Granville-Phillips 340 Instruction Manual

Series 340

Granville-Phillips® Series 340

Vacuum Gauge Controller

Instruction Manual

Instruction manual part number 340005

Revision C - January 2013

Series 340

Granville-Phillips® Series 340

Vacuum Measurement Controller

This Instruction Manual is for use with all Granville-Phillips Series 340 Vacuum Measurement Controllers. A list of applicable catalog numbers is provided on the following page.

Customer Service/Support

For customer service within USA, 8 AM to 5 PM

Mountain Time Zone, weekdays excluding holidays:

Granville-Phillips

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: +1-800-776-6543

Phone: +1-303-652-4400

FAX: +1-303-652-2844

Email: co-csr@brooks.com

Brooks Automation, Inc.

15 Elizabeth Drive

Chelmsford, MA 01824 USA

Phone: +1-978-262-2400

For customer service, 24 hours per day, 7 days per week, every day of the year including holidays within the USA:

Phone: +1-800-367-4887

www.brooks.com

Instruction Manual

©2013 Brooks Automation, Inc. All rights reserved.

Granville-Phillips® and Convectron® are registered trademarks of Brooks Automation, Inc. All other trademarks and registered trademarks are the properties of their respective owners.

Granville-Phillips® Series 340 Vacuum Gauge Controller

Catalog numbers for Series 340 Controllers

Controller for one Ionization gauge and two Convectron Gauges, with one-line display, resistive degas, and remote input/output interface

Half-rack mount: |

340501 - # |

# |

||||

Left mount for 19-inch rack: |

340502 - # |

# |

||||

Center mount for 19-inch rack: |

340503 - # |

# |

||||

Bench-top mount: |

340504 - # |

# |

||||

Display options (Measurement units): |

|

|

|

|

|

|

|

|

|

|

|

|

|

Torr |

T |

|

|

|

|

|

|

|

|

||||

mbar |

M |

|

|

|

|

|

|

|

|

|

|

||

Pascal |

P |

|

|

|

|

|

Powercord options: |

|

|

|

|

|

|

North America 115 Vac and Japan 100 Vac |

1 |

|

|

|

|

|

|

|

|

|

|

||

North America 240 Vac |

2 |

|

|

|

|

|

Universal Europe 220 Vac |

3 |

|

|

|

|

|

United Kingdom 240 Vac |

4 |

|

|

|

|

|

|

|

|

|

|

||

This Instruction Manual is also for use with the following catalog numbers:

340001, 340003, 340004, 340018, 340019, 341579

20340042, 20340045, 20340046, 20340-341-T1, 20340-341-T2, 20340-341-T3

Table of Contents

Chapter 1 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Safety Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Equipment Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3 Implosion / Explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.7 FCC Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8 Canadian Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2 Introduction & Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.1 Available Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.2 Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2 Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 Damaged Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 340 VGC Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 Electrometer/Ion Gauge Pressure Range Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.3 Convectron Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3.4 Remote Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Initial VGC Setup and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.1 Line Voltage Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2 Mounting Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Ionization Gauge Types and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.1 Ion Gauge Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Convectron Gauge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.1 Important Precautions for Gauge Tube Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3.2 Gauge Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3.3 Compression Mount (Quick Connect). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.4 1/8 NPT Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.5 NW16KF Flange Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3.6 Other Mounting Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3.7 Convectron Gauge Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 System Grounding Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4.1 System Ground Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1 Series 340 VGC Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.1.1 Sensor Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.2 Power ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.3 Electrometer Module Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.4 Ion Gauge ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.5 Degas ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1.6 Remote Input/Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.1 Ionization Gauge Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.2.2 Convectron Gauge Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Series 340 Vacuum Gauge Controller |

5 |

Instruction Manual - 340005 - Rev. C |

|

4.3 |

Convectron Gauge Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

|

4.3.1 |

Reading Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

4.3.2 Special Considerations For Use Below 10-3 Torr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

|

4.3.3 Use With Gases Other Than N2 and Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

|

4.3.4 Indicated vs. True Pressure Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

4.4 |

Convectron Gauge Module Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

|

Chapter 5 |

Electrometer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

5.1 |

Introduction to the Electrometer Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

5.2 |

Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

|

5.2.1 Display Update Rate Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

5.3 |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

|

5.3.1 Displaying Sensitivity, Pressure, and Emission with the Calibration Switch . . . . . . . . . . . . . . . . . . |

46 |

|

|

5.3.2 |

Emission Range Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

5.3.3 |

Emission Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

5.3.4 |

Sensitivity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

|

5.3.5 |

Relative Gas Sensitivities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

5.3.6 |

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

5.4 |

Electrometer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

|

5.4.1 |

Electrometer Minimum Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

5.4.2 |

Electrometer Scale Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

5.4.3 |

Overpressure Shutdown Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

5.4.4 |

A/D Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

Chapter 6 Convectron Gauge Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

||

6.1 |

Introduction to the Convectron Gauge Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

6.2 |

Units of Measure for a Convectron Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

6.3 |

Ionization Gauge Filament Auto Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

6.4 |

Process Relay Turn ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

|

|

6.4.1 Setting the Internal CGB & CGA Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

|

6.5 |

Process Relay Turn ON Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

|

6.6 |

Gauge Zero and Atmospheric Pressure Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

|

|

6.6.1 |

Zero Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

|

6.6.2 |

Atmosphere Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

6.7 |

Convectron Gauge Analog Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

|

Chapter 7 Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

||

7.1 |

Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

|

7.2 |

Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

|

7.3 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

59 |

|

|

7.3.1 |

Power Input Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

59 |

|

7.3.2 |

Power Supply Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

59 |

|

7.3.3 Ionization Gauge Filament Turn ON and Emission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

|

7.3.4 |

Degas Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

|

7.3.5 |

Electrometer Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

|

7.3.6 |

Convectron Gauge Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

Chapter 8 |

Index |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

Series 340 Vacuum Gauge Controller |

6 |

Instruction Manual - 340005 - Rev. C |

|

Chapter 1

Safety Instructions

1.1 Safety Introduction

BEGIN BY READING THESE IMPORTANT THESE SAFETY INSTRUCTIONS AND NOTES and repeated with additional information at appropriate points in this instruction manual.

These safety alert symbols in this manual or on the Product rear panel, mean caution − personal safety, property damage or danger from electric shock. Read these instructions carefully.

Throughout this instruction manual the word “product” refers to the Series 340 Vacuum Gauge Controller and all of its approved parts and accessories.

NOTE: These instructions do not and cannot provide for every contingency that may arise in connection with the installation, operation, or maintenance of this product. If you require further assistance, contact Brooks Automation, Inc. at the address on the title page of this manual.

This product is designed and tested to offer reasonably safe service provided it is installed, operated, and serviced in strict accordance with these safety instructions.

Failure to comply with these instructions may result in serious personal injury, including death, or property damage.

These safety precautions must be observed during all phases of operation, installation, and service of this product. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and intended use of the instrument.

Brooks Automation, Inc. disclaims all liability for the customer's failure to comply with these requirements.

The service and repair information in this manual is for the use of Qualified Service Personnel. To avoid shock, do not perform any procedures in this manual or perform any servicing on this product unless you are qualified to do so.

•Read Instructions – Read all safety and operating instructions before operating the product.

•Retain Instructions – Retain the Safety and Operating Instructions for future reference.

•Heed Warnings – Adhere to all warnings on the product and in the operating instructions.

•Follow Instructions – Follow all operating and maintenance instructions.

•Accessories – Do not use accessories not recommended in this manual as they may be hazardous.

Series 340 Vacuum Gauge Controller |

7 |

Instruction Manual - 340005 - Rev. C |

|

1 Safety Instructions

To reduce the risk of fire or electric shock, do not expose this product to rain or moisture.

Objects and Liquid Entry − Never push objects of any kind into this product through openings as they may touch dangerous voltage points or short out parts that could result in a fire or electric shock. Be careful not to spill liquid of any kind onto the products.

Do not substitute parts or modify instrument.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the product. Return the product to a service facility designated by Brooks Automation, Inc. for service and repair to ensure that safety features are maintained. Do not use this product if it has unauthorized modifications.

Replacement Parts − When replacement parts are required, be certain to use the replacement parts that are specified by Brooks Automation, Inc. or that have the same characteristics as the original parts. Unauthorized substitutions may result in fire, electric shock or other hazards.

Safety Check − Upon completion of any service or repairs to this product, ask the Qualified Service Person to perform safety checks to determine that the product is in safe operating order.

Finite Lifetime − After ten years of normal use or even non−use, the electrical insulation in this product may become less effective at preventing electrical shock. Under certain environmental conditions which are beyond the manufacturer’s control, some insulation material may deteriorate sooner. Therefore, periodically inspect all electrical insulation for cracks, crazing, or other signs of deterioration. Do not use if the electrical insulation has become unsafe.

Be aware that when high voltage is present in any vacuum system, a life threatening electrical shock hazard may exist unless all exposed conductors are maintained at earth ground.

This hazard is not peculiar to this product.

Be aware that an electrical discharge through a gas may couple dangerous high voltage directly to an ungrounded conductor almost as effectively as would a copper wire connection. A person may be seriously injured or even killed by merely touching an exposed ungrounded conductor at high potential.

This hazard is not unique to this product.

It is the user's responsibility to ensure that the automatic signals provided by the product are always used in a safe manner. Carefully check the system programming before switching to automatic operation.

8 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

1 Safety Instructions

1.2 Equipment Grounding

Where an equipment malfunction could cause a hazardous situation, always provide for fail−safe operation. As an example, in an automatic backfill operation where a malfunction might cause high internal pressures, provide an appropriate pressure relief device.

Proper Grounding

All components of a vacuum system used with this or any similar high voltage product must be maintained at earth ground for safe operation. The power cord of this product shall be connected only to a properly grounded outlet. Be aware, however, that grounding this product does not guarantee that other components of the vacuum system are maintained at Earth ground.

Complying with the usual warning to connect the power cable only to a properly grounded outlet is necessary but not sufficient for safe operation of a vacuum system with this or any similar high voltage producing product.

Verify that the vacuum port to which the Ionization Gauge or Convectron Gauge is mounted is electrically grounded. It is essential for personnel safety as well as proper operation that the envelope of the gauge be connected to a facility ground. Use a ground lug on a flange bolt if necessary.

1.3 Implosion / Explosion

Install suitable devices that will limit the pressure to the level that the vacuum system can safely withstand. In addition, install suitable pressure relief valves or rupture disks that will release pressure at a level considerably below the pressure that the system can safely withstand.

Glass ionization gauges, if roughly handled, may implode under vacuum causing flying glass which may injure personnel. If pressurized above atmospheric pressure, glass tubes may explode. A substantial shield should be placed around vacuum glassware to prevent injury to personnel.

Danger of injury to personnel and damage to equipment exists on all vacuum systems that incorporate gas sources or involve processes capable of pressurizing the system above the limits it can safely withstand.

For example, danger of explosion in a vacuum system exists during backfilling from pressurized gas cylinders because many vacuum devices such as ionization gauge tubes, glass windows, glass bell jars, etc., are not designed to be pressurized.

Install suitable devices that will limit the pressure from external gas sources to the level that the vacuum system can safely withstand. In addition, install suitable pressure relief valves or rupture disks that will release pressure at a level considerably below that pressure which the system can safely withstand.

Suppliers of pressure relief valves and pressure relief disks can be located via an internet search, and are listed in the Thomas Register under “Valves, Relief” and “Discs, Rupture.”

Series 340 Vacuum Gauge Controller |

9 |

Instruction Manual - 340005 - Rev. C |

|

1 Safety Instructions

Confirm that these safety devices are properly installed before installing the product. In addition, check that:

a.The proper gas cylinders are installed,

b.Gas cylinder valve positions are correct on manual systems, and

c.The automation is correct on automated gas delivery systems.

d.Vacuum gauges with compression fittings may be forcefully ejected if the vacuum system is pressurized.

Series 275 Convectron Gauges should not be used above 1000 Torr true pressure.

Series 275 Convectron gauges are furnished calibrated for N2. They also measure the pressure of air correctly within the accuracy of the controller.

If accurate conversion data is not used, or is improperly used, a potential overpressure explosion hazard can be created under certain conditions.

Do not attempt to use a Series 275 gauge calibrated for N2 to measure or control the pressure of other gases such as argon or CO2 unless accurate conversion data for N2 to the other gas is properly used. See Section 4.3.3 on page 35.

If used improperly, Convectron gauges can supply misleading pressure indications that can result in dangerous overpressure conditions within the system.

Do not operate in an explosive atmosphere.

Do not operate the product in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a definite safety hazard.

Do not use the product to measure the pressure of explosive or combustible gases or gas mixtures. The sensor wire of the Convectron Gauge normally operates at only 125 ˚C, but it is possible that Controller malfunction can raise the sensor temperature above the ignition temperature of combustible mixtures.

Danger of explosion or inadvertent venting to atmosphere exists on all vacuum systems which incorporate gas sources or involve processes capable of pressurizing the system above safe limits.

It is the installer's responsibility to ensure that the automatic signals provided by the product are always used in a safe manner. Carefully check manual operation of the system and the set point programming before switching to automatic operation.

Where an equipment malfunction could cause a hazardous situation, always provide for fail-safe operation. As an example, in an automatic backfill operation where a malfunction might cause high internal pressures, provide an appropriate pressure relief device.

The fumes from solvents such as trichloroethylene, perchloroethylene, toluene, and acetone can be dangerous to health if inhaled. Use only in well ventilated areas exhausted to the outdoors. Acetone and toluene are highly flammable and should not be used near an open flame or energized electrical equipment.

10 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

1 Safety Instructions

1.4 Damage Requiring Service

Disconnect the product from all power sources and refer servicing to Qualified Service Personnel under the following conditions:

a.When any cable or plug is damaged.

b.If any liquid has been spilled onto, or objects have fallen into, the product.

c.If the product has been exposed to rain or water.

d.If the product does not operate normally even if you follow the operating instructions. Adjust only those controls that are covered by the operation instructions. Improper adjustment of other controls may result in damage and will often require extensive work by a qualified technician to restore the product to its normal operation.

e.If the product has been dropped or the enclosure has been damaged.

If the product exhibits a distinct change in performance, service may be required.

1.5 Service Guidelines

Some minor problems are readily corrected on site. If the product requires service, please contact our Customer Service Department at 303-652-4400 for troubleshooting help over the phone.

If the controller must be returned to the factory for service, request a Return Authorization (RA) from Brooks Automation / Granville-Phillips. Do not return products without first obtaining an RA. In some cases a hazardous materials document may be required. The Brooks Automation / Granville-Phillips Customer Service Representative will advise you if the hazardous materials document is required.

When returning equipment to Brooks Automation / Granville-Phillips, be sure to package the products to prevent shipping damage. Circuit boards and modules separated from the controller chassis must be handled using proper anti-static protection methods and must be packaged in anti-static packaging. Brooks Automation / Granville-Phillips will supply return packaging materials at no charge upon request. Shipping damage on returned products as a result of inadequate packaging is the Buyer's responsibility. Before you return the module, obtain an RA number by contacting Granville-Phillips customer service:

•Phone 1-303-652-4400 or 1-800-776-6543 within the USA, 8 AM to 5 PM Mountain Time Zone, weekdays excluding holidays.

•Phone 1-800-367-4887 24 hours per day, seven days per week within the USA.

•Email co-csr@brooks.com

•For Global Customer Support, go to www.brooks.com, click on Service and Support, then click on Global Service and Repair Centers to locate the Brooks Automation office nearest you.

Series 340 Vacuum Gauge Controller |

11 |

Instruction Manual - 340005 - Rev. C |

|

1 Safety Instructions

1.6 Warranty Information

Brooks Automation, Inc. provides an eighteen (18) month warranty from the date of shipment for new Granville-Phillips Products. The Brooks Automation, Inc. General Terms and Conditions of Sale provides the complete and exclusive warranty for Brooks Automation products. This document may be located on our web site at www.brooks.com, or may be obtained by contacting a Brooks Automation Customer Service Representative.

1.7 FCC Verification

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with this instruction manual, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and the receiver.

•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

•Consult the dealer or an experienced radio or television technician for help.

1.8 Canadian Users

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numerique de la classe B respecte toutes les exigences du Reglement sur le material broilleur du Canada.

12 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

Chapter 2

Introduction & Specifications

2.1 General Description

The Series 340 Vacuum Gauge Controller (VGC) measures pressures from less than 1 x 10-9 Torr (1.3 x 10-9 mbar or 1.3 x 10-7 pascal) to atmosphere by use of a single ionization gauge and two Convectron Gauges. Pressure readout is via a front panel display and analog outputs. Resistance heating degas is standard. An interlock is provided to allow degas only when the ion gauge tube is ON and the displayed pressure is below 5 x 10-5 Torr. Pressure reading during degas is not possible.

The 340 VGC is a modular instrument with infrequently used controls housed behind a hinged front panel, thus reducing front panel clutter and allowing the VGC to reside in a half-rack space.

2.1.1 Available Options

2.1.1.1 Remote Input/Output

The 340 VGC can be ordered with a factory installed remote I/O option which provides an ion gauge (IG) status relay, remote gauge on/off input and remote degas on/off input functions.

2.1.1.2 Process Control Relays

The 340 VGC can be ordered with a factory installed process relay option which provides automatic ion gauge turn-ON from Convectron channel "1" and a Convectron Gauge process relay output that is user selectable to operate from channel "1" or "2".

2.1.1.3 Ion Gauge Cables

The VGC is capable of operating an ion gauge located up to 50 feet away from the controller by using standard cables. Degas power delivered to the gauge decreases with cable length. Cables are available for use with glass or nude Bayard Alpert (B-A) gauges.

2.1.2 Mounting Options

The 340 VGC can be ordered with a variety of mounting options to fit your needs. This includes half rack (standard), full rack, or bench mounting. See Figure 3-2 on page 20 for dimensional illustrations.

2.2 Receiving Inspection

Inspect all material received for shipping damage. Confirm that your shipment includes all material and options ordered. If materials are missing or damaged, the carrier that made the delivery must be notified within 15 days of delivery in accordance with Interstate Commerce regulations in order to file a valid claim with the carrier.

2.2.1 Damaged Material

Any damaged material, including all containers and packaging, should be held for carrier inspection. If your shipment is not correct for reasons other than shipping damage, contact our Customer Service Department, 6450 Dry Creek Parkway, Longmont, Colorado 80503, phone 303-652-4400, email csr-co@brooks.com.

Series 340 Vacuum Gauge Controller |

13 |

Instruction Manual - 340005 - Rev. C |

|

2Introduction & Specifications

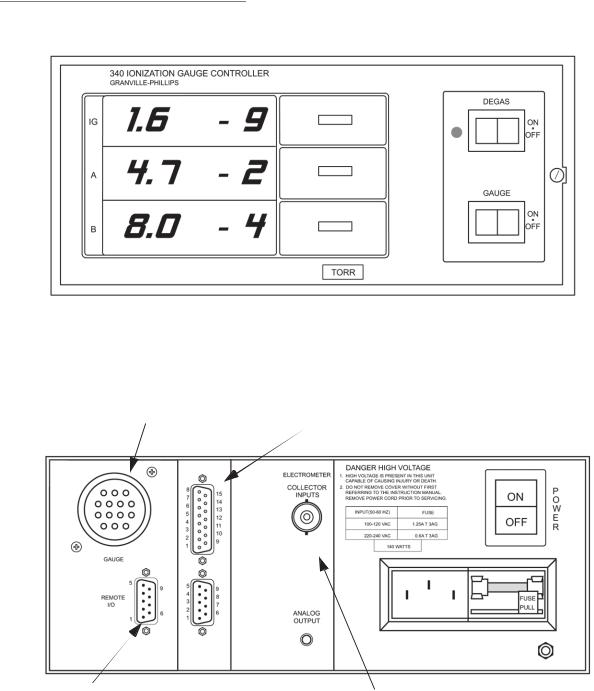

Figure 2-1 Front of Series 340 Vacuum Gauge Controller

Power Supply / Ion Gauge |

Convectron Gauge Module |

Connector / Remote I-O PCB |

PCB (See Chapter 6) |

Ion Gauge Remote I/O 9-pin

Connector (See Remote

Input/Output on page 32)

Figure 2-2 Rear of Series 340 Vacuum Gauge Controller

Electrometer Module

PCB (See Chapter 5)

14 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

2Introduction & Specifications

2.3 Specifications

2.3.1 340 VGC Specifications

Table 2-1 Series 340 VGC Physical Specifications

Parameter |

Specification |

|

|

Width |

24.13 cm (9.5 in.) with 1/2-rack mounting brackets |

|

|

Height |

8.89 cm (3.5 in.) |

|

|

Depth |

35.56 cm (14 in.) includes 7.62 cm (3 in.) for connectors and cables |

|

|

Weight |

4.8 kg (10.5 lb.) |

|

|

Environmental Temperature |

0 oC to 40 oC |

Table 2-2 Series 340 VGC Electrical Specifications

Parameter |

Specification |

|

|

Voltage |

90-130 VAC or 200-260 VAC |

|

|

Frequency |

50 to 60 Hz |

|

|

Power |

100 watts max |

|

|

Fuse Ratings |

1.25 A (90-130 V) |

|

.60 A (200-260 V) |

|

|

2.3.2 Electrometer/Ion Gauge Pressure Range Specifications

Table 2-3 Emission Range for Non UHV Ion Gauges

.01mA to .1mA |

.1mA to 1mA |

1mA to 10mA |

|

|

|

1 x 10-7 to 1 x 10-1 Torr |

1 x 10-8 to 1 x 10-2 Torr |

1 x 10-9 to 1 x 10-3 Torr |

An internal overpressure limiter is factory adjusted to trip at a pressure of 1 decade below the upper limits specified above. Refer to Section 5.4.3 for readjustment instructions.

Series 340 Vacuum Gauge Controller |

15 |

Instruction Manual - 340005 - Rev. C |

|

2Introduction & Specifications

Table 2-4 Pressure Display Specifications

Parameter |

|

Specification |

|

|

|

|

|

Electronic Accuracy |

Typical ± 3% of reading at ambient temperature of 25 ± 5 oC |

||

Display Units |

Torr unless otherwise requested. Adjustment and internal selector switch provides readout |

||

|

in mbar or pascal. |

||

|

|

|

|

Display Resolution |

Scientific notation, 2 significant digits. |

||

|

|

|

|

Display Update Time |

0.5 sec. typical as shipped. Internal switch selectable to 3 sec. reading averaged. |

||

|

|

|

|

Table 2-5 Electrometer/Ion Gauge Specifications |

|||

|

|

|

|

Parameter |

|

Specification |

|

|

|

|

|

Sensitivity |

|

3/Torr to 50/Torr (the factory setting is 10/Torr) |

|

|

|

|

|

Emission Current |

|

10 μA to 10 mA in 3 decade ranges (factory setting is 1 mA) |

|

|

|

|

|

Collector Potential |

|

0 Vdc |

|

|

|

|

|

Grid Potential |

|

+180 Vdc |

|

|

|

|

|

Filament Potential |

|

+30 Vdc |

|

|

|

|

|

Degas |

|

I2R: 8 VAC, 10 A maximum |

|

Analog Output |

|

0-10 Vdc; Logarithmic; 1 V/decade |

|

|

|

|

|

2.3.3 Convectron Specifications

Table 2-6 Convectron Gauge Specifications

Parameter |

Specification |

|

|

Gauge Type |

Granville-Phillips Series 275 |

|

|

Pressure Range |

1 x 10-4 Torr to 990 Torr, N equivalent |

|

2 |

|

|

Gas Type |

N2, Air |

|

|

Maximum Gauge Temperature |

+150 oC |

Gauge Operating Temperature |

+4 oC to +50 oC |

16 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

2Introduction & Specifications

Table 2-7 Convectron Module Specifications

Parameter |

Specification |

|

|

Display Resolution |

2 significant digits (1 significant digit in the 10-4 decade) |

Analog Output |

Nonlinear 0 to 5.3 Vdc (+5% corresponding to 0 to 1000 Torr) |

|

|

Display Update Time |

0.5 sec. typical. Switchable to 3 sec./ reading average |

|

|

Ion Gauge Turn ON Range |

OFF, 5 mTorr to 50 mTorr |

|

|

Process Relay Setting |

Resistive load. |

Max switched power |

30 W or 60 VA |

Max switched current |

2 A |

Max switched voltage |

30 Vdc or 300 VAC |

Contact rating |

1 A at 30 Vdc, 0.5 A at 125 VAC |

|

|

Process Relay Turn ON Range |

OFF, 5 mTorr to 200 mTorr |

|

|

2.3.4 Remote Input/Output

Table 2-8 Remote I/O Specifications

Parameter |

Specification |

|

|

Gauge and Degas On/Off Inputs |

Less then 0.4 V @ 10 μA for 25 msec (min). Must go to greater than 3.5 |

|

V for 105 msec (min) before next low state. |

|

|

Filament Status Relay Contact Rating |

4 A, 250 VAC resistive load or 30 Vdc. |

|

|

Series 340 Vacuum Gauge Controller |

17 |

Instruction Manual - 340005 - Rev. C |

|

2Introduction & Specifications

NOTES:

18 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

Chapter 3

Installation

3.1 Initial VGC Setup and Installation

3.1.1 Line Voltage Selection

Verify that the line voltage selector card displays the line voltage value of the available local AC line voltage. If the card does not display the correct line voltage value as shown in Table 3-1, perform the following procedure and refer to Figure 3-1.

Table 3-1 Selector Card Line Voltage Settings and Fuse Selection

Line Voltage Setting (VAC) |

Setting |

Selector Card Fuse F2 Type |

|

|

|

90-105 |

100 |

1.25A SB |

|

|

|

105-130 |

120 |

1.25A SB |

|

|

|

200-230 |

220 |

.60A SB |

|

|

|

230-260 |

240 |

.60A SB |

|

|

|

Figure 3-1 Line Voltage Selector on the rear of the 340 VGC

1.On the rear panel (lower right), slide the cover over fuse F2 to the left.

2.Remove the fuse (F2) by pulling the fuse extractor tab FUSE PULL outward and to the left. Leave the extractor tab in the full-left position.

3.Use a pointed tool or small wire hook to extract the line selector card from its holder and pull the card straight out.

4.Reinsert the card so that the correct line voltage (100, 120, 220, or 240V) as shown in Figure

3-1 is readable from the rear of the VGC.

.

Operation of the Series 340 Vacuum Gauge Controller with the line voltage selector card improperly set can cause damage to the Controller and injury to personnel.

5.Verify that fuse F2 is the correct value as shown in Table 3-1. Position the fuse extractor tab FUSE PULL to the right-hand position and install the fuse (F2) in the fuse holder.

6.Slide the cover to the right over the fuse.

Series 340 Vacuum Gauge Controller |

19 |

Instruction Manual - 340005 - Rev. C |

|

3 Installation

3.1.2 Mounting Configurations

Figure 3-2 illustrates the various configurations available for mounting the Series 340 Vacuum Gauge Controller.

NOTE: The 340 controller should be mounted in a location with free air flow and ambient temperature less than 40 oC.

340501-##

340503-## |

340502-## |

Figure 3-2 340 VGC Mounting Configurations

20 |

Series 340 Vacuum Gauge Controller |

|

Instruction Manual - 340005 - Rev. C |

3 Installation

3.2 Ionization Gauge Types and Installation

The 340 VGC operates a Bayard-Alpert type or equivalent ionization gauge. It is ideally suited for a nude ionization gauge such as the Granville-Phillips 274022 or 274023 which have an X-ray limit in the low 10-11 Torr range. Coated Iridium filament type gauges are recommended since at higher pressures they provide longer operating life and greater burnout resistance.

When installing an ion gauge, note that if it is placed near the pump, the pressure in the gauge may be considerably lower than in the rest of the system. If placed near a gas inlet or source of contamination, the pressure in the gauge may be higher.

If an unshielded gauge is placed near an electron beam evaporation source or used in a sputtering system, spurious electrons or ions may disturb the measurement. Screens or other shielding should be placed between the gauge and the system if spurious charged particles or severe electromagnetic interference is present. Consideration should also be given to electrostatic shielding of glass tubulated gauges when measuring pressures near their x-ray limits.

Brooks Automation, Inc./Granville-Phillips offers 3 cable types for ion gauges. One has a standard connector for the series 274 tubulated gauges; one has a standard connector for series 274 nude gauges; and one has individual pin sockets for use with nonstandard pin configurations as well as Granville-Phillips nude gauges.

Figure 3-3 shows typical gauge base configurations using the cables listed above and shown in Figure 3-4, 3-5, and 3-6.

NOTE: To use the second filament of a dual filament gauge, the cable connector at the gauge is removed and rotated 180o, then reinstalled.

Figure 3-3 Standard Gauge Base Configuration

Series 340 Vacuum Gauge Controller |

21 |

Instruction Manual - 340005 - Rev. C |

|

Loading...

Loading...