Page 1

Page 2

Page 3

GENERAL DESCRIPTION

RV series electronic balances are destined for high accuracy weighing in

laboratory practice.

RV series balances are equipped with internal calibration system for accuracy

control during balance operation.

All balances are Metrologically tested. According to an order balances can be

calibrated or legally verified.

Balances with legal verification are marked with the following legal and securing

items:

- Green metrological mark placed on the balance name plate,

- Notified body stamp (number of notified body) on the balance name plate,

- Protective seals placed on: an edge of balance name plate, the casing mounting

screw and in the place of access to adjustment switch,

Renewing of balance legal verification is required when protective seal is violated

or after period of 3 years starting from 1st December of year when first legal

verification was performed. In order to renew legal verification please contact

your Distributor.

Certificates:

Certificate of ISO quality system Certificate of balance type approval

DIN EN ISO 9001:2000 TCM 128/06-4428

PACKING LIST

1. Balance

2. Pan elements:

- For balances with round pan (RV-300 and RV-500): a pan support and a

pan.

- For balances with rectangular pan (RV-3000 and RV-4000): gum nuts (4pcs)

and a pan,

3. Draft shield with cover (RV-300 and RV-500)

4. Feeder 12V / 850mA

5. User manual,

Page 4

SAFETY RULES

It is necessary to follow safety rules of work with the

balance shown below. Obeying those rules is the

condition to avoid electrical shock or damage of the

balance or connected peripheral devices.

• Repairs and necessary regulations can be done by authorised personnel

only.

• To avoid fire risk use a feeder of an appropriate type (supplied with the

balance) and supply voltage have to be compatible with specified

technical data.

• Do not use the balance when its cover is opened.

• Do not use the balance in explosive conditions.

• Do not use the balance in high humidity environment.

• If the balance seems not to operate properly, switch it off and do not use

until checked by authorised service.

According to current acts of low about protection of

natural environment, wasted balances should not be

put into waste containers together with ordinary

waste.

• Wasted balance after operation period can be delivered to units

authorized for gathering wasted electronic devices or to the place where

it was bought.

Page 5

TECHNICAL DATA

Model

RV-300

RV-500

RV-3000

RV-4000

Capacity (Max)

300g

500g

3000g

4000g

Min load (Min)

0,02g

0,02g

0,5g

0,5g

Reading unit (d)

0,001g

0,001g

0,01g

0,01g

Verification unit (e)

0,01g

0,01g

0,1g

0,1g

Tare range

-300g

-500g

-3000g

-4000g

Accuracy class

II

Working temperature

+18 ÷ +33°C

Weighing time

<3s

Pan dimension

f115m

m

165x165mm

Balance dimension (with legs)

215(235 with legs)x345x90mm

Balance weight

5kg

Power supply

~230V 50Hz 6VA / =12V 800mA

Recommended external calibration weight (OIML)

F1 100g

F1 200g

F1 2000g

F1 2000g

Caution:

F1 is international symbols of calibration weight classes according to

O.I.M.L. Some requirements for weight accuracy are connected with those

classes.

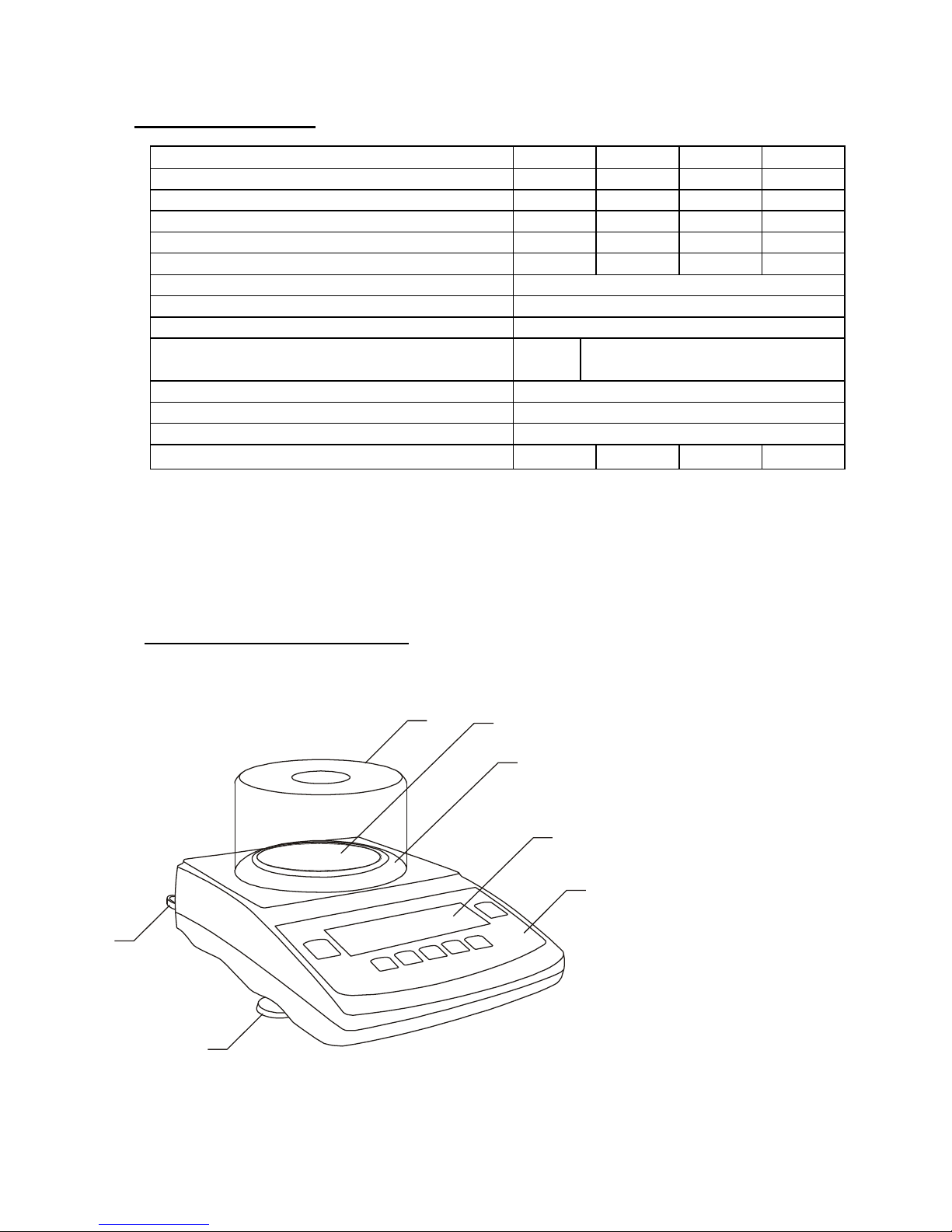

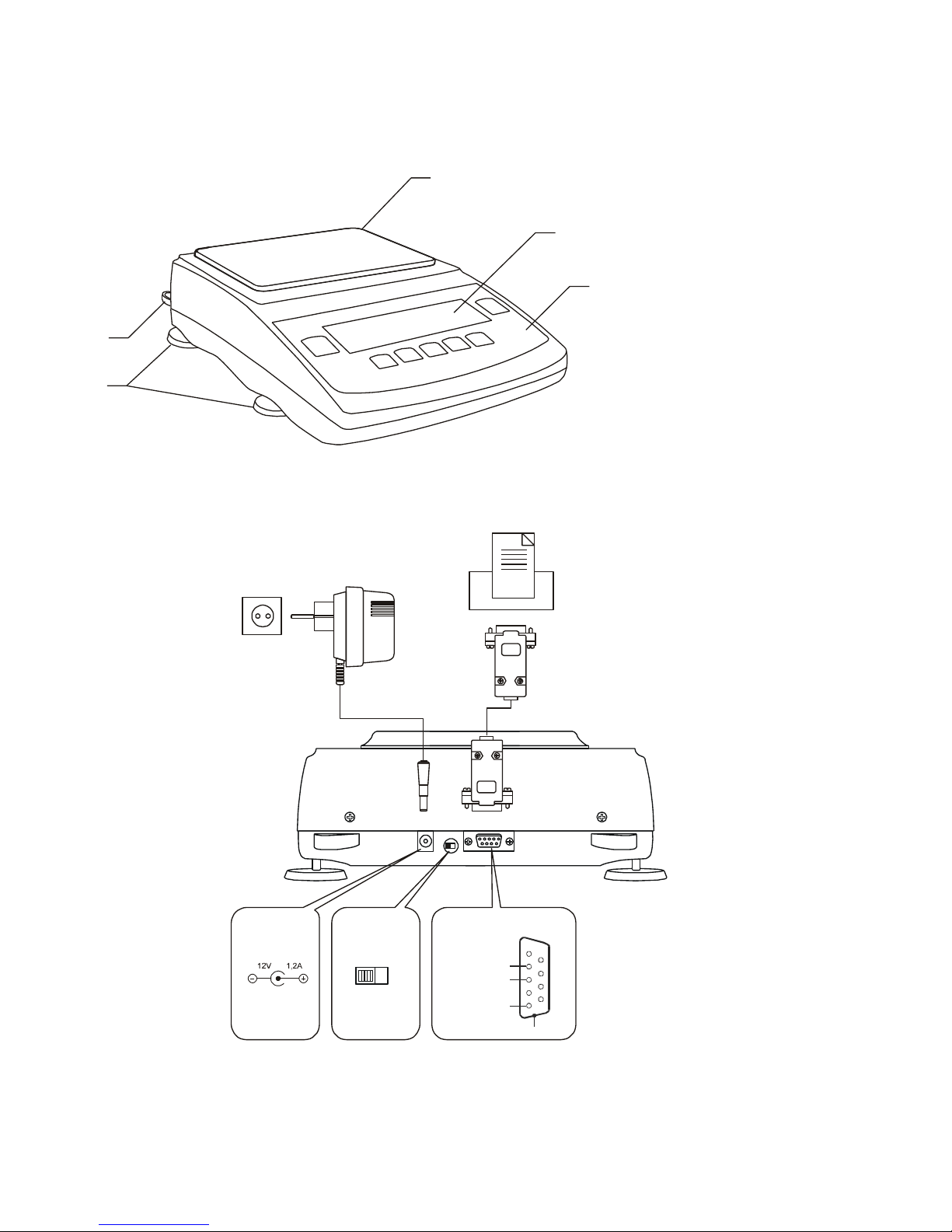

GENERAL BALANCE VIEW

RV-300 and RV-500

1 – Pan

2 – Pan support

3 – Pan ring

4 – Display LCD

5 – Keys

6 – Rotating legs

7 – Water level

8 – Draft shield

.

7

6

1

2

4

3

5

8

Page 6

RV-3000 and RV-4000 balances:

1 – Pan

2 – Nuts (under pan)

4 – LCD display

5 – Keys

6 – Rotating legs

7 – Water level

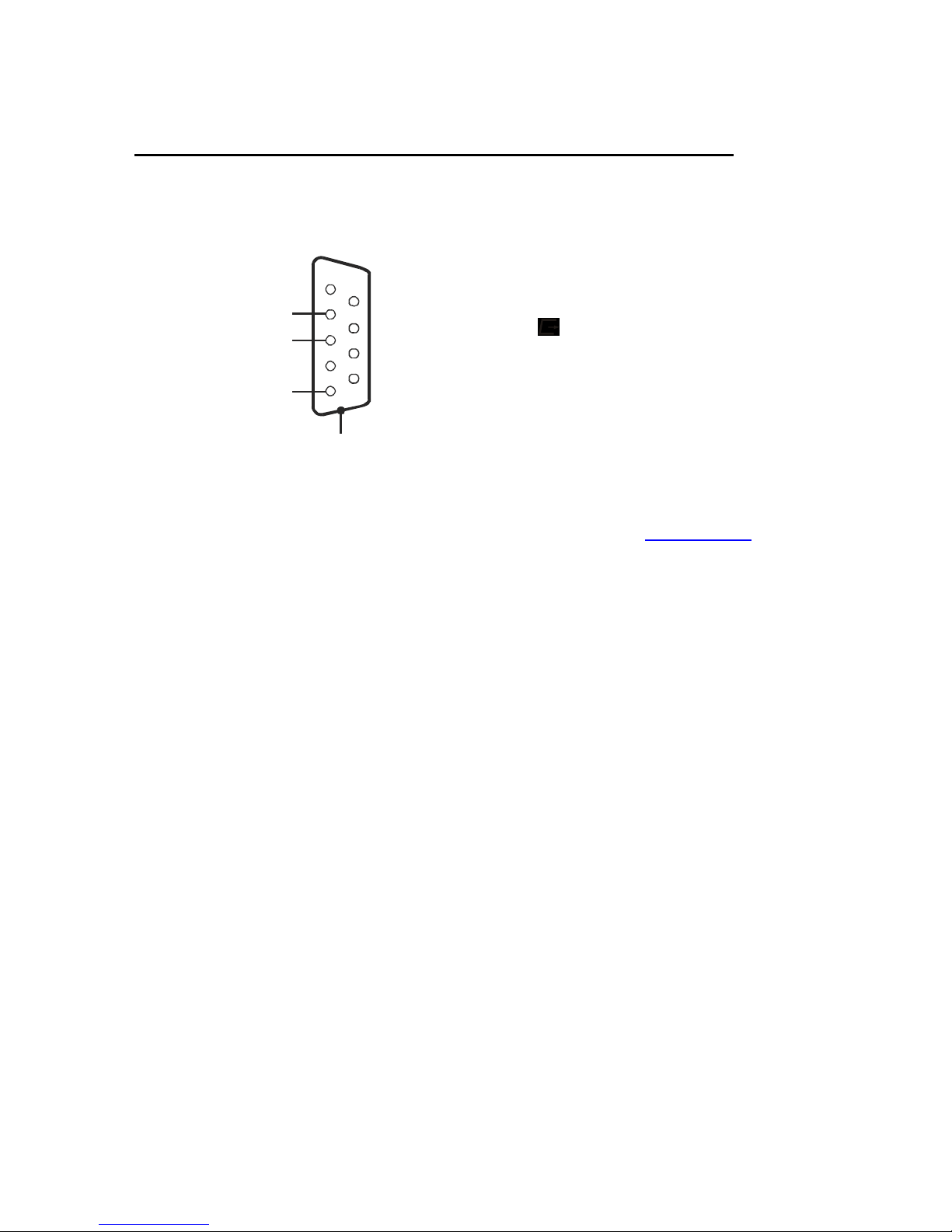

Connectors view:

Feeder

~230V/50Hz

Printer

or computer

ON

OFF

Adjustment

switch

RxD (receiver)

TxD (transmitter)

GND

Case

RS232C

Feeder

1

2

3

4

5

6

7

8

9

7

6

1

2

4

5

Page 7

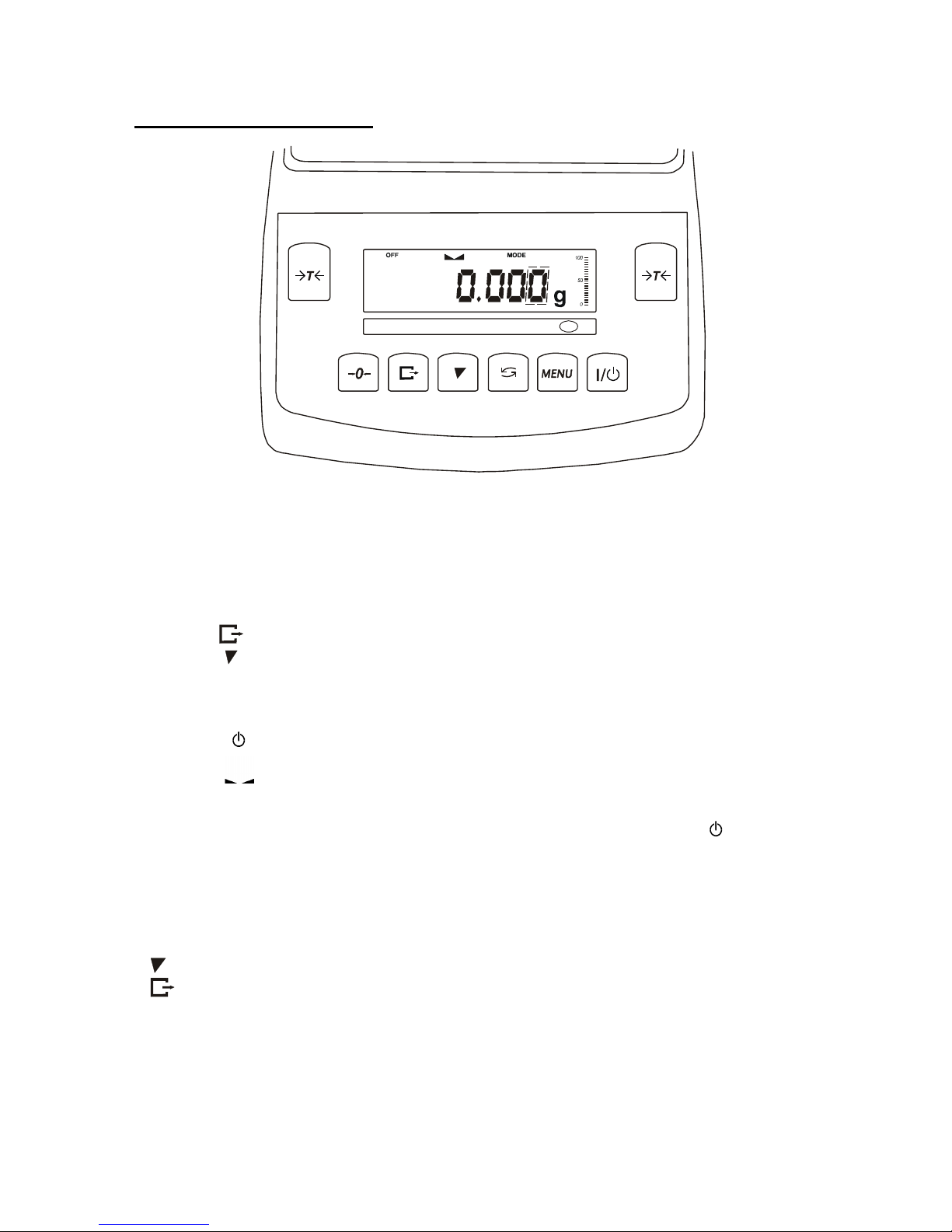

KEYS AND INDICATORS

Description of basic functions for keys and indicators:

®T¬

- taring (enter mass subtracted from weighed mass)/ confirmation

of selected menu options,

®0¬

- zeroing (option),

- result printout (transmission),

- internal calibration / accelerated options viewing

✣

- switch: special function / weighing,

MENU

- enter to special function menu,

I/

- switch on / switch off (standby),

indicator

- shows stabilization of weighing result,

linear indicator

- indicator of balance load (0-100%),

OFF indicator

- appears after the balance is switched off with I / key,

distinction of last

digit

- informs that reading unit value is lower than acceptable indication

error (balances with legal verification, d¹e)

Max, Min, d, e, II

- metrological parameters of the balance.

The use of keys during entering numeric values (special functions):

- increment current digit,

- insert comma,

®T¬ - move to next position,

MENU - finish entering.

Max Min e d

II

Page 8

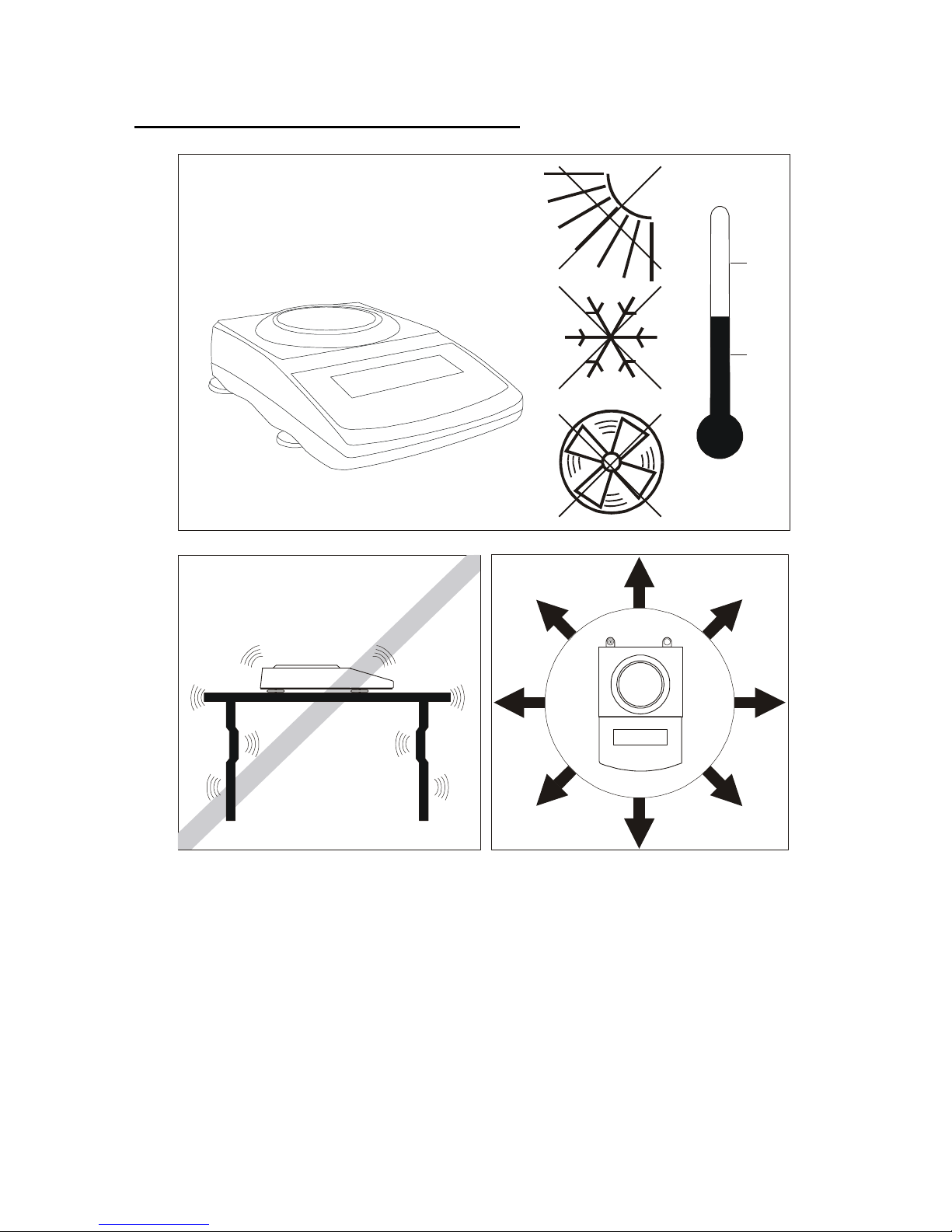

PREPARING WORKING ENVIRONMENT

+18°C

+33°C

Location for the balance should be chosen with care in order to limit influence of the

factors that can interrupt working balance. This location has to maintain proper

temperature for working balance and necessary space for its operating. The balance

should stay on stable table made of material that does not influence magnetically on

the balance.

Rapid air blasts, vibrations, dust, rapid temperature changes or air humidity over 90%

are not allowed in balance surrounding. The balance should be far from heat sources

and devices emitting strong electromagnetic or magnetic fields.

Page 9

PREPARING THE BALANCE TO WORK

1. Take the balance, the feeder and

mechanical elements of the pan out.

It is recommended to keep the

original scale package in order to

transport the balance safely in

future.

2. Place the balance on a stable

ground not affected by mechanical

vibrations and airflows.

3. Level the balance with rotating

legs 6 so that the air bubble in water

level 7 at the back of the balance is

in the middle.

4. (For RV-300 and RV-500) Gently

insert the mandrel of pan support 2

into balance mechanism socket

through the pan ring 3 and the pan 1

on.

5. (For RV-3000 and RV-4000)

Place nuts 2 on mandrels that are

visible in balance cover holes, put

the pan 1 on nuts.

If the balance was taken from a lower temperature surrounding to a room

with higher temperature, e.g. in winter, moisture can liquefy on the balance

casing. Do not connect power supply to the balance, because this can cause

damage or improper work of the balance. In this case leave the balance for

at least 4 hours unplugged for acclimatization.

7

6

1

2

3

7

6

1

2

Page 10

GENERAL OPERATION PRINCIPLES

1. Weighed sample should be placed in the centre of the pan

2. The balance allows taring in the whole measuring range. To tare the balance press

®T¬

key (on the left or on the right). Taring does not extend measuring range, but

only subtracts tare value from mass value of a sample placed on the pan. To make

the control of pan load easier and to avoid crossing measurement range, the

balance has a load indicator calibrated 0÷100% Max.

3. Weighing result should be read when the indicator " " lights, which signalises

stabilisation of a result.

4. When the balance is not used but should be ready to work immediately, it can be

switched off by pressing I/ key. The backlight of balance reading system is then

switched off and the balance enters into "standby" mode, in which the balance

maintains internal temperature and ability to start working with maximum accuracy.

Standby mode is signalled by the OFF indicator. To switch the balance on press I/

key.

5. In direct sale use (d=e), make sure that ®0¬ zero indicator is displayed before

sample is placed on the pan. If not, press ®0¬ key and wait until the balance is

zeroed and zero indicator appears. In other balances the key does not operate.

6. Balance mechanism is a precise device sensitive to mechanical shocks and

strokes.

7. After every change of balance position, level the balance and perform internal

calibration using key.

8. The balance cannot be used to weigh ferromagnetic materials due to decrease of

weighing accuracy.

START-UP

Plug feeder into 230V power supply socket. When the pan is empty plug feeder output

connector into 12V socket at back of the balance. Autotests and internal calibration will

be performed.

Do not overload the balance more than 20% of maximum capacity.

Do not press the pan with a hand.

For transportation take off the pan (move it gently and lift it up) and pan

support (lift it up) and protect from any damages.

Page 11

Steps after start-up of the balance:

Tests of electronic components.

Test of internal calibration motor test

(engine heard).

Displaying balance program version.

Starting internal calibration.

Zeroing the balance.

Loading internal weight.

Zeroing the balance

Balance is ready to work.

INTERNAL CALIBRATION

The balance is equipped with internal calibration system, which general task is to

maintain required measurement accuracy on the balance.

Internal calibration is the process of putting internal weight on automatically by balance

mechanism and correcting accuracy in balance firmware. The correction is necessary

because of differences between values of gravitational acceleration in the place where

the balance was manufactured and in the place where it is operated, as well as due to

changes of balance level and temperature.

Internal calibration is performed in the following situations:

C-1

C-5

-------

-------

0.000g

AC-...

LO A D C

C

-CAL-

Page 12

- When key is pressed,

- After defined time interval (for legally verified balances - 2 hours),

- After temperature change (for legally verified balances – more than 2oC).

In legally verified balances time interval is set to 2 hours and defined temperature

change is 2oC. In not legally verified balances those values can be set as calibration

options. Starting internal calibration process is signalled with - CAL - message.

In order to perform internal calibration, proceed with the following:

1. Empty the pan.

2. Press key (to leave internal calibration, press second time when “------“ is

displayed).

During calibration internal weight is put three times on and obtained results are

compared.

Discrepancy of results is signalled with a message and causes the balance being

blocked.

Until calibration process is finished do not perform any operation on the balance. Any

vibrations and shocks interfere calibration process and may delay it or deteriorate

accuracy of its result.

When internal calibration is performed successfully the balance indicates zero on the

display at empty pan.

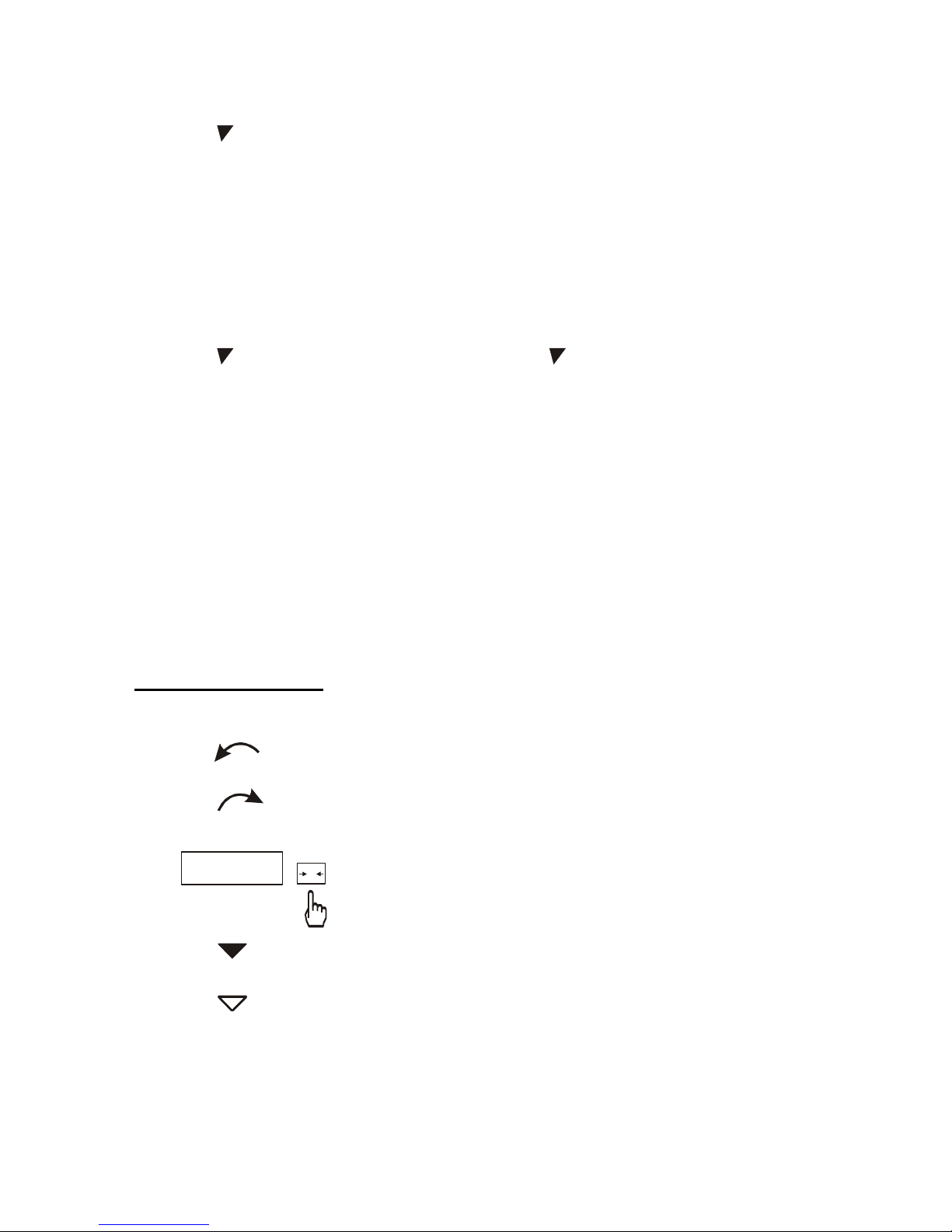

BASIC FUNCTIONS

Following symbol graphic will be used in instruction:

- Loaded pan

- Unloaded pan

- Press a key when ... (on left)

- Forced change

- Automatic change

1 2 g

T

Page 13

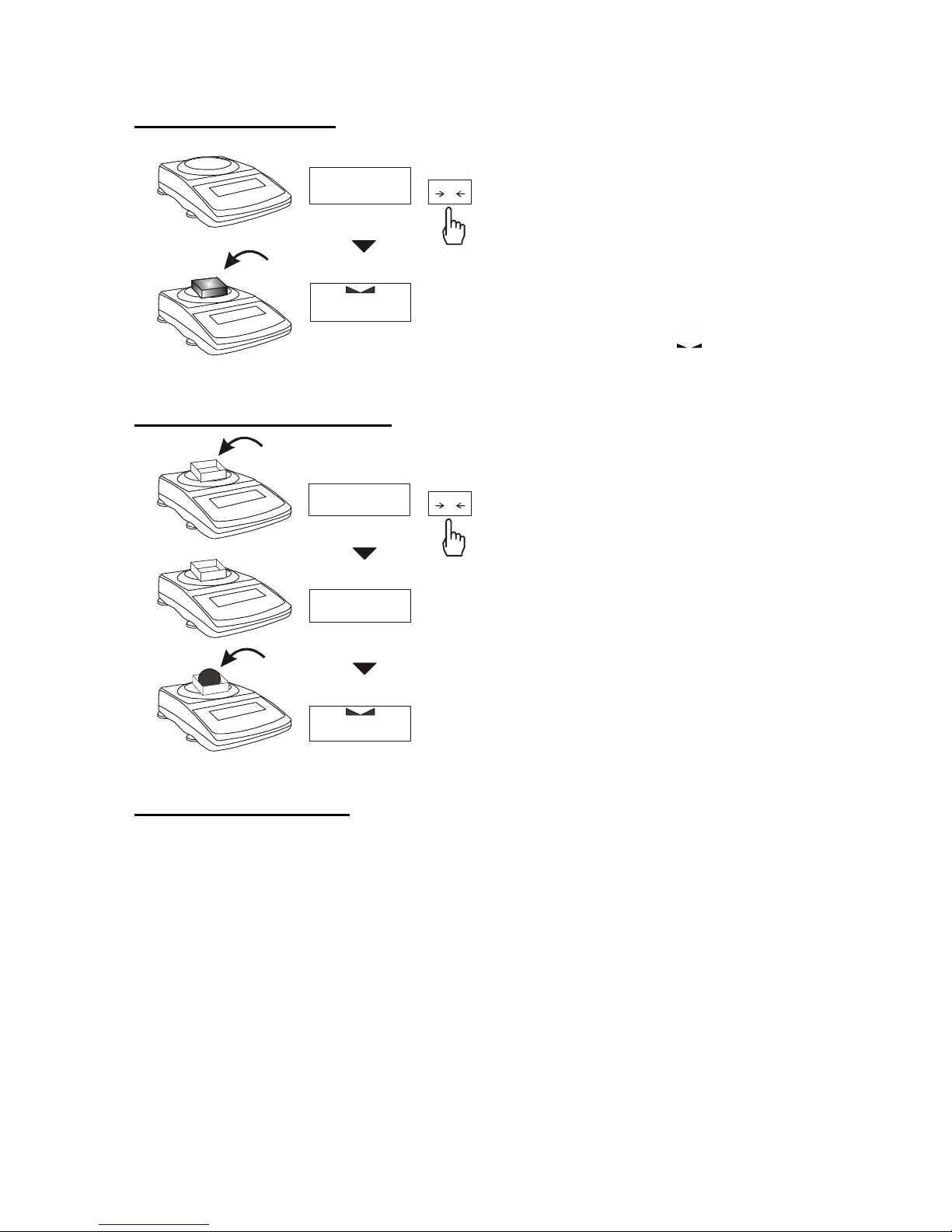

NORMAL WEIGHING

When a pan is empty and

indication is different than zero

press ®T¬ key.

Weighing result should be read

when the indicator " " lights.

WEIGHING WITH TARE

A balance is equipped with tare

equal to its range.

BALANCE CHECKING

As weight indication depends on gravitational acceleration, it is advised to check

balance indication accuracy before and after series of measurement using any load

with known weight.

To check a balance with legal verification use calibration weight as stated in Technical

Data table with valid calibration certificate. In case permissible error is exceeded it is

advised to contact the nearest service to calibrate a balance.

0.00 g

43.04 g

23.13 g

0.00 g

63.24 g

T

T

Page 14

CONNECTING THE BALANCE TO A COMPUTER OR PRINTER

The balance may send data to a computer or a printer via RS232C interface.

When cooperating with a computer, the

balance sends weighing result after

initialising signal from a computer or after

pressing key.

When cooperating with the balance, a

computer should be equipped with a

program that enables receiving and

processing data from the balance.

GRAM PRECISION offers computer programs to cooperate with balances. Demo

versions and program descriptions are available on the website: www.gram.es:

- Komunikacja – free serial port testing program,

- ProCell – residual program for cooperation with Microsoft EXCEL and other

Microsoft Windows applications (demo version).

Detailed information for programmers:

The balance sends data with a following method:

Computer ® Balance: initiation signal S I CR LF (53h 49h 0Dh 0Ah),

Balance ® Computer: weighing result in the following format:

(16Bytes, LONG protocol - 8bits, 1stop, no parity, 4800bps),

Bytes description:

1

- „-„ mark or space

2

- space

3¸4

- digit or space

5÷9

- digit, decimal point or space

10

- digit

11

- space

12

- k, l, c, p or space

13

- g, b, t, c or %

14

- space

15

- CR

16

- LF

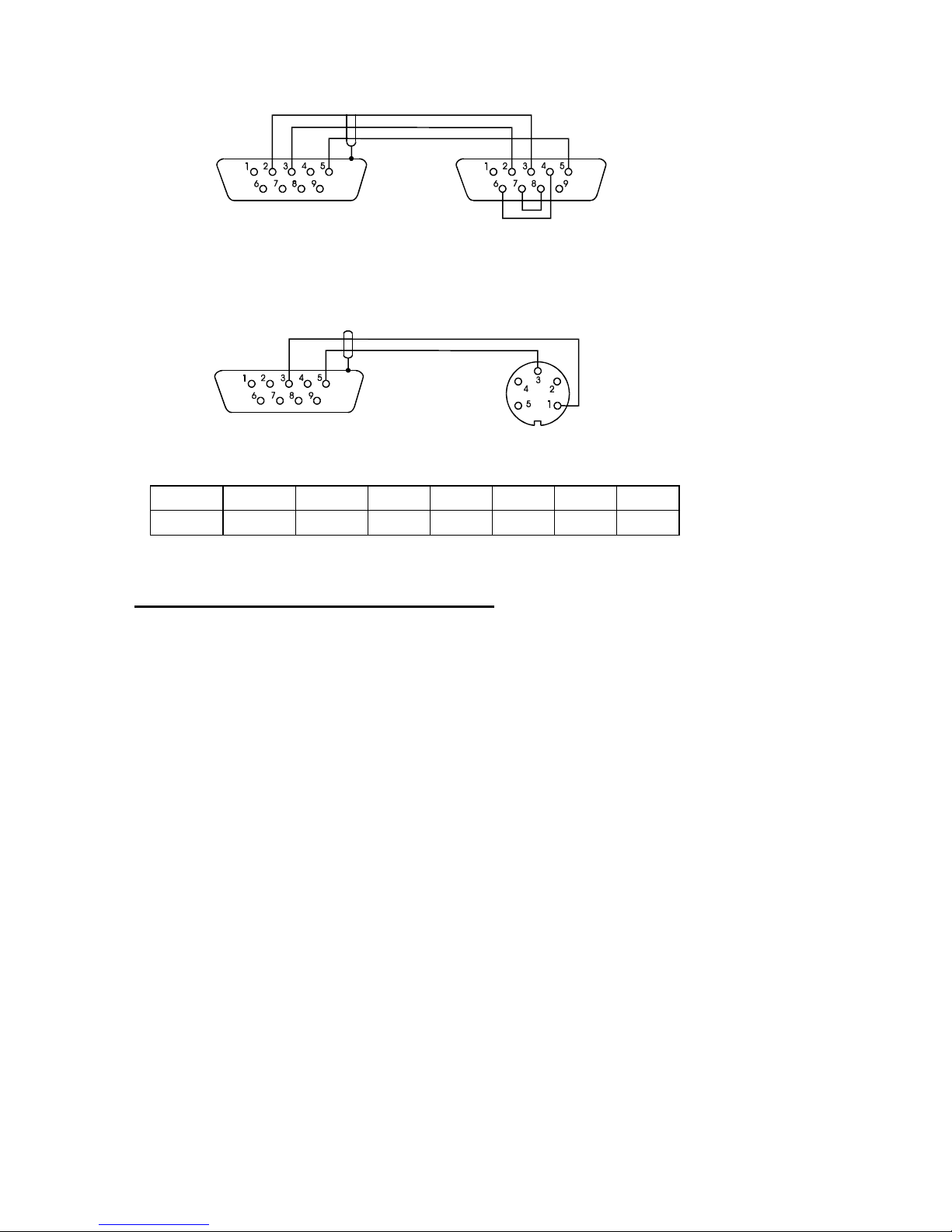

Connection cable WK-1 (balance – computer / 9-pin):

RxD (receiver)

TxD (transmitter)

GND

Case

RS232C

1

2

3

4

5

6

7

8

9

Page 15

Connection cable WD-1 (balance - KAFKA printer):

Setup of printer internal switch – printer AXIS C-001:

SW-1

SW-2

SW-3

SW-4

SW-5

SW-6

SW-7

SW-8

on

off

on

off

off

on

off

off

SPECIAL FUNCTIONS DESCRIPTION

q Menu customization function (ACtIV),

q Removal of all function from menu (dEFAUL).

q Autozeroing function (AutoTar),

q Pieces counting function (PCS),

q Function for setting serial port working (SEndIng),

q Function for setting serial port parameters (RS232),

q Extended calibration function (CALIbr),

q Changing measurement unit (UnIt),

q Percentage weighing function (PErCEnt),

q Recipe weighing function (rECIPE),

q Entering tare function (tArE),

q Force measurement (F),

q Maximum value indication function (UP),

q Anti-disturbance filter function (FILtEr),

q Weighing large animals function (LOC),

q Average calculating function (AVErAGE),

q Determining solids and liquids density function (hYdro)*

q Statistical calculations (StAt)- option*

q Paperweight calculation function (PAPEr)*

Function with additional equipment require:

§ Options with the clock:

- Setting current date and time function (dAtE)

- Total weight function (totAL)

§ Options with the transoptors connectors:

- Checkweighing function (thr)

BALANCE COMPUTER

BALANCE PRINTER

Page 16

*Depending on scale memory space limitation this function replaces other special

function

Other special functions may be enabled as an option on customer request (described

in additional brochure when ordered).

Function menu is displayed after press MENU button. Functions are displayed with

increasing numbers: F1-PCS, F2-AUt, etc.

For easy access to the most frequently used functions, use ACtIV

function to select functions to be displayed in functions menu.

When special function is active, MODE indicator is displayed.

MENU CUSTOMIZATION FUNCTION (ACtIV)

Among available user functions it is

possible to select these, which should be

displayed after pressing MENU key. It

allows avoiding displaying whole list of

available functions, which makes

operation time longer.

Operation sequence shown in the

pictures on the left causes adding

function for setting serial interface

RS232C parameters (rS232) to function

menu.

After switching on ACTIV function a dot is

displayed on the right side (to distinguish

from regular menu). Chosen functions are

displayed with a dot on the left side.

In every moment, it is possible to restore

primary (manufacture) settings choosing

dEFAULt special function.

In order to delete this function from menu

in last operation choose rS oFF instead of

rS on.

0.00

ACtIV

rS o n

rS o FF

o

PCS

rS232

T

T

T

Page 17

AUTOZEROING (AUtOtAr)

When AUtotAr function is activated, a

balance automatically keeps zero

indication if a pan is empty or if zero

indication was acquired by pressing

®T¬

key.

To leave the function press MENU

key, then with ®T¬ key chose

AUtOtAr and AUt oFF .

Note: Autozeroing function is activated

automatically for 10 min. after

switching-on

0.01g

AUt OtAr

AUT

AUt o n

AUt o FF

0.00g

MENU

T

T

Page 18

PIECE COUNTING FUNCTION (PCS)

This function enables to count identical

pieces, e.g. turnbuckles or buttons.

A measurement is performed in two

phases:

- first phase - single piece weight

calculation on the basis of defined

pieces amount (5, 10, 20, 50, 100, 200

or 500 pieces),

- second phase – pieces counting.

It is advised that single piece weight is

not less than one reading unit and

sample weight used in first phase is

bigger than 100 reading units.

To leave function press F key and then

with ®T¬, key chose PCS and PCS

oFF .

Note:

Err-3 communicate signalises that a

sample was not put on a pan. The

same communicate appears if single

piece weight is less than one reading

unit (it is possible to count pieces but

measuring error is bigger).

To chose previously used pieces

amount select “..” in first phase.

During pieces counting ®T¬ key

function does not change

0 pc s

0.00 g

12.05 g

23.04 g

PC S

PCS oFF

PCS on

5

5

12

12 pc s

MENU

T

T

T

T

Page 19

SERIAL PORT WORKING MODE SELECTION

The function enables to set the serial

port working mode.

- StAb – transmission after using key

and indication stabilization,

- no – StAb – transmission after using

key without stabilization,

- Auto – after putting and taking off the

weighed object without using ,

- Cont. – about 10 results per second.

Auto mode is suggested when

working with printer.

0.00g

SEn d I n G

Auto

St b

0.00g

MENU

T

T

Page 20

SERIAL PORT PARAMETERS SETTING (RS-232)

The function enables to set the

following transmission parameters

(standard parameters underlined:

- transmission speed (bAud: 1200,

4800, 9600, ...),

- the number of bits in a byte (bit: 7, 8),

- parity control (PArItY: 0, 1; Odd: 0, 1),

To set desired transmission

parameters activate RS232 function,

choose appropriate parameter and

press ®T¬ key to accept needed

parameter value. The example at the

left presents how to set transmission

speed value to 9600bps.

To leave the function choose out

option

0.00g

rS232

baud

-9600

-4800

bIt

out

Odd

PA r I t Y

MENU

T

T

T

T

T

T

T

Page 21

ADJUSTING THE BALANCE (Calibr)

If balance indications exceed permissible error it is necessary to adjust a balance. To

calibrate a balance use calibration weight as stated in Technical Data table (or of better

accuracy) with valid calibration certificate.

To adjust a balance it is necessary to break protective marks – please contact

the nearest service for legal verification in a place of installation or the

nearest Measurements Office.

In legalized scales to perform calibration it is needed to change adjuster position.

Adjuster is situated under adjuster securing element.

Calibration report (CAL Prn):

Data:

CALIBRATION REPORT

--------------------------------------------------------------------------FACTORY NUMBER: ...

PROGRAM NUMBER: (version, date)

ON

OFF

Przełącznik

adjustacji

Cecha

zabezpieczająca

dostęp do

przełącznika

adjustacji

Adjuster

Adjuster securing

element

Page 22

Operation sequence:

Remove a protective mark from a calibration

switch at the back of a balance.

Switch to Pr ON position using small

screwdriver (signalised on a display).

Press MENU to call special functions. Press

®T¬

to choose CALIbr and CAL on.

Press several times to select desired

weight value. It is advised to use as great

weight value as possible.

Press ®T¬ to accept.

When LOAD appears put the weight no

a pan.

Wait.

When unLOAD appears take off the weight.

Switch to Pr OFF position using small

screwdriver ( Pr ON disappears).

T

m

m

unLOAD

m

m

LO A D

CC

1

2

...

MENU

T

T

0.00g

0.00g

CALIbr

CAL on

...

ONOFF

Page 23

WEIGHING UNIT SELECTION (UnIt)

Use this function to choose weighing

unit:

- carats (1 ct= 0,2 g),

- pounds (1 lb=0,454kg),

- grams.

The example presents how to set

carats as weighing unit.

PERCENTAGE WEIGHING FUNCTION (PErCEnt)

This function enables to display

weighing result as a percentage of

a reference sample.

A measurement is performed in two

phases:

- first phase – weighing a reference

sample,

- second phase – measuring specific

sample as a percentage of

the reference sample.

Weighing result is displayed in different

format, depending on the reference

sample weight value. For values of

0÷3,5% of weighing range the format is

“100.0”, for values 3,5÷35% it is

“100.00” and 35÷100% - “100.00”

The function has the following options:

- PEr oFF – disables the function,

- PEr on – stores current indication as

100% and activates percentage

weighing,

Note:

Err-3 communicate signalises that a

sample was not put on a pan. The

same communicate appears if 100%

piece weight is less than 0,5*Min of

scale

When the function is activated ->T<- key function does not change.

1.60g

Un I t

ct

CArAt

8.00

MENU

T

T

0.00 g

19.07 g

PEr C En t

PEr oFF

PEr on

100.00%

50.00%

100%

50%

MENU

T

T

Page 24

WEIGHT SUMMATION (rECIPE)

This function enable to weigh few

ingredients in one container and to

display aggregated sum of all

ingredients.

The function has the following options:

-rEC oFF – leave the function and

display aggregated sum of all

ingredients,

-rEC on – activate the function,

-rEC Con - return to previous series of

weighing.

Before weighing each ingredient (A, B,

C, etc.) remember to tare the balance.

To read aggregated sum of all

previously weighed components press

✣ key or use rEC oFF option. To return

to ingredients weighing press ✣ key

again.

Note:

When rECIPE function is active, the

sign o is displayed at the left of the

display.

When rEC oFF option was used, SUM

indicator disappears after pressing

®T¬

key.

0.00 g

rEC IPE

rEC oFF

rEC on

10.01g

10.02g

10.03g

0.00g

0.00g

30.06g

A

B

C

MENU

T

T

T

T

o

o

o

o

o

SUM

Page 25

TARE MEMORIZING FUNCTION (tArE)

This function enables to measure gross weight of a sample placed in a container of a

known weigh value (stored in the memory) and to display calculated net weight of the

sample. Tare value is recalled from the memory with ®T¬ (or ®0¬ when pan is

unloaded). Tare value may be entered using the keypad or by sampling container weight

from the pan.

Inserting tare value using keypad:

After pressing MENU key and

choosing tArE function using ®T¬

key ,functions below are displayed:

- tAr OFF – function off,

- tAr on – function on with tare

inscribed earlier,

- PAn – actual mass on pan setting

as tare,

- VALUE – inscribing tare using: ,

, ®T¬ i MENU.

Choose tare inscribing function using

®T¬

key.

After inscribing scale works with new

tare value. The scale will show nett

mass (the actual object mass minus

tare value).

Each using of ®T¬ key (or ®0¬,

when the pan is unloaded) will cause

zeroing, and deleting memorized tare

value (user will see minus indication) .

ATTENTION:

Tare value is also memorized after the

scale is turned off.

0.00g

0.00g

tArE

50.00g

VALUE

-20.00g

T

T

2

2 -

20

MENU

T

Page 26

FORCE MEASUREMENT FUNCTION (F)

Function activation casues displaying

measurement results in force units (mN).

Press MENU key .

Using ®T¬ key choose F function, and

then F on.

Attention: 1mN»0,1019g

FUNCTION FOR MAXIMUM VALUE INDICATION (UP)

This function allows holding on display maximum value shown by the scale in a while

Before measurement the scale should

be tared.

After using MENU key, choosing UP

function , and then UP_on, the highest

mass result will be hold on display.

Pressing ®T¬ key will cause result

zeroing.

ATTENTION:

Autozeroing function and the

stabilisation indicator are deactivated

when UP function is running. Weighing

result is continuously averaged from 5

measurements.

0.00 g

0.000

F

F on

MENU

T

T

0.00 g

UP

UP oFF

UP on

0.00g

9.90g

9.90g

MENU

T

T

MAX

MAX

MAX

Page 27

ANTI-DISTURBANCE FILTER FUNCTION (FILtEr)

This function allows using digital filter with

selected intensivity during weighing. Filter

reduces the influence of mechanical

vibrations (air blasts, base vibrations) on

measurement result.

Press MENU key and select FILtEr

pressing ®T¬ key.

The following options will be shown

successively on display:

- FIL OFF – filter off

- FIL-1 - filter I (weak)

- FIL-2 - filter II (medium)

- FIL-3 - filter III (sharp)

- FIL-4 - filter IV (very sharp)

Select on of four filters. This will cause

starting weighing with selected filter.

In order to go back to normal weighing

use MENU key once more and choose

FILtEr and FIL OFF.

0.00

0.00

FILtEr

FIL- 0

FIL- 1

FIL- 2

FIL- 4

T

T

Page 28

FUNCTION FOR WEIGHING ANIMALS (LOC)

The function allows weighing animal moving on the scale.

Press MENU key.

When LOC is displayed press ®T¬ key.

The following options appear on display

successively:

- LOC oFF – out of function,

- LOC on –automatic measurement after

loading the scale,

- LOC Prn – measurement initiated by

pressing key.

When LOC on is displayed press ®T¬

key.

Tare the scale using ®T¬ key if

necessary and place the animal on the

pan.

Wait until the weighing result is averaged

– scale display will be blinking. Then

scale will show stable averaged result

and will send it through serial port. Final

result is displayed on the display and

send via serial port to computer or

printer.

The result remains on display for about

30 second.

Important notes:

1. The loads less than Min are not averaged.

2. In the case when placing the animal takes more than 5s, it is advised to use LOC-2

option (measurement initiated manually). It will allow performing measurement in right

moment pressing key.

0.00g

LO C

LOC oFF

LOC on

25.00g

25.00g

PrIn t

MENU

T

T

Page 29

DATE AND TIME SETTING (dAtE)

This function enables to set current

date and time of internal balance clock

and enable/disable date and time on

weighing result printouts.

Options:

- dAt oFF – deactivate date printout,

- dAt on – activate date printout (using

key),

-dAt SEt – change date and time.

The example at the left presents how

to set current date and time.

Time format: h gg – mm

(g - hour, m - minute)

Date format: d mm – dd

(m - month, d - day).

Year format: r - rr

(r - two last digits of a year).

0.00g

dAtE

dAt SEt

dAt oFF

h13 - 18

h13 - 1

8

h13 - 1

9

h13 - 19

0.00g

d04 - 05

r - 06

- -

MENU

T

T

T

T

Page 30

AVERAGE CALCULATION FUNCTION (AVErAGE)

The function allows for calculating average value of performed measurement series.

During series of measurements successive results are registered automatically when

scale indication is stabilised.

Press MENU key and select AUErAG

pressing ®T¬ key.

The following will be shown successively

on display:

- AUE oFF – leaving function,

- AUE on – measurement with average

calculation.

- out

Select AUE on using®T¬ key. It will

allow weighing with simultaneous storing

results into summing register for average

calculation

Measurement registration is performed

automatically in the moment when scale

indication becomes stable. Short time

displaying of „ - - ” denotes that load can

be taken off and new one can be put on.

Results above scale Min are registered

only. Number of measurements is limited

to 9999.

In order to read average value key

should be used.

- first pressing causes displaying number

of measurements (n).

- second displaying causes displaying

average value (=).

- third pressing allows continuing

average calculation.

If a printer is connected to scale the

following report will be printed :

In order to finish calculation press MENU key and then select AUEr i AUE OFF.

Date: ... Time. ...

MEASUREMENS No = ...

AVERAGE VALUE = ...

0.00 g

0.00 g

AUErAGE

AUE on

1.00 g

2.00 g

2

1.50 g

_

_

0.00 g

0.00 g

0.00 g

MENU

T

T

n

Page 31

0.00g

thr

thr on

thr oFF

SEt - 1

SEt - 0

SEt - 2

5

5 -

50

62.00g

MENU

MENU

T

T

T

T

T

T

OK

TRESHOLD COMPARING FUNCTION (thr)

This function allows comparing weighing result with two programmed reference values:

lower and upper threshold. Comparison result is signalled with indicators (MIN, OK,

MAX) and sound signal generated when threshold values are exceeded.

Operation sequence:

Press MENU key and choose thr

pressing ®T¬ key.

The following options are displayed

successively:

- trESh oFF – deactivate the function,

- trESh on – activate the function,

- trESh Prn – check last threshold values

(press key several times),

- thr CFG – function configuration

(working mode, buzzer, flashing setting).

Choose thr on option using ®T¬ key.

The following options for entering

thresholds are displayed:

- SEt-0 - go to weighing with signalling

threshold excess,

- SEt-1 - set lower threshold value,

- SEt-2 - set upper threshold value,

- SEt-3 - set zero signalisation threshold.

Using ®T¬ key select SEt-1 option.

Set lower threshold value using the

following keys:

- digit increase,

- decimal point,

®T¬ - move to next digit,

MENU - finish.

Then select SEt-2 option and enter upper

threshold value.

Choosing Set-3 option will cause starting

work with signalisation of exceeding

thresholds and zero.

To leave the function, press MENU key

and then choose thr and thr-0 options.

Page 32

If the comparison result is :

- smaller than lower threshold – the scale signals MIN (yellow colour),

- between threshold values - the scale signals OK (green colour, with the short sound

signal),

- greater than upper threshold - the scale signals MAX (red colour, long sound signal).

The checkweighing results can be use to control:

- optical indicator (Indication mode),

- batching devices (Batching mode).

If we choose thr CFG option following options will appear:

- thr Out (working mode setting),

- thr buZ (buzzer work settings: EHC – buzzer turns on after exceeding threshold; STB

– signal on after result stabilization in OK section),

- thr FLA (flashing on when lower or upper threshold is exceeded)

- out

User can choose from 3 working modes for thr out.

After choosing thr Out option following options display:

- Out off,

- Out IPL (batching mode),

- Out bSt ( level mode),

- Out SGn (indication mode).

Standard scale is set for cooperation with optical indicator.

On the chart below output states are shown during increasing load on the scale for both

working modes:

Indication mode: Batching mode:

Page 33

P3

P1

P2

P3

zero

zero

treshold

treshold

thr I

thr I

thr I

thr II

thr II

thr II

P1

P2

Level mode:

In Batching mode on P1 (thr I) and P2 (thr II) outputs short-circuit impulses appears for

time of 0,5s. On P3 (zero) output short-circuit state appears when indication does not

exceed threshold value signalling zero load.

Relays connection diagram:

P3

zero

treshold

Outputs:

P1

P2

Min

threshold

Max

threshold

Max

treshold

Min

threshold

Page 34

Relays output is the open collector transoptor output with load capacity 25mA / 24V.

Transmitter inputs must be protected with diodes, e.g. 1N4148.

It is advised to use MS3K/P electronic board (sold separately), consisting of RM96P

transmitters, with DC24V input voltage and AC250V, 3A output.

Important notes:

1. After switching the scale on, both thresholds are set to maximum values.

2. When setting upper threshold value, pay attention that its value is not below lower

threshold value.

3. Setting lower and upper threshold value is possible after sending appropriate orders

from computer, what is described in scale user manual

.

Imax < 25mA

Page 35

TOTAL WEIGHT FUNCTION (totAL)

The function allows calculating total weight for series of measurements, which can be

greater than scale capacity. It allows calculating total weight as well as average value.

Press MENU key.

When totAL is displayed press ®T¬ key.

The following options appear successively:

- tot Prn - report printout without clearing

total register,

- tot oFF - clearing total register, report

printout and leaving the function,

- tot □ - working with receipt printout after

each measurement,

- tot - working without receipt printout.

Press ®T¬ key when tot □ is displayed.

Perform measurement series pressing

key for storing results into total register.

In order to display results press ✣ key . Also

it can be done by using totAL function

and choosing option tot Prn.

The results are display in the following

sequence:

- total weight (º)

- number of registered measurements (n),

- average value (=),

Pressing again ✣ key enablespozwala

kontynuować sumowanie ważeń bez

zmiany zawartości rejestów.

In order to go back to total weighing without

zeroing total register press key third

time.

0.00 g

0.00 g

totAL

tot

150.01g

120.00g

20

0.00g

0.00g

MENU

T

T

n

TO TA L

Page 36

To leave the function with clearing total register, select total function from menu and

choose tot-0 option. When It will cause the scale prints the communicate informing

about clearing registers.

The form of receipt after each measurement:

Report form:

Note:

When the scale has not an internal clock, Date and Time do not appear on printout.

Maximum number of measurements 99 999.

Maximum total load 99 999 000d.

The weighing unit of the total value from the register (Total) is the same as the weighing

unit stated on the keypad or is 1000 times greater, what is signalled by “o” indicator at

the left of the display.

If the registered value is too big to be displayed, “E” communicate appears on the

display.

If the number of series is too high and cannot be displayed, “Err1”communicate appears

on the display.

DENSITY DETERMINATION (hYdro)

The description below describes density determination using HYDRO kit. In case belowbalance weighing, operation sequence does not change.

Date: ... Time. ...

measurement no weight

measurement no weight

Date: ... Time. ...

TOTAL WEIGHT =

NUMBER OF SAMPLES =

AVERAGE VALUE =

Page 37

Solids density determination

This function calculates material

density basing on its weight in air and

in water using the formula below:

where, m1 – weigh in air

m2 – weight in water

rL - density of liquid

If distilled water is used, enter its exact

temperature (accurate to 0,5°C) – the

balance will calculate its density

automatically.

To enter the value use the following

keys:

- digit increase,

- decimal point,

®T¬ - next digit,

MENU - end.

When using liquid other than distilled

water, choose OTHER (instead of

H2O) option and enter its density

according to its temperature.

Phase I: measurement in air.

Phase II: measurement in liquid.

To print measurement result and

begin next measurement press

key.

L

mm

m

rr

*

21

1

-

=

0.000g

SO LI d

H2O

t C

LO A D _ H

LO A D _ L

10.000g

9.000g

18

hYdro

hyd on

-

-

MENU

MENU

T

T

T

T

T

Page 38

To print a density determination report after all necessary measurements, connect a

printer to the balance and press P key. A sample for solid mass density determination

is shown below:

Date: ...

Time ...

MEASUREMENT NO.

= ...

WEIGHT in air

= ... g

WEIGHT in a liquid

= ... g

DENSITY

Liquid density

Liquid temperature

= ... g/cm

3

= ... g/cm

3

= ... oC

Operation sequence (weighing in air and in liquid) for below-balance weighing:

Phase I: measurement in air.

Phase II: measurement in liquid.

Page 39

LIQUID DENSITY DETERMINATION

This function determines liquid density

basing on plunger weight in air and in

examined liquid with known volume,

using the formula below:

where

m1 – plunger weight in air

m2 – plunger weigh in a liquid

V – plunger volume

Plunger volume is stored on its

hanger.

To enter the value use the following

keys:

- digit increase,

- decimal point,

®T¬ - next digit,

MENU - end.

Phase I: measurement in air.

Phase II: measurement in liquid.

To print measurement result and

begin next measurement press

key.

To print a density determination report after all necessary measurements, connect a

printer to the balance and press key. A sample for liquid density determination is

shown below:

Date: ...

Time ...

MEASUREMENT NO.

= ...

WEIGHT in air

= ... g

WEIGHT in a liquid

= ... g

LIQUID DENSITY

PLUNGER VOLUME

= ... g/cm

3

= ... g/cm

3

V

mm21-

=

r

MENU

MENU

T

T

T

T

0.000g

LI q u Id

PLu n G

5.51

LO A D _ H

LO A D _ L

22.001g

11.500g

hYdro

hYd on

-

-

Page 40

LEAVING THE FUNCTION

To stop using the function, follow

operation sequence as shown on the

picture.

In other case the balance begins next

density measurement.

PRINTOUT LAGUAGE SELECTION (LAnGUAG)

LAnGUAG function enables to select printouts language (calibration reports, total

printouts and hYdro).

Press MENU key.

When LAnGUAG function appears press ®T¬

key.

On the screen will succesively appear:

- POLISh ,

- ENGLISh,

- GErMAn,

- rUSSIAn,

- UkrAIn ,

- CZECH,

- SPAnISH,

- out.

Choose the proper language and press ®T¬

while it’s displaying.

LO A D _ H

- -

0.000g

0.000g

6.6635

-

-

MENU

Page 41

Example of printouts in polish and English language:

- calibration report

RAPORT Z KALIBRACJI

NUMER FABRYCZNY

NUMER PROGRAMU

MASA KALIBRACYJNA PIERWOTNA

MASA KALIBRACYJNA

RÓŻNICA MAS

CALIBRATION REPORT

FACTORY NUMBER

PROGRAM NUMBER

CALIBRATION PRIMARY MASS

CALIBRATION MASS

DIFFERENCE MASS

- total function report

UWAGA ! WYZEROWANIE

REJESTRÓW

stan przed wyzerowaniem

TOTAL

WARTOŚĆ ŚREDNIA

LICZBA NAWAŻEK

PRZEKROCZENIE ZAKRESU

WARNING! ZEROING REGISTER

results before zeroing

TOTAL

AVERAGE VALUE

NUMBER OF MEAS

RANGE EXCESS

PAPERWEIGHT CALCULATION (PAPEr)

This function enables to calculate paperweight of 1m2 of paper basing on samples of

known area. For quick access, the function is accessible directly by pressing ✣ key.

The balance must be tared just before

the measurement.

Place the specific sample quantity of

the same area (possible values: 1, 2,

5, 10, 20, 50, 100).

Press MENU key to access Function

Menu. To enter the function press

®T¬

key when “PAPEr” is displayed.

PCS is the number of samples placed

on the pan. To choose previously used

value, select old option.

"ArEA" is the area of a single sample.

It is possible to choose standard

values (0,02 or 0,1g/m2) or enter

specific value (“A” option).

To enter the value use the following

keys:

- digit increase,

- decimal point,

®T¬ - next digit,

MENU - end.

The result of paperweight

measurement is finished with “=” mark

pointing g/m2 unit.

The balance is ready for the next

measurements.

13.3

g/m=

2

0.000 g

5

1.338 g

PA PEr

PC S

n= 5

P= 0.02

ArEA

MENU

T

T

T

T

T

T

Page 42

✣ key causes passage to mass measurement and enables next samples (with

other quantity and surface of a single sample) measurement start.

STATISTICALS CALCULATIONS FUNCTION (StAt)

Attention: Function is available on demand and it replaces other special functions.

This function evaluates from series of measurements (max 500) statistical parameters

of weighting process. Adding successively measurements to register is automatic and

it occur after the scale is loaded and its indications stabilize.

After each loading printout is made with: number of measurements, result, date and

time.

Next measurement is made after taking off earlier load.

For the obtained measurements series the scale evaluates:

- n - number of samples

- sum x - sum of all samples

å

=nxxsum _

- x -average value (sum x)/n

- min -minimal value from n samples

- max -maximal value from n samples

- max-min -maximal value minus minima value

- S -standard deviation

2

)(

)1(

1

å

-

-

=

n

n

xx

n

S

- srel -variance factor

x

S

srel =

Statistical calculations results can be printed.

Page 43

1. Press MENU key.

2. When StAt is displayed press ®T¬ key.

Following options will show successively

on display:

- StA Prn – monitoring and printout of

statistical data,

- StA oFF – function off,

- StA o – function on, working with single

weight results printout,

- StA - – function on, working without

single weight results printout,

- StA CFG – function configuration:

-Auto – automatic work (sample is

confirmed after putting load and

indication stabilization),

-ManuAL – manual work (confirmed

by pressing key).

- out – out of function.

3. Press ®T¬ key when StA o is

displayed .

4. Put successively samples of product on

the pan, (take off after indication

stabilization) in order to inscribe them

into measurement register.

5. In order to obtain statistical results for

measurement series press MENU key

and ®T¬ key when the StAt. sign is

displayed and then StA Prn.

Successive results are displayed after

pressing ✣ key:

n – sample number.

= - average mass,

º - standard devation,

º% - relative standard devation,

MIN – minimal mass,

MAX – maximal mass,

After pressing ®T¬ key during StA End displayed, user can end displaying statistics.

This will cause printout of calculated statistics and histogram :

0.00 g

0.00 g

0.00 g

St A t

St A t

StA o

StA Prn

1.00 g

2.00 g

0.00 g

0.00 g

MENU

MENU

T

T

T

T

2

n

1.50 g

_

_

Page 44

LSL - allowable lower value,

USL - allowable upper value,

A, B, C, .. – measurement intervals,

nA ... – amount of measurements in A interval;

measurement is in A interval if it is bigger

or equal to A interval threshold

and smaller

than B interval threshold.

nB ... - amount of measurements in B interval;

measurement is in B interval if it is bigger

or equal to B interval threshold

and smaller

than C interval threshold.

Thresholds are printed under histogram.

-NG - amount of measurements under

allowable lower value

+NG - amount of measurements above

allowable upper value

To finish work with this function and zeroing

result register press F key, then during "StAt"

and "F." is displayed, press ®T¬ key. This

will cause printing message about register

zeroing.

Data: ... Hour. ...

SAMPLES = ...

TOTAL MASS = ...

AVER MASS = ...

MIN MASS = ...

MAX MASS = ...

MAX – MIN = ...

S = ...

SREL = ...

*HISTOGRAM*

LSL ...

USL ...

DIV ...

-NG ...

LSL

A nA

B nB

C nC

D nD

E nE

F nF

G nG

H nH

I nI

J nJ

USL

+NG ...

A ~ ...

B ~ ...

C ~ ...

D ~ ...

E ~ ...

F ~ ...

G ~ ...

H ~ ...

I ~ ...

J ~ ...

...

Measurement made by : ____________

Page 45

TROUBLESHOOTING AND MAINTENANCE

1. The balance should be kept clean.

2. Take care that no dirt is between the casing and the pan. If a dirt is noticed, take off

the pan (lift it up), clean a dirt and then mount the pan.

3. In case of improper operation caused by a short-lasting lack of power supply, switch

the balance off by unplugging it from the mains, and then after several seconds switch

it on.

4. All repairs of the balance should be performed by authorised service centre.

5. To repair a balance, please contact nearest service centre. The list of authorised

service centres is given in guarantee card.

6. Balances can be sent for repair as messenger delivery only in original package, if

not, there is a risk of damaging the balance and loosing guarantee.

FAILURE MESSAGES:

Message

Possible cause

Recommendation

C-1 ... 6

(more than 1 min.)

negative result in one of

autotests

if message still remains,

contact service centre

L

no pan on the balance

put the pan on

mechanical damage

contact service centre

H

overweight of the balance

take a load off the pan

mechanical damage

contact service centre

load left on the pan

take a load off the pan

indicator

does not work

unstable balance position,

ground vibration,

air flows

locate the balance in place

where stable results are

maintained

damage of the balance

contact service centre

- - - - - -

taring not finished

contact service centre

Pr-on

Calibration switch is in ON

position or switch is damaged

Change switch position into

OFF or contact authorised

service

Page 46

Page 47

Page 48

Loading...

Loading...