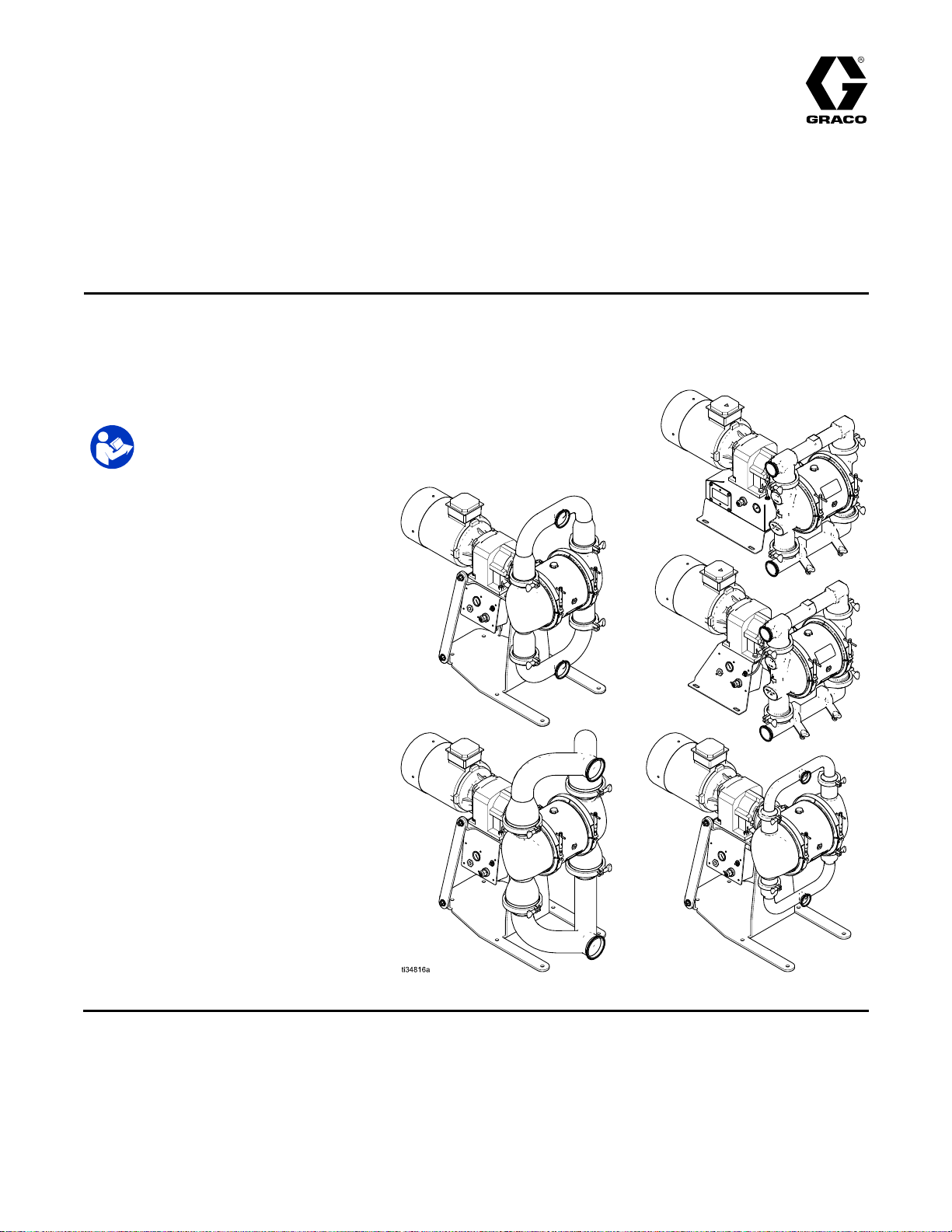

Graco SaniForce 2150, SaniForce 3000, SaniForce 4000 Repair Manual

Repair/Parts

SaniForce®

SaniForce® SaniForce®

Electric

Electric Electric

Inch,

2 22- --Inch, Inch,

Not

Not Not

stated.

stated. stated.

Formaximumworkingpressure,see

TechnicalSpecicationsheets.

Seepage10forapprovals.

3 33- --Inch, Inch,

approved

approved approved

See

See See

Important

Important Important

Readallwarningsandinstructionsinthismanualandinyour

Operationmanualbeforeusingtheequipment.Save Save

instructions.

instructions. instructions.

Operated

- --Operated Operated

Inch,

and

and and

for

for for

Approvals

Approvals Approvals

Safety

Safety Safety

2150,

2150, 2150,

Inch

4 44- --Inch Inch

use

use use

explosive

in ininexplosive explosive

page

page page

Instructions

Instructions Instructions

3000,

3000, 3000,

Diaphragm

Diaphragm Diaphragm

pumps

pumps pumps

with

electric

with with

electric electric

atmospheres

atmospheres atmospheres

for

more

for for

information.

more more

information. information.

4000,

4000, 4000,

Pump

Pump Pump

drive

for

uid

drive drive

for for

or

hazardous

or or

hazardous hazardous

For

For For

Save

transfer

uid uid

transfer transfer

professional

professional professional

these

these these

applications.

applications. applications.

(classied)

(classied) (classied)

use

use use

locations

locations locations

only.

only. only.

3A5133L

EN

unless

unless unless

otherwise

otherwise otherwise

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents

Contents Contents

RelatedManuals................................................2

Warnings...........................................................3

CongurationNumberMatrixfor2150FG

Pumps..................................................6

CongurationNumberMatrixfor2150,3000,

and4000HSPumps.............................8

Approvals...........................................................10

OrderingInformation...........................................11

Troubleshooting..................................................12

Related

Related Related

ManualNumberTitle

3A5132

Manuals

Manuals Manuals

SaniForce™2150,3000,4000,Electric-OperatedDiaphragmPump,Operation

Repair................................................................14

PressureReliefProcedure............................14

CheckValveRepair.....................................14

StandardDiaphragmRepair.........................17

OvermoldedDiaphragmRepair.....................19

CenterSectionRepair..................................21

InstallCompressorKits.................................26

ReplacetheCompressor..............................27

Parts..................................................................28

KitsandAccessories....................................38

TechnicalSpecications......................................39

2

3A5133L

Warnings

Warnings Warnings

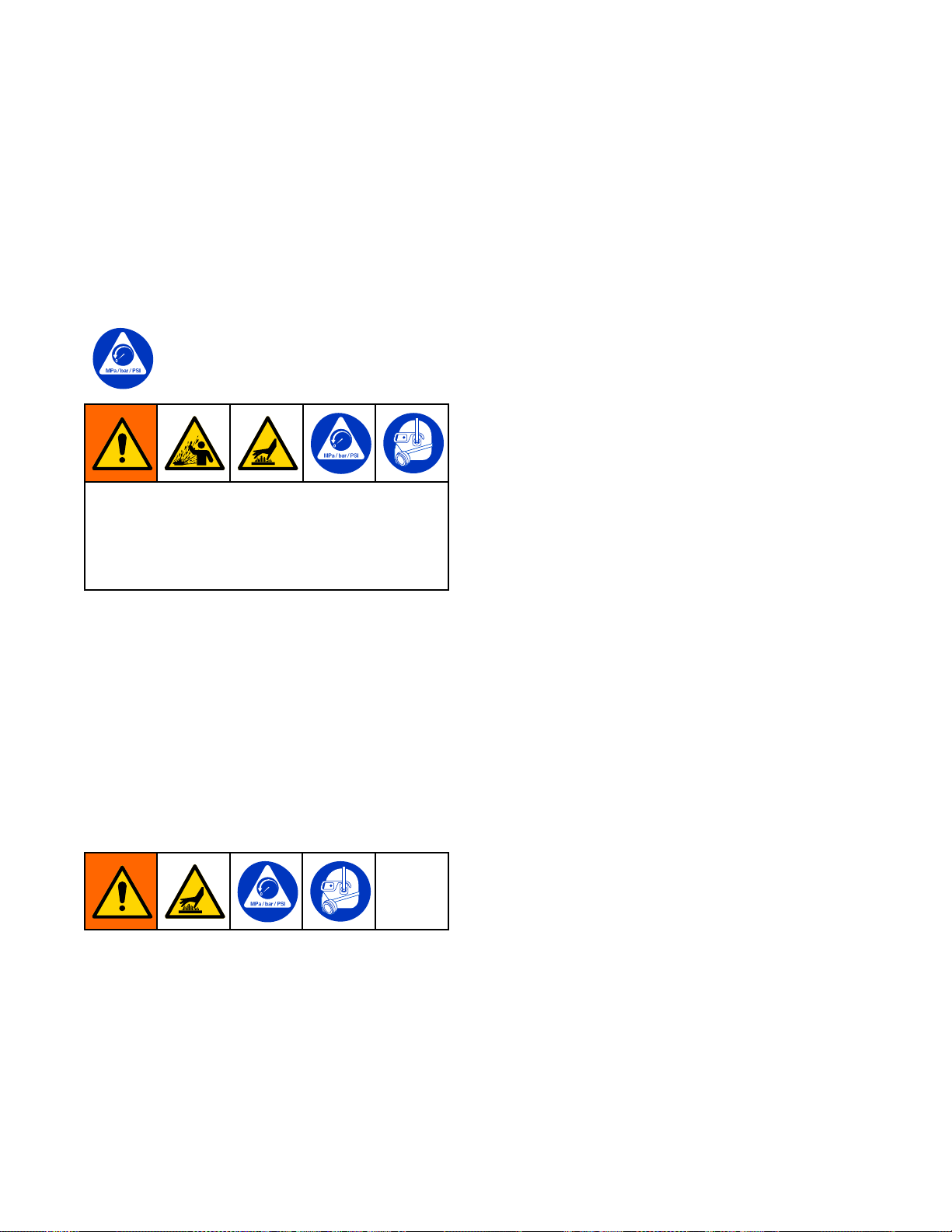

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

DANGER

SEVERE

SEVERE SEVERE

Thisequipmentcanbepoweredbymorethan240V.Contactwiththisvoltagewill

causedeathorseriousinjury.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesand

beforeservicingequipment.

•Thisequipmentmustbegrounded.Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocal

codesandregulations.

ELECTRIC

ELECTRIC ELECTRIC

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

Warnings

WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolvent,inwork work

theequipmentcancausestaticsparking.Tohelppreventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticsparking).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Useonlygroundedlines.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

Staticchargemaybuilduponplasticpartsduringcleaningandcoulddischargeandignite

ammablevapors.Tohelppreventreandexplosion:

•Cleanplasticpartsonlyinwellventilatedarea.

•Donotcleanwithadrycloth.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Solventowingthrough

Grounding

ifstaticsparkingoccursoryoufeelashock. ..Donotuse

instructions.

3A5133L3

Warnings

WARNING

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

EQUIPMENT

EQUIPMENT EQUIPMENT

HAZARD

HAZARD HAZARD

•FollowthePressure Pressure

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkuidlines,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

Forcompleteinformationaboutyourmaterial,requestSafetyDataSheet(SDS)from

distributororretailer.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routeuidlinesandcablesawayfromtrafcareas,sharpedges,movingparts,andhot

surfaces.

•Donotkinkoroverbenduidlinesoruseuidlinestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PRESSURIZED

PRESSURIZED PRESSURIZED

Pressure

MISUSE

MISUSE MISUSE

Relief

Procedure

Relief Relief

Procedure Procedure

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.

ALUMINUM

ALUMINUM ALUMINUM

PARTS

PARTS PARTS

whenyoustopspraying/dispensingandbefore

Specications

Specications Specications

Pressure

HAZARD

HAZARD HAZARD

Relief

Relief Relief

inallequipmentmanuals.

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Technical

Useofuidsthatareincompatiblewithaluminuminpressurizedequipmentcancauseserious

chemicalreactionandequipmentrupture.Failuretofollowthiswarningcanresultindeath,

seriousinjury,orpropertydamage.

•Donotuse1,1,1-trichloroethane,methylenechloride,otherhalogenatedhydrocarbon

solventsoruidscontainingsuchsolvents.

•Donotusechlorinebleach.

•Manyotheruidsmaycontainchemicalsthatcanreactwithaluminum.Contactyourmaterial

supplierforcompatibility.

4

3A5133L

WARNING

THERMAL

THERMAL THERMAL

Fluidssubjectedtoheatinconnedspaces,includinglines,cancreatearapidriseinpressure

duetothethermalexpansion.Over-pressurizationcanresultinequipmentruptureandserious

injury.

•Openavalvetorelievetheuidexpansionduringheating.

•Replacelinesproactivelyatregularintervalsbasedonyouroperatingconditions.

EXPANSION

EXPANSION EXPANSION

HAZARD

HAZARD HAZARD

Warnings

PLASTIC

PLASTIC PLASTIC

Manysolventscandegradeplasticpartsandcausethemtofail,whichcouldcauseserious

injuryorpropertydamage.

•Useonlycompatiblesolventstocleanplasticstructuralorpressure-containingparts.

•SeeTechnical Technical

thesolventmanufacturerforinformationandrecommendationsaboutcompatibility.

•SeeTechnical Technical

andsolventmanufacturer’sSafetyDataSheet(SDS)andrecommendations.

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheet(SDS)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

BURN

BURN BURN

Equipmentsurfacesanduidthat’sheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

PARTS

PARTS PARTS

Technical

Technical

FLUID

FLUID FLUID

HAZARD

HAZARD HAZARD

CLEANING

CLEANING CLEANING

Specications

Specications Specications

Specications

Specications Specications

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

SOLVENT

SOLVENT SOLVENT

inallequipmentmanualsformaterialsofconstruction.Consult

inthisandallotherequipmentinstructionmanuals.Readuid

HAZARD

HAZARD HAZARD

EQUIPMENT

EQUIPMENT EQUIPMENT

HAZARD

HAZARD HAZARD

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

3A5133L5

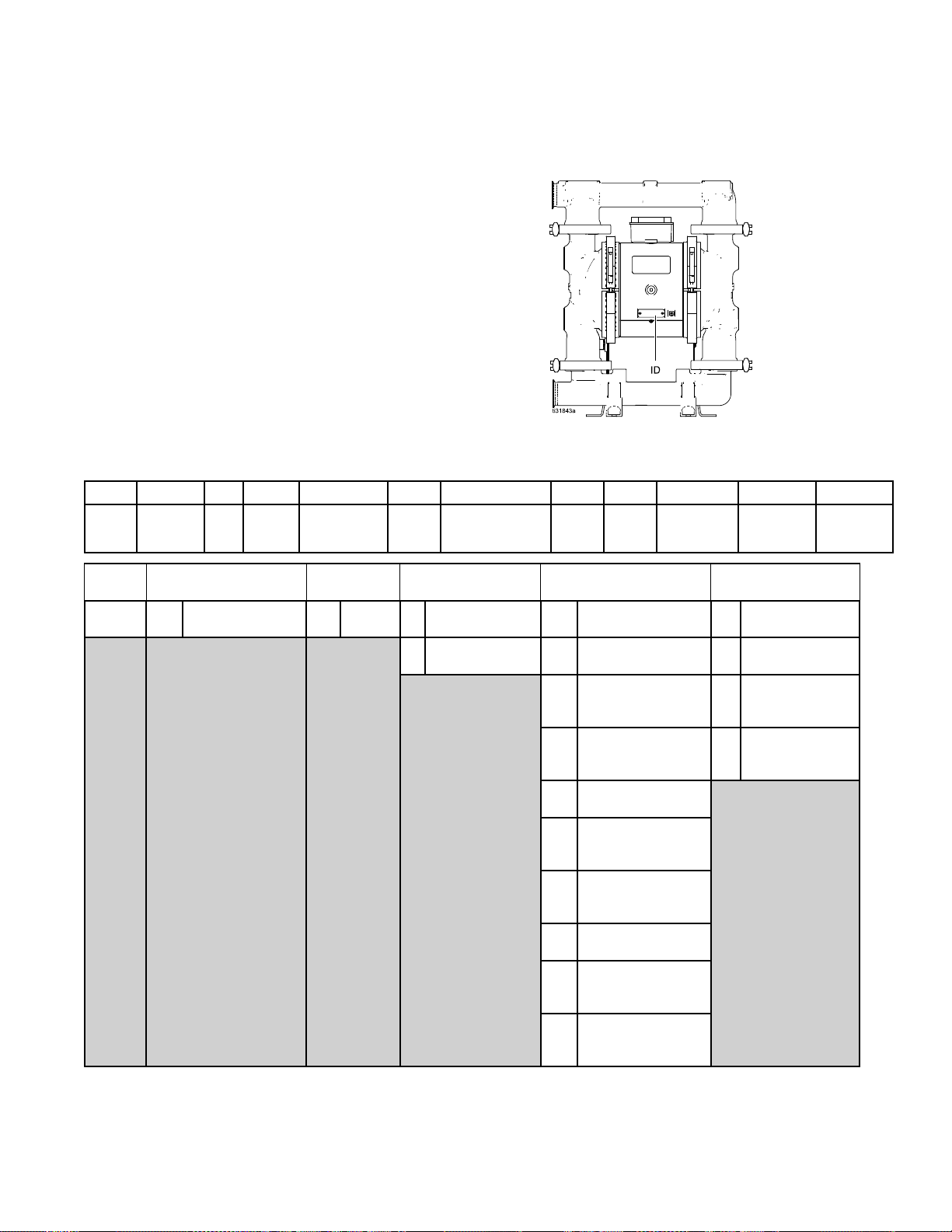

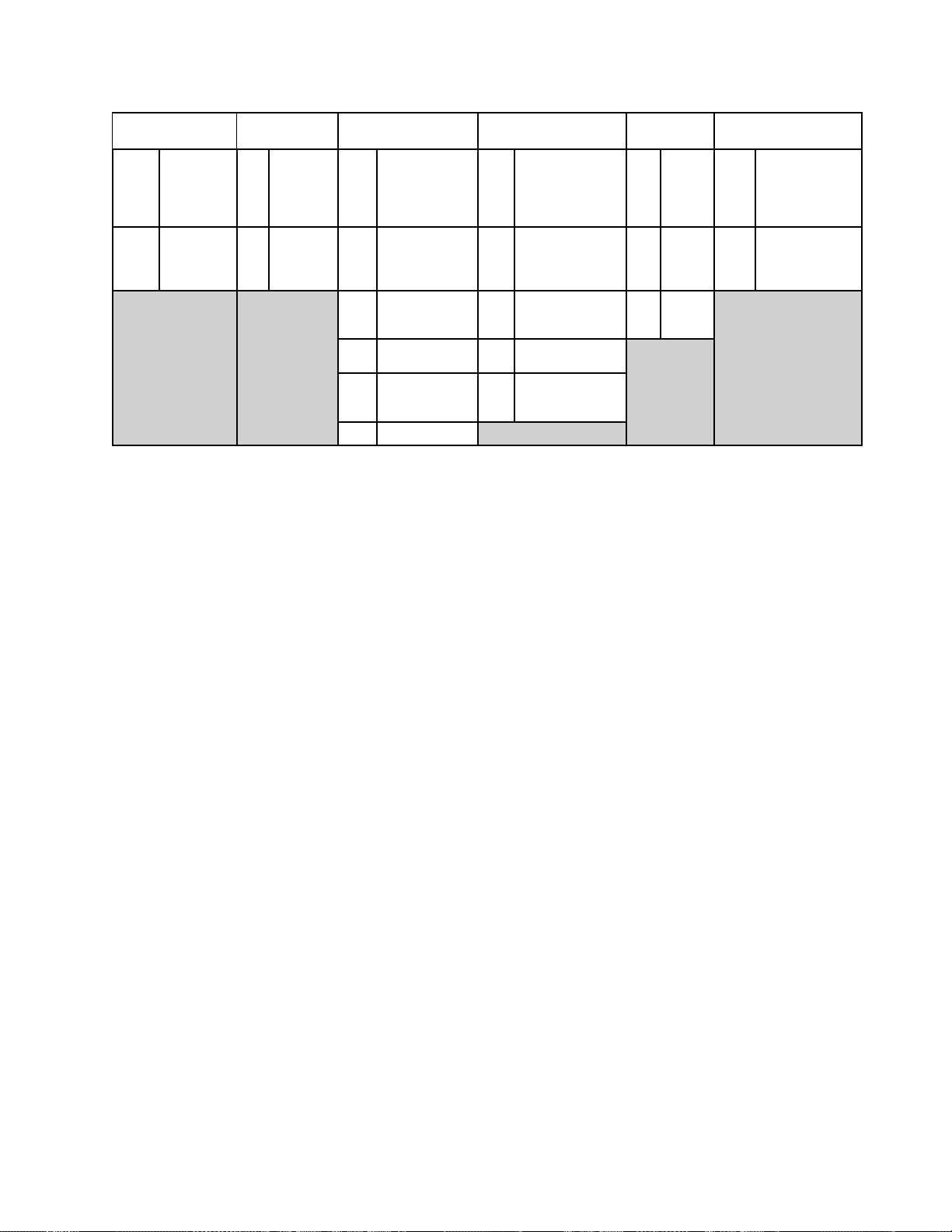

CongurationNumberMatrixfor2150FGPumps

Conguration

Conguration Conguration

Checktheidenticationplate(ID)forthe

CongurationNumberofyourpump.Usethe

followingmatrixtodenethecomponentsofyour

pump.

Whenyoureceiveyourpump,recordthe9character

partnumberfoundontheshippingbox(e.g.,

SP1B.0014):

_____________

AlsorecordthecongurationnumberonthepumpID

platetoassistyouwhenorderingreplacementparts:

_____________________________________

Sample

Sample Sample

2150

2150 2150

Pump

Model

Pump

Pump Pump

2150

2150 2150

Conguration

Conguration Conguration

FG

FG FG

Wetted

Section

Wetted

Wetted Wetted

FG

FG FG

E

E E

Drive

Section

Section Section

FoodGrade

Number

Number Number

Number:

Number: Number:

A

A A

Center

Section

2150FG

2150FG 2150FG

04

04 04

Gear

Boxand

Compressor

Drive

Drive Drive

E

E E

EA04AS13SSPTPTPT21

- --EA04AS13SSPTPTPT21 EA04AS13SSPTPTPT21

A

A A

Motor

Type

Type Type

Electric

Matrix

Matrix Matrix

Center

Center Center

Material

Material Material

Aluminum

A

A A

StainlessSteel

S

S S

S13

S13 S13

FluidCoversand

Manifolds

Section

Section Section

for

2150

for for

2150 2150

SS

SS SS

Seats

Gearbox

Gearbox Gearbox

Compressor

Compressor Compressor

94

94 94

04

04 04

05

05 05

06

06 06

14

14 14

15

15 15

16

16 16

24

24 24

25

25 25

26

26 26

FG

FG FG

PT

PT PT

Balls

orChecks

and

and and

NoGearboxor

Compressor

HighSpeedGear

Ratio

HighSpeed

GearRatio/120V

Compressor

HighSpeed

GearRatio/240V

Compressor

MidSpeedGear

Ratio

MidSpeed

GearRatio/120V

Compressor

MidSpeed

GearRatio/240V

Compressor

LowSpeedGear

Ratio

LowSpeed

GearRatio/120V

Compressor

LowSpeed

GearRatio/240V

Compressor

Pumps

Pumps Pumps

PT

PT PT

Diaphragms

PT

PT PT

Manifold

Seals

Motor

Motor Motor

Standard

A

A A

InductionMotor

ATEXInduction

C

C C

Motor

Flameproof

D

D D

InductionMotor

NoMotor

G

G G

21

21 21

Certication

63A5133L

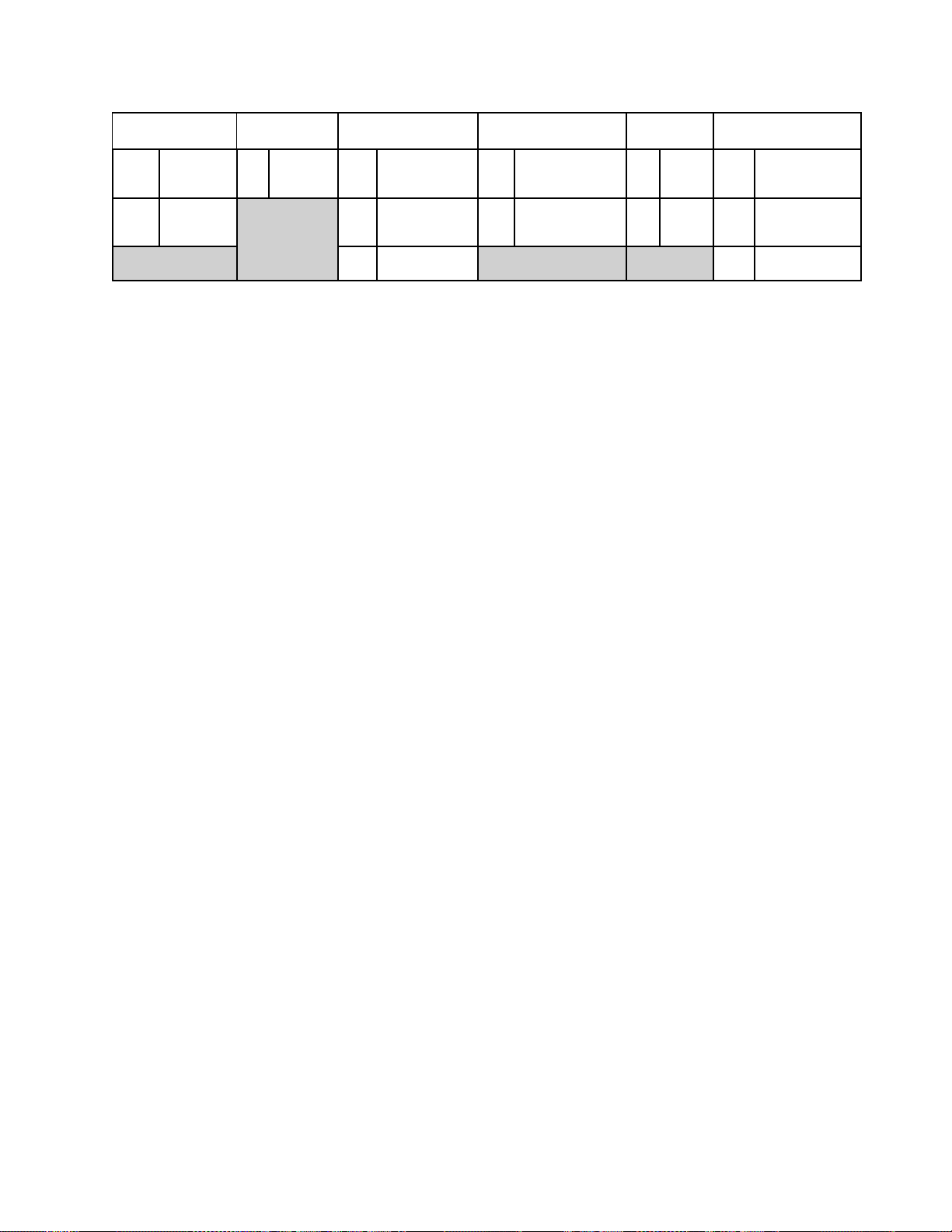

CongurationNumberMatrixfor2150FGPumps

Fluid

Covers

Fluid Fluid

Covers Covers

Manifolds

Manifolds Manifolds

S13

S13 S13

S14

S14 S14

Stainless

steel,

TriClamp

Stainless

steel,DIN

and

Seat

and and

Material

Seat Seat

Material Material

316

SS

SS SS

Stainless

Steel

Ball

or

Ball Ball

Material

Material Material

CW

CW CW

PT

PT PT

SP

SP SP

Check

or or

Check Check

Polychloroprene

Weighted

PTFE

Santoprene

Diaphragm

Diaphragm Diaphragm

PT

PT PT

SP

SP SP

Material

Material Material

PTFE/EPDM

2-Piece

Santoprene/EPDM

2–Piece

Manifold

Manifold Manifold

Seals

Seals Seals

EPDMblank

EP

EP EP

PTFE

PT

PT PT

Certication

Certication Certication

nocertication

EN10204type

21

21 21

31

31 31

2.1

EN10204type

3.1

3A5133L

7

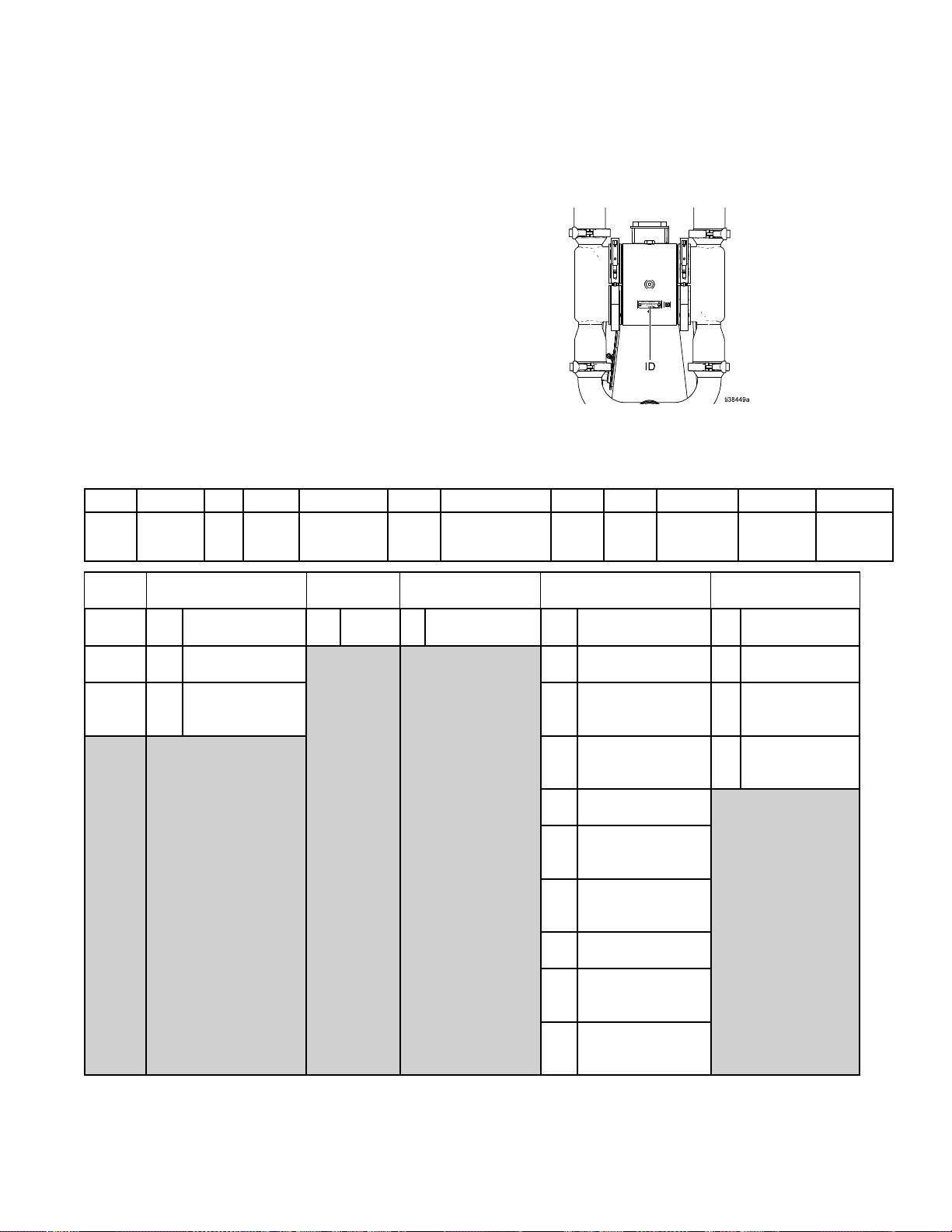

CongurationNumberMatrixfor2150,3000,and4000HSPumps

Conguration

Conguration Conguration

HS

HS HS

Sample

Sample Sample

2150

2150 2150

Pump

Model

Pumps

Pumps Pumps

Checktheidenticationplate(ID)forthe

CongurationNumberofyourpump.Usethe

followingmatrixtodenethecomponentsofyour

pump.

Whenyoureceiveyourpump,recordthe9character

partnumberfoundontheshippingbox(e.g.,

SP1B.0014):

_____________

AlsorecordthecongurationnumberonthepumpID

platetoassistyouwhenorderingreplacementparts:

_____________________________________

Conguration

Conguration Conguration

HS

HS HS

Wetted

Section

E

E E

Drive

Number

Number Number

Number:

Number: Number:

S

S S

Center

Section

2150HS

2150HS 2150HS

04

04 04

Gear

Boxand

Compressor

ES04ASSASSPTPSEP21

- --ES04ASSASSPTPSEP21 ES04ASSASSPTPSEP21

A

A A

Motor

Matrix

Matrix Matrix

SSA

SSA SSA

FluidCoversand

Manifolds

for

2150,

for for

2150, 2150,

SS

SS SS

Seats

3000,

3000, 3000,

PT

PT PT

Balls

orChecks

PS

PS PS

Diaphragms

and

and and

4000

4000 4000

EP

EP EP

Manifold

Seals

21

21 21

Certication

Pump

Pump Pump

2150

2150 2150

3000

3000 3000

4000

4000 4000

Wetted

Wetted Wetted

HS

HS HS

3A

3A 3A

PH

PH PH

Section

Section Section

HighSanitation

3ACertied

Pharmaceutical

Drive

Type

Drive Drive

Type Type

Electric

E

E E

Center

Center Center

Material

Material Material

S

S S

StainlessSteel

Section

Section Section

Gearbox

Gearbox Gearbox

Compressor

Compressor Compressor

94

94 94

04

04 04

05

05 05

06

06 06

14

14 14

15

15 15

16

16 16

24

24 24

25

25 25

26

26 26

and

and and

NoGearboxor

Compressor

HighSpeedGear

Ratio

HighSpeed

GearRatio/120V

Compressor

HighSpeed

GearRatio/240V

Compressor

MidSpeedGear

Ratio

MidSpeed

GearRatio/120V

Compressor

MidSpeed

GearRatio/240V

Compressor

LowSpeedGear

Ratio

LowSpeed

GearRatio/120V

Compressor

LowSpeed

GearRatio/240V

Compressor

Motor

Motor Motor

Standard

A

A A

InductionMotor

ATEXInduction

C

C C

Motor

Flameproof

D

D D

InductionMotor

NoMotor

G

G G

83A5133L

CongurationNumberMatrixfor2150,3000,and4000HSPumps

Fluid

Covers

Fluid Fluid

Covers Covers

Manifolds

Manifolds Manifolds

SSA

SSA SSA

SSB

SSB SSB

Stainless

Steel,

Tri-Clamp

(HS/3-A/

PH)

Stainless

Steel,DIN

(HS/3A/PH)

and

Seat

and and

Material

Seat Seat

Material Material

316

FL

FL FL

Stainless

Steel

Flapper

316

SS

SS SS

Stainless

Steel

Ball

or

or or

Flapper,check,

StainlessSteel

Buna-N

Polychloroprene

Weighted

FKMFluoroelastomer

PTFE

Santoprene

Check

Check Check

Ball Ball

Material

Material Material

—

— —

BN

BN BN

CW

CW CW

FK

FK FK

PT

PT PT

SP

SP SP

Diaphragm

Diaphragm Diaphragm

BN

BN BN

EO

EO EO

FK

FK FK

PS

PS PS

SP

SP SP

Material

Material Material

Buna-N

EPDM

Overmolded

FKM

Fluoroelastomer

PTFE/Santoprene2-Piece

Santoprene/EPDM

2Piece

Manifold

Manifold Manifold

Seals

Seals Seals

Buna-N

BN

BN BN

EPDM

EP

EP EP

FKM

FK

FK FK

Certication

Certication Certication

EN10204type

21

21 21

31

31 31

2.1

EN10204type

3.1

3A5133L9

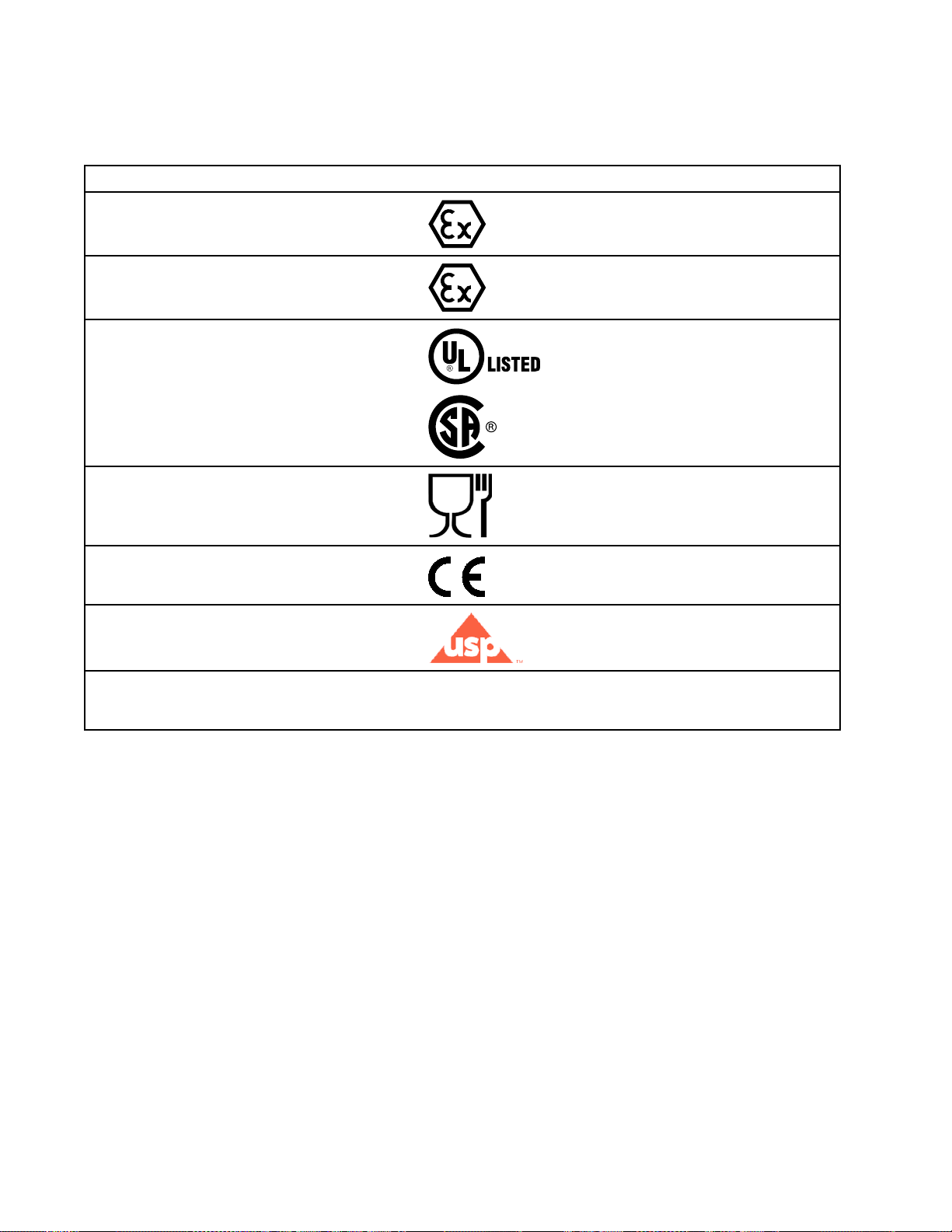

Approvals

Approvals

Approvals Approvals

Approvals

Approvals Approvals

✦PumpswithmotorcodeCareapprovedto:

✚PumpswithmotorcodeGareapprovedto:

★MotorscodedDareapprovedto:

DiaphragmmaterialscodedEO,PT,orPS

combinedwithcheckmaterialscodedFLor

PTcomplywith:

AllModels(exceptgearboxandcompressor

codes05,15,and25,ormotorcodeD)are

approvedto:

DiaphragmmaterialscodedEO,PTorPS

combinedwithcheckmaterialscodedFLor

PTcomplywith:

II2G

ExhdIIBT3Gb

II2G

ExhIIBT3Gb

ClassI,Div1,GroupD,T3B

ClassII,Div1,GroupF&G,T3B

EC1935/2004

ClassVI

AlluidcontactmaterialsareFDA-compliant

andmeettheUnitedStatesCodeofFederal

Regulations(CFR).

103A5133L

OrderingInformation

Ordering

Ordering Ordering

To

To To

Visitwww.graco.com

To

To To

Please

Please Please

OR

OR OR

UsetheOnline Online

To

To To

Please

Please Please

Information

Information Information

Find

Find Find

Specify

Specify Specify

Order

Order Order

Your

Your Your

call

your

call call

your your

Online

call

your

call call

your your

Nearest

Nearest Nearest

the

Conguration

the the

Conguration Conguration

distributor.

distributor. distributor.

Diaphragm

Diaphragm Diaphragm

Replacement

Replacement Replacement

distributor.

distributor. distributor.

Distributor

Distributor Distributor

of

New

of of

a aaNew New

Pump

Selector

Pump Pump

Selector Selector

Parts

Parts Parts

Tool

Tool Tool

at atatwww.graco.com www.graco.com

Pump

Pump Pump

www.graco.com

. ..SearchforSelector Selector

Selector

.

3A5133L

11

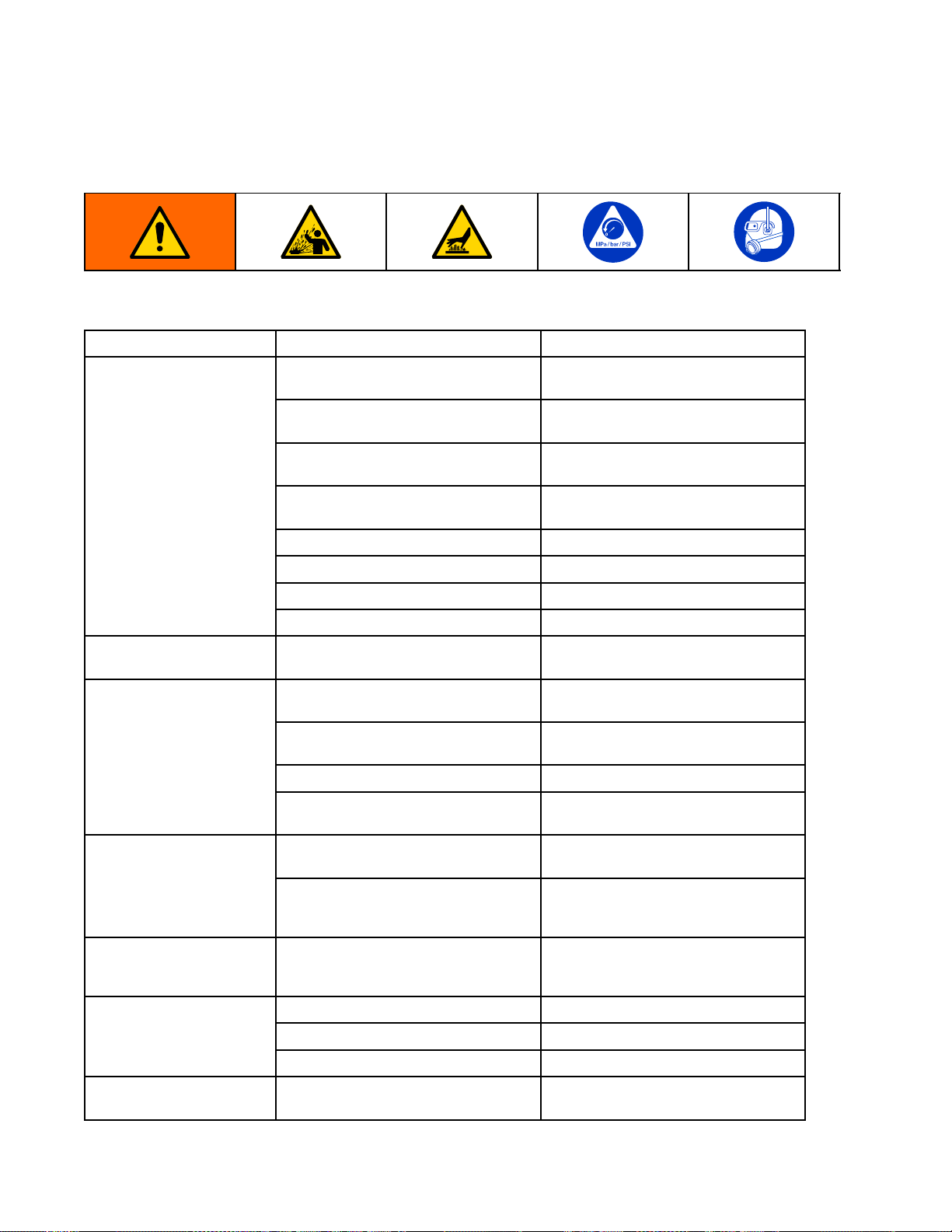

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

•FollowthePressureReliefProcedure,page14,

beforecheckingorservicingtheequipment.

Problem

Problem Problem

Pumpcyclesbutwillnot

primeand/orpump.

Thecentersectionis

excessivelyhot.

Pumpfailstoholduid

pressureatstall.

NOTE:

NOTE: NOTE:

arenot100%uidtight.

Flapperchecks

Cause

Cause Cause

Pumpisrunningtoofast,causing

cavitationbeforeprime.

Centersectionhasnoairpressure,

orairpressureistoolow.

Checkvalveballisseverelywornor

wedgedinseatormanifold.

Thepumphasinsufcientsuction

pressure.

Seatisseverelyworn.

Outletorinletisrestricted.

Inletttingsormanifoldsareloose.

Manifoldo-ringsaredamaged.

Thedriveshaftisbroken.

Checkvalveballs,seats,oro-rings

areworn.

Manifoldscrewsoruidcover

screwsareloose.

•Checkallpossibleproblemsandcausesbefore

disassembly.

Solution

Solution Solution

Slowdownthecontroller(VFD)

Applyairpressuretocentersection

peryourapplicationrequirements.

Replacetheballandseat.

Increasethesuctionpressure.See

theOperationmanual.

Replacetheballandseat.

Removetherestriction.

Tighten.

Replaceo-rings.

Replace.

Replace.

Tighten.

Themotorisoperating,

butthepumpwillnot

cycle.

Pumpowrateiserratic.

Pumpmakesunusual

noises.

12

Diaphragmshaftboltisloose.

Flapvalvesinstalledupside-down.

Motororcontrolleriswired

improperly.

Theleakdetector(ifinstalled)has

tripped.

Thejawcouplingbetweenthe

motorandgearboxisnotconnected

properly.

Suctionlineisclogged.

Checksarestickyorleaking.Cleanorreplace.

Diaphragm(orbackup)ruptured.

Pumpisoperatingnearoratstall

pressure.

Tighten.

Installtheappervalvewiththetext

sidefacingtheseat.

Wirepermanual. Pumpwillnotcycle.

Checkdiaphragmforruptureor

incorrectinstallation.Repairor

replace.

Checktheconnection.

Inspect;clear.

Replace.

Adjustairpressureorslowthepump

speed.

3A5133L

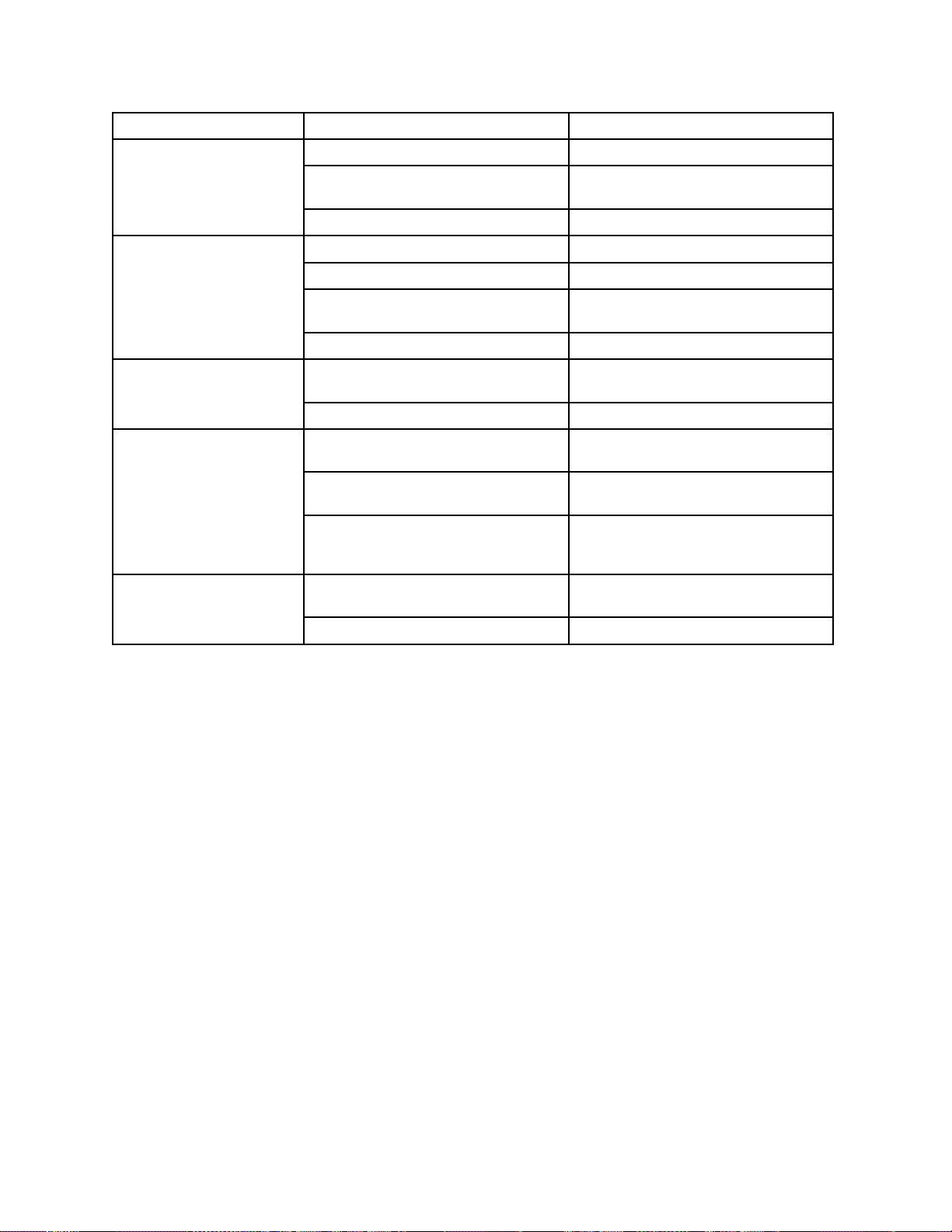

Troubleshooting

Problem

Problem Problem

Airconsumptionishigher

thanexpected.

Airbubblesinuid.

Pumpleaksuid

externallyfromjoints.

Thecontrollerfaultsor

shutsdown.

Cause

Cause Cause

Attingisloose.

Looseordamagedo-ringsorshaft

seal.

Diaphragm(orbackup)ruptured.

Suctionlineisloose.

Diaphragm(orbackup)ruptured.

Loosemanifolds,damagedseatsor

o-rings.

Loosediaphragmshaftbolt.

Loosemanifoldscrewsoruidcover

screws.

Manifoldo-ringswornout.

AGFCIhastripped.Removethecontrollerfromthe

Supplypowerispoor.Determineandxthesourceofthe

Operationalparametersare

exceeded.

Solution

Solution Solution

Tighten.Inspectthreadsealant.

Replace.

Replace.

Tighten.

Replace.

Tightenmanifoldboltsorreplace

seatsoro-rings.

Tighten.

Tighten.

Replaceo-rings.

GFCIcircuit.

powerproblem.

Seeperformancechart;ensure

pumpisoperatingwithinthe

continuousdutyrange.

regenerationfaultfrom

VFD

NOTE:

NOTE: NOTE:

ForproblemswithaVariableFrequencyDevice(VFD),seeyourVFDmanual.

Inletcheckclogged/improperly

installed

BrokendiaphragmboltReplacebolt

Removedebris/installproperly Excessivemotor

3A5133L13

Repair

Repair

Repair Repair

NOTE:

NOTE: NOTE:

looselyassembleinitiallytoensureacceptable

alignment.Onceallcomponentsareinplace,tighten

allclamps.

Pressure

Pressure Pressure

1.Turnoffthepumpanddisconnectpowertothe

2.Closethemasterairvalve(J)toshutofftheair

3.Opentheuiddrainvalve(L)torelieveuid

4.Closethepumpairinletport(E)onthepneumatic

Whenreassemblinguidsectioncomponents,

Relief

Relief Relief

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Thisequipmentstayspressurizeduntilpressureis

manuallyrelieved.Tohelppreventseriousinjury

frompressurizeduid,suchassplashinguid,

followthePressureReliefProcedurewhenyou

stopdispensingandbeforecleaning,checking,or

servicingtheequipment.

system.

tothepump.

pressure.Haveacontainerreadytocatchthe

drainage.

enclosure.

Procedure

Procedure Procedure

Disassemble

Disassemble Disassemble

1.FollowthePressureReliefProcedure,page14.

Disconnectpowerfromthemotor.Disconnectall

uidandairlines.

2.Removetheclamps(31)holdingtheoutlet

manifold(3)totheuidcovers(2),thenremove

theoutletmanifold.

3.Removetheballcheckvalveassemblies:

a.Onthe2150FG,removetheseats(6),balls

(7),ando-rings(8).

b.Onthe2150HS,removetheballstops(28),

balls(7),andgaskets(8a).

4.Repeatfortheinletmanifold.

5.Tocontinuewithdiaphragmdisassembly,see

DisassembletheStandardDiaphragms,page17.

Reassemble

Reassemble Reassemble

1.Cleanallpartsandinspectforwearordamage.

Replacepartsasneeded.

2.Reassembleinthereverseorder,followingall

notesintheillustration.Puttheinletmanifoldon

rst.Besuretheballchecksandmanifoldsare

assembledexactly exactly

uidcovers(2),thearrows(A)must must

theoutletmanifold(3).Foruidcoverswithout

arrows,thetallestopeningintheuidcovermust must

beattachedtotheoutletmanifold.

the

Ball

the the

the

the the

exactly

Check

Ball Ball

Check Check

Ball

Check

Ball Ball

Check Check

asshown.Ifpresentonthe

Valve

Valve Valve

Valve

Valve Valve

must

pointtoward

must

Check

Check Check

Tools

Tools Tools

•O-ringpick

NOTE:

NOTE: NOTE:

andseatsinarangeofmaterials.O-ringkitsalso

areavailable.

NOTE:

NOTE: NOTE:

alwaysreplacetheseatswhenreplacingtheballs.

Also,replacetheo-ringseverytimethemanifoldis

removed.

14

Valve

Valve Valve

Required

Required Required

Kitsareavailablefornewcheckvalveballs

Toensureproperseatingofthecheckballs,

Repair

Repair Repair

3A5133L

Loading...

Loading...