Granville-Phillips 475 Series Instruction Manual

Series 475

Granville-Phillips® Series 475 Convectron

Vacuum Measurement Controller

®

Instruction Manual

Instruction manual part number 475101

Revision G - January 2015

Series 475

Granville-Phillips® Series 475 Convectron

®

Vacuum Measurement Controller

This Instruction Manual is for use with all Granville-Phillips

Series 475 Vacuum Measurement Controllers. A list of

applicable catalog numbers is provided on the following page.

This product is RoHS compliant.

Customer Service/Support

For Customer Service or Technical Support 24 hours per day,

7 days per week, every day of the year including holidays:

Phone: +1-800-227-8766 or +1-303-652-4691

MKS, Granville-Phillips Division

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: 1-303-652-4691 or 1-800-776-6543

FAX: 1-303-652-2844

Email: gp-csr@mksinst.com

Corporate Office

MKS Instruments, Inc.

2 Tech Drive, Suite 201

Andover, MA 01810 USA

Phone: 1-978-645-5500

www.mksinst.com

Instruction Manual

© 2015, MKS Instruments, Inc. All rights reserved. Granville-Phillips® and Convectron

are registered trademarks of MKS Instruments, Inc. All other trademarks and registered

trademarks are the properties of their respective owners.

®

Granville-Phillips Series 475 Convectron

Vacuum Measurement Controller

Catalog numbers for Series 475 Convectron Vacuum Measurement Controller with Graphic Display

1/8 DIN Panel Mount or Benchtop Mount

Controller:

1/8 DIN Panel Mount or Benchtop Mount 475001 - X X - X

Interface:

None 0

RS-232 A

RS-485/422 B

Setpoints:

No setpoints 0

Two setpoints 2

Measurement Units:

Tor r T

mbar M

Pascal P

Power Supply:

Universal, CE Compliant

Power Cords:

North American 115 VAC & Japan 100 VAC 1

North American 240 VAC 2

Universal Europe 220 VAC 3

United Kingdom 240 VAC 4

475008 - X

Convectron Gauges

Gold-Plated Tungsten Sensor

275071 1/8 inch NPT / 1/2 inch compression fitting

275185 1/4 inch VCR-type female fitting

275233 3/8 inch VCO-type male fitting

275282 1/2 inch VCR-type female fitting

275256 1.33 inch (NW16CF) rotatable ConFlat-type flange

275238 2.75 inch (NW35CF) rotatable ConFlat-type flange

275203 NW16KF flange

275196 NW25KF flange

275316 NW40KF flange

Platinum Sensor

275320-PP 1/8 inch NPT, ½ inch compression fitting

275320-PQ 1/4 inch VCR-type female fitting

275320-PR 1/2 inch VCR-type female fitting

275320-PF 1.33 inch CF (NW16CF) rotatable ConFlat-type flange

275320-PG 2.75 inch CF (NW35CF) rotatable ConFlat-type flange

275320-PD NW16KF flange

275320-PE NW25KF flange

275320-PK NW40KF flange

275320-PB 15 mm OD tubulation, metric O-ring compression fitting

Table of Contents

Chapter 1 Safety & Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Caution and Warning Statements . . . . . . . . . . . . . . . . . . . . . 9

1.2 Reading and Following Instructions . . . . . . . . . . . . . . . . . . . 9

1.3 System Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Explosive Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Explosion / Implosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.6 Overpressure Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.7 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.8 Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.9 Extended Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.10 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.11 Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.12 Specifications & Compliance . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Pre-Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Install Pressure Relief Devices . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Mount the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6 Install the Convectron Gauge . . . . . . . . . . . . . . . . . . . . . . . . 20

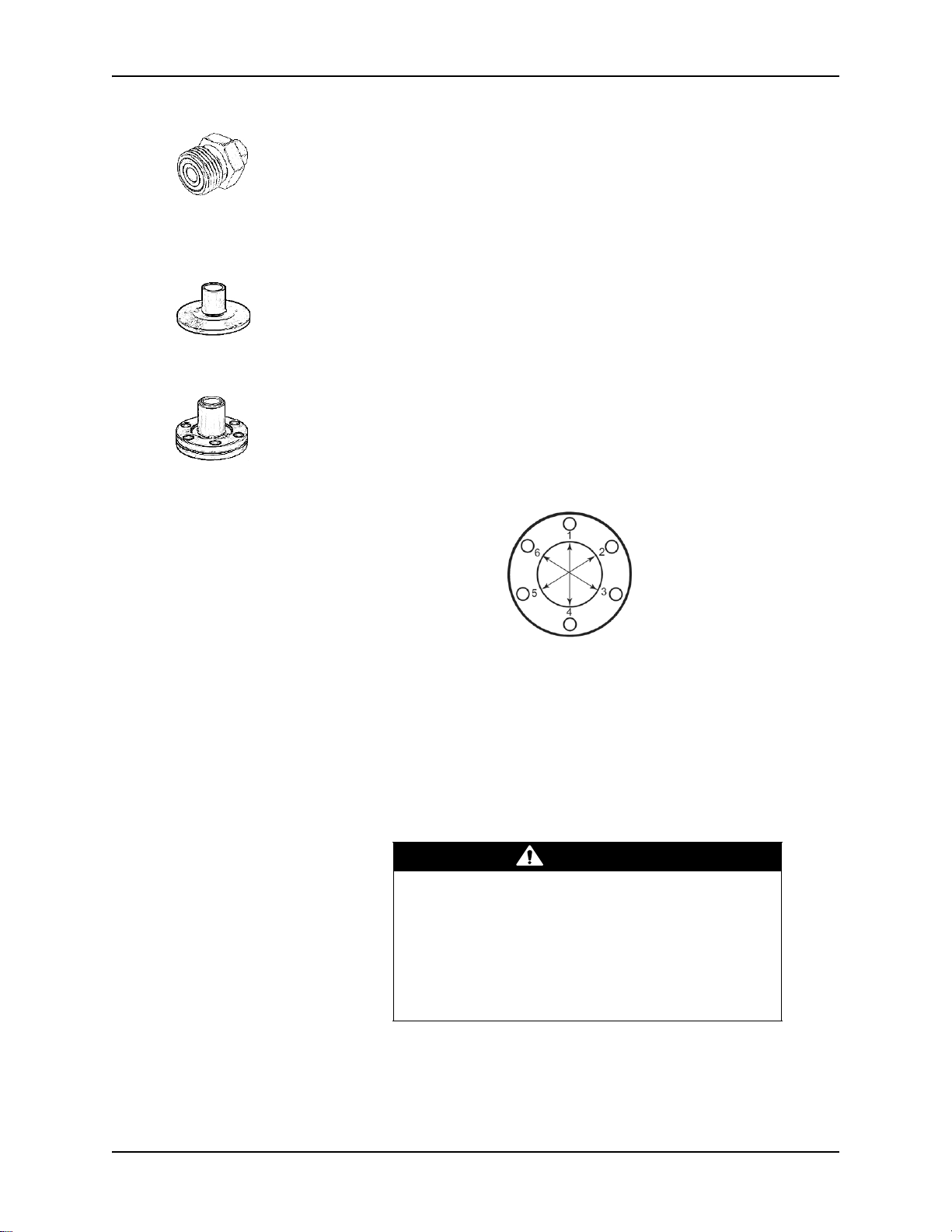

Install Vacuum Chamber Fittings . . . . . . . . . . . . . . . . . . . . . 21

Ground the Convectron Gauge . . . . . . . . . . . . . . . . . . . . . . . 22

2.7 Connect the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.8 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.9 Configure the Relays for the Application . . . . . . . . . . . . . . . . 26

2.10 Requirements for Process Control Option . . . . . . . . . . . . . . . 26

Chapter 3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Preparing for Pressure Measurement . . . . . . . . . . . . . . . . . . . 27

3.2 Button Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Initial Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.4 Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Diagnose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5 Configure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Setpoint Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

RS-232 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

RS-485/422 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pressure Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Gas Species . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pressure Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Restore Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Save Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Gauge Sensor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 5

Table of Contents

Correction Factor Parameters . . . . . . . . . . . . . . . . . . . . . . . . 38

3.6 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.7 Preparing For Convectron Gauge Operation . . . . . . . . . . . . . 40

3.8 Convectron Gauge Theory of Operation . . . . . . . . . . . . . . . . 40

3.9 Convectron Gauge Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.10 Using Gases Other than N2 or Air . . . . . . . . . . . . . . . . . . . . 41

Effects on User Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Indicated vs. True Pressure for Gases Other Than N

or Air . 42

2

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.11 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Calibration Ranges for Different Gas Species . . . . . . . . . . . . 51

Vacuum Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Atmosphere Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Convectron Gauge Use Below 10

-3

Torr . . . . . . . . . . . . . . . . 52

NIST Traceable System Calibration . . . . . . . . . . . . . . . . . . . . 52

3.12 Convectron Gauge Analog Output Signal . . . . . . . . . . . . . . . 53

Default Analog Output of 0 to 7 V . . . . . . . . . . . . . . . . . . . . 55

Optional Analog Output of 1 to 8 V . . . . . . . . . . . . . . . . . . . 55

Optional Nonlinear Analog Output “S Curve” . . . . . . . . . . . 55

3.13 Analog Output Mode Programming . . . . . . . . . . . . . . . . . . . 56

3.14 Process Control Setpoints & RS-232 or RS-485 Interface . . . . 56

Chapter 4 Process Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.1 Process Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2 Connecting Process Control Relays . . . . . . . . . . . . . . . . . . . . 58

4.3 Setpoint Display and Adjustment . . . . . . . . . . . . . . . . . . . . . 58

4.4 Process Control Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.5 Process Control Factory Default Settings . . . . . . . . . . . . . . . . 59

4.6 Process Control Relay Trip Points . . . . . . . . . . . . . . . . . . . . . 60

Chapter 5 RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.1 RS-232 Theory of Operation for the 475 Controller . . . . . . . 61

5.2 Connecting the RS-232 Computer Interface . . . . . . . . . . . . . 61

5.3 RS-232 Handshake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4 Command-Response Timing . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.5 Preparing the RS-232 Computer Interface . . . . . . . . . . . . . . . 64

5.6 RS-232 Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.7 RS-232 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

RS-232 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 6 RS-485 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.1 RS-485/422 Computer Interface Setup . . . . . . . . . . . . . . . . . 77

6.2 RS-485/422 Computer Interface Factory Default Settings . . . 77

6.3 RS-485/422 Computer Interface Settings . . . . . . . . . . . . . . . . 77

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Bus Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Transceiver Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.4 RS-485/422 Physical Configurations . . . . . . . . . . . . . . . . . . . 78

Connecting the RS-485/422 Computer Interface . . . . . . . . . . 80

6.5 Communications Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.6 RS-485/422 Command Syntax . . . . . . . . . . . . . . . . . . . . . . . 81

6.7 RS-485/422 Response Syntax . . . . . . . . . . . . . . . . . . . . . . . . 81

6 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Table of Contents

Command Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

6.8 Command-Response Timing . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.9 RS-485 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

RS-485 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Chapter 7 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

7.1 Continuous Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.2 Diagnostics Requiring User Interaction . . . . . . . . . . . . . . . . . 96

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Measurement Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.3 Convectron Gauge Simulator . . . . . . . . . . . . . . . . . . . . . . . . 97

Simulate a Process Operation Prior to Full System Integration 97

Analog Output Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Controller Calibration Verification . . . . . . . . . . . . . . . . . . . . 98

Chapter 8 Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.1 Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.2 Service Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.3 Damage Requiring Service . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.4 Error Codes and Possible Solutions . . . . . . . . . . . . . . . . . . . . 101

8.5 Convectron Gauge Test Procedure . . . . . . . . . . . . . . . . . . . . 103

8.6 Cleaning Contaminated Convectron Gauges . . . . . . . . . . . . . 103

8.7 Reset to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 7

Table of Contents

8 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Chapter 1 Safety & Introduction

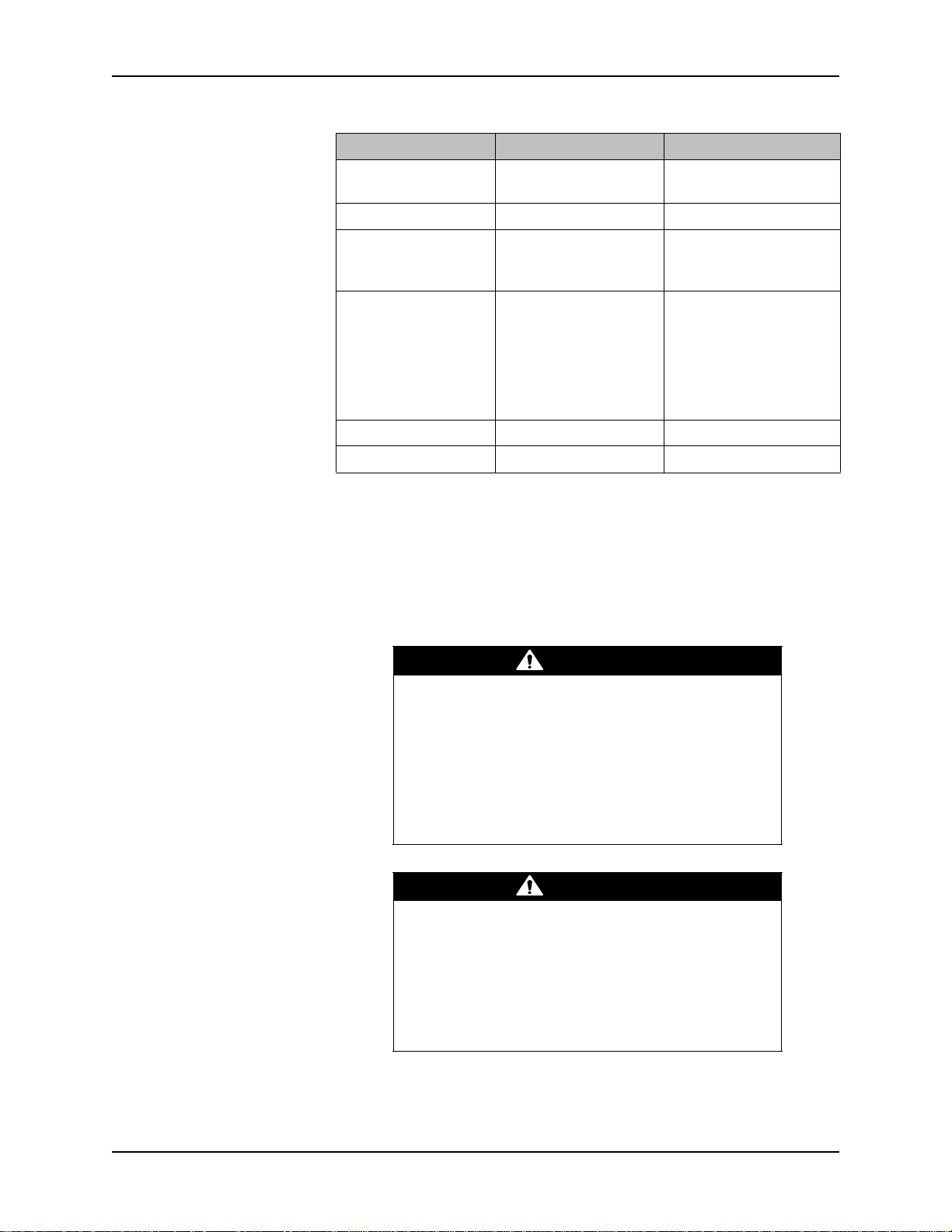

CAUTION

WARNING

1.1 Caution and Warning Statements

This manual contains caution and warning statements with which you must

comply to prevent inaccurate measurement, property damage, or personal

injury.

Caution statements alert you to hazards or unsafe

practices that could result in minor personal injury or

property damage.

Each caution statement explains what you must do to

prevent or avoid the potential result of the specified

hazard or unsafe practice.

Warning statements alert you to hazards or unsafe

practices that could result in severe personal injury or

death due to electrical shock, fire, or explosion.

Each warning statement explains what you must do

to prevent or avoid the potential result of the

specified hazard or unsafe practice.

Each caution or warning statement explains:

1. The specific hazard that you must prevent or unsafe practice that you

must avoid,

2. The potential result of your failure to prevent the specified hazard or

avoid the unsafe practice, and

3. What you must do to prevent the specified hazardous result.

1.2 Reading and Following Instructions

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 9

You must comply with all instructions while you are installing, operating, or

maintaining the Controller. Failure to comply with the instructions violates

standards of design, manufacture, and intended use of the Controller.

Granville-Phillips and Brooks Automation disclaim all liability for the

customer's failure to comply with the instructions.

• Read instructions – Read all instructions before installing or operating the

Controller.

• Retain instructions – Retain the instructions for future reference.

• Follow instructions – Follow all installation, operating and maintenance

instructions.

• Heed warnings and cautions – Adhere to all warnings and caution

statements on the Controller and in these instructions.

• Parts and accessories – Install only those replacement parts and

accessories that are recommended by Granville-Phillips. Substitution of

parts is hazardous.

Chapter 1

WARNING

Read these safety notices and warnings before

installing, using, or servicing this equipment. If you

have any doubts regarding the safe use of this

equipment, contact the Granville−Phillips Customer

Service department at the address listed in this user

manual.

Each warning statement explains what you must do

to prevent or avoid the potential result of the

specified hazard or unsafe practice.

1.3 System Grounding Ion producing equipment, such as ionization gauges, mass spectrometers, sputtering systems, etc., from many manufacturers may, under some conditions, provide sufficient electrical conduction via a plasma to couple a high voltage electrode potential to the vacuum chamber. If exposed conductive parts of the gauge, Controller, and chamber are not properly grounded, they may attain a potential near that of the high voltage electrode during this coupling. Potential fatal electrical shock could then occur because of the high voltage between these exposed conductors and ground.

All components in a vacuum system used with this or any similar high

voltage product must be maintained at Earth ground for safe operation.

Connect power cords only to properly grounded outlets or sources.

1.4 Explosive Gases Do not use the Series 475 Controller or a Series 275 Convectron Gauge in an environment of explosive or combustible gases or gas mixtures. Operation of any electrical instrument in such an environment constitutes a definite safety hazard. Do not use the product to measure the pressure of explosive gases or gas mixtures. The sensor wire of a Convectron Gauge normally operates at 125 degrees Centigrade. If a malfunction causes the sensor wire to reach a higher temperature, it could raise the sensor wire temperature to above the ignition point of combustible materials or gases.

Danger of explosion or inadvertent venting to atmosphere exists in all

vacuum systems which incorporate gas sources or involve processes capable

of pressuring the system above safe limits.

1.5 Explosion / Implosion Danger of injury to personnel and damage to equipment exists on all vacuum systems that incorporate gas sources or involve processes capable of pressuring the system above the limits it can safely withstand.

For example, danger of explosion in a vacuum system exists during

backfilling from pressurized gas cylinders because many vacuum devices

such as ionization gauge tubes, glass windows, glass belljars, etc., are not

designed to be pressurized.

1.6 Overpressure

Conditions

Do NOT subject Series 275 Convectron Gauges to pressures above 1000

Torr.

Install suitable devices that will limit the pressure from external gas sources

to the level that the vacuum system can safely withstand. In addition, install

suitable pressure relief valves or rupture disks that will release pressure at a

10 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Safety & Introduction

level considerably below that pressure which the system can safely

withstand.

Suppliers of pressure relief valves and pressure relief disks are listed in

Thomas Register under "Valves, Relief", and "Discs, Rupture".

Confirm that these safety devices are properly installed before installing the

Series 275 Convectron Gauge. In addition, check that (1) the proper gas

cylinders are installed, (2) gas cylinder valve positions are correct on manual

systems, and (3) the automation is correct on automated systems.

Using the N

calibration to pressurize a vacuum system above 1 Torr with

2

certain other gases can cause dangerously high pressures which can cause

explosion of the system. See Indicated vs. True Pressure for Gases Other

Than N

or Air on page 42.

2

If used improperly, Convectron Gauges can supply misleading pressure

indications that can result in dangerous overpressure conditions within the

system.

1.7 Operation It is the installer's responsibility to ensure that the automatic signals provided by the process control module are always used in a safe manner.

Carefully check manual operation of the system and the setpoint

programming before switching to automatic operation. Where an equipment

malfunction could cause a hazardous situation, always provide for fail-safe

operation. As an example, in an automatic backfill operation where a

malfunction might cause high internal pressures, provide an appropriate

pressure relief device.

1.8 Certification MKS Instruments, Inc. certifies that this product met its published specifications at the time of shipment from the factory. MKS Instruments further certifies that its calibration measurements are traceable to the National Institute of Standards and Technology to the extent allowed by the Institute's calibration facility. See the CE Declaration of Conformity inside envelope for the CE tests performed.

1.9 Extended Warranty MKS Instruments, Inc. provides an extended warranty period to five (5) years from the date of shipment for the Granville-Phillips Series 475 Controllers. The MKS Instruments, Inc. General Terms and Conditions of Sale provides the complete and exclusive warranty for Granville-Phillips products. This document is located on our web site at www.mksinst.com, or may be obtained by contacting a Granville-Phillips Customer Service Representative.

1.10 Service Guidelines Some minor problems are readily corrected on site. If the product requires service, contact the MKS, Granville-Phillips Division Customer Service Department at +1-800-227-8766 or +1-303-652-4691 for troubleshooting help over the phone.

If the product must be returned to the factory for service, request a Return

Material Authorization (RMA) from Granville-Phillips. Do not return

products without first obtaining an RMA. In some cases a hazardous

materials document may be required. The MKS/Granville-Phillips Customer

Service Representative will advise you if the hazardous materials document

is required.

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 11

Chapter 1

When returning a products to Granville-Phillips, be sure to package the

products to prevent shipping damage. Circuit boards and modules separated

from the gauge assembly must be handled using proper anti-static protection

methods and must be packaged in anti-static packaging. Granville-Phillips

will supply return packaging materials at no charge upon request. Shipping

damage on returned products as a result of inadequate packaging is the

Buyer's responsibility.

For Customer Service or Technical Support 24 hours per day, 7 days per

week, every day of the year including holidays:

Phone: +1-800-227-8766 or +1-303-652-4691

Email: gp-csr@mksinst.com

MKS, Granville-Phillips Division

6450 Dry Creek Parkway

Longmont, CO 80503 USA

Phone: 1-303-652-4691 or 1-800-776-6543

FAX: 1-303-652-2844.

1.11 Damage Requiring

Service

Turn OFF power to the Controller and refer servicing to qualified service

personnel under the following conditions:

• If any liquid has been spilled onto, or objects have fallen into the

Controller.

• If a circuit board is faulty.

• If the Convectron Gauge sensing wire is open or the gauge is

contaminated.

• If the Controller has been exposed to moisture.

• If the Controller does not operate normally even if you follow the

operating instructions. Adjust only those controls that are explained in this

instruction manual. Improper adjustment of other controls may result in

damage and will often require extensive work by a qualified technician to

restore the Controller to its normal operation.

• If the Controller has been dropped or the enclosure has been damaged.

• If the Controller exhibits a distinct change in performance.

12 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Safety & Introduction

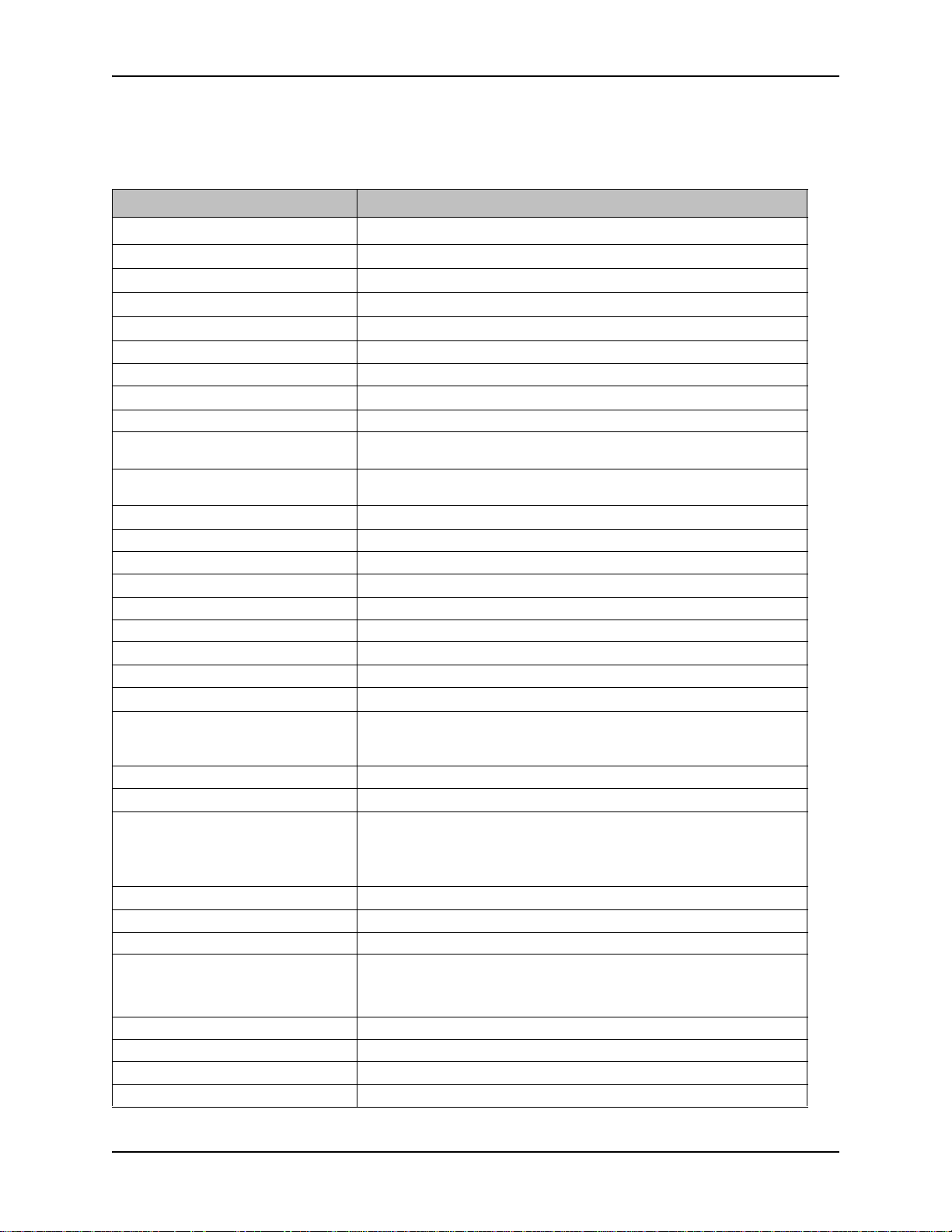

1.12 Specifications

& Compliance

Table 1-1 Specifications & Compliance for the Series 475 Controller and 275 Convectron Gauge

Parameter Specification

Measurement Range for N2 / Air

1,2

Torr

mbar

pascal

Resolution

Display Vacuum Fluorescent

Update rate Every 0.5 sec.

Input power

3

Weight 720 gr. (25 oz.)

Operating environment

Operating conditions Suitable for continuous operation, category 1 for insulation overvoltage,

Non-operating temperature

Compliance

EMC EN61326-1

Safety EN61010-1

IP rating IP20

Environmental RoHS compliant

Setpoint relays (Optional) (2) single-pole, double-throw (SPDT) (Limit overvoltage to <2.4kv)

Contact rating 5 A @ 250 VAC resistive load

Range

Resolution 1 significant digit in the 10

Communication Interface

(Optional)

RS-232

Data format ASCII, software selectable:

Baud rate Software selectable, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 38400

Hardware Handshake RTS / CTS

RS-485

Data format ASCII, software selectable:

Baud rate Software selectable, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 38400

Bus type Software selectable: two-wire or four-wire configurations

Convectron Gauge

Sensor material Gold-plated tungsten, platinum

See notes 1 and 2, below

-4

to 999 Torr

1x10

-4

to 1333 mbar

1x10

-2

to 133.3 kpa

1x10

-4

Torr, 1x10-4 mbar, 1x10-2 Pascal

1x10

12 to 24 Vdc, 6 W continuous (Inrush <1.4A for <7 msec) (see note 3, below)

o

C to 40 oC ambient, indoor use only, ordinary protection from moisture,

0

maximum altitude 3000 meters

pollution degree 2, Class 1

o

-40

C to 85 oC

-4

1x10

to 1000 Torr, 0.1 to 1333 mbar, 0.01 to 133.3 kPa

-4

range

2 significant digits in the 10

3 significant digits in the 10

-3

range

-2

range and above

"8 bits, no parity, 1 stop bit

"7 bits, even parity, 1 stop bit

"7 bits, odd parity, 1 stop bit

selectable hardware handshake

"8 bits, no parity, 1 stop bit

"7 bits, even parity, 1 stop bit

"7 bits, odd parity, 1 stop bit

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 13

Chapter 1

Table 1-1 Specifications & Compliance for the Series 475 Controller and 275 Convectron Gauge

Parameter Specification

Other materials exposed to gas 304 stainless steel, borosilicate glass, Kovar, alumina, NiFe alloy, polymide

Internal volume

Weight 85 gm (3 oz.)

Mounting orientation Horizontal preferred

Gauge operating temperature

Gauge bakeout temperature

Cable bakeout temperature

3

(2.5 in.3)

40 cm

o

0

C to 50 oC ambient

o

C maximum, non-operating, cable disconnected

150

o

C maximum

105

1. Measurements will change with different gases and mixtures. Correction

parameters must be used for gases other than N2 or Air.

2. Do NOT use Convectron Gauges with flammable or explosive gases. See

Section 1.4.

3. The 24 Vdc input power must be supplied from a power supply certified to

IEC Standard with a safety extra low voltage certified output.

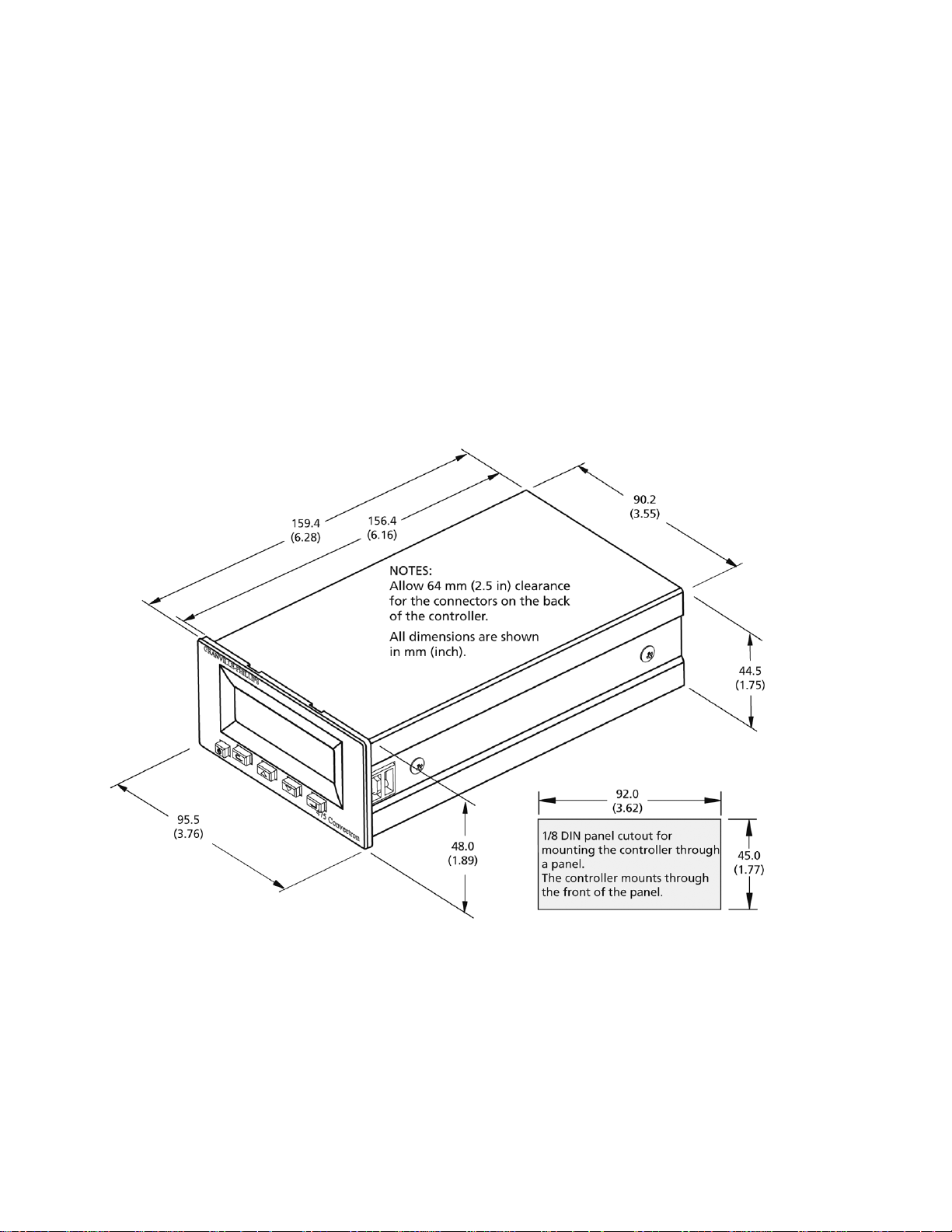

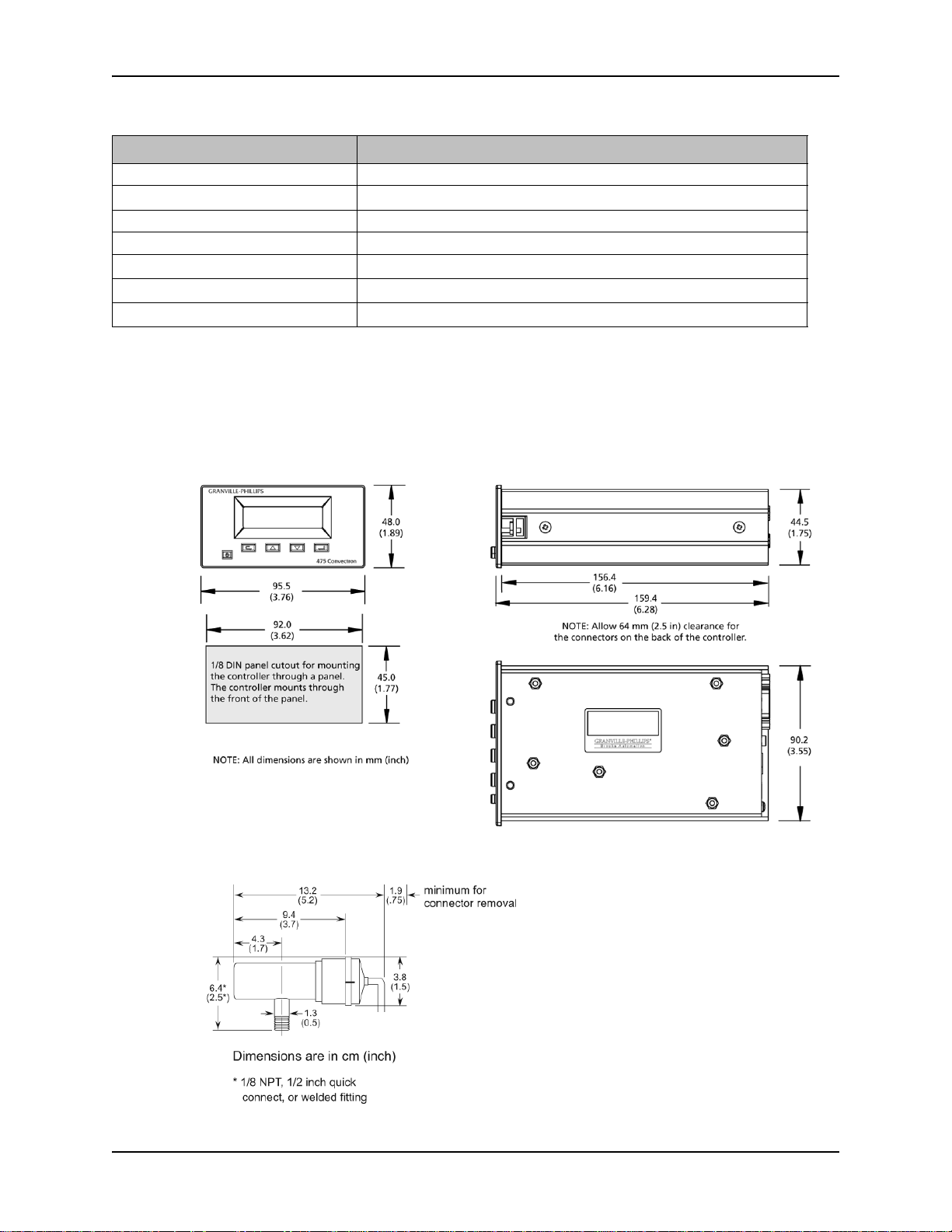

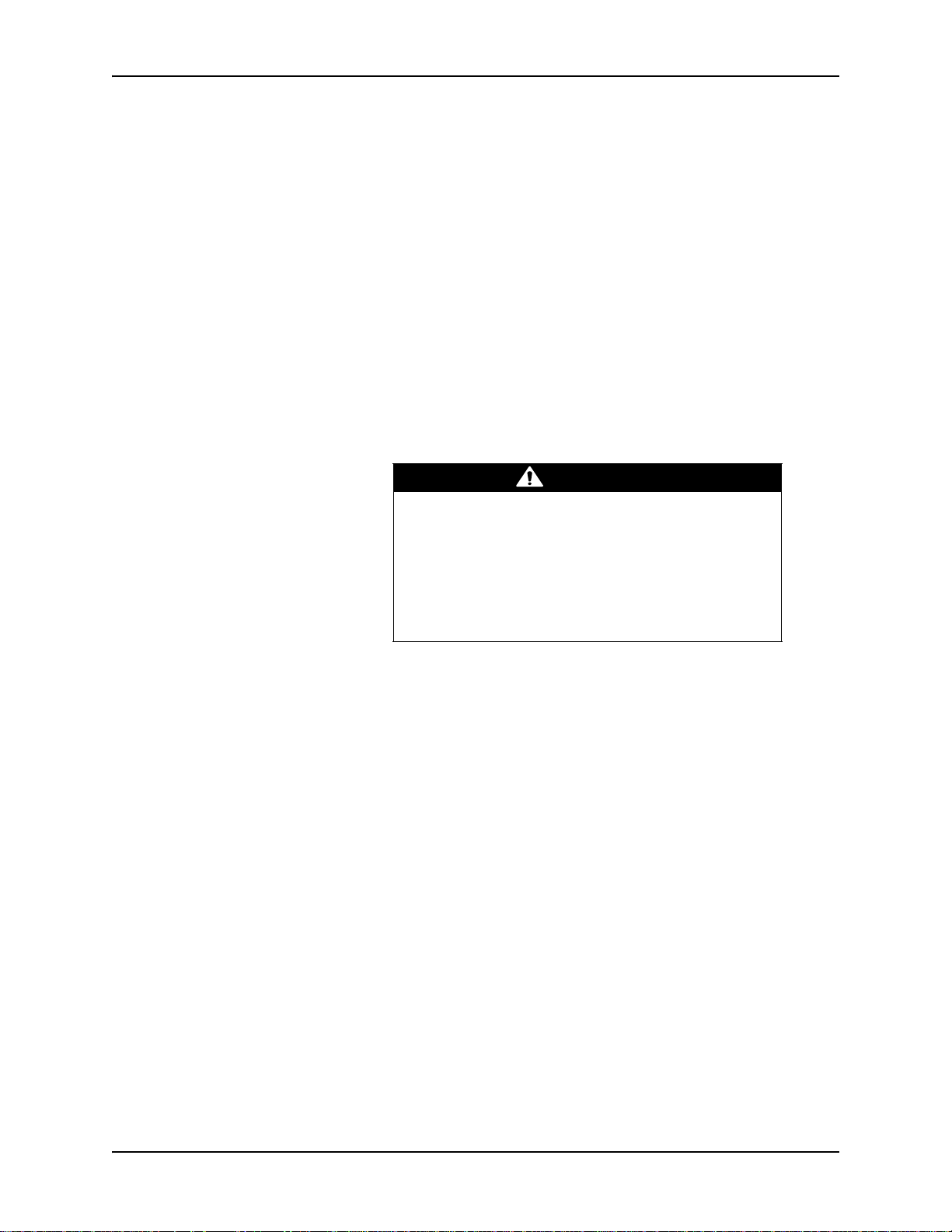

Figure 1-1 475 Convectron Gauge Controller Dimensions

Figure 1-2 Series 275 Convectron Gauge Dimensions

14 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Chapter 2 Installation

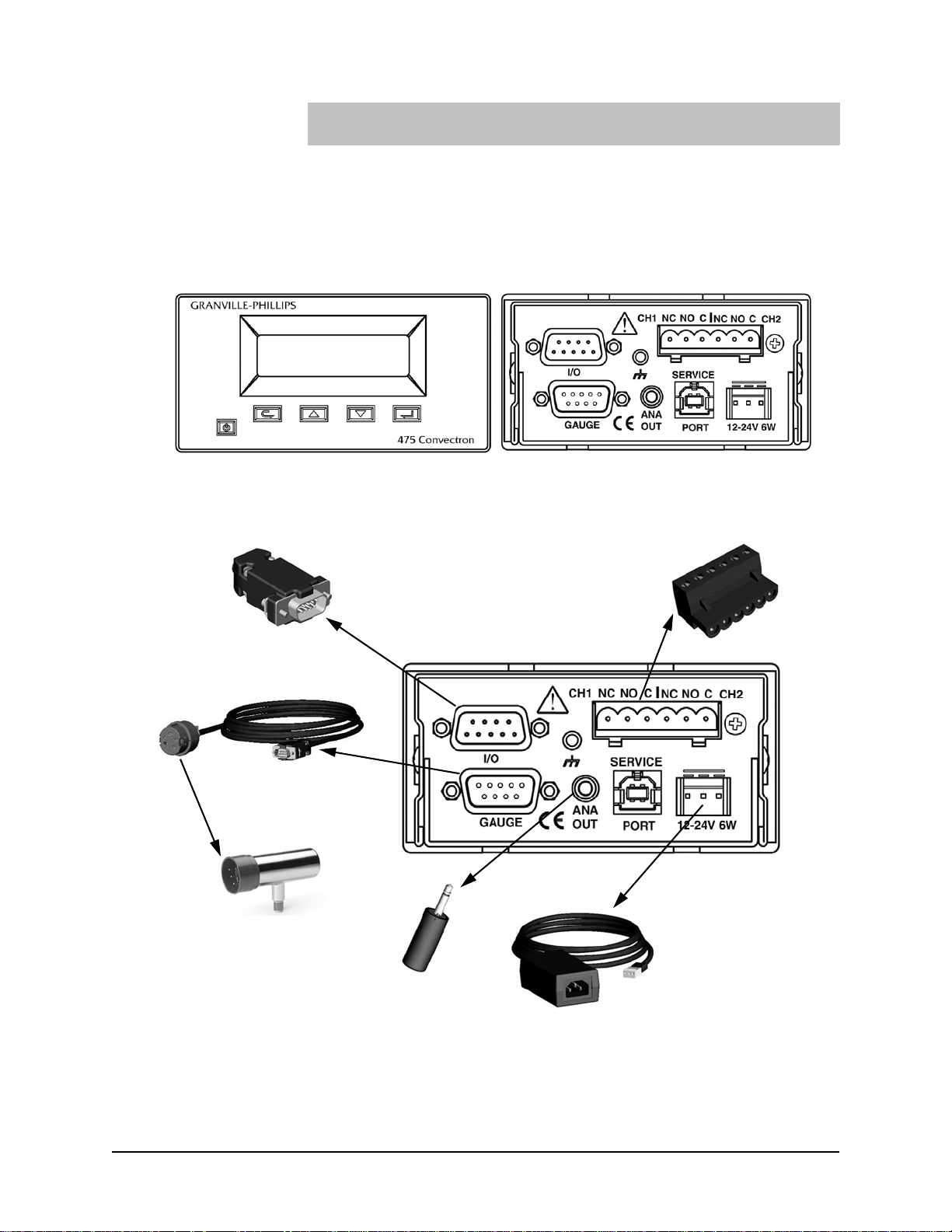

Analog output

connector

I/O output connector

2-channel process

control connector

Convectron Gauge

24 Vdc power supply

cable and converter

Gauge cable

NOTE: The Service Port is

for factory use only.

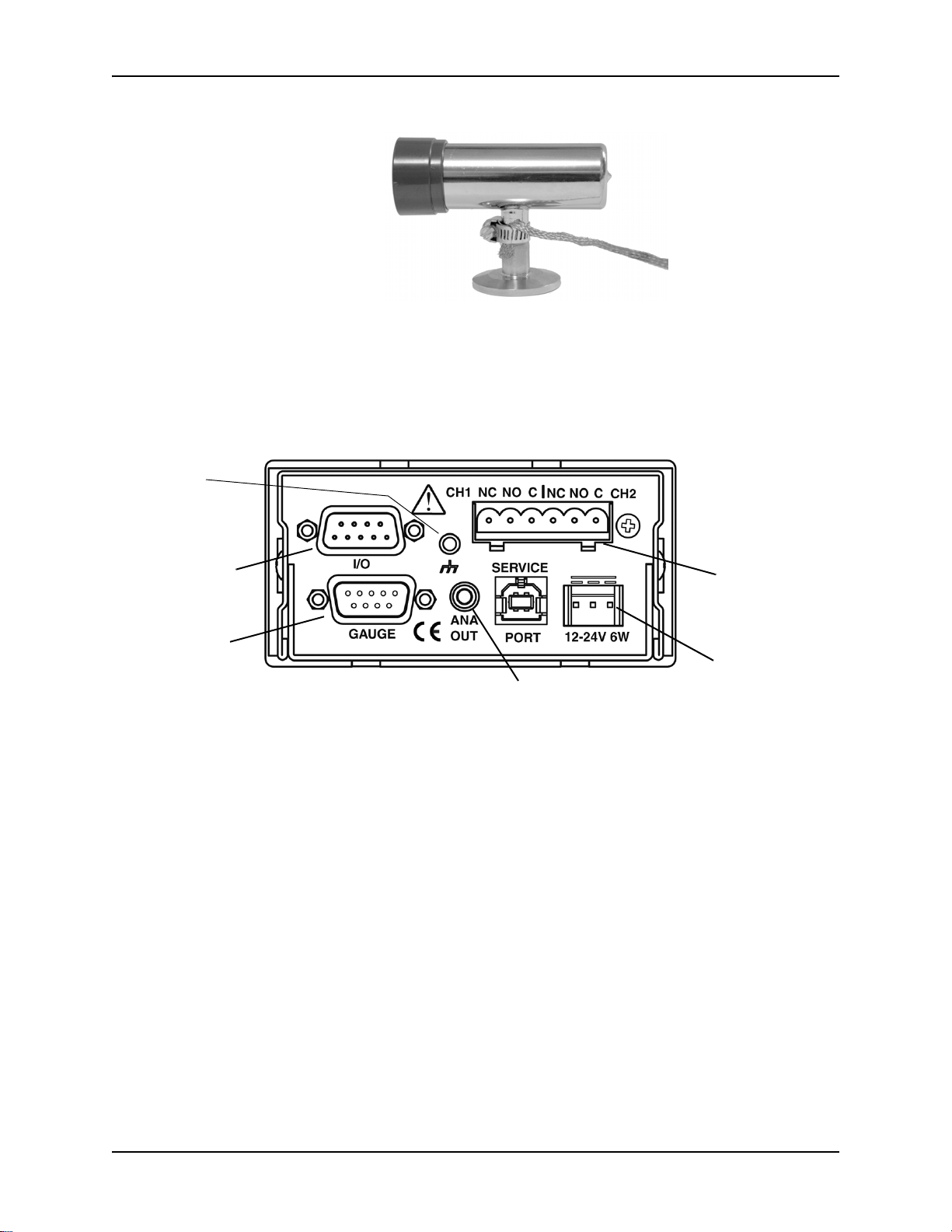

2.1 System Components Figure 2-1 and Figure 2-2 illustrate all available options and system capabilities, including Controllers with process control and RS-232 or RS-485 computer interface options.

Figure 2-1 Series 475 Convectron Controller Front and Rear Panels

Figure 2-2 Convectron Vacuum Measurement System Components

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 15

Chapter 2

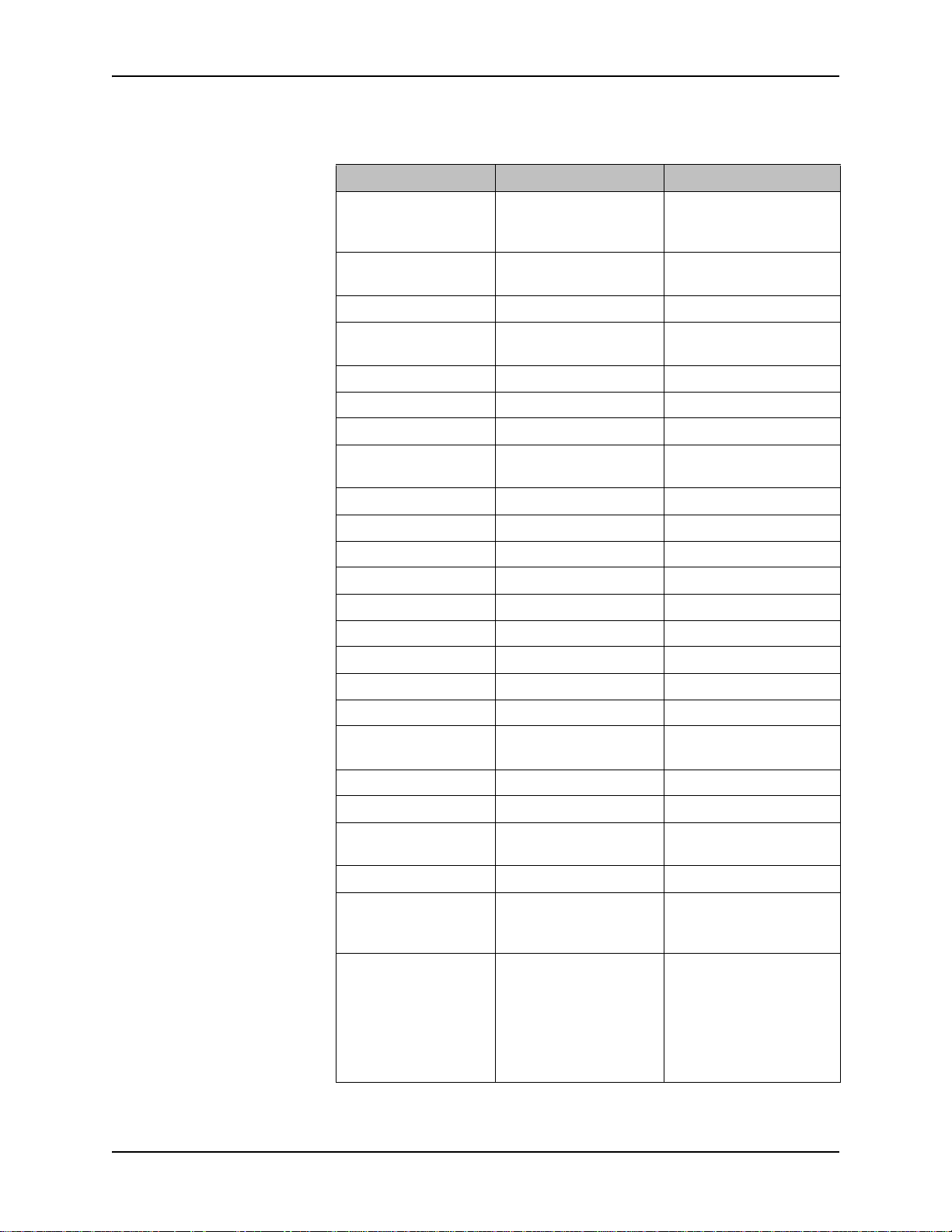

Table 2-1 475 Controller Factory Defaults

Setting Range or Selection Factory Default Setting

Units of Measure Torr, mbar, pascal Torr, mbar, or pascal as

selected when the

Controller was purchased.

Gas Species N

, Ar, O2, He, CO2,

2

N

2

FS, CF

Correction Factor 0.1 to 1.5 None

Correction Factor

1E-3 Torr to 999 Torr 999 Torr

Maximum Pressure

Front Panel Display

• Brightness 1, 2, or 3 3 (Bright)

• Setpoints displayed Yes, No No

Gauge Sensor Gold-Plated Tungsten,

Gold-Plated Tungsten

Platinum

SetPoints/Outputs

• SP1 Pressure 1E-4 Torr to 1000 Torr 1.00E-4

• SP2Pressure 1E-4 Torr to 1000 Torr 1.00E-4

• SP1 Hysteresis 5 to 1000 percent 10

• SP2 Hysteresis 5 to 1000 percent 10

• SP1 Polarity Normal, Reverse Normal

• SP2 Polarity Normal, Reverse Normal

• SP1 Enable Disable, Enable Disable

• SP2 Enable Disable, Enable Disable

• Analog Out Mode Log 0-7V, Log 1-8V,

Log 0 V-7 V

S-curve

• Analog Out Offset 0.0V to 5.0V 0V

Low-Pass Filter (LPF) Disable, Enable Enable

Pressure Response

0 to 200 ms 0 ms

Delay (ms)

RS-232

• Baud Rate Baud Rate: 1200, 2400,

19200 baud

4800, 9600, 14400,

19200, 28800, 38400

• Data Format Bits:

• 8N1 (8 data bits,

8 data bits, No parity, 1

stop bit

No parity, 1 stop bit)

• 7E1 (7 data bits,

Even parity, 1 stop bit)

• 7O1 (7 data bits,

Odd parity, 1 stop bit)

16 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Installation

WARNING

WARNING

Table 2-1 475 Controller Factory Defaults

Setting Range or Selection Factory Default Setting

• Hardware

Handshake

RS-485

• Baud Rate Baud Rate: 1200, 2400,

• Data Format Bits:

• Bus Type Two-wire or four-wire Four-wire

• Transceiver Mode Fast or Slow Fast

RTS / CTS or None None

19200 baud

4800, 9600, 14400,

19200, 28800, 38400

8 data bits, No parity, 1

• 8N1 (8 data bits,

No parity, 1 stop bit)

• 7E1 (7 data bits,

Even parity, 1 stop bit)

• 7O1 (7 data bits,

Odd parity, 1 stop bit)

stop bit

2.2 Pre-Installation

Considerations

This chapter guides you through the basic setup procedures for the 475

Controller, including mounting the Controller, installing a Convectron

Gauge, connecting vacuum chamber fittings, and connecting wiring.

If your application requires different settings than the factory defaults listed

in Table 2-1, see Chapters 3, 4, and 5 for instructions on changing the

settings. You can reconfigure options before or after completing the basic

setup procedures described in this chapter.

Installing, removing, or replacing the 475 Controller

in a high-voltage environment can cause an electrical

discharge through a gas or plasma, resulting in

property damage or personal injury due to electrical

shock or fire.

Vent the vacuum chamber to atmospheric pressure

and shut OFF power to the Controller before you

install, remove, or replace the Controller.

Exposing the Controller to moisture can cause fire or

electrical shock resulting in product damage or

personal injury.

To avoid exposing the Controller to moisture, install

the Controller in an indoor environment. Do not

install the Controller in any outdoor environment. Do

not spill any liquid onto the Controller.

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 17

Chapter 2

CAUTION

2.3 Installation Procedure The Controller installation procedure includes the following steps:

1. Install the appropriate pressure relief devices in the vacuum system.

2. Establish the desired location and orientation for the Series 475

Controller.

3. Install the Convectron Gauge that connects to the Controller.

4. Assemble and connect the Controller wiring.

5. Adjust the process control relays for the process pressures that will be

used.

2.4 Install Pressure Relief Devices

2.5 Mount the Controller To locate and orient the Controller, refer to Figure 2-3 and follow the

Before you install the Controller, install appropriate pressure relief devices in

the vacuum system.

Granville-Phillips does not supply pressure relief valves or rupture disks.

Suppliers of pressure relief valves and pressure relief disks can be located via

an on-line search, and are listed on ThomasNet.com under “Relief Valves”

and “Rupture Discs. Confirm that these safety devices are properly installed

before installing and operating the product.

Operating the Controller above 1000 Torr (1333

mbar, 133 kPa) true pressure could cause pressure

measurement error or product failure.

To avoid measurement error or product failure due to

overpressurization, install pressure relief valves or

rupture disks in the system if pressure exceeds 1000

Torr (1333 mbar, 133 kPa).

instructions below.

• For greatest accuracy and repeatability, locate the Controller in a stable,

room-temperature environment. Ambient temperature should never

exceed 40 °C (104 °F) operating, non-condensing, or 85 °C (185 °F)

non-operating.

• Provide adequate ventilation for the Controller to dissipate 6 Watts.

• Locate the Controller away from internal and external heat sources and in

an area where ambient temperature remains reasonably constant.

• Do not locate the Controller where it will be exposed to corrosive gases

such as mercury vapor or fluorine.

See Install the Convectron Gauge on page 20 for Convectron Gauge

installation instructions.

18 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Figure 2-3 Controller Dimensions

Installation

The Controller may be free-standing or panel-mounted. For free standing

(benchtop) use, install the provided self-adhesive rubber feet on the bottom

of the Controller.

To use the Controller in a free-standing (benchtop) configuration:

1. Apply the four provided adhesive rubber mount feet on the bottom of the

Controller.

Figure 2-4 Mount Feet on the Bottom of the Controller

To mount the Controller in a panel, refer to Figure 2-5 and Figure 2-6, and

follow these steps:

• Panel opening dimensions are 92 mm x 45 mm (3.6 inches x 1.77 inch).

• Panel thickness is 3 mm (1/8 inch).

• Provide a minimum of 64 mm (2.5 inch) clearance behind the Controller

to allow for cables.

1. Prepare the panel opening per the dimensions listed on Figure 2-3 and

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 19

Chapter 2

the bullet points listed above.

2. Remove the Front Panel (bezel) as shown in Figure 2-5. Hold the

Controller in your hands and use your thumbs to push on the bezel. Push

the bottom of the bezel loose, then the top.

Figure 2-5 Remove the Front Panel (bezel)

3. Insert the Controller through the front of the panel.

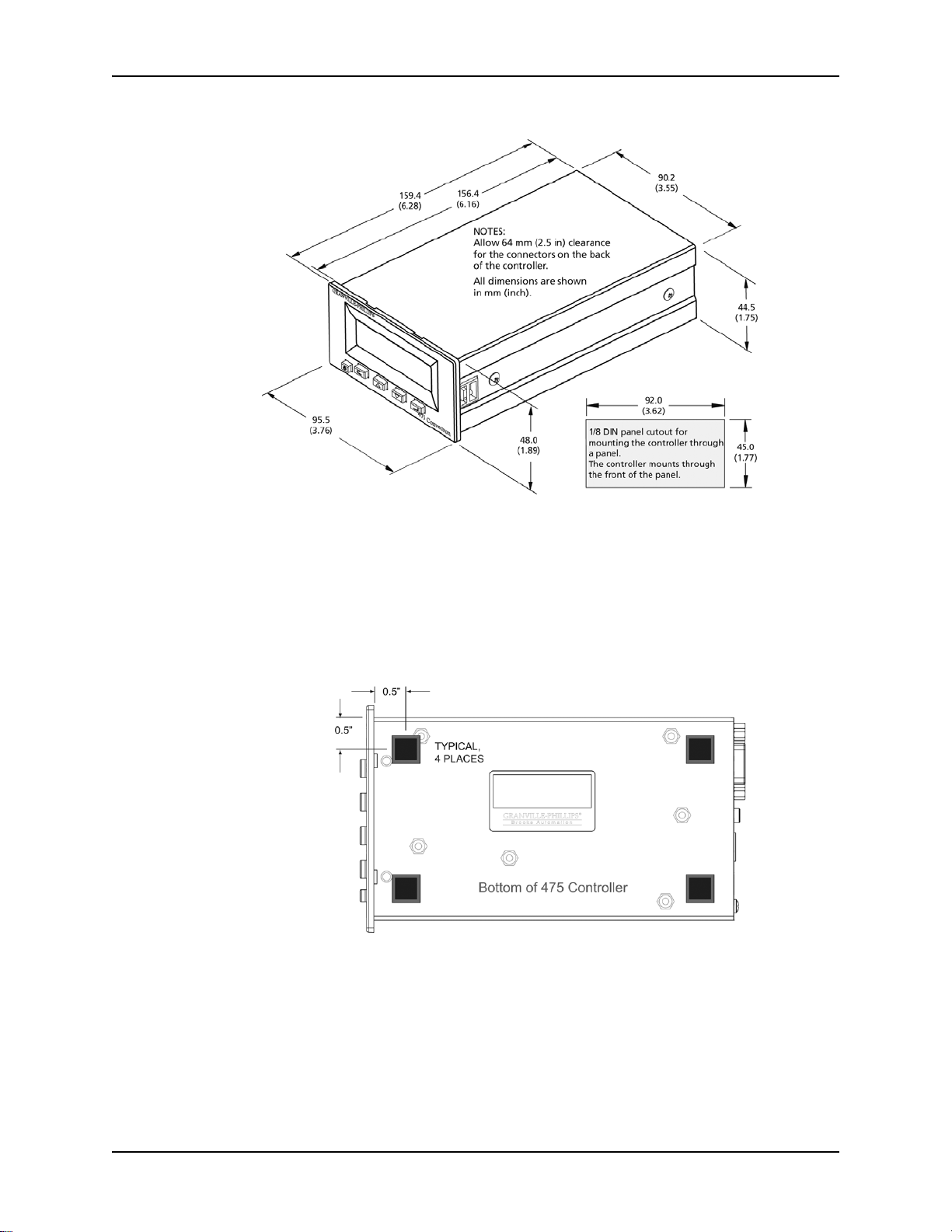

2.6 Install the Convectron Gauge

Figure 2-6 Pawl Screw Used to Secure Controller to Panel

4. Use a Phillips head screwdriver to rotate the Pawl Screw to lock the

Controller to the panel. See Figure 2-6.

5. Replace the bezel by aligning it with the keys and push the top and the

bottom of the bezel to snap it into place.

To install Convectron Gauges, refer to Figure 2-7 and follow the instructions

below.

• Orient the Convectron Gauge to prevent condensation of process vapors

on the internal surfaces through line-of-sight access to its interior. If vapor

condensation is likely, orient the port downward to help liquids drain out.

• For proper operation above about 1 Torr, install Convectron Gauges with

the gauge axis horizontal.

20 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Installation

WARNING

Figure 2-7 Convectron Gauge Installation

• Do not locate the Convectron Gauge near the pump, where gauge

pressure might be lower than normal vacuum pressure.

• Do not locate the gauge near a gas inlet or other source of contamination,

where inflow of gas or particulates causes atmospheric pressure to be

higher than system atmosphere.

• Do not locate the gauge where it will be subjected to vibration, which

causes convection cooling, resulting in inaccurate high pressure readings.

• Do not locate the gauge where it will subjected to extreme temperature

fluctuations. For greatest accuracy and repeatability the gauge should be

located in a stable room temperature environment.

Install Vacuum Chamber Fittings

Do not use a compression mount/quick connect fitting for positive pressure

applications. The gauge may be forcefully ejected. The gauge port fits a

standard 1/2-inch compression/quick connect mounting such as an

®

Ultra-Torr

fitting.

Failure to install appropriate pressure relief devices

for high-pressure applications can cause product

damage or personal injury.

For automatic backfilling and other applications in

which malfunction or normal process conditions can

cause high pressures to occur, install appropriate

pressure relief devices.

1/8 NPT Pipe Thread The 1/8 NPT pipe thread accommodates a standard 1/8 NPT female fitting.

1. Wrap the threads of the port to the vacuum chamber with thread sealant

tape.

2. Tighten the gauge just enough to achieve a seal. Do NOT over tighten.

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 21

Chapter 2

WARNING

VCR Type Fitting 1. Remove the plastic or metal bead protector cap from the fitting.

2. If a gasket is used, place the gasket into the female nut.

3. Assemble the components and tighten them to finger–tight.

4. While holding a back-up wrench stationary, tighten the female nut 1/8

turn past finger-tight on 316 stainless steel or nickel gaskets, or 1/4 turn

past finger-tight on copper or aluminum gaskets.

KF Flange The KF mounting system requires O-rings and centering rings between

mating flanges.

1. Tighten the clamp wing nut to compress the mating flanges together.

2. Seal the O-ring.

ConFlat Flange To minimize the possibility of leaks with ConFlat flanges, use high strength

stainless steel bolts and a new, clean OFHC copper gasket. Avoid scratching

the seal surfaces. To avoid contamination, install metal gaskets.

1. Finger tighten all bolts.

2. Use a wrench to continue tightening 1/8 turn at a time in criss-cross

order (1, 4, 2, 5, 3, 6) until the flange faces make contact. Further tighten

each bolt about 1/16 turn.

Ground the Convectron Gauge

22 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

• If the Convectron Gauge has a VCR type fitting or ConFlat flange, it will

be properly grounded via the vacuum chamber connection.

• If the Convectron Gauge has a KF flange or an NPT fitting, use a length of

#12 AWG braided copper wire which connects to the Convectron Gauge

and to the vacuum chamber ground connection. See Figure 3.

Improper grounding could cause product failure or

personal injury.

• Follow ground network requirements for the facility.

• Maintain all exposed conductors at earth ground.

• Make sure the vacuum port to which the gauge is

mounted is properly grounded.

Installation

Analog output connector

I/O (RS-232

or RS-485)

connector

2-channel

process control

(setpoint)

connector

Convectron

Gauge

connector

Power supply

connector

NOTE: The Service Port is

for factory use only.

Chassis

ground

connection

Figure 2-8 Convectron Gauge to Vacuum Chamber Ground Connection

2.7 Connect the Wiring The 475 Controller has connectors for Convectron Gauge cable, RS-232,

RS-485/422, setpoints, analog output cable, and power supply wiring, as

illustrated in Figure 2-9 (

Figure 2-9 Convectron Gauge, Output, and Power Connections

shown with the optional RS-232 and setpoint connectors).

• Connect a #12 AWG ground wire to the chassis ground connection on the

rear of the Controller and to a known Earth ground. Do NOT connect a

ground wire from the Controller directly to the vacuum chamber or system

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 23

Chapter 2

WARNING

Locking Tab

ground.

Improper grounding can cause product damage or

personal injury.

Follow ground network requirements for the facility.

• Maintain all exposed conductors at earth ground.

• Connect the power cord to a properly grounded

outlet.

• Make sure the vacuum port to which the gauge is

mounted is properly grounded.

• Connect the gauge envelope to a facility ground or

shield the envelope. If necessary, use a ground lug on

the flange bolt. Ground the gauge envelope by using

a metal hose clamp on the gauge connected by a #12

AWG (minimum size) copper wire to the grounded

vacuum chamber.

• Connect the Convectron Gauge cable between the gauge and the

Controller. See Figure 2-9.

• Connect the power supply by inserting the power cord with the locking

tab up. See Figure 2-10.

NOTE: The 475 Controller is internally limited to 28 Vdc maximum

and 1.4 A. Do not connect the input to high voltage.

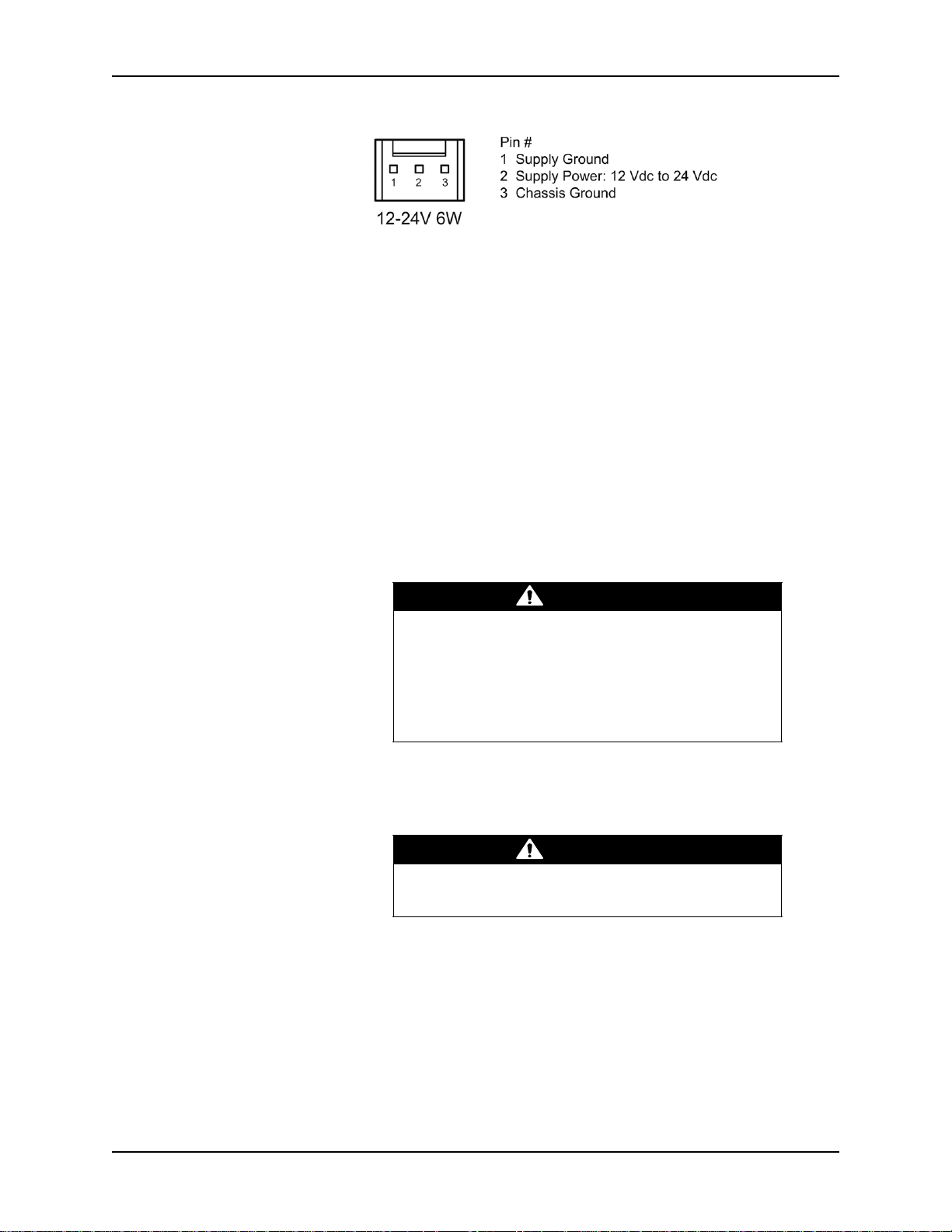

Power supply wiring depends on the power supply voltage and the type of

mounting. There are two ways to supply power to the 475 Controller:

1. Use a CE-compliant power supply: 90 to 250 VAC input, 24 Vdc output,

with connection plugs to accommodate the local AC plug type (catalog

number 475008-1 through -4 -- See page 4 of this Instruction Manual).

2. User supplied power to the Controller using a wire adapter and plug to

connect to a 12 to 24 Vdc supply voltage (Granville-Phillips part number

167820). If you use the wire adapter, the wires to be connected to the

user supplied power are marked on the end of the cable:

Outside: Supply ground for 12 to 24 Vdc power supply

Center: +12 to 24 Vdc power < 0.5 A @ 12 V (i.e. < 6 Watts) continuous

(Inrush limited to <1.4 A for <7 msec)

Colored End: Safety chassis ground.

Both options accommodate the same orientation and connection plug. The

locking tab mechanism is on the top side of the connector when you plug it

into the rear panel. See Figure 2-10.

Figure 2-10 Locking Tab for Power Supply Cord

24 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Installation

See Convectron Gauge Analog

Output Signal

on page 53

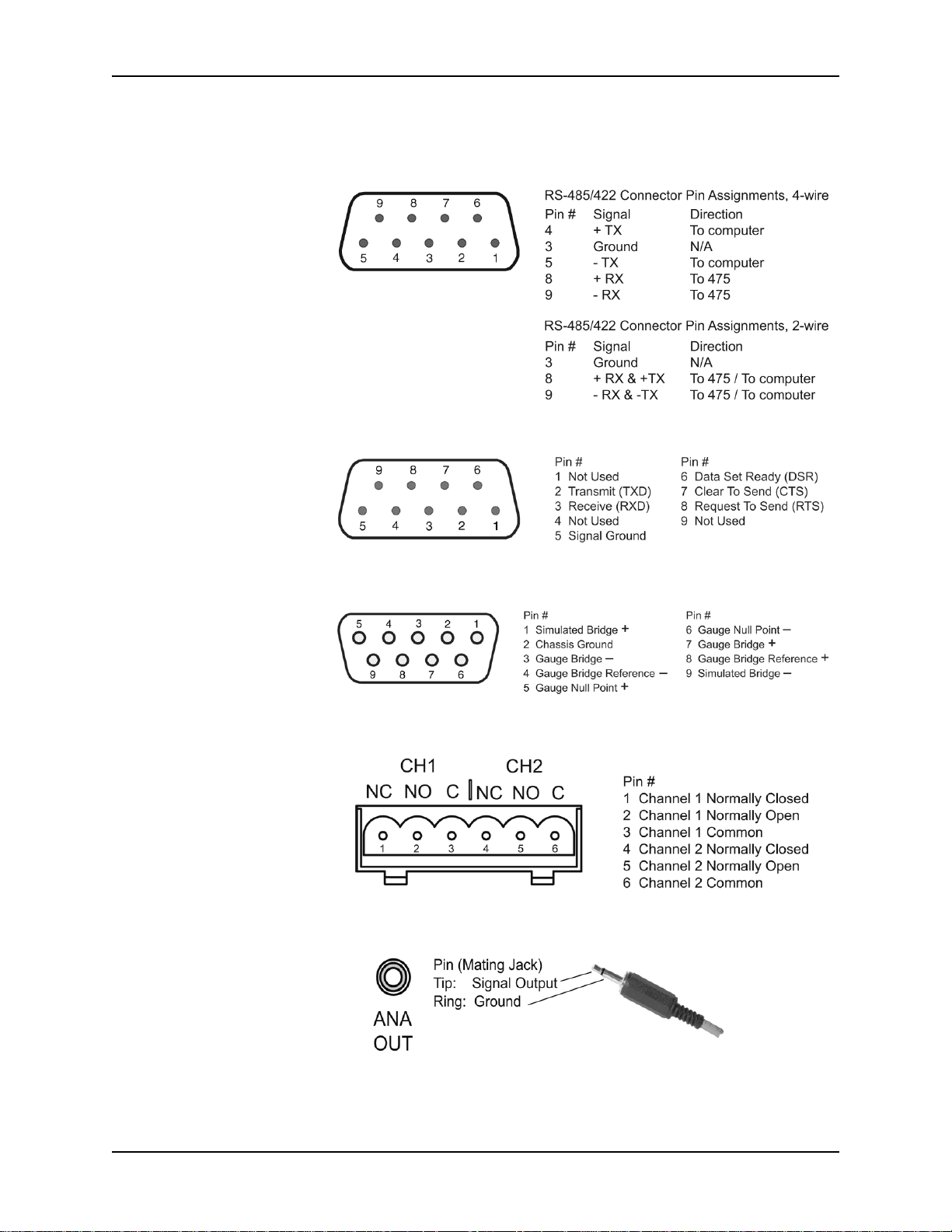

2.8 Connectors The following figures illustrate the connectors on the back of the 475 Controller.

Figure 2-11 I/O (RS-485/RS-422) 9-Pin Connector (pins)

Figure 2-12 I/O (RS-232) 9-Pin Connector (pins)

Figure 2-13 Convectron Gauge 9-Pin Connector (sockets)

Figure 2-14 2-Channel Process Control Connector (pins)

Figure 2-15 Analog Output Connector (socket)

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 25

Chapter 2

WARNING

CAUTION

Figure 2-16 3-Pin Power Supply Connector

2.9 Configure the Relays

for the Application

• To configure the setpoint relays for the process control option, see

page 57.

• To configure the setpoint relays using the RS-232 option, see PCE Relays

on page 69.

• To configure the setpoint relays using the RS-485 option, see PCE Relays

on page 87.

If the Controller will measure the pressure of a gas other than N

or air, you

2

must adjust relay setpoints for the process gas. The true pressure of a gas

other than N

or air may be substantially different from the pressure that the

2

output indicates. For example, outputs might indicate a pressure of 10 Torr

(13.3 mbar, 1.33 kPa) for argon, although the true pressure of the argon is

250 Torr (333 mbar, 33.3 kPa). Such a substantial difference between

indicated pressure and true pressure can cause over pressurization resulting

in an explosion. See Using Gases Other than N2 or Air on page 41 and Gas

Species on page 35.

Failure to use accurate pressure conversion data for

or air to other gases can cause an explosion due to

N

2

overpressurization.

If the Controller will measure any gas other than N

2

or air, before putting the Controller into operation,

adjust relays for the process gas that will be used.

2.10 Requirements for

Process Control

Option

If you are using the process control option, you must prepare for process

control operation before turning ON the Controller. See Chapter 4 for

complete process control setup instructions.

Failure to check system setup configuration before

switching to automatic operation can cause errors.

26 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Chapter 3 Operation

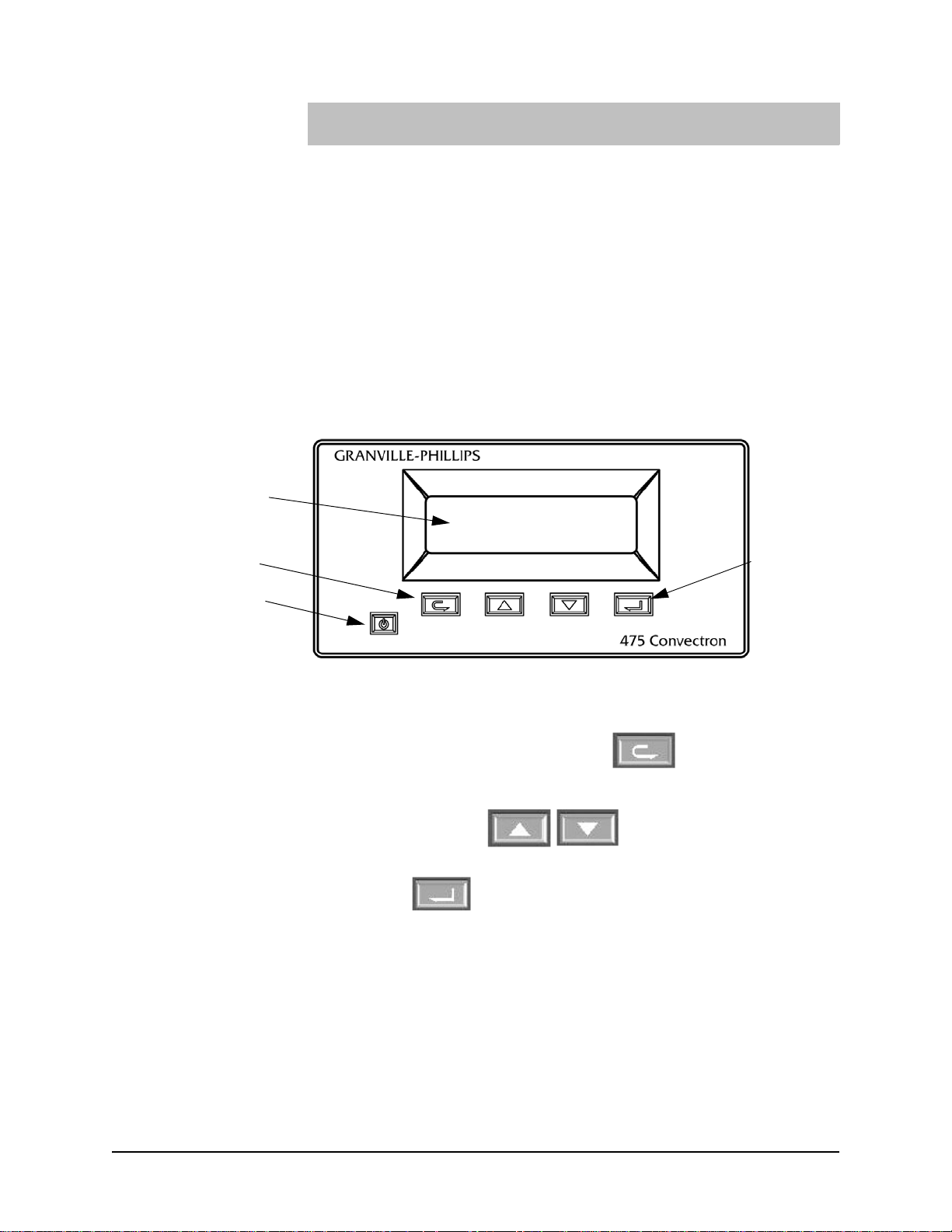

Power ON/OFF

Button

Vacuum Fluorescent

Display Screen

Back Button

Enter

Button

3.1 Preparing for

Pressure

Measurement

Figure 3-1 Series 475 Convectron Gauge Controller Front Panel

Before you prepare for process measurement, make sure:

• The Controller was properly set up and installed per the instructions in

Chapter 2.

• The gas in your vacuum system is air or N

you must follow the instructions in Using Gases Other than N2 or Air on

page 41 and Indicated vs. True Pressure for Gases Other Than N

on page 42.

• You are reasonably familiar with the general theory of operation of

thermal conductivity gauges. See Convectron Gauge Theory of Operation

on page 40.

. If you are using other gases

2

or Air

2

3.2 Button Overview • The POWER button is press ON, press OFF. In case of power failure, the

3.3 Initial Power Up 1. Press the Power ON/OFF button (see Figure 3-1). The display screen will

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 27

Controller will restart if it was ON when power was interrupted.

• Use the BACK button to exit menus.

• Use the UP and DOWN buttons to make menu selections and change

parameter settings.

• Use the ENTER button to enter menus and to execute parameter changes.

Figure 3-2 page 28 illustrates the button menu flow.

illuminate.

2. Run the self diagnostics tests to allow the 475 Controller to perform a self

diagnostics test. See Diagnose beginning on page 29 to run the tests.

Chapter 3

Figure 3-2 Series 475 Convectron Gauge Controller System Menu Flowchart

3.4 Menu Overview All functions, settings, and options can be accessed and displayed by using

the four buttons on the front panel of the Controller. Some of the displayed

settings are for information only, and others can be changed and saved. Use

either the UP or DOWN button to scroll through the menu selections.

The five main menu selections are Calibrate, Configure, Diagnose, Keypad,

and Product Info. See Figure 3-2. Each of these menu selections and their

relevant sub-selections are explained in the following sections of this

chapter.

When using a PC and the RS-232 option, additional information is provided

in the Process Control Chapter and the RS-232 Chapter.

When using a PC and the RS-485 option, additional information is provided

in the Process Control Chapter and the RS-485 Chapter.

28 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Operation

3.4.1 Product Information

Product information allows the user to read the product revision and

installed options.

1. Press the UP or DOWN button to scroll to “Product Info” and press the

ENTER button.

2. Press the UP or DOWN button to browse the product information.

3. “Code Version” displays the software part number and revision.

4. “Setpoints” displays the number of relays.

5. “Serial Number” is the same as the label on the product.

6. “NIST Calibration” displays “Yes” if the gauge and Controller have been

calibrated on NIST traceable instrumentation, or displays “No” if there’s

no NIST calibration or it has been voided. See NIST Traceable System

Calibration on page 52 for more detailed information.

7. “Serial Interface” displays if the RS-232 or RS-485 serial interface is

installed.

8. Press the BACK button a few times or wait one minute to return to

pressure display.

3.4.2 Keypad The keypad consists of five momentary switches; one is used as a power switch, four are used for user interaction with the display menu.

The keypad can be enabled or disabled.

Disabling the keypad prevents unwanted key presses. When disabled, any

key press (EXCEPT the Power key) causes a "keypad disabled" notification to

be shown for two seconds. The "current pressure screen" is shown by default.

1. Press the UP or DOWN button to scroll to “Keypad” and press the

ENTER button.

2. Press the UP or DOWN button to select “Enable” or “Disable” and press

the ENTER button.

3. Press the BACK button a few times or wait one minute to return to

pressure display.

4. To re-enable the keypad, enter the sequence Up, Down, Back, Enter

within five seconds.

3.4.3 Diagnose During the diagnostics “Test Measurement” function, pressure reporting is

suspended and the Convectron simulator is switched ON. (See Convectron

Gauge Simulator beginning on page 97.) For the "Auto Test”, the Convectron

simulator simulates five different equally-spaced Analog to Digital (A/D)

voltages across the whole range (0.317 to 5.635V). These voltages are

measured and compared by the external A/D and the internal

microcontroller A/D. The Convectron simulator is switched OFF, pressure

reporting resumed, and a pass/fail is reported to the user. See Chapter 7 for

more information on the diagnostics.

The same process is used for the "Manual Test", except the user can enter

either pressure or bridge voltage and pass/fail criteria is not determined by

the microcontroller.

During the Analog Output diagnostic function, pressure reporting is

suspended to the analog output, and the analog output is tested at discrete

points between 0 V and 10.5 V.

1. Press the UP or DOWN button to scroll to “Diagnose” and press the

Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G 29

Chapter 3

ENTER button.

2. Press the UP or DOWN button to select “Auto Test”, “Meas. Circuit”, or

“Analog Output” and press the ENTER button.

• Auto Test All

Performs the “Auto Test” described above.

1. Press the ENTER button to allow the 475 Controller to automatically

perform a self diagnostics test.

• Test Measurement Circuit

The “Auto Test” mode automatically tests the Measurement Circuits. In the

“Manual Test” mode, you can enter a voltage signal for the Bridge Voltage,

or a pressure rating to simulate system pressure.

1. Press the UP or DOWN button to select “Auto Test” or “Manual Test”

and press the ENTER button.

2. In the “Auto Test” mode, press the ENTER button to allow the 475

Controller to perform the diagnostics check.

3. In the “Manual Test” mode, use the UP or DOWN button to select either

Bridge Voltage or “Pressure” and press the Enter button.

4. Press the UP or Down button to enter the desired voltage in the “Bridge

Voltage” mode, or the desired pressure in the “Pressure” mode.

• Test Analog Output

The “Auto Test” mode automatically tests the Analog Output Circuits. In the

“Manual Test” mode, you can enter a voltage to apply to the Analog Output

to simulate system pressure or for system setup.

1. Press the UP or DOWN button to select “Auto Test” or “Manual Test”

and press the ENTER button.

2. In the “Auto Test” mode, press the ENTER button to allow the 475

Controller to perform the diagnostics check.

3. In the “Manual Test” mode, press the UP or Down button to enter the

desired voltage to be output.

4. Press ENTER to perform the diagnostics check.

3.4.4 Calibrate When the Calibrate function is selected, the 475 Controller reads the current pressure in the vacuum chamber and determines whether you can calibrate at atmosphere or vacuum based on the current pressure.

See Calibration and NIST Traceable System Calibration on page 52 for more

detailed information.

1. Press the UP or DOWN button to scroll to “Calibrate” and press the

ENTER button.

Either “Calibrate Vacuum” or “Calibrate Atmosphere” will be shown

depending on the current reported pressure.

NOTE: “Invalid Pressure for Cal” will be displayed if the pressure is

out of range to perform the calibration.

• Calibrate Atmosphere

1. Press the UP or DOWN button to select the desired calibration setting

and press the ENTER button.

2. Press the BACK button a few times or wait one minute to return to

30 Series 475 Convectron Gauge Controller Instruction Manual 475101 - Rev. G

Loading...

Loading...