Page 1

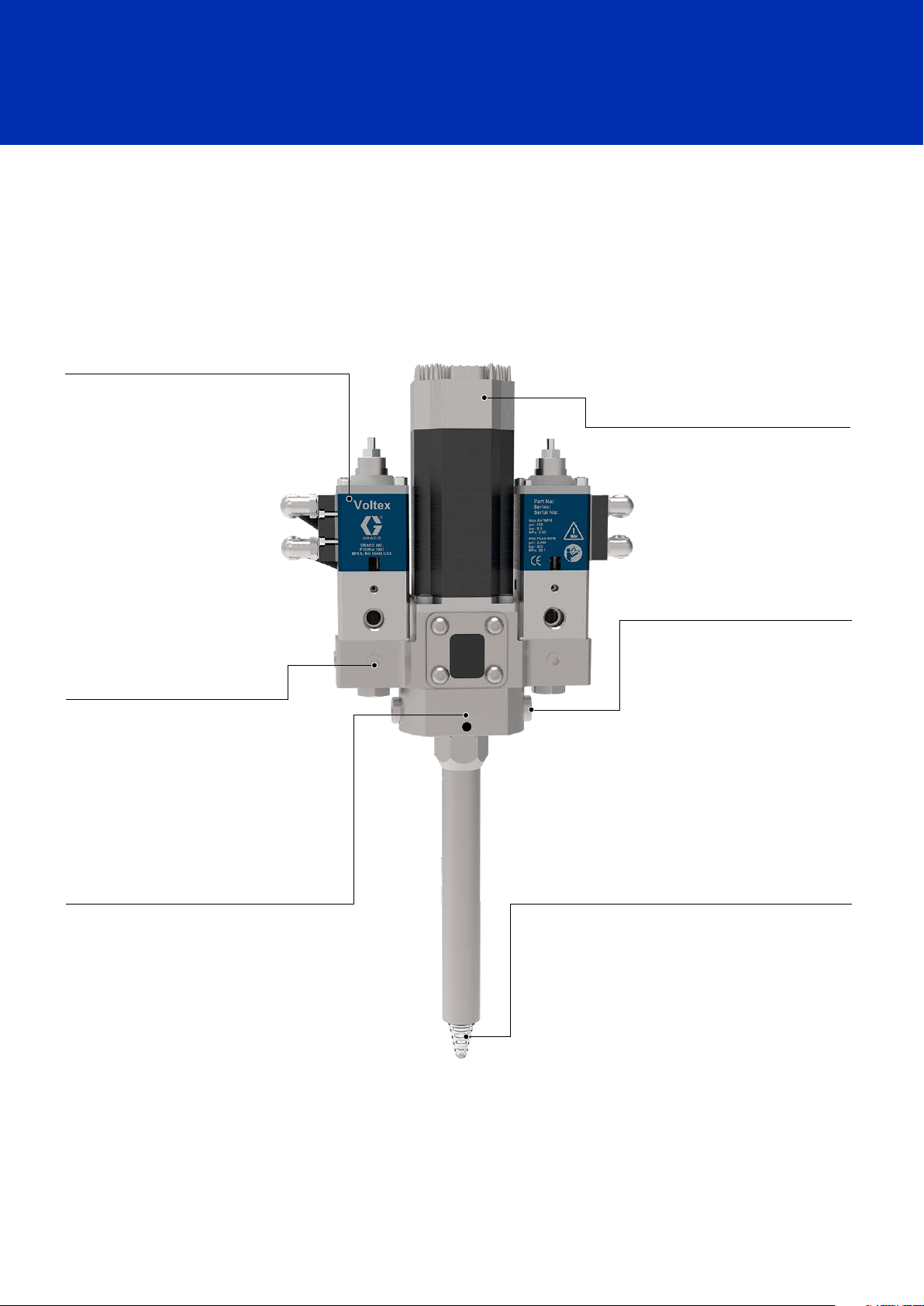

Voltex™ Dispense Valve

Rotary Static Mix Valve for Two-Component Foaming Urethanes and

Silicones

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Voltex Dynamic Mix Valve

Capable of dispensing foaming urethanes and silicones with ease and control, the Voltex Dynamic Mix Valve is the

final component to complete your two-component dispensing solution. In order to mix with confidence, this rotary

static dynamic mix valve is engineered with reliable servo motor, innovative error detection technology, and fully

integrated precision controls. These features, along with the valve’s flexibility, make it an attractive technology for

a wide variety of dispensing applications.

Application Flexibility

Independent A/B component

control, front/back mounting

capability, and plumbing options

to optimize applications.

Precision Repeatability

Servo electric motor delivers

reliable mix due to the

advanced RPM and torque

controls.

Versatile Design

Multiple accessory fluid ports

for pressure sensors, cleaning/

flushing, or air nucleation assist.

Long lasting rotary seal and sturdy

mixer shroud stand up to tough-toblend materials.

Process Control

Built with orifice inserts for

pressure balancing and check

valves that prevent downtime.

Minimize DowntimeDurable Components

Easy maintenance and

cleaning with disposable

mixing elements.

2

Page 3

Voltex Dynamic Mix Valve

Markets and Applications

Built with independent A/B component controls, flexible mounting, and seamless metering system integration, the Voltex

Dynamic Mix Valve fits the demands of the most challenging potting, gasketing, bonding, and sealing applications.

Dispense and Dispose Mixers

• Spiral mixing action thoroughly mixes two-component materials

• No solvent flushing means less mess and reduced disposal expenses

• Rugged, chemical-resistant mixer housing and mixing elements

Controller Options

• Choose from wall or table mounting styles to fit your production setup

GENERAL INDUSTRY

AUTOMOTIVEBATTERY FILTRATION

Tabletop without ADM

Wall mount with ADM

3

Page 4

Compatible Systems and Controls

Electric Fixed Ratio (EFR) System

Easily integrate the EFR with the Voltex Dynamic Mix Valve for

a complete two-component meter, mix and dispense solution.

The EFR is ideal for applications requiring precision dispense

and superior control over sealant materials.

PR70

When coupled with the Voltex Dynamic Mix Valve and control

box, the ADM equipped PR70 accurately meters, mixes and

dispenses two-component medium to low-viscosity materials

for potting, gasketing, sealing, and encapsulation applications.

Hydraulic Fixed Ratio (HFR) System

A meter, mix and dispense system for materials ranging from

epoxies to elastomers. Compatible with Voltex Dynamic Mix

Valve and ADM control box for high throughput applications

requiring on-ratio dispensing, precision dispense, and

consistent material flow.

Process Controls

An Easy to Use Control Module

With the Voltex Dynamic Mix Valve and controls, you can be confident that

you’re accurately dispensing material every time. Quickly optimize your

process with RPM and ramp up settings.

Simple Diagnostics

The controls also incorporate simple diagnostic screens which allow you to

quickly check all the process variables and define predictive maintenance

parameters.

4

Page 5

Technical Specifications

VOLTEX DYNAMIC MIX VALVE

Part Number

Maximum Static Fluid Pressure 3000 psi (20.7 MPa, 207 bar)

Maximum Dynamic Fluid Pressure 69 Bar (1000 psi, 6.9 MPa)

Maximum Air Pressure 8.3 Bar (120 psi, 0.83 MPa)

Maximum Motor Speed 4400 rpm

Typical Maximum Flow < 50 cc/sec

Fluid Inlet Size 1/4 in. NPT (female)

Fluid Outlet Shroud Thread 7/8 in. - 14 UNF (male)

Fluid Auxiliary Ports (6x on fluid housing) 1/8 in. NPT (female)

Approximate Size (W x D x H) 220.47 x 88.65 x 246.10 mm (8.68 x 3.49 x 9.69 in)

Air Line Size 8mm (5/16 in.)

Mounting Screw Size M6 X 1.0 (4x each side)

Maximum Operating Temperature 60°C (149°F)

25T670

Weight

CONTROLLER

Controller Mount Type (wall and table)

Required Line Voltage 100-240 VAC, 50/60 Hz, 1 Phase

Machine Operating Voltage

Maximum Harness Length (between valve and controller)

Weight

25T671 Voltex Tabletop Control Box for PR70 or HFR,

with ADM

25T672 Voltex Tabletop Control Box for EFR,

No ADM

25T673 Voltex Wall Mount Control Box for PR70 or HFR,

with ADM

5.32 kg (11.7 lbs)

M6 X 1.0 (4x)

24-VDC Components

48 VDC Motor

63m (206 ft.

14.5 kg (32 lbs)

12.7 kg (27.9 lbs)

15.3 kg (33.8 lbs)

25T674 Voltex Wall Mount Control Box for EFR,

No ADM

13.5 kg (29.7 lbs)

5

Page 6

Ordering Information

VOLTEX DYNAMIC MIX VALVE

Part Number 25T670

ORIFICES

Choose your orifice to balance pressures.

25T700

25T701 0.51mm (0.020") 25T707 1.07mm (0.042") 25T713 1.70mm (0.067")

25T702 0.61mm (0.024") 25T708 1.19mm (0.047") 25T714 1.82mm (0.073")

25T703 0.71mm (0.028") 25T709 1.32mm (0.052") 25T715 2.18mm (0.086")

25T704 0.79mm (0.031") 25T710 1.40mm (0.055") 25T716 Undrilled (no orifice)

25T705

0.41mm (0.016")

0.89mm (0.035")

MIXERS AND SHROUDS

Choose mixer size based on application.

10 Pack 50 Pack Compatible Shroud

8mm x 12 element

10mm x 12 element 25S026 25S027 4-419-903

13mm x 12 element

25T706

25T711

0.99mm (0.039")

1.52mm (0.060")

25S024 25S025 4-419-904

25S028 25S029 4-419-902C

25T712

25T675

1.60mm (0.063")

Multiple Orifice Kit

All orifice options come in packs of two (2), The multiple orifice kit includes two (2) of each size including the undrilled orifices.

CONTROL BOX

Choose a controller depending on system integration, and mounting style.

25T671

25T672 Voltex Tabletop Control Box for EFR, No ADM

25T673 Voltex Wall Mount Control Box for PR70 or HFR, with ADM

25T674

INTEGRATION CABLE KIT

Choose cable based on metering system and length required.

123651

121728 4m (13.12 ft) CAN Cable for EFR

121005 15m (49.21 ft) CAN Cable for EFR

25T887 3m (9.84 ft) Integration Cable Kit for HFR

Voltex Tabletop Control Box for PR70 or HFR, with ADM

Voltex Wall Mount Control Box for EFR, No ADM

2m (6.56 ft) CAN Cable for EFR

25T888 6m (19.70 ft) Integration Cable Kit for HFR

25T889 3m (9.84 ft) Integration Cable Kit for PR70

25T890

6

6m (19.70 ft) Integration Cable Kit for PR70

Page 7

Ordering Information

POWER CABLE

One power cable is required for the Voltex controller.

121055

121054 Power Cable, NEMA 6-15P (USA), 250V, 10A, 2.4m (8 ft)

121056 Power Cable, CEE 7/7 (France, Germany, Iceland, Netherlands, Norway, Turkey), 250V, 10A, 2.4m (8 ft)

121057 Power Cable, BS1363 (UK, Ireland, Malaysia, Singapore), 250V, 10A, 2.4m (8 ft)

121058 Power Cable, SI32 (Israel), 250V, 10A, 2.4m (8 ft)

124864 Power Cable, AS/NZS 3112 (Australia, New Zealand), 250V, 10A, 2.4m (8 ft)

124861 Power Cable, CEI 23-50 (Italy), 250V, 10A, 2.4m (8 ft))

124863 Power Cable, SEV 1011 (Switzerland), 250V, 10A, 2.4m (8 ft)

124862 Power Cable, 107-2-D1 (Denmark), 250V, 10A, 2.4m (8 ft)

121060

Power Cable, NEMA 5-15P (USA, Mexico, Puerto Rico, Canada, Taiwan), 115V, 10A, 2.2m (7.5 ft)

Power Cable, SANS 164-1 / BS 546 (South Africa, India), 250V, 16A, 2.4m (8 ft)

ACCESSORIES

Pressure Transducers

Buy two of each part to monitor A/B pressure

simultaneously.

16A093

25R640

Pressure Transducer Extension Cables

124409

17H363 7.5m (24.6 ft) Extension Cable

17H364

Pressure Transducer

Fitting, Pressure Transducer

3m (9.8 ft) Extension Cable

16m (52.5 ft) Extension Cable

MANUAL

Pressure Gauges

25T721 Material Pressure Kit (2 included)

Air Nucleation

25T717 Air Nucleation Kit (single side)

Integration Extension Cables

25T718

25T719 6m (19.7 ft) Extension Harness Kit

25T720

3m (9.8 ft) Extension Harness Kit

15m (49.2 ft) Extension Harness Kit

3A8115 Voltex Dynamic Mix Valve Instruction Manual

7

Page 8

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Distribution Center

Graco Distribution BV

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Fluid Equipment

(Shanghai) Co.,Ltd

Building 7, No. 1-2, Wenshui

Road 299

Jing’an District

Shanghai 200436

P.R. China

Tel: 86 512 6260 5711

Fax: 86 21 6495 0077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 432, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

38, Samsung 1-ro 1-gil

Hwaseong-si, Gyeonggi-do, 18449

Republic of Korea

Tel: 82 31 8015 0961

Fax: 82 31 613 9801

Europe

+32 89 770 700

FAX +32 89 770 777

WWW.GRACO.COM

All written and visual data contained in this document are based on the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Graco is certified ISO 9001.

©2021 Graco Distribution BV 350410ENEU Rev. A 04/21 Printed in Europe.

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

For more information on Graco‘s intellectual property, see www.graco.com/patent or www.graco.com/trademarks.

Loading...

Loading...