Page 1

Operation

SaniForce 2150e, 3000e, 4000e,

Electric-Operated Diaphragm Pump

2–Inch, 3–Inch, and 4–Inch pumps with electric drive for fluid transfer applications.

Not approved for use in explosive atmospheres or hazardous locations unless otherwise stated. See

Approvals page for more information. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in your

Repair/Parts manual.

For Maximum Working Pressure, see

Technical Data sheets

See page 7 for approvals.

Save these instructions.

3A5132F

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Related Manuals ................................................ 2

Warnings ........................................................... 3

Configuration Number Matrix............................... 6

Ordering Information........................................... 8

Installation.......................................................... 9

General Information ..................................... 9

Tighten Clamps Before First Use .................. 9

Tips to Reduce Cavitation............................. 9

Mount the 2150T Pump................................ 12

Mount the HS Pump..................................... 13

Ground The System..................................... 14

Air Line........................................................15

Fluid Supply Line .........................................15

Fluid Outlet Line...........................................15

Electrical Connections .................................. 16

Leak Sensor Wiring...................................... 18

Compressor Wiring......................................19

Operation ........................................................... 20

Initial Configuration (AC with VFD)................ 20

Related Manuals

Manual Number Title

Sanitize the Pump Before First Use............... 20

Transfer Mode Vs. Low Pulsation

Mode............................................. 20

Start and Adjust the Pump............................ 20

Pressure Relief Procedure............................ 21

Pump Shutdown .......................................... 21

VFD Operation...................................................22

VFD Control Panel....................................... 22

Adjust the Speed ......................................... 22

Maintenance ...................................................... 23

Maintenance Schedule ................................. 23

Lubrication...................................................23

Tighten Connections ....................................23

Flushing and Storage...................................23

Performance Data .............................................. 24

Dimensions (2150T Pump) .................................. 28

Dimensions (3000HS Flapper Pumps) ................. 31

Technical Data ................................................... 33

3A5133 SaniForce™ 2150e, 3000e, 4000e, Electric-Operated Diaphragm Pump,

Repair/Parts

2

3A5132F

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific

risks. When these symbols appear i n the body of this manual or on warning labels, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where appli cable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and remove power before disconnecting any cables and before servicing or installing

equipment. For cart-mounted models, unplug the power cord. For all other units, disconnect

power at the main switch.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

and regulations.

• Wait five minutes for capacitor discharge b efore opening equipment.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in

or solvent flowing through the equipment can cause static sparking. To help prevent fire and

explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (po tential static arc).

• Ground all equipment in the work area. See

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Use only grounded hoses.

•

Stop operation immediately

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Static charge may build up on plastic parts during cleaning and could discharge and ignite

flammable vapors. To help prevent fire and explosion:

• Clean plastic parts only in well vent ilated area.

• Donotcleanwithadrycloth.

• Do not operate electrostatic guns in equipment work area.

if static sparking occurs or you feel a shock.Do not use

Grounding

work area

instructions.

canigniteorexplode.Paint

3A5132F 3

Page 4

Warnings

WARNING

PRESSURIZED EQUIPMENT HAZARD

Fluid from the equipment, leaks, or rup tured components can splash in the eyes or on skin

and cause serious injury.

• Follow the

cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs o r alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See

• Use fluids and solvents that are compatible with equipment wetted parts. See

in all equipment manuals. Read fluid and solve nt manufacturer’s warnings. For complete

information about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Turn off all equipment and follow the

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

Pressure Relief Procedure

Technical Data

when you stop spraying/dispensing and before

in all equipment manuals.

Technical Data

Pressure Relief Procedure

when equipment is not in use.

PRESSURIZ E D ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your material

supplier for compatibility.

4

3A5132F

Page 5

Warnings

WARNING

THERMAL EXPANSION HAZARD

Fluidssubjectedtoheatinconfinedspaces,includinghoses,cancreatearapidriseinpressure

due to the thermal expansion. Over-pressurization can result in equipment rupture and serious

injury.

• Openavalvetorelievethefluidexpansionduringheating.

• Replace hoses proactively at regular intervals based on your operating conditions.

PLASTIC PARTS CLEANING SOLVENT HAZARD

Many solvents can degrade plastic parts and cause them to fail, which could cause serious

injury or property damage.

• Use only compatible water-based solvents to clean plastic structural or pressure-containing

parts.

•See

Technical Data

solvent manufacturer’s Safety Data Sheet (SDS) and recommendations.

in this and all other equipment instruction manuals. Read fluid and

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of i t according to applicable

guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid

severe burns:

• Do not touch hot fluid or equipme nt.

PERSONAL PROTECTI V E EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and glo ves as recommended by the fluid and solvent

manufacturer.

3A5132F 5

Page 6

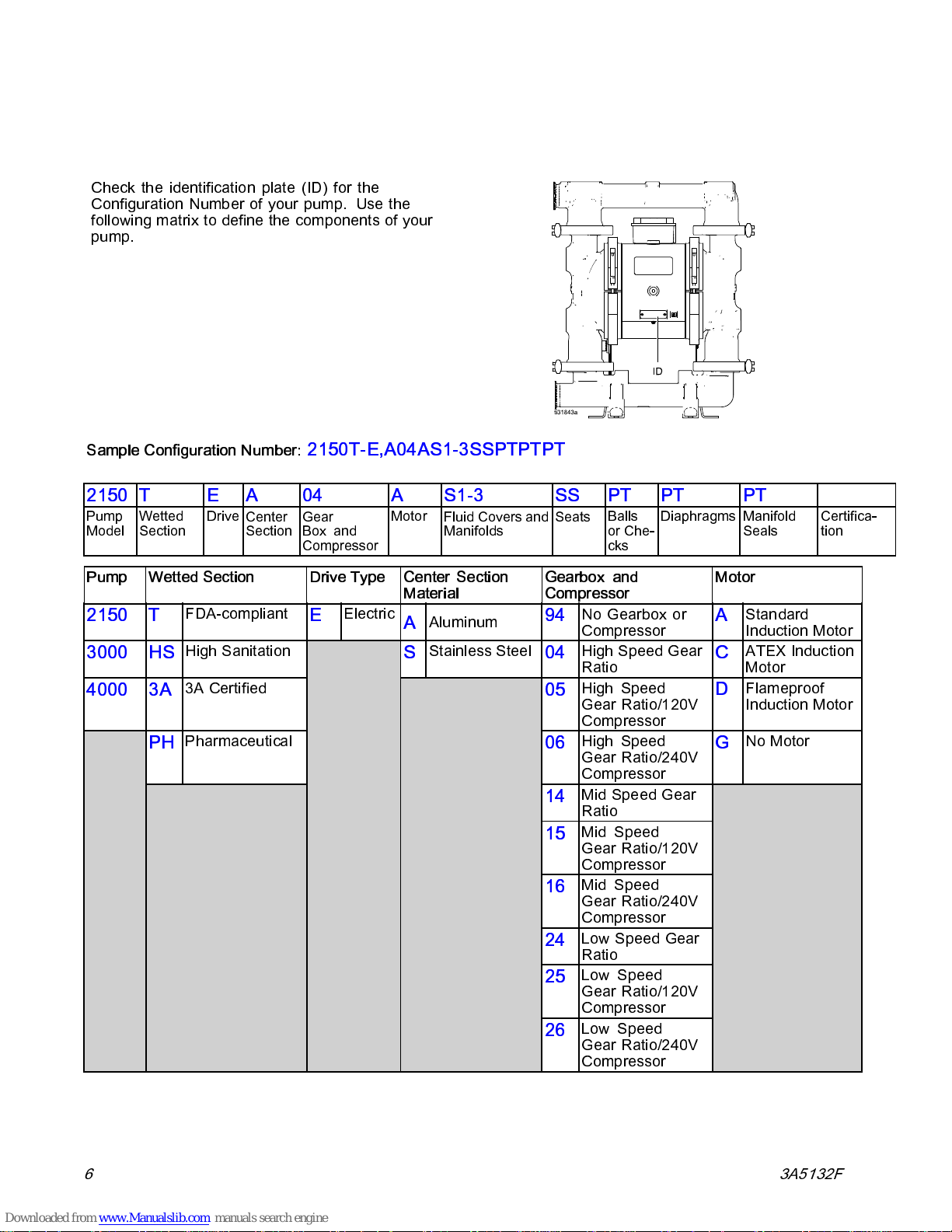

Configuration Number Matrix

Configuration Number Matrix

Check the identification plate (ID) for the

Configuration Number of your pump. Use the

following matrix to define the components of your

pump.

Sample Configuration Number:

2150

Pump

Model

Pump

2150

3000 HS

4000 3A

TEA

Wetted

Section

Wetted Section

T

PH

Drive

Center

Section

FDA-compliant

High San

3A Certified

Pharmaceutical

itation

2150T-E,A04AS1-3SSPTPTPT

04

Gear

Box and

Compressor

Drive Type

Electric

E

A

Motor

S1-3 SS

Fluid Covers and

Manifolds

Center Section

Material

Aluminu

A

Stainle

S

m

ss Steel

PT PT PT

Seats

Gearbox and

Compressor

94

04

05

06

14

15

16

24

25

26

Balls

or Che-

cks

No Gearbox or

Compressor

High Spe

Ratio

High Speed

Gear Ratio/120V

Compressor

High Speed

Gear Ratio/240V

Compressor

peed Gear

Mid S

Ratio

Mid Speed

Gear Ratio/120V

Compressor

Mid Speed

Gear Ratio/240V

Compressor

w Speed Gear

Lo

Ratio

Low Speed

Gear Ratio/120V

Compressor

Low Speed

Gear Ratio/240V

Compressor

Diaphragms

ed Gear

Manifold

Seals

Motor

Standard

A

Induction Motor

ATEX Induction

C

Motor

Flameproof

D

Induction Motor

No Motor

G

Certifica-

tion

6 3A5132F

Page 7

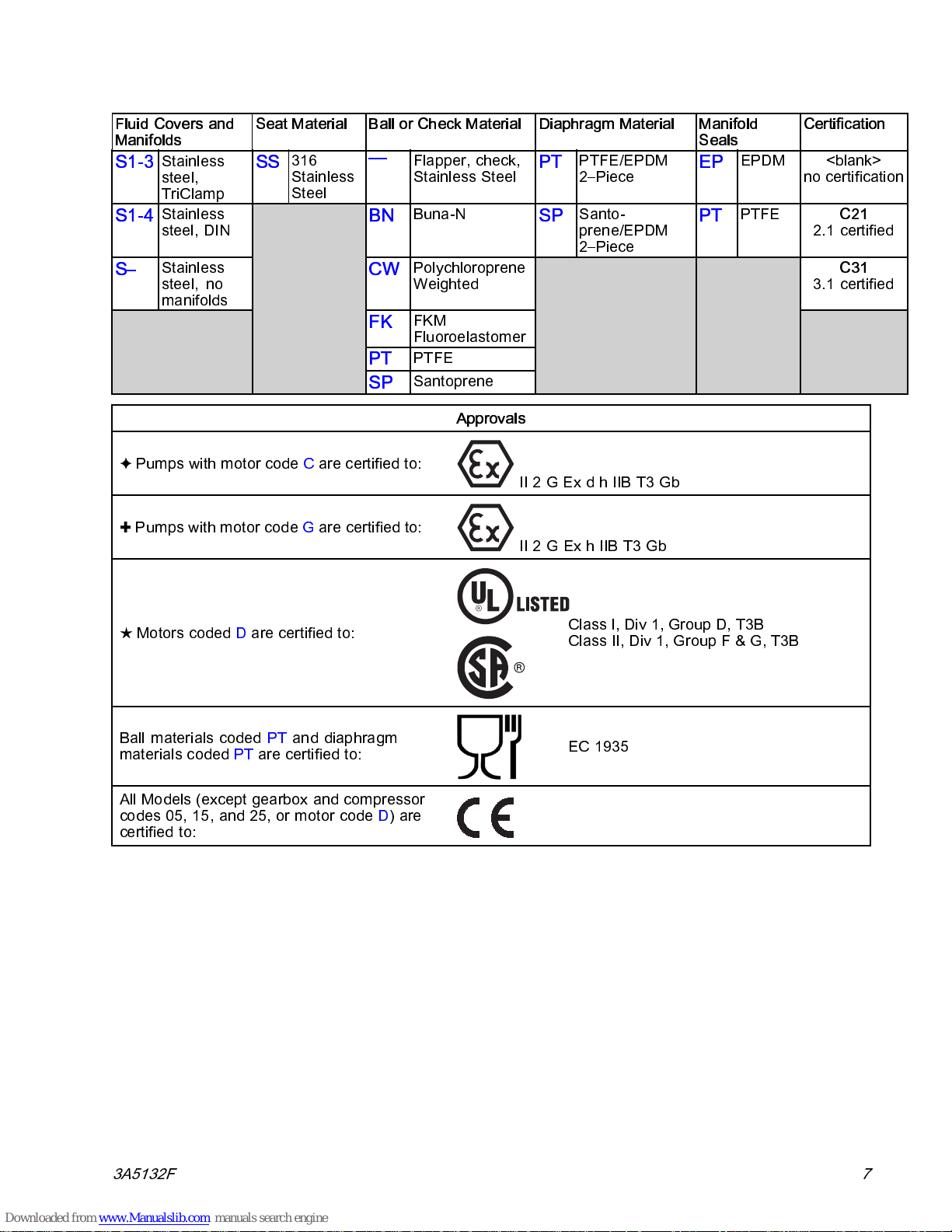

Configuration Number Matrix

Fluid Covers and

Manifolds

S1-3

S1-4

S–

Stainless

steel,

TriClamp

Stainless

steel, DIN

Stainless

steel, no

manifolds

Seat Material Ball or Check Material

SS

316

Stainless

Steel

—

BN

CW

FK

PT

SP

✦ Pumps with motor code C are certified to:

✚ Pumps with motor code G arecertifiedto:

Flapper, check,

Stainless Steel

Buna-N

Polychloroprene

Weighted

FKM

Fluoroelastomer

PTFE

Santoprene

Approvals

Diaphragm Material

PTFE/EPDM

PT

2–Piece

Santo-

SP

prene/EPDM

2–Piece

II 2 G Ex d h IIB T3 Gb

II2GExhIIBT3Gb

Manifold

Seals

EPDM <blank>

EP

PTFE

PT

Certification

no certification

C21

2.1 certified

C31

3.1 certified

★ Motors coded D arecertifiedto:

Ball materials coded PT and diaphragm

materials coded PT are certified to:

All Models (except gearbox and compressor

codes 05, 15, and 25, or motor code D)are

certified to:

Class I, Div 1, Group D, T3B

Class II, Div 1, Group F & G, T3B

EC 1935

3A5132F

7

Page 8

Ordering Information

Ordering Information

To Find Your Nearest Distributor

1. Visit www.graco.com.

2. Click on

To Specify the Configuration of a New Pump

Please call your distributor.

OR

Where to Buy

and use the

Distributor Locator.

Use the

Online Diaphragm Pump Selector Tool at www.graco.com.

To Order Replacement Parts

Please call your distributor.

Go to the

Process Equipment Page.

8 3A5132F

Page 9

Installation

Installation of this equipment involves potentially

hazardous procedures. Only trained and qualified

personnel who have read and who understand

the information in this manual should install this

equipment.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations

General Information

The Typical Installation shown i s only a guide for

selecting and installing system components. Contact

your Graco distributor for assistance in planning a

system to suit your needs. Always use Genuine

Graco Parts and accessories. Be sure all accessories

are adequately sized and pressure rated to meet the

system’s requirements.

Reference letters in the text, for example (A), refer to

the callouts in the figures.

Tighten Clamps Before First Use

After you unpack the pump, and before you use it

for the first time, check all clamps and tighten as

necessary.

Installation

Tips to Reduce Cavitation

Cavitation in a double diaphragm pump is the

formation and collapse of bubbles in the pumped

liquid. Frequent or excessive cavitation can cause

serious damage, including pitting and early wear of

fluid chambers, balls, and seats. It may result in

reduced efficiency of the pump. Cavitation damage

and reduced efficiency both result in increased

operating costs.

Cavitation depends on the va por pressure of the

pumped liquid, the system suction pressure, and the

velocity pressure. It can be reduced by changing any

of these factors.

1. Reduce vapor pressure: Decrease the

temperature of the pumped liquid.

2. Increase suction pressure:

a. Lower the installed position of the pump

relative to the liquid level in the supply.

b. Reduce the friction length of the suction

piping. Remember that fit tings add friction

length to the piping. Reduce the number of

fittings to reduce the friction length.

c. Increase the size of the suction piping.

NOTE:

exceed 25% of the outlet working pressure.

3. Reduce liquid velocity: Slow the cyclic rate of

the pump.

Pumped liquid viscosity is also very important but

normally is controlled by factors that are process

dependent and cannot be changed to reduce

cavitation. Viscous liquids are more difficult to pump

and more prone to cavitation.

Be sure the inlet fluid pressure does not

3A5132F 9

Graco recommends taking all the above factors

into account in system design. To maintain pump

efficiency, supply only enough power to the pump to

achieve the required flow.

Graco distributors can supply site specific

suggestions to improve pump performan ce and

reduce operating costs.

Page 10

Installation

Figure 1 Typical Installation for pumps without a

compressor

System Component s Accessories / Components Not Supplied

B Fluid inlet port A* Power cord to VFD

C Fluid outlet port F* Grounded, flexible air supply line

D Mounting feet G Bleed-type master air valve

E Air inlet port H Air filter/regulator assembly

P Pump Ground J Master air valve (for accessories)

R Center section regulator K* Grounded, flexible fluid supply line

10 3A5132F

L Fluid drain valve (may be required for your

pump installation)

M

Fluid shutoff valve

N* Grounded, flexible fluid outlet line

* Required. Supplied by cus tomer.

Page 11

Installation

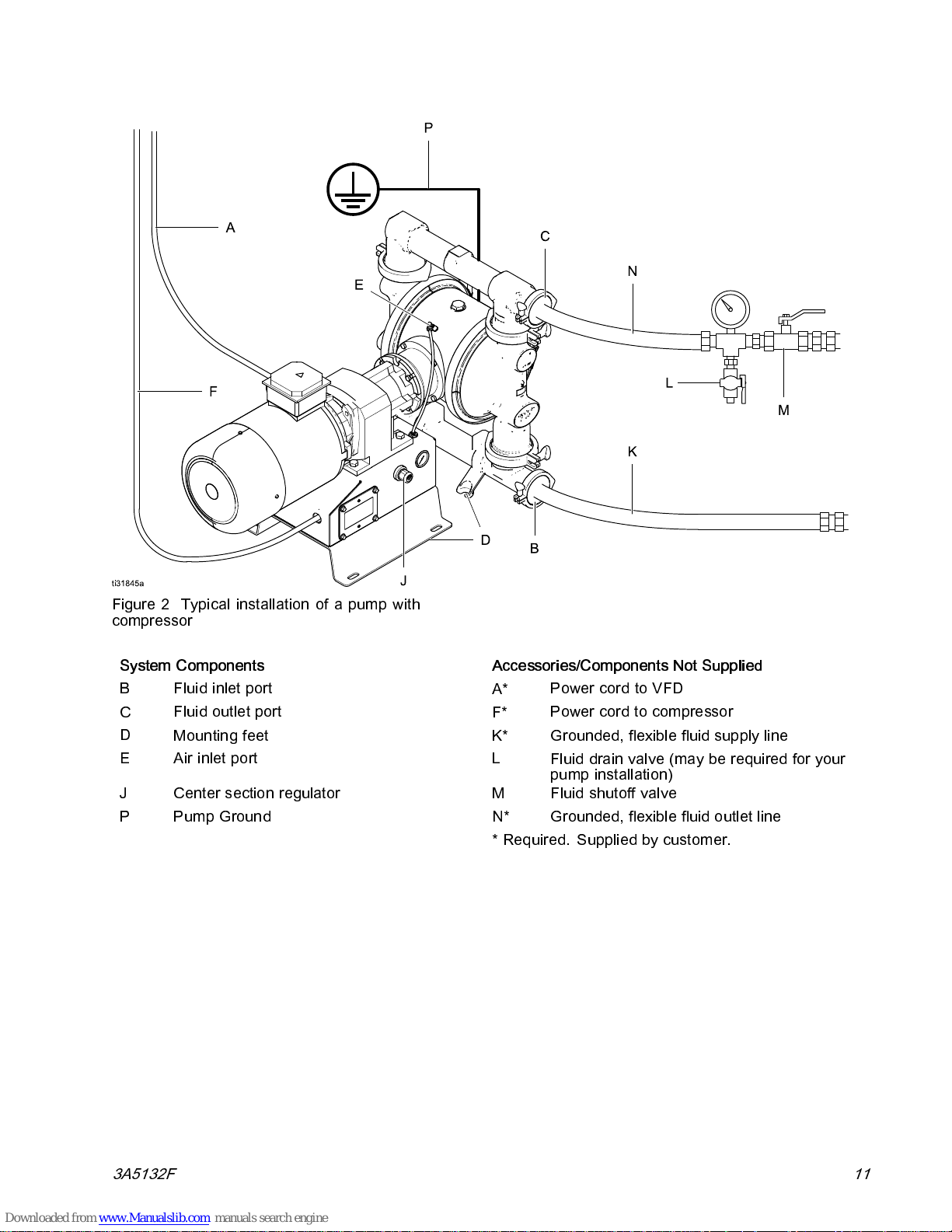

Figure 2 Typical installation of a pump with

compressor

System Components Accessories/Components Not Supplied

B Fluid inlet port

C

D

Fluid outlet port

Mounting feet K* Grounded, flexible fluid supply line

E Air inlet port L

A*

F*

Power cord to VFD

Power cord to compressor

Fluiddrainvalve(mayberequiredforyour

pump installation)

J

P

Center section regulator

Pump Ground N* Grounded, flexible fluid outlet line

M

Fluid shutoff valve

* Required. Supplied by customer.

3A5132F

11

Page 12

Installation

Mount the 2150T Pump

To avoid serious injury or death from toxic flu id or

fumes:

• Never move or lift a pum p under pressure. If

dropped, the fluid section may rupture. Always

follow the Pressure Relief Procedure, page 21,

before moving or lifting the pump.

• Do not expose pump or the plastic components

to direct sunlight for prolonged periods.

Prolonged exposure to UV radiation will degrade

natural polypropylene components of the pumps.

NOTICE

The pump is heavy. To prevent damage from

dropping, always use a lift to move the pump. Do

not use the manifolds to lift the pump. Use at least

two straps.

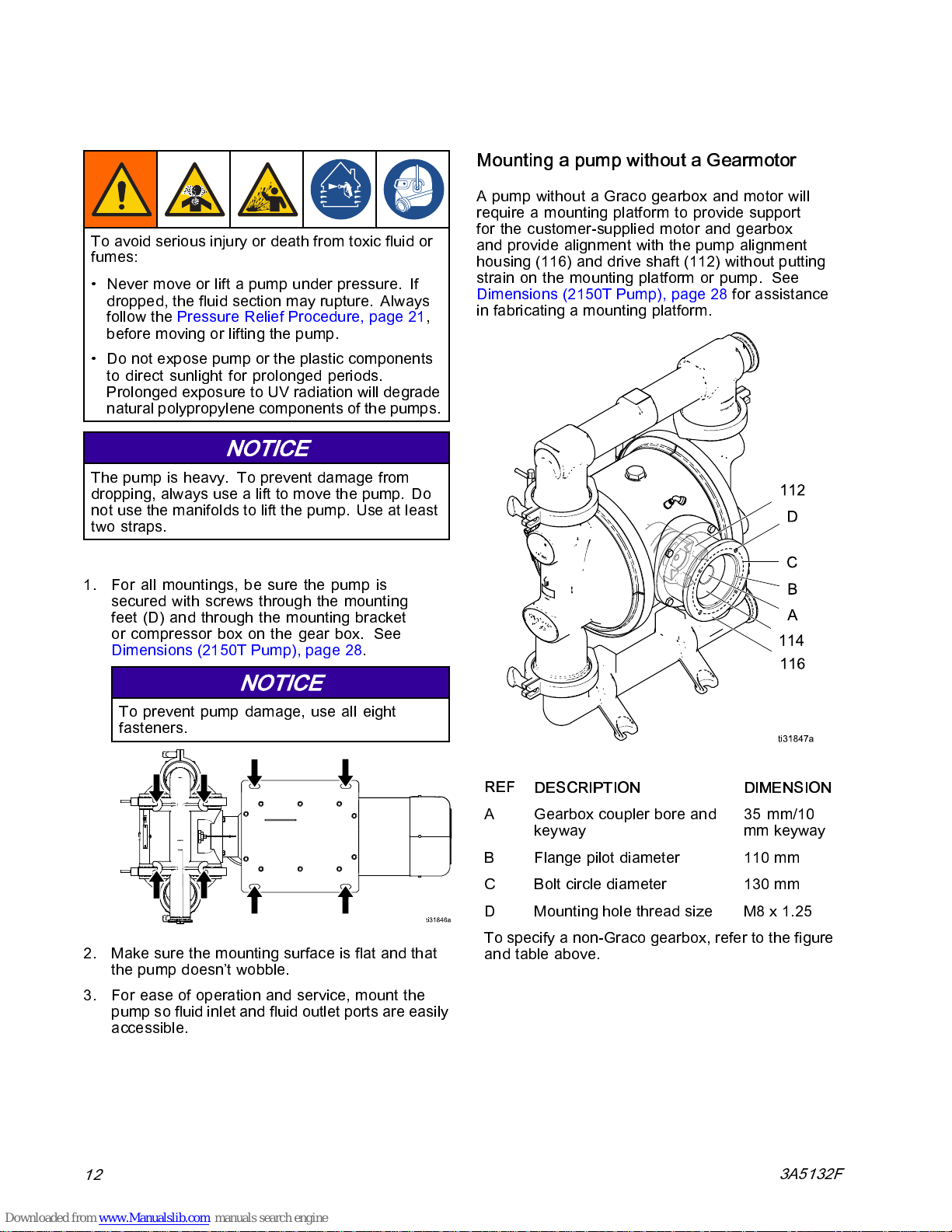

Mounting a pump without a Gearmotor

A pump without a Graco gearbox and motor will

require a mounting platform to provide support

for the customer-supplied motor and gearbox

and provide alignment with the pump alignment

housing (116) and drive shaft (112) without putting

strain on the mounting platform or pump. See

Dimensions (2150T Pump), page 28 for assistance

in fabricating a mounting platform.

1. For all mountings, be sure the pump is

d with screws through the mounting

secure

feet (D) and through the moun ting bracket

or comp

Dimensions (2150T Pump), page 28.

ressor box on t he gear box. See

NOTICE

vent pump damage, use all eight

To pre

fasteners.

2. Ma

3. Fo

ke sure the mounting surface is flat and that

the pump doesn’t wobble.

r ease of operation and servi ce, mount the

pump so fluid inlet and fluid outlet ports are easily

cessible.

ac

REF

A

B Flange pilot diameter 110 mm

C

D Mounting hole thread size M8 x 1.25

To specify a non-Graco gearbox, refer to the figure

and table above.

DESCRIPTION DIMENSION

Gearbox coupler bore and

keyway

Bolt circle diameter 130 mm

35 mm/10

mm keyway

12

3A5132F

Page 13

Mount the HS Pump

To avoid serious injury or death from toxic fluid or

fumes:

• Never move or lift a pump under pressure. If

dropped, the fluid section may rupture. Always

follow the Pressure Relief Procedure, page 21,

before moving or lifting the pump.

NOTICE

The pump is heavy. To prevent damage from

dropping, always use a lift to move the pump. Do

not use the manifolds to lift the pump. Use at least

two straps.

Installation

1. For all mountings, be sure the pump is secured

with screws through the moun ting bracket.

2. Make sure the mounti ng surface is flat and

that the pump base doesn’t wobble. See

Dimensions (3000HS Flapper Pumps), page 31.

NOTICE

To prevent pump damage, use all fasteners.

3. For ease of operation and service, mount the

pump so fluid inlet and fluid outlet ports are easily

accessible.

4. Attachthepumpbasetothemountingsurface.

3A5132F 13

Page 14

Installation

Ground The System

The equipment must be grounded to reduce the

risk of static sparking. Static sparking can cause

fumes to ignite or explode. Improper grounding

can cause electric shock.Grounding provides an

escape wire for the electrical current.

•

Always

described below.

•Followyou

ndtheentirefluidsystemas

grou

r local fire codes.

•

Air Line and Fluid hoses:

hoses with a maximum of 500 ft (150 m) combined

hose length to ensure grounding continuity. Check

electrical resistance of hoses. If total resistance

to ground exceeds 29 megohms, replace hose

immediately.

•

Fluid supply container:

•

Solvent pails used when flushing:

code. Use only conduc tive metal pails, placed

onagroundedsurface. Donotplacethepail

on a nonconductive surface, such as paper or

cardboard, which interrupts grounding continuity.

•

VFD:

Ground the variable frequency drive through

aproperconnectiontoapowersource.Referto

the VFD manual for grounding instructions.

Use only grounded

Follow local code.

Follow local

Before operating the pump, ground the system as

explained

•

Pump:

the grounding screw. Insert one end of a 12–gauge

minimum ground wire behind the ground screw

and tighten the screw securely. Connect the clamp

end of the grounding wire to a true earth ground. A

ground wire and clamp, Part 238909, is available

from Graco.

•

Motor:

box. Use it to ground the motor to the controller.

below.

All pumps have a ground screw. Loosen

Motors have a ground screw in the electrical

Check your system electrical continuity after the

initial installation, and then set up a regular schedule

for checking continuity to be sure proper grounding

is maintained. The resistance should not exceed 1

ohm.

14

3A5132F

Page 15

Installation

Air Line

Models that Include a Compressor:

An air line is already connected from the compressor

to the pump air inlet.

Using Your Own Compressor:

Install a gro unded, flexible air hose from the

compressor to the pump air inlet (E).

UsingShopAir:

1. Install an air filter/regulator assembly (H). The

fluid stall pressure will be the same as the setting

of the air regulator. The filter removes harmful

dirt and moisture from the compressed air supply.

2. Locate a bleed-type master air valve (G) close to

the pump and use it to relieve trapped air. Be

sure the valve is easily accessible from the pump

and located downstream from the regulator.

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious

injury from splashing.

3. Locate another master air valve (J) upstream

from all air line accessories and use it to isolate

them during cleaning and repair.

4. Install a grounded, flexible air hose (F) between

the accessories and the pump air inlet.

Fluid Supply Line

1. Use flexible, grounded fluid hoses.

2. For best sealing results, use a standard tri-clamp

or DIN style sanitary gasket of a flexible material

such as EPDM, Buna-N, fluoroelastomer, or

silicon.

3. If the inlet fluid pressure to the pump is more

than 25% of the outlet working pressure, the

ball check valves will not close fast enough,

resulting in inefficient pump operation. Excessive

inlet fluid pressure also will shorten diaphragm

life. Approximately 3–5 psi (0.02–0.03 MPa,

0.21–0.34 bar) should be adequate for m ost

materials.

4. For maximum suction lif t (wet and dry), see

Technical Data, page 33. For best results, always

install the pump as close as possible to the

material source. Minimize suction requirements

to maximize pump performance.

Fluid Outlet Line

1. Use flexible, grounded fluid hoses.

2. For best sealing results, use a standard tri-clamp

or DIN style sanitary gasket of a flexible material

such as EPDM, Buna-N, fluoroelastomer, or

silicon.

3. Install a fluid drain valve (L) near the fluid outlet.

4. Install a shutoff valve (M) in the fluid outlet line.

3A5132F 15

Page 16

Installation

Electrical Connections

6. Close the motor elec tric al box. Torque the bolts

to 20 in-lb (2.2 N•m).

Wire Connections at the ATEX Motor

(Motor Code C)

Wire Connections at the Motor

(Motor Code A)

NOTE:

manufacturer’s manual. Use a motor starter with

overload p

electrical devices must co mply with all local codes

and regula

The motor must be wired to the VFD. Install the

wiring at the motor as follows:

1. Remove 4 bolts to open the motor’s electrical

box.

2. Install a strain relief in one of the ports at the

bottom of the junction box.

3. Connect the green ground wire to the ground

screw.

4.

For 230 V motors:

connect L1 to T1, L2 to T2, and L3 to T3.

w the instructions in the motor

Follo

rotection. Wire size, fuse size, and other

tions.

Bridge as shown, then

T4 T5 T6

T7 T8 T9

T1 T2 T3

Install the wiring at the motor as follows:

1. Open the motor’s electrical box.

2. Install wiring system with proper connections to

the motor electrical box.

3. Connect the green ground wire to the ground

screw.

4.

For 400V Wiring:

Bridge as shown, then connect

wire L1 to U1, L2 to V1, and L3 to W1.

W2 U2 V2

U1 V1 W1

L2 L3L1

Figure 5 Connections for 400V Wiring

5.

For 230V Wiring:

ConnectwireL1toU1,L2to

V1, and L3 to W1. Bridge as shown.

W2 U2 V2

U1 V1 W1

L2 L3L1

Figure 3 Wire Connections for a 230 V Motor

5.

60 V motors:

For 4

Bridge as shown, then

connect L1 to T1, L2 to T2, and L3 to T3.

T4 T5 T6

T7 T8 T9

T1 T2 T3

L2 L3L1

Figure 4 Wire Connections for a 460 V Motor

16 3A5132F

L2 L3L1

Figure 6 Connections for 230V Wiring

6. Torque termi nal s to 20 in-l b (2.3 N•m).

7. Close the motor el ectrical box. Torque the

screwsto20in-lb(2.3N•m).

8. Connect thermostat wires P1 and P2 to external

overload detection. Thermostat is NC (normally

closed).

Page 17

Installation

Wire Connections at the Explosionproof

Motor (Motor Code D)

Install the wiring at the motor as follows:

1. Open the motor’s electrical box.

2. Install wiring system with proper connections to

the motor electrical box.

3. Connect the green ground wire to t he ground

screw.

4.

For 460V Wiring:

T2, and L3 to T3, and bridge the other wires, as

shown.

T1

T2

T3

T4

T7

T5

T8

T6

T9

Figure 7 Connections for 460V Wiring

5.

For 230V Wiring:

Then, connect L1 to T1/T7, L2 to T2/T8, and L3

to T3/T9.

T1

T7

T2

T8

T3

T9

T4

T5

T6

Figure 8 Connections for 230V Wiring

6. Connect thermostat wires P1 and P2 to external

overload detection. Thermostat is NC (normally

closed).

7. Close the motor electrical box. Torque the

screws to 20 in-lb (2.3 N•m).

ConnectwireL1toT1,L2to

L1

L2

L3

Bridge the wires as shown.

L1

L2

L3

Wire Connections at the Variable Frequency

Drive (VFD)

NOTE:

manufacturer’s manual.

Install the wiring at the VFD as follows:

1. Connect the wires to the motor. See

2. Open the VFD’s electrical box.

3. Install strain reliefs in both ports at the bottom of

4. Connect the green ground wire to the ground

5. Connect the wires from the motor terminals to the

Figure 9 Wire Connections from the Motor to the VFD

Follow the instructions in the VFD

Electrical Connections, page 16.

the VFD box.

screw.

matching terminals in the VFD box, as shown.

U/T1 V/T2 W/T3 PE

PES

PES

PES

PES

PES

PE

PE

3A5132F

17

Page 18

Installation

Main Power Connections at the VFD

All electrical wiring must be completed by a

qualified electrician and comply with all local codes

and regulations.

Connect the power supply wires to the VFD, as

follows:

1. Connect the

as detailed above.

2. Connect th

supply to the ground screw. The ground wire

from the mo

3. Connect the power supply wires to the power

terminal

and regulations.

4. Close the

wiring between the motor and VFD,

e green ground wire of the power

tor is also connected to this screw.

s in the VFD box, following all lo cal codes

VFD electrical box.

Leak Sensor Wiring

Follow these instructions to wire the Leak Sensor to

aVFD.

NOTE

: The leak sensor is designed to operate as

a normally-closed circuit.

1. Turn off power to the VFD.

2. Open the access cover on the VFD.

3. For a Graco VFD, perform the following:

a. Wire one lead to terminal 4 on t he rail.

b. Wire a second lead to terminal 13A on the

rail.

c. Close the access cover.

d. Turn on power to the VFD.

e. Go to screen P121.

f. Change the value to 21 and press the Mode

button.

4. For a non-Graco VFD, perform the following:

a. Attach the two leads to the detection circuit

in the VFD.

NOTE

: Refer to the VFD manual for proper

connection points.

b. Close the access cover.

c. Turn on power to the VFD.

d. Configure the VFD to monitor the leak sensor

circuit.

5. Refer to the VFD manual for information on how

to configure the VFD to generate a fault or stop

thepumpwhenaleakisdetected.

18 3A5132F

Page 19

Compressor Wiring

Installation

To avoid inju

ry from fire, explosion, or electric

shock, all electrica l wiring must be done by a

qualified el

ectrician and comply with all local codes

and regulations.

Follow thes

e instructions to wire Graco Compressor

24Y544 (120V) or 24Y545 (240V).

NOTE:

Use only copper wire with an insulation rating

of 75°C or higher.

1. Remove the cover from the compressor’s

electrical box.

Figure 10

2. Install wiring system with proper conn ections (i.e.

conduit/fittings, power cable/cable grip) to the

compressor electrical box.

3. Connect line power (120VAC or 240 VAC,

depending on your compressor) to L1 and L2/N.

Connect supply ground to

2

12 AWG (4 mm

)wirewhenthesystemis

. Use minimum

configuredfora16Acircuitand14AWG(2.5

2

) when configured for a 12A circuit. Torque

mm

terminals to 10 in-lb (1.2 N•m).

4. Reinstall the cover of the electrical box. Torque

screws to 60 in-lb (6.8 N•m ).

KEY

A

To power supply

3A5132F 19

A

L2

L1

Page 20

Operation

Operation

Initial Configuration (AC with VFD)

Configure the VFD according to the mo tor nameplate

information.

Sanitize the Pump Before First Use

It is the user’s responsibility to properly sanitiz e

the pump before first use. It is up to the user

whether this will include disassembling and cleaning

individual parts or simply flushing pump with a

sanitizing solution. As necessary, follow the steps

under Start and Adjust the Pump, page 20,or

Flushing and Storage, page 23 .

Transfer Mode Vs. Low Pulsation

Mode

When the air pressure is at least 10 psi higher than

the desired outlet pressure, the pump is in Transfer

Mode and no pulsation damping is occurring. To

reduce outlet pulsation, start by setting the air

pressure

Continue to adjust the air pressure relative to the

outlet fluid pressure. Lower relative air pressures

produce more pulsation damping. Higher relative air

pressures produce better pump efficiency.

equal

to the desired outlet fluid pressure.

Start and Adjust the Pump

1. Be sure the pump is properly grounded. See

Ground The System, page 14.

2. Check fittings to be sure they are tight. Use a

compatible liquid thread sealant on male threads.

Tighten fluid inlet and fluid outlet fittings securely.

3. Placethesuctiontube(ifused)influidtobe

pumped.

NOTE:

than 25% of outlet working pressure, the ball

check valves will not close fast enough, resulting

in inefficient pump operation.

If fluid inlet pressure to the pump is more

NOTICE

Excessive fluid inlet pressure can reduce

diaphragm life.

4. Place the end of the fluid hose into an appropriate

container.

5. Close the fluid drain valve.

6. Turn the air regulator kn ob to match th e desired

fluid stall pressure. Open all bleed-type master

air valves.

7. If the fluid hose has a dispensing device, hold it

open. Be sure all fluid shutoff valves are open.

8. Set the desired frequency on the VFD.

9. Press the start (run) button on the VFD.

10. If you are flushing, run the pump long enough to

thoroughly clean the pump and hoses.

20 3A5132F

Page 21

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is relieved manually. To help prevent serious

injury from pressurized fluid, such as splashing

in the eyes or on skin, follow the Pressure Relief

Procedure when you stop pumping and before you

clean, check, or service the equipment.

1. Remove power from the system.

2. Open the dispensing valve, if used.

3. Open the fluid drain valve (L), if used, to relieve

fluid pressure. Have a container ready to catch

the drainage.

4. Shut off the air supply to the pump.

5. Back out center section regulator to reliev e air

pressure in center section.

Pump Shutdown

At the end of the work shift and before you check,

adjust, clean, or repair the system, follow the

Pressure Relief Procedure, page 21.

3A5132F

21

Page 22

VFD Operation

VFD Operation

VFD Control Panel

NOTE:

VFD. For complete in formation about another

manufacturer’s VFD, see the manufacturer’s

instructions supplied with the VFD.

• The control panel display shows the status of the

• The green RUN key starts the motor.

• The red STOP key stops the motor.

• Use the arrow keys to speed up or slow down the

• The blue M key accesses the VFD menu. See the

This information is specific to Graco’s

motor.

motor.

manufacturer’s instructions for menu descriptions

and information.

NOTE:

If the M key is pressed, use the arrow keys

to scroll through the VFD menu.

FWDAUTO

REV

RUN

STOP

Figure 11 VFD Control Panel

Adjust the Speed

VFD settings are preset at the factory for most

applications. To change the speed of the pump, use

the arrow keys on the VFD control panel to increase

or decrease the motor speed.

22

3A5132F

Page 23

Maintenance

To avoid injury from fire, explosion, or electric

shock, all electrica l wiring must be done by a

qualified electrician and comply with all local codes

and regulations.

Maintenance Schedule

Maintenance

Flushing and Storage

To avoid inj

shock, always ground equipment and waste

container

splashing, always flush at the lowest possible

pressure.

ury from fire, explosion, or electric

. To avoid static sparking and injury from

.

Establish a preventive maintenance schedule

based on the pump’s service histo ry. Scheduled

maintenance is especially important to prevent spills

or leakage due to diaphragm failure.

Lubrication

The pump is lubricated at the factory. It is designed

to require no further lubrication for the life of the

bearings. There is no need to add an inline lubricator

under normal operating conditions.

Tighten Connections

Before each use, check all hoses for wear or damage

and replace as necessary. Check to be sure a ll

connections are tight and leak-free. Check mounting

bolts.

• Flush before first use.

• Flush at the end of the day, before storing, and

before repairing equipment.

• Flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

• Always flush the pump and relieve the pressure

before storing it for any length of time.

NOTICE

Flush the pump often enough to prevent the

fluid you are pumping from drying or freezing in

the pump and damaging it. Store the pump at

32°F (0°C) or higher. Exposure to extreme low

temperatures may result in damage to plastic parts.

3A5132F 23

Page 24

Performance Data

Performance Data

Test Conditions:

the inlet submerged. The air pressure was set at 100

psi (6.9 bar).

How to Use the Charts

1. Choose a flow rate and outlet pressure that fall s

below the Power Limit Curve. Conditions outside

of the curve will decrease the life of the pump.

Thepumpwastestedinwaterwith

2. Set the VFD frequency corresponding to the

desired flow rate. Flow rates will increase with

outlet pressure lower than 10 psi (0.7 bar) and

with high inlet head pressure.

3. To prevent inlet cavitation erosion, the

Positive Suction Head Available (NPSHa)

system should be above the

Head Required (NPSHr)

Net Positive Suction

line shown on the chart.

Net

of your

High speed gear ratio pumps with gearmotor and compressor (04), (05), or (06)

KEY

A

Power Limit Curve

B

Net Positive Suction Head Required

The shaded area is recommended for continuous

duty.

2150T FDA Pump

ncy — Hz (Pump Speed Cycles per Minute)

Freque

20

10

(53)30(80)40(106)50(133)60(160)70(186)80(212)90(238)

(27)

100

Outlet

Pressure

PSI

(bar, MPa)

(6.9, 0.69)

90

(6.2, 0.62)

80

(5.5, 0.55)

70

(4.8, 0.48)

60

(4.1, 0.41)

50

(3.5, 0.35)

40

(2.8, 0.28)

30

(2.1, 0.21)

20

(1.4, 0.14)

10

(0.7, 0.07)

0

020

(76)

40

(151)

A

35

(10.67)

30

(9.14)

25

(7.62)

20

(6.10)

15

(4.57)

10

B

60

(227)

80

(303)

100

(379)

120

(454)

(3.05)

5

(1.52)

0

140

(530)

NPSHr

feet WC

(meters

WC)

24

Fluid Flow — gpm (lpm)

3A5132F

Page 25

3000HS Flapper Pump

Condition

Performance Data

10 Hz 20 Hz 30 Hz 40 Hz 50 Hz 60 Hz

Maximum fluid flow, gpm (lpm)

Displacement per cycle, gallons (liters)

Medium spee

d gear ratio pumps with gearmotor and compressor (14), (15), or

(16)

KEY

A

Power Limit Curve

B

Net Positive Suction Head Required

The sha

duty.

2150T F

ded area is recommended for continuous

DA Pump

Frequency — Hz (Pump Speed Cycles per Minute)

20

(36)30(54)40(73)50(91)60(109)

100

(6.9, 0.69)

90

(6.2, 0.62)

80

(5.5, 0.55)

70

(4.8, 0.48)

Outlet

Pressure

PSI

(bar, MPa)

60

(4.1, 0.41)

50

(3.5, 0.35)

40

(2.8, 0.28)

30

(2.1, 0.21)

20

(1.4, 0.14)

10

(0.7, 0.07)

0

020

(76)

18.4

(69.5)

0.69

(2.6)

A

40

(151)

31.6

(120)

0.59

(2.2)

70

(127)

(145)

B

40.8

(154)

0.51

(1.9)

90

(163)

80

60

(227)

44.8

(170)

0.42

(1.6)

80

(303)

51.7

(196)

0.39

(1.5)

100

(379)

35

(10.67)

30

(9.14)

25

(7.62)

20

(6.10)

15

(4.57)

10

(3.05)

5

(1.52)

0

62.5

(237)

0.39

(1.5)

NPSHr

feet WC

(meters

WC)

3A5132F 25

Fluid Flow — gpm (lpm)

Page 26

Performance Data

Low speed gear ratio pumps with gearmotor and compressor (24), (25), or (26)

KEY

A

Power Limit Curve

B

Net Positive Suction Head Required

The shaded area is recommended for continuous

duty.

2150T FDA Pump

Frequency — Hz (Pump Speed Cycles per Minute)

90

30

(114)

(100)

40

(151)

50

(189)

60

(227)

35

(10.67)

30

(9.14)

25

(7.62)

20

(6.10)

15

(4.57)

10

(3.05)

5

(1.52)

0

NPSHr

feet WC

(meter

WC)

s

Outlet

Pressure

PSI

(bar, MPa)

100

(6.9, 0.69)

(6.2, 0.62)

(5.5, 0.55)

(4.8, 0.48)

(4.1, 0.41)

(3.5, 0.35)

(2.8, 0.28)

(2.1, 0.21)

(1.4, 0.14)

(0.7, 0.07)

20

(22)30(33)40(45)50(56)60(67)70(78)80(89)

90

80

70

60

50

40

30

20

10

0

010

(38)

A

B

20

(76)

26 3A5132F

Fluid Flow — gpm (lpm)

Page 27

Performance Data

How to Calculate Your System’s Net Positive Suction Head – Available

(NPSHa)

For a given flow rate, there must be a minimum

fluid head pressure supplied to the pump to prevent

cavitation. This minimum head is shown on the

Performance Curve, labeled as NPSHr. The units

are feet WC (Water Column) absolute. The NPSHa

NPSHa = Ha±Hz–Hf–H

Where:

Ha

is the absolute pressure on the surface of the liquid in the supply tank. Typically, this is atmospheric

pressure for a vented supply tank, e.g. 34 feet at sea level.

Hz

is the vertical distance in feet between the surface of the liquid in the supply tank and the centerline of the

pump inlet. Value should be positive if the level is higher th an the pump and negati ve if the level is lower

than the pump. Always be sure to use the lowest level the liquid can reach in the tank.

Hf

isthetotalofthefrictionlossesinthesuctionpiping.

Hvp

is the absolute vapor pressure of the liquid at the pumping temperature.

of your system must be greater than the NPSHr to

prevent cavitation and therefore increase efficiency

andthelifeofyoupump. TocalculatetheNPSHaof

your system, use the following equation:

vp

3A5132F

27

Page 28

Dimensions (2150T Pump)

Dimensions (2150T Pump)

Stainless steel pump with c ompressor

28 3A5132F

Page 29

Dimensions (2150T Pump)

Stainless steel pump without compressor

3A5132F 29

Page 30

Dimensions (2150T Pump)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

10.4

(26.4)

13.9

(35.3)

13.5

(34.3)

20.4

(51.8)

20.4

(51.8)

21.2

(53.8)

19.0

(48.3)

2.5

2.5

2.5

2.5

2.5

2.5

2.5

(6.4)

(6.4)

(6.4)

(6.4)

(6.4)

(6.4)

(6.4)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

37.4

37.5

43.8

33.9

34.9

41.4

30.4

(95.0)

(95.3)

(111.3)

(86.1)

(88.6)

(105.2)

(77.1)

6.3

6.3

6.3

6.3

6.3

6.3

6.3

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

43.7

(111.0)

43.7

(111.0)

50.1

(127.3)

40.2

(102.1)

41.2

(104.6)

47.7

(121.2)

36.6

(93.0)- - -

8.2

8.2

8.2

8.2

8.2

8.2

8.2

(20.8)

(20.8)

(20.8)

(20.8)

(20.8)

(20.8)

(20.8)

6.3

6.3

6.3

6.3

6.3

6.3

6.3

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

8.3

8.3

8.3

8.3

8.3

8.3

6.4

(21.1)

(21.1)

(21.1)

(21.1)

(21.1)

(21.1)

(16.3)

10.2

(25.9)

10.2

(25.9)

10.2

(25.9)

10.2

(25.9)

10.2

(25.9)

10.2

(25.9)

11.6

(29.5)

12.8

(32.5)

12.8

(32.5)

12.8

(32.5)

12.8

(32.5)

12.8

(32.5)

12.8

(32.5)

12.8

(32.5)

0.6

0.6

0.6

0.6

0.6

0.6

0.6

(1.5)

(1.5)

(1.5)

(1.5)

(1.5)

(1.5)

(1.5)

1.4

1.4

1.4

1.4

1.4

1.4

1.4

(3.6)

(3.6)

(3.6)

(3.6)

(3.6)

(3.6)

(3.6)

21.9

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

24.4

(62.0)

B

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

26.0

(66.0)

C

(55.6)

21.9

(55.6)

Motor and Gearbox Code – Dimensions shown in inches (cm)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

21.9

(55.6)

Ref. 94G 04A 05A, 06A 14A 15A, 16A 24A 25A, 26A 04C 14C 24C 04D 14D 24D

Table 1 Dimensions for SaniForce 2150T Pumps

A

19.0

19.4

19.4

20.2

20.2

---

D

(48.3)

(49.3)

(49.3)

(51.3)

(51.3)

2.5

2.5

2.5

2.5

2.5

2.5

E

(6.4)

(6.4)

(6.4)

(6.4)

(6.4)

(6.4)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

22.0

(55.9)

F

30.4

32.2

32.2

34.6

34.6

8.3

G

(77.1)

(81.9)

(81.9)

(87.9)

(87.9)

(21.1)

6.3

6.3

6.3

6.3

6.3

6.3

H

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

36.6

(93.0)

38.5

(97.8)

38.5

(97.7)

40.9

(103.8)

40.9

(103.8)

14.6

(37.1)

J

8.2

8.2

8.2

8.2

8.2

8.2

K

(20.8)

(20.8)

(20.8)

(20.8)

(20.8)

(20.8)

6.3

6.3

6.3

6.3

6.3

6.3

L

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

(16.0)

8.3

6.4

8.3

6.4

8.3

---

M

(21.1)

(16.3)

(21.1)

(16.3)

(21.1)

10.2

11.6

10.2

11.6

10.2

---

N

(25.9)

(29.5)

(25.9)

(29.5)

(25.9)

13.6

12.8

13.6

12.8

13.6

---

P

(34.5)

(32.5)

(34.5)

(32.5)

(34.5)

---

0.6

0.6

0.6

0.6

0.6

R

(1.5)

(1.5)

(1.5)

(1.5)

(1.5)

1.4

1.4

1.4

1.4

1.4

---

S

(3.6)

(3.6)

(3.6)

(3.6)

--- --- --- --- --- --- --- --- --- --- --- ---

(3.6)

13.9

(35.3)

T

3

0

3A5132F

Page 31

Dimensions (3000HS Flapper Pumps)

Dimensions (3000HS Flapper Pumps)

Pump w

3A5132F 31

ithout compressor

Page 32

Dimensions (3000HS Flapper Pumps)

(84)

33.2

(84)

33.2

(84)

33.2

(84)

33.2

(84)

33.2

(84)

33.2

40.1

(102)

40.1

(102)

40.1

(102)

40.1

(102)

40.1

(102)

40.1

(102)

41.9

(106)

41.9

(106)

41.9

(106)

41.9

(106)

41.9

(106)

41.9

(106)

(76)

29.8

(76)

29.8

(76)

29.8

(76)

29.8

(76)

29.8

(76)

29.8

7.0

7.0

7.0

7.0

7.0

7.0

(18)

(18)

(18)

(18)

(18)

(18)

(57)

22.3

(57)

22.3

(57)

22.3

(57)

22.3

(57)

22.3

(57)

22.3

23.0

23.1

29.4

39.5

40.5

47.0

(58)

(59

(75)

(100)

(103)

(119)

(28)

11.1

(28)

11.1

(28)

11.1

(28)

11.1

(28)

11.1

(28)

11.1

9.0

9.0

9.0

9.0

9.0

9.0

(23)

(23)

(23)

(23)

(23)

(23)

(66)

26.0

(66)

26.0

(66)

26.0

(66)

26.0

(66)

26.0

(66)

26.0

(38)

15.0

(38)

15.0

(38)

15.0

(38)

15.0

(38)

15.0

(38)

15.0

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

(84)

33.2

(84)

33.2

(84)

33.2

(84)

33.2

(84)

33.2

(84)

33.2

40.1

(102)

40.1

(102)

40.1

(102)

40.1

(102)

40.1

(102)

40.1

(102)

41.9

(106)

41.9

(106)

41.9

(106)

41.9

(106)

41.9

(106)

41.9

(106)

(76)

29.8

(76)

29.8

(76)

29.8

(76)

29.8

(76)

29.8

(76)

29.8

7.0

7.0

7.0

7.0

7.0

7.0

(18)

(18)

(18)

(18)

(18)

(18)

(57)

22.3

(57)

22.3

(57)

22.3

(57)

22.3

(57)

22.3

(57)

22.3

36.0

36.0

37.8

37.8

41.0

41.0

(91)

(91)

(96

(96)

(104)

(104)

(28)

11.1

(28)

11.1

(28)

11.1

(28)

11.1

(28)

11.1

(28)

11.1

9.0

9.0

9.0

9.0

9.0

9.0

(23)

(23)

(23)

(23)

(23)

(23)

(66)

26.0

(66)

26.0

(66)

26.0

(66)

26.0

(66)

26.0

(66)

26.0

(38)

15.0

(38)

15.0

(38)

15.0

(38)

15.0

(38)

15.0

(38)

15.0

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

0.63

(1.6)

Ref. 04A 05A, 06A 14A 15A, 16A 24A 25A, 26A 04C 14C 24C 04D 14D 24D

A

B

C

D

Table 2 Dimensions for SaniForce 3000HS Pumps

3

2

E

F

G

H

J

K

L

M

3A5132F

Page 33

Technical Data

Technical Data

SaniForce Electric Double Diaphragm Pump

US

Maximum fluid working pressure

2150 100 psi 0.69 MPa, 6.9 bar

3000HS, 4000HS

Air pressu re operating range

2150 20to100psi 0.14to0.69MPa,1.4

3000HS, 4000HS

Air i nle t size

Maximum suction lift (reduced if checks don’t s eat well due to damage, blockage, or extreme speed of cycling)

2150(@20Hz) Wet: 30 ft

3000HS, 4000HS Wet: 30 ft

Maximum size pumpable soli ds

2150T, 2 in. balls 1/4 in. 6.3 mm

3000HS, 3 in. fla pper

4000HS, 4 in. fla pper

Minimum ambient air temperature for operation and

storage.

NOTE:

in damage to plastic parts.

Fluid displacement per cycle (free-flow)

Maximum free-flow delivery (continuous duty)

Maximum pump speed (continuous duty)

Fluid Inlet and Outlet Size

2150T, Stainless Steel

2150HS

3000HS, 3A , PH, Stai nles s Steel

4000HS, 3A , PH, Stai nles s Steel

Electric Motor

AC, Sta nda rd CE (04A, 05A, 06A)

Exposure to extreme low temperatures may result

2150T 0.6 gallons 2.27 liters

3000HS, 4000HS

2150T 100 gpm 378 lpm

3000HS, 4000HS

Power 7.5 HP 5.5 kW

Number of Motor Poles

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

Voltage 3–phase 230V / 3–Phase 460V

60 psi 0.41 MPa, 4.1 bar

20 to 60 psi 0.14 to 0.41 MPa, 1.4

3/8 in. npt(f)

Dry: 14 ft

Dry: 8.4 ft

2.6 in. 66.0 mm

3.8 in 96.5 mm

32° F 0° C

0.69 gallons 2.61 liters

62.5 gpm 237 lpm

60 Hz/160 cpm

2.5 in sanitary connection or 65 mm DIN 11851

2 in. sanitary connection

3 in. sanitary connection

4 in. sanitary connection

4–Pole

6:1

11.25

Metric

to 6.9 bar

to 4.1 bar

Wet: 9.1 m

Dry: 4.3 m

Wet: 9.1 m

Dry: 2.5 m

3A5132F 33

Page 34

Technical Data

Maximum Amperage Load

19.5 A (230V) / 9.75 A (460V)

IE Rating IE3

AC, S tand ard CE (14A,15A,16A)

Power 5.0 HP 3.7 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

16.46

Voltage 3–phase 230V / 3–Phase 460V

Maximum Amperage Load

13.0 A (230V) / 6.5 A (460V)

AC, S tand ard CE (24A,25A,26A)

Power 3.0 HP 2.2 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

26.77

Voltage 3–phase 230V / 3–Phase 460V

Maximum Amperage Load

7.68 A (230V) / 3.84 A (460V)

IE Rating IE3

AC, ATEX (04C)

Power 7.5 HP 5.5 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

11.88

Voltage 3–phase 240V / 3–Phase 415V

Maximum Amperage Load

20 A (230V) / 11.5 A (460V)

AC, ATEX (14C)

Power 5.0 HP 4.0 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

16.46

Voltage 3–phase 240V / 3–Phase 415V

Maximum Amperage Load

14.7 A (230V) / 8.5 A (460V)

AC, ATEX (24C)

Power 3.0 HP 2.2 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

26.77

Voltage 3–phase 240V / 3–Phase 415V

Maximum Amperage Load

8.5 A (230V) / 5.0 A (460V)

34 3A5132F

Page 35

Technical Data

AC, E xp los ionp roof (04D)

Power 7.5 HP 5.5 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

11.88

Voltage 3–phase 230V / 3–Phase 460V

Maximum A mp erag e Load

20.0 A (230V) / 10.0 A (460V)

AC, E xp los ionp roof (14D)

Power 5.0 HP 3.7 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

16.46

Voltage 3–phase 230V / 3–Phase 460V

Maximum A mp erag e Load

13.0 A (230V) / 6.5 A (460V)

AC, E xp los ionp roof (24D)

Power 3.0 HP 2.2 kW

Number of Motor Poles

4–Pole

Speed 1800 rpm (60 Hz) or 1500 rpm (50 Hz)

Constant Torque

Gear Ratio

6:1

26.77

Voltage 3–phase 230V / 3–Phase 460V

Maximum A mp erag e Load

8 A (230V) / 4 A (460V)

Leak Sensor

Contact Ratings:

State

Voltage

Normally closed

240V Max (AC/DC)

Current 0.28 A max at 120 VAC

0.14 A max at 240 VAC

0.28 A max at 24 VDC

0.07 A max at 120 VDC

Power 30 W max

Ambient Temperature

-20° to 40°C (-4° to 104°F)

Ex Ratings:

Classification: “simp le apparatus” in accordance with UL/EN/IEC 60079-11, clause 5.7

Class I, Group D, Class II, Group F&G, Temp

Code T3B

Parameters Ui=24V

3A5132F 35

= 280 mA

I

i

=1.3W

P

i

=2.4pF

C

i

=1.00µH

L

i

II 2 G Ex ib IIC T3

Page 36

Technical Data

Noise Data

Sound Power (measured per ISO-9614–2)

at 90 psi fluid pressure and 80 cpm

at 60 psi fluid pressure and 160 cpm (full flow)

84 dBa

92 dBa

Sound Pressure [tested 3.28 ft (1 m) from equipment]

at 90 psi fluid pressure and 80 cpm

at 60 psi fluid pressure and 160 cpm (full flow)

74 dBa

82 dBa

Wetted Parts

Wetted parts include material(s) chosen for seat, ball, and diaphragm opti ons,

plus the pump’s material of

construction: Aluminum, Polypropylene, Stainless Steel, Conductive Polypropylene, or PVDF

Non-wetted parts

Non-wetted parts include aluminum, coated carbon steel, PTFE, stainless steel, polypropylene

36 3A5132F

Page 37

motor

Technical Data

2150T Pumps

Motor/Gearbox

253 433 196 407 185 599 271 509 231 500 227 299 136

557

04A 14A 24A

Center

lb kg lb kg lb kg

Section

––– ––– ––– –––

450 204

Stainless

Steel

Standard AC ATEX AC Flameproof AC No Gear-

Standard AC

Motor/Gearbox

04A 14A 24A 04C 14C 24C 04D 14D 24D 03G

442 200 410 186 390 177

Pump

Material

Center

Section lbkglbkglbkglbkglbkglbkglbkglbkglbkglbkg

Aluminum 360 163 328 149 308 139 475 215 351 159 325 147 517 234 427 194 418 190 217 9 8

Steel

Stainless

3000HS Flapper Pump

Pump

Material

3A5132F

3

7

Page 38

Technical Data

Variable Frequency Drives (2 hp)

Model Hp/kW Input Voltage Range

Nominal Output Voltage

†

17K696 3.0/2.2 170–264 Vac 208–240 Vac, 3 phase

17K697 3.0/2.2 340–528 Vac 400–480 Vac, 3 phase

25B446 5.0/4.0 170–264 Vac 208–240 Vac, 3 phase

25B447 5.0/4.0 340–528 Vac 400–480 Vac, 3 phase

25B448 7.5/5.5 170–264 Vac 208–240 Vac, 3 phase

25B449 7.5/5.5 340–528 Vac 400–480 Vac, 3 phase

†

Output voltage is dependent on input voltage.

Component/Model U.S. Metric

Compressor

28 lb 13 kg

Fluid Temperature Range

NOTICE

Temperature limits are based on mechanical stress only. Certain chemic als wil l further limit the fluid

temperature range. Stay within the temperature range of the most-restricted wetted component. Operating

at a fluid temperature that is too high or too low for the components of your pump may cause equipment

damage.

Stainless Steel PumpFluidTemperature

Range

Diaphragm/Ball/Seat Material Fahrenheit Celsius

Polychloroprene check balls (CW) 10° to 180°F -12° to 82°C

PTFE check balls or two-piece

PTFE/EPDM diaphragm (PT)

Buna–N check balls (BN) 0° to 180°F -18° to 82°C

FKM Fluoroelastomer check balls (FK)* -40° to 275°F -40° to 135°C

Santoprene check balls or 2–piece

diaphragm (SP)

*

The maximum temperature listed is based on the ATEX standard for T4 temperature

classification.

40° to 220°F 4° to 104°C

-40° to 180°F -40° to 82°C

38 3A5132F

Page 39

Notes

Notes

3A5132F 39

Page 40

Graco Standar

d Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be

free from def

of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the

date of sale,

only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage

or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance,

negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for

malfunction, damage or wear caused by the incompatibility of Graco equipment with structures, accessories,

equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized

Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace

free of charge any defective parts. The equipment will be returned to the original purchaser transportation prepaid.

If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made at a

reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer

agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost

sales, injury to person or property, or any other incidental or consequential loss) shall be available. Any action for

breach of warranty must be brought within two (2) years of the date of sale..

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS

OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO

Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco

will provide purchaser with reasonable assistance in making any claim for breach of these warranties..

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco

supplying equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto,

whether due to a breach of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and

legal proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn

up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais,

ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou en rapport,

directement ou indirectement, avec les procédures concernées.

ects in material and workmanship on the date of sale to the original purchaser for use. With the exception

repair or replace any part of the equipment determined by Graco to be defective. This warranty applies

. These items sold, but not manufactured by

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

To place an order,

Phone:

612-623-6921

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

contact your Graco Distributor or call to identify the nearest distributor.

or Toll Free:

Graco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English. MM 3A5132

International Offices:

Copyright 2017, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

1-800-328-0211

Graco Headquarters:

www.graco.com

Revision F, January 2019

Fax:

Belgium, China, Japan, Korea

612-378-3505

Minneapolis

Loading...

Loading...