Page 1

1

Page 2

2

Page 3

3

INDEX

1. KEYPAD AND LCD DISPLAY ........................................................................ 5

2. BEFORE USING THE SCALE ........................................................................ 8

3. ON / OFF .................................................................................................. 10

4. INITIAL RESET TO ZERO ........................................................................... 10

5. OPERATION ............................................................................................. 11

5.1. USE OF THE SCALE ....................................................................... 11

5.2. TARE AND TARE RECORD IN MEMORY ....................................... 12

5.3. ZEROING ...................................................................................... 14

5.4. LCD DISPLAY TEST ........................................................................ 14

5.5. HIGH-RESOLUTION MODE........................................................... 15

5.6. HOLD MODE ................................................................................ 15

5.7. H-L MODE (CONTROL OF UPPER/LOWER LIMITS) ...................... 16

5.8. DOSAGE MODE............................................................................ 17

5.9. PIECE COUNTER MODE ............................................................... 18

5.10. PLU - SELECTION OF PRODUCT CODE ......................................... 20

5.11. PRINTING A WEIGHING TICKET ................................................... 21

6. CONFIGURATION OPTIONS MENU .......................................................... 23

7. AUTO-OFF OPTION ................................................................................. 26

8. BACKLIGHTING THE DISPLAY ................................................................... 26

9. SOUND WHEN PRESSING A KEY ............................................................. 27

10. TARE OPTIONS ........................................................................................ 27

11. Hold MODE ............................................................................................. 27

12. KEYPAD LOCK .......................................................................................... 29

13. COMMUNICATION .................................................................................. 29

13.1. Remote indicator mode .............................................................. 32

13.2. XTREM mode ............................................................................... 32

13.3. PR4/PR6/Q2 printer .................................................................... 33

13.4. Frame format RD3 ....................................................................... 33

13.5. Frame format USB ....................................................................... 34

13.6. Frame format PC0 ....................................................................... 34

13.7. Communication protocol ............................................................ 37

14. TICKET PRINT OPTIONS .......................................................................... 38

15. CONFIGURING THE SCALE ....................................................................... 39

15.1. Settings menu ............................................................................. 40

15.2. Scale calibration .......................................................................... 40

16.3 Table of geographical adjustment values ................................... 42

16. DIGITAL FILTER ........................................................................................ 43

Page 4

4

17. WEIGHING OF LIVE ANIMALS .................................................................. 43

18. MOVEMENT FILTER ................................................................................. 43

19. INFORMATION TO BE VIEWED ................................................................ 44

20. DIGITAL OUTPUTS ................................................................................... 44

21. TECHNICAL SPECS .................................................................................... 46

22. CONNECTIONS ......................................................................................... 48

23. ERROR MESSAGES ................................................................................... 50

24. NOTES ...................................................................................................... 51

Page 5

5

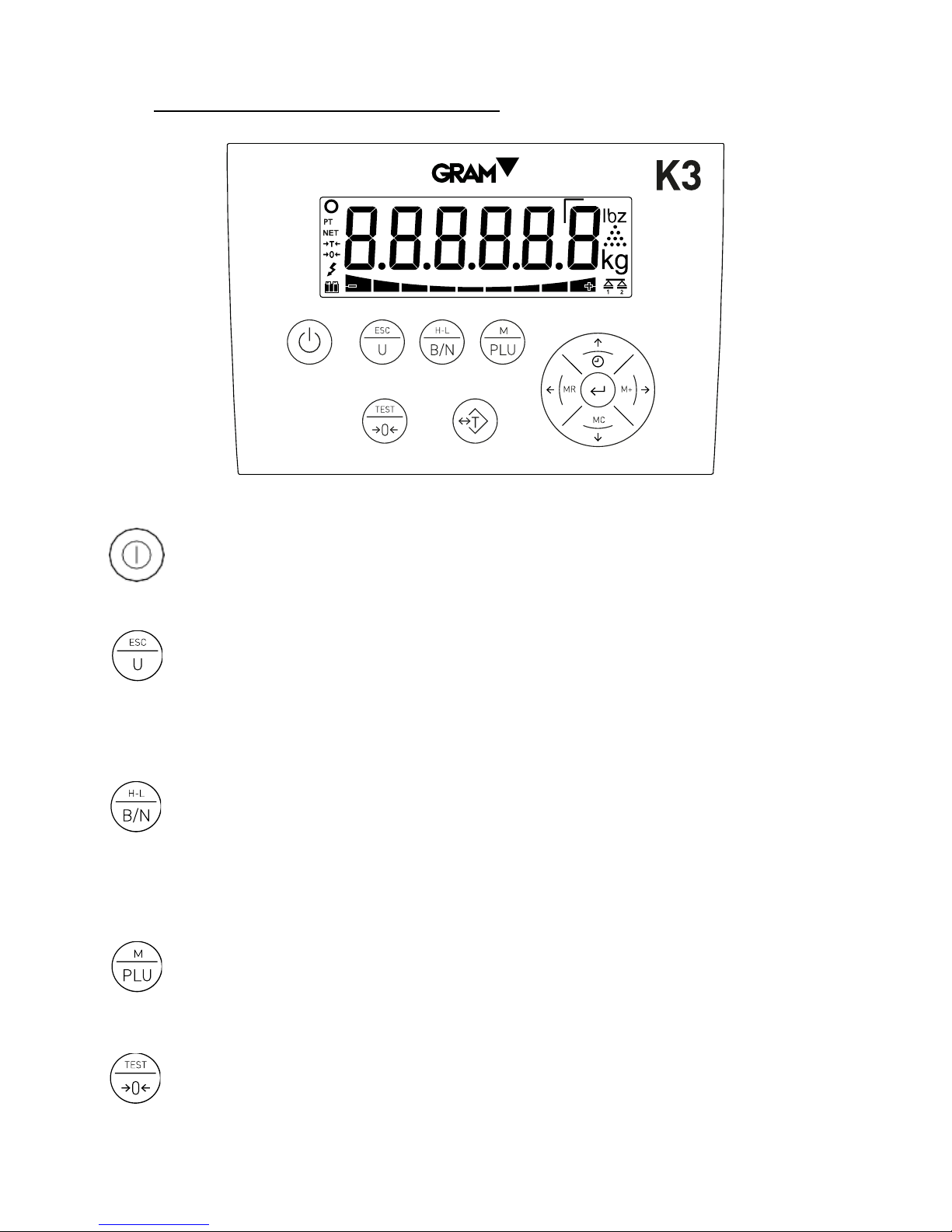

1. KEYPAD AND LCD DISPLAY

Switches the unit On / Off. Pressing it lights up the indicator. With

the indicator on, keeping it pressed for two seconds switches it off.

Piece counter mode. Activates or deactivates the piece counter

mode. Double-pressing it gives access to the options menu of the

piece counter mode. In menu mode you have the function of exiting

the menu and returning to normal mode (Escape).

Gross/Net. When the tare is used, when pressed it shows the gross

weight (total weight on the scale) and when pressed again it shows

the net weight. Keeping it pressed for more than one second

automatically selects the “Weight Limit” mode. Double-pressing it

gives access to the limits configuration menu.

PLU - product code. Pressing it gives access to the product code

memory (PLU). Keeping it pressed for more than one second leads to

the scale configuration and settings menu. Double-pressing it

activates or deactivates the HOLD mode.

Zero / Test / High-resolution. Zeroing the scale. Pressing it for more

than one second shows the display test, capacity, division and

Page 6

6

software version. Double-pressing the key activates the highresolution mode. When editing the value of an alphanumerical data,

it switches between upper case, lower case and numbers / symbols.

Tare. Pressing it once subtracts the weight of any receptacle or box

placed on the platform until the weight is removed from the platform

and this key is pressed again. Keeping it pressed switches between

“fixed tare” and “normal tare” mode. Double-pressing it gives access

to the tare memory, for selecting a record or editing the associated

tare value.

M+ and right arrow. When pressed, it adds the weight indicated in

the display to the total, initiates the accumulated ticket if it was not

yet initiated and sends the ticket data to the printer. In addition, for a

few moments it shows the accumulated total. In menu mode it

displays the next option.

MR and left arrow. When pressing on it on the main screen, it closes

and sends the totalizer ticket data and shows the accumulated weight

total. In menu mode it returns to the previous menu.

Enter. When pressing on it on the main screen, it sends the current

weight data to the printer (single ticket). Keeping it pressed for two

seconds activates the blocking/unblocking of the keypad. In menu

mode it confirms the selection/modification made.

Clock and Up Arrow. A short press displays the accumulated value in

the total. Pressing it for more than a second displays the date and

time. In menu mode, when editing the content of a parameter, it

increases the value (digit) of the display.

MC and Down Arrow. In menu mode, when editing a parameter, the

value (digit) shown in the display decreases. If kept pressed for more

than one second, it runs the “Clear” function: It voids the tare,

cancels the “hold” mode and resets the accumulated weight total.

Page 7

7

Displays the weight on the scale platform.

In HOLD mode, the reading is shown intermittently to signal that it is not indicating the real weight on the scale but the la test

stable weight recorded.

Unit of measurement in which the weight is indicated.

Piece counter mode: The display shows the number of units, not the weight.

Stable weight reading: There is a weight on the platform that is not fluctuating. Intermittent or switched off to indicate

that there is movement in the scale.

Negative sign.

This reading may be negative if a tare is activated (in preset tare mode) or to indicate a problem when setting it to zero.

Indicates net weight. The net weight is the real weight on the scale minus the tare. It is only displayed if a tare has been used.

Tare activated.

The reading flashes when “normal” tare mode has been activated.

A “preset” tare is retained even after the weight is removed from the scale platform.

Tare in memory. The tare being subtracted from the weight is a value recorded in the indicator memory, not necessarily a

measured value.

Scale set to zero: The weight on the load receptor is lower than ¼ interval (division).

Reading in high-resolution mode. It shows a division 10 times smaller than the one defined in the weighing scale range.

In double range mode, it indicates that the scale’s range 1 is being used.

In double range mode, it indicates that the scale’s range 2 is being used.

The weight is below the lower limit.

The 4 segments of this indicator are activated proportionally to the difference between the weight on the scale and the value of

the lower limit. The thickest segment indicates that the weight is lower than the value set as the lower limit in a proportion of 100%

or more.

The weight is within the interval encompassed between the lower limit and the upper limit.

The weight is above the upper limit.

The 4 segments of this indicator are activated proportionally to the difference between the weight on the scale and the value of

the upper limit. The thickest segment indicates that the weight is higher than the value set as the upper limit in a proportion of

100% or more.

Battery-operated. Not connected to the mains. The load level is indicated.

AC/DC supply connected to the power outlet.

Page 8

8

2. BEFORE USING THE SCALE

1. AC/DC adapter, output 12 Vdc – 1 A

2. Space allocated for optional enlargements

3. Connector for the C1 load receptor platform

4. RS-232 data output

5. Connector for the XTREM platform

Connect the AC/DC power source to the unit and to a power outlet suitable

for charging the battery before its first use.

Connect the load receptor platform cable in the C1 connector of the K3

indicator.

Page 9

9

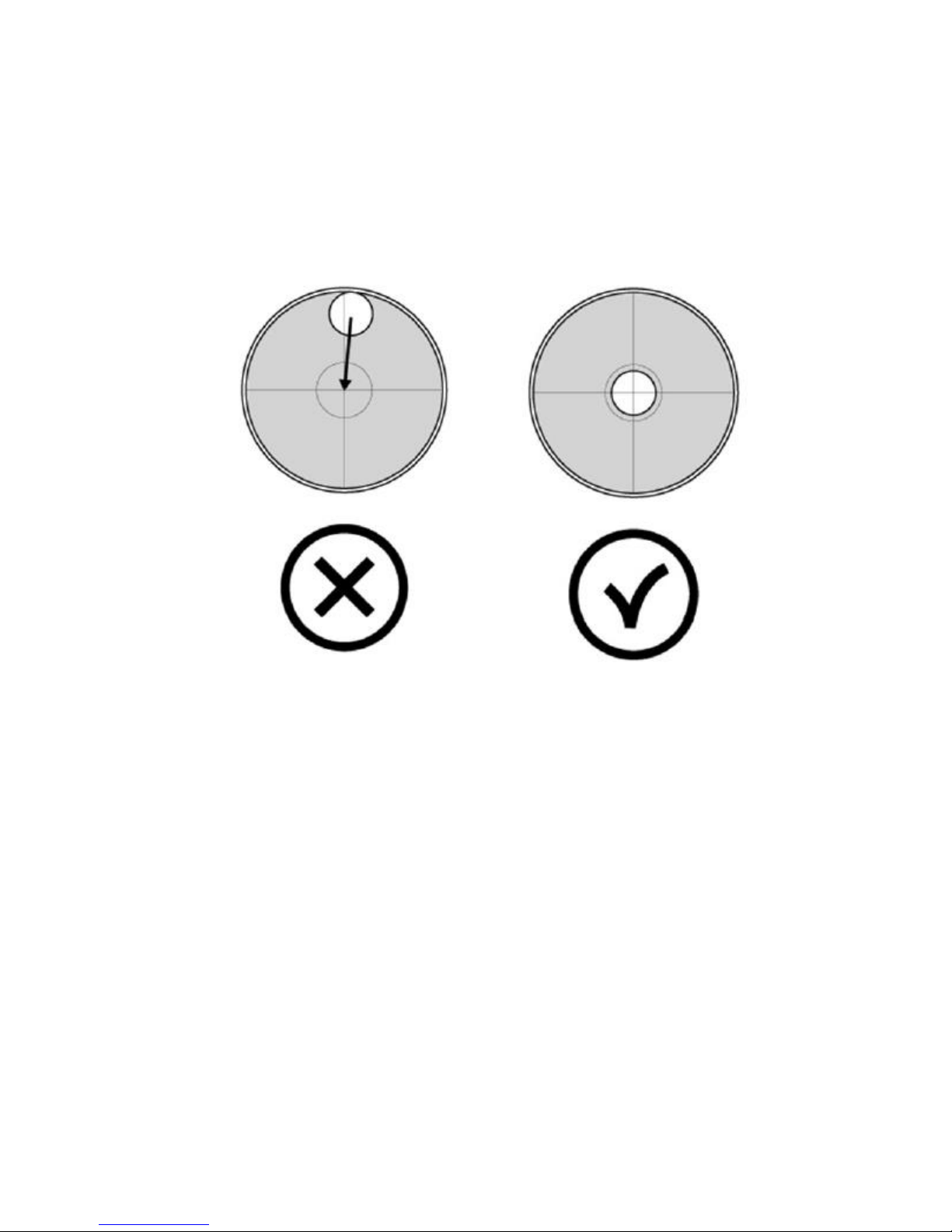

The load receptor platform should be placed on a flat surface free of any

irregularities.

For the proper functioning of the instrument, the platform should be

horizontally levelled. Before using the scale, check the bubble level included

in the actual platform and adjust the levelling feet if necessary.

Both the K3 indicator and the weight sensors included in the platform are

sensitive to changes in ambient temperature. To achieve maximum precision,

we recommend you keep the scale switched on for at least 30 minutes in its

set-up site before using it.

Page 10

10

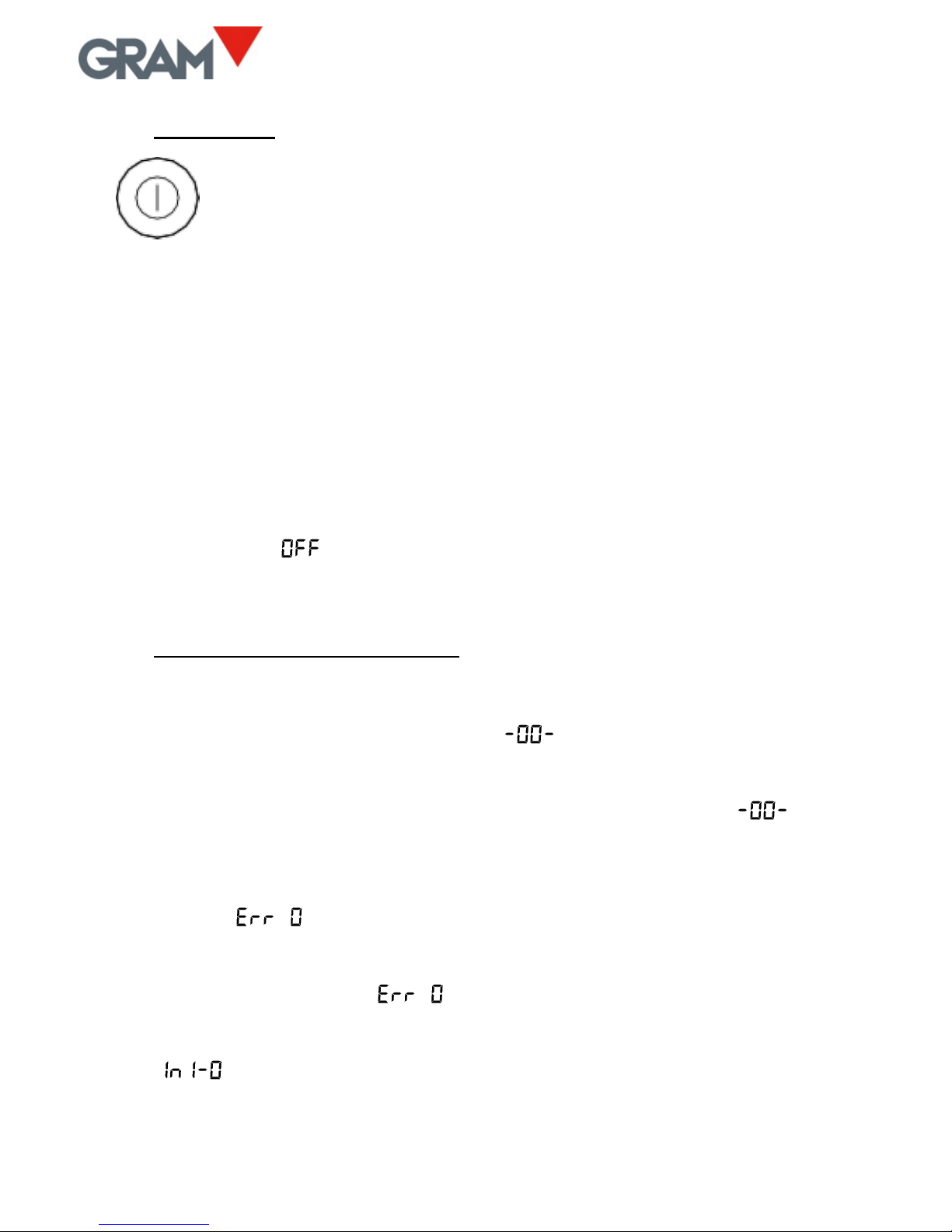

3. ON / OFF

Press on the key. The display switches on and performs the

following sequence:

1. All segments and symbols switch on for a second on the LCD display

to verify that they are functioning properly.

2. It then shows the unit’s firmware version code during one second.

3. Finally, for one second it displays the scale’s maximum capacity and

the interval.

After the power-up sequence the scale is ready for use.

To switch off the unit, press on the same power-on key and keep it pressed

for 2 seconds. An message will appear to warn that the device will be

switched off when the key is released.

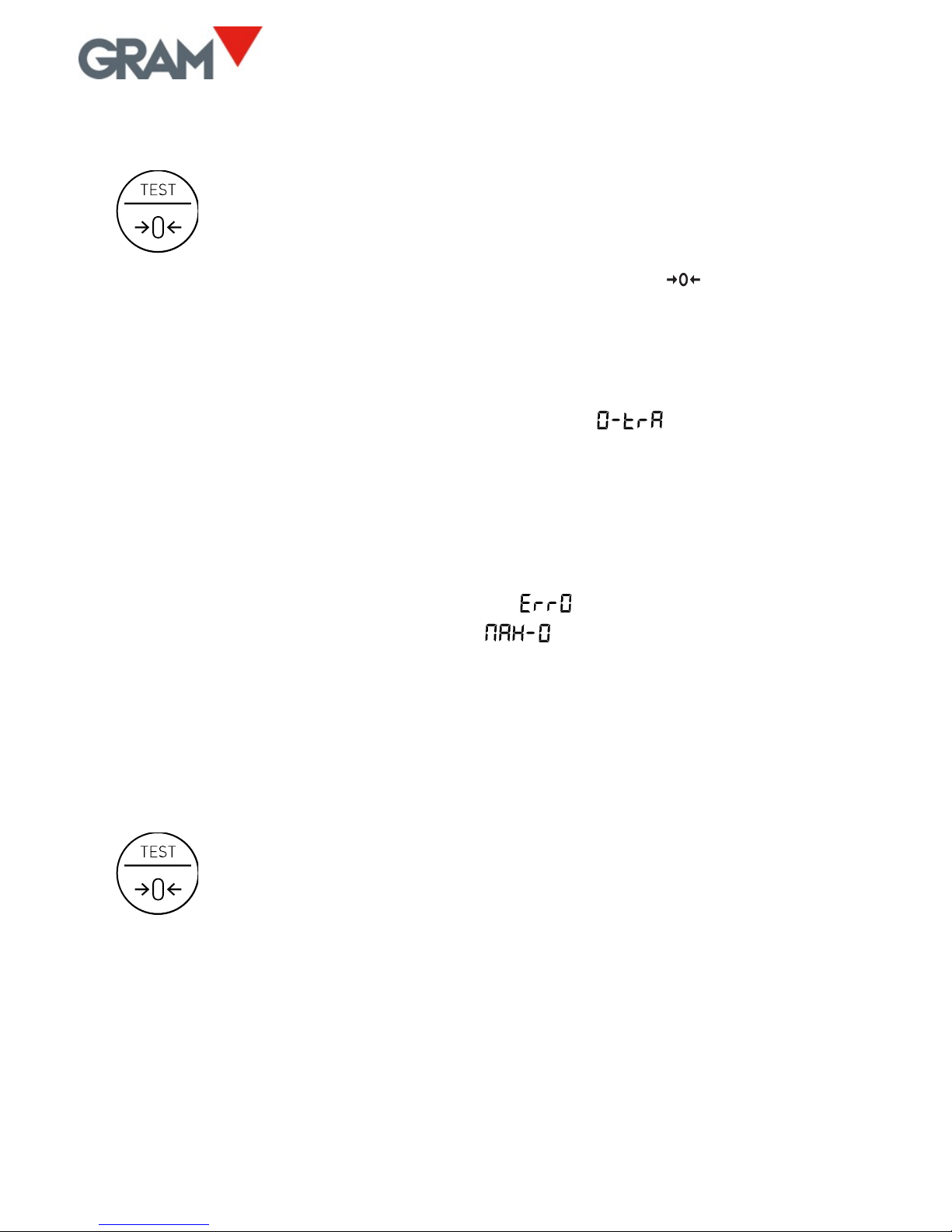

4. INITIAL RESET TO ZERO

When switching on the unit, it will automatically set to zero. This will be

indicated in the display with the message .

Automatically resetting to zero at the start requires the scale to remain

stable for at least 5 seconds. For as long as the scale is moving, the

indication will be maintained for a maximum of 10 seconds.

If this time period is exceeded without obtaining a stable reading, the display

will show an message followed by the weight on the scale.

If the weight on the load receptor is higher than 10% of the scale’s maximum

capacity, the error message will be displayed, followed by the weight

on the scale.

The option in the configuration menu activates or deactivates the

initial zeroing.

Page 11

11

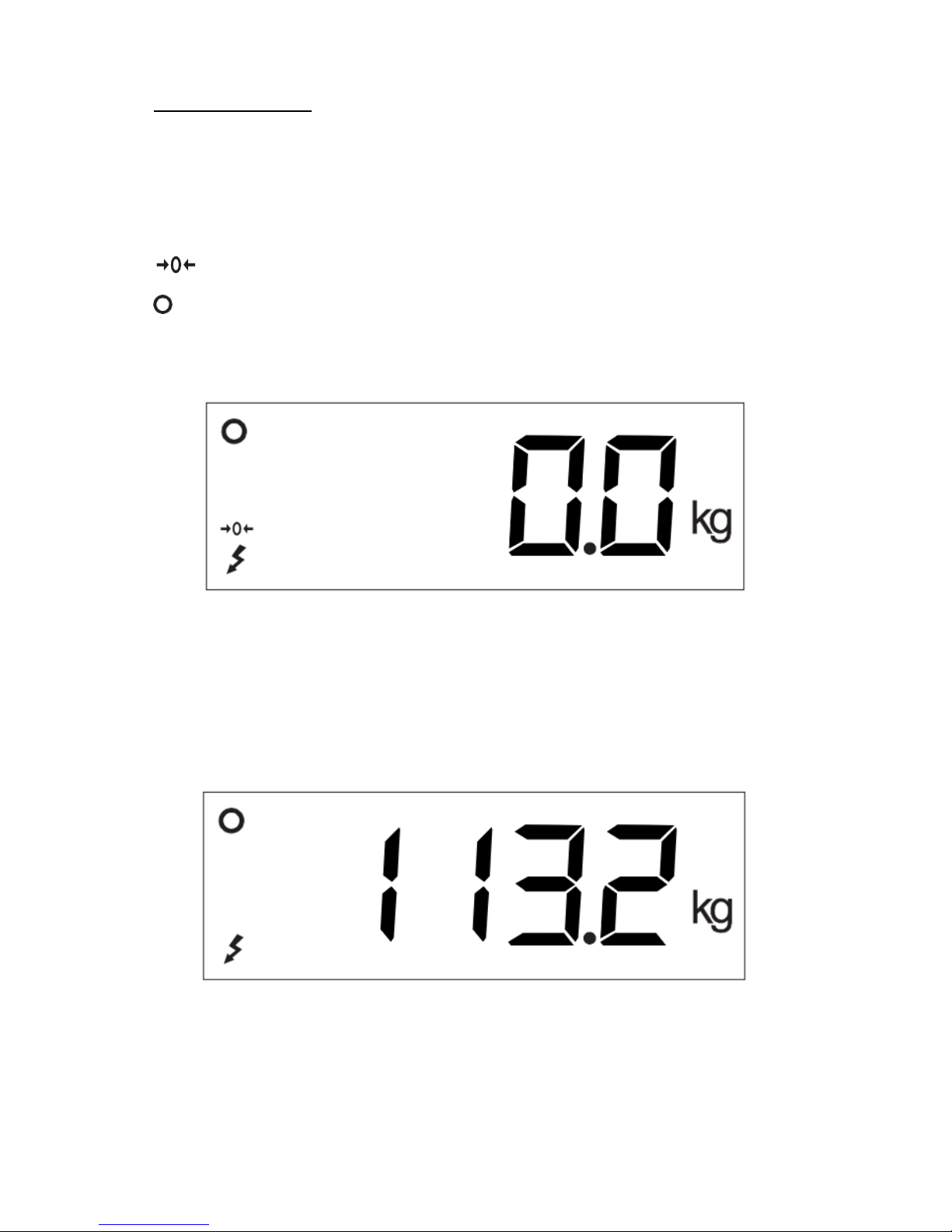

5. OPERATION

5.1. USE OF THE SCALE

Once the unit is switched on, the weight display will indicate that the scale:

• is set to zero, meaning that there is no load placed on the platform.

• the reading is stable, that is to say, there is no external influencing

factor (such as an air current or the vibration of a nearby engine) that

may be producing significant disruption.

To find out the weight of any object within the scale’s maximum range, place

it on the load receptor platform: The zero reading and the stability reading

disappears from the indicator; the weight value will increase until the

stability reading becomes visible again. The value indicated in the display is

the result of the measurement.

Page 12

12

5.2. TARE AND TARE RECORD IN MEMORY

A short press on this key activates the tare function: The scale

memorizes the weight currently on the load receptor and

subtracts it from the total weight until the tare function is

deactivated or cancelled.

The tare function only operates if the weight is stable. If the stability indicator

is switched off, pressing this key has no effect. It is possible to change this

feature by changing the option in the configuration menu to “NO”.

It can be “Normal Tare” or “Fixed Tare” depending on the operating mode

selected in the configuration menu (see option ).

• Preset tare. The tare remains after emptying the load receptor. The >T<

indication on the display stays constant, non-flashing. When the scale is

emptied, the display shows the tare value with a negative sign. To cancel

the tare, press on the tare button again after emptying the plate.

• Normal tare. The tare is automatically deactivated when the plate is

emptied. The >T< indicator is switched on intermittently in the LCD

display.

Keeping this key pressed for 2 seconds switches the operating mode from

“fixed tare” to “normal tare”. The default operating mode for tare is “preset

tare”, although this value can be changed in the options menu (see option

).

It is possible to apply a tare previously memorized in the unit. The K3

indicator has up to 20 tare records, numbered from 1-20. Double-press the

tare key to access this record and select one of the memorized tares.

The display will show the message; press on the key, enter the tare

record number you wish to select and validate by double-pressing the key.

The display will show for one second the tare value associated to the selected

record. It will then return to the weight reading mode and will apply the tare.

Page 13

13

Should no tare value have been entered previously for the selected record,

the display shows the option of the configuration menu, which allows

the tare value to be entered.

When a memorized tare is used, the display shows the (“preset tare”)

reading.

To add a value to the tare memory or to modify the value associated to a tare

record, follow this procedure:

1. Double-press the tare key and select the desired record in the

option as indicated in the previous paragraph.

2. Once the record is selected, the display will again show the

message. Pressing on the → key on the display will show the

(“value”) option; pressing on the key will display the tare value

associated to the selected record. If no value has previously been

entered for the selected record, the K3 indicator will show the

current weight on the scale in the field for editing.

3. Enter the desired value by using the → arrow keys to change the

next digit and the ↑↓ keys to modify the value of each digit. Doublepress the key to validate the content of the display and store it in

the indicator memory.

To cancel the tare when the operating mode is “fixed tare”, with the load

receptor empty press the tare button again. The “clear” function (keep the

MC button pressed for more than one second) also deactivates the tare. The

scale’s zeroing key also deactivates the tare.

When the tare function is activated, a short press on the “B/N”

key switches between a view of the net weight and gross weight

every time the button is pressed. While net weight is displayed,

the “NET” indication will appear on the LCD display.

Page 14

14

5.3. ZEROING

Zeroing the scale: A short press on this key sets it to zero. The

scale is deemed to be “set to zero” when the weight on the load

receptor is lower than ¼ of division.

While the scale is “set to zero”, the reading is shown in the display.

When the scale is set to >0< the automatic “zero tracking” device is in

operation. This function automatically sets to zero when variations of less

than ¼ division occur if they do not add up to more than ½ division during

one second. This function can be deactivated in the option of the

configuration menu.

Pressing on the >0< key also deactivates the tare if it happens to be

activated.

The zeroing of the scale is limited to 4% of its maximum capacity. Should this

margin be exceeded, the display shows the error message. It is

possible to change this margin with the option in the configuration

menu.

5.4. LCD DISPLAY TEST

Keeping this key pressed for more than one second shows the

LCD display test (all segments and pictograms switched on),

the unit’s firmware version code and, finally, the scale’s

maximum capacity and interval.

Page 15

15

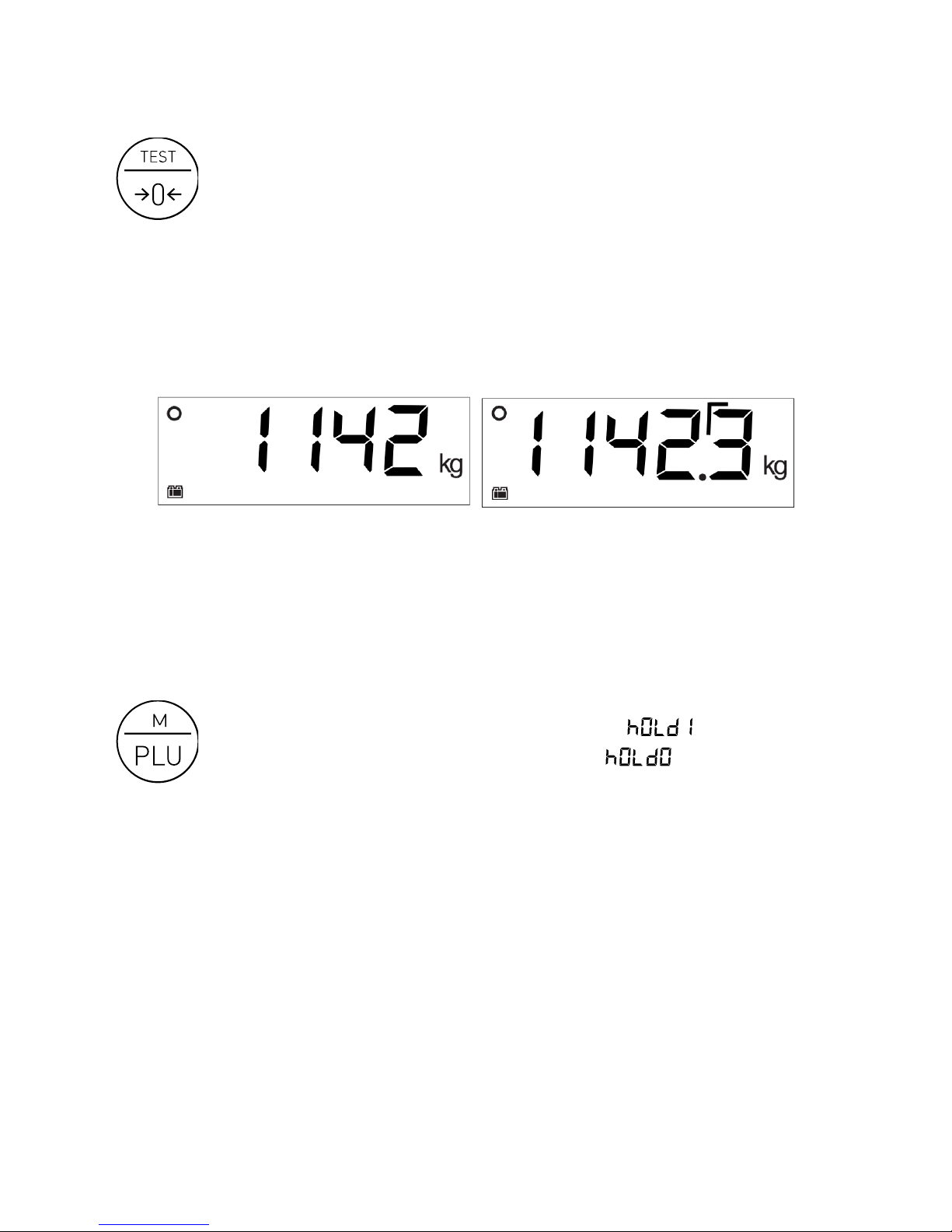

5.5. HIGH-RESOLUTION MODE

Double-pressing the TEST key activates the high-resolution mode.

In this mode the scale’s resolution is enlarged by x10, allowing the

weight to be viewed with a 10-times-smaller division.

An additional digit appears in the weight display, and the decimal point is

shifted to the left by one position. This additional digit is indicated with a

straight angle in its top left corner:

1 Example for a scale with a 1-kg division in normal mode and in high-resolution mode

5.6. HOLD MODE

Double-pressing the PLU key activates / deactivates the “HOLD”

mode. For an instant, the display shows the message to

indicate that it has been activated, or the message to

indicate that it has been deactivated.

When this operating mode is activated, the weight of the last load placed on

the plate always remains on the display. This means that, even when the load

is removed from the plate, the display continues to show the last indicated

weight. If the load has been removed, the weight is shown intermittently to

indicate that the hold mode is in operation.

Page 16

16

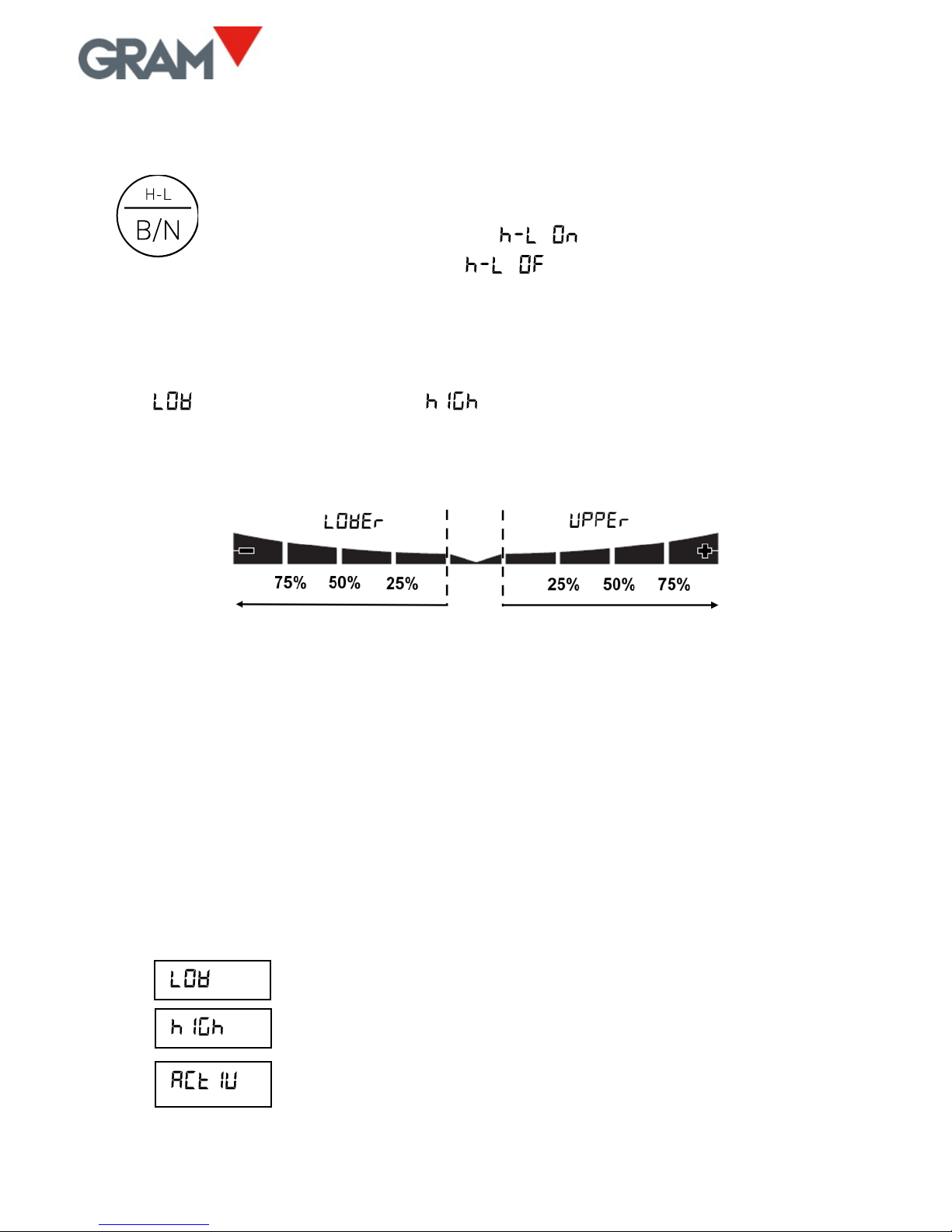

5.7. H-L MODE (CONTROL OF UPPER/LOWER LIMITS)

Keeping this key pressed for more than one second activates or

deactivates the upper and lower limit control mode. For an

instant, the display shows the message to indicate that it

has been activated, or the message to indicate that it has

been deactivated.

When the limit control is activated, a reading lights up in the bottom part of

the LCD display to signal whether the net weight on the plate is lower than

the value or higher than the value. When the weight lies between

the two values, a sign appears indicating that the weight is in the interval

defined by the lower limit and the upper limit.

The colour of the display’s backlighting changes to red when the weight is

outside the interval defined by the upper and lower limit, and changes to

green when the weight is within said interval.

The 4 segments of this reading are activated proportionally to the difference

between the net weight on the scale and the value of the lower or upper

limit. The thicker segment indicates that the weight is below the value set as

the limit in a proportion of 100% or more.

Double-press on the H-L key to access the configuration and change the

lower and upper limits. The possible options are:

Value for the lower limit, including the decimal part.

Value for the upper limit, including the decimal part.

Yes / No: Activating the limit control when switching on

the unit.

Page 17

17

5.8. DOSAGE MODE

The dosage mode is activated and configured by accessing the options menu

in the section (see section 20 in this manual).

Pressing the tare key initiates the dispense cycle, closing the K1

and K3 relay contacts. The display changes to blue to indicate that

the dispense cycle has been initiated.

Upon reaching the weight set point established for (coarse flow),

contact K1 is opened and the display colour changes to indicate that the fine

flow is in operation.

Upon reaching the weight set point established for (fine flow),

contact K3 is opened and contact K2 is closed to indicate that the dispense

cycle has finished. The light of the LCD display changes to green to indicate

that the dispense cycle has finished.

Relay K2 (signalling the end of the dispense cycle) stays closed until the

weight is removed from the scale. It is not possible to initiate a new dispense

cycle if the cycle end outlet (K2 relay contact) stays closed.

To stop and pause a dispense cycle being run, press on the “tare” key. This

action will open the K1 and K3 relay contacts, halting the filling until the tare

key is pressed again.

To cancel a dispense cycle being run, double-press on the tare key.

Page 18

18

5.9. PIECE COUNTER MODE

Pressing the “U” key activates or deactivates the piece counter

mode. In this work mode, the reading shows the number of pieces

on the scale instead of the weight.

The number of pieces is calculated by dividing the net weight on the scale by

a unit weight value.

The K3 indicator has a memory space for 20 unit weight records.

When pressing on the “U” key and changing to piece counter mode, the

message and the message appear for a moment to indicate the

unit weight record number being used (the number at the end of the

message will change from 1 to 20 depending on the selected record). When

deactivating the piece counter mode, the message appears for a

moment before returning to weight reading mode.

If the unit weight value of the selected record is outside the scale’s

measurement range, the indicator will automatically show the

option in the configuration menu of the piece counter mode. This option

allows the unit weight to be automatically calculated from a sample with a

known number of pieces.

In piece counter mode, the measurement unit is the “number of units” and is

indicated by the pictogram.

The number of pieces is always a whole number; there is no decimal fraction.

It can be a negative value if the fixed tare is kept activated and the load

receptor is completely emptied.

Page 19

19

In piece counter mode, all of the scale’s functions remain available: tare and

memorized tare, high resolution, limit control, PLU selection, ticket printing

or adhesive label.

If limit control mode is activated, the value for the lower limit and for the

upper limit refers to the number of pieces, not to the net weight on the scale.

Double-pressing on the “U” key gives access to the piece counter options

menu. The possible options are:

Selecting record number (1-20).

Automatic unit weight calculation from a sample with a

known number of pieces. For the selected record number.

Manual input of the divisor of the A/D converter count

value for calculating the number of pieces for the selected

record number.

For automatically calculating the unit weight of a piece, these are the steps to

follow:

1. Make sure that the scale is set to zero (the reading should

appear on the display). If necessary, place an empty receptacle on

the load receptor to contain the sample of pieces and perform a tare.

2. Double-press on the “U” key. The first option in the piece counter

configuration menu will appear, . Press the key.

3. Enter the piece counter record number with which you wish to work

(1 to 20) and double-press the key to validate.

4. When the message appears again, press the → key to go to

the option and press the key to access it.

5. Use the scroll keys → and . Enter in the display the number of

pieces contained in the prepared sample to calculate the unit weight

(minimum 10 pieces).

6. Double-press on the key to validate. For a few seconds the display

will show the message intermittently while it automatically

calculates the unit weight.

Page 20

20

EdIt

7. Once this process is complete, the unit weight for the selected record

is stored in the unit’s memory and the indicator will automatically

switch to piece counter mode, using the unit weight that has just

been calculated.

If the calculation of the unit weight produces a value outside the indicator’s

measurement range, the message will appear and the operation will

be cancelled.

5.10. PLU - SELECTION OF PRODUCT CODE

When pressing on the PLU key, the indicator jumps to the product

codes configuration menu to select or edit a record.

The K3 indicator has a memory with 85 PLU records.

This memory allows a 6-character alphanumerical information field to be

associated to each one of these records. This information is printed on the

weighing labels if a PLU record has previously been selected.

The possible options are:

Selection of the number of PLU records (1-85).

Inputting the 6-character alphanumerical code associated

to the selected record.

When inputting the content of the alphanumerical field, the “TEST” key

allows switching between upper case, lower case and numbers or symbols.

To cancel the selected PLU, access the option, enter the “0” value and

validate by double-pressing the key.

Page 21

21

5.11. PRINTING A WEIGHING TICKET

In “weight indicator” mode and in “piece counter” mode, the key

acts as a print key.

When pressing this key, a ticket is printed with the weight shown on the LCD

display. The ticket shows print date and time, the ticket’s serial number,

gross weight, tare and net weight. If the indicator is in piece counter mode,

the ticket shows the number of pieces, the unit weight and the tare.

The date and time are only available if the optional real-time clock accessory

is installed.

Additionally you can print a 3-line header and a footer line with constant

information.

1 Weighing ticket in weight indicator mode and in piece counter mode

Page 22

22

The print key will only be effective if the weight on the scale is stable (the

stability indicator is switched on).

This gross/tare/net ticket is only possible provided no ticket with

accumulated total has been initiated, which has a different format.

To initiate a totalizer ticket, weigh the first object to be included in

the ticket and press the M+ key. The weight shown on the display is

printed and added to the accumulated total. Repeat this operation

to add and print each one of the subsequent weighings.

At the end of each weighing sum, the total accumulated sum

appears in the display. To complete the ticket and print the line for

the total, press on the MR key. You can view the total at any time

before completing the ticket by pressing on the key.

2 Example of totalizer ticket

Page 23

23

6. CONFIGURATION OPTIONS MENU

To access the configuration options menu, keep the “M” key

pressed for two seconds. The display shows the message for

½ second to indicate that from then on the indicator will start

showing the different selection options. In “menu” mode, use the arrow keys

to change to the next option or change the value of one digit in the display

when editing the value of a parameter.

Returns to the menu’s previous level without making any

change.

When in the main menu, exit the menu mode and return to

normal operation mode (weight mode).

Moves to the next menu option in the “left” direction or

changes between the different values. It is possible to assign to

a particular option.

Moves to the next level of the options menu or shows the

current value of an option. When changing the selected value

for an option (using the and → keys), pressing this key will

validate the change. In “edition” mode (manual input of a

parameter value), one short press moves you to the next digit

on the display. A long hold or a double-press validates the

entered value.

Moves to the next menu option in the “right” direction or

changes between the different values. It is possible to assign to

a particular option.

To change the value of one digit in the display when inputting a

data item.

Page 24

24

La siguiente tabla resume las diferentes opciones de configuración y ajuste:

•

Options for automatically switching off the unit

•

Options for backlighting the LCD display

•

Activating sound when pressing on a key

•

Activating fixed tare

•

Activating automatic tare

•

Requiring stability for performing a tare

•

Operational style in “hold” mode

•

Activating keypad lock

•

Transmission speed of serial port

•

Serial port 1: Data transmission mode

•

Format of frame data sent

•

Serial port 1: “Wireless” option installed

•

… … …

Serial port 1: Wi-Fi network selection

•

Serial port 2: Data transmission mode

•

Format of frame data sent

Inputting date and time

Editing ticket number

•

Automatic paper cutting

•

Decimal separator for USB keypad adapter

•

Measurement unit of the scale

Maximum capacity (Max1 in the event of 2 ranges and intervals)

•

Division (e1 interval)

•

Position of decimal point

•

Activating double range or double interval option

Max2 in the event of 2 ranges / intervals

•

e2 in the event of double range

•

Activating initial auto-zero

•

Action range of zeroing device

Page 25

25

•

Activating zero-tracking device

•

Activating zero reading

Procedure for calibrating the scale

•

Activating automatic correction depending on geographical location

…

Selecting geographical location

Zero value in AD/C counts

Conversion factor of AD/C counts to measurement units

Printing of the configuration

Resetting the configuration to default values

AD/C pre-calibration procedure

•

Digital filtering level

•

Additional filtering for weighing moving objects or live animals

•

Activating movement filter

•

Selecting information to be viewed on the display

Piece counter: Selecting unit weight record (1-20)

Piece counter: Calculating unit weight from a sample.

Piece counter: Manually inputting the factor for calculating unit weight

•

Digital outputs: Operating mode

Digital outputs: ON/OFF test for each relay

Checkweigher mode: Lower limit

Checkweigher mode: Upper limit

•

Checkweigher mode: Activating limit control

Dosage mode: Set point for speed 1

Dosage mode: Set point for speed 2

•

Dosage mode: Selecting the “filling” or “emptying” mode of a receptacle.

•

Dosage mode: Activating dosage mode

Tares in memory: Selecting record number (1-20)

Tares in memory: Tare value for the selected record number

PLU memory: Selecting record number (1-85)

PLU memory: Alphanumerical description associated to the selected record

Batch number to be printed on the ticket

NOTE: The • symbol in the above table shows the default value for each

configuration parameter.

Page 26

26

7. AUTO-OFF OPTION

This option programs the device’s automatic switch-off after a time on idle

(not being used). The device is understood to be on idle if there is no

variation in the weight indication, and no key is pressed.

The possible options are the following:

The device always remains switched on. Option

selected at source.

The device switches off automatically after 30 minutes

of inactivity.

The device switches off automatically after 1 hour of

inactivity.

The device switches off automatically after 1:30 hours

of inactivity.

8. BACKLIGHTING THE DISPLAY

This option controls the performance of the LCD display backlight. Together

with the Auto-off option, it reduces power consumption and extends battery

life. The unit is deemed to be inactive if the scale is set to zero and there are

no changes in the weight reading and no key is pressed. The possible options

are the following:

The backlight switches off automatically after 10

seconds of inactivity. This is the option selected at

source.

The backlight is always switched off.

The backlight is always switched on.

Page 27

27

9. SOUND WHEN PRESSING A KEY

This function activates (“On”) or deactivates (“Off”) the emission of a sound

when one of the keypad buttons is pressed.

The factory setting for this option is “On”.

10. TARE OPTIONS

The possible options are:

Preset tare: The tare will be kept until the tare key is

pressed again with an empty load receptor platform.

It is the default option.

Auto-tare: When a stable weight is detected, the

indicator sets a tare automatically. When the plate is

emptied, the tare disappears (reverts to zero).

Yes (default option): The weight needs to be stable

to set a tare.

11. Hold MODE

The hold mode is activated by double-pressing the key. When this

operating mode is activated, the weight value for the last load placed on the

platform always remains in the display.

You previously need to select in the options menu the operating mode for

the hold function.

Page 28

28

To select the desired hold mode, keep the key pressed until the LCD

display shows the message giving access to the options in the configuration

menu.

Press the → key until the display shows the option and then press the

key to access this submenu.

It is possible to select three operating styles for the hold mode:

• The mode is disabled (this is the default option).

• The display shows the last stable weight placed on the scale

platform.

• The display shows the highest weight value measured by the

instrument since the last load was placed on the scale platform.

Press the → key to select the desired operating mode and then press to

validate.

The SAVE message will appear to indicate that the configuration has been

stored in the unit’s non-volatile memory. Once this option is selected, it is

recorded in the non-volatile memory and it is no longer necessary to repeat

this operation until you decide to change the mode of use.

Once the operating mode is selected for the hold key, press repeatedly on

the ESC key to return to the weight reading mode.

Double-pressing the key activates or deactivates the hold mode. When

this operating mode is activated, the last stable weight of the load deposited

on the platform will always remain in the display. In other words, even if the

load is removed from the platform, the display will continue to show the last

stable weight reading. If the load has been removed, the weight is viewed

intermittently to indicate that the hold mode is in operation.

Page 29

29

12. KEYPAD LOCK

This function locks the keypad except for the on / off button and access to

the options menu.

When a key is pressed with the keypad lock activated, no action is performed

and the display shows for 1 second. That is to say, while the keypad is

locked it is not possible to set a tare, reset to zero, print a ticket or reset total

accumulated weight.

This option stays in the memory and is not deactivated when the device is

switched off and on.

The keypad lock can be activated / deactivated by keeping the key pressed

for more than 2 seconds .

13. COMMUNICATION

The K3 indicator can be connected to other devices to send and receive

information via an RS-232 interface (standard) or a Wi-Fi 802.11 interface

(optional). The K3 indicator can have up to 2 serial RS232 outputs. The

second serial output is supplied optionally.

In the menu it is possible to configure the different data transmission

options from the indicator.

It allows the speed to be selected at which the serial

interface will be connected. The possible options are:

9600 bauds, 19200 bauds, 38400 bauds, o 57600 bauds.

The transmission format for each byte is 8 bits, without

parity bit, 1 stop bit (“8,n,1”) and it is not configurable.

Page 30

30

Configuration of serial port 1.

Configuration of serial port 2.

Each one of the serial ports is configured independently, allowing different

devices with differentiated running modes to be connected. The

configuration options available are the following:

Mode in which the data transmission will be made:

• When pressing the print key.

• Continuously, at a rate of 5 frames sent per second.

• Automatically every time there is a new stable

weight on the scale.

• Operation as remote indicator (only available for

COM1).

• Operation as a digital weight reading for a scale

equipped with XTREM. This option is only available for

the COM1 port.

• The serial port is deactivated, both for transmitting

and for receiving data.

Format of frame data to be transmitted. Enables selecting

the following options.

Connection to model PR4 printer. A ticket is sent in a format

for this printer model.

Connection to model PR6 printer. A ticket is sent in a format

for this printer model.

Page 31

31

Frame data in a compatible format with the GRAM model

Z3 weight indicator. For connecting to PC with Virtual Key

application.

Frame data in a format for the GRAM USB adapter cable.

Frame data in a format for the GRAM USBFR adapter cable

(emulating “AZERTY” keypad).

Frame data in a format for the GRAM RD3 model weight

repeater display.

Connection to Q2 labeller. A ticket is sent in a format for

this printer model.

Connection to SOLETI labeller. A ticket is sent in a format

for this printer model.

Frame data in a format for connection from another GRAM

weight indicator running as a remote display. (Only

available for COM1).

Wireless mode for use with GRAM wireless adapters. (Only

available for COM1).

“Wi-Fi 802.11” mode for use with Wi-Fi GRAM adapters.

(Only available for COM1).

Page 32

32

13.1. Remote indicator mode

The K3 indicator can operate as a remote display for another scale by using

the “GRAM remote” communication protocol. When a K3 indicator is not

configured as a remote indicator, it obtains the weight information from

another scale via the RS232 serial port. The connection available for load cell

is deactivated.

To configure a K3 indicator as a remote display, select the option in

the section of the options menu for the COM1 serial port.

The scale to which the “remote indicator” will be connected should have the

option selected in the section of the configuration options

menu for the RS232 serial port to which the cable will be connected.

Moreover, in the section of this RS232 communications port, you

should select the option (data transmission in continuous mode).

13.2. XTREM mode

When selecting the option as the operating mode for the serial port

in the options menu , the K3 indicator will operate as the

terminal of a digital scale equipped with the XTREM weight transmitter.

The weight measurement is performed by the XTREM equipment (installed in

the scale’s weight load receptor), whereas the K3 indicator is just a terminal

in which the weight reading is viewed and the instrument’s different

functions (tare, semi-automatic zero, zero-tracking device, printout of results,

piece counter, etc.) are operated.

For as long as the XTREM digital scale is not connected to the COM1 serial

port of the K3 indicator, a communication error occurs and the display shows

the “-“ sign moving along the display. For as long as this error situation is

occurring (there is no communication with the digital scale) it is not possible

to access any K3 indicator function, including the options menu.

Page 33

33

In the event of this error occurring:

• Make sure that the green LED on the XTREM scale is on (fixed or

flashing) and that the red LED that indicates a malfunction is off.

• Check that the cable of the XTREM scale is properly connected to the

COM1 serial port of the K3 indicator.

• Verify that the K3 indicator is configured at the same transmission

speed as the XTREM scale (option → ). The

transmission speed of the serial port configured as a default option in

a new unit is 9600 bauds, both for the K3 indicator and for the

XTREM weight transmitter.

If necessary, to return to the operating mode of the K3 as an analogue weight

indicator and to have access to the options and configuration menu, press

the following keys at the same time: and .

13.3. PR4/PR6/Q2 printer

When selecting this option, the scale will send weight information in a ticket

print format for GRAM PR4, PR6 printers or Q2 labeller.

The ticket can have up to 3 header lines and 1 footer line. The header and

footer content is programmable by the user.

The options for configuring this document are in the section of the

main menu.

If selecting a PR6 printer, the A-Cut (automatic paper cutting) option in the

Ticket menu automatically changes to ON.

13.4. Frame format RD3

Format compatible with GRAM RD3 weight repeater display.

When selecting this transmission format, the weight indicated by the S2 scale

appears simultaneously in the RD3 repeater.

Page 34

34

13.5. Frame format USB

Format compatible with the GRAM USB adapter for PC-type computer with

Microsoft Windows operative system.

From the PC’s point of view, the GRAM USB adapter is a keypad emulation that

transforms the information transmitted by indicator K3 into a keypad input.

This option should be selected to make the data transmission from indicator K3

compatible with a keypad input in the PC. If using a French “AZERTY” keypad,

select the format.

13.6. Frame format PC0

The indicator sends the following byte frames (always 14 bytes in length).

0 1 2 3 4 5 6 7 8 9 10

11

12

13

02h

69h

20h

20h

20h

30h

2Eh

30h

30h

30h

6Bh

67h

0Dh

03h

STX

‘I’

spc

spc

spc

0 . 0 0 0 k g

CR

ETX

0 Start of text.

1 Status (tare, zero, net, stable, unstable).

2 Sign (blank space if value is positive, or ‘-‘ if negative.

3..9 Numerical value (ASCII) of the weight shown on the LCD display, including the

decimal point.

10..11 Measurement unit: ‘g’, ‘kg’, ‘oz’, ‘lb’.

12 Carriage return.

13 End of text.

Page 35

35

The status byte is built from the binary values of the display indications (tare, zero,

gross/net and stability). 20h is added to the result to ensure that the result is

printable.

Bit 0 (01h) The transmitted value is the gross weight.

Bit 1 (02h) A tare is set.

Bit 2 Not used, always 0.

Bit 3 (08h) The indicator is set to zero.

Bit 4 Not used, always 0.

Bit 5 Not used, always 0.

Bit 6 (40h) The weight is stable.

Bit 7 Not used, always 0.

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

N/A

Stability

N/A

N/A

Zero

N/A

Tare

B / W

Examples:

The status byte is 61h (‘a‘)

61h – 20h = 41h ➔

Bit 7

Bit 6

(stable)

Bit 5

Bit 4

Bit 3

(no zero)

Bit 2

Bit 1

(Tare off)

Bit 0

(Gross)

0 1 0 0 0 0 0

1

The status byte is 69h (‘i‘)

69h – 20h = 49h ➔

Bit 7

Bit 6

(stable)

Bit 5

Bit 4

Bit 3

(zero)

Bit 2

Bit 1

(Tare off)

Bit 0

(Gross)

0 1 0 0 1 0 0

1

The status byte is 62h (‘b‘)

62h – 20h = 42h ➔

Bit 7

Bit 6

(stable)

Bit 5

Bit 4

Bit 3

(no zero)

Bit 2

Bit 1

(Tare on)

Bit 0

(Net)

0 1 0 0 0 0 1

0

Page 36

36

The status byte is 63h (‘c‘)

63h – 20h = 43h ➔

Bit 7

Bit 6

(stable)

Bit 5

Bit 4

Bit 3

(no zero)

Bit 2

Bit 1

(Tare on)

Bit 0

(Gross)

0 1 0 0 0 0 1

1

The status byte is 6Ah (‘j‘)

6Ah – 20h = 4Ah ➔

Bit 7

Bit 6

(stable)

Bit 5

Bit 4

Bit 3

(zero)

Bit 2

Bit 1

(Tare on)

Bit 0

(Net)

0 1 0 0 1 0 1

0

The status byte is 6Bh (‘k‘)

6Ah – 20h = 4Ah ➔

Bit 7

Bit 6

(stable)

Bit 5

Bit 4

Bit 3

(zero)

Bit 2

Bit 1

(Tare on)

Bit 0

(Gross)

0 1 0 0 1 0 1

1

Page 37

37

13.7. Communication protocol

The K3 indicator is equipped with a communication protocol that allows the unit to

be commanded remotely.

The table below lists the available commands and the response of the K3 indicator.

COMMAND

RESPONSE

v

Returns a message with the identification of the “GRAM K3

Vxxxx” firmware version.

$

Weight request. The indicator transmits a frame of weight

information in a PC0 format.

z

The scale performs auto-zeroing.

t

The scale performs a tare.

f

Increases the value of the digital filter (1..4). If the filter is 4,

the ‘f’ command sets the filter to 1.

H1

Programs line 1 of the ticket header and responds “H1 OK”.

H2

Programs line 2 of the ticket header and responds “H2 OK”.

H3

Programs line 3 of the ticket header and responds “H3 OK”.

F1

Programs the ticket’s footer line and responds “F1 OK”.

For commands H1, H2, H3 and F1, the format is the following:

0 1 2 3 4 5 6 … 30

31

32

33

34

35

STX

C C L L L L … L L L L L ETX

Where:

STX = ASCII 2

ETX = ASCII 3

C = Command (2 characters)

L = 32-character ASCII text line

Page 38

38

14. TICKET PRINT OPTIONS

This menu has various options for configuring the information that appears

printed in the tickets generated by the K3 indicator.

Setting the time on the scale’s internal clock. Only if the

optional real-time clock board is installed.

Value of the next ticket number to be printed. It is

automatically increased with each print, whether it is a single

ticket or a ticket with accumulated total.

Automatic paper cutting ON/OFF. This function is only

possible with ESC/Pos printers equipped with paper cutting

device.

Programming the ticket header and footer is not performed via the scale’s

keypad but via the RS-232 serial port. In the downloads zone of our website a

program for PC is available with Microsoft Windows operative system for

performing this function.

Page 39

39

15. CONFIGURING THE SCALE

This menu features the options for parameterizing and setting the measurement

scale of the instrument.

Measurement unit: g, kg, oz, lb.

Maximum capacity of the scale. Enter the value, including

the decimal digits.

Division: The smallest increment that the instrument can

measure. Possible values are 1, 2, 5, 10, 20 or 50.

Position of decimal point.

Configuration menu for the instrument’s options

associated with “zero”.

Initial zero setting at start Yes / No.

Allows you to select the limit of the zero-setting device.

Possible options are MAX (zero is allowed for any weight

on the scale) or OIML (follows established rules by the

OIML R76 / EN 45501 technical regulation).

Zero tracking device activated or deactivated.

Show zero indicator in the display Yes/No.

Settings menu for the instrument.

Page 40

40

15.1. Settings menu

The settings menu can be directly accessed when switching on the unit. To do

this, switch on the unit and, while the LCD test appears with all segments on,

at the same time press on the and keys (a short press, not

sustained).

Calibration using a known weight (automatically sets the

initial zero and pending calibration).

Gravity adjustment depending on the scale’s geographical

location:

ON / OFF correction (activates/deactivates automatic

correction according to geographical location).

Geographical location code (see attached table).

Manual input (keypad) of the initial zero (in ADC accounts).

Manual input of the span slope, 5 digits.

Prints a ticket with the configuration and calibration settings

in the device’s memory.

Resets all configurations to factory settings.

ADC span pre-calibration. Only to be used at factory using the

correct load cell reference.

15.2. Scale calibration

1. With the platform free of any load, select the “ ” option.

2. The display will show that the initial zero value is in progress with the

blinking message “ ”.

Page 41

41

3. Once the zero value has been calibrated, place the calibration weight (a

known mass weight) on the load receptor.

4. Enter the weight value in the indicator, including the decimal positions.

Use the cursor movement keys to move through the different positions

on the display.

5. Once you enter the weight value, double-press on the key to validate

and move to next step. The display will show the blinking message

“ “ while acquiring the calibration value.

6. Lastly, it will show the message “ ” for a few seconds, asking for the

code of the geographical location where you did the calibration. The

geographical location code is a value from 0 to 31, which you have to

choose from the attached table. Use the and → keys to change the

value and validate by pressing on the key.

7. Lastly, the message “ ” will briefly appear, indicating that the

calibration has been saved in the non-volatile memory. The indicator

returns to normal use mode, displaying the weight on the load receptor.

If the automatic correction of weight reading according to geographical

latitude and height (option “ ”) is activated, the next time the scale is

switched on after a calibration, once the display test and the initial welcome

message are completed, the user will be asked to input the value

corresponding to the geographical zone where the scale will be used.

Once the value has been entered for the geographical zone in which the scale

is used, it is recorded in the non-volatile memory and will not be requested

again.

The geographical area where the scale is used can be modified later

whenever you wish by entering the menu with → → →

→ → (for nn {0-31}).

The automatic correction of the setting according to geographical area can be

disabled by entering the menu with → → → →

→ .

Page 42

42

16.3 Table of geographical adjustment values

Geographical latitude in

the northern or southern

hemisphere in degrees

and minutes.

Elevation above sea level in metres

0

325

650

975

1300

1625

1950

2275

2600

2925

3250

325

650

975

1300

1625

1950

2275

2600

2925

3250

3575

Elevation above sea level in feet

0

1060

2130

3200

4260

5330

6400

7460

8530

9600

10660

1060

2130

3200

4260

5330

6400

7460

8530

9600

10660

11730

00°00' - 05°46'

5 4 4 3 3 2 2 1 1 0 0

05°46' - 09°52'

5 5 4 4 3 3 2 2 1 1 0

09°52' - 12°44'

6 5 5 4 4 3 3 2 2 1 1

12°44' - 15°06'

6 6 5 5 4 4 3 3 2 2 1

15° 06' - 17°10'

7 6 6 5 5 4 4 3 3 2 2

17°10' - 19°02'

7 7 6 6 5 5 4 4 3 3 2

19°02' - 20°45'

8 7 7 6 6 5 5 4 4 3 3

20°45' - 22°22'

8 8 7 7 6 6 5 5 4 4 3

22°22' - 23°54'

9 8 8 7 7 6 6 5 5 4 4

23°54' - 25°21'

9 9 8 8 7 7 6 6 5 5 4

25°21' - 26°45'

10 9 9 8 8 7 7 6 6 5 5

26°45' - 28°06'

10

10 9 9 8 8 7 7 6 6 5 28°06' - 29°25'

11

10

10 9 9 8 8 7 7 6 6

29°25' - 30°41'

11

11

10

10 9 9 8 8 7 7 6 30°41' - 31°56'

12

11

11

10

10 9 9 8 8 7 7

31°56' - 33°09'

12

12

11

11

10

10 9 9 8 8 7 33°09' - 34°21'

13

12

12

11

11

10

10 9 9 8 8

34°21' - 35°31'

13

13

12

12

11

11

10

10 9 9 8 35°31' - 36°41'

14

13

13

12

12

11

11

10

10 9 9

36°41' - 37°50'

14

14

13

13

12

12

11

11

10

10 9 37°50' - 38°58'

15

14

14

13

13

12

12

11

11

10

10

38°58' - 40°05'

15

15

14

14

13

13

12

12

11

11

10

40°05' - 41°12'

16

15

15

14

14

13

13

12

12

11

11

41°12' - 42°19'

16

16

15

15

14

14

13

13

12

12

11

42°19' - 43°26'

17

16

16

15

15

14

14

13

13

12

12

43°26' - 44°32'

17

17

16

16

15

15

14

14

13

13

12

44°32' - 45°38'

18

17

17

16

16

15

15

14

14

13

13

45°38' - 46°45'

18

18

17

17

16

16

15

15

14

14

13

46°45' - 47°51'

19

18

18

17

17

16

16

15

15

14

14

47°51' - 48°58'

19

19

18

18

17

17

16

16

15

15

14

48°58' - 50°06'

20

19

19

18

18

17

17

16

16

15

15

50°06' - 51° 13'

20

20

19

19

18

18

17

17

16

16

15

51°13' - 52°22'

21

20

20

19

19

18

18

17

17

16

16

52°22' - 53°31'

21

21

20

20

19

19

18

18

17

17

16

53°31' - 54°41'

22

21

21

20

20

19

19

18

18

17

17

54°41' - 55°52'

22

22

21

21

20

20

19

19

18

18

17

55°52' - 57°04'

23

22

22

21

21

20

20

19

19

18

18

57°04' - 58°17'

23

23

22

22

21

21

20

20

19

19

18

58°17' - 59°32'

24

23

23

22

22

21

21

20

20

19

19

59°32' - 60°49'

24

24

23

23

22

22

21

21

20

20

19

60°49' - 62°09'

25

24

24

23

23

22

22

21

21

20

20

62°09' - 63°30'

25

25

24

24

23

23

22

22

21

21

20

63°30' - 64°55'

26

25

25

24

24

23

23

22

22

21

21

64°55' - 66°24'

26

26

25

25

24

24

23

23

22

22

21

66°24' - 67°57'

27

26

26

25

25

24

24

23

23

22

22

67°57' - 69°35'

27

27

26

26

25

25

24

24

23

23

22

69°35' - 71°21'

28

27

27

26

26

25

25

24

24

23

23

71°21' - 73°16'

28

28

27

27

26

26

25

25

24

24

23

73°16' - 75°24'

29

28

28

27

27

26

26

25

25

24

24

75°24' - 77°52'

29

29

28

28

27

27

26

26

25

25

24

77°52' - 80°56'

30

29

29

28

28

27

27

26

26

25

25

80°56' - 85°45'

30

30

29

29

28

28

27

27

26

26

25

85°45' - 90°00'

31

30

30

29

29

28

28

27

27

26

26

Page 43

43

16. DIGITAL FILTER

Every 100ms, the A/D converter of the S2 scale provides a reading of the

electrical output voltage of the connected load cell.

The digital filter consists of a moving average of these readings.

Possible values are 1 (moving average of 2 readings), 2 (4 readings),

3 (8 readings), or 4 (16 readings).

A smaller filter value implies that rapid oscillations in the weight become

more visible and vice versa.

17. WEIGHING OF LIVE ANIMALS

An additional filtering is available for weighing live animals or persons which,

when moving on the load receptor, cause disruption in the weight reading by

exerting a variable force on the load cells.

By activating this filtering in conjunction with the digital filter, an average

reading is obtained that discards the extreme values caused by the shifting

on the load receptor platform.

18. MOVEMENT FILTER

When activating the movement filter, the indicator does not show

inconsistent changes of more than one division with a duration of less than

100ms.

The result is that the indicator retains the last stable value while the weight

has no consistent movement (in the same direction).

Put another way, a sudden quick blow on the scale does not have any effect

on the reading. Although the weight value shown on the display is not

affected, the stability reading in the top left corner of the display will go off

to indicate this situation.

Page 44

44

19. INFORMATION TO BE VIEWED

Allows you to select the value that should be shown in the LCD display. The

options are the following:

The indicator shows the weight. It is the default option.

Filtered A/D converter counts.

Unfiltered A/D converter counts.

20. DIGITAL OUTPUTS

This section of the options menu allows the operation of the optional 3-relay

board available for the K3 indicator to be configured.

These 3 relay outputs can be used either for controlling an external signalling

of the high/low/ok limits in the running mode as a checkweigher (H-L mode)

or for the dosage of a product at two speeds. Moreover, it is possible to

select whether the dosage is performed for filling a receptacle on the scale

(loading) or for emptying a receptacle (unloading). The options in this section

of the menu are the following:

Running mode for controlling the optional relay board.

The relay outputs will be controlled by the H-L running

mode. The K1 relay closes when the weight on the

scale is greater than the limit . The K2 relay closes

when the weight is between the and limits.

The K3 relay closes when the weight is below the

value.

The relay outputs will be controlled by the dosage

mode.

Page 45

45

Allows each one of the 3 relays to be checked and

operated by the user.

Setting the upper and lower values for running the

“checkweigher” mode.

Value of the lower limit, including the decimal part.

Value for the upper limit, including the decimal

part.

Yes / No: Activating the limits control when

switching on the unit. The H-L key activates or

deactivates the limits control.

Setting of values for dosage.

Weight set point for speed 1.

Weight set point for speed 2.

Type of dosage. Loading (LOAd) or unloading

(unLOAd).

Yes / No: Activating the dosage mode when

switching on the unit.

Page 46

46

21. TECHNICAL SPECS

Load cell connection

Maximum input signal

±4 mV/V

Maximum input voltage

-0.3 to 5.3 V

Internal resolution

AD 20bits converter, 1000000 counts (100000

external)

Measurement frequency

10 samples per second

Linearity error

≤0.01% of the measurement range

Exciting voltage

5 Vdc

Minimum transducer

impedance

· Without relay board: 31,666 Ω

(12 cells x 380 Ω)

· With relay board: 47.5 Ω (8 cells x 380 Ω)

Cable length

30 m/mm2 max. (6 wires)

User interface

Main indicator

6-digit LCD 25.4 mm in height and weight

limits visualizer.

Backlit with 3-LED (RGB) back light panel

Keypad

11-key keypad

Acoustic warning

Piezoelectric intermittent-sound mini-buzzer

(2300±300 Hz y 85 dB)

Communications

Port Tx/Rx: (Port 1)

Two-way RS-232C

Port Tx/Rx: (Port 2)

Transmission-only RS-232C.

Transmission speed

1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200

Number of bits and parity

8 bits, no parity, 1 bit stop

Input / output options

Wi-Fi 802.11 board

Wi-Fi adapter for Ethernet communication via

TCP socket

RTC board

RTC for date and time

3-relay board

240VAC / Max current 15A / 360W

Page 47

47

Power

Network connection

Via 12-V supply; 1 A

Battery

6V-5AH;

Service time 25/60 hours depending on use.

Operating conditions and mechanical data

Operational

temperature range

+5ºC/+35ºC

Size (mm)

220 x 180 x 83

Weight (kg)

1.5 (including battery)

Assembly

Desktop

Optional: Swivel mount wall/column

Tightness

IP-65 (K3); IP-67 (K3i)

Thermal printer (K3iP and MK3P models)

Printer life

6000000 printed lines

Resolution

8 dots/mm

Print speed

30 mm/sec

Paper type

Thermal paper reel (57mm wide, 30 mm ø)

Print width

48 mm

Print sizes

6x8 points, 8x16 points, 12x24 points

Page 48

48

22. CONNECTIONS

C1 connector, load cell

PIN No.

SIGNAL

TYPE A

TYPE B

PIN 1

SIG -

Blue

White

PIN 2

SIG +

Brown

Green

PIN 3

MESH

Mesh

Mesh

PIN 4

EXC -

Black

Black

PIN 5

SENSE -

-

Blue

PIN 6

EXC +

Red

Red

PIN 7

SENSE +

-

Yellow

4 MULTI-PIN MOBILE MALE

(P700) 7 PINES

Page 49

49

5 MULTI-PIN MOBILE MALE

(P700) 8 PINES

6 MULTI-PIN MOBILE MALE (P700)

5 PINES

RS-232 serial output

XTREM scale connector

PIN No.

SIGNAL

PIN 4

RxD

PIN 5

TxD

PIN 6

GND

PIN No.

SIGNAL

PIN 1

+Vcc

PIN 2

TxD

PIN 3

RxD

PIN 4

No conectado

PIN 5

GND

Page 50

50

23. ERROR MESSAGES

ADC fault: No response from

ADC.

Malfunction in scale. Consult

helpdesk.

Sensor input signal too high

(>20mV).

Faulty load cell. Cabling in

poor condition.

Sensor input signal too low

(<-20mV).

Faulty load cell. Cabling in

poor condition.

Dead battery.

Connect the AC/DC adapter

to charge the battery.

a) Auto-zero device out of

range.

b) A stable measurement

could not be obtained when

attempting initial zeroing.

Empty the load receptor

before switching on the scale.

Calibration weight > Max.

Calibration weight should be

< Max.

The division should be >10 ADC

counts.

Resolution is too high.

Change the division to a

higher value.

A stable measurement could

not be obtained for setting the

scale.

Overload: Weight > Max+9·div

The keypad locking function is

activated.

Unlock the keypad by keeping

the key pressed for two

seconds.

The optional RTC is not present

or the circuit is damaged.

Consult helpdesk.

A totalizer ticket has now been

initiated.

Print the total before

initiating a new ticket.

Page 51

51

24. NOTES

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

Page 52

52

003/25032019

Loading...

Loading...