Page 1

Technical changes reserved.

GRAEF (d) February 2010 -CB

OPERATING MANUAL (original)

Semi-Automatic

Slicing Machine

HA 800 HA 810

Machine No. :

Year of construction :

Page 2

2

1 General Information ........................................................................................................5

1.1 Safety – Notes on the Warranty................................................................................5

1.1.1 Set-up and Instruction.....................................................................................5

1.1.2 Proper Use ......................................................................................................7

1.1.3 Natural Wear...................................................................................................8

1.1.4 Potential Sources of Danger............................................................................8

1.1.5 Workplace.......................................................................................................9

1.1.6 Authorised Users.............................................................................................9

1.1.7 Protective Clothing and Equipment.................................................................9

2 Description.....................................................................................................................10

2.1 Designation of the Machine Parts ...........................................................................10

2.2 Protective Devices...................................................................................................11

2.3 Technical data.........................................................................................................12

2.4 Basic Machine Equipment.......................................................................................13

2.5 Options ...................................................................................................................14

2.5.1 Additional Menu Standard Functions............................................................14

2.5.2 PLU Programming .........................................................................................14

3 Operation.......................................................................................................................15

3.1 Operating Controls..................................................................................................15

3.1.1 Operating Console ........................................................................................15

3.2 Programs.................................................................................................................17

3.2.1 Slicing in the Standard Mode (PLU 0000)......................................................17

3.2.2 Offset Function (Machines without Calibration Recognition)........................20

3.3 Using the Paper Clamp ...........................................................................................21

3.4 Slicing .....................................................................................................................21

3.5 HA 810 with Vario-Slice Carriage............................................................................23

3.5.1 Tilting the Carriage to the V Position ............................................................24

3.5.2 Tilting the Carriage to the Normal Position...................................................24

3.5.3 Cutting with the VS Carriage ........................................................................25

3.6 The Start Program ...................................................................................................25

3.7 Changing the Standard Program (PLU=0000).........................................................27

3.7.1 The “M+PLU” Additional Menu ...................................................................27

3.7.2 The “M” Additional Menu (OPTION HA 800) ...............................................30

3.7.3 Slicing in the PLU Mode ................................................................................34

3.7.4 Programming a PLU ......................................................................................35

4 Cleaning ........................................................................................................................40

4.1 Preparing for Cleaning ............................................................................................40

4.1.1 Disassembly of the Removable Parts.............................................................41

4.2 Cleaning the Different Parts of the Machine ...........................................................43

4.2.1 Blade and Blade Ring....................................................................................43

4.2.2 Carriage ........................................................................................................44

4.2.3 Chain Frame..................................................................................................45

4.3 Cleaning Schedule...................................................................................................47

Page 3

3

4.3.1 Cleaning Procedure.......................................................................................48

4.4 Assembly.................................................................................................................49

5 Maintenance..................................................................................................................51

5.1 Sharpening the Blade..............................................................................................51

5.1.1 Description of the Blade Sharpener...............................................................51

5.1.2 Preparing the Machine..................................................................................52

5.1.3 Sharpening the Blade....................................................................................52

5.2 Changing the Blade.................................................................................................54

5.3 Lubricating ..............................................................................................................55

6 Faults and Operating Errors ...........................................................................................56

7 Service ...........................................................................................................................57

Page 4

EC DECLARATION OF

CONFORMITY

GEBR. GRAEF GMBH + CO. KG, DONNERFELD 6, D- 59757 ARNSBERG

4

We herewith declare that the design of the following machine

Slicing Machine

Types

HA 800, HA 810

In the design supplied by us complies with the provisions of the following EC

directives:

EC Machine Directive 2006/42/EG

EC EMC Directive 2004/108/EG

EC Low Voltage Directive 2006/89/EG

The following harmonized standards and technical specifications have been

applied:

EN 1974

EN 61000-6-2

EN 61000-6-3

EN 61000-4-[2,3,4,5,6,11]

EN 61000-3-2

EN 55022

Name of the authorized representative: Reinhard Graef

Address of the authorized representative: see manufacture’s address

Changes to the machine not authorized by GRAEF invalidate the present

declaration.

Arnsberg, 11 December 2009 Hermann Graef

- Managing Director -

Page 5

General Information

5

1 General Information

1.1 Safety – Notes on the Warranty

The semi-automatic models HA 800 and HA 810 are equipped with safety devices. They

have been tested for safety.

Nevertheless, hazards cannot be entirely excluded if the machine is used improperly or

not as intended.

These hazards may endanger:

• The health of the user

• The machine and other property of the operator

All persons charged with installing, operating, servicing and repairing the machine must

• Be trained/instructed for the task

• Follow these operating instructions to the letter.

1.1.1 Set-up and Instruction

Store and transport machines in their original packaging until they are set up.

The GRAEF dealer is responsible for set-up and start-up as well as for providing

instructions on how to operate, clean and service the machine.

Customer installation and start-up, incorrect operation, modifications

and removal of the safety equipment are excluded from our area of liability.

Important!

The installation and instruction must be confirmed by your authorised

GRAEF dealer.

The slicing machines weigh approx. 56 kg.

Two adults are required to lift and carry the machine.

The centre of gravity is in the rear third of the machine, where the motor is located.

Always lift and carry the machine by the machine housing.

x For longer company-internal transport routes:

use a suitable handcart.

x Take off removable parts such as chain frame, tray and beater before transport.

!

Page 6

General Information

6

x Secure the carriage by inserting paper or cardboard between the thumb guard and

the stop plate.

x Set the slicing thickness below “0” by turning the slicing thickness control to the limit

position.

1.1.1.1 Set-up site requirements

The base must fulfil the following requirements:

x It must be sufficiently stable, strong, level, flat and non-slip.

x It must be of sufficient height to allow slicing while standing.

x It must meet the space requirements listed in “Workspace” (see Technical Data).

x It must be located away from busy corridors.

x It must not be close to any doors.

x It may not be in the swinging area of a door, nor in the entrance area of a door.

x When using Nirosta tables, Resopal supports or similar materials: Ensure that there is

no oil or grease on the surface.

x Ensure sufficient lighting of at least 300 lux

1.1.1.2 Unpacking the machine

Caution!

The machine may only be unpacked and set up by authorised customer service / sales

personnel. Check the required working space (with the machine switched off!):

• Hold the last slice clamp by the handle

• Lift up the last slice clamp

• Move the carriage all the way forward and back

If the carriage or last slice clamp comes into contact with other objects, you must provide

a larger work space.

!

Page 7

General Information

7

1.1.1.3 Electrical connection

x Check if the local supply voltage conforms to the specifications indicated on the

rating plate. If it does not, you may not connect the machine.

x The electrical socket must comply with the VDE (Association of German Electricians)

regulations.

x For rotary current models (400 V), check that

the running direction of the blade is correct.

x The blade must move downwards in direction

of the carriage as shown in the illustration.

x If the running direction is incorrect, use a

screwdriver to turn the phase change in the

network adapter plug by 180°.

x Moisture: Degree of protection IP 33! High humidity or condensation can damage the

machine.

x Lay and connect the power supply cord so that no-one can fall or trip over it.

x The machine is designed for use in sales rooms.

1.1.2 Proper Use

The HA 800 / HA 810 semi-automatic slicers are exclusively intended

for slicing only the following types of food:

sausage / meat / ham / cheese.

Do not attempt to slice frozen foods.

Do not attempt to slice vegetables or food with bones.

Remove any metal braces on the goods to be sliced.

Unauthorised modifications to the machine are prohibited for safety reasons.

The operating, maintenance and service instructions described in this instruction manual

must be strictly observed.

Page 8

General Information

8

1.1.3 Natural Wear

Natural wear is not covered by our warranty or liability.

1.1.4 Potential Sources of Danger

Caution!

Danger of injury!

Never reach into the area of the moving carriage.

Caution!

Danger of injury!

The blade is sharp and can sever body parts.

Your fingers, and especially your thumb, are at risk. For this reason, never reach into the

space between the last slice clamp and the blade or the limit stop if the limit stop plate is

not completely closed. When the machine is not in use, the stop plate must always be set

to the zero position.

Caution!

Injury through electric shock.

The machine operates with a mains voltage of 230 V or 400 V and must therefore not be

opened. The protective earth conductor system must be connected in any case, otherwise

there is a risk of severe electric shocks.

Caution!

Hazards posed by the chain frame.

Never put your hands near the chain frame during operation. The spikes can cause

serious injury.

The placing arm that removes the sliced food moves very quickly and can injure hands or

other parts of the body in case of contact.

Page 9

General Information

9

Caution!

Risk of injury.

In the area of the food holder, there is a risk of injury posed by the spikes an the food

holder suddenly dropping when inserting the product.

Caution!

Risk of injury.

When mounting parts which can be removed for cleaning.

1.1.5 Workplace

Only operate the machine if you are in a standing in a secure position.

Stand in front of the machine so that the power ON/OFF button is facing you.

Keep your workplace clean at all times.

The machine must be positioned on a solid, even and stable base that can support the

weight of the machine and the dynamic forces of the moving parts.

1.1.6 Authorised Users

The machine may only be operated by people

who have read and understood the operating instructions

who have been instructed thoroughly by the operator

who have been instructed on the dangers of the machine and the hygiene regulations.

The machine may only be serviced and repaired by authorised specialists.

Take precautions to prevent unauthorised persons from using, cleaning or servicing the

machine.

1.1.7 Protective Clothing and Equipment

Wear close-fitting clothes when operating the machine. Please also observe the hygiene

regulations. When executing cleaning or maintenance work in the area of the knife,

be sure to wear cut-resistant gloves with pulse protection.

When transporting the machine, be sure to always wear steel-toe-boots.

Page 10

Description

10

2 Description

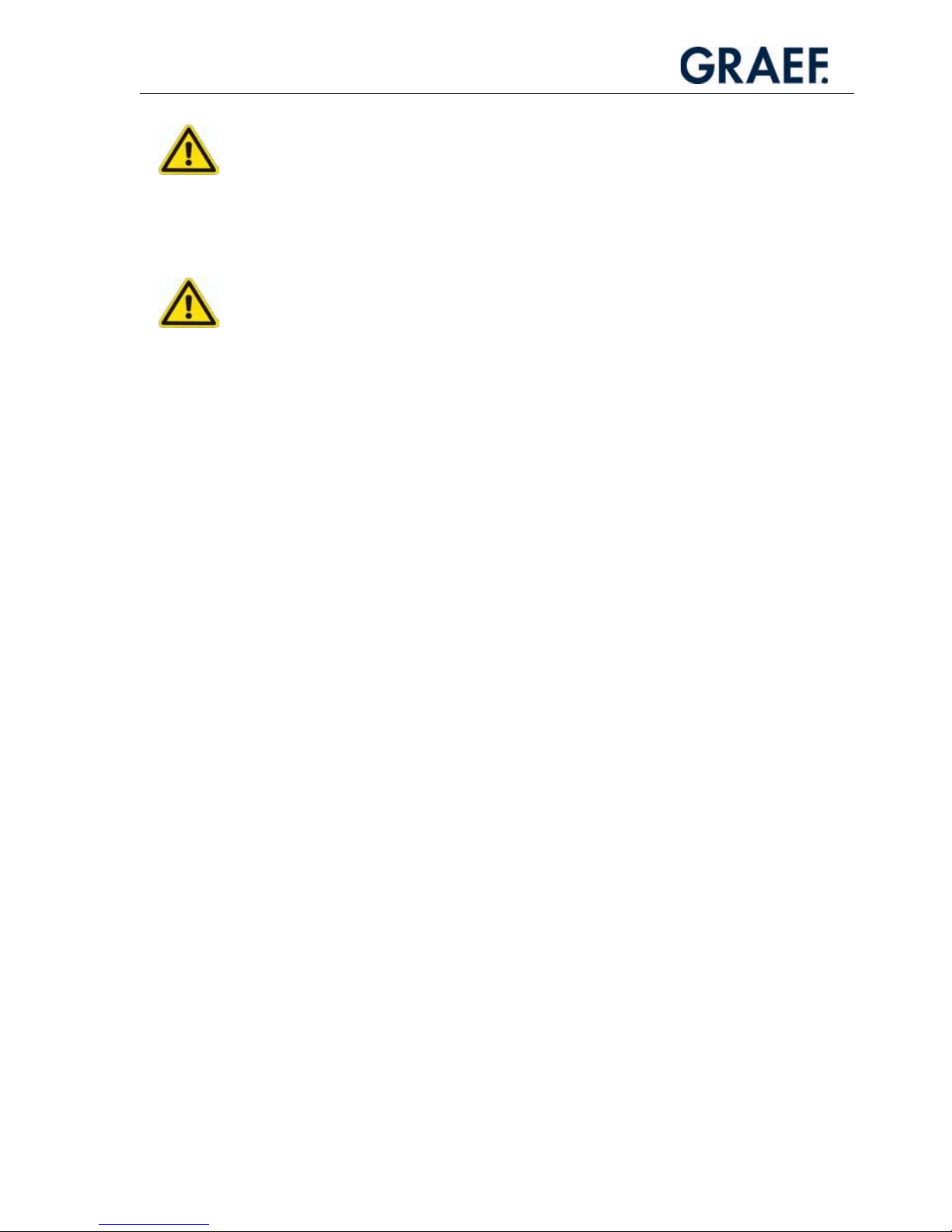

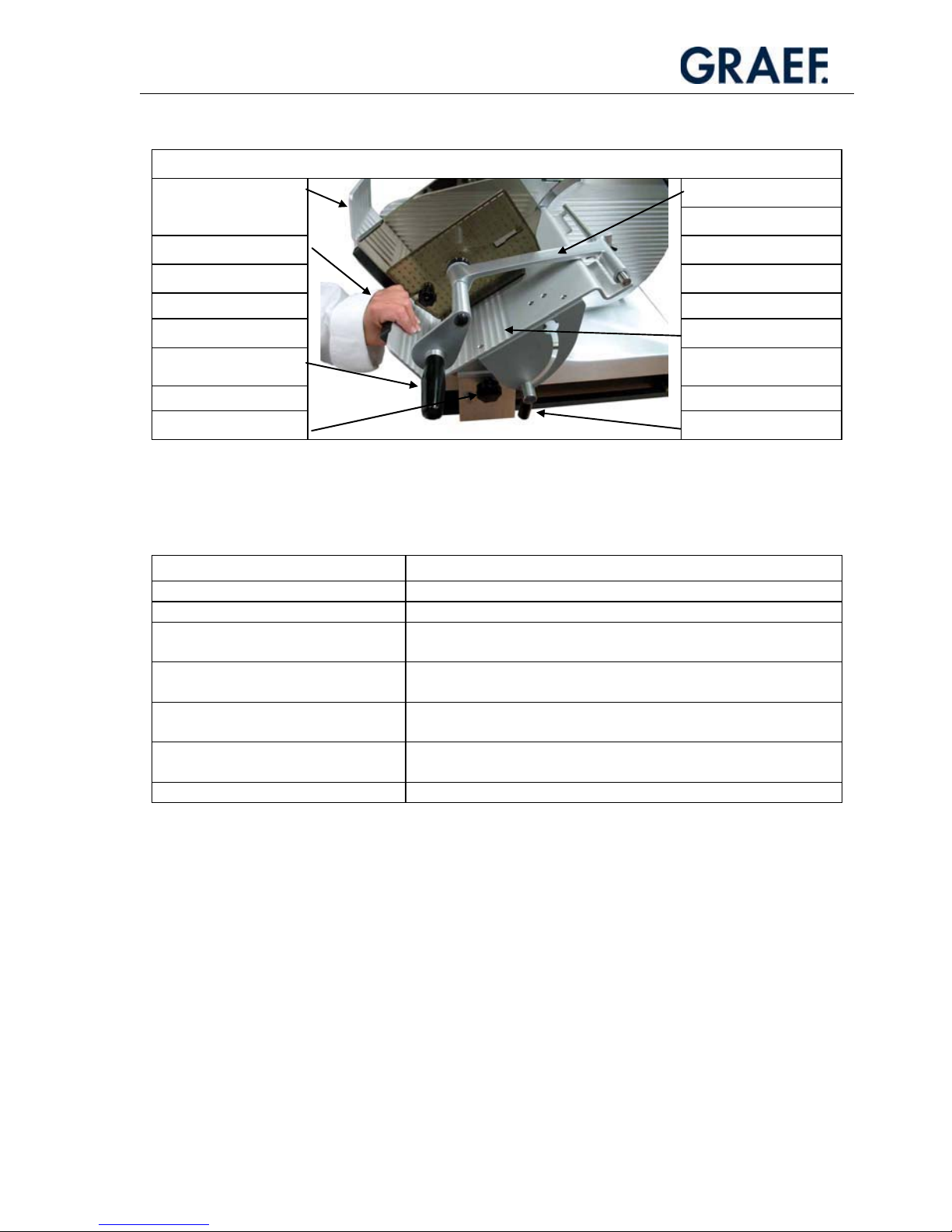

2.1 Designation of the Machine Parts

Stop plate

Blade cover plate

Blade

Last slice clamp

Guide rail

Thumb/finger guard Pusher guard

Carriage Last slice clamp handle

Carriage handle

Chain frame handle

Chains

On button Last slice clamp plate

Off button

Knurled nut

Operating console Slice thickness control

Blade guard ring

Thumb wheel Pressing roller

Scraper comb

Type plate

Placing arm

(removable beater)

Placing arm star grip Tray

Power cable Tray guide

Guide rail

Slicing guide rail

Locking screw

Bearing block star grip

Bearing block

Page 11

Description

11

HA 810 Special Features

Last slice clamp

Thumb guard

Hand rail

Vario-Slice carriage

Last slice clamp

handle

Bearing block star grip Tilting lever

2.2 Protective Devices

Device Function

Off button Switches the machine off immediately.

Blade guard ring Prevents accidental contact with the blade.

Limit stop lock Locks the limit stop when the carriage has been tipped off the

machine.

Thumb/finger guard Prevents accidental contact with the blade.

Chain frame cover Prevents access to the back or catching in the chain tips running to

the blade.

Undervoltage mechanism Prevents the machine from starting up again after an interruption

to the power supply, such as a power cut.

Blade sharpener with guard cover Prevents accidental contact with the blade.

Page 12

Description

12

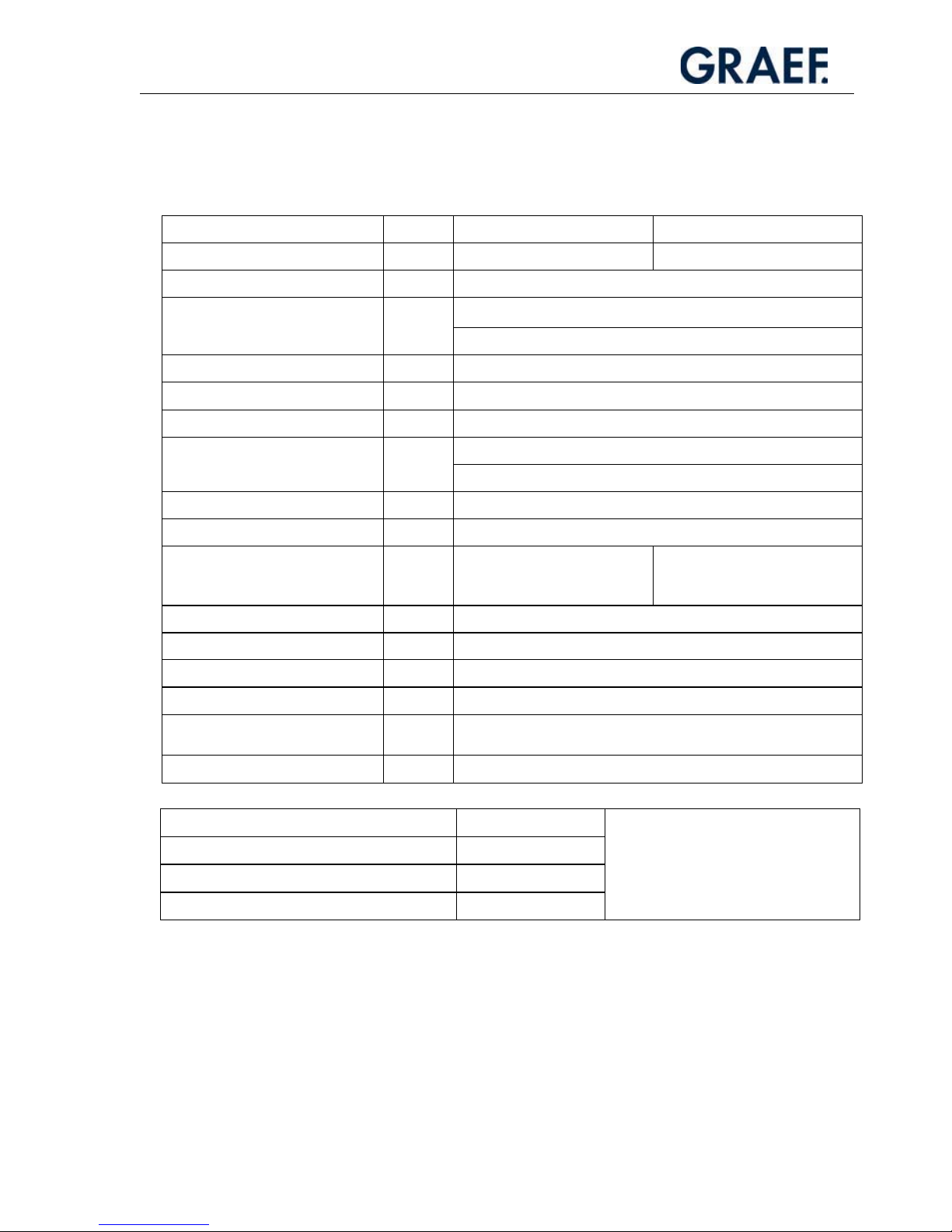

2.3 Technical data

HA 800 HA 810

Dimensions L x W x H 600 x 840 x 450 mm 600 x 840 x 500

Workspace L x W x H 700 x 900 x 640 mm

Minimum: 480 x 440 mm Space occupied L x W

Ideal: 540 x 440 mm

Weight W approx. 56 kg

Blade diameter D 300 mm

Blade speed N 229 rpm

Max. 250 x 180 mm Dimensions with chain frame L x H

Min. 30 x 30 mm

Dimensions without chain frame L x H Max. 260 x 195 mm

Carriage length L 300 mm

Largest distance between last slice

clamp and blade (clamping

distance)

L 150 mm 155 mm

Tray size L x W 300 x 255

Length of tray run T 160 mm

Slice thickness T 0.5 - 10 mm

Slicing speed maximum V Max. 160 strokes per minute

Noise level acc. To EN ISO 11204,

at idling

Leq < 69 dB (A)

Vibration total value < 2,5 m/s²

Power consumption P1 [W]

Frequency f [Hz]

Current I [A]

Voltage UN [V]

See type plate

Page 13

Description

13

2.4 Basic Machine Equipment

Semi-automatic slicing machine models HA 800 and HA 810 differ in terms of size and

some characteristics of the carriage.

All models share the same basic features:

General

x Smooth, accessible high quality anodized surfaces

x Stove-enamelled finished lower part

x Hard-chrome plated 300 mm blade with a narrow blade guard for ideal

slicing results

x Locked blade cover plate

x Slicing parameters as listed in the “Technical Data” table

x Operating console that is clearly laid out and easy to reach with waterproof

membrane keypad

Standard placing programs

x Stacking: up to 4 stacks

x Long fanning: up to 4 rows

x Cross fanning: up to 4 rows

x Circular placing

Variable starting program

x It is possible to determine which program is to appear after switching on, and

to store this information by pressing a button.

Carriage size differences:

x HA 800 o Carriage with 150 mm clamping distance (advance distance

between blade and endpiece holder)

x HA 810 o Carriage with 155 mm clamping distance (advance distance

between blade and endpiece holder)

Carriage characteristics:

x HA 810: In a tilted position, small cutting material can be sliced without the

guide rail.

Page 14

Description

14

2.5 Options

Important!

You can order the following options in addition to the basic equipment of the

slicing machine when you place your order. This means that none of the following

equipment is part of models HA 800 or HA 810. Please check your order

documentation to see which of these options are part of your machine.

2.5.1 Additional Menu Standard Functions

x Automatic calibre recognition (

only HA 800)

- Automatic cross section recognition of the food to be sliced

- Automatic adaptation of distances for optimum utilisation of the selected placing

pattern

x Placing format (

only HA 800)

- A placing pattern (L x B) can be entered to adjust to the selected packaging (tray,

film and so on)

x Carriage position recognition for Vario-Slice carriage

(HA 810 only)

- Optimum placing of product on the tray

x Counting mode

- Specification of the number of portions

- Specification of breaks during which the food to be sliced is taken off the tray in

continuous mode

- Specification of continuous mode as a standard function

2.5.2 PLU Programming

(Optional for all models)

x Storing up to 100 PLU with the following parameters:

- Placing type (stacking, fanning, ...)

- Number of stacks, rows

- Number of slices

- Number of portions

- Initial position of the placing pattern (cutting material positioning on the tray

surface)

- Distance between stacks, rows

!

Page 15

Operation

15

3 Operation

3.1 Operating Controls

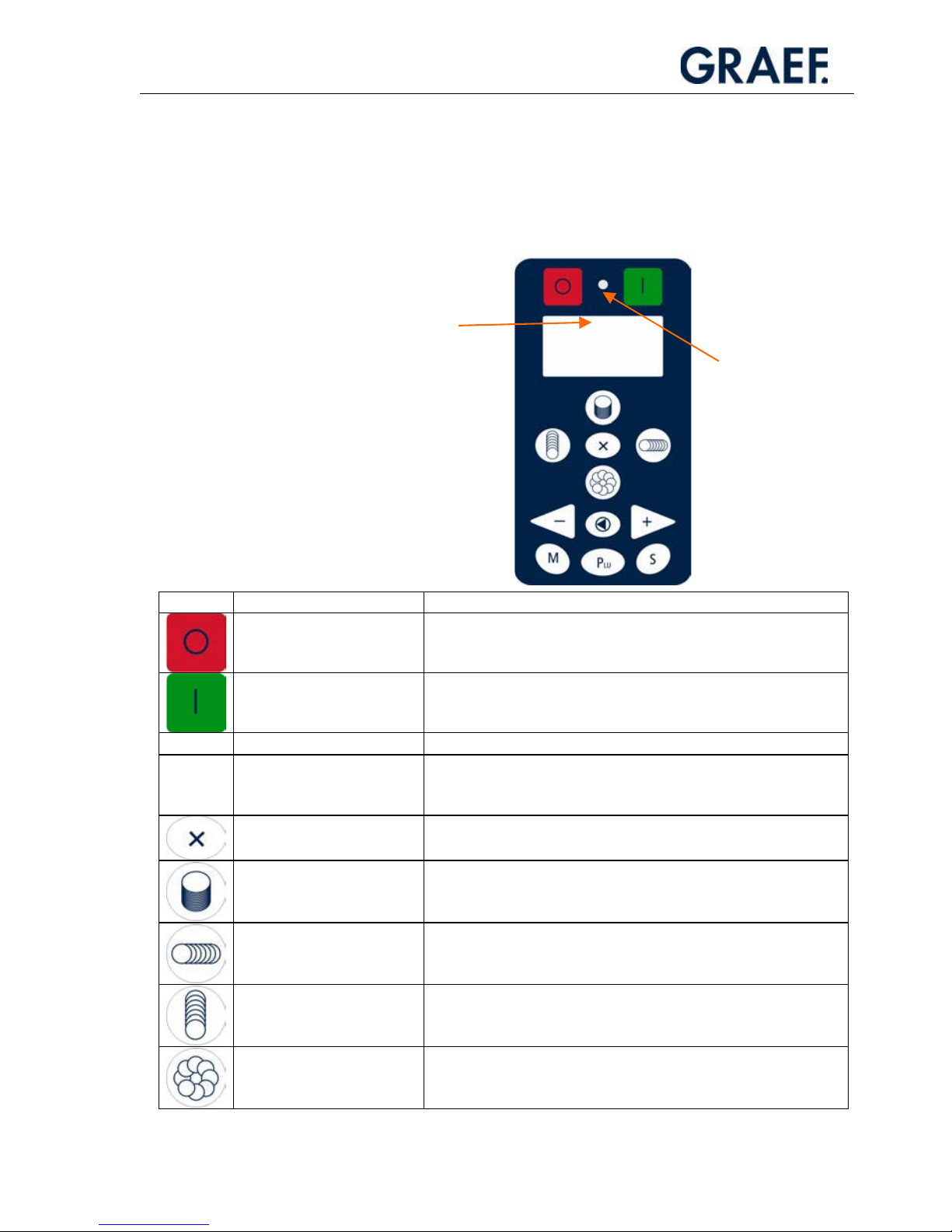

3.1.1 Operating Console

Symbol Designation Function

Main “OFF” switch

x Switches off the machine.

Main “ON” switch

x Switches on the machine. The machine is ready for slicing.

Signal lamp

x Shows that the machine is ready for operation.

Graphical display (only

display!)

x Indicates number of slices, cutting program, PLU, slice

thickness, menu program (PLU programming, maintenance

intervals etc.).

X button

x Generates 2, 3 or 4 stacks or rows.

Stacking button

x Selects the stacking function.

x Stores the set data (tray dimension, number of slices, cutting

mode, ...) when pressed until a beep is emitted.

Cross fanning button

x Selects the cross fanning function.

x Stores the set data (tray dimension, number of slices, cutting

mode, ...) when pressed until a beep is emitted.

Long fanning button

x Selects the long fanning function (press 1x briefly).

x Stores the set data (number of slices, slicing mode, ...) when

pressed until a beep is emitted.

Circular fanning button

x Selects the circular fanning function.

x Stores the set data (number of slices, slicing mode, ...) when

pressed until a beep is emitted.

Display (graphical

display)

Signal lamp

Page 16

Operation

16

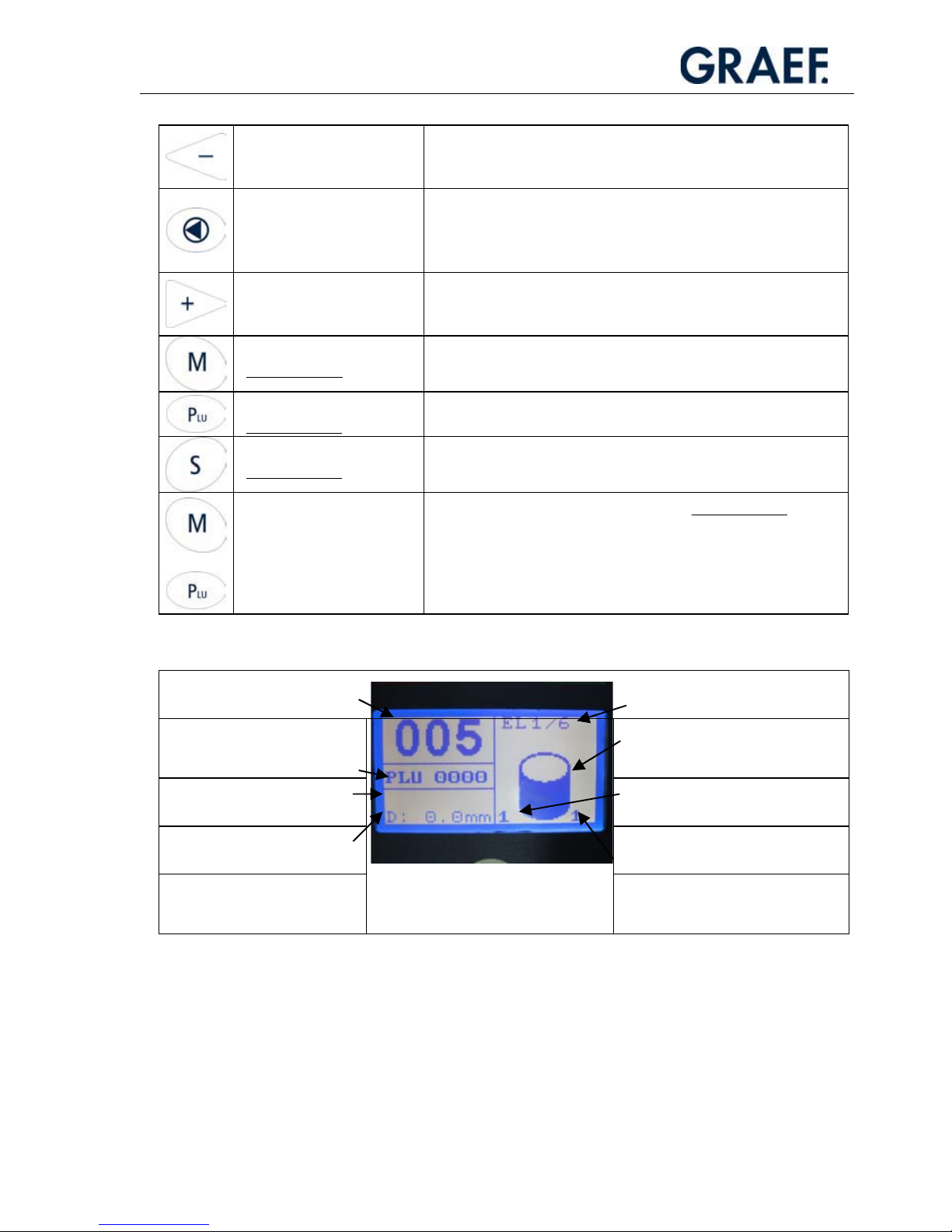

Minus button

x Reduces the edited value.

x Moves UP in the selection menu.

x Reduces the carriage strokes during operation.

Reset button

x Cancels the active cutting program.

x Resets to zero.

x Moves up within the menu hierarchy.

x Confirms an entry.

Plus button

x Increases an edited value.

x Moves down in the selection menu.

x Increases the carriage strokes during operation.

Menu button

(

only HA 800)

x Calls subprograms.

PLU button

(

only VA 800)

x Switches on PLU mode, the Plus/Minus buttons can then be

used to select the PLUs.

Carriage stroke button

(

only VA 800)

x On pressing this button, the carriage speed (lifting speed) can

be controlled using the Plus/Minus buttons.

+

Button combination M +

PLU

x Programs PLUs (new/change/delete).

(

only VA 800)

x Changes the standard placing program (PLU 0000).

Explanation of the values and symbols in the display

Slice count Portion specifications in

continuous mode “EL”

(No display in normal mode)

PLU

(0000 = Standard program)

Placing function

(stacking, fanning, ...)

S: Set value slicing thickness

(Display only in PLU mode)

Current value of the stack/row

D: Current slicing thickness

Number of stacks/ rows placed in

one layer

(can be set using the “X” button)

Page 17

Operation

17

3.2 Programs

You can either work in the standard mode or access specially defined placing programs

using PLU. The standard mode makes it possible to combine basic functions such as

stacking, long-fanning, cross-fanning or circular fanning with the following parameters:

number of slices and number rows/stacks.

3.2.1 Slicing in the Standard Mode (PLU 0000)

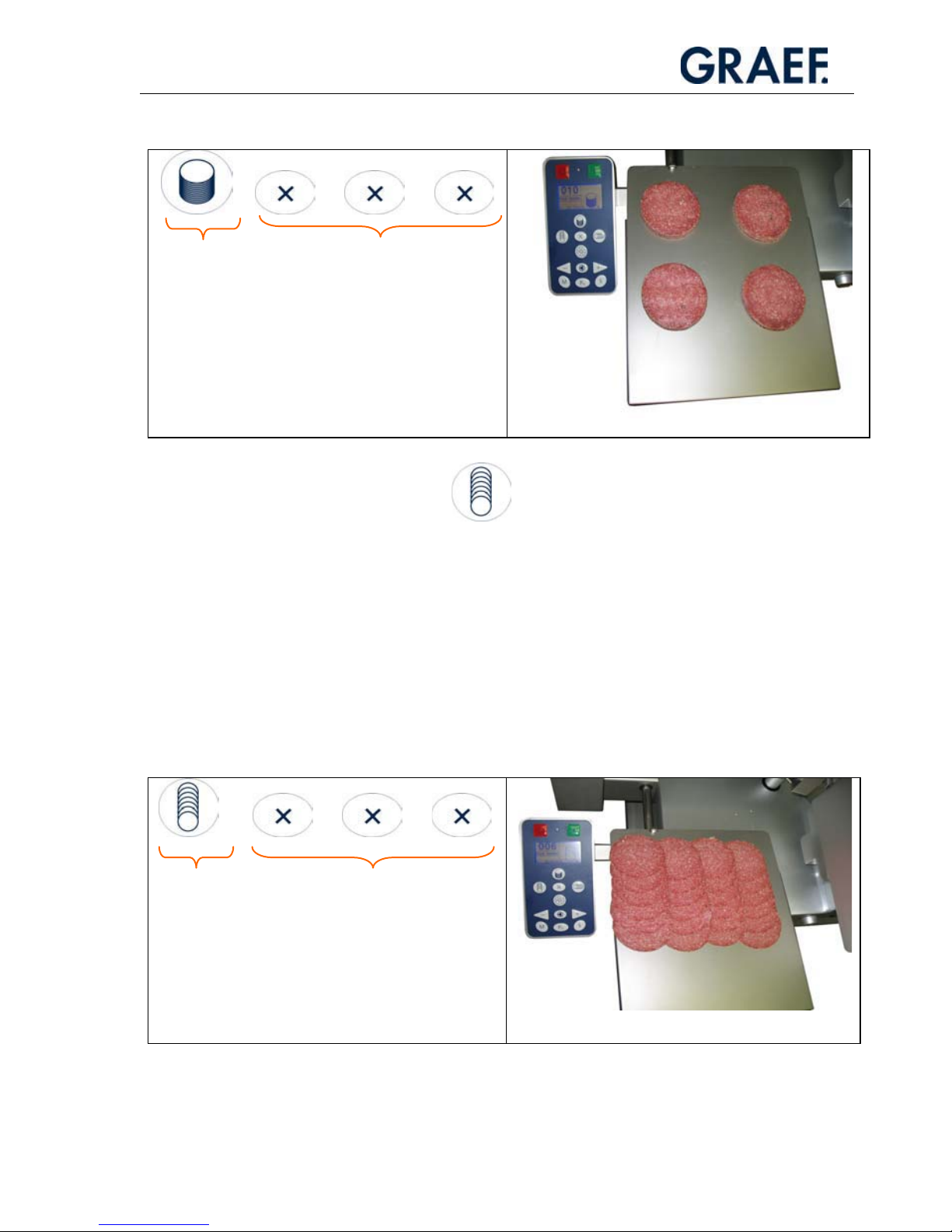

3.2.1.1 Stacking

The stacking function enables stack heights of up to 60 mm.

This function is selected by simply pressing the stack button. The display shows the

symbol for stacking. You can preset the number of slices using the +/- buttons. If multiple

stacks are desired, you can increase the number of stacks with the X button. Up to 4

stacks are possible.

When making preparations, it is recommended to set the slice counter to “000”. In this

way, the maximum stack height is always achieved.

If stacks are to be generated on portioning units (foils, PE trays, foam trays, trays etc.),

you can enter the outer dimensions of the portioning units L x W for central placing.

(Option only HA 800: the machine then uses the calibre recognition option to calculate

the best placing point.)

Other Operating Controls

Slice thickness control

x Sets the slice thickness.

x Sets the limit stop lock (carriage removable)

x Sets the sharpening mode (completely opened)

Last slice clamp

x Clamps and feeds the food to be sliced to the blade.

Guide rail

x Fixes food product on the carriage.

x Calibre scanning

x Optimum use of placing surface

Page 18

Operation

18

Example:

+ + +

=

3.2.1.2 Long Fanning

The long fanning function is for placing the individual slices in rows parallel to the stop.

The number of rows can be set using the “X” button. Up to 4 rows are possible with the

standard program. When making preparations, it is recommended to set the slice counter

to “000”. The machine then fans multiple layers on top of each other.

If rows are to be generated on portioning units (foils, PE trays, foam trays, trays etc.), you

can enter the outer dimensions of the portioning units L x W for central placing. (Option

only HA 800: the machine then uses the calibre recognition option to calculate the best

placing point.)

Example:

+ + +

+ 3 x “X button”

= 4 stacks

Select

“Stacking”

function

=

3 x “X button”

= 4 rows

Select

“Long fanning”

function

Page 19

Operation

19

3.2.1.3 Cross Fanning

The cross fanning function is for placing the individual slices in rows parallel to the chain

frame. The number of rows can be set using the “X” button. Up to 4 rows are possible

with the standard program. When making preparations, it is recommended to set the

slice counter to “000”. The machine then fans multiple layers on top of each other.

If rows are to be generated on portioning units (foils, PE trays, foam trays, trays etc.), you

can enter the outer dimensions of the portioning units L x W for central placing. (Option

only HA 800: The machine then uses the calibre recognition option to calculate the best

placing point.)

Example:

3.2.1.4 Circular Fanning

Circular fanning enables the slices to be placed in a circular pattern.

The diameter of the circle can be altered by adjusting the tray dimensions. In this way,

oval placing patterns are also possible.

Example:

Select

“Cross fanning” function

Select

“Circular fanning” function

Page 20

Operation

20

3.2.2 Offset Function (Machines without Calibration

Recognition)

On machines without calibration recognition, the “Offset function” can be used to

slightly adjust the laying position on the tray, for example, a stack can be placed on the

left, in the centre or on the right of the tray.

Example:

The stacking function has been selected. If

the function button (stacking) is pressed

again, three bars appear in the display.

The plus “+” and minus “-” buttons can be used to

change the position of the highlighted bar and the laying

position of the cutting material is moved on the tray

correspondingly.

OFFSET FUNCTION CHANGE OF LAYING POSITION

Stacking Left, centre, right

Long fanning Left, centre, right

Cross fanning Rear, centre, front

Circular fanning Larger Ø, medium Ø, smaller Ø

Page 21

Operation

21

3.3 Using the Paper Clamp

Press down the lever on the right of the tray to the

back.

Lay the paper (or film) on the tray and push to the

stop limits.

Pull the lever to the front and the paper (or film) is

clamped.

3.4 Slicing

Clean the machine completely, following the cleaning procedures, before you start

slicing.

Preparing the carriage:

x Bring the carriage to the initial position.

x Take hold of the handle of the last slice clamp

and swivel it upwards.

Page 22

Operation

22

x Push the guide rail towards the last slice clamp

as far as required by the food to be sliced.

x Place the sausage to the wall of the carriage

and hold in position with your left hand.

x Using the right hand, pull the guide rail until

about 4 mm before the food product and

tighten the locking screw (mini wing).

x Switch on the machine.

CAUTION!

The carriage is supported by a servo-drive as soon

as you push it towards the blade.

Page 23

Operation

23

x Use the slicing thickness control to set the

slicing thickness.

The value shown in the display is the slice thickness

in mm.

x Select the placing program and specify the

number of slices with the +/- buttons if

necessary.

x Take hold of the handle of the last slice clamp

and swivel it to the “down” position.

x Push the food to be sliced against the rail and

push the carriage towards the blade.

If the food to be sliced is smaller than 150 mm, use

the last slice clamp.

3.5 HA 810 with Vario-Slice Carriage

The Vario-Slice carriage allows you to slice round products, especially narrow ones, in a

tilted position without a guide rail. The procedure for slicing corresponds to that with the

standard carriage.

Page 24

Operation

24

3.5.1 Tilting the Carriage to the V Position

x Press the Off button to switch off the machine.

x Hold the carriage with your left hand by the

black handle.

x Swievel the rocker arm on the right towards you

so that the carriage unlatches.

x Using your left hand, tilt the carriage to the V

position until you hear the carriage latch in. Let

go of the lever while you tilt the carriage.

x You can now slice the product in the same way

as in the normal position.

CAUTION!

The carriage is supported by a servo-drive as soon

as you push it towards the blade.

IMPORTANT!

In the tilted position, the laying position on the tray is different to what it is in the

normal position.

3.5.2 Tilting the Carriage to the Normal Position

x Press the Off button to switch off the machine.

x Hold the carriage with your left hand by the

black handle and hold the carriage steady

before you unlatch the rocker arm.

x Swivel the rocker arm on the right towards

you so that the carriage unlatches.

x Caution! Do not allow the carriage to drop

down.

!

Page 25

Operation

25

x Using your left hand, tilt the carriage to the V

position until you hear the carriage latch in.

Let go of the lever while you tilt the carriage.

3.5.3 Cutting with the VS Carriage

x Swivel up the last slice clamp.

x Insert the product to be sliced.

x Lower the last slice clamp.

x If the food to be sliced is long, place the last slice clamp on the food. If the food is

short (shorter than 155 mm), place the last slice clamp behind the food.

x Switch on the machine.

x Pull the carriage towards yourself if the display has not yet been enabled, i.e. you can

only see the GRAEF logo.

x Select the program.

x Open the stop with the slicing thickness control (the slice thickness can be read off at

the display).

x Slicing now proceeds like on a manual machine; in other words, press the food gently

against the stop and push the carriage towards the blade.

x CAUTION!

The carriage is supported by a servo-drive as soon as you push it towards the blade.

3.6 The Start Program

The start program determines which placing function the machine will display when it is

switched on. You should select the program setting that is most commonly used.

All values that can be changed using the function buttons described above – number

of slices, function, – can be saved by pressing the corresponding function key for

2-3 seconds until the beep sounds. The last stored function is called again when the

machine is switched on again.

Page 26

Operation

26

Example:

START Program P1 P2 P3

Select function

Stacking

Circular

fanning

Long

fanning

Number of slices

10

10 8

Number of

rows/stacks

2

1 3

Press for 2-3

seconds

If programming is done in the sequence P1oP2oP3, the following happens after

switching on the machine:

“Long fanning” function, 3 rows of 8 slices, which is program “P3”.

On changing functions, i.e. by pressing a different button, e.g. Stack, the placing pattern

is set for the corresponding function.

The example above would result in the following stacking pattern: 2 stacks of 10 slices.

It is possible to save the various parameters of a function individually by pressing the

corresponding function button for a long time. However, as already mentioned, the most

recently saved program is always the START program.

Page 27

Operation

27

3.7 Changing the Standard Program (PLU=0000)

In addition to simple variants, like changing the

x Slice count

x Number of stacks/rows (1-4)

x Carriage stroke speed (slices per minute, only for fully automatic machines)

it is possible to adjust the following parameters

x Positions on the tray

x Placing format (option)

x Calibre mode (option)

x Counting mode (option)

in additional menus.

3.7.1 The “M+PLU” Additional Menu

Access the program menu by pressing buttons M+PLU. Here, in the “STANDARD” menu

item, you can change the basic functions relating to fanning distances and positioning on

the tray. Select “Reset” to return all functions to the default settings at any time.

IMPORTANT!

Always press and hold the “M” button and then press the “PLU” button in addition.

!

Navigation in the M+PLU

Page 28

Operation

28

y

x

DELTA Y

Y

0

Parameter Description Possible settings / Remarks

Stacking, ¦ shingling, — shingling

Dist trans

(Delta X)

Crosswise distance: distance

to the next stack in X

Stacking

Dist row Row distance: distance to the

next row

Long fanning

Dist slice Slice distance: distance to the

next slice

Cross fanning

X

Y

Y start

X start

Cross shingling

Stacking ¦ shingling — shingling

Dist cross

Dist length

X

start

Y start

Max.

height

o shingling General

Reset

Standard

Dist slice

Dist row

X

start

Y start

Slices/row

X start

Y

start

Dia circle

Slices/row

Round

Dist row

Dist slice

X

start

Y start

Slices/row

Standard

+

Page 29

Operation

29

Dist length Lengthways distance: distance

to the next slice in Y

Stacking

Dist slice Slice distance: distance to the

next slice

Long fanning

Dist row Row distance: distance to the

next row

Cross fanning

X start Moves the initial placing point

in X-direction

Stacking, long fanning, cross fanning

Y start Moves the initial placing point

in Y-direction

Stacking, long fanning, cross fanning

Max.

height

Maximum stacking height Only in stacking mode

Slices Slices per row or fan Not in stacking mode

Special circular fanning features

Diameter of the circle through

the central points of the slices

(partial diameter)

Note:

The outer diameter of the

“DA” circular fan is the result

of the cutting material calibre

DK + Dm

Example:

Salami DK = Ø 60

Set semi-circle Dm = 100

DK 60

Dm + 100

Dm

DA = 160

X start

(X0)

Smallest distance of the y axis

to the slice circle = start

position in X

Y start

(Y0)

Smallest distance of the x axis

to the slice circle = start

position in Y

Round Select option “0”

or “1” “0=oval or circle”

or “1= circle”

In option “0” it is also possible to create oval shapes by

changing the length and width in the placing format menu.

Option “1” always has the placing format of a geometrical

circle.

Dm

Y start

X start

Y

X

DA

Page 30

Operation

30

3.7.2 The “M” Additional Menu (OPTION HA 800)

You can access the placing format/ calibre mode/counting mode menu items by pressing

the

button. If the continuous mode function is activated in the counting mode, the

“Idle time” menu item appears additionally.

Navigation in “M” menu:

Placing format Calibre mode Idle time

Width

Length

Auto

Semi

Off

Height

Normal

Contin.

Counting mode

Page 31

Operation

31

3.7.2.1 Placing Format (Option HA 800)

The machine can determine the calibre of the food placed on it. It bases all its

calculations on a round calibre. You can therefore specify the placing format, i.e. the area

in which the sliced food is to be placed, through the parameters “Length (L)” and

“Width (W)”.

If, for example, you enter W = 200 L = 200, the sliced food will be placed on a square of

dimensions 200 mm x 200 mm.

Example:

You want to portion salami decoratively on a tray with dimensions

210 x 210 mm.

To make sure that the tray is covered completely, you make the following settings:

Width 210 mm

Length 210 mm

The circular fan therefore has a 210 mm outside diameter and is placed centrally onto the

tray.

3.7.2.2 Calibre mode (Option HA 800)

The machine has a calibre recognition function. Its calibre measuring device measures the

greatest length of the cross section of the product parallel to the carriage section.

This value is used for subsequent tasks

x Positioning on the tray

Exact placing on packaging such as film, paper or a tray

You can use the menu controls to set the calibre recognition function to different modes:

H

B

Food dimensions

Page 32

Operation

32

a) Activation of calibre recognition “Auto”

In this mode, the placing pattern is calculated automatically using the parameters,

product width (B) and preset tray dimensions. The fanning distance, the distance

between rows and the initial placing position on the tray are calculated by the software.

b) “Semi” Mode

In this function, the placing positions in “X” are calculated by the calibre recognition.

Parameters in “Y”, such as fanning distance for long fanning, are predetermined values

that can only be changed in parameter programming.

c) Deactivate “OFF”

The machine now operates with the preset fanning distance and initial placing position of

the placing pattern. The carriage travel remains constant, regardless of the calibre.

d) Partial activation “Height XXX “

Some products (flat, long products such as bacon) require the specification of the product

height. The calibre recognition only registers the product width and assumes that product

height and width are identical. The machine operates with numerical values in steps of

5 mm. These values can be selected with the arrow keys.

Example: A piece of bacon with a height of approx. 40 mm is assigned the value 40.

y

x

Lengthways

distance

Y start

Page 33

Operation

33

3.7.2.3 Counting mode

The counting mode specifies whether a placing pattern based on the specified basic

functions is to be placed once (normal mode) or is to be repeated (continuous mode).

Example for normal mode:

Basic function settings

Stacking – 10 slices – 4 stacks (= pressed “X button” 3 times)

When it is started, the machine slices 4 stacks of 10 slices and places them on the table.

Then the machine stops.

Example for continuous mode:

Basic function settings

Stacking – 10 slices – 4 stacks (= pressed “X button” 3 times)

When it is started, the machine places 4 stacks of 10 slices on the table.

The machine then returns to its initial position and repeats the cutting process. It

continues to do this until one of the following events happens:

x The specified number of portions has been sliced.

x All of the food has been sliced or

the operator has cancelled the slicing process.

You can specify the portions in continuous mode (repeat mode).

To do this, use the +/- buttons to specify the number of portions.

If you specify “0”, the machine will repeat the process until

the food has been sliced or the operator cancels the slicing process.

Another way to modify the continuous slicing mode is to add pauses between individual

layers. The pauses can be used to remove one layer from the table and add a new film or

tray for a new layer on the tray.

3.7.2.4 Idle Time

This menu item only appears if the continuous mode is active.

This is where you can define the pauses between the individual layers by using

the -/+ buttons.

Page 34

Operation

34

3.7.3 Slicing in the PLU Mode

Customer-specific placing patterns can be stored in the PLU programs.

Specify “Slicing in Standard Mode” when you are preparing the machine and when you

feed in the food to be sliced.

From the program selection onwards, proceed as follows:

x Press the PLU button.

x Use the arrow buttons (plus/minus) to select the desired PLU program number.

x Use the slicing thickness control to adjust the slice thickness stored in the PLU.

x Use the yellow Start button to start the cutting process.

NOTE

To access the standard mode (PLU 0000)

again from the PLU mode, press the PLU

button and then press the Reset button

immediately.

!

You can select the following functions in PLU mode:

Buttons Function

Change the idle time between two placing

patterns.

Change the portions.

Change the stroke speed.

Only for fully automatic machines.

Page 35

Operation

35

PLU MENU

new

change

delete

3.7.4 Programming a PLU

Access the program menu by pressing buttons M+PLU.

IMPORTANT!

Always press and hold the “M” button and then press the “PLU” button in addition.

Use the -/+ button to select “PLU”.

Press the M button to confirm.

The following menu appears:

Here you can access the “PLU” menu item, where you can create, change or delete

placing patterns.

Example: “new”

Use the arrow keys to navigate to “new”.

Confirm your selection with the M button.

The following menu appears:

Use the +/- buttons to change the preset value to the desired PLU.

Confirm your selection with the M button.

You can now program the selected PLU:

!

New PLU

PLU: 1

Page 36

Operation

36

Use the +/- buttons to select the individual parameters (mode, X number, slices,

arrangement, ... ).

Pressing the M button then takes you to the editor where you can determine the value

using the +/- buttons.

Pressing the reset button takes you back to the menu for the selected PLU.

PLU 1

Mode Stacking

X number 2

Slices 10

Pattern Lengthwise

Portions 1

X start 0

Y start 10

Dist cross 0

Dist length 100

Strokes / min 50

Thickness 10

Idle time 0

Page 37

Operation

37

Overview of PLU Parameters

(Designation in brackets = old designation before March 2007)

Parameter Description Possible settings / Remarks

Mode Selection of basic placing

program

Stacking

Long fanning

Cross fanning

Circular fanning

X number

(Multi)

Number of rows/ stacks 1 to 4

Circular fanning: no parameter available

Slices

(Preselection)

Number of slices per stack,

row, circle

Pattern Only in stacking mode.

Determines the offset

direction / pattern if there

are several stacks.

Lengthwise: stack offset in y-direction

Crosswise: stack offset in y-direction

Square: stack is arranged on the corners of a square.

Portions

(Tray)

Number of packing units,

portions

With packing machine: specification of the number of packing

units.

Without packing machine: specification of the number of layers

that can be sliced onto each other.

X start

(X0)

Moves the initial placing

point in X-direction.

Y start

(Y0)

Moves the initial placing

point in Y-direction.

Dist cross

(X-Delta)

Crosswise distance: distance

to the next stack in X

Stacking

Row dist

(X-Delta)

Row distance: distance to

the next row

Long fanning

Slice dist

(X-Delta)

Slice distance: distance to

the next slice

Cross fanning

Dist length

(Y-Delta)

Lengthways distance:

distance to the next slice in

Y

Stack mode

Slice dist

(Y-Delta)

Slice distance: distance to

the next slice

Long fanning

Row dist

(Y-Delta)

Row distance: distance to

the next row

Cross fanning

X

Y

Y start

X Start

Cross fanning

Page 38

Operation

38

Strokes / min

(Speed)

Carriage speed in strokes

/min

Only for fully automatic machines

Thickness Indication of desired

thickness. It is indicated on

the display next to the S.

To enable the entry with the +/- buttons without needing

decimals, the value to be entered is factored by 10.

In other words, entering “ 9” is equivalent to a slice thickness

of 0.9 mm.

Idle time Definition of the idle time

between two portions. This

enables the operator to take

goods from the tray without

needing to start the machine

again.

Input is made in steps of 0.5 s.

Maximum idle time: 120 s

Special circular fanning features

Diameter of the circle through

the central points of the slices

(partial diameter)

Note:

The outer diameter of the “DA”

circular fan is the result of the

cutting material calibre DK + Dm

Example:

Salami DK = Ø 60

Set semi-circle Dm = 100

DK 60

Dm + 100

Dm

DA = 160

X start

(X0)

Smallest distance of the y axis to

the slice circle = start position in

X

Y start

(Y0)

Smallest distance of the x axis

to the slice circle = start position

in Y

Dm

Y start

X start

Y

X

DA

Page 39

Operation

39

Example: Programming PLU “10”

Long fanning, 2 rows of 9 slices, with fanning distance 20, row distance 100,

1 portion, slice thickness 1.8 mm, slices per minute 50 (=strokes/min)

PLU 10

Mode Long fanning

X number 2

Slices 9

Portion 1

X0 45

Y0 20

DELTA X 100

DELTA Y 20

Strokes / min 50

Thickness 18

Idle time 0

Tra

y

X

0

Y

0

DELTA Y

DELTA X

Slices

X number of rows

/stacks

Page 40

Cleaning

40

4 Cleaning

The cleaning schedule is the basis for all cleaning procedures.

WARNING!

Rotating blade can cause serious injuries.

Do not reach into the blade. To

clean, switch off the machine and pull out the mains plug beforehand.

When cleaning the blade, always wear protective gloves with wrist guards.

CAUTION!

The carriage is a moving part.

IMPORTANT!

Follow the specified sequence when cleaning. Do not use any abrasive cleaners

when cleaning the machine. These scratch metallic surfaces and impair hygiene

and slicing performance. Use only the cleaners and disinfectants that have been

approved by us, diluted as specified.

Do not use any harsh or abrasive cleaners or disinfectants.

Never use a high-pressure or steam cleaner.

Failure to observe any of these points will invalidate any warranty claims.

4.1 Preparing for Cleaning

• Press the red Off button (O button)

• Pull the mains cable from the electrical socket.

• Turn the adjusting knob for setting the slicing thickness

clockwise past “0” to the limit stop.

CAUTION!

The spikes on the last slice clamp plate and the chain can cause injuries.

!

Page 41

Cleaning

41

IMPORTANT!

Do not lay removed parts on top of each other as this may damage parts.

Only clean the beater and the chain frame with the brush provided. Do not

press too hard.

4.1.1 Disassembly of the Removable Parts

Tray:

x Lift the tray as shown in the picture.

x Move the tray towards the operator and remove it

from the machine.

Placing arm:

x Remove the star grip while fixing the placing arm to

the beater rod.

x Take the placing arm from the machine.

Chain frame:

x Swing the pressing roller away from the limit stop

with your right hand.

x Pull the chain frame upwards by the handle with your

left hand and remove it from the machine.

!

1

2

2

1

Page 42

Cleaning

42

Guide rail:

x Swivel up the last slice clamp as preparation.

x Pull the guide rail to the carriage wall with your right

hand.

x Hold the guide rail as illustrated in the picture and lift

it until the guide piece jumps out of the guide.

x Remove the guide rail from the carriage.

Last slice clamp (spike plate):

x Swivel up the last slice clamp as preparation.

x Loosen the black knurled nut by a few turns.

x Pull the plate upwards and swing the lower holding

bolt out of the slot.

Taking off the carriage:

x The limit stop must be completely closed.

x The carriage must be pulled to the initial position.

x Fold down the last slice holder.

x Release the star grip.

x Pull out the carriage carefully upwards.

1

2

Page 43

Cleaning

43

Blade cover plate:

x Secure the blade clover plate from falling with your

right hand.

x Loosen the thumb wheel and pull it slightly out of the

guide.

x Carefully lift the blade cover plate away from the blade

with both hands and put it to one side.

4.2 Cleaning the Different Parts of the Machine

4.2.1 Blade and Blade Ring

WARNING!

The blade is sharp!

Only clean it when the carriage is tilted out

and the limit stop is closed.

x Push a dampened cleaning cloth between blade and

blade protection ring from the front.

x Using both hands, pull the cleaning cloth against the

blade guard ring once or twice.

Page 44

Cleaning

44

x Press a damp cloth against the blade surface and wipe

off the blade slowly from the centre to the edges.

x Clean the rear side of the blade in the same way.

x Rub the blade dry with a clean cloth in a similar

fashion.

4.2.2 Carriage

x Clean the bottom of the carriage with a damp

cleaning cloth when it is tilted out.

x Remove the food remains from the carriage surface

and then clean it according to the cleaning plan.

Last slice clamp plate:

x Use the brush to clean the spiked side.

x Wipe the smooth back with a cleaning cloth.

Page 45

Cleaning

45

4.2.3 Chain Frame

x Place the chain frame on its back on the table.

x Remove the wing bolt.

x Gently swing the guide comb out and place it on the

side.

x Swing the pressing roller to the side as shown on the

picture.

x Use a brush and cleaning liquid to clean the pressing

roller.

x Turn the pressing roller and fix it again by the gear

wheel so that you can clean the whole roller.

x Use the same procedure on the chain drive cylinder.

x Carefully clean the scraper fingers while the pressing

roller is swung away.

Page 46

Cleaning

46

x Gently jerk the protective cover out of its holding clips

and swivel it away from the chains.

x Clean the cover with a cleaning cloth on all sides.

CAUTION!

The chain tips can cause injuries!

x Hold the chain frame by its handle.

x Use a brush to clean the chains.

x Move the chains forward by turning the drive cylinder

to clean every part of the chains.

x Put the placing arm on its side on the table.

x Use the brush to clean the fingers gently.

x Use the same procedure on the back.

! IMPORTANT!

Bending the fingers can cause problems during

the placing of the slices!

Clean the removable and non-removable parts according to the cleaning schedule.

Page 47

Cleaning

47

4.3 Cleaning Schedule

Work Steps Cleansers Procedures Cleaning Equipment Note

1 Preparatory

measures

Close the slicing

thickness control. Pull

out the mains plug.

2 Disassembly of

removable parts

See operating

instructions.

3 Rough manual

cleaning

Remove remaining food

with plastic spatula.

Plastic spatula; also

for the removable

parts.

Start directly.

4 Cleaning 2%

e.g. Henkel

“P3 sterile”

Goldschmidt

“Somplex detsan”

“Somplex F”

Pre-rinse thoroughly

with water (max. 40 °C),

wait approx. 20 min.

Brush, pan, cleaning

cloth, hand spraying

device

All detached and

fixed machine parts

4aDisinfection as

additional measure

e.g. Henkel P3

alcodes

or Goldschmidt

0.5-2% TEGO 2000

TEGO IMC

Spray manually.

Do not exceed the time

for allowing the product

to act as specified in its

data sheet.

Disposable cleaning

cloth, hand sprayer

Additional safety

distance when

spraying approx.

30 cm

4bAcid cleaning

additional measure

Max. 3%, e.g.

Henkel “P3-riskan”

Goldschmidt

“Somplex Schaum

sauer”

Foam up manually,

allow to act for max.

12 min

Brush

Hand sprayer

To remove lime scale

if necessary

Disposable cleaning

cloth

Rest of machine

Hand sprayer Detached parts

5 Rinse Tap water Max. temperature 50 °C

Water hose Detached parts

6 Check Look for visible dirt.

7 Dry Rub dry,

allow to dry in the air.

Disposable cleaning

cloth

Machine, detached

parts, separate where

possible

8 Care Oils for use in the

food industry with

H1 certification, e.g.

Henkel P3 oil

Apply by spraying or

rubbing.

Disposable cleaning

cloth, hand sprayer

Rinse all components

that have touched

food before you start

work.

9 Assembly In reverse order to

disassembly

(operating manual)

Personnel must have

clean and disinfected

hands.

10 Precautionary

measures

Cover machine if the surrounding area is to be cleaned with spraying devices or highpressure equipment to protect it from water

Page 48

Cleaning

48

4.3.1 Cleaning Procedure

Take appropriate action to prevent pollution to the environment when you use hand

sprayers.

The information refers to single-shift operation.

You must also observe the safety and product data sheets that were included with the

cleansers and disinfecting agents.

If you do not observe them you may damage the machine.

We will not accept any warranty claims if cleaning agents not approved by Graef are

used.

Never clean detachable parts in a dishwasher.

Assembling the removed machine parts:

Assemble all the removed parts in the reverse order after cleaning.

Check carefully that all parts are fitted and fixed correctly. Parts that have been

improperly fastened can become loose during operation and cause damage to the

machine, or, even worse, injure the operator.

Page 49

Cleaning

49

4.4 Assembly

Please observe the following during assembly!

When you mount the chain frame, make sure

x That is carefully attached at all three holding points.

x If necessary, turn the clutch hub (2) manually until the

coupling engages.

x When placing on the pressing roller swing it away from

the stop limit.

x Correct position 1

x Correct position 2

1

2

3

1

2

3

Page 50

Cleaning

50

x Correct position 3

Carriage:

x Insert the carriage bold in the bearing block and push the

carriage carefully to the working position.

CAUTION!

Press the carriage on the bearing block by hand and make

absolutely sure you tighten the star grip.

A loose carriage can cause injuries to the operator, damage

the machine and result in poor slicing performance.

CAUTION!

Tighten the star grip on the placing arm. A

loose arm can cause problems and

damage the machine.

x Slide the tray in recess side first (1) under the holding piece

as far as possible, then push it down onto the holding bolt.

CAUTION!

Ensure that the tray fits properly and

tightly to prevent it from falling down

during operation.

2

Page 51

Maintenance

51

5 Maintenance

5.1 Sharpening the Blade

WARNING!

Rotating blade can sever fingers! Only sharpen the blade with the sharpener

provided. The sharpener has been adjusted for this machine and must be used

for this machine only.

The machine number and the number on the sharpening device must be

identical.

The blade may only be sharpened by personnel who have been trained to do so.

5.1.1 Description of the Blade Sharpener

Adjusting wheel

Scale:

x 0 =attaching position

x 1 = sharpening position

x 2 = honing position

Blade sharpener housing

Protective cover

Clamp arms

Knurled screw

Honing stone

Sharpening stone

Blade sharpener mounting

Page 52

Maintenance

52

5.1.2 Preparing the Machine

x Thoroughly clean the machine and the blade.

x Remove the last slice clamp, the guide rail, the feed

carriage (VA 802 only), the blade cover plate, the beater

and the chain frame.

x Put the last slice clamp down on the carriage and move

this to right, as far away as possible from the blade.

x Push the carriage about 5 cm towards the blade.

x Turn the slice thickness control for the slice thickness to

the “S” marking for sharpening.

5.1.3 Sharpening the Blade

x Set the blade sharpener to position “0” using the

adjusting knob.

x Put the blade sharpener on the limit stop.

x Both clamp arms (1) must touch the stop edge at the top.

x Push the sharpener towards the blade until the bolt head

(2) touches the blade ring.

x Place the blade sharpener with the thumb wheel on the

limit stop.

! IMPORTANT!

The blade can only be sharpened accurately if the

sharpener is positioned exactly.

x Switch on the machine with the green On button.

x Turn the adjusting knob to the grinding position “1”.

x Grinding begins.

x The duration of grinding depends on the condition of the

blade.

2

1

1

approx.

5 cm

Page 53

Maintenance

53

x Grind until a slight cutting ridge is formed.

x Switch off the machine with the red Off button.

x Slide a sharpened pencil slowly to the cutting edge as

illustrated.

x Do you feel any resistance at the blade cutting edge?

That is the cutting ridge produced from sharpening.

x If no edge has been formed, repeat the steps described

above.

x If a cutting ridge has formed on the blade edge, turn the

adjusting knob to the deburring position 2.

x Allow the machine to run for a few revolutions

(2-3 seconds) until the ridge is removed.

x After deburring, switch off the machine with the red Off

button.

Taking off the blade sharpener:

x Turn the adjusting knob of the blade sharpener to

position “0”.

! IMPORTANT!

The blade sharpener may only be taken off in this

position. Otherwise the blade and the sharpener

could be damaged!

x Undo the knurled screw on the blade sharpener and

carefully lift it off.

x Turn the slice thickness control as far as it will go in a

clockwise direction.

x Clean the blade and the machine.

x Put the detached last slice clamp, guide rail, feed carriage

(VA 802 only), beater and chain frame back on the

machine.

Page 54

Maintenance

54

5.2 Changing the Blade

WARNING !

The blade is sharp! It can cause serious injury even when

it is not moving. The blade may only be replaced

by authorised GRAEF service personnel.

CAUTION!

The blade must be replaced:

when the distance between

the blade guard ring and the blade

is larger than 6 mm.

Page 55

Maintenance

55

5.3 Lubricating

Use only the GRAEF special lubricating oil with H1 certification that is included in

delivery.

Chain frame:

x 2-3 drops in each of the 8 tensioning roller bearings.

Linear guide rod:

x Lubricating interval:

As required, whenever the last slice clamp is difficult to

move.

Tray gear rack:

x Drip some lubricant onto the surface of the rack and rub

in with a cotton cloth

x Lubricating interval:

At least once a week

Page 56

Faults an Operating Errors

56

6 Faults and Operating Errors

CAUTION!

Switch off the machine immediately if it emits unusual noises, malfunctions or if

you suspect it could cause injuries.

Call customer service if you cannot solve the problem yourself.

Fault Cause Measure

Carriage stops during operation

x Carriage blocked, for

example, by bone.

x Switch off the machine and

pull out the mains plug. Pull

back the carriage Remove the

blockage.

Carriage cannot be taken off

x The carriage is not in the

initial (starting) position.

x Slicing thickness control not

below “0”.

x Bring the carriage to the

initial position.

x Turn the thickness control

below “0”.

Bad slicing, slices are frayed

x Blade is blunt. x Sharpen the blade.

Poor sharpening results

x You are using the wrong

blade sharpener.

x Grinding disks are greasy.

x Use the blade sharpener that

was supplied with the

machine. The correct blade

sharpener will have the same

serial number as the machine!

x Replace the grinding discs

with new original ones. Clean

the blade and machine

completely before you start

slicing.

Placing arm makes noises and /

or jams in the chains

x Star grip is loose.

x Chain frame is not properly in

place.

x Fingers are bent.

x Tighten the star grip.

x Check whether the chain

frame is properly seated in all

three holders.

x Carefully straighten the

fingers until they no longer

collide with the chains.

Blade cannot be ground

x The clearance between the

blade and the blade guard

ring is larger than 6 mm.

x Replace the blade.

The last slice clamp is difficult to

move

x The last slice clamp bar is dry

or dirty.

x Clean off residues, lubricate

with a few drops of oil and

distribute oil by moving the

pusher backwards and

forwards.

Page 57

Faults an Operating Errors

57

Fault Cause Measure

The slices are uneven

x The food is not held properly

in place by the food holding

bar.

x Chain frame is not properly in

place.

x The placing arm is not

properly screwed on.

x Use the guide rail.

x Check that the chain frame is

firmly in position.

x Tighten the star grip.

Placing program cannot be

changed

x Program (not 0000) selected. x Press the PLU button and then

the Reset button; “PLU 0000”

appears in the display.

Slices, of bacon for example, are

placed too closely together in

fanning mode

x Calibre mode is set to AUTO. x Switch to SEMI or HIGH mode.

Calibre recognition without

function

x Guide rail is not placed on

the carriage.

x Calibre mode is set to OFF.

x Mount the guide rail.

x Switch to AUTO, SEMI or HIGH

calibre mode.

Sliced product does not reach

the Chain and collects between

the pressing roller and the

scraper

x Product residue has

accumulated on the scraper,

preventing sliced material

from passing through.

x Take off the chain frame.

Clean the product residue

from the scraper. Check

whether the scraper touches

the blade.

7 Service

IMPORTANT!

Only use genuine GRAEF spare parts.

The use of other parts will invalidate the warranty (see also the declaration of

conformity)

Contact your GRAEF customer service If you require service or spare parts.

!

Loading...

Loading...