Page 1

Service - Parts

ProMix™ II

For proportional mixing of plural component coatings. For professional use only.

For use in explosive atmospheres (except the EasyKey™).

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

310653E

ENG

Page 2

Manual Conventions

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

ProMix™ II Models . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 8

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

ProMix™ II Alarms . . . . . . . . . . . . . . . . . . . . . . 10

Fluid Manifold Troubleshooting . . . . . . . . . . . . . 11

Solenoid Troubleshooting . . . . . . . . . . . . . . . . . 12

Operator Station Troubleshooting . . . . . . . . . . . 12

Fluid Panel Control Board Diagnostics . . . . . . . 13

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Before Servicing . . . . . . . . . . . . . . . . . . . . . . . . 14

After Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing Air Filter Element . . . . . . . . . . . . . . . 14

EasyKey™ Display . . . . . . . . . . . . . . . . . . . . . . 15

Operator Station . . . . . . . . . . . . . . . . . . . . . . . . 19

Smart Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting to a PC . . . . . . . . . . . . . . . . . . . . . . . . 25

Connect Cable 118342 . . . . . . . . . . . . . . . . . . . 25

Updating Software . . . . . . . . . . . . . . . . . . . . . . . 26

Software Troubleshooting . . . . . . . . . . . . . . . . . 29

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pneumatic Diagram . . . . . . . . . . . . . . . . . . . . . . 30

ProMix™ II Electrical Schematic . . . . . . . . . . . . 31

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ProMix™ II Assembly . . . . . . . . . . . . . . . . . . . . 32

Flow Meter Kits . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operator Station . . . . . . . . . . . . . . . . . . . . . . . . 35

EasyKey™ Display . . . . . . . . . . . . . . . . . . . . . . 36

Smart Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . 38

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 40

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 40

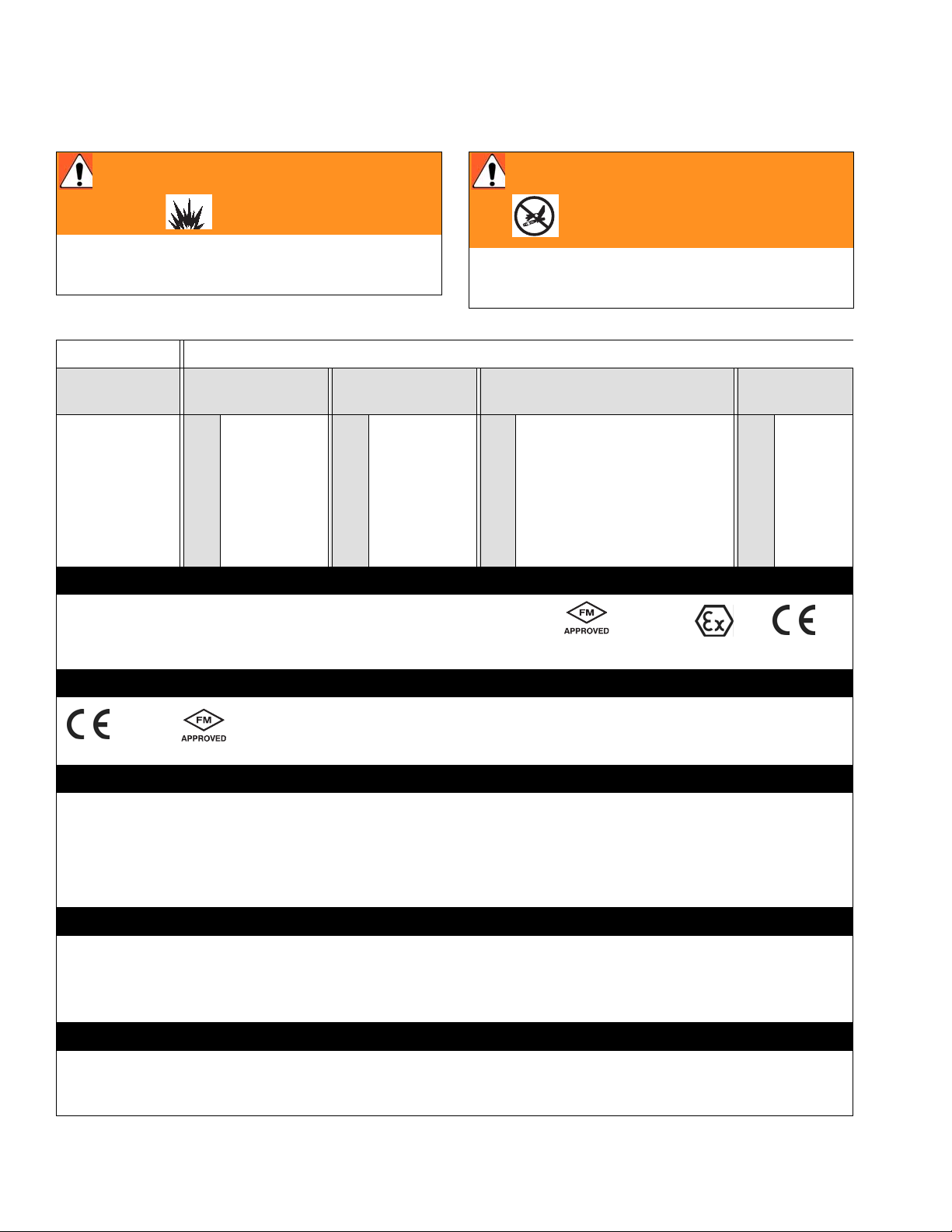

Manual Conventions

WARNING

Hazard Symbol

WARNING: a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Warnings in the instructions usually include a symbol

indicating the hazard. Read the general Warnings

section for additional safety information.

CAUTION

CAUTION: a potentially hazardous situation which, if

not avoided, may result in property damage or

destruction of equipment.

Note

Additional helpful information.

2 310653E

Page 3

Manual Conventions

310653E 3

Page 4

ProMix™ II Models

ProMix™ II Models

WARNING

Do not install equipment approved only for non-hazardous location in a hazardous area. Substitution of

components may impair intrinsic safety. See page 6.

PM

Enter Model number here

ProMix™ II

Unit

PM

A Meter B Meter Color Change

0 None 0 None 0 None, Single Color 0 No

1 G3000 1 G3000 1 2 Color, Low Pressure 1 Ye s

2 G3000HR 2 G3000HR 2 4 Color, Low Pressure

3 Coriolis 3 Coriolis 3 6 Color, Low Pressure

Hazardous Location Approval

Only models with a G3000 (1) or G3000HR (2) for both A and

B meters are approved for installation in a Hazardous Location - Class I, Div I, Group D, T3.

Non-hazardous Location Approval

WARNING

Changing the fluid manifold configuration may change

its pressure rating. Do not exceed the pressure rating

of the lowest rated component. See page 6.

Gun Flush

Box

4 2 Color, High Pressure

5 4 Color, High Pressure

6 6 Color, High Pressure

#53

Conforms to FM std

3600 & 3610 for use in Class I Div 1

Group D T3 Hazardous locations

CAN/CSA 22.2 No.157 & No. 1010.1-92

EEx ib IIA T3

ISSeP 04 ATEX 008

SYST

#53

CAN/CSA

22.2 No.1010.1

Maximum Working Pressure

Maximum working pressure rating is dependent on the A and B meter and color change option selected. The pressure rating is based on the rating of the lowest rated fluid manifold component. Refer to the component pressure

ratings below. Example: Model PM1140 has a maximum working pressure of 3000 psi (21 MPa, 207 bar).

Check the ID plate on your EasyKey™ Display or fluid panel for its maximum working pressure. See F

IG. 1,

page 5.

ProMix™ II Fluid Manifold Components Maximum Working Pressure

Color Change Option 1, 2, or 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300 psi (2.1 MPa, 21 bar)

Color Change Option 4, 5, or 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 psi (21 MPa, 207 bar)

Coriolis A and B Meters Option 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2300 psi (16 MPa, 159 bar)

No Meters or G3000 or G3000HR A and B Meters Option 0, 1, or 2 . . . . . . . . . . . . . . 4000 psi (28 MPa, 276 bar)

Flow Meter Fluid Flow Rate Range

G3000 Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75-3000 cc/min. (0.02-0.79 gal./min.)

G3000HR Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38-1500 cc/min. (0.01-0.40 gal./min.)

Coriolis Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-3800 cc/min. (0.005-1.00 gal./min.)

4 310653E

Page 5

Related Manuals

ProMix™ II ID Plate Locations

ID

IG. 1: EasyKey™ Display and Smart Fluid Panel

F

Related Manuals

Component Manuals in English

Manual Description

310633 ProMix™ II Operation

310653 ProMix™ II Service-Parts

310654 Fluid Mix Manifold

310655 Dispense Valve

308778 G3000, G3000HR Flow Meter

310696 Coriolis Flow Meter

310656 Color Change Kit

307731 Color Change Valve Assembly,

Low Pressure

307941 Color Change Valve, Low Pressure

308291 Color Change Valve Assembly, High

Pressure

308977 Color Change Valve, High Pressure

310695 Gun Flush Box Kit

308818 Printer

310669 ProMix™ II Data Download Kit

310745 Gun Air Shutoff Kit

This manual available in following languages:

Manual Language Manual Language

310653 English 310735 Chinese

310731 French 310736 Japanese

310732 Spanish 310807 Dutch

310733 Italian 310808 Finnish

310734 German 310809 Swedish

310653E 5

Page 6

Warnings

Warnings

The following warnings include general safety information for this equipment. More specific warnings are included in

the text where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment and conductive objects in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

INTRINSIC SAFETY

Only models with a G3000 (1) or G3000HR (2) for both A and B meters are approved for installation in a

Hazardous Location - Class I, Div I, Group D, T3. To help prevent fire and explosion:

• Do not install equipment approved only for non-hazardous location in a hazardous area. See the ID

label for the intrinsic safety rating for your model.

• Do not substitute system components as this may impair intrinsic safety.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and regulations.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

6 310653E

Page 7

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

310653E 7

Page 8

Pressure Relief Procedure

Pressure Relief

Procedure

I

WARNING

Follow Pressure Relief Procedure when you stop

spraying, before changing spray tips, and before

cleaning, checking, or servicing equipment. Read

warnings, page 6.

1. Engage the trigger lock.

2. Press Standby key on Operator Station.

Shut

off

3. Shut off air at the spray gun.

8. Engage trigger lock.

9. Press Standby on Operator Station.

10. If you suspect that the spray tip or hose is clogged

or that pressure has not been fully relieved after following the steps above, very slowly loosen tip

guard retaining nut or hose end coupling to relieve

pressure gradually, then loosen completely. Clear

hose or tip obstruction.

WARNING

Pressure upstream of component A and B dispense

valves (A, B) may not be fully relieved.

11. Before servicing or disconnecting flow meters, color

change valves, or other components between the

fluid supply shut off valves (T) and dispense valves

A and B, very slowly loosen swivel fitting (HH) to

relieve pressure gradually.

WARNING

If using an electrostatic gun, shut off electrostatics

before flushing.

4. Relieve fluid and air pressure at component A and

B and solvent feed pumps or pressure pots as

instructed in their separate manuals. Close all fluid

supply shutoff valves.

5. Press Mix on Operator Station.

6. Disengage trigger lock.

7. Hold a metal part of the gun

firmly to a grounded metal

pail. Trigger the gun to relieve

pressure.

T

HH

HH

A

B

T

8 310653E

Page 9

Shutdown

Shutdown

1. To stop production at any time, press Standby

on the Operator Station.

2.

3.

WARNING

If using an electrostatic gun with a gun flush

box, shut off the electrostatics before placing the

gun in the box.

If you have a gun flush box, place the gun inside

the box when the gun is not in use.

4. If shutdown time WILL exceed the pot life, purge

the ProMix™ II of mixed material. See ProMix™ II

Operation manual.

If shutdown time WILL NOT exceed the pot life,

you do not need to purge the system, but you must

relieve system pressure.

WARNING

Follow Pressure Relief Procedure on page 8 when

you stop spraying, before changing spray tips, and

before cleaning, checking, or servicing equipment.

Read warnings, page 6.

310653E 9

Page 10

Troubleshooting

Troubleshooting

WARNING

Follow Pressure Relief Procedure, page 8, before

cleaning, checking, or servicing equipment. Read

warnings, page 6.

CAUTION

Do not use the fluid in the line that was dispensed off

ratio as it may not cure properly.

ProMix™ II Alarms

Alarms E-Codes

Description E-Code

Communication Error E1

Purge Error E2

Potlife Exceeded Alarm E3

Ratio Alarm E4

Overdose Alarm E5

Dose Time A Alarm E6

Dose Time B Alarm E7

Autodump Complete Alarm E8

EasyKey in Setup Mode E9

The ProMix™ II has alarms to alert you of a problem

and prevent off-ratio spraying. If an alarm occurs, operation stops and the following occurs:

• A red LED illuminates steadily or flashes on the

Operator Station.

• Operator Station displays an alarm E-Code, E1 to

E9.

• Alarm sounds.

• Status bar on the EasyKey™ Display shows the

alarm E-Code with a description.

Red LED

E-Code

To Clear Alarm and Restart

When an alarm occurs, determine the E-Code

before clearing it. You can use the EasyKey™

Report screen (F

with date and time stamps.

F

IG. 2: Setup Mode - Report Screen

Except for Potlife Exceeded (E3) Alarm and Purge Error

(E2) Alarm, all alarms can be cleared by pressing the

Error Clear

To clear Pot Life Exceeded alarm, the system must be

key on the Operator Station.

IG. 2) to view the last 10 alarms

Operator Station

purged. Press the Purge key on the Operator Station. The system purges until the preset purge time is

complete. Refer to purging procedure in ProMix™ II

Operation manual.

For Additional Information

See ProMix™ II Operation manual for additional alarm

troubleshooting information.

10 310653E

Page 11

Fluid Manifold Troubleshooting

See FIG. 3. To remove the fluid manifold, see page 23.

See manual 310654 for complete information on the

fluid manifold.

31

A

10

20

Troubleshooting

32

B

B

10

B

K

16

D

D

16

OFF

C

20

16

C

16

OFF

A

A

C

A

D

Component A Side

A Supply Line A connection

A

Fluid Filter A, 100 mesh

C

A

D

Check Valve A

A

Flow Meter A (G3000 shown)

E

A

10

Fluid Shutoff Valve A

A

Dispense Valve A

43

C

16

Air Purge Valve

A

Sampling Valve A

20

A

Air Purge inlet

K

A

Dump Port A (option)

44

A

D

16

ON

B

A

44

B

43

B

43

ON

OFF

A

E

A

K

43

ON

A

A

43

43A OFF

B

44

T

43

B

Component B Side

B Supply Line B connection

B

Fluid Filter B, 100 mesh

C

B

D

Check Valve B

B

Flow Meter B (G3000 shown)

E

B

10

Fluid Shutoff Valve B

B

Dispense Valve B

43

D

16

Solvent Purge Valve

B

Sampling Valve B

20

B

Solvent Purge inlet

K

B

Dump Port B (option)

44

B

D

B

E

Other

31 Integrator

32 Static Mixer

T Mixer Fluid Outlet to gun

B

C

TI7334A

IG. 3. 248251 Fluid Manifold

F

310653E 11

Page 12

Troubleshooting

Solenoid Troubleshooting

Refer to the Pneumatic Diagram, page 30.

If the dispense or purge valves are not turning on or off correctly, it could be caused by one of the following.

Cause Solution

1. Air regulator pressure set too

high or too low.

2. Air or electrical lines damaged

or connections loose.

3. Solenoid failure

Purge

Solvent

Purge Air

Dispense B

Dispense A

FIG. 4

4. Solenoid, cable, or fluid panel

control board failure.

Check air pressure. 80 psi (550 kPa, 5.5 bar) is commonly used. Do not go

below 75 psi (517 kPa, 5.2 bar) or above 100 psi (0.7 MPa, 7 bar),

Visually inspect air and electrical lines for kinks, damage, or loose connections. Service as needed.

Manually operate the valves by removing the Smart Fluid Panel cover and

pressing and releasing solenoid valve override buttons. F

Use the control board diagnostics to check the signals (page 13). If signals

do not occur correctly, go to Cause 4.

Valves should snap open and shut quickly. If the valves actuate slowly, it

could be caused by:

• Air pressure to the valve actuators is too low. See Cause 1.

• Solenoid is clogged. Make sure air supply has 10 micron filter installed.

• Something is restricting the solenoid or tubing. Check for air output from

air line for corresponding solenoid when valve is actuated. Clear restriction.

• Packings on the mix manifold dispense valves are too tight. Torque

should be 25 in-lbs (2.8 N•m).

• A dispense valve is turned in too far. See ProMix™ II Operation manual

for settings,

• Fluid pressure is high and air pressure is low.

Check voltage level to solenoid by pulling solenoid connector and checking

voltage between pins.

IG. 4.

If voltage is 9-15 VDC, the solenoid is damaged. Replace solenoid or correct

electrical line problem.

If there is no voltage, replace the board.

Operator Station Troubleshooting

Problem Cause Solution

Nothing displayed Power is off Turn on power

Faulty cable Check or replace cable

Circuit board failure Replace circuit board

Error code E1 Faulty fiber optic cable between

EasyKey™ and fluid panel

12 310653E

Check or replace cable

Page 13

Fluid Panel Control Board Diagnostics

N PQ

Troubleshooting

A B C D E F G H J K L M

FIG. 5

LED Signal Description Diagnosis

A Dispense Valve A LED turns on when ProMix™ II sends a signal to actuate related

B Dispense Valve B

C Air Purge Valve

D Solvent Purge Valve

E Gun Flush Box Trigger

F Color Change Solvent

GColor 1

HColor 2

JColor 3

KColor 4

LColor 5

MColor 6

N Board OK LED blinks during normal operation

P Gun Flush Box Pressure Switch LED turns on when a gun is in Gun Flush Box

Q Air Flow Switch LED turns on when paint gun is triggered.

solenoid valve

310653E 13

Page 14

Service

Service

Before Servicing

WARNING

• To avoid electric shock, turn off EasyKey™ power

before servicing.

• Servicing EasyKey™ display exposes you to high

voltage. Shut off power at main circuit breaker

before opening enclosure.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and regulations.

• Do not substitute system components as this may

impair intrinsic safety.

• Read warnings, pages 6-7.

1. Follow Shutdown procedure, page 9, if service

time may exceed pot life time and before servicing

fluid components.

2. Close main air shutoff valve on air supply line and

on ProMix™ II.

3. Shut off ProMix™ II power (0 position). FIG. 6.

Replacing Air Filter Element

WARNING

Removing a pressurized air filter bowl could cause

serious injury. Depressurize air line before servicing.

Check the 5 micron air manifold filter daily and replace

element (part no. 114228) as needed.

1. Close main air shutoff valve on air supply line and

on unit. Depressurize air line.

2. Remove filter cover (A).

A

4. If servicing EasyKey™ Display, also shut off power

at main circuit breaker.

0 = OFF

F

IG. 6

After Servicing

After servicing the system, be sure to follow the

Start Up checklist and procedure in the ProMix™ II

Operation manual.

3. Unscrew filter bowl (B).

B

4. Remove and replace element (C).

C

5. Screw filter bowl (B) on securely. Install cover (A).

14 310653E

Page 15

Service

EasyKey™ Display

• Before Servicing

• Updating Software

• Replacing Display Board or Display Backlight

• Replacing Keypad

• Replacing Power Supply Board

• Replacing Power Supply Fuses

CAUTION

To avoid damaging circuit board when servicing, wear

grounding strap on wrist and ground appropriately.

Updating Software

There are 2 ways to update software:

• Upload new software from your PC: Requires Graco

RS-232 cable 118342 and software update file

obtained from your distributor. Follow Updating

Software procedure, page 26.

• Install new software chip: Requires Graco ProMix™

II Software Update Kit 234671. Kit includes display

board flash memory chip, chip extractor tool, and

grounding wrist strap. Follow Installing New Soft-

ware Chip procedure.

Installing New Software Chip

1. Follow Before Servicing procedure, page 14.

2. Unlock and open EasyKey™ door with its key.

3. Remove display board chip (C - FIG. 7) with

removal tool.

a. Press removal tool into flash chip socket open

holes.

b. Squeeze the tool to grip the chip and carefully

pull it straight out of the socket.

C

FIG. 7

4. Align beveled corner of new chip with beveled cor-

ner of socket and press chip into place. Make sure

the pins are not bent or touching.

5. Close and lock EasyKey™ door with key.

6. Turn EasyKey™ power on to test circuit boards.

310653E 15

Page 16

Service

Replacing Display Board or Display

Backlight

Before replacing the backlight, check the inverter

(D - F

IG. 8) on the display board for proper voltage.

a. Turn EasyKey™ power on.

b. Carefully measure AC voltage across the 2

pins of the inverter (D).

c. Voltage should be about 700 VAC. If not,

replace the circuit board.

Kits available:

Part No. Description

118337 Backlight Repair Kit

234447 Display Interface Replacement Kit

Includes membrane switch, graphic display,

display board, mounting plate, and screws.

WARNING

4. Remove 4 screws (508e) and display board assem-

bly (508b, 508c). F

IG. 9.

5. Separate graphic display (508b) from circuit board

(508c).

508e

508b

TI4862a

F

508c

IG. 9

6. If replacing display backlight, using Backlight

Kit 118337:

Servicing the EasyKey™ Display exposes you to high

voltage. To avoid electric shock, turn off EasyKey™

power and shut off power at main circuit breaker

before servicing.

1. Follow Before Servicing procedure, page 14.

2. Unlock and open EasyKey™ door with its key.

3. Note position of all connections (J2, J5, J6, J8, J9)

to display board then unplug the connectors. F

J5 (power)

J6 (RS232)

508c

J2

(membrane

switch)

D

J9

(F.O. in - black)

J8

(F.O. out - blue)

F

IG. 8

IG. 8.

508e

a. Unplug inverter connector (X).

X

(backlight power)

b. Remove the two small screws and nuts (AA) -

be careful not to drop them.

AA

16 310653E

Page 17

Service

c. Slide the backlight (F) out of the display board

(508b). Install new backlight (F)

F

508b

7. Align display board (508c) and graphic display

(508b). F

IG. 9. Press them together.

8. Mount display board with screws (508e).

9. Plug all connectors into display board (508c). FIG.

8.

10. Close and lock EasyKey™ door with key.

3. Disconnect keypad ribbon cable (J2) from the dis-

play board. F

IG. 8.

4. Peel keypad (508a) off plate (508d) and carefully

slide ribbon cable through slot in plate. F

IG. 10.

5. Remove adhesive liner from back of new keypad.

6. Slide the ribbon cable through the plate (508d) slot,

align the keypad (508a) with the recessed area on

the plate, and press it into place.

7. Connect the ribbon cable (J2) to the display board.

IG. 8.

F

8. Close and lock EasyKey™ door with key.

9. Turn EasyKey™ power on to test operation.

508d

508a

E3

11. Turn EasyKey™ power on to test circuit board.

Replacing Keypad

1. Follow Before Servicing procedure, page 14.

2. Unlock and open EasyKey™ door with its key.

TI4881a

FIG. 10

310653E 17

Page 18

Service

Replacing Power Supply Board

WARNING

Servicing the power supply board exposes you to high

voltage. To avoid electric shock, turn off EasyKey™

power and shut off power at main circuit breaker

before servicing.

1. Follow Before Servicing procedure, page 14.

2. Unlock and open EasyKey™ door with its key.

3. Disconnect cables (G1, G2, G3). FIG. 11.

4. Remove 2 screws (H) and remove cover (J).

5. Noting their location, remove 5 screws (Y) from

power supply board (521a). Remove board.

6. Apply thermal compound to the heatsink (Z) on the

back of the new power supply board (521a).

7. Install the new power supply board with the 5

screws (Y).

8. Install cover (J) with 2 screws (H).

9. Connect cables (G1, G2, G3).

10. Close and lock EasyKey™ door with key.

11. Turn on power at main circuit breaker.

12. Turn EasyKey™ power on to test operation.

Replacing Power Supply Fuses

WARNING

Servicing the power supply board exposes you to high

voltage. To avoid electric shock, turn off EasyKey™

power and shut off power at main circuit breaker

before servicing.

Fuse Part No. Description

F1, F2 114788 2 amp, time lag

F3, F4 15D979 .4 amp, quick acting

1. Follow Replacing Power Supply Board, steps

1-4.

2. Remove the fuse (F1, F2, F3, or F4) from its fuse

holder. F

IG. 11.

3. Snap new fuse into holder.

4. Follow Replacing Power Supply Board, steps

8-12.

Back of Board (521a)

FIG. 11

F1, F2

F3, F4

(power out fuses)

Z

H

J

Do not remove

this screw

H

Y

(line in fuses)

521a

24 Vdc input

line power in/out

G2

G3

G1

IS power to

fluid plate

TI4887b

18 310653E

Page 19

Service

Operator Station

CAUTION

To avoid damaging circuit board when servicing, wear

grounding strap on wrist and ground appropriately.

Replacing Circuit Board

1. Follow Before Servicing procedure, page 14.

2. Remove 4 screws (212) and lockwasher (213), and

remove cover (202).

3. Disconnect cable connector (219) from circuit

board (206).

4. Remove 4 screws (210) and circuit board (206).

5. Install new circuit board (206) with 4 screws (210).

6. Connect cable (219).

7. Install cover (202) with 4 screws (212).

8. Turn EasyKey™ power on to test operation.

Smart Fluid Panel

• Preparation

• Replacing Control Board

• Replacing Air Flow or Pressure Switch

• Replacing Solenoids

• Reassemble Smart Fluid Panel

Preparation

WARNING

Read warnings, page 6.

1. Follow Pressure Relief Procedure, page 8.

2. Close main air shutoff valve on air supply line and

on ProMix™ II.

3. Shut off ProMix™ II power (0 position). FIG. 13.

IG. 12

F

210

219

202

206

213

212

TI4869a

0 = OFF

F

IG. 13

4. Loosen the 4 screws (16), then remove the Smart

Fluid Panel cover (15). F

IG. 14.

15

16

IG. 14

F

310653E 19

Page 20

Service

5. Slide the panel (14) until its bottom slots (KK) align

with the top screw holes and secure the box in

place with the 2 screws. F

J10 J5 J3 J1J6J4

14

KK

IG. 15

F

CAUTION

To avoid damaging circuit board when servicing, wear

grounding strap on wrist and ground appropriately.

IG. 15.

J9 J8

706

TI4886a

4. Remove 4 screws (707). Remove control board

(706). F

IG. 16.

5. Install new control board (706) with 4 screws (707).

6. Connect cables to control board (706). FIG. 15.

Insert fiber optic cable connectors (J4, J6) into

board connectors (E), matching blue with blue,

black with black, and hand-tighten connectors (E).

F

IG. 17.

7. Fluid Panels with Color Change: Orient the

EEPROM (U25) so its notch lines up with the notch

marked on the fluid control board and install it in

the board. The EEPROM leads may need to be

bent slightly inward to fit in the socket.

U25

Replacing Control Board

1. Follow Preparation procedure, page 19.

2. Disconnect fiber optic wires and all cables (J1, J3,

J4, J5, J6, J8, J9, J10) from control board (706).

F

IG. 15.

3. Fluid Panels with Color Change: Carefully

remove color change EEPROM (U25) from the

control board with a chip puller. F

install in the new board.

Panels without color change do not include the

EEPROM.

706

707

IG. 17. Save it to

E

FIG. 17

8. Reassemble Smart Fluid Panel (page 22).

9. Turn EasyKey™ power on to test operation.

TI4868a

F

IG. 16

20 310653E

Page 21

Service

Replacing Air Flow or Pressure Switch

The air flow switch (702) detects whether there is

atomizing air flow to the gun (gun is triggered).

The pressure switch (717) detects if a gun is in the

gun flush box with the box door closed.

1. Follow Preparation procedure, page 19, and shut

off power at main circuit breaker.

2. Air Flow Switch (702): Disconnect wires from con-

nector (V). F

Pressure Switch (717): Disconnect wires from

switch, noting their connection points. F

IG. 18.

IG. 18.

3. Air Flow Switch (702): Unscrew nut from fitting

(704a), and remove assembly from enclosure.

Remove fittings from air flow switch (702).

Pressure Switch (717): Unscrew bushing (716)

from fitting (704b). Remove bushing from pressure

switch (717).

4. Apply pipe thread sealant to new air flow or pres-

sure switch threads and install.

5. Reconnect wires that were disconnected in step 2.

Switch wires are not polarized.

Solenoid Actuates

Standard

1

2

3

4

Optional

5

6

7

8

9

10

11

12

704b

702

Dispense Valve A

Dispense Valve B

Air Purge Valve A

Solvent Purge Valve B

Gun Flush Box Pilot Valve

Color Change Solvent Valve

Color Change Valve 1

Color Change Valve 2

Color Change Valve 3

Color Change Valve 4

Color Change Valve 5

Color Change Valve 6

716

717 V

706

6. Reassemble Smart Fluid Panel (page 22).

Replacing Solenoids

The Smart Fluid Panel has a minimum of 4 solenoids. If

you have a color change valve option installed, you have

additional (optional) solenoids for each additional color.

Refer to Pneumatic Diagram, page 30.

To replace a single solenoid.

1. Follow Preparation procedure, page 19, and shut

off power at main circuit breaker.

2. Disconnect 2 solenoid wires (N) from control board

(706). F

IG. 18.

3. Unscrew 2 screws (P) and remove solenoid (712).

704a

6

712

F

IG. 18

P

5

4

3

2

1

4. Install new solenoid (712).

12

11

10

N

9

8

7

TI4875

5. Connect 2 wires (N) to control board (706). Sole-

noid wires are polarized (red +, black –). Refer to

ProMix™ II Electrical Schematic, page 31.

6. Reassemble Smart Fluid Panel (page 22).

310653E 21

Page 22

Service

Reassemble Smart Fluid Panel

1. Remove screws and slide the panel (14) back into

place.

2. Secure the cover (15) and panel (14) with the 4

screws (16). F

F

IG. 19

IG. 19.

14

15

16

Servicing Flow Meters

3. Shut off ProMix™ II power (0 position).

4. Unscrew cable connector (110) from meter (1). FIG.

21.

5. Unscrew M6 screws (107) from bottom of meter

mounting plate (108) with socket wrench. F

IG. 20.

6. Unscrew fluid line from meter inlet (P).

The meter shield (R) is unattached and may fall off

when you remove the meter (1). F

IG. 21.

7. Unscrew meter (1) from dispense valve connector

IG. 21.

(H). F

8. Service meter as instructed in the meter manual.

P

107

108

WARNING

Read warnings, page 6.

• Coriolis Meter: To remove and service see Coriolis

meter manuals.

• G3000 or G3000H Meter: To remove, follow proce-

dure below. To service, see meter manual.

G3000 or G3000HR Meter

Removing

1. Follow Pressure Relief Procedure, page 8. Make

sure you complete step 11.

2. Close main air shutoff valve on air supply line and

on ProMix™ II.

IG. 20

F

F

IG. 21

110

R

1

H

22 310653E

Page 23

Service

Installing

9. Screw meter (1) securely onto the dispense valve

connector (H), using a wrench.

CAUTION

To avoid leakage, secure the meter (1) to the dispense valve connector (H) before connecting it to the

plate (108).

10. Secure meter (1) to plate (108) with screws (107).

11. Connect meter cable (110). See FIG. 22.

12. Connect fluid line (P).

13. Calibrate meter as instructed in ProMix™ II Opera-

tion manual.

J3*

1

2

3

4

5

6

7

8

Power (red)

Common (black)

Signal (white)

Shield

Power (red)

Common (black)

Signal (white)

Shield

*Connector on Smart Fluid Panel circuit board

Cable

Flow Meter A

Flow Meter B

Cable

Installing

6. Secure fluid manifold (17) to mounting plate (13)

with 4 screws (18).

7. Install meters (1). See steps 9-11, at left.

8. Connect air and fluid lines.

9. Calibrate meter as instructed in ProMix™ II Opera-

tion manual.

18

13

TI4859a

F

IG. 22: G3000 or G3000HR Cable Schematic

Servicing Fluid Manifold

WARNING

Follow Pressure Relief Procedure, page 8, before

servicing equipment. Read warnings, page 6.

Removing

1. Follow Servicing Flow Meters procedure, steps

1-7, page 22.

2. Disconnect air and fluid lines from the manifold

(17).

3. Holding onto the fluid manifold (17), remove the 4

screws (18). To ease screw removal, use a long

T-handle Allen wrench.

4. Remove fluid manifold (17).

Item 17

FIG. 23

5. Service fluid manifold as instructed in the Fluid Mix

Manifold manual.

310653E 23

Page 24

Service

Servicing Color Change Assembly

WARNING

Read warnings, page 6.

Removing

1. Follow Pressure Relief Procedure, page 8.

2. Close main air shutoff valve on air supply line and

on ProMix™ II.

3. Shut off ProMix™ II power (0 position).

4. Raise up the panel (14) by following steps 4-5,

page 19.

5. Disconnect fluid line (CC) from flow meter A (1).

6. Disconnect air and fluid lines from color change

assembly (EE).

Before disconnecting, verify that air and fluid lines

are clearly labeled to ease reassembly.

Installing

9. Mount color change assembly to panel wall.

10. Connect air and fluid lines.

11. Reassemble Smart Fluid Panel (page 22).

14

DD

6

S

5

4

2

EE

3

1

7. Remove mounting plate (DD) screws and color

change assembly (EE).

Mounting screws for the low pressure color change

assembly are located on the inside panel wall.

8. Service color change valves as instructed in the fol-

lowing manuals:

Manual Description

307731 Color Change Valve Assembly,

low pressure

307941 Color Change Valve,

low pressure

308977 Color Change Valve Assembly,

high pressure

308291 Color Change Valve,

high pressure

310656 Color Change Kit

1

CC

Low Pressure Color Change

DD

EE

TI4880

High Pressure Color Change

FIG. 24

24 310653E

Page 25

Connecting to a PC

Connecting to a PC

You can connect a PC to the EasyKey™ Display to:

• Update ProMix™ II software

• Use the Data Download software, included in Graco

ProMix™ II Data Download Kit 234668. This kit can

be used to:

• Update software

• View

➜ software versions

➜ material usage report

•Upload

➜ setup values

➜ a custom language to view on screen

• Download

➜ setup values

➜ job and alarm logs

• Clear

➜ job and alarm logs

➜ material usage report

• Reset

➜ factory defaults

➜ password

See Data Download Kit manual for further information.

Connect Cable 118342

The software is designed for COM1 cable connection. If

a COM1 port is not available, follow Changing the

Serial Port instructions, below.

If a serial port is not available, use an USB to Serial

Port Adapter.

Changing the Serial Port

1. After installing the software, start the Setup program

by double clicking on the ProMixII Setup desktop

icon or select the Setup program from the Start

menu (Start > Programs > Graco > ProMixII Setup).

2. Tera Term window opens, showing the current COM

port being used.

3. Click Setup > Serial Port.

4. The Serial Port Setup window opens. Click the

desired COM port in the Port list.

5. Click OK.

6. Click Setup > Save Setup.

7. Save the file as teraterm.ini in the directory C:\Program Files\Graco\Graco ProMixII Log 1.01.

Connect RS-232 cable 118342 between the EasyKey™

Display connector (A) and your PC COM1 port. See F

25.

Non-hazardous Area Only

Cable 118342

Laptop PC

F

IG. 25

IG.

310653E 25

Page 26

Connecting to a PC

Updating Software

Updating software will probably not ever be necessary,

but if it is, your PC must have terminal emulation software to communicate with the ProMix™ II, for example

Hy p er Te r m in a l or Te ra Te r m .

HyperTerminal is included with most standard Windows

installations.

Tera Term is freeware available at

http://hp.vector.co.jp/authors/VA002416/teraterm.html.

Both programs work, but Tera Term is easy to use and

has advanced features, such as macro language that

can automatically download data from ProMix™ II.

1. Contact your distributor for the latest software file,

and save the file to your PC.

2. Start your terminal software and enter communication parameters as shown in Communication

Parameters table, page 26.

If Using HyperTerminal

a. How to start HyperTerminal varies, depending

on your PC. In general, click Start > Programs >

Accessories > Communications >

HyperTerminal.

e. Click OK.

f. A dialogue box appears to set communication

parameters. Set the parameters as shown in

Communication Parameters table.

To access communication settings in the future: in

the Hyper Terminal window click File > Properties,

then click Configure.

If Using TeraTerm

a. Start TeraTerm program.

b. Click Setup > Serial Port.

Communication Parameters

Tera Term Hyper Terminal Value

Connect using Port Desired port in

list

Baud rate Bits per second 57600

Data Data bits 8

Parity Parity None

Stop Stop bits 1

Flow control Flow control None

b. Enter a name for the new connection. This

name will appear on an icon for the connection

on your desktop.

c. Click OK.

d. From the Connect Using list, click the PC port

you connected the cable to.

3. To activate the Graco software, press the PC Enter

key to start the software update program.

4. The main menu displays. Follow the instructions on

your screen. Refer to Example of Software Update

request, below.

If the main menu does not display, follow Software

Troubleshooting, page 29.

26 310653E

Page 27

Example of Software Update request Sequence

Connecting to a PC

Welcome to the Graco Control Application Menu

Build date: Apr 1 2004 10:17:00.

a. Software Update and Version Information

b. Data Transfer

c. Utility

Enter Selection [a-c]: a

a. Install EasyKey Software

b. Install Control Software

c. Display Software Versions

d. Display Entire Flash Checksum

e. Return to Main Menu

Enter Selection [a-e]: a

Are you sure? Enter yes to continue:yes

*****Welcome to the Graco EasyKey Display Boot Software.*****

Version: 1.01.000 Built Apr 1 2004 10:17:00

Warning: you are about to erase your application software.

Type ‘yes’ to continue upgrading software (reboot to cancel).

yes

Sector 1 erased.

Sector 2 erased.

Sector 3 erased.

Sector 4 erased.

Sector 5 erased.

Main menu appears.

Option a selected.

Option a selected.

Yes entered to continue.

Boot software screen appears.

Yes entered to continue.

Status screen lists each sector when it

is completely erased.

Hyperterminal: Go to (Menu Transfer -> Send Text File) and select *

.rec file.

Tera Term: Go to (File -> Send File) and select *.rec file.

Downloading (may take up to 5

minutes)

download

indicator

Download successful. 5943 records. 190142 bytes. 2046976175

checksum

Instructional information appears.

You must follow preceding instructions

for Hyperterminal or Tera Term before

downloading begins. Download is in process, when downloading indicator line

spins.

Download is complete when this message appears.

310653E 27

Page 28

Connecting to a PC

5. After the EasyKey™ Display software is updated,

the Smart Fluid Panel software automatically begins

updating. The status screen in F

IG. 26 will appear

on the EasyKey™ Display. Wait until automatic

6. After the update is complete, the EasyKey™ Display

automatically reboots and the Graco screen briefly

appears. Verify the software versions on the screen

are correct.

update is complete.

download

status bar

“Programming Successful”

appears when download

completes

FIG. 27

F

IG. 26

7. To verify software versions, go to the Graco software main menu and follow the screen instructions.

Refer to Example of Software Version request,

below.

Example of Software Version request Sequence

software

versions

Welcome to the Graco Control Application Menu

Main menu appears.

Build date: Apr 1 2004 10:17:00.

a. Software Update and Version Information

b. Data Transfer

c. Utility

Enter Selection [a-c]: a

Option a selected.

a. Install EasyKey Software

b. Install Control Software

c. Display Software Versions

d. Display Entire Flash Checksum

e. Return to Main Menu

Enter Selection [a-e]: c Option c selected.

EasyKey Boot: 1.01.000, checksum=d0cac6, built: Apr 1 2004

10:17:00

Software version information appears

for EasyKey™ and Smart Fluid Panel

EasyKey: 1.01.000, checksum=19bb13d, built: Apr 1 2004

10:04:11

Fluid Plate Control: 1.01.000

a. Install EasyKey Software

b. Install Control Software

c. Display Software Versions

d. Display Entire Flash Checksum

e. Return to Main Menu

Enter Selection [a-e]: e Option e selected to return to main

menu.

28 310653E

Page 29

Software Troubleshooting

If the Control Application Menu does not appear,

✓

check the following.

Is the ProMix™ II power on?

Is the cable 118342 and any adapters used fully

seated in both the PC and ProMix™ II ports?

Are any other programs using the same PC com-

munication port as ProMix™ II?

Typical communication conflicts occur with fax

and handheld computer software. Close or deactivate conflicting software.

Try switching to another PC communication port.

If using Hyper Terminal, try closing, then restart-

ing the program. Sometimes new communications

parameters do not take affect until the software is

restarted.

Try pressing the PC Enter key multiple times to

display the main menu.

To isolate the problem, try communicating with a

different:

•PC

• RS-232 cable

• ProMix™ II system if available

Connecting to a PC

310653E 29

Page 30

Schematics

Schematics

Pneumatic Diagram

A/A

SAFETY

SHUTOFF

TO GUN

OUT

BOX

FLUSH

SWITCH

C

GUN

P

MANUAL DRAIN

5 MICRON

3/8 AIR FILTER

PRESS

S

A

AIR

FLOW

IN

SWITCH

TO MANIFOLD 1/4 TUBE

AIR SUPPLY

AIR SUPPLY

DISPENSE

12 VDC

SOLENOID

A

B

A

12 VDC

VALVE

DISPENSE

SOLENOID

12 VDC

A

B

AIR

PURGE

VALVE

CHECK VALVE

SOLENOID

A

B

PURGE

VALVE

SOLVENT

12 VDC

5/32 TUBE

SOLENOID

A

B

TO GUN FLUSH BOX PILOT

12 VDC

5/32 TUBE

CHANGE

VALVE

SOLENOID

A

B

CC SOLVENT OPEN

COLOR

SOLENOID

A

B

VALVE

B

AIR EXHAUST MUFFLER

12 VDC

MANIFOLD

X

FLUSH AIR TO FLUID INLET 1/4 TUBE

AIR EXHAUST MUFFLER

SOLENOID

12 VDC

SOLENOID

12 VDC

SOLENOID

12 VDC

SOLENOID

12 VDC

SOLENOID

12 VDC

SOLENOID

12 VDC

5/32 TUBE

CHANGE

VALVE 1

A

B

CC 6 OPEN

COLOR

5/32 TUBE

CHANGE

VALVE 2

A

B

CC 6 OPEN

COLOR

5/32 TUBE

CHANGE

VALVE 3

A

B

CC 6 OPEN

COLOR

5/32 TUBE

CHANGE

VALVE 4

A

B

CC 6 OPEN

COLOR

5/32 TUBE

CHANGE

VALVE 5

A

B

CC 6 OPEN

COLOR

5/32 TUBE

CHANGE

VALVE 6

A

B

CC 6 OPEN

COLOR

MANIFOLD

FIG. 28

30 310653E

Page 31

ProMix™ II Electrical Schematic

MEMBRANE

SWITCH

WITH

RIBBON

CABLE

J3

FLOW METER A

CABLE

FLOW METER B

CABLE

1 2 3 4 5 6 7 8 9

OPERATOR

STATION

BOARD

1 2 3 4 5

J4

CABLE

10

COLOR 6

COLOR 5

MANIFOLD

12 VDC

SOLENOID

COLOR 4

COLOR 3

COLOR 2

COLOR 1

CC SOL

G.F.B.

MANIFOLD

12 VDC

SOLENOID

FLUSH B

FLUSH A

MIX B

MIX A

Schematics

AIR FLOW SWITCH

PRESSURE SWITCH

J3

FLUID PANEL CONTROL BOX

85-250

VAC

L N GND

NON-HAZARDOUS AREA HAZARDOUS AREA

1 2 3

TERMINAL

BLOCK

1 2 3

1 2 3

85-250 VAC

L

N

PWR (RED)

COM (BLACK)

SIG (WHITE)

SHIELD

PWR (RED)

1 2 3 4 5 6 7

FLUID

PANEL

GND LUG

POWER

ROCKER

SWITCH

1 2 1A

N

L

L

COM (BLACK)

SIG (WHITE)

SHIELD

8

CONTROL

BOARD

HARNESS

1B

2A

2B

OPEN

OPEN

N

GND

1 2 3

J10

+12VDC I/S

+12VDC I/S (WHITE)

COM

COM (BLACK)

J5

SHIELD

CABLE

SHIELD

B (GRN)

A (WHT )

1 2 3 4 5

HARNESS

+

HARNESS

PWR (RED)

COM (BLK)

SHIELD

-

BLACK

RED

BLACK

RED

J8

12

11

10 9 8 7 6 5 4 3 2

LARM

A

+

-

+

BLACK

RED

BLACK

GRACO SHELL

COMMUNICATIONS

RJ12 CONNECTOR

1 2 3 4 5

-

RED

BLACK

TX (WHITE)

RED

BLACK

RED

1

1 2 3 4 5 6 7 8 9

6

RX (BLACK)

CMN (RED)

TX

OPEN

BLACK

RED

BLACK

J9

12

11

10 9 8 7 6 5 4 3 2

PRINTER

CONNECTOR

9-PIN D-SUB

CMN

RED

BLACK

RED

BLACK

RED

BLACK

RED

BLACK

RED

1

SIG

J1

1 2 3

FO OUT

FO IN

COM

SIG

FO IN

CABLE

FO OUT

COM

4

WARNING

Do not install equipment approved only for non-hazardous location in a hazardous area. Substitu-

tion of components may impair intrinsic safety. See page 6.

OPERATOR INTERFACE

1

2

POWER

SUPPLY

-

+

+

+24 VDC

+24 VDC

-

COMMON

COMMON

1 2 3 4 5

J1

BARRIER

BOARD

1 2 3

J5

1 2 3

J4

J5

1 2 3

DISPLAY

BOARD

1 2 3 4 5 6 7 8 9

J2

MEMBRANE

SWITCH

4

WITH

RIBBON

CABLE

J6-RS 232

1 2 3 4 5

10

11

6

1 2 3 4 5 6 7 8 9

J3

DISPLAY

10

11

12

13

14

15

16

17

18

19

20

FIG. 29

310653E 31

Page 32

Parts

Parts

ProMix™ II Assembly

ProMix™ II Component Options Table

Ref.

No.

Option Part No. Description Qty.

1 Flow Meter A Kit

0None 0

1 234564 G3000; page 34 1

2 234566 G3000HR; page 34 1

3 234563 Coriolis; see manual

310696

2 0 Flow Meter B Kit 0

1 234564 G3000; page 34 1

2 234566 G3000HR; page 34 1

3 234563 Coriolis; see manual

310696

3 Color Change Valve Kit; see

manual 310656

0None 0

1 234568 Low pressure, 2 color 1

2 234569 Low pressure, 4 color 1

3 234570 Low pressure, 6 color 1

4 234572 High pressure, 2 color 1

5 234573 High pressure, 4 color 1

6 234574 High pressure, 6 color 1

4 Gun Flush Box; see man-

ual 310695

0None 0

1 234588 Gun Flush Box 1

Standard ProMix™ II Parts Table

Ref.

No. Part No. Description Qty.

9 234443 EasyKey™ Display; page 36 1

10 234441 Operator Station; page 35 1

11 15D320 Cable, fiber-optic 1

12 234453 Cable, power 1

13 15D244 Mounting Plate, manifold 1

1

14 248252 Smart Fluid Panel; page 38 1

15 15D247 Cover 1

16 113783 Screw, machine; 1/4-20 UNC x

.5 in.

17 248251 Mix Manifold; see manual 310654

1

for mix manifold and 310655 for

fluid valve

18 112925 Screw, cap; 1/4-20 UNC x .375 in. 4

19* 114124 Air Filter; 1/8 npt 1

20 119143 Fitting; 3/8 npt x 1/4 in. OD tube 1

21 101765 Grommet 3

22† 054175 Tube, nylon; 1/4 in. OD, 3ft. (.91 m) **

23 104029 Ground Clamp 1

24 110874 Washer 1

30▲ 290331 Warning Label 1

33 15D670 Pneumatic Diagram Label 1

34† 054757 Tube, nylon, green; .156 in. OD,

12 ft. (3.66 m)

35† 054754 Tube, nylon, red; .156 in. OD, 12 ft.

(3.66 m

37† 054134 Tube, nylon; .375 in. OD, 2 ft.

(3.66 m)

38† 234631 Instruction Manual CD 1

39 223547 Grounding Wire; 25 ft. (7.62 m) 1

40 617569 Reducer; 1/4 to 3/8 in. tube 1

41 104641 Fitting; 3/4-20 UNEF x 1/4 npt 1

42 15E058 Fitting; 1/4 npt x 1/4 in. OD tube 1

43† 15E110 Instruction Card 1

4

1

**

**

**

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

* Replacement element 114228 available.

†Not shown

** Order length needed.

32 310653E

Page 33

11

12

14, 15

17

16

Parts

33

49 10

3

1

2

21

18

13

34

TI4893a

30

23, 24

21, 41, 42

19

35

TI4860a

40

310653E 33

20

Page 34

Parts

Flow Meter Kits

Part No. 234564, G3000

Part No. 234566, G3000HR

Ref.

No. Part No. Description Qty.

101 239716 G3000 Flow Meter, 234564 only;

see manual 308778

244292 G3000HR Flow Meter, 234566

only; see manual 308778

102 195283 Shield 1

104 166846 Adapter, 1/4 npt x 1/4 npsm 1

105 114339 Swivel Union; 1/4 npt x 1/4 npsm 1

106 501867 Check Valve; 1/4-18 npt 1

107 114182 Screw, machine; M6 x 16 2

108 15D248 Mounting Plate 1

109† 112925 Screw, cap; 1/4-20 UNC x .375 in. 2

110 234628 Cable Assembly; 42 in. (107 cm) 1

†Not shown

1

1

110

102

101

107

108

104

105 106

34 310653E

Page 35

Operator Station

Part No. 234441

Parts

Ref.

No. Part No. Description Qty.

201* Enclosure 1

202* Cover 1

203 15D187 Keypad Membrane 1

204 234448 Cable 1

205 104029 Ground Clamp 1

206 248124 Circuit Board 1

207 15D432 Gasket 1

210 107388 Screw, machine; 4-40 UNC x

.375 in.

212 114993 Screw, machine; M4 x .7 x 8 4

213 115322 Lock Washer, 4 mm 4

215 110874 Washer 1

217† 223547 Ground Wire, 25 ft. (7.6 m) ( 1

218* Suppressor 1

219 119248 Connector, 5 position, 3.81 mm 1

220 111987 Connector, strain relief 1

215

205

Kit available:

Part No. Description

15D547 Operator Station Paint Shields, package

of 10

†Not shown.

* Not a replacement part.

4

202

207

219

206

201

218

220

204

Pin 1 ______ Green ______ Pin 1

Pin 2 ______ White ______ Pin 2

Pin 3 ______ Red ______ Pin 3

Pin 4 ______ Black ______ Pin 4

Pin 5 ______ Shield ______ Pin 5

CONNECTION DIAGRAM

210

213

212

203

TI4861a

310653E 35

Page 36

Parts

EasyKey™ Display

Part No. 234443

Ref.

No. Part No. Description Qty.

501* Enclosure 1

502 15D568 Alarm 1

503▲ 118334 Warning Label 1

505 15D255 Jack, RJ12 1

506 116320 Power Switch 1

507 117787 Latch with key; includes 507a 1

507a 117818 • Key 1

508 234447 Display Kit; includes 8a-8e 1

508a 15D223 • Keypad Membrane 1

508b 117769 • Graphic Display 1

508c 248182 • Display Circuit Board 1

508d* • Plate 1

508e* • Screw; #4-40 x 1 in. 4

509* Connector, D-sub solder cup 1

510 111987 Connector, strain relief 1

514 110911 Nut, hex; M5 4

515 111307 Lock Washer; M5 8

518 C19293 Nut, machine hex; 10-32 UNF 6

519 194337 Grounding Wire, door 1

520† 223547 Grounding Wire, unit; 25 ft. (7.6 m) 1

521* Back Plate; includes 521a-521f 1

521a◆255785 • KIT, Retrofit, Circuit Board;

includes items 521b-521f; see

312899

521b 15D979 • Fuse, quick acting; 0.4 amp 2

521c 114788 • Fuse, time lag; 2 amp 2

521d* • Screw, machine; 10-24 UNC x

.375 in.

521e* • Cover, vented 1

521f 120369 • Power Supply, 24 Vdc 1

522* Harness 1

525* Suppressor 1

Kits available:

Part No. Description

118337 Backlight Repair Kit

118342 PC Connection RS-232 Cable

197902 EasyKey™ Display Paint Shields, package

of 10

234671 ProMix™ II Software Upgrade Kit; includes

software chip, chip extractor tool, and

grounding wrist strap

234668 ProMix™ II Data Download Kit; includes

data download CD and cable 118342

234670 ProMix™ II Printer Kit; includes printer and

cables to connect to ProMix™ II. Order

appropriate power supply separately.

Power Supply

114442: U.S.

114443: Europe

114444: Japan

1

Printer Paper Roll 514037

Single roll

2

▲ Replacement Danger and Warning labels, tags,

and cards are available at no cost.

†Not shown.

* Not a replacement part.

◆ If your EasyKey™ has been converted with Retrofit

Kit 255785 and you need to replace only the circuit

board, order Part No. 255786 Board Replacement

Kit.

36 310653E

Page 37

508e

Parts

508c

508a

508d

518

521d

507

521b

515

508b

525

TI4531a

501

506

514, 515

519

510

522521

521c

521a

521f

509

505

521e

502

503

Alarm

TI4530b

310653E 37

Page 38

Parts

Smart Fluid Panel

Part No. 248252

Ref.

No. Part No. Description Qty.

701† Solenoid Enclosure 1

702 119159 Air Flow Switch 1

703 110249 Elbow, 90 degree; 1/4-18 npt 1

704 104641 Bulkhead Fitting; 3/4-20 UNEF x

1/4-18 npt

705 113029 Nipple, 1/4 npt 1

706 248163 Circuit Board 1

707 514023 Screw, 4-40 x .5” 4

708 15D648 Connection Harness 1

709 111987 Connector, strain relief 3

710 C06061 Muffler 2

711 115671 Connector; 1/8 npt x 1/4 in. OD tube 1

712 117356 Solenoid Valve, 12 VDC (IS) 4

713 114230 Solenoid Manifold 1

714 552183 Plate 2

715 100139 Pipe Plug; 1/8 npt 7

716 100030 Bushing; 1/4 npt 1

717 513937 Pressure Switch 1

718 114263 Connector; 1/8 npt x 5/32 in. OD tube 8

719 114669 Screw, machine; M5 x 10 2

720 15D647 Connection Harness 1

721 112512 Wire Ferrule, orange 8

Ref.

No. Part No. Description Qty.

722 112514 Wire Ferrule, AWG-18 4

723 15D916 Fitting, straight; 1/4 npt x 5/32 in. OD

tube

724 116772 Connector, 4 position, 3.81 mm 1

725 119163 Connector, 8 position, 3.81 mm 1

726 117369 Connector, 11 position, 3.81 mm 1

727 115841 Elbow; 1/4 npt x 3/8 in. OD tube 1

2

728 514019 Terminal Connector 2

729 065145 Copper Wire **

730 15D579 Solenoid Connection Label 1

† Not a replacement part.

** Order length needed.

Color Change Kits

Used to convert a single color unit to a color change

unit. Includes color change valves, solenoids, and

mounting hardware.

Part Description

234568 2 color, low pressure

234569 4 color, low pressure

234570 6 color, low pressure

234572 2 color, high pressure

234573 4 color, high pressure

234574 6 color, high pressure

1

Single Color Panel Shown

701

705

723

727

702

704

703

704

715

714

716

717

728,722,729

725

722,724

709

720

708

706

707

726*

4

3

2

1

730

(inside)

718

* Only solenoid 1-4 (712) and one connector (726) are included. Other solenoids/connector are included with an optional

color change kit.

38 310653E

715

712*

713

711710

721

709

719

Page 39

Technical Data

Technical Data

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . .see page 4

Maximum working air pressure. . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75–100 psi (0.5–0.7 MPa, 5.2–7 bar)

Air filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 micron (minimum) filtration required

Mixing ratio range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.1:1–30:1*

On-ratio accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to +

Fluids handled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . one or two component:

• solvent and waterborne paints

• polyurethanes

•epoxies

• acid catalyzed varnishes

• moisture sensitive isocyanates

Viscosity range of fluid . . . . . . . . . . . . . . . . . . . . . . . . . . .20–5000 cps*

Fluid filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 mesh minimum

Fluid flow rate range*

G3000 Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G3000HR Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coriolis Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Power Supply Requirements . . . . . . . . . . . . . . .85–250 Vac, 50/60 Hz, 2 amps maximum draw

Operating temperature range . . . . . . . . . . . . . . . . . . . . . . 41–122° F (5–50° C)

Environmental Conditions Rating . . . . . . . . . . . . . . . . . . . Indoor use, Pollution degree (2). Installation category II.

Noise Level

Sound pressure level . . . . . . . . . . . . . . . . . . . . . . . . .

Sound power level . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303, 304 SST, 17–4 SST, Tungsten carbide (with nickel

Weight

Base System Total (no meters color change valves

or gun flush box). . . . . . . . . . . . . . . . . . . . . . . . . . . . .66.6 lbs (30.2 kg)

EasyKey™ Display. . . . . . . . . . . . . . . . . . . . . . . . 22.2 lbs (10.1 kg)

Smart Fluid Panel (no meters) . . . . . . . . . . . . . . .41.3 lbs (18.7 kg)

Operator Station. . . . . . . . . . . . . . . . . . . . . . . . . . 3.3 lbs (1.5 kg)

Optional Components

G3000/G3000HR Flow Meter . . . . . . . . . . . . . . . 6 lbs. (2.7 kg) each

Coriolis Flow Meter . . . . . . . . . . . . . . . . . . . . . . .33 lbs. (15 kg) each

Low Pressure Color Change Stack (6 color) . . . .3.0 lbs (1.4 kg)

High Pressure Color Change Stack (6 color) . . . .11.0 lbs (5.0 kg)

Gun Flush Box . . . . . . . . . . . . . . . . . . . . . . . . . . .22 lbs. (9.6 kg)

75–3000 cc/min. (0.02–0.79 gal./min.)

38–1500 cc/min. (0.01–0.40 gal./min.)

20–3800 cc/min. (0.005–1.00 gal./min.)

15 amp maximum circuit breaker required

8 to 14 AWG power supply wire gauge

below 70 dBA

below 85 dBA

binder), perfluoroelastomer; PTFE; CV75

1%, user selectable

* Dependent on programmed K-factor and application. The ProMix™ II maximum allowable flow meter pulse fre-

quency is 425 Hz (pulses/sec.). For more detailed information on viscosities, flow rates, or mixing ratios, consult

your Graco distributor.

See individual component manuals for additional technical data.

310653E 39

Page 40

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the

warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 310653

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2004, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 11/2009

Loading...

Loading...