Page 1

Instructions – Parts List

Parts

HVLP 3800 and 4900

ProCompt Turbine Sprayers

309242K

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

120V AC 50/60 Hz

HVLP 3800 ProCompt with Three-Stage Turbine

Model 233423

6 psi (41 kPa, 0.4 bar) Maximum Working Pressure

HVLP 4900 ProCompt with Four-Stage Turbine

Model 233455

8 psi (55 kPa, 0.5 bar) Maximum Working Pressure

Model descriptions are in Turbine

Components Table on page 4.

Related Manuals

HVLP–Turbine Gun 309205. . . . . . . . . . . . .

4900 HVLP ProComp

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

TI0875

Page 2

Table of Contents

Symbols

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification and Function 5. . . . . . . . . . . .

Setup 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutdown 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 22. . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 22. . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Ground the equipment. See Grounding on page 6.

D If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

D When flammable liquid is sprayed or used for flushing or cleaning the equipment, the turbine must

be placed at least 20 feet (6.1 m) away from areas where hazardous concentrations of flammable

vapors are likely to occur.

D Use additional air hose if necessary to ensure that the turbine is operated in a clean, dry, well-ven-

tilated area.

D Never place the turbine inside a spray booth! Use this equipment outdoors or in extremely well-

ventilated areas.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Electrically disconnect all equipment in the spray area.

D Extinguish all open flames or pilot lights in the spray area.

D Do not smoke in the spray area.

D Do not turn on or off any light switch in the spray area while operating or if fumes are present.

D Do not operate a gasoline engine in the spray area.

2 309242

Page 3

INSTRUCTIONS

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before you operate the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest-rated system component.

HVLP 3800 ProCompt turbine has a working pressure of 6 psi (0.4 bar, 41 kPa).

HVLP 4900 ProCompt turbine has a working pressure of 8 psi (0.5 bar, 55 kPa).

D Use fluids and solvents that are compatible with the equipment wetted parts. See Specifications

on page 21 for wetted parts information.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

D Wear hearing protection when operating this equipment.

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Do not point the gun at anyone or at any part of the body.

D Do not put your hand or fingers over the gun fluid nozzle.

D Do not stop or deflect leaks with your hand, body, glove, or rag.

D Do not “blow back” fluid; this is not an air spray system.

D Follow the Pressure Relief Procedure on page 10 if the fluid nozzle clogs and before you clean,

check, or service the equipment.

D Tighten all fluid connections before you operate the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state, and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

D Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in the turbine spray system, which contains aluminum and/or galvanized-coated parts. Such use could result in a serious chemical reaction, with the possibility of

explosion, which could cause death, serious injury, and/or substantial property damage.

309242 3

Page 4

General Information

HVLP ProCompt Turbine Sprayers

The HVLP 3800 ProCompt and the HVLP 4900

ProCompt turbines, compressor and spray guns can

spray most coatings or finishes currently being used

for automotive refinish, industrial, aerospace, marine,

wood, plastic, and architectural applications.

To produce high-quality paint finishes, the spray gun

typically utilizes inbound air pressure of 6 psi (0.4 bar,

41 kPa) for the HVLP 3800 ProCompt and 8 psi (0.5

bar, 55 kPa) for the HVLP 4900 ProCompt. A cone of

air, produced by the gun, carries and directs the paint

from the gun to the surface, minimizing overspray and

increasing transfer efficiency. This enables painters to

comply with new clean air laws that are designed to

reduce VOC (volatile organic compounds) emissions,

eases paint application by requiring fewer paint passes

to obtain coverage, and saves on both material and

clean-up time.

See HVLP–Turbine Gun manual 309205 for more

information on the operation and use of the turbine

spray gun.

Unpacking Turbine

Unpack the Graco Turbine Sprayer from the shipping

carton, and inspect for any possible shipping damage.

If there is any damage, call your distributor.

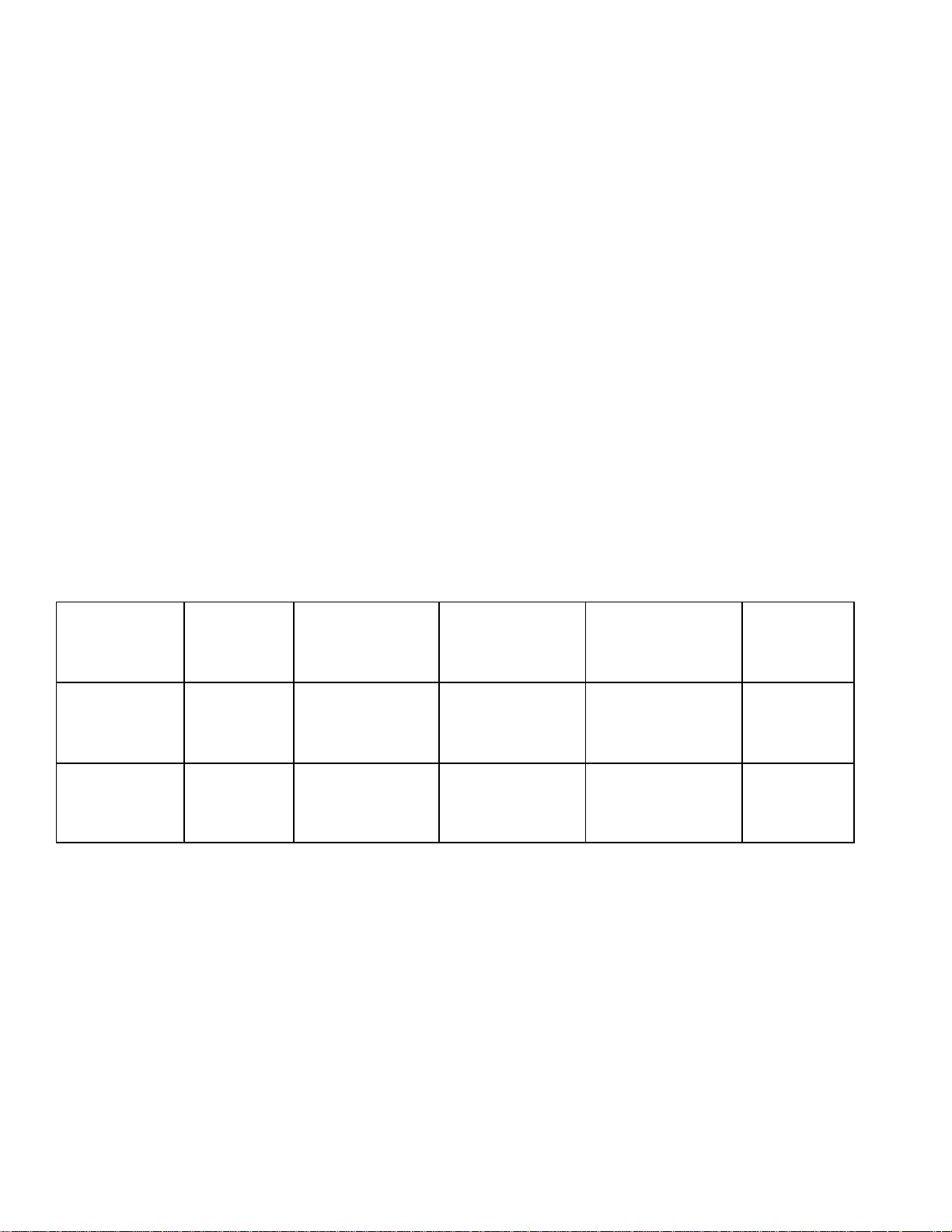

HVLP ProCompt Turbine Configurations

Graco turbines come in the following basic configurations:

D HVLP 3800 ProCompt three-stage turbine sprayer

D HVLP 4900 ProCompt four-stage turbine sprayer

HVLP 3800 and 4900 ProCompt Turbine Components Table

30-ft (9 m) Turbine

System Model 2–qt Remote

Pressure Pot

HVLP 3800

ProCompt

HVLP 4900

ProCompt

233423 287819 241413

233455 287819 241413

Air Hose

30-ft (9 m) Com-

pressor Air Hose

240071

240071

Gun /

Fluid Set

244118 non-

bleeder style

pressure–fed gun

with 244124 (#3)

244118 non-

bleeder style

pressure–fed gun

with 244124 (#3)

Extra/Fluid

Sets

244125 (#4)

244126 (#5)

244123 (#2)

244125 (#4)

244126 (#5)

244127 (#6)

4 309242

Page 5

Component Identification and Function

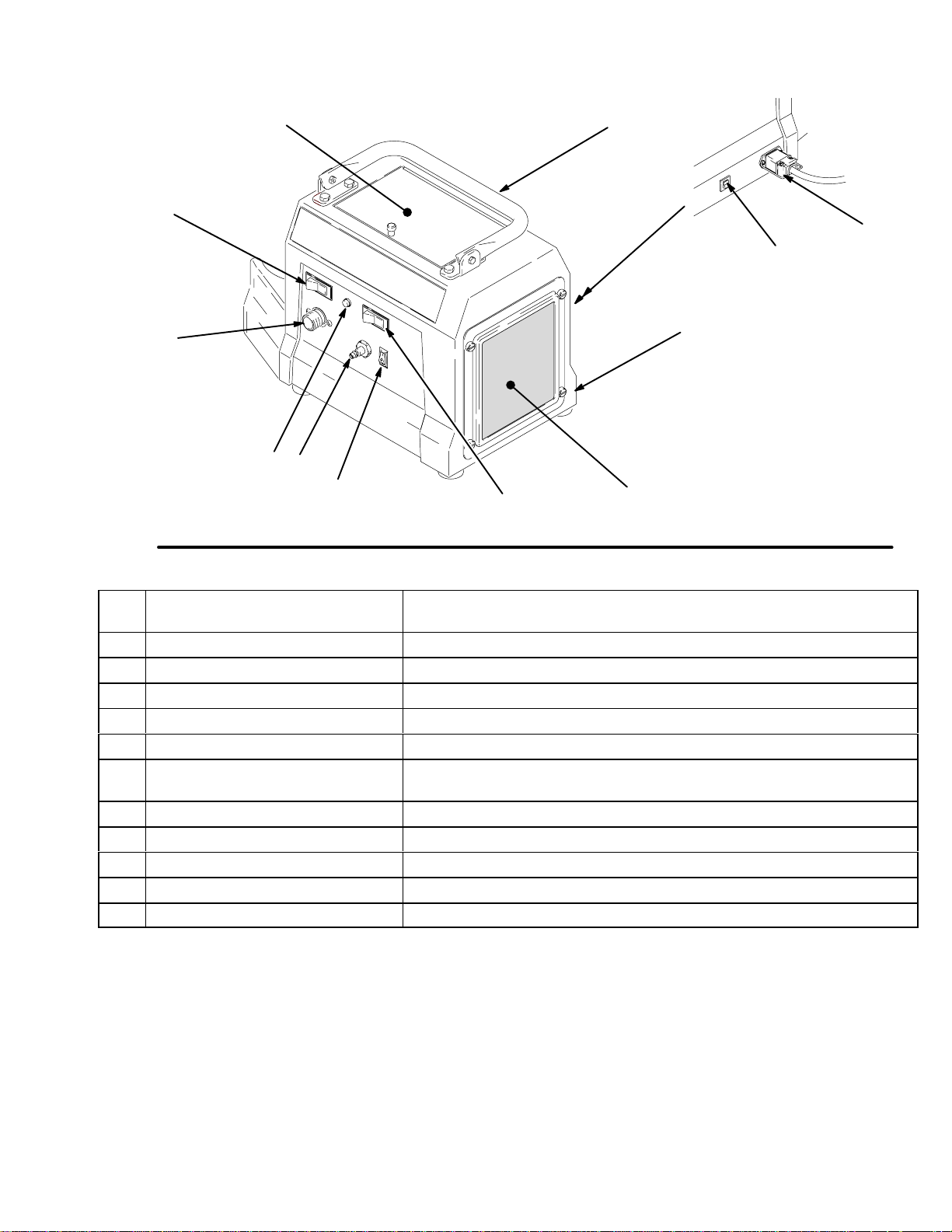

Fig. 1

C

B

A

H

L

M

G

D

J

K

E

F

TI0876

A Turbine air outlet Connection for turbine air supply to HVLP–Turbine Gun (HVLP 4900

ProCompt units include quick connector)

B Turbine power switch ON/OFF switch for sprayer turbine

C Storage compartment Provides storage for fluid set components

D Turbine handle Folds flat for minimum storage space

E Turbine cover Houses air filter and provides dual air flow to motor and turbine

F Air filters (pre-filter and main) Provide filtered air for turbine spray gun and turbine motor

G Two-speed switch Allows two-speed operation of turbine sprayer motor (used on HVLP

4900 ProCompt units)

H Air filter indicator light Indicates air filter performance and maintenance

J Connector and power cord Provides power for turbine sprayer (power cord provided with turbine)

K Resettable circuit breaker Provides protection for turbine motor

L Compressor air outlet Connection for compressor air supply to 2–quart remote pressure pot

M Compressor power switch On/Off switch for compressor

309242 5

Page 6

Setup

Grounding

WARNING

Improper installation or alteration of the grounding

plug will result in a risk of electric shock, fire, or

explosion that could cause serious injury or death.

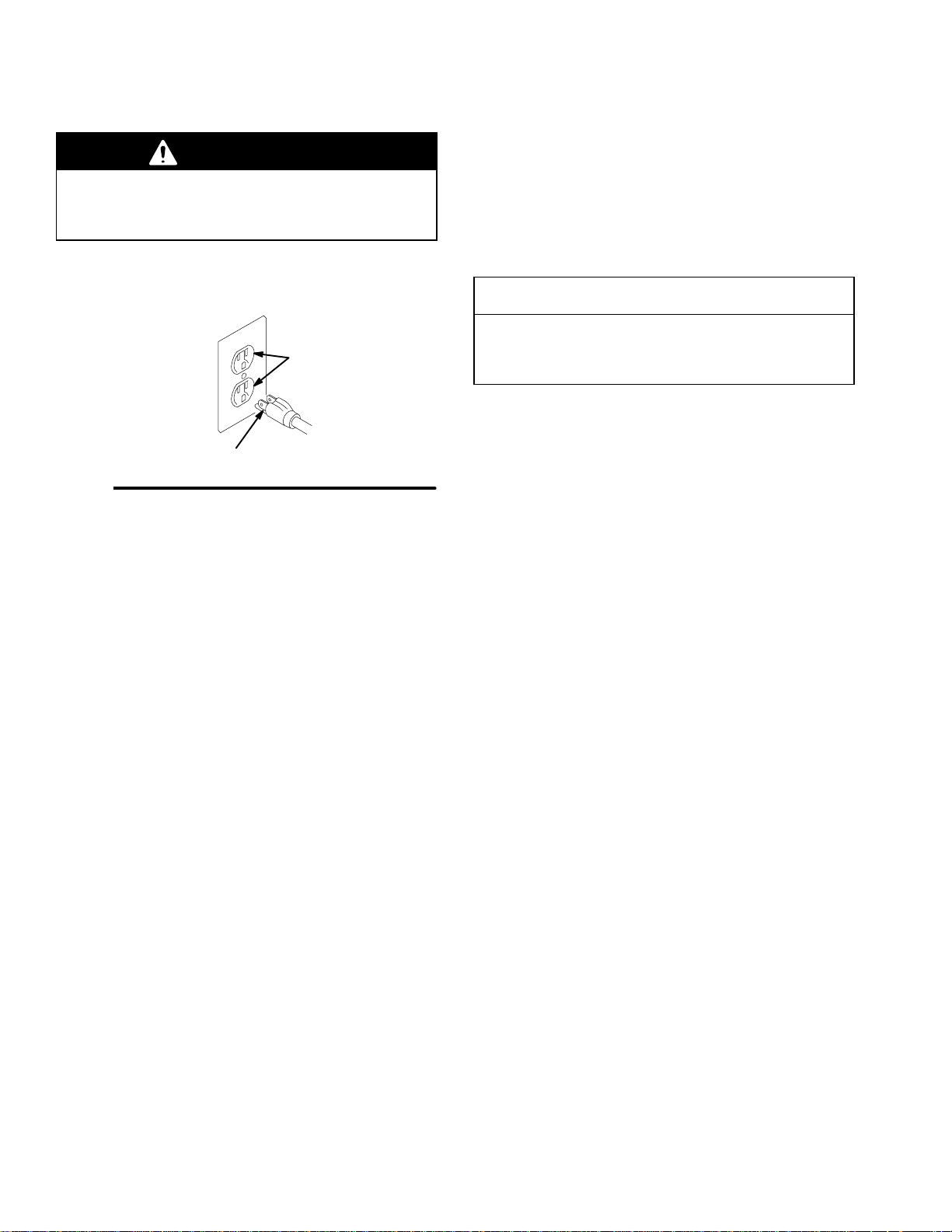

This equipment requires a 120V AC, 60 Hz, 15A circuit

with a grounding receptacle. See Fig. 2.

grounded outlets

grounding prong

Fig. 2

Extension cord must be 3-wire, 12 AWG, 50 ft (15 m)

or shorter.

Do not alter the ground prong or use an adapter.

Setup/Use Options

HVLP Turbine Sprayers have a variety of user options.

See Fig. 3.

D See HVLP–Turbine Gun manual 309205 for in-

formation on turbine spray gun setup and operation.

Prepare the Fluid

D Always strain the fluid before you spray; this

includes color, reducer, and hardeners if used.

D When using a turbine spray system, use a slow-

er drying reducer or thinner to compensate for the

faster drying time caused by the warm air of the

turbine. Do not over reduce.

CAUTION

The performance of the turbine sprayer varies with

the viscosity of the material and the length of the

hose. Keep the hose short to prevent pressure drop.

Paint Reduction — Automotive Type Finishes

Reduce and catalyze all paint to manufacturer’s specifications. To compensate for the faster drying time of

turbine systems, use a reducer that is one step slower

than what is used for conventional air spray.

Paint Reduction — Industrial or Domestic

Coatings

Reduce and catalyze all paint to manufacturer’s specifications. If no reductions are given, first thoroughly

mix the fluid to be sprayed. Then gradually mix in the

proper reducer, testing the fluid until you have the

correct spraying consistency.

To test the consistency, remove the stir stick from the

thinned paint. When the paint stream running off the

stir stick breaks into droplets, the first few drops should

be about one second apart.

6 309242

Page 7

Setup

Connect the Fluid and Air Supply

See Fig. 3

D The compressor provides the air supply for the

remote pressure pot.

D The circled letters in Fig. 3 indicate hose line con-

nections.

1. Connect gun air supply hose (A) between turbine

air outlet (B) and gun air inlet (C). DO NOT use

wrench to tighten connections; hand tighten only.

The HVLP 4900 ProCompt turbine uses a quick

connector at outlet (B). A wrench is not required

for hose connection.

E

C

2. If using a spray gun cup (D):

Connect the cup to the gun fluid inlet (E).

If using accessory remote pressure pot (F): Connect fluid supply hose (G) between remote pressure pot fluid outlet (H) and gun fluid inlet (E).

Connect pressure pot air hose (J) between pressure pot air regulator inlet (K) and the compressor

air outlet (L).

Connect to Electric Supply

Plug turbine power cord into grounded outlet.

NOTE: Extension cord must be 3-wire, 12 AWG, 50 ft

(15 m) or shorter.

D

cup-over option

(see manual 309205)

G

Y

remote pressure pot setup for spray gun

X

X

B

L

HVLP 4900 ProCompt

Turbine

A

E

D

cup setup for spray gun

G

H

C

A

X

JK

Z

Y

Z

to

4958C

TI0875

F

compressor

ti7064a

2-quart remote pressure pot

Fig. 3

309242 7

Page 8

Fill the Cup or Remote Pressure Pot

Setup

Spray Gun Cup

WARNING

The spray gun cup is pressurized by the gun’s air

supply. To reduce the risk of serious injury from

pressurized fluid or accidental spray from the gun,

always turn off the air supply to the gun before you

remove the spray gun cup.

Only fill the cup 3/4 full to help keep the air pressure

tube clean, then install the cover. The under-cup cover

has a latch (H) to secure it to the cup. The over-cup (J)

has threads that keep the lid in place when tightened in

place on the cup.

H

J

1. Relieve pressure from remote pressure pot as

follows (see Fig. 5):

a. Turn off air supply to pressure pot.

b. Turn pressure relief knob (133). Wait until

pressure is completely relieved before you

remove cover. Close knob.

2 quart

Fig. 5

2. Remove pressure pot cover and fill. Secure cover.

Fig. 4

Accessory Remote Pressure Pot

WARNING

The accessory remote pressure pots remain pressurized until pressure is manually relieved. To

reduce the risk of serious injury from pressurized

fluid or accidental spray from the gun, always

relieve pressure in the pressure pot before you

loosen or remove the cover.

02845

NOTE: Lightly coat the cover threads with petroleum

jelly.

CAUTION

If the 2-quart remote pressure pot is accidentally

tipped over or held at too great of an angle, fluid may

leak into the air regulator and cause damage. Take

precautions to avoid this. If fluid does get into the

regulator, clean it immediately.

NOTE: Always spray with the least amount of pot

pressure required to provide the desired spray pattern

and rate of application, typically 10 psi. Spraying at

pot pressures higher than necessary wastes paint and

can result in an orange peel finish.

8 309242

Page 9

Setup

Prepare Surface to be Sprayed

To get proper adhesion, make sure surface is completely clean.

Operating Turbine

WARNING

Sparks can be expected in the normal operation of

the turbine motor. These sparks can ignite fumes

from flammable liquids, dust particles, and other

flammable substances in the spray area. This can

cause serious injury and property damage. Be sure

to follow the precautions below:

D When flammable liquid is sprayed or used for

flushing or cleaning equipment, the turbine must

be placed at least 20 feet (6.1 m) away from

areas where hazardous concentrations of

flammable vapors are likely to occur.

D Use additional air hose if necessary to ensure

that the turbine is operated in a clean, dry, well

ventilated area.

D Never place the turbine inside a spray booth!

Use this equipment outdoors or in extremely

well ventilated areas.

D Avoid all ignition sources such as: static elec-

tricity from plastic drop cloths, open flames like

pilot lights, hot objects like cigarettes, arcs from

connecting or disconnecting power cords, and

turning light switches on and off. Extinguish or

remove all sources of ignition.

HVLP ProCompt Compressor Cold

Weather Operation

The HVLP ProCompt uses a diaphragm compressor.

A new diaphragm may be stiff in cold weather. If cold

enough, the diaphragm is too stiff to allow the compressor motor to start (the unit hums). If this occurs,

follow these steps:

1. Turn compressor OFF. Turn turbine ON and allow

to warm up for a few minutes.

2. Turn compressor ON. If compressor does not

start, proceed to step 3.

3. Turn turbine and compressor OFF.

4. Unplug turbine from power source.

5. Loosen four thumbscrews (16), remove filter

retainer (15), prefilter (22), and main filter (21).

See Fig. 7.

6. Hand spin cooling fan on compressor for a few

revolutions.

1. Turn turbine ON a few minutes before spraying to

allow warm-up.

NOTE: When the turbine is not in use for an extended

period of time, turn it off. The turbine does not shut off

automatically.

2. Be sure turbine filter is clean before operating. See

page 11 to check and clean filter.

NOTE: To adjust the spray gun pattern see the turbine

gun manual.

7. Reinstall filters and filter retainer.

8. Plug in turbine.

9. Turn turbine and compressor ON. If necessary,

repeat steps 3–9 above.

309242 9

Page 10

Pressure Relief Procedure

Shutdown

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of a serious

injury from pressurized fluid, accidental spray from

the gun, or splashing fluid, follow the Pressure

Relief Procedure whenever you:

D Are instructed to relieve the pressure

D Stop spraying

D Check or service any of the system equipment

D Install or clean the fluid nozzles

1. Turn off air supply to gun.

2. Turn off turbine sprayer.

WARNING

The turbine hose outlet may be hot. Carefully check

the hose end before you remove the hose.

3. If using remote pressure pot, relieve pressure by

following the pressure relief procedure on page 8.

NOTE: Elevate spray gun and pull trigger. This will

allow fluid in fluid hose to drain back into remote

pressure pot.

4. If using a spray gun cup, unlatch cup cover;

loosen or remove cup from cover to relieve cup

pressure.

5. Clean spray gun and cup as instructed in the

HVLP–Turbine Gun manual 309205.

10 309242

Page 11

Maintenance

Daily

The turbine systems are lifetime lubricated. The only

maintenance required is filter cleaning and replacement.

The turbine filter must be clean at all times to provide

sufficient air flow to cool motor and atomize the fluid.

Check turbine pre-filter (22) daily for cleanliness.

Check the main filter (21) weekly, minimum. Clean as

necessary.

NOTE: To check filter, turn on turbine and place piece

of paper against pre-filter. If air intake holds paper in

place, filter is okay.

The HVLP 3800 and 4900 ProCompt sprayers have

an air filter indicator light on the front panel. If the filter

is good the light is out. If the filter is clogged or has low

airflow the light will come on as in Fig. 6 below.

D Soak filter for 15 minutes in water and mild

detergent. Rinse filter until clean. Air dry. Do

not use compressed air on damp or wet filter.

WARNING

To avoid damage to the turbine and possible electric shock, never install a damp filter in the turbine.

CAUTION

To keep out dirt, do not operate the turbine sprayer

without both filters installed.

1

20

21

22

Fig. 6

8049A

To clean filter:

1. Turn off and unplug turbine.

2. Loosen four thumbscrews (16), remove filter

retainer (15) and pre-filter (22). See Fig. 7.

3. Remove main filter (21) and clean by using one of

the following three methods:

D Tap filter gently on flat surface, dirty side

down.

CAUTION

To prevent damage to filter, do not use compressed

air on a wet filter.

D Direct compressed air (100 psi [7 bar, 70 kPa]

maximum) through filter panel in the opposite

direction of arrows on side of filter (from the

clean side to the dirty side).

16

15

Fig. 7

TI0877

Weekly

Check hose for cracks, leaks, and holes. Replace if

necessary.

Annually or Every 600 Hours, Whichever

Comes First

Replace motor brushes 600 hours after turbine sprayer

operation. If brushes are not replaced, motor failure

will occur.

NOTE: It is recommended that an authorized service

center perform the motor brush replacement procedure

on page 16.

309242 11

Page 12

Notes

12 309242

Page 13

Troubleshooting

PROBLEM CAUSE SOLUTION

No fluid delivery No material, no remote

container pressurization, hose

or pickup tube clogged

Compressor not

starting

Cold weather operation See HVLP ProCompt Compressor Cold Weather

Check container for material.

Check for leaks at the container gasket (2-quart

pressure pot cover. Tighten cover if loose.

Check for air flow from male quick-disconnect at

compressor outlet (should be approx. 1/4 CFM).

Turn pressure regulator clockwise. Look for pressure

on gauge. (If no pressure on gauge, check air line and

fittings).

Check hole in 2-quart pressure pot cover at needle

valve. Clean if necessary.

Check for obstructions.

Check if fluid pickup tube is unplugged. Tighten.

Blow out and clear material hose.

Operation on page 9.

Turbine not starting No power Check outlet for power. Cycle red rocker switch.

Check that correct IEC (modular) cord is used and

plugged in.

Check circuit breaker (38). Push to reset.

Poor atomization Dirty filter Clean filter.

Extension cord too long Extension cord must be 3-wire, 12 AWG, 50 ft (15 m)

or shorter.

Hose too long Replace with shorter hose. See Accessories page 20

for shorter hose and Part No.

Circuit breaker trips Filter clogged Clean filter and replace as necessary.

High ambient temperature Move turbine to cooler area.

Excessive brush wear Remove cover and turbine, and check for free motor

rotation and for brush wear. Replace motor brushes if

necessary.

Excessive current draw Return to authorized service center.

309242 13

Page 14

Repair

WARNING

Turn off turbine and unplug power for the following

procedures.

Turbine Sprayer Disassembly (unless

otherwise indicated, refer to Fig. 8 and 9).

1. If necessary, clean and replace filter according to

maintenance procedure on page 11.

2. Loosen the four thumbscrews (16), remove the

filter retainer (15) prefilter (22) and main filter (21).

See Parts Drawing on page 18.

3. Remove hose clamp (88) and disconnect the air

hose (84 ) from the “out” side of the compressor

(64 ).

4. Disconnect the compressor wiring harness (a)

from the compressor (64 )

5. Remove the four cap screws (27) and bumpers

(7).

6. Place the turbine on its back. Carefully separate

the turbine cover (1) from the turbine baseplate (2)

while guiding the compressor air hose (84) and

wiring harness (a) through the air passage (b) in

turbine cover (1). Place the turbine baseplate

upright on a work surface.

7. Repair or replace items as required.

8. After completing servicing place turbine baseplate

(2) on its back.

9. Slide turbine cover (1) onto turbine baseplate

approximately 1–2 in. (to get it started).

10. Reaching between the turbine cover (1) and baseplate (2) carefully guide the compressor air hose

(84) and wiring harness (a) through air passage (b)

through the compressor mounts (c) in the turbine

cover (1).

11. Gently pull the free ends of the compressor air

hose (84) and wiring harness (a) with your other

hand to take up the slack.

12. Maintain tension on the compressor air hose (84)

and wiring harness and slide the turbine cover (1)

fully onto the turbine base plate.

13. Replace four capscrews (27) and bumpers (7).

14. Reconnect compressor air hose (84) and wiring

harness (a).

CAUTION: Keep excess tubing and wiring clear of

compressor cooling fan (d) by securing to compressor

mount (c) with wire tie (e).

15. Reassemble filter, filter retainer, and prefilter.

14 309242

Page 15

Repair

1

2

b

c

d

Fig. 8

Fig. 9

27

A

e

84

88

64

ti0911b

TI0911

Power Cord Replacement

7

2

1

7949A

Replace power cord by unplugging from IEC connector

(A). Install new cord. See Fig. 9

309242 15

Page 16

Repair

Motor Brush Replacement

NOTE: It is recommended that this procedure be

performed by an authorized service center.

1. Use Turbine Sprayer Disassembly procedure at

left to take turbine apart. Use Turbine/Motor

Replacement on page 16 to replace turbine.

2. Remove plastic fan cover.

3. Remove brushes. Check commutator for excessive wear.

Note: Do not install new brushes in a turbine in which

the commutator has been damaged by the brush

holders. A motor with this type of damage cannot be

repaired.

Turbine/Motor Replacement

The HVLP 3800 ProCompt and HVLP 4900 ProComptTurbines each use a different turbine/motor.

See the Turbine/Motor Replacement Kits in the Parts

List on page 19 for a listing of replacement kit parts.

See Parts Drawing on page 18.

4. Install new motor brushes using reverse order.

Keep lead wires from all rotating parts and motor

frame.

CAUTION

Do not run the motor with the air inlet or outlet

sealed off.

5. Reassemble turbine.

6. Run motor 30 to 45 minutes at half-rated voltage

to seat motor brushes.

Note: If half-rated voltage is not available, run repaired

unit in series with another turbine for 30 to 45 minutes.

1. Use Turbine Sprayer Disassembly procedure on

page 14 to take turbine apart.

2. Remove turbine gasket (25).

3. Remove 3 screws (6).

4. Remove plate (82) and 3 spacers (83).

5. Remove turbine motor wires from spade connectors.

6. Rotate turbine (24) from outlet fitting (18) and lift

up from turbine spacers (23).

7. Install new turbine gaskets (25 and 41).

8. Reassemble turbine.

HVLP 3800 ProCompt

Fig. 10

9. Connect ground wire to turbine housing as required.

10. Reconnect wires according to applicable turbine.

See Fig. 10 or Fig. 11 schematics.

16 309242

HVLP 4900 ProCompt

Fig. 11

Page 17

Notes

309242 17

Page 18

Parts Drawing

81

13

14

27

6

26

1

25

82

27

28

6

80

29

26

6

64

20

21

22

15

88

16, 17

18

4

46

47

34

33

31

74

18 309242

19

32, 40

5

42

87

85

72

24

39

84

86

83

23

41

12

10

38

67

36

68

7

27

4

2

37

6

65

Page 19

Parts List

Ref

No. Part No. Description Qty

1 276666 COVER, turbine 1

2 196946 BASE PLATE, turbine

(HVLP 3800) 1

197108 BASE PLATE, turbine

(HVLP 4900)

4 114669 SCREW, pan hd 2

5 196982 DUCT, turbine 1

6 114670 SCREW, cap, hx hd 6

7 113817 BUMPER 4

10 114064 CONNECTOR, male 1

12 114410 SCREW, pan hd, torx 4

13 244166 LID, tool box 1

14 197054 FOAM PAD, tool box 1

15 197057 RETAINER, filter 1

16 192895 SCREW, captive 4

17 158486 PACKING, o–ring 4

18 192779 FITTING, outlet 1

19 156698 PACKING, o–ring 1

20 192789 GASKET, filter 2

21 240273 FILTER, main, paper 1

22† 240274 FILTER, pre 1

23 192780 SPACER, turbine 3

24* 240270 TURBINE KIT, 3 stage; 120 volts

(HVLP 3800) 1

241123 TURBINE KIT, 4 stage; 120 volts

(HVLP 4900) 1

25 192788 GASKET, turbine 1

26 192784 BRACKET, handle 2

27 114531 SCREW, cap, hx hd 8

28 113414 NUT, lock 2

29 192785 HANDLE, turbine 1

31 114658 SWITCH, rocker (HVLP 4900) 1

32 114279 SENSOR, pressure 1

33 114280 LIGHT, indicator, 120V 1

34 114293 SWITCH, rocker, red 1

36 111593 SCREW, grounding 1

37 102063 WASHER, lock, external tooth 1

38 114403 BREAKER, circuit; 15A, 120V 1

39 192905 PLATE, deflector 1

40 193059 GASKET, sensor 1

Ref

No. Part No. Description Qty

41 192845 GASKET, duct 1

42 192846 GASKET, duct 1

46 114287 FITTING, barbed 1

47 192810 HOSE, air 1

50 244118 GUN, HVLP (not shown) 1

51 241413 HOSE, turbine air, 30 ft (not shown)

1

52 240071 HOSE, compressor, air, 30 ft

(not shown) 1

53 103473 STRAP, tie (not shown) 1

54 244124 FLUID SET, #3 (not shown) 1

64 244231 COMPRESSOR kit, 120V 1

65 240281 CORD SET, 15 ft 120V 1

67Y 193095 LABEL, danger 1

68Y 193096 LABEL, warning 1

69Y 193126 LABEL, caution (not shown) 1

72 197152 FITTING, quick connect 1

74 116255 SWITCH, rocker 1

75 244122 #2/4/5/6 ACCESSORY KIT

(HVLP 4900) Not shown 1

80 240488 HOSE, air, 1/4 in., clear 1

81 114538 SCREW, mach, pan hd 2

82 194094 PLATE, turbine 1

83 SPACER, turbine

194096 HVLP 3800 3

194097 HVLP 4900 3

84 197284 TUBE, air 1

85 197153 FITTING, valve, barbed 1

86 244135 VALVE, duckbill 1

87 101936 NUT, jam 1

88 116767 CLAMP, hose 1

† Pre-filters are available in 5 packs. Order Part No.

240274.

* Turbine Brush Kits are also available. Order part

number 240546

Y Replacement Danger and Warning labels, tags, and

cards are available at no cost.

309242 19

Page 20

Accessories

2-Quart (1.9 liter) Pressure Pot 287819

50 psi (345 kPa, 3.5 bar) Maximum Inlet Air Pressure

2-quart (1.9 liter) capacity, aluminum cup.

Includes air pressure regulator, gauge, pressure relief

valve, and rigid hook handle.

WARNING

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in the turbine spray system, which contains aluminum and/or

galvanized-coated parts. Such use could result in a serious chemical reaction, with the possibility

of explosion, which could cause death, serious injury, and/or substantial property damage.

127

120

124

121

119

112

137

130

138

134

136

133

114

123

131

101

103

140

122

139

128

129

109

(Handle is

shipped loose,

inside of 2-qt

container.)

ti7063a

Ref.

No. Part No. Description Qty.

101 104655 PRESSURE GAUGE 1

103 104815 PRESSURE REGULATOR 1

109 287818 POT, 2 quart (1.9 liter), aluminum 1

112 120132 GASKET 1

287820 GASKET KIT 5–pack 1

114 169969 FITTING 1

119 240474 HOSE, fluid; 60 in. long; 1/4 in. ID 1

120 240482 HOSE, air; 54 in. (1.37 m) long 1

121 M70854 HOSE CLAMP 1

122 110440 FITTING TEE 1

123 189557 RESTRICTOR 1

124 M70399 QUICK DISCONNECT, male 1

127 M70402 QUICK DISCONNECT 1

128 120123 LID, cup 1

129 120131 VALVE KIT, check repair 1

130 120130 HANDLE 1

131 120129 NUT, handle 1

133 120127 VALVE, pressure release 1

134 120128 FITTING, outlet 1

136 120125 TUBE, fluid 1

137 120126 CUP, 2 quart 1

138 193218 STRAINER 1

139 120131 FITTING, inlet 1

140 120133 VALVE, pressure relief 1

20 309242

NOTE:

D See HVLP Finish Systems brochure 300564 for all

accessories.

D Non–silicone lubricant 111265 (4 oz.) is available

for fluid seals and wear areas.

Page 21

Specifications

Power requirements 120V AC, 50/60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amps at 120 volts

HVLP 3800 & HVLP 4900 1 phase, 14A minimum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power cord (extension cord must be 3-wire, 12 AWG, 50 ft [15 m] or shorter)

HVLP 3800 & HVLP 4900 No. 14 AWG, 3 wire, 15 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unrestricted flow rate

HVLP 3800 80 cfm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HVLP 4900 82 cfm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbine stages

HVLP 3800 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HVLP 4900 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum turbine hose length

HVLP 3800 & HVLP 4900 60 ft (18 m). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cup volume 1 quart (0.95 liter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts

Bare spray gun stainless steel, brass, hard-coated aluminum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray gun cup aluminum, polyethylene. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-quart (1.9 liter) accessory remote pressure pot aluminum, brass, polyethylene. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbine shipping weight

HVLP 3800 34 lb (15.4 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HVLP 4900 36 lb (16.3 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turbine diameter 5.7 in (144.78 mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound level per ISO 3744

Sound power level 89.0 dB(A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound pressure level 78.0 dB(A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

309242 21

Page 22

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–690–2894 Toll Free

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

MM 309242

22 309242

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

PRINTED IN USA 309242

12/2000 Rev. 11/2005

Loading...

Loading...