Page 1

Repair Instructions

XD40

XD50

XD40

™

and XD50

™

332203F

Hose Reels Repair

Instructions for repairing hose reels used in applications requiring long range dispense,

transfer or evacuation of motor oils, diesel fuels*, lubricants, water, waste oil and air.

Not for use with gasoline or other flammable fluids. Not approved for use in hazardous or

explosive atmosphere locations. For professional use only.

*less than 20% biofuel content

Models

(see page 3 for addition model information)

Spring Hose Reels

XD40 - Floor, Truck-bed or Overhead Mounted

XD50 - Floor or Truck-bed Mounted

Related Manual:

3A2990 - Installation and Operating Instructions

Important Safety Instructions

Read all warnings and instructions in this

manual and the XD40 and XD50 Operation

Manual. Save these instructions.

EN

Page 2

Table of Contents

Table of Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

XD40 Bare Reels . . . . . . . . . . . . . . . . . . . . . . . . 3

XD40 NPT, Reel with Hose - Air/Water . . . . . . . . 4

XD40 NPT, Reel with Hose - Oil . . . . . . . . . . . . . 4

XD40 NPT, Reel with Hose -

Waste Oil Evacuation . . . . . . . . . . . . . . . . . . 5

XD40 NPT, Reel with Hose - Diesel Fuel . . . . . . 5

XD40 NPT, Reel with Hose - Antifreeze . . . . . . . 5

XD50 Bare Reels . . . . . . . . . . . . . . . . . . . . . . . . 6

XD50 NPT, Reel with Hose - Air/Water . . . . . . . . 6

XD50 NPT, Reel with Hose - Oil . . . . . . . . . . . . . 6

XD50 NPT, Reel with Hose -

Waste Oil Evacuation . . . . . . . . . . . . . . . . . . 7

XD50 NPT, Reel with Hose - Diesel Fuel . . . . . . 7

XD50 NPT, Reel with Hose - Antifreeze . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Repair Information . . . . . . . . . . . . . . . . . 10

Bare Reels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hose Reel Disassembly . . . . . . . . . . . . . . . . . . . . 11

Hose Reel Reassembly . . . . . . . . . . . . . . . . . . . . . 19

Additional Repair and Replacement Instructions 27

Removing and Installing New Hose on Reel . . . 27

First Time Hose Installation . . . . . . . . . . . . . . . 30

Roller Guide Replacement . . . . . . . . . . . . . . . . 32

Latch Replacement . . . . . . . . . . . . . . . . . . . . . . 34

Adjusting Spring Tension . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 39

XD40/XD50 Parts Drawing . . . . . . . . . . . . . . . . . . 40

XD40/XD50 Parts List . . . . . . . . . . . . . . . . . . . . . . 41

Related Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 1: Spring Tension Pre-turns . . . . . . . . . . . . 47

Air / Water Models . . . . . . . . . . . . . . . . . . . . . . 47

Oil Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Waste Oil Evacuation Models . . . . . . . . . . . . . . 47

Fuel Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Graco 7-Year Hose Reel Warranty . . . . . . . . . . . . 48

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 48

2 332203F

Page 3

Models

Models

Understanding the Bare Reel Model Number

Bare reels are assigned a model number. This number identifies the frame size, port size, spring and pressure associated with

that reel. For example an XD4010DLP model is an XD Model hose reel, size 40 frame, 1 inch port, D spring, low pressure.

• XD Frame Size: 40 or 50

• Port Size: 10 = 1 inch / 15 = 1.5 inch

• Spring Designation: A, B, C or D

• Pressure: LP - Low Pressure applications such as Air/Water, Fuel, and Waste Oil Evacuation typically under 300 psi (2.1

MPa, 21 bar) / MP - Medium Pressure applications such as Oil Dispense typically under 2000 psi (13.8 MPa, 138 bar)

• Inlet Seal Material - F - Fluorocarbon/FKM for general reels / N - Nitrile/Buna-n for anti-freeze

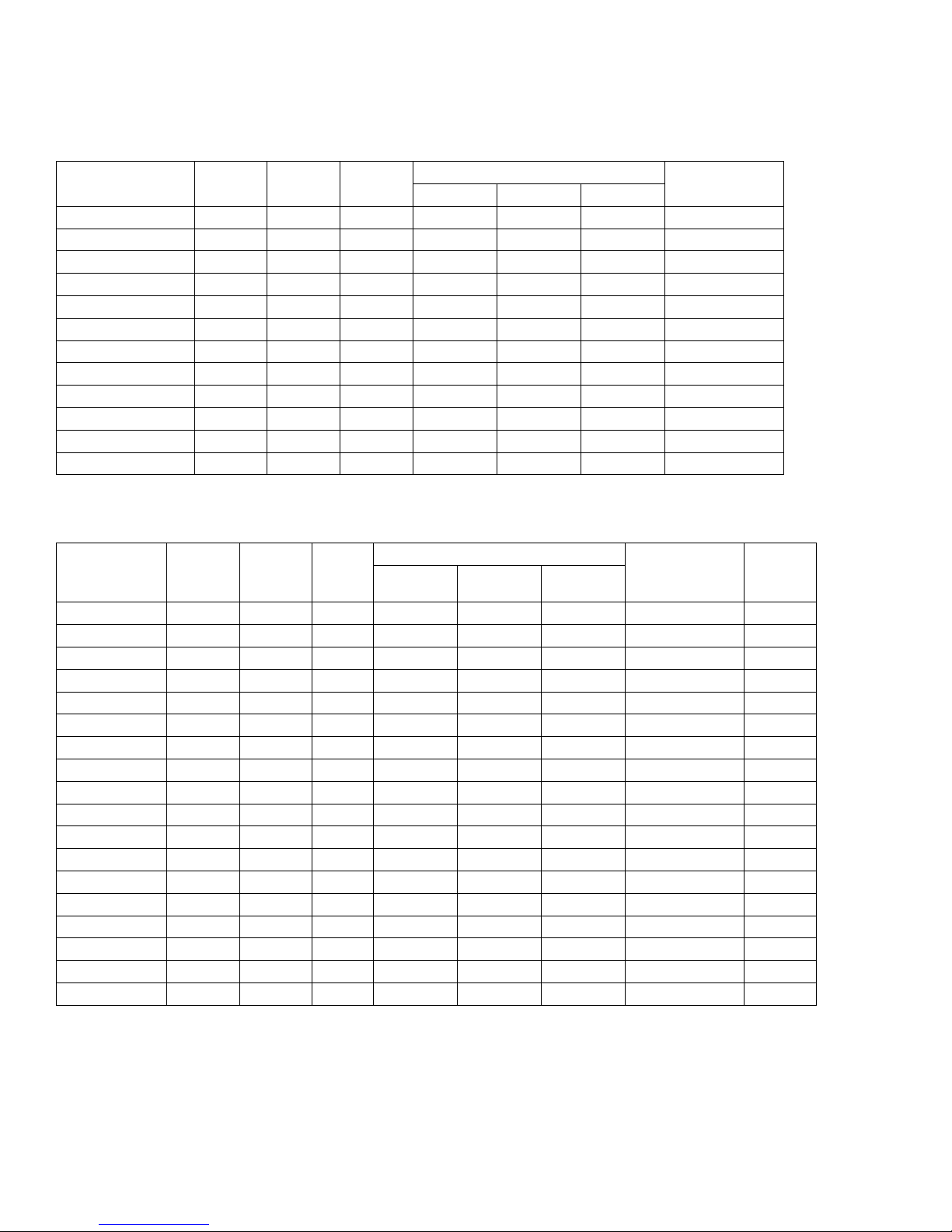

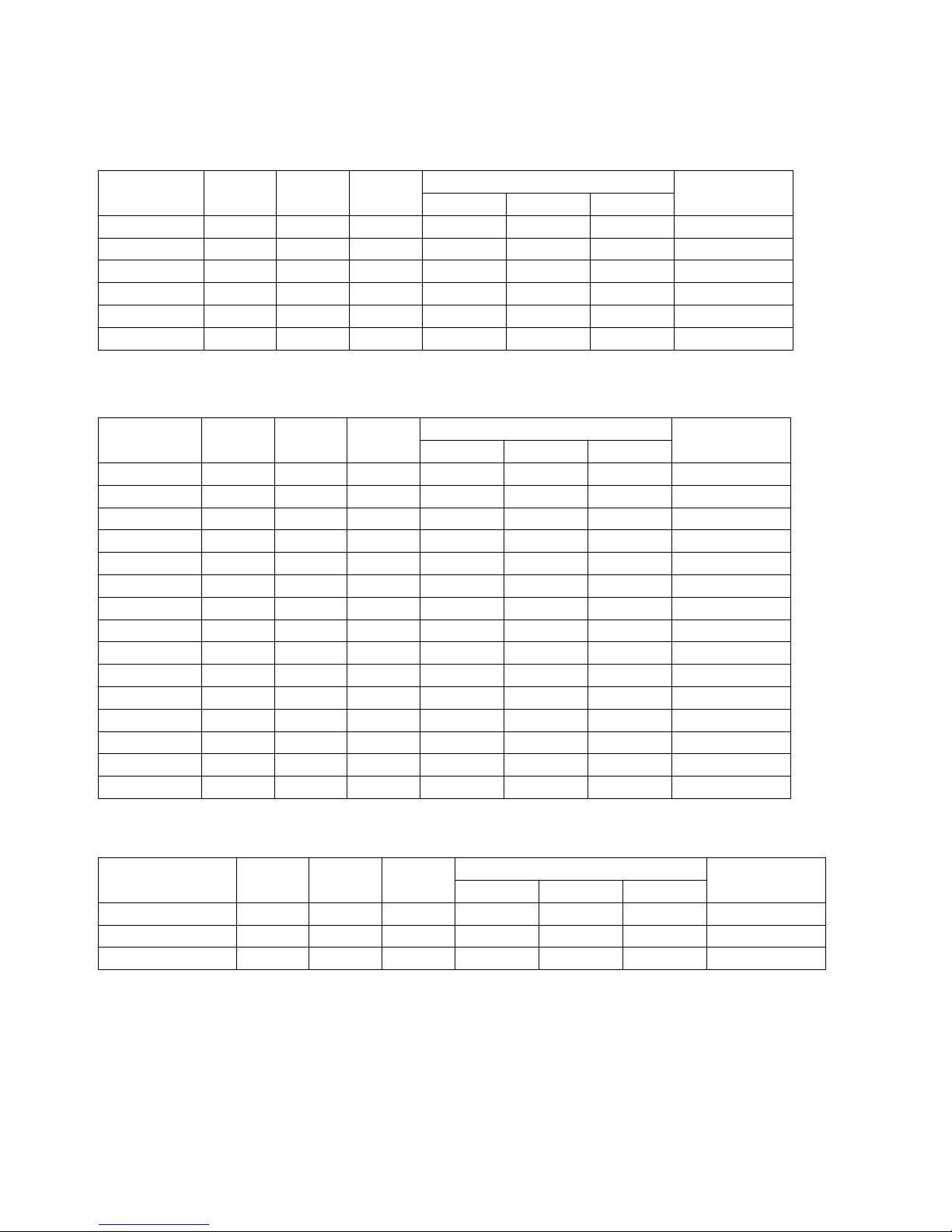

XD40 Bare Reels

Bare Reel Model

XD4010DLPF 24P313 24P364 24P407 Blue D 600 4.1 41

XD4010DLPF 24P315 24P366 24P408 Yellow D 600 4.1 41

XD4010DLPF 24P316 24P367 24P409 White D 600 4.1 41

XD4010CLPF 24P317 24P368 24P410 Blue C 600 4.1 41

XD4010CLPF 24P318 24P369 24P411 Yellow C 600 4.1 41

XD4010CLPF 24P319 24P370 24P412 White C 600 4.1 41

XD4010CMPF 24P320 24P371 24P413 Blue C 2000 13.8 138

XD4010CMPF 24P322 24P372 24P414 Yellow C 2000 13.8 138

XD4010CMPF 24P323 24P373 24P415 White C 2000 13.8 138

XD4010BMPF 24R854 24R864 24R867 Blue B 2000 13.8 138

XD4010BMPF 24R855 24R865 24R868 Yellow B 2000 13.8 138

XD4010BMPF 24R856 24R866 24R869 White B 2000 13.8 138

XD4010AMPF 24P324 24P374 24P416 Blue A 2000 13.8 138

XD4010AMPF 24P325 24P375 24P417 Yellow A 2000 13.8 138

XD4010AMPF 24P326 24P376 24P418 White A 2000 13.8 138

XD4010DLPN 26A140 NA NA Blue D 600 4.1 41

XD4010DLPN 26A141 NA NA Yellow D 600 4.1 41

XD4010DLPN 25A142 NA NA White D 600 4.1 41

NPT

Models

BSPP

Models

BSPT

Models

Color Spring

Maximum Working Pressure

PSI

MPa bar

332203F 3

Page 4

Models

XD40 NPT, Reel with Hose - Air/Water

Bare Reel Model Model Color Spring

XD4010DLPF 24P327 Blue D 300 2.1 21 1/2 inch x 100 ft.

XD4010DLPF 24P328 Yellow D 300 2.1 21 1/2 inch x 100 ft.

XD4010DLPF 24P329 White D 300 2.1 21 1/2 inch x 100 ft.

XD4010DLPF 24P330 Blue D 300 2.1 21 3/4 inch x 75 ft.

XD4010DLPF 24P331 Yellow D 300 2.1 21 3/4 inch x 75 ft.

XD4010DLPF 24P332 White D 300 2.1 21 3/4 inch x 75 ft.

XD4010CLPF 24P333 Blue C 300 2.1 21 3/4 inch x 100 ft.

XD4010CLPF 24P334 Yellow C 300 2.1 21 3/4 inch x 100 ft.

XD4010CLPF 24P335 White C 300 2.1 21 3/4 inch x 100 ft.

XD4010DLPF 24P336 Blue D 300 2.1 21 1 inch x 50 ft.

XD4010DLPF 24P337 Yellow D 300 2.1 21 1 inch x 50 ft.

XD4010DLPF 24P338 White D 300 2.1 21 1 inch x 50 ft.

PSI

MPa bar

Maximum Working Pressure

Hose Size

XD40 NPT, Reel with Hose - Oil

Bare Reel

Model

XD4010AMPF 24P339 Blue A 2000 13.8 138 1/2 inch x 100 ft.

XD4010AMPF 24P340 Yellow A 2000 13.8 138 1/2 inch x 100 ft.

XD4010AMPF 24P341 White A 2000 13.8 138 1/2 inch x 100 ft.

XD4010CMPF 24P342 Blue C 1530 10.5 105 3/4 inch x 75 ft. X

XD4010CMPF 24P343 Yellow C 1530 10.5 105 3/4 inch x 75 ft. X

XD4010CMPF 24P344 White C 1530 10.5 105 3/4 inch x 75 ft. X

XD4010BMPF 24R857 Blue B 1530 10.5 105 3/4 inch x 75 ft.

XD4010BMPF 24R859 Yellow B 1530 10.5 105 3/4 inch x 75 ft.

XD4010BMPF 24R860 White B 1530 10.5 105 3/4 inch x 75 ft.

XD4010AMPF 24P345 Blue A 1530 10.5 105 3/4 inch x 100 ft.

XD4010AMPF 24P346 Yellow A 1530 10.5 105 3/4 inch x 100 ft.

XD4010AMPF 24P347 White A 1530 10.5 105 3/4 inch x 100 ft.

XD4010CMPF 24P348 Blue C 1275 8.79 88 1 inch x 50 ft. X

XD4010CMPF 24P349 Yellow C 1275 8.79 88 1 inch x 50 ft. X

XD4010CMPF 24P350 White C 1275 8.79 88 1 inch x 50 ft. X

XD4010BMPF 24R861 Blue B 1275 8.79 88 1 inch x 50 ft.

XD4010BMPF 24R862 Yellow B 1275 8.79 88 1 inch x 50 ft.

XD4010BMPF 24R863 White B 1275 8.79 88 1 inch x 50 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

Truck

Mount

Only

4 332203F

Page 5

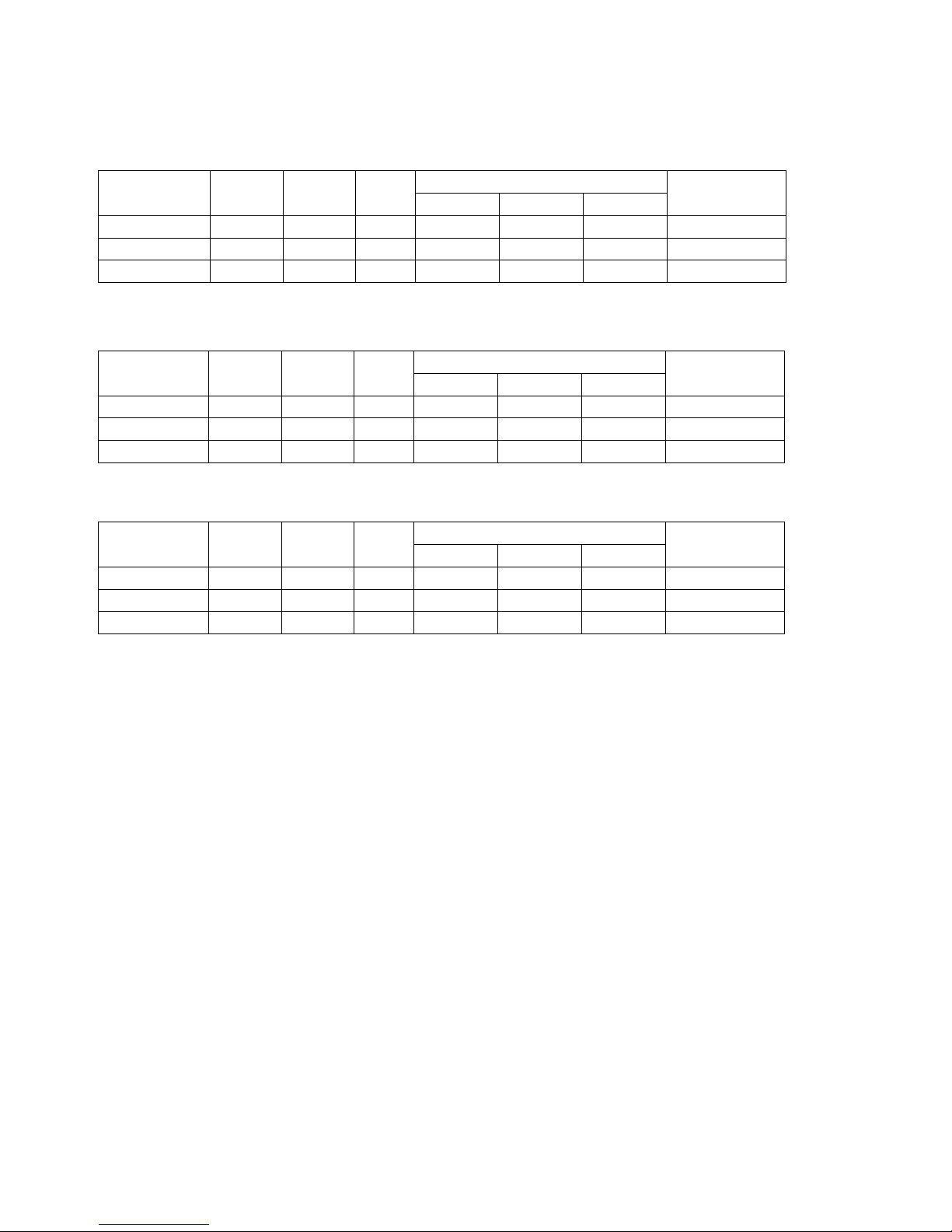

XD40 NPT, Reel with Hose - Waste Oil Evacuation

Models

Bare Reel

Model

XD4010CLPF 24P351 Blue C 250 1.7 17 1 inch x 50 ft.

XD4010CLPF 24P352 Yellow C 250 1.7 17 1 inch x 50 ft.

XD4010CLPF 24P353 White C 250 1.7 17 1 inch x 50 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

XD40 NPT, Reel with Hose - Diesel Fuel

Bare Reel

Model

XD4010CLPF 24P354 Blue C 250 1.7 17 1 inch x 50 ft.

XD4010CLPF 24P355 Yellow C 250 1.7 17 1 inch x 50 ft.

XD4010CLPF 24P356 White C 250 1.7 17 1 inch x 50 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

XD40 NPT, Reel with Hose - Antifreeze

Bare Reel

Model

XD4010DLPN 24P984 Blue D 300 2.1 21 3/4 inch x 100 ft.

XD4010DLPN 24P985 Yellow D 300 2.1 21 3/4 inch x 100 ft.

XD4010DLPN 24P986 White D 300 2.1 21 3/4 inch x 100 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

332203F 5

Page 6

Models

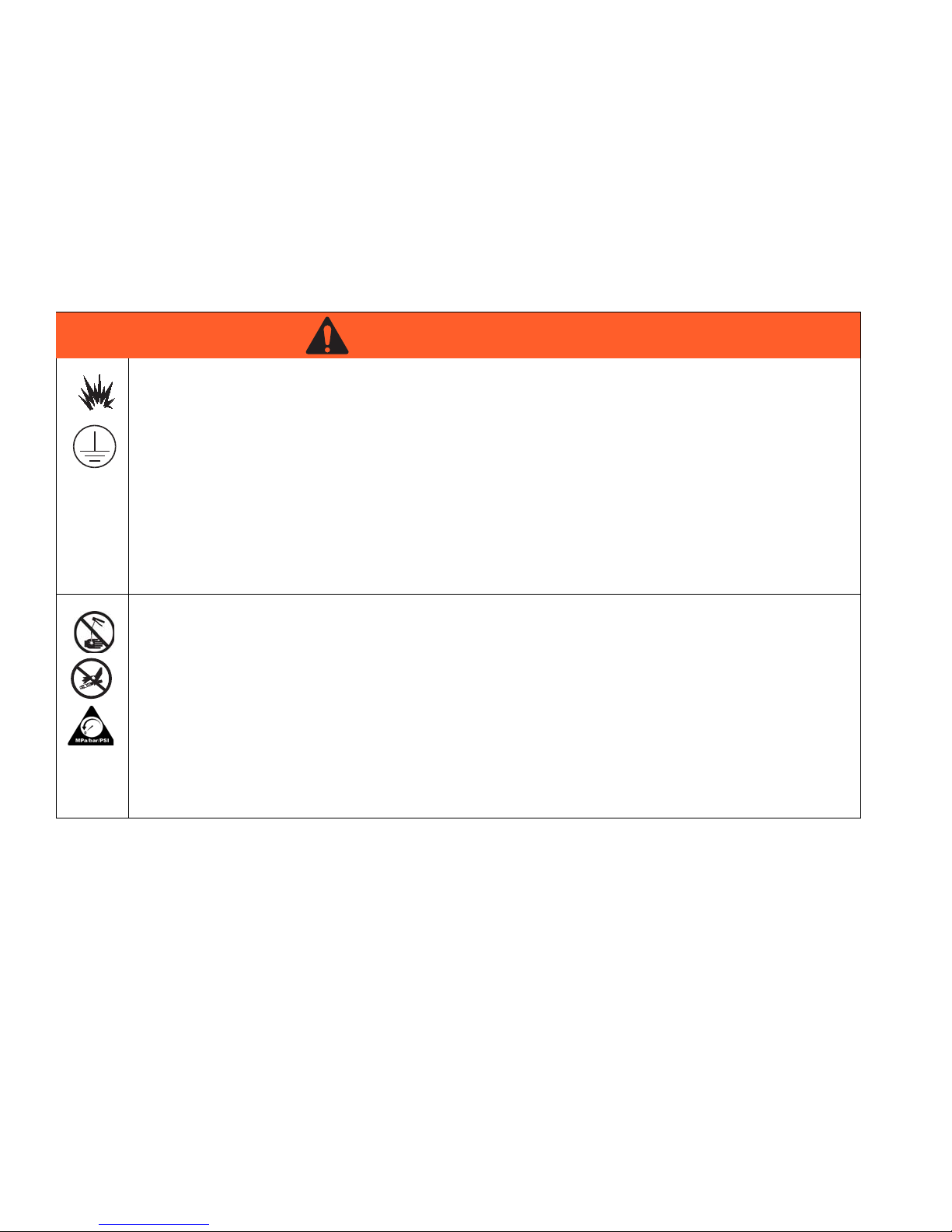

XD50 Bare Reels

Bare Reel

Model

XD5010ALPF 24P455 24P500 24P549 Blue A 1 600 4.1 41

XD5010ALPF 24P456 24P503 24P550 Yellow A 1 600 4.1 41

XD5010ALPF 24P457 24P504 24P551 White A 1 600 4.1 41

XD5015BLPF 24P461 24P508 24P555 Blue B 1.5 600 4.1 41

XD5015BLPF 24P462 24P509 24P556 Yellow B 1.5 600 4.1 41

XD5015BLPF 24P463 24P510 24P558 White B 1.5 600 4.1 41

XD5010BLPF 24P464 24P511 24P559 Blue B 1 600 4.1 41

XD5010BLPF 24P465 24P512 24P560 Yellow B 1 600 4.1 41

XD5010BLPF 24P466 24P513 24P561 White B 1 600 4.1 41

XD5015ALPF 24P467 24P514 24P563 Blue A 1.5 600 4.1 41

XD5015ALPF 24P468 24P515 24P564 Yellow A 1.5 600 4.1 41

XD5015ALPF 24P469 24P516 24P565 White A 1.5 600 4.1 41

XD5010AMPF 24P458 24P505 24P552 Blue A 1 2000 13.8 138

XD5010AMPF 24P459 24P506 24P553 Yellow A 1 2000 13.8 138

XD5010AMPF 24P460 24P507 24P554 White A 1 2000 13.8 138

XD5010ALPN 24A143 NA NA Blue A 1 600 4.1 41

XD5010ALPN 24A144 NA NA Yellow A 1 600 4.1 41

XD5010ALPN 24A145 NA NA White A 1 600 4.1 41

NPT

Models

BSPP

Models

BSPT

Models

Color Spring

Porting

Size

(Inches)

Maximum Working Pressure

PSI

MPa bar

XD50 NPT, Reel with Hose - Air/Water

Bare Reel

Model

XD5010ALPF 24P470 Blue A 300 2.1 21 1 inch x 75 ft.

XD5010ALPF 24P471 Yellow A 300 2.1 21 1 inch x 75 ft.

XD5010ALPF 24P472 White A 300 2.1 21 1 inch x 75 ft.

XD5010ALPF 24P473 Blue A 300 2.1 21 1 inch x 100 ft.

XD5010ALPF 24P474 Yellow A 300 2.1 21 1 inch x 100 ft.

XD5010ALPF 24P475 White A 300 2.1 21 1 inch x 100 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

XD50 NPT, Reel with Hose - Oil

Bare Reel

Model

XD5010AMPF 24P476 Blue A 1275 8.79 88 1 inch x 75 ft.

XD5010AMPF 24P477 Yellow A 1275 8.79 88 1 inch x 75 ft.

XD5010AMPF 24P478 White A 1275 8.79 88 1 inch x 75 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

6 332203F

Page 7

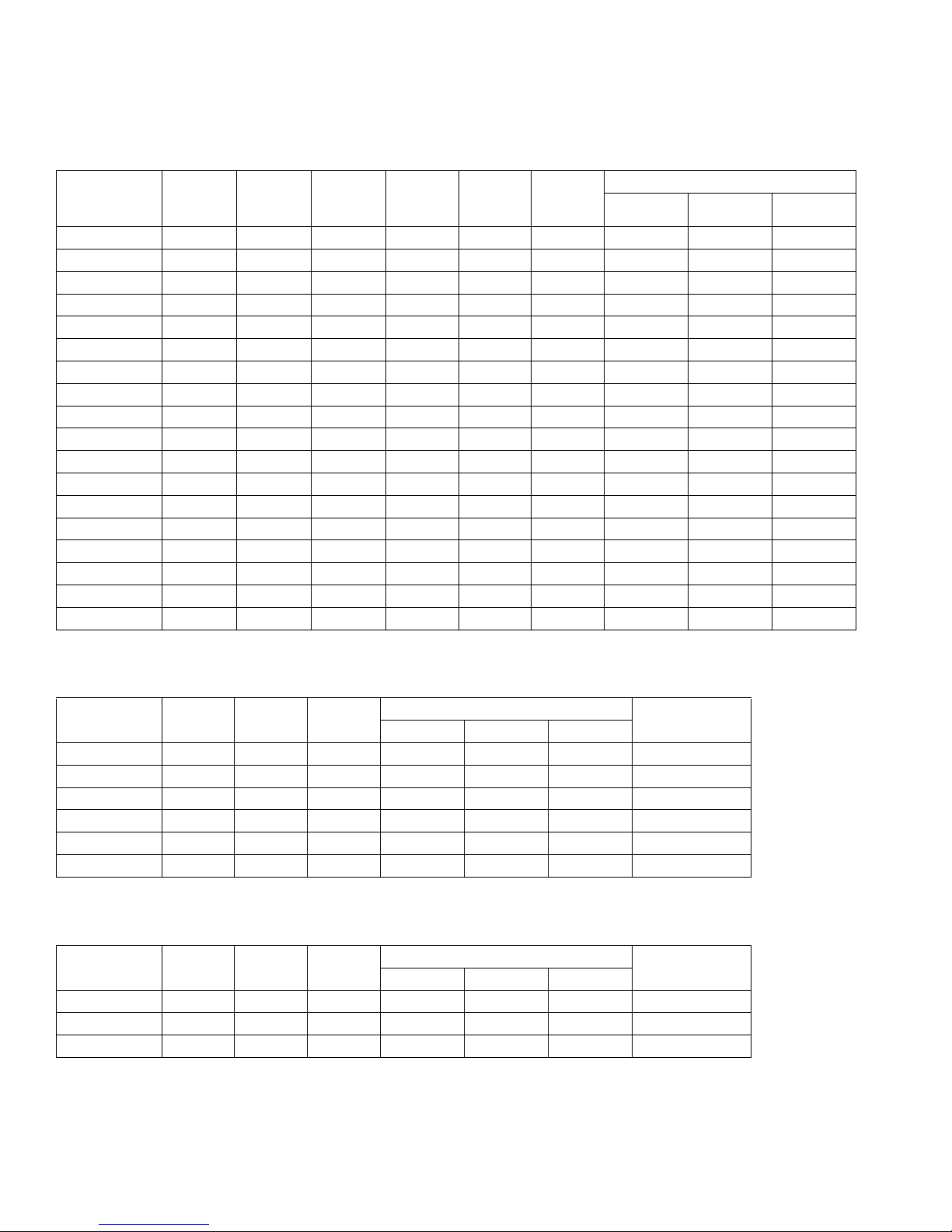

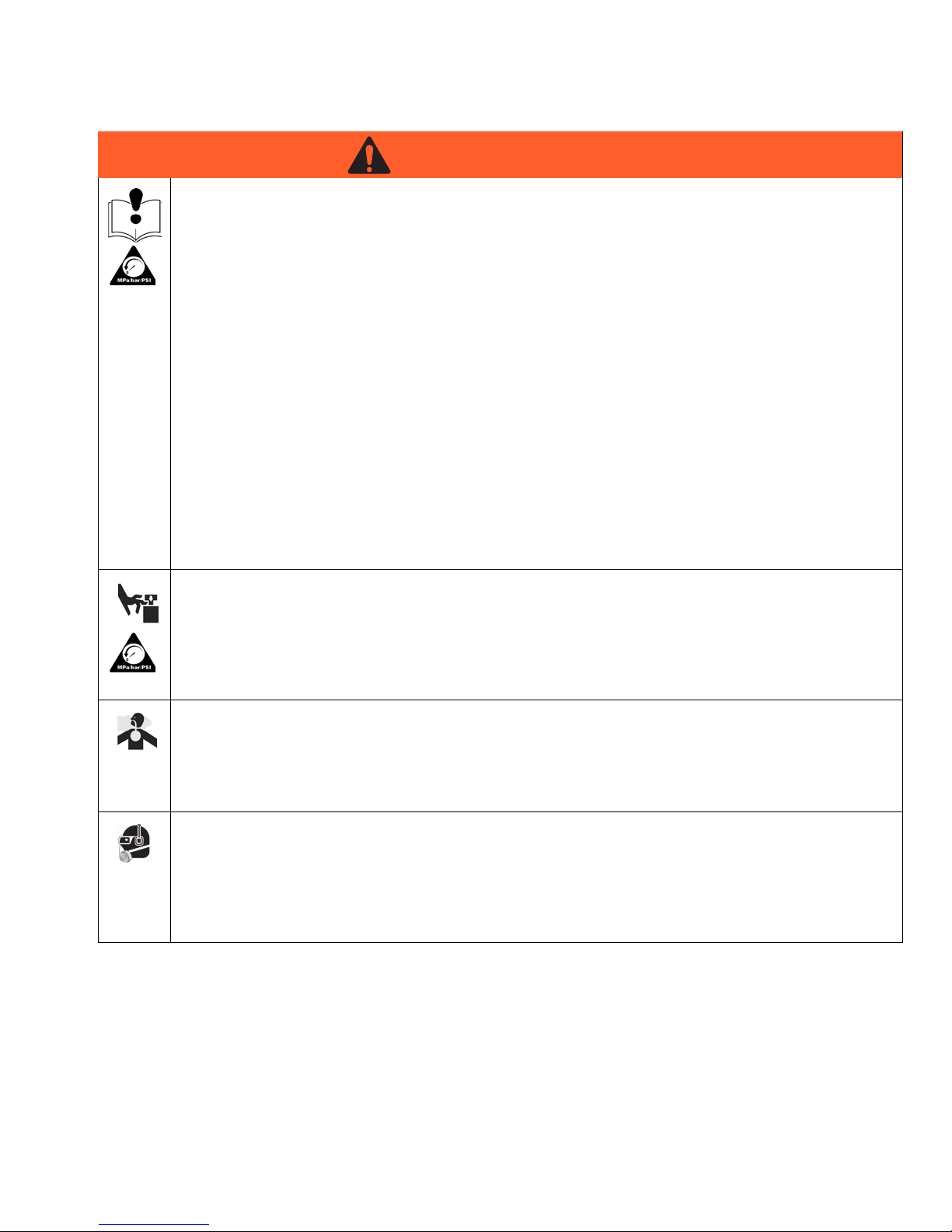

XD50 NPT, Reel with Hose - Waste Oil Evacuation

Models

Bare Reel

Model

XD5015BLPF 24P479 Blue B 200 1.4 14 1.25 inch x 35 ft.

XD5015BLPF 24P480 Yellow B 200 1.4 14 1.25 inch x 35 ft.

XD5015BLPF 24P481 White B 200 1.4 14 1.25 inch x 35 ft.

XD5015BLPF 24P482 Blue B 200 1.4 14 1.25 inch x 50 ft.

XD5015BLPF 24P483 Yellow B 200 1.4 14 1.25 inch x 50 ft.

XD5015BLPF 24P484 White B 200 1.4 14 1.25 inch x 50 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

XD50 NPT, Reel with Hose - Diesel Fuel

Bare Reel

Model

XD5010BLPF 24P485 Blue B 250 1.7 17 1 inch x 75 ft.

XD5010BLPF 24P486 Yellow B 250 1.7 17 1 inch x 75 ft.

XD5010BLPF 24P487 White B 250 1.7 17 1 inch x 75 ft.

XD5010ALPF 24P488 Blue A 250 1.7 17 1 inch x 100 ft.

XD5010ALPF 24P489 Yellow A 250 1.7 17 1 inch x 100 ft.

XD5010ALPF 24P490 White A 250 1.7 17 1 inch x 100 ft.

XD5015BLPF 24P491 Blue B 250 1.7 17 1.25 inch x 35 ft.

XD5015BLPF 24P492 Yellow B 250 1.7 17 1.25 inch x 35 ft.

XD5015BLPF 24P493 White B 250 1.7 17 1.25 inch x 35 ft.

XD5015BLPF 24P494 Blue B 250 1.7 17 1.25 inch x 50 ft.

XD5015BLPF 24P495 Yellow B 250 1.7 17 1.25 inch x 50 ft.

XD5015BLPF 24P496 White B 250 1.7 17 1.25 inch x 50 ft.

XD5015ALPF 24P497 Blue A 150 1.0 10 1.5 inch x 50 ft.

XD5015ALPF 24P498 Yellow A 150 1.0 10 1.5 inch x 50 ft.

XD5015ALPF 24P499 White A 150 1.0 10 1.5 inch x 50 ft.

Model Color Spring

Maximum Working Pressure

PSI

MPa bar

Hose Size

XD50 NPT, Reel with Hose - Antifreeze

Bare Reel Model Model Color Spring

XD5010ALPN 24P987 Blue A 300 2.1 21 1 inch x 100 ft.

XD5010ALPN 24P988 Yellow A 300 2.1 21 1 inch x 100 ft.

XD5010ALPN 24P989 White A 300 2.1 21 1 inch x 100 ft.

332203F 7

Maximum Working Pressure

PSI

MPa bar

Hose Size

Page 8

Warnings

WARNING

WARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Only use hoses that are compatible with the fluid you are dispensing.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

+

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

8 332203F

Page 9

Warnings

WARNING

WARNINGWARNING

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

332203F 9

Page 10

General Repair Information

General Repair

Information

• Always use all the new parts included in repair kit.

Do not reuse old parts.

• Unless otherwise indicated, reference numbers

used in the following instructions refer to the Parts

Drawing on page 40 and the Parts List beginning on

page 40.

• See Related Kits (page 43) or contact Graco Customer Service to identify the kit needed for your

repair.

• All instructions assume the hose reel has been

installed and is in service.

Bare Reels

Instructions for bare reels are included in the XD40 and

XD50 Hose Reels Installation and Operation instruction

manual provided with your hose reel and on Graco.com.

Grounding

The equipment must be bonded (grounded) to the

truck. Grounding reduces the risk of static shock

due to static build up on the equipment. Refer to

your pump instruction manual for grounding

instructions.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

1. Turn off power supply to fluid pump.

2. Isolate the supply pump fluid supply line.

3. Open the dispensing valve until pressure is fully

relieved.

If you suspect the dispensing valve or extension is

clogged or that pressure has not been fully relieved after

following the steps above, VERY SLOWLY loosen

coupler or hose end coupling to relieve pressure

gradually, then loosen completely. Clear the obstruction.

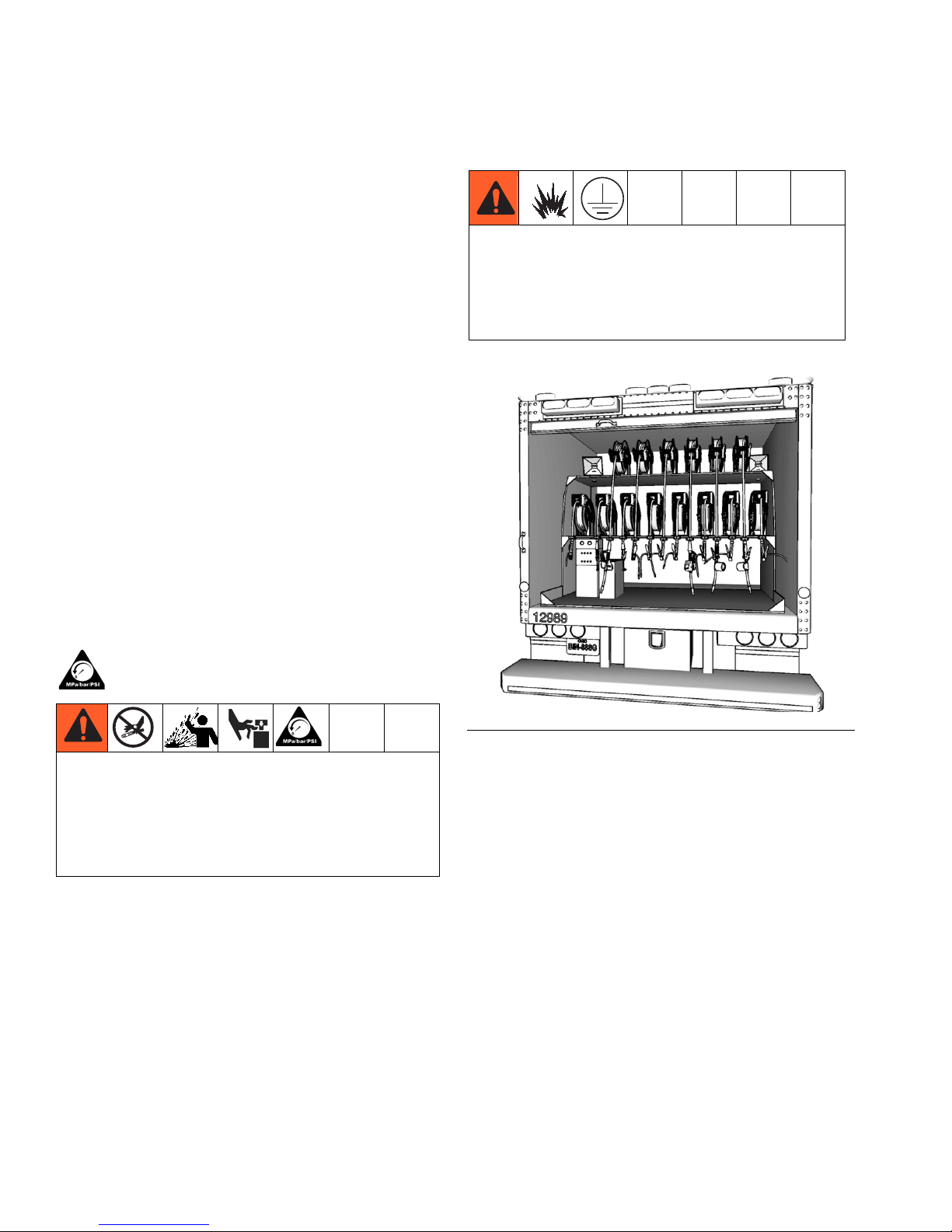

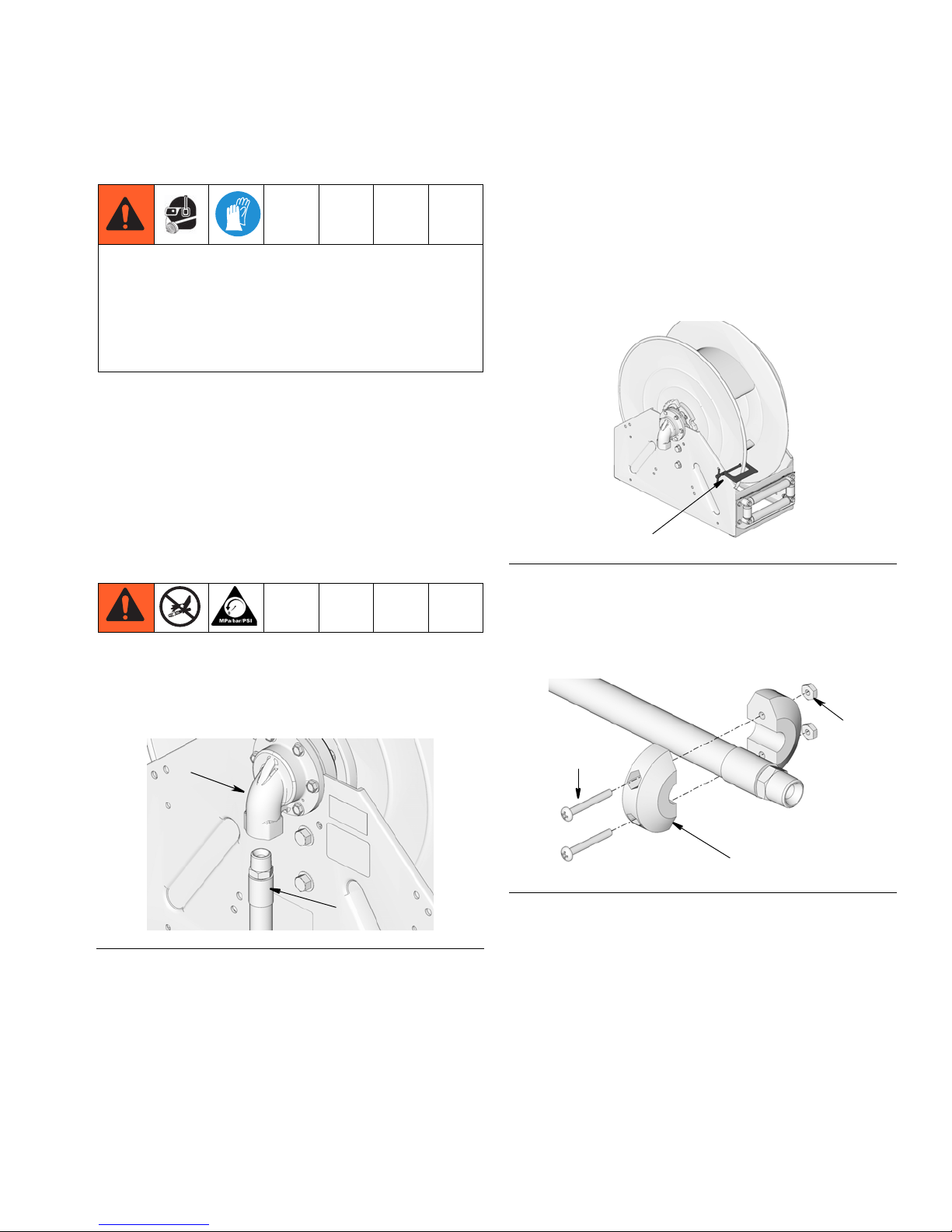

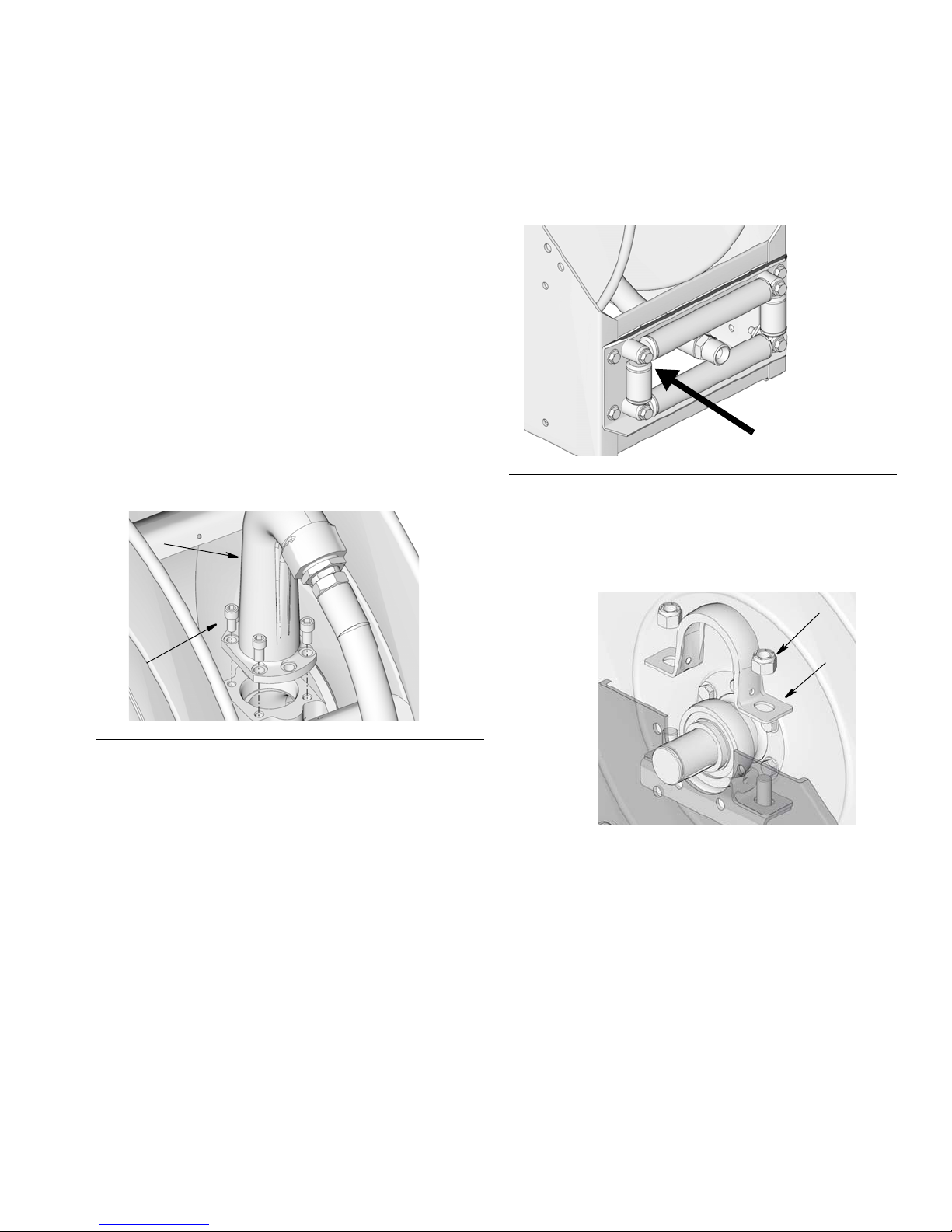

FIG. 1

10 332203F

Page 11

Hose Reel Disassembly

6

a

A

45

46

47

• Always wear heavy, non-slippery gloves to protect

your hands from being cut on the hose reel.

• Never allow the reel to spin freely. Doing so

causes the spool to spin out of control, which

could cause serious injury if you are hit by the

hose or dispense valve.

NOTE:

• Throughout these instructions the inlet-side refers to

the side of the spool the fluid inlet (6) is installed.

The spring-side refers to the side of the spool the

spring (10) is installed.

Hose Reel Disassembly

4. Engage latch.

Securely attach a c-clamp (A) to the reel spool abutting frame, as shown in F

reel from unintentionally becoming unlatched and

spinning freely.

IG. 3, to help prevent the

• Additional procedures are provided at the end of the

Hose Reel Disassembly section of this manual.

1. Relieve pressure, page 10.

2. Disconnect inlet hose (a) from inlet (6).

FIG. 2

FIG. 3

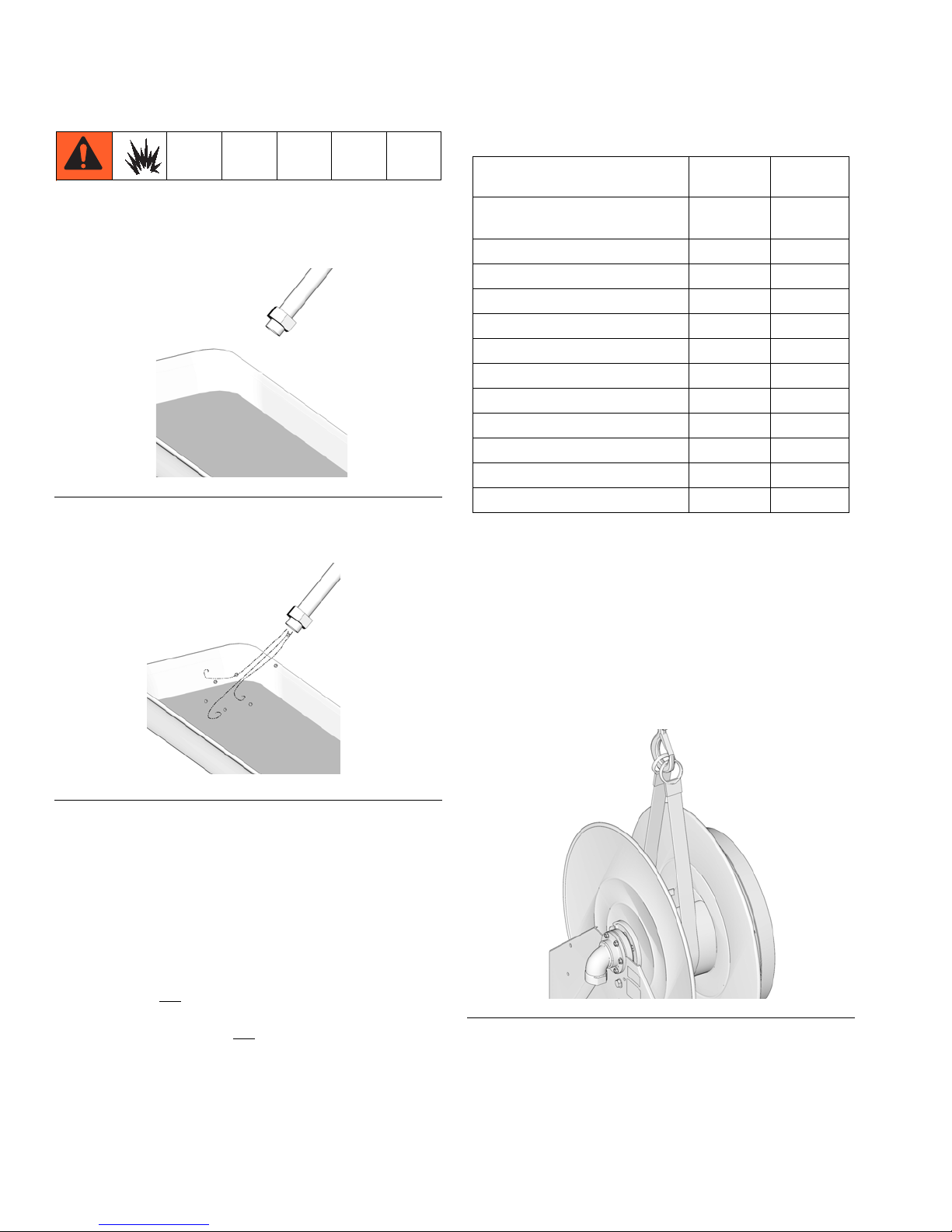

5. Remove dispense valve and ball stop.

To remove ball stop: remove nuts (47), screws (46) and

ball stop (45) from end of hose (F

FIG. 4

If you are only replacing the ball stop, stop disassembly instructions here.

IG. 4).

3. Pull out enough hose to perform flushing procedure (Step 7, page 12).

332203F 11

Ball Stop Kits: 218341, 222225, 237872, 24R060,

24R061 are available from Graco. Ball stop reassembly instructions are provided in Step 14, page 26.

6. If you are not replacing the ball stop, set these

pieces aside to use for reassembly.

Page 12

Hose Reel Disassembly

Procedure Table

7. Flush fluid from reel and hose.

a. Place end of hose in a waste container.

FIG. 5

b. Blow out entire lubricant supply line with air.

Procedure

Remove dispense valve and ball

stop

Add/Remove spring tension X

Remove /Replace spring canister X

Remove/Replace outlet and seals X

Remove/Replace inlet and seals X

Remove/Replace bearings X

Remove/Replace ratchet X

Remove spool from frame X

Remove shaft from spool X

Remove/Replace hose X

Replacing roller guide X

Replace latch X

Un-install

Reel

Reel

Installed

X

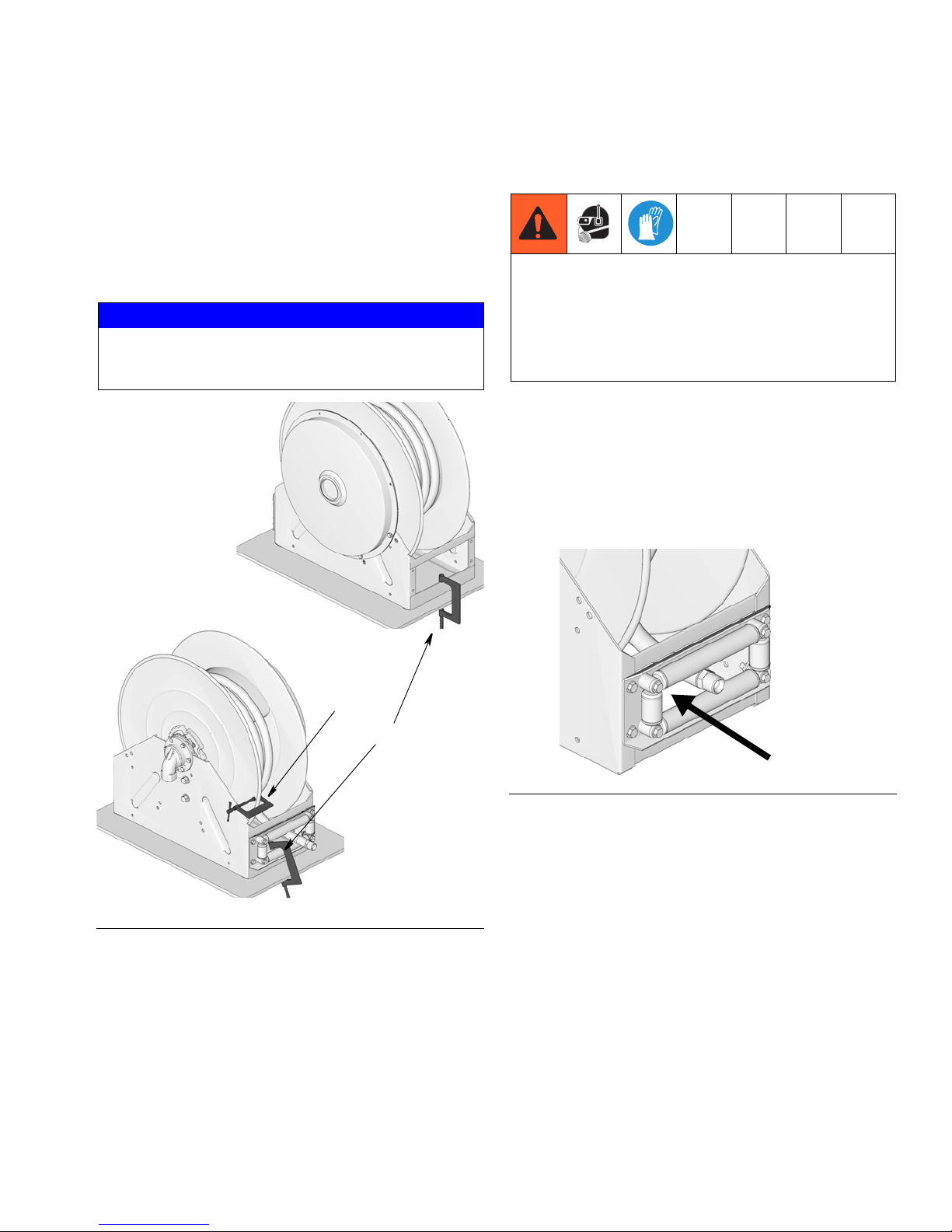

a. Unbolt reel and remove it from mounting loca-

tion.

NOTE: For overhead installations always use a hoist or

other suitable lifting device to raise or lower hose reel

position.

FIG. 6

c. Cap end of hose to prevent fluid spills.

8. Remove Hose Reel From Service.

The hose reel must be taken out of service to perform

some of the repair and service procedures described in

this manual.

Refer the following Procedures Table to identify which

procedures do not

service before you perform the repair or maintenance

procedure and those that do

taken out of service.

For procedures that do not require the hose reel is taken

out of service, skip Step 8a - b and continue hose reel

disassembly instructions with Step 9, page 13.

require the hose reel be taken out of

require the hose reel be

Secure a lifting strap around spool as shown in F

IG. 7.

See Technical Data (page 44) for hose reel weights.

FIG. 7

12 332203F

Page 13

Hose Reel Disassembly

B

A

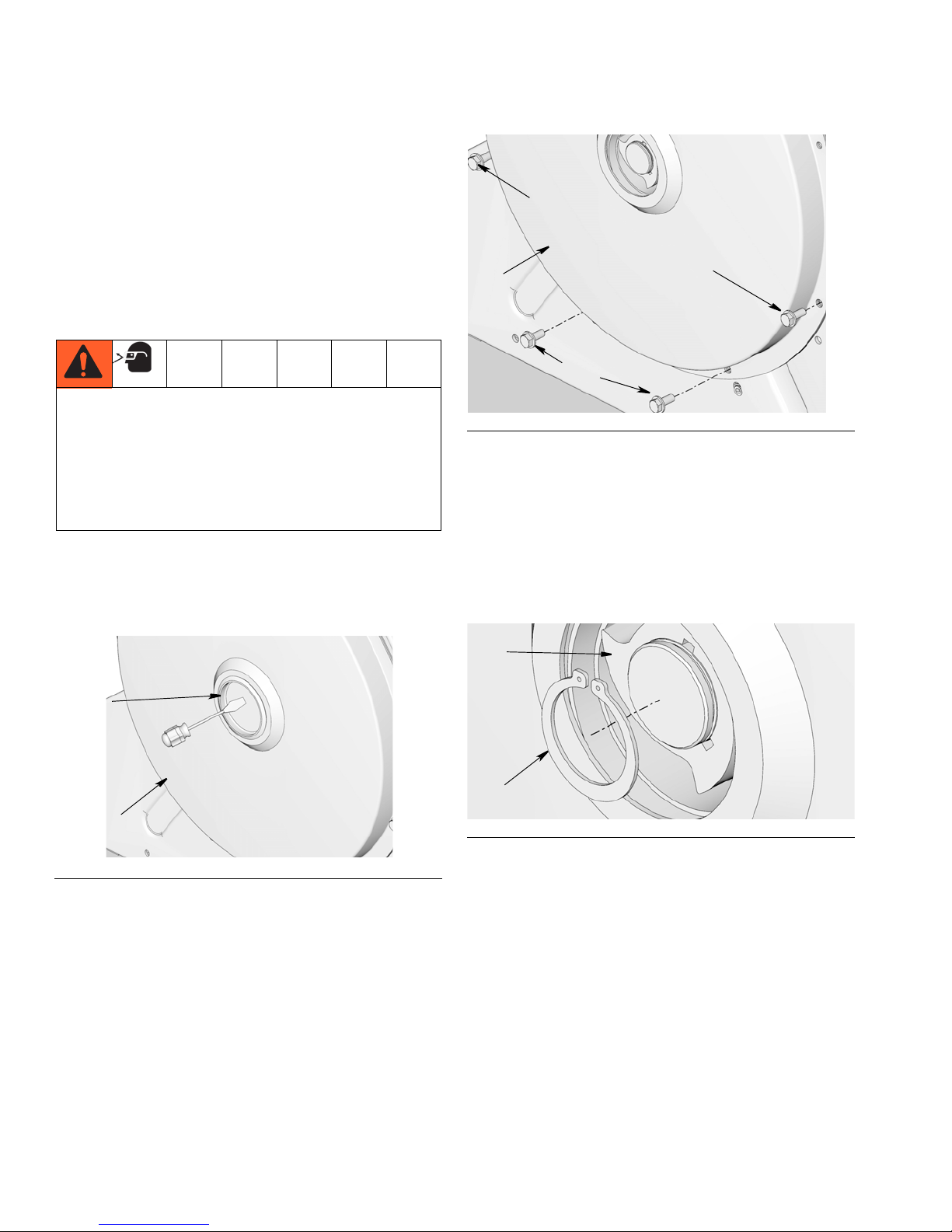

b. Use 2, large c-clamps (B) to secure the hose

reel to a flat surface (F

IG. 8).

NOTE: Graco recommends placing a rag over

the bottom roller and the back frame to protect

these surfaces from damage when the c-clamps

are tightened down.

NOTICE

The front c-clamp should only be tightened enough to

prevent the reel from moving. Overtightening this clamp

could damage the bottom roller.

9. Unwind reel to remove spring tension

before beginning disassembly.

• Always wear heavy, non-slippery gloves to protect

your hands from being cut on the hose reel.

• Never allow the reel to spin freely. Doing so

causes the spool to spin out of control, which

could cause serious injury if you are hit by the

hose or dispense valve.

a. Verify the ratchet and latch are still engaged and

the c-clamp is still installed.

b. Feed the loose end of hose through the hose

rollers and manually wrap hose and secure the

hose to reel spool (F

IG. 9).

FIG. 8

332203F 13

FIG. 9

c. Place a piece of tape on the side of reel flange

as a visual reference point for counting reel

rotations.

d. Remove c-clamp (A).

e. Rotate spool in the tightening direction to disen-

gage latch.

f. Use your hands to unwind reel by rotating the

spool in the opposite direction turned to add

spring tension, until it the reel reaches a free

state.

NOTE: Count the number of turns while unwinding the

spool and record the number for use when tensioning

the spring later.

Page 14

Hose Reel Disassembly

32

10

9a/9b

10

9c

9d

14

13

10.Remove spring canister from reel.

NOTE: The power spring typically doesn’t need to be

replaced unless it is broken. Verify the spring is broken

by confirming the absence of any spring tension. If there

is still tension on the spring and you have determined it

is not broken, the spring canister can be reused for reassembly.

The hose reel MUST be taken out of service for this

procedure.

HOSE REEL SPRING HAZARD

Do not attempt to service the spring inside of the

spring canister. It is under extreme tension, even if

the spring is broken, and could be propelled out of

the opened canister and cause serious injury. The

only service you should perform on the reel spring is

replacement of the spring canister.

a. Insert a flat screwdriver blade into the plastic

end cap (32) and pry it off the spring canister

(10) (F

reused.

IG. 10). Discard end cap, it cannot be

FIG. 11

c. Remove the spring canister (10) from the spool.

If you are not replacing the canister, lift canister

slightly to clear hub (13) and set canister aside

for reassembly. If you are replacing the spring

canister, discard canister.

d. Use a snap ring pliers to remove snap ring (14)

(F

IG. 12).

FIG. 10

b. Remove all bolts (9) from the spring canister

(10).

NOTE: Remove the bottom two bolts (9a and

9b) first. Then use your free hand to support the

spring while removing the other two bolts 9c

and 9d (F

IG. 11).

14 332203F

FIG. 12

e. Remove hub (13) and key (12) (F

IG. 12).

If you are only replacing the Power Spring, stop disassembly instructions here.

Power Spring Kits: 24R062, 24R063, 24R064, 24R065

are available from Graco. Power Spring reassembly

instructions begin with Step 11 page 23.

11. If you are not replacing the power spring, set the

spring canister aside to use for reassembly.

Page 15

Hose Reel Disassembly

30

37

38

7

12.Unwind reel to remove hose from spool.

NOTE:

• Because the spring is no longer installed on the

reel, the hose should pull off the reel very easily.

• In some procedures you do not have to remove the

spring before taking the hose off the reel. Hose

removal instructions when the spring is installed on

the reel are provided on page 27.

13. Remove bolts (37) and outlet (30) from spool (F

13).

NOTE:

• The hose does not have to be removed from the

outlet unless your are replacing the hose. Hose

replacement instructions are provided in

Removing and Installing New Hose on Reel on

page 27.

IG.

• The outlet (30) will not fit through the roller

guides. Pull the dispense end of the hose

through the rollers as shown in F

IG. 14 to

remove hose from the reel.

FIG. 14

14.Remove spring side bearing retainer (7),

spacers (15) and bearing (8).

a. Remove nuts (38) (FIG. 15).

FIG. 13

FIG. 15

b. Insert a flat blade screw driver under the

retainer (7) to pry it up and remove it (F

IG. 15).

c. Remove spacers (15) and bearing (8).

15. If you are not replacing these parts, set them aside

for use for reassembly.

332203F 15

Page 16

Hose Reel Disassembly

6

4

36

2

1

41

a

42

16.Remove inlet (6) .

NOTE: Notice the position of the inlet to ensure correct

orientation of this part for reassembly.

a. Medium Pressure Models ONLY: On the inlet

side, remove bolts (4), inlet (6) and shim (36)

(F

IG. 16).

NOTE: Do not lose the shim (36). You will need

it for reassembly.

19. Lay spool (2) on it’s side on a clean, sturdy work surface.

20.Remove Inlet Side Bearings.

NOTE: Separate instructions are provided for Medium

Pressure Hose Reels and Low Pressure Hose Reels

(depending on your hose reel model). Medium Pressure

Hose Reel instructions begin below, Low Pressure

instructions begin on page 17.

Medium Pressure Hose Reels Inlet Side Bearing

Removal

a. Use a snap ring pliers to remove snap ring (41)

(F

IG. 18).

NOTICE

Be careful not to scratch or score the surface of the (a)

when using the snap ring pliers to remove the snap ring

(41). Damage to this surface could result in fluid leakage. Protect the surface by wrapping it with black electric tape.

FIG. 16

If you are only replacing the Inlet and/or Inlet Seals,

stop disassembly instructions here.

Inlet Kits: 24R067, 24R068, 24R074, 24R075, 24R677,

and 24R678 are available from Graco. Inlet reassembly instructions begin with Step 9 page 23.

17. If you are not replacing these parts, set them aside

for use for reassembly.

18. Lift up spool (2) to remove it from base (1) (F

IG. 17).

FIG. 18

b. Use a spanner wrench to remove bearing

retainer (42) nut. Once it is loose you can use

your hand to unscrew and remove it (F

IG. 19).

FIG. 17

16 332203F

FIG. 19

Page 17

c. Remove bearing retainer (5).

42

35

5

41

a

49

31

4

NOTE: Be careful when you remove the bearing retainer

(5) that the bearing balls (35) do not fall out (F

IG. 20).

FIG. 20

Hose Reel Disassembly

FIG. 21

b. Slide bearing seal and retainer assembly (49)

off shaft (F

IG. 22).

If you are only replacing the Medium Pressure Bearing, stop disassembly instructions here.

Medium Pressure Bearing Kit: 24R071 is available

from Graco. Reassembly instructions begin with

Step 5b page 21.

d. If you are not replacing the Medium Pressure

bearing, set these parts aside to use for reassembly.

Low Pressure Hose Reels Inlet Side Bearing

Removal

a. Use a snap ring pliers to remove snap ring (41)

(F

IG. 21).

NOTICE

Be careful not to scratch or score the surface of the (a)

when using the snap ring pliers to remove the snap ring

(41). Damage to this surface could result in fluid leakage. Protect the surface by wrapping it with black electric tape.

FIG. 22

If you are only replacing the Low Pressure Bearing,

stop disassembly instructions here.

Low Pressure Bearing Kit: 24R070 is available from

Graco. Reassembly instructions begin with Step 5b

page 21.

c. If you are not replacing the low pressure bear-

ing, set these parts aside to use for reassembly.

21.Remove bolts (4) holding ratchet (31) to

spool (F

IG. 23).

332203F 17

FIG. 23

Page 18

Hose Reel Disassembly

a

4

3

2

11

2

9

NOTE: Place a piece of tape as a marker at the

location of the non-threaded hole (a) that does not

have a screw, located on the inlet side of the spool,

to ensure the inlet is reinstalled on the correct side

and in the correct position during reassembly.

FIG. 24

If you are only replacing the Ratchet, stop disassembly instructions here.

Ratchet Kit 24R338 is available from Graco. If you

are only replacing the Ratchet, stop disassembly

instructions here. Reassembly instructions are provided in Step 2, page 20.

If you are not replacing the ratchet, set these parts aside

to use for reassembly.

22.Remove Swivel (3) from spool.

Low Pressure Spring Swivel Replacement Kit

24R336 and Medium Spring Swivel Replacement Kit

24R337 are available from Graco. See Parts page 40,

for additional information about ordering these kits.

Reassembly instructions are provided in Step 1,

page 19.

23.Remove Shaft (11) from spool.

FIG. 26

e. Remove bolts (9) holding shaft (11) (spring

side) to the spool and remove shaft from inside

of spool.

d. Remove swivel (3) from inside of spool (2) (FIG.

25).

FIG. 25

18 332203F

C and D Spring Shaft Replacement Kit 24R953 and A

and B Spring Shaft Replacement Kit 24R954 are

available from Graco. See Parts page 40, for additional information about ordering these kits. Reassembly instructions are provided in Step 3, page 20.

Page 19

Hose Reel Reassembly

3

Ref. B

Top View

Section View A-A, Showing Outlet Installed Correctly

3

AA

Ref B

Ref. C

3

Top View

Correctly Installed Swivel (3) and Outlet

Incorrectly Installed Swivel (3) On the

3a

Wrong Side of the Spool (2)

a

4

Hose Reel Reassembly

FIG. 27

1. Install swivel (3) inside spool on the

inlet side.

NOTE: The swivel (3) must be installed on the correct side of the spool (2) and oriented correctly

inside the spool to ensure correct hose reel operation.

a. Slide the swivel through the hole in the center of

the spool and rotate the swivel until flat surface

(3a) is as parallel as possible to the floor.

b. Temporarily install one bolt (4) through a hole to

hold the swivel in the installed position (F

c. Rotate the spool (2) until the flat surface (3a) of

the swivel is parallel to the floor or table top and

matches F

Swivel and Outlet illustration. This is how your

swivel should look inside the spool when it is

correctly installed.

IG. 27, Top View, Correctly Installed

IG. 28).

d. Mark the position of the missing threaded screw

hole (a) (F

ence for lining up the ratchet (31) for installation

in Step 2, page 20.

Notice the location of swivel (3) in Ref. B in the

Correctly Installed Swivel and Outlet illustration

(F

IG. 27). This is the correct swivel (3) installa-

tion position.

Ref. C shown in the Incorrectly Installed Swivel

On the Wrong Side of the Spool illustration (F

27) shows the appearance of the swivel (3)

inside the spool when it is incorrectly installed.

IG. 28) on the swivel to use as a refer-

IG.

FIG. 28

332203F 19

Page 20

Hose Reel Reassembly

31

3

31

4

11

2

9

Refer to these two figures to verify swivel (3) is

properly oriented and installed on the correct

side of the spool (2).

NOTE: Always compare your swivel installation

to the illustrations in F

IG. 27 before permanently

installing the ratchet (31) and bolts (4). When

the swivel (3) is correctly installed in the correct

side of the spool, the swivel orientation will

EXACTLY match the Top View, Correctly

Installed Swivel and Outlet illustration as shown

with the swivel facing UP.

If the swivel (3) is incorrectly installed in the

spool (3) the reel will not function properly.

2. Install Ratchet.

a. Slide ratchet (31) over swivel (3) (FIG. 29).

NOTE: When the ratchet is positioned correctly,

all 5 bolt holes will be accessible. If you do not

have 5 holes available to accommodate all 5

bolts, rotate the ratchet until all 5 holes are

open.

b. Install bolts (4) to secure ratchet (31) to spool

(F

IG. 30). Before tightening bolts, verify swivel

(3) is installed in the correct orientation as

shown in F

IG. 27, page 19. Wrench tighten

bolts. Then torque to 25 to 35 ft. lbs (33.9 to

47.45 N.m).

FIG. 30

3. Install shaft (11) inside spool (2) using

bolts (9) (FIG. 31). Wrench tighten bolts. Then

torque to 25 to 35 ft. lbs (33.9 to 47.45 N.m).

FIG. 29

20 332203F

FIG. 31

4. Lay spool on a flat surface or table - inlet side down.

NOTE: Protect surface by wrapping it with black

electric tape.

Page 21

Hose Reel Reassembly

35

5

42

51

50

11

49

41

a

5. Install Bearings.

Medium Pressure Models Bearing Replacement:

FIG. 32

g. Install bearing retainer (5) and bearing retainer

nut (42). Use a spanner wrench on the bearing

nut and tighten it securely. Torque to 20 ft. lbs

(27.12 N.m).

Low Pressure Ratchet and Bearing Models:

a. Slide new bearing retainer assembly (49) onto

shaft. Refer to F

IG. 33 for the correct orientation

of the bearing retainer for assembly.

NOTE: Unless otherwise noted, Steps b - g refer to F

32.

a. Inspect seals, bearing balls, bearing nut and

bearing retainer for nicks and cuts. Replace

seals and any parts that are scratched or damaged.

b. If reusing bearing balls (35) clean bearing balls

with a soft, dry cloth.

c. Grease bearing balls (35).

NOTICE

Use 3 to 3.5 cc of grease only. Over- greasing bearing balls will cause the bearing to prematurely lock

up.

d. Apply a thin layer of grease to seal (51). Install

seal around bearing retainer nut (42).

e. Apply of thin layer of grease to the shaft o-ring

(50). Install o-ring around shaft (11).

f. Apply a thin layer of grease to inside surfaces of

bearing retainer (5). Install balls (35) in retainer.

Distribute balls evenly and verify there are 24

and they are seated flat.

IG.

FIG. 33

Install snap ring (41) over shaft on the inlet

6.

side, using a snap ring pliers (F

IG. 34). Do not

scratch the sealing surface (a).

FIG. 34

NOTICE

Be careful not to scratch or score the surface of the (a)

when using the snap ring pliers to remove the snap ring

(41). Damage to this surface could result in fluid leakage. Protect the surface by wrapping it with black electric tape.

332203F 21

Page 22

Hose Reel Reassembly

2

1

6

33b

33a

33b

6

33a

6

7. Install spool (2) on reel frame (1).

FIG. 35

NOTE: Folding the o-ring into a U-shape before

installation will help seat it correctly inside the

inlet assembly. Then use your fingers to press

the o-ring into the groove.

8. Visually inspect inlet seal and o-ring.

Also, use your finger to feel surface of seal and

o-ring for nicks. Replace these parts if damaged.

To replace seals:

a. Use a pick to remove the damaged white seal

(33a) and black o-ring (33b) from the inlet

assembly (6) (F

Be careful not to scratch or score the surface of the

inlet (6) when using the pick to remove the seal (33a)

and o-ring (33b) . Damage to this surface could result

in fluid leakage.

FIG. 36

IG. 36).

NOTICE

FIG. 37

d. Install the white seal (33a) over the o-ring (33b)

(F

IG. 38).

NOTE: Folding the seal into a U-shape before

installation will help seat it correctly inside the

inlet assembly. Then use your fingers to press

the seal into the groove.

FIG. 38

NOTE: Be careful when installing these parts that they

are lying flat inside the groove and do not have any

kinks or bends which could result in fluid leakage due to

a poorly seated seal.

b. Apply a thin layer of grease to the black o-ring

(33b) and white seal (33a).

c. Install the new black o-ring (33b) first. Use your

fingers to press it into the groove located inside

22 332203F

the neck of the inlet assembly (6) (F

IG. 37).

Page 23

Hose Reel Reassembly

6

4a

4b

36

31

4

38

7

48

7

15

b

11

9. Install inlet on hose reel.

a. Remove black electric tape if previously

installed.

b. Position inlet (6) in the desired orientation on

the base.

Medium Pressure Models ONLY: Align shim

(36) between inlet (6) and ratchet (31) (F

FIG. 39

c. First install the side 2 bolts (4a and 4b) as

shown in F

Tighten bolts just enough to hold everything in

place.

IG. 39 through frame and inlet (6).

IG. 39).

11.Install power spring.

a. Separate dust seal (48) from foam disc and

remove backing. Adhere the new dust seal (48)

to pillow block gear retainer (7).

FIG. 41

b. Rotate shaft (11) so the key-way (b) faces up.

Install three spacers (15) over shaft (F

IG. 42).

d. Install the remaining bolts (4) (F

tighten and then torque all bolts to 13-16 ft. lbs

(17.6-20.3 N•m).

10 Install spring side bearing retainer.

a. On the spring side, install retainer (7) and nuts

(38).

b. Torque nuts to 25 to 35 ft lbs (33.9 to 47.45

N.m) (F

FIG. 40

IG. 40).

IG. 39). Hand

FIG. 42

c. Install the new spring canister (10) over the

shaft.

NOTE: For easier installation, a screwdriver can

be used to position the center spring coil over

shaft.

332203F 23

Page 24

Hose Reel Reassembly

9c

9d

10

9a

9b

Correct Hub Orientation

Incorrect Hub Orientation

12

13

13

14

32

34 30

d. First install the outer two bolts (9c and 9d). Then

replace the bottom bolts (9a and 9b)(F

Torque to 25 to 35 ft. lbs (33.9 to 46.45 N.m).

FIG. 43

e. Install key (12). Align hub (13) in the opening.

Push it into place inside the spool. The key

should be in the top position.

F

IG. 44 shows examples of the hub installed

correctly and installed incorrectly.

IG. 43).

f. Install snap ring (14)) (F

FIG. 45

g. Install plastic end cap (32).

IG. 45).

NOTE: When correctly oriented the hub should

easily slide into the opening.

FIG. 46

12.Inspect outlet o-ring.

To replace o-ring:

a. Use a pick to remove o-ring (34) from outlet (30)

(F

IG. 47).

FIG. 44

24 332203F

FIG. 47

Page 25

Hose Reel Reassembly

34

30

A

NOTICE

Be careful not to scratch or score the surface of the outlet (30) when using the pick to remove the o-ring (34) .

Damage to this surface could result in fluid leakage.

NOTE: If the o-ring (34) is not damaged, you do not

need to replace this part. Use a brush to apply a thin

layer of grease around the o-ring and threads of the outlet fitting (30). Then continue installation instructions

with Step 13

b. Apply a thin layer of grease to the new o-ring

(34) and install new o-ring over outlet (30) as

shown in F

IG. 48.

NOTE:

• Adhere a piece of tape to the side of the reel

flange as a visual reference point for counting

reel rotations.

• Wind direction is determined by the direction the

spool rotates when the hose is extended during

operation.

Never allow the reel to spin freely. Doing so causes

the spool to spin out of control, which could cause

serious injury if you are hit by the hose or dispense

valve.

c. Securely attach a c-clamp (A) to the reel spool

as shown in F

IG. 49 to help prevent the reel from

unintentionally becoming unlatched and spinning freely.

FIG. 48

13.Install outlet to spool.

Always wear heavy, non-slippery gloves when adjusting the spring tension to protect your hands from being

cut on the hose reel.

a. Pre-wind hose reel as needed to accommodate

the length of hose you are installing. Refer to

Table 1, Spring Tension and Pre-Turns, page 47

to determine the number of turns needed for

your hose and reel model.

b. Engage the latch. Listen for the loud click when

the spool has latched.

FIG. 49

d. If hose was removed from outlet (30) during dis-

assembly, or if you are installing a new hose;

feed one end of hose through rollers (F

FIG. 50

e. Securely attach hose to outlet (30).

IG. 50).

332203F 25

Page 26

Hose Reel Reassembly

30

37

45

46

47

f. Reinstall outlet (30) to swivel (3). Replace and

tighten all bolts (37) securely. Torque bolts to 24

to 30 ft. pounds (32.54 to 40.67 N.m) (F

IG. 51).

NOTE:

• Low Pressure Models (shown in F

IG. 51) use 4

bolts (37).

• Medium Pressure Models (not shown) use 6

bolts (37).

• Always use all bolts provided.

15. Uncoil and extend the hose.

NOTICE

Always hold on to the hose while it is rewinding to avoid

damage to the reel.

16. Remove c-clamp. Pull the hose firmly enough to

release the latch, then slowly allow the hose to

retract.

17. Remove cap from end of hose and install dispense

valve.

18. Pressurize hose and verify spring tension.

19. If necessary, adjust spring tension. See Spring Tension Adjustment instructions, page 35 and refer to

the Table 1: Spring Tension and Pre-turns (page 47)

to determine the number of spool rotations needed

to correctly set the spring tension for your reel

model and hose.

FIG. 51: Low Pressure Model (shown)

14.Install ball stop.

FIG. 52

To install the ball stop:

a. Position each half of the stop (45) near the out-

let end of the hose (F

b. Thread screws (46) through holes in stop pieces

(45).

IG. 52).

c. Tighten nuts (47)until the outside edges of the

stop contact each other.

26 332203F

Page 27

Additional Repair and Replacement Instructions

45

46

47

Additional Repair and Replacement Instructions

Removing and Installing New

Hose on Reel

Use this procedure to remove the hose from the reel and

install a new hose on the bare reel. For this procedure

the spring canister is not removed from the spool.

1. Relieve pressure, page 10.

2. Verify there is sufficient access to the back of the

hose reel (opposite hose exit) to enable outlet

removal. Access is installation dependent. If hose

access is not available the hose reel must be taken

out of service. See Step 8, Remove Hose Reel

From Service, page 12.

3. Flush fluid from reel and hose.

a. Place end of hose in a waste container.

b. Blow out entire lubricant supply line with air.

FIG. 54

c. Cap end of hose to prevent fluid spills.

• Always wear heavy, non-slippery gloves when

adjusting the spring tension to protect your hands

from being cut on the hose reel.

• Never allow the reel to spin freely. Doing so

causes the spool to spin out of control, which

could cause serious injury if you are hit by the

hose or dispense valve.

4. Pull the hose out far enough to engage the latch.

Listen for the loud click when the spool has latched.

5. Remove dispense valve and ball stop.

To remove ball stop: remove nuts (47), screws (46) and

ball stop (45) from end of hose (F

FIG. 53

FIG. 55

332203F 27

IG. 55).

Page 28

Additional Repair and Replacement Instructions

A

30

37

30

30

6. Extend all the hose from spool and engage latch.

7. Securely attach a c-clamp (A) to the reel spool as

shown in F

IG. 56 to help prevent the reel from unin-

tentionally becoming unlatched and spinning freely.

FIG. 56

8. With hose still attached to outlet, remove bolts (37)

and outlet (30) from spool (F

IG. 57).

9. Using two wrenches on the flats, working in opposite directions, loosen and remove the hose from the

outlet fitting (F

IG. 58).

NOTE: If a reducer (35) was previously installed, it

can be reused if required or removed to accommodated a larger hose diameter.

FIG. 58

FIG. 57

10. Apply pipe thread sealant or wrap hose threads with

PTFE tape.

11. Attach end of the new hose to the outlet (30) using

two wrenches on the flats, working in opposite directions, to securely tighten the hose to the outlet fitting

(F

IG. 59).

28 332203F

FIG. 59

Page 29

Additional Repair and Replacement Instructions

(G)

30

34

30

37

12. Verify outlet o-ring (34) is in place on outlet (30).

Apply a thin layer of grease (G) to o-ring as shown

in F

IG. 60.

FIG. 60

d. Install outlet (30) to spool. Replace and tighten

all bolts (37) securely. Torque bolts to 24 to 30

ft. pounds (32.54 to 40.67 N.m) (F

IG. 61).

NOTE:

13. Uncoil and extend hose.

14. Remove c-clamp (A) (installed in Step 7, page 28).

15. Disengage latch by pulling on hose to release it.

Always wear heavy, non-slippery gloves when adjusting the spring tension to protect your hands from being

cut on the hose reel.

16. Use your hand to guide the hose as it rewinds onto

the reel.

17. Adjust spring tension if needed. See Adjusting

Spring Tension, page 35.

18. Remove cap from end of hose and install dispense

valve to end of hose.

• Low Pressure Models (shown in F

bolts (37).

• Medium Pressure Models (not shown) use 6

bolts (37).

• Always use all bolts provided.

FIG. 61: Low Pressure Model Shown

IG. 51) use 4

332203F 29

Page 30

Additional Repair and Replacement Instructions

37

30

53

45

46

47

b

c

a

First Time Hose Installation

• Never allow the reel to spin freely. Doing so

causes the spool to spin out of control, which

could cause serious injury if you are hit by the

hose.

• Always wear heavy, non-slippery gloves when

adjusting the spring tension to protect your hands

from being cut on the hose reel.

1. Be sure hose reel is secured to a flat surface or

installed in it’s service location. See Disassembly,

Step 8b, page 13.

2. Verify the spring is not under tension. If there is

spring tension, follow Removing Spring Tension procedure provided on page 37.

3. For easier hose installation, Graco recommends

removing the outlet (30) from the spool. To do this

remove bolts (37) holding outlet to the spool (F

62).

4. Apply pipe thread sealant or wrap PTFE tape

around the threads of reducer (53) (if needed). Then

install reducer (53) in the end of the outlet (F

Use two wrenches on the flats, working in opposite

directions, to securely tighten the reducer to the outlet fitting.

IG.

IG. 62).

5. Install ball stop to dispense end of hose.

FIG. 63

To install the ball stop:

a. Position each half of the stop (45) near the out-

let end of the hose (F

IG. 52).

b. Thread screws (46) through holes in stop pieces

(45).

c. Tighten nuts (47)until the outside edges of the

stop contact each other.

6. Uncoil and extend hose.

7. Feed opposite end of the hose, through the rollers

(a), then under the reel (b), and around the back (c)

of the spool.

NOTE: A reducer (53) is not required for all installations. It is only necessary if the hose diameter is

smaller than the diameter of the outlet (30).

FIG. 62: Low Pressure Outlet shown. Medium

Pressure models use 6 bolts.

30 332203F

FIG. 64

Page 31

Additional Repair and Replacement Instructions

30

A

(G)

30

34

8. Apply pipe thread sealant or wrap hose threads with

PTFE tape.

9. Attach end of the hose to the outlet (30) using two

wrenches on the flats, working in opposite directions, to securely tighten the hose to the outlet fitting

(F

IG. 65).

FIG. 65

10. Place a piece of tape on the side of the reel flange

as a visual reference point for counting reel rotations.

11. Pre-wind hose reel as needed to accommodate the

length of hose you are installing. Refer to Table 1,

Spring Tension and Pre-Turns, page 47 to determine the number of turns needed for your hose and

reel model.

13. Securely attach a c-clamp (A) to the reel spool as

shown in F

IG. 66 to help prevent the reel from unin-

tentionally becoming unlatched and spinning freely.

FIG. 66

14. Verify outlet o-ring (34) is in place on outlet (30).

Apply a thin layer of grease (G) to o-ring as shown

in F

IG. 67.

NOTE: Wind direction is determined by the direction

the spool rotates when the hose is extended during

operation.

Never allow the reel to spin freely. Doing so causes

the spool to spin out of control, which could cause

serious injury if you are hit by the hose or dispense

valve.

12. Engage the latch. Listen for the loud click when the

spool has latched.

FIG. 67

332203F 31

Page 32

Additional Repair and Replacement Instructions

30

37

A

15. Install outlet (30) to spool. Replace and tighten all

bolts (37) securely. Torque bolts to 24 to 30 ft.

pounds (32.54 to 40.67 N.m) (F

IG. 68).

NOTE:

• Low Pressure Models (shown in F

IG. 68) use 4

bolts (37).

• Medium Pressure Models (not shown) use 6

bolts (37).

• Always use all bolts provided.

Roller Guide Replacement

Disassembly

1. Relieve pressure, page 10.

Never allow the reel to spin freely. Doing so causes

the hose to spin out of control, which could cause

serious injury if you are hit by the hose or dispense

valve.

2. Pull the hose out far enough to engage the latch.

Listen for the loud click when the spool has latched.

3. Securely attach a c-clamp (A) to the reel spool as

shown in F

tentionally becoming unlatched and spinning freely.

IG. 69 to help prevent the reel from unin-

FIG. 68: Low Pressure Model Shown.

16. Remove c-clamp (A) (installed in Step 13, page 31).

17. Disengage latch by pulling on hose to release it.

Always wear heavy, non-slippery gloves when adjusting the spring tension to protect your hands from being

cut on the hose reel.

18. Use your hand to guide the hose as it rewinds onto

the reel.

19. Adjust spring tension if needed. See Adjusting

Spring Tension, page 35.

20. Remove cap from end of hose and install dispense

valve to end of hose.

FIG. 69

32 332203F

Page 33

Additional Repair and Replacement Instructions

45

46

47

28

43

9

28

43

9

4. Remove dispense valve and ball stop.

To remove ball stop:

Remove nuts (47), screws (46) and ball stop (45)

from end of hose (F

IG. 70). Cap end of hose (if

needed) to prevent fluid spills.

FIG. 70

5. Remove screws (9) and nuts (28) to remove roller

plate (43) (F

IG. 71).

Roller Guide Reassembly

1. Route end of the hose through the hose rollers (FIG.

72).

FIG. 72

2. Align plate (43) with front of hose reel base (F

73).

IG.

FIG. 71

332203F 33

FIG. 73

3. Replace screws (9) and nuts (28) (F

IG. 73).

4. Wrench tighten. Then torque to 24-35 ft. lbs (33.9 to

46.45 N.m).

Page 34

Additional Repair and Replacement Instructions

45

46

47

A

5. Install ball stop and dispensing valve.

FIG. 74

To install the ball stop:

a. Position each half of the stop (45) near the out-

let end of the hose (F

IG. 52).

b. Thread screws (46) through holes in stop pieces

(45).

c. Tighten nuts (47)until the outside edges of the

stop contact each other.

Latch Replacement

Latch Disassembly

I

1. Relieve pressure, page 10.

Never allow the reel to spin freely. Doing so causes

the spool to spin out of control, which could cause

serious injury if you are hit by the hose or dispense

valve.

2. Securely attach a c-clamp (A) to the reel spool as

shown in F

ning freely (F

IG. 3 to help prevent the reel from spin-

IG. 75).

d. Remove cap from end of hose and install dis-

pense valve to hose end.

6. Remove c-clamp.

7. Disengage latch.

FIG. 75

34 332203F

Page 35

Additional Repair and Replacement Instructions

21

18

1

(A)

A

3. Remove large bolts (18) holding latch assembly (21)

to base (1) (F

IG. 76). Discard latch assembly.

FIG. 76

Latch Reassembly

1. Align latch assembly (21) with reel base (1) and orient it as shown in F

IG. 76.

Adjusting Spring Tension

If the hose cannot be pulled all the way out or if it does

not retract all the way back onto the hose reel, you need

to adjust the spring tension.

• Never allow the reel to spin freely. Doing so

causes the spool to spin out of control, which

could cause serious injury if you are hit by the

hose or dispense valve.

• Always wear heavy, non-slippery gloves when

adjusting the spring tension to protect your hands

from being cut on the hose reel.

1. If the hose reel has been in service, relieve pressure, page 10.

2. Pull the hose out far enough to engage the latch.

2. Replace bolts (18).

3. Wrench tighten bolts. Then torque to 24-35 ft. lbs

(33.9 to 46.45 N.m).

4. Remove c-clamp installed in Latch Disassembly,

Step 2.

NOTE: Listen for the loud click when the spool has

latched.

3. Attach a c-clamp (A) to the reel spool as shown in

F

IG. 77 to help prevent the reel from unintentionally

becoming unlatched and spinning freely.

FIG. 77

If a ball stop and dispensing device are NOT installed on

the hose end, skip Step 4 and continue instructions with

Step 5.

332203F 35

Page 36

Additional Repair and Replacement Instructions

45

46

47

A

4. Remove dispense valve, nuts (47), screws (46) and

ball stop (45) from end of hose (F

IG. 84). Cap end of

hose to prevent fluid spills.

FIG. 78

5. Feed the loose end of the hose through the hose

rollers and manually wrap and secure the hose onto

the reel spool (F

IG. 79).

• Refer to the Table 1: Spring Tension and Preturns (page 47) to determine the number of

spool rotations needed to correctly set the

spring tension for your reel model and hose.

9. Check the spring tension. When it is set correctly

after pulling the hose completely off the spool it will

retract fully.

NOTICE

Always hold on to the hose while it is rewinding to avoid

damage to the reel.

10. Repeat Steps 8 and 9 until you have the proper

amount of spring tension.

NOTICE

Do not increase the spring tension so much that the

spring winds up tightly before the hose is fully

extended. A spring that is wound too tightly:

• Stops the reel from rotating before the hose is fully

extended, which puts excessive strain on the hose

and reel spring.

FIG. 79

6. Place a piece of tape on the side of the reel flange

as a visual reference point for counting reel rotations.

7. Remove c-clamp (A) installed in Step 3.

8. Rotate reel spool keeping the hose wrapped on the

reel.

NOTE:

• Each rotation of the reel spool increases or

decreases enough spring tension to retract or

let out approximately 5 feet (1.5 m) of hose.

- Wind spring, in one turn increments, tighter to

increase tension.

- Unwind spring, in one turn increments, to

decrease spring tension.

• Can cause the latch and ratchet to lock, making

disengagement by pulling the hose impossible.

11. Rotate spool to engage latch to prevent spool rotation or unwinding.

12. Securely attach a c-clamp (A) to the reel spool as

shown in F

IG. 80 to help prevent the reel from unin-

tentionally becoming unlatched and spinning freely.

FIG. 80

36 332203F

Page 37

Additional Repair and Replacement Instructions

45

46

47

A

13. Route end of the hose through the hose rollers (FIG.

81).

FIG. 81

14. Install ball stop and dispensing valve (F

IG. 82).

Removing Spring Tension

1. Relieve pressure, page 10.

Always wear heavy, non-slippery gloves when adjusting the spring tension to protect your hands from being

cut on the hose reel.

2. Pull the hose out far enough to engage the latch.

NOTE: Listen for the loud click when the spool has

latched.

3. Securely attach a c-clamp (A) to the reel spool as

shown in F

tentionally becoming unlatched and spinning freely.

IG. 83 to help prevent the reel from unin-

FIG. 82

To install the ball stop:

a. Position each half of the stop (45) near the out-

let end of the hose (F

IG. 52).

b. Thread screws (46) through holes in stop pieces

(45).

c. Tighten nuts (47)until the outside edges of the

stop contact each other.

15. If hose reel was taken out of service, reinstall hose

reel. See XD40/XD50 Hose Reels Installation and

Operation instructions.

16. Remove cap from end of hose and install dispense

valve to hose end.

17. Remove c-clamp (A).

18. Pressurize hose reel and reverify spring tension.

FIG. 83

332203F 37

Page 38

Additional Repair and Replacement Instructions

45

46

47

4. Remove dispense valve, nuts (47), screws (46) and

ball stop (45) from end of hose (F

IG. 84). Cap end of

hose (if needed) to prevent fluid spills.

FIG. 84

5. Feed loose end of hose through the hose rollers and

manually wrap and secure hose onto reel spool

(F

IG. 85).

FIG. 85

6. Place a piece of tape on the side of the reel flange

as a visual reference point for counting reel rotations.

7. Remove c-clamp (A).

8. Rotate spool in the tightening direction to disengage

latch.

9. Use your hands to unwind reel by rotating the spool

in the opposite direction turned in step 8, until it the

reel reaches a free state. Always keep at least one

hand on the spool to prevent free-spool rotation.

NOTE: Count the number of turns while unwinding the

spool and record the number for use when tensioning

the spring later.

38 332203F

Page 39

Troubleshooting

Problem Cause Solution

Troubleshooting

Power spring not correctly adjusted Increase spring pre-load. See Add-

ing Spring Tension, page 35.

Hose too stiff Use correct hose for application.

See Parts, beginning on page 40 for

the correct hose for you application.

Excessive swivel friction and hose

bending torque

Excessive hanging weight of hose

and dispense valve

Poor Retraction

Incorrect hose reel / spring for the

application

Inlet bearing failure Rebuild or replace inlet bearing,

Spring bearing failure Rebuild or replace spring bearing.

Power spring not correctly adjusted Decrease spring pre-load. See

Excessive Hose Extension Forces

Fluid leakage from inlet housing Worn inlet seal Replace inlet seal. See Inlet / Inlet

Excessive swivel friction Reduce operating pressure.

Design constraints exceeded for

spring reel

Reduce operating pressure.

Reduce installation height to recommended values. Do not exceed

installation height of 15 ft. (4.57 m).

See Parts, beginning on page 40 for

the correct hose for you application.

Use recommended reel/spring combination for application.

Do not use low pressure (LP) reels

for Medium Pressure oil dispense.

See page 21.

Adjusting Spring Tension, page 35.

Select a power reel for the application.

Seal and O-Ring Replacement

page 21.

Reel doesn’t latch. Latch pawl broken Replace latch. See Latch Replace-

Reel doesn’t retract hose all the way Power spring broken. Replace spring canister. See Power

Fluid leakage from outlet seal Seal failed Replace outlet seal. See Outlet /

332203F 39

ment page 33.

Spring Replacement, page 21.

Spring hub key broken. Replace key.

Outlet Seal Replacement page 23.

Page 40

XD40/XD50 Parts Drawing

6

4

33

41

49

31

4 or 29

2

52

30

37

34

8

13

48

10

14

32

12

9

15

38

7

47

46

45

44

1

28

43

9

23

27

40/26

39/25

24

57

56

55

18

16

3

31

33

41

5

35

42

50

51

Medium Pressure

Models

Low Pressure

Models

36

11

XD40/XD50 Parts Drawing

40 332203F

Page 41

XD40/XD50 Parts List

XD40/XD50 Parts List

Ref Part No. Description Qty

1 BASE, reel 1

2 SPOOL, hose reel, XD40 models 1

16P906^ SWIVEL, Low Pressure models 1

3

16P907$ SWIVEL, Medium Pressure mod-

els

4$&@ 112586 SCREW, cap, hex head, Low

Pressure models

SCREW, cap, hex head, Medium

Pressure models

5@

16P901 RETAINER, bearing, Medium

Pressure models

6 SWIVEL, inlet 1

7

¤

112953 BEARING, ball 1

¤

8

9

¥¿ 110963 SCREW, cap, flange head 14

10† SPRING, enclosed 1

126150

126151

11

12†

14†

23

113267 KEY, square 1

¤¥

¿

13†

106082 RING, retaining 1

¤¥

¿

¤

15

16 24R066 KIT, latch 1

18 SCREW. latch 2

126757 POST, corner 4

§

24

§ 190376 CAP, roller 8

190378 TUBE, roller, XD40, 1 inch hose

§

25

16P123 TUBE, roller, XD50, 1-1/4 and

§ 190377 TUBE, roller 2

26

27

§ 112960 SCREW, cap, flange head 4

28 110996 NUT, hex, flange head 8

RETAINER, bearing, pillow block 1

¥ SHAFT, XD40, low pressure, C

and D springs

¿ SHAFT, XD 40, Medium Pres-

sure and ALL XD50 low and

medium pressure , A and B

springs

HUB, reel, XD40, low pressure, C

and D springs

HUB, reel, XD 40, Medium Pressure and ALL XD50 low and

medium pressure , A and B

springs

SPACER, spring, hub 3

and smaller

1-1/2 inch hoses

11

Ref Part No. Description Qty

29 126596 SCREW, cap, hex head, Low

Pressure models

30‡

1

5

1

1

1

1

2

2

31& 16P903 RATCHET 1

32†

¤^$

112961 CAP, end 1

¥¿

33 129038 SEAL, XD inlet, general, FKM 1

126787 SEAL, XD, inlet, antifreeze,

105318 PACKING, o-ring 1

34‡

35@ BALL, chrome, 0.375, grade 10,

36 SHIM, frame, Medium Pressure

108751 SCREW, cap, low pressure 4

37‡

108751 SCREW, cap, medium pressure 6

38

¤

167030 PIN, roller, XD40 models, 1 inch

§

39

16P124 PIN, roller, XD50 models, 1-1/4

40

§ 190363 PIN, roller 2

41@ 126643 RING, retaining, 1.969 shaft 1

42@ INSERT, bearing, medium pres-

16T624 PLATE, roller, XD40 models, 1

43

16P081 PLATE, roller, XD50 models,

126359 HOSE, coupled, 1/2 inch x 100 ft,

126360 HOSE, coupled, 3/4 inch x 75 ft,

44

126361 HOSE, coupled, 3/4 inch x 100 ft,

126362 HOSE, coupled, 1 inch x 50 ft,

26C124 HOSE, coupled, 1/2 inch x 100 ft,

SWIVEL, outlet 1

Buna-n

Medium Pressure models

models

NUT, nylock, st, 1/2 - 13, zinc 2

hose and smaller

and 1-1/2 inch hoses

sure

inch hose and smaller

1-1/4 and 1-1/2 inch hoses

air/water, npt, XD40 models,XD4010DLP

air/water, npt, XD40 models,

XD4010DLP

air/water, npt, XD40 models,

XD4010CLP

air/water, npt, XD40 models,

XD4010DLP

oil, npt, XD40 models,

XD4010AMP

6

1

24

1

2

2

1

1

1

1

1

1

1

1

332203F 41

Page 42

XD40/XD50 Parts List

Ref Part No. Description Qty

126376 HOSE, coupled, 3/4 inch x 75 ft,

oil, npt, XD40 models,

XD4010BMP

126377 HOSE, coupled, 3/4 inch x 100 ft,

oil, npt, XD40 models,

XD4010AMP

126503 HOSE, coupled, 1 inch x 50 ft,

oil, npt, XD40 models,

XD4010BMP

126379 HOSE, coupled, 1 inch x 50 ft,

waste oil evacuation, npt, XD40

models, XD4010CLP

24R102 HOSE, coupled, 1 inch x 50 ft,

fuel, npt, XD40 models, XD4010CLP

126363 HOSE, coupled, 1 inch x 75 ft,

air/water, npt, XD50 models,

XD5010ALP

126364 HOSE, coupled, 1 inch x 100 ft,

air/water, npt, XD50 models,

XD5010ALP

126504 HOSE, coupled, 1 inch x 75 ft,

44

(cont)

oil, npt, XD50 models,

XD5010AMP

126380 HOSE, coupled, 1.25 inch x 35 ft,

waste oil evacuation, npt, XD50

models, XD5015BLP

126688 HOSE, coupled, 1.25 inch x 50 ft,

waste oil evacuation, npt, XD50

models, XD5015BLP

24R103 HOSE, coupled, 1 inch x 75 ft,

fuel, npt, XD50 models,

XD5010BLP

24R106 HOSE, coupled, 1 inch x 100 ft,

fuel, npt, XD50 models,

XD5010ALP

24R108 HOSE, coupled, 1.25 inch x 35 ft,

fuel, npt, XD50 models,

XD5015BLP

24R110 HOSE, coupled, 1.25 inch x 50 ft,

fuel, npt, XD50 models,

XD5015BLP

24R114 HOSE, coupled, 1.25 inch x 50 ft,

fuel, npt, XD50 models,

XD5015ALP

45 STOP, hose 2

46 117588 SCREW, machine, phil, pan head 2

47 101324 NUT, hex, jam 2

¤^$

48†

126467 SEAL, dust 1

¥¿

Ref Part No. Description Qty

1

49 24R514 RETAINER, bearing 1

50@ 16W910 O-RING, buna 1

51@ 126731 O-RING, buna 1

1

100380 FITTING, bushing, reducer /2

inch x 1 inch npt

1

502851 FITTING, bushing, reducer, 3/4

52

inch x 1 inch npt

121446 FITTING, bushing, reducer, 1-1/4

1

55 LABEL, identification 1

inch x 1-1/2 inch npt

56 16T815 LABEL, XD40 1

1

1

1

1

1

1

1

1

1

1

57 15W036 LABEL, warning 1

Replacement Danger and Warning labels, tags and cards

are available at no cost.

See the Related Kits Table provided on page 43, to identify the

correct kit to use for your hose reel model.

‡ Parts are included in Outlet Kit 24R056, 24R057, 24R059,

24R665, 24R666, 24R667, 24R668, 24R670, 24R673.

Parts are included in Outlet Kit 24R053, 24R055, 24R058.

Parts are included in Ballstop Kit 222225, 218341, 237872.

24R060, 24R061.

† Parts are included in Power Spring Kit 24R062, 24R063,

24R064, 24R065.

Parts are included in Latch Kit 24R066.

Parts are included in Inlet Kit 24R067, 24R068, 24R674,

24R675, 24R677, 24R678, 129137.

Parts are included in Low Pressure Bearing Kit 24R070.

@ Parts are included in Medium Pressure Bearing Kit 24R071.

Parts are included in Roller Guide Kit 24R072, 24R074.

§ Parts are included in Roller Guide Kit 24R073, 24R075.

¤ Parts are included in Spring Side Bearing Kit 24R339.

^ Parts are included in Low Pressure Swivel Kit 24R336.

$ Parts are included in Medium Pressure Swivel Kit 24R337.

& Parts are included in Ratchet Kit 24R338.

¥

Parts are included in C and D Spring Shaft Replacement Kit

24R953.

¿ Parts are included in A and B Spring Shaft Replacement Kit

24R954.

1

1

1

42 332203F

Page 43

XD40/XD50 Parts List

Related Kits

Part No. Description

24R053

24R055

24R056

24R057

24R058

24R059

24R665

24R666

24R667

24R668

24R670

24R673

222225

218341

237872 KIT, ballstop, 1 inch, includes parts 45, 46, 47

24R060

24R061

24R062

24R063

24R064

24R065

24R066 KIT, latch, includes 17, 18, 19, 20, 21, 22, 23

24R067

24R068

24R674

KIT, outlet, 1/2 inch, npt, XD40, includes

parts 30, 34, 37, 52

KIT, outlet, 3/4 inch, npt, XD40, includes

parts 30, 34, 37, 52

KIT, outlet, 1 inch, npt, XD40, includes parts

30, 34, 37

KIT, outlet, 1 inch, npt, XD50, includes parts

30, 34, 37

KIT, outlet, 1-1/4 inch, npt, XD50, includes

parts 30, 34, 37, 52

KIT, outlet, 1-1/2 inch, npt, XD50, includes

parts 34, 30, 37

KIT, outlet, 1 inch, BSPP, XD40, includes

parts 30, 34, 37

KIT, outlet, 1 inch, BSPT, XD40, includes

parts 30, 34, 37

KIT, outlet, 1 inch, BSPP, XD50, includes

parts 30, 34, 37

KIT, outlet, 1 inch, BSPT, XD50, includes

parts 30, 34, 37

KIT, outlet, 1.5 inch, BSPP, XD50, includes

parts 30, 34, 37

KIT, outlet, 1.5 inch, BSPT, XD50, includes

parts 30, 34, 37

KIT, ballstop,1/2 inch, includes parts 45, 46,

47

KIT, ballstop, 3/4 inch, includes parts 45, 46,

47

KIT, ballstop, 1-1/4 inch, includes parts 45,

46, 47

KIT, ballstop, 1-1/2 inch, includes parts 45,

46, 47

KIT, power spring, D, includes 10, 12, 13, 14,

32, 48

KIT, power spring, C, includes 10, 12, 13, 14,

32, 48

KIT, power spring, B, includes 10, 12, 13, 14,

32, 48

KIT, power spring, A, includes 10, 12, 13, 14,

32, 48

KIT, inlet, 1 inch, npt, general, includes 6, 29,

33

KIT, inlet, 1-1/2 inch, npt, general, includes 6,

29, 33

KIT, inlet, 1 inch, BSPP, general, includes 6,

29, 33

Part No. Description

24R675

24R677

24R678

129137

24R070

24R071

24R072

24R073

24R074

24R075

24R076 KIT, support arm, XD40

24R077 KIT, support arm, XD50

24R336

24R337

24R339

24R111

24R112

24R115

24R117

24R953

24R954

237932

KIT, inlet, 1 inch, BSPT, general, includes 6,

29, 33

KIT, inlet, 1-1/2 inch, general, BSPP, includes

6, 29, 33

KIT, inlet, 1-1/2 inch, BSPT, general, includes

6, 29, 33

KIT, inlet, 1 inch, npt, antifreeze, includes 6,

29, 33

KIT, bearing, low pressure bearing, includes

29, 41, 49

KIT, bearing, medium pressure, includes 4, 5,

35, 41, 42, 50, 51

KIT, roller guide, XD40, includes 9, 23, 24,

25, 26, 27, 28, 39, 40, 43

KIT, roller guide, XD40, includes 23, 24, 25,

26, 27, 39, 40

KIT, roller guide, XD50, includes 9, 23, 24,

25, 26, 27, 28, 39, 40, 43

KIT, roller guide, XD50, includes 23, 24, 25,

26, 27, 39, 40

KIT, Low Pressure Shaft, includes parts 3, 4,

32, 48

KIT, Medium Pressures shaft, includes parts

3, 4, 32, 48

KIT, bearing, spring side, includes 7, 8, 12,

14, 15, 32, 48

KIT, inlet hose, 1 inch, air/water and oil,

includes 1 inch swivel fitting and 1 inch x 28

inch coupled hose

KIT, inlet hose, 1 inch, waste oil evacuation,

includes 1 inch swivel fitting and 1 inch x 28

inch coupled hose

KIT, inlet hose, 1 inch, fuel, includes 1 inch