Page 1

Instructions/Parts List

®

Triton

3D150

Diaphragm Pump

Used to pump waterborne and solvent-based paints and catalysts.

Part No. 253704, Series B

3:1 Ratio Air-operated Double Diaphragm Pump, with BSPP Fittings

Part No. 253705, Series B

311688D

3:1 Ratio Air-operated Double Diaphragm Pump, with NPT Fittings

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

300 psi (2.1 MPa, 21 bar) Maximum Fluid Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2006, Graco Inc. is registered to I.S. EN ISO 9001

TI2125A

II 2 G

Page 2

Contents

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . . . . . . . . . . . . 5

Tightening Threaded Fasteners Before First Use 5

Mounting the Pump . . . . . . . . . . . . . . . . . . . . . . . 6

Air Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fluid Suction Line . . . . . . . . . . . . . . . . . . . . . . . . 7

Fluid Outlet Line . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Flushing the Pump Before First Use . . . . . . . . . 10

Starting and Adjusting the Pump . . . . . . . . . . . 10

Pump Shutdown . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flushing and Storage . . . . . . . . . . . . . . . . . . . . 11

Tightening Threaded Connections . . . . . . . . . . 11

Preventive Maintenance Schedule . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Prepare the Pump for Repair . . . . . . . . . . . . . . . 13

General Repair Notes . . . . . . . . . . . . . . . . . . . . 13

Fault Indications . . . . . . . . . . . . . . . . . . . . . . . . 13

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Replace the Diaphragms . . . . . . . . . . . . . . . . . . 14

Repair the Air Valve . . . . . . . . . . . . . . . . . . . . . . 16

Repair the Shaft and Bearings . . . . . . . . . . . . . 18

Replace the Ball Check Valves . . . . . . . . . . . . . 20

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Performance Chart . . . . . . . . . . . . . . . . . . . . . . . . . 25

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 28

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 28

2 311688D

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

Warning

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

• This equipment is for professional use only.

• Read all instruction manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

• Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 24 for the maximum working pressure of this equipment.

• Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Techni-

cal Data section of all equipment manuals. Read the fluid and solvent manufacturer's warnings.

• Do not use hoses to pull equipment.

• Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82°C (180°F) or below -40°C (-40°F).

• Wear hearing protection when operating this equipment.

• Comply with all applicable local, state, and national fire, electrical, and safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Spray from the gun, hose leaks, or ruptured components can splash fluid in the eyes or on the skin and

cause serious injury.

• Do not point the gun at anyone or at any parts of the body.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure on page 10 whenever you are instructed to relieve pressure;

stop spraying; clean, check, or repair the equipment; and install or clean the spray nozzle.

• Tighten all fluid connections before operating the equipment.

• Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result

in a fire or explosion and serious injury.

• Ground the equipment and the object being sprayed. Refer to Grounding on page 9.

• If there is any static sparking or you feel an electric shock while using this equipment, stop the

equipment immediately. Do not use the equipment until you identify and correct the problem.

• Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid being

sprayed.

• Keep the work area free of debris, including solvent, rags, and gasoline.

• Eliminate all ignition sources such as pilot lights, cigarettes, and static arcs from plastic drop cloths.

Do not plug in or unplug power cords or turn lights on or off in the spray area.

311688D 3

Page 4

Warnings

Warning

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

• Know the specific hazards of the fluid you are using.

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

• Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

• If a diaphragm fails, fluid is exhausted along with the air. When pumping hazardous fluids, place the

pump in an appropriate container to catch the fluid if a diaphragm ruptures.

MOVING PARTS HAZARD

Moving parts, such as the diaphragm shaft, can pinch or amputate your fingers.

• Before servicing the equipment, follow the Pressure Relief Procedure on page 10 to prevent the

equipment from starting unexpectedly.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

4 311688D

Page 5

Installation

Installation

General Information

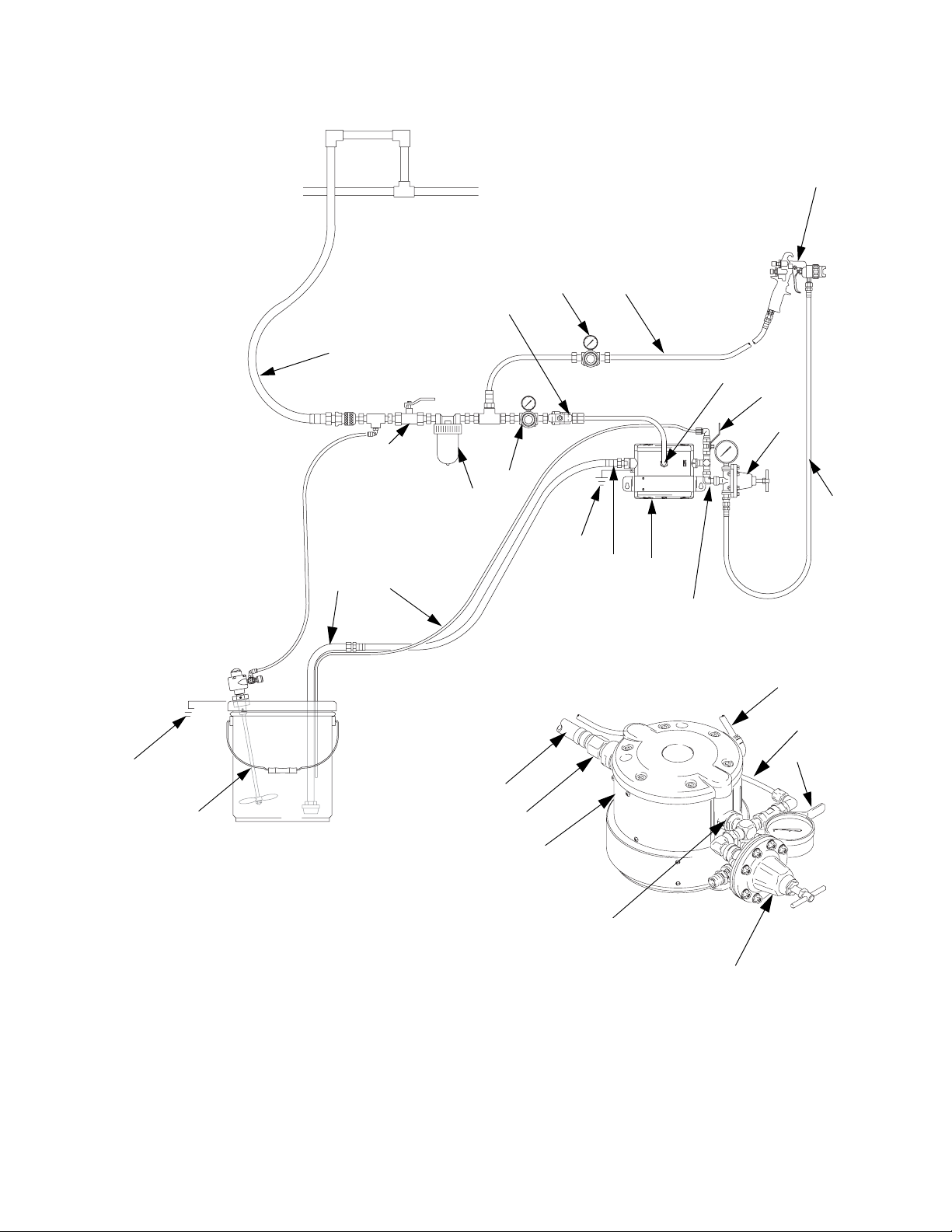

•FIG. 2 is only a guide for installing system compo-

nents and accessories. It is not an actual system

design. Contact your Graco distributor for assistance in designing a system to suit your particular

needs.

• Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure-rated for your system.

• Reference numbers and letters in parentheses refer

to the reference numbers in the figures and the

parts list on page 22.

Tightening Threaded Fasteners

Before First Use

See the Repair section for torque specifications.

• After unpacking the pump and before using it for the

first time, check and retorque all diaphragm cover

bolts (38, 39).

• After the first day of operation, retorque the fasteners again.

• As a general guidline, retorque fasteners every two

months.

311688D 5

Page 6

Installation

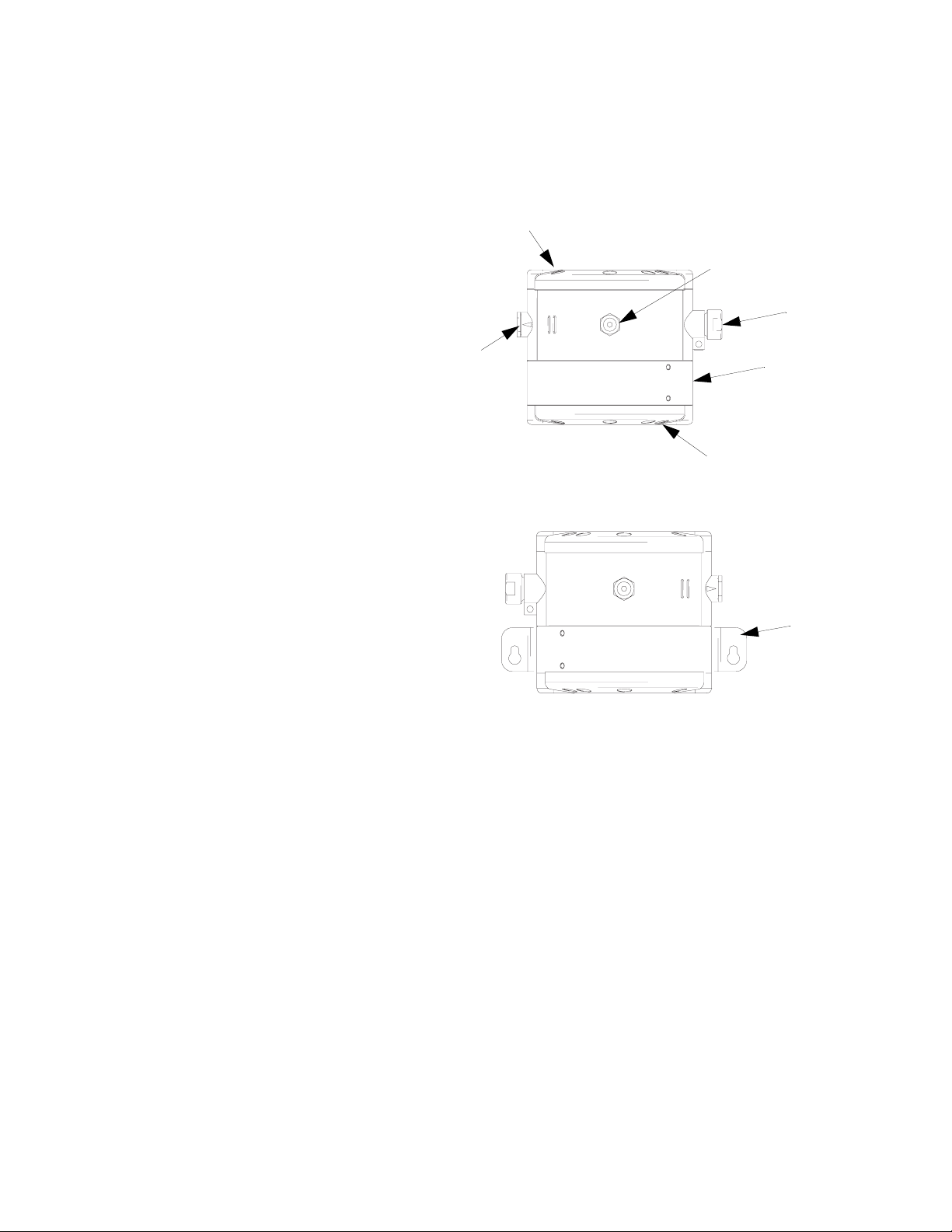

Mounting the Pump

• For ease of operation and service, mount the pump

so the air inlet, fluid inlet, and fluid outlet ports are

easily accessible.

• Mount the pump in a well-ventilated area with sufficient clearance on all sides for operator access and

servicing.

• The pump must be mounted horizontally as shown

in F

IG. 1. Be sure that the pump is level in all direc-

tions and that the cylinder housing (54) is positioned

on the bottom. See F

• The pump can be floor mounted or mounted on a

wall using mounting kit 246495.

• Be sure the mounting can support the weight of the

pump, hoses, and accessories as well as the stress

caused during operation. The pump has two mounting holes for 0.31 in. (8 mm) screws. See the

Dimension drawing on page 26.

IG. 1.

5. Mount the bracket with the pump attached to the

wall and tighten.

Hexagonal screw (2 required)

Compressed air

connection

Fluid

Inlet

Fluid

Outlet

Floor Mount

Hexagonal

screw

(2 required)

Cylinder

Housing (54)

TI2133A 2

Wall mount using kit 246495:

1. Use the bracket (15C022) as a template to drill 2

0.38 (9.6 mm) diameter holes in the wall.

2. Loosely attach bracket (15C022) to the wall with

anchors and screws (8 mm) long enough to prevent

the bracket from vibrating during operation.

3. Remove bracket from the wall and fasten it to the

pump using the 4 screws (116899) and 1 lock

washer (100028) included in the kit.

4. The lock washer must be used in the unpainted hole

to ensure proper grounding of the bracket.

Wall Mount

F

IG. 1. Mounting the Pump

Wall

Mount

Bracket

TI2469A

6 311688D

Page 7

Installation

Air Line

1. Install the air line accessories as shown in FIG. 2.

Be sure the air line supplying the accessories is

grounded.

a. The fluid pressure can be controlled with either

an air regulator (F) to control the air into the

pump, or with a fluid regulator (H) to control the

fluid out of the pump.

b. Install a bleed-type master air valve (B) close to

the pump. This valve is required in your system

to relieve air trapped between it and the pump

when the valve is closed. Trapped air can cause

the pump to cycle unexpectedly which could

result in serious injury including splashing in the

eyes or on the skin, or injury from moving parts.

Be sure the bleed valve is easily accessible

from the pump, and is located downstream from

the air regulator.

c. Install a second air valve (E) upstream from all

air line accessories to isolate them during

cleaning and repair.

d. Install an air line filter (D) to remove contami-

nates such as dirt, moisture, and oil from the

compressed air supply.

2. The air valve does not require lubrication.

• For maximum suction lift (wet and dry) information,

see Technical Data on page 24.

• Use an agitator to prevent fluid from settling out.

Part number 245081 Agitator Kit (accessory) is

available.

Fluid Outlet Line

1. Use electrically conductive fluid hoses (P). See FIG.

2. Screw the fluid fitting into the pump outlet (N)

snugly while supporting the outlet with a wrench.

See Technical Data on page 24 to determine the

fluid outlet size of your pump.

2. Install a fluid regulator (H) at the pump fluid outlet to

control fluid pressure, if desired. See Air Line step

1a for an alternative method to control pressure.

3. Install a fluid drain valve (J) near the fluid outlet.

A fluid drain (J) valve is required in your system to

relieve pressure in the hose if it is plugged. The drain

valve reduces the risk of serious injury, including

splashing in the eyes or on the skin, or contamination

from hazardous fluids when relieving pressure. Install

the valve close to the pump fluid outlet. To use the

valve as a circulation valve, connect a tube (K)

between the valve and pail.

3. Install a grounded, flexible air hose between the

accessories and the pump air inlet. See Technical

Data on page 24 to determine the air inlet size of

your pump. Use a minimum 1/2 in.(13 mm) ID air

hose.

Fluid Suction Line

•See Technical Data on page 24 to determine the

fluid inlet size of your pump.

• Use conductive hoses (see F

tion line into the pump inlet snugly while supporting

the inlet with a wrench. Use a compatible liquid

thread sealant on connections to prevent air from

entering the fluid line.

311688D 7

IG. 2). Screw the suc-

Some systems may require installation of a pressure

relief valve at the pump outlet to prevent overpressurization and rupture of the pump or hose.

Thermal expansion of fluid in the outlet line can cause

overpressurization. This can occur when using long

fluid lines exposed to sunlight or ambient heat, or

when pumping from a cool to a warm area (for example, from an underground tank).

Overpressurization can also occur if the pump is

being used to feed fluid to a piston pump and the

intake valve of the piston pump does not close, causing fluid to back up in the outlet line.

CAUTION

Page 8

Key:

A TRITON 3D150 Pump

B Bleed-type master air valve

(required for pump)

C Air supply line

D Air line filter

E Air line shutoff valve

F Pump air regulator

G Gun air regulator (used in

spray system only)

H Fluid pressure regulator

(used in spray system

only)

J Drain/circulation valve

KDrain tube

L Suction tube

M Pump fluid inlet

N Pump fluid outlet

P Fluid hose (shown

connected to gun in spray

system)

R Gun air hose (used in

spray system only)

S Spray gun (used in spray

system only)

T Pump air inlet

U Agitator (used in spray

system only)

W Ground wire

Installation

S

G

R

B

C

T

J

H

E

F

D

P

W

M

L

K

A

N

W

U

FIG. 2. Typical Installation

TI2373A

T

K

J

L

M

A

N

H

TI2127A

8 311688D

Page 9

Installation

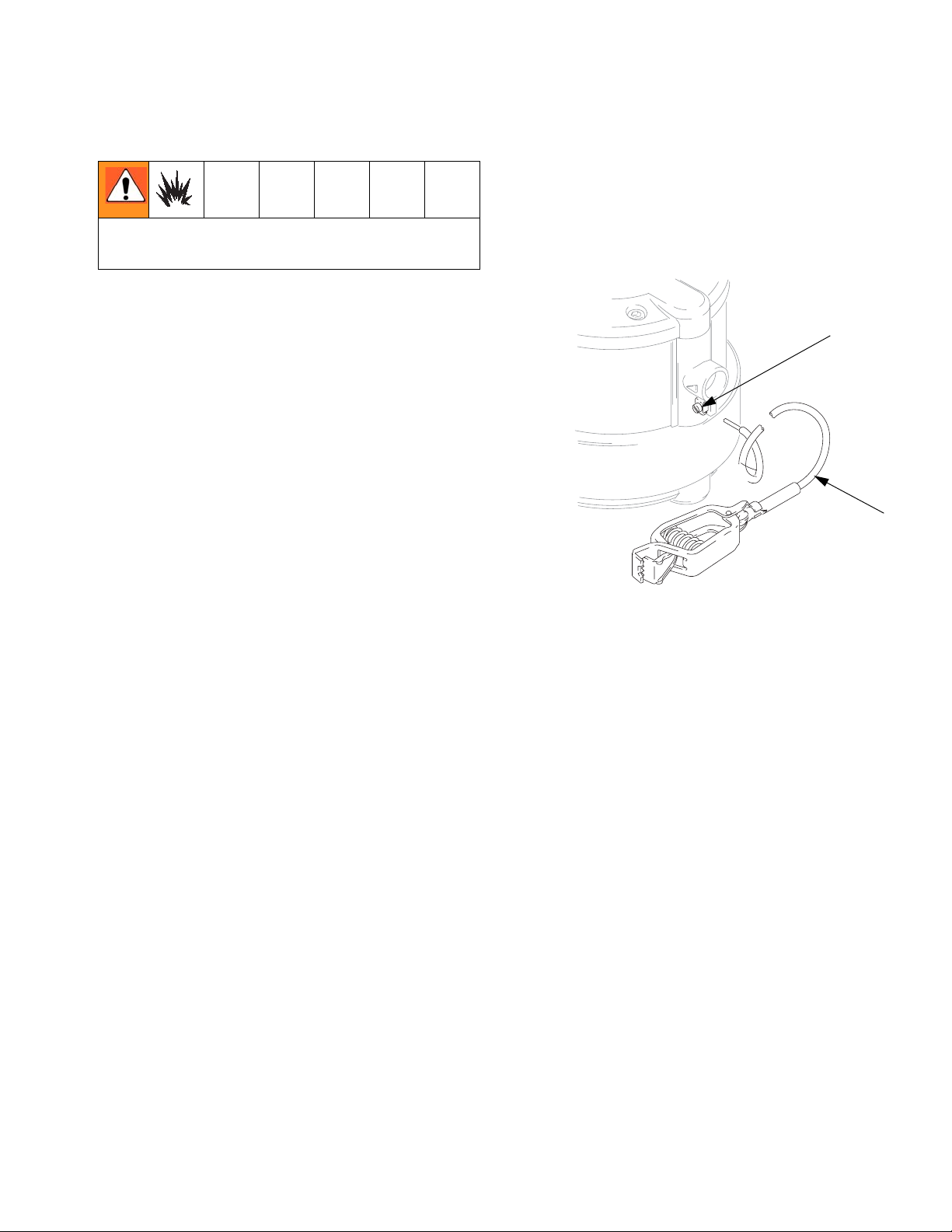

Grounding

Before operating the pump, ground the system as

explained below. Read the warnings on page 3.

Ground all of this equipment:

• Pump: use a ground wire and clamp. See F

Loosen the grounding screw (X). Insert one end of a

12 ga (1.5 mm

2

) minimum ground wire (Y) under the

clamp and tighten the screw securely. Connect the

other end of the wire to a true earth ground. For a

ground wire and clamp, order Part No. 222011.

• Air and fluid hoses: Use only electrically conductive

hoses.

• Air compressor: Follow manufacturer’s recommendations.

• Fluid supply drum: Follow your local code.

IG. 3.

• All fluid pails used when flushing: Follow your local

code. Use only conductive metal pails placed on a

grounded surface. Do not place the pail on a nonconductive surface, such as paper or cardboard,

which interrupts the grounding continuity.

X

TI2126A

F

IG. 3. Grounding the Pump

Y

311688D 9

Page 10

Operation

Operation

Pressure Relief Procedure

Read the warnings on page 3, and follow the Pressure Relief procedure below whenever you:

• are instructed to relieve pressure

• stop spraying

• check or service any of the equipment

• install or clean the fluid nozzle.

1. Shut off the air to the pump.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve all fluid pressure, having a container ready to catch the

drainage.

Flushing the Pump Before First

Use

4. Place the end of the fluid hose (P), see F

an appropriate container.

5. Close the fluid drain valve (J).

6. With the pump air regulator (F) closed, open the

bleed-type master air valve (B).

7. If the fluid hose has a dispensing device, hold it

open while continuing with the following step.

8. Slowly open the air regulator (F) until the pump

starts to cycle. Allow the pump to cycle slowly until

all air is pushed out of the lines and the pump is

primed.

If you are flushing, run the pump long enough to thoroughly clean the pump and hoses. Close the air regulator. Remove the suction tube (L) from compatible

flushing fluid and place it in the fluid to be pumped.

Operating the pump dry for extended periods or

operating at pressures higher than the recommended maximum input air pressure will reduce

diaphragm life.

IG. 2, into

The pump was tested in oil. If oil could contaminate the

fluid you are pumping, flush the pump thoroughly with a

compatible flushing fluid. Follow the steps under Start-

ing and Adjusting the Pump.

Starting and Adjusting the Pump

1. Be sure the pump is properly grounded. Refer to

Grounding on page 9.

2. Check all fittings to be sure they are tight. Be sure to

use a compatible liquid thread sealant on all male

threads. Re-torque diaphragm cover bolts (38, 39)

before start-up.

3. Place the suction tube (L) in the fluid to be pumped.

Pump Shutdown

Short Term Shutdown

For a short term shutdown, relieve the pressure (see

procedure on this page).

Long Term Shutdown

For a long term shutdown, such as several hours or

overnight:

1. Flush the pump thoroughly.

2. Leave compatible flushing fluid in the pump.

3. Relieve the pressure (see procedure on this page).

10 311688D

Page 11

Maintenance

Maintenance

Lubrication

CAUTION

Lubrication of the pump is not required. Oil is

exhausted through the muffler, which could contaminate the fluid supply or other equipment. Excessive

lubrication can also cause the pump to malfunction.

Flushing and Storage

Flush the pump often enough to prevent the fluid you

are pumping from curing, drying, or freezing in the pump

and damaging it. Follow the Pressure Relief Procedure

on page 10 before storing it for any length of time. Use a

compatible flushing fluid.

Tightening Threaded

Connections

1. Before each use, check all hoses for wear or damage, and replace as necessary.

2. Check to be sure all threaded connections are tight

and leak-free.

3. Check and re-torque all screws and fasteners at

least every two months.

Preventive Maintenance

Schedule

• Establish a preventive maintenance schedule,

based on the service history of the pump. This is

especially important for prevention of spills or leakage due to diaphragm failure.

311688D 11

Page 12

Troubleshooting

Troubleshooting

Relieve the pressure (page 10) before checking or

servicing the equipment.

Problem Cause Solution

Pump cycles at stall or fails to hold

pressure at stall.

Pump will not cycle, or cycles once

and stops.

Pump operates erratically. Clogged suction line. Inspect; clear.

Air bubbles in fluid. Loose suction line. Tighten.

Pump running irregularly. Stroke frequency dropping, coming to standstill.

Air escapes continually. Damaged air valve cup (15) or seat. Replace damaged parts. See page

Pump does not start, or pressure

fluctuates.

Worn check valve balls (26), seats

(31), or ball guides (32).

Stuck or dirty air valve. Disassemble and clean air valve. See

Check valve ball (26) severely worn

and wedged in seat (31).

Check valve ball (26) wedged in seat

(31) due to overpressurization.

Clogged fluid dispensing valve. Relieve pressure and clear valve.

Pinched hose line. Check lines.

Sticky or leaking check valves. Clean or replace balls (26) and seats

Ruptured diaphragm (9). Replace. See page 13.

Restricted exhaust. Remove restriction.

Ruptured diaphragm (9). Replace. See page 13.

Worn parts. Replace worn parts. Check com-

Icing caused by: compressed air too

moist, stroke frequency too high,

local temperature too low.

Foreign matter inside pump. Check air filter.

Worn check valve seats. Replace. See page 20.

Inlet strainer blocked, maximum suc-

tion exceeded, hose or seal defective.

Contaminated fluid. Pump installed or

operated incorrectly.

Check all possible problems and causes before

disassembling the pump.

Replace. See page 20.

page 16. Use filtered air.

Replace ball and seat. See page 20.

Replace. See page 20. Do not

exceed the maximum fluid working

pressure, see page 24.

(31). See page 20.

pressed air supply.

Remove ice by changing operating

conditions.

16.

Clean strainer. Replace defective

parts.

Check fluid supply. Follow installation and operation instructions in this

manual.

12 311688D

Page 13

Repair

Repair

Prepare the Pump for Repair

1. Flush the pump if possible, page 11.

2. Relieve the pressure, page 10.

3. Disconnect the air and fluid hoses.

4. Remove the pump from its mounting and take it to

the work bench.

General Repair Notes

• A qualified technician should make all repairs.

• Inspect and clean all parts thoroughly before

reassembly.

• Use only genuine Graco replacement parts,

available from your Graco distributor.

• Be careful not to damage sealing surfaces.

• Replace all o-rings removed from the pump.

• Follow all lubrication, torque, and repair notes

in the repair procedures.

Fault Indications

During operation, check for indications of worn or damaged parts, such as:

• major pressure fluctuations

• change in the pump’s operating sound

• irregular operation.

Always replace worn or damaged parts immediately to

prevent additional damage.

Tools Required

• 3, 4, and 6 mm allen wrenches

• 12, 19, and 22 mm open end wrenches

• internal snap ring pliers

• o-ring pick

• needlenose pliers

• vise with soft jaws

• Do not use silicone or silicone-based grease.

311688D 13

Page 14

Repair

Replace the Diaphragms

Wear gloves when removing or assembling the diaphragms to reduce the risk of cuts.

Diaphragm Repair Kit 246011 is available. Parts

included in the kit are marked, for example (9*).

For the best results, replace both diaphragms.

Always replace the ball check seals (29) whenever the fluid covers are removed. These seals

are included in each of the repair kits.

Disassembly

1. Prepare the pump for repair of the cylinder-side diaphragm.

a. Remove the 6 screws (39) and fluid cover (37)

from the housing side of the pump.

d. Grip the cylinder-side diaphragm firmly and

unscrew it from the rod by hand.

e. Install a new diaphragm (9*) firmly, by hand.

3. Prepare the pump for repair of the housing-side diaphragm.

a. Press on the cylinder-side diaphragm so that it

protrudes into the cylinder. This will fully extend

the diaphragm on the housing side.

b. Install new ball check seals (29*).

c. Replace the fluid cover and install the 6 screws.

Torque the screws to 16 N•m (12 ft-lb).

4. Repair the housing-side diaphragm.

a. Remove the 6 screws and the fluid cover from

the housing side.

b. Remove the ball check seals.

b. Press on the exposed diaphragm (9) to fully

extend the cylinder-side diaphragm.

c. Replace the housing-side cover and tighten the

6 screws.

The housing-side cover must be reassembled

tightly enough to prevent the shaft from turning

when the cylinder-side diaphragm is loosened.

2. Repair the cylinder-side diaphragm.

a. Remove the 6 screws (38) and fluid cover (37)

from the cylinder side.

b. Remove the ball check seals (29).

c. The exposed diaphragm should be in the fully

extended position (protruding out from the cylinder). If it is not, reassemble the cylinder-side

seals and cover and repeat step 1.

c. The exposed diaphragm should be in the fully

extended position (protruding out from the cylinder). If it is not, reassemble the cylinder-side

seals and cover and repeat step 3.

d. Grip the housing-side diaphragm firmly and

unscrew it from the rod by hand.

e. Install a new diaphragm (9*) firmly, by hand.

f. Install new ball check seals (29*).

g. Replace the fluid cover and install the 6 screws

(39*). Torque the screws to 16 N•m (12 ft-lb).

Spare diaphragms should be stored in a cool, dry place

and be used within 8 months to prevent diaphragm failure due to material aging.

14 311688D

Page 15

Repair

Torque to 16 N•m (12 ft-lb).

1

Housing Side 9*

1

37

39

29*

7

54

†‡◆

†‡◆

29*

1

†‡◆

29*

FIG. 4 Replace the Diaphragms

29*

†‡◆

Cylinder Side 9*

38

TI"

37

1

311688D 15

Page 16

Repair

Repair the Air Valve

Air Valve Repair Kit 245066 is available. Parts

included in the kit are marked, for example (33†).

For the best results, use all parts in the kit.

Disassembly

1. Prepare the pump for repair, page 13.

2. Remove the air valve sheet metal cover (36) and felt

dampener (34).

3. Unscrew the cylinder screws (21).

4. Remove the valve cover (20) with the flat gasket

(19†).

5. Use two screwdrivers to lift out the air valve plate

(16†) and replace o-rings (17†◆) and (18†◆).

Remove two o-rings (55).

6. Remove the air valve cup (15†).

7. Remove one retaining clip (14) with pliers DIN

5256C nominal size 12-25 diameter.

Reassembly

Lubricate all o-rings when reassembling the

pump.

1. Assemble in reverse order.

Orient the new flat gasket (19) on the air valve

plate (16) so that the channels in the plate are

completely covered.

The hole in the air valve plate (16) aligns with the

arrow on the housing.

Align

8. Screw cylinder screw (21) into the plug (12) and pull

it out. Replace o-ring (13†◆).

9. Repeat steps 8 and 9 for clip and plug on opposite

side.

10. Reach into the housing and press out the carriage

(10).

11. Replace o-rings (11†◆).

2. Replace all parts with the new ones supplied in kit

245066.

Four profile seals (29) are provided in kit 245066

as in all 308HP kits. These seals need to be

replaced only if the fluid covers are removed.

16 311688D

Page 17

Repair

ti2130B

1

11†◆

10

1

11†

14

Lubricate.

1

Torque to 3.1 N•m (28 in-lb)

2

Align arrow on housing with point on air valve plate.

3

14

13†◆

1

12

15†

17†

◆

1

18†◆

◆

1

16†

3

19†

◆

14

12

13†

20

2

21

55

◆

1

44

34

36

FIG. 5. Repair the Air Valve

311688D 17

Page 18

Repair

Repair the Shaft and Bearings

Parts marked with a (♦) are included in Shaft

repair kit 233841. For the best results, use all

parts in the repair kit.

Parts marked with a (❖) are included in Bearing

repair kit 15J647.

Disassembly

1. Remove the diaphragms. See page 13.

2. Disassemble the air valve. See page 16.

3. Remove the housing (54).

• Sleeve clamp (6) is visible inside the air valve

cavity. Spread the sleeve clamp (6) with pliers

DIN 5254A, nominal size 19, and at the same

time, slide the shaft assembly (7) out from the

end where housing (54) was removed.

The valve carriage (5) will remain free inside the

diaphragm housing.

4. Remove clip (42) and bearing (3).

Reassembly

1. Replace o-ring (2) in bearing, lubricate internal

o-rings.

2. Install new bearing (3) and clip (42) inside housing

(54).

3. Insert shaft assembly (7) into diaphragm housing (1)

through the valve carriage, spreading the sleeve

clamp to allow full insertion. Be careful to release

sleeve clamp (6) in the correct location along the

shaft to engage it in all three grooves.

4. Reinstall the housing (54).

5. Replace o-rings on the carriage, air valve plate, and

plugs and reinstall the air valve section. (See page

16.)

6. Replace the diaphragms (page 13).

7. Replace the ball check seals (29) (page 20) and

reinstall the fluid covers.

18 311688D

Page 19

Repair

1

Lubricate.

Torque to 12 ft-lb (16 N•m)

2

Align arrow on housing with point on air valve plate.

3

Torque to 28 in-lb (3.1 N•m)

4

39

2

1

◆✘

37

1

54

*9

42❖

†‡◆29

42❖

❖3

❖

43

2

◆❖

29*

†‡◆

*9

37

❖

◆❖2

43

3

❖

1

5

6

†◆11

1

†◆11

1

10

12

*†‡◆29

◆❖2

❖

42

43❖

29*†‡◆

3❖

15

†

17†◆

18†◆

1

1

21

4

34

38

2

13†◆

14

7◆

1

55

†16

3

4

†◆19

20

ti2131

36

44

FIG. 6. Repair the Shaft

311688D 19

Page 20

Replace the Ball Check Valves

Repair

Ball Check Valve Repair Kit 245067 is available.

Parts included in the kit are marked with a (‡). For

the best results, use all parts in the kit.

Disassembly

1. Remove fluid covers (see page 13). Do not remove

housing (54).

2. Remove the inlet and outlet ball checks (26-32).

Note that the orientation of the inlet check parts is

different than the outlet check parts. (See F

If the inlet seats (31) are difficult to remove, drive

them out from the opposite side using a brass rod

and hammer.

3. Replace all parts provided in Kit 245067.

IG. 7.)

Reassembly

1. Reinstall the inlet and outlet ball checks on one side

of the pump. The inlet and outlet checks are assembled differently, install them exactly as shown in F

7.

2. Install one fluid cover loosely to prevent the ball

checks from falling out.

Align the through holes in the housing with each

other and with the covers.

3. Turn the pump over and install the ball checks on

the opposite side, exactly as shown.

4. Reinstall the fluid covers. (See page 13.)

IG.

20 311688D

Page 21

Repair

ti2128B

1

Torque to 12 ft-lb (16 N•m)

2

Align

1

29

‡

32

‡

26‡

Outlet Ball

Checks

27

‡26

‡28

‡29

‡28

‡26

‡32

‡32

1

‡29

31‡

30‡✖

2

Inlet Ball

Checks

30‡✖

31‡

26‡

32‡

29‡

1

FIG. 7. Replace the Ball Check Valves

311688D 21

Page 22

Parts

Part No. 253704, Series B

Part No. 253705, Series B

39

Parts

37

35

33

40

12

14

†◆13

†‡◆29

*

‡27

‡32

‡26

‡28

22

10

24

25

23

†◆11

*9

❖42

◆❖2

◆❖2

❖42

†

†16

†◆19

54

20

55

34

◆❖2

43❖

❖42

*9

37

38

21

3❖

44

†‡◆

29*

32

‡

26‡

31

‡

30

‡✖

3❖

43❖

45

41

5

6

15

1★

4

43❖

3❖

†◆17

†◆18

◆

7

36

♦8

ti2132g

22 311688D

Page 23

Parts

Part No. 253704 BSPP, Series B

Part No. 253705 NPT, Series B

Ref.

Part No. Description Qty

No.

1 ★ HOUSING, diaphragm 1

2 ◆❖ O-RING 3

3 ❖ BEARING 3

4 117158 O-RING 1

5 197645 CARRIAGE, valve 1

6 15A289 CLAMP, sleeve 1

7 ◆ SHAFT, pump, diaphragm 1

8 ◆ O-RING 1

9 * DIAPHRAGM 2

10 197649 CARRIAGE 1

11 †◆ O-RING 2

12 197651 PLUG 2

13 †◆ O-RING 2

14 197653 CLIP, id 2

15 † CUP, air valve 1

16 † PLATE, air valve 1

17 †◆ O-RING 2

18 †◆ O-RING 1

19 †◆ GASKET, flat 1

20 197659 COVER, valve 1

21 116474 SCREW, cap, socket head; M4x20

Torque to 3.1 N•m (2.3 ft-lb)

22 117160 VALVE, safety 1

23 197661 DAMPENER, noise 1

24 197662 PLATE, screw 1

25 116475 SCREW, cap, socket head; M4x12 2

26 ‡ BALL, matrix 4

27 ‡ SEAL, profile 2

28 ‡ SEAT, valve, outlet 2

29 *†‡◆ SEAL, profile 4

30 ‡✖ O-RING

31 ‡ SEAT, valve, inlet 2

32 ‡ GUIDE, ball 4

33 197670 DAMPENER, felt, side 1

Ref.

Part No. Description Qty

No.

34 197671 DAMPENER, felt, air inlet side 1

35 15J372 COVER, exhaust 1

36 15J574 COVER, sheet metal, air valve 1

37 15A282 COVER, fluid 2

38 117240 SCREW, cap, socket head; M8x70

Torque to 12 N•m (8.8 ft-lb)

39 115264 SCREW, cap, socket head; M8x16

Torque to 12 N•m (8.8 ft-lb)

40 15A286 ADAPTER, pump diaphragm, for

253704

198832 ADAPTER, pump diaphragm, for

253705

41 116343 CLAMP, grounding 1

42 ❖ CLIP, ID, C-spring 3

43 ❖ O-RING 3

44 116595 SCREW, M4 button head 2

45 111307 WASHER (used with #41, 116343) 1

46▲ 188621 LABEL, warning (not shown) 1

54 258001 HOUSING, cylinder 1

★ Included in Diaphragm Housing Repair Kit. Order

4

2

Kit 261665 for 253704 pumps and 261666 for

253705 pumps.

◆ Included in Shaft Repair Kit 233841.

❖ Included in Bearing Repair Kit. Order Kit 15J647.

* Included in Diaphragm Repair Kit 246011.

† Included in Air Valve Repair Kit 245066.

‡ Included in Ball Check Valve Repair Kit 245067.

✖ Available in 10-pack kit 15D564.

▲ Replacement Warning labels, signs, tags, and cards

are available at no cost.

6

6

1

1

311688D 23

Page 24

Technical Data

Technical Data

Category Data

Maximum fluid working pressure 300 psi (2.1 MPa, 21 bar)

Maximum air input pressure 100 psi (0.7 MPa, 7 bar)

Ratio 3:1

Maximum permissible stroke frequency in cycles/min 20

Volume per cycle (double stroke) 5 oz/cycle (150 cc/cycle)

Operating temperature range 50-176°F (10-80°C)

Dry suction lift 5 ft (1.5 m)

Wet suction lift 21 ft (6.5 m)

Air inlet size 1/4 npt (253705); 3/8 BSPP (253704)

Fluid inlet size 3/4 npt (253705); M26x1.5 (253704)

Fluid outlet size 3/8 npt (253705); 3/8 BSPP (253704)

Weight (approximate) 28 lb (12.7 kg)

Wetted parts stainless steel, acetal, fluorocarbon, PTFE, nylon

Sound Pressure Levels in dB(A) at 50 cpm (measured at 1 meter from unit)

Inlet Air Pressure Sound Pressure

29 psi (0.2 MPa, 2.0 bar) 72

58 psi (0.4 MPa, 4.0 bar) 76

87 psi (0.6 MPa, 6.0 bar) 78

100 psi (0.7 MPa, 7.0 bar) 80

24 311688D

Page 25

Performance Chart

Performance Chart

Triton performance test, 40, 70, 100 psi (.27, .48, .69 MPa; 2.7, 4.8, 6.9 bar)

Cycles per minute

100 psi (.69 MPa, 6.9 bar)

70 psi (.48 MPa, 4.8 bar)

40 psi (.27 MPa, 2.7 bar)

Outlet Pressure in PSI

Outlet Flow in gallons per minute

100 psi

70 psi

40 psi

Air Flow in SCFM

311688D 25

Page 26

Dimensions

P

Dimensions

66 mm

(2.6 in.)

184 mm

(7.2 in.)

102 mm

Fluid Outlet;

253705 3/8 npt

253704 3/8 BSPP

234 mm

(9.2 in.)

Fluid Inlet;

253705 3/4 npt

253704 M26x1.5

104 mm

(4.1 in.)

TI2133A 1 TI2133A 2

(4.0 in.)

Air Inlet

253705 1/4 npt

253704 3/8 BSP

9 mm (0.35 in.)

diameter

mounting holes

26 311688D

Page 27

Dimensions

311688D 27

Page 28

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1-800-328-0211 Toll Free

612-623-6921

612-378-3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 311688

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

10/2006, Revised 10/2007

Loading...

Loading...