Page 1

Modu-Flo® System

BY

LUBRIQUIP

®

Operation and Service Instructions

Bulletin 42000

© LUBRIQUIP , INC., 1988. All Right s Reserved.

Modular

R

Pumping

Packages

Revised November 2005

Page 2

Page 3

R

TABLE OF CONTENTS

42000Modu-Flo® System

Section/Para Page

1 INTRODUCTION .............................................. 1-1

1.1 GENERAL ............................................................. 1-1

1.2 GENERAL SYSTEM OPERA TION......................... 1-2

2 RESERVOIRS AND TANKS............................. 2-1

2.1 DESCRIPTION...................................................... 2-1

2.2 MOUNTING INSTRUCTIONS ............................... 2-1

2.3 PREPARATION FOR USE.....................................2-2

2.4 GREASE RESERVOIR MAINTENANCE

(OPTIONS GP1 THROUGH GP5 AND GM1

THROUGH GM4) .................................................. 2-3

2.5 OIL RESERVOIR MAINTENANCE

(OPTIONS OP1 THROUGH OP4) ........................ 2-7

2.6 OIL T ANK MAINTENANCE

(OPTIONS T1, T2 and T3) .................................. 2-11

3 PUMPS............................................................ 3-1

3.1 DESCRIPTION...................................................... 3-1

3.2 PREPARATION FOR USE.....................................3-3

3.3 PNEUMATIC PUMP MAINTENANCE

(OPTIONS A1 THROUGH A6) .............................. 3-3

3.4 HYDRAULIC PUMP MAINTENANCE

(OPTIONS H1 AND H3) ........................................ 3-9

3.5 HYDRAULIC PUMP MAINTENANCE

(OPTION H2)....................................................... 3-13

Section/Para Page

5.3 OIL T ANK AND RESERVOIR 15 AMP

LOW-LEVEL ASSEMBL Y MAINTENANCE

(OPTIONS L1, L2 and L3) .................................... 5-2

5.4 OIL T ANK RESERVOIR 10-WA TT LOW-LEVEL

ASSEMBLY MAINTENANCE (OPTIONS L5, L6

AND L7) ................................................................5-4

5.5 GREASE RESERVOIR LOW-LEVEL ASSEMBL Y

MAINTENANCE (OPTION L4)............................... 5-5

6 HIGH-PRESSURE AND BLOWOUT

SWITCHES...................................................... 6-1

6.1 DESCRIPTION...................................................... 6-1

6.2 HIGH-PRESSURE SWITCH ADJUSTMENT ........ 6-2

6.3 MOUNTING INSTRUCTIONS ............................... 6-3

6.4 HIGH-PRESSURE SWITCH MAINTENANCE

(OPTION P1) ......................................................... 6-3

6.5 RESERVOIR BLOWOUT SWITCH MAINTE-

NANCE (OPTIONS P2 and P3) ............................6-4

6.6 TANK BLOWOUT SWITCH MAINTENANCE

(OPTION P4) ......................................................... 6-6

7 PNEUMA TIC SOLENOID OPTIONS ................ 7-1

8 CONTROLLERS .............................................. 8-1

8.1 DESCRIPTION...................................................... 8-1

8.2 WIRING ................................................................. 8-2

4 MANIFOLDS.................................................... 4-1

4.1 DESCRIPTION...................................................... 4-1

4.2 PREPARATION FOR USE.....................................4-1

4.3 MAINTENANCE ..................................................... 4-1

5 LOW-LEVEL SWITCHES ................................ 5-1

5.1 DESCRIPTION...................................................... 5-1

5.2. MOUNTING INSTRUCTIONS ............................... 5-1

LIST OF ILLUSTRATIONS

Number Title Page

1-1. Modu-Flo Functional Schematic ......................... 1-3

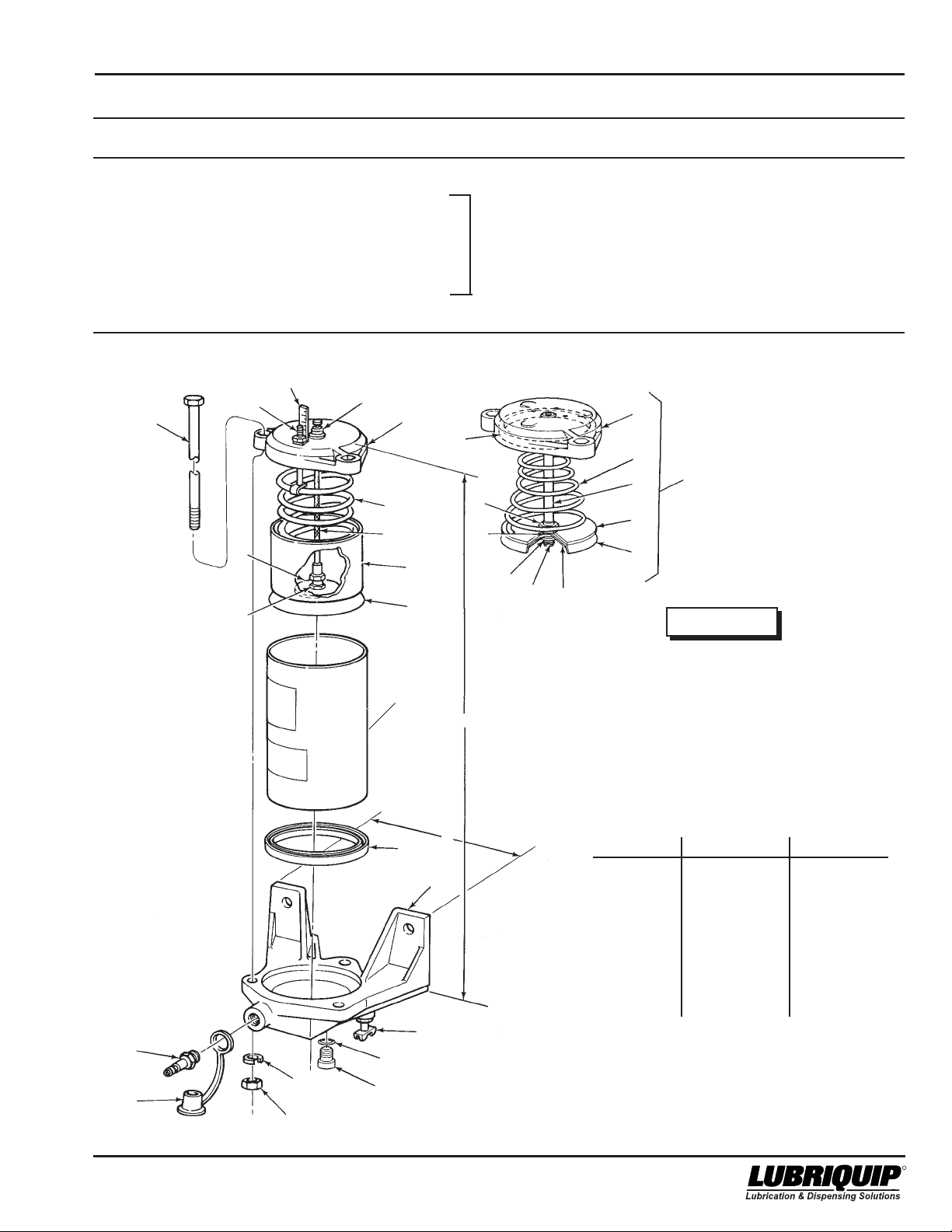

2-1. Grease Reservoir - Exploded View.....................2- 5

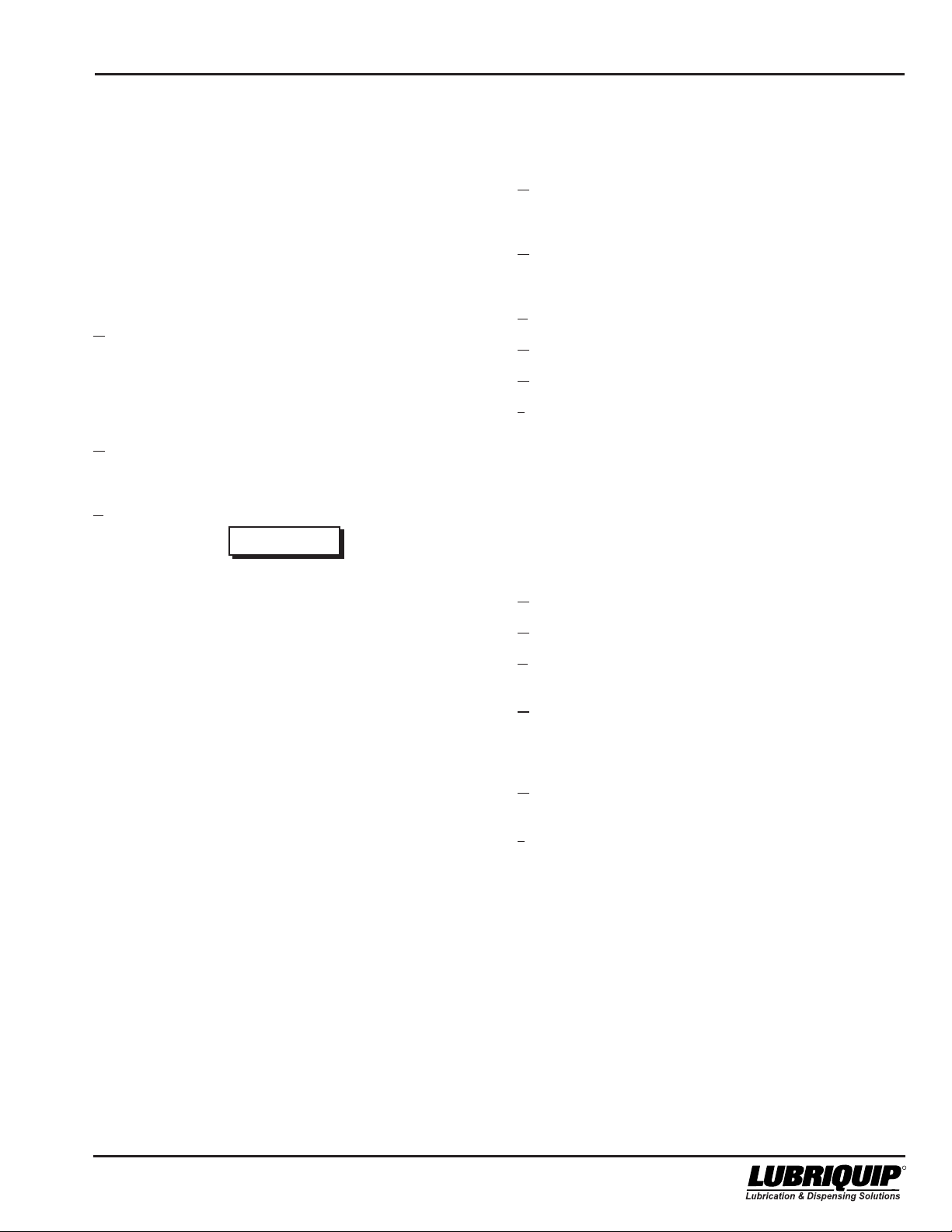

2-2. Oil Reservoir - Exploded View ............................ 2-9

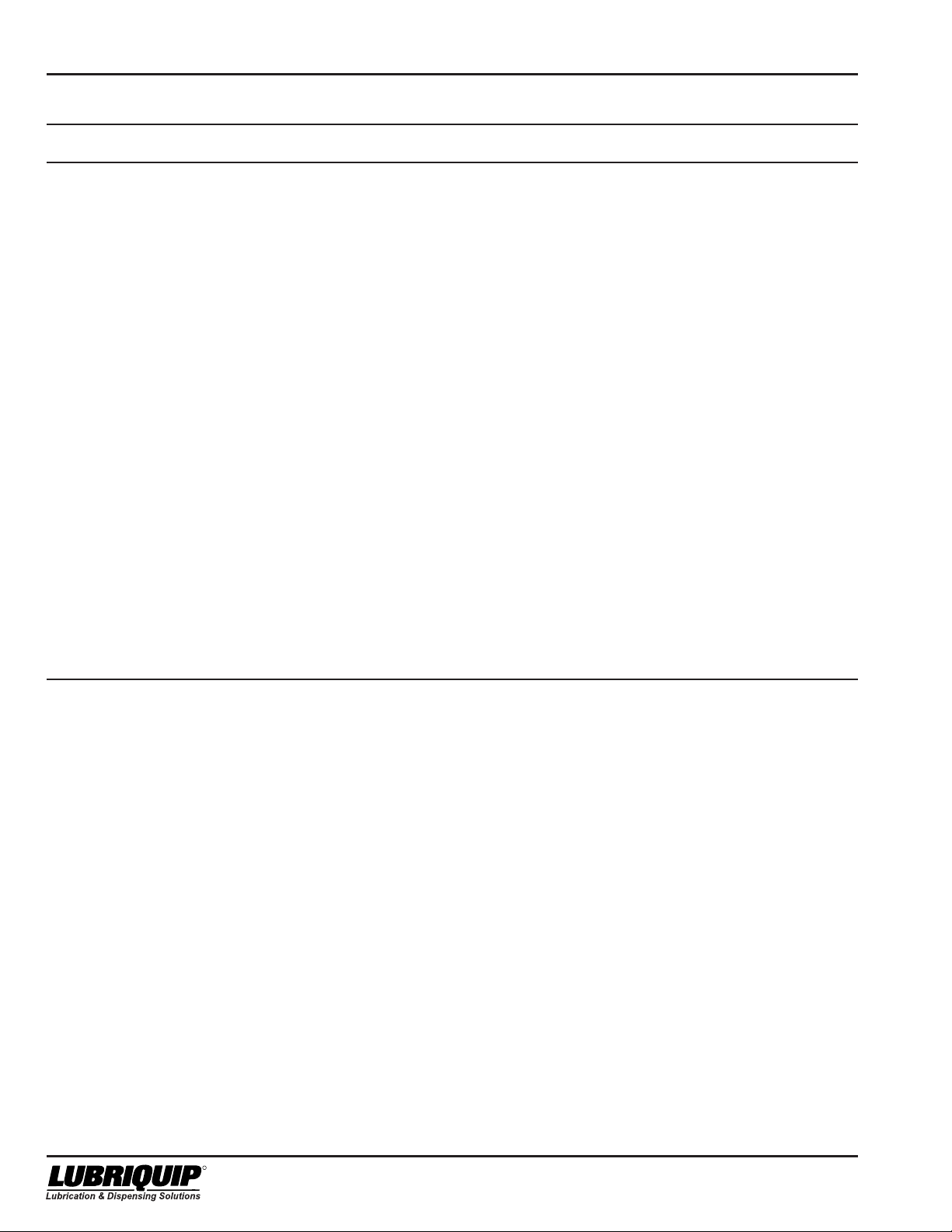

2-3. Oil Tank - Exploded View ..................................2-13

3-1. Typical Pump Operation ...................................... 3-2

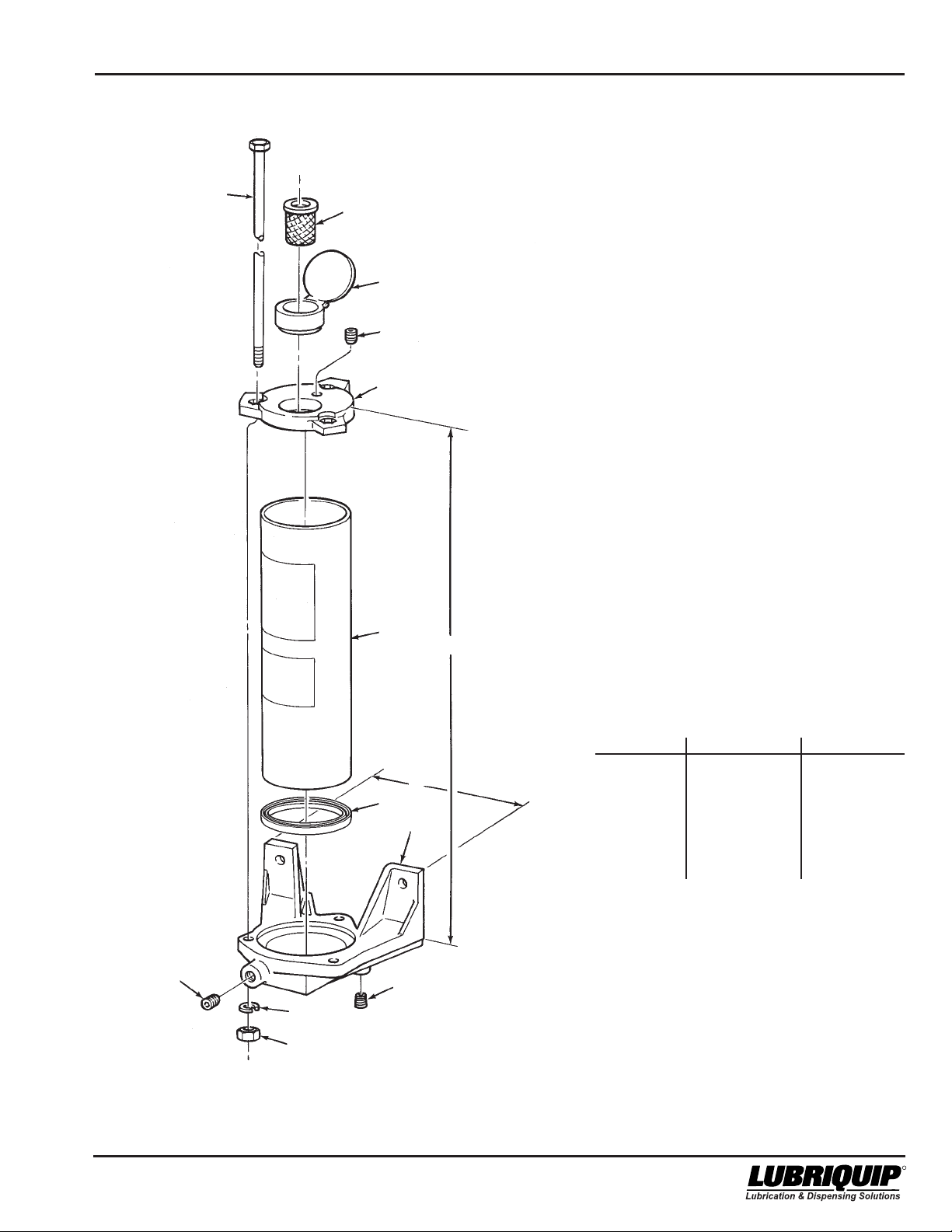

3-2. Pneumatic Pump, Exploded View ...................... 3 -7

3-3. Hydraulic Pump Options H1 and H3 -

Exploded View................................................... 3 -11

3-4. Hydraulic Pump Option H2 - Exploded View .... 3-15

4-1. Typical Manifold Assembly.................................. 4 -3

5-1. Oil Tank and Reservoir 15 Amp Low-Level

Assembly ............................................................5-3

9 SYSTEM OPERA TION ..................................... 9-1

9.1 GENERAL ............................................................. 9-1

9.2 SYSTEM INFORMATION ....................................... 9-1

9.3 OPERATING TIPS ................................................. 9-1

9.4 MATERIAL CONSIDERATIONS............................. 9-2

10 TROUBLESHOOTING ................................... 10-1

10.1 GENERAL ........................................................... 10-1

Number Title Page

5-2. Oil Tank and Reservoir 10-Watt

Low-Level Assembly ........................................... 5-5

5-3. Grease Reservoir Low-Level Assembly ............. 5-6

6-1. High-Pressure Switch ......................................... 6-2

6-2. High-Pressure Switch (Rear View) ..................... 6 -4

6-3. Reservoir Blowout Switch Assembly (Front

View)....................................................................6-5

6-4. Tank Blowout Switch Assembly .......................... 6- 7

7-1. Pneumatic Solenoid ........................................... 7-1

8-1. DC Timer Wiring Schematic ............................... 8 -2

8-2. AC Timer Wiring Schematic................................ 8- 2

8-3. TC1000 Timer/Counter Wiring Schematic ......... 8 -3

8-4. WMP Maxi-Monitor Wiring Schematic .................8-3

i

Page 4

Modu-Flo® System 42000

LIST OF TABLES

Number Title Page

2-1. Reservoirs and Tanks ......................................... 2-2

2-2. Grease Reservoir Parts List ............................... 2-4

2-3. Oil Reservoir Parts Lists ..................................... 2- 8

2-4. Oil Tank Parts List ............................................. 2-12

3-1. Pumps................................................................. 3-2

3-2. Pneumatic Pump Parts List ................................ 3 -5

3-3. Hydraulic Pump Options H1 and H3

Parts List ........................................................... 3-10

3-4 Hydraulic Pump Option H2 Parts List...............3-14

4-1. Operating Ports on Modu-Flo Manifolds ............. 4-2

4-2. Manifolds and Manifold Accessories .................. 4 -2

5-1. Low-Level Switch Assemblies ........................... 5-2

5-2. Oil Tank and Reservoir 15 Amp Low-Level

Assemblies Parts List ........................................5-3

Number Title Page

5-3. Oil Tank and Reservoir 10-Watt Low-Level

Assemblies Parts List ........................................5-5

5-4. Grease Reservoir Low-Level Assembly

Parts List ............................................................. 5-6

6-1. Blowout Discs and Kits ....................................... 6 -1

6-2. High-Pressure and Blowout Switch

Assemblies......................................................... 6-2

6-3. Pressure Switch Settings ...................................6-3

6-4. High-Pressure Switch Parts List ........................6-4

6-5. Reservoir Blowout Switch Parts List .................. 6-5

6-6. Tank Blowout Switch Parts List ........................... 6- 6

7-1. Pneumatic Solenoid Parts List ........................... 7-1

10-1. Modu-Flo Troubleshooting ...............................10-1

R

ii

Page 5

42000Modu-Flo® System

R

OPERATION AND

SERVICE INSTRUCTIONS

SECTION 1

INTRODUCTION

1.1 GENERAL................................................................... 1-1

1.1.1 Standard Components ...................................1-1

1.1.2 Modu-Flo Options ........................................... 1-1

1.2 GENERAL SYSTEM OPERA TION .............................. 1-1

1.1 GENERAL

1.1.1 Standard Components. A wide choice of modular

components may be assembled to meet a given application.

1.1.1.1 All Modu-Flo systems consist of the following

components:

a. A reservoir or tank for holding the lubricant. Reservoirs

are cylindrical units for grease or oil and are equipped

with a spring-loaded follower for grease applications.

Tanks are rectangular and are used for applications

using oil. Further information on reservoirs may be

found in Section 2.

b. A pump for dispensing a specific volume of lubricant.

Pumps may be pneumatically or hydraulically operated.

A selection of power ratios and displacement ranges

are available. Further information on pumps may be

found in Section 3.

c. A manifold attached to the base of the reservoir to

provide a mounting base for any pump. The manifold

has all the necessary porting to allow lubricant to flow

from the reservoir to the pump and from the pump to the

lubricant lines. Ports are also provided for pneumatic or

hydraulic inputs to operate the pump. Accessories such

as gauges and blowout assemblies are available and

may be connected to the manifold. If the pump is to be

located some distance from the reservoir, a wallmounted manifold is available. Further information on

manifolds is contained in Section 4.

Modu–Flo®

System

1.1.2 Modu-Flo Options.

1.1.2.1 Options which are available for any system include

the following:

a. Low-level switches which mount to the reservoir or tank

and provide a low-level fault signal to a customerdesignated component. Level switch options are

described in Section 5.

b. High-pressure indicators which are installed into the

pump outlet circuit and provide an over-pressure signal

to external components. Pressure switch options are

discussed in Section 6.

c. A pneumatic solenoid valve which mounts directly to the

manifold. The solenoid valve is a three-way, normallyclosed type. Use of the solenoid allows the pump to be

cycled by various controller options. The solenoid is

equipped with a manual override button which may be

used to simplify system testing, line filling and line

bleeding.

d. Several types of controllers are used which can be

adapted to the system. Controller options are discussed in Section 8. Controllers available are as

follows:

(1) Timers which may be set to cycle the pump at given

intervals. Both AC and DC models are available.

(2) A TC-1000 timer can operate the lube system on

either a time or machine cycle basis. It is available

in 12 or 24 VDC or 115 or 230 VAC.

1-1

(3) A WMP Maxi-Monitor which provides a dispense

signal on either a time or machine cycle basis. The

WMP also monitors and displays the status of the

lube system it is controlling. The Maxi-Monitor is

available in either 115 or 230 VAC.

Page 6

Modu-Flo® System 42000

1.2 GENERAL SYSTEM OPERATION

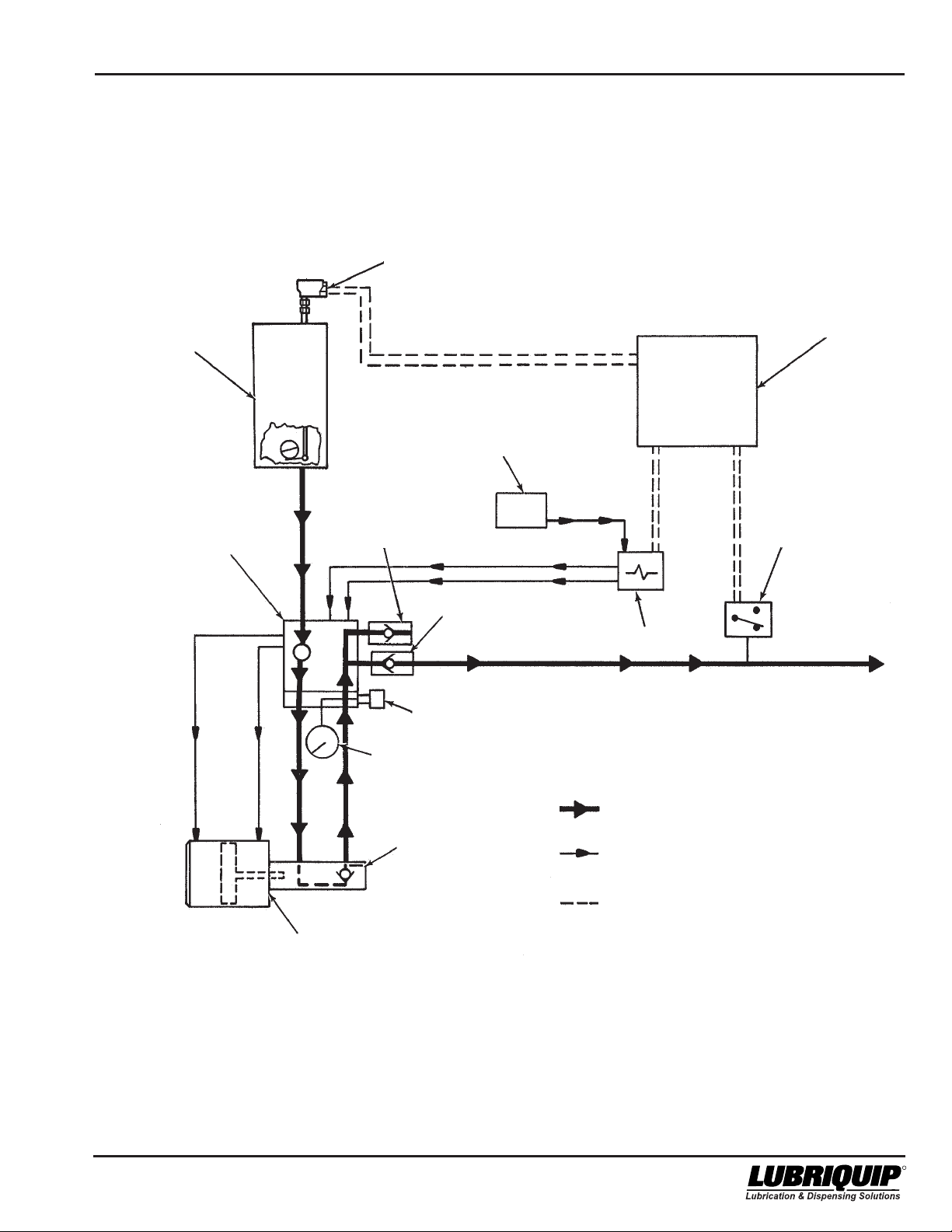

1.2.1 Figure 1-1 shows a functional schematic of a Modu-

Flo system.

1.2.1.1 The following steps outline the operating sequence

of a Modu-Flo system:

a. Lubricant stored in the reservoir or tank flows to the

manifold. The manifold may be mounted directly to the

reservoir or tank, or it may be mounted on a wall.

b. The manifold directs lubricant into the pump to fill the

pump chamber.

c. A controller energizes a solenoid valve to dispense and

the solenoid sends air or hydraulic fluid to the manifold.

Porting in the manifold directs the air or hydraulic fluid to

the pump, causing the pump to dispense lube to the

manifold outlet port.

d. When the controller releases the solenoid, air or

hydraulic fluid is redirected, causing the pump to retract.

On single-acting pneumatic pumps a spring pushes the

pump to the retracted position.

e. Lubricant from the reservoir flows through the manifold

and refills the empty chamber in the pump.

f. A pressure gauge, blowout disc, and high-pressure

switch are options which may be connected to the output

lube on the manifold. A signal from the pressure switch

can be used to actuate an alarm or warning light.

g. Low-level switch options are available for all tanks or

reservoirs. The switch provides an electrical signal

when lubricant level is low.

R

1-2

Page 7

R

RESERVOIR

OR TANK

42000Modu-Flo® System

LOW LEVEL

SWITCH

CONTROLLER

PNEUMATIC/

HYDRAULIC SUPPLY

MANIFOLD

PUMP

SYSTEM FILL

CHECK

GAUGE

TEST/AIR

PURGE PORT

PRESSURE

SWITCH

LUBE OUTLET

CHECK

SOLENOID

BLOWOUT

ASSEMBLY

LUBE LINES

PNEUMATIC/HYDRAULIC

LINES

ELECTRICAL LINES

1-3/(1-4 Blank)

Figure 1-1. Modu-Flo Functional Schematic

Page 8

Page 9

42000Modu-Flo® System

R

OPERATION AND

SERVICE INSTRUCTIONS

SECTION 2

RESERVOIRS AND TANKS

2.1 DESCRIPTION .......................................................... 2-1

2.1.1 Reservoir Description ................................... 2-1

2.1.2 Tank Description ........................................... 2-1

2.1.3 Reservoirs and Tanks Available ................... 2-1

2.2 MOUNTING INSTRUCTIONS ................................... 2-1

2.3 PREP ARATION FOR USE ......................................... 2-2

2.3.1 Filling Oil Reservoirs and Tanks ................... 2- 2

2.3.2 Filling Grease Reservoirs ............................. 2-2

2.4 GREASE RESERVOIR MAINTENANCE

(OPTIONS GP1 THROUGH GP5 AND GM1 THROUGH

GM4) .......................................................................... 2-3

2.4.1 General..........................................................2-3

2.4.2 Grease Reservoir Maintenance .................... 2-3

2.4.3 Disassembly of Grease Reservoirs ............. 2-3

2.4.4 Assembly of Grease Reservoirs................... 2-3

Modu–Flo®

System

2.4.5 Grease Reservoir Parts Lists ....................... 2-3

2.5 OIL RESERVOIR MAINTENANCE

(OPTIONS OP1 THROUGH OP4)............................. 2-7

2.5.1 General..........................................................2-7

2.5.2 Oil Reservoir Maintenance ............................ 2 -7

2.5.3 Disassembly of Oil Reservoir ....................... 2-7

2.5.4 Assembly of Oil Reservoir ............................. 2- 7

2.5.5 Oil Reservoir Parts Lists ............................... 2-7

2.6 OIL T ANK MAINTENANCE

(OPTIONS T1, T2 and T3)....................................... 2-11

2.6.1 General........................................................ 2-11

2.6.2 Oil Tank Maintenance .................................. 2-11

2.6.3 Disassembly of Oil Tanks........................... 2-11

2.6.4 Assembly of Oil Tanks ................................. 2 -11

2.6.5 Oil Tank Parts List ....................................... 2 -11

2.1 DESCRIPTION

2.1.1 Reservoir Description. Reservoirs are cylindrical in

shape and are used for either grease or oil lubricants. If a

reservoir is to be used for grease it will be equipped with a

spring-loaded follower which will apply pressure on the

grease to force it into the pump. Reservoirs use cylinders

made of metal or plastic. If a metal cylinder is used, the

reservoir will be equipped with a level indicator to allow a

visual check of lubricant level. Plastic cylinders are clear,

allowing personnel to actually see the amount of lubricant

present. The base of all reservoirs has the necessary

tapped holes for either direct mounting of a manifold or for

installing hose or tubing to a remote-located manifold.

2.1.2 Tank Description. Tanks are rectangular

weldments used for holding oil. All tanks are equipped with

a sight glass to allow personnel to easily check the lubricant

level. A pad mounted to the tank base provides the necessary tapped holes for either direct mounting of a manifold or

for installing hose or tubing to a remote-located manifold.

2.1.3 Reservoirs and Tanks Available. Table 2-1 lists the

tanks and reservoirs available for use. Listings in the option

column are used to identify the reservoir or tank selected

when a Modu-Flo system is ordered. The option used is

designated by the entry in the ordering code as shown

below:

MPP - XXX - XXX - XX - XX - XX - XX - XX - XXX - XX

Reservoir Option

2.2 MOUNTING INSTRUCTIONS

2.2.1 Reservoirs and tanks may be mounted to any

vertical surface. All units have 7/16 inch holes for attaching

bolts or screws. Cylindrical reservoirs have two holes, six

inches apart, drilled in the base bracket. All tanks have four

holes drilled in flanges according to the following rectangular dimensions:

9-7/8 wide by 7 inches high for T1 tanks

11-1/8 wide by 7 inches high for T2 tanks

16-3/8 wide by 7 inches high for T3 tanks

2.2.1.1 Make sure the mounting location allows clearance

for any accessories attached to the tank or reservoir. Oil

reservoirs and all tanks have a fill cup on the top. Make sure

there is enough room above the fill cup to permit personnel

to perform a filling operation without difficulty. Drill the required holes and attach the reservoir or tank to the vertical

surface. Securely tighten all attaching hardware. Make sure

that the reservoir or tank is level.

2-1

Page 10

Modu-Flo® System 42000

T able 2-1. Reservoirs and Tanks

Part Number Type (Use) Reservoir Capacity Option

521-001-060 Tank (oil) 12 pint (5.68 liters) T1

521-001-070 Tank (oil) 24 pint (11.4 liters) T2

521-001-080 Tank (oil) 40 pint (18.9 liters) T3

185-100-080 Reservoir, Plastic (oil) 5 pint (2.37 liters) OP1

185-100-060 Reservoir, Plastic (oil) 12 pint (5.68 liters) OP2

185-100-070 Reservoir, Plastic (oil) 20 pint (9.46 liters) OP3

185-100-750 Reservoir, Plastic (oil) 6 pint (2.84 liters) OP4

185-100-040 Reservoir, Plastic (grease) 5 lbs (2.27 kg) GP1

185-100-000 Reservoir, Plastic (grease) 12 lbs (5.44 kg) GP2

185-100-010 Reservoir, Plastic (grease) 20 lbs (9.07 kg) GP3

185-100-760 Reservoir, Plastic (grease) 6 lbs (2.72 kg) GP4

185-101-080 Reservoir, Plastic (grease) 3 lbs (1.36 kg) GP5

185-100-050 Reservoir, Metal (grease) 5 lbs (2.27 kg) GM1

185-100-020 Reservoir, Metal (grease) 12 lbs (5.44 kg) GM2

185-100-030 Reservoir, Metal (grease) 20 lbs (9.07 kg) GM3

185-100-770 Reservoir, Metal (grease) 6 lbs (2.72 kg) GM4

185-101-100 Reservoir, Plastic (grease) 40 lbs (18.14 kg) -185- 101- 110 Reservoir, Plastic (grease) w/low level indicator 40 lbs (18.14 kg) -185-100-120 Reservoir, Plastic (grease) w/low level micro switch 40 lbs (18.14 kg) --

* These assemblies are not available through the normal MPP system, only by ordering the full part number.

*

*

*

2.3 PREPARATION FOR USE

NOTE

Before filling any reservoir or tank, a manifold

should be attached to the base. The manifold

has a check valve built into it which will prevent

the lubricant from dripping out of the reservoir or

tank. If the system has a remote-located manifold, make sure there is hose or tubing connected from the bottom of the reservoir or tank to

the remote manifold.

2.3.1 Filling Oil Reservoirs and T anks. Reservoirs and

tanks for oil have a fill cup mounted on top. Wipe the area

around the fill cup to avoid contamination during filling. Open

the fill cup cap and slowly pour the oil into the fill cup. A

strainer attached to the fill cup will remove large particles

which may be present in the oil. When filling is complete,

close fillcup cap and wipe any spillage.

2.3.2 Filling Grease Reservoirs.

WARNING

If a high-pressure, high-volume supply pump is

used to fill grease reservoirs, excess pressure

may not be completely released by the bleed

hole in the reservoir wall. This could cause the

reservoir to fracture, exposing personnel to flying

particles and lubricant. Safety glasses must be

worn during filling operations and the supply

pump must be turned off and disconnected

when filling is complete.

2.3.2.1 Filling of grease reservoirs requires that an external

supply source be connected to the fill stud located in the

base of the reservoir. To avoid introducing air into the system,

make sure there is enough grease in the supply source to fill

R

the reservoir without being disconnected. Operate the supply

source at a steady speed to allow air-free filling of the reservoir. Too fast of a fill speed may result in air pockets. The

level of grease is checked by visual means. In reservoirs

with plastic cylinders, the grease level may be seen through

the cylinder. Reservoirs with metal cylinders have a levelindicator rod mounted on the cap which will indicate when

the fill is complete.

NOTE

Excess lube forced into the reservoir after it has

reached full level will be vented from a bleed

hole in the reservoir tube. (See Warning above.)

2.3.2.2 When filling is complete, turn off the supply source

and disconnect it from the fill stud. A check valve in the fill stud

will prevent lubricant from being forced back out. A plastic dust

cap is attached to the fill stud and should be installed over the

fill stud to keep dirt from entering the system.

NOTE

For first time grease filling, or if the grease reservoir has been allowed to go empty, open the

petcock in the bottom right side of the reservoir.

Slowly begin to fill the reservoir, allowing air

trapped under follower to exhaust out the open

petcock. When grease free of air flows from the

petcock, close petcock and continue to fill the

reservoir until follower is at vent hole in reservoir

tube (any remaining air and small amount of

grease will exit vent).

Loosen system mainline connection at pump

outlet. Operate pump until lubricant free of air

flows from outlet port. Tighten mainline connection at pump. Pump is now free of air.

Note, for extreme cases where the pump will not

take a prime, it may be helpful to inject serveral

2-2

Page 11

42000Modu-Flo® System

R

ounces of heavy oil through the grease fill quick

disconnect. The pump will then prime on oil

pulling the grease behind it. If it becomes necessary to use this method, all injected oil should

be discharged at the loosened system supply

connection along with any air.

Refer to bulletin 12411 (Portable Filler-Pak) for

manual operated fill pump.

2.4 GREASE RESERVOIR MAINTENANCE

(OPTIONS GP1 THROUGH GP5 AND

GM1 THROUGH GM4)

2.4.1 General. Maintenance tips, disassembly, and as-

sembly procedures for grease reservoirs are discussed in

Paragraphs 2.4.2, 2.4.3 and 2.4.4. An exploded view of a

typical grease reservoir is shown in Figure 2-1 and should

be referred to during the discussion.

2.4.2 Grease Reservoir Maintenance.

2.4.2.1 Maintenance on the grease reservoir consists of the

steps described below:

a. Visually inspect the reservoir for lubricant leaking

between reservoir tube (8, Figure 2-1) and base (10).

This may indicate a bad gasket (9) or that the hex nuts

(12) are not tight. Torque the nuts to 5 ft lbs. If the

leakage continues, replace gasket (9). Check for cracks

and nicks in tube (8). Replace the tube as required.

b. Visually inspect the reservoir tube (8) for dents which

may restrict the movement of the follower cups (6 and 7).

Replace the tube as required.

WARNING

Disconnect and lock out power before opening

electrical enclosures or conduit connections.

Serious injury may result from electrical shock.

2.4.3 Disassembly of Grease Reservoirs. Figure 2-1

shows a typical grease reservoir but does not include other

Modu-Flo components which may be mounted to the reservoir. These components include the manifold, pump, level

switches and high-pressure blowout switches. Disassembly

of the reservoir may require that some of these components

be removed. The manifold and pump do not normally require

removal, but may be removed if desired. The level and blowout switches may or may not require removal, depending on

the level of disassembly required. The electrical connections

to the switches probably should be disconnected in order to

remove various parts without restriction of movement by the

electrical cord. The removal of these components is explained in other sections of the manual. Refer to the table of

contents to find where the components are discussed.

2.4.3.1 The disassembly procedure may be performed with

the reservoir mounted to the mounting surface. However,

some mounting locations may be too restrictive to provide

access to all components. If your particular installation requires dismounting of the reservoir, make sure the reservoir

is drained of lubricant before removing the attaching hardware. This will reduce the weight of the reservoir and reduce

the chance of spillage. The disassembly procedure is as

follows:

WARNING

Do not attempt to remove retaining ring (2) or

cable assembly (5) (Figure 2-1) (or retaining

ring (25) or guide rod (5) for Option GP5). Injury

could result from sudden expansion of spring

(4).

a. Slowly open petcock (11) and allow lubricant to be forced

from the reservoir into a bucket or similar container.

Remove fill stud (15) and petcock (11) if necessary.

Properly dispose of emptied grease.

b. Remove hex nuts (12) and lockwashers (13) from tie

rods (1). Remove tie rods (1) from cap (3).

c. Lift reservoir tube (8) from base (10) keeping reservoir

cap (3) in position on top of the tube.

d. Slide reservoir tube (8) away from reservoir cap (3) until

it is free of follower cup (7).

e. Remove gasket (9) from bottom of reservoir tube (8).

f. Further disassembly is only possible at the factory. If

damage is apparent on the follower cups (6 and 7),

cable assembly or guide rod (5), spring (4) or reservoir

cap (3) the unit cannot be serviced and the reservoir

assembly must be replaced.

2.4.4 Assembly of Grease Reservoirs.

NOTE

Before assembly, lubricate followers and tube

inner diameter with the lubricant which is used

in the system.

2.4.4.1 Assemble the grease reservoir according to the

following procedure:

a. Slide reservoir tube (8, Figure 2-1) over follower cup (7)

being careful not to distort the follower cup lips. Slide

reservoir tube (8) up until it contacts reservoir cap (3).

b. Install new gasket (9) on bottom of reservoir tube (8).

c. Place reservoir tube (8) with gasket (9) on base (10) and

rotate reservoir cap (3) until holes in the cap line up with

holes in the base (10).

d. Install tie rods (1) through holes in reservoir cap (3) and

base (10).

e. Install lockwashers (13) and hex nuts (12) on tie rods (1)

and torque to 5 ft lbs.

f. Install fill stud (15), dust cap (14) and petcock (11) in

base. Make sure petcock (11) is in the closed position.

2.4.4.2 When the assembly steps listed in the above paragraph have been completed, any Modu-Flo components

which were removed to ease disassembly should be reinstalled on the reservoir.

2.4.5 Grease Reservoir Parts Lists. Table 2-2 identifies

the parts indexed in Figure 2-1.

2-3

Page 12

Modu-Flo® System 42000

T able 2-2. Grease Reservoir Part s List

Item

Number Part Number Description Quantity

185-100-040 RESERVOIR ASSEMBLY, 5 lbs (2.27 kg), plastic (GP1) -185-100-000 RESERVOIR ASSEMBL Y , 12 lbs (5.44 kg), plastic (GP2) -185-100-010 RESERVOIR ASSEMBL Y , 20 lbs (9.07 kg), plastic (GP3) -185-100-760 RESERVOIR ASSEMBLY, 6 lbs (2.72 kg), plastic (GP4) -185-101-080 RESERVOIR ASSEMBLY, 3 lbs (1.36 kg), plastic (GP5) -185-100-050 RESERVOIR ASSEMBLY, 5 lbs (2.27 kg), metal (GM1) -185-100-020 RESERVOIR ASSEMBL Y , 12 lbs (5.44 kg), metal (GM2) -185-100-030 RESERVOIR ASSEMBL Y , 20 lbs (9.07 kg), metal (GM3) -185-100-770 RESERVOIR ASSEMBLY, 6 lbs (2.72 kg), metal (GM4) --

1 415-700-272 BOLT, Tie (5 lb., 12 lb.) 3

415-700-271 BOLT, Tie (20 lb.) 3

415-700-273 BOLT, Tie (6 lb.) 3

2 RING, Retaining 1

3 CAP, Reservoir 1

4 SPRING 1

5 CABLE ASSEMBLY 1

6 GUIDE, Follower 1

7 CUP Seal 1

9 501-423-001 GASKET (6” Tube) (3,6,12, 20 lb.) 1

415-020-190 BOLT, Tie (3 lb.) 3

Items 2 through 7

are not serviceable

GUIDE ROD 1

by the user; replace

entire reservoir.

501-414-000 GASKET (4” Tube) (5 lb.) 1

10 521-000-500 BASE, Aluminum (6” Tube) (6, 12, 20 lb.) 1

521-000-530 BASE (4” Tube) (5 lb.) 1

521-008-950 BASE, Black (6” Tube) (3 lb.) 1

11 501-970-000 PETCOCK 1

12 410-040-020 NUT, Hex, 5/16-18 3

13 421-010-020 LOCKWASHER, 5/16 inch 3

14 506-165-000 CAP, Dust 1

15 506-189-001 Reservoir Fill Stud 1

16 410-060-120 NUT, Hex, 5/16-18 1

17 511-041-000 PLATE, Backup 1

18 521-003-630 INDICATOR, Level (12 lb. Metal) 1

521-003-640 INDICAT OR, Level (20 lb. Metal) 1

521-004-310 INDICAT OR, Level (6 lb. Metal) 1

521-003-620 INDICAT OR, Level (5 lb. Metal) 1

19 185-100-720+ TUBE, Reservoir, plastic, 13 inches (330.2mm) x 1

185-100-730+ TUBE, Reservoir, plastic, 13 inches (330.2 mm) 1

185-100-740+ TUBE, Reservoir, plastic, 20 inches (508 mm) x 6.0 1

185-100-990+ TUBE, Reservoir, plastic, 8.5 inches (215.9 mm) x 6.0 1

185-100-191+ TUBE, Reservoir, plastic, 5 inches (127 mm) x 6.0 1

185-101-187+ TUBE, Reservoir, metal, 13 inches (330.2 mm) x 1

185-101-188+ TUBE, Reservoir, metal, 13 inches (330.2 mm) x 6.0 1

185-101-189+ TUBE, Reservoir, metal, 20 inches (508 mm) x 6.0 1

185-101-190+ TUBE, Reservoir, metal, 8.5 inches (215.9 mm) x 6.0 1

Mating fill coupler 506-322-000 (order separately)

*

*

4 inches (100 mm) outer diameter (5 lb.)

x 6.0 inches (152.4 mm) outer diameter (12 lb.)

inches (152.4 mm) outer diameter (20 lb.)

inches (152.4 mm) outer diameter (6 lb.)

inches (152.4 mm) outer diameter (3 lb.)

4 inches (100 mm) outer diameter (5 lb.)

inches (152.4 mm) outer diameter (12 lb.)

inches (152.4 mm) outer diameter (20 lb.)

inches (152.4 mm) outer diameter ( 6 lb.)

+ Reservoir Tube Kit includes gasket (item 9).

R

2-4

Page 13

R

T able 2-2. Grease Reservoir Part s List - Continued

Item

Number Part Number Description Quantity

20 439-060-181 GASKET, T op V ent (3 lb.) 1

21 BUSHING, Follower 1

22 WASHER, Follower 1

23 WASHER, Support 1

24 NUT, Jam, 3/4-16 1

25 O-RING 1

26 RING, Retaining 1

27 527-000-230 PLUG, Low Level (3 lb.) 1

28 527-000-240 GASKET (3 lb.) 1

NOTE:

USED ON META L

RESERVOIRS ONL Y

18

1

17

16

2

3

4

5

6

7

Items 21 through 26

are not serviceable

by the user; replace

entire reservoir.

20

24

25

21

26

23

3

4

5

22

7

FOR

OPTION

GP5

ONL Y

WARNING

42000Modu-Flo® System

15

14

Do not attempt to remove retaining ring (2) or cable assembly (5),

19+

8

B

A

9

10

11

*

13

12

27

28

* Mating fill coupler 506-322-000 (order separately)

+ Reservoir Tube Kit includes gasket (item 9).

(Figure 2-1) (or retaining ring (26)

or guide rod (5) for Option GP5).

Injury could result from sudden

expansion of spring (4).

DIMENSIONS

OPTION A B

GP1, GM1, 7.25 inches 15 inches

GP2, GM2 (184 mm) (381 mm)

GP3, GM3 7.25 inches 22 inches

(184 mm) (559 mm)

GP4, GM4 7.25 inches 10.5 inches

(184 mm) (267 mm)

GP5 7.25 inches 6.87 inches

(184 mm) (174 mm)

Figure 2-1. Grease Reservoir - Exploded View

2-5/(2-6 Blank)

Page 14

Page 15

42000Modu-Flo® System

R

2.5 OIL RESERVOIR MAINTENANCE

(OPTIONS OP1 THROUGH OP4)

2.5.1 General. Maintenance tips, disassembly, and as-

sembly procedures for oil reservoirs are discussed in Paragraphs 2.5.2, 2.5.3 and 2.5.4. An exploded view of a typical oil

reservoir is shown in Figure 2-2 and should be referred to

during the discussion.

2.5.2 Oil Reservoir Maintenance.

2.5.2.1 Maintenance on the oil reservoir consists of the

following:

a. Visually check for oil leakage between reservoir tube (6,

Figure 2-2) and base (8). Leakage may indicate that the

gasket (7) is defective or that nuts (9) are not tight.

Torque nuts (9) to 5 ft lbs. If leakage continues, replace

gasket (7). Check for cracks and nicks on tube (6).

Replace the tube as required.

b. Visually check screen (2) in fill cup (3) to make sure it is

not clogged. If necessary, remove the screen for cleaning.

c. Check reservoir bottom for debris. Clean as required.

WARNING

Disconnect and lock out power before opening

electrical enclosures or conduit connections.

Serious injury may result from electrical shock.

2.5.3 Disassembly of Oil Reservoir. Figure 2-2 shows a

typical oil reservoir but does not include other Modu-Flo

components which may be mounted to the reservoir. These

components include the manifold, pump, level switches and

high-pressure blowout switches. Disassembly of the reservoir may require that some of these components be removed. The manifold and pump do not normally require

removal, but may be removed if desired. The level and blowout switches may or may not require removal, depending on

the level of disassembly required. The electrical connections

to the switches should be disconnected in order to remove

various parts without restriction of movement by the electrical

cord. The removal of these components is explained in other

sections of the manual. Refer to the table of contents to find

where the components are discussed.

2.5.3.1 The disassembly procedure may be performed with

the reservoir mounted to the mounting surface. However,

some mounting locations may be too restrictive to provide

access to all components. If your particular installation requires dismounting of the reservoir, make sure the reservoir

is drained of lubricant before removing the attaching hardware. This will reduce the weight of the reservoir and reduce

the chance of spillage. The disassembly procedure is as

follows:

a. Remove pipe plug (4, Figure 2-2) from base (8) and

allow oil to drain from reservoir into bucket or similar

container. Properly dispose of emptied oil.

b. Remove three hex nuts (9) and three lockwashers (10)

from tie rods (1). Remove tie rods (1) from reservoir cap

(5).

c. Remove reservoir cap (5) from reservoir tube (6).

d. Remove fill screen (2) from fill cup (3) and clean screen.

e. Remove reservoir tube (6) from base (8).

f. Remove and discard gasket (7) from reservoir tube (6).

2.5.4 Assembly of Oil Reservoir.

NOTE

Before assembly, lubricate followers and tube

inner diameter with the lubricant which is used

in the system.

2.5.4.1 Assemble the oil reservoir according to the following procedure:

a. Install screen (2, Figure 2-2) in fill cup (3).

b. Install new gasket (7) on reservoir tube (6).

c. Position reservoir tube (6) on base (8) and position

reservoir cap (5) on tube.

d. Rotate reservoir cap (5) until tie rods (1) can be installed

through holes in cap and in base (8). The heads of tie

rods (1) must fit into the hexagon depressions on the

upper surface of the reservoir cap (5).

e. Install lockwashers (10) and hex nuts (9) on tie rods (1).

Torque nuts to 5 ft lbs.

f. Install pipe plug (4) in base (8).

2.5.4.2 When the assembly steps listed in the above paragraph have been completed, any Modu-Flo components

which were removed to ease disassembly should be reinstalled on the reservoir.

2.5.5 Oil Reservoir Parts Lists. Table 2-3 identifies the

parts indexed in Figure 2-2.

2-7

Page 16

Modu-Flo® System 42000

T able 2-3. Oil Reservoir Parts List s

Item

Number Part Number Description Quantity

185-100-080 RESERVOIR ASSEMBLY, 5 pint (2.37 liters), plastic (OP1) -185-100-060 RESERVOIR ASSEMBLY, 12 pin t (5 .68 l ite rs), plastic (OP2) -185-100-070 RESERVOIR ASSEMBLY, 20 pin t (9 .46 l ite rs), plastic (OP3) -185-100-750 RESERVOIR ASSEMBLY, 6 pint (2.84 liters), plastic (OP4) --

1 415-700-272 BOLT, Tie (5 pint, 12 pint) 3

415-700-273 BOLT, Tie (6 pint) 3

415-700-271 BOLT, Tie (20 pint) 3

2 534-304-003 SCREEN (40 Mesh) 1

3 534-147-000 CUP, Fill 1

4 508-975-000 PLUG, Pipe, 1/4 inch NPT 3

5 521-000-600 CAP, Reservoir (4” Tube) (5 pint) 1

501-474-029 CAP, Reservoir (6” Tube) (6,12, 20 pint) 1

6 185-100-720+ TUBE, Reservoir, 13 inches (330.2 mm) x 4 inches1

(100 mm) outer diameter (5 pint)

185-100-990+ TUBE, Reservoir, 8.5 inches (215.9 mm) x 6.0 inches 1

(152.4 mm) outer diameter (6 pint)

185-100-730+ TUBE, Reservoir, 13 inches (330.2 mm) x 6.0 inches 1

(152.4 mm) outer diameter (12 pint)

185-100-740+ TUBE, Reservoir, 20 inches (508 mm) x 6.0 inches1

(152.4 mm) outer diameter (20 pint)

7 501-414-000 GASKET (4” Tube) (5 pint) 1

501-423-001 GASKET (6” Tube) (6, 12, 20 pint) 1

8 521-000-530 BASE (4” Tube) (5 pint) 1

521-000-500 BASE (6” Tube) (6, 12, 20 pint) 1

9 410-040-020 NUT, Hexagon, 5/16-18 3

10 421-010-020 LOCKWASHER, 5/16 inch 3

+ Reservoir Tube Kit includes gasket (Item 7).

R

2-8

Page 17

42000Modu-Flo® System

R

1

2

3

4

5

6+

B

DIMENSIONS

OPTION A B

OP1, OP2 7.25 inches 15 inches

A

7

OP3 7.25 inches 22 inches

8

(184 mm) (381 mm)

(184 mm) (559 mm)

OP4 7.25 inches 10.5 inches

(184 mm) (267 mm)

4

4

10

9

+ Reservoir Tube Kit includes gasket (Item 7).

Figure 2-2. Oil Reservoir - Exploded View

2-9/(2-10 Blank)

Page 18

Page 19

42000Modu-Flo® System

R

2.6 OIL TANK MAINTENANCE

(OPTIONS T1, T2 and T3)

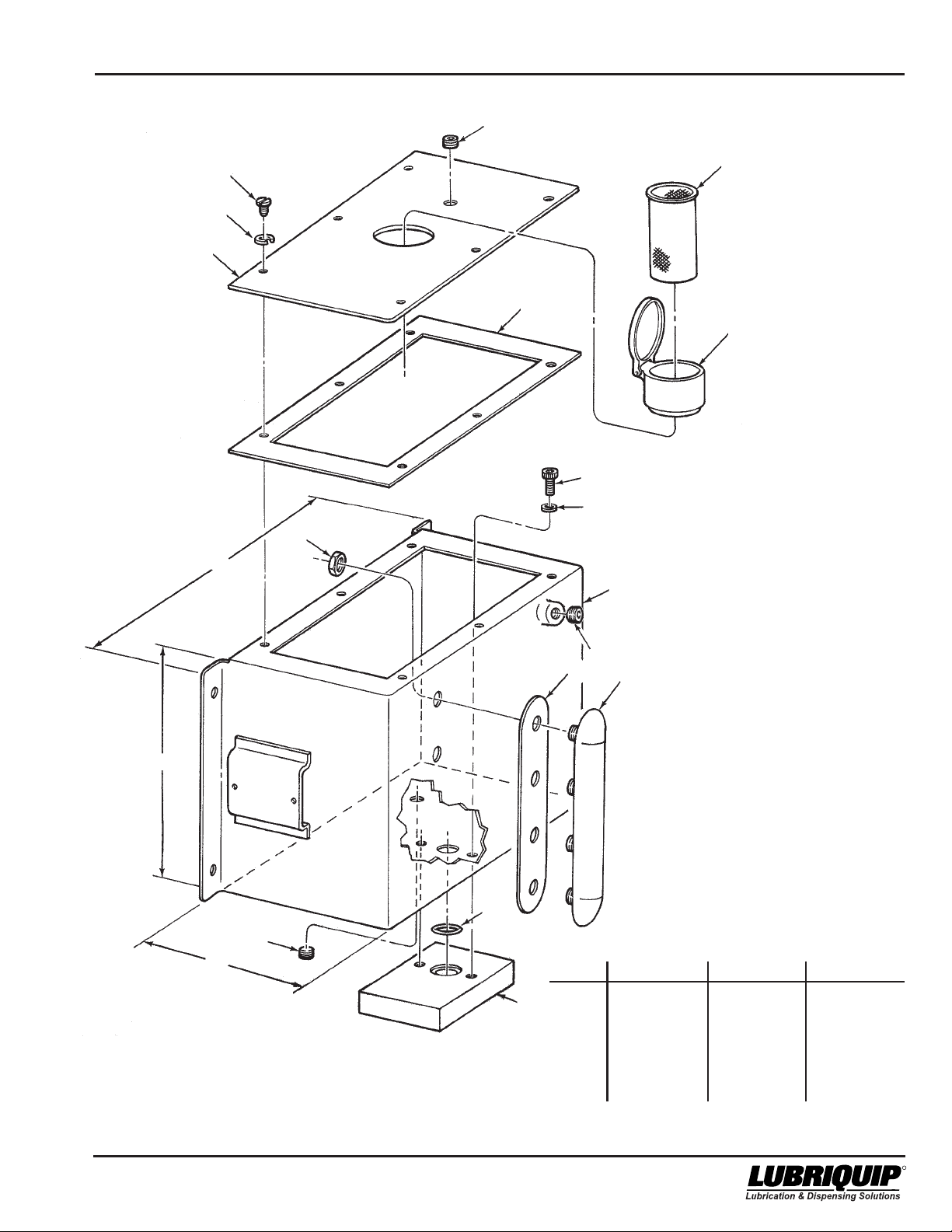

2.6.1 General. Maintenance tips, disassembly and as-

sembly procedures for oil tanks are discussed in Paragraphs 2.6.2, 2.6.3 and 2.6.4. An exploded view of a typical oil

tank is shown in Figure 2-3 and should be referred to during

the discussion.

2.6.2 Oil T ank Maintenance.

2.6.2.1 Maintenance on the oil tanks consists of the follow-

ing:

a. Visually check for oil leakage between the tank (9, Figure

2-3), the pump mounting pad (12) and the level sight

glass (11). Leakage in either of these areas indicates

the components are loose or that gasket (10) or o-ring

(13) is defective. The cover (1) will need to be removed

to either tighten the components or replace defective

seals.

b. Visually check fill screen (4) to make sure it is not

clogged. If necessary, remove the screen for cleaning.

c. Check that the tank is securely fastened to the wall or

supporting structures. Securely tighten any loose

attaching hardware.

WARNING

Disconnect and lock out power before opening

electrical enclosures or conduit connections.

Serious injury may result from electrical shock.

2.6.3 Disassembly of Oil Tanks. Figure 2-3 shows a

typical oil tank but does not include other Modu-Flo components which may be mounted to the tank. These components include the manifold, pump, level switches and blowout switches. Disassembly of tank may require that some of

these components be removed. The manifold and pump do

not normally require removal, but may be removed if desired.

The level and blowout switches may or may not require

removal, depending on the level of disassembly required.

The electrical connections to the switches should be disconnected in order to remove various parts without restriction of

movement by the electrical cord. The removal of these components is explained in other sections of the manual. Refer

to the table of contents to find where these components are

discussed.

2.6.3.1 The disassembly procedure may be performed with

the tank mounted to the mounting surface. However, some

mounting locations may be too restrictive to provide access

to all components. If your particular installation requires

dismounting of the tank, make sure the tank is drained of

lubricant before removing the attaching hardware. This will

reduce the weight of the tank and reduce the chance of spillage. The disassembly procedure is as follows:

a. Remove pipe plug (3, Figure 2-3) from base of tank

weldment (9) and allow oil to drain into bucket or similar

container. Properly dispose of emptied oil.

b. Remove self-threading screws (2) attaching cover (1) to

tank weldment (9) and remove cover and cover gasket

(6).

c. Remove fill screen (4) from fill cup (5) and clean screen.

d. Remove two screws (7) and aluminum gaskets (8) to

release pump mounting pad (12) from tank weldment

(9). Remove and discard o-ring (13) from pump mount-

ing pad (12).

NOTE

Step e should be performed only if the sight

glass is dirty or leaking. Threads cut on nylon

studs of sight glass may prevent the sight glass

from being used.

e. Remove four self-threading nuts (14) and remove sight

glass (11) and gasket (10). Discard gasket (10) and

sight glass (11).

2.6.4 Assembly of Oil Tanks.

NOTE

Before assembly, lubricate all o-rings with the

lubricant which is used in the system.

2.6.4.1 Assemble the oil tanks according to the following

procedure:

a. Install one aluminum gasket (8, Figure 2-3) on each

screw (7) and insert threads of screws through holes in

bottom of tank weldment (9).

b. Install new o-ring (13) in pump mounting pad (12) and

align threaded holes in pump mounting pad with screws

(7) protruding from bottom of tank weldment (9). Thread

screws (7) into pump mounting pad (12) until pump

mounting pad is snug against bottom of tank weldment

(9). Torque screws (7) to 10 ft lbs.

c. Position new gasket (10) on sight glass (11) and install

sight glass on tank weldment (9). Secure sight glass

(11) with four self-threading nuts (14).

d. Install screen (4) into fill cup (5).

e. Position cover gasket (6) and cover (1) on tank

weldment (9) and secure with self-threading screws (2).

f. Install pipe plug (3) in bottom of tank weldment (9).

2.6.4.2 When the assembly steps listed in the above paragraph have been completed, any Modu-Flo components

which were removed to ease disassembly should be reinstalled on the tank.

2.6.5 Oil Tank Parts List. Table 2-4 identifies the parts

indexed in Figure 2-3.

2-11

Page 20

Modu-Flo® System 42000

T able 2-4. Oil Tank Parts List

Item

Number Part Number Description Quantity

521-001-060 RESERVOIR ASSEMBLY, 12 pin t, ( 5.68 lit ers) (T1) -521-001-070 RESERVOIR ASSEMBL Y , 24 pint, (11.4 liters) (T2) -521-001-080 RESERVOIR ASSEMBLY, 40 pin t, ( 18.9 lit ers) (T3) --

1 521-000-810 COVER, (12 pint) 1

2 415-640-040 SCREW, Self-threading, 1/4-28 x 5/16 inch (12 pint) 6

3 508-975-000 PLUG, Pipe, 1/4 inch NPT 2

4 534-304-003 SCREEN (40 Mesh) 1

5 534-147-000 CU P, Fill 1

6 521-003-420 GASKET, Cover, (12 pint) 1

7 419-170-010 SCREW, Socket-head, 3/8-16 x 1/2 inch 2

8 439-050-060 GASKET, 3/8 stat-o-seal 2

9 WELDMENT, Reservoir 1

10 439-060-110 GASKET 1

11 438-028-283 SIGHT GLASS 1

12 521-000-921 PAD, Pump mounting 1

13 423-700-096 O-RING 1

14 410-701-986 NUT, Self-threading 4

15 421-010-010 Lockwasher, 1/4 inch (12 pint) 6

16 412-150-040+ Plug, 3/8 NPT 1

521-000-830 COVER, (24 pint) 1

521-000-850 COVER, (40 pint) 1

415-640-040 SCREW, Self-threading, 1/4-28 x 5/16 inch (24, 40 pint) 8

521-003-380 GASKET , Cover , (24 pint) 1

521-003-340 GASKET , Cover , (40 pint) 1

*

*

Not available as a

item replacement

*

*

421-010-010 Lockwasher, 1/4 inch (24, 40 pint) 8

* Reservoirs with separate aluminum pump mounting pads

only. Steel pump mounting pads are welded in place and

are not replaceable.

+

Used on reservoirs with front pressure-fill port only.

R

2-12

Page 21

42000Modu-Flo® System

R

3

2

4

15

1

6

5

7*

8*

14

A

* Reservoirs with separate aluminum

pump mounting pads only. Steel pump

mounting pads are welded in place

and are not replaceable.

+

Used on reservoirs with front pressure-fill

port only.

9

16+

10

11

C

*

13

3

B

OPTION A B C

T1 10.75 inches 7.25 inches 10.70 inches

12*

T2 12 inches 13.22 inches 10.59 inches

T3 17.25 inches 13.22 inches 10.59 inches

(273 mm) (184 mm) (272 mm)

(305 mm) (336mm) (269 mm)

(438 mm) (336 mm) (269 mm)

DIMENSIONS

2-13/(2-14 Blank)

Figure 2-3. Oil Tank - Exploded View

Page 22

Page 23

42000Modu-Flo® System

R

OPERATION AND

SERVICE INSTRUCTIONS

SECTION 3

PUMPS

3.1 DESCRIPTION .......................................................... 3-1

3.1.1 General..........................................................3-1

3.2 PREP ARATION FOR USE ......................................... 3-3

3.2.1 Mounting ........................................................ 3-3

3.2.2 Output Adjustment ......................................... 3-3

3.3 PNEUMATIC PUMP MAINTENANCE

(OPTIONS A1 THROUGH A6)................................... 3-3

3.3.1 General..........................................................3-3

3.3.2 Pneumatic Pump Maintenance Tips ............ 3-3

3.3.3 Disassembly of Pneumatic Pump ................ 3-3

3.3.4 Assembly of Pneumatic Pump ..................... 3-4

3.3.5 Pneumatic Pump Parts List .......................... 3-4

3.4 HYDRAULIC PUMP MAINTENANCE

(OPTIONS H1 and H3).............................................. 3-9

3.4.1 General..........................................................3-9

3.4.2 Hydraulic Pump Options H1 and H3

Maintenance Tips .......................................... 3-9

Modu–Flo®

System

3.4.3 Disassembly of Hydraulic Pump

Options H1 and H3 ....................................... 3- 9

3.4.4 Assembly of Hydraulic Pump Options H1

and H3 ........................................................... 3-9

3.4.5 Hydraulic Pump Options H1 and H3

Parts List ..................................................... 3-10

3.5 HYDRAULIC PUMP MAINTENANCE

(OPTION H2) ...........................................................3-13

3.5.1 General........................................................3-13

3.5.2 Hydraulic Pump Option H2

Maintenance Tips ........................................ 3-13

3.5.3 Disassembly of Hydraulic Pump

Option H2 ....................................................3-13

3.5.4 Assembly of Hydraulic Pump Option H2 .... 3-13

3.5.5 Hydraulic Pump Option H2 Parts List ......... 3-14

3.1 DESCRIPTION

3.1.1 General. There are six models available for use.

Three models are pneumatically operated and three are

hydraulically operated. The pneumatic models may be

single or double acting. An internal spring will return the

piston to the reload position in single-acting pumps. All

hydraulic models are double-acting.

3.1.1.1 All models are designed to mount directly to either

the pump-to-reservoir manifold or the pump-to-wall manifold. When the pump is properly mounted on a manifold, the

manifold will have all the porting for air and lubricant

connections to and from the pump.

3.1.1.2 Operating sequences for single-acting and doubleacting pumps are listed below. Figure 3-1 shows a sectional view of a typical pump and will help in understanding

pump operation.

a. With single-acting models, air under pressure is

supplied through the inlet port (SA) to chamber (C). This

moves the air and lube pistons to the right. This closes

the lube inlet port and forces the lubricant already in

chamber (B) past the check valve and into the system.

Air in chamber (A) must vent out port (DA). A plastic pipe

plug with a vent hole is installed in port (DA). After a

preset time interval the solenoid valve shuts off the air

supply and vents chamber (C) through port (SA). The

spring returns the air and lube pistons, opening

chamber (B) to the lube reservoir.This completes a

single pump cycle and chamber (B) is primed, ready for

the next cycle.

b. The double-acting models have an additional air or

hydraulic supply line connected to port (DA). When the

pistons have been moved to the right, air or hydraulic

supply to port (SA) is shut off and vented. Then, air or

hydraulic fluid under pressure is supplied to port (DA),

which returns the pistons to their original position. This

more powerful return action allows an increased cycle

rate of the pump.

3.1.1.3 All pneumatic pumps have a lube-to-air pressure

ratio of 30:1. The pumps operate on input pressure ranging

from 40 to 150 psi (3 to 10 bar). The HLJ-5M and HLJ-25M

hydraulic pumps have a lube-to-hydraulic ratio of 5.5:1. The

HLJ-5X has a lube-to-hydraulic ratio of 2.2:1. The hydraulic

pumps operate on input pressures ranging from 200 to

2000 psi (14 to 138 bar). It should be noted that lower input

pressures may prevent the pumps from building sufficient

pressure to crack a rupture disc or activate a high-pressure

device. In pneumatic systems, with an inlet air pressure of

40 psi (3 bar), only 1200 psi (83 bar) could be developed. In

hydraulic systems, with 200 psi (14 bar) only 1100 psi

(76 bar) could be developed. Neither of these pressures

would be high enough to crack a 1450 psi disc. The system

could be blocked and not functioning without giving any

indication to plant personnel. The supply pressure, either

penumatic or hydraulic, should be adjusted high enough to

ensure that a blocked line will cause sufficient pressure to

be developed.

3-1

Page 24

Modu-Flo® System 42000

3.1.1.4 In pneumatically-operated systems, pressure

surges often occur when the solenoid is energized. These

surges can be minimized by installing air flow devices in the

solenoid pneumatic lines.

3.1.1.5 Table 3-1 lists the available pumps along with other

data. Note that the part number on the pneumatic pump is

the same for two different pump models. This is because

any pneumatic pump may be used as either single- or

SINGLE ACTING

(S.A.) PORT

CHAMBER (A)

CHAMBER (C)

double-acting. Listings in the option column are used to

identify the pump selected when a Modu-Flo system is

ordered. The option used is designated by the entry in the

ordering code as shown below:

MPP - XXX - XXX - XX - XX - XX - XX - XX - XXX - XX

Pump Option

LUBE INLET

PORT

LUBE OUTLET

PORT

CHECK

VALVE

CHAMBER (B)

RETURN

SPRING

AIR PISTON

LUBE PISTON

DOUBLE ACTING

(D.A.) PORT

Figure 3-1. Typical Pump Operation

Table 3-1. Pumps

Input

Volume

Output Maximum Per Full

Part Displacement Range Strokes/ Stroke/Cycle

Number Model Action cu in (cm

A. Pneumatic Pumps

521-000-001 AL-5 Single 0.010 to 0.030 (0.164 to 0.492) 65 1.06 (17.4) A1

Double 100 2.09 (34.3)

521-000-021 AL-25 Single 0.030 to 0.120 (0.492 to 1.966) 25 4.20 (68.8) A3

Double 100 8.28 (135.7)

521-000-041 AL-50 Single 0.060 to 0.240 (0.983 to 3.933) 20 8.40 (137.6) A5

Double 60 16.56 (271.4)

3

) per stroke Minute cu.in. (cm3) Option

B. Hydraulic Pumps

521-000-011 HLJ-5 Double 0.010 to 0.030 (0.164 to 0.492) 1 0 0 0.35 (5.7) H1

521-000-031 HLJ-25 Double 0.030 to 0.120 (0.492 to 1.966) 50 1.38 (22.6) H2

521-005-900 HLJ-5X Double 0.030 to 0.092 (0.492 to 1.51) 1 0 0 1.28 (21.0) H 3

R

3-2

Page 25

42000Modu-Flo® System

R

3.2 PREPARATION FOR USE

3.2.1 Mounting. Any pump mounts directly to any manifold

with four socket-head capscrews. Care must be taken to

ensure that the outlet of the manifold is lined up with the inlet

on the pump. The face of the pump which mates with the

manifold has several o-rings. When the pump is being

installed, care must be taken to ensure these o-rings are not

moved out of position. The o-rings provide a seal for the

movement of air and lubricant between the manifold and

pump. If an o-ring is missing, air or lubricant may leak. After

being secured to the manifold, no further connections can be

made to the pump.

3.2.2 Output Adjustment. Adjustment of the pump output

may be made with the pump removed from or still attached

to the manifold.

3.2.2.1 The procedure for output adjustment is listed below.

The items referenced are found in Figure 3-2. The adjustment procedure is the same for both pneumatic and hydraulic pumps.

a. Remove adjustment cap (22) from adjustment screw

(13), holding jam nut (21) if necessary.

b. Butt adjustment cap (22) against jam nut (21) and use

the stamped numbers on the cap to determine how

much adjustment is needed.

c. Loosen jam nut (21) and use a flat screwdriver to turn

adjustment screw (13). Turn adjustment screw in for

less output, turn out for more output.

d. Tighten jam nut (21) and install adjustment cap (22)

over the adjustment screw (13).

3.2.2.2 When adjusting pump output, one complete turn of

the adjusting screw will change the output by the following

amounts:

a. 0.0018 cubic inch for pump options A1 and A2.

b. 0.006 cubic inch for pump options A3 and A4.

c. 0.009 cubic inch for pump options A5 and A6.

d. 0.0018 cubic inch for pump option H1.

e. 0.006 cubic inch for pump option H2 and H3.

3.3 PNEUMATIC PUMP MAINTENANCE

(OPTIONS A1 THROUGH A6)

3.3.1 General. Maintenance tips, disassembly and

assembly procedures for pneumatic pumps are discussed

in Paragraphs 3.3.2 through 3.3.4. An exploded view of a

typical pneumatic pump is shown in Figure 3-2 and should

be referred to during the discussion.

3.3.2 Pneumatic Pump Maintenance Tips.

3.3.2.1 The only maintenance required on the pneumatic

pump is to check for the following:

a. Check four socket-head screws (11, Figure 3-2) to make

sure they are tight. Loose screws could allow air and/or

lubricant to leak between the pump and the manifold.

This condition could result in erratic pump output.

b. Check jam nut (21) to make sure it is tight against

adjustment screw body (19). If the jam nut is loose, the

adjustment screw (13) could rotate and cause the pump

output to change. This condition could also result in

lubricant leakage or in air being sucked into the lubricant.

3.3.2.2 If internal components of the pump are defective it

will usually result in erratic pump operation or output. Section

9 of this manual lists causes and solutions for problems

which could occur in the Modu-Flo system. Before disassembling any pump, refer to Section 10. The problem may

be caused by other conditions which can be checked first

before disassembling the pump.

3.3.3 Disassembly of Pneumatic Pump. The procedure

below describes complete disassembly of a pump. However, you only need to disassemble to your specific area of

concern.

3.3.3.1 The disassembly procedure for the pneumatic

pump is as follows:

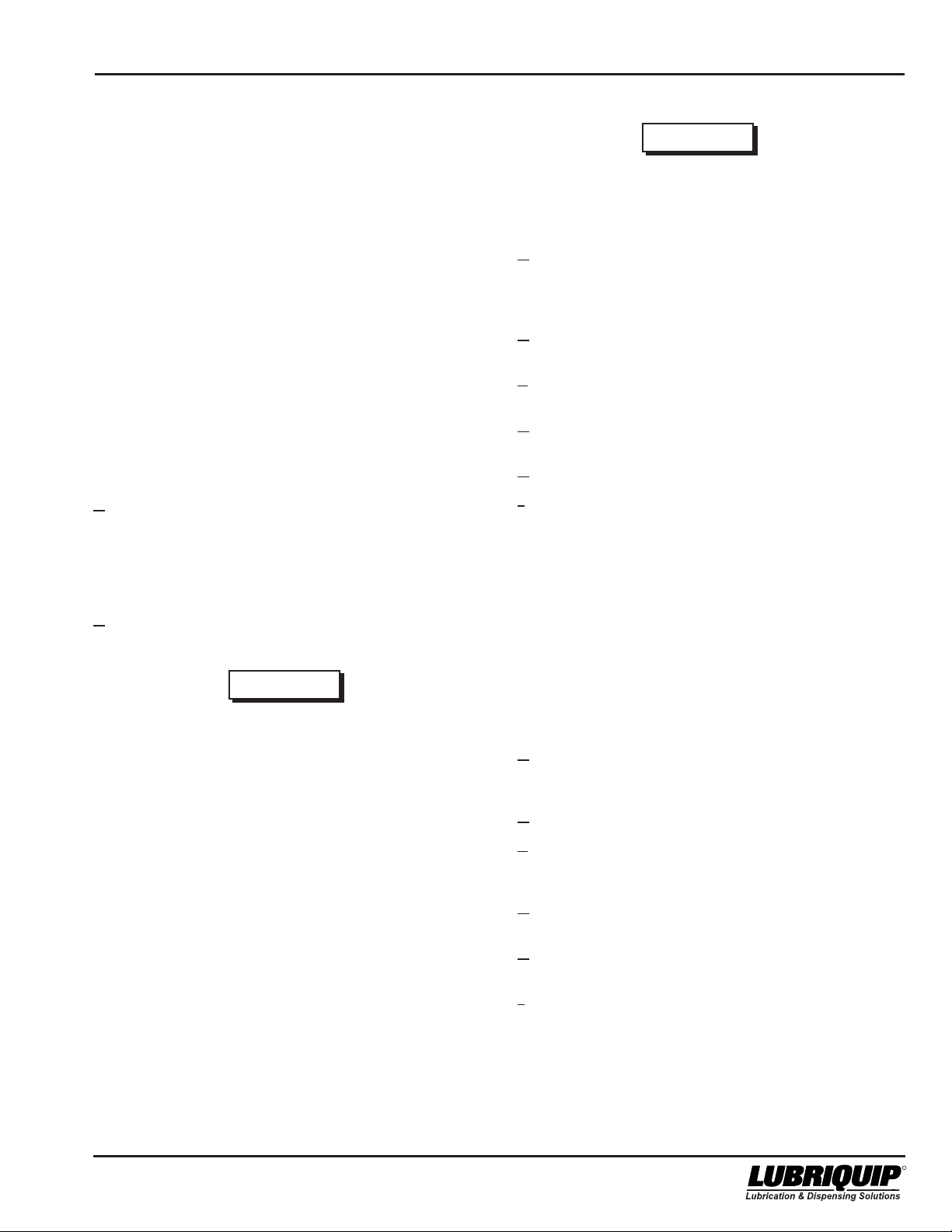

NOTE

Figure 3-2 shows air cylinder (7) separated from

pump body (10). To achieve disassembly to this

level requires special tools to remove air cylinder retainer (23). Normally, this level of disassembly is only performed at the factory. If scoring

or wear marks are evident on the inner diameter

of air cylinder (7) or pump body (10), the pump

assembly cannot be serviced and should be

replaced.

a. Separate pump from manifold by removing four socket-

head screws (11, Figure 3-2). Remove and discard three

o-rings (9) and one o-ring (18).

b. Remove enclosure screw (14). Remove and discard

gasket (15). Remove check valve spring (16), ball (32),

and check seat (29). Remove and discard o-ring (30)

from seat (29).

c. Remove adjustment screw body (19) and o-ring (12)

from pump body (10). Discard o-ring (12). Removal of

adjustment screw (13) from adjustment screw body (19)

will change output setting when pump is reassembled.

If adjustment screw (13) requires removal, perform the

following:

(1) Remove adjustment screw cap (22) from adjust-

ment screw (13). Butt the adjustment screw cap

(22) against jam nut (21) and use the stamped

numbers on the cap to measure how far the

adjustment screw (13) extends from the jam nut.

Record this dimension.

(2) Remove jam nut (21) and two gaskets (20). Discard

gaskets.

(3) Remove adjustment screw (13) by screwing it

towards the hex portion of the adjustment screw

body (19) until it is free.

d. Remove retainer ring (4).

3-3

Page 26

Modu-Flo® System 42000

e. Insert wooden dowel or soft rod into pump body (10) and

push lube piston (5) until cylinder cap (3) is out of air

cylinder (7). Remove and discard o-ring (2) from cylinder

cap (3).

f. Continue to push lube piston (5) through pump body

(10) until air piston (1) is exposed and can be removed

from air cylinder (7). Remove air piston (1), lube piston

(5), and piston-return spring (24) from air cylinder (7).

g. Remove retainer ring (25) and spring retainer (26) from

air piston (1).

h. Remove retainer ring (27) to separate lube piston (5)

from air piston (1). Remove and discard o-rings (6 and

28).

3.3.4 Assembly of Pneumatic Pump.

3.3.4.1 Assemble the pneumatic pump according to the

following procedure:

NOTE

Use new o-rings, gaskets and return spring

when assembling pump. Lubricate all o-rings

and sliding parts with the lubricant which is

used in the system.

a. Install new o-ring (6) on lube piston (5).

b. Install new o-ring (28) on air piston (1). Install lube

piston (5) into air piston (1) and secure with retainer ring

(27).

c. Install spring retainer (26) in air piston (1) and secure

with retainer ring (25).

d. Install piston-return spring (24) in air cylinder (7). Push

air piston (1) through air cylinder (7) and into pump body

(10).

e. Install new o-ring (2) on cylinder cap (3) and secure in

air cylinder (7) with retainer ring (4).

f. Insert smaller end of adjustment screw (13) into

adjustment screw body (19). Rotate adjustment screw

(13) until smaller end is protruding from hex portion of

adjustment screw body (19).

g. Install new o-ring (12) on adjustment screw body (19)

and install adjustment screw body in pump body (10).

Tighten securely.

h. Install jam nut (21) and two new gaskets (20), one on

each side of jam nut, on adjustment screw (13). Butt

adjustment screw cap (22) against jam nut (21) and turn

adjustment screw (13) until the length it extends beyond

the jam nut is the same as the length recorded during

disassembly.

i. Install adjustment screw cap (22) on adjustment screw

(13).

j. Install new o-ring (30) on check seat (29) and install

seat into pump body.

k Install steel ball (32) and check valve spring (16) into

pump body (10). Place new gasket (15) on enclosure

screw (14). Install enclosure screw (14) into pump body

(10) and tighten securely.

l Install three new o-rings (9) and one new o-ring (18) into

pump body (10). Securely attach to manifold with four

socket-head screws (11).

3.3.4.2 When the assembly steps listed above have been

completed, adjust the pump output as described in Paragraph 3.2.2.

3.3.5 Pneumatic Pump Parts List. Table 3-2 identifies

the parts indexed in Figure 3-2.

R

3-4

Page 27

R

Table 3-2. Pneumatic Pump Parts List

Item

Number Part Number Description Quantity

521-000-001 PUMP ASSEMBLY (AL5) -521-000-021 PUMP ASSEMBLY (AL25) --

1 521-000-110 PISTON, Air (AL5) 1

2 422-010-290+ O-RING, Part of kit 560-001-021 (AL5) 1

3 521-000-100 CAP, Cylinder (AL5) 1

4 418-050-310+ RING, Retainer, part of kit 560-001-021 (AL5) 1

5 PISTON, Lube 1

*

6 527-000-790+ O-RING, Part of kit 560-001-021 (AL5) 1

7 521-000-080 CYLINDER, Air (AL5) 1

8 422-010-200+ O-RING, Part of kits 560-001-021, 560-001-031 and 560-001-041 1

9 423-700-113+ O-RING, Part of kits 560-001-021, 560-001-031 and 560-001-041 5

10 BODY, Pump 1

*

11 419-130-070+ SCREW, Socket-head, 1/4-20 x 1-1/4 inch 4

12 422-011-140+ O-RING, Part of kits 560-001-021, 560-001-031 and 560-001-041 1

13 521-003-000 SCREW , Adjustment (AL5) 1

14 521-008-460 SCREW, Enclosure 1

15 500-132-000+ GASKET, Part of kits 560-001-021, 560-001-031 and 560-001-041 1

16 511-893-000+ SPRING, Check valve, part of kits 1

17 401-030-030+ BALL, Steel, 3/16 inch diameter, part of kits 1

18 423-700-114+ O-RING, Part of kit 560-001-021, 560-001-031, 560-001-041 1

19 521-003-030 BODY, Adjustment screw (AL5) 1

20 439-040-050+ GASKET, Part of kit 560-001-021 (AL5) 2

21 410-702-028+ NUT, Jam, hexagon, 5/16-24 (AL5) 1

22 521-002-970 CAP, Adjustment screw (AL5) 1

23 521-000-150 RETAINER, Air cylinder 1

24 521-000-070+ SPRING, Piston return, part of kit 560-001-021 (AL5) 1

25 418-050-110+ RING, Retainer, part of kit 560-001-021 (AL5) 1

26 521-000-520 RETAINER, Spring (AL5) 1

521-000-041 PUMP ASSEMBLY (AL50) -521-000-220 PISTON, Air (AL25) 1

521-000-400 PISTON, Air (AL50) 1

422-010-350+ O-RING, Part of kit 560-001-031 (AL25) 1

422-010-380+ O-RING, Part of kit 560-001-041 (AL50) 1

521-000-210 CAP, Cylinder (AL25) 1

521-000-390 CAP, Cylinder (AL50) 1

418-050-450+ RING, Retainer, part of kit 560-001-031 (AL25) 1

418-050-520+ RING, Retainer, part of kit 560-001-041 (AL50) 1

423-700-111+ O-RING, Part of kit 560-001-031 (AL25) 1

423-700-112+ O-RING, Part of kit 560-001-041 (AL50) 1

521-000-200 CYLINDER, Air (AL25) 1

521-000-450 CYLINDER, Air (AL50) 1

521-003-010 SCREW, Adjustment (AL25) 1

521-003-020 SCREW, Adjustment (AL50) 1

560-001-021, 560-001-031 and 560-001-041

560-001-021, 560-001-031 and 560-001-041

521-003-040 BODY, Adjustment screw (AL25) 1

521-003-050 BODY, Adjustment screw (AL50) 1

439-040-070+ GASKET, Part of kit 560-001-031 (AL25) 2

439-040-080+ GASKET, Part of kit 560-001-041 (AL50) 2

410-702-033+ NUT, Jam, hexagon, 7/16-20 (AL25) 1

410-702-034+ NUT, Jam, hexagon, 1/2-20 (AL50) 1

521-002-980 CAP, Adjustment screw (AL25) 1

521-002-990 CAP, Adjustment screw (AL50) 1

521-000-480+ SPRING, Piston return, part of kit 560-001-031 (AL25) 1

521-000-420+ SPRING, Piston return, part of kit 560-001-041 (AL50) 1

418-050-160+ RING, Retainer, part of kits 560-001-031 and 560-001-041 (AL25 AL50) 1

521-000-510 RETAINER, Spring (AL25) 1

521-000-430 RETAINER, Spring (AL50) 1

42000Modu-Flo® System

+ Included in Repair Kit. Refer to Page 3-6

* Not Available as Replacement Parts.

3-5

Page 28

Modu-Flo® System 42000

Table 3-2. Pneumatic Pump Parts List - Continued

Item

Number Part Number Description Quantity

27 418-150-050+ RING, Retainer, part of kit 560-001-021 (AL5) 1

418-150-070+ RING, Retainer, part of kit 560-001-031 (AL25) 1

418-150-080+ RING, Retainer, part of kit 560-001-041 (AL50) 1

28 423-700-118+ O-RING, Part of kit 560-001-021 (AL5) 1

423-700-119+ O-RING, Part of kit 560-001-031 (AL25) 1

423-700-120+ O-RING, Part of kit 560-001-041 (AL50) 1

29 521-008-450+ SEAT, Check valve, part of kits 560-001-021, 560-001-031, and 1

560-001-041

30 422-010-080+ O-RING, Part of kits 560-001-021, 560-001-031, and 560-001-041 1

33 521-000-050 SCREW, Enclosure 1

34 401-010-010+ BALL, Steel 1/8” Dia. 1

35 417-450-020+ SCREW, Set 10-32”x1/4” 1

36 411-700-763+ ROLL PIN 1

-- 560-001-021 REPAIR KIT (consists of Items 2, 4, 6, 8, 9, 11, 12, 15 thru 18, 1

20, 21, 24, 25, 27 thru 30 and 34 thru 36) (AL5)

560-001-031 REPAIR KIT (consists of Items 2, 4, 6, 8, 9, 11, 12, 15 thru 18, 1

20, 21, 24, 25, 27 thru 30 and 34 thru 36) (AL25)

560-001-041 REPAIR KIT (consists of Items 2, 4, 6, 8, 9, 11, 12, 15 thru 18, 1

20, 21, 24, 25, 27 thru 30 and 34 thru 36) (AL50)

-- 521-001-391 PUMP ADJUSTMENT ASSEMBLY (consists of Items 13 and 19 thru 22) (AL5) 1

-- 521-001-401 PUMP ADJUSTMENT ASSEMBLY (consists of Items 13 and 19 thru 22) (AL25) 1

-- 521-001-411 PUMP ADJUSTMENT ASSEMBLY (consists of Items 13 and 19 thru 22) (AL50) 1

+ Included in Repair Kit. Refer to Repair Kits above.

R

3-6

Page 29

42000Modu-Flo® System

R

+

4

3

2

+

1

5*

6+

22

25

20+

+

**

26

21+

27+

20

28

+

23

19

+

14

35+

15+

16+

TEST/AIR

***

PURGE PORT

34+

6

‘

6

17+

30+

9+

29+

12+

24+

10*

11+

18+

33

15+

36+

16+

7

8+

9+

17+

13**

CHECK V ALVE COMPONENTS

* Not Available as Replacement Parts.

+ Included in Repair Kit. Refer to Page 3-6.

** Included in Pump Adjustment Assembly. Refer to Page 3-6.

SEE NOTE ON PAGE 4.2

***

Figure 3-2. Pneumatic Pump, Exploded View

3-7/(3-8 Blank)

PREVIOUS TO L93

(December 1993)

Page 30

Page 31

42000Modu-Flo® System

R

3.4 HYDRAULIC PUMP MAINTENANCE

(OPTIONS H1 and H3)

3.4.1 General. Maintenance tips, disassembly and

assembly procedures for Options H1 and H3 hydraulic pump

are discussed in Paragraphs 3.4.2 through 3.4.4. An

exploded view of the pump is shown in Figure 3-3 and

should be referred to during the discussion.

3.4.2 Hydraulic Pump Options H1 and H3 Maintenance

Tips.

3.4.2.1 The only maintenance required on the hydraulic

pump Options H1 and H3 is to check for the following:

a. Check four socket-head screws (8, Figure 3-3) to make

sure they are tight. Loose screws could allow hydraulic

fluid and/or lubricant to leak between the pump and the

manifold. This condition could result in erratic pump

output.

b. Check for leakage past gasket (12). Replace gasket if

required.

c. Check jam nut (19) to make sure that it is tight against

adjustment screw body (17). If the jam nut is loose, the

adjustment screw (10) could rotate and cause the pump

output to change. This condition could also result in

lubricant leakage or in air being sucked into the lubricant.

3.4.2.2 If internal components of the pump are defective it

will usually result in erratic pump operation or output. Section

10 of this manual lists causes and solutions for problems

which could occur in the Modu-Flo system. Before disassembling any pump, refer to Section 10. The problem may

be caused by other conditions which can be checked first

before disassembling the pump.

3.4.3 Disassembly of Hydraulic Pump Options H1 and

H3. The procedure below describes complete disassembly

of a pump. However, you only need to disassemble to your

specific area of concern.

3.4.3.1 The disassembly procedure for the hydraulic pump

Options H1 and H3 is as follows:

a. Separate pump from manifold by removing four socket-

head screws (8). Remove and discard three o-rings (15)

and one o-ring (16).

b. Remove enclosure screw (11). Remove and discard

gasket (12), check valve spring (13), steel ball (24),

check seat (22), and o-ring (23).

c. Remove adjustment screw body (17) and o-ring (9) from

body (7). Discard o-ring (9). Removal of adjustment

screw (10) from adjustment screw body (17) will change

output setting when pump is reassembled. If adjustment screw (10) requires removal, perform the following:

(1) Remove adjustment screw cap (20) from adjust-

ment screw (10). Butt the adjustment screw cap

(20) against jam nut (19) and use the stamped

numbers on the cap to measure how far the

adjustment screw (10) extends from the jam nut.

Record this dimension.

(2) Remove jam nut (19) and two gaskets (18). Discard

gaskets (18).

(3) Remove adjustment screw (10) by screwing it

towards the hex portion of the adjustment screw

body (17) until it is free.

d. Remove cylinder cap (6) from body (7). Remove and

discard o-ring (5).

e. Removal of the piston and its associated components is

different for each option. Perform the appropriate

following steps:

(1) For Option H1, use a wood dowel or a soft rod to

push hydraulic piston (2) and lube piston (1) from

pump body (7). Remove and discard o-rings (4) and

(21). Inspect piston (2) and pump body (7) inner

diameter for scoring or wear marks. If damage is

present the pump assembly cannot be serviced and

should be replaced.

(2) For Option H3, use a wood dowel or a soft rod to

push the piston (27) from the pump body (7).

Remove and discard o-rings (26 and 29) and

backup rings (25 and 28). Inspect piston (27) and

pump body (7) inner diameter for scoring or wear

marks. If damage is present, the pump assembly

cannot be serviced and should be replaced.

f. For the H1 option only, separate hydraulic piston (2) and

lube piston (1) by removing groove pin (3).

3.4.4 Assembly of Hydraulic Pump Options H1 and H3.

NOTE

Use new o-rings and gaskets when assembling

pump. Lubricate all o-rings and sliding parts

with the lubricant which is used in the system.

3.4.4.1 Assemble the hydraulic pump Options H1 and H3

according to the following procedure:

a. For the H1 option only, insert lube piston (1) into hydrau-

lic piston (2). Install groove pin (3) to secure the assembly.

b. Assembly of the piston and its associated components

is different for each option. Perform the appropriate

following steps:

(1) For Option H1, install new o-ring (4) on hydraulic

piston (2). Install new o-ring (21) on lube piston (1).

Insert pistons into body (7).

(2) For Option H3, install new o-ring (26) and backup

rings (25) on cylinder cap end of piston (27). Install

new o-ring (29) and backup rings (28) on the other

end of the piston (27).

c. Install new o-ring (5) on cylinder cap (6). Screw cylinder

cap (6) into body (7) and securely tighten it.

d. Insert smaller end of adjustment screw (10) into

adjustment screw body (17). Rotate adjustment screw

(10) until smaller end is protruding from hex portion of

adjustment screw body (17).

e. Install new o-ring (9) on adjustment screw body (17) and

install adjustment screw body in body (7). Tighten

securely.

3-9

Page 32

Modu-Flo® System 42000

f. Install jam nut (19) and two new gaskets (18), one on

each side of jam nut, on adjustment screw (10). Butt

adjustment screw cap (20) against jam nut (19) and

turn adjustment screw (10) until the length it extends

beyond the jam nut is the same as the length recorded

during disassembly.

g. Install adjustment screw cap (20) on adjustment screw

(10).

h. Install new o-ring (23) on check seat (22) and install

seat assembly into pump body.

i. Install steel ball (24) and check valve spring (13) into

body (7). Place new gasket (12) on enclosure screw

(11). Screw enclosure screw into body (7) and tighten

securely.

j. Install three new o-rings (15) and one o-ring (16) into

body (7). Securely attach pump assembly to manifold

with four socket-head screws (8).

3.4.4.2 When the assembly steps listed above have been

completed, adjust the pump output as described in Paragraph 3.2.2.

3.4.5 Hydraulic Pump Options H1 and H3 Parts List.

Table 3-3 identifies the parts indexed in Figure 3-3.

T able 3-3. Hydraulic Pump Options H1 and H3 Part s List

Item

Number Part Number Description Quantity

521-000-011 PUMP ASSEMBL Y, HLJ-5 (Option H1) -521-005-900 PUMP ASSEMBL Y, HLJ-5X (Option H3) --

1 PISTON, Lube (HLJ-5) 1

*

2 521-000-190 PISTON, Hydraulic (HLJ-5) 1

3 411-101-630+ PIN, Groove, part of kit 560-001-051 (HLJ-5) 1

4 422-021-110+ O-RING, Part of kit 560-001-051 (HLJ-5) 1

5 422-011-160+ O-RING, Part of kit 560-001-051 (HLJ-5) 1

422-021-160+ O-RING, Part of kit 560-001-940 (HLJ-5X) 1

6 521-000-180 CAP, Cylinder 1

7 BODY, Pump, HLJ-5 1

*

8 419-130-070 SCREW, Socket-head, 1/4-20 x 1-1/4 inch, part of repair kit 560-001-051 4

9 422-011-140+ O-RING, Part of kit 560-001-051 (HLJ-5) 1

422-021-140+ O-RING, Part of kit 560-001-940 (HLJ-5X) 1

10 521-003-000 SCREW, Adjustment 1

11 521-008-460 SCREW, Enclosure 1

12 500-132-000+ GASKET, Part of kits 560-001-051 and 560-001-940 1

13 511-893-000+ SPRING, Check valve, part of kits 560-001-051 and 560-001-940 1

14 401-030-030+ BALL, Steel, 3/16 inch, part of kits 560-001-051 and 560-001-940 1

15 423-700-113+ O-RING, Part of kits 560-001-051 and 560-001-940 3

16 423-700-114+ O-RING, Part of kits 560-001-051 and 560-001-940 1

17 521-003-030 BODY, Adjustment screw (HLJ-5) 1

521-005-710 BODY, Adjustment screw (HLJ-5X) 1

18 439-040-050+ GASKET, Stat-O-Seal, part of kit 560-001-051 (HLJ-5) 2

439-050-050+ GASKET, Stat-O-Seal, part of kit 560-001-940 (HLJ-5X) 2

19 410-702-028 NUT, Jam, Part of Kit 560-001-051 1

20 521-002-970 CAP, Adjustment screw (HLJ-5) 1

521-010-360 CAP, Adjustment screw (HLJ-5X) 1

21 527-000-790+ O-RING, Part of kit 560-001-051 (HLJ-5) 1

22 521-008-450+ SEAT, Check valve, part of kits 560-001-051 and 560-001-940 1

23 422-010-080+ O-RING, Part of kits 560-001-051 and 560-001-940 1

25 423-700-057+ RING, Backup, part of kit 560-001-940 (HLJ-5X) 2

26 423-700-060+ O-RING, Part of kit 560-001-940 (HLJ-5X) 1

27 PISTON (HLJ-5X) 1

*

28 423-700-058+ RING, Backup, part of kit 560-001-940 (HLJ-5X) 2

29 423-700-059+ O-RING, Part of kit 560-001-940 (HLJ-5X) 1

30 521-000-050 SCREW, Enclosure 1

31 401-010-010 BALL, Steel 1/8” Dia., Part of Kit 560-001-051 1

32 417-450-020 SCREW, Set 10-32”x1/4” 1

-- 560-001-051 REPAIR KIT (consists of Items 3, 4, 5, 8, 9, 12 thru 16, 18, and 21 thru 23) 1

-- 560-001-940 REPAIR KIT (consists of Items 5, 9, 12 thru 16, 18, 22 thru 26, 28 1

and 29)