3A6419B EN

888-541-9788

http://magnum.graco.com/magop/

Important Safety Instructions

Read all warnings and instructions in this manual, related manuals, and on the unit. Be familiar

with the controls and the proper usage of the equipment. Save these instructions.

Magnum Products Operational Videos

http://magnum.graco.com/magop/

For portable spray applications of architectural paints and coatings only.

Not approved for use in explosive atmospheres or hazardous locations.

Before You Spray

110474

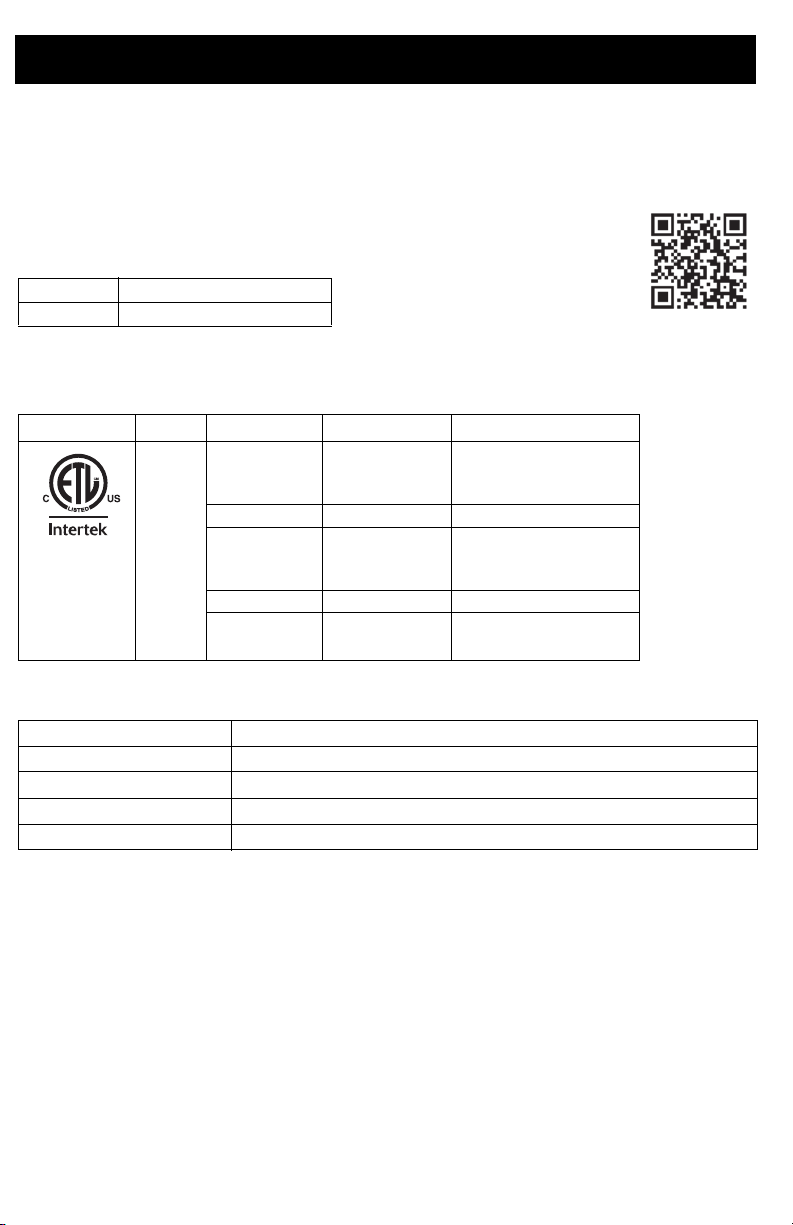

Certified to

CAN/CSA

C22.2 No. 68

Conforms to

UL 1450

Before You Spray

Review Warnings for Important Safety Information

Important! Read carefully and practice good safety habits.

Related Manuals

312830 SG Spray Guns

3A3172 ProXChange™ Pump

Models

3000 psi (207 bar, 20.7 MPa) Maximum Working Pressure

VAC Model Stand (Series) Cart (Series)

17G177 (A)

120

USA

ProX17

ProLTS170

ProX19

ProLTS190 17H206 (A)

ProX21

17K438 (A)

CAN177 (A)

17H198 (A)

17G179 (A)

CAN179 (A)

17G181 (A)

CAN181 (A)

Magnum Products Operational Videos

http://magnum.graco.com/magop/

17G178 (A)

CAN178 (A)

17G180 (A)

17K439 (A)

CAN180 (A)

17G182 (A)

CAN182 (A)

Online Resources

Visit Our Website: magnum.graco.com

Operational Videos: magnum.graco.com/magop/

Manuals: magnum.graco.com/support/#manuals

Parts Online: magnum.graco.com/partsonline/

Material Compatibility: magnum.graco.com/downloads/MaterialCompatibility.pdf

2 3A6419B EN

Contents

Contents

Before You Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Know Your Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ProX and ProLTS Stand Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Know Your Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ProX and ProLTS Cart Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Know Your Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flush Storage Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Strain the Paint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fill Pump (Prime Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fill Gun and Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Refilling Paint Pail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Blockages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjust Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Spray Pattern Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Spray Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Triggering Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Aiming Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Aligning Spray Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Spray Tip and Pressure Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Clear Spray Tip Clog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Spray Tip Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning from a Pail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleanup with Power Flush Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning InstaClean Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Clean the Gun and Gun Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Short Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lacquer Conversion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cleaning Fluid Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Static Grounding Instructions (Oil-Based materials) . . . . . . . . . . . . . . . . . . . . . . . . 30

Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3A6419B EN 3

Contents

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Airless Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spray Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Storage/Priming Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Inlet Valve Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ProX17, ProX19, ProLTS170 Stand Sprayer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ProX17, ProX19, ProLTS170 Stand Sprayer Parts List . . . . . . . . . . . . . . . . . . . . . . 41

ProX21 Stand Sprayer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

ProX21 Stand Sprayer Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

ProX17, ProX19, ProLTS190 Cart Sprayer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ProX17, ProX19, ProLTS190 Cart Sprayer Parts List . . . . . . . . . . . . . . . . . . . . . . . 45

ProX21 Cart Sprayer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

ProX21 Cart Sprayer Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ProXChange Pump Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ProXChange Pump Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wiring Diagram - 110/120V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 3A6419B EN

Notes

Notes

3A6419B EN 5

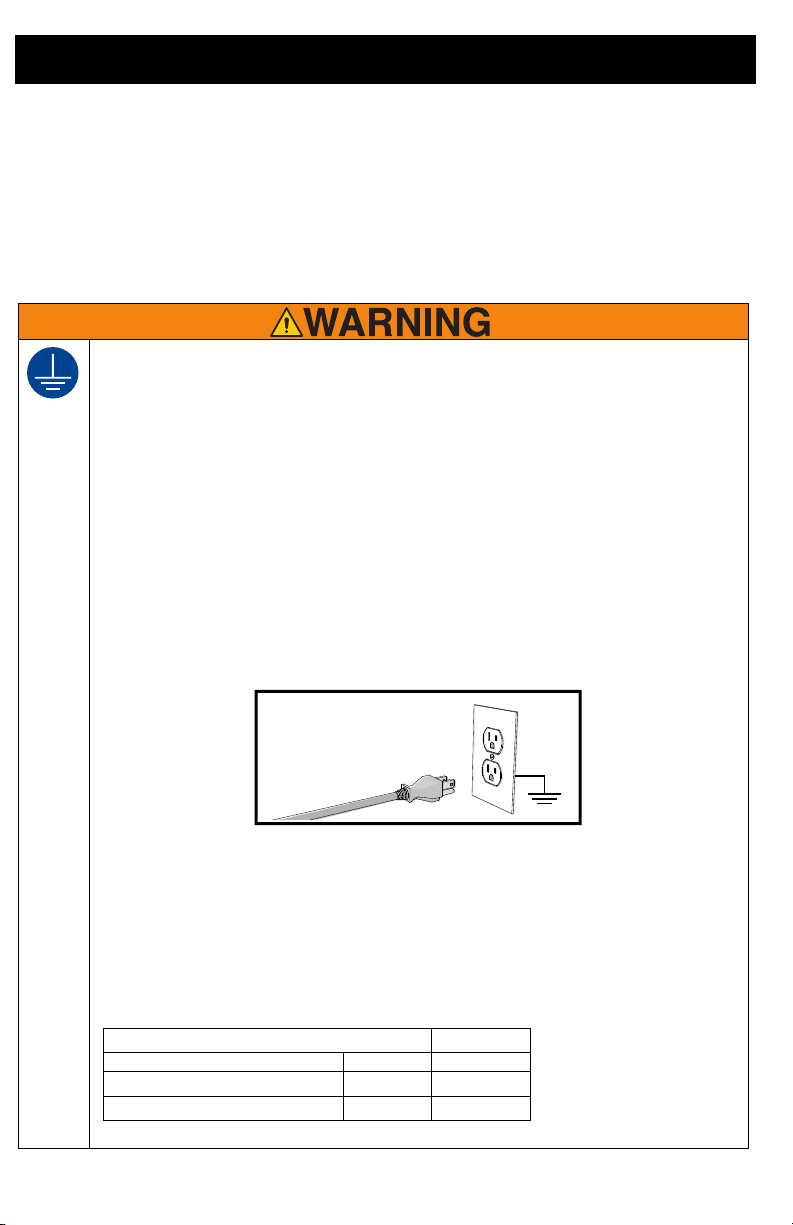

Warnings

ti3509b

Conductor Size Length

AWG (American Wire Gauge) Metric Maximum

16

1.5 mm

2

25 ft. (8 m)

12

2.5 mm

2

50 ft. (15 m)

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual

where applicable.

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces

the risk of electric shock by providing an escape wire for the electric current. This product is

equipped with a cord having a grounding wire with an appropriate grounding plug. The plug

must be plugged into an outlet that is properly installed and grounded in accordance with all

local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding

wire to either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes

is the grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not

completely understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed

by a qualified electrician.

• This product is for use on a nominal 120V circuit and has a grounding plug similar to the

plugs illustrated below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use a 3-to-2 adapter with this product.

Extension Cords:

•

Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle

that accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary use 12

AWG (2.5mm

2

) minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and overheating.

6 3A6419B EN

Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To

help prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition

such as cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static

electricity creates a risk of fire or explosion in the presence of paint or solvent fumes. All

parts of the spray system, including the pump, hose assembly, spray gun, and objects in

and around the spray area shall be properly grounded to protect against static discharge

and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer

hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

Do not use pail liners unless they are anti-static or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2

adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area.

• Sprayer generates sparks. Keep pump assembly in a well ventilated area a least 20 feet

(6.1 m) from the spray area when spraying, flushing, cleaning, or servicing. Do not spray

pump assembly.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the spray

area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable

materials.

• Know the contents of the paints and solvents being sprayed. Read all Safety Data Sheets

(SDSs) and container labels provided with the paints and solvents. Follow the paint and

solvents manufacturer’s safety instructions.

• Keep a working fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

3A6419B EN 7

Warnings

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In

the event that injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop

leaks with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip

clogs while spraying, follow the Pressure Relief Procedure for turning off the unit and

relieving the pressure before removing the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment

energized or under pressure while unattended. Follow the Pressure Relief Procedure

when the equipment is unattended or not in use, and before servicing, cleaning, or

removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3000 psi (207 bar, 20.7 MPa). Use Graco

replacement parts or accessories that are rated a minimum of 3000 psi (207 bar, 20.7

MPa).

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning

properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the

controls.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at

all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by

Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

• Do not spray with a hose shorter than 25 feet.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in w hich you are using

it.

8 3A6419B EN

Warnings

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut, or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure and disconnect all power sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth

defects or other reproductive harm. Wash hands after handling.

3A6419B EN 9

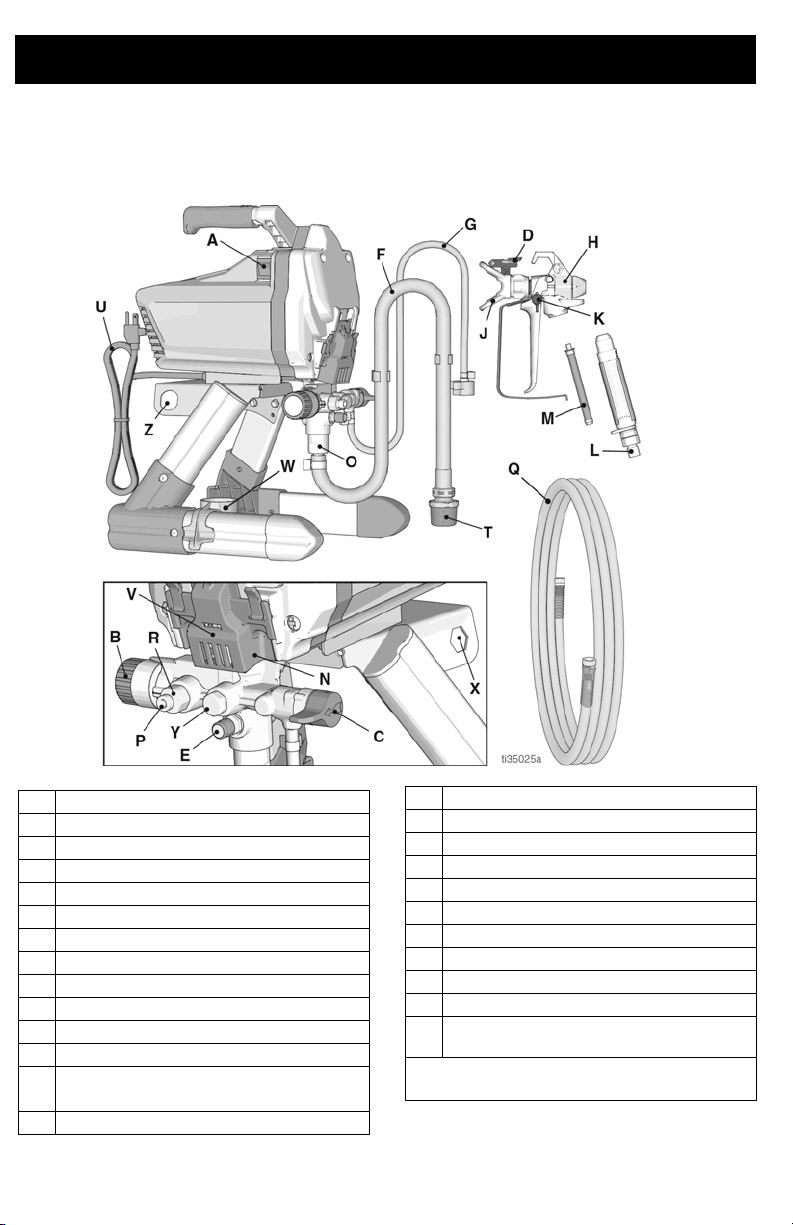

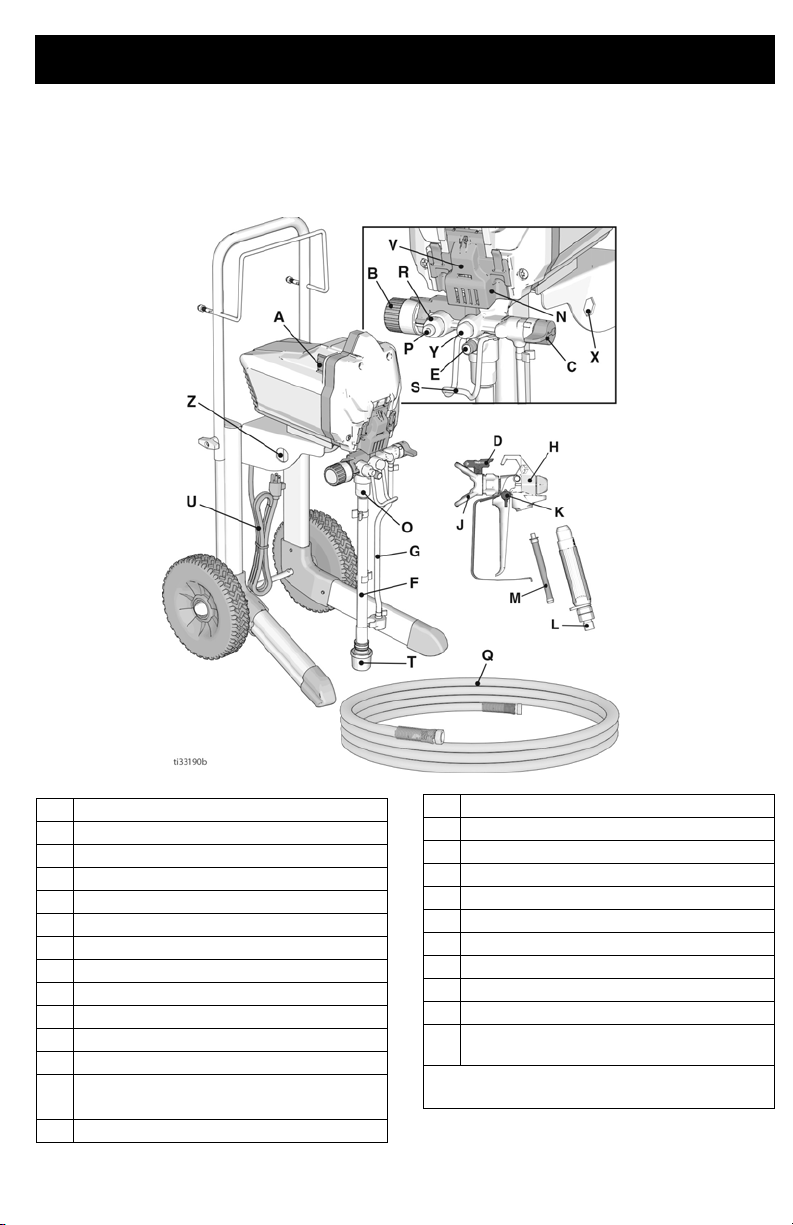

Know Your Sprayer

Know Your Sprayer

ProX and ProLTS Stand Models

A Power - ON/OFF Switch

B Pressure Control Knob

C Prime/Spray Valve

D Spray Tip

E PushPrime™ Button

F Suction Tube

G Drain Tube (with diffuser)

H Airless Spray Gun

J Spray Tip Guard

K Gun Trigger Lock

LGun Fitting

M Gun Filter (inside handle)

N ProXChange™ Pump (behind Easy

Access Door)

OInlet Valve

10 3A6419B EN

P Airless Hose Connection

Q Airless Hose

R InstaClean™ Filter (inside fluid outlet)

T Inlet Screen

U Power Cord

V Easy Access Door

W Suction Tube Drip Cup

X Pump Removal Tool

YOutlet Valve

Z Inlet Valve Removal Tool

Model/Serial Tag (Not shown, located

on bottom of unit.)

See Quick Reference, page 31 for more

information.

Know Your Sprayer

ProX and ProLTS Cart Models

Know Your Sprayer

A Power - ON/OFF Switch

B Pressure Control Knob

C Prime/Spray Valve

D Spray Tip

E PushPrime Button

F Suction Tube

G Drain Tube (with diffuser)

H Airless Spray Gun

J Spray Tip Guard

K Gun Trigger Lock

LGun Fitting

M Gun Filter (inside handle)

N ProXChange™ Pump (behind Easy

Access Door)

OInlet Valve

3A6419B EN 11

P Airless Hose Connection

Q Airless Hose

R InstaClean Filter (inside fluid outlet)

S Pail Hanger

T Inlet Screen

U Power Cord

V Easy Access Door

X Pump Removal Tool

YOutlet Valve

Z Inlet Valve Removal Tool

Model/Serial Tag (Not shown, located

on bottom of unit.)

See Quick Reference, page 31 for more

information.

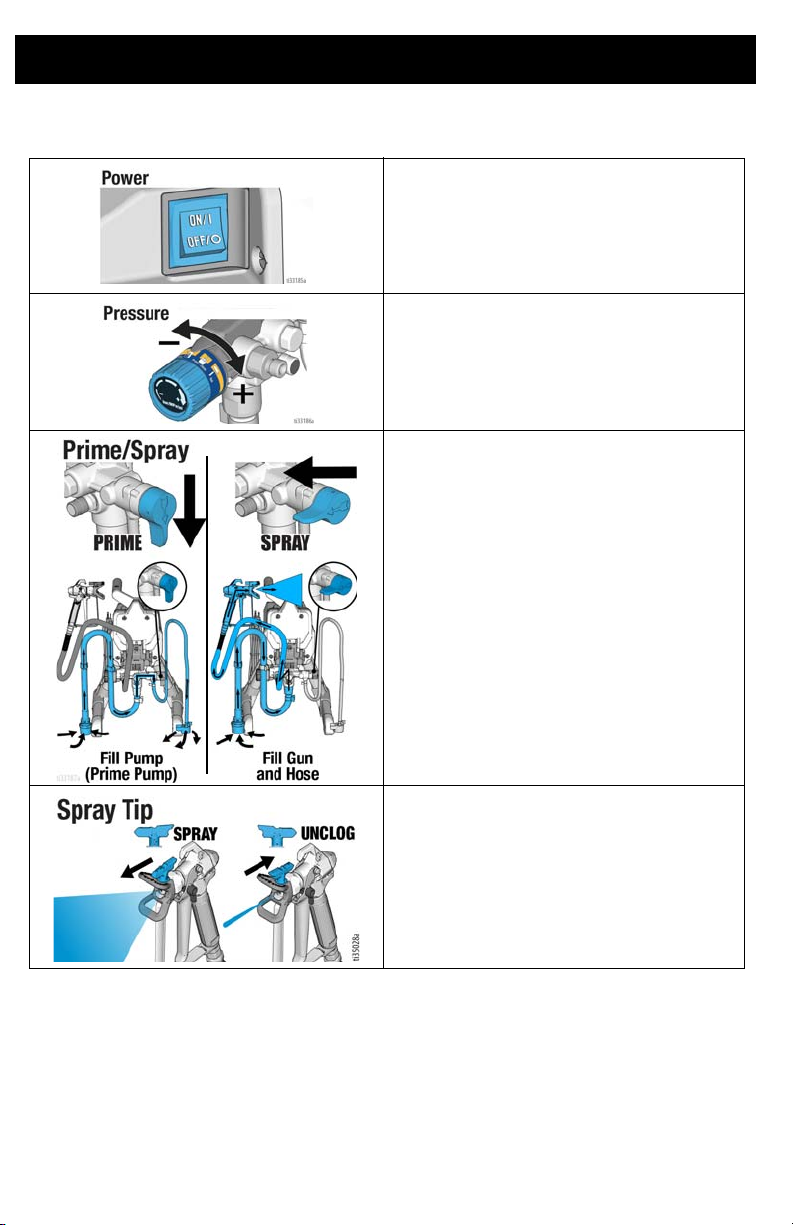

Know Your Controls

Know Your Controls

The ON/OFF power switch controls the main

power to your sprayer.

The Pressure Control knob increases or

decreases the pressure and flow of the paint.

The Prime/Spray Valve directs the fluid to

either the Drain Tube or the hose and gun. It

is used to prime the sprayer, which means to

evacuate the air out of the pump, hose, and

gun.

Your gun will not spray if there is air in the

system. It is necessary to prime the pump,

hose, and gun any time air enters the Suction

Tube.

The Spray Tip is the key to airless spray

technology. High pressure paint pumped

through the very small hole in the Spray Tip

comes out as a spray.

The Spray Tip has the ability to be reversed

and quickly clear clogs.

12 3A6419B EN

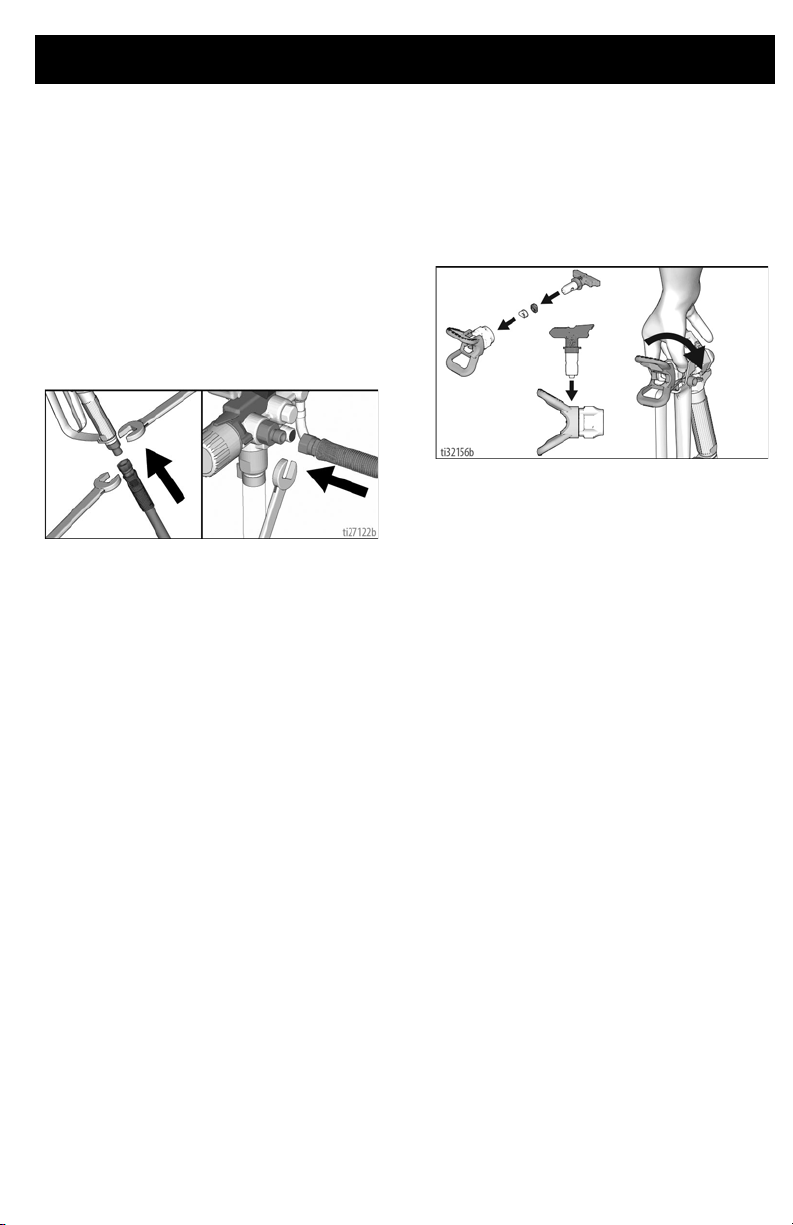

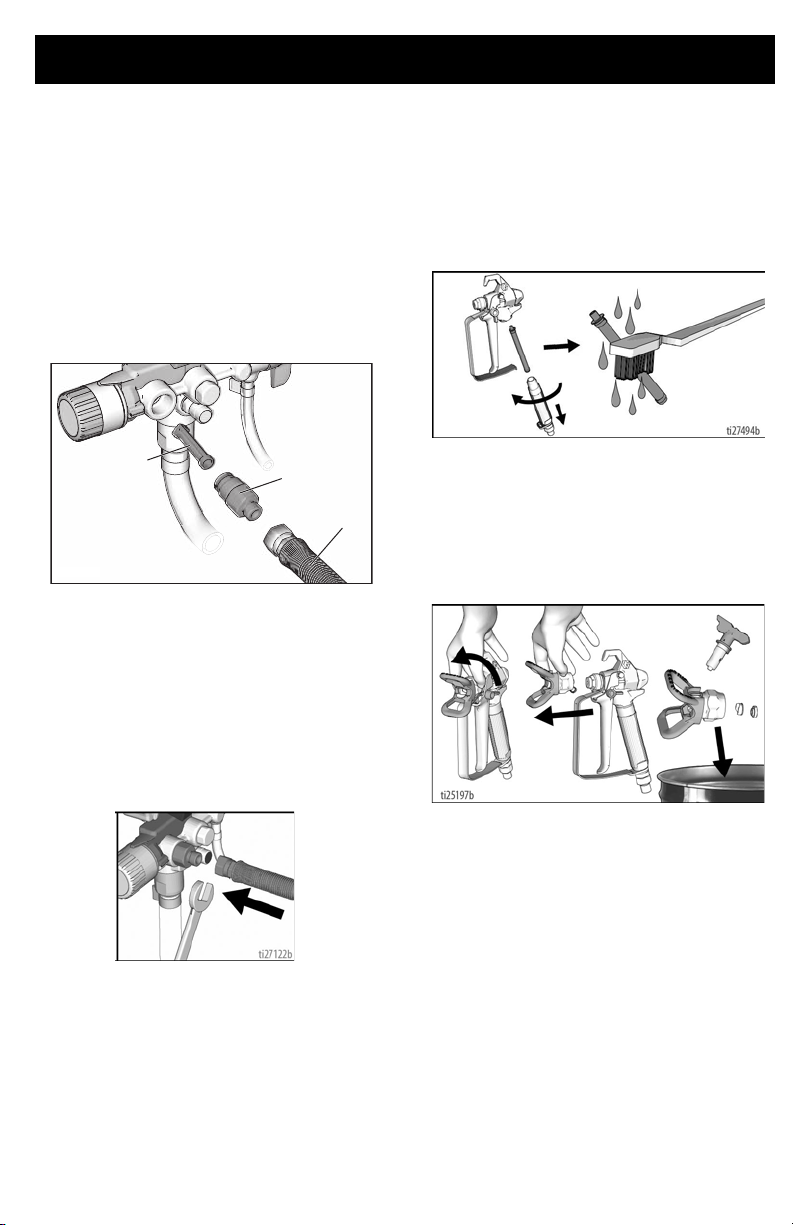

Set Up

Set Up

Assemble Your Sprayer

1. Connect airless hose to airless hose

connection (P) on sprayer. Use wrench

to tighten securely.

2. Connect the other end of the hose to

the gun. Use two wrenches to tighten

securely to gun (see image below).

If hose is already connected, make sure

connections are tight.

3. Assure Spray Tip is properly inserted

into the Spray Tip Guard, and the Spray

Tip Guard assembly is tightened

securely to gun. See Spray Tip

Installation, page 21.

4. Perform the Pressure Relief

Procedure, page 14.

3A6419B EN 13

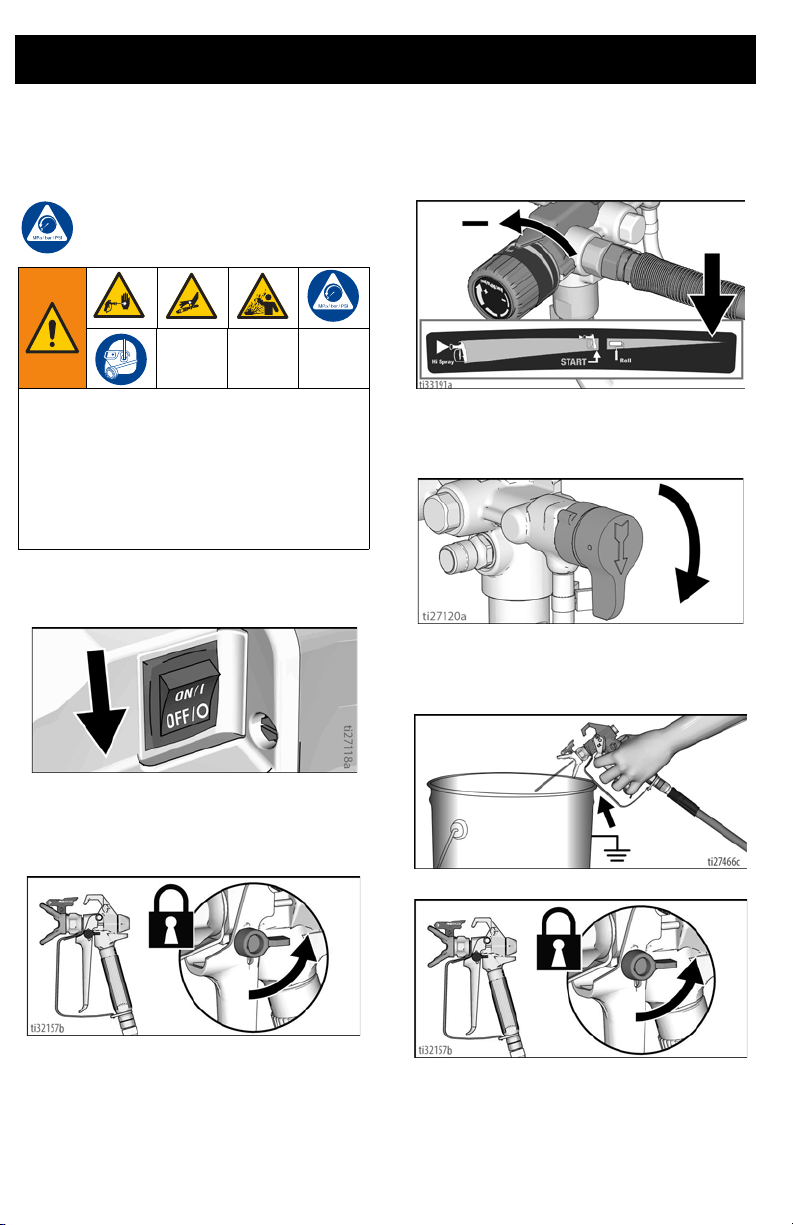

Start Up

Start Up

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection or splashed

fluid, follow the Pressure Relief

Procedure whenever sprayer is stopped

and before sprayer is cleaned or checked,

and before equipment is serviced.

1. Turn ON/OFF switch to the OFF

position.

3. Turn pressure control knob to lowest

setting.

4. Put Drain Tube into a waste pail and

turn Prime/Spray Valve down to PRIME

position to relieve pressure.

5. Hold the gun firmly to a pail. Point gun

into pail. Disengage the trigger lock and

trigger the gun to relieve pressure.

2. Engage the trigger lock. Always engage

the trigger lock when sprayer is stopped

to prevent the gun from being triggered

accidentally.

6. Engage the trigger lock.

7. If you suspect that pressure has not

been fully relieved, see Blockages,

page 17.

NOTE: Leave Prime/Spray Valve in the

PRIME position until you are ready to spray.

14 3A6419B EN

Start Up

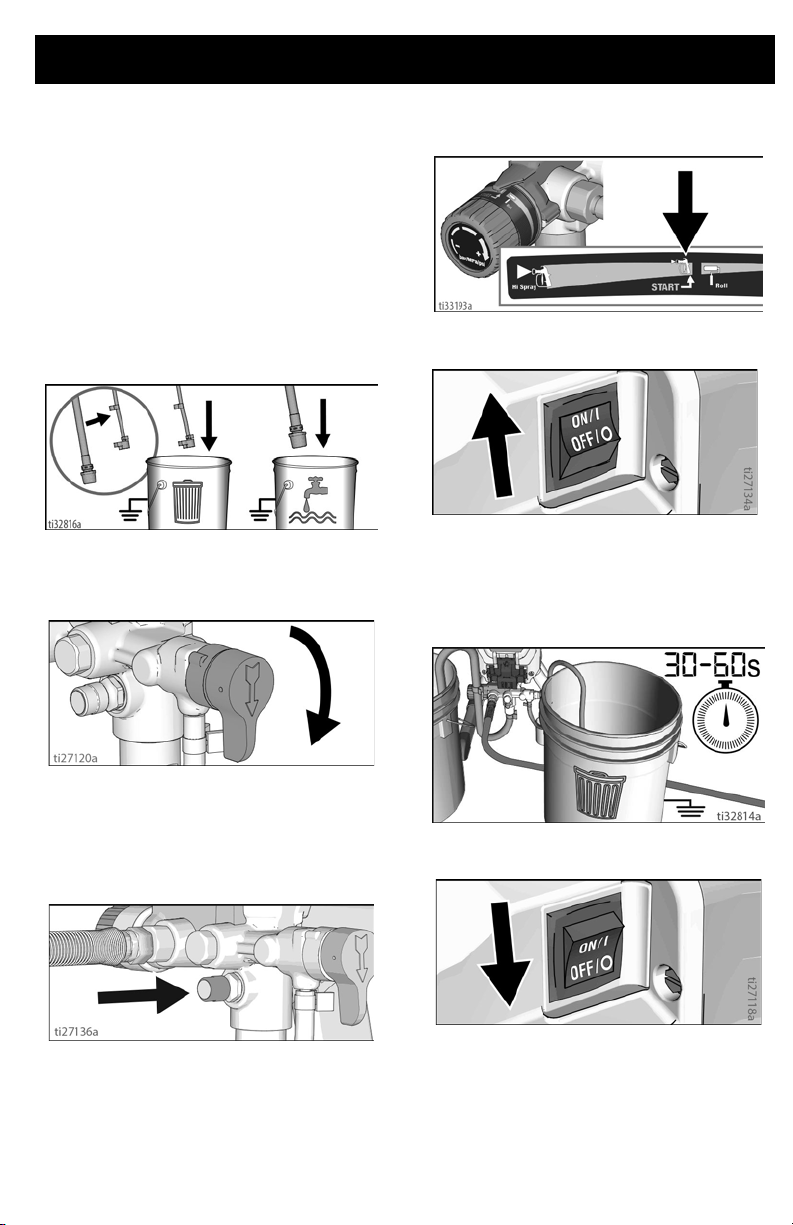

Flush Storage Fluid

It is important that you flush storage fluid

from the sprayer before using it.

1. Make certain ON/OFF switch is OFF.

2. Separate Drain Tube (smaller) from

Suction Tube (larger). Place Drain

Tube in a waste pail.

3. Submerge Suction Tube into pail filled

with water if spraying water-based

material, or mineral spirits if spraying

oil-based material.

4. Turn Prime/Spray Valve down to

PRIME position.

7. Align setting indicator with the START

setting on the pressure control knob.

8. Turn ON/OFF switch to ON position.

9. When sprayer starts pumping, flushing

fluid will flow up the Suction Tube and

out the Drain Tube. Allow fluid to flow

out of Drain Tube, into waste pail, for 30

to 60 seconds.

5. Plug power supply cord into a properly

grounded electrical outlet.

6. Press the PushPrime button twice to

loosen Inlet Valve ball.

3A6419B EN 15

10. Turn the ON/OFF switch to OFF position.

NOTE: If flushing fluid fails to come out of the

Drain Tube, see Storage/Priming Tool,

page 32.

Start Up

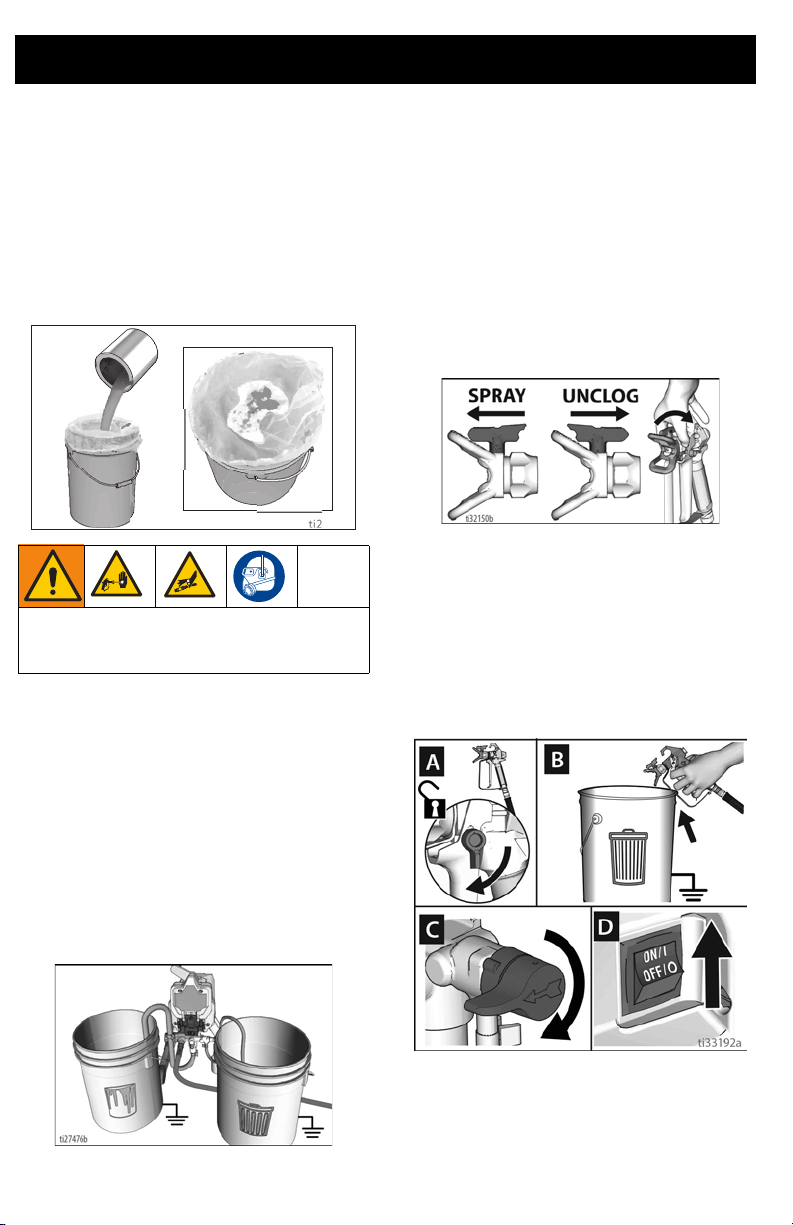

Strain the Paint

Disposable paint strainer bags are used to

remove coarse particles and debris from

new or previously opened paint or stain, and

are available where paint is sold. To avoid

priming problems and Spray Tip clogs it is

recommended to strain all paints and stains

before spraying. Stretch a disposable paint

strainer bag over a clean pail and pour the

paint through the strainer.

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

ti26894a

Fill Pump (Prime Pump)

The Prime/Spray Valve directs the fluid to

either the Drain Tube or the hose and gun. It

is used to prime the sprayer, which means to

evacuate the air out of the pump, hose, and

gun.

Your gun will not spray if there is air in the

system. It is necessary to prime the pump,

hose, and gun any time air enters the suction

tube.

1. Move Suction Tube to paint pail and

submerge Suction Tube in paint.

2. Turn ON/OFF switch to ON position.

3. Wait to see paint coming out of Drain

Tube.

4. Turn ON/OFF switch to OFF position.

NOTE: If paint does NOT flow up the Suction

Tube and out the Drain Tube, see Flush

Storage Fluid, page 15.

Fill Gun and Hose

1. Rotate Spray Tip to UNCLOG position

and ensure the Spray Tip Guard is tight.

2. Hold gun against waste pail. Point gun

into waste pail.

a. Disengage trigger lock (A).

b. Pull and hold gun trigger (B).

c. Turn Prime/Spray Valve horizontal

to SPRAY position (C).

d. Turn ON/OFF switch to ON position

(D).

3. Trigger gun into waste pail until only

paint comes out of the gun.

16 3A6419B EN

Start Up

4. Release trigger. Engage trigger lock.

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

NOTE: Inspect for leaks. If leaking occurs,

perform Pressure Relief Procedure, page

14, then tighten all fittings and repeat Fill

Pump (Prime Pump), page 16.

5. Transfer Drain Tube to paint pail and clip

to Suction Tube.

6. Rotate Spray Tip back to SPRAY

position and ensure the Spray Tip Guard

is tight.

Refilling Paint Pail

When the paint pail runs low and the gun

stops spraying, refill the paint pail and repeat

the Fill Pump (Prime Pump) procedure,

then the Fill Gun and Hose procedure.

You are now ready to spray!

NOTE: It is normal for the motor to stop once

the sprayer is primed and under pressure. If

the motor continues to run, the sprayer is not

primed. Repeat the Fill Pump (Prime Pump)

and Fill Gun and Hose processes.

Blockages

If paint does not come out of the gun, or if

performing pressure relief procedure and

you suspect pressure has not been fully

relieved:

1. VERY SLOWLY loosen the hose

connection to the gun and disconnect

the airless spray hose from the gun.

2. Turn Prime/Spray Valve horizontal to

SPRAY position.

3. While holding hose firmly, point end of

hose into paint pail and turn ON/OFF

switch to ON position.

a. If fluid does not flow out of hose,

replace the hose and continue to

step 4.

b. If fluid flows out of hose, see Clean

the Gun and Gun Filter, page 27.

4. Reassemble the hose and gun, and

repeat Fill Gun and Hose, page 16.

3A6419B EN 17

Spraying

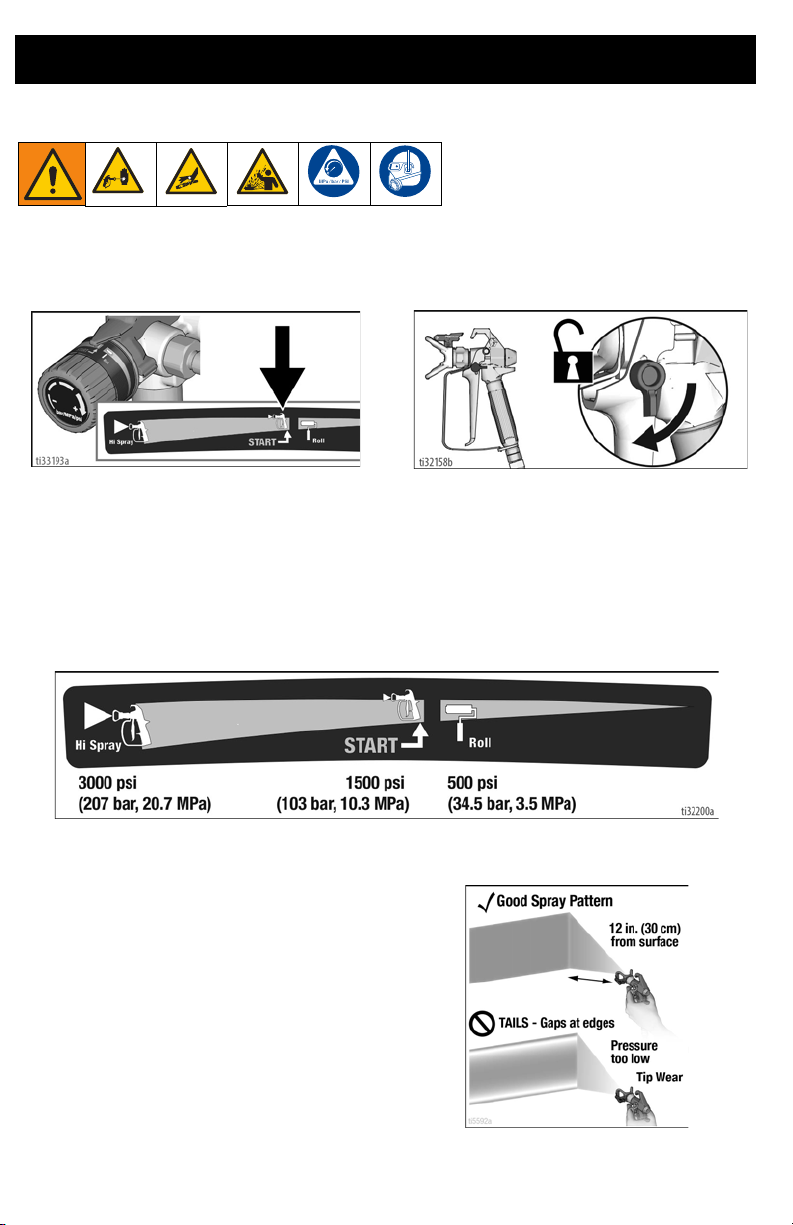

Spraying

Start

1. Turn pressure control knob to START

position.

2. Disengage trigger lock.

Adjust Pressure Control

To select a setting, align symbol on pressure control knob with setting indicator on sprayer.

1. For best spray results with lowest overspray, adjust pressure control to “START” setting.

2. Test the spray pattern on a test area or piece of cardboard.

3. If needed, increase Pressure Control Knob setting to minimum setting that results in an

acceptable spray pattern.

Spray Pattern Quality

A good spray pattern is evenly distributed as

it hits the surface.

• Spray should be atomized (evenly dis-

tributed, no gaps at edges).

• Increase Pressure Control Knob if

needed until spray is even and without

gaps at edges.

• Spray Tip may be worn or a smaller tip

may be needed. See Spray Tip and

Pressure Selection, page 20.

• Material may need to be thinned. If

material needs to be thinned follow

manufacturer’s recommendations.

18 3A6419B EN

Spray Techniques

Use a piece of scrap cardboard to practice

these basic spraying techniques before you

begin spraying the surface.

• Hold gun 12 in. (30 cm) from surface

and aim straight at surface. Tilting gun

to direct spray angle causes an uneven

finish.

• Flex wrist to keep gun pointed straight.

Fanning gun to direct spray at angle

causes uneven finish.

Spraying

Aiming Gun

Aim center of spray of gun at bottom edge of

previous stroke, overlapping each stroke by

half.

Aligning Spray Pattern

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

1. Relieve pressure. See Pressure Relief

Procedure, page 14. Engage trigger

lock.

2. Align guard horizontally to spray a horizontal pattern.

3. Align guard vertically to spray a vertical

pattern.

Triggering Gun

Pull trigger after starting stroke. Release

trigger before end of stroke. Gun must be

moving when trigger is pulled and released.

3A6419B EN 19

Spraying

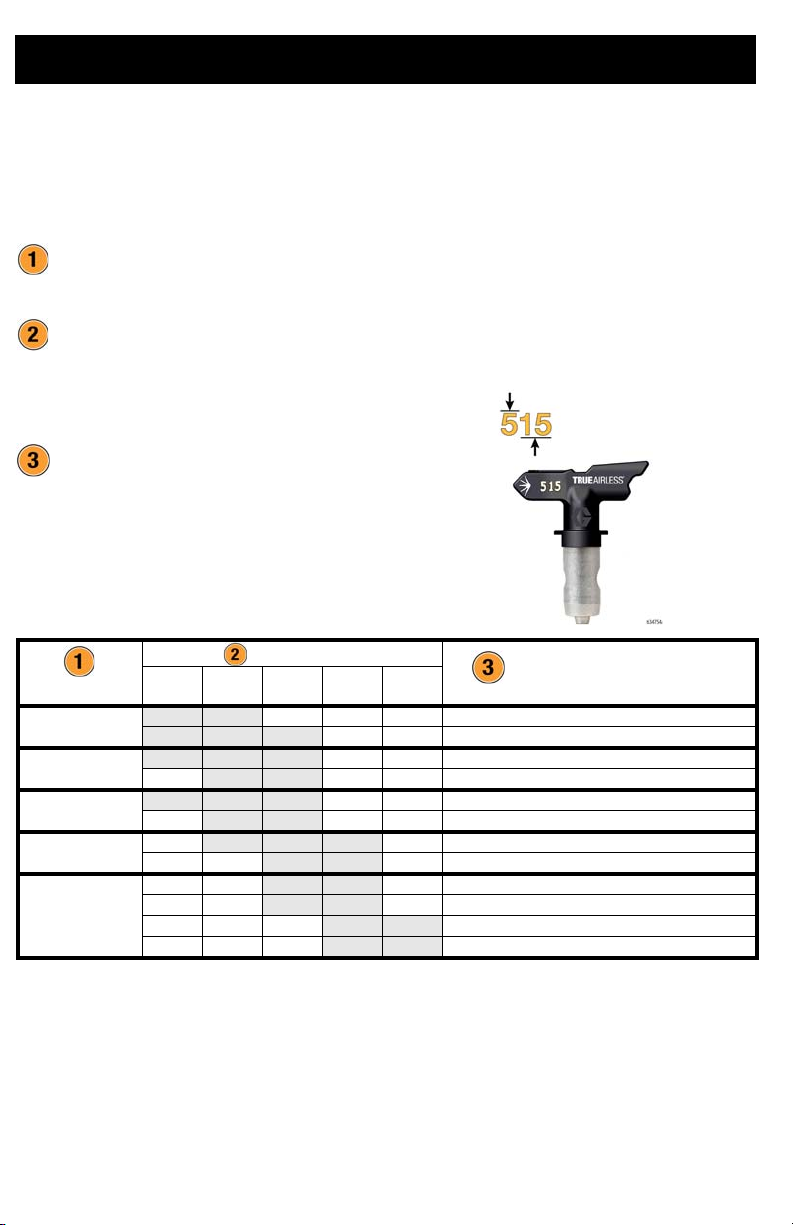

Spray Tip and Pressure Selection

Spray Tips come in a variety of sizes for spraying a wide range of materials. Your sprayer

includes a 515 Spray Tip for use with most paints on large surfaces such as walls and ceilings.

If you are spraying stain or need a different spray fan width, refer to the Spray Tip chart below

to select the best Spray Tip for your project. Additional Spray Tip sizes are available where paint

sprayers are sold.

1. What material are you spraying?

• The thicker the material, the larger

Spray Tip size you will need.

2. What spray fan width is needed for your

project?

• Narrow spray fan for smaller

projects

• Wider spray fan for larger projects

3. Confirm your sprayer can be used with

your Spray Tip size.

Fan Width

4 in Fan

Material

Stain and Sealer

Semi Transparent

Stain

Solid Stain

Interior

Paint/Primer

Exterior

Paint/Primer

6 in Fan

Width

209 309

211 311 411

211 311 411

211 311 411

8 in Fan

Width

313 413

313 413

315 415 515

10 in Fan

Width

Width

417 517

415 515

417 517

519 619

521 621

• As you spray, the Spray Tip wears and as a result, the hole size gets larger. Starting with

a Spray Tip hole size smaller than the maximum will allow you to spray longer within the

compatibility of the sprayer.

• Spray Tips wear with use and need periodic replacement.

Tip Number Calculation:

• The first digit is half of the fan width

(#5 x 2 = 10 inch fan width).

• The last two digits are the size of the

tip opening in thousandths of an

inch.

12 in Fan

Width

Sprayer Compatibility

Each Sprayer Supports a Maximum Spray Tip Size

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX17/ProLTS170, ProX19/ProLTS190, ProX21

ProX19/ProLTS190, ProX21

ProX21

20 3A6419B EN

Spraying

UNCLOG

SPRAY

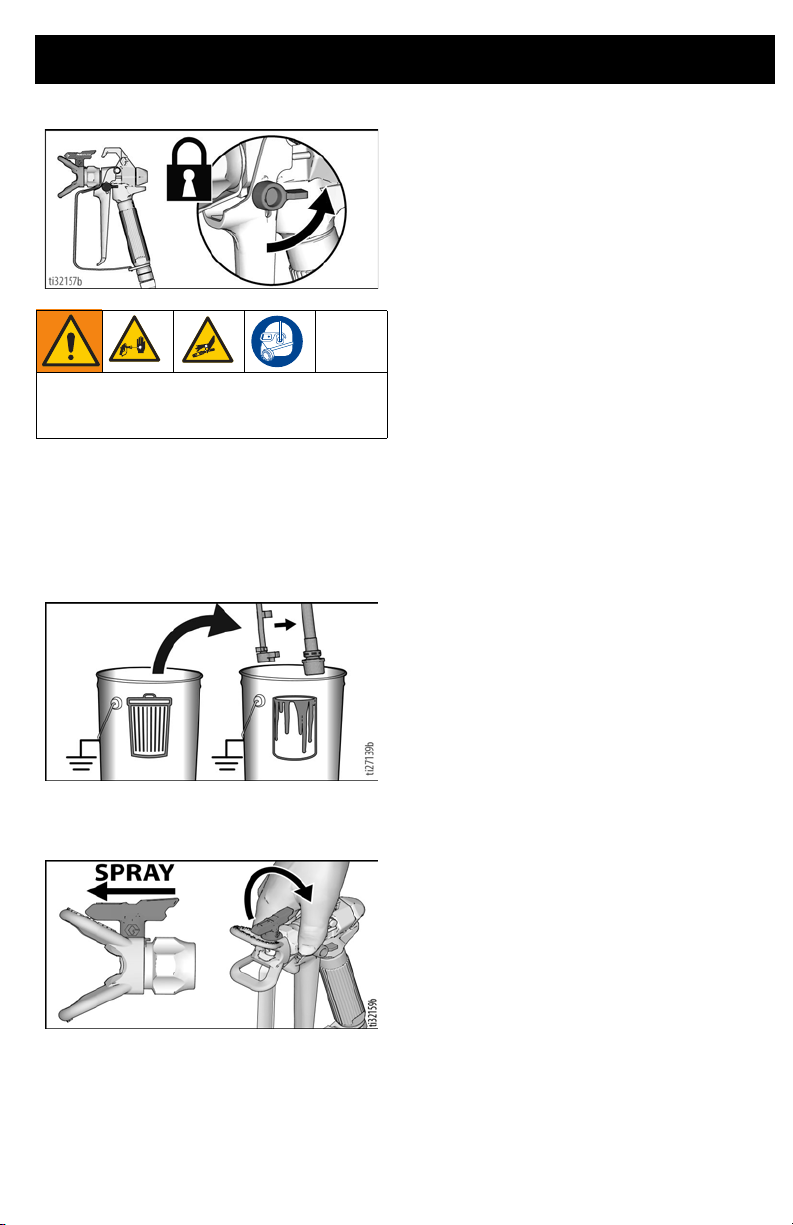

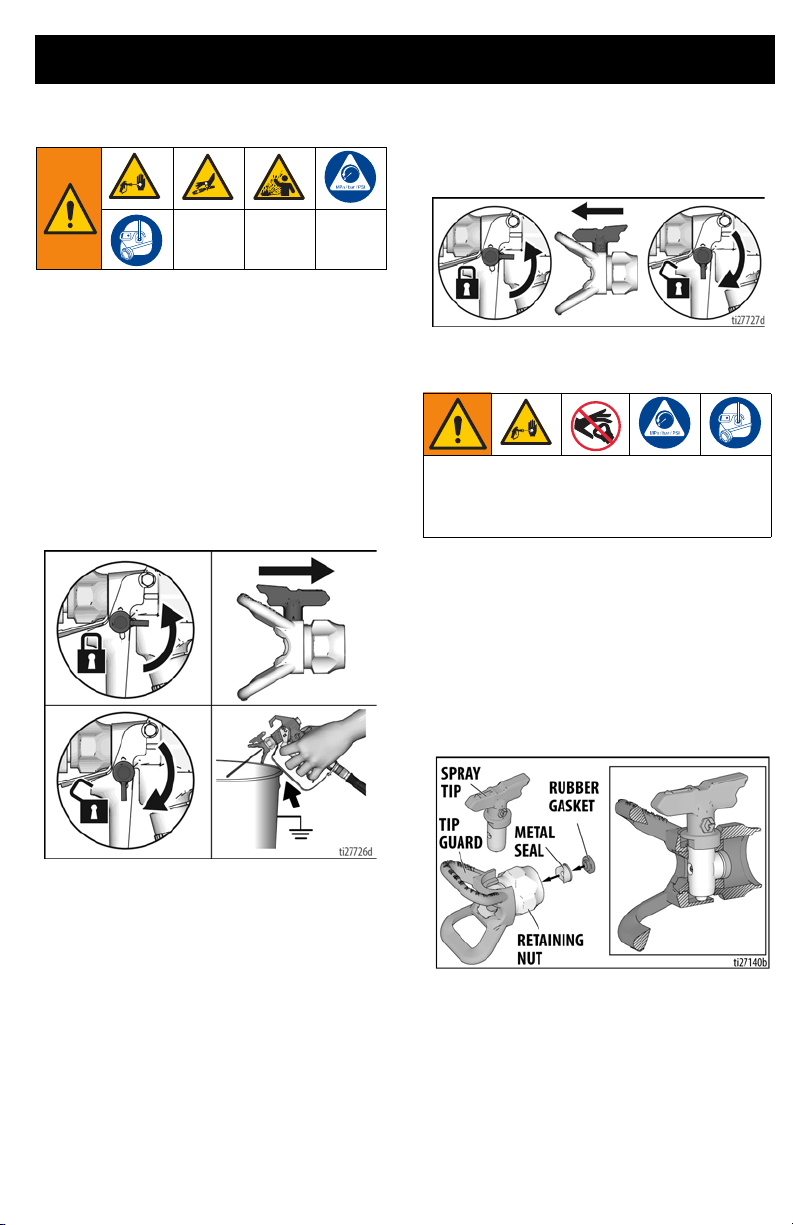

Clear Spray Tip Clog

In the event that particles or debris clog the

Spray Tip, the Spray Tip can be reversed to

quickly and easily clear particles without

disassembling the sprayer.

See Strain the Paint, page 16 for additional

information.

1. Engage trigger lock. Rotate Spray Tip to

UNCLOG position. Ensure spray tip

remains fully seated, pushed all the way

into the Spray Tip Guard. Disengage

trigger lock. Trigger gun at waste area to

clear clog.

2. Engage trigger lock. Rotate Spray Tip

back to SPRAY position. Disengage

trigger lock and continue spraying.

Spray Tip Installation

To avoid serious injury from skin injection

do not put your hand in front of the spray tip

when installing or removing the spray tip

and spray tip guard.

To prevent Spray Tip leaks make certain

Spray Tip and Spray Tip Guard are installed

properly.

1. Perform Pressure Relief Procedure,

page 14.

2. Engage trigger lock.

3. Verify Spray Tip Guard parts are

assembled in the order shown.

NOTE: If Spray Tip is difficult to rotate when

turning to the UNCLOG position perform,

Pressure Relief Procedure, page 14, then

turn Prime/Spray Valve horizontal to SPRAY

position and repeat step 1.

3A6419B EN 21

Spraying

a. Use Spray Tip to align gasket and

seal in the Spray Tip Guard.

b. Spray Tip must be pushed all the

way into the Spray Tip Guard.

Rotate Spray Tip while pushing

down.

c. Turn the arrow shaped handle on

the Spray Tip forward to the SPRAY

position.

4. Screw Spray Tip Guard assembly onto

the gun and tighten.

22 3A6419B EN

Cleanup

7

124a

Cleanup

Cleaning the sprayer after each use results in

a trouble free start up the next time the

sprayer is used.

• For short term shutdown periods (over-

night to two days), refer to Short Term

Storage, page 28.

• For cleanup after using water-based

materials only (by use of a garden

hose), refer to Cleanup with Power

Flush Valve, page 25.

• For cleanup from pails, refer to Clean-

ing from a Pail, below.

• For cleanup after using oil-based or

solvent-based flammable materials,

see Cleaning Fluid Compatibility,

page 30.

Cleaning from a Pail

1. Perform Pressure Relief Procedure,

page 14.

2. Remove Spray Tip Guard assembly

from gun and place in waste pail.

4. Separate Drain Tube (smaller) from

Suction Tube (larger).

ti2

5. Place empty waste and flushing fluid

pails side by side.

6. Place Suction Tube in flushing fluid. For

water-based paints, use water. For

non-water-based paints, use mineral

spirits, paint thinner, or compatible

flushing fluid. Place Drain Tube in

waste pail.

7. Turn Pressure Control Knob to the

START position.

3. Lift Suction Tube and Drain Tube from

paint pail. Let paint drain into the pail.

3A6419B EN 23

Cleanup

ti25196b

8. Turn Prime/Spray valve down to

PRIME position.

9. Turn ON/OFF switch to ON position.

10. Flush until approximately 1/3 of the

flushing fluid is emptied from the pail.

11. Turn ON/OFF switch to OFF position.

NOTE: Step 12 is for returning paint in hose

to paint pail. One 50 ft (15.2 m) hose holds

approximately 1 quart (1 liter) of paint.

12. To recover paint in hose, point gun into

paint pail while holding gun firmly to the

pail.

a. Disengage trigger lock (A).

b. Pull and hold gun trigger (B).

c. Turn Prime/Spray Valve horizontal

to SPRAY position (C).

d. Turn ON/OFF switch to ON position

(D).

e. Continue to hold gun trigger until

you see paint diluted with flushing

fluid starting to come out of gun.

13. While continuing to trigger gun, quickly

move gun to redirect spray into waste

pail. Continue triggering gun into waste

pail until flushing fluid dispensed from

gun is relatively clear.

14. Turn pressure control knob to the lowest setting.

15. Stop triggering gun. Engage the trigger

lock.

16. Turn Prime/Spray Valve down to

PRIME position.

17. Turn ON/OFF switch to OFF position.

18. Follow Short Term Storage or Long

Term Storage, page 28.

24 3A6419B EN

Cleanup

Cleanup with Power Flush Valve

(Water-based materials only)

Power flushing is a faster method of cleanup.

It can only be used after spraying

water-based coatings.

1. Perform Pressure Relief Procedure,

page 14.

2. Engage trigger lock. Remove Spray Tip

Guard assembly from gun and place in

waste pail.

3. Place empty waste and paint pails side

by side.

4. Lift Suction Tube and Drain Tube from

paint pail. Let paint drain into the pail.

5. Place suction and Drain Tube in waste

pail.

7. Screw Power Flush Valve (included

with sprayer) to garden hose. Close

Power Flush Valve.

8. Turn on water. Open Power Flush

Valve. Rinse paint off Suction Tube,

Drain Tube and inlet screen. Close

Power Flush Valve.

9. Unscrew inlet screen from Suction

Tube. Place inlet screen in waste pail.

Connect garden hose to Power Flush

Valve on Suction Tube. Leave Drain

Tube in waste pail.

10. Turn ON/OFF switch to ON position.

11. Open Power Flush Valve.

12. Circulate water through sprayer, into

waste pail, for 20 seconds.

6. Turn pressure control knob to the

START position.

3A6419B EN 25

13. Turn ON/OFF switch to OFF position.

NOTE: Step 14 is for returning paint in hose

to paint pail. One 50 ft (15.2 m) hose holds

approximately 1 quart (1 liter) of paint.

14. To recover paint in hose, point gun into

paint pail while holding gun firmly to the

pail.

a. Disengage trigger lock (A).

b. Pull and hold gun trigger (B).

Cleanup

c. Turn Prime/Spray Valve horizontal

to SPRAY position (C).

d. Turn ON/OFF switch to ON position

(D).

e. Continue to hold gun trigger until

you see paint diluted with flushing

fluid starting to come out of gun.

15. While continuing to trigger gun, quickly

move gun to redirect spray into waste

pail. Continue triggering gun into waste

pail until flushing fluid dispensed from

gun is relatively clear.

16. Turn pressure control knob to the lowest setting.

17. Stop triggering gun. Engage the trigger

lock.

18. Turn Prime/Spray Valve down to

PRIME position.

19. Turn ON/OFF switch to OFF position.

20. Follow Short Term Storage or Long

Term Storage, page 28.

26 3A6419B EN

Cleanup

C

B

A

t

Cleaning InstaClean Filter

The InstaClean Filter prevents debris from

entering paint hose. After each use, remove

and clean it to ensure peak performance.

1. Perform Pressure Relief Procedure,

page 14.

2. Disconnect airless spray hose (A) from

sprayer.

3. Unscrew fluid outlet (B).

4. Remove InstaClean filter (C).

27179a

5. Check InstaClean Filter (C) for debris. If

needed, clean filter with water or

flushing fluid and a soft brush.

a. Install closed (square) end of

InstaClean Filter (C) in sprayer.

b. Screw outlet valve (B) into sprayer.

6. Tighten outlet valve and reconnect

hose (A) to sprayer. Use two wrenches

to tighten securely.

Clean the Gun and Gun Filter

1. Perform Pressure Relief Procedure,

page 14.

2. Remove the gun handle by unscrewing

the handle from the gun head.

3. Clean gun filter with water or flushing

fluid and a brush every time you flush

the system. Replace gun filter if damaged.

4. Remove Spray Tip Guard assembly and

clean with water or flushing fluid and a

brush.

5. See Spray Tip Installation, page 21 to

properly reinstall Spray Tip Guard

assembly.

6. Wipe paint off outside of gun using a soft

cloth moistened with water or flushing

fluid.

3A6419B EN 27

Storage

ti27185a

ti27186a

ti25196b

Storage

With proper storage, the sprayer will be ready

to use the next time it is needed.

Short Term Storage

(up to 2 days)

1. Disconnect power (unplug power cord).

Perform Pressure Relief Procedure,

page 14.

2. Leave Suction Tube and Drain Tube in

paint pail.

3. Cover paint and pail tightly with plastic

wrap.

4. Engage trigger lock.

5. Leave gun attached to hose.

6. Remove Spray Tip and Spray Tip

Guard and clean with water or flushing

fluid and a brush.

7. Wipe paint off outside of gun using a

soft cloth moistened with water or flushing fluid.

Long Term Storage

(more than 2 days)

TM

Pump Armor

against freezing and corrosion.

• Do not store the sprayer full of water.

• Do not allow water to freeze in sprayer.

• Do not store sprayer under pressure.

• Store sprayer indoors.

1. Perform Cleanup, page 23.

2. Remove Pump Armor bottle cap and

foil seal.

fluid protects the sprayer

3. If needed, unscrew Inlet Screen from

Suction Tube. Turn Prime/Spray Valve

down to PRIME position.

28 3A6419B EN

Storage

ti27190a

4. Place drain tube in waste pail. Turn

pressure control to the START position.

5. ProX21 only:

Place Suction Tube in Pump Armor

fluid bottle. Turn Power Switch ON.

All other models:

While holding the Suction Tube above

the sprayer, pour approximately 2

ounces (1/4 cup) of Pump Armor into

Suction Tube and turn Power Switch

ON.

7. Screw Inlet Screen back to Suction

Tube. Ensure that spray gun and hose

stay attached to sprayer.

8. Turn Spray/Prime Valve horizontal to

SPRAY position for storage.

9. Turn ON/OFF switch to OFF position.

Disconnect power (unplug power cord).

10. Secure a plastic bag around Suction

Tube and Drain Tube to catch any

drips.

6. When Pump Armor is flushed through

the sprayer and out the Drain Tube,

turn Power Switch OFF. Replace and

tighten child-proof cap for storage.

3A6419B EN 29

Reference

ti24584a

Reference

Static Grounding Instructions

(Oil or Solvent-Based

Lacquer Conversion Kit

To spray lacquers and other solvent-based

flammable materials with models other than

ProX21, you must purchase a lacquer

conversion kit and follow Static Grounding

Instructions (Oil or Solvent-Based

Flammable Materials), page 30. Refer to

Parts List for kit part numbers.

Flammable Materials)

The equipment must be grounded to

reduce the risk of static sparking. Static

sparking can cause fumes to ignite or

explode. Grounding provides an escape

wire for the electric current.

Cleaning Fluid Compatibility

• When spraying water-based materi-

als, flush the system thoroughly with

water.

• When spraying lacquers or oil-based

materials, flush the system thoroughly

with mineral spirits or compatible

oil-based flushing fluid and follow

Static Grounding Instructions (Oil or

Solvent-Based Flammable Materials), page 30.

• To spray water-based materials after

spraying oil-based materials, flush the

system thoroughly with water first. The

water flowing out of Drain Tube should

be clear before you begin spraying the

water-based material.

• To spray lacquers or oil-based materi-

als after spraying water-based materials, flush the system thoroughly with

mineral spirits or a compatible oil-based

flushing fluid first. Follow Static

Grounding Instructions (Oil or Solvent-Based Flammable Materials),

page 30. The fluid flowing out of the

Drain Tube should not contain any

water.

• To avoid fluid splashing back on your

skin or into your eyes, always aim gun

at inside wall of pail.

30 3A6419B EN

Always use a metal pail for oil-based

materials when sprayer is flushed or pressure

is relieved.

Follow local code. Use only conductive metal

pails, placed on a grounded surface such as

concrete.

Do not place pail on a non-conductive surface

such as paper or cardboard which interrupts

grounding continuity.

Always ground a metal pail: connect a

ground wire to the pail. Clamp one end to the

pail and the other end to a true earth ground

such as a water pipe.

To maintain ground continuity when

sprayer is flushed or pressure is relieved:

hold metal part of gun firmly to the side of a

grounded metal pail, then trigger the gun.

Reference

Quick Reference

Page 10Name

A

B

C

D

E PushPrime Button Taps the inlet ball when pushed to loosen it.

F Suction Tube Draws fluid from paint pail into pump.

G Drain Tube Drains fluid in system during priming and pressure

H Airless Spray Gun Dispenses fluid.

J Spray Tip Guard Reduces risk of fluid injection injury.

K Gun Trigger Lock Prevents accidental triggering of spray gun.

L Gun Fitting Threaded connection for Airless Hose.

M Gun Filter (inside handle) Filters fluid entering spray gun to reduce Spray Tip

N ProXChange™ Pump Pumps and pressurizes fluid and delivers it to Airless

O Inlet Valve Allows paint to flow from paint bucket into the sprayer.

P Airless Hose Connection Threaded connection for airless hose.

Q Airless Hose Transports high-pressure fluid from pump to spray gun.

R InstaClean Filter

S Pail Hanger For transporting pail by its handle.

T Inlet Screen Prevents debris from entering pump.

U Power Cord Plugs into power source.

V Easy Access Door Permits quick access to the pump. Open pump door by

W Suction Tube Drip Cup Holds the Suction Tube during transport to catch drips.

X Pump Removal Tool Cut out in the frame provides the tools to quickly

Y Outlet Valve Allows paint to flow from the sprayer to the gun.

Z Inlet Valve Removal Tool Cut out in the frame provides the tools to quickly

Power - ON/OFF Switch

Pressure Control Knob Increases (clockwise) and decreases

Prime/Spray Valve • In PRIME position directs fluid to Drain Tube.

Spray Tip • Atomizes fluid being sprayed, forms spray pattern

Power Flush Valve Connects garden hose to Suction Tube for power

Description

Turns sprayer ON and OFF.

(counter-clockwise) fluid pressure in pump, hose, and

spray gun. To select function, align symbol on pressure

control knob with setting indicator.

• In SPRAY position directs pressurized fluid to paint

hose.

• Automatically relieves system pressure in

overpressure situations.

and controls fluid flow according to hole size.

• Reverse position unclogs plugged Spray Tips

without disassembly.

relief.

clogs.

Hose.

• Filters fluid coming out of pump to reduce Spray

Tip clogs and improve finish.

• Self cleans only during pressure relief.

pulling out on the tabs while sliding door up.

remove the pump packing without additional tools.

remove the inlet valve without additional tools.

flushing water-based fluids.

3A6419B EN 31

Maintenance

Maintenance

Routine maintenance is important to ensure proper operation of your sprayer.

Maintenance Activity

1. Inspect motor shroud openings for

blockage every time you spray.

2. Clean/inspect inlet screen, InstaClean

filter, and gun filter every time you spray.

Replace if the filter cannot be cleaned or

is damaged.

NOTICE

Protect the internal drive parts of this

sprayer from water. Openings in shroud

allow cooling of mechanical parts and

electronics inside. If water gets into these

openings, the sprayer could malfunction or

be permanently damaged.

Airless Hoses

Check hose for damage every time you

spray. Do not attempt to repair hose if hose

jacket or fittings are damaged. Do not use

hoses shorter than 25 ft. (7.6 m). Wrench

tighten, using two wrenches.

Spray Tips

• Always clean Spray Tips with compati-

ble cleaning fluid and brush after spraying.

• Tips may require replacement after 15

gallons (57 liters) or they may last

through 60 gallons (227 liters) depending on abrasiveness of paint. See

Spray Pattern Quality, page 18.

Storage/Priming Tool

Perform these steps if you are experiencing

difficulty priming your sprayer.

For ProX21, see Inlet Valve Removal, page

33.

1. Perform Pressure Relief Procedure,

page 14.

2. Remove Pump Armor bottle cap. Insert

small fluid tube into bottom of Storage/Prime Tool, and thread tool onto

the bottle. NOTE: For best results,

make sure the bottle is full of Pump

Armor.

3. Remove sprayer Suction Tube. Insert

tool into the inlet and push up firmly

until it stops.

32 3A6419B EN

Maintenance

ti27479a

4. Squeeze Pump Armor bottle until Pump

Armor flows into the Drain Tube.

5. Remove tool. Replace and tighten

child-proof cap for storage.

6. Reinstall the sprayer Suction Tube.

Ensure that the tube is snug on the inlet

and the clamp is engaged.

Inlet Valve Removal

An integrated tool is included in the frame to

remove the inlet valve assembly from the

pump. If you suspect that the inlet valve is

clogged or stuck, remove the valve assembly

and clean or replace.

1. Insert pump inlet into frame and loosen

the inlet valve. Remove inlet valve.

2. Remove inlet valve.

NOTICE

Do not lose the ball and spring inside the

inlet valve assembly. It may fall out when the

inlet valve is removed. Pump will not prime

without the ball and spring.

3A6419B EN 33

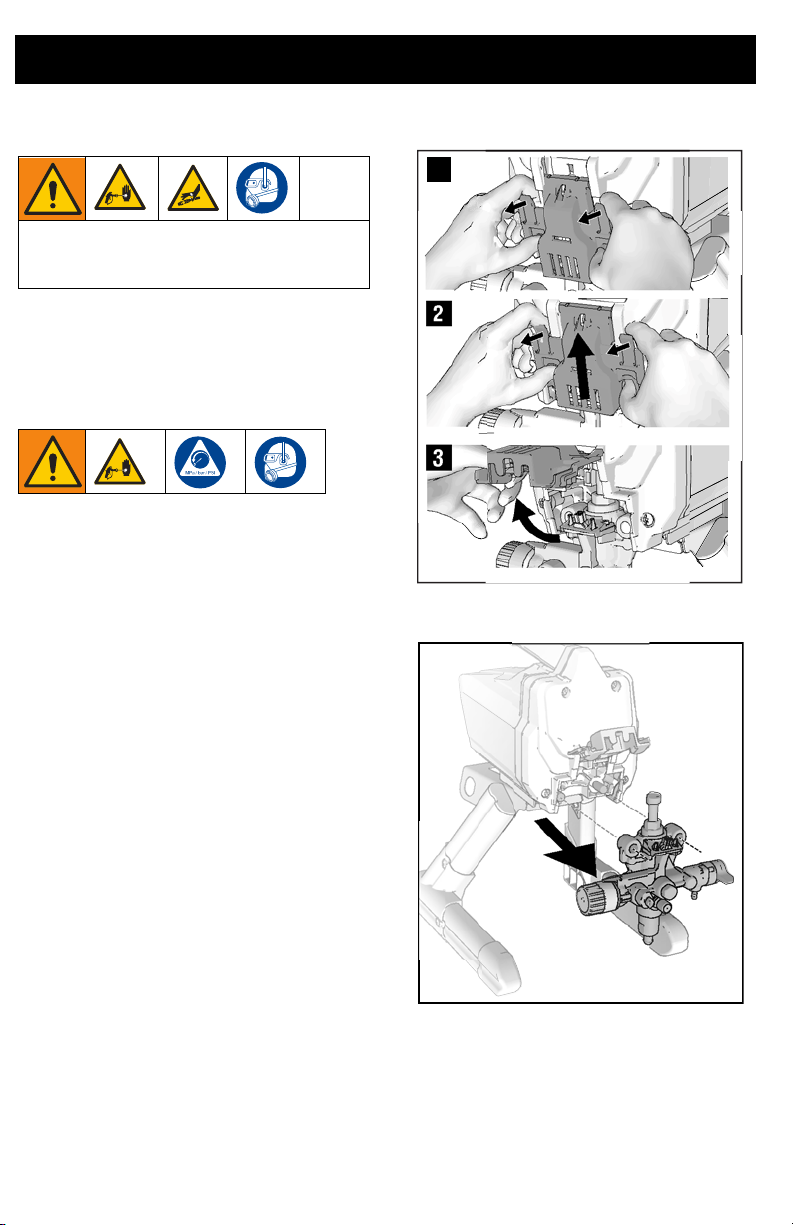

Maintenance

1

3

ti27463a

2

3. Perform a power flush. See Cleanup

with Power Flush Valve, page 25.

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

4. Inspect for leaks. If leaks occur, perform

Pressure Relief Procedure, page 14,

then tighten all fittings and repeat step 3.

Pump Repair

When pump packings wear, paint will begin

to leak down outside of pump. Purchase a

pump repair kit and install according to

instructions provided with kit, before your

next job. See ProXChange Pump Parts

List, page 49, or consult a Graco/MAGNUM

authorized retailer, distributor, or service

center.

Each time the pump kit is replaced, check

pump inlet and outlet valves for wear or

damage. Replace if worn or damaged.

Always replace inlet and outlet valves every

second time the pump kit is replaced.

3. Now lift the door so that it swings out of

the way.

4. Slide pump assembly off the mounting

pins.

Pump Removal

Remove airless hose, suction tube, and drain

tube. Always perform Pressure Relief

Procedure, page 14 before starting any

pump repairs and unplug the sprayer.

1. Unplug the sprayer from the power

source.

2. Pull tabs on sides of the easy access

door towards you while pushing the

entire door up.

ti26930a

34 3A6419B EN

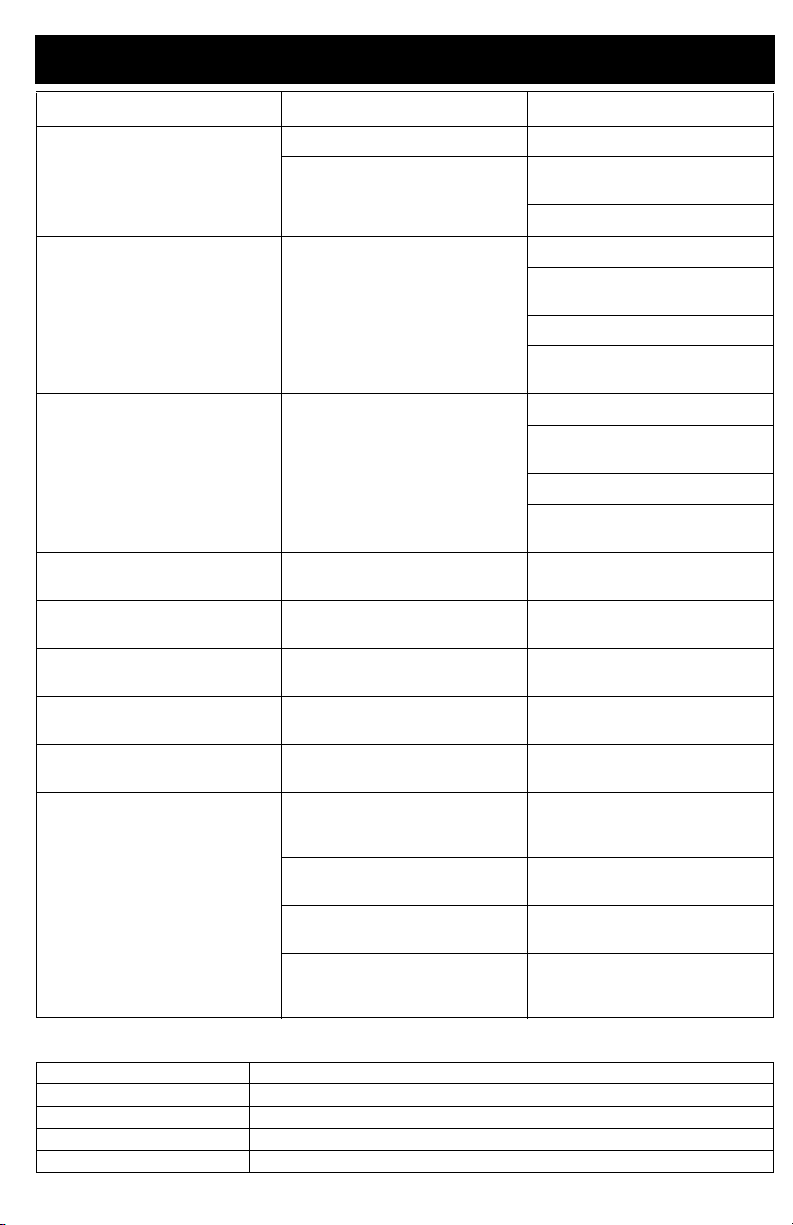

ProXChange Removal Tool

ti26931a

1

ti27478a

2

3

An integrated tool is included in the frame to

remove the ProXChange packing assembly.

See ProXChange Pump manual for

complete repair instructions.

Pump Installation

1. Slide pump assembly onto the

mounting pins.

Maintenance

a. Move pump rod up or down until

cap is level with the opening in the

yoke.

ti27037a

b. Push on pump rod to slide pump

assembly back on to mounting

pins.

2. Swing Easy Access Door closed while

pushing the entire door down.

ti27036a

3. Install hose, suction tube, and drain

tube.

4. Plug sprayer into power source.

NOTE: Door must be fully closed and

latched before sprayer will operate.

3A6419B EN 35

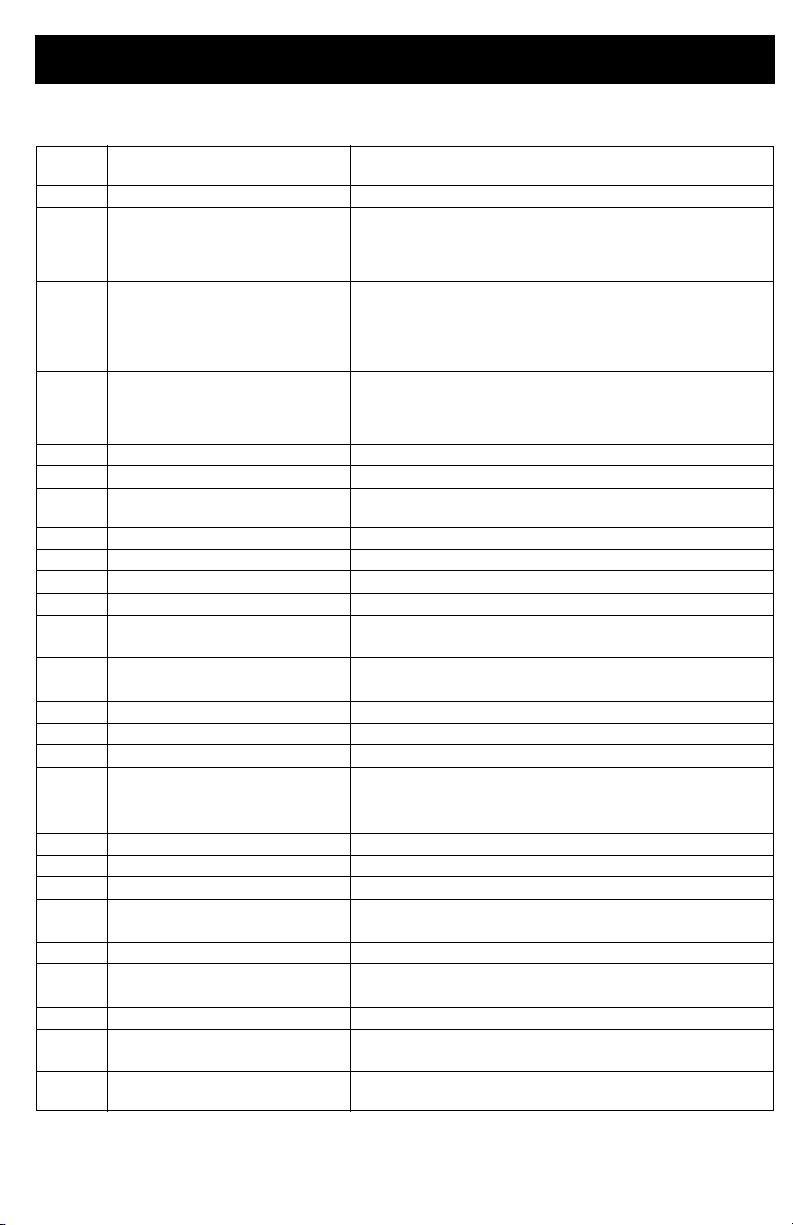

Troubleshooting

Call Us Toll-Free: 1-888-541-9788

or visit us at:

www.magnum.graco.com

Troubleshooting

1. Follow Pressure Relief Procedure,

page 14, before checking or repairing.

2. Solutions at the beginning of each problem listed are the most common.

Problem Cause Solution

3. Check everything in this Troubleshooting Table before you bring the sprayer

to an authorized service center.

Have a Question?

ti24021a

Motor does not run:

(verify sprayer is plugged in, and

ON/OFF switch is on)

Easy Access Door not fully closed Verify that Easy Access Door is

Pressure control is set at zero

pressure.

Electric outlet is not providing power. Test outlet with known working

Extension cord is damaged. Replace extension cord. See page 5.

Sprayer electric cord is damaged. Check for broken insulation or wires.

Pu mp is se iz ed

(Paint has hardened in pump

or

Water is frozen in pump.)

Motor or control is damaged. Consult a Graco/ Magnum authorized

closed and latched. See step 2 of

Pump Installation, page 35.

Turn pressure control knob clockwise

to increase pressure setting.

device.

Reset circuit breaker or replace fuse.

Find working outlet.

Reset building circuit breaker or

replace fuse.

Replace electric cord if damaged.

Turn ON/OFF switch off and unplug

sprayer from outlet.

If frozen do NOT try to start sprayer

until it is completely thawed or it may

damage the motor, control board

and/or drive train.

Place sprayer in warm area for

several hours. Check for free moving

pump by removing shroud and

spinning fan.

If not frozen, check for hardened paint

in pump. If paint has hardened in

pump. See Pump Repair, page 34.

If motor does not turn with pump

removed, consult a Graco/ Magnum

authorized retailer, distributor, or

service center.

retailer, distributor, or service center.

36 3A6419B EN

Troubleshooting

Problem Cause Solution

Sprayer runs, but pump does not

prime or looses prime while in use.

(Pump cycles but does not pull paint

into Suction Tube or build pressure.)

Prime/Spray Valve is in SPRAY

position.

Inlet screen is clogged or Suction

Tube is not completely immersed in

paint.

Inlet or outlet valve ball is stuck or

dirty.

Turn Prime/Spray Valve down to

PRIME position until paint exits Drain

Tube.

Clean debris off inlet screen and

make sure Suction Tube is completely

immersed in paint.

Press PushPrime button twice to

loosen inlet valve and reprime

sprayer. See Fill Pump (Prime

Pump), page 16.

See Storage/Priming Tool, page 32.

Then reprime pump.

Remove inlet and/or outlet valves and

clean, replace and reprime. See Fill

Pump (Prime Pump), page 16.

• Make certain to not lose the

ball and spring of the inlet

valve assembly or the

sprayer will not function.

See Inlet Valve Removal,

.

page 33

• Make certain the outlet ball

moves free in the housing

before replacing.

Suction Tube is leaking. Inspect Suction Tube connection for

Debris in paint causing obstruction. Strain the paint. See Strain the

Prime/Spray Valve is worn or

obstructed with debris.

cracks or vacuum leaks.

Paint, page 16.

Take sprayer to Graco/MAGNUM

authorized service center.

3A6419B EN 37

Troubleshooting

Problem Cause Solution

Pump is primed, but can not achieve

good spray pattern.

Spray Tip may be partially clogged. See Clear Spray Tip Clog, page 21.

Reversible Spray Tip is in UNCLOG

position.

Debris in paint causing obstruction. Strain the paint. See Clear Spray Tip

Pressure is set too low. Align pressure control knob setting

InstaClean Filter is clogged. Clean or replace InstaClean filter. See

Spray gun filter is clogged. Clean or replace gun filter. See Clear

Spray Tip selected is too large for

capability of sprayer.

Spray Tip is worn beyond the

capability of sprayer.

Spray Tip gasket and seal worn or

missing.

Inlet screen is clogged or Suction

Tube is not immersed in paint.

Extension cord is too long or not

heavy enough gauge.

Inlet valve or outlet valve is worn or

clogged with debris.

Material is too thick. Thin material. Follow manufacturers

Airless hose is too long (if extra

section was added).

Rotate arrow-shaped handle on

Spray Tip so it points forward to

SPRAY position. See page 21.

Clog, page 21.

indicator to desired spray setting. See

Clear Spray Tip Clog, page 21.

Cleaning InstaClean Filter, page 27.

Spray Tip Clog, page 21.

Replace Spray Tip. See Spray

Techniques, page 19.

Replace Spray Tip. See Spray

Techniques, page 19.

Replace gasket and seal. See Spray

Techniques, page 19.

Clean debris off inlet screen and

make sure Suction Tube is immersed

in paint.

Replace extension cord. See

Extension Cords:, page 6.

Check for worn or contaminated inlet

valve or outlet valve.

- Prime sprayer with paint

- Trigger gun momentarily

- When trigger is released, pump

should cycle momentarily and stop

- If pump continues to cycle, pump

valves may be worn or contaminated

with debris

- See Storage/Priming Tool, page

32.

- Clean and reinstall valves.

- Replace valves with appropriate kits.

For kit part numbers, see

ProXChange Pump Parts List,

page 49.

recommendations.

Remove section of airless hose.

38 3A6419B EN

Troubleshooting

Problem Cause Solution

Spray gun stopped spraying while

trigger is pulled.

Spray Tip is clogged. See Clear Spray Tip Clog, page 21

Sprayer lost prime. Reprime sprayer. See Fill Pump

(Prime Pump), page 16.

See Troubleshooting, page 36.

When paint is sprayed, it runs down

the wall or sags.

Material is going on too thick. Move gun faster.

Choose a Spray Tip with smaller hole

size.

Choose Spray Tip with wider fan.

Make sure gun is far enough from

surface.

When paint is sprayed, coverage is

inadequate.

Material is going on too thin. Move gun slower.

Choose Spray Tip with larger hole

size.

Choose Spray Tip with narrower fan.

Make sure gun is close enough to

surface.

Fan pattern varies dramatically while

spraying.

Pressure control switch is worn and

causing excessive pressure variation.

Take sprayer to Graco/M

authorized service center.

AGNUM

Cannot trigger spray gun. Spray gun trigger lock is engaged. Rotate trigger lock to disengage

trigger lock.

Paint is coming out of pressure

control switch.

Pressure control switch is worn. Take sprayer to Graco/M

authorized service center.

Paint is leaking through Drain Tube. Sprayer is over pressurizing. Take sprayer to Graco/M

AGNUM

AGNUM

authorized service center.

Paint leaks down outside of pump. Pump packings are worn. Replace pump. See Pump Repair,

page 34.

Motor is hot and runs intermittently.

Motor automatically shuts off due to

excessive heat. Damage can occur if

cause is not corrected.

Vent holes in enclosure are plugged

or sprayer is covered.

Extension cord is too long or not a

Keep vent holes clear of obstructions

and overspray and keep sprayer open

to air.

Replace extension cord.

heavy enough gauge.

Unregulated electrical generator

being used has excessive voltage.

Use electrical generator with a proper

voltage regulator.

Motor needs to be replaced. Take sprayer to Graco/Magnum

authorized retailer, distributor, or

service center.

Online Resources

Visit Our Website: magnum.graco.com

Operational Videos: magnum.graco.com/magop/

Manuals: magnum.graco.com/support/#manuals

Parts Online: magnum.graco.com/partsonline/

Material Compatibility: magnum.graco.com/downloads/MaterialCompatibility.pdf

3A6419B EN 39

ProX17, ProX19, ProLTS170 Stand Sprayer

Ref. Torque

140-160 in-lb (16-18 N•m)

30-35 in-lb (3.5-4.0 N•m)

110-120 in-lb (12-14 N•m)

45-55 in-lb (5-6 N•m)

123

4

See page 48.

1

2

3

4

3

2

2

2

ProX17, ProX19, ProLTS170 Stand Sprayer Parts

40 3A6419B EN

ProX17, ProX19, ProLTS170 Stand Sprayer

ProX17, ProX19, ProLTS170 Stand Sprayer Parts List

Ref. Part Description

1 17F756 KIT, repair, motor,

1a 287770 FAN 1

2 17J863 KIT, gear and yoke 1

3 17J173 CORD, power 1

4 17J864 KIT, yoke 1

6 117493 SCREW, mach, hex,

7 17J874 KIT, pump complete 1

8 17J865 SHIELD, motor, blue

9 118444 SCREW, mach, hwhd

10 17J866 COVER, front includes

10a 128551 CABLE, jumper, PC 1

10b 17F262 COVER, wire 1

12 115478 SCREW, mach, Torx,

13 15X737 SWITCH, bracket 1

14 17F233 COVER, pump,

15 17J867

15a 119276 FUSE, 12.5A slow

16 117501 SCREW, plastite 1

17 24Y329

18 115498

19 17G328 PLATE, motor mount 1

20 16E836 KIT, right leg includes

21 16E837

21a 15J695 CAP, tube 2

22 260212 SCREW, hwh, thread

23 15J699

24 276864 HANDLE, sprayer 1

25 116139 GRIP, handle 1

27 LABEL, front

17J031

120V includes 1a, 22

washer head

includes 9 and labels

10-24 x 0.5 in.

9, 10a, 10b, 12, 14

pan hd

locking

KIT, control board

120V includes 15a, 16

blow

KIT, switch, repair

includes 13

SCREW, mach, slot,

hex whd

21a, 22, 23

KIT, left leg includes

21a, 22, 23

forming

CAP, tube 2

ProX17 1

Qty.

Ref. Part Description

1

1

1

3

1

4

1

1

1

1

1

1

1

12

17J033

17J032

30 247340 HOSE, cpld,

31

243012 Models 17G177,

246506 Model 17K438 1

32 115099 WASHER, hose 1

34 244035 DEFLECTOR, barbed 1

35 115489 CLAMP, drain tube 2

36 195084 TUBE, drain 1

37 24V074 KIT, tube, suction

37a 197607 TUBE, suction

38 116295 CLAMP, tube 1

39 195400 CLIP, spring 2

40 KIT, inlet screen 1

288716 ProX17 and ProX19

257002 ProLTS170

45 17H422 CUP, suction/drain 1

56

17J027 LABEL, warning 1

57 179960 CARD, medical alert

60 17Y786 GUIDE, Magnum quick

61 115648 VALVE, power flush

62 17S980 FLUID, pump armor, 8

64 17Y794 TAG, hang, tip (not

65 15G026 TAG, warning, hose,

17L305 KIT, conversion, lacquer,

Replacement Danger and Warning labels,

tags, and cards are available at no cost.

ProX19 1

ProLTS170 1

1/4 in. x 50 ft

GUN, spray, SG3

17G179, 17H198

includes 32, 34, 35, 36,

37a, 38, 39, 40

includes 32

(not shown)

guide, (not shown)

(not shown)

oz (not shown)

shown)

(not shown)

stand (sold separate)

Qty.

1

1

1

1

1

1

1

1

1

1

3A6419B EN 41

ProX21 Stand Sprayer Parts

Ref. Torque

140-160 in-lb (16-18 N•m)

30-35 in-lb (3.5-4.0 N•m)

110-120 in-lb (12-14 N•m)

123

See page

48.

2

3

1

3

2

2

2

2

ProX21 Stand Sprayer Parts

42 3A6419B EN

ProX21 Stand Sprayer Parts

ProX21 Stand Sprayer Parts List

Part Description

Ref.

1 MOTOR, 120V includes

17K684 Series A 1

17F757 Series B 1

1a 16X980 FAN 1

2 17J869 KIT, gear and yoke 1

3 17J173 CORD, power 1

4 17J864 KIT, yoke 1

6 117493 SCREW, mach, hex,

7 17J875 KIT, pump complete 1

8 SHIELD, motor, blue

17K688 Series A 1

17J865 Series B 1

9 118444 SCREW, mach, hwhd

10 17J866 COVER, front includes

10a 128551 CABLE, jumper, PC 1

10b 17F262 COVER, wire 1

12 115478 SCREW, mach, Torx,

13 15X737 SWITCH, bracket 1

14 17F233 COVER, pump, locking 1

15 17J867

15a 119276 FUSE, 12.5A slow blow 1

16 117501 SCREW, plastite 1

17 24Y329

18 115498

19 17G329 PLATE, pump 1

20 15E823 FRAME, standmount 1

22 260212 SCREW, hwh, thread

23 15G857 CAP, leg 4

24 276864 HANDLE, sprayer 1

1a, 22

washer head

includes 9, 56

10-24 x 0.5 in.

9, 10a, 10b, 12, 14

pan hd

KIT, control board 120V

includes 15a, 16

KIT, switch, repair

includes 13

SCREW, mach, slot,

hex whd

forming

Qty.

Part Description

Ref.

25 116139 GRIP, handle 1

27 17J035 LABEL, front, ProX21 1

30 247340 HOSE, cpld,

31 243012 GUN, spray,SG3 1

37 17J870 KIT, suction set

37a 17J719 HOSE, suction 1

1

43 122667 SCREW, drill, hex,

44 17J884 TUBE, drain includes 461

45 15G838 CUP, suction/drain 1

46 244035 DEFLECTOR, barbed 1

47 245673 KIT, strainer 1

3

48 404989 STRAP, tie 1

49 115099 WASHER, hose 1

1

50 117559 O-ring 2

56 17J027 LABEL, warning 1

57 179960 CARD, medical alert

4

60 17Y786 GUIDE, Magnum quick

61 115648 VALVE, power flush

1

62 244168 FLUID, pump armor, 8

64 17Y794 TAG, hang, tip (not

1

65 288686 ADAPTER, power flush

1

66 15G026 TAG, warning, hose,

4

Replacement Danger and Warning labels,

tags, and cards are available at no cost.

1/4 in. x 50 ft

includes 37a, 44, 46,

47, 48, 49, 50

washer head

(not shown)

guide, (not shown)

(not shown)

oz (not shown)

shown)

(not shown)

(not shown)

Qty.

1

1

1

1

1

1

1

1

1

1

3A6419B EN 43

ProX17, ProX19, ProLTS190 Cart Sprayer

Ref. Torque

30-35 in-lb (3.5-4.0 N•m)

110-120 in-lb (12-14 N•m)

45-55 in-lb (5-6 N•m)

234

2

2

3

3

2

See page 48.

4

2

ProX17, ProX19, ProLTS190 Cart Sprayer Parts

44 3A6419B EN

ProX17, ProX19, ProLTS190 Cart Sprayer

ProX17, ProX19, ProLTS190 Cart Sprayer Parts List

Part Description

Part Description

Ref.

1 17F756 MOTOR, 120V

includes1a, 22

1a 287770 FAN 1

2 17J863 KIT, gear and yoke 1

3 17J173 CORD, power 1

4 17J864 KIT, yoke 1

7 17J874 KIT, pump complete 1

8 17J865 SHIELD, motor, blue

includes 9 and labels

9 118444 SCREW, mach, hwhd

10-24 x 0.5 in.

10 17J866 COVER, front includes

9, 10a, 10b, 12, 14

10a 128551 CABLE, jumper, PC 1

10b 17F262 COVER, wire 1

12 115478 SCREW, mach, Torx,

pan hd

13 15X737 SWITCH, bracket 1

14 17F233 COVER, pump, locking 1

15 17J867 KIT, control board 120V

includes 15a, 16

15a 119276 FUSE, 12.5A slow blow 1

16 117501 SCREW, plastite 3

17 24Y329 KIT, switch, repair

includes 13

18 115498 SCREW, mach, slot,

hex whd

19 17G541 PLATE, motor, mount 1

20 LEG, right

262014 ProX17 includes 22, 54, 551

17K185 ProX19 and ProLTS190

includes 54, 55

21 LEG, left

262012 ProX17 includes 22, 54, 551

17K186 ProX19 and ProLTS190

includes 54, 55

22 260212 SCREW, hwh, thread

forming

26 24V073 TUBE, suction,

assembly includes 26a,

43, 44, 45, 46, 47, 48,

49, 61

26a 16H348 TUBE, suction

includes 49

27 LABEL, front

17J031 ProX17 1

17J033 ProX19 1

17J034 ProLTS190 1

30 247340 HOSE, cpld,

1/4 in. x 50 ft

31 GUN, spray, SG3

Qty.

Ref.

1

1

3

1

1

1

1

1

1

8

1

1

1

243012 Models 17G178,

17G180, 17H206

246506 Model 17K439 1

34 112612 CAP, hub 2

35 WHEEL includes 34

24Y324 ProX17 2

17K546 ProX19, ProLTS190 2

36 115480 KNOB, T-handle 2

37 120689 NUT, hex, acorn,

5/16-18

38 17J430 HOOK, pail 1

39 AXLE, cart

15R602 ProX17 1

16W362 ProX19, ProLTS190 1

40 16H350 RACK, hose 1

41 HANDLE, cart

16H354 ProX17 1

16H353 ProX19, ProLTS190 1

42 120788 SCREW, carriage 2

43 115489 CLAMP, drain tube 1

44 195108 TUBE, drain 1

45 195400 CLIP, spring 1

46 244035 DEFLECTOR, barbed 1

47 STRAINER, inlet 1

288716 ProX17 and ProX19

257002 ProLTS190

48 116295 CLAMP, tube 1

49 115099 WASHER, hose 1

54 15J699 CAP, tube 2

55 CAP, tube

15J695 ProX17 2

16W505 ProX19, ProLTS190

right

16W517 ProX19, ProLTS190 left 1

56 17J027 LABEL, warning 1

57 179960 CARD, medical alert

(not shown)

60 17Y786 GUIDE, Magnum quick

guide, (not shown)

61 115648 VALVE, power flush

(not shown)

62 17S980 FLUID, pump armor, 8

oz (not shown)

64 17Y794 TAG, hang, tip (not

shown)

65 15G026 TAG, warning, hose,

(not shown)

17J873 KIT, conversion, lacquer,

cart (sold separate)

Replacement Danger and Warning labels,

tags, and cards are available at no cost.

Qty.

1

2

1

1

1

1

1

1

1

3A6419B EN 45

ProX21 Cart Sprayer Parts

Ref. Torque

30-35 in-lb (3.5-4.0 N•m)

110-120 in-lb (12 -14 N•m)

2

3

2

2

3

3

2

See page 48.

2

ProX21 Cart Sprayer Parts

46 3A6419B EN

ProX21 Cart Sprayer Parts

ProX21 Cart Sprayer Parts List

Part Description

Ref.

1 KIT, repair, motor, 120V

17K684 Series A 1

17F757 Series B 1

1a 16X980 FAN 1

2 17J869 KIT, gear and yoke 1

3 17J173 CORD, power 1

4 17J864 KIT, yoke 1

7 17J875 KIT, pump complete 1

8 SHIELD, motor, blue

17K688 Series A 1

17J865 Series B 1

9 118444 SCREW, mach, hwhd

10 17J866 COVER, front includes

10a 128551 CABLE, jumper, PC 1

10b 17F262 COVER, wire 1

12 115478 SCREW, mach, Torx,

13 15X737 SWITCH, bracket 1

14 17F233 COVER, pump, locking 1

15 17J867

15a 119276 FUSE, 12.5A slow blow 1

16 117501 SCREW, plastite 3

17 24Y329

18 115498

20 17C485 FRAME 1

22 260212 SCREW, hwh, thread

26 17J871 TUBE, suction, intake

26a 17L281 TUBE, suction 1

27 17J035 LABEL, front, ProX21 1

includes 1a, 22

includes 9, 56

10-24 x 0.5 in.

9, 10a, 10b, 12, 14

pan hd

KIT, control board 120V

includes 15a, 16

KIT, switch, repair

includes 13

SCREW, mach, slot,

hex whd

forming

includes 26a, 44, 46,

47, 49, 50 51, 52, 53

Qty.

Part Description

Ref.

30 247340 HOSE, cpld,

31 243012

34 119452 CAP, hub 2

35 119451 WHEEL,

38 17J430 HOOK, pail 1

41 287489 HANDLE, assembly,

42 109032 SCREW, machine, pnh 4

44 17L393 TUBE, drain 1

46 244035 DEFLECTOR, barbed 1

47 245673 STRAINER, inlet 1

49 115099 WASHER, hose 1

3

50 103413 PACKING, O-ring 1

51 15B652 WASHER, suction 1

1

52 15E813 NUT, jam 1

53 195400 CLIP, spring 1

56 17J027 LABEL, warning 1

57 179960 CARD, medical alert

60 17Y786 GUIDE, Magnum quick

61 115648 VALVE, power flush

1

62 244168 FLUID, pump armor,

64 17Y794 TAG, hang, tip (not

1

1

65 288686 ADAPTER, power flush

66 15G026 TAG, warning, hose,

4

1

Replacement Danger and Warning labels,

tags, and cards are available at no cost.

1/4 in. x 50 ft

GUN, spray,SG3 1

semi-pneumatic

Hi-cart

(not shown)

guide, (not shown)

(not shown)

8 oz (not shown)

shown)

(not shown)

(not shown)

Qty.

1

2

1

1

1

1

1

1

1

1

3A6419B EN 47

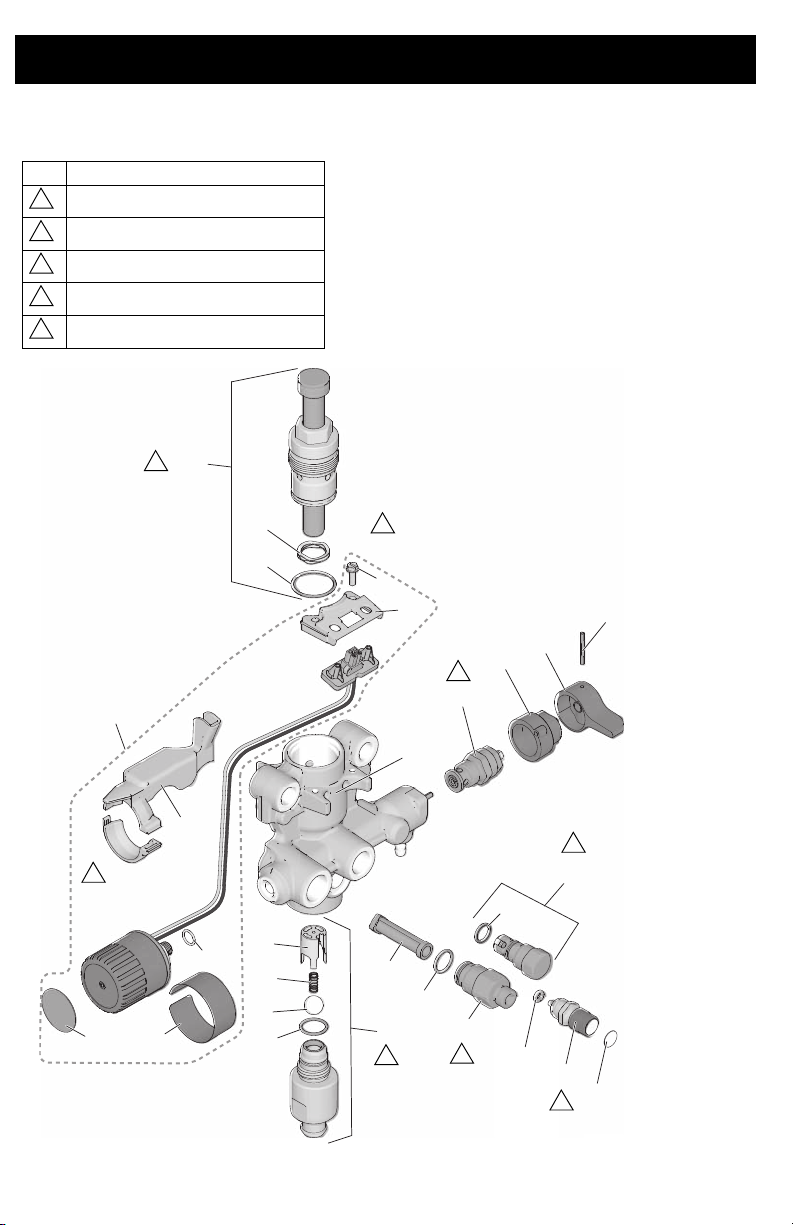

ProXChange Pump Parts

Ref. Torque

140-160 in-lb (16-18 N•m)

30-35 in-lb (3.4-4.0 N•m)

30-35 ft-lb (40-48 N•m)

220-250 in-lb (25-28 N•m)

320-380 in-lb (36-43 N•m)

12345

1

28a

28c

28b

6

4

6a

2

3

8

9

10

11

25

30

16

28

21

7

7b

7a

5

15

14

13

12

42

ti27261a

29

1

2

3

5

5

4

4

4

ProXChange Pump Parts

48 3A6419B EN

ProXChange Pump Parts

ProXChange Pump Parts List

i

Part Description

Ref.

1 17G447 HOUSING, pump

2 17D364 GUIDE, ball

3 128336 SPRING, compression

4 105445 BALL, 0.5 in. 1

5 117501 SCREW, mach, slot

6 KIT, inlet housing

17J876 ProX17, ProX19

17J877 ProX21

6a 124582 O-ring

7 17J878 KIT, PushPrime

7a 16P303 PACKING, O-ring 1

7b 17G540 LABEL, PushPrime

235014 VALVE, drain, assy

8

9 224807 BASE, valve

10 187625 HANDLE, valve, drain

11 111600 PIN, grooved

12 288747 KIT, filter

HWH

includes 7a, 7b

Qty.

1

1

1

2

1

1

1

1

1

1

1

1

1

1

Part Description

Ref.

13 120776 PACKING, O-ring

14 24Y327 KIT, repair outlet

includes 12,13

15 17J880 KIT, outlet valve repair

includes 42

16 128323 SPRING, valve

21 16D531 PACKING, O-ring

25 24Y472 KIT, repair, piston pump 1

28 17J881 KIT, pressure control

includes 5, 28a, 28b,

28c, 29, 30

28a 15A464 LABEL, control

28b 17V191 LABEL, control

28c 106555 O-ring 1

29 17F227 BRACKET, electrical

connector

30 17F229 KIT, shield, wire 1

42 122486 PACKING, O-ring 1

Qty.

1

1

1

1

1

1

1

1

1

3A6419B EN 49

Wiring Diagram - 110/120V

ti27233a

M

Wiring Diagram - 110/120V

50 3A6419B EN

Notes

Notes

3A6419B EN 51

Technical Specifications

Technical Specifications

US Metric

Sprayer

Maximum fluid working pressure 3000 psi 207 bar, 20.7 MPa

Maximum Delivery

ProX17, ProLTS170 0.34 gpm 1.3 lpm

ProX19, ProLTS190 0.38 gpm 1.4 lpm

ProX21 0.47 gpm 1.8 lpm