Granville-Phillips - AKA Brooks 275 User Manual

Series 275

Granville-Phillips® Series 275

®

Mini-Convectron

Vacuum Gauge Module

with Nonlinear Analog Outputs and Process

Control Relays

Instruction Manual

Instruction manual part number 275512

Revision A - February 2013

Series 275

Granville-Phillips® Series 275

®

Mini-Convectron

Vacuum Gauge Module

with Nonlinear Analog Outputs and Process

Control Relays

This Instruction Manual is for use with all Granville-Phillips Series

275 Mini-Convectron Vacuum Gauge Modules With Nonlinear

Analog Outputs and Process Control Relays. A list of applicable

catalog numbers is provided on the following page.

Customer Service/Support

For customer service within USA, 8 AM to 5 PM

Mountain Time Zone, weekdays excluding holidays:

Granville-Phillips

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: +1-800-776-6543

Phone: +1-303-652-4400

FAX: +1-303-652-2844

Email: co-csr@brooks.com

Brooks Automation, Inc.

15 Elizabeth Drive

Chelmsford, MA 01824 USA

Phone: +1-978-262-2400

For customer service, 24 hours per day, 7 days per week,

every day of the year including holidays within the USA:

Phone: +1-800-367-4887

www.brooks.com

Instruction Manual

© 2013 Brooks Automation. All rights reserved.

Granville-Phillips

All other trademarks and registered trademarks are the properties of their respective owners.

®

and Convectron

®

are registered trademarks of Brooks Automation, Inc.

Catalog numbers for Series 275 Mini-Convectron Modules (CE Marked)

With electrical connector. Operating power: 11.5 Vdc to 26.5 Vdc

Mini-Convectron Module with one setpoint relay

1/8 NPT / 1/2 inch tubulation 275800-EU

1/4 inch VCR-type female fitting 275801-EU

1/2 inch VCR-type female fitting 275863-EU

3/8 inch VCO-type male fitting 275802-EU

1.33 inch (NW16CF) ConFlat-type flange 275803-EU

2.75 inch (NW35CF) ConFlat-type flange 275804-EU

NW16KF flange 275806-EU

NW25KF flange 275807-EU

NW40KF flange 275808-EU

Mini-Convectron Module with two setpoint relays

1/8 NPT / 1/2 inch tubulation 275870-EU

1/4 inch VCR-type female fitting 275871-EU

1/2 inch VCR-type female fitting 275867-EU

3/8 inch VCO-type male fitting 275872-EU

1.33 inch (NW16CF) ConFlat-type flange 275873-EU

2.75 inch (NW35CF) ConFlat-type flange 275874-EU

NW16KF flange 275876-EU

NW25KF flange 275877-EU

NW40KF flange 275878-EU

Mini-Convectron Module with two setpoint relays and 3-digit digital display

Display in Torr

1/8 NPT / 1/2 inch tubulation 275904-EU

1/4 inch VCR-type female fitting 275905-EU

1/2 inch VCR-type female fitting 275906-EU

3/8 inch VCO-type male fitting 275907-EU

1.33 inch (NW16CF) ConFlat-type flange 275908-EU

2.75 inch (NW35CF) ConFlat-type flange 275909-EU

NW16KF flange 275911-EU

NW25KF flange 275912-EU

NW40KF flange 275913-EU

Display in Pascal

1/8 NPT / 1/2 inch tubulation 275904-EU-P

1/4 inch VCR-type female fitting 275905-EU-P

1/2 inch VCR-type female fitting 275906-EU-P

3/8 inch VCO-type male fitting 275907-EU-P

1.33 inch (NW16CF) ConFlat-type flange 275908-EU-P

2.75 inch (NW35CF) ConFlat-type flange 275909-EU-P

NW16KF flange 275911-EU-P

NW25KF flange 275912-EU-P

NW40KF flange 275913-EU-P

Table of Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 About These Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Caution and Warning Statements . . . . . . . . . . . . . . . . . . . . 8

1.4 System Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Implosion / Explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7 Reading and Following Instructions . . . . . . . . . . . . . . . . . . 10

Chapter 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Module Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Installing Pressure Relief Devices . . . . . . . . . . . . . . . . . . . . 12

2.3 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Step 1 Locate and orient the module . . . . . . . . . . . . . . . . . . . . . . . 13

Locate the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Orient the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Step 2 Attach the module to the vacuum chamber . . . . . . . . . . . . . 16

1/8 NPT pipe thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

VCR type fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

KF flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

ConFlat flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Step 3 Assemble and connect the wiring . . . . . . . . . . . . . . . . . . . . 17

Connecting Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Step 4 Configure the setpoint relays for the application . . . . . . . . . 19

Step 5 Calibrate the Convectron gauge . . . . . . . . . . . . . . . . . . . . . 19

Atmospheric Pressure Calibration . . . . . . . . . . . . . . . . . . . . 19

Vacuum Chamber Pressure Calibration . . . . . . . . . . . . . . . . 19

Chapter 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 Preparing to Operate the Module . . . . . . . . . . . . . . . . . . . . 21

3.2 Nonlinear Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Commonly used Gases Other than N2 or Air . . . . . . . . . . . . 26

Other Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 Setpoint Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Preparing to Adjust Setpoint Relays . . . . . . . . . . . . . . . . . . . 38

Adjusting Setpoint Relays . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.4 Reading Relay Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5 Calibrating Convectron Gauge at Atmospheric Pressure . . . 42

3.6 Calibrating Convectron Gauge at Vacuum Chamber Pressure 44

3.7 Modules Operating at Low Pressure . . . . . . . . . . . . . . . . . . 44

3.8 Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 5

Table of Contents

Chapter 4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Symptoms, Causes, and Solutions . . . . . . . . . . . . . . . . . . . . 49

4.3 Convectron Gauge Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.4 Convectron Gauge Removal and Replacement . . . . . . . . . . 51

Removing the Convectron Gauge . . . . . . . . . . . . . . . . . . . . 51

Replacing the Convectron Gauge . . . . . . . . . . . . . . . . . . . . 51

4.5 Returning a Product for Repair . . . . . . . . . . . . . . . . . . . . . . 52

Appendix A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix B Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

Chapter 1 Before You Begin

1.1 About These Instructions These instructions explain how to install, operate, and maintain the

Granville-Phillips® Mini-Convectron® vacuum gauge module.

• This chapter explains caution and warning statements, which must be

adhered to at all times; explains your responsibility for reading and

following all instructions; defines the terms “module” and “Convectron

gauge”; and tells you how to contact customer service.

• Chapter 2 explains how to install the module.

• Chapter 3 explains how to operate the module, which has two

programmable setpoint relays.

• Chapter 4 explains troubleshooting, Convectron gauge testing, removal

and replacement, and module return procedures.

• Appendix A provides specifications for the module.

• Appendix B explains terminology and explains how the Convectron

convection-enhanced Pirani heat-loss gauge measures pressure.

Table 1-1 Terms Describing the Mini-Convectron Module and Components

Term Description

Module The Mini-Convectron vacuum gauge module, which contains a Convectron

convection-enhanced Pirani heat-loss pressure gauge.

Convectron gauge The Convectron convection-enhanced Pirani heat-loss gauge, which measures

pressure within the vacuum chamber

Before You Begin Installation Operation Maintenance

1.2 Customer Service For customer service:

• Phone 1-303-652-4400 or 1-800-776-6543 within USA

• Phone 1-800-367-4887 24 hours per day, 7 days per week within the

USA

• Email co-csr@brooks.com

• For Global Customer Support, go to www.brooks.com and click on

Services to locate the Brooks Automation office nearest you.

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 7

Chapter 1

CAUTION

WARNING

1.3 Caution and Warning Statements

This manual contains caution and warning statements with which you must

comply to prevent inaccurate measurement, property damage, or personal

injury.

Caution statements alert you to hazards or unsafe

practices that could result in minor personal injury or

property damage.

Each caution statement explains what you must do to prevent or

avoid the potential result of the specified hazard or unsafe

practice.

Warning statements alert you to hazards or unsafe

practices that could result in severe property damage or

personal injury due to electrical shock, fire, or explosion.

Each warning statement explains what you must do to prevent

or avoid the potential result of the specified hazard or unsafe

practice.

Caution and warning statements comply with American Institute of

Standards Z535.1–2002 through Z535.5–2002, which set forth voluntary

practices regarding the content and appearance of safety signs, symbols,

and labels.

Each caution or warning statement explains:

a. The specific hazard that you must prevent or unsafe practice that you

must avoid,

b. The potential result of your failure to prevent the specified hazard or

avoid the unsafe practice, and

c. What you must do to prevent the specified hazardous result.

1.4 System Grounding Grounding, though simple, is very important! Be certain that ground

circuits are correctly used on your ion gauge power supplies, gauges, and

vacuum chambers, regardless of their manufacturer. Safe operation of

vacuum equipment, including the Mini-Convectron Module, requires

grounding of all exposed conductors of the gauges, the controller and the

vacuum system. LETHAL VOLTAGES may be established under some

operating conditions unless correct grounding is provided.

8 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

Before You Begin

Ion producing equipment, such as ionization gauges, mass spectrometers,

sputtering systems, etc., from many manufacturers may, under some

conditions, provide sufficient electrical conduction via a plasma to couple

a high voltage electrode potential to the vacuum chamber. If exposed

conductive parts of the gauge, controller, and chamber are not properly

grounded, they may attain a potential near that of the high voltage electrode

during this coupling. Potential fatal electrical shock could then occur

because of the high voltage between these exposed conductors and ground.

1.5 Implosion / Explosion Danger of injury to personnel and damage to equipment exists on all

vacuum systems that incorporate gas sources or involve processes capable

of pressuring the system above the limits it can safely withstand.

For example, danger of explosion in a vacuum system exists during

backfilling from pressurized gas cylinders because many vacuum devices

such as ionization gauge tubes, glass windows, glass belljars, etc., are not

designed to be pressurized.

Do not attach cables to glass gauge pins while the gauge is under vacuum.

Accidental bending of the pins may cause the glass to break and implode.

Cables, once installed, should be secured to the system to provide strain

relief for the gauge tube pins.

Install suitable devices that will limit the pressure from external gas sources

to the level that the vacuum system can safely withstand. In addition, install

suitable pressure relief valves or rupture disks that will release pressure at a

level considerably below that pressure which the system can safely

withstand.

Suppliers of pressure relief valves and pressure relief disks are listed in

Thomas Register under "Valves, Relief", and "Discs, Rupture".

Confirm that these safety devices are properly installed before installing the

the Mini-Convectron Module. In addition, check that (1) the proper gas

cylinders are installed, (2) gas cylinder valve positions are correct on

manual systems, and (3) the automation is correct on automated systems.

Before You Begin Installation Operation Maintenance

1.6 Operation It is the installer's responsibility to ensure that the automatic signals

provided by the process control module are always used in a safe manner.

Carefully check manual operation of the system and the setpoint

programming before switching to automatic operation. Where an

equipment malfunction could cause a hazardous situation, always provide

for fail-safe operation. As an example, in an automatic backfill operation

where a malfunction might cause high internal pressures, provide an

appropriate pressure relief device.

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 9

Chapter 1

1.7 Reading and Following Instructions

You must comply with all instructions while you are installing, operating,

or maintaining the module. Failure to comply with the instructions violates

standards of design, manufacture, and intended use of the module.

Granville-Phillips and Brooks Automation disclaim all liability for the

customer's failure to comply with the instructions.

• Read instructions – Read all instructions before installing or operating the

product.

• Follow instructions – Follow all installation, operating and maintenance

instructions.

• Retain instructions – Retain the instructions for future reference.

• Heed warnings and cautions – Adhere to all warnings and caution

statements on the product and in these instructions.

Parts and accessories – Install only those replacement parts and accessories

that are recommended by Brooks Automation, Inc./Granville-Phillips.

Substitution of parts is hazardous.

10 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

Chapter 2 Installation

WARNING

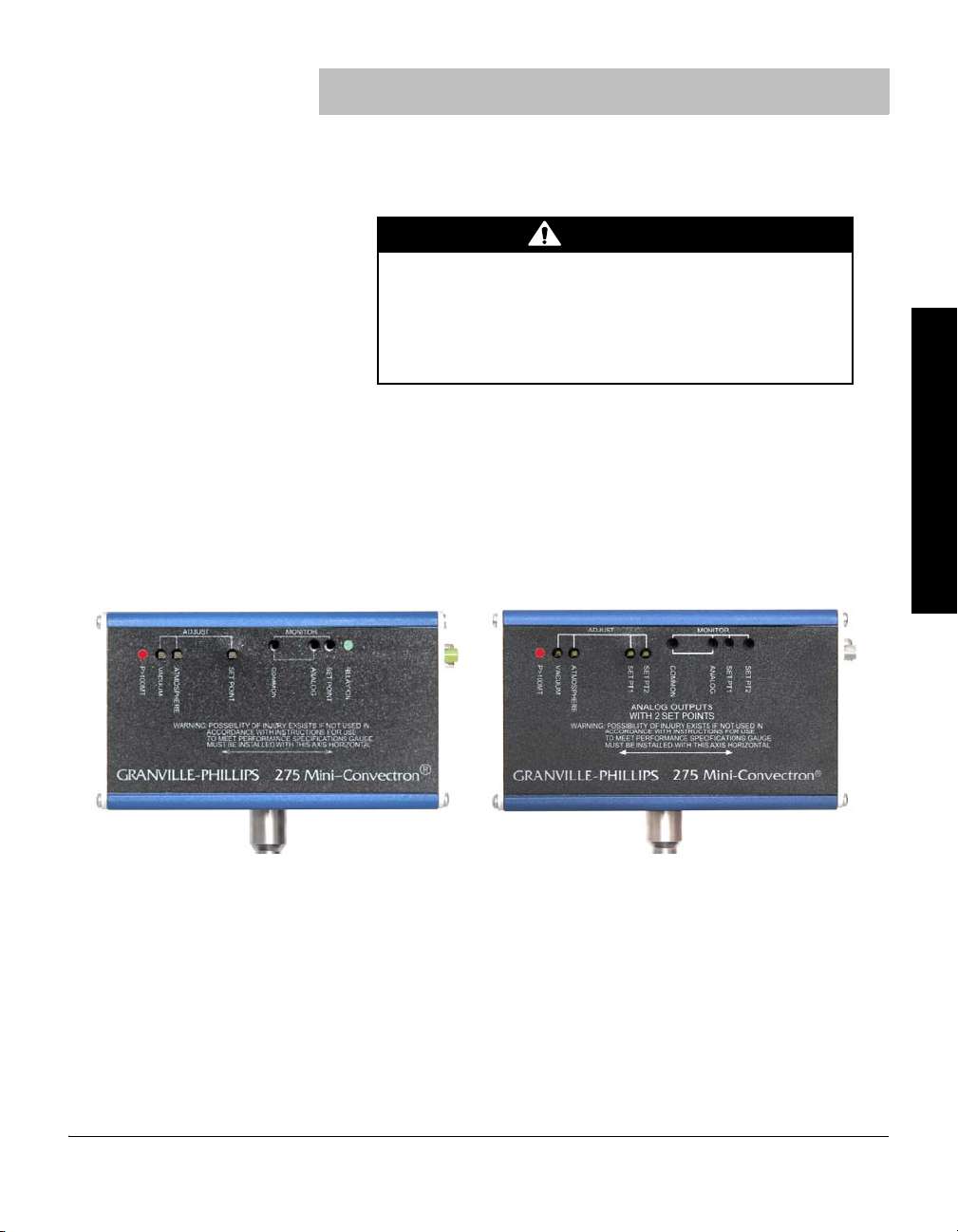

Mini-Convectron module with

one setpoint relay, no display

Mini-Convectron module with

two setpoint relays, no display

2.1 Module Components The Mini-Convectron module contains a Convectron convection-enhanced

Pirani heat-loss gauge.

Using the module to measure the pressure of flammable

or explosive gases can cause a fire or explosion resulting

in severe property damage or personal injury.

Do not use the module to measure the pressure of flammable or

explosive gases.

The module is shipped with an instrument screwdriver and a 15-pin female,

high-density subminiature D connector that mates to the male connector on

the module.

Figure 2-1 illustrates the module without the digital display. The module

without the display may have one setpoint relay or two setpoint relays.

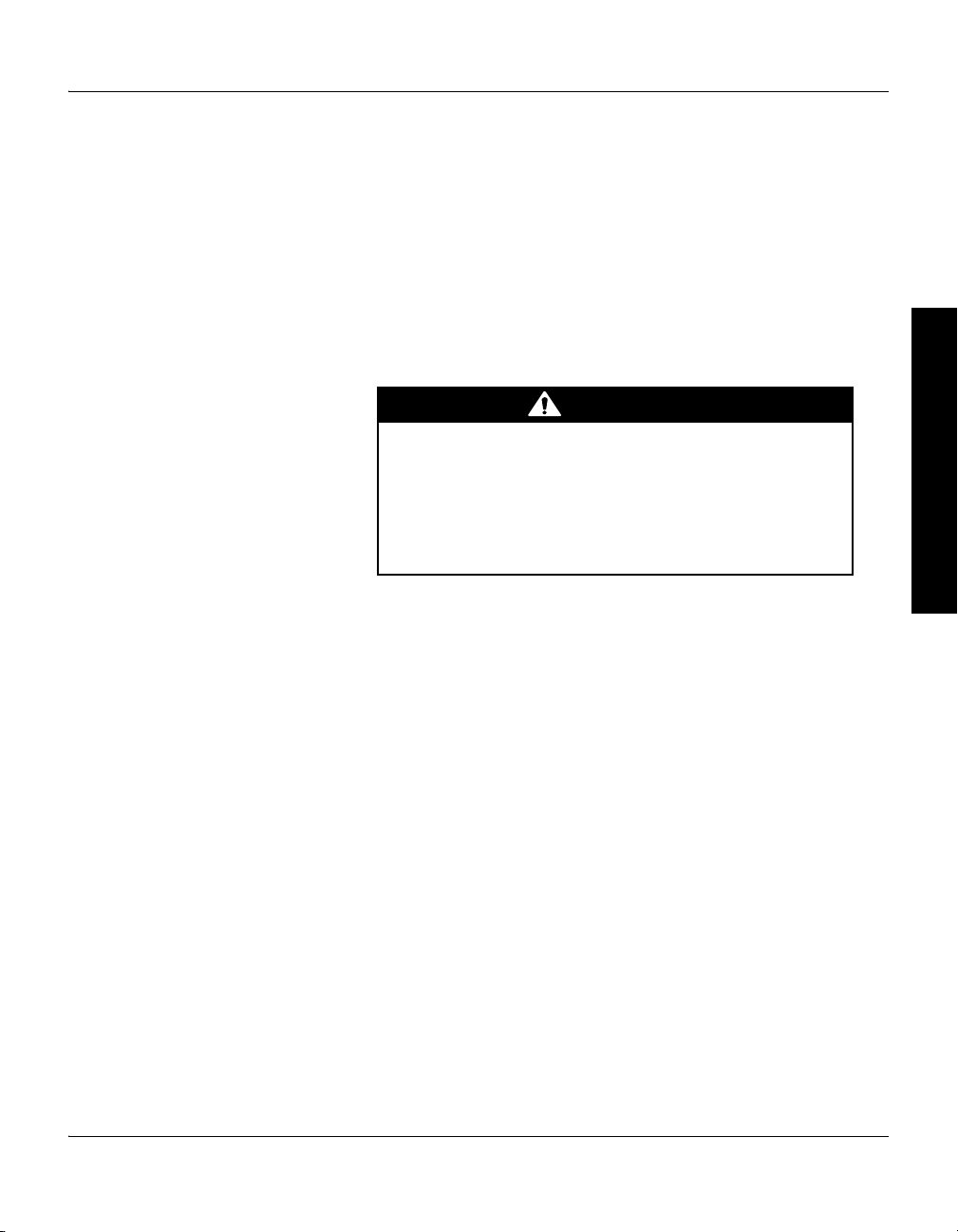

Figure 2-2 illustrates the module with the 3-digit digital display. The module

with the display has two setpoint relays.

Figure 2-1 Mini-Convectron Module without Digital Display

Before You Begin Installation Operation Maintenance

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 11

Chapter 2

CAUTION

Figure 2-2 Mini-Convectron Module with two Setpoint Relays and 3-Digit Digital Display

2.2 Installing Pressure Relief Devices

Before you install the module, install appropriate pressure relief devices in

the vacuum system.

Brooks Automation, Inc. does not supply pressure relief valves or rupture

disks. Suppliers of pressure relief valves and rupture disks are listed in the

Thomas Register under “Valves, Relief” and “Discs, Rupture.”

Operating the module above 1000 Torr (1333 mbar, 133

kPa) true pressure could cause pressure measurement

error or product failure.

To avoid measurement error or product failure due to

overpressurization, install pressure relief valves or rupture

disks in the system if pressure exceeds 1000 Torr (1333 mbar,

133 kPa).

12 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

2.3 Installation Procedure The module installation procedure includes the following steps:

WARNING

1. Locating and orienting the module.

2. Attaching the module vacuum chamber fitting to its mate on the

vacuum chamber.

3. Assembling and connecting module wiring.

4. Configuring the setpoint relays to the desired voltage levels.

5. Calibrating the Convectron gauge at atmospheric and vacuum

pressures.

Failure to use accurate pressure conversion data for N2

or air to other gases can cause an explosion due to

overpressurization.

If the module will measure any gas other than N2 or air, before

putting the module into operation, adjust setpoint relays for the

process gas that will be used.

Step 1 Locate and orient the module

To locate and orient the module, refer to Figure 2-3, Figure 2-4, and

Table 2-1, and follow the instructions below.

Installation

Before You Begin Installation Operation Maintenance

Locate the Module • For greatest accuracy and repeatability, locate the module in a stable,

room-temperature environment. Ambient temperature should never

exceed 40 °C (104 °F) operating, non-condensing, or 85 °C (185 °F)

non-operating.

• Locate the module away from internal and external heat sources and in

an area where ambient temperature remains reasonably constant.

• Do not locate the module where it requires long lengths of tubing or has

constricted tubing. Length of tubing depends on the application. Longer

tubing will affect vacuum pressure limit and response time.

• Do not locate the module near the pump, where gauge pressure might be

lower than normal vacuum chamber pressure.

• Do not locate the module near a gas inlet or other source of

contamination, where inflow of gas or particulates causes atmospheric

pressure to be higher than system atmosphere.

• Do not locate the module where it will be exposed to corrosive gases

such as mercury vapor or fluorine.

• Do not locate the module where it will vibrate. Vibration causes

convection cooling, resulting in inaccurate high pressure readings.

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 13

Chapter 2

11

(4.3)

4.1

(1.6)

6.4

(2.5)

5.5

(2.2)

Dim. H

Figure 2-3 Mini-Convectron Module Dimensions

Table 2-1 Mini-Convectron Vacuum Connections

Vacuum Connections Dim. H

cm in.

1/8 NPT pipe thread, ½-inch inside diameter 2.2 0.9

½-inch 4 VCR

®

type fitting, female 3.0 1.2

½-inch 8 VCR type fitting, female 3.9 1.5

NW16KF flange 3.1 1.2

NW25KF flange 3.1 1.2

NW40KF flange 3.7 1.5

1.33-inch (NW16CF) ConFlat

®

flange 3.8 1.5

2.75-inch (NW35CF) ConFlat flange 3.8 1.5

14 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

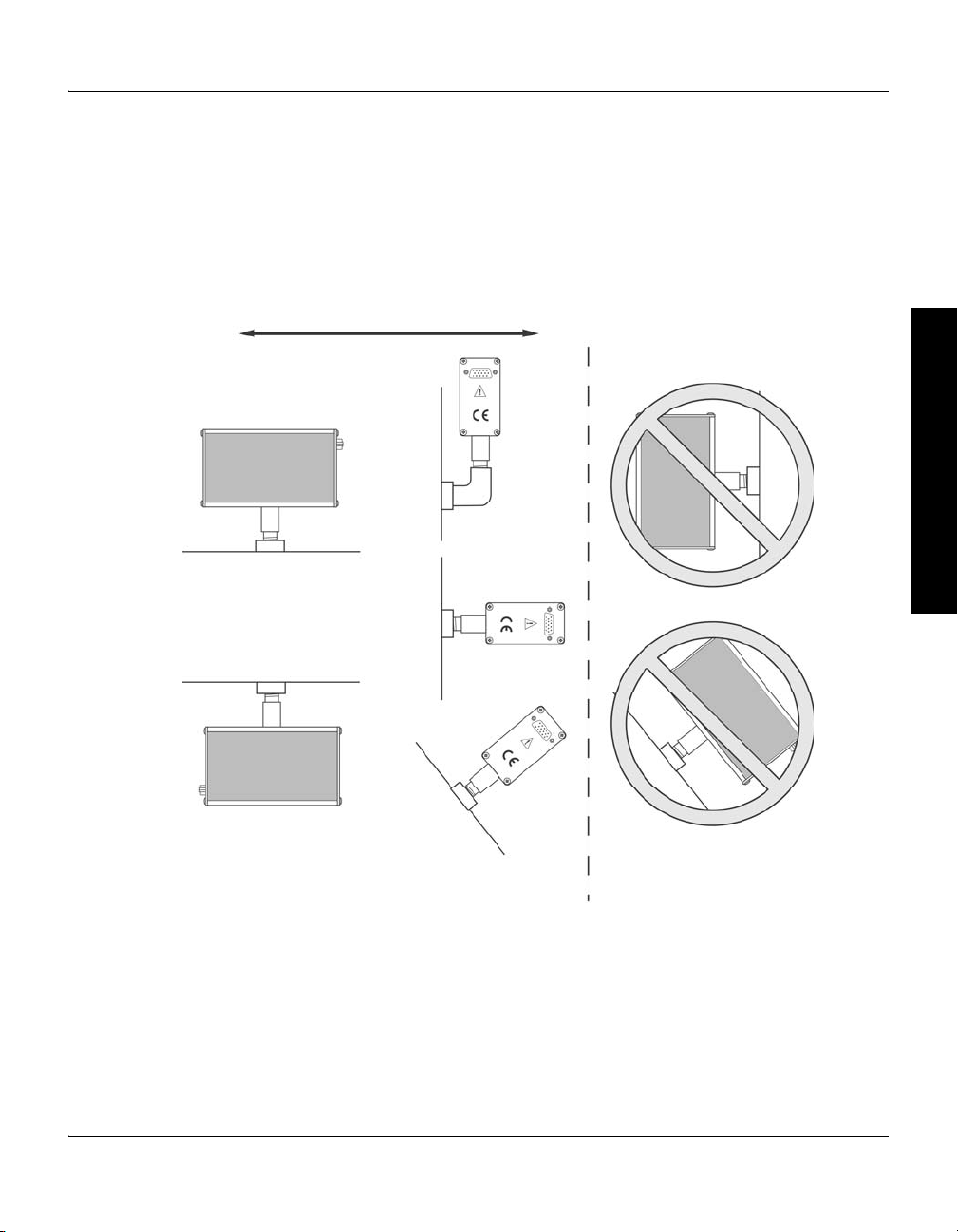

Orient the Module For proper operation of the module above 1 Torr, orient the module so the

Mount the Module Axis Horizontally to Ensure

Accurate Measurement Above 1 Torr

Vacuum chamber

Vacuum chamber

Vacuum chamberVacuum chamber

V

a

c

u

u

m

c

h

a

m

b

e

r

V

a

c

u

u

m

Vacuum

Recommended Not recommended

Figure 2-4 Module Orientation

Installation

Before You Begin Installation Operation Maintenance

axis is horizontal (see Figure 2-4). Although the Convectron gauge will read

correctly below 1 Torr with the module mounted in any position, inaccurate

readings will result at pressures above 1 Torr if the module axis is not

horizontal.

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 15

Chapter 2

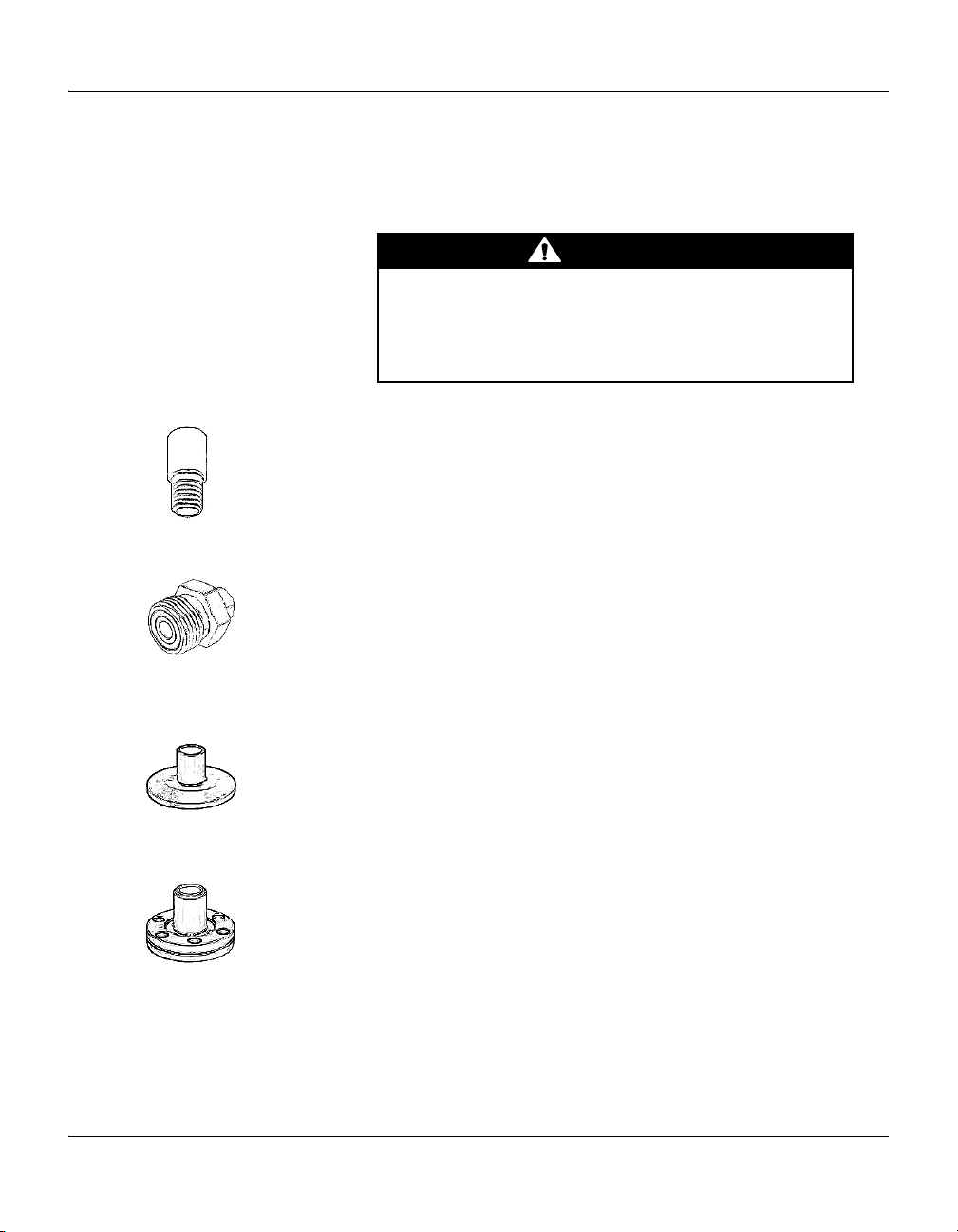

CAUTION

Step 2 Attach the module to the vacuum chamber

Attach the module vacuum chamber fitting to its mate on the vacuum

chamber.

Twisting the module to tighten the fitting to the vacuum

chamber can damage the module’s internal connections.

• Do not twist the module to tighten the fitting.

• Use appropriate tools to tighten the fitting.

1/8 NPT pipe thread The 1/8 NPT pipe thread accommodates a standard 1/8 NPT female fitting.

a. Wrap the threads of the port to the vacuum chamber with thread seal

tape.

b. Without using a wrench or other tool, tighten the module just enough

to achieve a seal.

VCR type fitting a. Remove the plastic or metal bead protector cap from the fitting.

b. If a gasket is used, place the gasket into the female nut.

c. Assemble the components and tighten them to finger-tight.

d. While holding a back-up wrench stationary, tighten the female nut 1/8

turn past finger-tight on 316 stainless steel or nickel gaskets, or 1/4 turn

past finger-tight on copper or aluminum gaskets.

KF flange The KF mounting system requires O-rings and centering rings between

mating flanges.

a. Tighten the clamp to compress the mating flanges together.

b. Seal the O-ring.

ConFlat flange To minimize the possibility of leaks with ConFlat flanges, use high strength

stainless steel bolts and a new, clean OFHC copper gasket. Avoid

scratching the seal surfaces. To avoid contamination, install metal gaskets.

a. Finger tighten all bolts.

b. Use a wrench to continue tightening 1/8 turn at a time in crisscross

order (1, 4, 2, 5, 3, 6) until flange faces make contact.

c. Further tighten each bolt about 1/16 turn.

16 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

Step 3 Assemble and connect the wiring

Analog output 5

Power ground 4

11.5–26.5 VDC power input 3

Setpoint 2 adjust 2

Setpoint 1 adjust 1

15 Relay 1 common

14 Relay 1 normally closed

13 Relay 2 normally closed

12 Relay 2 common

11 Relay 2 normally open

10 Relay 1 normally open

9 Relay disable

8 No connection

7 No connection

6 Signal common

Analog output 5

Power ground 4

11.5–26.5 VDC power input 3

Relay normally closed 2

Relay normally open 1

9 Setpoint output

8 Signal common

7 Relay disable

6 Relay common

Connecting Cable The cable is user-supplied. Brooks Automation does not supply the cable.

Install externally shielded cable and connect the shield at both ends.

At the module end of the cable, connect the shield to the outer shell of the

subminiature D connector.

On both versions of the module, connect the 11.5 to 26.5 Vdc power

supply to terminals 3 and 4.

• Terminal 4 (ground) is negative (–).

• Terminal 3 (input) is positive (+).

For grounding instructions, see page 18.

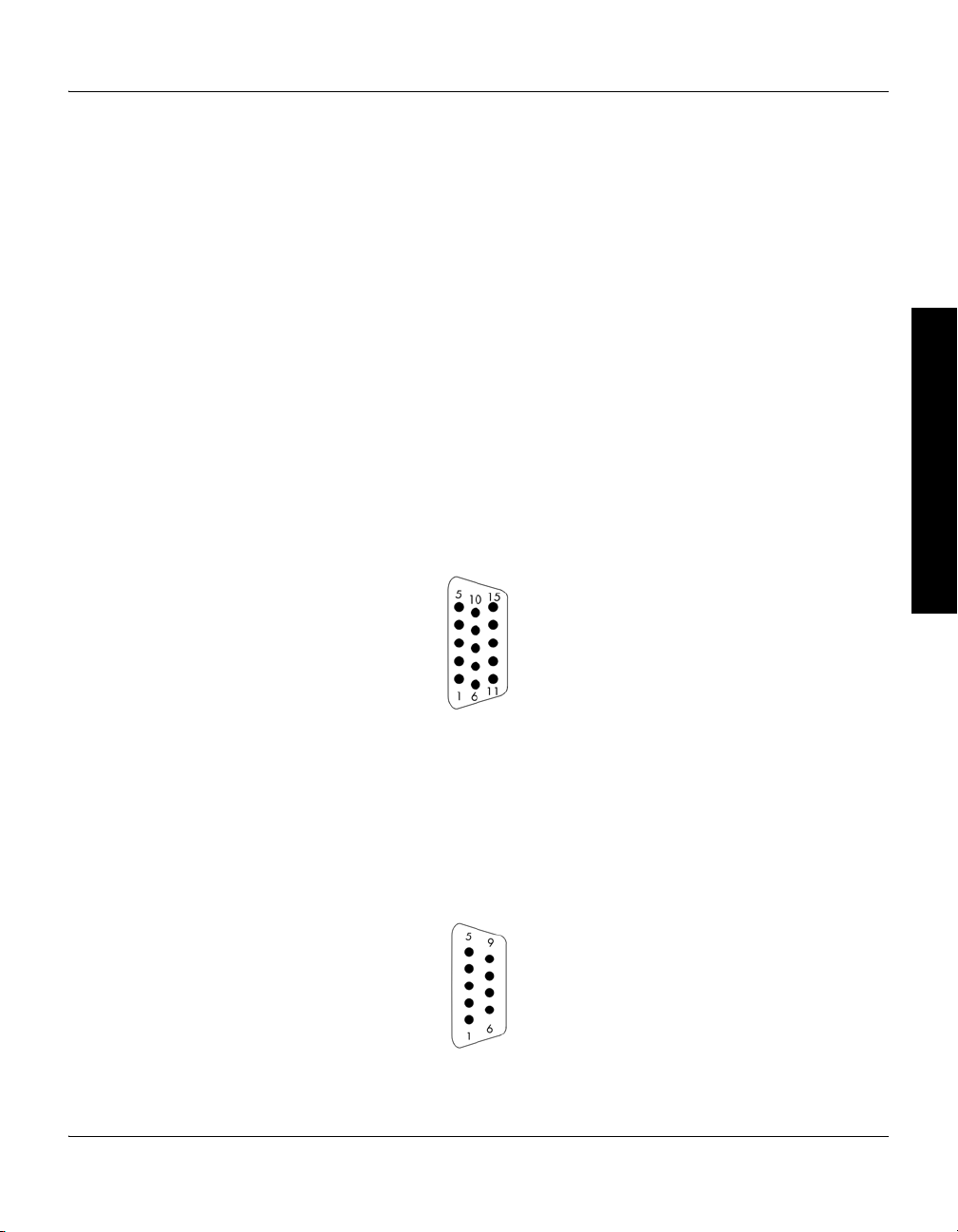

Wiring Terminals Figure 2-5 illustrates the 15-pin D subminiature wiring terminals for the

module with two setpoint relays.

Figure 2-6 illustrates the 9-pin D subminiature wiring terminals for the

module with one setpoint relay.

Figure 2-5 15-Pin Connector for Module with two Setpoint Relays

Installation

Before You Begin Installation Operation Maintenance

Figure 2-6 9-Pin Connector for Module with one Setpoint Relay

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 17

Chapter 2

WARNING

Metal hose clamp or other metal clamp

3.00 mm

2

(12 AWG) or larger ground wire

Fitting

Vacuum Chamber

Ground lug, bolt, or stud

Gauge stem

Grounding

Improper grounding could cause product failure,

property damage, or serious personal injury.

To reduce the risk of product failure, property damage, or

serious personal injury, follow ground network requirements

for the facility.

• Maintain all exposed conductors at earth ground.

• Ground the module housing to the vacuum chamber as

instructed below.

• Make sure the vacuum port to which the module is mounted

is properly grounded.

If the fitting allows continuous metal-to-metal contact between the housing

base and the vacuum chamber, the module is properly grounded via the

fitting. If the fitting requires a rubber gasket, rubber O-ring, Teflon tape, or

other material that prevents metal-to-metal contact between the housing

base and the vacuum chamber, refer to Figure 2-7 and follow these

instructions to ground the module to the vacuum chamber:

a. Attach a metal hose clamp or other metal clamp to the gauge stem of

the housing.

2

b. Install a 3.31 mm

(12 AWG) or larger copper wire between the clamp

and a metal ground lug, bolt, or stud on the vacuum chamber.

Figure 2-7 Ground Connection to the Vacuum Chamber

18 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

Installation

WARNING

Step 4 Configure the setpoint relays for the application

To configure setpoint relays for the module, see pages 34–41.

If the module will measure the pressure of a gas other than N

or air, you

2

must adjust relay setpoints for the process gas. The true pressure of a gas

other than N2 or air may be substantially different from the pressure that the

output indicates. For example, outputs might indicate a pressure of 10 Torr

(1.33 kPa, 13.3 mbar) for argon, although the true pressure of the argon is

250 Torr (33.3 kPa, 333.3 mbar). Such a substantial difference between

indicated pressure and true pressure can cause overpressurization resulting

in an explosion.

Failure to use accurate pressure conversion data for N2

or air to other gases can cause an explosion due to

overpressurization.

If the module will measure any gas other than N2 or air, before

connecting relays to system control devices, adjust setpoints for

the process gas that will be used.

Step 5 Calibrate the Convectron gauge

Before You Begin Installation Operation Maintenance

Calibration improves the accuracy and repeatability of the Convectron

gauge. To calibrate the Convectron gauge, see pages 42–44.

Atmospheric Pressure Calibration

An atmospheric calibration is performed on the Convectron gauge, using

, at the factory before the module is shipped. The factory calibration sets

N

2

the atmospheric calibration point to 760 Torr (101.3 kPa, 1013 mbar) of N2.

Because performance varies depending on the process gas, you may wish

to reset the atmospheric calibration point if a gas other than N

or air is

2

being used. Periodic resets of the atmospheric calibration point also

improve the accuracy and repeatability of the Convectron gauge near

atmospheric pressure, even if the process gas is N

Vacuum Chamber Pressure Calibration

Mini-Convectron Module Instruction Manual - 275512 - Rev. A 19

Periodic resets of the vacuum chamber pressure calibration point improve

the accuracy and repeatability of the Convectron gauge.

or air.

2

20 Mini-Convectron Module Instruction Manual - 275512 - Rev. A

Loading...

Loading...