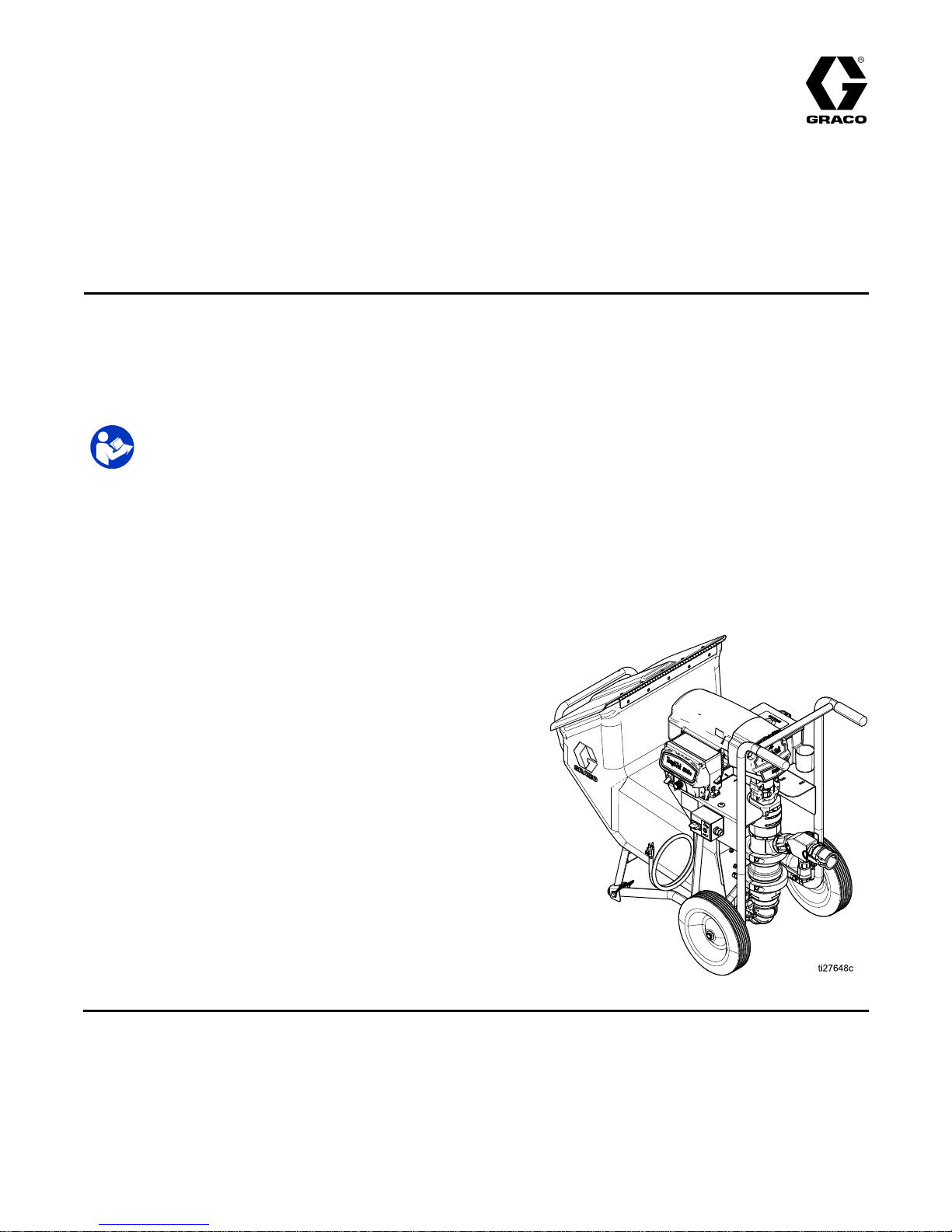

Graco ToughTek S340e Operation, Repair, And Parts

Operation,Repair,andParts

ToughTek® ToughTek®

ToughTek®

S340e S340e

S340e

Portable Portable

Portable

Stucco Stucco

Stucco

Pump Pump

Pump

3A3437F

EN

Electric Electric

Electric

sprayer sprayer

sprayer

for for

for

water water

water

- --based based

based

stucco stucco

stucco

base, base,

base,

nish nish

nish

coat coat

coat

materials, materials,

materials,

and and

and

Exterior Exterior

Exterior

Insulation Insulation

Insulation

and and

and

Finish Finish

Finish

Systems Systems

Systems

(EIFS). (EIFS).

(EIFS).

For For

For

professional professional

professional

use use

use

only. only.

only.

Not Not

Not

approved approved

approved

for for

for

use use

use

in ininexplosive explosive

explosive

atmospheres atmospheres

atmospheres

or or

or

hazardous hazardous

hazardous

locations. locations.

locations.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanualandinrelated

manuals.Save Save

Save

these these

these

instructions. instructions.

instructions.

For models and related manuals, see

page 3.

600 psi (4.13 MPa, 41.3 bar) Maximum

Fluid Working Pressure

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

Models...............................................................3

RelatedManuals................................................3

ReplacementPartsandAccessories....................4

Warnings...........................................................6

ComponentIdentication.....................................9

Overview.....................................................9

ComponentIdenticationTable.....................9

MotorPowerSwitch.....................................10

ConnectHosesandApplicator......................10

InstalltheRemoteSwitch(Optional)..............11

PrimewithMaterial......................................11

Grounding..........................................................12

PowerRequirements..........................................12

Setup.................................................................13

Flush.................................................................14

PrimewithWater................................................16

MixtheMaterial..................................................17

PrimewithMaterial.............................................17

Spray.................................................................18

PreventPack-out.........................................18

BeforeStartingorStoppingMaterial

Flow..............................................18

Spraying......................................................18

SprayAdjustments(PoleSprayApplicator)...........19

GeneralAdjustments....................................19

SprayingTechniques....................................19

MaterialFlowAdjustment.............................19

AirFlowValveAdjustment............................19

InstallingNozzleRetainingCap.....................19

SprayAdjustments(HTXTMApplicator)...............20

FluidDrain/PurgeValve......................................21

PressureReliefProcedure..................................21

HopperRemoval................................................22

Shutdown...........................................................22

LiftingInstructions...............................................22

Maintenance......................................................23

DailyMaintenance.......................................23

PreventativeMaintenance............................23

CorrosionProtection....................................23

WaterExposure...........................................23

Troubleshooting..................................................24

Mechanical/FluidFlow..................................24

Electrical.....................................................25

Repair................................................................27

ReplacePumpLower...................................27

Parts..................................................................30

TechnicalSpecications......................................37

GracoStandardWarranty....................................38

2

3A3437F

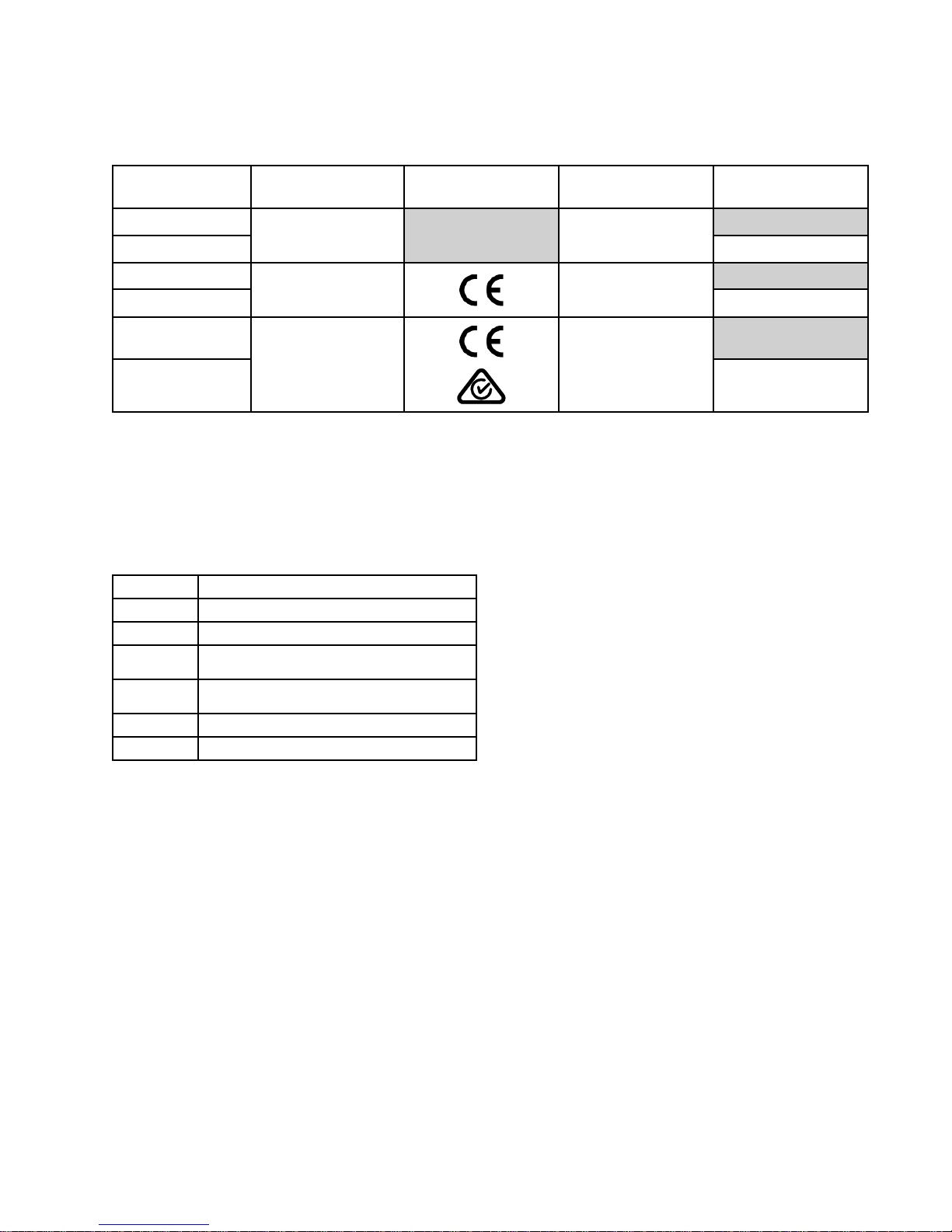

Models

Models Models

Models

Bare Bare

Bare

Model Model

Model

Electric Electric

Electric

Requirements Requirements

Requirements

Approval Approval

Approval

Country Country

Country

Remote Remote

Remote

On/Off On/Off

On/Off

Switch Switch

Switch

25A300

25A302

120V,15A,50/60

Hz,1Ф

NorthAmerica

✔

25C610

25C612

120V,15A,50/60

Hz,1Ф

UnitedKingdom

✔

25A304†

25A306†

230V,10A,50/60

Hz,1Ф

Europe,Asia,

Australia

✔

†

All 230V pumps include a Europe adapter and Australia adapter cord set.

Related Related

Related

Manuals Manuals

Manuals

Manualsareavailableatwww.graco.com.

ComponentmanualsinEnglish:

Manual Manual

Manual

Description Description

Description

3A3438

PoleSprayApplicator

3A3653

HTXFinishCoatApplicator

3A3112

ToughTek®F340eRemoteSwitch

AccessoryKit17G554

3A3439

ToughTek®S340ePumpLower

ConversionKit

3A5637

ToughTek®CamlockMortarHose

3A4554

ToughTek®MortarCouplingHose

3A3437F 3

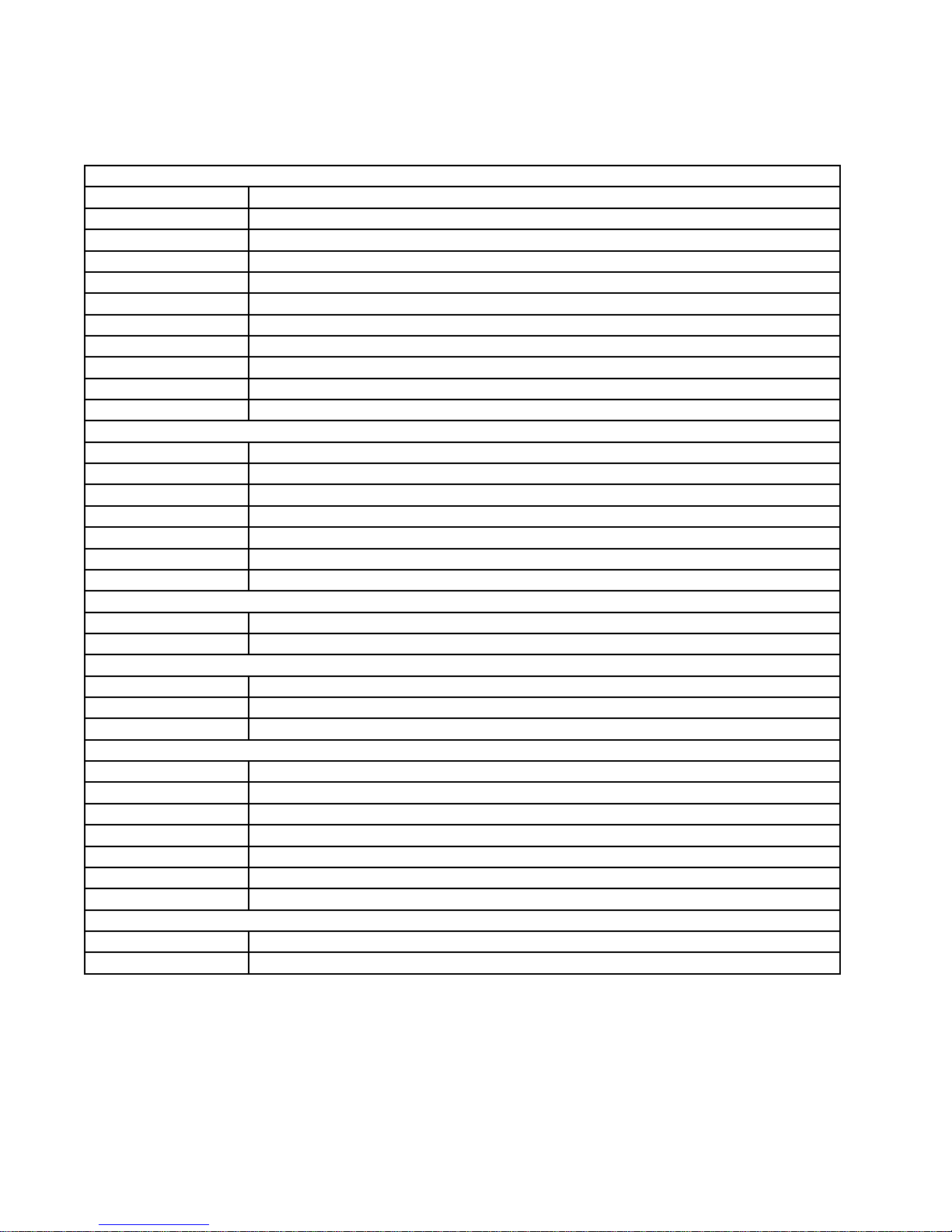

ReplacementPartsandAccessories

Replacement Replacement

Replacement

Parts Parts

Parts

and and

and

Accessories Accessories

Accessories

Accessories Accessories

Accessories

17G554

KIT,remoteswitch

17W604

KIT,remoteswitch,cable(switchand100ftcable)

17W829

KIT,remoteswitch,extensioncord(110ft)

248515

KIT,spongeball,30mmfor25mm(1.0in.)dia.hose(Qty.5)

25A227

KIT,spongeball,40mmfor35mm(1–3/8in.)dia.hose(Qty.5)

17G930KIT,spongeball,60mmfor50mm(2in.)dia.hose(Qty.5)

114271

STRAP,retaining

240296KIT,retainingstraps,4–pack

118665

TUBE,grease,FusionGun,4oz.

248279

TUBE,grease,FusionGun,4oz.,10–pack

206994

FLUID,TSL8oz.bottle

Lower Lower

Lower

Assembly Assembly

Assembly

25A233KIT,rebuild,pump

17G456

KIT,lower,clamp

16W490KIT,repair,10–pack,o-ring,cylinderend

25A467KIT,repair,checkballs

17G865

KIT,repair,3–pack,seal,throat,triplelip

17G864KIT,pumplower,S340e

25A178

KIT,conversion,F340etoS340e

Inlet Inlet

Inlet

17G863

KIT,repair,seat,inlet

15H833BALL,neo/sstcore1.75in.

Piston Piston

Piston

17G862

KIT,repair,seat,piston

17G798

BALL,neoprene,cscore,1.625in.

16W491KIT,repair,3–pack,seal,piston

Check Check

Check

Valve Valve

Valve

25A466

KIT,outlet,checkvalve,S340

17H192KIT,outlet,seat,o-ring

113082

PACKING,o-ring

17H194KIT,outlet,check,valve

102973BALL,metallic

17J712KIT,F340e,check,retainer

17G866KIT,tting,cam,checkvalve

Rubber Rubber

Rubber

Elbow Elbow

Elbow

17H193KIT,inlet,elbow

17H196KIT,elbow,bandclamp

4

3A3437F

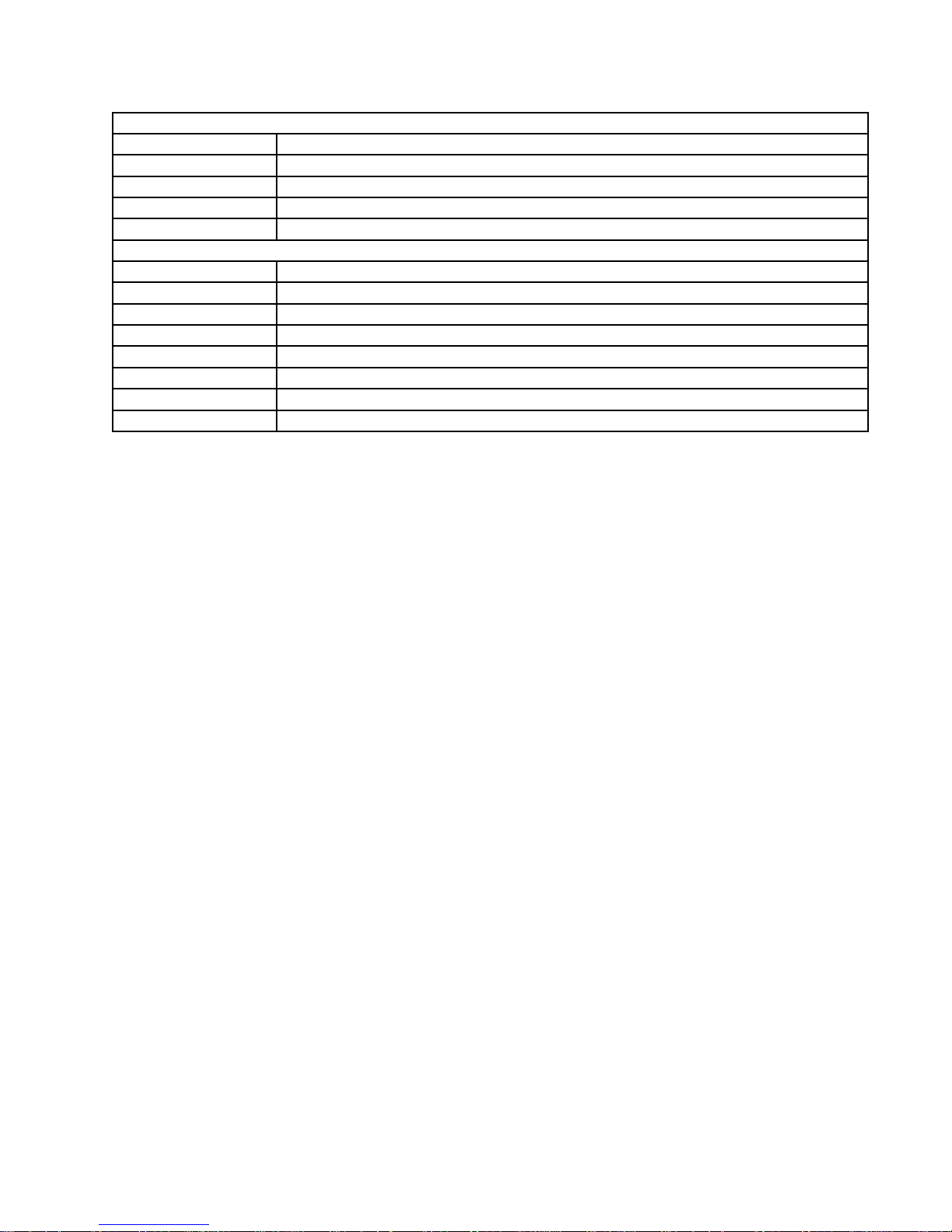

ReplacementPartsandAccessories

Hopper Hopper

Hopper

17J707KIT,F340e,hopperwithcover

17J709KIT,F340e,hopper,bracket

17J812KIT,F340e,stop,bracket

17J710KIT,F340e,adjustablelatch

17J708KIT,F340e,stop,brackets

Motor Motor

Motor

and and

and

Driver Driver

Driver

17J702

KIT,F340e,MCM,120V

25C512KIT,F340e,MCM,120V,UK

17J755

KIT,F340e,MCM,230V

17J711KIT,F340e,motor

17J714

KIT,F340e,nger,guard

17J704

KIT,F340e,front,cover

287282KIT,repair,shield,motor

17J705KIT,F340e,toolbox

3A3437F 5

Warnings

Warnings Warnings

Warnings

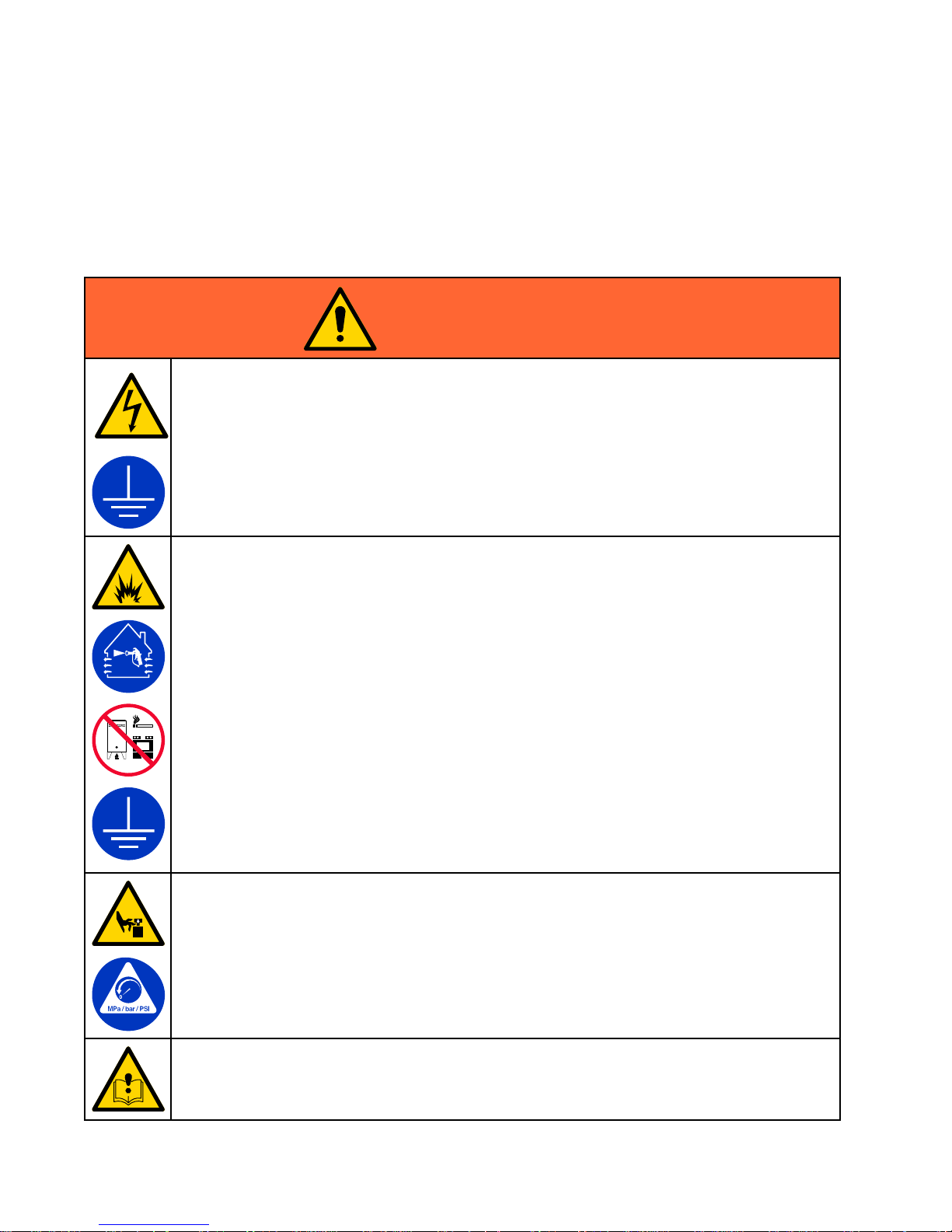

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpowercordbeforeservicingequipment.

•Connectonlytogroundedelectricaloutlets.

•Useonly3–wireextensioncords.

•Ensuregroundprongsareintactonpowerandextensioncords.

•Donotexposetorain.Storeindoors.

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Tohelp

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticsparking).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

instructions.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Neversprayorushsolventathighpressure.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Useonlygroundedhoses.

•Holdapplicatorrmlytosideofgroundedpailwhentriggeringintopail.Donotusepail

linersunlesstheyareantistaticorconductive.

•Stop Stop

Stop

operation operation

operation

immediately immediately

immediately

ifstaticsparkingoccursoryoufeelashock. ..Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

MOVING MOVING

MOVING

PARTS PARTS

PARTS

HAZARD HAZARD

HAZARD

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

anddisconnectallpowersources.

SUCTION SUCTION

SUCTION

HAZARD HAZARD

HAZARD

Powerfulsuctioncouldcauseseriousinjury.

•Neverplacehandsnearthepumpuidinletwhenpumpisoperatingorpressurized.

6 3A3437F

Warnings

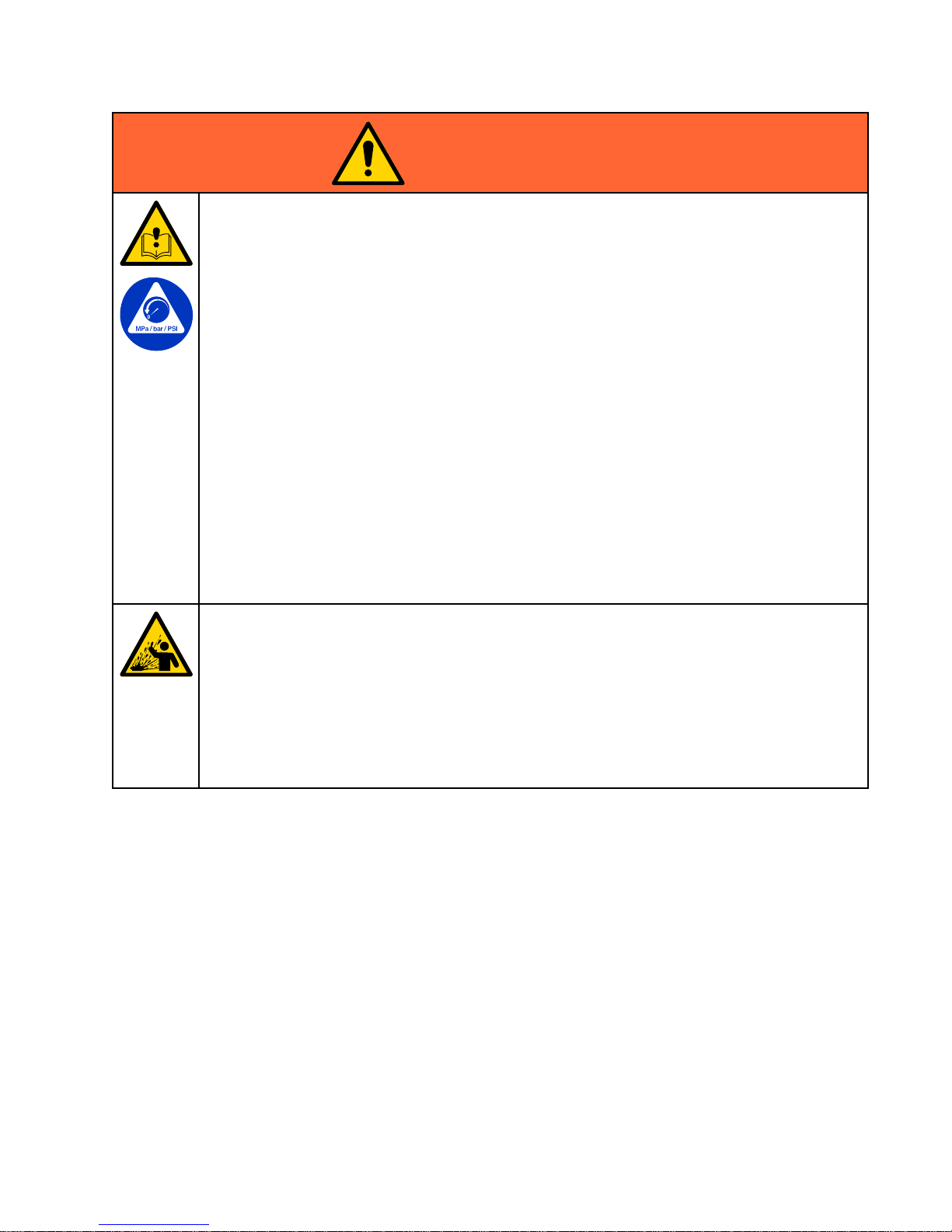

WARNING WARNING

WARNING

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestSafetyDataSheets(SDSs)fromdistributoror

retailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PRESSURIZED PRESSURIZED

PRESSURIZED

ALUMINUM ALUMINUM

ALUMINUM

PARTS PARTS

PARTS

HAZARD HAZARD

HAZARD

Useofuidsthatareincompatiblewithaluminuminpressurizedequipmentcancauseserious

chemicalreactionandequipmentrupture.Failuretofollowthiswarningcanresultindeath,

seriousinjury,orpropertydamage.

•Donotuse1,1,1-trichloroethane,methylenechloride,otherhalogenatedhydrocarbon

solventsoruidscontainingsuchsolvents.

•Donotusechlorinebleach.

•Manyotheruidsmaycontainchemicalsthatcanreactwithaluminum.Contactyourmaterial

supplierforcompatibility.

3A3437F

7

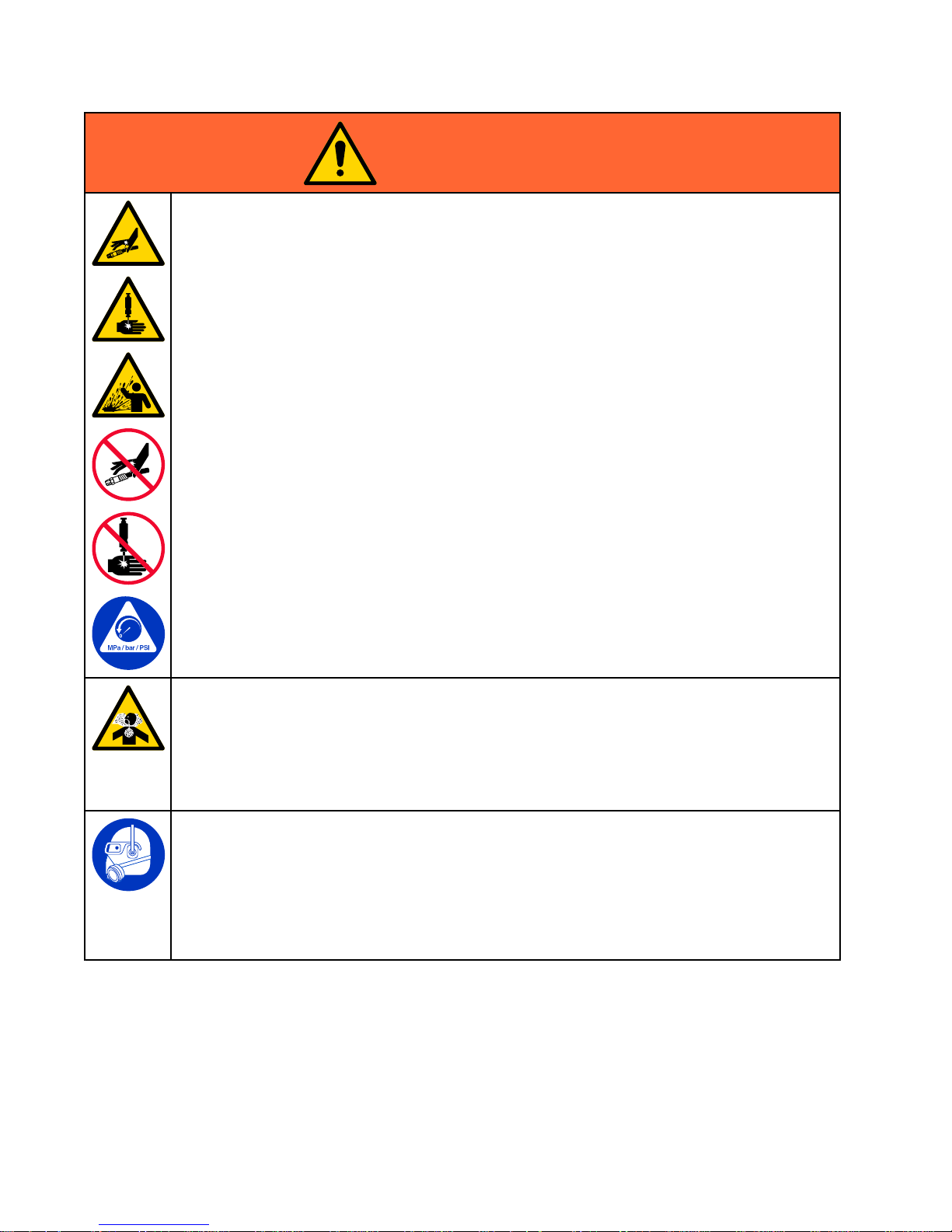

Warnings

WARNING WARNING

WARNING

SKIN SKIN

SKIN

INJECTION INJECTION

INJECTION

HAZARD HAZARD

HAZARD

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

Get

immediate immediate

immediate

surgical surgical

surgical

treatment. treatment.

treatment.

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopdispensingandbeforecleaning,

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

HAZARD HAZARD

HAZARD

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheets(SDSs)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

8 3A3437F

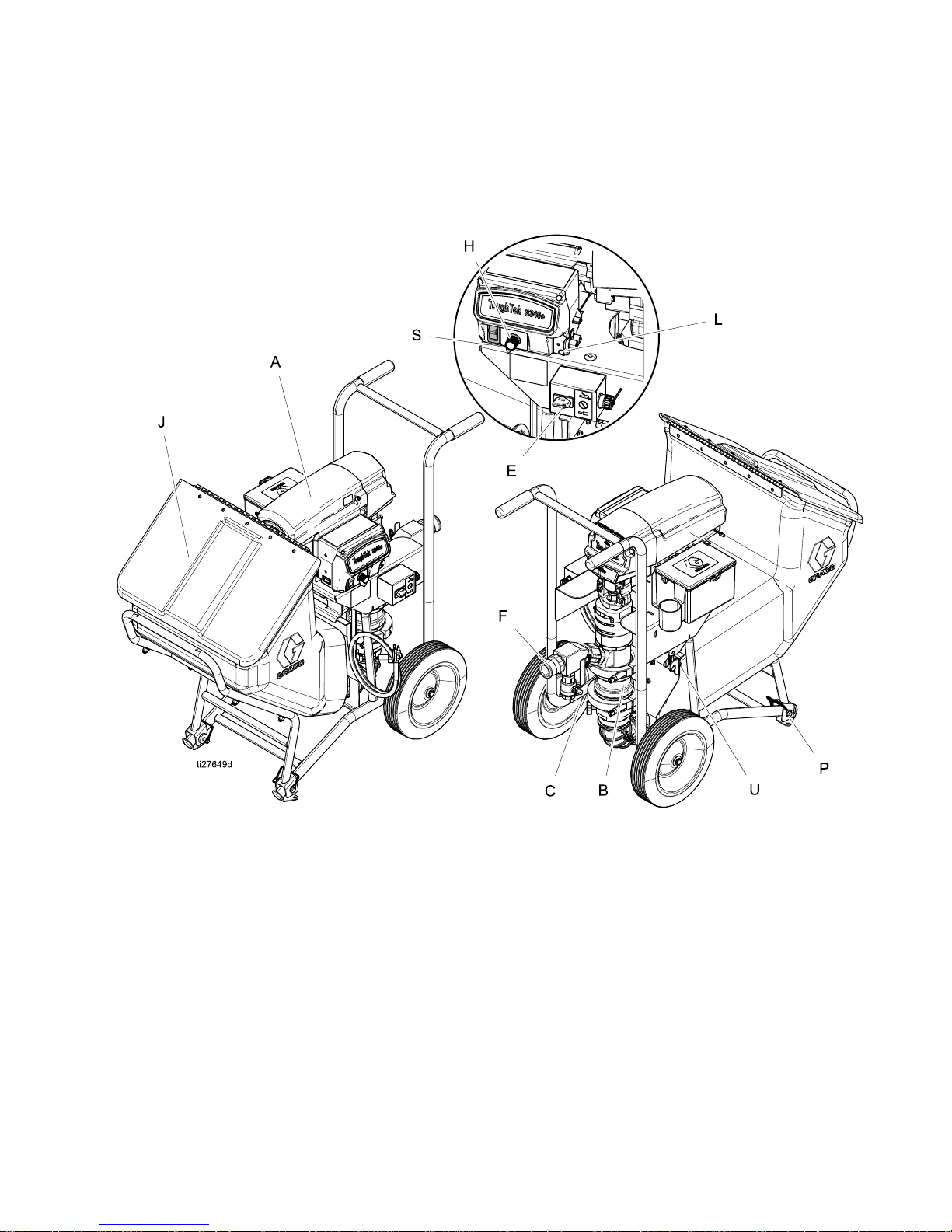

ComponentIdentication

Component Component

Component

Identication Identication

Identication

Overview Overview

Overview

Component Component

Component

Identication Identication

Identication

Table Table

Table

Key: Key:

Key:

AElectricMotor

BPumpLower

C

FluidDrain/PurgeValve

E

RemotePumpControlSwitch(optional)

F

FluidOutlet

HFlowAdjustmentKnob

JHopper

L

ControlBoardStatusLight

Key: Key:

Key:

PHopperPin

SMotorPowerSwitch

UHopperLatch

3A3437F 9

ComponentIdentication

Motor Motor

Motor

Power Power

Power

Switch Switch

Switch

Themotorpowerswitch(S)mustbeintheONforthe

sprayertopumpmaterial.

Motor Motor

Motor

Power Power

Power

Switch Switch

Switch

Settings: Settings:

Settings:

OFFPowerisoff.Themotorwillnotrun.

ON

Themotorwillruncontinuouslyat

aspeeddeterminedbytheow

adjustmentknob.

Connect Connect

Connect

Hoses Hoses

Hoses

and and

and

Applicator Applicator

Applicator

•Beforeconnectinghoses/applicator,inspectfor

damageorweartoboththehose/applicatorand

camlockttings.Fittingsshouldbecleanandfree

ofdebris,dents,cracksornicks.Thefemalecam

lockttingmusthavethegasketinstalled.

•Alwaysconnecthosesfromlargestdiameterto

smallestdiameter.

•Useaminimumof25ftofhosewithaworking

pressureofatleast600psi(4.1MPa,41bar).

•Whenfasteningcamlocks,makesurethepullring

staystotheoutsideofthecamlockarmtoallow

forcompleteandpropersealingofthecamlock.

Onceinstalled,useVelcrostrapstosecurecam

locksinplace.

10 3A3437F

ComponentIdentication

Install Install

Install

the the

the

Remote Remote

Remote

Switch Switch

Switch

(Optional) (Optional)

(Optional)

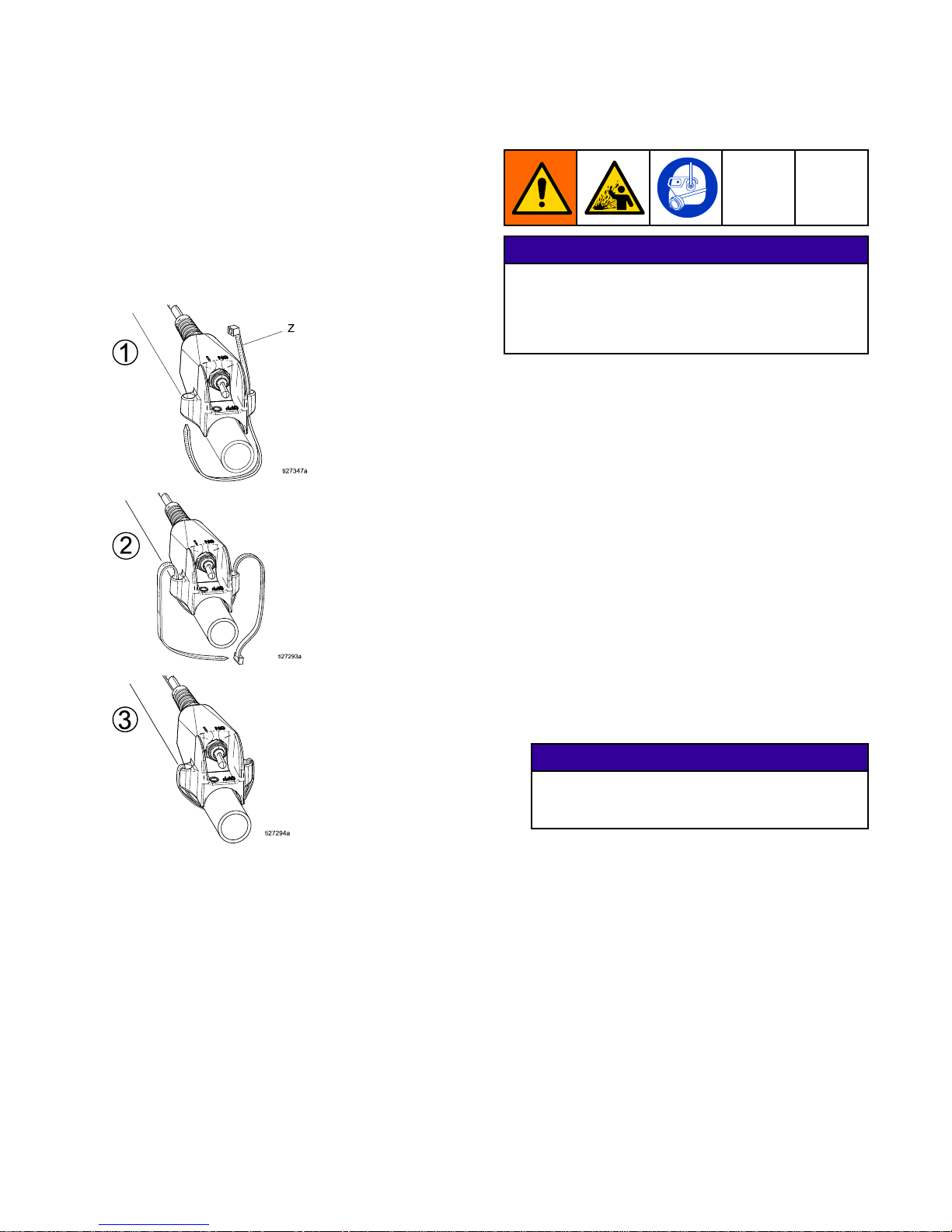

Theremoteswitchisanadditionalaccessorykitand

doesnotcomewithmodels25A300and25A304.

Thekitpartnumberis17G554.Seemanual3A3112

forremoteswitchinstallationandreplacement.

NOTE: NOTE:

NOTE:

Usezip-tie(Z)toinstalltheremoteswitch

tothehoseorpolesprayapplicator(followthe

illustrationsbelow).Theremoteswitchwillton

hoses/applicatorssized.75in.upto1.25in.

Prime Prime

Prime

with with

with

Material Material

Material

NOTICE NOTICE

NOTICE

Loadingmaterialintoadrysystemwillcausethematerial

tosticktointernalcomponentsandcure,causing

damageandrequiringreplacementofthoseparts.To

preventmaterialcuringinsystem,neverloadmaterial

intoadrysystem.

Theapplicatormustberemovedbeforepriming.

Alwayspushoutanyremainingwaterintoawaste

containerbeforecirculatingmaterial.Alwayscirculate

cleanmaterialbackintothehopperforseveralcycles

beforebeginningtospray.

1.Primethesystemwithwater.See

PrimewithWater,page16.

2.Mixthematerial.SeeMixtheMaterial,page17.

3.Turntheowadjustmentknob(H)

counterclockwiseuntilitstops.

4.Removetheapplicator.

5.Fillthecleanhopperwithmaterialtobesprayed.

6.Placethehoseoutletinawastecontainer.

7.Turnthemotorpowerswitch(S)toON.

8.Turntheowadjustmentknob(H)clockwise

slowlytoincreasepressureuntilwaterispurged

outandasteadystreamofmaterialowsfrom

theapplicator.

NOTICE NOTICE

NOTICE

Topreventdamagetopumpsealscausedby

cavitation,runthepumpslowlyuntilthesystemis

primed.

9.Tostopdispensing,turnadjustmentknob(H)

counterclockwiseuntilitstops.

10.Installapplicator.

NOTE: NOTE:

NOTE:

ForEIFSnishcoats,beforeinstallingthe

applicator,primethelargerIDhose,theninstall

andprimethetransitionttingandwhiphose.

11.Recirculateseveralcyclesofmaterialtomake

surethematerialisowingproperly.

12.Turntheowadjustmentknob(H)

counterclockwisetostopthepump.

13.Installtheairlineandatipontotheapplicator

(seeapplicatormanual).Thesystemisnow

primedandreadytospray.

3A3437F

11

Grounding

Grounding Grounding

Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

Groundthesprayerbypluggingitintoanoutletthat

isproperlyinstalledandgroundedinaccordancewith

alllocalcodesandordinances.Donotmodifythe

powercordprovided;ifitdoesnotttheoutlet,have

theproperoutletinstalledbyaqualiedelectrician.

Extension Extension

Extension

Cords Cords

Cords

•Useonlya3-wireextensioncordthathasa

groundingplugandagroundingreceptaclethat

acceptstheplugontheproduct.

•Makesureyourextensioncordisnotdamaged.

•Ifanextensioncordisnecessary,use12AWG(2.5

mm

2

)minimumtocarrythecurrentthattheproduct

draws.Anundersizedextensioncordresultsina

dropinlinevoltage,lossofpower,andoverheating.

NOTE: NOTE:

NOTE:

CertainGFCIoutletshavebeenknowntotrip

whileusingthisproduct.

For120Vunits,useadedicated15ampcircuit.

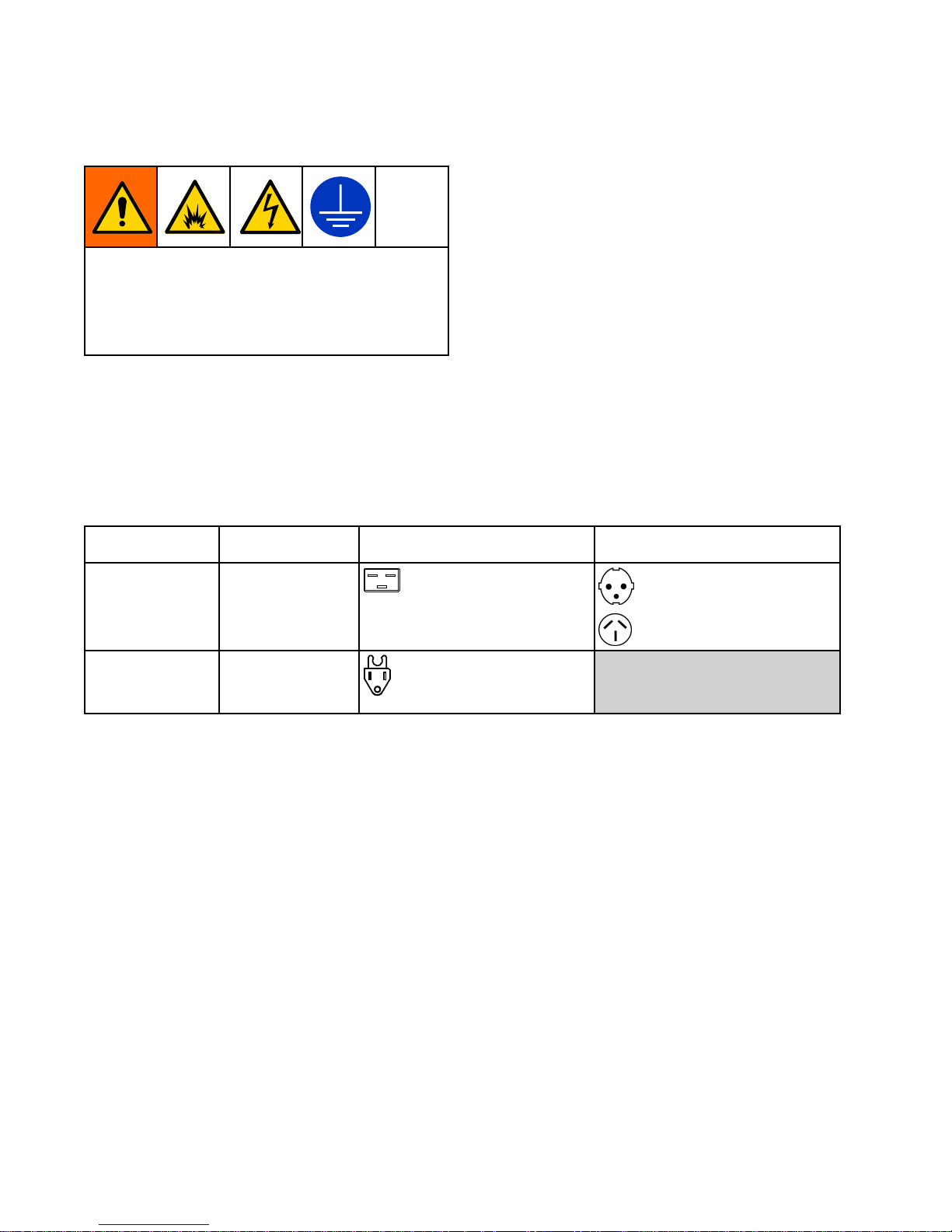

Power Power

Power

Requirements Requirements

Requirements

Model Model

Model

Required Required

Required

Power Power

Power

Source Source

Source

Power Power

Power

Cord Cord

Cord

Connectors Connectors

Connectors

Supplied Supplied

Supplied

Local Local

Local

Adapters Adapters

Adapters

EuroCEE7(Europe)

230V,1phase,

50/60Hz

Oneseparate

dedicatedcircuit

ratedatminimumof

10A

OneIEC3-20C20Plugs

AS/NZS(Australia)

120V,50/60Hz

Oneseparate

dedicatedcircuit

ratedatminimumof

15A

OneNEMA5–15APlug

12

3A3437F

Loading...

Loading...