Granville-Phillips Series 354 Instruction Manual

Series 354

Granville-Phillips® Series 354 Micro-Ion

Vacuum Gauge Module with

RS-485 Digital Interface

®

Instruction Manual

Instruction manual part number 354008

Revision C - September 2014

Series 354

Granville-Phillips® Series 354 Micro-Ion

®

Vacuum Gauge Module with

RS-485 Digital Interface

This instruction manual is for use with Granville-Phillips

Series 354 Micro-Ion Vacuum Gauge Modules with

RS-485 Digital Interface. A list of applicable catalog

numbers is provided on the following page.

For Customer Service or Technical Support 24 hours per day,

7 days per week, every day of the year including holidays:

Phone: +1-800-227-8766 or +1-303-652-4691

MKS, Granville-Phillips Division

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: 1-303-652-4691 or 1-800-776-6543

FAX: 1-303-652-2844

Email: gp-csr@mksinst.com

Corporate Office

MKS Instruments, Inc.

2 Tech Drive, Suite 201

Andover, MA 01810 USA

Phone: 1-978-645-5500

www.mksinst.com

Instruction Manual

© 2014 MKS Instruments, Inc. All rights reserved.

Granville-Phillips

All other trademarks and registered trademarks are the properties of their respective owners.

®

and Micro-Ion® are registered trademarks of MKS Instruments, Inc.

Granville-Phillips® Series 354 Micro-Ion

®

Vacuum Gauge Module with RS-485 Digital Interface

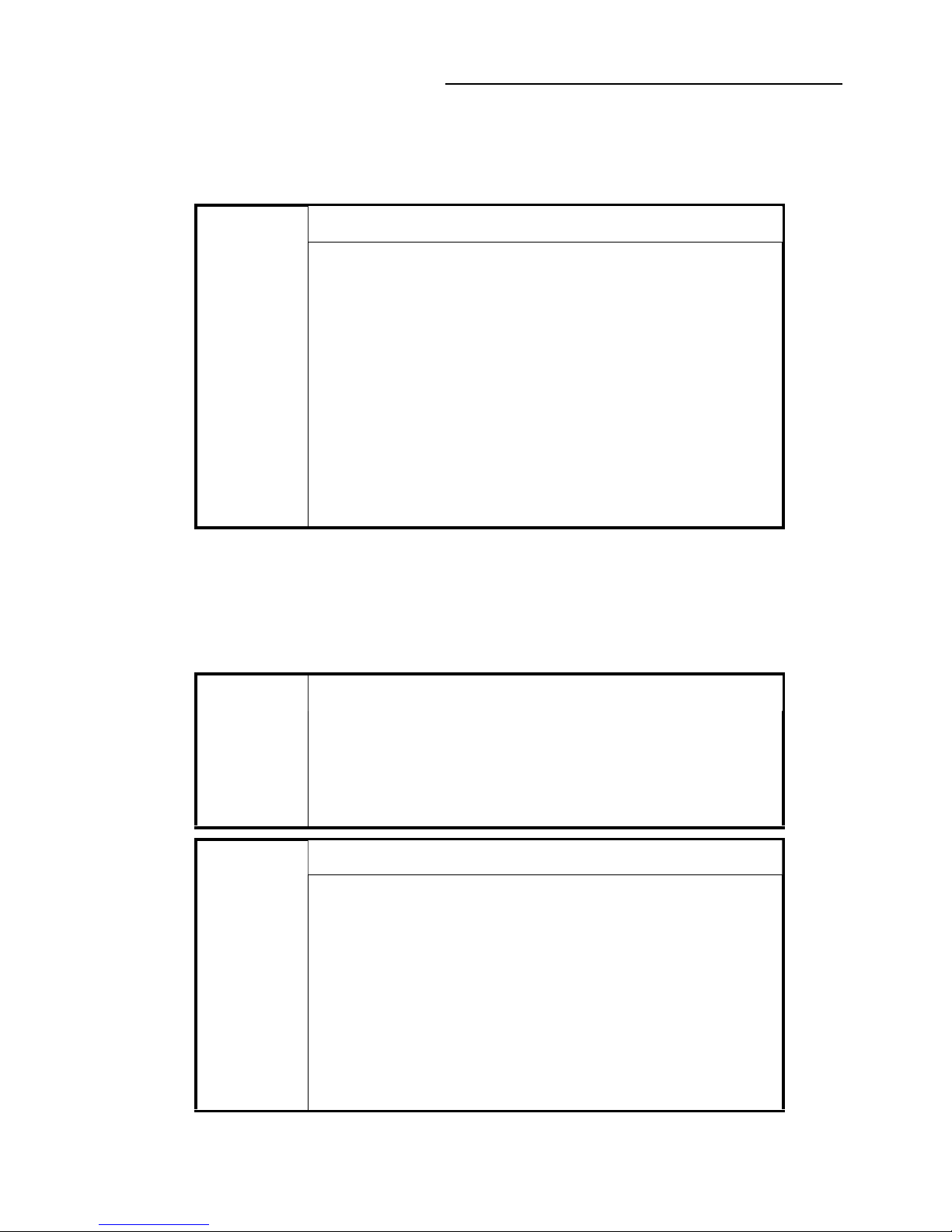

Catalog numbers for Series 354 Micro-Ion Modules

Power supply and cable are not included.

RS-485 interface, 1 setpoint relay:

Same as 354005, but with Varian Syntax (Torr only)

RS-485 interface, 1 setpoint relay:

Same as 354005, but with 90 Degree elbow (Torr only) 20

RS-485 interface, 1 setpoint relay:

No digital display (Torr Only

Filaments:

dual yttria-coated iridium Y

dual tungsten T

Flange/Fitting:

NW16KF D

NW25KF E

NW40KF K

1.33 inch (NW16CF) Conflat-type F

2.75 inch (NW35CF) Conflat-type G

1/2 inch VCR-type male H

NW16KFL M

NW40KFL L

NW25KFL N

354029 - Y E - T

354017

354005 - X X - T

Table of Contents

Chapter 1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 International Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6 FCC Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Safety Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Over-Pressure Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 System and Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Power Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5 Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.1 Power Indicator Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.2 Address Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.3 Input/Output Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.4 Mounting Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.7 Emission Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.8 Overpressure Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.9 Degas Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 4 Installation and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3 I/O Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4.1 Firmware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4.1.1 Resetting the Data Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.5 Calculating a Gas Sensitivity Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6 Very-High and Ultra-High Vacuum Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6.1 Micro-Ion Vacuum Gauge Module Process Chamber Baking . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 5 RS-485 Digital Interface Specifications and Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.2 Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.3 Receive/Transmit Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 7 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Micro-Ion Vacuum Gauge (with Digital Interface) Module Initialization . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2.1 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 Degas Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.3.1

7.4 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . 41

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

5

7.5 Micro-Ion Gauge Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.6 Ion Gauge Continuity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.7 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

1 General Information

Chapter 1

1General Information

1.1 Receiving Inspection

On receipt of the equipment, inspect all material for damage. Confirm that the shipment includes

all items ordered. If items are missing or damaged, submit a claim as stated below for a domestic or

international shipment, whichever is applicable.

If materials are missing or damaged, the carrier that made the delivery must be notified within 15

days of delivery, or in accordance with Interstate Commerce regulations for the filing of a claim.

Any damaged material including all containers and packaging should be held for carrier inspection.

Contact MKS, Granville-Phillips Division Customer Support for assistance if your shipment is not

correct for reasons other than shipping damage.

1.2 International Shipment

Inspect all materials received for shipping damage and confirm that the shipment includes all items

ordered. If items are missing or damaged, the airfreight forwarder or airline making delivery to the

customs broker must be notified within 15 days of delivery.The following illustrates to whom the

claim is to be directed.

• If an airfreight forwarder handles the shipment and their agent delivers the shipment to customs,

the claim must be filed with the airfreight forwarder.

• If an airfreight forwarder delivers the shipment to a specific airline and the airline delivers the

shipment to customs, the claim must be filed with the airline.

Any damaged material including all containers and packaging should be held for carrier inspection.

Contact Granville-Phillips Customer Support for assistance if your shipment is not correct for

reasons other than shipping damage.

1.3 Warranty

MKS Instruments, Inc. provides an eighteen (18) month warranty from the date of shipment for new

Granville-Phillips Products. The MKS General Terms and Conditions of Sale provides the complete

and exclusive warranty for Granville-Phillips products. This document may be located on our web

site at www.mksinst.com, or may be obtained by contacting a Granville-Phillips Customer Service

Representative.

1.4 Certification

MKS Instruments, Inc. certifies that this product met its published specifications at the time of

shipment from the factory. MKS Instruments, Inc. further certifies that its calibration measurements

are traceable to the National Institute of Standards and Technology to the extent allowed by the

Institute's calibration facility.

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

7

1 General Information

1.5 Service Guidelines

Some minor problems are readily corrected on site. If the product requires service, contact the MKS,

Granville-Phillips Division Customer Service Department at +1-800-227-8766 or +1-303-652-4691

for troubleshooting help over the phone.

If the product must be returned to the factory for service, request a Return Material Authorization

(RMA) from Granville-Phillips. Do not return products without first obtaining an RMA. In some

cases a hazardous materials document may be required. The MKS/Granville-Phillips Customer

Service Representative will advise you if the hazardous materials document is required.

When returning a products to Granville-Phillips, be sure to package the products to prevent

shipping damage. Circuit boards and modules separated from the gauge assembly must be handled

using proper anti-static protection methods and must be packaged in anti-static packaging.

Granville-Phillips will supply return packaging materials at no charge upon request. Shipping

damage on returned products as a result of inadequate packaging is the Buyer's responsibility.

For Customer Service or Technical Support 24 hours per day, 7 days per week, every day of the year

including holidays:

Phone: +1-800-227-8766 or +1-303-652-4691

Email: gp-csr@mksinst.com

MKS, Granville-Phillips Division

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: 1-303-652-4691 or 1-800-776-6543

FAX: 1-303-652-2844

1.6 FCC Verification

This equipment was tested and complies with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with this instruction manual, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio or television technician for help.

8

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

2 Safety

Chapter 2

2Safety

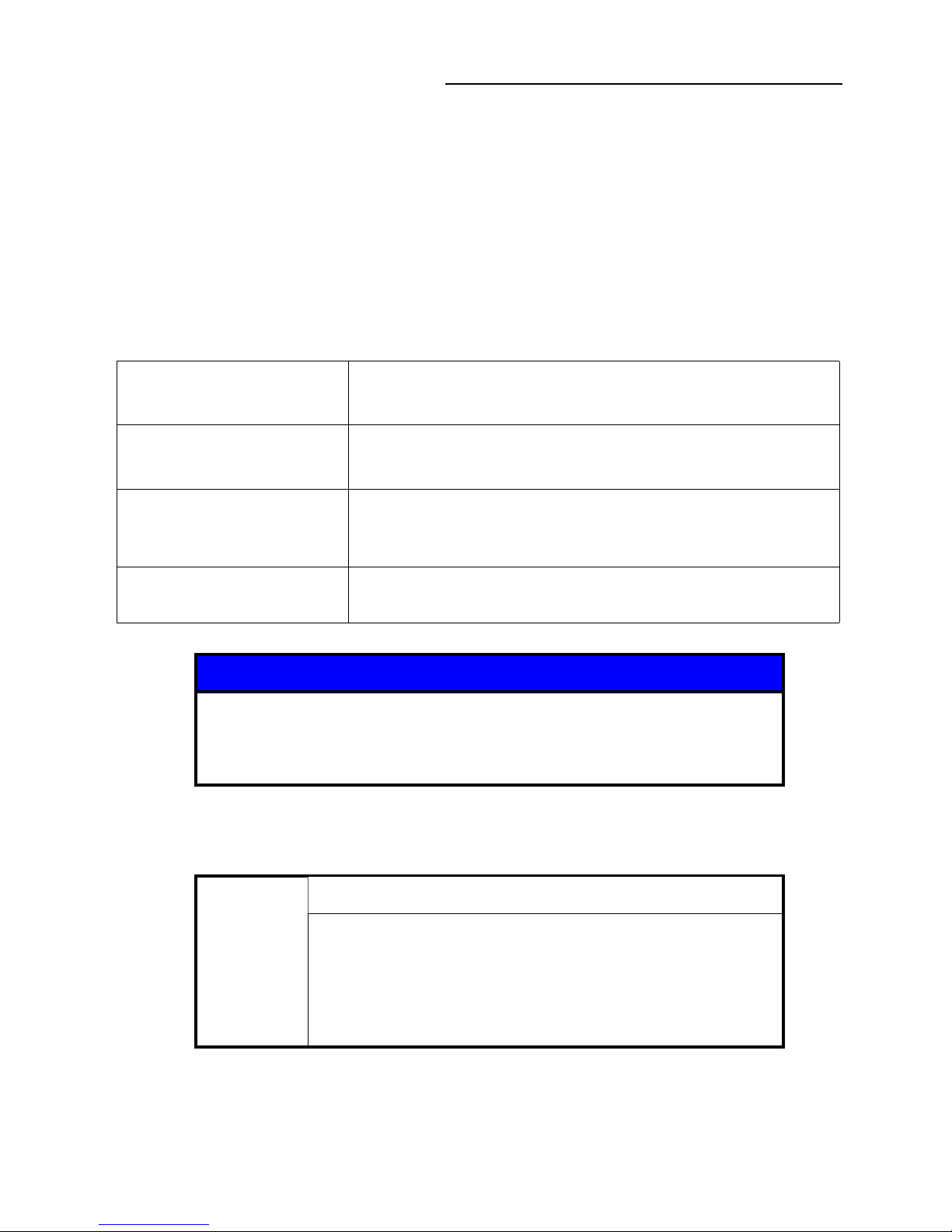

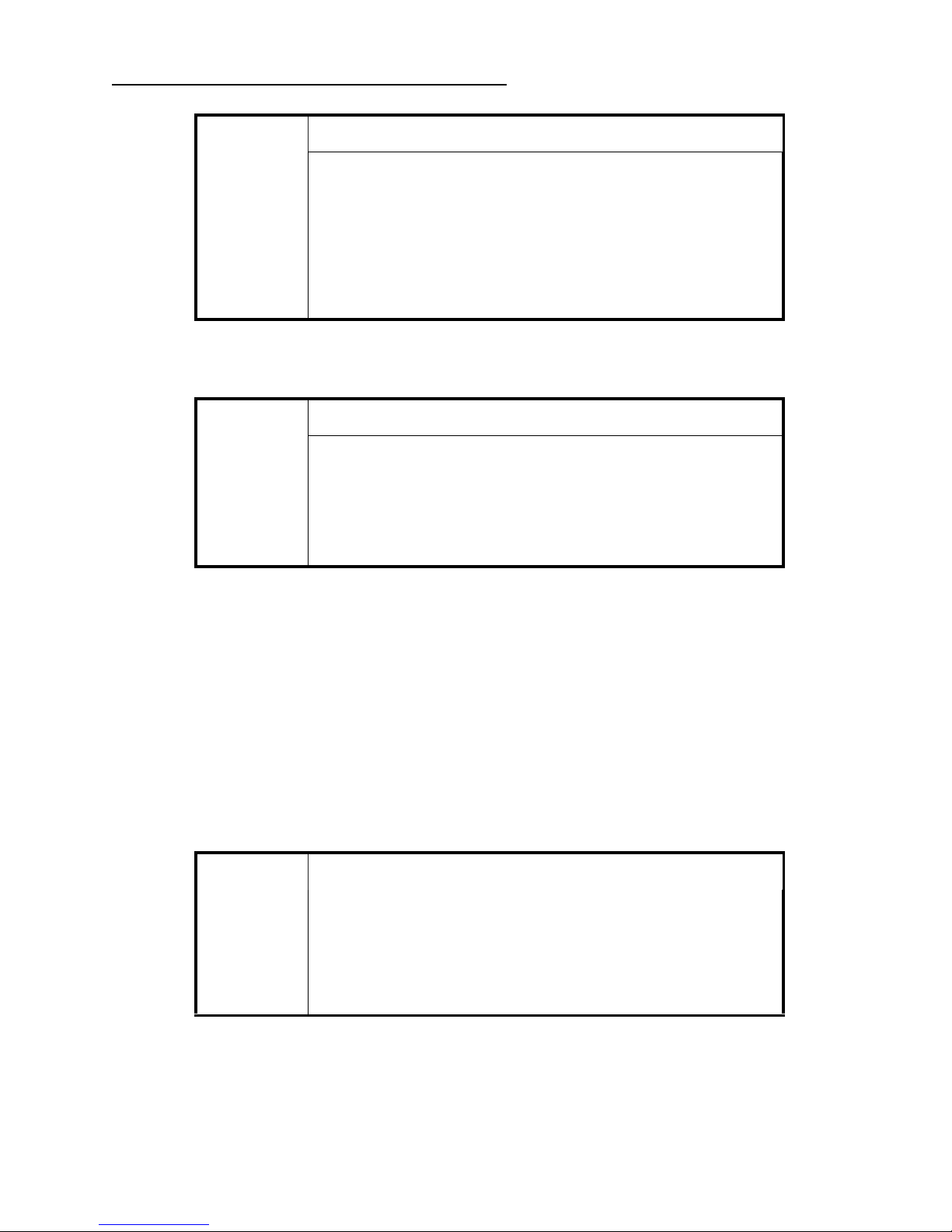

2.1 Safety Introduction

START BY READING THESE IMPORTANT SAFETY INSTRUCTIONS AND NOTES collected here

for your convenience and repeated with additional information at appropriate points throughout

this instruction manual.

These safety alert symbols in this manual or on the Product mean caution - personal safety, property

damage or danger from electric shock. Read these instructions carefully.

Danger indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Warning indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

Caution indicates a hazardous situation or unsafe

practice which, if not avoided, may result in minor or

moderate personal injury.

Indicates a situation or unsafe practice which, if not

avoided, may result in equipment damage.

Notice

These instructions do not and cannot provide for every contingency that

may arise in connection with the installation, operation, or maintenance of

this product. If you require further assistance, contact Granville-Phillips at

the address on the title page of this instruction manual.

This product was designed and tested to offer reasonably safe service provided it is installed,

operated, and serviced in strict accordance with these safety instructions.

Safety Precautions

Failure to comply with these instructions may result in serious

personal injury, including death, or property damage.

Always observe and follow all safety notices that are

provided throughout this instruction manual and on the

product.

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

9

2 Safety

These safety precautions must be observed during all phases of operation, installation, and service

of this product. Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and intended use of the instrument. MKS

Instruments, Inc. disclaims all liability for the customer's failure to comply with these requirements.

• Read Instructions – Read all safety and operating instructions before operating the product.

• Retain Instructions – Retain the Safety and Operating Instructions for future reference.

• Heed Warnings – Adhere to all warnings on the product and in the operating instructions.

• Follow Instructions – Follow all operating and maintenance instructions.

• Accessories – Do not use accessories not recommended in this manual as they may be

hazardous.

Electrical Shock or Personal Injury

The service and repair information in this manual is for the use

of Qualified Service Personnel. To avoid possible electrical

shock or personal injury, do not perform any procedures in

this manual or perform any servicing on this product unless

you are qualified to do so.

Electrical Shock or Fire

To reduce the risk of fire or electric shock, do not expose this

product to rain or moisture.

Objects and Liquid Entry - Never push objects of any kind into

this product through openings as they may touch dangerous

voltage points or short out parts that could result in a fire or

electric shock. Be careful not to spill liquid of any kind onto the

products.

10

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

2 Safety

2.2 Grounding Requirements

See Grounding, Section 4.2 in the Installation chapter for more detailed requirements regarding

gauge and system grounding.

Proper Grounding

All components of a vacuum system used with this or any

similar high voltage product must be maintained at Earth

ground for safe operation.

Be aware that grounding this product does not guarantee that

other components of the vacuum system are maintained at

Earth ground.

Verify that the vacuum port to which the Series 354 Micro-Ion

Gauge is mounted is electrically grounded. It is essential for

personnel safety as well as proper operation that the

envelope of the gauge be connected to a facility ground. See

Section 4.2 for detailed grounding instructions.

Connect power cords only to properly grounded outlets or

sources.

2.3 High Voltage

High Voltage is present in the Micro-Ion Gauge Module when the module is powered ON.

Hazardous voltages may still be present in the module for some time after disconnecting power to

the module. Refer to the Installation and Service chapters for more information.

High Voltage

Be aware that when high voltage is present in any vacuum

system, a life threatening electrical shock hazard may exist

unless all exposed conductors are maintained at Earth ground.

This hazard is not unique to this product.

High Voltage

All conductors in, on, or around the vacuum system that are

exposed to potential high voltage electrical discharges must

either be shielded at all times to protect personnel or must be

connected to Earth ground at all times.

Ion producing equipment, such as ionization gauges, mass

spectrometers, sputtering systems, etc., may under some

conditions provide sufficient conduction via a plasma to couple

a high voltage electrode to the vacuum chamber. If conductive

parts of the chamber are not grounded, they may attain a

potential near that of the high voltage electrode during this

coupling.

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

11

2 Safety

Be aware that an electrical discharge through a gas may

couple dangerous high voltage directly to an ungrounded

conductor almost as effectively as would a copper wire

connection. A person may be seriously injured or even killed

by merely touching an exposed ungrounded conductor at high

potential.

This hazard is not unique to this product.

2.4 Over-Pressure Conditions

Install suitable devices that will limit the pressure to the level the

vacuum system can safely withstand. In addition, install

suitable pressure relief valves or rupture disks that will release

pressure at a level considerably below the pressure that the

system can safely withstand.

High Voltage

Over-Pressure Conditions

Suppliers of pressure relief valves and pressure relief disks can be located via an online search, and

are listed in the Thomas Register under “Valves, Relief”, and “Discs, Rupture”. Confirm that these

safety devices are properly installed before installing the product.

Ensure the following precautions are complied with at all times:

(1) the proper gas cylinders are installed

(2) the gas cylinder valve positions are correct on manual systems

(3) the automation is correct on automated gas delivery systems

Vacuum gauges with compression fittings may be forcefully ejected if the vacuum system is

pressurized.

2.5 System and Environment

Explosive Environment

Do not use the Series 354 Micro-Ion Gauge in an environment

of explosive or combustible gases or gas mixtures. Operation

of any electrical instrument in such an environment constitutes

a definite safety hazard. Do not use the product to measure

the pressure of explosive gases or gas mixtures.

12

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

Chemical Fumes / Explosive Environment

The fumes from solvents such as trichloroethylene,

perchloroethylene, toluene, and acetone can be dangerous to

health if inhaled. Use only in well ventilated areas exhausted

to the outdoors.

Acetone and toluene are highly flammable and should not be

used near an open flame or energized electrical equipment.

Potential Automatic Operation

It is the installer's responsibility to ensure that the automatic

signals provided by the product are always used in a safe

manner. Carefully check the system programming before

switching to automatic operation.

2 Safety

Vacuum Chamber High Pressures

Where an equipment malfunction could cause a hazardous

situation, always provide for fail-safe operation. As an

example, in an automatic backfill operation where a

malfunction might cause high internal pressures, provide an

appropriate pressure relief device.

2.6 Responsibility

It is the responsibility of the Customer to comply with all local, state, and federal ordinances,

regulations, and laws applicable to the installation, operation and service of this equipment.

It is the responsibility of the end user to provide sufficient lighting at work to meet local regulations.

Operation and Service of this equipment in strict accordance with the methods and procedures

supplied by MKS, Granville-Phillips Division is the responsibility of the Customer.

MKS Instruments, Inc. assumes no liability, whatsoever, for any personal injuries or damages

resulting from the operation or service of this equipment in any manner inconsistent or contrary to

the methods supplied in Granville-Phillips literature including, but not limited to, manuals,

instructions, bulletins, communications, and recommendations.

For emergencies and for product safety related matters, contact Granville-Phillips Customer Service

Department. See Section 1.5 or Section 7.7 for detailed information regarding how to contact

Granville-Phillps Customer Service Representatives.

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

13

2 Safety

2.7 Damage Requiring Service

Disconnect the product from all power sources and refer servicing to Qualified Service Personnel

under the following conditions:

a. When any cable or plug is damaged.

b. If any liquid has been spilled onto, or objects have fallen into the product.

c. If the product has been exposed to rain or water.

d. If the product does not operate normally even if you follow the operating instructions.

Adjust only those controls that are covered by the operation instructions. Improper

adjustment of other controls may result in damage and will often require extensive work

by a qualified technician to restore the product to its normal operation.

e. If the product has been dropped or the enclosure has been damaged.

f. When the product exhibits a distinct change in performance. This indicates a need for

service.

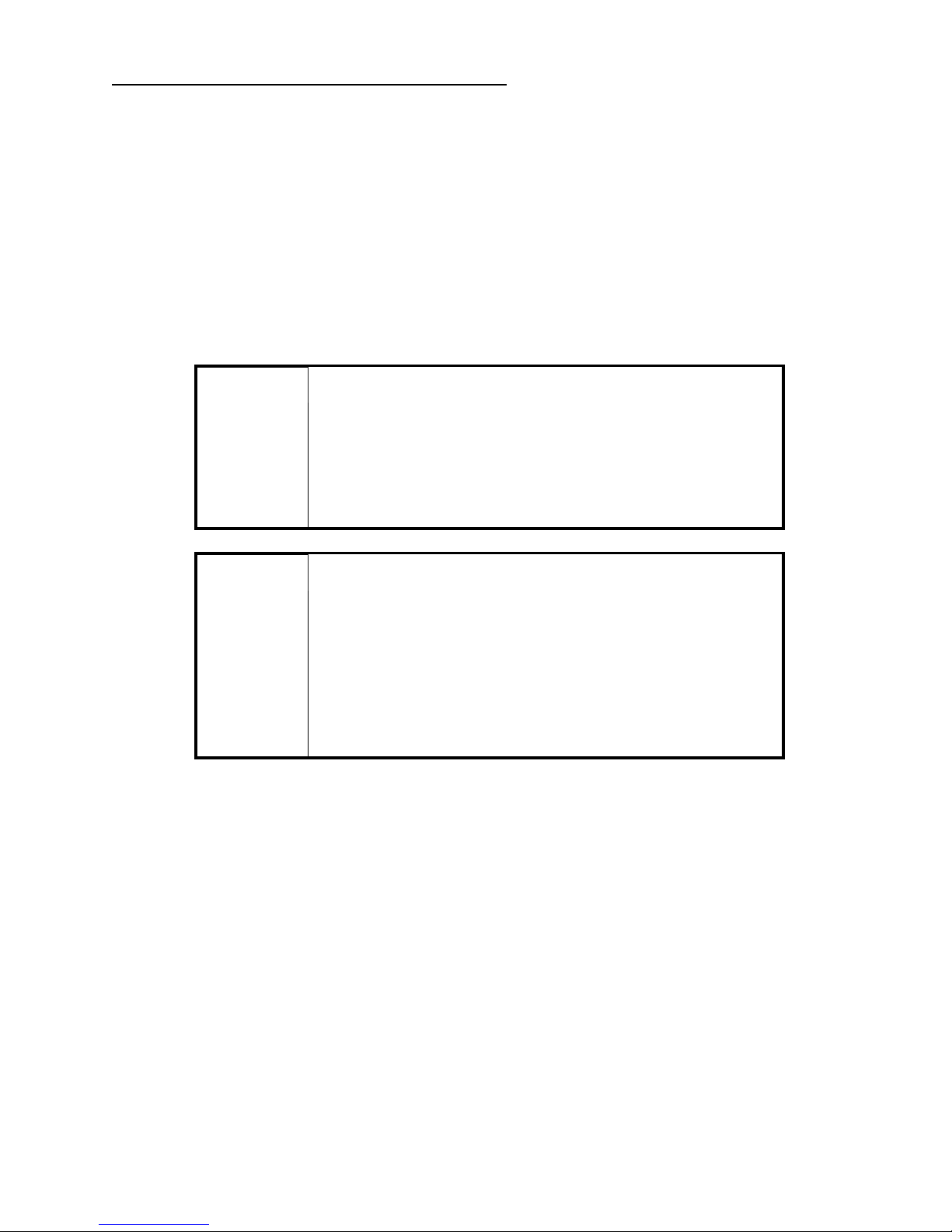

Notice

Do not substitute parts or modify the instrument.

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification to the product.

Return the product to a service facility designated by Granville-Phillips for

service and repair to ensure that safety features are maintained. Do not use

this product if it has unauthorized modifications.

Notice

Safety Check - Upon completion of any service or repairs to this product,

ask the Qualified Service Person to perform safety checks to determine that

the product is in safe operating order.

Notice

Finite Lifetime - After ten years of normal use or even non-use, the electrical

insulation in this product may become less effective at preventing electrical

shock. Under certain environmental conditions which are beyond the

manufacturer’s control, some insulation material may deteriorate sooner.

Therefore, periodically inspect all electrical insulation for cracks, crazing, or

other signs of deterioration. Do not use if the electrical insulation has

become unsafe.

14

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

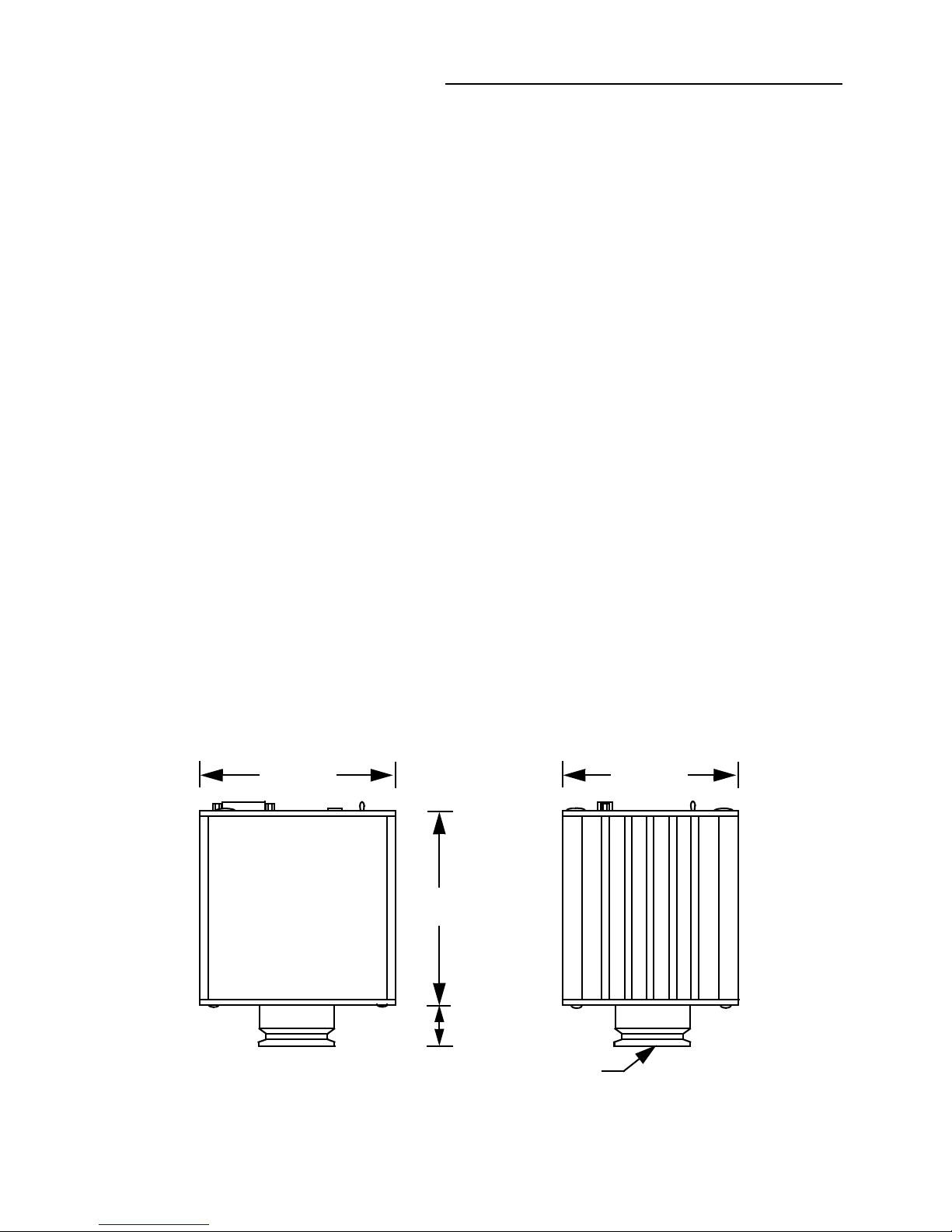

3.1 General Description

2.80 in

(71.12 mm)

3.00 in

(76.20 mm)

MOUNTING FLANGE

2.60 in

(66.04 mm)

See Dimension H

on Table 3-1

3 Introduction

Chapter 3

3Introduction

The Model 354 Micro-Ion Vacuum Gauge Module, shown in Figure 3-1, is a modular instrument

-9

that is capable of measuring vacuum pressures from 1 x 10

Torr to 5 x 10-2 Torr - N2 equivalent (or

air).

The 354 Micro-Ion Vacuum Gauge Module is a small rugged unit that has a wider measurement

range, more burnout resistance, and generates less heat than typical glass gauges. Additional

benefits include:

• Compact, Convenient, Cost Saving Vacuum Measurement

• Rugged Metal Construction

• Robust Filament Design

• Increased Uptime

• Rapid response during Pumpdown

• Cooler Operation

• Easy Compatibility with Computer Controlled Processes

The RS-485 digital interface version provides industry-standard digital RS485 communications over

networks as well as direct connections to a personal computer. The setpoint relay, filament, and

degassing of the gauge tube can be easily controlled via the RS-485 digital interface.

The setpoint relay can be used to control various devices such as; safety interlock, valve, digital

input for a scanner, or programmable logic controller. The setpoint relay trip points can be set to

customized pressure settings to turn power ON or OFF to the appropriate device.

3.2 Dimensions

Figure 3-1: Series 354 Micro-Ion Vacuum Gauge Dimensions

Series 354 Micro-Ion Vacuum Gauge Module

Instruction Manual - 354008 - Rev. C

15

Loading...

Loading...