Page 1

Instructions

ProMix® PD2K

Advanced Web

3A3170A

Interface

Installation and program setup instructions to allow communication between a PC and the

ProMix® PD2K Proportioner, via an Ethernet. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

Kit 24T805, ProMix® PD2K Advanced Web Interface

(AWI)

Kit 15V337, Advanced Web Interface (AWI)

EN

Important Safety Instructions

Read all warnings and instructions in this

manual and in your PD2K Proportioner

manual. Save all instructions.

Page 2

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Install the Advanced Web Interface (AWI) M odu le 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Connect the A WI Module to the PD2K and PC . . 5

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Configuration for PD2K . . . . . . . . . . . . . . . . . . . . 8

Configuration for AWI and PD2K . . . . . . . . . . . . . 9

Related Manuals

Component Manuals in English

Manual Description

332562 ProMix PD2K Electronic Proportioner

332459 Advanced Web Interface Kit

3A3180

ProMix

®

PD2K Modbus TCP Installation Kit

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Navigation Overview . . . . . . . . . . . . . . . . . . . . . 12

Monitor Screen . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 24

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 3A3170A

Page 3

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on wa rning labels, refer back to these w arnings. Product -specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in the work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in a well-ventilated area.

• Eliminate all ignition sources such as pilot lights, cigar ettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep the work area f ree of debris, including solvent, rags, and gasoline.

• Do not plug or unplug pow er cord s , or turn pow er or light switches on or off when fla mmab le fu mes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold the gun firmly to the side of a grounded pail when triggering into a pail. Do not use pail liners

unless they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you f eel a shock. Do not use the equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maxim um working pressure or temperature r ating of the lowest rat ed system component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Specifi-

cations in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, requ est Safe ty Data Sheets (SDSs) from y our distribut or or retailer .

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for it s intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and ani mals away from the work area.

• Comply with all applicable safety regulations.

3A3170A 3

Page 4

Install the Advanced Web Interface (AWI) Module

Install the Advanced Web Interface (AWI) Module

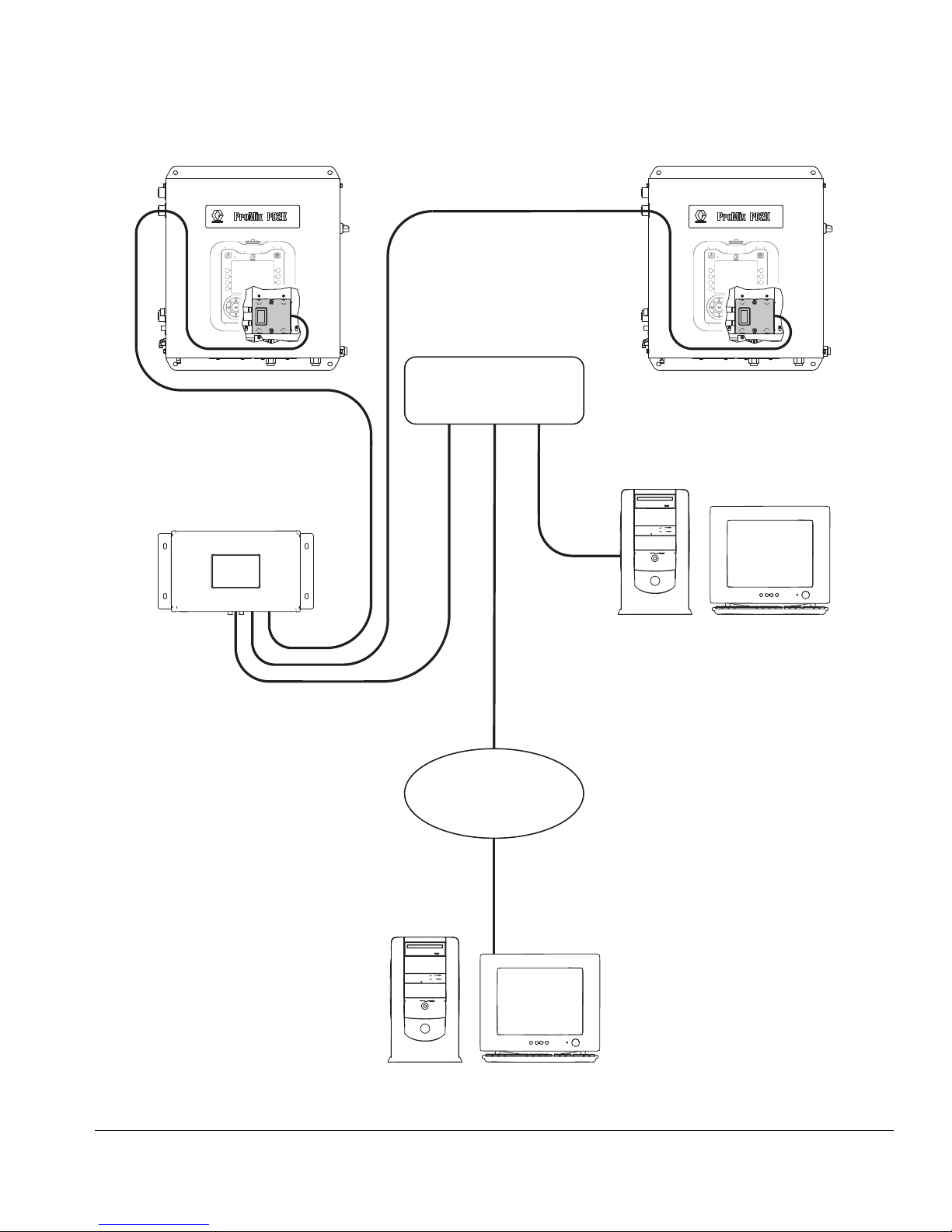

Overview

The Graco Advanced Web Interface (AWI) Accessory

allows communication between multiple ProMix PD2Ks

and a PC over an Ethernet, enabling users to monitor

the ProMix PD2K, view and change system setup

parameters, and create reports.

Location

The AWI module may be installed in a local ProMix network or in a Local Area Network (LAN).

Do not install equipment approved only for a non-hazardous location in a hazardous location.

Mounting

1. Ensure that the wall and mounting hardware are

strong enough to support the weight of the equipment, fluid, hoses, and stress caused during operation.

2. Using the equipment as a template, mark the

mounting holes on the wall at a convenient height

for the opera to r t o ensure th at th e e quipmen t is ea sily accessible for maintenance.

3. Drill mounting holes in the wall.

4. Install anchors as needed.

5. Bolt the equipment securely.

4 3A3170A

Page 5

Install the Advanced Web Interface (AWI) Module

PD2K

AWI

Connecting the AWI Module to

the PD2K and PC

NOTICE

To avoid damaging the circuit board when servicing,

wear a grounding strap on your wrist and ground

appropriately.

1. Shut off the ProMix PD2K power (0 position) and

shut off the power at the main circuit breaker.

4. Run a CAT5 cable from the Modbus TCP module

and connect it to any port in the AWI module. Connect another CAT5 cable from the AWI module to

the PC or LAN.

2. Install the Modbus TCP module, Kit 24T805. For

instructions, see the ProMix PD2K Modbus TCP

Installation Kit manual 3A3180.

3. Install the AWI mod ule, Kit 15V337. F or instructions,

see the Advanced Web Interface Kit manual

332459.

5. Power up the AWI module. For instructions, see the

Connections section of the Advan ced We b Interf ace

Kit manual 332459.

NOTE: Multiple AWI server hubs can be connected to

the AWI master module in the series.

3A3170A 5

Page 6

Install the Advanced Web Interface (AWI) Module

AWI Module

AWI Hub

FIG. 1: ProMix Network Typical Installation

6 3A3170A

Page 7

LAN

LAN Switch

AWI Module

Install the Advanced Web Interface (AWI) Module

FIG. 2: Local Area Network (Manual) Typical Installation

3A3170A 7

Page 8

Configuration

Configuration

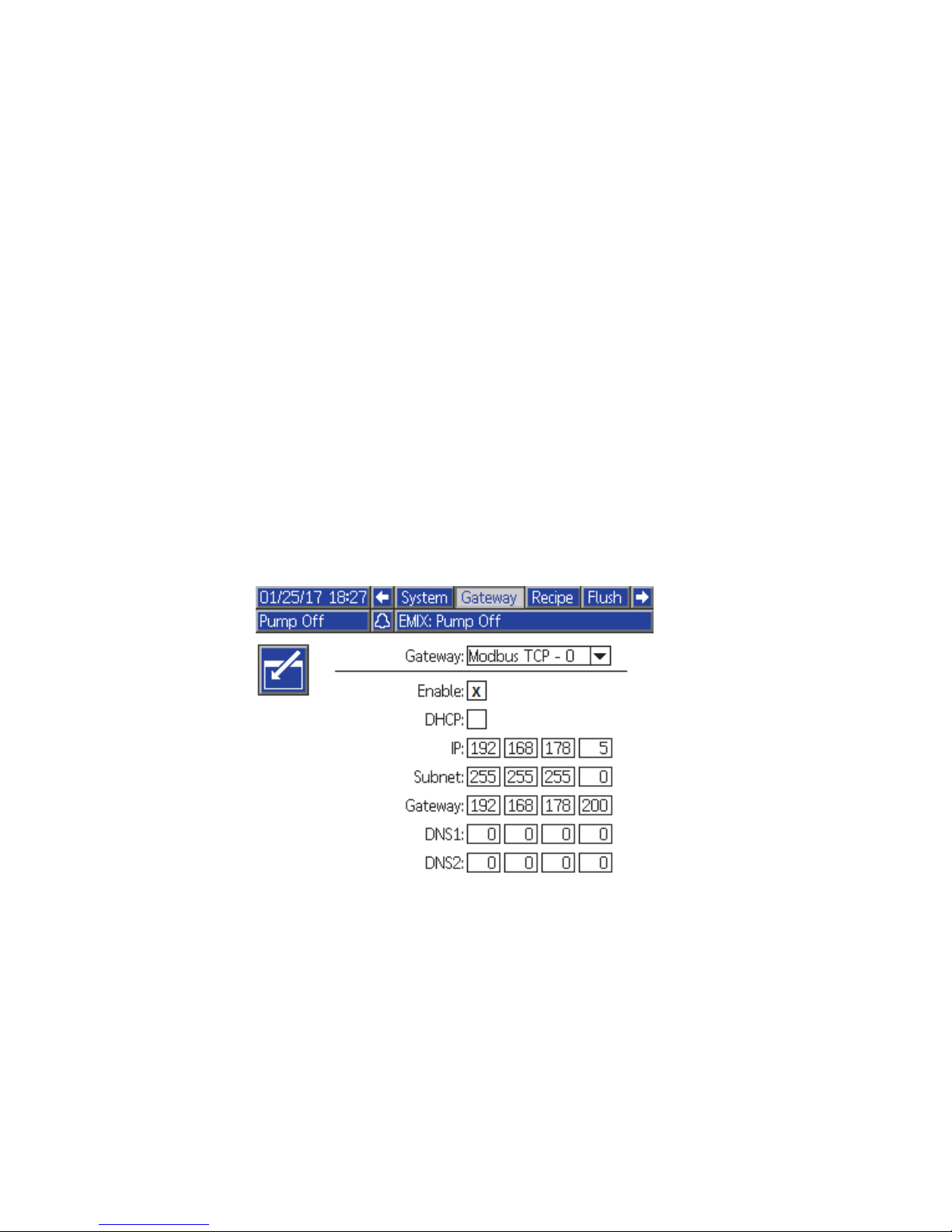

Setting Up PD2K

1. Follow the system configuration steps in the Advanced Web Interface Kit manual 332459.

2. Connect the Graco Modbus TCP gateway in a series with the PD2K system. For instructions, see the ProMix

PD2K Modbus TCP Installation Kit manual 3A3180.

3. On the PD2K ADM, go to System Screen 4 (Gate way Setup) and configure your gateway. For more information,

see System Screen 4 in the ProMix PD2K Electronic Proportioner manual 332562.

a. Before setting the IP, subnet, gateway, or DNS information, clear the Enable check box.

b. Set the network configurations.

If your network contains PD2K and AWI only, use the following default settings:

- IP: 192.168.178.5

- Subnet: 255.255.255.0

- Gateway: 192.168.178.200. The last number must be within a range of 200 and 210.

If you are configuring AWI on your existing Local Area Network, use the settings for your network IP, subnet,

and gateway. Contact your network administrator for these settings.

c. After you update the settings on System Screen 4, verify that the Enable check box is selected.

NOTE: If you change the IP address on the PD2 K system, make sure that you cycle power on the PD2K and AWI

systems.

8 3A3170A

Page 9

Setting Up AWI

Follow these steps to set up AWI for each PD2K.

1. Verify that you are using AWI version 3.02.009 or later.

2. Add a new gateway.

a. On the Network tab, under Gateway, click Add to add a new gateway. For more information, see Add or

Remove Gateways in the Advanced Web Interface Kit manual 332459.

Configuration

b. F rom the Gateway Type list, select modbus_tcp_rtu.

c. In the Gateway Name field, type a name for the gateway (for example, PD2K Gateway).

3A3170A 9

Page 10

Configuration

d. In the Gateway Address field, type the IP address from System Screen 4 of the PD2K. See step 3 in the

Setting Up PD2K section.

e. Click Add.

3. Add the PD2K device.

a. On the Network tab, under Devices, click Add.

b. F rom the Gateway list, select your gateway (for example, PD2K Gateway).

10 3A3170A

Page 11

c. In the Device Address field, type 1.

Configuration

d. Click Add. The newly added PD2K system appears on the Network window.

4. Click the device icon to navigate to the PD2K AWI.

3A3170A 11

Page 12

Operation

Operation

Navigation Overview

Top Navigation

Tabs at the top of the screen provide quick access to various PD2K options.

• Monitor – Click this tab to access the real time PD2K system monitor, which is similar to the ADM run screen.

• Setup – Click this tab to access system configuration screens.

• Materials – Click this tab to access the material-valve assignment screen.

• Reports – Click this tab to generate reports on materials, jobs, and events.

Side Navigation

• Click Network to navigate back to the Network screen.

• Under the icon for the device, the system displays the device name, software version, and the IP address.

• Under Configuration, click Save or Restore to save or restore PD2K device configurations.

12 3A3170A

Page 13

Operation

Monitor Screen

The Monitor screen displa ys re al-time system information such as pump modes, flow r ates , materials , and pr essure .

For more information, see the Run Mode Screens section of the ProMix PD2K Electric Proportioner manual 332562.

3A3170A 13

Page 14

Operation

Setup Screens

The setup screens allow you to configure general and advanced system information along with recipes and flush

sequences. To change numerical configuration v alues, type the v alue and press ENTER. To change list values, select

the item from the list.

System Configuration Screen

The system configuration screen allows y ou to configure syst em setup inf ormation such as tolerances , hose settings,

and flow control. The system configurat ion screen appears as the default screen when you click the Setup tab.

For more information, see the sections for System Screens 1, 2, and 3 in the ProMix PD2K Electric Proportioner

manual 332562.

14 3A3170A

Page 15

Operation

Recipe Configuration Screen

The recipe configuration screen allows you to configure information for a recipe, such as color, flush, catalyst, pressure, ratio, and potlife time.

To access the recipe configuration screen, click the Setup tab and then click Recipe.

For more information, see the Recipe Screens section of the ProMix PD2K Electric Proportioner manual 332562.

3A3170A 15

Page 16

Operation

Flush Sequence Configuration Screen

The flush sequence configuration scree n allows y ou to conf igure inf ormation f or a flush sequen ce, such as gun purge

time, initial flush, final flush, wash cycles, and strokes per cycle.

To access the recipe configuration screen, click the Setup tab and then click Flush.

For more information, see the Flush Screen section of the ProMix PD2K Electric Proportioner manual 332562.

16 3A3170A

Page 17

Operation

Advanced System Configuration Screen

The advanced system configuration screen allows you to configure data for display, units, and USB.

To access the recipe configuration screen, click the Setup tab and then click Advanced.

For more information, see the sections for Advanced System Screens 1, 2, 3, and 4 in the ProMix PD2K Electric Pro-

portioner manual 332562.

3A3170A 17

Page 18

Operation

System Material-Valve Assignment Screen

The material-valve assignment screen a ssociates a PD2K v alv e to a material in master material list. This association

is required for material reports.

To enter information for each material in you r system, see the Materials Tab section in the Advanced Web Interface

Kit manual 332459.

18 3A3170A

Page 19

Operation

Reports

The AWI can pull mate rial and job information from the system and combine this information into three reports:

material-based reports, job-based reports, and event-based reports.

Material-Based Reports

Material-based reports contain information on material used within the system. Reports can be aggregated from multiple PD2K systems.

NOTE: If you changed any recipe configuration, click Update before creating the report.

Select the following report filters and then click Create.

• Date Range: Enter the date and t ime y ou w a nt the r eport to start. The report runs from that date until the current

date and time.

• Materials: Select the materials to include in the report.

• Report: Select VOCs and HAPs to include in the report. Select the report format (CSV or JSON).

• Units: Select the PD2K units to include in the report.

3A3170A 19

Page 20

Operation

Material-based report columns include the following:

• Material ID

• Material name

• Material part number

• Sprayed amount (in CCs)

• Total amount (in CCs)

• Sprayed VOCs (in CCs)

• Total VOCs (in CCs)

• Sprayed HAPs (in CCs)

• Total HAPs (in CCs)

NOTE: If the date range is too large, the results are limite d to the last 1000 jobs. Narrow the filters to view less information in the report.

20 3A3170A

Page 21

Operation

Job-Based Reports

Job-based reports include logs of completed PD2K jobs.

Select the following report filters and then click Create.

• Date Range: Enter the date and t ime y ou w a nt the r eport to start. The report runs from that date until the current

date and time.

• Report: Select the report format (CSV or JSON).

• Filter by: Enter a user ID to include information for a specific user in the report.

Job-based report columns include the following:

•Date

•Time

•Job number

•Part number

• Recipe number

•Ratio

• Material A sprayed amount (in CCs)

3A3170A 21

• Material B sprayed amount (in CCs)

• Material A total amount (in CCs)

• Material B total amount (in CCs)

• Solvent total (in CCs)

• Error (Y if an error is present or N if an error is not

present)

NOTE: If the date range is too large, the results are limited to the last 1000 jobs. Narrow th e filters to view less

information in the report.

Page 22

Operation

Event-Based Reports

Event-based reports include logs of all the events in the system.

Select the following report filters and then click Create.

• Date Range: Enter the date and ti me y ou w a nt the r eport to start. The report runs from that date until the current

date and time.

• Report: Select the report format (CSV or JSON).

• Filter by:

- Select the type of event (alarm, deviation, advisory, or record) to include in the report.

- Enter an event code to include in the report. See the Events Screen section of the ProMix PD2K Electronic

Proportioner operation manual 332562 for instructions to access a list of events.

- Enter the job number to include in the report. Leave this field blank to include all jobs.

Event-based report columns include the following:

•Date

•Time

• Event code

• Event type

22 3A3170A

• Event action

•Event job

NOTE: If the date range is too large, the results are lim-

ited to the last 1000 jobs. Narrow the filters to view less

information in the report.

Page 23

Operation

3A3170A 23

Page 24

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés , donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2018, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

Revision A,

January 2018

Loading...

Loading...