Page 1

Trabon® Modular MXP

Divider Valves

DESCRIPTION

Modular MXP Divider Valves use a stackable subplate design.

The valve section containing the displacement piston is bolted

to an individual subplate. A complete divider valve assembly

consists of an inlet section, an end section, and a minimum of

three (3) to a maximum of ten (10) stacked subplates and valve

sections. These components are bolted together with three (3)

tie rods.

A complete divider valve assembly with a maximum of ten (10)

subplates and valve sections can serve up to 20 lubrication

points.

Because outlet connections are made to the subplate, valve

sections may be changed without disturbing existing tubing.

More lubrication points may be added to an existing assembly by

installing additional subplates, valve sections, and outlet tubing.

A bypass is available allowing points of lubrication to be deleted

(installing a bypass section) or added (removing an installed

bypass section and replacing it with a valve section).

The amount of lubricant dispensed by each valve section is

determined by the size of the piston. A twin valve section

dispenses equal amounts of lubricant to two (2) outlets. A single

valve section combines the lubricant from both ends of the piston

and dispenses it to one outlet. Existing twin valve sections may

be converted to singles by installing an external singling kit. By

installing an external crossport kit, lubricant from adjacent valve

sections can be combined for larger output needs.

A cycle indicator pin, attached to the valve piston, is available

to visually check divider valve cycling. A cycle switch may be

added to produce an electrical signal for monitoring divider valve

functioning. Proximity switches are also available for monitoring

divider valve assemblies having high cycle rates.

Alternate outlet ports allow high pressure (performance)

indicators to be added to assist in locating crushed lines or

blocked lube points. These ports are sealed with plugs with

performance indicators are not used.

FEATURES

• Stackable subplate/valve design simplifi es system planning,

installation and maintenance; helps to minimize initial as well

as spare parts inventory costs.

• Series progressive operation provides added opportunities to

use feedback for local or remote monitoring.

• Modular valve section design permits adding valve sections

(maximum of ten (10) sections per assembly) to meet

changed lubrication requirements. Adding or bypassing of

lube points can be done without removing the assembly or

disturbing previously installed connections or lube lines.

Choice of SAE BSPP (ISO 1179) or NPSF inlet and outlet

sections.

• Built-in outlet check valves prevent the lubricant in the outlet

lines for reentering the valve section, help keep lines full to

assure lube delivery and help maintain system pressure for

more effective monitoring.

• Optional cycle indicator pin plus optional cycle switch provide

electric fault warning in case of faulty valve cycling and/or

lube line blockage.

• MXPO base sections (without check valves) are available for

circulating oil applications.

Page 2

Trabon® Modular MXP Divider Valves

L10132

Modular MX Divider Valves are positive displacement, series

progressive types. Each valve piston must complete its stroke,

dispensing a measured amount of lubricant to the bearings it

serves before the inlet fl ow is ported to the next valve piston.

The valves will continue to operate in this manner as long as

fl uid is supplied to the inlet of the divider valve assembly. When

fl ow to the divider valve inlet ceases, the valve pistons will stop

their movement. When fl ow resumes, the valve pistons will

begin moving from the same point at which they stopped.

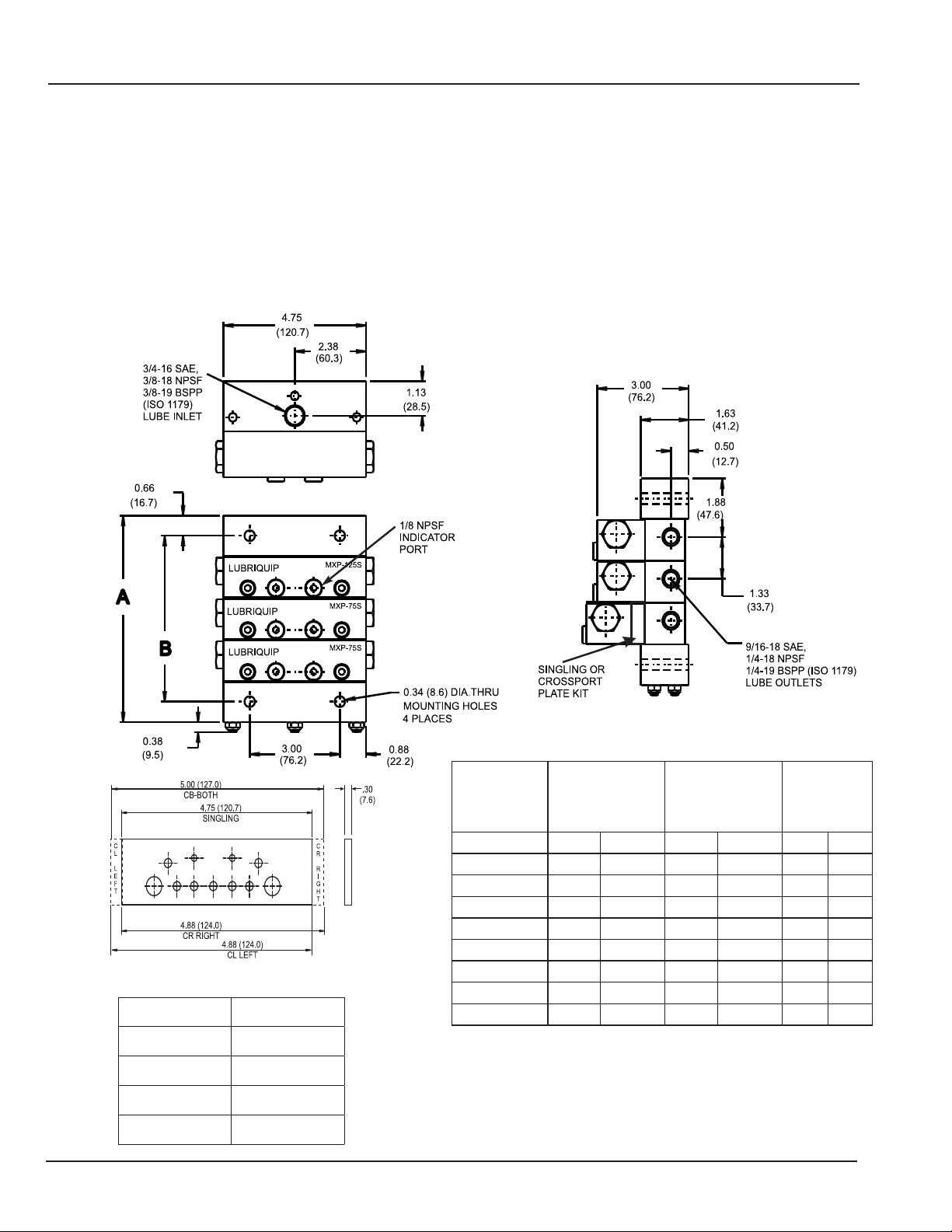

DIMENSIONS

Inches/(mm)

Because the valves are positive displacement, a blocked line

downstream of a valve piston will prevent piston movement and

create high pressure. When performance indicators are used,

the blocked line may be located by identifying which indicator

pin is extended. Pressure switches and relief type performance

indicators and broken line indicators are also available.

PRODUCT I.D.

STYLE TAB(S)

CR RIGHT RIGHT

CL LEFT LEFT

CB-BOTH RIGHT & LEFT

SINGLING NONE

NUMBER OF

SECTIONS

3 6.66 (169.21) 5.35 (135.89) 18.2 8.3

4 8.01 (203.45) 6.70 (170.13) 22.6 10.2

5 9.36 (237.69) 8.05 (204.37) 26.9 12.2

6 10.71 (271.93) 9.39 (238.61) 31.3 14.2

7 12.05 (306.17) 10.74 (272.85) 35.6 16.2

8 13.40 (340.41) 12.09 (307.09) 39.9 18.1

9 14.75 (374.65) 13.44 (341.33) 44.3 20.1

10 16.10 (408.89) 14.79 (375.57) 48.6 22.1

A-DIM B-DIM WEIGHT

Inches (mm) Inches (mm) Lbs (Kg)

Page 2

Page 3

Trabon® Modular MXP Divider Valves

L10132

SPECIFICATION

Material Zinc Plated Steel

O-Ring Seal 90 Durometer Viton

Max Cycle Rate:

w/Cycle Pin 60 CPM

w/o Cycle Pin, or w/ Prox Cycle Sw 200 CPM

Pressure (max) 3,000 psi (207 bar)

Temperature (max) 350ºF (177ºC)

Lubricant Oil or Grease

Torque:

Tie Rod Nut 6-9 ft lbs

Valve Section Mounting Screw 12-13 ft lbs

Indicator Port Plug 12-15 ft lbs

Enclosure Plug 46-50 ft lbs

ACCESSORIES

Description Part No. Old Part No.

Crossport Plate (Left) 563524 527-300-970

Crossport Plate (Right) 563525 527-300-980

Singling Plate – 527-301-000

Indicator Port Adaptor (7/16-20 SAE) – 527-300-851

Outlet Plug 1/4-18 NPTF 557391 508-975-000

Outlet Plug 9/16-18 SAE 556430 412-700-494

Outlet Plug 1/4-19 BSPP 556427 412-700-455

Performance Indicators See bulletin L15401

Accessories and Parts See bulletin L10161

Check Valves See bulletin L15825

Broken Line Indicators See bulletin L15416

Cycle Indicator Proximity Switch See bulletin L15600

DIVIDER VALVE COMPONENT ORDERING INFORMATION

Size Description

25T .025 Twin Outlet .025 .410 562813 106-300-010 – –

25S .025 Single Outlet .050 .820 562819 106-300-070 – –

50T .050 Twin Outlet .050 .820 562814 106-300-020 562825 106-300-130

50S .050 Single Outlet .100 1.639 562820 106-300-080 562830 106-300-180

75T .075 Twin Outlet .075 1.230 562815 106-300-030 562826 106-300-140

75S .075 Single Outlet .150 2.459 562821 106-300-090 562831 106-300-190

100T .100 Twin Outlet .100 1.639 562816 106-300-040 562827 106-300-150

100S .100 Single Outlet .200 3.278 562822 106-300-100 562832 106-300-200

125T .125 Twin Outlet .125 2.049 562817 106-300-050 562828 106-300-160

125S .125 Single Outlet .250 4.098 562823 106-300-110 562833 106-300-210

150T .150 Twin Outlet .150 2.459 562818 106-300-060 562829 106-300-170

150S .150 Single Outlet .300 4.917 562824 106-300-120 562834 106-300-220

B.P. Bypass – – 562835 106-300-410 – –

Inlet (NPSF) 15R993 527-300-000

Inlet (SAE) 15R994 527-300-001

Inlet (BSPP) 561029 527-300-760

Intermediate Base (NPSF) 563519 527-300-100

Intermediate Base (SAE) 563521 527-300-710

Intermediate Base (BSPP) 563522 527-300-740

MXPO Base (NPSF) 563527 527-301-160

MXPO Base (SAE) – 527-301-150

End 563518 527-300-090

*Tie Rod 3 Section 557766 527-300-270

*Tie Rod 4 Section 557767 527-300-280

*Tie Rod 5 Section 557768 527-300-290

*Tie Rod 6 Section 557769 527-300-300

*Tie Rod 7 Section 557770 527-300-310

*Tie Rod 8 Section 557771 527-300-320

*Tie Rod 9 Section 557772 527-300-330

*Tie Rod 10 Section 563520 527-300-340

*Tie Rod Nut 555406 410-440-020

*Three (3) Tie Rods and three (3) Nuts are required per divider assembly

Displacement Per Valve Cycle

cu.in cc

Valve

Section

Part No.

Valve

Section

Old Part No.

w/Cycle Pin

Right Side

Part No.

w/Cycle Pin

Right Side

Old Part No.

Page 3

Page 4

ORDERING INFORMATION

MXP - XXX - X - XX - XXX - X - XX

PORTING OPTIONS

SAE - STRAIGHT THREAD O-RING SEAL

NPT - NPSF PIPE THREAD

BSP - BSPP (ISO 1179)

ACCESSORY OPTIONS*

P - ASSEMBLY OF PERFORMANCE INDICATORS IN

ALL WORKING OUTLETS

*OMIT IF NOT REQUIRED

NUMBER OF SECTIONS

03 - THREE 07 - SEVEN

04 - FOUR 08 - EIGHT

05 - FIVE 09 - NINE

06 - SIX 10 - TEN

VALVE CAPACITY

BP - BYPASS 100 - .100 cu.in.

25 - .025 cu.in. 125 - .125 cu.in.

50 - .050 cu.in. 150 - .150 cu.in.

75 - .075 cu.in.

TYPE OF SECTION

T - TWIN STANDARD

S - SINGLE STANDARD - RH OUTLET

L - SINGLE STANDARD - LH OUTLET

B - TWIN W/CYCLE PIN RIGHT SIDE

C - SINGLE W/CYCLE PIN RIGHT SIDE - RH OUTLET

D - SINGLE W/CYCLE PIN RIGHT SIDE - LH OUTLET

CROSSPORTING OPTIONS

CR - RIGHT HAND SIDE

CL - LEFT HAND SIDE

CB - BOTH SIDES

NOTES:

1. Capacity sections are specifi ed starting from inlet

section and must equal number of manifold sections

in subplate.

2. When capacity section is crossported, its outlet is

plugged and the output volume is diverted to next

section, farthest from inlet section.

3. Last capacity section, farthest from inlet, cannot be

crossported.

4. Single output capacity sections can be crossported

on one side only.

5. All crossporting is accomplished external using the

crossport kits listed on page 3.

6. When capacity section is singled, only one outlet

in its subplate can be used. Other outlet must be

plugged.

7. By-pass block cannot be supplied on a three section

assembly; all manifolded assemblies must have a

minimum of three working capacity sections.

8. Contact Graco for part numbers of stainless steel

components

9. Divider Systems should be limited to fi rst and second

stages only. Third staging is not recommended.

Refer to Trabon® bulletin L20101, L20105 and

L20115 for further information on system design.

Ordering Example

5 section MXP divider valve with SAE ports and performance indicators

in each working outlet consisting of:

1-100 Twin Valve w/Cycle Pin Right Side

1-150 Single Valve Crossport Right Side

1-150 Single Valve Right Side Outlet

1-125 Twin Valve

1-Bypass Section

Order Code: MSP-SAE-P-5-100B-150SCR-150S-125T-BP

Graco endorses the SAE recommendation of ISO 18/14 (ISO 4406) oil cleanliness

for most bearing applications. Some high speed bearings may require cleaner oil.

Consult the bearing manufacturer for recommendation.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L10132 Rev. B 1/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...