Page 1

SERIES

FH

100 / 200 / 2000 / 6000

OPERATION MANUAL

Page 2

2

INDEX English

Safety information 4

Installation 4

Preparatory before using 5

Storage 5

Unfolding the package 5

Package list 6

Installation of the balance 6

Usage Conditions 6

Install the balance with wind shield 7

Install the balance with round weighing pan 7

Connect the Power Adapter 7

Install the External Facilities 7

Warm-up Time 7

Adjust the Level Gauge Purpose 8

Display and keys description 8

Calibration 10

Procedure 10

Basic weighing 11

Counting mode 11

Percent deviation 12

Weighing units 13

Enabling weighing units 13

User setups 16

Print setups 16

Setting the baud rate 17

Restoring the factory default setup 18

Communication with a computer 18

RS-232 Interface hardware 19

Page 3

3

Pin description 20

Routine maintenance and troubleshooting 20

Troubleshooting 20

Clearance 21

Clearing the stainless steel surface 21

Safety check 22

Troubleshooting 22

Technical conditions 24

Guarantee 25

Page 4

4

ENGLISH

SAFETY INFORMATION

To avoid unnecessary demage to the balance, please pay attention to the

following tips:

• Please do not use this balance in dangerous área.

• Only the trained technicians could operate this balance.

• Please turn off the power of the balance before connect it or disconnect

it with other facilities.

• If the environment requires a higher safety standard, please follow the

relevant installation instructions.

• Excessive electromagnetic interference will make the displayed value

in this balance change. Once the interference is dismissed, the balance

could operate in normal way.

• Please avoid any liquid on the surface of the balance. A piece of lightly

damp cloth is allowed to wipe the balance.

INSTALLATION

• Please make sure the local voltage is in line with the rated voltage on

the name board.

• Please pay special attention when use RS-232 as the pins location

might be incompatible with our facilities. Please check the pins

locations before the connection and turn off the connection of different

configuration.

Page 5

5

• If the facility or the power cord has apparent damage, please turn off

the power, put it or them in a safe place and do not use it or them

before they are fixed.

• This balance could only be connected to our accessories or optional

fittings. We are not responsible for any modification the operator

makes to our balance, including using the facilities and cable which are

not supplied by us. However, we are always ready to offer the operation

norms information.

• Please do not open the balance. If the guarantee lable is damaged, our

quality guarantee will automatically cease being effective.

• If the balance does not work well, please contact your local distributor

or our customer service center.

PREPARATORY BEFORE USING

STORAGE

This balance requires an environment which is free from excessive high or

low temperature, corrosive, vibration, air current and collision.

Unfolding the package

• Unfold the package and check if there is any outer damage of the

balance.

• If there is outer damage, please refer to section routain maintenance

and troubleshooting.

• Please keep all the package for possible transportation in the

Page 6

6

future. When pack the balance, please remove all the cables to avoid

unnecessary damage.

Package list

• The balance.

• Weighing pan.

• Pan support.

• Power adapter.

• User manual.

INSTALLATION OF THE BALANCE

Put it in a proper place, please avoid the following situations:

• Much heat and direct sunlight.

• Air currents and vibrations.

• Excessive moisture.

Usage Conditions

Please do not lay the balance in a quite damp palce for a long time. If the

balance is transferred from a lower temperature environment to a higher

temperature environment, please lay it there with power off foraround 2 hours.

Page 7

7

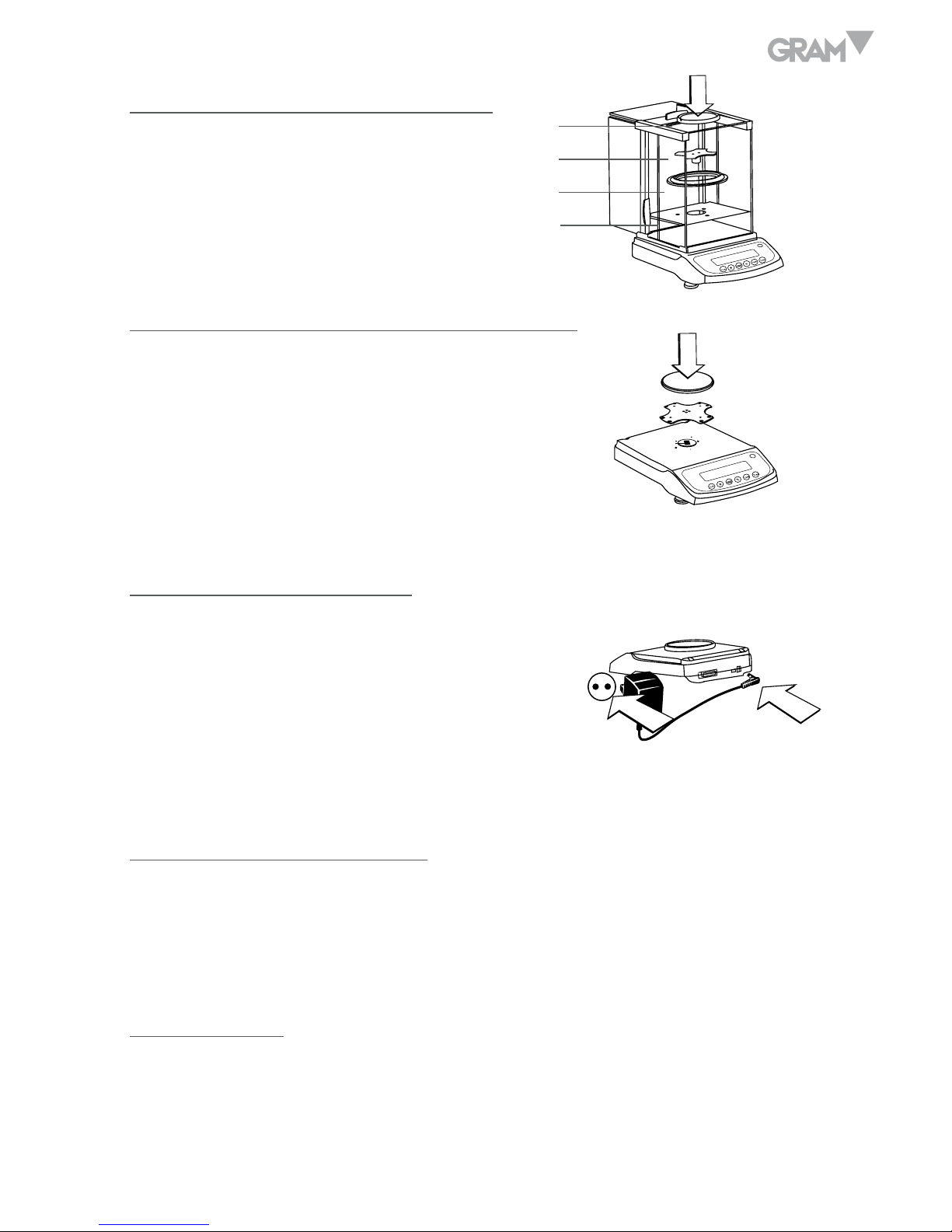

Install the balance with wind shield

• Assemble the parts in the

indicated order.

1

2

4

3

2

1

Install the balance with round weighing pan

• Installation Sequence.

• Pan support.

• Weighing pan.

Connect the Power Adapter

Only the power adapter offered by us is allowed.

• Connect the power adapter to the balance.

• Connect the power adapter to the power socket.

Install the External Facilities

Turn off the balance before connect it or disconnectit with external facilities

such as the printer or the computer).

Warm-up Time

To assure the measure accuracy, the balance must be warmed up for 30

minutes before normal operation.

Page 8

8

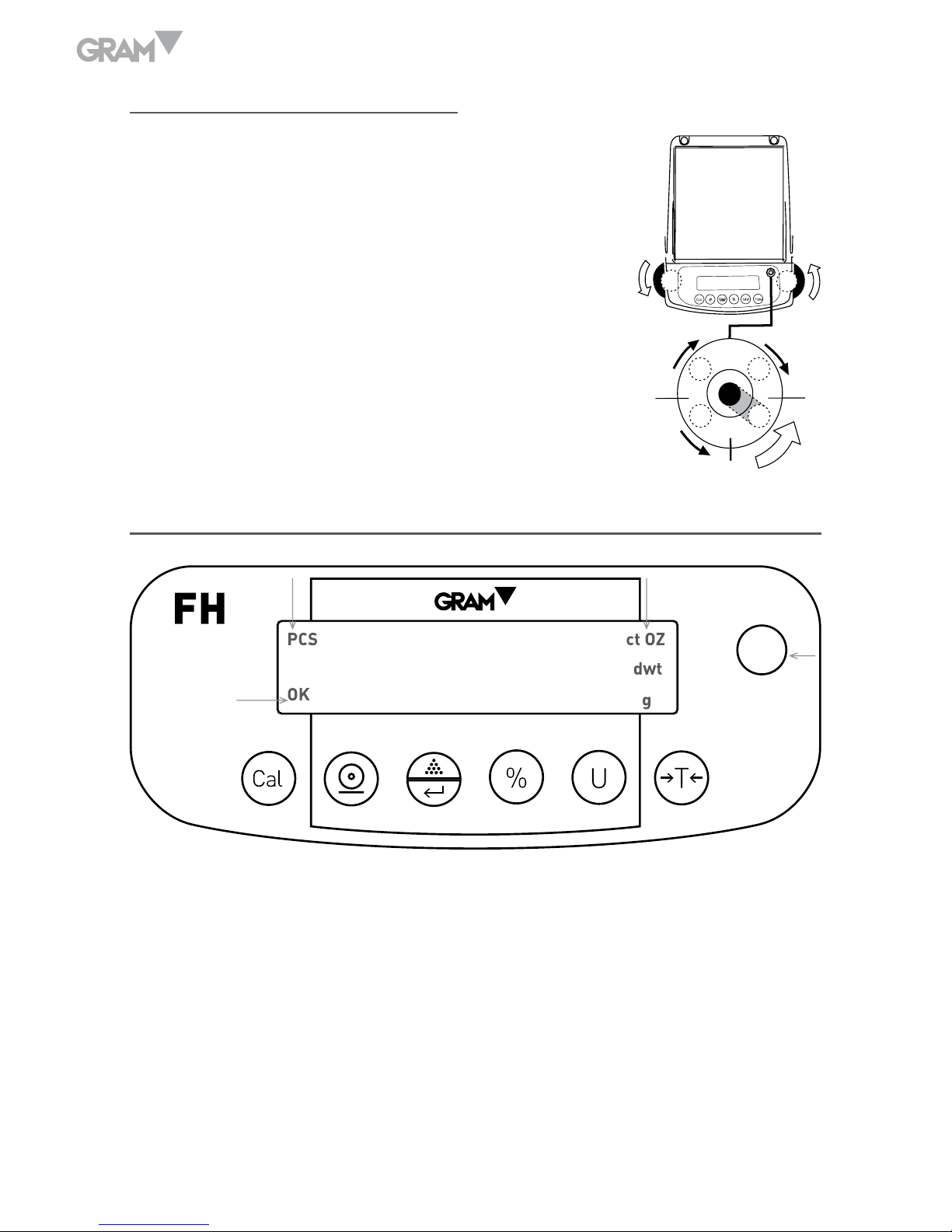

Adjust the Level Gauge Purpose

• Adjust the level guage of the balance. The

level guage needs to be adjusted once its

place is changed. The two front bottom bolts

are used to adjust the level guage.

• Spin the two bolts as shown in the figure until

the bubble in the level gauge is in the ceter of

the circle.

• Normally, it needs to be adjusted repeatedly.

L

R

R

R

L

L

DISPLAY AND KEYS DESCRIPTION

1

3

4

2

1. Count sign.

2. Weighing units.

3. Stability sign.

4. Level gauge.

OK - Reading shown is stable

g - Reading shown is given in grams

Page 9

9

OZ - Reading shown is given in ounces (1g = 0.03527396200 oz)

ct - Reading shown is given in carats (1g = 5.0000000000 ct)

dwt - Reading shown is given in pennyweight (1g = 0.64301493100 dwt)

% - Reading shown is given in percent weight

PCS - Reading shown is given in as a counting

------- The balance is developing a stable reading

UNABLE – Error operation

HHHHH – The weight on the pan excedes the capacity of the balance

LLLLLL – The pan is not properly seated or has been removed

Calibration / Adjustment key

Print / Output key

Count / Function confirmation key

Percentage key

Unit conversion key

Tare key

Page 10

10

CALIBRATION

To decide the accuracy of the balance through test the difference between

thereading and the actual weight of the object on the weighing pan.

Prerequisite of calibration:

1. There is no loading on the weighing pan.

2. Press the key.

3. The interior signals are stable.

Procedure

1. Adjust the level guage and warm it up for 25 minutes.

2. Press the key.

3. Press the key, the display will read its full range, such as 3000.

4. Press the key repeatedly, it reads the calibration point within the

range (such as 2000, 1000…).

5. Choose one calibration point and place the right weight on the pan. Press

the key, the display will show CAL---.

6. When the external calibration is finished, the balance reads the value of

the weight on the pan (such as 3000).

Page 11

11

BASIC WEIGHING

Procedure

1. Plug in the power, the balance will automatically proceed system

initialization and deduct the tare weight.

2. Place the container on the weighing pan.

3. Press the key.

4. Place the simple object in the container.

5. Print the weight value pressing the key.

COUNTING MODE

Displayed sign: PCS

Procedure

1. Place the empty container on the weighing pan.

2. Press the key.

3. Choose the amount of the reference samples. Press the key, the

balance reads “qTy10”, press the key, choose the number of

samples (10, 25, 50, 100). The bigger number, the more accurate for the

counting results.The choosed reference number will be saved until a

new reference number is set or the power is off.

4. Place the right samples on the weighing pan or in the container.

5. Press key, the balance reads the amount number of the samples.

Page 12

12

6. Add the rest of ítems, the balance will show the total pieces.

7. If you want print the result, press the key.

8. To return to normal weighing mode, press the key, the symbol PCS

disappears.

PERCENT DEVIATION

Displayed sign: %

Procedure

1. Press the

key.

2. Put the reference object on the weighing pan. When the reading is stable,

press the key, it reads “100.000” or “100.00”, which relates to the

accuracy 100.00% of the balance. Meanwhile, it displays “%”.

3. Remove the reference object, the balance Reads “0.000” or “0.00”.

4. Place the goal object on the weighing pan.

5. Wait for the OK on the display, read the display, the display indicates

percent deviation from the reference.

6. Press the

key, the balance returns to normal weighing mode.

To test the percentage a weight in a container varies from a reference, please

follow the below steps:

1. Put an empty container on the weighing pan. Press the

key.

2. Place the standard object into the container.

Page 13

13

3. Press the

key. Wait for the stable display, it reads “100.000” or

“100.00”.

4. Remove the container with standard object. Put another same

container on the weighing pan, wait for the stable display, it reads

“0.000” or “0.00”.

5. Add the goal object in the container, wait for tyhe stable display, the

value displayed is the percentage the weight of the goal object varies

from the standard weight.

6. Press the

key to return to normal weighing mode.

7. If necessary, the weight of the goal object could be printed out.

WEIGHING UNITS

1. Press the key

to select the desired unit weight (g, oz, dwt) or

weighing mode (normal weighing, counting or percentage mode).

Enabling weighing units

The units function can be programmed to turn certain weighing units on or off.

To enable or disable certain units of measure, perform the following procedure.

1. Press the

key while pressing

key, the balance reads “PrInT”.

2. Press the

key repeatedly until it reads “unIT”.

3. Press the

key, the display reads “g yes” which means g available for use.

Press the

key to confirm. To disable “g” as the unit, press the

key, then the display reads “g no”, press the

key to confirm.

4. Follow the steps above to enable or disable Oz, Ct or dwt as the unit of measure.

Page 14

14

Page 15

15

Page 16

16

USER SETUPS

The balance could be set up to meet individual requirement.

1. Press the

key while pressing the

key to enter to setup program.

2. Press the

key to choose the ítem to be set up, then press

to confirm.

3. Anytime to exit the setup program, press the

key, it reads “ESC”,

then press the

to confirm.

PRINT SETUPS

There are three print types:

STABLE Print: print a stable reading when it is attained.

INSTANT Print: print immediately after press the key.

INTERVAL Print: print at predeterminated time intervals.

Note: The print function is separate from the line feed setup, i.e set the print

function first then set the number of line feeds.

To set the print type, use the following procedure:

1. Press the

key while pressing the

key, the display will show “PrInt”.

2. Press the

key, the display will show “STAbLE”, which indicates

stable print as the default.

3. Press the

key to choose the print type and confirm pressing the .

4. Press the

key until the display reads “InTEr”, press the

key, the

display will show “SEC”.

Page 17

17

5. Press the

key repeatedly to see the predeterminated time interval and

press the

to confirm. The message “0 SEC” means countinous print.

6. Press the

key to return to weighing mode.

7. After entering print setup, press the

key repeatedly to see

predetermined line foods (1-18) Choose the proper line feeds, press the

to return to normal weighing mode.

SETTING THE BAUD RATE

1. Press the

key while pressing the

key, the display will show “PrInT”.

2. Press the

key, the balance reads “bAud”.

3. Press the

key, the balance reads “300”.

4. Press the

key repeatedly, the balance display the other baud rates.

Choose the proper rate and press

key to confirm. The balance reads

“ParITy” and begins parity check.

5. Press the

key, the balance reads “nOnE” (no check) for the first.

6. Press the

key, it reads the other check types; “Odd” indicates odd

check and “EvEn” indicates even check.

7. Choose the proper check type and press the

key to confirm, the

balance now returns to normal weighing mode.

Page 18

18

RESTORING THE FACTORY DEFAULT SETUP

1. Press the

key while pressing the

key the display will show

“PrInT”.

2. Press the

key repeatedly until it reads “InITIA”.

3. Press the

key to confirm, the display reads “BUSY” and the returns

to weighing mode. Factory default setup is finished.

COMMUNICATION WITH A COMPUTER

The balance keyboard functions can be accessed via the RS-232 interface.

The following commands are available:

U –

: units conversion

T –

: tare function

C –

: calibration with external standard weight

P –

: print function

% -

: percent function

# -

: instant print

M –

: counting function

When a balance is connected to a computer, it is suggested that immediate

print # be used. In response to this command the balance will transmit

whatever number or message appears on the balance display.

The string format output is shown below:

Page 19

19

A B C D E F G H I J K L M

A - +/-: Signs field, usually no display as a space when it is a positive

number, “-” is displayed when it is a negative number.

B – G: Number and decimal field, spaces are used when there are less

than six digits.

H – I: Spaces fields.

J: Unit field, it describes the units of the number being transmitted. Your

balance will transmit G for grams, O for ounces and C for carats.

K: Stable character, it corresponds to the OK indicator on the display. S

means the reading is stable, space means the reading is not stable.

L: Return character.

M: Line feeds character, it indicates the line feeds.

RS-232 INTERFACE HARDWARE

This balance adopts the transmit and receive lines of standard RS-232.

The data format is:

1 start bit.

8 data bits include parity.

1 stop bit.

The instruction to connect the balance to external device is as follows:

Page 20

20

Pin description

2 – TXD - - - scale transmits data

3 – RXD - - - scale receives data

5 – GRD - - - signal ground

Note: “Handshake” signals, such as “clear to send” (CTS) are not used. The

peripheral must have a mínimum buffer (15 characters).

It is suggested that the máximum recommended cable lenght is 15 meters,

the load impedance of the device connected should be between 3000 and

7000 ohms with no more than 2500 pf shunt capacitance.

ROUTINE MAINTENANCE AND TROUBLESHOOTING

Troubleshooting

Only the trained professionals are allowed to do repair work. There is a risk

for the user if non-professionals do the repair.

Page 21

21

Clearance

• Turn off the balance and unplug the data cables.

• Avoid the liquid into the balance.

• Any corrosive cleaner (solvent) is forbidden to use.

• Wipe the balance with a piece of soft cloth.

• Remove the weighing pan before wipe the balance.

• Remove the shield ring and pan support with the weighing pan which

helps avoid damage to the weighing system.

Clearing the stainless steel surface

All the stainless Steel components need to clean regularly. Remove the

weighing pan and thoroughl clean it with a damp cloth or sponge. The

cleaner applicable to stainless Steel are recommended. Wipe the stainless

Steel surface of the balance first and then clear the stainless Steel weighing

pan. Make sure there is no dirt and then wipe the stainless Steel component

again. Dry the balance by air. If necessary, smear the proper oil on the surface

as additional protection.

Note: After remove the weighing pan and the pan support, avoid any liquid or

solid pellet into the installation hole.

Page 22

22

Safety check

If the balance could not work normally:

• Cut off the power immediatelly, keep and do not use it again.

• Keep it in a safe place to make sure it won´t be used for the moment.

• Inform the nearest Service Center or your Distributor. The repairman

must have had profesional training.

TROUBLESHOOTING

DISPLAY REASON SOLUTION

- - - - - -

The balance could not get

a stable reading or the

transducer is damaged.

Contact your local service

center.

HHHHH

The real weight is 5% higher

than its capacity or the

transducer is damaged.

Unload or contact your local

service center.

LLLLLLL

a) The weighing pan is not on.

b) There is wrong connect with

the pan.

c) The transducer is damaged.

a) Install the right weighing

pan and press the

key.

b) Clear the connect.

c) Contact your local service

center.

Page 23

23

NOCAL

Calibration is unresponsive.

Refer to calibration section,

check if it is the right

calibration weight.

UNABLE

Lack of data or wrong data

with which the balance could

not perform the function.

Refer to user manual.

UNSTABLE

READING

Unstable the ambient

environment (excessive

vibration or air current) or

there is wrong connect with

the pan.

Put the balance in another

place.

Clear the wrong connect.

NO DISPLAY

No work voltage no

connection with transformer.

Check the power supply

circuit and the instrument,

connect the transformer.

Apparent wrong

weighing display

No calibration or the tare

weight is deducted.

Calibrate the balance

Deduct the tare weight

before weighing.

If there is any other trouble, please contact your local distributor or service center.

Page 24

24

TECHNICAL CONDITIONS

AC-DC adapter

Input: 220V/110V, output: 7.5V (+15% to -20%) 48-60Hz

Power consumption: Maximam=16W, Average=8W

Page 25

25

GUARANTEE

This scale is guaranteed for one year from the delivery date. The guarantee

covers any fabrication defect of the material.

During this period GRAM PRECISION, SL, covers the manpower and the

spare parts necessary for the reparation of the scale.

This guarantee does not cover the failures caused by an inappropriate use

or overcharge.

The guarantee does not cover the freight cost (transport) necessary to

repair the scale.

Page 26

Gram Precision S.L.

Travesía Industrial, 11 · 08907 Hospitalet de Llobregat · Barcelona (Spain)

Tel. +34 902 208 000 · +34 93 300 33 32

Fax +34 93 300 66 98

comercial

@gram.es

www.gram-group.com

002/14032017

Loading...

Loading...