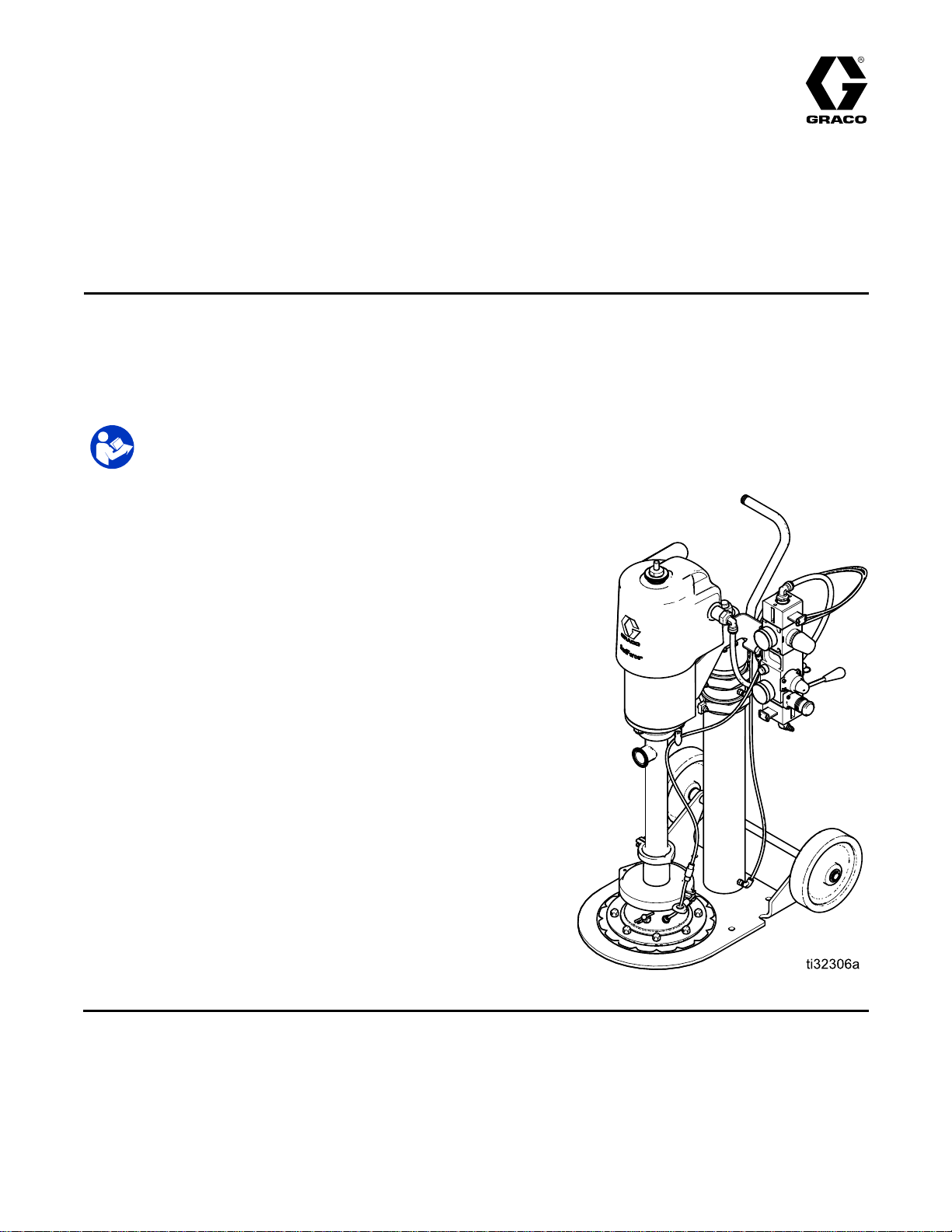

Graco SaniForce SPU.A01AAA1AA0C21, SaniForce SPU.A01AAA1AA0C31, SaniForce SPU.A01AAB1AA0C21, SaniForce SPU.A01AAB1AA0C31 Operation

Operation

SaniForce™

SaniForce™ SaniForce™

Pail

Pail Pail

For

For For

For

For For

Maximum Working Air Pressure: 100

psi (0.7 MPa, 7 bar)

Maximum Working Fluid Pressure: 650

psi (4.5 MPa, 45 bar)

Unloader

Unloader Unloader

use

with

food

use use

with with

professional

professional professional

Important

Important Important

Readallwarningsandinstructionsinthismanualandinmanuals

identiedintheRelatedManualstableonpage2.Save Save

instructions.

instructions. instructions.

grade

food food

grade grade

use

use use

Safety

Safety Safety

System

System System

bulk

bulk bulk

only.

only. only.

Instructions

Instructions Instructions

3A5400B

EN

supply

supply supply

of

medium

of of

medium medium

to

high

to to

viscosity

high high

viscosity viscosity

Save

product.

product. product.

all

all all

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents

Contents Contents

Models...............................................................2

RelatedManuals................................................2

Warnings...........................................................3

CongurationMatrix............................................5

Installation..........................................................6

GeneralInformation.....................................6

LocatethePumpSystem..............................6

Grounding...................................................7

FluidOutletLine...........................................7

Operation...........................................................8

PressureReliefProcedure............................8

FlushthePumpBeforeFirstUse..................8

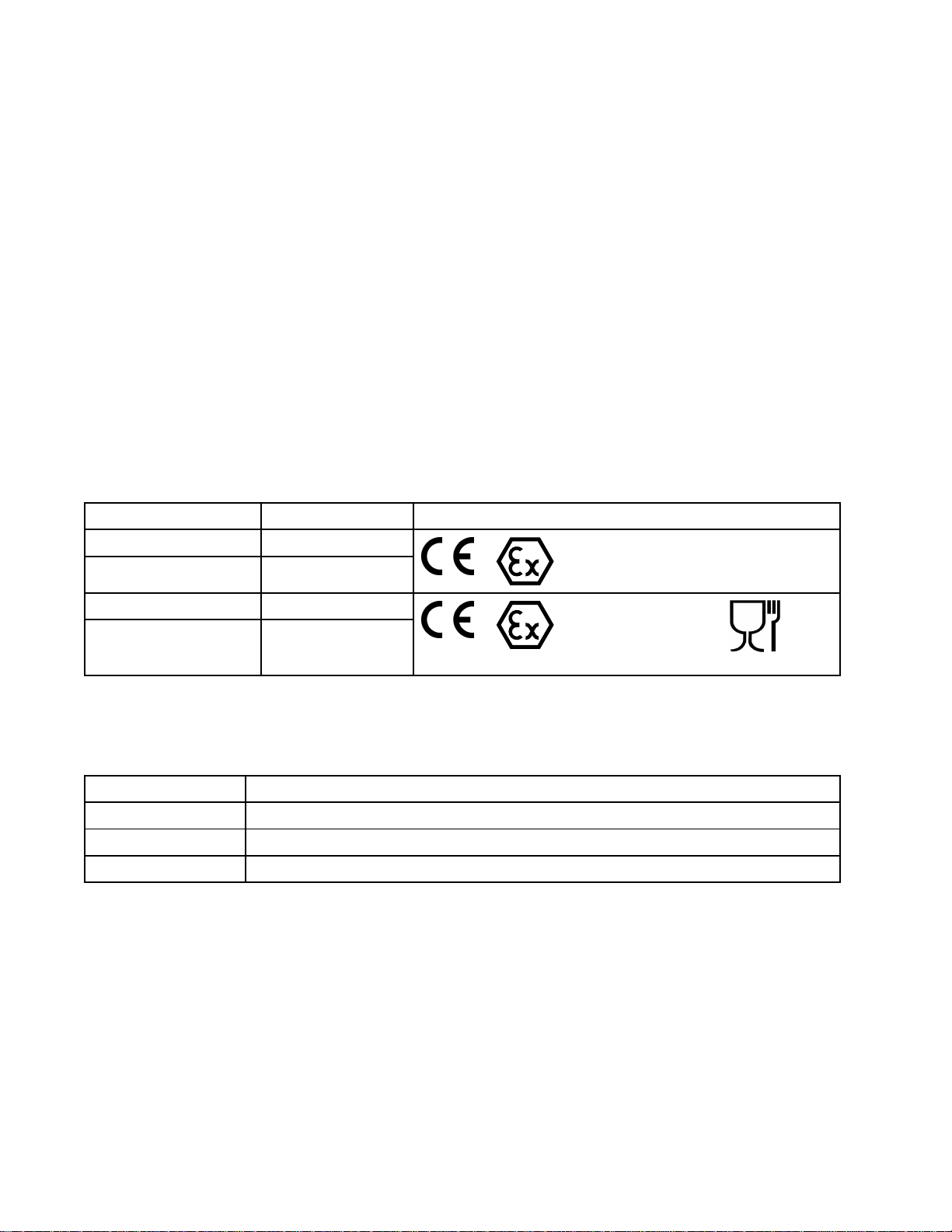

Models

Models Models

Model

Model Model

SPU.A01AAA1AA0C21

SPU.A01AAA1AA0C31

SPU.A01AAB1AA0C21

SPU.A01AAB1AA0C31

Certication

Certication Certication

EN10204,type2.1

EN10204,type3.1

EN10204,type2.1

EN10204,type3.1

StartandAdjustRam...................................8

StartandAdjustthePump............................8

ChangePail.................................................9

PumpShutdown..........................................9

Maintenance......................................................10

Lubrication...................................................10

FlushingandStorage...................................10

CleaningthePlaten......................................11

Dimensions........................................................12

TechnicalData...................................................13

GracoStandardWarranty....................................14

Approvals

Approvals Approvals

II2GD

ExhIIAT4GbX

ExhIIIA100°CDbX

II2GD

ExhIIAT4GbX

ExhIIIA100°CDbX

EC1935/2004

Related

Related Related

ManualNumberTitle

3A5564

3A5401

3A5800

2

Manuals

Manuals Manuals

SaniForce6:1SanitaryPumps,InstructionsandParts

SaniForcePailUnloaderSystem,Parts

SaniForceAirControls,Instructions/Parts

3A5400B

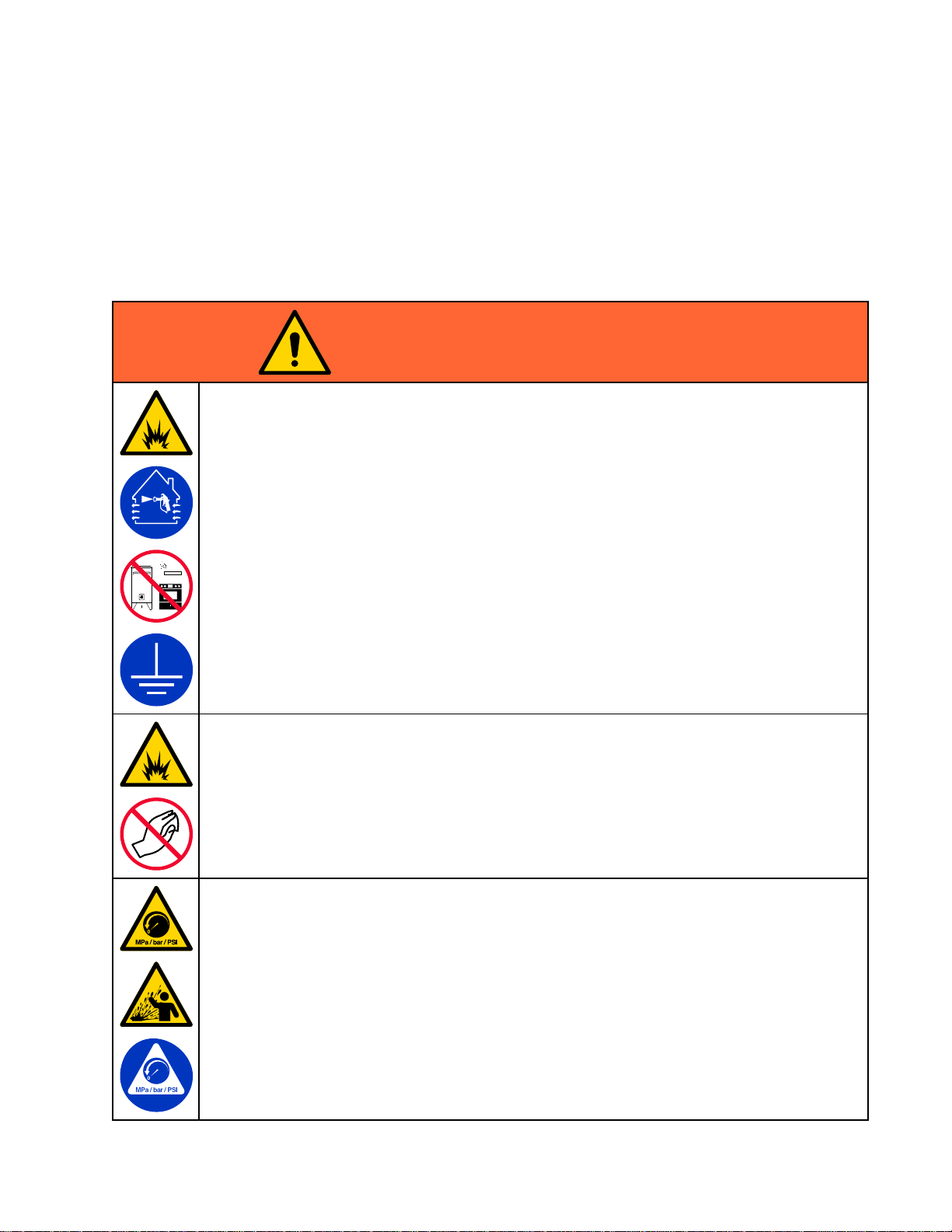

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

orsolventowingthroughtheequipmentcancausestaticsparking.Tohelppreventreand

explosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticsparking).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Useonlygroundedhoses.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Paint

Grounding

ifstaticsparkingoccursoryoufeelashock.Donotuse

instructions.

Warnings

SPECIAL

SPECIAL SPECIAL

Equipmentmustcomplywiththefollowingconditionstoavoidhazardousconditionwhich

cancausereorexplosion:

•Cleanplasticpartsonlyinwellventilatedarea.

•Donotcleanwithadrycloth.

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

•FollowthePressure Pressure

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

3A5400B 3

CONDITIONS

CONDITIONS CONDITIONS

EQUIPMENT

EQUIPMENT EQUIPMENT

Pressure

FOR

SAFE

FOR FOR

Relief

Procedure

Relief Relief

Procedure Procedure

USE

SAFE SAFE

USE USE

HAZARD

HAZARD HAZARD

whenyoustopspraying/dispensingandbefore

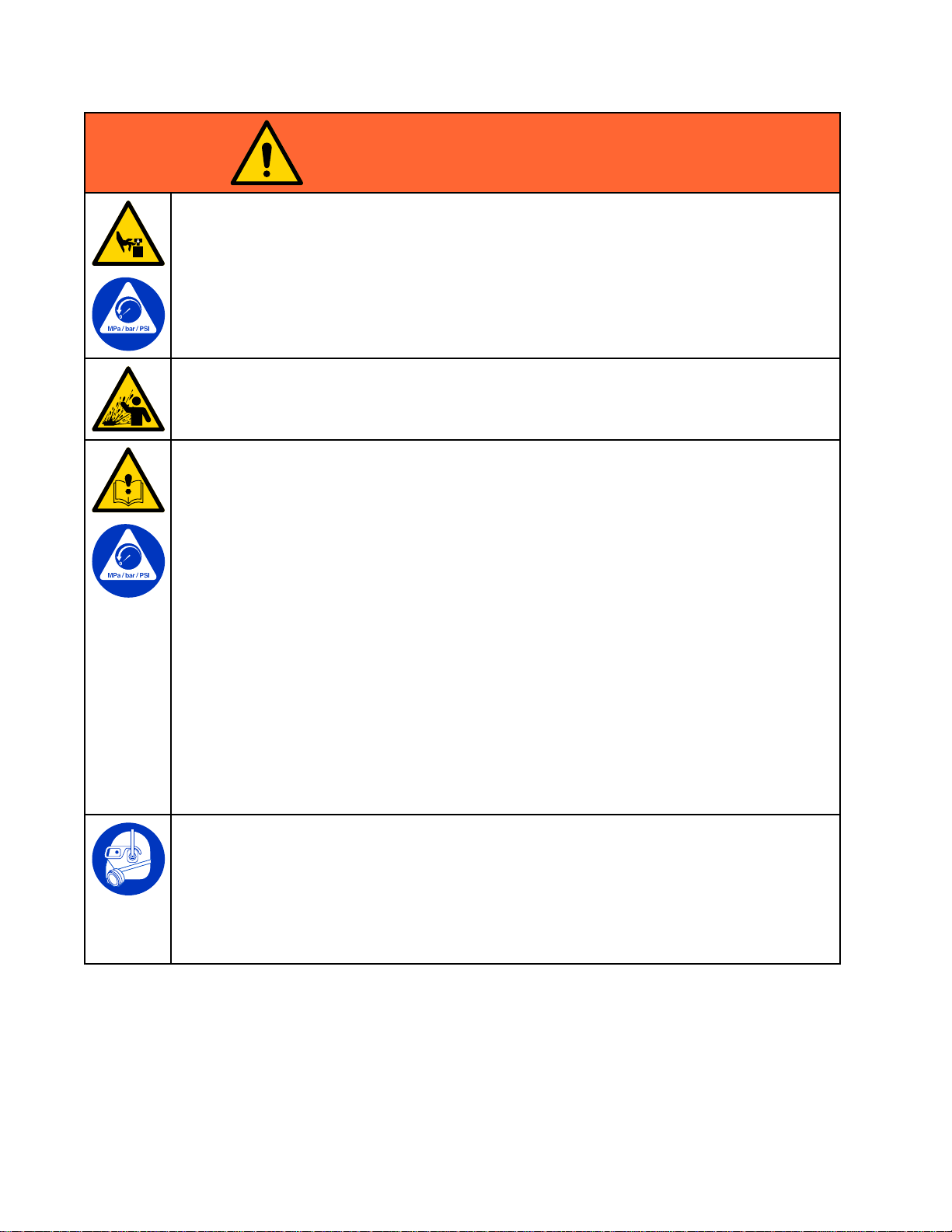

Warnings

WARNING

MOVING

MOVING MOVING

Movingpartscanpinchoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

anddisconnectallpowersources.

SPLATTER

SPLATTER SPLATTER

Duringblowoffofplaten,splattermayoccur.

•Useminimumairpressurewhenremovingplatenfromcontainer.

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestSafetyDataSheet(SDS)fromdistributororretailer.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PERSONAL

PERSONAL PERSONAL

HAZARD

HAZARD HAZARD

MISUSE

MISUSE MISUSE

PROTECTIVE

PROTECTIVE PROTECTIVE

HAZARD

HAZARD HAZARD

Technical

EQUIPMENT

EQUIPMENT EQUIPMENT

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Technical

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Data

Data Data

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

4

3A5400B

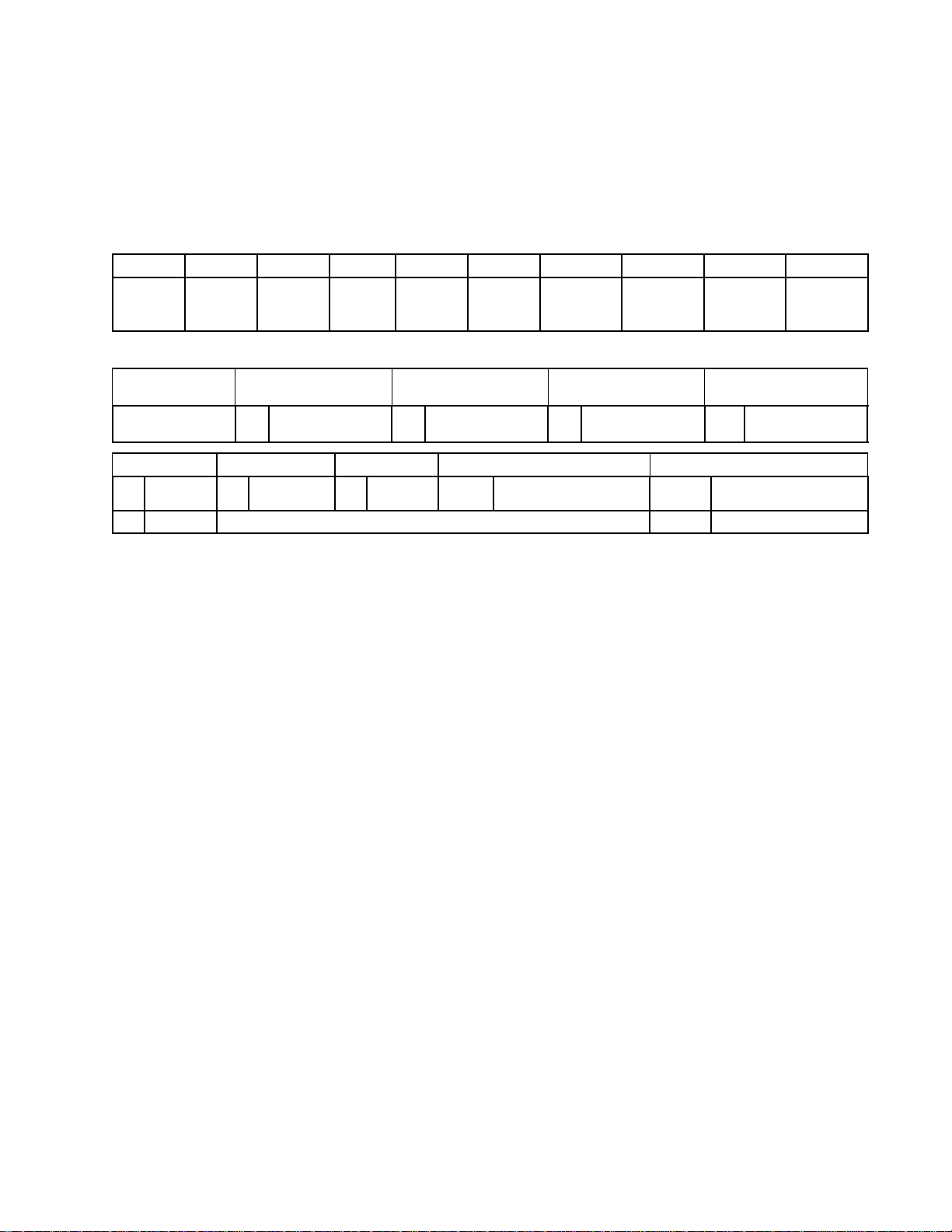

CongurationMatrix

Conguration

Conguration Conguration

Checktheidenticationplate(ID)forthe

CongurationNumberofyourpump.Usethe

Sample

Sample Sample

SPU

SPU SPU

Sanitary

PailUnloaderl

NOTE:

NOTE: NOTE:

SPU

SPU SPU

Seal

Seal Seal

A

A A

B

B B

Conguration

Conguration Conguration

A

A A

FramePumpPlaten

Somecombinationsarenotpossible.Pleasecheckwithyourlocalsupplier.

Sanitary

Sanitary Sanitary

Unloader

Unloader Unloader

Material

Material Material

PTFE

Buna-N

Pail

Pail Pail

01 01

A

A A

Controls

Controls Controls

Exposed

1

1 1

pneumatic

01

Number:

Number: Number:

StainlessSteel

Matrix

Matrix Matrix

SPU

SPU SPU

A

A A

Frame

Frame Frame

Accessoriess

Accessoriess Accessoriess

Mobile

AA

AA AA

followingmatrixtodenethecomponentsofyour

system.

A01AAA1AA0C21

A01AAA1AA0C21 A01AAA1AA0C21

5–7gallonplastic

pail

AA

AA AA

Accessories

Platen

Platen Platen

C21

C21 C21

C31

C31 C31

0

0 0

WashBin

Seal

Seal Seal

Static

A

A A

Certication

Certication Certication

EN10204type2.1

EN10204type3.1

C21

C21 C21

Certication

Style

Style Style

A

A A

Seal

Style

01

01 01

A

A A

Seal

Material

Pump

Pump Pump

6:1Priming

Piston

0

0 0

None

1

1 1

Controls

A

A A

Wash

Bin

Wash Wash

Bin Bin

3A5400B 5

Loading...

Loading...