Page 1

Tri-Lube Grease Pump

Package User Manual

Tri-Lube

Grease Pump

Package

Page 2

Tri-Lube Grease Pump Package User Manual L42255

TABLE OF CONTENTS

SECTION/PARAGRAPH PAGE

1.0 INTRODUCTION

1.1 GENERAL.................................................................... 1-1

1.2 SAFETY INSTRUCTIONS .............................................. 1-1

1.3 DESCRIPTION ............................................................. 1-1

1.4 OPERATION ................................................................ 1-2

2.0 INSTALLATION

2.1 MOUNTING ................................................................. 2-1

2.2 WIRING ....................................................................... 2-1

2.3 FILLING RESERVOIR .................................................... 2-2

2.4 PURGING AIR FROM PUMP .......................................... 2-2

2.5 ADDING PUMP ELEMENTS .......................................... 2-3

2.6 PUMP ADJUSTMENTS ................................................. 2-3

LIST OF ILLUSTRATIONS

NUMBER TITLE PAGE

1-1 PUMP OPERATION ..................................................... 1-2

2-1 PUMP DIMENSIONS .................................................. 2-1

2-2 ELECTRICAL DIAGRAMS ............................................ 2-1

2-3 TYPICAL PUMP PACKAGE .......................................... 2-2

2-4 ADD PUMP ELEMENTS .............................................. 2-2

2-5 RELIEF VALVE ADJUSTMENT ...................................... 2-3

2-6 OUTPUT ADJUSTMENT .............................................. 2-3

3-1 RESERVOIR COVER.................................................... 3-1

3-2 RESERVOIR & FOLLOWER ......................................... 3-1

3-3 RESERVOIR & PADDLE .............................................. 3-2

3-4 RESERVOIR & BEARING ............................................. 3-2

SECTION/PARAGRAPH PAGE

3.0 SERVICE AND REPAIR

3.1 REQUIRED TOOLS ....................................................... 3-1

3.2 REPLACING COVER, LL & FOLLOWER .......................... 3-1

3.3 REPLACING RESERVOIR .............................................. 3-2

3.4 REPLACING ECCENTRIC SHAFT BEARING .................... 3-2

3.5 REPLACING CAM ASSEMBLY ....................................... 3-2

3.6 REPLACING DC GEARMOTOR ...................................... 3-3

3.7 REPLACING AC MOTOR ............................................... 3-4

4.0 PARTS LISTS ............................................4-1 THRU 4-3

5.0 TROUBLESHOOTING ................................................. 5-1

NUMBER TITLE PAGE

3-5 ECCENTRIC ............................................................... 3-2

3-6 DC MOTOR COVER .................................................... 3-3

3-7 DC MOTOR LEADS .................................................... 3-3

3-8 MOTOR ATTACH SCREWS .......................................... 3-3

3-9 PUMP DISASSEMBLED .............................................. 3-3

3-10 AC MOTOR & REDUCER ............................................ 3-4

3-11 AC MOTOR ................................................................ 3-4

4-1 DC PUMP PARTS ....................................................... 4-1

4-2 AC PUMP PARTS ....................................................... 4-2

4-3 11 LB RESERVOIR PARTS .......................................... 4-3

LIST OF TABLES

NUMBER DESCRIPTION PAGE

2-1 OUTPUT ADJUSTMENT .............................................. 2-3

4-1 DC PUMP PARTS LIST ............................................... 4-1

NUMBER DESCRIPTION PAGE

4-2 AC PUMP PARTS LIST ............................................... 4-2

4-3 11 LB RES. PARTS LIST ............................................. 4-3

Page 3

Tri-Lube Grease Pump Package User Manual L42255

OPERATION AND SERVICE INSTRUCTIONS

SECTION 1

INTRODUCTION

1.1 GENERAL ........................................................................................1-1

1.2 SAFETY INSTRUCTIONS ..................................................................1-1

1.3 DESCRIPTION ..................................................................................1-1

1.4 OPERATION .....................................................................................1-2

1.1 GENERAL

1.1.1 This User Manual is intended to familiarize the user with

the Tri-Lube grease pump and its various features.

It contains important information for safe, correct

and economical operation of the grease pump. Following

the instructions will help avoid hazards, reduce

downtime and repair costs, increase the reliability and

prolong the service life of the entire system.

1.1.2 This User Manual must be read and used by those who

will work with the complete lubrication system.

1.1.3 Other useful Graco/Trabon Bulletins are:

Bulletin 40000 – Series Progressive System a.

Installation Guide.

Bulletin 30103 – How to Remove Air from a Series b.

Progressive System.

Bulletin 30101 – How to locate Blockage in a Series c.

Progressive System.

1.2 SAFETY INSTRUCTIONS

Read all of the applicable instructions before a.

operating your lubrication system.

Keep all operating instructions near system for b.

future reference.

Incorrect use or unauthorized system changes may c.

result in bearing damage caused by under or over

lubrication.

Any existing safety equipment must not be modified d.

when attaching the lubrication pump and system to

the machine.

If any safety equipment is removed to allow e.

mounting of the lubrication pump or system, it

must be re-assembled prior to machine and/or

lubrication system operation.

Keep lubrication system away from any high heat f.

source.

Disconnect and lock out electrical power source g.

before attempting any repairs to the Tri-Lube Pump

Package.

1-1

Use only original replacement parts. h.

1-1

Page 4

Tri-Lube Grease Pump Package User Manual L42255

1.3 DESCRIPTION

1.3.1 All Tri-Lube Pump Packages consist of the following

components:

A reservoir for holding the lubricant. Reservoirs are a.

cylindrical in shape and are made from transparent

plastic or metal depending on the specific model.

Each reservoir is equipped with a low level switch

activated by the follower assembly and a rotating

paddle to assist priming of the pump.

A pump element is available with either a fixed or b.

adjustable output. All pump elements are equipped

with an adjustable relief valve that relieves to

atmosphere. A second or third pump element can be

added in the field to supply additional output volume

or additional lube points where required.

A gearmotor (12 or 24 VDC) or a motor and gear c.

reducer (115 or 230 VAC, 1 ph, or 230/460 VAC, 3

ph) which drives the pump.

A pump body which houses the pump drive d.

eccentric and to which all other components are

attached.

1.4 OPERATION

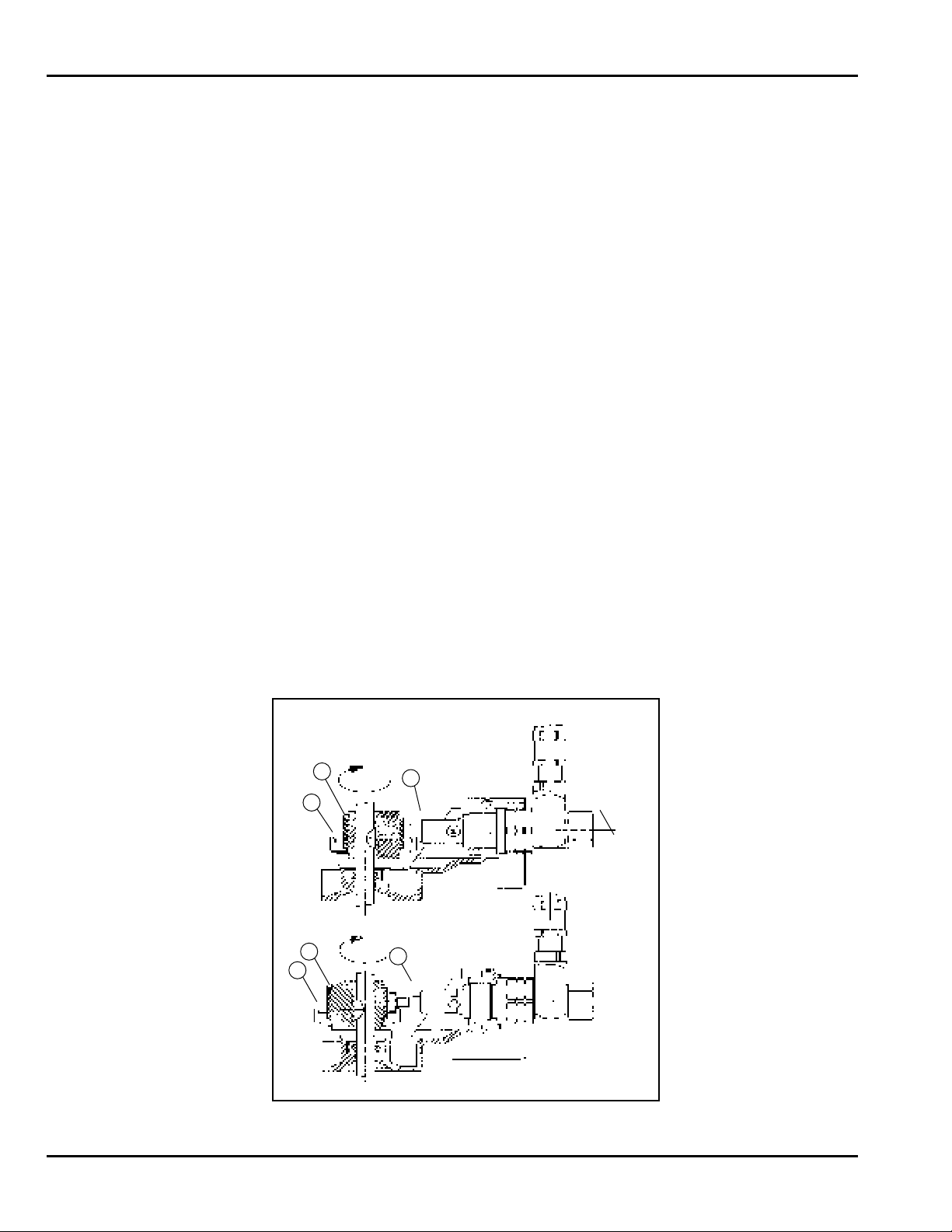

1.4.1 Figure 1-1 shows the general relationship of the pump

element and the drive eccentric. The following steps

outline the operating sequence:

Grease in the reservoir keeps the pump body full a.

during normal operation and maintains a head

pressure to accomplish two objectives.

Provide constant lubrication to the moving •

pump components.

Supply lubricant to the piston chamber in the •

pump cylinder.

A rotating cam (Item 1) forces the pump piston b.

(Item 2) forward displacing lubricant from the pump

cylinder, past an internal discharge check valve and

out of the pump outlet.

As the cam (Item 1) continues to rotate, the pull-c.

back ring (Item 3) pulls the pump piston (Item

2) back to the prime position allowing grease to

re-prime the piston chamber for the next stroke.

Also attached to the eccentric shaft is a paddle (not

shown) with an angled surface that forces grease

into the pump chamber as it rotates and also aids

in dispersing any small air pockets that might be

present in the grease.

Fixed Pump Element

1

3

1

3

2

2

Lube

Outlet

Figure 1-1

1-2

Page 5

Tri-Lube Grease Pump Package User Manual L42255

W2

U2 V2

U1

V1

W1

FA N

SHAFT

OPERATION AND SERVICE INSTRUCTIONS

SECTION 2

INSTALLATION

2.1 MOUNTING .....................................................................................2-1

2.2 WIRING ...........................................................................................2-1

2.3 FILLING RESERVOIR ........................................................................2-2

2.4 PURGING AIR FROM PUMP ..............................................................2-2

2.5 ADDING PUMP ELEMENTS ..............................................................2-3

2.6 PUMP ADJUSTMENTS .....................................................................2-3

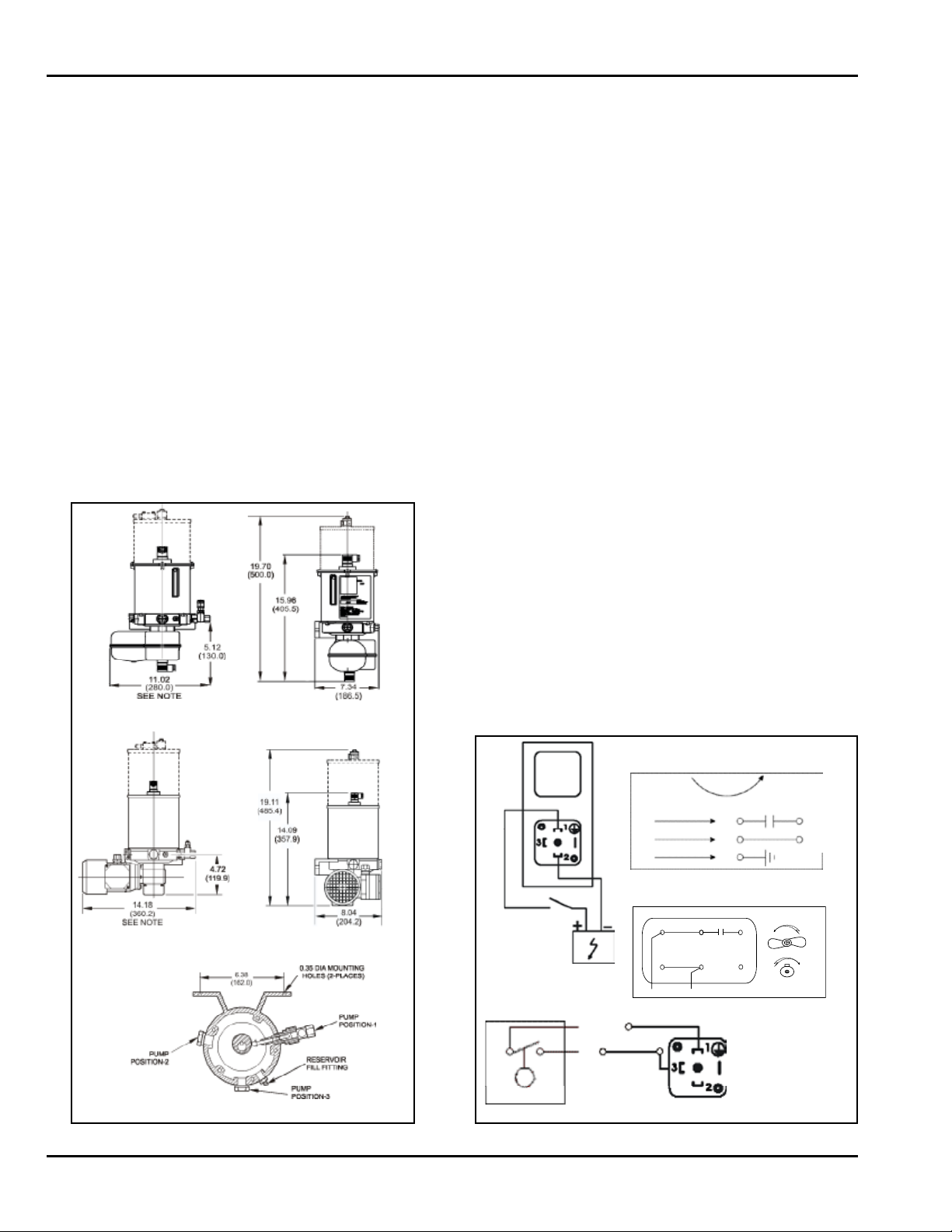

2.1 MOUNTING THE PUMP

2.1.1 The pump should be mounted in a vertical position with

the reservoir at the top and in a protected location, but

where it is accessible for filling and routine maintenance.

DC Motor, Front View

DC Motor, Side View

2.1.2 The pump is mounted using two 5/16” or two 8 mm

bolts (furnished by user) that pass through the mounting

feet on the pump body. The mounting bolt length will

depend on the thickness of the mounting surface

and whether the holes are to be tapped for the bolts or

locked in place with nuts and washers. Mounting

dimensions are shown in Figure 2-1

2.2 WIRING THE PUMP

2.2.1 Electrical connections are shown in Figure 2-2

2.2.2 Wiring to the AC motors should be 16 AWG stranded

wire with insulation rated for 300 V max and 105ºC.

2.2.3 The DC pump motors and all low level switches may be

wired with 18 AWG stranded wire cable.

Figure 2-2b(AC)

Cantoni & ABB Motors

FAN

CAPACITOR

L1

L2

GND

Figure 2-2c (DC)

Moto Technica 1ph Motors

U2

Z2 U1

Z1

AC Motor, Front View AC Motor, Side View

Figure 2-2a (DC)

Figure 2-2d (AC & DC)

COMMON

NC

Top View, DC and AC

Figure 2-1

2-1

LOW LEVEL SWITCH WIRING SCHEMATIC

Figure 2-2

Page 6

Tri-Lube Grease Pump Package User Manual L42255

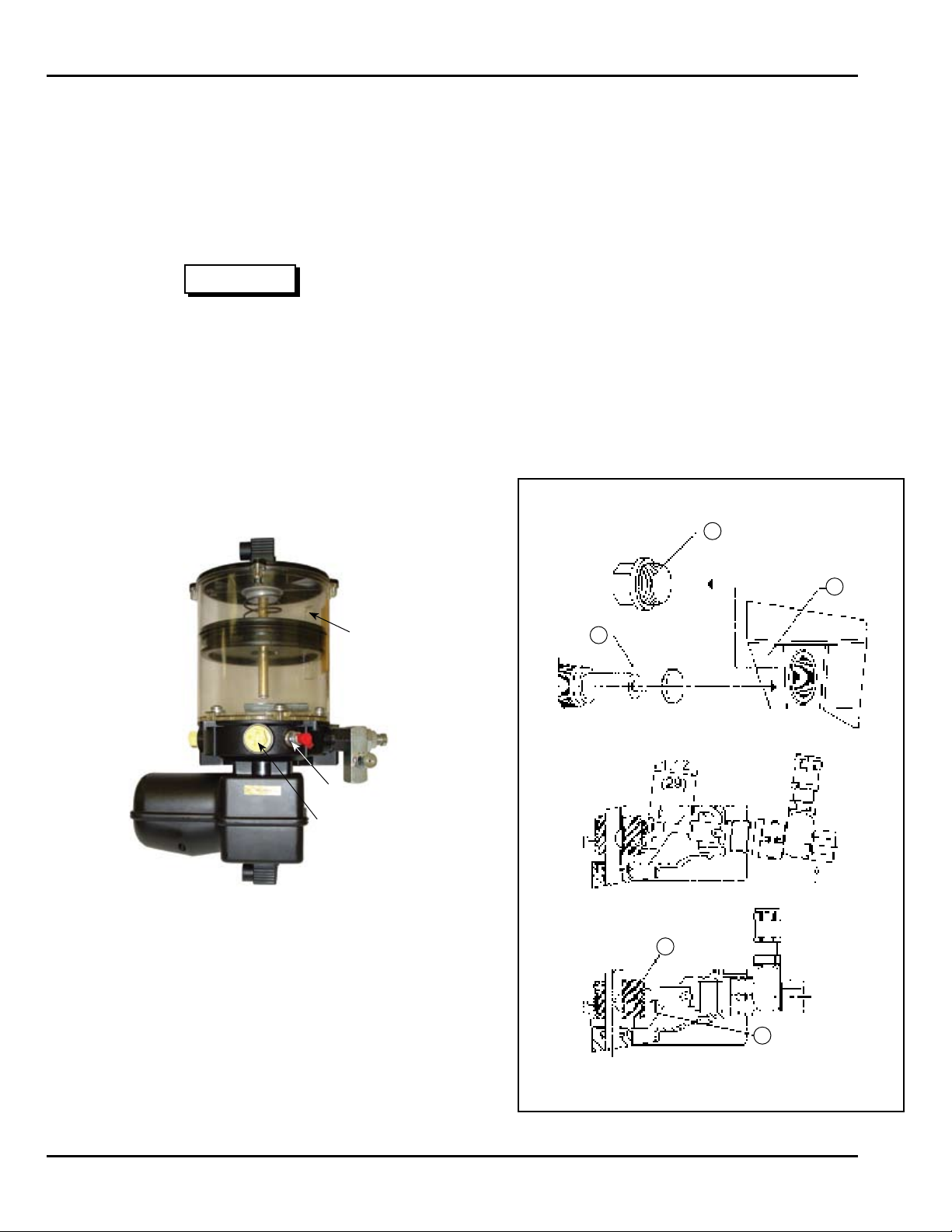

2.3 FILLING THE RESERVOIR

2.3.1 The reservoir should be filled with clean air

free grease of the type recommended by the machine

builder and having an NLGI grade number consistent with

the ambient operating temperature of the equipment

(grease must be pumpable at the lowest anticipated

operating temperature).

CAUTION

Do not fill the reservoir with grease heavier than

NLGI #2. For temperatures below -5OF (-20OC), use

NLGI #1 or lighter grease.

2.3.2 Filling is accomplished by connecting a suitable transfer

pump to the fill fitting in the front of the pump housing

(See Figure 2-3). Before connecting the transfer pump,

make sure that both the lube fitting and the coupler are

clean and that the hose and transfer pump are full of

clean grease that is free of air.

2.3.4 For subsequent re-filling, unless the reservoir

has been allowed to run dry or air was pumped

into the reservoir, it will not be necessary to

remove the yellow plug or fill above the vent hole.

2.4 PURGING THE PUMP AND SYSTEM

OF AIR

2.4.1 Operate the pump with the main line

disconnected until grease free of air is seen at

the pump outlet.

2.4.2 Fill and purge system lines and divider valves

following the procedures outlined in Trabon

Bulletin L30103.

2.4.3 Once all lines and dividers have been purged free

of air, reconnect pump to mainline.

1

3

Vent Hole

Fill Fitting

Pump Position

Plug

Figure 2-3

2.3.3 For the initial filling, or if the reservoir has been allowed

to run dry, removing one of the pump position yellow

plugs from the pump body will facilitate expelling air

from the body and reservoir. Slowly start to fill the

reservoir until grease free of air flows from the open

pump position. At this point, stop the transfer pump and

re-install the yellow plug. After the plug is installed, fill

slowly until the follower seal is slightly above the vent

hole in the reservoir tube. This will allow air remaining

below the follower to escape. When grease free of air is

seen at the vent, stop filling.

2

Figure 2-4a

Figure 2-4b

3

4

Figure 2-4c

Figure 2-4

2-2

Page 7

Tri-Lube Grease Pump Package User Manual L42255

2.5 ADDING PUMP ELEMENTS

CAUTION

To avoid personal injury or severe internal damage to

the drive-train, or pump element, these procedures

must be followed carefully.

2.5.1 Disconnect power to the pump motor.

2.5.2 Remove sealing plug 1 (figure 2-4a).

2.5.3 Pull out pump piston 2 until it extends approximately

1-1/8” (29 mm) from end of cylinder to end of mushroom

head.

2.5.4 Insert element into housing at approximately a 15 degree

angle as shown in figure 2-4b.

NOTE: If pump is full of grease, it will be necessary

to clear a path through the grease using a clean

screwdriver.

2.5.5 Rotate element down (figure 2-4c) engaging mushroom

head between cam 3 and retracting ring 4.

2.5.6 Tighten element 18-22 fl-lbs (25-30 N-m). Do not over

torque as housing threads will be stripped.

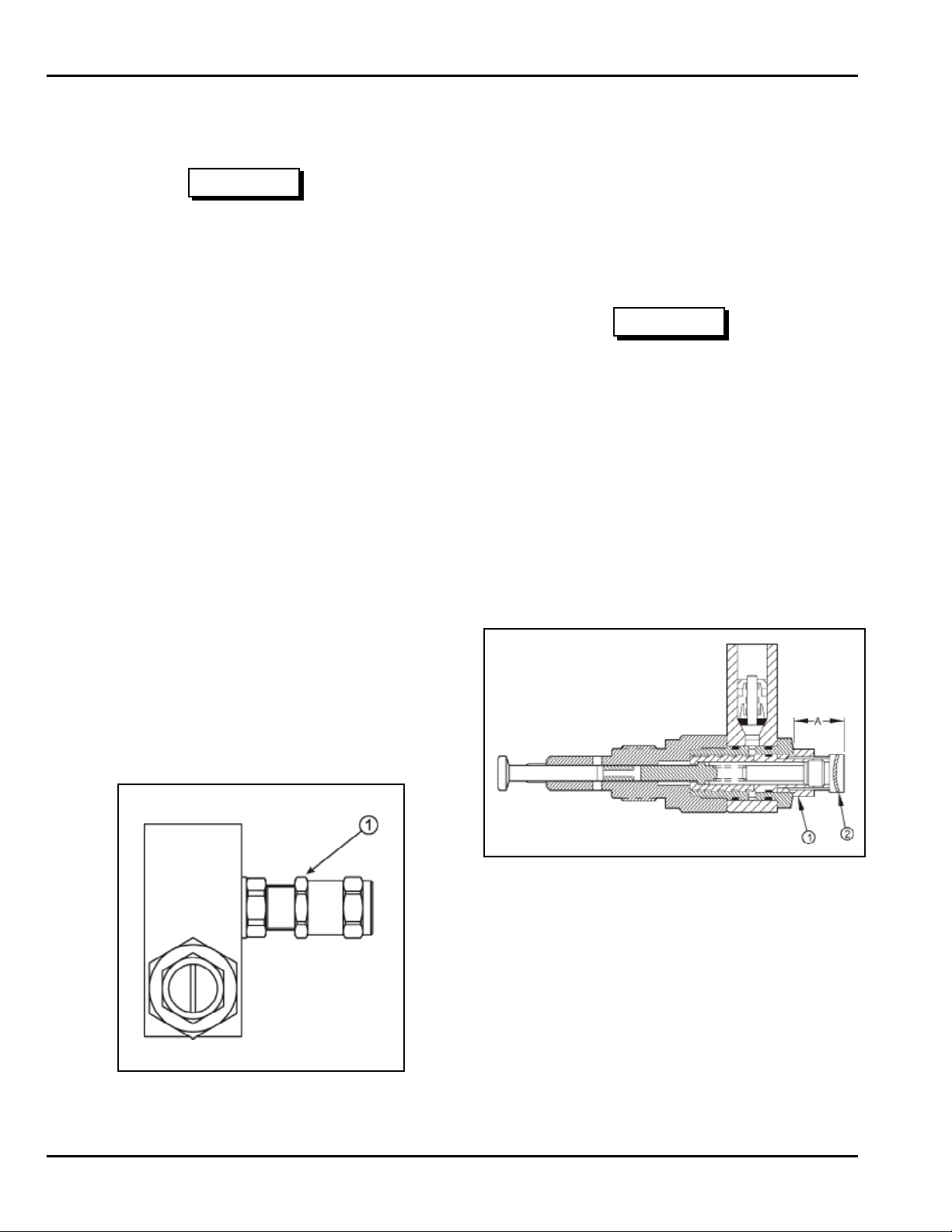

2.6 PUMP ADJUSTMENTS

2.6.1 Adjusting the Relief Valve. Each pumping element

incorporates an adjustable relief valve to protect the

system against overpressure. The relief setting can be

adjusted by loosening the locking nut (1) (See Figure

2-5) and turning the cap clockwise to increase the relief

pressure, and counterclockwise to decrease the relief

pressure, as required by the system application.

CAUTION

Do not adjust above 2900 psi (200 bar) for DC pumps

or 5075 psi (350 bar) for AC pumps as pump or motor

damage may result.

2.6.2 Pump Output Adjustment. The nominal delivery

rate of the pumping element can be adjusted by

loosening the locking nut (1) (See Figure 2-6) and

rotating the adjustment screw (2)clockwise to reduce

delivery, or counterclockwise to increase delivery

of the lubricant. The output adjustment table describes

the equivalent outputs that can be obtained by varying

the distance “A” of the adjustment screw. (See Table 1)

2.5.7 Fill reservoir with clean grease (See Section 2-3) and run

pump for 1 minute to check for grease output. If none is

seen, it could indicate that the element was not properly

installed.

Figure 2-5

Figure 2-6

2-3

Page 8

Tri-Lube Grease Pump Package User Manual L42255

2-4 (Blank)

Page 9

Tri-Lube Grease Pump Package User Manual L42255

OPERATION AND SERVICE INSTRUCTIONS

SECTION 3

SERVICE AND REPAIR

3.1 REQUIRED TOOLS ...........................................................................3-1

3.2 REPLACING COVER, LOW LEVEL & FOLLOWER ................................3-1

3.3 REPLACEMENT RESERVOIR .............................................................3-2

3.4 REPLACING ECCENTRIC SHAFT BEARING ........................................3-2

3.5 REPLACING ECCENTRIC & PISTON RETRACT RING ...........................3-2

3.6 REPLACING DC GEARMOTOR ..........................................................3-3

3.7 REPLACING AC MOTOR ...................................................................3-4

Cover Attaching

Screws

3.1 REQUIRED TOOLS

3.1.1 The following standard hand tools plus a vice with

padded jaws are required for disassembly and repair of

the Tri-Lube Pump Package.

Number 2 and 3 Phillips Screwdrivers (#3 must have a.

a long blade).

4 mm Allen Wrench.b.

8 mm Open End Wrench.c.

27 mm Open End wrench.d.

3/8 in Ratchet Wrench and Extensions.e.

3/8 in drive 17 mm Socket.f.

3.2 REPLACING LOW LEVEL SWITCH,

RESERVOIR COVER AND FOLLOWER

ASSEMBLY (SEE FIG. 3.1 & 3.2)

NOTE: Replacement Low Level Switches are available as

part of a Low Level Switch/Cover/Follower Assembly only.

3.2.1 Remove four cover screws.

Pump

Position

Plug

Figure 3-1

Low Level, Cover,

Follower Assembly

3.2.2 With slight rocking motion of cover, withdraw follower/

low level switch assembly from reservoir.

3.2.3 If suction below follower cannot be broken by rocking

motion, remove one or more pump position plug.

3.2.4 Reassemble in reverse order.

3-1

Pump Position

Plug Removed

Figure 3-2

Page 10

Tri-Lube Grease Pump Package User Manual L42255

3.3 REPLACING RESERVOIR (SEE FIG 3.3 & 3.4)

3.3.1 Following removal of reservoir cover and follower

assembly as outlined in 3.2 above, remove any grease

using a clean scoop and clean rags.

3.3.2 Remove paddle retaining nut. Note: nut and shaft have

left hand threads.

3.3.3 Remove paddle drive adapter (adapter and shaft have left

hand threads).

3.3.4 Remove five reservoir to pump body attaching screws

from inside reservoir.

3.3.5 Remove reservoir from pump body. Note: If eccentric

shaft bearing will be reused and remains in old reservoir,

remove it from the old reservoir bearing cavity (bearing is

a light push fit in cavity).

3.3.6 Reassemble in reverse order.

3.4 REPLACING ECCENTRIC SHAFT BEARING

(SEE FIG 3-4)

Paddle

Nut (Left Hand

Threads)

Figure 3-3

Reservoir Attaching

Screws (5)

3.4.1 Following removal of the reservoir as described in 3.3

above, the bearing will either be on the eccentric shaft

or in the bearing cavity of the reservoir (bearing is a

lightpush fit in both components). Remove the old

bearing and check both the eccentric shaft and the

bearing cavity for scoring.

If none is found, the new bearing may be installed a.

in the bearing cavity.

If scoring in either location is found it may be a.

possible to clean up the surface with fine (600 grit)

wet or dry paper.

If severe, or if the scoring cannot be cleaned up a.

replace the damaged components along with the

bearing.

3.5 REPLACING ECCENTRIC AND PISTON

RETRACT RING (SEE FIG 3-5)

3.5.1 Following removal of the reservoir cover and the

reservoir as outlined in 3.2 & 3.3 above, remove spacer

from eccentric shaft. Note: If pump element was not

previously removed, remove it now following the

instructions in Section 2.5.

Bearing

Pump Motor

Attaching

Screws (3)

Figure 3-4

Eccentric & Pull Back

Ring

3.5.2 Eccentric and retract ring can now be slipped off

eccentric shaft as a unit.

NOTE: Do not attempt to disassemble eccentric from

retract ring as individual repair parts are not available.

3.5.3 Reassemble in reverse order.

Figure 3-5

3-2

Page 11

Tri-Lube Grease Pump Package User Manual L42255

3.6 REPLACING DC GEARMOTOR (SEE FIG 3-6,

3-7, 3-8 & 3-9)

3.6.1 Following removal of the reservoir cover, reservoir and

eccentric assembly as outlined in 3.2, 3.3 and 3.5 above,

remove key from eccentric shaft.

3.6.2 Remove spacer from shaft.

3.6.3 Invert pump unit and remove eight retaining screws

from lower motor housing. Separate lower housing from

upper housing.

3.6.4 Cut motor leads approximately 3 in from old gearmotor.

3.6.5 Remove lower housing leaving leads in place and set

aside.

3.6.6 Remove three motor attaching screws with copper

washers from inside pump housing.

3.6.7 Separate pump housing, upper motor housing and

gearmotor using care to avoid damaging the eccentric

shaft seal.

3.6.8 Make sure replacement gearmotor is correct voltage (24

VDC or 12 VDC).

Upper Cover

Lower Cover

DC Gear

Motor

Figure 3-7

Motor

Attaching

Screws (3)

3.6.9 Trim new gearmotor leads to approximately 3 in length

and strip ¼ in insulation from each lead

3.6.10 Strip ¼ in of insulation from mating power leads.

Use wire nuts or crimp type wire connectors to splice

leads making sure that red is connected to red and blue

to blue.

3.6.11 Reassemble in reverse order.

Motor Cover

Motor Cover

Attaching Screws (8)

Upper Motor

Cover

Figure 3-8

Pump

Housing

DC

GearMotor

3-3

Figure 3-6

Figure 3-9

Page 12

Tri-Lube Grease Pump Package User Manual L42255

3.7 REPLACING AC MOTOR (SEE FIG’S 3-10 & 3-11)

3.7.1 Turn off power to motor.

3.7.2 Remove cover from motor conduit box.

3.7.3 Tag motor leads and remove from terminals.

3.7.4 Remove four motor mounting bolts that attach motor to

gear reducer.

3.7.5 Slide motor shaft with key out of hollow input shaft of

gear reducer.

3.7.6 Reassemble in reverse order making sure that key is

aligned with keyway in hollow input shaft of gear reducer.

AC

Motor

Motor Mounting Bolts

(4)

Figure 3-10

Gear

Reducer

AC

Motor

Figure 3-11

2-3-4

3-4

Page 13

Tri-Lube Grease Pump Package User Manual L42255

OPERATION AND SERVICE INSTRUCTIONS

SECTION 4

PARTS LIST

4-1 DC PUMP PACKAGE-4.4 LB (2 KG) RESERVOIR ................................................ 4-1

4-2 AC PUMP PACKAGE-4.4 LB (2 KG) RESERVOIR ................................................4-2

4-3 11 LB (5 KG) RESERVOIR ................................................................................. 4-3

DC PUMP PACKAGE – 4.4 LB (2 KG) RESERVOIR ORDERING INFORMATION

Item Description Quantity Part No. Old Part No.

1 Switch, LL, Cover, Follower 4.4 Lb (2 Kg) 1 – 529-905-111

2 Reservoir, 4.4 Lb (2 Kg), Plastic 1 Disc 529-905-053

8 O-Ring, Reservoir to Body Seal 1 – 529-905-083

11 Eccentric Assembly (All DC Units) 1 – 529-905-084

13 Seal, 22 x 10 x 7 mm 1 – 529-905-058

14 Gearmotor 24 VDC 1 558943 529-905-060

15 Gearmotor 12 VDC 1 – 529-905-059

18 Bearing, S.R. Ball, 26 x 10 x 8 mm 1 – 529-905-055

20 Plug, Pump Position 2 – 529-905-068

22 Fill Fitting (1/8 GMH) 1 – 529-905-086

23 Element, Pump, Fixed 1-3 558944 529-905-090

24 Element, Pump, Adjustable 1-3 558945 529-905-100

27 Connector, Electrical with Cover 1 – 529-905-115

28 O-Ring, Cover Seal 1 – 529-905-052

29 O-Ring, Follower Rod Seal 1 – 529-905-066

30 O-Ring, Follower Plate Seal 1 – 529-905-065

31 Upper Gearmotor Cover 1 – 529-905-087

32 Lower Gearmotor Cover 1 – 529-905-088

Table 4-1

Figure 4-1

4-1

Page 14

Tri-Lube Grease Pump Package User Manual L42255

20

24

1

26

25

13

16

12

10

7

2

30

33

29

32

33

AC PUMP PACKAGE – 4.4 LB (2 KG) RESERVOIR ORDERING INFORMATION

Item Description Quantity Part No. Old Part No.

1 Switch, LL, Cover, Follower 4.4Lb (2Kg) 1 – 529-905-111

2 Reservoir, 4.4 Lb (2 Kg. Plastic) 1 Disc 529-905-053

7 O-Ring, Reservoir to Body Seal 1 – 529-905-083

10 Eccentric Assembly (4.4lb, AC) 1 – 529-905-084

10 Eccentric Assembly (11 lb, AC) 1 – 529-905-085

12 Seal, 22 x 10 x 7 mm 1 – 529-905-058

16 Reducer, Gear, 80:1 1 – 529-905-089

20 Bearing, S.R. Ball, 26 x 10 x 8 mm 1 – 529-905-055

24 Motor, 230/460 VAC, 3 ph 1 – 529-905-082

25 Motor, 115 VAC, 1 ph 1 556011 126-410-000

26 Motor, 230 VAC, 1 ph 1 556012 126-410-001

29 Element, Pump, Fixed 1-3 558944 529-905-090

30 Element, Pump, Adjustable 1-3 558945 529-905-100

32 Fill Fitting (1/8 GMH) 1 – 529-905-086

33 Plug, Pump Position 2 – 529-905-068

Table 4-2

Figure 4-2

4-2

Page 15

Tri-Lube Grease Pump Package User Manual L42255

11 LB (5 KG) RESERVOIR

Item Description Quantity Part No. Old Part No.

2 Switch, Low Level 1 – 529-905-071

6 Cover 1 – 529-905-072

7 Reservoir 1 – 529-905-073

9 Seal, Follower Rod 1 – 529-905-074

10 Seal, “V”, Follower 1 – 529-905-076

15 Gasket 1 – 529-905-080

24 Follower 1 – 529-905-075

Table 4-3

Figure 4-3

4-44-3

Page 16

Tri-Lube Grease Pump Package User Manual L42255

4-4 (Blank)

Page 17

Tri-Lube Grease Pump Package User Manual L42255

OPERATION AND SERVICE INSTRUCTIONS

SECTION 5

TROUBLESHOOTING

5.1 PUMP DOES NOT PRODUCE FLOW ..............................................................5-1

5.2 LL SWITCH DOES NOT SIGNAL LL ...............................................................5-1

5.1 PUMP DOES NOT PRODUCE FLOW

5.1.1 Make sure that reservoir contains an adequate

supply of air free grease that is pumpable at the

operating temperature being encountered.

If reservoir is empty, refill following the instructions a.

in section 2.3 and purge pump free of air.

If grease is too heavy for the temperature conditions, b.

empty reservoir and refill with grease of the correct

NLGI grade number (refer to section 2.3).

If grease contains air pockets and pump is air c.

bound, empty reservoir and refill with grease that is

free of air (refer to section 2.3).

5.1.2 On adjustable pumps, make sure the output adjustment

is not set to minimum (refer to section 2.6.2).

5.1.3 Make sure that power of correct voltage is being supplied

to motor and that motor is operating.

If power is not present, check fuses and wiring and a.

correct any problems found (refer to section 2-2).

If power is present and motor does not operate, a.

remove pump element (Refer to section 2-5) and

check for motor operation.

5.2 LOW LEVEL SWITCH DOES NOT SIGNAL

LOW LEVEL

5.2.1 Make sure that level switch is properly wired (see figure

3-1) and correct any problems found.

5.2.2 Make sure that the follower tracks the drop in grease

level to the bottom of the reservoir.

If follower appears stuck in reservoir at mid travel, a.

there is most likely a pocket of air between the

bottom of the follower and the top of the grease

column. Purge air pocket by filling reservoir until

follower is just above vent hole in reservoir side

wall and grease free of air is seen at vent (refer to

section 2.3).

If follower tracks fall of grease level and switch does a.

not signal, replace Level/Switch/Cover/Follower

assembly (refer to section 3.1).

5-1

If motor still does not operate, replace motor (refer a.

to section 3-4 and 3-5).

If motor operates, check for bent or binding a.

components (pump piston and cylinder, cam and

retract ring or gear reducer). Replace any damaged

components (refer to sections 3.3, 3.4 and 3.5).

Page 18

Look to GRACO, Inc.

for all of your

Centralized Lubrication System needs.

Products include:

DIVIDER VALVES: for oil and grease.... to 7500 PSI...

1 to 20 points from a single valve assembly....up to 400 points

from a Master/Secondaries circuit....or systems that handle an

entire plant.

PUMPS: fixed and variable displacement....manual and air,

hydraulic, electric motor or mechanically driven.

TIMER AUTOMATIC CONTROLS: from simple on/off

to complete flow and pressure monitoring, either timer-or machineactuated.

ACCESSORY VALVES: balancing, check and flow.

INDICATORS: performance and broken line.

ACCESSORIES: fittings, brackets, clamps, filters and strainers.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L42255 Rev. B 3/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...