Page 1

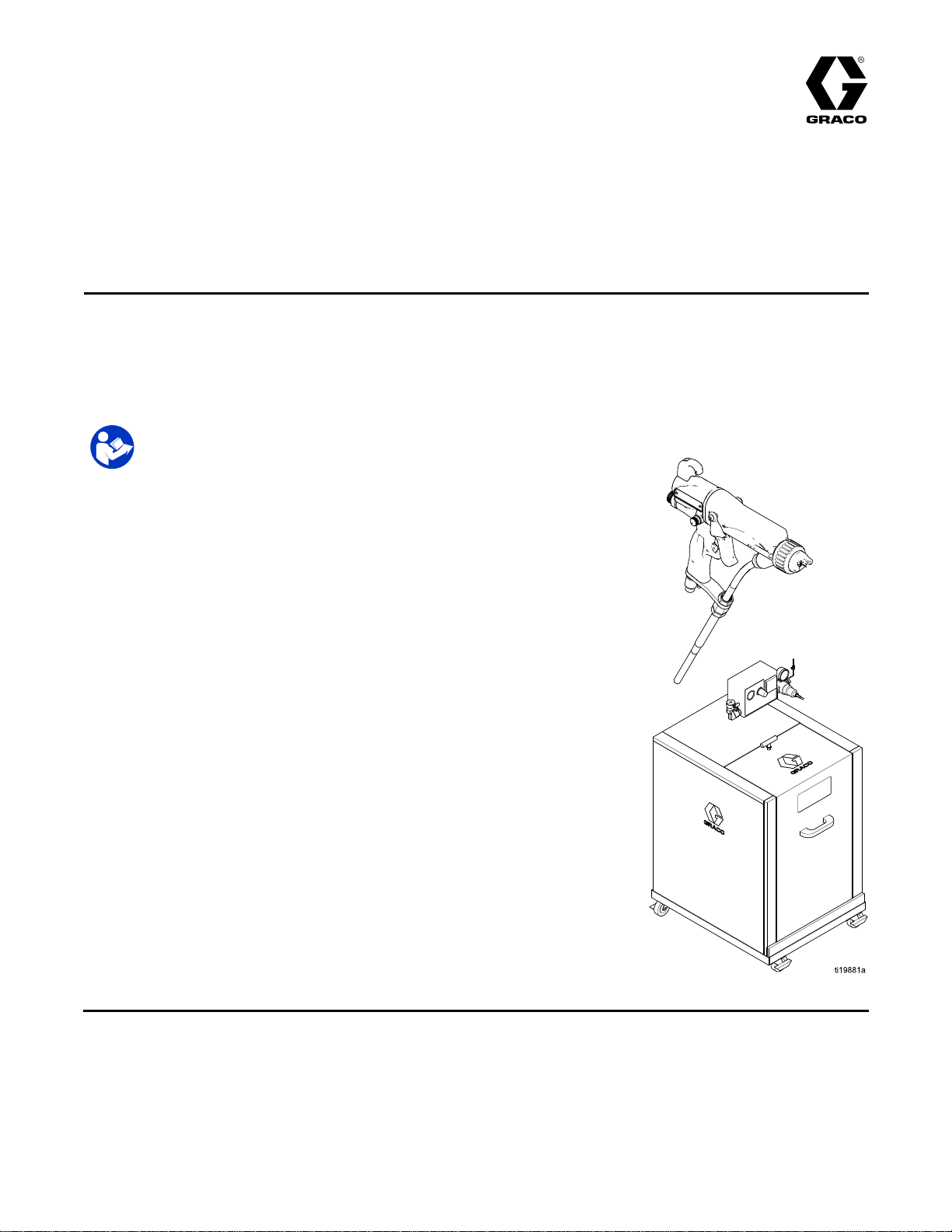

Instructions-Parts

WB100

WB100 WB100

Pro

Pro Pro

Air

Air Air

one

one one

For

For For

100psi(0.7MPa,7.0bar)Maximum

FluidWorkingPressure

100psi(0.7MPa,7.0bar)MaximumAir

WorkingPressure

Seepages3and4formodelpart

numbersandapprovalinformation.

Xp™

Xp™ Xp™

spray

spray spray

of

the

of of

the the

professional

professional professional

Important

Important Important

Readallwarningsandinstructionsinthismanual.Save Save

instructions.

instructions. instructions.

Isolation

Isolation Isolation

60

WB

60 60

WB WB

system

system system

conditions

conditions conditions

for

use

for for

use

use use

Safety

Safety Safety

when

use use

when when

for

non

for for

non non

- --ammability ammability

only.

only. only.

Instructions

Instructions Instructions

System

System System

Gun

Gun Gun

electrostatically

electrostatically electrostatically

ammability

and

and and

3A2496H

EN

spraying

spraying spraying

listed

on

listed listed

on on

conductive,

conductive, conductive,

page

3.

page page

3. 3.

Save

these

these these

waterborne

waterborne waterborne

uids

that

meet

at

uids uids

that that

meet meet

least

at at

least least

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models.................................................................3

RelatedManuals..................................................4

Warnings.............................................................5

GunOverview......................................................8

HowtheElectrostaticSprayGunWorks...........8

SprayingWaterborneFluids

Electrostatically................................8

Controls,Indicators,andComponents.............9

SmartGuns.................................................10

Installation..........................................................15

SystemRequirements..................................15

WarningSign...............................................15

InstalltheSystem.........................................15

VentilatetheSprayBooth.............................15

AirSupplyLine............................................16

GroundtheCabinet......................................16

ConnecttheWaterborneFluidHose..............17

Grounding...................................................22

AgitatorKitAccessory..................................24

FluidRegulatorKitAccessory.......................25

GunSetup..........................................................26

GunSetupProcedure...................................26

SoftSprayGunSetupProcedure..................30

HVLPGunSetupProcedure.........................31

RoundSprayGunSetupProcedure..............33

AbrasiveMaterialGunSetup

Procedure......................................35

MoldReleaseGunSetupProcedure.............36

CheckGunElectricalGrounding...................38

FlushBeforeUsingEquipment......................38

Operation...........................................................39

PressureReliefProcedure............................39

FluidVoltageDischargeandGrounding

Procedure......................................39

FilltheFluidSupply......................................40

Startup........................................................40

Shutdown....................................................41

Maintenance......................................................42

DailyCareandCleaningChecklist................42

Flushing......................................................42

CleantheGunDaily.....................................44

DailySystemCare.......................................46

ElectricalTests...................................................47

TestGunResistance....................................47

TestPowerSupplyResistance.....................48

TestElectrodeResistance............................49

TestGroundStripResistance.......................50

TestCylinderResistance..............................50

Troubleshooting..................................................51

VoltageLossTroubleshooting.......................51

SprayPatternTroubleshooting......................54

GunOperationTroubleshooting....................55

ElectricalTroubleshooting............................56

Repair................................................................58

PreparetheGunforService.........................58

AirCapandNozzleReplacement..................59

AirCap,SprayTip,andNozzle

Replacement(Model

L60M19)........................................60

ElectrodeReplacement................................61

NeedleReplacement(ModelL60M19)...........62

FluidPackingRodRemoval..........................62

PackingRodRepair.....................................63

BarrelRemoval............................................65

BarrelInstallation.........................................65

PowerSupplyRemovaland

Replacement..................................66

AlternatorRemovalandReplacement...........67

FanAirAdjustmentValveRepair..................69

AtomizingAirRestrictorValveRepair............70

ESOn-OffandFluidAdjustmentValve

Repair............................................71

AirValveRepair...........................................72

SmartModuleReplacement..........................73

AirSwivelandExhaustValve

Replacement..................................74

Parts..................................................................75

StandardWaterborneAirSprayGun

Assembly.......................................75

SmartWaterborneAirSprayGun

Assembly.......................................77

MoldReleaseSmartAirSprayGun

Assembly.......................................79

IsolationEnclosure.......................................81

TubingandWiring.......................................84

PackingRodAssembly.................................86

AlternatorAssembly.....................................87

ESOn-OffandFluidAdjustmentValve...........88

FanAirAdjustmentValveAssembly..............89

AtomizingAirRestrictorValve

Assembly.......................................89

AirCapAssembly........................................90

SmartModuleAssembly...............................90

RoundSprayAssembly................................91

FluidNozzles.....................................................93

FluidNozzleSelectionChart.........................93

FluidNozzlePerformanceCharts..................94

AirCaps.............................................................96

AirCapSelectionGuide...............................96

AirConsumptionCharts.............................101

SprayTipSelectionChart(ModelL60M19MRG

GunOnly)...........................................102

AEMFineFinishSprayTips........................102

AEFFineFinishPre-OriceSpray

Tips.............................................103

RoundSprayTips......................................104

RepairKitsandAccessories..............................105

Dimensions......................................................109

TechnicalSpecications....................................111

2

3A2496H

Page 3

Models

2575

Models

Models Models

FMapprovedforusewithuidsthatmeetthefollowingcondition:

•MaterialdoesnotsustainburninginaccordancewiththeStandardTest

MethodforSustainedBurningofLiquidMixtures,ASTMD4206.

0.35

0.35 0.35

Part

Part Part

24N580WB100WaterborneIsolationEnclosure233825withstandardelectrostaticairspraygun

24P629WB100WaterborneIsolationEnclosure233825withsmartelectrostaticairspraygun

24P630WB100WaterborneIsolationEnclosure246511withstandardelectrostaticairspraygun

24P631WB100WaterborneIsolationEnclosure246511withsmartelectrostaticairspraygun

233825WB100

24P734WB100

246511WB100

L60T17ProXp60

with

50

hose

J, J,J,with with

FM12ATEX0080

FM12ATEX0080 FM12ATEX0080

No

No No

50 50

ft ftfthose hose

EN

50059

EN EN

50059 50059

Ta

0°C

Ta Ta

50°C

0°C 0°C

– ––50°C 50°C

Model

Model Model

WB

max

max max

•Materialswhichcannotbeignited,inanymixturewithair,byanenergy

Description

Description Description

L60T17,groundedairhose235070,andshieldedwaterborneuidhose24M732.

L60M17,groundedairhose235070,andshieldedwaterborneuidhose24M732.

L60T18,groundedairhose235070,andunshieldedwaterborneuidhose24M733.

L60M18,groundedairhose235070,andunshieldedwaterborneuidhose24M733.

WaterborneIsolationEnclosureforshieldedhoses.Doesnotincludehosesandgun.

WaterborneIsolationEnclosure246511withMRGsmartelectrostaticairspraygun

L60M19,groundedairhose235070,andunshieldedwaterborneuidhose24M733.

WaterborneIsolationEnclosureforunshieldedhoses.Doesnotincludehoses

andgun.

StandardElectrostaticAirSprayGun,forwaterbornecoatings.

ModelsCompliantwithEN50059whenused

withuidsthatmeetthefollowingcriteria:

sourceoflessthan500mJ.

L60M17ProXp60

L60T18ProXp60

L60M18ProXp60

L60M19ProXp60

WBMRG

24M732

24M733

25N916

25N917

-——

-——

-——

-——

WB

WB

WB

SmartElectrostaticAirSprayGun,forwaterbornecoatings.

StandardElectrostaticAirSprayGun,forwaterbornecoatings.

SmartElectrostaticAirSprayGun,forwaterbornecoatings.

SmartElectrostaticAirSprayGun,formoldreleaseapplications.

ShieldedWaterborneFluidHoseAssembly,25ft(7.6m).

UnshieldedWaterborneFluidHoseAssembly,25ft(7.6m).

ShieldedWaterborneFluidHoseAssembly,50ft(15.2m).

UnshieldedWaterborneFluidHoseAssembly,50ft(15.2m).

3A2496H3

Page 4

RelatedManuals

Related

Related Related

Manual

Manual Manual

3A2498

307263ProbeandMeter,Instructions

309455TestFixture,HighVoltageProbe,andkVMeter,Instructions

406999

No.

No. No.

Manuals

Manuals Manuals

Description

Description Description

RoundSprayKit,Instructions

VoltageTesterConversionKit,Instructions

4

3A2496H

Page 5

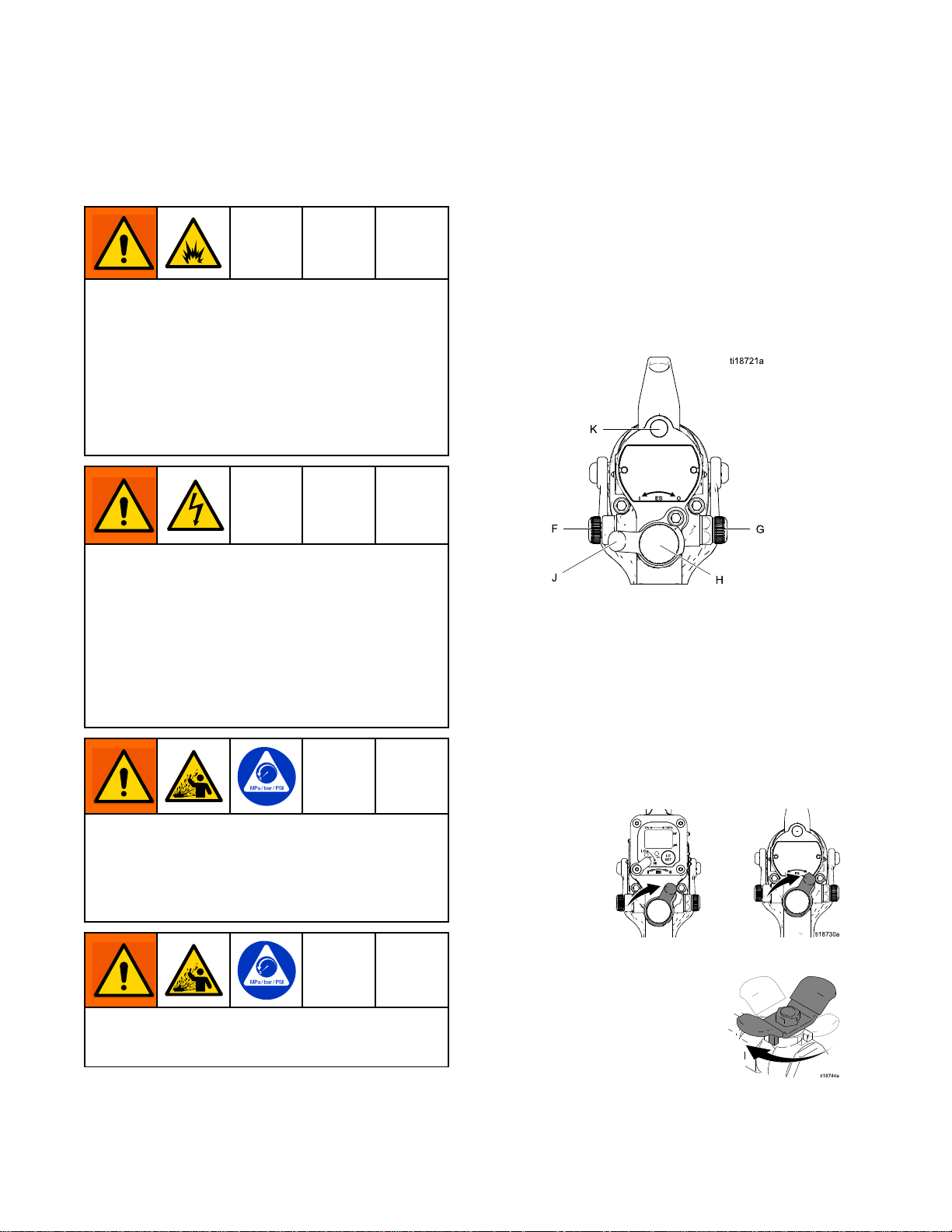

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Combustibledustinwork work

•Fluidsusedmustmeetthefollowingammabilityrequirements:

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Checkgunresistance,hoseresistance,andelectricalgroundingdaily.

•Useandcleanequipmentonlyinwellventilatedarea.

•Interlockthegunairsupplytopreventoperationunlessventilationairowisabovethe

minimumrequiredvalue.

•Onlyusenon-ammablesolventswhenushingorcleaningequipment.

•Alwaysturntheelectrostaticsoffwhenushing,cleaningorservicingequipment.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Donotplugorunplugpowercordsorturnlightsonoroffwhenammablefumesarepresent.

•Keepsprayareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

FM,

FMc

•FM, FM,

MaterialdoesnotsustainburninginaccordancewiththeStandardTestMethodfor

SustainedBurningofLiquidMixtures,ASTMD4206.

CE

•CE CE

Materialswhichcannotbeignited,inanymixturewithair,byanenergysourceof

lessthan500mJ.

operation

operation operation

Approved:

FMc FMc

Approved: Approved:

EN

50059

- --EN EN

50059 50059

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Tohelppreventreandexplosion:

Compliant:

Compliant: Compliant:

ifstaticsparkingoccursoryoufeelashock.Donotuse

Warnings

3A2496H5

Page 6

Warnings

WARNING

WARNING WARNING

ELECTRIC

ELECTRIC ELECTRIC

Impropergrounding,setup,orusageofanisolatedwaterbornesystemcanresultinelectric

shock.Tohelppreventelectricshock:

•Groundallequipment,personnel,objectbeingsprayed,andconductiveobjectsinorclose

tosprayarea.SeeGrounding Grounding

•Connecttheelectrostaticguntoavoltageisolationsystemthatwilldischargethesystem

voltagewhennotinuse.

•Allcomponentsoftheisolationsystemthatarechargedtohighvoltagemustbecontained

withinanisolationenclosurethatpreventspersonnelfrommakingcontactwiththehigh

voltagecomponentsbeforethesystemvoltageisdischarged.

•FollowtheFluid Fluid

thevoltage;beforecleaning,ushing,orservicingthesystem;beforeapproachingthefrontof

thegun;andbeforeopeningtheisolationenclosurefortheisolateduidsupply.

•Donotenterahighvoltageorhazardousareauntilallhighvoltageequipmenthasbeen

discharged.

•Donottouchthegunnozzleorelectrode,orcomewithin4in.(102mm)oftheelectrode

duringgunoperation.FollowtheFluid Fluid

•Interlockthegunairsupplywiththevoltageisolationsystemtoshutofftheairsupplyanytime

theisolationsystemenclosureisopened.

•Onlyusethered-coloredGracoelectricallyconductivegunairhosewiththisgun.Donot

useblackorgray-coloredGracoairhoses.

•Donotsplicehosestogether.InstallonlyonecontinuousGracowaterborneuidhose

betweentheisolateduidsupplyandthespraygun.

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

SHOCK

SHOCK SHOCK

Fluid

HAZARD

HAZARD HAZARD

Grounding

Voltage

Voltage Voltage

EQUIPMENT

EQUIPMENT EQUIPMENT

instructions.

Discharge

Discharge Discharge

HAZARD

HAZARD HAZARD

and

Grounding

and and

Grounding Grounding

Fluid

Voltage

Voltage Voltage

Procedure

Procedure Procedure

Discharge

Discharge Discharge

and

and and

wheninstructedtodischarge

Grounding

Grounding Grounding

Procedure

Procedure Procedure

.

•FollowthePressure Pressure

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

whenyoustopspraying/dispensingandbefore

63A2496H

Page 7

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts..SeeTechnical Technical

Specications

Specications Specications

Forcompleteinformationaboutyourmaterial,requestaSafetyDataSheet(SDS)from

yourdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PLASTIC

PLASTIC PLASTIC

Manysolventscandegradeplasticpartsandcausethemtofail,whichcouldcauseserious

injuryorpropertydamage.

MISUSE

MISUSE MISUSE

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.

CLEANING

CLEANING CLEANING

SOLVENT

SOLVENT SOLVENT

Specications

Specications Specications

Pressure

HAZARD

HAZARD HAZARD

Relief

Relief Relief

inallequipmentmanuals.

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Technical

•Useonlycompatiblewater-basedsolventstocleanplasticstructuralorpressure-containing

parts.

•SeeTechnical Technical

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheet(SDS)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

Technical

thesolventmanufacturerforinformationandrecommendationsaboutcompatibility.

FLUID

FLUID FLUID

guidelines.

manufacturer.

Specications

Specications Specications

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

inallequipmentmanualsformaterialsofconstruction.Consult

EQUIPMENT

EQUIPMENT EQUIPMENT

3A2496H

7

Page 8

GunOverview

Gun

Gun Gun

How

How How

Works

Works Works

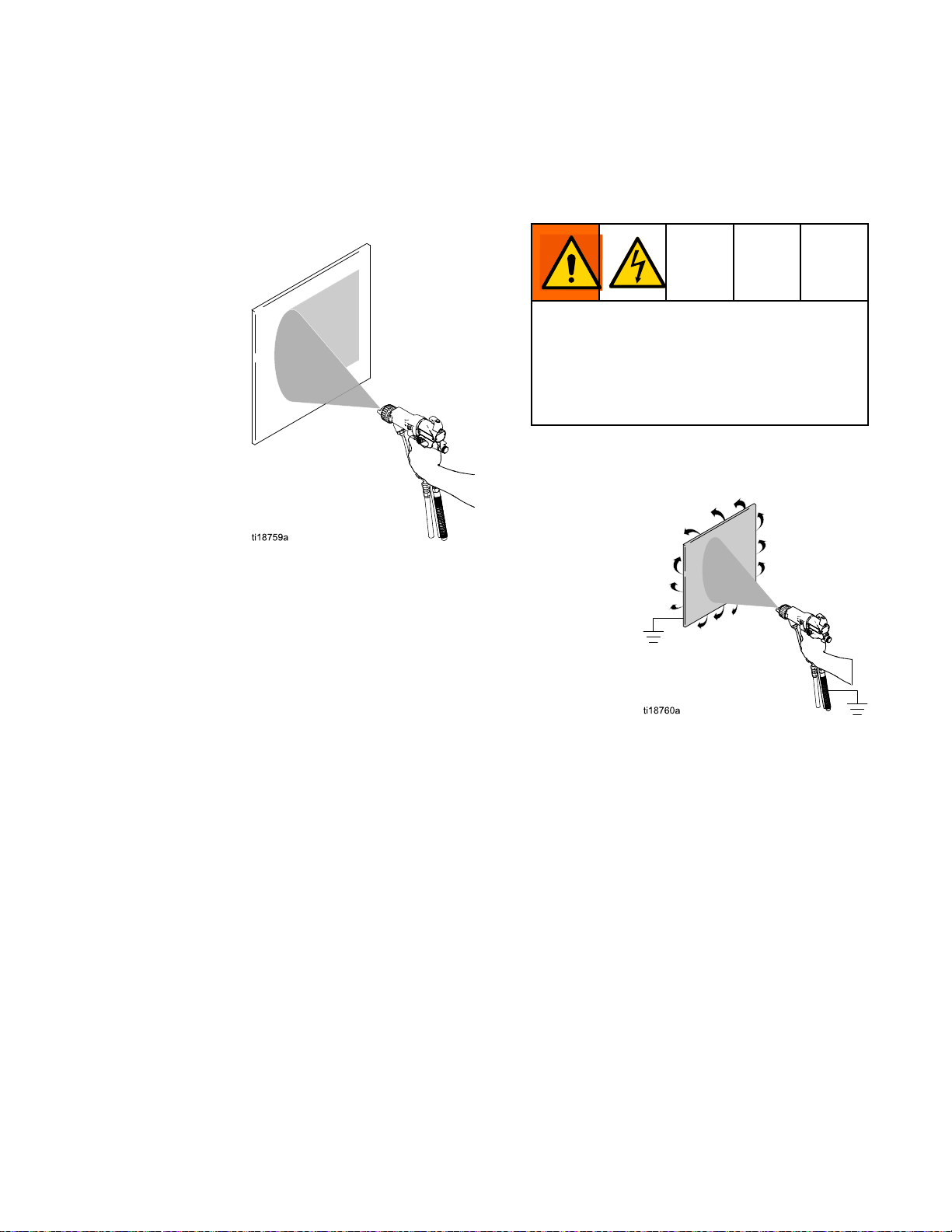

Theairhosesuppliesairtothespraygun.Partofthe

airoperatesthealternatorturbineandtherestofthe

airatomizestheuidbeingsprayed.

Thealternatorgeneratespower,whichisconverted

bythepowercartridgetosupplyhighvoltagetothe

gun’selectrode.

Thepumpsuppliesuidtotheuidhoseandgun,

wheretheuidiselectrostaticallychargedasit

passestheelectrode.Thechargeduidisattracted

tothegroundedworkpiece,wrappingaroundand

evenlycoatingallsurfaces.

Spraying

Spraying Spraying

Electrostatically

Electrostatically Electrostatically

Thiselectrostaticairspraygunisdesignedtospray

only

only only

ammabilityrequirements:

Overview

Overview Overview

the

Electrostatic

the the

Electrostatic Electrostatic

Waterborne

Waterborne Waterborne

waterborneuidswhichmeetthefollowing

Spray

Spray Spray

Fluids

Fluids Fluids

Gun

Gun Gun

CE-EN

•CE-EN CE-EN

Materialswhichcannotbeignited,inanymixture

withair,byanenergysourceoflessthan500mJ.

Whenconnectedtoavoltageisolationsystem,

alloftheuidinthespraygun,uidhose,and

isolateduidsupplyischargedtohighvoltage,

whichmeansthatthesystemhasmoreelectrical

energythanasolvent-basedsystem.Therefore,

onlynon-ammableuids(asdenedunder

Models,page3)canbesprayedwiththesystemor

beusedtoclean,ush,orpurgethesystem.

Precautionsmustbetakenwhenusingelectrostatic

waterborneequipmenttoavoidpotentialshock

hazards.Whenthespraygunchargestheisolated

uidtohighvoltage,itissimilartocharginga

capacitororabattery.Thesystemwillstoresomeof

theenergywhilesprayingandretainsomeofthat

energyafterthespraygunisshutoff.Donottouch

thegunnozzleorcomewithin4in.(102mm)of

theelectrodeuntilthestoredenergyisdischarged.

Theamountoftimeittakestodischargethe

energydependsonthesystemdesign.Followthe

FluidVoltageDischargeandGroundingProcedure,

page39,beforeapproachingthefrontofthegun.

50059

50059 50059

Compliant:

Compliant: Compliant:

FM,

FMc

•FM, FM,

Materialdoesnotsustainburninginaccordance

withtheStandardTestMethodforSustained

BurningofLiquidMixtures,ASTMD4206.

Approved:

FMc FMc

Approved: Approved:

NOTE:

NOTE: NOTE:

voidiftheelectrostaticspraygunisconnectedtoa

non-Gracovoltageisolationsystemorifthegunis

operatedabove60kV.

TheGracowarrantyandapprovalsare

83A2496H

Page 9

GunOverview

Controls,

Controls, Controls,

Theelectrostaticgunincludesthefollowingcontrols,indicators,andcomponents.ForinformationonSmart

guns,alsoseeSmartGuns,page10.

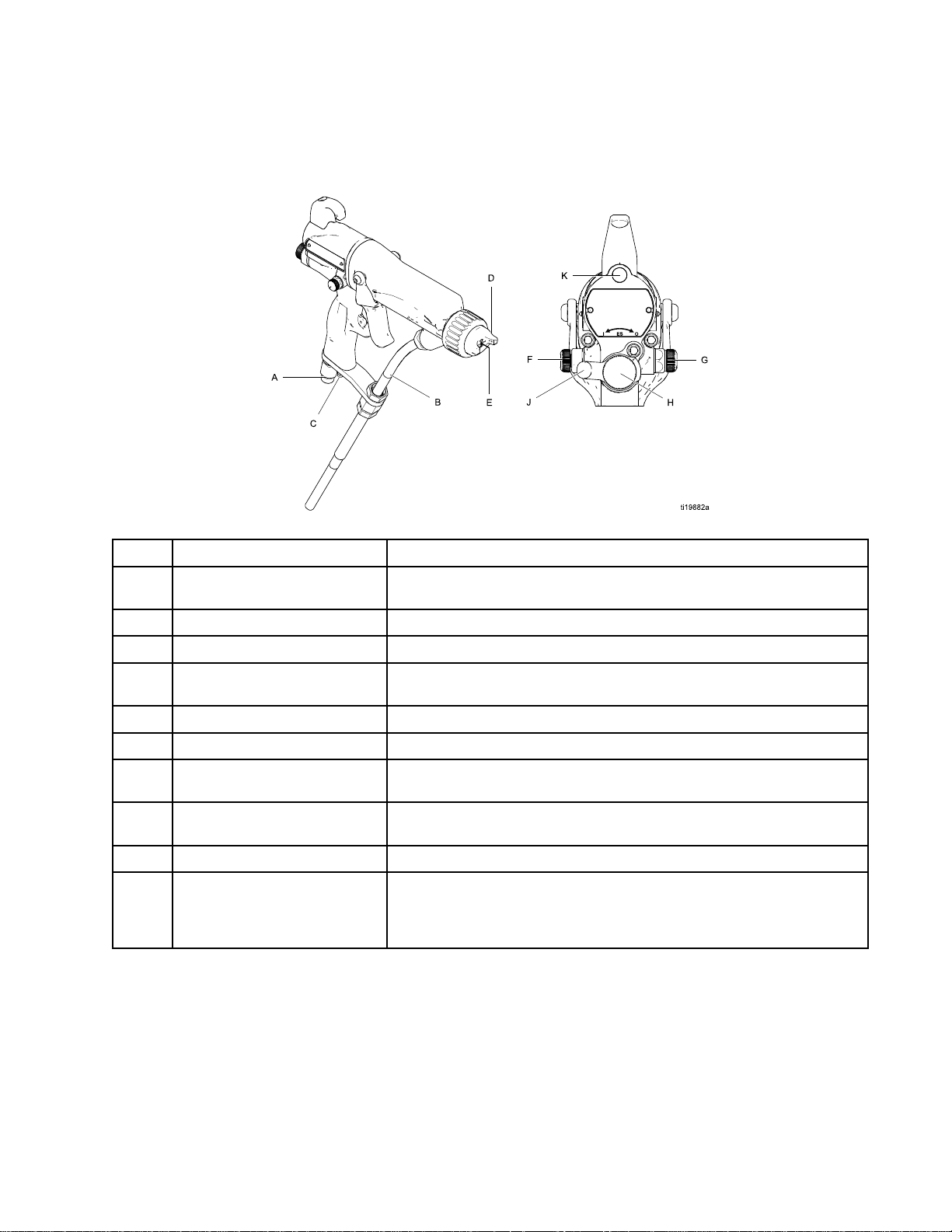

Figure1GunOverview

Item

Item Item

Indicators,

Indicators, Indicators,

Description

Description Description

and

Components

and and

Components Components

Purpose

Purpose Purpose

A

BFluidInlet

C

D

EElectrodeNeedle

FFanAirAdjustmentValve

G

HFluidAdjustmentKnob

J

K

AirSwivelInlet1/4npsm(m)left-handthread,forGracored-coloredgroundedair

TurbineAirExhaust

AirCapandNozzleSeeAirCaps,page96andFluidNozzles,page93foravailable

AtomizingAirRestrictor

Valve

ESOn-OffValveTurnselectrostaticsON(I)orOFF(O).

ESIndicator(standard

gunonly;forSmart

gunindicator,see

OperatingMode,page10)

supplyhose.

Gracowaterborneuidsupplyhose

Barbedtting,forsuppliedexhausttube.

sizes.

Supplieselectrostaticchargetotheuid.

Adjustsfansizeandshape.Canbeusedtodecreasepatternwidth.

Restrictsaircapairow.Replacewithplug(included)ifdesired.

Adjustsuidowbylimitinguidneedletravel.Useonlyinlowow

conditions,toreducewear.

LitwhenESisON(I).Colorindicatesalternatorfrequency.Seethe

LEDindicatortableonpage36.

3A2496H9

Page 10

GunOverview

Smart

Smart Smart

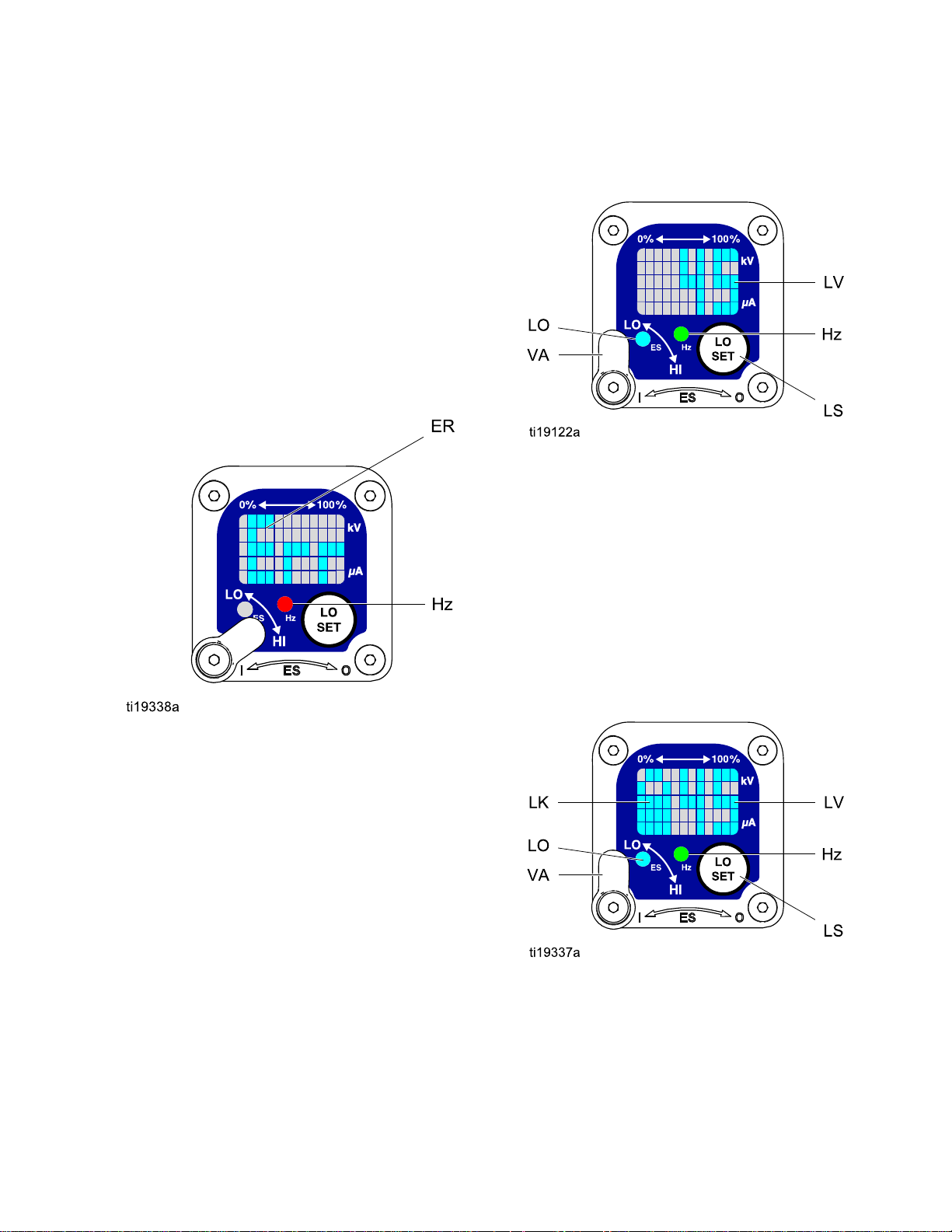

TheSmartGunmoduledisplayssprayingvoltage,

current,alternatorspeed,andthevoltagesetting(low

orhigh).Italsoallowstheusertochangetoalower

sprayingvoltage.Themodulehastwomodes:

•OperatingMode

•DiagnosticMode

Operating

Operating Operating

Bar

Bar Bar

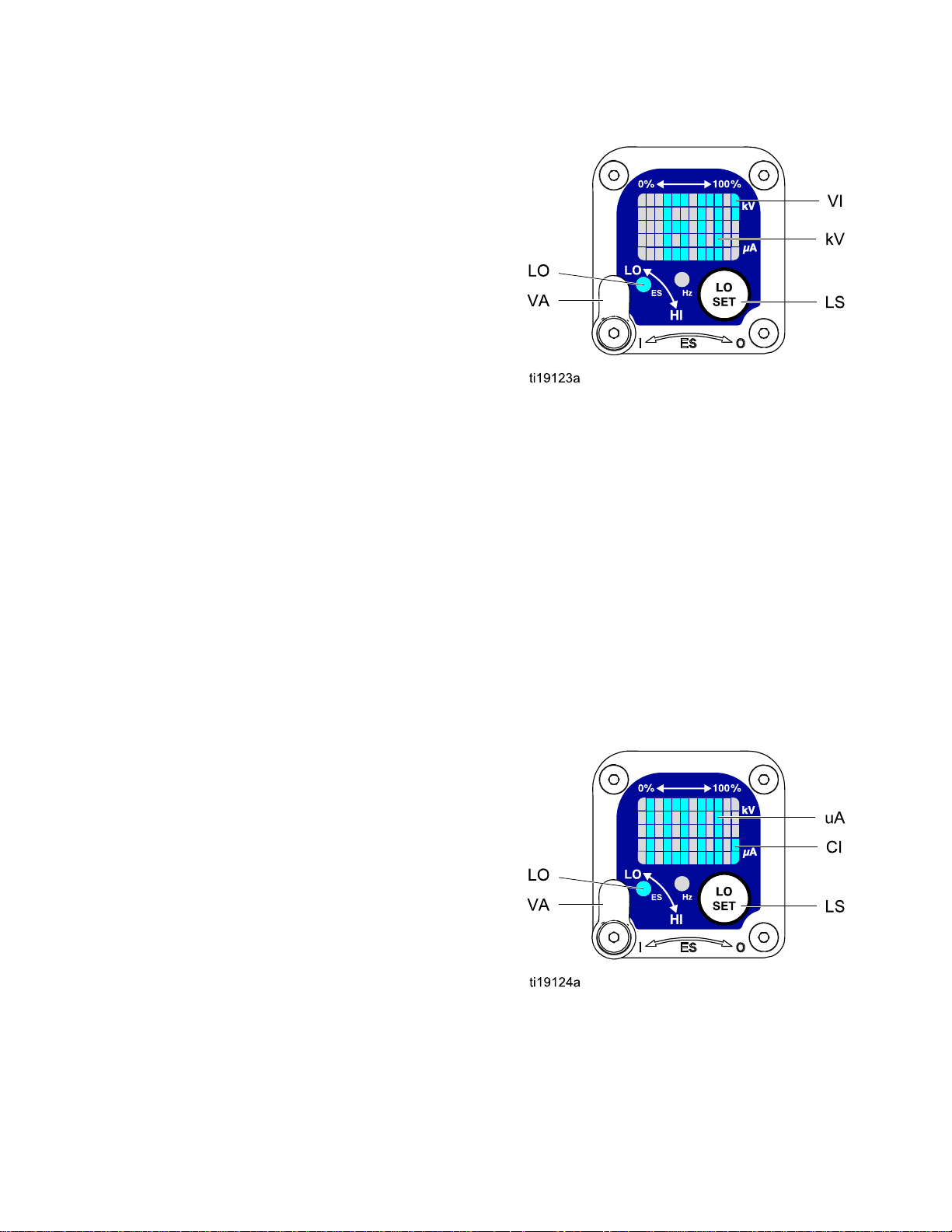

SeeFig.2andSmartGunKey,page12.The

OperatingModedisplaysgundataduringnormal

spraying.Thedisplayusesabargraphtoshowthe

voltagelevelinkiloVolts(kV)andthecurrentlevelin

microAmperes(uA).Thebargraphrangeisfrom0

to100%foreachvalue.

IfthebargraphLEDsareblue,thegunisreadyto

spray.IftheLEDsareyelloworred,thecurrentis

toohigh.Theuidmaybetooconductive,orsee

ElectricalTroubleshooting,page56forotherpossible

causes.

Guns

Guns Guns

Mode

Mode Mode

Graph

Graph Graph

Voltage

Voltage Voltage

Thevoltageadjustmentswitch(VA)allowsthe

operatortochangefromlowtohighvoltage.

•Thehighvoltagesettingisdeterminedbythe

maximumvoltageofthegunandisnotadjustable.

•Thelowvoltageindicator(LO)lights

whentheswitchissettoLO.Thelow

voltagesettingisuseradjustable.See

AdjustingtheLowVoltageSetting,page11.

NOTE:

NOTE: NOTE:

haslostcommunicationwiththepowersupply.See

ErrorDisplay,page11forfurtherinformation.

Adjustment

Adjustment Adjustment

IftheErrordisplayappears,theSmartmodule

Switch

Switch Switch

Hz

Indicator

Hz Hz

Indicator Indicator

TheHzindicatorfunctionsthesameastheES

indicatoronstandardguns.Theindicatorlightsto

showthealternatorspeedstatus,andhasthree

colors:

•Greenindicatesthealternatorspeediscorrect.

•Iftheindicatorchangestoamberafteronesecond,

increasetheairpressure.

•Iftheindicatorchangestoredafteronesecond,

theairpressureistoohigh.Decreaseairpressure

untiltheindicatorisgreen.Tomaintainahigher

airpressure,installESOn/OffValveRestrictorKit

26A160.Then,adjustthepressureasneededto

ensuretoensuretheindicatorremainsgreen.

Figure2SmartGunModuleinOperatingMode

103A2496H

Page 11

GunOverview

Error

Error Error

IftheSmartmodulelosescommunicationwith

thepowersupply,theErrordisplayappears,the

Hzindicatorturnsred,andtheSmartmoduleis

disabled.SeeFig.3andSmartGunKey,page12.

ThiscanoccurinOperatingModeorDiagnostic

Mode.SeeElectricalTroubleshooting,page56.

CommunicationmustberestoredtomaketheSmart

modulefunctional.

NOTE:

NOTE: NOTE:

appear.Ifthegunhasbeendisassembled,wait8

secondsbeforesprayingtoensurethatanError

conditionhasnotoccurred.

NOTE:

NOTE: NOTE:

displaywillnotappear.

Display

Display Display

Ittakes8secondsfortheErrordisplayto

Ifthereisnopowertothegun,theError

NOTE:

NOTE: NOTE:

returntotheOperatingScreen.

NOTE:

NOTE: NOTE:

LockSymbol,page11.

Figure4LowVoltageSettingScreen(Unlocked)

Lock

Lock Lock

Thelowvoltagesettingmaybelocked.Whenlocked,

animage(LK)appearsonthescreen.SeeFig.5

andSmartGunKey,page12.

After2secondsofinactivitythedisplaywill

Thelowvoltagesettingmaybelocked.See

Symbol

Symbol Symbol

Figure3ErrorDisplay

Adjusting

Adjusting Adjusting

Thelowvoltagesettingisuseradjustable.Toaccess

thelowvoltagesettingscreenwheninOperating

Mode,presstheLOSETbutton(LS)momentarily.

Thescreenwilldisplaythecurrentlowvoltage

setting.SeeFig.4andSmartGunKey,page12.

Therangeis30–60kV.

SettheVoltageAdjustmentswitch(VA)toLO.Press

theLOSETbuttonrepeatedlytoincreasethesetting

inincrementsof5.Whenthedisplayreachesthe

maximumsetting(60kV)itwillreturntotheminimum

setting(30kV).Continuepressingthebuttonuntil

youreachthedesiredsetting.

the

Low

the the

Voltage

Low Low

Voltage Voltage

Setting

Setting Setting

•WheninHImode,thelowvoltagesettingisalways always

locked.ThelocksymbolwillappearwhentheLO

SETbuttonispressed.

•WheninLOmode,thelocksymbolwill

only

only only

appearifthelockisenabled.See

LowVoltageLockScreen,page14,tolockor

unlockthelowvoltagesetting.

Figure5LowVoltageSettingScreen(Locked)

always

3A2496H

11

Page 12

GunOverview

Smart

Smart Smart

Table

Table Table

Item

Item Item

VA

LO

kV

uA

LSLOSETbuttonPressmomentarilytoentertheLowVoltageSettingscreen.

Gun

Key

Gun Gun

Key Key

Key

for

Figs.

1 11Key Key

for for

Description

Description Description

VoltageAdjustmentSwitchTwo-positionswitchsetsSmartgunvoltagetolowsetting(LO)or

LowVoltageMode

Indicator

Voltage(kV)DisplayDisplaysactualsprayingvoltageofthegun,inkV.InOperatingMode,

Current(uA)DisplayDisplaysactualsprayingcurrentofthegun,inuA.InOperatingMode,

2–9.

Figs. Figs.

2–9. 2–9.

Purpose

Purpose Purpose

highsetting(HI).ThisswitchisfunctionalinOperatingModeandin

DiagnosticMode.

Lights(blue)whentheSmartgunissettoLowVoltage.

displayisabargraph.InDiagnosticMode,voltageisdisplayedas

anumber.

displayisabargraph.InDiagnosticMode,currentisdisplayedas

anumber.

Pressandholdforapproximately5secondstoenterorexitDiagnostic

Mode.

WhileinDiagnosticMode,pressmomentarilytoadvancethrough

screens.

WhileontheLowVoltageLockScreen(inDiagnosticMode),press

andholdtoturnthelockonoroff.

LVLowVoltageDisplayDisplaysthelowvoltagesettingasanumber.Thesettingcanbe

changed.SeeFig.4.

LKLowVoltageLocked

LD

ERErrorDisplay

VIVoltageIndicator

CICurrentIndicatorInDiagnosticMode,thetwobottomrightLEDsofthescreenlight,

ASAlternatorSpeedDisplayInDiagnosticMode,Hzlevelisdisplayedasanumber.SeeFig.8.

Hz

LODisplayAppearsontheLowVoltageLockScreen.SeeFig.9.

AlternatorSpeedIndicatorInOperatingMode,indicatorcolorvariestoshowthealternatorspeed

Appearsifthelowvoltagesettingislocked.SeeFig.5andFig.9.

AppearsiftheSmartmodulelosescommunicationwiththepower

supply.SeeFig.3.

InDiagnosticMode,thetwotoprightLEDsofthescreenlight,

indicatingthatthevaluedisplayedisinkV.SeeFig.6.

indicatingthatthevaluedisplayedisinuA.SeeFig.7.

status:

•Greenindicatesthealternatorspeedisatthecorrectlevel.

•Iftheindicatorchangestoamberafteronesecond,thealternator

speedistoolow.

•Iftheindicatorchangestoredafteronesecond,thealternatorspeed

istoohigh.TheindicatoralsoturnsrediftheErrordisplayappears.

InDiagnosticMode,theindicatorisgreenwhenintheAlternator

Speed(Hertz)screen.

12

3A2496H

Page 13

GunOverview

Diagnostic

Diagnostic Diagnostic

DiagnosticModeincludesfourscreenswhichdisplay

gundata:

•Voltage(kiloVolts)Screen

•Current(microAmperes)Screen

•AlternatorSpeed(Hertz)Screen

•LowVoltageLockScreen

NOTE:

NOTE: NOTE:

lowvoltagesetting;thesettingisnotadjustablein

DiagnosticMode.However,thevoltageadjustment

switch(VA)canbesettoHIorLOinOperatingMode

andDiagnosticMode.

ToenterDiagnosticMode,pressandholdtheLOSET

(LS)buttonforapproximately5seconds.Thedisplay

willgototheVoltage(kiloVolts)Screen,page13.

Toadvancetothenextscreen,presstheLOSET

buttonagain.

ToexitDiagnosticMode,pressandholdtheLOSET

buttonforapproximately5seconds.Thescreenwill

returntoOperatingMode.

NOTE:

NOTE: NOTE:

Mode,thelastscreenviewedwillbedisplayedwhen

thegunisretriggered.

NOTE:

NOTE: NOTE:

fromtheLowVoltageLockScreen.See

LowVoltageLockScreen,page14fordetails.

Mode

Mode Mode

YoumustbeinOperatingModetoadjustthe

IfthegunisdetriggeredwhileinDiagnostic

DiagnosticModecannotbeexited

Figure6Voltage(kiloVolts)Screen

Current

Current Current

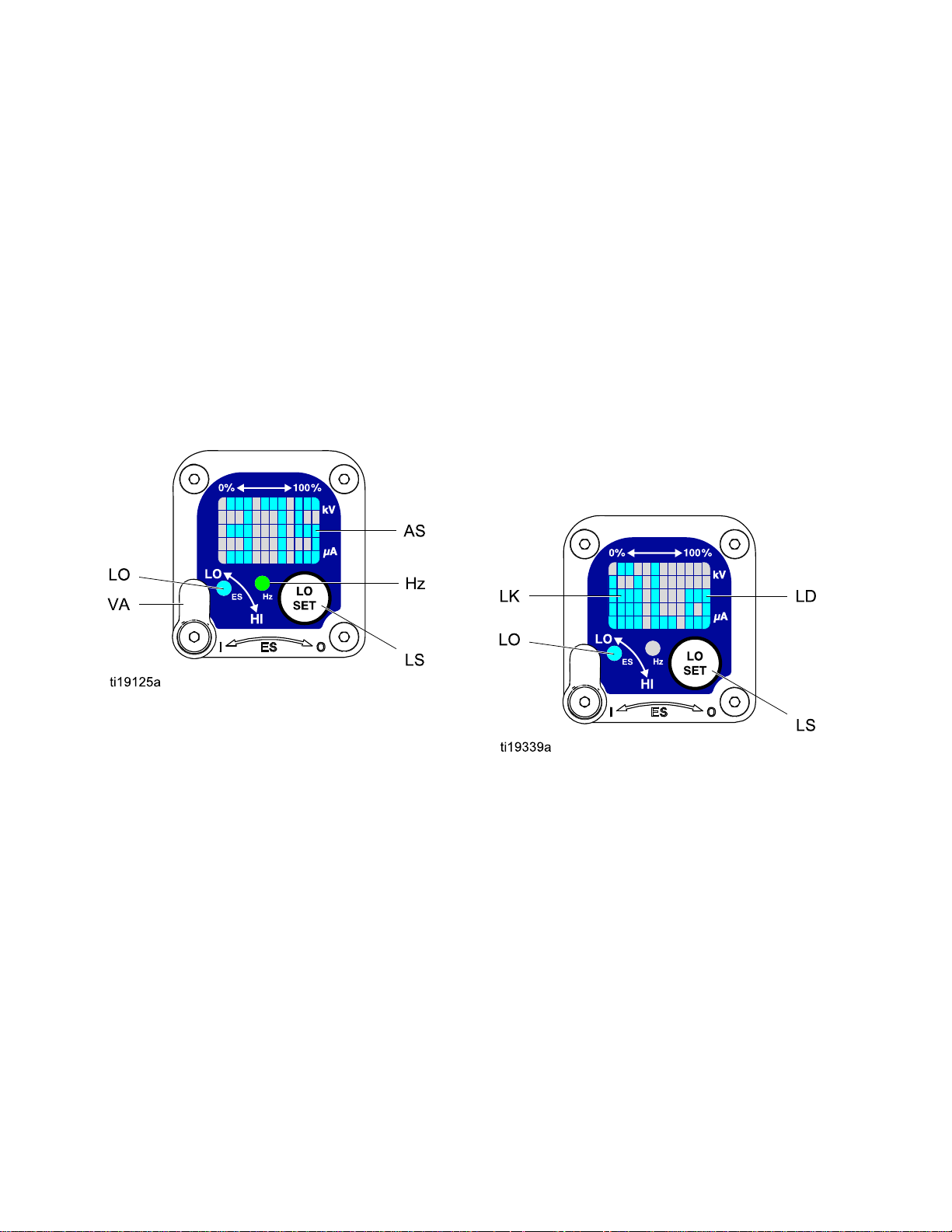

TheCurrent(microAmperes)Screenisthesecond

screenintheDiagnosticMode.SeeFig.7and

SmartGunKey,page12.Toenterthisscreen,press

theLOSETbuttonwhileintheVoltage(kiloVolts)

Screen.

Thisscreendisplaysthesprayingcurrentofthegun

asanumber(uA),roundedtothenearest5uA.The

twobottomrightLEDs(CI)ofthedisplaypanellight,

indicatingthattheCurrent(microAmperes)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

(microAmperes)

(microAmperes) (microAmperes)

Screen

Screen Screen

Voltage

Voltage Voltage

TheVoltage(kiloVolts)Screenistherstscreento

appearafterenteringDiagnosticMode.SeeFig.6

andSmartGunKey,page12.Toenterthisscreen,

pressandholdtheLOSETbuttonforapproximately

5secondswhileintheOperatingMode.

Thisscreendisplaysthesprayingvoltageofthe

gunasanumber(kV),roundedtothenearest5kV.

ThetwotoprightLEDs(VI)ofthedisplaypanel

light,indicatingthattheVoltage(kiloVolts)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

Current(microAmperes)Screen,page13.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

(kiloVolts)

(kiloVolts) (kiloVolts)

Screen

Screen Screen

PresstheLOSETbuttontoadvancetothe

AlternatorSpeed(Hertz)Screen,page14.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

Figure7Current(microAmperes)Screen

3A2496H13

Page 14

GunOverview

Alternator

Alternator Alternator

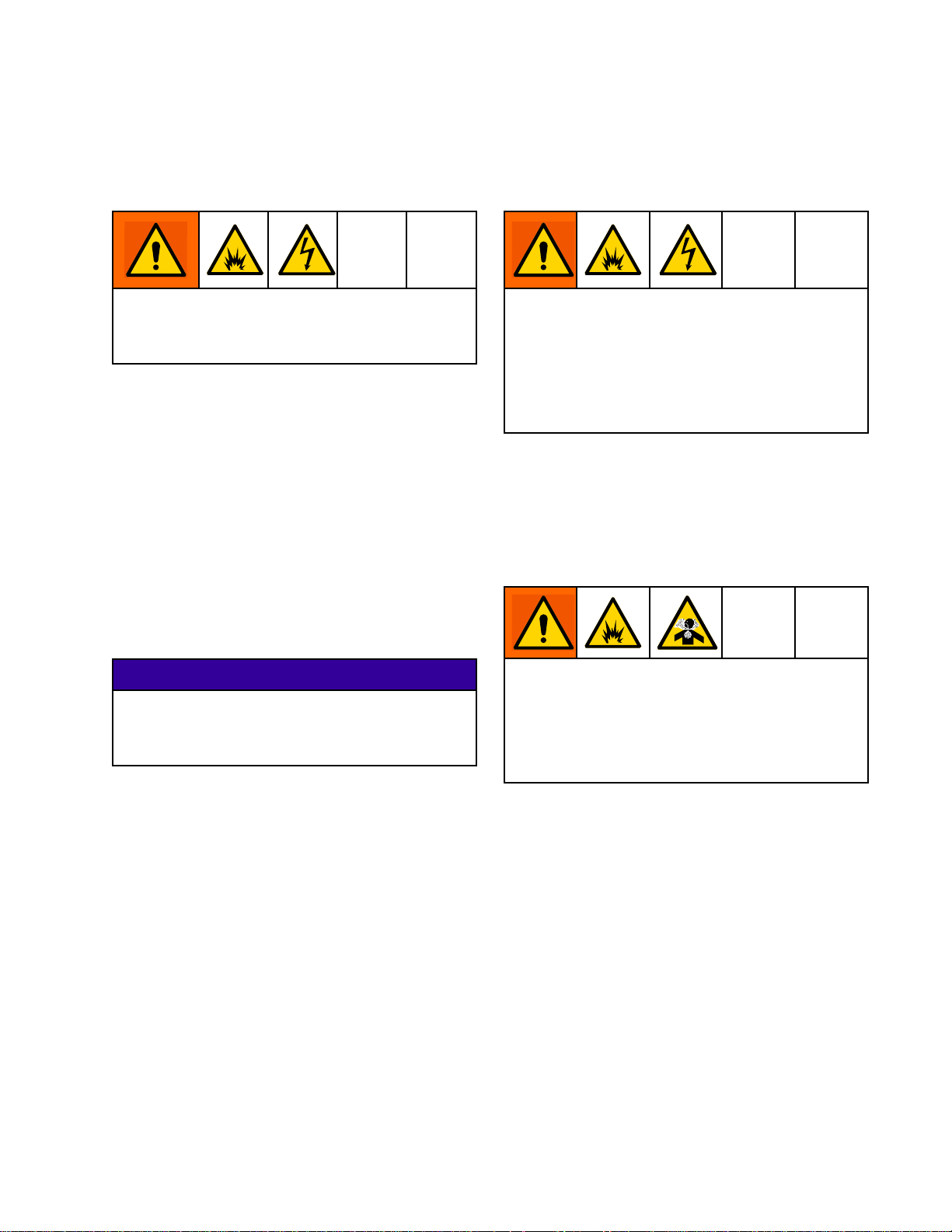

TheAlternatorSpeed(Hertz)Screenisthethird

screenintheDiagnosticMode.SeeFig.8and

SmartGunKey,page12.Toenterthisscreen,

presstheLOSETbuttonwhileintheCurrent

(microAmperes)Screen.

Thisscreendisplaysthealternatorspeedasa3

digitnumber(AS),roundedtothenearest5Hz.The

displayisareadoutandcannotbechanged.Ifthe

alternatorspeedisgreaterthan999Hz,thedisplay

willshow999.

TheHzindicatorlightsgreentoshowthatyouare

viewingtheAlternatorSpeed(Hertz)Screen.

PresstheLOSETbuttontoadvancetothe

LowVoltageLockScreen,page14.Pressandhold

forapproximately5secondstoreturntoOperating

Mode.

Speed

Speed Speed

(Hertz)

(Hertz) (Hertz)

Screen

Screen Screen

Low

Voltage

Low Low

Voltage Voltage

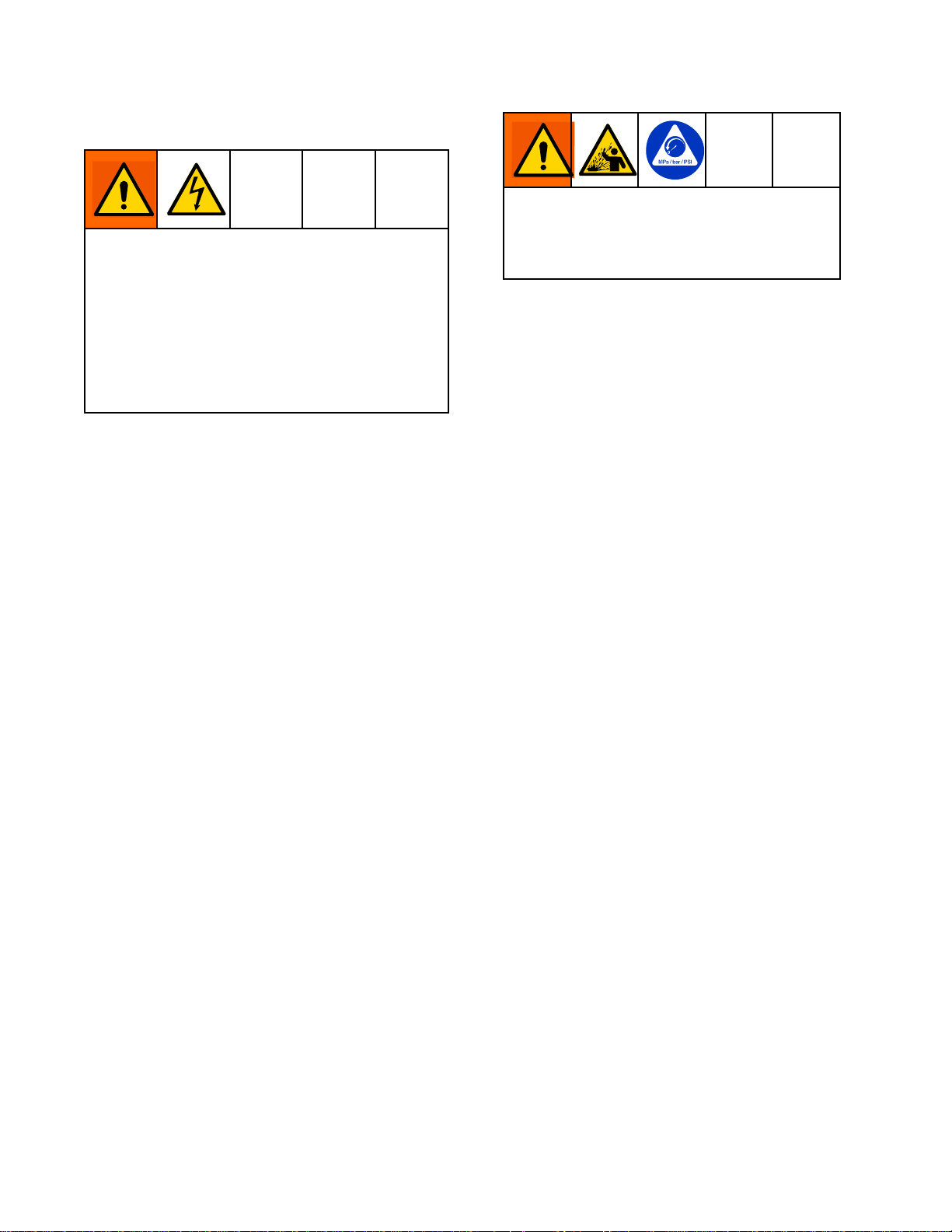

TheLowVoltageLockScreenisthefourth

screenintheDiagnosticMode.SeeFig.9and

SmartGunKey,page12.Toenterthisscreen,press

theLOSETbuttonwhileintheAlternatorSpeed

(Hertz)Screen.

ThisscreendisplaysthestatusoftheLowVoltage

Lock.Ifthesettingislocked,thelockimage(LK)

appearstotheleftoftheLodisplay(LD).Ifthesetting

isunlocked,thelockimagedoesnotappear.

Tochangethelockstatus,pressandholdthe

LOSETbuttonuntilthelockimageappearsor

disappears.Ifthelockisset,theimagewillalso

appearontheLowVoltageSettingScreenwhenin

lowvoltagemode(seeFig.4).

NOTE:

NOTE: NOTE:

screen,becausepressingandholdingtheLOSET

buttonisusedtoturnthelockonoroff.Toexit,

pressLOSETmomentarilytoreturntotheVoltage

(kiloVolts)Screen,thenexitDiagnosticModefrom

there.

DiagnosticModecannotbeexitedfromthis

Lock

Screen

Lock Lock

Screen Screen

Figure8AlternatorSpeed(Hertz)Screen

Figure9LowVoltageLockScreen

14

3A2496H

Page 15

Installation

Installation

Installation Installation

System

System System

Theuseofmultiplegunswithoneisolationcabinet

maycauseelectricshock,re,orexplosion.To

helppreventinjuryorequipmentdamage,useonly

onegunperisolationcabinet.

AGracovoltageisolationsystemmusthavethe

followingfeatures:

•Anisolationenclosurethatpreventspersonsfrom

makingcontactwiththehighvoltagecomponents

beforethesystemvoltageisdischarged.All

componentsoftheisolationsystemthatare

chargedtohighvoltagemustbecontainedwithin

theenclosure.

•Ableedresistortodrainoffthesystemvoltage

whenthespraygunisnotinuse.Ametalpartof

theuidsupplyunitmustbeelectricallyconnected

tothebleedresistor.

•Asafetyinterlockthatautomaticallydischargesthe

systemvoltagewhenanyoneopenstheisolation

enclosure.

Requirements

Requirements Requirements

Install

Install Install

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseelectricshock

orotherseriousinjuryifworkisnotperformed

properly.

•Donotinstallorservicethisequipmentunless

•Complywithalllocalcodesandregulations

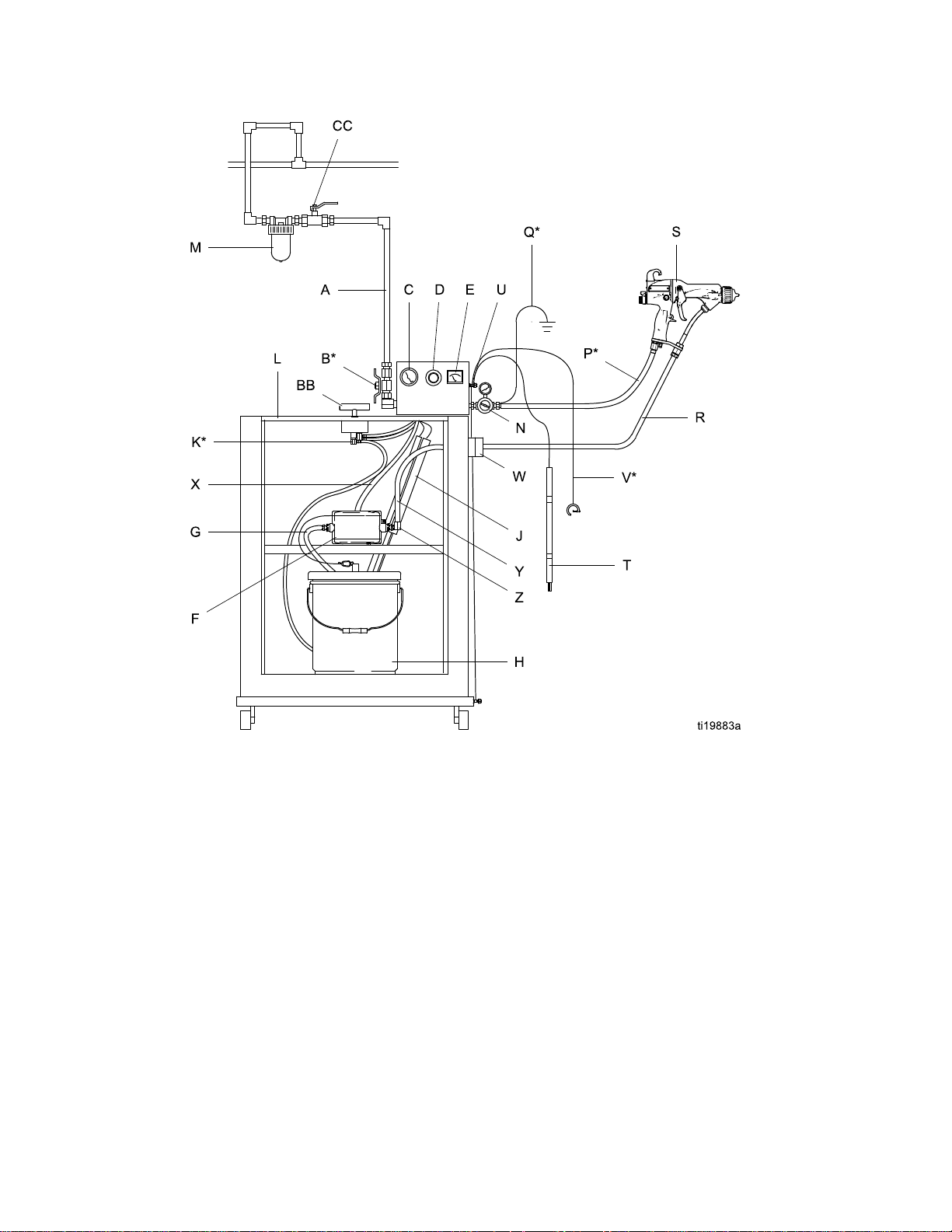

Fig.19showsatypicalelectrostaticairspraysystem.

Itisnotanactualsystemdesign.Forassistance

indesigningasystemtosuityourparticularneeds,

contactyourGracodistributor.

Ventilate

Ventilate Ventilate

the

the the

youaretrainedandqualied.

System

System System

the

Spray

the the

Spray Spray

Booth

Booth Booth

NOTICE

NOTICE NOTICE

Thesystemshouldnothaveanyseverearcing

occurringwhentheisolationmechanismopens

andcloses.Severearcingwillshortenthelifeof

thesystemcomponents.

NOTE:

NOTE: NOTE:

voidiftheelectrostaticspraygunisconnectedtoa

non-Gracovoltageisolationsystemorifthegunis

operatedabove60kV.

Warning

Warning Warning

Mountwarningsignsinthesprayareawherethey

caneasilybeseenandreadbyalloperators.An

EnglishWarningSignisprovidedwiththegun.

TheGracowarrantyandapprovalsare

Sign

Sign Sign

Donotoperatethegununlessventilatingairowis

abovetheminimumrequiredvalue.Providefresh

airventilationtoavoidthebuildupofammableor

toxicvaporswhenspraying,ushing,orcleaning

thegun.Interlockthegunairanduidsupply

topreventoperationunlessventilatingairowis

abovetheminimumrequiredvalue.

Thesprayboothmusthaveaventilationsystem.

Electricallyinterlockthegunairanduidsupplywith

theventilatorstopreventgunoperationanytimethat

theventilationairowfallsbelowminimumvalues.

Checkandfollowalllocalcodesandregulations

regardingairexhaustvelocityrequirements.Verify

theoperationoftheinterlockatleastonceayear.

NOTE:Theminimumallowableairexhaustvelocity

is60feet/minute(19linearmeters/minute).High

velocityairexhaustwilldecreasetheoperating

efciencyoftheelectrostaticsystem.

3A2496H15

Page 16

Installation

Air

Supply

Air Air

Supply Supply

Toreducetheriskofelectricshock,theairsupply

hosemustbeelectricallyconnectedtoatrueearth

ground.Use Use

Hose.

Hose. Hose.

Toreducetheriskofelectricshockorother

seriousinjury,youmustusethered-coloredGraco

ElectricallyConductiveAirHoseforthegunair

supply,andyoumustconnectthehoseground

wiretoatrueearthground.Donotusetheblack

orgray-coloredGracoairhoses.

1.SeeFig.19.Installanairlinelter/water

separator(M)onthemainairsupplylineto

ensureadry,cleanairsupplytothegun.Dirtand

moisturecanruintheappearanceofyournished

workpieceandcancausetheguntomalfunction.

2.TheWB100systemincludesableed-typeair

regulator(N)onthegunairsupplyline(P),to

controlairpressuretothegun.

3.Connectthered-coloredGracoElectrically

ConductiveAirHose(P)betweenthegunair

regulator(N)andthegun’sairinlet.Thegunair

inletttinghasaleft-handthread.Connectthe

airsupplyhosegroundwire(Q)toatrueearth

ground.

Line

Line Line

Use

only

Graco

only only

Graco Graco

Grounded

Grounded Grounded

Air

Supply

Air Air

Supply Supply

Trappedaircancausetheuidsupplyunitto

cycleunexpectedly,whichcanresultinserious

injury,includingsplashinguidintheeyesor

ontheskin.Donotoperatetheequipment

withoutthebleed-typeairvalve(B)installed.

4.TheWB100systemincludesableed-typeair

valve(B).Thebleed-typeairvalveisrequired

toshutoffallairtothesystemandrelieveair

trappedbetweenthevalveandtheuidsupply

unitaftertheairregulatorisshutoff.Connectthe

mainairsupplyline(A)tothebleedvalve.

5.Installanadditionalbleed-typeairvalve(CC)

upstreamoftheairlter(M)toisolatethelter

forservicing.

Ground

Ground Ground

Connectthemaingroundwire(V)toatrueearth

ground.

the

Cabinet

the the

Cabinet Cabinet

163A2496H

Page 17

Installation

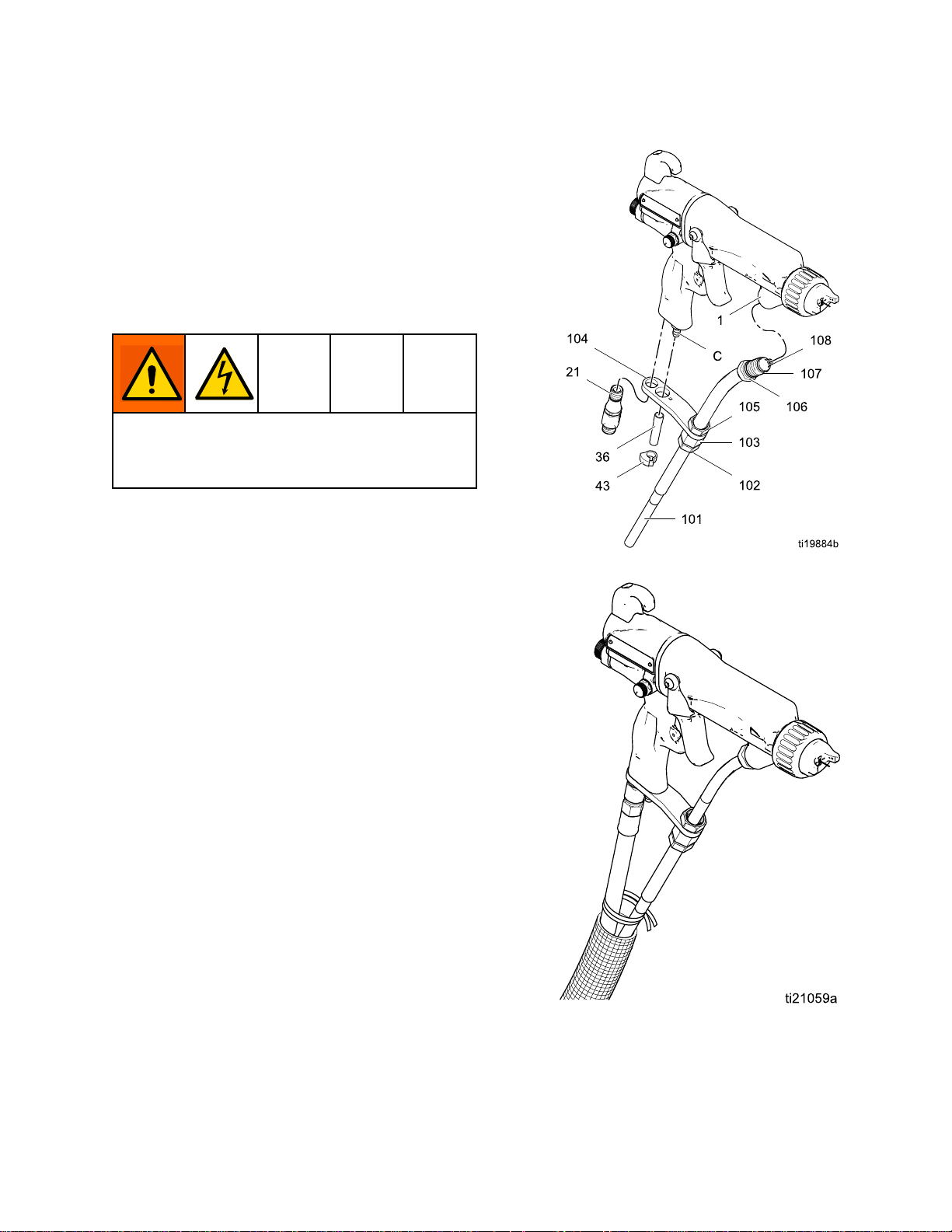

Connect

Connect Connect

AlwaysuseaGracowaterborneuidhosebetween

thevoltageisolationsystemuidoutletandthegun

uidinlet.Thewaterborneuidhose(101)consists

ofaninnerPTFEtube(T)andanabrasion-resistant

outerjacket(J).Shieldedhose24M732alsohas

aconductivelayer(C),Theconductivelayeris

connectedtogroundatthegunttingbracket(104).

Beforeconnectingthewaterborneuidhosetothe

gun,blowitoutwithairandushwithwaterto

removecontaminants.Flushthegunbeforeusingit.

Toreducetheriskofelectricshock,installonly

onecontinuousGracowaterbornehosebetween

theisolateduidsupplyandthegun.Donotsplice

hosestogether.

1.Removethegunairinlettting(21).

NOTE:

NOTE: NOTE:

failureoccurswherehighvoltagearcsthrough

theinnertube,voltagewillbedischargedto

groundthroughtheconductivehoselayer.When

properlyinstalled,theconductivehoselayeris

groundedthroughitsconnectiontothegrounded

enclosure.

Usingunshieldeduidhosesminimizesthe

systemcapacitance,resultinginfasterresponse

timesandalargereductionintheenergystored

inthesystem,ascomparedtoshieldedhoses.

However,withoutthegroundshield,aweak

staticchargecanoccasionallybuilduponthe

outersurfaceofthehose.Tominimizeany

staticchargefeltonthehosesurface,bundle

theairanduidhosetogether,andwrapwitha

protectivecover,asshown.

the

Waterborne

the the

Waterborne Waterborne

Inashieldedhosesystem,ifahose

Fluid

Fluid Fluid

Hose

Hose Hose

Figure10ConnecttheFluidHose

Figure11BundlingtheAirandFluidHoses

3A2496H

17

Page 18

Installation

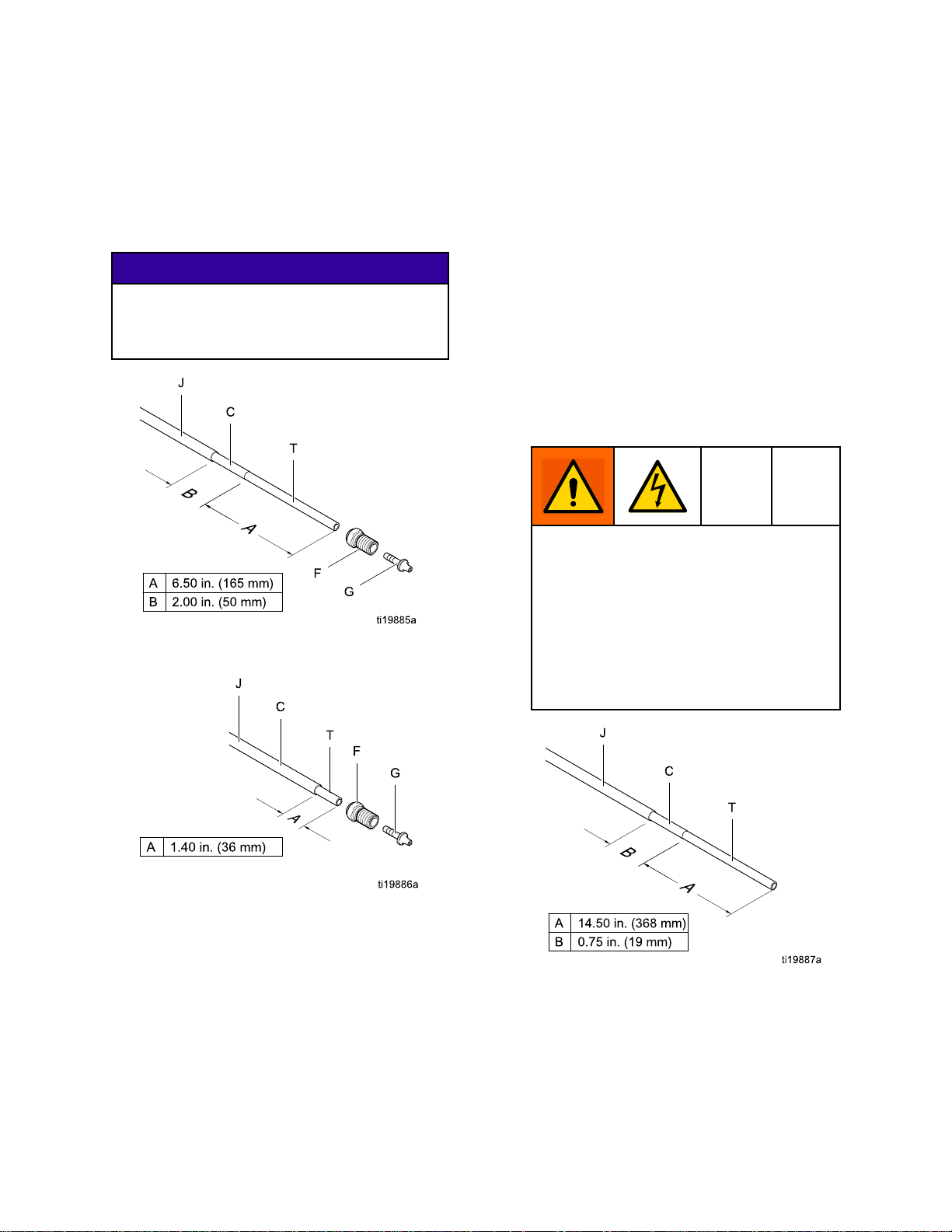

2.Fortheuidhosetotproperly,itmustbe

strippedandassembledtothedimensionsshown

inFig.12.Applydielectricgreasetotheinner

tube(T)ofthehose.Slidethetting(F)onto

thetube(T).Pressthebarbedtting(G)intothe

tubeuntilitsshoulderbottomsonthetube.A

newGracowaterborneuidhosecomesfully

assembledtothesedimensions.

NOTICE

NOTICE NOTICE

Becarefulnottocutintotheinnertube(T)of

thehosewhenstrippingthehose.Nicksor

cutsinthePTFEtubewillcausepremature

hosefailure.

Figure12ShieldedHose24M732Dimensions

atGun

4.Loosenthestrainreliefnut(102)sothebracket

canmovefreelyonthehose.

5.Alignthebracket(104)holeswiththeairinletand

exhaustoutlet.Securewiththeairinlettting

(21).Tightenthestrainreliefnut(102)tosecure

thehose.

6.Checkthatthenut(105)istightenedsecurelyto

theferrulehousing(103).

7.Presstheexhausttube(36)ontotheexhaust

valvebarb(C).Securewiththeclamp(43).

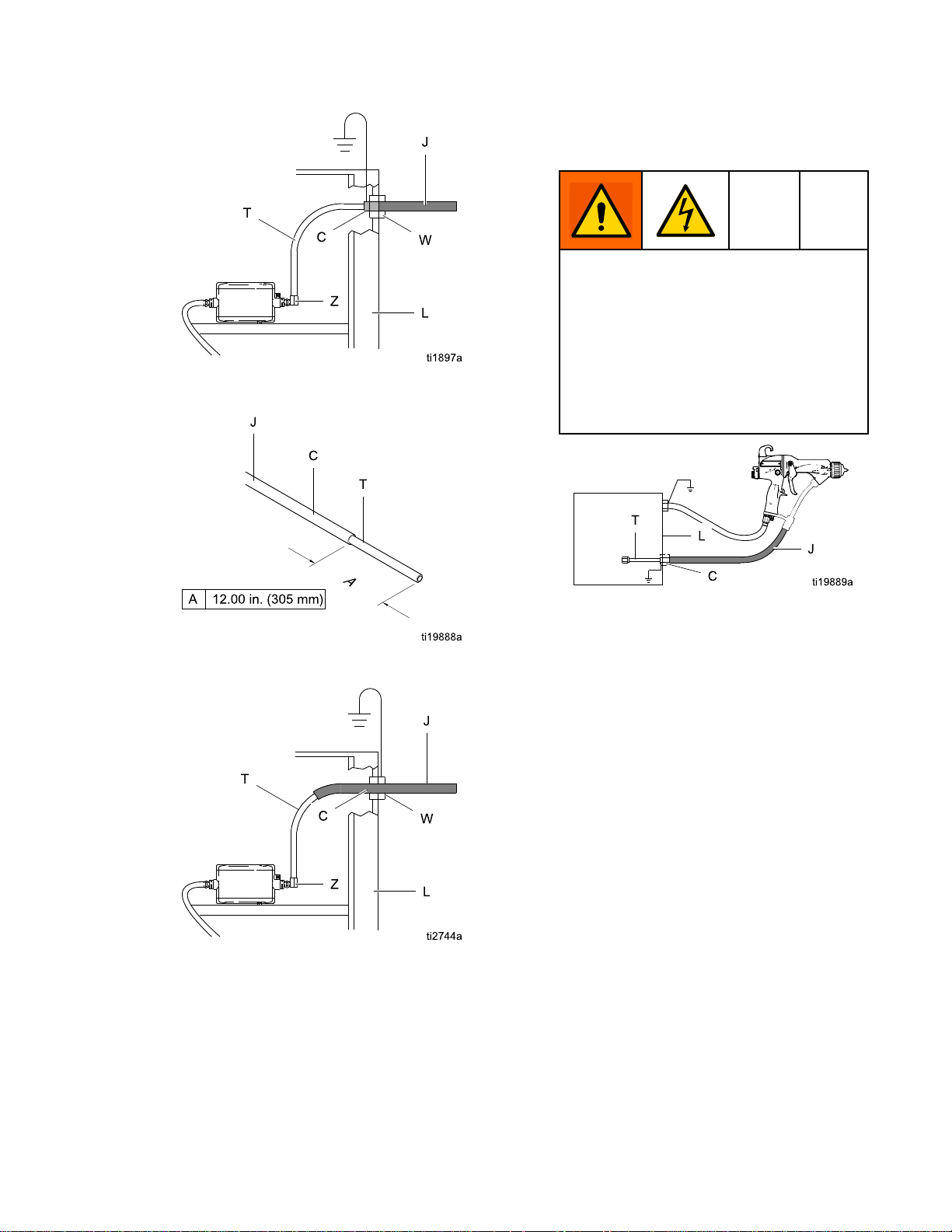

8.Connecttheotherendofthehosetotheisolated

uidsupplyasfollows:

GracoWB100Enclosure:

a.

thestrainrelieftting(W).Ensureconductive

layer(C)haspassedthroughtting.Tighten

to55in-lb(6.2N•m).Pullbackonhoseto

checkitissecure.

For

Shielded

For For

Shielded Shielded

Conductivehoselayer(C)mustbe

groundedthroughitsconnectiontothe

isolationsystem’sgroundedenclosure(L)

orgroundedfence.Tomaintaingrounding

continuity,theconductivehoselayer(C)

mustbeengagedintheferrulewhenthe

strainreliefnutistightened.Failureto

properlyinstallthehoseinthestrainrelief

couldresultinanelectricshock.

Hose

Hose Hose

Slidehosethrough

Systems:

Systems: Systems:

Figure13UnshieldedHose24M733Dimensions

atGun

3.Generouslyapplydielectricgrease(44)tothe

o-ring(107)andthethreadsofthetting(106).

Pullthettingback1-1/2in.(38mm)andapply

greasetotheexposedPTFEhosetollthearea

betweenthehoseandthetting.Makesurethe

barrelinletiscleananddry,thenscrewthetting

intotheuidinletofthegunbarrel(1).

Figure14ShieldedHose24M732

DimensionsatWB100Enclosure

183A2496H

Page 19

Installation

Figure15ShieldedHose24M732

ConnectionatWB100Enclosure

Non-GracoIsolatedEnclosure:

b.

hoseasinstructedintheisolationsystem

manual.

For

Shielded

For For

Shielded Shielded

Conductivehoselayer(C)mustbe

groundedthroughitsconnectiontothe

isolationsystem’sgroundedenclosure(L)

orgroundedfence.Tomaintaingrounding

continuity,theconductivehoselayer(C)

mustbeengagedintheferrulewhenthe

strainreliefnutistightened.Failureto

properlyinstallthehoseinthestrainrelief

couldresultinanelectricshock.

Hose

Systems:

Hose Hose

Systems: Systems:

Connect

Figure16UnshieldedHose24M733

DimensionsatWB100Enclosure

Figure17UnshieldedHose24M733

ConnectionatWB100Enclosure

Figure18ShieldedFluidHoseConnection

atNon-GracoIsolationEnclosure

c.Connecttheendofthetube(T)tothepump

uidoutlettting(Z).

NOTE:

NOTE: NOTE:

arevoidiftheelectrostaticspraygunis

connectedtoanon-Gracovoltageisolation

systemorifthegunisoperatedabove60kV.

TheGracowarrantyandapprovals

3A2496H19

Page 20

Installation

Figure19TypicalInstallation,ProXpWB100

WaterborneSystem

203A2496H

Page 21

Installation

Typical

Typical Typical

Installation

Installation Installation

Item

Item Item

A

B*Bleed-TypeAirShutoffValve

CPumpAirPressureGauge

DPumpAirPressureRegulator

EkVMeter

FPump

GPumpSuctionHose

H

J*

K*EnclosureSafetyInterlock

LIsolatedEnclosure

M

N

P*GracoRedGroundedAirHose(left-handthreads)

Q*GunAirHoseGroundWire

Key

Key Key

Description

Description Description

MainAirSupplyLine

PaintContainer

BleedResistor

GunAirLineFilter

GunAirPressureRegulator

R

SWaterborneElectrostaticAirSprayGun

T

U

V*MainGroundWire

W

X

Y

Z

AA

BB

CCAccessoryBleed-TypeAirShutoffValve

*Theseitemsarerequiredforsafeoperation.TheyareincludedwiththeWB100system.

GracoWaterborneFluidHose

GroundingRod

GroundTerminal

StrainReliefFitting

PumpAirSupplyLine

GroundingCylinder

PumpFluidOutletFitting

IsolatedEnclosureDoor(notshown,toillustrateinternalcomponents.Doormustbeclosed

andlockedtooperatesystem).

EnclosureT-HandleLockingScrew(partofdoorassembly)

3A2496H

21

Page 22

Installation

Grounding

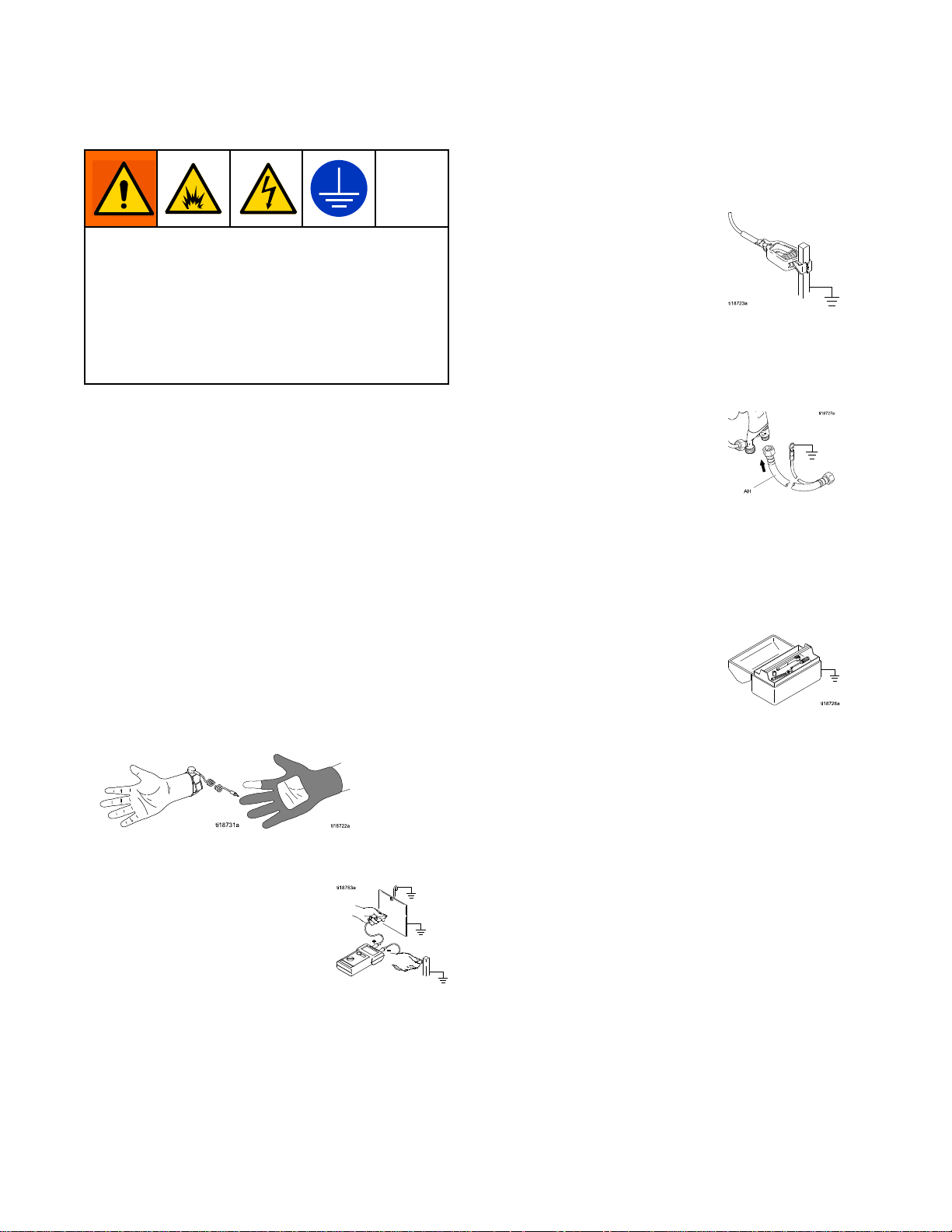

Grounding Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundallequipment,personnel,objects

beingsprayed,andconductiveobjectsinorclose

tothesprayarea.Theresistancemustnotexceed

1megohm.Groundingprovidesanescapewire

fortheelectriccurrent.

Whenoperatingtheelectrostaticgun,any

ungroundedobjects(suchaspeople,containers,and

tools)inthespraylocationcanbecomeelectrically

charged.

Thefollowingareminimumgroundingrequirements

forabasicelectrostaticsystem.Yoursystemmay

includeotherequipmentorobjectswhichmustbe

grounded.Yoursystemmustbeconnectedtoa

trueearthground.Checkgroundconnectionsdaily.

Checkyourlocalelectricalcodesandregulationsfor

detailedgroundinginstructions.

Allpersonsenteringthesprayarea:

•

shoeshavingconductivesolessuchasleather,

orwearpersonalgroundingstraps.Donot

wearshoeswithnon-conductivesolessuchas

rubberorplastic.Ifglovesarenecessary,wear

theconductiveglovessuppliedwiththegun.If

non-Gracoglovesareworn,cutoffngersorpalm

areaofglovestoensureyourhandcontactsthe

groundedgunhandle.

•

Objectbeingsprayed:

cleanandgroundedatalltimes.

Keeptheworkpiecehangers

mustwear

•

VoltageIsolationSystem:

voltageisolationsystemtoatrueearthground.

SeeGroundtheCabinet,page16.

•

ElectrostaticAirSprayGun:

byconnectingthered-coloredGracoGrounded

AirHosetothegun,andconnectingtheair

hosegroundwiretoatrueearthground.See

CheckGunElectricalGrounding,page38.

•

GracoShieldedWaterborneFluidHose

(24M732):

conductivelayer.Installasinstructedunder

ConnecttheWaterborneFluidHose,page17.

•

Allelectricallyconductiveobjectsordevicesinthe

sprayarea:

•

Fluidandwastecontainers:

wastecontainersinthesprayarea.Donotusepail

linersunlesstheyareconductiveandgrounded.

Whenushingthespraygun,thecontainerused

tocatchtheexcessuidmustbeelectrically

conductiveandgrounded.

Aircompressors:

•

tothemanufacturer'srecommendations.

•

Allairlines

groundedhoseswithamaximumof100feet(30.5

m)combinedhoselengthtoensuregrounding

continuity.

Thehoseisgroundedthroughthe

mustbeproperlygrounded.

Groundtheequipmentaccording

mustbeproperlygrounded.Useonly

Electricallyconnectthe

Groundthegun

Groundalluidand

22

3A2496H

Page 23

•

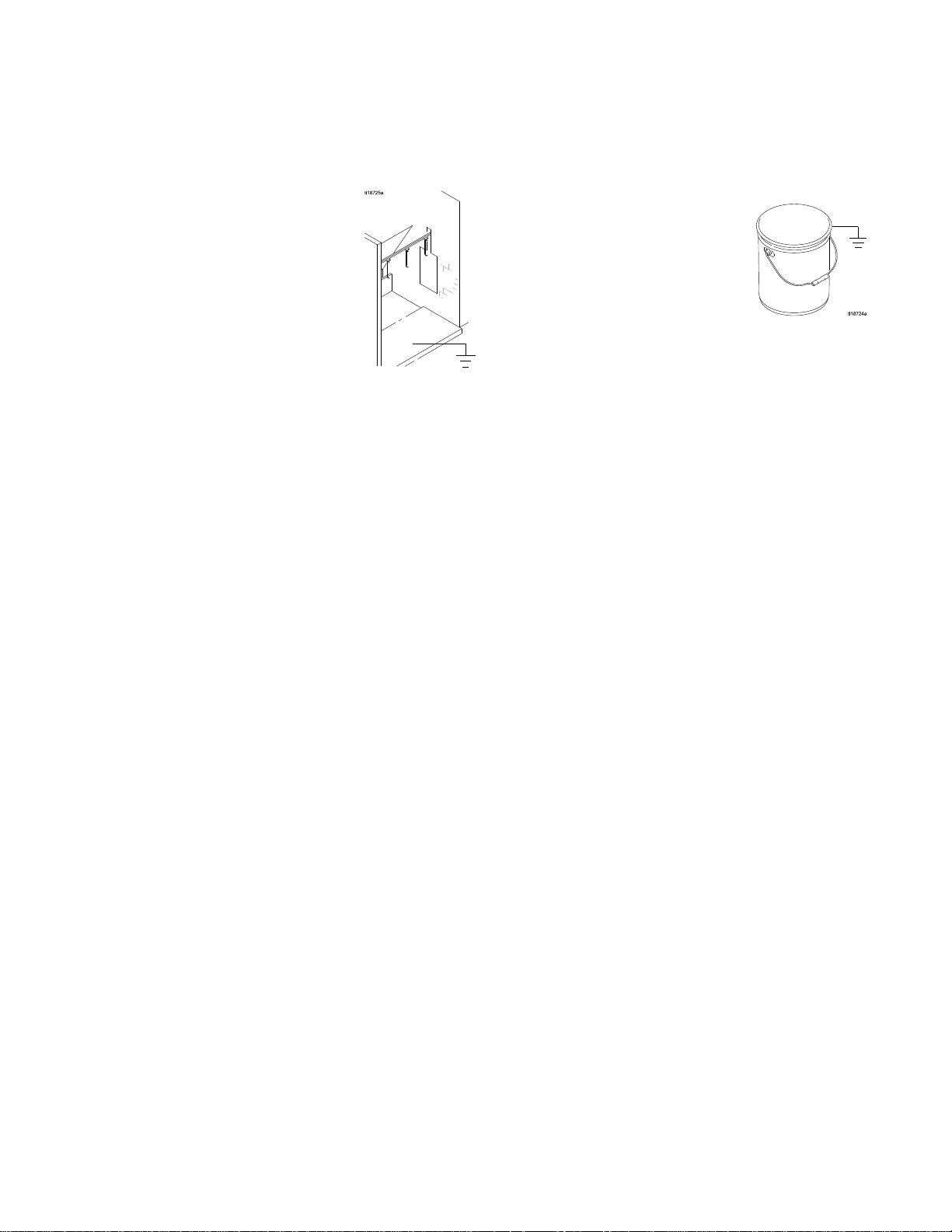

Theoorofthesprayarea:

conductiveandgrounded.Donotcovertheoor

withcardboardoranynon-conductivematerial

whichwouldinterruptgroundingcontinuity.

mustbeelectrically

•

Allsolventpails:

metalcontainers,whichareconductive.Donot

useplasticcontainers.Useonlynon-ammable

solvents.Donotstoremorethanthequantity

neededforoneshift.

Useonlyapproved,grounded

Installation

3A2496H23

Page 24

Installation

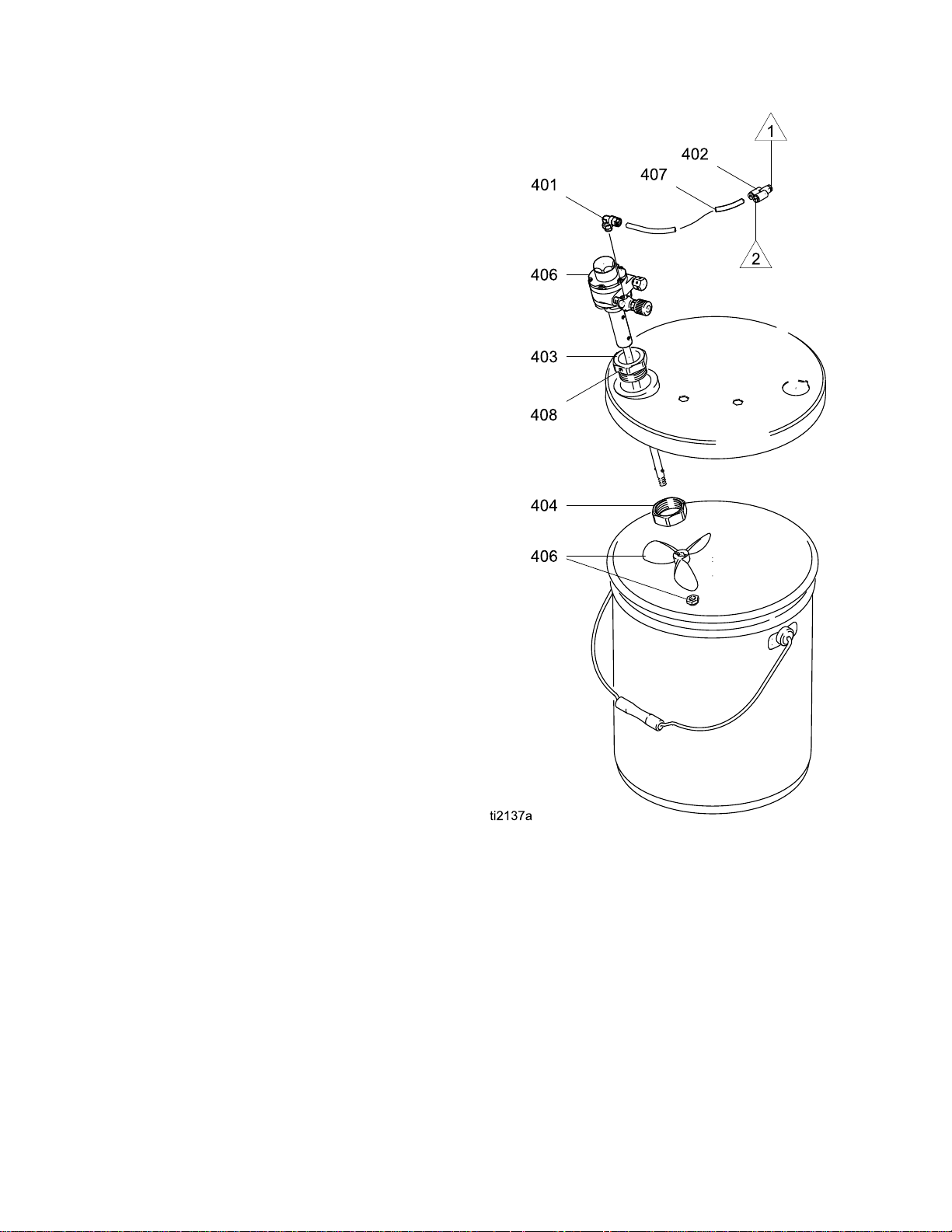

Agitator

Agitator Agitator

ToaddanagitatortotheGracoisolationsystem,order

PartNo.245895.See245895AgitatorKit,page108,

forthekitpartslist.

1.Dischargethesystemvoltage(seeFluidVoltage

DischargeandGroundingProcedure,page39).

2.Relievethepressure(see

PressureReliefProcedure,page39).

3.Opentheisolatedenclosuredoor.

4.Removethebackofthecontrolbox(258).

5.Removetube(A2)fromelbow(282)attheair

manifold;seeTubingandWiring,page84.

InstalltheYtting(402)intotheelbow.Install

tubes(A2)and(407)intotheYtting.Routethe

agitatortube(407)intothecabinet.

6.Replacethebackofthecontrolbox(258).

7.Assembletheotherpartsofthekitasshown.

Securetheagitatorwiththesetscrew(408).

8.Returnthesystemtoservice.

Kit

Accessory

Kit Kit

Accessory Accessory

Figure20245895AgitatorKit

24

3A2496H

Page 25

Installation

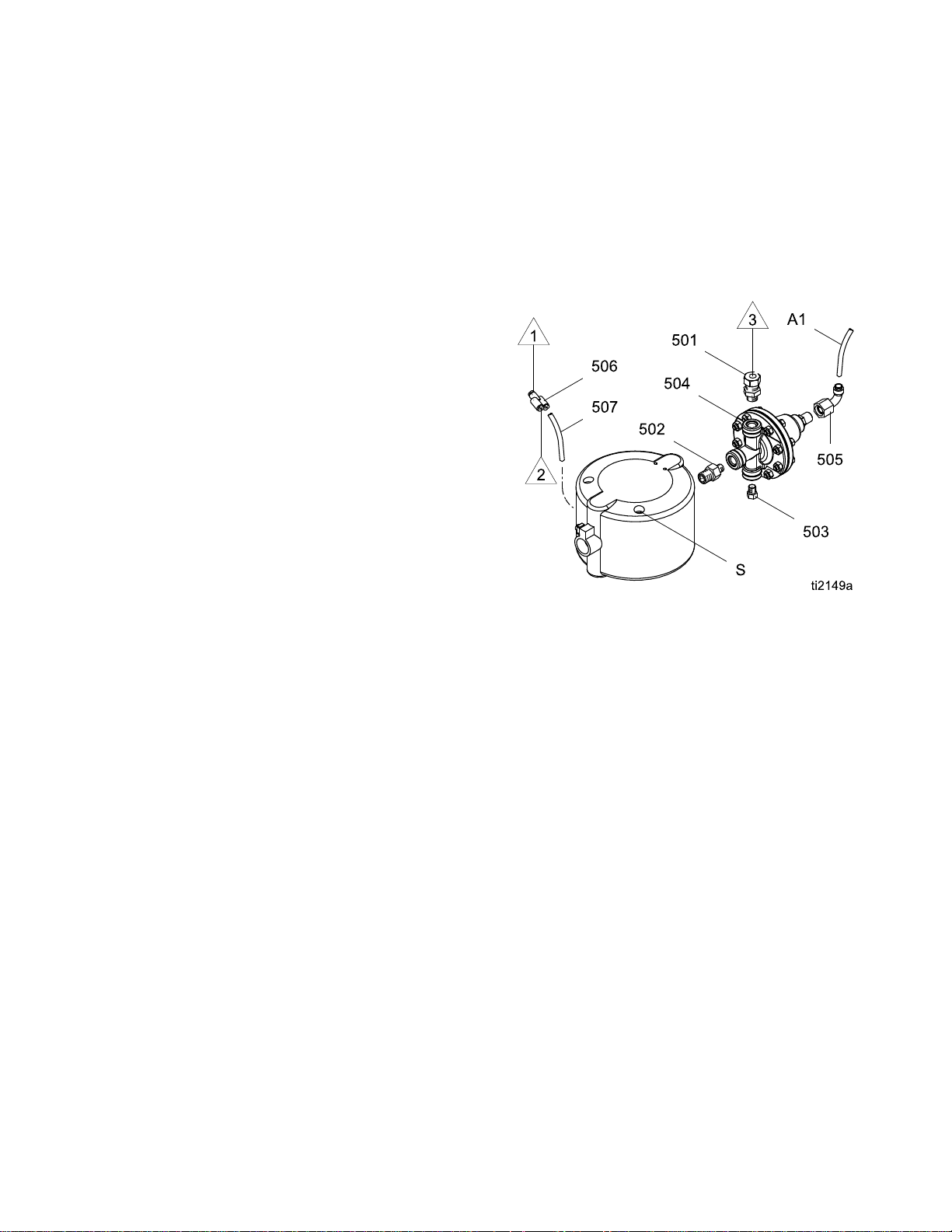

Fluid

Fluid Fluid

ToaddauidregulatortotheGracoisolation

system,orderPartNo.245944.See

245944FluidRegulatorKit,page108forthe

kitpartslist.

1.Dischargethesystemvoltage(seeFluidVoltage

2.Relievethepressure(see

3.Opentheisolatedenclosuredoor.

4.Removethe1/4in.(6mm)ODtube(A1)fromthe

5.Removethewaterborneuidhosefromthepump

6.Unscrewthetwopumpmountingscrews(S)and

7.Removethebackofthecontrolbox(258).

8.Removetube(A2)fromelbow(282)attheair

9.Replacethebackofthecontrolbox(258).

10.Assembletheuidregulatorkitasshown.

11.Reinstallthepumpintheisolationenclosure.

Regulator

Regulator Regulator

DischargeandGroundingProcedure,page39).

PressureReliefProcedure,page39).

pumpairinlet;seeTubingandWiring,page84.

uidoutlettting(231)andremovethetting.

removethepumpfromtheisolationenclosure.

manifold;seeTubingandWiring,page84.

InstalltheYtting(506)intheelbow.Install

tubes(A2)and(507)intotheYtting.Routethe

tube(507)intothecabinet.

Usethetwomountingholestotheleftofthe

holesusedpreviously,toallowclearanceforthe

uidregulator.

Kit

Accessory

Kit Kit

Accessory Accessory

12.Connecttube(A1)totheairinletofuidregulator

(504).Connecttube(507)tothepumpairinlet.

13.Connectthewaterborneuidhosetotheuid

regulatoroutlettting(501).

14.Returnthesystemtoservice.

NOTE:

NOTE: NOTE:

217)willnowoperatetheairpiloteduidregulator

(504).Thepumpwillnowoperateattheinletair

pressure.

Figure21245944FluidRegulatorKit

Thecabinetairregulatorandgauge(216,

3A2496H25

Page 26

GunSetup

Gun

Gun Gun

Gun

Gun Gun

Toreducetheriskofreandexplosion,uidsused

mustmeetthefollowingammabilityrequirements:

•FM, FM,

•CE CE

Contactwiththechargedcomponentsofthespray

gunwillcauseanelectricshock.Donottouchthe

gunnozzleorelectrodeorcomewithin4in.(102

mm)ofthefrontofthegunduringoperationor

untilperformingtheFluidVoltageDischargeand

GroundingProcedure,page39.

FollowtheFluidVoltageDischargeandGrounding

Procedure,page39whenyoustopsprayingand

wheneveryouareinstructedtodischargethe

voltage.

Setup

Setup Setup

Setup

Setup Setup

FM,

FMc

FMc FMc

Materialdoesnotsustainburninginaccordance

withtheStandardTestMethodforSustained

BurningofLiquidMixtures,ASTMD4206.

CE

EN

- --EN EN

Materialswhichcannotbeignited,inanymixture

withair,byanenergysourceoflessthan500mJ.

Procedure

Procedure Procedure

Approved:

Approved: Approved:

50059

50059 50059

Compliant:

Compliant: Compliant:

Foradditionalstepstosetupspecialtyguns,

seeSoftSprayGunSetupProcedure,page30,

RoundSprayGunSetupProcedure,page33,

HVLPGunSetupProcedure,page31,

AbrasiveMaterialGunSetupProcedure,page35,

andMoldReleaseGunSetupProcedure,page36.

Seethegurebelowtolocatetheelectrostaticgun

controls.

Figure22ElectrostaticGunControls

1.Thegunisshippedwiththeuidnozzleandair

capinstalled.Checkthattheretainingringis

tight.

NOTE:

NOTE: NOTE:

sizeuidnozzleoraircap,see

FluidNozzleSelectionChart,page93and

AirCapSelectionGuide,page96.

Toinstallthenozzleandaircap,see

AirCapandNozzleReplacement,page59.

2.TurnOFF(O)theESOn-Offswitch(J).

Toselectadifferent

Toreducetheriskofcomponentrupture,which

cancauseseriousinjury,donotexceedthe

maximumworkingpressureofthelowestrated

systemcomponent.Thisequipmenthasa100psi

(0.7MPa,7bar)maximumworkingairanduid

pressure.

3.Shutofftheairbleedvalvetothegun.

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page39wheneveryou

areinstructedtorelievethepressure.

4.Checkgunresistance.Followthestepsin

TestGunResistance,page47.

263A2496H

Page 27

GunSetup

5.Connectthewaterbornehose.Followthesteps

inConnecttheWaterborneFluidHose,page17.

6.ConnecttheredGracogroundedairhosetothe

gunairinlet.Thegunairinletttinghasleft-hand

threads.SeeAirSupplyLine,page16.

7.FollowallstepsinGrounding,page22.

8.Followallstepsin

CheckGunElectricalGrounding,page38.

Readingmustbelessthan100ohms.

9.Connecttheexhausttubeandsecurewiththe

clampprovided.

10.Flushifneeded.SeeFlushing,page42.

11.Positiontheaircapasneeded.

13.Fullyopentheuidadjustmentvalve(H)

counterclockwise.

14.Fullyopentheatomizingairrestrictorvalve(G)

clockwise.

15.TurnON(I)theESOn-Offswitch(J).

12.Fullyopenthefanairadjustmentvalve(F)

counterclockwise.

3A2496H

WhentheESOn-OffswitchisturnedON(I),

theuidsupplyischargedwithhighvoltage

untilthevoltageisdischarged.Contactwith

thechargedcomponentsofthespraygunwill

causeanelectricshock.Donottouchthegun

nozzleorelectrodeorcomewithin4in.(102

mm)ofthefrontofthegunduringoperation.

27

Page 28

GunSetup

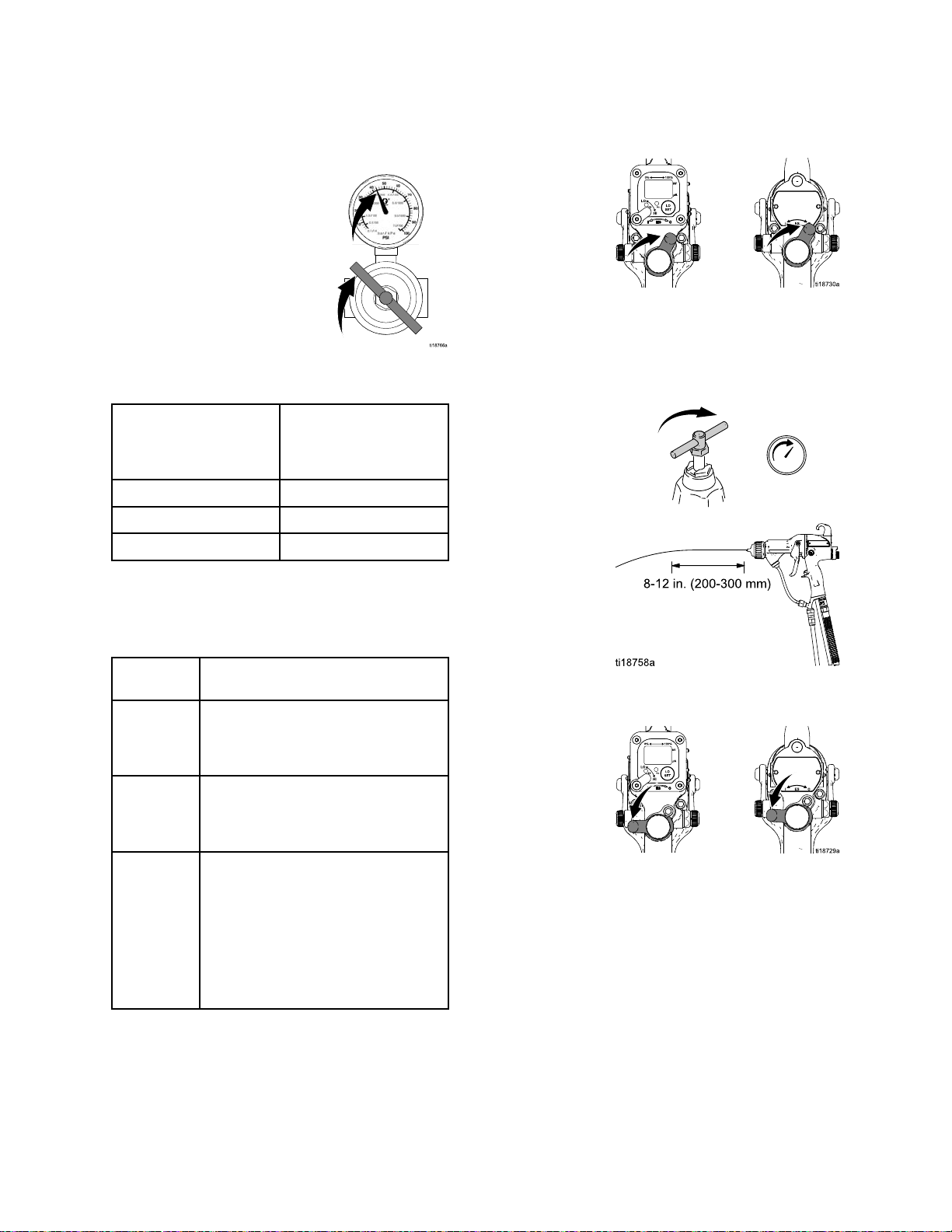

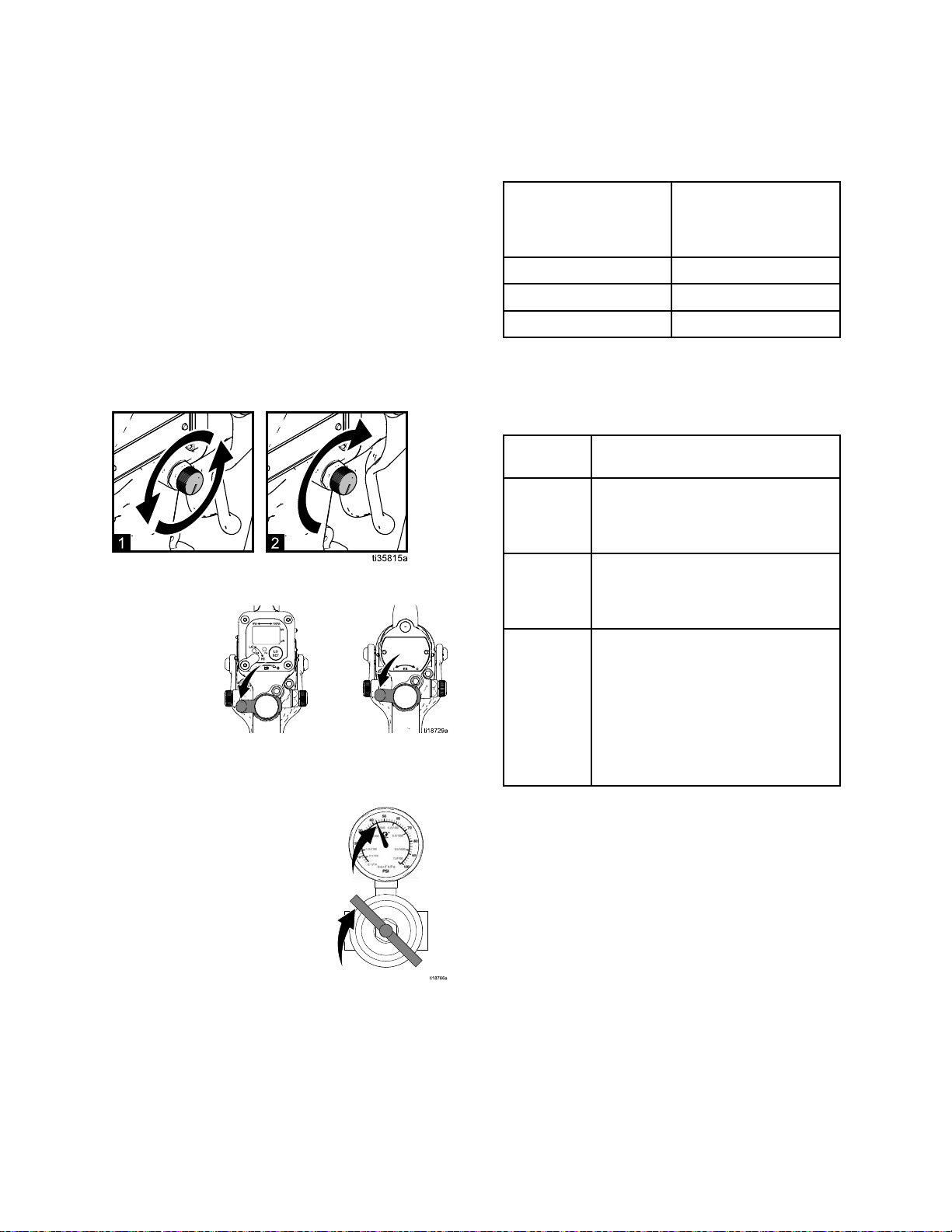

16.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

Table

Table Table

using

using using

mm)

mm) mm)

Pressure

2 22. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

Drop

Drop Drop

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

18.Shutofftheairtothegun.TurnOFF(O)theES

On-Offswitch(J).

19.Startthepump.Adjusttheuidregulatoruntilthe

streamfromtheguntravels8-12in.(200-300

mm)beforefallingoff.Typically,ifuidpressure

isbelow5psi(.04MPa,0.4bar)orabove30psi

(0.21MPa,2.1bar),achangeofnozzlesizeis

recommended.

Air

Regulator

Air Air

Regulator Regulator

psi

in ininpsi psi

with

gun

with with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered

triggered triggered

17.VerifythattheESindicator(K)[Hzindicatoron

Smartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Amber

LED

3 33. ..LED LED

Color

Color Color

Green

Red

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A160.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

20.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

283A2496H

Page 29

GunSetup

21.Sprayatestpattern.Checktheatomization.

•Ifover-atomizationoccursatminimum

pressure,adjusttheatomizingairrestrictor

valve.

•Ifatomizationisinadequate,increaseair

pressureordecreaseuidow.

22.Adjustthefanairadjustmentvalve.

•Fullyopenthefanairadjustmentvalve,

counterclockwise,forthelongestpattern.

•Turnthevalveclockwisetorestrictthefanair

andcreateashorterpattern.

WhentheESOn-OffswitchisturnedON(I),

theuidsupplyischargedwithhighvoltage

untilthevoltageisdischarged.Contactwith

thechargedcomponentsofthespraygunwill

causeanelectricshock.Donottouchthegun

nozzleorelectrodeorcomewithin4in.(102

mm)ofthefrontofthegunduringoperation.

23.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page51.

3A2496H29

Page 30

GunSetup

Soft

Spray

Soft Soft

Spray Spray

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

Toconvertaguntoachieveasoftspraypatternfor

smallorlightweightparts,dothefollowing:

1.Installasoftsprayaircap.See

AirCapSelectionGuide,page96.

2.Forbestresults,installa1.0mm

or1.2mmuidnozzle.See

FluidNozzleSelectionChart,page93.

3.Followsteps1–13inthe

GunSetupProcedure,page26.

4.Adjusttheatomizingair.Fullyclosetheatomizing

airrestrictorvalve(G)counterclockwise.Then,

opentheatomizingairrestrictorvalve(G)one

halfturntooneturn.

5.TurnON(I)theESOn-Offswitch(J).

Table

Table Table

using

using using

mm)

mm) mm)

7.VerifythattheESindicator(K)[Hzindicatoron

Smartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Amber

Pressure

4 44. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

Color

Color Color

Green

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

LED

5 55. ..LED LED

Drop

Drop Drop

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Colors

Colors Colors

Description

Description Description

Air

Regulator

Air Air

Regulator Regulator

psi

(MPa,

in ininpsi psi

(MPa, (MPa,

with

gun

with with

triggered

gun gun

triggered triggered

Setting

Setting Setting

bar)

bar) bar)

6.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

Red

8.Continuewithsteps18–23inthe

GunSetupProcedure,page26.

NOTE:

NOTE: NOTE:

productionrateof3.5oz/min(100cc/min).For

bestsoftsprayresults,limittheproductionrate

to7oz/min(200cc/min)orless.

NOTE:

NOTE: NOTE:

much,adjusttheatomizingairrestrictorvalve

(G)counterclockwiseslightlytolimittheairow.

Toimproveatomization,adjusttheatomizingair

restrictorvalve(G)clockwiseslightlytoincrease

theairowordecreasetheuidow.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A160.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Thesoftsprayaircapisoptimizedfora

Iftheobjectbeingsprayedismovingtoo

303A2496H

Page 31

GunSetup

HVLP

HVLP HVLP

TosprayHVLP,airpressureattheaircapmustbe

10PSI(0.07MPa,0.7bar)orless.Tosetupan

HVLPgun,dothefollowing:

1.InstallanHVLPaircap.See

2.Followsteps1–11inthe

3.Fullyopentheuidadjustmentvalve(H)

4.Adjusttheairintheaircap.

Gun

Gun Gun

AirCapSelectionGuide,page96.

GunSetupProcedure,page26.

counterclockwise.

a.Fullyclosethefanairadjustmentvalve(F)

clockwise,thenopenitcounterclockwisetwo

turns.

b.Fullyclosetheatomizingairrestrictorvalve

(G)counterclockwise,thenopenitclockwise

oneturn.

Setup

Setup Setup

Procedure

Procedure Procedure

Table

Table Table

using

using using

mm)

mm) mm)

NOTE:

NOTE: NOTE:

volumeofairtoatomizepaintatlow

pressure.Gunairregulatorstaticpressure

settingsof70PSIorhigheraretypically

required.Toachievetherequiredgunair

pressures,useashorterlengthairhoseora

largerdiameterairhose.SeeGroundedAir

HosesinHoses,page107.

e.VerifythattheESindicator(K)[Hzindicator

onSmartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Pressure

6 66. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

Color

Color Color

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

TheHVLPaircaprequiresahigh

LED

7 77. ..LED LED

Drop

Drop Drop

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

Indicator

Indicator Indicator

Colors

Colors Colors

Description

Description Description

Air

Regulator

Air Air

Regulator Regulator

Setting

Setting Setting

(MPa,

(MPa, (MPa,

with

gun

with with

gun gun

psi

in ininpsi psi

bar)

bar) bar)

triggered

triggered triggered

Green

Amber

c.TurnON(I)theESOn-Offswitch(J).

Red

d.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangesto

amberafteronesecond,theair

pressureistoolow.Increase

airpressureuntiltheindicator

isgreen.

Iftheindicatorchangesto

redafteronesecond,theair

pressureistoohigh.Decrease

airpressureuntiltheindicator

isgreen.Tomaintainahigher

applicationairpressure,install

ESOn/OffValveRestrictorKit

26A160.Adjustthepressure

asneededtoensurethe

indicatorremainsgreen.

3A2496H31

Page 32

GunSetup

f.VerifythattheaircappressuresmeetHVLP

requirementsof10PSI(0.07MPa,0.7

bar)orlessusingtheHVLPvericationkit

25E919.Seemanual3A6833.Adjustthe

fanairadjustmentvalve(F)andatomizing

airrestrictorvalvetoachieve10PSIorless

asneeded.

g.VerifythattheESindicator(K)[Hzindicator

onSmartguns]remainsgreen.

5.Continuewithsteps18–23inthe

GunSetupProcedure,page26.

323A2496H

Page 33

GunSetup

Round

Round Round

Toachievearoundspraypattern,dothefollowing:

1.Installaroundspraykit.SeeRoundSpray

2.Followsteps1–11inthe

3.Fullyopentheuidadjustmentvalve(H)

4.Adjusttheairintheaircap.

Spray

Spray Spray

AccessoriesinGunAccessories,page105.To

achieveasoftpatternforsmallpartsorincreased

transferefciency,selectthemediumpatternor

smallpatternmodels.

GunSetupProcedure,page26.

counterclockwise.

a.Fullyclosetheatomizingairrestrictorvalve

(G)counterclockwise.Then,openthe

atomizingairrestrictorvalve(G)oneturn.

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

6.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

Table

Table Table

using

using using

mm)

mm) mm)

Pressure

8 88. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

Drop

Drop Drop

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

Air

Regulator

Air Air

Regulator Regulator

psi

in ininpsi psi

with

gun

with with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered

triggered triggered

b.Fullyclosethefanairadjustmentvalve(F)

clockwise.

5.TurnON(I)theESOn-Offswitch(J).

50(15.3)80(0.56,5.6)

7.VerifythattheESindicator(K)[Hzindicatoron

Smartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Amber

LED

9 99. ..LED LED

Color

Color Color

Green

Red

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A160.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

3A2496H33

Page 34

GunSetup

8.Shutofftheairtothegun.TurnOFF(O)theES

On-Offswitch(J).

9.Startthepump.Adjusttheuidregulatorto

achievetheproductionratethatyouwant.

NOTE:

NOTE: NOTE:

aproductionrateof5oz/min(150cc/min).For

bestroundsprayresults,limittheproductionrate

to10oz/min(300cc/min)orless.

10.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

Theroundsprayaircapisoptimizedfor

11.Sprayatestpattern.Checktheatomization.

NOTE:

NOTE: NOTE:

objectbeingsprayedismovingtoomuch,

adjusttheatomizingairrestrictorvalve(G)

counterclockwiseslightlytolimittheairow.To

improveatomization,adjusttheatomizingair

restrictorvalve(G)clockwiseslightlytoincrease

theairowordecreasetheuidow.

12.Adjustthepatternsize.

•Forthelargestspraypattern,fullyclosethefan

•Forthesmallestspraypattern,fullyopenthe

13.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page51.

Iftheatomizationistoone,orifthe

airadjustmentvalve(F)clockwise.

fanairadjustmentvalve(F)counterclockwise.

343A2496H

Page 35

GunSetup

Abrasive

Abrasive Abrasive

NOTE:

NOTE: NOTE:

taskseachday:

•Cleanthegun.SeeCleantheGunDaily,page44.

•Inspecttheelectrodeandreplaceifdamaged.See

ElectrodeReplacement,page61.

Toextendwearlifewithabrasive,metallic,and

extremelyabrasivematerials,dothefollowing:

1.Toconvertagunforabrasivematerials:

•Selectaprecisionhighwear

orhighwearnozzle.See

FluidNozzleSelectionChart,page93.

Sizethenozzleproperlytoreduceuid

pressurebelow30psi(0.21MPA,2.1bar),

producingan8-12in(200-300mm)uid

stream.

•Use24N632ESOn-OffandFixedFluidValve.

2.Followsteps1–18inthe

GunSetupProcedure,page26.

3.Startthepump.Adjusttheuidregulatoruntilthe

streamfromtheguntravels8-12in.(200-300

mm)beforefallingoff.Typically,ifuidpressure

isbelow5psi(.04MPa,0.4bar)orabove30psi

(0.21MPa,2.1bar),achangeofnozzlesizeis

recommended.

Material

Material Material

Toextendwearlife,performthefollowing

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

4.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

5.Sprayatestpattern.Checktheatomization.If

over-atomizationoccursatminimumpressure,

adjusttheatomizingairrestrictorvalve.If

atomizationisinadequate,increaseairpressure

ordecreaseuidow.

NOTE:

NOTE: NOTE:

knobinthefullowpositionatalltimesor

install24N632ESOn-OffandFixedFluidValve.

Alwaysuseanexternaluidregulator.Donot

usetheuidadjustmentknobtosettheuid

pressure.

Operatethegunwiththeuidadjustment

NOTE:

NOTE: NOTE:

toextendelectrodewirewearlife.Reducethe

guninletairpressureoradjusttheatomizingair

restrictorvalve(G)counterclockwisetoreduce

atomizingairwhentheapplicationallows.

6.Adjustthefanairadjustmentvalve.

•Fullyopenthefanairadjustmentvalve,

•Turnthevalveclockwisetorestrictthefanair

NOTE:

NOTE: NOTE:

extendelectrodewirewearlife.Reducethegun

inletairpressureoradjustthefanairadjustment

valve(F)clockwisetoreducefanairwhenthe

applicationallows.

7.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page51.

Usetheminimumatomizingairpressure

counterclockwise,forthelongestpattern.

andcreateashorterpattern.

Usetheminimumfanairpressureto

3A2496H35

Page 36

GunSetup

Mold

Mold Mold

Tosetupamoldreleasegun,dothefollowing:

1.ModelL60M19MoldReleaseGunissupplied

2.Followsteps2–10inthe

3.Theuidoutputandpatternwidthdependonthe

4.Alignthespraytiptabwiththegrooveintheair

Release

Release Release

withPartNo.24N748Nozzle,24N727AirCap,

andaspraytipofchoice.Ifyourequireadifferent

sizespraytip,seeSprayTipSelectionChart

(ModelL60M19MRGGunOnly),page102,or

consultwithyourGracodistributor.Toinstall

thetip,seeAirCap,SprayTip,andNozzle

Replacement(ModelL60M19),page60.

GunSetupProcedure,page26.

sizeofthespraytip,theuidviscosity,andthe

uidpressure.UsetheSprayTipSelectionChart

(ModelL60M19MRGGunOnly),page102,asa

guideforselectingtheappropriatespraytipfor

yourapplication.

cap.Installthetip.

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

9.Sprayatestpattern.Examinetheparticlesizein

thecenterofthepattern(tailswillberemoved

instep21).Increasethepressureinsmall

increments.Sprayanotherpattern.Compare

particlesize.Continueincreasingpressureuntil

theparticlesizeremainsconstant.Donotexceed

3000psi(21MPa,210bar).

10.TurnON(I)theESOn-Offswitch.

5.Installtheaircapandretainingring.Orientate

theaircapandtightentheretainingringsecurely.

6.Closetheatomizingairadjustmentvalve(G)and

thefanairadjustmentvalve(F).

7.CheckthattheESOn-OffswitchisOFF(O).

8.Startthepump.Settheuidregulatorto400psi

(2.8MPa,28bar).

11.CheckthattheESindicator(K)[Hzindicatoron

Smartguns]islit.Seethefollowingtable.

Table

10

LED

Table Table

10 10

Indicator

Indicator Indicator

Color

Color Color

Green

Amber

Red

Indicator

. ..LED LED

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A294.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

363A2496H

Page 37

GunSetup

12.Setthegunairregulatortodeliveraminimum

of45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.See

thetablebelow.

Table

11

Table Table

Length

Length Length

(using

(using (using

mm]

mm] mm]

13.Turntheatomizingairadjustmentvalve

counterclockwiseuntilanytailsdisappear.

Pressure

11 11

. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)52(0.36,3.6)

25(7.6)57(0.40,4.0)

50(15.3)68(0.47,4.7)

75(22.9)80(0.56,5.6)

100(30.5)90(0.63,6.3)

Drop

Drop Drop

Air

Air Air

(m)

in.

[8

in. in.

[8 [8

hose)

hose) hose)

in ininpsi psi

[with

[with [with

14.Ifdesiredatomizationisnotachieved,change

thetipsize.Thesmallerthetiporice,thener

theatomization.

15.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page51.

Regulator

Regulator Regulator

psi

gun

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered]

triggered] triggered]

NOTE:

NOTE: NOTE:

openthefanairadjustmentvalveslightly.(Excessive

fanairowcancausepaintbuildupontheaircap.)

Ifanarrowerpatternisneededoccasionally,

3A2496H37

Page 38

GunSetup

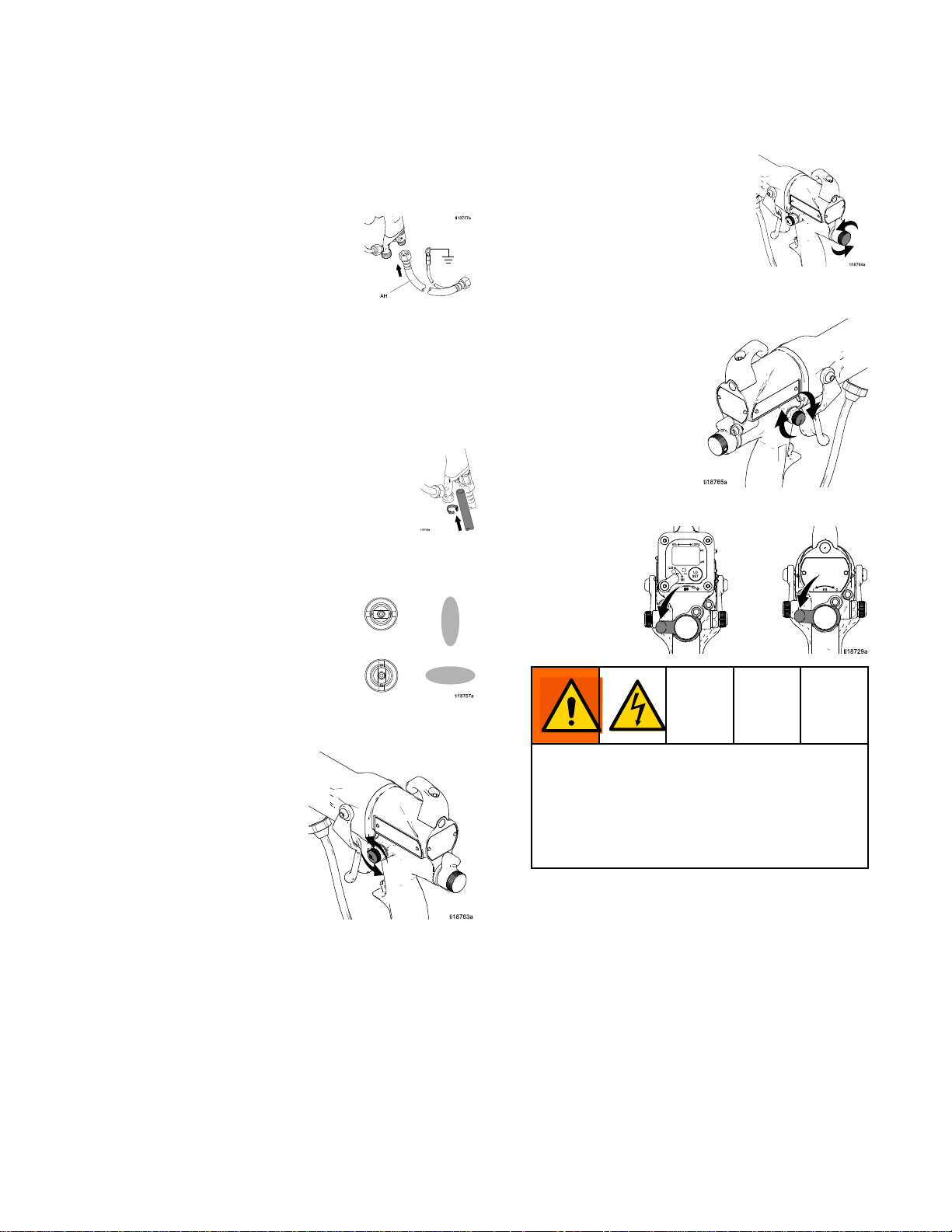

Check

Check Check

MegohmmeterPartNo.241079(AA-seeFig.

21)isnotapprovedforuseinahazardousarea.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

•Orallsprayingdevicesinthehazardousarea

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

GracoPartNo.241079Megohmmeterisavailable

asanaccessorytocheckthatthegunisproperly

grounded.

1.Haveaqualiedelectricianchecktheelectrical

2.TurnOFF(O)theESOn-Offswitch.

Gun

Gun Gun

area;

areturnedoff,ventilationfansinthehazardous

areaareoperating,andtherearenoammable

vaporsinthearea(suchasopensolvent

containersorfumesfromspraying).

groundingcontinuityofthespraygunandair

hose.

Electrical

Electrical Electrical

Grounding

Grounding Grounding

7.Iftheresistanceisgreaterthan100ohms,check

thetightnessofthegroundconnectionsandbe

suretheairhosegroundwireisconnectedtoa

trueearthground.Iftheresistanceisstilltoo

high,replacetheairhose.

Figure23CheckGunElectricalGrounding

8.Usinganohmmeter(AA)measuretheresistance

betweenthecabinetgroundlug(214)andatrue

earthground(CC).Theresistancemustbeless

than100ohms.

3.Turnofftheairanduidsupplytothegun.Follow

thePressureReliefProcedure,page39.The