Page 1

Advantage M8

Card Printer & Embosser

Operation Manual

MANUAL NO. Advantage M8-UM-153

NBS Technologies Inc.

Page 2

y

y

Essential Safety Precautions

This operating manual provides the safety precautions and the handling methods required to use the

product. Before using this machine, be sure to read this operating manual for safe and proper

operation. After reading, keep it in a safe place for later reference.

For any questions, contact your distributor.

z This product is designed to emboss/encode/print specified plastic cards. Do not use this for

any other application purposes.

z In this operating manual, items to be especially observed are marked with signs or symbols

for safe and proper use of the product. As they are important contents, be sure to observe

and follow them.

Warning Improper handling may cause death or severe injury.

Caution Improper handling may cause injury or property damage.

Never do this.

Be sure to follow instructions.

Product Handling

Do not overload one electrical outlet by using a power strip and multi-outlet adapter.

It may cause electric shock or fire.

Do not disassemble or modify. It may cause an electric shock or fire.

If it is necessary to remove a cover for maintenance, inspection, cleaning, or repair,

contact your distributor.

Only use with rated voltage and the rated frequency.

Failure to do so may cause an electric shock or fire.

Do not use a damaged power cord or loose outlet.

cause an electric shock or fire.

It ma

Check that the power plug does not have dust before inserting it into the outlet. Every six

months to one year, pull the power plug out of the outlet and inspect the plug for

cleanliness. Dust ma

Used only at altitudes not more than 2000m above sea level.

Used only in non-tropical conditions. (Operating environment Temperature 10 to 32

degrees Celsius/ Humidity 20 to 65% R.H (non-condensing))

Warning

cause an electric shock or fire.

Page 3

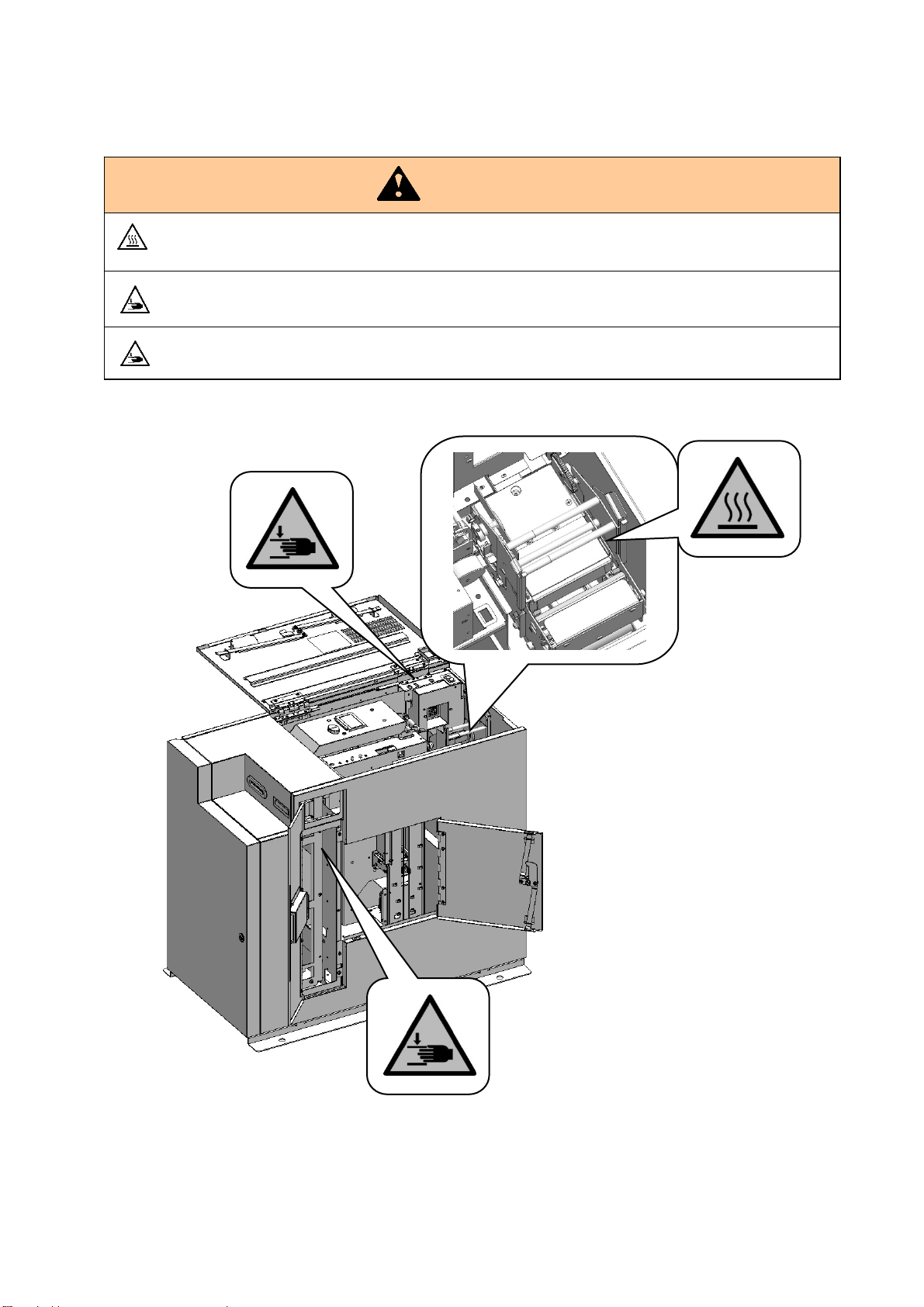

Continued from Product Handling

The Tipper Unit might be hot. To reduce the risk of injury from the heat,

allow the Tipper Unit to cool before touching.

Please take care not to get your hand or finger caught, when you open and close

the upper

Please take care not to get your hand or finger caught in the moving units, when you take

out remaining card or conduct maintenance work. It may cause an injury.

Warning

Page 4

p

Continued from Product Handling

Do not use a card contaminated with dirt or flaws.

It may cause a breakdown.

Do not wipe with benzene, solvents or thinner. It may cause discoloration or deformation

of this machine. For heavy contaminents, apply dilute mild detergent to a cloth, wring it

thoroughly, then wipe off the contaminents with it, finally wipe with a dry, soft cloth.

Never open the covers of this machine during operation.

It may cause injury.

When not using for a long period, be sure to pull the power plug out of the outlet.

Failure to do so may cause a fire.

When pulling out the power plug, hold the tip of the power plug.

Failure to do so may cause an electric shock.

Product Installation

Avoid installing in direct sunlight or near to a bright light source or a window.

It may interfere with proper operation.

Avoid installing in a place with extremely high temperatures/humidity or a place with rapid

humidity changes. It may cause condensation, resulting in a breakdown or improper

eration.

o

Avoid installing in a dusty place.

It may cause a breakdown.

Avoid installing in a place with heavy vibration.

It may interfere with proper operation.

Avoid installing in a place with an unstable base or a where the surface is not flat place.

It may interfere with proper operation or fall, resulting in injury.

Power supply connection of this product should be done by a technician with necessary

knowledge and qualification. It may cause electric shock or fire.

Ensure a good electrical ground is established.

Failure to do so may cause an electric shock.

Do not insert the power plug into the outlet until the connection is completed.

Only connect cables when the host computer and this machine are turned off.

LAN connector and USB connector are sensitive to ESD.

Connect these communication cables when the machine is powered off.

Caution

Caution

Page 5

y

y

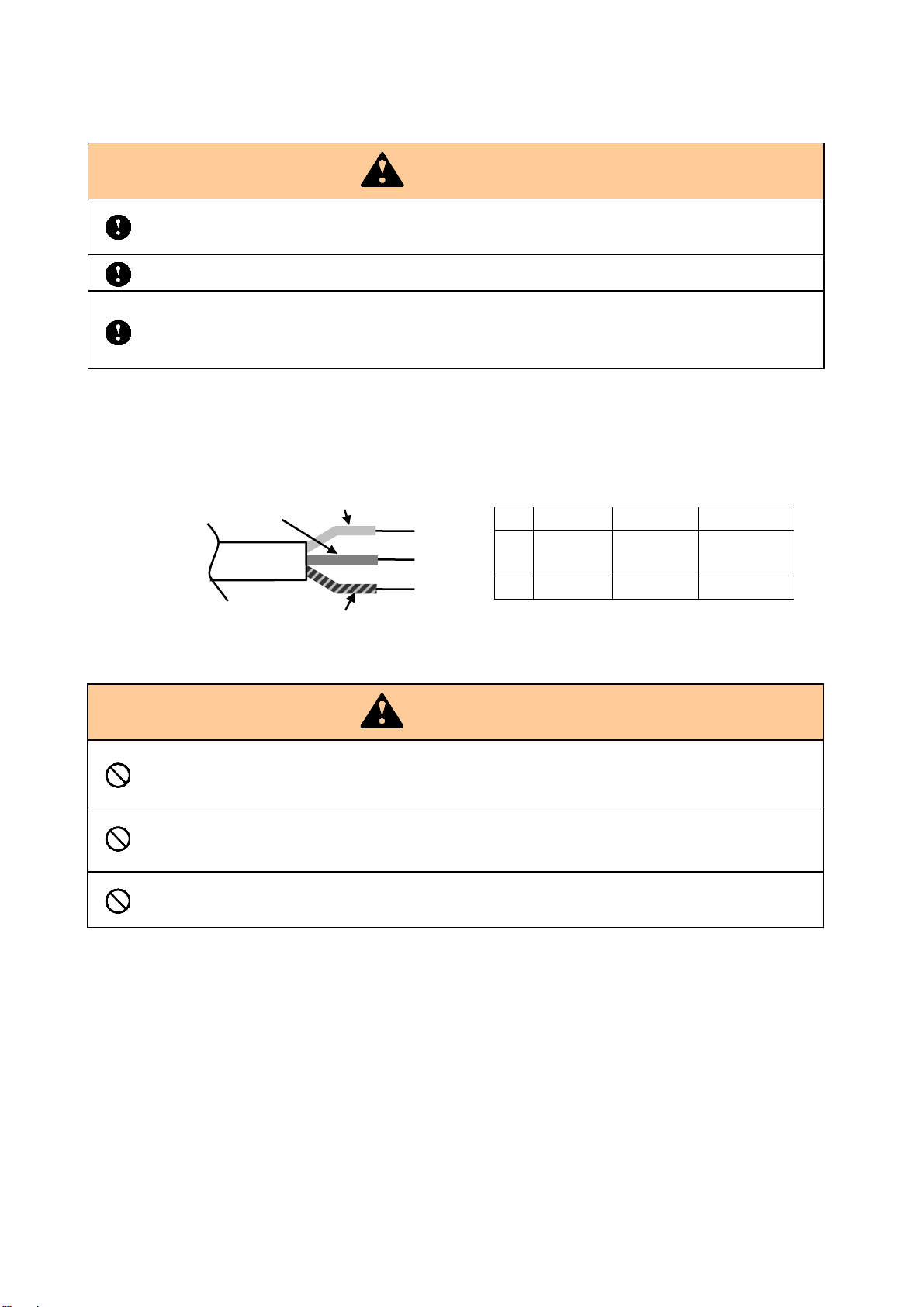

Continued from Product Installation

Power supply connection of this product should be done by a technician with necessary

knowledge and qualification. It may cause electric shock or fire.

Connect the supplied power cord to the inlet on the back.

Connect the end of the power cord to the switchboard and use it, or use an appropriate plug to install it.

Plug is not included. Please prepare separately the plug which satisfies the laws and regulations of the

country/region where this product is installed.

Card Handling

When connecting a cable, be sure to insert it as far as it will go and lock if a lock function is

equipped.

Install in a place more than 10 cm away from the side wall.

Use the supplied power cord only for this machine.

N

When you are touching the cards, it is recommendable for you to wear gloves. If finger

prints contaminate the surface of the card, it may cause bad print quality. To carry a card it

is recommended that it is held b

Do not put or store cards in a dusty place, a place with high temperatures or near electric

appliances that may emit a strong magnetic field (such as a mobile phone and monitor). It

cause deformation of cards or deletion of magnetic data.

ma

Do not bend the cards or damage the magnetic strip. It may interfere with proper reading

of magnetic information.

Caution

L

GND

The wire covering color is either 1 or 2.

Caution

its edges.

L N GND

1 Brown Blue

2 Black White Green

Green/

Yellow

Page 6

Federal Communications Commission (FCC)

Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case the user will be required to correct

the interference at his own expense.

Caution

Changes or modifications not expressly approved by the party responsible for compliance could void the

user's authority to operate this equipment.

This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.

Industry Canada(IC)

Statement

This device contains license-exempt transmitter(s)/ receiver(s) that comply with Innovation, Science and

Economic Development Canada’s licence-exempt RSS(s). Operation is subject to the following two

conditions:

(1) This device may not cause interference.

(2) This device must accept any interference, including interference that may cause undesired operation of

the device.

L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR

d’Innovation, Sciences et Développement économique Canada applicables aux appareils radio exempts de

licence. L’exploitation est autorisée aux deux conditions suivantes :

1. L’appareil ne doit pas produire de brouillage;

2. L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en

compromettre le fonctionnement.

Caution:

Exposure to Radio Frequency Radiation. The installer of this radio equipment must ensure that the antenna

is located or pointed such that it does not emit RF field in excess of Health Canada limits for the general

population; consult Safety Code 6, obtainable from Health Canada’s website www.hc-sc.gc.ca.

Exposition à des radiations de fréquences radio. Cet appareil émettant des ondes radio, l'installateur doit

s'assurer que l'antenne est positionnée ou orientée de telle sorte que l'appareil émette des champs RF ne

dépassant pas les limites recommandées par Santé Canada pour le grand public; consultez Code de

sécurité 6, disponible à Santé Canada ou sur leur site web www.hc-sc.gc.ca.

Page 7

Table of contents

Essential Safety Precautions

Product Handling

Product Installation

Card Handling

Contents of the package ············································································································ 1

Name of Each Part ··················································································································· 2

Front ·································································································································· 2

Back ·································································································································· 2

Inside of Front Cover ············································································································· 3

Inside of Top Cover ··············································································································· 3

Inside of Right side door ········································································································· 4

Preparation before Use ············································································································· 5

Installation and connection of the main body ·············································································· 5

Card setting ························································································································· 6

How to use the machine ·········································································································· 10

Setting and Checking the IP Address ······················································································ 10

Card Issuing ······················································································································ 1 1

Exchange of Thermal Transfer Ribbon ···················································································· 12

Exchanging Tipper Foil ········································································································ 14

Exchanging Indent Film ········································································································ 18

Picking up cards from Output Stacker ····················································································· 21

Picking up cards from Reject Stacker ······················································································ 22

Eco mode ·························································································································· 23

Error Message ······················································································································ 24

Error during standby ············································································································ 24

Consumable error ··············································································································· 25

Error during operation ·········································································································· 26

Error and warning during printing or encoding operation ····························································· 28

Error Reset ··························································································································· 30

Removing the card remaining in Input Hopper ·········································································· 30

Removing the card remaining in Main Transfer Unit ··································································· 32

Removing the card remaining in Print /Encode Unit ··································································· 35

Removing the card remaining in Vertical Rotation Unit ································································ 39

Removing the card remaining in Carriage Unit ·········································································· 40

Removing the card remaining in Emboss Unit ··········································································· 42

Removing the card remaining in Card Insertion/Exit Slot ····························································· 45

Cleaning ······························································································································ 46

Cleaning Thermal Print Head ································································································ 46

Washing Cleaning Roller ······································································································ 49

Cleaning Card transfer rollers ································································································ 52

Specifications ························································································································ 54

General Specifications ········································································································· 54

Embosser Specifications ······································································································ 55

Encoder Specifications ········································································································· 55

Printer Specifications ··········································································································· 55

Restriction of Usable card ····································································································· 55

User environment ··············································································································· 56

Page 8

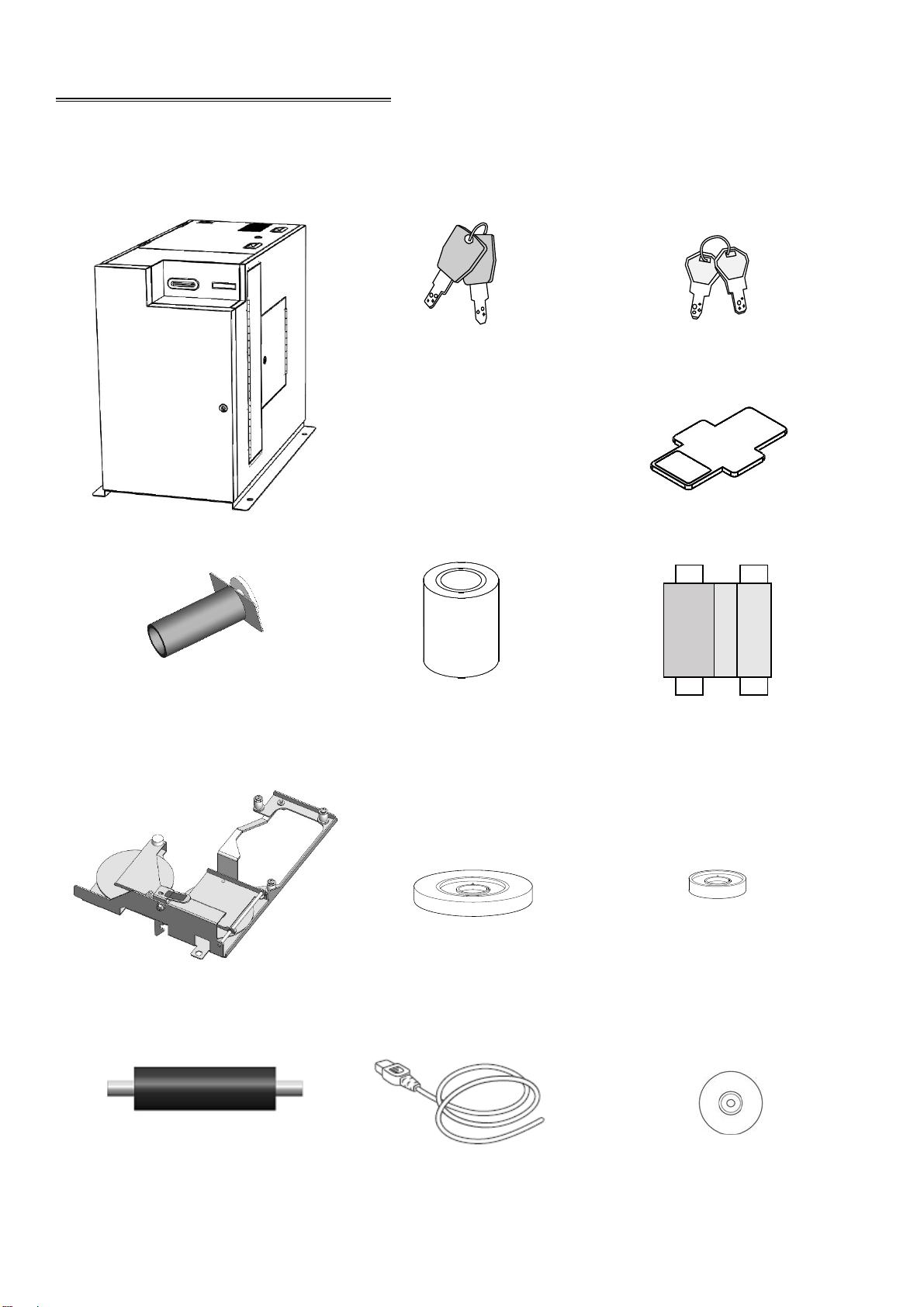

Contents of the package

The package contains the following items.

(Please contact your dealer if you cannot find anything.)

Cover key (2 pieces x 3) Cassette key (2 pieces x 2)

Main Body Weight (6 pieces)

Reel hardware for tipper Tipper Foil Thermal Transfer Ribbon

(with paper core)

Indent Cassette Indent film Indent film empty core

Cleaning Roller Power cable CD (Operation Manual (pdf))

.

1

Page 9

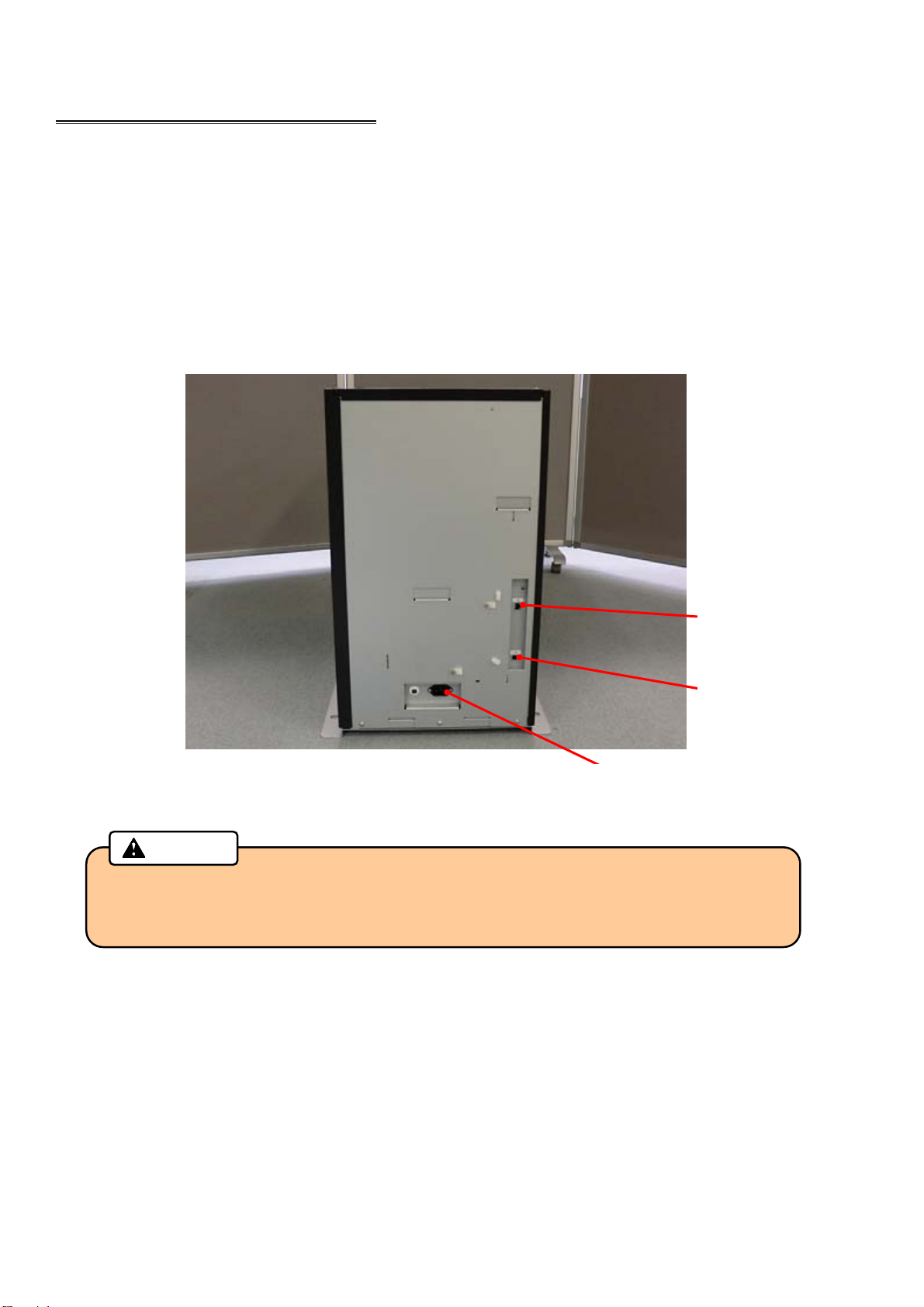

Name of Each Part

Front

Card

Insertion /Exit

Slot

Front Cover

Back

Circuit

Breaker

Power Switch

Top Cover

Main display

Right side door

LAN

Connector

USB

Connector

AC Inlet

2

Page 10

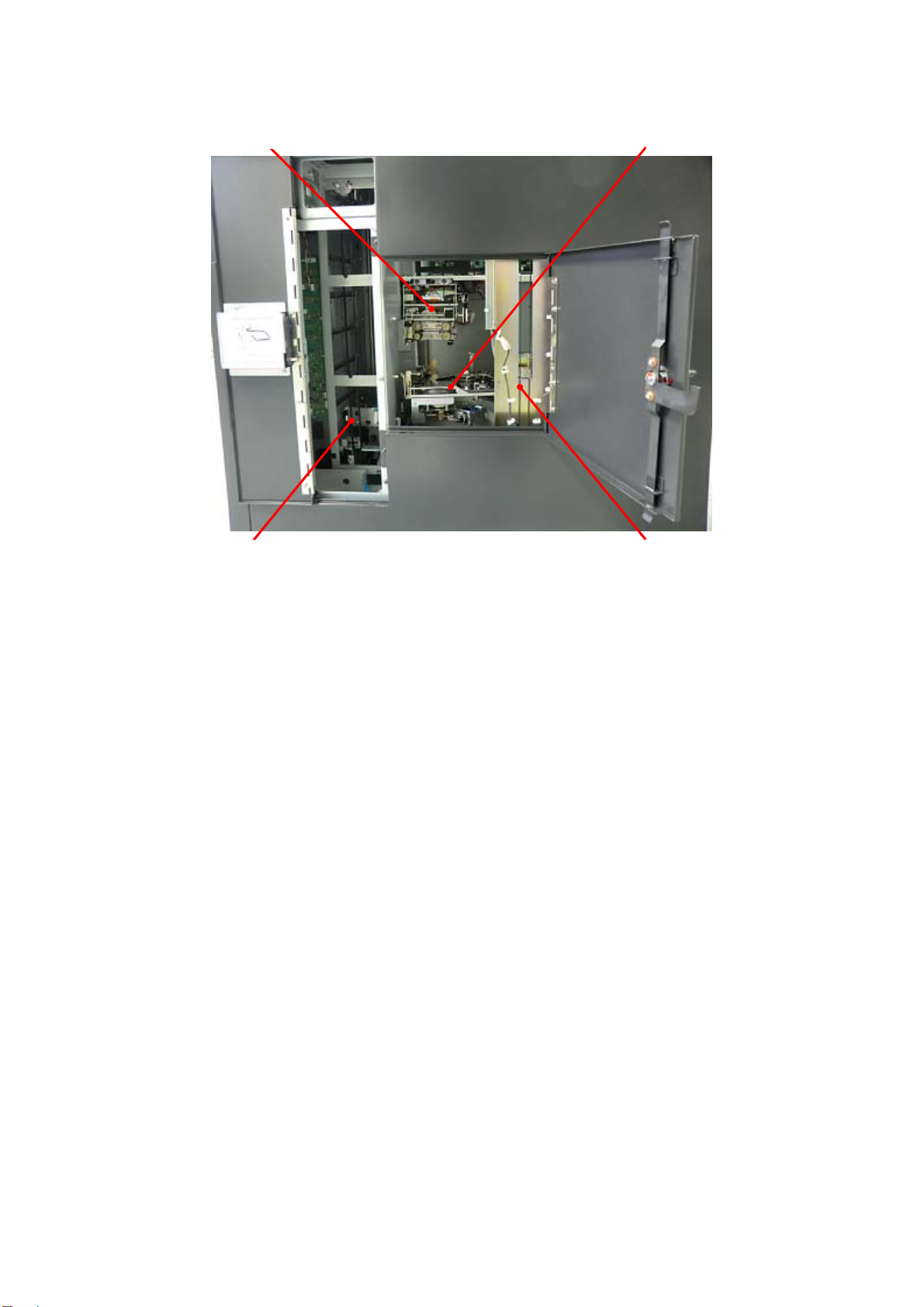

Inside of Front Cover

Output Stacker Unit

Input Hopper

Inside of Top Cover

Print /Encode Unit

Hopper Cassettes

Print /Encode Unit display

Reject Stacker Unit

Tipper Unit

3

Page 11

Inside of Right side door

Vertical Rotation unit

Emboss Unit

Main Transfer Unit

(* Elevator part to be

called “Carrier” in

this manual.)

Carriage Unit

(* Transfer unit to carry a card to the

Vertical Rotation unit, Emboss

Unit and Tipper Unit to be called

“Carriage” in this manual.)

4

Page 12

Preparation before Use

For installation, please read “Product Installation” in this document in advance.

Installation and connection of the main body

1. Place the main body on the installation space.

2. Install the Tipper Foil according to the procedure “Exchanging Tipper Foil” on page 14.

3. Connect the host computer and the main body with connection cable.

4. Connect the power cord to the AC inlet and AC outlet.

Caution

・ Communication connectors (LAN, USB) are very sensitive to static electricity.

You should turn off the power before you connect or remove the cables on the rear

side to protect the machine against the static electricity.

5. Install the ribbon according to the procedure “Exchange of Thermal Transfer Ribbon” on page 12.

AC Inlet

LAN

Connector

USB

Connector

5

Page 13

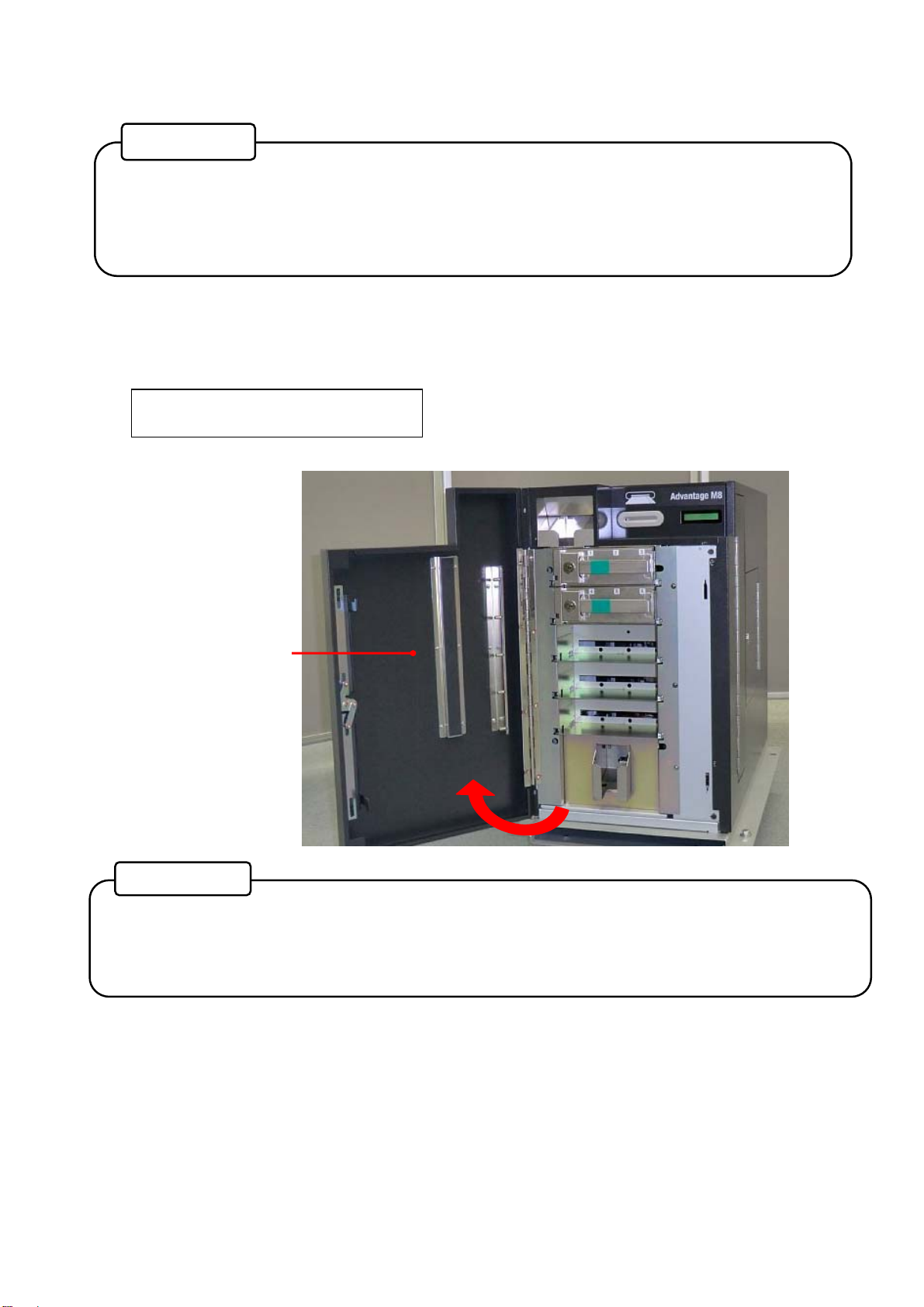

Card setting

Reference

• Front Cover of the main body can only be opened by unlocking both the physical cover

key and electrical lock.

• For unlocking the electrical lock, you need to connect a LAN cable and run application

software.

1. Turn the power ON.

Unlock the Front cover with the application software and the key turning clockwise. When the Front

Cover is opened, the buzzer will beep, and the following error message will be indicated on the Main

display.

CV401 Front

Reference

• After unlocking the electrical lock, the Front Cover must be opened promptly.

If the Front Cover is left closed for a while, it will be locked by the electrical lock

automatically.

Front Cover

6

Page 14

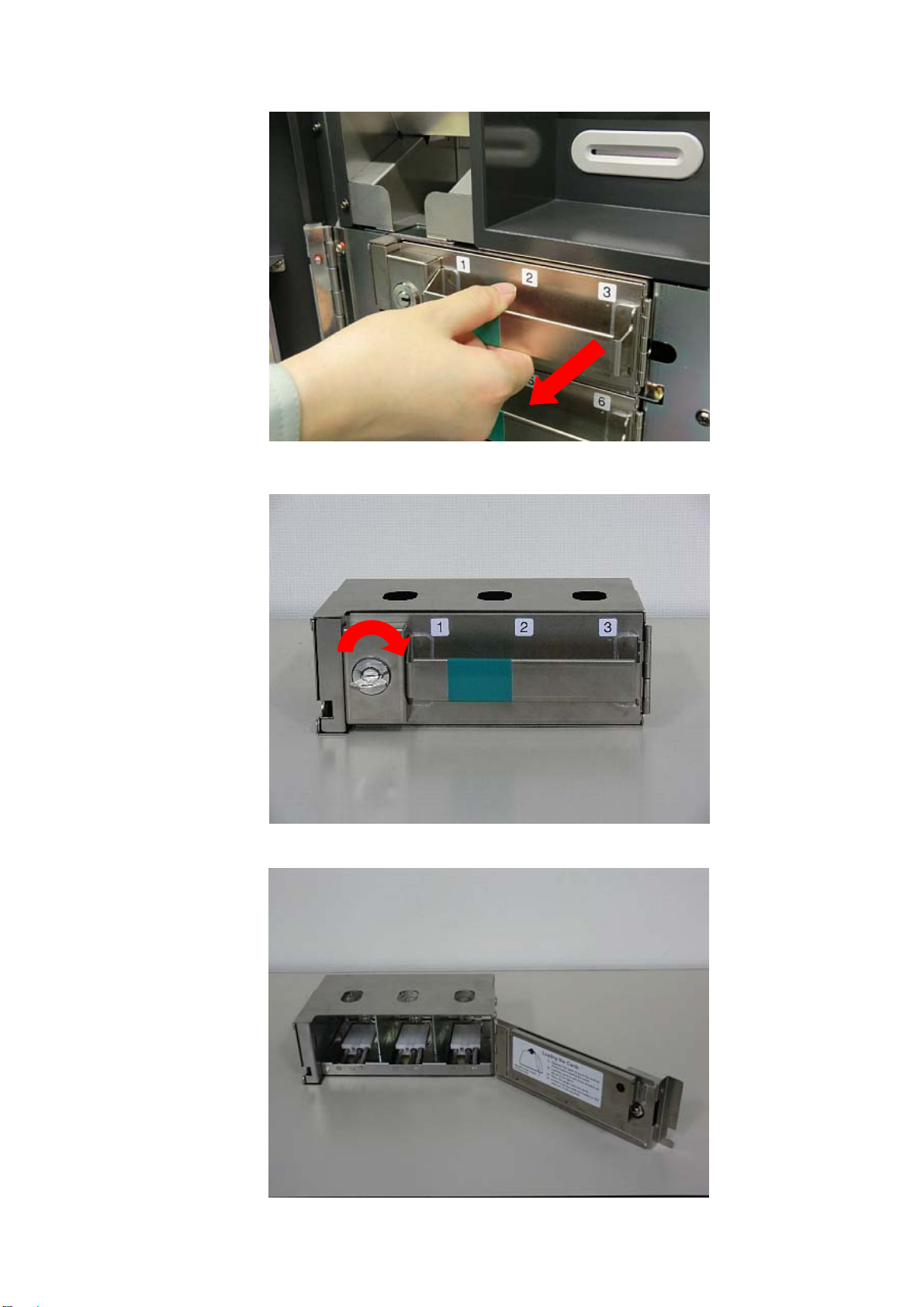

2. Pull out the Hopper Cassette from the main body.

3. Open the Hopper cover by turning the Hopper cassette key clockwise.

7

Turn the hopper cassette key clockwise.

Open the Hopper Cover.

Page 15

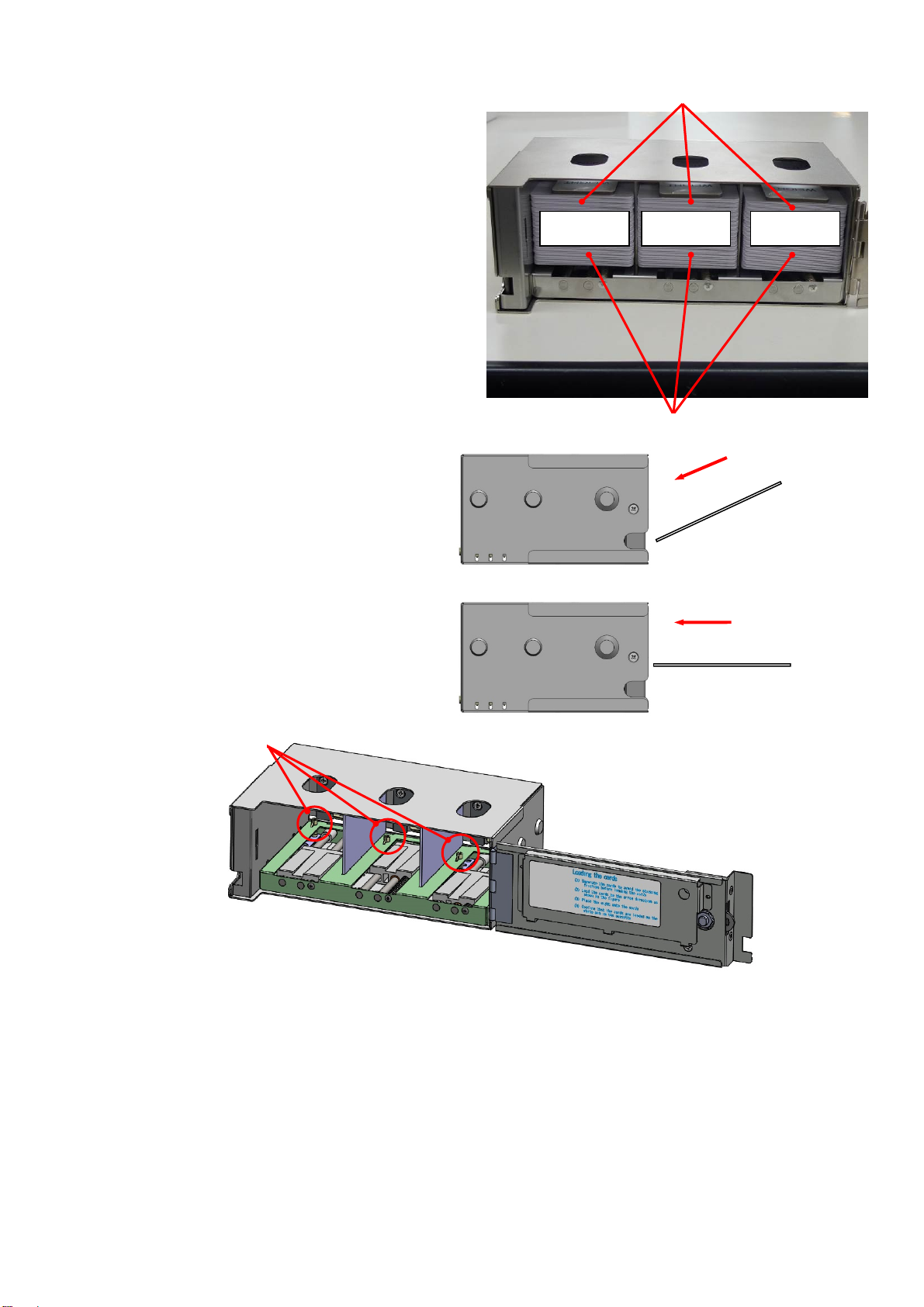

4. Before putting cards into the hopper, they

must be separated to prevent them from

sticking to each other. Then place the cards

into the desired Hoppers. Place a weight on

top of the cards. Close the Hopper cover

and lock by turning the cassette key

counterclockwise.

Each Hopper can hold a maximum of 50

cards.

Please refer to the Illustration inside of the

cassette to find card setting direction.

Placing the cards in an extremely skew

or acute angle may interfere with proper

card seating and cause card jams.

Set the cards on the sensor pin softly

while keeping them horizontally.

Sensor pin

If the edge of a card is out of the Gate, it may cause card jams. In this case, please remove all cards

from the cassette temporally and reseat them according to the step 4 as above.

Max 50

Weight

Max 50 Max 50

Card

NG

OK

8

Page 16

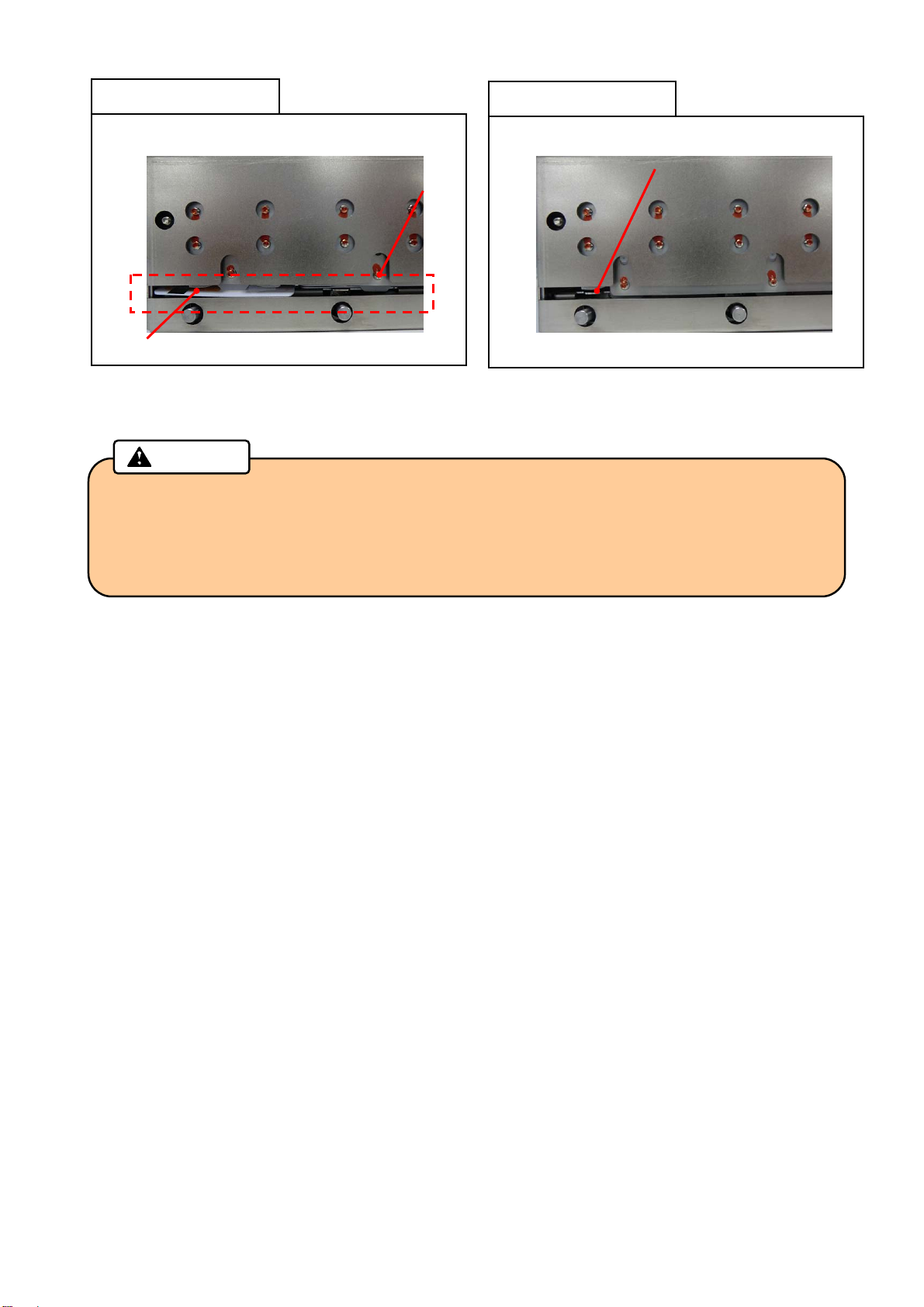

Bad setting example

NG

Card

5. Insert the cassette into the main body until it clicks. Close the Front Cover to lock with the key.

• After separating the cards to prevent them from sticking to each other , check that there is

no foreign object in the input hopper, then place the cards into the cassette.

Card comes out of the Gate

Caution

Gate

Good setting example

OK

Card is placed in cassette properly

• If you see a card edge at the gate, all cards must be taken out from the cassette and

reseated again.

9

Page 17

How to use the machine

Setting and Checking the IP Address

For issuing the cards, this product requires being connected to a host computer by LAN and USB.

To connect to a LAN, you need to set up an IP address.

How to check the existing IP address is described as follows.

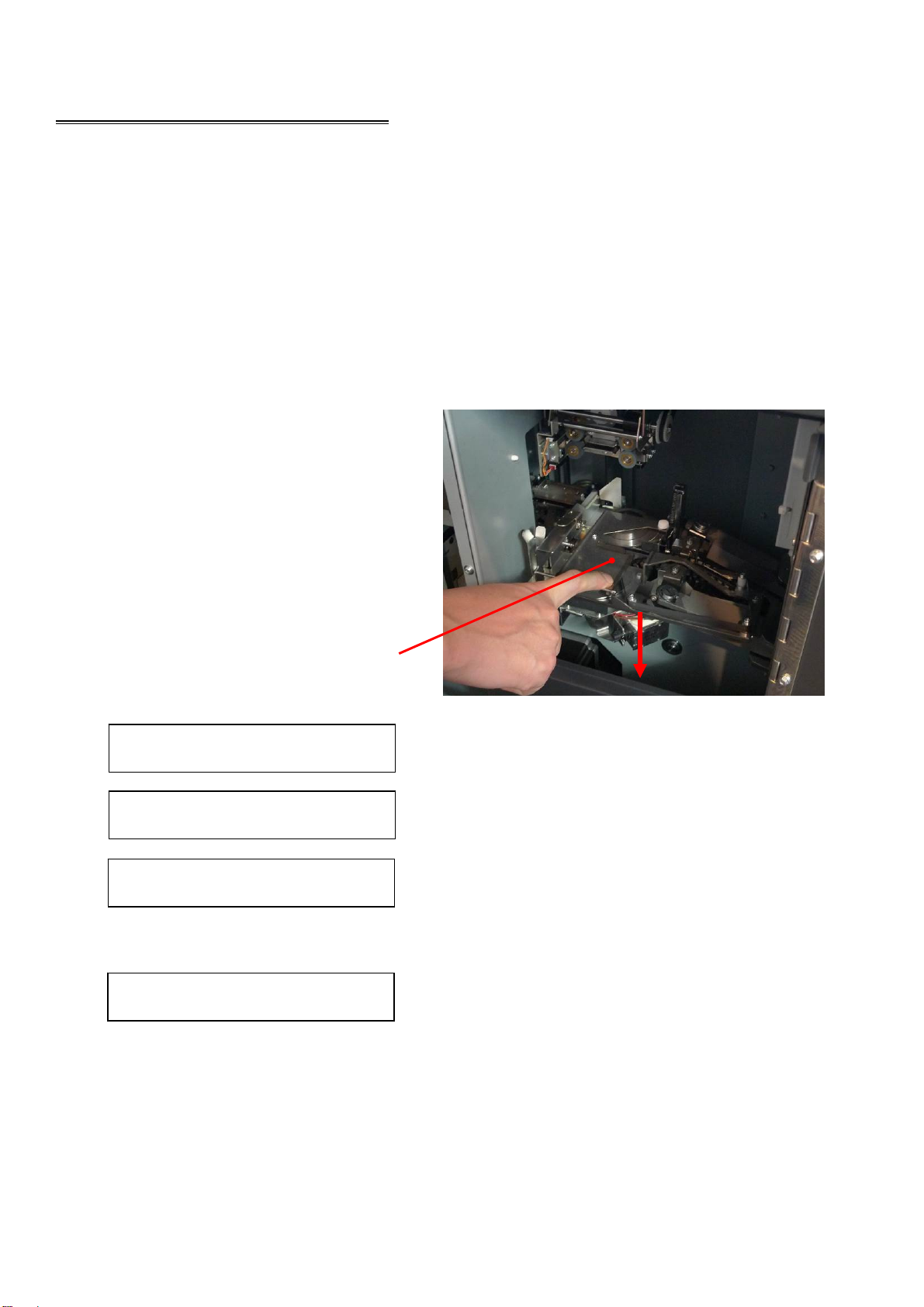

1. Turn the power OFF, then open the Right side door by turning the key clockwise.

2. While pushing down on the Indent Cassette, turn the power ON.

3. When the buzzer starts beeping, release

the Indent Cassette.

4. The IP address, Subnet mask, and

Gateway will be displayed on the Main

display scrolling every two seconds

repeatedly.

Push the Indent Cassette downward.

Ixxx.xxx.xxx.xxx

Sxxx.xxx.xxx.xxx

Gxxx.xxx.xxx.xxx

While getting an IP address from DHCP server, the Main display shows as follow.

Please wait...

After received IP address, the address is indicated on the Main display.

5. Close the Right side door and lock by the key, then turn the power OFF.

Displayed IP address

Displayed Subnet mask

Displayed Gateway

10

Page 18

Card Issuing

1. Turn the power ON after connecting the power cable and the communication cables.

2. The following message will be indicated on the Main display.

TP Warm-up xx%

(Warming up is not completed when using Tipper.)

Not initialized

(Warming up is completed when using Tipper, or not using Tipper.)

3. Initialization triggered by the host computer.

Initializing...

(During initialization)

4. When initialization is completed, the message will be changed.

Issuing Mode

5. When received Issuing data from the host computer, Issuing operation is started.

Card Issuing

6. Issued card will be stored in the Card Stacker or ejected to the Card Insertion/Exit Slot.

7. Error card will be transferred to the Reject Box.

Reference

• If any error is detected during initialization, an error message is indicated on the Main

display.

Please refer to “Error message” in this manual about the details and its measures.

Caution

• Do not insert a card or cover the Card Insertion/Exit Slot during the operation.

• If you open the Front cover, Side door, or the Top cover during the operation, it will stop

issuing the card. Do not reuse the canceled card because the data was not be

processed correctly. You can restart the machine by turning off and on.

• In the case when the machine got turned off because of power failure or other reasons,

open the Front cover to remove the Hopper cassette. Make sure that the card does not

come out from the rear side of the Hopper cassette, and then turn on the machine

again.

11

Page 19

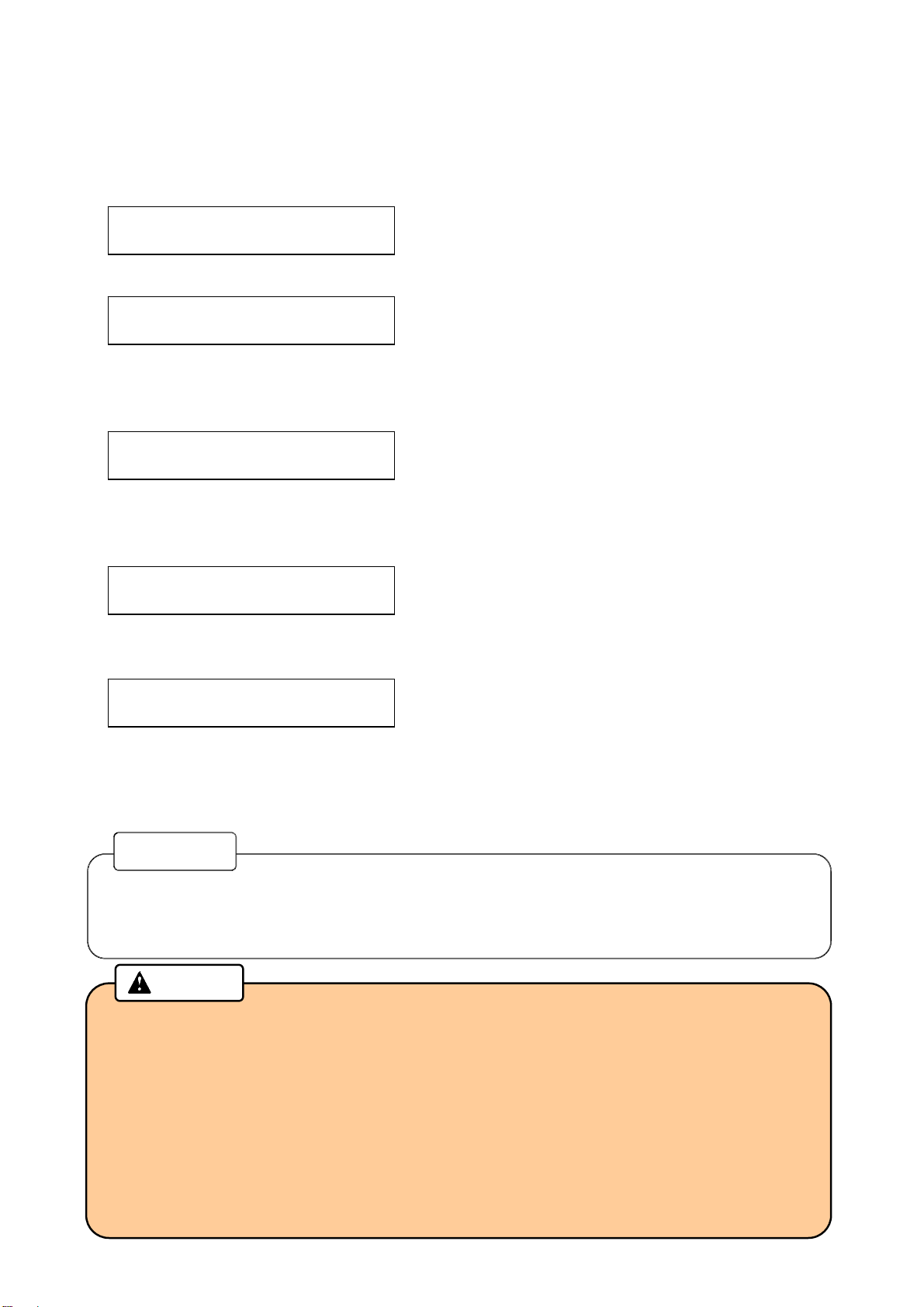

Exchange of Thermal Transfer Ribbon

1. Unlock the Top Cover by turning the key clockwise during the power ON, and then open the Top Cover.

The buzzer will beep, and the following error message will be indicated on the Main display.

CV402 Top / Side

2. Push the Print /Encode Unit Cover Open Button to open the cover.

3. Detach the Thermal Transfer Ribbon from the Print /Encode Unit.

Turn this key clockwise.

Print /Encode Unit Cover Open Button

Open Top Cover.

Open Print /Encode Unit cover. Print /Encode Unit

12

Page 20

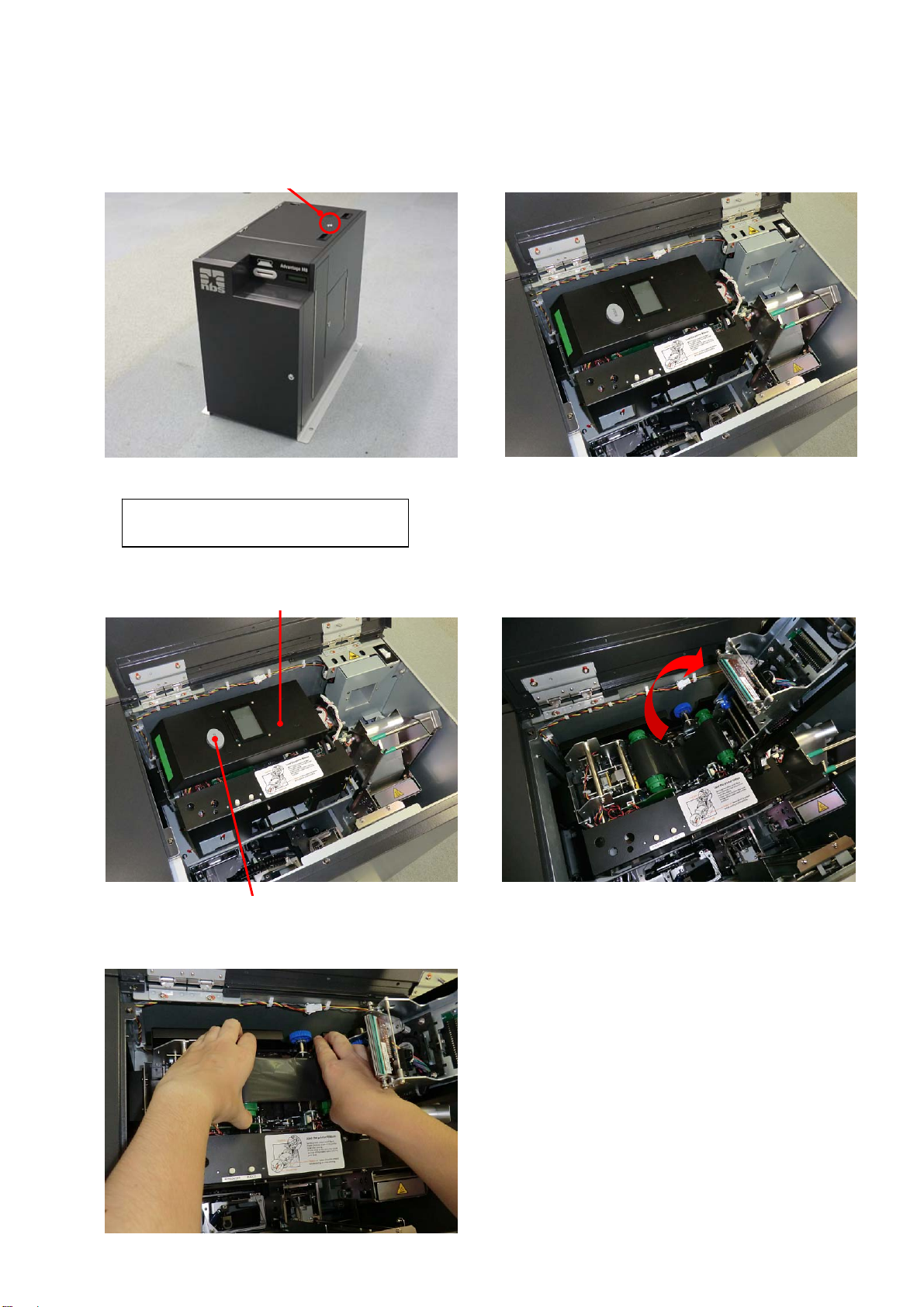

4. Install new Thermal Transfer Ribbon as shown in the picture below, and remove the slack of the ribbon.

Unused side Used side

5. Close the Print/Encode Unit cover until it clicks.

6. Push the RIBBON SET button.

7. Close the Top Cover, and then lock the Top Cover key.

“RIBBON SET” button

Caution

• Be sure to push the "RIBBON SET" button after installing a new ribbon. Otherwise, a print

failure will occur.

• Be sure to remove the slack of the Thermal Transfer Ribbon before closing the cover. The slack

will adversely affect the print quality.

Turn the unused side of the ribbon

counter-clockwise to remove the slack

Thermal Transfer Ribbon

13

Page 21

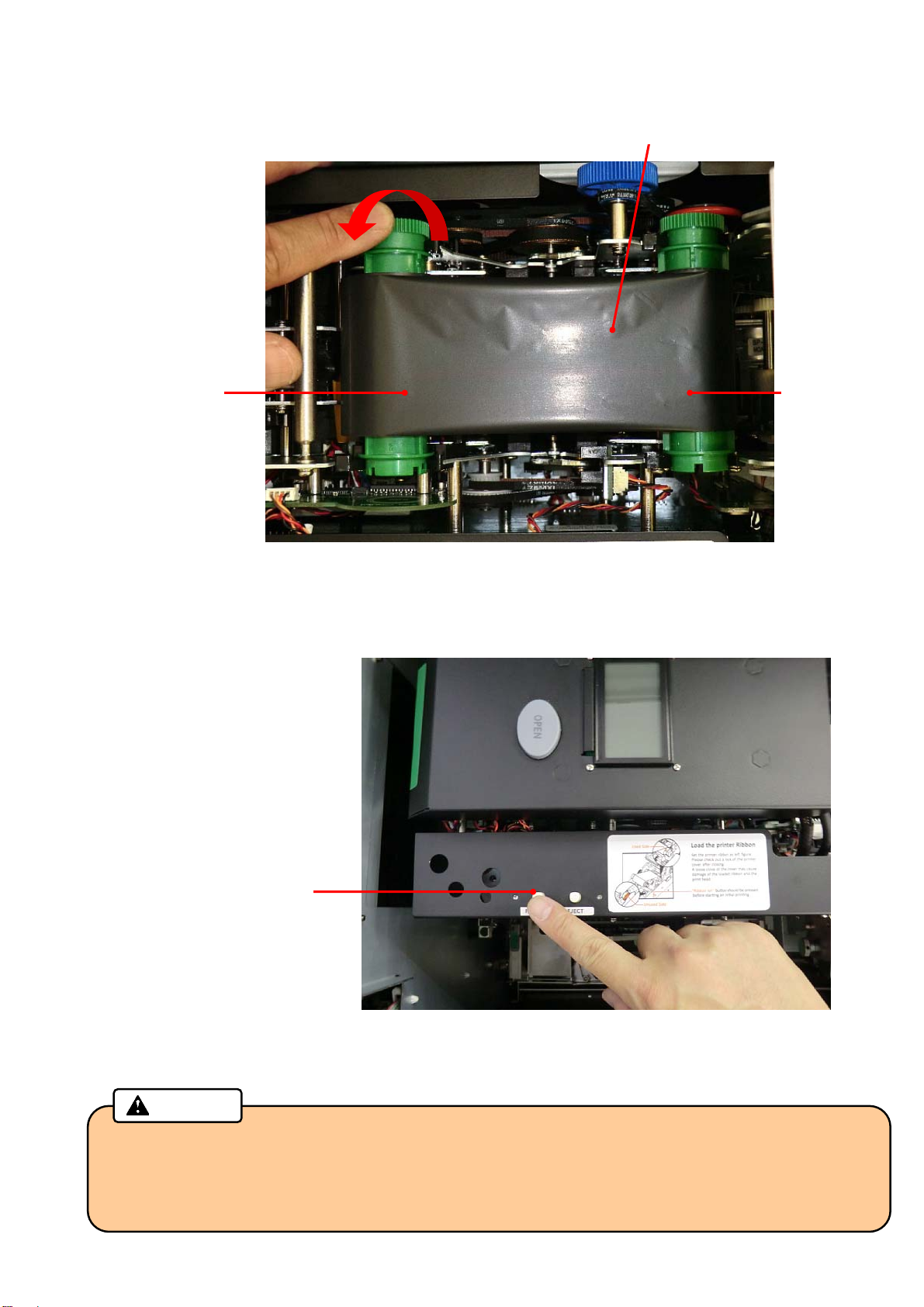

Exchanging Tipper Foil

1. Turn off the power, and then open the Top Cover by turning the key clockwise.

2. Grab the handle of the Tipper Unit to pull out from the main body.

• There is a very high-temperature part in the Tipper Unit.

Caution

Make sure to grab the handle to avoid a burn when you pull up the Tipper Unit.

Turn this key clockwise.

Open Top Cover.

Handle

14

Page 22

3. Remove the used Tipper Foil and paper core from the Tipper Unit. Pull each knob of the reel

flange/unreel flange while holding the used tipper foil or the paper core to remove.

Unreel Flange Knob

• Be sure to exchange the Tipper Foil after it is sufficiently cooled down.

4. Remove the used Tipper Foil from the reel hardware, then Install the empty paper core to it.

Confirm there is no gap between the paper core and the flange of the reel hardware.

Paper Core

Paper Core

Caution

Used Tipper Foil

Reel Flange Knob

Reel Hardware

Confirm there is no gap

between the paper core

and the Flange of reel

hardware

15

Page 23

pp

5. Insert the Reel hardware to the Tipper Unit while pulling the knob of reel hardware. At this time, fit a

mounting hole of the Reel hardware into a pin on the cassette.

6. Insert the Tipper foil into the Unreel flange while pulling the knob in the direction of the arrow.

7. Pull out the Tipper foil, and fix the edge of the foil to the paper core with an adhesive tape.

New Tipper Foil

Unreel Flange

Turn the Reel flange knob counter-clockwise approximately one turn to wind the foil on the reel.

Knob

Fit this hole to the pin of

er Unit

Ti

Turn the knob one rotation Fix the foil to the Paper Core

16

Page 24

8. Gently slide the tipper Unit into the tipper holder along the guide rail.

Slide in the Tipper

Unit along the

guide rail slowly.

9. Close the Top Cover and lock with the key.

Guide Fin

17

Page 25

Exchanging Indent Film

1. Turn off the power, then turn the Right side door key clockwise to open. If carriage disturbs your access,

push it to the right side.

2. Release lock by pushing the lock lever with holding the Indent Cassette handle, and remove Indent

Cassette upward and forward from the Emboss Unit.

Emboss Unit

Carriage Unit

Lock lever

Handle

Indent Cassette

18

Page 26

3. Remove a thumb-screw and open the Film Guide.

Thumb- screw

4. Remove the Empty Core and used film. Then set the new film to the left and the Empty Core to the right.

5. Peel off the fixing tape on the edge of the new film, and set the film according to the guidance figure for

“Film Setting”. Fix the edge of the film onto the Empty Core with the fixing tape.

At this time, the film should not lie off the core largely.

6. Turn the empty core three times counter-clockwise to remove the slack of the indent film.

Close the Film Guide, and fix the thumb-screw.

Film Guide

Empty Core

New film

Empty Core

Used film

Used film

Guidance figure for

“Film Setting,”

19

Page 27

7. Install the Indent Cassette to the main body. Insert the Guide shaft into the Guide hole of the cassette

while grabbing the lock lever and the handle, and install the cassette until it clicks.

(Refer to the guidance figure for “Indent Cassette Setting” on the Right side door.)

Guide Hole

Guide Shaft

8. After attaching the cassette, check that the film has no slack.

Close the Right side door, and lock with the key.

• Be sure to remove the slack of the Indent Film before installing the Indent Cassette.

• Before installing the halfway used film again, be sure to wind the used part completely.

Caution

The slack may adversely affect the print quality.

Push down the Indent Cassette until it clicks.

Guide Hole

Guide Shaft

20

Page 28

Picking up cards from Output Stacker

1. Turn the power ON and unlock the Front cover by application software.

Then open the Front cover by turning the key clockwise.

When the Front Cover is opened, the buzzer will beep and the following error message will be indicated

on the Main display.

CV401 Front

2. Pick up the cards from the Output Stacker.

3. Close the Front cover, and then lock the Front Cover with the key.

Output Stacker Unit

Turn this key clockwise.

Open Front Cover.

21

Page 29

Picking up cards from Reject Stacker

1. Turn the power ON and unlock the Front cover by application software.

Then open the Front cover by turning the key clockwise.

When the Front Cover is opened, the buzzer will beep and the following error message will be indicated

on the Main display.

CV401 Front

2. Pick up the cards from the Reject Stacker.

3. Close the Front cover, and then lock the Front Cover with the key.

Open Front Cover. Turn this key clockwise.

Reject Stacker Unit

22

Page 30

Eco mode

1. This product has the following two different type Eco (Economy Energy) mode. Each mode can be set

independently.

• Tipper Heater OFF

• Motor OFF

2. Eco mode can be set for the heater and motor as follows:

i. No ( Not change to Eco Mode)

ii. 10 minutes (When the machine has been kept on standby for 10 minutes or more, it shifts to the Eco

mode )

iii. 30 minutes (When the machine has been kept on standby for 30 minutes or more, it shifts to the Eco

mode )

iv. 60 minutes (When the machine has been kept on standby for 60 minutes or more, it shifts to the Eco

mode )

(Factory default setting is “No” for both of Hopper and Motor)

3. During Eco mode, the following message will be indicated on the Main display.

Eco mode Tipper

Eco mode Motor

Eco mode Both

4. Eco mode is canceled by receiving “Clear Eco Mode” command from the host computer.

Tipper is in Eco mode.

Motor is in Eco mode.

Both Tipper and Motor are in Eco mode.

23

Page 31

Error Message

When an error such as operation failure or a malfunction of the machine occurs, the buzzer will beep, and an

error message will be indicated on the Main display or the Print /Encode Unit display.

If the same error occurs repeatedly, please contact your distributor.

Error during standby

An error code is indicated on the Main display when a sensor is defective while standby or the machine is not

ready for starting operation.

You can check the error message on display and the PC screen either.

Error Message Details and Countermeasures

CV301 Lock error Detect electric lock anomaly on Front Cover.

CV302 Unlock err Detect electri c unlo c k anomaly on Front Cover.

CV401 Front Detect Front Cover is open(during standby).

<Close the cover to clear the error>

CV402 Top / Side Detect Top / Right side door is open(during waiting).

<Close the cover to reset the error>

CV512 Sensor err Detect cover sensor anomaly.

<Power OFF and ON>

EJ101 Card full Out Stacker is full.

<Open Front Cover and pick up the cards.>

IH512 Sensor err Detect In Hopper sensor error.

<Power OFF and ON>

RJ101 Card full Reject unit is full by cards.

<Open Front Cover and pick up the cards.>

SY221 Fan1 error Detect abnormality of Cooling Fan.

<Power OFF and ON>

24

Page 32

Consumable error

An error code is indicated on the Main display when a consumable is not set properly or has run out.

Please install the required consumable according to the following messages.

Error Message Details

ID101 No film No Indent film.

ID121 No cst Indent film cassette has not set.

IH101 No card 1 No card in Hopper 1

IH102 No card 2 No card in Hopper 2

IH103 No card 3 No card in Hopper 3

IH104 No card 4 No card in Hopper 4

IH105 No card 5 No card in Hopper 5

IH106 No card 6 No card in Hopper 6

IH107 No card 7 No card in Hopper 7

IH108 No card 8 No card in Hopper 8

IH109 No card 9 No card in Hopper 9

IH110 No card 10

IH111 No card 11

IH112 No card 12

IH113 No card 13

IH114 No card 14

IH115 No card 15

IH121 No cst 1 Hopper cassette 1 is not set.

IH122 No cst 2 Hopper cassette 2 is not set.

IH123 No cst 3 Hopper cassette 3 is not set.

IH124 No cst 4 Hopper cassette 4 is not set.

IH125 No cst 5 Hopper cassette 5 is not set.

TP101 No foil Nof Tipper Foil

TP121 No cst Tipper Unit is not set.

No card in Hopper 10

No card in Hopper 11

No card in Hopper 12

No card in Hopper 13

No card in Hopper 14

No card in Hopper 15

25

Page 33

Error during operation

An error code is indicated on the Main display when the machine does not run properly during operation or

initialization. If the same error occurs repeatedly, please contact your distributor.

Error Message Details and Countermeasures

CA201 Card jam Card Jam (caused by malfunction of motor or sensor in Main Transfer Unit)

< Power OFF, and remove the card >

CA221 Pusher err Pusher motor error detected

<Power OFF and ON >

CA303 Home err Y Home detection error. ( Carrier vertical direction)

<Power OFF and ON >

CA304 Home err Z Home detection error.( Carrier horizontal direction)

<Power OFF and ON>

CA421 Card exist Detect a card remaining on Carrier.

< Power OFF, and remove the card>

CG302 Home err X Home detection error. (horizontal direction)

<Power OFF and ON >

CG303 Home err Y Home detection error . (vertical direction)

<Power OFF and ON >

CG421 Card exist Detect a card remaining on carriage.

< Power OFF, and remove the card>

CM501 Unknown Receive unknown commands.

<Make sure host PC and this product are connected correctly by LAN or USB.>

CM502 Sequence Detect sequence error.

<Make sure host PC and this product are connected correctly by LAN or USB.>

CM503 Parameter Detect parameter error.

<Make sure host PC and this product are connected correctly by LAN or USB.>

CM513 Receive Detect receiving error.

<Make sure host PC and this product are connected correctly by LAN or USB.>

CM514 Send Detect sen ding error.

<Make sure host PC and this product are connected correctly by LAN or USB.>

CV411 Front Detect Front Cover open during card issuance operation.

<Close Front Cover, initialize from host PC.>

CV412 Top / Side Detect Top /Right side door open during card issuance operation.

<Close Top/Right side door, and initialize from host PC.>

DR307 D Pos err Home detection error.( Emboss Drum)

<Power OFF and ON >

DR401 D Rota err Detect an error during drum rotation.

<Power OFF and ON >

EM211 Press err Detect an error during embossing operation.

< Power OFF, remove the card>

26

Page 34

Error Message Details and Countermeasures

EM501 Area err

The data to emboss outside of emboss available area was sent.

<Make sure if emboss data is inside of available area.>

ID401 Cst down

Cassette not moved down position.

<Power OFF and ON >

ID402 Cst up

Cassette not moved up position.

<Power OFF and ON >

ID403 Feed err

Error detected during film rotate operation.

<Power OFF and ON >

ID501 Area err

The data to emboss outside of indent available area was sent.

<Make sure if emboss data is inside of indent available area.>

IN201 Card jam

Card Jam. (caused by malfunction of motor or sensor in Input hopper Unit)

< Power OFF, and remove the card>

IN401 Card eject

IN403 Timeout

The issued card was not pulled out even after a certain period of time.

<

Open Front Cover , and remove the card from Reject Unit.>

Insert waiting time out.

<Insert card within 30 seconds after starting card issuing by application

software.>

IN421 Card exist

Detect a card remaining in Insert slot.

< Remove the card.>

SY101 No Card

Not find a card.

<Make sure if a card does not fall inside the machine.>

SY501 Not init

Card issuance command was sent before initialization.

<Initialize the machine from host PC.>

SY904 FRAM error

Detect FRAM (for data storage) error.

<Power OFF and ON >

TP211 Press err

Detect an error during Tipper foil pressing operation.

<Power OFF and ON >

TP301 HP err

Detect an error during searching home position.

<Power OFF and ON >

TP401 Wup err

Heater temperature does not reach to the established value.

<Power OFF and ON >

TP901 Temp err

Heater temperature could not reach to the established value even after the

specified time has passed.

<Power OFF and ON >

VR201 Card jam

Card Jam.(caused by malfunction of motor or sensor in Vertical Rotation Unit.)

< Power OFF, and remove the card.>

VR221 V Rota err

Detect an error during rotating operation.

<Power OFF and ON >

VR421 Card exist

Detect a card remaining on Vertical Rotation Unit.

< Power OFF, and remove the card>

Caution

・ When serious errors listed above has occurred, be sure to shut down all power before

checking and making any countermeasure action.

・ Be sure to shut down all power and wait more than one hour before checking or

making a measure for Tipper Unit. The Tipper Unit has a high-temperature area, and it

may be the cause of an injury or a burn.

27

Page 35

Error and warning during printing or encoding operation

If an error or warning is indicated by the application software, and no error or warning is indicated on the Main

display, make sure whether it is indicated on the Print /Encode Unit display.

To check the Print /Encode Unit display, please open the Top Cover.

If the same error or warning occurs repeatedly, please contact your distributor.

A. Errors

(1) TPH(Thermal Print Head)

Code Message Details and Countermeasures

10 Top Cover (TPH Module) Print /Encode Unit cover is opened during card printing operation.

<Make sure that the cover is closed properly>

11 TPH Up/Down Failure Up/down movement of the Thermal Print Head is interrupted.

<Repair service is required. Contact your distributor>

13 Abnormal TPH Thermistor

Temperature

(2) Card Feeding

Code Message Details and Countermeasures

12 Card Jammed The card is jammed in Print /Encode Unit.

(3) Ribbon

Code Message Details and Countermeasures

14 Ribbon Encoder Error Run out of Thermal Transfer Ribbon or encoder error occurs.

An abnormal temperature of Thermal Print Head is detected.

<Repair service is required. Contact your distributor>

<Remove the card>

<Make sure that Thermal Transfer Ribbon is not installed

incorrectly, or Thermal Transfer Ribbon has not run out>

(4) Card

Code Message Details and Countermeasures

17 IC Module Up/ Down Error IC Content module position error occurs.

<Repair service is required. Contact your distributor>

50 [Changer] Module Response

Timeout

51 [Changer] Module Transmission

Timeout

52 [Changer] Home Position Failure The Flipper can not be moved back to home position.

53 [Changer] Card Flipper Failure An error occurs when the Flipper turn up.

54 [Changer] Card Input Time out The Print /Encode Unit stops when the card is entering the Flipper.

55 [Changer] Card Input Jam The card fails to enter the Flipper on time.

56 [Changer] Card Output Jam The card is jammed in the Flipper.

57 [Changer] Card Exist The card is not ejected from the Flipper.

Flipper communication error occurs.

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

Flipper communication error occurs.

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

28

Page 36

t

(5) Miscellaneous

Code Message Details and Countermeasures

15 Media Error The media error occurs.

<Make sure whether the card is not set in the wrong direction>

16 EEPROM Error An EEPROM read/ write error occurs.

<Turn the power OFF and back O N>

B. Warning

(1) Card

Code Message Details and Countermeasures

23 [IC] Contact Error

24 [MS] Encoder Error

25 [MS] Read Error

26 [MS] Read STX Error

27 [MS] Read Parity Error

28 [MS] Read ETX Error No ETX is found in read data.

29 [MS] Read LRC Error LRC is inconsistent in dat a that is read from magnetic stripes.

30 IC Module Response Timeout IC module communication failed.

33 Card Eject Error Flipper module communication failed.

34 Card Input Timeou

(2) Ribbon

Code Message Details and Countermeasures

35 Ribbon Life Low Thermal Transfer Ribbon life is reduced to 10% or less.

36 No Ribbon Life Thermal Transfer Ribbon is fully consumed.

38 RF Tag Ribbon Error Thermal Transfer Ribbon is not installed properly.

(3) Miscellaneous

Code Message Details and Countermeasures

20 Command Error Print /Encode Unit receives non-conforming command.

21 Parameter Error The parameter is not valid.

22 Main Communication Part

Timeout

C. Trouble shooting

Symptom Countermeasures

The ribbon is frequently cut, or some part

of data is not printed.

The Print /Encode Unit is unable to find

the programs.

Print /Encode Unit fails to contact IC chip.

<Make sure whether the card is not set in the wrong direction>

Print /Encode Unit fails to encode magnetic stripes.

<Make sure whether the card is not set in the wrong direction>

Print /Encode Unit fails to read magnetic stripes.

<Make sure whether the card is not set in the wrong direction>

No STX is found in read data.

<Make sure whether the card is not set in the wrong direction>

A p arity error occurs when Print /Encode Unit read the data from

magnetic stripes.

<Make sure whether the card is not set in the wrong direction>

<Make sure whether the card is not set in the wrong direction>

<Make sure whether the card is not set in the wrong direction>

<Make sure whether the card is not set in the wrong direction>

<Turn the power OFF, and remove the card from Print /Encode Unit,

turn the power ON>

The card input is interrupted.

<Make sure whether any cards are not jammed in the path from the

Input Hopper to Print /Encode Unit>

<Prepare to replace Thermal Transfer Ribbon>

<Replace the Thermal Transfer Ribbon with a new one>

<Make sure whether Thermal Transfer Ribbon is not installed in the

wrong direction>

<Contact your distributor>

<Contact your distributor>

The command is not sent on time.

<Contact your distributor>

Check the X-coordinate in the printer driver.

<The recommended starting value for the X- coordinate is 14 ± 2>

Make sure host PC and this product are connected correctly by

LAN or USB.

<Reboot the PC>

29

Page 37

Error Reset

Removing the card remaining in Input Hopper

1. Turn the power ON and unlock the Front cover by the application software.

Then open the Front cover by turning the key clockwise.

2. Remove the Hopper Cassette that has the remaining card.

3. Remove the card from the rear side of the Hopper Cassette.

Turn this key clockwise.

Pull to remove the card

Hopper Cassettes

Hopper Cassette

Remaining Card

30

Page 38

* If the card cannot be pulled out from the rear side of the Hopper Cassette, open the Hopper Cover by

turning its key clockwise.

Remove all weight and cards, and pull out the remaining card from the Hopper.

4. Close the Hopper Cover and install the Hopper Cassette to the machine.

Close the Front Cover and lock the Key by turning it counterclockwise.

Remaining card

Hopper Cover

Remove the

remaining card

from the front.

31

Page 39

Removing the card remaining in Main Transfer Unit

1. Turn the power OFF, and open the Right side door by turning the key clockwise.

2. Check if any cards are remaining in the Carrier of the Main Transfer Unit.

Turn this key clockwise

Carrier of the Main Transfer Unit

Open Right side door

32

Page 40

If the remaining card is not on the Carrier, turn the Knob (X) to carry the card toward the Carrier.

When you cannot access the Carrier, grip Knob (Z) and pull the Carrier forward.

Turn the Knob (X) clockwise to

carry the card to the right side.

Turn the Knob (X) counter-clockwise

to carry the card to the left side.

33

Page 41

3. Grip the Knob (Y) and move the Carrier to the height between the Vertical Rotation Unit and the Indent

Unit.

While holding the Knob (Y), turn the Knob (X) clockwise to bring out the card from the Carrier. Pull out the

card by hand.

4. Close the Right side door and lock with the key.

Knob (Y)

Knob (X)

Vertical Rotation Unit Indent Unit

Pull out the card

from the Carrier

by hand.

Hold the Carrier

while removing

the card.

34

Page 42

Removing the card remaining in Print /Encode Unit

1. Turn the power OFF, open Right side door by turning the key clockwise.

Open Top Cover by turning the key clockwise.

2. Push down the button to open the Print /Encode Unit cover.

Turn this key clockwise

Turn this key clockwise.

Print /Encode Unit cover

Print /Encode Unit Cover Open Button

Open Right side door

Open Top Cover.

Open Print /Encode Unit cover.

35

Page 43

3. Detach the Thermal Transfer Ribbon from the Print /Encode Unit.

4. Transfer the card toward the Main Transfer Unit by turning Knob counterclockwise.

Transfer the remaining card

to Main Transfer Unit

5. Pull out the card from the left side of the Print /Encode Unit.

Remaining Card Pull out the card from the Print/Encode Unit.

Turning knob counterclockwise

Remaining card

36

Page 44

6. Reattach the Thermal Transfer Ribbon as shown in the picture below.

Remove the slack of the ribbon by turning the unused side of the ribbon counter-clockwise.

Turn the unused side of the

ribbon counter-clockwise.

Unused side

7. Close the Print/Encode Unit cover until it clicks.

8. Close the Top Cover, and then lock the Top Cover with the key.

9. Close the Right side door, and then lock the Right side door with the key.

10. Turn the power ON, and initialize the machine.

11. Open the Top Cover by turning the key clockwise while power ON.

* Ignore buzzer beeping and the following error message in the Main display to proceed next step.

CV402 Top / Side

Thermal Transfer Ribbon

Used side

37

Page 45

12. Push the RIBBON SET button.

“RIBBON SET” button

13. Close the Top Cover, and then lock the Top Cover with the key.

Caution

• Do not forget to push "RIBBON SET" button after installing a new ribbon. Otherwise, a print

failure will occur.

• Be sure to remove the slack of the Thermal Transfer Ribbon before closing the cover. The

slack will adversely affect the print quality.

38

Page 46

Removing the card remaining in Vertical Rotation Unit

1. Turn the power OFF, and open the Right side door by turning the key clockwise.

2. Remove the remaining card from the right side of the Vertical Rotation Unit.

3. Close Right side door, and then lock the Right side door with the key.

Turn this key clockwise

Open Right side door

Vertical Rotation Unit

Remaining Card

39

Page 47

Removing the card remaining in Carriage Unit

1. Turn the power OFF, and then open the Top Cover by turning the key clockwise.

2. Check where the Carriage Unit stops.

In the case when the Carriage Unit stops around the Tipper Unit, wait more than one hour until the T ip per

Unit is cooled down.

After the Tipper Unit has completely cooled down, proceed to the step 3.

Turn this key clockwise.

Tipper Unit

If the Carriage Unit stops at the

upper right position, wait until

the Tipper unit is cooled down.

Open Top Cover.

40

Page 48

3. Open needle lever by pushing shaft with holding the remaining card.

Remove the card from the Carriage Unit.

* Be careful not to drop the card into the machine (Unless holding the card, it will drop into the machine

when needle lever is opened).

Remaining

Card

Open Needle Lever by pushing the shaft

4. Close Top Cover and lock by the key.

Caution

• Tipper Unit has a very high-temperature part.

If you make the above process, turn off the power and wait at least 1 hour until the Unit has

been completely cooled down to prevent your arms or hands from getting burned.

Needle Lever

Shaft

Push the shaft backward

with holding the card

Carriage Unit

41

Page 49

Removing the card remaining in Emboss Unit

1. Turn the power OFF, and open the Right side door by turning the key clockwise.

Open the Top Cover by turning the key clockwise.

Emboss Unit

Turn this key clockwise

Emboss Type

Remaining Card

(Card is remaining between emboss type in Emboss Unit.)

Open Right side door

Remaining

Card

Emboss Unit

Open Top Cover Turn this key clockwise

* In the case when the card is

remaining in Emboss Unit

and held by Needle lever of

Carriage Unit, remove the

card from the Carriage by

opening the needle lever as

shown on page 40 in this

manual.

42

Page 50

2. Ensure an Emboss type is aligned to the emboss pin.

If they are not aligned each other, it may damage the

Emboss type.

・When the Emboss Type is not aligned to the Emboss Pin, rotate the Emboss Drum to set the Emboss Type

to the right position.

Emboss Type

Emboss Pin

Emboss Unit

Emboss Drum

Emboss Type and Emboss Pin are aligned.

43

Page 51

3. Turn the Crankshaft clockwise by a flat-head screwdriver to open the press bars completely while holding

the card. Then remove the card.

If the Crankshaft got turned too much, Press Bars would return to the Press Position. In this case, turn the

screwdriver counter-clockwise.

4. Make sure that the Emboss Type is aligned to the Emboss Pin again.

Keep the Press Bars opening until the Right side door is closed.

5. Close the Right side door, and then lock the Right side door with the key.

Caution

• There is a high-temperature area in the Tipper Unit.

To perform the above process, turn off the power and wait at least 1 hour until the Unit

has been completely cooled down to prevent your arms or hands from getting burned.

• When turning the Crankshaft, make sure the Emboss type is aligned to the Emboss pin.

(In the case when the emboss type is in the wrong position, the type may be damaged.)

• After completing the above process, make sure the following.

“Emboss type is aligned to Emboss pin.”

“Press Bars has left opened.”

Press Bar

Crankshaft

Press Bar

44

Page 52

Removing the card remaining in Card Insertion/Exit Slot

1. If a card was not ejected completely from the Card Insertion/Exit Slot, pull out the card by hand.

Card

Insertion/Exit

Slot

2. Remove the card according to the pro cedure “Remov e the card in Main Transfer Unit” on page 30 when

you cannot pull the card out by hand.

Pull

Remaining

Card

45

Page 53

Cleaning

Cleaning Thermal Print Head

If you find stain or contamination on the issued cards, clean the Thermal Print Head with a Cleaning pen

(sold separately).

1. Unlock the Top Cover by turning the key clockwise during the power on, and then open the Top Cover.

The buzzer will beep, and the following error message will be indicated on the Main display.

CV402 Top / Side

2. Push the Print /Encode Unit Cover Open Button to open the cover.

Turn this key clockwise.

Print /Encode Unit

Print /Encode Unit Cover Open Button

Open Top Cover.

Open Print /Encode Unit cover.

Thermal Print Head

46

Page 54

3. Clean the Thermal Print Head by using a Cleaning pen.

Reference

• Recap the pen after cleaning for reuse.

Caution

• Do not touch the Thermal Print Head with your fingers.

4. Wind the unused side of the Thermal Transfer Ribbon counter-clockwise to remove the slack.

Unused side Used side

5. Close the Print /Encode Unit cover until it clicks.

Caution

• Before closing the Print /Encode Unit cover, make sure the alcohol on the Thermal Print

Head has evaporated.

Wind the ribbon

Thermal Transfer Ribbon

47

Page 55

6. Push the RIBBON SET button.

“RIBBON SET” button

8. Close the top cover, and then lock the top cover with the key.

• Do not forget to push "RIBBON SET" button after installing a new ribbon. Otherwise, a print

• Be sure to remove the slack of the Thermal Transfer Ribbon before closing the cover. The slack

Caution

failure will occur.

will adversely affect the print quality.

48

Page 56

Washing Cleaning Roller

Cleaning roller will remove stain or contamination on cards and will get dirty gradually. If you find stain or

contamination on the issued cards, wash the Cleaning roller. We recommend washing the Cleaning roller

when replacing the Thermal Transfer Ribbon.

1. Unlock the Top Cover by turning the key clockwise during the power on, and then open the Top Cover.

The buzzer will beep, and the following error message will be indicated on the Main display.

CV402 Top / Side

2. Push the Print/Encode Unit Cover Open Button to open the cover.

Turn this key clockwise.

Print /Encode Unit Cover Open Button

Open Top Cover.

Open Print /Encode Unit cover. Print /Encode Unit

49

Page 57

3. Detach the Thermal Transfer Ribbon from the Print /Encode Unit.

4. Remove the Cleaning roller from the Print /Encode Unit.

5. Wash the Cleaning roller with running water.

6. Install the Cleaning roller to Print /Encode Unit after drying.

Cleaning roller

Detach this side first to take out the Cleaning Roller

50

Page 58

r

7. Reattach the Thermal Transfer Ribbon as shown in the picture below and remove the slack of the

ribbon.

Unused side Used side

8. Close the Print /Encode Unit cover until it clicks.

9. Push RIBBON SET button.

“RIBBON SET” button

10. Close the top cover, and then lock the top cover with the key.

• Do not forget to push "RIBBON SET" button after installing a new ribbon. Otherwise, a print

• Be sure to remove the slack of the Thermal Transfer Ribbon before closing the cover. The slack

Caution

failure will occur.

will adversely affect the print quality.

Turn unused side of the ribbon

counte

-clockwise to remove the slack

Thermal Transfer Ribbon

51

Page 59

Cleaning Card transfer rollers

1. Turn the power OFF, and open the Right side door by turning the key clockwise.

Vertical Rotation Unit

Turn this key clockwise

Main Transfer Unit

Open Right side door

52

Page 60

2. Clean the Card transfer rollers on the Main Transfer Unit.

Clean the two Drive Rollers (lower side) and the two Passive Rollers (upper side) while turning the knob.

Use a waste cloth or a cotton swab absorbed with Ethanol.

3. Clean the Card transfer rollers on the Vertical Rotation Unit.

Clean the Drive Roller and the three Passive Rollers while turning the white gear.

Use a waste cloth or a cotton swab absorbed with Ethanol.

Drive Roller

Passive Rollers

Drive Rollers

Passive Roller

Gear

Knob

53

Page 61

Specifications

The following specifications may be changed without notice.

General Specifications

Name Card Printer & Embosser

Model Advantage M8

Usable card

(Allocable PVC Card)

Connection Interface

Display

Input Hopper

Out Stacker

Rejected Cards

Card Counter

Magnetic stripe / IC : ISO 7810 ID-1

* Height of warped card must be less than 1mm including thickness of the card.

USB2.0(Full Speed) (cable 3m in length or less)

LAN 10BASE-T/100BASE-TX

Liquid Crystal Display(16 digits ×1 line)Character back light

Number of cassettes 2 (*Option total 5 cassettes are available.)

6 (3 hoppers per cassette)

(*When setting optional cassettes:

Number of hoppers

Input Hopper Capacity

Card Presence Detection Out of Card detection

Manual insert mode Available

Output Stacker Capacity Approximately 20 cards

Card presence detection Card-full detection

Reject stacker capacity Approximately 25 cards

Card presence detection Card-full detection

Resettable Software counter

Non resettable Mechanical counter

3 cassettes are set : 9

4 cassettes are set : 12

5 cassettes are set : 15)

300 cards (50 cards per hopper)

(*When setting optional cassettes:

3 cassettes are set : 450 cards

4 cassettes are set : 600 cards

5 cassettes are set : 750 cards.)

Dimensions 456mm (W) x 658mm (H) x 771mm (D)

Weight

Power voltage AC220 - 230V 3.0A 50Hz/60Hz AC100 - 120V 4.5A 50Hz/60Hz

User environment

Security

Applicable Standard

* About option, please contact your distributor.

54

81kg(including 2 Hopper cassettes)* excluding card weight

Operating environment

Temperature 10 to 32 degrees Celsius

Humidity 20 to 65% R.H(non-condensing)

Guaranteed accuracy environment

Temperature 18 to 28

Humidity 40 to 65% R.H.(non-condensing)

Key lock for Front Cover, Right side door and Top Cover (Same for all key rocks)

Software rock (Front)

Key lock for Hopper cassette (Same for all key rocks)

Safety : CE marking (Low Voltage), EMC : CE marking(EMC), FCC Class A

degrees Celsius

Page 62

Embosser Specifications

Emboss ISO 7811-1

Emboss printing

type capacity

54 characters (standard) 80 characters at maximum (Including indent

printing types.)

Alphabet (10 CPI) 26 characters “A to Z”

Emboss printing

character type

Possible emboss area

Emboss cross-feed pitch

Indent printing

character type

Indent Film Detection Film-end detection

Possible Indent area

Tipper Foil color Silver, (Gold)

Tipping Foil Detection Foil-end detection

Number (10 CPI) 10 characters “0 to 9”

Number (7 CPI) 10 characters “0 to 9” (OCR-7B)

Symbol (10 CPI) 8 characters “- / . ' , ( ) &”

Lower limit:(5.1 ㎜ from lower end of the card to character center line)

Upper limit:(21.4 ㎜ from lower end of the card to character center line)

Left limit:(7.7 ㎜ from left end of the card to character center line)

Right limit:(75.5 ㎜ from left end of the card to character center line)

1/7inch(Up to 19 digits can be embossed)

1/10inch(Up to 27 digits can be embossed)

10 characters “0 to 9” (OCR-B (14CPI)) (*Option Reverse italic)

Lower limit:(15.2 ㎜ from lower end of the card to character center line)

Upper limit:(37.8 ㎜ from lower end of the card to character center line)

Left limit:(3.7 ㎜ from left end of the card to character center line)

Right limit:(81.3 ㎜ from left end of the card to character center line)

Tipper heater

warm up time

Within 6 minutes

Encoder Specifications

Magnetic Stripe Encode ISO 7811-2/-6(T rack 1, 2, 3: Hi-Co &Lo-Co )

IC Encode ISO 7816 , EMV Level 1 and PBOC 3.0

Contactless IC Encode Mifare® standard, ISO-14443A&B

Printer Specifications

Print Mode

Print Side Dual side

Print resolution 300dpi

Color(Dye-sublimation), Mono(Thermal transfer)

Restriction of Usable card

Cannot print on not flat area such as signature panel or hologram sheet.

55

Page 63

User environment

100%

80%

60%

40%

20%

Temperature ×Humidity = 900

0%

0°C 10°C 20°C 30°C 40°C

Guaranteed

accuracy

environmen

Operating environment

Guaranteed

accuracy

environment

Operating

environment

Temperature

Humidity 40 to 65% R.H.

Temperature 10 to 32 degrees

Humidity 20 to 65% R.H.

18 to 28 degrees

Celsius

Celsius

56

Page 64

Specifications are subject to change without notice.

Advantage M8 Operation Manual

Sales origin : NBS Technologies Inc.

Manufacturer : NBS Card Corporation

Advantage M8-UM-153

June 7, 2018 4rd edition

57

Loading...

Loading...