Page 1

Instructions – Parts List

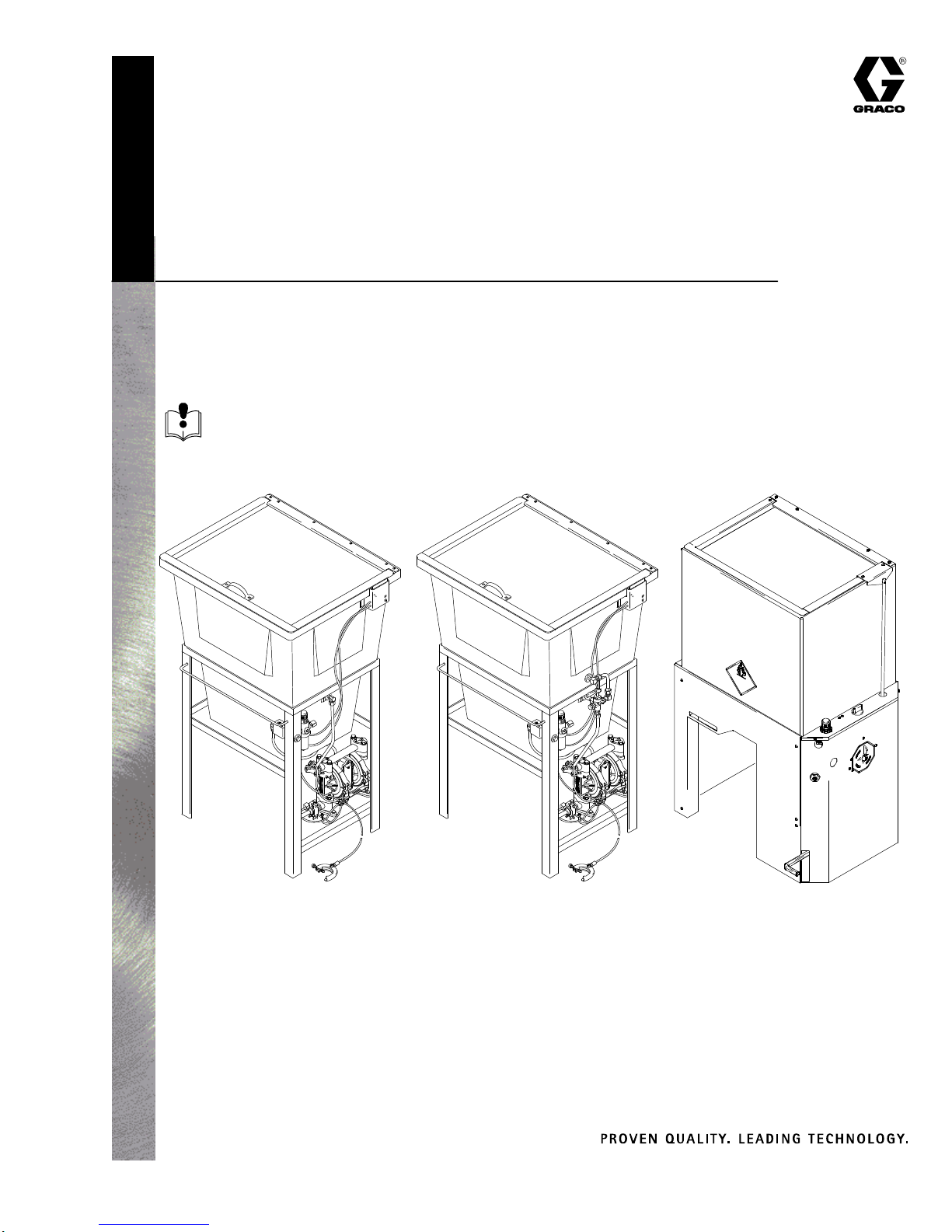

PRO-WASHt Gun Washer

With Huskyt 307 Pump

100 psi (0.7 MPa, 7 bar) Maximum Working Pressure

Read warnings and instructions.

See page 2 for List of Models and page 5 for

Gun Washer Descriptions.

308393J

Model 112634 Model 112635

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 1999, Graco Inc. is registered to I.S. EN ISO 9001

03297

03298

Model 117438

Page 2

Table of Contents

Symbols 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gun Washer Descriptions 5. . . . . . . . . . . . . . . . . . . . .

Kit Descriptions 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensional Drawing 8. . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutdown and Care 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

Model 112634 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 112635 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 117438 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

2 308393

Page 3

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. This equip-

ment has a 100 psi (0.7 MPa, 7 bar) maximum fluid working pressure at 100 psi (0.7 MPa, 7

bar) maximum incoming air pressure.

Do not operate the gun washer at a pressure above the maximum working pressure rating of the

gun(s) being cleaned.

Route the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

Do not use the hoses to pull the equipment.

Do not move pressurized equipment.

Use fluids or solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Comply with all applicable local, state and national fire, electrical and other safety regulations.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Wear the appropriate protective clothing, gloves, eyewear and respirator.

Pipe and dispose of the exhaust air safely. If the diaphragm fails, the fluid may be exhausted along

with the air. See your separate pump instruction manual for further information.

308393 3

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

Ground the equipment. See Grounding on page 10.

Provide fresh air ventilation to avoid the buildup of flammable fumes from the solvent.

Extinguish all the open flames or pilot lights in the gun washer area.

Electrically disconnect all the equipment in the gun washer area.

Keep the gun washer area free of debris, including solvent, rags, and gasoline.

Do not turn on or off any light switch in the gun washer area while operating or if fumes are

present.

Do not smoke in the gun washer area.

Do not operate a gasoline engine in the gun washer area.

Follow the gun manufacturers solvent and other cleaning recommendations.

Use solvent with the highest possible flash point.

Use non-conductive solvent when cleaning electrostatic guns.

Do not allow solvent to enter the air passage of an electrostatic gun.

Do not flush an electrostatic gun with the electrostatics ON-OFF lever in the ON position.

If there is any static sparking while using the equipment, stop operation immediately. Identify

and correct the problem.

Drain the solvent into a proper storage container when the gun washer(s) is not in use.

PRESSURIZED EQUIPMENT HAZARD

Spray from hose leaks, ruptured components, or from operating the gun washer with an open lid can

splash fluid in the eyes or on the skin and cause serious injury.

A safety device has been installed to shut off the pump when the gun washer lid is opened. Do not

tamper with or alter this device.

Open the gun washer lid slowly.

Do not prop the gun washer lid open with an object or by any other means.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Follow the Pressure Relief Procedure on page 12 whenever you: are instructed to relieve the

pressure; stop operating the gun washer; and clean, check, or service the equipment.

Tighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

4 308393

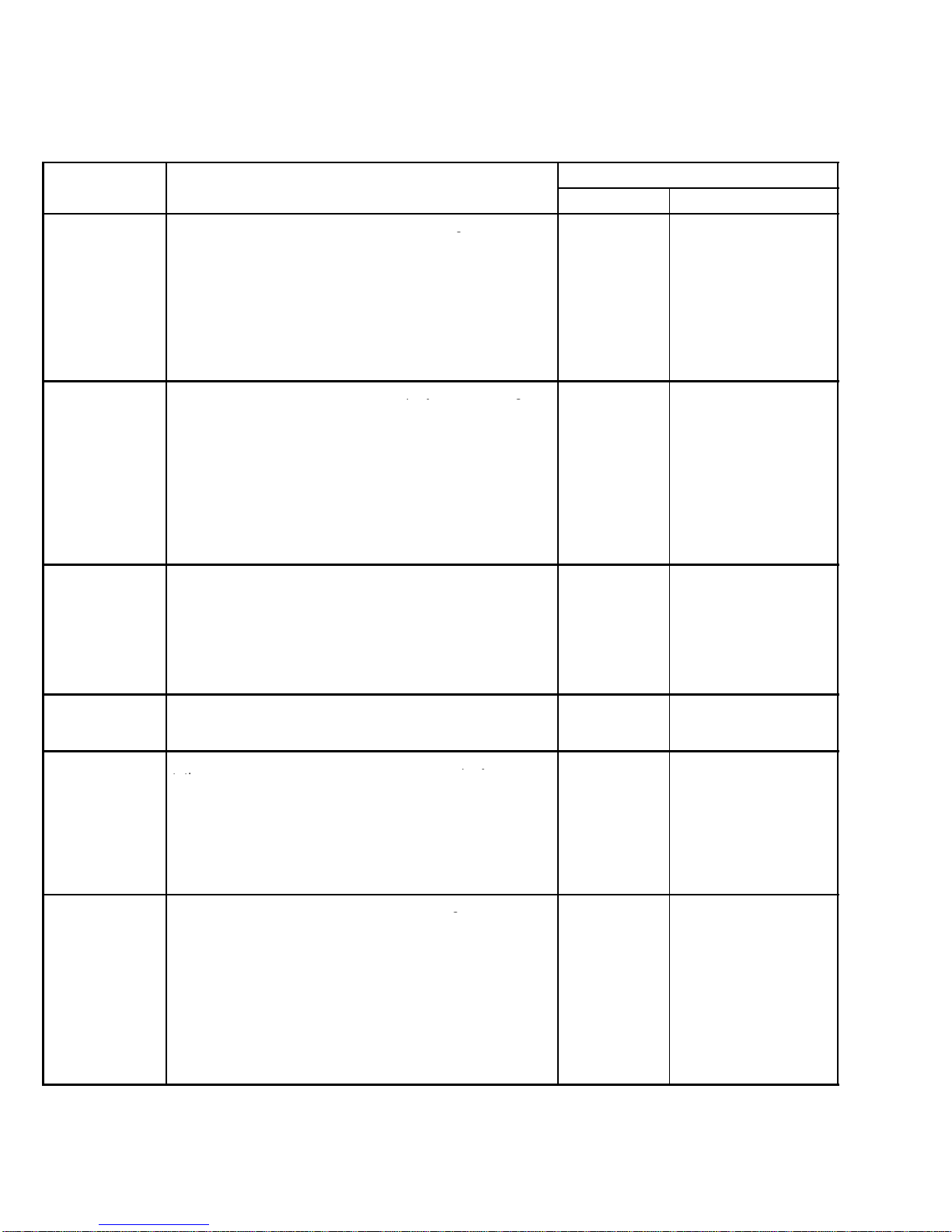

Page 5

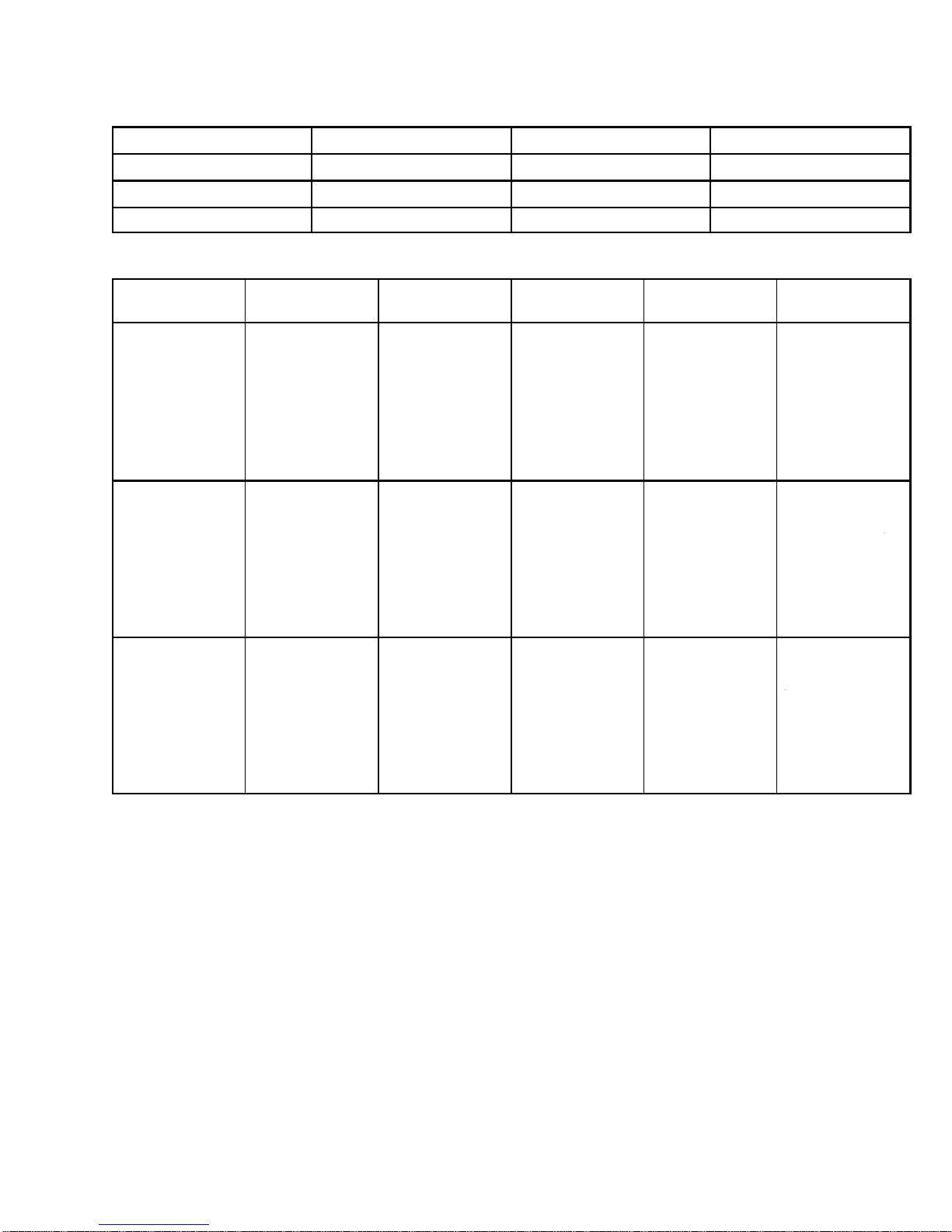

Gun Washer Descriptions

)

less guns

(

Materials of Construction

Gun Washer Model No. Tank Fluid Manifold Lid

112634

112635

117438

*Standard Cleaning Station Configuration Includes:

plastic carbon steel aluminum

plastic stainless steel aluminum

stainless steel stainless steel stainless steel

Gun Washer

Model No.

112634

112635

117438

Description Part No. Quantity Used to Clean Other Features

Long gun support 512800 1 Pressure feed, air

spray, & HVLP

guns

Short gun support 112847 1 Siphon air spray,

air-assisted, & airless guns

Spray nozzle 512799 2 Siphon & pressure

cups

Long gun support 512800 2 Pressure feed, air

spray, & HVLP

guns

Short gun support 112847 1 Siphon air spray,

air-assisted, & air-

Spray nozzle 512799 1

Long gun support 512800 2 Pressure feed, air

Short gun support 112847 1 Siphon air spray,

Spray nozzle 512799 1 Siphon & pressure

Siphon & pressure

cups

spray, & HVLP

guns

air-assisted, & airless guns

cups

Hose wash, (Pot

wash capability;

order kit 236906)

Hose wash, Foot

pedal lid opener

(Pot wash

capability; order kit

236906)

* The standard gun supports can be replaced with cleaning kits to fit the type of guns or containers being washed.

See descriptions on page 6.

308393 5

Page 6

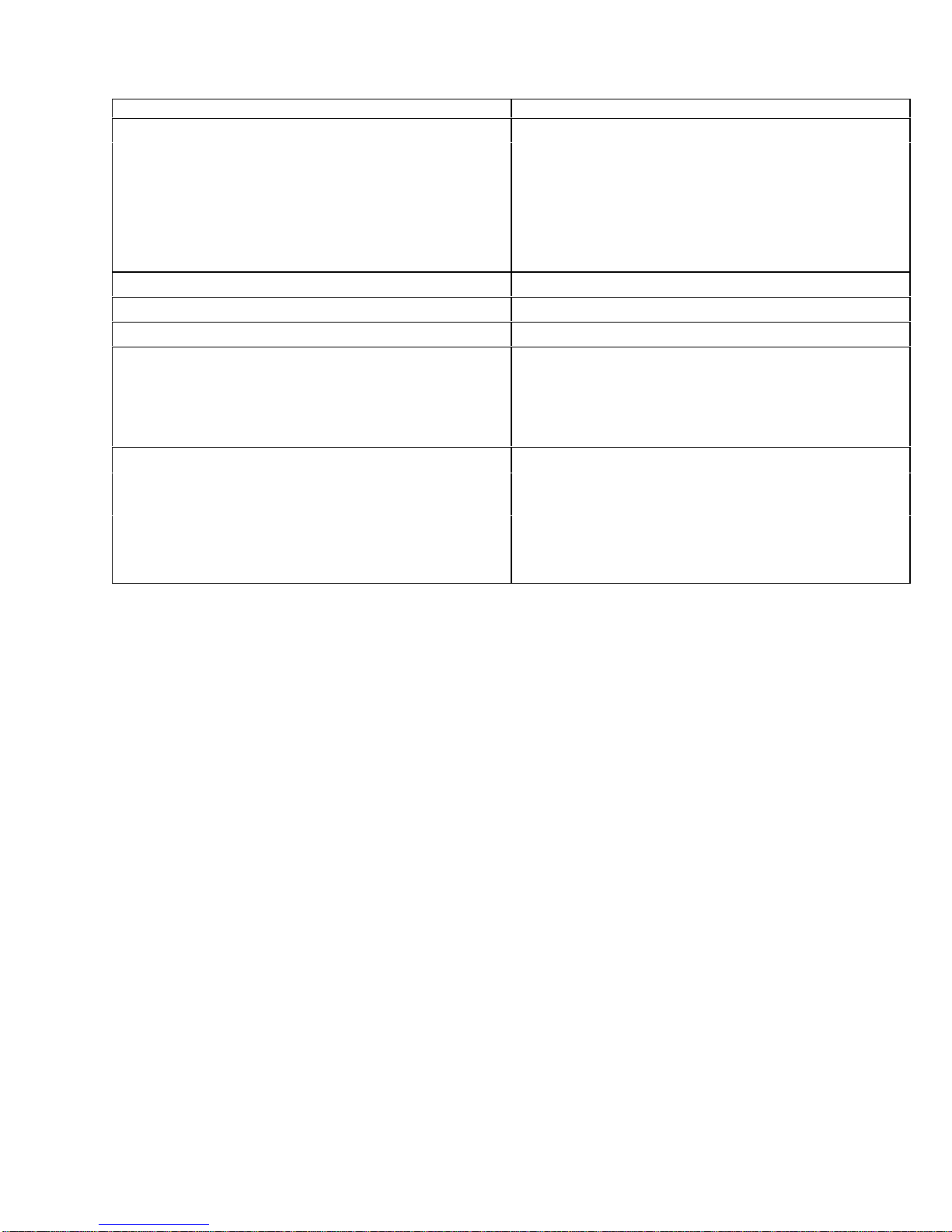

Kit Descriptions

g

py g

py

g

Gun, Pressure Cup and Paint Container Cleaning Kits**

To customize the gun washer, order one kit for each cleaning station.

Kit Includes

Kit Part No. Typically Used to Clean Part No. Description

236659

236681

236905

Graco PRO AA4500 air-assisted electrostatic guns

Graco PRO 3500 and PRO 4500 air spray electrostatic guns

HVLP, air-assisted, air spray, and airless conventional guns

195903 Air cap blank

188406 Tip housing

183459 Washer (2)

236689 PRO AA4500 support

512835 Fluid inlet adapter

512827 Plug

512802 Wire trigger lock

189573 Air cap blank

187423 Air cap nut

176930 Retaining ring

512884 Short gun support

(thick stem)

512835 Fluid inlet adapter

512827 Plug

512802 Wire trigger lock

512800 Long gun support

236906

245270

245271

Pressure pots and other paint containers; see page 14 for

maximum container size (for use with gun washer models

112635 & 117438 only)

Graco PRO Xs2, PRO Xs3, and PRO Xs4 air spray electrostatic guns

Graco PRO Xs4 AA air-assisted electrostatic guns

112847 Short gun support

(thin stem)

512835 Fluid inlet adapter

512802 Wire trigger lock

112695 Male coupler assy.

112696 Female coupler assy.

198741 Air cap blank

245300 Gun support

512835 Fluid inlet adapter

512827 Plug

512802 Wire trigger lock

112851 Snap clip

198786 Air cap blank

188406 Housing tip

183459 Washer (2)

245300 Gun support

512835 Fluid inlet adapter

512827 Plug

512802 Wire trigger lock

112851 Snap clip

**To install the accessory kits, see the instruction manuals included with the kits.

6 308393

Page 7

Technical Data

Category Data

Air Pressure Operating Range

Model 112634 25–100 psi

(0.2–0.7 MPa, 1.7–7 bar)

Model 112635 25–100 psi

(0.2–0.7 MPa, 1.7–7 bar)

Model 117438 25–100 psi

(0.2–0.7 MPa, 1.7–7 bar)

Maximum Tank Capacity 5 gallons (19 liters)

Air Inlet 1/4 npt(f)

Fluid Drain Valve 1 in. npt(m)

Approximate Dry Weight

Model 112634 63 lbs. (28.6 kg)

Model 112635 65 lbs. (29.5 kg)

Model 117438 86 lbs. (39 kg)

Wetted Parts

Model 112634 Carbon Steel, Polyethylene (tank), Stainless Steel,

Aluminum, Brass, PTFE, Acetal

Model 112635 Stainless Steel, Aluminum, Polyethylene (tank), Brass,

Acetal, PTFE

Model 117438 Stainless Steel, Brass, Acetal, PTFE

308393 7

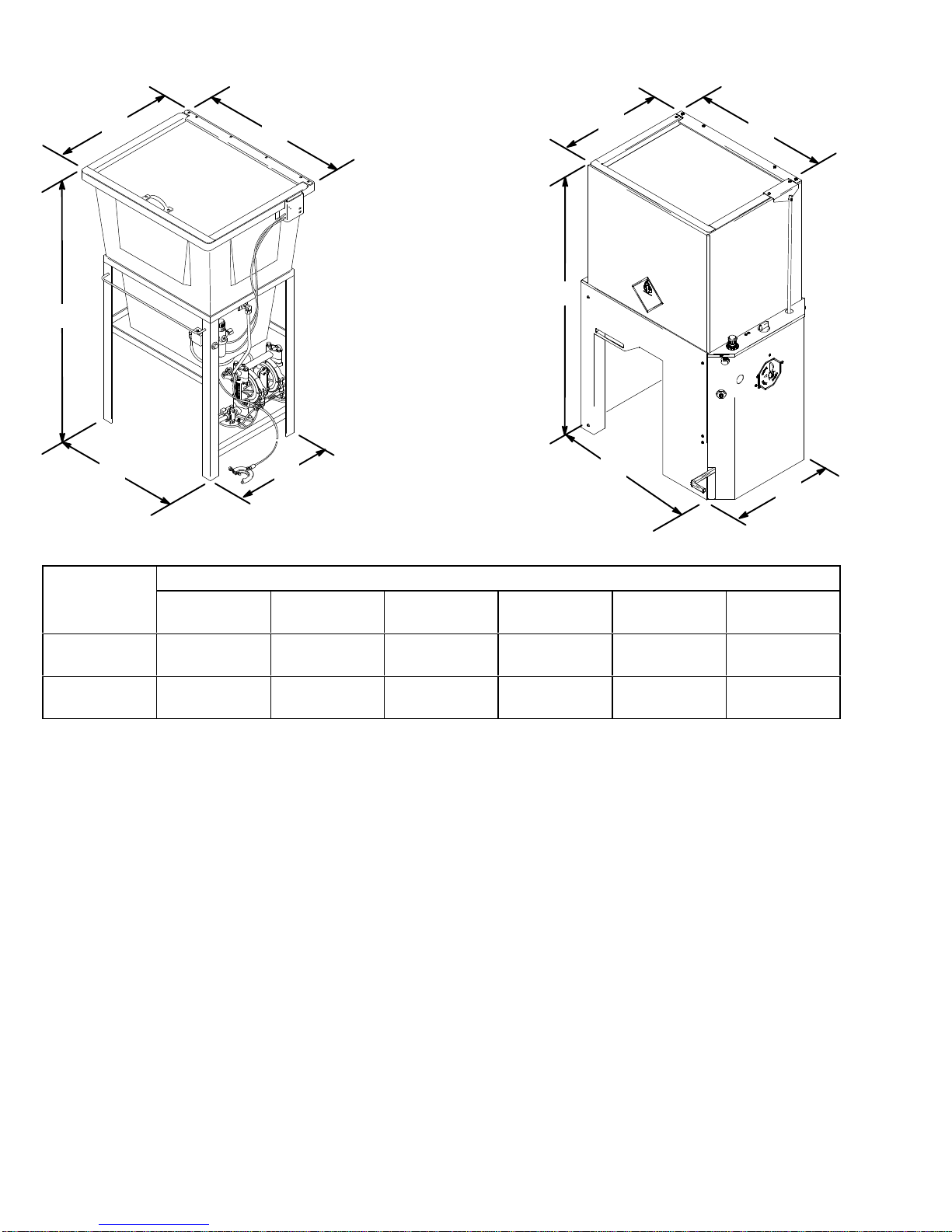

Page 8

Dimensions

A

B

C

Model 112634 and 112635

E

D

03297

A

B

C

Model 117438

E

D

Model Measurements, inches (mm)

A B–with lid

112634 and

112635

117438 19.25

20.75

(527)

(489)

closed

42.25

(1073)

42.00

(1067)

B–with lid

opened

61.00

(1549)

56.50

(1435)

C D E

20.50

(521)

25.50

(648)

16.25

(413)

18.00

(457)

25.12

(638)

24.5

(622)

8 308393

Page 9

Notes

308393 9

Page 10

Installation

Install the Gun Washer

WARNING

FIRE HAZARD

To prevent hazardous concentrations of

flammable and/or toxic vapors, the gun

washer must be installed in a properly

ventilated paint mixing room or spray booth. Never

operate the gun washer unless ventilation fans are

operating.

Check and follow all the National, State and Local

codes regarding ventilation requirements.

Make sure the gun washer is standing on a level, solid

surface.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding can cause a

hazardous condition and result in fire or

explosion and serious injury. Ground the

gun washer and all other equipment

used or located in the gun washer area.

Check your local electrical code for

detailed grounding instructions for your area and

type of equipment. Also read the section FIRE

AND EXPLOSION HAZARD, on page 4.

Connect the Air Line

1. Install an air pressure regulator (D) on the gun

washer air supply line to control air pressure to the

gun washer. See Fig. 2.

2. Install a bleed-type master air valve (E) upstream

and within easy reach of the gun washer to relieve

air trapped between this valve and the pump after

the air is shut off.

WARNING

PRESSURIZED EQUIPMENT HAZARD

The bleed-type master air valve (E) is required in

your system to relieve air trapped between this

valve and the pump after the air is shut off.

Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury, including

splashing in the eyes or on the skin.

3. Install a 1/4 in. npt male coupler (F), that is compatible with the quick disconnect of your air supply

line, into the air inlet adapter (G). See Fig. 1.

4. Connect the air line (H) to the coupler (F).

1. Ground the gun washer and its pump by connecting the clamp end (A) of the gun washer’s 15 ft.

(4.6 m) ground wire (B) to a true earth ground (C).

See Fig. 2.

2. Use only grounded air and fluid hoses with a maximum of 500 ft. (150 m) combined hose length to

ensure grounding continuity.

3. Ground the air compressor according to manufacturer’s recommendations.

4. Ground all solvent pails used when flushing and

draining according to local code. Use only metal

pails, which are conductive. Do not place the pail

on a non-conductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

Fig. 1

G

F

03302

10 308393

Page 11

Installation

Typical Installation and Grounding

D

E

H

Fig. 2

AB

F

C

03301

308393 11

Page 12

WARNING

Operation

Pressure Relief Procedure

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, swallowed, or

inhaled.

Know the specific hazards of the fluid you are

using. Read the fluid manufacturer’s warnings.

Wear the appropriate protective clothing,

gloves, eyewear and respirator.

WARNING

FIRE AND EXPLOSION HAZARD

To avoid igniting flammable liquid solvent

vapors and reduce the risk of serious

injury, fire, or explosion:

Keep all ignition sources, such as

static electricity, sparks, arcs, open

flames, and hot objects, away from

the gun washer.

Cleanup solvent leaks or spills immediately. Re-

pair leaking components before operating the

gun washer again.

Use solvent with the highest possible flashpoint.

Follow the FIRE AND EXPLOSION HAZARD

warnings on page 4.

CAUTION

WARNING

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting accidentally. To

reduce the risk of an injury from accidental spray,

splashing fluid, or moving parts, follow the Pres-

sure Relief Procedure whenever you:

are instructed to relieve the pressure,

shut down the gun washer,

check, clean, or service any of the system

equipment.

1. Disconnect the air supply.

2. Drain the solvent into a proper solvent container.

Place the container under the fluid drain valve on

the bottom of the tank and open the fluid drain

valve.

Filling the Gun Washer Fluid Tank

1. Make sure the fluid drain valve is in the closed

position. Fill the gun washer fluid tank with solvent

as instructed for your gun washer model, below.

2. Models 112634 and 112635: Carefully pour sol-

vent into the fluid tank until the fluid level is at least

1/2 inch (12.7 mm) above the filter in the lower

portion of the cabinet.

Use only non-conductive solvents when cleaning

electrostatic guns. Conductive solvents can cause

the gun to malfunction.

Follow the gun manufacturers solvent and other

cleaning recommendations.

12 308393

Model 117438: Carefully pour solvent into the fluid

tank until the fluid level is just below the bottom of

the manifold assembly.

NOTE: Do not pour more than 5 gallons (18.9 liters) of

a compatible solvent into the fluid tank.

Page 13

Operation

Preparing Guns/Cups for the Gun Washer

1. Remove the pressure cup or fluid line and the air

line from the spray gun.

2. Drain any excess fluid in the gun or cup into a fluid

container. The solvent in the gun washer will last

longer if pressure cups are thoroughly emptied

before placing them in the gun washer.

CAUTION

All pressure gauges must be removed before placing

the equipment in the gun washer to avoid damaging

the gauges.

3. To lock the gun trigger in the open position, install

the wire trigger lock around the gun handle and

trigger as shown in Fig. 3.

If the wire trigger lock does not fit on your electrostatic gun, wrap the chain around the trigger and

handle to hold the trigger in an open position.

Placing Guns in the Gun Washer

(See Fig. 3, page 14)

The following are guns typically cleaned with the gun

washer and how to position them in the gun washer for

cleaning. To clean guns not mentioned here, use the

fluid inlet adapter and long or short gun supports as

needed. Refer also to the chart on page 5 for typical

cleaning station usage. Follow the procedure on page

16 to operate the gun washer.

Siphon Feed Guns

Set the gun siphon stem over the short gun support.

Pressure Feed Guns with Cup Lid

(2 Qt. Capacity Cups)

Set the cup cover stem over the short gun support as

shown in Fig. 3.

Pressure Feed Guns

Set the gun fluid inlet over the long gun support as

shown in Fig. 3.

Electrostatic Guns

The PRO-Wash gun washer is approved to clean the

Graco PRO 3500, PRO 4500, PRO AA4500, PRO

Xs2, PRO Xs3, PRO Xs4, and PRO Xs4 AA electrostatic guns. Consult the manufacturer of any other

electrostatic gun before using the PRO-Wash.

A kit, part no. 236659, 236681, 245270, or 245271 is

required to clean Graco electrostatic PRO guns.

See page 6 for kit descriptions.

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of electrostatic shock,

fire, or explosion; which could result in

serious injury and property damage, be

sure to follow these precautions.

Only use non-conductive solvents when clean-

ing electrostatic guns.

Make sure the ES ON-OFF valve lever (electro-

statics) is turned to OFF before cleaning the

gun.

Never allow solvent to enter the air passage of

any electrostatic gun.

Never place the gun air inlet over a gun support.

Only use the fluid inlet adapter provided with the

gun washer. Install it on the gun fluid inlet as

instructed below.

The following is a general procedure for cleaning electrostatic guns. See the manual supplied with kits

236659 and 245271 (Manual 308411) or kits 236681

and 245270 (Manual 308412) for specific cleaning

instructions.

1. Install the electrostatic gun cleaning parts as

instructed in the manual supplied with the kit.

2. Make sure the ES ON-OFF lever (electrostatics)

is turned to OFF. Refer to your gun manual.

3. Screw the fluid inlet adapter onto the PRO-gun

fluid inlet as shown in Fig. 3.

Gravity Feed Guns

Set the gun fluid inlet over the long gun support as

shown in Fig. 3.

4. Place the gun in the gun washer, setting the fluid

inlet adapter over the gun support provided in the

electrostatic gun cleaning kit.

308393 13

Page 14

Operation

Placing Cups and Pots in the Gun Washer

2 Quart Pressure Cups

Set the pressure cup over the spray nozzle. Refer to

Fig. 3.

Pressure Pots and Other Paint Containers

A kit, part no. 236906, is available for use with gun

washer models 112635 and 117438 to clean pressure

pots and other paint containers. The maximum height

and width of the container the pressure washers can

clean are shown below. See the manual supplied with

Typical Cleaning Station Use

the kit (Manual 308414) to install and use this option.

See page 5 for kit description.

Container:

Gun Washer

Model No.

112635 14 in. (356 mm) 11 in. (279 mm)

117438 14.5 in. (368 mm) 11 in. (279 mm)

Maximum

Height

Maximum

Diameter

NOTE: See page 6 for descriptions of Gun, Pressure

Cup, and Paint Container Cleaning Kits.

Wire Trigger Lock

Long Gun Support

Fluid Inlet Adapter

Spray Nozzle

Fig. 3

14 308393

Cup Cover Stem

Short Gun Support

03304

Page 15

Operation

Model 112635 – Using the Hose Wash

1. Place the hose entirely inside the gun washer.

2. Connect one end of the hose to the Hose Wash

Bulkhead fitting. See Fig. 4.

Hose Wash Bulkhead

Model 117438 – Using the Hose Wash

1. Remove the brass plugs from the Hose Wash

Bulkhead. See Fig. 5.

Hose Wash Bulkhead

Hose Wash

Bulkhead

Fig. 5

2. Install a female fluid quick coupler with 1/4 in. npt

male threads (suitable for lacquer thinner) into the

Hose Wash Bulkheads.

Fig. 4

3. Turn the hose/gun wash selector to HOSE WASH.

NOTE: When the selector is set for Hose Wash,

the solvent is routed through the hose wash bulkhead fitting instead of the gun supports and spray

nozzles.

3. Connect the paint line to the couplers.

4. Set the pointer on the shield to hose clean and

operate the gun washer.

NOTE: When the selector is set for Hose Wash,

the solvent is routed through the Hose Wash Bulkhead fitting instead of the gun supports and spray

nozzles.

308393 15

Page 16

Operation

Operating the Gun Washer

WARNING

PRESSURIZED EQUIPMENT HAZARD

Do not operate the gun washer with the

lid open. Serious injury, including blindness, could result.

A safety device has been installed to shut off

the pump when the gun washer lid is opened.

Do not tamper with or alter this device.

Open the gun washer lid slowly.

The gun washer lid has been designed to close

automatically unless supported by hand (Models

112634 and 112635) or by foot (Model 117438).

Do not bypass this safety feature by propping

the cover open with an object or by any other

means.

WARNING

EQUIPMENT MISUSE HAZARD

To avoid component rupture, which could result in

serious injury or property damage, never use an air

supply pressure above the gun washer’s maximum

working pressure of 100 psi (0.7 MPa, 7 bar).

Never operate the gun washer at a pressure above

the maximum working pressure rating of the gun(s)

being cleaned.

2. Make sure all adapter chains and cables are inside

the gun washer tank.

3. If one or more of the gun mounts is not being

used, place a stream blocking device, such as a

pint-size can, over the stem supports and the cup

spray nozzle not being used to prevent those jets

of solvent from hitting the underside of the gun

washer lid.

4. Close the gun washer lid.

5. Press the start button on the reset valve block to

start the gun washer. Guns, cups, or other paint

containers will be cleaned in about 30 to 60

seconds.

NOTE: The cleaning operation should not exceed

60 seconds. Longer operation will not improve the

cleaning process and will cause unnecessary wear

on the pump.

If the lid is opened while the gun washer is operating, the air supply will automatically shut off and

spraying will stop. To restart the pump, close the

lid and press the start button.

6. Remove the gun from the gun washer and blow or

wipe any solvent remaining on the gun exterior.

7. Hang up the gun until it is used again.

1. Set the air pressure to the gun washer between

40–75 psi (0.3–0.5 MPa, 2.8–5.2 bar), using an air

regulator on the gun washer air supply line.

NOTE: All gun washer models include a pump air filter/

regulator that has been preset at the factory; do not

readjust it. See Fig. 4, page 15.

CAUTION

Do not change the setting on the Husky pump’s air

filter/regulator as this will damage the regulator.

CAUTION

Always hang the gun with its nozzle pointing down to

avoid having solvent run into the gun air passages.

Solvent in the gun air passages can cause poor atomization and can damage the gun.

Pump Operation and Maintenance

See the pump instruction manual provided with the gun

washer for operation and maintenance of the pump.

16 308393

Page 17

Shutdown and Care

Gun Washer Shutdown and Care

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of an injury from accidental

spray, splashing fluid, or moving parts, follow the

Pressure Relief Procedure, covered in steps 1

and 2 below, when you shut down the gun washer

and before you check, clean, or service any of the

system equipment.

1. Disconnect the air supply.

2. Drain the solvent from the gun washer tank daily,

when you shut down the system. Place a proper

solvent container under the fluid drain valve on the

bottom of the tank and open the fluid drain valve.

WARNING

FIRE AND EXPLOSION HAZARD

The PRO-Wash gun washer is classified

as a temporary storage container. To reduce the risk of fire or explosion, be sure

to drain the solvent into a proper storage

container and store it according to the

local code for flammable liquids when

shutting down your system.

Air Cut-off Switch and Reset Block

WARNING

EQUIPMENT MISUSE HAZARD

A safety device has been installed to shut off the

pump when the gun washer lid is opened. Do not

tamper with or alter this device. Serious injury, including blindness, could result.

The air connections between the air cut-off switch and

reset block are color coded. They must always be connected as shown in Fig. 6.

Air Cut-off Switch and Reset Block

Air Supply

Black Color

3. Wipe the inside of the tank with a cloth or use a

brush to remove any built-up paint residue.

4. Thoroughly clean the gun washer filter (item 12 in

the Parts Drawings) with a brush.

5. Change the solvent completely when it is no longer

thoroughly cleaning the painting equipment. If the

gun washer is being filled with old solvent, be sure

to filter the solvent before filling the gun washer

tank.

NOTE: If the solvent is thoroughly filtered daily to

remove paint residue, it can usually be reused for 2 to

8 weeks (depending on gun washer usage).

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of fire or explosion,

always clean-up any solvent leaks or

spills immediately. Repair any leaking

components before operating the gun

washer again.

Lid Closed Signal

Blue Color

Start

Switch

Fig. 6

Limit

Switch

Pump

Coupler

Air Filter/

Regulator

Main

Air

03306

308393 17

Page 18

Shutdown and Care

Check the Gun Washer Electrical Continuity

WARNING

FIRE AND EXPLOSION HAZARD

There must be electrical continuity between the gun washer’s fluid tank, divider plate, frame, and main ground wire.

To reduce the risk of static sparking, fire,

or explosion, check the electrical conti-

nuity between all gun washer metallic

parts and true earth ground after servicing the gun

washer. Make sure the gun washer is properly

grounded before operating it again.

Grounding Circuits

Jumper Wire from Lid

to Fluid Manifold

Check your local electrical code for detailed grounding

instructions for your area and type of equipment.

If electrical continuity is lost, check the grounding connections and reconnect them as needed. See Fig. 7 for

the gun washers grounding circuits.

Jumper Wire from Fluid Drain

Valve to Pump Grounding Bar

Jumper Wire from Pump In-

let to Pump Grounding Bar

Fig. 7

18 308393

Jumper Wire from Pump Outlet to

Pump Grounding Bar

Ground Wire to

True Earth Ground

Model 112635 shown

03307

Page 19

Notes

308393 19

Page 20

Reference

Fluid

Manifold

Detail

Parts for Model 112634

27

E

2

E

Pump Ground Bar

Detail

13

26

NOTE: The circled letters indicate

the continuation points of illustrations of tubes or wires.

Ref. A

D

C

1

B

A

D

E

C

5

B

12

4

28

A

6

E

E

E

E

8

20 308393

28

15

16

03309

Page 21

Parts for Model 112634

Model 112634 Gun Washer

Ref.

No. Part No. Description Qty.

1 112871 OUTLET TUBE, pump 1

2 512803 SWITCH, air cut-off 1

4 112870 INTAKE TUBE, pump 1

5 512804 BLOCK, reset valve 1

6 D31211 PUMP, Husky 307; See manual

308553 to order parts 1

8 512838 REGULATOR, air filter 1

12 512829 FILTER, fluid 1

13 112873 VALVE, fluid drain; brass 1

15 512871 WIRE, grounding 1

16 103538 CLAMP, grounding 1

17 512799 NOZZLE, spray; plastic 14

18* ––– GUN SUPPORT, long; brass 1

Fluid Manifold Detail

21

Ref.

No. Part No. Description Qty.

19* ––– GUN SUPPORT, short; brass 1

20* ––– TRIGGER LOCK, wire;

stainless steel 2

21* ––– ADAPTER, gun fluid inlet; brass 2

26 112703 FRAME, gun washer 1

27 186527 LABEL, warning, gun washer 1

28 513049 JUMPER, ground 4

* These parts are included in Gun Washer Kit

236905, which may be purchased separately. See

page 6 for other kits that are available.

Replacement Danger and Warning labels, tags and

cards are available at no cost.

18*

*17

*20

19*

Ref. A

03312

308393 21

Page 22

Parts for Model 112635

27

Reference

Fluid

Manifold

Detail

E

E

Pump Ground Bar

Detail

2

NOTE: The circled letters indicate

the continuation points of illustrations of tubes or wires.

Ref. A

D

C

14

1

B

A

28

A

D

13

C

5

B

26

8

22 308393

E

E

E

6

12

E

4

E

15

28

16

03310

Page 23

Parts for Model 112635

Model 112635 Gun Washer

Ref.

No. Part No. Description Qty.

1 112871 OUTLET TUBE, pump 1

2 512803 SWITCH, air cut-off 1

4 112870 INTAKE TUBE, pump 1

5 512804 BLOCK, reset valve 1

6 D31211 PUMP, Husky 307; See manual

308553 to order parts 1

8 512838 REGULATOR, air filter 1

12 512829 FILTER, fluid 1

13 112873 VALVE, fluid drain; brass 1

14 112875 VALVE, 3-way 1

15 512871 WIRE, grounding 1

16 103538 CLAMP, grounding 1

17 512799 NOZZLE, spray; plastic 13

18* ––– GUN SUPPORT, long; brass 2

Fluid Manifold Detail

*20

21

*17

Ref.

No. Part No. Description Qty.

19* ––– GUN SUPPORT, short; brass 1

20* ––– TRIGGER LOCK, wire;

stainless steel 3

21* ––– ADAPTER, gun fluid inlet; brass 3

26 112703 FRAME, gun washer 1

27 186527 LABEL, warning, gun washer 1

28 513049 JUMPER, ground 4

* These parts are included in Gun Washer Kit

236905, which may be purchased separately. See

page 6 for other kits that are available.

Replacement Danger and Warning labels, tags and

cards are available at no cost.

19*

18*

*18

Ref. A

03313

308393 23

Page 24

Parts for Model 117438

36

14

23

39

37

12

35

E

E

Pump Ground Bar

Detail

29

E

28

6

24 308393

38

E

32

15

16

Page 25

Parts for Model 117438

Model 117438 Gun Washer

Ref.

No. Part No. Description Qty.

6 D31211 PUMP, Husky 307; See manual

308553 to order parts 1

12 112875 VALVE, 3-way 1

14 112873 VALVE, ball 1

15 512871 WIRE, grounding 1

16 103538 CLAMP, grounding (not shown) 1

17 512799 NOZZLE, spray; plastic 13

18* ––– GUN SUPPORT, long; brass 2

19* ––– GUN SUPPORT, short; brass 1

20* 512802 TRIGGER LOCK, wire;

stainless steel 3

21* 512835 ADAPTER, gun fluid inlet; brass 3

23 513284 GASKET, lid 1

Fluid Manifold Detail

Ref.

No. Part No. Description Qty.

28 513049 JUMPER, ground 4

29 117415 KNOB, timer 1

35 117422 FILTER, fluid 1

36 117428 BRUSH, gun wash, manual 1

37 117432 VALVE, OR 1

38 117433 VALVE, limit 1

39 117434 TIMER 1

* These parts are included in Gun Washer Kit

236905, which may be purchased separately. See

page 6 for other kits that are available.

Replacement Danger and Warning labels, tags and

cards are available at no cost.

*18

17

*21

*20

19*

18*

03313

308393 25

Page 26

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS W ARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , o r a ny

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty , and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 308393

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1991, Graco Inc. is registered to ISO 9001

26 308393

Graco Headquarters: Minneapolis

www.graco.com

Revision J, June 2017

Loading...

Loading...