Graef VA 802, VA 804, VA 806 Operating Manual

OPERATING MANUAL (Original)

Fully Automatic

Slicing Machine

VA 802 VA 804 VA 806

Machine No.: :

Year of construction :

Technical specifications subject to change

GRAEF (h) Jan. 2010 -CB

1

General Information ........................................................................................................5

1.1 Safety – Notes on the Warranty................................................................................5

1.1.1. Set-up and Instruction.....................................................................................5

1.1.2. Proper Use ......................................................................................................7

1.1.3. Natural Wear...................................................................................................7

1.1.4. Potential Sources of Danger............................................................................8

1.1.5. Workplace.......................................................................................................9

1.1.6. Authorised Users.............................................................................................9

1.1.7. Protective Clothing and Equipment.................................................................9

2. Description.....................................................................................................................10

2.1. Designation of the Machine Parts...............................................................................10

2.2. Protective Devices..............................................................................................11

2.3. Technical Dimensions.........................................................................................12

2.4. Basic Machines Equipment ................................................................................13

2.5. Options ..............................................................................................................14

2.5.1. Semi-automatic Function ..............................................................................14

2.5.2. Additional Menu Standard Functions............................................................14

2.5.3. PLU Programming .........................................................................................14

3. Operation.......................................................................................................................15

3.1. Operating Controls.............................................................................................15

3.1.1. Operating Terminal .......................................................................................15

3.2. Programmes................................................................................................................17

3.2.1. Slicing in the Standard Mode (PLU=0000) ....................................................17

3.2.2. Slicing ...........................................................................................................21

3.2.3. Semi-automatic Function (Option) ................................................................23

3.2.4. VA 806 guide rail and endpiece holder .........................................................25

3.3. Start Programme................................................................................................26

3.4. Changing the Standard Programme (PLU=0000)...............................................27

3.4.1. The “M+PLU“ Additional Menu ...................................................................27

3.4.2. The “M“ Additional Menu (OPTION) ............................................................30

3.4.3. Slicing in the PLU Mode ................................................................................33

3.4.4. Programming a PLU ......................................................................................34

4. Cleaning ........................................................................................................................40

4.1. Preparing for Cleaning .......................................................................................40

4.1.1. Disassembly of the Removable Parts.............................................................41

4.2. Cleaning the Different Parts of the Machine ......................................................43

4.2.1. Blade and Blade Ring....................................................................................43

4.2.2. Carriage ........................................................................................................44

4.2.3. Chain Frame..................................................................................................45

4.3. Cleaning Schedule..............................................................................................47

4.4. Cleaning items ...................................................................................................48

4.5. Assembly............................................................................................................48

2

5 Maintenance..................................................................................................................51

5.1. Sharpening the Blade.........................................................................................51

5.1.1. Description of the Blade Sharpener .....................................................................51

5.1.2. Preparing the Machine..................................................................................52

5.1.3. Sharpening the Blade....................................................................................52

5.2. Changing the Blade............................................................................................54

5.3. Lubricating .........................................................................................................55

6. Faults and Operating Errors...........................................................................................56

7. Service...........................................................................................................................58

3

EC DECLARATION OF CONFORMITY

GEBR. GRAEF GMBH + CO. KG, DONNERFELD 6, D- 59757 ARNSBERG

We herewith declare that the design of the machine specified below

Slicing Machine

Of the types

VA 802, VA 802H, VA 804, VA 804FB, VA 806, VA 806FB

in the design supplied by us complies with the provisions of the following EC

directives:

EC Machinery Directive 2006/42/EC

EC EMC Directive 2004/108/EC

EC Low Voltage Directive 2006/95/EC

The following harmonized standards and technical specifications have been applied:

EN 1974

EN 61000-6-2

EN 61000-6-3

EN 61000-4-[2,3,4,5,6,11]

EN 61000-3-2

EN 55022

Name of the authorized representative: Reinhard Graef

Address of the authorized representative: see manufacturer’s address

Changes to the machine not authorized by GRAEF invalidate the present

declaration.

Arnsberg, 11 December 2009 Hermann Graef

- Managing Director -

4

General Information

1 General Information

1.1 Safety – Notes on the Warranty

Fully automatic models VA 802, VA 804 and VA 806 are fitted with safety equipment.

They have been tested for safety.

Nevertheless, if the machine is used improperly or not as intended, there can be

hazards to.

• The health of the user

• The machine and other property of the operator

All persons charged with installing, operating, servicing and repairing the machine must

• Be trained/instructed for the task.

• Follow these operating instructions to the letter.

1.1.1. Set-up and Instruction

Store and transport machines in their original packaging until they are set up.

The GRAEF dealer is responsible for set-up and start-up as well as for providing

instructions on how to operate, clean and service the machine.

Customer installation and start-up, incorrect operation, modifications

and removal of the safety equipment will invalidate our liability.

Important!

The installation and instruction must be confirmed by your authorised

GRAEF dealer.

!

Depending on the design, the slicing machines weigh more than 68 kg.

Two adults are required to lift and carry the machine.

The centre of gravity is in the rear third of the machine, where the motor is located.

Always lift and carry the machine by the machine housing.

x For longer company-internal transport routes.

Use a suitable handcart.

x Take off removable parts such as chain frame, tray and beater before transport

x Fasten the carriage by inserting paper or cardboard between the thumb and the

stop plate

x Set the slicing thickness below “0“ before transport by turning the slicing

thickness

5

General Information

1.1.1.1. Set-up site requirements

The base must fulfil the following requirements:

x It must be sufficiently stable, strong, level, flat and non-slip.

x It must be of sufficient height to allow slicing while standing.

x It must meet the space requirements listed in “Workspace“ (see Technical

Dimensions).

x It must be located away from busy corridors.

x It must not be close to any doors.

x It may not be in the swinging area of a door, nor in the entrance area of a door.

x When using Nirosta tables, Resopal supports or similar materials: Ensure that there is

no oil or grease on the surface.

x Ensure sufficient lighting of at least 300 lux

1.1.1.2. Unpacking the machine

Caution!

The machine may only be unpacked and set up by authorised customer service / sales

personnel. Check the required working space (with the machine switched off!):

!

• Hold the last slice clamp by the handle.

• Lift up the last slice clamp

• Move the carriage all the way forward and back

If the carriage or last slice clamp comes into contact with other objects, you must provide

a larger work space.

1.1.1.3. Electrical connection

x Check if the local supply voltage conforms to the specifications indicated on the

rating plate. If it does not, you may not connect the machine.

x The electrical socket must comply with the VDE regulations (Association of German

Electricians).

6

General Information

x For rotary current models (400 V), check that

the running direction of the blade is correct.

x The blade must move downwards in direction

of the carriage as shown in the illustration.

x If the running direction is incorrect, use a

screwdriver to turn the phase change in the

network adapter plug by 180°.

x Moisture: Degree of protection IP 33! High humidity or condensation can damage the

machine.

x Lay and connect the power supply cord so that no-one can fall or trip over it.

x The machine is designed for use in sales rooms.

1.1.2. Proper Use

The fully automatic slicers VA 802/804/806 are designed

to slice only the following types of food:

Sausage / meat / ham / slicing cheese

Do not attempt to slice frozen foods.

Do not attempt to slice vegetables or food that has bones.

Remove any metal braces on the goods to be sliced.

Unauthorised modifications to the machine are prohibited for safety reasons.

The operating, maintenance and service instructions

described in this instruction manual must be strictly observed.

1.1.3. Natural Wear

Natural wear is not covered by our warranty or liability.

7

General Information

1.1.4. Potential Sources of Danger

Caution!

Danger of injury!

Never reach into the area of the moving carriage.

Caution!

Danger of injury!

The blade is sharp and can sever body parts.

Your fingers, and especially your thumb, are at risk. For this reason, never reach into the

space between the last slice clamp and the blade or the limit stop if the limit stop plate is

not completely closed. When the machine is not in use, the stop plate must always be set

to the zero position.

Caution!

Injury through electric shock.

The machine operates with a mains voltage of 230 V or 400 V and must therefore not be

opened. The protective earth conductor system must be connected in any case, otherwise

there is a risk of severe electric shocks.

Caution!

Hazards posed by the chain frame.

Never put your hands near the chain frame during operation. The spikes can cause

serious injury.

The placing arm that removes the sliced food moves very quickly and can injure hands or

other parts of the body in case of contact.

Caution!

Risk of injury.

In the area of the food holder, there is a risk of injury posed by the spikes and the food

holder suddenly dropping when inserting the product.

Caution!

Risk of injury.

When mounting parts which can be removed for cleaning.

8

General Information

1.1.5. Workplace

Only operate the machine if you are standing in a secure position.

Stand in front of the machine so that the power on/off button is facing you.

Keep your workplace clean at all times.

The machine must be positioned on a solid, even and stable base that can support the

weight of the machine and the dynamic forces of the moving parts.

1.1.6. Authorised Users

The machine may only be operated by people who:

Have read and understood the operating instructions

Have been instructed thoroughly by the operator

Have been instructed on the dangers of the machine and the hygiene regulations

The machine may only be serviced and repaired by specialists.

Take precautions to prevent unauthorised persons from using, cleaning or servicing the

machine.

1.1.7. Protective Clothing and Equipment

Wear close-fitting clothes when operating the machine. Please also observe the hygiene

regulations.

When executing cleaning or maintenance work in the area of the knife, be sure to wear

cut-resistant gloves with pulse protection.

When transporting the machine, be sure to always wear steel-toe boots.

9

Operation

2. Description

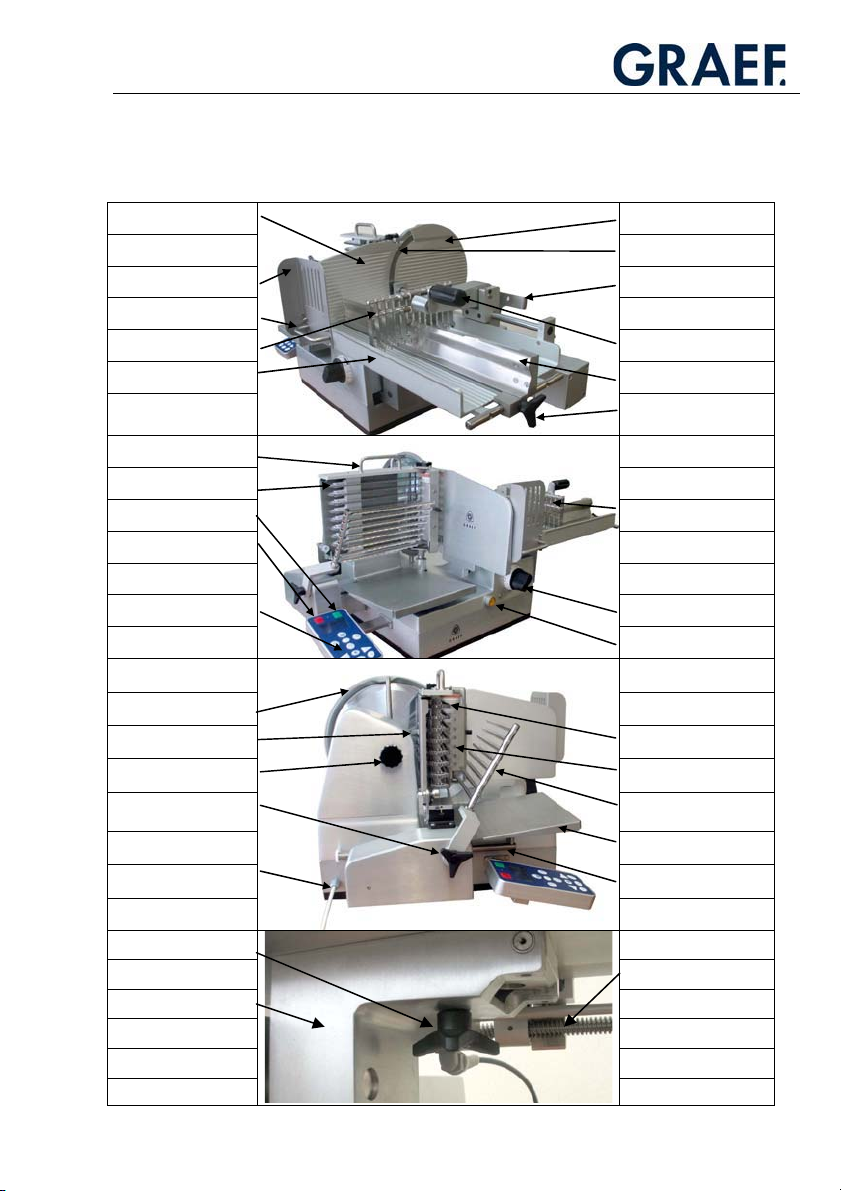

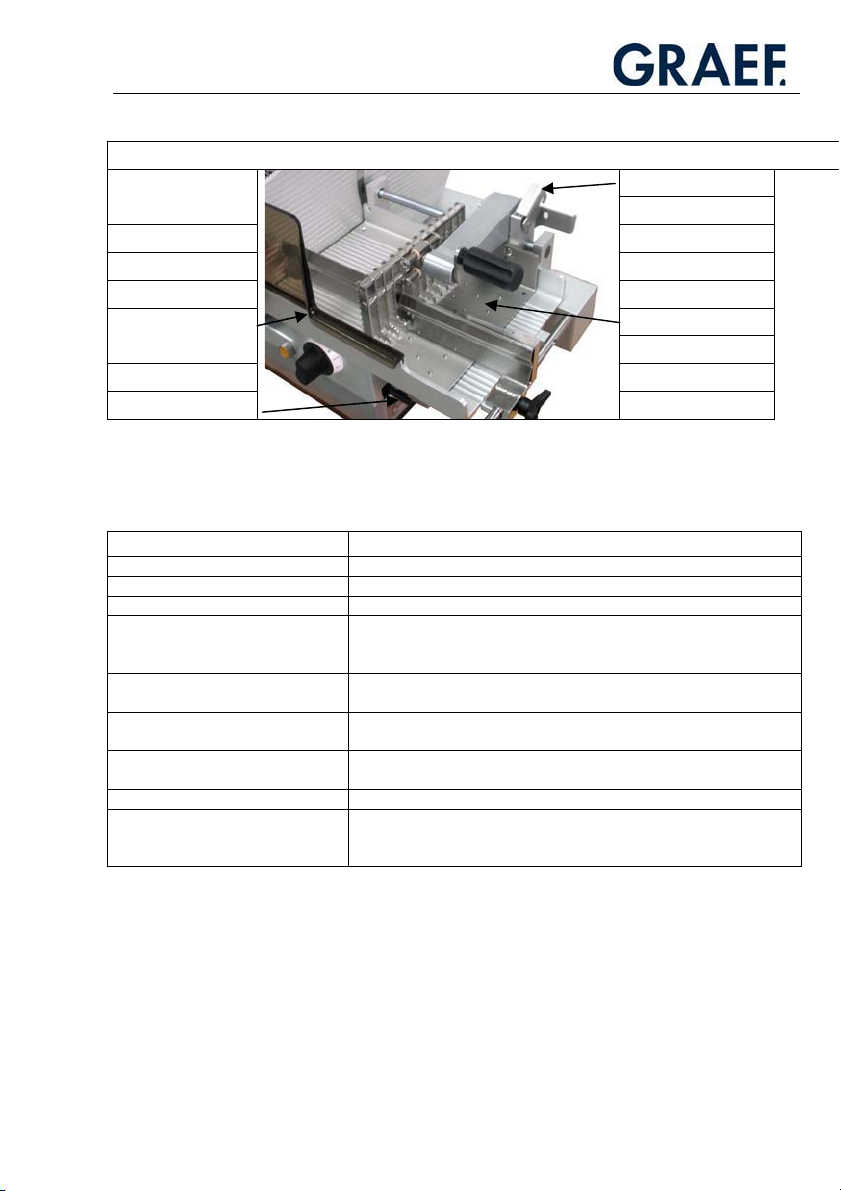

2.1. Designation of the Machine Parts

Stop plate Blade cover plate

Blade

Thumb/finger guard Return lever

Carriage handle

Last slice clamp Last slice clamp handle

Carriage Guide rail

Locking screw

Chain frame handle

Chains

On button

Off button

Operator Slice thickness control

Last slice clamp

Start-stop button

Blade guard ring

Scraper Pressing roller

Thumb wheel Scraper comb

Placing arm star grip

Tray

Power cable Tray guide

Carriage star grip

Feeder shaft

Bearing block

Placing arm

(removable beater)

10

Operation

Special Features VA 802

Lock (VA 802H)

Thumb guard

with hand support

T-handle (VA 802H)

Feed carriage

2.2.Protective Devices

Device Function

Off button Switches the machine off immediately

Blade guard ring Prevents accidental contact with the blade

Limit stop lock Locks the limit stop when the carriage has been tipped off the machine

Carriage drive starting lockout Prevents the carriage and blade drive from switching on when the

Thumb/finger guard Prevents accidental contact with the blade

Chain frame cover Prevents access to the back or catching in the chain tips running to the

Undervoltage mechanism Prevents the machine from starting up again after an interruption to the

Blade sharpener with guard cover Prevents accidental contact with the blade

Sharpening mode Prevents the carriage drive from being switched on during the

slicing thickness is below “Zero“ or the carriage has been tipped off

(cleaning mode)

blade

power supply, such as a “power cut”

sharpening process. The blade drive can only be switched on and off

using the on and off buttons.

11

Operation

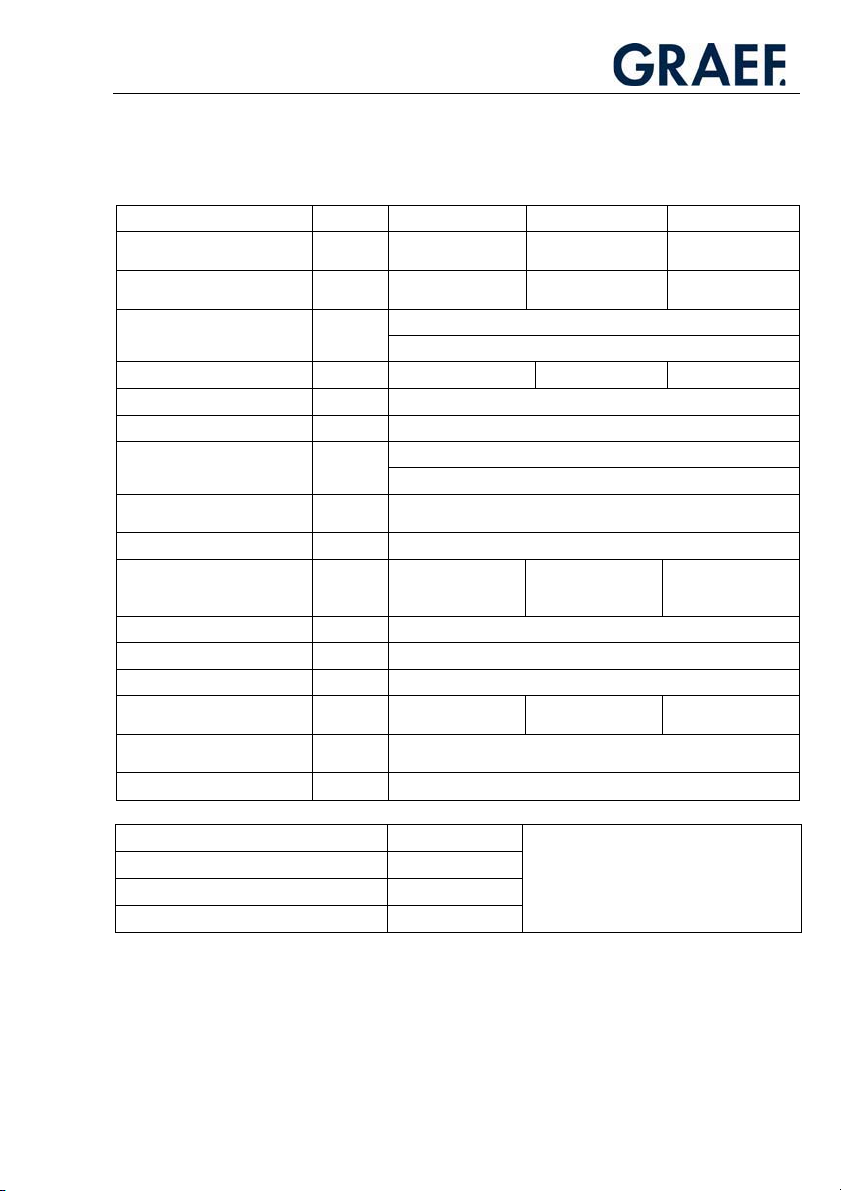

2.3.Technical Dimensions

VA 802 VA 804 VA 806

Dimensions L x W x H 600 x 880 x 500 mm 600 x 1060 x 500 mm 600 x 1240 x 500

Workspace L x W x H 700 x 920 x 640 mm 700 x 1100 x 640 mm 700 x 1280 x 640

Minimum: 480 x 440 mmSpace occupied L x W

Ideal: 540 x 440 mm

Weight W Approx. 68 kg Approx. 70 kg Approx. 72 kg

Blade diameter D 300 mm

Blade speed N 229 rpm

Max. 250 x 180 mmDimensions with chain frame L x H

Min. 30 x 30 mm

Dimensions without chain

frame

Slicing length L 250 mm

Largest distance between last

slice clamp and blade

(clamping distance)

Tray size L x W 300 x 255

Length of tray run s 160 mm

Slice thickness T 0.5 - 10 mm

Slicing speed maximum V Max. 70 strokes per

Emissions – noise level acc. to

EN ISO 11204, at idling

Vibration total value < 2,5m/s² (for VA 802H)

L x H Max. 260 x 195 mm

L 230 mm 420 mm 600 mm

Leq < 69 dB (A)

minute

Max. 60 strokes per

minute

mm

mm

Max. 55 strokes per

minute

Power consumption P1 [W]

Frequency f [Hz]

Current I [A]

Voltage UN [V]

See type plate

12

Operation

2.4. Basic Machines Equipment

The models VA 802, VA 804 and VA 806 of the automatic slicing machine series VA 800

differ in size and have some different carriage characteristics.

All models share the same basic features:

General information

x Smooth, accessible high quality anodized surfaces

x Baking finished lower part

x Hard- chrome plated 300 mm blade with a narrow blade guard for ideal

slicing results

x Locked blade cover plate

x Carriage with motorized feeding of food to be sliced

x Carriage stroke rate that can be adjusted without levels

x Slicing parameters as listed in the “Technical Dimensions“ table

x Control panel that is clearly laid out and easy to reach, and has a membrane

keypad that is proof against dripping water

Standard placing programmes

x Stacking: up to 4 stacks

x Long fanning: up to 4 rows

x Cross fanning: up to 4 rows

x Circular placing

Variable starting programme

x It is possible to determine which programme is to appear after switching on,

and to store this information by pressing a button.

Carriage size differences:

x VA 802 o Carriage with 230 mm clamping distance

x VA 804 o Carriage with 420 mm clamping distance

x VA 806 o Carriage with 600 mm clamping distance

13

Operation

2.5. Options

Important!You can order the following options in addition to the basic

equipment of the slicing machine when you place your order. This means that none

of the following equipment is part of models VA 802, VA 804 or VA 806. Please

check your order documentation to see which of these options are part of your

!

machine.

2.5.1. Semi-automatic Function

(model VA 802 only)

x Switching to “semi-automatic“ mode with servo-drive assisted carriage for easy

manual carriage movement

2.5.2. Additional Menu Standard Functions

(for all models)

x Automatic calibre recognition

- Automatic cross section recognition of the food to be sliced

- Automatic adjustment of the carriage run to the cross section of the product

- Automatic adjustment of placing distances for optimum use of the selected

placing pattern

x Placing format

- Entering of the placing pattern L x B for adapting to the selected packaging

(tray, film and so on)

x Counting mode

- Specification of the number of portions

- Specification of breaks during which the food to be sliced is taken off the tray in

continuous mode

- Specification of continuous mode as a standard function

2.5.3. PLU Programming

(for all models)

x Storing up to 100 PLU with the following parameters:

- Placing type (stacking, fanning, ...)

- Number of stacks, rows

- Number of slices

- Number of portions

- Initial position of the placing pattern

- Distance between stacks, rows

14

Operation

3. Operation

3.1. Operating Controls

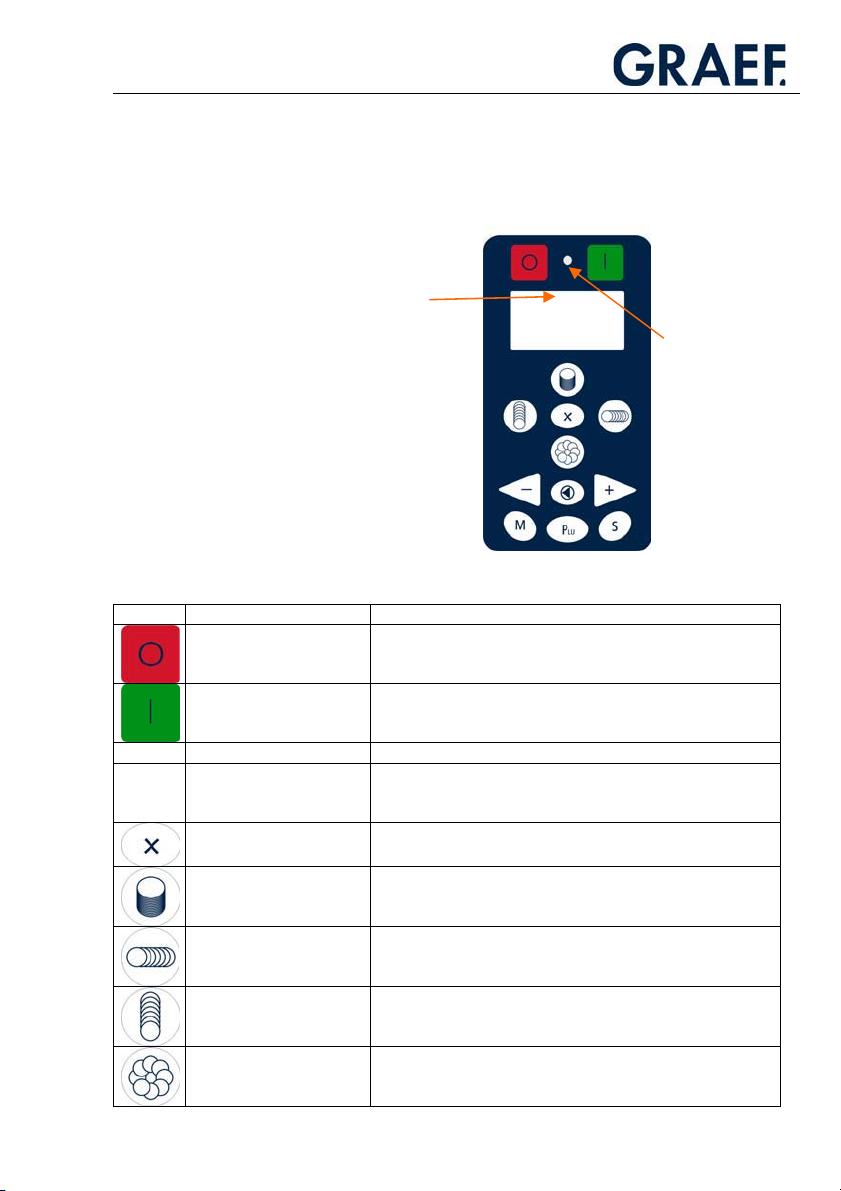

3.1.1. Operating Terminal

Display

(graphical display)

Signal lamp

Symbol Designation Function

Main “OFF“ switch

Main “ON” switch

Signal lamp

Graphical display

(only display!)

X button

Stacking button

Cross shingling button

Long shingling button

Circular shingling button

x Switches off the machine

x Switches on the machine. The machine is ready for slicing.

x Shows that the machine is ready for operation

x Indicates number of slices, cutting programme, PLU, slice

thickness, menu programme (PLU programming, maintenance

intervals etc.)

x Generates 2, 3 or 4 stacks or rows

x Selects the stacking stack function

x Stores the set data (tray dimension, number of slices, cutting

mode, ...) when pressed until a beep is emitted

x Selects the cross fanning function

x Stores the set data (tray dimension, number of slices, cutting

mode, ...) when pressed until a beep is emitted

x Selects the long fanning function (press 1x briefly)

x Stores the set data (number of slices, slicing mode, ...) when

pressed until a beep is emitted

x Selects the circular fanning function

x Stores the set data (number of slices, slicing mode, ...) when

pressed until a beep is emitted

15

Operation

Minus button

Reset button

Plus button

Menu button

PLU button

Carriage stroke button

Button combination M +

PLU

+

x Reduces the edited value

x Moves UP in the selection menu

x Reduces the carriage strokes during operation

x Cancels the active cutting programme

x Resets to zero

x Moves up within the menu hierarchy

x Confirms an entry

x Increases an edited value

x Moves down in the selection menu

x Increases the carriage strokes during operation

x Activates sub-programmes (customer service)

x Switches on PLU mode, the plus/minus buttons can then be

used to select the PLUs

x On pressing this button, the carriage speed (lifting speed) can

be controlled using the plus/minus buttons.

x Programmes PLUs (new/change/delete)

x Changes the standard placing programme (PLU 0000)

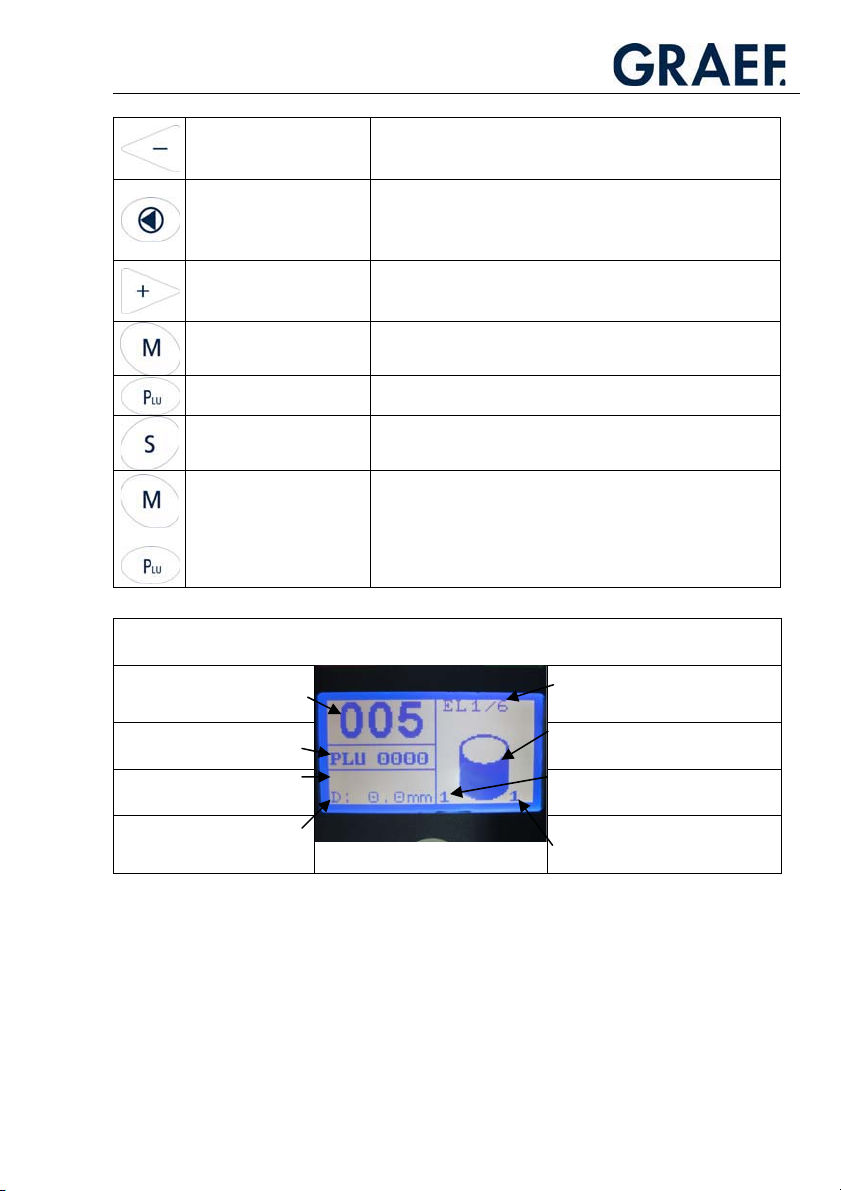

Explanation of the values and symbols in the display

Slice count Portion specifications in continuous

PLU

(0000= Standard programme)

T: Set value slicing thickness

(Display only in PLU mode)

D: Current slicing thickness Number of stacks/rows placed in

(can be set using the “X“ button)

mode “EL”

(No display in normal mode)

Placing function

(stacking, fanning, ...)

Current value of the stack/row

one layer

16

Operation

Other Operating Controls

x Sets the slice thickness

Slice thickness regulator

Last slice clamp

Return lever

Yellow Start-Stop button

x Sets the limit stop lock

x Sets the sharpening mode

x Clamps and feeds the food to be sliced to the blade

x Releases the last slice clamp from the feeder shaft so

that it can be moved freely, e.g. when new food is

being clamped

x Starts the cutting process

x Stops the cutting process

3.2. Programmes

You can either work in the standard mode or access specially defined placing

programmes through PLU. The standard mode makes it possible to combine basic

functions such as stacking, long-shingling, cross-shingling or circular shingling with the

following parameters: number of slices, stroke speed and number rows/stacks.

3.2.1. Slicing in the Standard Mode (PLU=0000)

3.2.1.1. Stackinging

The stacking function enables stack heights of up to 60 mm.

This function is selected by simply pressing the stack button. The display shows the

symbol for stacking. You can preset the number of slices using the plus/minus buttons.

If multiple stacks are desired, you can increase the number of stacks with the “X“ button.

Up to 4 stacks are possible.

When making preparations, it is recommended to set the slice counter to “000”.

In this way, the maximum stack height is always achieved.

If stacks are to be generated on portioning units (foils, PE trays, foam trays, trays etc.),

you can enter the outer dimensions of the portioning units L x W for central placing.

(Option: the machine then uses the calibre recognition option to calculate the best

placing point).

17

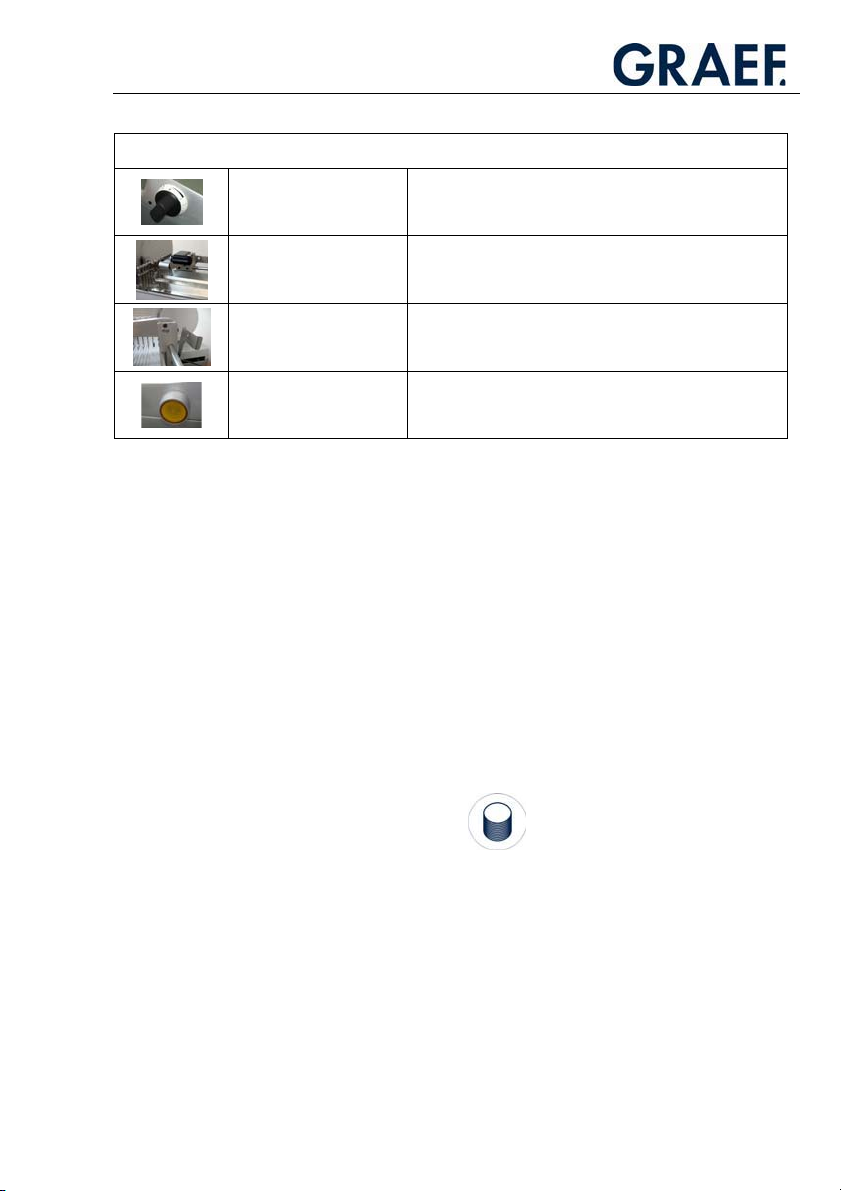

Example:

Operation

+ + +

Select function

“Stacking”

=

+ 3 x “X button”

= 4 stacks

3.2.1.2. Long shingling

The long fanning function is for placing the individual slices in rows parallel to the stop.

The number of rows can be set using the “X“ button. Up to 4 rows are possible with the

standard programme. When making preparations, it is recommended to set the slice

counter to “000”. The machine then fans multiple layers on top of each other.

If rows are to be generated on portioning units (foils, PE trays, foam trays, trays etc.), you

can enter the outer dimensions of the portioning units L x W for central placing. (Option:

the machine then uses the calibre recognition option to calculate the best placing point).

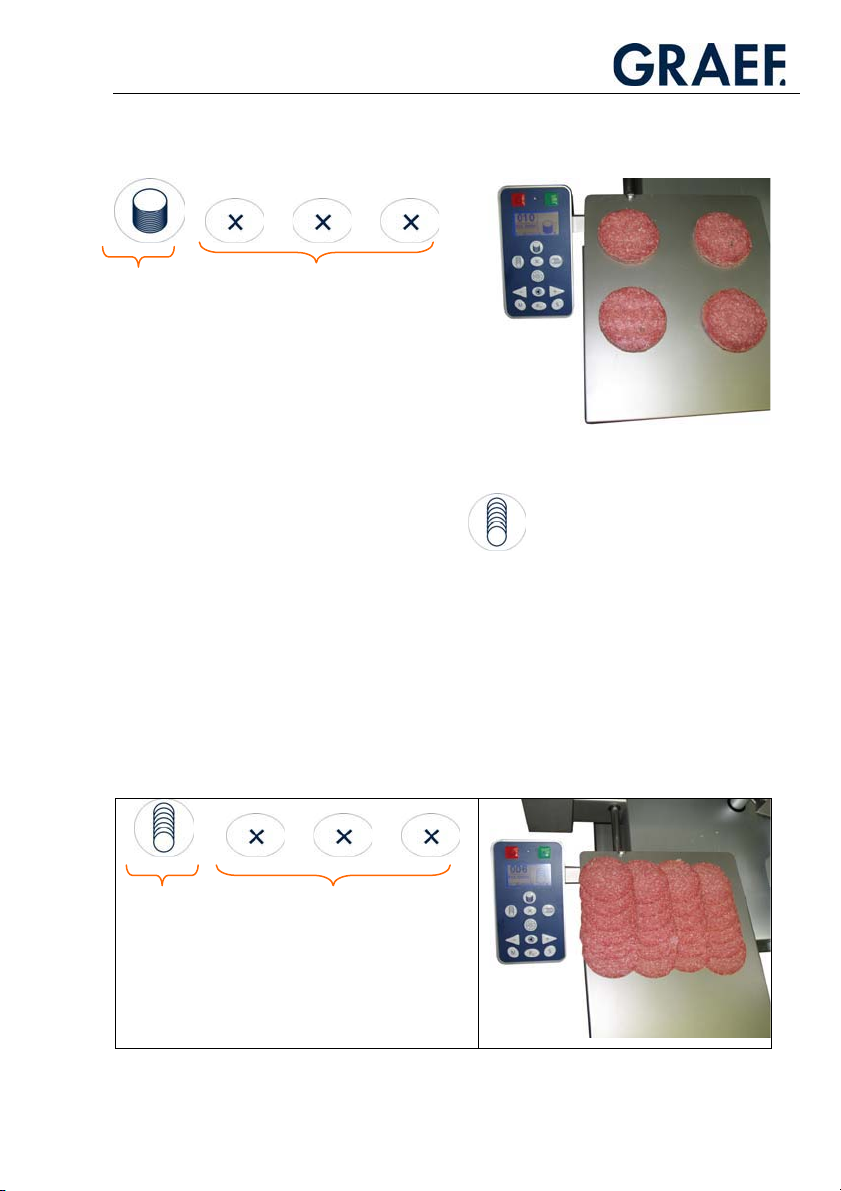

Example:

+ + +

=

Select function

“Long shingling”

+ 3 x “X button”

= 4 rows

18

Loading...

Loading...