Graco Pro Xp H60T10, Pro Xp H85T10, Pro Xp H85M10, Pro Xp H60M10, Pro Xp H85M57 Instructions Manual

...Page 1

Instructions-Parts

Pro

Pro Pro

Air

Air Air

For

For For

For

For For

use

use use

3000psi(21MPa,210bar)Maximum

FluidWorkingPressure

100psi(0.7MPa,7bar)MaximumAir

WorkingPressure

Seepage3formodelpartnumbersand

approvalinformation.

Xp™

Xp™ Xp™

Assisted

- --Assisted Assisted

use

use use

use

use use

only.

only. only.

Class

in ininClass Class

Group

in ininGroup Group

Important

Important Important

Thisequipmentcouldpresenthazardsifnotoperatedaccordingto

theinformationinthismanual.Read Read

this

manual

this this

manual manual

Electrostatic

Electrostatic Electrostatic

Spray

Spray Spray

Div.

I, I,I,Div. Div.

II,

II, II,

Safety

Safety Safety

before

before before

Hazardous

I IIHazardous Hazardous

Zone

Zone Zone

Explosive

1 11Explosive Explosive

Instructions

Instructions Instructions

using

using using

Gun

Gun Gun

Locations

Locations Locations

Atmosphere

Atmosphere Atmosphere

Read

the

equipment.

the the

equipment. equipment.

using

Group

using using

Group Group

Locations

Locations Locations

all

warnings

all all

warnings warnings

Save

Save Save

and

and and

these

instructions.

these these

instructions. instructions.

materials.

D DDmaterials. materials.

using

Group

using using

Group Group

instructions

instructions instructions

IIA

materials.

IIA IIA

materials. materials.

in

in in

3A2495K

EN

For

professional

For For

professional professional

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

Approvals...........................................................3

RelatedManuals................................................3

Warnings...........................................................4

GunOverview....................................................7

HowtheElectrostaticAASprayGun

Works............................................7

Controls,Indicators,andComponents...........8

SmartGuns.................................................9

Installation..........................................................14

WarningSign...............................................14

VentilatetheSprayBooth.............................14

AirSupplyLine............................................15

FluidSupplyLine.........................................15

Grounding...................................................17

GunSetup..........................................................21

GunSetupProcedure...................................21

CheckGunElectricalGrounding...................24

CheckFluidResistivity.................................25

CheckFluidViscosity...................................25

FlushBeforeUsingEquipment......................25

Operation...........................................................26

PressureReliefProcedure............................26

Startup........................................................27

Shutdown....................................................27

Maintenance......................................................28

DailyCareandCleaningChecklist................28

Flushing......................................................28

CleantheGunDaily.....................................30

DailySystemCare.......................................31

ElectricalTests...................................................32

TestGunResistance....................................32

TestPowerSupplyResistance.....................33

TestGunBarrelResistance..........................34

Troubleshooting..................................................35

SprayPatternTroubleshooting......................35

GunOperationTroubleshooting....................36

ElectricalTroubleshooting............................37

Repair................................................................39

PreparetheGunforService.........................39

AirCap,SprayTip,andFluidSeatHousing

Replacement..................................40

ElectrodeReplacement................................41

FluidTubeRemovalandReplacement...........42

FluidFilterReplacement...............................42

GunBarrelRemoval.....................................43

GunBarrelInstallation..................................43

FluidNeedleReplacement............................44

PowerSupplyRemovaland

Replacement..................................45

AlternatorRemovalandReplacement...........46

FanAirAdjustmentValveRepair..................48

AtomizingAirAdjustmentValve

Repair............................................48

ESOn-OffValveRepair...............................49

AirValveRepair...........................................50

SmartModuleReplacement..........................51

AirSwivelandExhaustValve

Replacement..................................52

Parts..................................................................53

StandardAir-AssistedSprayGun

Assembly.......................................53

SmartAir-AssistedSprayGun

Assembly.......................................55

AlternatorAssembly.....................................57

ESOn-OffValveAssembly...........................58

FanAirAdjustmentValveAssembly..............59

AirCapAssembly........................................60

SmartModuleAssembly...............................60

SprayTipSelectionChart....................................61

AEMFineFinishSprayTips..........................61

AEFFineFinishPre-OriceSpray

Tips...............................................62

RoundSprayTips........................................63

RecommendedFilterSizes...........................64

RepairKitsandAccessories................................65

GunAccessories..........................................65

InlineFluidFilterKitAccessories...................65

OperatorAccessories...................................66

SystemAccessories.....................................66

Signs..........................................................66

TestEquipment...........................................66

Hoses.........................................................67

Dimensions........................................................68

TechnicalSpecications......................................69

GracoProXpWarranty.......................................70

2

3A2495K

Page 3

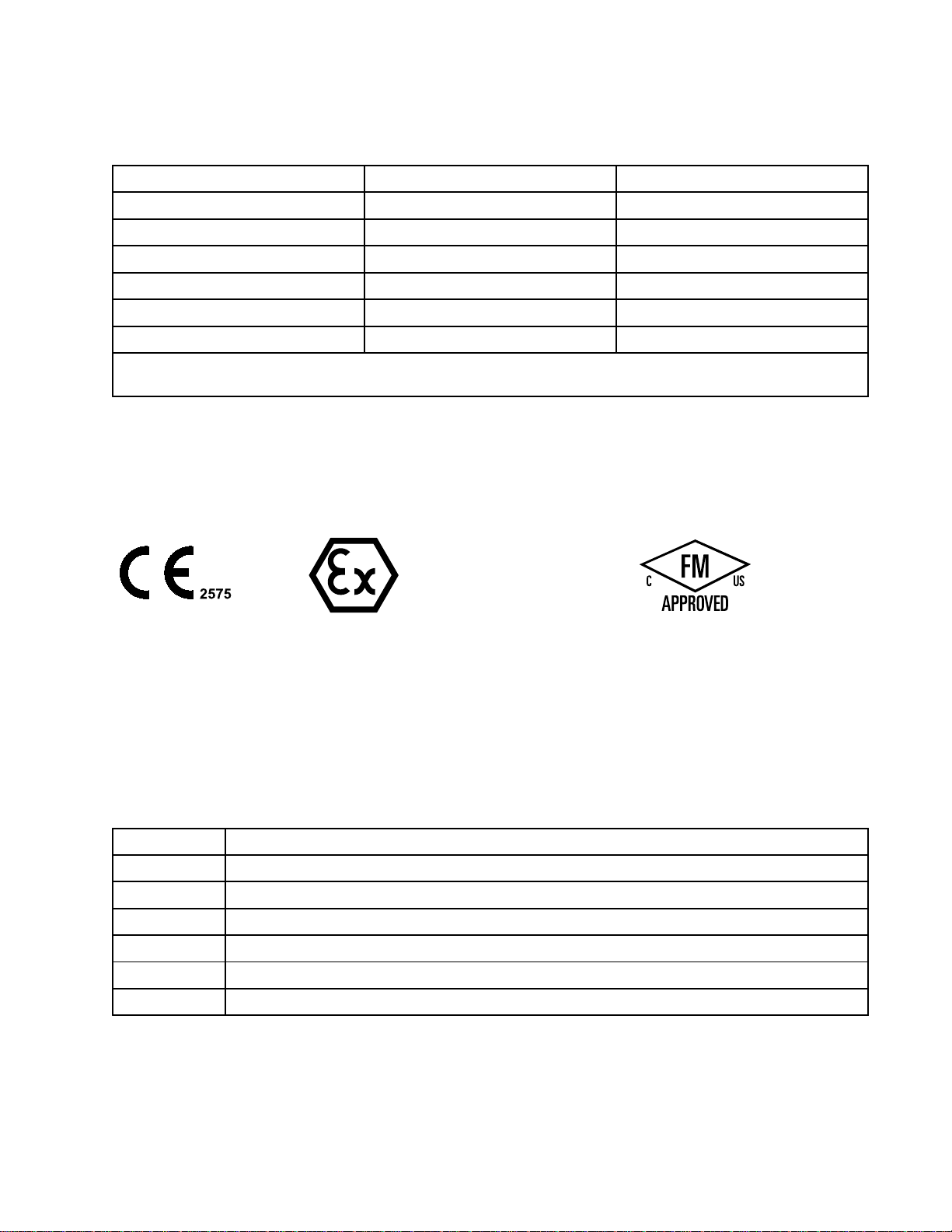

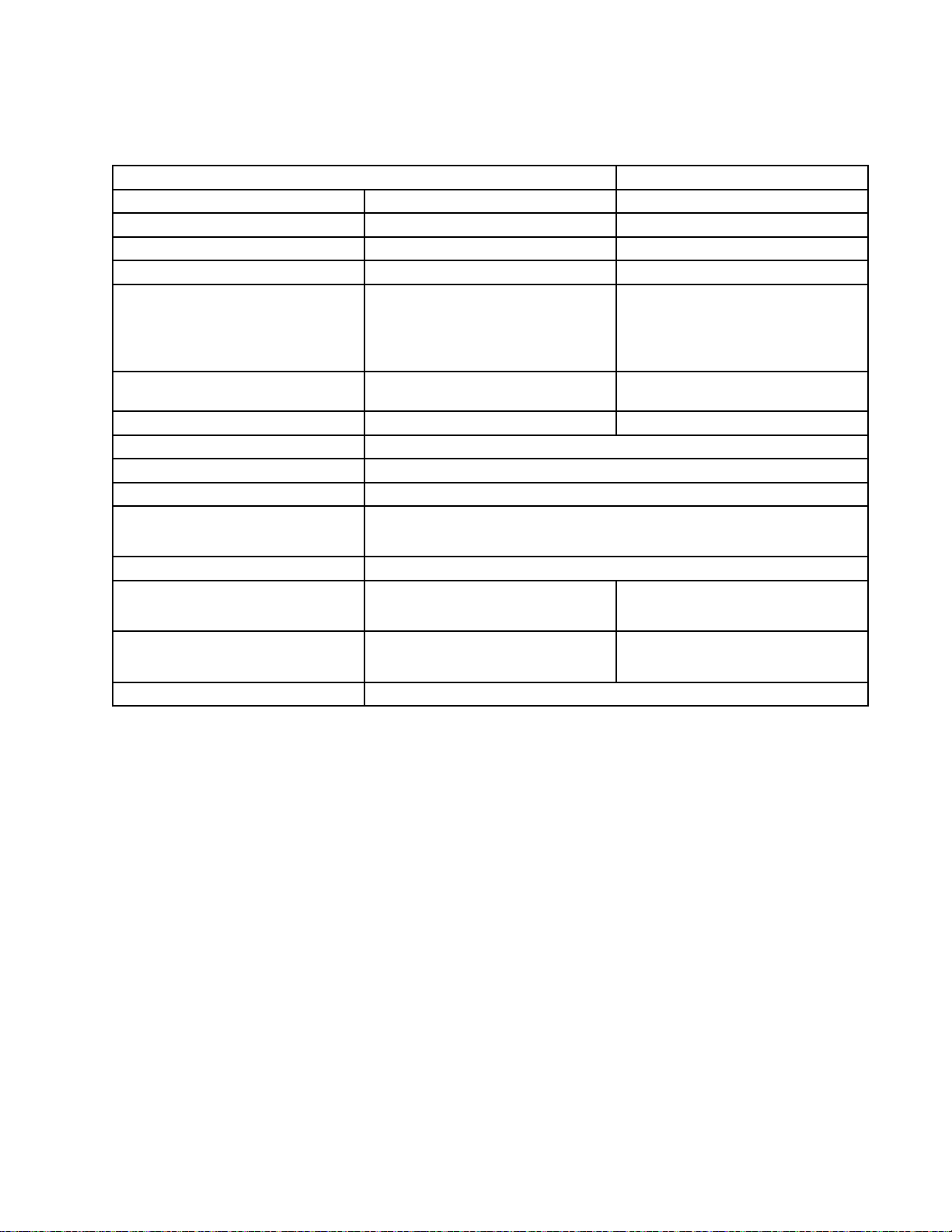

Models

2575

Models

Models Models

Part

No.

Part Part

No. No.

kV

kV kV

Display

Display Display

H60T1060

H60M1060

H85T1085

H85M1085

H85T57*

H85M57*

*HighAirFlowGunModels,equippedwithESOn-OffwithAirRestrictorValve,whichlimitsairowtothe

turbine.Forapplicationsthatrequirehighairowattheaircap.

Approvals

Approvals Approvals

85

85

G

II IIII2 22G G

0.24mJT6

Standard

Smart

Standard

Smart

Standard

Smart

FM12ATEX0068

EN50050–1

Ta0°C–50°C

Related

Related Related

Manual

Manual Manual

3A2499

307263ProbeandMeter,Instructions

308393

309227

309455TestFixture,HighVoltageProbe,andkVMeter,Instructions

406999

No.

No. No.

Manuals

Manuals Manuals

Description

Description Description

RoundSprayKit,Instructions

GunWasherKit,Instructions

GunFlushBoxModule,Instructions

VoltageTesterConversionKit,Instructions

3A2495K3

Page 4

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanual,referbacktotheseWarnings.Product-specic

hazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughoutthebodyofthismanual

whereapplicable.

WARNING

WARNING WARNING

FIRE,

EXPLOSION,

FIRE, FIRE,

EXPLOSION, EXPLOSION,

Flammablefumes,suchassolventandpaintfumes,inwork work

Paintorsolventowingthroughtheequipmentcancausestaticsparking.Tohelpprevent

re,explosion,andelectricshock:

•Electrostaticequipmentmustbeusedonlybytrained,qualiedpersonnelwhounderstand

therequirementsofthismanual.

•Groundallequipment,personnel,objectbeingsprayed,andconductiveobjectsinorcloseto

sprayarea.Resistancemustnotexceed1megohm.SeeGrounding Grounding

•OnlyusegroundedGracoconductiveairsupplyhoses.

•Donotusepaillinersunlesstheyareconductiveandgrounded.

Stop

•Stop Stop

•Checkgunresistance,hoseresistance,andelectricalgroundingdaily.

•Useandcleanequipmentonlyinwellventilatedarea.

•Interlockthegunairanduidsupplytopreventoperationunlessventilationairowisabove

•UseonlyGroupIIAorGroupDmaterials.

•Usecleaningsolventswithhighestpossibleashpointwhenushingorcleaningequipment.

•Neversprayorushsolventathighpressure.

•Tocleantheexterioroftheequipment,cleaningsolventsmusthaveaashpointatleast15°

•Alwaysturntheelectrostaticsoffwhenushing,cleaningorservicingequipment.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

•Donotplugorunplugpowercordsorturnlightsonoroffwhenammablefumesarepresent.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepthesprayareacleanatalltimes.Usenon-sparkingtoolstocleanresiduefromthe

•Keepaworkingreextinguisherintheworkarea.

operation

operation operation

equipmentuntilyouidentifyandcorrecttheproblem.

theminimumrequiredvalue.

Cor59°Faboveambienttemperature.Non-ignitableuidsarepreferred.

plasticdropcloths(potentialstaticsparking).

boothandhangers.

AND

ELECTRIC

AND AND

ELECTRIC ELECTRIC

immediately

immediately immediately

ifstaticsparkingoccursoryoufeelashock.Donotuse

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplodee.

Grounding

instructions.

4

3A2495K

Page 5

WARNING

WARNING WARNING

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromgun,hoseleaks,orrupturedcomponentswillpierceskin.Thismay

looklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

treatment.

treatment. treatment.

•Donotspraywithouttipguardandtriggerguardinstalled.

•Engagetriggerlockwhennotspraying.

•Donotpointgunatanyoneoratanypartofthebody.

•Donotputyourhandoverthespraytip.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

HAZARD

HAZARD HAZARD

Get

immediate

immediate immediate

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

whenyoustopsprayingandbeforecleaning,checking,

Warnings

surgical

surgical surgical

3A2495K5

Page 6

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

Forcompleteinformationaboutyourmaterial,requestSafetyDataSheets(SDSs)from

yourdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PLASTIC

PLASTIC PLASTIC

Manycleaningsolventscandegradeplasticpartsandcausethemtofail,whichcouldcause

seriousinjuryorpropertydamage.

MISUSE

MISUSE MISUSE

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.

CLEANING

CLEANING CLEANING

SOLVENT

SOLVENT SOLVENT

Specications

Specications Specications

Pressure

HAZARD

HAZARD HAZARD

Relief

Relief Relief

inallequipmentmanuals.

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Technical

•Useonlycompatiblesolventstocleanplasticstructuralorpressure-containingparts.

•SeeTechnical Technical

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheet(SDS)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

Technical

thesolventmanufacturerforinformationandrecommendationsaboutcompatibility.

FLUID

FLUID FLUID

guidelines.

manufacturer.

Specications

Specications Specications

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

inallequipmentmanualsformaterialsofconstruction.Consult

HAZARD

HAZARD HAZARD

EQUIPMENT

EQUIPMENT EQUIPMENT

63A2495K

Page 7

GunOverview

Gun

Gun Gun

How

How How

Works

Works Works

Thisisnotanairspraygun.Tohelpprevent

seriousinjuryfrompressurizeduid,suchasskin

injection,andsplashinguid,readandfollowthe

Skin

Skin Skin

Theair-assistedsprayguncombinesairlessand

airsprayingconcepts.Thespraytipatomizes

andshapestheuidintoafanpattern,asdoes

aconventionalairlessspraytip.Airfromtheair

capfurtheratomizestheuidandcompletesthe

atomizationoftheuidtailstoproduceauniform

pattern.

Asthegunistriggered,partoftheregulatedair

operatesthealternatorturbineandtherestofthe

airhelpsatomizetheuidbeingsprayed.The

Overview

Overview Overview

the

Electrostatic

the the

Electrostatic Electrostatic

Injection

Injection Injection

Hazard

Hazard Hazard

Warnings

Warnings Warnings

AA

AA AA

Spray

Spray Spray

onpage5.

Gun

Gun Gun

alternatorgeneratespower,whichisconvertedby

thepowercartridgetosupplyhighvoltagetothe

gun’selectrode.

Theuidiselectrostaticallychargedasitpasses

theelectrode.Thechargeduidisattractedtothe

groundedworkpiece,wrappingaroundandevenly

coatingallsurfaces.

Theregulatedairthatisdirectedtotheaircapcan

befurthercontrolledusingthegun’satomizingair

adjustmentvalve.Thisvalvecanbeusedtorestrict

airowtotheaircapwhilemaintainingsufcientair

owtothealternator.Theatomizingairadjustment

valvedoesnotcontrolpatternwidth.Tochange

patternwidth,useanewtipsize,orusethefan

adjustmenttonarrowthepatternwidth.

Thehighworkinguidpressureofthisgunprovides

thepowerneededtoatomizehighersolidsmaterials.

NOTE:

NOTE: NOTE:

gun’satomizingairadjustmentvalvecompletelyoff.

Closingthisvalvedoesnotaffectalternatoroperation.

Forairlessatomization,ifdesired,turnthe

3A2495K

7

Page 8

GunOverview

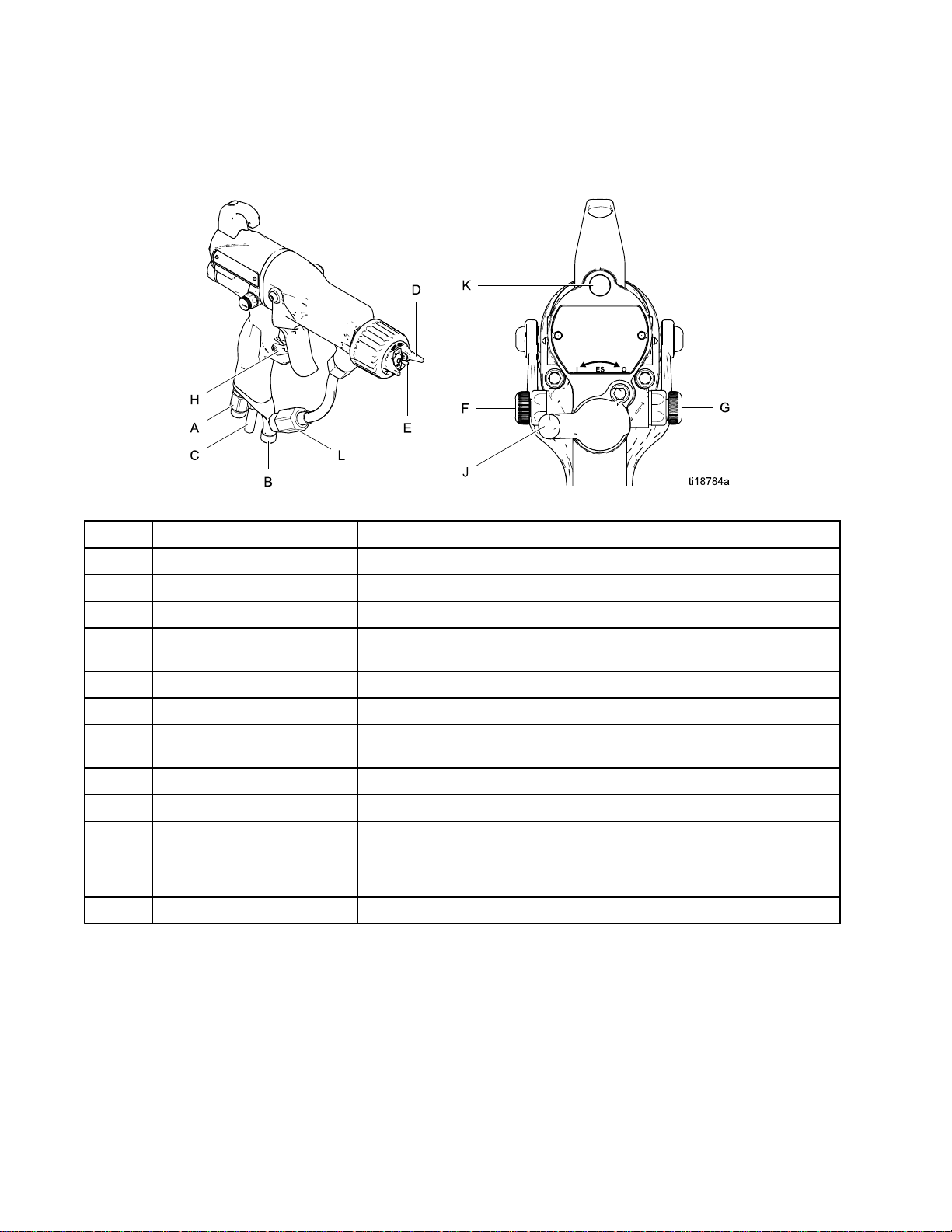

Controls,

Controls, Controls,

Theelectrostaticgunincludesthefollowingcontrols,indicators,andcomponents(seeFig.1).Forinformation

onSmartguns,alsoseeSmartGuns,page9.

Figure1GunOverview

Item

Item Item

A

Indicators,

Indicators, Indicators,

Description

Description Description

AirSwivelInlet1/4npsm(m)left-handthread,forGracogroundedairsupplyhose.

and

Components

and and

Components Components

Purpose

Purpose Purpose

BFluidInlet

C

D

EElectrode

FFanAirAdjustmentValve

G

H

J

K

LInlineFluidFilter

TurbineAirExhaust

AirCap/TipGuardand

SprayTip

AtomizingAirAdjustment

Valve

TriggerSafetyLockLockstriggertopreventgunfromspraying.

ESOn-OffValveTurnselectrostaticsON(I)orOFF(O).

ESIndicator(standard

gunonly;forSmart

gunindicator,see

OperatingMode,page9)

1/4npsm(m),foruidsupplyhose.

Barbedtting,forsuppliedexhausttube.

SeeSprayTipSelectionChart,page61,foravailablesizes.

Supplieselectrostaticchargetotheuid.

Adjustsfansizeandshape.Canbeusedtodecreasepatternwidth.

Adjustsatomizingairow.

LitwhenESisON(I).Colorindicatesalternatorfrequency.Seethe

LEDindicatortableintheGunSetupProcedure,page21.

Providesnalltrationofuid.Locatedinsideuidtubetting.

83A2495K

Page 9

GunOverview

Smart

Smart Smart

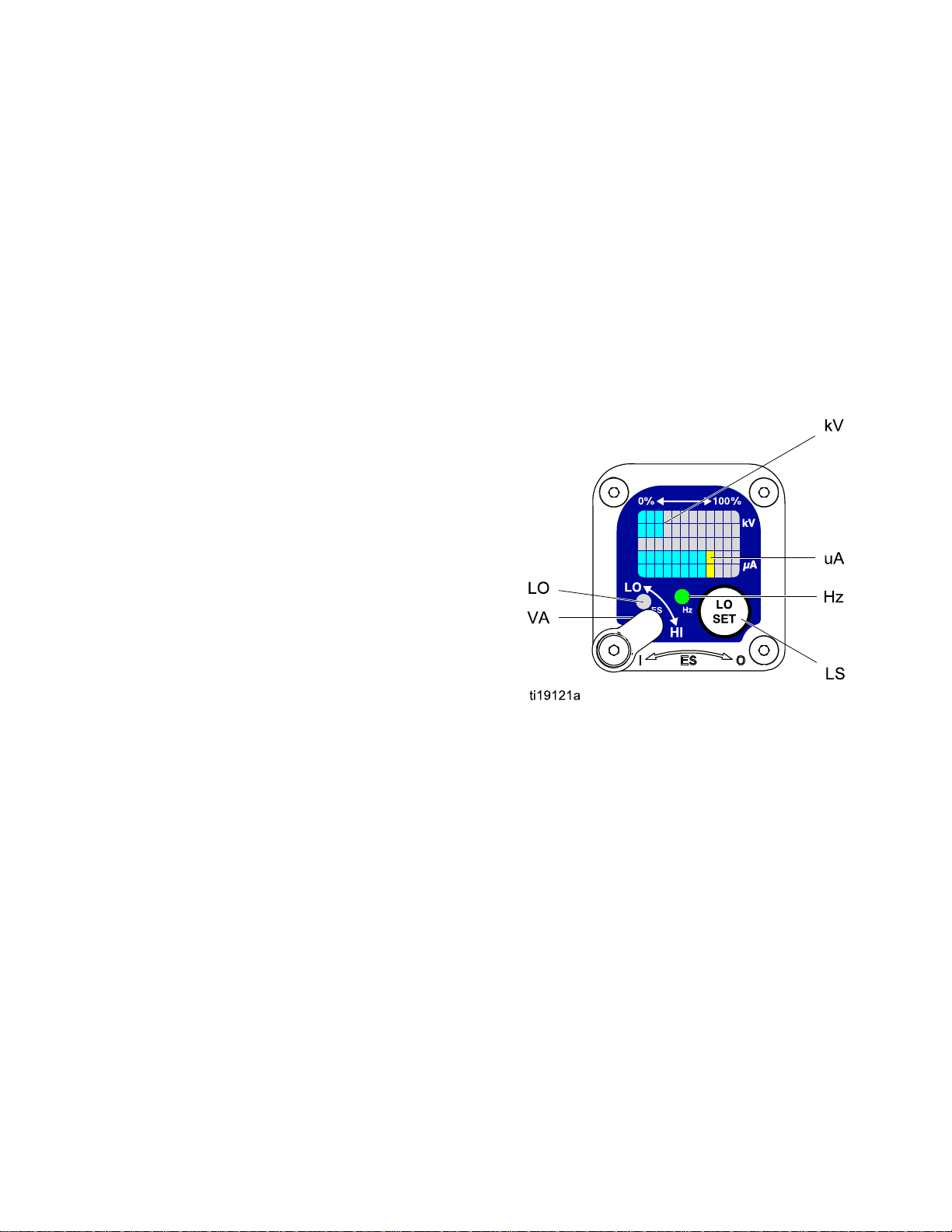

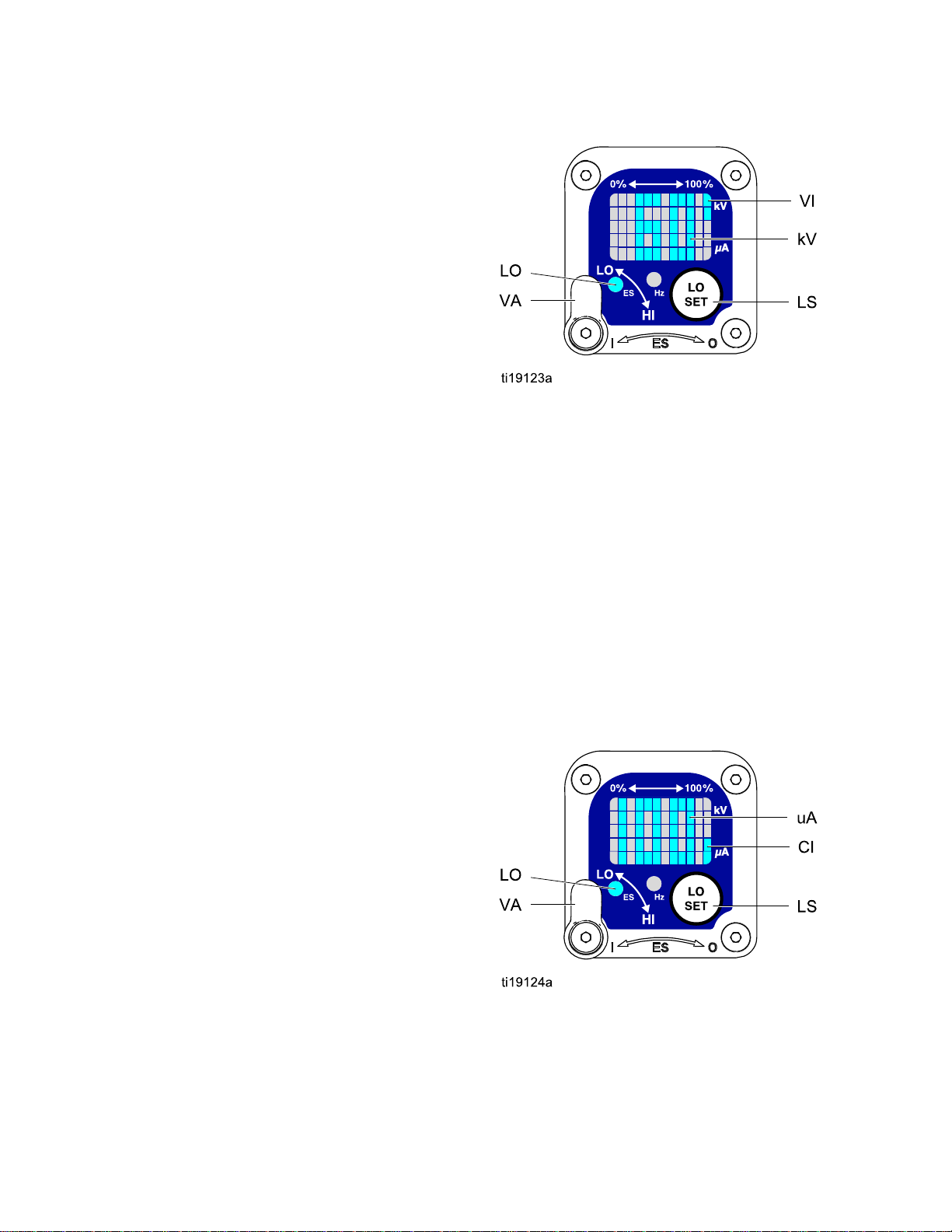

TheSmartGunmoduledisplayssprayingvoltage,

current,alternatorspeed,andthevoltagesetting(low

orhigh).Italsoallowstheusertochangetoalower

sprayingvoltage.Themodulehastwomodes:

•OperatingMode

•DiagnosticMode

Operating

Operating Operating

Bar

Bar Bar

SeeFig.2andSmartGunKey,page11.The

OperatingModedisplaysgundataduringnormal

spraying.Thedisplayusesabargraphtoshowthe

voltagelevelinkiloVolts(kV)andthecurrentlevelin

microAmperes(uA).Thebargraphrangeisfrom0

to100%foreachvalue.

IftheuAbargraphLEDsareblue,thegunisready

tospray.IftheLEDsareyelloworred,thecurrentis

toohigh.Theuidmaybetooconductive,orsee

ElectricalTroubleshooting,page37forotherpossible

causes.

Guns

Guns Guns

Mode

Mode Mode

Graph

Graph Graph

Voltage

Voltage Voltage

Thevoltageadjustmentswitch(VA)allowsthe

operatortochangefromlowtohighvoltage.

•Thehighvoltagesettingisdeterminedbythe

maximumvoltageofthegunandisnotadjustable.

•Thelowvoltageindicator(LO)lights

whentheswitchissettoLO.Thelow

voltagesettingisuseradjustable.See

AdjustingtheLowVoltageSetting,page10.

NOTE:

NOTE: NOTE:

haslostcommunicationwiththepowersupply.See

ErrorDisplay,page10,forfurtherinformation.

Adjustment

Adjustment Adjustment

IftheErrordisplayappears,theSmartmodule

Switch

Switch Switch

Hz

Indicator

Hz Hz

Indicator Indicator

TheHzindicatorfunctionsthesameastheES

indicatoronstandardguns.Theindicatorlightsto

showthealternatorspeedstatus,andhasthree

colors:

•Greenindicatesthealternatorspeediscorrect.

•Iftheindicatorchangestoamberafteronesecond,

increasetheairpressure.

•Iftheindicatorchangestoredafteronesecond,

theairpressureistoohigh.Decreaseairpressure

untiltheindicatorisgreen.Tomaintainahigher

airpressure,installESOn/OffValveRestrictorKit

26A294.Then,adjustthepressureasneededto

ensuretoensuretheindicatorremainsgreen.

Figure2SmartGunModuleinOperatingMode

3A2495K9

Page 10

GunOverview

Error

Error Error

IftheSmartmodulelosescommunicationwith

thepowersupply,theErrordisplayappears,the

Hzindicatorturnsred,andtheSmartmoduleis

disabled.SeeFig.3andSmartGunKey,page11.

ThiscanoccurinOperatingModeorDiagnostic

Mode.SeeElectricalTroubleshooting,page37.

CommunicationmustberestoredtomaketheSmart

modulefunctional.

NOTE:

NOTE: NOTE:

appear.Ifthegunhasbeendisassembled,wait8

secondsbeforesprayingtoensurethatanError

conditionhasnotoccurred.

NOTE:

NOTE: NOTE:

displaywillnotappear.

Display

Display Display

Ittakes8secondsfortheErrordisplayto

Ifthereisnopowertothegun,theError

foryourgun.Continuepressingthebuttonuntilyou

reachthedesiredsetting.

NOTE:

NOTE: NOTE:

returntotheOperatingScreen.

NOTE:

NOTE: NOTE:

LockSymbol,page10.

Figure4LowVoltageSettingScreen(Unlocked)

Lock

Lock Lock

After2secondsofinactivitythedisplaywill

Thelowvoltagesettingmaybelocked.See

Symbol

Symbol Symbol

Figure3ErrorDisplay

Adjusting

Adjusting Adjusting

Thelowvoltagesettingisuseradjustable.Toaccess

thelowvoltagesettingscreenwheninOperating

Mode,presstheLOSETbutton(LS)momentarily.

Thescreenwilldisplaythecurrentlowvoltage

setting.SeeFig.4andSmartGunKey,page11.

Thepossiblerangesare:

•85kVguns:40–85kV

•60kVguns:30–60kV

SettheVoltageAdjustmentswitch(VA)toLO.Press

theLOSETbuttonrepeatedlytoincreasethesetting

inincrementsof5.Whenthedisplayreachesthe

maximumsettingitwillreturntotheminimumsetting

the

Low

the the

Voltage

Low Low

Voltage Voltage

Setting

Setting Setting

Thelowvoltagesettingmaybelocked.Whenlocked,

animage(LK)appearsonthescreen.SeeFig.5

andSmartGunKey,page11.

•WheninHImode,thelowvoltagesettingisalways always

locked.ThelocksymbolwillappearwhentheLO

SETbuttonispressed.

•WheninLOmode,thelocksymbolwill

only

only only

appearifthelockisenabled.See

LowVoltageLockScreen,page13,tolockor

unlockthelowvoltagesetting.

Figure5LowVoltageSettingScreen(Locked)

always

103A2495K

Page 11

GunOverview

Smart

Smart Smart

Table

Table Table

Item

Item Item

VA

LO

kV

uA

LSLOSETbuttonPressmomentarilytoentertheLowVoltageSettingscreen.

Gun

Key

Gun Gun

Key Key

Key

for

Figs.

1 11Key Key

for for

Description

Description Description

VoltageAdjustmentSwitchTwo-positionswitchsetsSmartgunvoltagetolowsetting(LO)or

LowVoltageMode

Indicator

Voltage(kV)DisplayDisplaysactualsprayingvoltageofthegun,inkV.InOperatingMode,

Current(uA)DisplayDisplaysactualsprayingcurrentofthegun,inuA.InOperatingMode,

2–9.

Figs. Figs.

2–9. 2–9.

Purpose

Purpose Purpose

highsetting(HI).ThisswitchisfunctionalinOperatingModeandin

DiagnosticMode.

Lights(blue)whentheSmartgunissettoLowVoltage.

displayisabargraph.InDiagnosticMode,voltageisdisplayedas

anumber.

displayisabargraph.InDiagnosticMode,currentisdisplayedas

anumber.

Pressandholdforapproximately5secondstoenterorexitDiagnostic

Mode.

WhileinDiagnosticMode,pressmomentarilytoadvancethrough

screens.

WhileontheLowVoltageLockScreen(inDiagnosticMode),press

andholdtoturnthelockonoroff.

LVLowVoltageDisplayDisplaysthelowvoltagesettingasanumber.Thesettingcanbe

changed.SeeFig.4.

LKLowVoltageLocked

LD

ERErrorDisplay

VIVoltageIndicator

CICurrentIndicatorInDiagnosticMode,thetwobottomrightLEDsofthescreenlight,

ASAlternatorSpeedDisplayInDiagnosticMode,Hzlevelisdisplayedasanumber.SeeFig.8.

Hz

LODisplayAppearsontheLowVoltageLockScreen.SeeFig.9.

AlternatorSpeedIndicatorInOperatingMode,indicatorcolorvariestoshowthealternatorspeed

Appearsifthelowvoltagesettingislocked.SeeFig.5andFig.9.

AppearsiftheSmartmodulelosescommunicationwiththepower

supply.SeeFig.3.

InDiagnosticMode,thetwotoprightLEDsofthescreenlight,

indicatingthatthevaluedisplayedisinkV.SeeFig.6.

indicatingthatthevaluedisplayedisinuA.SeeFig.7.

status:

•Greenindicatesthealternatorspeedisatthecorrectlevel.

•Iftheindicatorchangestoamberafteronesecond,thealternator

speedistoolow.

•Iftheindicatorchangestoredafteronesecond,thealternatorspeed

istoohigh.TheindicatoralsoturnsrediftheErrordisplayappears.

InDiagnosticMode,theindicatorisgreenwhenintheAlternator

Speed(Hertz)screen.

3A2495K

11

Page 12

GunOverview

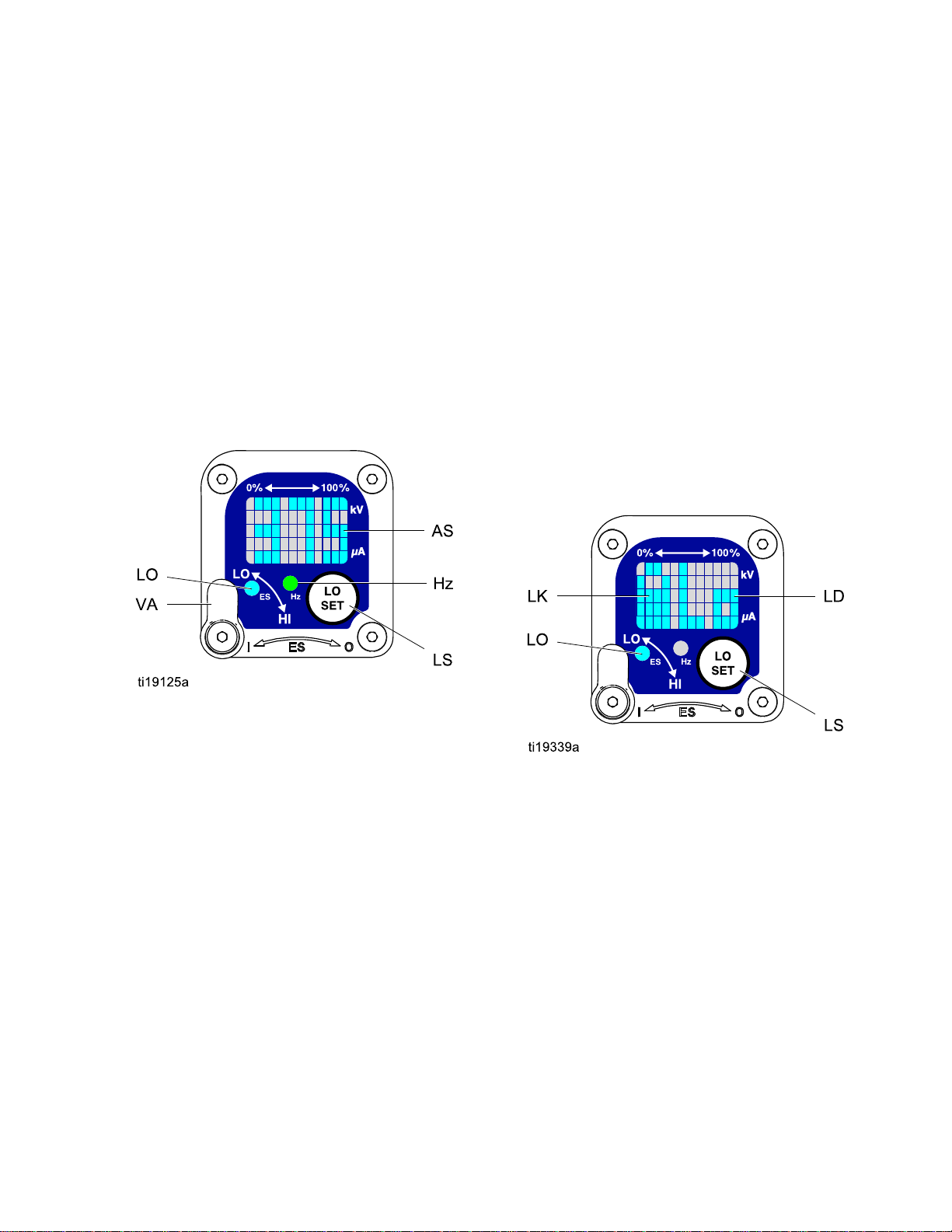

Diagnostic

Diagnostic Diagnostic

DiagnosticModeincludesfourscreenswhichdisplay

gundata:

•Voltage(kiloVolts)Screen

•Current(microAmperes)Screen

•AlternatorSpeed(Hertz)Screen

•LowVoltageLockScreen

NOTE:

NOTE: NOTE:

lowvoltagesetting;thesettingisnotadjustablein

DiagnosticMode.However,thevoltageadjustment

switch(VA)canbesettoHIorLOinOperatingMode

andinDiagnosticMode.

ToenterDiagnosticMode,pressandholdtheLOSET

(LS)buttonforapproximately5seconds.Thedisplay

willgototheVoltage(kiloVolts)Screen,page12.

Toadvancetothenextscreen,presstheLOSET

buttonagain.

ToexitDiagnosticMode,pressandholdtheLOSET

buttonforapproximately5seconds.Thescreenwill

returntoOperatingMode.

NOTE:

NOTE: NOTE:

Mode,thelastscreenviewedwillbedisplayedwhen

thegunisretriggered.

NOTE:

NOTE: NOTE:

fromtheLowVoltageLockScreen.See

LowVoltageLockScreen,page13fordetails.

Mode

Mode Mode

YoumustbeinOperatingModetoadjustthe

IfthegunisdetriggeredwhileinDiagnostic

DiagnosticModecannotbeexited

Figure6Voltage(kiloVolts)Screen

Current

Current Current

TheCurrent(microAmperes)Screenisthesecond

screenintheDiagnosticMode.SeeFig.7and

SmartGunKey,page11.Toenterthisscreen,press

theLOSETbuttonwhileintheVoltage(kiloVolts)

Screen.

Thisscreendisplaysthesprayingcurrentofthegun

asanumber(uA),roundedtothenearest5uA.The

twobottomrightLEDs(CI)ofthedisplaypanellight,

indicatingthattheCurrent(microAmperes)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

(microAmperes)

(microAmperes) (microAmperes)

Screen

Screen Screen

Voltage

Voltage Voltage

TheVoltage(kiloVolts)Screenistherstscreento

appearafterenteringDiagnosticMode.SeeFig.6

andSmartGunKey,page11.Toenterthisscreen,

pressandholdtheLOSETbuttonforapproximately

5secondswhileintheOperatingMode.

Thisscreendisplaysthesprayingvoltageofthe

gunasanumber(kV),roundedtothenearest5kV.

ThetwotoprightLEDs(VI)ofthedisplaypanel

light,indicatingthattheVoltage(kiloVolts)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

Current(microAmperes)Screen,page12.Press

andholdforapproximatelyvesecondstoreturnto

OperatingMode.

(kiloVolts)

(kiloVolts) (kiloVolts)

Screen

Screen Screen

PresstheLOSETbuttontoadvancetothe

AlternatorSpeed(Hertz)Screen,page13.Press

andholdforapproximatelyvesecondstoreturnto

OperatingMode.

Figure7Current(microAmperes)Screen

12

3A2495K

Page 13

GunOverview

Alternator

Alternator Alternator

TheAlternatorSpeed(Hertz)Screenisthethird

screenintheDiagnosticMode.SeeFig.8and

SmartGunKey,page11.Toenterthisscreen,

presstheLOSETbuttonwhileintheCurrent

(microAmperes)Screen.

Thisscreendisplaysthealternatorspeedasa3digit

number(AS),roundedtothenearest10Hz.The

displayisareadoutandcannotbechanged.Ifthe

alternatorspeedisgreaterthan999Hz,thedisplay

willshow999.

TheHzindicatorlightsgreentoshowthatyouare

viewingtheAlternatorSpeed(Hertz)Screen.

PresstheLOSETbuttontoadvancetothe

LowVoltageLockScreen,page13.Pressandhold

forapproximately5secondstoreturntoOperating

Mode.

Speed

Speed Speed

(Hertz)

(Hertz) (Hertz)

Screen

Screen Screen

Low

Voltage

Low Low

Voltage Voltage

TheLowVoltageLockScreenisthefourth

screenintheDiagnosticMode.SeeFig.9and

SmartGunKey,page11.Toenterthisscreen,press

theLOSETbuttonwhileintheAlternatorSpeed

(Hertz)Screen.

ThisscreendisplaysthestatusoftheLowVoltage

Lock.Ifthesettingislocked,thelockimage(LK)

appearstotheleftoftheLodisplay(LD).Ifthesetting

isunlocked,thelockimagedoesnotappear.

Tochangethelockstatus,pressandholdthe

LOSETbuttonuntilthelockimageappearsor

disappears.Ifthelockisset,theimagewillalso

appearontheLowVoltageSettingScreenwhenin

lowvoltagemode(seeFig.4).

NOTE:

NOTE: NOTE:

screen,becausepressingandholdingtheLOSET

buttonisusedtoturnthelockonoroff.Toexit,

pressLOSETmomentarilytoreturntotheVoltage

(kiloVolts)Screen,thenexitDiagnosticModefrom

there.

DiagnosticModecannotbeexitedfromthis

Lock

Screen

Lock Lock

Screen Screen

Figure8AlternatorSpeed(Hertz)Screen

Figure9LowVoltageLockScreen

3A2495K13

Page 14

Installation

Installation

Installation Installation

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseelectricshock

orotherseriousinjuryifworkisnotperformed

properly.

•Donotinstallorservicethisequipmentunless

youaretrainedandqualied.

•Besureyourinstallationcomplieswithlocal,

state,andnationalcodesfortheinstallation

ofelectricalapparatusinaClassI,Div.I,

hazardouslocationoraGroupII,ZoneI

explosiveatmospherelocation.

•Complywithalllocalcodesandregulations.

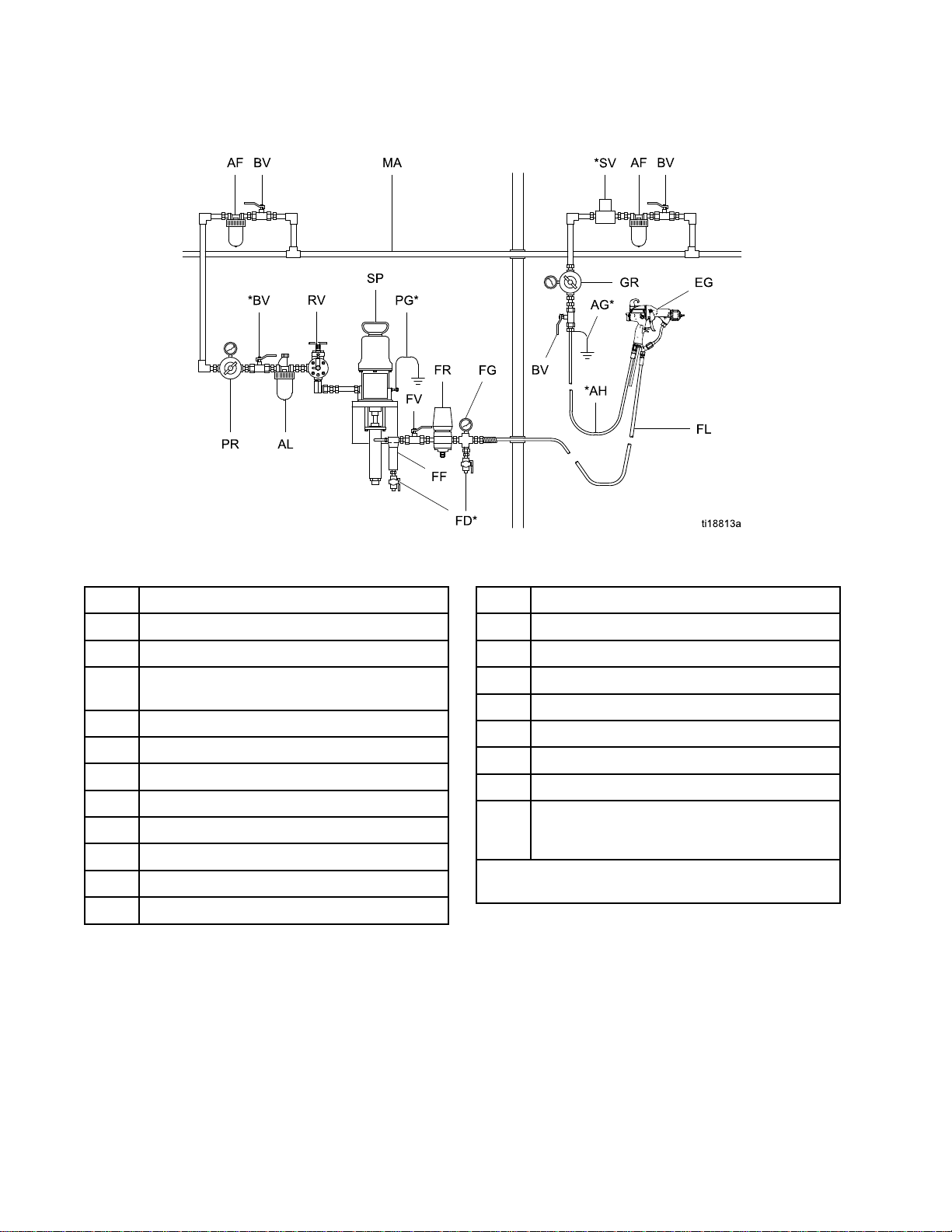

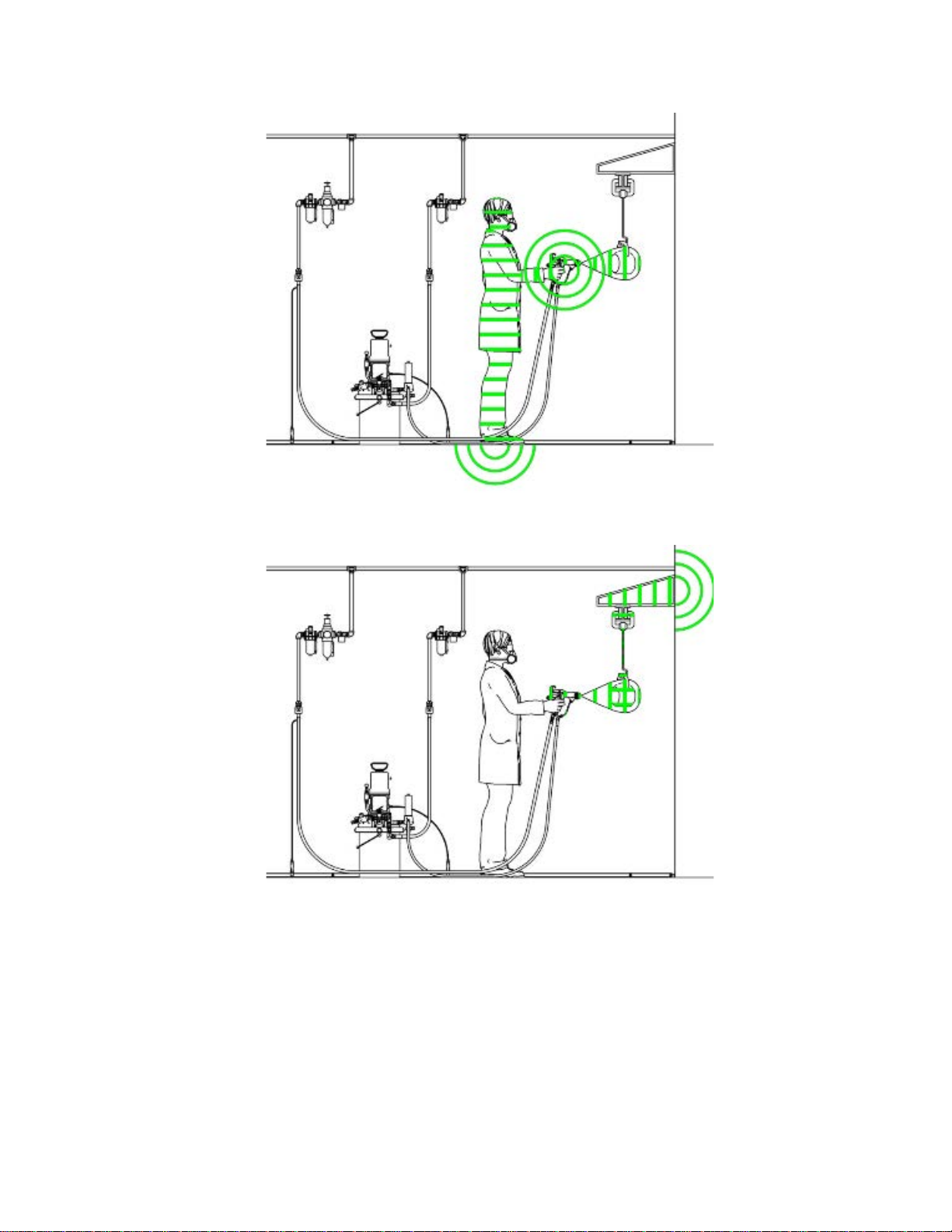

Fig.10(TypicalInstallation)showsatypical

electrostaticair-assistedspraysystem.Itisnotan

actualsystemdesign.Forassistanceindesigning

asystemtosuityourparticularneeds,contactyour

Gracodistributor.

Warning

Warning Warning

Sign

Sign Sign

Ventilate

Ventilate Ventilate

Donotoperatethegununlessventilatingairowis

abovetheminimumrequiredvalue.Providefresh

airventilationtoavoidthebuildupofammableor

toxicvaporswhenspraying,ushing,orcleaning

thegun.Interlockthegunairanduidsupply

topreventoperationunlessventilatingairowis

abovetheminimumrequiredvalue.

Thesprayboothmusthaveaventilationsystem.

Electricallyinterlockthegunairanduidsupplywith

theventilatorstopreventgunoperationanytimethat

theventilationairowfallsbelowminimumvalues.

Checkandfollowalllocalcodesandregulations

regardingairexhaustvelocityrequirements.Verify

theoperationoftheinterlockatleastonceayear.

NOTE:Theminimumallowableairexhaust

velocityis60feet/minute(19linearmeters/minute).

High-velocityairexhaustwilldecreasetheoperating

efciencyoftheelectrostaticsystem.

the

Spray

the the

Spray Spray

Booth

Booth Booth

Mountwarningsignsinthesprayareawherethey

caneasilybeseenandreadbyalloperators.An

EnglishWarningSignisprovidedwiththegun.

14

3A2495K

Page 15

Air

Supply

Air Air

Supply Supply

Toreducetheriskofelectricshock,theairsupply

hosemustbeelectricallyconnectedtoatrueearth

ground.Use Use

Hose.

Hose. Hose.

1.SeeFig.10.UsetheGracoGroundedAirSupply

Hose(AH)tosupplyairtothegun.Thegunair

inletttinghasaleft-handthread.Theairsupply

hosegroundwire(AG)mustbeconnectedtoa

trueearthground.Donotconnecttheairsupply

hosetothegunairinletyet.

2.Installanairlinelter/waterseparator(AF)onthe

gunairlinetoensureadry,cleanairsupplytothe

gun.Dirtandmoisturecanruintheappearance

ofyournishedworkpieceandcancausethe

guntomalfunction.

Toreducetheriskofseriousinjurydueto

componentrupture,includingskininjection,

pumppressuremustbelimitedbythepumpair

regulator.Donotrelyonthegunuidregulator

tolimittheuidpressuretothegun.

Line

Line Line

Use

only

Graco

only only

Graco Graco

Grounded

Grounded Grounded

Air

Supply

Air Air

Supply Supply

Installation

4.Installableed-typeairvalve(BV)onthepump

airsupplyline.Thebleed-typeairvalve(BV)is

requiredinyoursystemtoshutoffairtothepump

andrelieveairtrappedbetweenthevalveand

thepumpaftertheairregulatorisshutoff.Install

anadditionalbleed-typeairvalveonthemainair

line(MA)toisolatetheaccessoriesforservicing.

5.Installanairbleedvalve(BV)oneachgunair

supplylinetoshutoffairtothegun(s)andrelieve

airtrappedbetweenthevalveandthegunafter

theairregulatorisshutoff.

Fluid

Fluid Fluid

1.Blowouttheuidline(FL)withairandushit

2.Installauidpressureregulator(FR)ontheuid

3.Installauidlter(FF)nearthepumpoutlet,to

Supply

Supply Supply

withsolvent.Usesolventwhichiscompatible

withtheuidtobesprayed.Donotconnectthe

uidsupplylinetothegunuidinletyet.

linetocontroluidpressuretothegun.

removeparticlesandsedimentwhichcouldclog

thespraynozzle.

NOTE:

NOTE: NOTE:

additionalltration.

Thegunincludesaninlineuidlterfor

Line

Line Line

Theuidsupplypumpmustbepreventedfrom

producingauidpressuregreaterthanthe

3000psi(21MPa,210bar)

FluidPressure

supplypressuretoa30:1ratiopumpmustnot

exceed100psi(0.7MPa,7bar).

3.Installbleed-typeairregulators(PR,GR)on

thepumpandgunairsupplylinestocontrolair

pressuretothepumpandgun.

Trappedaircancausethepumptocycle

unexpectedly,whichcanresultinserious

injury,includingskininjectionandsplashing

uidintheeyesorontheskin.Donotoperate

theequipmentwithoutthebleed-typeairvalve

(BV)installed.

ofthegun.Forexample,theair

MaximumWorking

Toreducetheriskofseriousinjury,including

skininjectionandsplashinguidintheeyesor

ontheskin,donotoperateequipmentwithout

theuiddrainvalve(FD)installed.

4.Theuiddrainvalve(FD)isrequiredinyour

systemtoassistinrelievinguidpressureinthe

displacementpump,hose,andgun.Triggering

theguntorelievepressuremaynotbesufcient.

Installadrainvalveclosetothepump'suid

outlet.

3A2495K15

Page 16

Installation

NON

HAZARDOUS

NON NON

- --HAZARDOUS HAZARDOUS

LOCATION

LOCATION LOCATION

HAZARDOUS

HAZARDOUS HAZARDOUS

LOCATION

LOCATION LOCATION

Figure10TypicalInstallation

Typical

Typical Typical

Item

Item Item

AF

AG*GunAirHoseGroundWire

AH*GracoGroundedAirHose(left-hand

ALPumpAirLineLubricator

BV*PumpBleed-TypeAirShutoffValve

EGElectrostaticAirSprayGun

FD*

FFFluidFilter

FGFluidPressureGauge

FL

FRFluidPressureRegulator

Installation

Installation Installation

Description

Description Description

AirFilter/WaterSeparator

threads)

FluidDrainValve

FluidSupplyLine

Key

Key Key

Item

Item Item

FV

GRGunAirPressureRegulator

MA

PG*PumpGroundWire

PRPumpAirPressureRegulator

RVPumpRunawayValve

SPSupplyPump

SV*VentilationFanInterlockSolenoidValve

*Theseitemsarerequiredforsafeoperation.They

mustbepurchasedseparately.

Description

Description Description

FluidShutoffValve

MainAirSupplyLine

NOTE:

NOTE: NOTE:

aGracoaccessory.

Thesolenoidvalveisnotofferedas

163A2495K

Page 17

Grounding

Grounding Grounding

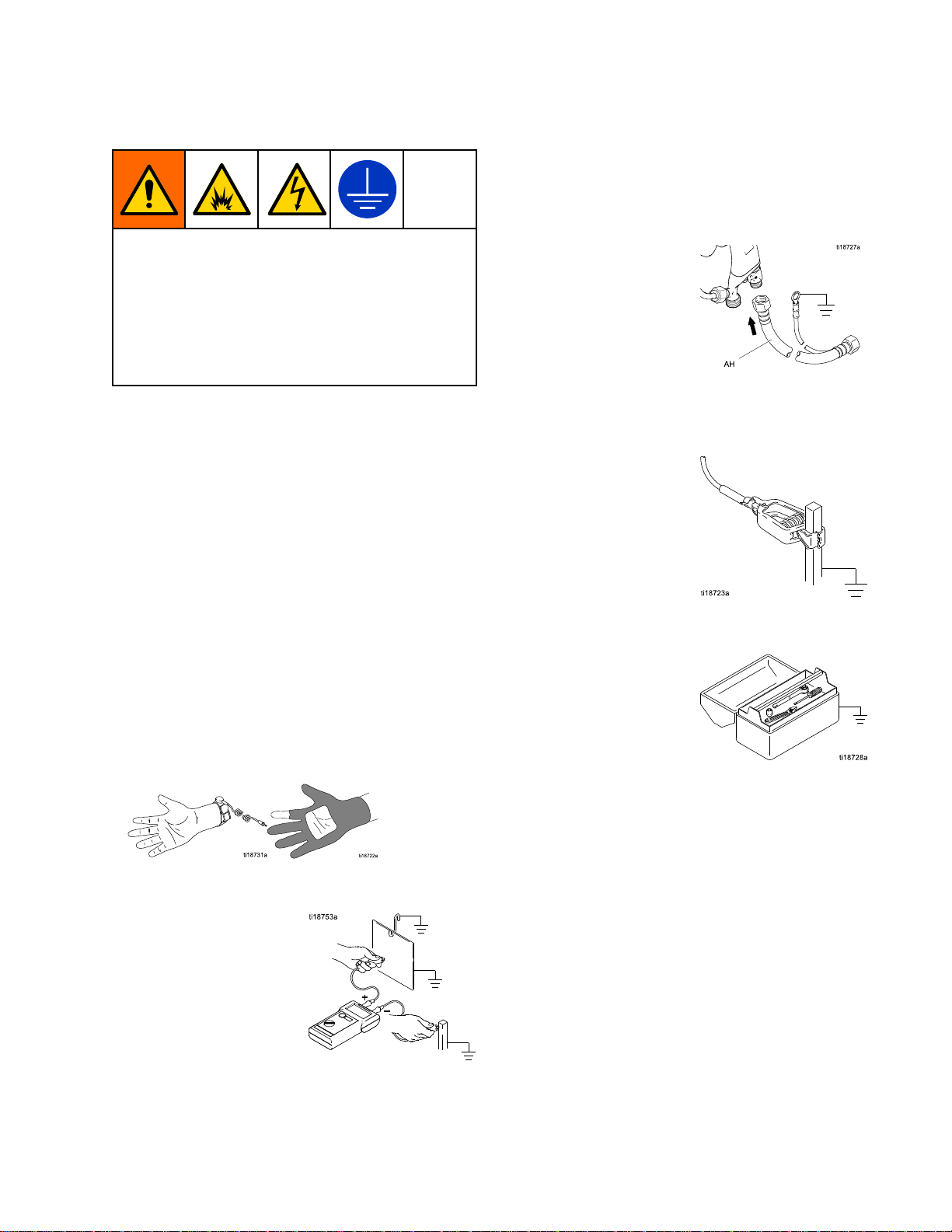

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundallequipment,personnel,objects

beingsprayed,andconductiveobjectsinorclose

tothesprayarea.Theresistancemustnotexceed

1megohm.Groundingprovidesanescapewire

fortheelectriccurrent.

Whenoperatingtheelectrostaticgun,any

ungroundedobjects(suchaspeople,containers,and

tools)inthespraylocationcanbecomeelectrically

charged.

Thefollowingareminimumgroundingrequirements

forabasicelectrostaticsystem.Yoursystemmay

includeotherequipmentorobjectswhichmustbe

grounded.Yoursystemmustbeconnectedtoa

trueearthground.Checkgroundconnectionsdaily.

Checkyourlocalelectricalcodesandregulationsfor

detailedgroundinginstructions.

•

ElectrostaticAir-AssistedSprayGun:

thegunbyconnectingtheGracoGrounded

AirHosetothegun,andconnectingtheair

hosegroundwiretoatrueearthground.See

CheckGunElectricalGrounding,page24.

•

Pump/uidsource:

byconnectingitsgroundwiretoatrueearth

ground.

Groundthepump/uidsource

Installation

Ground

Allpersonsenteringthesprayarea:

•

shoeshavingconductivesolessuchasleather,

orwearpersonalgroundingstraps.Donot

wearshoeswithnon-conductivesolessuchas

rubberorplastic.Ifglovesarenecessary,wear

theconductiveglovessuppliedwiththegun.If

non-Gracoglovesareworn,cutoffngersorpalm

areaofglovestoensureyourhandcontactsthe

groundedgunhandle.Conductiveglovesand

footwearmustnotexceed100megohmperEN

ISO20344,EN1149–5.

•

Objectbeingsprayed:

cleanandgroundedatalltimes.

Keeptheworkpiecehangers

mustwear

•

Allelectricallyconductiveobjectsordevicesinthe

sprayarea:

•

Fluidandwastecontainers:

wastecontainersinthesprayarea.Donotusepail

linersunlesstheyareconductiveandgrounded.

Whenushingthespraygun,thecontainerused

tocatchtheexcessuidmustbeelectrically

conductiveandgrounded.

•

Aircompressors:

tothemanufacturer'srecommendations.

•

Allairanduidlines

Useonlygroundedhoseswithamaximumof100

feet(30.5m)combinedhoselengthtoensure

groundingcontinuity

Theoorofthesprayarea:

•

conductiveandgrounded.Donotcovertheoor

withcardboardoranynon-conductivematerial

whichwouldinterruptgroundingcontinuity

mustbeproperlygrounded.

Groundalluidand

Groundtheequipmentaccording

mustbeproperlygrounded.

mustbeelectrically

3A2495K

17

Page 18

Installation

•

Flammableliquidsinthesprayarea:

inapproved,groundedcontainers.Donotuse

mustbekept

plasticcontainers.Donotstoremorethanthe

quantityneededforoneshift.

•

Allsolventpails:

metalcontainers,whichareconductive.Donot

useplasticcontainers.Useonlynon-ammable

solvents.Donotstoremorethanthequantity

neededforoneshift.

Useonlyapproved,grounded

183A2495K

Page 19

Installation

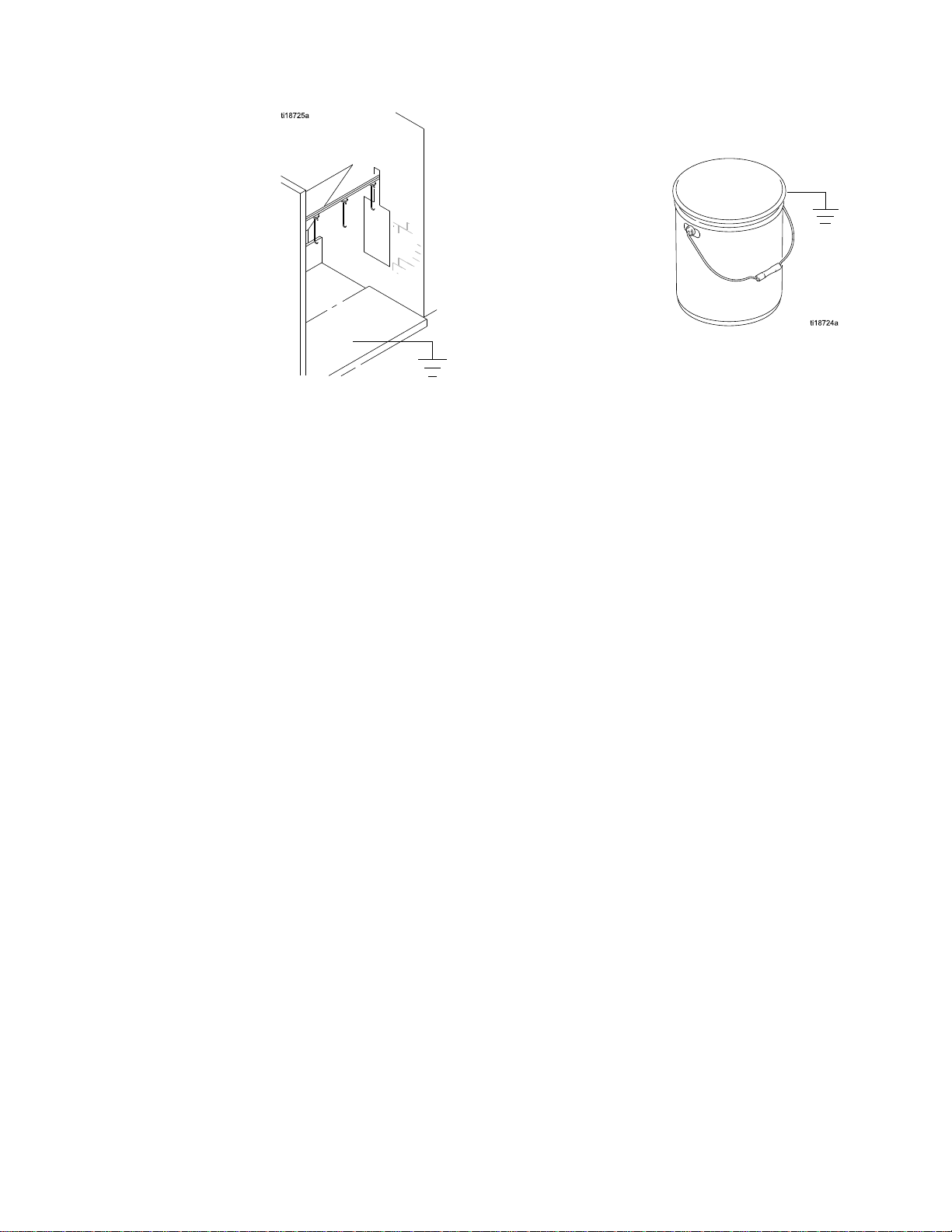

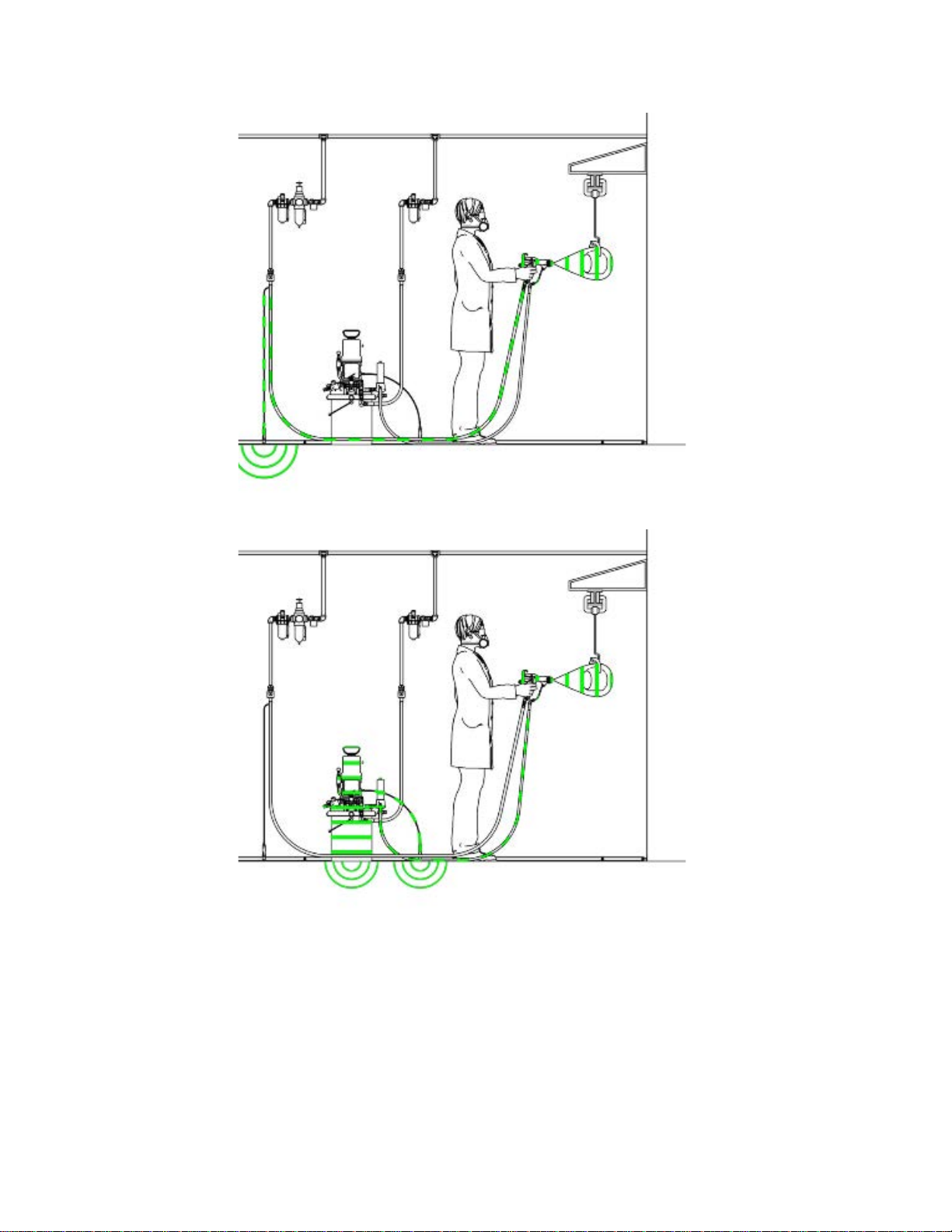

Figure11GroundtheOperatorOperatorisgroundedthroughthegunhandleand

conductiveshoes.

Figure12GroundtheObjectbeingSprayedObjectbeingsprayedisgroundedthroughcontact

withthehangerandconveyorsystem.

3A2495K19

Page 20

Installation

Figure13GroundtheGunGunisgroundedthroughtheconductiveairhose.

Figure14GroundtheFluidSupplyFluidsupplylineandsourcemustbegrounded.

203A2495K

Page 21

GunSetup

Gun

Gun Gun

Gun

Gun Gun

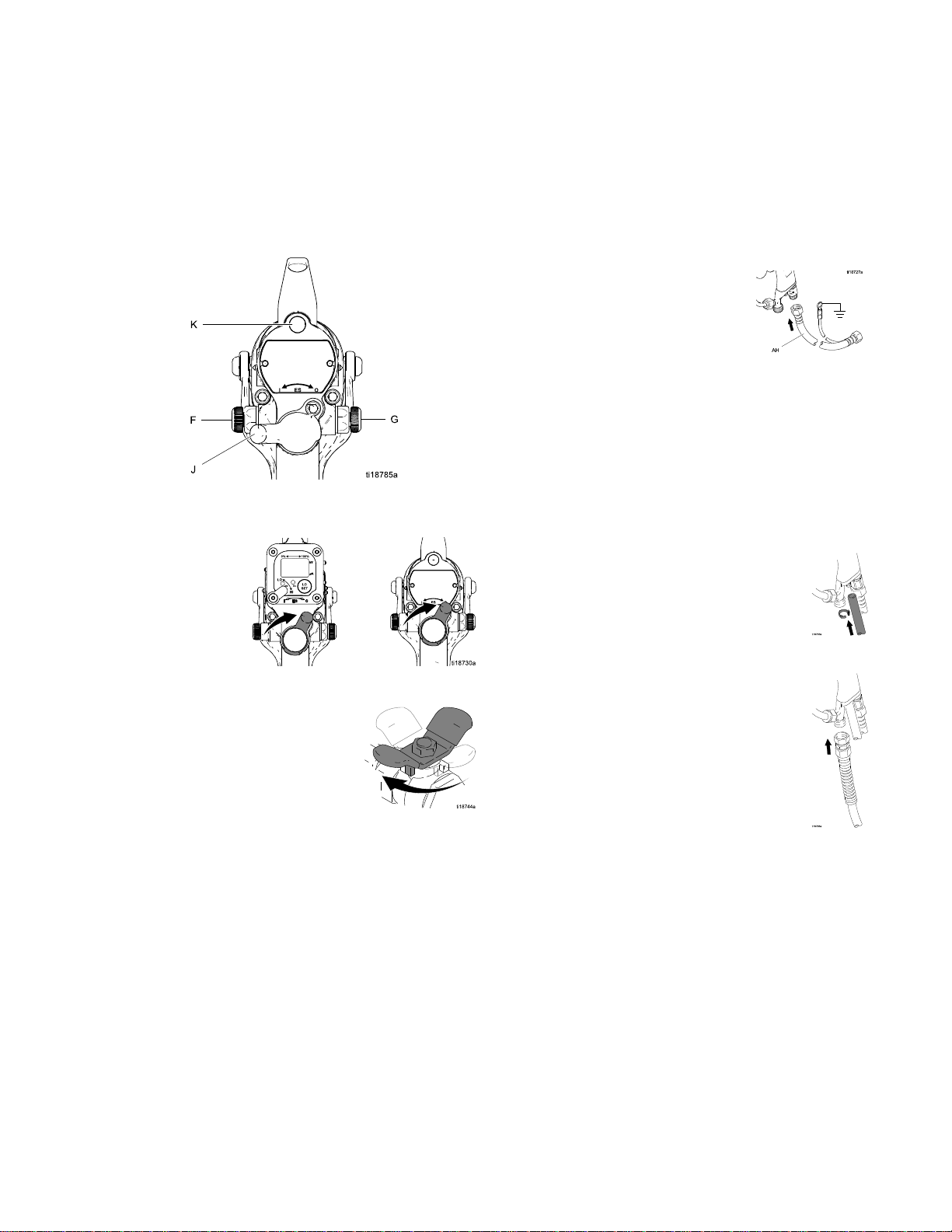

Seethegurebelowtolocatetheelectrostaticgun

controls.

Figure15ElectrostaticGunControls

1.TurnOFF(O)theESOn-Offswitch(J).

Setup

Setup Setup

Setup

Setup Setup

Procedure

Procedure Procedure

4.ConnecttheGracogroundedairhosetothegun

airinlet.Thegunairinletttinghasleft-hand

threads.

5.FollowallstepsunderGrounding,page17.

6.Followallstepsunder

CheckGunElectricalGrounding,page24.

Readingmustbelessthan1megohm.

7.Verifythatthematerialresistivitymeets

requirementsforelectrostaticspray.See

CheckFluidResistivity,page25.

8.Connecttheexhausttubeandsecurewiththe

clampprovided.

2.Shutofftheairbleedvalvetothegun.

3.Checkgunresistance.See

TestGunResistance,page32.

9.Connecttheuidhosetothegunuidinlet.

10.Flushifneeded.SeeFlushing,page28.

3A2495K

21

Page 22

GunSetup

Toreducetheriskofaskininjectioninjury,alwaysfollowthe

PressureReliefProcedure,page26,

beforeremovingorinstallingthespraytip,air

cap,ortipguard.

15.CheckthattheESOn-OffswitchisOFF(O).

11.Theuidoutputandpatternwidthdepend

onthesizeofthespraytip,theuid

viscosity,andtheuidpressure.Usethe

SprayTipSelectionChart,page61,asaguide

forselectingtheappropriatespraytipforyour

application.

12.Alignthespraytiptabwiththegrooveintheair

cap.Installthetip.

13.Installtheaircapandretainingring.Orientate

theaircapandtightentheretainingringsecurely.

14.Closetheatomizingairadjustmentvalve(G)and

thefanairadjustmentvalve(F).

16.Startthepump.Settheuidregulatorto400psi

(2.8MPa,28bar).

17.Sprayatestpattern.Examinetheparticlesizein

thecenterofthepattern(tailswillberemoved

instep21).Increasethepressureinsmall

increments.Sprayanotherpattern.Compare

particlesize.Continueincreasingpressureuntil

theparticlesizeremainsconstant.Donotexceed

3000psi(21MPa,210bar).

18.TurnON(I)theESOn-Offswitch.

22

3A2495K

Page 23

GunSetup

19.CheckthattheESindicator(K)[Hzindicatoron

Smartguns]islit.Seethefollowingtable.

Table

Table Table

Indicator

Indicator Indicator

Amber

20.Setthegunairregulatortodeliveraminimum

of45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.See

thetablebelow.

LED

2 22. ..LED LED

Color

Color Color

Green

Red

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A294.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

21.Turntheatomizingairadjustmentvalve

counterclockwiseuntilanytailsdisappear.

22.Ifdesiredatomizationisnotachieved,change

thetipsize.Thesmallerthetiporice,thener

theatomization.

23.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page35.

Table

Table Table

mm]

mm] mm]

Pressure

3 33. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

(using

(using (using

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)52(0.36,3.6)

25(7.6)57(0.40,4.0)

50(15.3)68(0.47,4.7)

75(22.9)80(0.56,5.6)

100(30.5)90(0.63,6.3)

Drop

Drop Drop

Air

Air Air

(m)

in.

[8

in. in.

[8 [8

hose)

hose) hose)

NOTE:

NOTE: NOTE:

Regulator

Regulator Regulator

psi

in ininpsi psi

[with

gun

[with [with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered]

triggered] triggered]

openthefanairadjustmentvalveslightly.(Excessive

fanairowcancausepaintbuildupontheaircap.)

Ifanarrowerpatternisneededoccasionally,

3A2495K23

Page 24

GunSetup

Check

Check Check

MegohmmeterPartNo.241079(AA-seeFig.16)

isnotapprovedforuseinahazardouslocation.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

•Orallsprayingdevicesinthehazardous

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

GracoPartNo.241079Megohmmeterisavailable

asanaccessorytocheckthatthegunisproperly

grounded.

1.Haveaqualiedelectricianchecktheelectrical

2.TurnOFF(O)theESOn-Offswitch.

Gun

Gun Gun

location;

locationareturnedoff,ventilationfansinthe

hazardouslocationareoperating,andthereare

noammablevaporsinthearea(suchasopen

solventcontainersorfumesfromspraying).

groundingcontinuityofthespraygunandair

hose.

Electrical

Electrical Electrical

Grounding

Grounding Grounding

5.Makesurethegroundedairhoseisconnected

andthehosegroundwireisconnectedtoatrue

earthground.

6.Measuretheresistancebetweenthegunhandle

(BB)andatrueearthground(CC).Usean

appliedvoltageof500minimumto1000volts

maximum.Theresistanceshouldnotexceed1

megohm.SeeFig.16.

7.Iftheresistanceisgreaterthan1megohm,check

thetightnessofthegroundconnectionsandbe

suretheairhosegroundwireisconnectedtoa

trueearthground.Iftheresistanceisstilltoo

high,replacetheairhose.

3.Turnofftheairanduidsupplytothegun.Follow

thePressureReliefProcedure,page26.

4.Disconnecttheuidhose.

24

Figure16CheckGunElectricalGrounding

3A2495K

Page 25

GunSetup

Check

Check Check

Toreducetheriskofre,explosion,orelectric

shock,checktheuidresistivityinanon-hazardous

locationonly.ResistanceMeter722886andProbe

722860arenotapprovedforuseinahazardous

location.

Checkthattheresistivityoftheuidbeingsprayed

meetstherequirementsforanelectrostaticairspray

system.GracoPartNo.722886ResistanceMeter

and722860Probeareavailableasaccessories.

Followtheinstructionsincludedwiththemeterand

probe.

Fluidresistivityreadingsofatleast20megohms-cm

generallyprovidethebestelectrostaticresultsand

arerecommended.

Table

Table Table

Fluid

Fluid Fluid

Fluid

4 44. ..Fluid Fluid

Resistivity

Resistivity Resistivity

Resistivity

Resistivity Resistivity

Megohms Megohms

Levels

Levels Levels

Megohms

cm

- --cm cm

Check

Check Check

Aviscositycupandstopwatchareneededtocheck

uidviscosity.

1.Completelysubmergetheviscositycupin

2.Watchthestreamofuidcomingfromthebottom

3.Recordtheuidtype,elapsedtime,andsizeof

4.Iftheviscosityistoohighortoolow,contactthe

Flush

Flush Flush

Theequipmentwastestedinuidatthefactory.To

avoidcontaminatingyouruid,ushtheequipment

withacompatiblesolventbeforeusingtheequipment.

SeeFlushing,page28.

Fluid

Fluid Fluid

theuid.Liftthecupoutquickly,startingthe

stopwatchassoonasthecupiscompletely

removed.

ofthecup.Assoonasthereisabreakinthe

stream,shutoffthestopwatch.

theviscositycup.

materialsupplier.Adjustasnecessary.

Before

Before Before

Viscosity

Viscosity Viscosity

Using

Using Using

Equipment

Equipment Equipment

1–55–2020–200200–2000

Testelectrostatic

performance

Goodelectrostatic

results

Bestelectrostatic

results

Goodelectrostatic

results

3A2495K25

Page 26

Operation

Operation

Operation Operation

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchasskininjection,

splashinguidandmovingparts,followthe

PressureReliefProcedurewhenyoustopspraying

andbeforecleaning,checking,orservicingthe

equipment.

1.TurnOFF(O)theESOn/Offswitch.

2.Engagethetriggerlock.

Relief

Relief Relief

Procedure

Procedure Procedure

4.Disengagethetriggerlock.

5.Triggerthegunintoagroundedmetalwaste

containertorelievetheuidpressure.

6.Engagethetriggerlock.

7.Openthepumpdrainvalve,havingawaste

containerreadytocatchthedrainage.Leave

thepumpdrainvalveopenuntilyouareready

tosprayagain.

3.Turnofftheairbleedvalvestotheuidsource

andtothegun.

8.Ifthespraytiporhoseiscompletelycloggedor

pressureisnotfullyrelieved,slowlyloosenthe

hoseendcoupling.Nowclearthespraytipor

hose.

263A2495K

Page 27

Operation

Startup

Startup Startup

FollowallstepsunderGunSetupProcedure,page21.

Checkthefollowinglistdaily,beforestartingto

operatethesystem,tohelpensureyouofsafe,

efcientoperation.

•Alloperatorsareproperlytrainedtosafelyoperate

anautomaticelectrostaticairspraysystemas

instructedinthismanual.

•Alloperatorsaretrainedinthe

PressureReliefProcedure,page26.

•Thewarningsignprovidedwiththegunismounted

inthesprayareawhereitcanbeeasilyseenand

readbyalloperators.

•Thesystemisthoroughlygroundedandthe

operatorandallpersonsenteringthesprayarea

areproperlygrounded.SeeGrounding,page17.

•Theconditionofthegun’selectrical

componentshasbeencheckedasinstructedin

ElectricalTests,page32.

•Ventilationfansareoperatingproperly.

•Workpiecehangersarecleanandgrounded.

•Alldebris(includingammableuidsandrags)is

removedfromthesprayarea.

•Allammableuidsinthespraybootharein

approved,groundedcontainers.

•Allconductiveobjectsinthesprayareaare

electricallygroundedandtheoorofthespray

areaiselectricallyconductiveandgrounded.

Shutdown

Shutdown Shutdown

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page26wheneveryou

areinstructedtorelievethepressure.

1.Flushthegun.SeeFlushing,page28.

2.FollowthePressureReliefProcedure,page26.

3.Hangthegunfromitshook,withthenozzle

pointingdown.

3A2495K

27

Page 28

Maintenance

Maintenance

Maintenance Maintenance

Daily

Daily Daily

Checkthefollowinglistdailyuponcompletionof

equipmentusage.

Care

Care Care

Flushthegun.SeeFlushing,page28.

Cleantheuidandairlinelters.

Cleantheoutsideofthegun.See

CleantheGunDaily,page30.

Cleantheaircapandspraytipdaily,at

aminimum.Someapplicationsrequire

morefrequentcleaning.Replacethespray

tipandaircapiftheyaredamaged.See

CleantheGunDaily,page30.

Checktheelectrodeandreplace

ifbrokenordamaged.See

ElectrodeReplacement,page41.

Checkforuidleakagefromthegunanduid

hoses.Tightenttingsorreplaceequipment

asneeded.

Checkelectricalgrounding.See

CheckGunElectricalGrounding,page24.

and

Cleaning

and and

Cleaning Cleaning

Checklist

Checklist Checklist

Flushing

Flushing Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithauidthatiscompatiblewiththeuid

beingdispensedandtheequipmentwettedparts.

Toreducetheriskofre,explosion,orelectric

shock:

•TurnOFF(O)theESOn-Offswitchbefore

ushingthegun.

•Alwaysgroundequipmentandwastecontainers.

•Flushequipmentonlyinawell-ventilatedarea.

•UseonlyGroupIIAushingmaterials.

Non-ignitableuidsarepreferred.

•Toavoidstaticsparkingandinjuryfrom

splashing,alwaysushatthelowestpossible

pressure.

NOTICE

NOTICE NOTICE

Donotusemethylenechlorideasaushingor

cleaningsolventwiththisgunasitwilldamage

nyloncomponents.

1.TurnOFF(O)theESOn-Offswitch.

2.FollowthePressureReliefProcedure,page26.

3.Removeandcleantheaircapandspraytip.

283A2495K

Page 29

Maintenance

4.Changetheuidsourcetosolvent,ordisconnect

theuidlineandconnectasolventsupplyline

tothegun.

5.Pointthegunintoagroundedmetalpail.Flush

untilcleansolventowsfromthegun.

6.FollowthePressureReliefProcedure,page26.

Engagethetriggerlock.

7.Shutoffordisconnectthesolventline.

8.Alignthespraytiptabwiththegrooveintheair

cap.Checktheconditionofthetipgasket(27a),

andreplaceifdamaged.Installthetip.

9.Reinstalltheaircap,tipguard,andretainingring.

10.Hangthegunfromitshook,withthenozzle

pointingdown.

11.Whenreadytosprayagain,reconnect

theuidsupplyline.Followthe

GunSetupProcedure,page21.

3A2495K29

Page 30

Maintenance

Clean

Clean Clean

•Cleanallpartswithanon-conductive,compatible

•Fluidintheairpassagescouldcausethegunto

1.TurnOFF(O)theESOn-Offswitch.

2.FollowthePressureReliefProcedure,page26.

3.Removetheaircap/tipguardandspraytip.

the

Gun

the the

Gun Gun

solvent.Conductivesolventscancausethegun

tomalfunction.

malfunctionandcoulddrawcurrentandreduce

theelectrostaticeffect.Fluidinthepowersupply

cavitycanreducetheturbinelife.Whenever

possible,pointthegundownwhencleaningit.

Donotuseanycleaningmethodwhichcould

allowuidintothegunairpassages.

Daily

Daily Daily

NOTICE

NOTICE NOTICE

6.Cleantheoutsideofthegunwithacompatible

solvent.Useasoftcloth.Pointthegundownto

preventsolventfromenteringthegunpassages.

Donotimmersethegun.

4.Flushthegun,seeFlushing,page28.

5.FollowthePressureReliefProcedure,page26.

303A2495K

Page 31

Maintenance

7.Cleantheaircap/tipguardandspraytipwitha

softbrushandcompatiblesolvent.

8.Ifnecessary,useatoothpickorothersofttoolto

cleantheaircapholes.Donotusemetaltools.

Daily

Daily Daily

1.FollowthePressureReliefProcedure,page26.

2.Cleantheuidandairlters.

3.Checkforuidleaks.Tightenallttings.

4.Cleanworkpiecehangers.Usenon-sparking

System

System System

tools.

Care

Care Care

9.Alignthespraytiptabwiththegrooveintheair

cap.Checktheconditionofthetipgasket(27a),

andreplaceifdamaged.Installthetip.

10.Installtheaircapandretainingring.Orientate

theaircapandtightentheretainingringsecurely.

5.Checkthemovementofthetriggerandvalves.

Lubricateifnecessary.

6.CheckGunElectricalGrounding,page24.

7.Hangthegunfromitshook,withthenozzle

pointingdown.

3A2495K31

Page 32

ElectricalTests

Electrical

Electrical Electrical

Electricalcomponentsinsidethegunaffect

performanceandsafety.Usethefollowing

procedurestotesttheconditionofthepowersupply

andgunbody,andelectricalcontinuitybetween

components.

Thegunbodyresistorcartridgeispartofthebody

andisnotreplaceable.Toavoiddestroyingthegun

body,donotattempttoremovethebodyresistor.

UsemegohmmeterPartNo.241079(AA)withan

appliedvoltageof500V.Connecttheleadsas

shown.

MegohmmeterPartNo.241079(AA-seeFig.17)

isnotapprovedforuseinahazardouslocation.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

Tests

Tests Tests

NOTICE

NOTICE NOTICE

Test

Test Test

1.Flushanddrytheuidpassage.

2.Measureresistancebetweentheelectrode

Gun

Gun Gun

needletip(25a)andtheairswivel(21).The

resistanceshouldbe:

•106–150megohmsfor60kVguns

•150–195megohmsfor85kVguns

Ifoutsidethisrange,goto

TestPowerSupplyResistance,page33.Ifin

range,seeElectricalTroubleshooting,page37for

otherpossiblecausesofpoorperformance.

Resistance

Resistance Resistance

•Thegunhasbeenremovedfromthehazardous

location;

•Orallsprayingdevicesinthehazardous

locationareturnedoff,ventilationfansinthe

hazardouslocationareoperating,andthereare

noammablevaporsinthearea(suchasopen

solventcontainersorfumesfromspraying).

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

Figure17TestGunResistance

323A2495K

Page 33

ElectricalTests

Test

Test Test

1.Removethepowersupply(11).SeePower

2.Removethealternator(15)

3.Measureresistancefromthepowersupply's

4.Ifoutsidethisrange,replacethe

5.Ifyoustillhaveproblems,referto

6.Besurethespring(11a)isinplacebefore

Power

Power Power

SupplyRemovalandReplacement,page45.

fromthepowersupply.See

AlternatorRemovalandReplacement,page46.

groundstrips(EE)tothespring(11a).The

resistanceshouldbe:

•86–110megohmsfor60kVguns

•130–160megohmsfor85kVguns

powersupply.Ifinrange,goto

TestGunBarrelResistance,page34.

Electrical

Electrical Electrical

otherpossiblecausesofpoorperformance,or

contactyourGracodistributor.

reinstallingthepowersupply.

Supply

Supply Supply

Troubleshooting

Troubleshooting Troubleshooting

Resistance

Resistance Resistance

page

, ,,page page

37

37 37

, ,,for

Figure18TestPowerSupplyResistance

3A2495K33

Page 34

ElectricalTests

Test

Test Test

1.Insertaconductiverod(B)intothegunbarrel

2.Measuretheresistancebetweentheconductive

3.Iftheresistanceisstilloutsidetherange,

4.Iftheresistanceisinrange,replacethe

Gun

Gun Gun

(whichwasremovedforthepowersupplytest)

andagainstthemetalcontact(C)inthefrontof

thebarrel.

rod(B)andtheconductivering(9).The

resistanceshouldbe10–30megohms.Ifthe

resistanceisincorrect,makesurethemetal

contact(C)inthebarrelandtheconductivering

(9)arecleanandundamaged.

removetheconductivering(9)andmeasurethe

resistancebetweentheconductiverod(B)and

thewireleadatthebottomoftheconductivering

groove.

conductivering(9)withanewone.Insertthe

endsoftheconductiveringintotheslots(S)at

thefrontofthebarrel,thenpresstheringrmly

intothegroove(G).

Barrel

Barrel Barrel

Resistance

Resistance Resistance

Figure19TestGunBarrelResistance

Theconductivering(9)isaconductive(metal)

contactring,notasealingo-ring.Toreduce

theriskofre,explosion,orelectricshock:

•Donotremovetheconductiveringexcept

toreplaceit.

•Neveroperatethegunwithouttheconductive

ringinplace.

•Donotreplacetheconductiveringwith

anythingbutagenuineGracopart.

5.Iftheresistanceisstilloutsidetherange,replace

thegunbarrel.

343A2495K

Page 35

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseanelectricshock

orotherseriousinjuryiftheworkisnotperformed

properly.Donotinstallorservicethisequipment

unlessyouaretrainedandqualied.

CheckallpossibleremediesintheTroubleshootingChartbeforedisassemblingthegun.

Spray

Spray Spray

NOTE:

NOTE: NOTE:

Problem

Problem Problem

Flutteringorspittingspray.

Irregularpattern.

Pattern

Pattern Pattern

Somespraypatternproblemsarecausedbytheimproperbalancebetweenairanduid.

Troubleshooting

Troubleshooting Troubleshooting

Cause

Cause Cause

Nouid.Rellsupply.

Airinuidsupply.Checkuidsource.Rell.

Fluidbuildup;partiallypluggedtip.

Worn/damagedtiporaircapholes.

Toreducetheriskofaskininjectioninjury,always

followthePressureReliefProcedure,page26,

wheneveryouareinstructedtorelievethe

pressure.

Solution

Solution Solution

Clean.See

CleantheGunDaily,page30.

Cleanorreplace.

Patternpushedtooneside;air

capgetsdirty.

Tailsinpattern.

Fluidbuilduponaircap/tipguard.

3A2495K35

Aircapholesplugged.

Airpressuretoolow.

Fluidpressuretoolow.Increase.

Airpressuretoohigh.Decrease.

Fluidpressuretoolow.Increase.

Aircapholesplugged.

Clean.See

CleantheGunDaily,page30.

Openatomizingairadjustment

valve.

Clean.See

CleantheGunDaily,page30.

Page 36

Troubleshooting

Gun

Gun Gun

Operation

Operation Operation

Problem

Problem Problem

Excessivesprayfog.

“OrangePeel”nish.

Fluidleaksfromtheuidpacking

area.

Airleaksfromthefrontofthegun.

Fluidleakagefromthefrontofthe

gun.

Troubleshooting

Troubleshooting Troubleshooting

Cause

Cause Cause

Atomizingairpressuretoohigh.

Fluidtoothin.

Atomizingairpressuretoolow.

Spraytipistoolarge.Usesmallertip.SeeSprayTip

Poorlymixedorltereduid.Remixorrelteruid.

Fluidtoothick.Reduceviscosity.

Wornuidneedlepackingsorrod.Replacepackings.SeeFluid

Airvalveisnotseatingproperly.

Wornordamageduidneedleball.SeeFluidNeedleReplacement,

Solution

Solution Solution

Closeatomizingairvalvepartway,

ordecreaseairpressureaslow

aspossible;minimum45psi(0.32

MPa,3.2bar)neededatgunfor

fullvoltage.

Increaseviscosityorincreaseuid

owrate.

Openatomizingairvalvemoreor

increasegunairinletpressure;

uselowestairpressurenecessary.

SelectionChart,page61.

NeedleReplacement,page44.

Replaceairvalve.See

AirValveRepair,page50.

page44.

Wornuidseathousing.SeeAirCap,SprayTip,andFluid

Loosespraytip.Tightenretainingring.

Damagedtipseal.

Gundoesnotspray.

Dirtyaircap.Damagedorpluggedaircap.

Excessivepaintwrapbackto

operator.

Lowuidsupply.Adduidifnecessary.

Damagedspraytip.Replace.

Dirtyorcloggedspraytip.

Damageduidneedle.SeeFluidNeedleReplacement,

Poorgrounding.

Incorrectdistancefromguntopart.Shouldbe8–12in.(200–300mm).

SeatHousingReplacement,page

40.

SeeAirCap,SprayTip,andFluid

SeatHousingReplacement,page

40.

Clean.See

CleantheGunDaily,page30.

page44.

Cleanaircap.See

CleantheGunDaily,page30.

SeeGrounding,page17.

363A2495K

Page 37

Troubleshooting

Electrical

Electrical Electrical

Problem

Problem Problem

Poorwrap.

Troubleshooting

Troubleshooting Troubleshooting

Cause

Cause Cause

ESOn/OffswitchisOFF(O).TurnON(I).

Gunairpressuretoolow(ES

indicatorisamber).

Atomizingairpressuretoohigh.Decrease.

Fluidpressuretoohigh.Decrease,orreplaceworntip.

Incorrectdistancefromguntopart.Shouldbe8-12in.(200-300mm).

Poorlygroundedparts.Resistancemustbe1megohmor

Faultygunresistance.

Lowuidresistivity.See

Fluidleaksfromtheuidneedle

packingsandcausesashort.

Faultyalternator.

ESOn/OffswitchisOFF(O).TurnON(I). ESorHzindicatorisnotlit.

Solution

Solution Solution

Checkairpressuretogun;

minimum45psi(0.32MPa,3.2

bar)neededatgunforfullvoltage.

less.Cleanworkpiecehangers.

See

TestGunResistance,page32.

CheckFluidResistivity,page25.

SeeFluidNeedleReplacement,

page44.

SeeAlternatorRemovaland

Replacement,page46.

Operatorgetsshockfrom

workpiece.

Nopower.

Operatornotgroundedorisnear

ungroundedobject.

Gunnotgrounded.SeeCheckGunElectrical

Workpiecenotgrounded.Resistancemustbe1megohmor

Checkpowersupply,alternator,

andalternatorribboncable.See

PowerSupplyRemovaland

Replacement,page45and

AlternatorRemovaland

Replacement,page46.

SeeGrounding,page17. Operatorgetsmildshock.

Grounding,page24,and

TestGunResistance,page32.

less.Cleanworkpiecehangers.

3A2495K37

Page 38

Troubleshooting

Problem

Problem Problem

Voltage/currentdisplaystaysred

(smartgunsonly).

ESorHzindicatorisamber.

ESorHzindicatorisred.

ErrordisplayappearsandHz

indicatorisred(Smartgunsonly).

Cause

Cause Cause

Gunistooclosetothepartbeing

sprayed.

Checkuidresistivity.See

Dirtygun.

Alternatorspeedistoolow.Increaseairpressureuntil

Alternatorspeedistoohigh.Decreaseairpressureuntil

Smartmodulehaslost

communicationwiththepower

supply.

Solution

Solution Solution

Gunshouldbe8–12in.(200–300

mm)fromthepart.

CheckFluidResistivity,page25.

SeeCleantheGunDaily,page30.

indicatorisgreen.Toavoid

over-atomization,usethe

atomizingairrestrictorvalveto

reducetheatomizingairtotheair

cap.

indicatorisgreen,orinstallES

On-OffwithAirRestrictor,which

limitstheairowtotheturbine.

Checkforgoodconnections

betweenSmartModuleand

powersupply.SeeSmartModule

Replacement,page51and

PowerSupplyRemovaland

Replacement,page45.

383A2495K

Page 39

Repair

Repair

Repair Repair

Prepare

Prepare Prepare

Installingandrepairingthisequipmentrequires

accesstopartsthatmaycauseelectricshockor

otherseriousinjuryiftheworkisnotperformed

properly.Donotinstallorservicethisequipment

unlessyouaretrainedandqualied.

Toreducetheriskofinjury,followthe

PressureReliefProcedure,page26,before

checkingorservicinganypartofthesystem

andwheneveryouareinstructedtorelievethe

pressure.

•Checkallpossibleremediesin

Troubleshooting,page35,beforedisassembling

thegun.

the

Gun

the the

Gun Gun

for

Service

for for

Service Service

•Useavisewithpaddedjawstopreventdamage

toplasticparts.

•Lubricatethesomeneedleassemblyparts(20)

andcertainuidttingswithdielectricgrease(57),

asspeciedinthetext.

•Lightlylubricateo-ringsandsealswithnon-silicone

grease.OrderPartNo.111265Lubricant.Donot

over-lubricate.

•OnlyusegenuineGracoparts.Donotmixoruse

partsfromotherProGunmodels.

•AirSealRepairKit24N789isavailable.The

kitmustbepurchasedseparately.Kitpartsare

markedwithanasterisk,forexample(3*).

1.Flushthegun.SeeFlushing,page28.

2.Relievethepressure.See

PressureReliefProcedure,page26.

3.Disconnectthegunairanduidlines.

4.Removethegunfromtheworksite.Repairarea

mustbeclean.

3A2495K39

Page 40

Repair

Air

Cap,

Air Air

Cap, Cap,

Spray

Spray Spray

Tip,

and

Tip, Tip,

Fluid

and and

Fluid Fluid

Seat

Seat Seat

Housing

Housing Housing

Replacement

Replacement Replacement

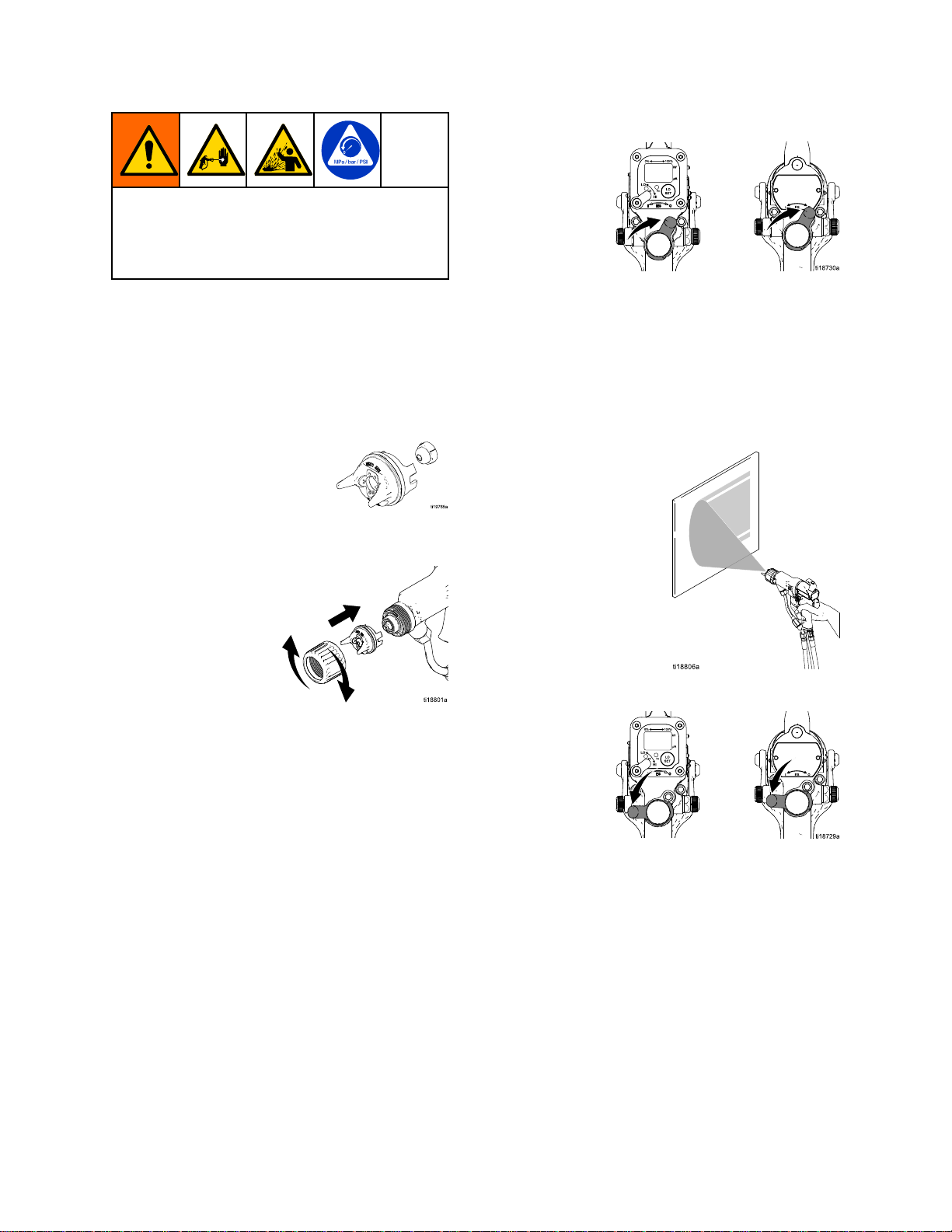

1.SeePreparetheGunforService,page39.

2.Removetheretainerring(22)andaircap/tip

guardassembly(25).

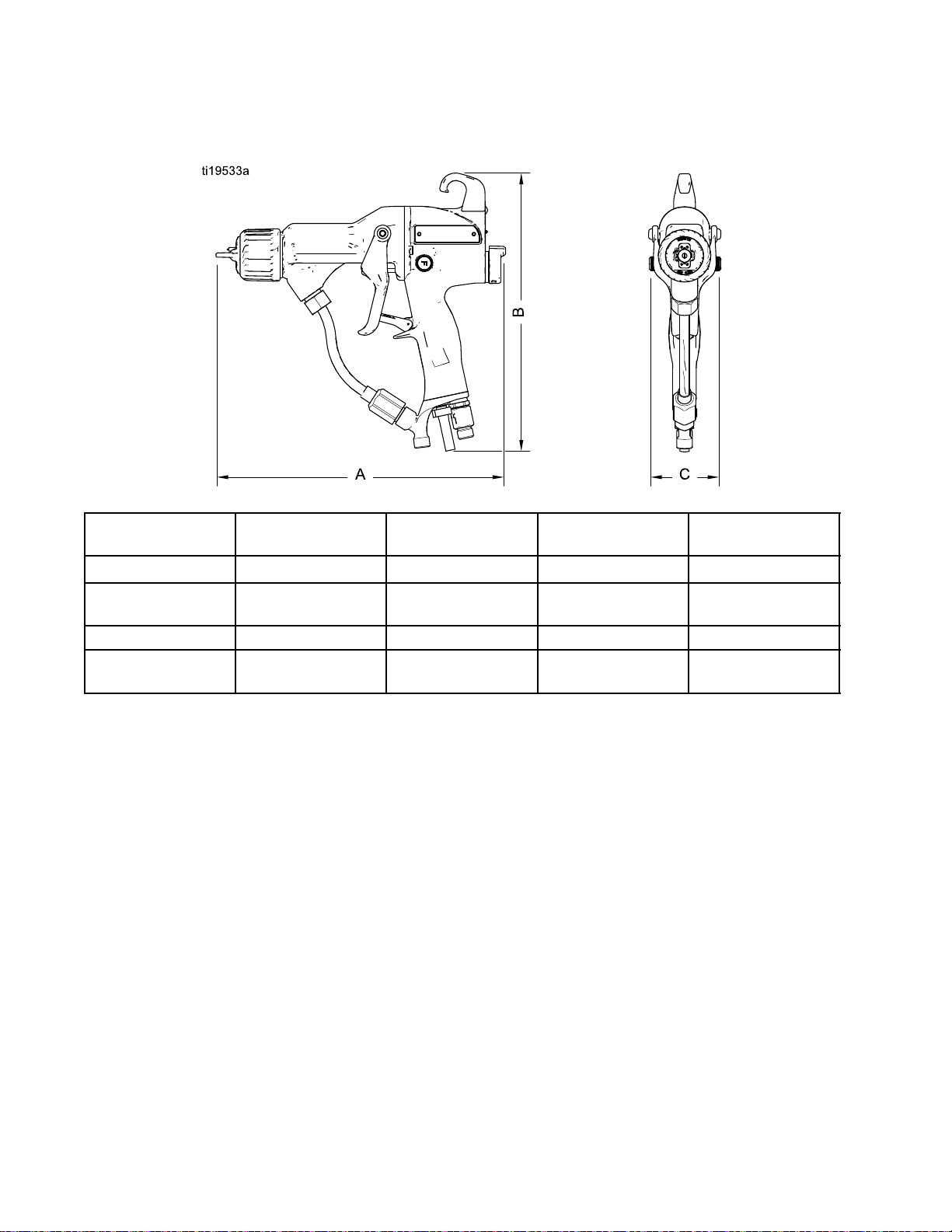

Figure20RemoveAirCap

3.Disassembletheaircapassembly.Checkthe

conditionoftheu-cup(22a),o-ring(25b),andtip

gasket(27a).Replaceanydamagedparts.

4.Toreplacetheelectrode(25a),see

ElectrodeReplacement,page41.

Theconductivering(9)isaconductivemetal

contactring,notasealingo-ring.Toreduce

theriskofre,explosion,orelectricshock:

•Donotremovetheconductiveringexcept

toreplaceit.

•Neveroperatethegunwithouttheconductive

ringinplace.

•Donotreplacetheconductiveringwith

anythingbutagenuineGracopart.

5.Triggerthegunandremovetheuidseathousing

(24),usingthemulti-tool(61).

Figure21DisassembleAirCapAssembly

Figure22TipGasket

Figure23ReplaceFluidSeatHousing

403A2495K

Page 41

Repair

NOTICE

NOTICE NOTICE

Donotovertightentheuidseathousing(24).

Overtighteningmaydamagethehousingand

thegunbarrel,resultinginimproperuid

shutoff.

6.Triggerthegunandinstalltheuidseathousing

(24).Tightenuntilsnug,then1/4turnmore.

7.Checkthatthespraytipgasket(27a)isinplace.

Alignthespraytiptabwiththegrooveintheair

cap(25).Installthespraytip(27)intheaircap.

8.Makesurethattheelectrode(25a)isinstalled

correctlyintheaircap.

9.Checkthattheaircapo-ring(25b)isinplace.

10.Checkthattheu-cup(22a)isinplaceonthe

retainingring(22).Thelipsoftheu-cupmust

faceforward.

NOTICE

NOTICE NOTICE

Toavoiddamagingthetipguard,orientthe

aircapassembly(25)beforetighteningthe

retainingring(22).Donotturntheaircap

whentheretainingringistight.

11.Orientatetheaircapandtightentheretaining

ringsecurely.

12.SeeTestGunResistance,page32.

Electrode

Electrode Electrode

Toreducetheriskofre,explosion,orelectric

shock,donotoperatethespraygunwithoutthe

electrodeinstalledintheaircap.

1.Followthestepsin

PreparetheGunforService,page39.

2.Removetheaircapassembly(25).See

AirCap,SprayTip,andFluidSeatHousing

Replacement,page40.

3.Pulltheelectrode(25a)outofthebackoftheair

cap,usinganeedle-nosepliers.

4.Pushthenewelectrodethroughtheaircaphole.

Makesuretheshortend(BB)oftheelectrode

engagesthehole(CC)inthebackoftheair

cap.Presstheelectrodeinplacermlywithyour

ngers.

5.Installtheaircapassembly.

6.FollowthestepsinTestGunResistance,page32.

Replacement

Replacement Replacement

Figure24ReplaceElectrode

3A2495K

41

Page 42

Repair

Fluid

Fluid Fluid

1.SeePreparetheGunforService,page39.

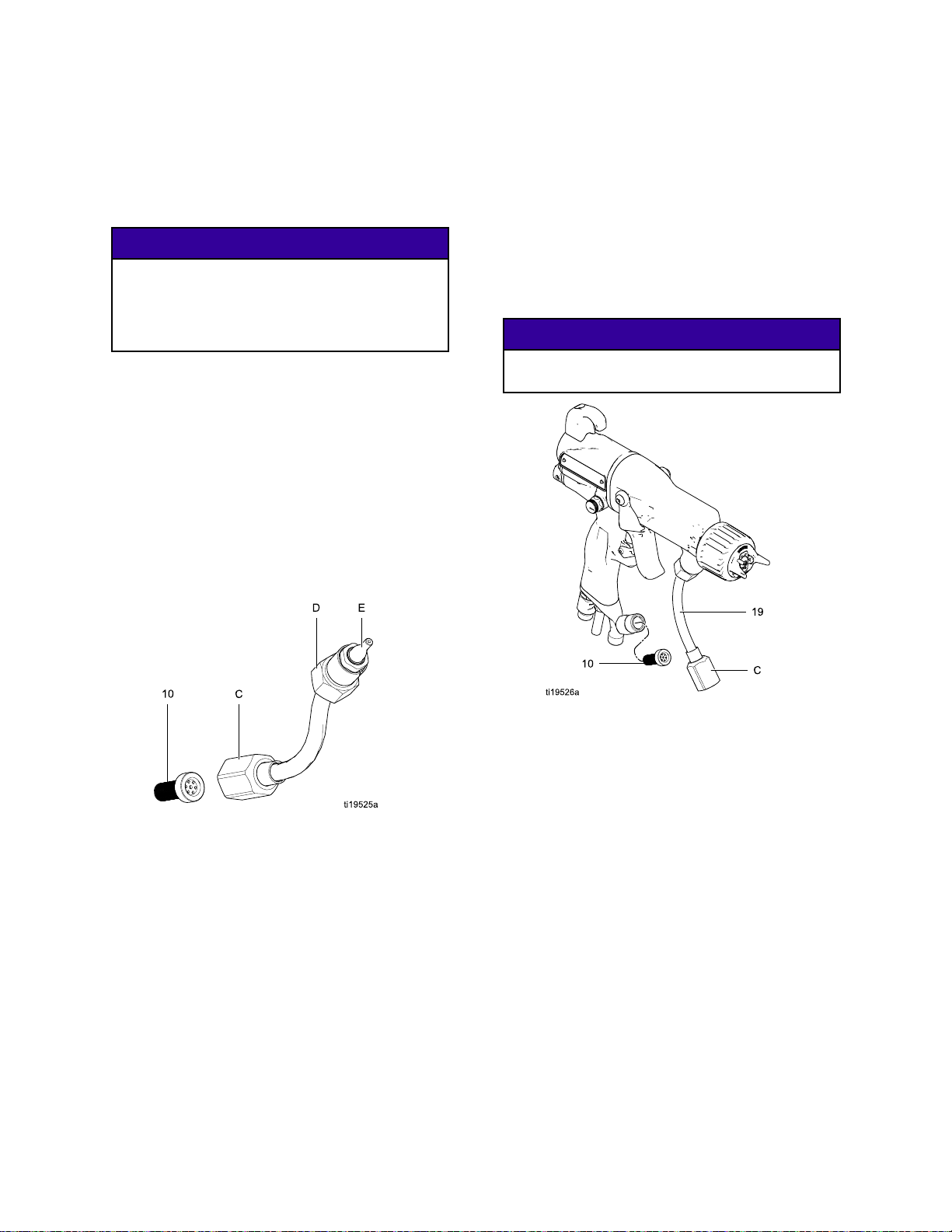

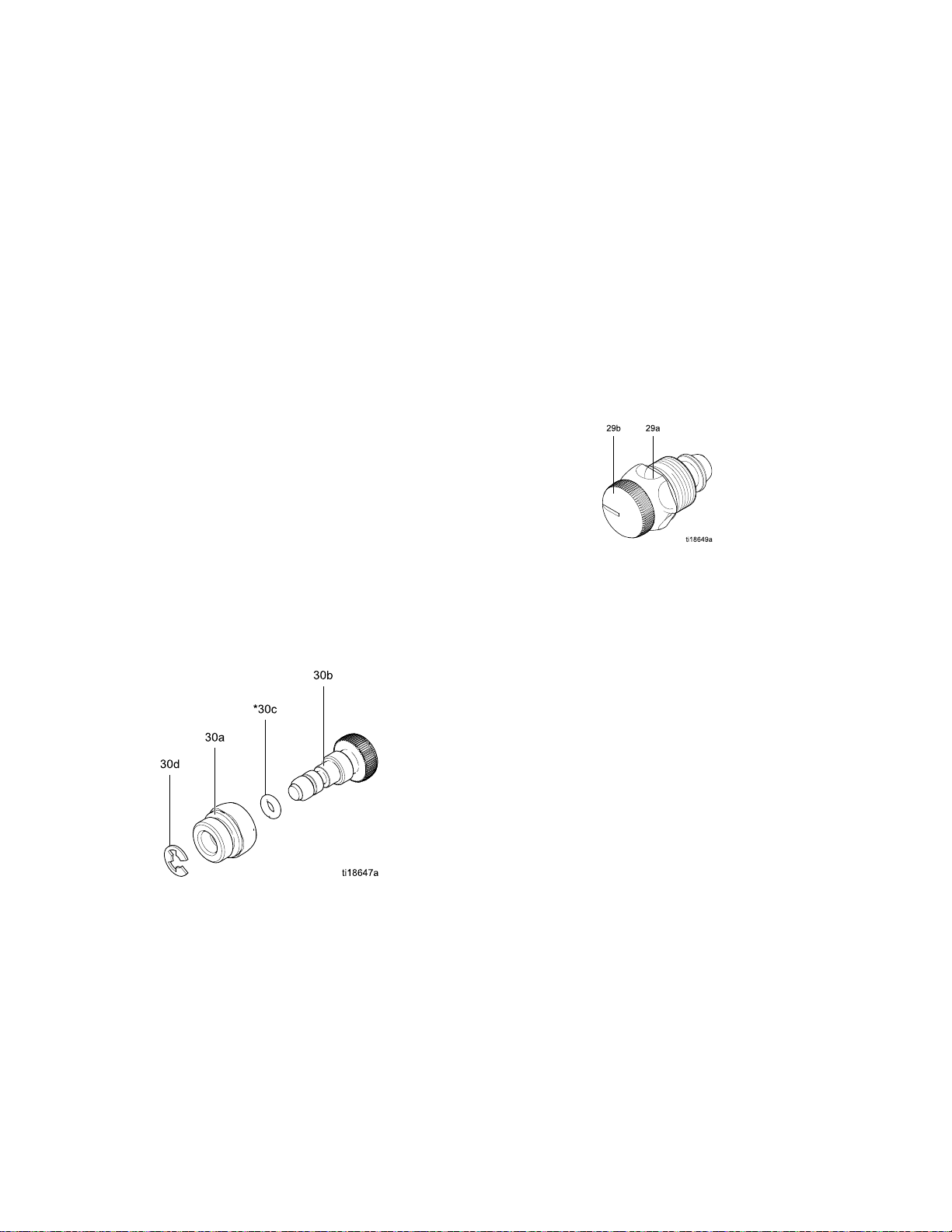

2.Disconnectthebottomuidtubenut(C).

3.Carefullyunscrewthetopuidtubenut(D).

4.Applydielectricgrease(57)totheentirelengthof

5.Applylowstrengthsealanttotheuidtubenut

6.Installtheuidtubeintothegunbarreland

7.Makesuretheuidlter(10)isinplaceinthe

Tube

Tube Tube

Becarefulnottodamagetheuidtube

assembly(19)whencleaningorinstalling

it,especiallythesealingsurface(E).Ifthe

sealingsurfaceisdamaged,theentireuid

tubeassemblymustbereplaced.

theplasticextensionontheuidtube.

threads.

tightenthetopnut(D)untilsnug,then1/2turn

tighter.Therewillbeagapbetweenthenutand

barrel.Donotover-tightenthenut.

uidtting.Tightenthebottomnut(C)securely

ontothetting.Makesurethetopnutremains

tight.

Removal

Removal Removal

and

Replacement

and and

Replacement Replacement

NOTICE

NOTICE NOTICE

Fluid

Fluid Fluid

1.SeePreparetheGunforService,page39.

2.Disconnectthebottomuidtubenut(C).

3.Removetheuidlter(10)fromtheuidtting.

4.Installtheuidlter(10)intheuidtting.Tighten

Filter

Filter Filter

Cleanorreplacethelter,asneeded.

thebottomnut(C)ontothettingandtorqueto

140–150in-lb(15.8–16.9N•m).Makesurethe

topnutremainstightat20–30in-lb(2.3–3.4N•m).

Besuretheuidtube(19)isnottwistedafter

tighteningthebottomnut(C).

Replacement

Replacement Replacement

NOTICE

NOTICE NOTICE

Figure25FluidTube

Figure26ReplaceFluidFilter

42

3A2495K

Page 43

Repair

Gun

Gun Gun

1.SeePreparetheGunforService,page39.

2.Disconnectthebottomuidtubenut(N).

3.Loosenthetwoscrews(6).

4.Holdthegunhandle(16)withonehandandpull

NOTE:

NOTE: NOTE:

removethealternator/powersupplyassemblyfrom

thebarrel.

Barrel

Barrel Barrel

Carefullyseparatethetubeassembly(T)from

thebracket(7).

Toavoiddamagingthepowersupply(11),

pullthegunbarrelstraightawayfromthegun

handle.Ifnecessary,gentlymovethegun

barrelfromsidetosidetofreeitfromthegun

handle.

thebarrel(1)straightoffthehandle.

Ifthepowersupplyremainsinthebarrel,

Removal

Removal Removal

NOTICE

NOTICE NOTICE

Gun

Gun Gun

1.Besurethegasket(5*)andgroundingspring

2.Makesurethespring(11a)isinplaceonthe

3.Tightenthetwoscrews(6)oppositelyandevenly

4.Makesuretheuidlter(10)isinplaceinthe

5.FollowthestepsinTestGunResistance,page32.

Barrel

Barrel Barrel

(37a)areinplace.Makesurethegasketair

holesarealignedproperly.Replacethegasketif

damaged.

tipofthepowersupply(11).Liberally Liberally

dielectricgrease(57)tothetipofthepower

supply.Placethegunbarrel(1)overthepower

supplyandontothegunhandle(16).

(aboutahalfturnpastsnug,or20in-lbs,2.3

N•m).

Toavoiddamagingthegunbarrel,donot

over-tightenthescrews(6).

uidtting.Tightenthebottomnut(N)ontothe

ttingandtorqueto140–150in-lb(15.8–16.9

N•m).Makesurethetopnutremainstight.

Installation

Installation Installation

Liberally

NOTICE

NOTICE NOTICE

apply

Figure27GunBarrelRemoval

Figure28GunBarrelInstallation

3A2495K43

Page 44

Repair

Fluid

Fluid Fluid

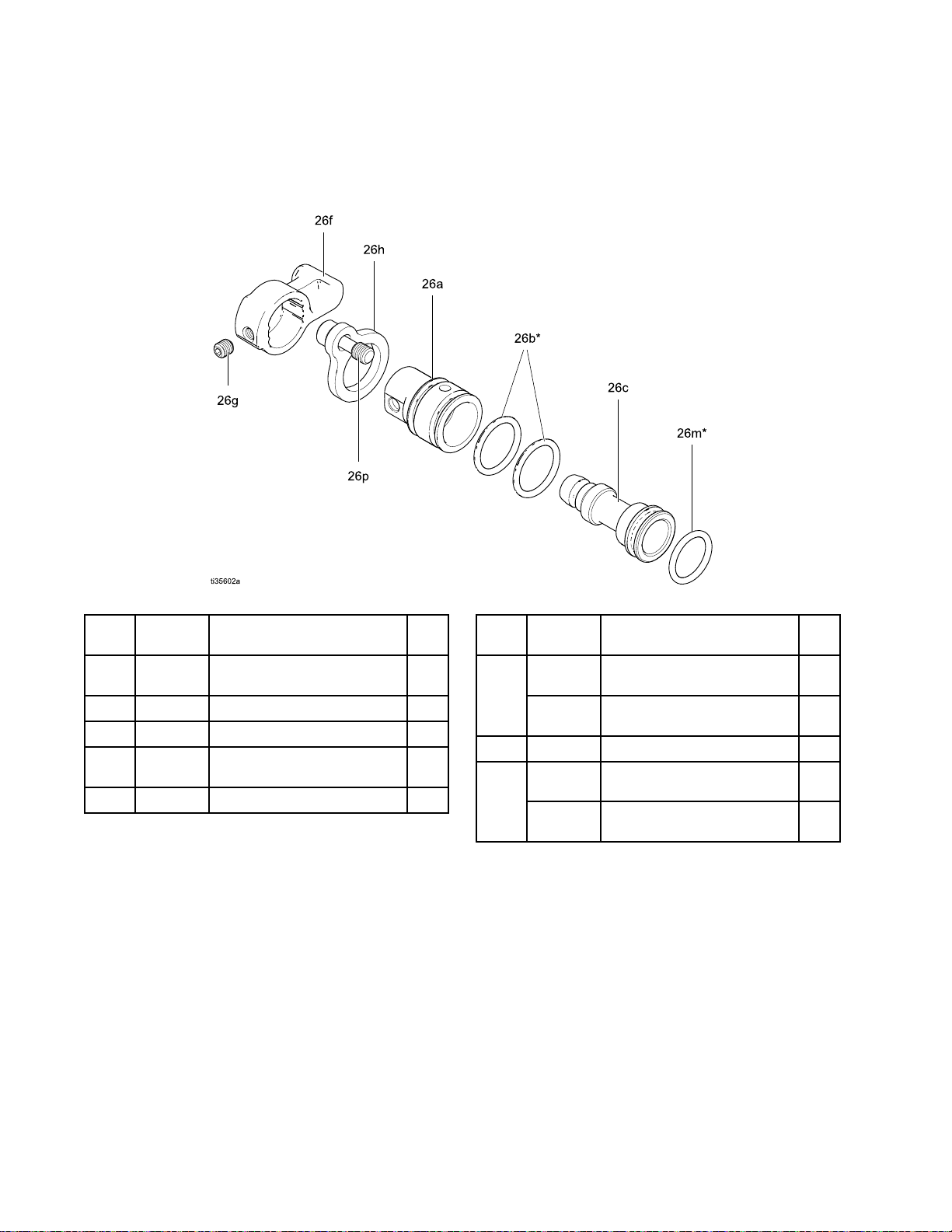

1.SeePreparetheGunforService,page39.

2.Removetheaircapassemblyanduidseat

3.Removethegunbarrel.See

4.Removethetriggerscrews(13)andtrigger(12).

5.Unscrewthespringcap(37).Removethespring

6.Besuretheseathousing(24)isremoved.Place

7.Usingtheexternalhexendoftheplasticmulti-tool

Needle

Needle Needle

housing.SeeAirCap,SprayTip,andFluidSeat

HousingReplacement,page40.

GunBarrelRemoval,page43.

(20a).

the2mmballendwrench(60)inthebackof

theuidneedleassembly.Pushthetoolforward

sothetwosegmentsoftheneedleengage,and

turnitcounterclockwiseabout12fullturnsto

unthreadtheneedle.

(61),carefullypushstraightontheuidneedle

ballfromthefrontofthebarreluntiltheuidseals

releasefromthebore.

Topreventneedleassemblyseparationor

damage,becertainneedleisdisengaged

beforeremoving.

Replacement

Replacement Replacement

NOTICE

NOTICE NOTICE

Figure29RemoveCapandSprings

8.Removetheuidneedleassemblyfromtheback

ofthegunbarrel.

9.Installtheuidneedleassemblyinthegunbarrel.

Pushinontheneedlewiththedriver(60)and

tighten.

10.Installthespring(20a).

11.Installthespringcap(37).Makesurethe

groundingspring(37a)isinplace.

12.Installthetrigger(12)andscrews(13).

13.Installthegunbarrel.See

GunBarrelInstallation,page43.

14.Installtheseathousingandaircapassembly.

SeeAirCap,SprayTip,andFluidSeatHousing

Replacement,page40.

15.SeeTestGunResistance,page32.

Figure30RemoveFluidNeedle

Figure31ReplaceFluidNeedle

44

3A2495K

Page 45

Repair

Power

Power Power

•Inspectthegunhandlepowersupplycavityfordirt

ormoisture.Cleanwithaclean,dryrag.

•Donotexposegasket(5)tosolvents.

1.SeePreparetheGunforService,page39.

2.SeeGunBarrelRemoval,page43.

3.Graspthepowersupply(11)withyourhand.

4.Inspectthepowersupplyandalternatorfor

5.Toseparatethepowersupply(11)fromthe

6.SeeTestPowerSupplyResistance,page33.

7.

Supply

Supply Supply

Becarefulwhenhandlingthepowersupply

(11)toavoiddamagingit.

Withagentlesidetosidemotion,freethepower

supply/alternatorassemblyfromthegunhandle

(16),thencarefullypullitstraightout.

Modelsonly,

fromthesocketatthetopofthehandle.

damage.

alternator(15),disconnectthe3-wireribbon

connector(PC)fromthepowersupply.

Modelsonly,

(40)fromthepowersupply.Slidethealternator

upandoffthepowersupply.

Replacethepowersupplyifnecessary.

Torepairthealternator,see

AlternatorRemovalandReplacement,page46.

Smartmodelsonly:

circuit(40)tothepowersupply.