Page 1

Instructions-Parts

Pro Pro

Pro

Xp™ Xp™

Xp™

Electrostatic Electrostatic

Electrostatic

Air Air

Air

Spray Spray

Spray

Gun Gun

Gun

3A2494D

EN

For For

For

use use

use

in ininClass Class

Class

I, I,I,Div. Div.

Div.

I IIHazardous Hazardous

Hazardous

Locations Locations

Locations

using using

using

Group Group

Group

D DDspray spray

spray

materials. materials.

materials.

For For

For

use use

use

in in

in

Group Group

Group

II, II,

II,

Zone Zone

Zone

1 11Explosive Explosive

Explosive

Atmosphere Atmosphere

Atmosphere

Locations Locations

Locations

using using

using

Group Group

Group

IIA IIA

IIA

spray spray

spray

materials. materials.

materials.

For For

For

professional professional

professional

use use

use

only. only.

only.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.

Save Save

Save

these these

these

instructions. instructions.

instructions.

100 psi (0.7 MPa, 7.0 bar) Maximum

Fluid Working Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum Air

Working Pressure

See See

See

page page

page

3 33for for

for

model model

model

part part

part

numbers numbers

numbers

and and

and

approval approval

approval

information. information.

information.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents Contents

Contents

Models...............................................................3

Warnings...........................................................4

GunOverview....................................................7

HowtheElectrostaticSprayGun

Works............................................7

Controls,Indicators,andComponents...........8

SmartGuns.................................................9

Installation..........................................................15

WarningSign...............................................15

VentilatetheSprayBooth.............................15

AirSupplyLine............................................16

FluidSupplyLine.........................................16

GunSetup..........................................................18

GunSetupChecklist....................................18

Grounding...................................................21

CheckGunElectricalGrounding...................25

CheckFluidResistivity.................................26

CheckFluidViscosity...................................26

FlushBeforeUsingEquipment......................26

GuidelinesforAbrasiveMaterials..................26

Operation...........................................................27

PressureReliefProcedure............................27

Startup........................................................27

Shutdown....................................................27

Maintenance......................................................28

Flushing......................................................28

CleantheGunDaily.....................................29

DailySystemCare.......................................30

ElectricalTests...................................................31

TestGunResistance....................................31

TestPowerSupplyResistance.....................32

TestElectrodeResistance............................32

Troubleshooting..................................................33

SprayPatternTroubleshooting......................33

GunOperationTroubleshooting....................34

ElectricalTroubleshooting............................35

Repair................................................................37

PreparetheGunforService.........................37

AirCapandNozzleReplacement..................38

ElectrodeReplacement................................39

FluidPackingRodRemoval..........................40

PackingRodRepair.....................................40

BarrelRemoval............................................42

BarrelInstallation.........................................42

PowerSupplyRemovaland

Replacement..................................43

AlternatorRemovalandReplacement...........44

FluidTubeRemovalandReplacement...........46

FanAirAdjustmentValveRepair..................47

AtomizingAirRestrictorValveRepair............48

ESOn-OffandFluidAdjustmentValve

Repair............................................49

AirValveRepair...........................................50

SmartModuleReplacement..........................51

AirSwivelandExhaustValve

Replacement..................................52

Parts..................................................................53

StandardAirSprayGunAssembly................53

RoundSprayAssembly................................55

StandardHighConductivityAirSprayGun

Assembly.......................................56

SmartHighConductivityAirSprayGun

Assembly.......................................58

SmartAirSprayGunAssembly.....................60

PackingRodAssembly.................................62

AlternatorAssembly.....................................63

ESOn-OffandFluidAdjustmentValve...........64

FanAirAdjustmentValveAssembly..............65

AtomizingAirRestrictorValve

Assembly.......................................65

SmartModuleAssembly...............................66

HighConductivityFluidTube

Assembly.......................................67

AirCapsandFluidNozzles.................................68

FluidNozzleSelectionChart.........................68

FluidNozzlePerformanceCharts..................68

AirCapSelectionChart................................70

AirConsumptionCharts...............................71

RepairKits,RelatedManuals,and

Accessories..........................................73

GunAccessories..........................................73

OperatorAccessories...................................74

SystemAccessories.....................................74

TestEquipment...........................................74

Hoses.........................................................75

Dimensions........................................................76

TechnicalData...................................................77

GracoProXpWarranty.......................................78

2

3A2494D

Page 3

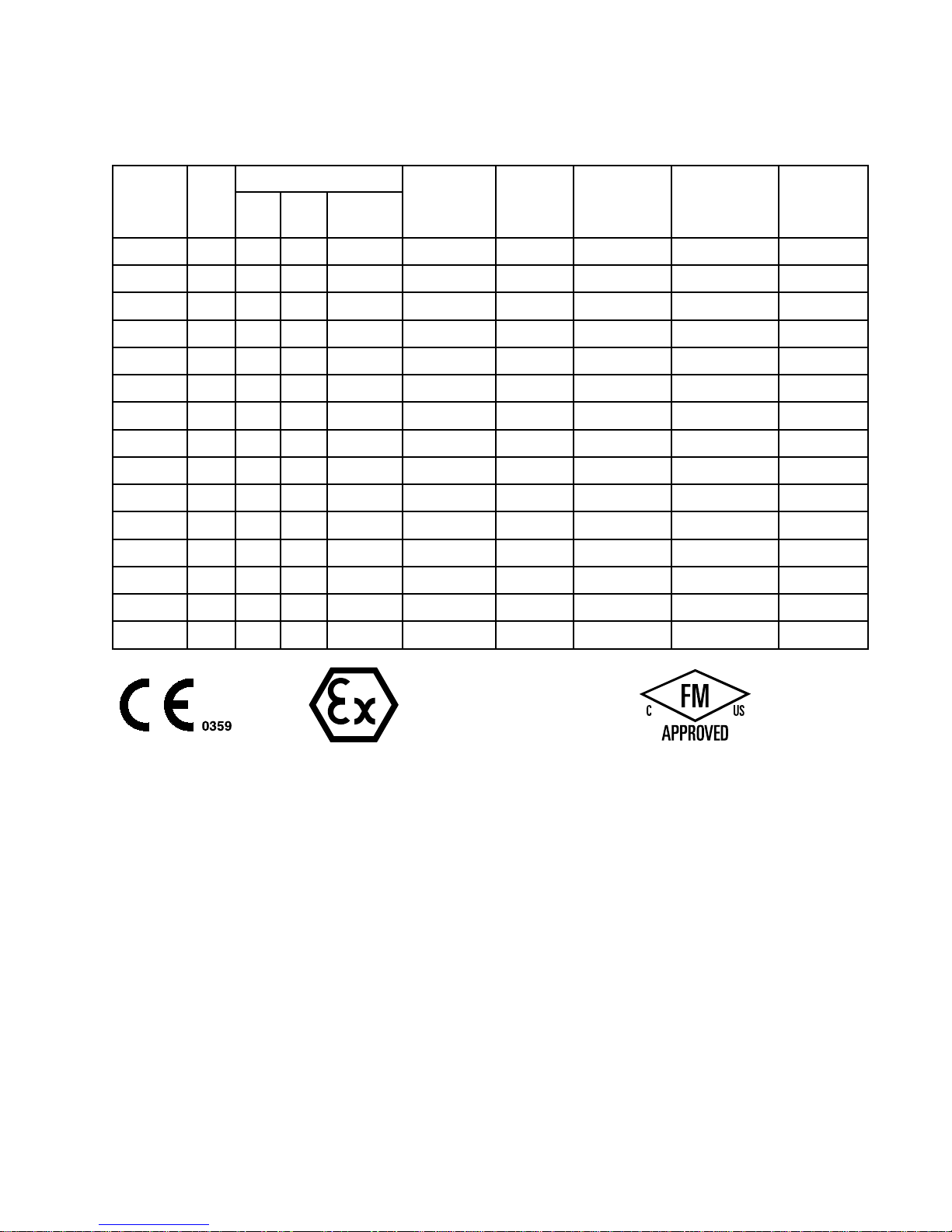

Models

Models Models

Models

Nozzle Nozzle

Nozzle

Part Part

Part

No. No.

No.

kV kV

kV

1.5 1.5

1.5

mm mm

mm

1.2 1.2

1.2

mm mm

mm

Round Round

Round

Spray Spray

Spray

Standard Standard

Standard

Display Display

Display

Smart Smart

Smart

Display Display

Display

Standard Standard

Standard

Coatings Coatings

Coatings

High High

High

Conductivity/ Conductivity/

Conductivity/

High High

High

Wear Wear

Wear

Increased Increased

Increased

Transfer Transfer

Transfer

Efciency Efciency

Efciency

L40T1040

✔✔✔

L40T1440

✔✔✔✔

L40T1540

✔✔✔✔

L40T1640

✔✔✔

L60T1060

✔✔✔

L60T1160

✔✔✔

L60T1260

✔✔✔

L60T1660

✔✔✔

L60M1060

✔✔✔

L60M1260

✔✔✔

L60M1660

✔✔✔

L85T1085

✔✔✔

L85T1685

✔✔✔

L85M1085

✔✔✔

L85M1685

✔✔✔

II IIII2 22G G

G

EEx0.24mJT6

FM12ATEX0068

EN50050

Ta0°C–50°C

3A2494D 3

Page 4

Warnings

Warnings Warnings

Warnings

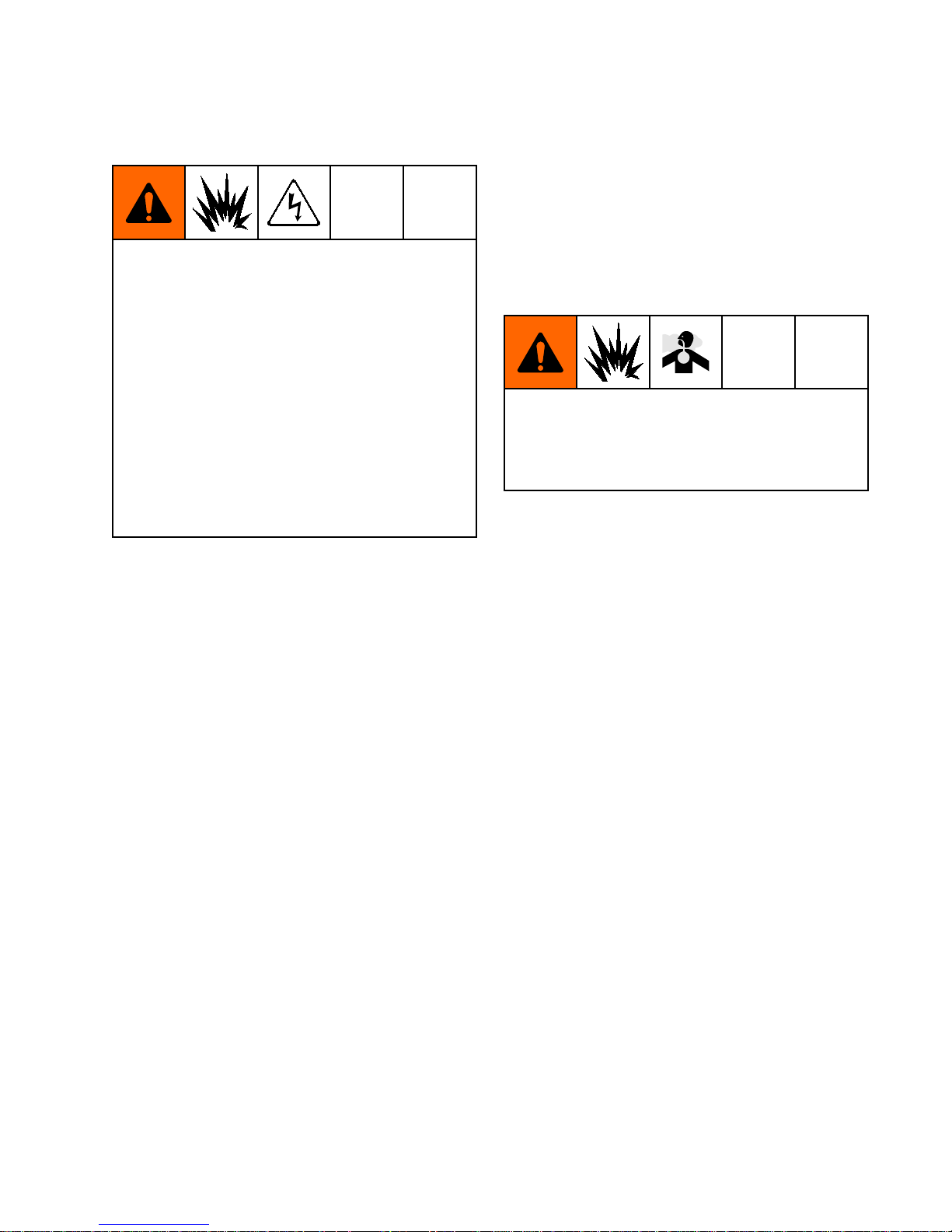

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

FIRE, FIRE,

FIRE,

EXPLOSION, EXPLOSION,

EXPLOSION,

AND AND

AND

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Tohelp

preventre,explosion,andelectricshock:

•Electrostaticequipmentmustbeusedonlybytrained,qualiedpersonnelwhounderstand

therequirementsofthismanual.

•Groundallequipment,personnel,objectbeingsprayed,andconductiveobjectsinorcloseto

sprayarea.Resistancemustnotexceed1megohm.SeeGrounding Grounding

Grounding

instructions.

•OnlyusegroundedGracoconductiveairsupplyhoses.

•Donotusepaillinersunlesstheyareconductiveandgrounded.

•Stop Stop

Stop

operation operation

operation

immediately immediately

immediately

ifstaticsparkingoccursoryoufeelashock.Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Checkgunresistance,hoseresistance,andelectricalgroundingdaily.

•Useandcleanequipmentonlyinwellventilatedarea.

•Interlockthegunairsupplytopreventoperationunlessventilatingfansareon.

•Usecleaningsolventswithhighestpossibleashpointwhenushingorcleaningequipment.

•Tocleantheexterioroftheequipment,cleaningsolventsmusthaveaashpointatleast

5°Caboveambienttemperature.

•Alwaysturntheelectrostaticsoffwhenushing,cleaningorservicingequipment.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Donotplugorunplugpowercordsorturnlightsonoroffwhenammablefumesarepresent.

•Keepsprayareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

4

3A2494D

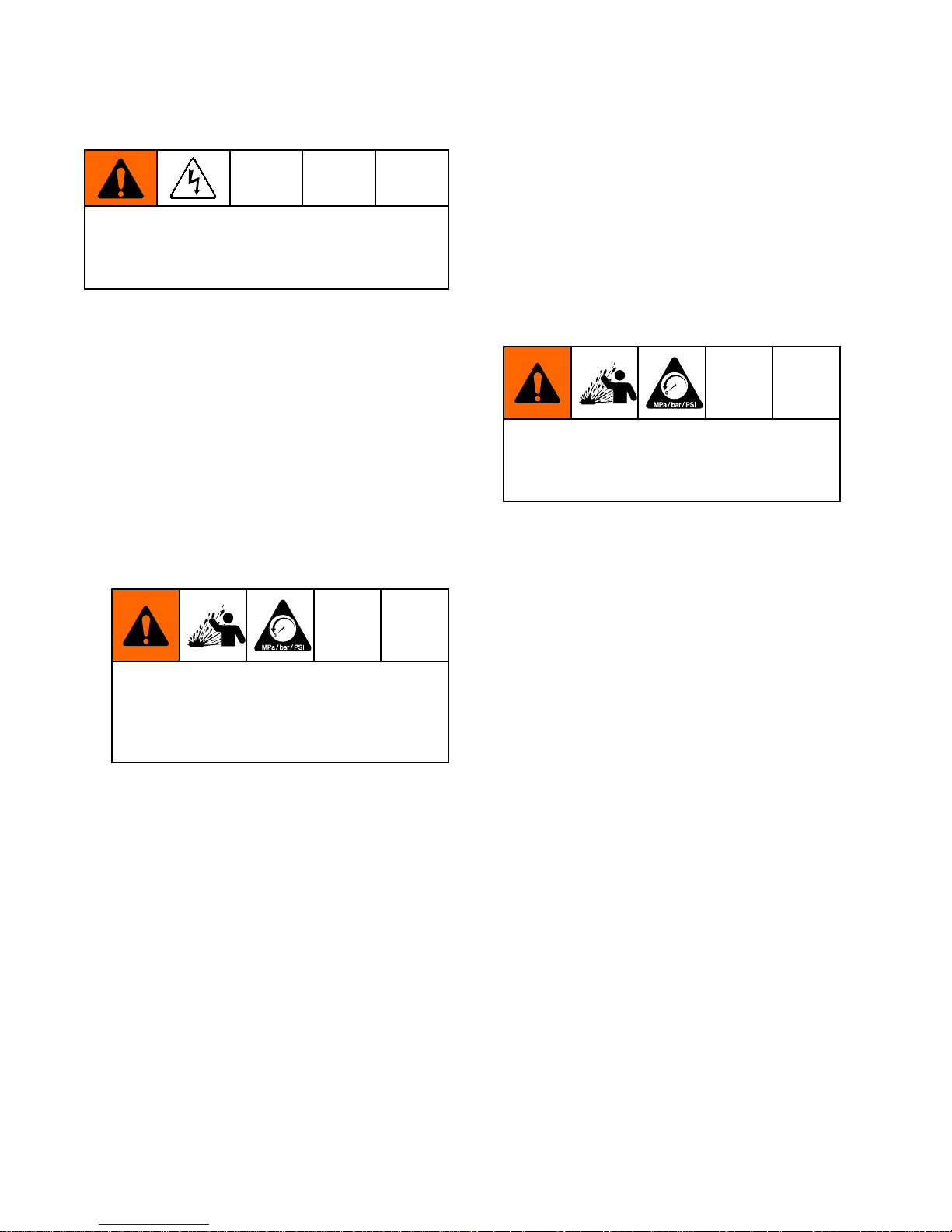

Page 5

Warnings

WARNING WARNING

WARNING

PRESSURIZED PRESSURIZED

PRESSURIZED

EQUIPMENT EQUIPMENT

EQUIPMENT

HAZARD HAZARD

HAZARD

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopspraying/dispensingandbefore

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

PLASTIC PLASTIC

PLASTIC

PARTS PARTS

PARTS

CLEANING CLEANING

CLEANING

SOLVENT SOLVENT

SOLVENT

HAZARD HAZARD

HAZARD

Manysolventscandegradeplasticpartsandcausethemtofail,whichcouldcauseserious

injuryorpropertydamage.

•Useonlycompatiblewater-basedsolventstocleanplasticstructuralorpressure-containing

parts.

•SeeTechnical Technical

Technical

Data Data

Data

inthisandallotherequipmentinstructionmanuals.Readuidand

solventmanufacturer’sMSDSsandrecommendations.

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDS’stoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

3A2494D 5

Page 6

Warnings

WARNING WARNING

WARNING

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

6 3A2494D

Page 7

GunOverview

Gun Gun

Gun

Overview Overview

Overview

How How

How

the the

the

Electrostatic Electrostatic

Electrostatic

Spray Spray

Spray

Gun Gun

Gun

Works Works

Works

Theairhosesuppliesairtothespraygun.Partof

theairoperatesthealternatorturbineandtherest

oftheairatomizestheuidbeingsprayed.The

alternatorgeneratespower,whichisconvertedby

thepowercartridgetosupplyhighvoltagetothe

gun’selectrode.

Thepumpsuppliesuidtotheuidhoseandgun,

wheretheuidiselectrostaticallychargedasit

passestheelectrode.Thechargeduidisattracted

tothegroundedworkpiece,wrappingaroundand

evenlycoatingallsurfaces.

3A2494D

7

Page 8

GunOverview

Controls, Controls,

Controls,

Indicators, Indicators,

Indicators,

and and

and

Components Components

Components

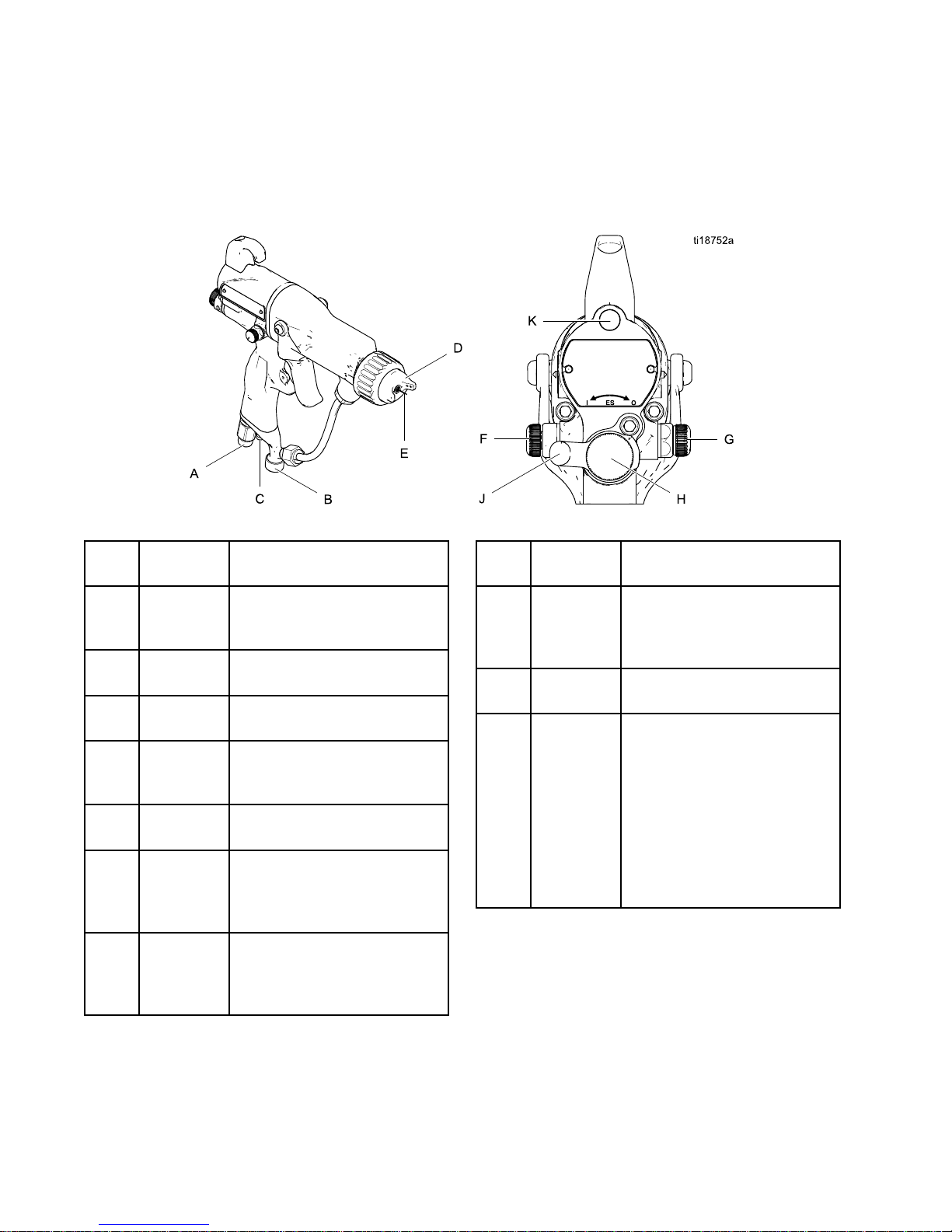

Theelectrostaticgunincludesthefollowing

controls,indicators,andcomponents(seeFig.

1).ForinformationonSmartguns,alsosee

SmartGuns,page9.

Figure1GunOverview

Item Item

Item

Descrip- Descrip-

Description tion

tion

Purpose Purpose

Purpose

A

AirSwivel

Inlet

1/4npsm(m)left-handthread,

forGracogroundedairsupply

hose.

BFluidInlet

3/8npsm(m),foruidsupply

hose.

C

TurbineAir

Exhaust

Barbedtting,forsupplied

exhausttube.

D

AirCap

and

Nozzle

SeeAirCapsandFluid

Nozzles,page68,foravail-

ablesizes.

EElectrode

Needle

Supplieselectrostaticcharge

totheuid.

FFanAir

Adjustment

Valve

Adjustsfansizeandshape.

Canbeusedtodecrease

patternwidth.

G

Atomizing

Air

Restrictor

Valve

Restrictsaircapairow.

Replacewithplug(included)

ifdesired.

Item Item

Item

Descrip- Descrip-

Description tion

tion

Purpose Purpose

Purpose

HFluidAd-

justment

Knob

Adjustsuidowbylimiting

uidneedletravel.Useonly

inlowowconditions,to

reducewear.

J

ESOn-Off

Valve

TurnselectrostaticsON(I)or

OFF(O).

K

ESIndicator(standardgun

only;for

Smartgun

indicator,see

Operating

Mode,

page9)

LitwhenESisON(I).Colorindicatesalternatorfrequency.

SeetheLEDindicatortable

intheGunSetupChecklist,

page18.

8 3A2494D

Page 9

GunOverview

Smart Smart

Smart

Guns Guns

Guns

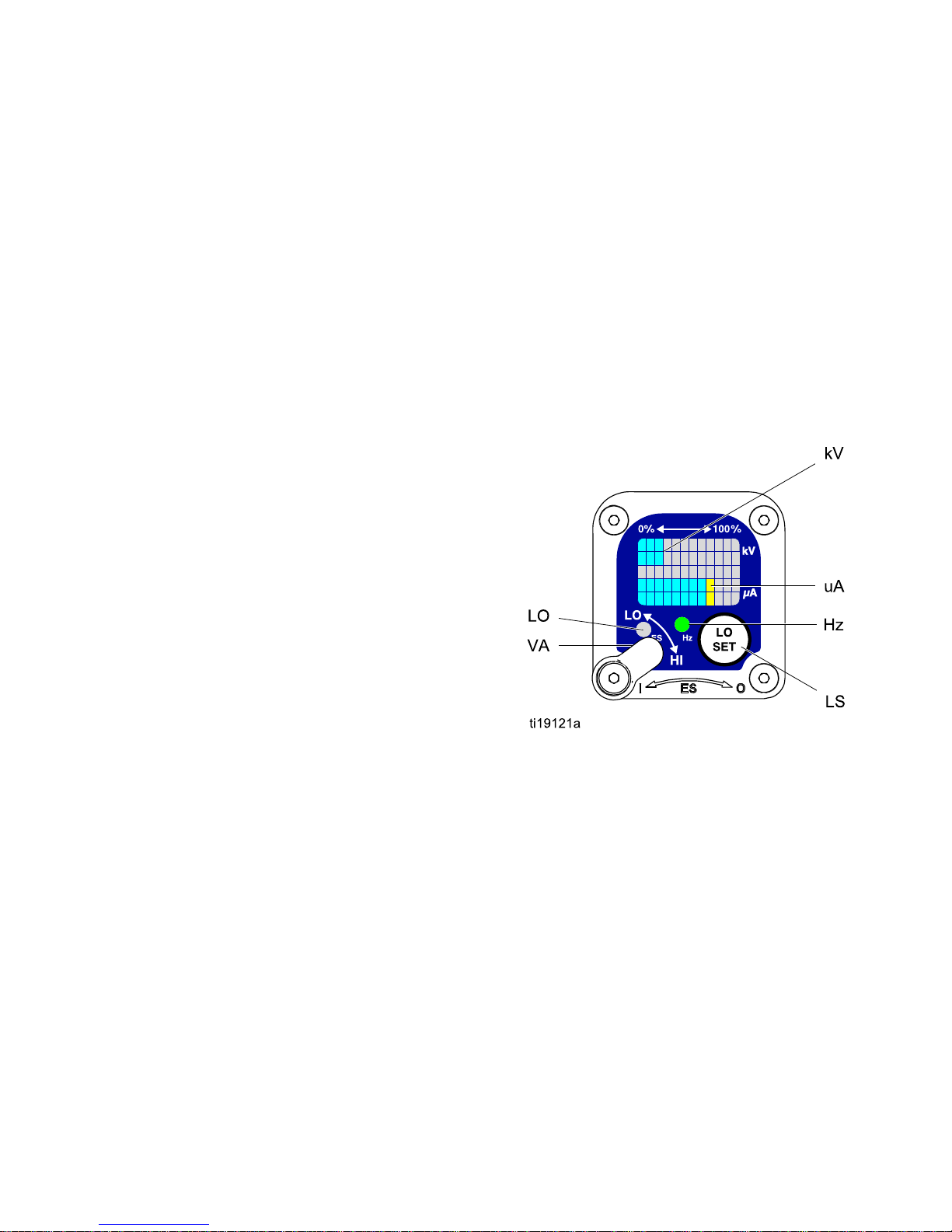

TheSmartGunmoduledisplayssprayingvoltage,

current,alternatorspeed,andthevoltagesetting(low

orhigh).Italsoallowstheusertochangetoalower

sprayingvoltage.Themodulehastwomodes:

•OperatingMode

•DiagnosticMode

Operating Operating

Operating

Mode Mode

Mode

Bar Bar

Bar

Graph Graph

Graph

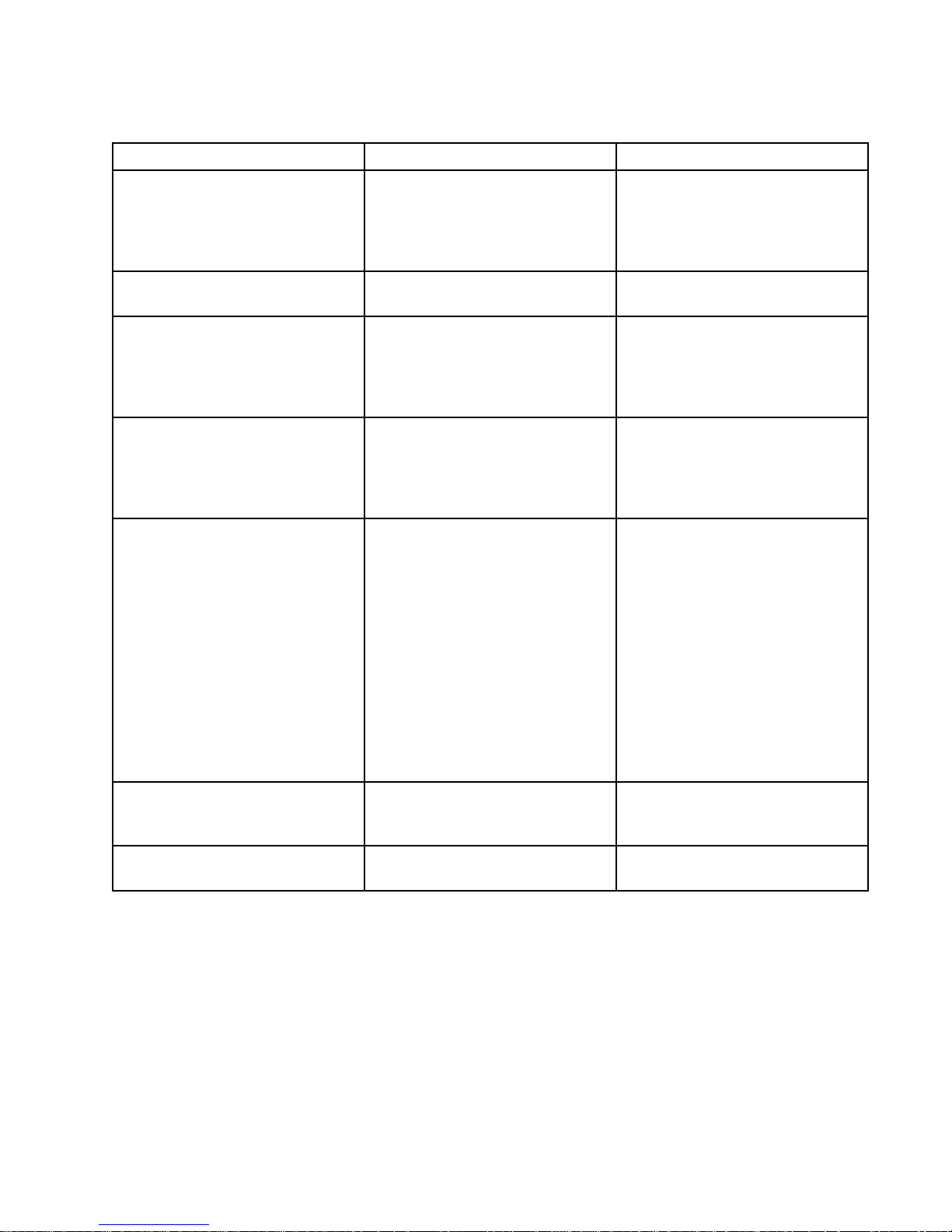

SeeFig.2,andTable1onpage10.TheOperating

Modedisplaysgundataduringnormalspraying.The

displayusesabargraphtoshowthevoltagelevelin

kiloVolts(kV)andthecurrentlevelinmicroAmperes

(uA).Thebargraphrangeisfrom0to100%foreach

value.

IfthebargraphLEDsareblue,thegunisreadyto

spray.IftheLEDsareyelloworred,thecurrentis

toohigh.Theuidmaybetooconductive,orsee

ElectricalTroubleshooting,page35forotherpossible

causes.

Hz Hz

Hz

Indicator Indicator

Indicator

TheHzindicatorfunctionsthesameastheES

indicatoronstandardguns.Theindicatorlightsto

showthealternatorspeedstatus,andhasthree

colors:

•Greenindicatesthealternatorspeediscorrect.

•Iftheindicatorchangestoamberafter1second,

increasetheairpressure.

•Iftheindicatorchangestoredafter1second,

reducetheairpressure.

Voltage Voltage

Voltage

Adjustment Adjustment

Adjustment

Switch Switch

Switch

Thevoltageadjustmentswitch(VA)allowsthe

operatortochangefromlowtohighvoltage.

•Thehighvoltagesettingisdeterminedbythe

maximumvoltageofthegunandisnotadjustable.

•Thelowvoltageindicator(LO)lights

whentheswitchissettoLO.Thelow

voltagesettingisuseradjustable.See

AdjustingtheLowVoltageSetting,page10.

NOTE: NOTE:

NOTE:

IftheErrordisplayappears,theSmartmodule

haslostcommunicationwiththepowersupply.See

ErrorDisplay,page10,forfurtherinformation.

Figure2SmartGunModuleinOperatingMode

3A2494D 9

Page 10

GunOverview

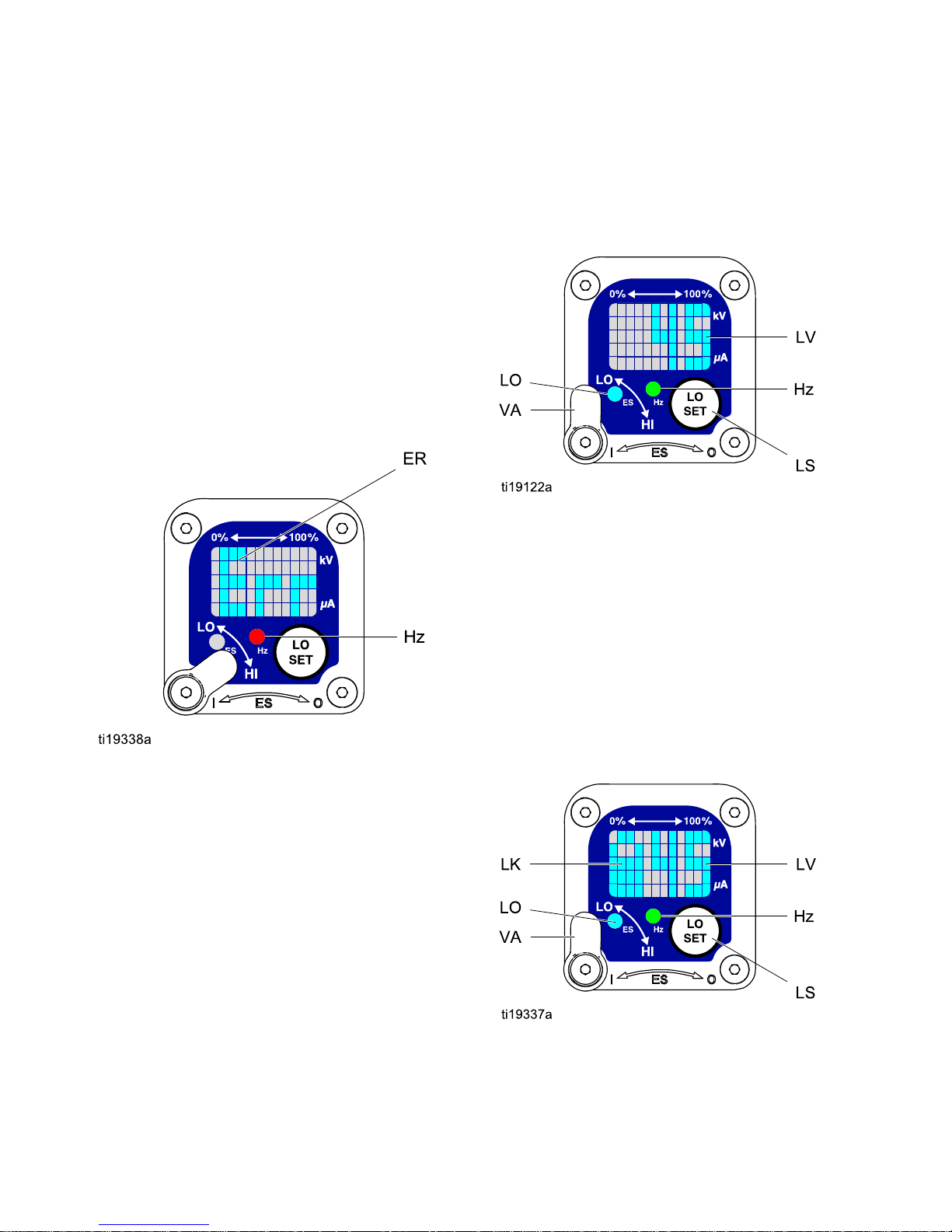

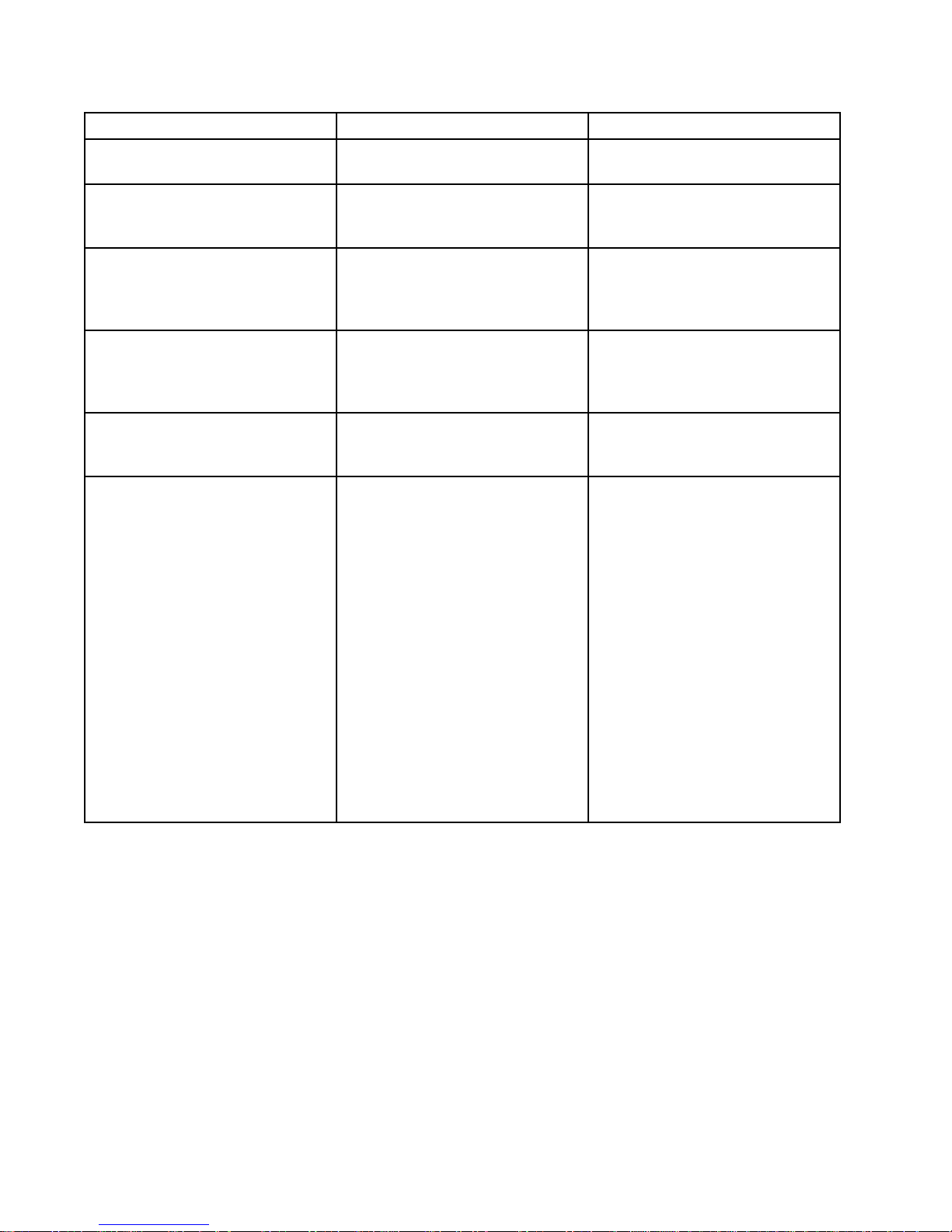

Error Error

Error

Display Display

Display

IftheSmartmodulelosescommunicationwith

thepowersupply,theErrordisplayappears,the

Hzindicatorturnsred,andtheSmartmoduleis

disabled.SeeFig.3,andTable1onpage10.

ThiscanoccurinOperatingModeorDiagnostic

Mode.SeeElectricalTroubleshooting,page35.

CommunicationmustberestoredtomaketheSmart

modulefunctional.

NOTE: NOTE:

NOTE:

Ittakes8secondsfortheErrordisplayto

appear.Ifthegunhasbeendisassembled,wait8

secondsbeforesprayingtoensurethatanError

conditionhasnotoccurred.

NOTE: NOTE:

NOTE:

Ifthereisnopowertothegun,theError

displaywillnotappear.

Figure3ErrorDisplay

Adjusting Adjusting

Adjusting

the the

the

Low Low

Low

Voltage Voltage

Voltage

Setting Setting

Setting

Thelowvoltagesettingisuseradjustable.Toaccess

thelowvoltagesettingscreenwheninOperating

Mode,presstheLOSETbutton(LS)momentarily.

Thescreenwilldisplaythecurrentlowvoltage

setting.SeeFig.4,andTable1onpage10.The

possiblerangesare:

•85kVguns:40–85kV

•60kVguns:30–60kV

SettheVoltageAdjustmentswitch(VA)toLO.Press

theLOSETbuttonrepeatedlytoincreasethesetting

inincrementsof5.Whenthedisplayreachesthe

maximumsettingitwillreturntotheminimumsetting

foryourgun.Continuepressingthebuttonuntilyou

reachthedesiredsetting.

NOTE: NOTE:

NOTE:

After2secondsofinactivitythedisplaywill

returntotheOperatingScreen.

NOTE: NOTE:

NOTE:

Thelowvoltagesettingmaybelocked.See

LockSymbol,page10.

Figure4LowVoltageSettingScreen(Unlocked)

Lock Lock

Lock

Symbol Symbol

Symbol

Thelowvoltagesettingmaybelocked.Whenlocked,

animage(LK)appearsonthescreen.SeeFig.5,

andTable1onpage10.

•WheninHImode,thelowvoltagesettingisalways always

always

locked.ThelocksymbolwillappearwhentheLO

SETbuttonispressed.

•WheninLOmode,thelocksymbolwill

only only

only

appearifthelockisenabled.See

LowVoltageLockScreen,page14,tolockor

unlockthelowvoltagesetting.

Figure5LowVoltageSettingScreen(Locked)

10 3A2494D

Page 11

GunOverview

Table Table

Table

1 11. ..Key Key

Key

for for

for

Figs. Figs.

Figs.

2–9. 2–9.

2–9.

Item Item

Item

Description Description

Description

Purpose Purpose

Purpose

VA

VoltageAdjustmentSwitch

Two-positionswitchsetssmart

gunvoltagetolowsetting(LO)or

highsetting(HI).Thisswitchis

functionalinOperatingModeand

inDiagnosticMode.

LO

LowVoltageModeIndicator

Lights(blue)whenthesmartgun

issettoLowVoltage.

kV

Voltage(kV)Display

Displaysactualsprayingvoltage

ofthegun,inkV.InOperating

Mode,displayisabargraph.

InDiagnosticMode,voltageis

displayedasanumber.

uA

Current(uA)Display

Displaysactualsprayingcurrent

ofthegun,inuA.InOperating

Mode,displayisabargraph.

InDiagnosticMode,currentis

displayedasanumber.

LSLOSETbutton

Pressmomentarilytoenterthe

LowVoltageSettingscreen.

Pressandholdforapproximately5

secondstoenterorexitDiagnostic

Mode.

WhileinDiagnosticMode,press

momentarilytoadvancethrough

screens.

WhileontheLowVoltageLock

Screen(inDiagnosticMode),

pressandholdtoturnthelockon

oroff.

LVLowVoltageDisplayDisplaysthelowvoltagesetting

asanumber.Thesettingcanbe

changed.SeeFig.4.

LKLowVoltageLocked

Appearsifthelowvoltagesetting

islocked.SeeFig.5andFig.9.

3A2494D

11

Page 12

GunOverview

Item Item

Item

Description Description

Description

Purpose Purpose

Purpose

LD

LODisplay

AppearsontheLowVoltageLock

Screen.SeeFig.9.

ERErrorDisplay

AppearsiftheSmartmoduleloses

communicationwiththepower

supply.SeeFig.3.

VIVoltageIndicatorInDiagnosticMode,thetwotop

rightLEDsofthescreenlight,

indicatingthatthevaluedisplayed

isinkV.SeeFig.6.

CICurrentIndicator

InDiagnosticMode,thetwo

bottomrightLEDsofthescreen

light,indicatingthatthevalue

displayedisinuA.SeeFig.7.

ASAlternatorSpeedDisplay

InDiagnosticMode,Hzlevelis

displayedasanumber.SeeFig.

8.

Hz

AlternatorSpeedIndicatorInOperatingMode,indicatorcolor

variestoshowthealternator

speedstatus:

•greenindicatesthealternator

speedisatthecorrectlevel.

•Iftheindicatorchangestoamber

after1second,thealternator

speedistoolow.

•Iftheindicatorchangestored

after1second,thealternator

speedistoohigh.Theindicator

willalsoturnrediftheError

displayappears.

InDiagnosticMode,theindicator

isgreenwhenintheAlternator

Speed(Hertz)screen.

12

3A2494D

Page 13

GunOverview

Diagnostic Diagnostic

Diagnostic

Mode Mode

Mode

DiagnosticModeincludesfourscreenswhichdisplay

gundata:

•Voltage(kiloVolts)Screen

•Current(microAmperes)Screen

•AlternatorSpeed(Hertz)Screen

•LowVoltageLockScreen

NOTE: NOTE:

NOTE:

YoumustbeinOperatingModetoadjustthe

lowvoltagesetting;thesettingisnotadjustablein

DiagnosticMode.However,thevoltageadjustment

switch(VA)canbesettoHIorLOinOperatingMode

andinDiagnosticMode.

ToenterDiagnosticMode,pressandholdtheLOSET

(LS)buttonforapproximately5seconds.Thedisplay

willgototheVoltage(kiloVolts)Screen,page13.

Toadvancetothenextscreen,presstheLOSET

buttonagain.

ToexitDiagnosticMode,pressandholdtheLOSET

buttonforapproximately5seconds.Thescreenwill

returntoOperatingMode.

NOTE: NOTE:

NOTE:

IfthegunisdetriggeredwhileinDiagnostic

Mode,thelastscreenviewedwillbedisplayedwhen

thegunisretriggered.

NOTE: NOTE:

NOTE:

DiagnosticModecannotbeexited

fromtheLowVoltageLockScreen.See

LowVoltageLockScreen,page14fordetails.

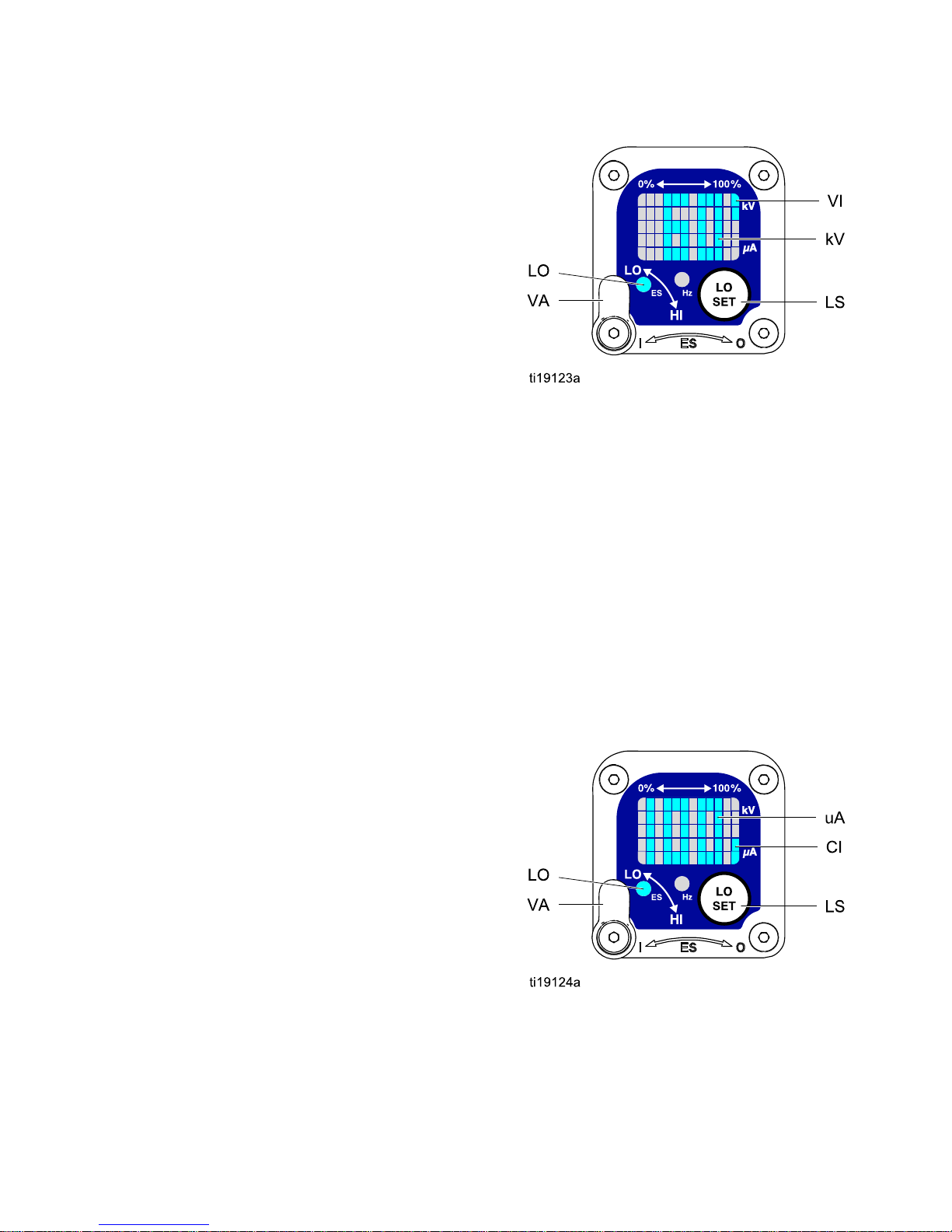

Voltage Voltage

Voltage

(kiloVolts) (kiloVolts)

(kiloVolts)

Screen Screen

Screen

TheVoltage(kiloVolts)Screenistherstscreento

appearafterenteringDiagnosticMode.SeeFig.6,

andTable1onpage10.Toenterthisscreen,press

andholdtheLOSETbuttonforapproximately5

secondswhileintheOperatingMode.

Thisscreendisplaysthesprayingvoltageofthe

gunasanumber(kV),roundedtothenearest5kV.

ThetwotoprightLEDs(VI)ofthedisplaypanel

light,indicatingthattheVoltage(kiloVolts)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

Current(microAmperes)Screen,page13.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

Figure6Voltage(kiloVolts)Screen

Current Current

Current

(microAmperes) (microAmperes)

(microAmperes)

Screen Screen

Screen

TheCurrent(microAmperes)Screenisthesecond

screenintheDiagnosticMode.SeeFig.7,andTable

1onpage10.Toenterthisscreen,presstheLO

SETbuttonwhileintheVoltage(kiloVolts)Screen.

Thisscreendisplaysthesprayingcurrentofthegun

asanumber(uA),roundedtothenearest5uA.The

twobottomrightLEDs(CI)ofthedisplaypanellight,

indicatingthattheCurrent(microAmperes)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

AlternatorSpeed(Hertz)Screen,page14.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

Figure7Current(microAmperes)Screen

3A2494D 13

Page 14

GunOverview

Alternator Alternator

Alternator

Speed Speed

Speed

(Hertz) (Hertz)

(Hertz)

Screen Screen

Screen

TheAlternatorSpeed(Hertz)Screenisthethird

screenintheDiagnosticMode.SeeFig.8,andTable

1onpage10.Toenterthisscreen,presstheLOSET

buttonwhileintheCurrent(microAmperes)Screen.

Thisscreendisplaysthealternatorspeedasa3digit

number(AS),roundedtothenearest10Hz.The

displayisareadoutandcannotbechanged.Ifthe

alternatorspeedisgreaterthan999Hz,thedisplay

willshow999.

TheHzindicatorlightsgreentoshowthatyouare

viewingtheAlternatorSpeed(Hertz)Screen.

PresstheLOSETbuttontoadvancetothe

LowVoltageLockScreen,page14.Pressandhold

forapproximately5secondstoreturntoOperating

Mode.

Figure8AlternatorSpeed(Hertz)Screen

Low Low

Low

Voltage Voltage

Voltage

Lock Lock

Lock

Screen Screen

Screen

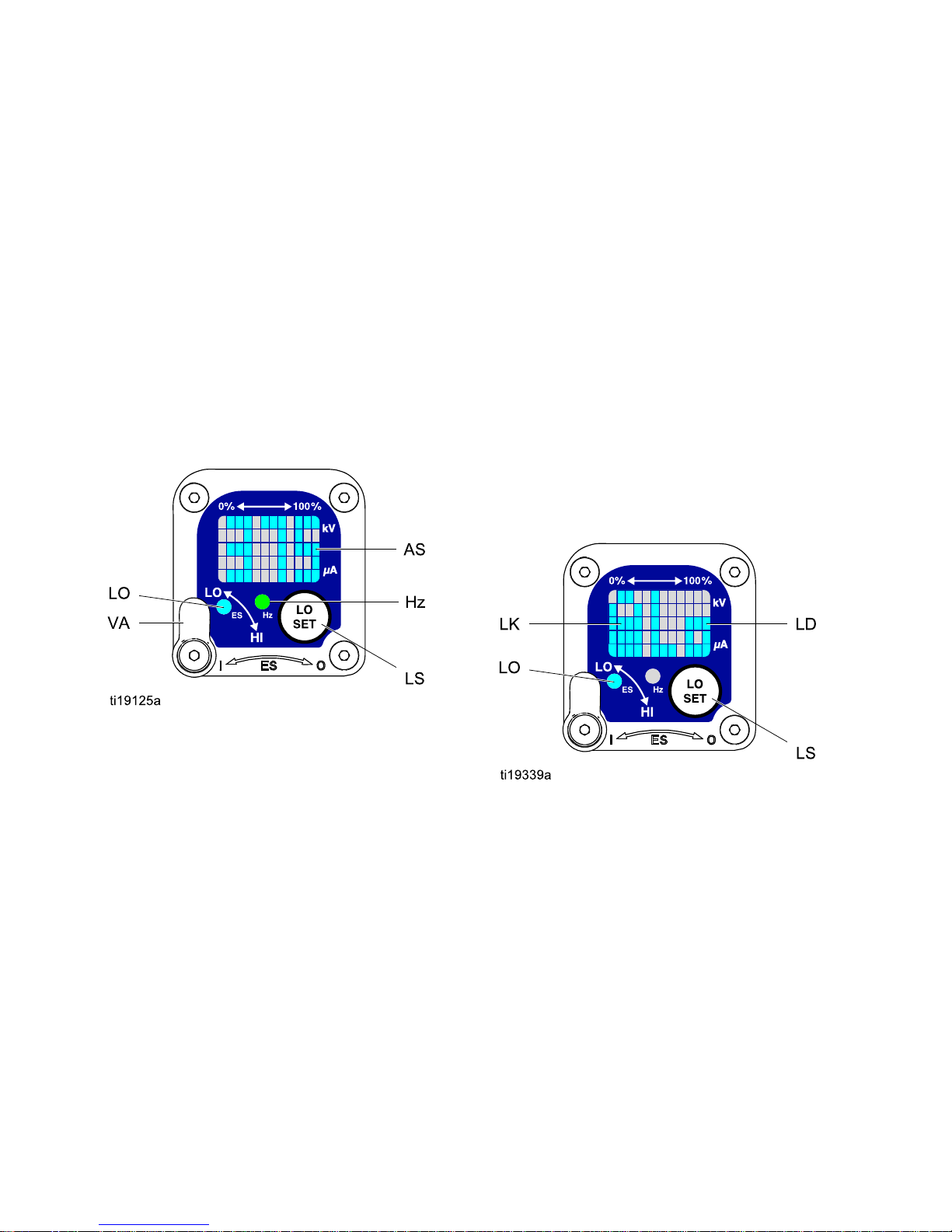

TheLowVoltageLockScreenisthefourthscreenin

theDiagnosticMode.SeeFig.9,andTable1on

page10.Toenterthisscreen,presstheLOSET

buttonwhileintheAlternatorSpeed(Hertz)Screen.

ThisscreendisplaysthestatusoftheLowVoltage

Lock.Ifthesettingislocked,thelockimage(LK)

appearstotheleftoftheLodisplay(LD).Ifthesetting

isunlocked,thelockimagedoesnotappear.

Tochangethelockstatus,pressandholdthe

LOSETbuttonuntilthelockimageappearsor

disappears.Ifthelockisset,theimagewillalso

appearontheLowVoltageSettingScreenwhenin

lowvoltagemode(seeFig.4).

NOTE: NOTE:

NOTE:

DiagnosticModecannotbeexitedfromthis

screen,becausepressingandholdingtheLOSET

buttonisusedtoturnthelockonoroff.Toexit,

pressLOSETmomentarilytoreturntotheVoltage

(kiloVolts)Screen,thenexitDiagnosticModefrom

there.

Figure9LowVoltageLockScreen

14

3A2494D

Page 15

Installation

Installation Installation

Installation

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseelectricshock

orotherseriousinjuryifworkisnotperformed

properly.

•Donotinstallorservicethisequipmentunless

youaretrainedandqualied.

•Besureyourinstallationcomplieswithlocal,

state,andnationalcodesfortheinstallation

ofelectricalapparatusinaClassI,Div.I,

HazardousLocationoraGroupII,ZoneI

ExplosiveAtmosphereLocation.

•Complywithallapplicablelocal,state,and

nationalre,electrical,andothersafety

regulations.

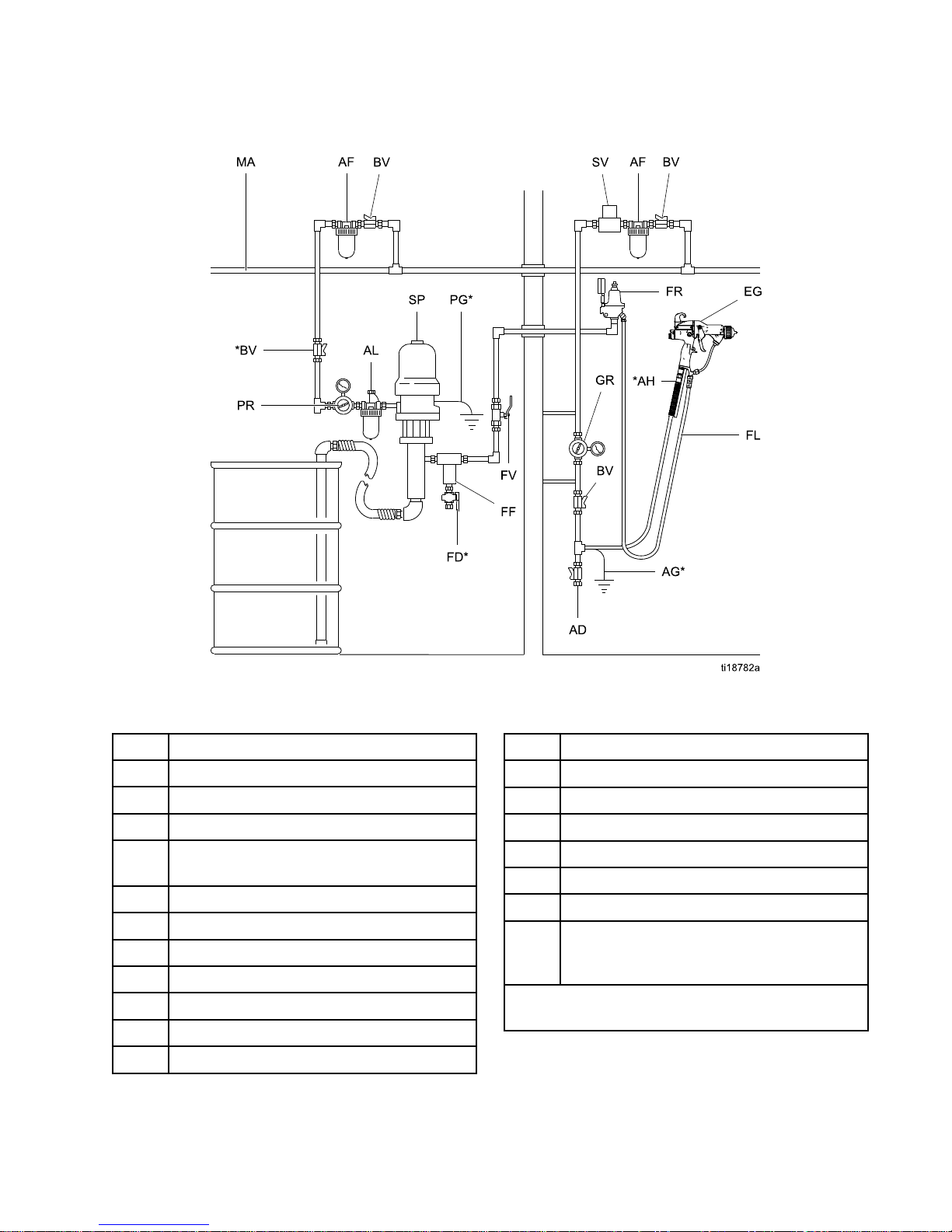

Fig.10showsatypicalelectrostaticairspraysystem.

Itisnotanactualsystemdesign.Forassistance

indesigningasystemtosuityourparticularneeds,

contactyourGracodistributor.

Warning Warning

Warning

Sign Sign

Sign

Mountwarningsignsinthesprayareawherethey

caneasilybeseenandreadbyalloperators.An

EnglishWarningSignisprovidedwiththegun.

Ventilate Ventilate

Ventilate

the the

the

Spray Spray

Spray

Booth Booth

Booth

Providefreshairventilationtoreducetheriskofre

orexplosioncausedbythebuildupofammableor

toxicvaporswhenspraying,ushing,orcleaning

thegun.Donotoperatethegununlessventilation

fansareoperating.

Electricallyinterlockthegunairsupplywiththe

ventilatorstopreventgunoperationwithout

ventilatingfansoperating.Checkandfollowalllocal,

state,andnationalcodesregardingairexhaust

velocityrequirements.

Highvelocityairexhaustwilldecreasetheoperating

efciencyoftheelectrostaticsystem.Airexhaust

velocityof100ft/min(31linearmeters/minute)should

besufcient.

3A2494D 15

Page 16

Installation

Air Air

Air

Supply Supply

Supply

Line Line

Line

Toreducetheriskofelectricshock,theairsupply

hosemustbeelectricallyconnectedtoatrueearth

ground.Use Use

Use

only only

only

Graco Graco

Graco

Grounded Grounded

Grounded

Air Air

Air

Supply Supply

Supply

Hose. Hose.

Hose.

1.SeeFig.10.UsetheGracoGroundedAirSupply

Hose(AH)tosupplyairtothegun.Thegunair

inletttinghasaleft-handthread.Theairsupply

hosegroundwire(AG)mustbeconnectedtoa

trueearthground.Donotconnecttheairsupply

hosetothegunairinletyet.

2.Installanairlinelter/waterseparator(AF)onthe

gunairlinetoensureadry,cleanairsupplytothe

gun.Dirtandmoisturecanruintheappearance

ofyournishedworkpieceandcancausethe

guntomalfunction.

3.Installbleed-typeairregulators(PR,GR)on

thepumpandgunairsupplylinestocontrolair

pressuretothepumpandgun.

Trappedaircancausethepumptocycle

unexpectedly,whichcanresultinserious

injury,includingsplashinguidintheeyesor

ontheskin.Donotoperatetheequipment

withoutthebleed-typeairvalve(BV)installed.

4.Installableed-typeairvalve(BV)onthepump

airsupplyline.Thebleed-typeairvalve(BV)is

requiredinyoursystemtoshutoffairtothepump

andrelieveairtrappedbetweenthevalveand

thepumpaftertheairregulatorisshutoff.Install

anadditionalbleed-typeairvalveonthemainair

line(MA)toisolatetheaccessoriesforservicing.

5.Installanairbleedvalve(BV)oneachgunair

supplylinetoshutoffairtothegun(s)andrelieve

airtrappedbetweenthevalveandthegunafter

theairregulatorisshutoff.

Fluid Fluid

Fluid

Supply Supply

Supply

Line Line

Line

1.Blowouttheuidline(FL)withairandushit

withsolvent.Usesolventwhichiscompatible

withtheuidtobesprayed.Donotconnectthe

uidsupplylinetothegunuidinletyet.

2.Installauidregulator(FR)ontheuidlineto

controluidpressuretothegun.

3.Installauidlter(FF)nearthepumpoutlet,to

removeparticlesandsedimentwhichcouldclog

thespraynozzle.

Toreducetheriskofseriousinjury,including

splashinguidintheeyesorontheskin,do

notoperateequipmentwithouttheuiddrain

valve(FD)installed.

4.Theuiddrainvalve(FD)isrequiredinyour

systemtoassistinrelievinguidpressureinthe

displacementpump,hose,andgun.Triggering

theguntorelievepressuremaynotbesufcient.

Installadrainvalveclosetothepump'suid

outlet.

16 3A2494D

Page 17

Installation

NON NON

NON

- --HAZARDOUS HAZARDOUS

HAZARDOUS

AREA AREA

AREA

HAZARDOUS HAZARDOUS

HAZARDOUS

AREA AREA

AREA

Figure10TypicalInstallation

Typical Typical

Typical

Installation Installation

Installation

Key Key

Key

Item Item

Item

Description Description

Description

ADAirLineDrainValve

AF

AirFilter/WaterSeparator

AG*GunAirHoseGroundWire

AH*GracoGroundedAirHose(left-hand

threads)

ALPumpAirLineLubricator

BV*PumpBleed-TypeAirShutoffValve

EGElectrostaticAirSprayGun

FD*

FluidDrainValve

FFFluidFilter

FL

FluidSupplyLine

FRFluidPressureRegulator

Item Item

Item

Description Description

Description

FV

FluidShutoffValve

GRGunAirPressureRegulator

MA

MainAirSupplyLine

PG*PumpGroundWire

PRPumpAirPressureRegulator

SPSupplyPump

SV*VentilationFanInterlockSolenoidValve.

NOTE: NOTE:

NOTE:

Thesolenoidvalveisnotoffered

asaGracoaccessory.

*Theseitemsarerequiredforsafeoperation.They

mustbepurchasedseparately.

3A2494D

17

Page 18

GunSetup

Gun Gun

Gun

Setup Setup

Setup

Gun Gun

Gun

Setup Setup

Setup

Checklist Checklist

Checklist

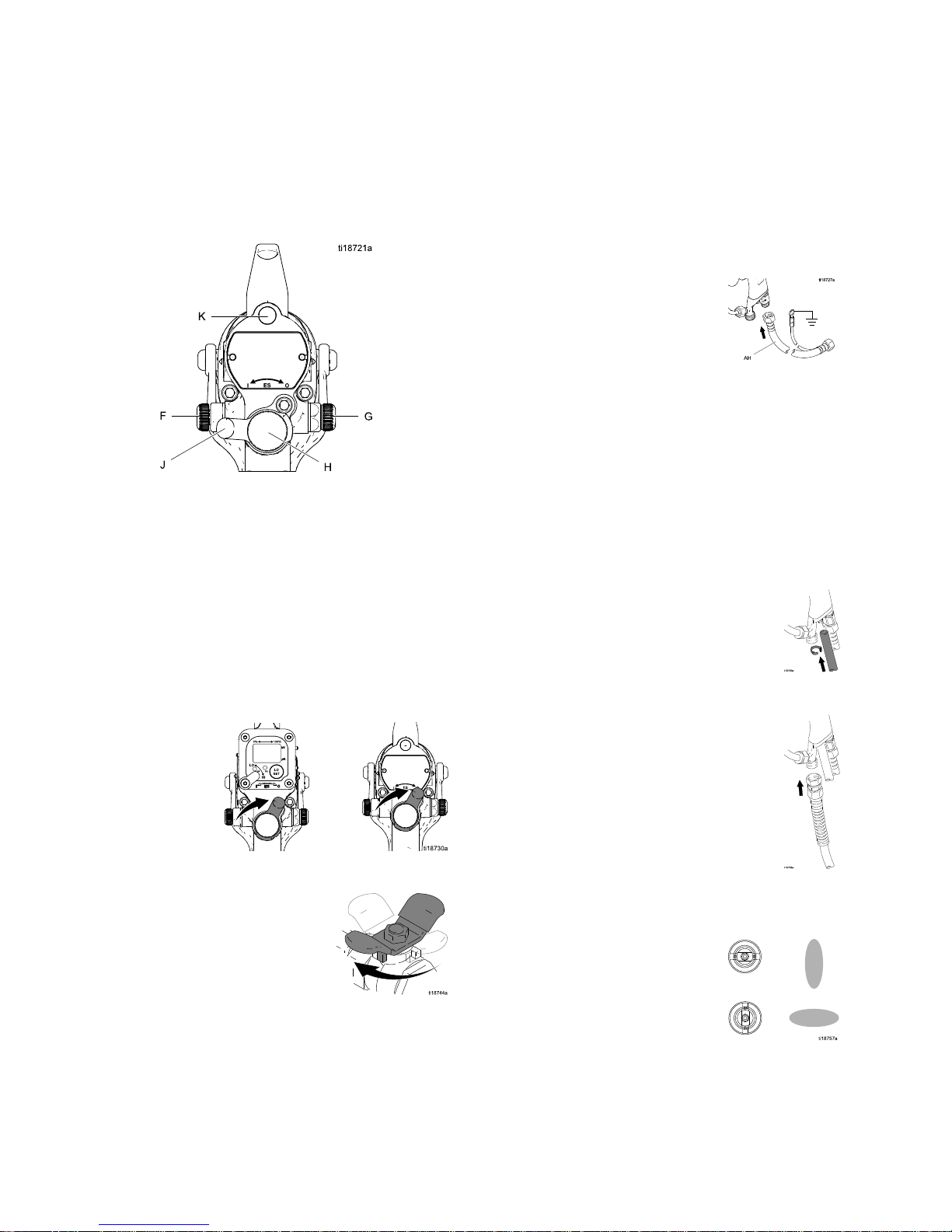

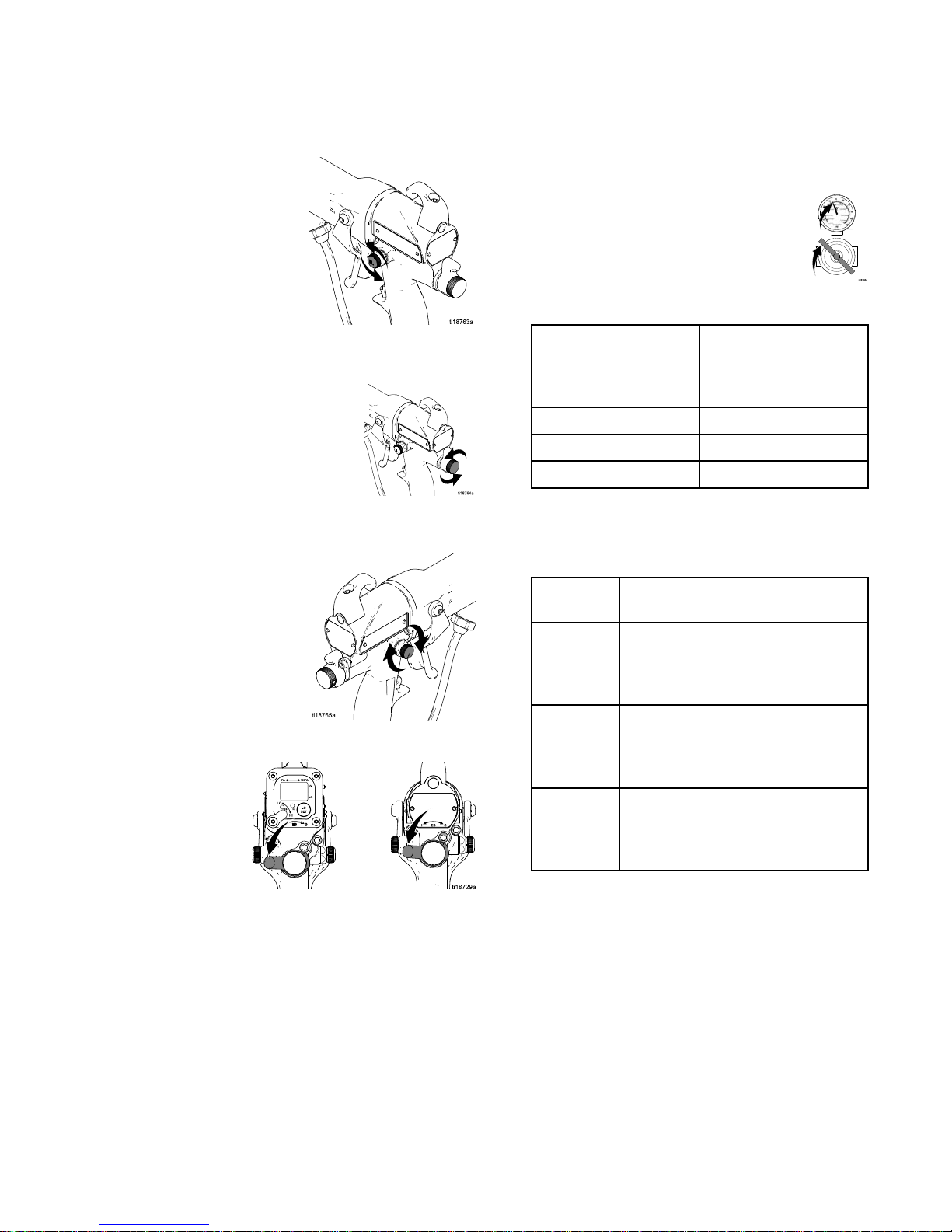

SeeFig.11tolocatetheelectrostaticguncontrols.

Figure11ElectrostaticGunControls

1.Thegunisshippedwiththeuidnozzleandair

capinstalled.Checkthattheretainingringis

tight.

NOTE: NOTE:

NOTE:

Toselectadifferent

sizeuidnozzleoraircap,see

FluidNozzleSelectionChart,page68and

AirCapSelectionChart,page70.To

installthenozzleandaircap,see

AirCapandNozzleReplacement,page38.

2.TurnOFF(O)theESOn-Offswitch(J).

3.Shutofftheairbleedvalvetothegun.

4.Checkgunresistance.See

TestGunResistance,page31.

5.ConnecttheGracogroundedairhosetothegun

airinlet.Thegunairinletttinghasleft-hand

threads.

6.FollowallstepsunderGrounding,page21.

7.Followallstepsunder

CheckGunElectricalGrounding,page25.

Readingmustbelessthan1megohm.

8.Verifythatthematerialresistivitymeets

requirementsforelectrostaticspray.See

CheckFluidResistivity,page26.

9.Connecttheexhausttubeandsecurewiththe

clampprovided.

10.Connecttheuidhosetothegunuidinlet.

11.Flushifneeded,seeFlushing,page28.

12.Positiontheaircapasdesired.

18 3A2494D

Page 19

GunSetup

13.Fullyopenthefanairadjustmentvalve(F)

counterclockwise.

14.Fullyopentheuidadjustmentvalve(H)

counterclockwise.

15.Fullyopentheatomizingairrestrictorvalve(G)

clockwise.

16.TurnON(I)theESOn-Offswitch(J).

17.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.See

thetablebelow.

Table Table

Table

2 22. ..Pressure Pressure

Pressure

Drop Drop

Drop

Air Air

Air

Hose Hose

Hose

Length Length

Length

in ininft ftft(m) (m)

(m)

(using (using

(using

5/16 5/16

5/16

in. in.

in.

[8 [8

[8

mm] mm]

mm]

diameter diameter

diameter

hose) hose)

hose)

Air Air

Air

Regulator Regulator

Regulator

Setting Setting

Setting

in ininpsi psi

psi

(MPa, (MPa,

(MPa,

bar) bar)

bar)

[with [with

[with

gun gun

gun

triggered] triggered]

triggered]

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

18.CheckthattheESindicator(K)[Hzindicatoron

Smartguns]islit.Seethefollowingtable.

Table Table

Table

3 33. ..LED LED

LED

Indicator Indicator

Indicator

Colors Colors

Colors

Indicator Indicator

Indicator

Color Color

Color

Description Description

Description

Green

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Amber

Iftheindicatorchangestoamber

after1second,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Red

Iftheindicatorchangestored

after1second,theairpressureis

toohigh.Decreaseairpressure

untiltheindicatorisgreen.

3A2494D 19

Page 20

GunSetup

19.Shutofftheairtothegun.TurnOFF(O)theES

On-Offswitch(J).

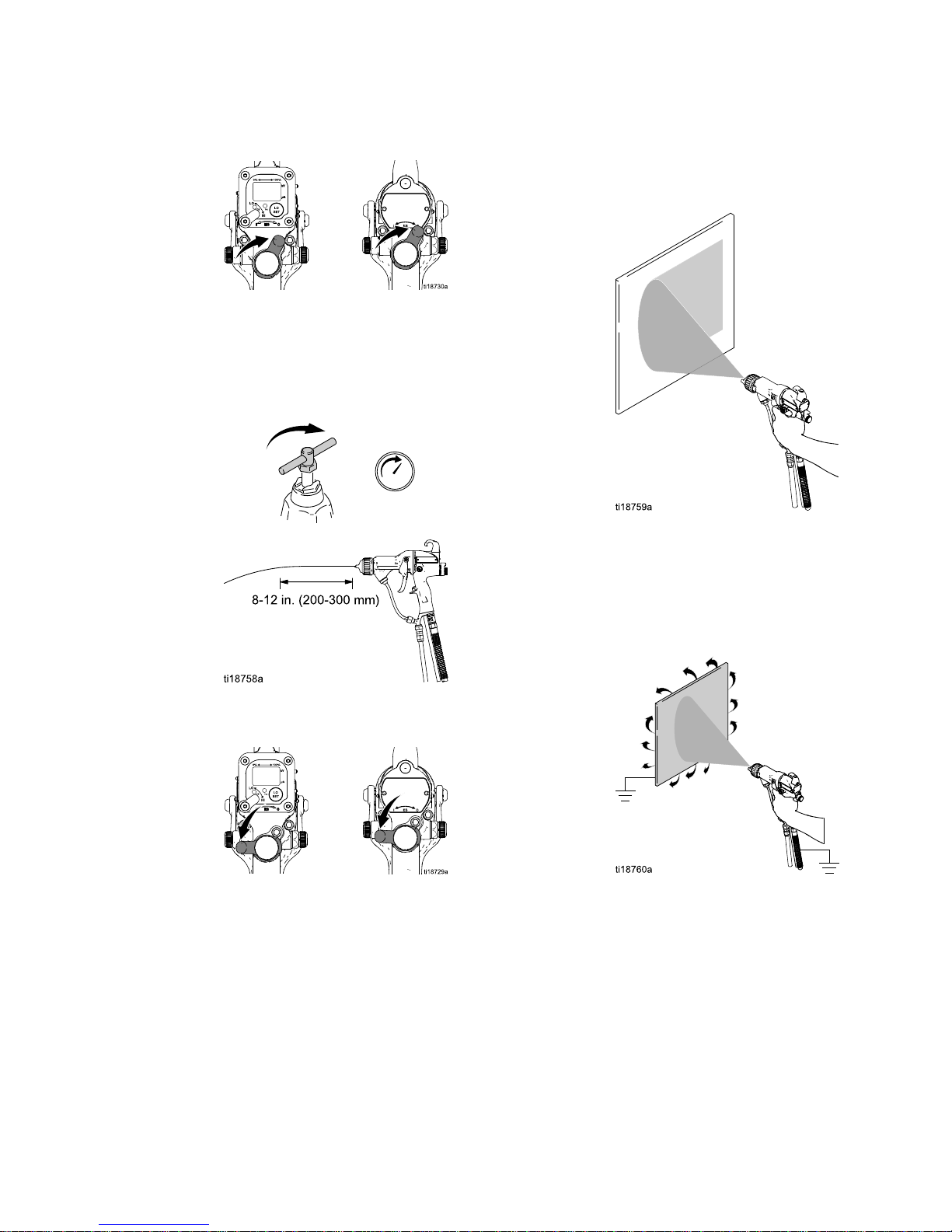

20.Startthepump.Adjusttheuidregulatoruntilthe

streamfromtheguntravels8-12in.(200-300

mm)beforefallingoff.Typically,ifuidpressure

isbelow5psi(.04MPa,0.4bar)orabove30psi

(0.21MPa,2.1bar),achangeofnozzlesizeis

recommended.

21.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

22.Sprayatestpattern.Checktheatomization.If

over-atomizationoccursatminimumpressure,

adjusttherestrictorvalve.Ifatomizationis

inadequate,increaseairpressureordecrease

uidow.

23.Adjustthefanairadjustmentvalve:clockwisefor

anarrowerpattern,counterclockwiseforawider

pattern.

24.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page33.

20 3A2494D

Page 21

GunSetup

Grounding Grounding

Grounding

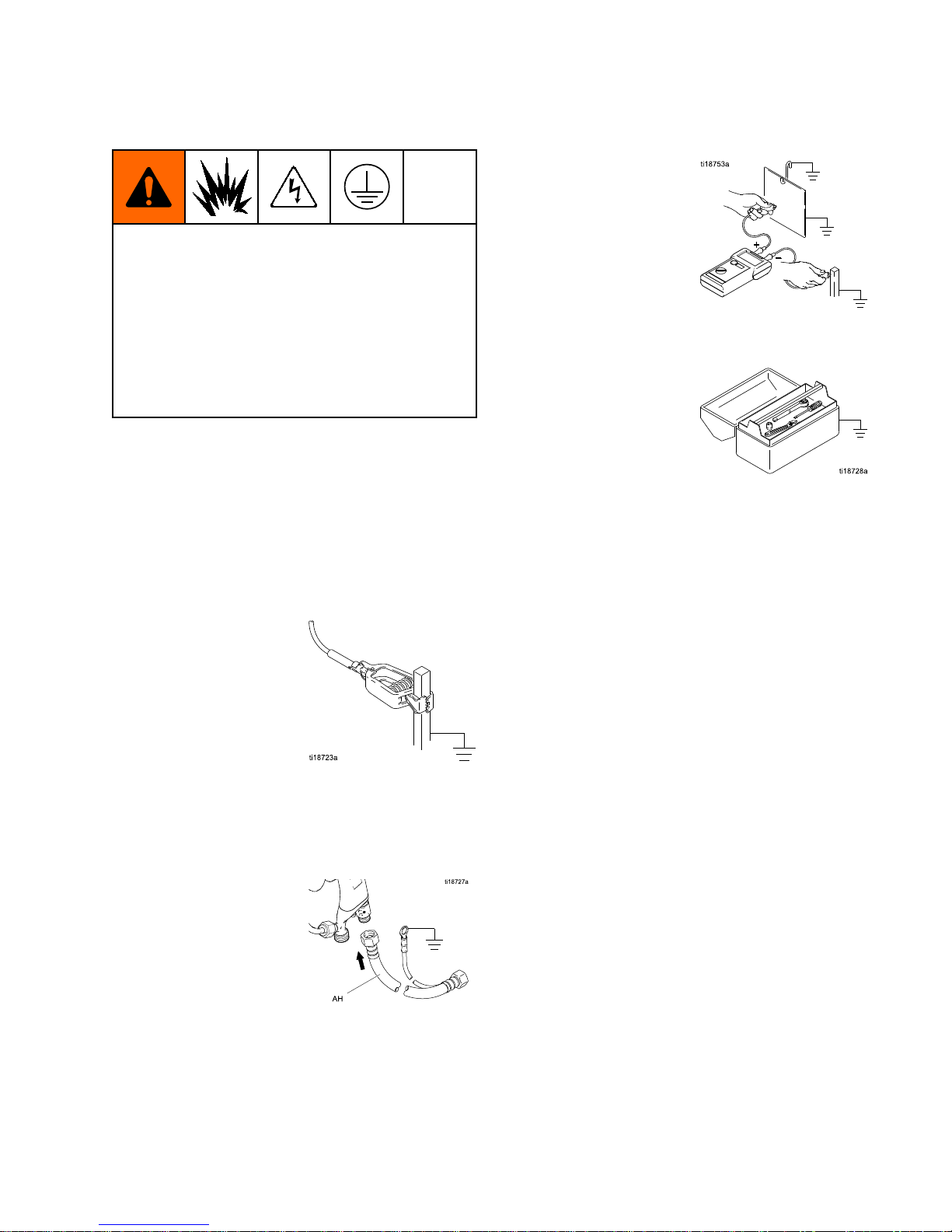

Whenoperatingtheelectrostaticgun,any

ungroundedobjectsinthesprayarea(people,

containers,tools,etc.)canbecomeelectrically

charged.Impropergroundingcanresultinstatic

sparking,whichcancauseare,explosion,or

electricshock.Groundallequipment,personnel,

objectbeingsprayed,andconductiveobjects

inorclosetothesprayarea.Resistancemust

notexceed1megohm.Followthegrounding

instructionsbelow.

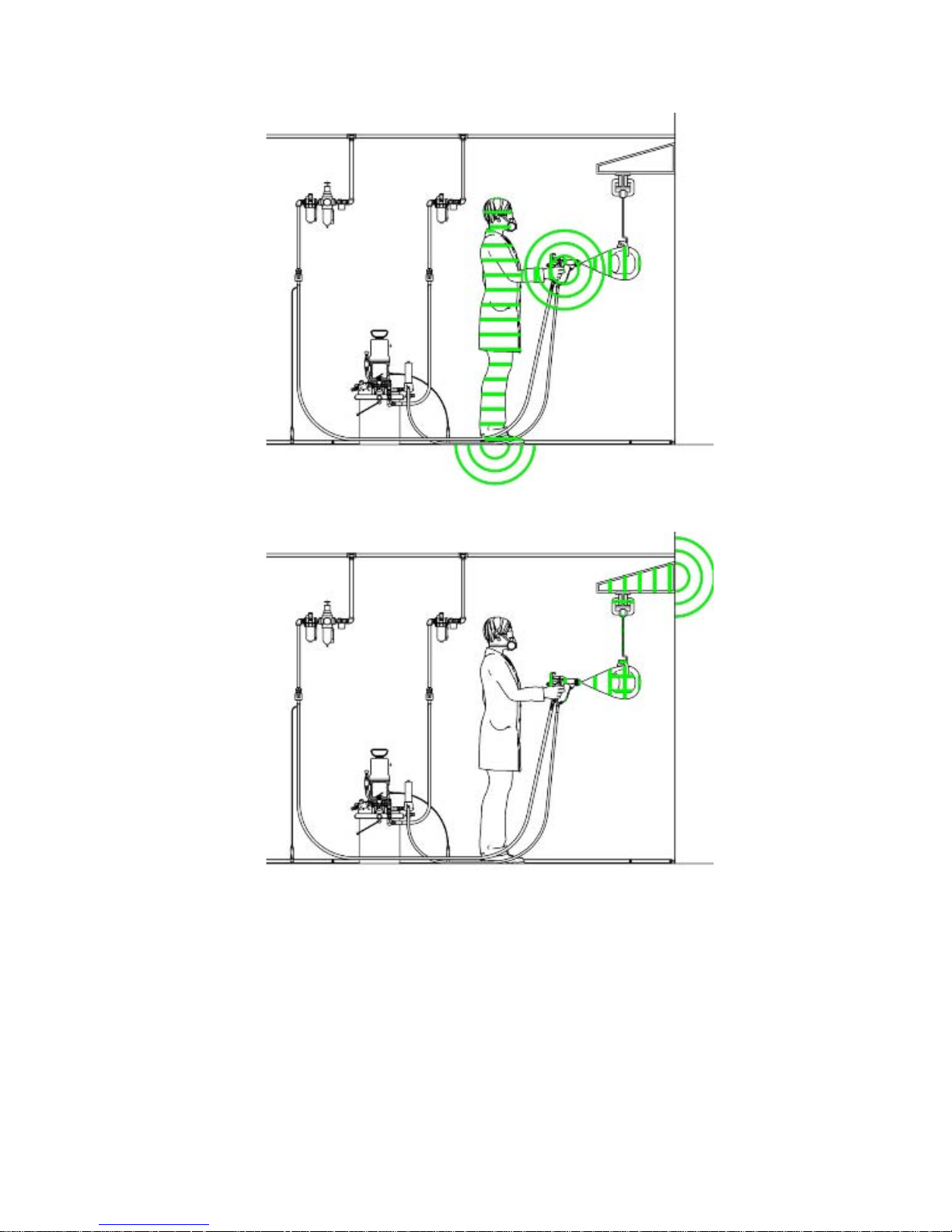

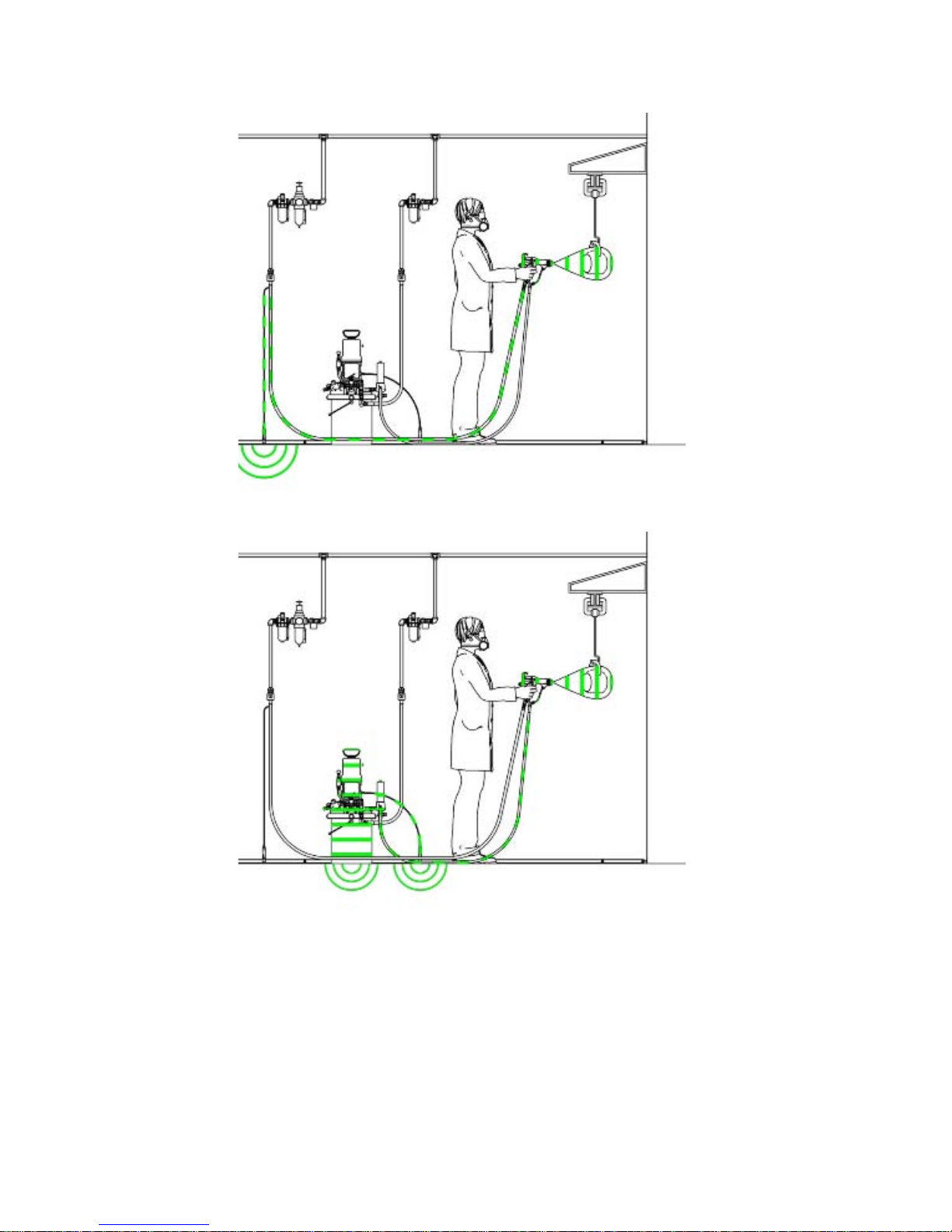

Thefollowingareminimumgroundingrequirements

forabasicelectrostaticsystem(seeFigs.12–15).

Yoursystemmayincludeotherequipmentorobjects

whichmustbegrounded.Checkyourlocalelectrical

codefordetailedgroundinginstructions.Yoursystem

mustbeconnectedtoatrueearthground.

•

Pump/uid source:

groundthepump/uidsource

byconnectingitsgroundwiretoatrueearth

ground.

•

Electrostatic Air Spray Gun:

groundthegun

byconnectingtheGracoGroundedAirHose

(AH)tothegun,andconnectingtheairhose

groundwiretoatrueearthground.See

CheckGunElectricalGrounding,page25.

•

Object being sprayed:

keeptheworkpiecehangers

cleanandgroundedatalltimes.

•

All electrically conductive objects or devices in the

spray area:

mustbeproperlygrounded.

•

Fluid and waste containers:

groundalluidand

wastecontainersinthesprayarea.Donotusepail

linersunlesstheyareconductiveandgrounded.

Whenushingthespraygun,thecontainerused

tocatchtheexcessuidmustbeelectrically

conductiveandgrounded.

•

Air compressors:

groundtheequipmentaccording

tothemanufacturer'srecommendations.

•

All air and uid lines

mustbeproperlygrounded.

Useonlygroundedhoseswithamaximumof100

feet(30.5m)combinedhoselengthtoensure

groundingcontinuity.

3A2494D

21

Page 22

GunSetup

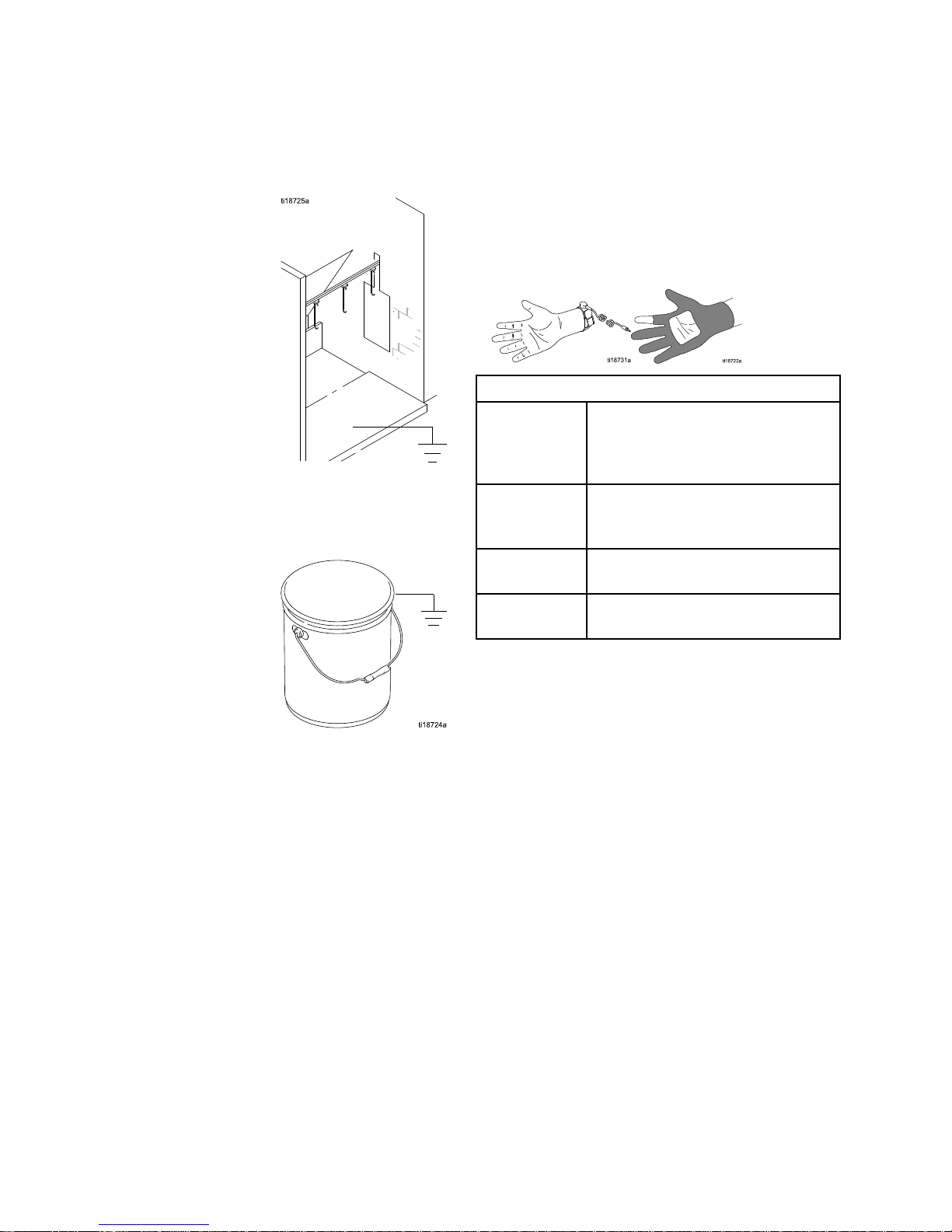

•

The oor of the spray area:

mustbeelectrically

conductiveandgrounded.Donotcovertheoor

withcardboardoranynon-conductivematerial

whichwouldinterruptgroundingcontinuity.

•

Flammable liquids in the spray area:

mustbekept

inapproved,groundedcontainers.Donotuse

plasticcontainers.Donotstoremorethanthe

quantityneededforoneshift.

•

All persons entering the spray area:

mustwear

shoeshavingconductivesolessuchasleather,

orwearpersonalgroundingstraps.Donot

wearshoeswithnon-conductivesolessuchas

rubberorplastic.Ifglovesarenecessary,wear

theconductiveglovessuppliedwiththegun.If

non-Gracoglovesareworn,cutoffngersorpalm

areaofglovestoensureyourhandcontactsthe

groundedgunhandle.

Key Key

Key

to totoFigs. Figs.

Figs.

12–15 12–15

12–15

Fig.12

Operatorisgroundedthrough

bareskincontactwiththegun

handleandconductiveshoes.A

conductiveglovecanalsobeused.

Fig.13

Objectbeingsprayedisgrounded

throughcontactwiththehanger

andconveyorsystem.

Fig.14

Gunisgroundedthroughthe

conductiveairhose.

Fig.15Fluidsupplylineandsourcemust

begrounded.

22

3A2494D

Page 23

GunSetup

Figure12GroundtheOperator

Figure13GroundtheObjectBeingSprayed

3A2494D 23

Page 24

GunSetup

Figure14GroundtheGun

Figure15GroundtheFluidSupply

24

3A2494D

Page 25

GunSetup

Check Check

Check

Gun Gun

Gun

Electrical Electrical

Electrical

Grounding Grounding

Grounding

MegohmmeterPartNo.241079(AA-seeFig.

16)isnotapprovedforuseinahazardousarea.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

area;

•Orallsprayingdevicesinthehazardousarea

areturnedoff,ventilationfansinthehazardous

areaareoperating,andtherearenoammable

vaporsinthearea(suchasopensolvent

containersorfumesfromspraying).

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

GracoPartNo.241079Megohmmeterisavailable

asanaccessorytocheckthatthegunisproperly

grounded.

1.Haveaqualiedelectricianchecktheelectrical

groundingcontinuityofthespraygunandair

hose.

2.TurnOFF(O)theESOn-Offswitch.

3.Turnofftheairanduidsupplytothegun.Follow

thePressureReliefProcedure,page27.

4.Disconnecttheuidhose.

5.Makesurethegroundedairhose(AH)is

connectedandthehosegroundwireis

connectedtoatrueearthground.

6.Measuretheresistancebetweenthegunhandle

(BB)andatrueearthground(CC).Usean

appliedvoltageof500minimumto1000volts

maximum.Theresistanceshouldnotexceed1

megohm.SeeFig.16.

7.Iftheresistanceisgreaterthan1megohm,check

thetightnessofthegroundconnectionsandbe

suretheairhosegroundwireisconnectedtoa

trueearthground.Iftheresistanceisstilltoo

high,replacetheairhose.

Figure16CheckGunElectricalGrounding

3A2494D 25

Page 26

GunSetup

Check Check

Check

Fluid Fluid

Fluid

Resistivity Resistivity

Resistivity

Toreducetheriskofre,explosion,orelectric

shock,checktheuidresistivityinanon-hazardous

areaonly.ResistanceMeter722886andProbe

722860arenotapprovedforuseinahazardous

area.

Failuretofollowthiswarningcouldcausere,

explosion,orelectricshockandresultinserious

injuryandpropertydamage.

GracoPartNo.722886ResistanceMeterand

722860Probeareavailableasaccessoriestocheck

thattheresistivityoftheuidbeingsprayedmeets

therequirementsofanelectrostaticairspraysystem.

Followtheinstructionsincludedwiththemeterand

probe.Readingsof25megohms-cmandabove

providethebestelectrostaticresults.

Ahighconductivitykitorhighconductivityhosemay

berequiredforreadingslessthan25megohm-cm.

Table Table

Table

4 44. ..Fluid Fluid

Fluid

Resistivity Resistivity

Resistivity

Levels Levels

Levels

Megohms Megohms

Megohms

- --cm cm

cm

1–77–2525–200200–2000

HighConductivity

Kitrecommended

HighConductivity

Kitmaybe

needed

Bestelectrostatic

results

Goodelectrostatic

results

Check Check

Check

Fluid Fluid

Fluid

Viscosity Viscosity

Viscosity

Tocheckuidviscosityyouwillneed:

•aviscositycup

•astopwatch.

1.Completelysubmergetheviscositycupin

theuid.Liftthecupoutquickly,startingthe

stopwatchassoonasthecupiscompletely

removed.

2.Watchthestreamofuidcomingfromthebottom

ofthecup.Assoonasthereisabreakinthe

stream,shutoffthestopwatch.

3.Recordtheuidtype,elapsedtime,andsizeof

theviscositycup.

4.Iftheviscosityistoohighortoolow,contactthe

materialsupplier.Adjustasnecessary.

Flush Flush

Flush

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

Theequipmentwastestedinuidatthefactory.To

avoidcontaminatingyouruid,ushtheequipment

withacompatiblesolventbeforeusingtheequipment.

Guidelines Guidelines

Guidelines

for for

for

Abrasive Abrasive

Abrasive

Materials Materials

Materials

Whensprayingabrasivematerials,followthese

guidelines:

•OrderPartNo.24N704Electrode(blue)for

abrasivematerials.

•Sizethenozzleproperlytoreduceuidpressure

below30psi(0.21MPa,2.1bar),producingan

8–12in.(200–300mm)uidstream.

•Operatethegunwiththeuidadjustmentknobin

thefullowpositionatalltimes.Useanexternal

uidregulator,nottheuidadjustmentknob,toset

theuidpressure.

•Usetheminimumatomizingandfanairpressures

possibletoachieveagoodpattern.

•Followallproceduresunder

CleantheGunDaily,page29.

•Inspecttheelectrodedailyandreplaceifdamaged.

SeeElectrodeReplacement,page39.

26 3A2494D

Page 27

Operation

Operation Operation

Operation

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

1.TurnOFF(O)theESOn/Offswitch.

2.Turnofftheairbleedvalvestotheuidsource

andtothegun.

3.Triggerthegunintoagroundedmetalwaste

containertorelievetheuidpressure.

4.Openthepumpdrainvalve,havingawaste

containerreadytocatchthedrainage.Leave

thepumpdrainvalveopenuntilyouareready

tosprayagain.

5.Ifthenozzleorhoseiscompletelycloggedor

pressureisnotfullyrelieved,slowlyloosenthe

hoseendcoupling.Nowclearthenozzleorhose.

Startup Startup

Startup

FollowallstepsunderGunSetupChecklist,page18.

Shutdown Shutdown

Shutdown

1.Flushthegun,seeFlushing,page28.

2.FollowthePressureReliefProcedure,page27.

3.Hangthegunfromitshook,withthenozzle

pointingdown.

3A2494D

27

Page 28

Maintenance

Maintenance Maintenance

Maintenance

Flushing Flushing

Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithauidthatiscompatiblewiththeuid

beingdispensedandtheequipmentwettedparts.

Toreducetheriskofre,explosion,orelectric

shock,turnOFF(O)theESOn-Offswitchbefore

ushingthegun.

NOTICE NOTICE

NOTICE

Donotusemethylenechlorideasaushingor

cleaningsolventwiththisgunasitwilldamage

nyloncomponents.

1.TurnOFF(O)theESOn-Offswitch.

2.FollowthePressureReliefProcedure,page27.

3.Changetheuidsourcetosolvent,ordisconnect

theuidlineandconnectasolventsupplyline

tothegun.

4.Pointthegunintoagroundedmetalpail.Flush

untilcleansolventowsfromthegun.

5.FollowthePressureReliefProcedure,page27.

6.Shutoffordisconnectthesolventline.

7.Hangthegunfromitshook,withthenozzle

pointingdown.

8.Whenreadytosprayagain,reconnect

theuidsupplyline.Followthe

GunSetupChecklist,page18.

28 3A2494D

Page 29

Maintenance

Clean Clean

Clean

the the

the

Gun Gun

Gun

Daily Daily

Daily

1.TurnOFF(O)theESOn-Offswitch.

2.Flushthegun.SeeFlushing,page28.

3.FollowthePressureReliefProcedure,page27.

4.Cleantheoutsideofthegunwithacompatible

solvent.Useasoftcloth.Pointthegundownto

preventsolventfromenteringthegunpassages.

Donotimmersethegun.

5.Removetheaircap.

6.Cleantheaircap,retainingring,andnozzlewith

asoftbrushandcompatiblesolvent.

7.Ifnecessary,useatoothpickorothersofttoolto

cleantheaircapholes.Donotusemetaltools.

8.Reinstalltheaircap.Tightensecurely.

3A2494D 29

Page 30

Maintenance

Daily Daily

Daily

System System

System

Care Care

Care

1.FollowthePressureReliefProcedure,page27.

2.Cleantheuidandairlters.

3.Checkforuidleaks.Tightenallttings.

4.Cleanworkpiecehangers.Usenon-sparking

tools.

5.Checkthemovementofthetriggerandvalves.

Lubricateifnecessary.

6.CheckGunElectricalGrounding,page25.

7.Hangthegunfromitshook,withthenozzle

pointingdown.

30 3A2494D

Page 31

ElectricalTests

Electrical Electrical

Electrical

Tests Tests

Tests

Usethefollowingprocedurestotestthecondition

ofthepowersupplyandgunbody,andelectrical

continuitybetweencomponents.

UsemegohmmeterPartNo.241079(AA)andan

appliedvoltageof500V.Connecttheleadsas

shown.

MegohmmeterPartNo.241079(AA-seeFig.

17)isnotapprovedforuseinahazardousarea.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

area;

•Orallsprayingdevicesinthehazardousarea

areturnedoff,ventilationfansinthehazardous

areaareoperating,andtherearenoammable

vaporsinthearea(suchasopensolvent

containersorfumesfromspraying).

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

Test Test

Test

Gun Gun

Gun

Resistance Resistance

Resistance

1.Flushanddrytheuidpassage.

2.For For

For

Model Model

Model

L40T14 L40T14

L40T14

and and

and

L40T15 L40T15

L40T15

guns guns

guns

only: only:

only:

Test

thebarrelcontinuitytoverifythatthemetalpin

inthebarrelisproperlygrounded.Measure

resistancebetweenthemetalpin(GP)andthe

airswivel(21).Theresistanceshouldbeless

than100ohms.Iftheresistanceis100ohmsor

more,replacethegunbody.

3.For For

For

all all

all

guns: guns:

guns:

Triggerthegunandmeasure

resistancebetweentheelectrodeneedletip(3)

andtheairswivel(21).Theresistanceshouldbe:

•75–120megohmsfor40kVguns

•104–148megohmsfor60kVguns

•148–193megohmsfor85kVguns

Ifoutsidethisrange,testthegun

untriggered.Ifstilloutsidethisrange,goto

TestPowerSupplyResistance,page32.Ifinrange,

seeElectricalTroubleshooting,page35forother

possiblecausesofpoorperformance.

Figure17TestGunResistance

3A2494D 31

Page 32

ElectricalTests

Test Test

Test

Power Power

Power

Supply Supply

Supply

Resistance Resistance

Resistance

1.Removethepowersupply(11).SeePower

SupplyRemovalandReplacement,page43.

2.Removethealternator(15)

fromthepowersupply.See

AlternatorRemovalandReplacement,page44.

3.Measureresistancefromthepowersupply's

groundstrips(EE)tothespring(11a).The

resistanceshouldbe:

•60–85megohmsfor40kVguns

•86–110megohmsfor60kVguns

•130–160megohmsfor85kVguns

4.Ifoutsidethisrange,replacethe

powersupply.Ifinrange,goto

TestElectrodeResistance,page32.

5.Ifyoustillhaveproblems,referto

ElectricalTroubleshooting,page35for

otherpossiblecausesofpoorperformance,or

contactyourGracodistributor.

6.Besurethespring(11a)isinplacebefore

reinstallingthepowersupply.

Figure18TestPowerSupplyResistance

Test Test

Test

Electrode Electrode

Electrode

Resistance Resistance

Resistance

Removetheelectrode(3).See

ElectrodeReplacement,page39.Measure

theresistancebetweenthecontact(HH)andthe

electrodewire(GG).Theresistanceshouldbe8-30

megohms.Ifoutofrange,replacetheelectrode.

NOTE: NOTE:

NOTE:

Ifthegunresistanceisstilloutofrangeafter

testingthepowersupplyandelectrode:

•Checkthattheconductiveo-ring(4a)ismaking

contactwiththebarrelpin.

•Checkthatthepowersupplyspring(11a)ismaking

contactwiththebarrelpin.

Figure19TestElectrodeResistance

32 3A2494D

Page 33

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseanelectricshock

orotherseriousinjuryiftheworkisnotperformed

properly.Donotinstallorrepairthisequipment

unlessyouaretrainedandqualied.

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page27,whenever

youareinstructedtorelievethepressure.

CheckallpossibleremediesintheTroubleshootingChartbeforedisassemblingthegun.

Spray Spray

Spray

Pattern Pattern

Pattern

Troubleshooting Troubleshooting

Troubleshooting

Somespraypatternproblemsarecausedbytheimproperbalancebetweenairanduid.

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Nouid.Rellsupply.

Loose,dirty,damaged

nozzle/seat.

Cleanorreplacenozzle,see

CleantheGunDaily,page29,or

AirCapandNozzleReplacement,

page38.

Flutteringorspittingspray.

Airinuidsupply.Checkuidsource.Rell.

Improperspraypattern.Damagedordirtynozzleoraircap.

Cleanorreplace.SeeAirCapand

NozzleReplacement,page38.

Fluidbuilduponaircapornozzle.

Clean.See

CleantheGunDaily,page29.

Fanairpressuretoohigh.Decrease.

Fluidtoothin.Increaseviscosity.

Fluidpressuretoolow.Increase.

Fanairpressuretoolow.Increase.

Fluidtoothick.Reduceviscosity.

Toomuchuid.Decreaseow.

Didnotapply50%overlap.Overlapstrokes50%. Streaks.

Dirtyordamagedaircap.

Cleanorreplaceaircap.See

CleantheGunDaily,page29,or

AirCapandNozzleReplacement,

page38.

3A2494D 33

Page 34

Troubleshooting

Gun Gun

Gun

Operation Operation

Operation

Troubleshooting Troubleshooting

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Atomizingairpressuretoohigh.

Closerestrictorvalvepartway,or

decreaseairpressureaslowas

possible;minimum45psi(0.32

MPa,3.2bar)neededatgunfor

fullvoltage.

Excessivesprayfog.

Fluidtoothin,oruidowistoo

low.

Increaseviscosityorincreaseuid

owrate.

Atomizingairpressuretoolow.

Openatomizingairvalvemoreor

increasegunairinletpressure;

uselowestairpressurenecessary.

Poorlymixedorltereduid.Remixorrelteruid.

“OrangePeel”nish.

Fluidtoothick.Reduceviscosity.

Fluidleaksfromtheuidpacking

area.

Wornpackingsorrod.

SeePackingRodRepair,page40.

Airleaksfromthefrontofthegun.

Airvalveisnotseatingproperly.

SeeAirValveRepair,page50.

Wornordamageduidpacking

rodorelectrode.

Replacepackingrod(2e)

orelectrode(3).See

PackingRodRepair,page40or

ElectrodeReplacement,page39.

Wornuidnozzleseat.Replacenozzle(4).See

AirCapandNozzleReplacement,

page38.

Looseuidnozzle.

Tighten.

Fluidleakagefromthefrontofthe

gun.

Damagednozzleo-ring.

SeeAirCapandNozzle

Replacement,page38.

Lowuidsupply.Adduidifnecessary.

Dirtyorcloggeduidnozzle.Clean.See

CleantheGunDaily,page29.

Gundoesnotspray.

Closedordamageduid

adjustmentvalve.

Openvalve,orsee

ESOn-OffandFluidAdjustment

ValveRepair,page49.

Dirtyaircap.

Misalignedaircapanduidnozzle.Cleanuidbuildupoffaircap

anduidnozzleseat.See

CleantheGunDaily,page29.

Poorgrounding.

SeeGrounding,page21.

Excessivepaintwrapbackto

operator.

Incorrectdistancefromguntopart.Shouldbe8–12in.(200–300mm).

34 3A2494D

Page 35

Troubleshooting

Electrical Electrical

Electrical

Troubleshooting Troubleshooting

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

ESOn/OffswitchisOFF(O).TurnON(I).

Gunairpressuretoolow(ES

indicatorisamber).

Checkairpressuretogun;

minimum45psi(0.32MPa,3.2

bar)neededatgunforfullvoltage.

Atomizingairpressuretoohigh.Decrease.

Incorrectdistancefromguntopart.Shouldbe8-12in.(200-300mm).

Poorlygroundedparts.Resistancemustbe1megohmor

less.Cleanworkpiecehangers.

Faultygunresistance.

See

TestGunResistance,page31.

Lowuidresistivity.See

CheckFluidResistivity,page26.

Fluidleaksfromthepacking(2c)

andcausesashort.

SeePackingRodRepair,page40.

Poorwrap.

Faultyalternator.

SeeAlternatorRemovaland

Replacement,page44.

ESOn/OffswitchisOFF(O).TurnON(I). ESorHzindicatorisnotlit.

Nopower.

Checkpowersupply,alternator,

andalternatorribboncable.See

PowerSupplyRemovaland

Replacement,page43and

AlternatorRemovaland

Replacement,page44.

Operatornotgroundedorisnear

ungroundedobject.

SeeGrounding,page21. Operatorgetsmildshock.

Gunnotgrounded.SeeCheckGunElectrical

Grounding,page25,and

TestGunResistance,page31.

Operatorgetsshockfrom

workpiece.

Workpiecenotgrounded.Resistancemustbe1megohmor

less.Cleanworkpiecehangers.

3A2494D 35

Page 36

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Gunistooclosetothepartbeing

sprayed.

Gunshouldbe8–12in.(200–300

mm)fromthepart.

Checkuidresistivity.See

CheckFluidResistivity,page26.

Voltage/currentdisplaystaysred

(smartgunsonly).

Dirtygun.

SeeCleantheGunDaily,page29.

ESorHZindicatorisamber.

Alternatorspeedistoolow.Increaseairpressureuntil

indicatorisgreen.Toavoid

over-atomization,usethe

atomizingairrestrictorvalveto

reducetheatomizingairtotheair

cap.

ESorHzindicatorisred.

Alternatorspeedistoohigh.Decreaseairpressureuntil

indicatorisgreen.

ErrordisplayappearsandHz

indicatorisred(Smartgunsonly).

Smartmodulehaslost

communicationwiththepower

supply.

CheckforgoodconnectionsbetweentheSmartModuleandthe

powersupply.SeeSmartModule

Replacement,page51and

PowerSupplyRemovaland

Replacement,page43.

36 3A2494D

Page 37

Repair

Repair Repair

Repair

Prepare Prepare

Prepare

the the

the

Gun Gun

Gun

for for

for

Service Service

Service

Installingandrepairingthisequipmentrequires

accesstopartsthatmaycauseelectricshockor

otherseriousinjuryiftheworkisnotperformed

properly.Donotinstallorservicethisequipment

unlessyouaretrainedandqualied.

•Checkallpossibleremedies

inTroubleshooting,page33beforedisassembling

thegun.

•Useavisewithpaddedjawstopreventdamage

toplasticparts.

•Lubricatesomepackingrodparts(2)andcertain

uidttingswithdielectricgrease(44),asspecied

inthetext.

•Lightlylubricateo-ringsandsealswithnon-silicone

grease.OrderPartNo.111265Lubricant.Donot

over-lubricate.

•OnlyusegenuineGracoparts.Donotmixoruse

partsfromotherProGunmodels.

•AirSealRepairKit24N789isavailable.The

kitmustbepurchasedseparately.Kitpartsare

markedwithanasterisk,forexample(6a*).

•FluidSealRepairKit24N790isavailable.The

kitmustbepurchasedseparately.Kitpartsare

markedwithasymbol,forexample(2a‡).

1.Flushthegun.SeeFlushing,page28.

2.Relievethepressure.See

PressureReliefProcedure,page27.

3.Disconnectthegunairanduidlines.

4.Removethegunfromtheworksite.Repairarea

mustbeclean.

3A2494D 37

Page 38

Repair

Air Air

Air

Cap Cap

Cap

and and

and

Nozzle Nozzle

Nozzle

Replacement Replacement

Replacement

NOTICE NOTICE

NOTICE

Triggerthegunwhileremovingthenozzletohelp

drainthegunandpreventanypaintorsolventleft

inthegunfromenteringtheairpassages.

1.SeePreparetheGunforService,page37.

2.Removetheretainingring(6)andaircap(5).

3.Triggerthegunwhileremovingtheuidnozzle

(4)assemblywiththemulti-tool(41).

Thenozzlecontactring(4a)isaconductive

contactring,notasealingo-ring.Toreduce

theriskofsparkingorelectricshock,donot

removethenozzlecontactring(4a)exceptto

replaceitandneveroperatethegunwithout

thecontactringinplace.Donotreplacethe

contactringwithanythingbutagenuineGraco

part.

NOTICE NOTICE

NOTICE

Usenon-siliconegrease,PartNo.111265,on

thesmallo-ring(4b).Donotover-lubricate.Do

notlubricatetheconductivecontactring(4a).

4.Makesuretheconductivecontactring(4a)and

thesmallo-ring(4b)areinplaceonthenozzle

(4).Lightlylubricatethesmallo-ring(4b).

NOTE: NOTE:

NOTE:

Theconductivecontactring(4a)may

showsomewearatthepointwhereitmakes

contactwiththebarrelpin.Thisisnormaland

doesnotrequirereplacement.

5.Makesuretheelectrodeneedle(3)isnger-tight.

6.Triggerthegunwhileinstallingtheuidnozzle

(4)withthemulti-tool(41).Tightenuntiltheuid

nozzleseatsinthegunbarrel(1/8to1/4turn

pasthand-tight).

7.Installtheaircap(5)andretainingring(6).Make

suretheu-cup(6a*)isinplacewiththelipsfacing

forward.

8.SeeTestGunResistance,page31.

Figure20AirCapandNozzleReplacement

38 3A2494D

Page 39

Repair

Electrode Electrode

Electrode

Replacement Replacement

Replacement

1.SeePreparetheGunforService,page37.

2.Removetheaircapandnozzle.See

AirCapandNozzleReplacement,page38.

3.Unscrewtheelectrode(3)withthemulti-tool(41).

NOTICE NOTICE

NOTICE

Toavoiddamagingtheplasticthreads,bevery

carefulwheninstallingtheelectrode.

4.Applylow-strength(purple)Loctite®orequivalent

threadsealanttotheelectrodeandpackingrod

threads.Installtheelectrodenger-tight.Donot

overtighten.

5.Installtheuidnozzleandaircap.See

AirCapandNozzleReplacement,page38.

6.SeeTestGunResistance,page31.

Figure21ElectrodeReplacement

3A2494D 39

Page 40

Repair

Fluid Fluid

Fluid

Packing Packing

Packing

Rod Rod

Rod

Removal Removal

Removal

1.SeePreparetheGunforService,page37.

2.Removetheaircapanduidnozzle.See

AirCapandNozzleReplacement,page38.

3.Removetheelectrode.See

ElectrodeReplacement,page39.

4.Loosenthetriggerscrews(13)andremovethe

trigger(12).

5.Removethepackingrod(2),usingthemulti-tool

(41).Removethespring(17).

6.Checkallpartsforwearordamageandreplace

ifnecessary.

Figure22FluidPackingRodRemoval

Packing Packing

Packing

Rod Rod

Rod

Repair Repair

Repair

NOTE: NOTE:

NOTE:

Youmayreplacethepackingrodasindividual

partsorasanassembly.

Adjust Adjust

Adjust

the the

the

Air Air

Air

Flow Flow

Flow

Lead Lead

Lead

and and

and

Lag Lag

Lag

NOTE: NOTE:

NOTE:

Thegunbeginsemittingairbeforetheuid

isdischargedandtheuidstopsbeforetheairow

stops.Thepackingrodassemblyispre-adjustedat

thefactoryforproperairleadandlag.Adjustonly

ifnecessary,asfollows.

1.Removethespring(17)fromthenut(2k).

2.Useahexwrenchtoholdtheendofthepacking

rod.Turnbothadjustmentnuts(2j,2k)outto

increasethelead/lagtimefortheairow.The

recommendedadjustmentisonehalfturnand

notmorethanonefullturn.

3.Tightenthenutstogethertoxtheminthenew

position.

40 3A2494D

Page 41

Repair

Assemble Assemble

Assemble

the the

the

Packing Packing

Packing

Rod Rod

Rod

NOTE: NOTE:

NOTE:

Beforeinstallingtheuidpackingrodintothe

gunbarrel,makesuretheinternalsurfacesofthe

barrelareclean.Removeanyresiduewithasoft

brushorcloth.Checktheinsideofthebarrelfor

marksfromhighvoltagearcing.Ifmarksarepresent,

replacethebarrel.

1.Placethepackingnut(2f)andseal(2b‡)onthe

uidrod(2e).Flatsonthepackingnutmustface

thebackoftheuidrod.Thesealo-ringmust

faceawayfromthepackingnut.

2.Filltheinnercavityofthespacer(2h‡)with

dielectricgrease(44).Placethespaceronthe

uidrod(2e)inthedirectionshown.Generously

applydielectricgreasetotheoutsideofthe

spacer.

3.Placetheuidpacking(2c‡)onthepackingrod

(2e)withitslipsfacingthefrontoftherod.Install

theneedlepacking(2d‡)withthemaleend

towardtheuidpacking,theninstallthehousing

(2g).

4.Lightlytightenthepackingnut(2f).Thepacking

nutisproperlytightenedwhenthereis3lb(13.3

N)ofdragforcewhenslidingthepackinghousing

(2g)assemblyalongtherod.Tightenorloosen

thepackingnutasneeded.

5.Installtheo-ring(2a‡)ontheoutsideofhousing

(2g).Lubricatetheo-ringwithnon-silicone

grease,PartNo.111265.Donotover-lubricate.

6.Installthespring(17)againstthenut(2j)as

shown.

7.Installthepackingrodassembly(2)intothe

gunbarrel.Usingthemulti-tool(41),tightenthe

assemblyuntiljustsnug.

8.Installtheelectrode.See

ElectrodeReplacement,page39.

9.Installthenozzleandaircap.See

AirCapandNozzleReplacement,page38.

10.Installthetrigger(12)andscrews(13).

11.SeeTestGunResistance,page31.

Figure23PackingRod

3A2494D

41

Page 42

Repair

Barrel Barrel

Barrel

Removal Removal

Removal

1.SeePreparetheGunforService,page37.

2.Carefullyloosenthenut(N)fromthebracketuid

tting(20).Pullthetube(T)outofthetting.

Makesurebothferrules(7,8)andthenutstay

withthetube.

3.Loosenthetwoscrews(27).

NOTICE NOTICE

NOTICE

Toavoiddamagingthepowersupply(11),pull

thegunbarrel(1)straightawayfromthegun

handle(16).Ifnecessary,gentlymovethegun

barrelfromsidetosidetofreeitfromthegun

handle.

4.Holdthegunhandle(16)withonehandandpull

thebarrel(1)straightoffthehandle.

NOTE: NOTE:

NOTE:

Ifthepowersupplyremainsinthebarrel,

removethealternator/powersupplyassemblyfrom

thebarrel.

Figure24BarrelRemoval

Barrel Barrel

Barrel

Installation Installation

Installation

1.Besurethegasket(28*)andgroundingspring

(18)areinplace.Makesurethegasketair

holesarealignedproperly.Replacethegasketif

damaged.

2.Makesurethespring(11a)isinplaceonthetipof

thepowersupply(11).Liberally Liberally

Liberally

applydielectric

grease(44)tothetipofthepowersupply.Place

thebarrel(1)overthepowersupplyandontothe

gunhandle(16).

3.Tightenthetwoscrews(27)oppositelyand

evenly(aboutahalfturnpastsnug).Donot

over-tightenthescrews(27).

4.Assembletheuidtube(T)intothebrackettting

(20).Ensurethattheferrules(7,8)areinplace.

Tightenthenut(N)securelyontothetting.

Makesurethetopttingremainstight.

5.SeeTestGunResistance,page31.

Figure25BarrelInstallation

42

3A2494D

Page 43

Repair

Power Power

Power

Supply Supply

Supply

Removal Removal

Removal

and and

and

Replacement Replacement

Replacement

•Inspectthegunhandlepowersupplycavityfordirt

ormoisture.Cleanwithaclean,dryrag.

•Donotexposegasket(28)tosolvents.

1.SeePreparetheGunforService,page37.

2.SeeBarrelRemoval,page42.

NOTICE NOTICE

NOTICE

Becarefulwhenhandlingthepowersupply

(11)toavoiddamagingit.

3.Graspthepowersupply(11)withyourhand.

Withagentlesidetosidemotion,freethepower

supply/alternatorassemblyfromthegunhandle

(16),thencarefullypullitstraightout.

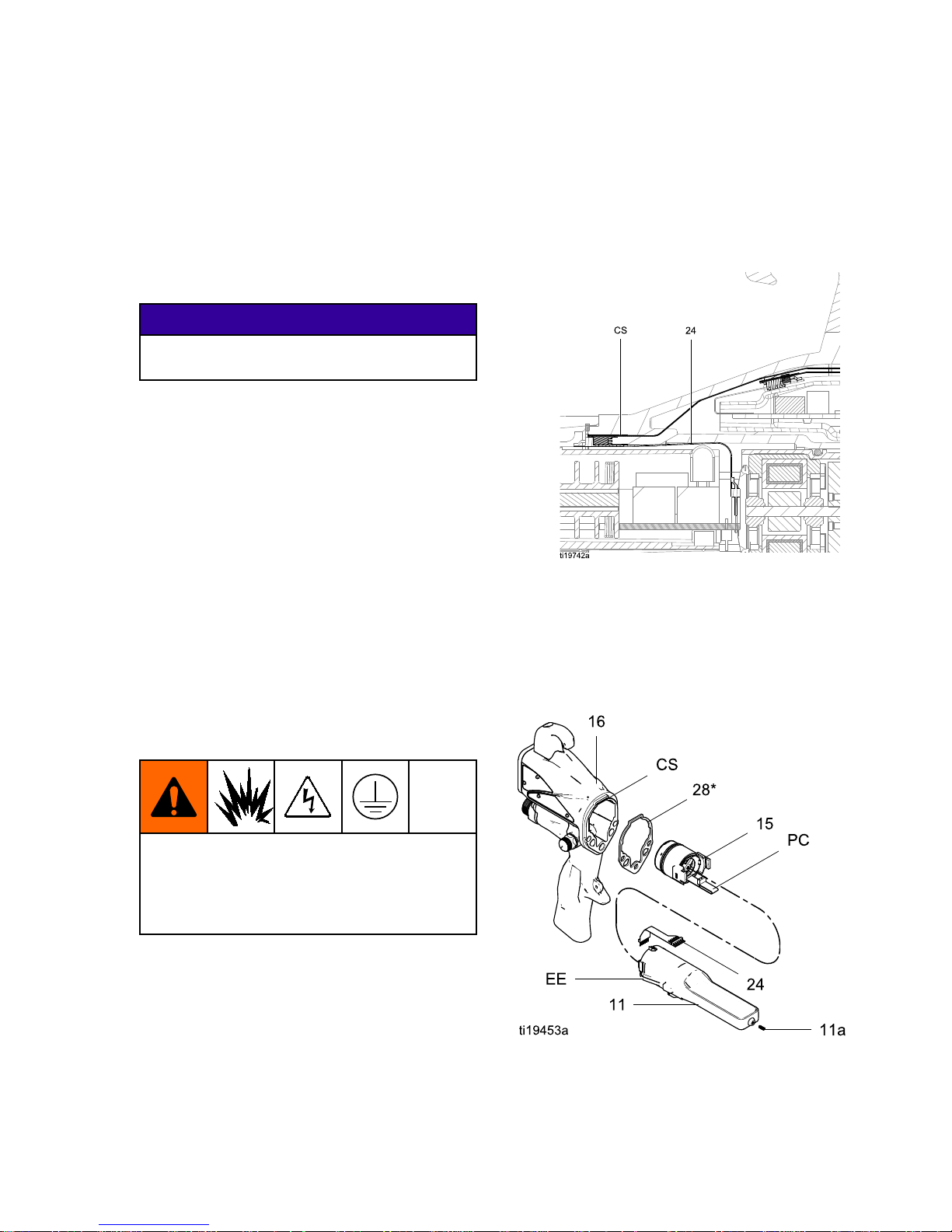

On Smart

Models only,

disconnecttheexiblecircuit(24)

fromthesocketatthetopofthehandle.

4.Inspectthepowersupplyandalternatorfor

damage.

5.Toseparatethepowersupply(11)fromthe

alternator(15),disconnectthe3-wireribbon

connector(PC)fromthepowersupply.

On Smart

Models only,

disconnectthe6–pinexiblecircuit

(24)fromthepowersupply.Slidethealternator

upandoffthepowersupply.

6.SeeTestPowerSupplyResistance,page32.

Replacethepowersupplyifnecessary.

Torepairthealternator,see

AlternatorRemovalandReplacement,page44.

Topreventdamagetothecableandpossible

interruptionofthegroundcontinuity,bendthe

alternator’s3–wireribboncable(PC)upward

andback,sothebendfacesthepowersupply

andtheconnectorisatthetop.

7.

Smart models only:

connectthe6–pinexible

circuit(24)tothepowersupply.

8.Connectthe3-wireribbonconnector(PC)tothe

powersupply.Tucktheribbonforward,under

thepowersupply.Slidethealternator(15)down

ontothepowersupply(11).

9.Insertthepowersupply/alternatorassemblyin

thegunhandle(16).Makesurethegroundstrips

(EE)makecontactwiththehandle.OnSmart

models,aligntheconnectorofthe6–pinexible

circuit(24)withthesocket(CS)atthetopofthe

handle.Pushtheconnectorsecurelyintothe

socketasyouslidethepowersupply/alternator

assemblyintothehandle.

Figure26ConnectFlexibleCircuit

10.Makesurethegasket(28*),groundspring(18),

andpowersupplyspring(11a)areinplace.

Assemblethebarrel(1)tothehandle(16).See

BarrelInstallation,page42.

11.SeeTestGunResistance,page31.

Figure27PowerSupply

3A2494D 43

Page 44

Repair

Alternator Alternator

Alternator

Removal Removal

Removal

and and

and

Replacement Replacement

Replacement

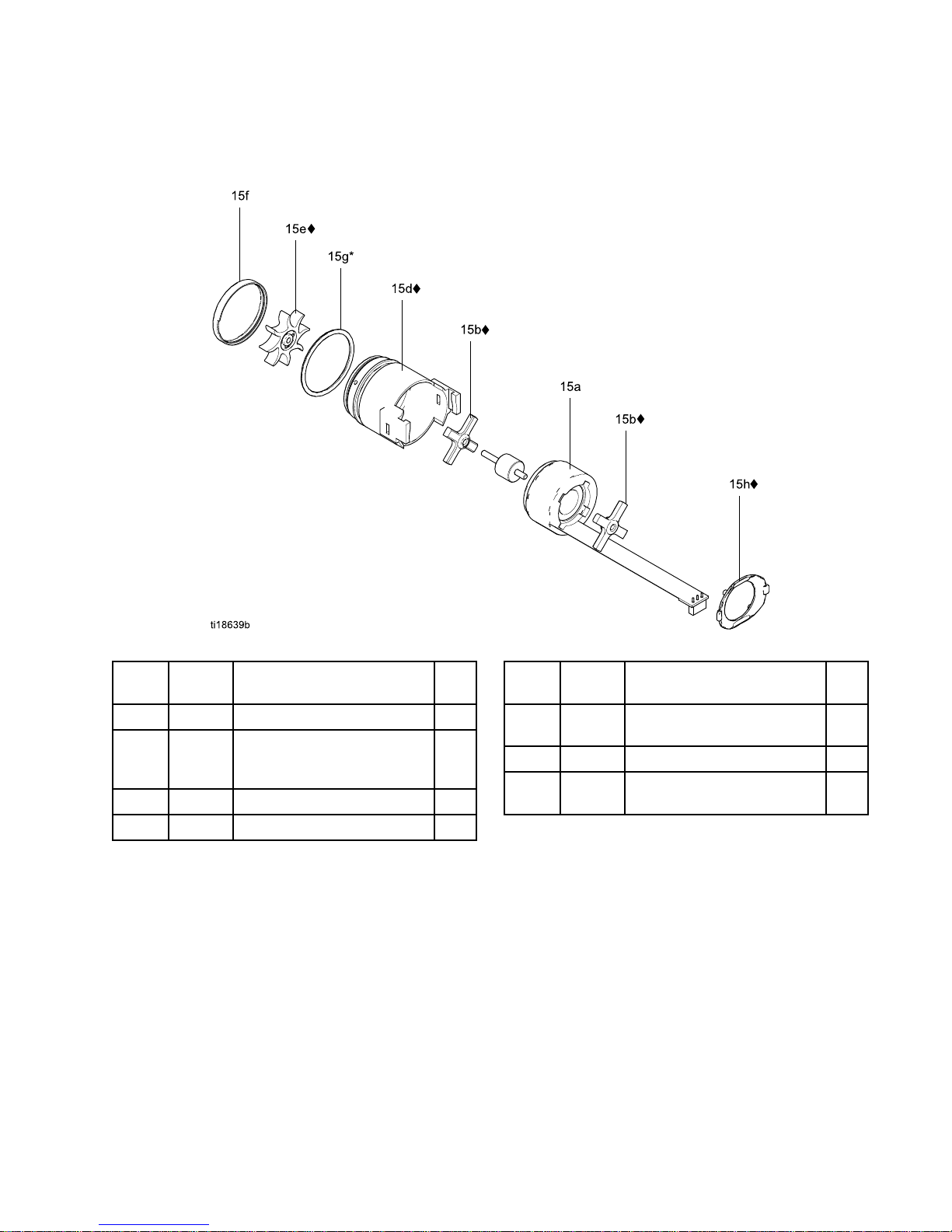

NOTE: NOTE:

NOTE:

Replacealternatorbearingsafter2000hours

ofoperation.OrderPartNo.24N706BearingKit.

Partsincludedinthekitaremarkedwithasymbol(♦).

1.SeePreparetheGunforService,page37.

2.Removethepowersupply/alternatorassembly

anddisconnectthealternator.SeePowerSupply

RemovalandReplacement,page43.

3.Measureresistancebetweenthetwoouter

terminalsofthe3-wireconnector(PC);itshould

be2.0–6.0ohms.Ifoutsidethisrange,replace

thealternatorcoil(15a).

4.Usingaatbladescrewdriver,prytheclip(15h)

offthehousing(15d).Removethecap(15f),

usingathinbladeorscrewdriver.

5.Ifnecessary,rotatethefan(15e)soitsblades

clearthefourbearingtabs(T)ofthehousing

(15d).

Figure28FanOrientation

6.Pushthefanandcoilassembly(15a)outthe

frontofthehousing(15d).

Figure29AlternatorCross-Section

NOTICE NOTICE

NOTICE

Donotscratchordamagethemagnet(M)or

shaft(S).Donotpinchordamagethe3–wire

connector(PC)whendisassemblingand

reassemblingthebearings.

7.Holdthecoilassembly(15a)onaworkbench

withthefanendfacingup.Usingawideblade

screwdriver,prythefan(15e)offtheshaft(S).

8.Removethetopbearing(15b2).

9.Removethebottombearing(15b1).

10.Installthenewbottombearing(15b1♦)onthe

longendoftheshaft(S).Theattersideofthe

bearingmustfaceawayfromthemagnet(M).

Installinthecoil(15a)sothebearingbladesare

ushwiththesurfaceofthecoil.

11.Pressthenewtopbearing(15b2♦)ontotheshort

endoftheshaftsothebearingbladesareush

withthesurfaceofthecoil(15a).Theatterside

ofthebearingmustfaceawayfromthecoil.

44

3A2494D

Page 45

Repair

12.Holdthecoilassembly(15a)onaworkbench

withthefanendfacingup.Pressthefan(15e♦)

ontothelongendoftheshaft(S).Thefanblades

mustbeorientedasshown.

13.Carefullypressthecoilassembly(15a)into

thefrontofthehousing(15d♦).The3–wire

connector(PC)mustbepositionedbelowthe

widernotch(W)ofthehousingtabs,asshownin

Fig.45.Besurethecoilalignmentpins(P)are

positionedasshowninFig.44.

14.Rotatethefan(15e)soitsbladesclearthefour

bearingtabs(T)atthebackofthehousing.

Ensurethatthebladesofthebottombearing

(15b1♦)alignwiththetabs.

15.Seatthecoilfullyintothehousing(15d♦).Secure

withtheclip(15h♦),ensuringthatitstabsengage

theslotsinthehousing.

16.Ensurethattheo-ring(15g)isinplace.Install

thecap(15f).

17.Installthealternatoronthepowersupply,and

installbothpartsinthehandle.SeePower

SupplyRemovalandReplacement,page43.

Figure30Alternator

3A2494D 45

Page 46

Repair

Fluid Fluid

Fluid

Tube Tube

Tube

Removal Removal

Removal

and and

and

Replacement Replacement

Replacement

1.Removethenut(22)fromthebracket(20).

2.Loosenthetting(9)toremovetheuidtube

(14)fromthebarrel(1).

3.Applydielectricgrease(44)tothethreadsofthe

tting(9)andtheo-ring(10).Ensuretheferrules

(7,8)areinplace.

NOTE: NOTE:

NOTE:

On40kVguns,theo–ring(10★)isnot

used,andferrules(7★)and(8★)arepartofthe

toptting(9).

NOTE: NOTE:

NOTE:

On60and85kVkVguns,checkthatthe

sleeve(SL)isinplacenearthetopoftheuid

tube.

4.Slidethetting(9)ontotheuidtube(14)and

threadthettingintothebarrel(1).Torqueto

25–35in-lb(2.8–3.9N•m).

5.Withtheferrules(7,8)seatedtothebracket(20),

screwthenut(22)securelyontothebracket.

Makesurethetopttingremainstight.

Figure31FluidTube

46 3A2494D

Page 47

Repair

Fan Fan

Fan

Air Air

Air

Adjustment Adjustment

Adjustment

Valve Valve

Valve

Repair Repair

Repair

1.SeePreparetheGunforService,page37.

2.Placeawrenchontheatsofthevalvehousing

(30a)andunscrewthevalvefromthehandle

(16).

NOTE: NOTE:

NOTE:

Youmayreplacethevalveasan

assembly(gotostep9)orreplaceonlytheo-ring

(steps3–9).

3.Removetheretainingring(30d).

4.Turnthevalveshaft(30b)counterclockwiseuntil

itcomesfreefromthevalvehousing(30a).

5.Inspecttheo-ring(30c).Removeifdamaged.

6.Cleanallpartsandinspectforwearordamage.

NOTE: NOTE:

NOTE:

Usenon-siliconegrease,PartNo.

111265.Donotover-lubricate.

7.Whenreassemblingthefanairvalve(30),lightly

lubricatethevalvethreadsandscrewtheshaft

(30b)fullyintothehousing(30a)untilbottomed.

Installtheo-ring(30c*),lubricate,andunscrew

thevalvestemuntiltheo-ringentersthehousing.

8.Reassembletheretainingring(30d).Unscrew

thevalvestemfromthehousinguntilitisstopped

bytheretainingring.

9.Screwthevalveassembly(30)intothegun

handle(16),usingawrenchontheatsofthe

housing.Torqueto15in-lb(1.7N•m).

Figure32FanAirAdjustmentValve

3A2494D

47

Page 48

Repair

Atomizing Atomizing

Atomizing

Air Air

Air

Restrictor Restrictor

Restrictor

Valve Valve

Valve

Repair Repair

Repair

1.SeePreparetheGunforService,page37.

2.Placeawrenchontheatsofthevalvehousing

(29a)andunscrewthevalvefromthehandle

(16).

NOTE: NOTE:

NOTE:

Youmayreplacethevalveasan

assembly(gotostep9)orreplaceonlytheo-ring

(steps3–9).

3.Unscrewthevalvestem(29e).Removethe

retainingring(29d).

4.Turnthevalvebody(29b)counterclockwiseuntil

itcomesfreefromthevalvehousing(29a).