Page 1

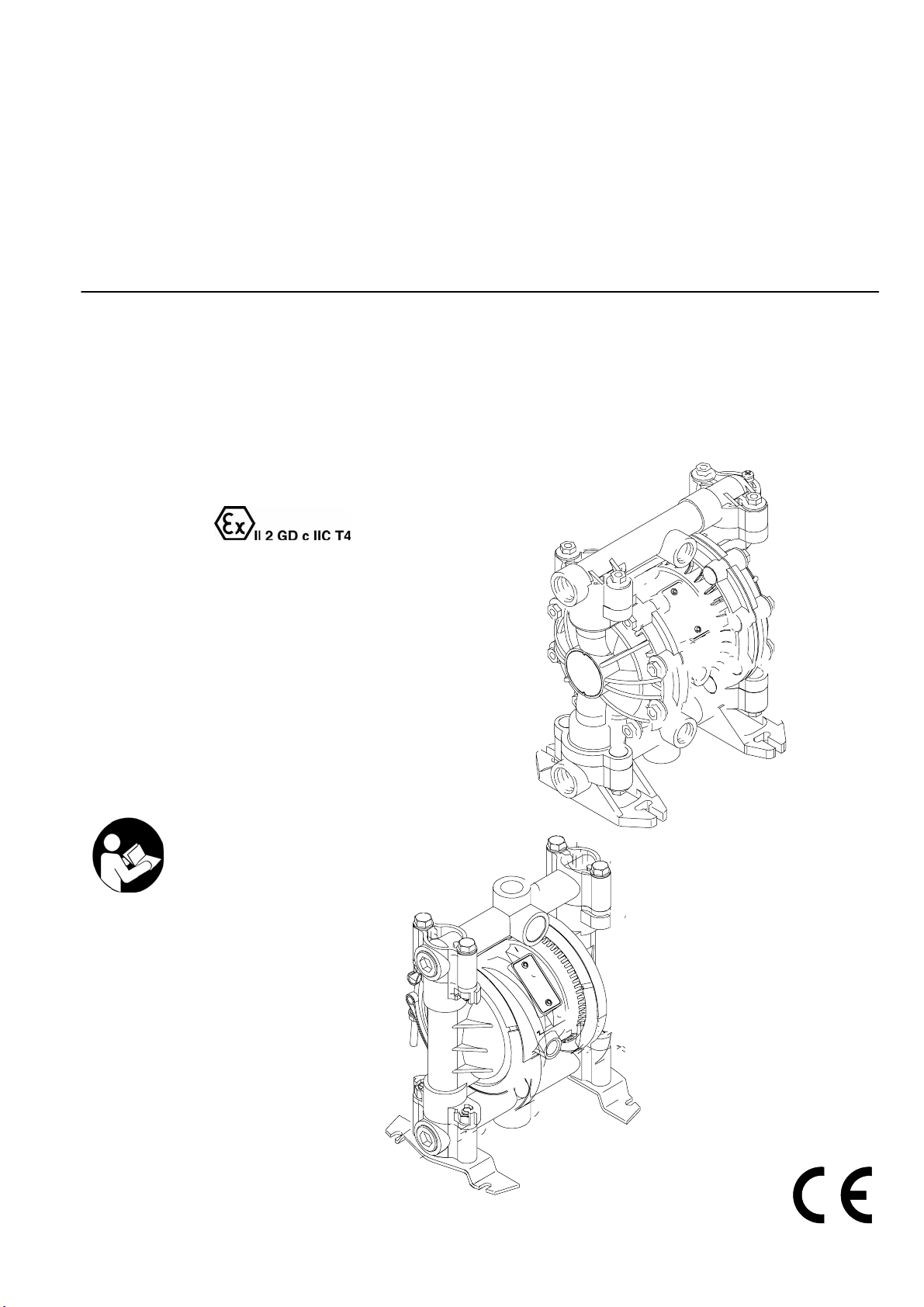

INSTRUCTIONS–PARTS LIST

Air-Operated

Diaphragm Pumps

For fluid transfer applications. For professional use only.

100 psi; 0.7 MPa; 7 bar Maximum Fluid Working Pressure

100 psi; 0.7 MPa; 7 bar Maximum Air Input Pressure

ALUMINUM AND STAINLESS STEEL*

These pumps a

*

M 60

*

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

re

cert

ified.

9065A

VERDERAIR VA 15

M 60

Page 2

Table of Contents

Symbols

Safety Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERDERAIR VA 15 and VERDERAIR VA 20

Pump Listing 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERDERAIR VA 15 and VERDERAIR VA 20

Repair Kits 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

VERDERAIR VA 15 and VERDERAIR VA 20

Common Parts 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERDERAIR VA 15 Parts Drawing 25. . . . . . . . . . . . . . . . .

VERDERAIR VA 15 Fluid Section Parts List 26. . . . . . . . . .

VERDERAIR VA 20 Parts Drawing 28. . . . . . . . . . . . . . . . .

VERDERAIR VA 20 Fluid Section Parts List 29. . . . . . . . . .

Torque Sequence 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERDERAIR VA 15:

Technical Data 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERDERAIR VA 20:

Technical Data 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VERDERAIR VA 15 and VERDERAIR VA 20

Performance Charts 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Services/Guarantee 37. . . . . . . . . . . . . . . . . . . . . . . .

Warning Symbol

Warning

This symbol alerts you to the possibility of serious injury or

death if you do not follow the instructions.

Caution Symbol

Caution

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

INSTRUCTIONS

Warning

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your VERDER distributor.

Do not alter or modify this equipment. Use only genuine VERDER parts and accessories.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated component in your system. This equipment

has a 100 psi; 0.7 MPa (7 bar) maximum working pressure at 100 psi; 0.7 MPa (7 bar) maximum incoming air pressure.

Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the Technical Data

section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose VERDER

hoses to temperatures above 180F (82C) or below –40C (–40C).

Wear hearing protection when operating this equipment.

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 819.6900

Do not use 1.1.1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use could result in a chemical reaction,

with the possibility of explosion.

Page 3

Warning

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or

swallowed.

Know the specific hazards of the fluid you are using.

Do not lift a pump under pressure. If dropped, the fluid section may rupture. Always follow the Pressure Relief

Procedure on page 10 before lifting the pump.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state, and

national guidelines.

Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and solvent

manufacturer.

Pipe and dispose of the exhaust air safely, away from people, animals, and food handling areas. If the

diaphragm fails, the fluid is exhausted along with the air. Read Air Exhaust Ventilation on page 6.

Never use an acetal pump to pump acids. Take precautions to avoid acid or acid fumes from contacting the

pump housing exterior. Stainless steel parts will be damaged by exposure to acid spills and fumes.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and result in a fire

or explosion and serious injury.

Ground the equipment. Refer to Grounding on page 8.

Never use a non–conductive polypropylene or PVDF pump with non-conductive flammable fluids as specified

by your local fire protection code. Refer to Grounding on page 8 for additional information. Consult your fluid

supplier to determine the conductivity or resistivity of your fluid.

If there is any static sparking or you feel an electric shock while using this equipment, stop pumping

immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid being pumped.

Pipe and dispose of the exhaust air safely, away from all sources of ignition. If the diaphragm fails, the fluid is

exhausted along with the air. Read Air Exhaust Ventilation on page 6.

Keep the work area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the work area.

Extinguish all open flames or pilot lights in the work area.

Do not smoke in the work area.

Do not turn on or off any light switch in the work area while operating or if fumes are present.

Do not operate a gasoline engine in the work area.

819.6900 3

Page 4

Installation

General Information

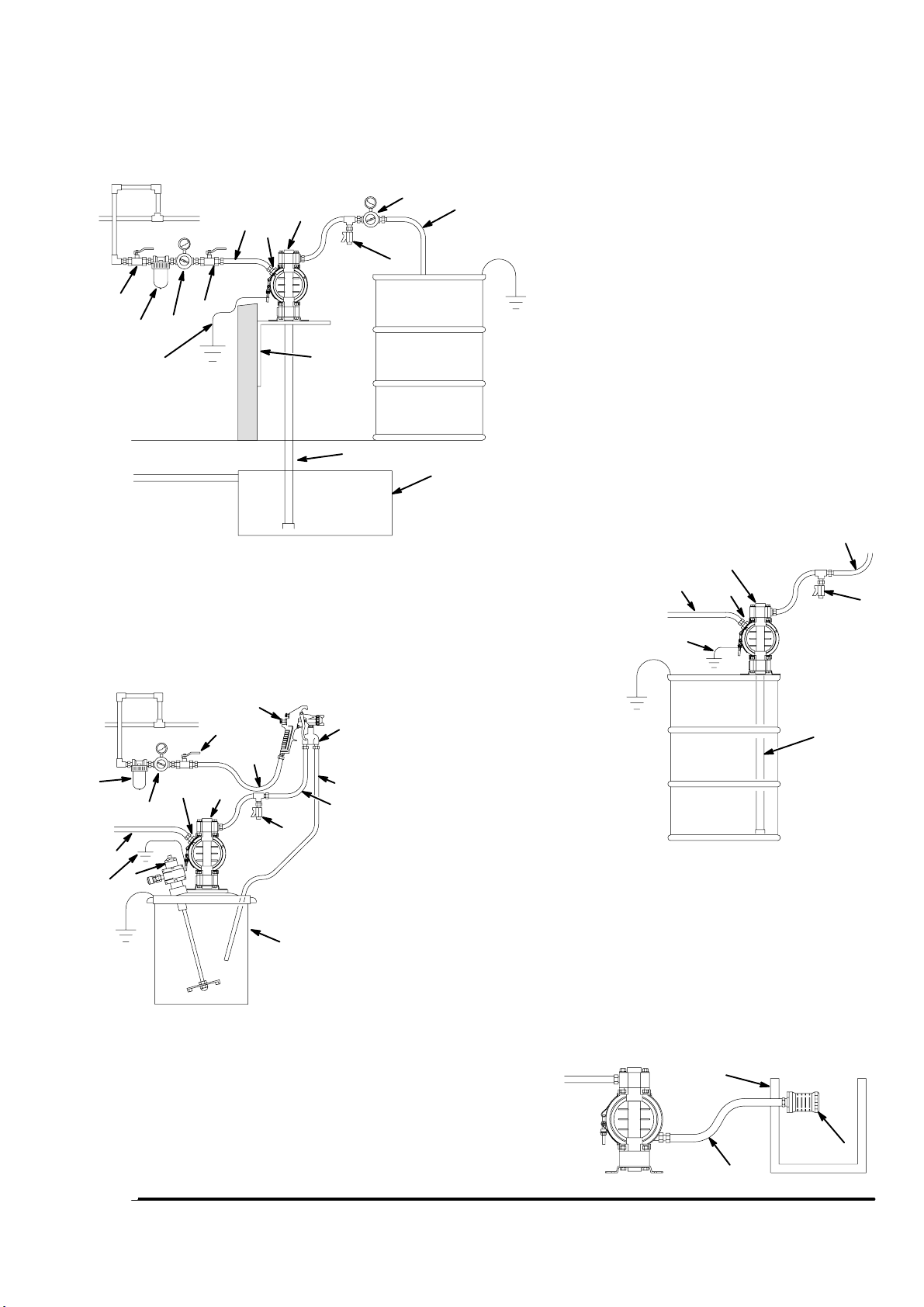

The Typical Installations in Fig. 2 are only guides for

selecting and installing system components. Contact your

VERDER distributor for assistance in planning a system

to suit your needs.

Always use Genuine VERDER Parts and Accessories.

Use a compatible, liquid thread sealant on all male

threads. Tighten all connections firmly to avoid air or fluid

leaks.

Tightening Threaded Fasteners Before First

Use

Before using the pump for the first time, check and retorque

all external fasteners. See Torque Sequence, page 30. After

the first day of operation, retorque the fasteners. Although

pump use varies, a general guideline is to retorque fasteners

every two months.

Toxic Fluid Hazard

Caution

Safe Operating Temperatures

Minimum (all pumps): 40_ F (4_ C)

Maximum

Acetal: 180F (82 C)

Polypropylene: 150F (66 C)

Aluminum, stainless steel, PVDF: 225F (107 C)

These temperatures are based upon mechanical stress only

and may be significantly altered by pumping certain chemicals. Consult engineering guides for chemical compatibilities

and temperature limits, or contact your VERDER distributor.

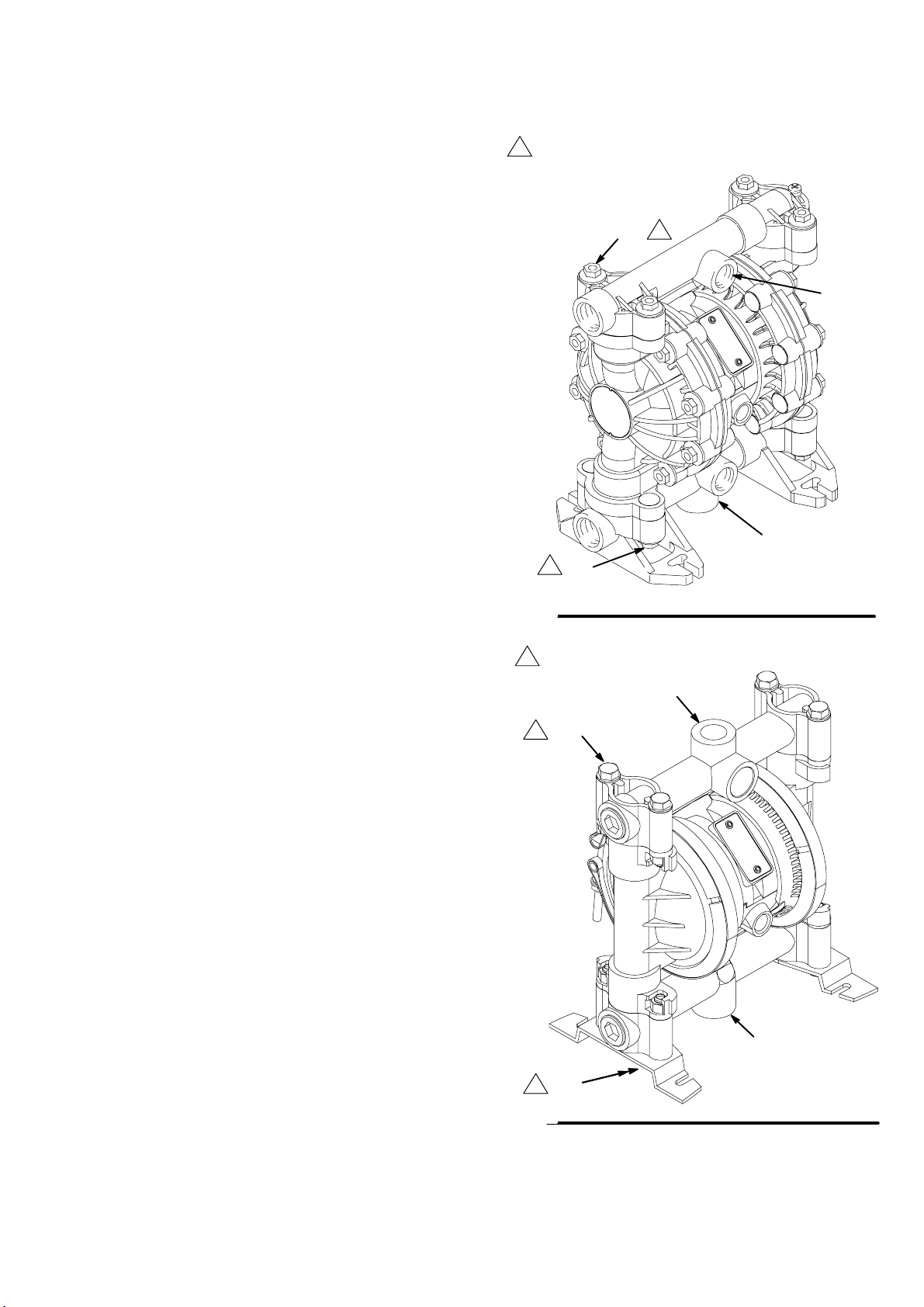

Mountings

These pumps can be used in a variety of installations.

Be sure the mounting surface can support the weight of

the pump, hoses, and accessories, as well as the stress

caused during operation.

Read Toxic Fluid Hazard on

page 3.

Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the Technical Data section of

all equipment manuals. Read the fluid and solvent

manufacturer’s warnings.

Fig. 2 shows some installation examples. On all installa-

tions, mount the pump using screws and nuts.

Pumping High-Density Fluids

High density fluids may prevent the lighter non-metallic check

valve balls from seating properly, which reduces pump performance significantly. Stainless steel balls should be used for

such applications.

4 819.6900

Page 5

Installation

Air Line

Warning

A bleed-type master air valve (B) is required in your system

to relieve air trapped between this valve and the pump.

See Fig. 2. Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury, including

splashing in the eyes or on the skin, injury from moving

parts, or contamination from hazardous fluids.

Caution

The pump exhaust air may contain contaminants. Ventilate

to a remote area if the contaminants could affect your fluid

supply. Read Air Exhaust Ventilation on page 6.

1. Install the air line accessories as shown in Fig. 2. Mount

these accessories on the wall or on a bracket. Be sure

the air line supplying the accessories is electrically conductive.

a. The fluid pressure can be controlled in either of two

ways. To control it on the air side, install an air regulator (G). To control it on the fluid side, install a fluid

regulator (J) near the pump fluid outlet (see Fig. 2).

b. Locate one bleed-type master air valve (B) close

to the pump and use it to relieve trapped air. Read

the Warning above. Locate the other master air

valve (E) upstream from all air line accessories and

use it to isolate them during cleaning and repair.

c. The air line filter (F) removes harmful dirt and

moisture from the compressed air supply.

2. Install an electrically conductive, flexible air hose (C)

between the accessories and the 1/4 npt(f) pump air

inlet. Use a minimum 1/4 in. ID air hose. Screw an air

line quick disconnect coupler (D) onto the end of the air

hose (C), and screw the mating fitting into the pump air

inlet snugly. Do not connect the coupler (D) to the fitting

yet.

Installation of Remote Pilot Airlines

1. Connect the air line to the pump as noted above.

2. Connect 1/4 OD tubing to the push type connectors (16)

on the underside of the pump.

NOTE: By replacing the push type connectors, other sizes

or types of fittings may be used. The new fittings will

require 1/8 in. npt threads.

3.

onnect the other end of the tubes to the external air

C

signal, such as Cycleflo (PN 819.9742) or Cycleflo II

(819.9743) controllers.

NOTE: The air pressure at the connectors must be at least

30% of the air pressure to the air motor for the pump

to operate.

Fluid Suction Line

If using a conductive (acetal or polypropylene) pump, use

conductive hoses. If using a non-conductive pump,

ground the fluid system. Read Grounding on page 8.

The fluid inlet port is 1/2 in. or 3/4 in..

At inlet fluid pressures greater than 15 psi; 0.1 MPa

(1 bar), diaphragm life will be shortened.

Fluid Outlet Line

Warning

A fluid drain valve (H) is required in your system to relieve

pressure in the hose if it is plugged. See Fig. 2. The drain

valve reduces the risk of serious injury, including splashing

in the eyes or on the skin, or contamination from hazardous fluids when relieving pressure. Install the valve close to

the pump fluid outlet.

1. Use electrically conductive fluid hoses (K). The pump

fluid outlet is 1/2 in. or 3/4 in. Screw the fluid fitting into

the pump outlet snugly. Do not over–tighten.

2. Install a fluid regulator (J) at the pump fluid outlet to control fluid pressure, if desired (see Fig. 2). See Air Line,

step 1a., for another method of controlling pressure.

3. Install a fluid drain valve (H) near the fluid outlet. Read

the warning above.

819.6900 5

Page 6

Installation

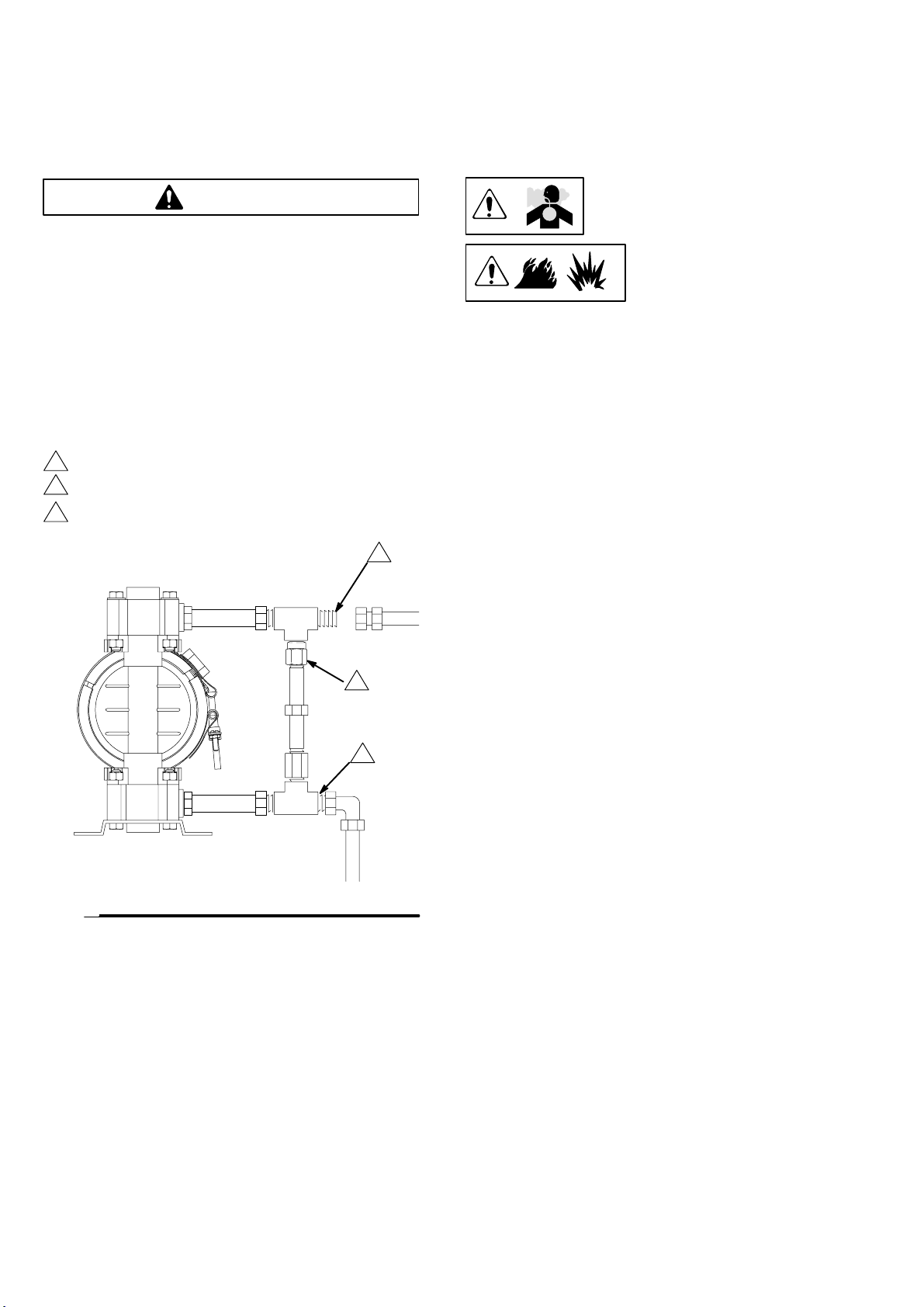

Fluid Pressure Relief Valve

Caution

Some systems may require installation of a pressure relief

valve at the pump outlet to prevent over–pressurization and

rupture of the pump or hose. See Fig. 1.

Thermal expansion of fluid in the outlet line can cause over–

pressurization. This can occur when using long fluid lines

exposed to sunlight or ambient heat, or when pumping from a

cool to a warm area (for example, from an underground tank).

Over–pressurization can also occur if the VERDERAIR pump

is being used to feed fluid to a piston pump, and the intake

valve of the piston pump does not close, causing fluid to back

up in the outlet line.

1

Install valve between fluid inlet and outlet ports.

2

Connect fluid inlet line here.

3

Connect fluid outlet line here.

3

Air Exhaust Ventilation

Read Toxic Fluid Hazard on

page 3.

Read Fire and Explosion

Hazard on page 3.

Be sure the system is properly ventilated for your type of

installation. You must vent the exhaust to a safe place,

away from people, animals, food handling areas, and all

sources of ignition when pumping flammable or hazardous

fluids.

Diaphragm failure will cause the fluid being pumped to

exhaust with the air. Place an appropriate container at the

end of the air exhaust line to catch the fluid. See Fig. 2.

The air exhaust port is 3/8 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can cause erratic

pump operation.

Fig. 1

See Venting Exhaust Air in Fig. 2. Exhaust to a remote

location as follows:

1

2

9073A

1. Remove the muffler (W) from the pump air exhaust port.

2. Install an electrically conductive air exhaust hose (X)

and connect the muffler to the other end of the hose.

The minimum size for the air exhaust hose is 3/8

in.(10 mm) ID. If a hose longer than 15 ft (4.57 m) is

required, use a larger diameter hose. Avoid sharp bends

or kinks in the hose.

3. Place a container (Z) at the end of the air exhaust line to

catch fluid in case a diaphragm ruptures. See Fig. 2.

6 819.6900

Page 7

Installation

ABOVE-GROUND TRANSFER INSTALLATION

C

A

D

H

E

F

B

G

Y

N

L

KEY

A Pump

C Electrically conductive air supply line

D Air line quick disconnect

H Fluid drain valve (required)

AIR SPRAY INSTALLATION

K Electrically conductive fluid supply hose

L Fluid suction line

Y Ground wire (required; see page 8 for

S

E

R

F

D

A

G

H

C

V

Y

U

P

KEY

A Pump

C Electrically conductive air line to pump

T

E Gun air line shutoff valve

F Air line filter

K

G Gun air regulator

H Fluid drain valve (required)

K Electrically conductive fluid supply hose

P Circulating valve

R Electrically conductive air line to gun

S Air spray gun

T Electrically conductive fluid return line

U 19-liter pail

V Agitator

Y Ground wire (required; see page 8 for

installation instructions)

J

K

9074A

M

installation instructions)

KEY

A Pump

B Bleed-type master air valve (required for pump)

C Electrically conductive air supply line

D Air line quick disconnect

E Master air valve (for accessories)

F Air line filter

G Pump air regulator

H Fluid drain valve (required)

J Fluid regulator (optional)

K Electrically conductive fluid supply hose

L Fluid suction line

M Underground storage tank

N Wall mounting bracket

Y Ground wire (required; see page 8 for installation

instructions)

208-LITER BUNG PUMP INSTALLATION

A

C

D

Y

K

H

L

9075A

Fig. 2

9076A

KEY

W Muffler

X Electrically Conductive Air Exhaust Hose

Z Container for Remote Air Exhaust

All wetted and non-wetted pump parts must be

compatible with the fluid being pumped.

VENTING EXHAUST AIR

Z

X

819.6900 7

W

04054

Page 8

Installation

Grounding

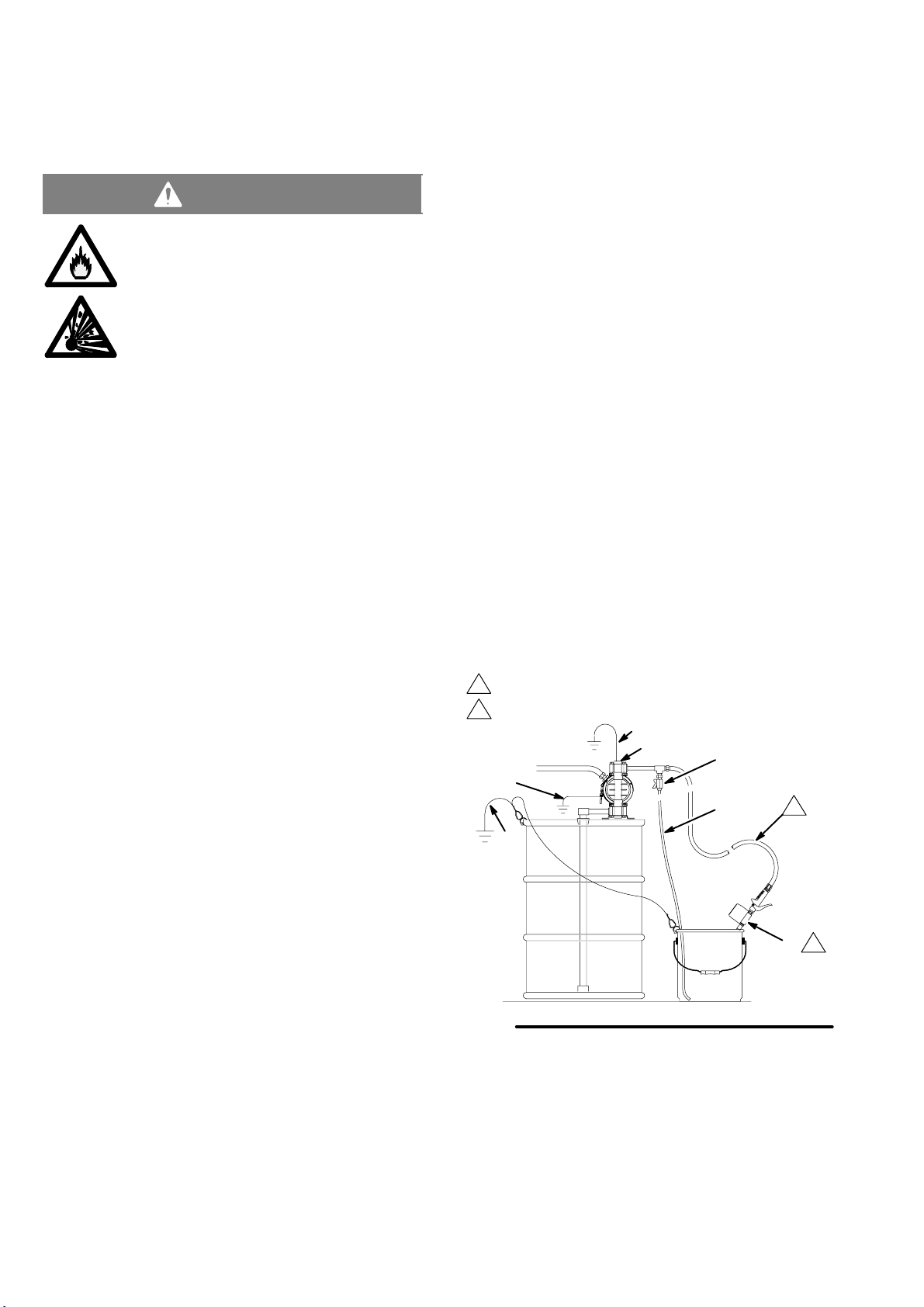

Warning

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before operating

the pump, ground the system as explained

below. Also read the section Fire and Explo-

sion Hazard on page 3.

The acetal and conductive polypropylene

VERDERAIR VA 15 pumps contain a conduc-

tive additive that makes the wetted parts con-

ductive. Attaching the ground wire to the grounding screw

(106) grounds the wetted parts. See grounding screw on

page 25.

T

he metal M60 pumps have a grounding strip connecting

the vee clamps (109). Attach a ground wire to the grounding

strip with the screw, lockwasher, and nut as shown in the

Grounding Detail on page 28.

The non–conductive polypropylene and PVDF VERDERAIR

VA 15 pumps are not conductive.

When pumping conductive flammable fluids, always ground

the entire fluid system by making sure the fluid system has

an electrical path to a true earth ground (see Fig. 3). Never

use a non–conductive polypropylene or PVDF pump with

non-conductive flammable fluids as specified by your local

fire protection code.

US Code (NFPA 77 Static Electricity) recommends a conductivity greater than 50 x 10

ter) over your operating temperature range to reduce

the hazard of fire. Consult your fluid supplier to determine

the conductivity or resistivity of your fluid. The resistivity

must be less than 2 x 10

–12

Siemans/meter (ohms/me-

12

ohm-centimeters.

Ground all of this equipment:

Pump: The metal pump has a grounding strip in front of

the center housing. The acetal and conductive polypropylene pumps have a grounding screw on the top manifold.

Connect the non-clamp end of the ground wire to the

grounding strip or grounding screw, and connect the

clamp end of the ground wire to a true earth ground. To

order a ground wire and clamp, order Part No. 819.0157.

Air and fluid hoses: Use only electrically conductive

hoses.

Air compressor: Follow the manufacturer’s recommenda-

tions.

Solvent pails used when flushing: Follow the local code.

Use only grounded metal pails, which are conductive. Do

not place the pail on a non-conductive surface, such as

paper or cardboard, which interrupts the grounding continuity.

Fluid supply container: Follow the local code.

GROUNDING A PUMP

KEY

A Pump

H Fluid drain valve (required)

S Dispense valve

T Fluid drain line

Y Fluid section grounding via grounding strip or grounding

screw (required for metal and acetal pumps)

Z Container ground wire (required)

1

Hose must be conductive.

2

Dispense valve nozzle must be in contact with container.

Y

A

H

Y

T

1

To reduce the risk of static sparking, ground the pump and all

other equipment used or located in the pumping area. Check

your local electrical code for detailed grounding instructions

for your area and type of equipment.

NOTE: When pumping conductive flammable fluids with a

non–conductive polypropylene or PVDF pump, al-

ways ground the fluid system. See the warning

above. Fig. 3 shows a recommended method of

grounding flammable fluid containers during filling.

8 819.6900

Fig. 3

Z

2

S

9079A

Page 9

Installation

Changing the Orientation of the Fluid Inlet and

Outlet Ports VM60)

You can change the

ports by repositioning the manifolds. For M60, , see Fig. 5.

1. Remove the four manifold nuts (109) or bolts (105).

2. Turn the manifold to the desired position, reinstall the

nuts or bolts, and torque to 80 to 90 in-lb (9 to 10 Nm).

See Torque Sequence, page 30.

NOTE: Make sure all manifold o-rings are positioned

NOTE: Pumps with duckbill check valves are shipped with

the inlet manifold on top and the outlet manifold on

the bottom. See page 14 for details.

orientation of the fluid inlet and outlet

correctly before you fasten the manifold.

Manifold o-rings (139) are shown in Fig. 7

and Fig. 8.

Torque to 80 to 90 in-lb (9 to 10 Nm). See Torque

1

Sequence, page 30.

1

109

1 109

outlet

inlet

Fig. 4

Torque to 80 to 90 in-lb (9 to 10 Nm). See Torque

1

Sequence, page 30.

outlet

1

105

9065A

inlet

Fig. 5

1

105

9071A

819.6900 9

Page 10

Operation

Pressure Relief Procedure

Warning

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious injury

from pressurized fluid, accidental spray, or splashing fluid,

follow this procedure whenever you:

Are instructed to relieve pressure;

Stop pumping;

Check, clean or service any system equipment;

Install or clean fluid nozzles.

1. Shut off the air to the pump.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve all fluid pressure,

and have a container ready to catch the drainage.

4. Check all fittings to be sure they are tight. Use a compatible liquid thread sealant on all male threads. Tighten the

fluid inlet and outlet fittings snugly. Do not over–tighten

the fittings into the pump.

5. Place the suction tube (if used) in the fluid to be pumped.

NOTE: If the inlet fluid pressure to the pump is more than

25% of the outlet working pressure, the ball check

valves will not close fast enough, resulting in inefficient pump operation.

6. Place the end of the fluid hose (K) into an appropriate

container.

7. Close the fluid drain valve (H).

8. With the pump air regulator (G) closed, open all bleedtype master air valves (B, E).

9. If the fluid hose has a dispensing device, hold it open

while continuing with the following step. Slowly open the

air regulator (G) until the pump starts to cycle. Allow the

pump to cycle slowly until all air is pushed out of the lines

and the pump is primed.

If you are flushing, run the pump long enough to

thoroughly clean the pump and hoses. Close the air

regulator. Remove the suction tube from the solvent

and place it in the fluid to be pumped.

Flush the Pump Before First Use

The pump was tested with water. Prior to first use, flush the

pump thoroughly with a compatible solvent. Follow the steps

under Starting and Adjusting the Pump.

Starting and Adjusting the Pump

1.

2.

3.

If lifting the pump, follow the Pressure

Relief Procedure above.

Read Toxic Fluid Hazard on

page 3.

Be sure the pump is

properly grounded.

Read Fire and Explo-

sion Hazard on

page 3.

Operation of Remote Piloted Pumps

1. Follow steps 1–8 above.

2. Open the air regulator (G).

Warning

The pump may cycle once before the external signal is

applied.

3. The pump will operate when air pressure is alternately

applied to the push type connectors (16).

NOTE: Leaving air pressure applied to the air motor for ex-

tended periods when the pump is not running may

shorten the diaphragm life. Using a 3–way solenoid

valve to automatically relieve the pressure on the air

motor when the metering cycle is complete prevents

this from occurring.

Pump Shutdown

At the end of the work shift, relieve the

pressure as described in Pressure Relief Procedure at left.

10 819.6900

Page 11

Maintenance

Lubrication

The air valve is lubricated at the factory to operate without

additional lubrication. If you want to provide additional lubrication, remove the hose from the pump air inlet and add two

drops of machine oil to the air inlet every 500 hours of operation or every month.

Caution

Do not over-lubricate the pump. Oil is exhausted through the

muffler, which could contaminate your fluid supply or other

equipment. Excessive lubrication can also cause the pump to

malfunction.

Flushing and Storage

Flush the pump to prevent the fluid you are pumping from

drying or freezing in the pump and damaging it. Use a compatible solvent.

Always flush the pump and relieve the pressure before you

store it for any length of time.

Read Pressure Relief Procedure on

page 10.

Tightening Threaded Connections

Before each use, check all hoses for wear or damage and

replace as necessary. Check to be sure all threaded connections are tight and leak-free.

Check fasteners. Tighten or retorque as necessary. Although pump use varies, a general guideline is to retorque

fasteners every two months. See Torque Sequence, page

30.

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based on

the pump’s service history. This is especially important for

prevention of spills or leakage due to diaphragm failure.

819.6900 11

Page 12

Troubleshooting

Read Pressure Relief Procedure on page 10, and relieve the pressure before you check or service the equipment. Check all possible problems and causes before disassembling the pump.

PROBLEM CAUSE SOLUTION

Pump will not cycle, or cycles once and

stops.

Pump cycles at stall or fails to hold

pressure at stall.

Pump operates erratically. Clogged suction line. Inspect; clear.

Air bubbles in fluid. Suction line is loose. Tighten.

Fluid in exhaust air. Diaphragm ruptured. Replace.

Pump exhausts air from clamps

(metal pumps).

Pump leaks fluid from check valves. Worn or damaged check valve o-rings. Inspect; replace.

Air valve is stuck or dirty. Use filtered air.

Leaky check valves or o-rings. Replace.

Worn check balls or duckbill valves or

guides.

Check ball wedged in guide. Repair or replace.

Worn diaphragm shaft seals. Replace.

Sticky or leaking check valve balls. Clean or replace.

Diaphragm ruptured. Replace.

Diaphragm ruptured. Replace.

Loose manifolds or damaged manifold

o-rings.

Loose fluid side diaphragm plates. Tighten.

Loose fluid side diaphragm plates. Tighten.

Worn diaphragm shaft seals. Replace.

Loose clamps. Tighten clamp nuts.

Air valve o-ring is damaged. Inspect; replace.

Replace.

Tighten manifold bolts or nuts; replace

o-rings.

12 819.6900

Page 13

Service

Air Valve M60 Pumps)

NOTE: Air Valve Repair Kit 819.9740 is available. Parts included in the kit are marked with a dagger () in Fig. 6 and in the Parts

Drawings and Lists. A tube of general purpose grease 819.0184 is supplied in the kit. Service the air valve as follows.

See Fig. 6.

1. Relieve the pressure. See Pres-

sure Relief Procedure on page 10.

2. Remove the cover (10) and the o-ring (4).

3. Remove the carriage plungers (7), carriages (8),

carriage pins (9), and valve plate (14) from the center

housing (11).

4. Clean all the parts, and inspect them for wear or

damage.

NOTE: If you are installing the new Air Valve Repair

Kit 819.9740, use all the parts in the kit.

5. Grease the lapped surface of the valve plate (14), and

install the valve plate with the lapped surface facing up.

6. Grease the bores of the center housing (11), install the

u-cup packings (2) on the carriage plungers (7), and

slide the carriage plungers into the carriage plunger

bores. See the following important installation notes:

NOTES:

When you install each u-cup packing (2) on each carriage

plunger (7), make sure the lips of the u-cup packing face

toward the clip end (the smaller end) of the carriage

plunger.

When you slide the carriage plungers (7) into the bores,

slide them in with the clip ends (the smaller ends) facing

toward the center of the center housing (11).

7. Grease the carriage pins (9), and slide the carriage pins

into the carriage pin bores.

8. Install the carriages (8). Make sure the carriages engage

the clip ends of the carriage plungers (7) and carriage

pins (9).

9. Grease the o-ring (4), and seat it in the groove around

the cover opening of the center housing (11).

10. Screw cover (10) into center housing, and torque cover

from 80 to 100 in–lb (9.0 to 13.6 Nm).

NOTE: Center housing (11) is shown separated from the

air covers, but it is not necessary to remove the air

covers for this service. Leave the center housing

and air covers assembled for this service.

5

Included in Air Valve Repair Kit 819.9740.

1

Torque to 80 to 100 in-lb (9.0 to 13.6 Nm).

2

Apply grease.

3

Apply grease to lapped face.

4

Apply grease to bores of center housing (11) before installing.

5

Seal lips face clip end (the smaller end) of carriage plunger (7).

Install with the clip ends (the smaller ends) facing toward center of

6

center housing (11).

Fig. 6

8

1

10

4

5

2

4

2

4 6

7

4 6

7

3

14

2

4

11

2

9

8

9

2

9069A

819.6900 13

Page 14

Service

Ball or Duckbill Check Valves

NOTE: Fluid Section Repair Kit is available. See page 23

to order the correct kit for your pump. Parts included

in the kit are marked with a double dagger () in

Fig. 7 and Fig. 8 and in the Parts Drawings and Lists.

General purpose grease 819.0184 and Adhesive

819.9741 are supplied in the kit.

1. Relieve the pressure. See Pres-

sure Relief Procedure on page 10.

2. Remove the top and bottom manifolds (102, 103).

3. Remove all parts shown with a dagger () in Fig. 7 and

Fig. 8.

4. Clean all parts, and replace worn or damaged parts.

5. Reassemble the pump.

NOTE: Torque the manifold nuts (109) or bolts (105) to

80 to 90 in-lb (9 to 10 Nm). See Torque Se-

quence, page 30.

Inlet and Outlet for Pumps with Duckbill

Check Valves

Pumps with duckbill check valves are shipped with the inlet

manifold on top and the outlet manifold on the bottom. To

make the inlet manifold on the bottom and the outlet manifold

on the top, rotate each of the four duckbill assemblies vertically 180 as shown below.

139

201

202

9080A

14 819.6900

Page 15

Service

Diaphragms M60

NOTE: Fluid Section Repair Kit is available. See page 23 to order the correct kit for your pump. Parts included in the kit are

marked with a double dagger () in Fig. 10 and in the Parts Drawings and Lists. General purpose grease 819.0184 and

Adhesive 819.9741 are supplied in the kit. Service the diaphragms as follows. See Fig. 10.

Disassembly

1. Relieve the pressure. See Pressure Relief Procedure on page 10.

2. Remove the manifolds (102) and fluid covers (101).

NOTE: Make sure all the check valve parts stay in

place. See Fig. 8 on page 15.

3. Remove the grounding strip from the vee clamps (109),

and remove the vee clamps.

4. Remove one of the fluid-side diaphragm plates (133)

(whichever one comes loose first when you use a

wrench on the hex of each), and pull the diaphragm

shaft out of the center housing (11).

5. Use a wrench on the flats of the diaphragm shaft (15) to

remove the other fluid-side diaphragm plate (133) from

the diaphragm shaft.

6. Remove the screws (141) and air covers (136), and

remove all old gasket (12) material from the ends of the

center housing (11) and the surfaces of the air covers.

7. Remove the diaphragm shaft u-cups (16) and pilot pin

o-rings (1).

8. Inspect all parts for wear or damage, and replace as

necessary.

3. Position the exhaust cover (13) and o-ring (4) on the

center housing (11).

4. Repeat steps 1 and 2 for the other end of the center

housing and the remaining air cover.

5. Apply medium-strength (blue) Loctite or equivalent to

the threads of the screws (140). Install on one end of

the diaphragm shaft (15) the following parts (see

proper order in Fig. 10): air-side diaphragm plate (6),

diaphragm (401), fluid-side diaphragm plate (133),

o-ring (115), and screw (140).

NOTE: The words “AIR SIDE” on the diaphragm (401)

and the flat side of the air-side diaphragm

plate (6) must face toward the diaphragm

shaft (15).

6. Put grease on the diaphragm shaft (15), and carefully

(do not damage the shaft u-cups) run the diaphragm

shaft (15) through the center housing (11) bore.

7. Repeat step 5 for the other end of the diaphragm

shaft (15), and torque the diaphragm shaft screws (140)

to 80 to 90 in-lb (9 to 10 Nm) at 100 rpm maximum.

8. Install the muffler (3).

When you install the vee clamps in step 9, orient the center

housing (11) so the air inlet is approximately 45 above horizontal and the muffler (3) is approximately horizontal.

Reassembly

1. Insert a diaphragm shaft u-cup (16) and a pilot pin

o-ring (1) into the end of the diaphragm shaft bore of

the center housing (11).

NOTE: Make sure the lips of the u-cup face out of the

center housing.

2. Line up the holes in the gasket (12) with the holes in the

end of the center housing (11), and use six screws (141)

to fasten an air cover (136) to the end of the center

housing (11). Torque the screws to 35 to 45 in-lb (4.0 to

5.1 Nm).

18 819.6900

9. Apply thin film of grease to inside of vee clamps (109).

10. Position the fluid covers (101), install the vee

clamps (109) around the fluid and air covers, install the

grounding strip on the vee clamps, and torque the vee

clamp nuts to 80 to 90 in–lb (9 to 10 Nm). See Torque

Sequence, page 30.

11. Make sure all the check valve parts are in place. See

Fig. 8 on page 15.

12. Install the manifolds (102), and torque the manifold

bolts (105) to 80 to 90 in-lb (9 to 10 Nm). See Torque

Sequence, page 30.

Page 16

Service

Diaphragms M60

105

7

102

101

11

1

16

4

13

141

2

3

12

136

3

109

4

402 6

5

102

105

4

401

3

15

1

115

6

7

Included in Fluid Section Repair Kit.

1

2

3

4

5

6

133

140

Install with lips facing out of center housing (11).

Torque to 35 to 45 in-lb (4.0 to 5.1 Nm).

Apply grease.

The words “AIR SIDE” on diaphragm and backup diaphragm must face toward

diaphragm shaft (15).

Flat side of the air-side diaphragm plate must face toward diaphragm shaft (15).

Apply medium-strength (blue) Loctite or equivalent to threads, and torque to

80 to 90 in-lb (9 to 10 Nm) at 100 rpm maximum.

16

Fig. 10

7

Torque to 80 to 90 in-lb (9 to 10 Nm). See Torque

Sequence, page 30.

9072A

819.6900 19

Page 17

M60 Pump Listing

Your Model No. is marked on the pump’s serial plate. See the listing of existing VERDERAIR VA 20 pumps below:

M60 Standard Air

Fluid

Ref. No.

810.6815 AL AC TF TF

810.6816 AL AC TF TPE

810.6817 AL AC SS TF

810.6818 AL AC TPE TPE

810.6819 AL AC SP SP

810.6820 AL AC BN BN

810.6821 AL AC FE FE

810.6822 AL SS TF TF

810.6823 AL SS TF TPE

810.6824 AL SS SS TF

810.6825 AL SS SS TPE

810.6826 AL SS SS SP

810.6827 AL SS SS BN

810.6828 AL SS SS FE

810.6829 AL SS TPE TPE

810.6830 AL SS SP SP

810.6831 AL SS BN BN

810.6832 AL SS FE FE

810.6833 AL PP TF TF

810.6834 AL PP TPE TPE

810.6835 AL PP SP SP

810.6836 AL PP BN BN

810.6837 SS AC TF TF

810.6838 SS AC SS TF

810.6839 SS SS TF TF

810.6840 SS SS SS TF

810.6841 SS SS SS TPE

810.6842 SS SS SS SP

810.6843 SS SS BN BN

810.6844 SS SS FE TF

810.6845 SS SS FE FE

810.6846 SS PP TF TF

810.6847 AL AC SS BN

810.6852 AL PP SP SP

810.6853 AL SS BN BN

810.6854 AL SS TF TF

810.6855 SS SS TF TF

Section

Valve

Seats

and

Guides

Checks Diaphragms

M60 for Solenoid Operation

Seats

Fluid

Ref. No.

810.6939 AL AC TF TF

810.6940 AL AC TF TPE

810.6941 AL AC SS TF

810.6942 AL AC TPE TPE

810.6943 AL AC SP SP

810.6944 AL AC BN BN

810.6945 AL AC FE FE

810.6946 AL SS TF TF

810.6947 AL SS TF TPE

810.6948 AL SS SS TF

810.6949 AL SS SS TPE

810.6950 AL SS SS SP

810.6951 AL SS SS BN

810.6952 AL SS SS FE

810.6953 AL SS TPE TPE

810.6954 AL SS SP SP

810.6955 AL SS BN BN

810.6956 AL SS FE FE

810.6957 AL PP TF TF

810.6958 AL PP TPE TPE

810.6959 AL PP SP SP

810.6960 AL PP BN BN

810.6961 SS AC TF TF

810.6962 SS AC SS TF

810.6963 SS SS TF TF

810.6964 SS SS SS TF

810.6965 SS SS SS TPE

810.6966 SS SS SS SP

810.6967 SS SS BN BN

810.6968 SS SS FE TF

810.6969 SS SS FE FE

810.6970 SS PP TF TF

810.6971 AL AC SS BN

Section

and

Guides

Checks Diaphragms

AL = Aluminium AC = Acetal BN = Buna-N TPE = Thermoplastic Polyester Elastomer PP = Polypropylene SP = Santoprene

SS = Stainless Steel TF = PTFE FE = Fluoroelastomer

810.6852, 810.6853, 810.6854, and 810.6855 have npt threads.

22 819.6900

Page 18

M 60 Repair Kits

NOTE: Order Repair Kits separately.

To order the Air Valve Repair Kit, order Part No. 819.9740.

Seats

and

Ref. No.

819.5183 PP FE FE

819.5176 PP BN BN

819.5172 PP BN ––

819.5169 PP SP SP

819.5162 PP TPE TPE

819.5149 PP TF TF

819.5148 PP TF ––

819.5135 SS FE FE

819.5130 SS FE ––

819.5128 SS BN BN

819.5124 SS BN ––

819.5107 SS SS TF

819.5101 SS TF TF

819.5100 SS TF ––

819.5080 AC BN BN

819.5076 AC BN ––

819.5066 AC TPE TPE

819.5059 AC SS TF

819.5054 AC TF TPE

8195053 AC TF TF

819.5052 AC TF ––

819.5010 SS Checks

819.5003 FE Diaphragms

819.5002 BN Diaphragms

819.5001 SP Diaphragms

819.4999 TF Diaphragms

819.5121 SS SP SP

Guides

Checks Diaphragms

AL = Aluminium AC = Acetal BN = Buna-N TPE = Thermoplastic Polyester Elastomer PP = Polypropylene SP = Santoprene

SS = Stainless Steel TF = PTFE FE = Fluoroelastomer

Kit Description

819.6992 Sensor

Includes 1 each of reed switch and carriage assembly

819.6993 Sensor with Counter

Includes 1 each of reed switch, counter, bracket, and

carriage assembly

819.6900 23

Page 19

M 60 Parts Drawing

Included in Air Valve Repair Kit 819.9740

Included in Fluid Section Repair Kits 819.4997 to

819.5189

10

8

7

2

* These parts are unique to the remote operated air motor.

105

102

103

107

112

202

201

139

202

301

201

139

139

106

104

101

401

16

12

402

141

4

14

9

17

11

1

16

4

13

3

15

16

6

106

112

202

301

102

105

117

139

201

139

202

201

139

108

109

140

133

115

Grounding Detail

123

122

121

110

9070A

28 819.6900

Page 20

M 60 Fluid Section Parts List

See page 24 for Air Motor Parts List

M 60 Fluid Section Parts List

Ref.

No.

115 819.6557 O-RING; PTFE 2 819.6557 O-RING; PTFE 2

139 819.4432 O-RING; PTFE 8 819.4432 O-RING; PTFE 8

Part No.

101 819.4457 COVER, fluid; aluminum 2 819.4467 COVER, fluid; sst 2

102 819.6964 MANIFOLD; aluminum; BSPT 2 819.6970 MANIFOLD; sst; BSPT 2

819.4458 MANIFOLD; aluminum; NPT (for

103 819.4434 LABEL, warning 1 819.4434 LABEL, warning 1

104 819.6965 LABEL, identification 1 819.6965 LABEL, identification 1

105 819.4459 SCREW; 3/8–16; 2.25 in. (57.2 mm) 8 819.4459 SCREW; 3/8–16; 2.25 in. (57.2 mm) 8

106 819.4460 NUT, hex; 3/8–16; sst 8 819.4460 NUT, hex; 3/8–16; sst 8

107 819.4461 WASHER, flat; 3/8 in.; sst 4 819.4461 WASHER, flat; 3/8 in.; sst 4

108 819.4462 BASE, feet 2 819.4462 BASE, feet 2

109 819.4433 CLAMP, vee 2 819.4433 CLAMP, vee 2

110 819.0198 NUT, clamp; 1/4–28 2 819.0198 NUT, clamp; 1/4–28 2

111 819.6354 STRIP, grounding 1 819.6354 STRIP, grounding 1

112 819.6967 PLUG, steel; BSPT 2 819.6971 PLUG; sst; BSPT 2

819.4463 PLUG, steel; NPT (for 810.6852,

117 819.4466 LABEL, warning 1

121 819.6880 SCREW; 10–24; 0.31 in. (8 mm) 1 819.6880 SCREW; 10–24; 0.31 in. (8 mm) 1

122 819.0187 LOCKWASHER; #10 1 819.0187 LOCKWASHER; #10 1

123 819.0185 NUT, hex; 10–24 1 819.0185 NUT, hex; 10–24 1

133 819.6968 PLATE, diaphragm, fluid side; sst 2 819.0356 PLATE, diaphragm, fluid side; sst

136 819.6969 COVER air 2 819.6969 COVER air 2

140 819.6556 SCREW, flange; hex head 2 819.6556 SCREW, flange; hex head 2

141 819.6936 SCREW, machine 12 819.6936 SCREW, machine 12

142 819.6943 RIVET (for plate 134) 2 819.6943 RIVET (for plate 134) 2

Aluminum Pumps Stainless Steel (sst) Pumps

Description Qty Part No. Description Qty

2 819.4468 MANIFOLD; sst; NPT

810.6852, 810.6853, and 810.6854

only)

2 819.4469 PLUG; sst; NPT (for 810.6855 only) 2

810.6853, and 810.6854 only)

(for 810.6855 only)

machined

2

2

Included in Fluid Section Repair Kit.

819.6900 29

Page 21

Torque Sequence

Always follow torque sequence when instructed to torque fasteners.

M 1

5

1. Left/Right Fluid Covers

Torque bolts to 80–90 in–lb (9–10 Nm)

1111

88

6

4

SIDE VIEW

3

5

7

2

2. Inlet Manifold

Torque bolts to 80–90 in–lb (9–10 Nm)

11

10

M

60

1. Left/Right Fluid Covers

Torque bolts to 80–90 in–lb (9–10 Nm)

2

FRONT VIEW

1

2. Inlet Manifold

Torque bolts to 80–90 in–lb (9–10 Nm)

5

3

9

BOTTOM VIEW

12

3. Outlet Manifold

Torque bolts to 80–90 in–lb (9–10 Nm)

13

15

TOP VIEW

16

14

4

4

BOTTOM VIEW

6

6

3. Outlet Manifold

Torque Bolts to 80–90 in–lb (9–10 Nm)

9

8

TOP VIEW

7

10

30 819.6900

Page 22

M 60 Technical Data

Maximum fluid working pressure 100 psi; 0.7 MPa (7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air pressure operating range 30 to 100 psi; 0.18 to 0.7 MPa (1.8 to 7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum air consumption 28 scfm; 0.793 cubic meters/min.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum free flow delivery 16 gpm; 61 l/min.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum pump speed 400 cpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Liters per cycle 0.15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum suction lift (water) 15 ft; 4.5 m dry,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 ft; 7.6 m wet

Maximum size pumpable solids 3.32 in.; 2.5 mm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound power level (measured per ISO standard 9614–2)

At 70 psig; 0.48 MPa (4.8 bar) at 50 cycles per minute 77 dBa. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

At 100 psig; 0.7 MPa (7 bar) at maximum cycles per minute 95 dBa. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound pressure level (measured 1 meter from pump)

At 70 psig; 0.48 MPa (4.8 bar) bar at 50 cycles per minute 67 dBa. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

At 100 psig; 0.7 MPa (7 bar) at maximum cycles per minute 85 dBa. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air inlet size 1/4 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air exhaust port size 3/8 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid inlet size. 3/4 bspt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

819.6852, 819.6853, 819.6854, and 819.6855 only 3/4 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid outlet size. 3/4 bspt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

819.6852, 819.6853, 819.6854, and 819.6855 only 3/4 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts (in addition to ball, seat, and diaphragm materials, which vary by pump)

Aluminum pumps aluminum, stainless steel, PTFE, zinc-plated steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stainless steel pumps 316 stainless steel, PTFE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-wetted external parts polypropylene, stainless steel, polyester (labels),. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

nickel-plated brass, epoxy-coated steel (feet)

Weight (approximate)

Aluminum pumps 8.5 lb; 3.9 kg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stainless steel pumps 18 lb; 8.2 kg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Santoprener is a registered trademark of the Monsanto Company.

Loctiter is a registered trademark of the Loctite Corporation.

819.6900 33

Page 23

M 60 Dimensions

FRONT VIEW

* Pumps with duckbill

check valves are shipped

with the inlet manifold on

top and the outlet manifold

on the bottom. To make

the inlet manifold on the

bottom and the outlet

manifold on the top, rotate

each of the four duckbill

assemblies vertically 180

as shown below.

139

201

202

SIDE VIEW

3/4 bspt(f)

Fluid Outlets *

62.5 mm

1/4 npt(f)

Air Inlet

187.2 mm

3/4 bspt(f)

Fluid Inlets *

112.8 mm108.0 mm

168.1 mm

3/4 bspt(f)

Fluid Outlet *

233.2 mm

198.1 mm

35.1 mm

3/4 bspt(f)

Fluid Outlet *

264.9 mm

109.0 mm

153.4 mm

3/4 bspt(f)

Fluid Inlets *

PUMP MOUNTING HOLE PATTERN

7.1 mm Diameter Slots

109.0 mm

168.1 mm

9078A

34 819.6900

Page 24

Performance Charts

Fluid Outlet Pressure

Test Conditions:

Pump tested in water with inlet submerged.

100

(0.7, 7)

A

80

(0.55, 5.5)

60

(0.41, 4.1)

40

(0.28, 2.8)

FLUID OUTLET PRESSURE – psi; MPa (bar)

20

(0.14, 1.4)

0

0246810121416

B

C

(7.6) (15.2) (22.7) (30.3) (37.9) (45.4) (53.0) (60.6)

Fluid Pressure Curves

A at 100 psi (0.7 MPa, 7 bar) air pressure

B at 70 psi (0.48 MPa, 4.8 bar) air pressure

C at 40 psi (0.28 MPa, 2.8 bar) air pressure

FLUID FLOW – gpm (lpm)

To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow (gpm/lpm) and operating air pressure (psi/MPa/bar):

1. Locate fluid flow rate along bottom of chart.

2. Follow vertical line up to intersection with selected fluid outlet pressure curve.

3. Follow left to scale to read fluid outlet pressure.

819.6900 35

Page 25

Performance Charts

ИИИИИ

ИИИИИ

ИИИИИ

ИИИИИ

Air Consumption

Test Conditions:

Pump tested in water with inlet submerged.

30

(0.84)

Air Consumption Curves

A at 100 psi (0.7 MPa, 7 bar) air pressure

25

(0.70)

(0.56)

(0.42)

(0.28)

AIR CONSUMPTION – scfm; cubic meter/min

(0.14)

B at 70 psi (0.48 MPa, 4.8 bar) air pressure

C at 40 psi (0.28 MPa, 2.8 bar) air pressure

20

15

10

5

0

0246810121416

(7.6) (15.2) (22.7) (30.3) (37.9) (45.4) (53.0) (60.6)

A

B

C

FLUID FLOW – gpm (lpm)

To find Pump Air Consumption (scfm or m/min) at a specific fluid flow (gpm/lpm) and air pressure (psi/MPa/bar):

1. Locate fluid flow rate along bottom of chart.

2. Read vertical line up to intersection with selected air consumption curve.

3. Follow left to scale to read air consumption.

36 819.6900

Page 26

Customer Services/Guarantee

CUSTOMER SERVICES

If you require spare parts, please contact your local distributor, providing the following details:

Pump Model

Type

Serial Number, and

Date of First Order.

GUARANTEE

All VERDER pumps are warranted to the original user against defects in workmanship or materials under normal use (rental use

excluded) for two years after purchase date. This warranty does not cover failure of parts or components due to normal wear,

damage or failure which in the judgement of VERDER arises from misuse.

Parts determined by VERDER to be defective in material or workmanship will be repaired or replaced.

LIMITATION OF LIABILITY

To the extent allowable under applicable law, VERDER’s liability for consequential damages is expressly disclaimed. VERDER’s

liability in all events is limited and shall not exceed the purchase price.

WARRANTY DISCLAIMER

VERDER has made an effort to illustrate and describe the products in the enclosed brochure accurately; however, such illustrations and descriptions are for the sole purpose of identification and do not express or imply a warranty that the products are merchantable, or fit for a particular purpose, or that the products will necessarily conform to the illustration or descriptions.

PRODUCT SUITABILITY

Many regions, states and localities have codes and regulations governing the sale, construction, installation and/or use of products for certain purposes, which may vary from those in neighbouring areas. While VERDER attempts to assure that its products

comply with such codes, it cannot guarantee compliance, and cannot be responsible for how the product is installed or used.

Before purchasing and using a product, please review the product application as well as the national and local codes and regulations, and be sure that product, installation, and use complies with them.

Original instructions. This manual contains English.

Revision ZAA, June 2013

819.6900 37

Page 27

EC-DECLARATION OF CONFORMITY

EG-VERKLARING VAN OVEREENSTEMMING, DÉCLARATION DE CONFORMITÉ CE, EG-KONFORMITÄTSERKLÄRUNG, DICHIARAZIONE DI

CONFORMITÀ CE, EF-OVERENSSTEMMELSESERKLÆRING, ΕΚ-ΔΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ, DECLARAÇÃO DE CONFORMIDADE – CE,

DECLARACIÓN DE CONFORMIDAD DE LA CE, EY-VAATIMUSTENMUKAISUUSVAKUUTUS, EG-DEKLARATION OM ÖVERENSSTÄMMELSE,

ES PROHLÁŠENÍ O SHODĚ, EÜ VASTAVUSDEKLARATSIOON, EC MEGFElELŐSÉGI NYILATKOZAT, EK ATBILSTĪBAS DEKLARĀCIJA, ES

ATITIKTIES DEKLARACIJA, DEKLARACJA ZGODNOŚCI UE, DIKJARAZZJONI-KE TA’ KONFORMITA`, IZJAVA ES O SKLADNOSTI, ES -

VYHLÁSENIE O ZHODE, ЕО-ДЕКЛАРАЦИЯ ЗА СЪВМЕСТИМОСТ, DEIMHNIÚ COMHRÉIREACHTA CE, CE-DECLARAŢIE DE CONFORMITATE

Model

Modèle, Modell, Modello, Μοντέλο,

Modelo, Malli, Mudel, Modelis, Mudell, Модел, Samhail

M 60

Part

Bestelnr., Type, Teil, Codice, Del, Μέρος, Peça,

Referencia, Osa, Součást, Részegység, Daļa,

Dalis, Część, Taqsima, Časť, Част, Páirt, Parte

Complies With The EC Directives:

Voldoet aan de EG-richtlijnen, Conforme aux directives CE, Entspricht den EG-Richtlinien, Conforme alle direttive CE, Overholder EF-direktiverne, Σύμφωνα με τις Οδηγίες της ΕΚ, Em

conformidade com as Directivas CE, Cumple las directivas de la CE, Täyttää EY-direktiivien vaatimukset, Uppfyller EG-direktiven, Shoda se směrnicemi ES, Vastab EÜ direktiividele,

Kielégíti az EK irányelvek követelményeit, Atbilst EK direktīvām, Atitinka šias ES direktyvas, Zgodność z Dyrektywami UE, Konformi mad-Direttivi tal-KE, V skladu z direktivami ES, Je v

súlade so smernicami ES, Съвместимост с Директиви на ЕО, Tá ag teacht le Treoracha an CE, Respectă directivele CE

2006/42/EC Machinery Directive

94/9/EC ATEX Directive (EX II 2 GD c IIC T4) – Tech File stored with NB 0359

Standards Used:

Gebruikte maatstaven, Normes respectées , Verwendete Normen, Norme applicate, Anvendte standarder , Πρότυπα που χρησιμοποιήθηκαν, Normas utilizadas, Normas aplicadas,

Sovellettavat standardit, Tillämpade standarder, Použité normy, Rakendatud standardid, Alkalmazott szabványok, Izmantotie standarti, Taikyti standartai, Użyte normy, Standards Użati,

Uporabljeni standardi, Použité normy, Използвани стандарти, Caighdeáin arna n-úsáid , Standarde utilizate

EN 1127-1 EN 13463-1

ISO 12100 ISO 9614-1

Notified Body for Directive

Aangemelde instantie voor richtlijn , Organisme notifié pour la directive , Benannte Stelle für diese Richtlinie, Ente certificatore della direttiva, Bemyndiget organ for direktiv , Διακοινωμένο

όργανο Οδηγίας, Organismo notificado relativamente à directiva, Organismo notificado de la directiva, Direktiivin mukaisesti ilmoitettu tarkastuslaitos, Anmält organ för direktivet, Úředně

oznámený orgán pro směrnici, Teavitatud asutus (direktiivi järgi), Az irányelvvel kapcsolatban értesített testület, Pilnvarotā iestāde saskaņā ar direktīvu, Apie direktyvą Informuota institucija,

Ciało powiadomione dla Dyrektywy, Korp avżat bid-Direttiva, Priglašeni organ za direktivo, Notifikovaný orgán pre smernicu, Нотифициран орган за Директива, Comhlacht ar tugadh fógra

dó, Organism notificat în conformitate cu directiva

810.0383–810.0418, 810.6758–810.6766, 810.6771, 810.6815–810.6847,

810.6852–810.6855, 810.6881–810.6890, 810.6939–810.6971, 810.7004

Approved By:

Goedgekeurd door, Approuvé par, Genehmigt von, Approvato da, Godkendt af , Έγκριση από, Aprovado por, Aprobado por, Hyväksynyt, Intygas av, Schválil, Kinnitanud, Jóváhagyta,

Apstiprināts, Patvirtino, Zatwierdzone przez, Approvat minn, Odobril, Schválené, Одобрено от, Faofa ag, Aprobat de

Frank Meersman

29 December 2009

Director

819.5963

Loading...

Loading...