Page 1

Operation

The manual provided with

this sprayer contains

English and Español.

X5™, X7™, ProX7™ & ProX9™

Airless Sprayers

US Patent 6,752,067

European Patent 1 208 287

Korean Patent 10-0668583

Taiwan Patent No. D124860 for "Pro X7 Airless Paint Sprayer (Design)"

Chinese Patent ZL200730154436.7 for Pro X7

- For portable spray applications of architectural paints and coatings -

(Specifications, page 2.)

IMPORTANT SAFETY INSTRUCTIONS.

Read all warnings and instructions in this

manual. Save these instructions. See page

2 for model and series information including

dispense rate, recommended hose length,

guns, and maximum working pressure.

MAGNUM X5

Model: 262800

X5 & X7 Models ONLY: Use water-based or

mineral spirit-type materials only. Do not use

materials having flash points lower than 70° F

(21° C). For more information about your

material, request MSDS from distributor or

retailer.

Visit our website;

http://M

AGNUM.Graco.com

312001G

ti11304a

AGNUM X7

M

Model: 262805

ti11305a

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2007, Graco Inc. is registered to I.S. EN ISO 9001

MAGNUM ProX7

Model: 261815

ti9369a

M

AGNUM ProX9

Model: 261820

ti9368a

Page 2

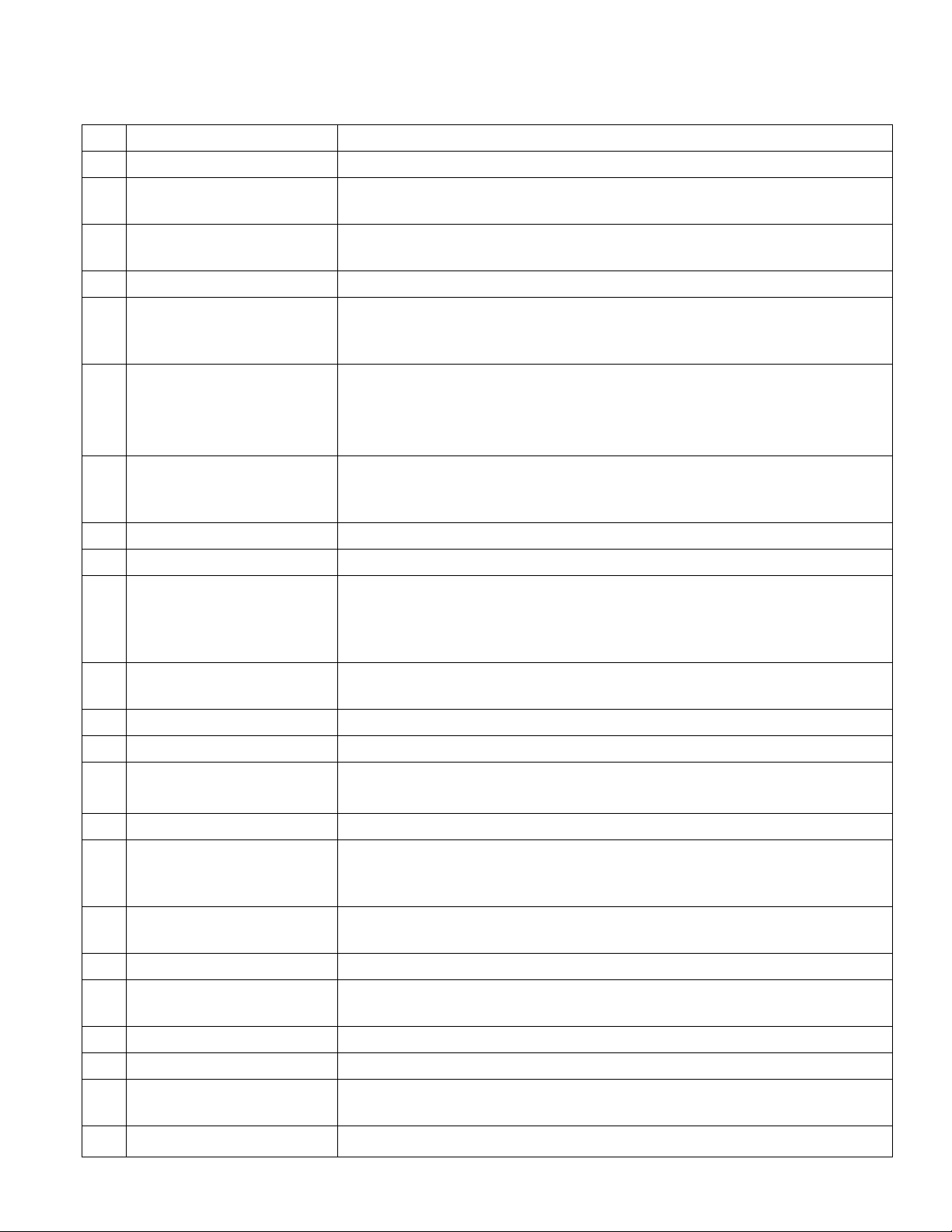

Specifications

a

Specifications

This equipment is not intended for use with flammable or combustible materials used in places such as

cabinet shops or other “factory”, or fixed locations. If you intend to use this equipment in this type of application, you must comply with NFPA 33 and OSHA requirements for the use of flammable and combustible

materials.

Model Name Series

Dispense

Rate gpm

Hose Length and

(lpm)

M

AGNUM X5 A

AGNUM X7 A

M

AGNUM ProX7 A

M

M

AGNUM ProX9 A

0.24 gpm

(0.91 lpm)

0.31 gpm

(1.17 lpm)

0.34 gpm

(1.29 lpm)

0.38 gpm

(1.44 lpm)

1/4 in. x 25 ft

(6.4 mm x 7.5 m)

1/4 in. x 25 ft

(6.4 mm x 7.5 m)

1/4 in. X 50 ft

(6.4 mm x 15 m)

1/4 in. X 50 ft

(6.4 mm x 15 m)

Getting Started

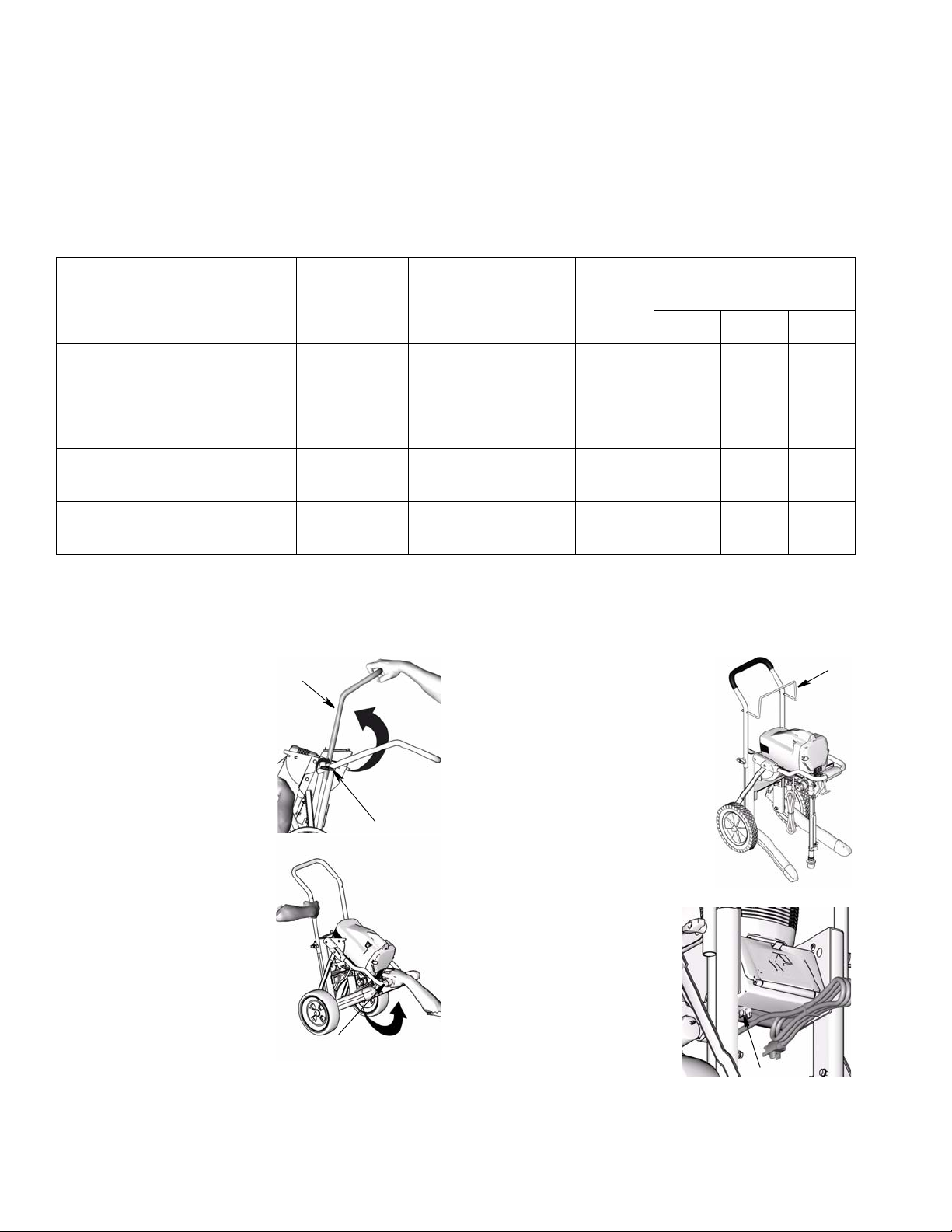

Fold-n-Store Cart (ProX Sprayers Only)

1. Unfold handle (a) and

align as shown.

2. Tighten wingnuts (b).

a

Gun

Diameter

Model

SG10 2800 19 193

SG10 3000 21 207

SG20 3000 21 207

SG20 3000 21 207

4. Install hose rack (d) to frame

handle. Install lock nuts.

Tighten securely.

Maximum Working

Pressure

PSI MPa bar

d

b ti9675

3. Grasp cart handle

securely with one hand.

ti9369a

With the other hand lift

and pull Fold-n-Store

handle (a) located in

front of sprayer frame,

™

5. Secure power cord in

clip (e) located beneath

storage compartment.

toward you. Lift up front

of sprayer until you hear

a click and the cart is

locked in place.

2 312001G

c

ti9679a

e

ti9719a

Page 3

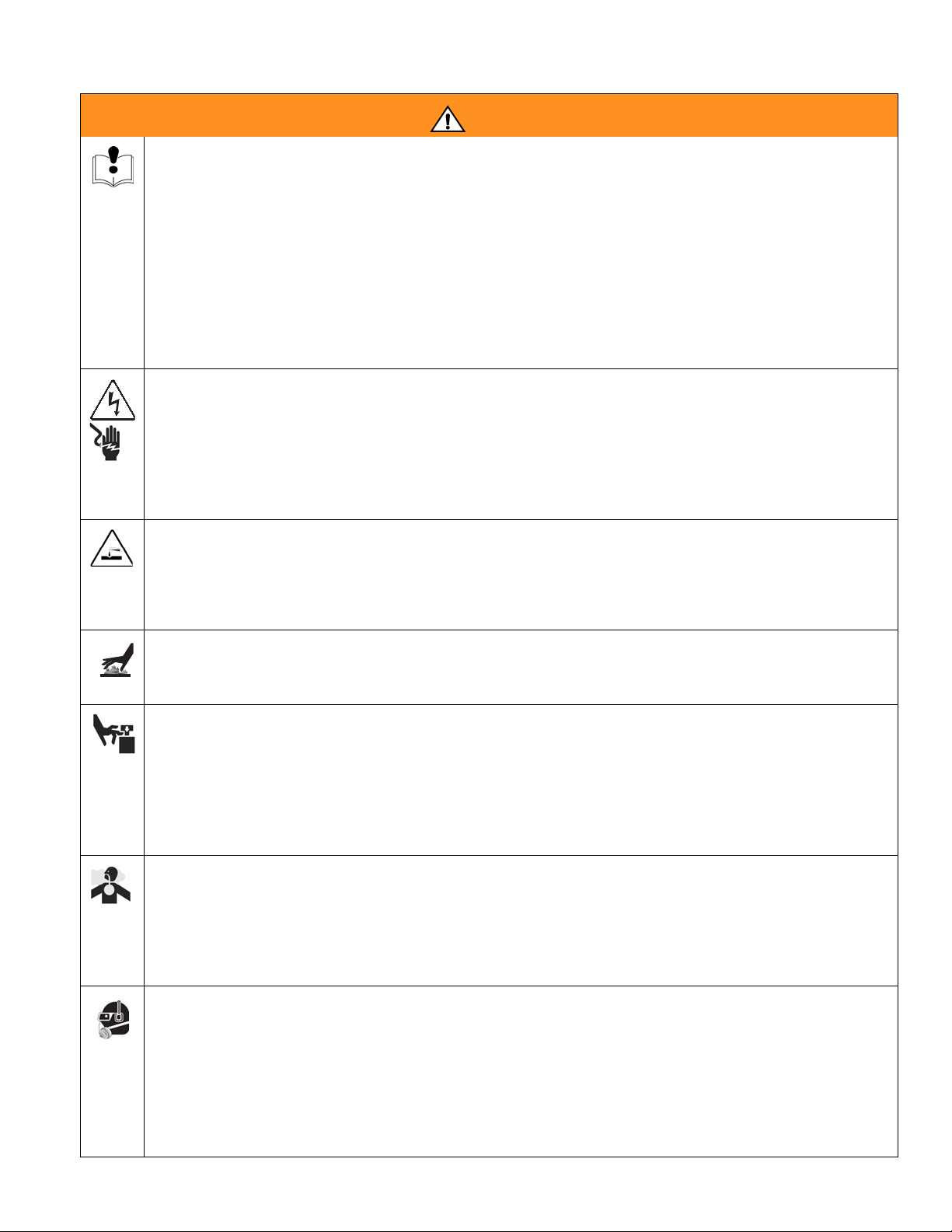

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to these warnings. Additional, product-specific warnings may be found throughout

the body of this manual where applicable.

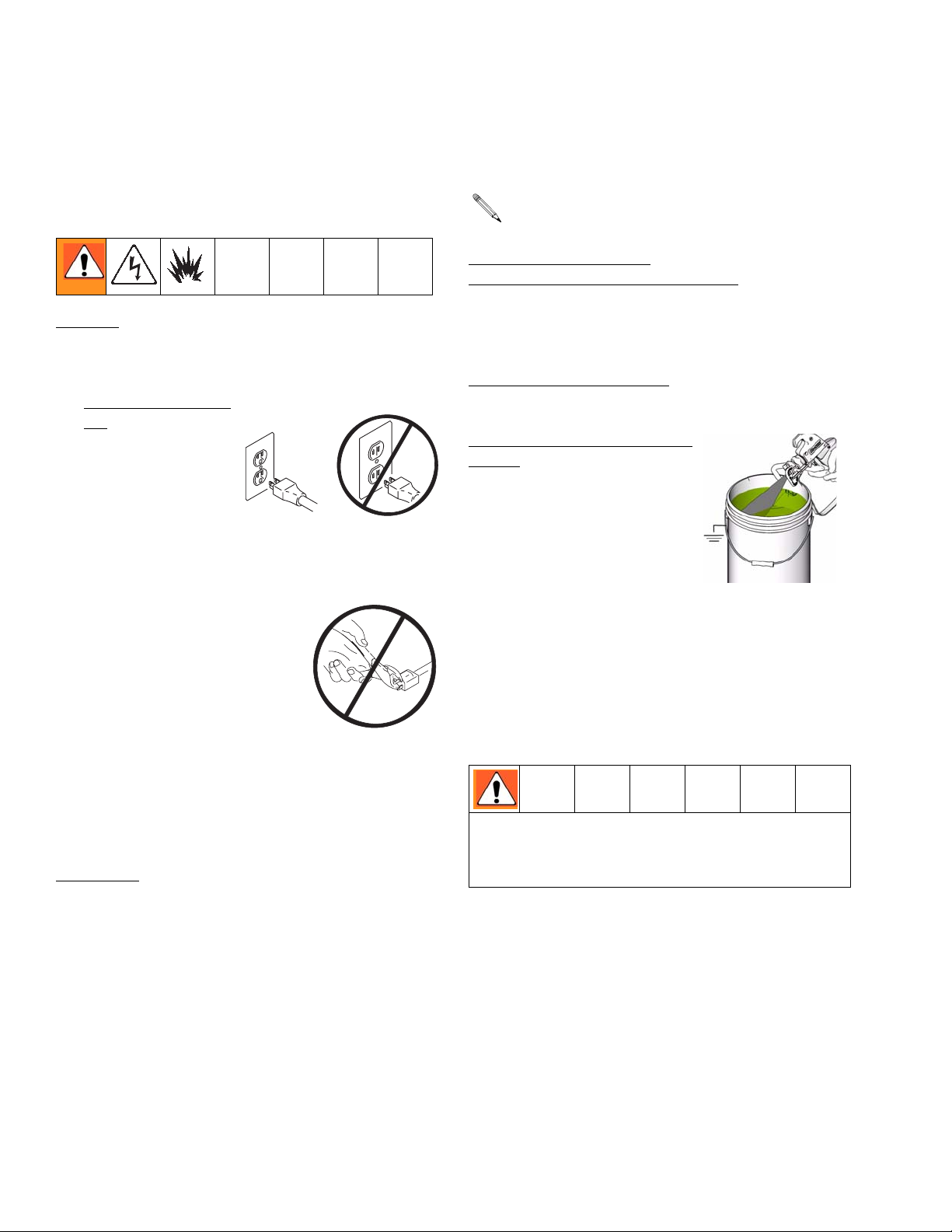

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

WARNING

GROUNDING

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire

to either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is

the grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by

a qualified electrician.

• This product is for use on a nominal 120V circuit and has a grounding plug similar to the plug

illustrated in the figure below.

ti9164a

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle

that accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12

AWG

(2.5 mm

2

) minimum to carry the current that the product draws.

An undersized cord results in a drop in line voltage and loss of power and overheating.

312001G 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition

such as cigarettes, motors, and electrical equipment. For X5 and X7 models: only use

water-based or mineral spirit-type materials with a flash point greater than 70

° F (21° C).

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of

the spray system, including the pump, hose assembly, spray gun, and objects in and around

the spray area shall be properly grounded to protect against static discharge and sparks. Use

Graco conductive or grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2

adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

Keep pump assembly in a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data

Sheets (MSDS) and container labels provided with the paints and solvents. Follow the paint

and solvents manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing

or cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

SKIN INJECTION HAZARD

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop

leaks with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs

while spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the

pressure before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in

use, turn off the unit and follow the Pressure Relief Procedure for turning off the unit.

• High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the

event that injection occurs, get immediate surgical treatment.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3000 psi. Use Graco replacement parts or accessories

that are rated a minimum of 3000 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

4 312001G

Page 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all

times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1, 1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use can cause serious

chemical reaction and equipment rupture, and result in death, serious injury, and property damage.

BURN HAZARD

Equipment surfaces can become very hot during operation. To avoid severe burns, do not touch

hot equipment. Wait until equipment has cooled completely.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure in this manual. Disconnect power or air

supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled,

or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, inhalation of

toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312001G 5

Page 6

Installation

Grounding and Electric

Requirements

Installation

Smaller gauge or longer extension cords may

reduce sprayer performance.

Sprayer must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for electrical current due to static build

up or in the event of a short circuit.

• The 120 Vac sprayers require a 120

Vac, 60 Hz, 15A circuit with a grounding receptacle.

• Never use an outlet

that is not grounded

or an adapter.

• Do not use the sprayer if the

electrical cord has a damaged ground prong.

• Only use an extension cord

with an undamaged 3-prong

plug.

Recommended extension cords for use with

this sprayer:

• 50 ft (15.0 m) 14 AWG (2.1 mm

• 100 ft (30.0 m) 12 AWG (3.3 mm

Spray gun

erly grounded fluid hose and pump.

: ground through connection to a prop-

ti5573a

ti5572a

2

)

2

)

Fluid supply container

Solvent pails used when flushing

code. Use only conductive metal pails, placed on a

grounded surface such as concrete. Do not place

the pail on a nonconductive surface, such as paper

or cardboard, which interrupts grounding continuity.

Grounding the metal pail

to the pail by clamping one end to pail and other

end to ground such as a water pipe.

Maintaining grounding continuity when flushing or

relieving pressure: hold

metal part of the spray gun

firmly to the side of a

grounded metal pail, then

trigger the gun.

: follow local code.

: follow local

: connect a ground wire

ti9207a

Thermal Overload

Motor has a thermal overload switch to shut itself

down if overheated. If unit overheats, allow approximately 45 minutes for unit to cool. Once cool,

switch will close and unit will restart.

To reduce risk of injury from motor starting unexpectedly when it cools, always turn power switch

OFF if motor shuts down.

6 312001G

Page 7

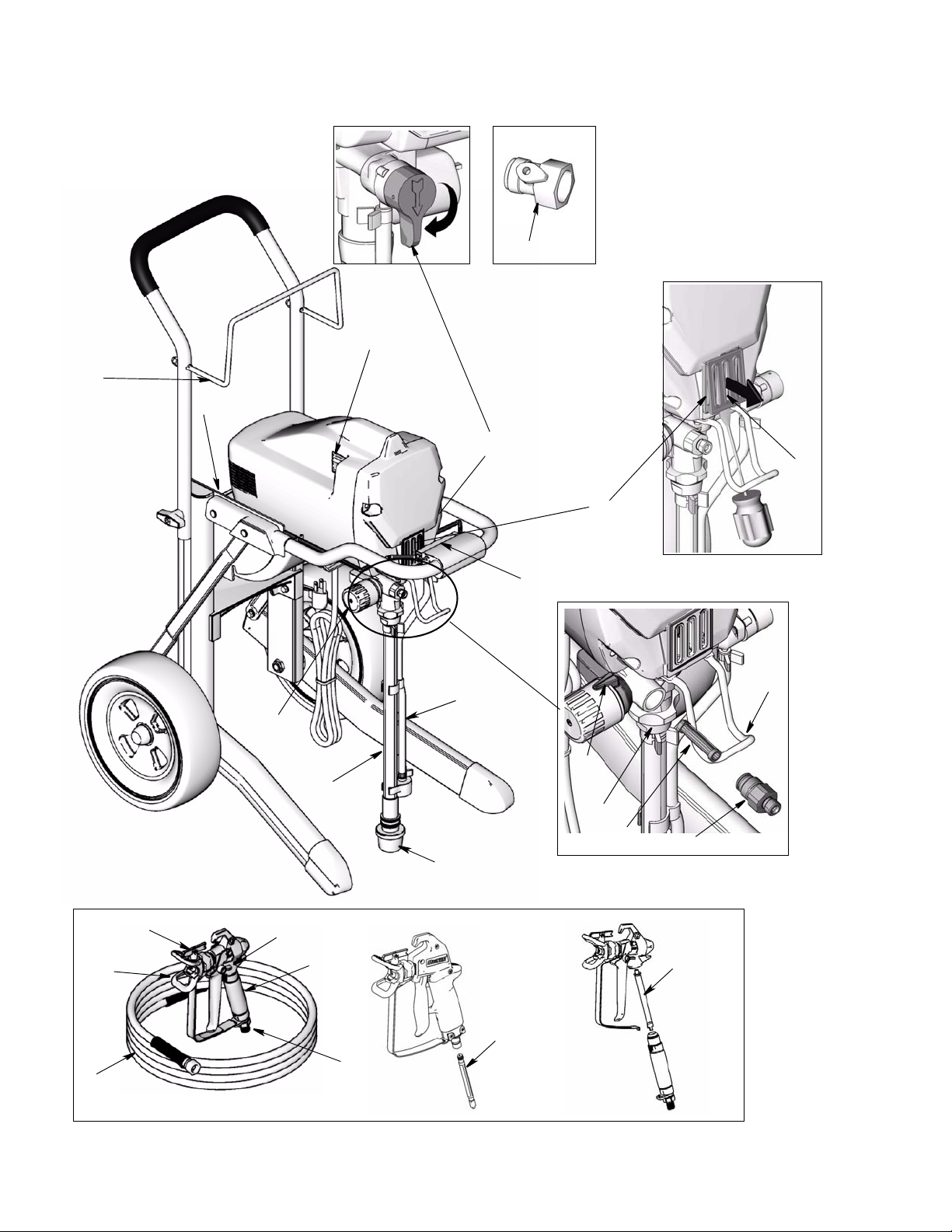

Component Identification

Component Identification

A Airless spray gun Dispenses fluid.

B Power switch Turns sprayer ON and OFF.

C Pressure control knob

C1 Setting Indicator

D Pump fluid outlet fitting Threaded connection for paint hose.

InstaClean

E

(ProX Sprayers Only)

ProX Power-Piston

Pump (behind Easy

F

Access door, not shown)

™

fluid filter

™

(ProX Sprayers Only)

Easy Access door

F1

(ProX Sprayers Only)

G Suction tube Draws fluid from paint pail into pump.

H Prime tube (with diffuser) Drains fluid in system during priming and pressure relief.

Increases (clockwise) and decreases (counter-clockwise) fluid pressure

in pump, hose, and spray gun.

To select function, align symbol on pressure control knob with setting

indicator, page 9.

• Filters fluid coming out of pump to reduce tip plugging and improve

finish.

• Self cleans only during pressure relief.

Pumps and pressurizes fluid and delivers it to paint hose.

Easy Access door permits quick access to outlet valve. To remove door,

insert flat blade of screwdriver into slot on the bottom of the door (as

shown on page, 7).

• In PRIME position (pointing down) directs fluid to prime tube.

J Prime/Spray valve

• In SPRAY position (pointing forward) directs pressurized fluid to

paint hose.

• Automatically relieves system pressure in overpressure situations.

Storage compartment

K

(ProX Sprayers Only)

Provides onboard storage for spray tips and/or tools.

L Inlet screen Prevents debris from entering pump.

M Paint hose Transports high-pressure fluid from pump to spray gun.

Fold-n-Store

N

(ProX Sprayers Only)

™

Handle

Used to fold cart frame for hanging on wall.

Q Tip guard Reduces risk of fluid injection injury.

• Atomizes fluid being sprayed, forms spray pattern and controls fluid

R Reversible spray tip

flow according to hole size.

• Reverse unclogs plugged tips without disassembly.

Gun trigger safety lever

S

(page 9)

Prevents accidental triggering of spray gun.

T Gun fluid inlet fitting Threaded connection for paint hose.

U Power Flush attachment

Connects garden hose to suction tube for power flushing water-base

fluids.

V Gun fluid filter Filters fluid entering spray gun to reduce tip clogs.

W Hose wrap Rack Stows paint hose. (X7, ProX7, and ProX9 only)

Pail hanger

X

(X7, Prox7, and ProX9)

AA

QuickAccess

312001G 7

™

Inlet

For transporting pail by its handle.

Permits quick access to inlet valve to clear debris (ProX9 only).

Page 8

ti9724a

Component Identification

W

ti9346a

U

B

K

J

F1

F

ti9670a

N

H

C

X

C1

G

ti9368a

ti9669a

AA

E

D

L

R

Q

M

S

ti9667a

A

V (SG10)

T

ti11455a

ti9668a

V (SG20)

8 312001G

Page 9

Operation

Operation

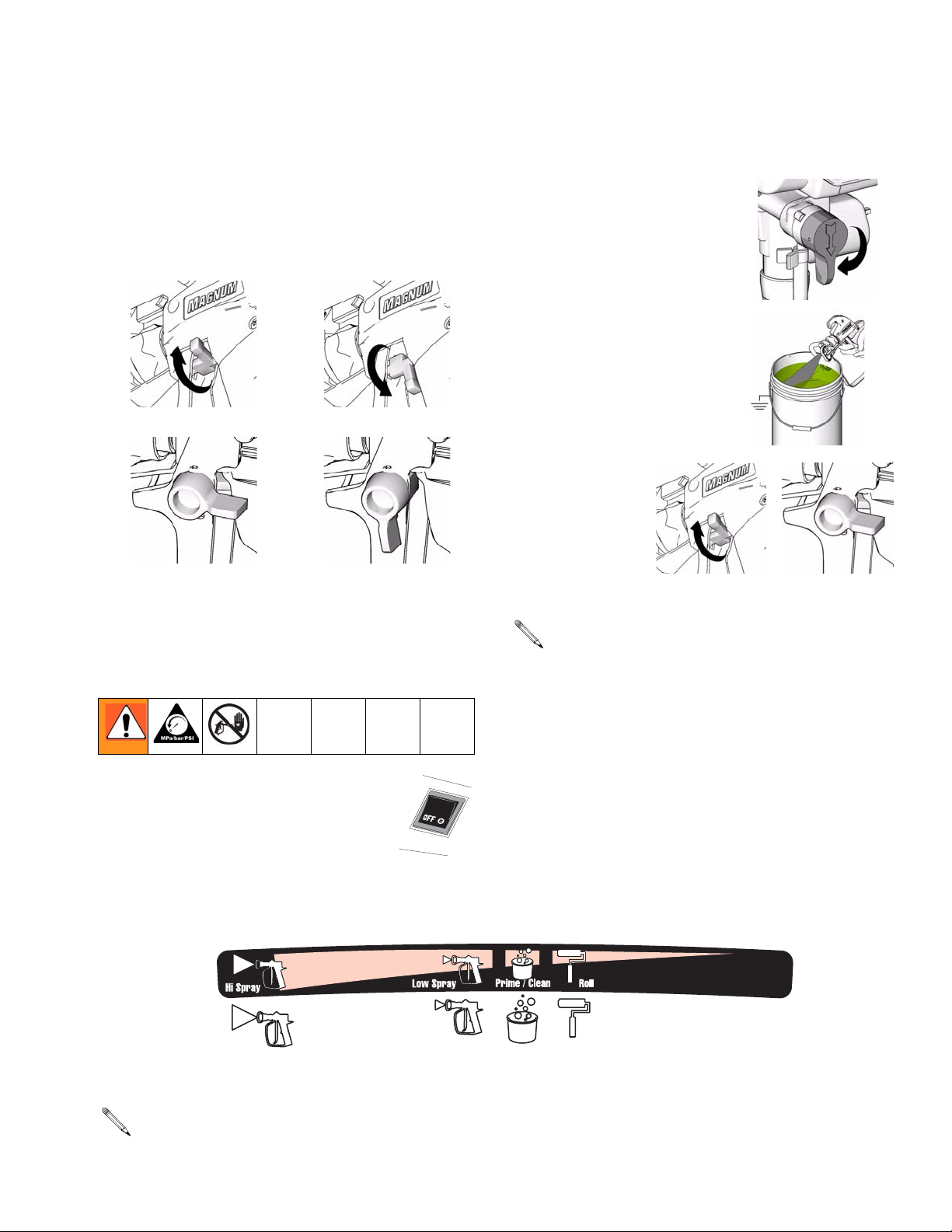

Trigger Lock

Always engage the trigger lock when you stop

spraying to prevent the gun from being triggered

accidentally by hand or if dropped or bumped.

ti8923a

Trigger Locked (SG10)

ti8908a

Trigger Locked (SG20)

Trigger Unlocked (SG10)

ti8909a

Trigger Unlocked (SG20)

ti8922a

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever

you stop spraying and before cleaning, checking,

servicing, or transporting equipment.

1. Turn power switch OFF and unplug

power cord.

2. Turn Prime/Spray valve to

PRIME to relieve pressure.

ti9346a

3. Hold gun firmly to

side of pail. Trigger

the gun to relieve

pressure.

ti9207a

4. Engage trigger

lock.

ti8923a

ti8908a

(SG10)

(SG20)

Leave Prime/Spray valve in the PRIME

position until you are ready to spray again.

If you suspect the spray tip or hose is clogged or

that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction. Read Unclogging Spray

Tip, page 13.

ti2810a

Pressure Control Knob Settings

ti5597a

High Pressure

Spray

Low Pressure

Spray

To select function, align symbol on pressure control knob with setting indicator on sprayer.

312001G 9

Prime/

Clean

Rolling

Page 10

Setup

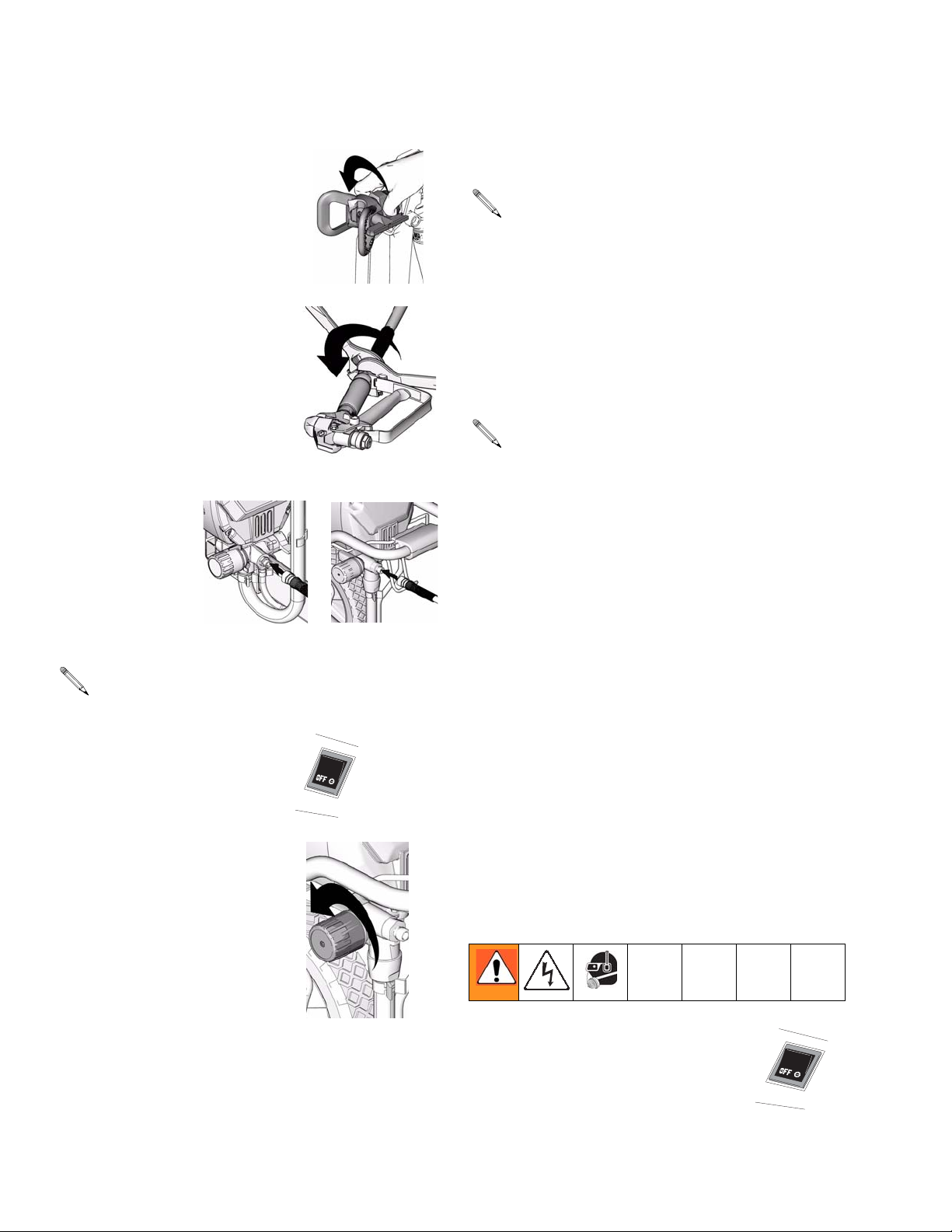

1. Unscrew tip and guard

assembly from gun.

2. Uncoil hose and connect

one end to gun. Use two

wrenches to tighten

securely

3. Connect other

end of hose to

sprayer.

ti11456a

(X5 & X7)

If hose is already connected, make sure

connections are tight.

4. Turn OFF power switch.

ti9714a

ti9681a

ti9674a

(ProX7 & ProX9)

Setup

Prime and Flush Storage Fluid

To spray lacquers with the ProX7 or ProX9,

you must purchase lacquer conversion kit

256212, and follow priming procedure for

oil-based materials. The X5 and X7 units are

not intended for lacquers.

Before you use your sprayer for the first time or begin a

new spraying project, you need to prime the sprayer and

flush the storage fluid out of the sprayer.

Oil- or Water-based Materials

• When spraying water-based materials,

flush the system thoroughly with water.

• When spraying oil-based materials, flush

the system thoroughly with mineral spirits

or compatible, oil-based flushing solvent.

•To spray water-based materials after

spraying oil-based materials, flush the

system thoroughly with water first. The

water flowing out of prime tube should be

clear and solvent-free before you begin

spraying the water-based material.

•To spray oil-based materials after spray-

ing water-based materials, flush the system thoroughly with mineral spirits or a

compatible oil-based flushing solvent first.

The solvent flowing out of the prime tube

should not contain any water.

• When flushing with solvents, ground pail

ti2810a

and gun. Read Grounding and Electric

Requirements, page 6.

5. Turn Pressure Control Knob

all the way left

(counter-clockwise) to

• To avoid fluid splashing back on your skin

or into your eyes, always aim gun at inside

wall of pail.

minimum pressure.

ti9344a

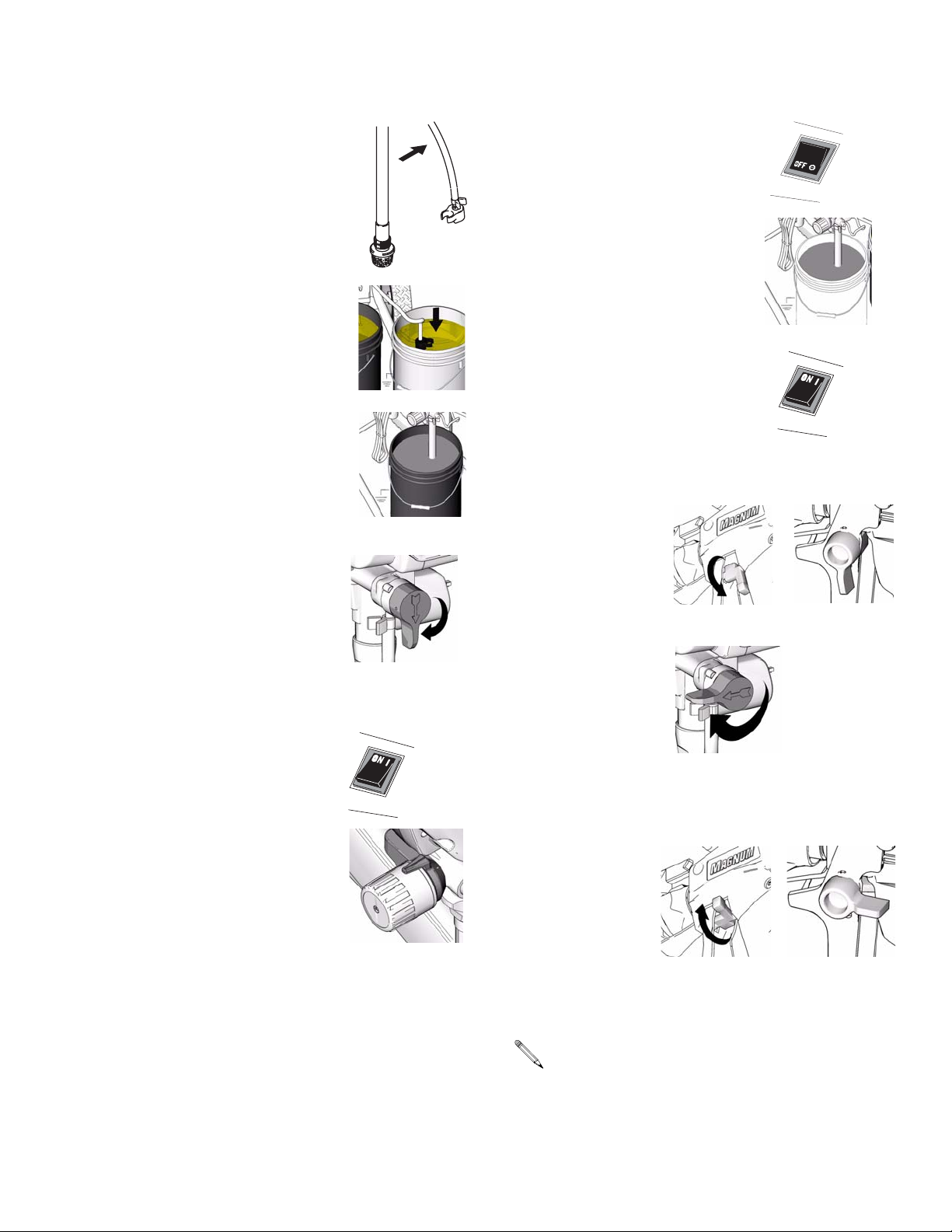

1. Make sure the power switch is

OFF and the sprayer is

unplugged.

ti2810a

10 312001G

Page 11

Setup

2. Separate prime tube (smaller)

from suction tube (larger).

3. Place prime tube in waste

pail.

4. Submerge suction tube in

water or flushing solvent.

5. Turn Prime/Spray Valve to

PRIME.

6. Plug sprayer in a grounded outlet.

7. Turn power switch ON.

ti2039a

ti9652a

ti9651a

ti9346a

10. Turn power switch OFF.

11. Transfer suction tube to

paint pail and submerge

suction tube in paint.

12. Turn power switch ON.

13. When you see

paint coming out

of prime tube:

a. Point gun into

waste pail.

b. Unlock gun

trigger lock.

c. Pull and hold

(SG10)

gun trigger.

d. Turn

Prime/Spray

valve to

SPRAY.

ti2810a

ti9653a

ti5580a

ti8922a

ti8909a

(SG20)

ti9345a

14. Continue to trigger gun into waste pail until you

ti5580a

8. Align setting indicator with

Prime/Clean setting on

Pressure Control knob until

pump starts, page 9.

ti9718a

9. When sprayer starts pumping, flushing solvent

and air bubbles will be purged from system.

Allow fluid to flow out of prime tube, into waste

pail, for 30 to 60 seconds.

see only paint coming out of gun.

15. Release trigger.

Engage trigger

lock.

16. Transfer prime

tube to paint

pail and clip

ti8923a

ti8908a

(SG10)

prime tube to

suction tube.

• Motor stopping indicates pump and hose

are primed with paint.

(SG20)

• If motor continues to run the sprayer is not

properly primed. To reprime repeat step 8.

312001G 11

Page 12

Setup

Install Tip and Guard on Gun

1. Engage trigger lock.

ti8923a

(

SG10

)

(

SG20

2. Verify tip and guard parts are assembled in

order shown.

retaining nut

guard

tip

ti8908a

)

black rubber gasket and

metal seat

ti8911a

Spraying Techniques

Preventing Excessive Tip Wear

• Spray should be atomized (evenly distributed,

no gaps at edges). Start at low pressure setting, increase pressure a little at a time until you

see a good spray pattern, without tails.

• Spray at lowest pressure that atomizes paint.

• If maximum sprayer pressure is not enough for

a good spray pattern, tip is too worn. See

Reversible Spray Tip Selection Chart, page 15.

tails-gaps

at edges

pressure

too low

good

spray pattern

ti5592a

Use tip to align seat

in guard

ti9574a

Tip must be pushed

all the way into guard

3. Screw tip and guard assembly

on gun. Tighten retaining nut.

ti5606a

ti9313a

If tails persist when spraying at the highest

pressure, a smaller tip is needed or the

material may need to be thinned.

Adjust Spray Pressure

This sprayer is set up for most airless spraying

applications. Details on tip selection, tip wear, coat

thickness, etc. are provided on page 14.

Motor only runs when gun is triggered. Sprayer

is designed to stop pumping when gun trigger

is released.

Align setting indicator with function symbol on

Pressure Control knob, page 9.

• Turning knob to right (clockwise), increases

pressure at gun.

• Turning it left (counter-clockwise), decreases

pressure.

• General spraying instructions are provided in

Getting Started with Basic Spraying Techniques section of this manual, page 16.

12 312001G

Page 13

Setup

Unclogging Spray Tip

To avoid fluid splashback:

• Never pull gun trigger when arrow-shaped handle is between SPRAY and UNCLOG positions.

• Tip must be pushed all the way into guard.

1. To UNCLOG

tip obstruction,

engage trigger

lock.

(SG10)

2. Point arrow-shaped

handle backward to

UNCLOG position.

ti8923a

ti8908a

(SG20)

4. Unlock

trigger

lock. Pull

trigger to

clear clog.

(SG10)

ti8922a

ti8909a

(SG20)

5. When obstruction is

cleared, engage trigger

lock and rotate

arrow-shaped handle

back to SPRAY position.

Point the arrow-shaped handle on the spray tip

forward to SPRAY and backward to UNCLOG

obstructions.

ti9049a

3. Aim gun at piece of

scrap or cardboard.

ti9048a

312001G 13

Page 14

Tip Selection

Selecting Tip Hole Size

Setup

Tips come in a variety of hole sizes for spraying a

range of fluids. Your sprayer includes an 0.015 in

(0.38 mm) tip for use in most spraying applications.

Use the following table to determine the range of

recommended tip hole sizes for each fluid type. If

you need a tip other than the one supplied, see the

Reversible Tip Selection Chart on page 15.

HINTS:

• As you spray, the tip wears and enlarges. Starting with a tip hole size smaller than the maximum will allow you to spray within the rated

flow capacity of the sprayer.

Tip Hole Size Stains Enamels Primers Interior Paints Exterior Paints

0.011 in. (0.28 mm)

0.013 in. (0.33 mm)

0.015 in. (0.38 mm)

0.017 in. (0.43 mm)

0.019 in. (0.48 mm)

✔

✔✔✔ ✔

✔✔ ✔ ✔

• Maximum tip hole sizes supported by the

sprayer:

– X5: 0.015 in. (0.38 mm)

– X7: 0.017 in. (0.43 mm)

– ProX7: 0.017 in. (0.43 mm)

– ProX9: 0.019 in. (0.48 mm)

Coatings

✔✔ ✔

✔

Choosing the Correct Tip

Consider coating and surface to be sprayed. Make

sure you use best tip hole size for that coating and

best fan width for that surface.

Tip Hole Size

Tip hole size controls flow rate - the amount of

paint that comes out of the gun.

HINTS:

• Use larger tip hole sizes with thicker coatings

and smaller tip hole sizes with thinner coatings.

• Maximum tip hole sizes supported by sprayer:

– X5: 0.015 in. (0.38 mm)

– X7: 0.017 in. (0.43 mm)

– ProX7: 0.017 in. (0.43 mm)

– ProX9: 0.019 in. (0.48 mm)

• Tips wear with use and need periodic replacement.

Fan Width

Fan width is the size of the spray pattern, which

determines the area covered with each stroke. Narrower fans deliver a thicker coat, and wider fans

deliver a thinner coat.

HINTS:

• Select a fan width best suited to the surface

being sprayed.

• Wider fans allow provide better coverage on

broad, open surfaces.

• Narrower fans provide better control on small,

confined surfaces.

14 312001G

Page 15

Setup

Understanding Tip Number

The last three digits of tip number (i.e.: 221413)

contain information about hole size and fan width

on surface when gun is held 12 in. (30.5 cm) from

surface being sprayed.

First digit when doubled

= approximate

fan width

413 tip has

a 0.013 in

hole size

Last two digits = tip hole size in thousands of an inch

413 tip has

8-10 in.

fan width

.

ti5559a

Reversible Tip Selection Chart

Tip

Part

No.

221311 6 - 8 in.

221411 8 - 10 in.

221313 6 - 8 in.

221413 8 - 10 in.

221415 8 - 10 in.

221515 10 - 12 in.

221417 8 - 10 in.

221517 10 - 12 in.

221619 12 - 14 in.

Fan Width 12 in.

(305 mm) from

surface Hole Size

(152 - 203 mm)

(203 - 254 mm)

(152 - 203 mm)

(203 - 254 mm)

(203 - 254 mm)

(254 - 305 mm)

(203 - 254 mm)

(254 - 305 mm)

(305 - 356 mm)

0.011 in.

(0.28 mm)

0.011 in.

(0.28 mm)

0.013 in.

(0.33 mm)

0.013 in.

(0.33 mm)

0.015 in.

(0.38 mm)

0.015 in.

(0.38 mm)

0.017 in.

(0.43 mm)

0.017 in.

(0.43 mm)

0.019 in.

(0.48 mm)

Example: For an 8 to 10 in. (203 to 254 mm) fan

width and 0.013 (0.33 mm) hole size, order Part No.

221413.

312001G 15

Page 16

Getting Started With Basic Techniques

Getting Started With Basic Techniques

Use a piece of scrap cardboard to practice these

basic spraying techniques before you begin spraying the surface.

• Hold gun 12 in. (30 cm) from surface and aim

straight at surface. Tilting gun to direct spray

angle causes an uneven finish.

12 in.

(30 cm)

even

finish

thick

uneven

finish

ti5585a

thin

• Flex wrist to keep gun pointed straight. Fanning

gun to direct spray at angle causes uneven finish.

even finish thin thick thin

Triggering Gun

Pull trigger after starting stroke. Release trigger

before end of stroke. Gun must be moving when

trigger is pulled and released.

ti2037a

Aiming Gun

Aim tip of gun at bottom edge of previous stroke,

overlapping each stroke by half.

ti2036a

ti2038a

16 312001G

Page 17

Shutdown and Cleaning

Shutdown and Cleaning

Pail Flushing

• For short term shutdown periods (overnight to two days) refer to Short Term Storage, page 22.

• For flushing after spraying oil-based coatings, use compatible oil-based flushing

fluid or mineral spirits. Read Priming and

Flushing Storage Fluid, page 10.

6. Place prime tube in waste

pail.

ti9652a

• For flushing after spraying water-based

coatings, use water. Read Priming and

Flushing Storage Fluid, page 10 or Power

Flush, page 19.

1. Relieve pressure, page 9.

2. Remove tip and guard assembly from gun and

place in flushing fluid.

3. Lift suction tube and prime tube from paint pail.

Let them drain into paint pail for a while.

4. Separate prime tube (smaller)

from suction tube (larger).

ti2039a

7. Submerge suction tube in

water or flushing solvent.

ti9651a

8. Turn pressure control knob to

the Prime/Clean setting.

ti9344a

9. Turn power switch ON.

ti5580a

10. Flush until approximately 1/3 of the flushing

fluid is emptied from the pail.

11. Turn power switch OFF.

5. Place empty waste and

water or solvent pails

ti2018a

side by side.

ti9726a

312001G 17

Page 18

Shutdown and Cleaning

Step 12 is for returning paint in hose back to

paint pail. One 50-ft hose holds approximately

1-quart (1-liter) of paint.

12. To preserve paint

in hose:

a. Point gun

into paint

pail.

ti8922a

b. Unlock gun

trigger lock.

(SG10)

c. Pull and hold

gun trigger.

d. Turn

Prime/Spray

valve to

SPRAY.

ti9345a

ti8909a

(SG20)

13. While continuing to trigger

gun, quickly move gun to

redirect spray into waste

pail. Continue triggering

gun into waste pail until

flushing fluid dispensed

from gun is relatively

clear.

ti8923a

14. Stop triggering

gun. Engage the

trigger lock.

(

SG10

15. Turn prime/spray

valve to Prime.

16. Turn power switch

OFF.

)

ti9346a

ti2018a

(

SG20

ti9745a

ti8908a

)

e. Turn power

switch ON.

ti5580a

f. Continue to hold gun trigger until you see

paint diluted with flushing fluid starting to

come out of gun.

17. Clean InstaClean Fluid Filter and gun, page 21.

18. Fill unit with Pump Armor

™

storage fluid. Read

Long Term Storage, page 22.

o preserve paint in hose, trigger gun into paint pail

to expel the remaining paint.

18 312001G

Page 19

Shutdown and Cleaning

Power Flush

Power flushing is a faster method of flushing. It can

only be used after spraying water-based coatings.

1. Relieve pressure, page 9.

2. Remove tip and guard assembly from gun and

place in waste pail.

3. Place empty waste and

paint pails side by side.

ti9726a

4. Lift suction tube and prime tube from paint pail.

Let them drain into paint for a while.

5. Place suction and prime tube in waste pail.

10. Unscrew inlet screen from suction

tube. Place inlet screen in waste

pail.

ti2040a

11. Connect garden hose to suction

tube with Power Flush attachment.

Leave prime tube in waste pail.

ti2042a

12. Turn power switch ON.

6. Turn Pressure Control knob to the

Prime/Clean setting.

7. Screw power flush attachment

to garden hose. Close valve.

8. Turn on water. Open valve.

Rinse paint off suction tube,

prime tube and inlet screen.

9. Turn lever to close power flush

attachment.

ti9344a

ti9413a

ti9727a

ti5580a

13. Open lever on Power

Flush attachment.

OPEN

ti2043a

14. Circulate water through sprayer, into waste pail,

for 20 seconds.

15. Turn power switch OFF.

ti2018a

312001G 19

Page 20

Shutdown and Cleaning

Step 16 is for returning paint in hose back to

paint pail. One 50-ft (15-m) hose holds approximately 1-quart (1-liter) of paint.

16. To preserve paint

in hose:

a. Point gun into

paint pail.

b. Unlock gun

trigger lock.

ti8922a

ti8909a

(SG10)

c. Pull and hold

gun trigger.

d. Turn

Prime/Spray

valve to

SPRAY.

ti9345a

(SG20)

18. Stop triggering

gun. Engage

trigger lock.

(

SG10

19. Turn prime/spray

valve to Prime.

20. Turn power switch OFF.

21. Turn off garden hose. Close

Power Flush attachment.

ti8923a

)

ti8908a

(

SG20

ti9346a

ti2810a

)

ti9413a

e. Turn power

switch ON.

ti5580a

f. Continue to hold gun trigger until you see

paint diluted with water starting to come out

of gun.

17. While continuing to

trigger gun, quickly move

gun to redirect spray into

waste pail. Continue

triggering gun into waste

pail until water coming

out of gun is relatively

clear.

ti9745a

22. Unscrew Power Flush

attachment from suction tube.

23. Clean InstaClean Fluid Filter

and gun, page 21.

24. Fill unit with Pump Armor

™

storage fluid. Read

Long Term Storage, page 22.

ti2047a

20 312001G

Page 21

Shutdown and Cleaning

Cleaning InstaClean™ Fluid

Filter (ProX Sprayers Only)

The InstaClean Fluid Filter prevents particles from

entering paint hose. After each use, remove and

clean it to insure peak performance.

1. Relieve pressure, page 9.

2.

a. Disconnect airless

spray hose (a) from

sprayer

b. Unscrew outlet fitting

(b).

c. Remove InstaClean

Fluid Filter (c).

3. Check InstaClean Fluid Filter (c) for debris. If

needed, clean filter with water and a soft brush.

a. Install closed

(square) end of

InstaClean Fluid

Filter (c) in sprayer.

c

ti9347a

a

4. Tighten outlet fitting and

reconnect hose (a) to

sprayer. Use two

wrenches to tighten

securely.

Cleaning Gun

• Clean gun fluid

filter (d) with

b

water or flushing

solvent and a

brush every time

you flush the

system. Replace

gun filter if

damaged.

• Remove tip and guard and

clean with water or flushing

solvent. A soft brush can be

used to loosen and remove

dried on material if needed.

• Wipe paint off outside of gun

using a soft cloth moistened

with water or flushing solvent.

ti11455a

(SG10)

a

ti9674a

d

d

ti9668a

(SG20)

ti9671a

b. Screw outlet fitting

(b) into sprayer.

312001G 21

c

b

ti9347a

Page 22

Storage

Storage

Short Term Storage

(up to 2 days)

1. Relieve pressure, page 9.

2. Leave suction tube and

prime tube in paint pail.

3. Cover paint pail and hoses

tightly with plastic wrap.

Long Term Storage

(more than 2 days)

• Always circulate Pump Armor storage fluid

through system after cleaning. Water left

in sprayer will corrode and damage pump.

• Follow Shutdown and Cleaning, page 17,

or Power Flush Cleaning, page 19.

1. Place suction tube in

Pump Armor storage

fluid bottle and prime

tube in waste pail.

ti9353a

ti2057a

2. Turn Prime/Spray valve

to PRIME.

4.

ti8923a

a. Engage trigger

lock.

b. Leave gun

attached to

(

SG10

hose.

)

c. If you have not

already

cleaned them,

remove tip and

guard from

ti9671a

gun and clean with water or flushing solvent. A soft brush can be used to loosen

and remove dried on material if needed.

d. Wipe paint off outside of gun using a soft

cloth moistened with water or flushing solvent.

(

SG20

ti9350a

ti8908a

)

ti9346a

3. Turn power switch ON.

ti5580a

4. Turn pressure control knob

clockwise until the pump

turns on.

ti9343a

5. When storage fluid comes

out of prime tube (5-10

seconds) turn power switch

OFF.

ti2018a

6. Turn Prime/Spray valve to

SPRAY to keep storage

fluid in sprayer during

storage.

ti9345a

22 312001G

Page 23

Storage

Stowing Sprayer

CAUTION

• Before storing sprayer make sure all water is

drained out of sprayer and hoses.

• Do not allow water to freeze in sprayer or hose.

• Do not store sprayer under pressure.

Fold-n-Store Storage

The sprayer cart can be folded for convenient and

compact storage.

Folding the Sprayer (ProX Sprayers Only)

1. Screw inlet screen onto

suction tube.

2. Coil hose. Leave it

connected to sprayer.

Wrap hose around hose

wrap bracket.

3. Secure a plastic bag around

suction tube to catch any

drips.

ti9433a

ti9366a

1. Grasp cart handle

securely with one hand.

With the other hand, lift

and pull Fold-n-Store

handle (a) in front of

sprayer frame, toward

you.

2. Push front of sprayer

down, toward floor

while holding cart

handle securely with

your other hand as

shown.

a

ti9425a

ti9432a

4. Store sprayer indoors.

ti5552a

b

312001G 23

ti9428a

Page 24

Unfolding the Sprayer (ProX Sprayers Only)

Storage

1. If folded for compact,

shelf storage, unfold

handle (a) and align

as shown.

2. Tighten wingnuts (b).

3. Remove suction tube

from hook (c) in the back

of the sprayer.

a

• The folded sprayer can be

stored on a wall as

shown.

Storage Options (ProX Sprayers Only)

ti9675a

b

ti9677a

• For compact, shelf

c

storage, loosen, but

do not remove, wingnuts (c) and fold handle down as shown.

ti9676a

c

ti9430a

4. Grasp cart handle

securely with one hand.

With the other hand lift

and pull Fold-n-Store

handle (a) located in

front of sprayer frame,

toward you. Lift up front

of sprayer until you hear

a click and the cart is

locked in place.

ti9431a

24 312001G

Page 25

Maintenance and Service

Maintenance and Service

CAUTION

Protect the internal drive parts of this sprayer

from water. Openings in shroud allow cooling of

mechanical parts and electronics inside. If water

gets into these openings, the sprayer could malfunction or be permanently damaged.

Caring for Sprayer

Keep sprayer and all accessories clean and in good working

order.

ti9354a

To avoid overheating motor,

keep vent holes in shroud clear

for air flow. Do not cover sprayer

while spraying.

Paint Hoses

Check hose for damage every time you spray. Do

not attempt to repair hose if hose jacket or fittings

are damaged. Do not use hoses shorter than 25 ft

(7.6 m). Wrench tighten, using two wrenches.

Tips

• Always clean tips with

compatible solvent and

brush after spraying.

• Tips may require

replacement after 15 gallons (57 liters) or they

may last through 60 gallons (227 liters) depending on abrasiveness of paint.

• Do not spray with worn tip.

ti2055a

Pump Packings

When pump packings wear,

paint will begin to leak down

outside of pump.

• Replace pump packings at

first sign of leaking or additional damage could occur.

ti9355a

312001G 25

• Purchase a pump repair kit

and install according to

instructions provided with

kit.

• Consult a Graco/M

authorized service center.

AGNUM

ti9356a

Page 26

Troubleshooting

Problem Cause Solution

Troubleshooting

Check everything in this Troubleshooting Table

before you bring the sprayer to a Graco/M

AGNUM

authorized service center.

Power switch is on and sprayer is

plugged in, but motor does not

run, and pump does not cycle.

Pressure is set at zero pressure. Turn pressure control knob clock-

wise to increase pressure setting.

Motor or control is damaged. Take sprayer to Graco/M

AGNUM

authorized service center.

Electric outlet is not providing

power.

• Try a different outlet or plug in

something that you know is

working to test outlet.

• Reset building circuit breaker

or replace fuse.

Extension cord is damaged. Replace extension cord. Read

Grounding and Electric Requirements, page 6.

Sprayer electric cord is damaged. Check for broken insulation or

wires. Replace electric cord if

damaged.

Paint and/or water is frozen or

hardened in pump.

Unplug sprayer from outlet. If frozen do NOT try to start sprayer

until it is completely thawed or you

may damage the motor, control

board and/or drivetrain.

Make sure power switch is OFF.

Place sprayer in a warm area for

several hours. Then plug in powercord and turn sprayer ON.

Slowly increase pressure setting

to see if motor will start.

If paint is hardened in sprayer,

pump packings, valves, drivetrain

or pressure switch may need to

be replaced. Take sprayer to

Graco/M

AGNUM authorized ser-

vice center.

26 312001G

Page 27

Troubleshooting

Problem Cause Solution

Pump does not prime. Prime/Spray Valve is in SPRAY

position.

Inlet screen is clogged or suction

tube is not immersed.

Pump was not primed with

flushing fluid.

Inlet valve check ball is stuck. Remove suction tube and place a

Inlet valve check ball or seat is

dirty

Outlet valve check ball is stuck. ProX7 and ProX9: Insert screw

Turn Prime/Spray Valve to PRIME

position (pointing down).

Clean debris off inlet screen and

make sure suction tube is

immersed in fluid.

Remove suction tube from paint.

Prime pump with water or

solvent-based flushing fluid, page

10.

pencil into the inlet section to dislodge the ball, allowing pump to

prime properly. OR Power Flush

sprayer, page 19.

AutoPrime may need replacement. Turn power switch ON and

listen for “tap” in pump. If you do

not hear “tap”, AutoPrime is damaged. Take sprayer to Graco/M

NUM authorized service center.

AG-

Remove inlet fitting. Clean or

replace ball and seat.

driver in slot and remove

™

Easy-Access

door, page 7.

Unscrew outlet valve with a 3/4 in.

socket. Remove and clean

assembly.

X5 and X7: Remove outlet fitting

and clean outlet check ball.

Suction tube is leaking. Tighten suction tube connection.

Inspect for cracks or vacuum

leaks.

Pump does not prime with fluid. Remove suction tube from paint.

Prime pump with water or solvent-based flushing fluid.

312001G 27

Page 28

Problem Cause Solution

Troubleshooting

Pump cycles but does not build up

pressure.

Pump cycles, but paint only dribbles or spurts when spray gun is

triggered.

Pump is not primed. Prime pump.

Inlet screen is clogged . Clean debris off inlet screen and

make sure suction tube is

immersed in fluid.

Suction tube is not immersed in

paint.

Make sure suction tube is

immersed in paint.

Suction tube is leaking. Tighten suction tube connection.

Inspect for cracks or vacuum

leaks. If cracked or damaged,

replace suction tube.

Prime/Spray Valve is worn or

obstructed with debris.

Take sprayer to Graco/M

authorized service center.

AGNUM

Pump check ball is stuck. Read Pump does not prime sec-

tion in Troubleshooting, page 27.

Pressure is set too low. Slowly turn Pressure Control

Knob clockwise to increase pressure setting which will turn motor

on to build pressure.

Spray tip is clogged. Unclog spray tip, page 13.

InstaClean fluid filter is clogged. Clean or replace InstaClean fluid

filter, page 21.

Spray gun fluid filter is clogged. Clean or replace gun fluid filter,

page 21.

Spray tip is too large or worn. Replace tip.

28 312001G

Page 29

Troubleshooting

Problem Cause Solution

Pressure is set at maximum but

cannot achieve a good spray

Reversible spray tip is in

UNCLOG position.

pattern.

Spray tip is too large for sprayer. Select smaller spray tip.

Spray tip is worn beyond

capability of sprayer.

Extension cord is too long or not

heavy enough gauge.

Spray gun fluid filter is clogged. Clean or replace spray gun fluid

InstaClean fluid filter is clogged. Clean or replace InstaClean fluid

Inlet screen is clogged. Clean debris off inlet screen.

Pump valves are worn. Check for worn pump valves.

Material is too thick. Thin material.

Hose is too long (if extra section is

added).

Spray gun stopped spraying. Pump was not primed with flush-

ing fluid.

Suction tube is leaking. Tighten suction tube connection.

Prime/Spray valve is plugged. Clean/replace prime tube as nec-

Spray tip is clogged. Unclog spray tip, page 13.

When paint is sprayed, it runs

Coat is going on too thick. Move gun faster.

down the wall or sags.

Rotate arrow-shaped handle on

spray tip so it points forward in

SPRAY position, page 13.

Replace spray tip.

Replace extension cord.

Grounding and Electrical

Requirements, page 6.

filter, page 21.

filter, page 21.

a. Prime sprayer with paint

b. Trigger gun momentarily.

When trigger is released,

pump should cycle

momentarily and stop. If

pump continues to cycle,

pump valves may be worn.

Remove section of hose.

Remove suction tube from paint.

Prime pump with water or solvent-based flushing fluid.

Inspect for cracks or vacuum

leaks.

essary. Take sprayer to

Graco/M

AGNUM authorized ser-

vice center if valve is plugged.

Choose a tip with smaller hole

size.

Choose tip with wider fan.

Make sure gun is far enough from

surface.

312001G 29

Page 30

Problem Cause Solution

Troubleshooting

When paint is sprayed, coverage

is inadequate.

Coat is going on too thin. Move gun slower.

Choose tip with larger hole size.

Choose tip with narrower fan.

Make sure gun is close enough to

surface.

Fan pattern varies dramatically

while spraying.

Pressure control switch is worn

and causing excessive pressure

Take sprayer to Graco/M

authorized service center.

AGNUM

variation.

OR

Sprayer does not turn on promptly

when resuming spraying.

Cannot trigger spray gun. Spray gun trigger lock is locked. Rotate trigger safety lever to

unlock trigger lock, page 9.

Paint is coming out of pressure

control switch.

Prime/Spray valve actuates

automatically relieving pressure

Pressure control switch is worn. Take sprayer to Graco/M

authorized service center.

System is over pressurizing. Take sprayer to Graco/M

authorized service center.

AGNUM

AGNUM

through prime tube.

Paint leaks down outside of pump. Pump packings are worn. Replace pump packings.

Motor is hot and runs intermit-

tently. Motor automatically shuts

off due to excessive heat. Damage can occur if cause is not corrected.

Thermal Overload, page 6.

Vent holes in enclosure are

plugged or sprayer is covered.

Extension cord is too long or not a

heavy enough gauge.

Unregulated electrical generator

being used has excessive voltage.

Keep vent holes clear of

obstructions and overspray and

keep sprayer open to air.

Replace extension cord. Read

Grounding and Electrical

Requirements, page 6.

Use electrical generator with a

proper voltage regulator. Sprayer

requires 120VAC, 60 Hz,

1500-Watt generator.

30 312001G

Page 31

Technical Data

Technical Data

MAGNUM X5 MAGNUM X7

Working pressure range 0-2800 psi (0-19 MPa, 0-193 bar) 0-3000 psi (0-21 MPa, 0-207 bar)

Electric motor

Operating horsepower 1/2 5/8

Maximum delivery (with tip) 0.24 gpm (0.91 lpm) 0.31 gpm (1.17 lpm)

Paint hose 1/4 in. x 25 ft (6.4 mm x 7.5 m) 1/4 in. x 25 ft (6.4 mm x 7.5 m)

Maximum tip hole size

Weight, sprayer only 16 lb (7.3 kg) 26 lb (11.8 kg)

Weight, sprayer, hose & gun 19.2 lb (8.7 kg) 29.2 lb (13.2 kg)

Dimensions (Upright):

Length 14.5 in. (36.8 cm) 19.3 in. (49.0 cm)

Width 12.4 in. (31.5 cm) 15.3 in. (38.9 cm)

Height 17.9 in. (45.5 cm) 37.0 in. (94.0 cm)

Dimensions (Folded):

Length N/A 19.3 in. (49.0 cm)

Width N/A 15.3 in. (38.9 cm)

Height N/A 29.2 in. (74.2 cm)

Power cord 18 AWG, 3-wire, 6 ft (1.8 m)

Fluid inlet fitting 3/4 in. internal thread (standard garden hose thread)

Fluid outlet fitting 1/4 NPSM external thread

Inlet screen (on suction tube) 35 mesh (450 micron)

Wetted parts, pump & hose stainless steel, brass, leather, ultra-high molecular weight polyethylene

Wetted parts, gun aluminum, brass, carbide, nylon, plated steel, stainless steel,

Generator requirement 1500 Watt minimum

Electrical power requirement 120 Vac, 60 Hz, 15A, 1 phase

6.0A (open frame, universal) 6.0A (open frame, universal)

0.015 in. (0.38 mm) 0.017 in. (0.43 mm)

(UHMWPE), carbide, nylon, aluminum, PVC, polypropylene,

fluroelastomer

UHMWPE, zinc

Storage temperature range ◆❖ -30° to 160°F (-35° to 71°C)

Operating temperature range ✔ 40° to 115°F (4° to 46°C)

◆

When pump is stored with non-freezing fluid. Pump damage will occur if water or latex paint freezes in

pump.

❖

Damage to plastic parts may result if impact occurs in low temperature conditions.

✔

Changes in paint viscosity at very low or very high temperatures can affect sprayer performance.

312001G 31

Page 32

Technical Data

MAGNUM ProX7 MAGNUM ProX9

Working pressure range 0-3000 psi (0-21 MPa, 0-207 bar) 0-3000 psi (0-21 MPa, 0-207 bar)

Electric motor 5.8A (open frame,

permanent magnet DC)

Operating horsepower 3/4 7/8

Maximum delivery (with tip) 0.34 gpm (1.29 lpm) 0.38 gpm (1.44 lpm)

Paint hose 1/4 in. x 50 ft (6.4 mm x 15 m) 1/4 in. x 50 ft (6.4 mm x 15 m)

Maximum tip hole size

0.017 in. (0.43 mm) 0.019 in. (0.48 mm)

Weight, sprayer only 43 lb (20 kg) 43 lb (20 kg)

Weight, sprayer, hose & gun 46 lb (21 kg) 46 lb (21 kg)

Dimensions (Upright):

Length 23.75 in. (60.32 cm) 23.75 in. (60.32 cm)

Width 17.5 in. (44.45 cm) 19.25 in. (48.89 cm)

Height 36.5 in. (92.71 cm) 36.5 in. (92.71 cm)

Dimensions (Folded):

Length 23.25 in. (59.05 cm) 23.25 in. (59.05 cm)

Width 17.5 in. (44.45 cm) 19.25 in. (48.89 cm)

9.4A (open frame,

permanent magnet DC)

Height 22.00 in. (55.88 cm) 22.00 in. (55.88 cm)

Power cord 16 AWG, 3-wire, 6 ft (1.8 m)

Fluid inlet fitting 3/4 in. internal thread (standard garden hose thread)

Fluid outlet fitting 1/4 NPSM external thread

Inlet screen (on suction tube) 35 mesh (450 micron)

Wetted parts, pump & hose stainless steel, brass, leather, ultra-high molecular weight polyethylene

(UHMWPE), carbide, nylon, aluminum, PVC, polypropylene,

fluroelastomer

Wetted parts, gun aluminum, brass, carbide, nylon, plated steel, stainless steel,

UHMWPE, zinc

Generator requirement 1500 Watt minimum

Electrical power requirement 120 Vac, 60 Hz, 15A, 1 phase

Storage temperature range ◆❖ -30° to 160°F (-35° to 71°C)

Operating temperature range ✔ 40° to 115°F (4° to 46°C)

◆

When pump is stored with non-freezing fluid. Pump damage will occur if water or latex paint freezes in

pump.

❖

Damage to plastic parts may result if impact occurs in low temperature conditions.

✔

Changes in paint viscosity at very low or very high temperatures can affect sprayer performance.

32 312001G

Page 33

Notes

Notes

312001G 33

Page 34

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from

defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special,

extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace

any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused

by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering,

or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by

Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts.

The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose

any defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no

other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within

two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS

SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors,

switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying

equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach

of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English.

Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis

et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les

procédures concernées.

TO PLACE AN ORDER or to identify the nearest Graco/MAGNUM distributor, contact us at 1-888-541-9788

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

MM 312001

This manual contains English

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

2/2007, revised 09/2008

34 312001G

Loading...

Loading...