Page 1

Instructions - Parts

Communications

Gateway Module

3A5186B

Therm-O-Flow® Installation Kit

For use with Therm-O-Flow 20 and 200 systems to provide fieldbus communication

capabilities. For professional use only.

Kit No. 25C994

Important Safety Instructions

Read all warnings and instructions in this

manual and in all related manuals. Save all

instructions.

EN

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mounting the CGM . . . . . . . . . . . . . . . . . . . . . . . 3

Connecting the CAN Cables . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Gateway Screens . . . . . . . . . . . . . . . . . . . . . . . . 5

EtherNet/IP Fieldbus Screens . . . . . . . . . . . . . . . 5

DeviceNet Fieldbus Screen . . . . . . . . . . . . . . . . 5

PROFIBUS Fieldbus Screen . . . . . . . . . . . . . . . . 6

PROFINET Fieldbus Screens . . . . . . . . . . . . . . . 6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Software Update Procedure . . . . . . . . . . . . . . . . 8

Available Internal Data . . . . . . . . . . . . . . . . . . . . . . 9

Automation Inputs (Signals from the Therm-O-Flow

to the PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Automation Outputs (Signals from the PLC to the

Therm-O-Flow) . . . . . . . . . . . . . . . . . . . . . . 11

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Kit No. 25C994 . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix A - I/O Signal Descriptions . . . . . . . . . 13

Heat Zone States . . . . . . . . . . . . . . . . . . . . . . . 13

Status Indication Bit Tables . . . . . . . . . . . . . . . 13

System Control Bits . . . . . . . . . . . . . . . . . . . . . 14

Temperature Setpoint Zone Designation Table 16

Appendix B - Data Exchange Interface . . . . . . . . 17

Data Exchange Interface Pointer Designation Tabl

18

Appendix C - Error/Event Tables . . . . . . . . . . . . . 22

Related Manuals

Manual Description

Models

The following kit includes the Communications Gateway

Module (CGM) parts and software that are required for

Therm-O-Flow 20 or Therm-O-Flow 200 machines using

a CGM. This kit enables the Therm-O-Flow machines to

connect to a fieldbus device.

Part No. Description

25C994 Thermo-O-Flow CGM Installation Kit

Kit 25C994 is used with the following CGM models,

each of which includes all of the remaining parts necessary to install the CGM. See Communications Gateway

Module Instructions - Parts, manual 312864, for repair

parts for these assemblies.

Part No. Fieldbus

CGMEP0 EtherNet/IP

CGMDN0 DeviceNet

CGMPB0 PROFIBUS

CGMPN0 PROFINET

Overview

The Communications Gateway Module (CGM) provides

a control link between the Therm-O-Flow (TOF) system

and a selected fieldbus. The control link provides the

means for remote monitoring and control by external

automation systems.

The data available to the fieldbus from the CGM

depends on the amount of channels installed on the

Therm-O-Flow system. A data map is available on a

token provided in this kit.

See Available Internal Data on page 9 for a list of internal data from the Therm-O-Flow system that can be

viewed or modified by the fieldbus device.

312864 Communications Gateway Module

Instructions - Parts

334130 Therm-O-Flow 200 Instructions - Parts

334129 Therm-O-Flow 20 Instructions - Parts

406987 GCA CAN Cables, Reference

2 3A5186B

NOTE: The following system network configuration files

are available at www.graco.com.

• EDS file: DeviceNet or Ethernet/IP fieldbus networks

Page 3

Installation

Recommended

Location for

Mounting Holes

3.25 in.

(82.6 mm)

2.75 in.

(69.9 mm)

#10-32 UNF

(M5 x 0.8)

CAN Cable Connectors

D

A

C

B

Installation

NOTE: Turn off the main power switch on the

Therm-O-Flow before starting. See the Therm-O-Flow

manuals referenced in Related Manuals on page 2 for

information about turning off the power.

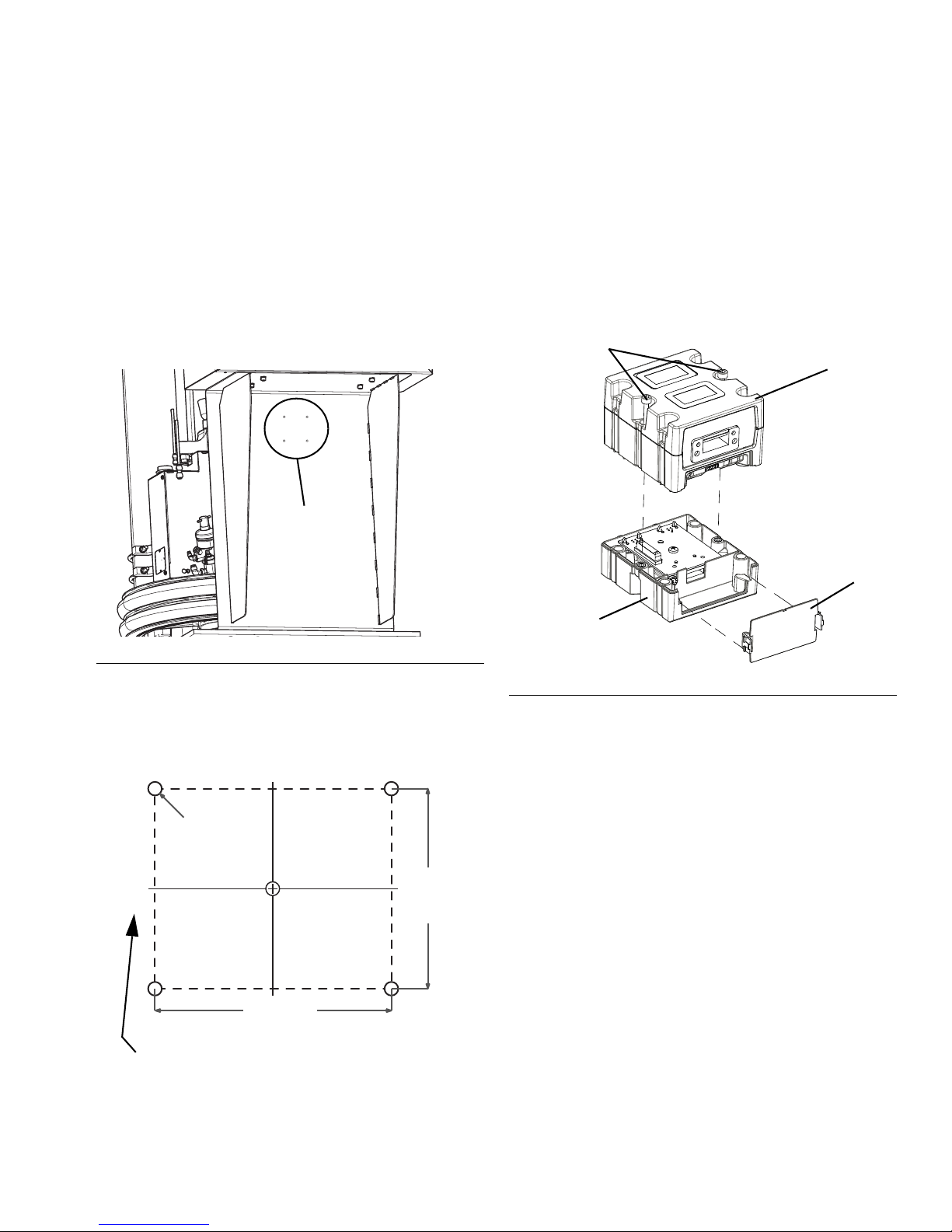

To install the CGM, you will need to drill mounting holes

on the Therm-O-Flow below the electrical control panel

in a location where the CAN cables can be connected to

the CGM. See Figure 1 for the recommended location.

Mounting the CGM

1. Drill the mounting holes.

2. Remove the access cover from the CGM (D).

Loosen the two screws (C) and remove the CGM

(A) from the base (B).

FIG. 1: Mounting Location

The center of the CGM should be 4 inches from the bottom of the electrical control panel and 8 inches from

each side. Refer to the following mounting dimensions

when drilling the holes for the CGM.

NOTE: Mount the CGM with the CAN cable connectors

on the left side to make it easier to connect the cables.

FIG. 2: Removing the CGM Access Cover

3. With the CAN connectors on the left side, mount the

base (B) in the mounting holes using the four

screws supplied in this kit. See Parts on page 12.

4. Mount the CGM (A) on the base (B) with the two

screws (C) that were removed in step 2.

5. Reattach the access cover (D).

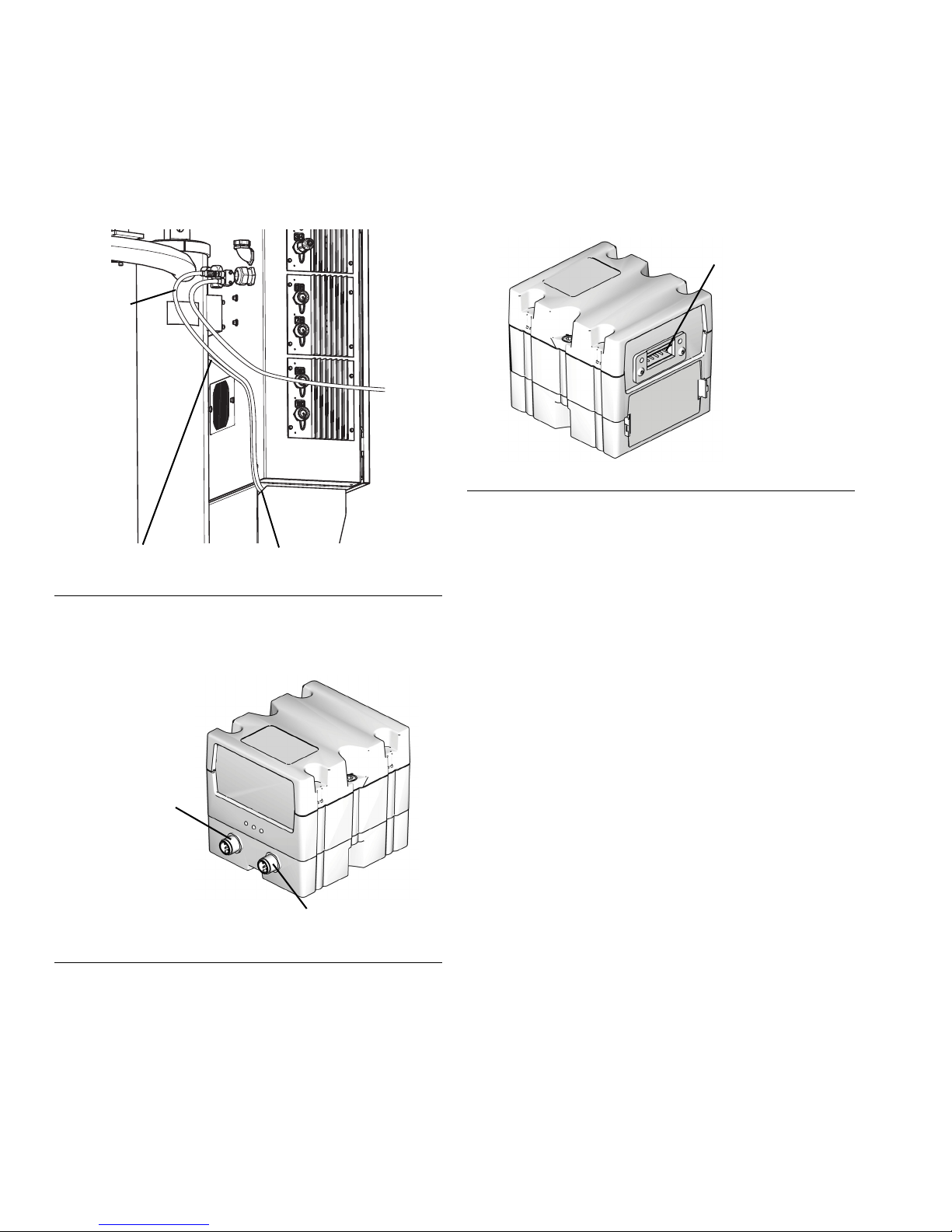

Connecting the CAN Cables

1. Disconnect the ADM’s CAN cable from the ADM

and from the splitter on the back of the

Therm-O-Flow’s electrical control panel.

2. Connect one end of the 1.5 m (4.9 ft) CAN cable

included in this kit to the ADM. Run the cable down

and through the opening underneath the electrical

control box as shown in Figure 3.

3A5186B 3

Page 4

Installation

CAN Cable from ADM

CAN Cable

from Splitter

Opening Leading to CGM

CAN Connector 1

CAN Connector 2

Fieldbus Connection

3. Connect the CAN cable that you removed from the

ADM to the available splitter connection on the back

of the electrical control panel. Run that cable

through the same opening as the other CAN cable.

FIG. 3: CAN Cable Connection

4. Connect the two cables to the CGM connectors.

Either cable can be connected to either connector.

7. Connect the Ethernet, DeviceNet, or PROFIBUS

cable to the CGM as applicable. Connect the other

end of the cable to the fieldbus device.

FIG. 5: Connecting the Fieldbus

8. Perform the Install or Update Data Map procedure

in Communications Gateway Module Instructions -

Parts, manual 312864.

9. See the Available Internal Data on page 9 for

details on the fieldbus pinout setup.

10. Perform Setup on page 5 to configure the fieldbus.

FIG. 4: CGM Connectors

5. Attach the two ferrite suppressors included in the kit

to the ends of the two cables closest to the CGM.

6. Use the adhesive cable tie included in the kit to

attach the CAN cables to the back of the control

box.

4 3A5186B

Page 5

Setup

Setup

NOTICE

To prevent damage to soft key buttons on the ADM, do

not press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Gateway Screens

Use the Gateway screens on the ADM to configure the

fieldbus. These screens are shown only if a CGM is correctly installed in your system. See Installation on page

3.

1. With the system on and enabled, press on the

ADM to access the Setup screens.

2. Use the ADM’s arrow keys to navigate to the main

Gateway screen.

EtherNet/IP Fieldbus Screens

Screen 2

Use the down arrow key on the ADM to navigate to

screen 2. This screen displays the hardware revision,

system serial number, and data map identification information.

DeviceNet Fieldbus Screen

NOTE: These screens are shown only if you have an

EtherNet/IP fieldbus CGM installed.

Screen 1

Press the key to access this screen. Use the arrow

keys to navigate to each field and the keypad to set the

IP address, DHCP settings, subnet mask, gateway, and

DNS information.

NOTE: This screen is shown only if you have a DeviceNet fieldbus CGM installed.

Press the key to access this screen. You can set

the device address and baud rate. You can also view

the hardware revision, system serial number, and data

map identification information.

3A5186B 5

Page 6

Setup

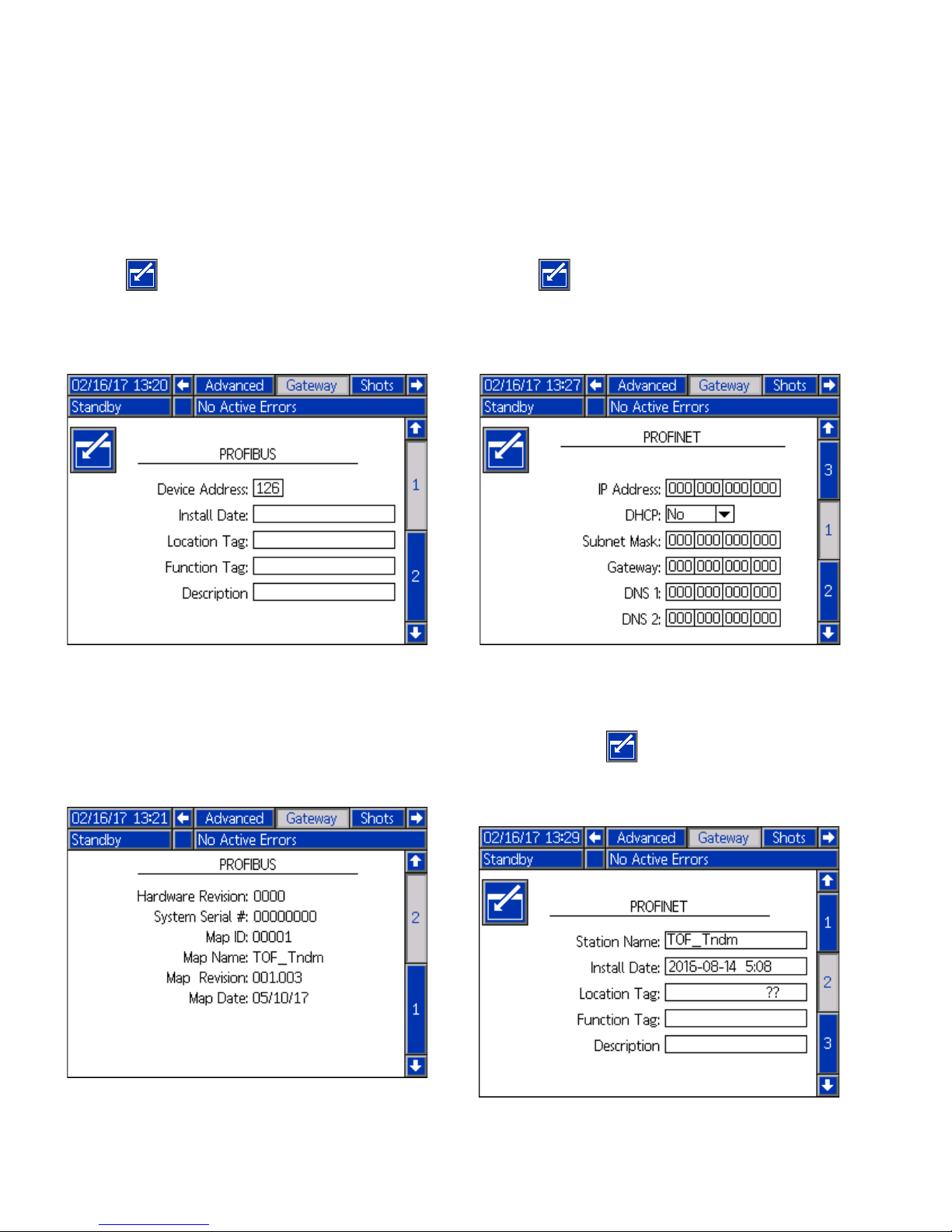

PROFIBUS Fieldbus Screen

NOTE: These screens are shown only if you have a

PROFIBUS fieldbus CGM installed.

Screen 1

Press the key to access this screen. Use the arrow

keys to navigate to each field and the keypad to set the

device address, install date, location tag, function tag,

and description.

PROFINET Fieldbus Screens

NOTE: These screens are shown only if you have a

PROFINET fieldbus CGM installed.

Screen 1

Press the key to access this screen. Use the arrow

keys to navigate to each field and the keypad to set the

IP address, DHCP settings, subnet mask, gateway, and

DNS information.

Screen 2

Use the down arrow key on the ADM to navigate to

screen 2. This screen displays the hardware revision,

system serial number, and data map identification information.

Screen 2

Use the down arrow key on the ADM to navigate to

screen 2. Press the key to access this screen. You

can set the station name, install date, location tag, function tag, and description.

6 3A5186B

Page 7

Screen 3

Use the down arrow key on the ADM to navigate to

screen 3. This screen displays the hardware revision,

system serial number, and data map identification information.

Setup

3A5186B 7

Page 8

Maintenance

Maintenance

Software Update Procedure

When software is updated on the ADM, the software is

then automatically updated on the CGM and all other

connected Graco Control Architecture components.

1. At the ADM, turn the power switch to Off.

2. Remove the ADM from the bracket.

3. Use a hex key to remove the token access panel.

6. The Graco Splash screen is displayed until communication with other modules is established.

7. Wait for the update to complete. An approximate

time to completion displays below the progress bar.

8. When the update is completed successfully, press

the key.

FIG. 6: Token Location

4. Insert and press the software upgrade token firmly

into the slot.

5. Turn the power switch to On.

NOTICE

A status is shown while software is updating to indicate progress. To prevent corrupting the software

load, do not remove the token until the status screen

disappears.

9. Remove the token and replace the token access

panel.

NOTE: The software version history for each system

can be viewed in the technical support section at

www.graco.com.

8 3A5186B

Page 9

Available Internal Data

Available Internal Data

See Appendix A - I/O Signal Descriptions on page 13 for additional details regarding each input/output. Unless

stated otherwise:

• Values are subject to the same maximum and minimum restrictions of the ADM.

• Some of the temperature data may have slight rounding errors compared to temperatures displayed on the ADM.

• On some controlling devices, the byte order may need to be reversed (byte order within instance, least significant

-> most significant.

Automation Inputs (Signals from the Therm-O-Flow to the PLC)

Instance

Number

1 0 -1 Pump Actual Temperature, Primary °C/°F

2 2 - 3 Platen Actual Temperature, Primary °C/°F

3 4 - 5 Zone #1 Actual Temperature, Primary °C/°F

4 6 - 7 Zone #2 Actual Temperature, Primary °C/°F

5 8 - 9 Zone #3 Actual Temperature, Primary °C/°F

6 10 - 11 Zone #4 Actual Temperature, Primary °C/°F

7 12 - 13 Zone #5 Actual Temperature, Primary °C/°F

8 14 - 15 Zone #6 Actual Temperature, Primary °C/°F

9 16 - 17 Zone #7 Actual Temperature, Primary °C/°F

10 18 - 19 Zone #8 Actual Temperature, Primary °C/°F

11 20 - 21 Zone #9 Actual Temperature, Primary °C/°F

12 22 - 23 Zone #10 Actual Temperature, Primary °C/°F

13 24 - 25 Zone #11 Actual Temperature, Primary °C/°F

14 26 - 27 Zone #12 Actual Temperature, Primary °C/°F

15 28 - 29 Pump Setpoint Temperature Indication, Primary/Secondary °C/°F

16 30 - 31 Platen Setpoint Temperature Indication, Primary/Secondary °C/°F

17 32 - 33 Zone #1 Setpoint Temperature Indication, Primary/Secondary °C/°F

18 34 - 35 Zone #2 Setpoint Temperature Indication, Primary/Secondary °C/°F

19 36 - 37 Zone #3 Setpoint Temperature Indication, Primary/Secondary °C/°F

20 38 - 39 Zone #4 Setpoint Temperature Indication, Primary/Secondary °C/°F

21 40 - 41 Zone #5 Setpoint Temperature Indication, Primary/Secondary °C/°F

22 42 - 43 Zone #6 Setpoint Temperature Indication, Primary/Secondary °C/°F

23 44 - 45 Zone #7 Setpoint Temperature Indication, Primary/Secondary °C/°F

24 46 - 47 Zone #8 Setpoint Temperature Indication, Primary/Secondary °C/°F

25 48 - 49 Zone #9 Setpoint Temperature Indication, Primary/Secondary °C/°F

26 50 - 51 Zone #10 Setpoint Temperature Indication, Primary/Secondary °C/°F

27 52 - 53 Zone #11 Setpoint Temperature Indication, Primary/Secondary °C/°F

28 54 - 55 Zone #12 Setpoint Temperature Indication, Primary/Secondary °C/°F

29 56 - 57 Pump, Platen, Zones 1 – 3 States, Primary

30 58 - 59 Zones 4 – 8 States, Primary

31 60 - 61 Zones 9 – 12 States, Primary

32* 62 - 63 Pump Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

33* 64 - 65 Platen Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

34* 66 - 67 Zone #1 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

35* 68 - 69 Zone #2 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

36* 70 - 71 Zone #3 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

37* 72 - 73 Zone #4 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

Input Byte

Index(es)

Description Units

3A5186B 9

Page 10

Available Internal Data

Instance

Number

Input Byte

Index(es)

Description Units

38* 74 - 75 Zone #5 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

39* 76 - 77 Zone #6 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

40* 78 - 79 Zone #7 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

41* 80 - 81 Zone #8 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

42* 82 - 83 Zone #9 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

43* 84 - 85 Zone #10 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

44* 86 - 87 Zone #11 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

45* 88 - 89 Zone #12 Setback Setpoint Temperature Indication, Primary/Secondary °C/°F

46** 90 - 91 Pump Actual Temperature, Secondary °C/°F

47** 92 - 93 Platen Actual Temperature, Secondary °C/°F

48** 94 - 95 Zone #1 Actual Temperature, Secondary °C/°F

49** 96 - 97 Zone #2 Actual Temperature, Secondary °C/°F

50** 98 - 99 Zone #3 Actual Temperature, Secondary °C/°F

51** 100 - 101 Zone #4 Actual Temperature, Secondary °C/°F

52** 102 - 103 Zone #5 Actual Temperature, Secondary °C/°F

53** 104 - 105 Zone #6 Actual Temperature, Secondary °C/°F

54** 106 - 107 Zone #7 Actual Temperature, Secondary °C/°F

55** 108 - 109 Zone #8 Actual Temperature, Secondary °C/°F

56** 110 - 111 Zone #9 Actual Temperature, Secondary °C/°F

57** 112 - 113 Zone #10 Actual Temperature, Secondary °C/°F

58** 114 - 115 Zone #11 Actual Temperature, Secondary °C/°F

59** 116 - 117 Zone #12 Actual Temperature, Secondary °C/°F

60** 118 - 119 Pump, Platen, Zones 1 – 3 States, Secondary

61** 120 - 121 Zones 4 – 8 States, Secondary

62** 122 - 123 Zones 9 – 12 States, Secondary

63** 124 - 127 Error / Event Code(s) Present †

64** 128 - 131 Error / Event Code(s) Needing Acknowledged †

65** 132 - 133 Status Word 1 Indication Bits

66** 134 - 135 Status Word 2 Indication Bits

67** 136 - 137 Data Exchange Interface Pointer Last Serviced

68** 138 - 141 Data Exchange Interface Input Value

69** 142 System Mode/State, Primary ‡

70** 143 System Mode/State, Secondary ‡

* Data instances (setback mode setpoint temperatures) are NOT provided for the PROFIBUS and PROFINET versions of the map since the

field protocols do not support that large of a map size. For PROFIBUS or PROFINET, you should use the data exchange interface to obtain

setback setpoint information.

** For the PROFIBUS or PROFINET versions of the map, 14 should be subtracted from the instance number and 28 should be subtracted for the

input byte count so that the PROFIBUS and PROFINET versions have 56 input instances containing 116 input bytes total.

Zone states are packed in groups of three bits, where each zone state equates to the following. Each zone is packed from bit 0, bit 3, bit 6, bit

9, and bit 12 corresponding to the order presented in the description. 000 - zone is not installed, 001 - zone is off, 010 - zone is in warm up

state, 011 - zone is in heat soak state, 100 - zone at temperature, 101 - zone in setback mode.

Temperature units match units of the ADM. Values are in tenths of a degree (for example, a value of 4005 corresponds to 400.5 °F). Setpoint

temperatures are either for the primary or secondary unit, depending on the system selected by the PLC in the System Control Word.

† See Appendix C - Error/Event Tables on page 22.

See the Status Indication Bit Tables on page 13.

See Appendix B - Data Exchange Interface on page 17.

‡ System Mode/State: 0 = System Off, 1 = Inactive, 2 = Warm Up, 3 = Heat Soak, 4 = Ready (at temperature, heat soak done, pump off), 5 =

Active (at ready and pump ON), 6 = Setback Mode.

10 3A5186B

Page 11

Available Internal Data

Automation Outputs (Signals from the PLC to the Therm-O-Flow)

Instance

Number

Output

Bytes

Description Units

1 0 System Activate/Stop *

2 1 Setpoint Zone Designation **

3 2 - 3 Setpoint Temperature for Selected Zone °C/°F**

4 4 - 5 System Control Bits

5 6 - 9 Error/Event Number Acknowledged †

6 10 - 11 Data Exchange Interface Pointer Output Designation

7 12 - 15 Data Exchange Interface Output Value

* Set this byte to one of the following: 0 = Do Nothing, 1 = Turns ON the System (same as pressing the key), 2-255 = Shuts Down the

System (same as pressing the key).

** Used to set the temperature setpoints to tenths of a degree (for example, 3005 = 300.5) in the selected units of measurement (°C or °F). See

the Temperature Setpoint Zone Designation Table on page 16.

See System Control Bits on page 14.

† See the Appendix C - Error/Event Tables on page 22

See Appendix B - Data Exchange Interface on page 17.

3A5186B 11

Page 12

Parts

6

7

15

20

13

CGM shown for mounting

purposes only.

Not included in kit.

Parts

Kit No. 25C994

FIG. 7: Kit 25C994 Parts

Ref Part Description Quantity

6 96/0650/99 SCREW, tapping, phillips pan hd 4

7 17T051 TOKEN, gca, map, tof cgm 1

917T053 SOFTWARE, gateway, tof, gsd 1

10 17T054 SOFTWARE, gateway, tof, eds 1

11 17T055 SOFTWARE, gateway, tof, gsdml 1

13 121901 SUPPRESSOR, box snap, ferrite 2

15 16H821 TOKEN, gca, upgrade, adm32 1

19 17T056 KIT, sample program 1

20 121002 CABLE, can, female/female 1.5 m 1

21 84/0805/89 CABLE, TIE MOUNT, 1 x 1 sq w/adhesive 1

Not shown.

NOTE: The CGM is not included in the kit. See Models on page 2 for available CGM modules.

12 3A5186B

Page 13

Appendix A - I/O Signal Descriptions

Appendix A - I/O Signal Descriptions

This section provides details about the CGM automation input and output signals.

Heat Zone States

The signal is 0 on power up. The following values of this signal correspond to the various heat zone states. Each

zone is bit packed into 3 bits for each zone designation in input instances 29-31 and 60-62 of the map.

Number Binary # Heat Zone State

0 000 Zone Not Installed

1 001 OFF

2 010 Warm Up

3 011 Heat Soak State

4 100 At Temperature

5 101 Setback Mode

Status Indication Bit Tables

The following tables reflect bit-packed data, which corresponds to the status words located at input instances 65 and

66.

Status Word 1 Indication Bits

Bit

Number

0 0x0001 0000 0000 0000 0001 System is ON

1 0x0002 0000 0000 0000 0010 Active System is Secondary (B) System

2 0x0004 0000 0000 0000 0100 Heat is Turned ON for Primary (A) System

3 0x0008 0000 0000 0000 1000 Heat is Turned ON for Secondary (B) System

4 0x0010 0000 0000 0001 0000 Setpoint Indications are for Secondary (B) System

5 0x0020 0000 0000 0010 0000 Setback Setpoint Indications are for Secondary (B) System

6 0x0040 0000 0000 0100 0000 Material Tracking is ON or Active

7 0x0080 0000 0000 1000 0000 Pump Priming is Active for Primary (A) System

8 0x0100 0000 0001 0000 0000 Pump Priming is Active for Secondary (B) System

9 0x0200 0000 0010 0000 0000 Pump is ON for Primary (A) System

10 0x0400 0000 0100 0000 0000 Pump is ON for Secondary (B) System

11 0x0800 0000 1000 0000 0000 Setback Mode is Active for Primary (A) System

12 0x1000 0001 0000 0000 0000 Setback Mode is Active for Secondary (B) System

13 0x2000 0010 0000 0000 0000 Data Exchange Interface is Active or in Transition

14-15 ------ ------ Reserved for Future Use

Hex

Equivalent

Binary Number Description

3A5186B 13

Page 14

Appendix A - I/O Signal Descriptions

Status Word 2 Indication Bits

Bit

Number

Hex

Equivalent

Binary Number Description

0 0x0001 0000 0000 0000 0001 Heat Soak Timer Active for Primary (A) System

1 0x0002 0000 0000 0000 0010 Heat Soak Timer Active for Secondary (B) System

2 0x0004 0000 0000 0000 0100 Turn ON Primary System (A), Heat Command Active

3 0x0008 0000 0000 0000 1000 Turn ON Secondary System (B), Heat Command Active

4 0x0010 0000 0000 0001 0000 Prime/Pump on A Command Active

5 0x0020 0000 0000 0010 0000 Prime/Pump on B Command Active

6 0x0040 0000 0000 0100 0000 Setback A Command Active

7 0x0080 0000 0000 1000 0000 Setback B Command Active

8 0x0100 0000 0001 0000 0000 Cross Over Command Active

9 0x0200 0000 0010 0000 0000 PLC Control Active Indication

10 0x0400 0000 0100 0000 0000

Heart Beat Indication for PLC from TOF (

Control Bits

)

See Note 7 in System

11 0x0800 0000 1000 0000 0000 Error/Event Reported is an Alarm

12-15 ------ ------ Reserved for Future Use

System Control Bits

The following table reflects the bit variables in output instance 4, which can be set or cleared to control the following

conditions.

Bit

Number

Hex

Equivalent

Binary Number Description Notes

0 0x0001 0000 0000 0000 0001 Turn ON Heat Command for System A Command 1

1 0x0002 0000 0000 0000 0010 Turn ON Head Command for System B Command 1

2 0x0004 0000 0000 0000 0100 Turn ON/Prime Pumps for System A Command 2

3 0x0008 0000 0000 0000 1000 Turn ON/Prime Pumps for System B Command 2

4 0x0010 0000 0000 0001 0000 Setback Command System A 3

5 0x0020 0000 0000 0010 0000 Setback Command System B 3

6 0x0040 0000 0000 0100 0000 Cross Over Command 4

7 0x0080 0000 0000 1000 0000 Pause Material Tracking/Counters Command 5

8 0x0100 0000 0001 0000 0000 Continue Material Tracking Command 5

9 0x0200 0000 0010 0000 0000 Command Setpoint Indications on Map for System B 6

10 0x0400 0000 0100 0000 0000 Command Setback Setpoint Indications for System B 6

11 0x0800 0000 1000 0000 0000 Heart Beat Output to TOF 7

12 0x1000 0001 0000 0000 0000 PLC Control Command 8

13-15 ------ ------ Reserved for Future Use

1 Same as pressing on the main Run screen.

2 Same as pressing on the main Run screen.

3 Same as pressing on the main Run screen.

4 Same as pressing on the main Run screen.

5 Same as pressing or on the main Run screen.

14 3A5186B

Page 15

Appendix A - I/O Signal Descriptions

6 After changing the state of the command XX setpoint indications on the map for the Secondary B system bit, the controlling PLC logic should

monitor the corresponding status indication bit and verify it corresponds to the command bit before monitoring the corresponding setpoint indication from the Therm-O-Flow.

7 The PLC or controlling logic needs to generate a dynamic signal at approximately a 0.333 Hz (1.5 seconds high, 1.5 seconds low) oscillation

rate. The signal is present to enable detection of a communication failure between the Therm-O-Flow system and the controlling logic. The

TOF system also generates the same rate dynamic signal indication (heart beat indication for PLC from TOF) signal for controlling logic to the

monitor.

8 The PLC Control Command bit needs to be set, and the controlling logic needs to generate a valid heart beat output (described in note 7) to

the Therm-O-Flo system before the TOF will grant the PLC requests or commands. If the heart beat output to TOF becomes a static signal

(always low or high) after an extended period of time while the TOF is in PLC control, the TOF reverts to a safe state, and generates a corre-

sponding alarm. This situation would be similar to an operator pressing the key

3A5186B 15

Page 16

Appendix A - I/O Signal Descriptions

Temperature Setpoint Zone Designation Table

The following table shows the setpoint designations in

output instance 2 used to command the Therm-O-Flow

temperature zones to the corresponding setpoint. Prior

to writing to instance 2, the PLC needs to write the

desired temperature setpoint (in tenths of a degree for

the selected temperature unit of measure) to output

instance 3 for the selected zone. After the zone designation has been written, the PLC can monitor the setpoint change by monitoring the correct setpoint

indications: input instances 15-28 or 32-45.

Zone

Number

Designation

0 No Zone Selected

1 Pump Setpoint Temperature, Primary

2 Platen Setpoint Temperature, Primary

3 Zone 1 Setpoint Temperature, Primary

4 Zone 2 Setpoint Temperature, Primary

5 Zone 3 Setpoint Temperature, Primary

6 Zone 4 Setpoint Temperature, Primary

7 Zone 5 Setpoint Temperature, Primary

8 Zone 6 Setpoint Temperature, Primary

9 Zone 7 Setpoint Temperature, Primary

10 Zone 8 Setpoint Temperature, Primary

11 Zone 9 Setpoint Temperature, Primary

12 Zone 10 Setpoint Temperature, Primary

13 Zone 11 Setpoint Temperature, Primary

14 Zone 12 Setpoint Temperature, Primary

15 Pump Setpoint Temperature, Secondary

16 Platen Setpoint Temperature, Secondary

17 Zone 1 Setpoint Temperature, Secondary

18 Zone 2 Setpoint Temperature, Secondary

19 Zone 3 Setpoint Temperature, Secondary

20 Zone 4 Setpoint Temperature, Secondary

21 Zone 5 Setpoint Temperature, Secondary

22 Zone 6 Setpoint Temperature, Secondary

23 Zone 7 Setpoint Temperature, Secondary

24 Zone 8 Setpoint Temperature, Secondary

25 Zone 9 Setpoint Temperature, Secondary

26 Zone 10 Setpoint Temperature, Secondary

27 Zone 11 Setpoint Temperature, Secondary

28 Zone 12 Setpoint Temperature, Secondary

61 Pump Setback Setpoint Temperature, Primary

62 Platen Setback Setpoint Temperature, Primary

Zone 1 Setback Setpoint Temperature, Pri-

63

mary

Zone 2 Setback Setpoint Temperature, Pri-

64

mary

Description

Zone 3 Setback Setpoint Temperature, Pri-

65

mary

Zone 4 Setback Setpoint Temperature, Pri-

66

mary

Zone 5 Setback Setpoint Temperature, Pri-

67

mary

Zone 6 Setback Setpoint Temperature, Pri-

68

mary

Zone 7 Setback Setpoint Temperature, Pri-

69

mary

Zone 8 Setback Setpoint Temperature, Pri-

70

mary

Zone 9 Setback Setpoint Temperature, Pri-

71

mary

Zone 10 Setback Setpoint Temperature, Pri-

72

mary

Zone 11 Setback Setpoint Temperature, Pri-

73

mary

Zone 12 Setback Setpoint Temperature, Pri-

74

mary

Pump Setback Setpoint Temperature, Sec-

75

ondary

Platen Setback Setpoint Temperature, Sec-

76

ondary

Zone 1 Setback Setpoint Temperature, Sec-

77

ondary

Zone 2 Setback Setpoint Temperature, Sec-

78

ondary

Zone 3 Setback Setpoint Temperature, Sec-

79

ondary

Zone 4 Setback Setpoint Temperature, Sec-

80

ondary

Zone 5 Setback Setpoint Temperature, Sec-

81

ondary

Zone 6 Setback Setpoint Temperature, Sec-

82

ondary

Zone 7 Setback Setpoint Temperature, Sec-

83

ondary

Zone 8 Setback Setpoint Temperature, Sec-

84

ondary

Zone 9 Setback Setpoint Temperature, Sec-

85

ondary

Zone 10 Setback Setpoint Temperature, Sec-

86

ondary

Zone 11 Setback Setpoint Temperature, Sec-

87

ondary

Zone 12 Setback Setpoint Temperature, Sec-

88

ondary

16 3A5186B

Page 17

Appendix B - Data Exchange Interface

Appendix B - Data Exchange Interface

The Data Exchange Interface is a bi-directional interface

that enables both transmitting and receiving data

between the Therm-O-Flow system and the controlling

logic (PLC). The interface allows a large amount of data

to exchange between the systems while only occupying

a very small data map to support the exchange. The

interface also allows for future expansion of data without

changing the map structure.

To get or receive data from the supply system, the controlling PLC needs to:

1. Write to the Data Exchange Interface Pointer Output

Designation location on the map (output instance 6)

a value corresponding to the data the PLC wants to

receive.

2. Wait for the Therm-O-Flow to provide the same

Pointer Designation number written in the previous

step at input instance 67 (Data Exchange Interface

Pointer Last Serviced).

3. Read the requested data at input instance 68, Data

Exchange Interface Input Value.

After valid data is present at the input instances, the

Therm-O-Flow system clears the bit. While the bit is set,

the controlling PLC should ignore the interface inputs

until the bit is cleared. After the Therm-O-Flow system

services the request, the designation pointer input

matches the designation pointer output. If the scan rate

of the controlling PLC or control logic is slow enough,

monitoring of the status bit may not be necessary.

NOTE: When changes are made over the Data

Exchange Interface, the Therm-O-Flow system display

screen may not update immediately. It may be necessary to navigate away from the screen, then back to it.

To write or transmit data to the supply system, the controlling PLC needs to:

1. Write the data for the Therm-O-Flow system to the

Data Exchange Interface Output Value location, output instance 7.

2. Write to the Data Exchange Interface Pointer Output

Designation location on the map (output instance 6)

a value corresponding to the data the PLC is going

to transmit to the supply system.

3. The Therm-O-Flow system echoes back to the PLC

the Pointer Designation and the Data Interface

Value after the Therm-O-Flow system processes

the data transmit request to input instances 67 and

68 respectively.

When the controlling logic is exchanging data over this

interface, the Therm-O-Flow system sets the Data

Exchange Interface Active or in Transition status bit

while it processes the request and writes to the Data

Exchange Interface input locations (input instances 67

and 68).

3A5186B 17

Page 18

Appendix B - Data Exchange Interface

Data Exchange Interface Pointer Designation Tabl

Description Comments

Pointer

Designation

0 Interface Not Active

1 Set Temperature Units

2 Read Temperature Units Write

3 Set Mass Units

4 Read Mass Units Read

5 Set Specific Gravity

6 Read Specific Gravity Read

7 Set High Temp. Alarm Offset

8 Get High Temp. Alarm Offset Read

9 Set High Temp. Deviation Offset Write

10 Get High Temp. Deviation Offset Read

11 Set Low Temp. Alarm Offset Write

Value - Setting

0 - °F

1 - °C

Value - Setting (0 - g, 1 - kg, 2 - lb)

Specific gravity in thousandths (for instance a SG setting of

1.055 = 1055).

In whole selected C or F units of measure.

Read/

Write

Read

Write

Write

Write

12 Get Low Temp. Alarm Offset Read

13 Set Low Temp. Deviation Offset Write

14 Get Low Temp. Deviation Offset Read

15 Set Prime Pump Duration

16 Get Prime Pump Duration Read

17 Read System Version

18 Read System Date

19 Read System Time

20 Read ADM Version

21 - 90 Reserved for Future Use

Prime pump duration setting in second increments

A 32-bit string in the format of 0xXXCCBBAA.

0xCC…Build Version

0xBB…Minor Version

0xAA…Major Version

A 32-bit string in the format of 0xXXDDCCBB.

0xDD…Year (0x0D corresponds to 2013)

0xCC…Month (0x0A corresponds to October)

0xBB…Day

A 32-bit string in the format of 0xDDHHMMSS.

0xHH…Hours

0xMM…Minutes

0xSS…Seconds

0xDD...Day of week (0x01 corresponds to Monday)

A 32-bit string in the format of 0xXXMMNNBB

0xMM...Major #

0xNN...Minor #

0xBB...Build #

Write

Read

Read

Read

18 3A5186B

Page 19

Appendix B - Data Exchange Interface

Description Comments

Read/

Write

Pointer

Designation

Read Pump A Resettable Mate-

91

rial counter

Read Pump B Resettable Mate-

92

rial counter

Reset Pump A Resettable mate-

93

rial counter

Reset Pump B Resettable mate-

94

rial counter

Read Pump A Resettable Cycle

95

counter

Read Pump B Resettable Cycle

96

counter

Reset Pump A Resettable Cycle

97

counter

Reset Pump B Resettable Cycle

98

counter

99-100

Reserved for Future Use

101 Get Heat Soak Timer A

102

Get Heat Soak Timer B Read

103 -

Reserved for Future Use

110

In selected mass units, times 10. So, for instance, if in Kg mode,

101 = 10.1 Kg.

No Data required for Data Exchange Interface Output Value

location (Same as pressing on the corresponding setup or

run screen).

In whole pump cycle units of measure.

No Data required for Data Exchange Interface Output Value

location (Same as pressing on the corresponding setup or

run screen).

Get Primary or Secondary Heat Soak timer Remaining Count in

Seconds (= 0 if not active)

Write

Write

Write

Write

Read

111 Get CV Percent (5051 = 50.51%) Get Control Variable for Pump, Primary Heat Zone Read

112

Get CV Percent (5051 = 50.51%) Get Control Variable for Platen, Primary Heat Zone Read

113

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 1, Primary Read

114

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 2, Primary Read

115

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 3, Primary Read

116

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 4, Primary Read

117

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 5, Primary Read

118

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 6, Primary Read

119

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 7, Primary Read

120

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 8, Primary Read

121

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 9, Primary Read

122

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 10, Primary Read

123

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 11, Primary Read

124

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 12, Primary Read

read

read

read

read

3A5186B 19

Page 20

Appendix B - Data Exchange Interface

Pointer

Designation

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139 -

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

Description Comments

Read/

Write

Get CV Percent (5051 = 50.51%) Get Control Variable for Pump, Secondary Heat Zone Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Platen, Secondary Heat Zone Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 1, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 2, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 3, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 4, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 5, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 6, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 7, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 8, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 9, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 10, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 11, Secondary Read

Get CV Percent (5051 = 50.51%) Get Control Variable for Heat Zone 12, Secondary Read

Reserved for Future Use

Get Pump A Setback Setpoint

Temperature

Get Platen A Setback Setpoint

Temperature

Get Zone 1, A Setback Setpoint

Temperature

Get Zone 2, A Setback Setpoint

Temperature

Get Zone 3, A Setback Setpoint

Temperature

Get Zone 4, A Setback Setpoint

Temperature

Get Zone 5, A Setback Setpoint

Temperature

Get Zone 6, A Setback Setpoint

Temperature

Get Zone 7, A Setback Setpoint

Temperature

Get Zone 8, A Setback Setpoint

Temperature

Get Zone 9, A Setback Setpoint

Temperature

Get Zone 10, A Setback Setpoint

Temperature

Get Zone 11, A Setback Setpoint

Temperature

Get Zone 12, A Setback Setpoint

Temperature

Provides the selected Primary System Zone Setback Mode setpoint temperature setting to the interface. Temperature Units

match units of the ADM. Values are in tenths of a degree (for

example, a value of 2505 corresponds to 250.5°F). These

pointer designations are typically used for PROFIBUS and

PROFINET applications.

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

20 3A5186B

Page 21

Appendix B - Data Exchange Interface

Pointer

Designation

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179 ~65k

Description Comments

Get Pump B Setback Setpoint

Temperature

Get Platen B Setback Setpoint

Temperature

Get Zone 1, B Sec. Setback Setpoint Temperature

Get Zone 2, B Setback Setpoint

Temperature

Get Zone 3, B Setback Setpoint

Temperature

Get Zone 4, B Setback Setpoint

Temperature

Get Zone 5, B Setback Setpoint

Temperature

Get Zone 6, B Setback Setpoint

Temperature

Get Zone 7, B Setback Setpoint

Temperature

Get Zone 8, B Setback Setpoint

Temperature

Get Zone 9, B Setback Setpoint

Temperature

Get Zone 10, B Setback Setpoint Temperature

Get Zone 11, B Setback Setpoint Temperature

Get Zone 12, B Setback Setpoint Temperature

Reserved for Future Use

Provides the selected Secondary System Zone Setback Mode

setpoint temperature setting to the interface. Temperature Units

match units of the ADM. Values are in tenths of a degree (for

example, a value of 2505 corresponds to 250.5°F). These

pointer designations are typically used for PROFIBUS and

PROFINET applications.

Read/

Write

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

Read

3A5186B 21

Page 22

Appendix C - Error/Event Tables

Appendix C - Error/Event Tables

The following table reflects codes provided in input

instances 63 and 64 and output instance 5. To acknowledge an error, when the PLC notices a non-zero error

code in instance 64, the PLC logic needs to write the

same code to output instance 5 to remove the error

message pop-up window from the ADM display. After

the event or error is acknowledged by the PLC, the

pop-up window disappears and the error code is cleared

from instance 64. If the condition is no longer present,

the error code is removed from instance 63. If multiple

conditions exist, the process may need to be repeated

for each condition.

The error codes described and presented on input 63

and 64 are the four digit codes presented below in

ASCCI format packed into a 32-bit double word. Each

character of the code occupies a byte within the 32-bit

double word, read right to left.

Error/Event

Code

0

A1A1

A1A2

A1A3

A1A4

A1A5

A1A6

A1A7

A1A8

A1A9

A1AA

A1AB

A1AC

A1AD

A1AE

A1B1

A1B2

A1B3

A1B4

A1B5

A1B6

A1B7

A1B8

A1B9

No Active Error

Low Current Unit A Zone 1

Low Current Unit A Zone 2

Low Current Unit A Zone 3

Low Current Unit A Zone 4

Low Current Unit A Zone 5

Low Current Unit A Zone 6

Low Current Unit A Zone 7

Low Current Unit A Zone 8

Low Current Unit A Zone 9

Low Current Unit A Zone 10

Low Current Unit A Zone 11

Low Current Unit A Zone 12

Low Current Unit A Pump

Low Current Unit A Platen

Low Current Unit B Zone 1

Low Current Unit B Zone 2

Low Current Unit B Zone 3

Low Current Unit B Zone 4

Low Current Unit B Zone 5

Low Current Unit B Zone 6

Low Current Unit B Zone 7

Low Current Unit B Zone 8

Low Current Unit B Zone 9

Description

A1BA

A1BB

A1BC

A1BD

A1BE

A1C1

A1C2

A1C3

A1C4

A1C5

A1C6

A1C7

A1CG

A1CV

A1CW

A1CX

A1CY

A2A1

A2A2

A2A3

A2A4

A2A5

A2A6

A2A7

A2A8

A2A9

A2AA

A2AB

A2AC

A2AD

A2AE

A2B1

A2B2

A2B3

A2B4

A2B5

A2B6

A2B7

A2B8

A2B9

A2BA

Low Current Unit B Zone 10

Low Current Unit B Zone 11

Low Current Unit B Zone 12

Low Current Unit B Pump

Low Current Unit B Platen

Low Current Fan MZLP 1

Low Current Fan MZLP 2

Low Current Fan MZLP 3

Low Current Fan MZLP 4

Low Current Fan MZLP 5

Low Current Fan MZLP 6

Low Current Fan MZLP 7

Low Current Fan Gateway

Low Current Fan AWB, Unit A

Low Current Fan AWB, Unit B

Low Current Fan System I/O, Unit A

Low Current Fan System I/O, Unit B

Low Current Unit A Zone 1

Low Current Unit A Zone 2

Low Current Unit A Zone 3

Low Current Unit A Zone 4

Low Current Unit A Zone 5

Low Current Unit A Zone 6

Low Current Unit A Zone 7

Low Current Unit A Zone 8

Low Current Unit A Zone 9

Low Current Unit A Zone 10

Low Current Unit A Zone 11

Low Current Unit A Zone 12

Low Current Unit A Pump

Low Current Unit A Platen

Low Current Unit B Zone 1

Low Current Unit B Zone 2

Low Current Unit B Zone 3

Low Current Unit B Zone 4

Low Current Unit B Zone 5

Low Current Unit B Zone 6

Low Current Unit B Zone 7

Low Current Unit B Zone 8

Low Current Unit B Zone 9

Low Current Unit B Zone 10

22 3A5186B

Page 23

Appendix C - Error/Event Tables

Error/Event

Code

A2BB

A2BC

A2BD

A2BE

Low Current Unit B Zone 11

Low Current Unit B Zone 12

Low Current Unit B Pump

Low Current Unit B Platen

Description

A2C1 Low Current Fan MZLP 1

A2C2 Low Current Fan MZLP 2

A2C3 Low Current Fan MZLP 3

A2C4 Low Current Fan MZLP 4

A2C5 Low Current Fan MZLP 5

A2C6 Low Current Fan MZLP 6

A2C7 Low Current Fan MZLP 7

A2CG Low Current Fan Gateway

A2CV Low Current Fan AWB, Unit A

A2CW Low Current Fan AWB, Unit B

A2CX Low Current Fan System I/O, Unit A

A2CY Low Current Fan System I/O, Unit B

A3A1 High Current Unit A Zone 1

A3A2 High Current Unit A Zone 2

A3A3 High Current Unit A Zone 3

A3A4 High Current Unit A Zone 4

A3A5 High Current Unit A Zone 5

A3A6 High Current Unit A Zone 6

A3A7 High Current Unit A Zone 7

A3A8 High Current Unit A Zone 8

A3A9 High Current Unit A Zone 9

A3AA High Current Unit A Zone 10

A3AB High Current Unit A Zone 11

A3AC High Current Unit A Zone 12

A3AD High Current Unit A Pump

A3AE High Current Unit A Platen

A3B1 High Current Unit B Zone 1

A3B2 High Current Unit B Zone 2

A3B3 High Current Unit B Zone 3

A3B4 High Current Unit B Zone 4

A3B5 High Current Unit B Zone 5

A3B6 High Current Unit B Zone 6

A3B7 High Current Unit B Zone 7

A3B8 High Current Unit B Zone 8

A3B9 High Current Unit B Zone 9

A3BA High Current Unit B Zone 10

A3BB High Current Unit B Zone 11

A3BC High Current Unit B Zone 12

A3BD High Current Unit B Pump

A3BE High Current Unit B Platen

A3C1 High Current Fan MZLP 1

A3C2 High Current Fan MZLP 2

A3C3 High Current Fan MZLP 3

A3C4 High Current Fan MZLP 4

A3C5 High Current Fan MZLP 5

A3C6 High Current Fan MZLP 6

A3C7 High Current Fan MZLP 7

A3CG High Current Fan Gateway

A3CV High Current Fan AWB, Unit A

A3CW High Current Fan AWB, Unit B

A3CX High Current Fan System I/O, Unit A

A3CY High Current Fan System I/O, Unit B

A4A1 High Current Unit A Zone 1

A4A2 High Current Unit A Zone 2

A4A3 High Current Unit A Zone 3

A4A4 High Current Unit A Zone 4

A4A5 High Current Unit A Zone 5

A4A6 High Current Unit A Zone 6

A4A7 High Current Unit A Zone 7

A4A8 High Current Unit A Zone 8

A4A9 High Current Unit A Zone 9

A4AA High Current Unit A Zone 10

A4AB High Current Unit A Zone 11

A4AC High Current Unit A Zone 12

A4AD High Current Unit A Pump

A4AE High Current Unit A Platen

A4B1 High Current Unit B Zone 1

A4B2 High Current Unit B Zone 2

A4B3 High Current Unit B Zone 3

A4B4 High Current Unit B Zone 4

A4B5 High Current Unit B Zone 5

A4B6 High Current Unit B Zone 6

A4B7 High Current Unit B Zone 7

A4B8 High Current Unit B Zone 8

A4B9 High Current Unit B Zone 9

A4BA High Current Unit B Zone 10

A4BB High Current Unit B Zone 11

A4BC High Current Unit B Zone 12

A4BD High Current Unit B Pump

A4BE High Current Unit B Platen

3A5186B 23

Page 24

Appendix C - Error/Event Tables

Error/Event

Code

Description

A4C1 High Current Fan MZLP 1

A4C2 High Current Fan MZLP 2

A4C3 High Current Fan MZLP 3

A4C4 High Current Fan MZLP 4

A4C5

A4C6

High Current Fan MZLP 5

High Current Fan MZLP 6

A4C7 High Current Fan MZLP 7

A4CG High Current Fan Gateway

A4CV High Current Fan AWB, Unit A

A4CW High Current Fan AWB, Unit B

A4CX High Current Fan System I/O, Unit A

A4CY High Current Fan System I/O, Unit B

A7A1 Unexp. Curr. Unit A Zone 1

A7A2 Unexp. Curr. Unit A Zone 2

A7A3 Unexp. Curr. Unit A Zone 3

A7A4 Unexp. Curr. Unit A Zone 4

A7A5 Unexp. Curr. Unit A Zone 5

A7A6 Unexp. Curr. Unit A Zone 6

A7A7 Unexp. Curr. Unit A Zone 7

A7A8 Unexp. Curr. Unit A Zone 8

A7A9 Unexp. Curr. Unit A Zone 9

A7AA Unexp. Curr. Unit A Zone 10

A7AB Unexp. Curr. Unit A Zone 11

A7AC Unexp. Curr. Unit A Zone 12

A7AD Unexp. Curr. Unit A Pump

A7AE Unexp. Curr. Unit A Platen

A7B1 Unexp. Curr. Unit B Zone 1

A7B2 Unexp. Curr. Unit B Zone 2

A7B3 Unexp. Curr. Unit B Zone 3

A7B4 Unexp. Curr. Unit B Zone 4

A7B5 Unexp. Curr. Unit B Zone 5

A7B6 Unexp. Curr. Unit B Zone 6

A7B7 Unexp. Curr. Unit B Zone 7

A7B8 Unexp. Curr. Unit B Zone 8

A7B9 Unexp. Curr. Unit B Zone 9

A7BA Unexp. Curr. Unit B Zone 10

A7BB Unexp. Curr. Unit B Zone 11

A7BC Unexp. Curr. Unit B Zone 12

A7BD Unexp. Curr. Unit B Pump

A7BE Unexp. Curr. Unit B Platen

A7C1 Unexp. Curr. Fan MZLP 1

A7C2 Unexp. Curr. Fan MZLP 2

A7C3 Unexp. Curr. Fan MZLP 3

A7C4 Unexp. Curr. Fan MZLP 4

A7C5 Unexp. Curr. Fan MZLP 5

A7C6 Unexp. Curr. Fan MZLP 6

A7C7 Unexp. Curr. Fan MZLP 7

A7CG Unexp. Curr. Fan Gateway

A7CV Unexp. Curr. Fan AWB, Unit A

A7CW Unexp. Curr. Fan AWB, Unit B

A7CX Unexp. Curr. Fan System I/O, Unit A

A7CY Unexp. Curr. Fan System I/O, Unit B

A8A1 No Current Unit A Zone 1

A8A2 No Current Unit A Zone 2

A8A3 No Current Unit A Zone 3

A8A4 No Current Unit A Zone 4

A8A5 No Current Unit A Zone 5

A8A6 No Current Unit A Zone 6

A8A7 No Current Unit A Zone 7

A8A8 No Current Unit A Zone 8

A8A9 No Current Unit A Zone 9

A8AA No Current Unit A Zone 10

A8AB No Current Unit A Zone 11

A8AC No Current Unit A Zone 12

A8AD No Current Unit A Pump

A8AE No Current Unit A Platen

A8B1 No Current Unit B Zone 1

A8B2 No Current Unit B Zone 2

A8B3 No Current Unit B Zone 3

A8B4 No Current Unit B Zone 4

A8B5 No Current Unit B Zone 5

A8B6 No Current Unit B Zone 6

A8B7 No Current Unit B Zone 7

A8B8 No Current Unit B Zone 8

A8B9 No Current Unit B Zone 9

A8BA No Current Unit B Zone 10

A8BB No Current Unit B Zone 11

A8BC No Current Unit B Zone 12

A8BD No Current Unit B Pump

A8BE No Current Unit B Platen

A8C1 No Current Fan MZLP 1

A8C2 No Current Fan MZLP 2

A8C3 No Current Fan MZLP 3

A8C4 No Current Fan MZLP 4

24 3A5186B

Page 25

Appendix C - Error/Event Tables

Error/Event

Code

Description

A8C5 No Current Fan MZLP 5

A8C6 No Current Fan MZLP 6

A8C7 No Current Fan MZLP 7

A8CG No Current Fan Gateway

A8CV No Current Fan AWB, Unit A

A8CW No Current Fan AWB, Unit B

A8CX No Current Fan System I/O, Unit A

A8CY No Current Fan System I/O, Unit B

AAMA No Current Fan Unit A

AAMB No Current Fan Unit B

AM31 High Current SSR MZLP 1

AM32 High Current SSR MZLP 2

AM33 High Current SSR MZLP 3

AM34 High Current SSR MZLP 4

AM35 High Current SSR MZLP 5

AM36 High Current SSR MZLP 6

AM37 High Current SSR MZLP 7

AM3G High Current SSR Gateway

AM3V High Current SSR AWB, Unit A

AM3W High Current SSR AWB, Unit B

AM3X High Current SSR System I/O, Unit A

AM3Y High Current SSR System I/O, Unit B

AM41 High Current Contactor MZLP 1

AM42 High Current Contactor MZLP 2

AM43 High Current Contactor MZLP 3

AM44 High Current Contactor MZLP 4

AM45 High Current Contactor MZLP 5

AM46 High Current Contactor MZLP 6

AM47 High Current Contactor MZLP 7

AM4G High Current Contactor Gateway

AM4V High Current Contactor AWB, Unit A

AM4W High Current Contactor AWB, Unit B

AM4X

AM4Y

High Current Contactor System I/O, Unit

A

High Current Contactor System I/O, Unit

B

AM71 Unexp. Curr. Contactor MZLP 1

AM72 Unexp. Curr. Contactor MZLP 2

AM73 Unexp. Curr. Contactor MZLP 3

AM74 Unexp. Curr. Contactor MZLP 4

AM75 Unexp. Curr. Contactor MZLP 5

AM76 Unexp. Curr. Contactor MZLP 6

AM77 Unexp. Curr. Contactor MZLP 7

AM7G Unexp. Curr. Contactor Gateway

AM7V Unexp. Curr. Contactor AWB, Unit A

AM7W Unexp. Curr. Contactor AWB, Unit B

AM7X

AM7Y

Unexp. Curr. Contactor System I/O, Unit

A

Unexp. Curr. Contactor System I/O, Unit

B

AM81 No Current Contactor MZLP 1

AM82 No Current Contactor MZLP 2

AM83 No Current Contactor MZLP 3

AM84 No Current Contactor MZLP 4

AM85 No Current Contactor MZLP 5

AM86 No Current Contactor MZLP 6

AM87 No Current Contactor MZLP 7

AM8G No Current Contactor Gateway

AM8V No Current Contactor AWB, Unit A

AM8W No Current Contactor AWB, Unit B

AM8X No Current Contactor System I/O, Unit A

AM8Y No Current Contactor System I/O, Unit B

CAC1 Comm. Error MZLP 1

CAC2 Comm. Error MZLP 2

CAC3 Comm. Error MZLP 3

CAC4 Comm. Error MZLP 4

CAC5 Comm. Error MZLP 5

CAC6 Comm. Error MZLP 6

CAC7 Comm. Error MZLP 7

CACG Comm. Error Gateway

CACH Gateway Heart Beat Lost

CACV Comm. Error AWB, Unit A

CACW Comm. Error AWB, Unit B

CACX Comm. Error System I/O, Unit A

CACY Comm. Error System I/O, Unit B

DAAX Pump Runaway Unit A

DABX Pump Runaway Unit B

DCAX Pump Diving Unit A

DCBX Pump Diving Unit B

DEAX Cycle Switch Err. Unit A

DEBX Cycle Switch Err. Unit B

EAAA Heat On Unit A

EAAB Heat On Unit B

EACA Mat. Counter Paused Unit A

EACB Mat. Counter Paused Unit B

EAPA Pump On Unit A

3A5186B 25

Page 26

Appendix C - Error/Event Tables

Error/Event

Code

Description

EAPB Pump On Unit B

EAUX USB Activity In Process

EB0X Stop Button Pressed

EBAA Heat Off Unit A

EBAB Heat Off Unit B

EBCA Mat. Counter Unpaused Unit A

EBCB Mat. Counter Unpaused Unit B

EBPA Pump Off Unit A

EBPB Pump Off Unit B

EBUX USB Drive Removed

EBRX Red Key locked out PLC

EC0X Setup Value(s) Changed

ECA1 Unit A Zone 1

ECA2 Unit A Zone 2

ECA3 Unit A Zone 3

ECA4 Unit A Zone 4

ECA5 Unit A Zone 5

ECA6 Unit A Zone 6

ECA7 Unit A Zone 7

ECA8 Unit A Zone 8

ECA9 Unit A Zone 9

ECAA Unit A Zone 10

ECAB Unit A Zone 11

ECAC Unit A Zone 12

ECAD Unit A Pump

ECAE Unit A Platen

ECB1 Unit B Zone 1

ECB2 Unit B Zone 2

ECB3 Unit B Zone 3

ECB4 Unit B Zone 4

ECB5 Unit B Zone 5

ECB6 Unit B Zone 6

ECB7 Unit B Zone 7

ECB8 Unit B Zone 8

ECB9 Unit B Zone 9

ECBA Unit B Zone 10

ECBB Unit B Zone 11

ECBC Unit B Zone 12

ECBD Unit B Pump

ECBE Unit B Platen

ECMA Maintenance Counter Changed Unit A

ECMB Maintenance Counter Changed Unit B

EHCA Heat Soak Complete Unit A

EHCB Heat Soak Complete Unit B

EHHA Heat Soak Started Unit A

EHHB Heat Soak Started Unit B

EHPA Pump Inactive Timeout Unit A

EHPB Pump Inactive Timeout Unit B

EHSA Setback Unit A

EHSB Setback Unit B

EHTA At Temp Unit A

EHTB At Temp Unit B

EHWA Warmup Unit A

EHWB Warmup Unit B

EKAA Auto-Crossover To A

EKAB Auto-Crossover To B

EKMA Manual-Crossover To A

EKMB Manual-Crossover To B

EL0X System Power On

EM0X System Power Off

EP0X Blue Token Detected

EQU1 Sys. Settings Downloaded

EQU2 Sys. Settings Uploaded

EQU3 Custom Lang. Downloaded

EQU4 Custom Lang. Uploaded

EQU5 Logs Downloaded

ERCA Pump Cycles Tot. Reset Unit A

ERCB Pump Cycles Tot. Reset Unit B

ERMA User Maint. Count Reset Unit A

ERMB User Maint. Count Reset Unit B

ERWA Pump Weight Tot. Reset Unit A

ERWB Pump Weight Tot. Reset Unit B

ETAA Timer Event On Unit A

ETAB Timer Event On Unit B

ETBA Timer Event Off Unit A

ETBB Timer Event Off Unit B

ETSA Timer Event Setback Unit A

ETSB Timer Event Setback Unit B

EVUX USB Disabled

L1AX Level Sensor Error Unit A

L1BX Level Sensor Error Unit B

L2AX Drum Empty Unit A

L2BX Drum Empty Unit B

L3AX Drum Low Unit A

26 3A5186B

Page 27

Appendix C - Error/Event Tables

Error/Event

Code

Description

L3BX Drum Low Unit B

M8MA Clean/Check Fan Unit A

M8MB Clean/Check Fan Unit B

MMUX USB Logs Full

MNAX Maintenance Due - User Unit A

MNBX Maintenance Due - User Unit B

T1A1 Low Temp. Unit A Zone 1

T1A2 Low Temp. Unit A Zone 2

T1A3 Low Temp. Unit A Zone 3

T1A4 Low Temp. Unit A Zone 4

T1A5 Low Temp. Unit A Zone 5

T1A6 Low Temp. Unit A Zone 6

T1A7 Low Temp. Unit A Zone 7

T1A8 Low Temp. Unit A Zone 8

T1A9 Low Temp. Unit A Zone 9

T1AA Low Temp. Unit A Zone 10

T1AB Low Temp. Unit A Zone 11

T1AC Low Temp. Unit A Zone 12

T1AD Low Temp. Unit A Pump

T1AE Low Temp. Unit A Platen

T1B1 Low Temp. Unit B Zone 1

T1B2 Low Temp. Unit B Zone 2

T1B3 Low Temp. Unit B Zone 3

T1B4 Low Temp. Unit B Zone 4

T1B5 Low Temp. Unit B Zone 5

T1B6 Low Temp. Unit B Zone 6

T1B7 Low Temp. Unit B Zone 7

T1B8 Low Temp. Unit B Zone 8

T1B9 Low Temp. Unit B Zone 9

T1BA Low Temp. Unit B Zone 10

T1BB Low Temp. Unit B Zone 11

T1BC Low Temp. Unit B Zone 12

T1BD Low Temp. Unit B Pump

T1BE Low Temp. Unit B Platen

T1C1 Low Temp. MZLP 1

T1C2 Low Temp. MZLP 2

T1C3 Low Temp. MZLP 3

T1C4 Low Temp. MZLP 4

T1C5 Low Temp. MZLP 5

T1C6 Low Temp. MZLP 6

T1C7 Low Temp. MZLP 7

T1CG Low Temp. Gateway

T1CV Low Temp. AWB, Unit A

T1CW Low Temp. AWB, Unit B

T1CX Low Temp. System I/O, Unit A

T1CY Low Temp. System I/O, Unit B

T2A1 Low Temp. Unit A Zone 1

T2A2 Low Temp. Unit A Zone 2

T2A3 Low Temp. Unit A Zone 3

T2A4 Low Temp. Unit A Zone 4

T2A5 Low Temp. Unit A Zone 5

T2A6 Low Temp. Unit A Zone 6

T2A7 Low Temp. Unit A Zone 7

T2A8 Low Temp. Unit A Zone 8

T2A9 Low Temp. Unit A Zone 9

T2AA Low Temp. Unit A Zone 10

T2AB Low Temp. Unit A Zone 11

T2AC Low Temp. Unit A Zone 12

T2AD Low Temp. Unit A Pump

T2AE Low Temp. Unit A Platen

T2B1 Low Temp. Unit B Zone 1

T2B2 Low Temp. Unit B Zone 2

T2B3 Low Temp. Unit B Zone 3

T2B4 Low Temp. Unit B Zone 4

T2B5 Low Temp. Unit B Zone 5

T2B6 Low Temp. Unit B Zone 6

T2B7 Low Temp. Unit B Zone 7

T2B8 Low Temp. Unit B Zone 8

T2B9 Low Temp. Unit B Zone 9

T2BA Low Temp. Unit B Zone 10

T2BB Low Temp. Unit B Zone 11

T2BC Low Temp. Unit B Zone 12

T2BD Low Temp. Unit B Pump

T2BE Low Temp. Unit B Platen

T2C1 Low Temp. MZLP 1

T2C2 Low Temp. MZLP 2

T2C3 Low Temp. MZLP 3

T2C4 Low Temp. MZLP 4

T2C5 Low Temp. MZLP 5

T2C6 Low Temp. MZLP 6

T2C7 Low Temp. MZLP 7

T2CG Low Temp. Gateway

T2CV Low Temp. AWB, Unit A

T2CW Low Temp. AWB, Unit B

3A5186B 27

Page 28

Appendix C - Error/Event Tables

Error/Event

Code

Description

T2CX Low Temp. System I/O, Unit A

T2CY Low Temp. System I/O, Unit B

T3A1 High Temp. Unit A Zone 1

T3A2 High Temp. Unit A Zone 2

T3A3 High Temp. Unit A Zone 3

T3A4 High Temp. Unit A Zone 4

T3A5 High Temp. Unit A Zone 5

T3A6 High Temp. Unit A Zone 6

T3A7 High Temp. Unit A Zone 7

T3A8 High Temp. Unit A Zone 8

T3A9 High Temp. Unit A Zone 9

T3AA High Temp. Unit A Zone 10

T3AB High Temp. Unit A Zone 11

T3AC High Temp. Unit A Zone 12

T3AD High Temp. Unit A Pump

T3AE High Temp. Unit A Platen

T3B1 High Temp. Unit B Zone 1

T3B2 High Temp. Unit B Zone 2

T3B3 High Temp. Unit B Zone 3

T3B4 High Temp. Unit B Zone 4

T3B5 High Temp. Unit B Zone 5

T3B6 High Temp. Unit B Zone 6

T3B7 High Temp. Unit B Zone 7

T3B8 High Temp. Unit B Zone 8

T3B9 High Temp. Unit B Zone 9

T3BA High Temp. Unit B Zone 10

T3BB High Temp. Unit B Zone 11

T3BC High Temp. Unit B Zone 12

T3BD High Temp. Unit B Pump

T3BE High Temp. Unit B Platen

T3C1 High Temp. MZLP 1

T3C2 High Temp. MZLP 2

T3C3 High Temp. MZLP 3

T3C4 High Temp. MZLP 4

T3C5 High Temp. MZLP 5

T3C6 High Temp. MZLP 6

T3C7 High Temp. MZLP 7

T3CG High Temp. Gateway

T3CV High Temp. AWB, Unit A

T3CW High Temp. AWB, Unit B

T3CX High Temp. System I/O, Unit A

T3CY High Temp. System I/O, Unit B

T4C1 High Temp. MZLP 1

T4C2 High Temp. MZLP 2

T4C3 High Temp. MZLP 3

T4C4 High Temp. MZLP 4

T4C5 High Temp. MZLP 5

T4C6 High Temp. MZLP 6

T4C7 High Temp. MZLP 7

T4CG High Temp. Gateway

T4CV High Temp. AWB, Unit A

T4CW High Temp. AWB, Unit B

T4CX High Temp. System I/O, Unit A

T4CY High Temp. System I/O, Unit B

T4A1 High Temp. Unit A Zone 1

T4A2 High Temp. Unit A Zone 2

T4A3 High Temp. Unit A Zone 3

T4A4 High Temp. Unit A Zone 4

T4A5 High Temp. Unit A Zone 5

T4A6 High Temp. Unit A Zone 6

T4A7 High Temp. Unit A Zone 7

T4A8 High Temp. Unit A Zone 8

T4A9 High Temp. Unit A Zone 9

T4AA High Temp. Unit A Zone 10

T4AB High Temp. Unit A Zone 11

T4AC High Temp. Unit A Zone 12

T4AD High Temp. Unit A Pump

T4AE High Temp. Unit A Platen

T4B1 High Temp. Unit B Zone 1

T4B2 High Temp. Unit B Zone 2

T4B3 High Temp. Unit B Zone 3

T4B4 High Temp. Unit B Zone 4

T4B5 High Temp. Unit B Zone 5

T4B6 High Temp. Unit B Zone 6

T4B7 High Temp. Unit B Zone 7

T4B8 High Temp. Unit B Zone 8

T4B9 High Temp. Unit B Zone 9

T4BA High Temp. Unit B Zone 10

T4BB High Temp. Unit B Zone 11

T4BC High Temp. Unit B Zone 12

T4BD High Temp. Unit B Pump

T4BE High Temp. Unit B Platen

T4MA High Temp. Transformer Unit A

T4MB High Temp. Transformer Unit B

28 3A5186B

Page 29

Appendix C - Error/Event Tables

Error/Event

Code

Description

T6A1 Sensor Err. Unit A Zone 1

T6A2 Sensor Err. Unit A Zone 2

T6A3 Sensor Err. Unit A Zone 3

T6A4 Sensor Err. Unit A Zone 4

T6A5 Sensor Err. Unit A Zone 5

T6A6 Sensor Err. Unit A Zone 6

T6A7 Sensor Err. Unit A Zone 7

T6A8 Sensor Err. Unit A Zone 8

T6A9 Sensor Err. Unit A Zone 9

T6AA Sensor Err. Unit A Zone 10

T6AB Sensor Err. Unit A Zone 11

T6AC Sensor Err. Unit A Zone 12

T6AD Sensor Err. Unit A Pump

T6AE Sensor Err. Unit A Platen

T6B1 Sensor Err. Unit B Zone 1

T6B2 Sensor Err. Unit B Zone 2

T6B3 Sensor Err. Unit B Zone 3

T6B4 Sensor Err. Unit B Zone 4

T6B5 Sensor Err. Unit B Zone 5

T6B6 Sensor Err. Unit B Zone 6

T6B7 Sensor Err. Unit B Zone 7

T6B8 Sensor Err. Unit B Zone 8

T6B9 Sensor Err. Unit B Zone 9

T6BA Sensor Err. Unit B Zone 10

T6BB Sensor Err. Unit B Zone 11

T6BC Sensor Err. Unit B Zone 12

T6BD Sensor Err. Unit B Pump

T6BE Sensor Err. Unit B Platen

T6C1 Sensor Err. MZLP 1

T6C2 Sensor Err. MZLP 2

T6C3 Sensor Err. MZLP 3

T6C4 Sensor Err. MZLP 4

T6C5 Sensor Err. MZLP 5

T6C6 Sensor Err. MZLP 6

T6C7 Sensor Err. MZLP 7

T6CG Sensor Err. Gateway

T6CV Sensor Err. AWB, Unit A

T6CW Sensor Err. AWB, Unit B

T6CX Sensor Err. System I/O, Unit A

T6CY Sensor Err. System I/O, Unit B

T8A1 No Temp. Rise Unit A Zone 1

T8A2 No Temp. Rise Unit A Zone 2

T8A3 No Temp. Rise Unit A Zone 3

T8A4 No Temp. Rise Unit A Zone 4

T8A5 No Temp. Rise Unit A Zone 5

T8A6 No Temp. Rise Unit A Zone 6

T8A7 No Temp. Rise Unit A Zone 7

T8A8 No Temp. Rise Unit A Zone 8

T8A9 No Temp. Rise Unit A Zone 9

T8AA No Temp. Rise Unit A Zone 10

T8AB No Temp. Rise Unit A Zone 11

T8AC No Temp. Rise Unit A Zone 12

T8AD No Temp. Rise Unit A Pump

T8AE No Temp. Rise Unit A Platen

T8B1 No Temp. Rise Unit B Zone 1

T8B2 No Temp. Rise Unit B Zone 2

T8B3 No Temp. Rise Unit B Zone 3

T8B4 No Temp. Rise Unit B Zone 4

T8B5 No Temp. Rise Unit B Zone 5

T8B6 No Temp. Rise Unit B Zone 6

T8B7 No Temp. Rise Unit B Zone 7

T8B8 No Temp. Rise Unit B Zone 8

T8B9 No Temp. Rise Unit B Zone 9

T8BA No Temp. Rise Unit B Zone 10

T8BB No Temp. Rise Unit B Zone 11

T8BC No Temp. Rise Unit B Zone 12

T8BD No Temp. Rise Unit B Pump

T8BE No Temp. Rise Unit B Platen

T8C1 No Temp. Rise MZLP 1

T8C2 No Temp. Rise MZLP 2

T8C3 No Temp. Rise MZLP 3

T8C4 No Temp. Rise MZLP 4

T8C5 No Temp. Rise MZLP 5

T8C6 No Temp. Rise MZLP 6

T8C7 No Temp. Rise MZLP 7

T8CG No Temp. Rise Gateway

T8CV No Temp. Rise AWB, Unit A

T8CW No Temp. Rise AWB, Unit B

T8CX No Temp. Rise System I/O, Unit A

T8CY No Temp. Rise System I/O, Unit B

TAAX Over Temp Switch Unit A

TABX Over Temp Switch Unit B

V1I1 Low Voltage 24VDC MZLP 1

V1I2 Low Voltage 24VDC MZLP 2

3A5186B 29

Page 30

Appendix C - Error/Event Tables

Error/Event

Code

Description

V1I3 Low Voltage 24VDC MZLP 3

V1I4 Low Voltage 24VDC MZLP 4

V1I5 Low Voltage 24VDC MZLP 5

V1I6 Low Voltage 24VDC MZLP 6

V1I7 Low Voltage 24VDC MZLP 7

V1IG Low Voltage 24VDC Gateway

V1IV Low Voltage 24VDC AWB, Unit A

V1IW Low Voltage 24VDC AWB, Unit B

V1IX Low Voltage 24VDC System I/O, Unit A

V1IY Low Voltage 24VDC System I/O, Unit B

V1M1 Low Voltage Line MZLP 1

V1M2 Low Voltage Line MZLP 2

V1M3 Low Voltage Line MZLP 3

V1M4 Low Voltage Line MZLP 4

V1M5 Low Voltage Line MZLP 5

V1M6 Low Voltage Line MZLP 6

V1M7 Low Voltage Line MZLP 7

V1MG Low Voltage Line Gateway

V1MV Low Voltage Line AWB, Unit A

V1MW Low Voltage Line AWB, Unit B

V1MX Low Voltage Line System I/O, Unit A

V1MY Low Voltage Line System I/O, Unit B

V4I1 High Voltage 24VDC MZLP 1

V4I2 High Voltage 24VDC MZLP 2

V4I3 High Voltage 24VDC MZLP 3

V4I4 High Voltage 24VDC MZLP 4

V4I5 High Voltage 24VDC MZLP 5

V4I6 High Voltage 24VDC MZLP 6

V4I7 High Voltage 24VDC MZLP 7

V4IG High Voltage 24VDC Gateway

V4IV High Voltage 24VDC AWB, Unit A

V4IW High Voltage 24VDC AWB, Unit B

V4IX High Voltage 24VDC System I/O, Unit A

V4IY High Voltage 24VDC System I/O, Unit B

V4M1 High Voltage Line MZLP 1

V4M2 High Voltage Line MZLP 2

V4M3 High Voltage Line MZLP 3

V4M4 High Voltage Line MZLP 4

V4M5 High Voltage Line MZLP 5

V4M6 High Voltage Line MZLP 6

V4M7 High Voltage Line MZLP 7

V4MG High Voltage Line Gateway

V4MV High Voltage Line AWB, Unit A

V4MW High Voltage Line AWB, Unit B

V4MX High Voltage Line System I/O, Unit A

V4MY High Voltage Line System I/O, Unit B

V6I1 Wiring Error 24VDC MZLP 1

V6I2 Wiring Error 24VDC MZLP 2

V6I3 Wiring Error 24VDC MZLP 3

V6I4 Wiring Error 24VDC MZLP 4

V6I5 Wiring Error 24VDC MZLP 5

V6I6 Wiring Error 24VDC MZLP 6

V6I7 Wiring Error 24VDC MZLP 7

V6IG Wiring Error 24VDC Gateway

V6IV Wiring Error 24VDC AWB, Unit A

V6IW Wiring Error 24VDC AWB, Unit B

V6IX Wiring Error 24VDC System I/O, Unit A

V6IY Wiring Error 24VDC System I/O, Unit B

V6M1 Wiring Error Line MZLP 1

V6M2 Wiring Error Line MZLP 2

V6M3 Wiring Error Line MZLP 3

V6M4 Wiring Error Line MZLP 4

V6M5 Wiring Error Line MZLP 5

V6M6 Wiring Error Line MZLP 6

V6M7 Wiring Error Line MZLP 7

V6MG Wiring Error Line Gateway

V6MV Wiring Error Line AWB, Unit A

V6MW Wiring Error Line AWB, Unit B

V6MX Wiring Error Line System I/O, Unit A

V6MY Wiring Error Line System I/O, Unit B

V8I1 No Voltage 24VDC MZLP 1

V8I2 No Voltage 24VDC MZLP 2

V8I3 No Voltage 24VDC MZLP 3

V8I4 No Voltage 24VDC MZLP 4

V8I5 No Voltage 24VDC MZLP 5

V8I6 No Voltage 24VDC MZLP 6

V8I7 No Voltage 24VDC MZLP 7

V8IG No Voltage 24VDC Gateway

V8IV No Voltage 24VDC AWB, Unit A

V8IW No Voltage 24VDC AWB, Unit B

V8IX No Voltage 24VDC System I/O, Unit A

V8IY No Voltage 24VDC System I/O, Unit B

V8M1 No Voltage Line MZLP 1

V8M2 No Voltage Line MZLP 2

30 3A5186B

Page 31

Appendix C - Error/Event Tables

Error/Event

Code

Description

V8M3 No Voltage Line MZLP 3

V8M4 No Voltage Line MZLP 4

V8M5 No Voltage Line MZLP 5

V8M6 No Voltage Line MZLP 6

V8M7 No Voltage Line MZLP 7

V8MG No Voltage Line Gateway

V8MV No Voltage Line AWB, Unit A

V8MW No Voltage Line AWB, Unit B

V8MX No Voltage Line System I/O, Unit A

V8MY No Voltage Line System I/O, Unit B

WJ1A Solenoid Error No Current Unit A

WJ1B Solenoid Error No Current Unit B

WJ2A Solenoid Error High Current Unit A

WJ2B Solenoid Error High Current Unit B

WSUX Config. Error USB

3A5186B 31

Page 32

Graco Information

Sealant and Adhesive Dispensing Equipment

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor, go to www.graco.com and select

“Where to Buy” in the top blue bar, or call to find the nearest distributor.

If calling from the US: 800-746-1334

If calling from outside the US: 0-1-330-966-3000

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2016, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A5186

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

Revision

B, December 2017

Loading...

Loading...