Page 1

INSTRUCTIONS-PARTS LIST

This manual contains IMPORTANT

WARNINGS

READ

AND INSTRUCTIONS

AND

RETAIN

FOR

REFERENCE

0

GRACO

SUPPLEMENTARY 1,NFORMATION

308-1

04

Rev

A

45:l

4050

psi

90

psi

Stubby Size, with Standard Air Motor and

Severe-Duty Displacement Pump, Model

NOTE

Ratio

(283 bar)

(6.3

bar)

This manual includes parts information for

Model SP 218-335 King Pump and Model SP

217-527 Displacement Pump.

as a supplement

307-728, which are supplied with your pump.

Referto Manuals307-013 and307-728forimportant safety warnings and instructions.

Read and understand those manuals before

operating the pump.

MAXIMUM

MAXIMUM

King"

WORKING PRESSURE

AIR INPUT PRESSURE

to

Manuals 307-013 and

It

Pump,

SP

217-527

is for use only

Model

SP

218-335

GRACO

INC.

RO.

BOX

COPYRIGHT 1990

1441 MINNEAPOLIS, MN 55440-1441

GRACO

INC.

Page 2

THIS

PTFE

MANUAL

Pressure Relief Procedure

To reduce the

fluid injection, splashing in the eyes or on the skin, or of a grounded metal pail, and trigger the gunlvalve

injury from moving parts, always follow this procedure

whenever

when installing, cleaning or changing spray tips/

nozzles, and whenever You stop spraying/disPensing.

1.

Engage the spray gun/dispensing valve safety sprayldispense again.

latch. If you suspect that the spray tiplnonle

2.

Shut off the air

3.

Close the bleed-tYPe master air valve (required in

your system).

4.

Disengage the gun/valve safety latch.

I

YOU

any

risk

shut

part

IS

FOR

USE

ONLY

AS

A

SUPPLEMENT

Read And Understand

OBSERVE ALL WARNINGS GIVEN IN THOSE INSTRUCTION MANUALS.

of serious bodily injury, including

Off

the Pump, when checking

Of

the

spray/dispensing system,

to

the pump.

All

Instruction Manuals Before Operating Equipment.

WARNING

01

TO

MANUALS

5.

Hold

a metal part of the gunhalve firmly to the side

to relieve pressure.

6.

Engage the gunlvalve safety latch.

7.

Open the drain valve (required

ing a container ready to catch the drainage.

Leave

pletely clogged,

lieved after following

loosen

and relieve pressure gradjally, ihen

pletely. Now clear the tiplnouie or

the

drain

the

tin

auard retainina nut or hose end couDlina

,

-

307-013

valve

or

that

pressure has not been fully

the

~~

AND

Open

steps above,

307-728.

in

your system), hav-

until

you

are

ready

or

hose

is

VERY

SLOWLY

loosen

hose.

com-

Lo6

to

re-

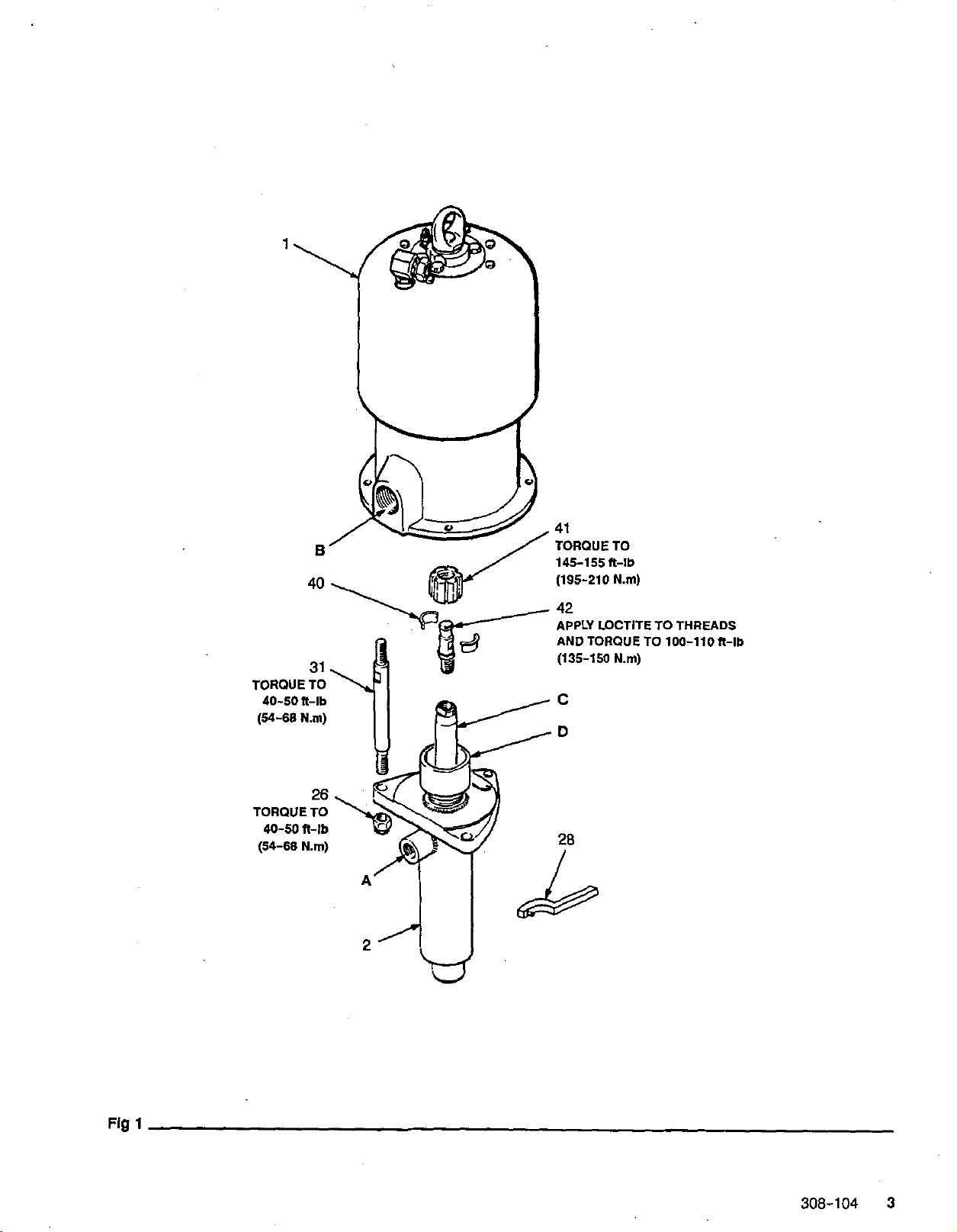

DISCONNECTING THE DISPLACEMENT PUMP

1.

Flush the pump if possible. Stop the pump at the bot-

tom

of

its

stroke. Follow tne

dure

Warnlng

2.

Disconnecttheairandfluidhoses.Removethepump

from its mounting.

3.

See

Fig

motor piston rod.

(40)

plers

locknuts (26) from the tie rods

displacement pump

NOTE:

4.

RECONNECTING THE DISPLACEMENT PUMP

1.

2.

3.

2 308-104

Do

not remove the connecting rod

displacement rod (C) unless the displacement

rod

the connecting rod for usewitn the new displace-

ment rod.

To service

ment Pump Model SP 217-527

the air motor, refer to instruction manual

(supplied).

See Fig

ing rod

its threads before assembling it

rod

(C),

Align the pump’s fluid outlet

OUtlet

(B)

(2)

pump

Place the coupling nut

(42).

Inse!ithecouplers

above.

1.

Screw the coupling nul

Be

careful not to

as

you lower the

(2)

is

being replaced. If that is necessary, save

the

displacement pump, refer to

1.

if

it was necessary to remove the connect-

(42),

apply a removable grade

and torque

of

the air motor. Position the displacement

on

to

the tie rods

Pressure Relief Proce-

(41)

off

of the air

lose

the

two

nut.

Unscrew the tie rod

(31).

Carefully pull the

away from the air motor

(42)

from

Displace-

at right. To sewice

306-968

of

Loctitee to

to

the displacement

100-110ft-lb (135-150

(A)

to the optional fluid

(31).

(41)

onto the connecting rod

(40)

into the coupling nut

Nm).

cou-

(1).

the

(41)

from the top. Screw the coupling

motor shaft snugly. Screw the locknuts

(31)

tie rods

3.

Mount the pump

the ground wire if it was disconnected during repair.

4.

TiOhten the tie rod locknuts

46-50R-lb

to

145-155fl-lb (195-210

5.

Start the

bar) air pressure, to check the tie rods for signs of

binding. Adjustthe tie rods as necessary to eliminate

binding. Tighten the packing nut/wet-cup

wrench

the wet-cup half full with Graco Throat Seal Liquid or

compatible solvent.

DISPLACEMENT PUMP MODEL SP 217-527

Refer to the Parts Drawing and List

NOS.

in

the parts list correspond with those

307-728.

To repair Displacement Pump SP

struction Manual

there, with the following exceptions:

1.

Packing Repair Kits

enced in

stack

The

v-packings

leather, as shown

2.

The method

217-527

scribed

graphs in this Supplement for instructions.

loosely.

and

reconnect

(54-68

pump

(28)

307-728

223-480,

to

in

N.m). Toiqie the ciiupling nit

Nm).

and run

supplied,

307-728

which

of

connecting Displacement Pump SP

the air motor is different from that de-

307-728.

it

slowly, at about

so

it

is just snug -no tighter. Fill

and follow all instructionsgiven

220-395

do

not

is

used

in

this stack are one and four

on

page

Refer to the preceding para-

nut

up onto the air

(26)

all

hoses. Reconnect

(31)

evenlv. and toroue to

40

(0)

on

page

5.

in

217-527,

and

include gland/packing

in

Mod

5.

refer to In-

223-643

onto the

(41)

psi

(2.8

withthe

The

Ref.

Manual

refer-

217-527.

Page 3

TORQUE

40-50 ft-lb

(54-68

N.m)

B

40

31

TO

2

41

TORQUE

145-155 It-lb

(195-210

TO

N.m)

42

APPLY

LOCTITE

AND

TORQUETO

(135-150

N.m)

TO

THREADS

100-110It-lb

Fig

1

308-104

3

Page 4

REF

PART

NO. NO. DESCRIPTION

1

207-647

2

.

SP 217-527 DISPLACEMENT PUMP

26 101-712 NUT,

28 102-176 WRENCH

31 167-911

39 172-447"' LABEL,

40 185-336

41' 185-337

42 186-575

***Extra warnings and tags are supplied at

306

and

307

numbers in descriptions refer to separate instruc-

tion manuals, supplied.

145-155R-lb

(195-210

APPLY LOCTITE TO THREADS

AND

(135-150

N.m)

TORQUE TO

N.m)

100-110R-lb

AIR

MOTOR

See

See

ROD,

306-968

page 5 for

lock;

tie;

for

parts

5/8-11

7" (178

parts

mm),

shoulder-to-shoulder

warning

(not

shown)

COUPLERS

COUPLING NUT

ROD,

connecting

ASSY

no

charge.

QN

1

1

3

1

3

1

2

1

1

40-50

ft-lb

4

308-104

Page 5

PARTS

PTFE

PTFE

DRAWING AND

LIST

~~~~~~,~~~;~~~~~~~~

,~~,~,.~,~,,~X..,l,*x.

,,,..

,*n

Model SP

Includes

217-527

items

Dlsplacernent Pump

1-29

REF

NO. PART NO. DESCRIPTION

1

207-470 HOUSING, pump; carbon steel

2 207-471 PACKING NUThVET-CUP;

3 207-472&* PISTON carbon steel

4 207-473 HOtSING, intake valve; carbon Steel

6 102-972** BALL, stainless steel; 7/8”

7 102-973** BALL, sta teel; 1-1/4“ dia

9

106-260**

11

167-890 PIN, ball

12 167-891

13 167-892 GUIDE,

14 178-894

15 167-894” GASK

16 167495” WASHER, flat: carbon steel

22 178-888

26 172-479*’* TAG, warning (not shown)

223-480*’

29

**Recommended

duce down time.

***€ma warnings and

carbon steel 1

tun

sten carbide

with tungsten carbide seat 1

O-RING;

carbon steel 1

RETAINER; carbon steel

SLEEVE

ROD,

GUNDlPACKlNG STACK

“tool

stop,

Intakevalve;

ball;

carbon steel

stainless steel

displacement; stainless steel 1

box”

spare paiis. Keep

tags

ere supplied at no charge.

with

seat

dia.

on

hand

OTY

to

re-

1

1

1

1

1

1

1

1

1

1

1

2

APPLY

AND

TORQUE

150-175 ft-lb

TORQUE

110-125

(150-170

SEALANT

TO

4’

TO

ft-lb

N.m)

1

To

be

sure

you

accessories,

chart below.

2.

Checkthepartsl1sttoidentilythecorrectpartnumber:donotuse

the ref. no. when ordering.

3.

Order

all

6

diglt

Part Number

I

receive the correct replacement parts,

always

give

all

of

the information requested in

parts

from your nearest

QtY

I

I

Graco

Part DesCrIDllon

distributor.

.

kits

4

the

or

1

I

308-104

5

Page 6

NOTES:

6

308-104

Page 7

NOTES:

308-104

7

Page 8

Maximum

PTFE

PTFE

Air

Pump cycles per

Maximum

Air consumption approx. 38

Wened

LoctiteQ

fluid

working pressure

input pressure operating range

1

gallon

....

recommended

......................................

mrts

.............

s

a

registered trademark of the

(3.8

numn

....

--

is a registered trademark

.................................

............................

liters)

............................................

soeed

for

-,

304,440

continuous

at

1

gpm

and

17-4

omrafion ........

~~~~

(3.8

literslmin) at

PH

Grades of Stainless Steel.

70

4050

psi

20-90

50

scfm

(283 bar)

psi (1.4-6.3 bar)

cycles

,

(1.0

16

mr min

~.~~

mJImin)

psi (4.9 bar) air pressure

C

teel,

Tu~ngsten Carbide, Chrome and Zinc Plating, Leather

Du

Pont

Co.

of

the

Loctite

Corp.

WARRANTY

in

Graco warrants all equipmenl manufactured by it and bearing its name to be free from defects

ship on the date of sale by an authorized Graco distributor to the original purchaser for

use.

for breach of this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part

material and workman-

As

purchaser’s sole remedy

of

the

equipment proven defective, This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommydations.

Thiswarrantydoesnot cover, andGraco shall not be liablefor, any malfunction, damage orwearcaused byfauityinstallation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility with Graco equipment of structures, accessories, equipment or materials not supplied by Graco, or the

improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials

not.supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco

distributor for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any

of

defective parts. The equipmentwill be returned to the original purchasertransportation prepaid. If inspection

ment does not disclose any defect

in

material or workmanship, repairs will be made at a reasonable charge, which

the equip-

charges may include the costs of parts, labor and transportation.

DISCLAIMERS AND LIMITATIONS

THETERMSOFTHlSWARRANTYCONSTl~EPURCHASER’SSOLEANDEXCUlSlVEREMEOYANDAREINLlEUOFANYOTHERWARRANTlES

(EXPRESSORIMPLIED),lNCLUDlNGWARRANTYOFMERCHANTABILITYORWARRANTYOFFlTNESSFORAPARTlCULARPURPOSE.ANDOF

ANY NON-CONTRACTUAL LIABILITIES, INCLUDING PRODUCT LIABILITIES, BASE0 ON NEGLIGENCE ORSTRICT LIABILITY. EVERY FORM OF

LIABILITY FOR DIRECT, SPECIAL

GRACO’SLlABlLlTYEXCEEDTHEAMOUNTOFTHEPURCHASEPRICE.ANYACTlONFORBREACHOFWARRANTYMUSTBEBR0UGHTWlTHIN

TWO

(2)

YEARS OF THE DATE OF SALE.

OR

CONSEQUENTIAL DAMAGES

..

OR

LOSS

IS

EXPRESSLY EXCLUDED AND DENIED. IN NO CASE SHALL

EQUIPMENT NOT COVERED BY GRACO WARRANTY

GRACO MAKES NO WARRANW, AN0 DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABlLrPl AND FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECTTO ACCESSORIES. EQUIPMENT, MATERIALS,

items sold, but not manufactured by Graco (such as electric motor, switches, hose, etc.) are subject to the warranty,

Of

their rnantifacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

OR

COMPONENTSSOLD BUT NOT MANUFACTURED BY GRACO.These

if

any,

warranties.

TO

PLACEAN

call this number to identify the distributor closest to you:

ORDER,

contact your Graco distributor, or

FOR

tion or assistance regarding the application of Graco

1-800-328-021 1

Toll Free

equipment:

Factory Branches: Atlanta, Chicago, Dallas, Detroit,

TECHNICAL ASSISTANCE, service repair informa-

1-800-543-0339

Los

Angeles, West Caidwell

Toll Free

(N.J.)

Subsidiary and Affiliate Companies: Canada: England; Switzerland; France; Germany; Hong Kong; Japan

GRACO INC.

P.O. BOX

1441

PRINTED IN USA.

MINNEAPOLIS, MN

3MI-104

9-90

55440-1441

Loading...

Loading...