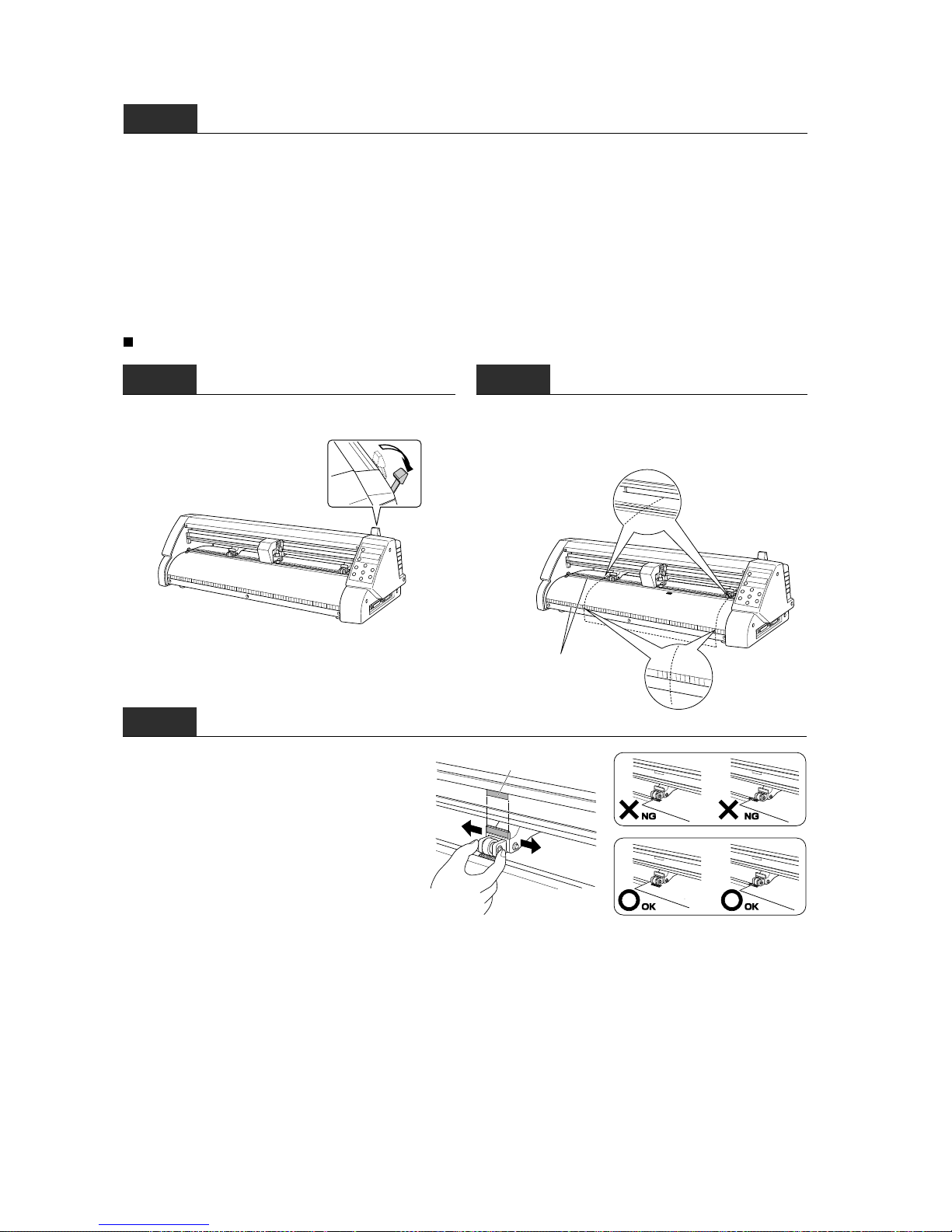

CE2000-120

Step 1

Lower the media set lever to raise the push

rollers.

Step 2

Trap the medium’s edges between the two

stoppers and then firmly fix each stopper in

place by tightening its plastic hexagon screw.

Gently pull the leading edge of the film toward

you to remove any slack in the film as it is fed

along the conveyance path from the main unit.

NOTE: In the case of a medium with a paper core that extends beyond the side edges of the

medium itself, the medium may ride over the stoppers when the remaining supply of the

medium runs low. When using this type of medium, be sure to replace it with a new roll

right before the medium starts riding over the stoppers.

Step 3

At this point, pull the leading edge out of the

front of the cutting plotter so that it completely

covers the media sensor. If its leading edge

has been pulled out so much that slack cannot

be provided at the back of the plotter, turn the

roll to adjust the length of the medium in front

of the cutting plotter by retracting the leading

edge.

Media sensor

Stopper

Page 27

3 – 7

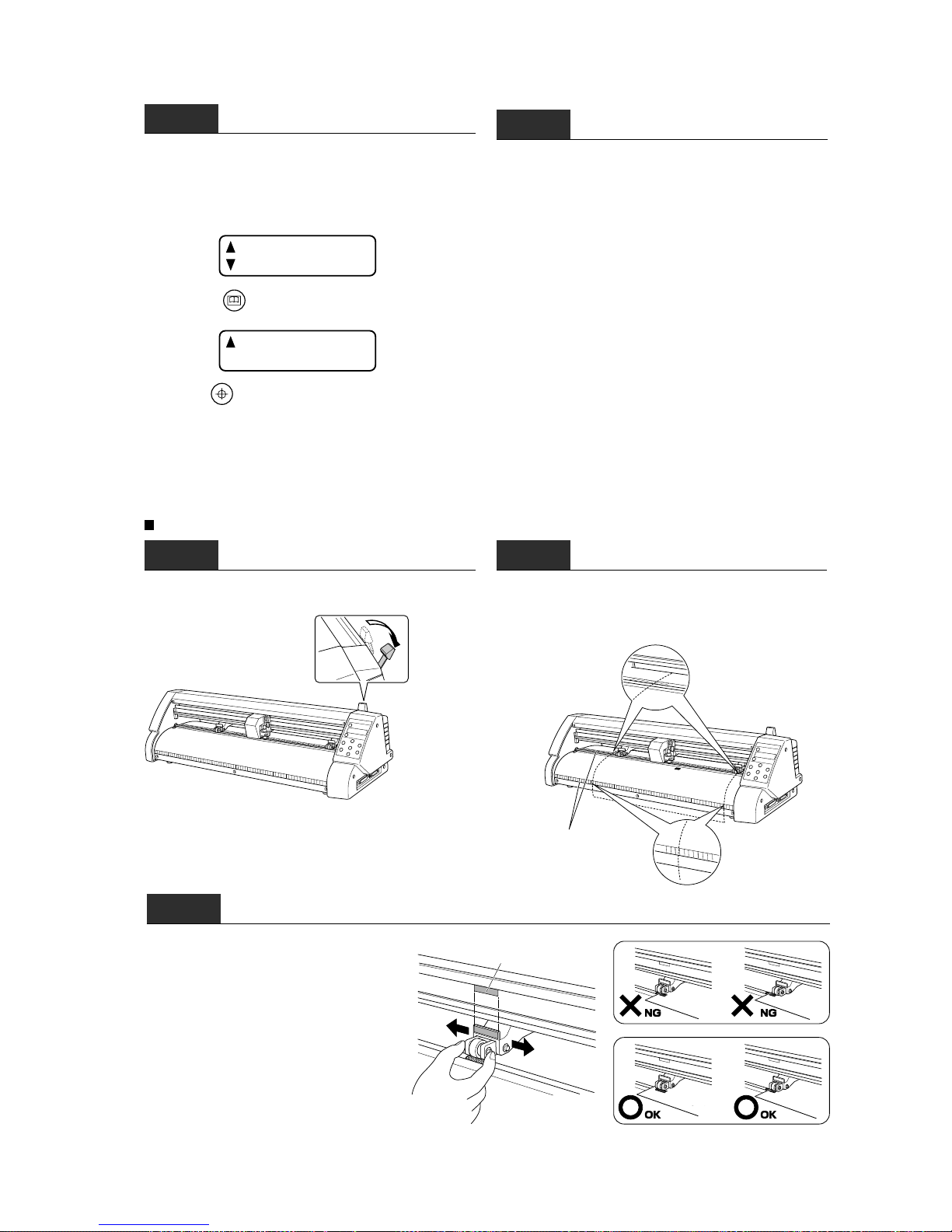

Step 4

Adjust the position of the right and left

push rollers to suit the width of the

medium. Position each push roller at its

corresponding edge of the medium so

that it is above the grit roller. Move the

push rollers so that they are positioned

inside the push roller alignment marks

provided. (To move the push rollers,

the media set lever must be in lowered

position.)

Push roller alignment mark

Position the push roller (2) so that it is at the midpoint of the film and is also over the center grit roller.

The film is held in place using the three rollers called push rollers (1), (2), and (3).

Push roller (3)

Push roller

Grit roller

Film

Push roller(1)

Position the push roller (2) so that it is at the midpoint of the

film and is also over the center grit roller.

Similar to the push rollers (1) and (3) in the figure below,

position the push roller (2) over a grit roller.

If the “RELOAD MEDIA!” message appears when you lower the media set lever, the right pinch roller

is not positioned over the wider grit roller on the right. This message also appears if the left pinch

roller is not positioned over a grit roller or is positioned over the wider grit roller on the right. Check

that the right pinch roller is positioned over the wider grit roller on the right and that the left pinch roller

is positioned over a grit roller other than the wider one on the right.

Step 5

If the cutting plotter has already been turned on when the push rollers are lowered by raising the media

set lever, a menu for selecting the media mode appears. Select the media mode (ROLL 1 or ROLL

2) to suit the roll medium you have just loaded.

ROLL 1

ROLL 2

To select ROLL 1, press the

F1/ORIGIN

key.

To select ROLL 2, press the

F2/TEST

key.

When ROLL 1 is selected, the leading edge and side edges of the medium are detected. Select this

mode when you wish to begin cutting from the medium’s leading edge. In this case, the origin point

is positioned along the leading edge.

When ROLL 2 is selected, only the medium’s side edges are detected. Select this mode when you

wish to begin cutting at a point past the medium’s leading edge. In this case, the position of the pen

carriage at the time the medium was loaded becomes the origin point.

Page 28

3 – 8

Step 6

After the medium size has been detected, the cutting plotter awaits cutting data.

If the INTERFACE conditions and COMMAND mode have not been selected yet, select these settings

at this time (see Section 3.4, “Selecting the COMMAND Mode and INTERFACE Conditions”). If they

have already been set, proceed to adjust the cutter pen. After the cutter pen has been adjusted (see

Chapter 4, “PREPARING FOR A CUTTING OPERATION”), the cutting plotter is ready to perform cutting

so send cutting data from your application software at the computer.

3.3.2 Loading Single Sheets

CE2000-60

Step 2

While using the front and rear medium alignment

scales as guidelines, load one sheet of the medium

so that its leading and trailing areas are positioned

identically.

Medium alignment scales

Step 3

Adjust the position of the right and left push

rollers to suit the width of the medium. Position

each push roller at its corresponding edge of

the medium so that it is above the grit roller.

Move the push rollers so that they are positioned inside the push roller alignment marks

provided. (To move the push rollers, the media

set lever must be in the lowered position.)

Push roller alignment mark

Step 1

Lower the media set lever to raise the push rollers.

Page 29

3 – 9

Step 4

If the cutting plotter has already been turned on

when the push rollers are lowered by raising the

media set lever, a menu for selecting the media

mode appears.

ROLL 1

ROLL 2

Press the

NEXT PAGE

key to proceed the display below.

SHEET

Press the

F1/ORIGIN

key to select the SHEET mode

in which the leading and trailing edges of the media

are detected.

CE2000-120

Step 1

Lower the media set lever to raise the push rollers.

Step 2

While using the front and rear medium alignment

scales as guidelines, load one sheet of the medium

so that its leading and trailing areas are positioned

identically.

Medium alignment scales

Step 3

Adjust the position of the right and left

push rollers to suit the width of the

medium. Position each push roller at its

corresponding edge of the medium so

that it is above the grit roller. Move the

push rollers so that they are positioned

inside the push roller alignment marks

provided. (To move the push rollers,

the media set lever must be in lowered

position.)

Push roller alignment mark

Step 5

After the medium size has been detected, the cutting

plotter awaits cutting data.

If the INTERFACE conditions and COMMAND mode

have not been selected yet, select these settings

at this time (see Section 3.4, “Selecting the

COMMAND Mode and INTERFACE Conditions”).

If they have already been set, proceed to adjust

the cutter pen. After the cutter pen has been adjusted

(see Chapter 4, “PREPARING FOR A CUTTING

OPERATION”), the cutting plotter is ready to perform

cutting so send cutting data from your application

software at the computer.

Page 30

3 – 10

Position the push roller (2) so that it is at the midpoint of the film and is also over the center grit roller.

The film is held in place using the three rollers called push rollers (1), (2), and (3).

Push roller (3)

Push roller

Grit roller

Film

Push roller(1)

Position the push roller (2) so that it is at the midpoint of the

film and is also over the center grit roller.

Similar to the push rollers (1) and (3) in the figure below,

position the push roller (2) over a grit roller.

If the “RELOAD MEDIA!” message appears when you lower the media set lever, the right pinch roller

is not positioned over the wider grit roller on the right. This message also appears if the left pinch

roller is not positioned over a grit roller or is positioned over the wider grit roller on the right. Check

that the right pinch roller is positioned over the wider grit roller on the right and that the left pinch roller

is positioned over a grit roller other than the wider one on the right.

Step 4

If the cutting plotter has already been turned on when the push rollers are lowered by raising the media

set lever, a menu for selecting the media mode appears.

ROLL 1

ROLL 2

Press the

NEXT PAGE

key to proceed the display below.

SHEET

Press the

F1/ORIGIN

key to select the SHEET mode in which the leading and trailing edges of the media

are detected.

Step 5

After the medium size has been detected, the cutting plotter awaits cutting data.

If the INTERFACE conditions and COMMAND mode have not been selected yet, select these settings

at this time (see Section 3.4, “Selecting the COMMAND Mode and INTERFACE Conditions”). If they

have already been set, proceed to adjust the cutter pen. After the cutter pen has been adjusted (see

Chapter 4, “PREPARING FOR A CUTTING OPERATION”), the cutting plotter is ready to perform cutting

so send cutting data from your application software at the computer.

Page 31

3 – 11

3.4 Selecting the COMMAND Mode and INTERFACE Conditions

3.4.1 Selecting the COMMAND Mode

Before sending data from the computer, you must set up the cutting plotter so that it can recognize

the format (command mode) of data sent by the application software. The cutting plotter can recognize

two data formats (command modes): Graphtec commands (GP-GL) or HP-GL. Select the COMMAND

mode to suit your application.

Step 3

Press the

F1/ORIGIN

key (INTERFACE) to display the menu below.

RS-232C

COMMAND

Step 4

Press the

F2/TEST

key (COMMAND) to display the menu below.

GP-GL

HP-GL COMMAND

The blinking square cursor indicates the currently selected command mode.

Step 5

To select the GP-GL command mode, press the

F1/ORIGIN

key.

To select the HP-GL command mode, press the

F2/TEST

key.

When the cursor appears in front of the desired command mode, press the

ENTER

key.

Step 6

If you have changed the COMMAND setting, the menu for selecting the media mode appears.

ROLL 1

ROLL 2

Select the mode to suit the currently loaded medium as described in Section 3.3, “Loading the Medium.”

Step 7

If the COMMAND setting is GP-GL, proceed to select the STEP SIZE.

If the COMMAND setting is HP-GL, proceed to select the ORIGIN POINT.

Step 2

Press

PAUSE

key to enter PAUSE status.

Press the

NEXT PAGE

key until the menu below appears.

INTERFACE

PEN UP/DOWN

Step 1

After loading a medium, check that the menu below

is displayed.

COND1 PEN 12

== READY ==

Page 32

3 – 12

3.4.2 Selecting the STEP SIZE or ORIGIN POINT

The STEP SIZE Setting

The STEP SIZE setting is only required when the COMMAND setting is GP-GL. In GP-GL command

mode, it is possible to change the minimum unit of distance which the cutter pen or pen can travel

to one of four settings: 0.01, 0.025, 0.05, or 0.1 mm. The default setting is 0.1 mm, so change this setting

if your application specifies a different step size (also referred to as “programmable resolution).

The ORIGIN POINT setting

The ORIGIN POINT setting is only required when the COMMAND setting is HP-GL. This setting allows

you to position the origin point at the lower left or center of the effective cutting/plotting area. The default

setting is L.L. (Lower Left), so change this setting if your application specifies a different origin position.

Step 1

At the menu shown in Step 3, press the

NEXT PAGE

key.

If the COMMAND setting is GP-GL, the menu below appears.

STEP SIZE

If the COMMAND setting is HP-GL, the menu below appears.

ORIGIN POINT

Step 2 (Selecting the STEP SIZE)

Press the

F1/ORIGIN

key (STEP SIZE) to display the menu below.

STEP SIZE

0.100 mm

To change the STEP SIZE setting, use the and POSITION keys.

When the desired STEP SIZE is displayed, press the

ENTER

key.

Step 2 (Selecting the ORIGIN POINT)

Press the

F1/ORIGIN

key (ORIGIN POINT) to display the menu below.

LOWER LEFT

CENTER ORIG PT

A blinking square cursor indicates the currently selected ORIGIN POINT.

To move the origin to the lower left, press the

F1/ORIGIN

key (L.L.)

To move the origin to the center, press the

F2/TEST

key (CENTER).

When the blinking cursor is positioned in front of the desired setting, press the

ENTER

key.

Page 33

3 – 13

3.4.3 Selecting the Interface Conditions

It is necessary to select the INTERFACE conditions if you are using the RS-232C serial interface.

INTERFACE settings include the data transfer rate (baud rate), data length, parity mode, and handshaking

mode. The INTERFACE conditions you select for the cutting plotter must match those of the computer’s

operating system. This section describes the procedure for selecting the cutting plotter’s INTERFACE

conditions. For information about the proper settings for your application or computer’s operation system,

refer to the manual provided with your application or operating system.

Step 1

After loading a medium, check that the menu below

is displayed.

COND1 PEN 12

== READY ==

Step 2

Press

PAUSE

key to enter PAUSE status.

Press the

NEXT PAGE

key until the menu below appears.

INTERFACE

PEN UP/DOWN

Step 3

Press the

F1/ORIGIN

key (INTERFACE) to display the menu below.

RS-232C

COMMAND

Step 4

Press the

F1/ORIGIN

key (RS-232C) to display the menu below.

RS-232C

960 N 8 H

The parameter which can be changed is indicated by the blinking square cursor. Use the and

keys to move the cursor to the desired parameter, then use the and keys to change its setting

as described in Step 5.

Step 5

The INTERFACE conditions consist of the baud rate, parity mode, data length, and handshaking mode.

The baud rate can be set to 9600, 4800, 2400, 1200, 600, or 300 bps.

The parity mode can be set to N (None), E (Even parity), or O (Odd parity).

The data length can be set to 8 or 7 bits.

The handshaking mode can be set to H (hard-wired handshaking) or Xon/Xoff handshaking. When

the COMMAND setting is HP-GL, however, ENQ/ACK handshaking can also be selected.

Be sure to set all of the INTERFACE conditions to match the corresponding settings of the application

software and the computer’s operating system.

Step 6

When all of the displayed settings are satisfactory, press the

ENTER

key.

Press the

PAUSE

key to return to READY status.

Page 34

4

4

PREPARING FOR A CUTTING OPERATION

4.1 Types and Features of Cutter Blades ............................. 4-2

4.2 Replacing the Cutter Blade and

Adjusting Its Length

................................................................ 4-2

4.3 Mounting the Cutter Pen Plunger ..................................... 4-5

4.4 Setting the Cutting Conditions ........................................... 4-6

4.4.1 Selecting a Set of Cutting Conditions ............................ 4-7

4.4.2 Specifying the Cutting FORCE ......................................... 4-8

4.4.3 Specifying the Cutting SPEED ......................................... 4-9

4.4.4 Specifying the CUTTER OFFSET ................................... 4-10

4.4.5 Specifying the Cutting QUALITY .................................... 4-11

4.5 Running a Cutting TEST ...................................................... 4-12

Page 35

4 – 2

Before you start cutting, it is important that you become familiar with the types and features of the cutter

blades which can be used with the cutting plotter. By selecting the optimum combination of cutter blade

and film, you can achieve higher cutting quality.

CAUTION

To avoid cutting your fingers, always handle the cutter blade with caution.

4.1 Types and Features of Cutter Blades

Part no. Blade diameter Compatible

Features

and material and offset plunger

CB09UA 0.9-mm diameter PHP32-CB09N The standard blade for cutting color

(Supersteel) 0.45 mm offset adhesive-backed film.

Suitable for cutting film with a thickness

under 0.25 mm.

Max. cutting distance: approx. 4,000 m.

CB15U 1.5-mm diameter PHP32-CB15N Capable of cutting thicker film than possible

(Supersteel) 0.75 mm offset with the CB09UA blade.

Suitable for cutting film with a thickness of

0.25 mm to 0.5 mm.

4.2 Replacing the Cutter Blade and Adjusting Its Length

The cutting plotter performs cutting using a cutter blade that is mounted in a cutter pen plunger. The

cutter pen plungers come in two diameters to suit the cutter blade to be mounted (the 0.9-mm cutter

pen plunger comes standard). Be sure to mount the cutter blade in its corresponding cutter pen plunger.

CAUTION

To avoid cutting your fingers, always handle the cutter blade with caution.

Structure of the Cutter Pen Plunger

PlungerCutter blade

Plunger cap Blade length adjustment knob

(blue : for 0.9-mm diameter blades)

(red : for 1.5-mm diameter blades)

Page 36

4 – 3

Replacing the Cutter Blade

Step 1

Turn the blade length adjustment knob

to retract the blade inside the plunger.

1.5-mm diameter

cutter blade

0.9-mm

cutter blade

1.5-mm

plunger cap

Spring

0.9-mm

plunger cap

Blade length

adjustment knob (red)

Blade length

adjustment knob (blue)

Plunger for

1.5-mm dia. blades

Plunger for

0.9-mm dia. blades

Step 2

Turn the plunger cap in the counter-clockwise direction to remove it from the plunger.

Step 3

Remove the blade from inside the plunger cap. In the case of the 0.9-mm blade, also remove the spring.

Step 4

Insert the new blade into the hole provided in the plunger cap. In the case of the 0.9-mm diameter

blade, insert the blade its the spring attached into the plunger cap.

Step 5

With the blade inserted in the plunger cap, screw on the plunger from above.

Page 37

4 – 4

Adjusting the Blade Length

CAUTION

• To avoid cutting your fingers, always handle the cutter blade with caution.

• If the blade is extended too far in relation to the thickness of the film being cut, it will

damage the cutting mat. Be sure to properly adjust the blade length.

Step 1

Adjust the blade length by turning the blade length adjustment knob as shown

in the figure below. Turn the knob in the “A” direction to extend the blade, or

in the “B” direction to extract the blade. Refer to the scale on the plunger mark

to determine how far to move the blade. When the knob is turned the distance

of one scale unit, the blade moves about 0.1 mm. A full turn of the knob moves

the blade about 0.5 mm.

BA

Step 2

First of all, align the blade’s tip with the tip of the cutter pen. From that position, extend the blade to

suit the thickness of film to be cut.

Step 3

Assuming that the film’s thickness is “t”, the blade length “ ”

should be equal to or slightly greater than “t”. Be sure that “ ”

is never greater than the combined thickness of the film and

its backing sheet.

If you cannot accurately determine the film’s thickness, adjust

the blade length by gradually increasing it until only traces of

the blade appear on the backing sheet as a result of running

a cutting test.

t

Backing sheet

Film surface

Page 38

4 – 5

4.3 Mounting the Cutter Pen Plunger

After the blade length has been properly adjusted, mount the cutter pen plunger in the cutting plotter

as described below.

Step 1

Loosen the pen holder’s screw and

then mount the cutter pen plunger

into the pen holder.

Be sure to press the

plunger in firmly so

that it contacts this

surface.

Step 2

When the cutter pen plunger is properly positioned, tighten the

pen holder’s screw.

Step 3

After the cutter pen plunger has been mounted, proceed to set the cutting conditions.

Page 39

4 – 6

4.4 Setting the Cutting Conditions

Before starting a cutting operation, set the BLADE TYPE, FORCE, SPEED, CUTTER OFFSET, and

QUALITY settings to provide the optimum cutting conditions.

The compatibility of the selected cutting conditions with the film to be cut is determined by the five

factors below.

(1) Cutter blade length : Adjust the blade length to suit the film’s thickness while referring to the table

below.

(2) FORCE : Selects the amount of pressure applied by the cutter blade while cutting the

film. Set the FORCE while referring to the table below.

(3) SPEED : Selects the speed at which the film is cut. Set the SPEED while referring

to the table below.

(4) QUALITY : Selects the acceleration rate of the cutter blade when cutting the film. Set

the QUALITY while referring to the table below.

(5) CUTTER OFFSET : Set this parameter to suit the cutter blade being used.

Optimum Cutting Conditions According to Film Type

Film type Thickness (mm) Blade used FORCE SPEED QUALITY

Film for outdoor signs 0.05 to 0.08 CB09UA 10 to 14 30 or less 2

Film for point-of-

0.08 to 0.10 CB09UA 14 to 17 30 or less 2

purchase signs

Transparent or semi-

0.08 to 0.10 CB09UA 14 to 20 30 or less 2

transparent film

Reflective film 0.08 to 0.10 CB09UA 14 to 20 30 or less 2

Fluorescent film 0.20 to 0.25 CB09UA or CB15U 20 to 24 10 to 20 1

Blade Part Nos., Displayed Blade Types, and Displayed CUTTER OFFSET Values

Display indication

CUTTER OFFSET

Blade

Part no. Blade type Default Specifiable Optimum

material

range setting

Supersteel

CB09UA 09U 0 ±518

blades

CB15U 15U 0 ±528

Other OTHER 1 1 to 45 1

Pens PEN None None 0

After a blade type has been selected, the CUTTER OFFSET is automatically adjusted by ±5 with respect

to the default CUTTER OFFSET value for that blade type.

Select the OTHER setting when using a blade type that is not displayed or when cutting a film using

the recommended cutting conditions results in poor finished quality.

Select the PEN setting for plotting with a pen. When the PEN setting is selected, no CUTTER OFFSET

setting is required.

Page 40

4 – 7

Reference Pen Conditions for Plotting Pens

Pen type FORCE SPEED QUALITY

Water based fiber-tip pen 10 to 12 30 2

To preserve the pen’s longevity, set the FORCE to the lowest possible setting that permits you to obtain

the desired plotted results. Set the SPEED after checking the plotted results for the absence of faint

lines and other problems.

NOTE : • If the SPEED and QUALITY are set to high values, the cut/plotted results have a

coarser finish but the overall cutting/plotting time is shortened.

• If the SPEED and QUALITY settings are set to low values, the cut/plotted results

have a finer finish but the overall cutting/plotting time is longer.

4.4.1 Selecting a Set of Cutting Conditions

Four different sets of user-defined cutting conditions can be registered in the plotter’s memory as COND

Nos. 1 through 4. To specify a set of cutting conditions, you must first select the destination COND No . By

selecting a different COND No ., you can easily s witch between pre-defined cutting conditions f or four types

of media.

Step 1

Each time you press the

NEXT PAGE

key at the menu below, the selected set of cutting conditions is sequentially

changed from COND1 through COND4. Pressing the

NEXT PAGE

key while COND4 is selected switches

the setting back to COND1.

COND1 PEN 12

== READY ==

Step 2

The currently selected blade type, CUTTER OFFSET, and FORCE settings appear. When the blade

type setting is PEN, the CUTTER OFFSET setting does not appear. When the blade type setting is

OTHER, an asterisk symbol (∗) appears in place of the blade type.

The blade type setting appears The blade’s CUTTER OFFSET

here as 09U, 15U, PEN, or ∗ setting appears here.

(the asterisk represents the No setting is displayed when

OTHER setting). the blade type setting is PEN.

COND1 PEN 12

The cutting FORCE setting appears here.

== READY ==

Page 41

4 – 8

4.4.2 Specifying the Cutting FORCE

This setting determines the pressure to be applied by the cutter pen during cutting. Set the FORCE

value to suit the medium you will be using, based on the guidelines in the table entitled “Optimum Cutting

Conditions According to Film Type” on page 4-6.

Step 1

After selecting the desired set of cutting conditions, check that the cutting plotter is in READY or PAUSE

status and then press the

F2/TEST

key to display the menu below.

TEST CUT

PEN SETTINGS

Step 2

Press the

F2/TEST

key (PEN SETTINGS) again to display the menu below.

SPEED

PEN FORCE

Step 3

Press the

F2/TEST

key (PEN FORCE) to display the menu below.

PEN FORCE

12

At the above menu, use the and keys to change the PEN FORCE value. (The PEN FORCE

can be set in a range from 1 to 31 for the CE2000-60, and from 1 to 39 for the CE2000-120.)

When the displayed PEN FORCE value is satisfactory, press the

ENTER

key to register your setting.

Step 4

Consecutively press the

NEXT PAGE

key until the READY or PAUSE menu reappears.

Page 42

4 – 9

4.4.3 Specifying the Cutting SPEED

This setting determines the speed with which cutting is performed. Set the SPEED value to suit the

medium you will be using, based on the guidelines in the table entitled “Optimum Cutting Conditions

According to Film Type” on page 4-6.

Step 1

After selecting the desired set of cutting conditions, check that the cutting plotter is in READY or PAUSE

status and then press the

F2/TEST

key to display the menu below.

TEST CUT

PEN SETTINGS

Step 2

Press the

F2/TEST

key (PEN SETTINGS) again to display the menu below.

SPEED

PEN FORCE

Step 3

Press the

F1/ORIGIN

key (SPEED) to display the menu below.

SPEED

30 cm/s

At the above menu, use the or key to change the SPEED setting. The SPEED setting can be set

in a range of 1 to 60 (in 1 cm/s steps from 1 to 10 and in 5 cm/s steps from 10 to 60). For the CE2000-120

model only, the numeral 60 is followed by the display of “∗∗” which represents the maximum SPEED setting

of 100 cm/s (in the diagonal direction only).

When the displayed SPEED value is satisfactory, press the

ENTER

key to register your setting.

Step 4

Consecutively press the

NEXT PAGE

key until the READY or PAUSE menu reappears.

Page 43

4 – 10

4.4.4 Specifying the CUTTER OFFSET

This setting adjusts the offset of the cutter blade according to the currently selected blade type. If the

blade type is set to PEN, a plotting pen can be used. When a cutter blade designation or OTHER is

selected, a cutter pen can be used. Because the tip of the blade mounted in the cutter pen plunger

is not positioned at the center of the pen, the cutting position is adjusted by specifying the CUTTER

OFFSET setting.

Since the cutting plotter has been preset with the optimum CUTTER OFFSET values for the CB09UA

and CB15U supersteel blade types, the optimum CUTTER OFFSET value can be easily selected by

simply selecting the corresponding blade number. Fine adjustment of these two settings is also possible

within a ±5 range.

Step 1

After selecting the desired set of cutting conditions, check that the cutting plotter is i n READY o r PAUSE

status and then press the

F2/TEST

key to display the menu below.

TEST CUT

PEN SETTINGS

Step 2

Press the

F2/TEST

key (PEN SETTINGS) again to

display the menu below.

SPEED

PEN FORCE

Step 3

Press the

NEXT PAGE

key to display the menu below.

CUTTER OFFSET

QUALITY

Step 4

Press the

F1/ORIGIN

key (CUTTER OFFSET) to display the menu below.

CUTTER OFFSET

09U 0

At the above menu, use the or key to change the CUTTER OFFSET setting.

Use the or key to select the blade type (09U, 15U, OTHER, or PEN).

When a blade number (09U or 15U) is displayed, the and keys can be used to finely adjust

the setting within a ±5 range.

When OTHER is displayed, the and keys can be used to specify the CUTTER OFFSET value

within a range of 1 to 45.

When PEN is displayed, no CUTTER OFFSET setting is required.

When the displayed CUTTER OFFSET value is satisfactory, press the

ENTER

key to register your setting.

Step 5

Consecutively press the

NEXT PAGE

key until the READY or PAUSE menu reappears.

Page 44

4 – 11

4.4.5 Specifying the Cutting QUALITY

This setting determines the acceleration rate of cutting.

Step 1

After selecting the desired set of cutting conditions, check that the cutting plotter is in READY or PAUSE

status and then press the

F2/TEST

key to display the menu below.

TEST CUT

PEN SETTINGS

Step 2

Press the

F2/TEST

key (PEN SETTINGS) again to display the menu below.

SPEED

PEN FORCE

Step 3

Press the

NEXT PAGE

key to display the menu below.

CUTTER OFFSET

QUALITY

Step 4

CE2000-60

Press the

F2/TEST

key (QUALITY) to display the menu below.

QUALITY

1

At the above menu, use the or key to switch the QUALITY setting between 1 and 2.

CE2000-120

NOTE : • The 2 setting can only be selected when the SPEED setting ranges from 1 through

30 cm/s. When the SPEED setting is 35 cm/s or higher, the QUALITY setting is fixed

to 1 (0.5 G).

• If you change the SPEED setting to 35 cm/s or higher while the QUALITY setting is

2, the QUALITY setting automatically switches to 1 even if you change the SPEED

setting to 30 cm/s or lower.

When the displayed QUALITY value is satisfactory, press the

ENTER

key to register your setting.

When the SPEED setting is “∗∗” (the maximum speed), the QUALITY setting is also displayed as “**” and

automatically assumes a fixed value.

Step 5

Consecutively press the

NEXT PAGE

key until the READY or PAUSE menu reappears.

Page 45

4 – 12

4.5 Running a Cutting TEST

After selecting the blade type and specifying the FORCE, SPEED, CUTTER OFFSET, and QUALITY

settings, run a cutting test to ensure that the selected cutting conditions actually produce the desired

cutting results by checking how far the blade cuts into the film and how corners are being cut. If the

cut results are not satisfactory, repeatedly specify the cutting conditions and then run the cutting test

until you achieve the optimum settings.

Step 1

Load film to be used for the test in the cutting plotter.

Step 2

After selecting the desired set of cutting conditions, check that the cutting plotter is in READY or PAUSE

status and then press the

F2/TEST

key to display the menu below.

TEST CUT

PEN SETTINGS

Step 3

Use the POSITION keys to move the cutter pen to the position from which you wish to initiate the test.

TEST CUT

PEN SETTINGS

At the above menu, press the

F1/ORIGIN

key to cut a triangle within a square.

Step 4

Perform fine adjustment of the CUTTER OFFSET value to suit the type of film you are using and its

thickness. Specify the FORCE so that faint cutting lines remain on the base sheet when the blade length

is properly adjusted.

The CUTTER OFFSET is too low.

Raise its value (by

+1 to +5)

Proper CUTTER

OFFSET setting.

The CUTTER OFFSET is too high.

Lower its value (by 1 to -5)

When fine adjustment is satisfactorily completed, you are ready to start a cutting operation. You can

now send actual cutting data to the cutting plotter for cutting.

Page 46

5.

5

5

USING THE BASIC FUNCTIONS

5.1 Moving the Initial Cutting Position (Origin Point) ..... 5-2

5.2 Moving the Pen Carriage in +100-mm Steps ............... 5-3

5.3 Clearing Data from the Internal Memory ....................... 5-3

5.4 Raising and Lowering the Pen ........................................... 5-4

5.5 Feeding the Medium ................................................................ 5-5

5.6 Selecting the LENGTH UNIT ................................................ 5-6

Page 47

5 – 2

5.1 Moving the Initial Cutting Position (Origin Point)

This function allows you to move the starting position for cutting or plotting to the desired position.

Original origin

New origin

Step 1

Use the POSITION keys to move the cutter pen

to the position of the new origin point.

Step 2

Press the

F1/ORIGIN

key. After the message below

is displayed for a few seconds, your new origin point

takes effect.

ORIGIN PT SET

When the Origin is Moved After Rotating the Coordinate Axes

When the origin point is moved after the coordinate axes have been rotated, movement of the origin

point conforms to the figure below.

New origin

Original origin

When the Coordinate Axes are Rotated After Moving the Origin Point

When the coordinate axes are rotated after moving the origin point, the origin point is initialized as

shown in the figure below. That is, the “a” distance is retained, but the “b” distance is initialized.

b

a

a

New origin

Original origin Original origin

Before rotation After rotation

When you wish to both move the origin and rotate the coordinate axes, be sure to rotate the coordinate

axes first.

NOTE : After a new origin point is set, the displayed coordinate values of X= and Y= represent

the respective distances from the new origin.

Page 48

5 – 3

5.2 Moving the Pen Carriage in +100-mm Steps

This function lets you move the pen carriage from its current position in +100-mm steps along the X

and Y axes.

To Move the Pen Carriage

While the READY or PAUSE menu is being displayed, hold down the

ENTER

key while you press the

key. If you repeat this operation, the pen carriage is further moved in +100-mm steps each time.

To Return the Pen Carriage to its Initial Position

While the READY or PAUSE menu is being displayed, hold down the

ENTER

key while you press the

key.

5.3 Clearing Data from the Internal Memory

This function clears the cutting plotter’s internal memory of data that was sent from the computer. Use

this function when you wish to discontinue a cutting operation that is in progress.

Step 1

Press the

PAUSE

key to enter PAUSE status.

Step 2

If data is being sent to the cutting plotter from the

computer, stop the data transmission.

Step 3

Press the

NEXT PAGE

key until the menu below appears.

CLEAR BUFFER

FEED

Step 4

Press the

F1/ORIGIN

key (CLEAR BUFFER) to display the prompt below.

CLEAR CLEAR

CANCEL OK?

Step 5

Press the

F1/ORIGIN

key (CLEAR) to clear the buffer.

Press the

F2/TEST

key (CANCEL) to cancel the CLEAR BUFFER operation.

Step 6

Press the

PAUSE

key to return to READY status.

Page 49

5 – 4

5.4 Raising and Lowering the Pen

Use this function to raise or lower the pen.

Step 1

Press the

PAUSE

key to enter PAUSE status.

Step 2

Press the

NEXT PAGE

key until the menu below appears.

INTERFACE

PEN UP/DOWN

At this menu, press the

F2/TEST

key once to lower the pen. To raise the pen, press the

F2/TEST

key

again.

Page 50

5 – 5

5.5 Feeding the Medium

When using cutting film, the FEED function advances the film and leaves faint tracks of the grit rollers

on the film to prevent the film from being dislocated while it is being fed during actual cutting.

Step 1

Press the

PAUSE

key to enter the PAUSE mode.

Step 2

Press the

NEXT PAGE

key until the menu below appears.

CLEAR BUFFER

FEED

Step 3

Press the

F2/TEST

key (FEED) to display the menu below.

SHEET FEED

FEED LENGTH 1 m

Use the and keys to specify the desired distance of the FEED operation. The distance can

be specified in a range of 1 m to 50 m.

Step 4

When the desired value is displayed, press the

ENTER

key to initiate the FEED operation (the film is advanced

out of the front of the cutting plotter and then fed back to its original position).

NOTE : If you press the

NEXT PAGE

key while the FEED operation is in progress, the FEED operation

is discontinued at that point and the film is returned to its original position.

CAUTION : When you press the

ENTER

key in Step 4, the FEED operation is immediately initiated.

Before executing the FEED operation, ensure that the front and back areas of the

cutting plotter are free of any obstacles that could obstruct the FEED operation.

Page 51

5 – 6

5.6 Selecting the LENGTH UNIT

Use this function to select either mm or inch as the LENGTH UNIT.

Step 1

Press the

PAUSE

key to enter PAUSE mode.

Step 2

Press the

NEXT PAGE

key until the menu below appears.

INTERFACE

PEN UP/DOWN

Step 3

Simultaneously press the

ENTER

and

NEXT PAGE

keys to display the menu below.

PEN UP SPEED

OFFSET FORCE

Step 4

Press the

NEXT PAGE

key until the menu below appears.

TEST

LENGTH UNIT

Step 5

At this menu, press the

F2/TEST

key (LENGTH UNIT) to display the menu below.

mm LENGTH

inch UNIT

The blinking square cursor indicates the currently selected LENGTH UNIT.

To select mm, press the

F1/ORIGIN

key.

To select inch, press the

F2/TEST

key.

When the blinking cursor is positioned in front of the desired setting, press the

ENTER

key.

Page 52

6

6

USING APPLIED FUNCTIONS

6.1 Rotating the Coordinate Axes ............................................ 6-2

6.2 Using the COPY Function..................................................... 6-3

6.3 Enabling the AUTO PRE FEED Mode .............................. 6-5

6.4 Adjusting the Distance Precision...................................... 6-6

6.5 Aligning the Coordinate Axes............................................. 6-7

6.6 Specifying the Page Length................................................. 6-9

6.7 Specifying the PLOT AREA................................................ 6-10

6.8 Expanding the Width of the Plot Area .......................... 6-12

Page 53

6 – 2

6.1 Rotating the Coordinate Axes

The ROTATE function allows you to rotate the initial cutting point and the coordinate system as shown

in the figure below. The ROTATE setting is retained in the cutting plotter’s internal memory, even while