Page 1

INSTRUCTIONS

ti11821

Preset Meter shown

SDM5 & SDM15 (Manual);

SDP5 & SDP15 (Preset)

312865R

Meters

For metered dispense of oils and 50:50 antifreeze/water mix fluids.

For professional use only.

Not approved for use in European explosive atmosphere locations.

Maximum Working Pressure: 1500 psi (10 MPa, 103 bar)

Maximum Working Pressure (50:50 antifreeze/water mix): 900 psi (6.2 MPa, 62 bar)

Maximum Flow Rate:14 gpm (53 lpm)

List of Models page 2

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

This dispense valve is designed to dispense

petroleum-based lubricants and antifreeze only.

Do not dispense windshield washer solvent with

this dispense valve.

EN

NOTICE

Page 2

Models

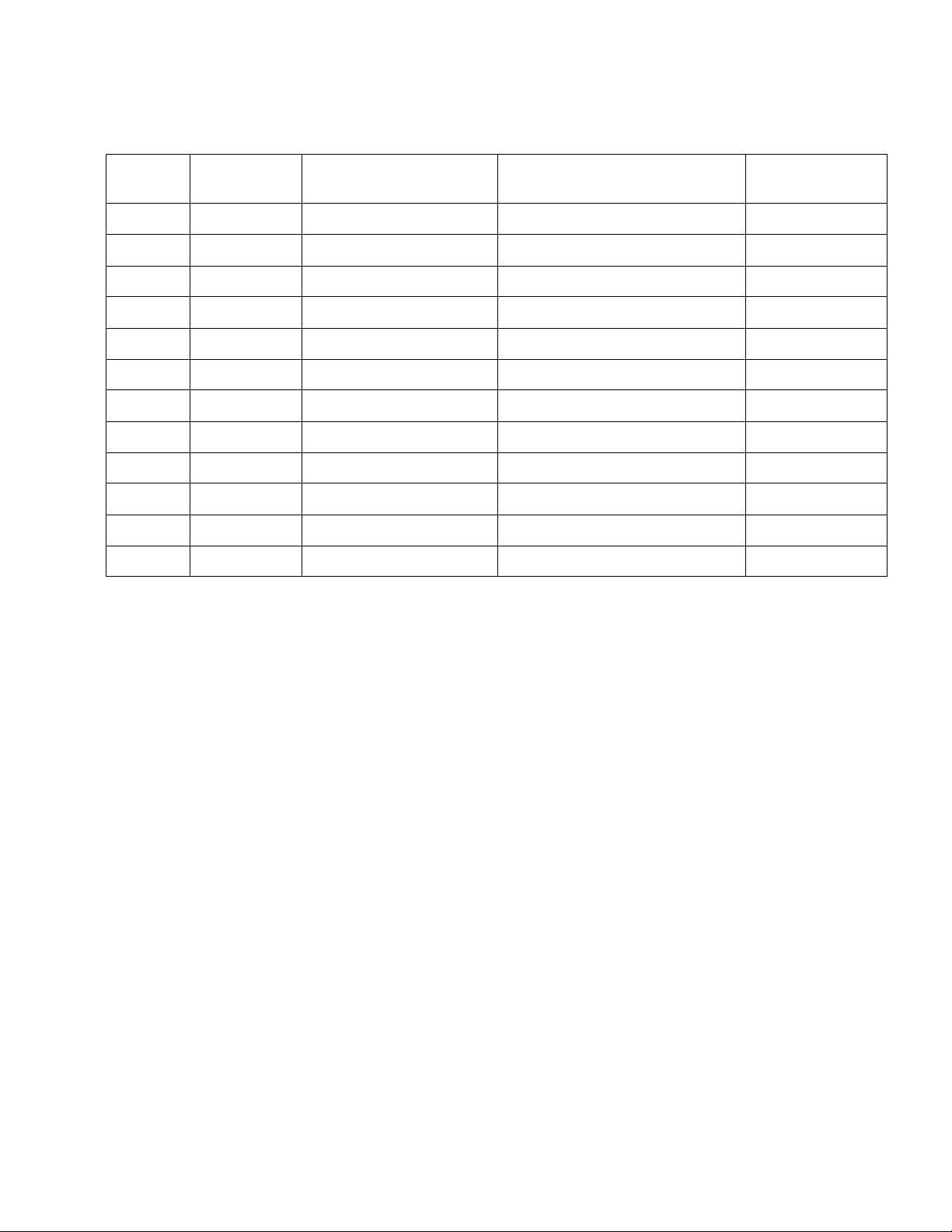

Models

SDM5 Manual Dispense Electronic Meters

Model

Number Swivel Extension Description Nozzle Fluid Type

255348 1/2” npt(f) Flexible Extension Automatic, non-drip, quick close Oil

255349 1/2” npt(f) Gear Lube Extension Non-drip, quick close Gear Lube

255350 1/2” npt(f) Rigid Extension Automatic, non-drip, quick close Oil

255802 1/2” npt(f) Rigid Extension Automatic, non-drip, quick close Anti-freeze

255803 1/2” npt(f) Flexible Extension Automatic, non-drip, quick close Anti-freeze

24H108 1/2-14 BSPP Flexible Extension Automatic, non-drip, quick close Oil

24H110 1/2-14 BSPP Gear Lube Extension Non-drip, quick close Gear Lube

24H112 1/2-14 BSPP Rigid Extension Automatic, non-drip, quick close Oil

24H130 1/2-14 BSPP Rigid Extension Automatic, non-drip, quick close Anti-freeze

24H132 1/2-14 BSPP Flexible Extension Automatic, non-drip, quick close Anti-freeze

24H109 1/2-14 BSPT Flexible Extension Automatic, non-drip, quick close Oil

24H111 1/2-14 BSPT Gear Lube Extension Non-drip, quick close Gear Lube

24H113 1/2-14 BSPT Rigid Extension Automatic, non-drip, quick close Oil

24H131 1/2-14 BSPT Rigid Extension Automatic, non-drip, quick close Anti-freeze

24H133 1/2-14 BSPT Flexible Extension Automatic, non-drip, quick close Anti-freeze

2 312865R

Page 3

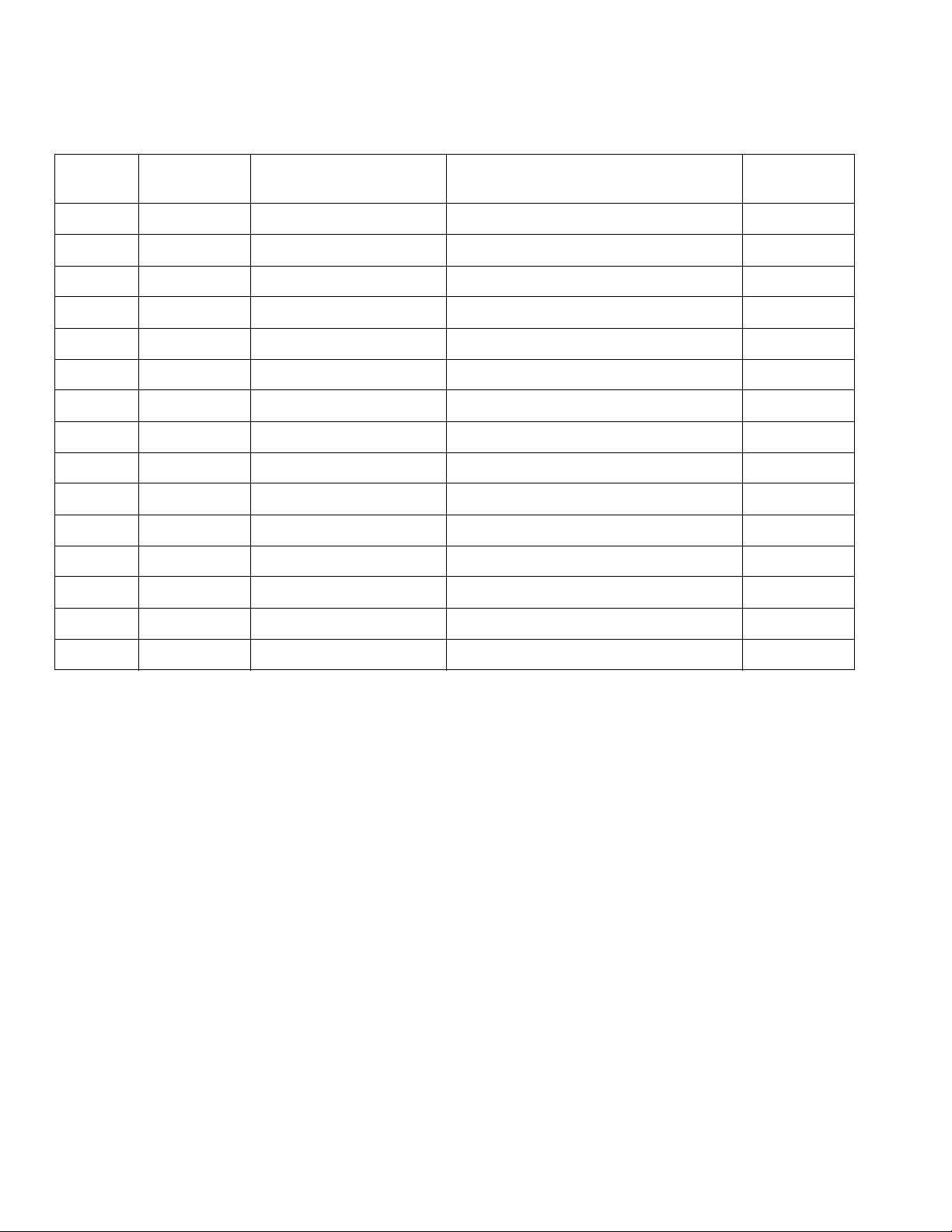

SDM15 Manual Dispense Electronic Meters

Model

Number Swivel Extension Description Nozzle Fluid Type

255800 3/4” npt(f) Rigid Extension Non-drip, quick close Oil or Antifreeze

255801 3/4” npt(f) Flexible Extension Non-drip, quick close Oil or Antifreeze

256836 1/2” npt(f) Rigid Extension Non-drip, quick close Oil or Antifreeze

256837 1/2 npt(f) Flexible Extension Non-drip, quick close Oil or Antifreeze

24H126 3/4-14 BSPP Rigid Extension Non-drip, quick close Oil or Antifreeze

24H128 3/4-14 BSPP Flexible Extension Non-drip, quick close Oil or Antifreeze

24H150 1/2-14 BSPP Rigid Extension Non-drip, quick close Oil or Antifreeze

24H152 1/2-14 BSPP Flexible Extension Non-drip, quick close Oil or Antifreeze

24H127 3/4-14 BSPT Rigid Extension Non-drip, quick close Oil or Antifreeze

24H129 3/4-14 BSPT Flexible Extension Non-drip, quick close Oil or Antifreeze

Models

24H151 1/2-14 BSPT Rigid Extension Non-drip, quick close Oil or Antifreeze

24H153 1/2-14 BSPT Flexible Extension Non-drip, quick close Oil or Antifreeze

312865R 3

Page 4

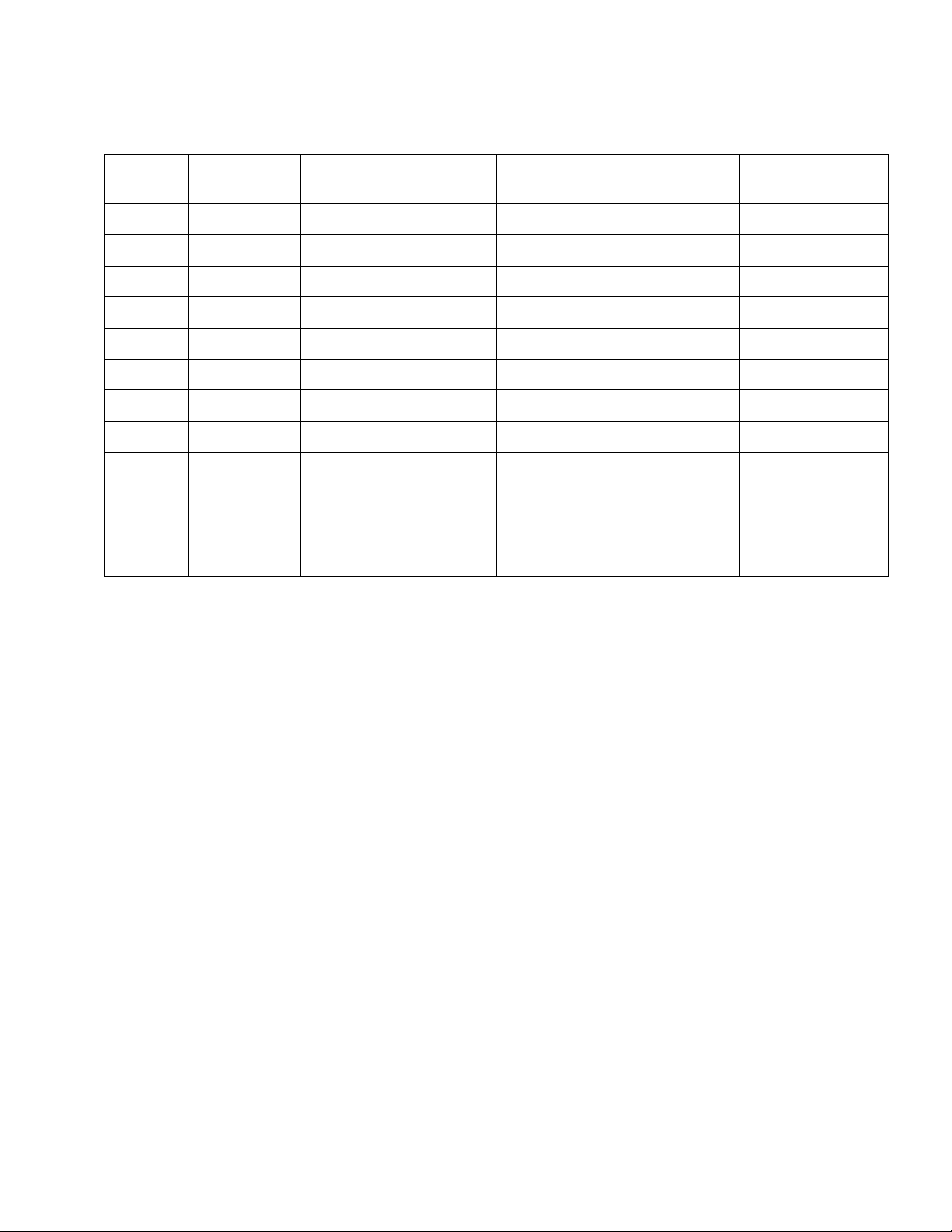

Models

SDP5 Preset Dispense Electronic Meters

Model

Number Swivel Extension Description Nozzle Fluid Type

255200 1/2” npt(f) Rigid Extension Automatic, non-drip, quick close Oil

255351 1/2” npt(f) Flexible Extension Automatic, Non-drip, quick close Oil

255352 1/2” npt(f) Gear Lube Extension Non-drip, quick close Gear Lube

255355 1/2” npt(f) Rigid Extension Automatic, non-drip, quick close Anti-freeze

255356 1/2” npt(f) Flexible Extension Automatic, non-drip, quick close Anti-freeze

24H106 1/2” BSPP Rigid Extension Automatic, non-drip, quick close Oil

24H114 1/2” BSPP Flexible Extension Automatic, Non-drip, quick close Oil

24H116 1/2” BSPP Gear Lube Extension Non-drip, quick close Gear Lube

24H122 1/2” BSPP Rigid Extension Automatic, non-drip, quick close Anti-freeze

24H124 1/2” BSPP Flexible Extension Automatic, non-drip, quick close Anti-freeze

24H107 1/2” BSPT Rigid Extension Automatic, non-drip, quick close Oil

24H115 1/2” BSPT Flexible Extension Automatic, Non-drip, quick close Oil

24H117 1/2” BSPT Gear Lube Extension Non-drip, quick close Gear Lube

24H123 1/2” BSPT Rigid Extension Automatic, non-drip, quick close Anti-freeze

24H125 1/2” BSPT Flexible Extension Automatic, non-drip, quick close Anti-freeze

4 312865R

Page 5

SDP15 Preset Dispense Electronic Meters

Model

Number Swivel Extension Description Nozzle Fluid Type

255353 3/4” npt(f) Rigid Extension Non-drip, quick close Oil or Antifreeze

255354 3/4” npt(f) Flexible Extension Non-drip, quick close Oil or Antifreeze

256838 1/2” npt(f) Rigid Extension Non-drip, quick close Oil or Antifreeze

256839 1/2” npt(f) Flexible Extension Non-drip, quick close Oil or Antifreeze

24H118 3/4-14 BSPP Rigid Extension Non-drip, quick close Oil or Antifreeze

24H120 3/4-14 BSPP Flexible Extension Non-drip, quick close Oil or Antifreeze

24H154 1/2-14 BSPP Rigid Extension Non-drip, quick close Oil or Antifreeze

24H156 1/2-14 BSPP Flexible Extension Non-drip, quick close Oil or Antifreeze

24H119 3/4-14 BSPT Rigid Extension Non-drip, quick close Oil or Antifreeze

24H121 3/4-14 BSPT Flexible Extension Non-drip, quick close Oil or Antifreeze

Models

24H155 1/2-14 BSPT Rigid Extension Non-drip, quick close Oil or Antifreeze

24H157 1/2-14 BSPT Flexible Extension Non-drip, quick close Oil or Antifreeze

312865R 5

Page 6

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

BATTERY SAFETY

The battery may leak, explode, cause burns, or cause an explosion if mishandled:

• You must use the battery type specified for use with the equipment.

• Sparking can occur when changing batteries. Only replace the battery in a non-hazardous location,

away from flammable fluids or fumes.

• Handle and dispose of battery properly - do not short circuit, charge, force over discharge, disassemble, crush, penetrate, incinerate, or heat the battery to a temperature exceeding 185° F (85° C).

6 312865R

Page 7

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

312865R 7

Page 8

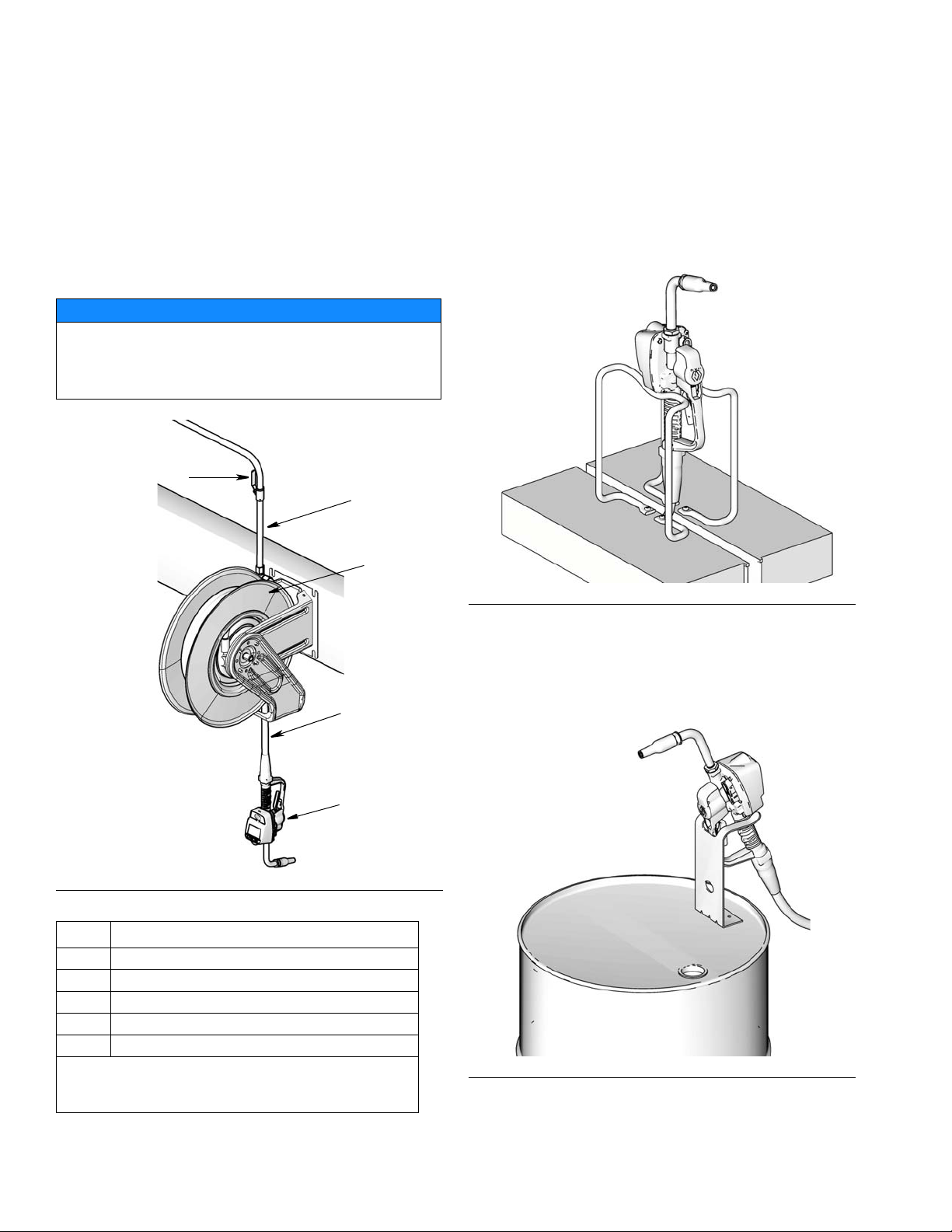

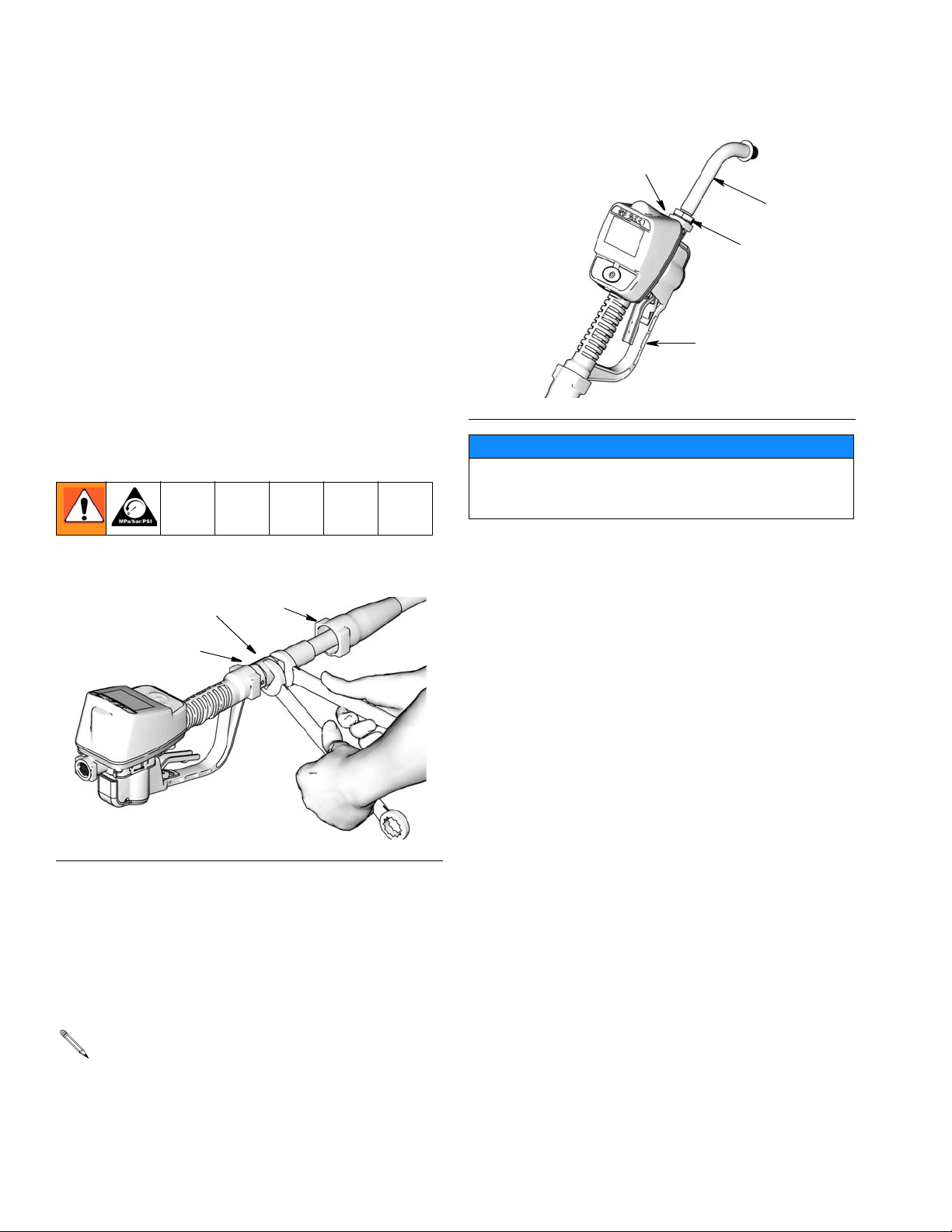

Installation

B

D

E

C

A

ti11010a

ti11822

ti11823

Installation

Typical Installations (FIG. 1)

The typical installation shown in FIG. 1 is only a guide. It

is not a complete system design. Contact your Graco

distributor for assistance in designing a system to suit

your needs.

NOTICE

The dispense valve is not designed for in-line

installation. Do not install with a shutoff valve on the

outlet side of the meter. Such installation could result in

damage to the meter housing cover.

Mounting Bracket (FIG. 2)

Mounting Bracket Kit 249440 is available for resting the

dispense valve on a console.

FIG. 2

F

IG. 1

ITEM DESCRIPTION

A Electronic metered dispense valve

B Fluid shut-off valve

CHose

D Hose reel fluid inlet hose

E Hose reel

A Thermal Relief Kit (not shown) is required. The kit

required will vary by pump selected. See Parts, page 42 for

a list of available kits.

Drum Mount Bracket (FIG. 3)

Mounting Bracket 15B750 is available for resting the

dispense valve on a drum.

IG. 3

F

8 312865R

Page 9

Installation

Pressure Relief Procedure

This equipment will stay pressurized until the pressure

has been manually relieved. To reduce the risk of

serious injury from pressurized fluid, accidental spray

from the dispense valve or splashing fluid, follow this

Pressure Relief Procedure when ever you:

• Are instructed to relieve pressure.

• Check, clean or service any system equipment.

• Install or clean fluid nozzles or filter.

1. Turn off power supply to the pump or close

upstream ball valve.

2. Trigger the dispense valve into a waste container to

relieve pressure.

3. Open any bleed-type master air valves and fluid

drain valves in the system.

4. Leave the drain valve open until you are ready to

pressurize the system.

Air compressor: Follow manufacturer’s

recommendations.

Fluid supply container: Follow local code.

To maintain grounding continuity when flushing or

relieving pressure: hold a metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

Pre-Installation Procedure

1. Relieve pressure, page 9.

2. Close the shut-off valve (B, F

3. Ground the hose and reel or console, page 9. Leave

at least two threads bare when using PTFE tape.

The bare threads ensure a ground is maintained.

IG. 1).

Installation Procedure

Grounding

FIRE HAZARD: Conductive metal surfaces on the

meter must not make contact with any positively

charged metal surface, including (but not limited to),

the starter solenoid terminal, alternator terminal or

battery terminal. Such contact could cause electrical

arcing and a fire.

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

Pump: Follow manufacturer’s recommendations.

Air and fluid hoses: Only use electrically conductive

hoses. Check electrical resistance of hoses. If total

resistance to ground exceeds 29 megohms, replace

hose immediately.

NOTICE

• If this is a new installation or if the fluid lines are

contaminated, flush the lines before you install the

metered valve. Contaminated lines could cause the

valve to leak.

• Never dispense compressed air with meter. Doing

so will damage meter.

Flushing

If this is an existing installation, go to Installing Meter

section, page 10. The following procedure, Steps 1-5

are the Flushing Procedure.

1. Close the fluid shut-off valve (B, F

each dispense position.

2. Make sure:

• main fluid outlet valve at the pump is closed,

• air pressure to the pump motor is adjusted,

and

• air valve is open.

IG. 1, page 8) at

312865R 9

Page 10

Installation

31

ti10983a

32

a

20

a

c

b

ti10615A

3. Slowly open the main fluid valve.

a. Place the hose end (with no dispense valve

connected) into a container for waste oil.

b. Secure the hose in the container so it will not

come out during flushing.

c. If you have multiple dispense positions, first

flush the dispense position farthest from the

pump and work your way toward the pump.

4. Slowly open the shut-off valve (B) at the dispense

position. Flush out a sufficient amount of oil to

ensure that the entire system is clean; then close

the valve.

5. Repeat Step 4 at all other positions.

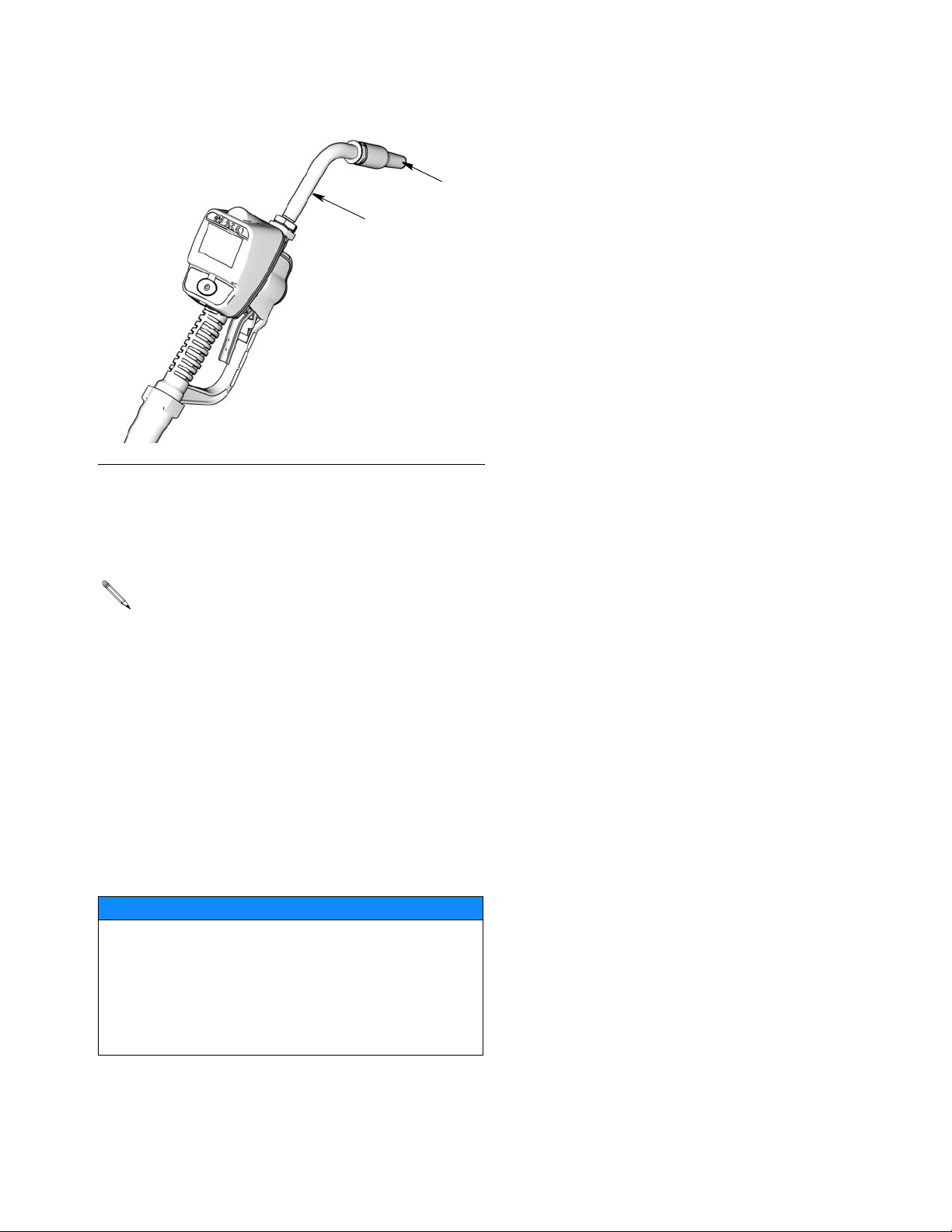

Installing Meter (FIG. 4

)

1. Relieve pressure, page 9.

Installing Tube Extension (FIG. 5)

FIG. 5

NOTICE

Do not use PTFE tape or thread sealant on threads of

extension tube (20). This could cause the fitting to

leak.

1.

a. Loosen nut (a) until it is completely off tube

threads.

b. Thread extension (20) into housing (b) until it

bottoms out.

c. Align extension (20) with meter housing and

handle (c).

d. Firmly tighten nut (a).

FIG. 4

2. Slide the swivel boot (32) back, over the hose, small

end first, to access the swivel fitting (a).

3. Apply thread sealant to the male threads of the hose

fitting. Thread the hose fitting into the meter swivel

(31). Use two wrenches to tighten securely (F

Make sure you let the sealant cure to the manufac-

IG. 4).

turer’s recommendations before circulating fluid

through the system.

10 312865R

Page 11

Installing Nozzle (FIG. 6)

20

33

ti10615A

F

IG. 6

1.

a. Thread new nozzle (33) onto extension (20).

b. With an open-end adjustable wrench on flats of

nozzle bushing, tighten firmly.

Installation

• Only tighten nozzle with wrench on flats of the

nozzle bushing.

• Do not disassemble the bushing from

nozzle. Disassembly will affect performance of

the nozzle.

2. Open automatic twist lock nozzle and all fluid

shut-off valves. Start pump to pressurize system.

See Operation Screens, Dispensing in either the

Manual or Preset Mode instructions beginning on

page 21 for complete meter operation information.

3. To ensure dispensing accuracy, purge all air from

the fluid lines and dispense valve before you use it.

4. Set the system flow to the desired flow rate.

NOTICE

Do not trigger meter when nozzle is closed. Fluid

will build up behind the nozzle, leak from the nozzle,

and unexpectedly be expelled when the nozzle is

opened. If you do accidentally trigger the meter with

the nozzle closed, point the nozzle into a waste

bucket and open the nozzle to relieve pressure and

expel the built up fluid.

312865R 11

Page 12

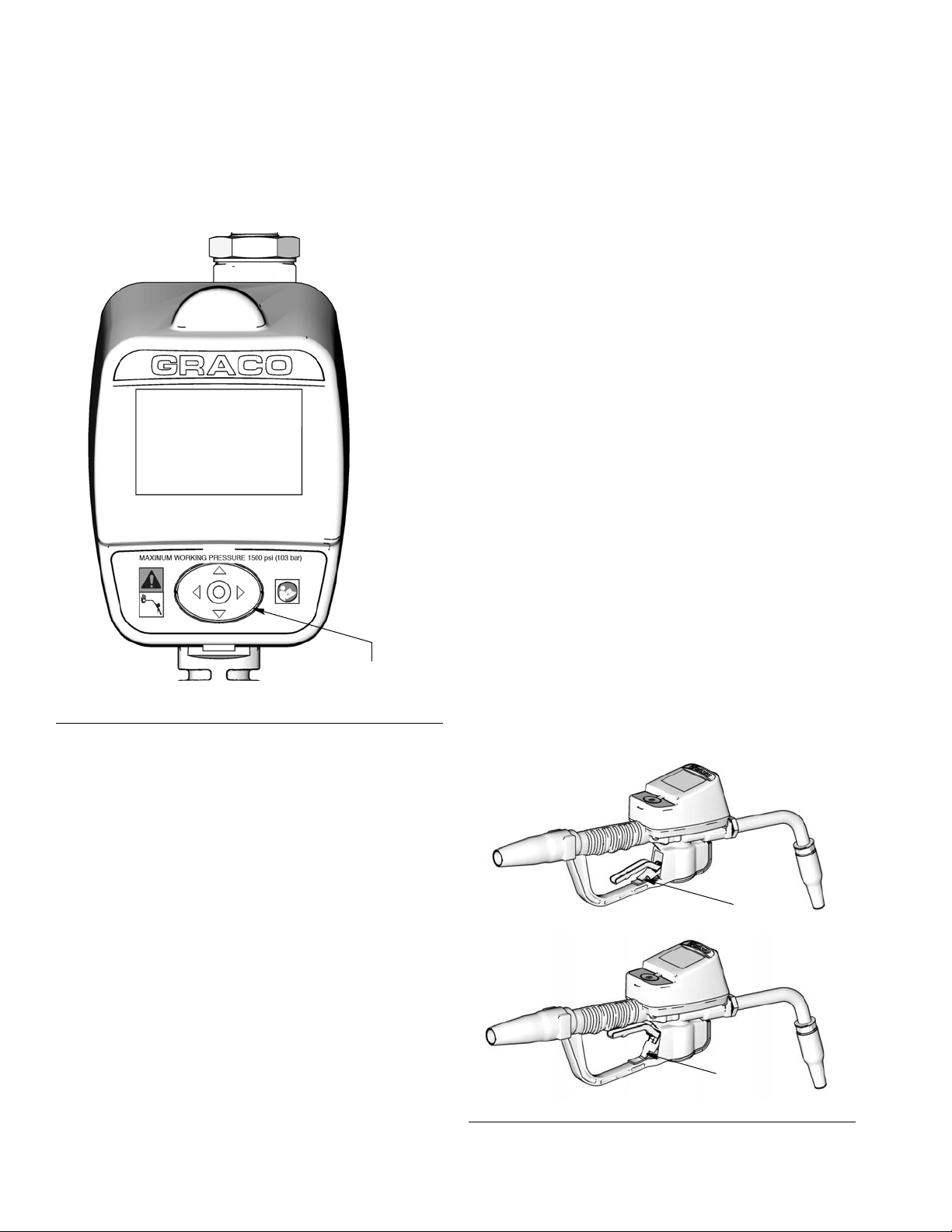

Meter Overview

ti11824

5-Way Menu

Navigation Button

Unlocked

Locked

Meter Overview

Navigation and Modes

F

IG. 7

Meter Display

Adjusting Screen Contrast using ARROWS

On the Setup Home Screen (page 13), use the LEFT

and RIGHT ARROWS to adjust the screen contrast.

• Darken the Screen: Press the RIGHT ARROW

multiple times.

• Brighten the Screen: Press the LEFT ARROW

multiple times.

Asleep/Awake Mode

• Asleep: Battery-saving mode. The display goes

blank after 2 minutes of inactivity during normal

operation. Unit continues to keep track of amount

dispensed while the display is asleep.

• Awake: Display comes awake from sleep mode

when you press any ARROW or the ENTER button

or when you squeeze the trigger to dispense fluid.

Locking and Unlocking Trigger

The Preset Meters only, include a locking trigger

feature that allows the user to lock the trigger in the

dispense position as shown in F

lock, firmly squeeze the trigger to the handle.

Preset Meters Only

IG. 8. To release the

5-Way Menu Navigation Button (FIG. 7)

• Includes 4 direction ARROWS (UP, DOWN, LEFT,

RIGHT) and a center, ENTER button.

• Pressing the direction ARROWS allows user to

easily scroll through menus. To select/store your

selection, you must press the center, ENTER

button.

• Pressing and holding a direction ARROW down

allows user to scroll through menus quickly.

FIG. 8

12 312865R

Page 13

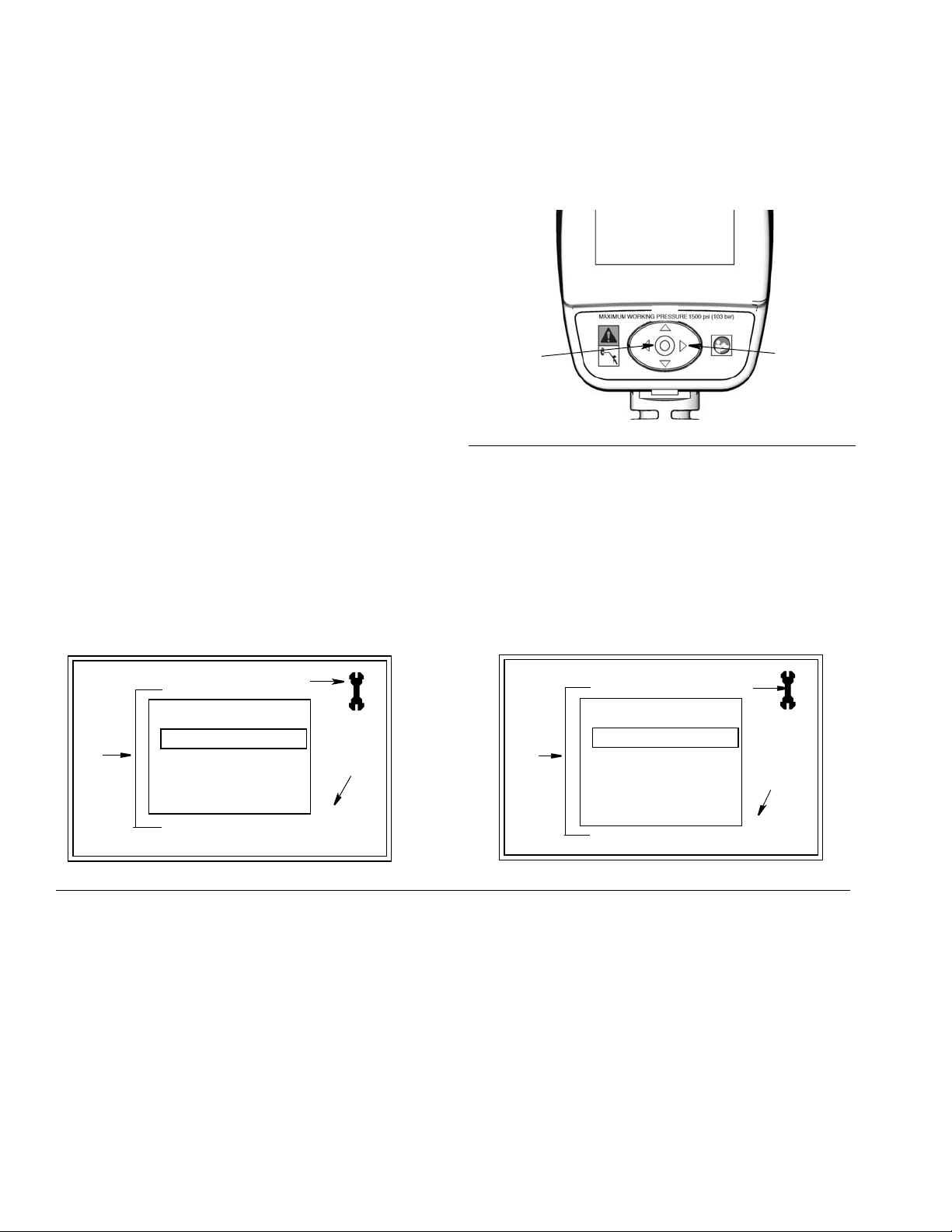

Setup Mode Screens

MOBIL

1

5W-20

10.56

QTS

a

ti12179a

MOBIL

1

5W-20

MANUAL

PRESET

TOTALS

MOBIL

1

5W-20

MANUAL

TOTALS

ti12184a

ti12175a

Manual Meters

Preset Meters

Setup Mode Screens

If you are in Operation Mode you must be on the Home Screen shown in FIG. 10, to access the Setup Mode Screens.

(A complete description of the Home Screen is provided on page 20).

To display the Home Screen:

1. Wake up the meter by pressing any button on the key pad.

2. When an operation mode screen displays (such as

the one shown in F

a. Use the RIGHT ARROW to move the curser

over the House icon (a).

b. Press center, ENTER button to display the

Home Screen (F

IG. 9):

IG. 10).

F

IG. 9

FIG. 10

312865R 13

Page 14

Setup Mode Screens

(a)

(b)

ti11824a

UNITS/LIMIT

CALIBRATE

PRESET

BANNER

LANGUAGE

HOME

1.23.45

Manual Meters

Preset Meters

B

A

UNITS/LIMIT

CALIBRATE

BANNER

LANGUAGE

HOME

1.23.45

B

A

ti12177a

ti12186a

1

1

Main Setup Screen (FIG. 12)

All Meters

The Main Setup Screen is the first screen displayed

when you enter the Setup Mode. This screen displays a

list of the available Setup Screens and also includes a

link back to the Home Screen.

Manual Meters Screens:

• UNITS/LIMIT

•CALIBRATE

• BANNER

• LANGUAGE

•HOME

Preset Meters include all the Manual Meter’s Setup

Screens and also a PRESET screen.

• UNITS/LIMIT

•CALIBRATE

• PRESET

• BANNER

• LANGUAGE

•HOME

Displaying Setup Screen from an Operation

Mode Screen

F

IG. 11

1. Hold down the RIGHT ARROW (a) only, for a few

seconds (F

2. Then at the same time, also press the center,

ENTER button (b) (F

until the Main Setup Screen shown in F

plays.

IG. 11).

IG. 11). Hold both buttons down

IG. 12 dis-

FIG. 12

Main Screen Features (F

A. Screen Identifier Icon: Wrench icon displays in the

upper right corner when user is on the Main Screen of

the Setup screens.

14 312865R

IG. 12)

B. Setup Screens: Screens available to user.

1. Use UP or DOWN ARROWS to select a screen

from the list.

2. Press center, ENTER button to confirm selection.

Selected screen displays.

1. Software Version Number: Reference number. You

may be asked to provide this number when contacting

Graco for technical support.

Page 15

Units/Limit Screen (FIG. 13)

QTS

UNITS = QTS

MANUAL LIMIT = 5.0

5.0

D

C

G

E

F

Preset Meters

Manual Meters

ti12191a

QTS

UNITS = QTS

C

D

E

For All Meters

Sets the units of measurement to pints, quarts, liters, or gallons.

F

IG. 13

Setup Mode Screens

Units/Limit Screen Features (F

IG. 13)

All meters include C - E

C. Units Mode: Displays measurement unit that was

selected using the Set Measurement Units

button (E).

D. Wrench Icon: Returns user to Main Setup Screen.

E. Set Measurement Units button/field: Sets unit of

measurement as pint, quart, gallon or liter.

To change/set the Unit of Measurement:

1. Use LEFT or RIGHT ARROW to move curser to the

Set Measurement field (E).

2. Use UP or DOWN ARROWS to display measurement unit choices: PTS, QTS, L, GAL.

3. Press center, ENTER button to confirm selection.

Selected measurement unit is displayed on screen

(C).

4. When you are finished making changes, use the

RIGHT ARROW to move curser over Wrench icon.

5. Press center, ENTER button to return to Main Setup

Screen.

Preset meters also include F - G

F. Set Manual Dispense Limit field: Sets maximum

quantity of fluid that can be dispensed in Manual Mode.

To change/set the Manual Dispense Limit:

1. Use RIGHT ARROW to move curser to Manual Dispense Limit field (F).

2. Use UP or DOWN ARROWS to increase and

decrease displayed amount.

3. When amount you want to use is shown in field,

press center, ENTER button to confirm amount.

Confirmed amount displays on screen (G).

4. When you have finished making changes, use the

RIGHT ARROW button to move curser over Wrench

icon.

5. Press center, ENTER button to return to Main Setup

Screen.

G. Manual Limit Confirmation: Displays maximum

quantity of fluid that can be manually dispensed at one

time. Amount is assigned on the task bar Set Manual

Dispense Limit field (F). Preset dispense amounts are

not affected by the manual dispense limit you set.

312865R 15

Page 16

Setup Mode Screens

D

J

M

K

L

L

Calibrate Screen 1

Calibrate Screen 2

ti12173a

ti12174a

Calibrate Screen (FIG. 14)

For All Meters

Recalibrates the meter for different fluids.

Table 1. Calibration Factors

Calibration Number

Fluids

Oil (10W - 30)

Gear Lube

Automatic

Quarts Liters

173 183

173 183

167 176

Transmission Fluid

Antifreeze

• Calibration factors at 70°F (21°C) at 2.0 gpm (7.6 lpm).

• Calibration number may vary slightly due to temperature

or flow rate.

159 168

All meters include D - M

D. Wrench Icon: Returns user to Main Screen.

J. Calibration Factor: Displays amount operator

dispensed during meter calibration.

K. Preset Calibration Factor: Preset calibration

amount displays.

Adjusting the Preset Calibration Factor:

1. Use your LEFT or RIGHT ARROW to move the

curser to the Calibration Factor Field (K) .

2. Use the UP or DOWN ARROW to manually adjust

the Preset Calibration Factor up or down (this can

only be done on Calibrate Screen 1 (F

IG. 14).

3. Press center, ENTER button to confirm new setting.

New setting displays in Calibration Factor field (J).

L. Start/End button: Clicked at the start and completion

of calibration. See Recalibrating the Meter (page 17).

M. Dispense: Only appears on Screen 2 (F

IG. 14).

Displays amount operator dispensed during calibration

test.

F

IG. 14

16 312865R

Page 17

Setup Mode Screens

Recalibrating the Meter (FIG. 14)

The meter is shipped from the factory with the default

calibration factor for 10W30 motor oil - at 70°F (21°C).

This calibration factor is sufficiently accurate for most

oils. If other fluids are used or if greater accuracy is

required, the meter can be recalibrated by performing

one of the following recalibration methods.

1. Choosing a Calibration Factor From the

Calibration Table 1

Calibration factors provided in Table 1 (page 16),

are only approximate, but sufficient for most appications. For the most accuracy, use method 2,

Manual Calibration Procedure.

1. Use LEFT or RIGHT ARROW to move the curser to

the Calibration Factor Field (K) .

2. Use the UP or DOWN ARROWS to manually adjust

the Preset Calibration Factor up or down until the

number displayed matches the calibration factor you

have chosen from Table 1.

3. Press center, ENTER button to confirm new setting.

New setting displays in Calibration Factor field (J).

4. Use the RIGHT ARROW button to move curser over

Wrench icon.

5. Press center, ENTER button, to return to Main

Setup Screen.

3. Dispense exactly 1 quart (or 1 liter) of fluid into a

calibrated 1 quart (or 1 liter) container.

The Calibration Factor will appear on the screen in

the Calibration Factor field (J).

4. Use the LEFT or RIGHT ARROWS to select END

(L) on Calibrate Screen 2.

5. Press the center, ENTER button to confirm selection. Calibrate Screen 1 will appear.

6. When you have finished making changes, use the

RIGHT ARROW button to move curser over Wrench

icon.

7. Press center, ENTER button, to return to Main

Setup Screen.

To attain the most accurate calibration:

• Use the manual calibration procedure (Method 2).

• Use a certified, graduated cylinder; either 1-Quart or

1-Liter volume in the system of Units to be used

(either English or SI) for real-time dispenses.

• Calibrate using the exact fluid to be dispensed, at

the temperature expected during dispense.

• After calibration check your results by measuring a

dispense.

• Be sure to remove all fluid from graduated cylinder

between calibration attempts.

OR

• Be sure meter is set to proper system of units for

container you are using.

2. Manual Calibration Procedure

See FIG. 14, page 16 for the Calibrate Screens 1 and 2

referenced in the following instructions.

Once the meter has been calibrated, the unit of

measure can be changed to any other unit, without

the need for recalibration.

• When an English unit (gallon, quarts, pints) is

set as the measurement unit on the Units/Limit

Screen, page 15, use a one quart graduated

cylinder to calibrate the meter.

• When a System International Unit (SI) (Liter) is

set as the measurement unit on the Units/Limit

Screen, use a one Liter graduated cylinder to

calibrate the meter.

1. Use the LEFT or RIGHT ARROWS to select START

(L) on Calibrate Screen 1.

2. Press the center, ENTER button to confirm selection. Calibrate Screen 2 will appear.

312865R 17

Page 18

Setup Mode Screens

PRESET

4.0

6.0

10

1

2

3

QTS

D

Q

P

ti12188a

Preset Screen (FIG. 15)

For Preset Meters Only

Sets the default preset amounts. Typically, you would

enter amounts you most frequently dispense.

F

IG. 15

Preset Meters include D, P and Q

D. Wrench Icon: Returns user to Main Screen.

To set Preset amounts (F

1. Use the LEFT or RIGHT ARROWS to select one of

the three amount fields (Q).

2. Use the UP or DOWN ARROWS to increase or

decrease the number appearing in the field until the

desired amount displays.

Pressing and holding the ARROW button down,

increases the scrolling speed.

3. Press center, ENTER button to confirm amount.

The amounts displayed do not automatically recalculate quantities when changing between measurement units. For example, if you change from quarts

to liters you must manually change the preset

amounts.

4. When you have finished making changes, use the

LEFT OR RIGHT ARROW button to move curser

over Wrench icon.

IG. 15):

P. Measurement Unit: Set on Units/Limit Screen,

page 15.

Q. Set Preset Amounts: Sets dispensing options for

the Preset Dispense mode.

Sets up to 3, default preset quantities. The amounts can

be listed in any order and do not have to be in a numeric

order.

5. Press center, ENTER button, to return to Main

Setup Screen.

18 312865R

Page 19

Setup Mode Screens

D

R

ti12181a

ENGLISH

LANGUAGE =

ENGLISH

D

S

T

Banner Screen (FIG. 16)

For All Meters

Creates the information banner displayed across top of

the Home, Manual and Preset Screens.

MOBIL1

-

20

F

IG. 16

Banner Screen Features D and R

D. Wrench Icon: Returns user to Main Screen.

R. Banner field: Information line. Provides space for up

to 11 numeric and alpha characters and/or spaces.

Using the DOWN ARROW button when a field is blank

will also provide the following characters for selection:

(period) “ . “; (forward slash) “ / “; or (dash) “ - ”.

To create a banner:

1. Use the UP or DOWN ARROWS to scroll through

numerals, then alpha characters and then

blank/spaces.

2. Press center, ENTER button to select characters.

When character is selected, curser automatically

moves to the next character field.

Use the RIGHT ARROW button to skip fields or if

you do not need to use all 11 spaces, to return

curser to the Wrench icon. After 11th character has

been confirmed, curser automatically moves to

Wrench icon (D).

3. Use the center, ENTER button, to return to the Main

Setup Screen.

W

5

Language Screen (FIG. 17)

For All Meters

Sets language preference for text displayed on meter.

Choices include English and Spanish.

FIG. 17

Language Screen Features D, S, and T

D. Wrench Icon: Returns user to Main Screen.

S. Language field: Identifies selected language.

T. Language field/button: When curser is over this

button, each time UP or DOWN arrow is pressed, the

name of the Language displayed on the button changes.

To select your language:

1. Use the LEFT or RIGHT ARROW to move the

curser to the Language field/button (T).

2. Use UP or DOWN ARROWS to view language

choices.

3. When the name of your language is displayed on

the field/button (T), press the center ENTER button

to confirm selection.

The selected language is then displayed on screen in

Language field (S).

After you press the center, ENTER button, the name on

the field/button will also change from “SPANISH” to

“EPANOL” and will appear this way on both the Language button (T) and in the Language field (S) on the

screen.

4. When you have finished making changes, use the

LEFT OR RIGHT ARROW button to move curser

312865R 19

over Wrench icon.

5. Press center, ENTER button, to return to Main

Setup Screen.

Page 20

Dispensing Fluid and Operation Mode Screens

MOBIL

1

5W-20

MANUAL

PRESET

TOTALS

C

A

D

B

Preset MetersManual Meters

MOBIL

1

5W-20

MANUAL

TOTALS

B

D

A

C

ti12175a

ti12184a

Dispensing Fluid and Operation Mode Screens

FIRE HAZARD: Conductive metal surfaces on the

meter must not make contact with any positively

charged metal surface, including (but not limited to),

the starter solenoid terminal, alternator terminal or

battery terminal. Such contact could cause electrical

arcing and a fire.

If you are in the Setup Mode, to display the Operation Mode Screens use the UP or DOWN ARROW button to select

HOME from the list. Press the Center ENTER button to display the Operation Mode Home Screen shown in F

A complete description of the Setup Mode Screens begins on page 13.

Home Screen (FIG. 18)

All Meters

IG. 18.

FIG. 18

All Meters include Include A - D

A. Screen Identifier Icon: House displays when user is

on the Home Screen.

B. Operation Screens: List/menu of screen choices

available to user. Operation Screen choices include:

Manual Meters

• MANUAL

• TOTALS

Preset Meters

• MANUAL

• PRESET

• TOTALS

20 312865R

1. Use UP or DOWN ARROWS to scroll through

options.

2. Press center, ENTER button to confirm selection

and display the screen.

C. Battery Indicator: Appears only on Home Screen.

Shows current battery charge strength. Appears and

flashes on all screens when battery’s charge is low.

D. Information Banner: Configurable information

banner. Data is input on Setup Mode Banner Screen,

page 19.

Page 21

Dispensing Fluid and Operation Mode Screens

MOBIL

1

5W-20

10.56

QTS

E

F

G

H

D

ti12178a

MOBIL

1

5W-20

MANUAL

PRESET

TOTALS

ti12180a

Preset shown

MOBIL

1

5W-20

10.56

QTS

G

H

ti12178a

Manual Dispense (FIG. 19)

All Meters

IG. 19

F

IG. 19 for terms D - H

See F

D. Information Banner: Configurable information

banner. Data is input on Setup Mode Banner Screen,

page 19.

E. Unit of Measurement: Identifies unit of

measurement, pint, quart, gallon or liter. Measurement

Unit is set on Setup Mode Units/Limits Screen, page

15.

To dispense in Manual Mode:

If display was asleep, press any button to wake it up.

FIG. 20

1. From HOME screen, use the UP or DOWN

ARROWS to select MANUAL (F

2. Press center, ENTER button to confirm selection.The Manual Dispense screen (F

appears.

IG. 20).

IG. 21)

F. Home Icon: Returns user to Home Screen.

G. Reset: Resets counter (H) to zero.

H. Counter: Before dispense has begun, display reads

0.00. As fluid is dispensed, counts up from zero.

To reset counter to zero after a dispense:

1. Use the LEFT or RIGHT ARROW button to move

2. Press center ENTER button. The displayed amount

312865R 21

curser to RESET (G).

in field H returns to zero.

F

IG. 21

3. Squeeze trigger to dispense fluid. If using a Preset

meter, trigger may be locked during the dispense.

Fluid flows. The amount displayed counts up from zero or

from the previously dispensed amount

IG. 21) and displays in field H.

(F

4. Release, or for Preset meters only, unlock trigger

when you have dispensed the desired amount of

fluid.

Fluid flow stops. Amount dispensed displays in field H.

5. Use LEFT or RIGHT ARROW to move curser to

RESET button (G). Press center ENTER button to

reset the displayed amount in field H to zero.

Page 22

Dispensing Fluid and Operation Mode Screens

E

F

G

H

D

J

L

ti122410a

Preset Dispense (FIG. 22)

Preset Meters Only

MOBIL

XXXXXXXXXXXXXXXX

F

IG. 22

See F

IG. 22 for terms D - L

D. Information Banner: Configurable information

banner. Data is input in Setup Mode, Banner Screen,

page 19.

5W-20

1

2.50

4.0

QTS

L. Preset Quantities: Use the UP or DOWN ARROW to

select field L on the task bar.

a. Use the UP or DOWN ARROWS to scroll

through the 3 available Preset Quantities (L).

Each time you press the UP or DOWN

ARROWS, one of the 3 preset amounts displays on the task bar in field L.

b. When the Preset Quantity you want to dispense

is shown in field L, press the center, ENTER

button to select it.

If a suitable preset quantity is not available, select

an amount that is closest to the amount you want to

dispense. Amounts can be modified following the

procedure described on page 23.

E. Unit of Measurement: Identifies unit of

measurement, pint, quart, gallon or liter. Unit is selected

in Setup Mode, Units/Limit Screen, page 15.

F. Home Icon: Returns user to Home Screen.

G. Reset: Resets counter (H) to zero.

H. Counter: Before dispense has begun, display reads

0.00. As fluid is dispensed, counts up from zero. At the

same time the Progression Bar (J) displays a real-time,

visual representation of the progress made toward

completing the dispense.

J. Progression Bar: Displays a real-time, visual

representation of the progress made toward completing

the dispense. Runs in conjunction with Counter (H).

For example, in F

of the total Preset Dispense of 5.0 quarts is shown. The

Progression Bar shows that approximately half the

dispense is complete.

IG. 22, a partial dispense of 2.5 quarts

22 312865R

Page 23

To modify the amount selected:

MOBIL

1

5W-20

2.50

QTS

4.0

XXXXXXXXXXXXXXXX

8.0

8.0

A

B

C

a. Use the UP or DOWN ARROW to scroll up or

down to increase or decrease the amount

shown in field L. Each time you press the UP or

DOWN ARROW the amount will increase or

decrease in increments of 0.1 units.

To speed up the scrolling progression, press

and hold the UP or DOWN ARROW.

b. IMPORTANT!!! When the new dispense

amount is shown in field L, the number

flashes, indicating a change has been made

that requires confirmation.

To confirm new amount you MUST PRESS

the center, ENTER button on the key pad

within 15 seconds. If you begin a dispense

without confirming the new amount, the Preset

Amount will return to the previous confirmed

amount shown in field L.

Dispensing Fluid and Operation Mode Screens

For example, in F

Preset Dispense amount (A) was 4.0 qts. The amount

was increased to 8.0 quarts and because it has not

been confirmed, is flashing on the screen (B). After the

user confirmed this change by pressing the center

ENTER button on the key pad, the new dispense

amount no longer flashes and is now set to dispense 8.0

quarts (C).

F

IG. 23

IG. 23 (below) the original, confirmed

To permanently modify the default Preset Quantities,

see To set Preset amounts: on page 18.

312865R 23

Page 24

Dispensing Fluid and Operation Mode Screens

ti12242a

MOBIL

1

5W-20

2.50

QTS

4.0

XXXXXXXXXXXXXXXX

G

H

ti12410a

J

To dispense in Preset Mode:

If the display was asleep, press any button to wake up

the display.

MOBIL

5W-20

1

MANUAL

PRESET

TOTALS

F

IG. 24

1. From HOME screen, use the UP or DOWN

ARROWS to select PRESET (F

2. Press center, ENTER button to confirm selection.The Preset Dispense screen (F

IG. 24).

IG. 25) appears.

3. Squeeze trigger to begin dispensing fluid. The trigger may be locked during the dispense.

Fluid flows. The amount displayed counts up from

zero or from the previously dispensed amount

(F

IG. 25) and displays in field H. A visual

representation of the dispense progression also

appears on the progression bar (J).

When the preset amount has been dispensed, fluid

flow stops automatically. The total dispensed

amount appears in field H.

If you want to stop fluid flow before the preset

amount is dispensed, release or unlock trigger. To

continue dispensing fluid, squeeze and/or lock

trigger again. Dispensed amount shown in field H

and on progression bar (J) continues to count up

toward preset amount.

If you want to continue dispensing fluid after preset

amount has been dispensed, squeeze trigger. The

meter continues dispensing fluid in Manual Mode

until you release trigger.

F

IG. 25

4. Use LEFT or RIGHT ARROW to move curser to

RESET button (G).

5. Press center ENTER button to reset the displayed

amount in field H to zero and clear the progression

bar (J).

24 312865R

Page 25

Dispensing Fluid and Operation Mode Screens

3485

14953

QTS

GAL

FG

M

N

ti12190a

ti12243a

Totals Screen (FIG. 26)

All Meters

F

IG. 26

See F

IG. 26 for terms F, G, M - P

F. Home Icon: Returns user to Home Screen.

G. Reset: Resets counter (M) to zero.

M. Resettable Total: Shows cumulative amount that

has been dispensed in all modes. Can be reset to zero

at any time with Reset button (G).

N. Total: Shows cumulative amount that has been

dispensed in all modes for the life of the unit. Cannot

be reset.

To display Totals Screen:

If the display was asleep, press any button to wake up

the display.

MOBIL

5W-20

1

MANUAL

PRESET

TOTALS

FIG. 27

1. From HOME screen, use the UP or DOWN

ARROWS to select TOTALS (F

2. Press center, ENTER button to confirm selection.The Totals screen (F

3. To reset Resettable Total field (M) to zero, use

LEFT or RIGHT ARROW to move curser over

RESET button (G).

4. Press center ENTER button to reset the displayed

amount in field M to zero.

IG. 27).

IG. 26) appears.

When the Total (N) reaches 999,999 the count

resets automatically to 000.

312865R 25

Page 26

Troubleshooting

Troubleshooting

• Relieve pressure, page 9, before you check or repair the meter. Be sure all other valves, controls and pump are

operating properly.

• When calling for Technical Assistance you may be asked to provide the Software Version that is being used by

your meter. Refer to F

meter.

Problem Cause Solution

Battery icon is blinking. Batteries are low. Replace batteries, page 29.

Display does not activate.

Cannot read display Contrast is set too high or too low to

IG. 10, page 13, item #1 for help determining where this information is shown on your

Batteries are defective. Replace batteries, page 29.

Electronic control is malfunctioning. Replace the electronic bezel assem-

bly. (See Manual Meters Parts page

36 or Preset Meters Parts page 38 to

identify which kit is required for your

meter).

Adjust contrast. See Adjusting

be viewed in work area

Screen Contrast Using LEFT or

RIGHT ARROWS, page 12.

1. Relieve pressure, page 9.

Filter is clogged.

Pump pressure is low. Increase pump pressure.

Twist lock nozzle not fully open. Aim nozzle into bucket or rag. Fully

Slow or no fluid flow.

Shut-off valve is not fully open. Fully open shut-off valve.

Foreign material is jammed in the

meter housing.

Displayed dispensed amount is not

accurate.

Meter leaks from cover/control. Poor seal at metering cover cham-

Unit needs to be calibrated for the

fluid that is being dispensed.

ber.

2. Clean or replace filter. Order Filter Kit 255885.

3. If the problem remains, contact

your Graco distributor for repair

or replacement.

open nozzle.

Do not trigger meter when nozzle

is closed! If you do accidentally trig-

ger the meter with the nozzle closed,

point nozzle into a waste bucket and

open the nozzle to relieve pressure

and expel built up fluid.

Contact your Graco distributor for

repair or replacement.

Calibrate the meter for the fluid that is

being dispensed. See Calibrate

Screen, page 16.

Contact your Graco distributor for

repair or replacement.

26 312865R

Page 27

Problem Cause Solution

Preset Models only - Trigger does not

reset sufficiently to dispense fluid.

Meter leaks from twist lock nozzle.

• It is important to distinguish

between the two causes of this

problem. A new nozzle will NOT

correct a fluid leak caused by a

faulty valve.

Meter leaks from swivel.

Unit does not stop dispensing when

assumed preset amount is dispensed.

Troubleshooting

Excessive dirt buildup is causing trip

rod to stick.

Twist lock nozzle has a damaged

seal.

Valve has damaged or obstructed

seals.

Clean trip rod or replace (page 30).

Order Kit 255889.

Replace nozzle. See Step 1 in Installation Procedure, page 11.

Clean valve stem and o-rings or

replace. Order Kit 255888.

Poor swivel/hose connection. Apply PTFE tape (leave a minimum 2

engaged threads uncovered for electrical continuity) or sealant to threads

of hose and tighten the connection.

See Step 3 in Installation Procedure,

page 10.

Poor swivel/meter housing connec-

Torque the fitting to 20-25 ft.-lbs.

tion.

Swivel seals have deteriorated and

Replace swivel.

leak.

Valve is dirty. Clean valve.

Low battery. Replace batteries, page 29.

Solenoid not functioning (Preset

Replace solenoid.

only).

312865R 27

Page 28

Troubleshooting

Error Codes

Error codes are listed below. Even in an error condition the unit keeps track of the amount dispensed. With any error

code displayed you can:

• Select Manual option on Home Screen.

Error code is cleared. Unit switches to Manual mode and dispensed amount is displayed.

• Select reset option.

Error code is cleared, Unit switches to Auto mode and the present amount is displayed.

Error Code Cause Solution

Err 1 Battery voltage is low Change battery, page 29.

Ensure that your flow rate is not

higher than 14 gpm (37.8 lpm). For

further assistance, contact your

Graco distributor.

Select Reset, item G, page 21.

Check for low battery symbol and

replace batteries if indicated, page

29. For further assistance, contact

your Graco distributor.

Navigate to Home screen. Then

re-enter Dispense Screen.

Select Reset, item G, page 21 and

dispense again.To change the

shut-off default amount, see

Units/Limits Screen, page 15.

Enter an amount that is not zero. See

Preset Dispense Screen, page 22.

Change battery, page 29.

Err 2

Err 4

Err 5

Err 6

Switch Error: Error occurred with

pick-up in internal gear.

or

Unit was dropped or unit encountered excessive vibration during shipping.

Flow has continued after it should

have shut off.

or

Flow has occurred in lockout condition.

In Manual Mode only.

The unit has dispensed the shut-off

default amount and has stopped fluid

flow.

A present dispense amount of zero

was entered for the dispense or is

stored as the default and a Preset

dispense was attempted.

Battery voltage is too low.

or

Err7

28 312865R

CAP ERROR: Error has occurred in

control.

Replace the electronic bezel assembly. (See Manual Meters Parts page

36 or Preset Meters Parts page 38 to

identify which kit is required for your

meter).

Page 29

Service

ti10984a

47

(b)

(a)

See Parts List, page 43, for reference numbers included in the following Service instructions.

Replacing the Battery

• Only use the size and type of batteries specified in

this manual.

Batteries required to meet life expectancy:

•Energizer E91

• Be sure to follow the correct polarity when

installing batteries in the battery compartment (F

28). Reversed batteries may damage this meter.

• Do not mix different types of batteries together or

old batteries with fresh ones. Always replace all 4

batteries with 4, fresh, new batteries.

IG.

Service

The low battery and dead battery displays are explained

in the Troubleshooting Table, page 26.

To change the battery:

1. Press firmly on battery compartment cover. Using a

flat screwdriver turn latch screw counter-clockwise

1/2 turn.

2. Remove the battery compartment cover and batteries.

3. Install new batteries. See F

IG. 28 for battery orienta-

tion.

FIG. 28

4. Replace cover. The cover is designed to only fit on

battery compartment one way. The notch (a) on

cover fits into slot (b) on compartment. (F

.

F

IG. 29

IG. 29).

5. Press down firmly on cover. Using a flat screwdriver

turn latch screw clockwise 1/2 turn.

312865R 29

Page 30

Service

A

A

ti11936a

ti11937a

B

C

B

ti11938a

D

D

ti11939a

C

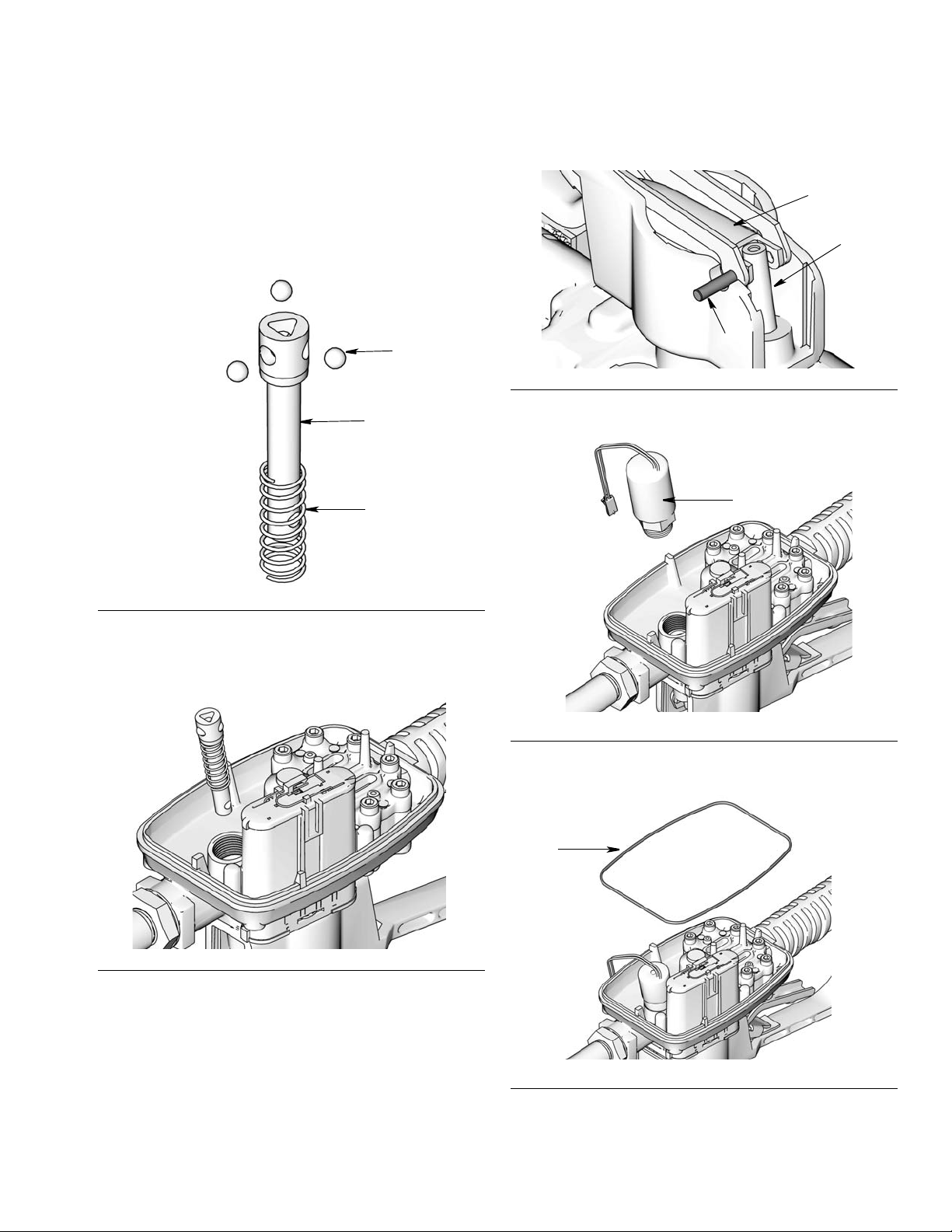

Trip Rod Repair

(SDP5 & SDP15 Meters Only)

Disassembly

1. Relieve Pressure, page 9.

2. Use a Torx (T20) wrench to remove 4 corner screws

(A) located on the bottom of the meter (F

Keep these screws for reassembly.

IG. 30).

4. With your finger, carefully

lift up clip (D) to discon-

nect battery lead (B) from battery module.

FIG. 32

NOTICE

Do not use a screw driver or any other tool to lift up

clip (D) when disconnecting battery lead (B) from battery module. If the clip is damaged or broken it cannot

be repaired; you will have to replace the battery module. Order Part No. 255197.

FIG. 30

3. Turn meter over and tilt cover back (F

You will not be able to completely remove the cover

until you disconnect the leads to the battery, solenoid and remove the reed switch PCB.

F

IG. 31

IG. 31).

5. Unsnap solenoid lead (C) (F

F

IG. 33

IG. 33).

30 312865R

Page 31

Service

ti11940a

D

5

ti11941a

9

ti12009a

12

ti12238a

6. Remove two screws (D) holding reed switch board

to the cover plate (F

IG. 34). Keep these screws for

reassembly. Remove cover assembly.

IG. 34

F

7. Remove and discard o-ring (5) (F

IG. 35).

down and out of groove on housing (F

IG. 36).

FIG. 36

9. Unscrew solenoid (12) and remove from meter

housing (F

IG. 37). If necessary, a pliers can be used

to loosen solenoid.

IG. 37

F

F

IG. 35

8. Remove guard (9) by inserting your thumb or finger

behind the cover and pry it loose. Then slide guard

312865R 31

Page 32

Service

ti12011a

19

19

ti12012a

ti12016a

6

ti12013a

6

10. Place meter in a vise as shown in FIG. 38. Use new

trip rod from your kit (2) or a non-metal rod or dowel

to push trip rod through meter housing (F

F

IG. 39) far enough to access pin (19) holding

IG. 38 and

together trip rod and trigger.

F

IG. 38

11. Use a pick to push pin (19) out (F

IG. 39).

13. Remove trip rod assembly from meter housing.

Be careful when you remove the trip rod assembly.

Cover the balls with your fingers or a rag to prevent

them from falling out.

F

IG. 41

Cleaning Trip Rod

a. If the trigger does not reset sufficiently to dis-

pense fluid, clean trip rod and spring with a soft

brush and cleaning fluid such as mineral spirits.

IG. 39

F

12. Remove trigger assembly (6) from meter housing.

F

IG. 40

b. Inspect trip rod and spring. If damaged, replace

using Trip Rod Replacement Kit 255889.

32 312865R

Page 33

Service

ti12014a

3

2

1

ti12015a

19

2

8

ti12238a

12

ti11941a

5

Reassembly

Use all the new parts provided in the kit. Do not reuse

the old parts.

1. Insert balls (3) in trip rod (2) (F

2. Slide spring (1) over trip rod (2) (F

IG. 42).

IG. 42).

5. Install trigger assembly (8) (F

IG. 44). Push pin (19)

through holes in trigger and trip rod assembly.

FIG. 44

6. Install solenoid (12). Finger tighten securely.

F

IG. 42

3. Insert trip rod assembly in opening in meter housing

(F

IG. 43).

IG. 45

F

7. Install o-ring (5).

IG. 43

F

4. Turn meter over and place in vise. Align holes in

trigger assembly with holes in trip rod (2). Use the

old trip rod or a non-metal rod or dowel to push trip

rod up and out of the meter housing (F

enough to see hole for pin (19) to slide into, however, do not install pin in this step.

IG. 44) far

IG. 46

F

312865R 33

Page 34

Service

ti11940a

D

ti11938ab

ED

D

ti11939a

C

8. Reinstall reed switch board in meter housing. Use 2

screws (D) to secure reed switch PCB to cover

plate. Tighten screws until they bottom out.

F

IG. 47

NOTICE

Do not use a screw driver or any other tool to lift up

clip (D) when reconnecting battery lead (B). If the clip

is damaged or broken it cannot be repaired; you will

have to replace the battery module. Order Part No.

255197.

9. Reconnect lead (B) to battery by carefully sliding

connector over battery terminals (E) until it snaps

securely into place under clip (D) (F

IG. 48

F

IG. 48).

10. Reconnect solenoid lead (C) (F

F

IG. 49

IG. 49).

11. Position cover over meter housing.

NOTICE

When replacing cover, be careful not to pinch wires.

34 312865R

Page 35

12. Replace 4 screws (A). Torque each to 15-25 inch

A

A

ti11936a

ti12009a

9

pounds.

F

IG. 50

13. Install guard (9).

Service

IG. 51

F

312865R 35

Page 36

SDM5 & SDM15 Manual Meters Parts

SDM5 & SDM15 Manual Meters Parts

(

Ref Part Description Qty

2 115477 SCREW, mach, torx pan hd 6

5 120812 O-RING, seal 1

6 15K418 TRIGGER, meter 1

9 15K464 GUARD, bumper 1

11 HOUSING, meter 1

17 255197 MODULE, battery 1

18 256493 KIT, repair, electronic bezel,

includes 18a and instruction man-

ual 312942

18a LABEL, control, overlay 1

19 120850 PIN, dowel M4 2

24 255888 KIT, repair, seals and spring only

includes 24a-24d and instruction

manual 312939

16F811 KIT, repair, valve, spring and seals

includes 24a-24f and instruction

manual 312939

24a PACKING, o-ring 1

24b PACKING, o-ring 1

24c O-RING, 3

24d SPRING, compression 6.1 x 76mm 1

24e CARTRIDGE, valve 1

24f STEM, valve 1

28 120853 PIN, dowel 1

31 247344 SWIVEL, straight, 1/2-14 NPT,

includes 31a (used with 255348,

255349, 255350, 255802, 255803,

255804, 256836, 256837)

247345 SWIVEL, straight, 3/4-14 NPT

includes 31a (used with 255800,

255801)

24H098 SWIVEL, straight, 1/2-14 BSPP,

includes 31a (used with 24H108,

224H110, 24H112, 24H130,

24H132, 24H150, 24H152)

24H100 SWIVEL, straight, 3/4-14 BSPP,

includes 31a (used with 24H126,

24H128)

24H097 SWIVEL, straight, 1/2-14 BSPT,

includes 31a (used with 24H109,

24H111, 24H113, 24H131,

24H133, 24H151, 24H153)

24H099 SWIVEL, straight, 3/4-14 BSPT

includes 31a (used with 24H127,

24H129)

31a 105765 O-RING 1

Ref Part Description Qty

32 15T366 BOOT, swivel, 3/4” hose, black,

NPT, BSPT (standard with meter)

15T367 BOOT, swivel, 3/4” hose, red, NPT,

BSPT

15T368 BOOT, swivel, 3/4” hose, blue,

NPT, BSPT

15T369 BOOT, swivel, 3/4” hose, green,

NPT, BSPT

15T370 BOOT, swivel, 3/4” hose, yellow,

NPT, BSPT

125961 BOOT, swivel, inlet, black, BSPP 1

126115 BOOT, swivel, inlet, red, BSPP 1

126116 BOOT, swivel, inlet, blue, BSPP 1

126117 BOOT, swivel, inlet, green, BSPP 1

126118 BOOT, swivel, inlet, yellow, BSPP 1

34 255885 KIT, filter, includes 34a-34c 1

34a FILTER, wire, 40 mesh 10

34b PACKING, o-ring 10

34c SPACER, strainer 10

39 15R057 BUSHING, stationary, rod 1

40 15R056 ROD, stationary 1

41 115999 RING, retaining 1

47 121413 BATTERY, pkg, 4 count, alkaline,

AA (page 29)

49 15T259 LABEL, CE 1

1

50 15T492 SPACER, 1/4 OD x 0.9 th 4

51 15T603 GUARD, right 1

52 15T604 GUARD, left 1

53 117436 SCREW, thd forming 2

1

Replacement Danger and Warning labels, tags and

cards are available at no cost.

1

1

1

1

1

1

1

1

1

1

36 312865R

Page 37

SDM5 & SDM15 Manual Meters Parts

34a

34b

34c

24b

24a

24e

24f

24c

24d

19

40

41

52

51

53

34

ti11916b

11

39

28

5

50

24c

49

18

9

32

31

31a

2

Torque to 15-25 IN. LBS

3

5

3

5

Torque to 20-30 FT. LBS

5

18a

17 / 47

6

312865R 37

Page 38

SDP5 & SDP 15 Preset Meters Parts

SDP5 & SDP 15 Preset Meters Parts

(

Ref Part Description Qty

2 115477 SCREW, mach, torx pan hd 6

3 255889 KIt, repair, trip rod, includes 3a-3c

and instruction manual 312944

3a BALL,5 MM, carbide 3

3b ROD 1

3c SPRING, compression 10.67 mm 1

5 120812 O-RING, seal 1

6 15K418 TRIGGER, meter 1

7 15K443 ARM, trip 1

8 15K446 PLATE, ratchet 1

9 15K464 GUARD, bumper 1

11 HOUSING, meter 1

12 15W093 SOLENOID 1

15 15K602 SPRING, torsion 1

17 255197 MODULE, battery 1

18 256494 KIT, repair, electronic bezel,

includes 18a and instruction man-

ual 312942

18a LABEL, control, overlay 1

19 120850 PIN, dowel M4 2

24 255888 KIT, repair, seals ands spring only,

includes 24a-24d and instruction

manual 312939

16F811 KIT, repair, valve and seal,

includes 24a-24f and instruction

manual 312939

24a PACKING, o-ring 1

24b PACKING, o-ring 1

24c PACKING, o-ring 3

24d SPRING, compression 6.1 x 76mm 1

24e CARTRIDGE, valve 1

24f STEM, valve 1

28 120853 PIN, dowel 1

31 247344 SWIVEL, straight, 1/2-14 NPT,

includes 31a (used with 255200,

255351, 255352, 255355, 255356,

256838, 256839)

247345 SWIVEL, straight, 3/4-14 NPT

includes 31a (used with 255353,

255354)

24H098 SWIVEL, straight, 1/2-14 BSPP,

includes 31a (used with 24H106,

224H114, 24H116, 24H122,

24H124, 24H154, 24H156)

24H100 SWIVEL, straight, 3/4-14 BSPP,

includes 31a (used with 24H118,

24H120)

24H097 SWIVEL, straight, 1/2-14 BSPT,

includes 31a (used with 24H107,

24H115, 24H117, 24H123,

24H125, 24H155, 24H157)

24H099 SWIVEL, straight, 3/4-14 BSPT

includes 31a (used with 24H119,

24H121)

Ref Part Description Qty

31a 105765 O-RING 1

32 15T366 BOOT, swivel, 3/4” hose, black

1

(standard with meter)

15T367 BOOT, swivel, 3/4” hose, red, NPT,

BSPT

15T368 BOOT, swivel, 3/4” hose, blue,

NPT, BSPT

15T369 BOOT, swivel, 3/4” hose, green,

NPT, BSPT

15T370 BOOT, swivel, 3/4” hose, yellow,

NPT, BSPT

125961 BOOT, swivel, inlet, black, BSPP 1

126115 BOOT, swivel, inlet, red, BSPP 1

126116 BOOT, swivel, inlet, blue, BSPP 1

1

34 255885 KIT, filter, includes 34a-34c 1

34a KIT, filter, wire, 40 mesh 10

34b PACKING, o-ring 10

34c SPACER, strainer 10

47 121413 BATTERY, pkg, 4 count, alkaline,

49 15T259 LABEL, CE 1

51 15T603 GUARD, right 1

52 15T604 GUARD, left 1

53 117436 SCREW, thd forming 2

Replacement Danger and Warning labels, tags and

1

1

1

1

1

1

126117 BOOT, swivel, inlet, green, BSPP 1

126118 BOOT, swivel, inlet, yellow, BSPP 1

AA (page 29)

cards are available at no cost.

1

1

1

1

1

1

38 312865R

Page 39

34a

34b

34c

24c

24b

24e

24f

24c

7

24d

15

6

19

8

3

18

24a

52

51

53

2

34

3a

3b

3c

ti10617a

11

28

49

5

9

18a

12

17 / 47

32

31

31a

Torque to 15-25 In. LBS

3

Torque to 20-30 FT. LBS

5

5

3

5

SDP5 & SDP 15 Preset Meters Parts

312865R 39

Page 40

Nozzle (33) and Extension (20) Kits

ti11826

ti11827

ti11825

ti11827

ti11831

ti11830

ti11826

ti11828

ti11825

ti11828

Nozzle (33) and Extension (20) Kits

Part No. Description Fluid Type

255852*

255853*

255854

Automatic, non-drip quick close nozzle with

rigid extension.

Automatic, non-drip quick close nozzle with

flexible extension

Non-drip, quick close nozzle with rigid

extension

Oil

Oil

Gear Lube

255855*

255856*

Non-drip, quick close nozzle with rigid extension

Non-drip, quick close nozzle with flexible

extension

Anti-freeze

Anti-freeze

*Used for dispensing 5gpm (22.7 lpm) or less.

40 312865R

Page 41

Part No. Description Fluid Type

ti11826

ti11829

ti11825

ti11829

Nozzle (33) and Extension (20) Kits

255857

255858

Non-drip, quick close, high-flow nozzle with

rigid extension

Non-drip, quick close, high flow nozzle with

flexible extension

Oil and

Anti-freeze

Oil and

Anti-freeze

312865R 41

Page 42

Nozzle (33) and Extension (20) Kits

Nozzle (33) Kits

255459* Automatic, non-drip, quick-close nozzle Qty Oil

• BODY, nozzle 1

• O-RING, packing 1

• SPRING, compression 1

• O-RING, packing 1

• STEM, nozzle, valve 1

• SEAT, valve 1

255460* Automatic, non-drip, quick-close nozzle Anti-freeze

• BODY, nozzle 1

• SPRING, compression 1

• O-RING, packing 1

• STEM, nozzle, valve 1

• O-RING, packing 1

• SEAT, valve 1

255461 Automatic, non-drip, high-flow nozzle Oil and Antifreeze

• STEM, nozzle 1

• BODY, nozzle 1

• O-RING, packing 1

• O-RING, packing 1

• O-RING, packing 1

255470 Non-drip, quick-close nozzle Gear Lube

• Housing 1

• Body, nozzle 1

• O-RING, packing 1

• O-RING, packing 1

• Plug, Hollow, hex 1

*Used for dispensing 5gpm (22.7 lpm) or less.

Thermal Relief Kits (page 8)

Part No. Description PSI (bar) Rating

112353 Diaphragm pump for fuel dispense, valve only 50 psi (.34 MPa, 3.4 bar)

235998

237601 Fire-Ball 425, 3:1 600 psi (4.1 MPa, 41 bar)

237893 Fire-Ball 300, 5:1 900 psi (6.2 MPa, 62 bar)

248296 Fire-Ball 300, 5:1 (same as 237893 without bung

238899 Diaphragm pump 150 psi (1 MPa, 10.4 bar)

240429 Fire-Ball 425, 6:1 and 10:1 1600 psi (11 MPa, 110 bar)

248324 Fire-Ball 425, 6:1 and 10:1 (same as 240429

42 312865R

Mini Fire-Ball

adapter and swivel. Includes 6-foot hose)

minus bung adapter and swivel. Includes 6-foot

hose)

™

225, 3:1

600 psi (4.1 MPa, 41 bar)

900 psi (6.2 MPa, 62 bar)

1600 psi (11 MPa, 110 bar)

Page 43

Technical Data

Technical Data

Flow range* 0.26 to 14 gpm (1 to 53 lpm)

Maximum Working Pressure 1500 psi (10 MPa, 103.4 bar)

Maximum Working Pressure

(50:50 antifreeze/water mix) 900 psi (6.2 MPa, 62 bar)

Units of Measure pints, quarts, gallons, liters (factory set to quarts)

Weight 5 pounds (2.26 kg)

Dimensions (without extension)

Length 13 inches (33 cm)

Width 3.75 inches (9.5 cm)

Height 5.75 inches (14.6 cm)

Units of measure factory set in quarts

maximum totalizer amount = 999,999 gallons or liters

maximum recorded dispensed volume = 999.99 units

maximum preset volume (Preset only) = 999.9 units

Inlet 1/2-14 npt or 3/4-14 npt,

or 1/2-14 BSPP or 3/4-14 BSPP,

or 1/2-14 BSPT or 3/4-14 BSPT

Outlet 3/4-16 straight thread o-ring boss

Operating temperature range 4 °F to 158°F (-16°C to 70°C)

Storage temperature range -40°F to 158°F (-40°C to 70°C)

Battery** 4AA alkaline or lithium batteries

Expected battery life in typical shop

environment

Wetted parts aluminum, stainless steel, PBT/PC, zinc,

nitrile rubber, CS

Fluid compatibility antifreeze, gear oil, crankcase oil, ATF

Meter pressure loss 80 psi @ 10 gpm

Accuracy† +/- 0.5 percent

1 year

*Tested in 10W motor oil. Flow rates vary with fluid pressure, temperature and viscosity.

**Battery required to meet life expectancy: Energizer

† At 2.5 gpm (9.5 lpm), at 70°F (21°C), with 10-weight oil and 1 gallon dispensed. May require calibration; out-of-box

accuracy is +/- 1.25 percent.

312865R 43

®

Alkaline E91.

Page 44

Graco Extended Metered Dispense Valve Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. Graco will, for a period of five (5) years from the date of sale, repair

or replace any non-electronic part of the equipment determined by Graco to be defective. Graco will also for a period of three (3) years from the

date of sale, repair, or replace any meter electronic components determined by Graco to be defective. This warranty applies only when the

equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008 Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312865

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised December 2014

Loading...

Loading...