Page 1

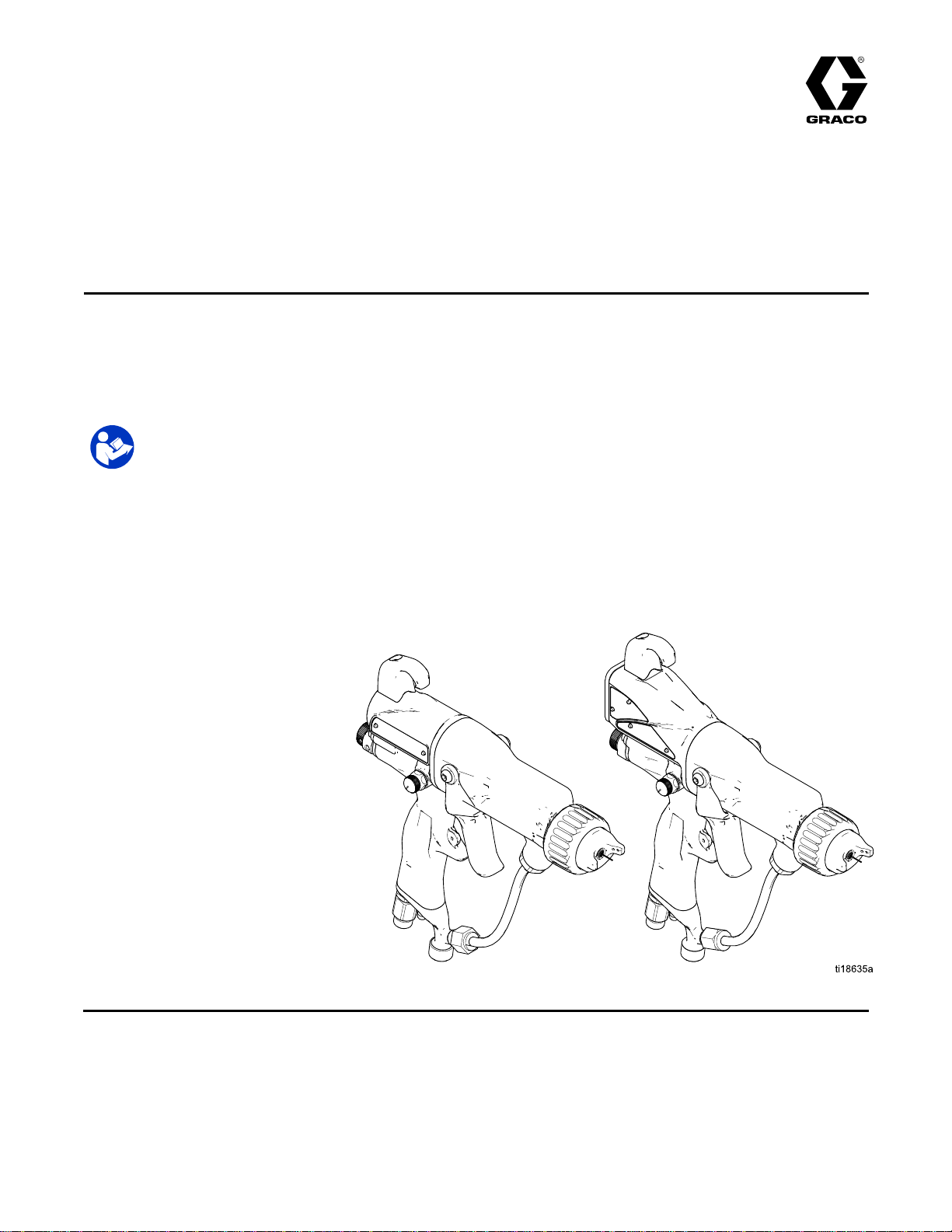

Instructions-Parts

Pro

Pro Pro

Air

Air Air

For

For For

For

For For

use

use use

100psi(0.7MPa,7.0bar)Maximum

FluidWorkingPressure

100psi(0.7MPa,7.0bar)MaximumAir

WorkingPressure

Seepage3formodelpartnumbersand

approvalinformation.

Xp™

Xp™ Xp™

Spray

Spray Spray

use

use use

use

use use

only.

only. only.

Class

in ininClass Class

Group

in ininGroup Group

Important

Important Important

Thisequipmentcouldpresenthazardsifnotoperatedaccordingto

theinformationinthismanual.Readallwarningsandinstructionsin

thismanualbeforeusingtheequipment.Save Save

Electrostatic

Electrostatic Electrostatic

Gun

Gun Gun

Div.

I, I,I,Div. Div.

II,

II, II,

Safety

Safety Safety

Hazardous

I IIHazardous Hazardous

Zone

Zone Zone

Explosive

1 11Explosive Explosive

Instructions

Instructions Instructions

3A2494P

EN

Locations

Locations Locations

Atmosphere

Atmosphere Atmosphere

using

Group

using using

Group Group

Locations

Locations Locations

Save

these

instructions.

these these

instructions. instructions.

materials.

D DDmaterials. materials.

using

Group

using using

Group Group

IIA

materials.

IIA IIA

materials. materials.

For

professional

For For

professional professional

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

Approvals...........................................................7

RelatedManuals................................................7

Warnings...........................................................8

GunOverview....................................................11

HowtheElectrostaticSprayGun

Works............................................11

Controls,Indicators,andComponents...........12

SmartGuns.................................................13

Installation..........................................................18

WarningSign...............................................18

VentilatetheSprayBooth.............................18

AirSupplyLine............................................19

FluidSupplyLine.........................................19

Grounding...................................................21

GunSetup..........................................................25

GunSetupProcedure...................................25

SoftSprayGunSetupProcedure..................28

HVLPGunSetupProcedure.........................29

RoundSprayGunSetupProcedure..............31

AbrasiveMaterialGunSetup

Procedure......................................33

CheckGunElectricalGrounding...................34

CheckFluidResistivity.................................35

CheckFluidViscosity...................................35

FlushBeforeUsingEquipment......................35

Operation...........................................................36

PressureReliefProcedure............................36

Startup........................................................37

Shutdown....................................................37

Maintenance......................................................38

DailyCareandCleaningChecklist................38

Flushing......................................................38

CleantheGunDaily.....................................40

DailySystemCare.......................................41

ElectricalTests...................................................42

TestGunResistance....................................42

TestPowerSupplyResistance.....................43

TestElectrodeResistance............................43

Troubleshooting..................................................44

SprayPatternTroubleshooting......................44

GunOperationTroubleshooting....................45

ElectricalTroubleshooting............................46

Repair................................................................47

PreparetheGunforService.........................47

AirCapandNozzleReplacement..................48

ElectrodeReplacement................................49

FluidPackingRodRemoval..........................50

PackingRodRepair.....................................50

BarrelRemoval............................................52

BarrelInstallation.........................................52

PowerSupplyRemovaland

Replacement..................................53

AlternatorRemovalandReplacement...........54

FluidTubeRemovalandReplacement...........56

FanAirAdjustmentValveRepair..................57

AtomizingAirRestrictorValveRepair............58

ESOn-OffandFluidAdjustmentValve

Repair............................................59

AirValveRepair...........................................60

SmartModuleReplacement..........................61

AirSwivelandExhaustValve

Replacement..................................62

Parts..................................................................63

GunModelswithStandardDisplay................63

GunModelswithSmartDisplay....................66

PackingRodAssembly.................................69

AlternatorAssembly.....................................70

ESOn-OffandFluidAdjustmentValve...........71

FanAirAdjustmentValveAssembly..............72

QuickAdjustFanValveAssembly.................72

AtomizingAirRestrictorValve

Assembly.......................................73

SmartModuleAssembly...............................74

RoundSprayAssembly................................75

HighConductivityFluidTubeAssembly:40

kV..................................................77

HighConductivityFluidTubeAssembly:60

kVand85kV..................................78

FluidNozzles.....................................................79

FluidNozzleSelectionChart.........................79

FluidNozzlePerformanceCharts..................80

AirCaps.............................................................82

AirCapSelectionGuide...............................82

AirConsumptionCharts...............................87

ElectrodeSelectionChart....................................88

RepairKitsandAccessories................................89

GunAccessories..........................................89

InlineFluidFilterKitAccessories...................90

OperatorAccessories...................................90

SystemAccessories.....................................90

Signs..........................................................91

TestEquipment...........................................91

Hoses.........................................................92

Dimensions........................................................93

TechnicalSpecications......................................94

CaliforniaProposition65.....................................94

2

3A2494P

Page 3

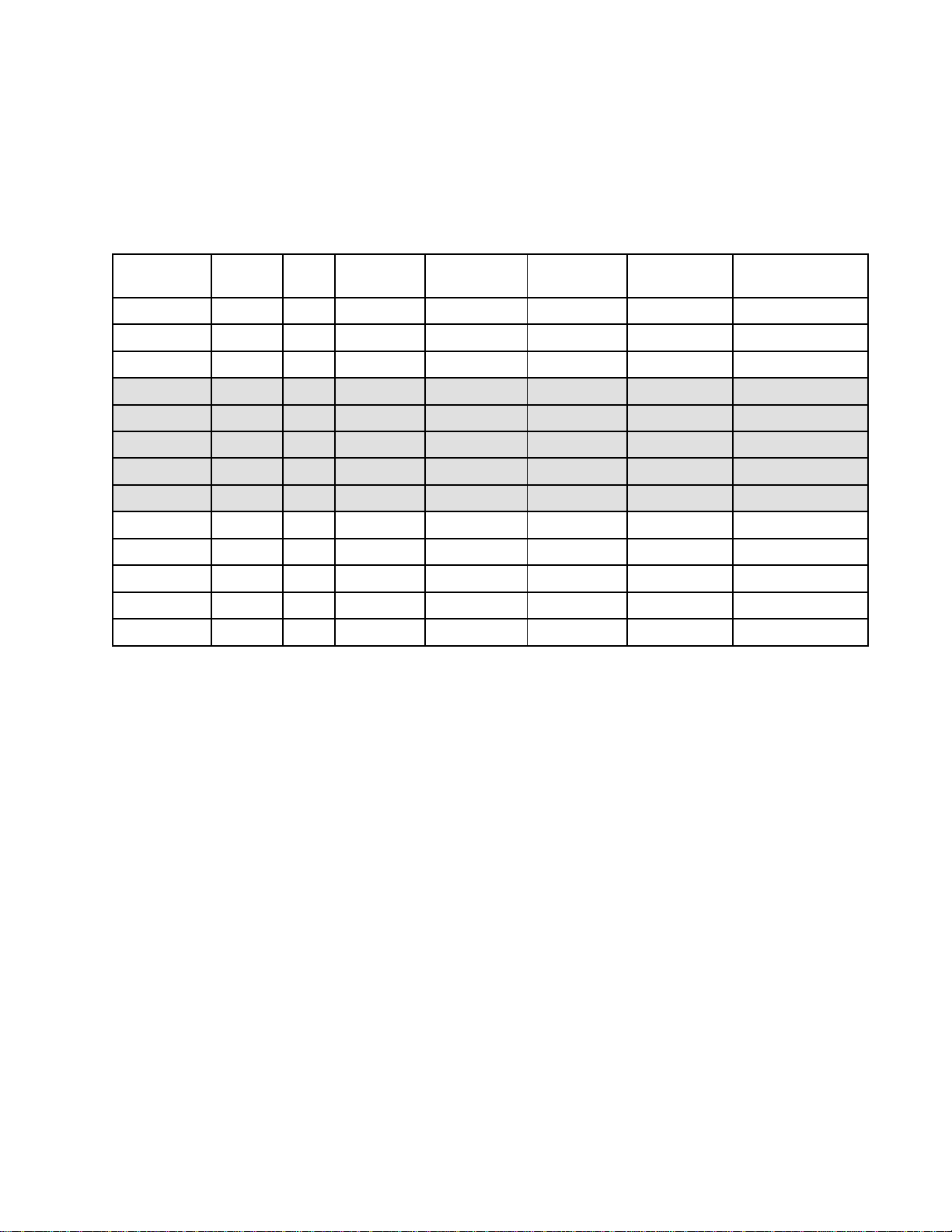

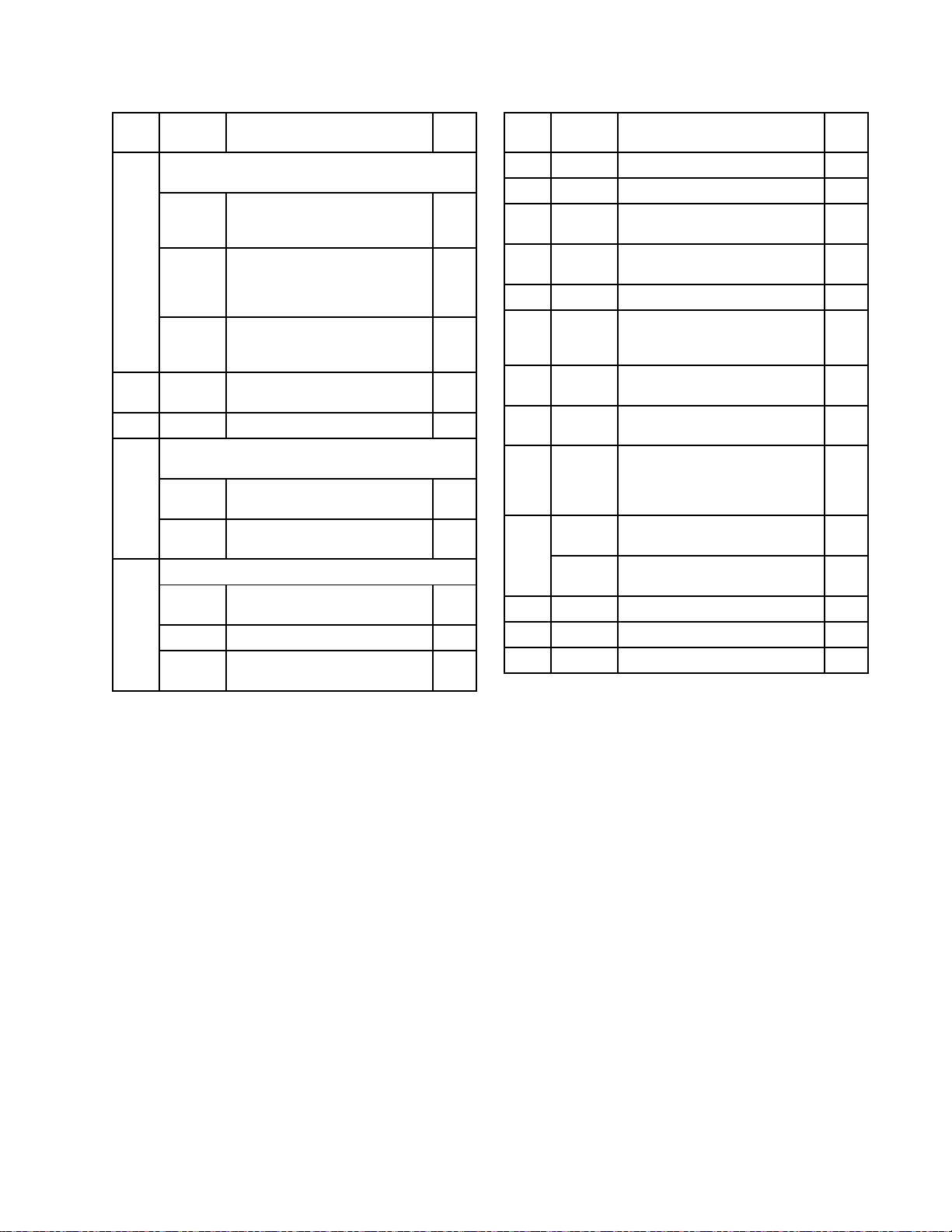

Models

Models

Models Models

General

General General

Equippedwithstandardelectrode,nozzle,aircapanduidtube.ForapplyingaClassAnishwithstandard

andspecialtycoatings.

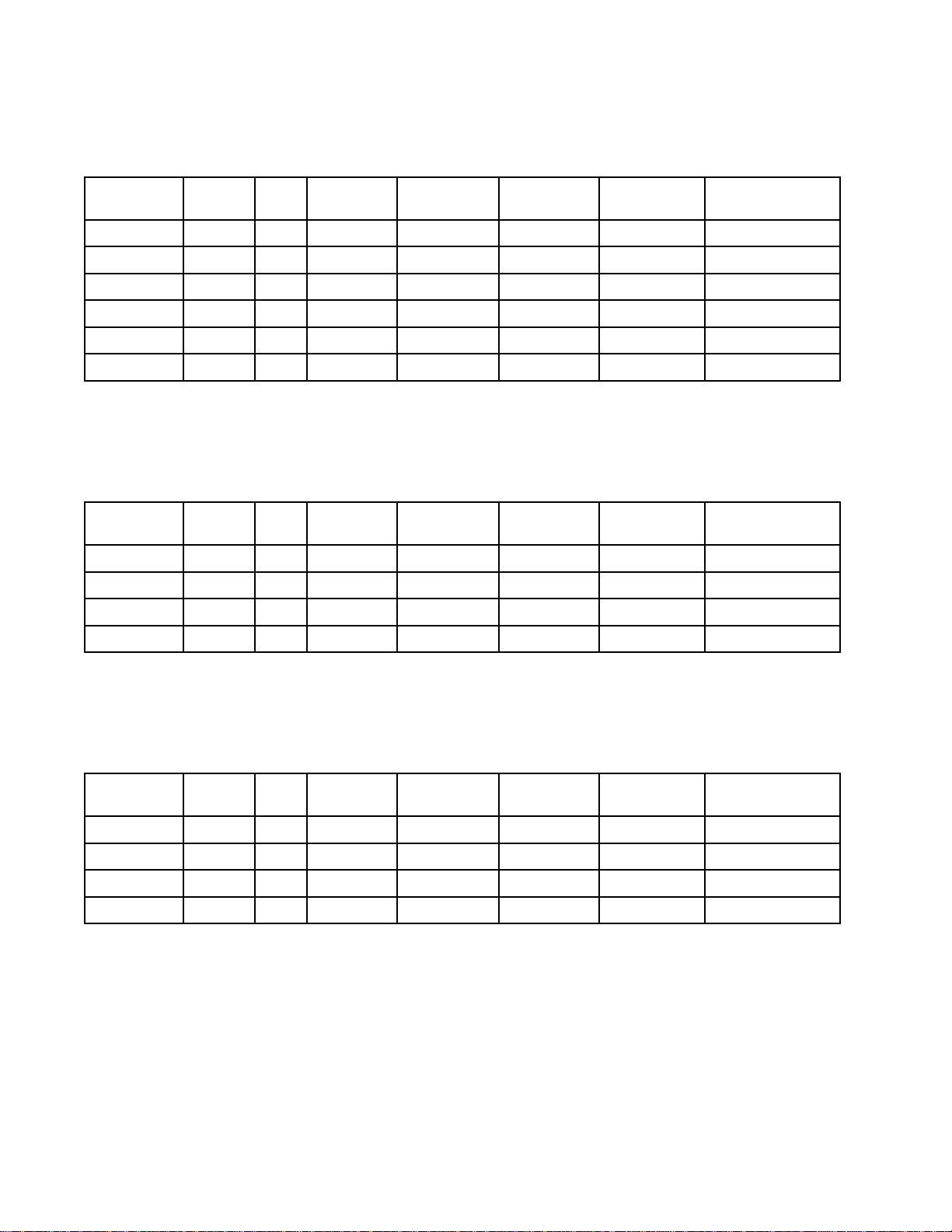

Part

Part Part

L40M10A40

L40T10

L40T12A40

L60M10

L60M12

L60T10

L60T12

L60T21A60

L85M10

L85M12A85

L85T10

L85T12A85

L85T50*

Gun

Gun Gun

No.

No. No.

Models

Models Models

Series

Series Series

C

C

C

C

C

C

C

A85

kV

kV kV

40

60

60

60

60

85

85

Display

Display Display

SmartStd1.5StdStdStd

StdStd1.5StdStdStd

StdStd1.2StdStdStd

SmartStd1.5StdStdStd

SmartStd1.2StdStdStd

StdStd1.5StdStdStd

StdStd1.2StdStdStd

StdStd1.0StdStdStd

SmartStd1.5StdStdStd

SmartStd1.2StdStdStd

StdStd1.5StdStdStd

StdStd1.2StdStdStd

StdStd1.5StdStdStd

Electrode

Electrode Electrode

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

Air

Cap

Air Air

Cap Cap

Fluid

Tube

Fluid Fluid

Tube Tube

*Equippedwithaquick-adjustfanvalve

3A2494P3

Page 4

Models

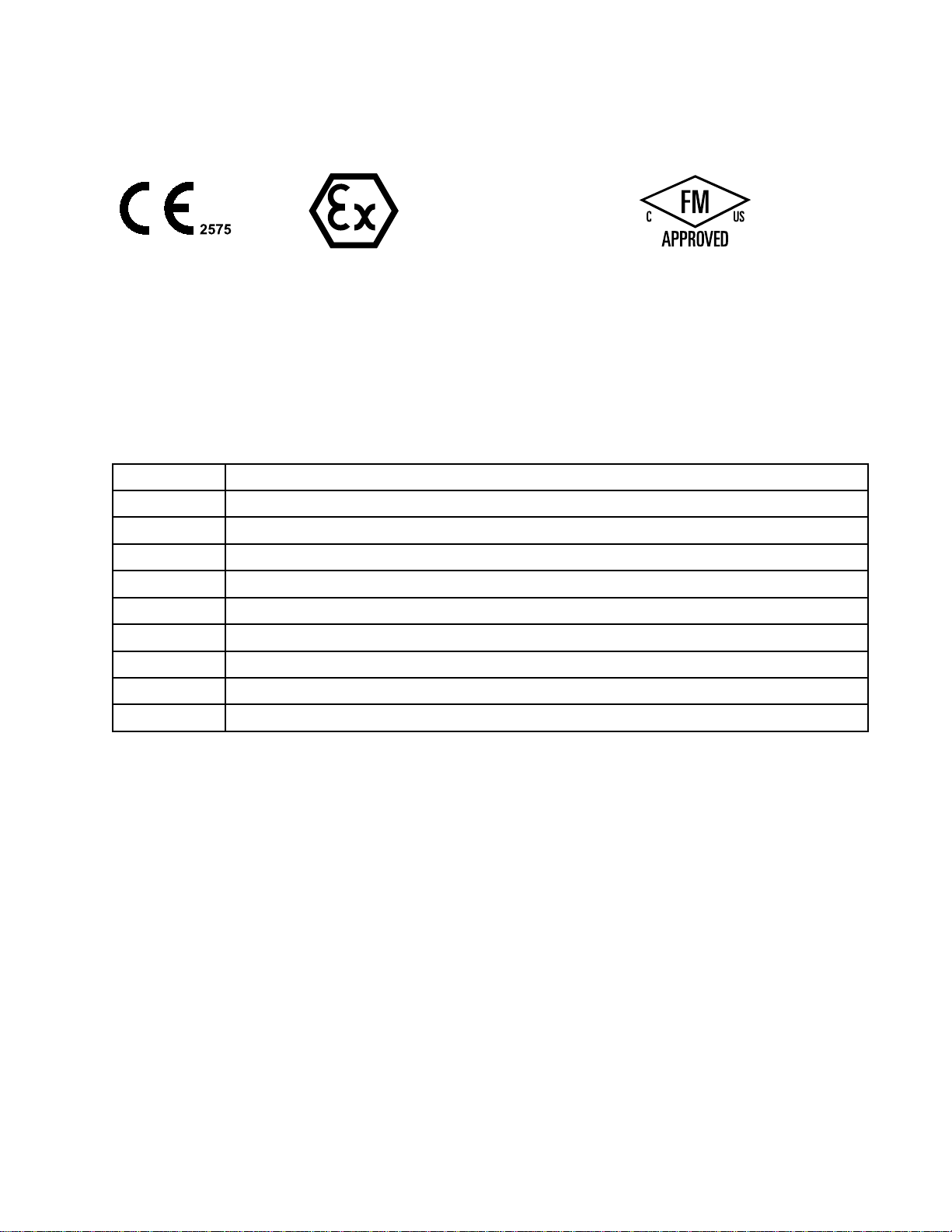

High

High High

EquippedwithalongerHighConductivityuidtubeforsprayinglowerresistivitymaterial.Mostmodelsare

alsoequippedwithhighwearelectrode,precisionhighwearnozzle,andstandardaircap.Forapplyinga

classAnishwithabrasiveandmetalliccoatings.

Conductivity

Conductivity Conductivity

Part

No.

Part Part

No. No.

L40M16A40

L40T13B40

L40T16

L40T26A40

L60M26A60

L60M16

L60T26A60

L60T13B60

L60T16

L85M16

L85M26A85

L85T16

Series

Series Series

C

C

C

C

C

Gun

Gun Gun

Models

Models Models

kV

kV kV

40

60

60

85

85

Display

Display Display

Smart

Std

Std

Std

Smart

Smart

Std

Std

Std

Smart

Smart

Std

Electrode

Electrode Electrode

HW1.5PHW

HW

HW1.5PHW

HW1.2PHW

HW1.2PHW

HW1.5PHW

HW1.2PHW

HW

HW1.5PHW

HW1.5PHW

HW1.2PHW

HW1.5PHW

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

1.5StdStdHC

1.5StdStdHC

Air

Cap

Air Air

Cap Cap

StdHC

StdHC

StdHC

StdHC

StdHC

StdHC

StdHC

StdHC

StdHC

StdHC

Fluid

Tube

Fluid Fluid

Tube Tube

L85T26A85

L85T56*

*Equippedwithaquick-adjustfanvalve

kV

Booster

kV kV

Booster Booster

The40kVBoosterprovidesthetransferefciencyofa60kVguninasmaller,morecompactsize.

Part

No.

Part Part

No. No.

L40M14A40

L40M15A40

L40T14

L40T15

A85

Gun

Gun Gun

Series

Series Series

C

C

Models

Models Models

kV

kV kV

40

40

Std

Std

Display

Display Display

SmartStd1.5StdStdStd

Smart

StdStd1.5StdStdStd

Std

HW1.2PHW

HW1.5PHW

Electrode

Electrode Electrode

HW1.5PHW

HW1.5PHW

StdHC

StdHC

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

Air

Cap

Air Air

Cap Cap

StdHC

StdHC

Fluid

Tube

Fluid Fluid

Tube Tube

4

3A2494P

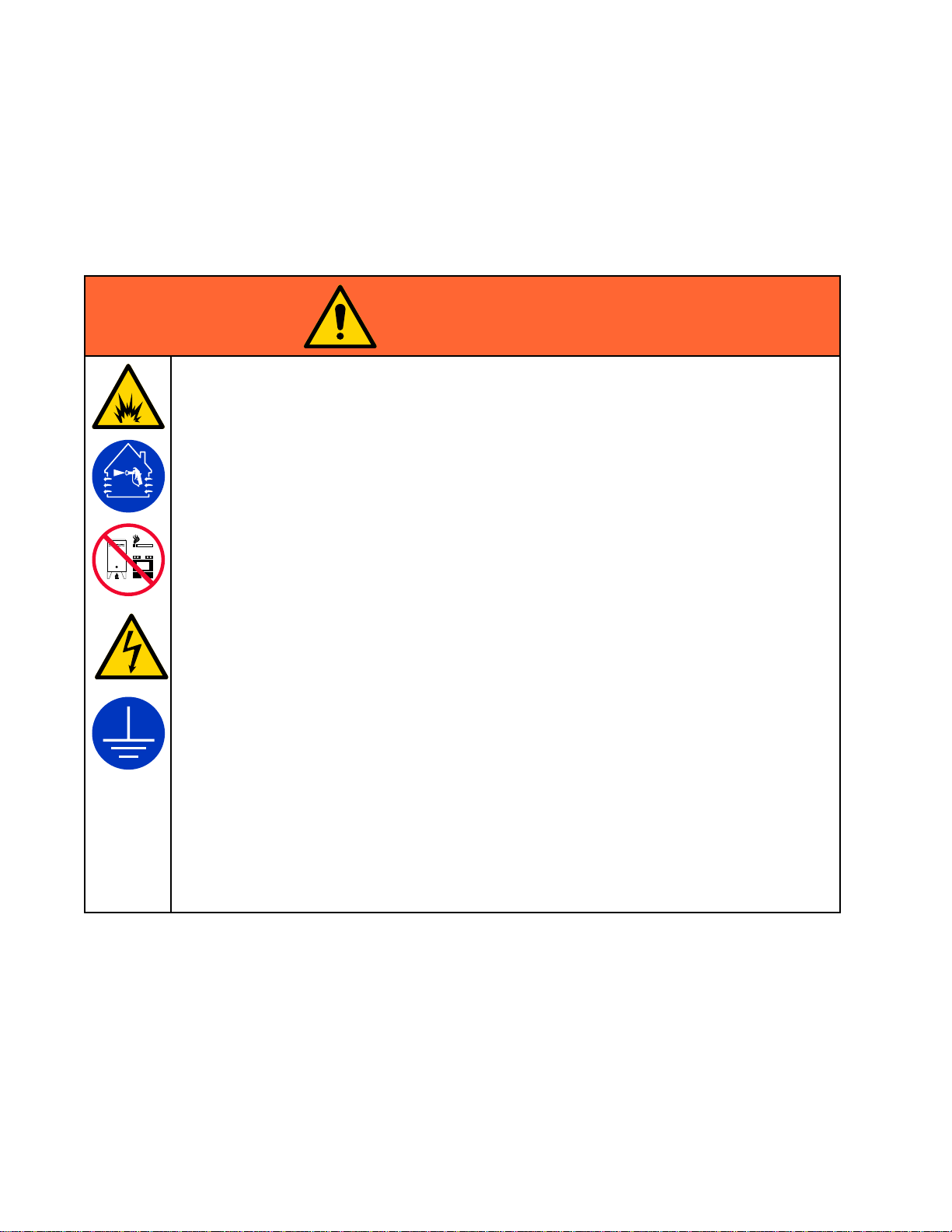

Page 5

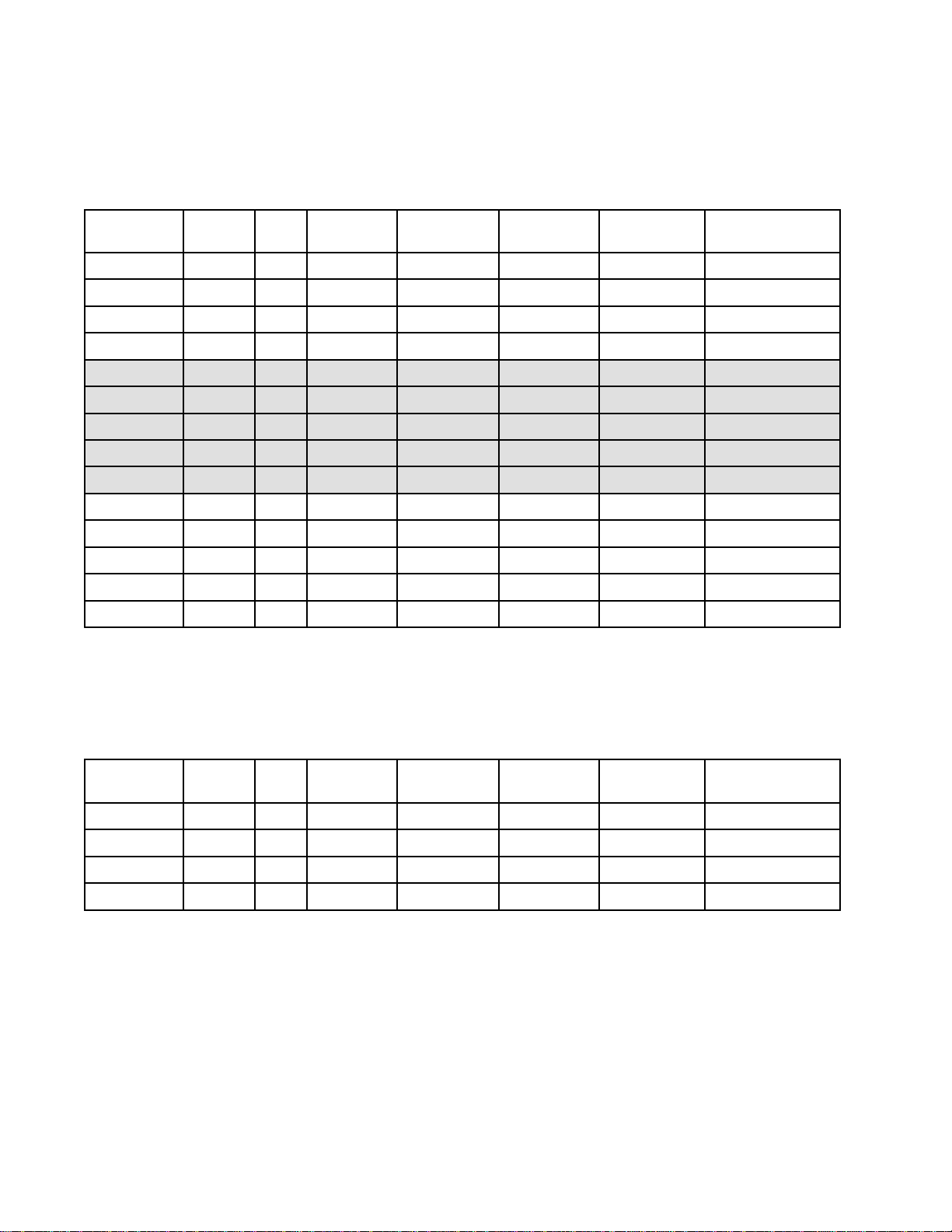

Models

Round

Round Round

Equippedwithroundspraynozzleandaircap.Forroundspraypatternapplications.

Part

Part Part

L40T31A40

L40T32A40

L60T11

L60T31A60

L60T32A60

L85T31A85

L85T32A85

Soft

Soft Soft

Equippedwithsoftsprayaircap.ForapplyingaclassAnishtosmall,lightweightparts.

Part

Part Part

L40T71A40

Spray

Spray Spray

No.

No. No.

Spray

Spray Spray

No.

No. No.

Gun

Gun Gun

Series

Series Series

C

Gun

Gun Gun

Series

Series Series

Models

Models Models

kV

kV kV

60

Models

Models Models

kV

kV kV

Display

Display Display

StdStdSmallPatternStd

StdStd

StdStd

StdStdSmallPatternStd

StdStd

StdStdSmallPatternStd

StdStd

Display

Display Display

StdStd1.0StdSoftSprayStd

Electrode

Electrode Electrode

Electrode

Electrode Electrode

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

MediumPattern

LargePattern

MediumPattern

MediumPattern

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

Fluid

Air

Cap

Air Air

Cap Cap

Air

Cap

Air Air

Cap Cap

Tube

Fluid Fluid

Tube Tube

Std

Std

Std

Std

Fluid

Tube

Fluid Fluid

Tube Tube

L60M71A60

L60M72A60

L60T71A60

L60T72A60

L85M71A85

L85T71A85

Aerospace

Aerospace Aerospace

Equippedwithaerospaceaircap,highwearelectrode,andprecisionhighwearnozzle.Forapplyinghigh

solidsandaerospacecoatings.

Part

No.

Part Part

No. No.

L85T73A85

L85T75A85

L85T78A85

Gun

Gun Gun

Series

Series Series

Models

Models Models

kV

kV kV

SmartStd1.0StdSoftSprayStd

SmartStd1.2StdSoftSprayStd

StdStd1.0StdSoftSprayStd

StdStd1.2StdSoftSprayStd

SmartStd1.0StdSoftSprayStd

StdStd1.0StdSoftSprayStd

Display

Display Display

Std

Std

Std

Electrode

Electrode Electrode

HW1.2PHW

HW1.5PHW

HW1.8PHW

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

Air

Cap

Air Air

Cap Cap

AEROStd

AEROStd

AEROStd

Fluid

Fluid Fluid

Tube

Tube Tube

3A2494P5

Page 6

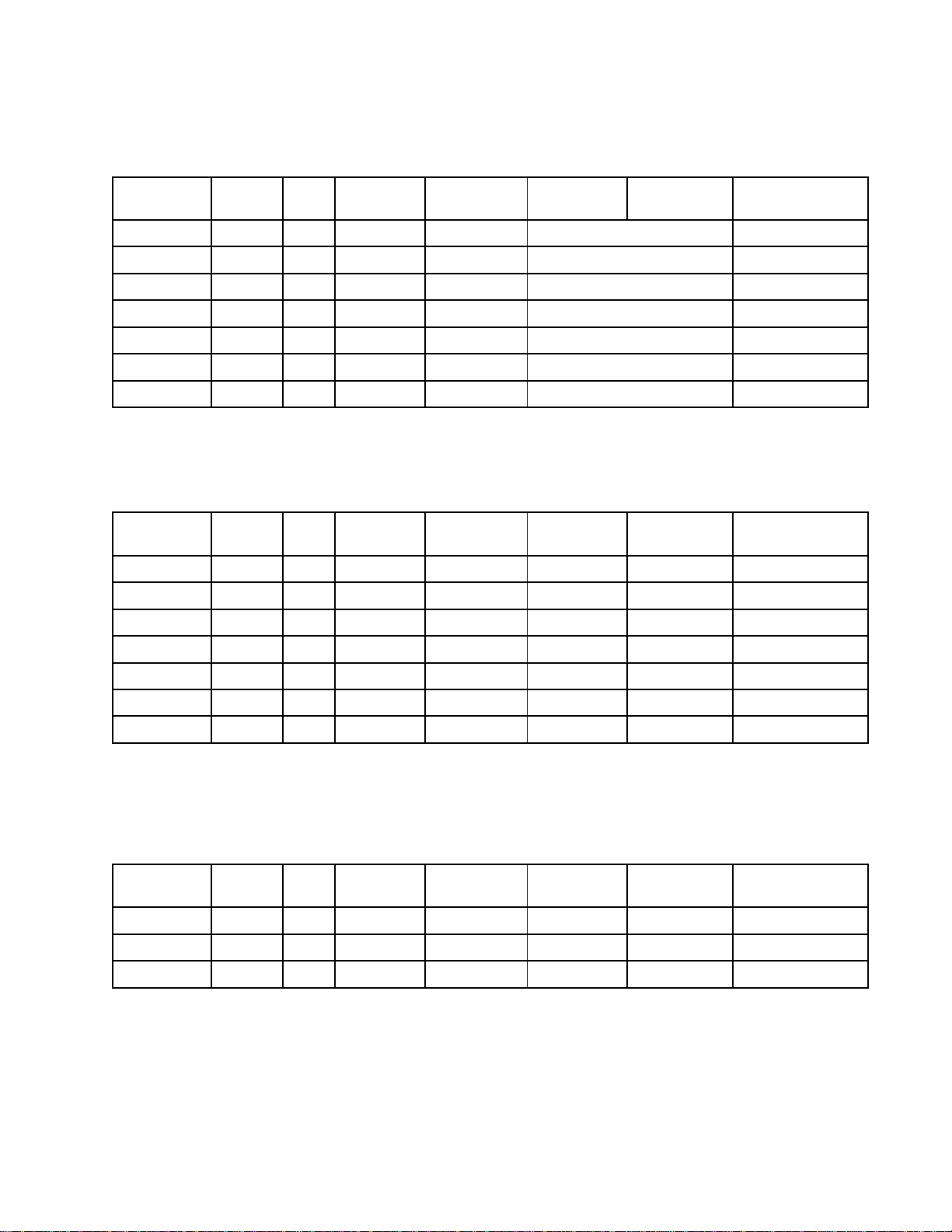

Models

HVLP

HVLP HVLP

EquippedwithHVLPaircap.

Part

Part Part

L40M77A40

L40T77A40

L60M77A60

L60T77A60

L85M77A85

L85T77A85

High

High High

EquippedwithESOn-OffwithAirRestrictorandFluidAdjustmentValve,whichlimitsairowtotheturbine.

Forapplicationsthatrequirehighairowattheaircap.

Part

Part Part

L60M57A60

Gun

Gun Gun

No.

No. No.

Air

Air Air

No.

No. No.

Models

Models Models

Series

Series Series

Flow

Flow Flow

Series

Series Series

kV

kV kV

Gun

Gun Gun

kV

kV kV

Display

Display Display

SmartStd1.5Std

StdStd1.5Std

SmartStd1.5Std

StdStd1.5Std

SmartStd1.5Std

StdStd1.5Std

Models

Models Models

Display

Display Display

SmartStd1.5StdStdStd

Electrode

Electrode Electrode

Electrode

Electrode Electrode

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

Air

Cap

Air Air

Cap Cap

HVLP

HVLP

HVLP

HVLP

HVLP

HVLP

Air

Cap

Air Air

Cap Cap

Fluid

Tube

Fluid Fluid

Tube Tube

Std

Std

Std

Std

Std

Std

Fluid

Tube

Fluid Fluid

Tube Tube

L60T57A60

L85M57A85

L85T57A85

Fixed

Fixed Fixed

EquippedwithESOn-OffandFixedFluidValve,whichextendselectrodeandnozzlelife.Forapplicationswith

abrasive,metallic,andextremelyabrasivematerials.

Part

Part Part

L60T98A60

L60T99A60

L85T90A85

L85T96A85

Fluid

Fluid Fluid

No.

No. No.

Flow

Flow Flow

Series

Series Series

Gun

Gun Gun

kV

kV kV

StdStd1.5StdStdStd

SmartStd1.5StdStdStd

StdStd1.5StdStdStd

Models

Models Models

Display

Display Display

StdShort

StdShort

Std

Std

Electrode

Electrode Electrode

HW1.5PHW

HW1.5PHW

Nozzle

Nozzle Nozzle

(mm)

(mm) (mm)

1.5PHW

1.5PHW

Air

Cap

Air Air

Cap Cap

StdStd

StdHC

StdStd

StdHC

Fluid

Tube

Fluid Fluid

Tube Tube

63A2494P

Page 7

Approvals

2575

Approvals

Approvals Approvals

G

II IIII2 22G G

0.24mJT6

FM12ATEX0068

EN50050-1

Ta0°C–50°C

Related

Related Related

Manual

Manual Manual

3A2498

3A6929

3A7005

3A6833

307263ProbeandMeter,Instructions

308393

309227

309455TestFixture,HighVoltageProbe,andkVMeter,Instructions

406999

No.

No. No.

Manuals

Manuals Manuals

Description

Description Description

RoundSprayKit,Instructions(largepattern)

RoundSprayKit,Instructions(smallandmediumpattern)

QuickAdjustFanValveKit,Instructions

HVLPVericationKit,Instructions

GunWasherKit,Instructions

GunFlushBoxModule,Instructions

VoltageTesterConversionKit,Instructions

3A2494P

7

Page 8

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

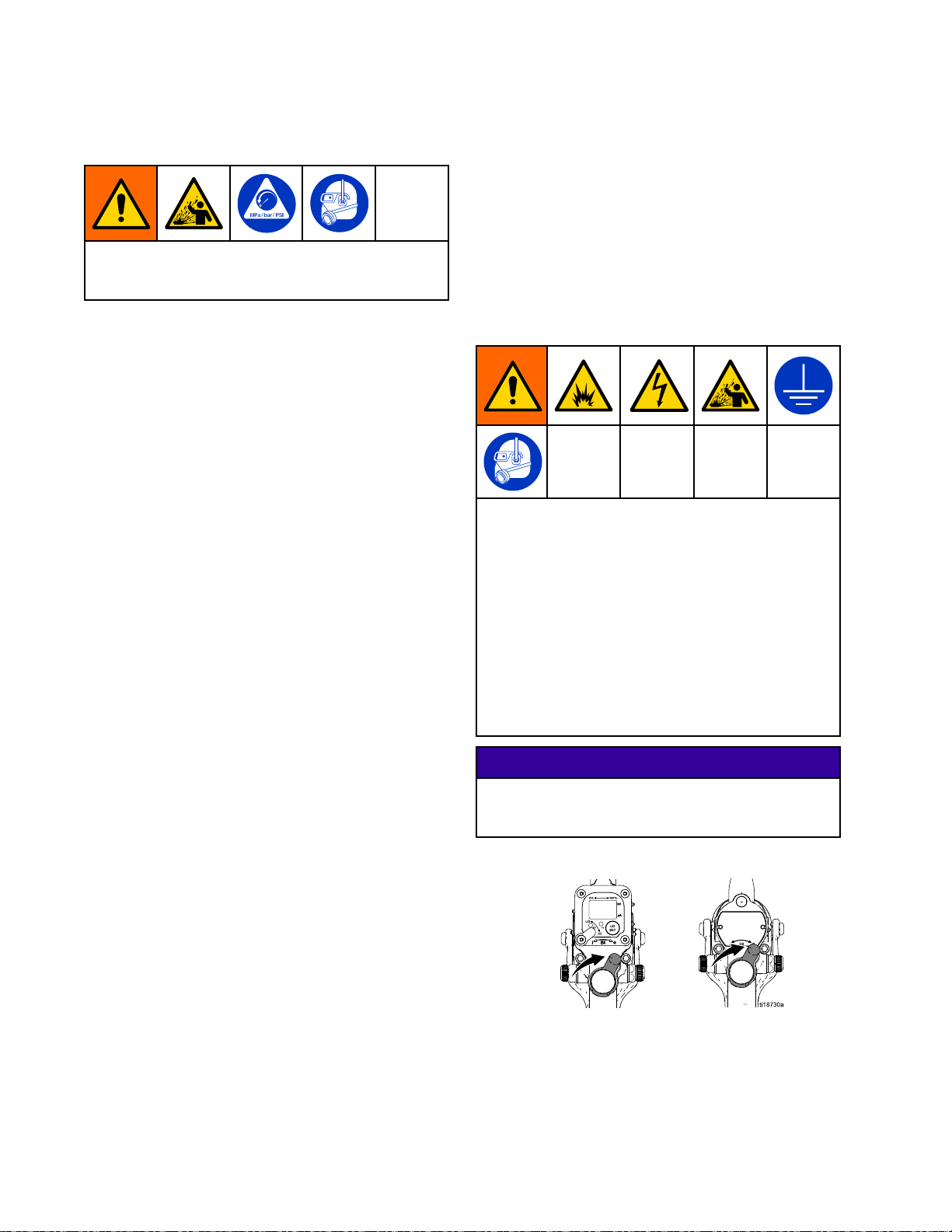

WARNING

WARNING WARNING

FIRE,

EXPLOSION,

FIRE, FIRE,

EXPLOSION, EXPLOSION,

Flammablefumes,suchassolventandpaintfumes,inworkareacanigniteorexplode.Paint

orsolventowingthroughtheequipmentcancausestaticsparking.Tohelppreventre,

explosion,andelectricshock:

•Electrostaticequipmentmustbeusedonlybytrained,qualiedpersonnelwhounderstand

therequirementsofthismanual.

•Groundallequipment,personnel,objectbeingsprayed,andconductiveobjectsinorcloseto

sprayarea.Resistancemustnotexceed1megohm.SeeGrounding Grounding

•OnlyusegroundedGracoconductiveairsupplyhoses.

•Donotusepaillinersunlesstheyareconductiveandgrounded.

Stop

•Stop Stop

•Checkgunresistance,hoseresistance,andelectricalgroundingdaily.

•Useandcleanequipmentonlyinwellventilatedarea.

•Interlockthegunairanduidsupplytopreventoperationunlessventilationairowisabove

•UseonlyGroupIIAorGroupDmaterials.

•Usecleaningsolventswithhighestpossibleashpointwhenushingorcleaningequipment.

•Neversprayorushsolventathighpressure.

•Tocleantheexterioroftheequipment,cleaningsolventsmusthaveaashpointatleast15°

•Alwaysturntheelectrostaticsoffwhenushing,cleaningorservicingequipment.

•Eliminateallignitionsourcessuchaspilotlights,cigarettes,portableelectriclamps,and

•Donotplugorunplugpowercordsorturnlightsonoroffwhenammablefumesarepresent.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepthesprayareacleanatalltimes.Usenon-sparkingtoolstocleanresiduefromthe

•Keepaworkingreextinguisherintheworkarea.

operation

operation operation

equipmentuntilyouidentifyandcorrecttheproblem.

theminimumrequiredvalue.

Cor59°Faboveambienttemperature.Non-ignitableuidsarepreferred.

plasticdropcloths(potentialstaticsparking).

boothandhangers.

AND

ELECTRIC

AND AND

ELECTRIC ELECTRIC

immediately

immediately immediately

ifstaticsparkingoccursoryoufeelashock.Donotuse

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

Grounding

instructions.

83A2494P

Page 9

WARNING

WARNING WARNING

PRESSURIZED

PRESSURIZED PRESSURIZED

Fluidfromtheequipment,leaks,orrupturedcomponentscansplashintheeyesoronskin

andcauseseriousinjury.

EQUIPMENT

EQUIPMENT EQUIPMENT

HAZARD

HAZARD HAZARD

Warnings

•FollowthePressure Pressure

cleaning,checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhoses,tubes,andcouplingsdaily.Replacewornordamagedpartsimmediately.

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

Forcompleteinformationaboutyourmaterial,requestaSafetyDataSheet(SDS)from

yourdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

PLASTIC

PLASTIC PLASTIC

Manycleaningsolventscandegradeplasticpartsandcausethemtofail,whichcouldcause

seriousinjuryorpropertydamage.

Pressure

MISUSE

MISUSE MISUSE

PARTS

PARTS PARTS

Relief

Procedure

Relief Relief

Procedure Procedure

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.

CLEANING

CLEANING CLEANING

SOLVENT

SOLVENT SOLVENT

whenyoustopspraying/dispensingandbefore

Specications

Specications Specications

Pressure

HAZARD

HAZARD HAZARD

Relief

Relief Relief

inallequipmentmanuals.

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Technical

•Useonlycompatiblesolventstocleanplasticstructuralorpressure-containingparts.

•SeeTechnical Technical

Technical

thesolventmanufacturerforinformationandrecommendationsaboutcompatibility.

Specications

Specications Specications

inallequipmentmanualsformaterialsofconstruction.Consult

3A2494P9

Page 10

Warnings

WARNING

WARNING WARNING

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadSafetyDataSheet(SDS)toknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

FLUID

FLUID FLUID

guidelines.

manufacturer.

OR

FUMES

OR OR

FUMES FUMES

PROTECTIVE

PROTECTIVE PROTECTIVE

HAZARD

HAZARD HAZARD

EQUIPMENT

EQUIPMENT EQUIPMENT

103A2494P

Page 11

GunOverview

Gun

Gun Gun

How

How How

Theairhosesuppliesairtothespraygun.Partof

theairoperatesthealternatorturbineandtherest

oftheairatomizestheuidbeingsprayed.The

alternatorgeneratespower,whichisconvertedby

thepowercartridgetosupplyhighvoltagetothe

gun’selectrode.

Overview

Overview Overview

the

Electrostatic

the the

Electrostatic Electrostatic

Spray

Spray Spray

Gun

Gun Gun

Works

Works Works

Thepumpsuppliesuidtotheuidhoseandgun,

wheretheuidiselectrostaticallychargedasit

passestheelectrode.Thechargeduidisattracted

tothegroundedworkpiece,wrappingaroundand

evenlycoatingallsurfaces.

3A2494P

11

Page 12

GunOverview

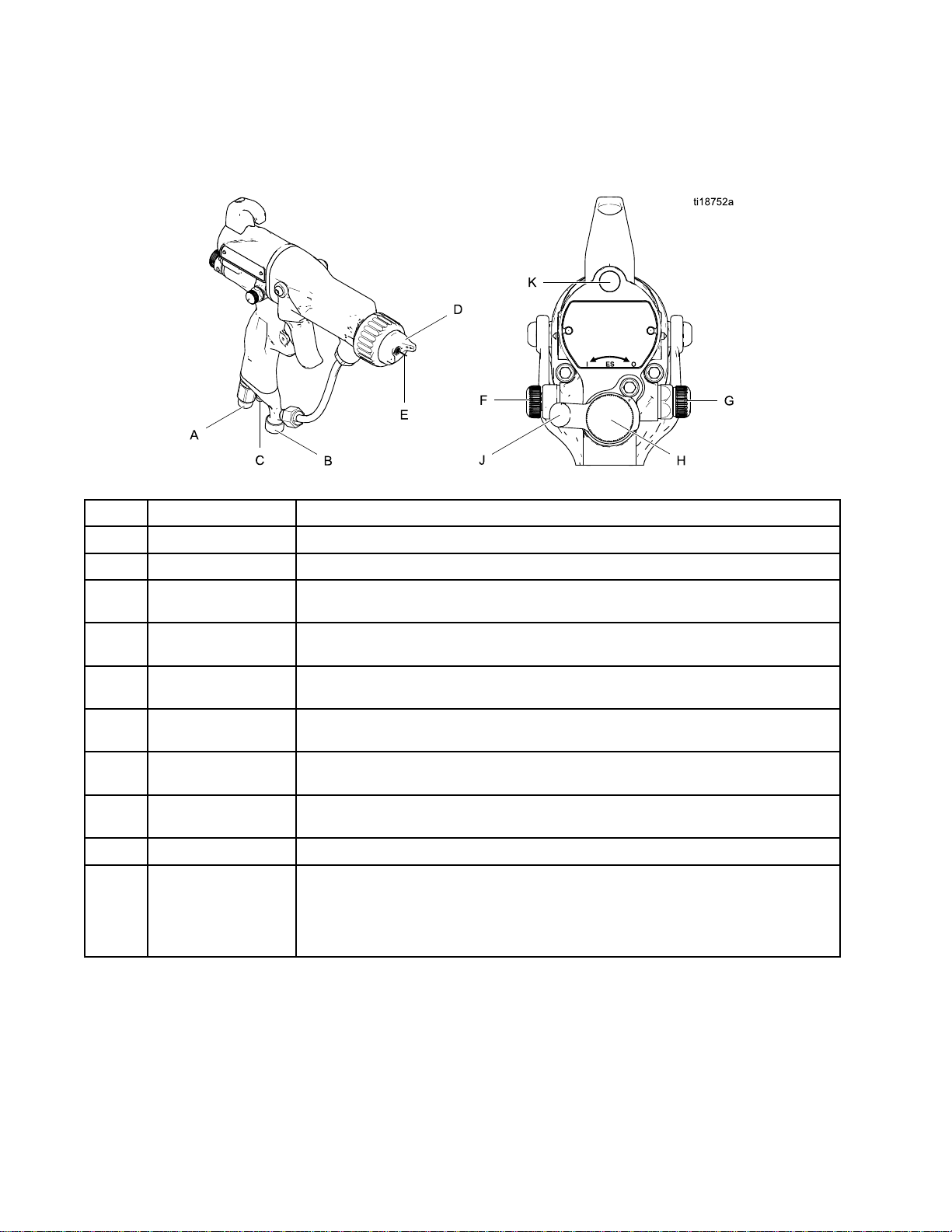

Controls,

Controls, Controls,

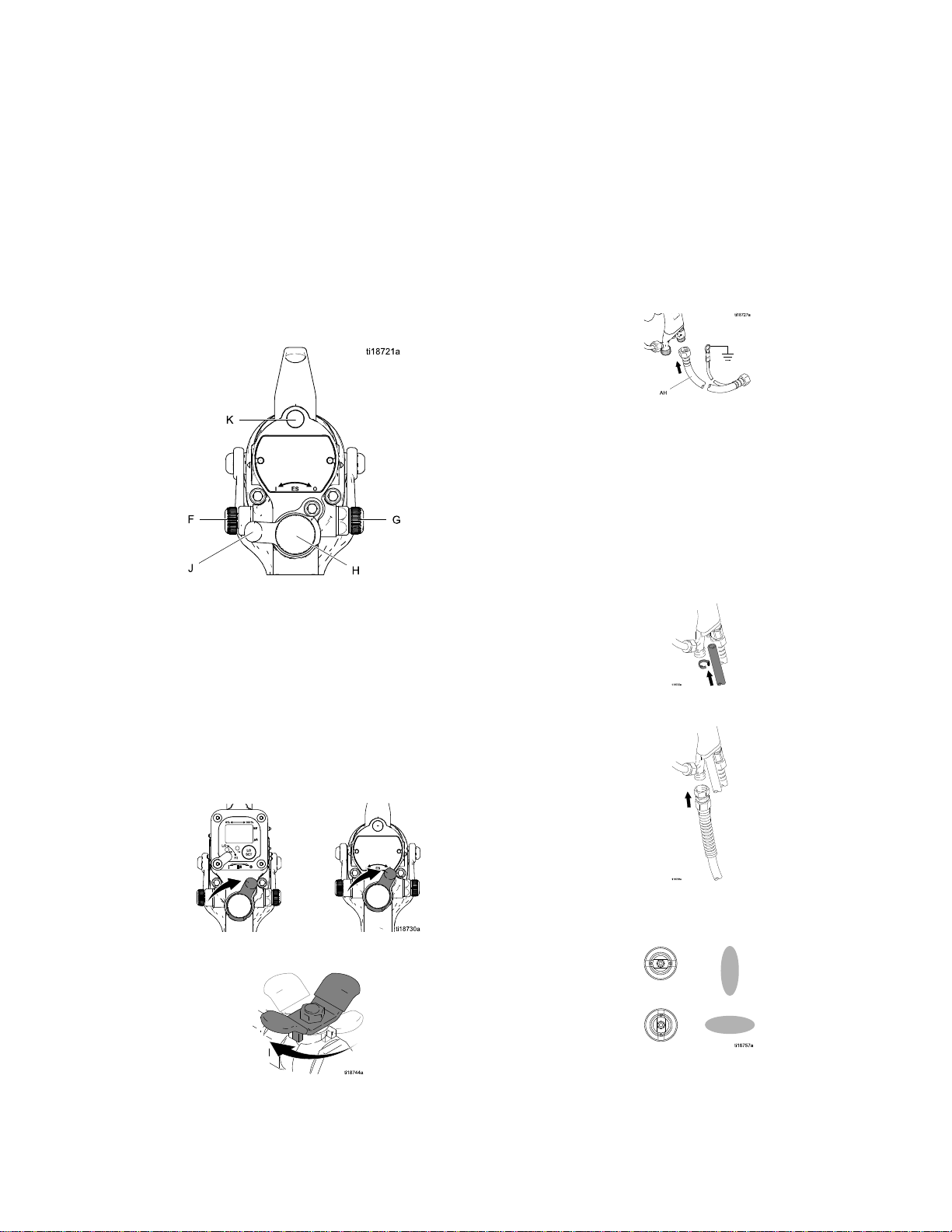

Theelectrostaticgunincludesthefollowingcontrols,indicators,andcomponents(seeFig.1).Forinformation

onSmartguns,seeSmartGuns,page13.

Figure1GunOverview

Item

Item Item

A

BFluidInlet

Indicators,

Indicators, Indicators,

Description

Description Description

AirSwivelInlet1/4npsm(m)left-handthread,forGracogroundedairsupplyhose.

and

Components

and and

Components Components

Purpose

Purpose Purpose

3/8npsm(m),foruidsupplyhose.

C

D

EElectrodeNeedle

FFanAirAdjustment

G

HFluidAdjustment

J

K

TurbineAir

Exhaust

AirCapandNozzleShapesthespraypattern.SeeAirCaps,page82and

Valve

AtomizingAir

RestrictorValve

Knob

ESOn-OffValveTurnselectrostaticsON(I)orOFF(O).

ESIndicator(standardgunonly;for

Smartgunindicator,seeOperating

Mode,page13)

Barbedtting,forsuppliedexhausttube.

FluidNozzles,page79foravailablesizes.

Supplieselectrostaticchargetotheuid.See

ElectrodeSelectionChart,page88.

Adjustsfansizeandshape.Canbeusedtodecreasepatternlength.

Restrictsaircapairow.Replacewithplug(included)ifdesired.

Adjustsuidowbylimitinguidneedletravel.Useonlyinlowow

conditions,toreducewear.

LitwhenESisON(I).Colorindicatesalternatorfrequency.SeetheLED

indicatortableintheGunSetupProcedure,page25.

12

3A2494P

Page 13

GunOverview

Smart

Smart Smart

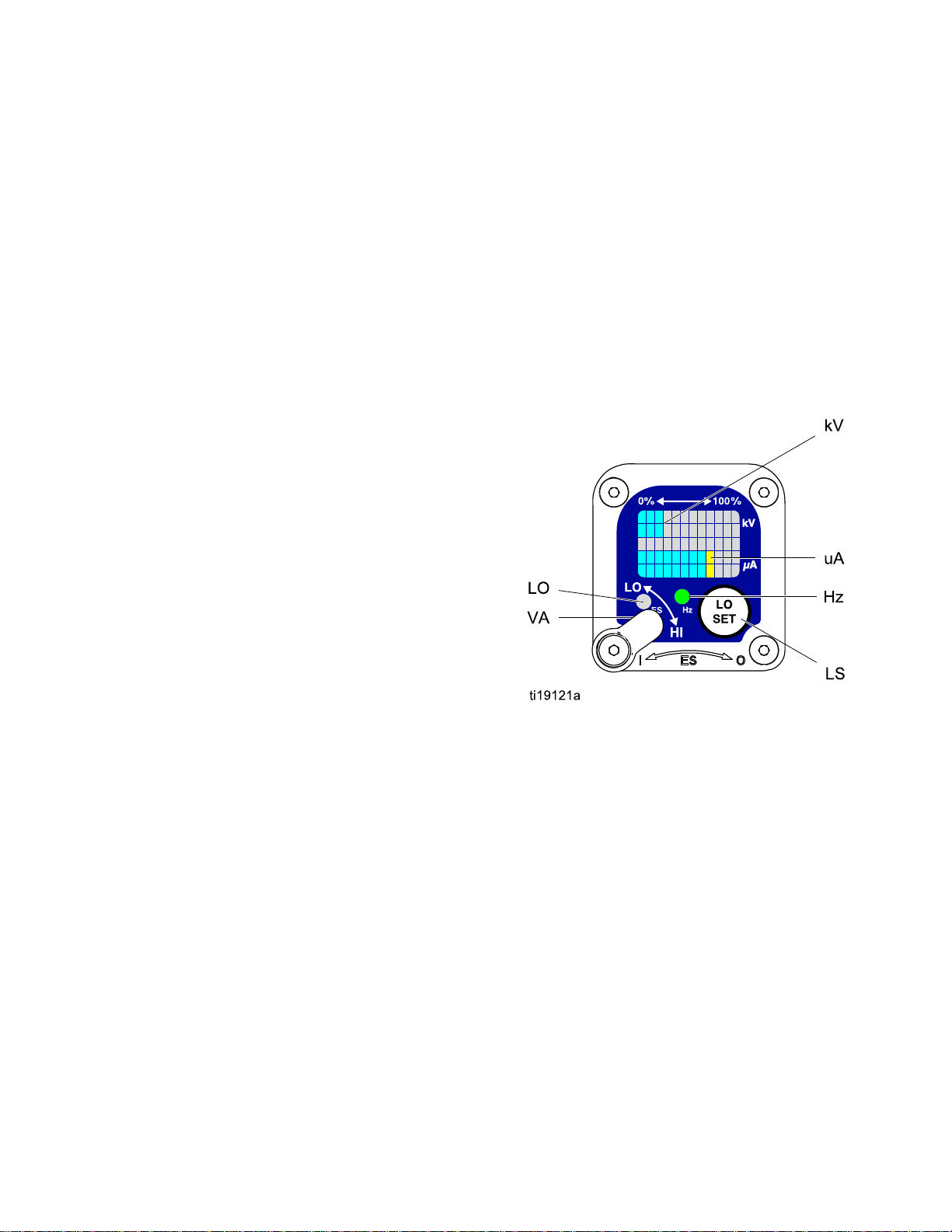

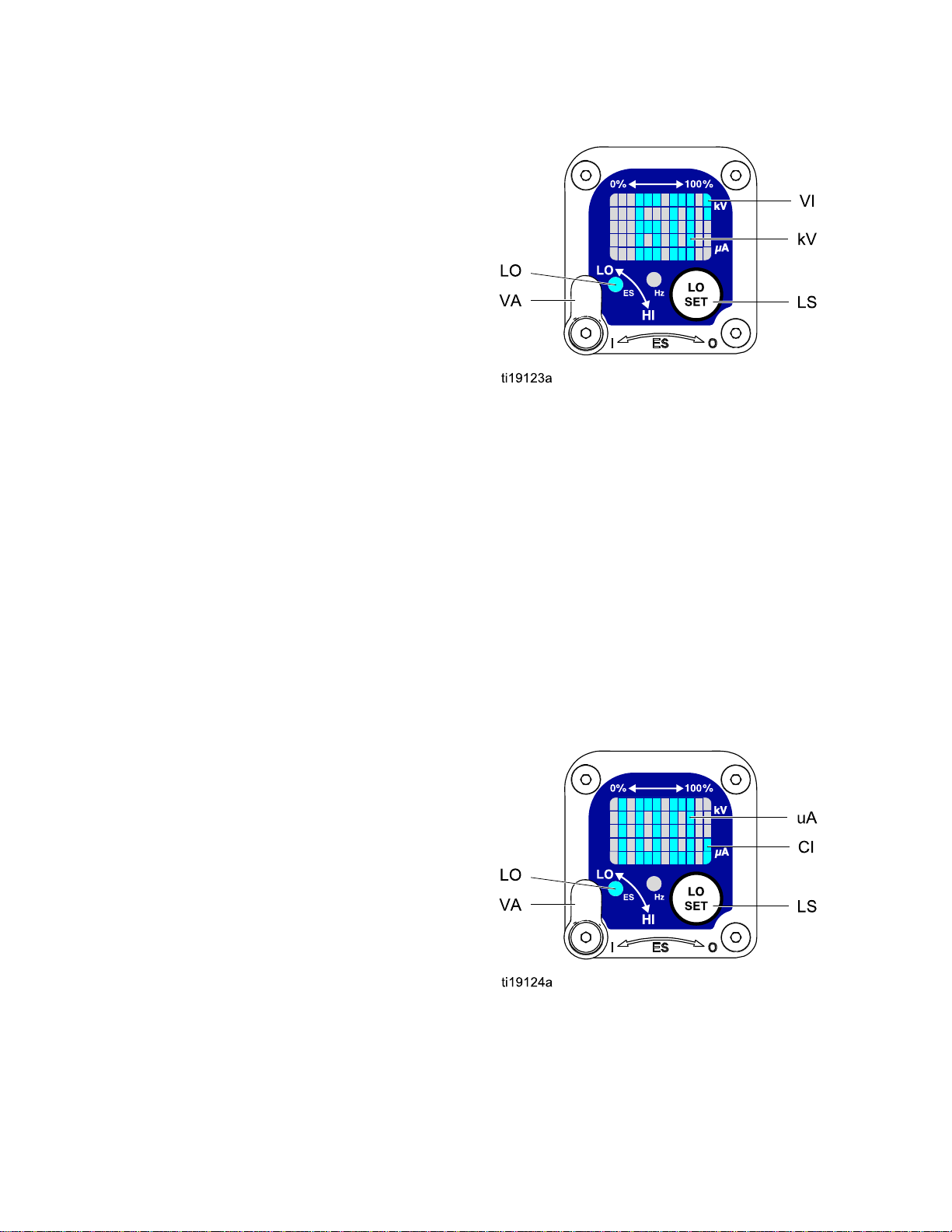

TheSmartGunmoduledisplayssprayingvoltage,

current,alternatorspeed,andthevoltagesetting(low

orhigh).Italsoallowstheusertochangetoalower

sprayingvoltage.Themodulehastwomodes:

•OperatingMode

•DiagnosticMode

Operating

Operating Operating

Bar

Bar Bar

SeeFig.2andSmartGunKey,page15.The

OperatingModedisplaysgundataduringnormal

spraying.Thedisplayusesabargraphtoshowthe

voltagelevelinkiloVolts(kV)andthecurrentlevelin

microAmperes(uA).Thebargraphrangeisfrom0

to100%foreachvalue.

IfthebargraphLEDsareblue,thegunisreadyto

spray.IftheLEDsareyelloworred,thecurrentis

toohigh.Theuidmaybetooconductive,orsee

ElectricalTroubleshooting,page46forotherpossible

causes.

Guns

Guns Guns

Mode

Mode Mode

Graph

Graph Graph

Voltage

Voltage Voltage

Thevoltageadjustmentswitch(VA)allowsthe

operatortochangefromlowtohighvoltage.

•Thehighvoltagesettingisdeterminedbythe

maximumvoltageofthegunandisnotadjustable.

•Thelowvoltageindicator(LO)lights

whentheswitchissettoLO.Thelow

voltagesettingisuseradjustable.See

AdjustingtheLowVoltageSetting,page14.

NOTE:

NOTE: NOTE:

haslostcommunicationwiththepowersupply.See

ErrorDisplay,page14,forfurtherinformation.

Adjustment

Adjustment Adjustment

IftheErrordisplayappears,theSmartmodule

Switch

Switch Switch

Hz

Indicator

Hz Hz

Indicator Indicator

TheHzindicatorfunctionsthesameastheES

indicatoronstandardguns.Theindicatorlightsto

showthealternatorspeedstatus,andhasthree

colors:

•Greenindicatesthealternatorspeediscorrect.

•Iftheindicatorchangestoamberafteronesecond,

increasetheairpressure.

•Iftheindicatorchangestoredafteronesecond,

theairpressureistoohigh.Decreaseairpressure

untiltheindicatorisgreen.Tomaintainahigher

airpressure,installESOn/OffValveRestrictorKit

26A160.Then,adjustthepressureasneededto

ensuretheindicatorremainsgreen.

Figure2SmartGunModuleinOperatingMode

3A2494P13

Page 14

GunOverview

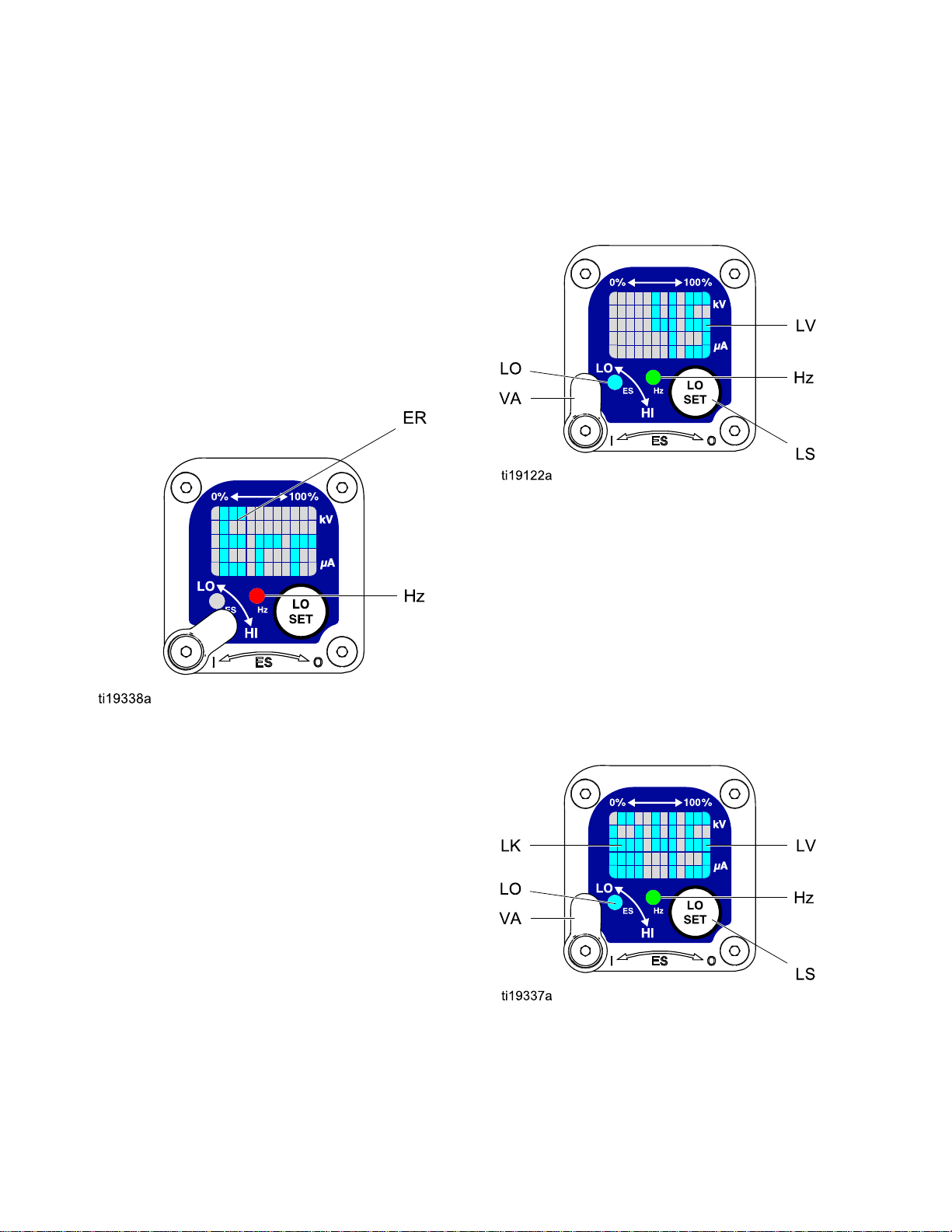

Error

Error Error

IftheSmartmodulelosescommunicationwith

thepowersupply,theErrordisplayappears,the

Hzindicatorturnsred,andtheSmartmoduleis

disabled.SeeFig.3andSmartGunKey,page15.

ThiscanoccurinOperatingModeorDiagnostic

Mode.SeeElectricalTroubleshooting,page46.

CommunicationmustberestoredtomaketheSmart

modulefunctional.

NOTE:

NOTE: NOTE:

appear.Ifthegunhasbeendisassembled,wait8

secondsbeforesprayingtoensurethatanError

conditionhasnotoccurred.

NOTE:

NOTE: NOTE:

displaywillnotappear.

Display

Display Display

Ittakes8secondsfortheErrordisplayto

Ifthereisnopowertothegun,theError

foryourgun.Continuepressingthebuttonuntilyou

reachthedesiredsetting.

NOTE:

NOTE: NOTE:

returntotheOperatingScreen.

NOTE:

NOTE: NOTE:

LockSymbol,page14.

Figure4LowVoltageSettingScreen(Unlocked)

Lock

Lock Lock

After2secondsofinactivitythedisplaywill

Thelowvoltagesettingmaybelocked.See

Symbol

Symbol Symbol

Figure3ErrorDisplay

Adjusting

Adjusting Adjusting

Thelowvoltagesettingisuseradjustable.Toaccess

thelowvoltagesettingscreenwheninOperating

Mode,presstheLOSETbutton(LS)momentarily.

Thescreenwilldisplaythecurrentlowvoltage

setting.SeeFig.4andSmartGunKey,page15.

Thepossiblerangesare:

•85kVguns:40–85kV

•60kVguns:30–60kV

•40kVguns:20–40kV

SettheVoltageAdjustmentswitch(VA)toLO.Press

theLOSETbuttonrepeatedlytoincreasethesetting

inincrementsof5.Whenthedisplayreachesthe

maximumsettingitwillreturntotheminimumsetting

the

Low

the the

Voltage

Low Low

Voltage Voltage

Setting

Setting Setting

Thelowvoltagesettingmaybelocked.Whenlocked,

animage(LK)appearsonthescreen.SeeFig.5

andSmartGunKey,page15.

•WheninHImode,thelowvoltagesettingisalways always

locked.ThelocksymbolwillappearwhentheLO

SETbuttonispressed.

•WheninLOmode,thelocksymbolwill

only

only only

appearifthelockisenabled.See

LowVoltageLockScreen,page17,tolockor

unlockthelowvoltagesetting.

Figure5LowVoltageSettingScreen(Locked)

always

14

3A2494P

Page 15

GunOverview

Smart

Smart Smart

Table

Table Table

Item

Item Item

VA

LO

kV

uA

LSLOSETbuttonPressmomentarilytoentertheLowVoltageSettingscreen.

Gun

Key

Gun Gun

Key Key

Key

for

Figs.

1 11Key Key

for for

Description

Description Description

VoltageAdjustmentSwitchTwo-positionswitchsetsSmartgunvoltagetolowsetting(LO)or

LowVoltageMode

Indicator

Voltage(kV)DisplayDisplaysactualsprayingvoltageofthegun,inkV.InOperatingMode,

Current(uA)DisplayDisplaysactualsprayingcurrentofthegun,inuA.InOperatingMode,

2–9.

Figs. Figs.

2–9. 2–9.

Purpose

Purpose Purpose

highsetting(HI).ThisswitchisfunctionalinOperatingModeandin

DiagnosticMode.

Lights(blue)whentheSmartgunissettoLowVoltage.

displayisabargraph.InDiagnosticMode,voltageisdisplayedas

anumber.

displayisabargraph.InDiagnosticMode,currentisdisplayedas

anumber.

Pressandholdforapproximately5secondstoenterorexitDiagnostic

Mode.

WhileinDiagnosticMode,pressmomentarilytoadvancethrough

screens.

WhileontheLowVoltageLockScreen(inDiagnosticMode),press

andholdtoturnthelockonoroff.

LVLowVoltageDisplayDisplaysthelowvoltagesettingasanumber.Thesettingcanbe

changed.SeeFig.4.

LKLowVoltageLocked

LD

ERErrorDisplay

VIVoltageIndicator

CICurrentIndicatorInDiagnosticMode,thetwobottomrightLEDsofthescreenlight,

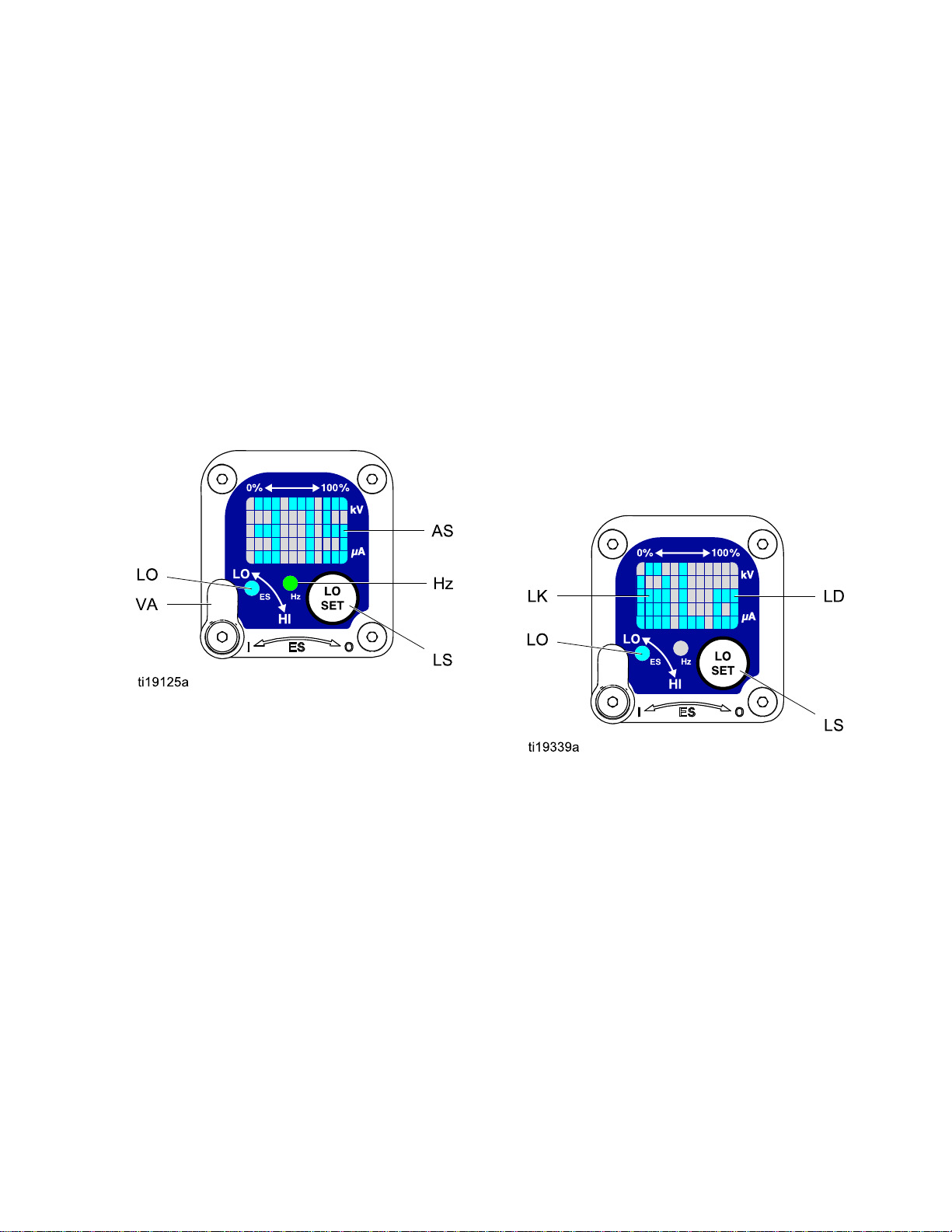

ASAlternatorSpeedDisplayInDiagnosticMode,Hzlevelisdisplayedasanumber.SeeFig.8.

Hz

LODisplayAppearsontheLowVoltageLockScreen.SeeFig.9.

AlternatorSpeedIndicatorInOperatingMode,indicatorcolorvariestoshowthealternatorspeed

Appearsifthelowvoltagesettingislocked.SeeFig.5andFig.9.

AppearsiftheSmartmodulelosescommunicationwiththepower

supply.SeeFig.3.

InDiagnosticMode,thetwotoprightLEDsofthescreenlight,

indicatingthatthevaluedisplayedisinkV.SeeFig.6.

indicatingthatthevaluedisplayedisinuA.SeeFig.7.

status:

•Greenindicatesthealternatorspeedisatthecorrectlevel.

•Iftheindicatorchangestoamberafteronesecond,thealternator

speedistoolow.

•Iftheindicatorchangestoredafteronesecond,thealternatorspeed

istoohigh.TheindicatoralsoturnsrediftheErrordisplayappears.

InDiagnosticMode,theindicatorisgreenwhenintheAlternator

Speed(Hertz)screen.

3A2494P15

Page 16

GunOverview

Diagnostic

Diagnostic Diagnostic

DiagnosticModeincludesfourscreenswhichdisplay

gundata:

•Voltage(kiloVolts)Screen

•Current(microAmperes)Screen

•AlternatorSpeed(Hertz)Screen

•LowVoltageLockScreen

NOTE:

NOTE: NOTE:

lowvoltagesetting;thesettingisnotadjustablein

DiagnosticMode.However,thevoltageadjustment

switch(VA)canbesettoHIorLOinOperatingMode

andinDiagnosticMode.

ToenterDiagnosticMode,pressandholdtheLOSET

(LS)buttonforapproximately5seconds.Thedisplay

willgototheVoltage(kiloVolts)Screen,page16.

Toadvancetothenextscreen,presstheLOSET

buttonagain.

ToexitDiagnosticMode,pressandholdtheLOSET

buttonforapproximately5seconds.Thescreenwill

returntoOperatingMode.

NOTE:

NOTE: NOTE:

Mode,thelastscreenviewedwillbedisplayedwhen

thegunisretriggered.

NOTE:

NOTE: NOTE:

fromtheLowVoltageLockScreen.See

LowVoltageLockScreen,page17fordetails.

Mode

Mode Mode

YoumustbeinOperatingModetoadjustthe

IfthegunisdetriggeredwhileinDiagnostic

DiagnosticModecannotbeexited

Figure6Voltage(kiloVolts)Screen

Current

Current Current

TheCurrent(microAmperes)Screenisthesecond

screenintheDiagnosticMode.SeeFig.7and

SmartGunKey,page15.Toenterthisscreen,press

theLOSETbuttonwhileintheVoltage(kiloVolts)

Screen.

Thisscreendisplaysthesprayingcurrentofthegun

asanumber(uA),roundedtothenearest5uA.The

twobottomrightLEDs(CI)ofthedisplaypanellight,

indicatingthattheCurrent(microAmperes)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

(microAmperes)

(microAmperes) (microAmperes)

Screen

Screen Screen

Voltage

Voltage Voltage

TheVoltage(kiloVolts)Screenistherstscreento

appearafterenteringDiagnosticMode.SeeFig.6

andSmartGunKey,page15.Toenterthisscreen,

pressandholdtheLOSETbuttonforapproximately

5secondswhileintheOperatingMode.

Thisscreendisplaysthesprayingvoltageofthe

gunasanumber(kV),roundedtothenearest5kV.

ThetwotoprightLEDs(VI)ofthedisplaypanel

light,indicatingthattheVoltage(kiloVolts)Screen

isdisplayed.Thedisplayisareadoutandcannot

bechanged.

PresstheLOSETbuttontoadvancetothe

Current(microAmperes)Screen,page16.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

(kiloVolts)

(kiloVolts) (kiloVolts)

Screen

Screen Screen

PresstheLOSETbuttontoadvancetothe

AlternatorSpeed(Hertz)Screen,page17.Press

andholdforapproximately5secondstoreturnto

OperatingMode.

Figure7Current(microAmperes)Screen

163A2494P

Page 17

GunOverview

Alternator

Alternator Alternator

TheAlternatorSpeed(Hertz)Screenisthethird

screenintheDiagnosticMode.SeeFig.8and

SmartGunKey,page15.Toenterthisscreen,

presstheLOSETbuttonwhileintheCurrent

(microAmperes)Screen.

Thisscreendisplaysthealternatorspeedasa3digit

number(AS),roundedtothenearest10Hz.The

displayisareadoutandcannotbechanged.Ifthe

alternatorspeedisgreaterthan999Hz,thedisplay

willshow999.

TheHzindicatorlightsgreentoshowthatyouare

viewingtheAlternatorSpeed(Hertz)Screen.

PresstheLOSETbuttontoadvancetothe

LowVoltageLockScreen,page17.Pressandhold

forapproximately5secondstoreturntoOperating

Mode.

Speed

Speed Speed

(Hertz)

(Hertz) (Hertz)

Screen

Screen Screen

Low

Voltage

Low Low

Voltage Voltage

TheLowVoltageLockScreenisthefourth

screenintheDiagnosticMode.SeeFig.9and

SmartGunKey,page15.Toenterthisscreen,press

theLOSETbuttonwhileintheAlternatorSpeed

(Hertz)Screen.

ThisscreendisplaysthestatusoftheLowVoltage

Lock.Ifthesettingislocked,thelockimage(LK)

appearstotheleftoftheLodisplay(LD).Ifthesetting

isunlocked,thelockimagedoesnotappear.

Tochangethelockstatus,pressandholdthe

LOSETbuttonuntilthelockimageappearsor

disappears.Ifthelockisset,theimagewillalso

appearontheLowVoltageSettingScreenwhenin

lowvoltagemode(seeFig.4).

NOTE:

NOTE: NOTE:

screen,becausepressingandholdingtheLOSET

buttonisusedtoturnthelockonoroff.Toexit,

pressLOSETmomentarilytoreturntotheVoltage

(kiloVolts)Screen,thenexitDiagnosticModefrom

there.

DiagnosticModecannotbeexitedfromthis

Lock

Screen

Lock Lock

Screen Screen

Figure8AlternatorSpeed(Hertz)Screen

Figure9LowVoltageLockScreen

3A2494P

17

Page 18

Installation

Installation

Installation Installation

Installingandservicingthisequipmentrequires

accesstopartswhichmaycauseelectricshock

orotherseriousinjuryifworkisnotperformed

properly.

•Donotinstallorservicethisequipmentunless

youaretrainedandqualied.

•Besureyourinstallationcomplieswithlocal,

state,andnationalcodesfortheinstallation

ofelectricalapparatusinaClassI,Div.I,

hazardouslocationoraGroupII,ZoneI

explosiveatmospherelocation.

•Complywithalllocalcodesandregulations.

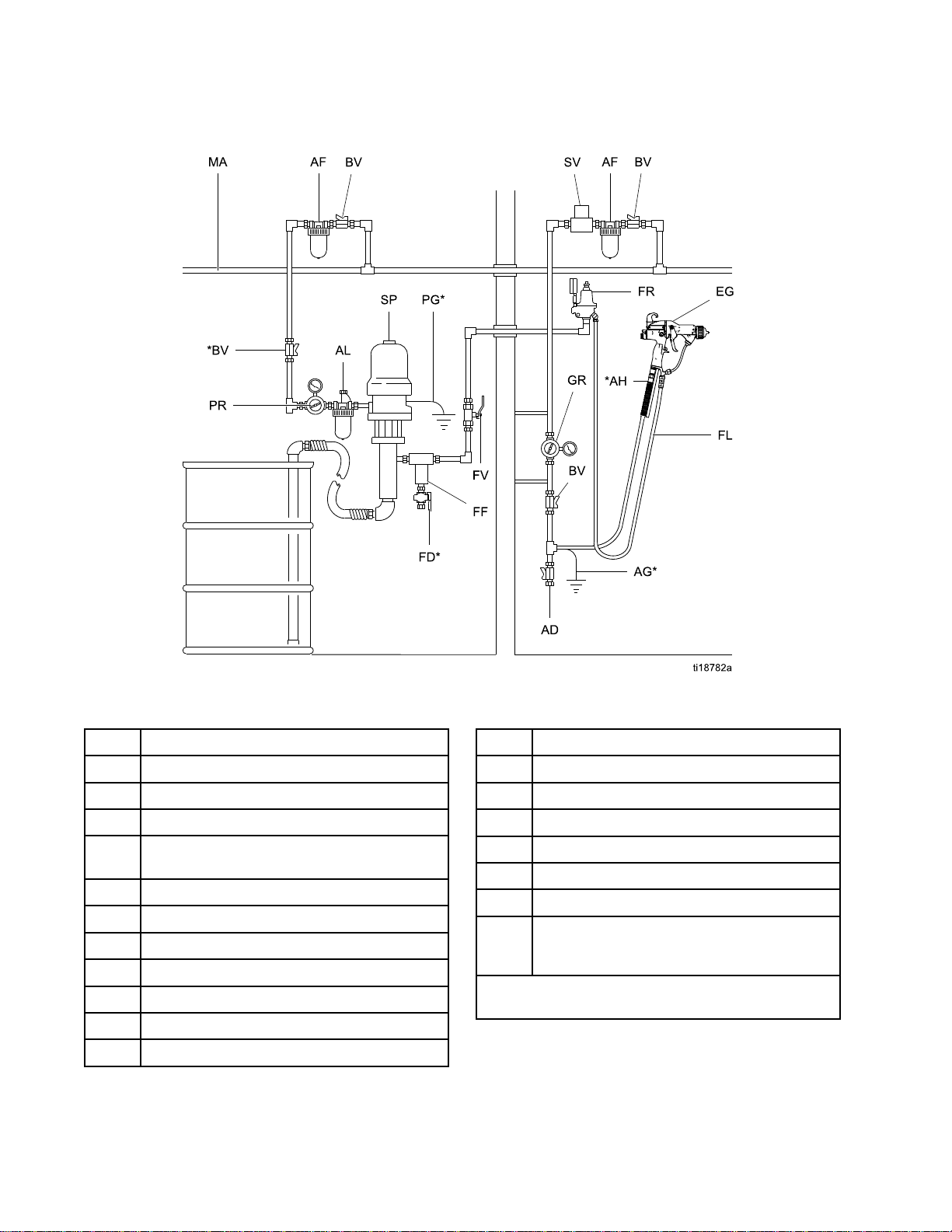

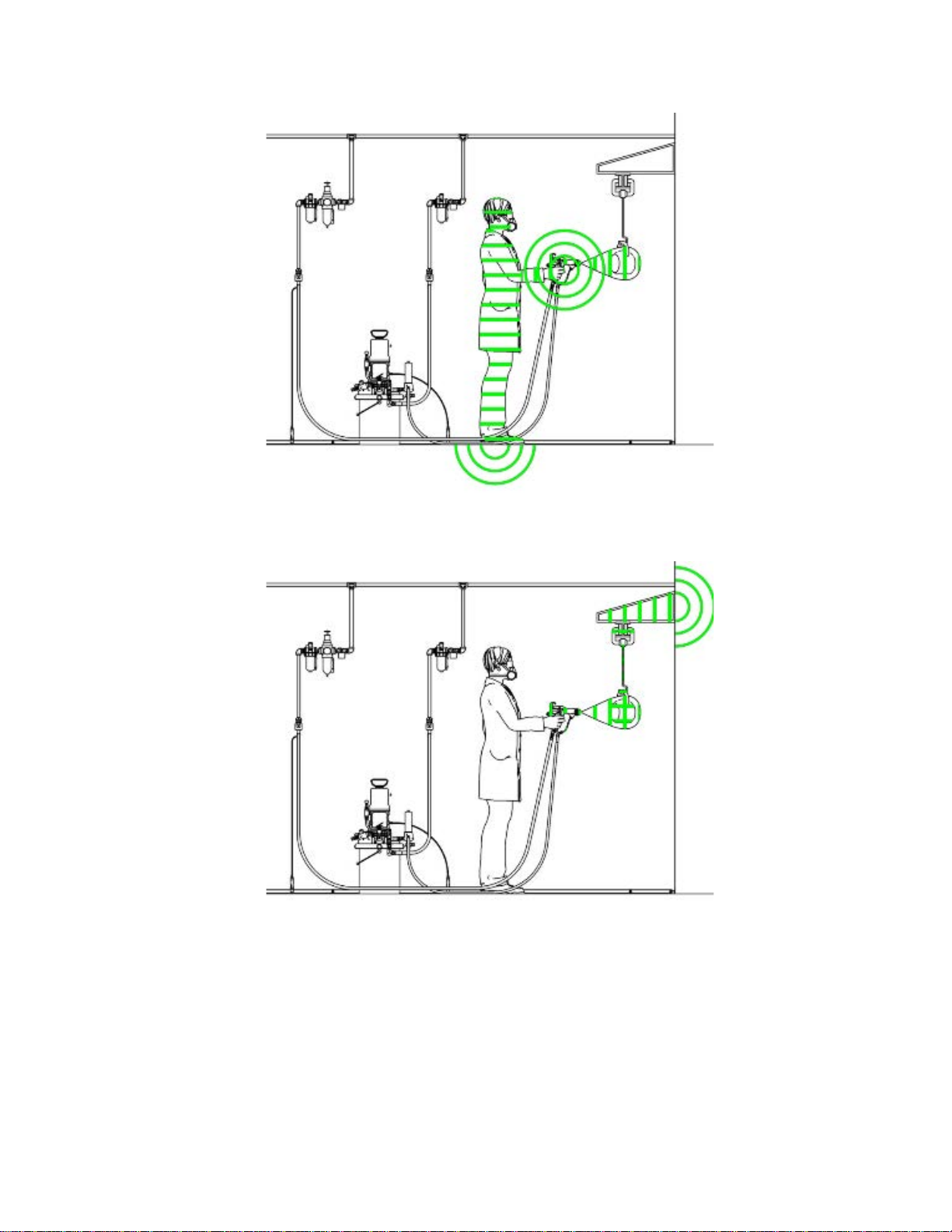

Fig.10(TypicalInstallation)showsatypical

electrostaticairspraysystem.Itisnotanactual

systemdesign.Forassistanceindesigningasystem

tosuityourparticularneeds,contactyourGraco

distributor.

Warning

Warning Warning

Sign

Sign Sign

Ventilate

Ventilate Ventilate

Donotoperatethegununlessventilatingairowis

abovetheminimumrequiredvalue.Providefresh

airventilationtoavoidthebuildupofammableor

toxicvaporswhenspraying,ushing,orcleaning

thegun.Interlockthegunairanduidsupply

topreventoperationunlessventilatingairowis

abovetheminimumrequiredvalue.

Thesprayboothmusthaveaventilationsystem.

Electricallyinterlockthegunairanduidsupplywith

theventilatorstopreventgunoperationanytimethat

theventilationairowfallsbelowminimumvalues.

Checkandfollowalllocalcodesandregulations

regardingairexhaustvelocityrequirements.Verify

theoperationoftheinterlockatleastonceayear.

NOTE:Theminimumallowableairexhaust

velocityis60feet/minute(19linearmeters/minute).

High-velocityairexhaustwilldecreasetheoperating

efciencyoftheelectrostaticsystem.

the

Spray

the the

Spray Spray

Booth

Booth Booth

Mountwarningsignsinthesprayareawherethey

caneasilybeseenandreadbyalloperators.An

EnglishWarningSignisprovidedwiththegun.

183A2494P

Page 19

Air

Supply

Air Air

Supply Supply

Toreducetheriskofelectricshock,theairsupply

hosemustbeelectricallyconnectedtoatrueearth

ground.Use Use

Hose.

Hose. Hose.

1.SeeFig.10.UsetheGracoGroundedAirSupply

Hose(AH)tosupplyairtothegun.Thegunair

inletttinghasaleft-handthread.Theairsupply

hosegroundwire(AG)mustbeconnectedtoa

trueearthground.Donotconnecttheairsupply

hosetothegunairinletyet.

2.Installanairlinelter/waterseparator(AF)onthe

gunairlinetoensureadry,cleanairsupplytothe

gun.Dirtandmoisturecanruintheappearance

ofyournishedworkpieceandcancausethe

guntomalfunction.

3.Installbleed-typeairregulators(PR,GR)on

thepumpandgunairsupplylinestocontrolair

pressuretothepumpandgun.

Line

Line Line

Use

only

Graco

only only

Graco Graco

Grounded

Grounded Grounded

Air

Supply

Air Air

Supply Supply

Installation

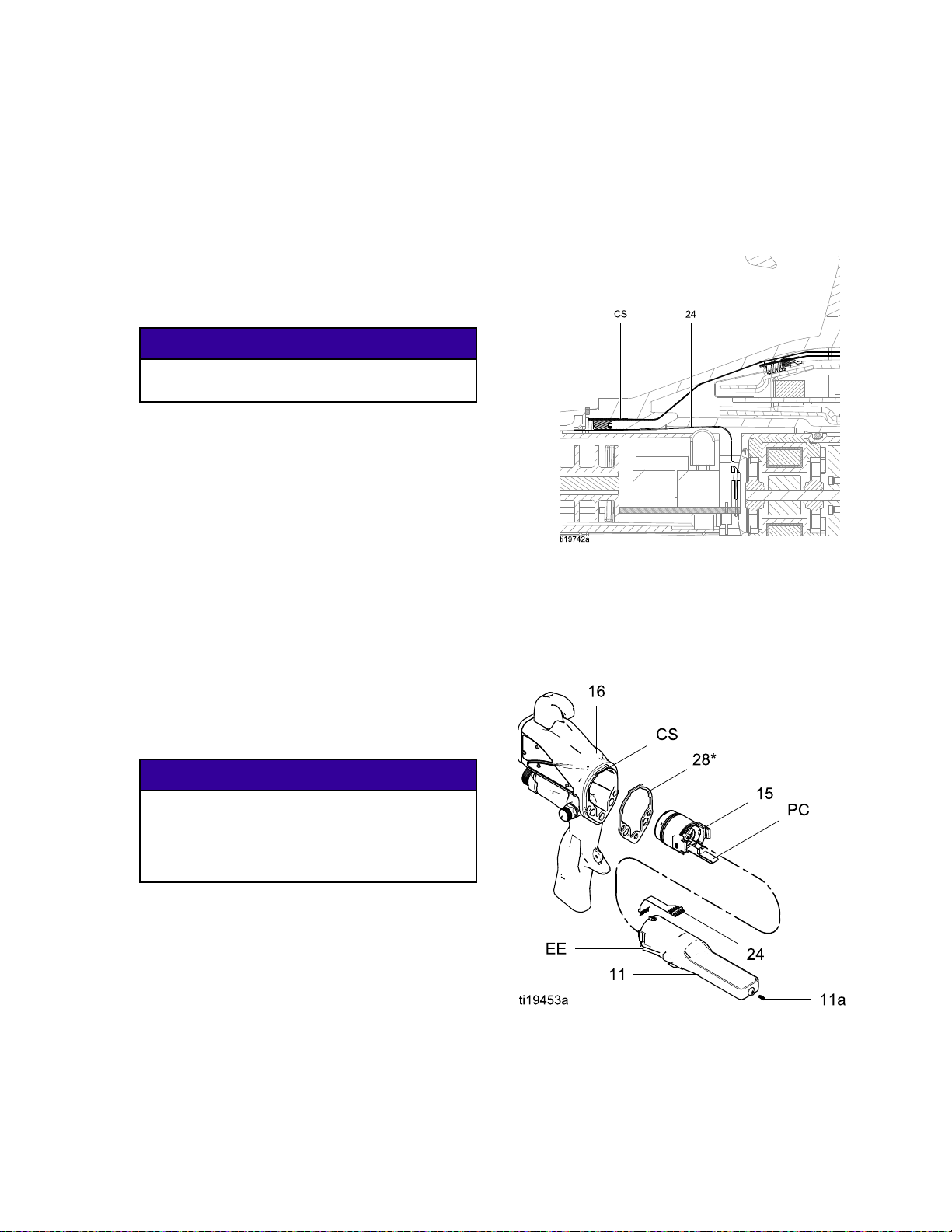

Fluid

Fluid Fluid

1.Blowouttheuidline(FL)withairandushit

2.Installauidregulator(FR)ontheuidlineto

3.Installauidlter(FF)nearthepumpoutlet,to

4.Theuiddrainvalve(FD)isrequiredinyour

Supply

Supply Supply

withsolvent.Usesolventwhichiscompatible

withtheuidtobesprayed.Donotconnectthe

uidsupplylinetothegunuidinletyet.

controluidpressuretothegun.

removeparticlesandsedimentwhichcouldclog

thespraynozzle.

Toreducetheriskofseriousinjury,including

splashinguidintheeyesorontheskin,do

notoperateequipmentwithouttheuiddrain

valve(FD)installed.

systemtoassistinrelievinguidpressureinthe

displacementpump,hose,andgun.Triggering

theguntorelievepressuremaynotbesufcient.

Installadrainvalveclosetothepump'suid

outlet.

Line

Line Line

Trappedaircancausethepumptocycle

unexpectedly,whichcanresultinserious

injury,includingsplashinguidintheeyesor

ontheskin.Donotoperatetheequipment

withoutthebleed-typeairvalve(BV)installed.

4.Installableed-typeairvalve(BV)onthepump

airsupplyline.Thebleed-typeairvalve(BV)is

requiredinyoursystemtoshutoffairtothepump

andrelieveairtrappedbetweenthevalveand

thepumpaftertheairregulatorisshutoff.Install

anadditionalbleed-typeairvalveonthemainair

line(MA)toisolatetheaccessoriesforservicing.

5.Installanairbleedvalve(BV)oneachgunair

supplylinetoshutoffairtothegun(s)andrelieve

airtrappedbetweenthevalveandthegunafter

theairregulatorisshutoff.

3A2494P19

Page 20

Installation

NON

HAZARDOUS

NON NON

- --HAZARDOUS HAZARDOUS

LOCATION

LOCATION LOCATION

HAZARDOUS

HAZARDOUS HAZARDOUS

LOCATION

LOCATION LOCATION

Figure10TypicalInstallation

Typical

Typical Typical

Item

Item Item

ADAirLineDrainValve

AF

AG*GunAirHoseGroundWire

AH*GracoGroundedAirHose(left-hand

ALPumpAirLineLubricator

BV*PumpBleed-TypeAirShutoffValve

EGElectrostaticAirSprayGun

FD*

FFFluidFilter

FL

FRFluidPressureRegulator

Installation

Installation Installation

Description

Description Description

AirFilter/WaterSeparator

threads)

FluidDrainValve

FluidSupplyLine

Key

Key Key

Item

Item Item

FV

GRGunAirPressureRegulator

MA

PG*PumpGroundWire

PRPumpAirPressureRegulator

SPSupplyPump

SV*VentilationFanInterlockSolenoidValve.

*Theseitemsarerequiredforsafeoperation.They

mustbepurchasedseparately.

Description

Description Description

FluidShutoffValve

MainAirSupplyLine

NOTE:

NOTE: NOTE:

asaGracoaccessory.

Thesolenoidvalveisnotoffered

203A2494P

Page 21

Installation

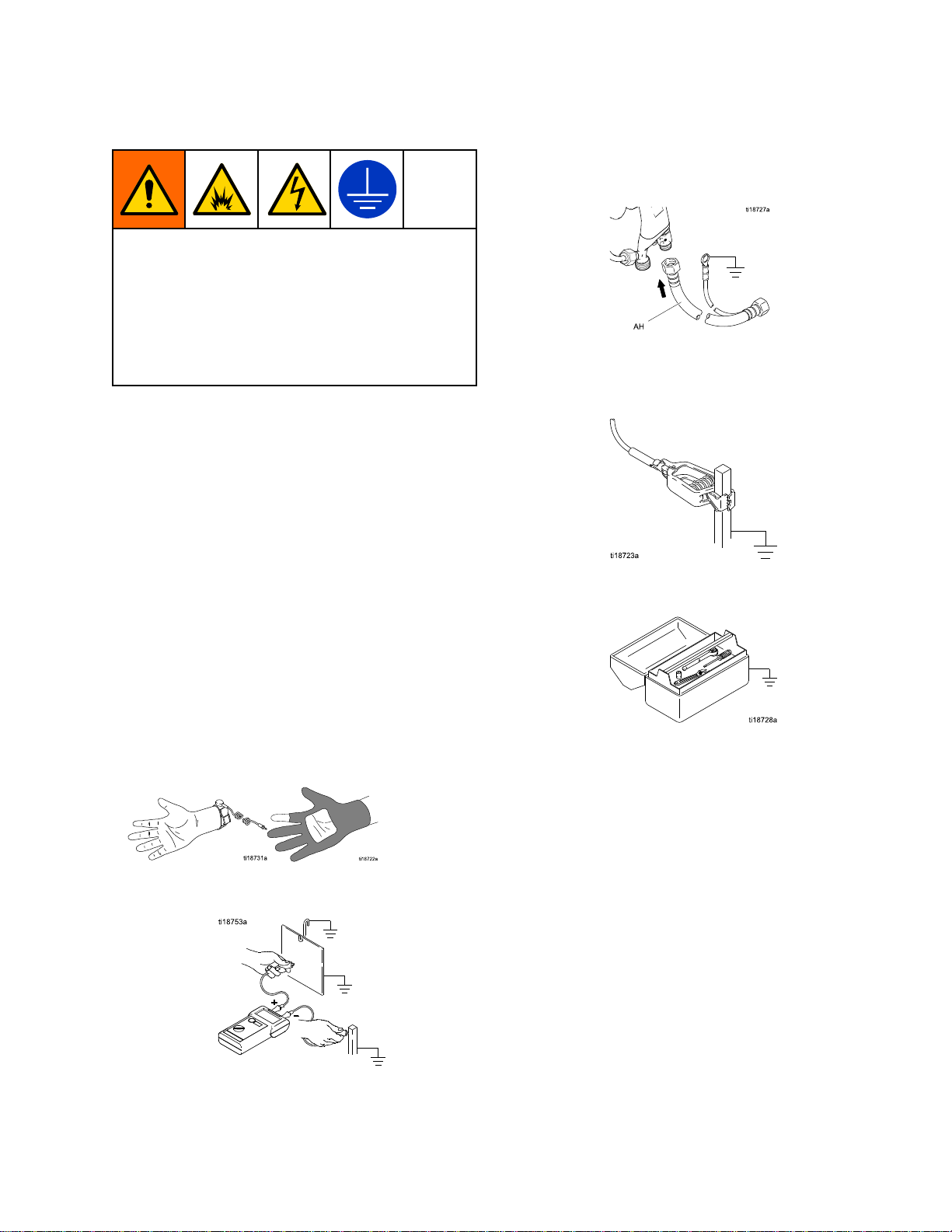

Grounding

Grounding Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundallequipment,personnel,objects

beingsprayed,andconductiveobjectsinorclose

tothesprayarea.Theresistancemustnotexceed

1megohm.Groundingprovidesanescapewire

fortheelectriccurrent.

Whenoperatingtheelectrostaticgun,any

ungroundedobjects(suchaspeople,containers,and

tools)inthespraylocationcanbecomeelectrically

charged.

Thefollowingareminimumgroundingrequirements

forabasicelectrostaticsystem.Yoursystemmay

includeotherequipmentorobjectswhichmustbe

grounded.Yoursystemmustbeconnectedtoa

trueearthground.Checkgroundconnectionsdaily.

Checkyourlocalelectricalcodesandregulationsfor

detailedgroundinginstructions.

Allpersonsenteringthesprayarea

•

shoeshavingconductivesolessuchasleather,

orwearpersonalgroundingstraps.Donot

wearshoeswithnon-conductivesolessuchas

rubberorplastic.Ifglovesarenecessary,wear

theconductiveglovessuppliedwiththegun.If

non-Gracoglovesareworn,cutoffngersorpalm

areaofglovestoensureyourhandcontactsthe

groundedgunhandle.Conductiveglovesand

footwearmustnotexceed100megohmperEN

ISO20344,EN1149–5.

•

Objectbeingsprayed:

cleanandgroundedatalltimes.

Keeptheworkpiecehangers

mustwear

•

ElectrostaticAirSprayGun:

byconnectingtheGracoGroundedAirHose

(AH)tothegun,andconnectingtheairhose

groundwiretoatrueearthground.See

CheckGunElectricalGrounding,page34.

•

Pump/uidsource:

byconnectingitsgroundwiretoatrueearth

ground.

•

Allelectricallyconductiveobjectsordevicesinthe

sprayarea

•

Fluidandwastecontainers:

wastecontainersinthesprayarea.Donotusepail

linersunlesstheyareconductiveandgrounded.

Whenushingthespraygun,thecontainerused

tocatchtheexcessuidmustbeelectrically

conductiveandgrounded.

Aircompressors:

•

tothemanufacturer'srecommendations.

•

Allairanduidlines

Useonlygroundedhoseswithamaximumof100

feet(30.5m)combinedhoselengthtoensure

groundingcontinuity.

mustbeproperlygrounded.

Groundthepump/uidsource

Groundtheequipmentaccording

mustbeproperlygrounded.

Groundthegun

Groundalluidand

3A2494P

21

Page 22

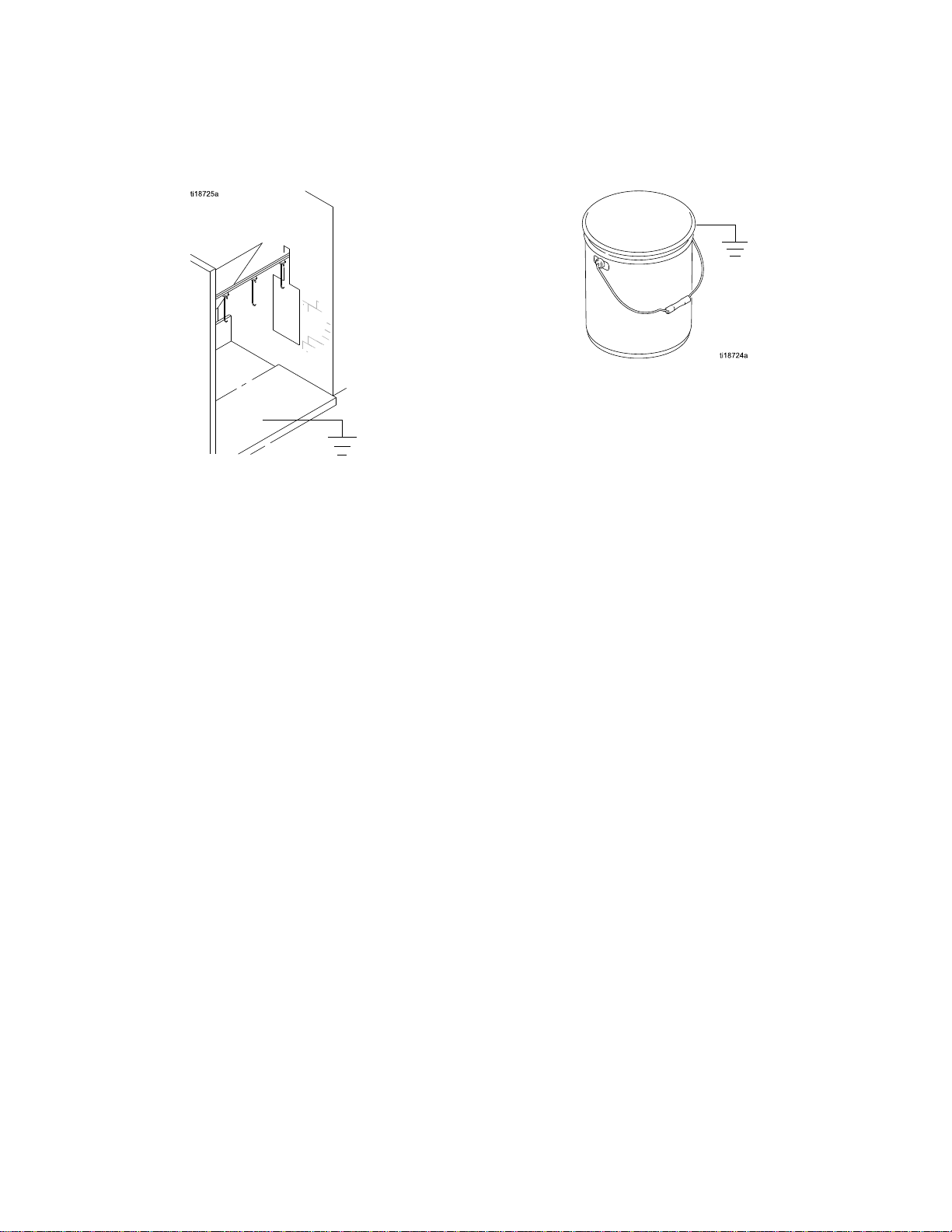

Installation

•

Theoorofthesprayarea

conductiveandgrounded.Donotcovertheoor

withcardboardoranynon-conductivematerial

whichwouldinterruptgroundingcontinuity.

mustbeelectrically

•

Flammableliquidsinthesprayarea

inapproved,groundedcontainers.Donotuse

plasticcontainers.Donotstoremorethanthe

quantityneededforoneshift.

•

Allsolventpails:

metalcontainers,whichareconductive.Donot

useplasticcontainers.Useonlynon-ammable

solvents.Donotstoremorethanthequantity

neededforoneshift.

Useonlyapproved,grounded

mustbekept

22

3A2494P

Page 23

Installation

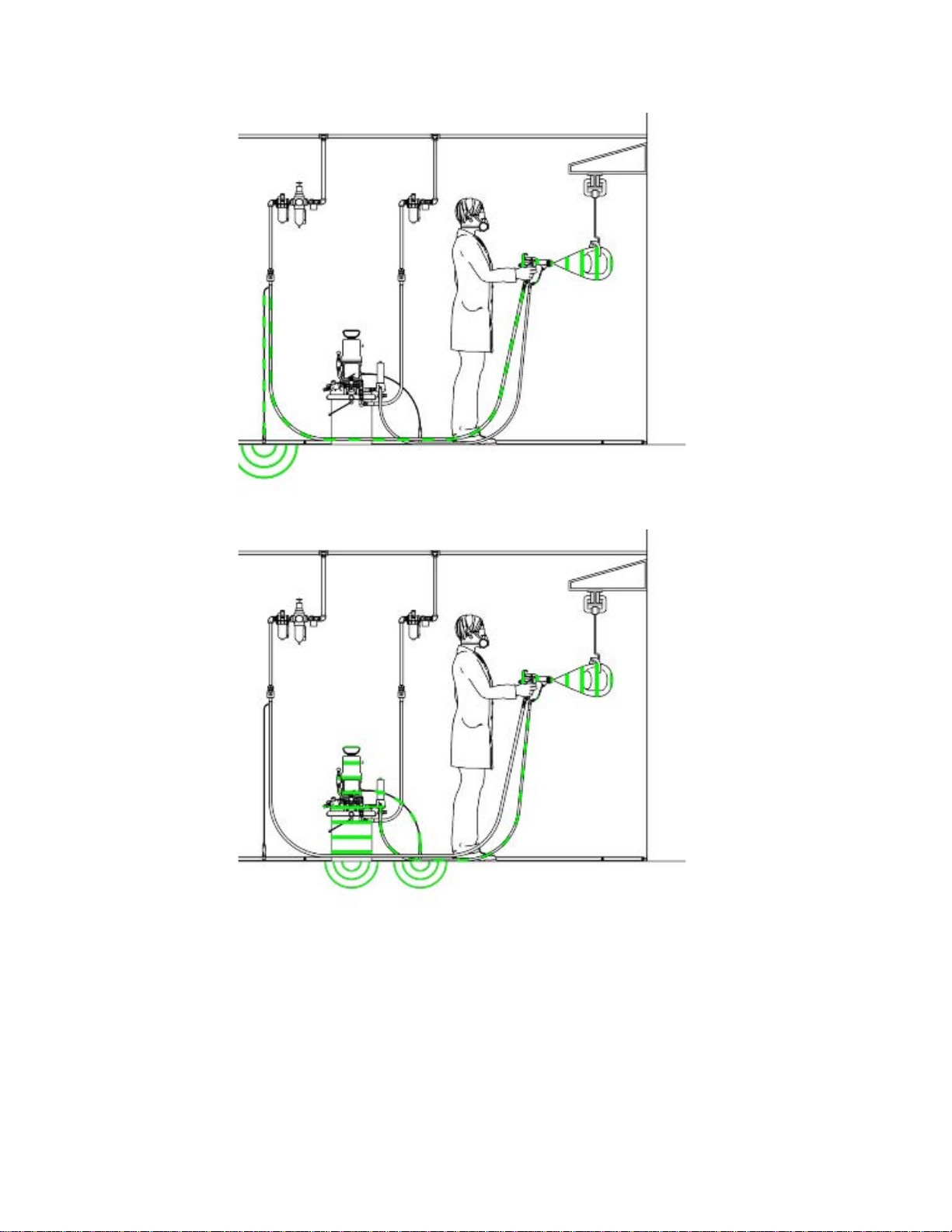

Figure11GroundtheOperatorOperatorisgroundedthroughbareskincontactwith

thegunhandleandconductiveshoes.Aconductive

glovecanalsobeused.

Figure12GroundtheObjectBeingSprayedObjectbeingsprayedisgroundedthroughcontact

withthehangerandconveyorsystem.

3A2494P23

Page 24

Installation

Figure13GroundtheGunGunisgroundedthroughtheconductiveairhose.

Figure14GroundtheFluidSupplyFluidsupplylineandsourcemustbegrounded.

24

3A2494P

Page 25

GunSetup

Gun

Gun Gun

Gun

Gun Gun

Foradditionalstepstosetupspecialtyguns,

seeSoftSprayGunSetupProcedure,page28,

RoundSprayGunSetupProcedure,page31,

HVLPGunSetupProcedure,page29,and

AbrasiveMaterialGunSetupProcedure,page33.

Seethegurebelowtolocatetheelectrostaticgun

controls.

Figure15ElectrostaticGunControls

Setup

Setup Setup

Setup

Setup Setup

Procedure

Procedure Procedure

4.Checkgunresistance.Followthestepsin

TestGunResistance,page42.

5.ConnecttheGracogroundedairhosetothegun

airinlet.Thegunairinletttinghasleft-hand

threads.

6.FollowallstepsinGrounding,page21.

7.Followallstepsin

CheckGunElectricalGrounding,page34.

Readingmustbelessthan1megohm.

8.Verifythatthematerialresistivitymeets

requirementsforelectrostaticspray.See

CheckFluidResistivity,page35.

9.Connecttheexhausttubeandsecurewiththe

clampprovided.

1.Thegunisshippedwiththeuidnozzleandair

capinstalled.Checkthattheretainingringis

tight.

NOTE:

NOTE: NOTE:

sizeuidnozzleoraircap,see

FluidNozzleSelectionChart,page79and

AirCapSelectionGuide,page82.

Toinstallthenozzleandaircap,see

AirCapandNozzleReplacement,page48.

2.TurnOFF(O)theESOn-Offswitch(J).

3.Shutofftheairbleedvalvetothegun.

Toselectadifferent

10.Connecttheuidhosetothegunuidinlet.

11.Flushifneeded.SeeFlushing,page38.

12.Positiontheaircapasneeded.

3A2494P25

Page 26

GunSetup

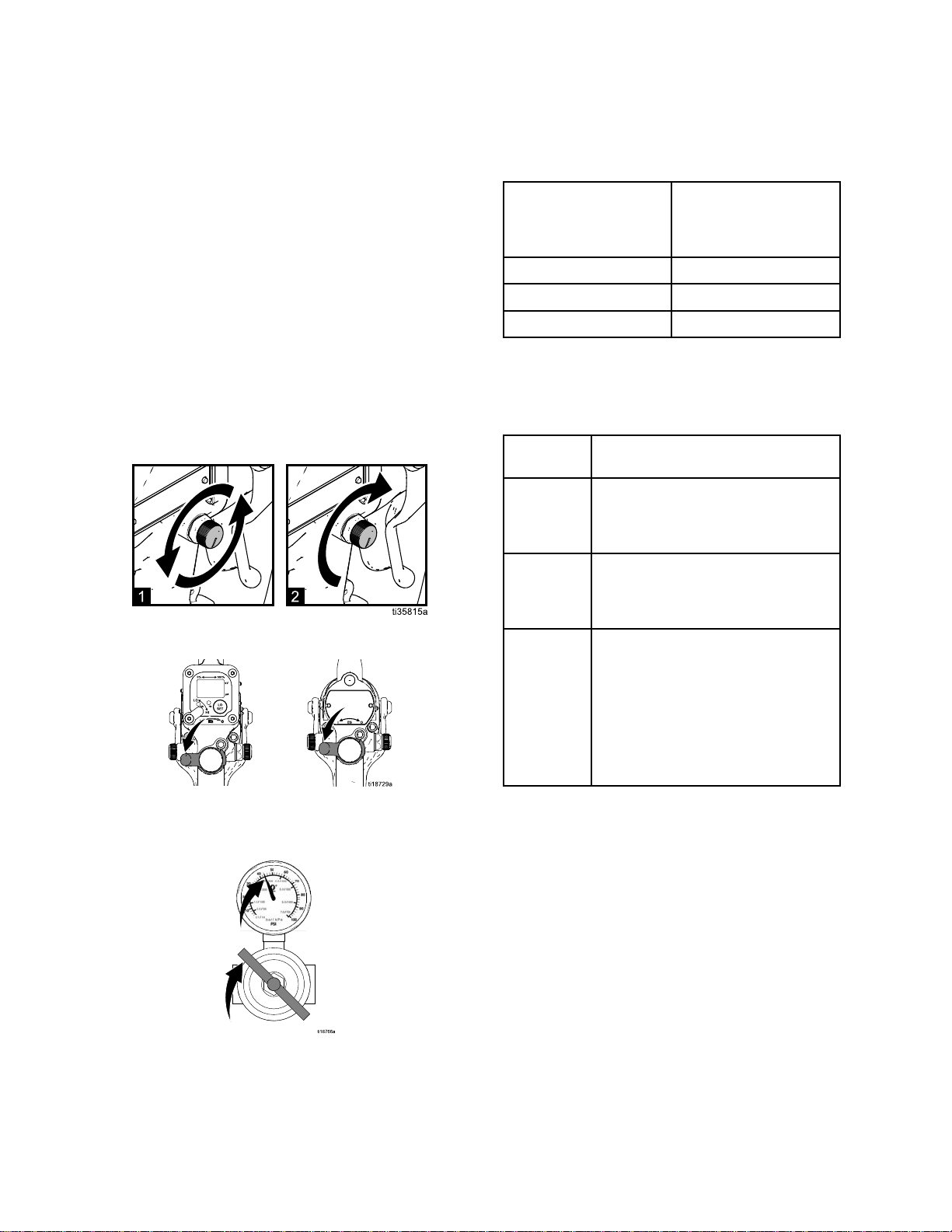

13.Fullyopenthefanairadjustmentvalve(F)

counterclockwise.

14.Fullyopentheuidadjustmentvalve(H)

counterclockwise.

15.Fullyopentheatomizingairrestrictorvalve(G)

clockwise.

17.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

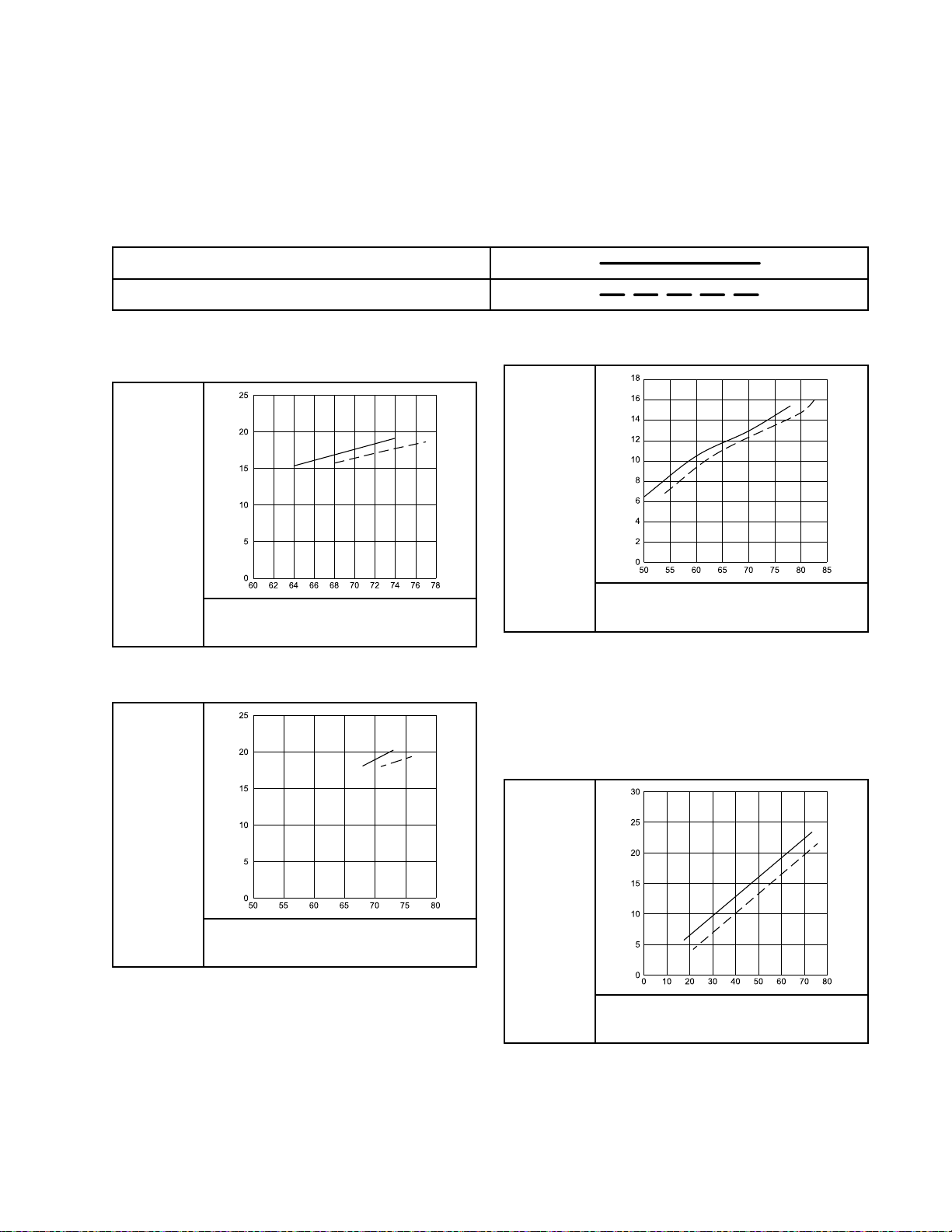

Table

Table Table

using

using using

mm)

mm) mm)

Pressure

2 22. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

Drop

Drop Drop

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

Air

Regulator

Air Air

Regulator Regulator

psi

in ininpsi psi

with

gun

with with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered

triggered triggered

16.TurnON(I)theESOn-Offswitch(J).

18.VerifythattheESindicator(K)[Hzindicatoron

Smartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Green

Amber

LED

3 33. ..LED LED

Color

Color Color

Red

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A160.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

263A2494P

Page 27

GunSetup

19.Shutofftheairtothegun.TurnOFF(O)theES

On-Offswitch(J).

20.Startthepump.Adjusttheuidregulatoruntilthe

streamfromtheguntravels8-12in.(200-300

mm)beforefallingoff.Typically,ifuidpressure

isbelow5psi(.04MPa,0.4bar)orabove30psi

(0.21MPa,2.1bar),achangeofnozzlesizeis

recommended.

22.Sprayatestpattern.Checktheatomization.

•Ifover-atomizationoccursatminimum

pressure,adjusttheatomizingairrestrictor

valve.

•Ifatomizationisinadequate,increaseair

pressureordecreaseuidow.

23.Adjustthefanairadjustmentvalve.

21.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

•Fullyopenthefanairadjustmentvalve,

counterclockwise,forthelongestpattern.

•Turnthevalveclockwisetorestrictthefanair

andcreateashorterpattern.

24.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page44.

3A2494P

27

Page 28

GunSetup

Soft

Spray

Soft Soft

Spray Spray

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

Toachieveasoftspraypatternforsmallorlightweight

parts,dothefollowing:

1.Selectasoftspraygunmodel.See

SoftSprayGunModels,page5.

•Toconvertagunforsoftspray,

installasoftsprayaircap.See

AirCapSelectionGuide,page82.

•Forbestresults,installa1.0

mmor1.2mmnozzle.See

FluidNozzleSelectionChart,page79.

2.Followsteps1–14inthe

GunSetupProcedure,page25.

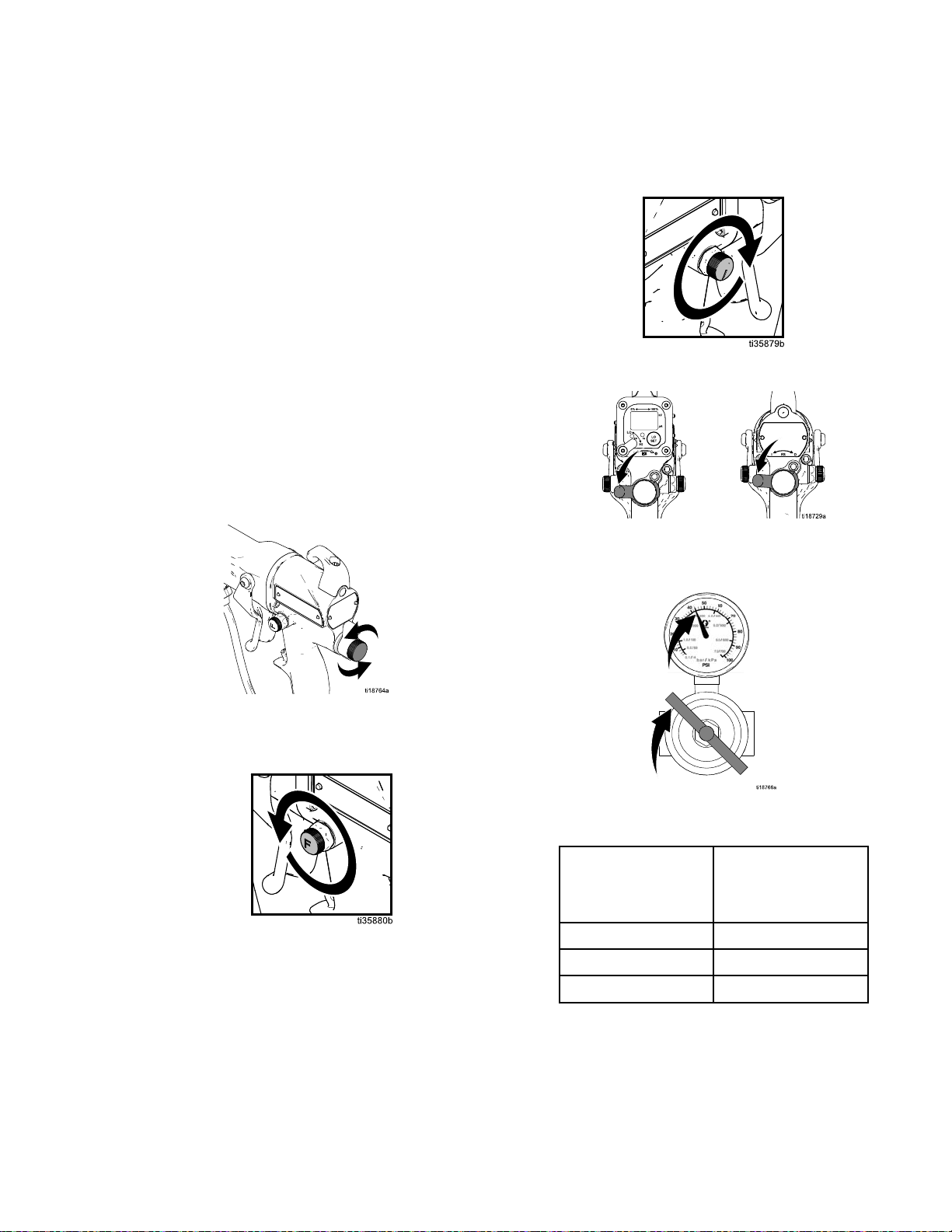

3.Adjusttheatomizingair.Fullyclosetheatomizing

airrestrictorvalve(G)counterclockwise.Then,

opentheatomizingairrestrictorvalve(G)one

halfturntooneturn.

4.TurnON(I)theESOn-Offswitch(J).

Table

Table Table

using

using using

mm)

mm) mm)

6.VerifythattheESindicator(K)[Hzindicatoron

Smartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Green

Amber

Pressure

4 44. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

Color

Color Color

Red

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

LED

5 55. ..LED LED

Drop

Drop Drop

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A160.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

Air

Regulator

Air Air

Regulator Regulator

psi

in ininpsi psi

with

gun

with with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

triggered

triggered triggered

bar)

bar) bar)

5.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

7.Continuewithsteps19–24inthe

GunSetupProcedure,page25.

NOTE:

NOTE: NOTE:

productionrateof3.5oz/min(100cc/min).For

bestsoftsprayresults,limittheproductionrate

to7oz/min(200cc/min)orless.

NOTE:

NOTE: NOTE:

much,adjusttheatomizingairrestrictorvalve

(G)counterclockwiseslightlytolimittheairow.

Toimproveatomization,adjusttheatomizingair

restrictorvalve(G)clockwiseslightlytoincrease

theairowordecreasetheuidow.

Thesoftsprayaircapisoptimizedfora

Iftheobjectbeingsprayedismovingtoo

283A2494P

Page 29

GunSetup

HVLP

HVLP HVLP

Mostairqualityauthoritiesacceptelectrostatic

sprayingasthemostefcientprocessandameans

tocomplywithenvironmentalregulation.Follow

theGunSetupProcedure,page25whenspraying

electrostaticallywithanHVLPaircap.

Whenelectrostaticsprayingcannotbeeffectively

usedoncertainpartsormaterials,anHVLPguncan

beusedtocomplywithenvironmentalregulationsin

mostareas.Tobeincompliancetheairpressures

attheaircapmustbelessthan10psi.Follow

theprocedurebelowtosetupthespraygunfor

non-electrostaticHVLPoperation.

1.SelectanHVLPgunmodel.See

2.Followsteps1–12inthe

3.Fullyopentheuidadjustmentvalve(H)

Gun

Gun Gun

HVLPGunModels,page6.

ToconvertagunforHVLP,installanHVLPair

cap.SeeAirCapSelectionGuide,page82.

GunSetupProcedure,page25.

counterclockwise.

Setup

Setup Setup

Procedure

Procedure Procedure

b.Fullyopentheatomizingairrestrictorvalve

(G)clockwise.

c.TurnOFF(I)theESOn-Offswitch(J).

d.Setthegunairregulatortodeliver30

psi(0.21MPa,2.1bar)atthegunwhen

triggered.

4.Adjusttheairintheaircap.

a.Fullyopenthefanairadjustmentvalve(F)

counterclockwise.

Table

Table Table

5.Shutofftheairtothegun.

Pressure

6 66Pressure Pressure

Air

Hose

Air Air

Hose Hose

(m)

in ininft ftft(m) (m)

5/16

inch

5/16 5/16

inch inch

diameter

diameter diameter

15(4.6)43(0.29,3)

25(7.6)50(0.34,3.4)

50(15.3)70(0.48,4.8)

Drop

Drop Drop

Length

Length Length

using

using using

(8

mm)

(8 (8

mm) mm)

hose

hose hose

Air

Regulator

Air Air

Regulator Regulator

Setting

Setting Setting

(MPa,

(MPa, (MPa,

gun

gun gun

psi

in ininpsi psi

bar)

with

bar) bar)

with with

triggered

triggered triggered

3A2494P29

Page 30

GunSetup

6.Startthepump.Adjusttheuidregulatoruntilthe

streamfromtheguntravels8-12in.(200-300

mm)beforefallingoff.Typically,ifuidpressure

isbelow5psi(.04MPa,0.4bar)orabove30psi

(0.21MPa,2.1bar),achangeofnozzlesizeis

recommended.

7.Turnontheairtothegun.

8.Sprayatestpattern.Checktheatomization.

•Ifover-atomizationoccursadjusttheatomizing

airrestrictorvalve.

•Ifatomizationisinadequate,increaseair

pressureordecreaseuidow.

9.Adjustthefanairadjustmentvalve.

•Ifdesired,turnthevalveclockwisetorestrict

thefanairandcreateashorterpattern.

10.VerifythattheaircappressuresmeetHVLP

requirementsof10PSI(0.07MPa,0.7bar)or

lessusingtheHVLPvericationkit25E919.See

manual3A6833.Adjustthefanairadjustment

valve(F)andatomizingairrestrictorvalveto

achieve10PSIorlessasneeded.

303A2494P

Page 31

GunSetup

Round

Round Round

Toachievearoundspraypattern,dothefollowing:

1.Selectaroundspraygunmodelorconvertan

2.Followsteps1–11inthe

3.Fullyopentheuidadjustmentvalve(H)

Spray

Spray Spray

existingguntoroundspray.

•Toselectaroundspraygunmodel,see

RoundSprayGunModels,page5.

•Toconvertagunforroundspray,installa

roundspraykit.SeeRoundSprayAccessories

inGunAccessories,page89.

•Toachieveasoftpatternforsmallparts

orincreasedtransferefciency,selectthe

mediumpatternorsmallpatternmodels.

GunSetupProcedure,page25.

counterclockwise.

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

5.TurnON(I)theESOn-Offswitch(J).

6.Setthegunairregulatortodeliveraminimum

45psi(0.32MPa,3.2bar)atthegunwhen

triggered,toensurefullsprayingvoltage.

4.Adjusttheairintheaircap.

a.Fullyclosetheatomizingairrestrictorvalve

(G)counterclockwise.Then,openthe

atomizingairrestrictorvalve(G)oneturn.

b.Fullyclosethefanairadjustmentvalve(F)

clockwise.

Table

Table Table

using

using using

mm)

mm) mm)

Pressure

7 77. ..Pressure Pressure

Air

Hose

Air Air

Hose Hose

Length

Length Length

in ininft ftft(m) (m)

5/16

5/16 5/16

diameter

diameter diameter

15(4.6)55(0.38,3.8)

25(7.6)65(0.45,4.5)

50(15.3)80(0.56,5.6)

Drop

Drop Drop

Air

Air Air

(m)

inch

(8

inch inch

(8 (8

hose

hose hose

Regulator

Regulator Regulator

psi

in ininpsi psi

with

gun

with with

gun gun

Setting

Setting Setting

(MPa,

(MPa, (MPa,

bar)

bar) bar)

triggered

triggered triggered

3A2494P31

Page 32

GunSetup

7.VerifythattheESindicator(K)[Hzindicatoron

Smartguns]islit.

Table

Table Table

Indicator

Indicator Indicator

Amber

8.Shutofftheairtothegun.TurnOFF(O)theES

On-Offswitch(J).

LED

8 88. ..LED LED

Color

Color Color

Green

Red

Indicator

Indicator Indicator

Whenspraying,theindicator

shouldremaingreen,indicating

sufcientairpressuretothe

alternatorturbine.

Iftheindicatorchangestoamber

afteronesecond,theairpressure

istoolow.Increaseairpressure

untiltheindicatorisgreen.

Iftheindicatorchangestored

afteronesecond,theairpressure

istoohigh.Decreaseairpressure

untiltheindicatorisgreen.To

maintainahigherapplicationair

pressure,installESOn/OffValve

RestrictorKit26A160.Adjustthe

pressureasneededtoensurethe

indicatorremainsgreen.

Colors

Colors Colors

Description

Description Description

10.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

11.Sprayatestpattern.Checktheatomization.

NOTE:

NOTE: NOTE:

objectbeingsprayedismovingtoomuch,

adjusttheatomizingairrestrictorvalve(G)

counterclockwiseslightlytolimittheairow.To

improveatomization,adjusttheatomizingair

restrictorvalve(G)clockwiseslightlytoincrease

theairowordecreasetheuidow.

Iftheatomizationistoone,orifthe

9.Startthepump.Adjusttheuidregulatorto

achievetheproductionratethatyouwant.

NOTE:

NOTE: NOTE:

aproductionrateof5oz/min(150cc/min).For

bestroundsprayresults,limittheproductionrate

to10oz/min(300cc/min)orless.

Theroundsprayaircapisoptimizedfor

12.Adjustthepatternsize.

•Forthelargestspraypattern,fullyclosethefan

airadjustmentvalve(F)clockwise.

•Forthesmallestspraypattern,fullyopenthe

fanairadjustmentvalve(F)counterclockwise.

13.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page44.

323A2494P

Page 33

GunSetup

Abrasive

Abrasive Abrasive

NOTE:

NOTE: NOTE:

taskseachday:

•Cleanthegun.SeeCleantheGunDaily,page40.

•Inspecttheelectrodeandreplaceifdamaged.See

ElectrodeReplacement,page49.

Toextendwearlifewithabrasive,metallic,and

extremelyabrasivematerials,dothefollowing:

1.Selectahighconductivityor

xeduidowgunmodel.See

HighConductivityGunModels,page4and

FixedFluidFlowGunModels,page6.

2.Toconvertagunforabrasivematerials:

•Selectahighwear,short,

orhardenedelectrode.See

ElectrodeSelectionChart,page88.

•Selectaprecisionhighwear

orhighwearnozzle.See

FluidNozzleSelectionChart,page79.

Sizethenozzleproperlytoreduceuid

pressurebelow30psi(0.21MPA,2.1bar),

producingan8-12in(200-300mm)uid

stream.

•Use24N632ESOn-OffandFixedFluidValve.

3.Followsteps1–19inthe

GunSetupProcedure,page25.

4.Startthepump.Adjusttheuidregulatoruntilthe

streamfromtheguntravels8-12in.(200-300

mm)beforefallingoff.Typically,ifuidpressure

isbelow5psi(.04MPa,0.4bar)orabove30psi

(0.21MPa,2.1bar),achangeofnozzlesizeis

recommended.

Material

Material Material

Toextendwearlife,performthefollowing

Gun

Gun Gun

Setup

Setup Setup

Procedure

Procedure Procedure

5.Turnontheairtothegun.TurnON(I)theES

On-Offswitch(J).

6.Sprayatestpattern.Checktheatomization.If

over-atomizationoccursatminimumpressure,

adjusttheatomizingairrestrictorvalve.If

atomizationisinadequate,increaseairpressure

ordecreaseuidow.

NOTE:

NOTE: NOTE:

toextendelectrodewirewearlife.Reducethe

guninletairpressureoradjusttheatomizingair

restrictorvalve(G)counterclockwisetoreduce

atomizingairwhentheapplicationallows.

7.Adjustthefanairadjustmentvalve.

•Fullyopenthefanairadjustmentvalve,

•Turnthevalveclockwisetorestrictthefanair

NOTE:

NOTE: NOTE:

extendelectrodewirewearlife.Reducethegun

inletairpressureoradjustthefanairadjustment

valve(F)clockwisetoreducefanairwhenthe

applicationallows.

8.Sprayatestpiece.Examinetheedges

forcoverage.Ifwrapispoor,see

Troubleshooting,page44.

Usetheminimumatomizingairpressure

counterclockwise,forthelongestpattern.

andcreateashorterpattern.

Usetheminimumfanairpressureto

NOTE:

NOTE: NOTE:

knobinthefullowpositionatalltimesor

install24N632ESOn-OffandFixedFluidValve.

Alwaysuseanexternaluidregulator.Donot

usetheuidadjustmentknobtosettheuid

pressure.

Operatethegunwiththeuidadjustment

3A2494P33

Page 34

GunSetup

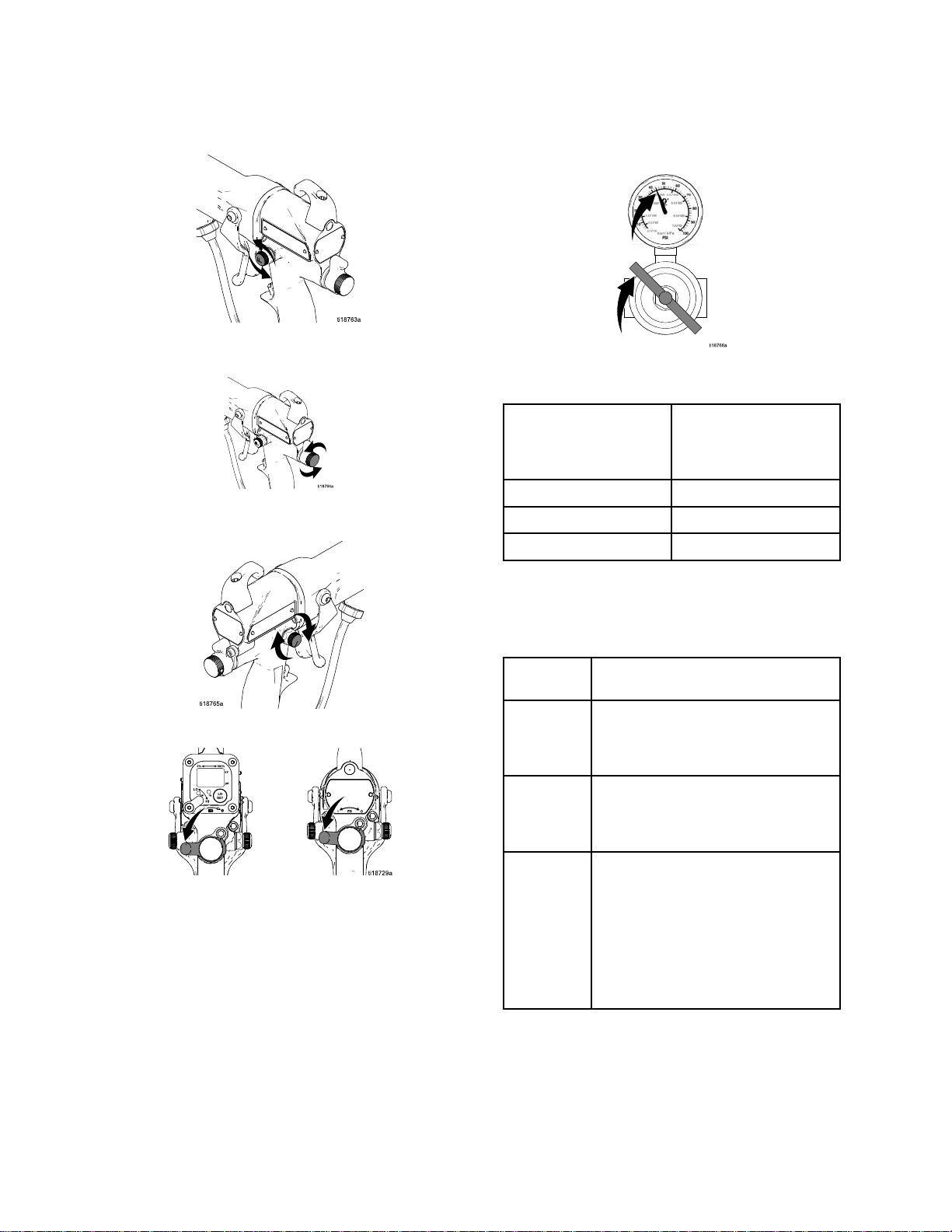

Check

Check Check

MegohmmeterPartNo.241079(AA-seeFig.16)

isnotapprovedforuseinahazardouslocation.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

•Orallsprayingdevicesinthehazardous

Failuretofollowthiswarningcouldcausere,

explosion,andelectricshockandresultinserious

injuryandpropertydamage.

GracoPartNo.241079Megohmmeterisavailable

asanaccessorytocheckthatthegunisproperly

grounded.

1.Haveaqualiedelectricianchecktheelectrical

2.TurnOFF(O)theESOn-Offswitch.

Gun

Gun Gun

location;

locationareturnedoff,ventilationfansinthe

hazardouslocationareoperating,andthereare

noammablevaporsinthearea(suchasopen

solventcontainersorfumesfromspraying).

groundingcontinuityofthespraygunandair

hose.

Electrical

Electrical Electrical

Grounding

Grounding Grounding

5.Makesurethegroundedairhose(AH)is

connectedandthehosegroundwireis

connectedtoatrueearthground.

6.Measuretheresistancebetweenthegunhandle

(BB)andatrueearthground(CC).Usean

appliedvoltageof500minimumto1000volts

maximum.Theresistanceshouldnotexceed1

megohm.SeeFig.16.

7.Iftheresistanceisgreaterthan1megohm,check

thetightnessofthegroundconnectionsandbe

suretheairhosegroundwireisconnectedtoa

trueearthground.Iftheresistanceisstilltoo

high,replacetheairhose.

3.Turnofftheairanduidsupplytothegun.Follow

thePressureReliefProcedure,page36.

4.Disconnecttheuidhose.

Figure16CheckGunElectricalGrounding

343A2494P

Page 35

GunSetup

Check

Check Check

Toreducetheriskofre,explosion,orelectric

shock,checktheuidresistivityinanon-hazardous

locationonly.ResistanceMeter722886andProbe

722860arenotapprovedforuseinahazardous

location.

Checkthattheresistivityoftheuidbeingsprayed

meetstherequirementsforanelectrostaticairspray

system.GracoPartNo.722886ResistanceMeter

and722860Probeareavailableasaccessories.

Followtheinstructionsincludedwiththemeterand

probe.

Fluidresistivityreadingsofatleast20megohms-cm

generallyprovidethebestelectrostaticresultsand

arerecommended.

Ahighconductivitykitorhighconductivityhosemay

berequiredforreadingslessthan20megohm-cm.

Table

Table Table

Fluid

Fluid Fluid

Fluid

9 99. ..Fluid Fluid

Resistivity

Resistivity Resistivity

Resistivity

Resistivity Resistivity

Levels

Levels Levels

Check

Check Check

Aviscositycupandstopwatchareneededtocheck

uidviscosity.

1.Completelysubmergetheviscositycupin

2.Watchthestreamofuidcomingfromthebottom

3.Recordtheuidtype,elapsedtime,andsizeof

4.Iftheviscosityistoohighortoolow,contactthe

Flush

Flush Flush

Theequipmentwastestedinuidatthefactory.To

avoidcontaminatingyouruid,ushtheequipment

withacompatiblesolventbeforeusingtheequipment.

SeeFlushing,page38.

Fluid

Fluid Fluid

theuid.Liftthecupoutquickly,startingthe

stopwatchassoonasthecupiscompletely

removed.

ofthecup.Assoonasthereisabreakinthe

stream,shutoffthestopwatch.

theviscositycup.

materialsupplier.Adjustasnecessary.

Before

Before Before

Viscosity

Viscosity Viscosity

Using

Using Using

Equipment

Equipment Equipment

Megohms

Megohms Megohms

1–77–2020–200200–2000

HighConductivity

Kitrecommended

HighConductivity

Kitmaybe

needed

cm

- --cm cm

Bestelectrostatic

results

Goodelectrostatic

results

3A2494P35

Page 36

Operation

Operation

Operation Operation

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchassplashing,

followthePressureReliefProcedurewhenyou

stopsprayingandbeforecleaning,checking,or

servicingtheequipment.

1.TurnOFF(O)theESOn/Offswitch.

2.Turnofftheairbleedvalvestotheuidsource

andtothegun.

Relief

Relief Relief

Procedure

Procedure Procedure

4.Openthepumpdrainvalve,havingawaste

containerreadytocatchthedrainage.Leave

thepumpdrainvalveopenuntilyouareready

tosprayagain.

5.Ifthenozzleorhoseiscompletelycloggedor

pressureisnotfullyrelieved,slowlyloosenthe

hoseendcoupling.Nowclearthenozzleorhose.

3.Triggerthegunintoagroundedmetalwaste

containertorelievetheuidpressure.

363A2494P

Page 37

Operation

Startup

Startup Startup

FollowallstepsunderGunSetupProcedure,page25.

Beforeoperatingthesystem,checkthefollowinglist

dailytoensuresafe,efcientoperation.

•Alloperatorsareproperlytrainedtosafelyoperate

anelectrostaticairspraysystemasinstructedin

thismanual.

•Alloperatorsaretrainedinthe

PressureReliefProcedure,page36.

•Thewarningsignprovidedwiththegunismounted

inthesprayareawhereitcanbeeasilyseenand

readbyalloperators.

•Thesystemisthoroughlygroundedandthe

operatorandallpersonsenteringthesprayarea

areproperlygrounded.SeeGrounding,page21.

•Theconditionofthegun’selectrical

componentshasbeencheckedasinstructedin

ElectricalTests,page42.

•Ventilationfansareoperatingproperly.

•Workpiecehangersarecleanandgrounded.

•Alldebris(includingammableuidsandrags)is

removedfromthesprayarea.

•Allammableuidsinthespraybootharein

approved,groundedcontainers.

•Allconductiveobjectsinthesprayareaare

electricallygroundedandtheoorofthespray

areaiselectricallyconductiveandgrounded.

Shutdown

Shutdown Shutdown

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page36wheneveryou

areinstructedtorelievethepressure.

1.Flushthegun.Followthestepsin

Flushing,page38.

2.FollowthePressureReliefProcedure,page36.

3.Hangthegunfromitshook,withthenozzle

pointingdown.

3A2494P37

Page 38

Maintenance

Maintenance

Maintenance Maintenance

Toreducetheriskofaninjury,followthe

PressureReliefProcedure,page36,whenever

youareinstructedtorelievethepressure.

Daily

Daily Daily

Checkthefollowinglistdailyuponcompletionof

equipmentusage.

Care

Care Care

Flushthegun.SeeFlushing,page38.

Cleantheuidandairlinelters.

Cleantheoutsideofthegun.See

CleantheGunDaily,page40.

Cleantheaircapanduidnozzledaily,

ataminimum.Someapplicationsrequire

morefrequentcleaning.Replacethespray

tipandaircapiftheyaredamaged.See

CleantheGunDaily,page40.

Checktheelectrodeandreplace

ifbrokenordamaged.See

ElectrodeReplacement,page49.

Checkforuidleakagefromthegunanduid

hoses.Tightenttingsorreplaceequipment

asneeded.

Checkelectricalgrounding.See

CheckGunElectricalGrounding,page34.

and

Cleaning

and and

Cleaning Cleaning

Checklist

Checklist Checklist

Flushing

Flushing Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithauidthatiscompatiblewiththeuid

beingdispensedandtheequipmentwettedparts.

Toreducetheriskofre,explosion,orelectric

shock:

•TurnOFF(O)theESOn-Offswitchbefore

ushingthegun.

•Alwaysgroundequipmentandwastecontainers.

•Flushequipmentonlyinawell-ventilatedarea.

•UseonlyGroupIIAushingmaterials.

Non-ignitableuidsarepreferred.

•Toavoidstaticsparkingandinjuryfrom

splashing,alwaysushatthelowestpossible

pressure.

NOTICE

NOTICE NOTICE

Donotusemethylenechlorideasaushingor

cleaningsolventwiththisgunasitwilldamage

nyloncomponents.

1.TurnOFF(O)theESOn-Offswitch.

383A2494P

Page 39

Maintenance

2.FollowthePressureReliefProcedure,page36.

3.Changetheuidsourcetosolvent,ordisconnect

theuidlineandconnectasolventsupplyline

tothegun.

4.Pointthegunintoagroundedmetalpail.Flush

untilcleansolventowsfromthegun.

5.FollowthePressureReliefProcedure,page36.

6.Shutoffordisconnectthesolventline.

7.Hangthegunfromitshook,withthenozzle

pointingdown.

8.Whenreadytosprayagain,reconnect

theuidsupplyline.Followthe

GunSetupProcedure,page25.

3A2494P39

Page 40

Maintenance

Clean

Clean Clean

•Cleanallpartswithanon-conductive,compatible

•Fluidintheairpassagescouldcausethegunto

1.TurnOFF(O)theESOn-Offswitch.

2.Flushthegun.Followthestepsin

3.FollowthePressureReliefProcedure,page36.

the

Gun

the the

Gun Gun

solvent.Conductivesolventscancausethegun

tomalfunction.

malfunctionandcoulddrawcurrentandreduce

theelectrostaticeffect.Fluidinthepowersupply

cavitycanreducetheturbinelife.Whenever

possible,pointthegundownwhencleaningit.

Donotuseanycleaningmethodwhichcould

allowuidintothegunairpassages.

Flushing,page38.

Daily

Daily Daily

NOTICE

NOTICE NOTICE

4.Cleantheoutsideofthegunwithacompatible

solvent.Useasoftcloth.Pointthegundownto

preventsolventfromenteringthegunpassages.

Donotimmersethegun.

403A2494P

Page 41

Maintenance

5.Cleantheaircap.

a.Removetheaircap.

b.Cleantheaircap,retainingring,andnozzle

withasoftbrushandcompatiblesolvent.

c.Ifnecessary,useatoothpickorothersoft

tooltocleantheaircapholes.Donotuse

metaltools.

Daily

Daily Daily

1.FollowthePressureReliefProcedure,page36.

2.Cleantheuidandairlters.

3.Checkforuidleaks.Tightenallttings.

4.Cleanworkpiecehangers.Usenon-sparking

5.Checkthemovementofthetriggerandvalves.

System

System System

tools.

Lubricateifnecessary.

Care

Care Care

d.Reinstalltheaircap.Tightensecurely.

6.CheckGunElectricalGrounding,page34.

7.Hangthegunfromitshook,withthenozzle

pointingdown.

3A2494P

41

Page 42

ElectricalTests

Electrical

Electrical Electrical

Electricalcomponentsinsidethegunaffect

performanceandsafety.Usethefollowing

procedurestotesttheconditionofthepowersupply

andgunbody,andelectricalcontinuitybetween

components.

UsemegohmmeterPartNo.241079(AA)andan

appliedvoltageof500V.Connecttheleadsas

shown.

MegohmmeterPartNo.241079(AA-seeFig.17)

isnotapprovedforuseinahazardouslocation.

Toreducetheriskofsparking,donotusethe

megohmmetertocheckelectricalgrounding

unless:

•Thegunhasbeenremovedfromthehazardous

location;

•Orallsprayingdevicesinthehazardous

locationareturnedoff,ventilationfansinthe

hazardouslocationareoperating,andthereare

noammablevaporsinthearea(suchasopen

solventcontainersorfumesfromspraying).

Tests

Tests Tests

Test

Test Test

1.Flushanddrytheuidpassage.

2.For For

3.For For

Ifoutsidethisrange,testthegun

untriggered.Ifstilloutsidethisrange,goto

TestPowerSupplyResistance,page43.Ifinrange,

seeElectricalTroubleshooting,page46forother

possiblecausesofpoorperformance.

Gun

Gun Gun

For

L40T15

L40T15 L40T15

verifythatthemetalpininthebarrelisproperly

grounded.Measureresistancebetweenthe

metalpin(GP)andtheairswivel(21).The

resistanceshouldbelessthan100ohms.Ifthe

resistanceis100ohmsormore,replacethegun

body.

For

resistancebetweentheelectrodeneedletip(3)

andtheairswivel(21).Theresistanceshouldbe:

•75–120megohmsfor40kVguns

•104–148megohmsfor60kVguns

•148–193megohmsfor85kVguns

Resistance

Resistance Resistance

Model

Model Model

all

all all

guns

guns guns

guns:

guns: guns:

L40M14,