Graco TrueCoat 360 16Y391, TrueCoat 360 DSP 16Y392, TrueCoat 360 VSP 17F329 Owner's Manual

For portable spray applications of water-based architectural paints and coatings only.

For Household Use Only.

Not approved for use in explosive atmospheres or ha zardous locations.

334179B

EN

Important Safety Instructions

Read all warnings and instructions in this manual and on the

unit, including the power cord. Be familiar with the controls and

the proper usage of the equipment. Save these instructions.

ti24623a

Scan QR code or click on link

for operational video.

http://graco.com/tc360opvid

Owners Manual

Project Series Paint Sprayers

WARNING

Use only water-based materials. Do not

use materials which state “FLAMMABLE”

on the packaging. For more information

about your material, request SDS from

distributor or retailer.

ti26063a

Contents

2 334179B

Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Power Tool Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sprayer Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Starting a New Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Refilling FlexLiner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

How to Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dual Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Spray Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Triggering Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Aiming Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Spray Pattern Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Cleaning Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning VacuValve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Common Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing Spray Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unclogging Spray Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Flushing a New Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Models 16Y391, 16Y392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts List- Models 16Y391, 16Y392 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Model 17F329 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Parts List- Model 17F329 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Graco Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

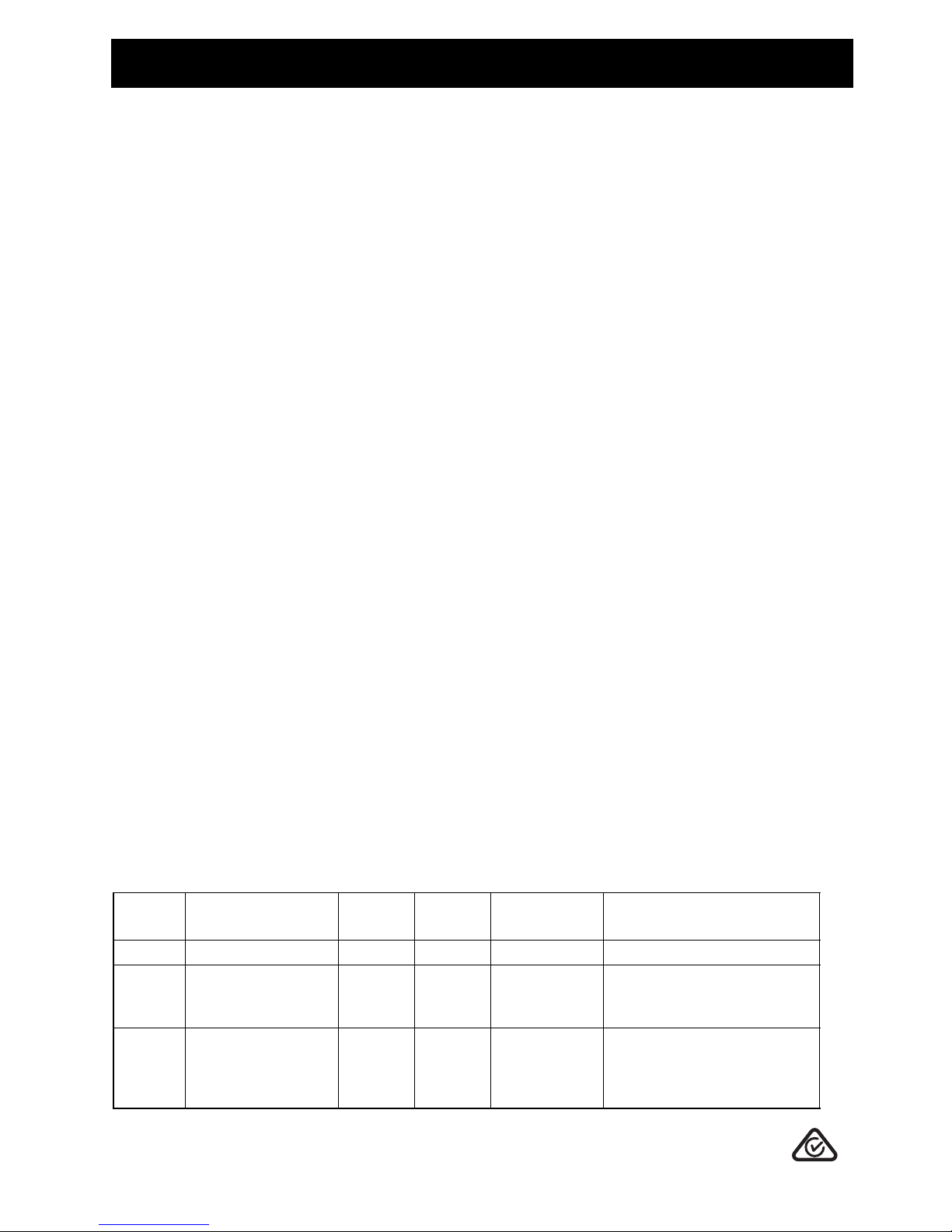

Model Name Voltage

Tip

Size

Description

Maximum Working

Pressure

16Y391

TrueCoat 360

230V 0.015 Single Speed 1200 psi (8.3 MPa, 83 bar)

16Y392

TrueCoat 360 DSP

230V 0.015 Dual Speed

Premium

900-1300 psi

(6.2 MPa, 62 bar - 8.9 MPa,

89 bar)

17F329

TrueCoat 360 VSP

230V 0.015 Variable

Speed

Premium

500-1300 psi

(3.5 MPa, 34.5 bar - 8.9

MPa,

89 bar)

Important User Information

334179B 3

Important User Information

Thank You for Your Purchase!

Before using your sprayer read this Owners Manual for complete instructions on proper use and

safety warnings.

Congratulations! You have purchased a high-quality paint sprayer made by Graco Inc.

This sprayer is designed to provide superior spray performance with water-based

architectural paints and coatings. This user information is intended to help you understand

the types of materials that can be used with your sprayer.

Please read the information on the material container label to determine if it can be used

with your sprayer. Ask for a Safety Data Sheet (SDS) from your supplier. The container

label and SDS will explain the contents of the material and the specific precautions

related to it.

Paints, coatings and clean-up materials generally fit

into one of the following 2 basic categories:

WATER-BASED: The container label should indicate that the material can be

cleaned up with soap and water. Your sprayer is compatible with this type of

material. Your sprayer is NOT compatible with harsh cleaners such as

chlorine bleach.

FLAMMABLE: This type of material contains flammable solvents such as

xylene, toluene, naphtha, MEK, lacquer thinner, acetone, denatured alcohol,

and turpentine. The container label should indicate that this material is

FLAMMABLE. This type of material is NOT compatible with your sprayer

and CANNOT be used.

General Power Tool Safety Information

4 334179B

General Power Tool Safety Information

WARNING

Read all safety warnings and all

instructions.

Failure to follow the warnings and instructions

may result in electric shock, fire and/or serious

injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool.

Work Area Safety

• Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

• Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

• Power tool plugs must matc h the outlet.

Never modify the plug in any way. Do

not use any adapter plugs with earthed

(grounded) power tools. Unmodified

plugs and matching outlets will reduce risk

of electric shock.

• Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

• Do not expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

• Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging

the power tool. Keep cord away from

heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the

risk of electric shock.

• When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric

shock.

• If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

Personal Safety

•

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the

influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

• Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate conditions

will reduce personal injuries.

• Prevent unintentional starting. Ensure

the switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool. Carrying power tools with your finger

on the switch or energizing power tools that

have the switch on invites accidents.

• Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in

personal injury.

• Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in

unexpected situations.

• Dress properly. Do not wear loose

clothing or jewelry. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewelry or long hair

can be caught in moving parts.

• If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

WARNING

General Power Tool Safety Information

334179B 5

Power Tool Use and Care

• Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was

designed.

• Do not use the power tool if the switch

does not turn it on and off. Any power

tool that cannot be controlled with the

switch is dangerous and must be repaired.

• Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing power

tools. Such preventive safety measures

reduce the risk of starting the power toll

accidentally.

• Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

• Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tool's operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

• Use the power tool, accessories etc. in

accordance with these instructions,

taking into account the working

conditions and the work to be

performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

Service

• Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

WARNING

Sprayer Safety Information

6 334179B

Sprayer Safety Information

The following warnings are for the setup, use, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to

procedure-specific risks. When these symbols appear in the body of this manual or on warning

labels, refer back to these Warnings. Product-specific hazard symbols and warnings not

covered in this section may appear throughout th e body of this manual where applicable.

WARNING

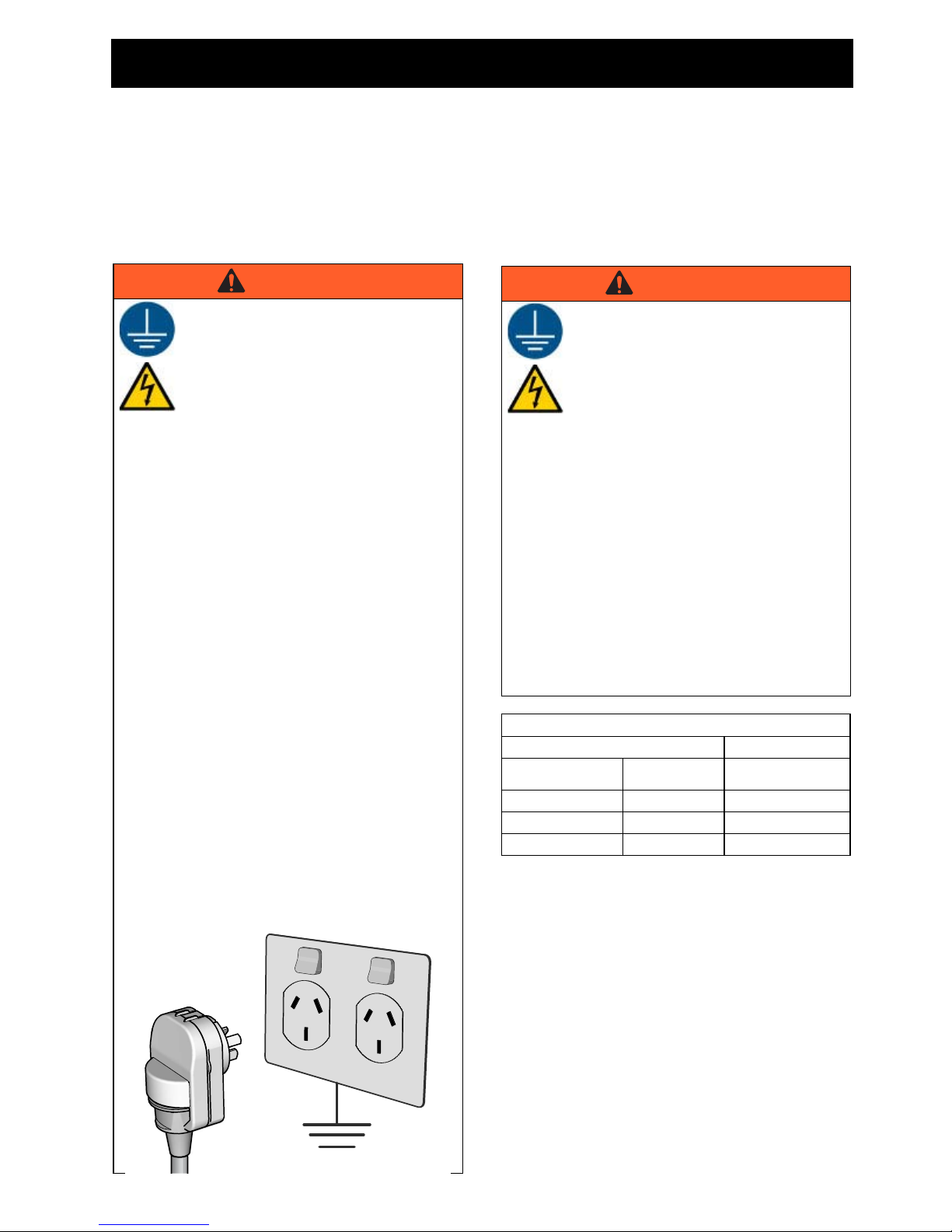

GROUNDING INSTRUCTIONS

This product must be grounded. In

the event of an electrical short circuit,

grounding reduces the risk of electric

shock by providing an escape wire for

the electric current. This product is

equipped with a cord having a

grounding wire with an appropriate

grounding plug. The plug must be

plugged into an outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

• Improper installation of the grounding plug

is able to result in a risk of electric shock.

• When repair or replacement of the cord or

plug is required, do not connect the

grounding wire to either flat blade terminal.

• The wire with insulation having an outer

surface that is green with or without yellow

stripes is the grounding wire.

• Check with a qualified electrician or

serviceman when the grounding

instructions are not completely

understood, or when in doubt as to

whether the product is properly grounded.

• Do not modify the plug provided; if it does

not fit the outlet, have the proper outlet

installed by a qualified electrician.

• This product is for use on a nominal 230V

circuit and has a grounding plug similar to

the plug illustrated in the figures.

• Only connect the product to an outlet

having the same configuration as the plug.

• Do not use an adapter with this product.

WARNING

Extension Cords:

• Use only a 3-wire extension

cord that has a grounding plug

and a grounding receptacle

that accepts the plug on the

product.

• An undersized cord results in a

drop in line voltage and loss of

power and overheating.When

in doubt use the next heavier

gauge. The smaller the gauge

number the heavier the cord.

• When using the sprayer outdoors, use an

extension cord suitable for outdoor use.

• Make sure your extension cord is not

damaged. When using an extension cord,

be sure to use a cord heavy enough to carry

the current that your sprayer draws. See

chart for appropriate sizes and lengths:

Extension Cord

Conductor Size Length

AWG (American

Wire Gauge)

Metric Maximum

18

1.0 mm

2

15 m (50 ft)

16

1.5 mm

2

30 m (100 ft)

14

2.5 mm

2

61 m (200 ft)

Sprayer Safety Information

334179B 7

WARNING

FIRE AND EXPLOSION

HAZARD

Flammable fumes, such as

solvent and paint fumes, in work

area can ignite or explode. To

help prevent fire and explosion:

• Sprayer generates sparks. Do

not spray or flush with flammable

liquids.

• Use only water-based materials.

• Keep spray area well-ventilated.

Keep a good supply of fresh air

moving through the area.

• Do not spray or clean with

flammable liquids.

• Paint or solvent flowing through the

equipment is able to result in static

electricity. Static electricity creates a risk of

fire or explosion in the presence of paint or

solvent fumes.

• Keep sprayer at least 10 in. (25 cm) away

from objects while spraying or flushing.

• Verify all containers and collection

systems are grounded to prevent static

discharge.

• Connect to a grounded outlet and use

grounded extension cords. Do not use a 3

to 2 adapter.

• Do not use paints or solvents containing

halogenated hydrocarbons.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or

similar spark producing products in the

spray area.

• Keep area clean and free of paint or

solvent containers, rags, and other

flammable materials.

• Know the contents of the paints and

solvents being sprayed. Read all Material

Safety Data Sheets (SDS) and container

labels provided with the paints and

solvents. Follow the paint and solvents

manufacturer’s safety instructions.

• Fire extinguisher equipment shall be

present and working.

WARNING

SKIN INJECTION HAZ ARD

High-pressure spray is able to

inject toxins into the body and

cause serious bodily injury. In

the event that injection occurs,

get immediate surgical

treatment.

• Do not aim the sprayer at, or spray any

person or animal.

• Keep hands and other body parts away

from the discharge. For example, do not try

to stop leaks with any part of the body.

• Disconnect power when not spraying.

• Always use the spray tip guard. Do not

spray without spray tip guard in place.

• Use caution when cleaning and changing

spray tips. In the case where the spray tip

clogs while spraying, follow the Pressure

Relief Procedure, page 16 for relieving

the pressure before removing the spray tip

to clean.

• Do not leave the unit energized or under

pressure while unattended. When the unit

is not in use, unplug the sprayer and follow

the Pressure Relief Procedure, page 16.

• Check parts for signs of damage. Replace

any damaged parts.

• This system is capable of producing 2000

psi. Use replacement parts or accessories

that are rated a minimum of 2000 psi.

• Do not carry the unit with a finger on the

trigger.

• Verify that all connections are secure

before operating the unit.

• Know how to stop the unit and bleed

pressure quickly. Be thoroughly familiar

with the controls.

Sprayer Safety Information

8 334179B

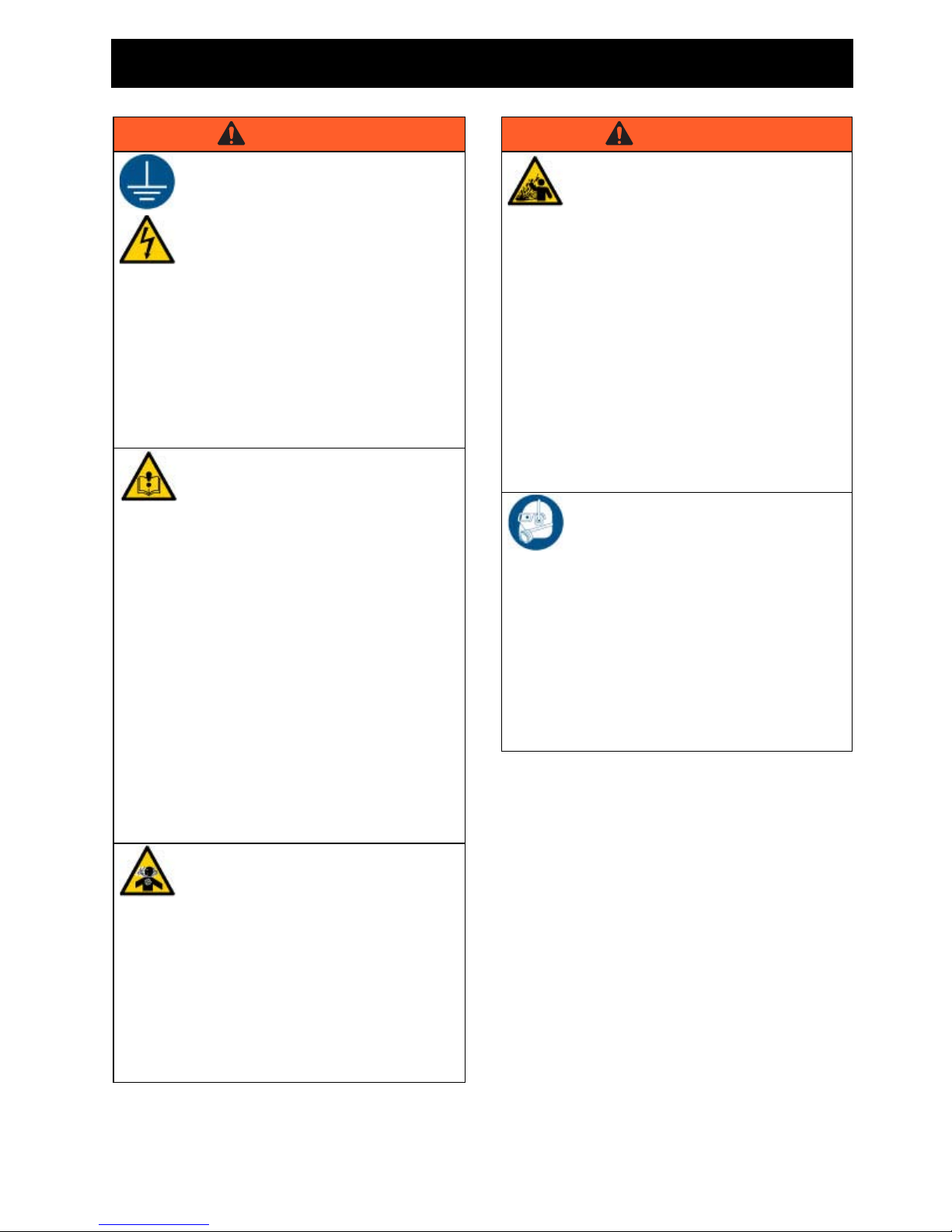

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded.

Improper grounding, setup, or usage

of the system can cause electric

shock.

• Turn off and disconnect power cord before

servicing equipment.

• Connect only to grounded electrical

outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power

and extension cords.

• Do not expose to rain or wet conditions.

Store indoors.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious

injury.

• Always wear appropriate gloves, eye

protection, and a respirator or mask when

painting.

• Do not operate or spray near children.

Keep children away from equipment at all

times.

• Do not overreach or stand on an unstable

support. Keep effective footing and

balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or

under the influence of drugs or alcohol.

• Use only in dry locations. Do not expose to

water or rain.

• Use in well-lit areas.

• Do not spray outdoors on windy days.

TOXIC FLUID OR FUMES

HAZARD

Toxic fluids or fumes can cause

serious injury or death if splashed in

the eyes or on skin, inhaled, or

swallowed.

• Read SDS’s to know the specific hazards

of the fluids you are using.

• Store hazardous fluid in approved

containers, and dispose of it according to

applicable guidelines.

WARNING

PRESSURIZED ALUMINUM

PARTS HAZARD

Use of fluids that are incompatible

with aluminum in pressurized

equipment can cause serious

chemical reaction and equipment

rupture. Failure to follow this warning

can result in death, serious injury, or

property damage.

• Do not use 1,1,1-trichloroethane,

methylene chloride, other halogenated

hydrocarbon solvents or fluids containing

such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals

that can react with aluminum. Contact your

material supplier for compatibility.

PERSONAL PROTECTIVE

EQUIPMENT

Wear appropriate protective equipment when

in the work area to help prevent serious

injury, including eye injury, hearing loss,

inhalation of toxic fumes, and burns. This

protective equipment includes but is not

limited to:

• Protective eye wear, and hearing

protection.

• Respirators, protective clothing, and

gloves as recommended by the fluid and

solvent manufacturer.

Component Identification

334179B 9

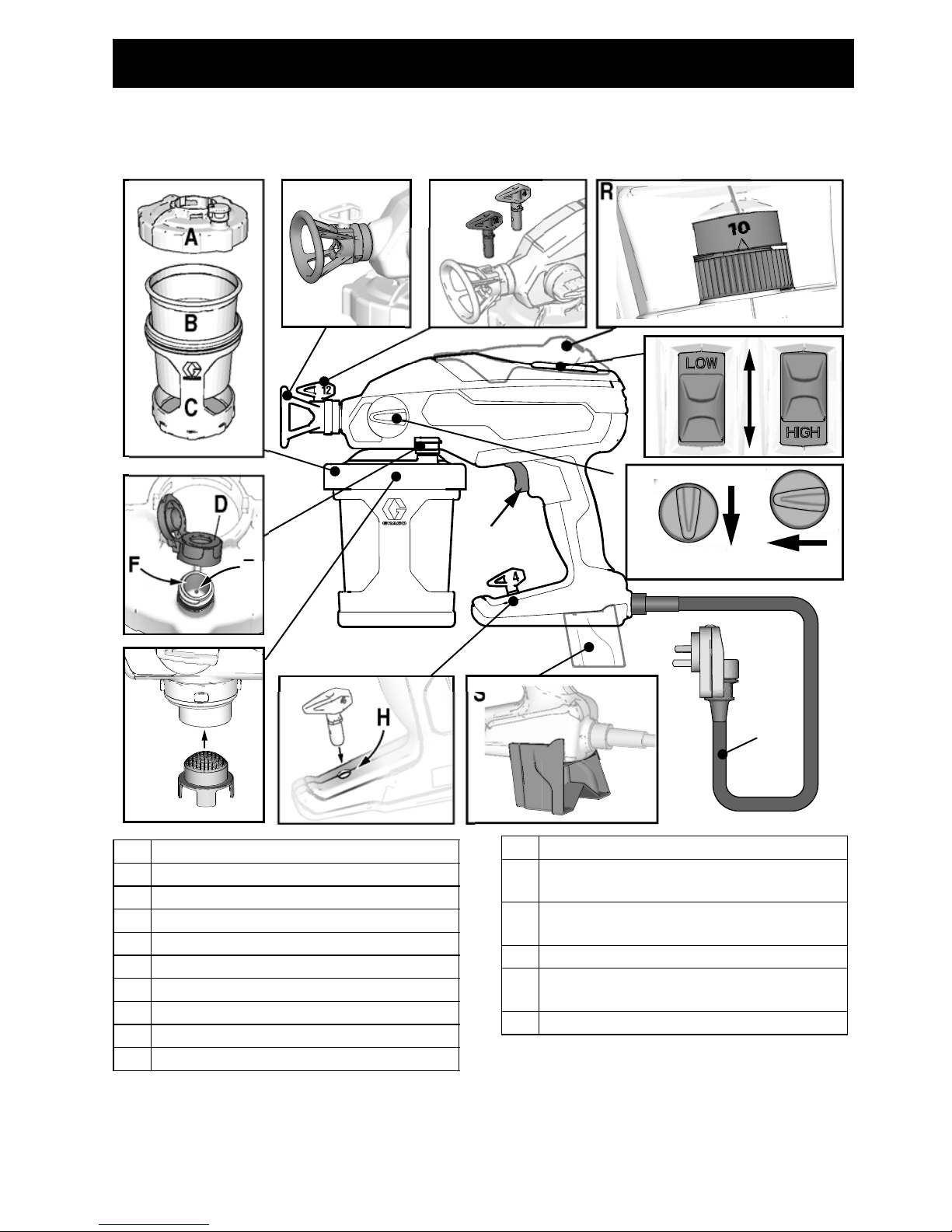

Component Identification

A

B

C

D

E

F

G

H

N

L

K

S

R

Spray

J

M

ti26060a

P

Prime Pump

A Cup Cover

B FlexLiner

C Cup Support

D VacuValve Cap

E VacuValve Air Hole

F VacuValve Reservoir

GStrainer

H Spray Tip Holder

J Prime Pump/Spray Knob

K Power Cord

L Sprayer Trigger

M Dual Speed Control, HIGH/LOW

Switch (DS and DSP models only)

N Spray Tip, Black (12-inch pattern)

Spray Tip, Gray (4-inch pattern)

P Spray Tip Guard

R Variable Speed Control (VSP models

only)

S Kickstand

Start Up

10 334179B

Start Up

Starting a New Job

If you are using the sprayer for the very first

time, see Flushing a New Sprayer, page 22.

Stir material according to manufactures

recommendations. If material was previously

opened, it is recommended to strain material

to avoid spray tip clogs.

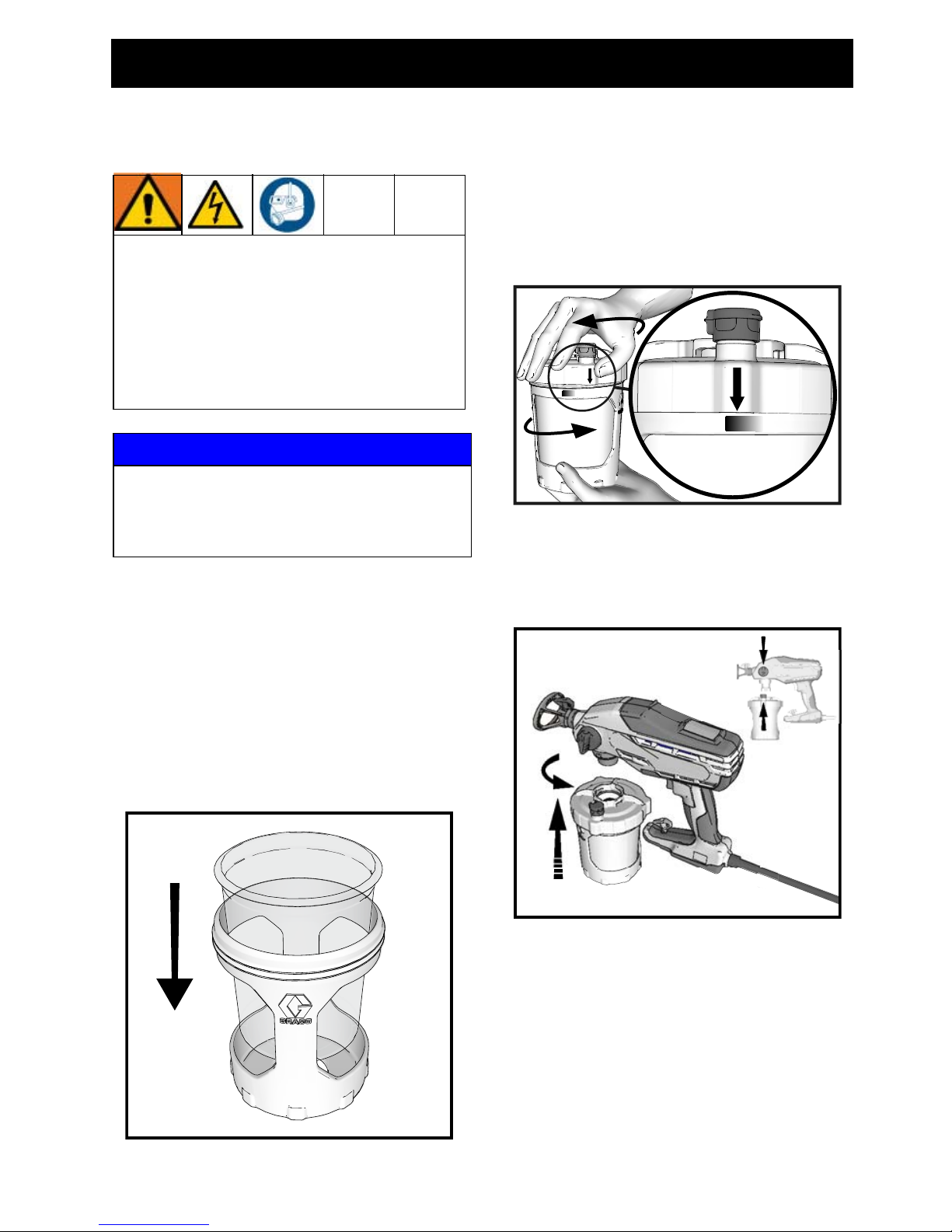

1. Install FlexLiner in the cup support.

2. Fill FlexLiner with material. Securely

tighten cup cover onto cup support.

Tighten so the arrow on the cup cover is

within range of the indicator on the cup

support.

3. Align VacuValve on cup cover with

Prime Pump/Spray knob. Push cup

assembly onto sprayer and twist

clockwise to lock.

Use only water-based materials. Do not

use materials which state “FLAMMABLE”

on the packaging. For more information

about your material, request SDS from

distributor or retailer.

Keep spray area well-ventilated. Keep

a good supply of fresh air moving through

the area.

NOTICE

Your sprayer is

NOT

compatible with harsh

cleaners such as chlorine bleach. Using

these cleaners will cause damage to the

sprayer.

ti23361a

ti24279a

ti23258b

Start Up

334179B 11

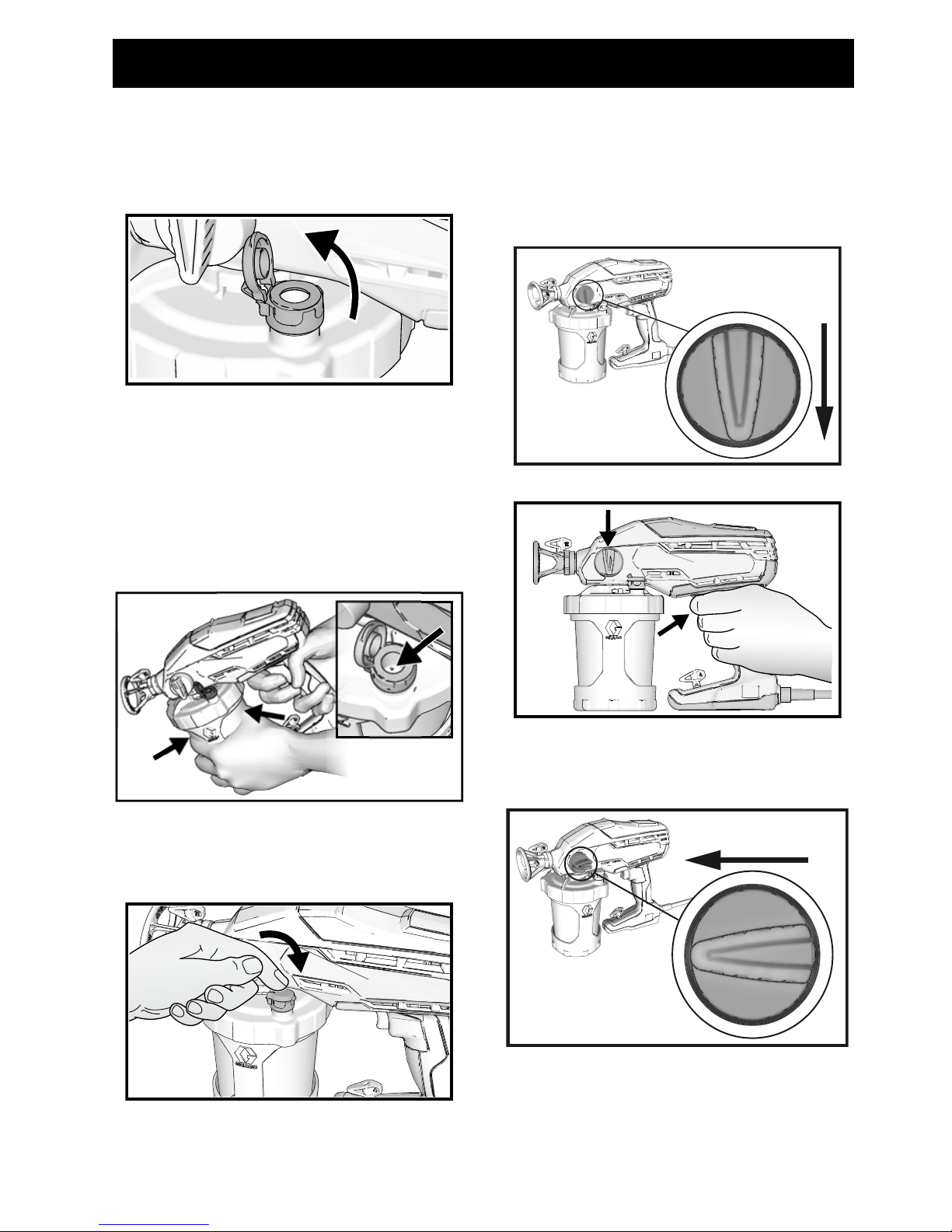

4. The VacuValve is an important part of

your new sprayer. It is used to evacuate

the air out of the FlexLiner. Open

VacuValve cap.

5. Tilt the sprayer so the VacuValve is the

highest point, causing an y ai r in the

FlexLiner to rise to the VacuValve.

Gently squeeze the FlexLiner to

evacuate all air through the VacuValve

air hole. Once you see material enter the

VacuValve reservoir, all air should be

evacuated from the FlexLiner.

6. Stop squeezing the FlexLiner and snap

the VacuValve cap closed. You will hear

the cap click when it is closed properly.

7. Plug sprayer into power source.

8. Turn Prime Pump/Spray knob down to

Prime Pump position. To fill sprayer with

fluid, point sprayer into a waste area and

hold the trigger in for 5–10 seconds.

9. Turn Prime Pump/Spray knob forward to

spray position.

ti23343a

ti23345a

ti23355a

ti23285a

Prime Pump

ti23354a

ti23288a

Spray

Loading...

Loading...