Granville-Phillips Micro-Ion DeviceNet 390 Series, Micro-Ion DeviceNet 390611 Series, Micro-Ion DeviceNet 390610 Series Instruction Manual

Series 390

Granville-Phillips® Series 390 Micro-Ion® ATM

Four-Sensor Combination Vacum Gauge Module

™

with DeviceNet

and Analog Output

and RS-485 Interface,

Instruction Manual

Instruction manual part number 390002

Revision E - August 2013

Series 390

Granville-Phillips® Series 390 Micro-Ion® ATM

Four-Sensor Combination Vacum Gauge Module

™

with DeviceNet

and Analog Output

This Instruction Manual is for use with all Granville-Phillips Series

390 Micro-Ion ATM Modules with DeviceNet and RS-485 Interface,

and Analog Output. A list of applicable catalog numbers is provided

on the following page.

These products are RoHS compliant.

Customer Service/Support

For customer service within USA, 8 AM to 5 PM

Mountain Time Zone, weekdays excluding holidays:

Granville-Phillips

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: +1-800-776-6543

Phone: +1-303-652-4400

FAX: +1-303-652-2844

Email: co-csr@brooks.com

Brooks Automation, Inc.

15 Elizabeth Drive

Chelmsford, MA 01824 USA

Phone: +1-978-262-2400

For customer service, 24 hours per day, 7 days per week,

every day of the year including holidays within the USA:

Phone: +1-800-367-4887

www.brooks.com

and RS-485 Interface,

Instruction Manual

© 2006-2013 Brooks Automation, Inc. All rights reserved.

Granville-Phillips

Brooks Automation, Inc. All other trademarks and registered trademarks are the

properties of their respective owners.

®

, Micro-Ion®, and Conductron® are registered trademarks of

Granville-Phillips® Series 390 Micro-Ion® ATM

Four-Sensor Combination Vacum Gauge

with DeviceNet

Catalog numbers for Series 390 Micro-Ion ATM Modules

Power supply and cable are not included.

DeviceNet interface - no display: 390610 - # - # # - #

DeviceNet interface - with digital display: 390611 - # - # # - #

Setpoints:

None 0

Two 2

Three 3

Ion Gauge Filaments:

Yttria-coated iridium Y

Tungsten T

Flange/Fitting:

NW16KF D

NW25KF E

NW40KF K

1.33 inch (NW16CF) Conflat-type F

2.75 inch (NW35CF) Conflat-type G

1/2 inch VCR-type male H

™ and RS-485 Interface, and Analog Output

Measurement Units:

Tor r T

mbar M

Pascal P

Table of Contents

Table of Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 About these instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Caution and warning statements . . . . . . . . . . . . . . . . . . . . . 9

1.3 System Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Implosion / Explosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6 Reading and following instructions . . . . . . . . . . . . . . . . . . . 11

1.7 Definitions of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Module components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Pressure relief devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Step 1 Locate the module . . . . . . . . . . . . . . . . . . . . . . . . 16

Step 2 Attach the module to the vacuum chamber . . . . . 18

VCR type fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

KF flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ConFlat flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Step 3 Assemble and connect wiring . . . . . . . . . . . . . . . . 19

Connecting cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CE Mark compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Module power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Gauge OFF/degas wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Relay, analog output, and RS-485 output wiring . . . . . . . . . 21

DeviceNet wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Step 4 Calibrate module at atmospheric pressure . . . . . . 24

2.4 Eliminating radio frequency interference . . . . . . . . . . . . . . . 24

Chapter 3 Operation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Interfaces, outputs, and relays . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Analog operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.3 DeviceNet operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 RS-485 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5 Automatic filament selection . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 4 Analog Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Output functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 Preparing to operate the module . . . . . . . . . . . . . . . . . . . . . 29

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 5

Table of Contents

4.3 Operational tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 LED status indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5 Reading pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.6 Micro-Ion gauge OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.7 Micro-Ion gauge degas . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.8 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Atmospheric pressure calibration . . . . . . . . . . . . . . . . . . . . 35

Vacuum pressure calibration . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 5 DeviceNet Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Pressure output and relay functions . . . . . . . . . . . . . . . . . . . 37

5.2 Preparing to operate the module . . . . . . . . . . . . . . . . . . . . . 37

5.3 Performance with DeviceNet protocol . . . . . . . . . . . . . . . . 38

5.4 DeviceNet protocol for the Micro-Ion ATM module . . . . . . 39

5.5 Operational tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.6 DeviceNet switches and indicators . . . . . . . . . . . . . . . . . . . 40

Address switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rate switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.7 Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.8 DeviceNet communication configuration . . . . . . . . . . . . . . 43

5.9 Pressure units and values . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Set or get pressure unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Data conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Get vacuum pressure or differential pressure . . . . . . . . . . . . 48

5.10 Get temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.11 Process control relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Get relay trip points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Get enable/disable status of relays . . . . . . . . . . . . . . . . . . . 55

Get activation or deactivation status of relays . . . . . . . . . . . 56

Get relay hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Get relay assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.12 Micro-Ion gauge controls . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Turn Micro-Ion gauge ON or OFF . . . . . . . . . . . . . . . . . . . 58

Get Micro-Ion gauge ON/OFF status . . . . . . . . . . . . . . . . . . 59

Set or get Micro-Ion gauge delay time . . . . . . . . . . . . . . . . . 59

Set or get filament mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Get active filament . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Initiate or terminate Micro-Ion gauge degas . . . . . . . . . . . . 62

Get Micro-Ion gauge degas ON/OFF state . . . . . . . . . . . . . . 63

Set or get Micro-Ion gauge emission current . . . . . . . . . . . . 63

5.13 Calibrate module at atmospheric pressure . . . . . . . . . . . . . . 65

5.14 Calibrate module at vacuum pressure . . . . . . . . . . . . . . . . . 65

5.15 Reset module to power-up state . . . . . . . . . . . . . . . . . . . . . 66

5.16 Get firmware version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.17 Get software and hardware revision levels . . . . . . . . . . . . . 66

6 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Table of Contents

5.18 Factory defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.19 DeviceNet error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Using polled I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Using explicit messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 6 RS-485 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1 Pressure output and relay functions . . . . . . . . . . . . . . . . . . . 73

6.2 Preparing to operate the module . . . . . . . . . . . . . . . . . . . . . 73

6.3 RS-485 physical layer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.4 Operational tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.5 Error responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.6 Data timing and response . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.7 RS-485 commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Command structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Symbols used in this manual . . . . . . . . . . . . . . . . . . . . . . . . 77

6.8 RS-485 command set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

TLU Toggling locked functions . . . . . . . . . . . . . . . . . . . 80

UNL Unlock interface functions . . . . . . . . . . . . . . . . . . 80

SA Set address offset . . . . . . . . . . . . . . . . . . . . . . . . . 81

SB Set baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

yuiop Restore RS-485 communication defaults . . . . . . . . 82

SU Set pressure unit . . . . . . . . . . . . . . . . . . . . . . . . . . 82

RU Read pressure unit . . . . . . . . . . . . . . . . . . . . . . . . 82

SD Set pressure indication for optional display . . . . . . 82

RD Read vacuum pressure . . . . . . . . . . . . . . . . . . . . . 83

RDD Read differential pressure . . . . . . . . . . . . . . . . . . . 83

PC Process control relay trip points . . . . . . . . . . . . . . 84

PCG Set trip point relay assignments . . . . . . . . . . . . . . . 87

PCE Set or read disable/enable state of relays . . . . . . . . 87

RPCS Read trip point relay status . . . . . . . . . . . . . . . . . . 88

IG Turn Micro-Ion gauge ON or OFF . . . . . . . . . . . . 88

IGS Read Micro-Ion gauge ON/OFF status . . . . . . . . . 88

IGM Set or read pressure indication when

Micro-Ion gauge is OFF . . . . . . . . . . . . . . . . . . . . 89

IOD Set or read Micro-Ion gauge delay ON/OFF state . 90

IDT Set or read Micro-Ion gauge delay time . . . . . . . . 91

SF Set Micro-Ion gauge filament mode . . . . . . . . . . . 92

RF Read Micro-Ion gauge filament status . . . . . . . . . . 96

DG Degas Micro-Ion gauge . . . . . . . . . . . . . . . . . . . . 96

DGS Read Micro-Ion gauge degas status . . . . . . . . . . . . 96

DGT Set or read Micro-Ion gauge degas time . . . . . . . . 97

SER Set emission current switch point . . . . . . . . . . . . . 97

RE Read Micro-Ion gauge emission current . . . . . . . . 99

TS Calibrate module at atmospheric pressure . . . . . . 99

TZ Calibrate module at vacuum pressure . . . . . . . . . . 100

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 7

Table of Contents

ATM Set or read atmospheric pressure output . . . . . . . . 101

RS Read module status RS-485 strings . . . . . . . . . . . . 101

RSX Read module status hexadecimal bits . . . . . . . . . . 103

RST Reset module to power-up state . . . . . . . . . . . . . . 105

FAC Reset values to factory defaults . . . . . . . . . . . . . . . 106

VER Read firmware version . . . . . . . . . . . . . . . . . . . . . 106

Chapter 7 Optional Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.1 Display capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Vacuum pressure display . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Differential pressure display . . . . . . . . . . . . . . . . . . . . . . . . 107

7.2 Display resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.3 Error conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Damage requiring service . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Symptoms, causes, and solutions . . . . . . . . . . . . . . . . . . . . 112

8.3 RS-485 error responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.4 RS-485 status strings and hexadecimal bits . . . . . . . . . . . . . 115

8.5 DeviceNet error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Using polled I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Using explicit messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.6 Overpressure shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.7 Micro-Ion gauge continuity test . . . . . . . . . . . . . . . . . . . . . . 116

8.8 Replacing the gauge assembly . . . . . . . . . . . . . . . . . . . . . . 118

8.9 Returning a Micro-Ion module for service . . . . . . . . . . . . . . 119

Appendix A Specifications & Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Appendix B Messaging Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Appendix C Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

8 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Chapter 1 Before You Begin

CAUTION

Before You Begin

Before You Begin Installation Operation Overview Analog Operation

1.1 About these instructions These instructions explain how to install, operate, and maintain the

Granville-Phillips

The module has a DeviceNet interface, an RS-485 interface, and one analog

output. The module may have no trip point relays, two trip point relays, or

three trip point relays.

• This chapter explains caution and warning statements, which must be

adhered to at all times; explains your responsibility for reading and

following all instructions; defines the terms that are used throughout this

instruction manual; and explains how to contact customer service.

• Chapter 2 explains how to install the module.

• Chapter 3 is an operational overview of the module.

• Chapter 4 explains analog output operation. The analog output does not

operate independently but must operate with the DeviceNet or RS-485

interface.

• Chapter 5 explains DeviceNet interface operation.

• Chapter 6 explains RS-485 interface operation.

• Chapter 7 explains how to use the optional display.

• Chapter 8 explains troubleshooting; Micro-Ion gauge testing, removal

and replacement; and module return procedures.

• Appendix A provides specifications for the module.

• Appendix B summarizes DeviceNet polled I/O and explicit messages.

• Appendix C explains how the Micro-Ion gauge, Conductron

sensor, atmospheric pressure diaphragm sensor, and vacuum pressure

diaphragm sensor measure pressure.

®

Micro-Ion® ATM vacuum gauge module.

®

heat-loss

1.2 Caution and warning statements

This manual contains caution and warning statements with which you must

comply with to prevent inaccurate measurement, property damage, or

personal injury.

Caution statements alert you to hazards or unsafe

practices that could result in inaccurate measurement,

minor personal injury or property damage.

Each caution statement explains what you must do to prevent or

avoid the potential result of the specified hazard or unsafe

practice.

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 9

Chapter 1

WARNING

Warning statements alert you to hazards or unsafe

practices that could result in severe property damage or

personal injury due to electrical shock, fire, or explosion.

Each warning statement explains what you must do to prevent

or avoid the potential result of the specified hazard or unsafe

practice.

Caution and warning statements comply with American Institute of

Standards Z535.1-2002 through Z535.5-2002, which set forth voluntary

practices regarding the content and appearance of safety signs, symbols,

and labels.

Each caution or warning statement explains:

a. The specific hazard that you must prevent or unsafe practice that you

must avoid,

b. The potential result of your failure to prevent the specified hazard or

avoid the unsafe practice, and

c. What you must do to prevent the specified hazardous result.

1.3 System Grounding Grounding, though simple, is very important! Be certain that ground

circuits are correctly used on your ion gauge power supplies, gauges, and

vacuum chambers, regardless of their manufacturer. Safe operation of

vacuum equipment, including the Series 390 ATM Module, requires

grounding of all exposed conductors of the gauges, the controller and the

vacuum system. LETHAL VOLTAGES may be established under some

operating conditions unless correct grounding is provided.

Ion producing equipment, such as ionization gauges, mass spectrometers,

sputtering systems, etc., from many manufacturers may, under some

conditions, provide sufficient electrical conduction via a plasma to couple

a high voltage electrode potential to the vacuum chamber. If exposed

conductive parts of the gauge, controller, and chamber are not properly

grounded, they may attain a potential near that of the high voltage electrode

during this coupling. Potential fatal electrical shock could then occur

because of the high voltage between these exposed conductors and ground.

1.4 Implosion / Explosion Danger of injury to personnel and damage to equipment exists on all

vacuum systems that incorporate gas sources or involve processes capable

of pressuring the system above the limits it can safely withstand.

For example, danger of explosion in a vacuum system exists during

backfilling from pressurized gas cylinders because many vacuum devices

such as ionization gauge tubes, glass windows, glass belljars, etc., are not

designed to be pressurized.

10 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Before You Begin

Install suitable devices that will limit the pressure from external gas sources

to the level that the vacuum system can safely withstand. In addition, install

suitable pressure relief valves or rupture disks that will release pressure at a

level considerably below that pressure which the system can safely

withstand.

Suppliers of pressure relief valves and pressure relief disks are listed in

Thomas Register under "Valves, Relief", and "Discs, Rupture".

Confirm that these safety devices are properly installed before installing the

Series 390 ATM Module. In addition, check that (1) the proper gas cylinders

are installed, (2) gas cylinder valve positions are correct on manual systems,

and (3) the automation is correct on automated systems.

1.5 Operation It is the installer's responsibility to ensure that the automatic signals

provided by the process control module are always used in a safe manner.

Carefully check manual operation of the system and the setpoint

programming before switching to automatic operation. Where an

equipment malfunction could cause a hazardous situation, always provide

for fail-safe operation. As an example, in an automatic backfill operation

where a malfunction might cause high internal pressures, provide an

appropriate pressure relief device.

Before You Begin Installation Operation Overview Analog Operation

1.6 Reading and following instructions

You must comply with all instructions while you are installing, operating,

or maintaining the module. Failure to comply with the instructions violates

standards of design, manufacture, and intended use of the module.

Granville-Phillips and Brooks Automation disclaim all liability for the

customer's failure to comply with the instructions.

• Read instructions – Read all instructions before installing or operating the

product.

• Follow instructions – Follow all installation, operating and maintenance

instructions.

• Retain instructions – Retain the instructions for future reference.

• Heed warnings and cautions – Adhere to all warnings and caution

statements on the product and in these instructions.

• Parts and accessories – Install only those replacement parts and

accessories that are recommended by Granville-Phillips. Substitution of

parts is hazardous.

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 11

Chapter 1

1.7 Definitions of terms

Table 1-1 lists terms used throughout this manual in reference to the

Micro-Ion ATM vacuum gauge module.

Table 1-2 lists terms describing DeviceNet protocol.

Table 1-3 lists terms describing DeviceNet data types.

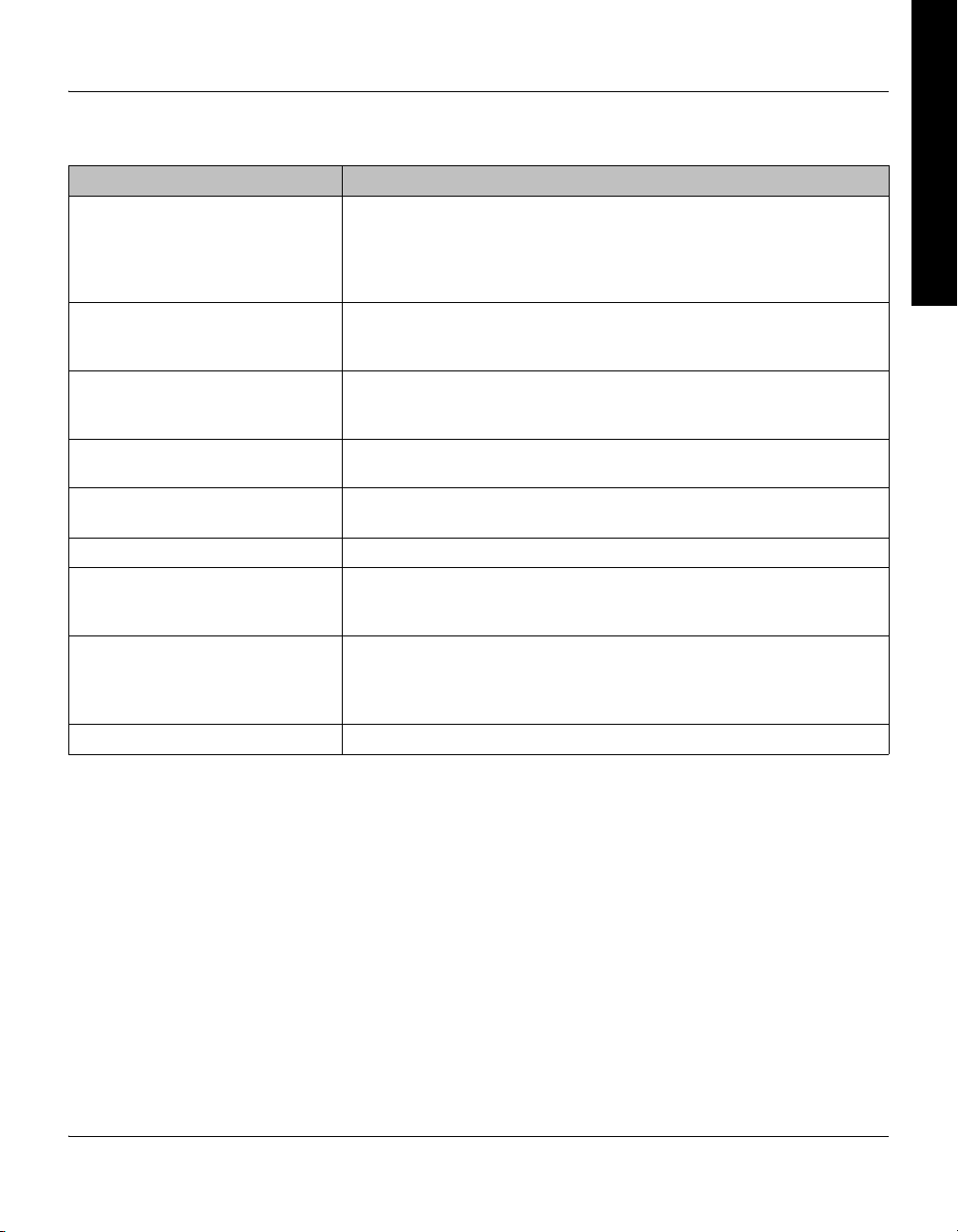

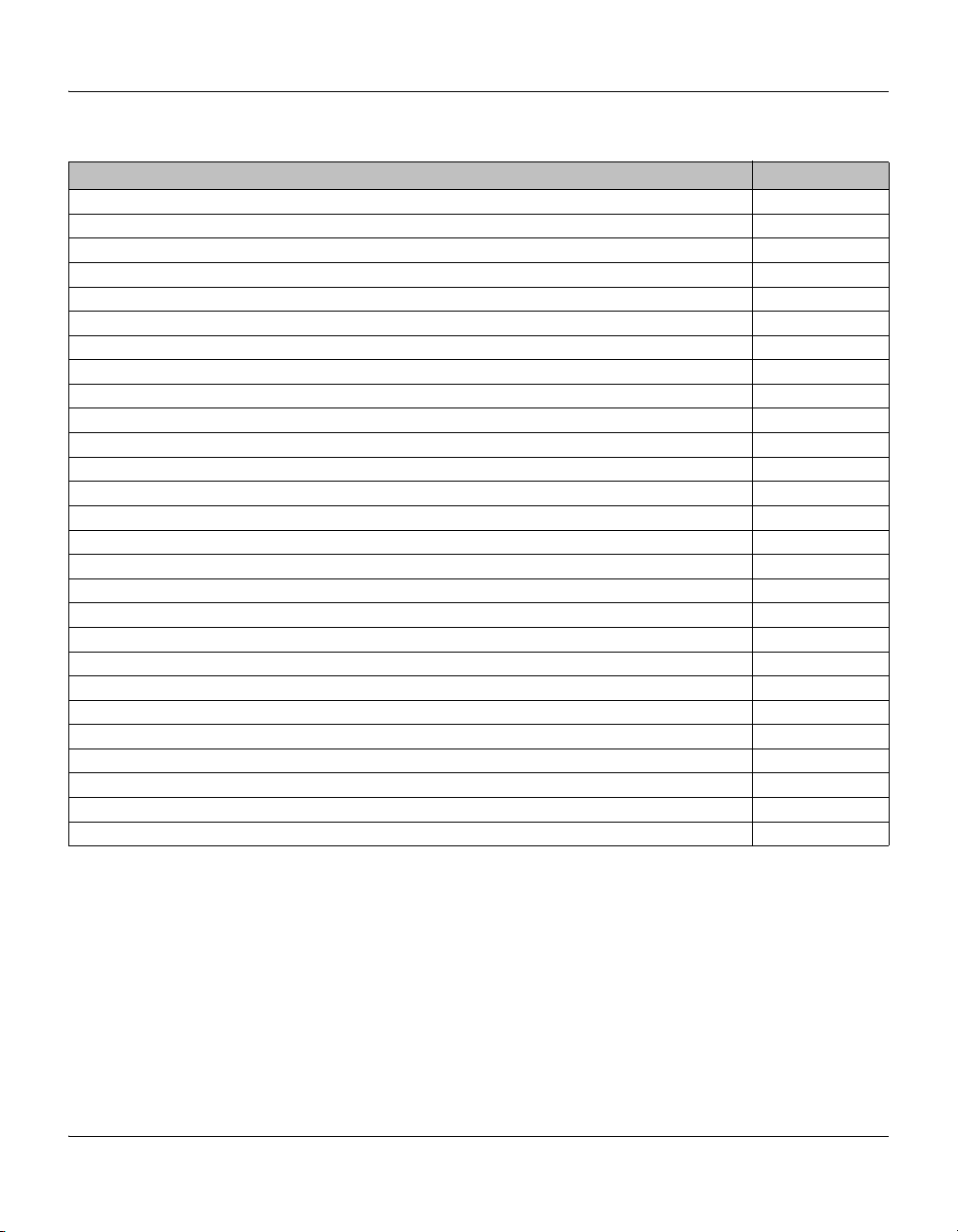

Table 1-1 Terms describing Micro-Ion ATM module and components

Term Description

Module The entire Micro-Ion ATM product, which includes the housing, gauge assembly,

Gauge assembly A removable assembly that contains a hot filament Micro-Ion gauge

Electronics assembly An assembly that contains the electronic circuitry, signal processing

Micro-Ion

Conductron

®

gauge The Bayard-Alpert type ionization gauge, which indicates pressure by producing

®

sensor The heat-loss sensor, which measures pressure as a function of heat loss from the

Vacuum pressure diaphragm sensor A Piezo resistive diaphragm sensor that measures vacuum pressure. Vacuum

Atmospheric pressure diaphragm

sensor

Vacuum pressure The pressure of the process gas inside the vacuum chamber, measured by the

Atmospheric pressure The ambient air pressure of the atmosphere outside the module, measured by the

Differential pressure The difference between atmospheric pressure and vacuum pressure. Differential

and electronics assembly.

(Bayard-Alpert type ionization gauge), a Conductron heat-loss sensor, a vacuum

pressure diaphragm sensor, and the vacuum chamber connection.

microcircuitry, and atmospheric pressure diaphragm sensor.

a current that is proportional to gas density.

gold-plated tungsten sensing wire.

pressure is compared to atmospheric pressure to determine the differential

between atmospheric and vacuum pressures.

A Piezo resistive diaphragm sensor that measures atmospheric pressure.

Atmospheric pressure is compared to vacuum pressure to determine the

differential between atmospheric and vacuum pressures.

Micro-Ion gauge, Conductron sensor, and vacuum pressure diaphragm sensor.

atmospheric pressure diaphragm sensor.

pressure zero is the pressure value at which vacuum pressure equals atmospheric

pressure.

12 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Before You Begin

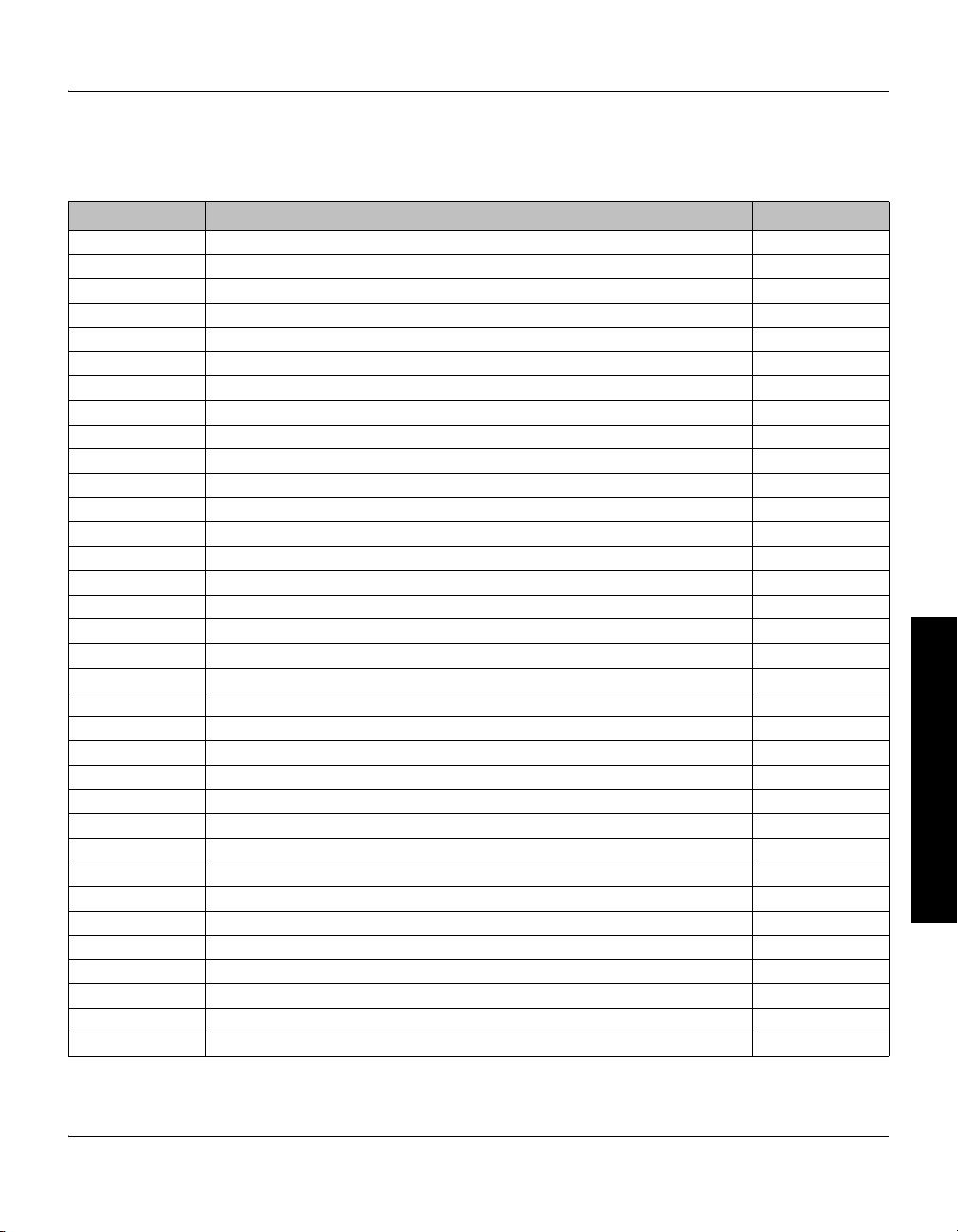

Table 1-2 Terms describing DeviceNet protocol

Term Description

Class Referred to in DeviceNet language as an “object”. The DeviceNet protocol is

divided into various objects that describe behaviors, attributes, or information.

For example, class 1 is the identity object that includes information about the

identity of the product, such as the vendor identification, product type, product

ID, serial number, and firmware revisions.

Instance Within a class there may be multiple instances. Within the Micro-Ion ATM

module there are four possible I/O instances (1–4). For example, the format for

polled I/O data is instance 2 in class 5.

Attribute Data that can be read from the device or written to the DeviceNet network.

Attributes exist for each instance within a class. For example, the serial number is

attribute 6, instance 1 in class 1 (the identity object).

Master data The messages sent from the network to the device to set conditions or values in

the device.

Device data The messages sent from the Micro-Ion ATM module to the network to

communicate values, attributes, or other information.

Data rate The rate at which data is transmitted (125, 250, or 500 kbaud, switch selectable).

Explicit messages Messages that are used for request/response communications enabling module

configuration and problem diagnosis. Explicit messages provide multi-purpose,

point-to-point communication paths between two modules or other devices.

Polled I/O messages Messages that are used for time-critical, control-oriented data. Polled I/O

messages provide a dedicated, special-purpose communication path between a

producing application (host) and one or more consuming applications (modules

or other devices).

Address The address of a device on the DeviceNet network.

Before You Begin Installation Operation Overview Analog Operation

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 13

Chapter 1

Table 1-3 Terms describing DeviceNet data types

Term Description

Data type The form of the data communicated from the Micro-Ion ATM module or another

node on the network. The module supports BOOL, BYTE, SSTRING, REAL, INT,

UINT, USINT, EPATH, and WORD data types.

BOOL data A single ON/OFF bit, where 1 = ON (true), 0 = OFF (false).

BYTE data An 8-bit string, from most significant to least significant bit.

STRUCT data A string of bits, each of which can be set to ON (true) = 1 or OFF (false) = 0.

SSTRING data A character string, one byte per character, with one byte length indicator.

REAL data A 32-bit floating point value in single precision IEEE 754 format.

INT data A 2-byte (16-bit) integer value from –32767 to +32767.

UINT data A 16-bit unsigned integer value from 0 to 65535.

USINT data An 8-bit unsigned integer value from 0 to 255.

EPATH DeviceNet path segments requiring abstract syntax encoding.

WORD data A 16-bit string.

1.8 Customer service

For customer service:

• Phone 1-303-652-4400 or 1-800-776-6543, 8 AM to 5 PM Mountain

Time Zone weekdays, excluding holidays within the USA.

• Phone 1-800-367-GUTS (1-800-367-4887) 24 hours per day, seven days

per week within the USA.

• Email co-csr@brooks.com

• For Global Customer Support, go to www.brooks.com and click on

Services to locate the Brooks Automation office nearest you.

14 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Installation

WARNING

WARNING

CAUTION

Chapter 2 Installation

2.1 Module components The Micro-Ion ATM module contains a Micro-Ion gauge (Bayard-Alpert

type ionization gauge), a Conductron heat-loss sensor, an atmospheric

pressure diaphragm sensor, and a vacuum pressure diaphragm sensor.

Using the module to measure the pressure of flammable

or explosive gases can cause a fire or explosion resulting

in severe property damage or personal injury.

Do not use the module to measure the pressure of flammable or

explosive gases.

Exposing the module to moisture can cause fire or

electrical shock resulting in severe property damage or

personal injury.

To avoid exposing the module to moisture, install the module in

an indoor environment. Do not install the module in any

outdoor environment.

Before You Begin Installation Operation Overview Analog Operation

2.2 Pressure relief devices Before you install the module, you should install appropriate pressure relief

devices in the vacuum system.

Brooks Automation does not supply pressure relief valves or rupture disks.

Suppliers of pressure relief valves and rupture disks are listed in the Thomas

Register under “Valves, Relief” and “Discs, Rupture.”

Operating the module above 1000 Torr (1333 mbar, 133

kPa) true pressure could cause pressure measurement

error or product failure.

To avoid measurement error or product failure due to

overpressurization, install pressure relief valves or rupture

disks in the system if pressure substantially exceeds 1000 Torr

(1333 mbar, 133 kPa).

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 15

Chapter 2

2.3 Installation procedure

The module installation procedure includes the following steps:

1. Determine the location of the module on the vacuum chamber.

2. Attach the module’s flange / fitting to its mating fitting on the vacuum

chamber.

3. Assemble and connect the module wiring.

4. Calibrate the module at atmospheric pressure.

This chapter also explains what to do if radio frequency interference (RFI)

disrupts operation of RS-485 version of the module.

Step 1 Locate the module

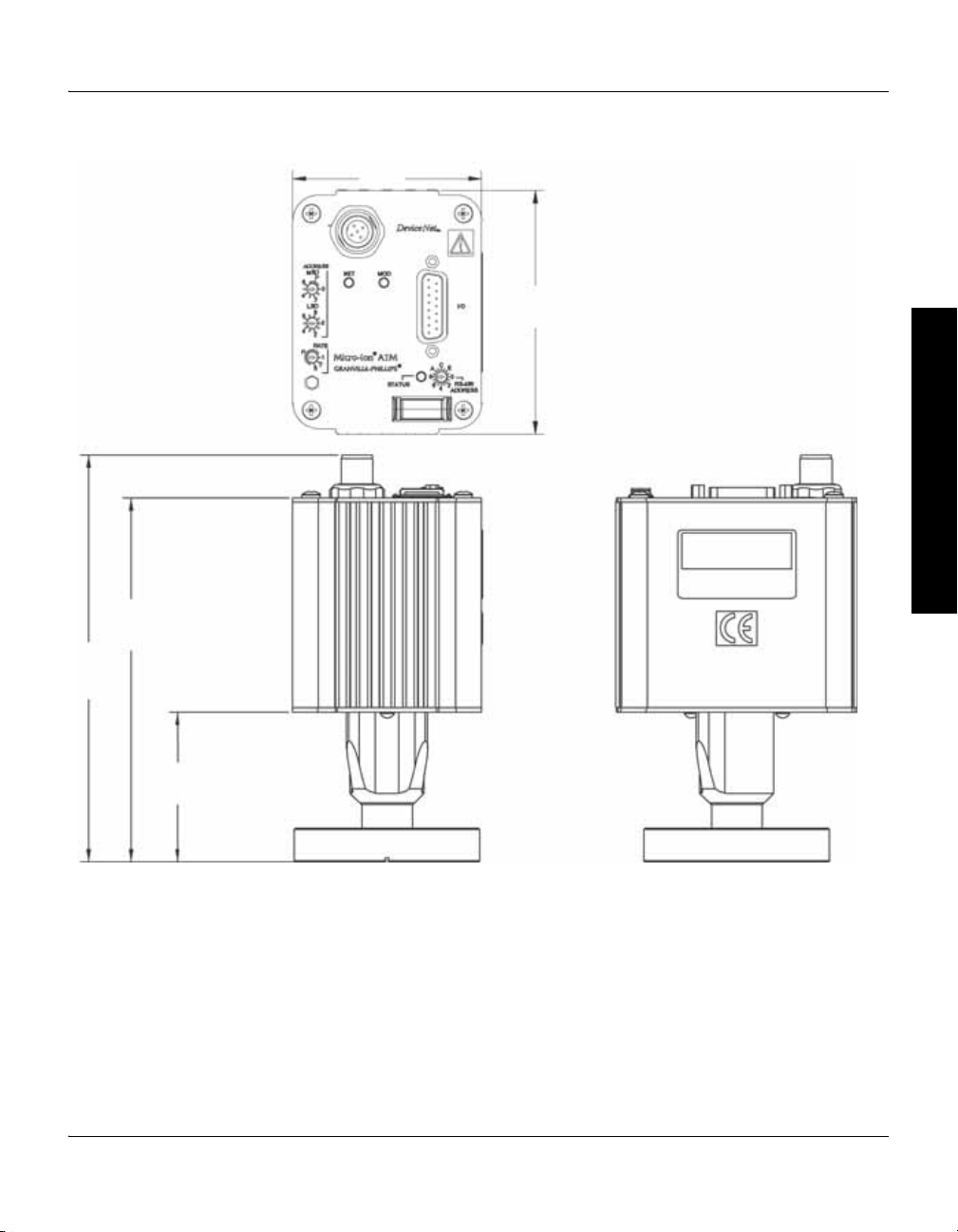

To locate the module, refer to Figure 2-1 and follow the guidelines below.

• For greatest accuracy and repeatability, locate the module in a stable,

room-temperature environment. Ambient temperature should never

exceed 40 °C (104 °F) operating, non-condensing, or 85 °C (185 °F)

non-operating. Bakeout temperature with the electronics removed from

the module is 105 °C (221 °F).

• Locate the module away from internal and external heat sources and in

an area where ambient temperature remains reasonably constant.

• Do not locate the module near the pump, where gauge pressure might be

lower than system vacuum pressure.

• Do not locate the module near a gas inlet or other source of

contamination, where inflow of gas or particulates causes atmospheric

pressure to be higher than system atmosphere.

• Do not locate the module where it will be exposed to corrosive gases

such as mercury vapor or fluorine.

16 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Figure 2-1 Dimensions

Dimensions in

cm

(in.)

7.1

(2.8)

9.1

(3.6)

15.1

(6)

13.6

(5.3)

5.6

(2.2)

Installation

Before You Begin Installation Operation Overview Analog Operation

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 17

Chapter 2

CAUTION

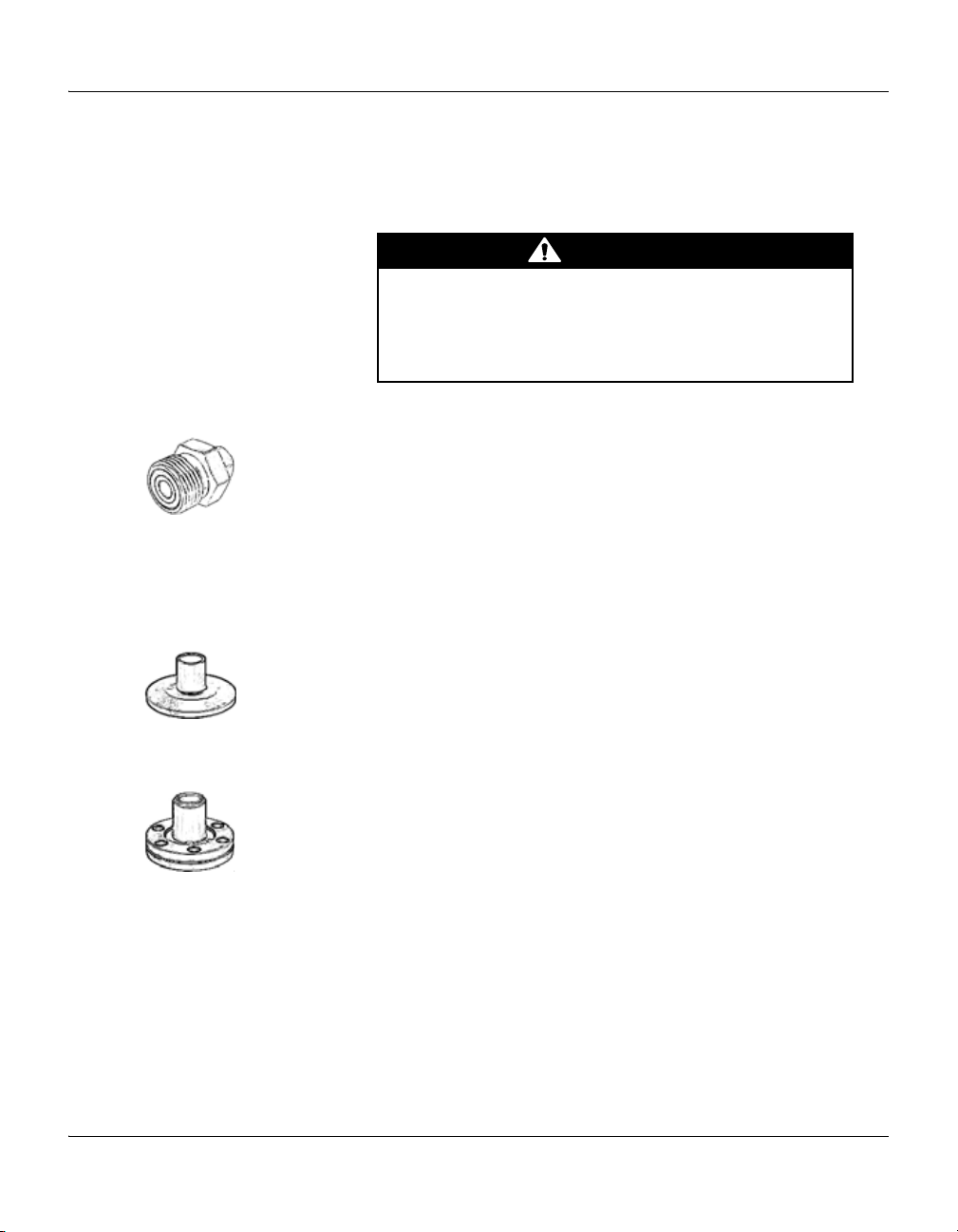

Step 2 Attach the module to the vacuum chamber

Attach the module’s flange/fitting to its mating fitting on the vacuum

chamber.

Twisting the module to tighten the fitting to the vacuum

chamber can damage the module’s internal connections.

• Do not twist the module to tighten the fitting.

• Use appropriate tools to tighten the fitting.

VCR type fitting VCR type fitting:

a. Remove the bead protector cap from the fitting.

b. Place the gasket into the female nut.

c. Assemble the components and tighten them to finger-tight.

d. While holding a back-up wrench stationary, tighten the female nut 1/8

turn past finger-tight on 316 stainless steel or nickel gaskets, or 1/4 turn

past finger-tight on copper or aluminum gaskets. Do not twist the

module to tighten the fitting.

KF flange The KF mounting system requires O-rings and centering rings between

mating flanges.

a. Tighten the clamp to compress the mating flanges together.

b. Seal the O-ring.

ConFlat flange To minimize the possibility of leaks with ConFlat

stainless steel bolts and a new, clean OFHC copper gasket. Avoid

scratching the seal surfaces. To avoid contamination, install new metal

gaskets.

a. Finger tighten all bolts.

b. Use a wrench to continue tightening 1/8 turn at a time in crisscross

order (1, 4, 2, 5, 3, 6) until flange faces make contact.

c. Further tighten each bolt about 1/16 turn.

18 Micro-Ion

®

flanges, use high strength

®

ATM Module Instruction Manual - 390002 - Rev. E

Step 3 Assemble and connect wiring

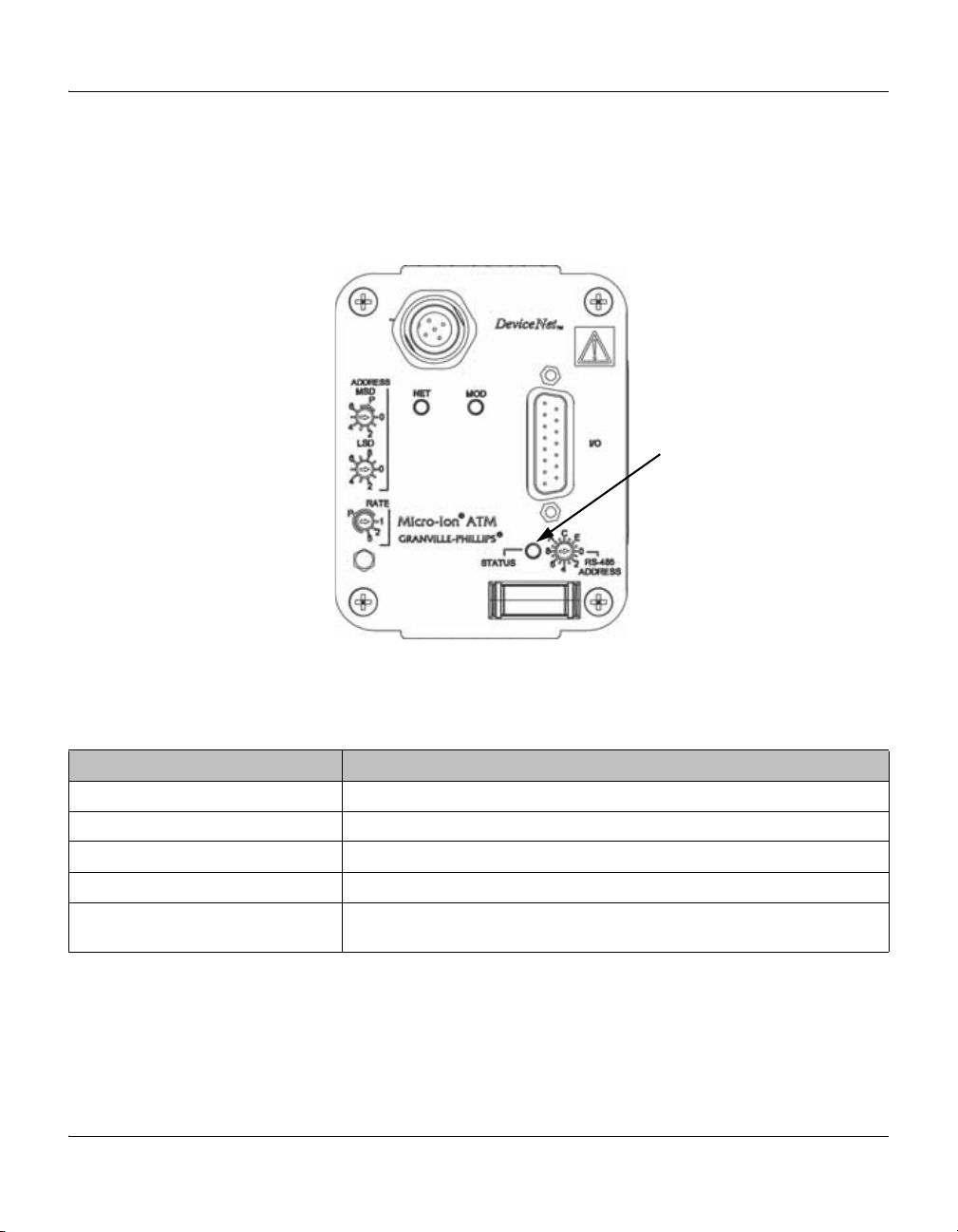

DeviceNet 5-pin micro connector

15-pin I/O connector

Connecting cable Cable is user-supplied. Brooks Automation does not supply cable. Install

externally shielded cable.

Wiring connects to the 15-pin I/O wiring connector or the DeviceNet 5-pin

micro connector. See Figure 2-2.

• Connect module power-supply wiring, analog output wiring, RS-485

output wiring, and relay wiring to the 15-pin connector.

• To turn the Micro-Ion gauge ON or OFF, install a switch between

terminals 3 and 5 on the 15-pin connector.

• To degas the Micro-Ion gauge, install a switch between terminals 7 and

8 on the 15-pin connector.

• Connect DeviceNet power-supply and network wiring to the DeviceNet

5-pin micro connector.

Figure 2-2 15-pin I/O connector and DeviceNet 5-pin micro connector

Installation

Before You Begin Installation Operation Overview Analog Operation

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 19

Chapter 2

CE Mark compliance

For CE mark compliance, use the following cable types (or equivalent):

Cable to 15-pin I/O connector

For the cable that connects to the 15-pin I/O connector, install shielded

cable with aluminum jacket and a tinned copper braid with a minimum of

65% coverage.

On the module end of the cable, install a metal housing, so the shield is

continuous from the cable to the gauge housing. Do not ground the shield

at the receiver or output device.

Acceptable raw cable parts:

• Belden cable 9947.

• Alpha cable 5110/15C SL005.

Acceptable connectors:

• Tyco series ADK for standard 15-pin subminiature-D connectors.

• Norcomp type 979-015-030-121.

DeviceNet cable

For DeviceNet cable, install raw cable that has a braided shield over the

aluminum foil-shielded signal and power wires.

On the module end of the cable, install a metal housing, so the shield is

continuous from the cable to the gauge housing. Do not ground the shield

at the receiver or output device.

• Acceptable raw cable is DeviceNet shielded cable type 578 from Turck.

• Acceptable connector is CM 8151-0 metal connector from Turck.

Module power supply Connect the module power supply to terminals 5 and 8 on the 15-pin I/O

wiring connector.

• Terminal 5 (ground) is negative (–).

• Terminal 8 (input) is positive (+).

The module requires 24 Vdc ±15% (1.5 A current at 20.4 V), 3.0 A current

at 30 W peak. Inrush current can momentarily exceed the 3.0 A peak.

Typical module operating power is 18 W for 4 mA emission when the

Micro-Ion gauge is ON.

Power inputs are reverse-bias protected.

The Micro-Ion gauge will not activate and an emission error will occur if

insufficient power is supplied during Micro-Ion gauge activation.

20 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Installation

Gauge OFF/degas wiring Install a switch between terminals 3 and 5 and between terminals 7 and 8

to enable Micro-Ion gauge degas and to switch the Micro-Ion gauge ON or

OFF.

Before You Begin Installation Operation Overview Analog Operation

Relay, analog output, and RS-485 output wiring

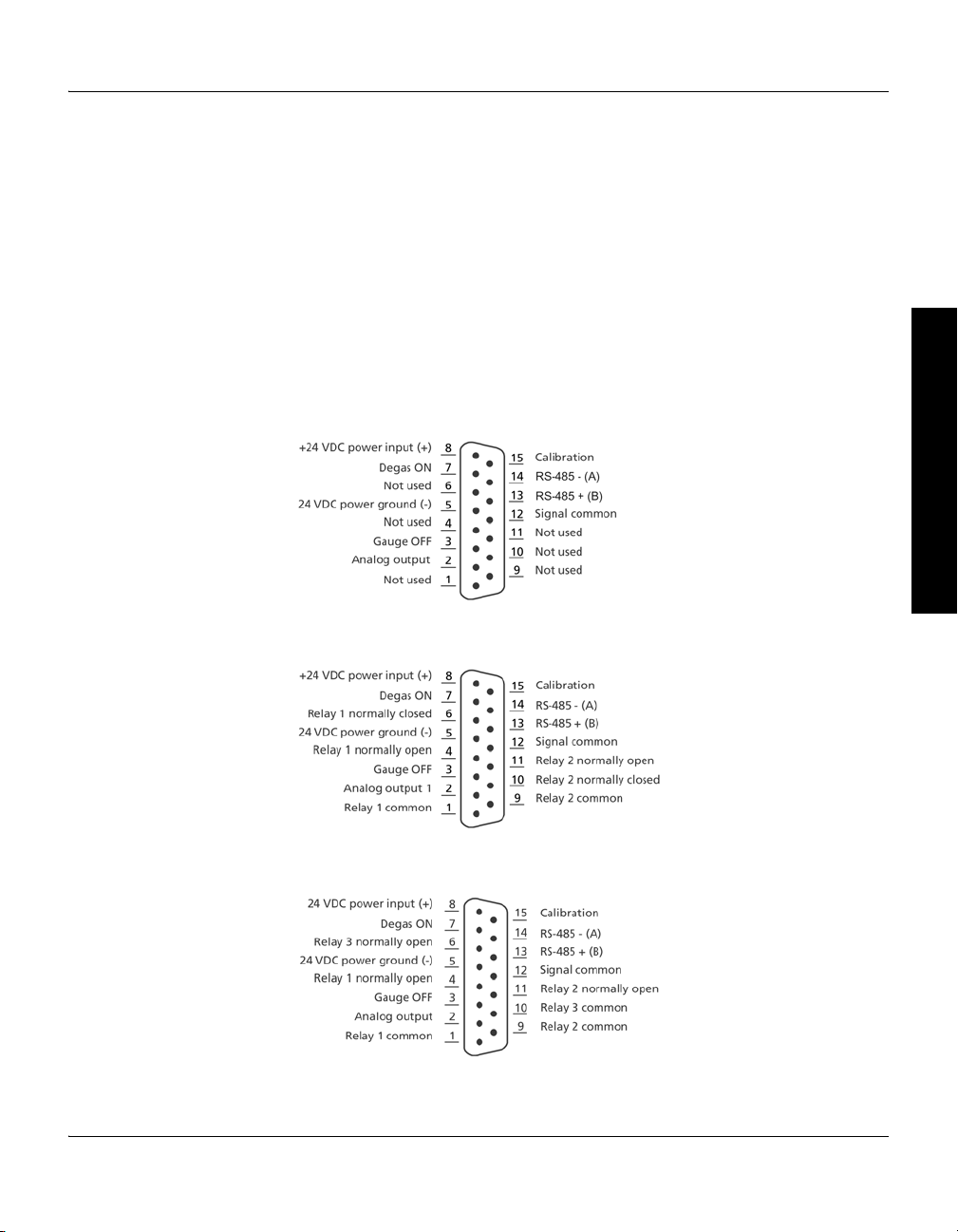

• If the module has no trip point relays, see Figure 2-3.

• If the module has two trip point relays, see Figure 2-4. Relays are

normally open/normally closed.

• If the module has three trip point relays, see Figure 2-5. Relays are

normally open.

Relay contacts are silver alloy-gold clad, rated for 1 A at 30 Vdc. The relays

can handle resistive or non-inductive loads.

Figure 2-3 Wiring terminals for Micro-Ion ATM module with RS-485 interface, one analog output, and no trip-point relays

Figure 2-4 Wiring terminals for Micro-Ion ATM module with RS-485 interface, one analog output, and two trip-point relays

Figure 2-5 Wiring terminals for Micro-Ion ATM module with RS-485 interface, one analog output, and three trip-point relays

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 21

Chapter 2

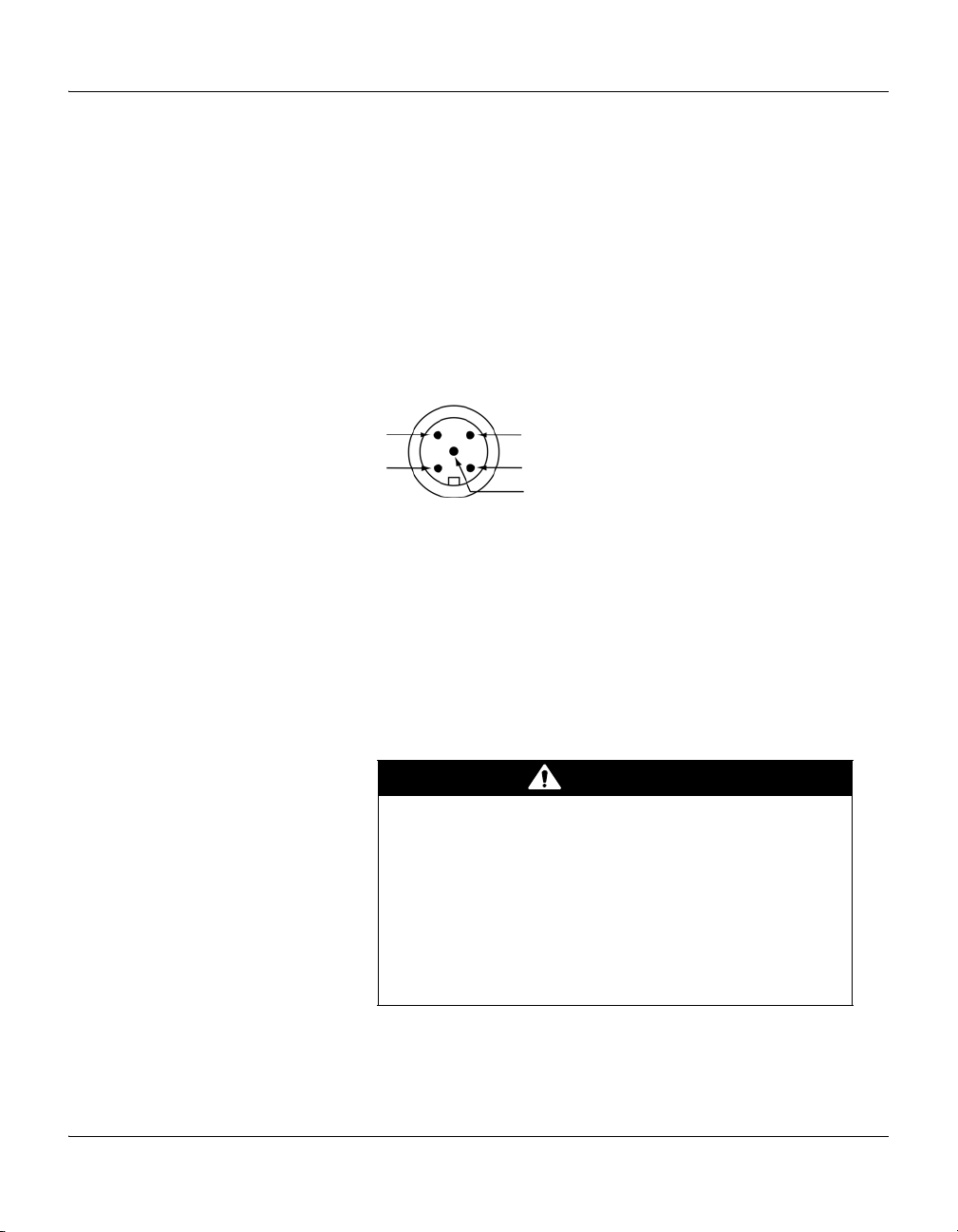

CAN_H 4

Shield 1

3

(–) VDC return

2 (+) 24 VDC

5 CAN_L

WARNING

DeviceNet wiring

Figure 2-6 DeviceNet 5-pin micro connector

Grounding

The module has a DeviceNet 5-pin micro connector for interfacing through

the customer supplied DeviceNet network cable. See Figure 2-6. The

DeviceNet connection is a standard 5-pin DeviceNet receptacle that

accepts a standard micro 5-pin female cable connection.

The module will use terminals 2 (Vdc return) and 3 (24 Vdc) on the 5-pin

DeviceNet micro connector for the network power supply.

• The DeviceNet interface requires 24 Vdc (11 to 26.4) at 0.2 A maximum.

• Maximum inrush current is 0.25 A.

• Power inputs are reverse-bias protected.

The module contains three separate and isolated grounds: the DeviceNet

ground, the analog ground, and the chassis ground.

• Typical isolation between DeviceNet and chassis grounds is 1 MΩ, up to

26 Vdc, if the DeviceNet drain is grounded.

• Above 30 Vdc the isolation approaches 0 Ω.

• The analog ground is galvanically isolated from the DeviceNet ground

and the chassis ground up to 1500 V.

The module generates 180 Vdc during normal operation and 250 Vdc

during Micro-Ion gauge degas.

Improper grounding could cause severe product failure

or personal injury.

Follow ground network requirements for the facility.

• Maintain all exposed conductors at earth ground.

• Ground the module housing to the vacuum chamber as

illustrated below.

• Make sure the vacuum port to which the module is mounted

is properly grounded.

22 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

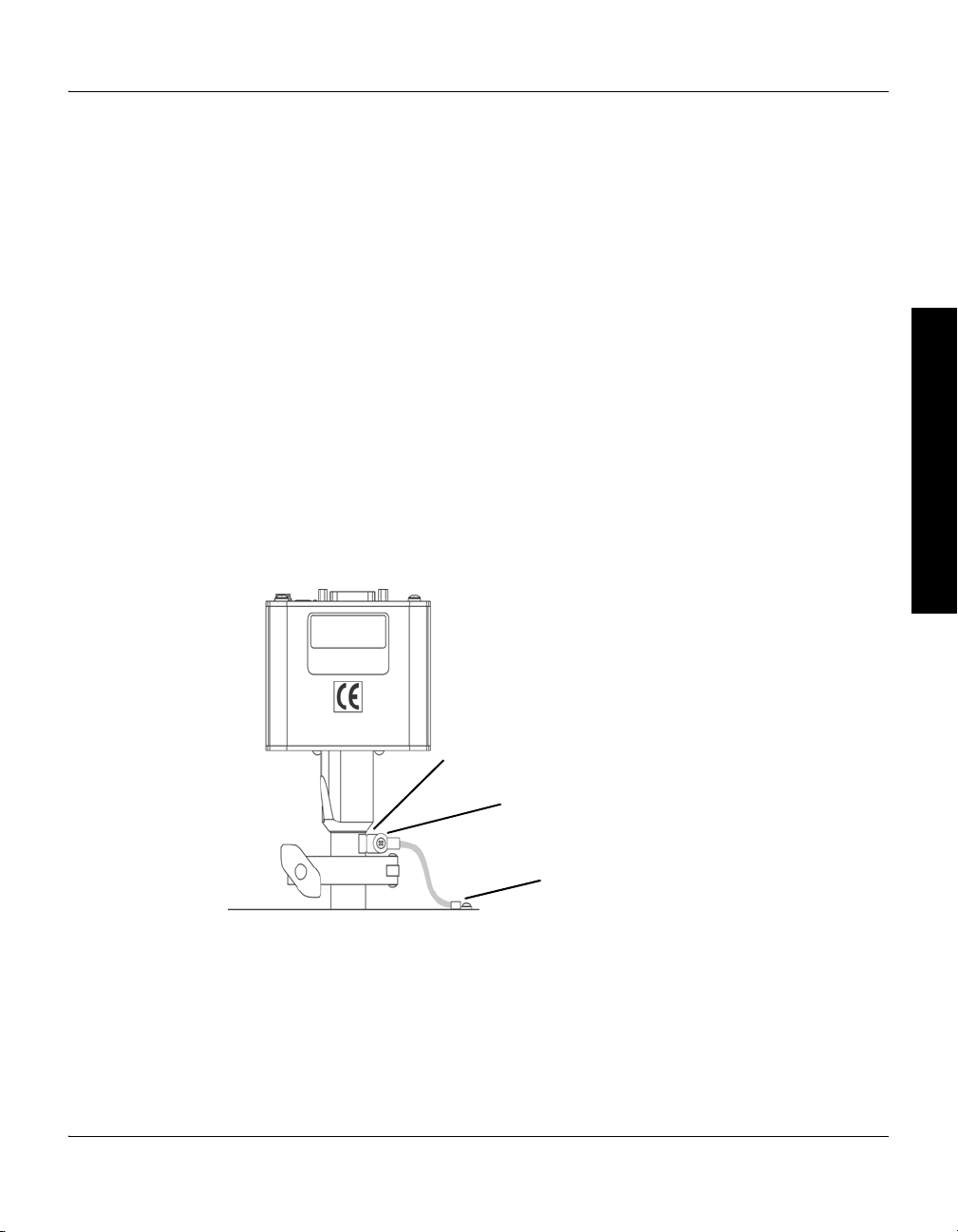

DeviceNet grounding

a. Bend the tab outward from the gauge base.

Vacuum chamber

b. Use the supplied nut to connect the

screw lug to the tab.

c. Connect the other screw lug to

the vacuum chamber.

The DeviceNet wiring will be properly grounded via the DeviceNet 5-pin

micro connector.

Chassis ground

If the module has a VCR type fitting or ConFlat flange, the module chassis

will be properly grounded via the vacuum chamber connection.

If the module has a KF flange, the module is shipped with a 3-foot length of

braided copper wire, which has a screw lug on each end, and a screw and

nut for connecting the copper wire to the gauge base. If a metal clamp and

metal gasket will not be installed, follow this procedure to ground the

module:

a. The gauge base has a tab that allows a connection to the copper wire.

b. Use the supplied screw and nut to connect one screw lug on the

c. Connect the other screw lug to an appropriately grounded point on the

Figure 2-7 Vacuum chamber ground connections

Installation

Before You Begin Installation Operation Overview Analog Operation

Bend the tab outward from the gauge base (see Figure 2-7).

braided copper wire to the tab.

vacuum system.

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 23

Chapter 2

Step 4 Calibrate module at atmospheric pressure

• To calibrate the module at atmospheric pressure using a momentary

switch installed between pins 15 and 5 on the 15-pin connector,

see page 35.

• To calibrate the module at atmospheric pressure using an RS–485

command, see page 99.

• To calibrate the module at atmospheric pressure using DeviceNet explicit

messaging, see page 65.

Atmospheric pressure calibration and differential pressure zero are

performed at the factory before the module is shipped. The module will not

operate properly unless you reset the atmospheric pressure calibration and

differential pressure zero at the ambient operating pressure.

2.4 Eliminating radio frequency interference

The module has been tested and found to comply with U.S. Federal

Communications Commission (FCC) limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits provide reasonable

protection against harmful interference when the module operates in a

commercial environment.

The module generates and can radiate radio frequency energy. If not

installed and used in accordance with the instructions in this manual, the

module may cause harmful interference to other electrical equipment.

24 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Operation Overview

Chapter 3 Operation Overview

Before You Begin Installation Operation Overview Analog Operation

3.1 Interfaces, outputs, and relays

The module has a DeviceNet interface, an RS-485 interface, and one analog

output. The module may have no trip point relays, two trip point relays, or

three trip point relays.

3.2 Analog operation Table 3-1 lists tasks that may be performed using the analog output. The

output represents vacuum pressure. Using the analog output requires

installing switches on the 15-pin subminiature D connector. The switches

enable you to initiate or terminate the Micro-Ion gauge degas, calibrate the

module at atmospheric pressure, or calibrate the module at vacuum

pressure.

The analog output does not operate independently but must operate with

the DeviceNet or RS-485 interface.

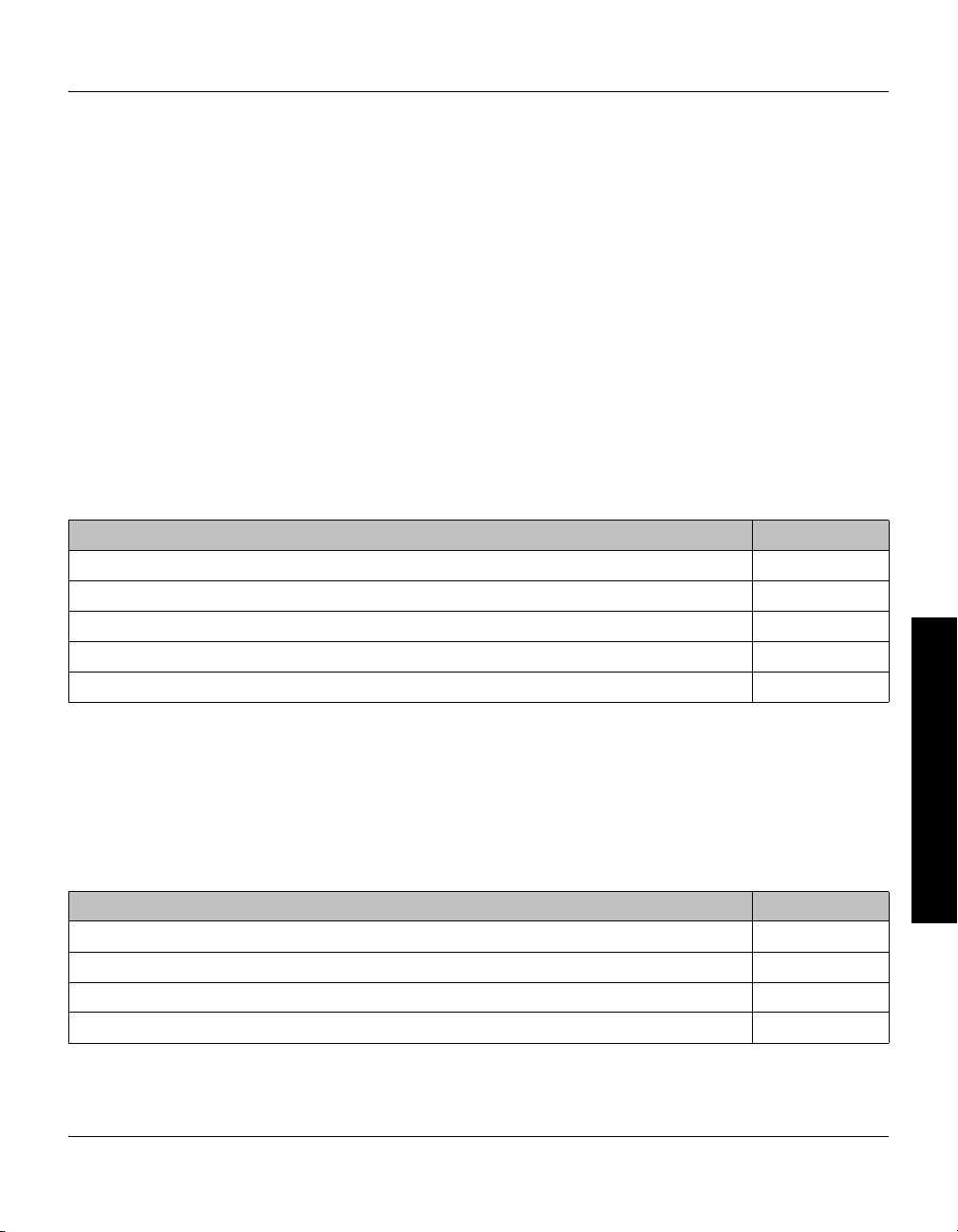

Table 3-1 Tasks and page references for operation using the 15-pin subminiature D connector

Task Instructions:

Read vacuum pressure Page 31

Turn the Micro-Ion gauge OFF Page 32

Initiate or terminate Micro-Ion gauge degas Page 33

Calibrate module at atmospheric pressure Page 35

Calibrate module at vacuum pressure Page 35

3.3 DeviceNet operation • Table 3-2 lists tasks that may be performed using DeviceNet polled I/O.

• Table 3-3 lists tasks that may be performed using DeviceNet explicit

messages.

• For a complete list of DeviceNet messages used by the module, see

Appendix B.

Table 3-2 Tasks and page references for DeviceNet polled I/O

Task Instructions:

Read vacuum pressure Page 48

Read differential pressure Page 48

Turn OFF the Micro-Ion gauge Page 58

Initiate or terminate Micro-Ion gauge degas Page 62

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 25

Chapter 3

Table 3-3 Tasks and page references for DeviceNet explicit messages

Task Instructions:

Configure DeviceNet communications Page 43

Set or get pressure unit Page 47

Get vacuum pressure Page 48

Get differential pressure Page 48

Get temperature Page 51

Set relay trip points Page 51

Set relay activation direction Page 51

Set relay hysteresis Page 51

Set relay assignments Page 51

Set disabled/enabled state of relays Page 51

Get relay trip points Page 55

Get disabled/enabled state of relays Page 55

Get activation or deactivation status of relays Page 56

Get relay hysteresis Page 57

Get relay assignments Page 57

Set or get Micro-Ion gauge ON/OFF state Page 58

Set or get Micro-Ion gauge delay time Page 59

Set or get Micro-Ion gauge filament mode Page 60

Get Micro-Ion gauge active filament Page 61

Set or get Micro-Ion gauge degas ON/OFF state Page 62

Set or get emission current switch point for Micro-Ion gauge Page 63

Calibrate module at atmospheric pressure Page 65

Calibrate module at vacuum pressure Page 65

Reset module to power-up state Page 66

Get firmware version for module Page 66

Get software and hardware revisions for module Page 66

Get status alarms and warnings Page 115

26 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Operation Overview

3.4 RS-485 operation Table 3-4 lists tasks that may be performed using the RS-485 output.

Table 3-4 Commands, tasks, and page references for RS-485 operation

Command Task Instructions:

TLU Toggle functions to locked or unlocked state Page 80

UNL Unlock interface functions Page 80

SA Set address offset Page 81

SB Set baud rate Page 82

yuiop Set RS–485 communication to default values Page 82

SU Set pressure unit Page 82

RU Read pressure unit Page 82

SD Set pressure indication for optional display Page 82

RD Read vacuum pressure Page 83

RDD Read differential pressure Page 83

PC Set or read relay trip points and activation direction Page 84

PCG Set relay assignments Page 87

PCE Set or read disabled/enabled state of relays Page 87

RPCS Read activation or deactivation status of relays Page 88

IG Set Micro-Ion gauge ON/OFF state Page 88

IGS Read Micro-Ion gauge ON/OFF state Page 88

IGM Set or read gauge and sensor ON/OFF mode Page 89

IOD Set Micro-Ion gauge delay ON/OFF state Page 90

IDT Set Micro-Ion gauge delay time Page 91

SF Set Micro-Ion gauge filament mode Page 92

RF Read Micro-Ion gauge filament status Page 96

DG Set Micro-Ion gauge degas ON/OFF state Page 96

DGS Read Micro-Ion gauge degas ON/OFF state Page 96

DGT Set or read Micro-Ion gauge degas time Page 97

SER Set emission current switch point for Micro-Ion gauge Page 97

RE Read Micro-Ion gauge emission current Page 99

TS Calibrate module at atmospheric pressure Page 99

TZ Calibrate module at vacuum pressure Page 100

ATM Set or read atmospheric pressure indicated by analog and RS–485 outputs Page 101

RS Read RS-485 character strings indicating module status Page 101

RSX Read 8-digit hexadecimal codes indicating module status Page 103

RST Reset module to power-up state Page 105

FAC Reset values to factory defaults Page 106

VER Read firmware version for module Page 106

Before You Begin Installation Operation Overview Analog Operation

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 27

Chapter 3

3.5 Automatic filament selection

As the vacuum system pumps down from atmosphere, the Conductron

sensor measures pressure until a sufficiently low pressure level is achieved,

then automatically turns ON the Micro-Ion gauge. The filaments in the

Micro-Ion gauge can burn out if they turn ON at a pressure that is too high.

Tungsten filaments are more likely than yttria-coated iridium filaments to

burn out if they turn ON at a pressure that is too high. To reduce the risk of

burnout, the default behavior of Micro-Ion gauge depends on the filament

material.

If a rapid increase in pressure from high vacuum levels to pressures of 1 Torr

(1.33 mbar, 133 Pa) or higher pressure occurs, tungsten filaments are almost

certain to burn out. This risk is not unique to the Micro-Ion gauge and exists

for all ion gauges containing tungsten filaments.

• At startup, the module software detects the filament material and sets the

behavior of the Micro-Ion gauge accordingly, as listed in Table 3-5.

• If the gauge assembly is replaced, the module software automatically sets

the behavior of the Micro-Ion gauge according to the filament material.

• For RS-485 communications, you can use the IOD, IDT, and SF

commands to change the behavior of the Micro-Ion gauge. See pages

90–92.

• For DeviceNet communications, you can use explicit messages to

change the behavior of the Micro-Ion gauge. See pages 60–61.

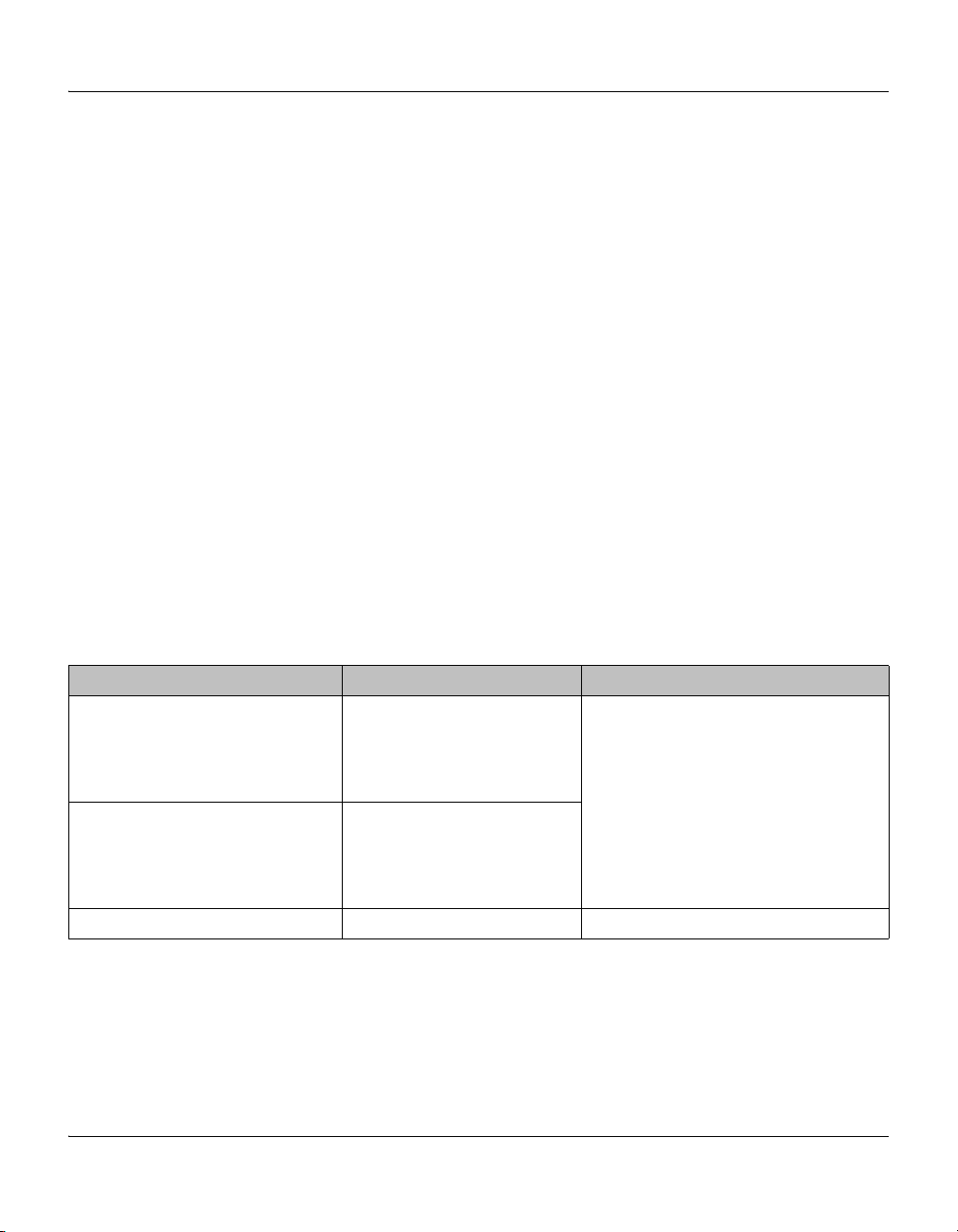

Table 3-5 Defaults for Micro-Ion gauge filament material

Function Default for tungsten filaments Default for yttria-coated iridium filaments

Micro-Ion gauge delay time Module software determines the

appropriate amount of time to

wait before the Micro-Ion gauge

turns ON with decreasing

pressure

Micro-Ion gauge added delay time Micro-Ion gauge waits an

additional 2 seconds, beyond

software-defined delay time, to

turn ON with decreasing

pressure.

Micro-Ion gauge filament mode Manual (see page 60 or page 94). Alternating (see page 60 or page 95).

Micro-Ion gauge turns ON, without delay,

as soon as operational pressure is achieved

with decreasing pressure.

28 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Analog Operation

WARNING

Chapter 4 Analog Operation

4.1 Output functions The module has a DeviceNet interface, an RS-485 interface, and one

analog output. The analog output represents vacuum pressure.

The analog output does not operate independently but must operate with

the DeviceNet or RS-485 interface.

Using the module to measure the pressure of flammable

or explosive gases can cause a fire or explosion resulting

in severe property damage, personal injury, or death.

Do not use the module to measure the pressure of flammable or

explosive gases.

Before You Begin Installation Operation Overview Analog Operation

4.2 Preparing to operate the module

4.3 Operational tasks Once the module is operating, you may perform the tasks listed in Table 3-1

Before putting the module into operation, you must perform the following

procedures:

1. Install the module in accordance with the instructions on pages 15–24.

2. Develop a logic diagram of the process control function.

3. Develop a circuit schematic that specifies exactly how each piece of

system hardware will connect to the module relays.

4. Attach a copy of the process control circuit diagram to this manual for

future reference and troubleshooting.

If you need application assistance, phone a Granville-Phillips application

engineer at 1-303-652-4400 or 1-800-776-6543 within the USA, or email

co-csr@brooks.com.

on page 25.

Micro-Ion®ATM Module Instruction Manual - 390002 - Rev. E 29

Chapter 4

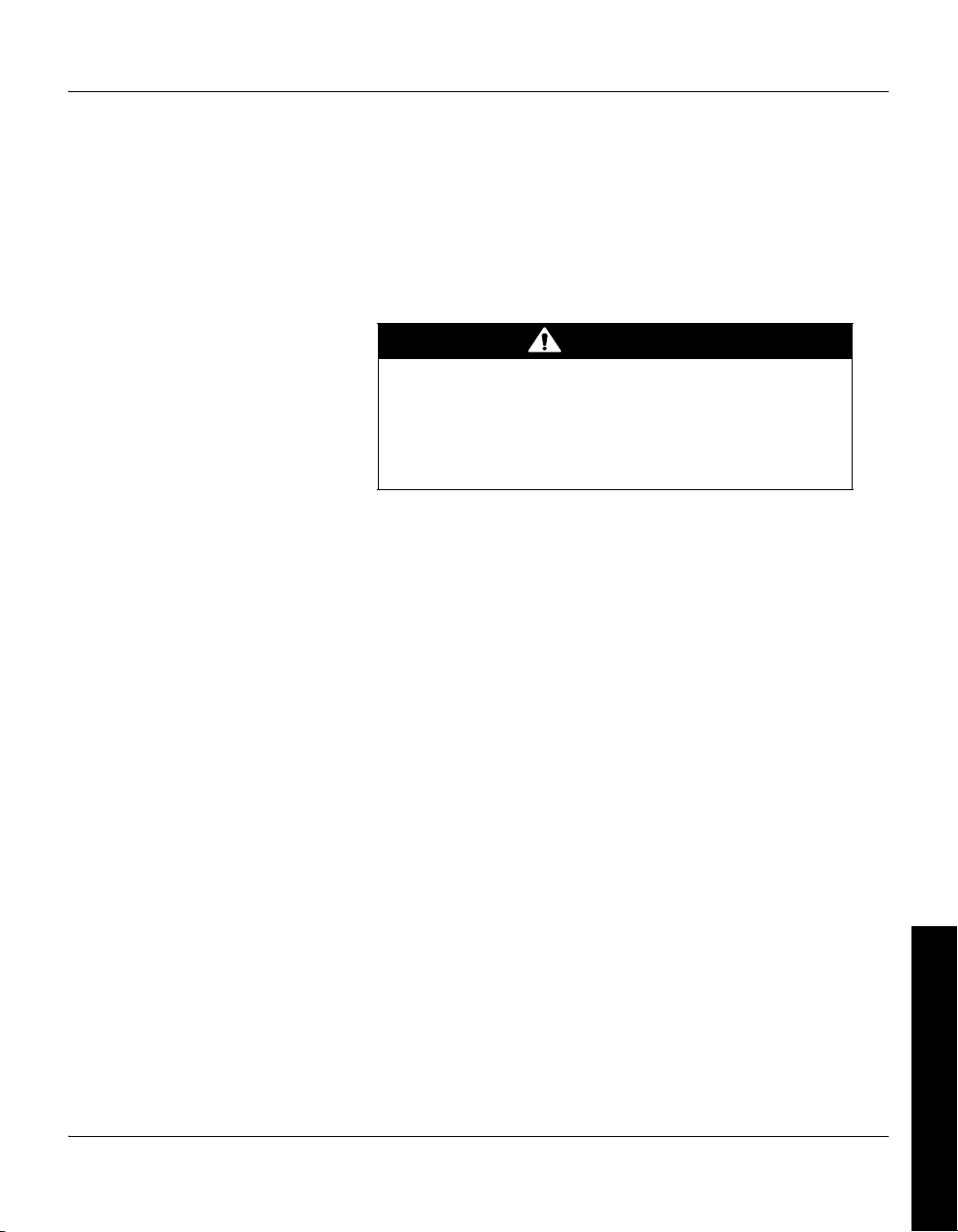

Status LED

4.4 LED status indicator

Figure 4-1 LED status indicator

• Figure 4-1 illustrates the LED status indicator on the top of the housing.

The LED behavior indicates the status of the module and Micro-Ion

gauge.

• Table 4-1 lists states indicated by the LED.

Table 4-1 LED status indications

LED behavior Indicated condition:

OFF Module power supply is OFF

Solid green Power is ON, Micro-Ion gauge is OFF

Blinking green Micro-Ion gauge is ON

Solid amber Micro-Ion gauge is ON but one filament is inoperable

Blinking amber • Both Micro-Ion gauge filaments are inoperable; replace gauge assembly

• Electronics may be defective; return module to factory

30 Micro-Ion

®

ATM Module Instruction Manual - 390002 - Rev. E

Loading...

Loading...