Graco ToughTek M680a Operation - Repair - Parts

Operation, Repair, Parts

WLD

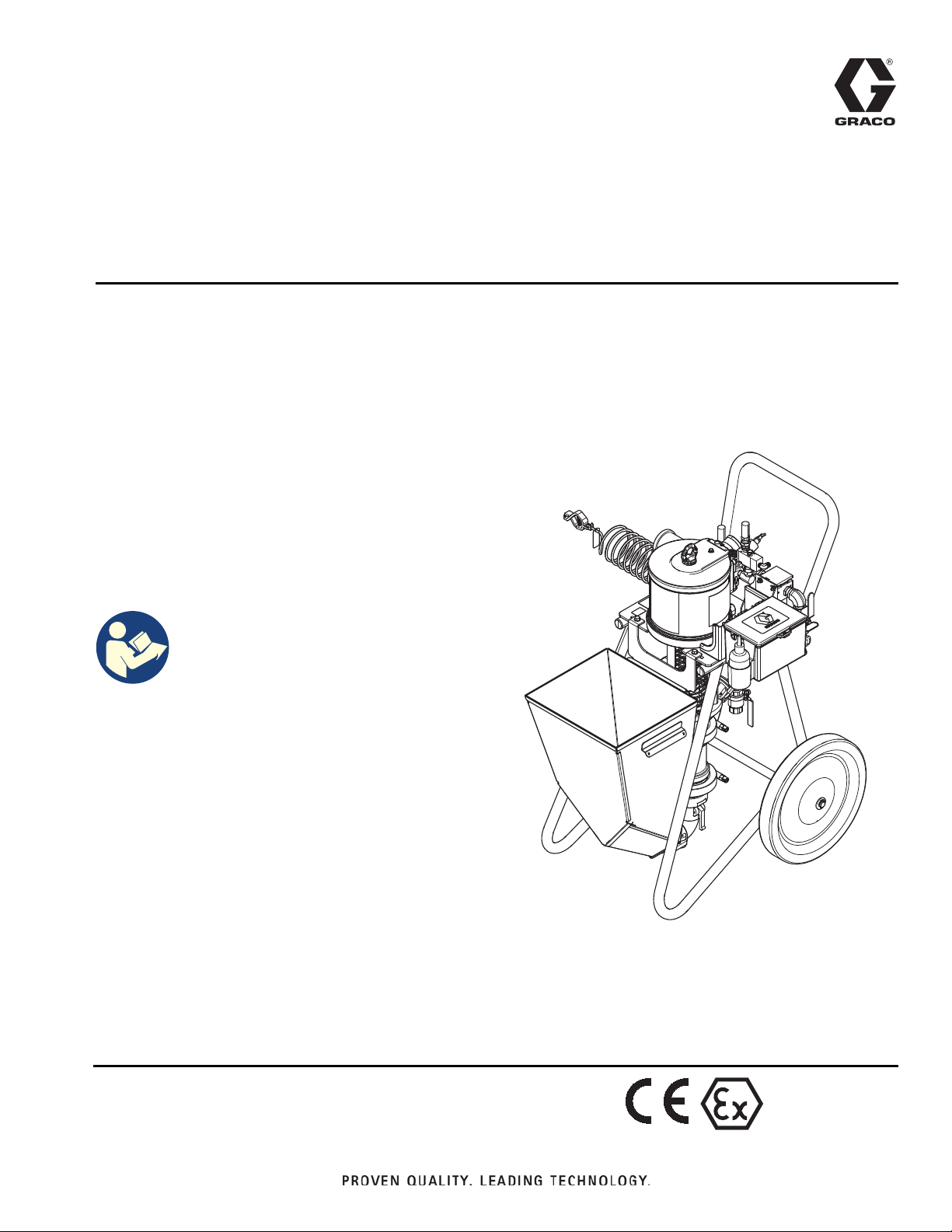

ToughTek® M680a CS Mortar

3A5275B

Spray er

Sprayer for water-based cementitious materials. Not for use with solvent-borne materials.

For professional use only.

600 psi (4.1 MPa, 41 bar) Maximum Fluid Working

Pressure

150 psi (1.0 MPa, 10 bar) Maximum Air Inlet Pressure

60 psi (0.41 MPa, 4.1 bar) Maximum Pump Air Regulator

Pressure

See page 2 for model information, including model

numbers and approvals.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

II 2 G

c IIA T5

Related Manuals

II 2 G

c IIA T5

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Spray P ackages . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System Components . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . 12

Wet Out the System . . . . . . . . . . . . . . . . . . . . . 13

Mix the Material . . . . . . . . . . . . . . . . . . . . . . . . . 15

Prime with Material . . . . . . . . . . . . . . . . . . . . . . 15

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Flush the Equipment . . . . . . . . . . . . . . . . . . . . . 19

Disassemble and Clean the Pump (Daily) . . . . 22

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preventive Maintenance . . . . . . . . . . . . . . . . . . 26

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . 26

Corrosion Protection . . . . . . . . . . . . . . . . . . . . . 26

Cart Maintenance . . . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replace Pump Components . . . . . . . . . . . . . . . 29

Replace Air Motor . . . . . . . . . . . . . . . . . . . . . . . 29

Replace Pump Lower . . . . . . . . . . . . . . . . . . . . 29

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ToughTek M680a CS Systems . . . . . . . . . . . . . 30

Pump Lower (25C964) . . . . . . . . . . . . . . . . . . . 32

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Hose Bundle Repair Parts . . . . . . . . . . . . . . . . . 34

Tec hnical Specifications . . . . . . . . . . . . . . . . . . . . 35

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

Related Manuals

Manuals are available at www.graco.com.

Component manuals in English:

Manual Description

332651 Mortar Spraying Tips

332767 Mortar Spraying Applicators

332768

312796

™

680 Applicator

HTX

®

Air Motors

NXT

Models

Model Description

25M572 ToughTek M680a CS Mortar Sprayer ✓✓

26A489 Flex Applicator Spray Package ✓

26A490 Pole Applicator Spray Package ✓

26A491 HTX Applicator Spray Package ✓

2 3A5275B

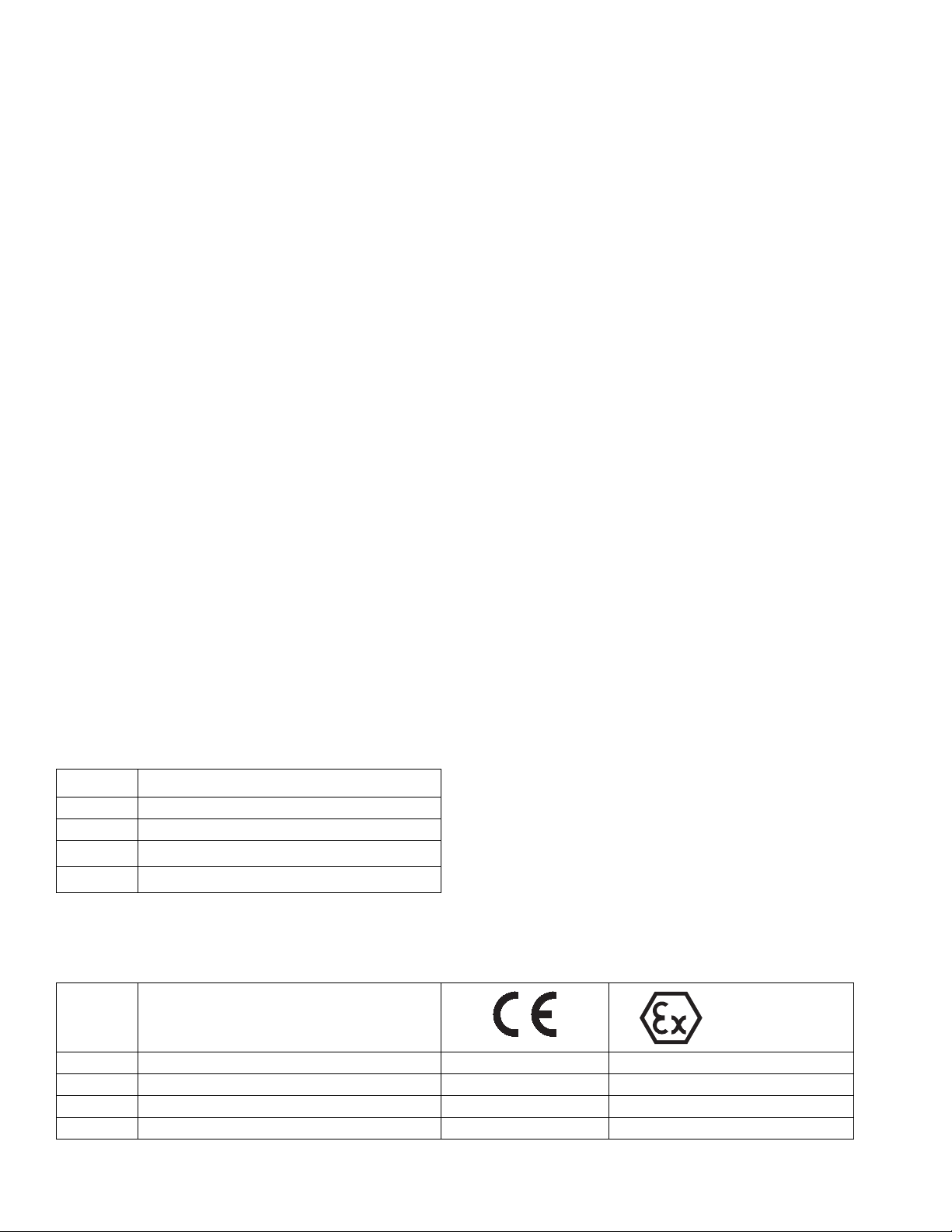

Spray Packages

WLD

ti31706a

WLD

WLD

Package Included Applicator

Part Description Part Applicator Type

27A489 System, M680a CS, Flex Applicator, Package 24T947 Flex

27A490 System, M680a CS, Pole Applicator, Package 24T946 Pole

27A491 System, M680a CS, HTX Applicator, Package 24U209 HTX

Packages include:

• (1) ToughTek M680a CS Mortar Sprayer

• (1) Fluid hose bundle

• (2) Air hose bundle

• (1) Applicator camlock reducer

• (1) Applicator (see above table and Applicators, page 4)

Models

Fluid Hose Bundle (27A004)

Includes 50 ft of 1 3/8 in. mortar hose with 1.5 in.

camlock connections.

FIG. 1: Fluid Hose Bundle

Air Hose Bundle (24T852)

Includes 25 ft of air hose with 1/4 in. quick disconnect air

fittings and 25 ft of air pilot line.

Applicator Camlock Reducer (17G767)

Connects a 1.5 in. male camlock hose outlet to a 1 in.

female camlock fitting on applicator.

FIG. 3: Applicator Camlock Reducer

ToughTek M680a CS Mortar Sprayer

(25M572)

Includes sprayer with 1.5 in. male camlock fluid outlet,

1/4 in. air quick disconnect, air pilot line connection, and

3/4 npt air supply inlet.

FIG. 2: Air Hose Bundle

FIG. 4: ToughTek M680a CS Mortar Sprayer

3A5275B 3

Models

WLD

WLD

WLD

Applicators

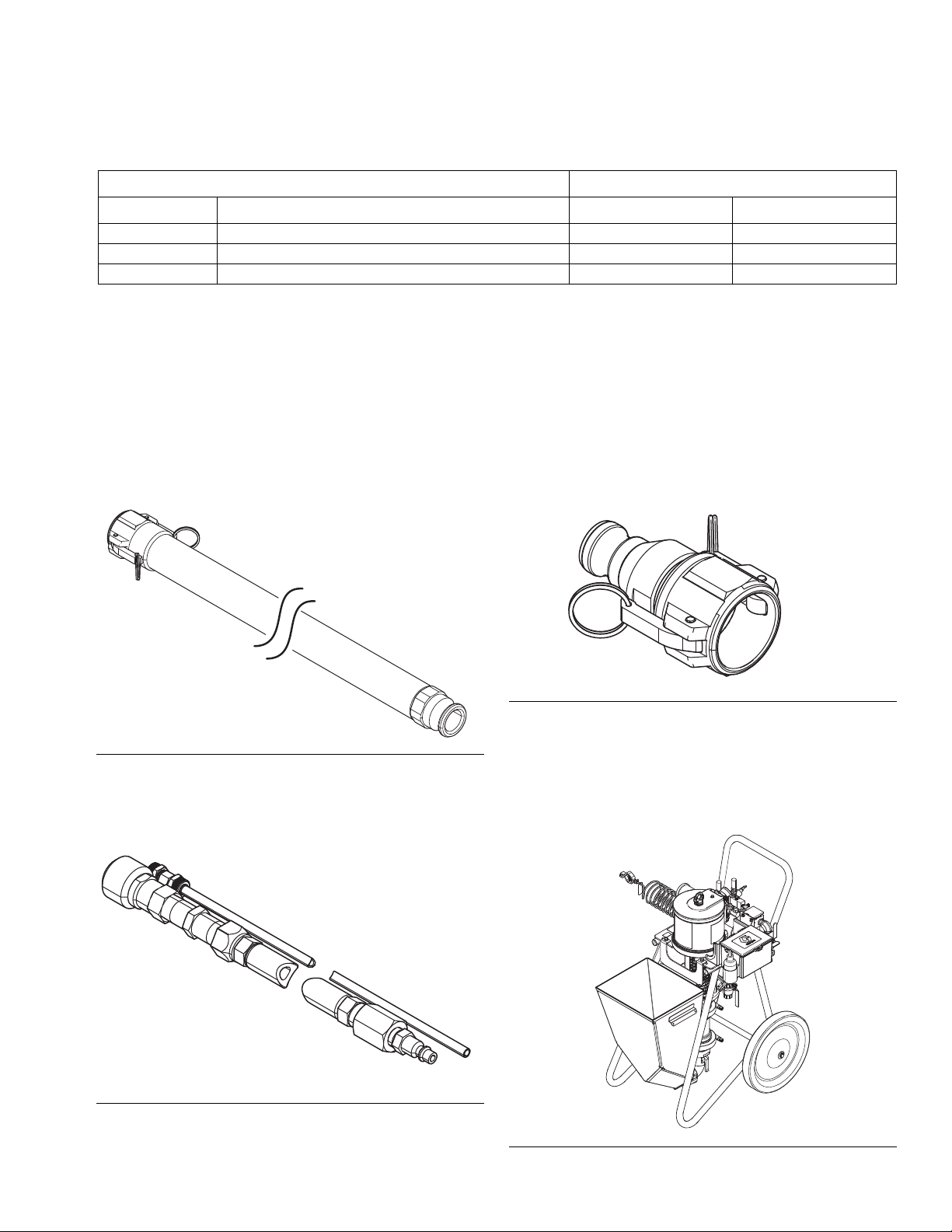

Flex Applicator

The flex applicator is for use in low pressure spraying

of materials that packout easily and will be

finish-troweled.

Includes 23 in. (58 cm) fle xible hose with a 1 in. camloc k

fluid inlet, angled spra y head, spray air volume control,

spray air shut off valve, and motor pilot signal control

valve; an adjustable-position center air injection tube, a

rubber tip retainer, and three tip sizes.

Pole Applicator

The pole applicator is for use in low-pressure spraying

in long-reach, open areas, using materials that packout

easily and will be finish-troweled. The pole applicator is

similar to the flex applicator but includes a pipe instead

of a hose.

FIG. 5: Flex Applicator

Includes a 30 in. (76 cm) aluminum pipe with a 1 in.

camlock fluid inlet, angled spray head, spray air volume

control, spray air shut-off valve, and motor pilot signal

control valve; an adjustable-position center air injection

tube, a rubber tip retainer, and three tip sizes.

HTX 680 Applicator

The HTX 680 applicator is for use in medium-pressure

spraying of materials that do not packout easily.

The HTX 680 uses venturi-type air injection f luid nozzles

and an aluminum screw on tip retainer. The applicator

includes a 1 in. camlock fluid inlet, angled alum inum

spray head, spray air volume control, spray air shut off

valve , and motor pilot signal contr ol valve. Also includes

four nozzle sizes, a Fine Finish adapter, and four Fine

Finish tips.

FIG. 6: Pole Applicator

FIG. 7: HTX 680 Applicator

4 3A5275B

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks.

When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings.

Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this

manual where applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, a nd plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when t riggering into pail. Do not u se p ail l iner s un less they

are anti-static or conductive.

• Stop operation immediately if static sparking occurs or y ou feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Reli ef Procedure when y ou stop dispensing and bef ore cleaning, checking , or

servicing equipme nt .

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

3A5275B 5

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Specifications in all equipment manuals.

• Use fluids that are compatible with equipment wetted parts. See Technical Specificat ions in all

equipment manuals. Read material manufacturer’s warnings. For complete information about your

material, request Safety Data Sheets (SDSs) from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alter ations or modifications ma y void agency approv als and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before chec king, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the manufacturer of the pumped

material.

SUCTION HAZARD

Powerful suction can cause serious injury.

• Never place hands near the pump fluid inlet when pump is operating or pressurized.

6 3A5275B

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to a v oid e quipment damage

and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Always clean the int ernal pump components after

flushing.

• Check with your material manufacturer for

chemical compatibility.

Warnings

3A5275B 7

Component Identification

WLE

$&

$$

$%

$'

$-

5

3

)

1

&

$

<

%

'

+

(

;

/

-

*

8

0

:

Component Identification

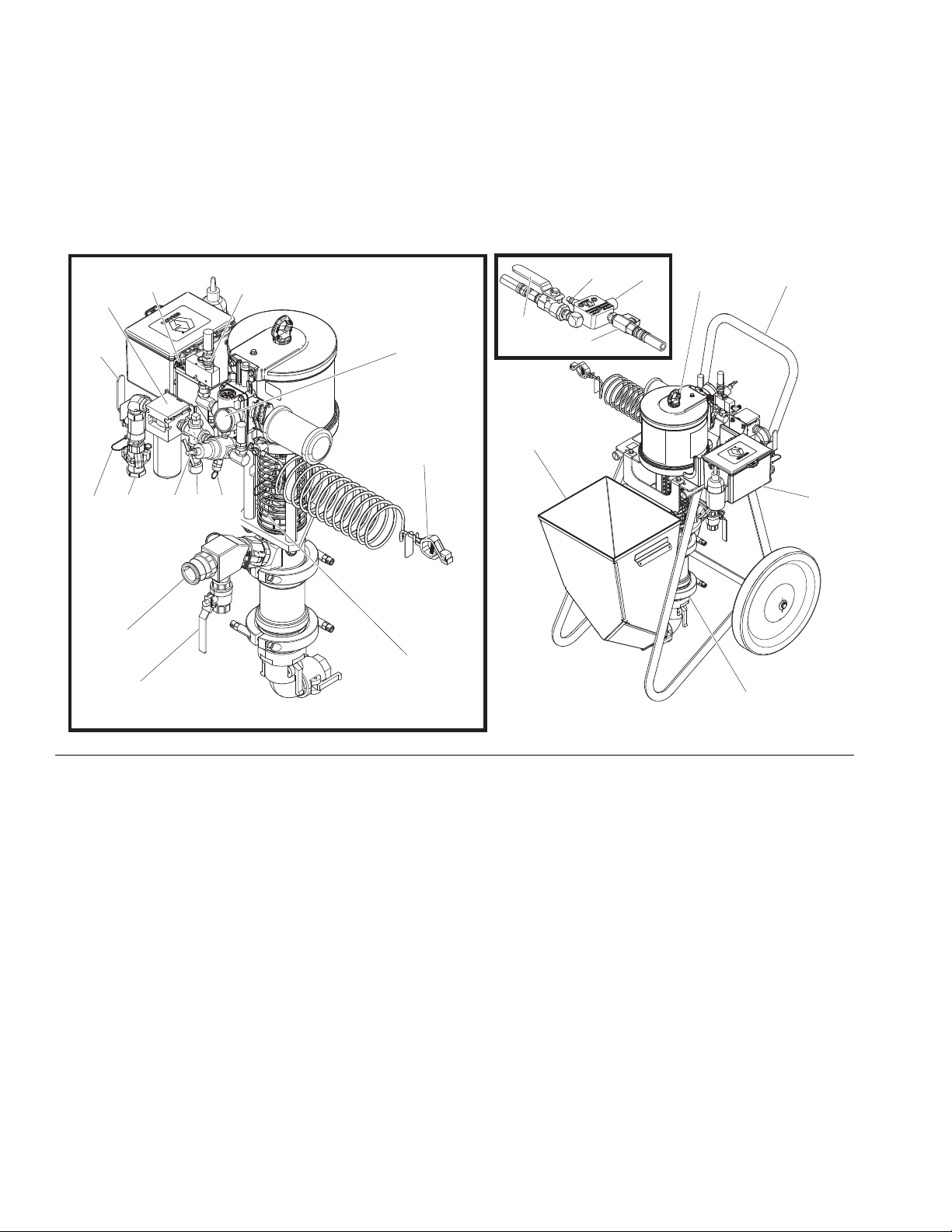

Overview

FIG. 8: Typical Installation

Key:

AA Material Hopper

AB Air Motor

AC Lower

AD Cart

AJ System Air Inlet

A Air Inlet, 3/4 npt(f) Claw (Chicago) Fittings

B Bleed Type Master Valve (required)

C Air Pressure Relief Valve

D Air Filter (40 micron)

E Motor Air Pressure Gauge

F Motor Air Pressure Regulator Adjustment Knob

G* Air Motor Pilot Ball Valve (starts/stops air motor

from applicator)

H Motor Air Pilot Valve

J Pressure Relief Ball Valve

L Grounding Wire, required (see Grounding, page

10)

M* Needle Valve for Air Assist Flow Control

N Air Supply Quick Disconnect to Applicator Air

Inlet Quick Disconnect

P Fluid Outlet, 1.5 in. Male Camlock Fitting

R Packing Nut/Wet Cup under Spring Guard

U* Air Assist Shutoff Ball Valve

W* Applicator Air Inlet Quick Disconnect

X Pilot Valve Signal (to Applicator)

Y Whip Check Hose Safety Cable

*Part of applicator

8 3A5275B

Component Identification

System Components

NOTE: System requires use of an applicator with an air

pilot line and air pilot valv e to oper ate . See Applicators,

page 4 for compatible applicators.

*Required system components

To avoid tip ping o v er, ensure cart is on a flat and lev e l

surface. Failure to do so could result in injury or

equipment damage.

*Bleed Type Master Air Valve (B)

• Be sure the valve is easily accessible from the

applicator.

• Required in your system to relieve air trapped

between it and the air motor when the valve is

closed.

- Open to supply air to the motor.

- Close to shut off air to the motor and bleed any

trapped air from the motor.

*Air Pressure Relief Valve (C)

Air Filter (D)

Removes harmful dirt and water from compressed air

supply.

Air Regulator Adjustment Knob (F)

Adjusts air pressure to the motor and fluid outlet

pressure of the pump. Read air pressure on gauge (E).

*Pressure Relief Ball Valve (J)

Open valve to relieve pressure if pump or hose packout

occurs. Close valve when spraying.

NOTICE

To prevent material hardening in the pressure relief

ball valve (J), flush the valve after each use. See

Flush the Equipment, page 19.

To help avoid serious injury from splashing fluid , ne v er

open a camlock hose or applicator fitting while there is

pressure in the fluid line. See Pressure Relief Proce-

dure, page 12.

Automatically opens to relieve air pressure if set

pressure exceeds preset limit.

3A5275B 9

Installation

L

ti21630a

ti1102

Installation

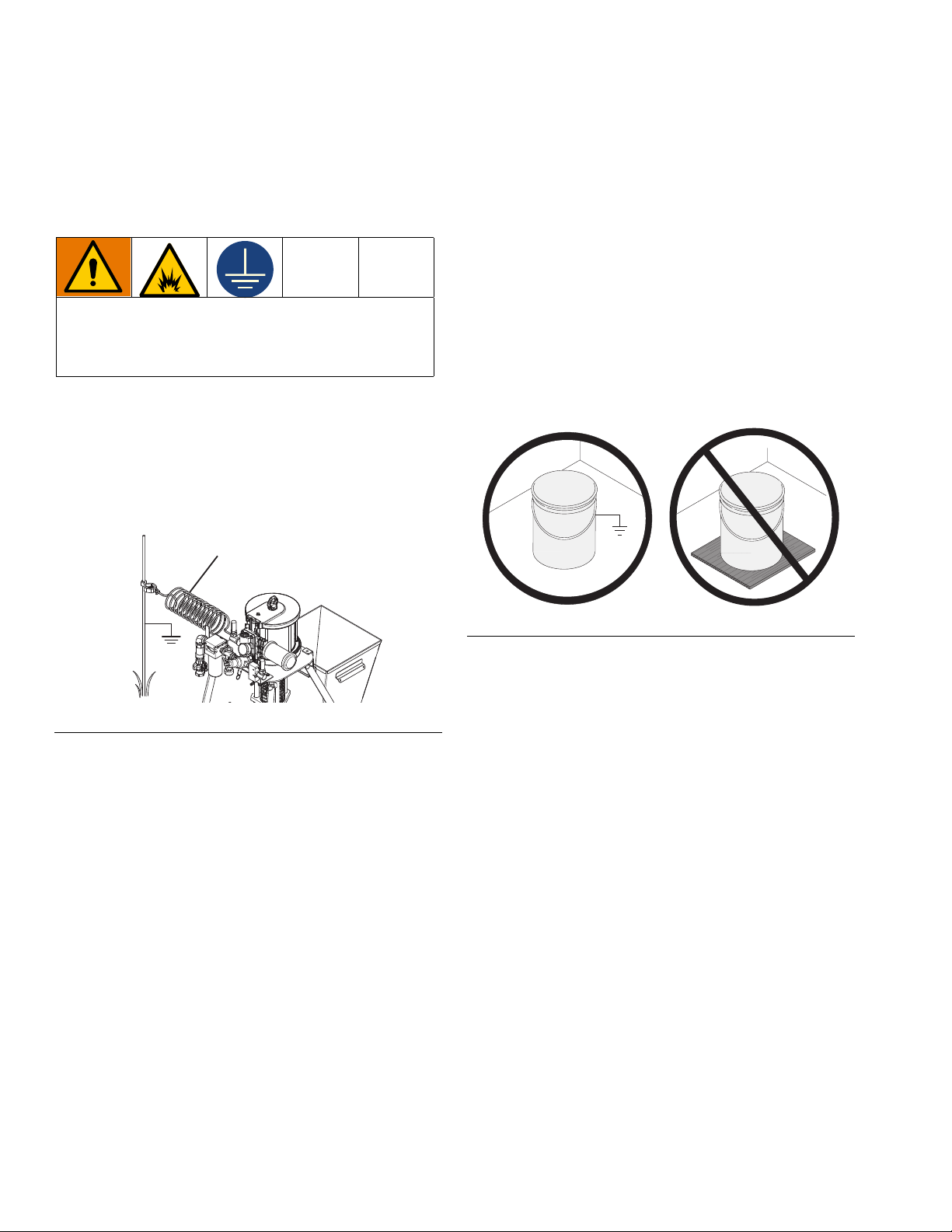

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grou nding pro vides an escape wire

for the electric current.

Tools Required

• Grounding wires and clamps for pails

• Two 5-gallon (19 L) metal pails

1. Connect the ground wire (L, 262908) to the ground

stud on the air motor.

2. Connect the other end of the ground wire to a true

earth ground.

3. Ground the object being sprayed, fluid supply

container, and all ot her eq uip ment in t he w ork area.

Follow your local code. Use only electrically

conductive air and fluid hoses.

4. Ground all pails. Use only metal pails, which are

conductive, placed on a metal sur f ace . Do not place

pail on a non-conductive surface, such as paper or

cardboard, which interrupts grounding continuity.

FIG. 10: Properly Grounded Pail

FIG. 9: Grounding Wire

10 3A5275B

Setup

R

ti21631a

B

A

ti21575a

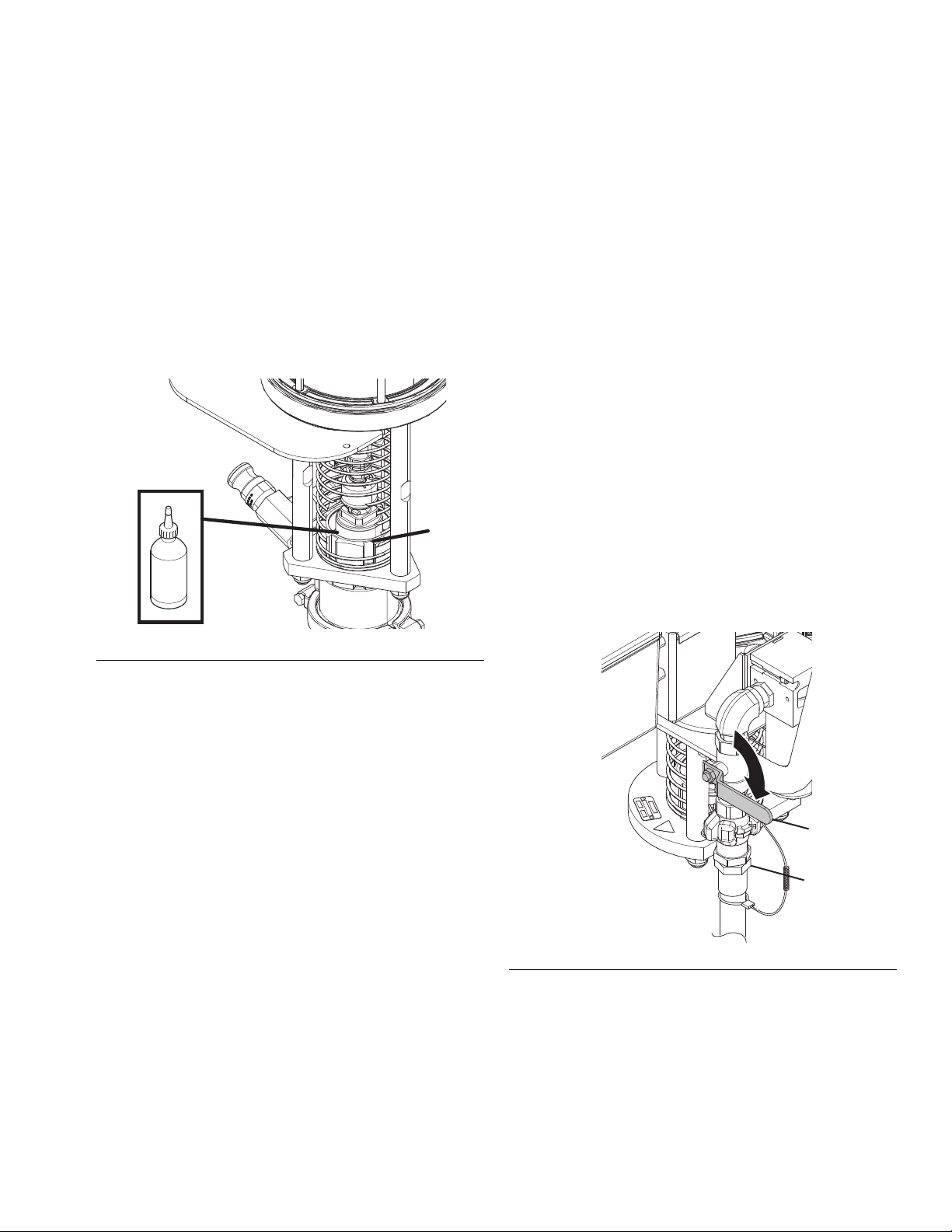

Setup

Tools required:

• Two adjustable wrenches

• Non-sparking hammer or plastic mallet

1. Ground sprayer. See Grounding, page 10.

2. Check Throat Seal Liquid (TSL) level in packing nut

(R). Fill 1/2 full with TSL.

9. Wrap blue velcro camlock retaining straps around

each camlock conn ection to secure.

NOTE: This includes the two camlocks between the

hopper and the pump lower, the camlock at the pump

outlet, the camlocks on the fluid hoses , and the ca mlock

on the applicator inlet. The retaining straps should be

tight and must not be able to slide off the camlocks.

10. Going from applicator back to the system, wrap a

zip tie around all hoses every few feet to secure

them together.

11. Connect air supply hose:

a. Close bleed type master air valve (B).

b. Expand end of whip check cable (Y) and slide it

over the end of your air hose.

c. Connect air supply hose to 3/4 npt(f) claw

fittings air inlet (A).

d. Install safety clips in claw fittings.

FIG. 11: Check Throat Seal Liquid Levels

3. Attach electrically conductive fluid hose to camlock

at pump outlet.

4. Attach large air line from hose bundle to main air

quick disconnect (N). See Component

Identification, page 8.

5. Attach large air line from hose bundle to motor pilo t

valve signal (X). Use wrench to secure air tube in

place. See Component Identification, page 8.

6. Attach applicator camlock reducer to applicator fluid

inlet.

7. Attach large air line from hose bundle to applicator

air inlet quick disconnect (W). See Component

Identification, page 8.

8. Attach small air tube from hose bundle to air motor

pilot ball valve (G) on applicator. Use wrench to

secure air tube place. See Component

Identification, page 8.

FIG. 12

12. Wet out the system with material flushin g agent

before using. See Wet Out the System, page 13.

3A5275B 11

Loading...

Loading...