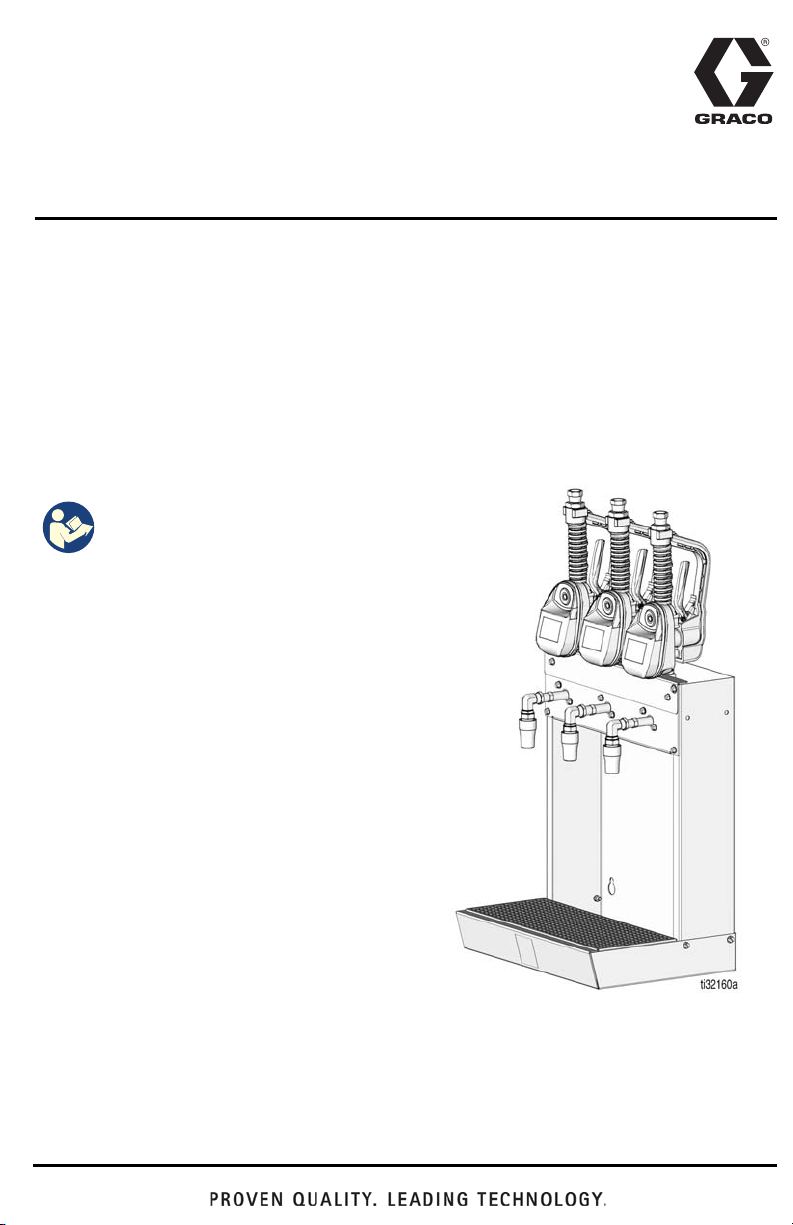

Page 1

Installation and Service

Pulse® Metered Dispense

Valve Oil Bar

For fixed mounting of up to three Pulse metered dispense valves.

Not approved for use in explosive atmospheres or hazardous locations. For professional

use only.

Model No.: 25D130 - Configures metered dispense valves for installation in the

oil bar.

NOTE: One Model 25D130 is required for each model 24N415 metered dispense valve.

Maximum Working Pressure: 1500 psi (103 bar,10 MPa)

Model No.: 25D121 - Oil Dispenser Bar

3A5573C

EN

Important Safety

Instructions

Read all warnings and instructions

in this manual and all related Pulse

system manuals. Save all

instructions.

Related Manuals

3A5412 - Pulse Metered Dispense Valve

Refer to Parts, page 8 for reference numbers

used in these instructions.

Page 2

Installation

3

9

1

7

Installation

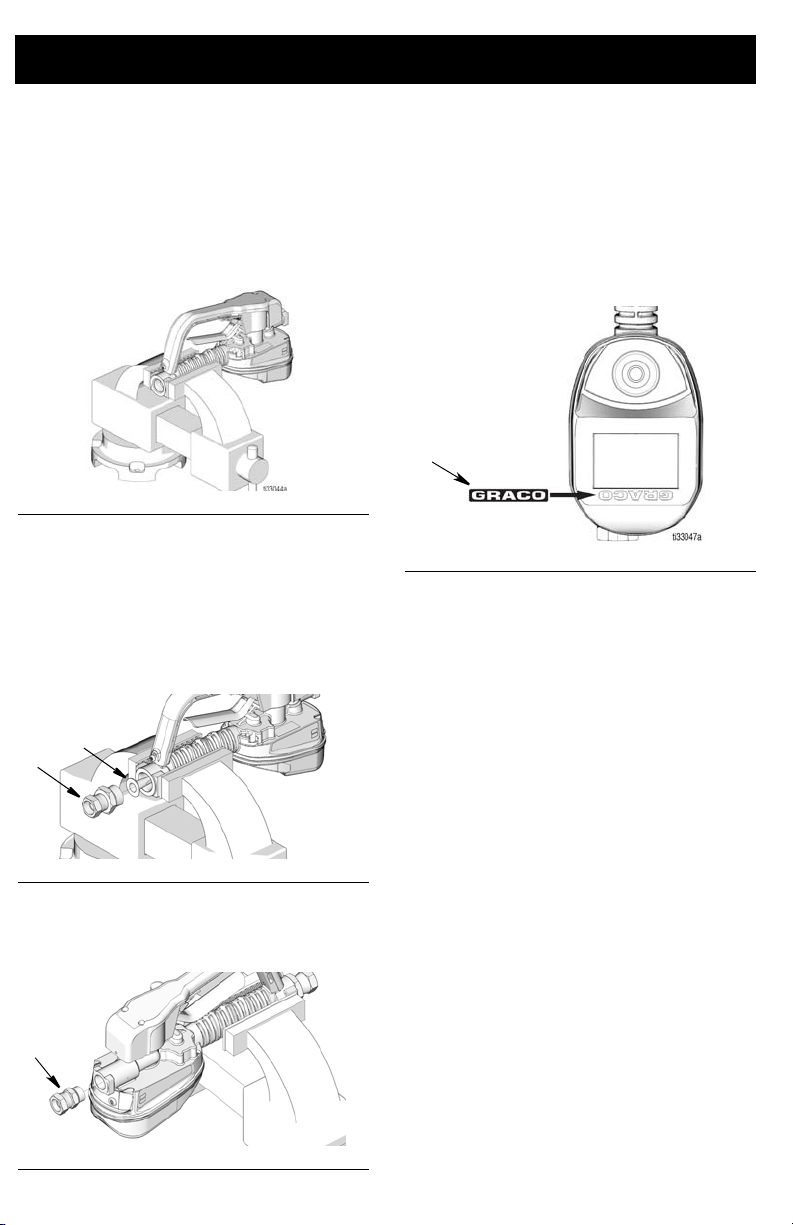

Prepare the Metered Dispense Valve for Installation

1. Secure the metered dispense valve in a

vise (FIG. 1).

FIG. 1

2. Install strainer (9) and fitting (3) in the

IG. 2). Use wrench to tighten fit-

inlet (F

ting.

NOTE: An o-ring is not required for the

strainer (9) installation. An o-ring is

required and installed on fitting (3).

4. Install Graco identification label (7) over

the existing GRACO identification label

in the orientation shown in F

IG. 4.

FIG. 4

5. Use the Utility Menu to flip the display for

easy viewing when the metered

dispense valve is installed in the Oil Bar.

See the Pulse Metered Dispense Valve

instruction manual for this procedure.

FIG. 2

3. Install fitting (1) in the outlet as shown

in FIG. 3. Tighten fitting with a wrench.

FIG. 3

2 3A5573C

Page 3

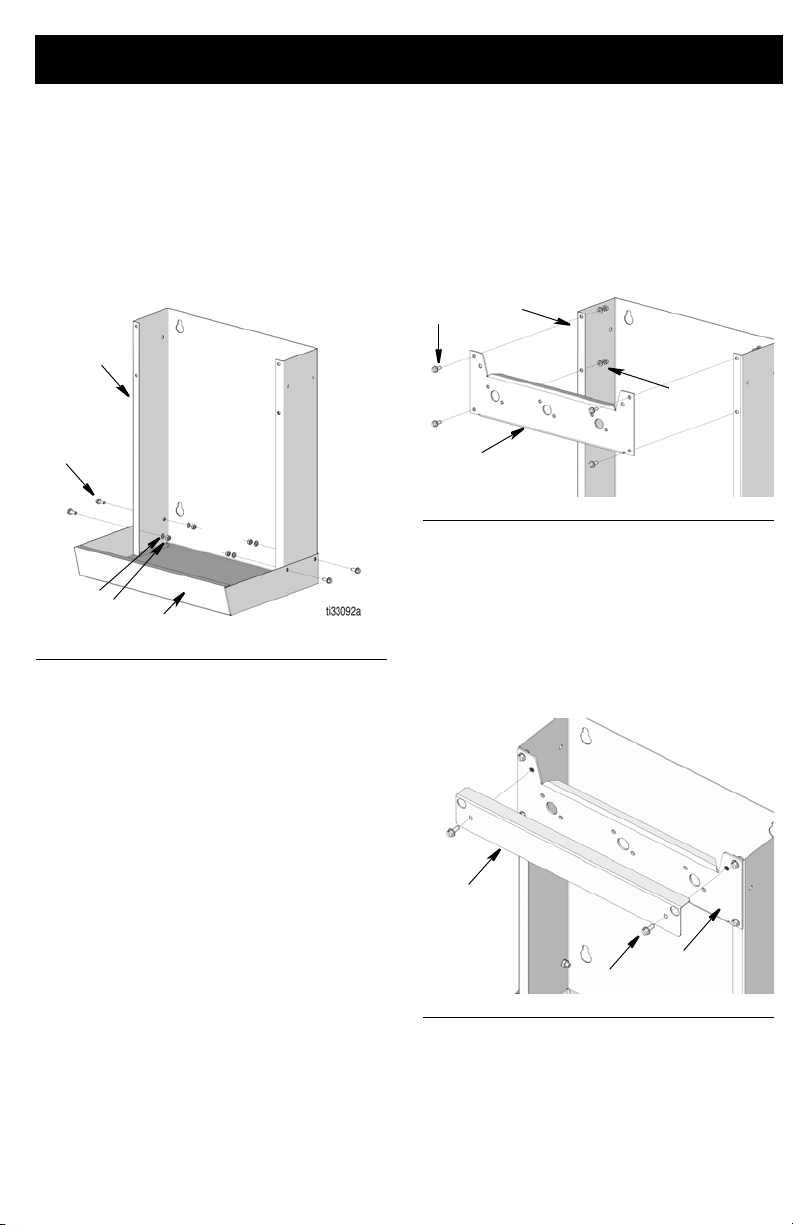

Assemble the Oil Bar

27

22

28

29

21

24

21

28, 29

27

25

27

24

Installation

The oil bar requires assembly prior to use.

1. Attach dispenser wrapper (21) to drain

pan (22) using screws (27), lock

washers(28) and nuts (29) and existing

holes. Tighten nuts securely. (See FIG.

5).

FIG. 5

2. Use the existing mounting holes in the

back of the oil bar to secure it to a wall.

Select a location that is easily accessible

to the user and will adequately support

the weight of the oil bar, metered

dispense valves and plumbing.

3. Attach the meter mounting plate (24) to

the wrapper dispenser (21) using screws

(27), lock washers(28) and nuts (29) and

existing holes. Tighten nuts securely.

Refer to F

orientation for these parts.

IG. 6 for the correct installation

FIG. 6

4. Connect cover panel plate (25) to meter

mounting plate (24) using screws (27)

and existing holes. Tighten screws

securely. Refer to F

installation orientation for these parts.

NOTE: Do not assemble cover panel

plate (25) prior to meter installation.

IG. 7 for the correct

NOTE: Fasteners for this installation are

not included in the kit and must be

provided by the user. When selecting

fasteners consider the weight of the oil

bar, metered dispense valves, plumbing

fixtures and dispensed oil in the

container placed on the shelf. See

Technical Specifications, page 10.

FIG. 7

3A5573C 3

5. Install pan strainer (23) in drain pan (22).

Page 4

Installation

8

2

Sealant

or PTFE

Tape

25

27

24

2

a

b

24

4

5

24

2

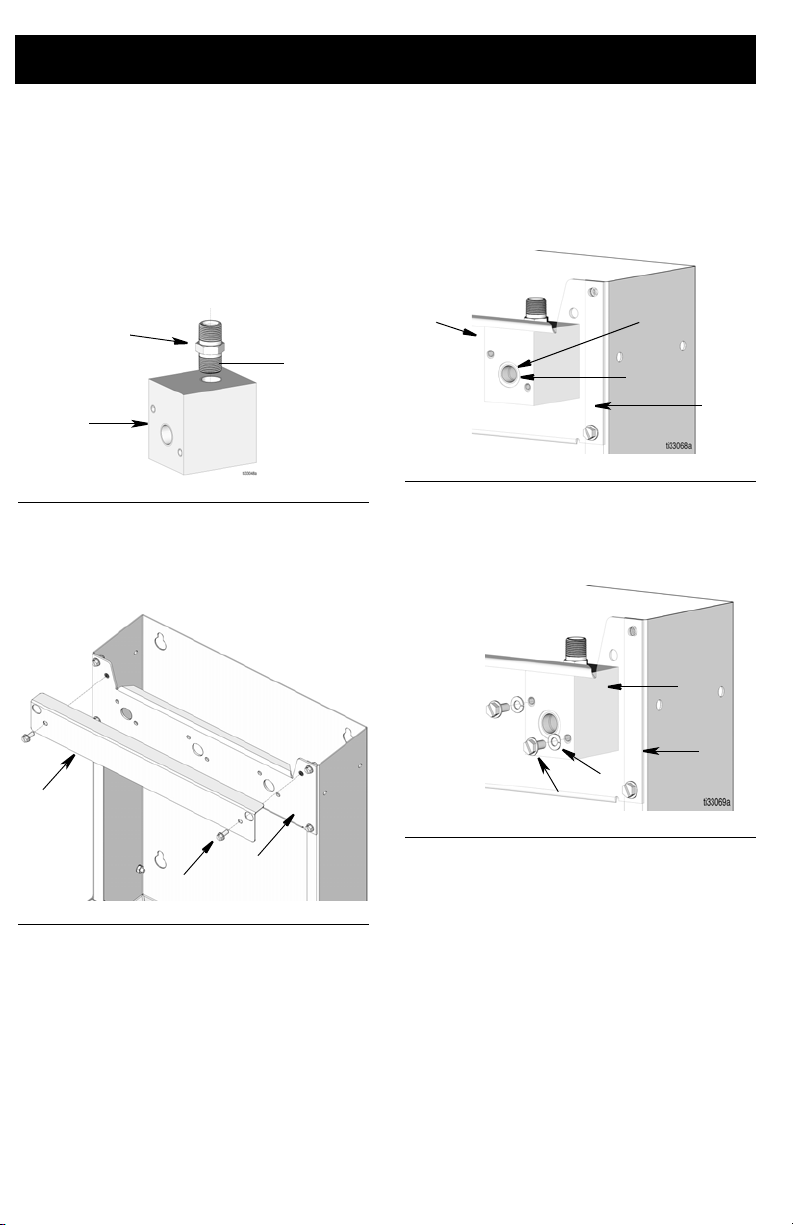

Install the Metered Dispense Valve in the Oil Bar

1. Wrap threads of pipe nipple (8) with

PTFE tape or thread sealant as shown in

FIG. 8. Install pipe nipple (8) in opening of

manifold (2). Tighten securely. Refer to

IG. 8 to determine the correct

F

installation position.

FIG. 8

2. If installed when assembling the Oil

Bar, remove screws (27) and remove

access panel (25).

3. Position manifold (2) inside oil bar,

orienting opening (a) on the front of the

manifold with opening (b) in the

mounting plate (24) as shown in F

IG. 10.

FIG. 10

4. Install screws (5) and washers (4) to hold

the manifold (2) in place. Tighten

securely.

FIG. 11

FIG. 9

4 3A5573C

Page 5

Installation

1

8

2

10

b

24

2

10

6

11

3

c

5. Install the metered dispense valve in oil

bar housing by connecting fitting (1) on

metered dispense valve to pipe nipple

(8) in manifold (2) as shown in FIG. 12.

Tighten securely.

NOTE: Do NOT apply thread sealant or

PTFE tape to threads of fitting (1).

FIG. 12

6. Wrap threads on the long end of nipple

adapter (10) with PTFE tape or thread

sealant as shown in F

IG. 13.

7. Install the end of the nipple adapter (10)

that was wrapped in the PTFE tape or

treated with thread sealant into the

manifold (2) through the hole (b) in the oil

bar mounting plate (24).

FIG. 14

8. Connect the swivel elbow (6) and high

flow nozzle (11) to nipple adapter (10) in

the orientation shown in F

securely.

NOTE: Do NOT apply thread sealant or

PTFE tape to threads.

IG. 15. Tighten

FIG. 13

FIG. 15

9. Connect fluid distribution lines (c) to

fitting (3).

3A5573C 5

FIG. 16

Page 6

Repair and Maintenance

WARNING

3

c

Repair and Maintenance

Pressure Relief Procedure

PRESSURIZED FLUID HAZARD

This equipment stays pressurized until

pressure is manually relieved. To help prevent serious injury from pressurized fluid,

such as skin injection, splashing fluid and

moving parts, follow the Pressure Relief

Procedure when you stop dispensing and

before cleaning, checking, or servicing the

equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment

when in the work area to help prevent

serious injury, including eye injury, hearing

loss, inhalation of toxic fumes, and burns.

1. Turn off power supply to the pump.

2. Place a container under the drain valve

on the oil bar (F

3. Pull trigger to dispense as much of the

fluid as possible to relieve pressure.

4. Leave the nozzle open until you are

ready to pressurize the system.

IG. 18). Open the nozzle.

Oil Bar Disassembly

1. Relieve pressure. See the Pressure

Relief Procedure.

2. Disconnect fluid distribution lines (c)

from fitting (3) (see F

FIG. 17

3. Pull trigger to dispense as much of the

fluid remaining in the line as possible

(F

IG. 18).

NOTE: A collection container should

already be in place and the nozzle

should be open after performing

Pressure Relief Procedure (Step 1).

IG. 17).

FIG. 18

6 3A5573C

Page 7

4. Remove screws (27) and access panel

25

27

24

1

8

2

10

6

11

5

4

1

(25) (see FIG. 19).

FIG. 19

5. Disconnect fitting (1) from pipe nipple (8)

in manifold (2) as shown in FIG. 20.

Repair and Maintenance

FIG. 21

7. Remove screws (5) and washers (4)

from manifold (2). Lift manifold (2)

straight up and out of the oil bar housing

(FIG. 22).

FIG. 22

8. To protect the metered dispense valve,

lay it face down on a padded surface

FIG. 20

6. Unscrew nipple adapter assembly (10, 6

and 11) from manifold (1).

while performing any maintenance or

service work on the metered dispense

valve or oil bar.

Oil Bar Reassembly

NOTE: The nipple adapter (10), elbow

(6) and swivel nozzle (11) do not have to

be disassembled. These pieces can be

removed form the manifold as a single

assembly (F

3A5573C 7

IG. 21).

To reassemble the oil bar, follow the

Installing Metered Dispense Valve in Oil

Bar instructions beginning on page 4.

Page 8

Parts

3

9

1

8

4

5

6

11

10

2

Parts

Model 25D130

Ref Part No. Description Qty

1 131244 FITTING,

2 131245 MANIFOLD,

3 131246 FITTING,

4 100016 WASHER, lock 2

5 108296 SCREW, hex 2

6 121079 SWIVEL, elbow,

7 130195 LABEL, brand, oil bar 1

8 156849 PIPE, nipple 1

9 15M308 STRAINER, wire

10 160790 FITTING, nipple,

11 255461 NOZZLE, high flow 1

3/4 ORB UNF X 3/8

NPSM

dispenser

1-1/16 ORB UNF X

1/2 NPSM

ORB X NPSM

mesh

adapter

1

1

1

1

1

1

Metered Dispense Valve 24N415 is shown for

reference only. It must be ordered separately.

8 3A5573C

Page 9

Model 25D121

21

23

26

22

25

24

28

27

30

29

29

Parts

Ref Part No. Description Qty

21 181316 WRAPPER,

22 16D537 PAN, drain, coating 1

23 181319 STRAINER, pan 1

24 131242 PLATE, mount 1

25 131243 PLATE, cover panel 1

26 104663 PLUG, pipe 1

dispenser

Ref Part No. Description Qty

1

27* 108296 SCREW, hex 18

28* 100016 WASHER, lock 16

29* 100015 NUT, hex 16

30* 159346 WASHER 6

* Extra parts included for connecting multiple oil

bars together.

3A5573C 9

Page 10

Technical Specifications

Technical Specifications

Oil Bar

US Metric

Maximum Working Pressure 1500 psi 103 bar, 10 MPa

Wetted Materials Carbon steel, aluminum, Buna-n rubber

Weight

Model 25D121 30 lbs 13.61 kg

Model 25D130 5 lbs 2.26 kg

10 3A5573C

Page 11

NOTES

NOTES

3A5573C 11

Page 12

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be

free from defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of

any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of

sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only when

the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or

wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence,

accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or

wear caused by the incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied

by Graco, or the improper design, manufacture, installation, operation or maintenance of structures, accessories,

equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco

distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge

any defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the

equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable charge, which

charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees

that no other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to

person or property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty

must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR

COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco

(such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying

equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to

a breach of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in

English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous

documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou en rapport, directement ou

indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A5573

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2018, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

the time of publication.

Graco Headquarters: Minneapolis

www.graco.com

Revision, September 2019

Loading...

Loading...